Patents

Literature

202results about How to "Improve economic indicators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

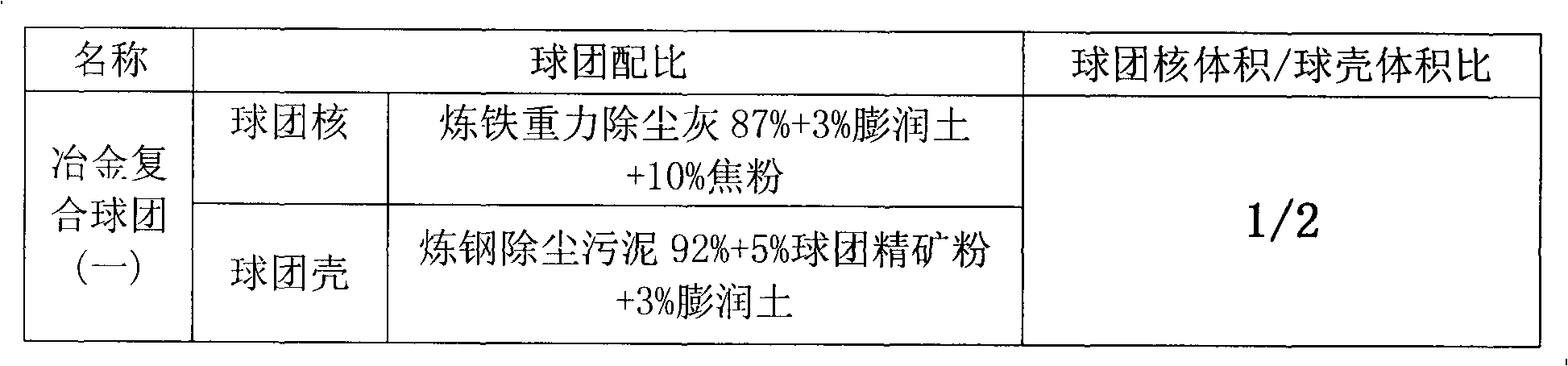

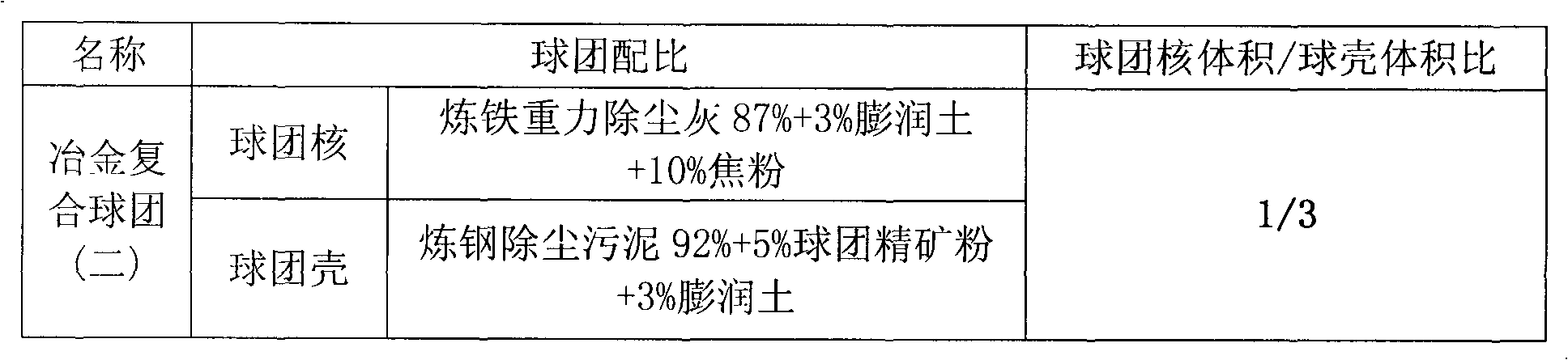

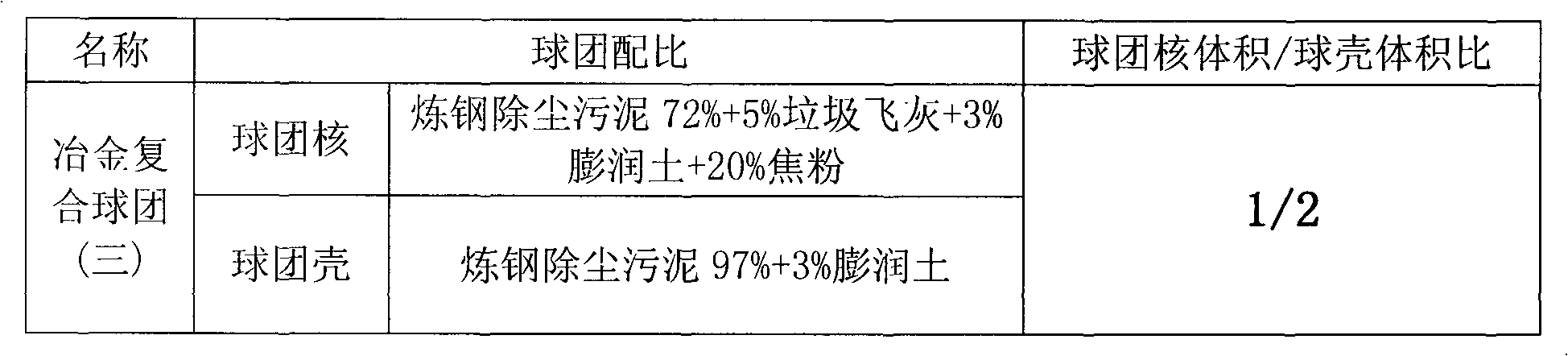

Metallurgical composite pelletizing prepared through twice pelletizing method, as well as preparation method and application thereof

ActiveCN101613800AImprove iron gradeIncrease valueBlast furnace detailsManufacturing convertersSocial benefitsAdhesive

The invention provides a metallurgical composite pelletizing prepared through a twice pelletizing method, as well as a preparation method and an application thereof. The pelletizing is provided with a pelletizing shell formed by a central pelletizing core and a pellet material coating the outside of the pelletizing core. The internal pelletizing core of the formed pelletizing is in a reducing atmosphere, the outside of the formed pelletizing is in an oxidizing atmosphere, and the metallurgical composite pelletizing undergoing twice pelletizing satisfies the metallurgical requirements. The pelletizing core takes an iron-containing material and reducing coal dust or coke powder as raw materials in which adhesive and waste fly dust are added, and is obtained by means of disk pelletization or pressure pelletization. The pelletizing shell takes the iron-containing material and the pelletizing core as raw materials in which the adhesive is added, and is obtained by means of disk pelletization and taking the pelletizing core as the center of the sphere. Various metallurgical performance indexes of the composite pelletizing are highly better than normal pellets. The composite pelletizing not only realizes the harmlessness and the recycling of the waste fly ash, but also can greatly improve the technical and economic indexes of iron making blast furnaces. In addition, the composite pelletizing not only achieves such social benefits as energy conservation, emission reduction, environment protection and environment pollution treatment, but also can create considerable economic benefits.

Owner:CHONGQING ANGRUIYUE SCI & TECH

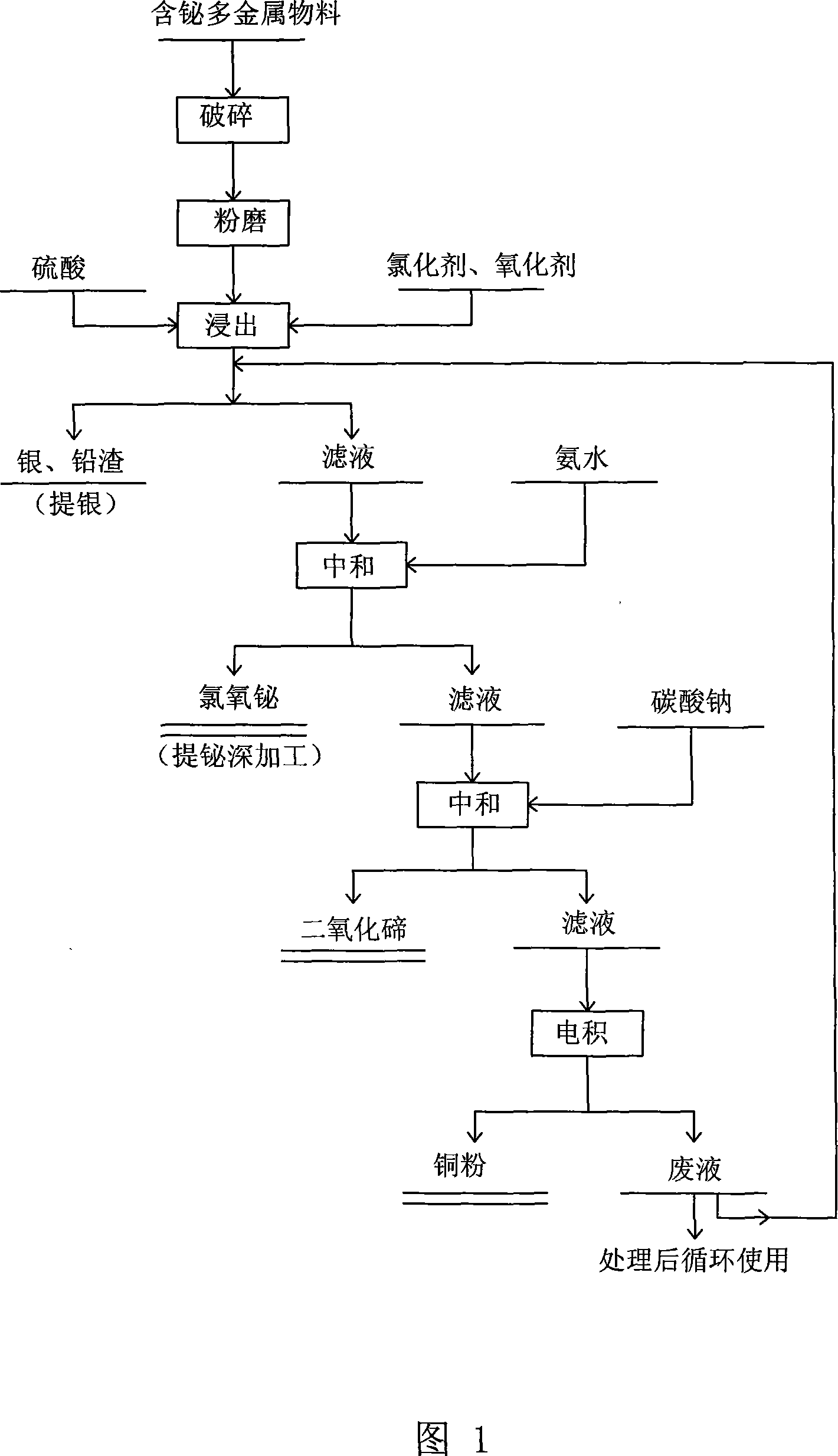

Comprehensive extraction of valent metal from bismuth-containing polymetallic material

InactiveCN101029353AHigh recovery rateImprove product added valuePhotography auxillary processesProcess efficiency improvementSesquioxideTe element

A method for extracting metal from bismuth-contained multi-metal material is carried out by leaching out copper and tellurium from bismuth-contained multi-metal by sulfuric acid, adding into chlorinating agent and oxidant to leach out metal bismuth, extracting silver from leaching-out slag with AgCl, PbSO4 and PbC12, adding ammonia water into leaching-out liquid, adjusting pH value to 1.5 to obtain bismuth oxychloride slag with 70% bismuth content, smelting into coarse bismuth by firing method or machining to obtain high-purity bismuth sesquioxide, adjusting pH value to 4.5 by Na2CO3, depositing tellurium to obtain tellurium dioxide and copper-contained solution, and electrically depositing to obtain copper powder with copper-contained content90%. It adopts wetting and firing metallurgical technology, has higher metal recovery rate and excellent leaching-out separation effect and effluent circulating utilization and no environmental pollution.

Owner:HUNAN JINWANG BISMUTH

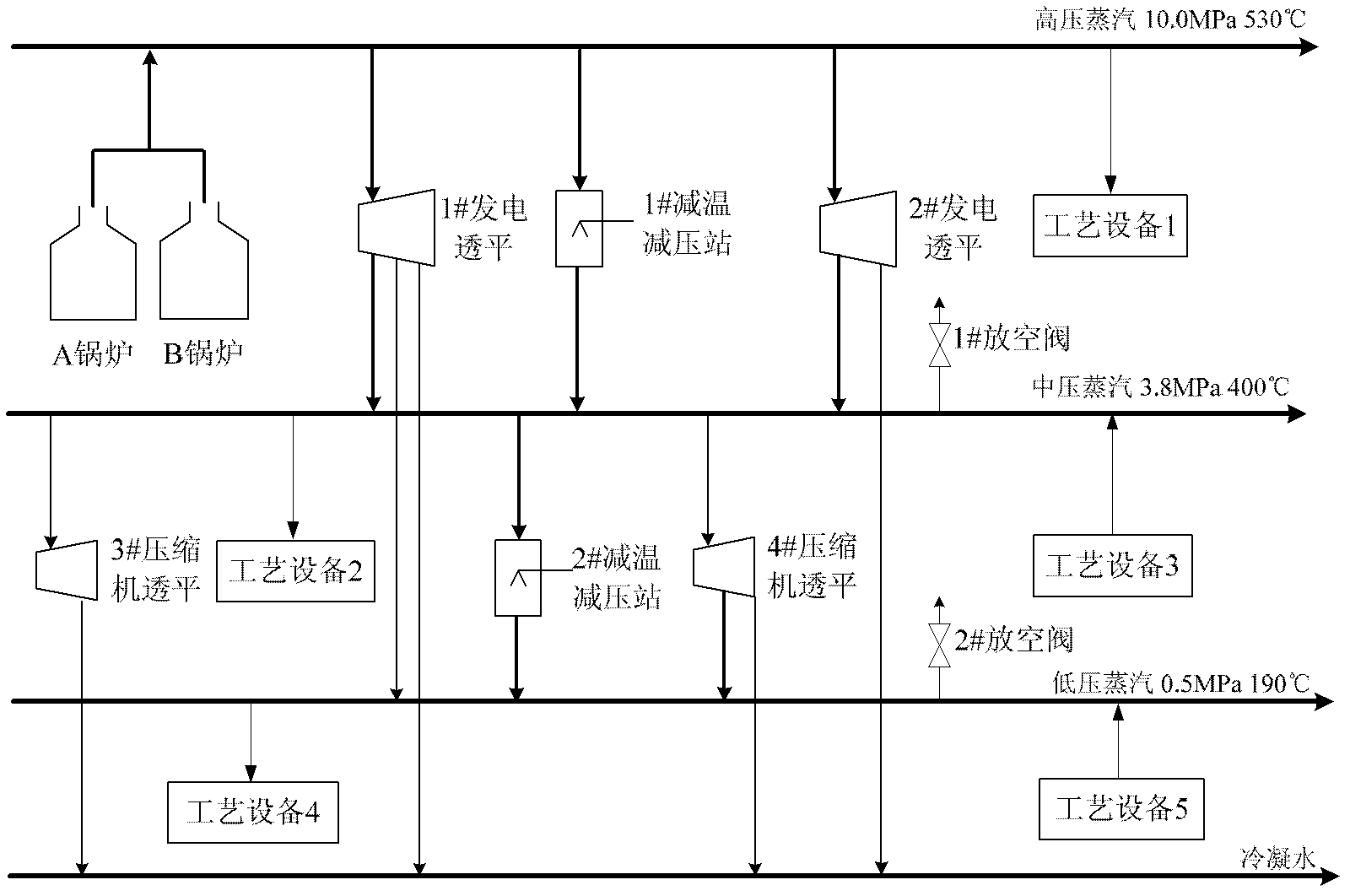

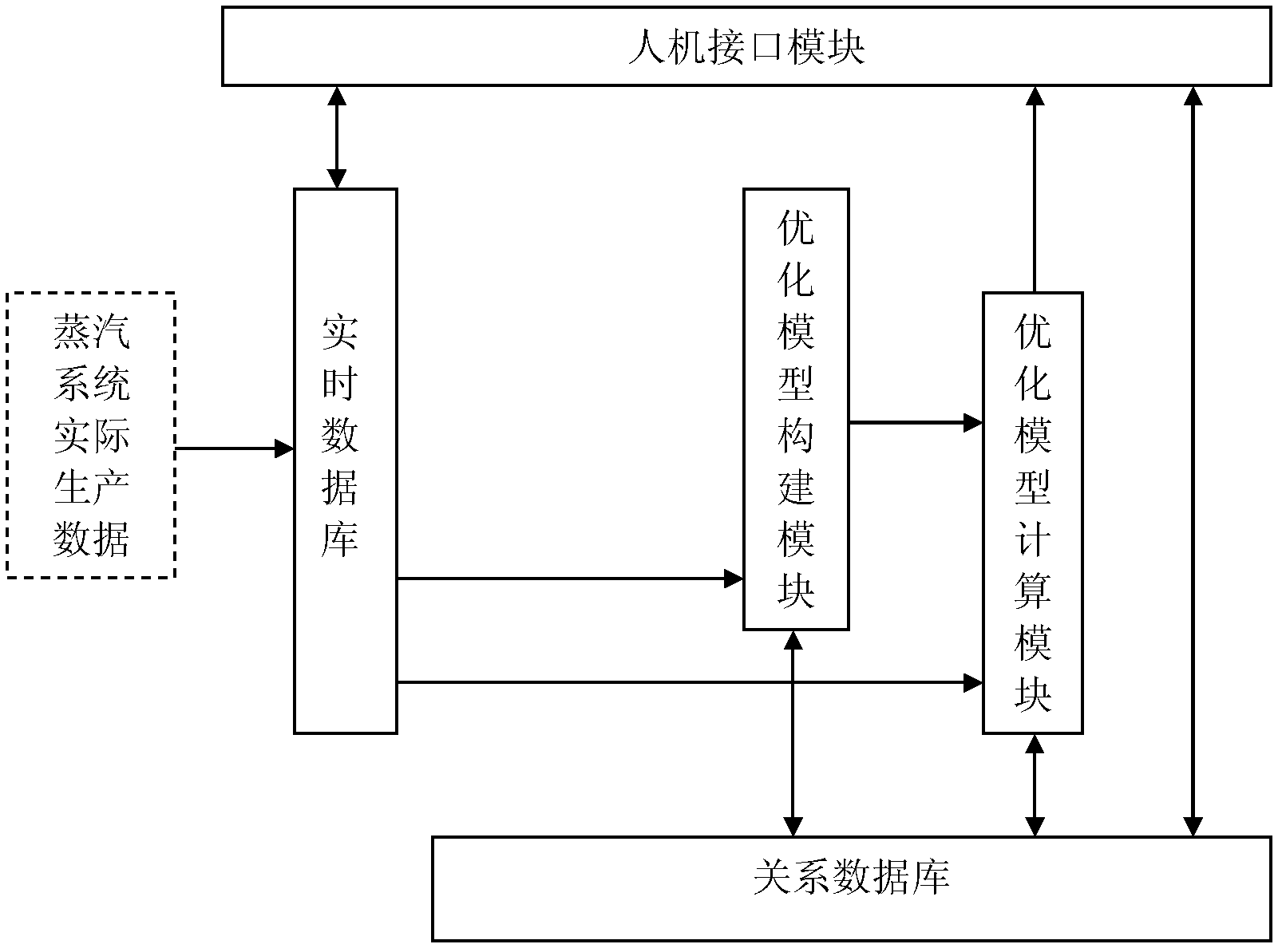

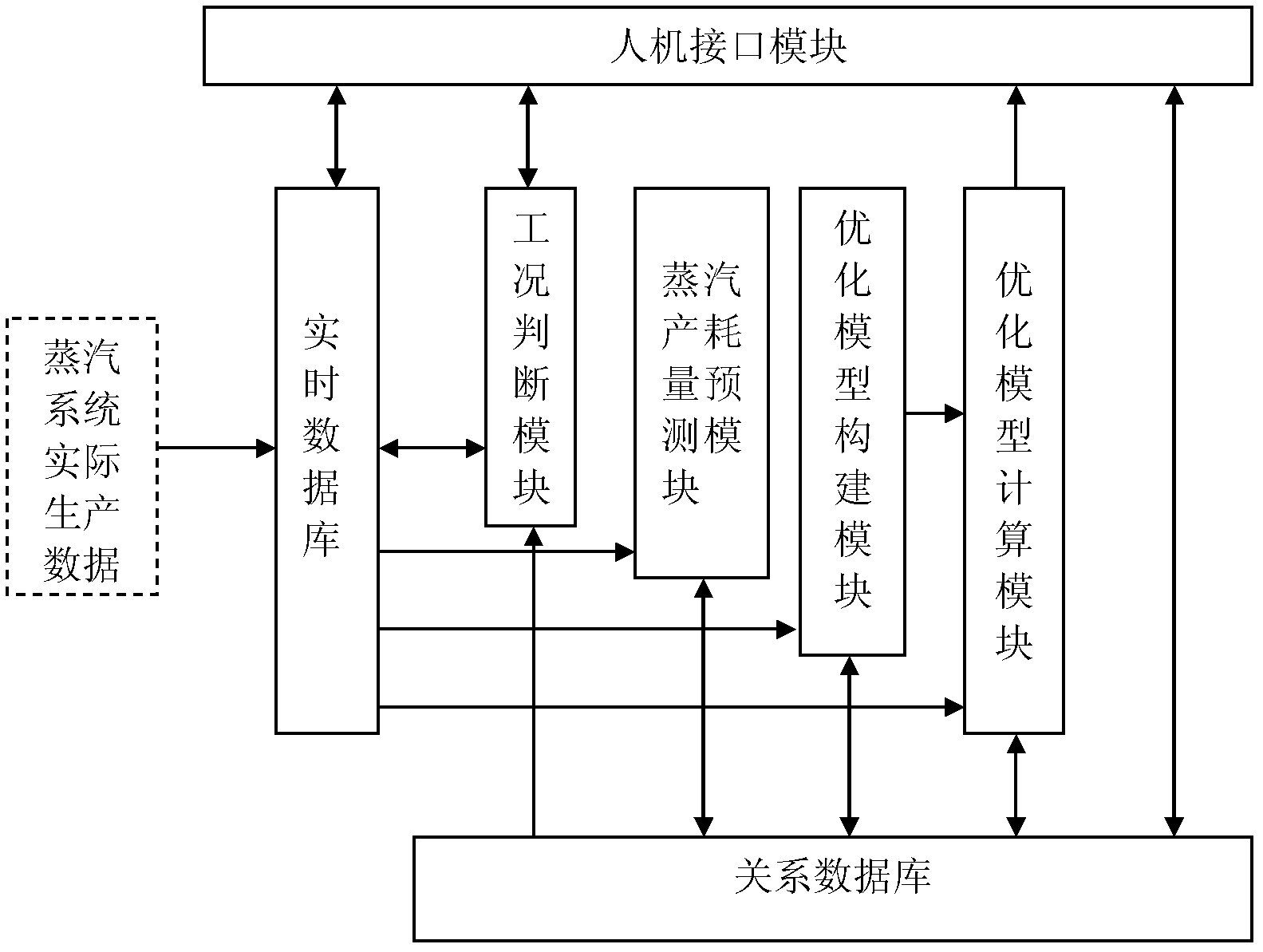

Operation optimizing system and method of steam system

InactiveCN102830616AReduce manufacturing costReduce consumptionAdaptive controlChemical industryRelational database

The invention relates to a steam system in field of chemical industry, metallurgy and the like and in particular relates to an operation optimizing system and an operation optimizing method of a steam system of the fields. The operation optimizing system of the steam system comprises a real-time database, a relation database, an optimization model constructing model, an optimization model calculating model and a man-machine interface module. The invention further provides the operation optimizing method of the steam system, which can construct an optimized model according to actual conditions of the steam system and can utilize an optimization algorithm to calculate to obtain an optimization operation scheme, so that field scheduling personnel and managers can schedule according to the optimization scheme, the economical efficiency of the operation of the steam system is improved, the energy consumption of an enterprise is reduced and the production cost of the enterprise is reduced.

