Three-point walking single cable face cable-dragging suspension basket

A single-cable surface and stay-cable technology, applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of construction quality, unfavorable control of beam line shape, complex structural system, underutilization of single-cable surface hanging baskets, etc. problem, to achieve the effect of reducing the weight of the hanging basket and fast construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

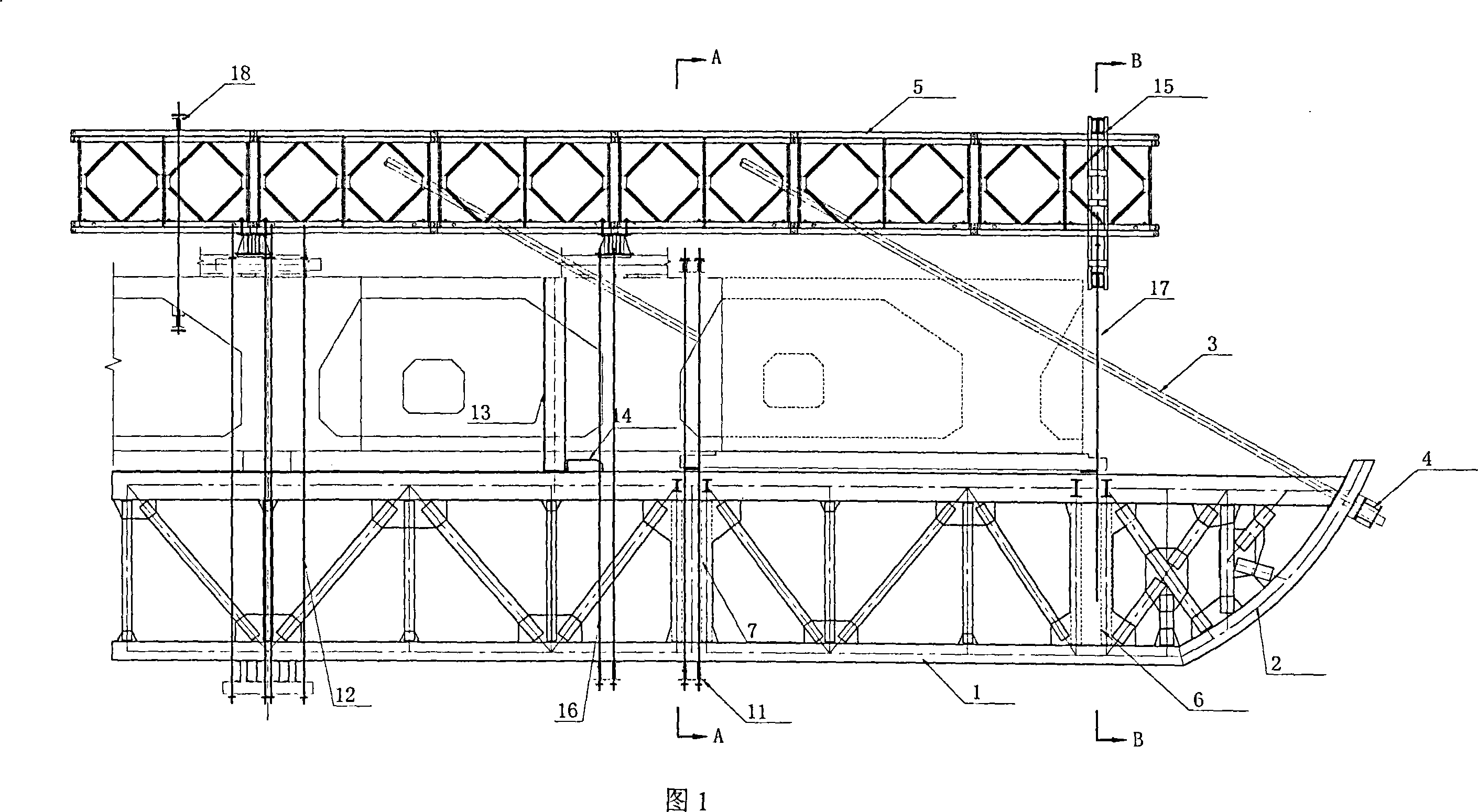

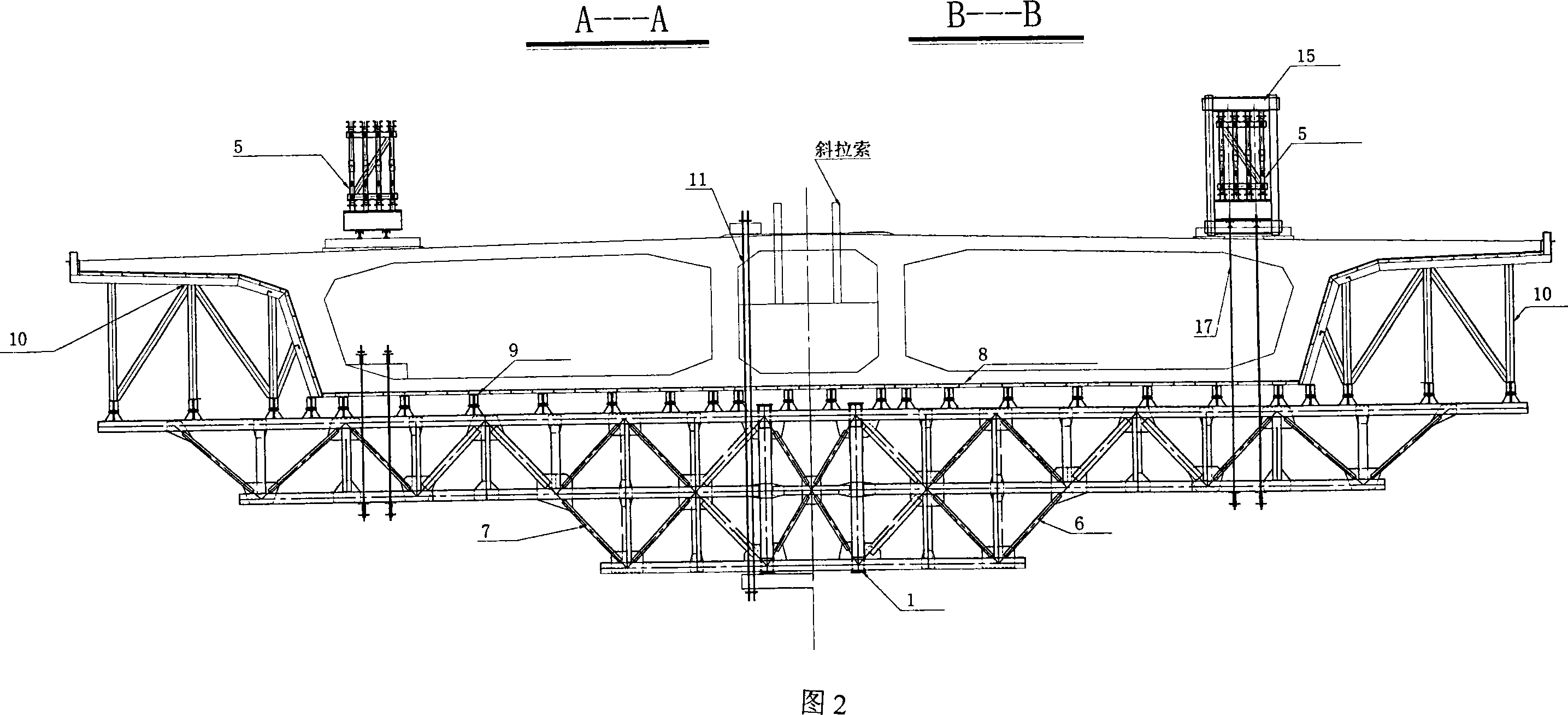

[0029]The length of the standard section of the main girder is 6m, and the weight of the standard section is about 370t. The stay cables are arranged on the central divider and anchored to the anchor beams in the box in the beam body. The stay cables are arranged in double rows, the distance between the cables on the beam is 6m, and the horizontal distance between the two rows of cables is 1.1m. The main beam is prestressed in longitudinal, horizontal and vertical directions.

[0030] The standard section of the main girder is constructed by cantilever casting with drag cables and hanging baskets.

[0031] (1), hanging basket structure

[0032] The main structure of the hanging basket is: the hanging basket is composed of the top longitudinal beam arranged on the top surface of the side web of the main beam, the longitudinal beam of the stay cable on the central axis of the bottom of the beam, the front and rear lower beams, the bottom formwork platform, the side formwork and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com