Patents

Literature

412 results about "Micro gas turbine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

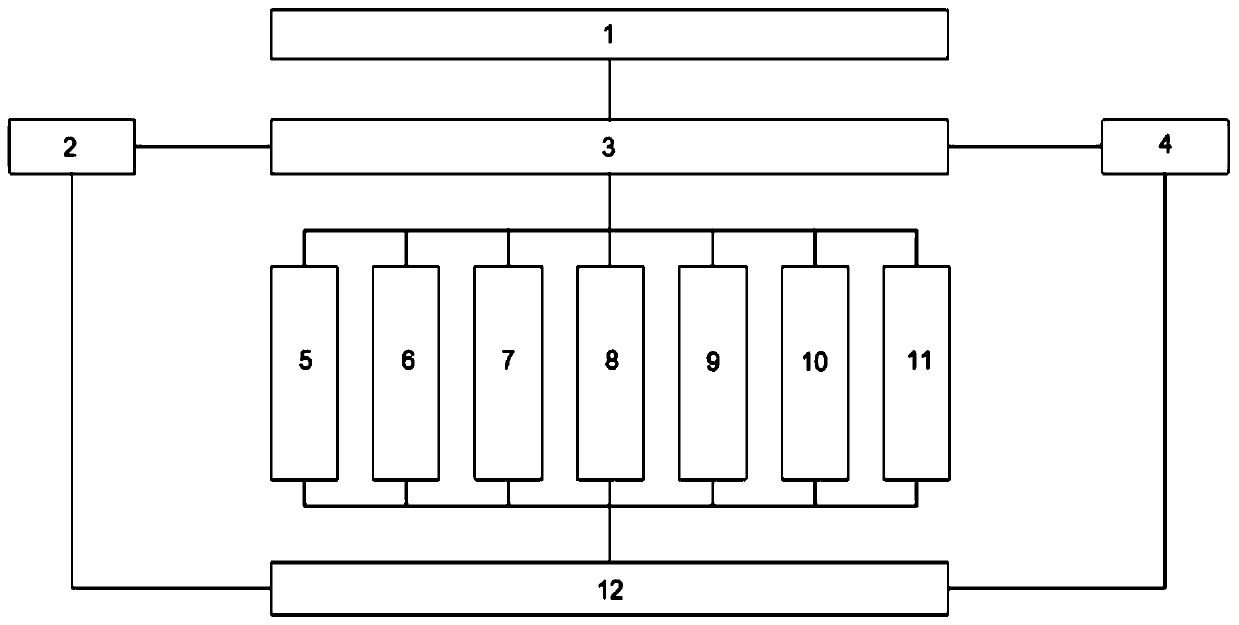

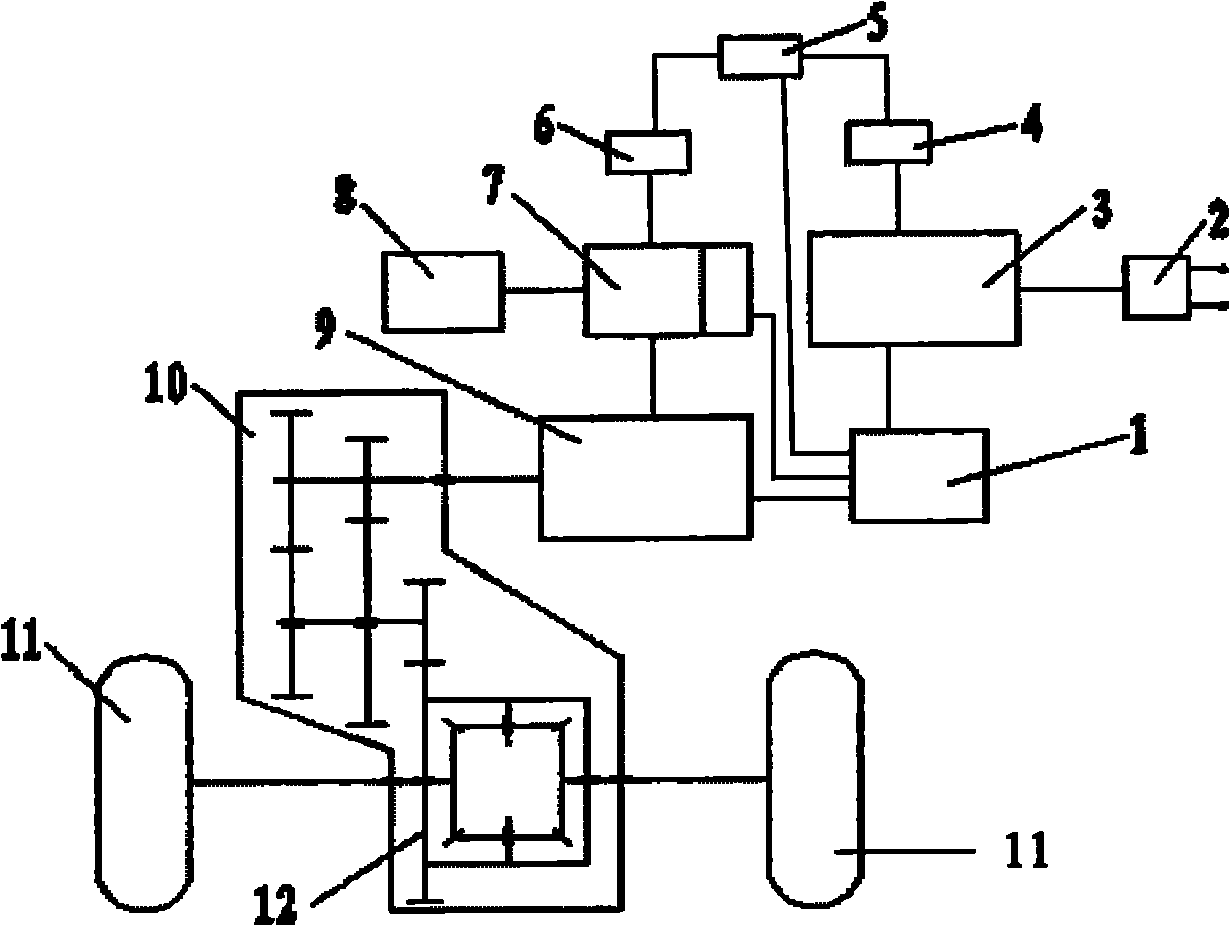

Minitype gas turbine generator wellhead shale gas supply device control system

PendingCN111350595AMeet the requirements of water hydrocarbon dew pointGuaranteed uptimeTurbine/propulsion fuel valvesGas turbine plantsMicro gas turbineHydrocarbon dew point

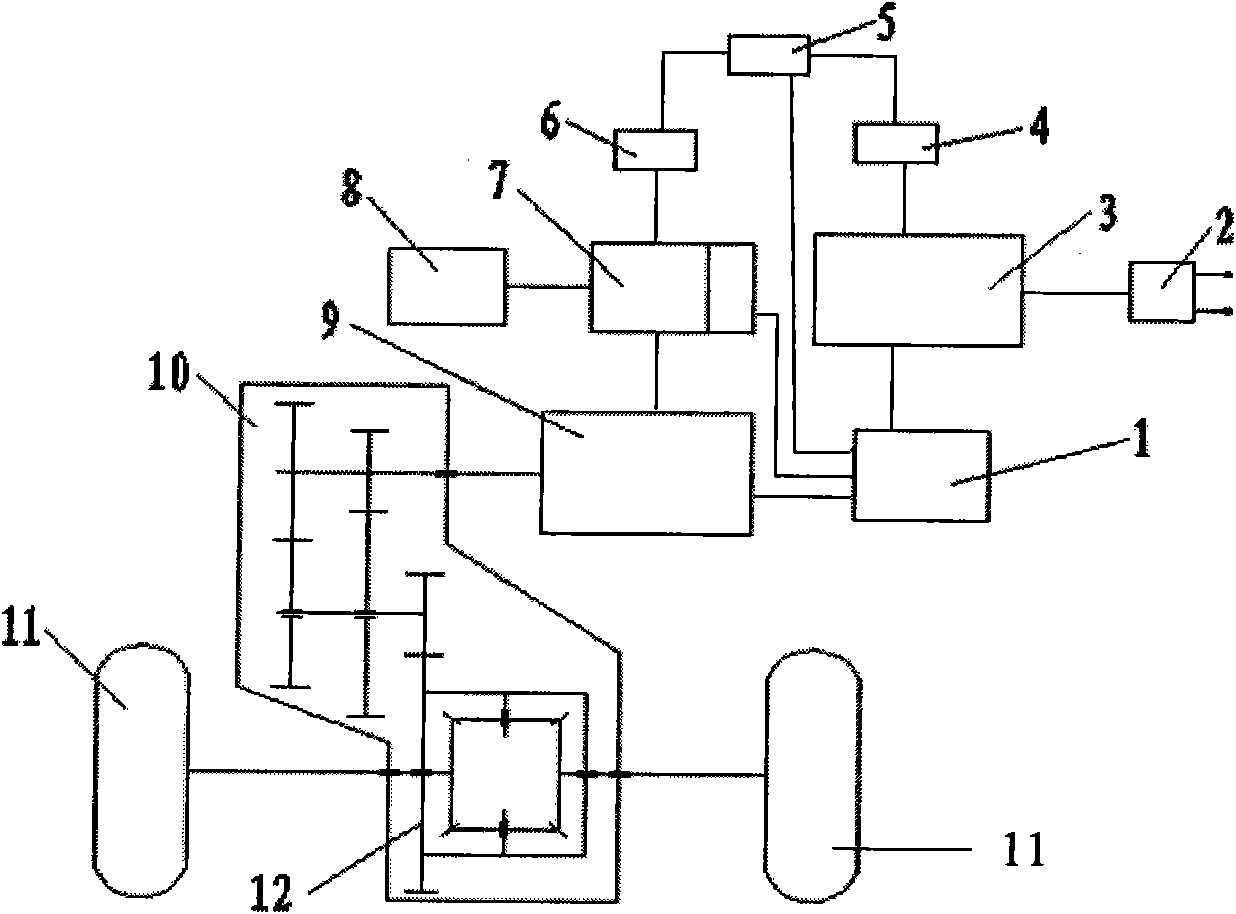

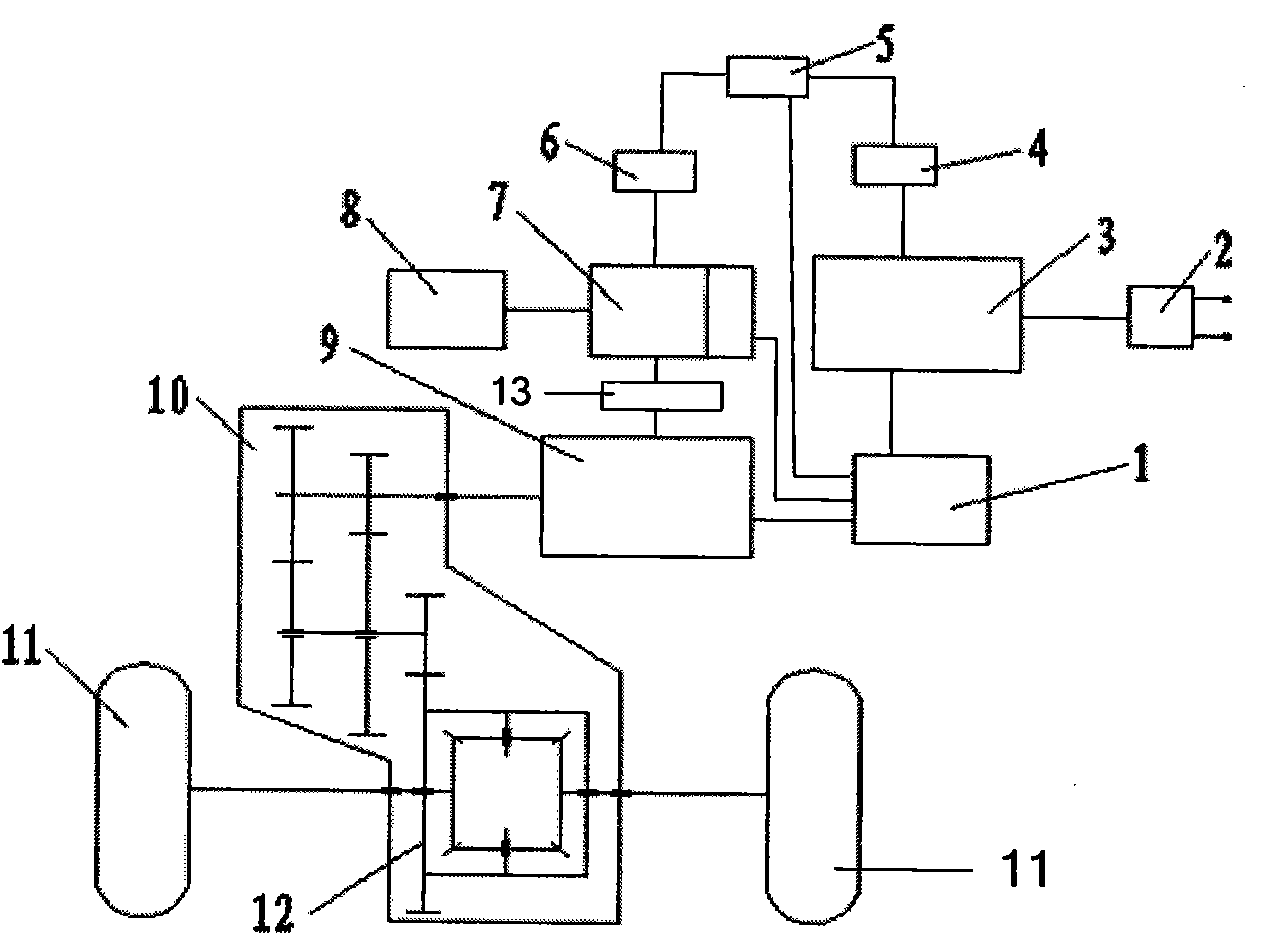

The invention discloses a minitype gas turbine generator wellhead shale gas supply device control system. A control protection system comprises a particle liquid drop control system, a temperature control system, a pressure control system, a liquid level control system, a water hydrocarbon dew point control system, a fine treatment control system and a system safety protection system which are independently arranged side by side, a working condition parameter signal acquisition system transmits acquired signals to a logic judgment command system, the logic judgment command system is correspondingly connected with a parameter setting system, the control protection system and a data storage remote transmission system, and a micro gas turbine power generation system is correspondingly connected with the parameter setting system, the control protection system and the data storage remote transmission system. The control system has the beneficial effects that stable control over the water hydrocarbon dew point is achieved, and normal and stable operation of the micro gas turbine is guaranteed; the pollution discharge is accurately controlled according to the fluctuation condition of theactual working condition, and the overall operation cost is reduced; and automatic liquid drainage under different working condition fluctuations is achieved, and the risks of tripping and blow-by arereduced.

Owner:JEREH OIL & GAS ENG

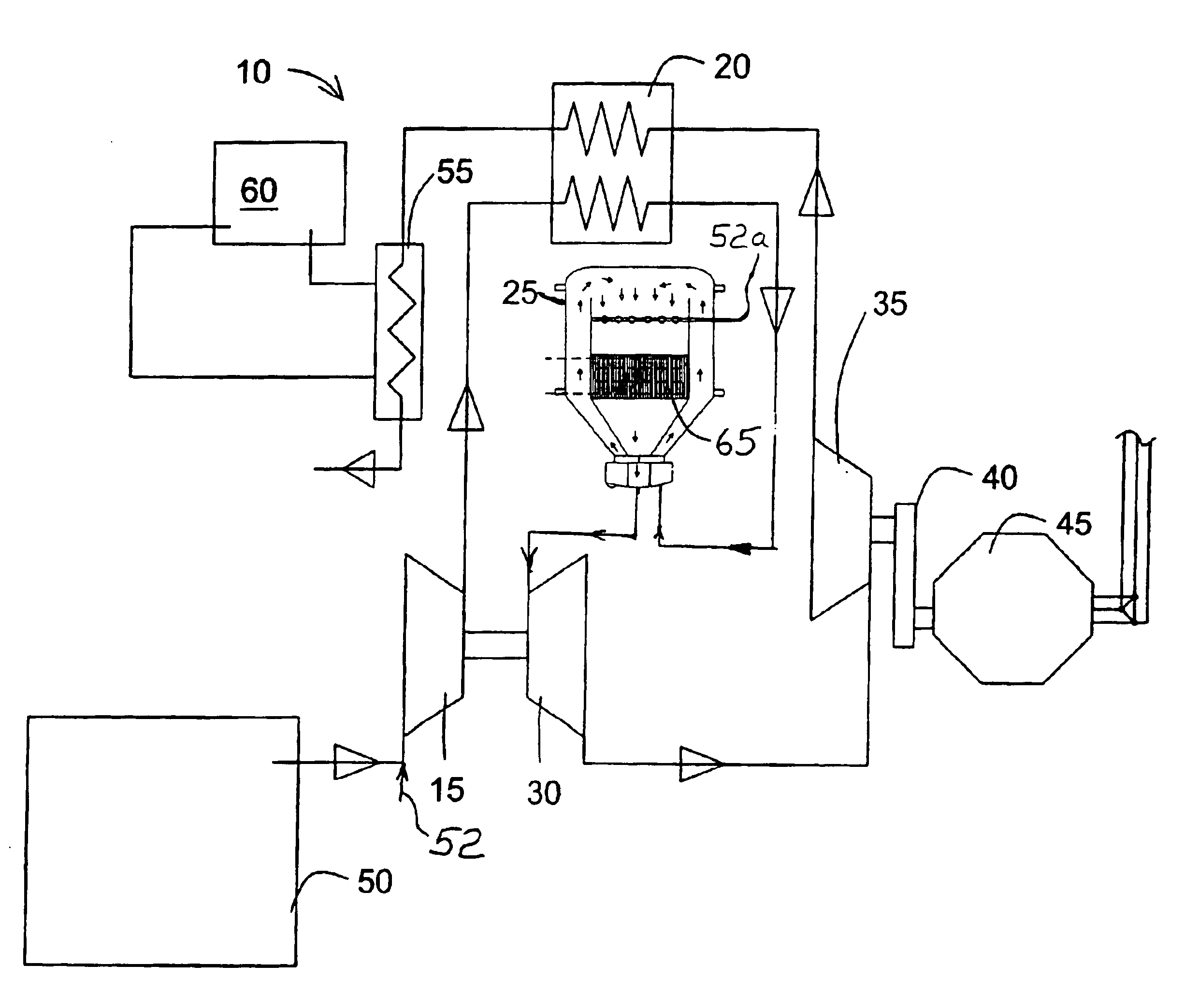

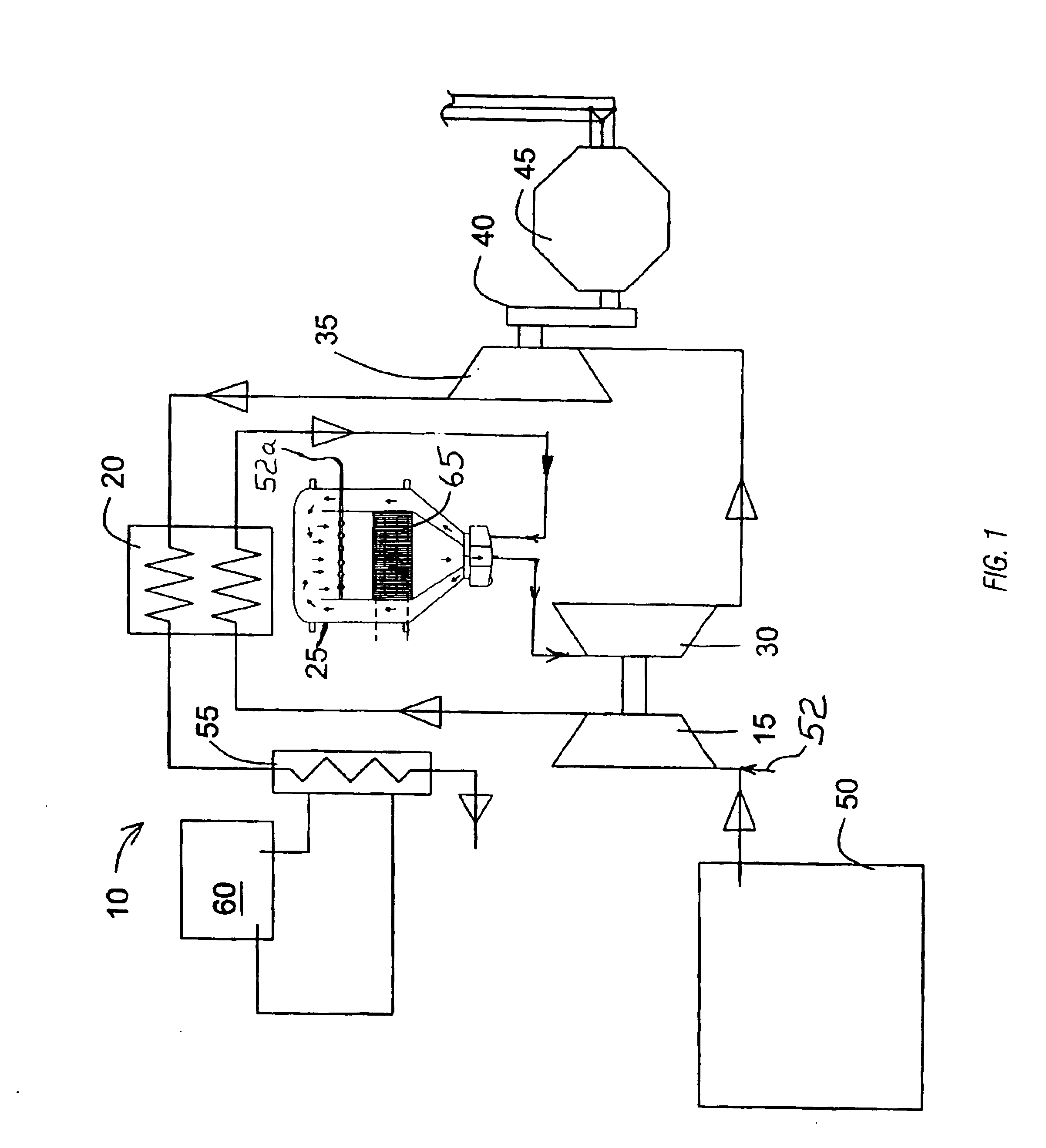

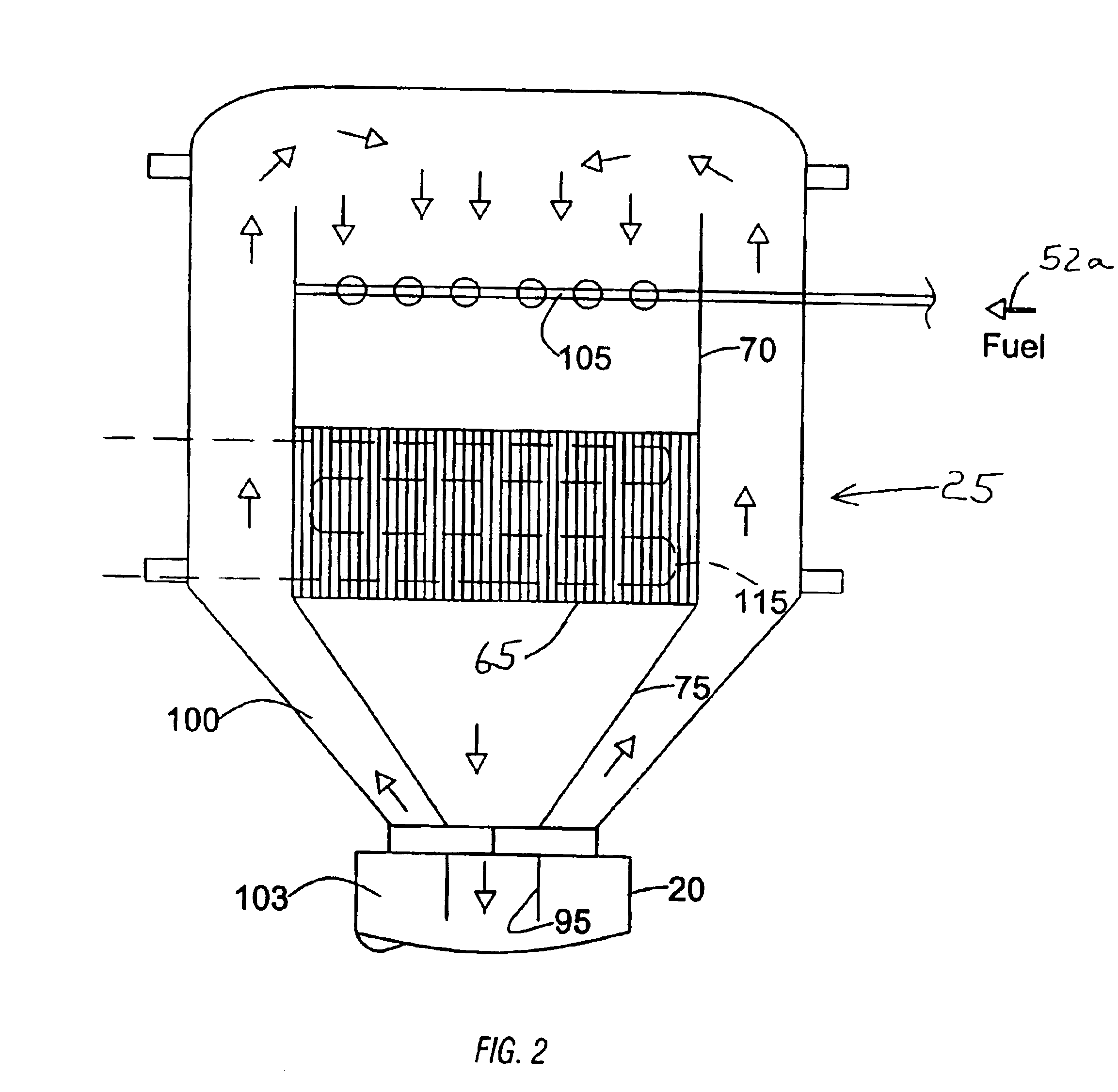

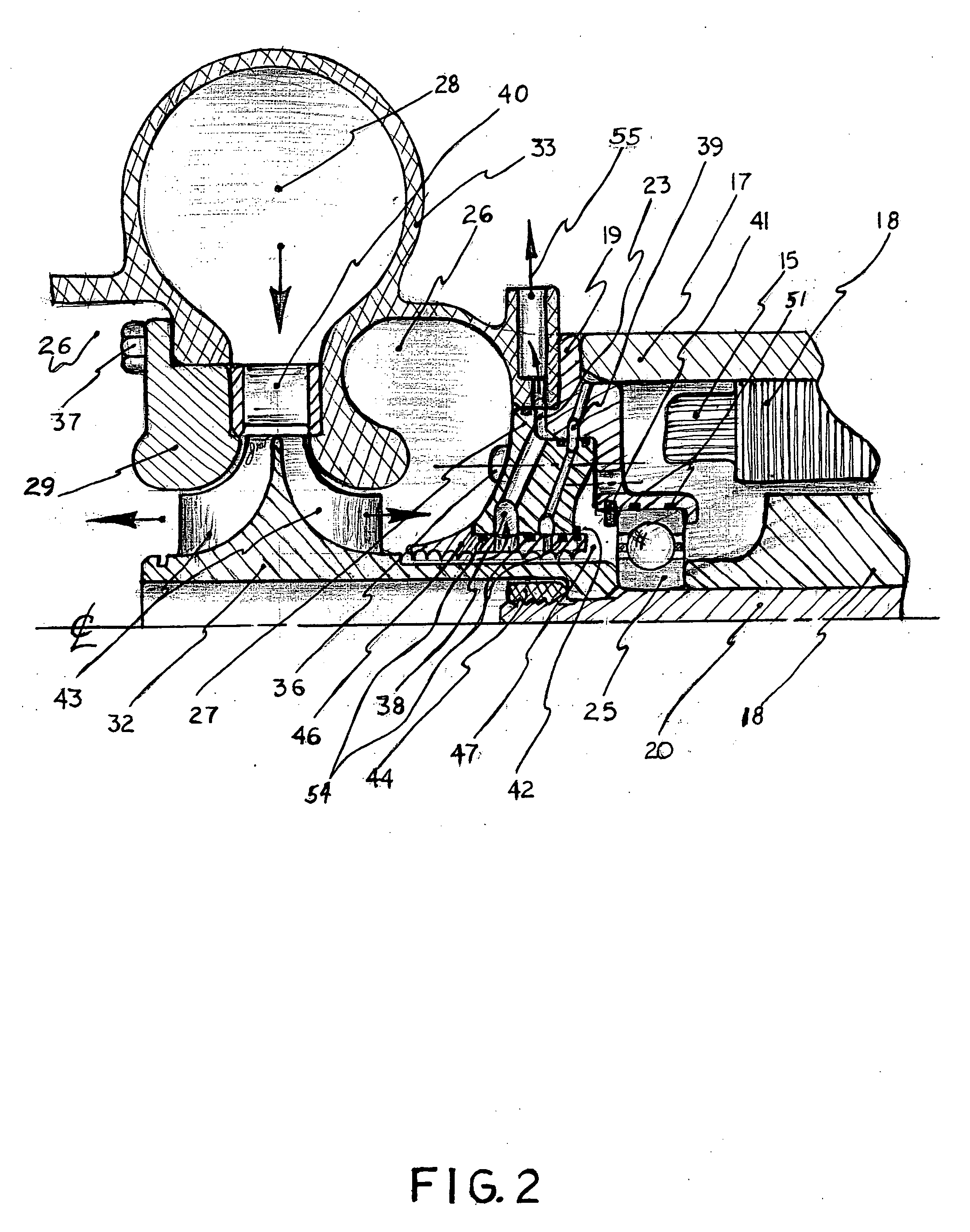

Microturbine for combustion of VOCs

ActiveUS6895760B2Usable electricityContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustorMicro gas turbine

A microturbine engine operable to combust a flow of VOCs without a combustor. The microturbine engine comprising a compressor having an inlet, the inlet receiving a mixture of air and VOCs, the compressor operable to produce a flow of compressed air and VOCs. The invention also includes a reaction chamber including a reactor bed. The flow of compressed air and VOCs is combusted within the reactor bed to produce a flow of products of combustion. The invention includes a turbine driven by the flow of products of combustion from the combustor and a generator coupled to the turbine. The generator is driven by the turbine at a speed to produce electrical power.