Owner:北京三博中自科技有限公司

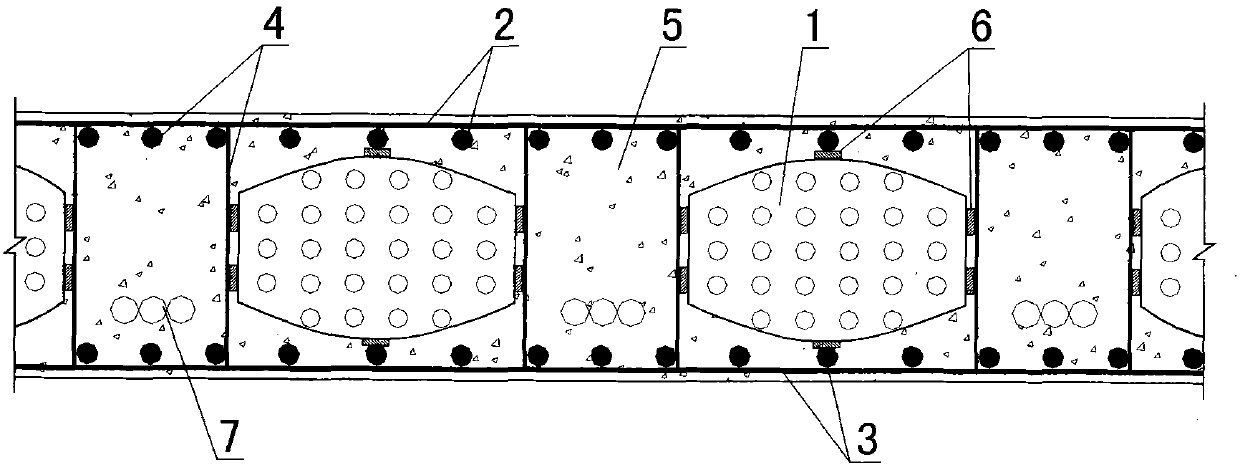

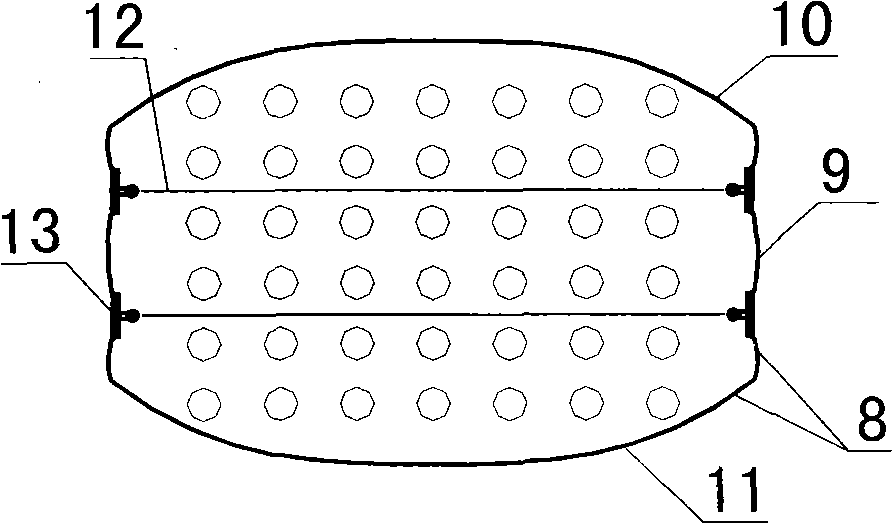

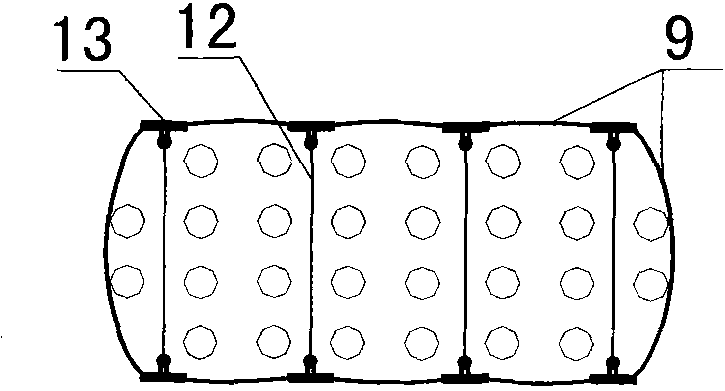

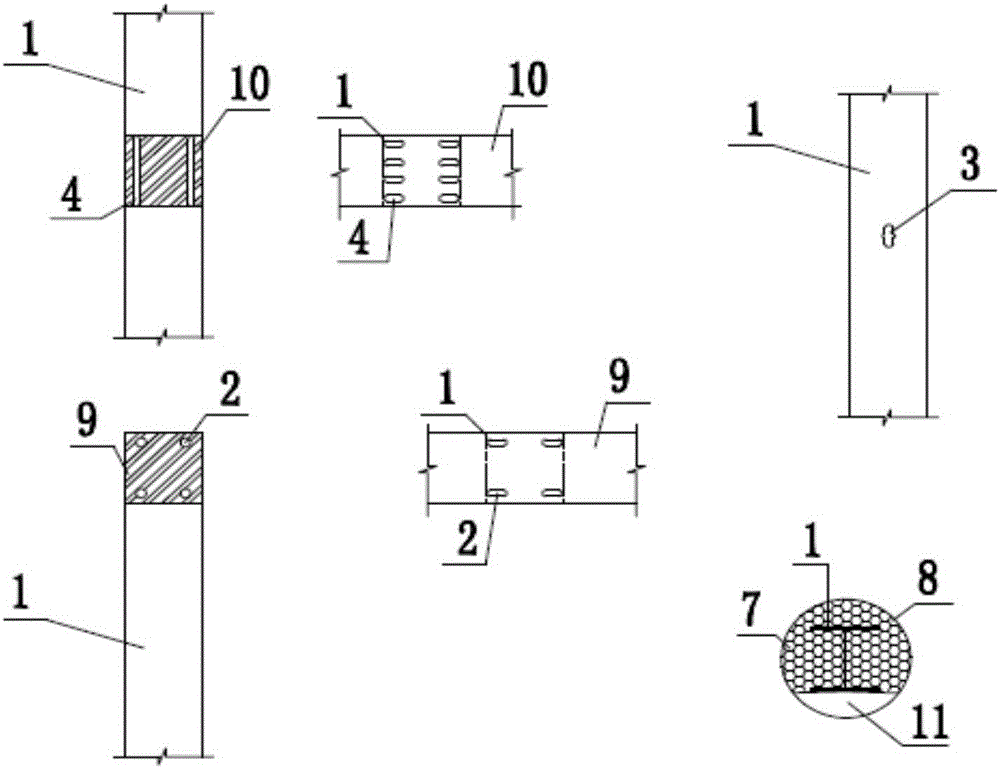

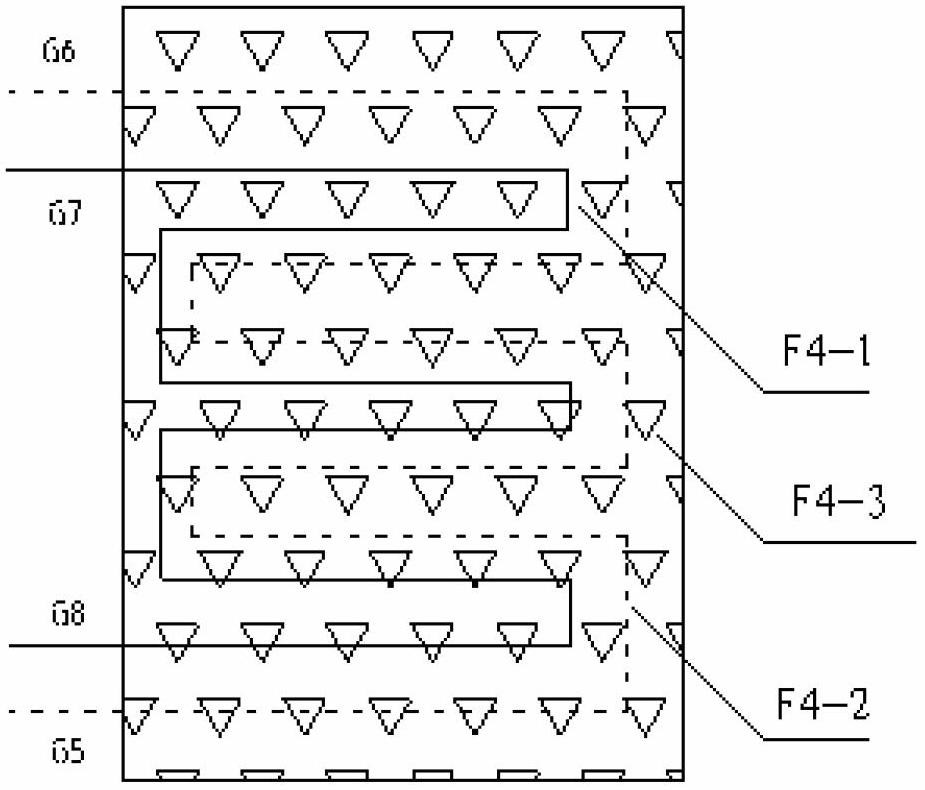

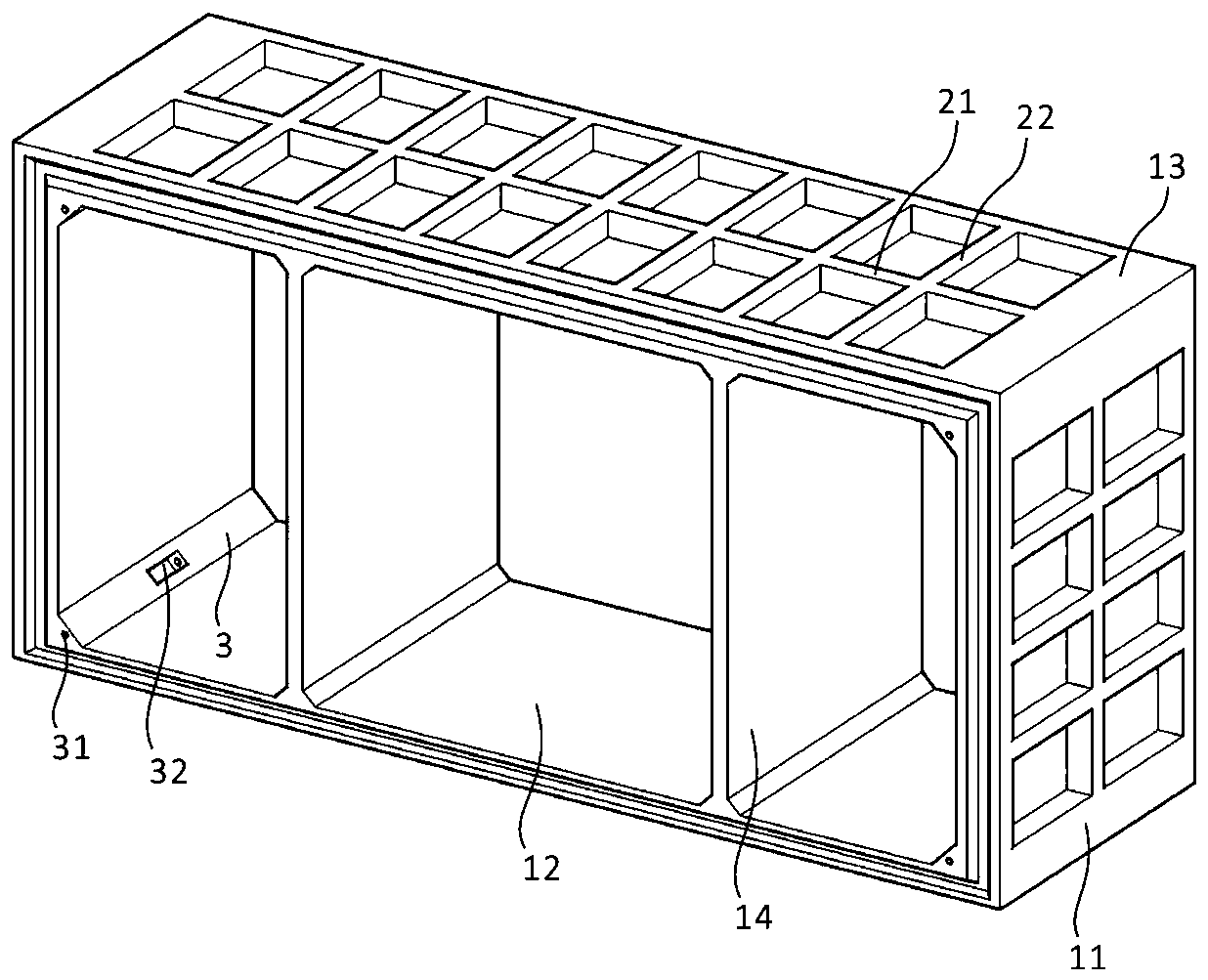

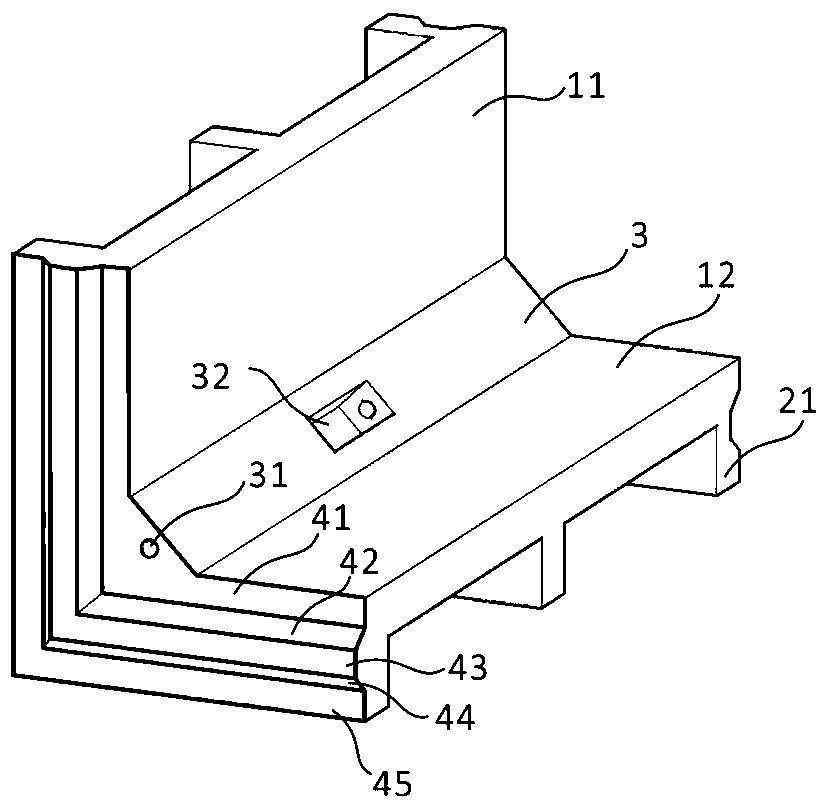

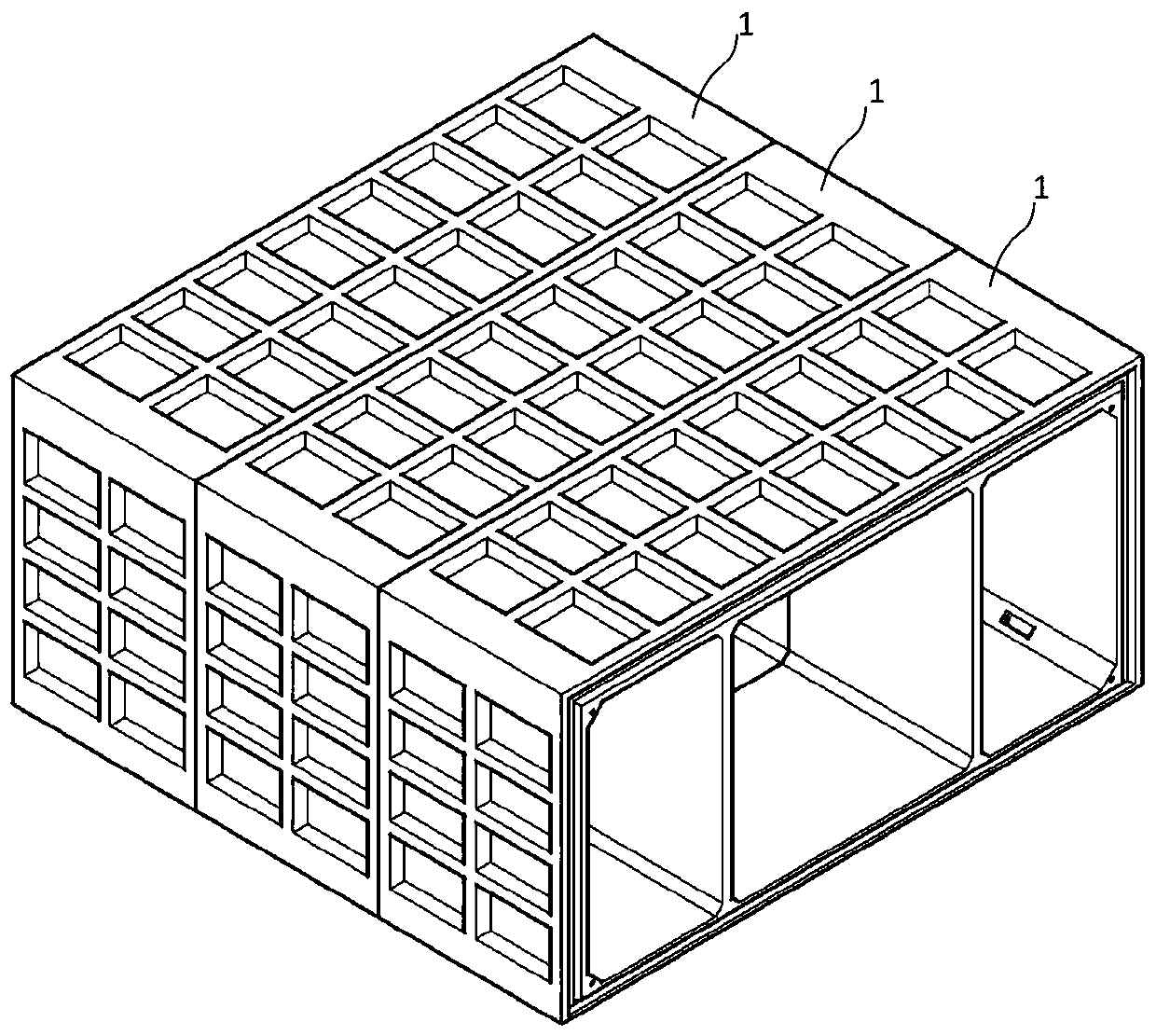

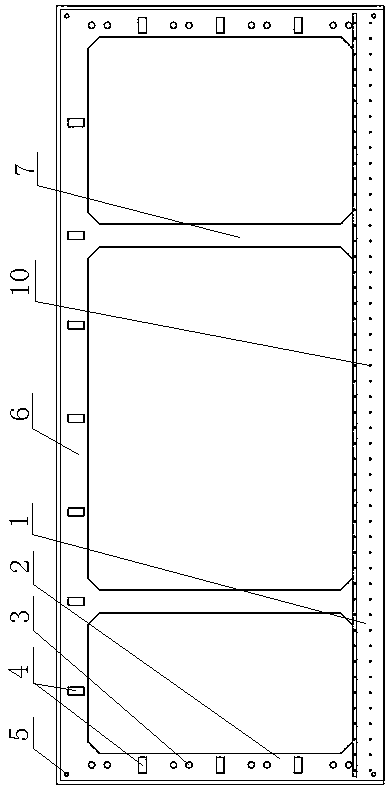

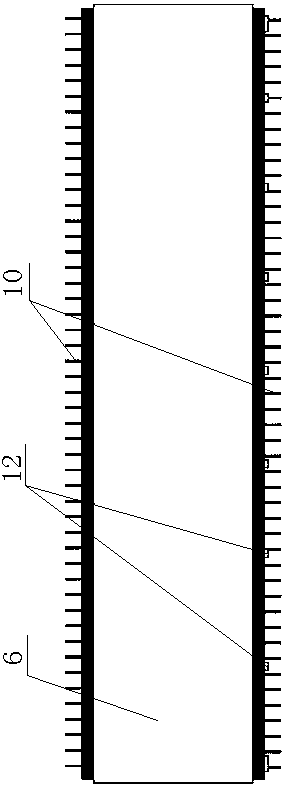

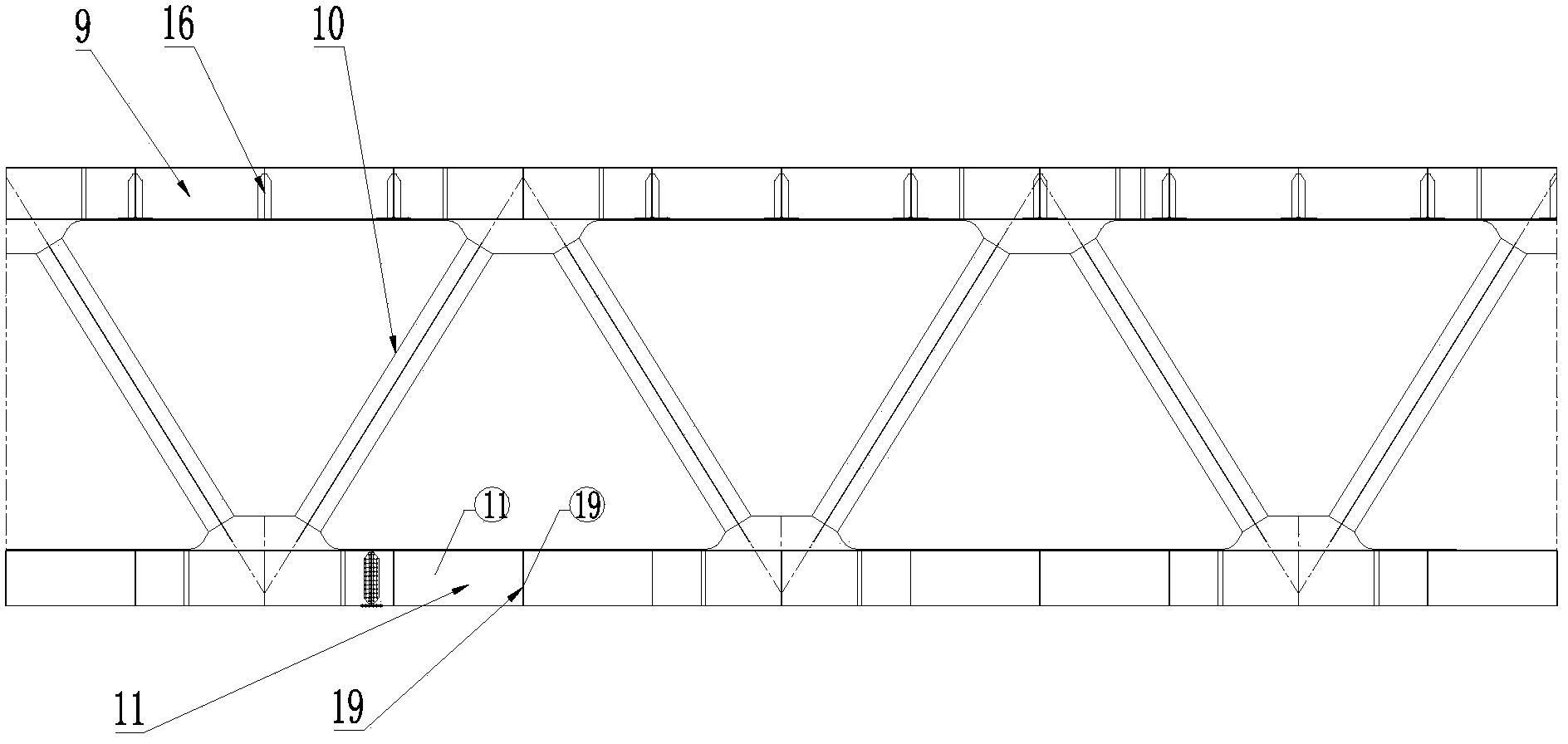

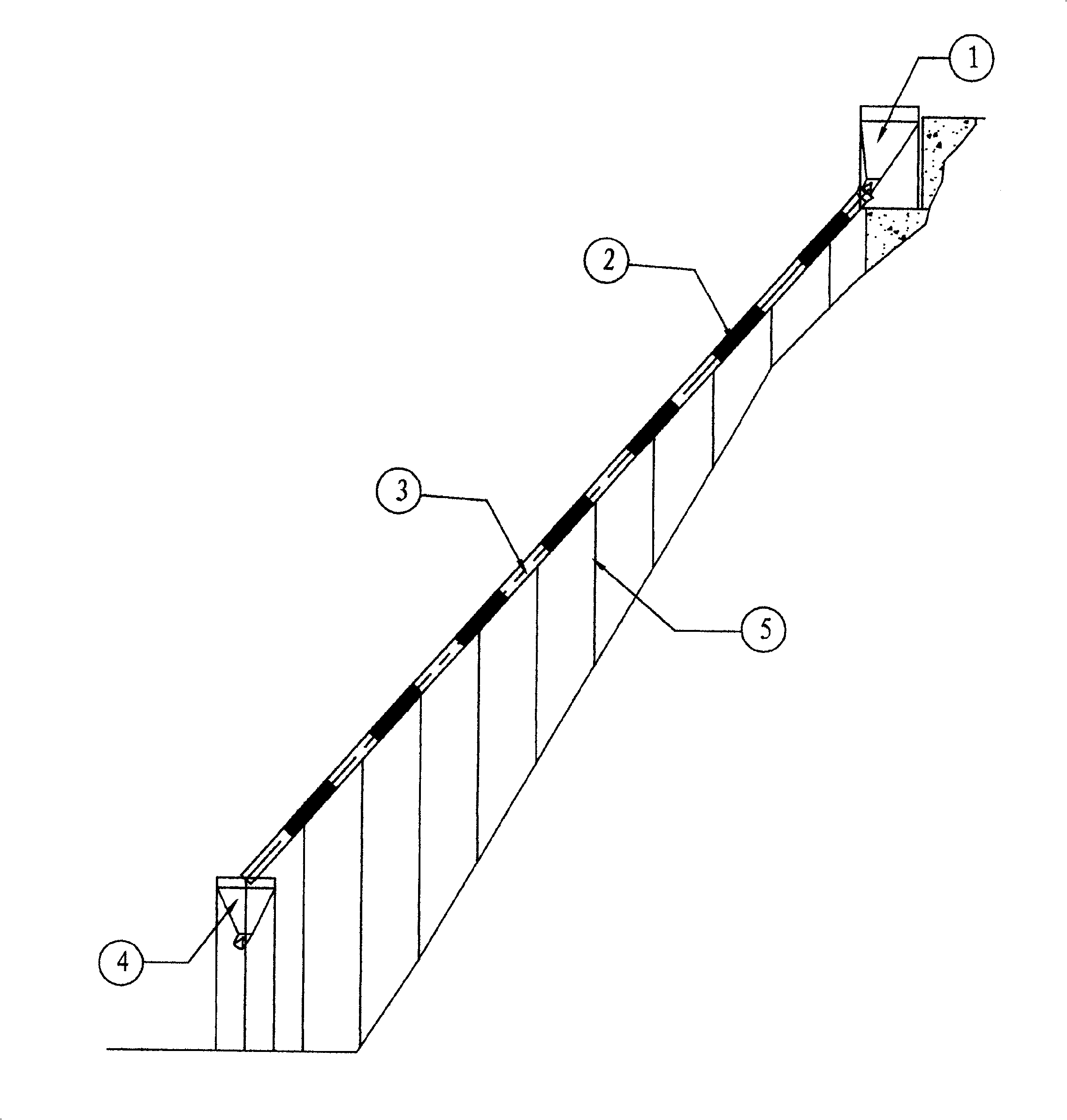

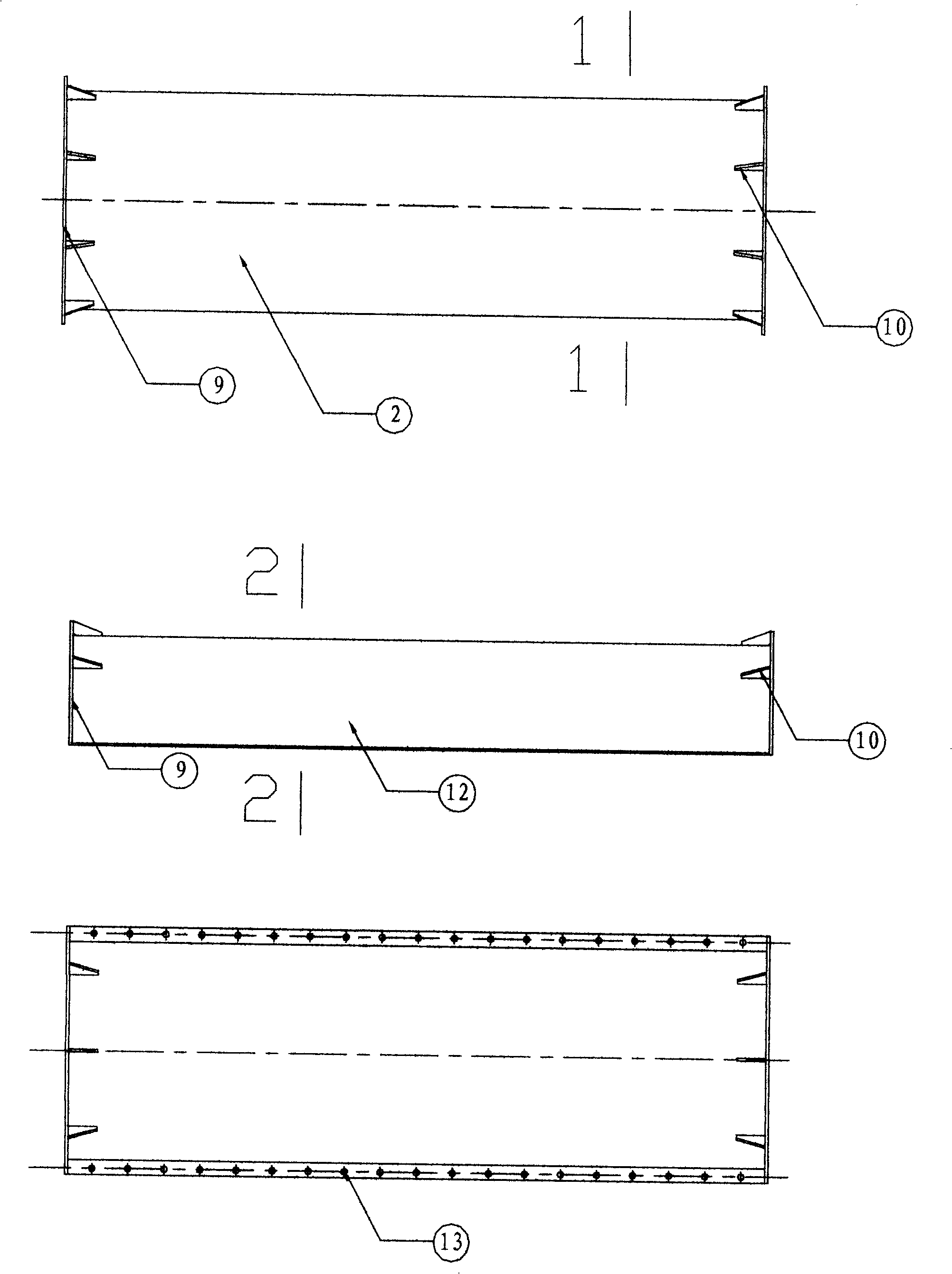

Hollow floor system filled with an air-filling bag and construction method thereof

InactiveCN101793070AGood technical and economic indicatorsReasonable forceFloorsEngineeringSteel bar

The invention relates to a hollow floor system filled with an air-filling bag and a construction method thereof, belonging to the field of the structure of the common building. The hollow floor system consists of the air-filling bag (1), upper steel bars (2), lower steel bars (3), hidden girder steel bars (4) and concrete (5), wherein the air-filling bag (1) is positioned among the upper steel bars (2), the lower steel bars (3) and the hidden girder steel bars (4); a bag wall (8) of the air-filling bag (1) consists of four side walls (9), an upper wall (10) and a lower wall (11); the shapes of at least two side walls (9) adjacent to the hidden girder steel bars (4) in the air-filling bag (1) are planes; the shapes of the upper wall (10) and the lower wall (11) are heaved-outward arc surfaces; and positioning pieces (12) are arranged among the inner sides of the side walls (9) so as to ensure that the two side walls (9) are parallel mutually. The hollow floor system has large span, better reliability, earthquake resistance and crack resistance, and good economy and applicability.

Owner:徐焱

