Operation optimizing system and method of steam system

A technology for steam system and operation optimization, which is applied in the field of steam system and can solve problems such as difficulty in ensuring timeliness and economic optimization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

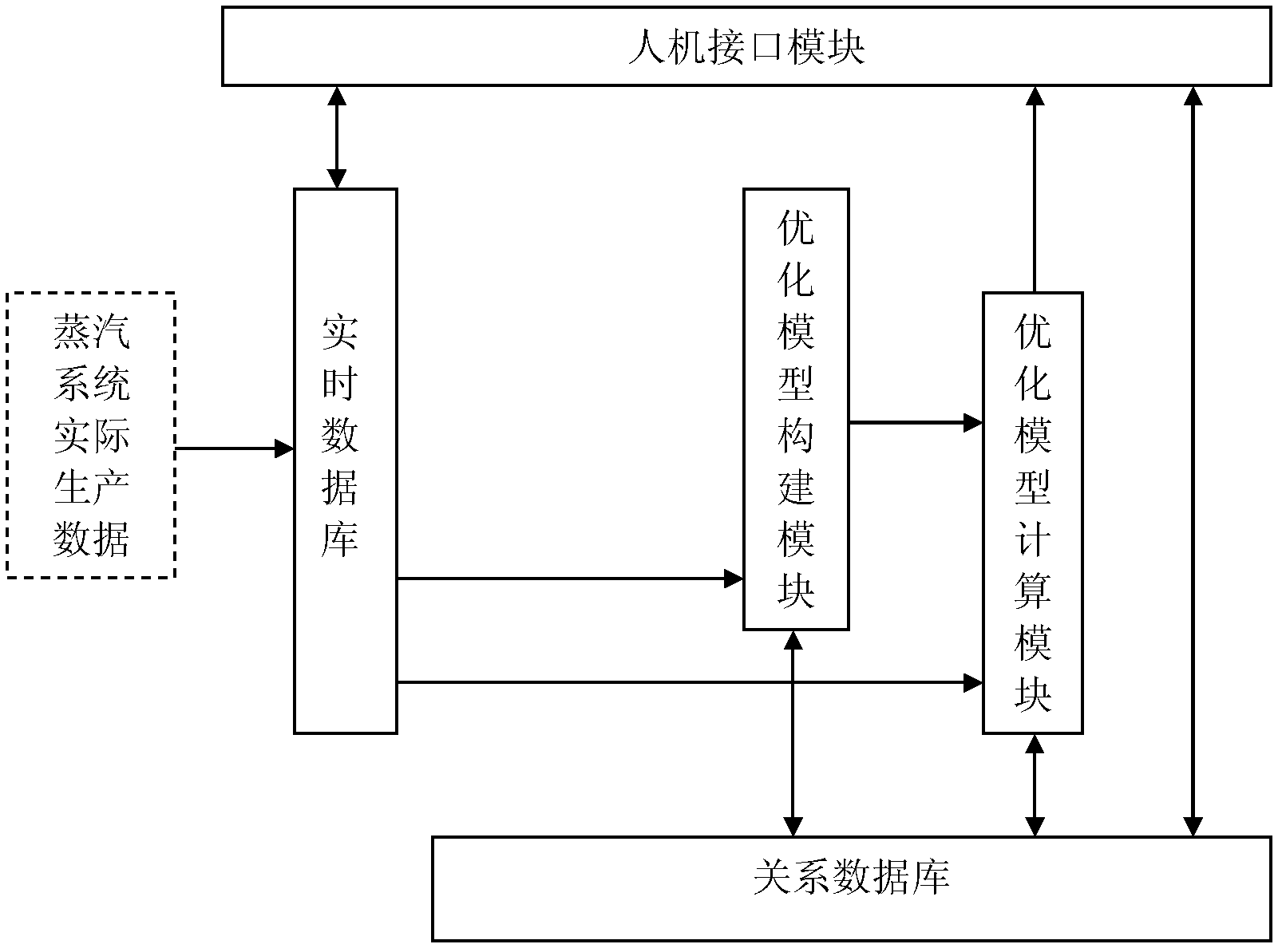

[0084] The present invention builds an optimization model based on actual production data, and can also jointly build an optimization model based on actual production data and data predicted by the forecast model, and provides an optimal operation plan through optimization calculations, reducing energy consumption and production costs for enterprises. Figure 2a and Figure 2c They are structural block diagrams of two implementations of an embodiment of the steam system operation optimization system, and the connections between the modules can be seen from the diagrams.

