Patents

Literature

3134 results about "Light cure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A dental curing light is a piece of dental equipment that is used for polymerization of light cure resin based composites. It can be used on several different dental materials that are curable by light.

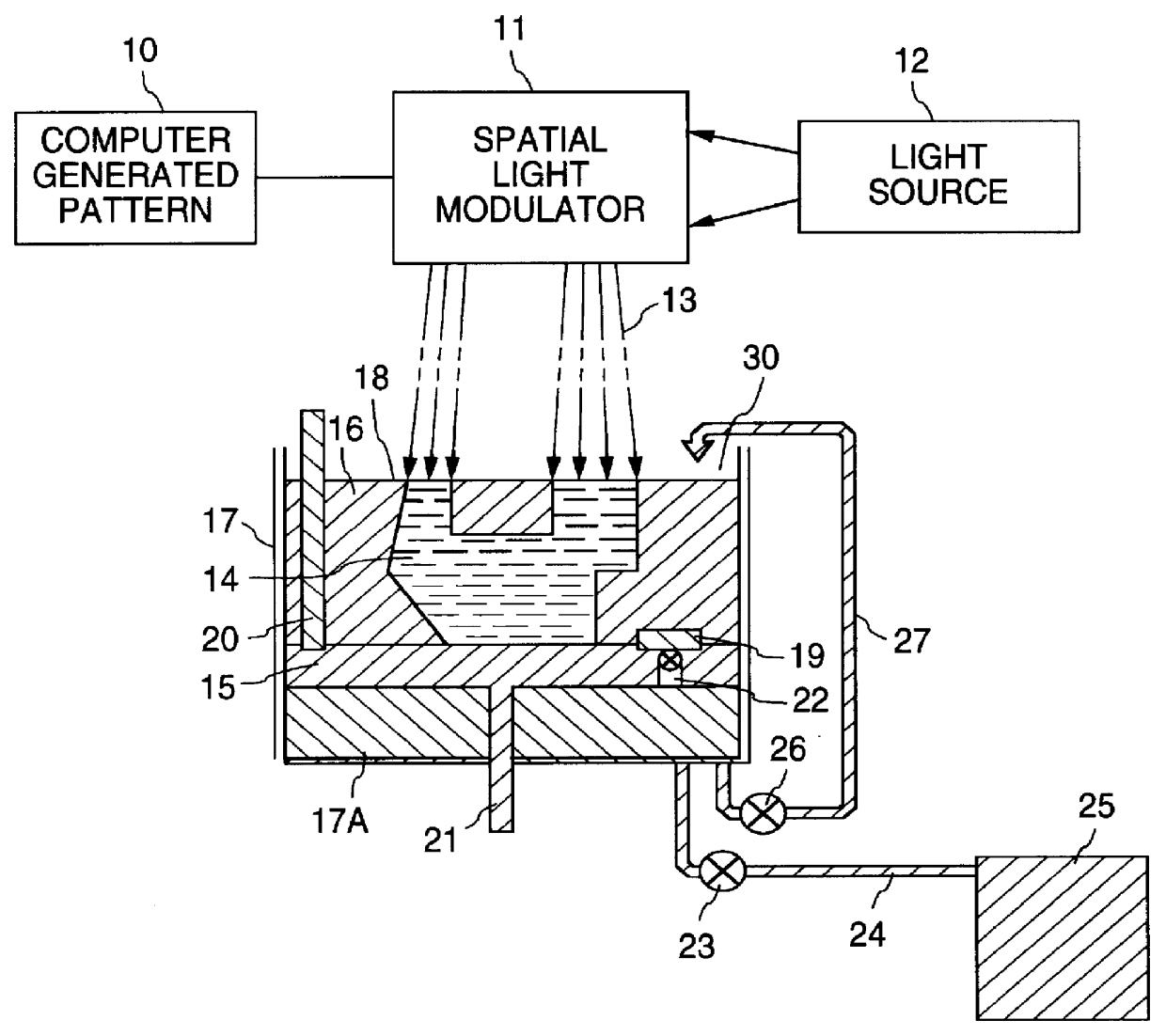

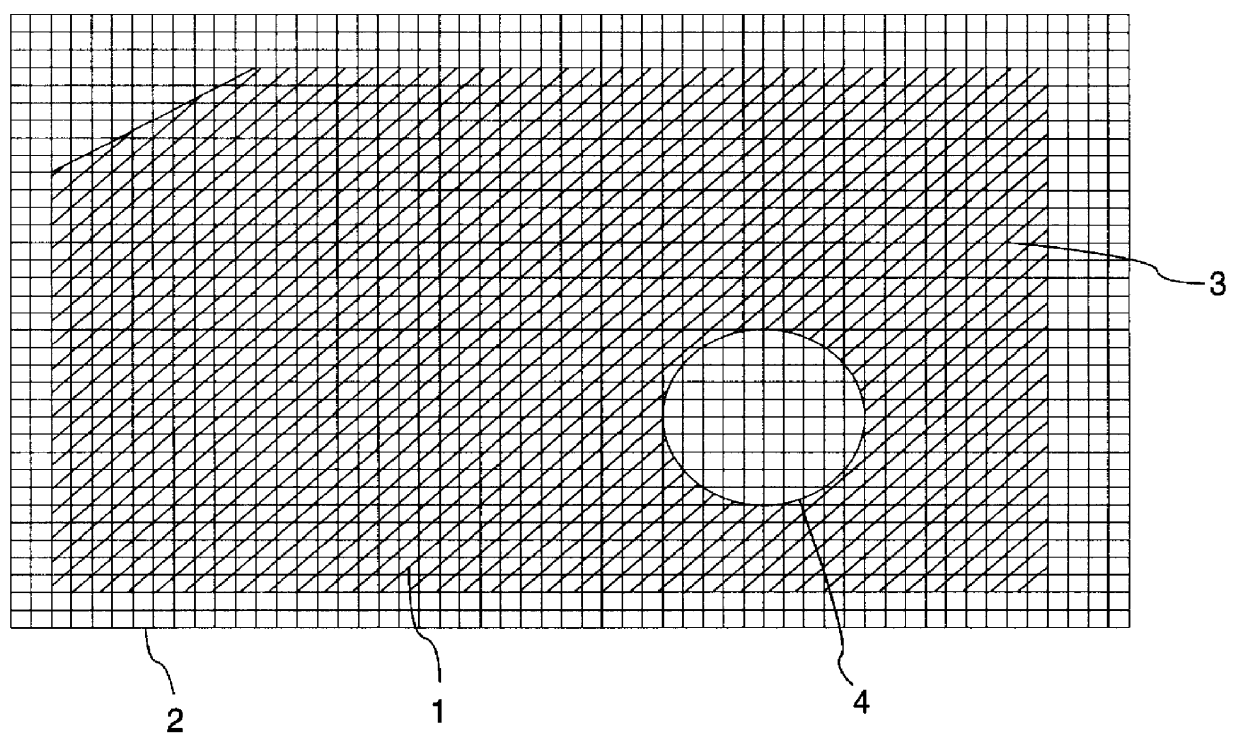

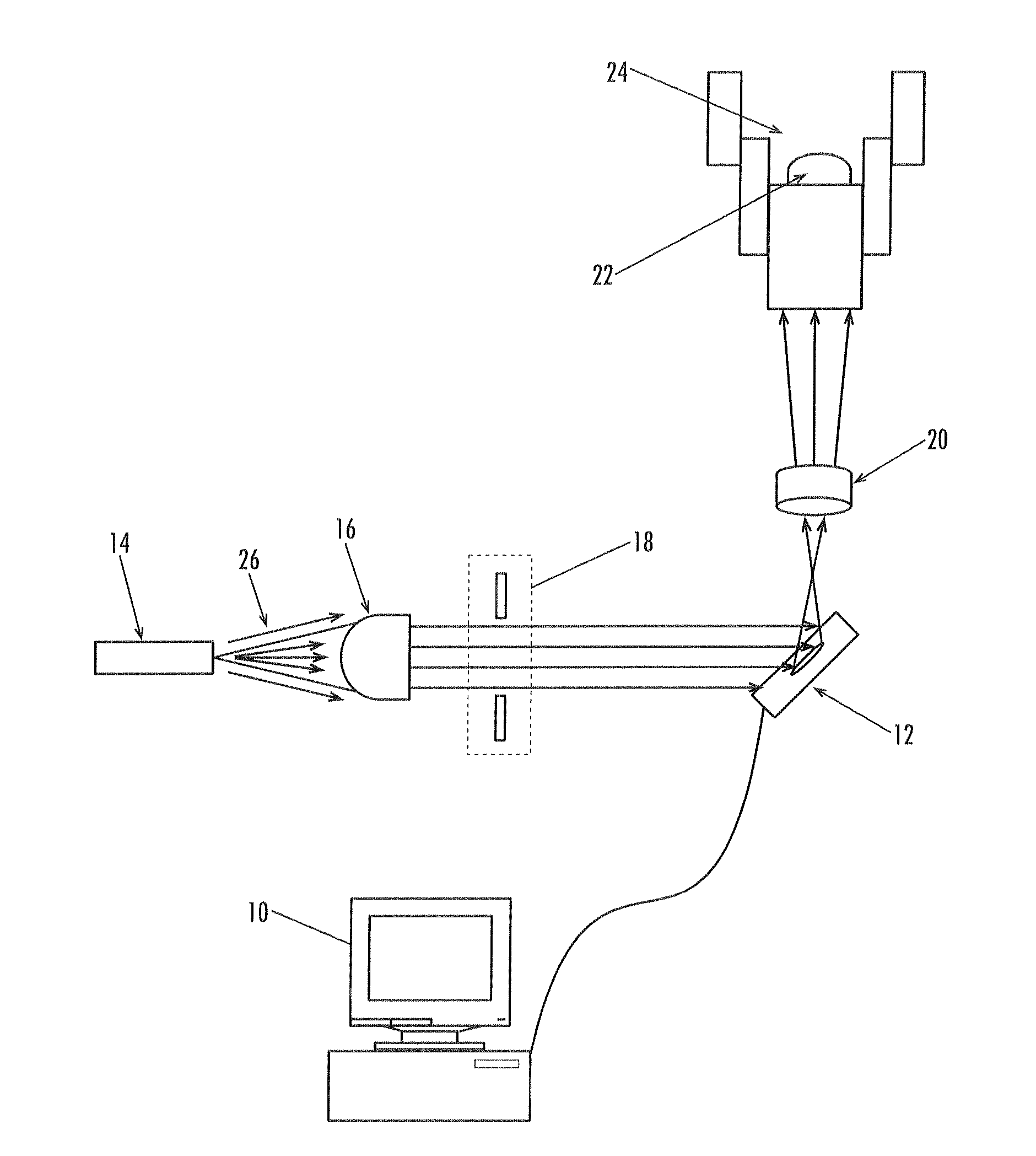

Apparatus and method for production of three-dimensional models by spatial light modulator

InactiveUS6051179AFacilitate cross-linkingHigh mechanical strengthAdditive manufacturing apparatusAnalogue computers for control systemsSpatial light modulatorWide beam

An apparatus and the method of its operation for rapid prototyping of a three-dimensional object which includes a radiant energy source of a wide beam of radiant energy of suitable intensity and wavelength for curing a layer of photo-curable resin contained in an open vat, a spatial light modulator (SLM) having an array of pixel elements which are individually digitally controllable by a computer, for modulating the radiant energy beam projected from the radiant energy source on a pixel by pixel basis, to form a series of time sequential images of the cross-sectional laminae of the object, an optical system for focusing each image formed by the SLM, one at a time, onto successive layers of photo-curable resin for predetermined exposure times to thereby form stacked laminae of cured resin, each lamina of cured resin being in the shape of a different one of the cross-sectional laminae, and a piston support for lowering each lamina of cured resin after it is formed by the SLM and for depositing a layer of resin corresponding to the thickness of one cross sectional lamina of the three-dimensional object before the step of projecting a new image by the SLM. The SLM, the piston support for lowering, and the optical system operate repeatedly and sequentially until a complete copy of the object is thereby produced.