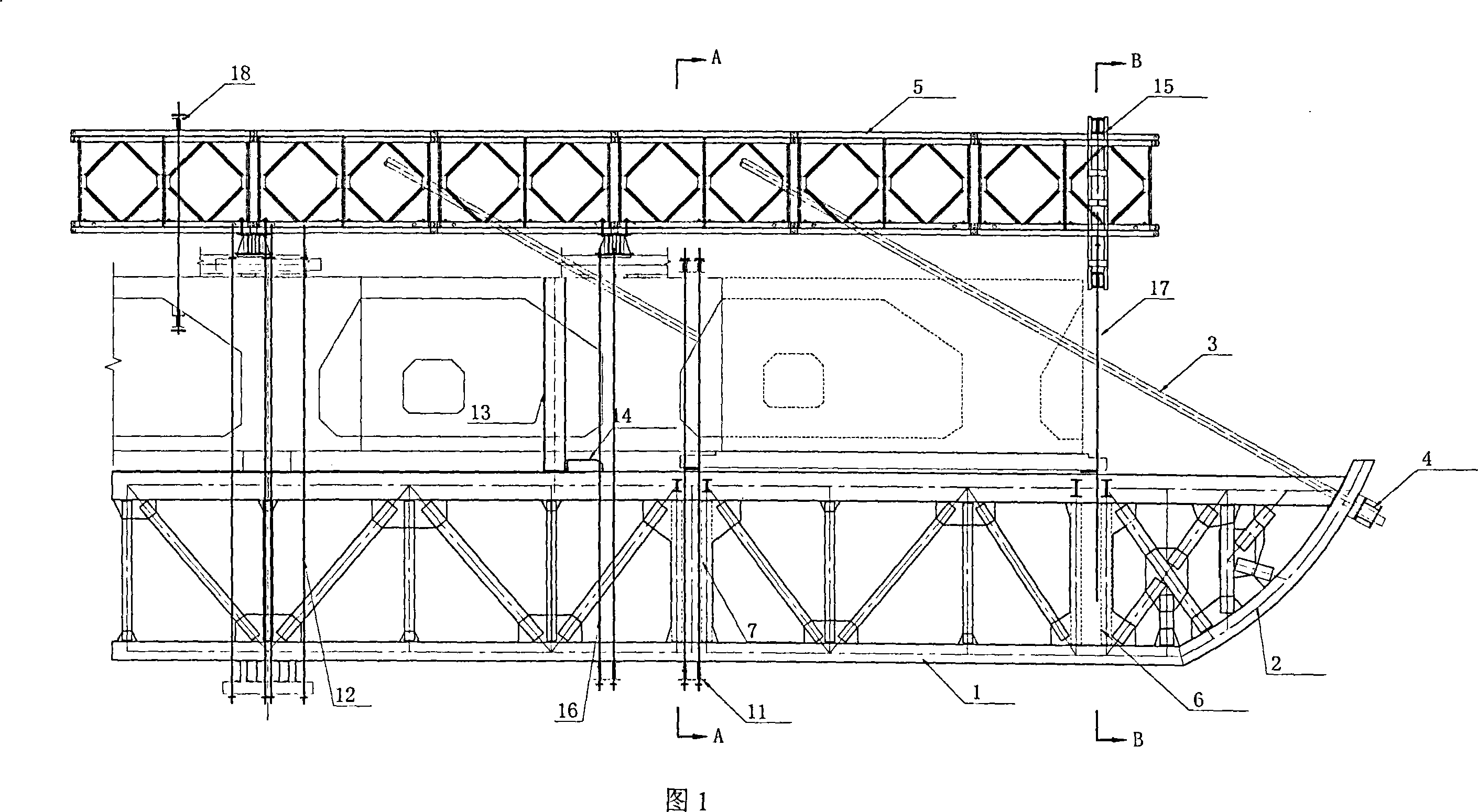

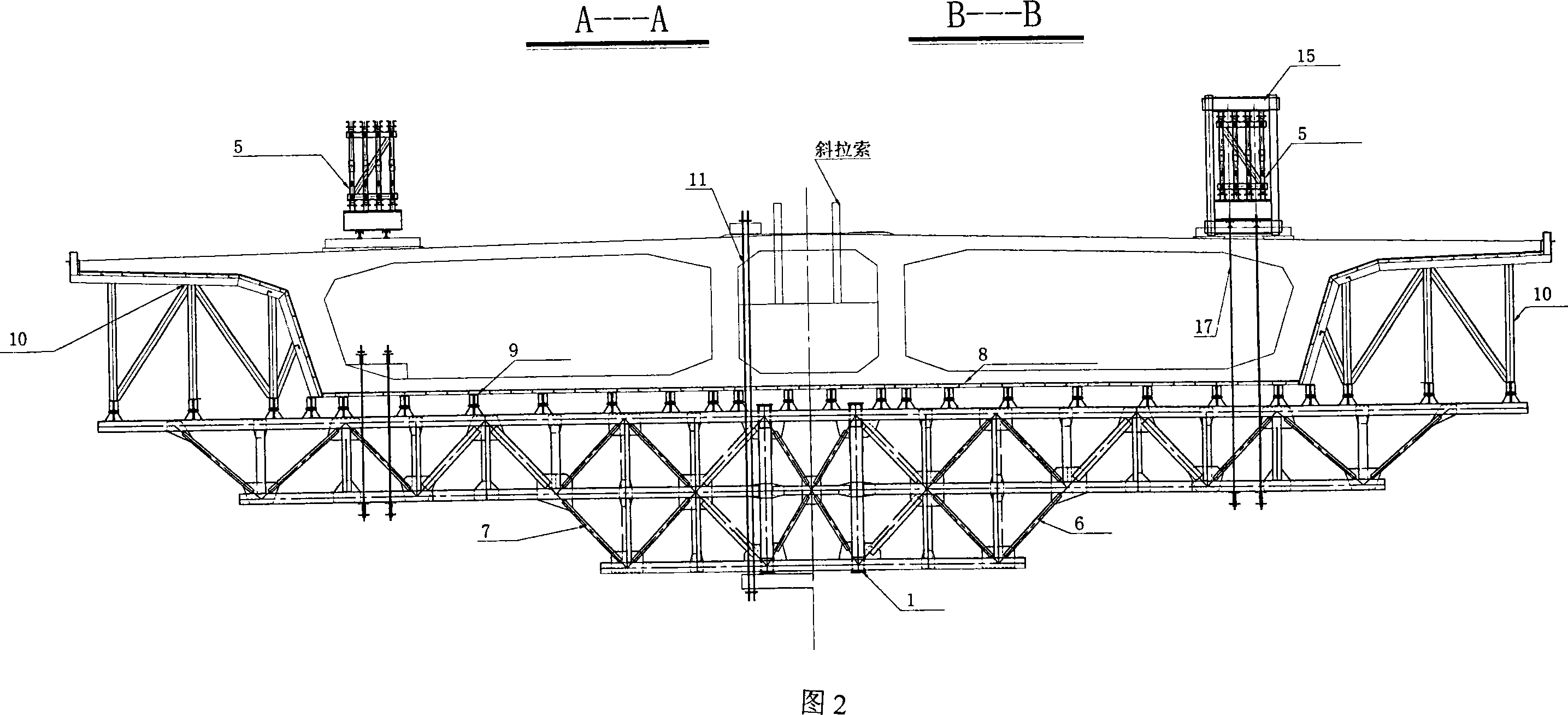

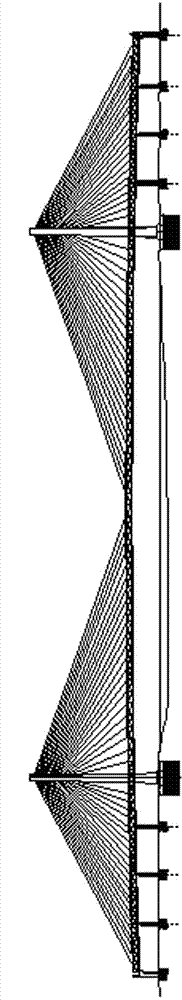

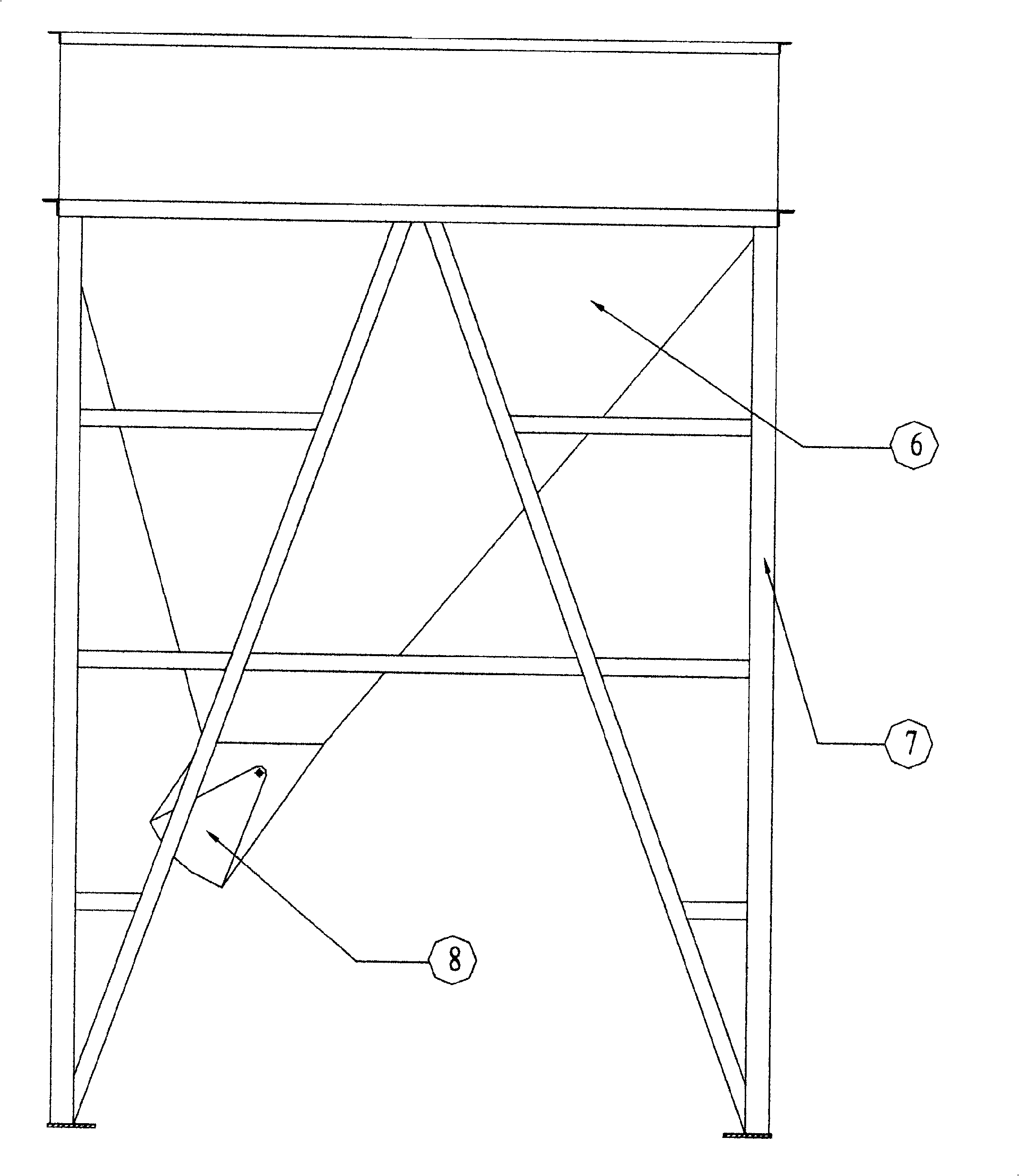

Three-point walking single cable face cable-dragging suspension basket

InactiveCN101173503ASmall structureImprove economic indicatorsBridge erection/assemblyStructural engineeringEngineering

The invention discloses a three-point travelling single-cable-plane guyed travelers, which is characterized in that: a top longitudinal beam is formed by assembling bailey beam and is arranged at a web plate at both sides of the top surface for main beam; the guyed longitudinal beam is a braced girder structure formed by assembling and welding profile steel and is arranged at the bottom part of central girder for the bridge; a travelling hanging frame is fixed on the top longitudinal beam which is connected with a front lower beam of the guyed longitudinal beam by the front suspension; shifting forward; horizontal jack is respectively arranged on two longitudinal beams and a guyed longitudinal beam, the three points are used for incremental launching. The invention has the advantages of realizing three point travelling using two front suspensions of the top longitudinal beam and the rear suspension of the guyed longitudinal beam, lowering structural facilities such as edge longitudinal beam specially designed for travelling, having small weight ratio for the travelers and the beam body section, having better economic index compared to the same kind of guyed travelers, using the rear suspension travelling frame arranged on the beam body completing pouring to support the guyed travelers, forming a stable three-point system due to two top longitudinal beams suspending the front lower beam, reaching stably and quickly shifting forward and decreasing the weight of the travelers.