Owner:FLEXENERGY ENERGY SYST

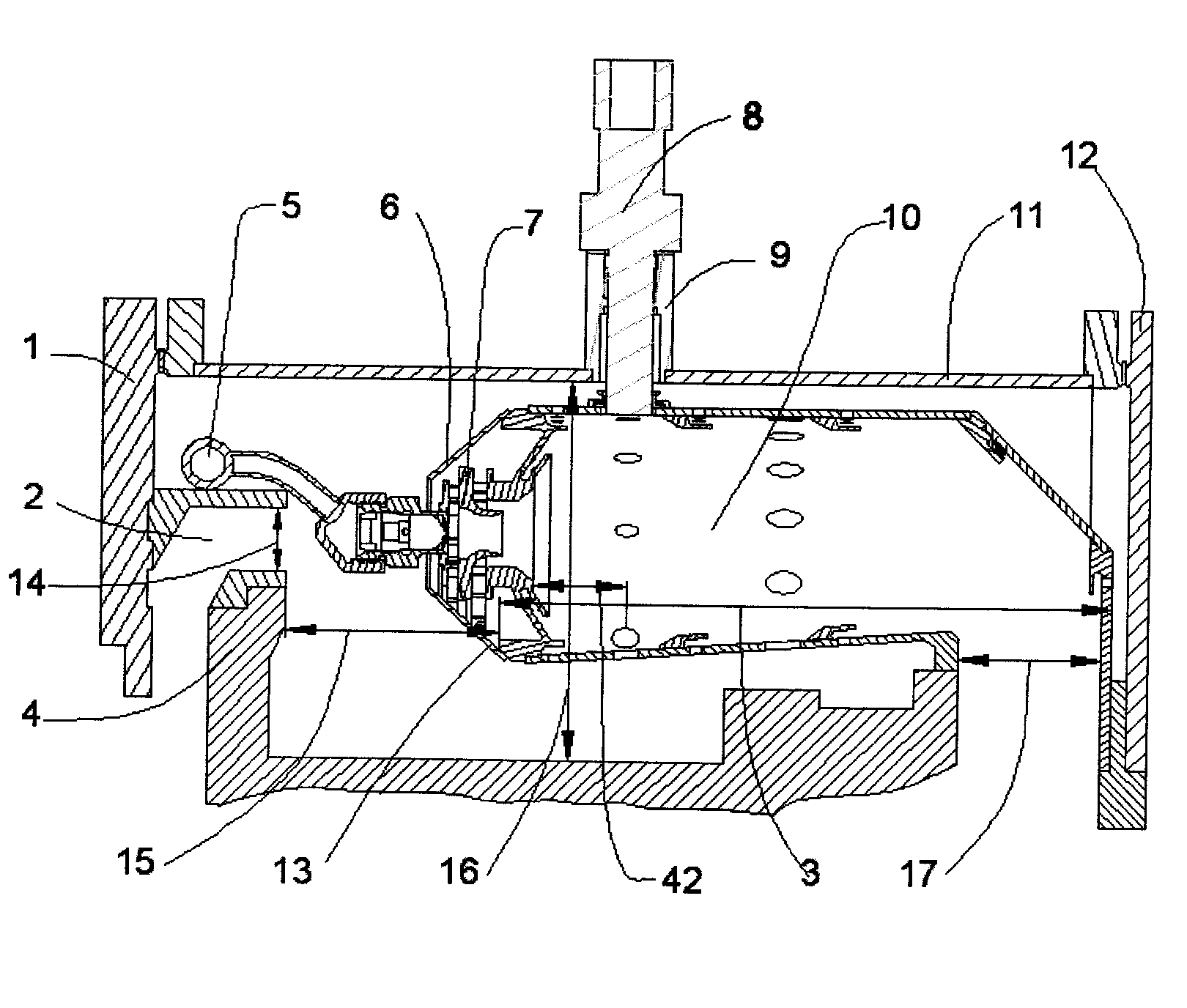

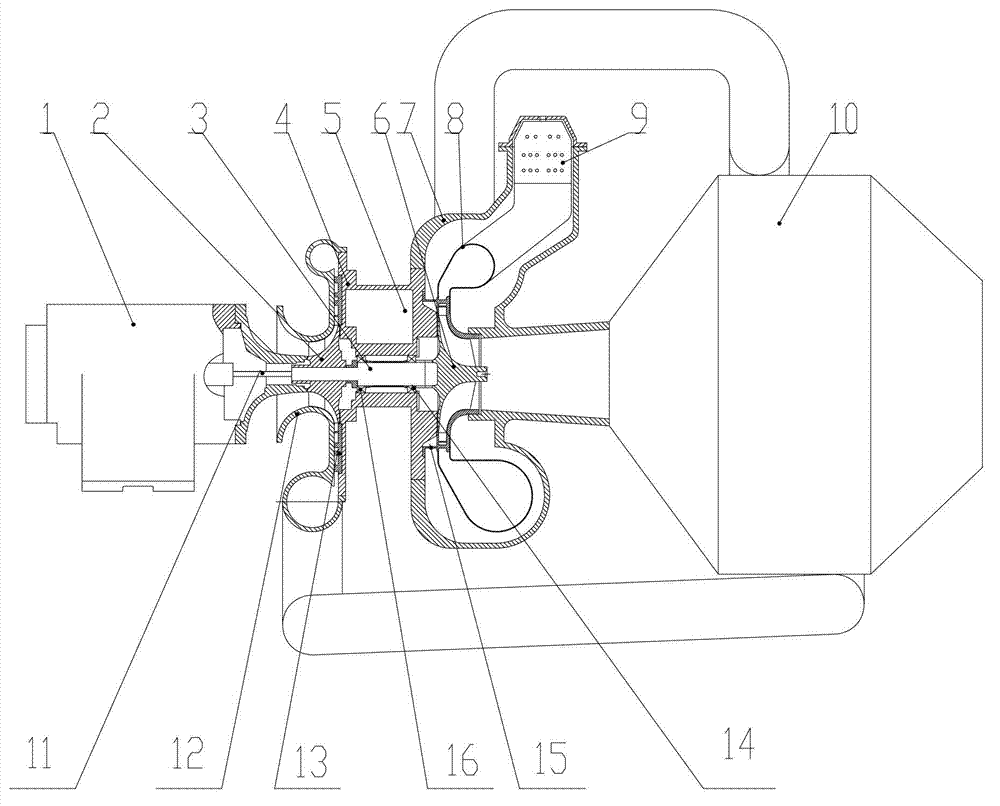

Miniature gas turbine combustion chamber

ActiveCN101818910AShorten the axial distanceImprove cooling effectContinuous combustion chamberCombustion chamberHigh energy

The invention discloses a miniature gas turbine combustion chamber, which has an annular structure and mainly comprises a flame tube, an outer casing, an inner casing, a swirler and a fuel oil supply system. The flame tube is formed by welding an outer flame tube, a head end wall and an inner flame tube; the rear end of the flame tube is connected with a rear flange of the casing of the combustion chamber through a screw; the rear end of the outer casing is connected with the rear flange of the casing through a bolt; and a front flange of the casing is connected with the front end of the casing through a bolt. An inlet of the combustion chamber is welded on the front flange of the casing; air radially enters the inlet of the combustion chamber; the front end of the inner casing is fixed in a hole of the inlet of the combustion chamber; the swirler is welded on the head end wall; the fuel oil supply system is fixed on an outer ring of the inlet of the combustion chamber; a main combustion hole, a mixing hole and an air film cooling hole are formed on the flame tube; and an air film slot tongue is welded on the lower part of the air film cooling hole for guiding cooling airflow. A high-energy DC igniter is inserted into the flame tube for realizing ignition starting of the totally annular combustion chamber; and gas is discharged out of the combustion chamber radially under the guiding of a slope of the outer flame tube and a vertical section of the outer flame tube. The miniature gas turbine combustion chamber is applied to a miniature gas turbine. Because the gas at the outlet directly impacts a centripetal turbine, the axial distance of the miniature gas turbine can be shortened, and the space is fully utilized.

Owner:BEIHANG UNIV

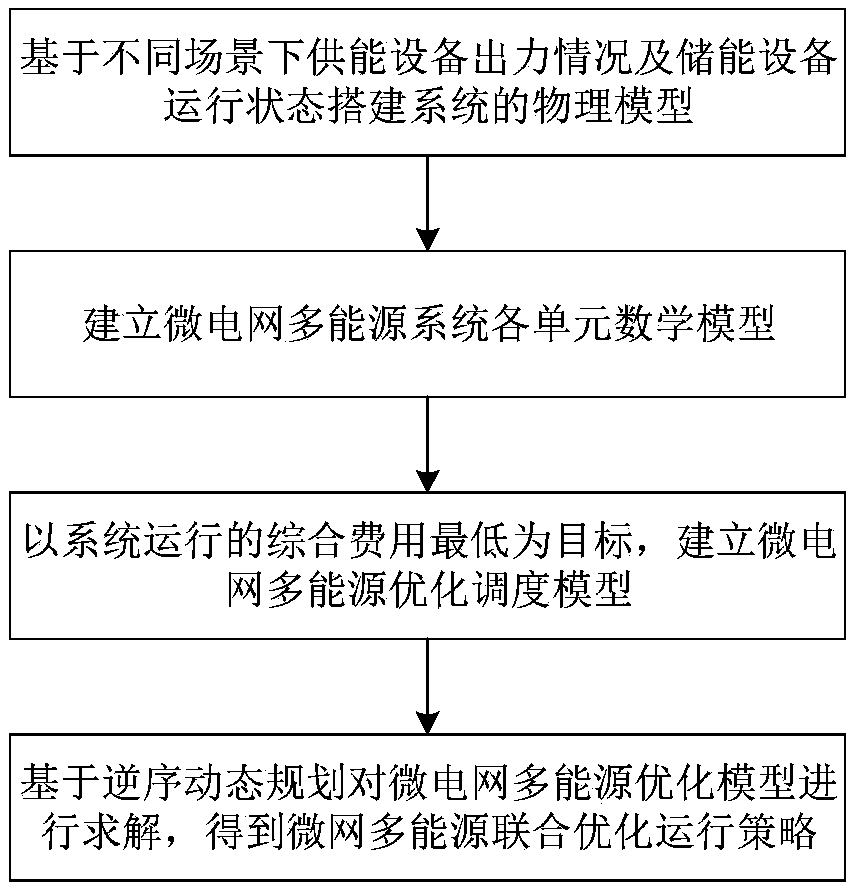

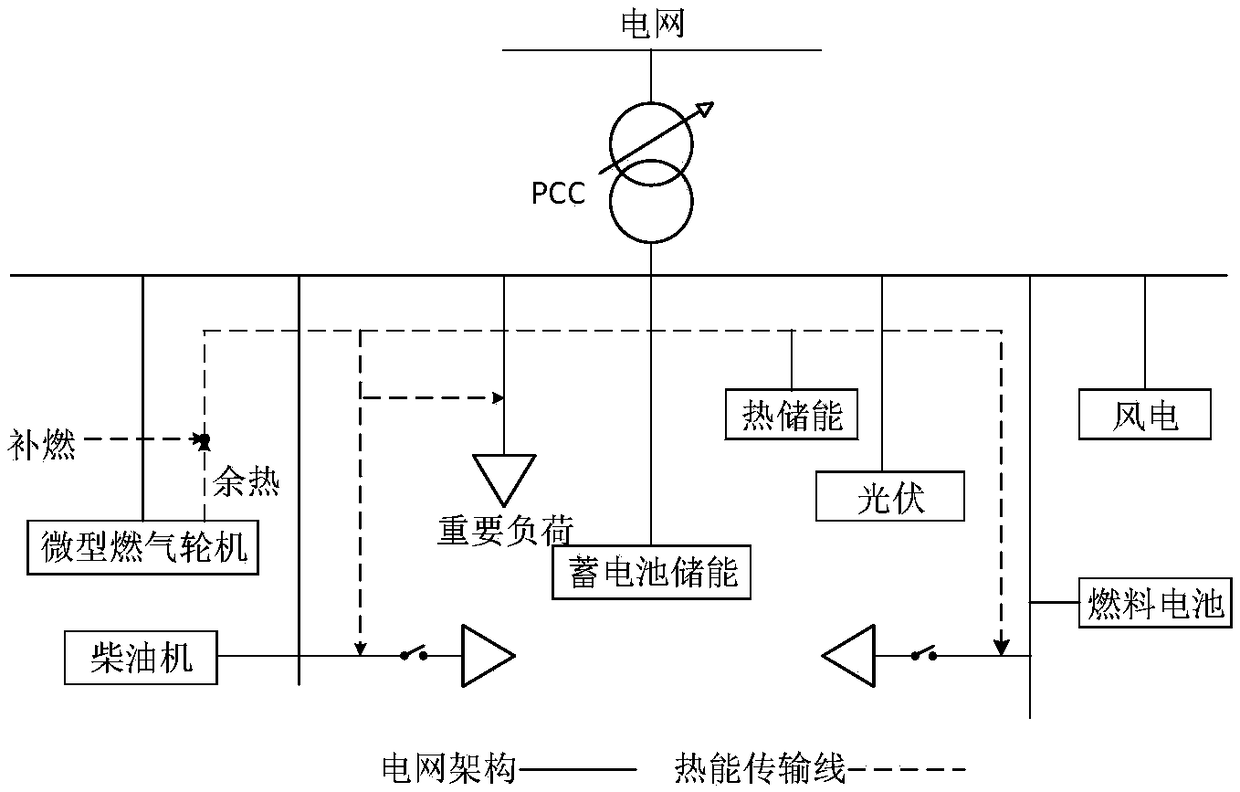

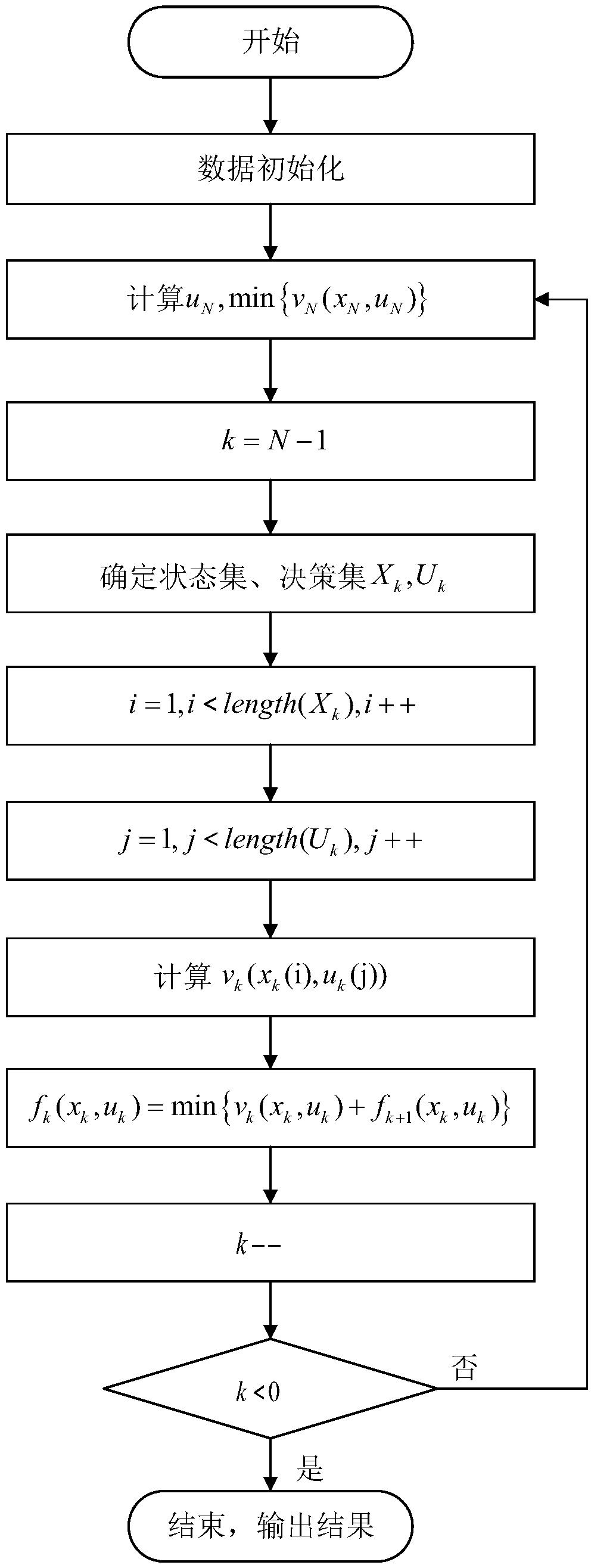

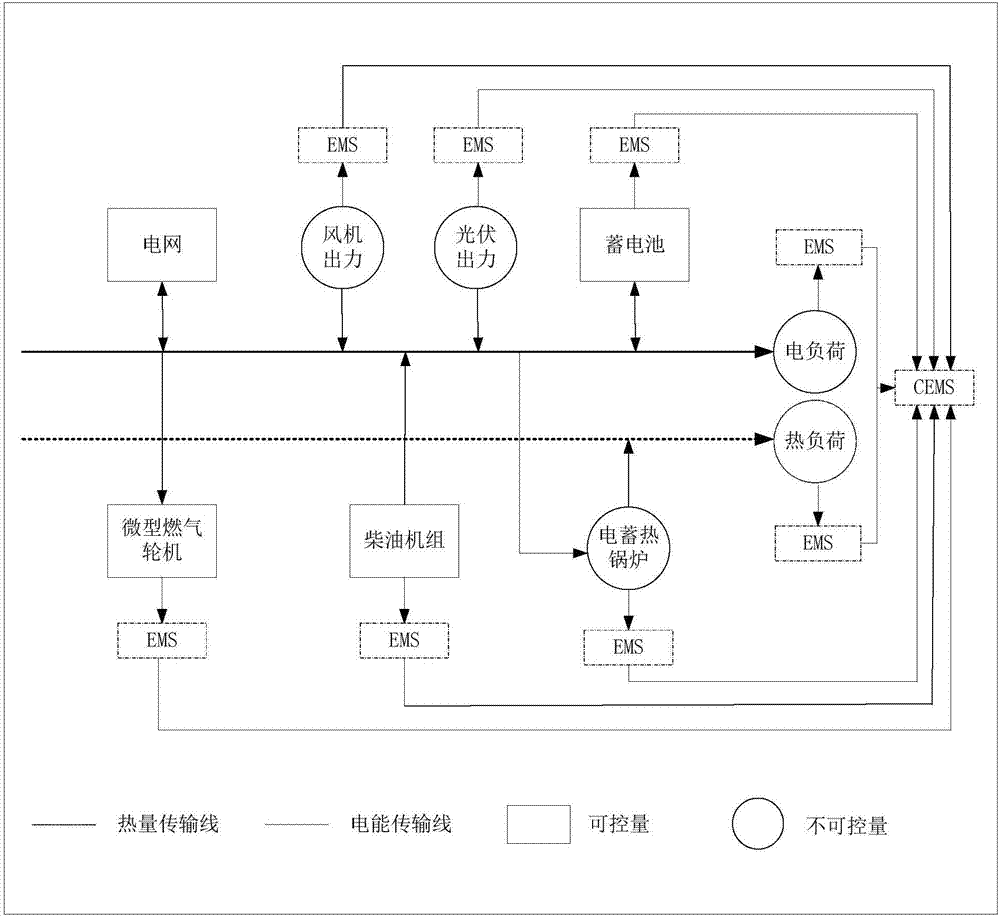

Microgrid multi-energy joint optimal scheduling method

ActiveCN109327042AEasy to guideGood motivationSingle network parallel feeding arrangementsWind energy generationMicrogridDynamic planning

The invention relates to a microgrid multi-energy joint optimal scheduling method. The method includes: step 1, on the basis of force application conditions of energy supply equipment and operating states of energy storage equipment in different scenes, constructing a physical model of a multi-energy system; step 2, establishing unit mathematical models, including a wind power generator model, a photovoltaic power generation model, a micro-gas turbine model, a fuel cell model and an energy storage model, of the microgrid multi-energy system; step 3, in order to realize lowest comprehensive cost in system operation, constructing a microgrid multi-energy optimal scheduling model by taking DG operation constraints, system safety constraints and multi-energy coupling characteristics into comprehensive consideration; step 4, on the basis of reversed order dynamic planning, solving the microgrid multi-energy optimal scheduling model to obtain a microgrid multi-energy joint optimal operatingstrategy. By the microgrid multi-energy joint optimal scheduling method, operating demands in different scenes can be met, electricity-thermal coordinated optimal scheduling schemes are provided for operating of a comprehensive energy microgrid in different scenes, and high integral operating efficiency and high economic benefits are realized.

Owner:NANJING UNIV OF POSTS & TELECOMM

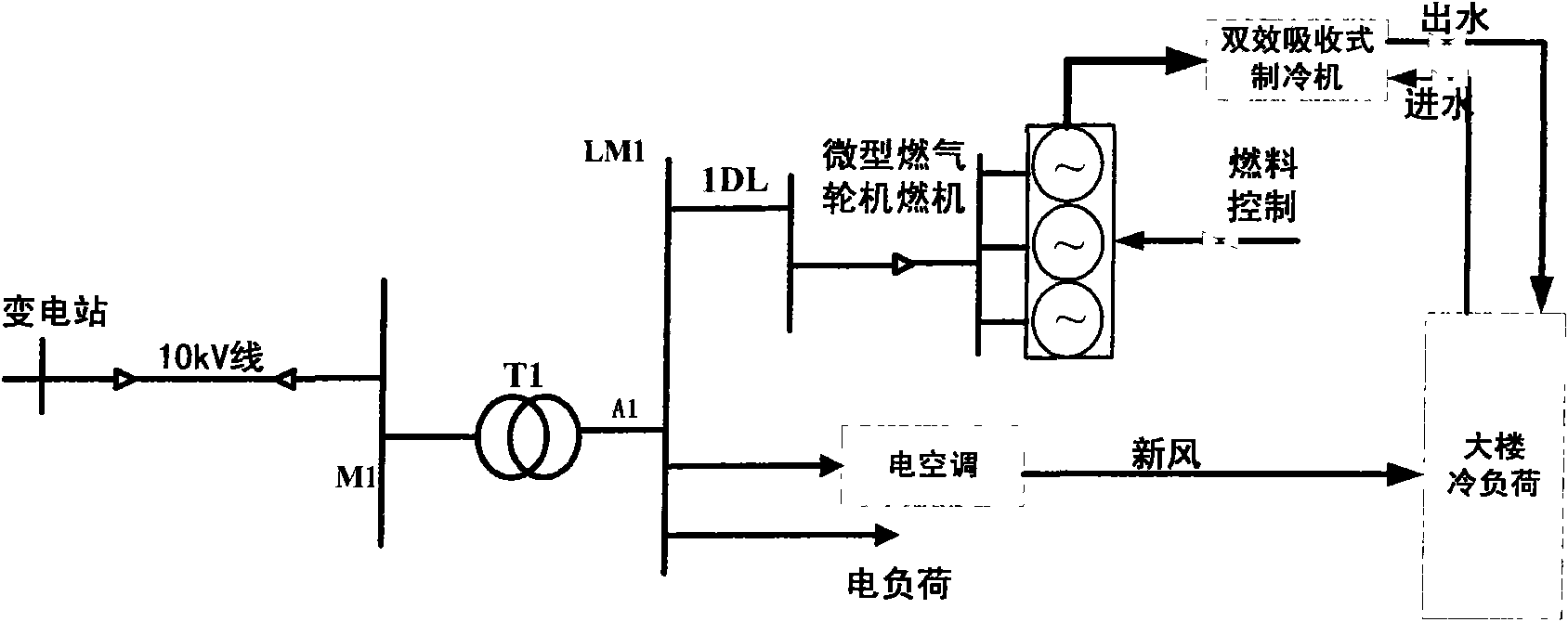

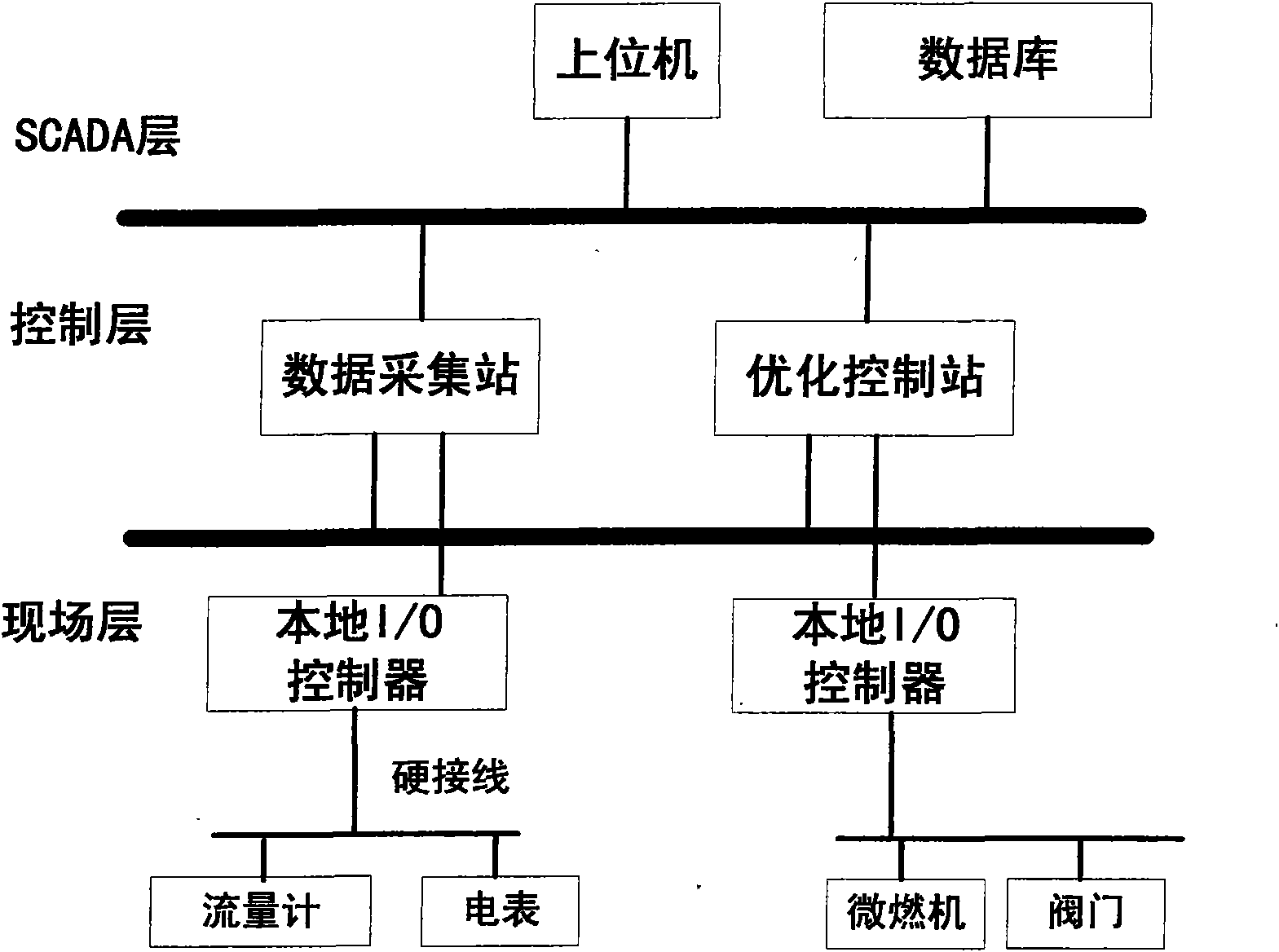

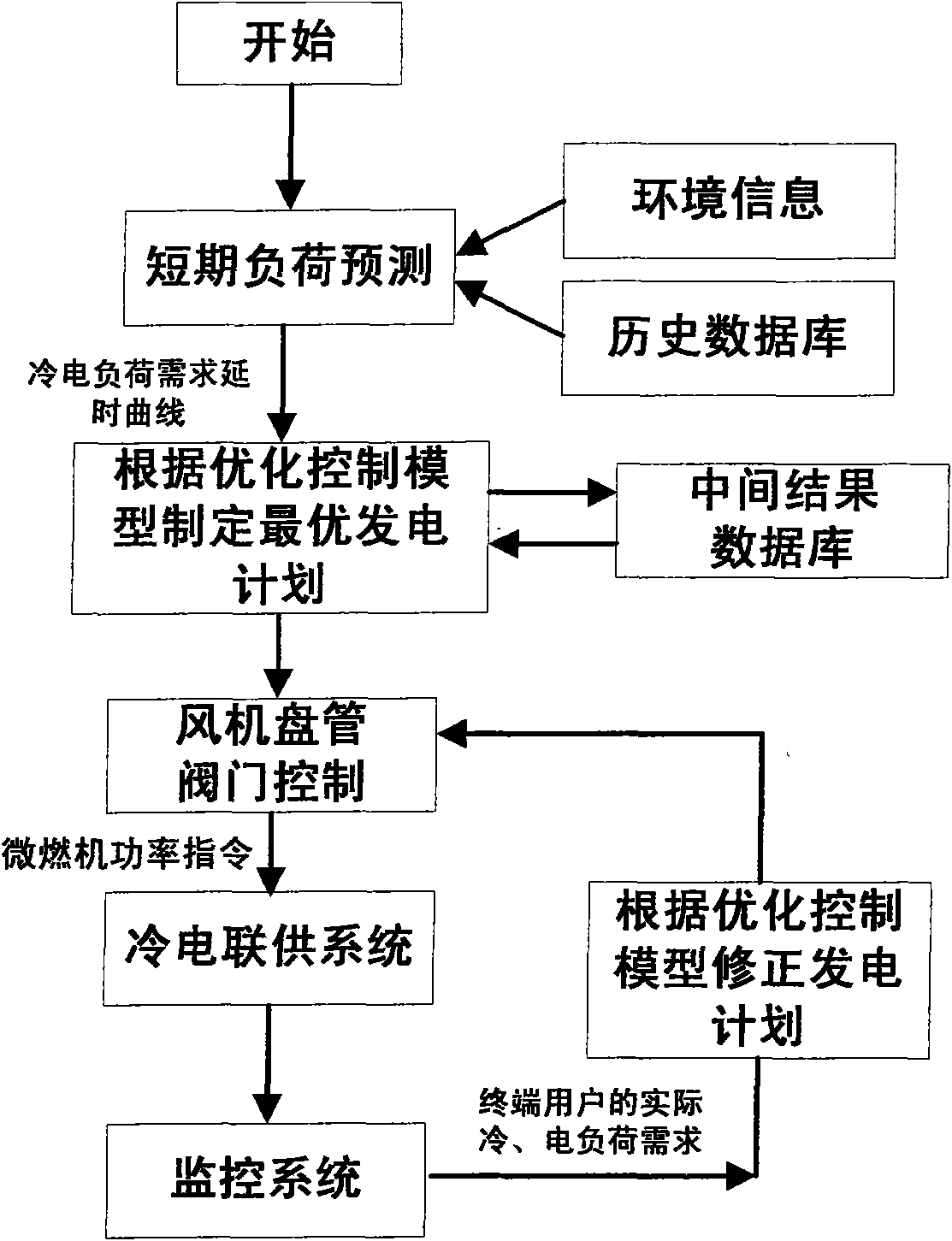

Control method of optimized running of combined cooling and power distributed energy supply system of micro gas turbine

ActiveCN101667013AIncrease economic benefitsHigh Utilization MetricsClimate change adaptationGas turbine plantsMathematical modelMicro gas turbine

The invention belongs to the technical field of energy management of distributed generation energy supply systems of electric power systems. The control method comprises the following steps: before running a combined system on every workday, extracting history cooling load data and power load data of a terminal user from a historical data base and obtaining the delay variation curve of the coolingload and the power load of the terminal user during the whole workday by lone-term load predicting; according to load predicting results, working out the optimal generated output plan of the combinedsystem by adopting optimization control mathematical model; during the running of the combined system, carrying out optimization control calculation again by utilizing the terminal user real-time cooling and power load need obtained from the distributed control system, and modifying the generating capacity and the refrigerating capacity of the combined system. The invention utilizes a distributedmonitoring system to monitor the actual cooling and power load need of the terminal user and can modify the load forecasting result in real time and adjusting the respective controlled variable of the combined system.

