Patents

Literature

2043results about "Machines using waste heat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat engine

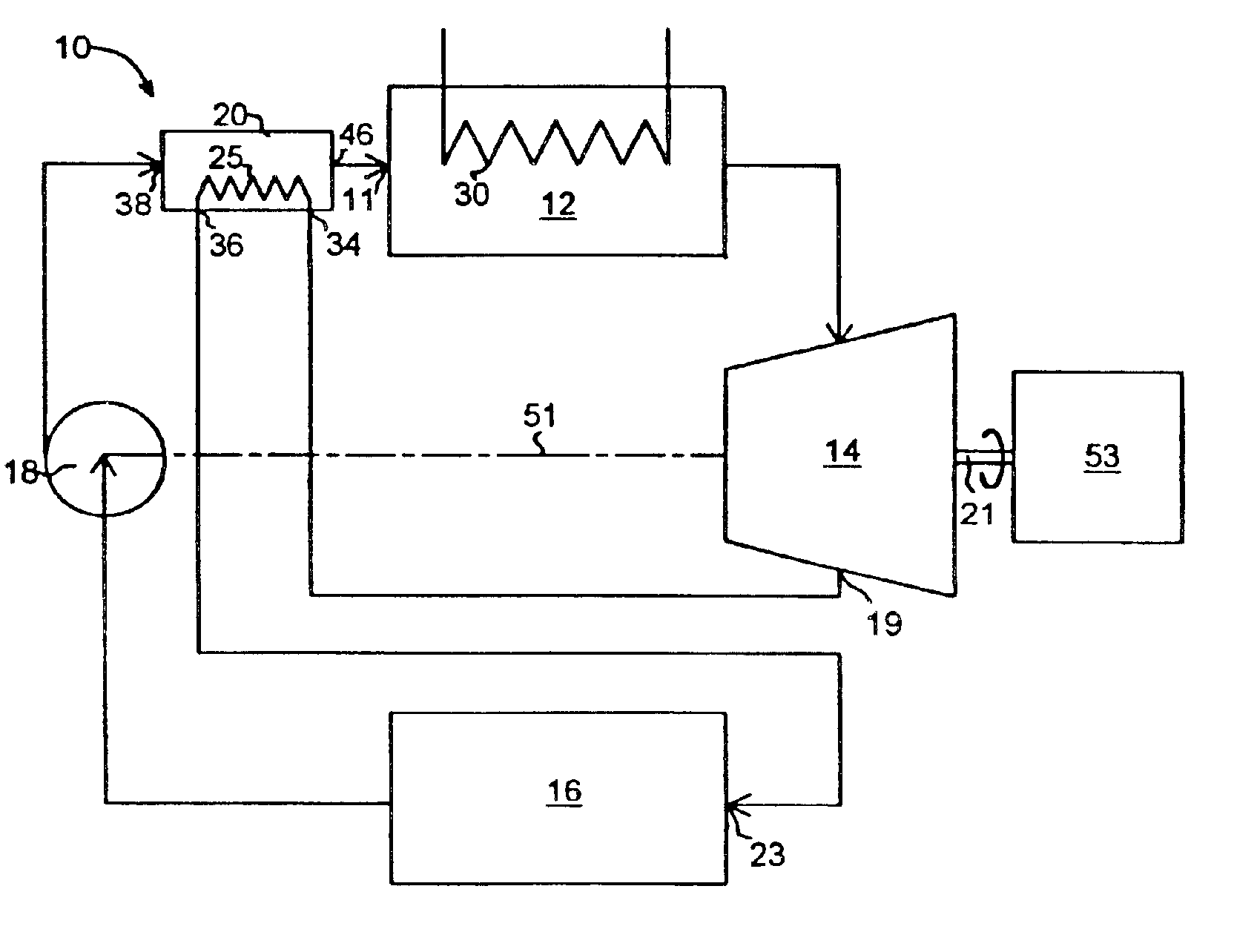

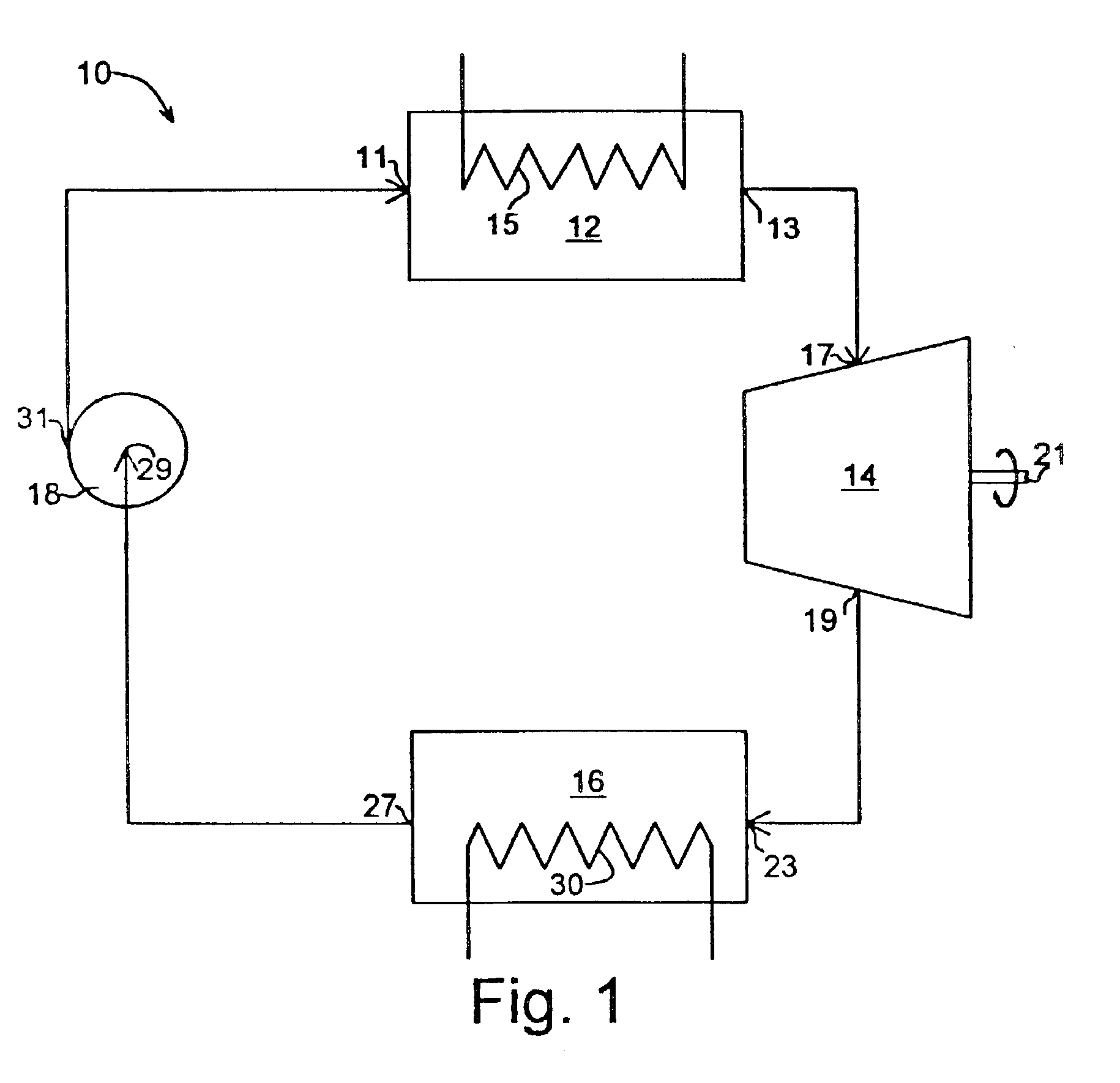

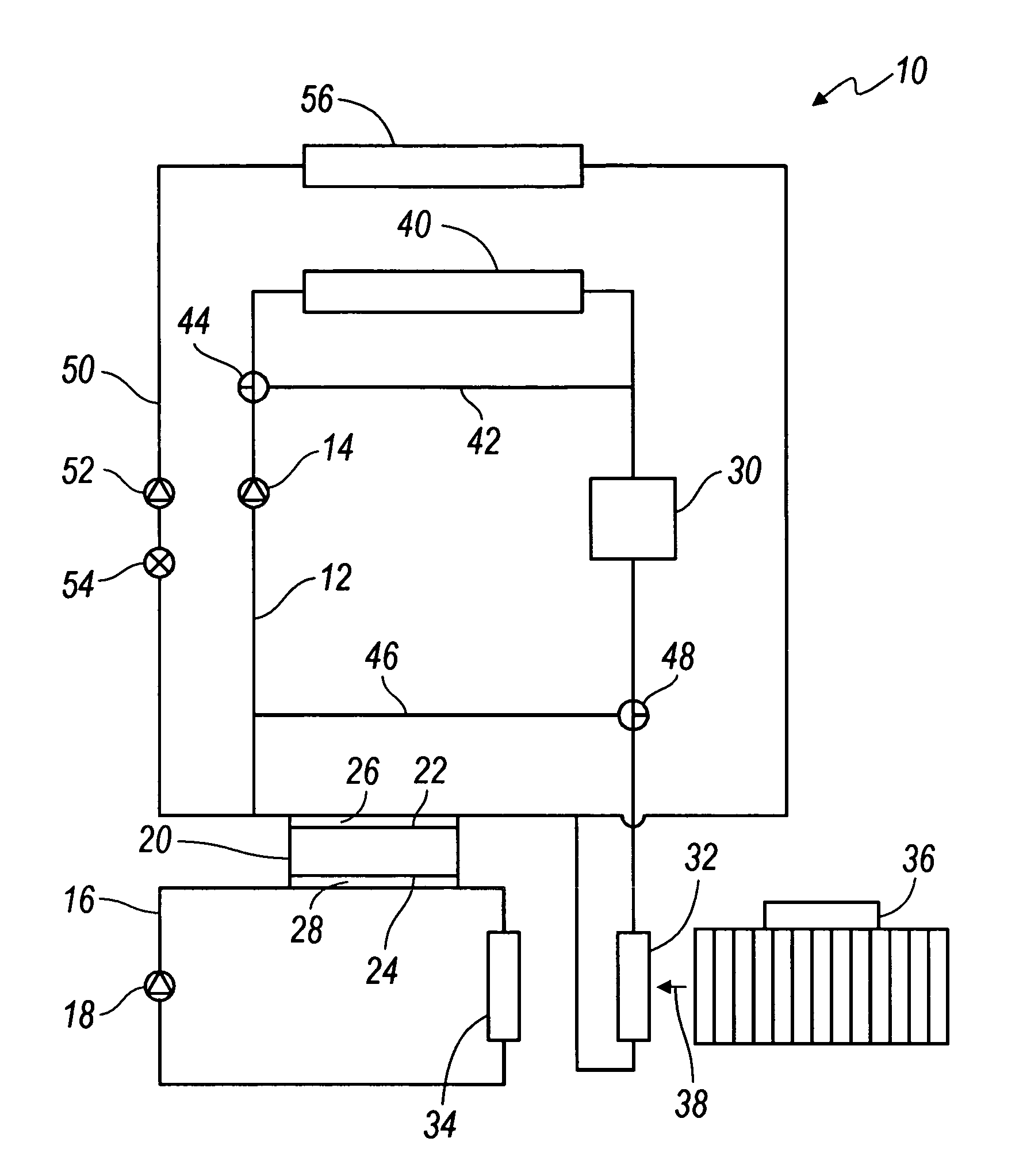

InactiveUS20030000213A1Easy to operateBoilers/analysersClimate change adaptationWorking fluidEngineering

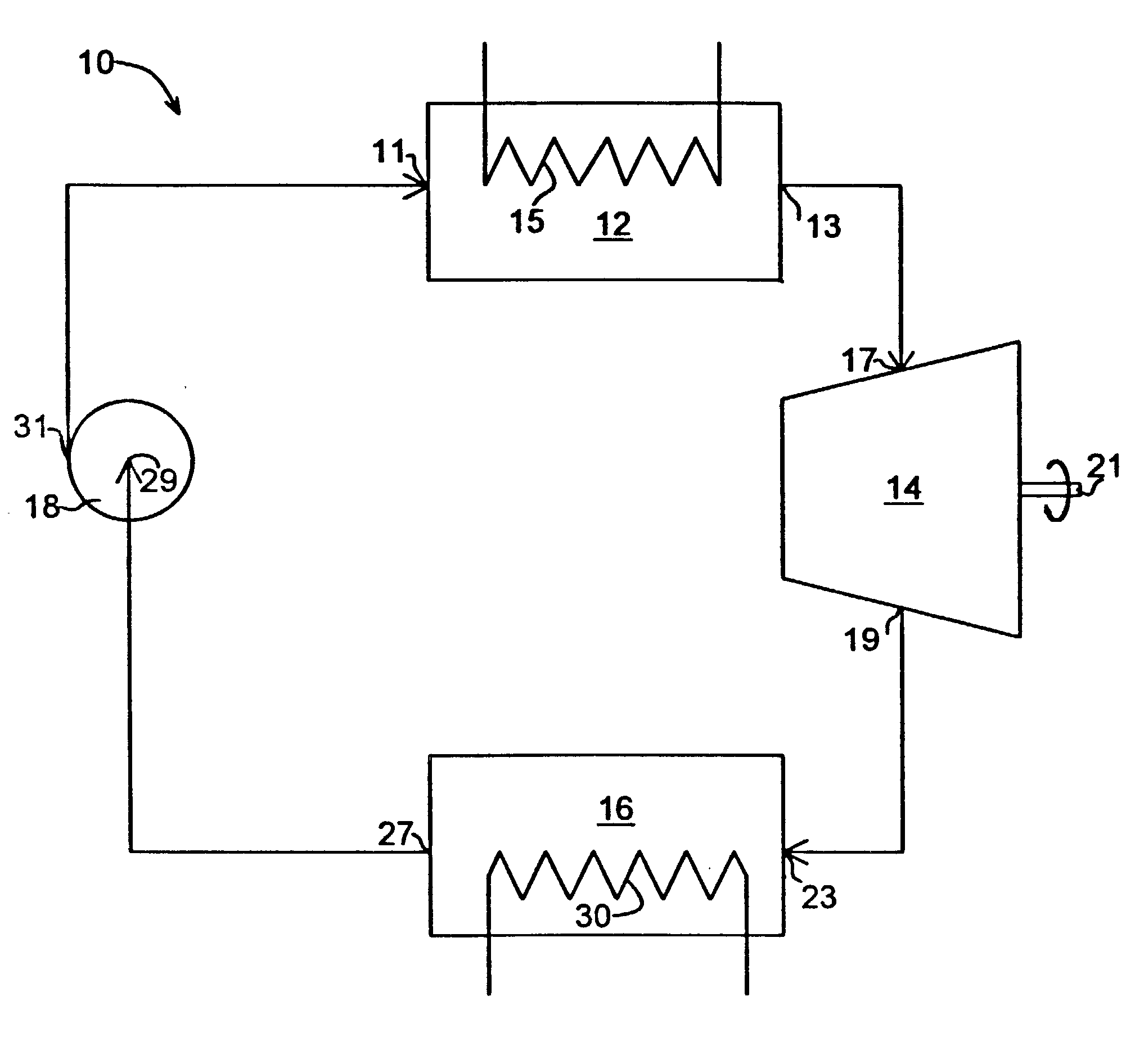

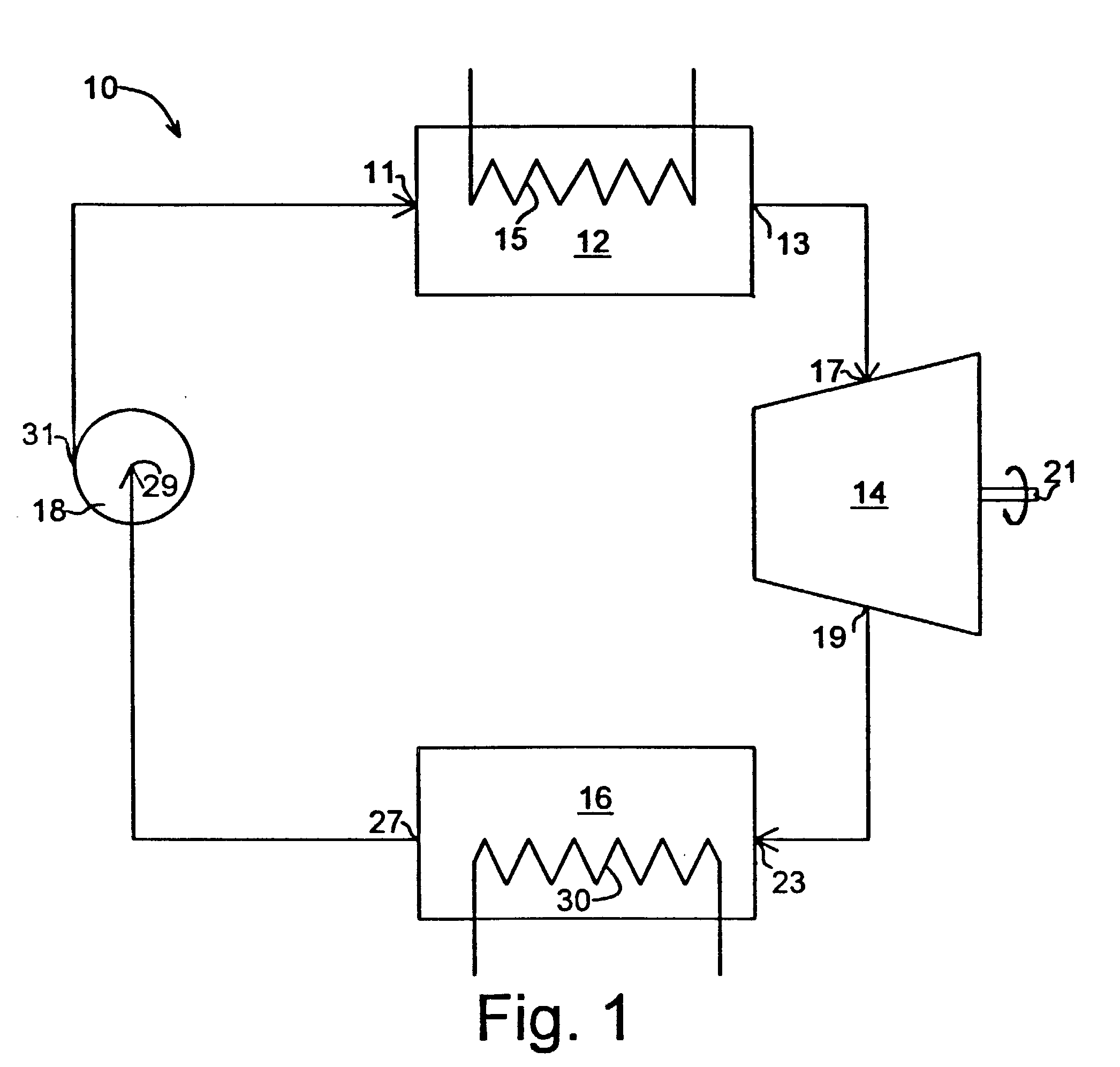

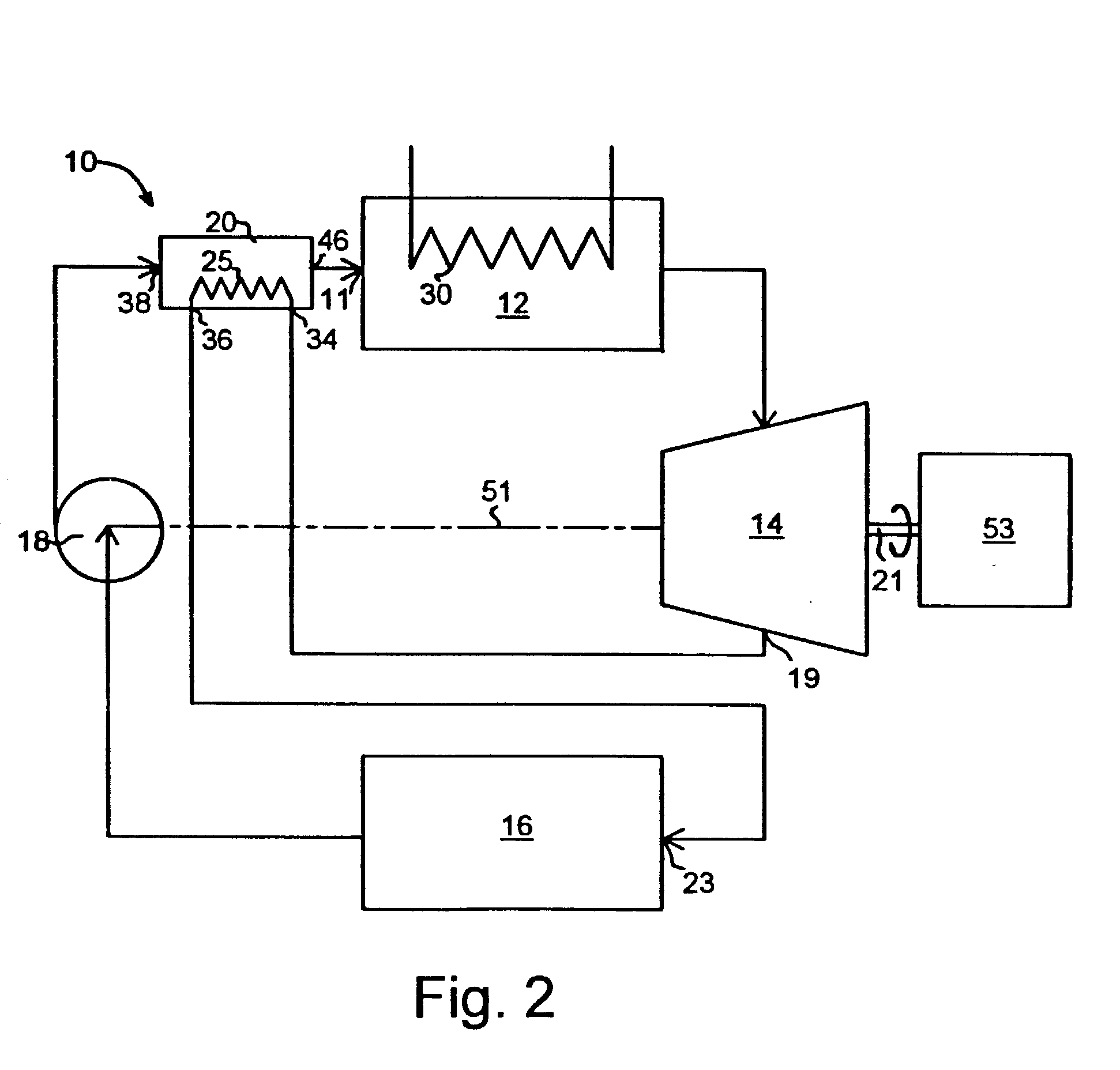

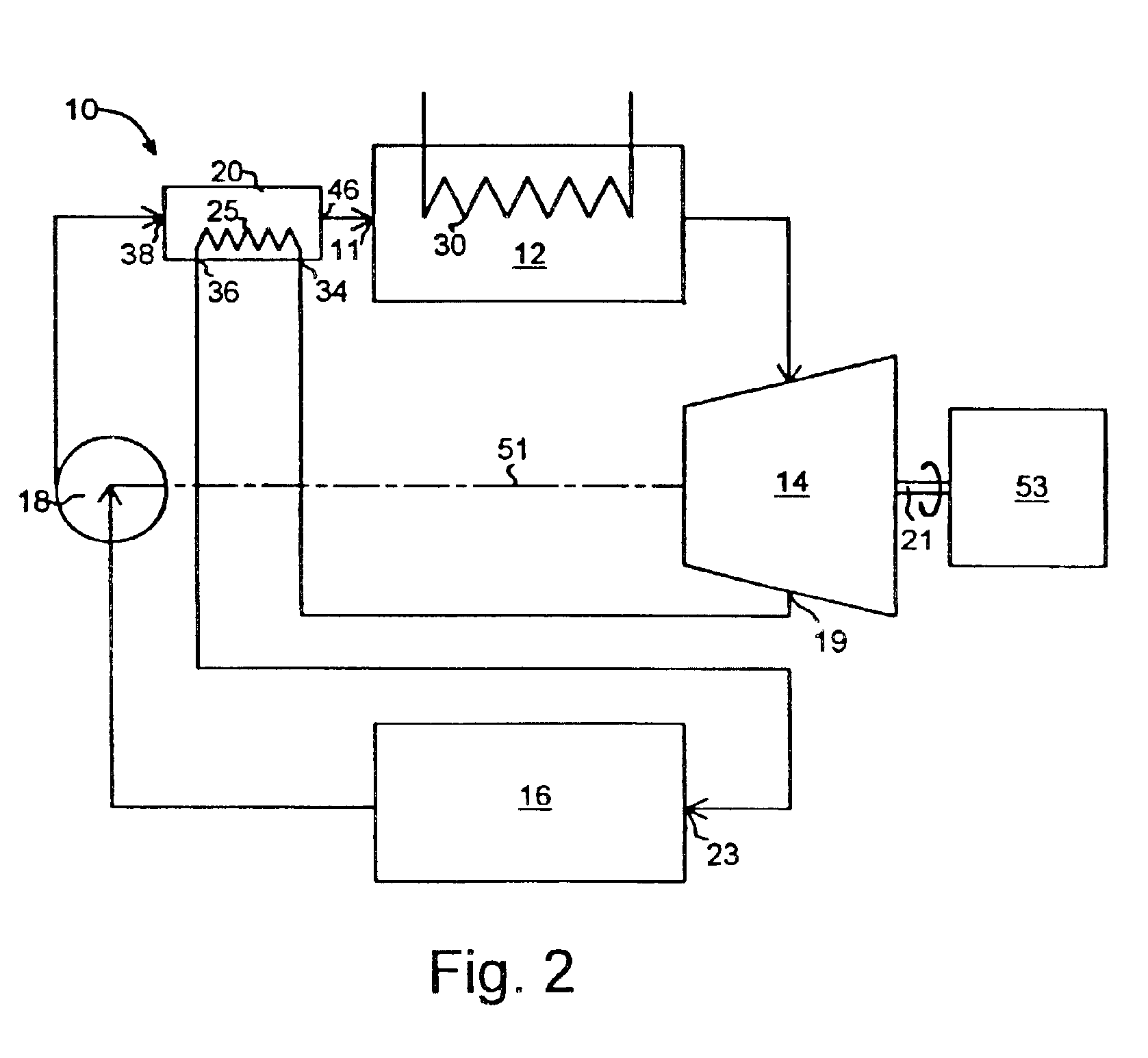

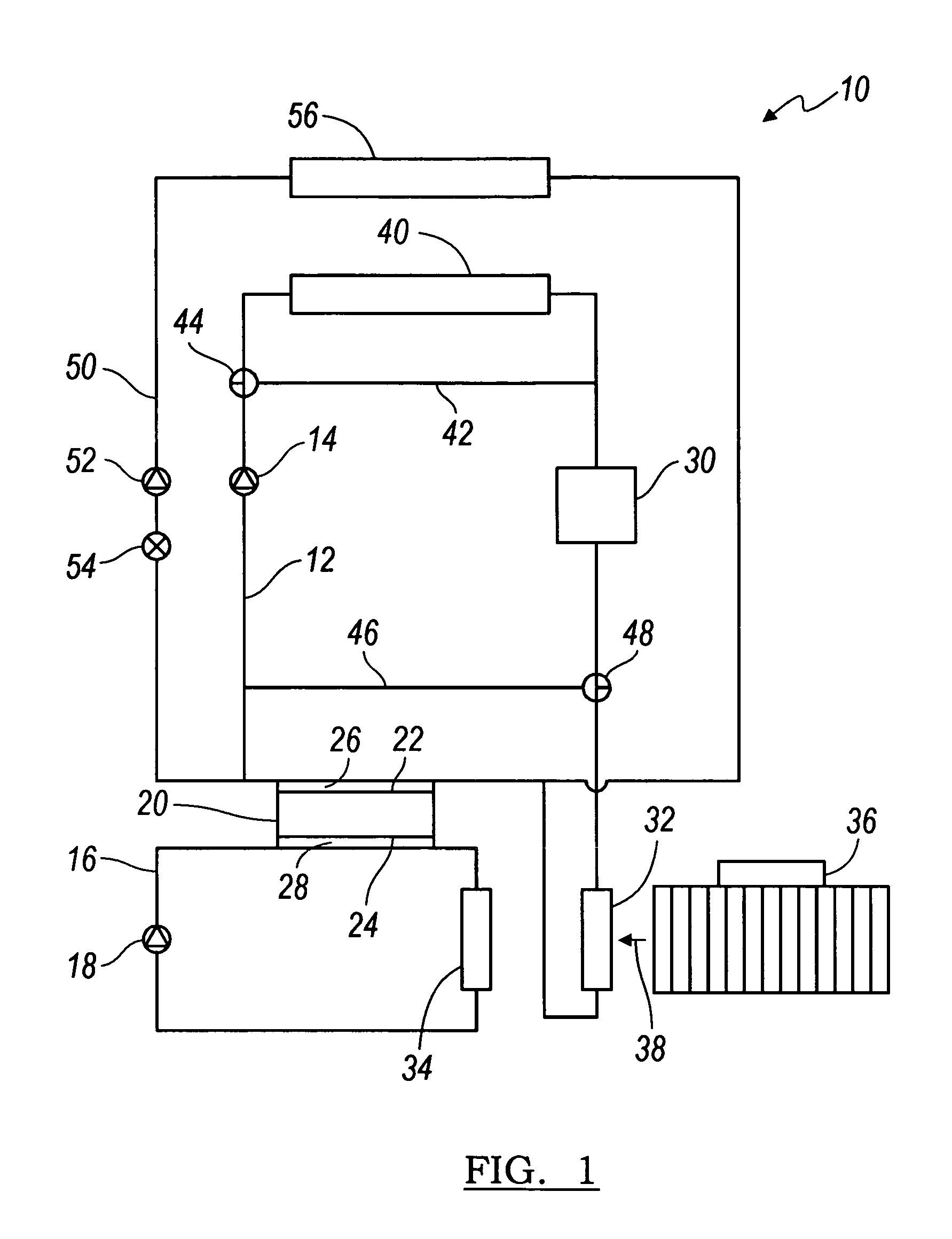

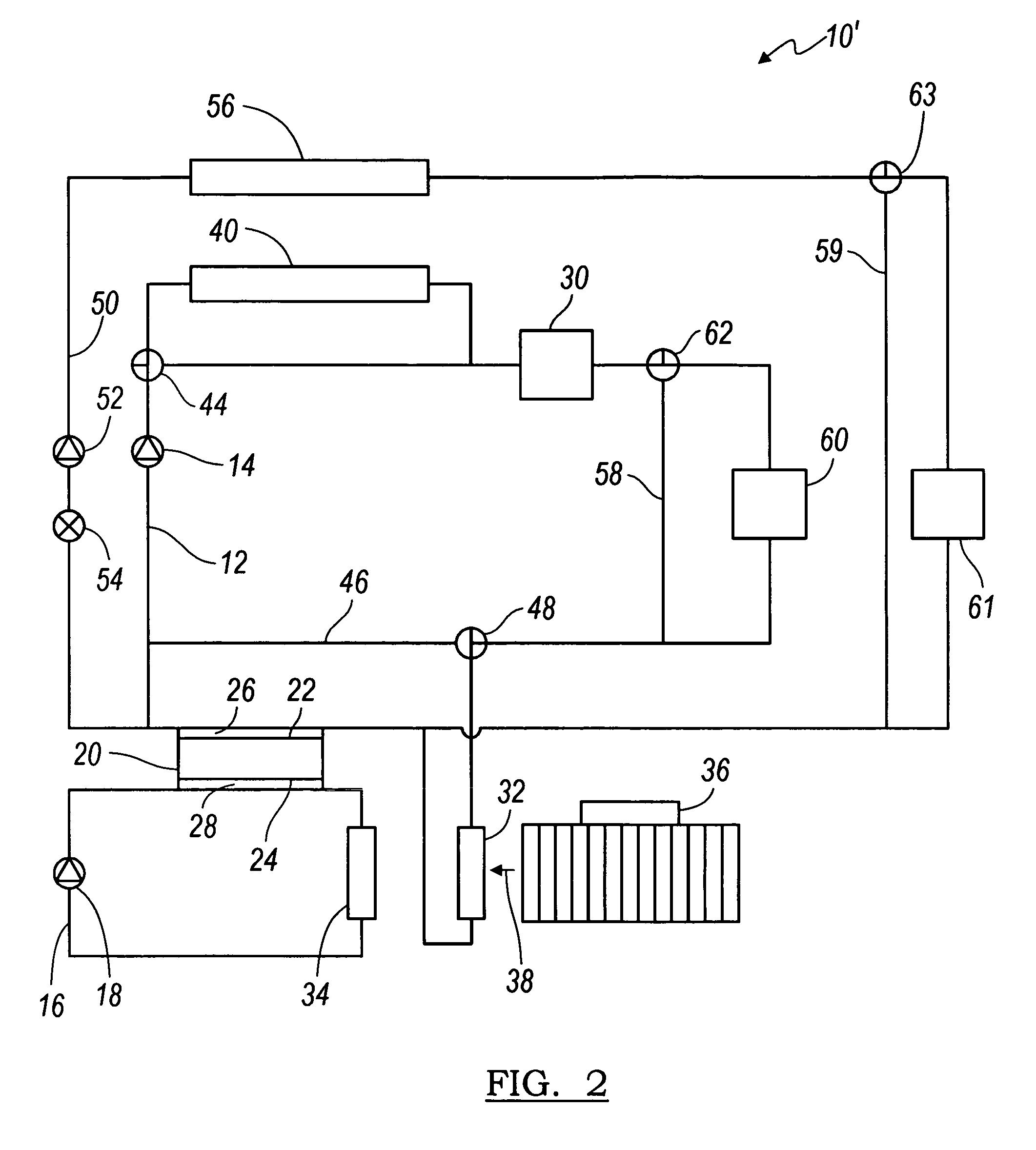

A heat engine (10) achieves operational efficiencies by: 1) recovering waste heat from heat engine expander (14) to preheat heat-engine working fluid, 2) using super-heated working fluid from compressor (402) to pre-heat heat-engine working fluid, and 3) using reject heat from condenser (93) and absorber (95) to heat the heat-engine boiler (12). A dual heat-exchange generator (72) affords continuous operation by using gas-fired heat exchanger (212) to heat generator (72) when intermittent heat source (40), e.g., solar, is incapable of heating generator (72). The combination of heat engine (10) and absorption and compression heat transfer devices (60, 410) allows use of low-temperature heat sources such as solar, bio-mass, and waste heat to provide refrigeration, heating, work output including pumping and heating of subterranean water and electrical generation.

Owner:OHIO STATE INNOVATION FOUND

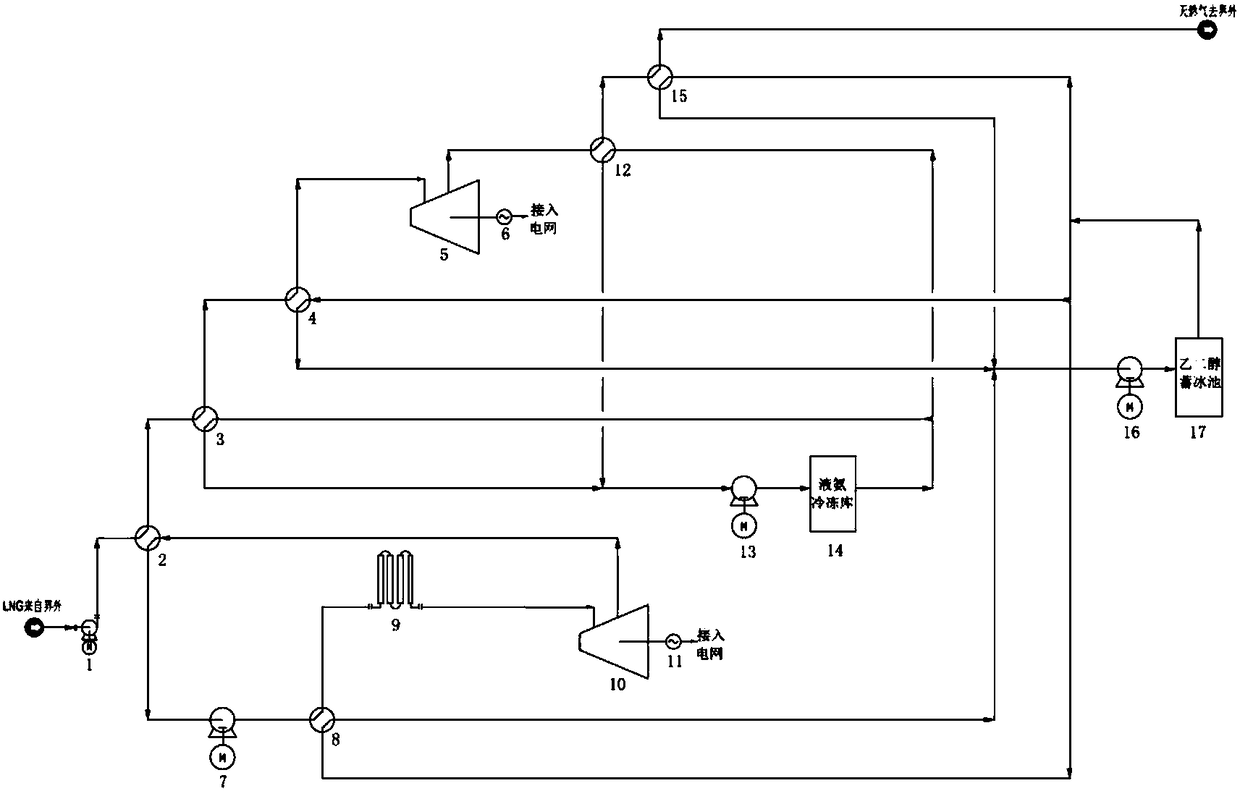

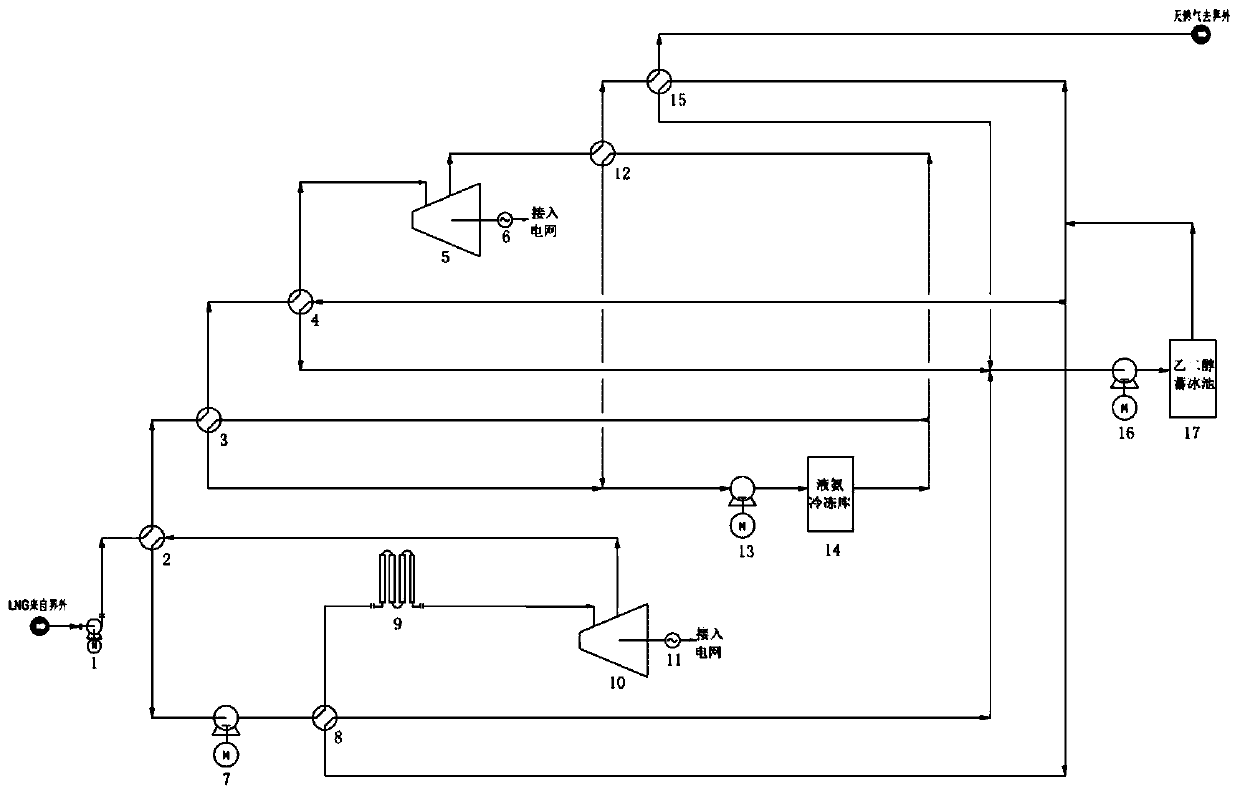

System for comprehensively utilizing LNG cold energy for power generation and cold supply

ActiveCN108087050AImprove utilization efficiencyClimate change adaptationCompression machines with several condensersIce storageRefrigeration

The invention relates to a system for comprehensively utilizing LNG cold energy for power generation and cold supply. The system comprises a LNG supercharging gasification direct expansion power generation system, a mixed working medium Rankine cycle power generation system, a liquid ammonia refrigeration house cold supply system and an ethylene glycol ice storage bath air conditioner cold supplycirculation system. The cold energy released in the LNG gasification process is utilized; high-grade electric energy is generated through LNG supercharging gasification direct expansion power generation and mixed working medium Rankine cycle power generation; cold is supplied to a refrigeration house through the cold energy released in the LNG gasification process for ammonia recycling; and cold is supplied to an air conditioner through the cold energy released in the LNG gasification process for ethylene glycol ice storage bath recycling. By means of the system, gradient utilization of the LNG cold energy is achieved, and the cold energy utilization efficiency is high.