Owner:GLOBAL FILTRATION SYST

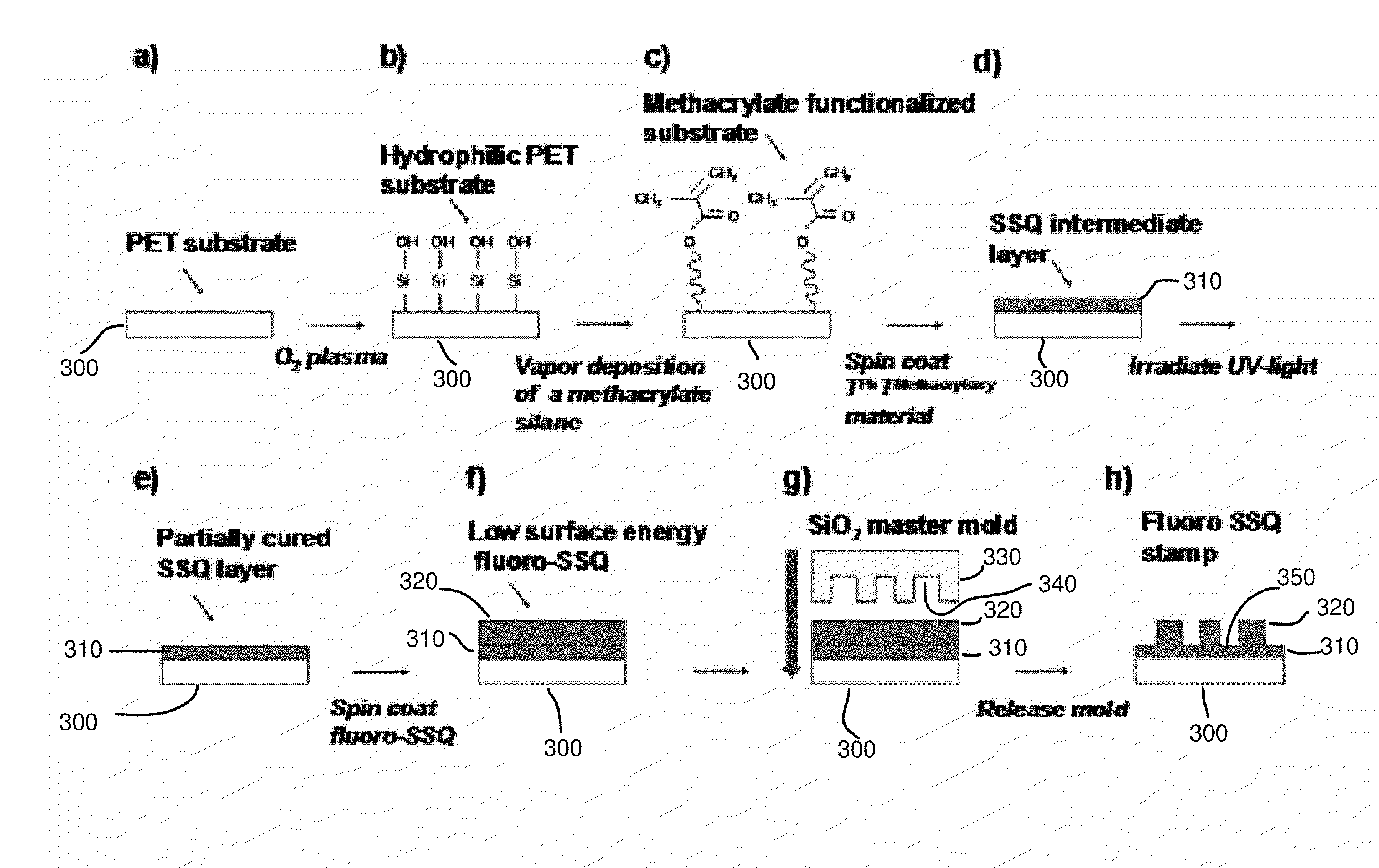

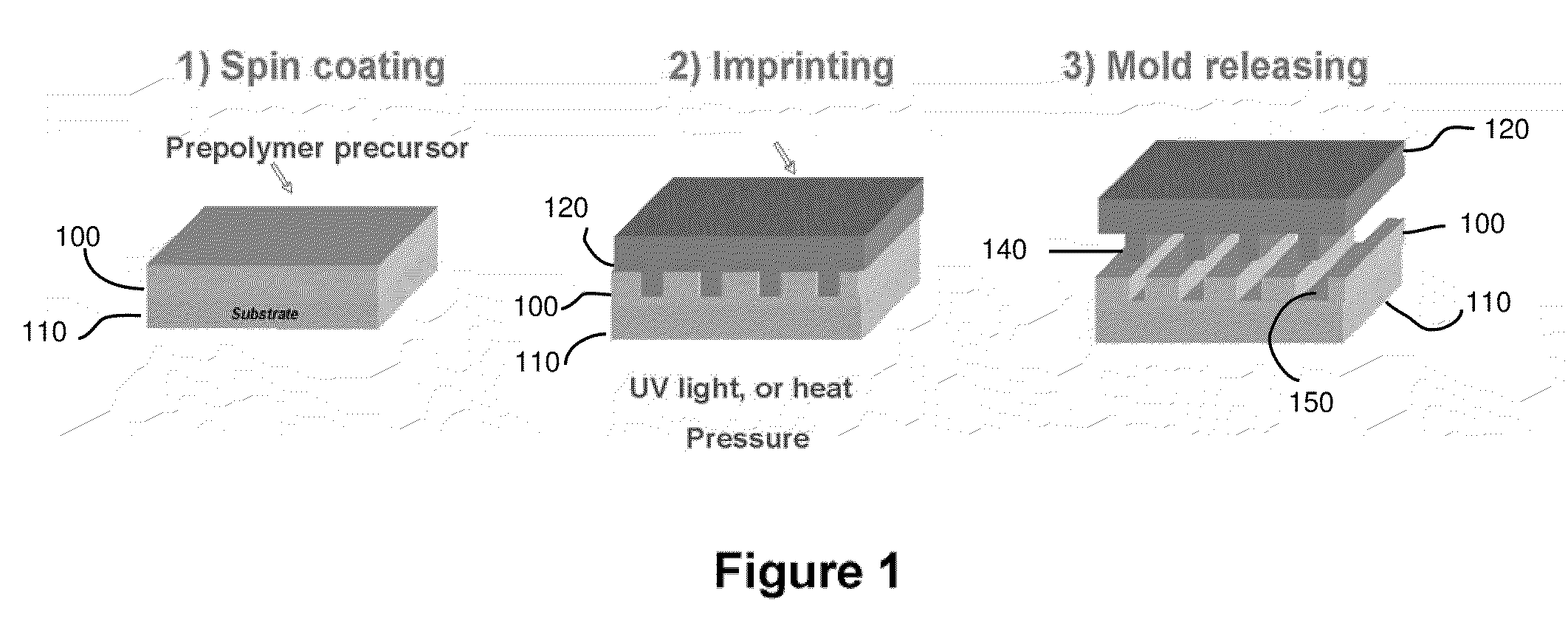

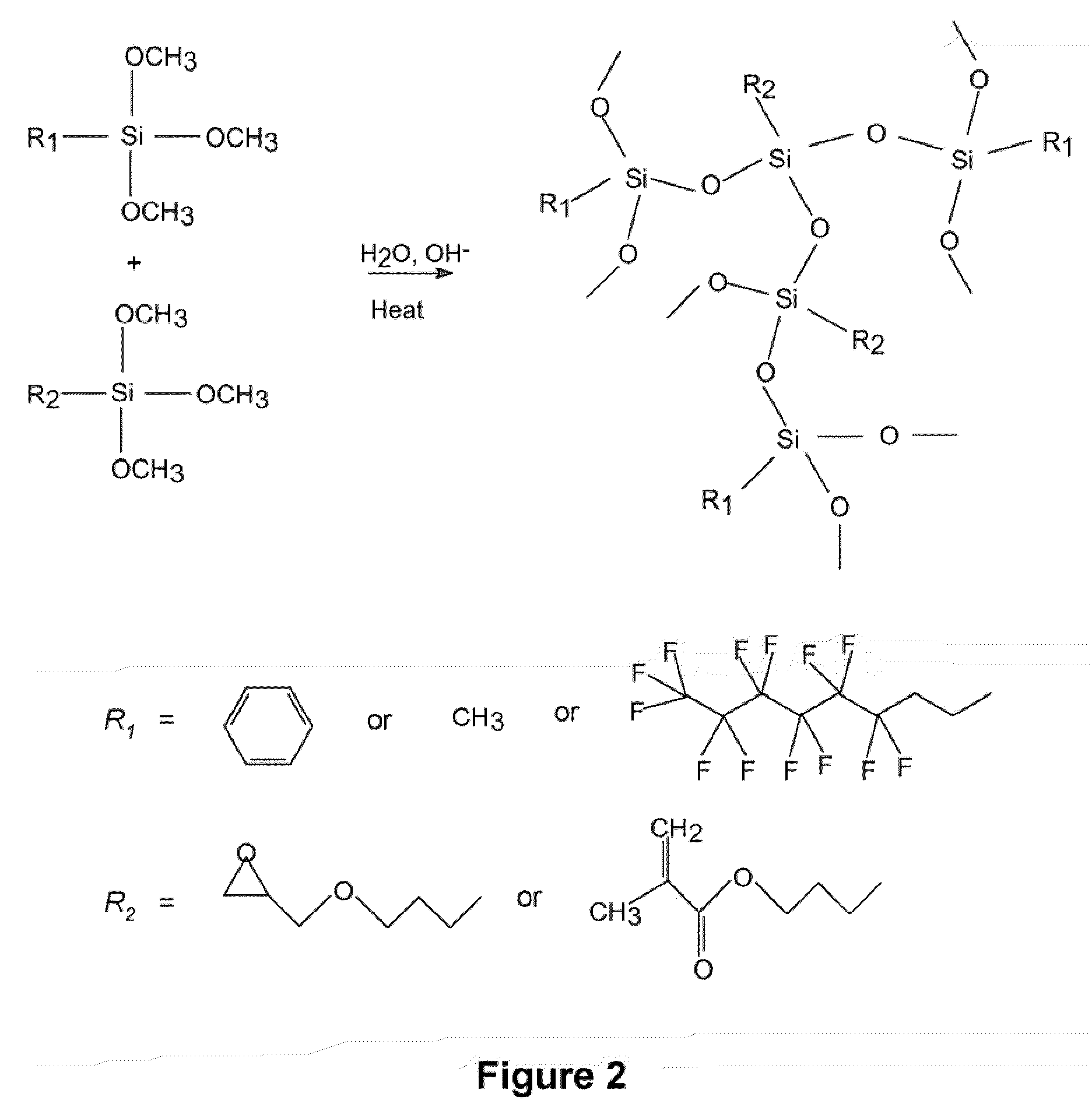

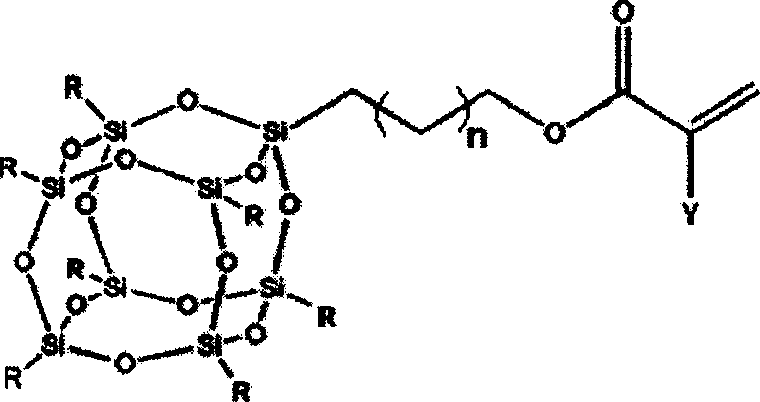

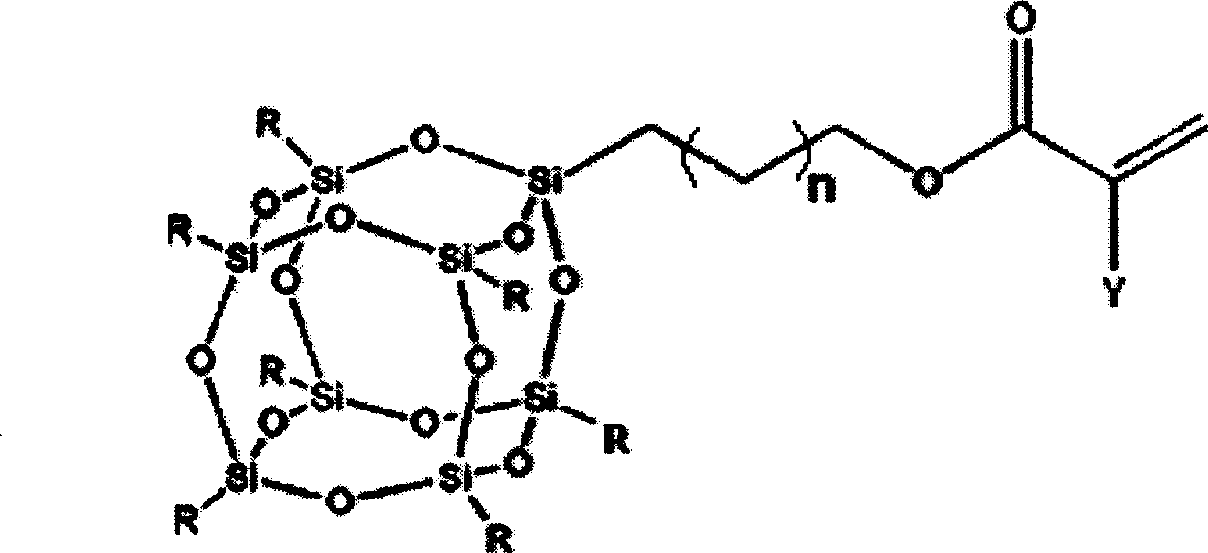

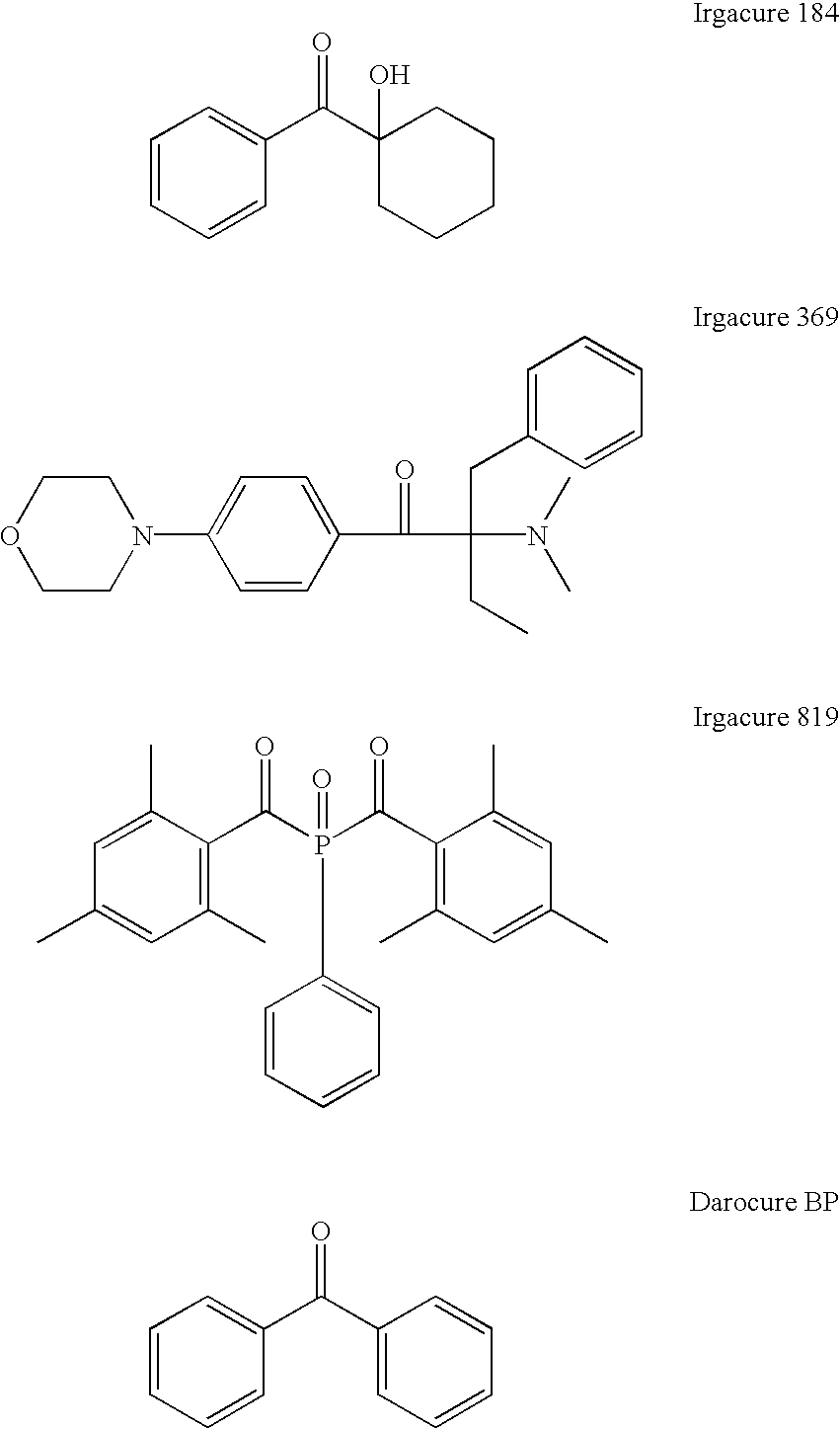

UV Curable Silsesquioxane Resins For Nanoprint Lithography

ActiveUS20090256287A1Simple compositionImprove methodPhotosensitive materialsNanoinformaticsNanolithographyResist

Radiation-curable silsesquioxane resin materials are employed for micro- and nanolithography. The resin materials can include a radiation-curable silsesquioxane resin and a photo-initiator having low viscosity. The low viscosity of the liquid system allows imprinting with low pressure and low temperature; e.g. room temperature. The resist's dry etching resistance is increased and the cured film is more easily separated from the mask. Due to its high modulus after cure, the material allows the fabrication of micro- and nano-features having high