Owner:THE 2ND ENG CO LTD MBEC

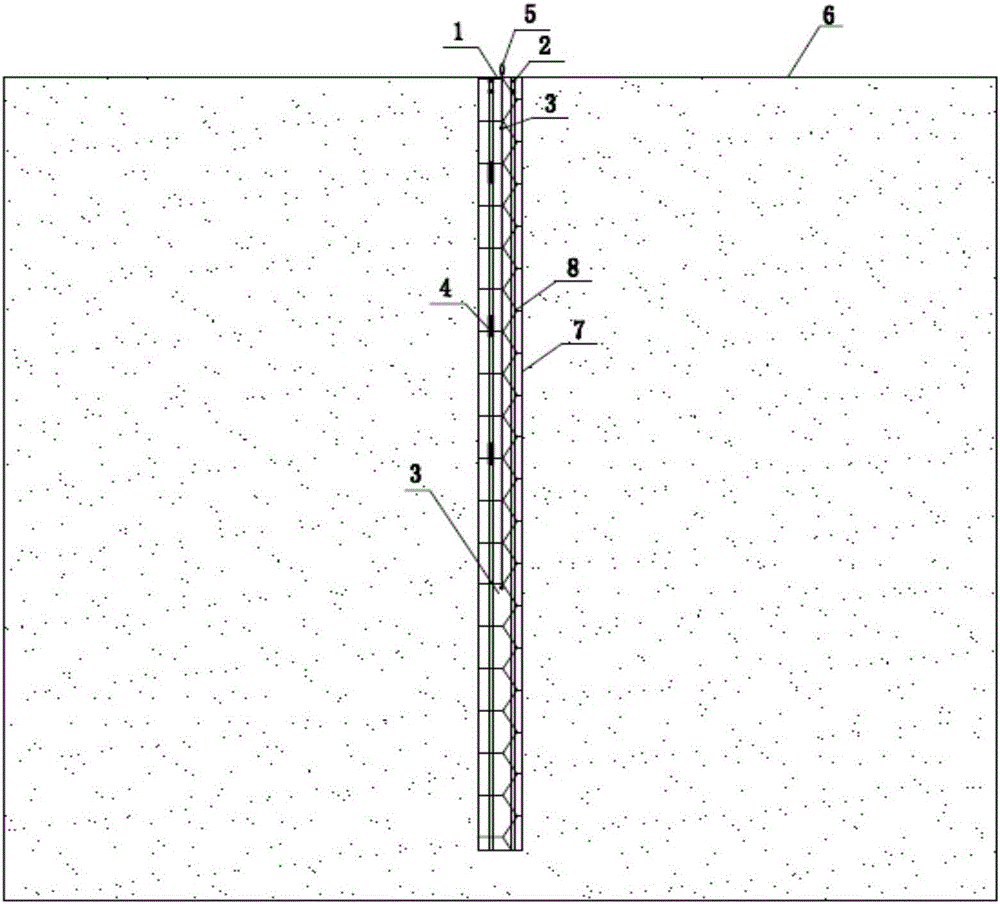

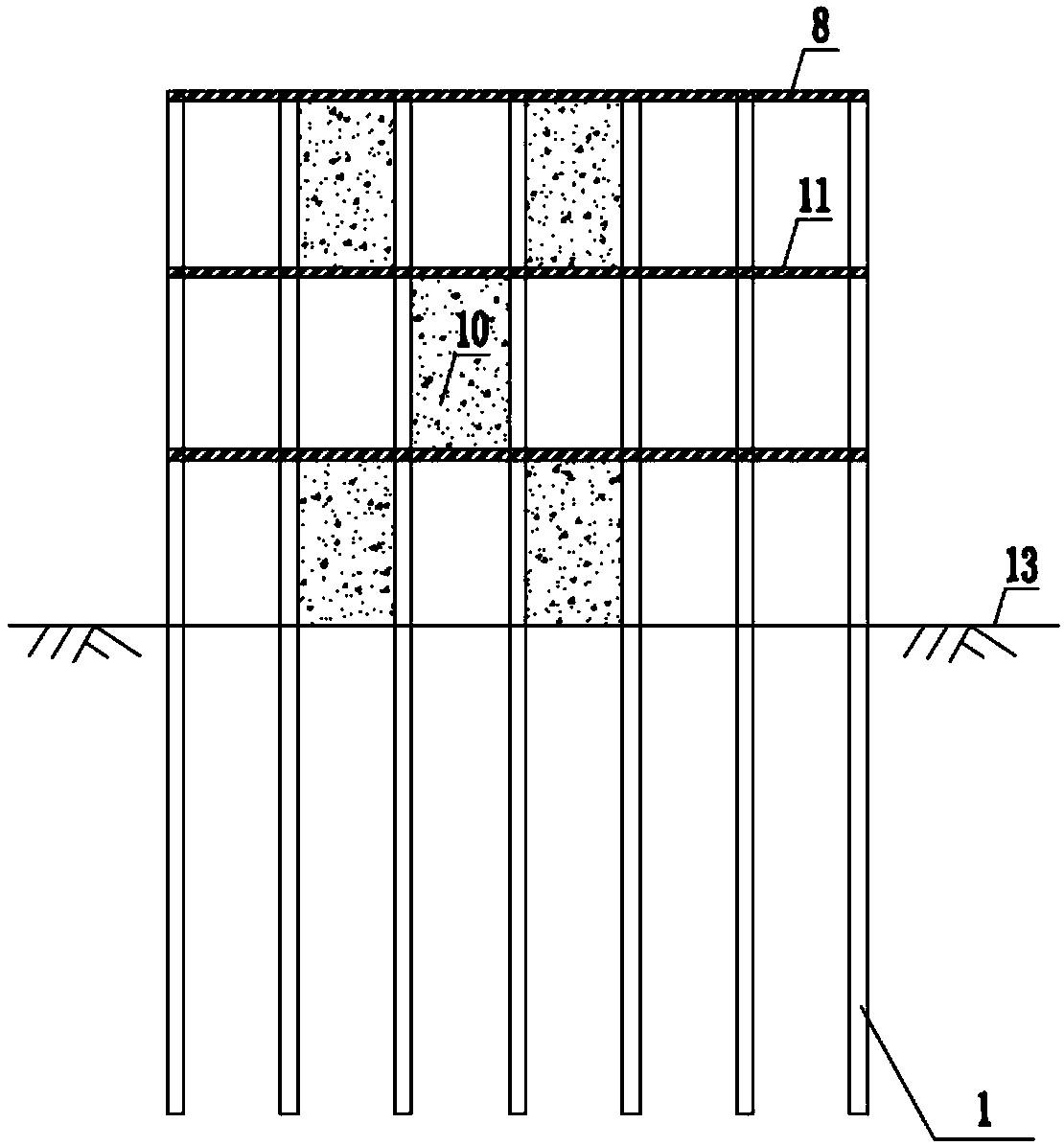

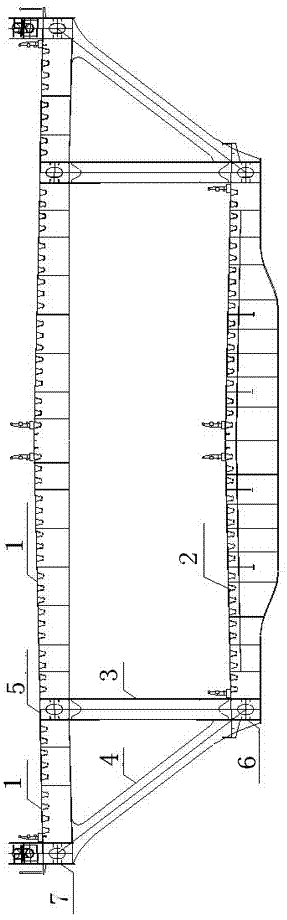

Design and construction method of rigid-flexible composite anti-seepage recoverable supporting structure

ActiveCN105735322AAdvanced technologyImprove economic indicatorsExcavationsSecurity MeasureStructure system

The invention relates to a design and construction method of a rigid-flexible composite anti-seepage recoverable supporting structure system. The method comprises steps as follows: (I) profile steel slope-protection piles are constructed; (II) H-shaped steel top beams and H-shaped steel breast beams are installed; (III) steel panels are installed; (IV) sequential vertical layered and sectioned excavation is performed, steps (II) and (III) are repeated, construction is performed to the design depth, and construction of the rigid-flexible composite anti-seepage recoverable supporting structure system is completed; (V) after the use function of a supporting structure is fulfilled, with the start of foundation pit backfill work, recovery work can be performed. The rigid-flexible composite anti-seepage recoverable supporting structure system constructed through the method really reflects characteristics of a temporary security measure adopted by foundation construction of foundation pit engineering and has the advantages of safety, reliability, quickness construction, advanced technology, capability of being recycled, excellent economic indices and the like.

Owner:SAFEKEY ENG TECHZHENGZHOU

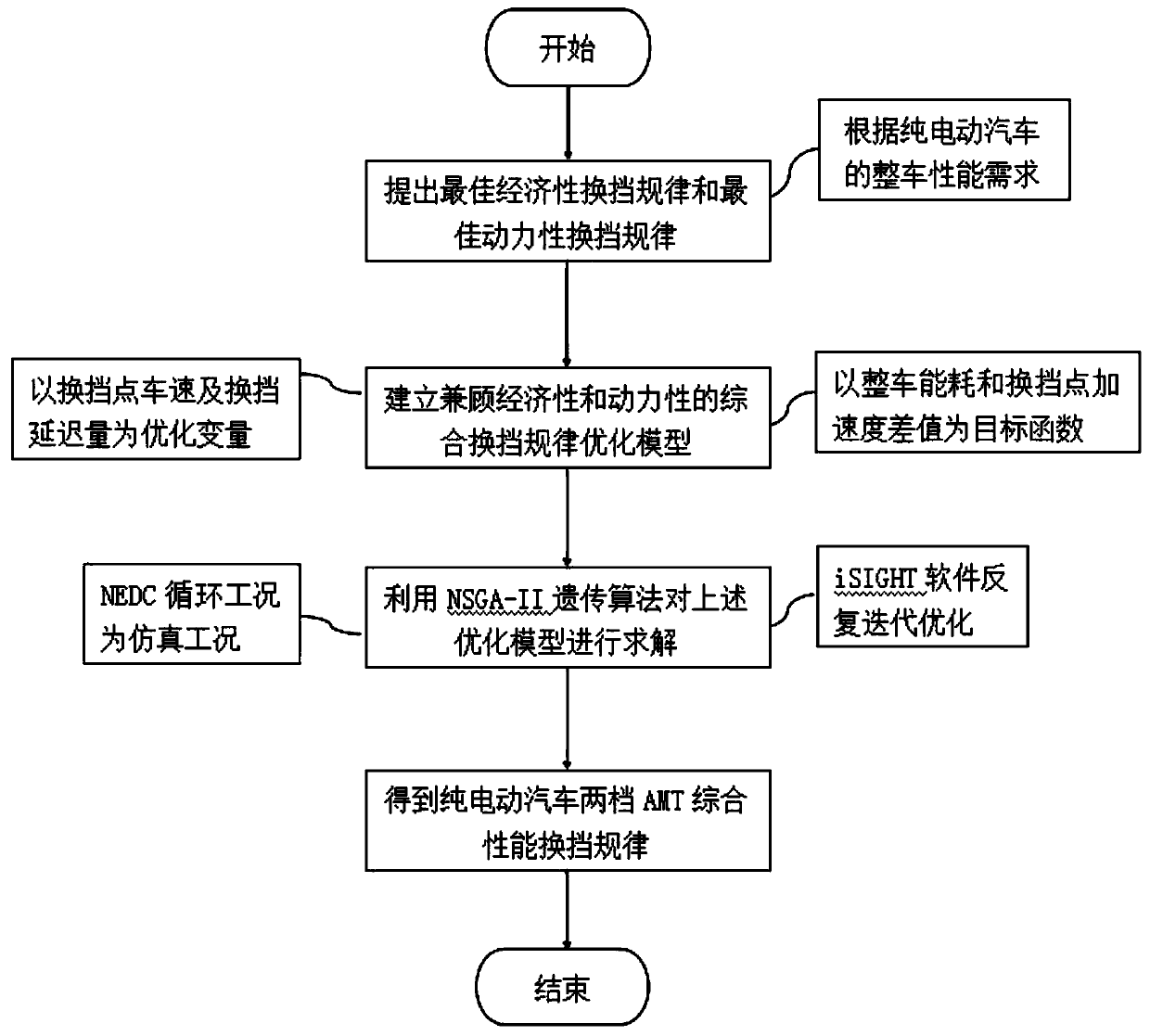

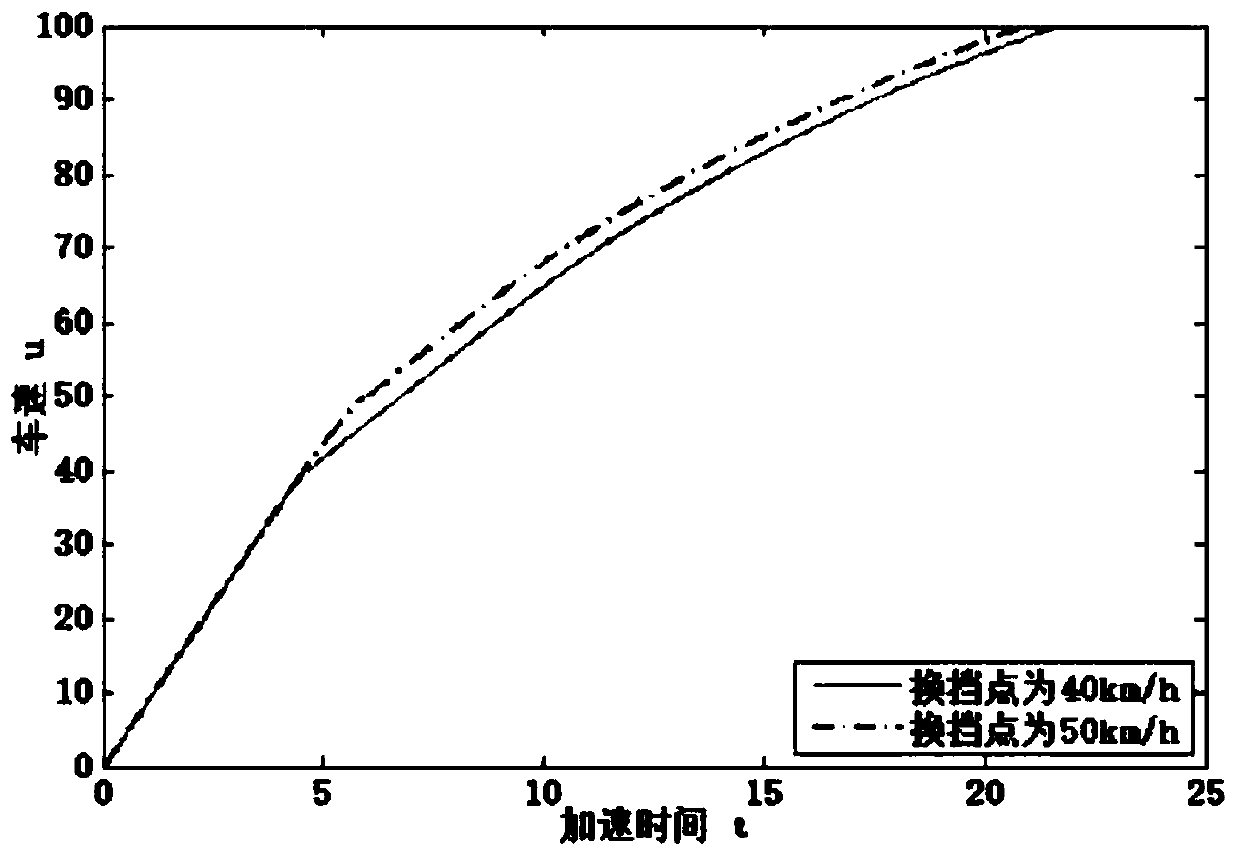

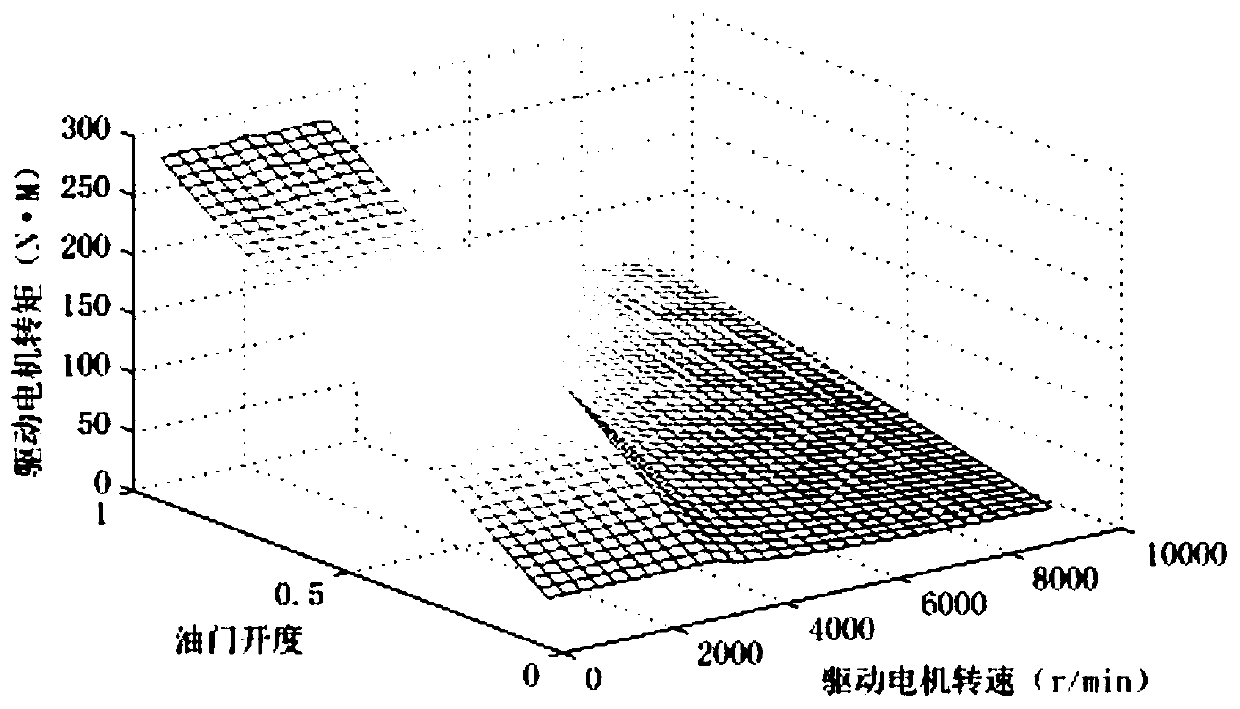

Two-gear AMT comprehensive gear shifting method of pure electric vehicle

InactiveCN110550034AReduce energy consumptionEnergy consumption unchangedInternal combustion piston enginesControl devicesAutomotive engineeringGenetic algorithm

The invention discloses a two-gear AMT comprehensive gear shifting method of a pure electric vehicle, and belongs to the technical field of new energy vehicle power systems. Firstly, an optimal dynamic gear shifting rule and an optimal economical gear shifting rule are provided according to overall performance demands of the pure electric vehicle; based on the two optimal gear shifting rules, withthe gear shifting point vehicle speed and the gear shifting delay quantity as optimization variables, and with the overall vehicle energy consumption and the gear shifting point acceleration difference value as target functions, a comprehensive performance gear shifting rule optimization model giving consideration to both economy and dynamic property is built; and finally, the optimization modelis solved by using a NSGA-II genetic algorithm to obtain comprehensive performance gear shifting rules.

Owner:HEBEI NORMAL UNIV

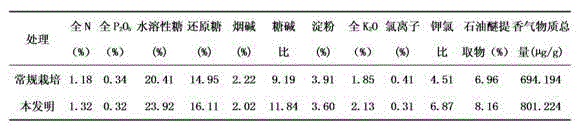

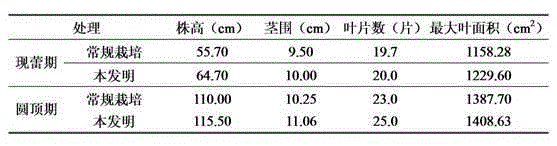

Tobacco culturing method applying large holes for concentrated fertilization

InactiveCN103141256AImprove qualityImprove efficiencyHorticultureFertilizer mixturesFertilizerRoot system

The invention relates to a tobacco culturing method applying large holes for concentrated fertilization. The method is applicable to plain areas of Henan province, and mainly comprises the steps that a base fertilizer is not applied in a culturing process; according to the planting density (16500-18000 plants / hm<2>), the large holes are dug at central positions of tobacco plants planted on a tobacco ridge in a tobacco seedling transplanting process; and various fertilizers are mixed uniformly, applied in the holes according to the calculated fertilization amount of each plant, and sealed after being mixed with soil in the holes sufficiently and uniformly. According to the method, soil water and fertilizer nutrition absorption of the tobacco plants and coordination of water, the fertilizers, air and heat are facilitated; a supply of mineral elements such as N, P,K and Cl is optimized; root development and thickening of the tobacco plants can be facilitated; the disease-resistant ability of tobaccos is improved; the growth advantage of a whole growth period is obvious; resource waste and environmental pollution due to blind fertilization are avoided; the production cost is lowered; effects of oil increasing, aroma enhancing, potassium increasing, alkali reducing, chlorine reducing and starch reducing are exerted in an aspect of improving the quality of tobacco leaves; the internal quality of the tobacco leaves is improved; and economic indicators of the tobacco leaves are increased remarkably.