Owner:TIANJIN UNIV +2

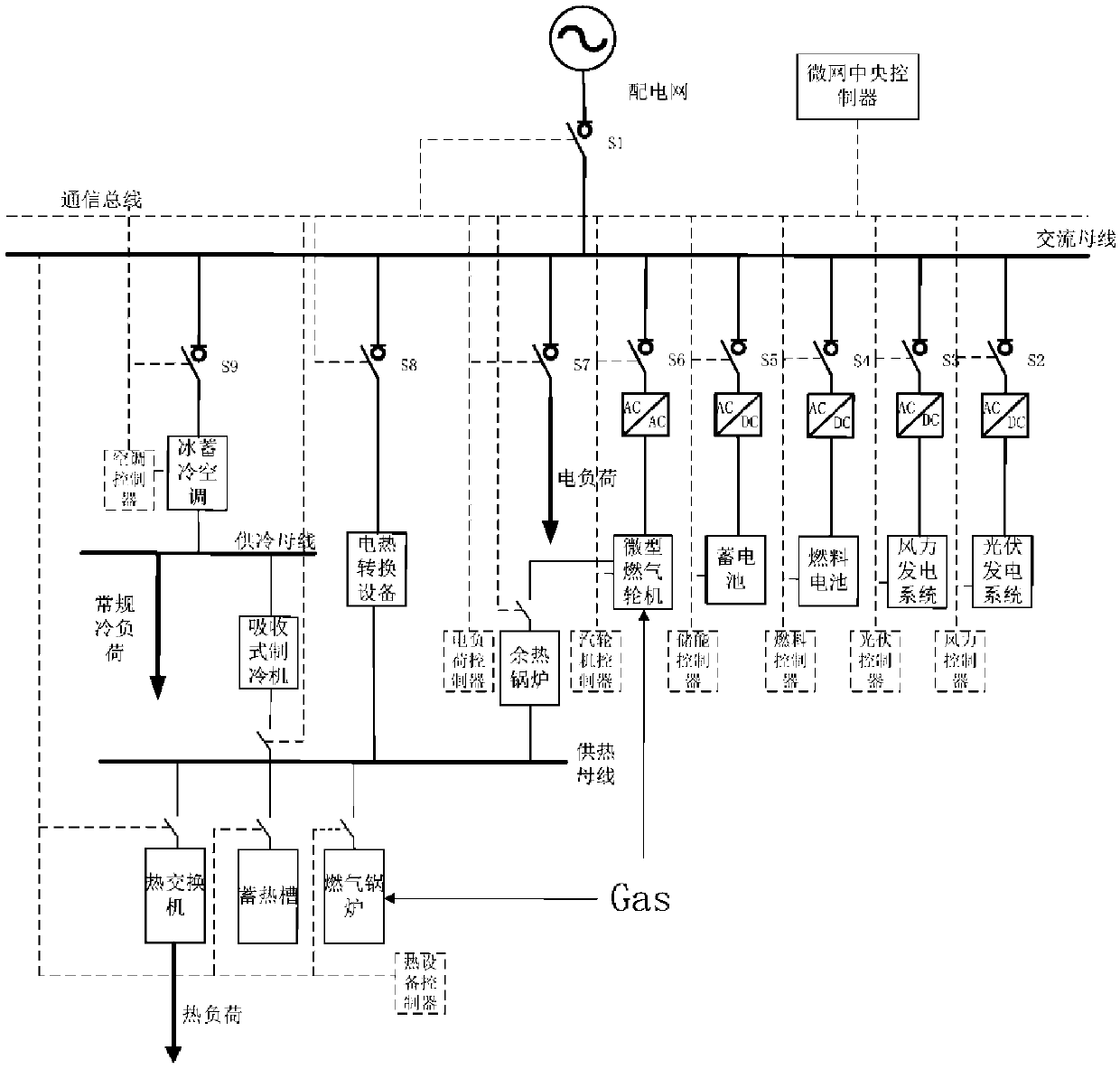

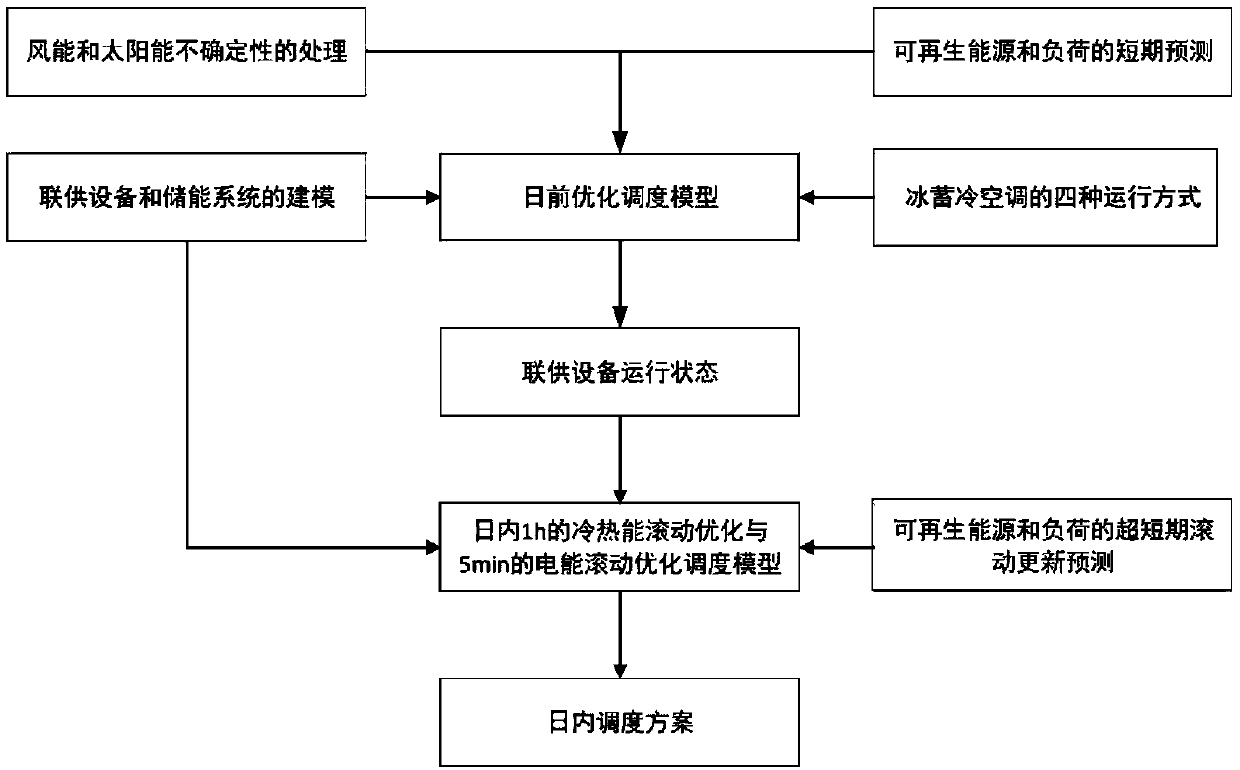

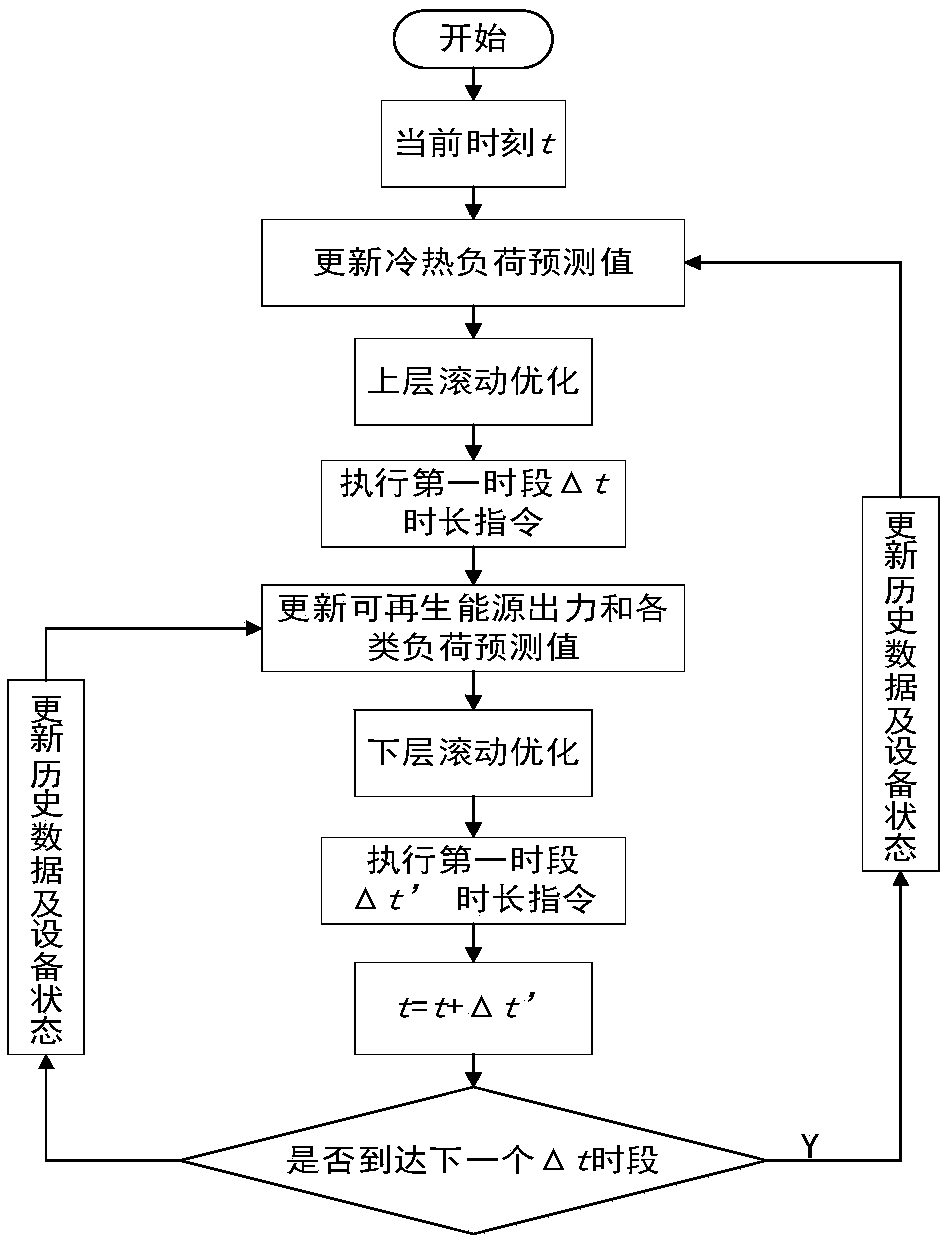

A multi-mode combined cooling, heating and power micro-grid system considering ice storage air conditioning

ActiveCN109004686AGuaranteed uptimeLow running costSingle network parallel feeding arrangementsWind energy generationAbsorption capacityMicro gas turbine

A multi-mode combined cooling, heating and power micro-grid system considering ice storage air conditioning is composed of a distributed power generation system composed of photovoltaic power generation, wind power generation, a fuel cell, a micro gas turbine and ice storage air conditioning, primary system composed of an energy storage system and other co-supply equipment, and a secondary dispatching control system. A CCHP-MG multi-time-scale optimal scheduling method is proposed, in a day-ahead plan, the uncertainty of renewable energy is described through multiple scenes, economic operationof CCHP-MG in a running optimization period is focused on; Intra-day scheduling is based on the scheme of the day-ahead plan, the difference and correlation of cooling, heating and power on scheduling time scale are considered, a two-layer rolling optimal scheduling scheme is proposed, the upper layer dispatches the combined cold and heat supply equipment, the lower layer adjusts power equipment,taking minimization of the adjustment cost as the goal, the smooth output of each co-supply equipment is obtained. The invention can remarkably improve the comprehensive utilization efficiency of energy and the local absorption capacity of the distributed renewable energy, and realize the economic and safe operation of the multi-energy micro-network.

Owner:CHINA THREE GORGES UNIV

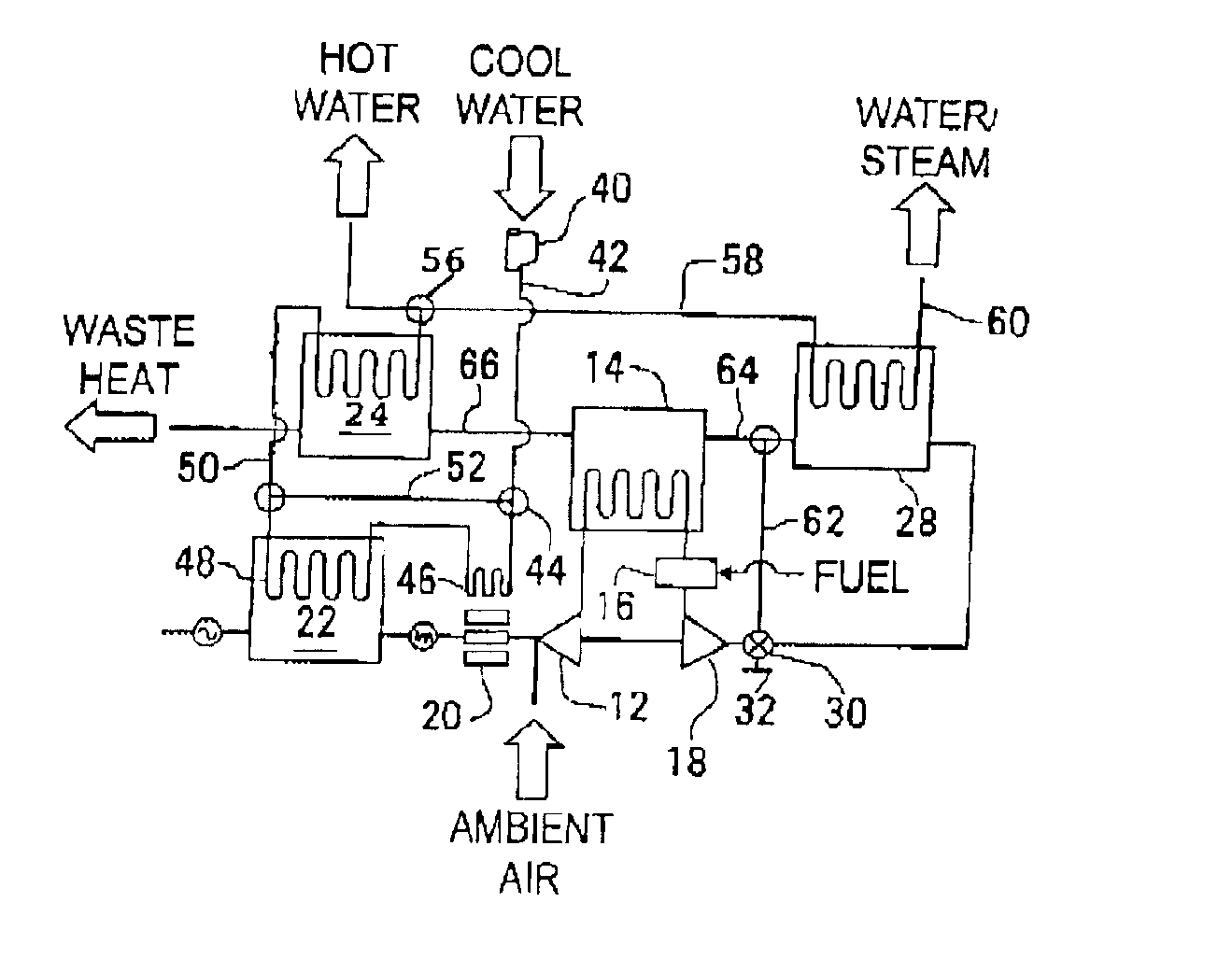

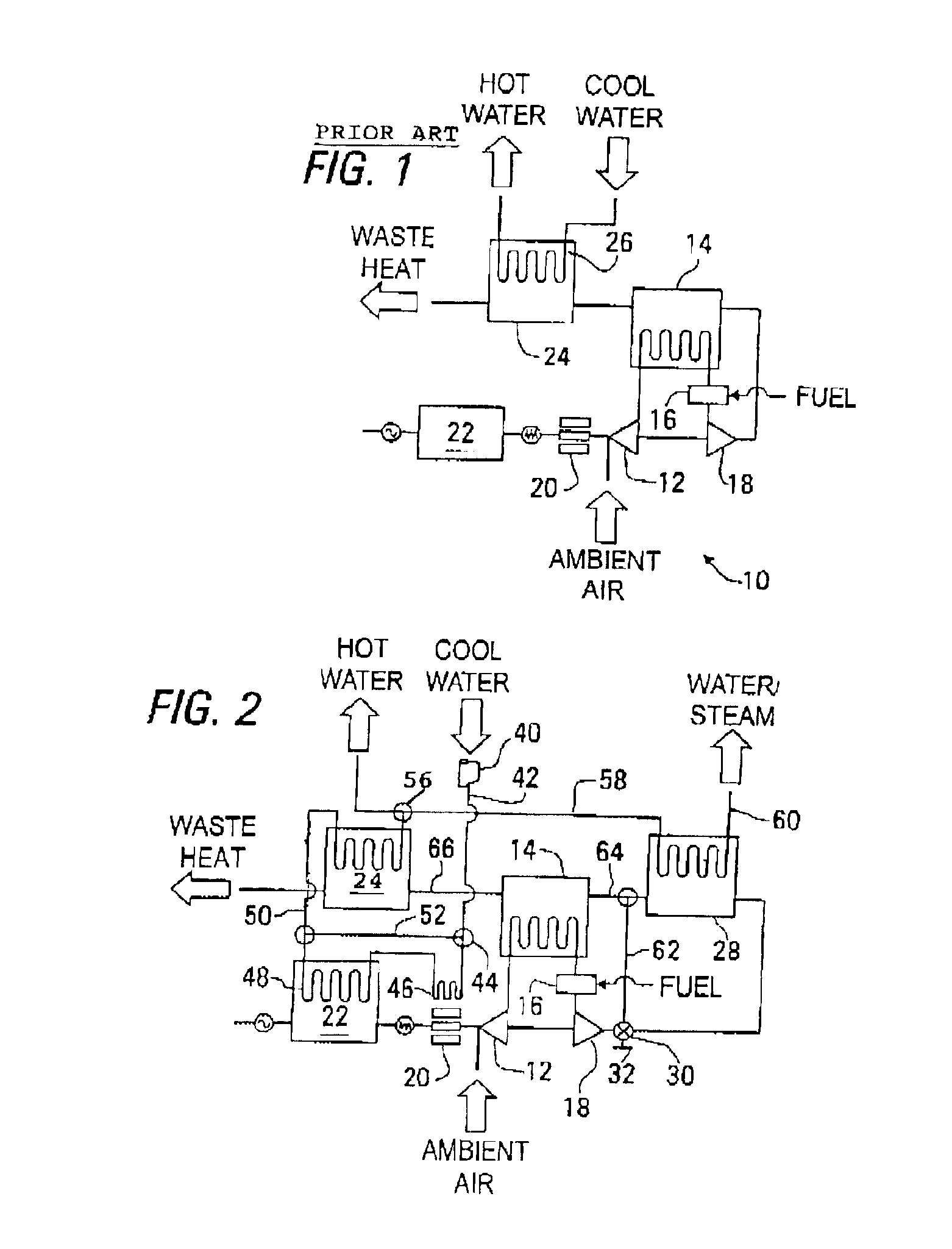

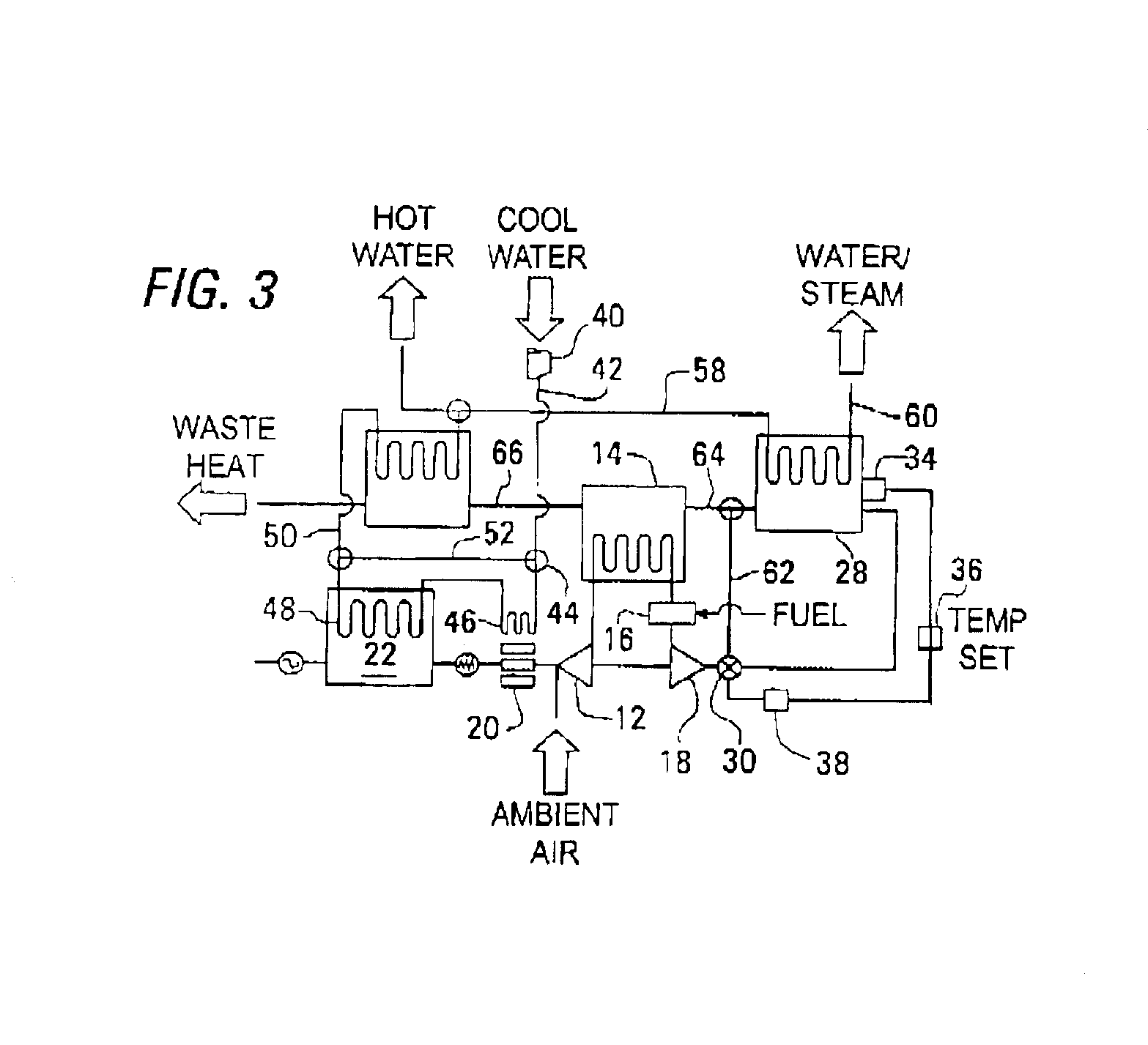

Microturbine exhaust heat augmentation system

InactiveUS6877323B2Efficiently transfer heatIncrease temperatureFluid heatersGas turbine plantsMicro gas turbineTransport medium

The microturbine engine that is typically utilized to power an electrical generating system and / or boiler, chiller and the like includes a second boiler and a by-pass system for providing heated water at two different levels or where one of the boilers provides steam. The turbine exhaust is utilized as the heat transport medium and is directly connected to one of the boilers while the other is connected to the recuperator. The system can optionally provide cooling to the electrical and electronic components of the system by providing a water circuit for leading water into the electric and electronic components prior to feeding the boilers. The system is designed to assure that the delta heat difference between the medium being heated and the waste heat of the turbine is sufficient so that the heat exchange will be done efficiently.

Owner:WELLS FARGO BANK NAT ASSOC

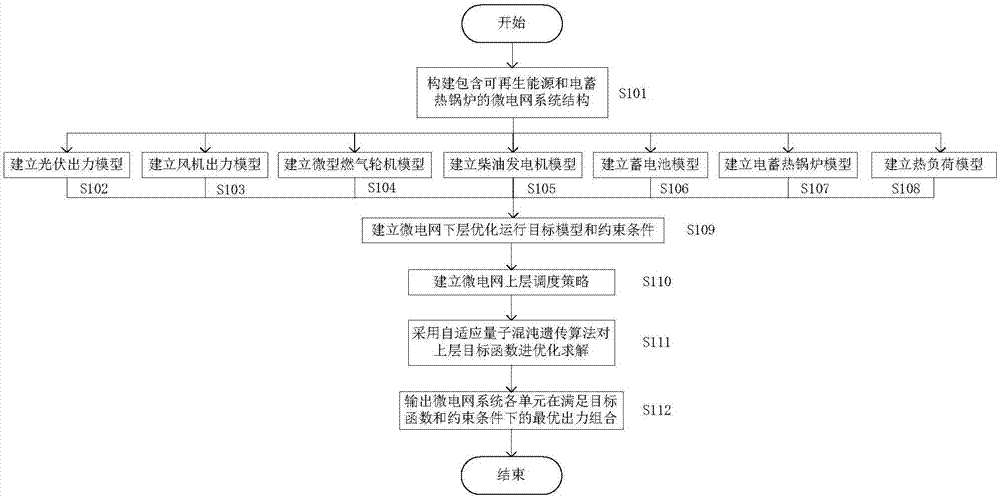

Double-layer-optimization-based optimized operation management method for electrical-thermal-storage boiler by microgrid

InactiveCN106936147AImprove practical abilityReduce Power MismatchFluid heatersLoad forecast in ac networkMicrogridMicro gas turbine

Owner:国网电力科学研究院武汉能效测评有限公司 +6

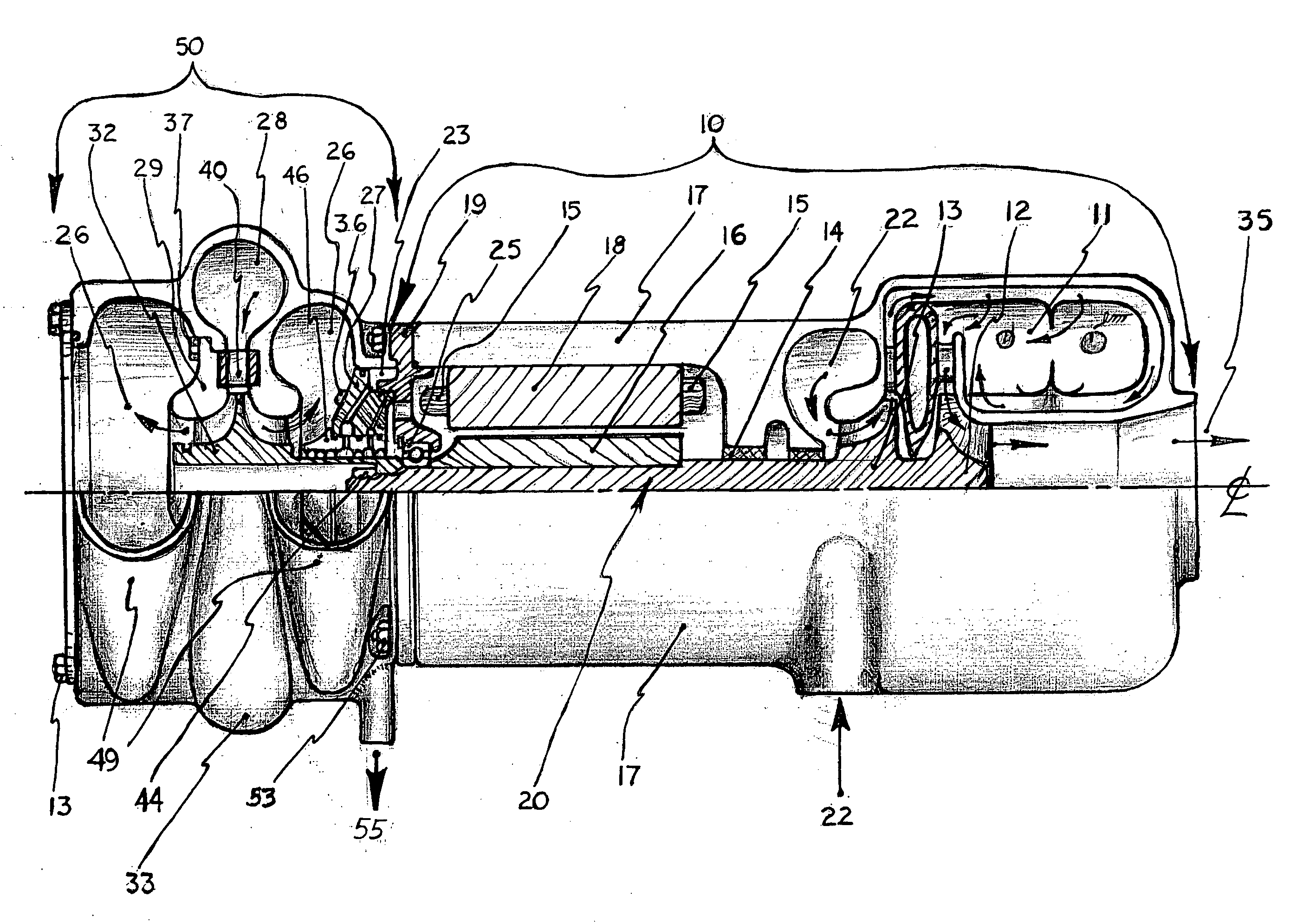

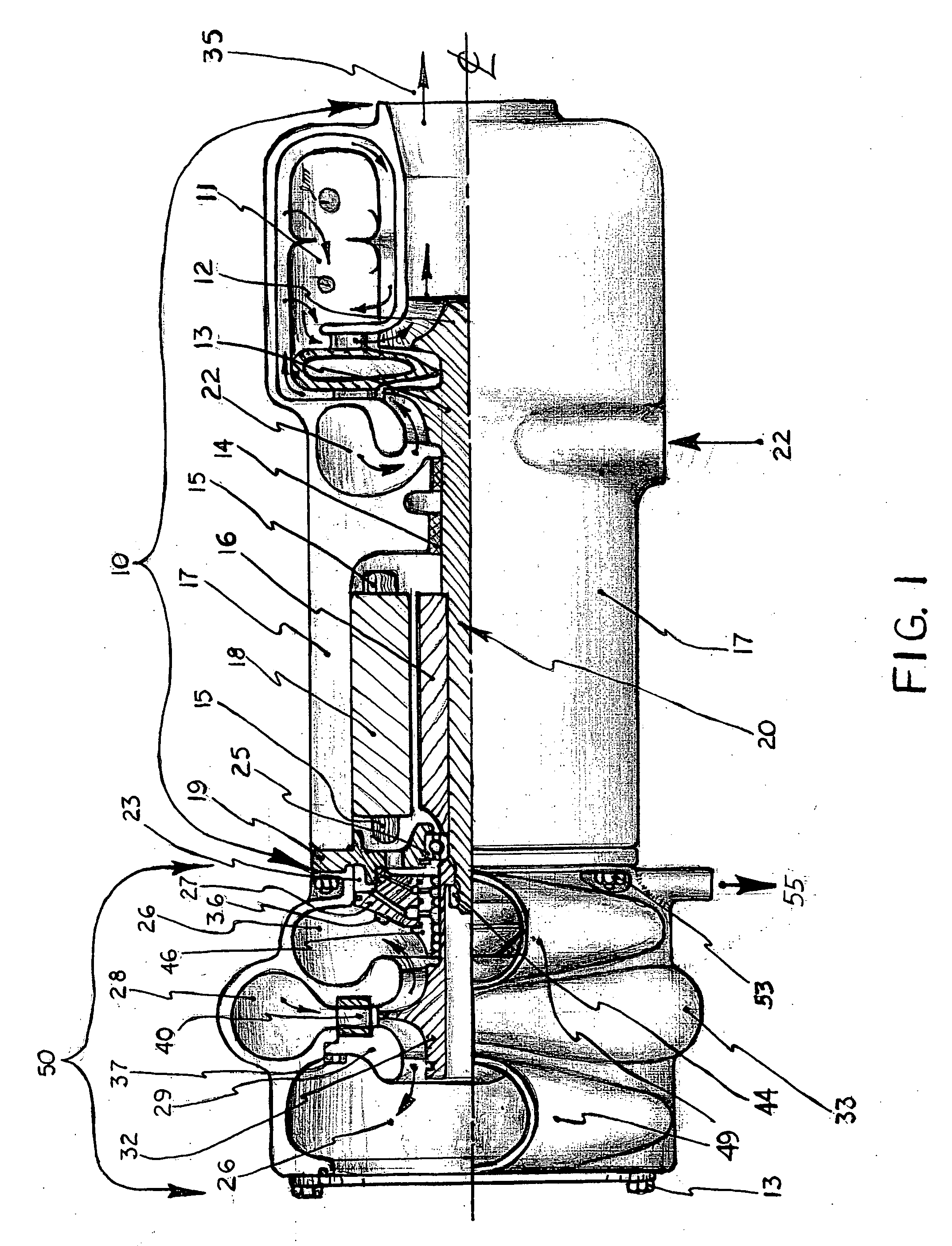

Rankine - microturbine for generating electricity

InactiveUS20060220388A1Improve output power efficiencyReduce installation costsEngine manufactureEngine fuctionsMicro gas turbineEngineering

An electrical output power generation system is provided. A gas turbine engine rotor spool with at least one alternator rotor and steam turbine rotor are integrated and within a engine body having a combustor or external heat source having fluid communication with the bladed compressor rotor and a gas turbine bladed rotor of the said rotor spool. The alternator rotor has permanent magnets retained and positioned in close proximity and co-axial to the electrical stator having iron laminat and electrical wires. Relative rotational motion between the electrical stator and alternator rotor cause magnetic flux and subsequent electricity to be generated. The steam energy to drive the said rotor spool integrated steam turbine rotor can be from the gas turbine engine exhaust waste heat and or thru external heat energy sources.