aspect ratios while providing a high throughput. Various pattern sizes, for example, ranging from tens of microns to as small as a few nanometers, may be achieved with the UV-curable material system.

Owner:RGT UNIV OF MICHIGAN

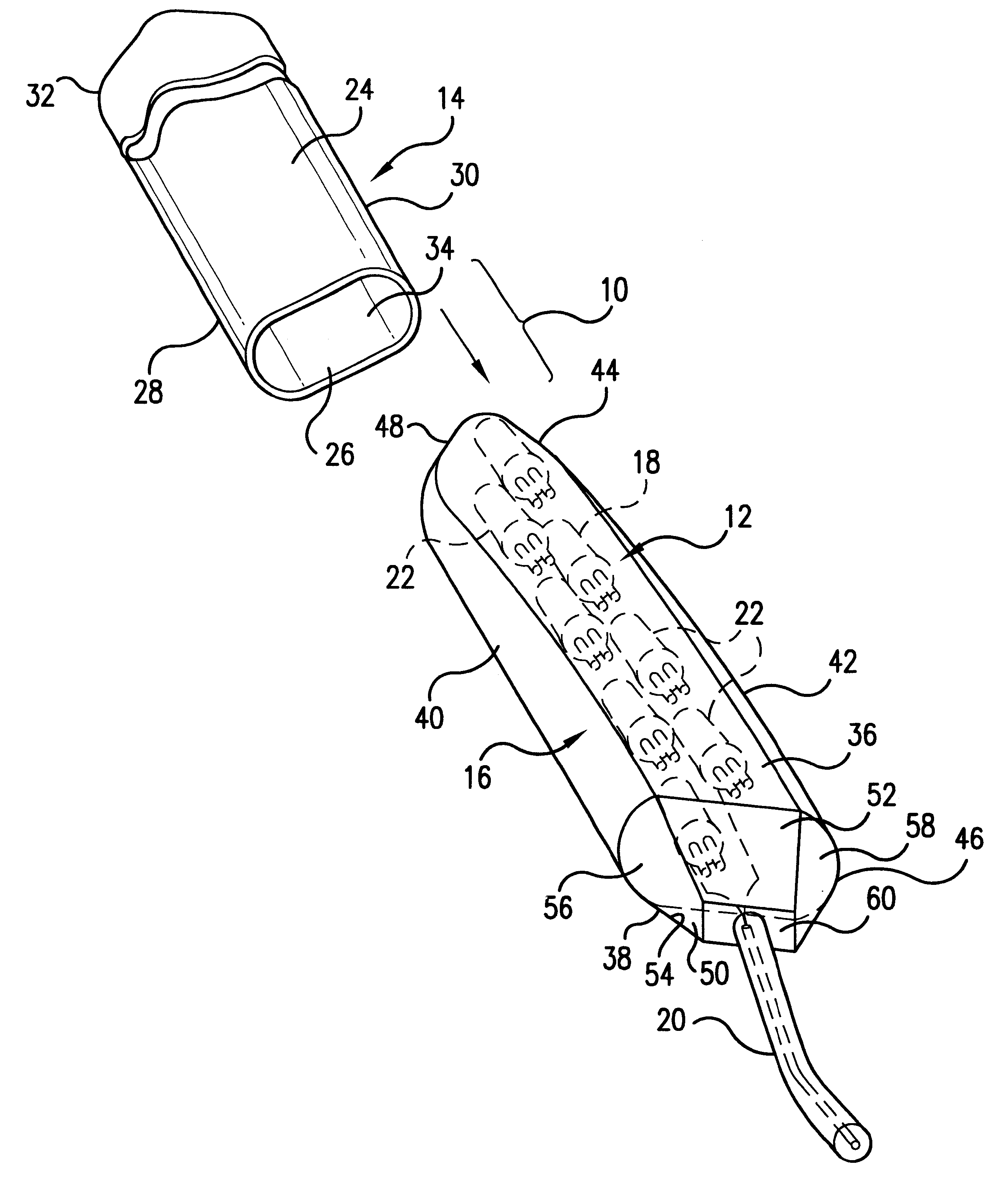

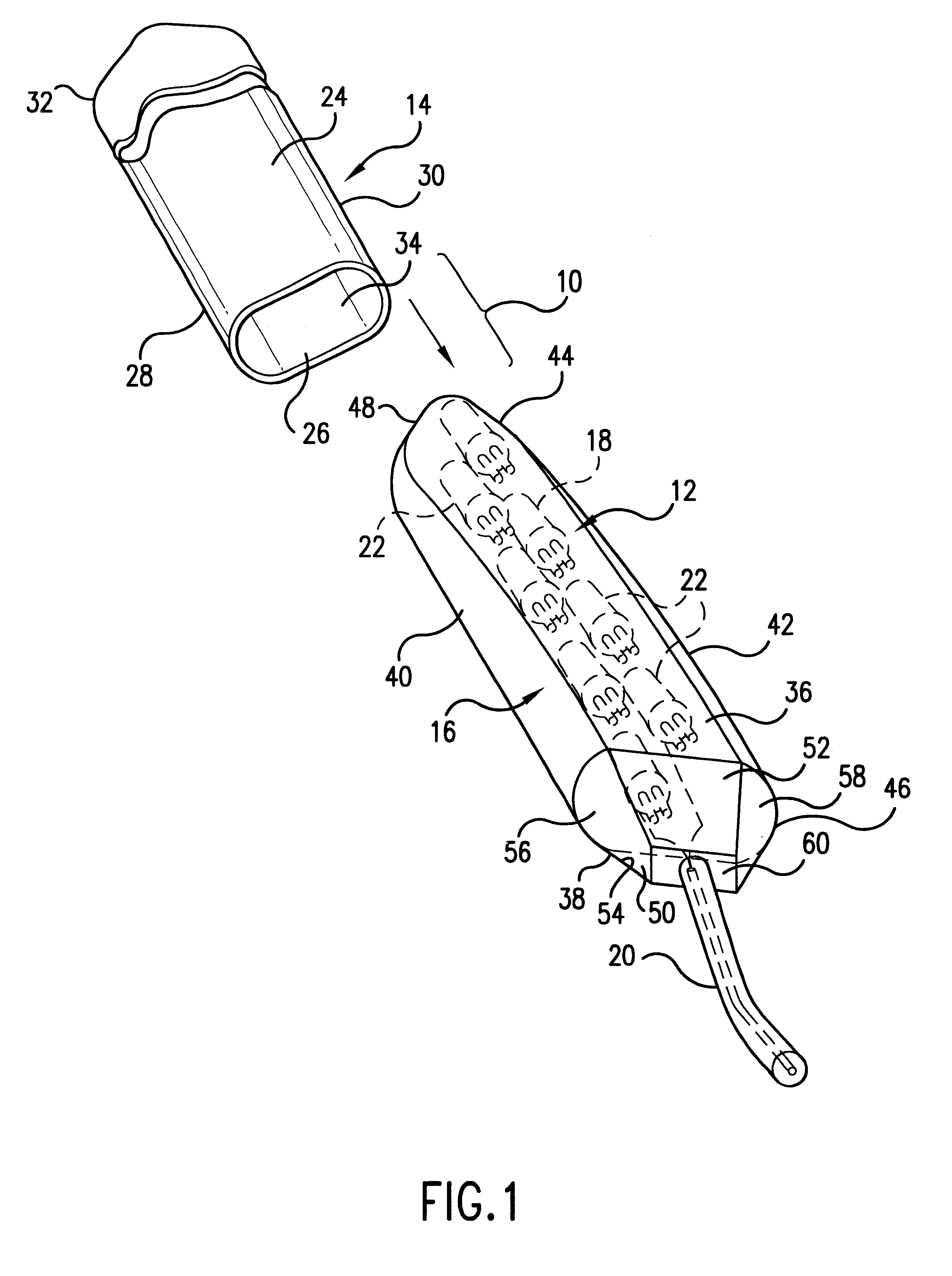

Dental curing apparatus for light-sensitive materials

InactiveUS6514075B1Compact designGuaranteed multiple useDental toolsLight therapyAdhesiveEngineering

A dental curing apparatus for light-sensitive materials is disclosed. A light source for curing an adhesive is housed within a clear, transparent and / or translucent housing constructed of either a solid, such as a poured resin, or a hollow structure. The housing shape is selected to conform to an approximate shape of dentition. The housing is mountable within a disposable oversertion sheath. During use, the light source for curing an adhesive transmits light which cures the adhesives, sealants and / or whitening or coloring agents.