Owner:HENAN AGRICULTURAL UNIVERSITY +1

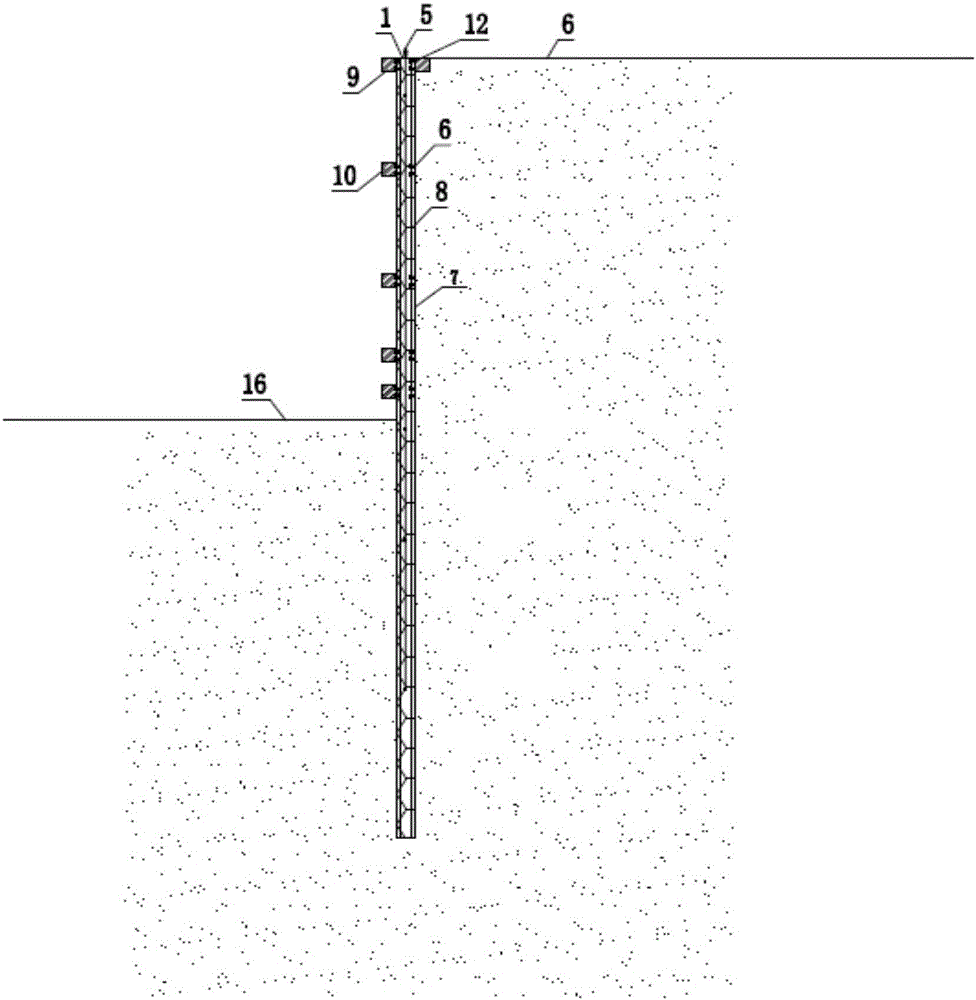

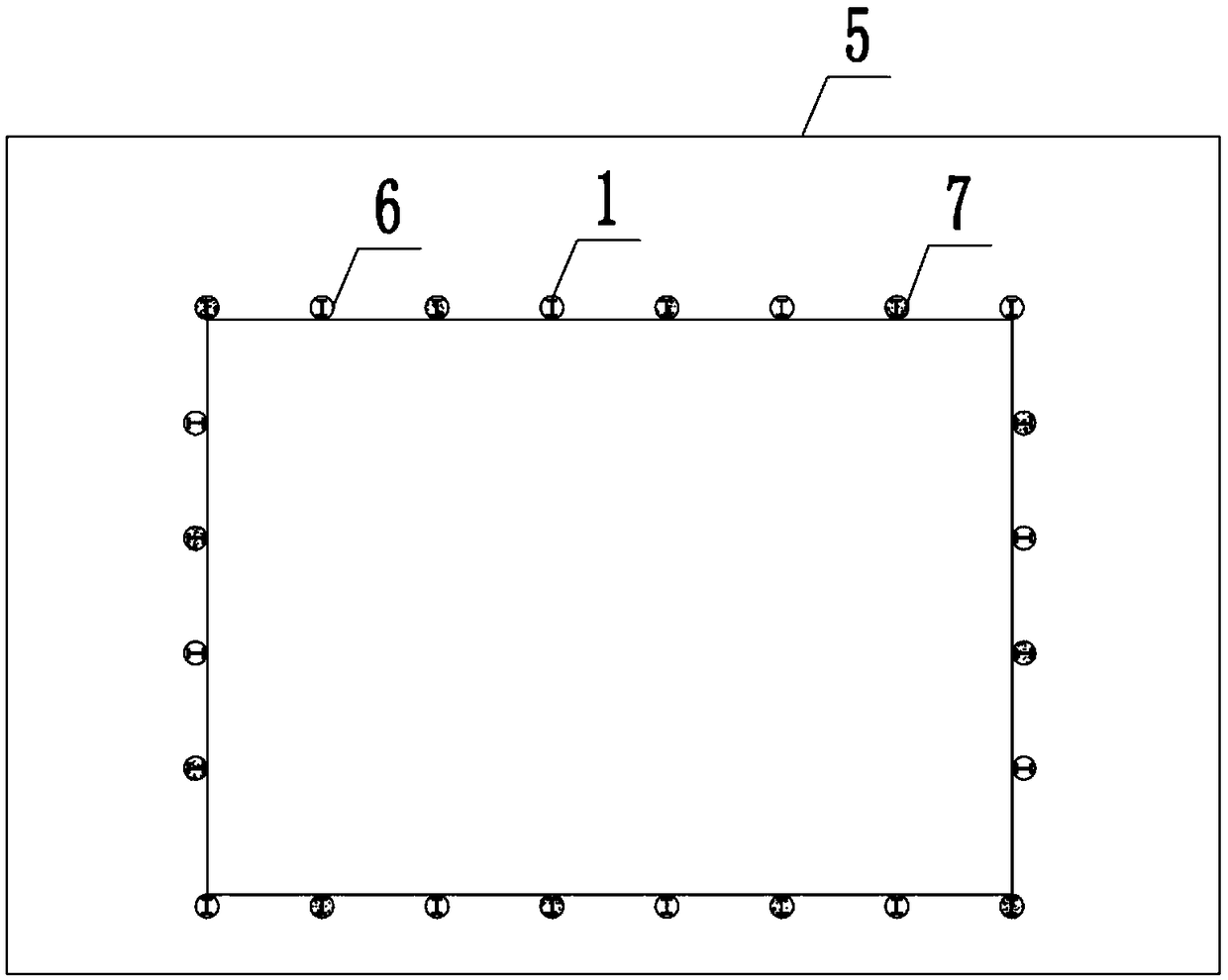

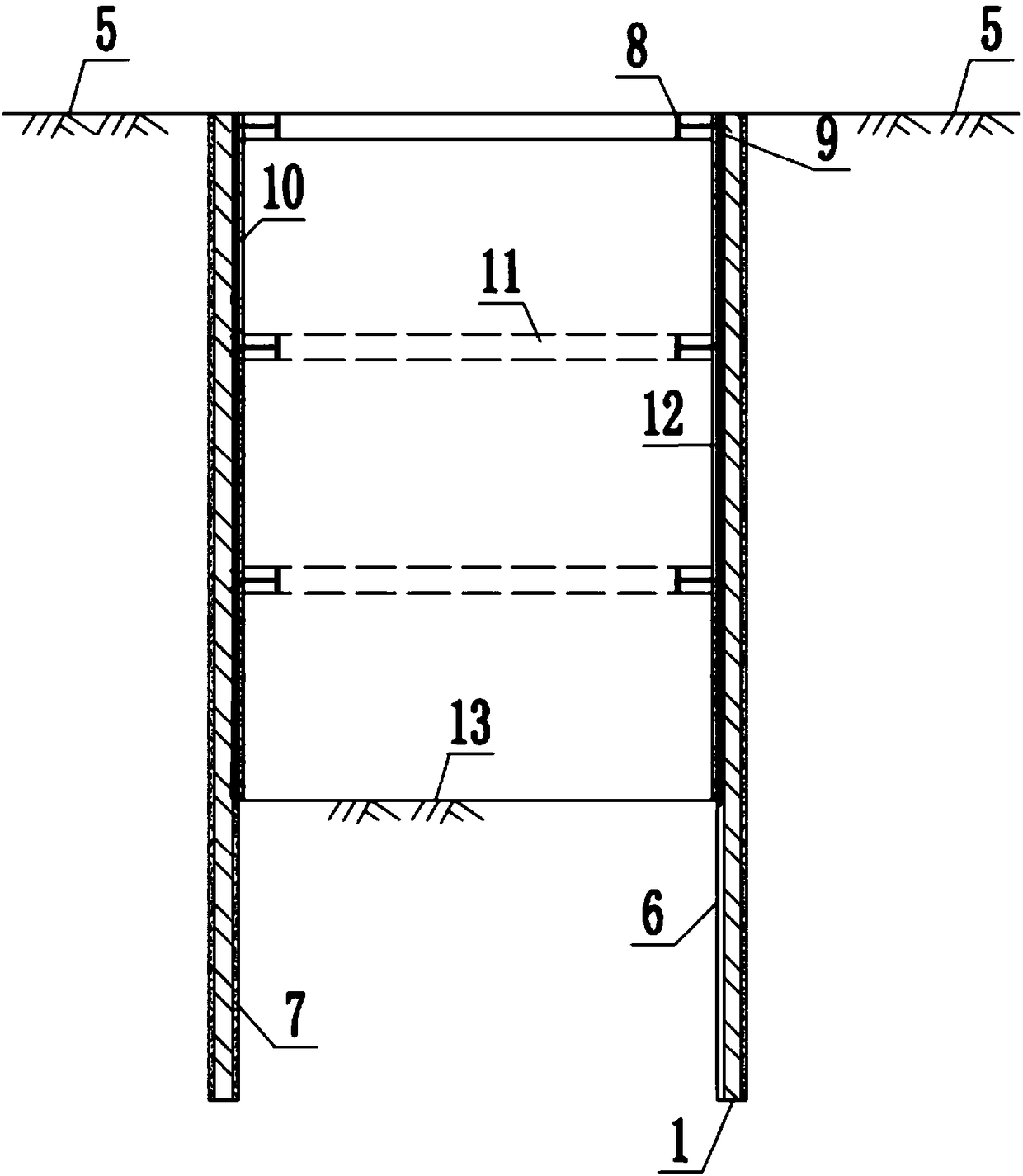

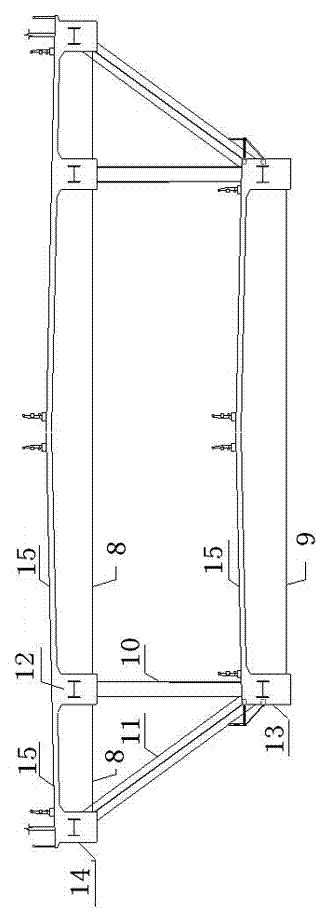

Design construction method of flexible compound fabricated recoverable rectangular working well supporting structure

InactiveCN109056746AMeet the positioning and installation accuracy requirementsAdvanced technologyExcavationsStructure systemHigh polymer

The invention relates to a standardized design construction method of a flexible compound fabricated recoverable rectangular working well supporting structure. The method comprises the following stepsthat (1) construction of minisize supporting piles is carried out; (2) construction of pile top crown beams; (3) a rectangular working well is excavated, panels and waist beams are installed, and high polymers are poured to side walls for sealing; (4) excavation is carried out layer by layer sequentially in the vertical direction, and the step (3) is carried out repeatedly till the design depth is met, that is, construction of the rectangular working well supporting structure is completed accordingly; and (5) after the supporting structure fulfills the usage function, the supporting structurerecovery work can be carried out as the backfilling work is started. Through standardized design construction of the established supporting structure system, one supporting structure can meet the construction requirement of most rectangular working wells in a region, the advantages of safety, reliability, quick and convenient construction, advanced technologies, high recoverability, superior economic indicators and the like are achieved, and the application and development prospects are considerable.

Owner:南方工程检测修复技术研究院

Charging method for blast furnace burden

The invention provides a method for mixed-loading blast furnace materials, ironstone and coke are loaded into the furnace hierarchically, characterized in that the ironstone loaded into the furnace is ore having two or more than two different alkalinity, and the ore is mixed according to the matching proportion of furnace alkalinity requirement prior to entering into the blast furnace. The invention solves the problem that each material layer in the original blast furnace owes the diverse formed softening, fusing, falling starting temperatures to diverse alkalinities, causing the bad air and liquid permeability of material post at the lower part of the blast furnace so as to have an influence on the stable operation of the blast furnace. The invention has the characteristics of reducing the alkalinities of initial slag and bosh slag of the high alkalinity sinter, dropping the melting point of the initial slag, promoting the fluidities of the initial slag and the bosh slag, thus improving the air and liquid permeability of material post at the lower part of the blast furnace and creating advantageous conditions for further increased production and coke saving.

Owner:ANGANG STEEL CO LTD

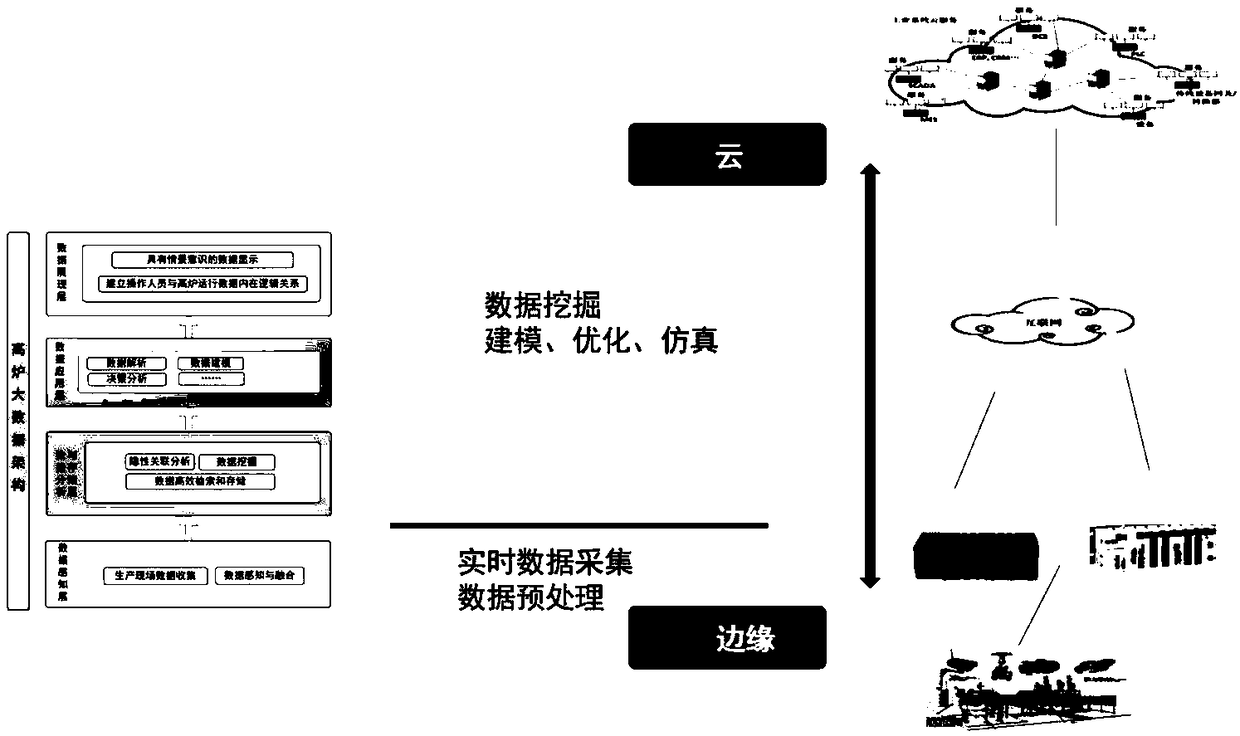

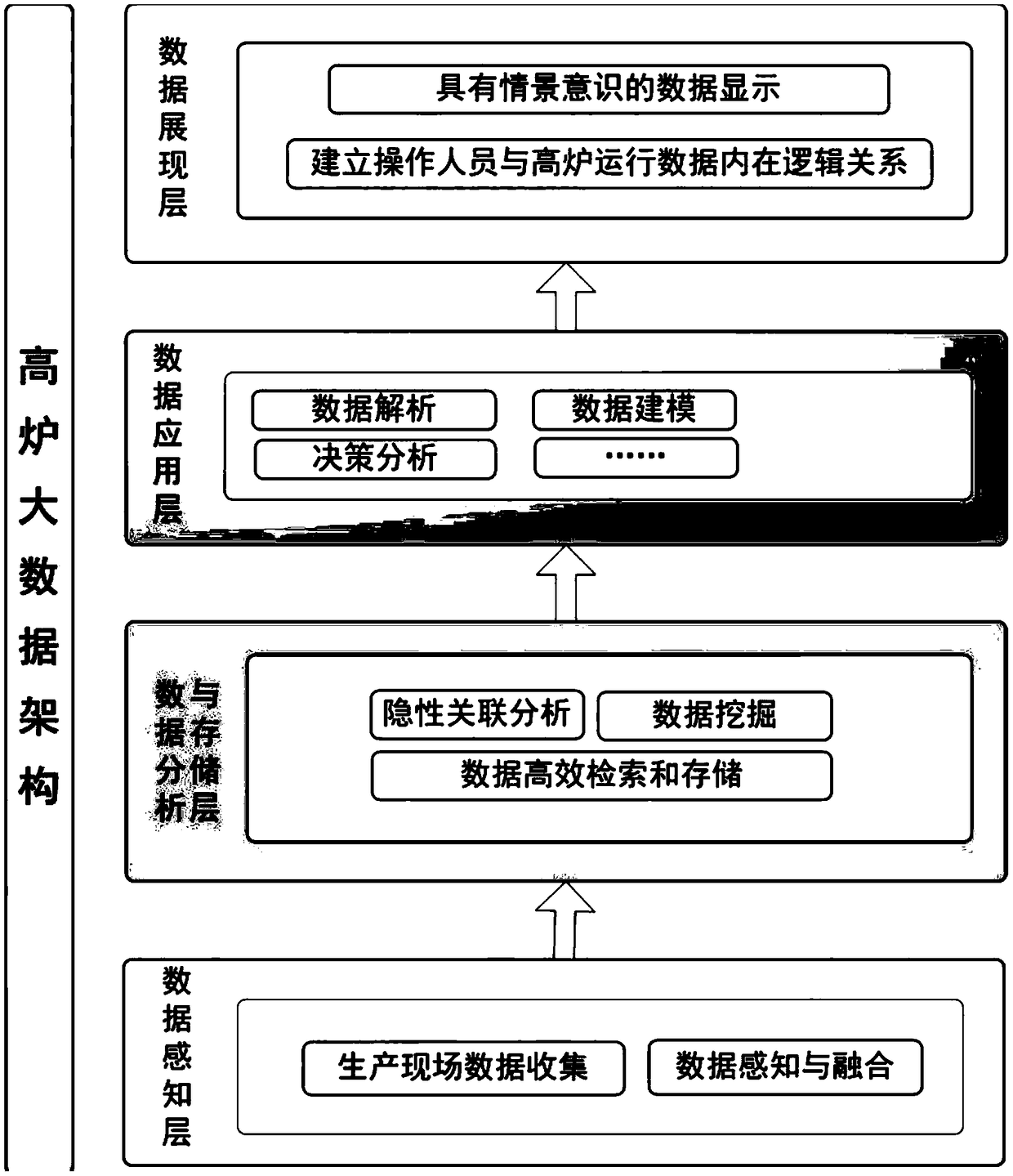

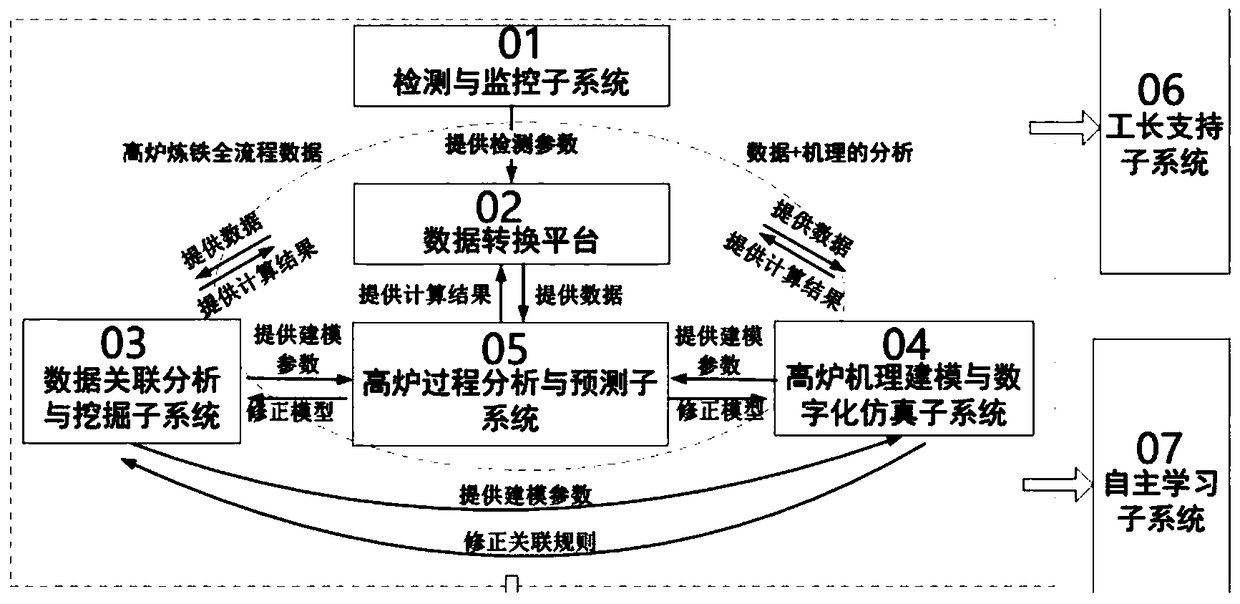

Blast furnace big data application system

ActiveCN108763550AImprove effectiveness and practicalityImprove controlSteel manufacturing process aspectsForecastingData conversionModel parameters

The invention discloses a blast furnace big data application system. The system comprises a detection and monitoring subsystem, a data conversion platform, a data association analysis and mining subsystem, a blast furnace mechanism modeling and digital simulation subsystem, a blast furnace process analysis and prediction subsystem and a foreman support subsystem, wherein the detection and monitoring subsystem is used to collect blast furnace iron-making process data; the data conversion platform is used to integrate the blast furnace iron-making data and acquire uniformly-represented blast furnace iron-making data; the data association analysis and mining subsystem is used to interact with the data conversion platform and further extract operation rules, modeling parameters and historicaldata traceability; the blast furnace mechanism modeling and digital simulation subsystem is used to establish a mathematical model for implementing blast furnace simulation; the blast furnace processanalysis and prediction subsystem is used to analyze a blast furnace production process; and the foreman support subsystem is used to push / display results of each of the above subsystems. The above system can make full use of data in multiple fields, gives a universal operation rule reference, enriches blast furnace iron-making analysis methods, provides tools for deeply knowing blast furnaces, and provides control suggestions or guidance for the long-life, high-quality, low-consumption and stable operation of the blast furnaces.