Owner:T M A POWER

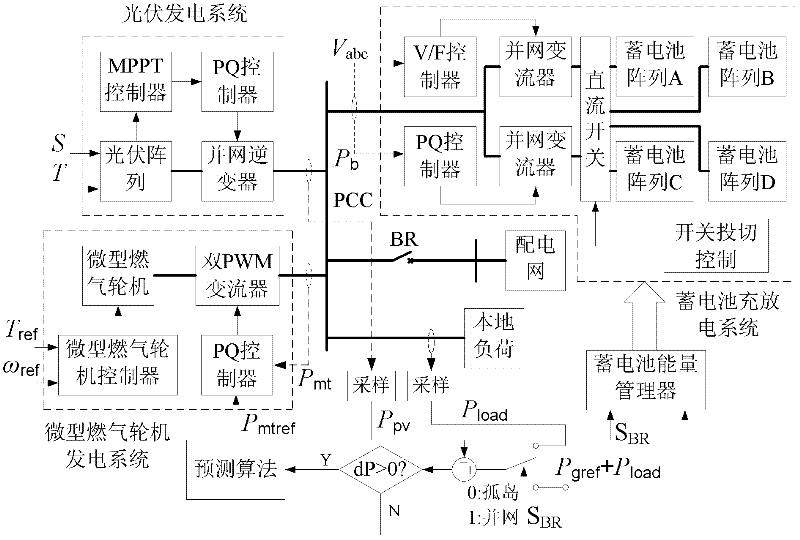

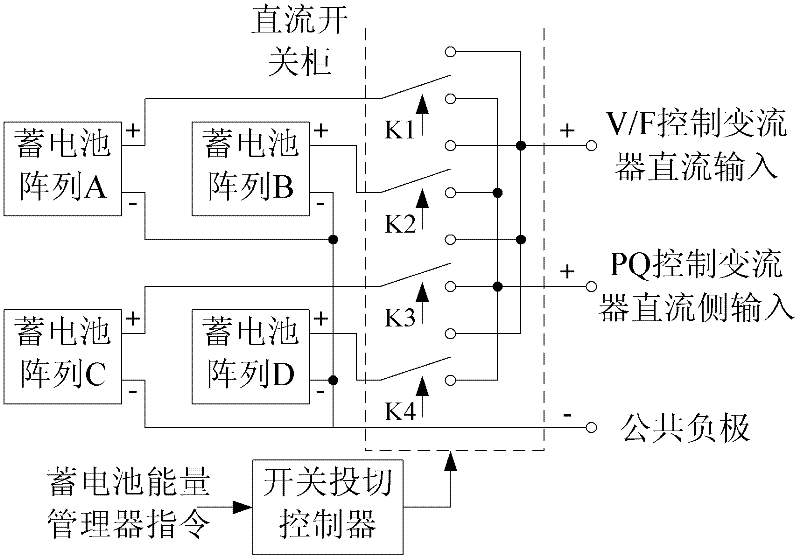

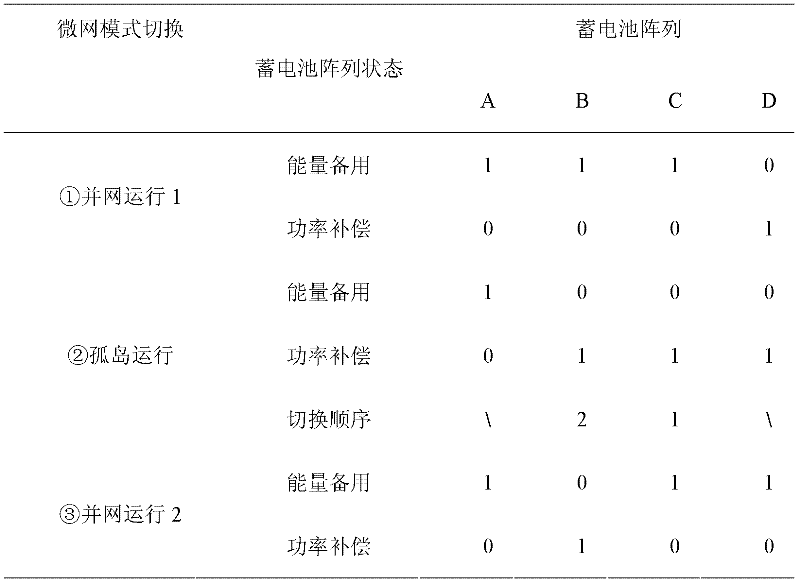

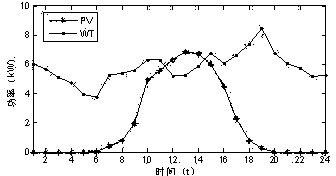

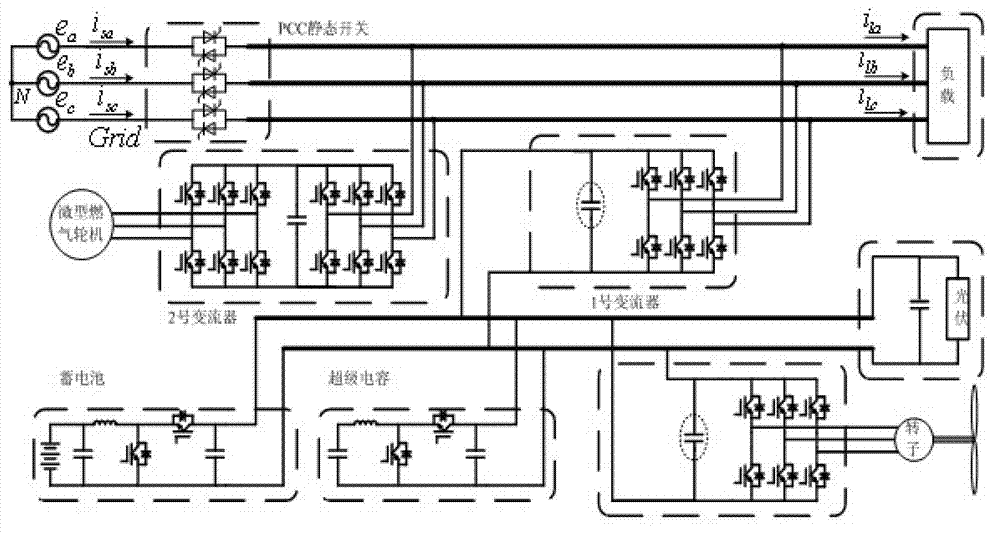

Photovoltaic and micro gas turbine mixed micro grid coordinated operation control method

InactiveCN102545255AReal-time calculation of DC reference voltageImprove adaptabilitySingle network parallel feeding arrangementsEnergy storagePrediction algorithmsMicro gas turbine

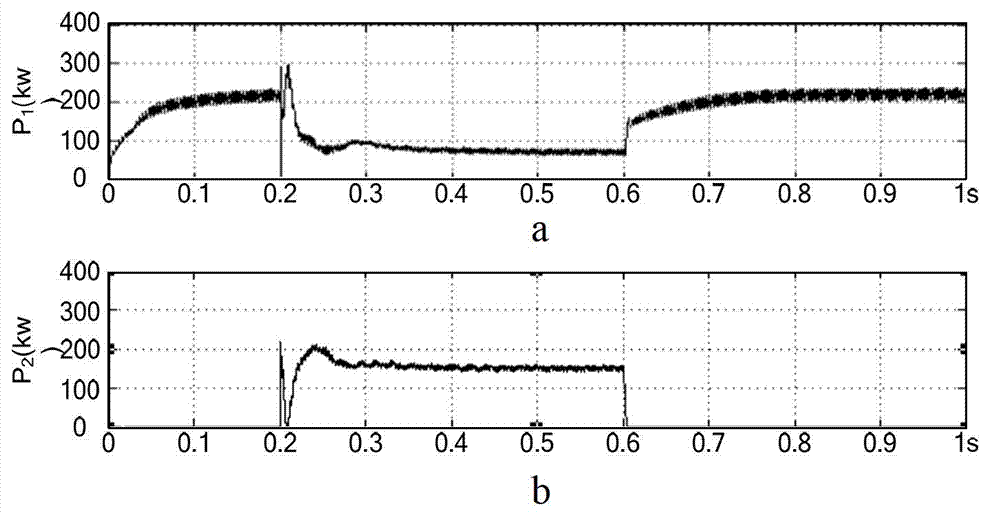

The invention discloses a photovoltaic and micro gas turbine mixed micro grid coordinated operation control method. According to the frequency characteristics of photovoltaic and load power, a frequency conversion long-time series method is put forward to predict the photovoltaic and load power so as to adjust the previous output of power of a micro gas turbine. During the synchronous operation of a mixed micro grid, by using the controllable smooth photovoltaic power fluctuation of the micro gas turbine, the mixed micro grid becomes a schedulable power source; and during island operation, a prediction algorithm is added in the power control of the micro gas turbine, and the output of the micro gas turbine is previously scheduled, so that the difference of the photovoltaic and load power is commonly compensated by the micro gas turbine and an energy storage battery, thereby realizing the stable operation of the mixed micro grid. According to the invention, the fluctuation of a photovoltaic generation system can be decreased, and the problems of slow dynamic response speed and delay of the micro gas turbine can be overcome, so that the coordinated operation control of the mixed micro grid under synchronous and island states can be realized.

Owner:CHONGQING UNIV

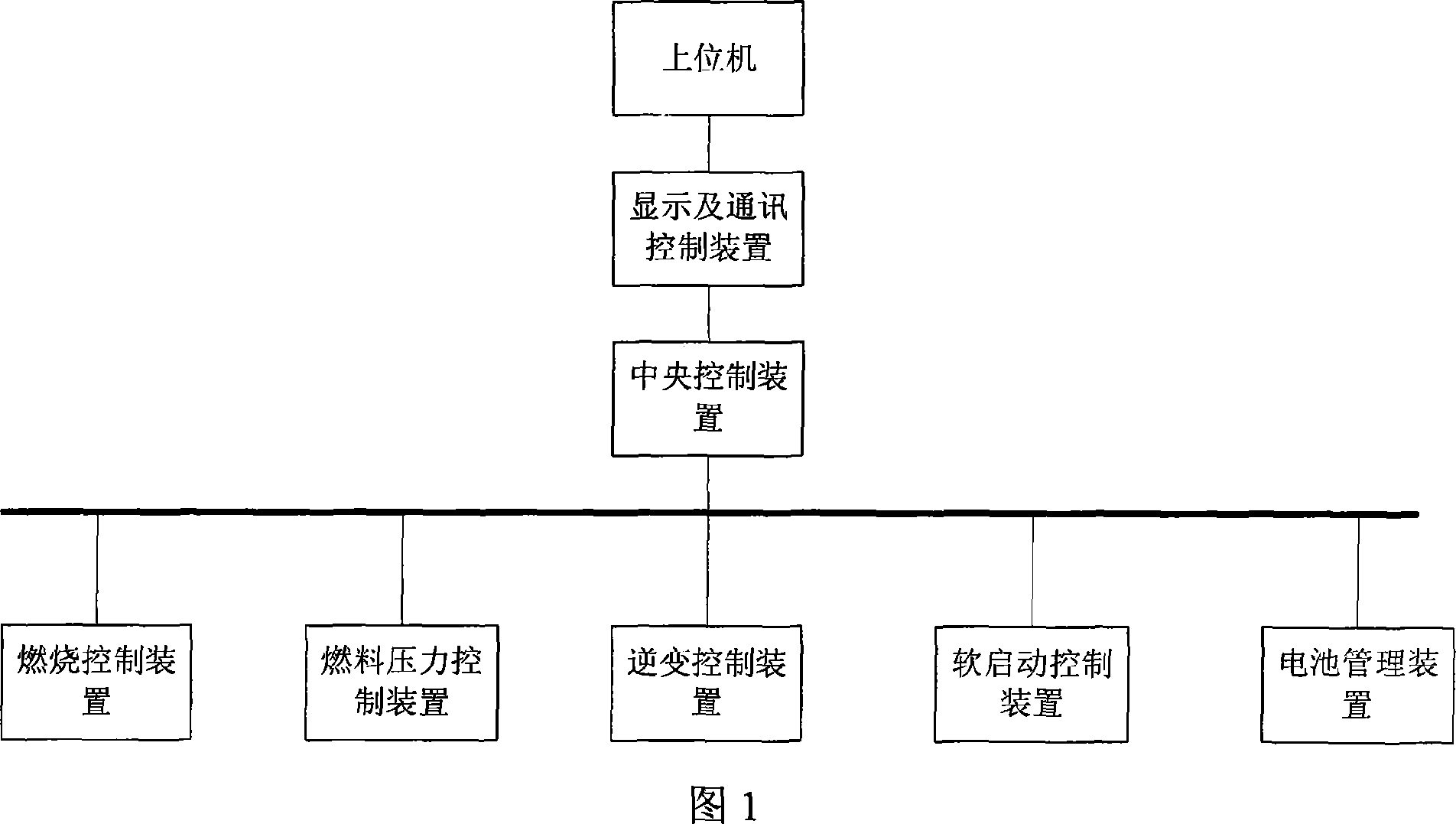

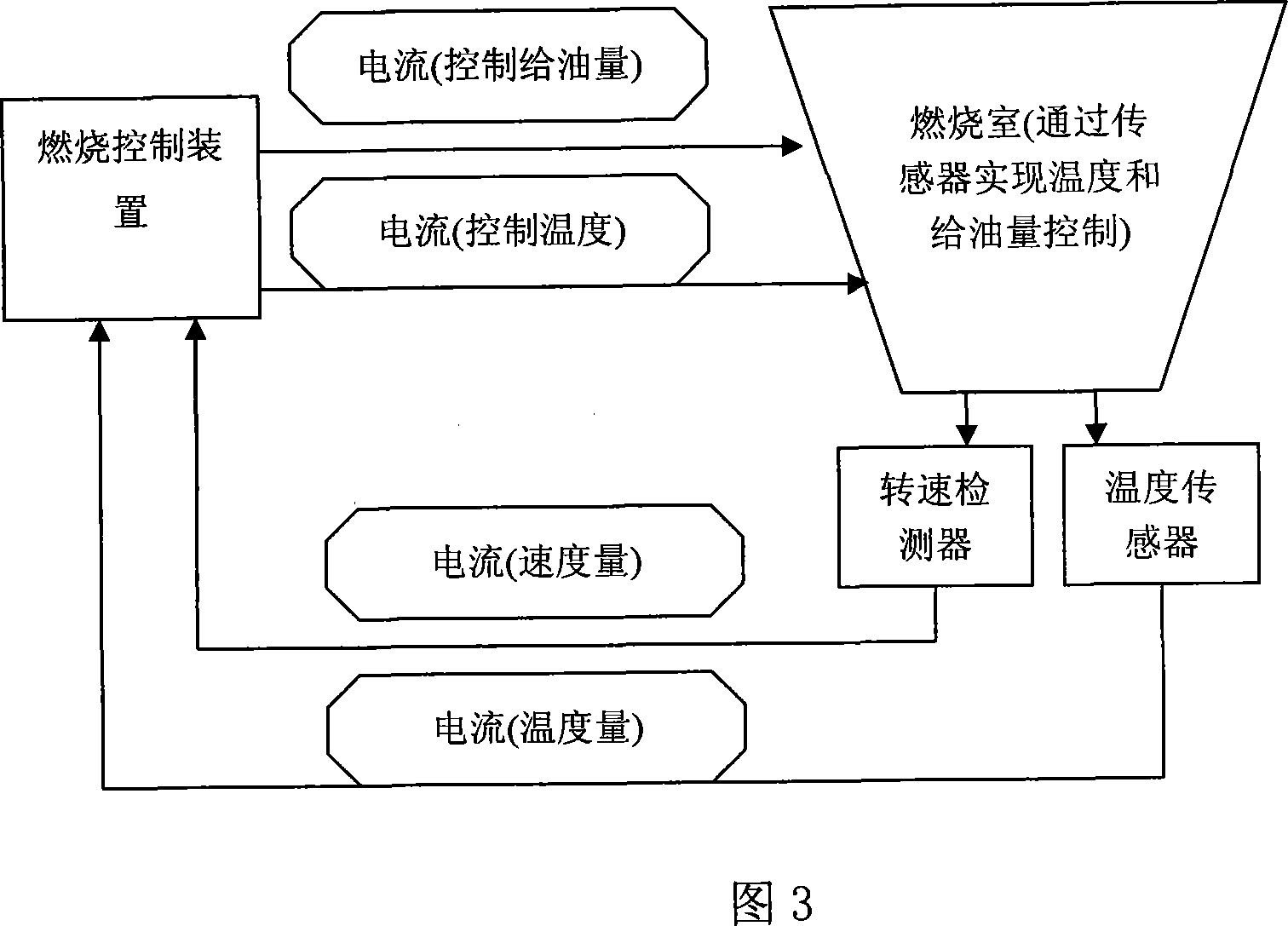

Combustion controlling device and controlling method for mini combustion turbine

InactiveCN101078373AHigh control precisionImprove securityProgramme-controlGas turbine plantsCombustorSelf-tuning

The invention relates to a combusting control device of micro gas turbine and the control method. The combusting control device identifies parameters of gas turbine on line and control them in time. The control method makes use of the combination of conventional PID control and intelligent fuzzy control theory so that the control device has on-line parameter self-tuning function, which comprises initialization and self-check for control device, combustor ignition, power closed-loop adjustment, shut-down control and on-line monitoring index of gas turbine function. The invention is provided with high control accuracy, safety, stability and low development cost.

Owner:NORTHEASTERN UNIV

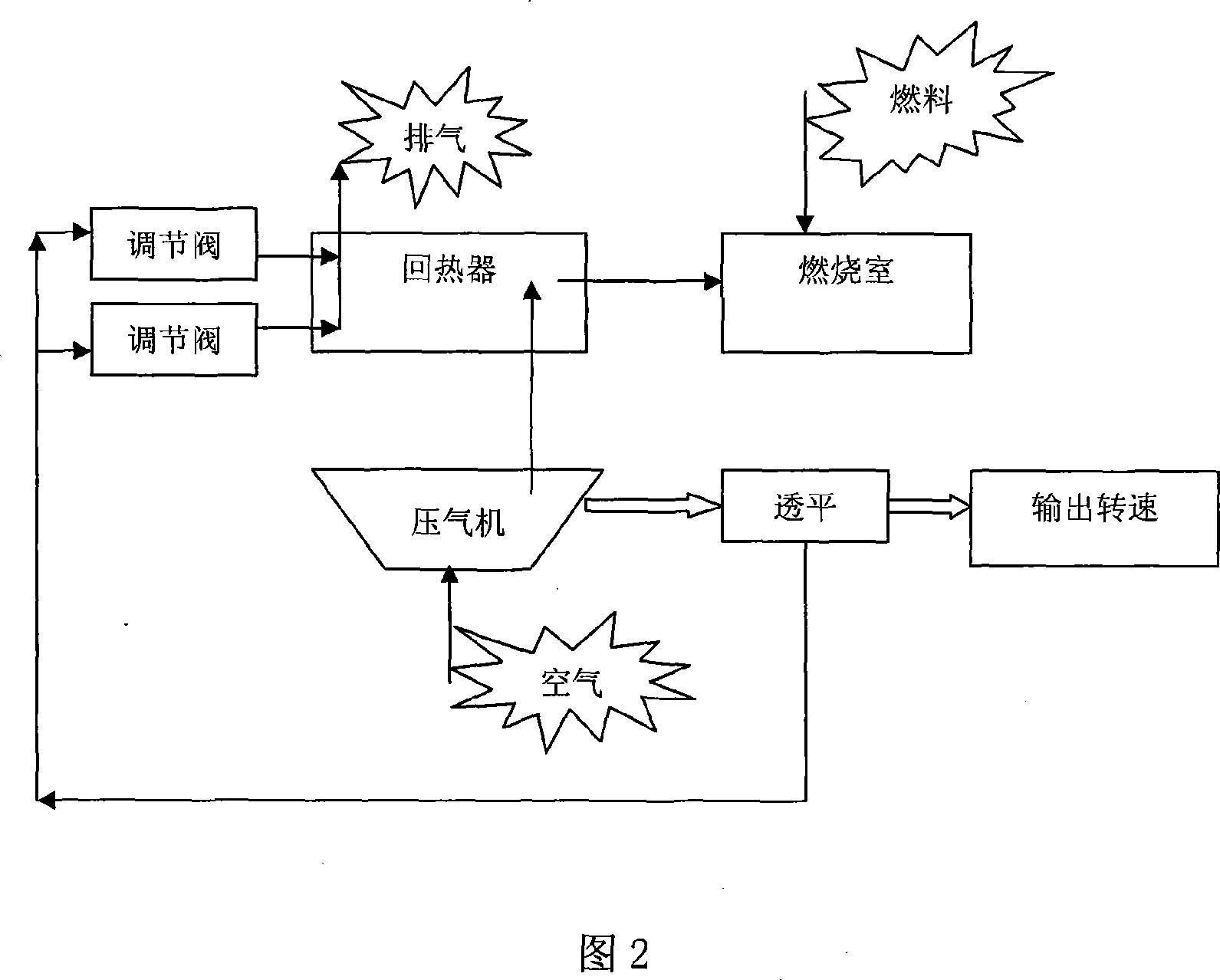

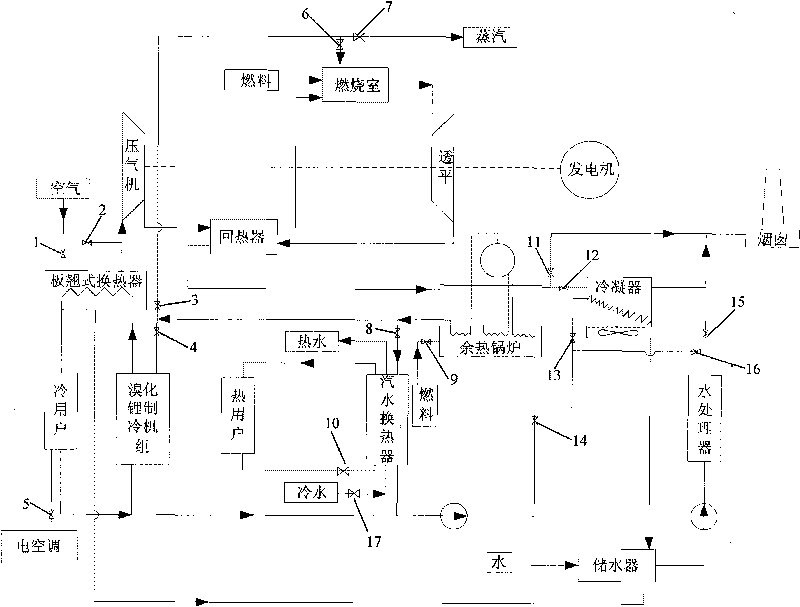

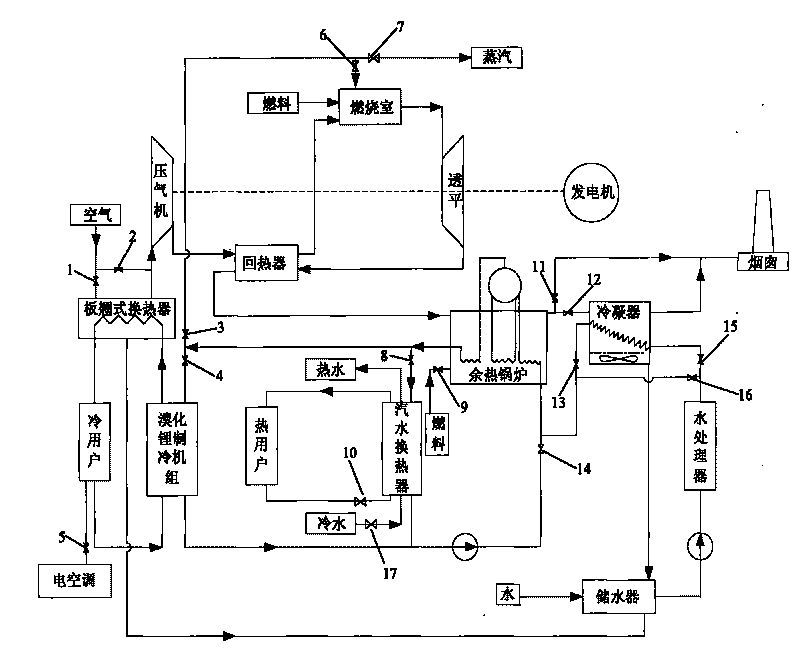

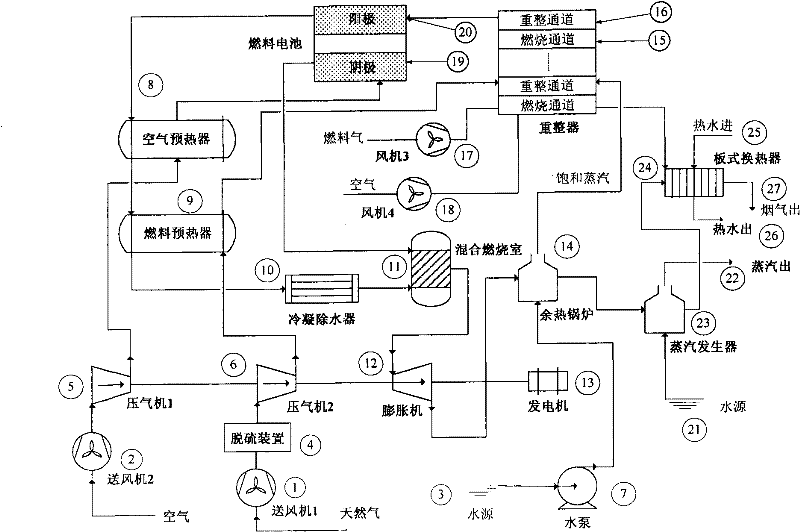

Heat and cool power cogeneration system of integrated multi-functional efficient mini-type gas turbine

InactiveCN101761392AIncrease power generationImprove power generation efficiencyClimate change adaptationGas turbine plantsElectricityCogeneration

The invention proposes a heat and cool power cogeneration system of an integrated multi-functional efficient mini-type gas turbine, which belongs to the novel heat and cool power cogeneration system device. To solve the frequent mismatching of cold and heat load and low efficiency operation of the conventional cogeneration system, measures such as steam reinjection, inlet gas cooling, gas fume and condensate water recovery are introduced on the basis of the heat and cool power cogeneration system of the mini-type gas turbine; in addition, the number of steam outlets and hot-water outlets is increased, thus forming the heat and cool power cogeneration system of the integrated multi-functional efficient mini-type gas turbine. The system is provided with various operation modes suitable for different occasions, can effectively solve the problem of mismatching of cold and heat load of the cogeneration system, so that the system can keep working in highly efficient mode.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

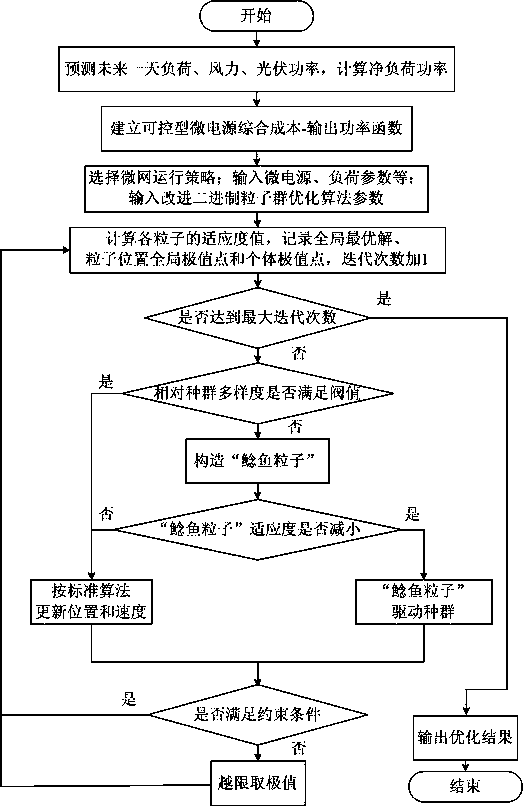

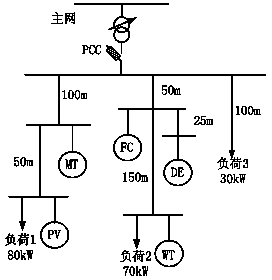

Microgrid optimization operation method based on improved binary system particle swarm optimization algorithm

The invention relates to a microgrid optimization method based on an improved binary system particle swarm optimization algorithm. For a microgrid containing various micro power sources, taking start-stop strategies of controllable micro power sources into account, a microgrid optimization operation mathematical model considering economic costs and environmental benefits is established. An improved binary system particle swarm optimization algorithm based on a catfish effect is provided, output of the micro power sources in the microgrid in each period of time is solved under different control strategies. A specific microgrid including wind, light, a micro gas turbine, a fuel cell and a diesel generator is used as an embodiment, and embodiment analysis is performed.