Owner:JACOB GREGORY S

UV-light solidifying paint having decorative effect and preparation method thereof

The invention relates to a UV-light solidifying paint having decorative effect and preparation method thereof, in particular to a light solidifying paint containing mica coated with metallic oxides as a paint. The paint is composed of the followings in proportions: the content of low polymer is 30-70wt%; the content of reactive diluent is 25-65wt%; the content of light trigger is 0.5-10wt%; the content of pearlescent pigment is 3-30wt%; the content of accessory ingredient is 0.2-8wt%; the content of solvent is 0-50wt%. As added pearlescent pigment has strong metallic performance, the prepared light solidifying paint has the character of strong pearl effect and also has very good water resisting property, higher rigidity and abrasive resistance. The paint can be applied to decoration on the surfaces of motor vehicles, electric appliance, furniture, articles for daily use, toys, walls, leather products, etc.

Owner:SICHUAN UNIV

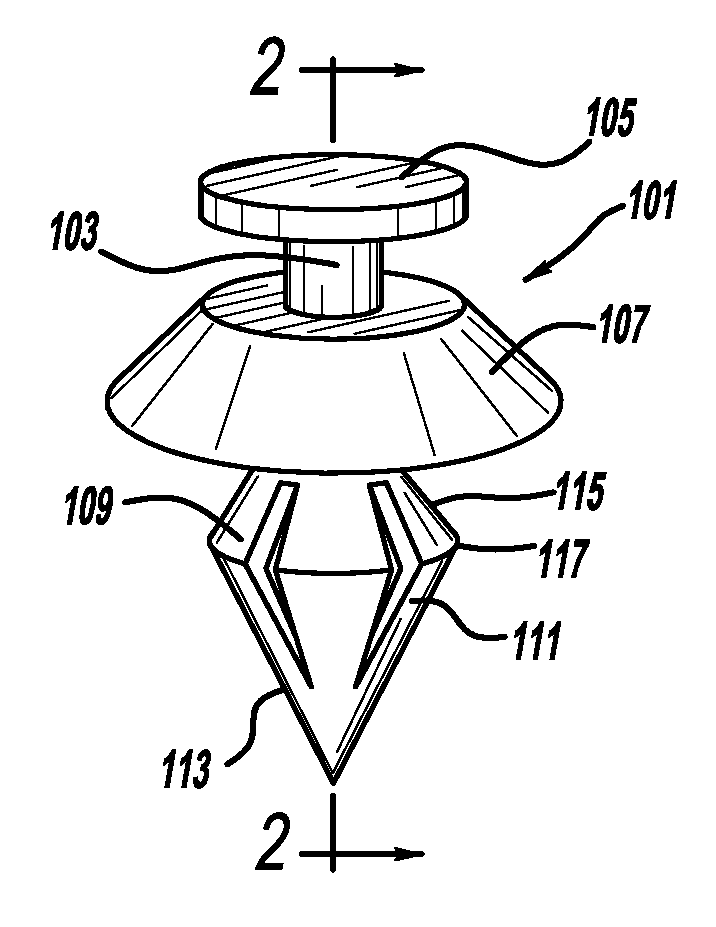

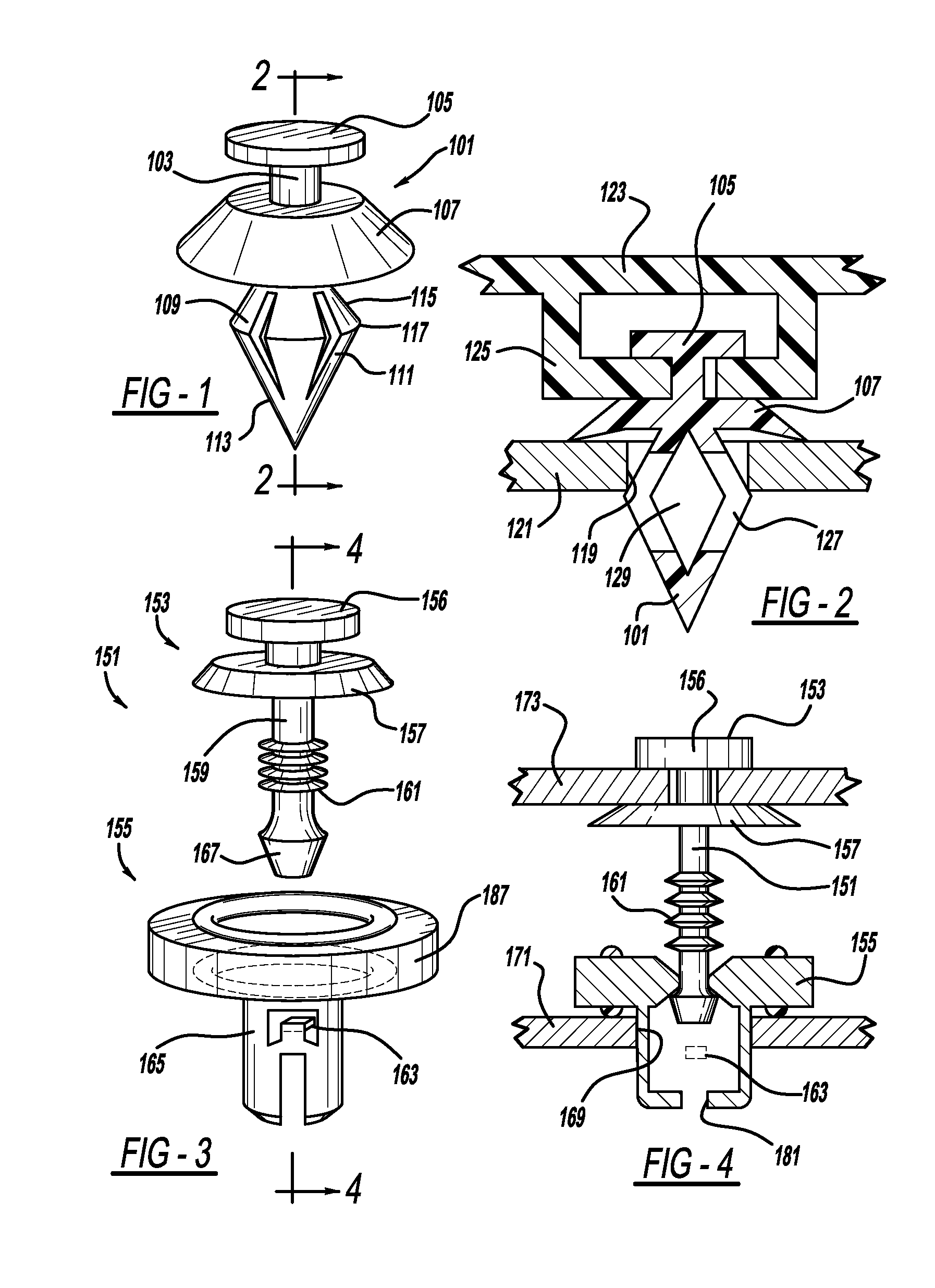

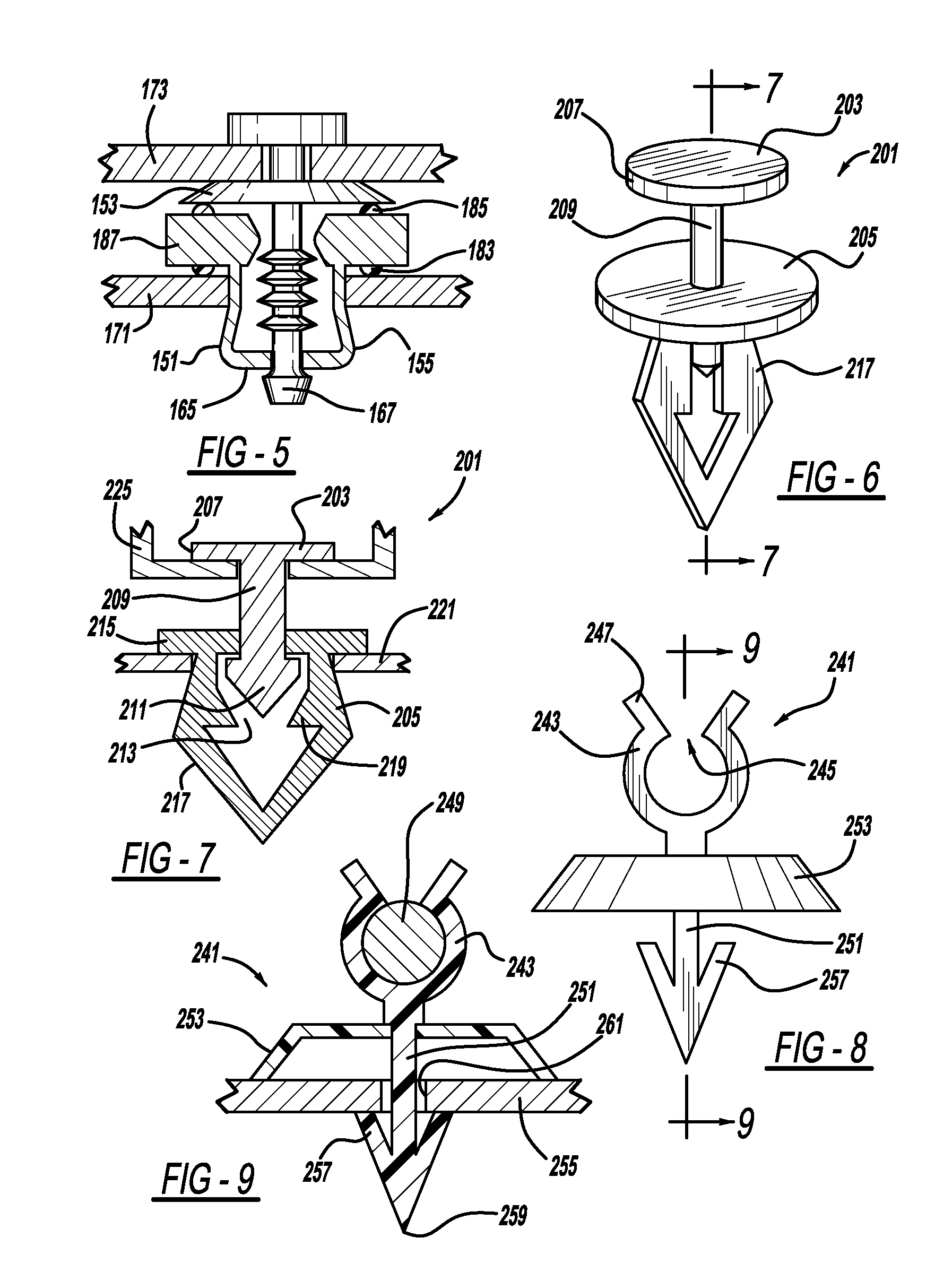

Fasteners manufactured by three-dimensional printing

InactiveUS20140086704A1Many timesQuick and inexpensive designDeformable pinsPinsEngineeringPrinting press

Owner:A RAYMOND & CO

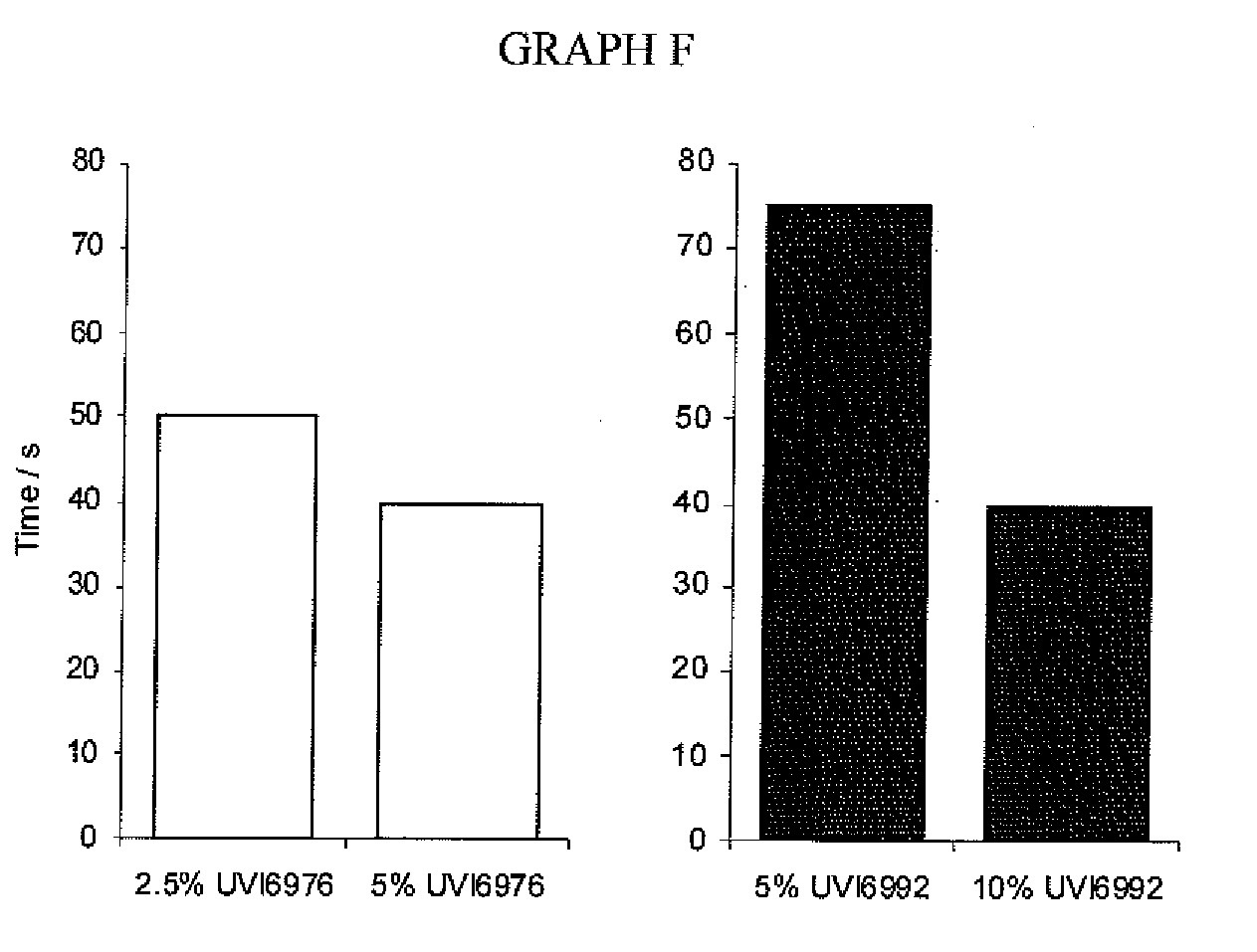

Light emitting apparatus and method for curing inks, coatings and adhesives

InactiveUS7175712B2Minimizing creationOptical radiation measurementDrying solid materials with heatUV curingEngineering