Owner:NORTHEASTERN UNIV

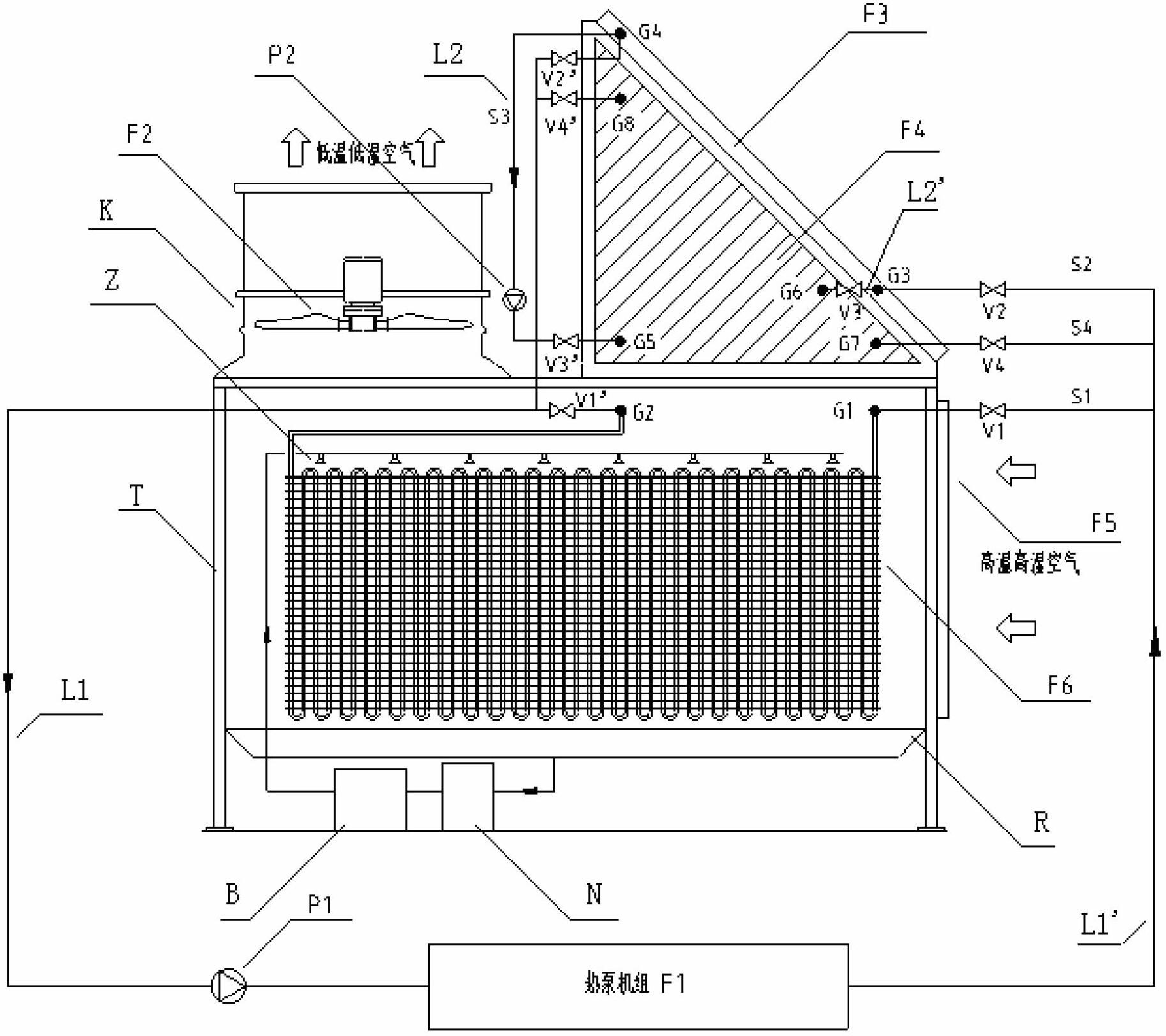

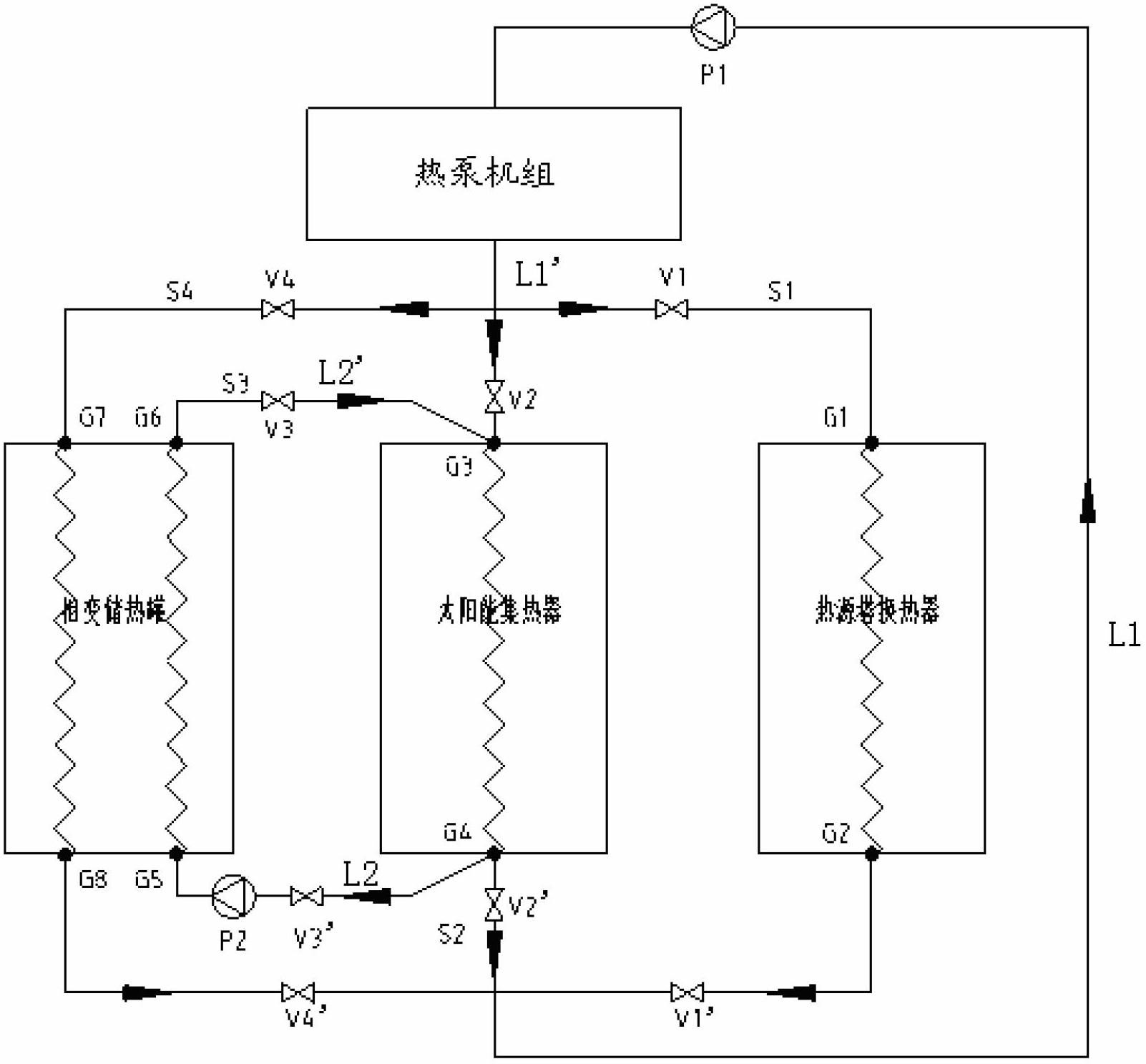

Solar heat-source tower heat pump composite heating device

ActiveCN102679435AImprove absorption and utilizationImprove work efficiencyCentral heating with accumulated heatLighting and heating apparatusPhotothermal conversionEngineering

The invention discloses a solar heat-source tower heat pump composite heating device. The device comprises a heat source tower heat pump heating system, a solar heat collector heating system, a phase-change heat storage system and a phase-change heating system. The composite heating device is convenient to install, compact in structure, high in integration rate, wide in application range and high in heat energy utilization rate and photothermal conversion efficiency, and can be widely used for various places in which heat is required to be supplied.

Owner:HUNAN UNIV

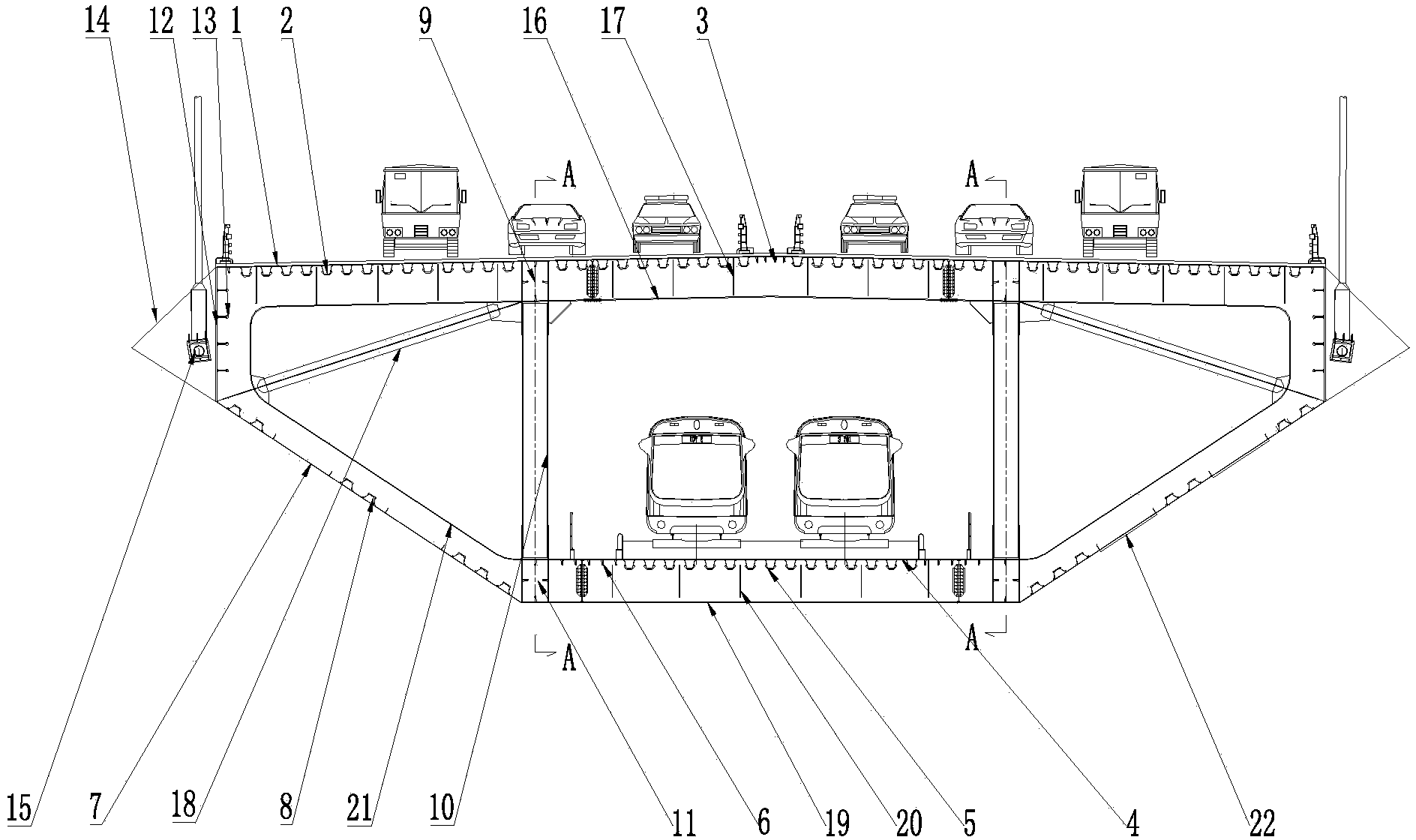

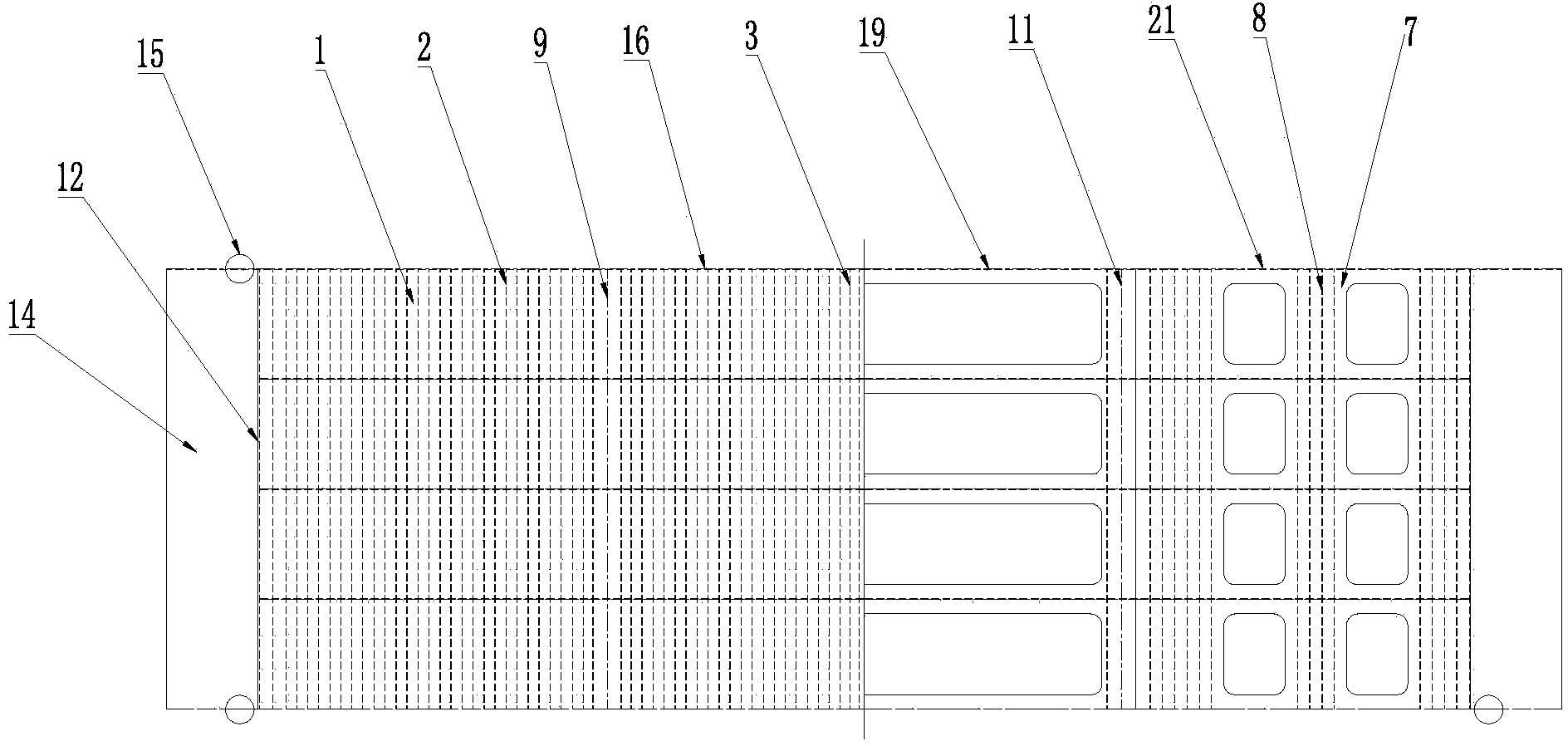

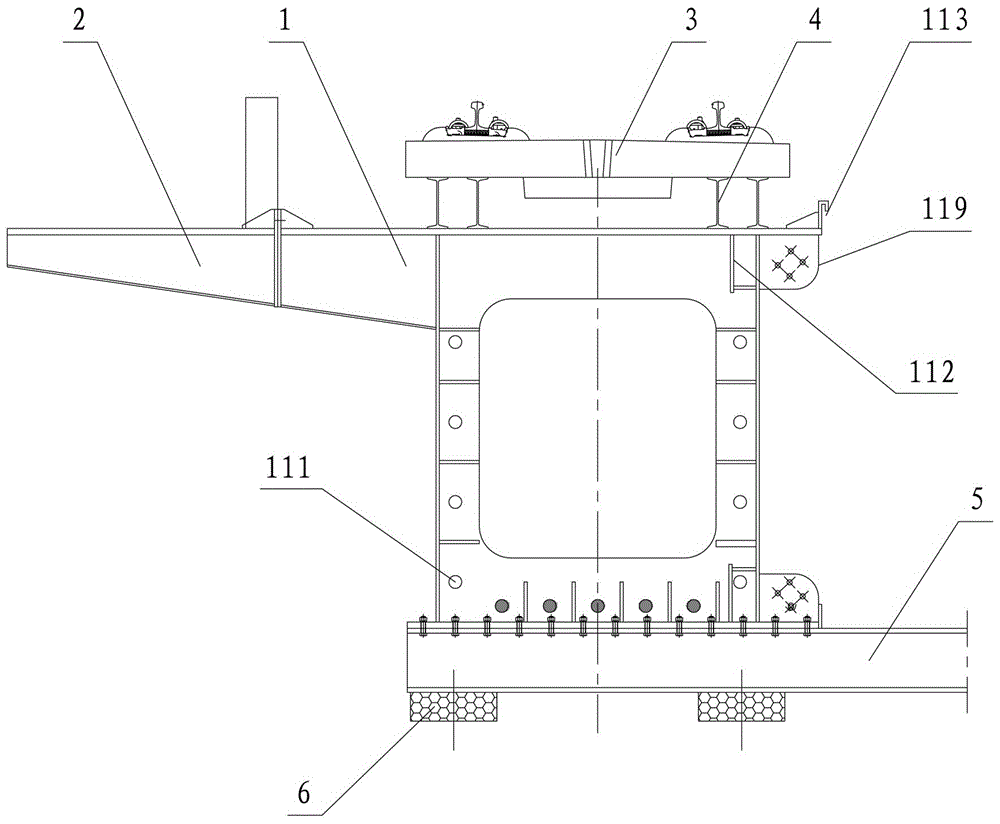

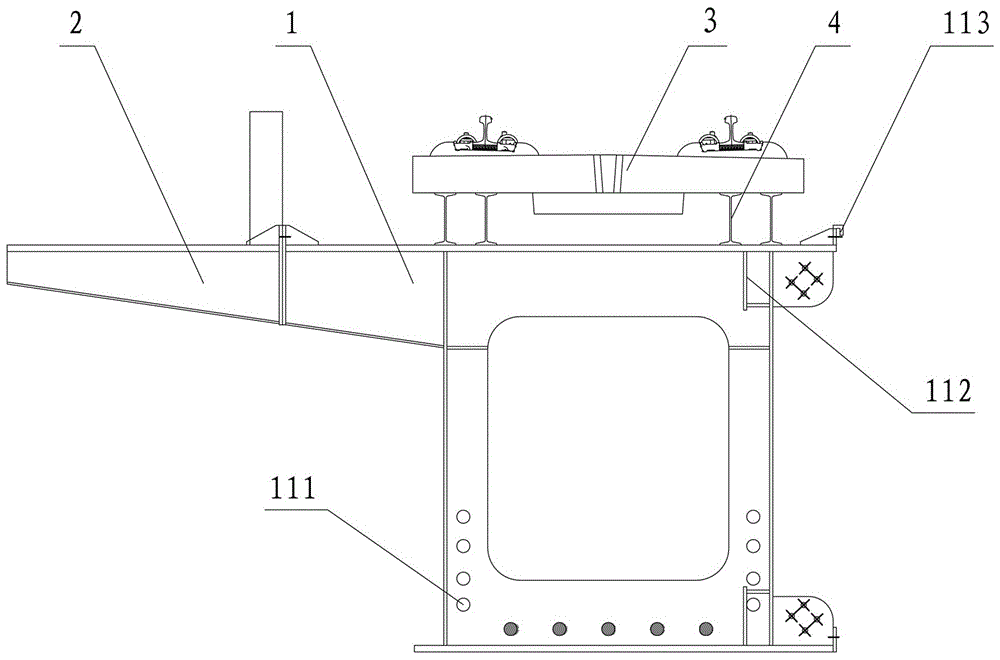

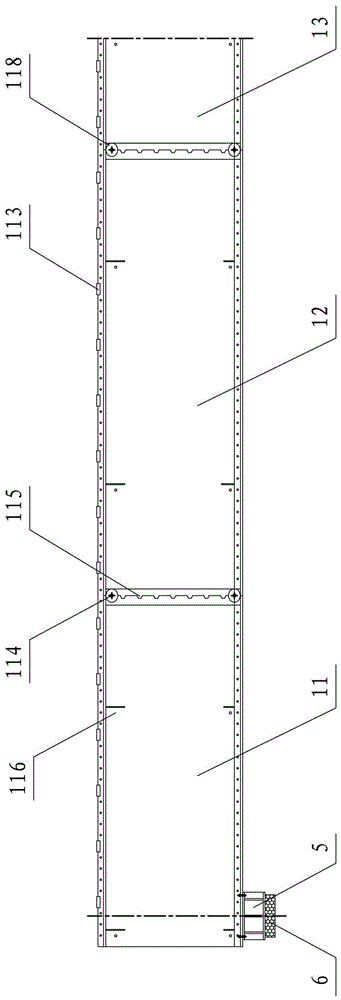

Main girder structure system of double-layer bridge deck cable-stayed bridge

InactiveCN104499415AImprove economic indicatorsShorten the lengthTruss-type bridgeCable stayedBridge deck

The invention discloses a main girder structure system of a double-layer bridge deck cable-stayed bridge. The structure system comprises a mid-span main girder and a side-span main girder, and is characterized in that the mid-span main girder adopts the combination of a plate truss and a steel truss girder, and the side-span main girder adopts a structure system of a composite truss girder. The structure system can effectively shorten the side-span span to prevent the side-span weight, keeps the appearance consistency of the whole bridge main girder, and has higher promotion values on such aspects as economy, bridge landscape and driving comfort.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

Very-high performance concrete prefabricated assembled pipe gallery and construction method

PendingCN107859065AReduce dosageLose weightArtificial islandsUnderwater structuresPre stressArchitectural engineering

The invention discloses a very-high performance concrete prefabricated assembled pipe gallery and a construction method. The pipe gallery is formed by inserting and splicing a plurality of concrete rectangular culvert monomers which are integrally formed front and back; each of the rectangular culvert monomers comprises a side plate, a bottom plate, a top plate and a partition plate; reinforcing rib structures are arranged on the outer side surfaces of the side plate and the top plate; axil angles are arranged at the connections of the side plate and the bottom plate and the side plate and thetop plate; prestress locking devices are arranged at the axil angles; inserting structures which are matched are arranged at the front and back ends of each of rectangular culvert monomers; and the inserting structures are waterproof devices. The construction method comprises the following steps: 1) preparation of the prefabricated rectangular culvert monomers; 2) excavation and support of foundation pits; 3) foundation treatment and cushion ply paving; 4) hoisting of the prefabricated rectangular culvert monomer sections; 5) penetrating and tensioning of the prestress ribs in position; 6) waterproof experiment of the pipe gallery; and 7) soil mass backfilling. The pipe gallery material dosage is reduced greatly, the self weight is reduced greatly, and the very-high performance concrete prefabricated assembled pipe gallery is convenient to transport and hoist, few in step, short in construction period and good in waterproofness and durability.

