Oil gas recovery method and device using absorption method and membrane separating method integration technology

A technology of membrane separation method and absorption method, which is applied in the direction of separation method, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of failing to meet emission standards and high concentration of tail gas emission, and achieve reduction of tail gas concentration, improvement of absorption efficiency, The effect of preventing environmental pollution and fire hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

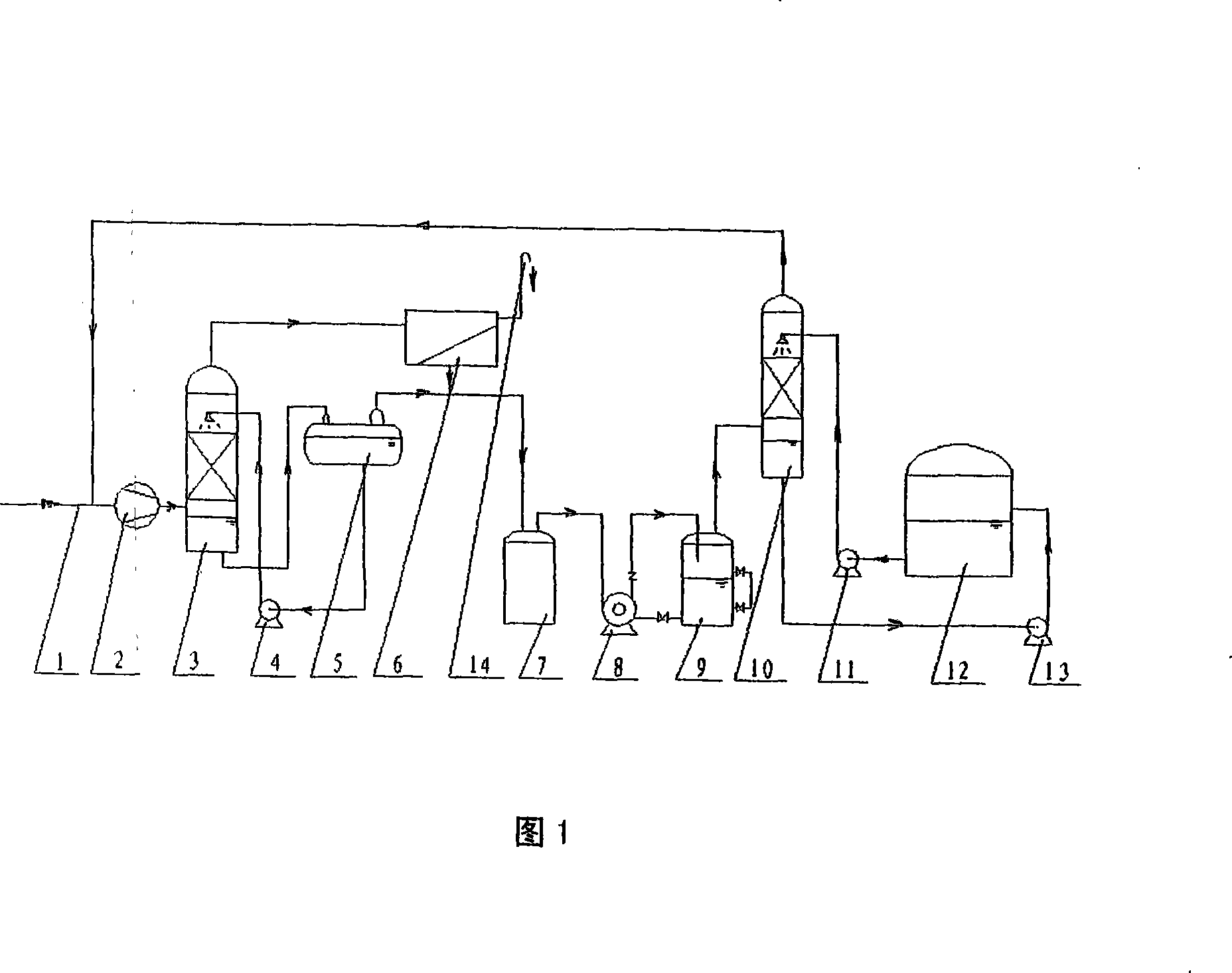

[0017] As shown in Fig. 1, the device of the present invention is provided with gas collecting pipe (1), compressor (2), absorption tower (3), solvent pump (4), desorption horizontal tank (5), membrane separator (6) from left to right successively ), buffer tank (7), vacuum pump (8), gas-liquid separation tank (9), recovery tower (10), lean oil pump (11), oil storage tank (12), rich oil pump (13) and above the membrane separator drain port (14).

[0018] The connection situation of each part is as follows among Fig. 1: gas collector (1) is connected with compressor (2); Compressor is connected with the bottom of absorption tower (3), and the top of absorption tower (3) is connected with membrane separator (6) ), the upper part of the absorption tower is connected with the outlet of the solvent pump (4), and the bottom of the absorption tower is connected with the top inlet of the desorption horizontal tank (5); the inlet of the solvent pump (4) is connected with the desorption...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com