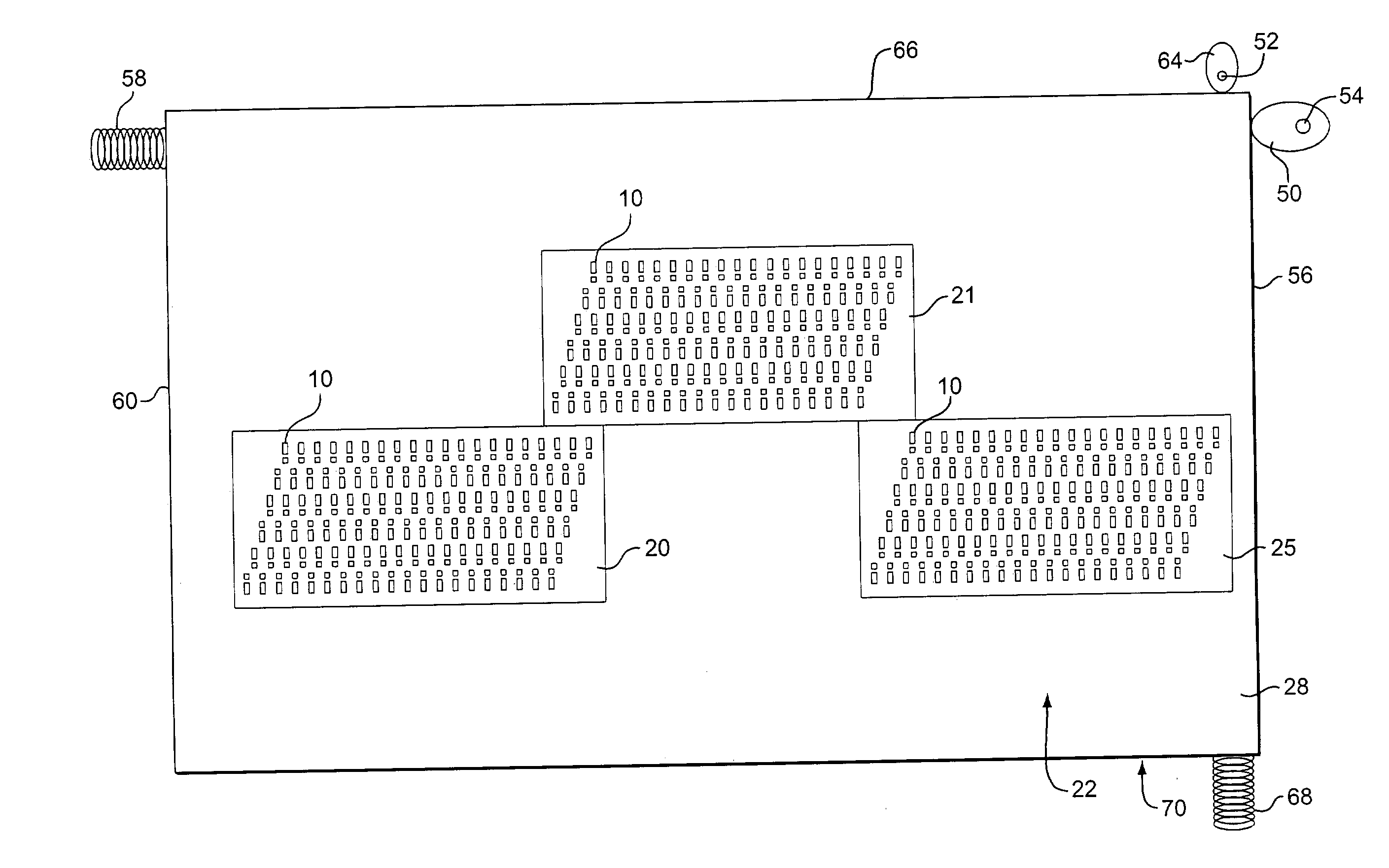

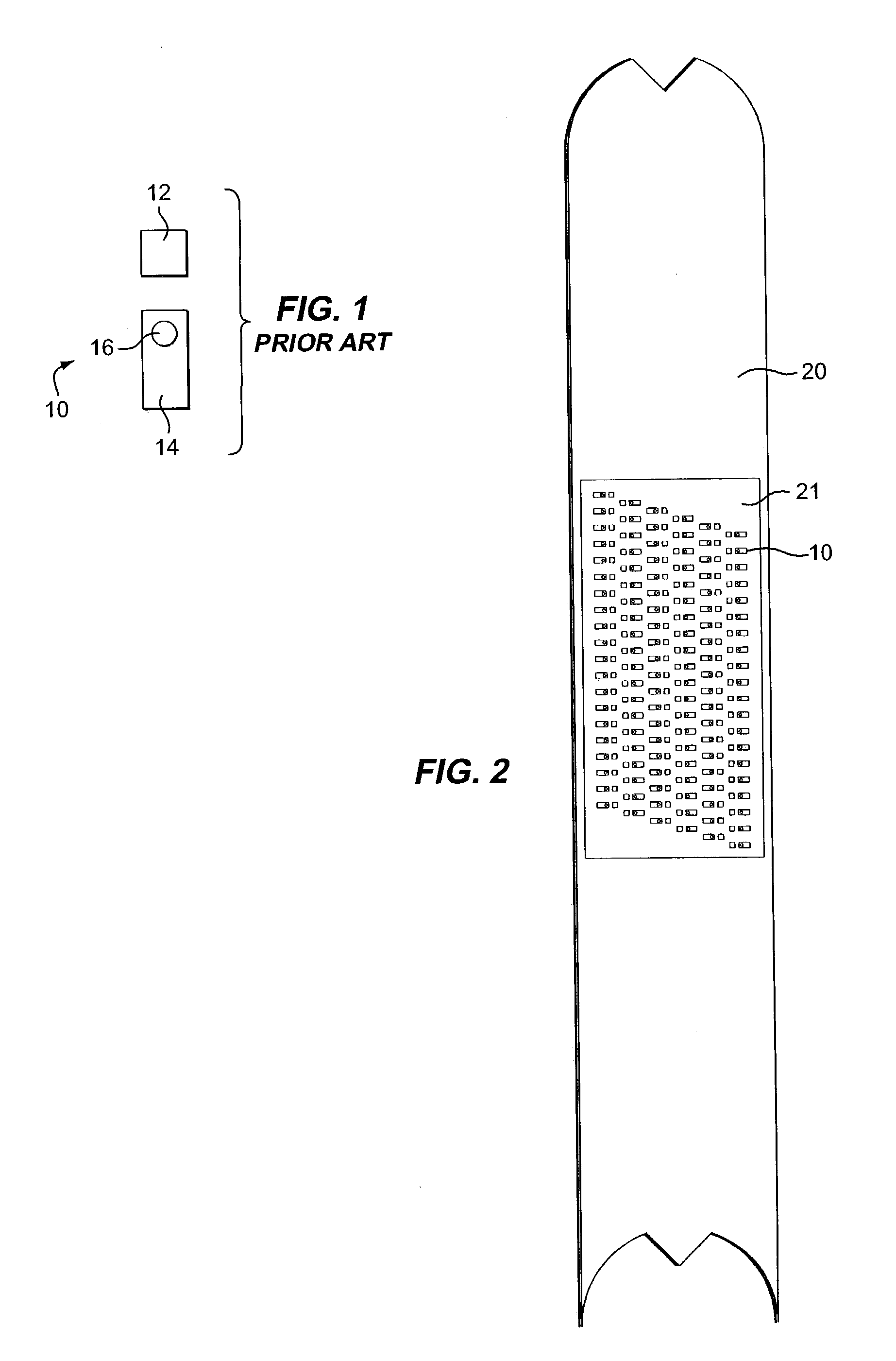

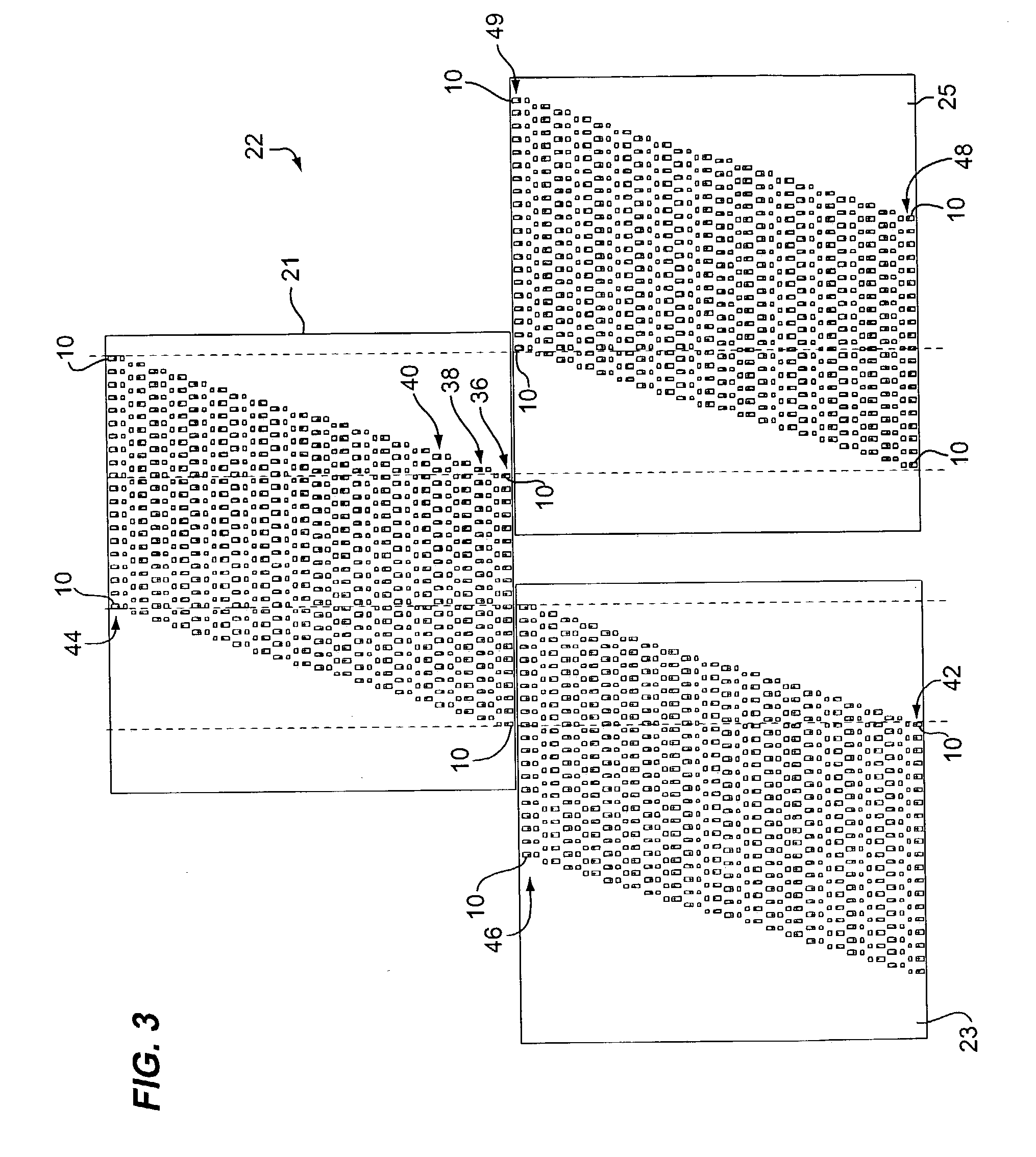

A UV curing apparatus and method is provided for enhancing the distribution and application of UV light to UV photo initiators in a UV curable ink, coating or adhesive. The UV curing apparatus and method comprises UV LED assemblies in a first row with the UV LED assemblies spaced from adjacent UV LED assemblies. At least one second row of a plurality of UV LED assemblies are provided next to the first row but with the UV LED assemblies of the second row positioned adjacent the spaces between adjacent UV LED assemblies in the first row thereby to stagger the second row of UV LED assemblies from the UV LED assemblies in the first row. Desirably, the rows of staggered UV LED assemblies are mounted on a panel. UV curable products, articles or other objects containing UV photo initiators that are in or on a web can be conveyed or otherwise moved past the rows of UV LED assemblies for effective UV curing. This arrangement facilitates more uniformly application of UV light on the UV curable ink, coating and / or adhesives in the UV curable products, articles or other objects. The apparatus can include one or more of the following: rollers for moving the web, mechanisms for causing the panel to move in an orbital or reciprocal path, and an injection tube for injecting a non-oxygen gas in the area of UV light curing.