Owner:SICHUAN HENGRI GAS ENG CO LTD

A system for comprehensive utilization of lng cold energy for power generation and cooling

ActiveCN108087050BImprove utilization efficiencyClimate change adaptationCompression machines with several condensersIce storageEngineering

The invention relates to a system for comprehensively utilizing LNG cold energy for power generation and cold supply. The system comprises a LNG supercharging gasification direct expansion power generation system, a mixed working medium Rankine cycle power generation system, a liquid ammonia refrigeration house cold supply system and an ethylene glycol ice storage bath air conditioner cold supplycirculation system. The cold energy released in the LNG gasification process is utilized; high-grade electric energy is generated through LNG supercharging gasification direct expansion power generation and mixed working medium Rankine cycle power generation; cold is supplied to a refrigeration house through the cold energy released in the LNG gasification process for ammonia recycling; and cold is supplied to an air conditioner through the cold energy released in the LNG gasification process for ethylene glycol ice storage bath recycling. By means of the system, gradient utilization of the LNG cold energy is achieved, and the cold energy utilization efficiency is high.

Owner:SICHUAN HENGRI GAS ENG CO LTD

Thermoelectric-based heating and cooling system

Disclosed is a heating, ventilation and air conditioning system for a vehicle that operates in a heating mode, a cooling mode or a demisting mode. The system includes a first circuit having first pump for circulating a first medium therein, a second circuit having a second pump for circulating a second medium therein and a thermoelectric module having a first surface in thermal contact with the first medium and a second surface in thermal contact with the second medium.

Owner:GENTHERM INC

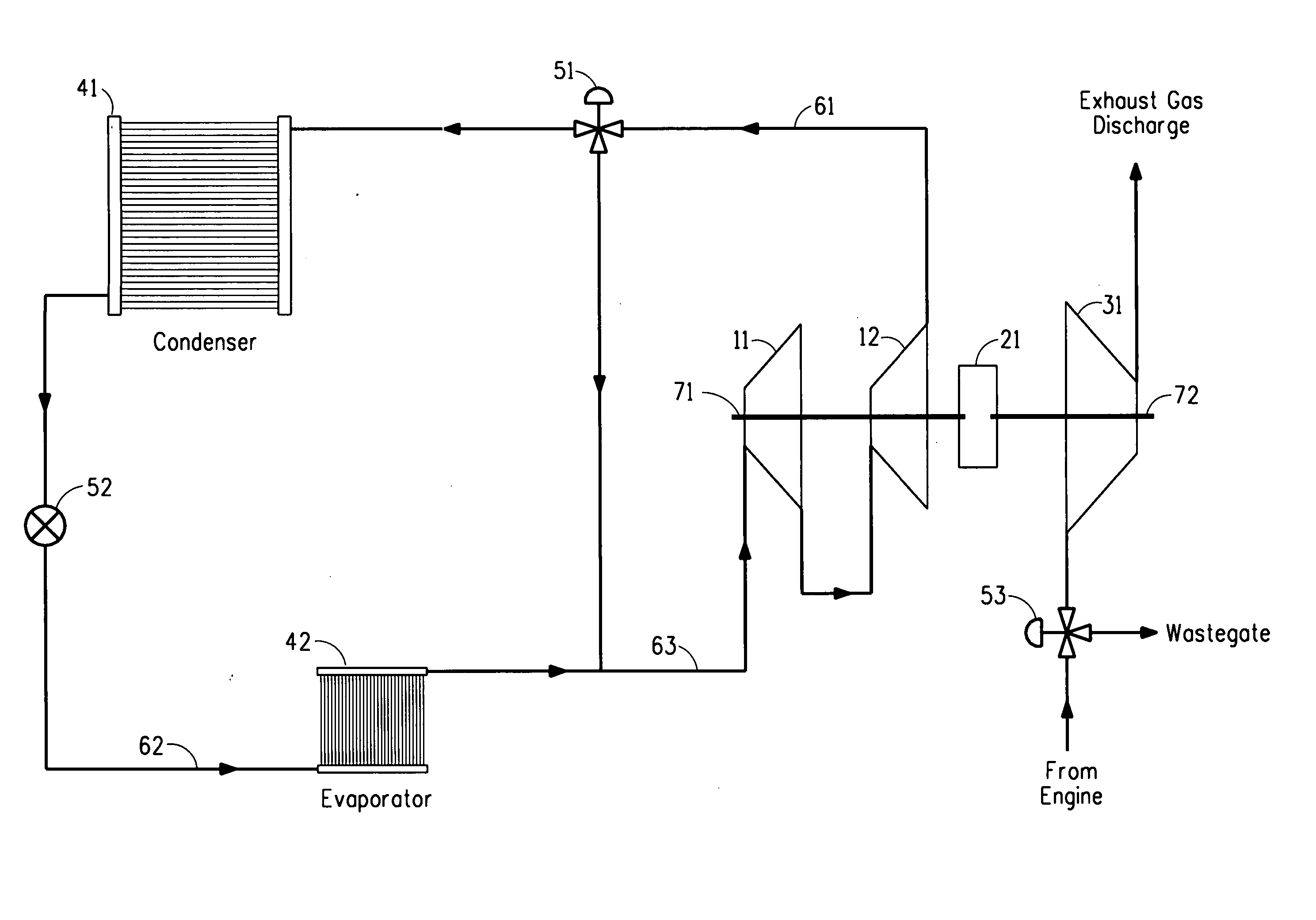

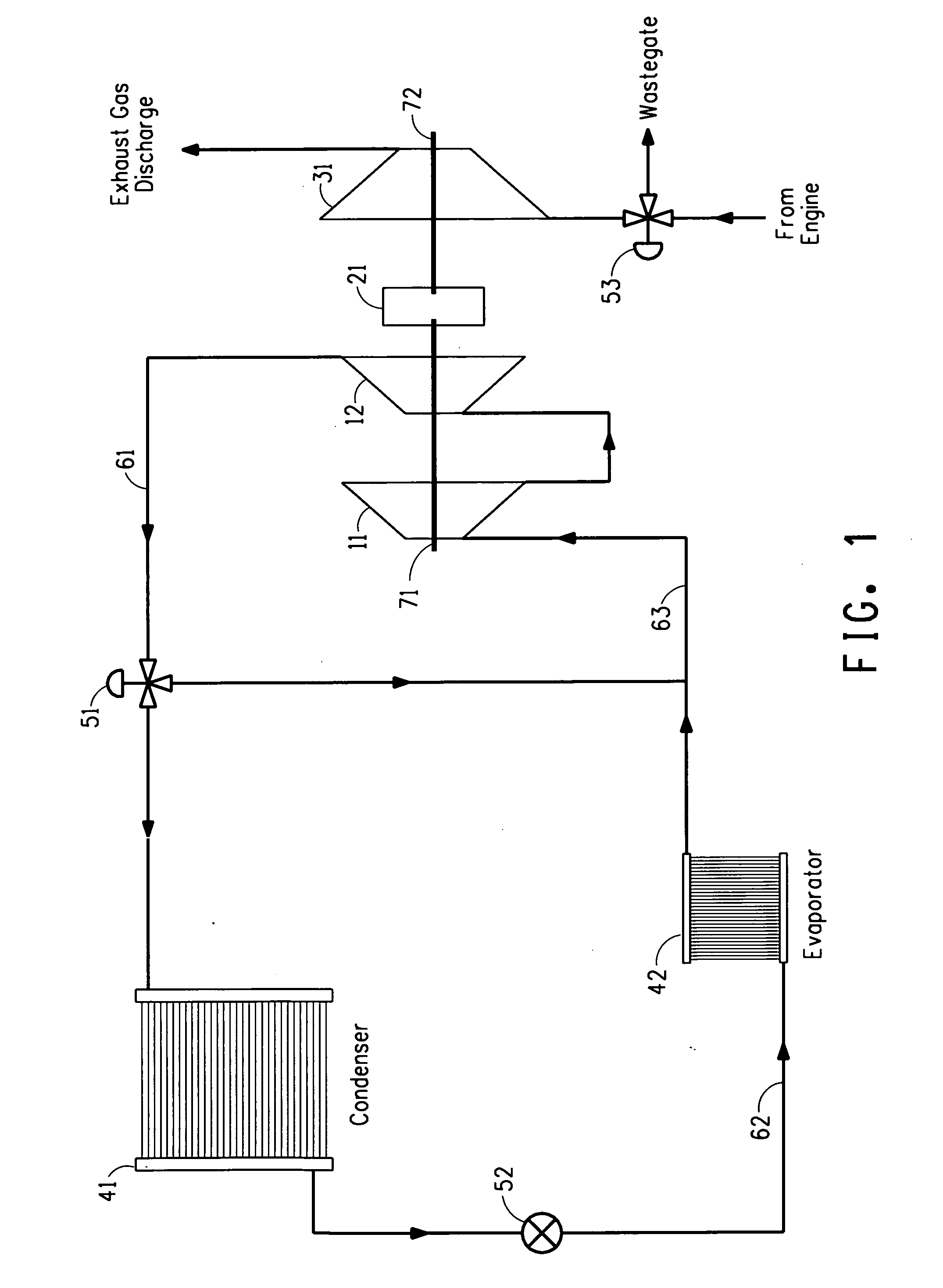

Refrigeration/air-conditioning apparatus powered by an engine exhaust gas driven turbine

InactiveUS20060242985A1Vary amountClimate change adaptationCompression machines with non-reversible cycleAir conditioningRefrigeration

Owner:EI DU PONT DE NEMOURS & CO

Heat engine

InactiveUS7062913B2Improve efficiencyBoilers/analysersClimate change adaptationWorking fluidEngineering

Owner:OHIO STATE INNOVATION FOUND

Thermoelectric power generation systems

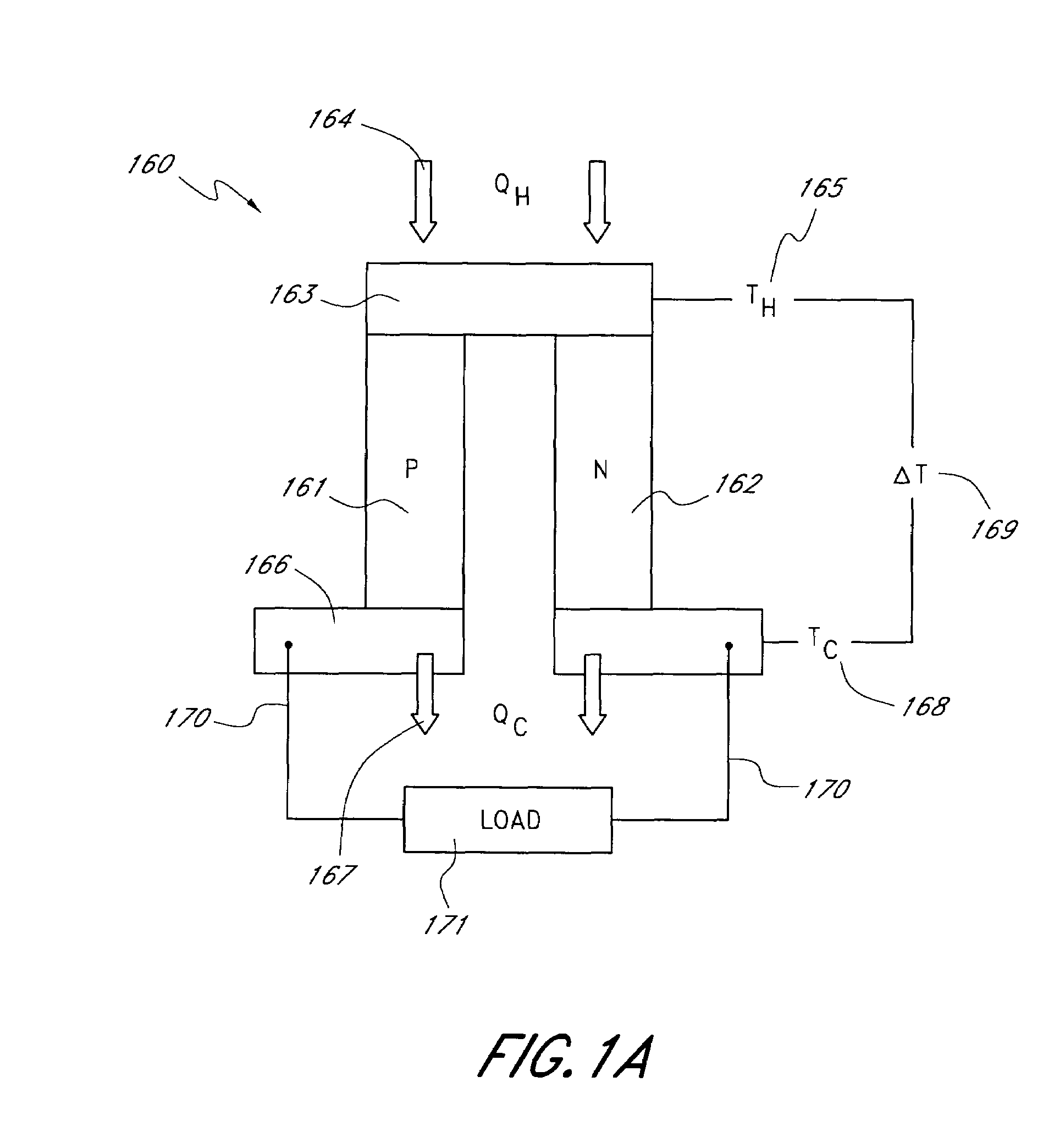

InactiveUS7273981B2Renewed interestImprove power densityAir-treating devicesThermoelectric device with peltier/seeback effectEngineeringThermal efficiency

Representative configurations for improved thermoelectric power generation systems to improve and increase thermal efficiency are disclosed.

Owner:GENTHERM INC

Energy storage systems

ActiveUS20110226440A1Low costReduce usageSolar heating energyRecuperative heat exchangersThermal energyThermal energy storage

There is herein described energy storage systems. More particularly, there is herein described thermal energy storage systems and use of energy storable material such as phase change material in the provision of heating and / or cooling systems in, for example, domestic dwellings.

