High-temperature-resistant toughened light-cured resin composition and preparation method thereof

A light-curing resin and composition technology, applied in the direction of additive processing, can solve the problems of low curing efficiency, slow printing speed, affecting the application and development of high-temperature resistant materials, etc., to achieve high curing efficiency, increase curing speed, and improve printing. slow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

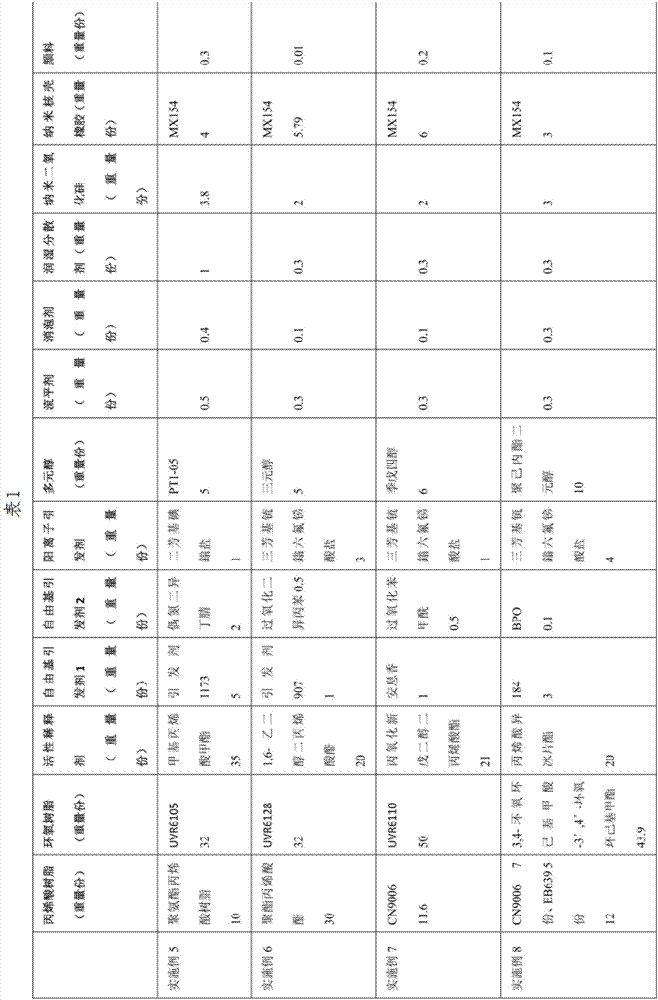

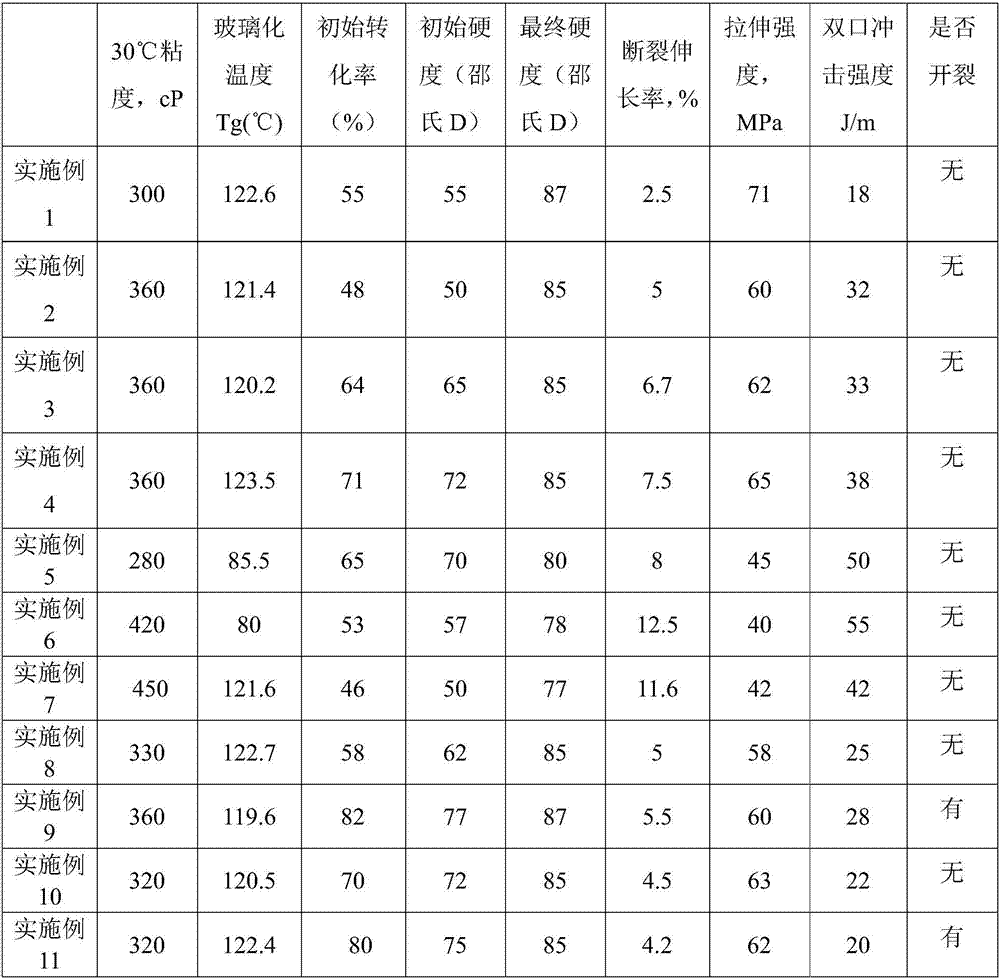

Embodiment 1

[0042] A new type of high temperature resistant and toughened photocurable resin composition is composed of the following raw materials: 7 parts by weight of CN9006 (Sartomer), 5 parts by weight of EB639 (Cytec), 3,4-epoxycyclohexylcarboxylic acid-3',4 47 parts by weight of '-epoxycyclohexyl methyl ester, 20 parts by weight of reactive diluent isobornyl acrylate, 1 184 3 parts by weight of free radical initiator, 4 parts by weight of triarylsulfonium hexafluoroantimonate (cation initiator) , 10 parts by weight of polycaprolactone diol, 0.3 parts by weight of leveling agent, 0.3 parts by weight of defoamer, 0.3 parts by weight of wetting and dispersing agent, 3 parts by weight of nano silicon dioxide, and 0.1 part by weight of titanium dioxide.

[0043] The preparation technology of described photocurable resin comprises the following steps:

[0044] Weigh 7 parts by weight of CN9006 (Sartomer), 5 parts by weight of EB639 (Cytec), 47 parts by weight of 3,4-epoxycyclohexylcarboxyl...

Embodiment 2

