Micro-channel battery thermal management device

A battery thermal management and micro-channel technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of low cooling and heating efficiency, poor operation stability, and high cost input, and achieve low cost input and high heat exchange efficiency. , the effect of speeding up the absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

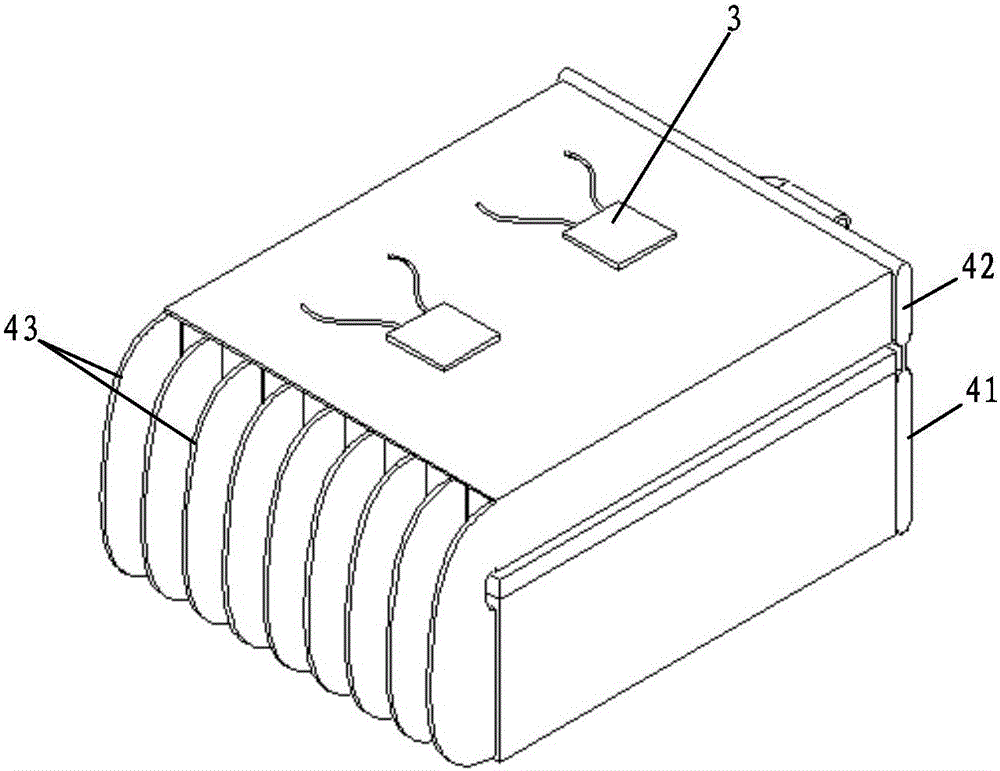

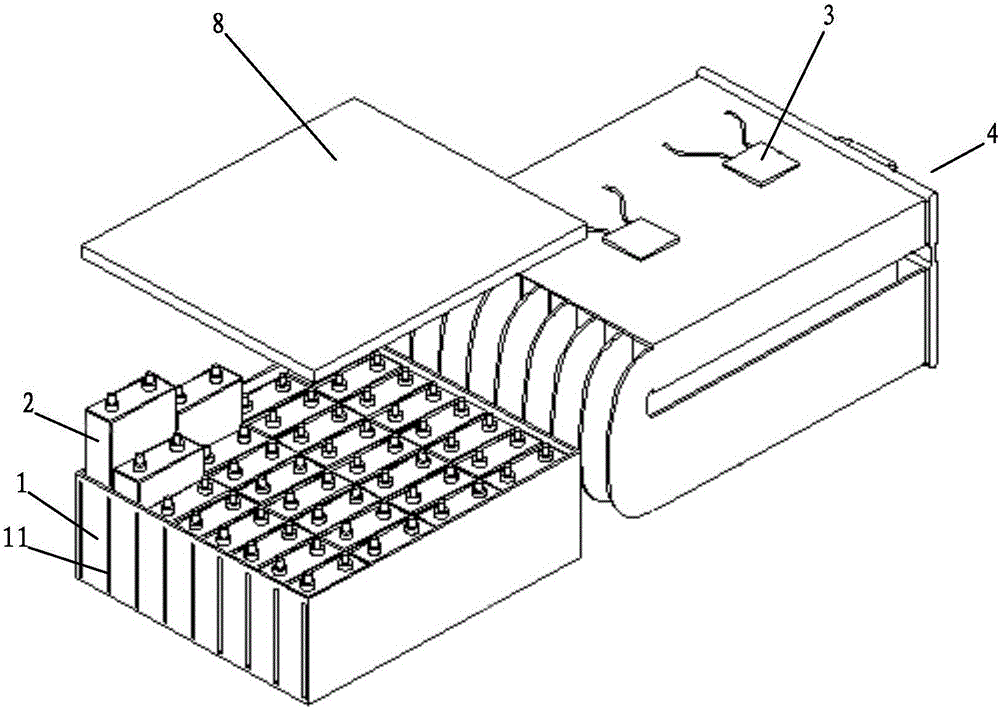

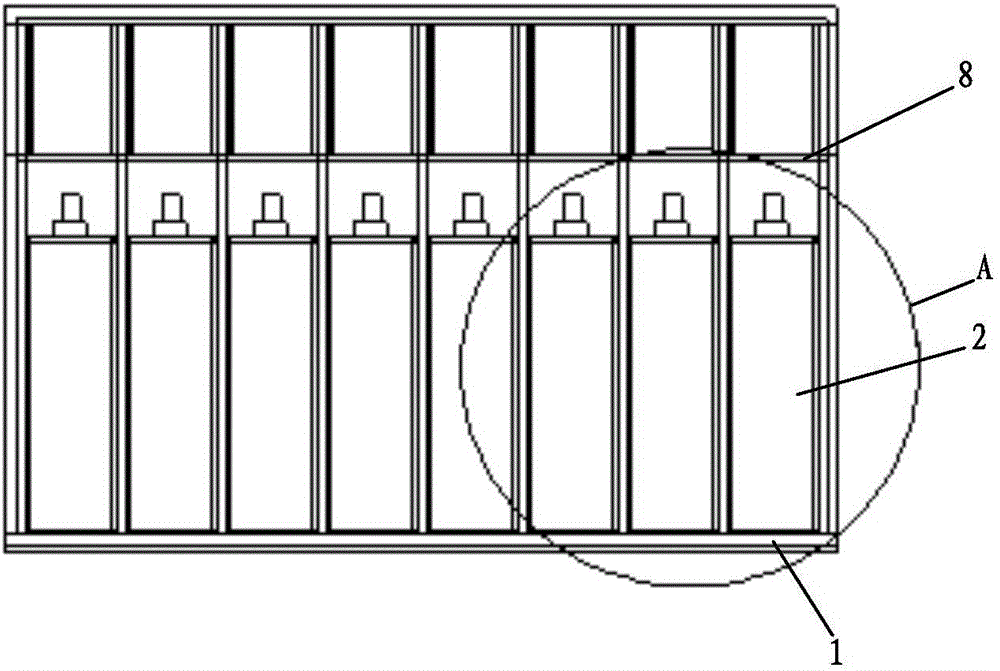

[0030] refer to figure 1 , figure 2 , Figure 5 with Figure 8 , this embodiment relates to a battery heat management device, including a box body 1, a battery 2, a semiconductor cooling chip 3, a heat exchange device 4 and a control device, the battery 2 is set in multiples, and is installed in the box body 1, A multi-row structure is formed, and the battery 2 between every two rows has a gap 21; one end of the heat exchange device 4 is inserted into the gap 21 and is in contact with the battery 2; the semiconductor cooling chip 3 is fixed Installed on the heat exchange device 4, the output end of the control device is connected to the control input end of the semiconductor refrigeration chip 3; the heat exchange device 4 includes an inlet collecting chamber 41, an outlet collecting chamber 42 and two The ends of the water pipes 43 are respectively connected with the inlet collecting chamber 41 and the outlet collecting chamber 42, and the water inlet of the inlet collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com