Owner:SUNAMP

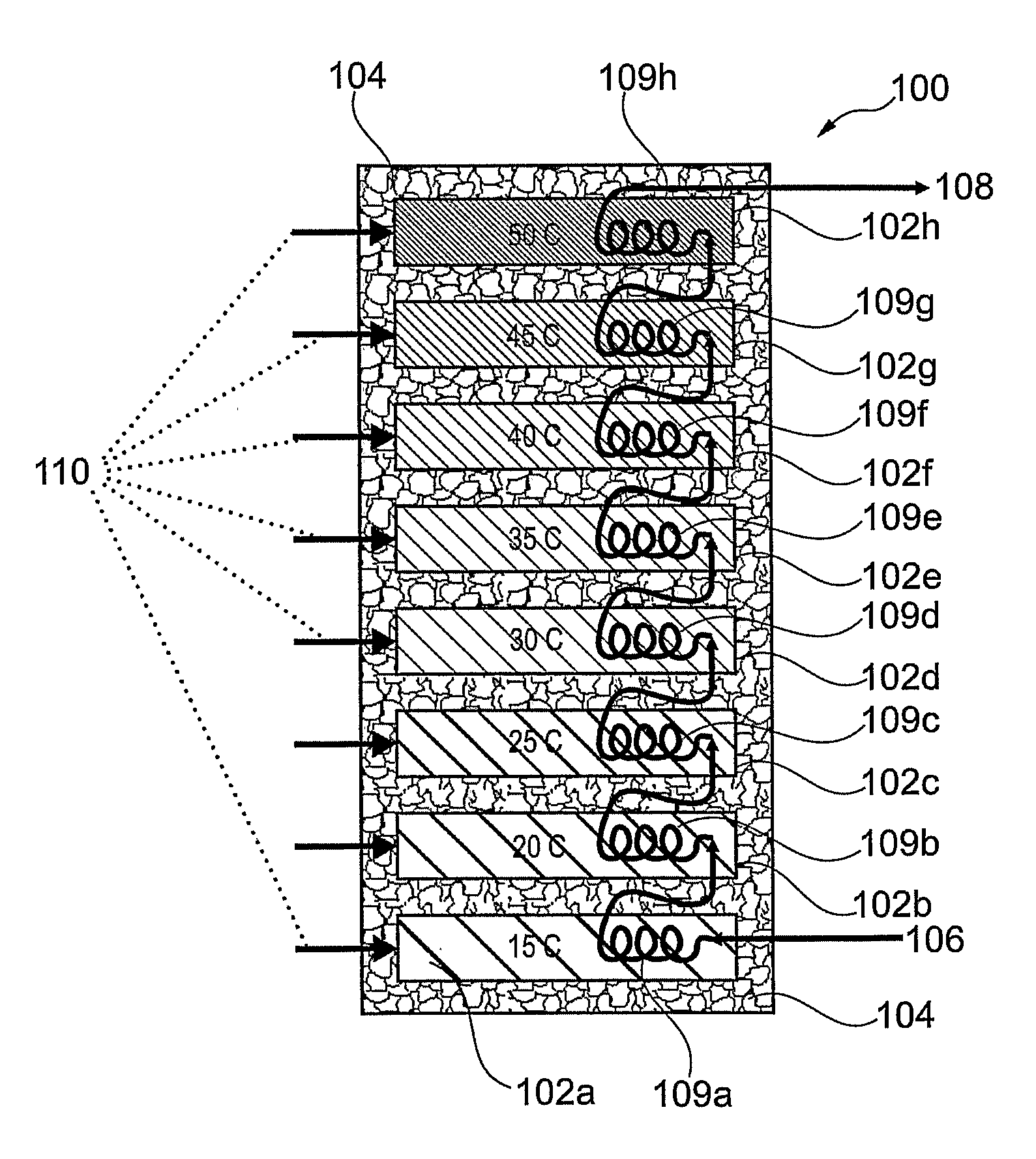

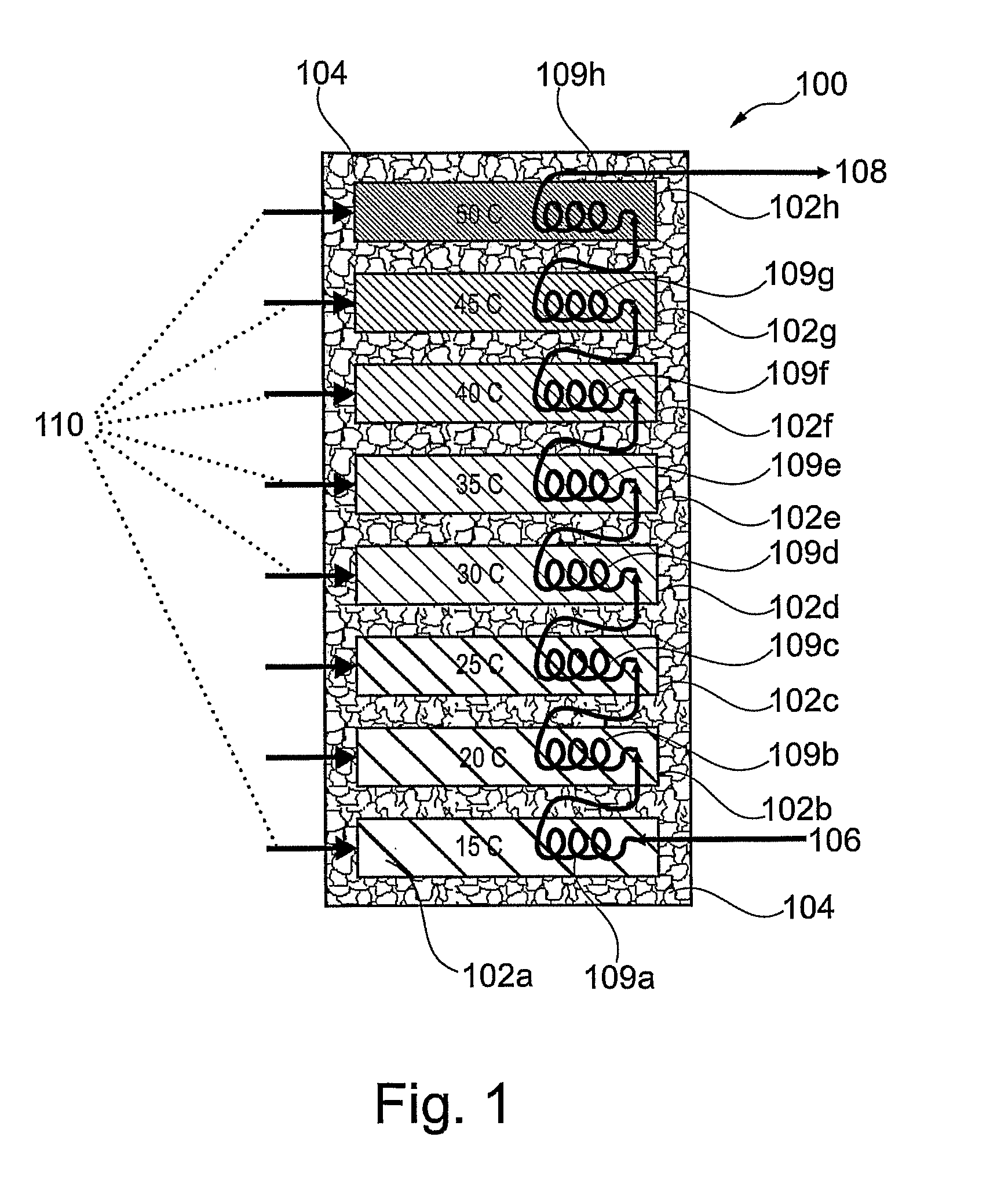

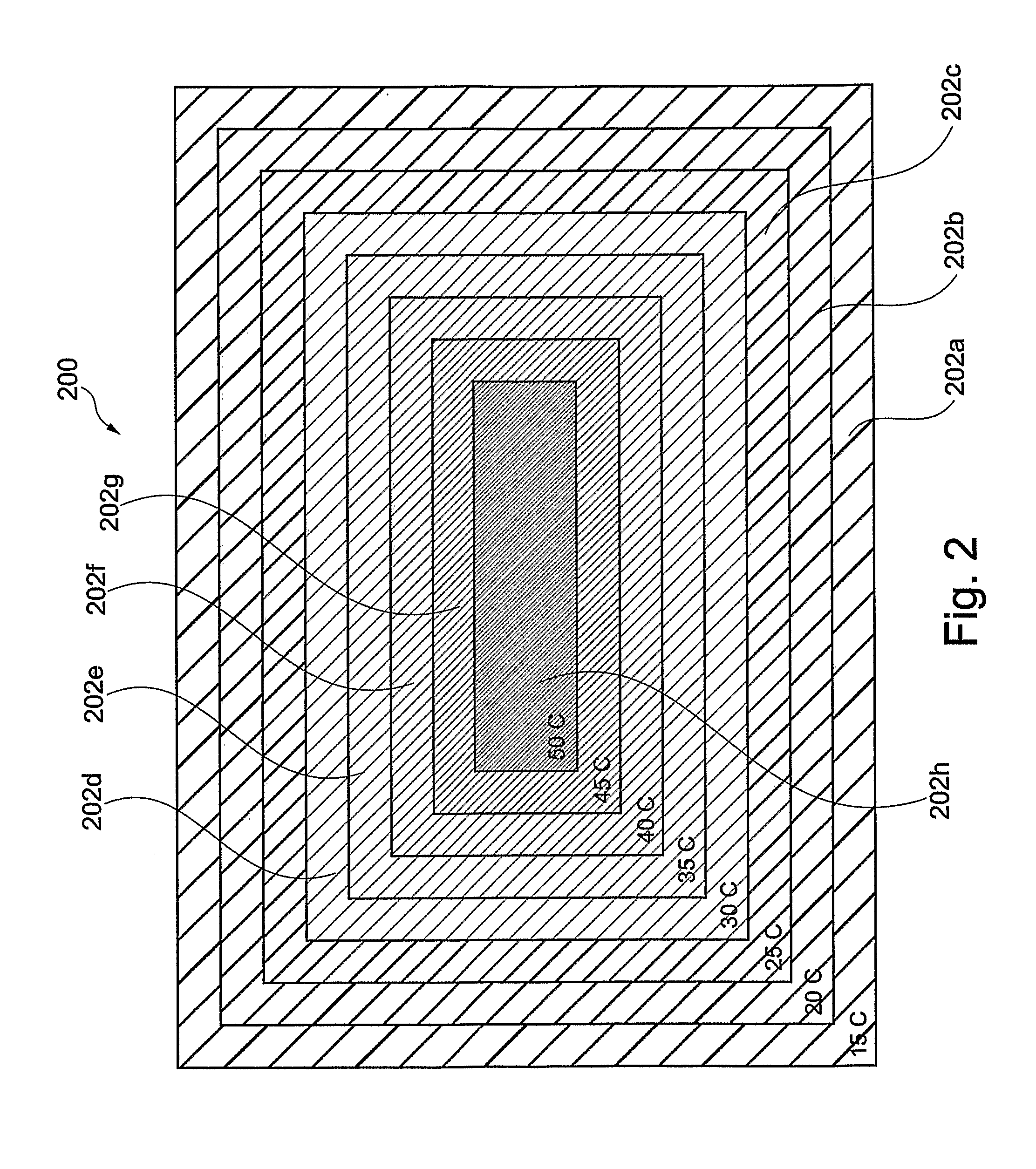

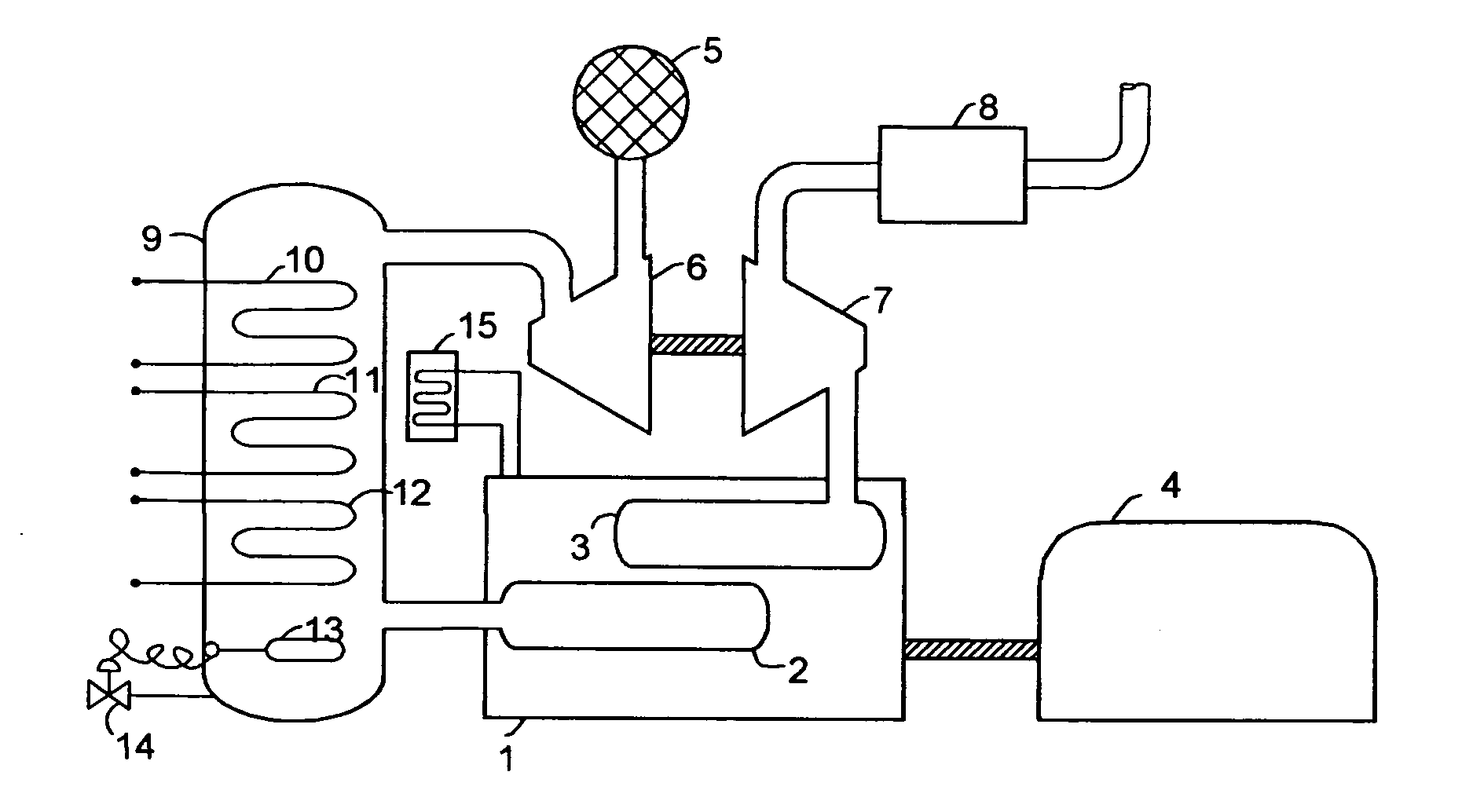

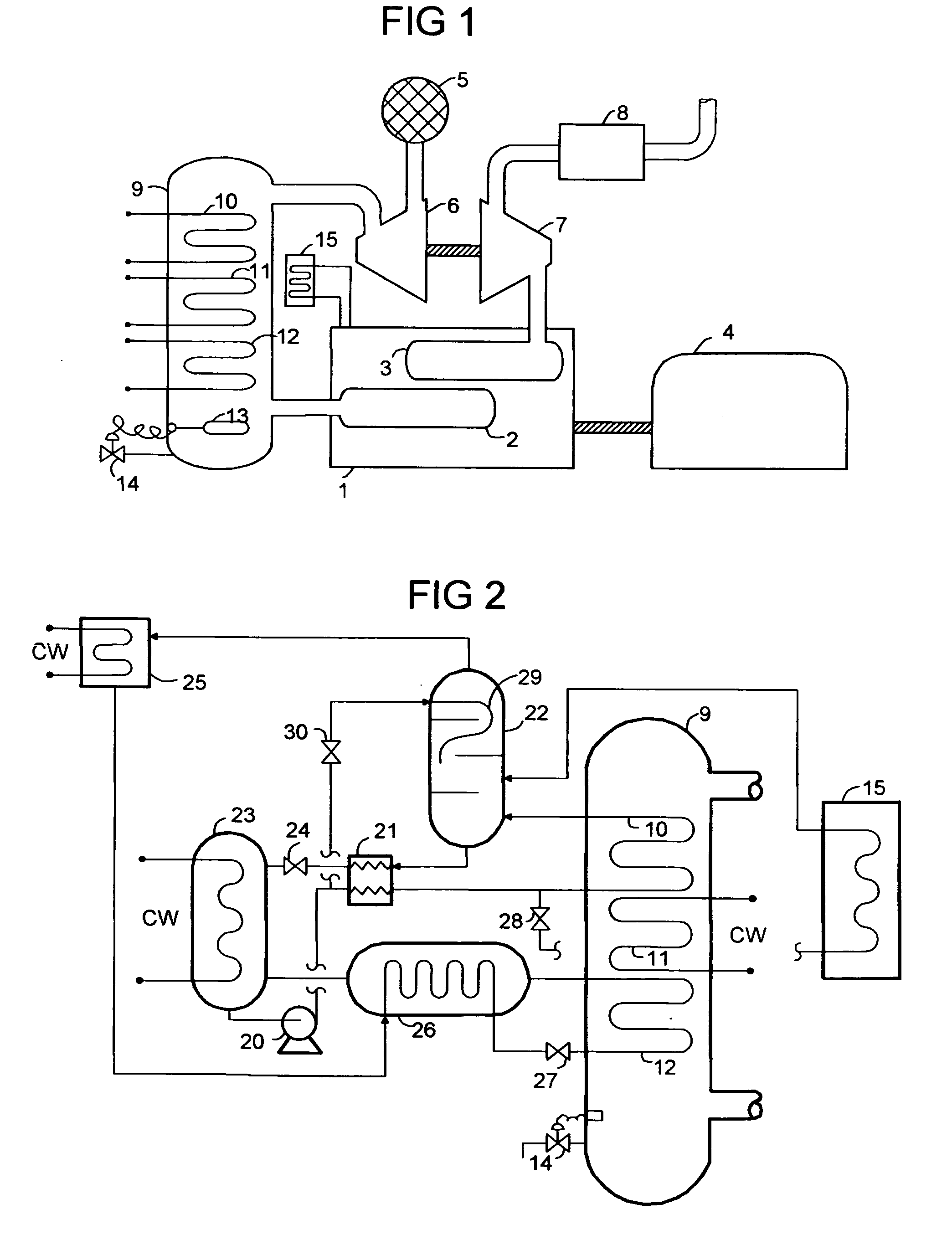

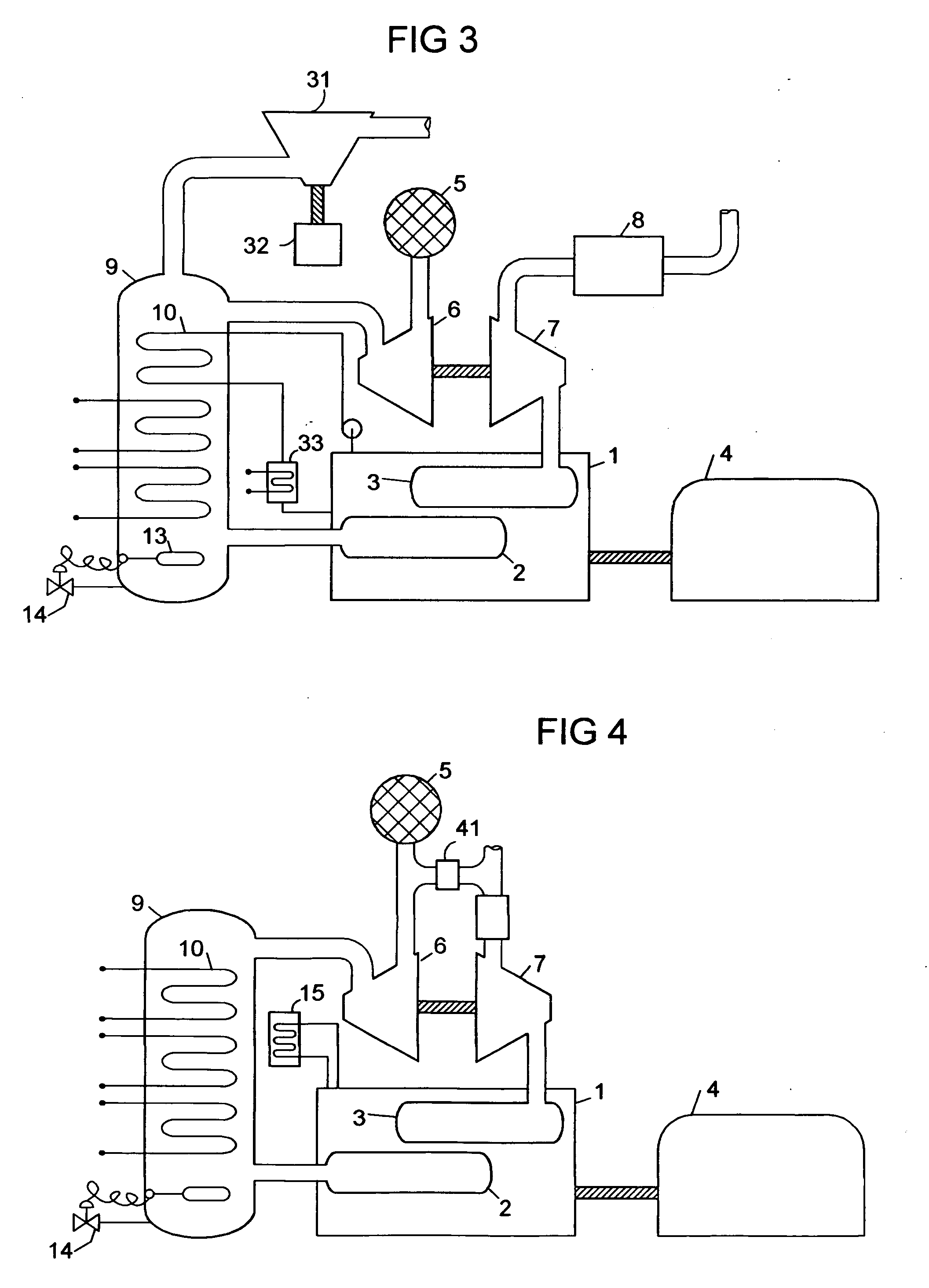

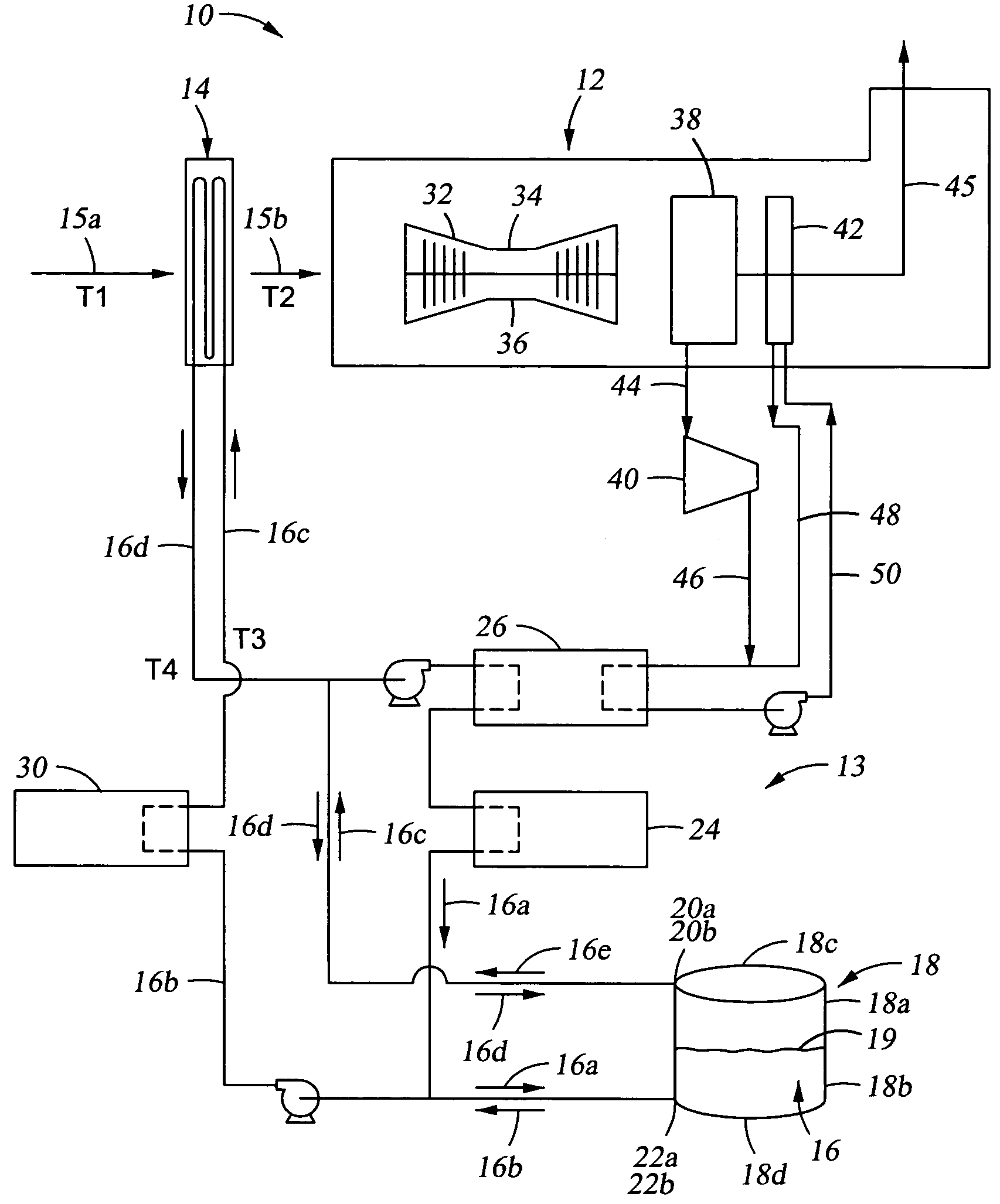

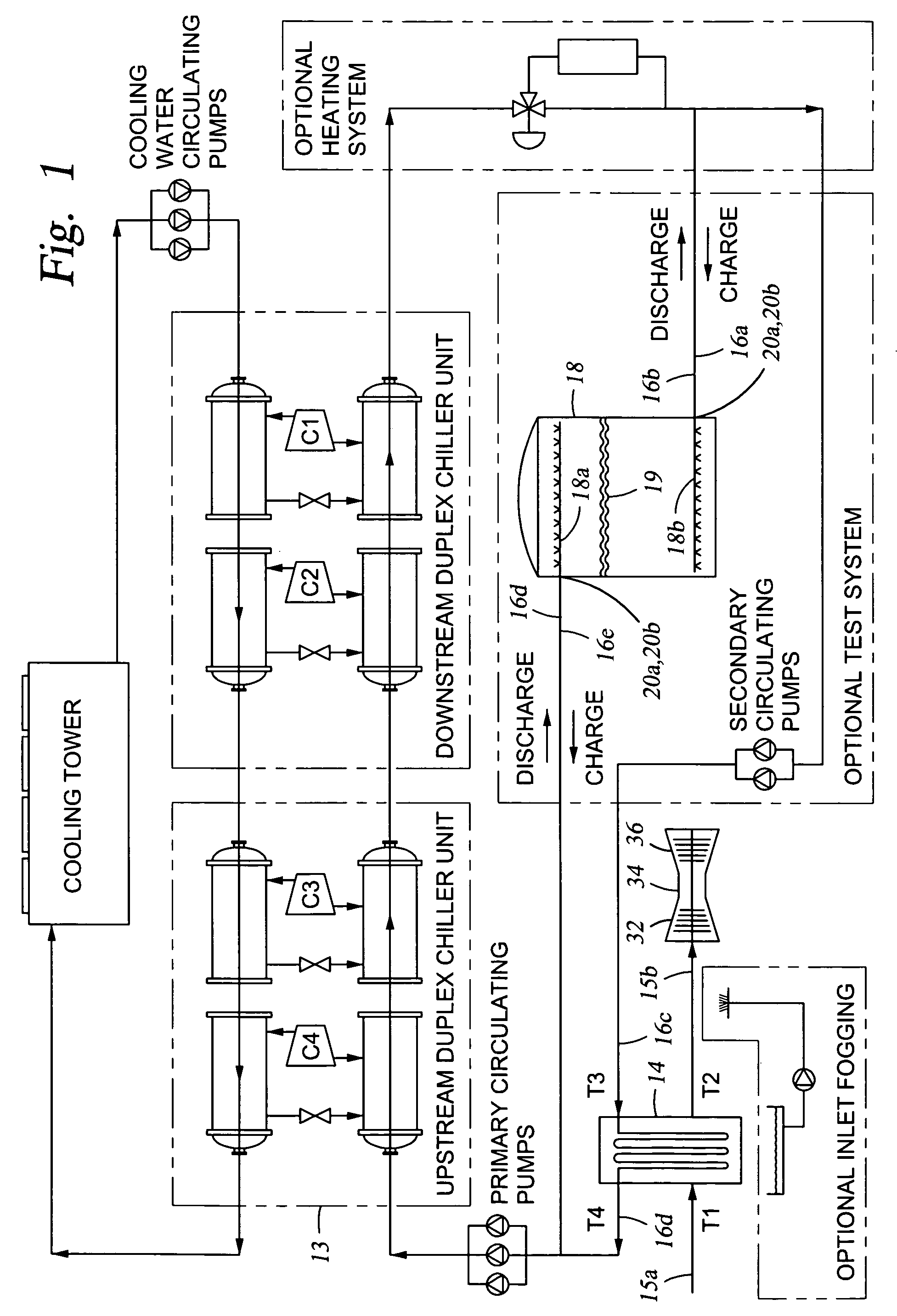

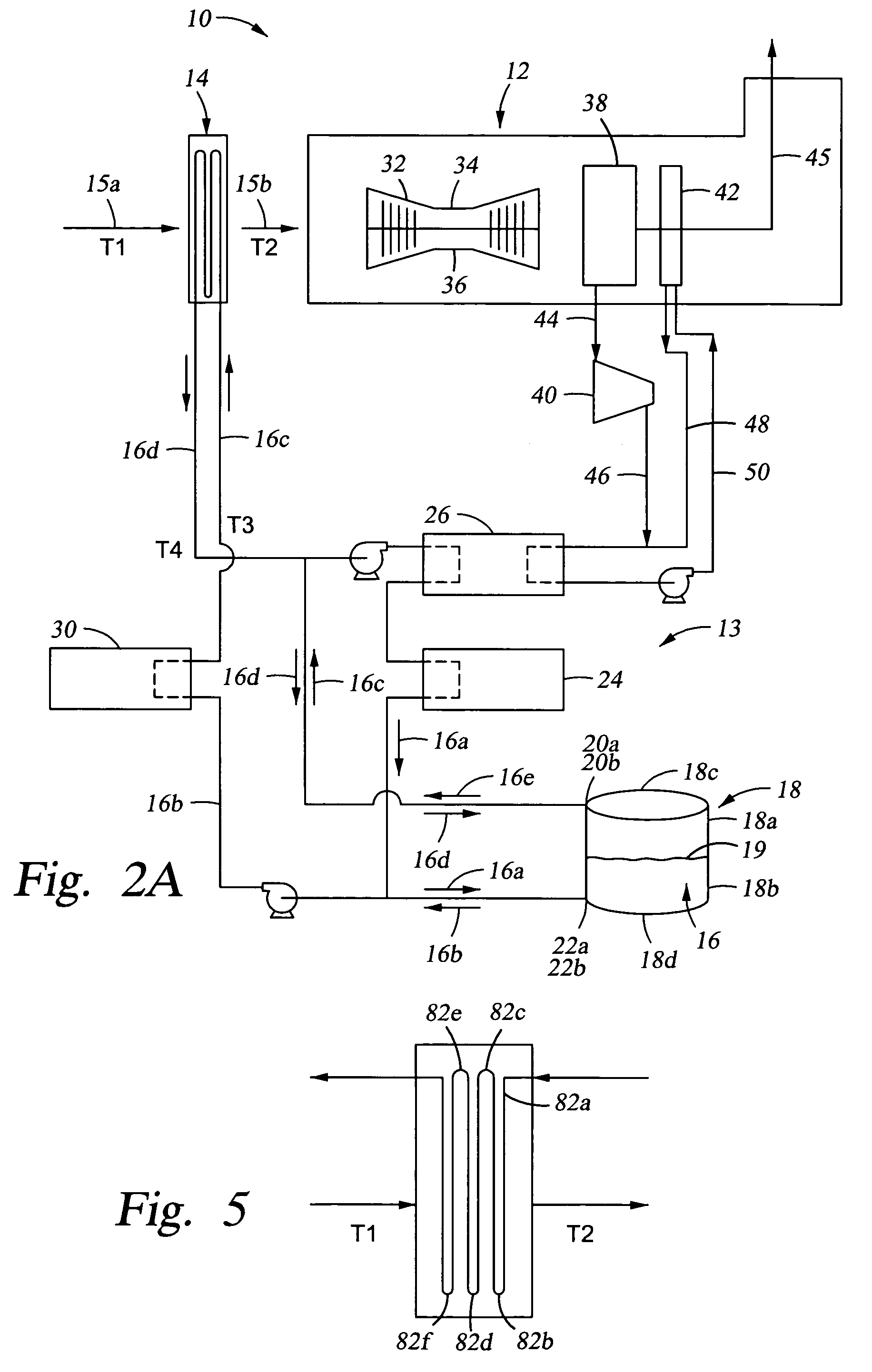

Charge air chiller

InactiveUS20090031999A1Maximum increase in energy efficiencyIncrease boost pressureInternal combustion piston enginesNon-fuel substance addition to fuelTurbochargerInlet valve

A system for chilling the pressurized charge air to a reciprocating engine is disclosed wherein the chilling is provided by a thermally activated refrigeration cycle powered by waste heat from the engine system. This reduces the required compression power, and also retards knock, making higher compression ratios possible. The chilling system is designed to minimize the amount of chilling required, and also to enable use of compression heat to power the chiller. The disclosed improvement also accommodates exhaust gas recirculation, plus providing activation heat from the exhaust gas, plus Miller cycle timing of the intake valves. Referring to FIG. 1, the charge air from turbocharger 5 is cooled in three stages: heat recovery stage 10; ambient-cooled stage 11; and chilling stage 12. Condensed moisture is removed from the charge air by valve 14 before the charge is supplied to inlet manifold 2.

Owner:ERICKSON DONALD CHARLES

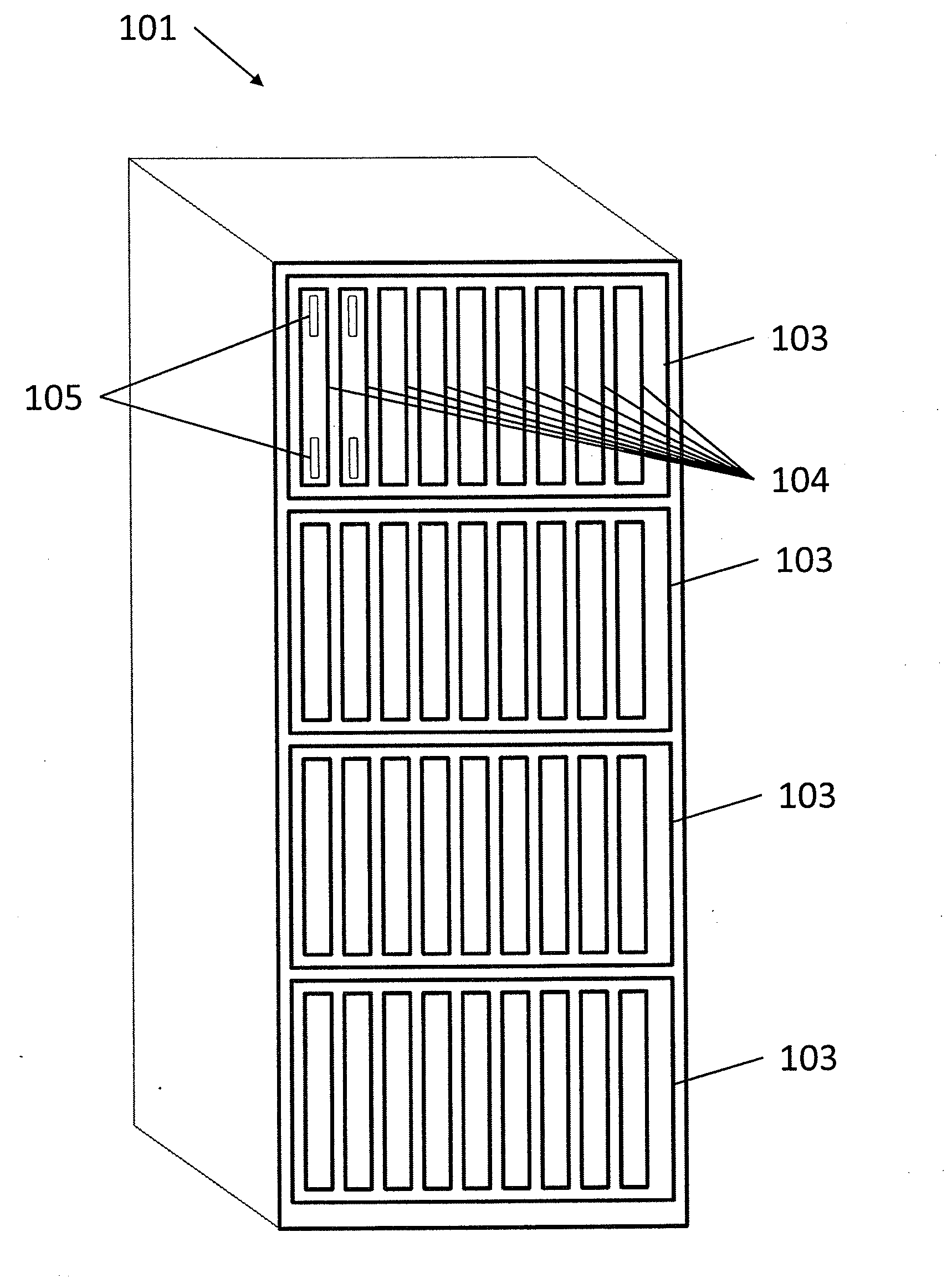

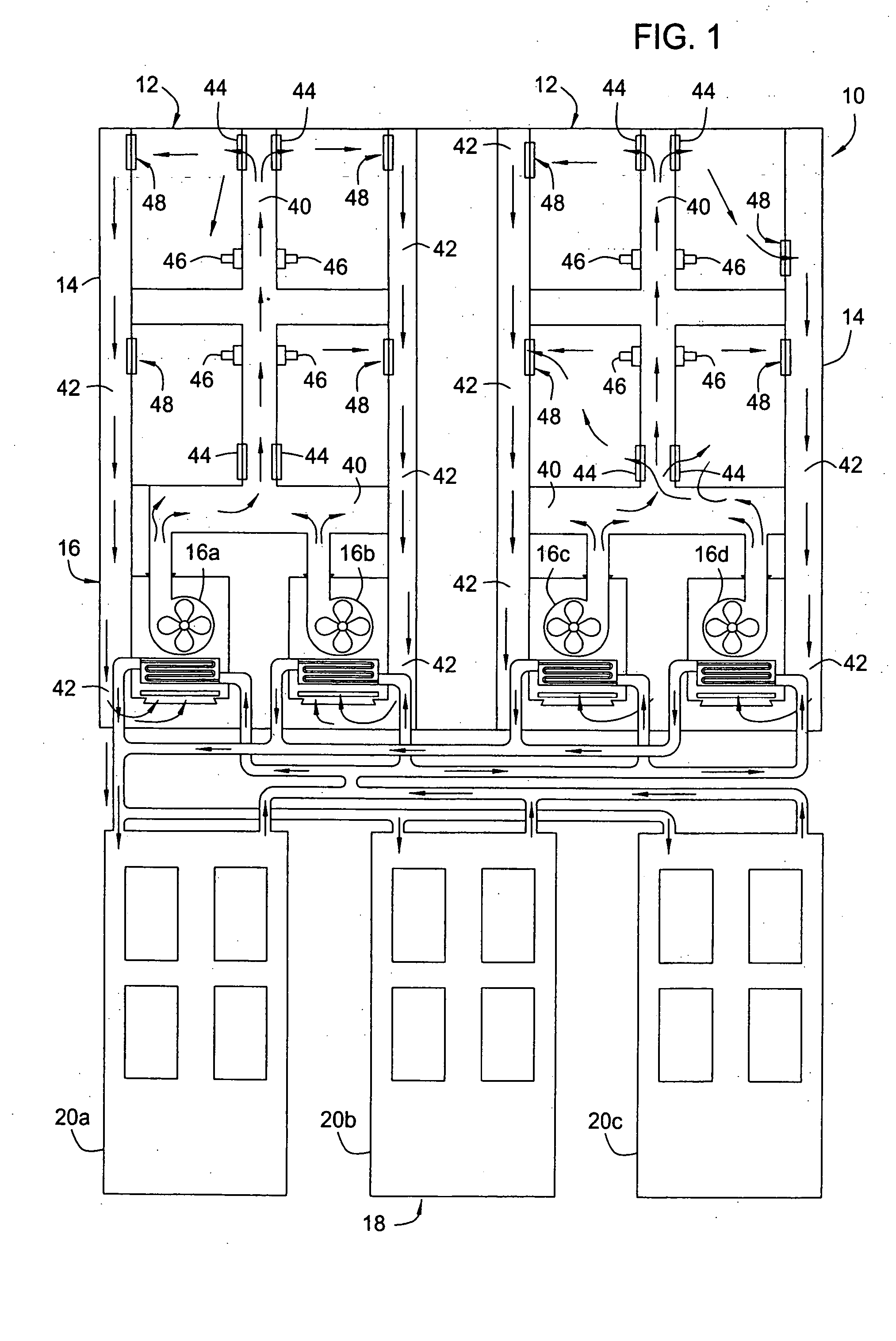

Liquid-Based Cooling System For Data Centers Having Proportional Flow Control Device

InactiveUS20110240281A1Efficient use ofMaximize engine efficiencyTemperature control using digital meansDigital data processing detailsProportional controlAdsorption chiller

A liquid-based cooling system provides a method of supplying a heated coolant fluid at a relatively constant temperature and pressure to one or more heat driven engines, such as adsorption chillers or heat pumps, by utilizing a proportional flow control device in association with each of a plurality of heat-producing electronic components to optimize the output of a plurality of liquid-cooled cold plates operatively mounted on such plurality of heat-producing electronic components. The proportional flow control devices may be electro-mechanical or solid state proportional control valves for water flow control. The proportion flow control devices are operatively connected to be actuated based upon the electrical signals typically generated to control the variable cooling fans of the electronic components.

Owner:INDAL IDEA PARTNERS

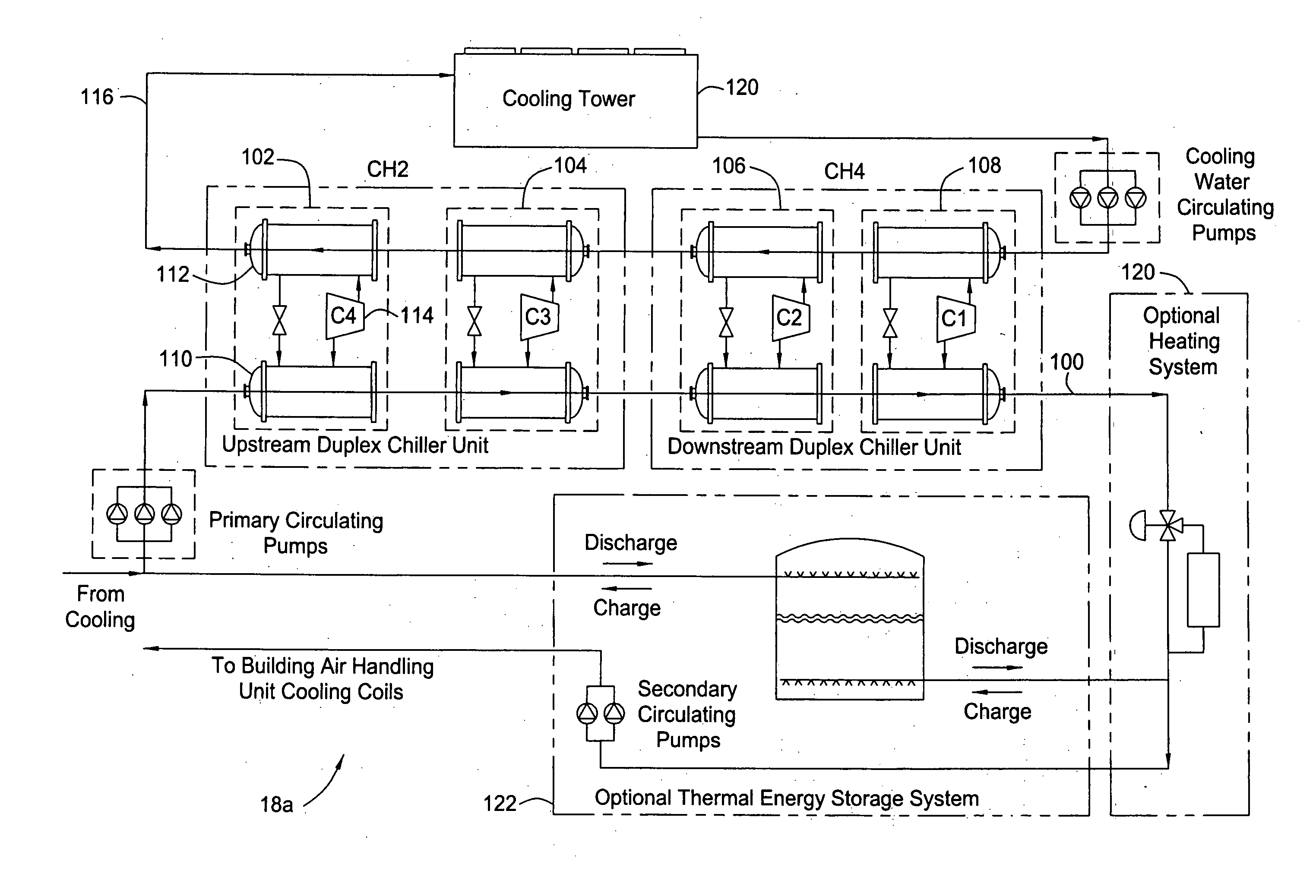

Packaged chilling systems for building air conditioning and process cooling

InactiveUS20050103032A1Domestic cooling apparatusClimate change adaptationChilled waterHandling system

Disclosed is a packaged chilling system for providing chilled water to an air conditioning system for a building that includes: a duct system; an air handling system; and a water chilling system; wherein: the duct system is in operable communication with a building that has a plurality of rooms, at least one of the rooms having a sensor for detecting the room air temperature in the room, the duct system comprising at least one supply duct for directing low temperature air from the air handling system to the building and at least one return duct for directing high temperature air from the building to the air handling system; the air handling system includes a plurality of air handling units, each air handling unit comprising an air inlet for receiving high temperature air from the building, a cooling coil that includes at least one conduit through which chilled water flows, the cooling coil having multiple passes and positioned for heat transfer contact with the high temperature air, and a fan for increasing the velocity of air in the air handling unit; the water chilling system is installed at a location proximate the building, and is operably connected to the air handling system; and the water chilling system includes a moveable support structure comprising a support base on which a plurality of water chilling system components are affixed, the components including at least one water chiller for lowering the temperature of water from a high temperature to a low temperature. This packaged chilling system may also be used to provide chilled water to industrial processes such as chemical plants, automotive plants, textile mills, paper mills, computer cooling, and factory air-conditioning.

Owner:TAS LTD

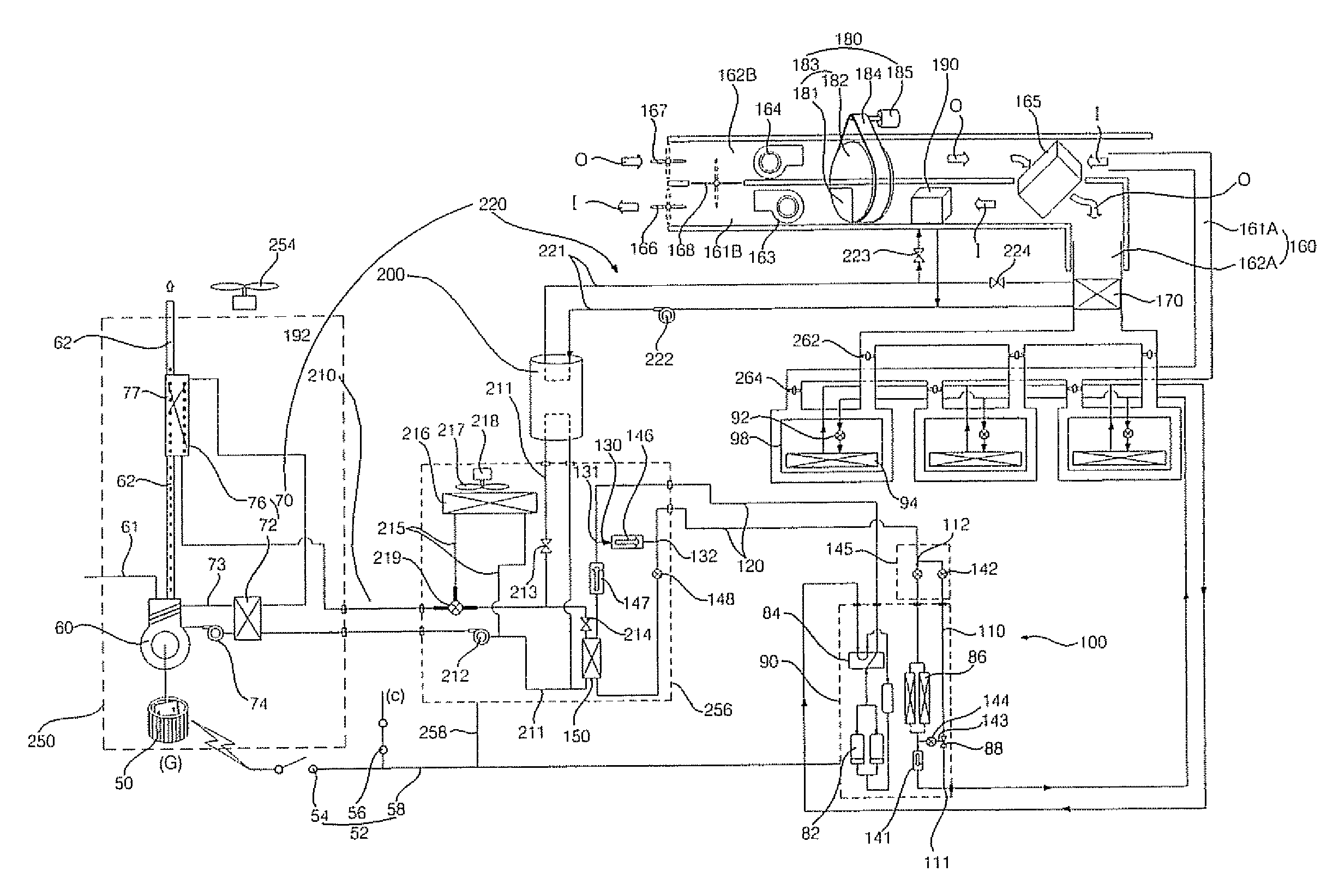

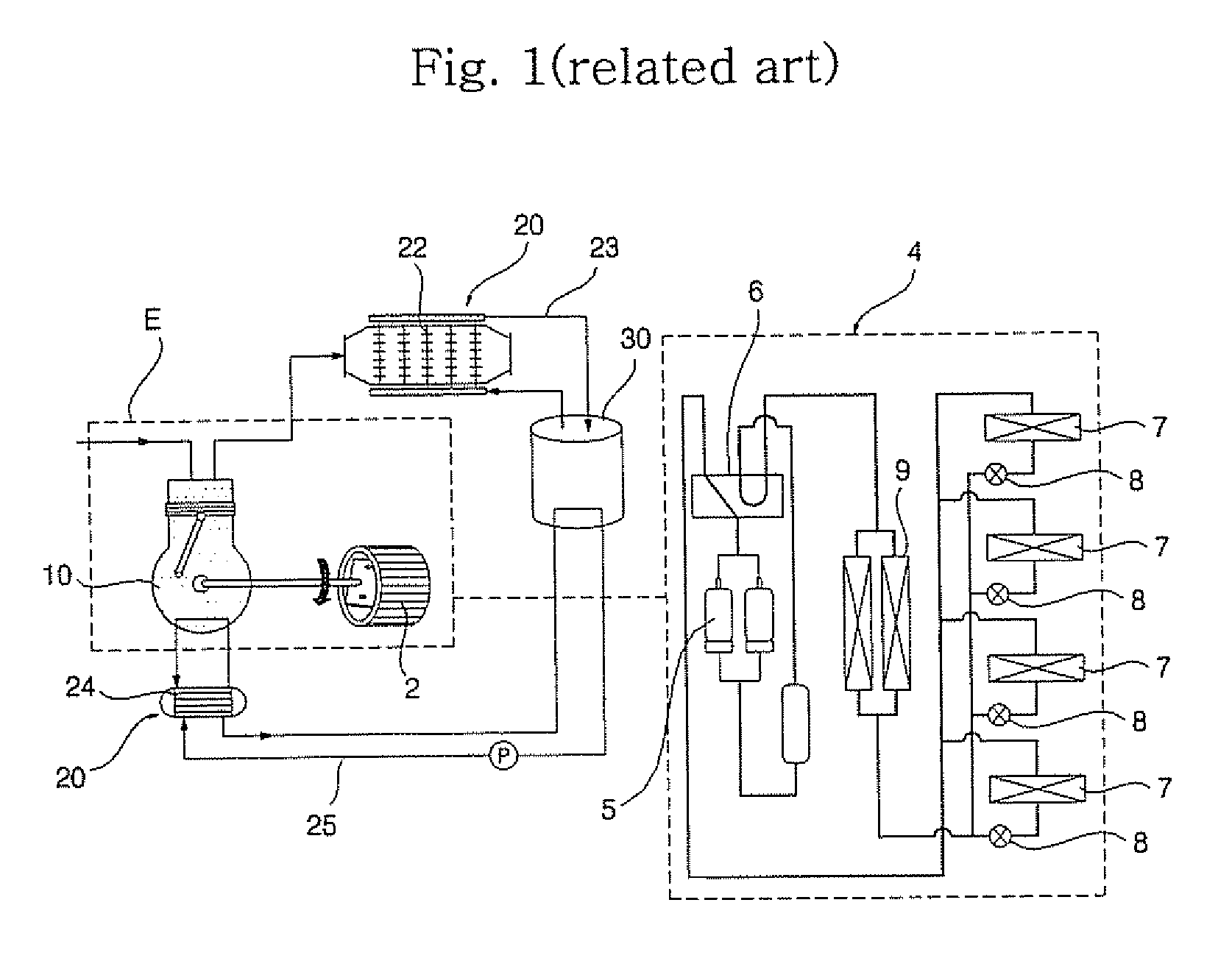

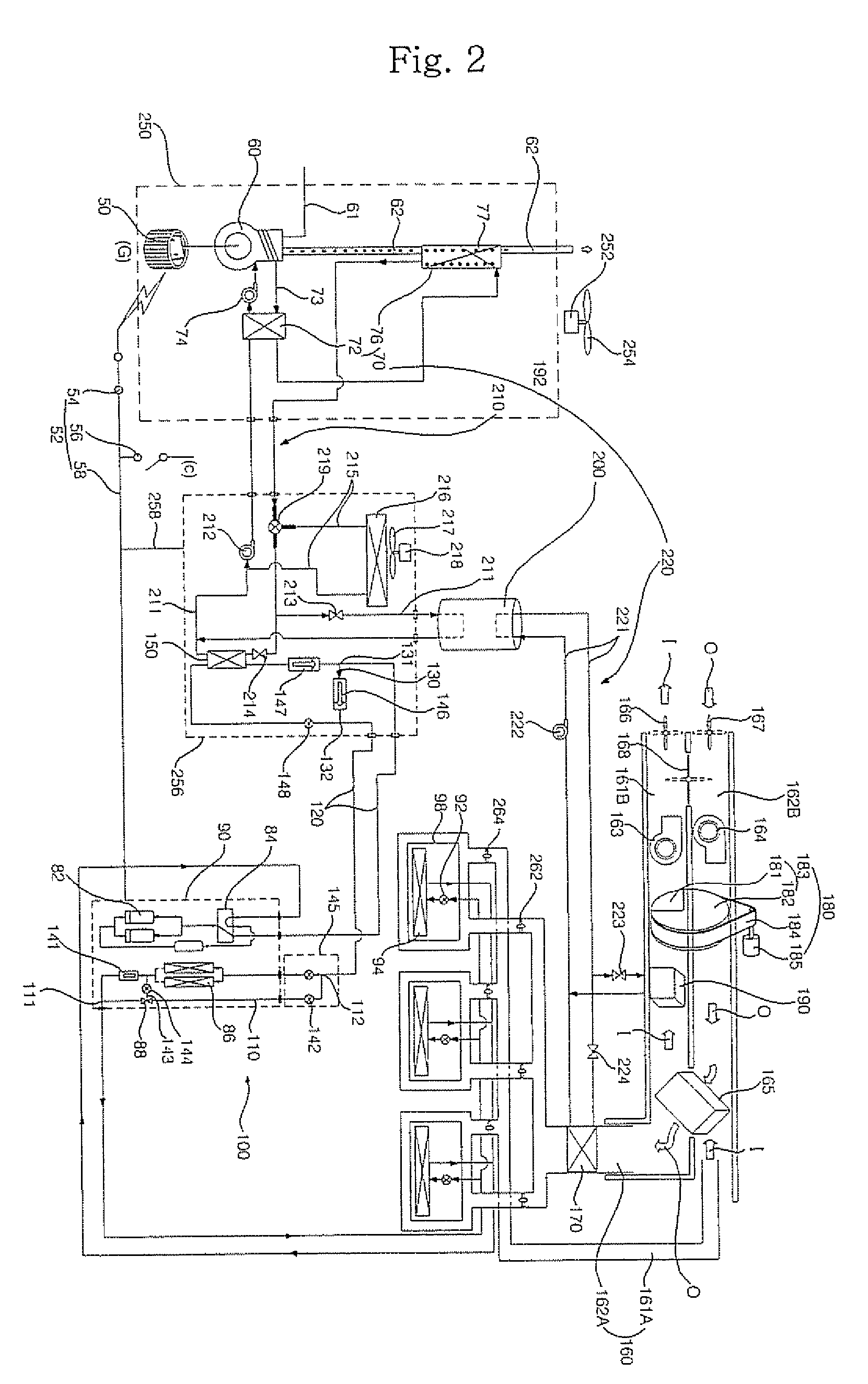

Cogeneration system

InactiveUS20060283967A1Maximum energy efficiencyImprove the heating effectMechanical apparatusHeat pumpsCogenerationProcess engineering

A cogeneration system is disclosed which includes a generator, a drive source for driving the generator, a waste heat supplying heat exchanger for enhancing the heating performance of a heat pump type air conditioner, an auxiliary heating heat exchanger using the waste heat of the drive source as a heat source for heating indoor air, and a regeneration heat supplying heat exchanger using the waste heat of the drive source as a heat source for regenerating a dehumidifier. The cogeneration system can use the waste heat of the drive source for diverse purposes in accordance with the indoor environment, and can have a maximal efficiency.

Owner:LG ELECTRONICS INC

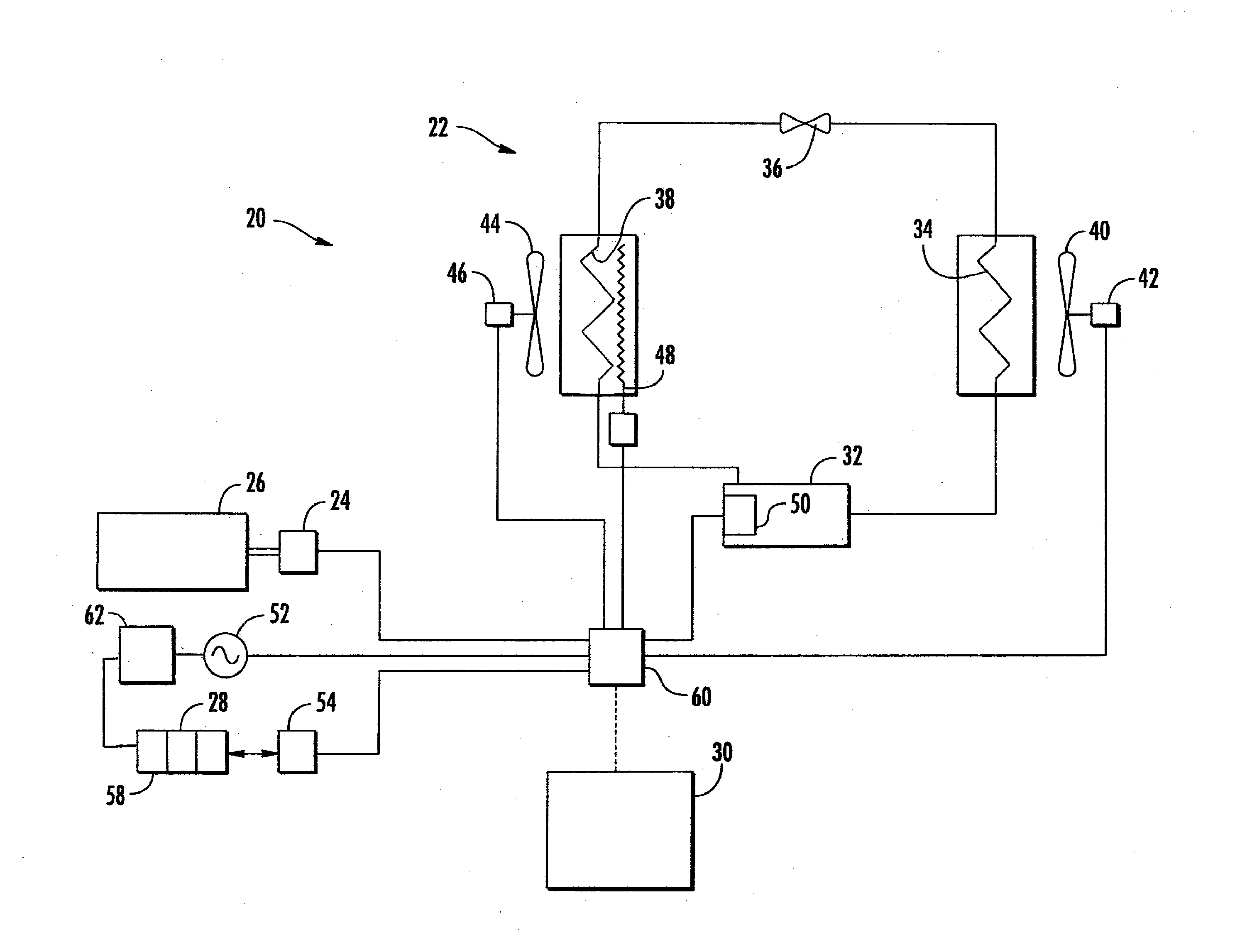

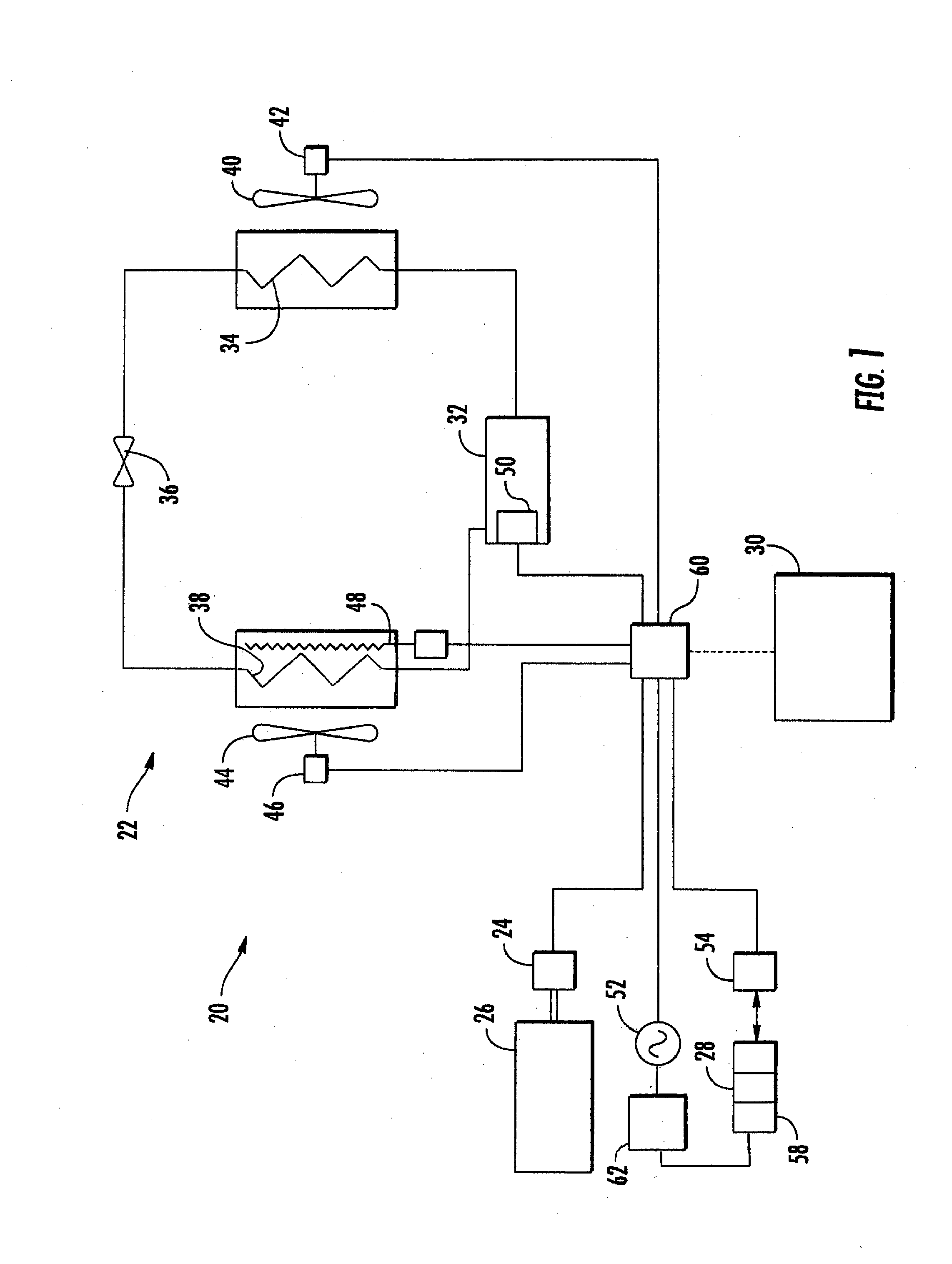

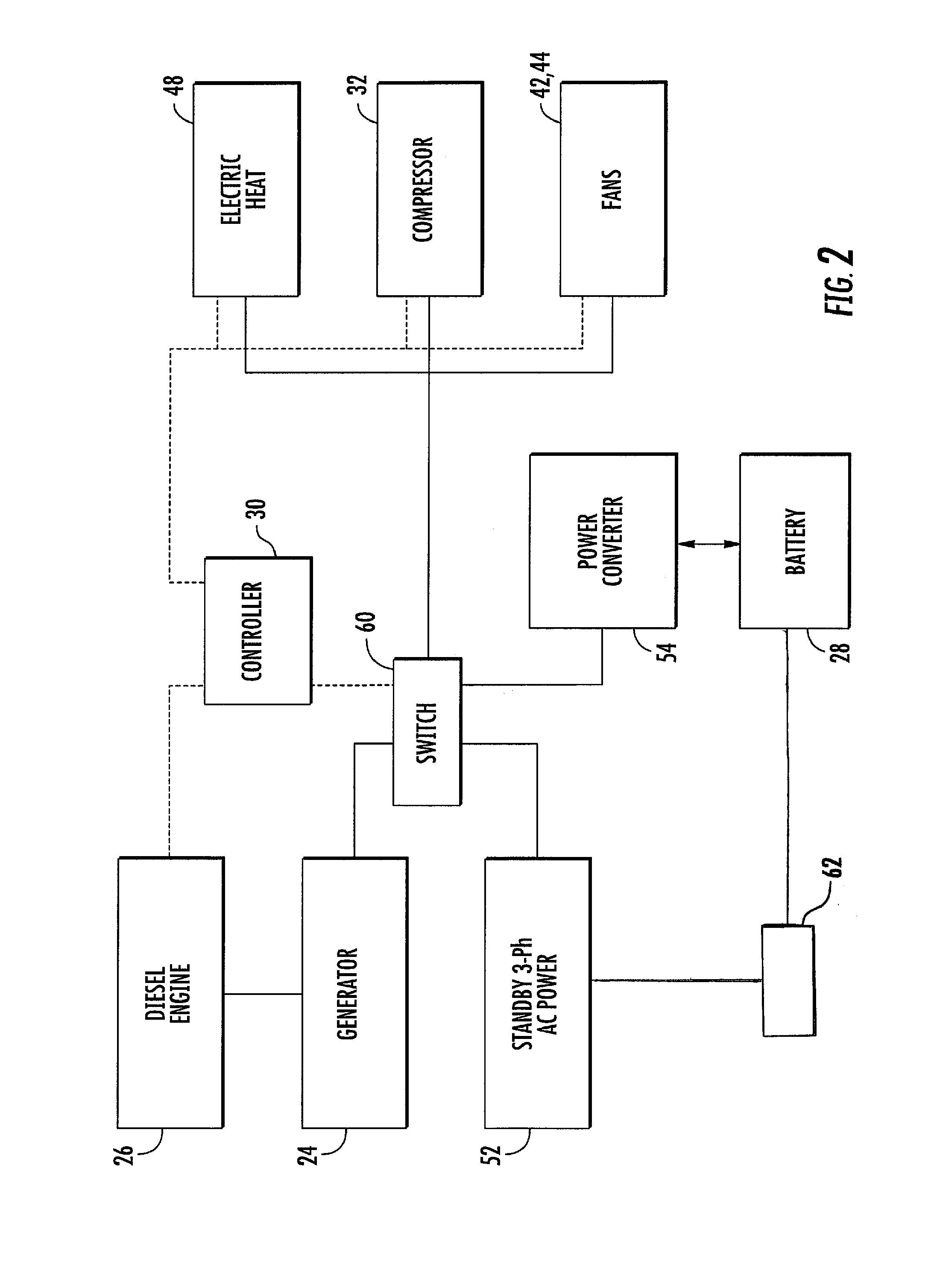

Transport Refrigeration System And Method For Operating

ActiveUS20140026599A1Reduce fuel consumptionReduce noiseAir-treating devicesDomestic cooling apparatusTemperature controlRefrigerant

A refrigeration system having a refrigeration unit (22) for providing temperature conditioned air to a temperature controlled space, an engine (26) and an electric generation device (24) driven by the engine, is provided with a battery system (28) for supplying electric power. A method of operating the transport refrigeration includes, during a high cooling demand mode, operating the engine (26) to drive the electric generation device (24) for supplying electric power and simultaneously employing the battery system (28) for supplying electric power to jointly power the plurality of power demand loads (50, 42, 46, 48) of the refrigerant unit.