[0046] A new type of high temperature resistant and toughened photocurable resin composition is composed of the following raw materials by weight: 7 parts by weight of CN9006 (Sartomer), 5 parts by weight of EB639 (Cytec), 3,4-epoxycyclohexylcarboxylic acid-3 43 parts by weight of ', 4'-epoxycyclohexyl methyl ester, 20 parts by weight of isobornyl acrylate reactive diluent, 1 184 3 parts by weight of free radical initiator, triarylsulfonium hexafluoroantimonate (cationic initiator) 4 parts by weight, 10 parts by weight of polycaprolactone diol, 0.3 parts by weight of leveling agent, 0.3 parts by weight of defoamer, 0.3 parts by weight of wetting and dispersing agent, 4 parts by weight of nano-core-shell rubber MX154, nano-silica 3 parts by weight, and 0.1 parts by weight of titanium dioxide.

[0047] The preparation technology of described photocurable resin comprises the following steps:

[0048] Weigh 7 parts by weight of aliphatic polyurethane acrylate CN9006 (Sartomer), 5...

Embodiment 3

[0050] A high-temperature-resistant photocurable resin composition is composed of the following raw materials by weight: 7 parts of CN9006 (Sartomer), 5 parts of EB639 (Cytec), 3,4-epoxycyclohexylcarboxylic acid-3',4'- 42.5 parts of epoxy cyclohexyl methyl esters, 20 parts of reactive diluent isobornyl acrylate, 1 184 3 parts of free radical initiators, 0.5 parts by weight of free radical initiator 2 dibenzoyl peroxide (BPO), cationic initiator triaryl 4 parts of sulfonium hexafluoroantimonate, 10 parts of polycaprolactone diol, 0.3 parts of leveling agent, 0.3 parts of defoaming agent, 0.3 parts of wetting and dispersing agent, 4 parts by weight of nano core-shell rubber MX154, nano 3 parts of silicon dioxide, 0.1 part of titanium dioxide.

[0051] The preparation process of the photocurable resin is as follows:

[0052] Weigh 7 parts of CN9006 (Sartomer), 5 parts of EB639 (Cytec), 42.5 parts of 3',4'-epoxycyclohexylmethyl 3,4-epoxycyclohexylcarboxylate, reactive diluent acr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com