Owner:CON TROL CURE

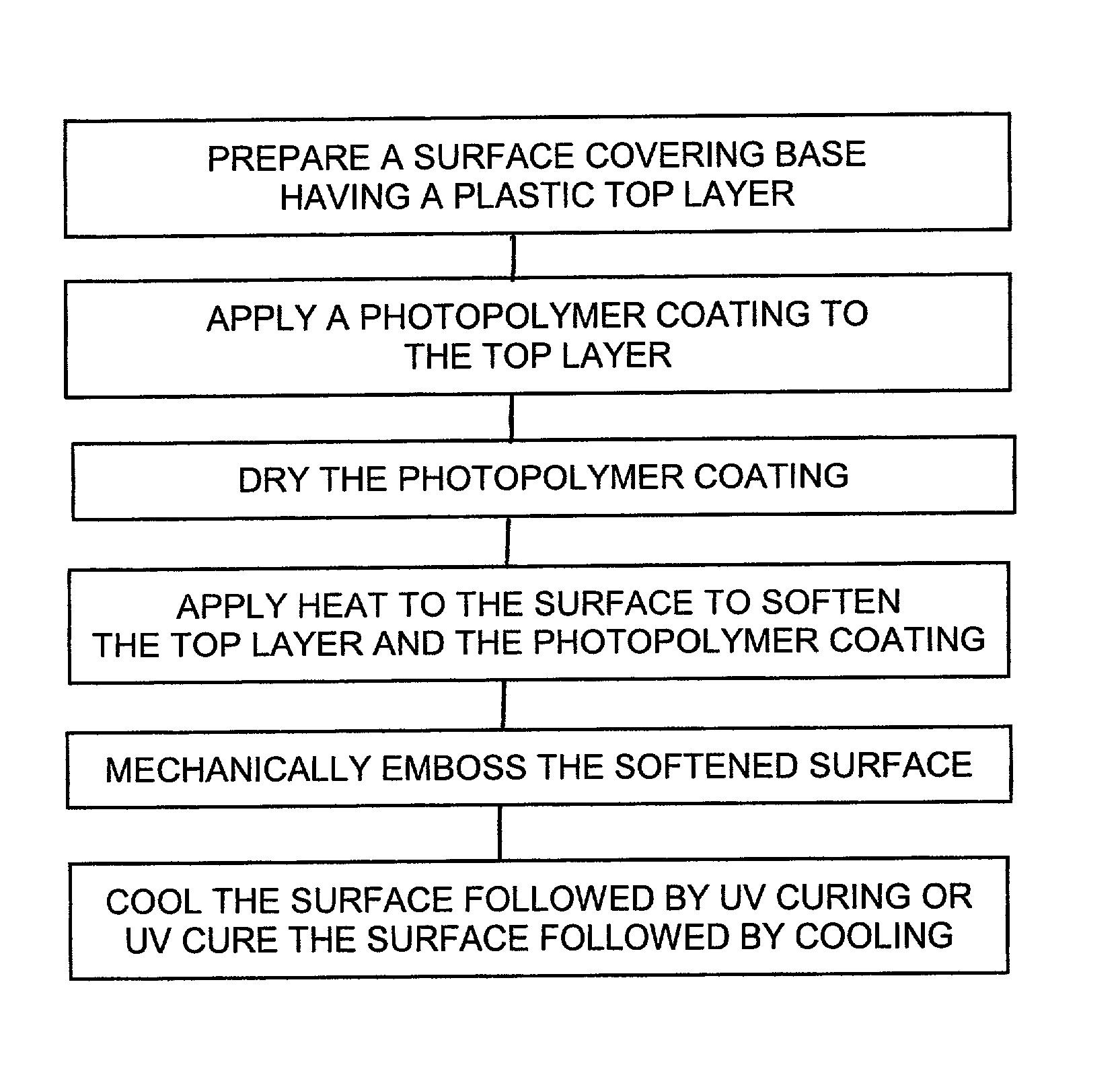

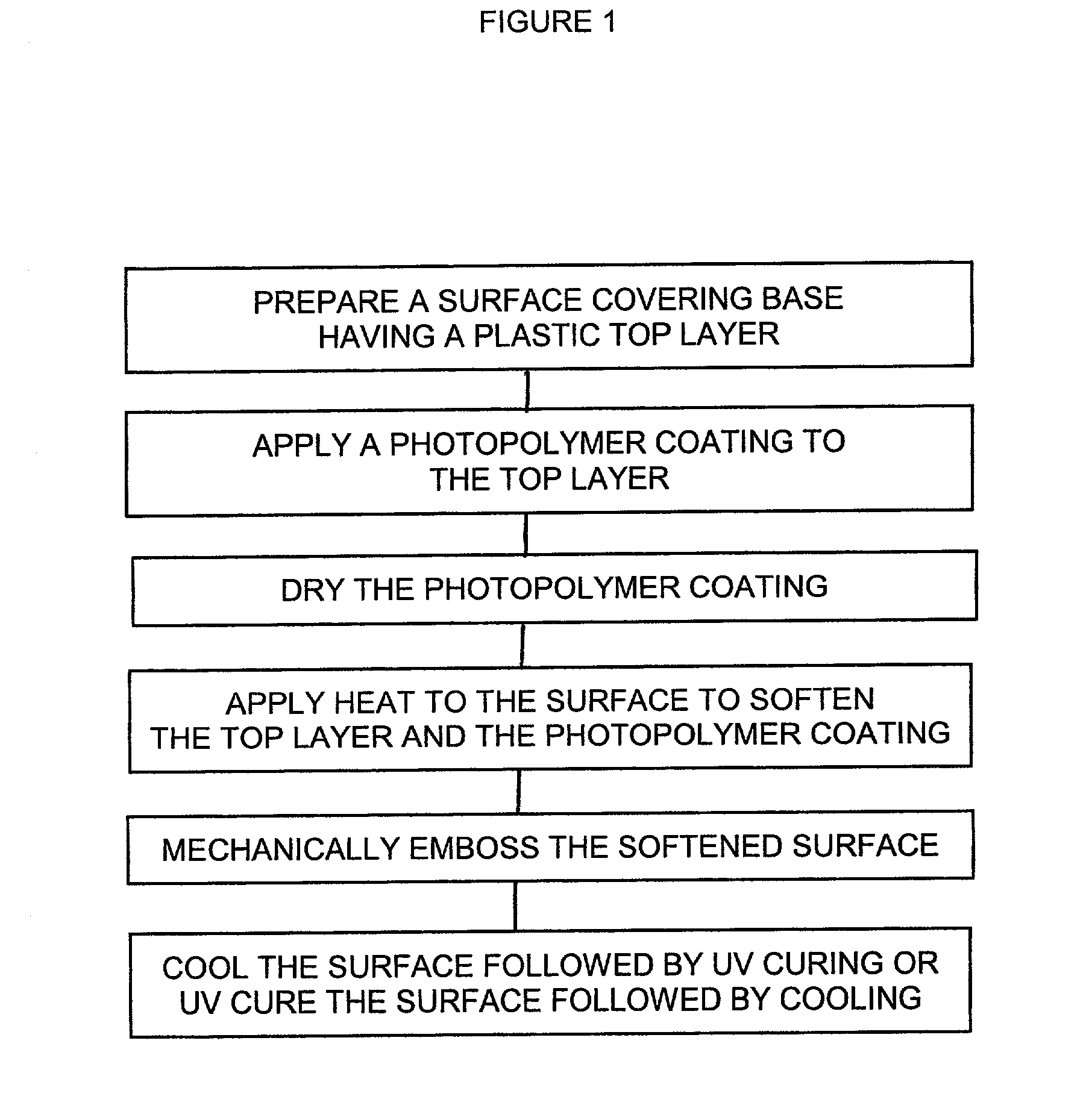

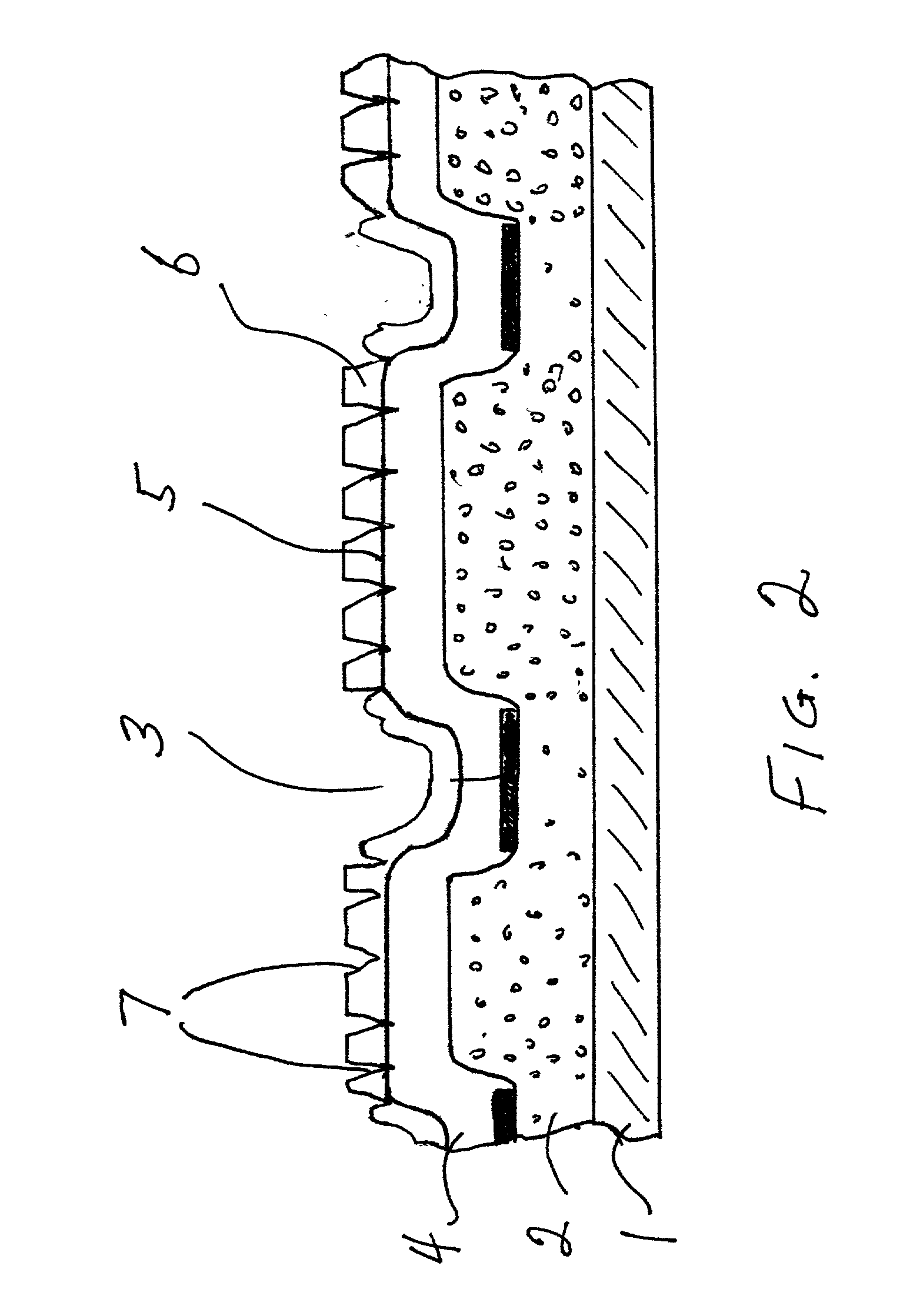

Polyurethane coated resilient surface covering having improved fidelity of texture and process of manufacture

Mechanically embossed resilient surface coverings having superior textural fidelity are prepared by mechanically embossing a polyurethane coated floorcovering before the polyurethane is cured. The mechanical embossing is conducted when the polyurethane is dry and the underlying plastic layer and the polyurethane are softened by heating. After the mechanical embossing step, the polyurethane is cured using ultraviolet (UV) light. The product can be cooled before or after UV curing. The invention is applicable to a variety of resilient surface covering products including floor and wall coverings which otherwise have a wearlayer which can be softened by heating. This includes surface coverings having the full range of decorative effects available in the art, including surface coverings which also have been, for example, chemically embossed, mechanically embossed, chemically and mechanically embossed or not embossed at all prior to application of the process of the invention.