Owner:CARRIER CORP

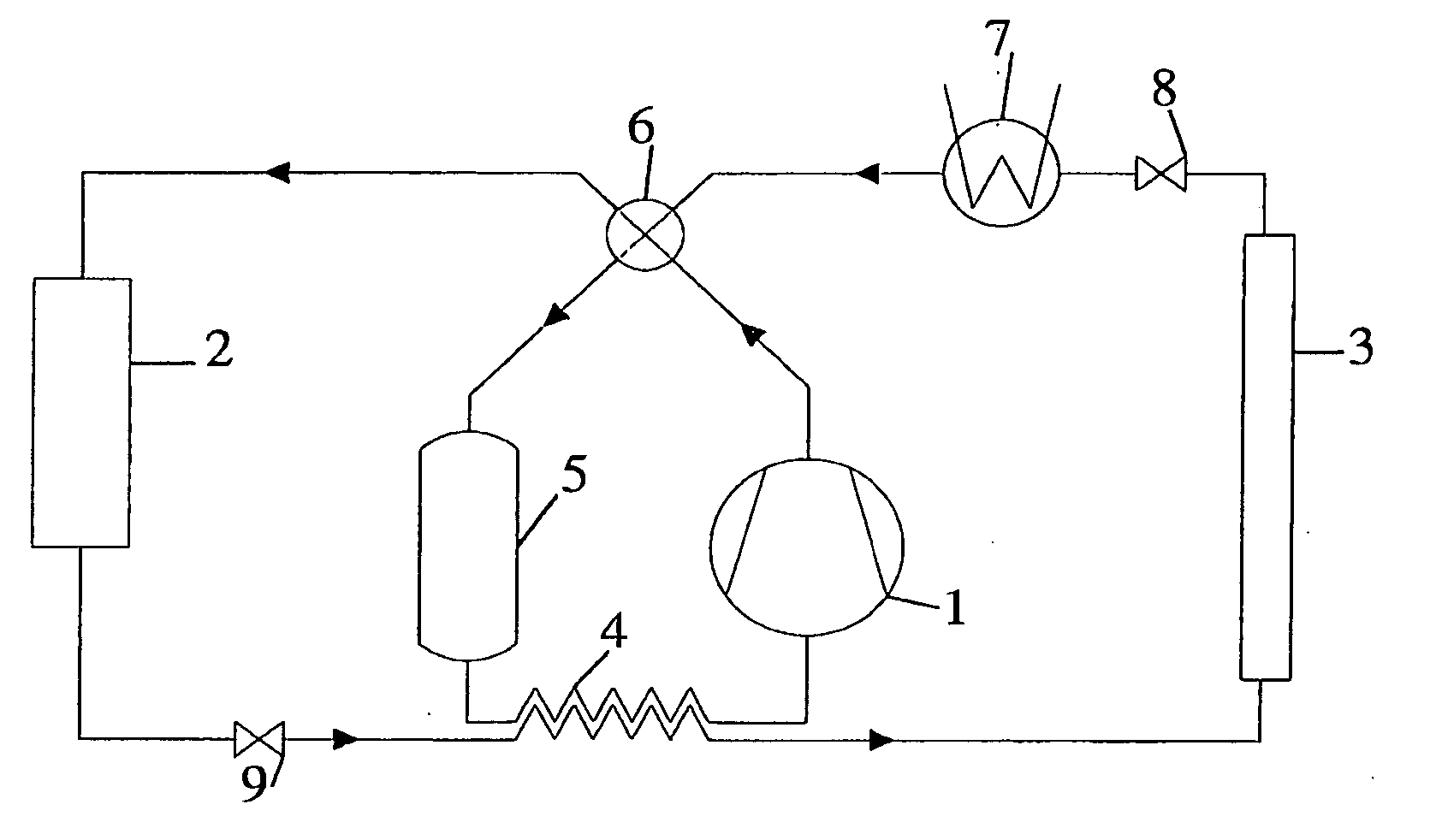

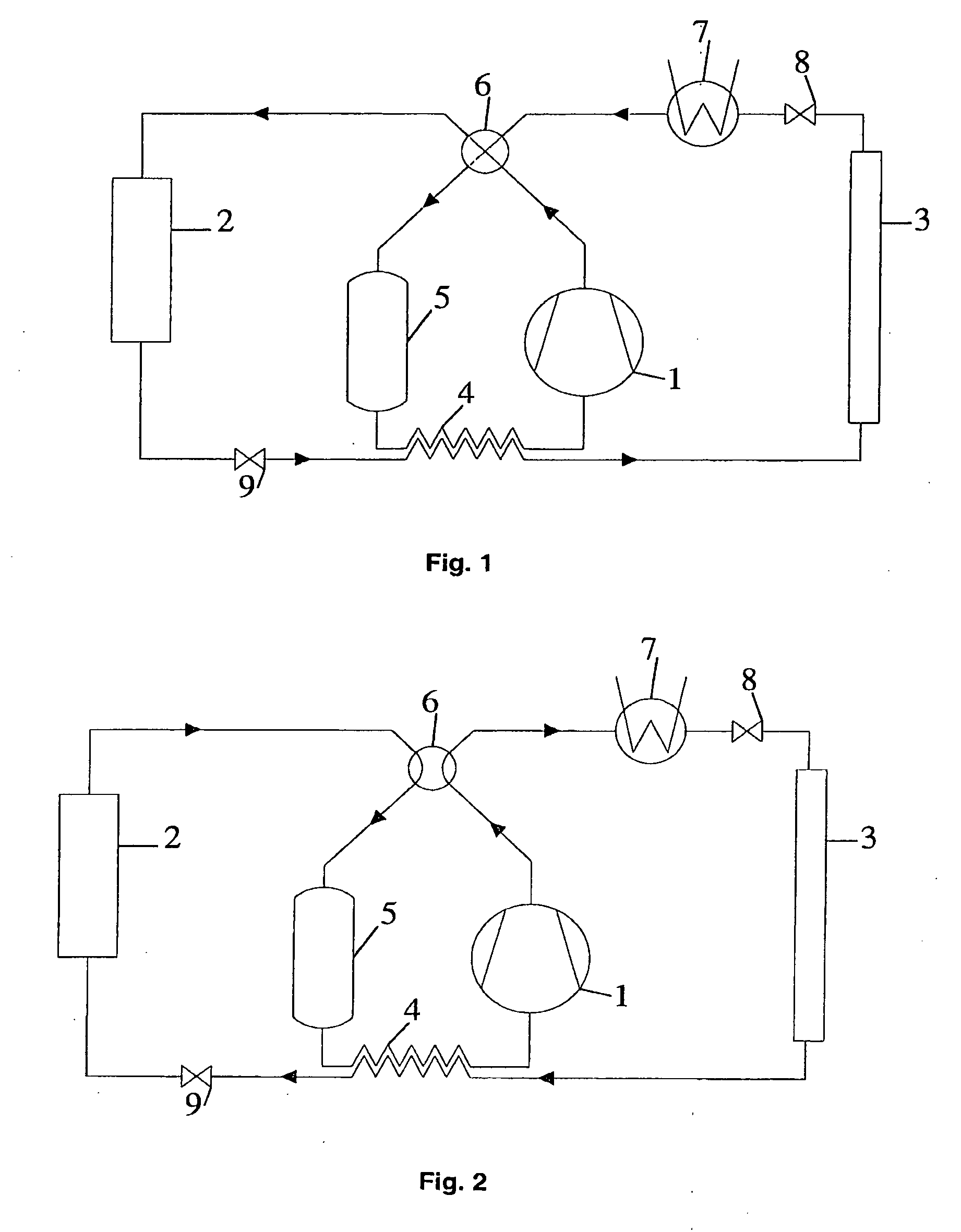

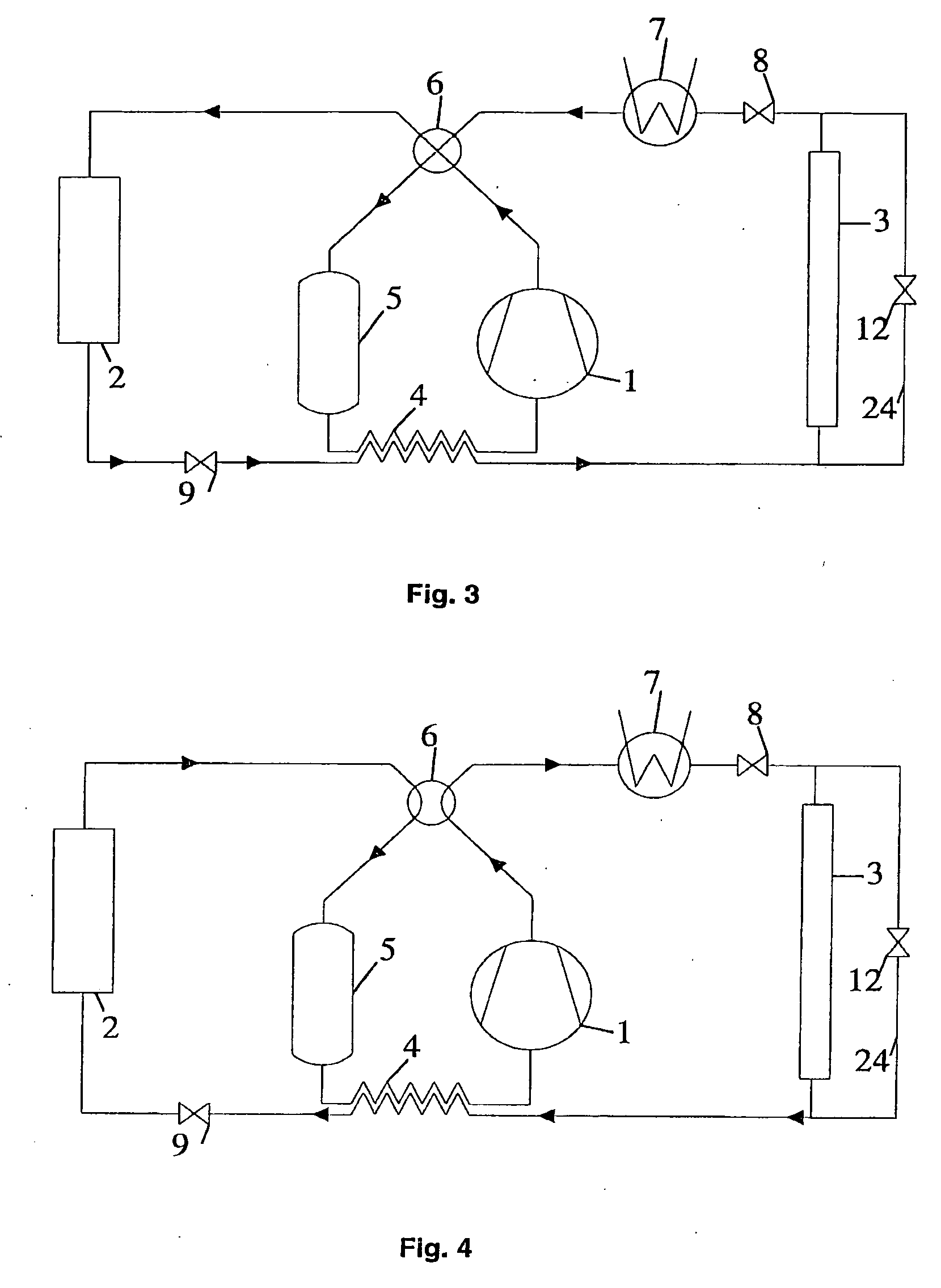

Vapor compression system for heating and cooling of vehicles

InactiveUS20050103487A1Heating fastReduce heat loadAir-treating devicesRailway heating/coolingEngineeringHeat pump

Reversible vapor compression system including a compressor (1), an interior heat exchanger (2), an expansion device (6) and an exterior heat exchanger (3) connected by means of conduits in an operable relationship to form an integral main circuit. A first means is provided in the main circuit between the compressor and the interior heat exchanger, and a second means is provided on the opposite side of the main circuit between the interior and exterior heat exchangers to enable reversing of the system from cooling mode to heat pump mode and vice versa.

Owner:SINVENT AS

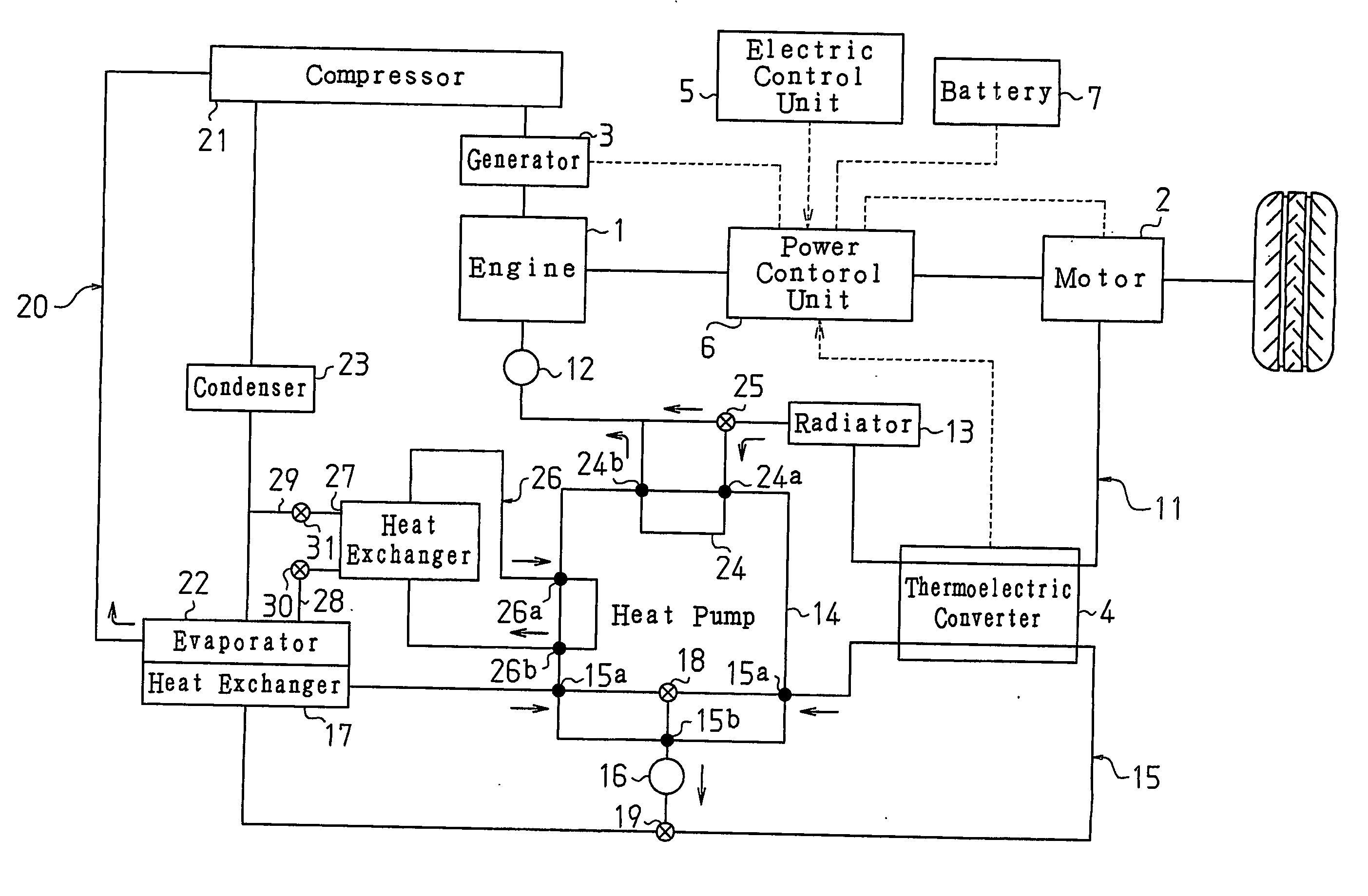

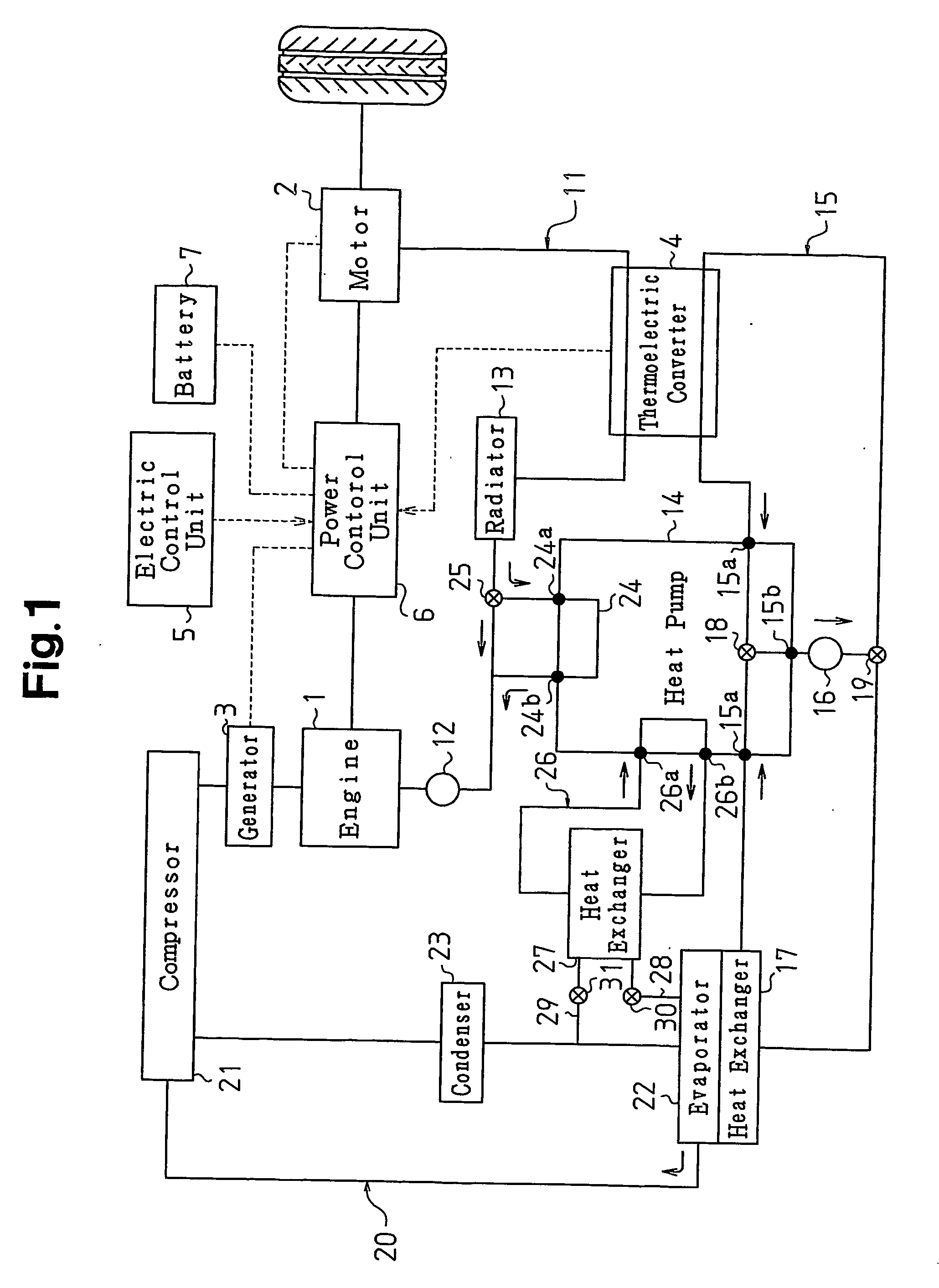

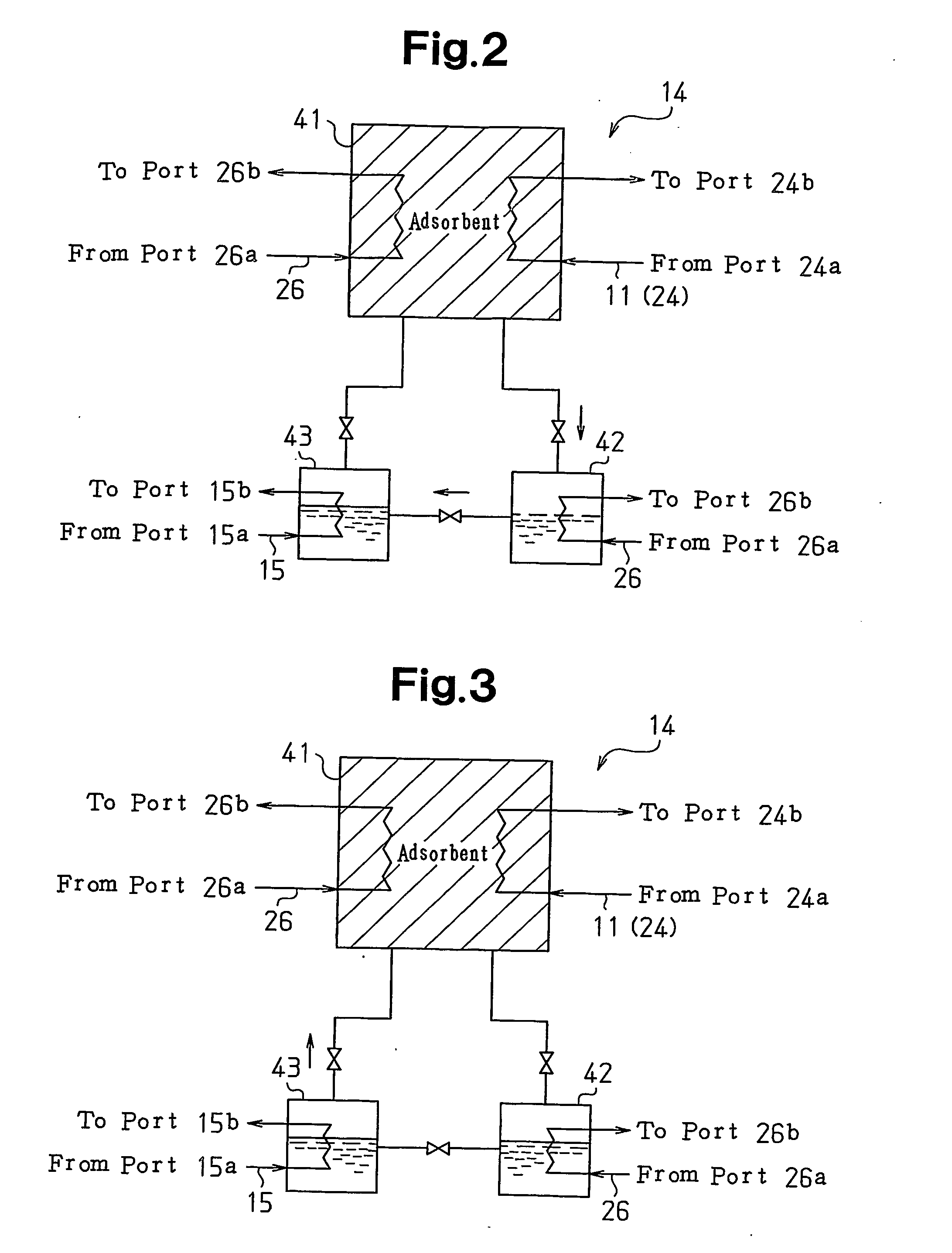

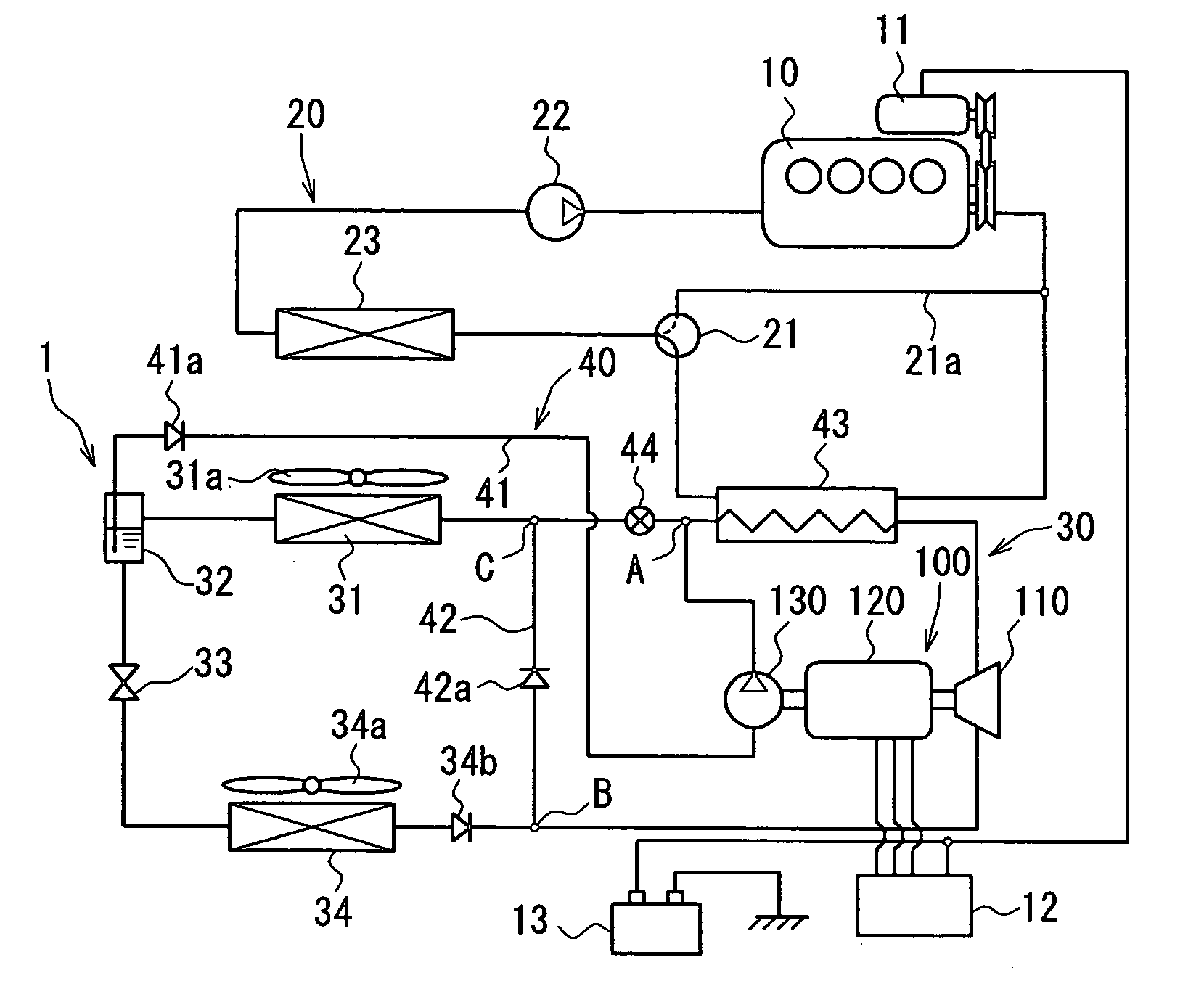

Energy recovery system

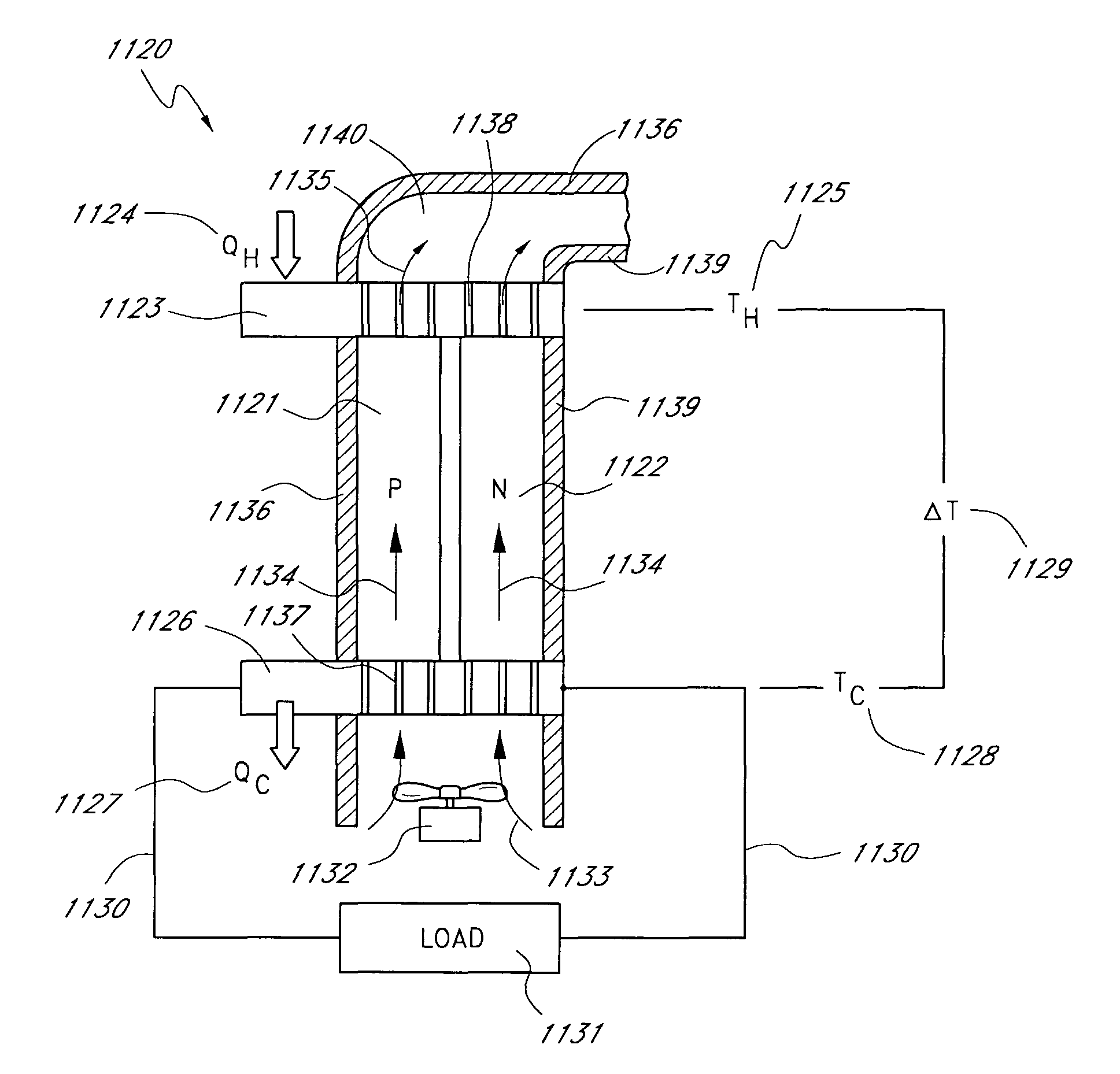

InactiveUS20050247336A1Improve energy efficiencyReliably generating electricityAir-treating devicesThermoelectric device with peltier/seeback effectElectricityEnergy recovery

An energy recovery system for hybrid automobile. The energy recovery system generates electricity by utilizing the temperature difference between a high temperature thermal medium and a low temperature thermal medium. As the high temperature thermal medium, engine coolant for cooling an engine is used. As the low temperature thermal medium, pump refrigerant for cooling by a heat pump is used. The heat pump maintains the pump refrigerant at a low temperature by using heat from the engine coolant. Therefore, while electricity is reliably generated at a thermoelectric converter, energy is efficiently used for cooling the pump refrigerant.

Owner:TOYOTA JIDOSHA KK

Method of chilling inlet air for gas turbines

InactiveUS7343746B2Lower the average temperature of the chilling waterLower inlet temperatureClimate change adaptationEvaporators/condensersPower stationCooling coil

A method for cooling inlet air to a gas turbine is provided. For example, a method is described including passing inlet air through a cooling coil that includes an opening for receiving the inlet air and that is operably connected to a gas turbine power plant. The gas turbine power plant may include at least one gas turbine, and at least one gas turbine inlet which receives the inlet air. The method may further include passing circulating water through a water chiller at a first flow rate to reduce the temperature of the circulating water, the water chiller including a conduit through which the circulating water is capable of passing and passing the circulating water having the first flow rate through the cooling coil in an amount sufficient to lower the temperature of the inlet air. Additionally, the method may include reducing the flow rate of the circulating water passing through the water chiller, passing the circulating water through a water chiller at a second flow rate to reduce the temperature of the circulating water, the second flow rate being lower than the first flow rate, and passing the circulating water having the second flow rate through the cooling coil in an amount sufficient to lower the temperature of the inlet air.