Owner:徐多

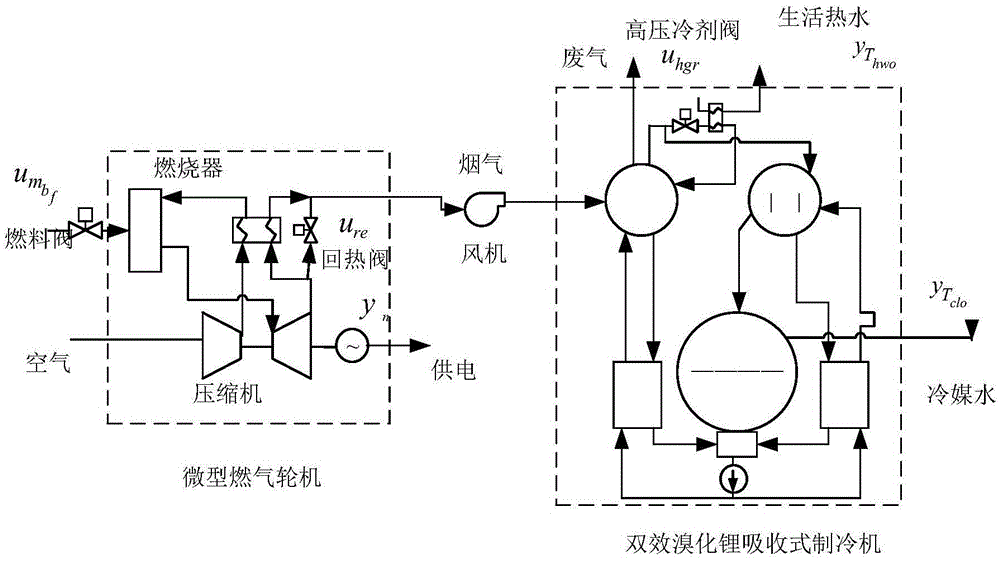

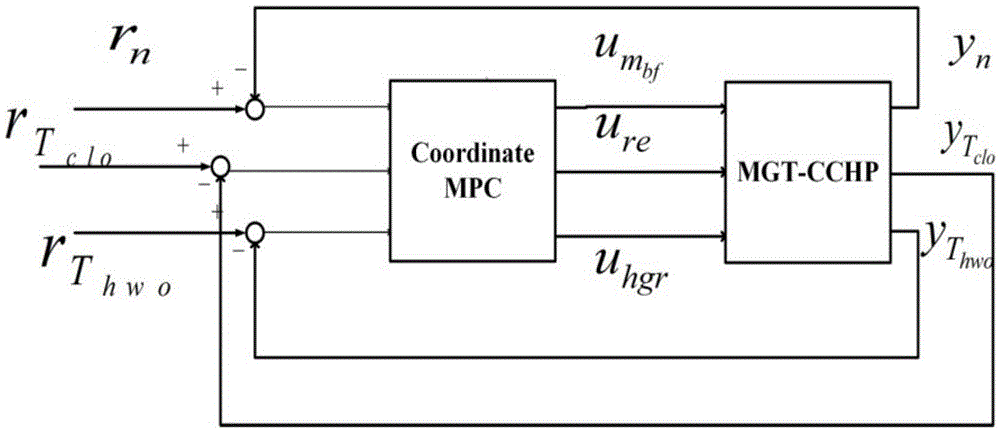

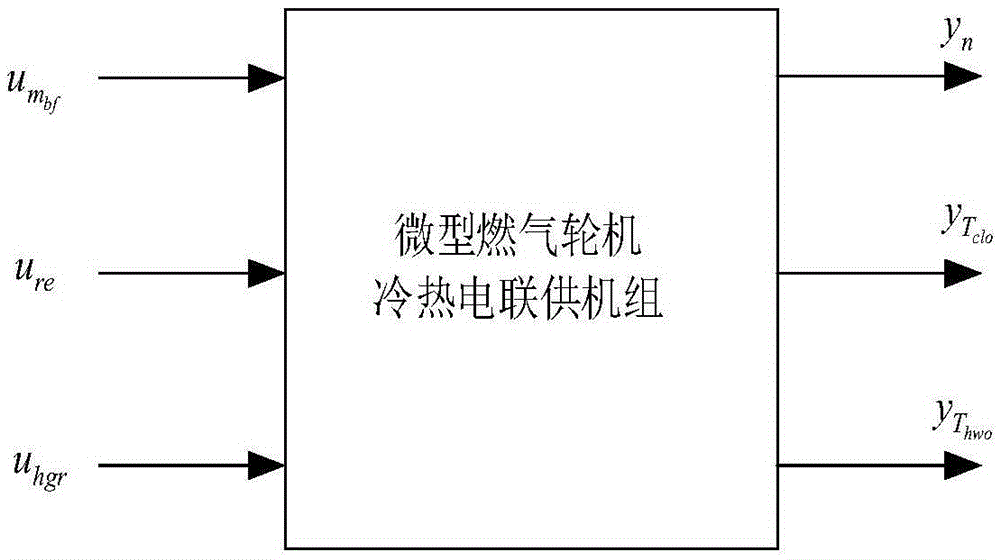

Coordinated control method of cooling-heating-power cogeneration system of micro gas turbine

ActiveCN105652665AOpening changes smoothlySolving intractable input volume constraintsAdaptive controlCogenerationMicro gas turbine

The invention discloses a coordinated control method of a cooling-heating-power cogeneration system of a micro gas turbine. The method includes an off-line stage and an online stage. The off-line stage includes the first step that a controlled system is simplified; the second step that when an MGT-CCHP system is in a stable operation state, Gaussian white noise disturbance is added into all input variables in sequence, and data of input variables and output variables is collected to serve as data of model identification; the third step that according to data of disturbance experiments, a discrete state space model of a three-input three-output system is identified through a subspace identification method. The online stage includes the first step that the value of a state vector x(k) of a current moment k is observed; the second step that according to the state vector x(k) of the current moment k, an input vector u(k-1) of a k-1 moment and the identified state space model, an expression of output vectors of P moments in the future is deduced; the third step that performance indexes are optimized; the fourth step that by means of a secondary planning method, an optimization problem with the minimum optimization performance index is solved, and a control gain of the current moment is obtained.

Owner:SOUTHEAST UNIV

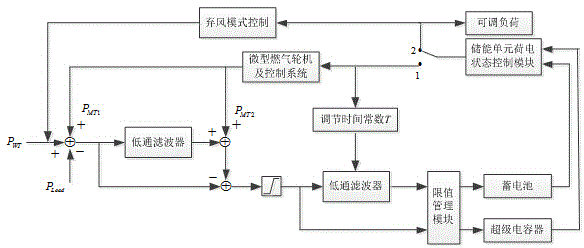

Energy coordinated optimization method for multi-element complementary new energy power generating system

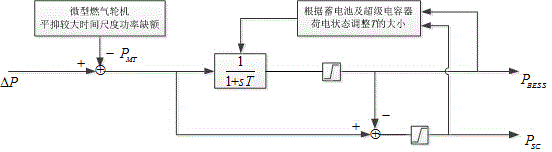

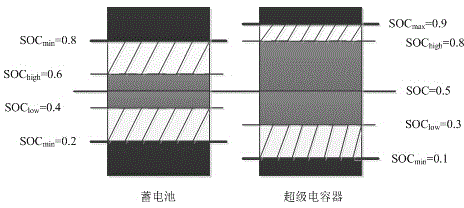

The invention discloses an energy coordinated optimization method for a multi-element complementary new energy power generating system. According to the method, through coordination control to a micro gas turbine, an accumulator and a supercapacitor, the system power fluctuation is stabilized, and the system power balance is ensured; the output power of the micro gas turbine is used for compensating power vacancy and stabilizing low frequency band power fluctuation, so that the configuration capacity of an energy storing device is reduced. As the wind power generation output power is high in fluctuation and comprises high-frequency components and low-frequency components, excepting for depending on the micro gas turbine to compensate the system power balance, the energy type energy storing device accumulator and the power type energy storing device supercapacitor can be utilized to ensure the accuracy and the quickness of power stabilization. A time constant T of a filter can be tracked and adjusted in real time to allow the vacancy power to be reasonably distributed between the energy storing devices, so that the charging state out-of-limit probability of the energy storing devices is reduced, the advantages of different energy storing devices are fully used, and the requirement on the system power balance is met.

Owner:STATE GRID XINJIANG ELECTRIC POWER CO ECONOMIC TECH RES INST

Range-extended electric automobile

InactiveCN101870264AIncrease mileageAdapt to high speedPropulsion using engine-driven generatorsVehicular energy storageElectricityMicro gas turbine

The invention discloses a range-extended electric automobile using a micro gas turbine generator set. The electric automobile comprises a power electronic converter, a vehicle-mounted charger, an energy storage device, an energy management unit, an overall controller, an electromotor, a speed changer, a micro gas turbine controller, the micro gas turbine generator set and a fuel tank; and under the control of the overall controller, the fuel tank supplies fuel to the micro gas turbine generator set, and the micro gas turbine generator set generates electricity to increase the running mileage of the vehicle. The ranged-extended pure electric automobile reduces the dependence on a charging foundation facility, can adapt to running of high-speed and suburb road conditions better, improves the adaptability of the vehicle, meanwhile diversifies the energy of the vehicle, is favorable for energy safety, and solves the refrigerating and heating problems of the pure electric automobile.

Owner:BEIHANG UNIV

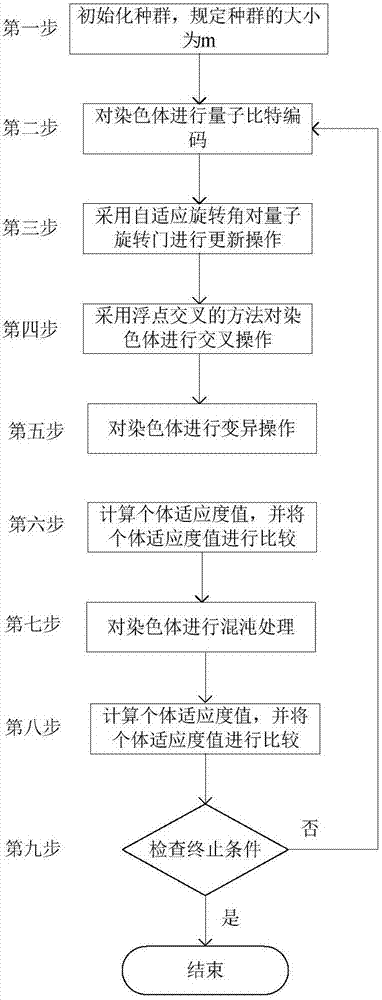

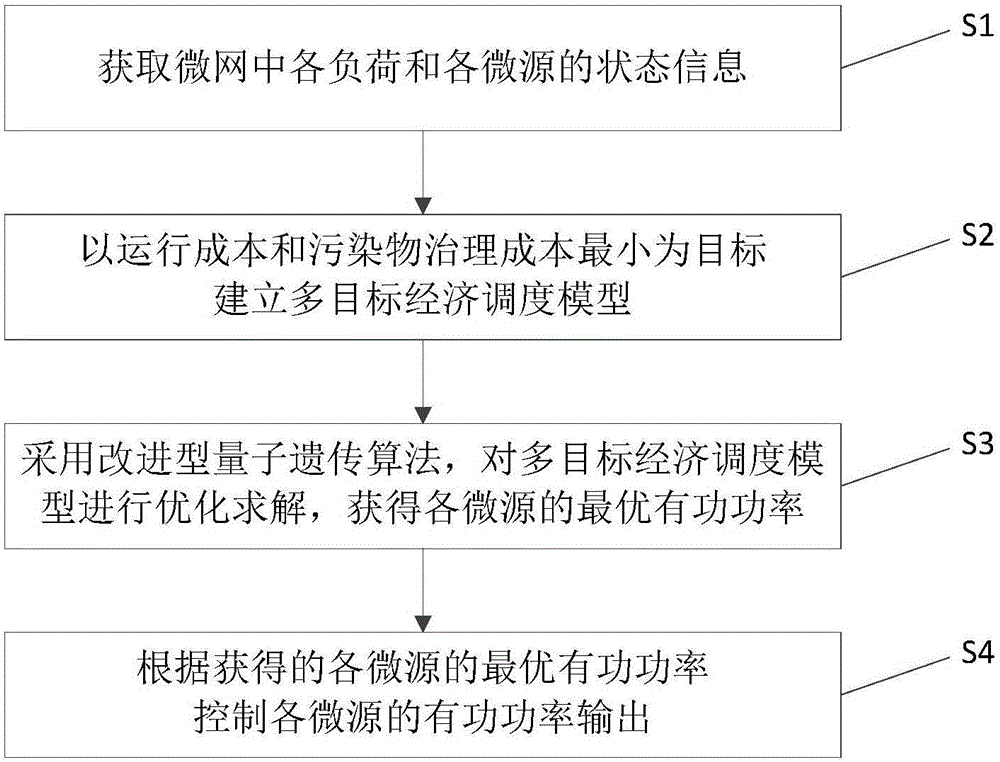

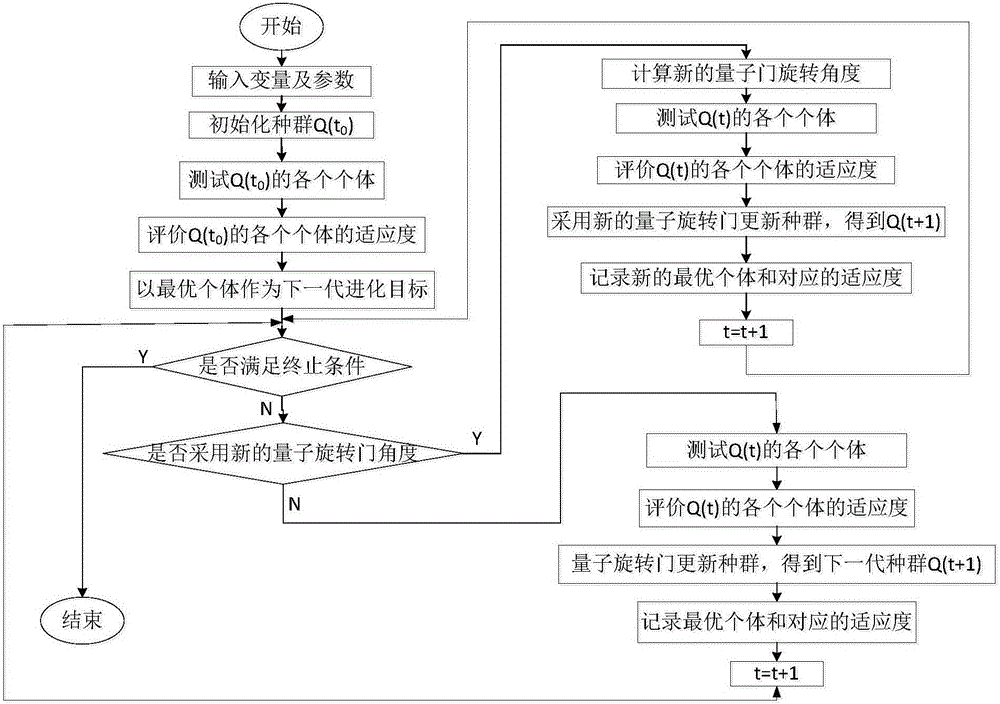

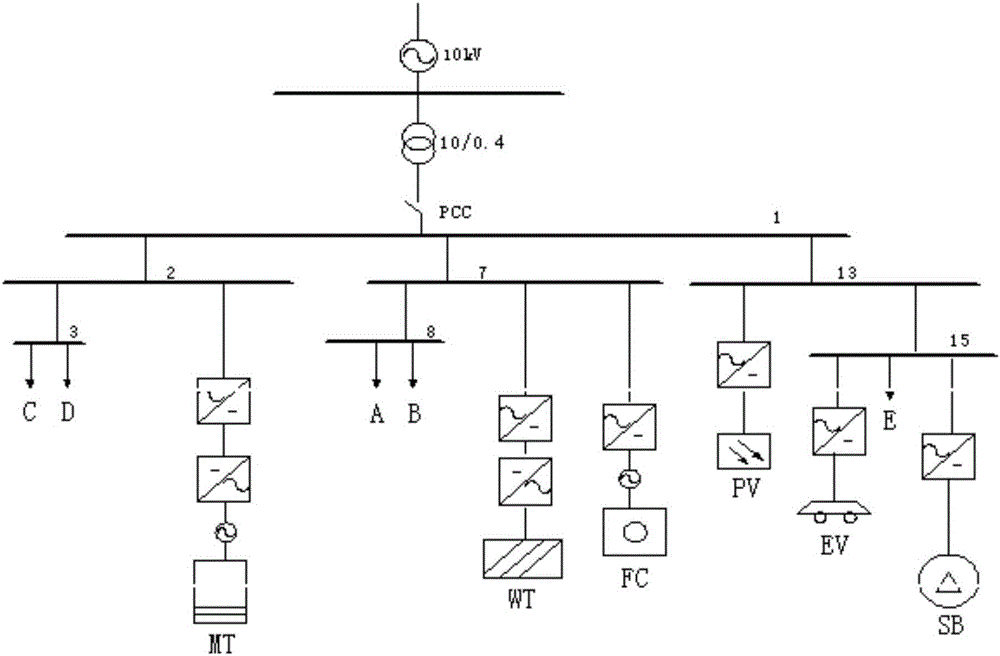

Micro-grid economic and optimal operation and scheduling method based on improved quantum genetic algorithm

InactiveCN105787605AGuaranteed uptimeFlexible operationGenetic modelsForecastingEnvironmental resistanceMicro gas turbine

The invention relates to a micro-grid economic and optimal operation and scheduling method based on an improved quantum genetic algorithm. The micro-grid is in a grid-connected mode operation state and comprises multiple micro sources and loads, wherein the loads comprise electric loads and thermal loads; and the micro sources comprise a micro turbine, a wind turbine, a photovoltaic cell, a fuel cell, a storage battery and an electric vehicle. The method comprises the following steps: S1, state information of each load and each micro source in the micro-grid is acquired; S2, with minimum of operation cost and pollutant treatment cost as a target, a multi-target economic scheduling model is built; S3, the improved quantum genetic algorithm is adopted for carrying out optimal solution on the multi-target economic scheduling model, and the optimal active power of each micro source is acquired; and S4, according to the optimal active power of each micro source, active power output by each micro source is controlled. Compared with the prior art, the micro-grid formed by distributed power sources operates in a more economic, flexible and environment-friendly mode, and power generation advantages of the distributed power sources can be taken.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

