Sliding-pressure operation unit optimizing control method in automatic gain control (AGC) mode

A sliding pressure operating unit and control method technology, applied in the direction of electric fluid pressure control, etc., can solve the problems affecting the unit pressure stability, increasing unit coal consumption, unit AGC adjustment quality, etc., to improve economic indicators, pressure setting, etc. fixed smoothing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

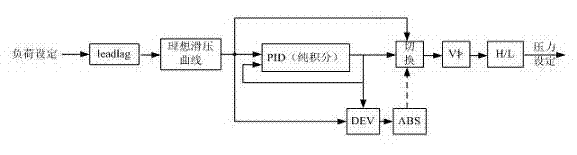

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0022] 1. After the load is set, use the leadlag (leadlag) module to filter the load setting to reduce the glitch generated during the transmission of the load set value, and play a role in the small fluctuation of the AGC command with the grid cycle. certain inhibitory effect;

[0023] 2. Set the ideal sliding pressure curve according to the best efficiency point of throttling and cycle efficiency;

[0024] 3. Use the pure integral module of PID to realize the automatic optimization of the sliding pressure setting, so that the pressure setting value after the PID calculation output is continuously approaching the ideal sliding pressure curve;

[0025] 4. Take the output of the ideal sliding pressure curve as the set value of the PID, and use the output of the PID as the control variable of the PID;

[0026] 5. The speed limit of the sliding pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com