Owner:TAS ENERGY +1

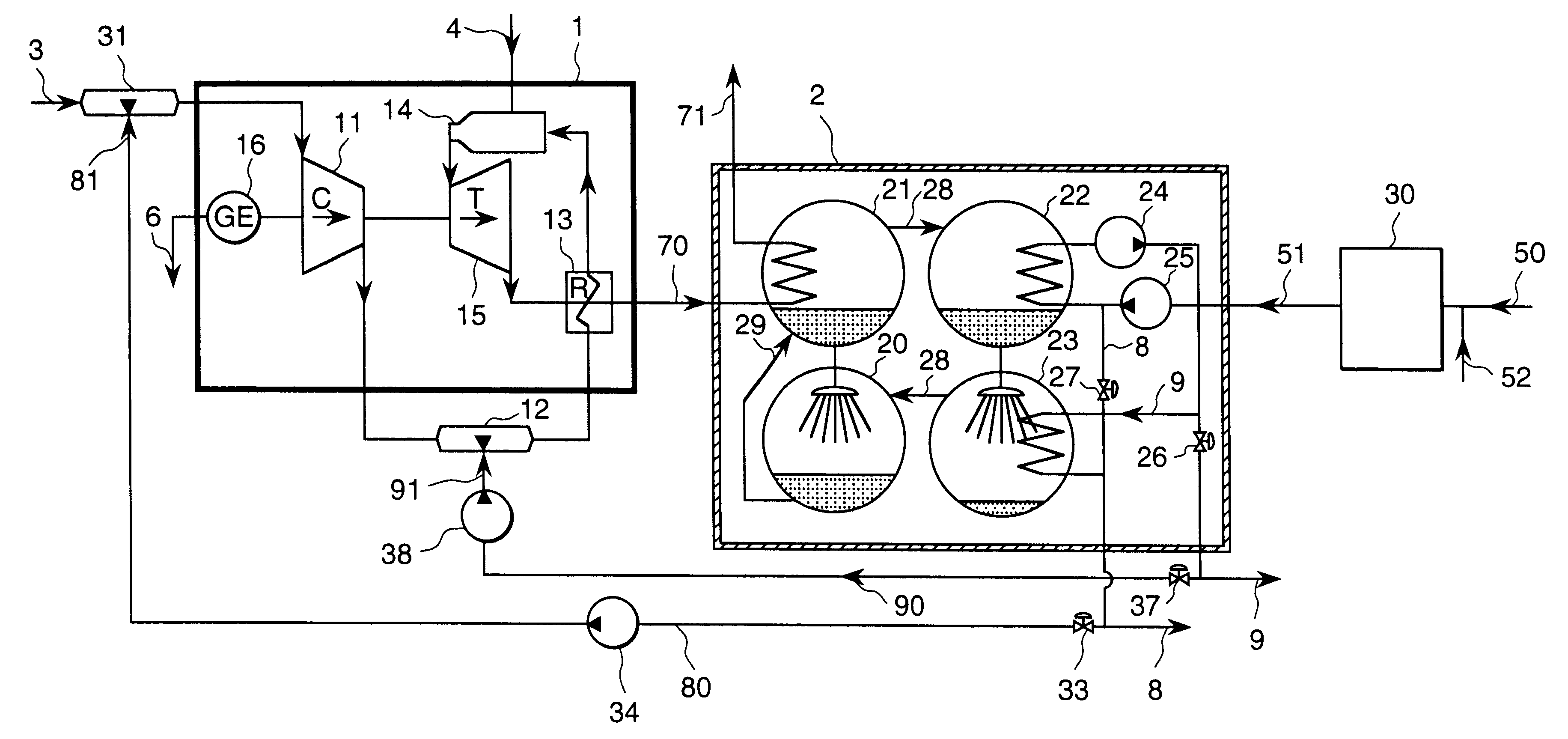

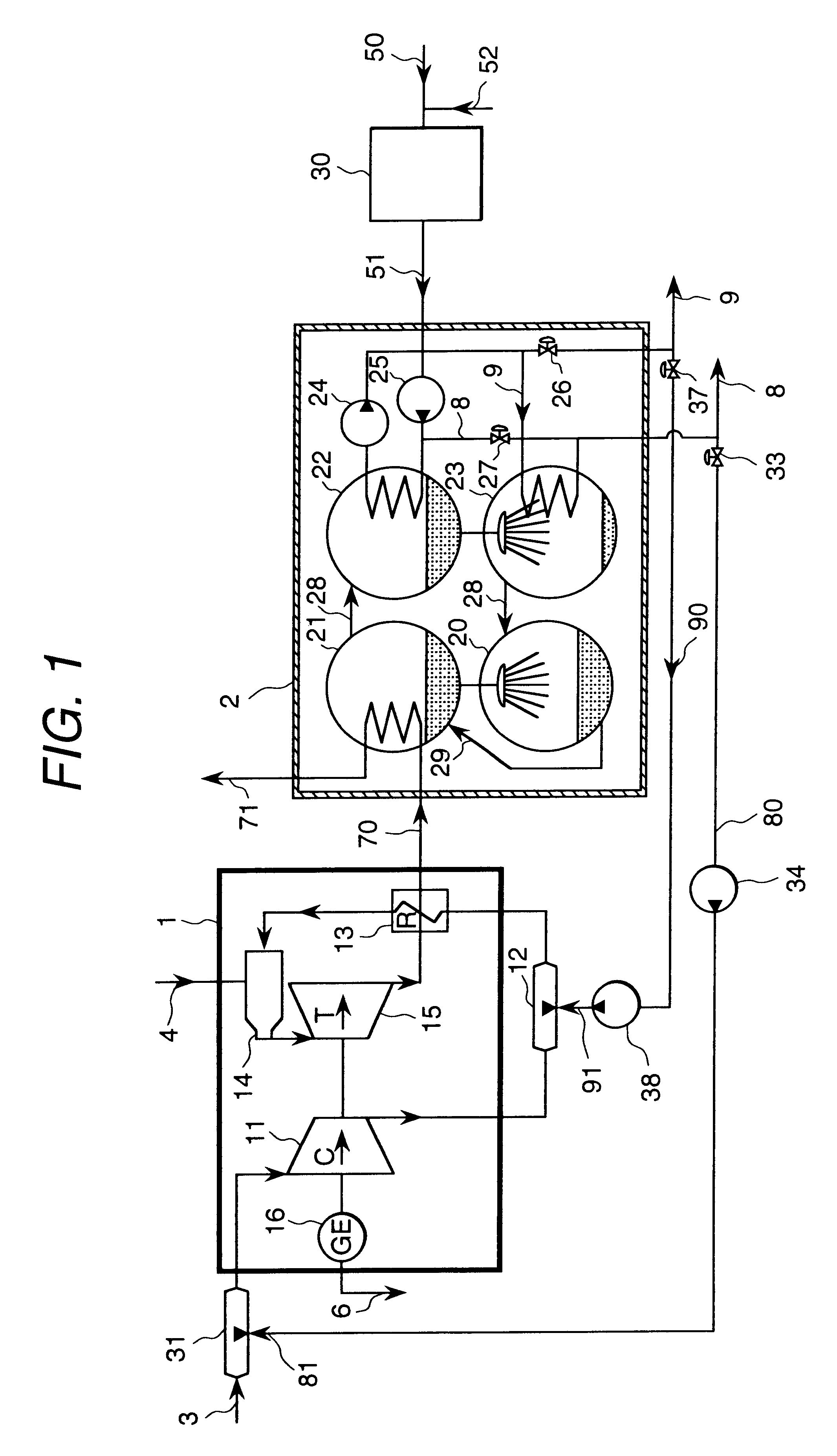

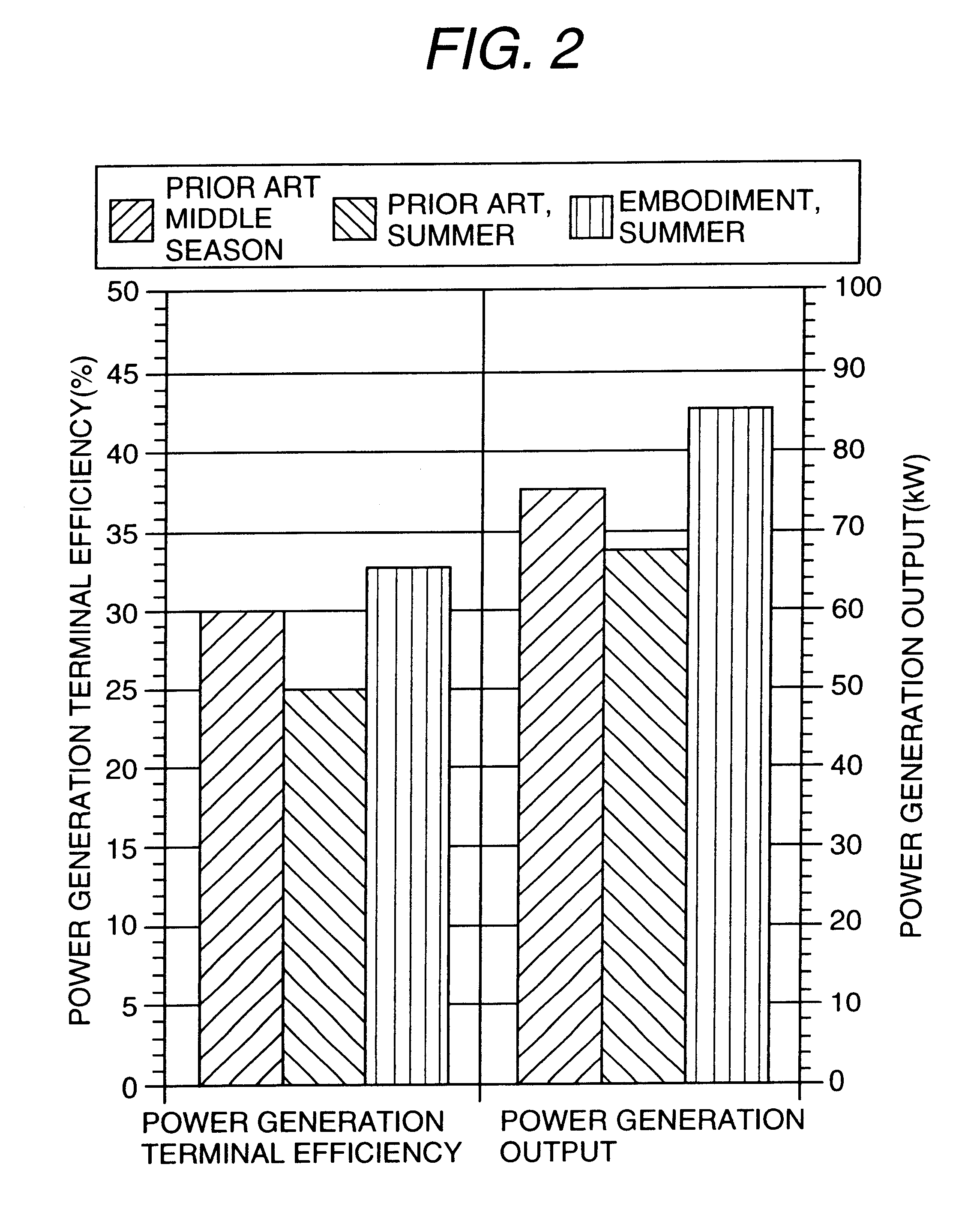

Heat and electric power supply system and operation method thereof

A heat and electric power supply system includes a regenerative gas turbine and an adsorption refrigerator recovering exhaust heat of exhaust gas from the gas turbine and is provided with inlet air cooling equipment including a spray device for spraying cold water from the adsorption refrigerator into an air-intake port of the regenerative gas turbine and a humidifier effecting humidification by hot water injection from the refrigerator into a compressor delivery port of the regenerative gas turbine. The cooling by cold water and humidification by hot water injection are effected according to operational conditions.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

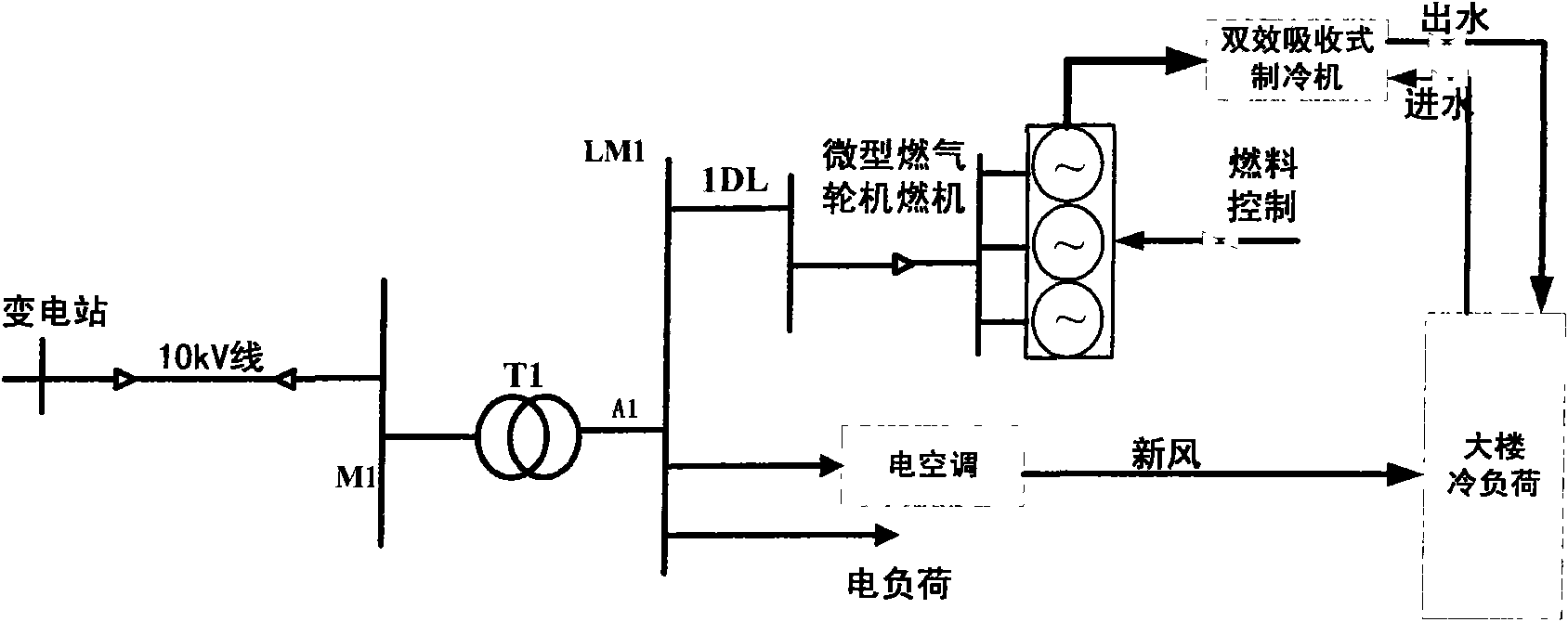

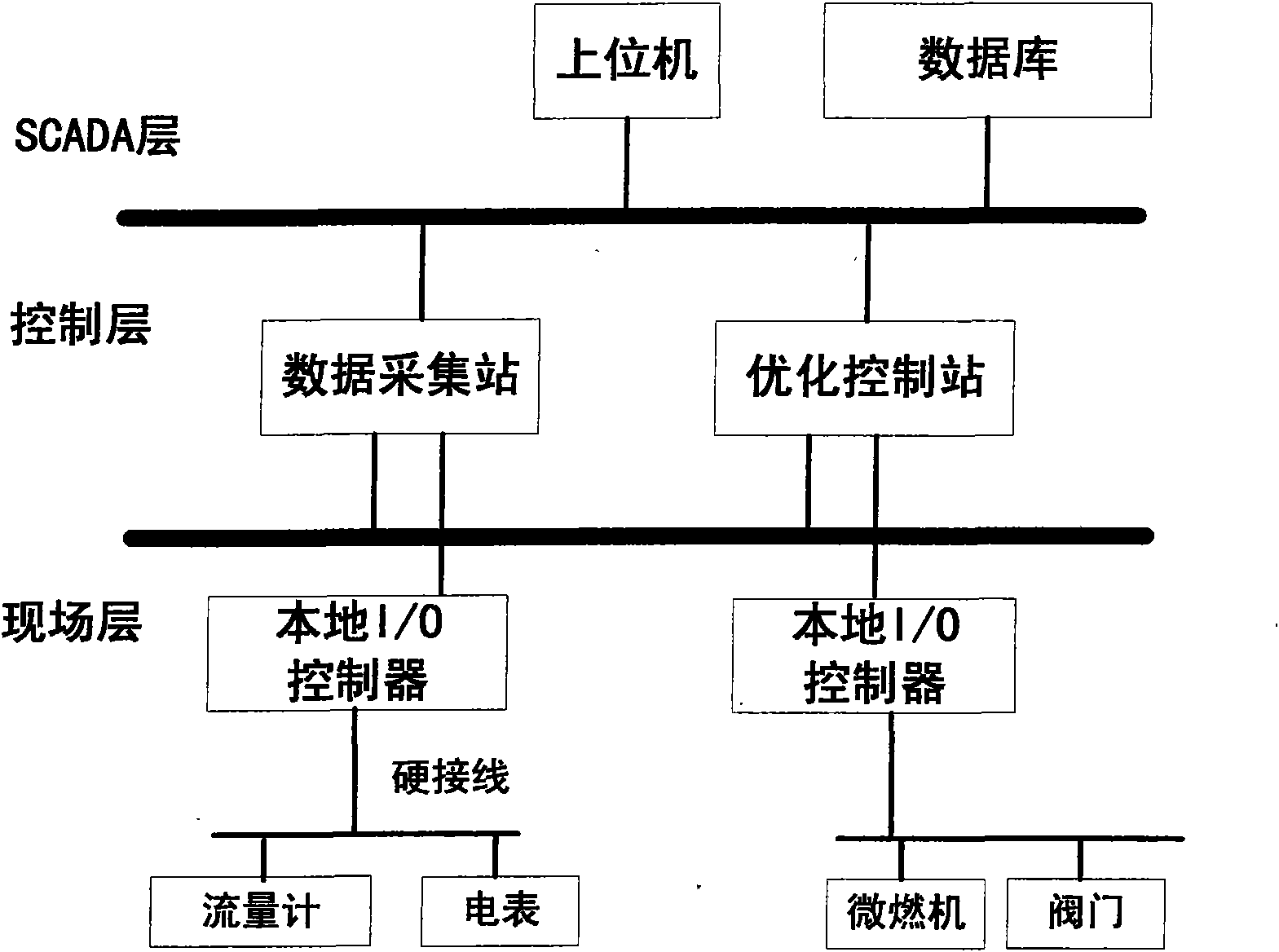

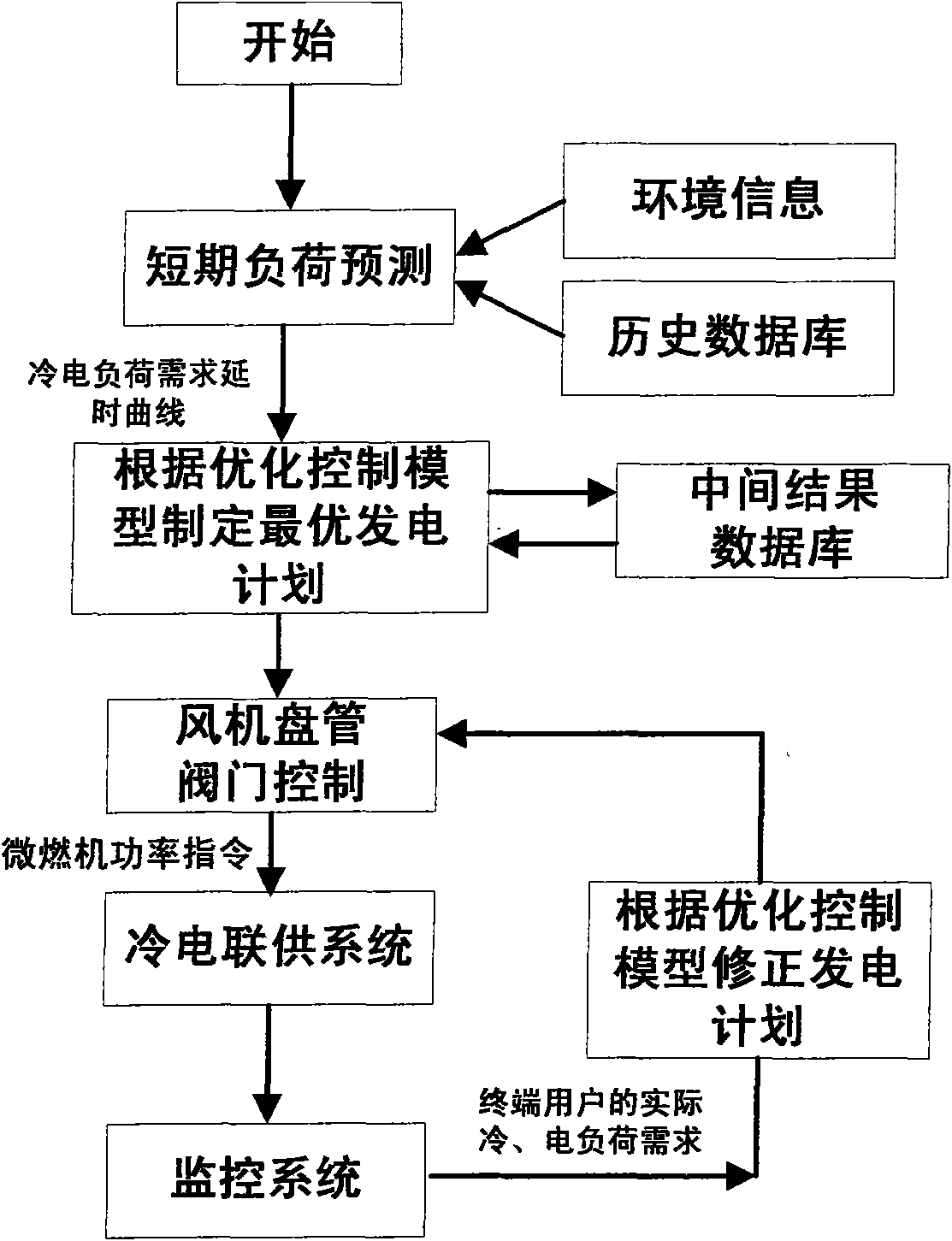

Control method of optimized running of combined cooling and power distributed energy supply system of micro gas turbine

ActiveCN101667013AIncrease economic benefitsHigh Utilization MetricsClimate change adaptationGas turbine plantsMathematical modelMicro gas turbine

The invention belongs to the technical field of energy management of distributed generation energy supply systems of electric power systems. The control method comprises the following steps: before running a combined system on every workday, extracting history cooling load data and power load data of a terminal user from a historical data base and obtaining the delay variation curve of the coolingload and the power load of the terminal user during the whole workday by lone-term load predicting; according to load predicting results, working out the optimal generated output plan of the combinedsystem by adopting optimization control mathematical model; during the running of the combined system, carrying out optimization control calculation again by utilizing the terminal user real-time cooling and power load need obtained from the distributed control system, and modifying the generating capacity and the refrigerating capacity of the combined system. The invention utilizes a distributedmonitoring system to monitor the actual cooling and power load need of the terminal user and can modify the load forecasting result in real time and adjusting the respective controlled variable of the combined system.

Owner:TIANJIN UNIV +2

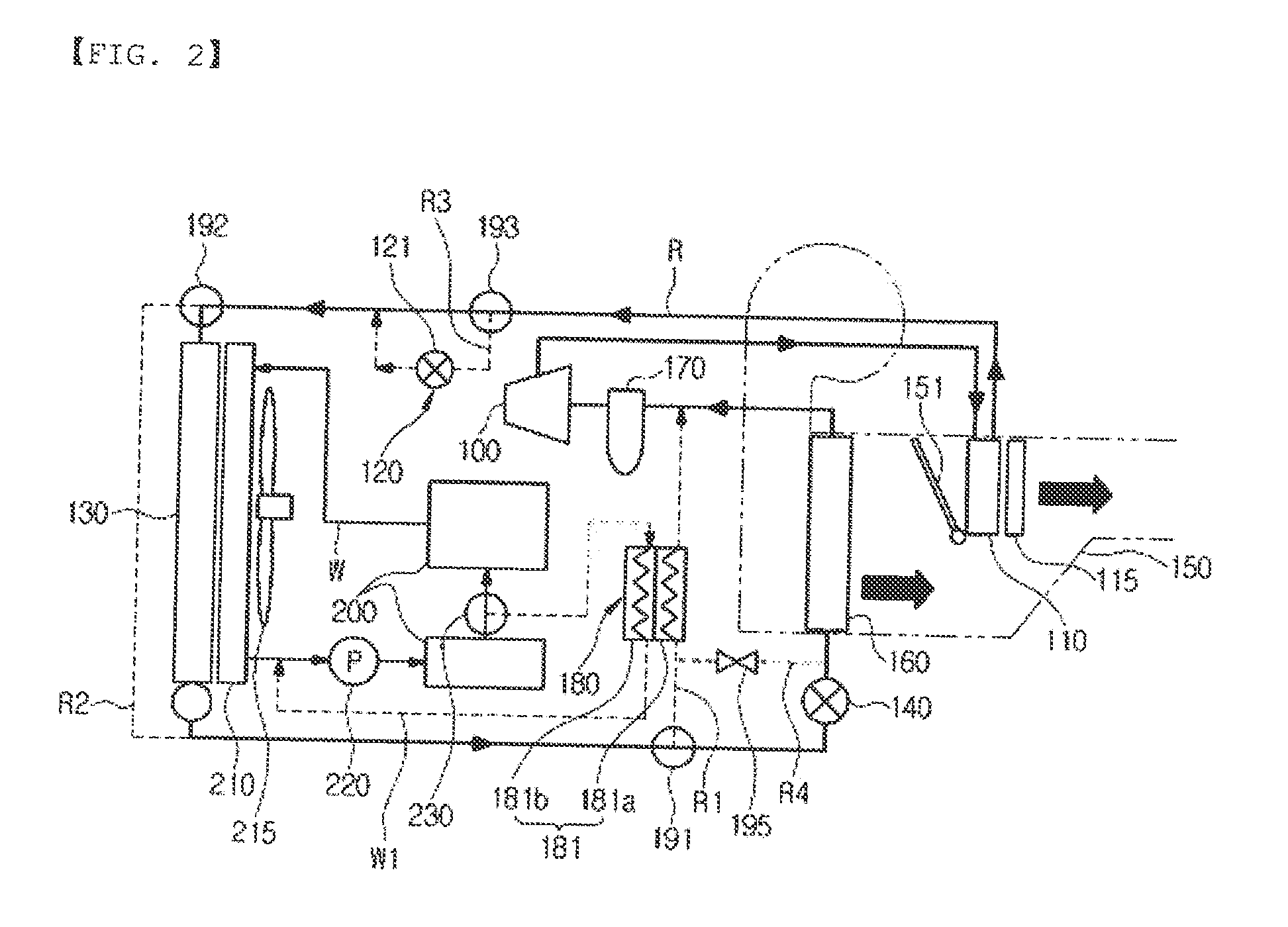

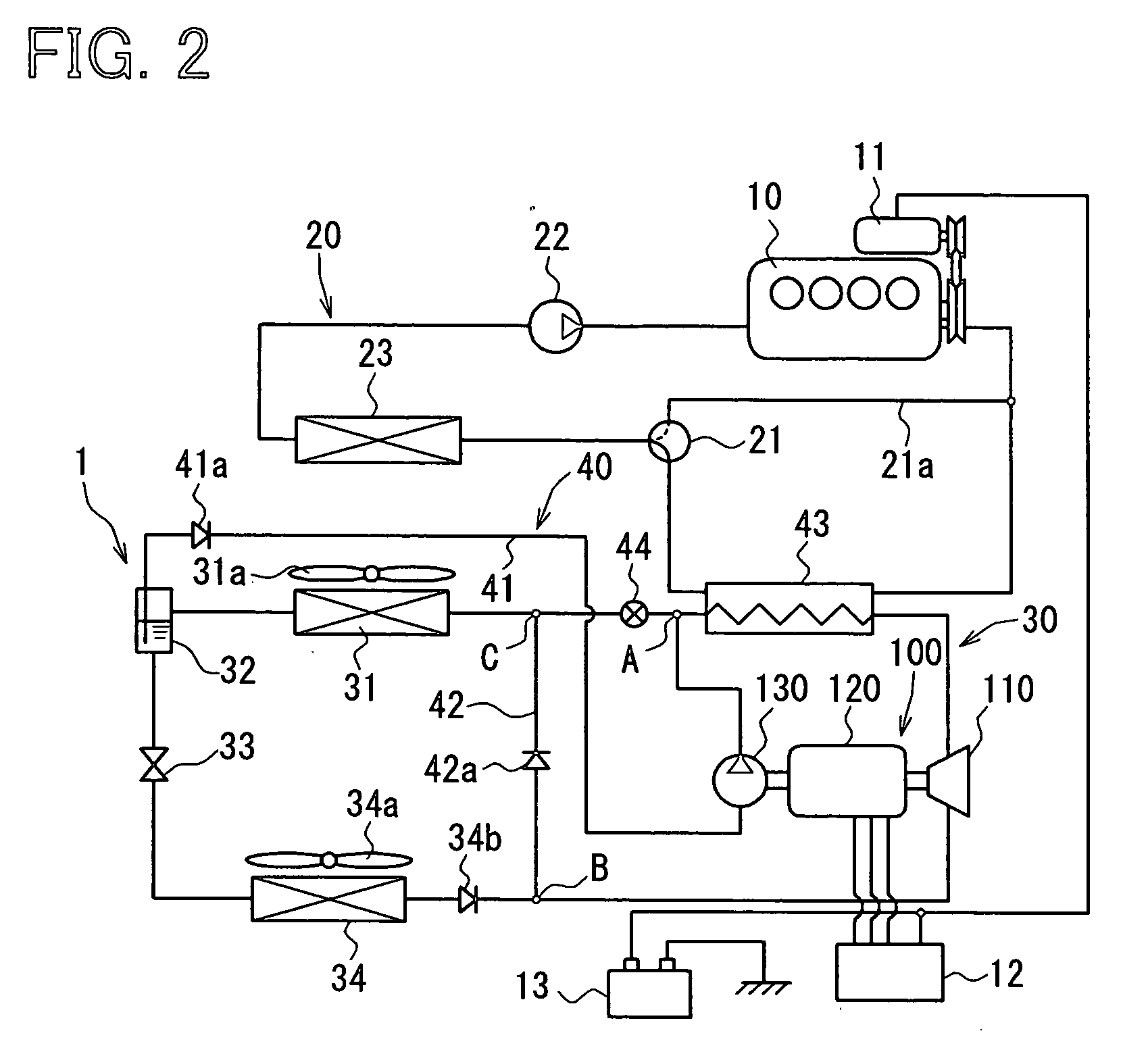

Heat pump system for vehicle

ActiveUS20120227431A1Minimize impactImprove heating performanceHeat pumpsCorrosion preventionElectricityEngineering

A heat pump system including a water-cooled type heat exchanger, which is a heat supply means, mounted on a first bypass line bypassing a second indoor heat exchanger to collect waste heat of vehicle electric devices to thereby enhance a heating efficiency of the heat pump system. The heat pump system for a vehicle includes: a branch line for connecting a refrigerant circulation line of the second indoor heat exchanger and the first bypass line with each other; a second bypass line, which bypasses an outdoor heat exchanger; and a control part that controls a flow of the indoor air to be introduced into an air-conditioning case, whereby the heat pump system can minimize influences of the outdoor air of low temperature even when the outdoor temperature is below zero, enhance the operation and the heating performance of the heat pump system by collecting waste heat of the vehicle electric devices and heat sources of the indoor air, and increase the mileage of the vehicle by minimizing operation of an electric heater.