Owner:HUNAN UNIV

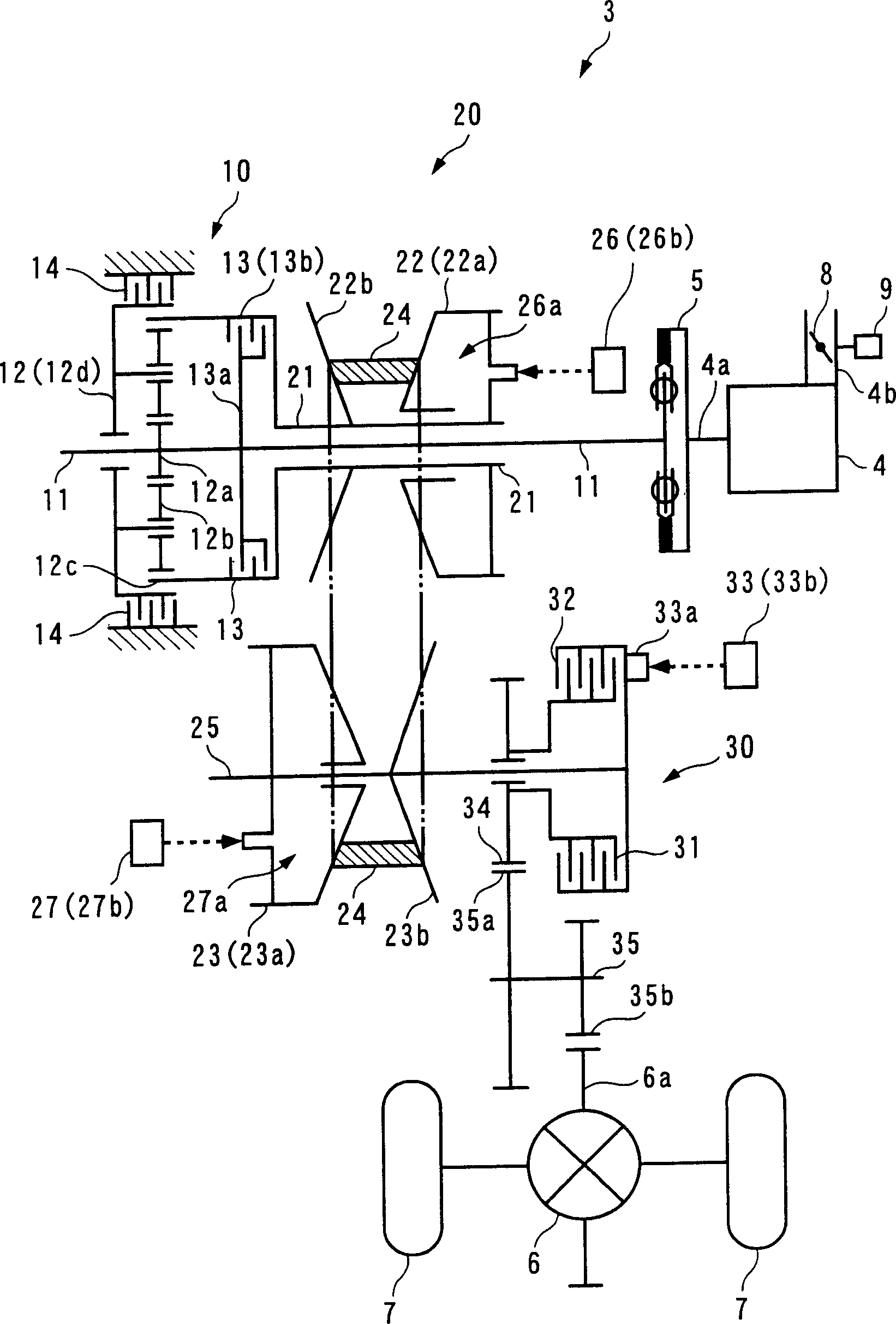

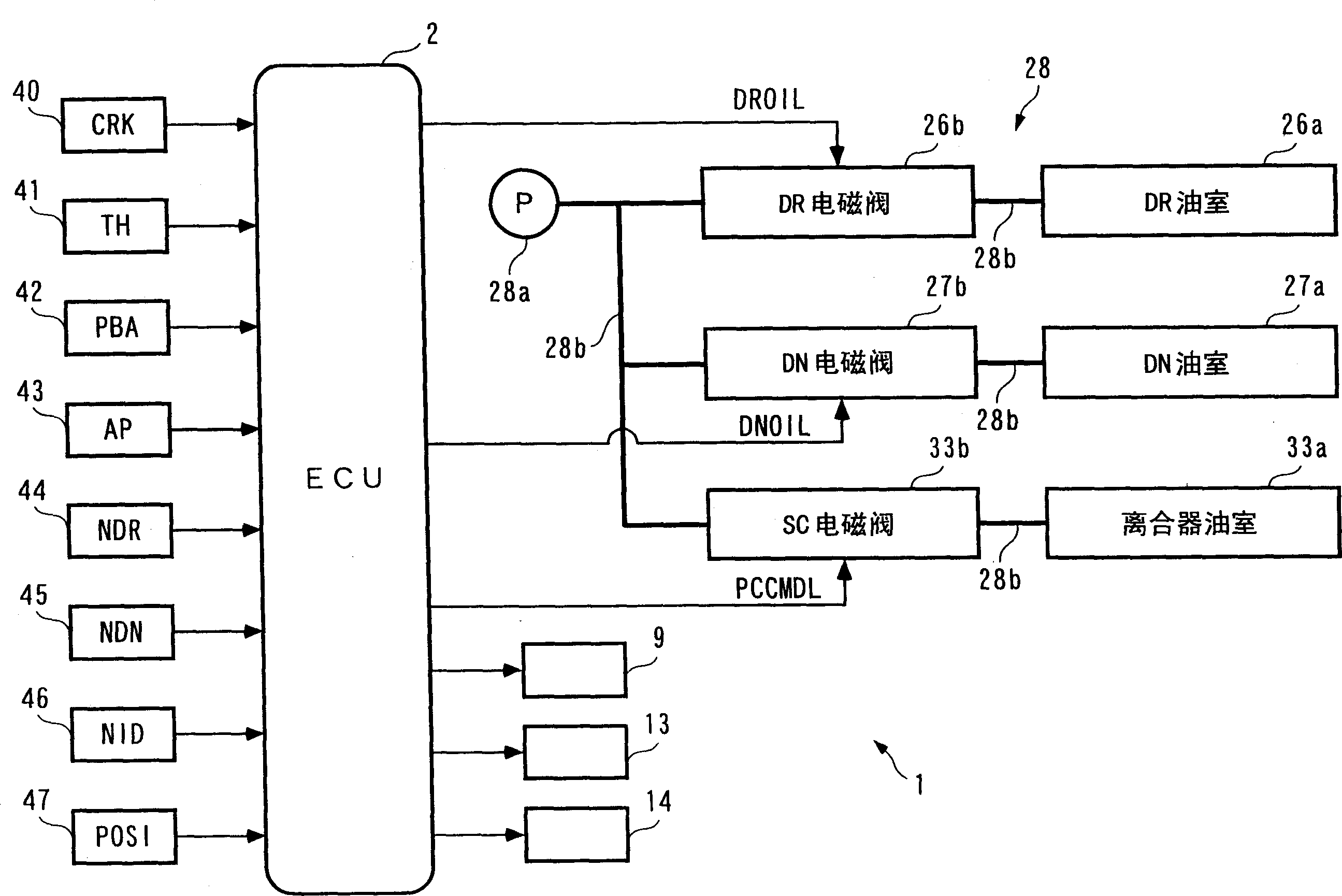

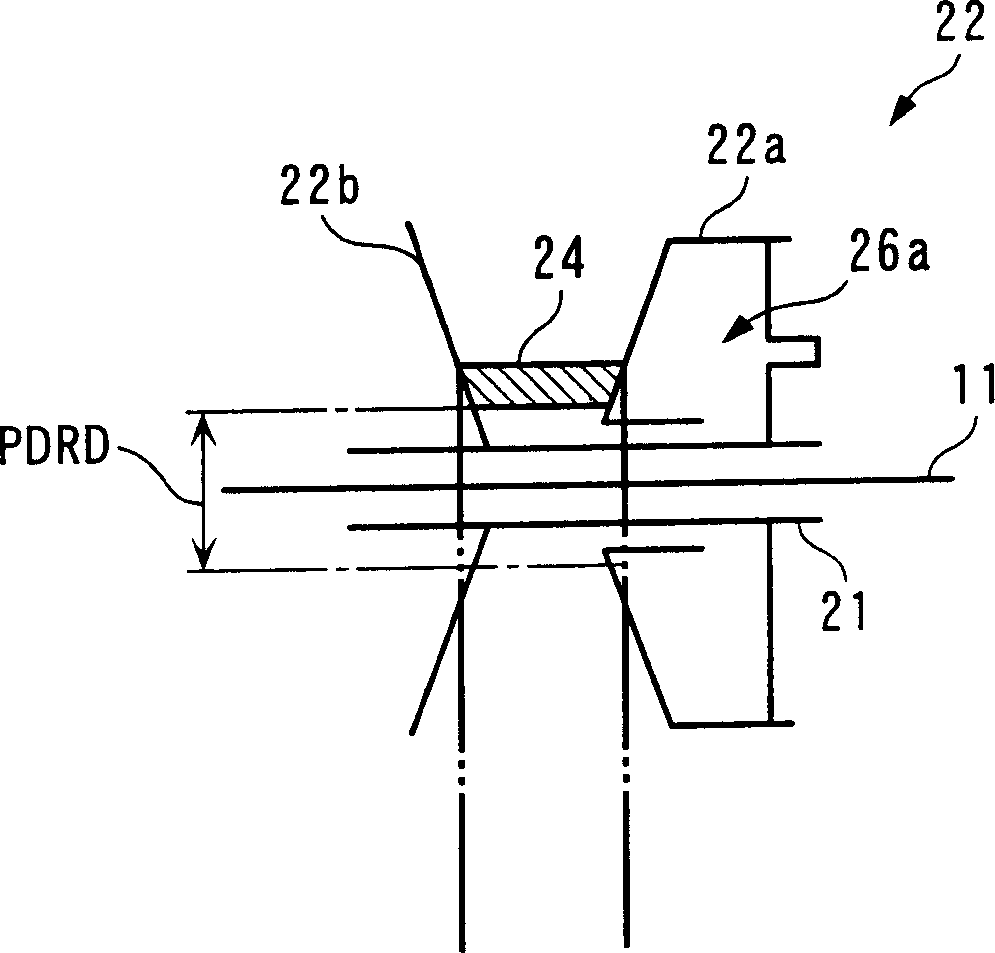

Vehicle control system

There is provided a control system for a vehicle, which is capable of increasing the service life of a transmission belt while preventing slippage thereof, and at the same time improving fuel economy and drivability. The control system for a vehicle sets a transmission transfer torque to be transmitted from a drive pulley of a continuously variable transmission to a driven pulley of the same, and a clutch transfer torque to be transferred by a clutch. When it is determined that the vehicle is traveling on a bad road, the clutch transfer torque is reduced, and the transmission transfer torque is set to a larger value as the clutch transfer torque is larger.

Owner:HONDA MOTOR CO LTD

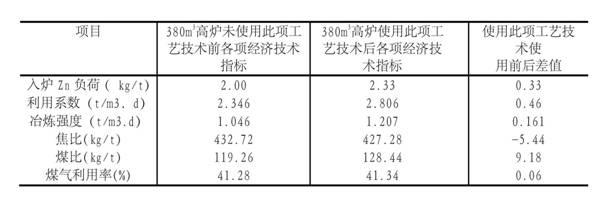

Method for distributing raw materials with high zinc content in blast furnace with bell-less top

InactiveCN102010922APrevent escapeAvoid cloggingBlast furnace componentsBlast furnace detailsThroatMaterial distribution

The invention discloses a method for distributing raw materials with high zinc content in a blast furnace with a bell-less top, which comprises the following steps of: (1) controlling ore batch weight to be greater than a critical value, and ensuring that the average thickness of ore at the furnace throat is 8 to 10 percent of the diameter of the furnace throat; (2) adopting a material distribution mode from a small angle to a large angle increasingly at distributor chutes on the furnace top, and ensuring that small particle burden and powder caused by mass flow particle segregation are distributed from the center of the blast furnace to a part 1 / 3 away from the edge of the furnace wall when a material tank discharges materials; (3) selecting double-ring single pile top large-angle distribution for ore and coke gears, distributing outer-ring ore according to the maximum angle, ensuring that the ore and coke angular difference is -2 degrees and the angular difference of the inner and outer rings of the ore and the coke is 6 degrees, controlling the materials distributed in the inner ring to account for 50 to 60 percent of the total burden, making the ring number of the outer ring distribution at least two, and ensuring that the outer-ring distribution pipe top covers the inner-ring distribution pipe top; (4) adopting a positive packaging and ore-coke unequal line packaging method; and (5) regularly performing tank turning operation on tank-combined blast furnace with the bell-less top, and controlling 4 to 5 tank turning cycle periods in a material column.

Owner:BAOSTEEL GROUP XINJIANG BAYI IRON & STEEL

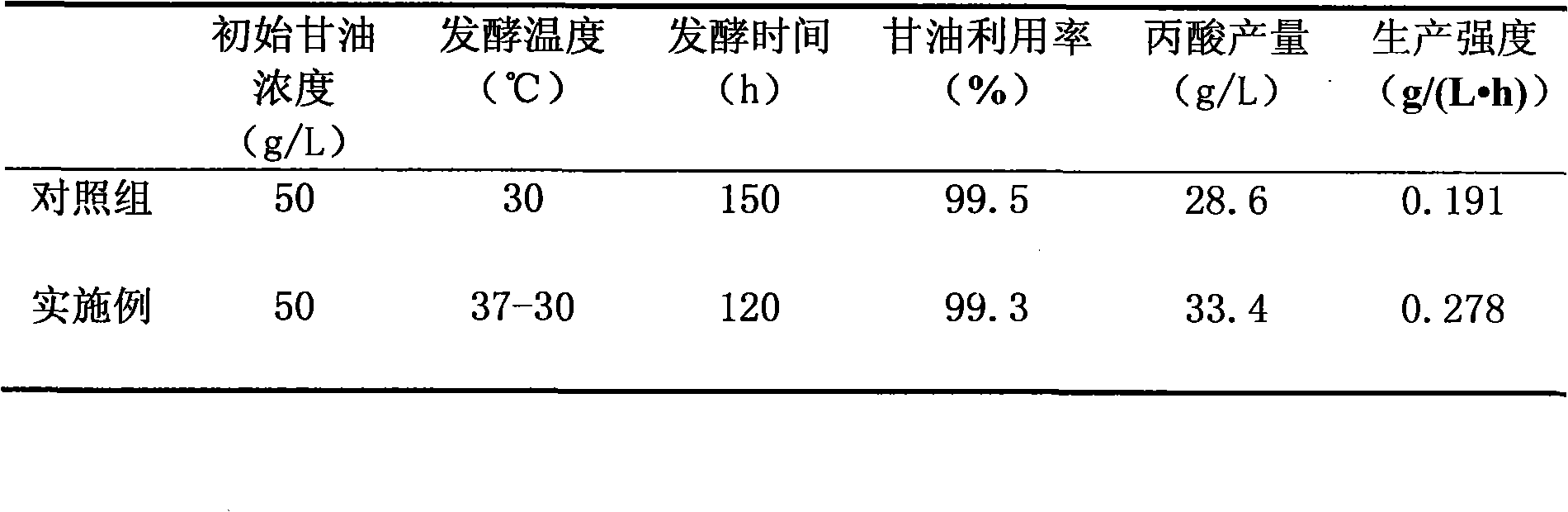

Production process for improving production intensity of propionic acid

ActiveCN101831465AImprove economic indicatorsIncrease production intensityMicroorganism based processesFermentationChemical industryPropanoic acid

The invention discloses a production process for improving production intensity of propionic acid, which comprises the following steps of: controlling a fermentation temperature to be 37 DEG C at the early stage (0 to 72 hours) of fermentation; and controlling the fermentation temperature to be 30 DEG C from the 72th hour to the fermentation end. Under the control of the strategy, the production intensity of the propionic acid is improved by 45.5 percent (0.278 vs 0.191g / (L.h)), the fermentation time is shortened by 20 percent (150 vs 120h), and the yield of the propionic acid can be improved by 16.8 percent (28.6 vs 33.4g / L). The propionic acid produced by using the strategy can be applied in the fields of food, chemical industry and the like, and the strategy has vital significance for production of other fermented products.

Owner:JIANGNAN UNIV

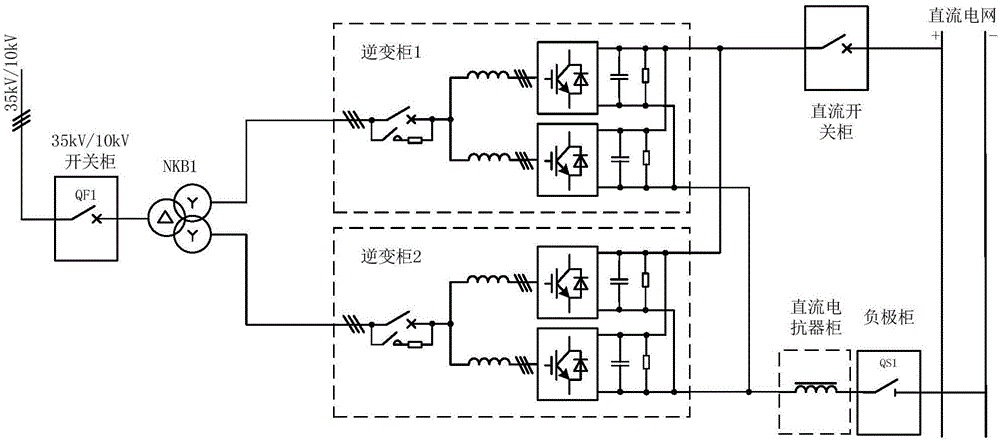

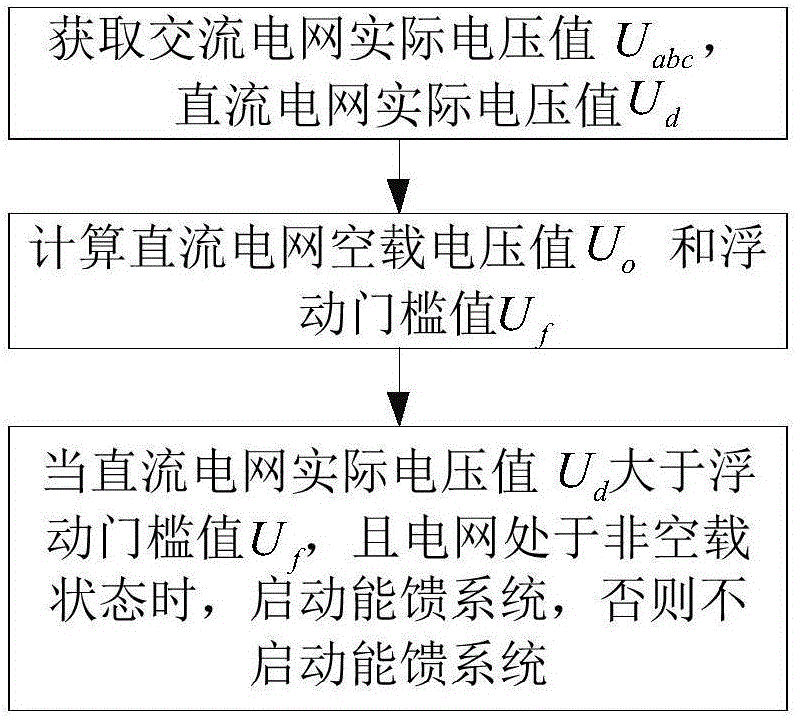

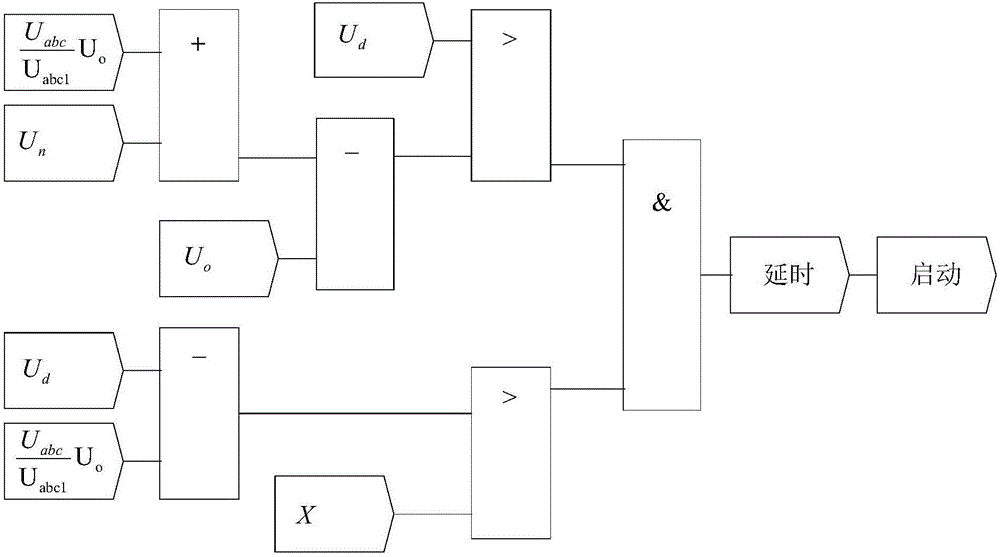

Energy feed system starting control method and control system based on floating threshold value

ActiveCN106169772ASolve the wrong start problemImprove economic indicatorsElectrodynamic brake systemsSingle network parallel feeding arrangementsControl systemComputer module

The invention discloses an energy feed system starting control method and control system based on a floating threshold value. The control method comprises the following steps: S1, obtaining an AC power network actual voltage value and a DC power network actual voltage value; S2, calculating a DC power network zero-load voltage value and the floating threshold value; and S3, when the DC power network actual voltage value is greater than the floating threshold value and a power network is at a non-zero-load state, starting an energy feed system, and otherwise, not starting the energy feed system. The control system comprises a measurement module, a calculation module and a starting control module. According to the invention, the method and system have the following advantages: whether the power network is at a zero-load state can be determined automatically, through arrangement of the floating threshold value, the problem of wrongly starting the energy feed system due to power network voltage fluctuations by use of a fixed threshold value can be effectively solved, unnecessary loss and energy consumption are reduced, and the economic indexes of the whole energy feed system are effectively improved; and an optimal starting threshold is selected according to network voltage actual conditions, the system response speed can be further improved, and it is ensured that the energy feed system is brought into greatest play.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

Anionic collector for normal temperature flotation of hematite and preparation method thereof

The invention relates to an anionic collector for normal temperature flotation of hematite and a preparation method thereof. The anionic collector is prepared from the following raw materials in parts by weight: 12.5-70.0 parts of gutter oil fatty acid, 12.5-70.0 parts of naphthenic acid, 2.0-20.0 parts of N-dilauroyl ethylenediamine sodium triacetate, 1.0-20.0 parts of coconut oil disodium polyoxyethylene sulfosuccinate and sodium hydroxide in an amount which is 0.2 times the total parts by weight of the gutter oil fatty acid and the naphthenic acid. The preparation method of the anionic collector comprises the following steps: stirring the gutter oil fatty acid, the naphthenic acid and the sodium hydroxide for 40-45 minutes at 85-95 DEG C to perform saponification; saponifying for 5-10 minutes after cooling to 30-40 DEG C, adding the N-dilauroyl ethylenediamine sodium triacetate and the coconut oil disodium polyoxyethylene sulfosuccinate, stirring for 5-10 minutes and curing to obtain the anionic collector. According to the method, ore concentration is performed at the normal temperature of 20-25 DEG C, so that the energy consumption is reduced, the energy is saved, the environment is protected, the cost is low, the collection capacity is high, the selectivity is good, the operation concentrate grade is kept, the operation recovery rate is improved, the cost of a flotation reagent is reduced, the waste cooking oil fatty acid is used as a raw material, and a new approach is developed for recycling of gutter oil.