Owner:TARKETT INC +1

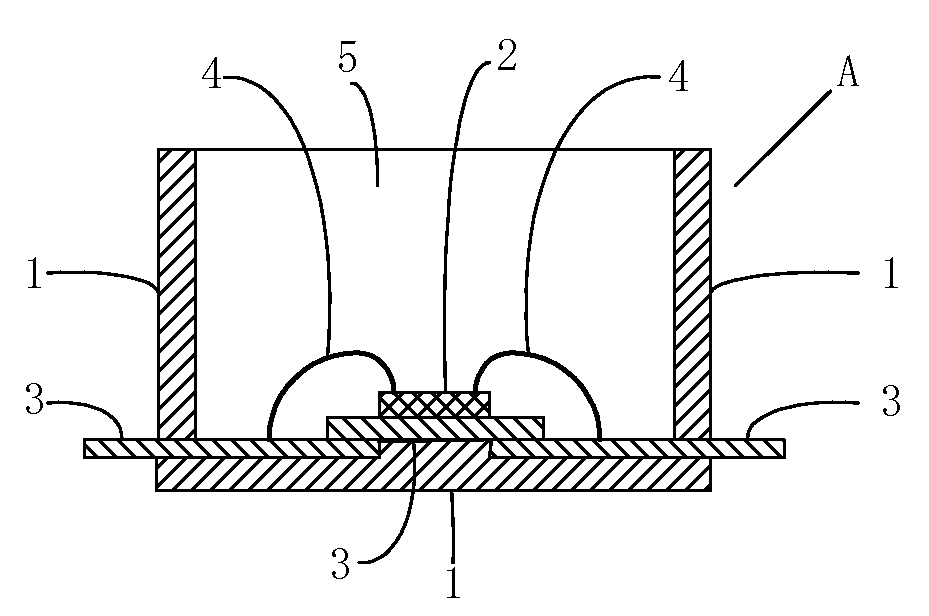

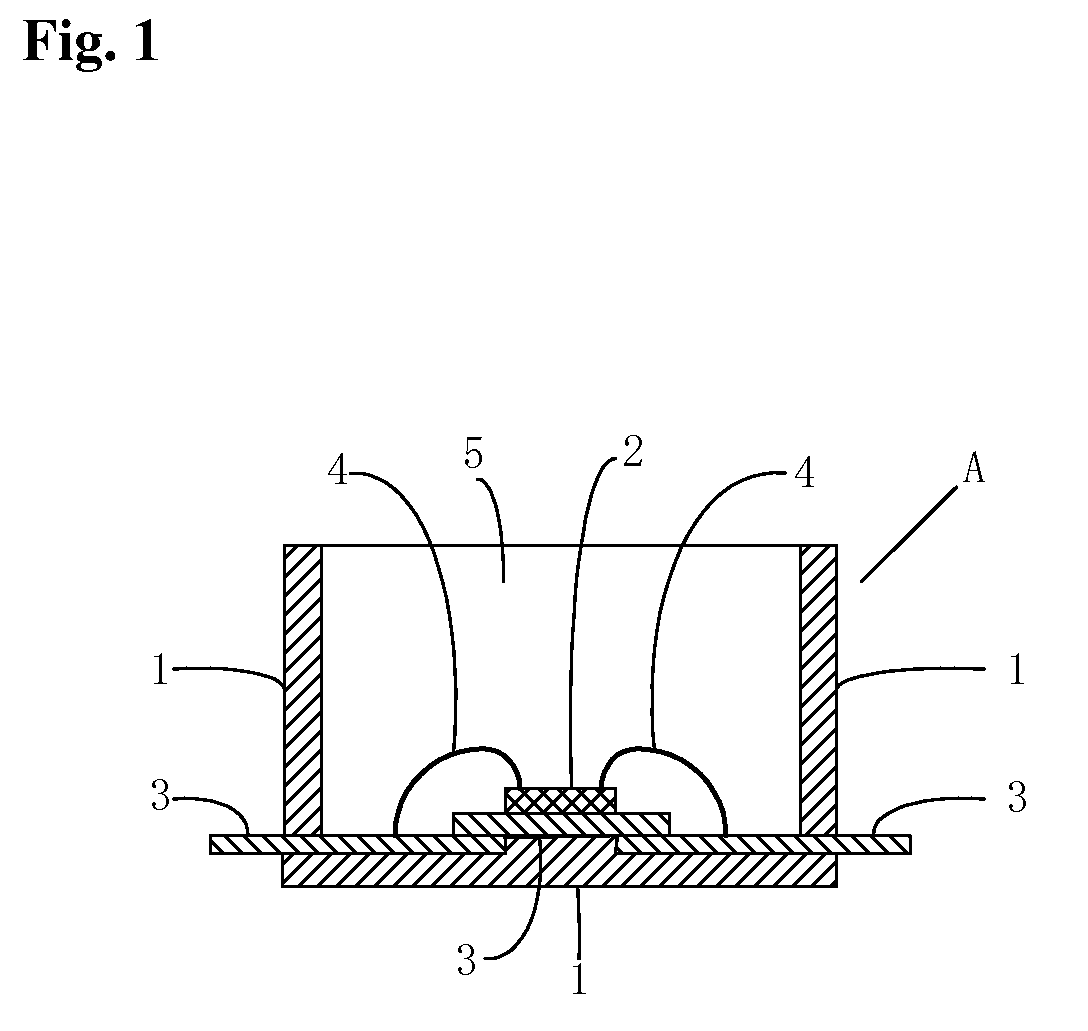

Curable Organopolysiloxane Resin Composition And Optical Part Molded Therefrom

ActiveUS20090118440A1Easy to prepareExtended validity periodSolid-state devicesSemiconductor devicesPolymer scienceOptical transmittance

A curable organopolysiloxane resin composition having a viscosity at 25° C. in the range of 0.001 to 5,000 Pa·s, a total acid number as specified by JIS K 2501 (1992) in the range of 0.0001 to 0.2 mg / g, and light transmittance in a cured state equal to or greater than 80%; an optical part comprised of a cured body of the aforementioned composition. The curable organopolysiloxane resin composition of the invention is characterized by good transparency, low decrease in transmittance when exposed to high temperatures, and excellent adhesion when required.

Owner:DOW CORNING TORAY CO LTD

Ceramic material for 3D light curing formation printing and preparation method of ceramic element

InactiveCN109400177AHigh ceramic contentEasy to printAdditive manufacturing apparatusOligomerAgent Combination

The invention relates to a ceramic material for 3D light curing formation printing and a preparation method of a ceramic element. The ceramic material is prepared from 30 to 70 vol percent of ceramicpowder and 30 to 70 vol percent of photosensitive resin premixed liquid, wherein the photosensitive resin premixed liquid is prepared from 37 to 50 weight percent of oligomers, 30 to 60 weight percentof reactive diluents, 0.1 to 5 weight percent of photoinitiators, 1 to 5 weight percent of dispersing agents, 0.1 to 0.6 weight percent of ultraviolet blocking agents, 0 to 0.05 weight percent of polymerization inhibitors, 1 to 4 weight percent of anti-foaming agents, 0.5 to 2.35 weight percent of anti-settling agents and 0.3 to 3 weight percent of leveling agents. In the degreasing and sinteringpost-treatment work procedures, specific parameters are used, so that a sintering element can reach good sintering density and mechanical performance. By optimizing the composition and the proportionof light curing ceramic resin, and selecting the excellent dispersing agent combination and the reasonable consumption, the ceramic powder can be better dispersed in the resin; the problems that theexisting light curing ceramic resin has poor flowability and low formation precision, and that a finally prepared ceramic product can easily generate cracks or deformation, and the like are solved.

Owner:西安点云生物科技有限公司

Ultraviolet curing pressure sensitive adhersive for polyethylene protective film and preparation method thereof

ActiveCN101649165AStrong adhesionStrong initial adhesionOrganic non-macromolecular adhesiveTectorial membraneSolvent

The invention discloses an ultraviolet curing pressure sensitive adhersive for the polyethylene protective film and a preparation method thereof. The ultraviolet curing pressure sensitive adhersive comprises the following components by weight percent: 30-80% of acrylate prepolymer, 0.03-4.5% of photoinitiator, 0.2-2.5% of photocuring crosslinking agent, 3-25% of tackifier and 5-40% of solvent. Theultraviolet curing pressure sensitive adhersive disclosed in the invention has good adhesive force to the polyethylene film and can realize good balance among initital adhesive force, peeling strength and cohesive force.

Owner:无锡达美新材料有限公司

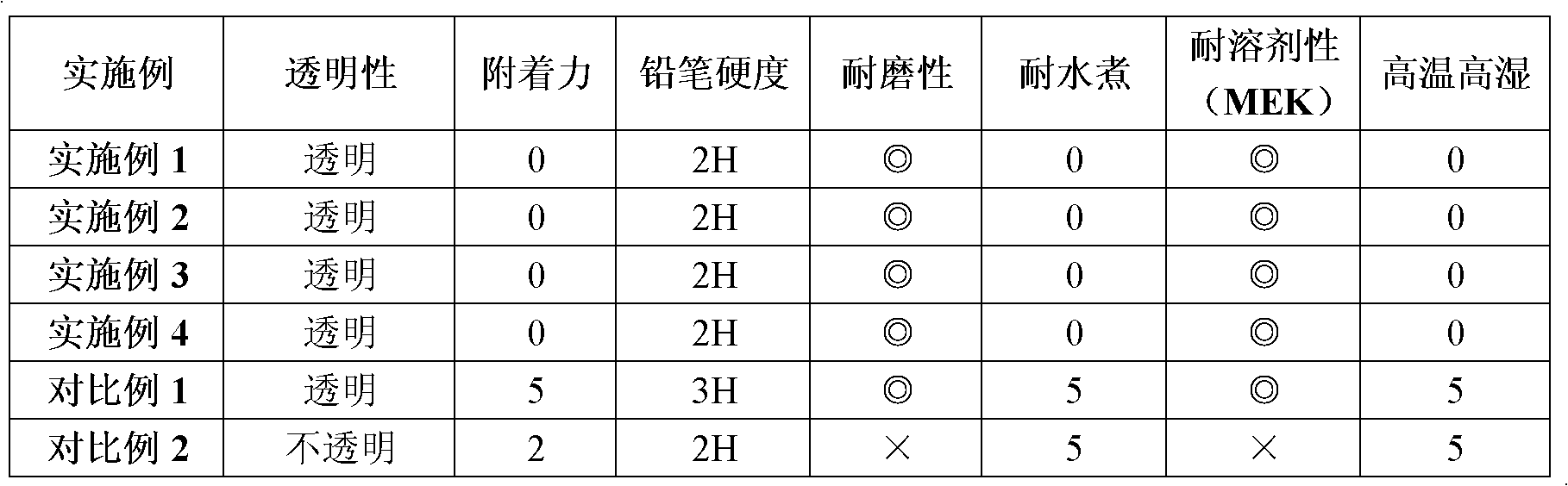

Ultraviolet-cured hard coating and application thereof

ActiveCN102236113AImprove wear resistanceImprove antifouling performanceLayered productsPolyurea/polyurethane coatingsUltravioletPliability

The invention discloses an ultraviolet-cured hard coating and an application thereof. The ultraviolet-cured hard coating comprises a transparent supporting body and a scratch-proof coating coated on the transparent supporting body; the scratch-proof coating comprises the following components in part by weight: 5 to 90 parts of light-cured prepolymer, 5 to 90 parts of thinning agent, 1 to 10 parts of photoinitiator, 0 to 80 parts of active thinning agent, 0 to 20 parts of inorganic nanopadding and 0 to 18 parts of aid. By the invention, the defects that the conventional hard coating is not hard enough, the scratch resistance and the wear resistance are limited, the flexibility is relatively low and the like are overcome; and the ultraviolet-cured hard coating has relatively low surface energy, relatively good antifouling effect, high strength, relatively good scratch resistance and wear resistance, and excellent adhesion, flexibility and transparence.