Owner:HANON SYST

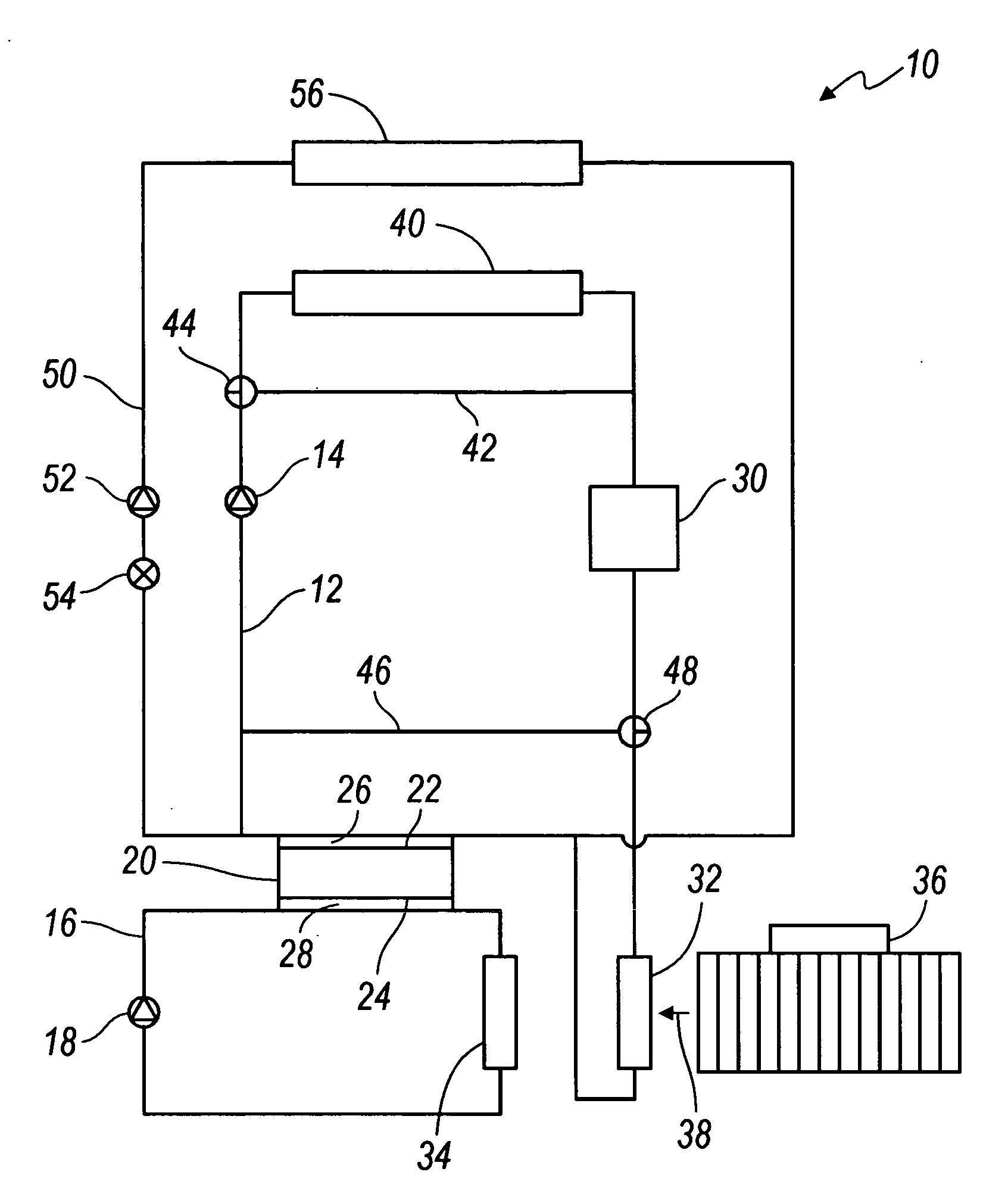

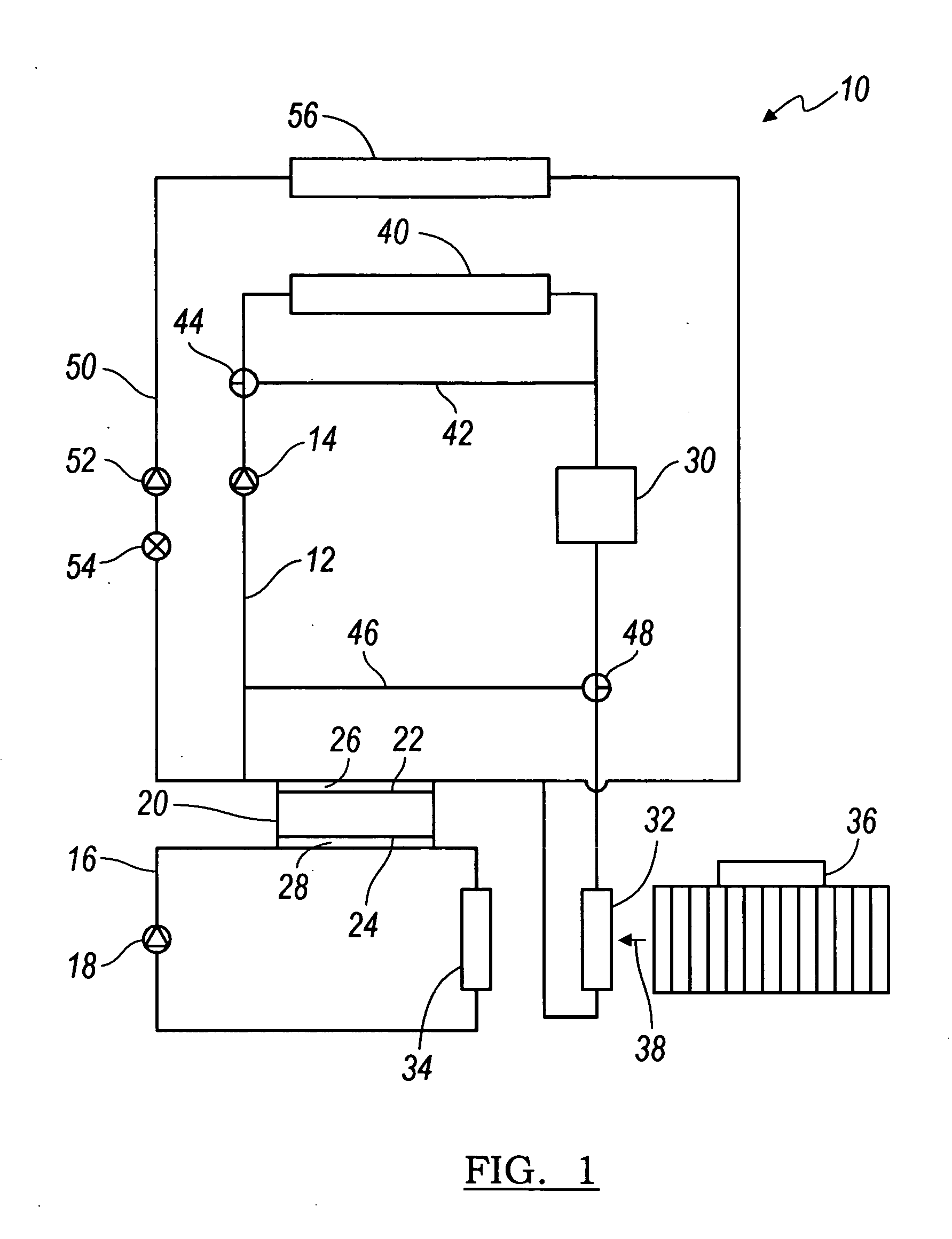

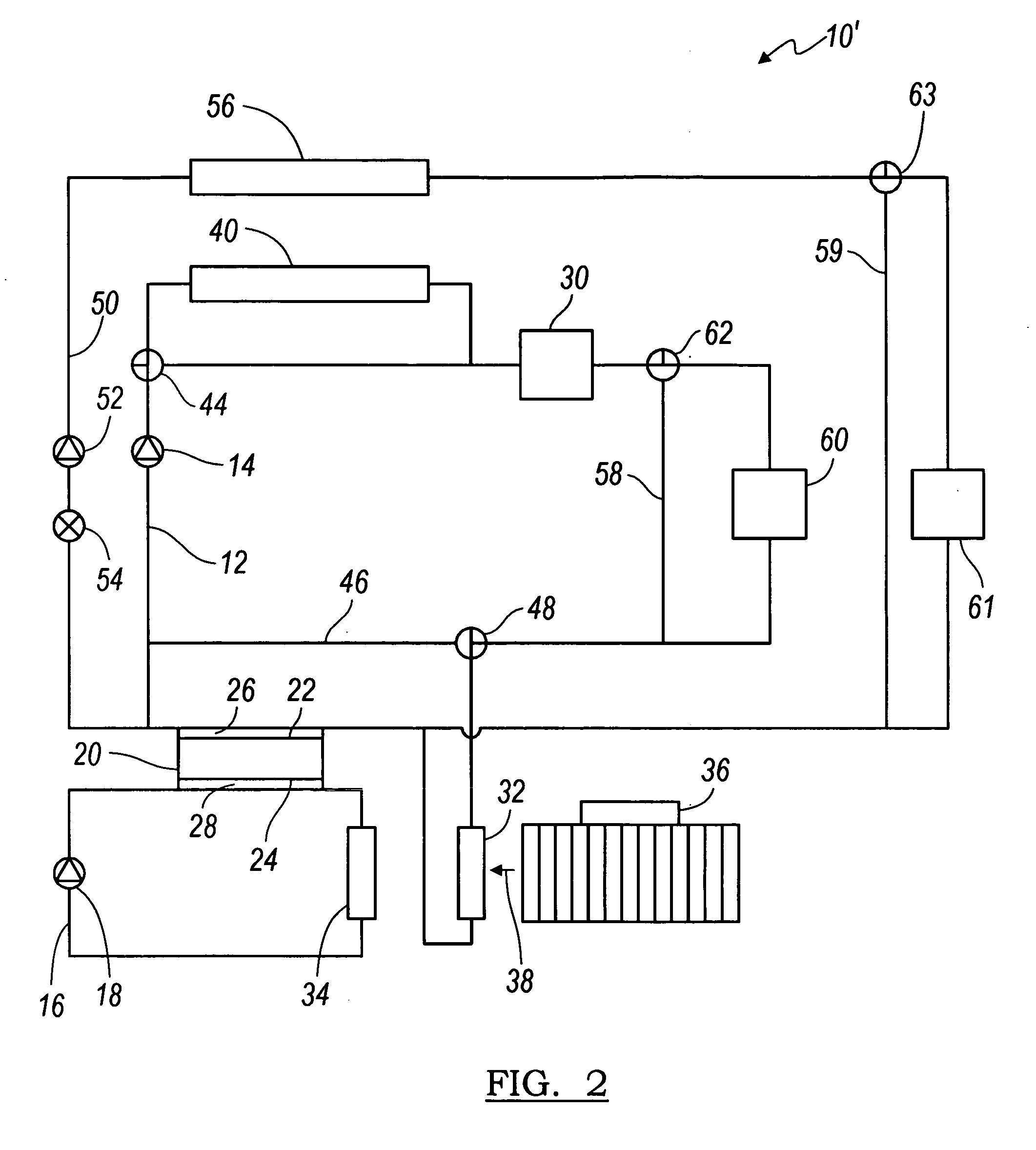

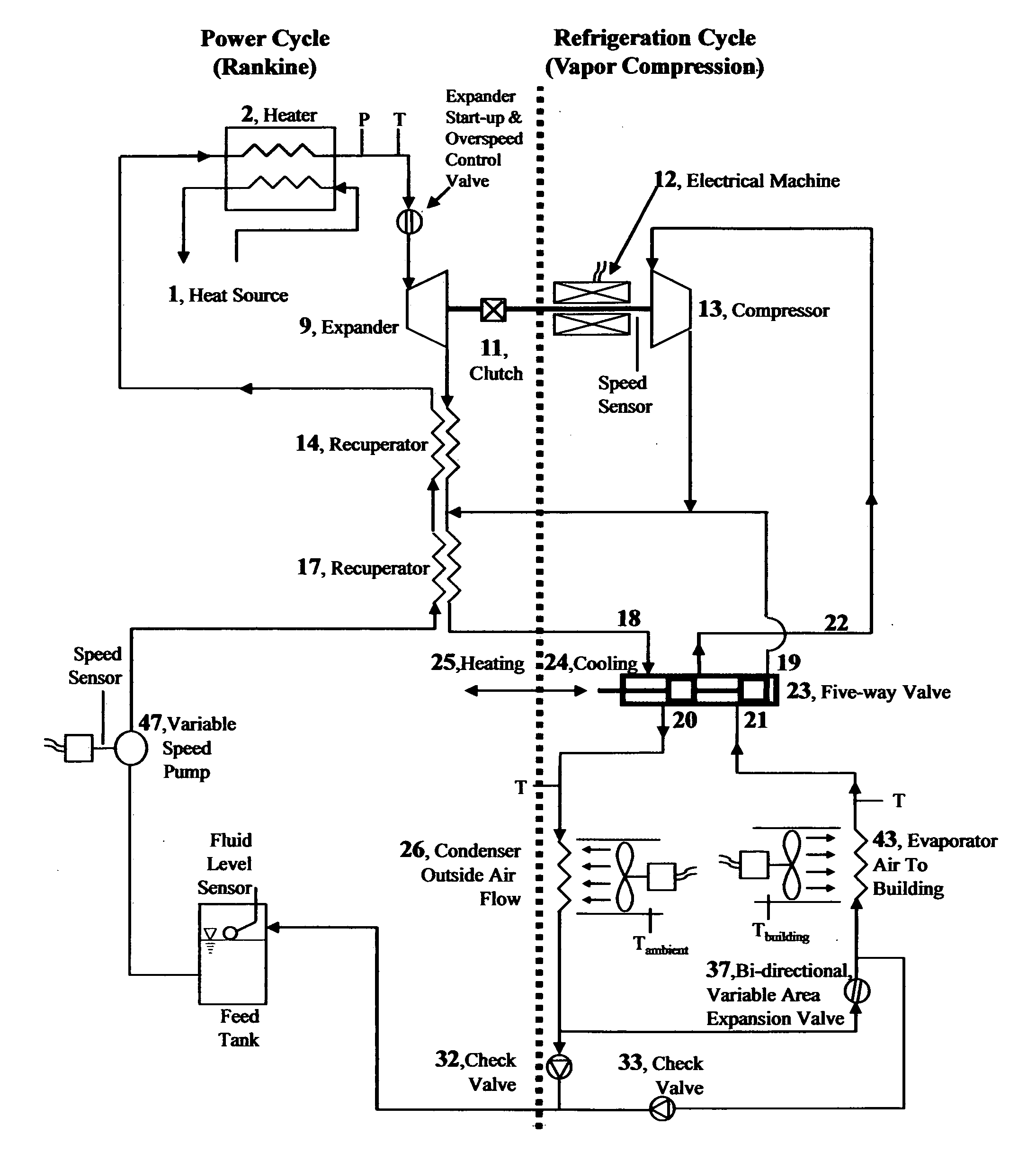

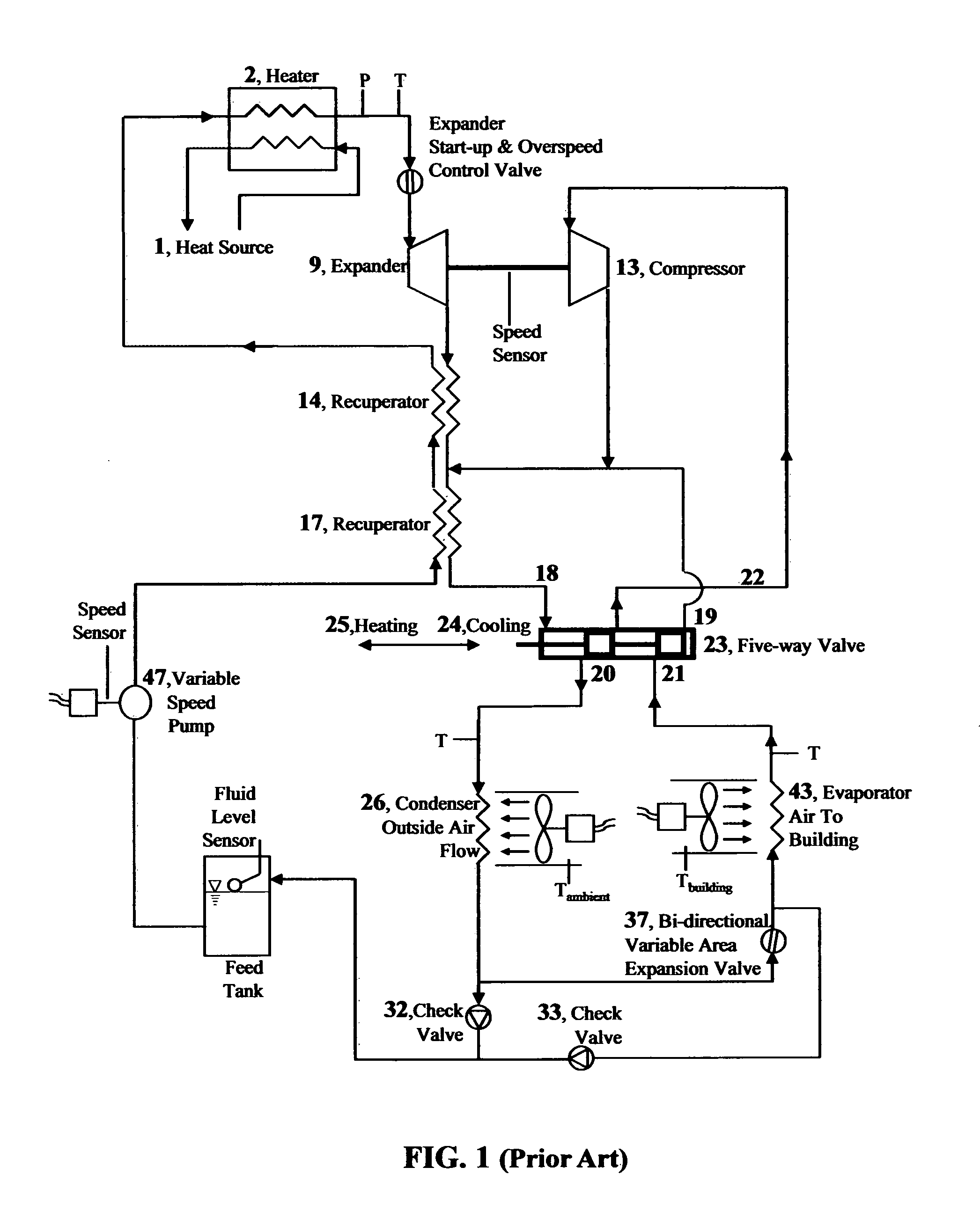

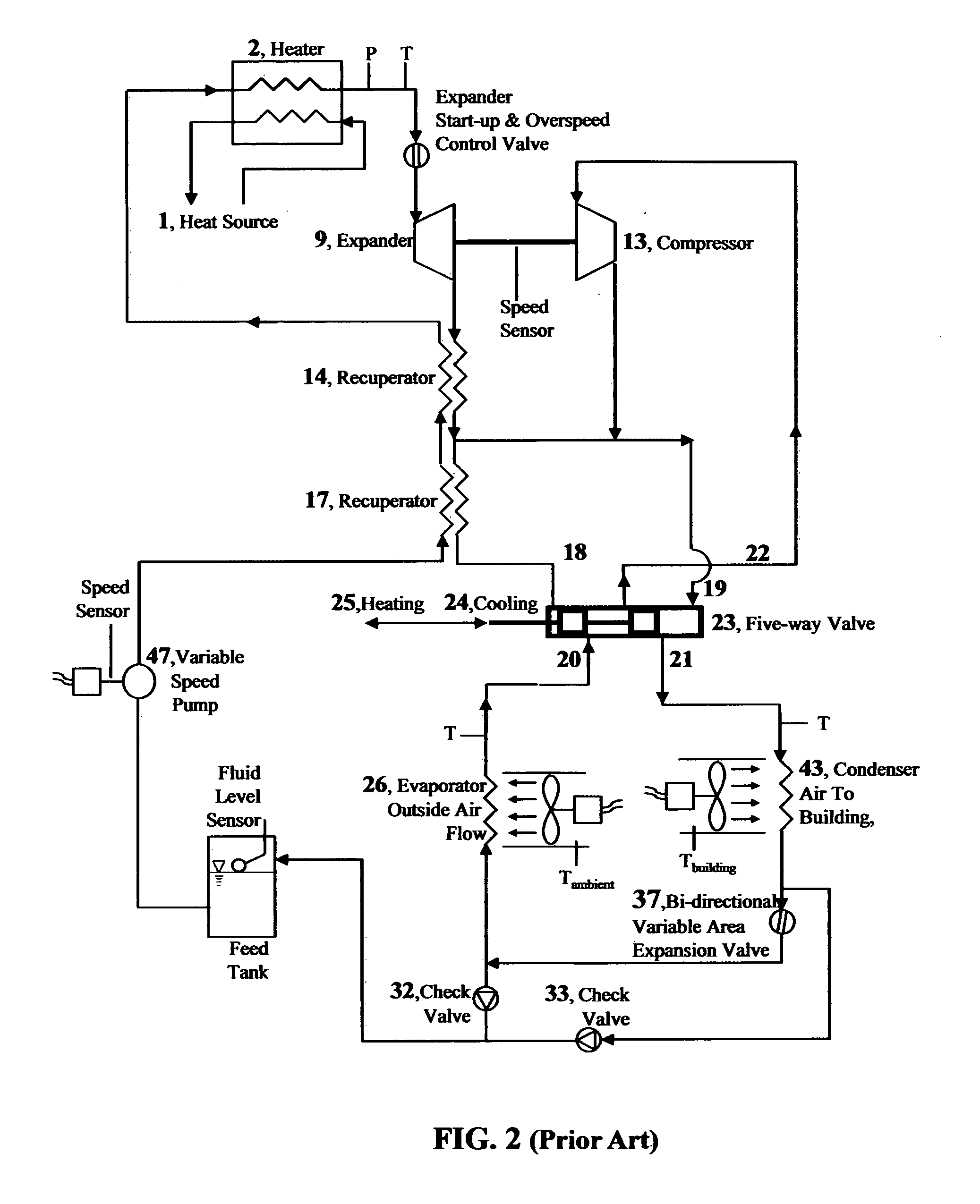

Integrated power, cooling, and heating apparatus utilizing waste heat recovery

ActiveUS20110296849A1Simple designCost-effective manufacturingClimate change adaptationCompression machines with cascade operationCost effectivenessElectric machine

The present invention provides an apparatus for utilizing waste heat to power a reconfigurable thermodynamic cycle that can be used to selectively cool or heat an environmentally controlled space, such as a room, building, or vehicle. The present invention also integrates an electric machine, which may operate as a motor or generator, or both, and an additional prime mover, such as an internal combustion engine. Different combinations of these components are preferable for different applications. The system provides a design which reasonably balances the need to maximize efficiency, while also keeping the design cost-effective.

Owner:BENSON DWAYNE M

Thermoelectric-based heating and cooling system

Disclosed is a heating, ventilation and air conditioning system for a vehicle that operates in a heating mode, a cooling mode or a demisting mode. The system includes a first circuit having first pump for circulating a first medium therein, a second circuit having a second pump for circulating a second medium therein and a thermoelectric module having a first surface in thermal contact with the first medium and a second surface in thermal contact with the second medium.

Owner:GENTHERM INC

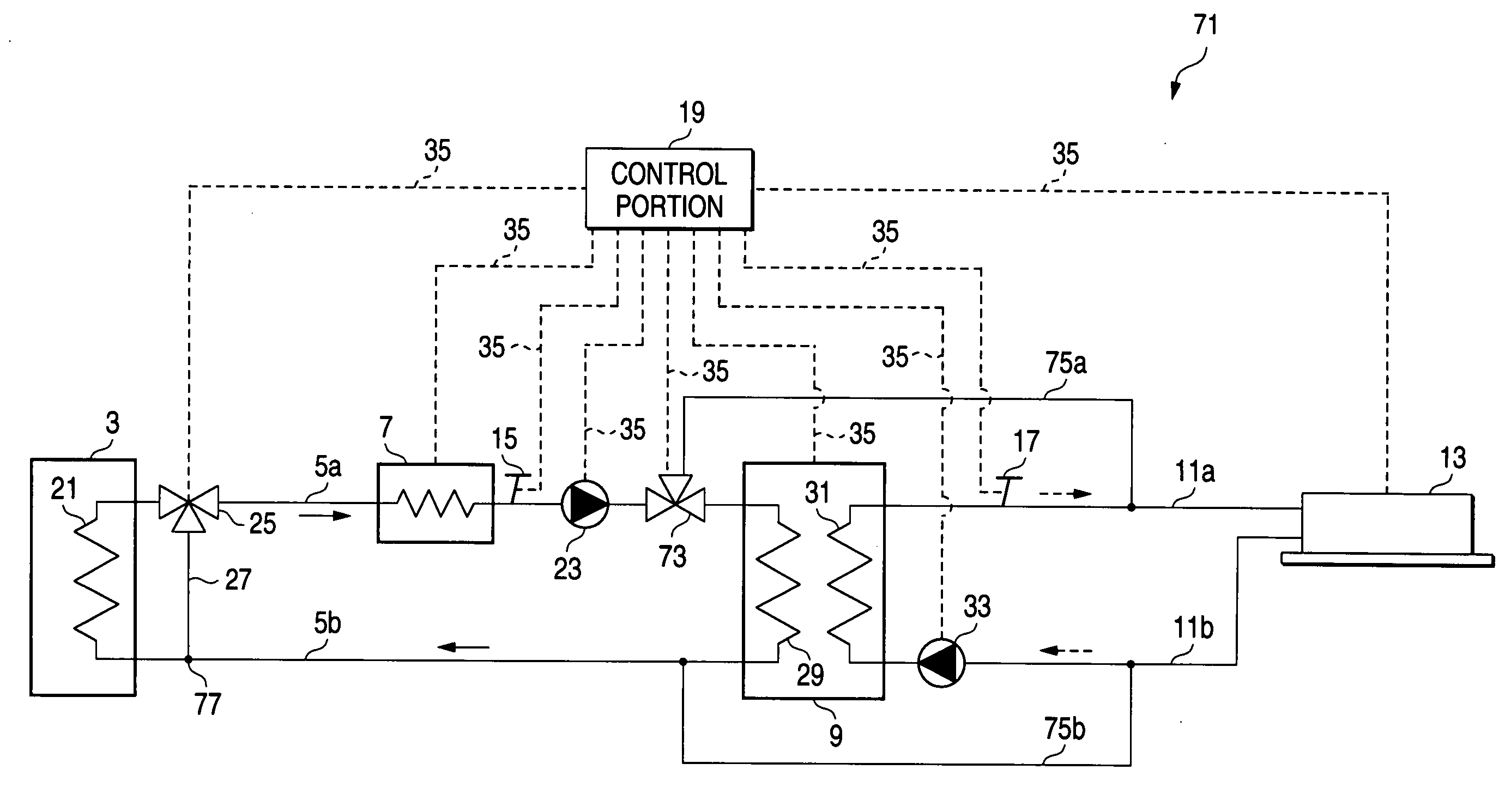

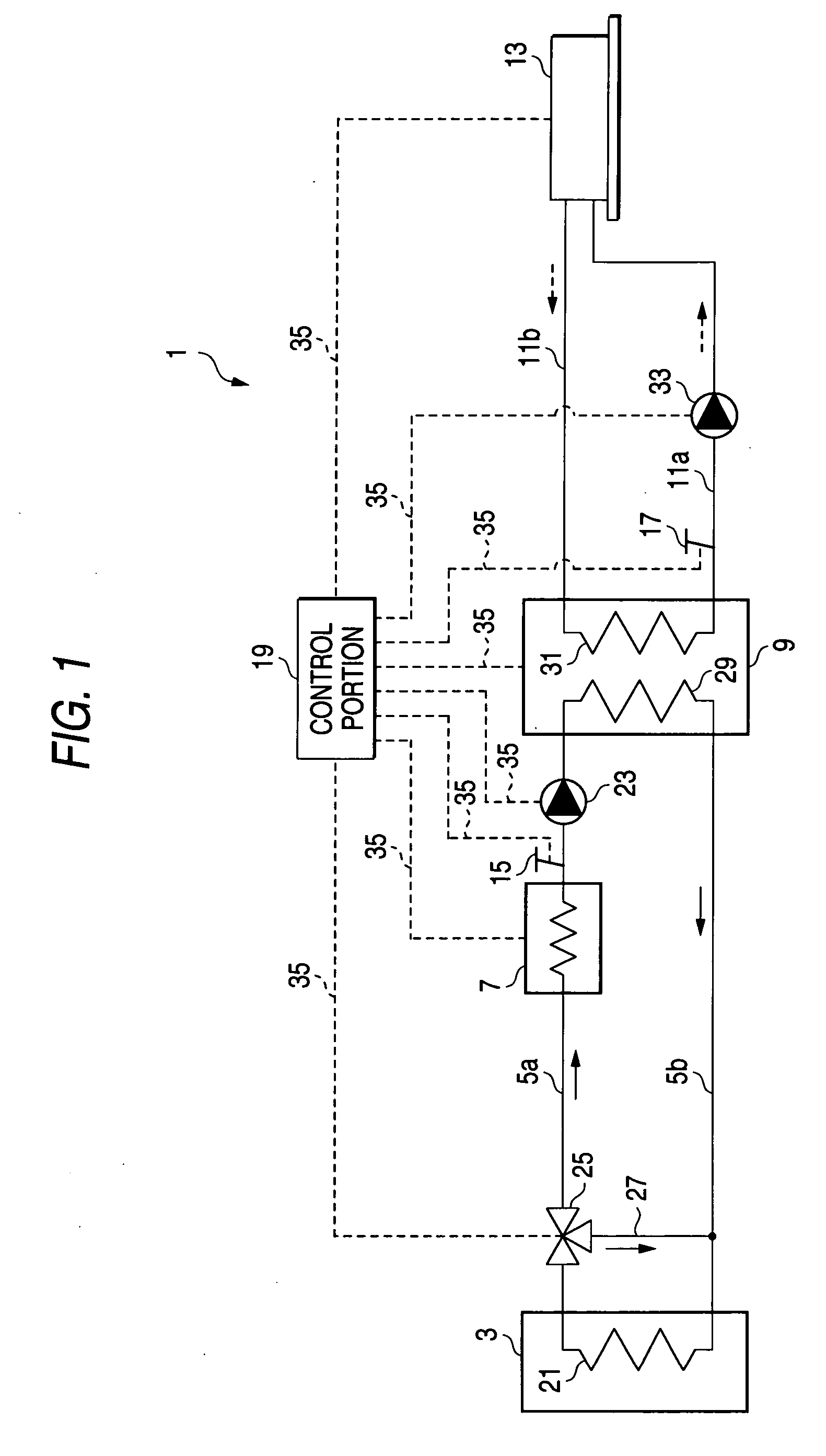

Air conditioner

InactiveUS20050262869A1Reduce energy consumptionImprove abilitiesClimate change adaptationEnergy efficient heating/coolingTemperature controlEngineering

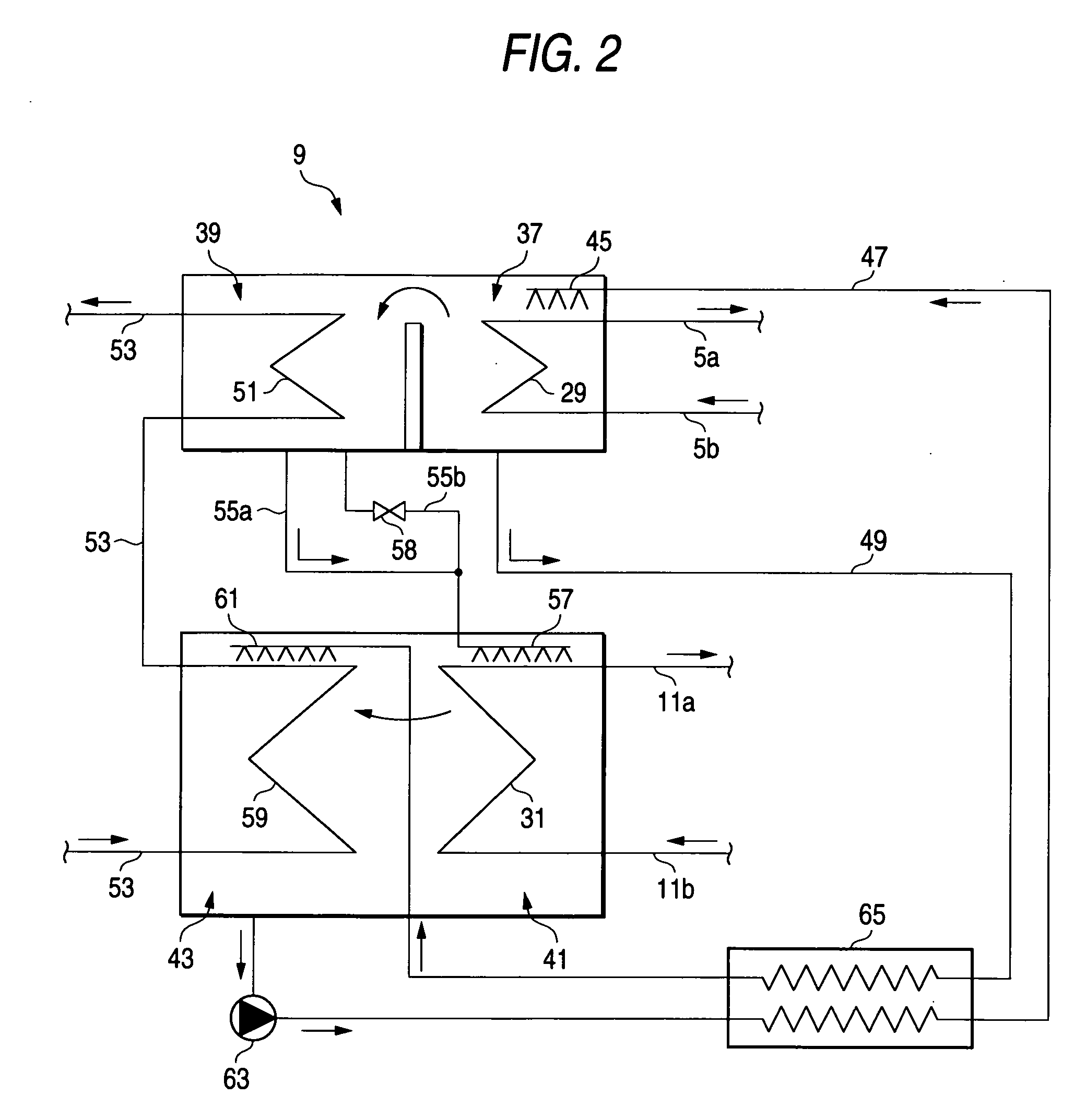

An air conditioner that comprises an exhaust heat recovery unit 3 for recovering exhaust heat in a heat transfer medium, a heat transfer medium passage 5a in which the heat transfer medium outputted from the exhaust heat recovery unit 3 flows, an auxiliary heating device 7, which is provided in the heat transfer medium passage 5a, for heating the heat transfer medium, an absorption chiller 9, to which the heat transfer medium passage 5a is connected, to be driven by heat of the heat transfer medium, a refrigerant passage 11a, through which a refrigerant outputted from the absorption chiller 9 flows, an indoor unit 13 to which the refrigerant is supplied through the refrigerant passage 11a, a heat transfer medium temperature detecting means 15 for detecting the temperature of the heat transfer medium flowing through the heat transfer medium passage 5a, a refrigerant temperature detecting means 17 for detecting the temperature of the refrigerant flowing through the refrigerant passage 11a, and a control portion 19 for controlling an operation of driving the auxiliary heating device 7. With this configuration, on startup, the control portion 19 controls an operation of driving the auxiliary heating device 7 according to the temperature of the heat transfer medium, which is detected by the heat transfer medium temperature detecting means 15, that when the temperature of the refrigerant, which is detected by the refrigerant temperature detecting means 17, is equal to or lower than a predetermined temperature, the control portion 19 decides that a startup operation is completed. Upon completion of the startup operation, the control portion 19 controls an operation of driving the auxiliary heating device 7 according to the temperature of the refrigerant, which is detected by the refrigerant temperature detecting means 17.

Owner:YAZAKI ENERGY SYST

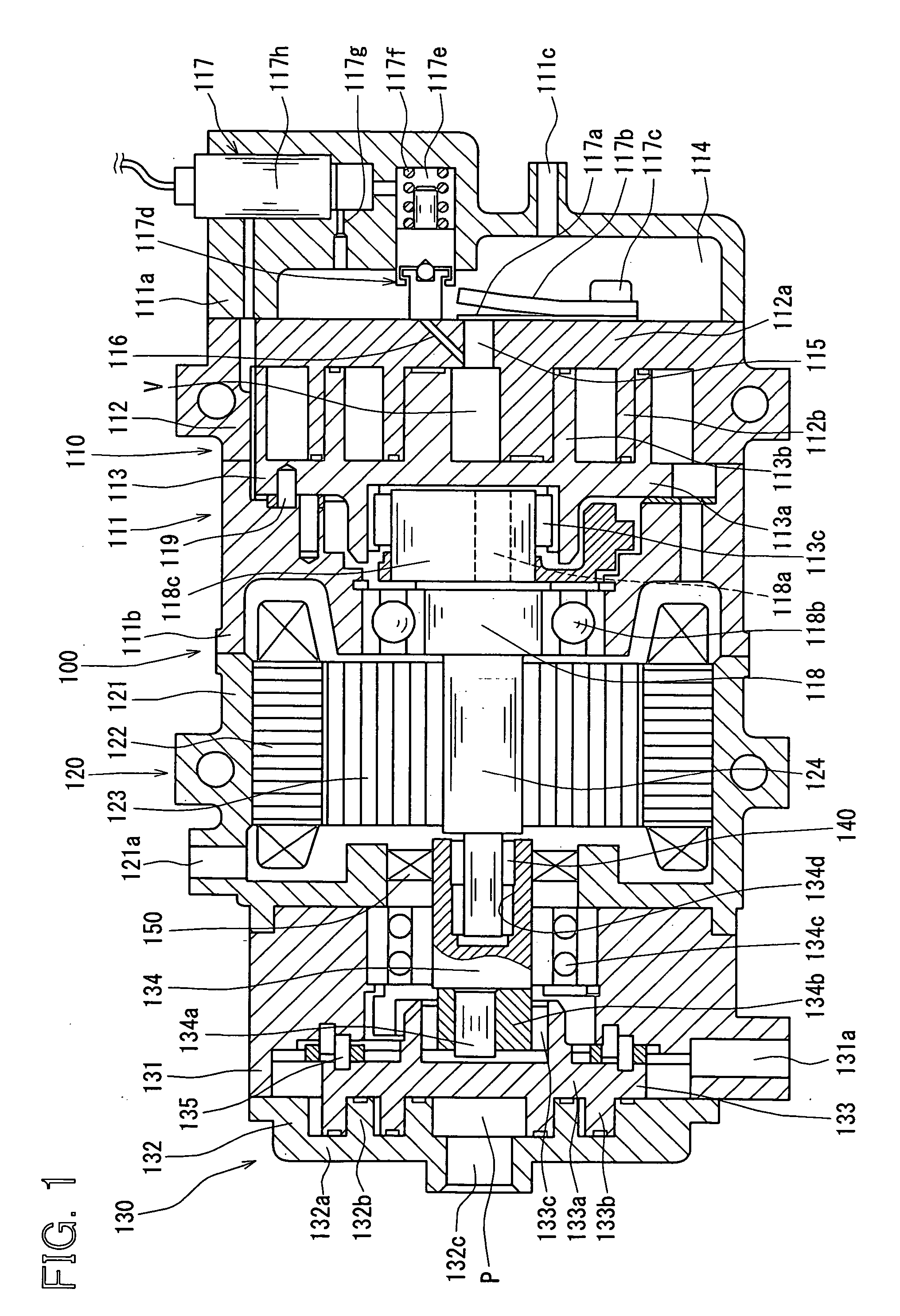

Fluid machine

InactiveUS20060254309A1Useless of driving forceAmount of collected is increasedOscillating piston enginesClimate change adaptationEngineeringHigh pressure

A fluid machine has a scroll type expansion device which is operated by a high temperature high pressure refrigerant. The refrigerant is heated by use of waste heat from an engine for a vehicle. The fluid machine further has a motor generator for generating electric power when it is driven by a rotational force produced at the expansion device, wherein a rotating shaft of the motor generator is coupled to a movable scroll of the expansion device via a crank mechanism. A biasing member is provided for biasing the crank mechanism in a direction that the movable scroll wrap is separated from a contact in a circumferential direction with a fixed scroll wrap. Pressure of the refrigerant in a working chamber in the center portion is thereby equalized to the pressure in the outer peripheral portion, at a startup period of the expansion mode.

Owner:DENSO CORP +1

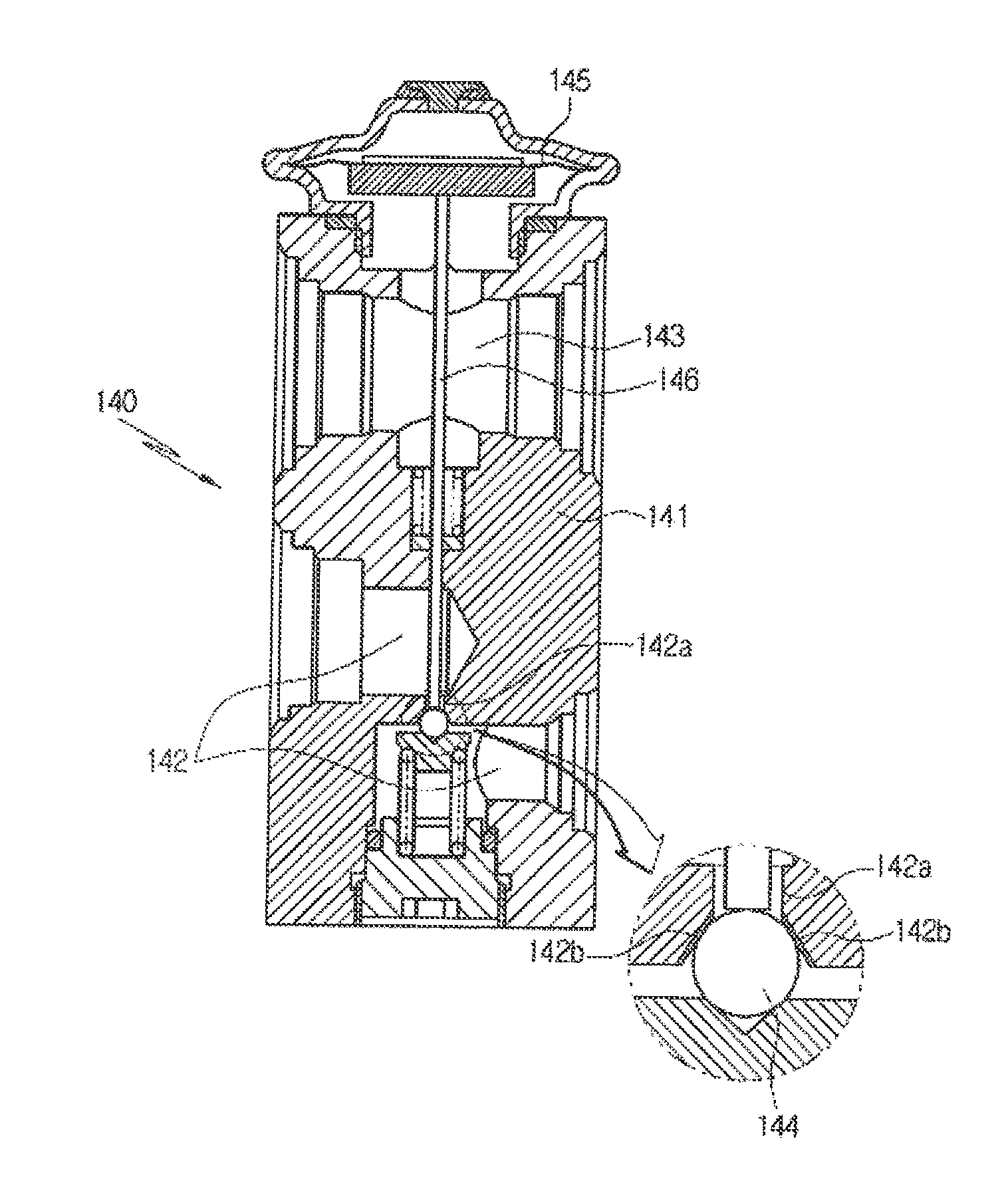

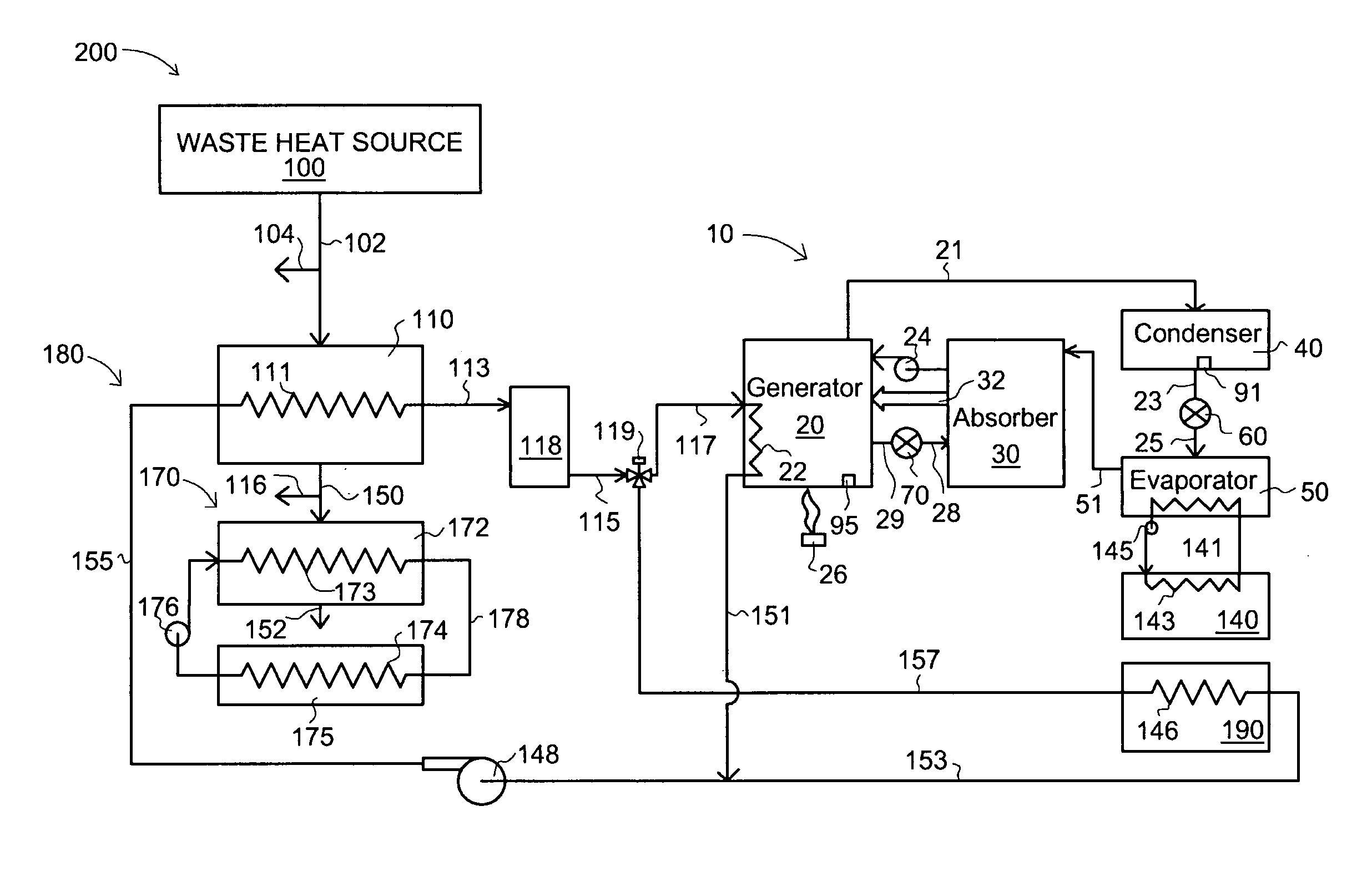

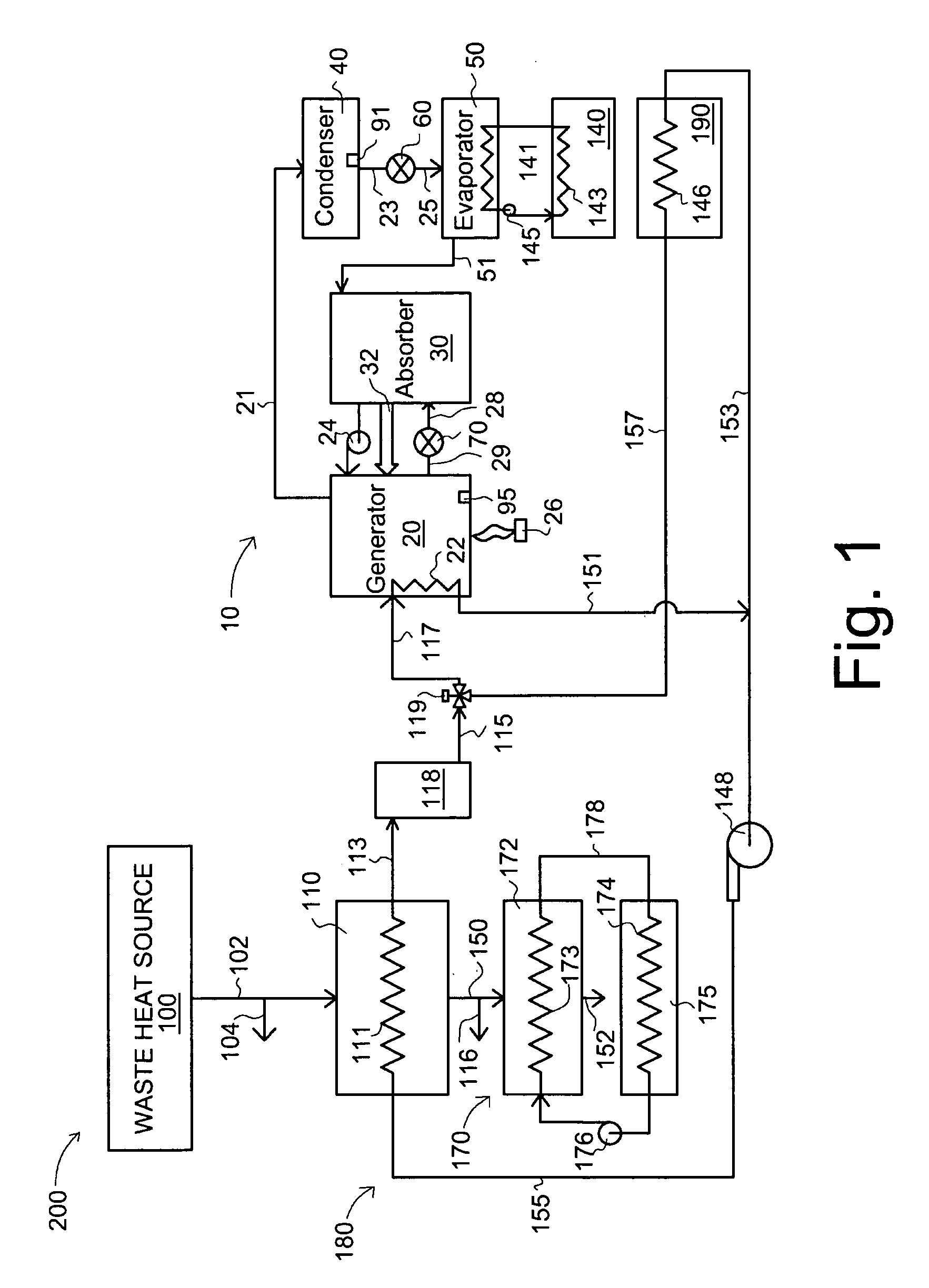

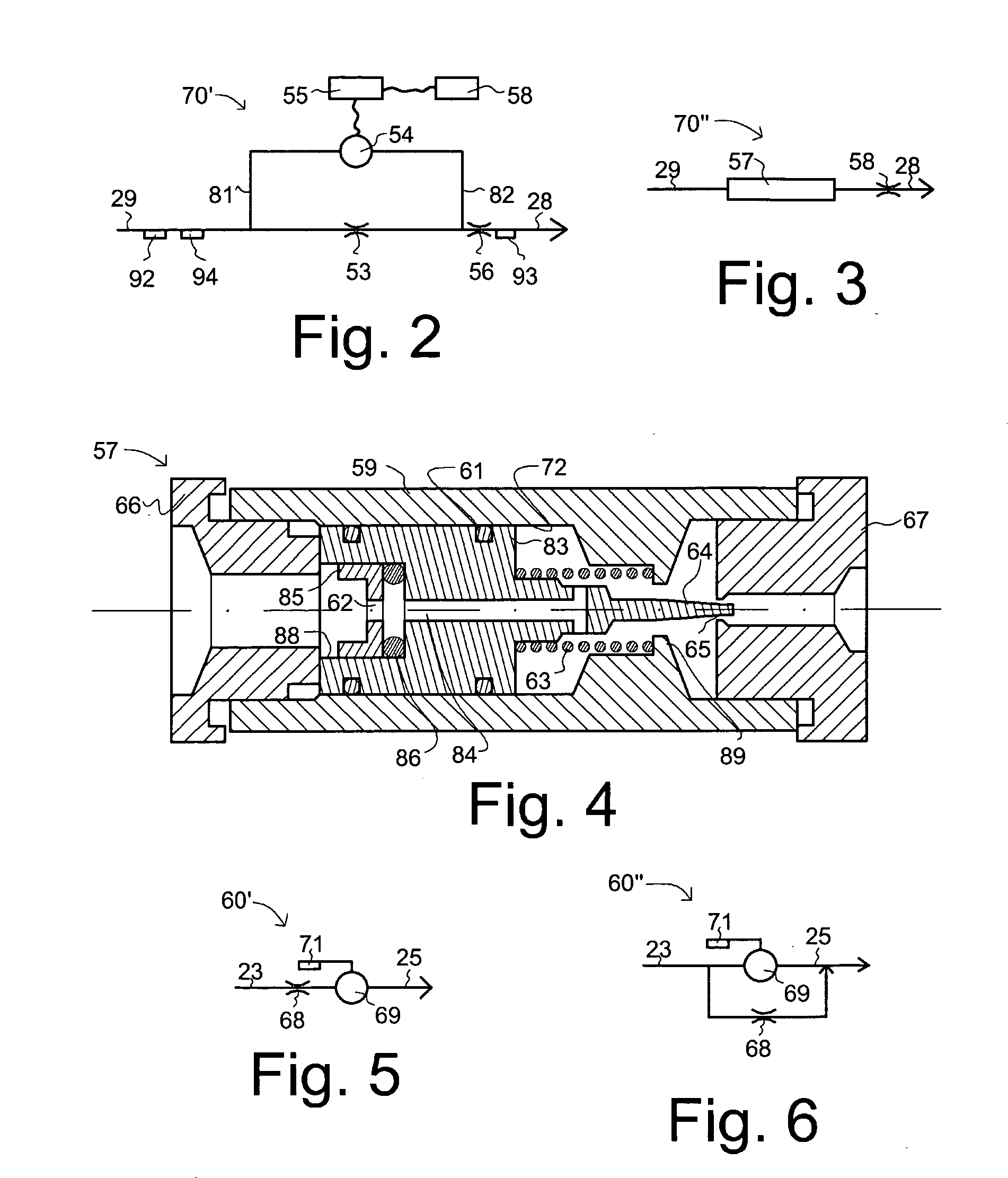

Absorption heat-transfer system

InactiveUS20050022963A1Reduce inlet pressureMechanical apparatusBoilers/analysersEngineeringRefrigerant

A waste heat source (100) is used to heat a high temperature heat transfer fluid which is used to heat an absorption heat transfer machine (10) having a generator (20), an absorber (30), a condenser (40), and an evaporator (50) operatively connected together. The high temperature heat transfer fluid can also be used to heat a load (190) such as a room space or a process. The waste heat source (100) can also be used to heat an intermediate heat transfer fluid, which can be used to heat a second load (175) such as a space, a process, or an absorption heat transfer machine. Novel flow control devices (70, 60) for controlling the flow of weak solution from generator (20) to absorber (30) or of refrigerant from condenser (40) to evaporator (50), respectively, are also described.