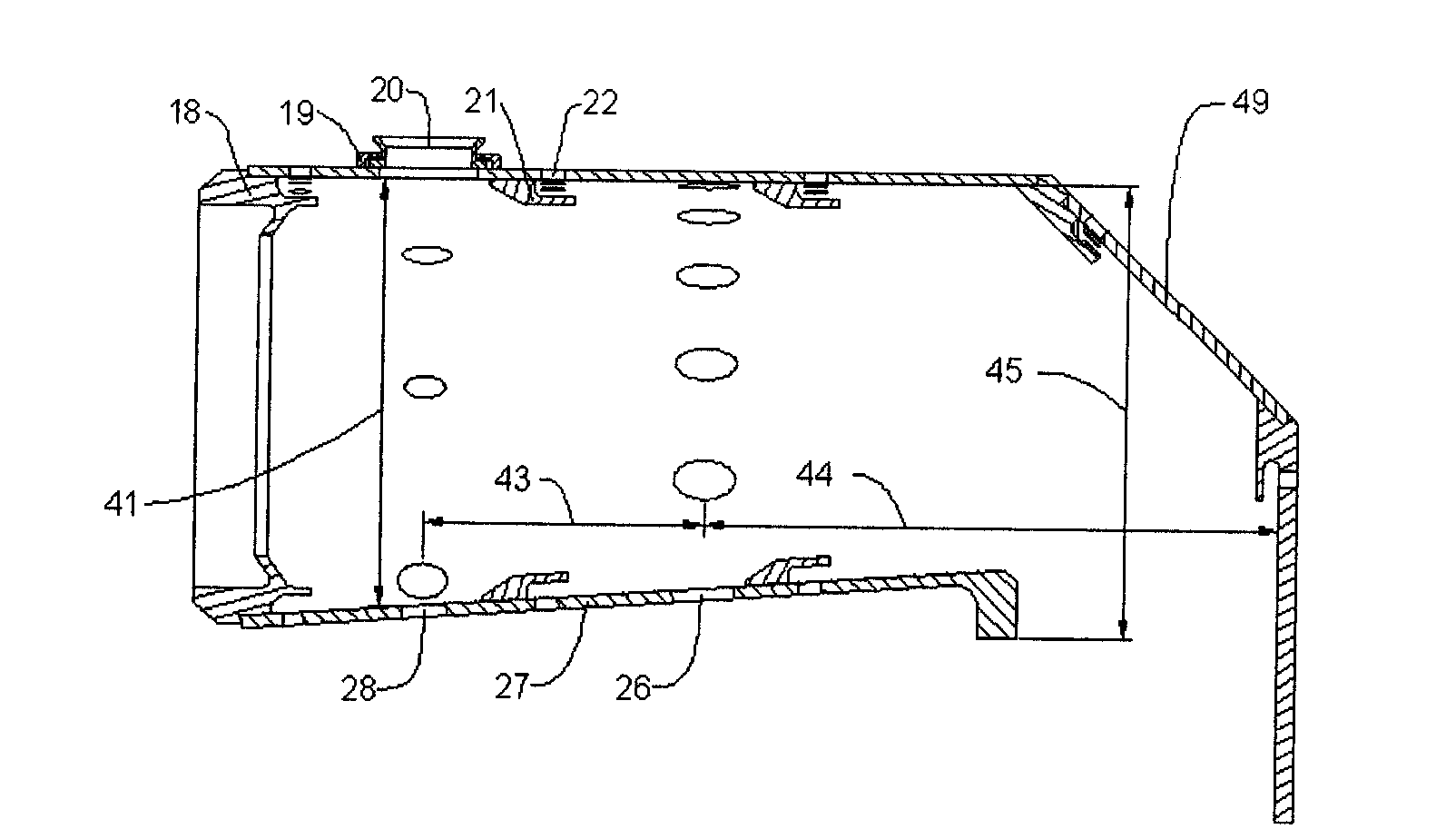

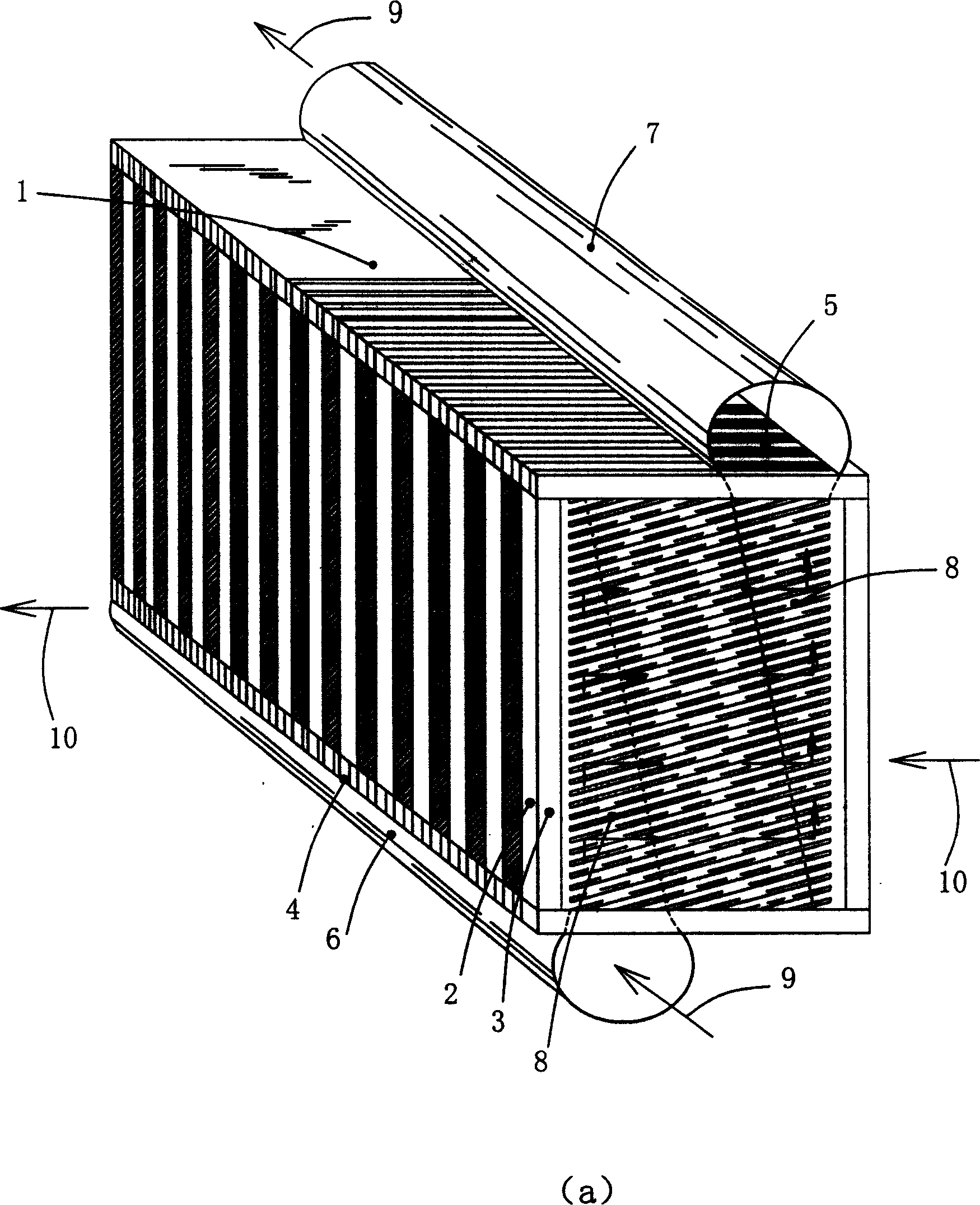

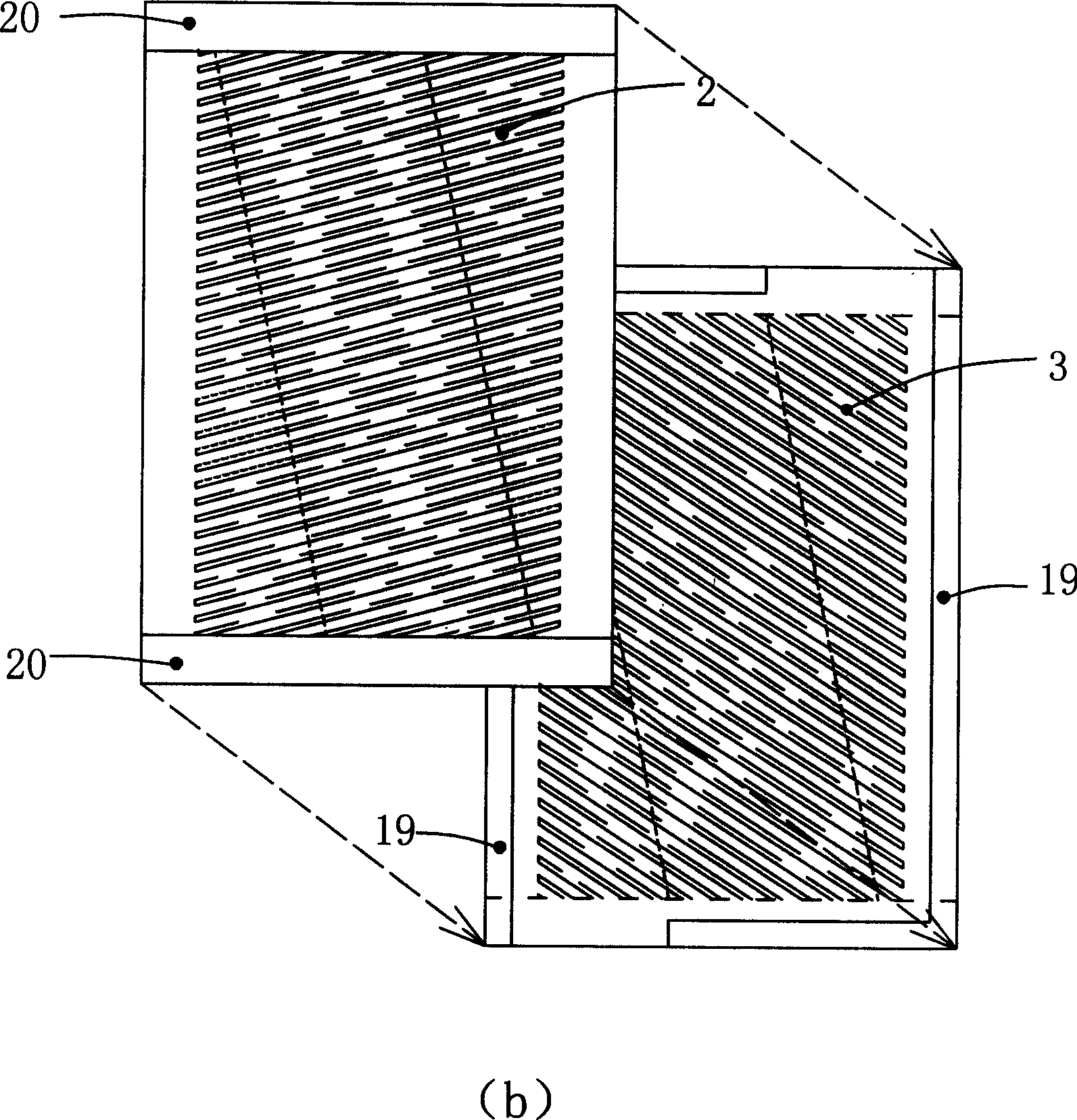

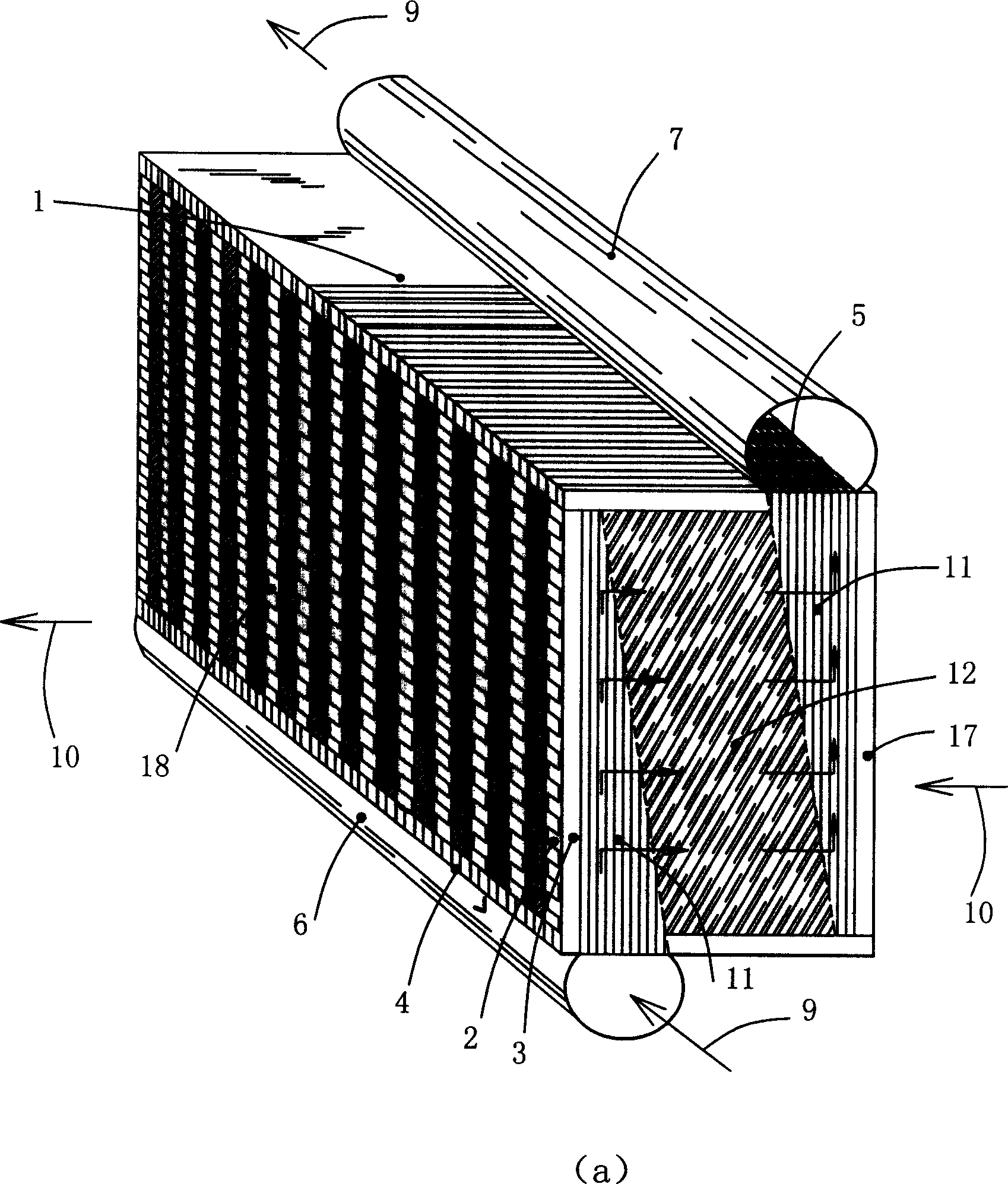

Heat regenerator of original surface for gas turbine

InactiveCN1560437AExtended service lifeImprove heat transfer efficiencyTurbine/propulsion engine coolingGas turbine plantsInlet channelMicro gas turbine

The invention relates to a regenerator for a micro gas turbine, concretely is a original surface heat exchanger for increasing the heat efficiency of the gas turbine, it can increase the compactness and the service life of regenerator. The gas inlet and outlet channels are arranged on the right lower horn and the left upper horn, the high pressure air flows into the regenerator through the air inlet channel, flows out from the air outlet channel, the left and right frames of the heat exchanging board are welded and formed a air in / out aperture, the fuel gas can flow into the regenerator through the aperture, flows out form aperture on another side, the centre is heat exchanging corrugation plates, the flatten area at two sides of the plates is used to place flow guiding plate, the heat exchanging board has a side frame for welding and sealing. The flow speed at two sides has a little difference, the heat exchanging effect is the best, and it can upgrade the heat exchanging efficiency.

Owner:XI AN JIAOTONG UNIV

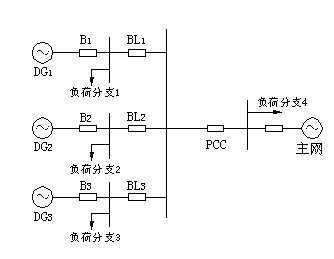

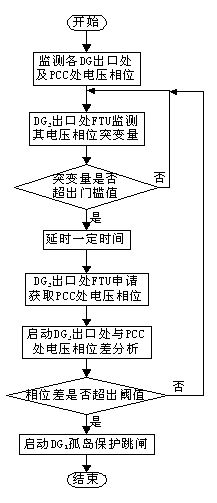

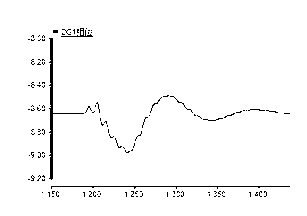

Comparative isolated island detection and protection method based on wide range information phase difference

ActiveCN103296643AEasy to detectEfficient acquisitionEmergency protective circuit arrangementsDistributed generatorTime delays

The invention relates to a comparative isolated island detection and protection method based on a wide range information phase difference, and belongs to the technical field of electrical power system protective relaying. According to the comparative isolated island detection and protection method based on wide range information phase difference, in the grid-connected operation processes of a distribution network system which includes distributed generators such as wind power generators, photovoltaic power generators and micro gas turbines, a feeder automation terminal in a power grid conducts real-time synchronous monitoring on voltage phases in the system. If the break variable of a voltage phase on an exit of the distributed generator is detected to be larger than a threshold value, the voltage phase difference between the voltage phase and a public coupling point is obtained through comparative analysis after certain time delay, the phase difference is compared with the setting threshold, the fact whether isolated island operation happens in the system is judged, isolated island protection is started in time, the distributed generator which is in an isolated island operation state is logged off the system. According to the comparative isolated island detection and protection method based on wide range information phase difference, the isolated island detection and isolated island protection are based on wide range information and emphasize on the utilization of the wide range information and the realization of the safety function, the effect is obvious, and reliability is high.

Owner:KUNMING UNIV OF SCI & TECH +2

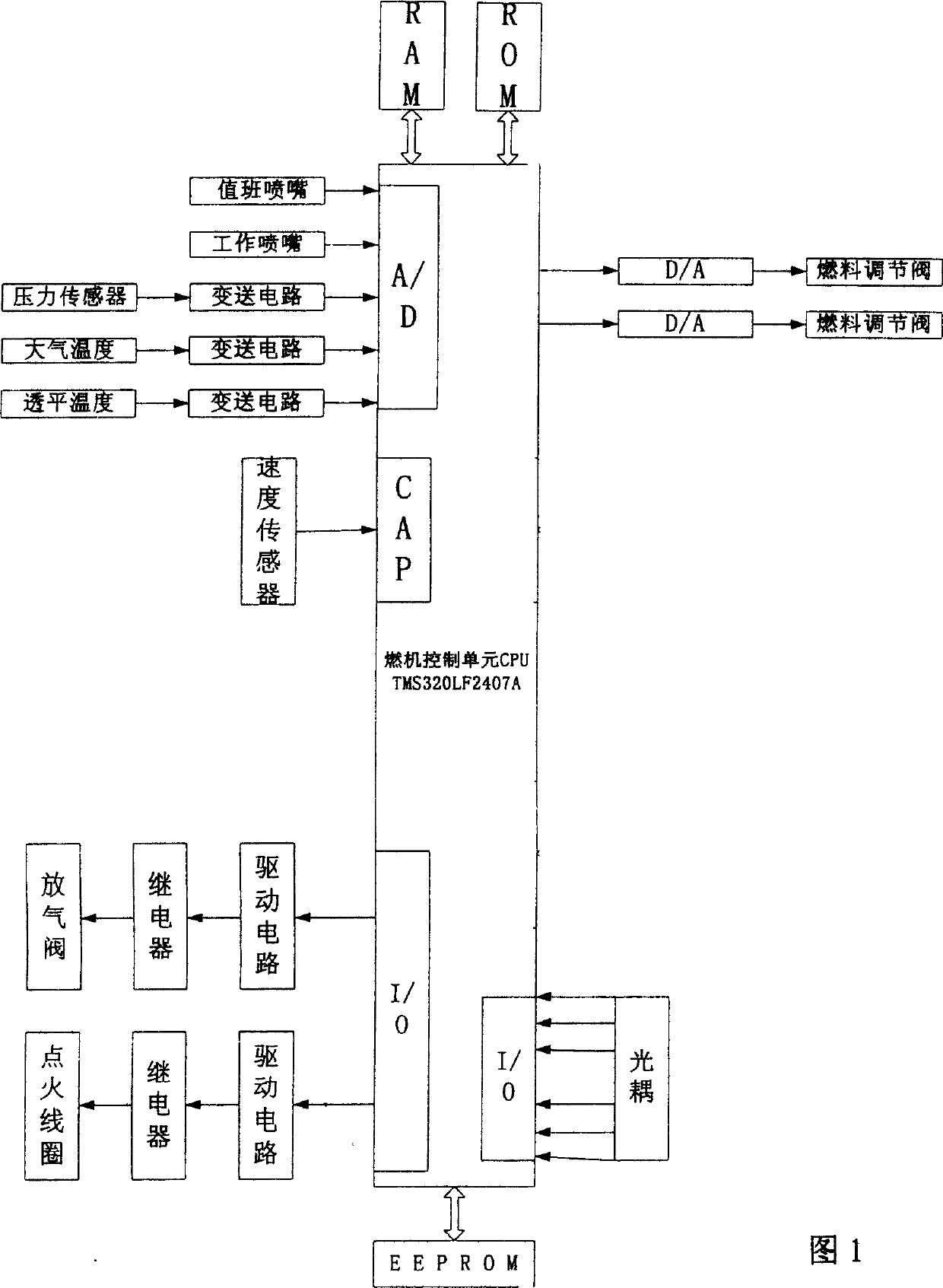

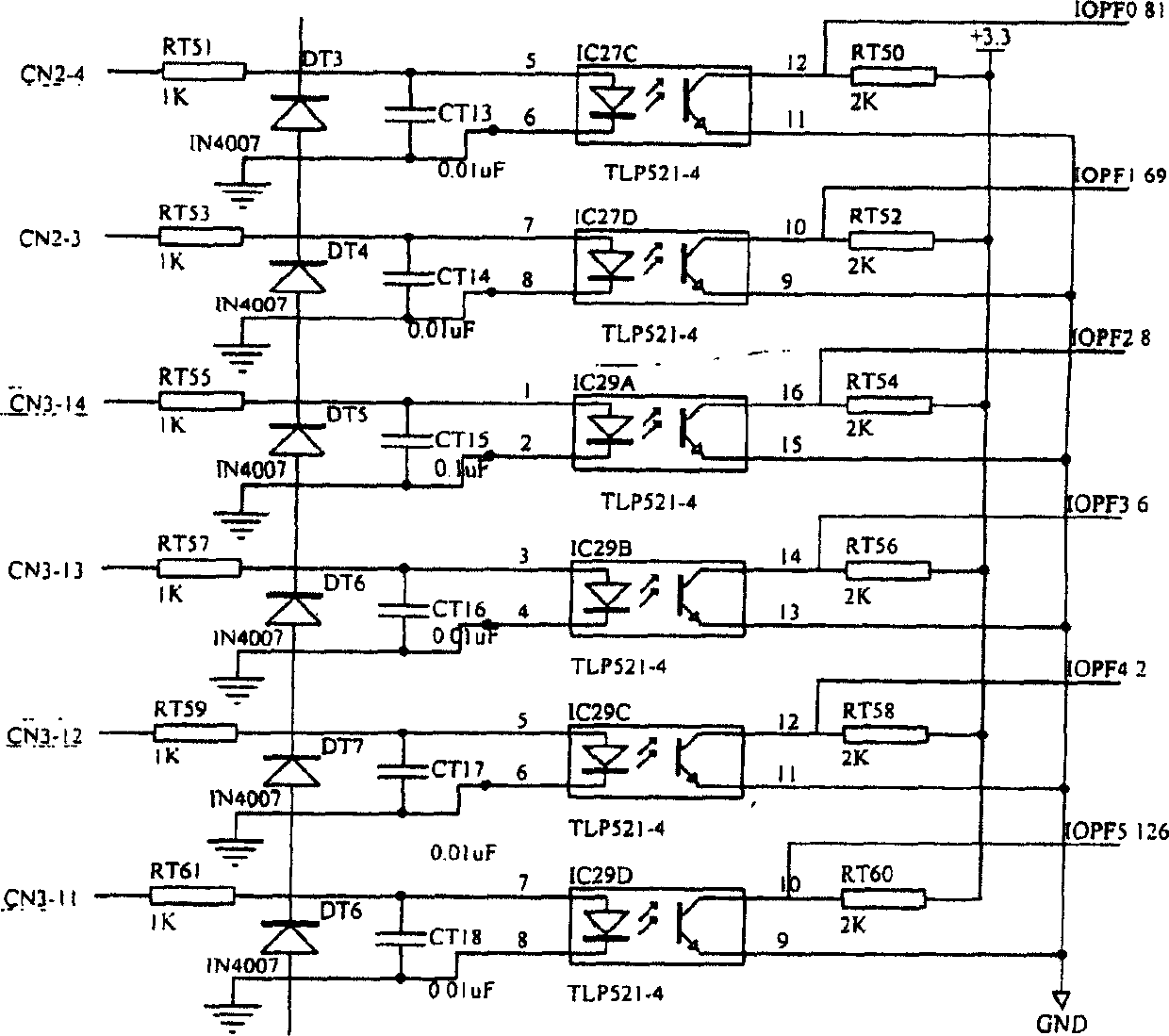

Combustion controller and controll method of miniature gas turbine

InactiveCN1869420AHigh control precisionImprove securityGas turbine plantsTurbine/propulsion fuel controlElectricityCoupling

The invention relates to a micro fuel gas turbine technology, whose structure includes turbine burning controller and control method. The controller includes PUT, detecting unit, output unit, photo-electricity coupling unit, and driving unit. The control method is realized by computer program module that includes system initialization, self-testing, burner firing, power closed loop adjusting block, stop and turbine capability index real time monitoring module. It adopts neural network PID controller adjusting method. It improves control accuracy, decreases technology cost and increases the stability and safety of the system.

Owner:NORTHEASTERN UNIV LIAONING

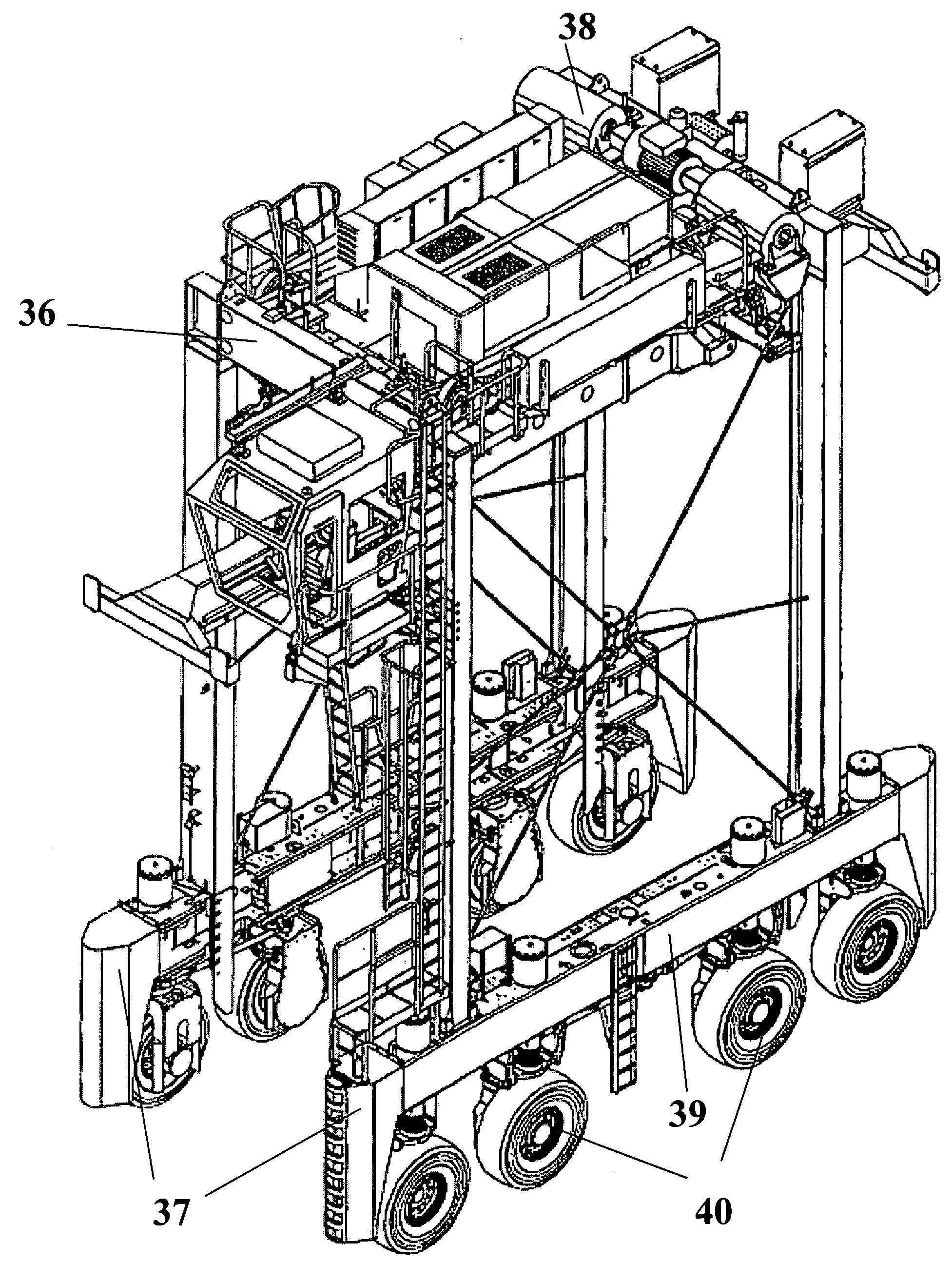

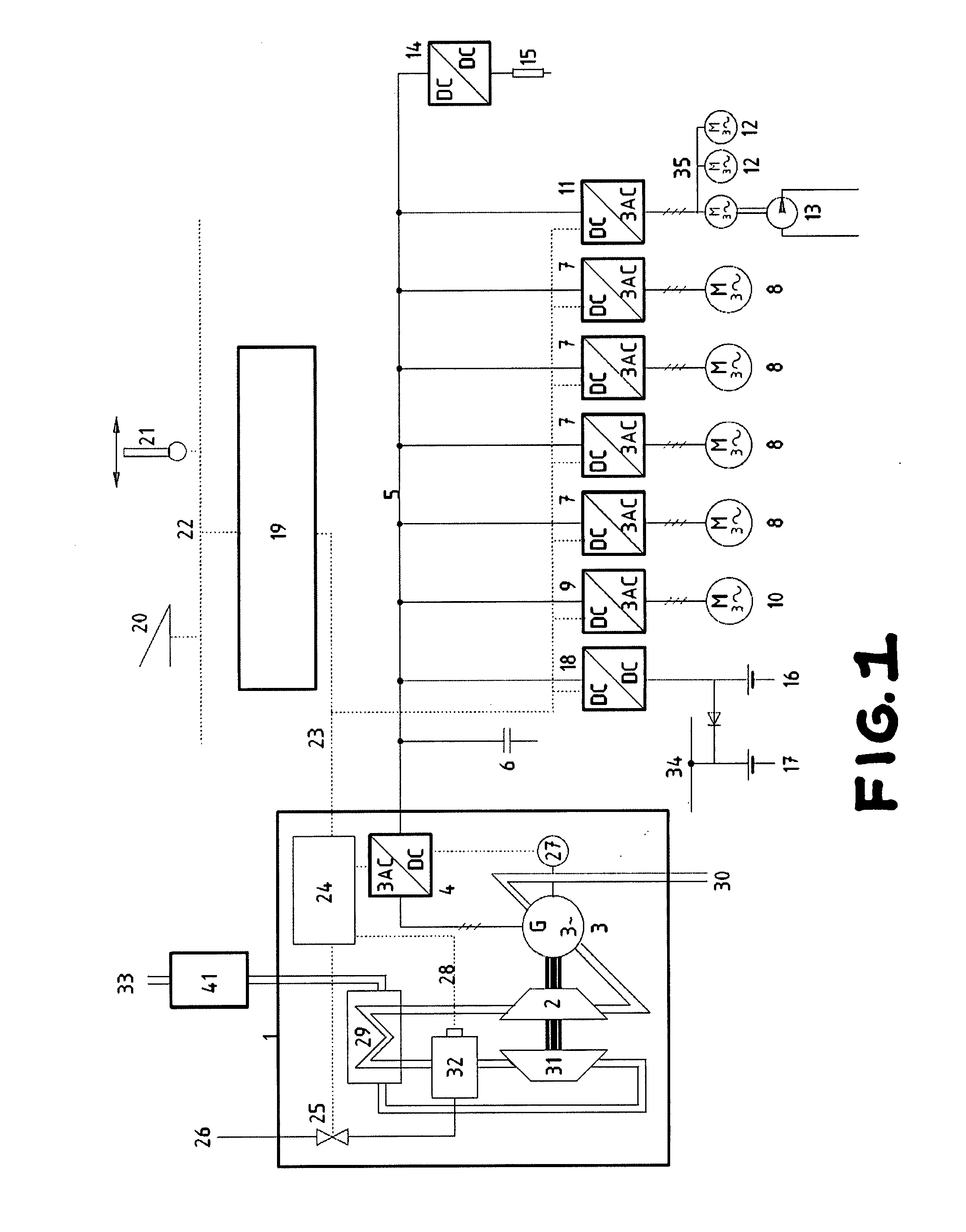

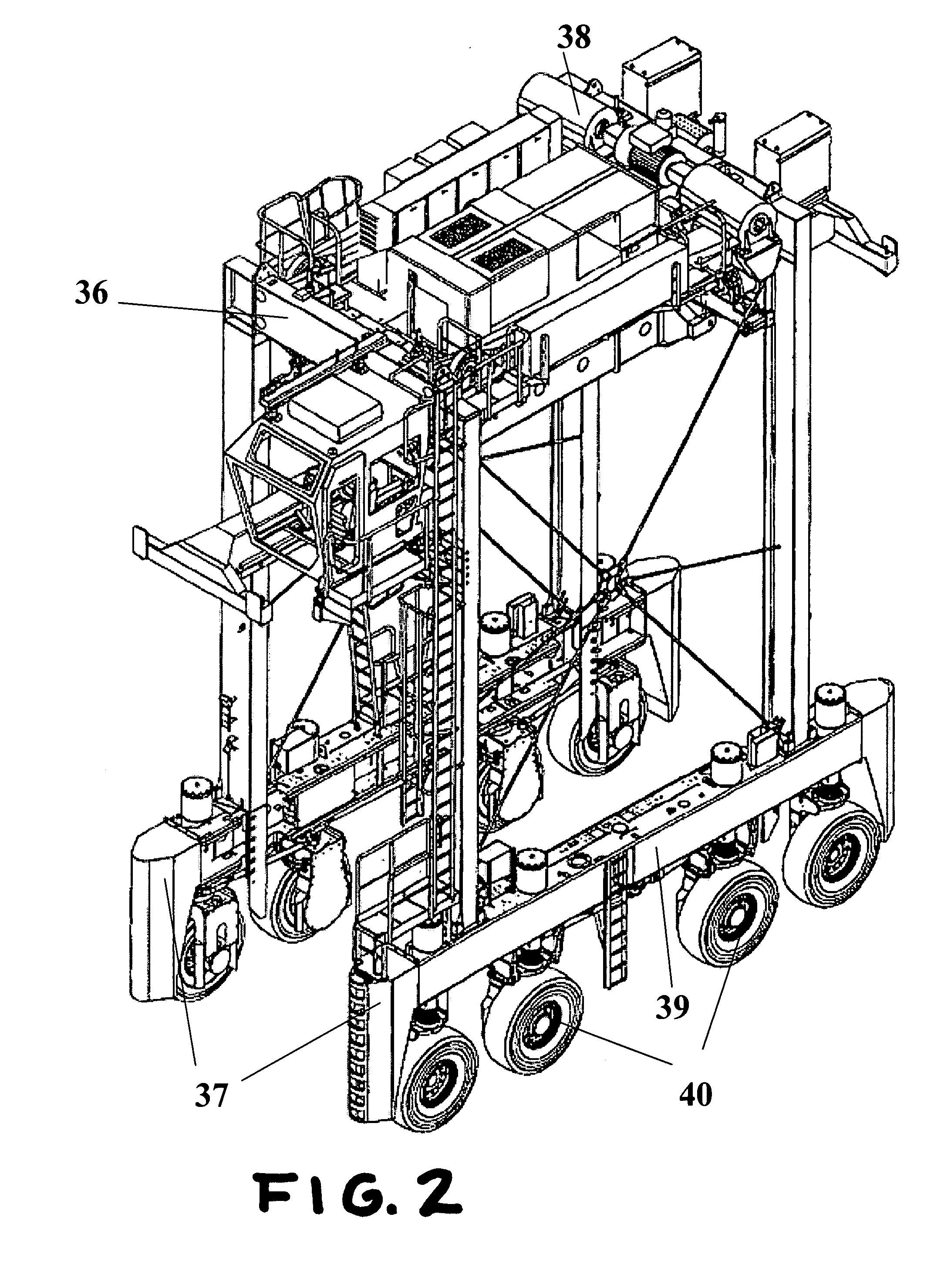

Straddle carrier having a low-emission and low-maintenance turbine drive

InactiveUS20080121444A1Less maintenance and replacementGentle processHybrid vehiclesVehicle sub-unit featuresElectricityDrive wheel

A straddle carrier having an electric drive system, consisting of a lower and an upper frame, which are connected with one another by means of supports. A lifting mechanism with hoists is disposed on the upper frame, and the lower frame consists of chassis carriers having electrically driven wheels, and a power generation unit that feeds its generated electric power into a direct voltage intermediate circuit, to which current inverters for supplying the travel, lifting, and auxiliary motors are connected. The power generation unit represents a micro gas turbine having an attached power generator, the power of which is passed to the travel, lifting, and auxiliary motors. The straddle carrier can be produced at low weight and maintained under advantageous conditions. Furthermore, the straddle carrier can be operated under environmentally friendly conditions.

