Accurate converter slag splashing method

A technology of slag splashing and converter, applied in the field of metallurgy, can solve the problems of large influence of converter smelting and low precision of slag splashing layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

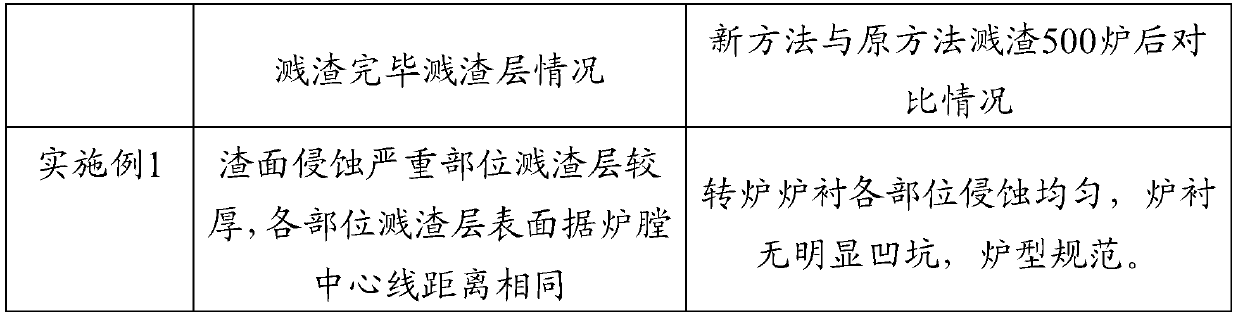

Embodiment 1

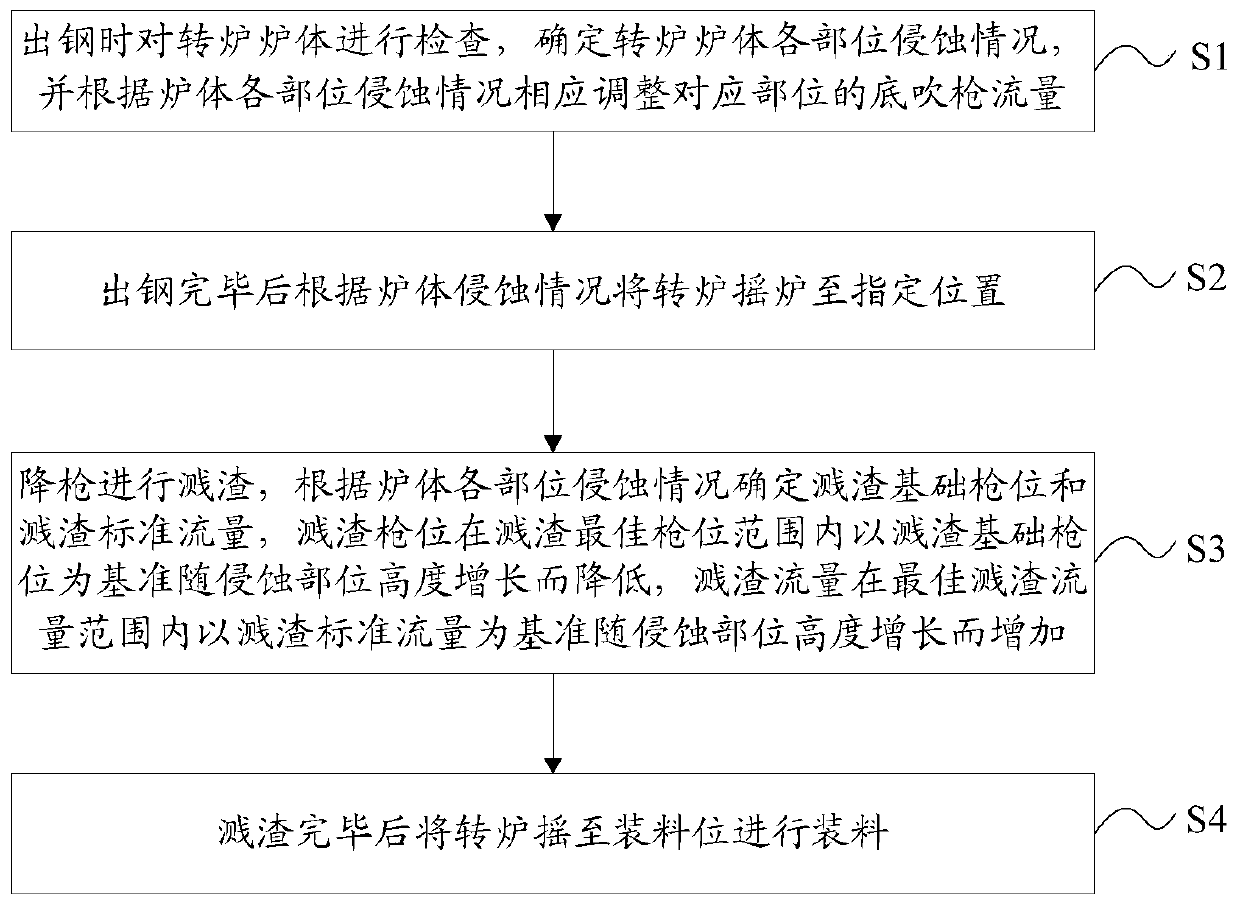

[0047] The precise slag splashing method for a 120-ton oxygen top-bottom combined blowing converter includes the following steps:

[0048] 1) Observe the furnace body when tapping, and confirm that the slag surface of the converter is seriously eroded at the furnace lining 5-6 meters from the bottom of the furnace, which is 50mm more concave than the normal part;

[0049] 2) Adjust the flow rate of the two bottom blow guns on the slag surface of the converter to 730Nm 3 / h, the flow rate of other bottom blowing guns maintains the standard flow rate (400Nm 3 / h);

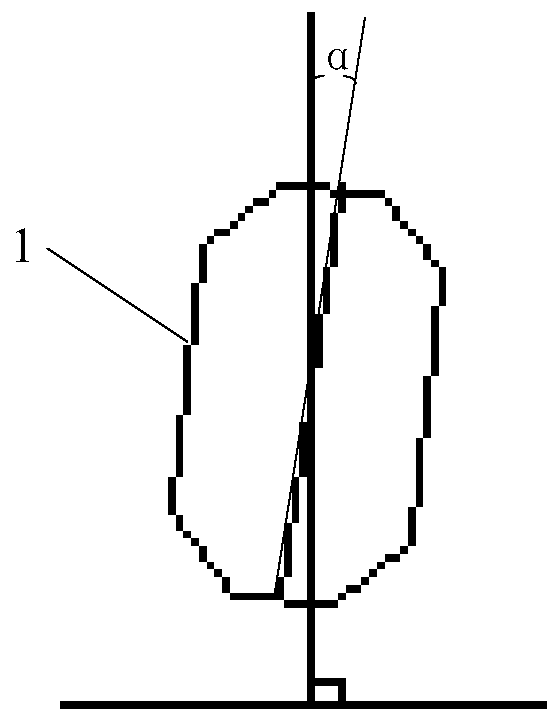

[0050] 3) After tapping, shake the converter until the furnace body deviates 2° from the slag surface vertically;

[0051] 4) Lower the lance for slag splashing, the slag splashing base gun position is controlled at 2629mm from the furnace bottom, the slag splashing gun position adjustment range is ±500mm from the slag splashing base gun position, and the slag splashing flow rate of the top lance is controlled at 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com