Owner:COOLING TECH

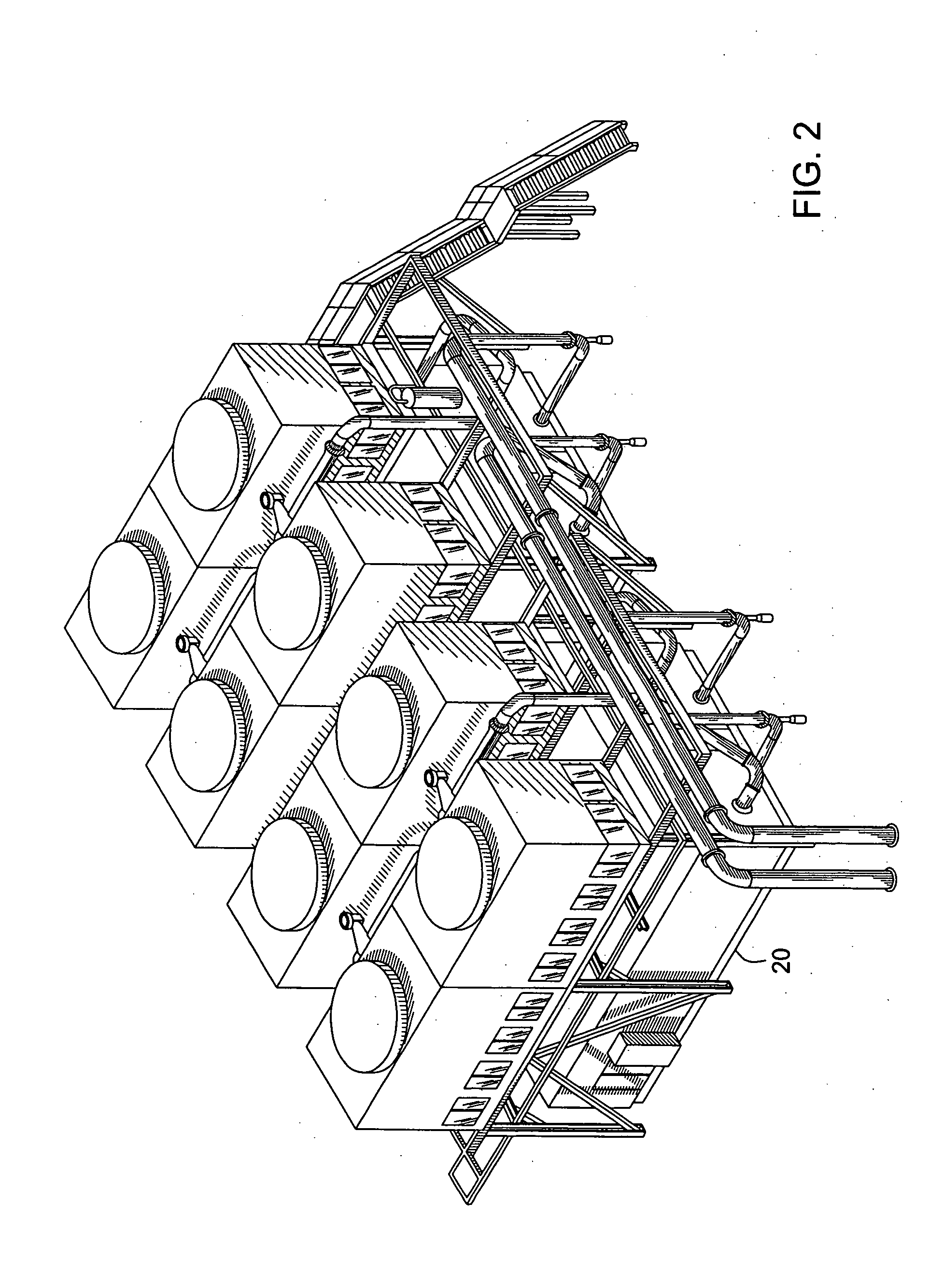

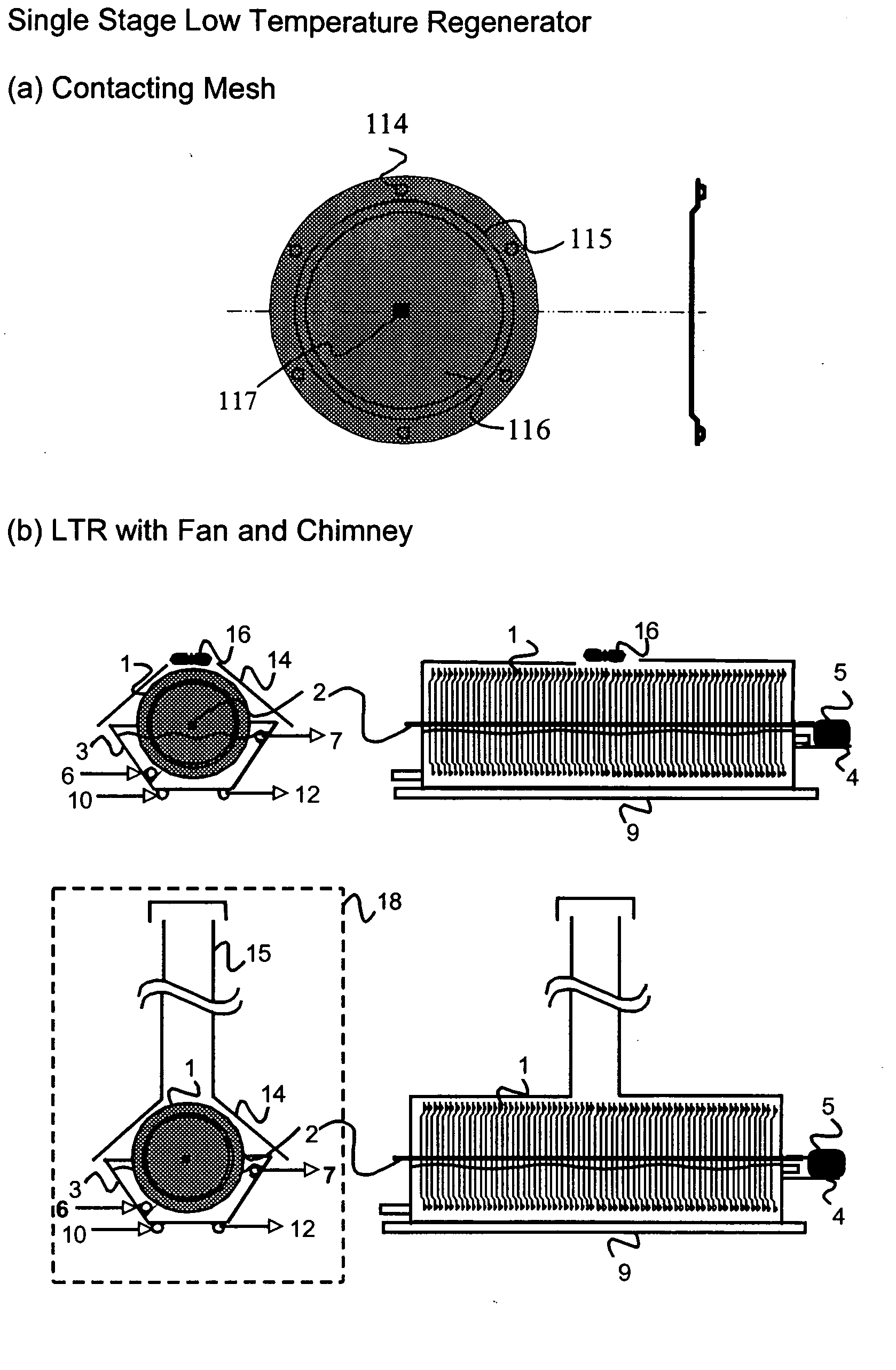

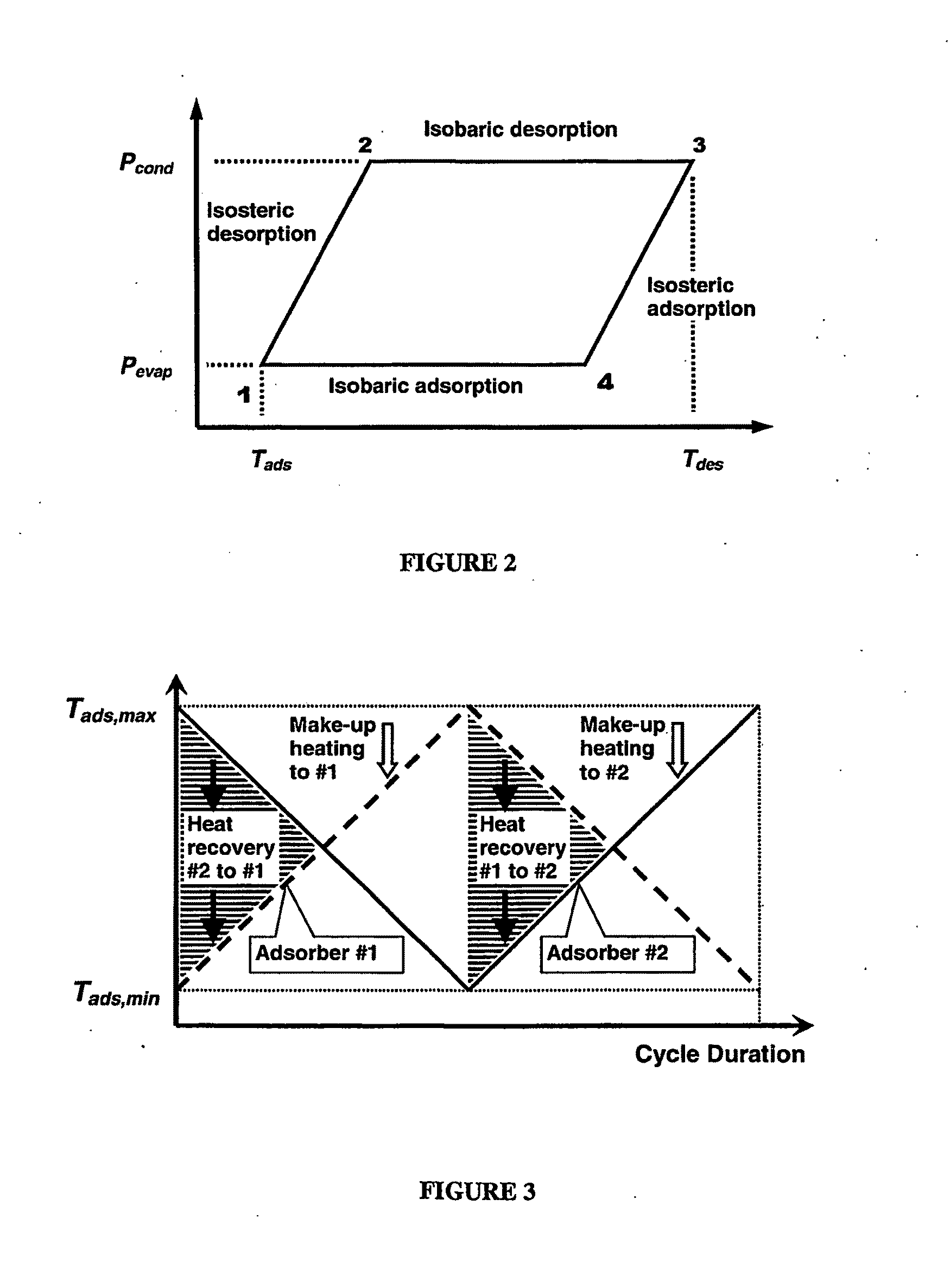

Energy efficient sorption processes and systems

InactiveUS20050262720A1Reduce the temperatureReduce power consumptionSolar heating energyInternal combustion piston enginesSorbentEngineering

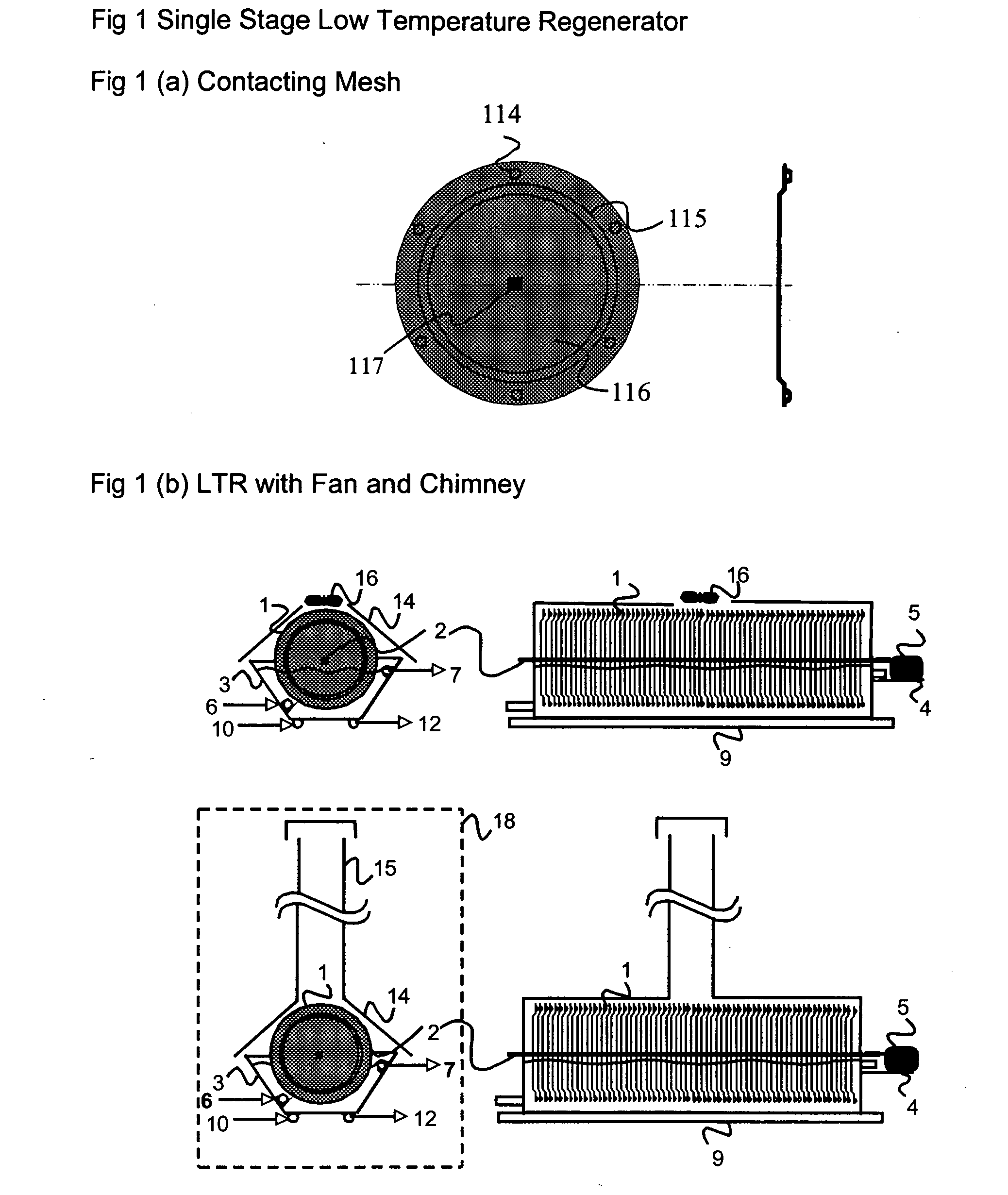

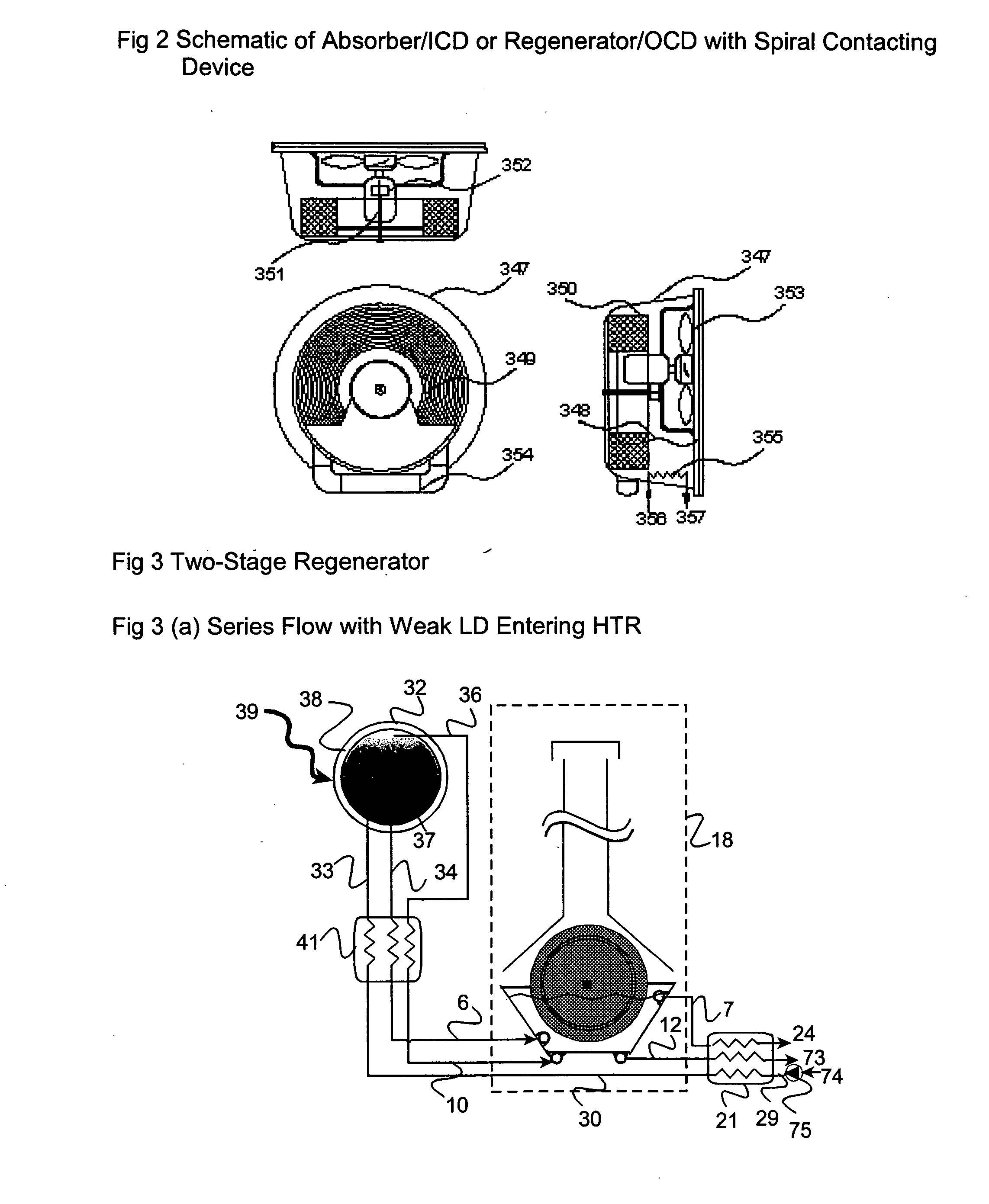

The present invention relates to novel energy efficient sorption processes and systems for cooling, dehumidifying and heating using multistage liquid desiccant regenerators, or hybrid cooling systems or adsorption cooling systems involving appropriate combinations of rotating contacting devises, adsorption modules with heat transfer passages in thermal contact with the adsorption module wall and switchable heat pipes. The sorption processes of this invention help in flexible designing of compact cooling, dehumidifing, heating systems easy operability. The adsorption module of this invention leads to lower cycle times as low as 5 minutes; makes it possible to achieve high system Coefficient of Performance (COP) up to 0.9 due to reduced thermal mass; offers high specific cooling power in the range of 50 to 750 W / kg of AC; is easy to manufacture and operates at low costs. The refrigeration cum heating system of this invention with heat pipe in thermal contact with the adsorption modules increase the heat transfer rates without increasing the thermal mass leading to increase of COP and the single or multistage pressure equalisation increases the internal regeneration of heat thereby increasing the COP, reducing the cycle time resulting in increased specific cooling power (SCP), reducing the required quantity of adsorbent / refrigerant making the module compact and cost effective.

Owner:INDIAN INST OF TECH

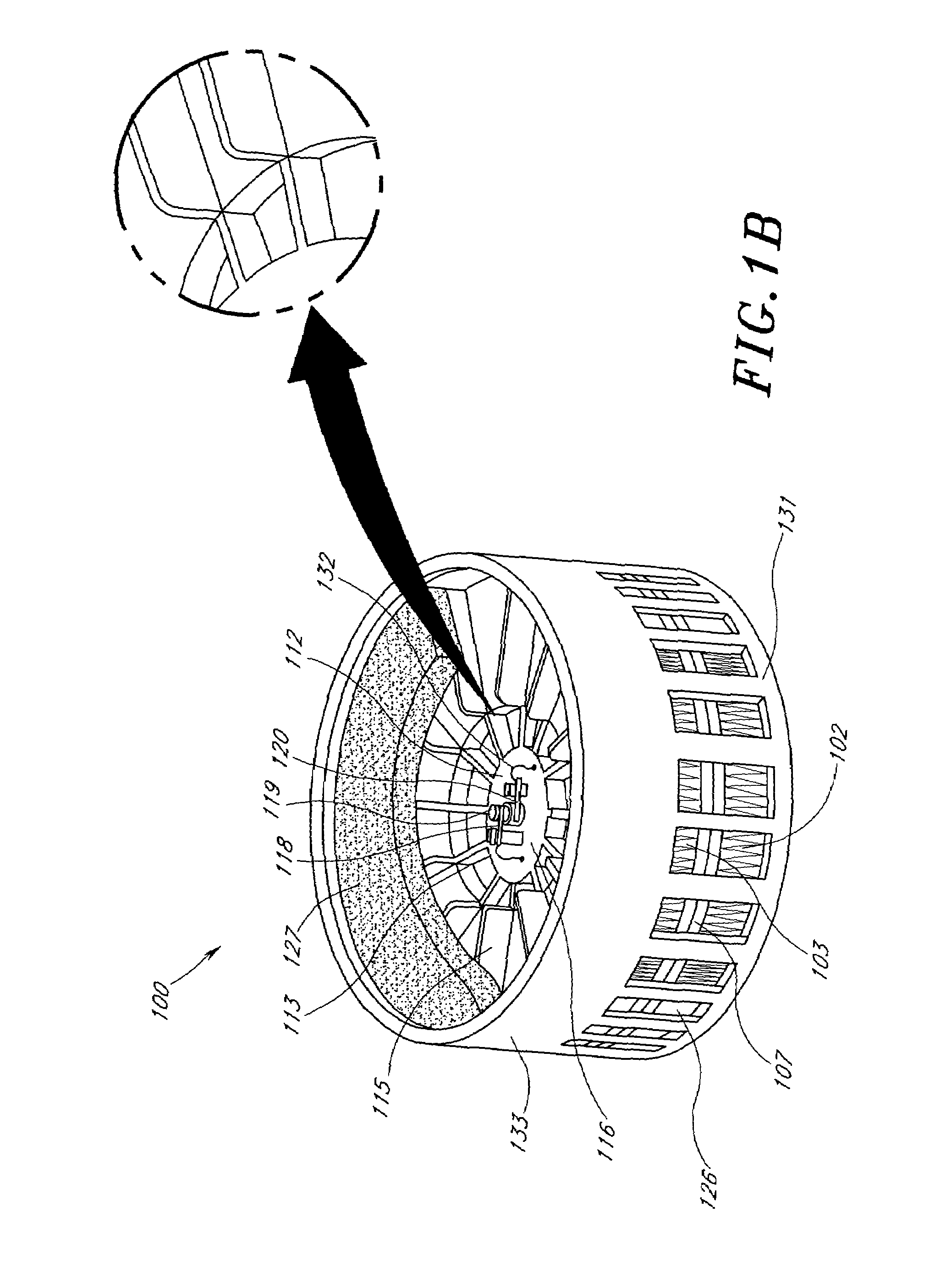

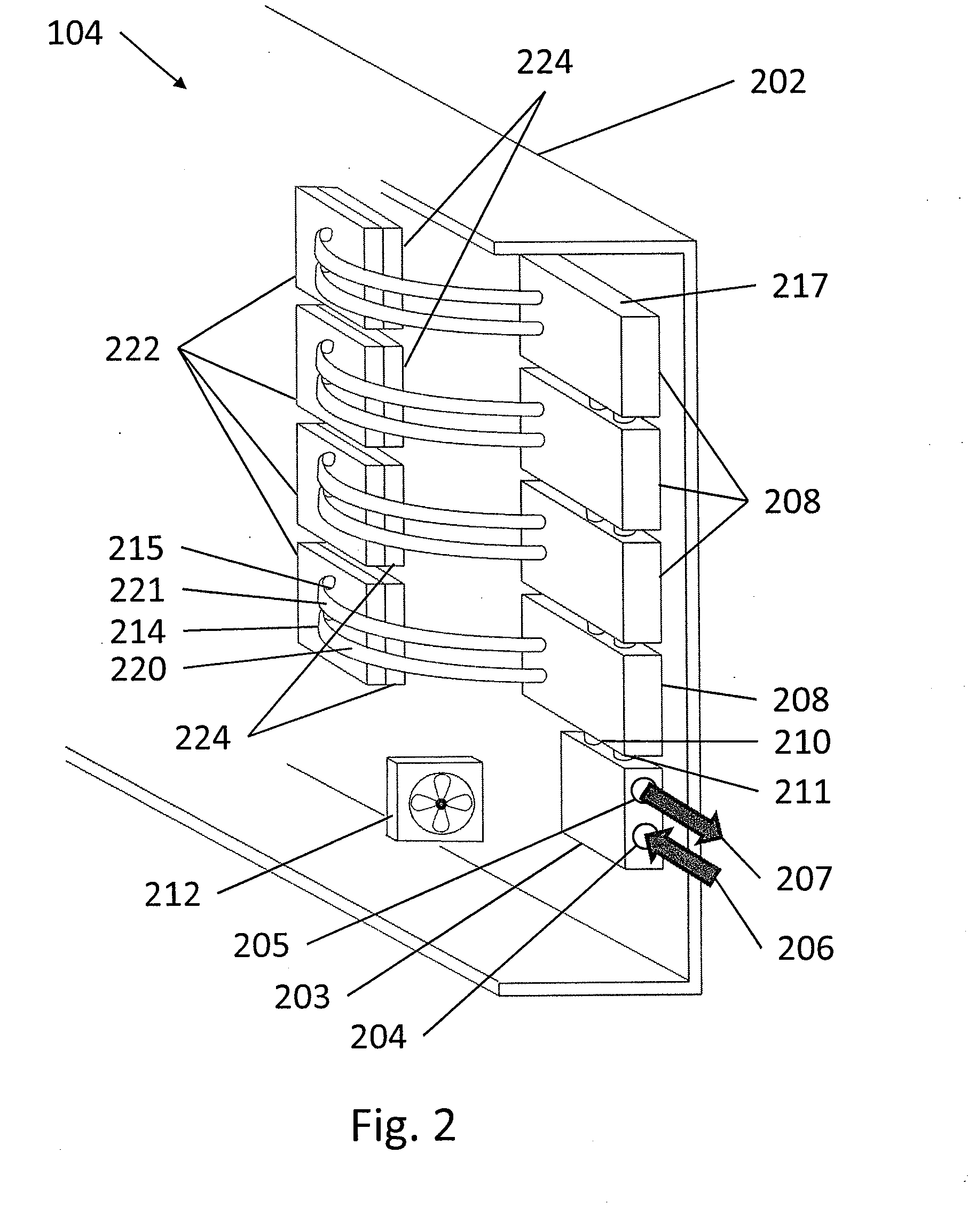

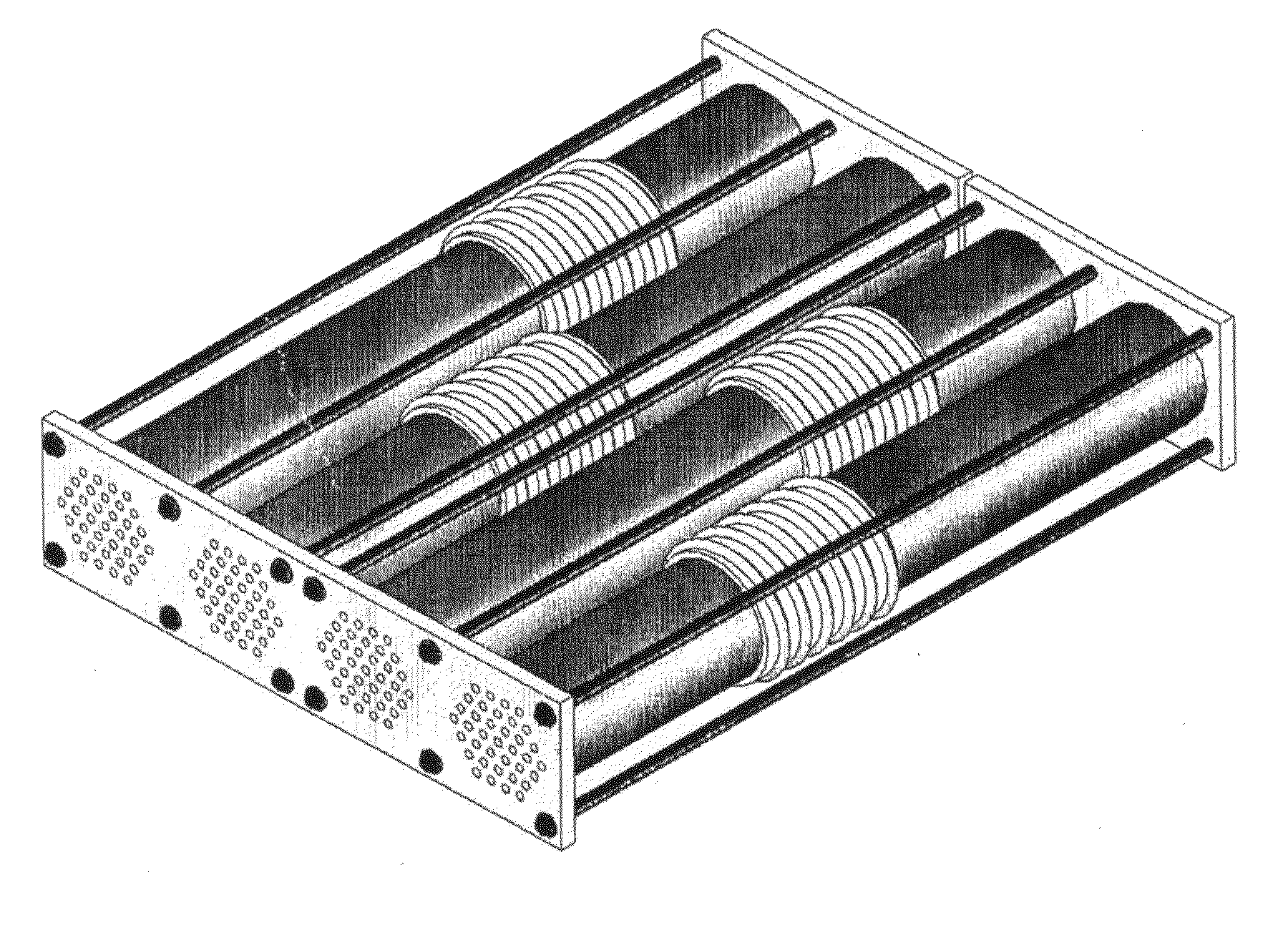

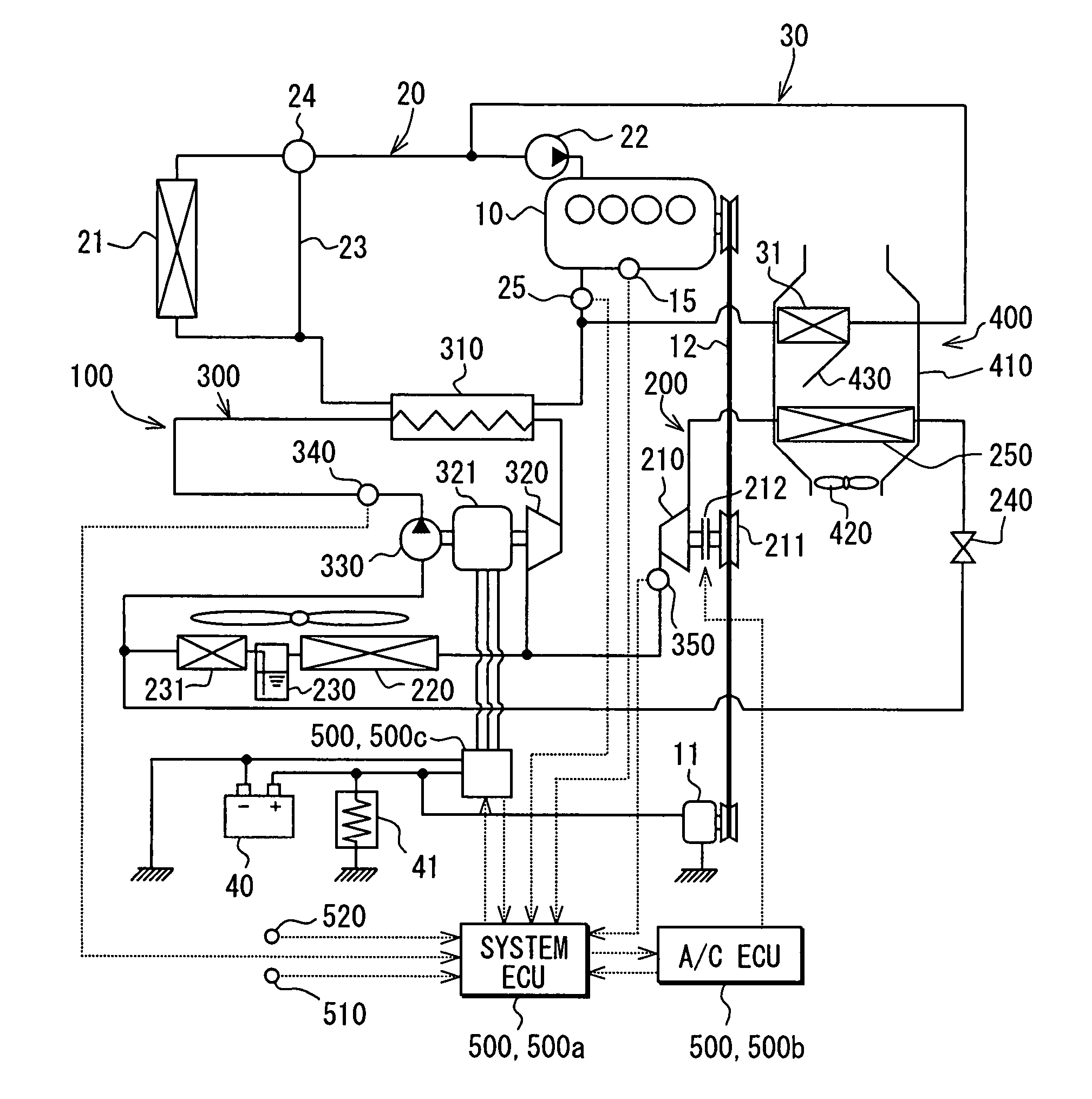

Automotive adsorption heat pump

InactiveUS20110005267A1Efficient and reliableLess expensiveClimate change adaptationVehicle heating/cooling devicesSorbentFresh air

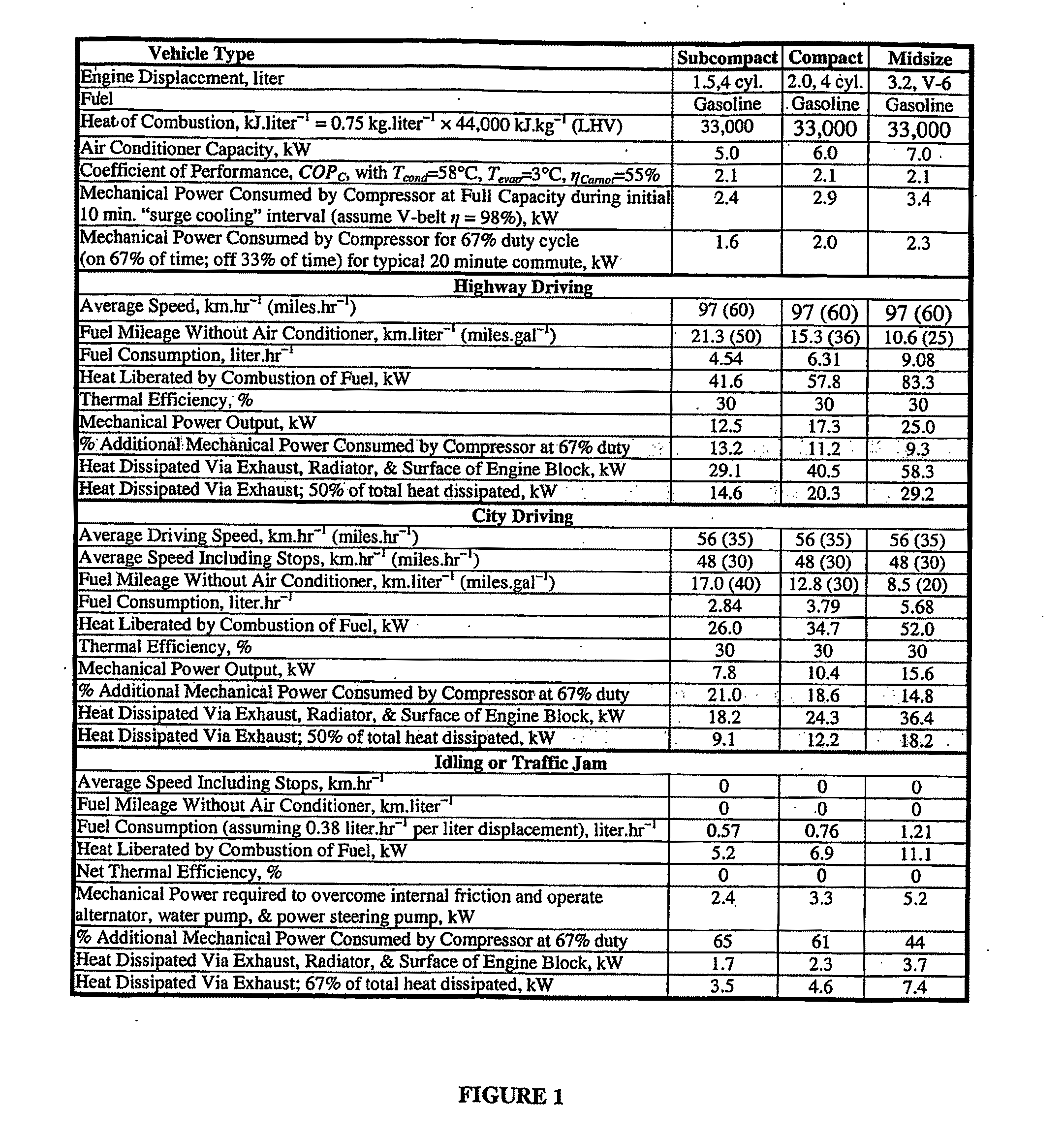

An adsorber unit has an outer shell, a plurality of internal tubes extending through the shell for carrying heat transfer fluid, each tube having outwardly projecting fins along its entire length, and a solid adsorbent material in the shell surrounding the tubes such that the fins project into the adsorbent material, the fins being of a material (e.g., metal) of higher thermal conductivity than the adsorbent material. Metal wool loosely packed inside the tubes, or internal radial fins swaged into the tubes, increase internal surface area thereby enhancing convective heat transfer. Metal wool loosely packed between the external fins, or fine wire metal coils lightly squeezed between the external fins, further increase external surface area of the heat exchanger in contact with the adsorbent thereby enhancing contact heat transfer. Performance is enhanced because the external fins and wool or wire coils transport heat more efficiently to all regions of the adsorbent, and permit less non-adsorbent heat exchanger material (e.g., metal) to be used for a given amount of adsorbent. Two or more such units are used in an adsorption heat pump. This design utilizes existing components (e.g., shell-&-tube heat exchanger, internally and externally finned tubing, and metal wool or wire coils) in a novel manner heretofore untried. In one exemplary embodiment, automobile air conditioning, exhaust heat is used to power such an air conditioner. The significant additional power used by the mechanical compressor of an automobile (12%-17% during commuting for subcompact to midsize cars) can be nearly eliminated by powering the air conditioner with otherwise wasted exhaust heat. The adsorbent is heated and cooled by light oil (called Heat Transfer Fluid, HTF) which in turn is heated and cooled by exhaust and fresh air. Such indirect heating and cooling achieves the required efficiency, and allows using phase change material (e.g., wax) to store and therefore fully utilize exhaust heat. A refrigerant reservoir is included which provides immediate cooling after start-up of a cold engine, while the exhaust system and heat pump are still heating up in order to start pumping refrigerant. Eliminating the mechanical compressor increases fuel mileage by 14-18% for midsize, compact, MS and subcompact cars, or 4.6-6.0% annually, given a four-month cooling season.