Owner:NOELL MOBILE SYST

Ultra-micro gas turbine

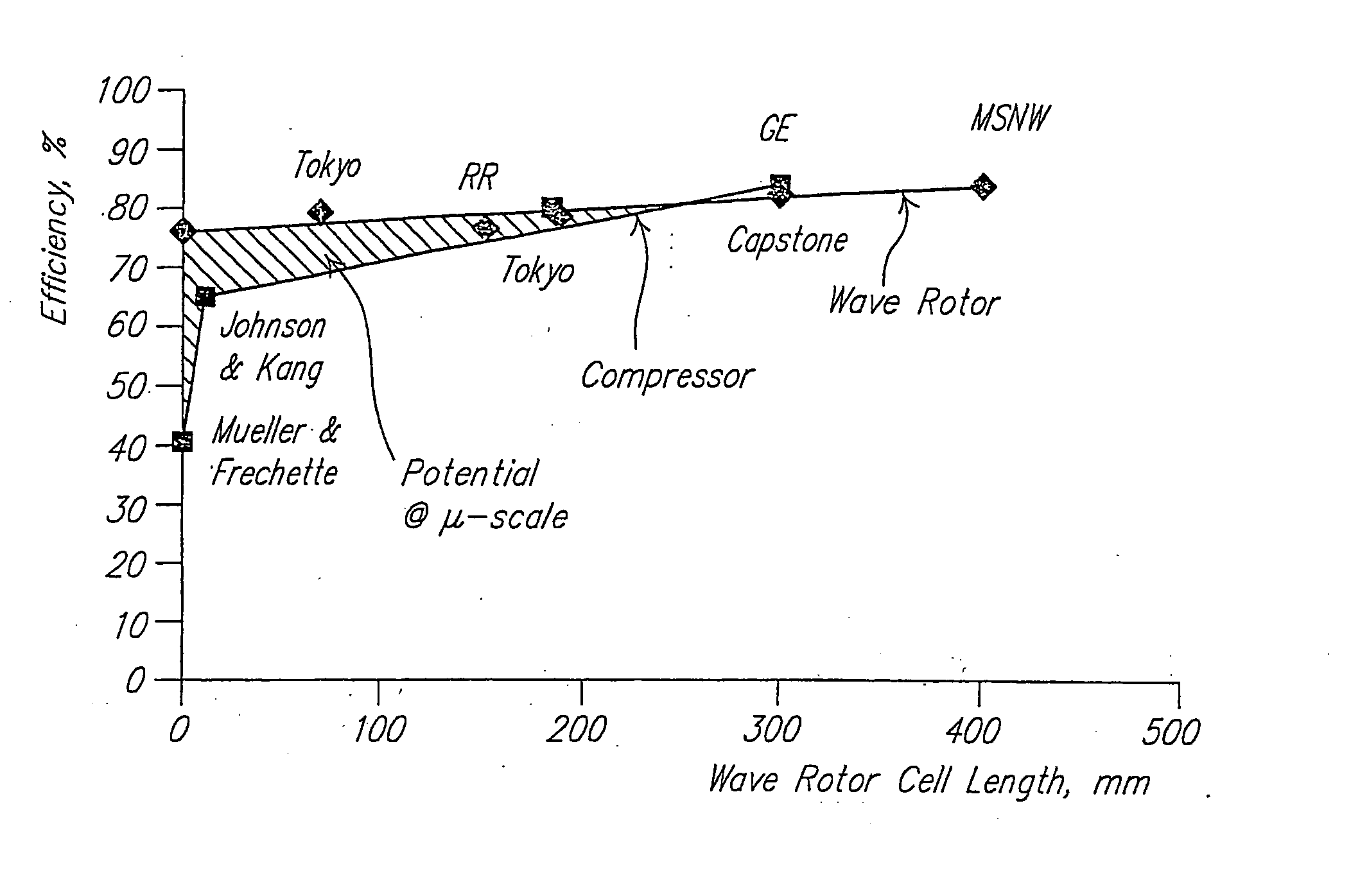

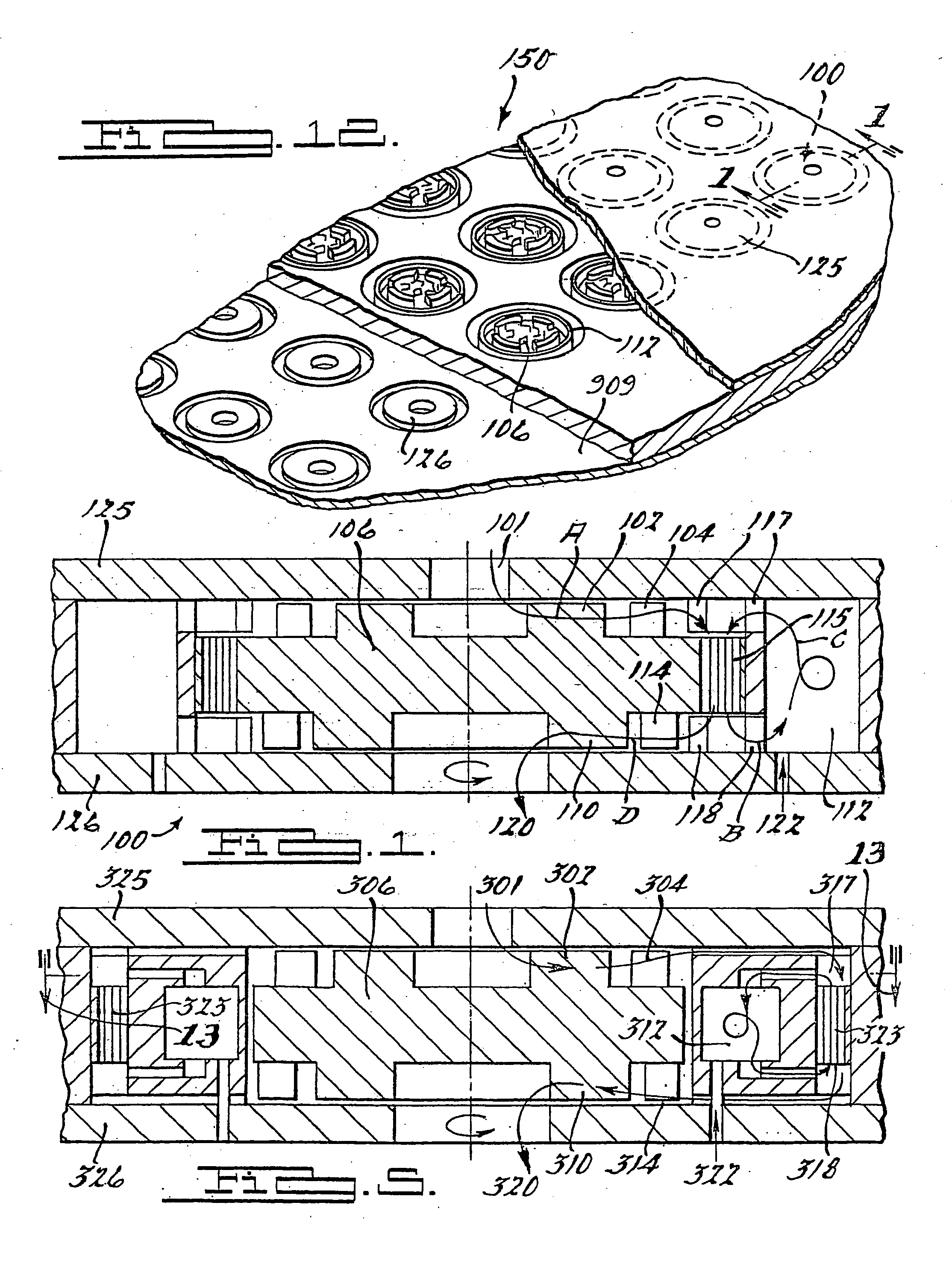

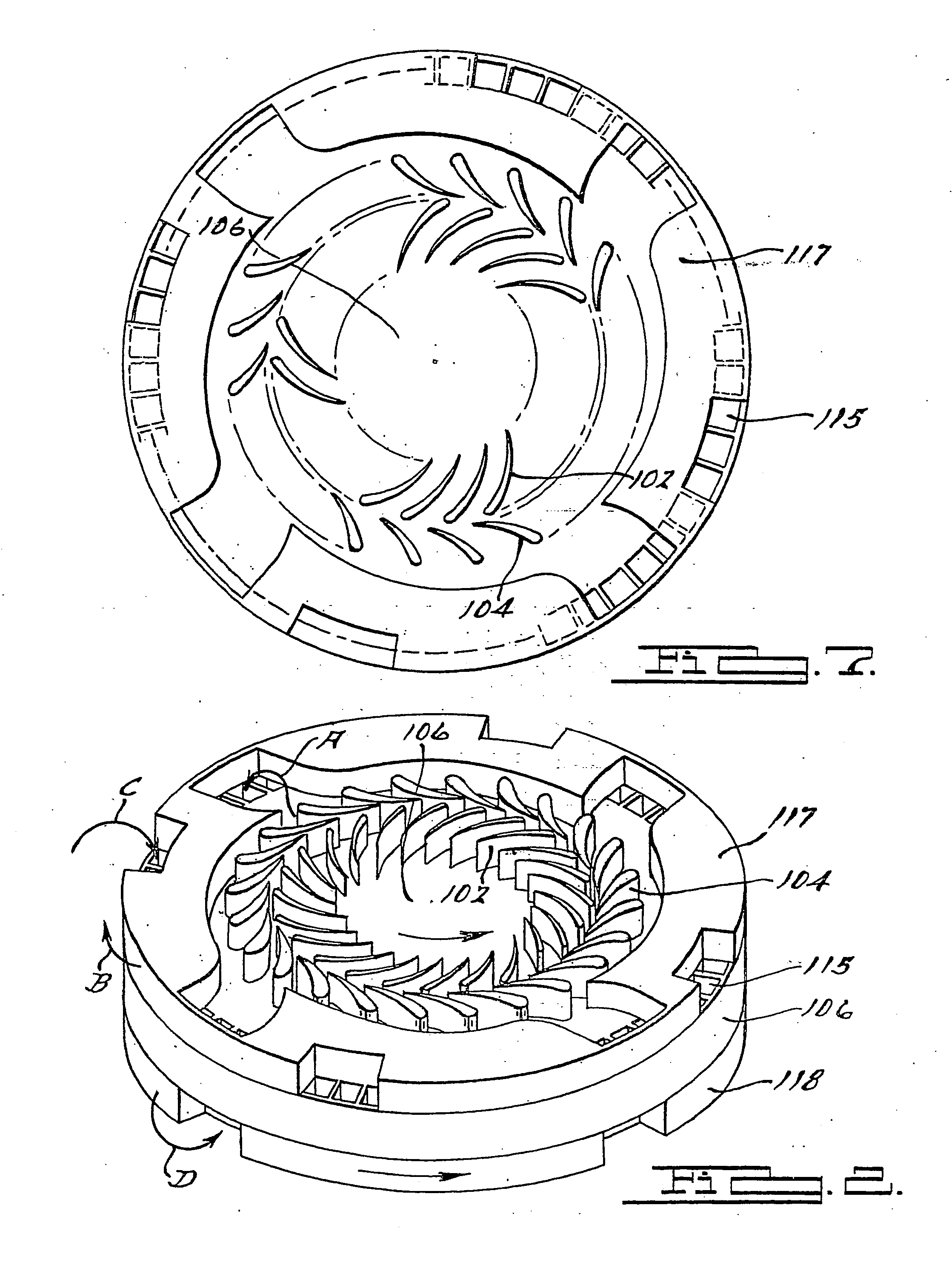

InactiveUS7934368B2Improve efficiencyReduce flow rateEngine manufactureEngine fuctionsCombustion chamberMicro gas turbine

The present invention provides an ultra micro gas turbine engine which includes a wave rotor. In various embodiments, the ultra micro gas turbine engine of the present invention includes a rotating disk which has a compressor, a wave rotor and a turbine, a first stationary member which includes an inlet and a first wave rotor port end plate, a second stationary member which includes an outlet and a second wave rotor port end plate and a combustion chamber which includes a fuel inlet and an igniter.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

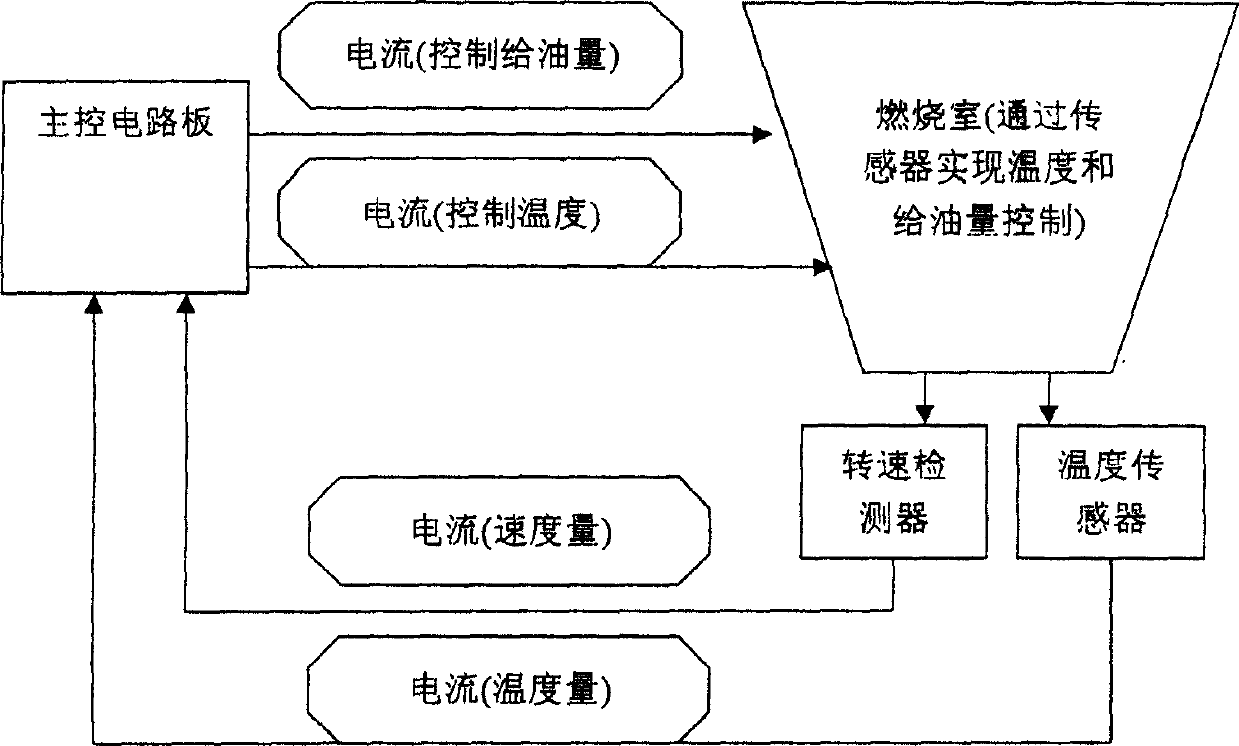

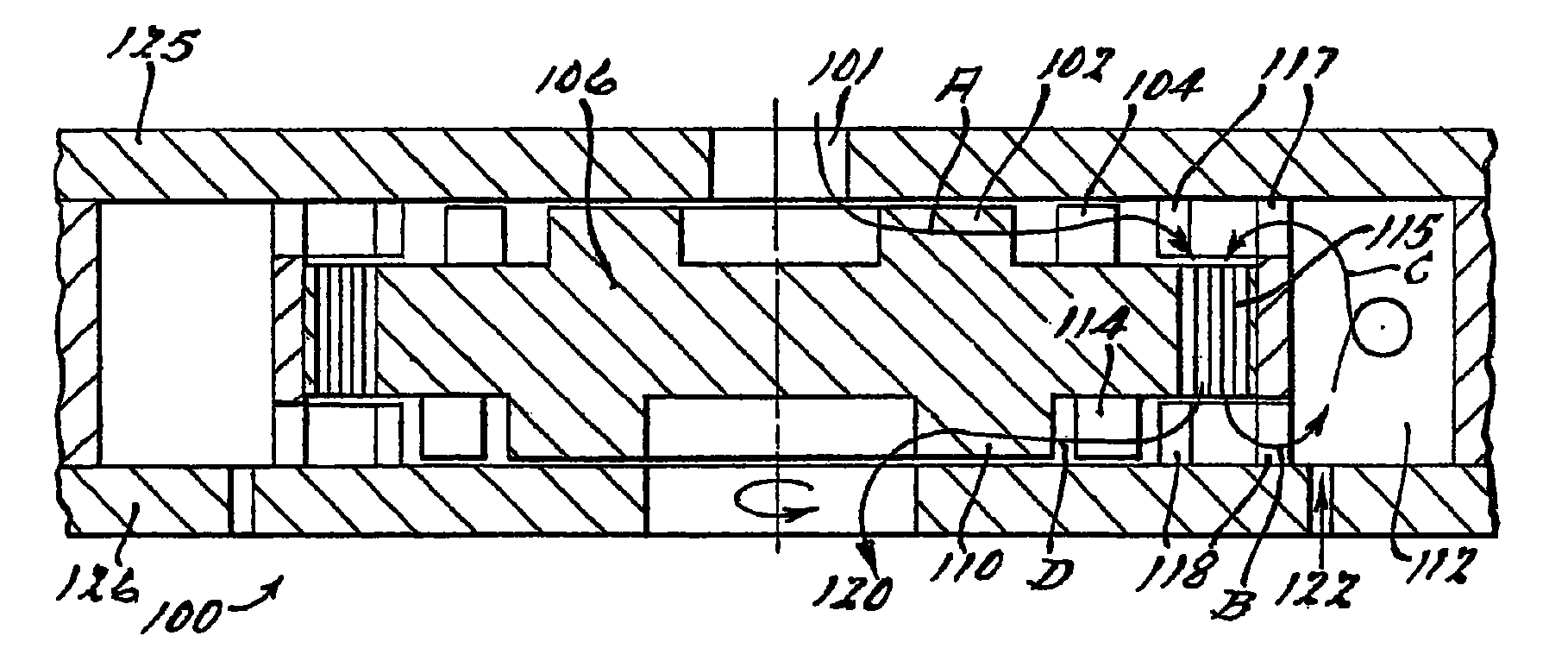

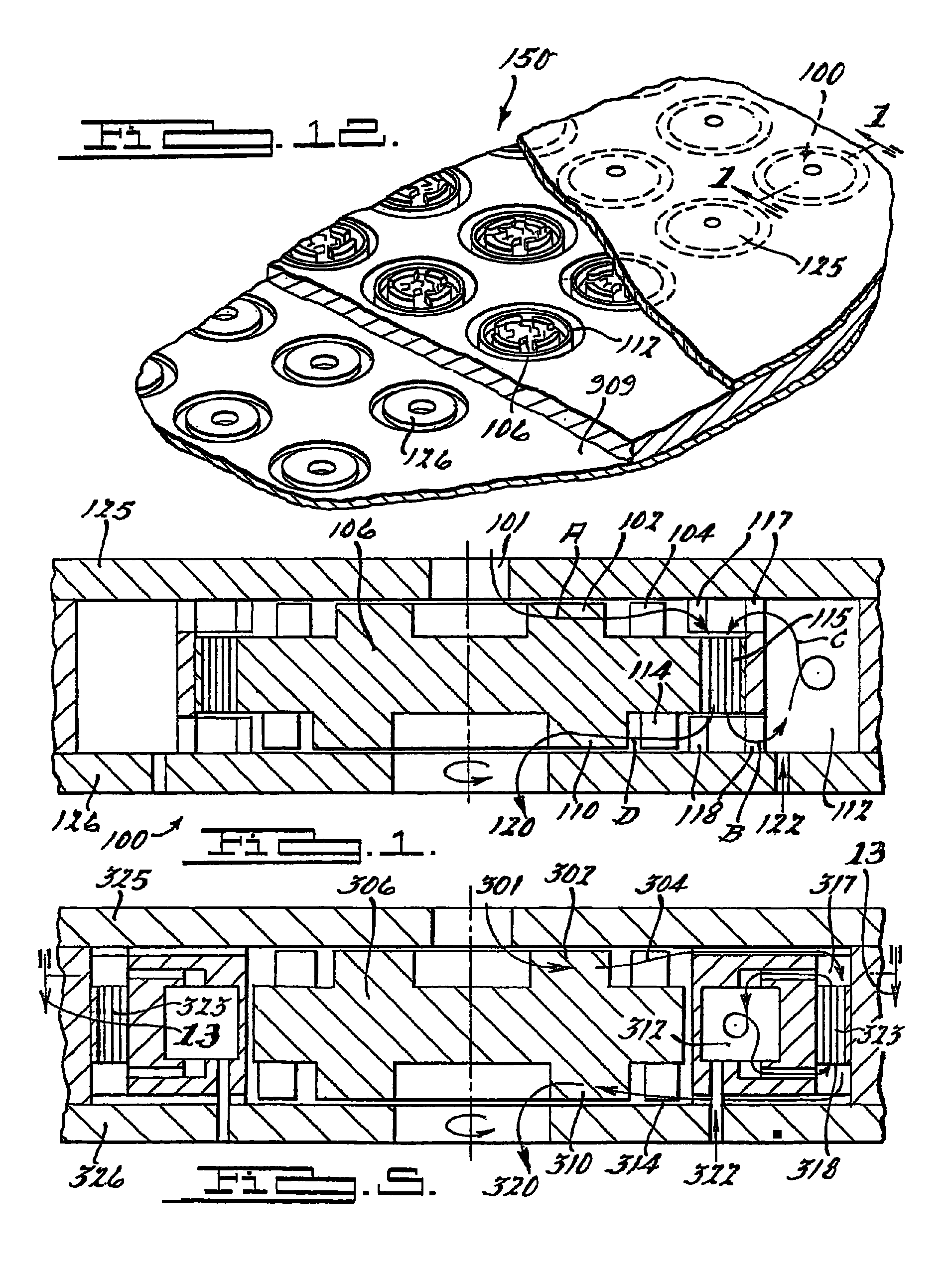

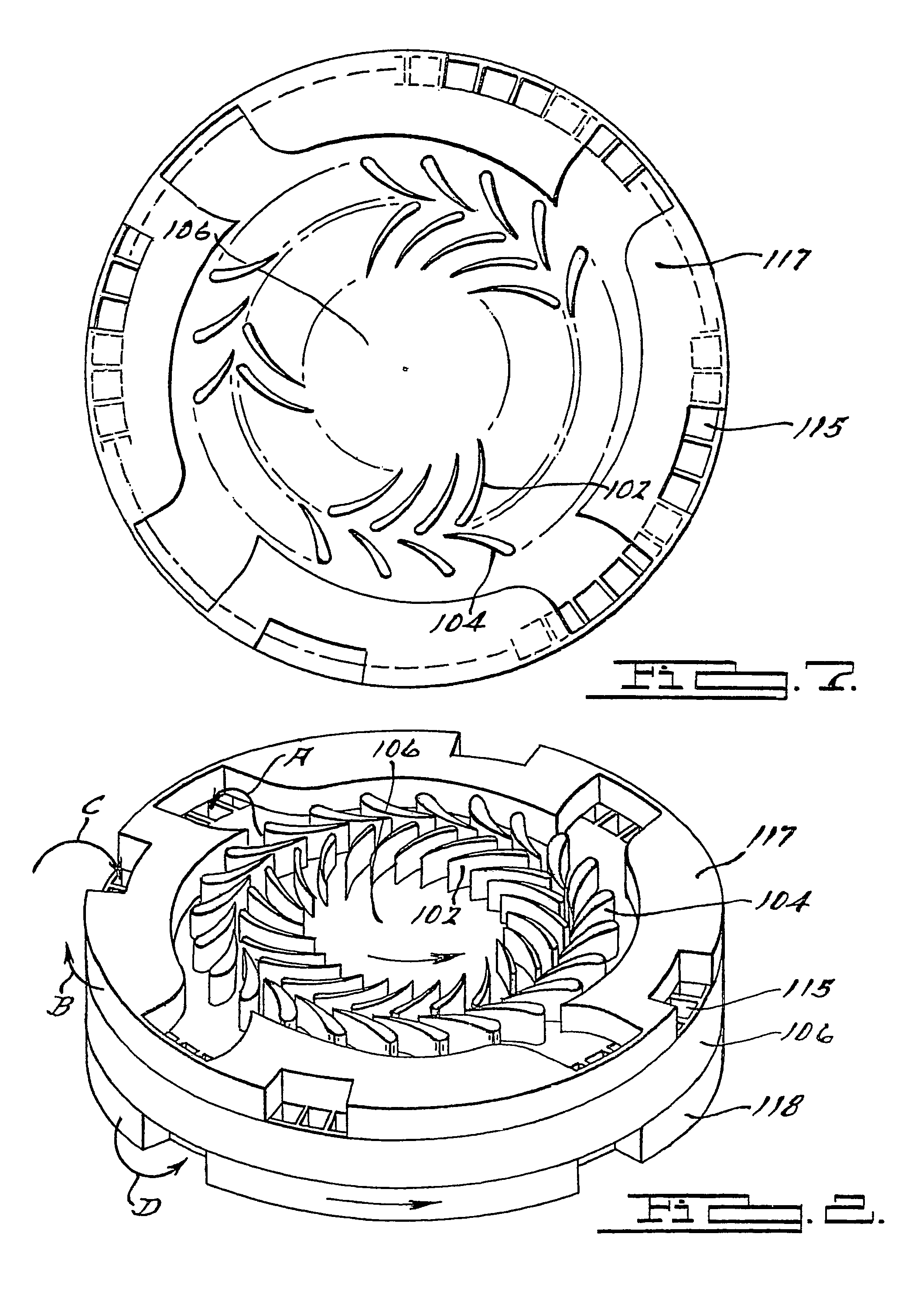

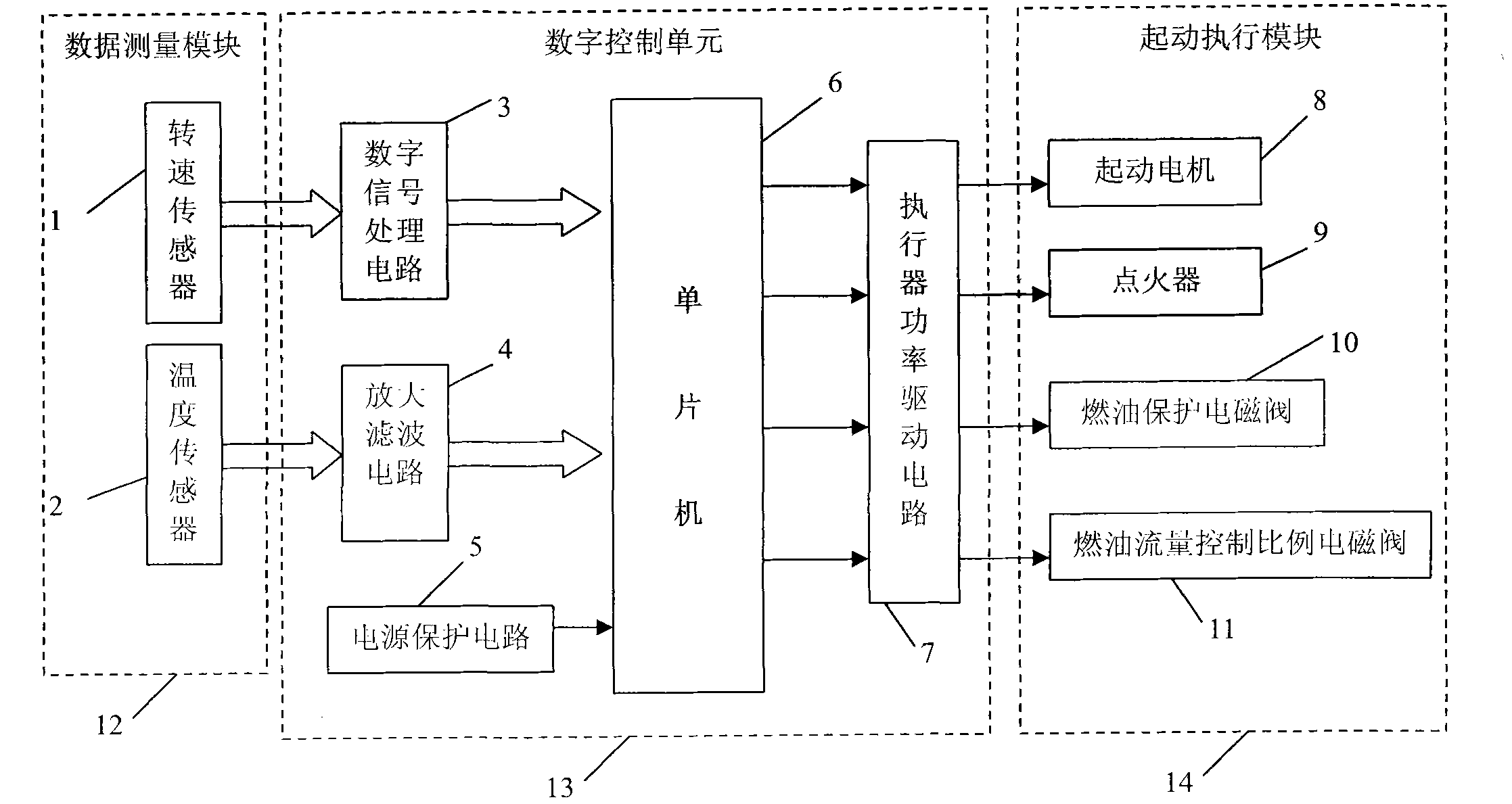

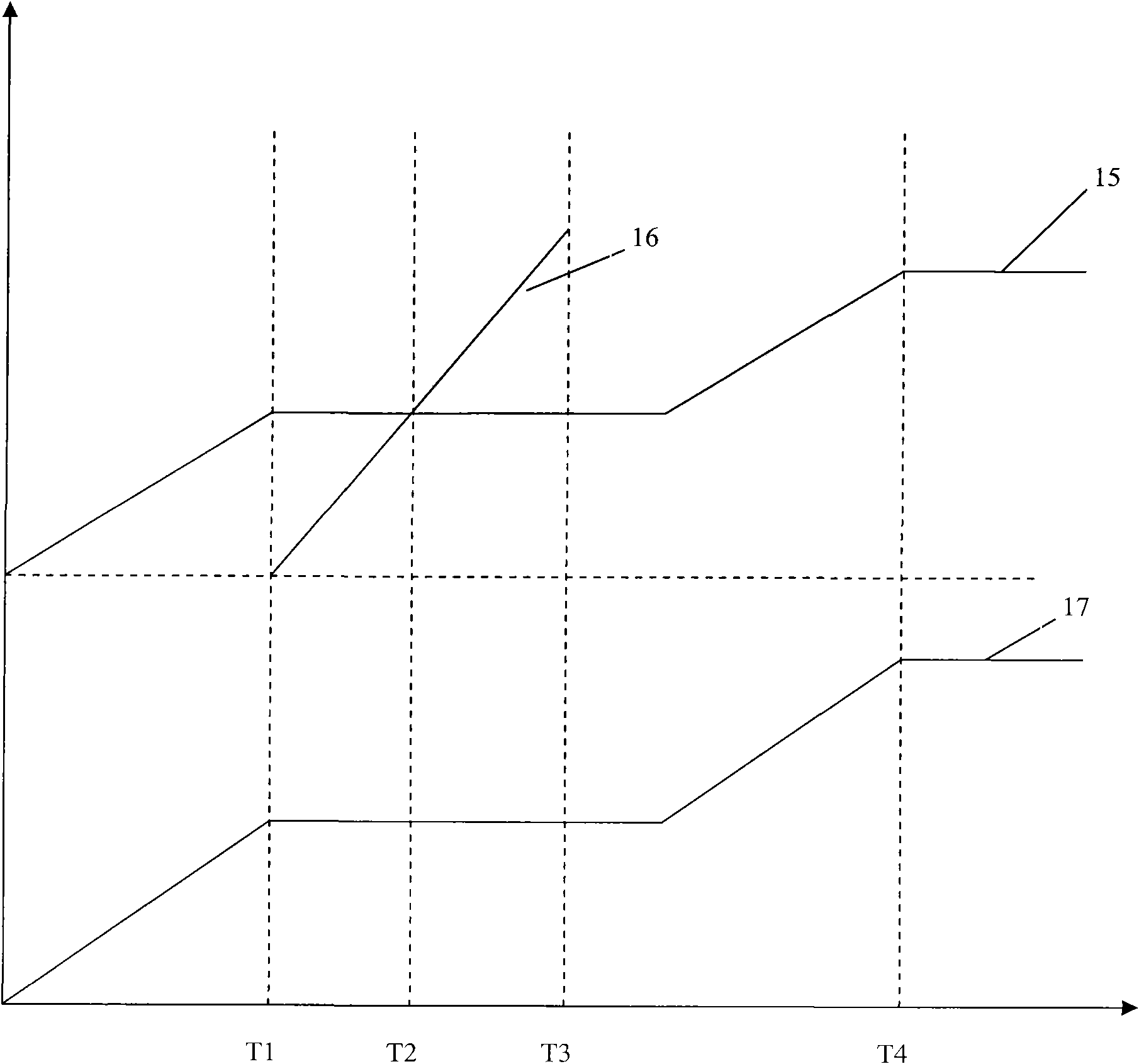

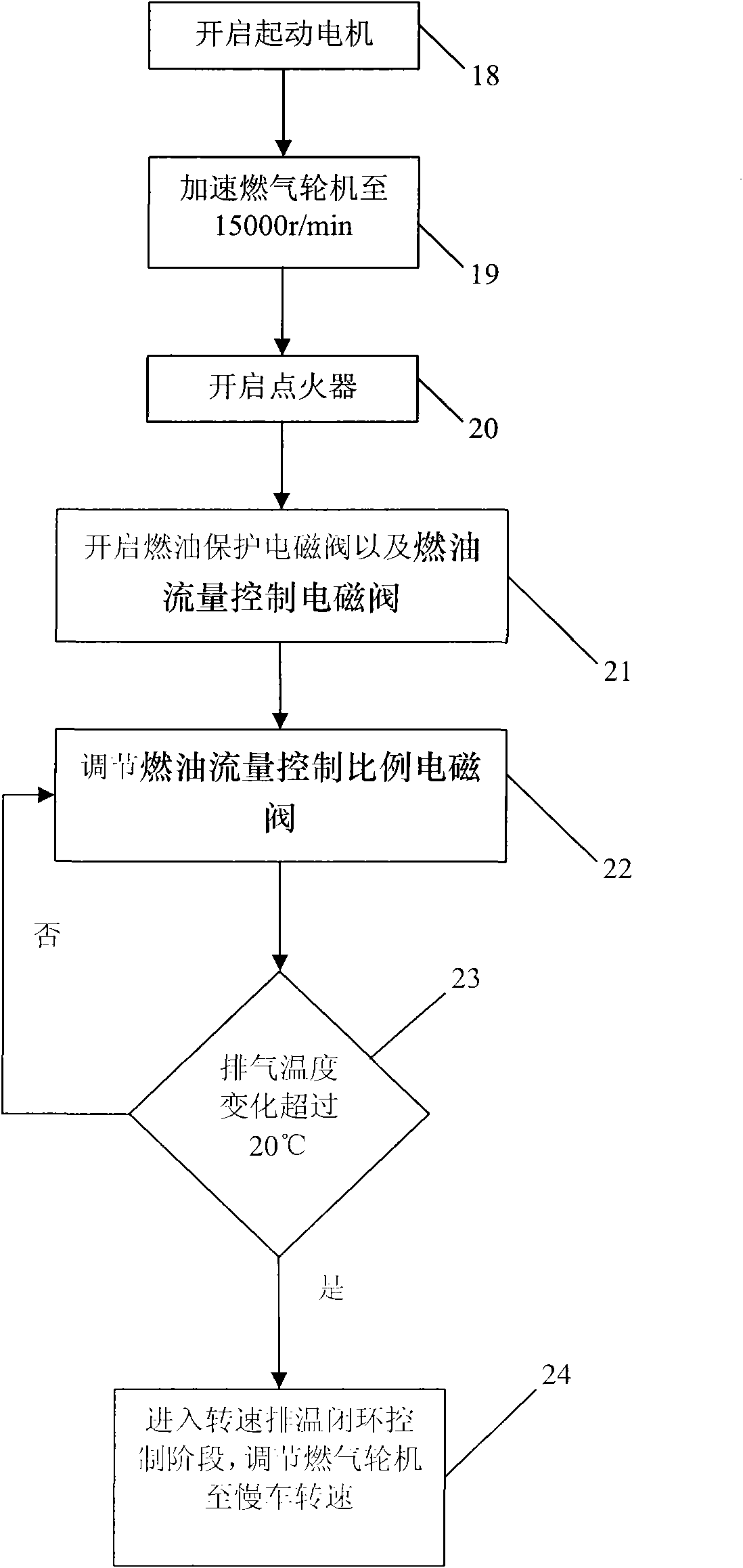

Starting control device of micro gas turbine and starting control method

InactiveCN101806251ASimple structureReduce in quantityGas turbine plantsJet propulsion plantsMicrocontrollerLoop control