[0085] Depend on Figure 2a It can be seen that a steam system operation optimization system includes a real-time database, a relational database, an optimization model building module, an optimization model calculation module, and a human-machine interface module. The functions of each module are as follows:

[0086] The man-machine interface module is used as the communication interface between the operat...

Embodiment 2

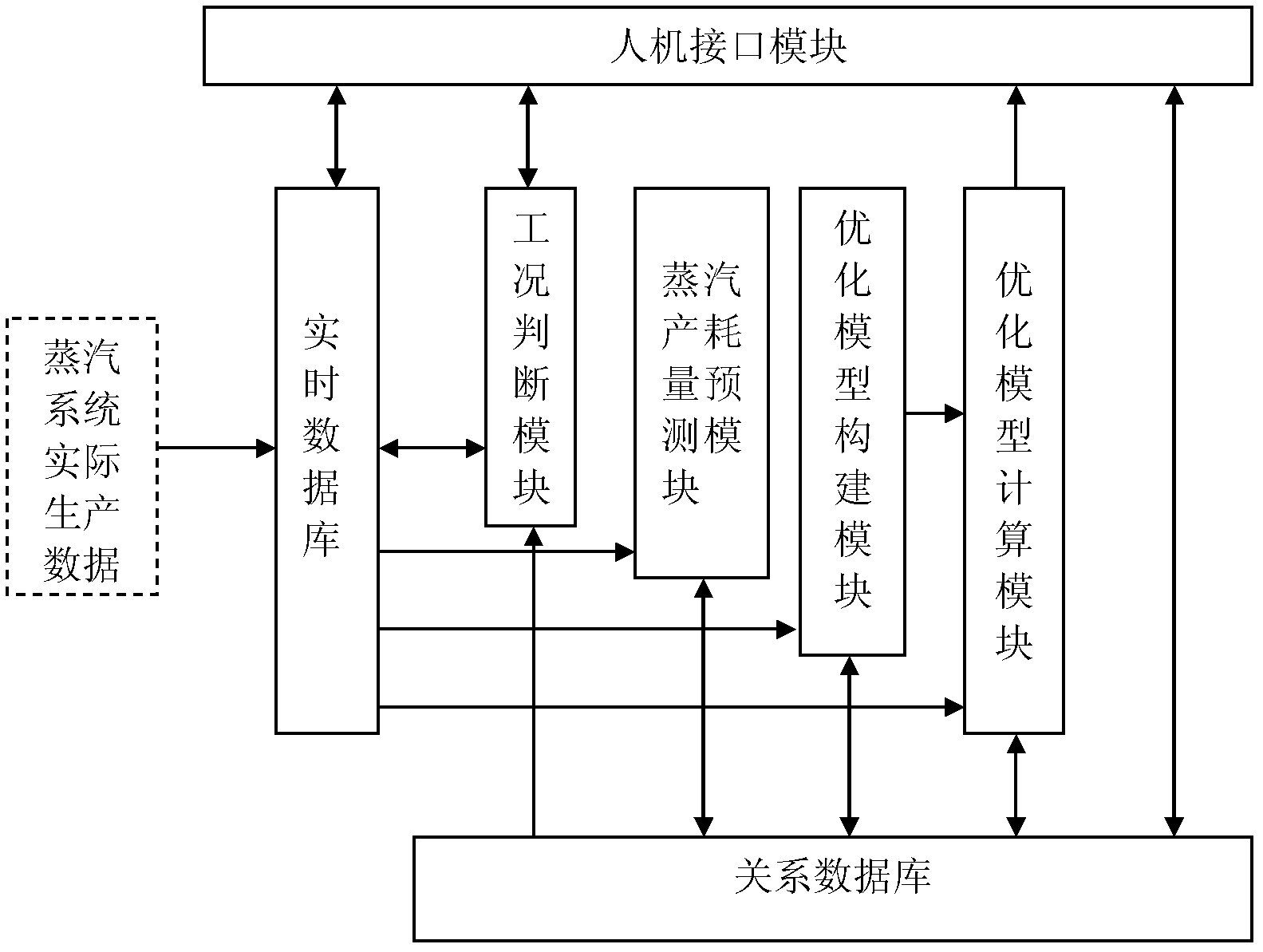

[0207] On the basis of the above steam system operation optimization system, it can be expanded, for example, it can also include a steam production and consumption prediction module, and / or a working condition judgment module, and / or a scheduling system, etc., such as Figure 2b and 2d shown. In this case, it is necessary to supplement the above configuration parameters with corresponding parameters, for example, the following parameters can also be included (numbered consecutively with the above configuration parameters):

[0208] 4. Prediction model parameters of steam production and consumption: configured when there is a steam production and consumption prediction module.