Owner:LAMBERT MICHAEL A +1

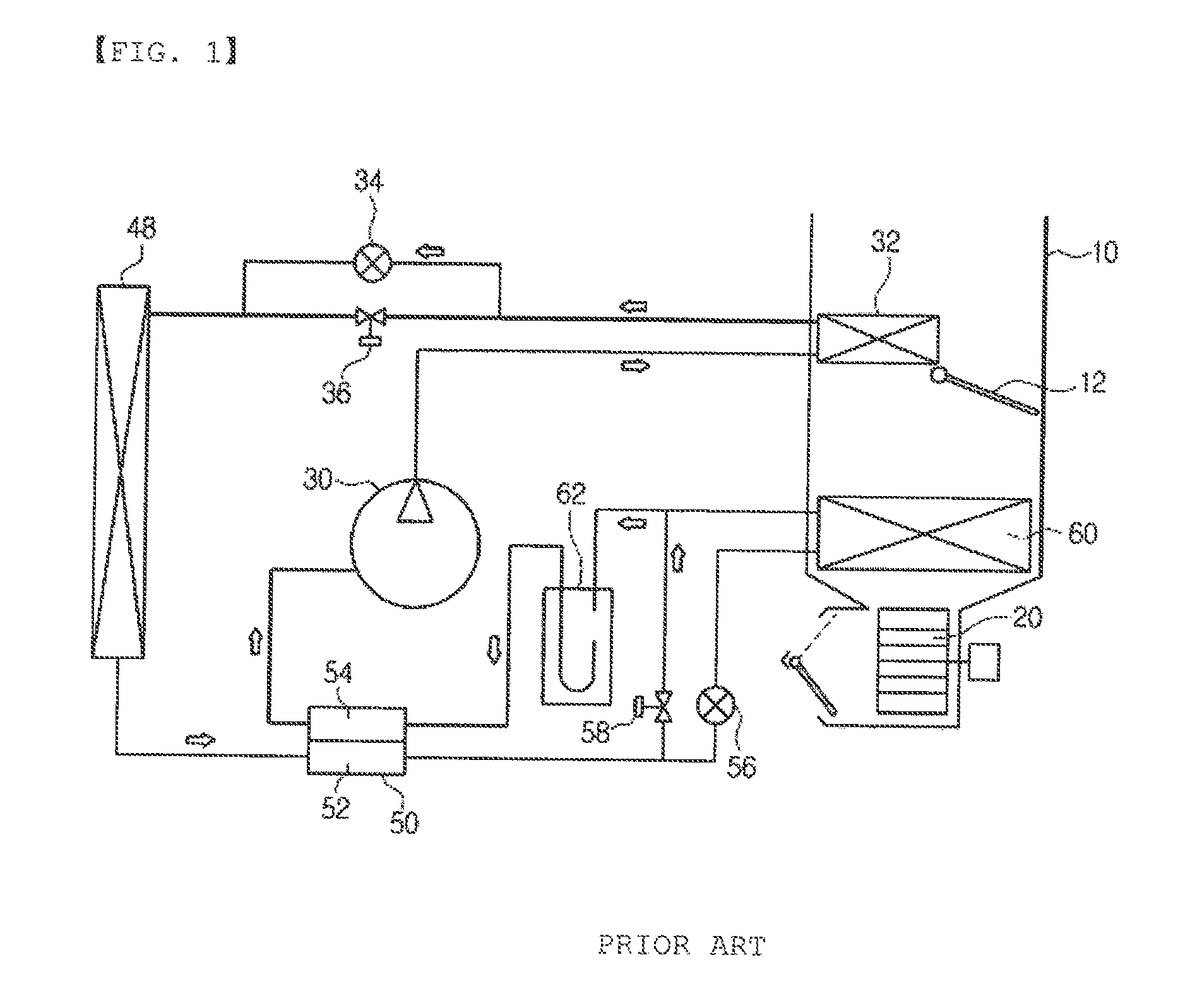

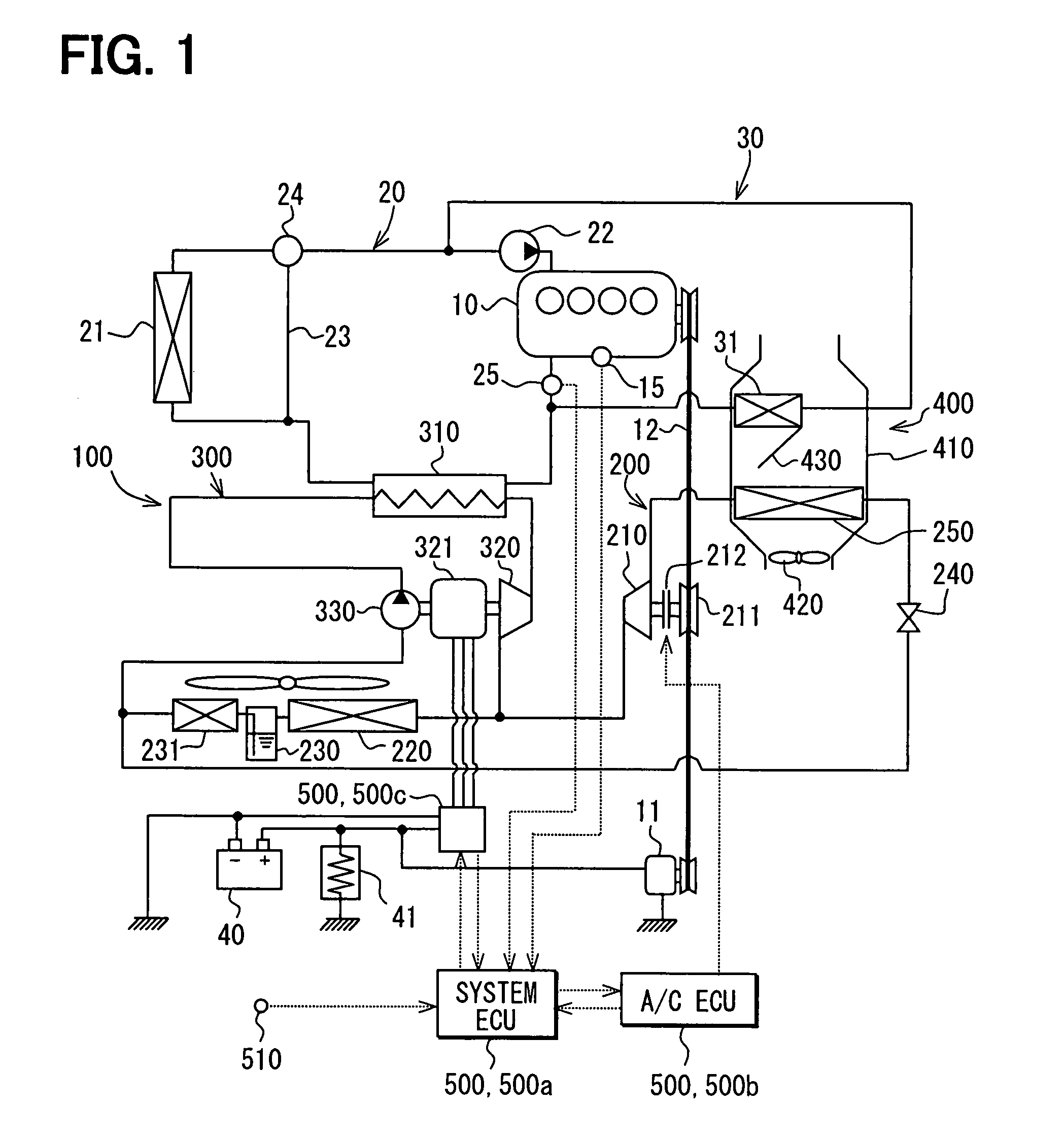

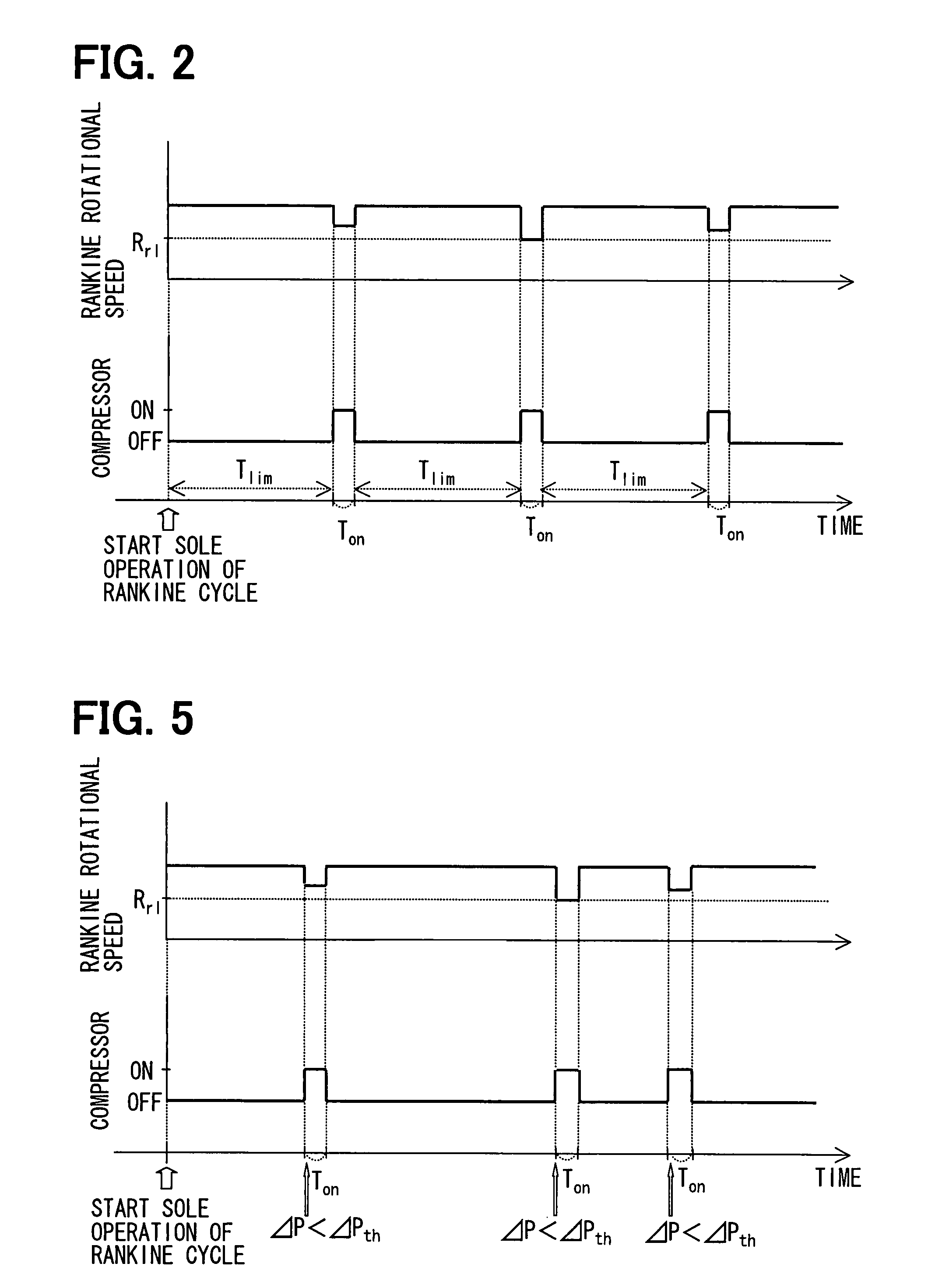

Refrigeration system including refrigeration cycle and rankine cycle

A controller reduces a rotational speed of a Rankine cycle from a predetermined normal rotational speed during an operation of a compressor in a predetermined state when the controller determines that a predicted refrigerant flow quantity, which is predicted by assuming that the compressor is operated in a sole operation of the Rankine cycle at the predetermined normal rotational speed of the Rankine cycle, exceeds a predetermined flow quantity. The predetermined state is a state that satisfies a predetermined condition, which relates to the sole operation of the Rankine cycle.

Owner:DENSO CORP +1

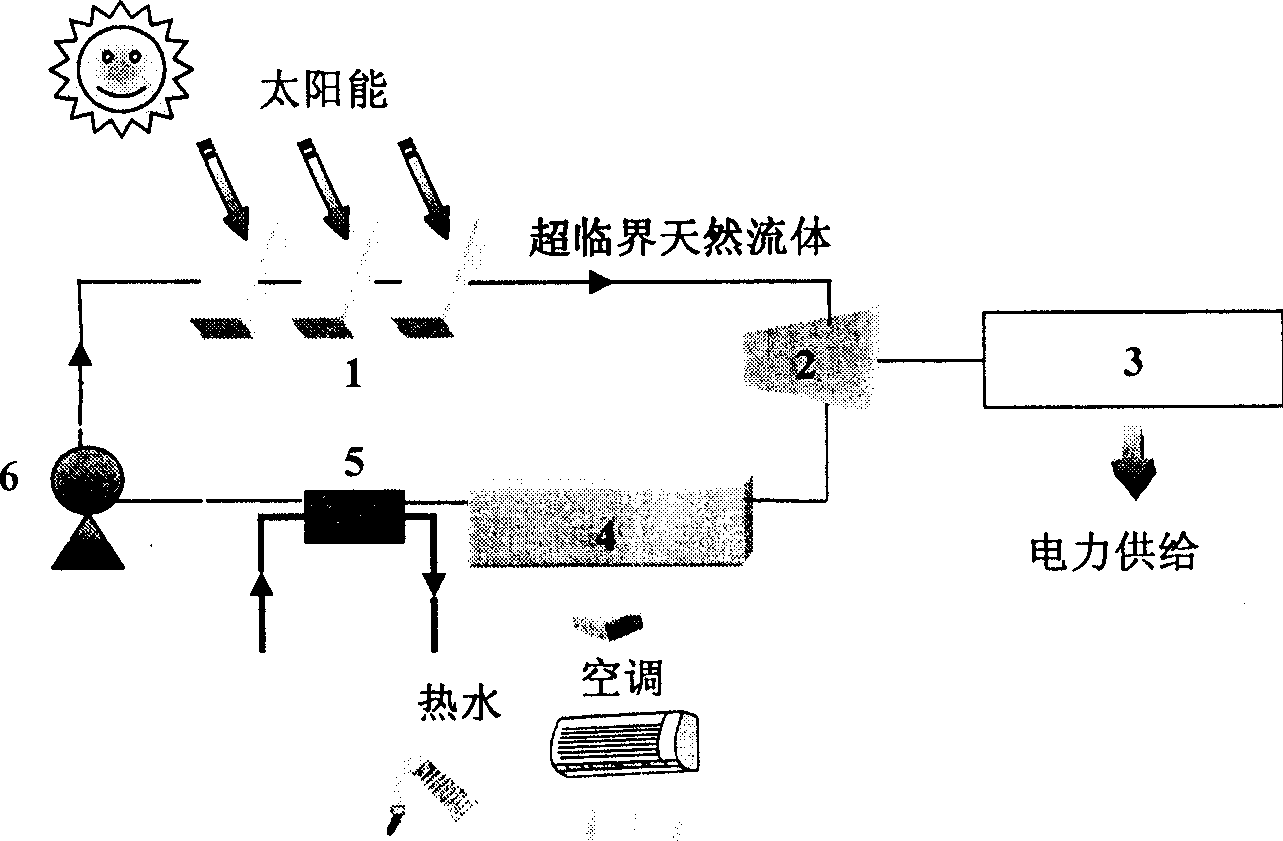

Electricity generating, air conditioning and heating apparatus utilizing natural medium and solar energy or waste heat

The invention relates to an electric generation, air conditioning and heating device which can use natural working substance, solar energy or waste heat. It comprises a solar energy collector or a waste heat collector, a pump, a turbine, a generator, a refrigerator, a heat exchanger and the pipeline. Wherein, the inlet and outlet of solar energy collector or waste heat collector are individually connected to the outlet of pump and the inlet of turbine to form the natural working substance circuit; the liquid natural working substance with low boiling point via the pressurizing of pump can reach hypercritical pressure condition and via the heating of solar energy collector or waste heat collector to form hypercritical liquid with high temperature and high pressure, then via the thermal insulation expanding, to form low pressure gas, and via the heat recycle to be cooled into liquid, at last via the pump to be feedback to the solar energy collector or the waste heat collector to realize the thermodynamics cycle. The hypercritical liquid with high temperature and high pressure can drive the turbine generator to generate electricity; and the heat recycle process uses the adsorption refrigerator to supply the cool and warm air conditioner as well as supply the hot water.

Owner:杜培俭

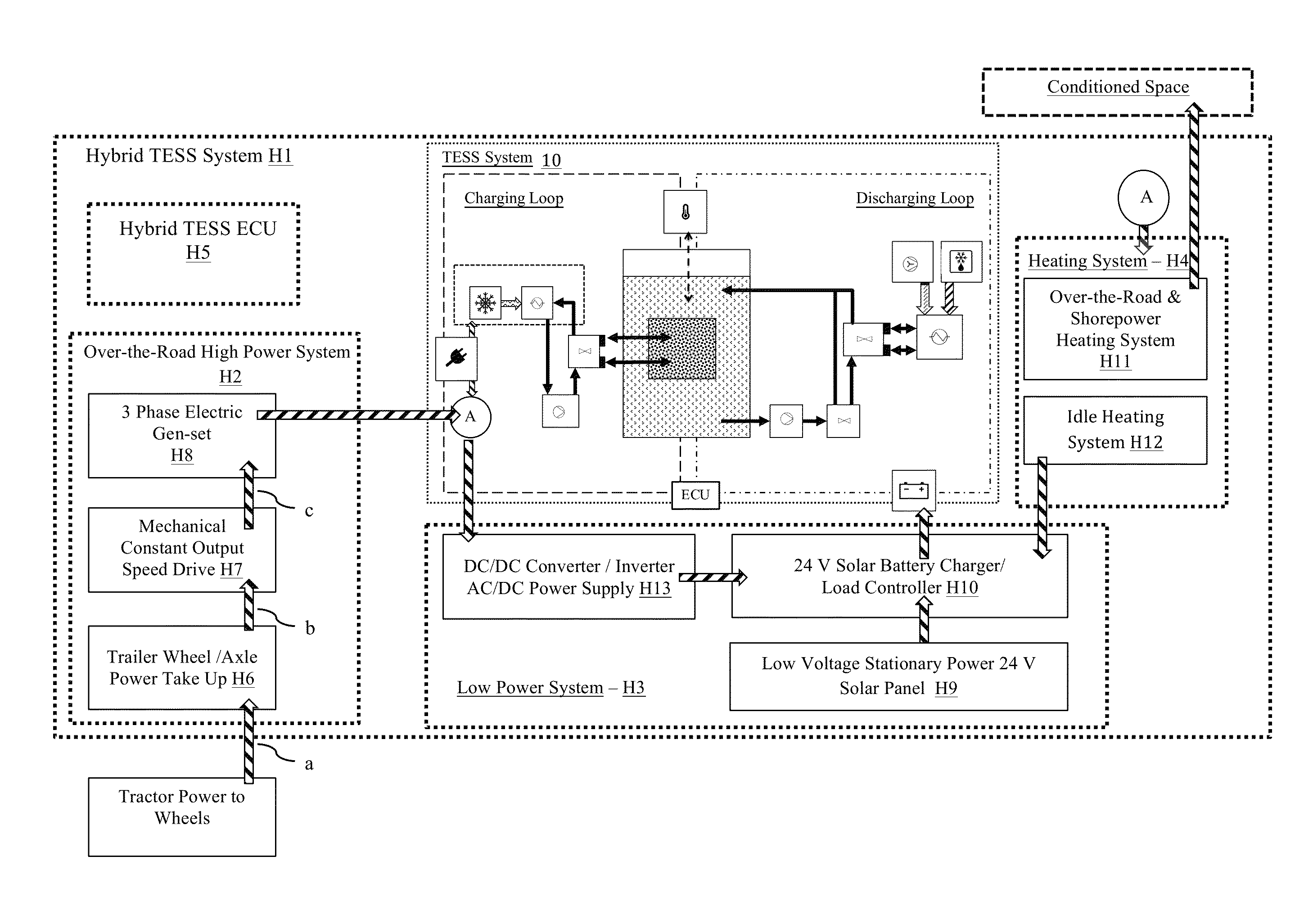

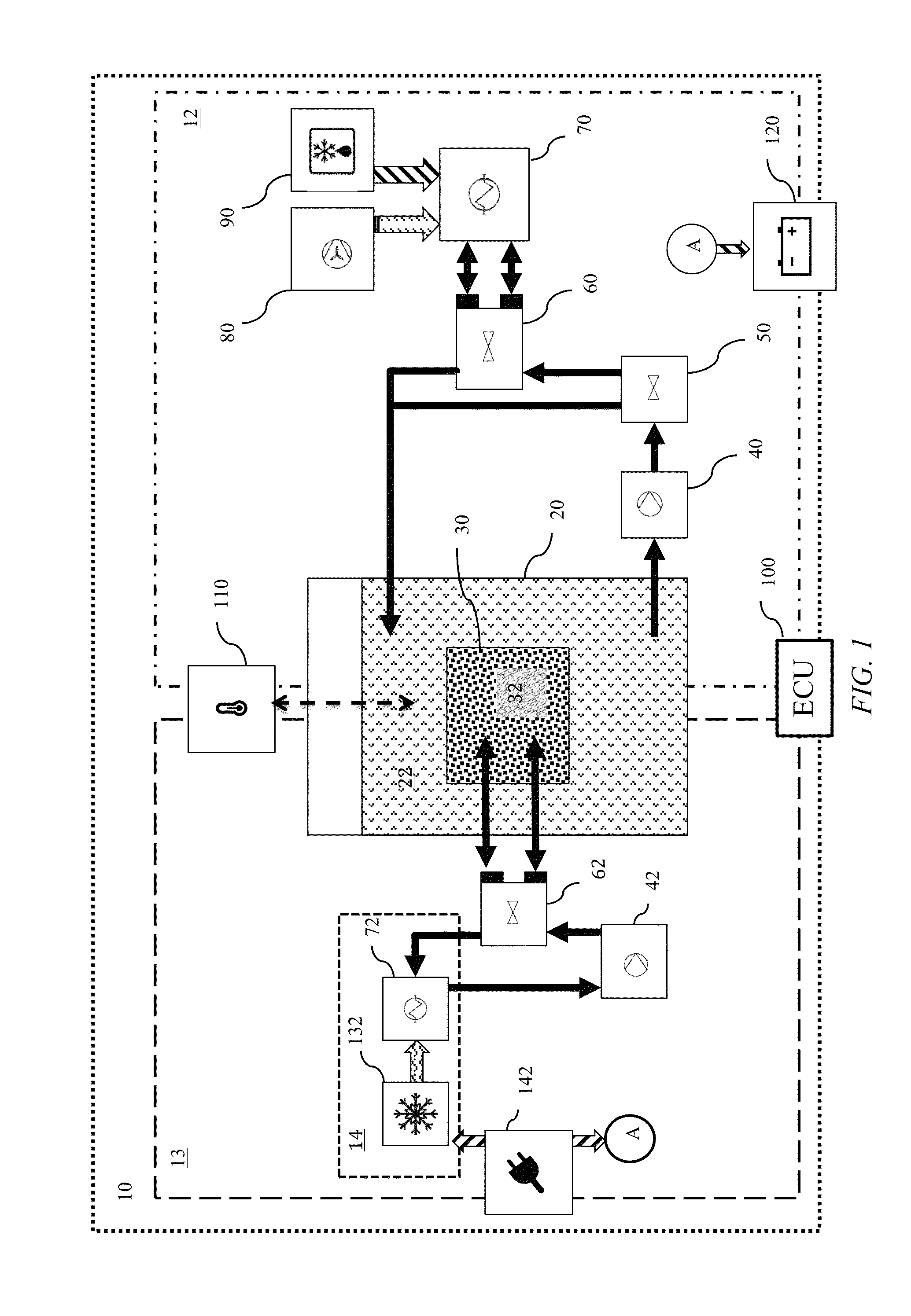

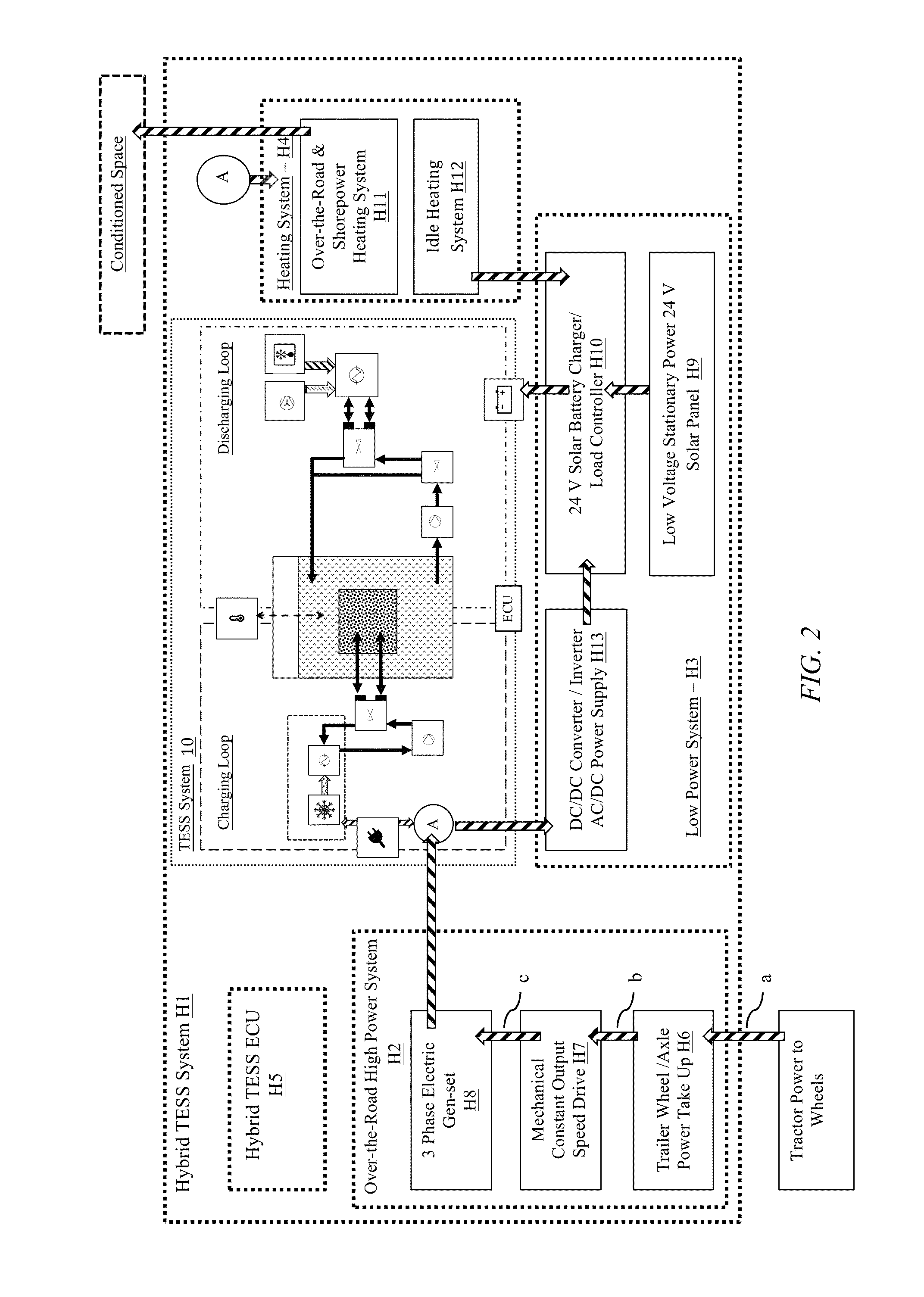

Transportation refrigeration system with integrated power generation and energy storage

InactiveUS9389007B1Avoids cost and weight and emission and regulatory impactMinimized in sizeAuxillary drivesRefrigerated goods vehicleThermal energyWorking fluid

A thermal energy storage system (TESS) that enables the discharge of refrigerated air for cooling cargo or passengers in large compartments, such as the trailer of a semi-truck, for a period of time well in excess of several hours. The TES system is able to provide refrigeration without operating a conventional VCC unit, the truck engine, or the TRU diesel APU engine during all or a significant portion of the period of the typical range of time that a 53 foot refrigerated the truck is traveling over the road. The TES system includes a phase change material (PCM) reservoir, a cooling system-to-WF heat exchanger in fluid communication with the PCM reservoir, and a PCM-to-target heat exchanger in fluid communication with the PCM reservoir. The PCM reservoir contains a phase change material, a working fluid (WF) and a working fluid-to-PCM heat exchanger.

Owner:NEW WEST TECH LLC

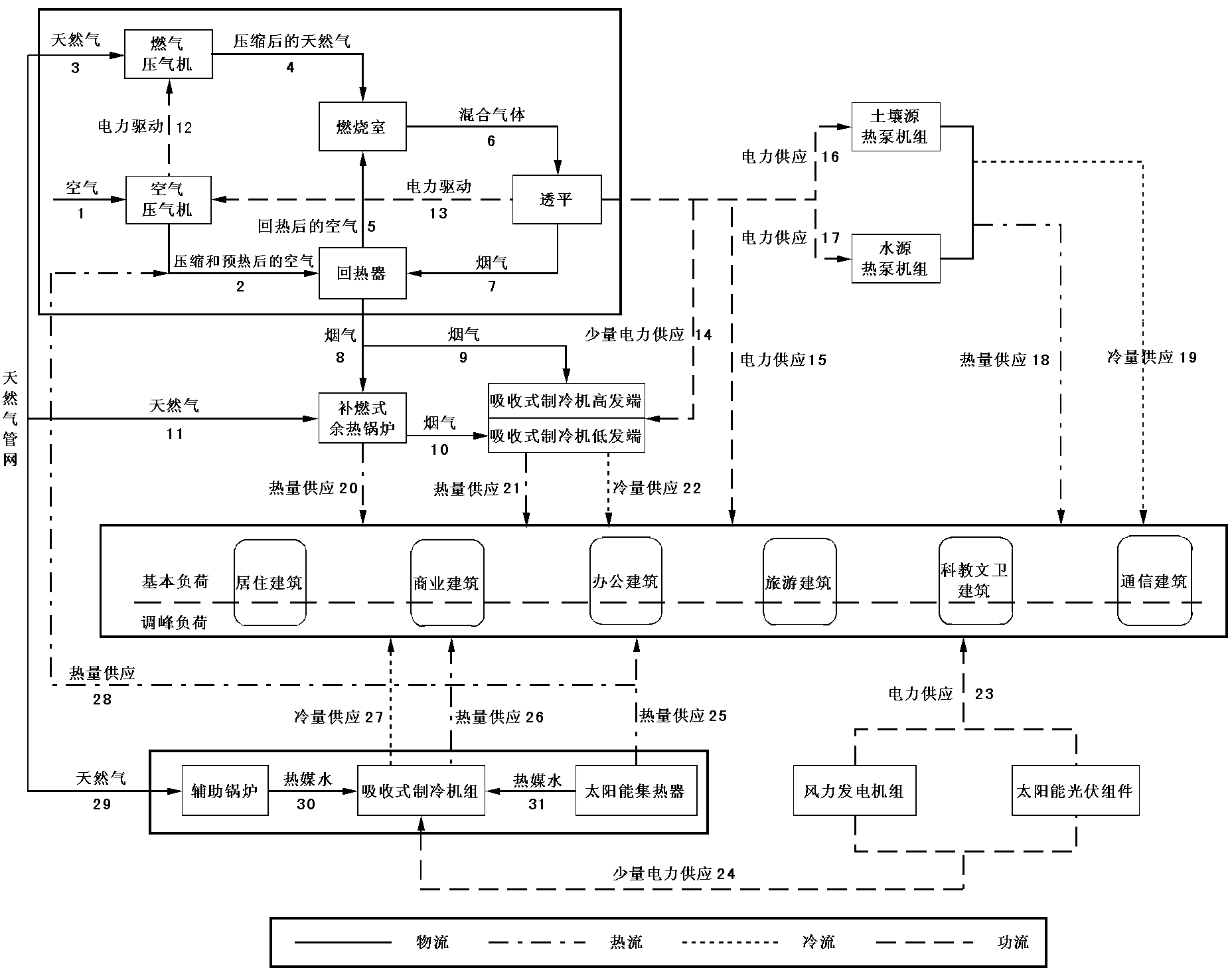

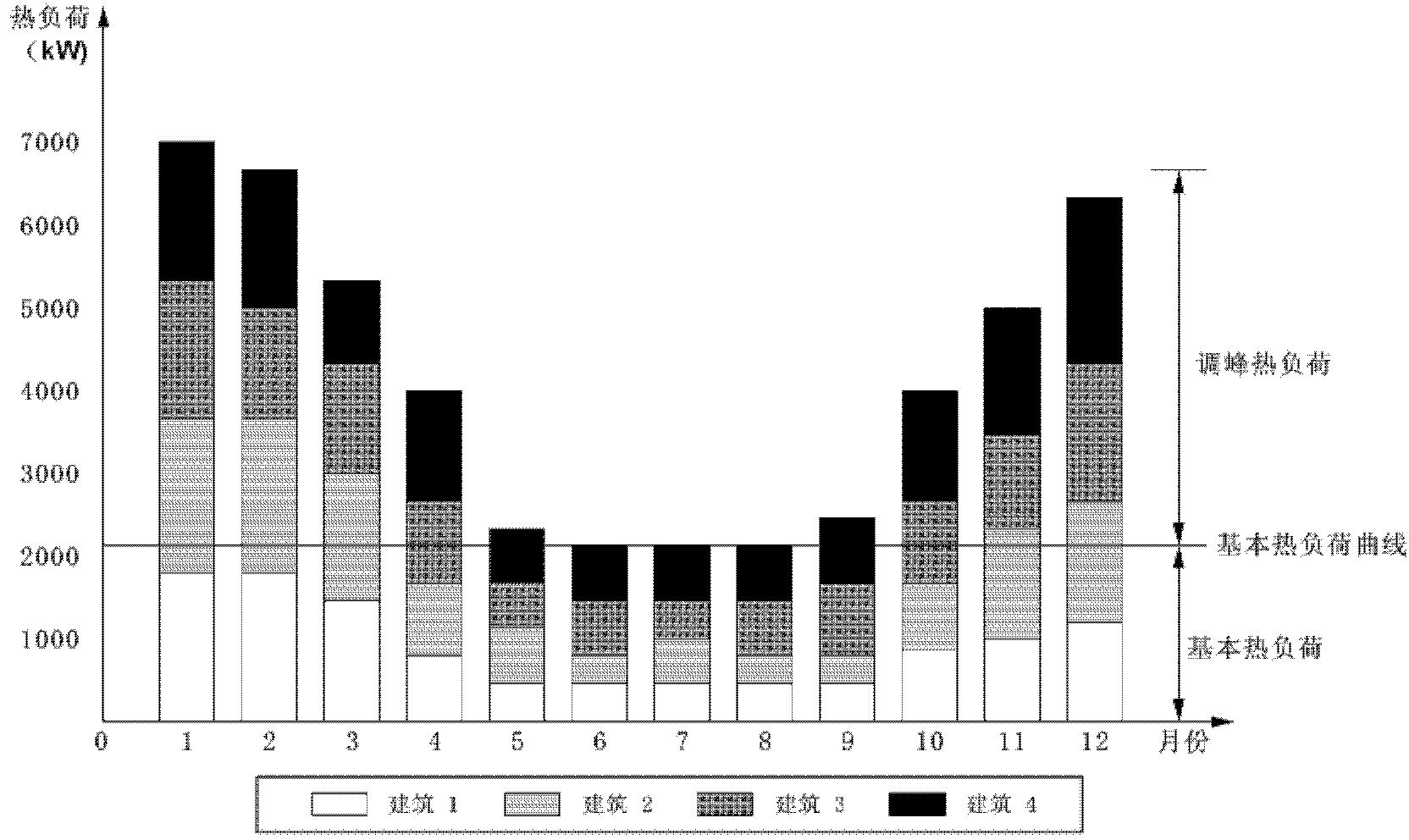

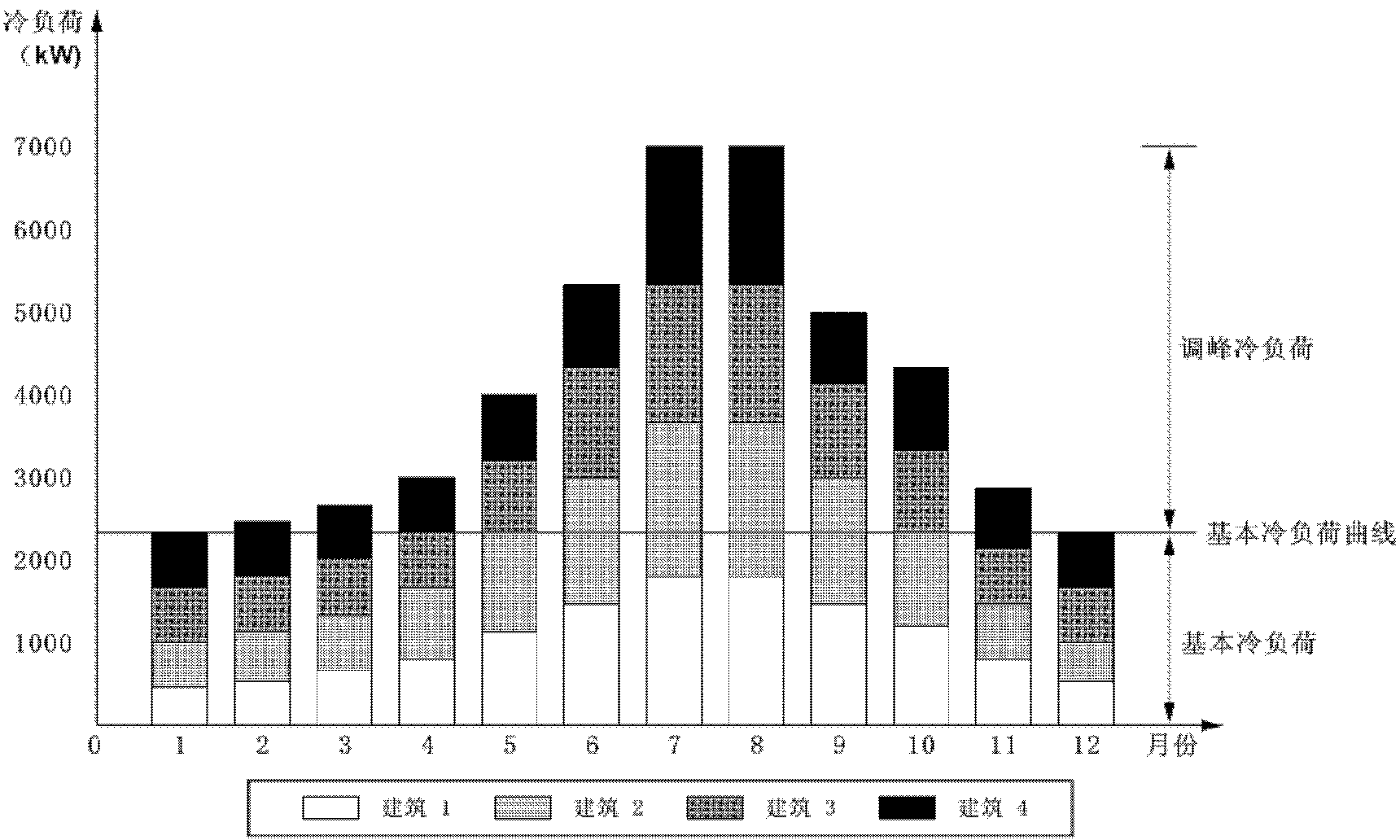

Integration system for religion architecture

InactiveCN103256119AReduce consumptionSimple structureClimate change adaptationGas turbine plantsEngineeringPrimary energy consumption

The invention discloses an integration system for religion architecture, which comprises a production power terminal, a transmission and distribution terminal and an energy consumption terminal, and the production power terminal at least comprises a gas turbine, an afterburning type exhaust-heat boiler, a flue gas type double effect absorption refrigeration set, a soil source heat pump set, a water source heat pump set, a solar energy absorption refrigeration set, a wind generating set and a solar energy photovoltaic component; the transmission and distribution terminal at least comprises a pipe network; the energy consumption terminal at least comprises an inhabitation building, a business building, an office building, a travel building, a science education culture health care building and communication building. The invention organically integrates the natural gas based gas turbine cooling heating and power generation combined system with the solar energy photovoltaic component, the solar heat collector, the solar energy absorption refrigeration set, the wind generating set, the soil source heat pump set and the water source heat pump set, thereby not only reducing primary energy consumption, improving total heat efficiency of the system, but also optimizing the energy structure, protecting environment, reducing greenhouse gas emission and playing an important role for responding to climate change.

Owner:HUNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com