The invention discloses a starting control device of a micro gas turbine and a starting control method. The starting control device comprises a data measurement module, a starting implementation module and a digital control unit, wherein the data measurement module consists of a rotating speed sensor and a temperature sensor, and the starting implementation module consists of a starting motor, an igniter, a fuel protection solenoid valve and a fuel flow control proportional solenoid valve. The starting control method comprises the following steps: controlling the starting motor through the digital control unit, driving a gas turbine to rotate at a set rotating speed, maintaining the rotating speed, adjusting fuel flow through controlling the fuel flow control proportional solenoid valve to realize proper proportional matching of fuel and air, igniting the mixed gas with the igniter, raising the rotating speed of the gas turbine, and making the gas turbine into an idling state through closed-loop control of a microcontroller according to the exhaust temperature and the rotating speed of the gas turbine, thereby completing the starting. The invention can effectively avoid the influence of changes in the fuel flow, the state of the gas turbine and the atmospheric conditions during the starting process, solve the problems of the micro gas turbine in the harsh environment such as difficult and unstable starting and the like, and ensure that the gas turbine can be started under any condition.

Owner:BEIHANG UNIV

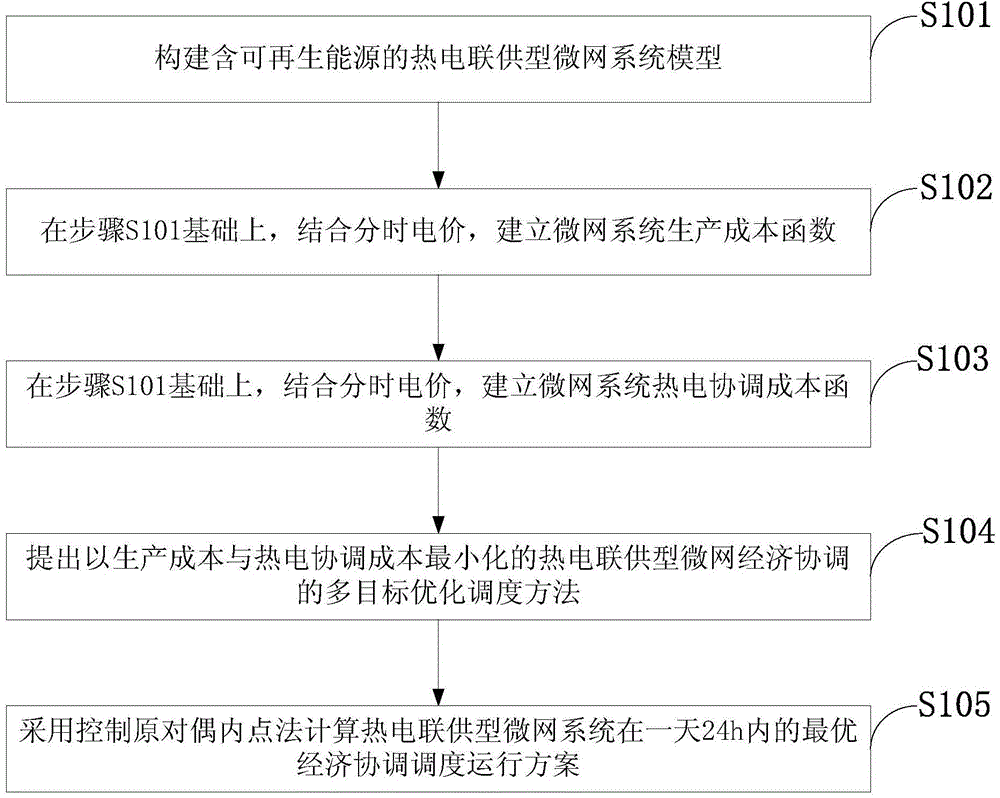

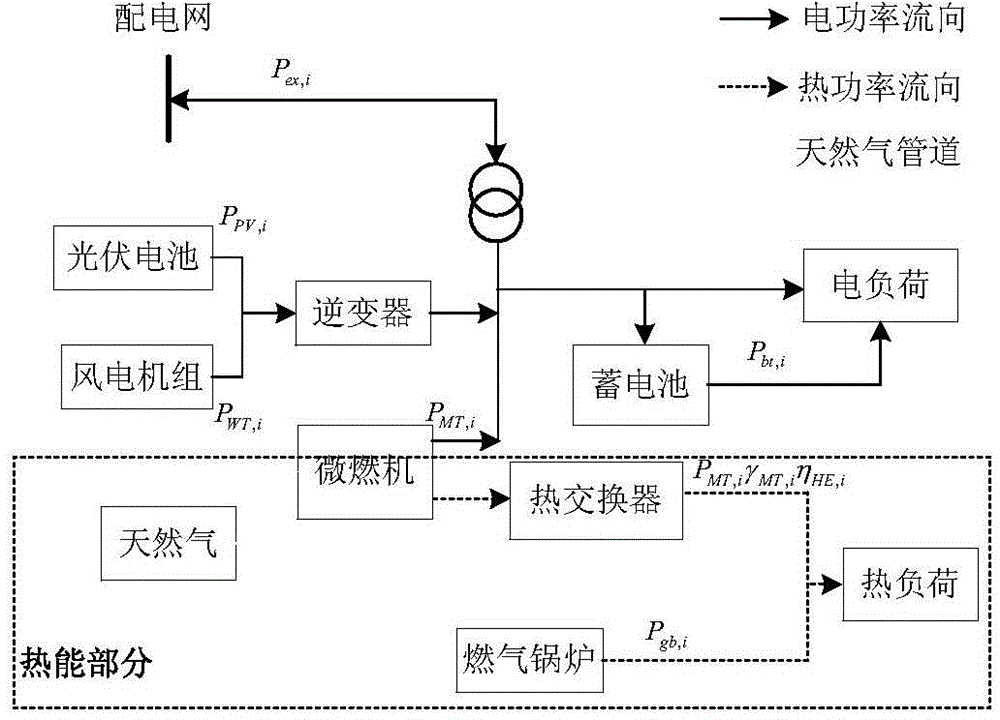

Co-generation type micro-grid economy coordination and optimization dispatching method

InactiveCN104537443AIncrease profitabilityImprove economic indicatorsForecastingInterior point methodMicro gas turbine

Owner:STATE GRID CORP OF CHINA +1

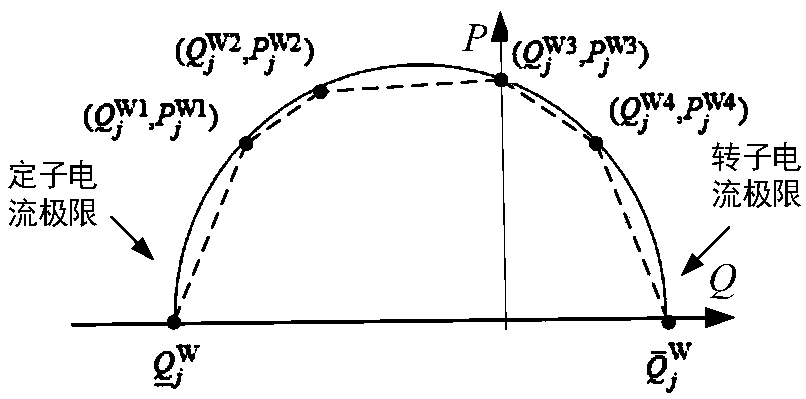

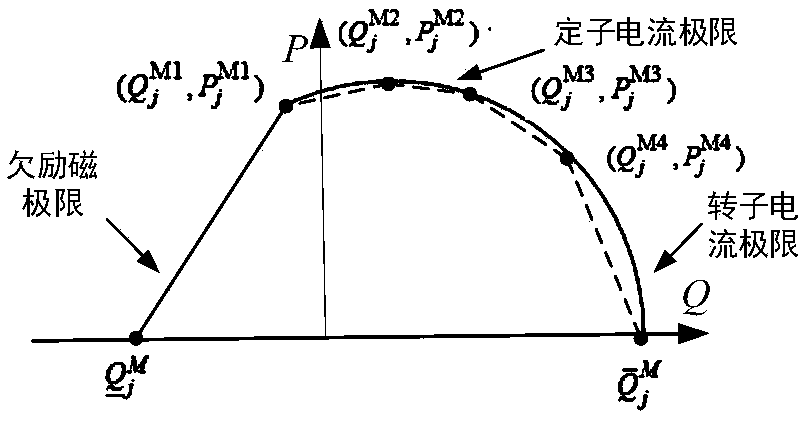

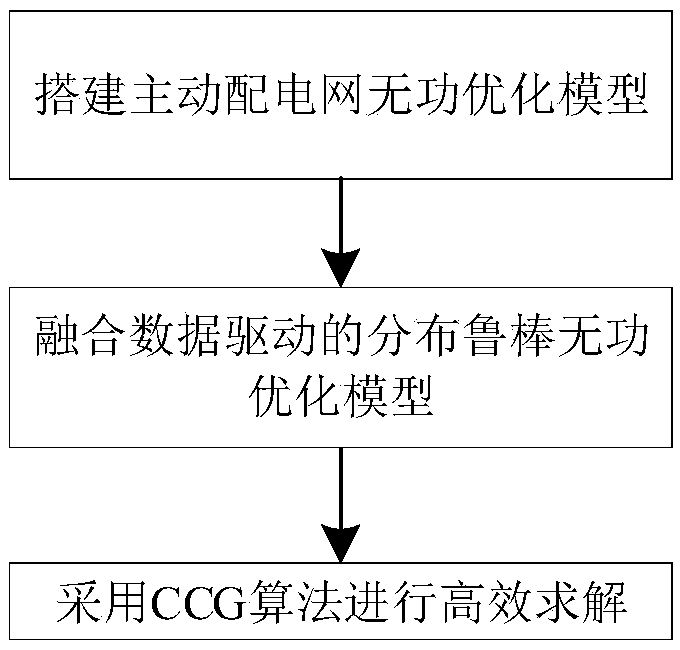

Active power distribution network distribution robust reactive power optimization method in consideration of DG reactive power support and switch reconstruction

ActiveCN108631328AFast solutionEfficient solutionSingle network parallel feeding arrangementsReactive power adjustment/elimination/compensationPower compensationEffective solution

The invention discloses an active power distribution network distribution robust reactive power optimization method in consideration of DG reactive power support and switch reconstruction. With the total network loss of the system in each period as an optimization objective and with regulation restrictions of equipment such as a substation OLTC and a discrete and continuous reactive power compensation device as constraint conditions, switch correlation modeling is included, the power grid radioactivity and the non-isolated island operation condition are thus ensured, the capacity curves of a double-fed fan and a micro gas turbine are modeled in details, the DG reactive power support capability is thus integrated, the linearization method with active and reactive power output coupling characteristics is also designed, and thus, the model can be quickly and reliably solved. A decomposition algorithm is used to decompose the model to a main problem and a sub problem for repeated iterativesolution, the solution speed can be quickened, and through carrying out equivalent conversion on absolute value constraint conditions, the solution problem is converted to a mixed integer programmingproblem, and the existing solution kit CPLEX is adopted for effective solution.

Owner:SICHUAN UNIV

Ultra-Micro Gas Turbine

InactiveUS20080041065A1Improve efficiencyInternal flow velocityEngine manufactureEngine fuctionsCombustion chamberMicro gas turbine

The present invention provides an ultra micro gas turbine engine which includes a wave rotor. In various embodiments, the ultra micro gas turbine engine of the present invention includes a rotating disk which has a compressor, a wave rotor and a turbine, a first stationary member which includes an inlet and a first wave rotor port end plate, a second stationary member which includes an outlet and a second wave rotor port end plate and a combustion chamber which includes a fuel inlet and an igniter.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

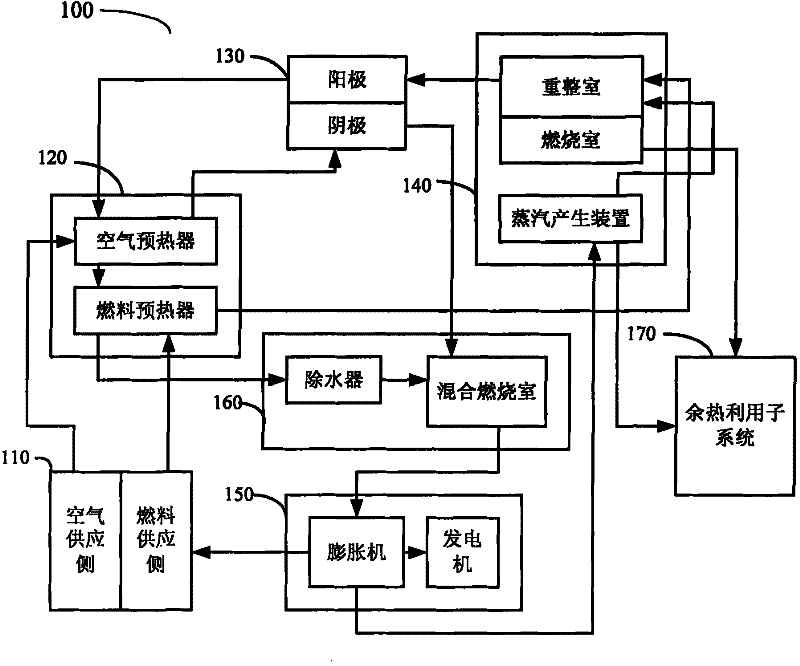

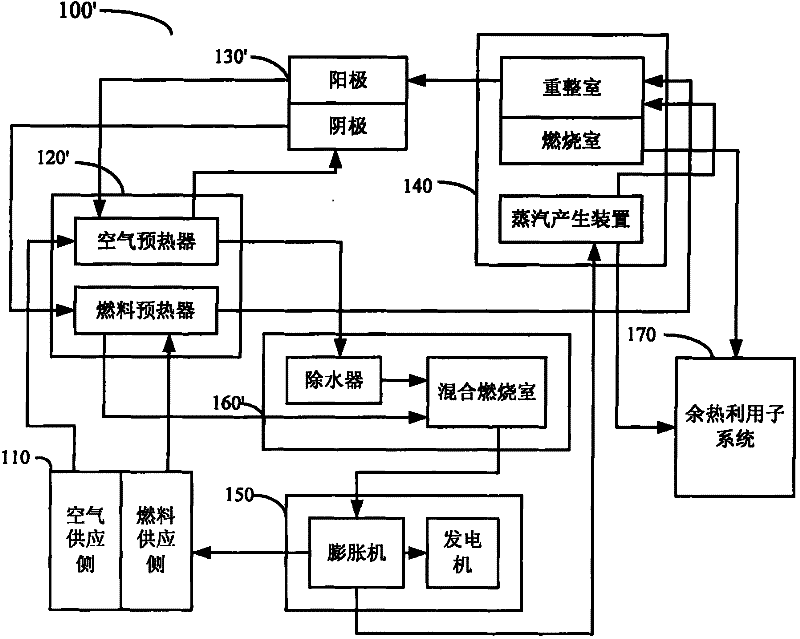

Combined heat and electricity generation system with fuel cell and gas turbine

ActiveCN102456898AIncrease profitEasy to control working conditionsFuel cell heat exchangeOther heat production devicesCombustionFuel cells

The invention discloses a combined heat and electricity generation system formed by the combination of a fuel cell and a gas turbine. The system comprises a feeding subsystem, a preheating subsystem, a fuel cell subsystem, a reforming subsystem, a gas turbine power generation subsystem and a waste heat utilization subsystem. A mixing combustion subsystem is provided between the fuel cell subsystem and the gas turbine power generation subsystem, and the subsystems are mutually connected with each other to form the combined heat and electricity generation system of cycle combination. According to the invention, the supercharged melted carbonate fuel cell is organically combined with the micro gas turbine to form the quality-exchanged combined cycle system, the power density of the system is high, and the waste heat recycle is fully and effectively carried out, so the whole energy utilization rate is improved as possible.

Owner:ENN SCI & TECH DEV

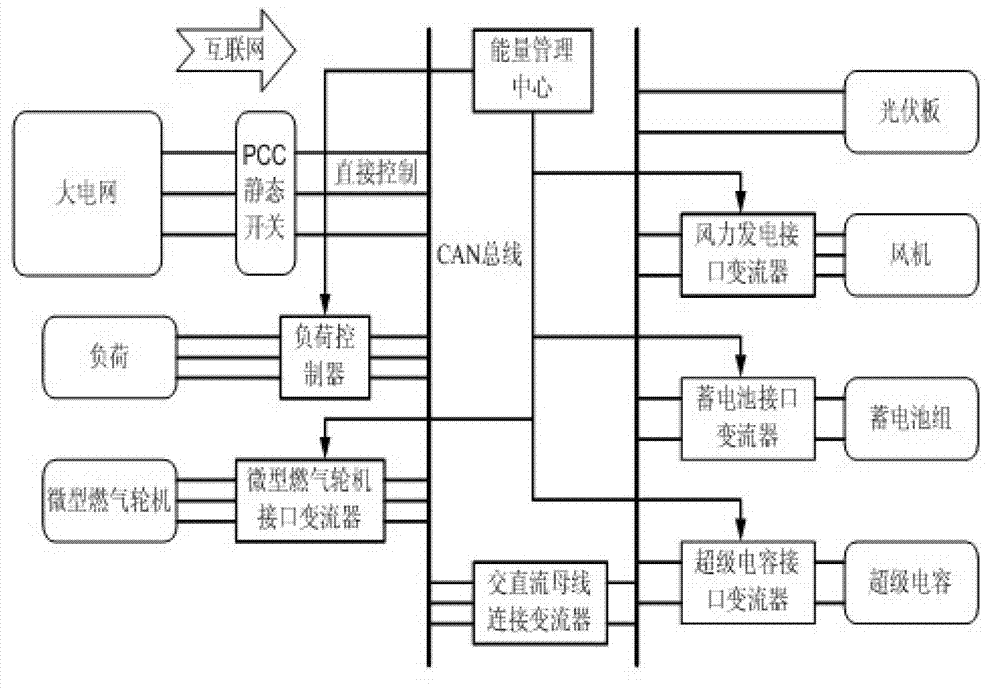

Box-type integrated multiple micro source interface micro power grid connected system device

InactiveCN103199560ALow costReduce communication costsClimate change adaptationEnergy industryFlue gasMicro gas turbine

The invention discloses a box-type integrated multiple micro source interface micro power grid connected system device. The exterior of the device is a box body of a container cabinet body, and the interior of the box body is of a three-room structure, wherein a front room is an operation room, a middle room is an equipment room, and a rear room is a refrigerating room. The box body adopts an alternative-direct current bus structure, wherein two buses are connected through a converter. In addition, each micro source (a micro flue gas turbine, a photovoltaic battery and a wind driven generator) and energy storage elements (a super capacitor and a storage battery) are connected on an input side of each inside corresponding converter through external terminals outside a container so as to put originally scattered converters into a box-type cabinet body, and are centralized and controlled through control chips taking charges of energy. Construction cost of communication equipment is left out, and work reliability of a micro network system is greatly improved. Compared with a traditional micro network, the box-type structure integrated device reserves operation characteristics of the original micro network, reduces micro network system installment, unloading and transportation difficulties, and is practical.

Owner:XI AN JIAOTONG UNIV

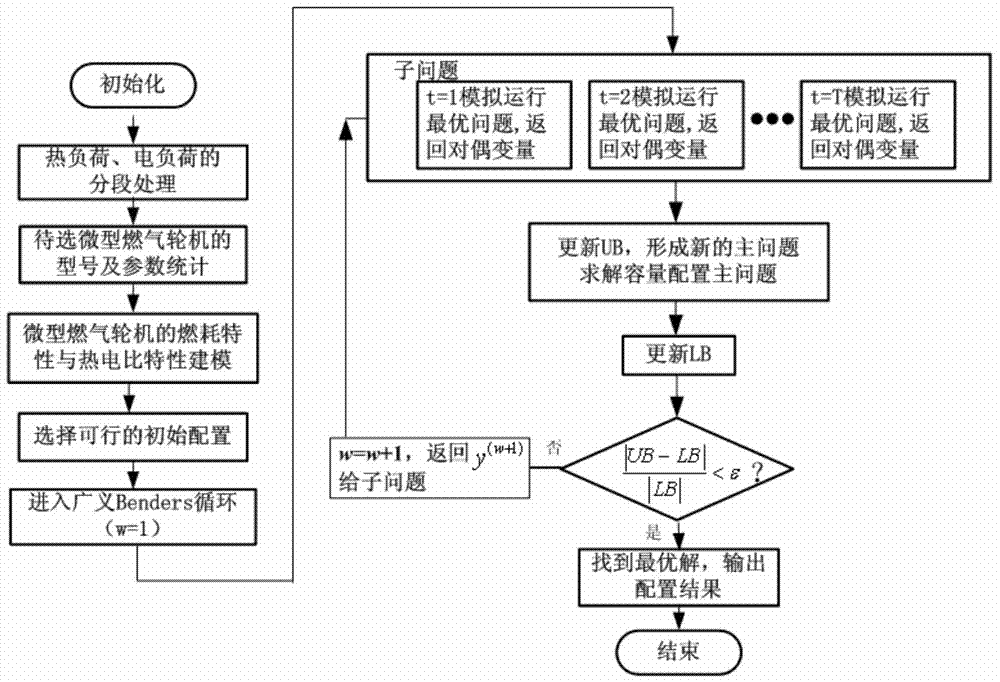

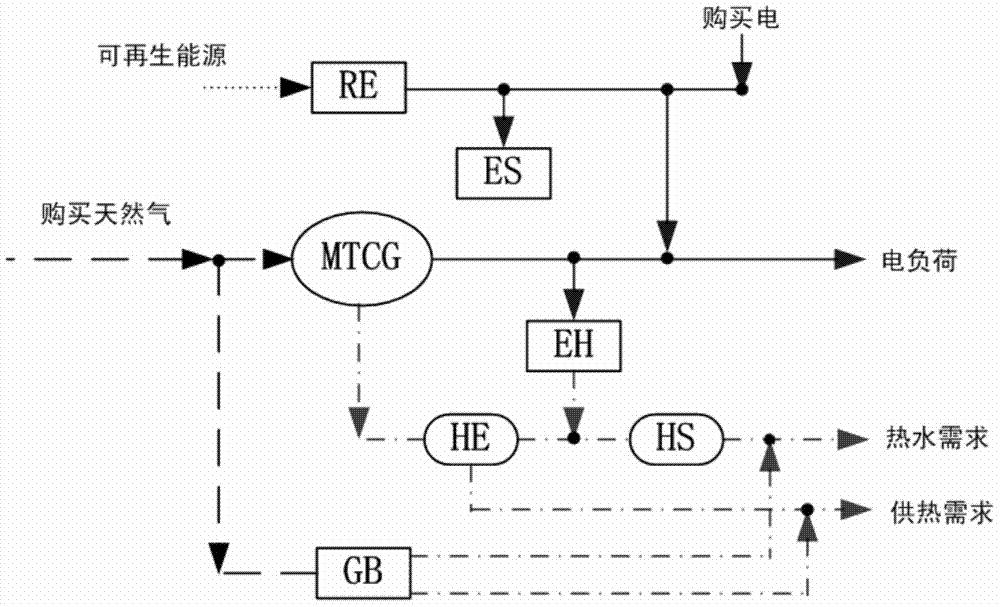

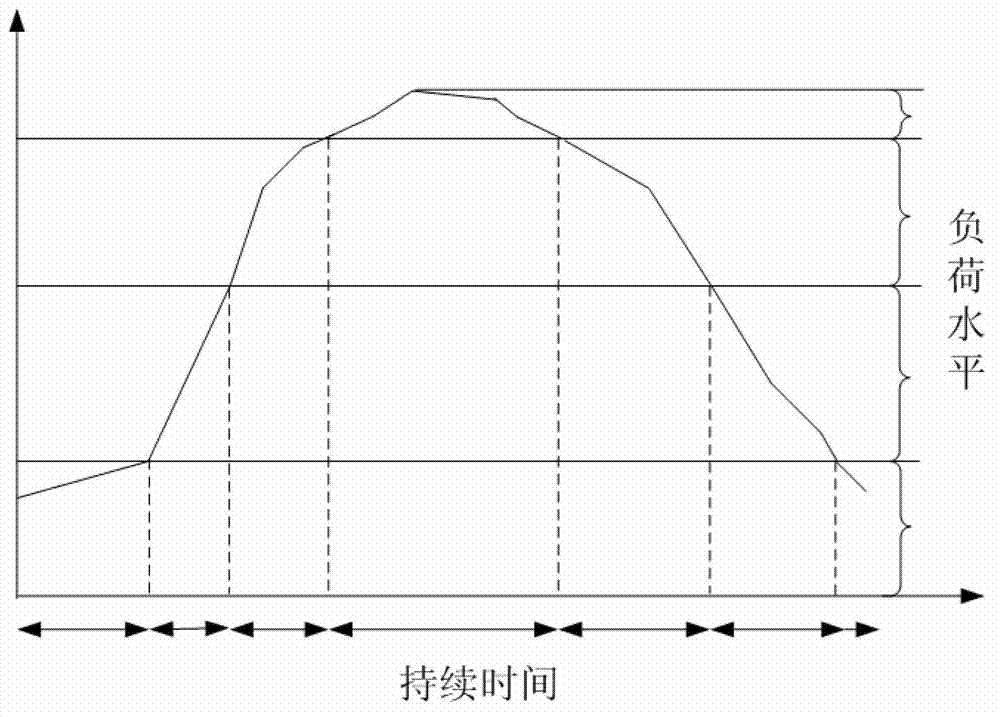

Unit type selection method of micro gas turbine combined heat and power system

Provided is a unit type selection method of a micro gas turbine combined heat and power system. The types and set numbers of micro gas turbines are selected reasonably according to different usage occasions, different heating loads, electrical load characteristics and system operation control requirements of the combined heat and power system, the utilization efficiency of fossil energy is improved, and the annual cash flow of the system is made to be minimum. According to the unit type selection method of the micro gas turbine combined heat and power system, the types and the set numbers of the units in the micro gas turbine combined heat and power system can be selected conveniently and optimally, and the planning and designing level of the micro gas turbine combined heat and power system is improved.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Micro gas turbine generating device

The invention relates to a micro gas turbine generating device which comprises a gas turbine, a heat regenerator and a high-speed permanent magnetic motor / generator, wherein the gas turbine comprises an air compressor box, a middle box, a turbine box, a combustor and a rotor system which are fixedly connected with each other; the high-speed permanent magnetic motor / generator is connected with the air compressor box; a volute air flow channel is arranged outside the air compressor box; the combustor is arranged on the turbine box; a fuel gas inlet of the heat regenerator is connected with the turbine box; an air inlet is connected with the volute air flow channel arranged on the air compressor box; and an air outlet is connected with the turbine box. The micro gas turbine generating device has a comprehensive heating efficiency being 29%, has a compact structure, is high-efficient, energy-saving and environment-friendly, and is widely applied to the field of urban distributed generation.

Owner:HARBIN DONGAN ENGINE GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com