[0209] The prediction model structure and prediction model parameters of steam production and consumption are determined according to the production process and production data, and the initial prediction model parameters need to be input manually.

[0210] Predictive Model Information Sheet

[0211...

Embodiment 3

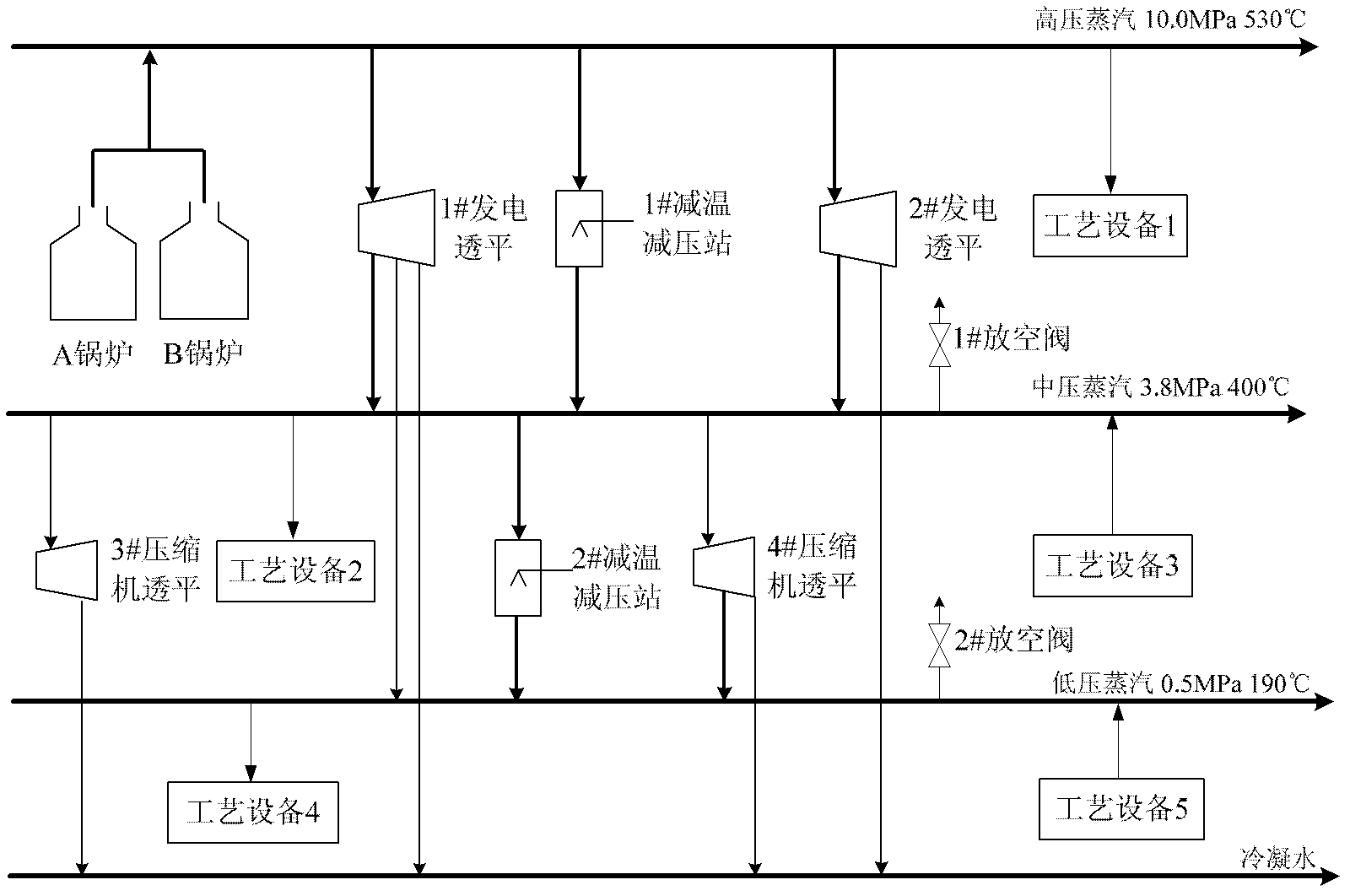

[0277] Figure 4 Shown is a specific example of a steam system. Depend on Figure 4 Select the following optimization variables and fill in their information.

[0278] Parameter list (omitting the pipe network configuration part)

[0279]

[0280]

[0281] The optimization objective is expressed as follows:

[0282] f = p coal ( g A ( X Aboiler ) + g B ( X Bboiler ) ) + ( p water + p e ) ( X Aboiler ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com