Ultraviolet curing equipment and method for optical fiber coating

A technology for optical fiber coating and curing equipment, applied in the field of optical fiber manufacturing equipment, can solve the problems of increasing the complexity of equipment structure, low utilization rate of mercury lamp energy, insufficient curing uniformity, etc., and achieves large light source layout space and high curing efficiency. , The effect of good curing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

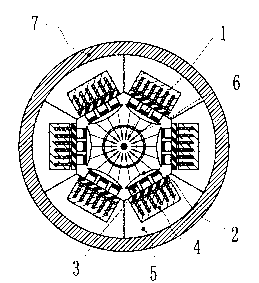

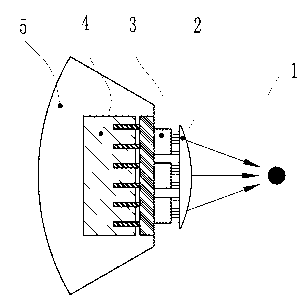

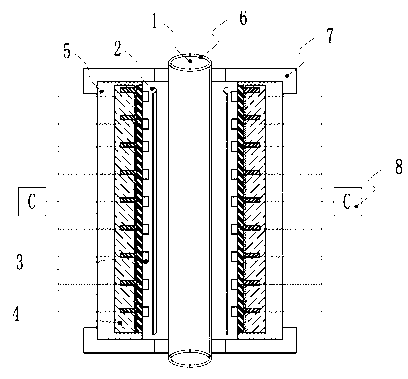

[0035] Embodiment 1: as Figure 1-3As shown, it includes a cylindrical installation base, and the cylindrical installation base is formed by splicing 6 strip-shaped arc blocks 5 along the circumferential direction, and is fixedly connected by upper and lower fixed end plates 7, and each strip The inner surface of the arc-shaped block is embedded with a UVLED light source module, so that the inner cavity of the cylindrical mounting base is installed along the circumferential direction and the axial direction. The UVLED light source module includes a UVLED light source 3 and a radiator 4. The wavelength of the light source is 365nm and 375nm, and the radiator is a liquid medium radiator; the UVLED light source module is connected with the control module 8 to control and adjust the intensity of ultraviolet light emitted by each UVLED light source module; the UVLED light source includes The UVLED array is equipped with a cylindrical focusing lens 2 in front of the UVLED light sour...

Embodiment 2

[0036] Embodiment 2: as Figure 4-5 As shown, it differs from the previous embodiment in that the cylindrical mounting base is in the shape of a hexagonal cylinder, and is formed by splicing six strip-shaped trapezoidal blocks 5 along the circumferential direction. Other structures are the same as the previous embodiment.

Embodiment 3

[0037] Embodiment 3: as Figure 6 As shown, it differs from the first embodiment in that the cylindrical mounting base is spliced by 4 strip-shaped arc blocks evenly spaced along the circumference, and on the inner surface of each strip-shaped arc block The UVLED light source modules are embedded so that the UVLED light source modules are evenly spaced along the inner cavity of the cylindrical mounting base. Other structures are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com