Owner:ANSTEEL GRP MINING CO LTD

Ultra-high-performance concrete prefabricating and splicing integration pipe gallery system and construction method

ActiveCN107842035AIncrease stiffnessImprove bearing capacityArtificial islandsUnderwater structuresArchitectural engineeringPipe

The invention provides an ultra-high-performance concrete prefabricating and splicing integration pipe gallery system which is formed by splicing a plurality of prefabricated sections. Each prefabricated section is prepared through ultra-high-performance concrete. Each prefabricated section is composed of a side plate, a bottom plate, a top plate and a partition plate. Each partition plate is fixed between the corresponding bottom plate and the corresponding top plate. The adjacent prefabricated sections are overlapped through ultra-high-performance concrete patches. The invention further discloses a construction method of the pipe gallery system. According to the integration pipe gallery system, the prefabricated sections of the integration pipe gallery system are made of materials like the ultra-high-performance concrete with high strength, high tenacity and high durability, the structure of the ultra-high-performance concrete patches and the like is combined, rigidity, bearing capacity and waterproof performance of a pipe gallery are improved, the wall thickness of the prefabricated sections is reduced compared with that of a traditional pipe gallery system, the dead weight of the pipe gallery is reduced remarkably, and transporting and hoisting are convenient. The material use amount of the pipe gallery is low to be 50% of that of the traditional pipe gallery system, the comprehensive production cost is reduced by 10-50% correspondingly, rigidity is large, the system is suitable for regions with poor foundation geologic conditions, the construction period of the pipe gallery system is short, and the influence on the construction environment is small.

Owner:HUNAN UNIV

Highway and railway layered steel box beam

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

High-speed railway rush repair beam capable of being converted into permanent bridge structure, and rush repair method of high-speed railway rush repair beam

The invention discloses a high-speed railway rush repair beam capable of being converted into a permanent bridge structure, and a rush repair method of the high-speed railway rush repair beam. The high-speed railway rush repair beam is formed by single-line uplink rush repair beams and single-line downlink rush repair beams which are independent of one another in a temporary traffic state; the single-line rush repair beams respectively adopt a structural form of a prestressed steel box girder, the steel box girders are manufactured in a way of segmentation, and segments of each steel box girder are connected in a manner of steel pin-shear key; a longitudinal external prestressed reinforcing steel bar is arranged above a lower wing plate of each steel box girder and at the inner side of a web of the steel box girder. By means of pouring a concrete structure layer above the steel box girders as well as arranging and tensioning transverse prestressed tendons between the single-line uplink rush repair beams and the single-line downlink rush repair beams, a double-track and whole-span prestressed steel-concrete composite beam is formed by the rush repair beams and can be used as the permanent bridge structure for normal operation. Compared with the existing rush repair steel beam, the high-speed railway rush repair beam is characterized in that the traffic speed is high, a beam part structure used for temporary rush repair is no longer dismantled, and the temporary rush repair beam is converted into the permanent bridge structure by the conversion of a structural system, so that beam-replacing construction of a damaged bridge is further avoided.

Owner:SHIJIAZHUANG TIEDAO UNIV

Aluminum electrolysis bath after-starting stable electrode-changing method

InactiveCN101240434AImprove economic indicatorsStable productionEnergy balancedAluminum electrolysis

The invention discloses a stable anode-changing method at the late period of an aluminum electrobath. The anode is changed from 13th day after aluminum electrobath startup, in order to assure successive production as changing anode in normal period, a residual anode capable of producing for 18 days is used in 16th day and 19th day after aluminum electrobath startup; a residual anode capable of producing for 20 days is used in 22th day after aluminum electrobath startup; a residual anode capable of producing for 11 days is used in 25th after aluminum electrobath startup; a residual anode capable of producing for 11 days is used in 28th day after aluminum electrobath startup; and a residual anode capable of producing for 7 days is used in 32th day after aluminum electrobath startup. The invention has no anode changing after successive 12 days after aluminum electrobath startup, energy balance of the electrobath is not affected during this period, firm and structured furnace wall is formed, so that the electrobath has effects of stability, high efficiency and low consumption, thus improving the economic index of an enterprise.

Owner:HENAN ZHONGFU IND

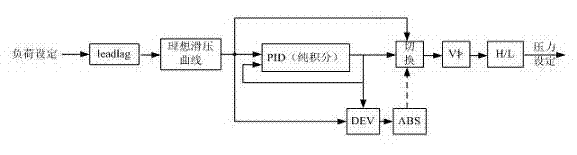

Sliding-pressure operation unit optimizing control method in automatic gain control (AGC) mode

ActiveCN102176176AGuaranteed speedReduce shockFluid pressure control using electric meansLower limitAutomatic Generation Control

The invention relates to a sliding-pressure operation unit optimizing control method in an automatic gain control (AGC) mode, and the method has the advantages of simplicity, effective reduction of oscillation occurrence, economic efficiency of unit operation and the like. The method comprises the following steps: 1) filtering load setting after load is set; 2) setting an ideal sliding-pressure curve according to the best efficiency points of throttling and circulating efficiencies; 3) realizing automatic optimizing of sliding-pressure setting by utilizing a pure integral module of proportion integration differentiation (PID); 4) increasing a high-low limit module after a pressure setting velocity is limited so as to prevent a pressure setting value from exceeding the range permitted by unit safety operation; and 5) manually setting the load setting by operators when the AGC is not carried out, wherein the load is prevented from small oscillation, corresponding pressure setting is prevented from small oscillation, and pressure setting in logics is switched to an operation bypass.

Owner:STATE GRID CORP OF CHINA +1

Roller compacted concrete full package chute vertical conveying technology

InactiveCN101338860ALittle changeChange delivery anglePipeline systemsRoller-compacted concreteTransportation technology

The invention discloses a novel roller compacted concrete full pipe chute vertical transportation technology. Utilizing the full piping principle and the concrete gravity action can maintain the chute to be full piping at any time. Due to adopting the full piping enclosed transportation, the technology can effectively control the aggregate separation and decrease the loss of VC value. The invention comprises the design idea, the design, assembly and operation of the full piping chute, an upper and lower concrete storage tank, and a feeding and discharging concrete radial gate. The invention shows that adopting the roller compacted concrete full pipe chute vertical transportation technology to the roller compacted concrete vertical transportation is feasible, the construction technology is more economic, simple and easy assembled and disassembled, and can be widely popularized in the project according to the actual condition.

Owner:SINOHYDRO BUREAU 16 CO LTD

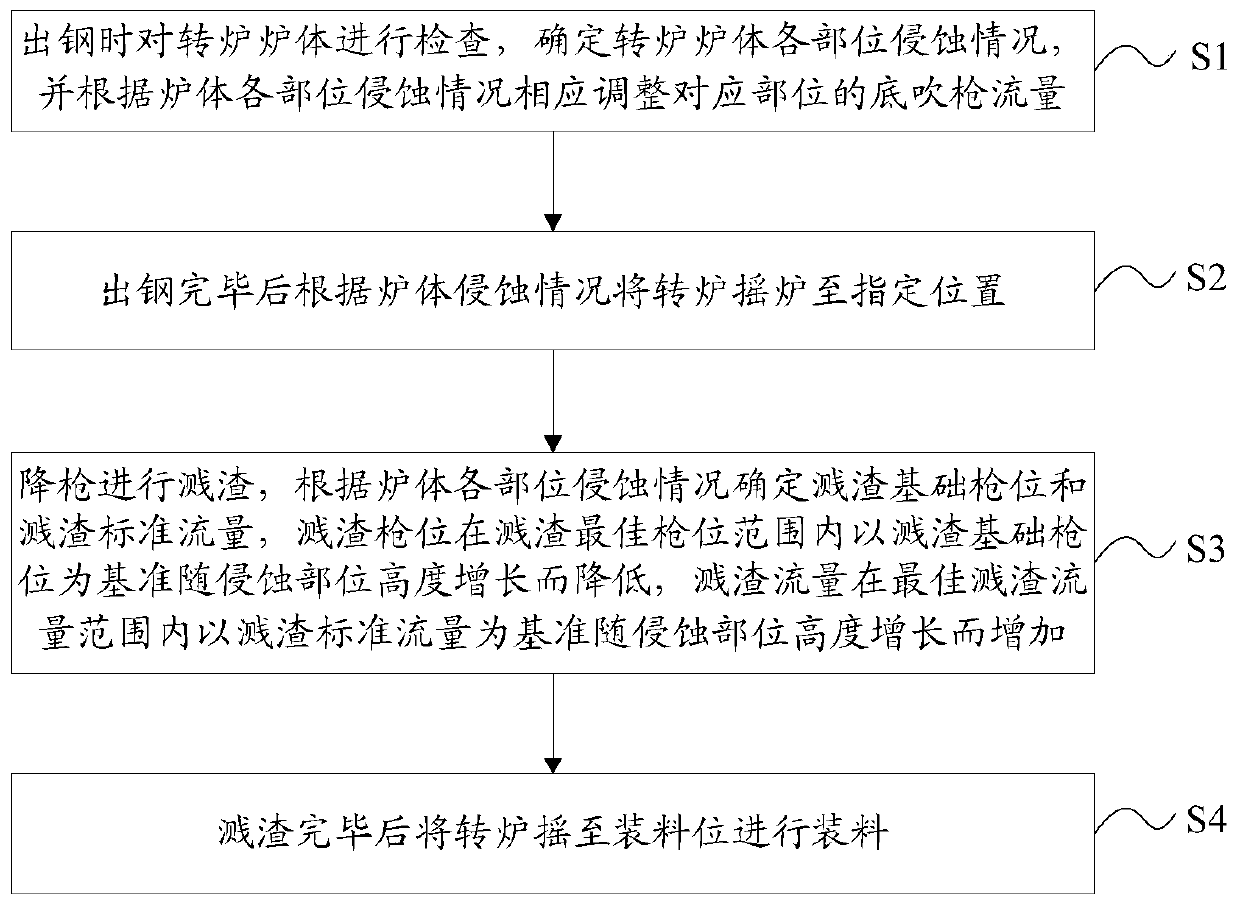

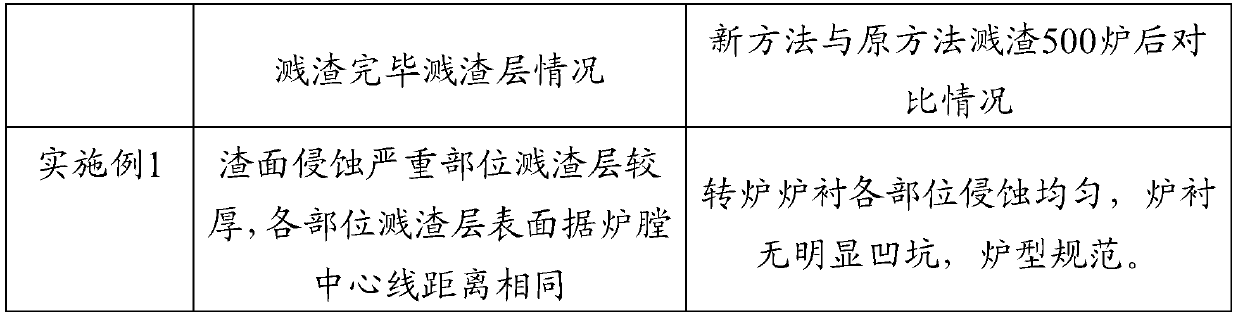

Accurate converter slag splashing method

InactiveCN109811110AGuaranteed uptimeRealize scientific and normative controlManufacturing convertersSmelting processOperational stability

The invention discloses an accurate converter slag splashing method. The accurate converter slag splashing method comprises the steps that during tapping, a converter body is checked, the erosion situation of various parts of the converter body is determined, and the bottom blow gun flow of corresponding parts is correspondingly adjusted according to the erosion situation of various parts of the converter body; after tapping is finished, a converter is rocked to the assigned position according to the converter body erosion situation; gun lowering is conducted for slag splashing, the slag splashing base gun position and flow are determined according to the erosion situation of various parts of the converter body, the slag splashing gun position is lowered within the optimal slag splashing gun position range along with increasing of the height of the erosion part, and the slag splashing flow is increased within the optimal slag splashing flow range along with increasing of the height ofthe erosion part; and after slag splashing is finished, the converter is rocked to the loading position for loading. By means of the method, the thickness of slag splashing layers of various parts ofthe converter body is accurately controlled, scientific and standard control over the converter profile is achieved, and running safety of the converter body is ensured. Through accurate control overthe slag splashing amount, scientific control over the converter profile is achieved, accordingly, operation stability is improved, the slag overflow amount in the smelting process is reduced, various economic indexes are increased, and the smelting cost is reduced.

Owner:SHANDONG IRON & STEEL CO LTD

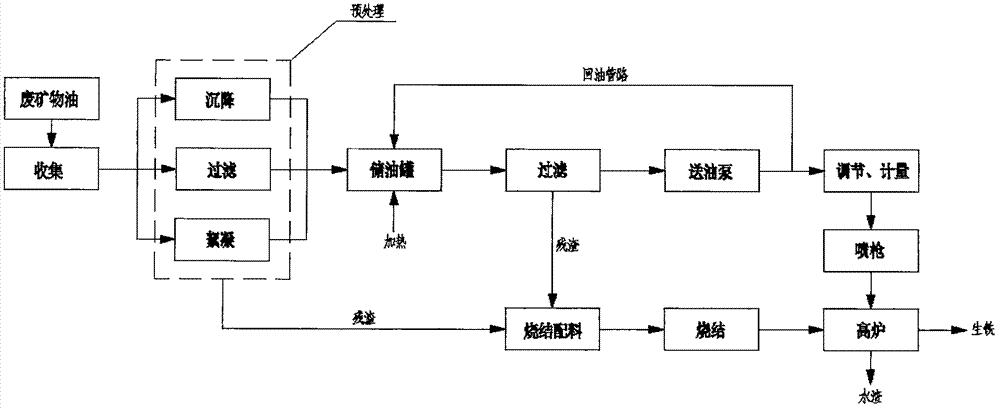

Method for harmlessness treatment of waste mineral oil by blast furnace injection mode

InactiveCN106916604AImprove economic indicatorsAvoid churnBlast furnace detailsTreatment with plural serial refining stagesCombustionPre treatment

The invention relates to a method for harmlessness treatment of waste mineral oil by a blast furnace injection mode. Through collection, pretreatment, blowing, combustion, and residue treatment on waste mineral oil having no regeneration value, and comprehensive utilization and thoroughly harmlessness treatment of a waste mineral oil resource are realized.

Owner:重庆君利丰环保有限公司

Copious cooling fast freezing infrared drying technology

InactiveCN109780821AImprove protectionNo pollution in the processDrying solid materials without heatLiquid waterFreeze-drying

The invention discloses a copious cooling fast freezing infrared drying technology and belongs to the technical field of chemical engineering and light industry machining. The copious cooling fast freezing infrared drying technology is characterized in that a gas turbine expanding refrigerating technology is adopted for performing copious cooling fast freezing on materials, compressed air at 0.5-0.9 Mpa is used, the initial air expanding pressure intensity ratio is 3-9, and fresh product vegetables and fruits and traditional Chinese medicinal materials except mineral drug are fast cooled to minus 20- minus 120 DEG C within 5-30 min, so that liquid water in a raw material organization structure fast solidifies, and becomes extremely micro ice crystal; and then, the materials are fed into aninfrared vacuum freezing drying bin to be heated, so that solid water in the materials sublimates into vaporous water, and the water content of the materials is lowered to 0-10%. The copious coolingfast freezing infrared drying technology has the characteristics of being high in freezing speed, low in cooling temperature, high in drying speed, uniform in material heating, uniform in material product quality and good in drying effect.

Owner:海尔生物医疗科技(成都)有限公司

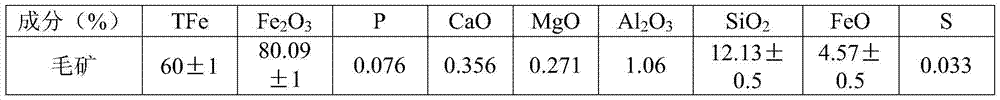

Sintering method for sea sand vanadium-titanium-iron concentrate

The invention belongs to the field of metal smelting, and particularly relates to a sintering method for sea sand vanadium-titanium-iron concentrate. The technical problems that the sea sand vanadium-titanium-iron concentrate belongs to high titanium type schreyerite, the sintering performance is poor, the yield of sinter, the utilization coefficient and indexes like the drum index are poor compared with indexes of common ore are solved. According to the scheme, the sintering method of the sea sand vanadium-titanium-iron concentrate comprises the following steps that firstly, in the even mixing process before sintering, a calcium manganate aqueous solution is added into the sinter, and a mixture is prepared; and b, ignition is carried out, the mixture is sintered to obtain the sinter. The method is easy and convenient to operate, practical and suitable for industrialized production.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

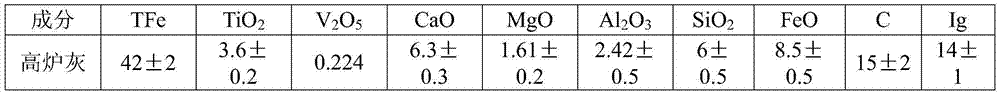

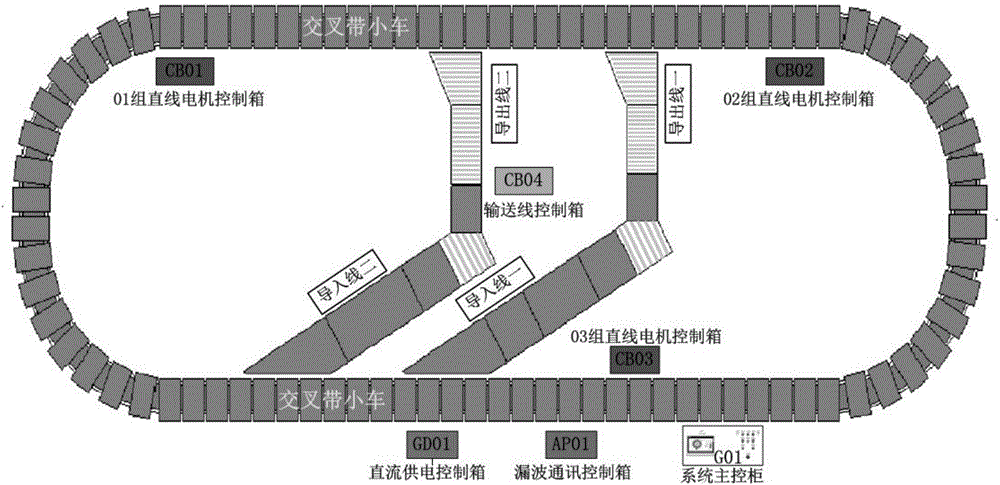

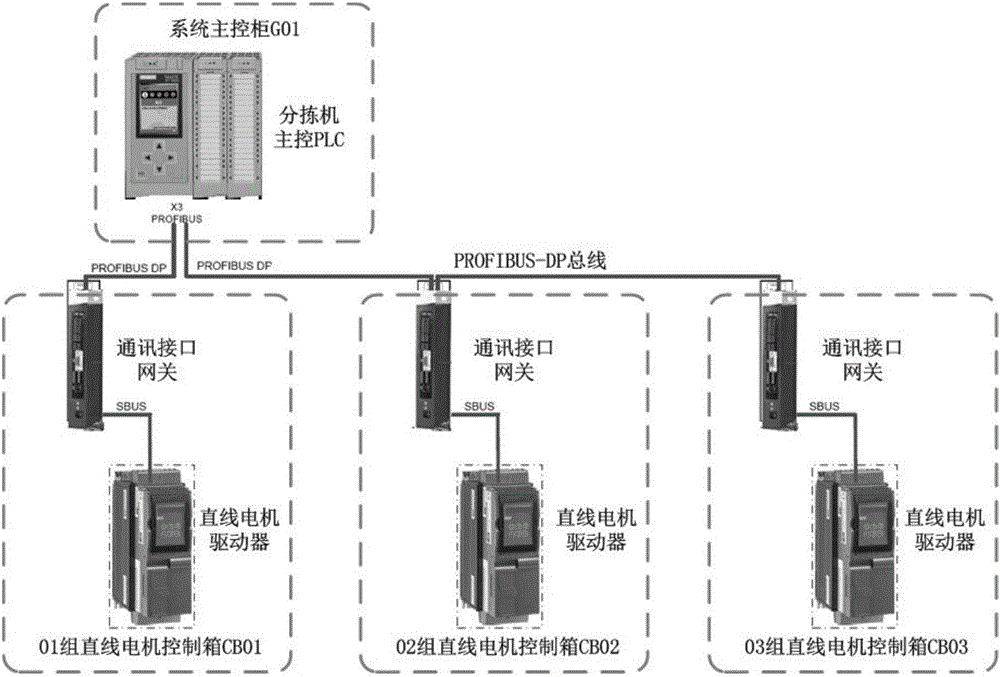

High-speed cross-belt sorting and conveying machine control system

ActiveCN105700459AEasy to installHigh capacity indexProgramme control in sequence/logic controllersEngineeringElectric control

A high-speed cross-belt sorting and conveying machine control system which is characterized in that an SLC synchronous linear motor is used for supplying a power for driving a sorting host machine; leaky wave technology is adopted between the sorting host machine and a sorting trolley for performing ProFiNET communication, CANopen-based DC servo driving technology is adopted for trolley conveying, and furthermore material synchronous leading logic control technology is utilized. The high-speed cross-belt sorting and conveying machine control system has beneficial effects of greatly improving conveying performance of a cross-belt sorting trolley, simplifying system wiring, improving maintainability, and facilitating number increase and number reduction of trolleys. A large number of quick connect plugs are used in the whole cross-belt sorting and conveying machine control system, and the trolleys are electrically connected with one another by means of standard plugs, thereby optimizing electrical wiring and device layout of an electric control system, saving expense of a certain number of electrical configurations (such as wiring terminals and cables) and realizing a relatively good economic index. Furthermore electrical mounting structure of the equipment is optimized. Equipment fault repairing and maintenance are facilitated.

Owner:KUNMING KSEC LOGISTIC INFORMATION IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com