Owner:中国航天科技集团公司第四研究院第四十二所

Ultraviolet-cured hydrophilic coating composition and preparation method thereof

InactiveCN102585691AHigh content of hydrophilic substancesCreate pollutionPolyurea/polyurethane coatingsPolyether coatingsHydrophilic coatingPolymer science

The invention relates to a highly-hydrophilic transparent ultraviolet-cured coating composition and a preparation method thereof. The ultraviolet-cured hydrophilic coating composition comprises light-cured resin, a polymerization monomer, a reactive diluent, a light initiator, an auxiliary and pigment. The preparation method comprises accurately weighing the light-cured resin according to a formula and pouring the light-cured resin into a mixing kettle, sequentially adding the polymerization monomer, the reactive diluent and the auxiliary into the mixing kettle, and stirring the mixture for 20-45 minutes; adding the light initiator into the mixing kettle, mixing for 15-35 minutes to obtain ultraviolet-cured hydrophilic coating, and storing the ultraviolet-cured hydrophilic coating away from the light; and when the ultraviolet-cured hydrophilic coating is used, adding the pigment and performing even mixing. The ultraviolet-cured hydrophilic coating composition can be coated on base materials of plastic, metal, glass and the like. An ultraviolet-cured coating has excellent hydrophilcity and good physical performance, adhesive force, hydrolytic resistance, salt fog resistance and alkali resistance.

Owner:CHANGSHA YUANPENG CHEM TECH

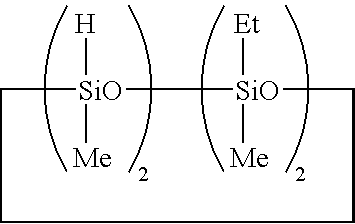

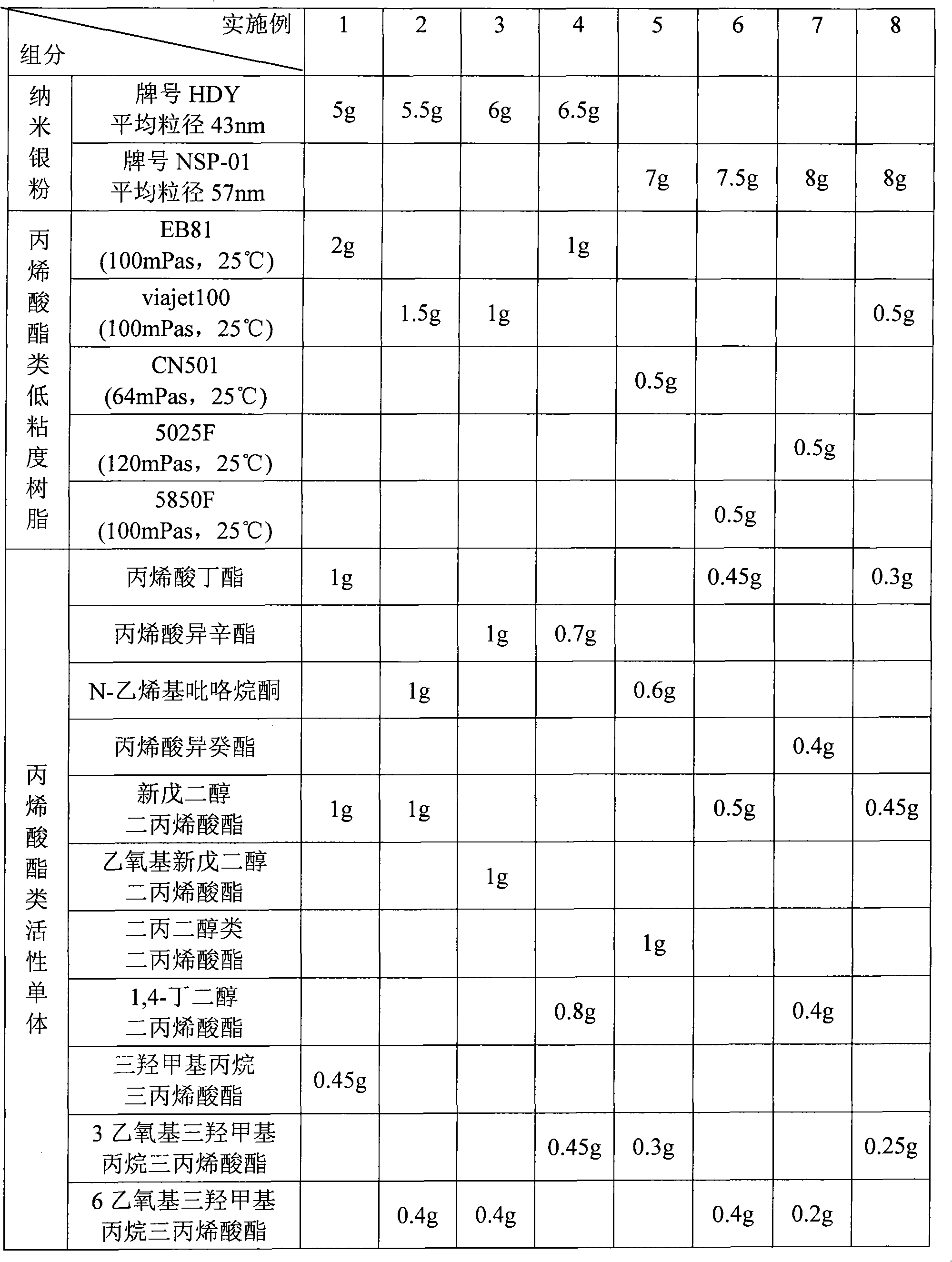

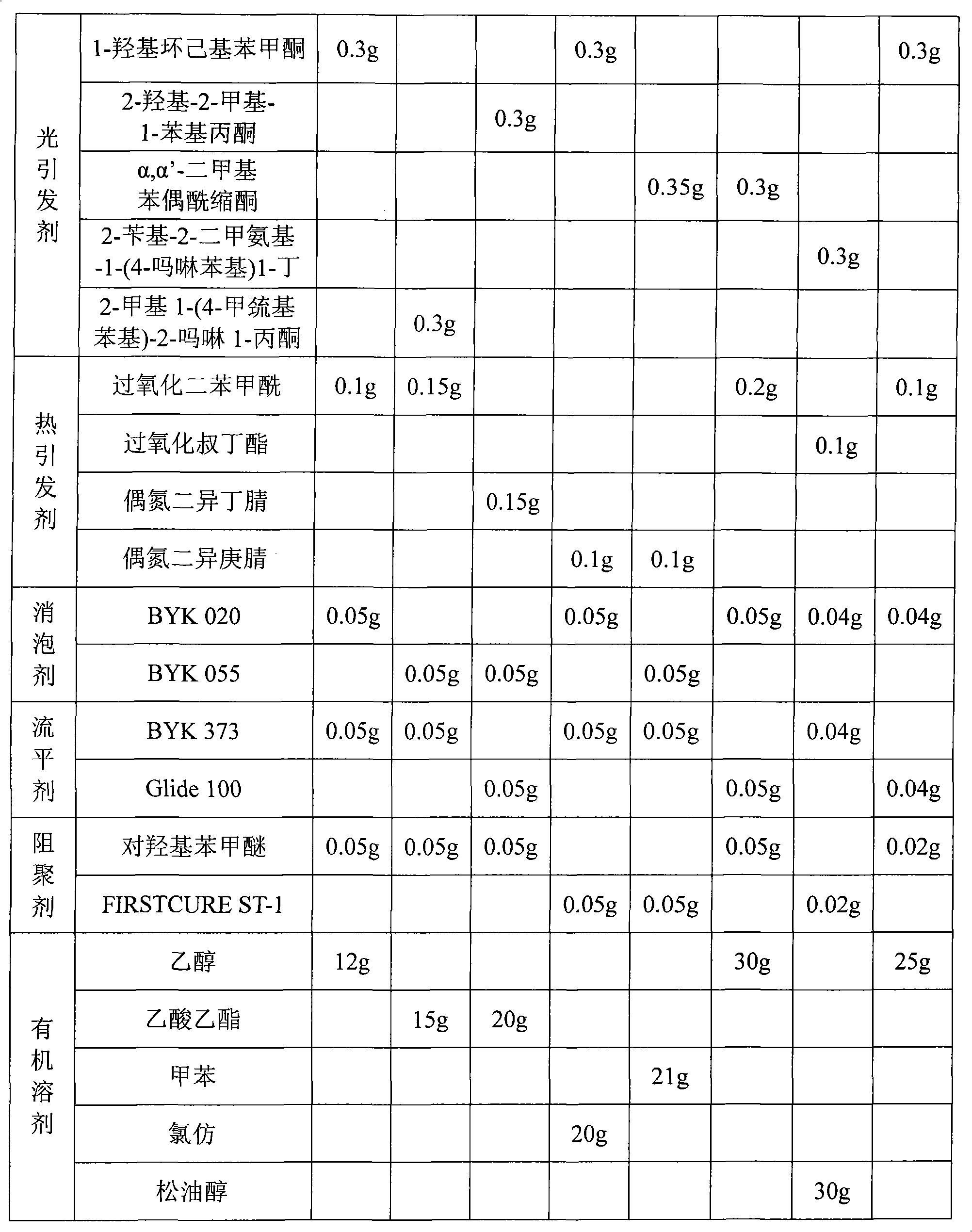

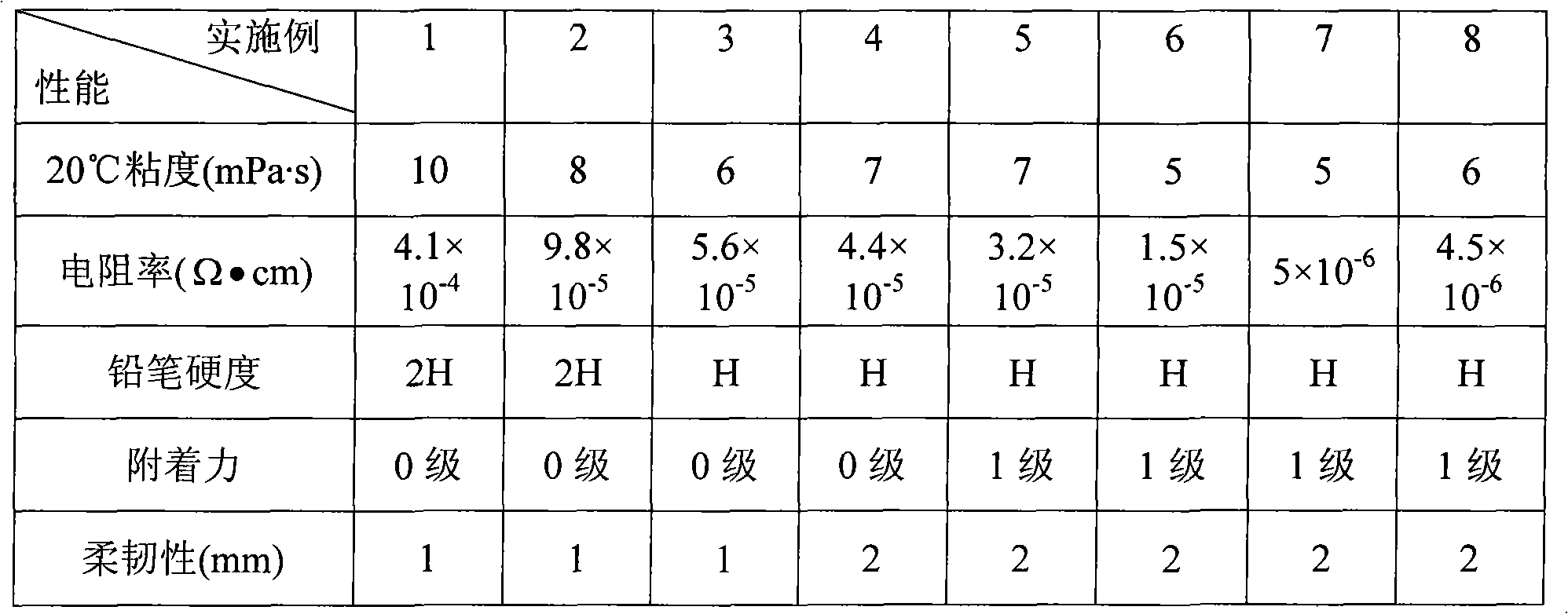

Photo-curing ink-jet nano conductive printing ink, and preparation and use method thereof

InactiveCN101348634AContinuous ejectionGuaranteed resistivityInksPrinted circuit manufactureDual curePliability

The invention relates to light-cured ink jet nanometer conductive printing ink for printed circuit boards, and preparation and use methods thereof. The preparation method comprises the following steps: an acrylic ester low viscosity resin and an acrylic ester active monomer are added into nanometer metal dispersing solution and the mixture adopts a double cured mode that the mixture is subjected to light cure firstly and heat treatment secondly, wherein the light-cured treatment ensures that a coat is cured rapidly and achieves good mechanical performance; and the heat treatment ensures that the nanometer metal is nodulized together to achieve good conductive performance. The light-cured ink jet nanometer conductive printing ink which adopts the ink jet technique can be painted in the specific area of a base material. A conductive path is obtained after the double cured treatment. The light-cured ink jet nanometer conductive printing ink has the advantages of short cured time, low cured temperature, good conductivity and high resolving capability. The manufactured conductive membrane has good adhesiveness, high hardness, good flexibility and excellent conductivity.

Owner:BEIJING UNIV OF CHEM TECH

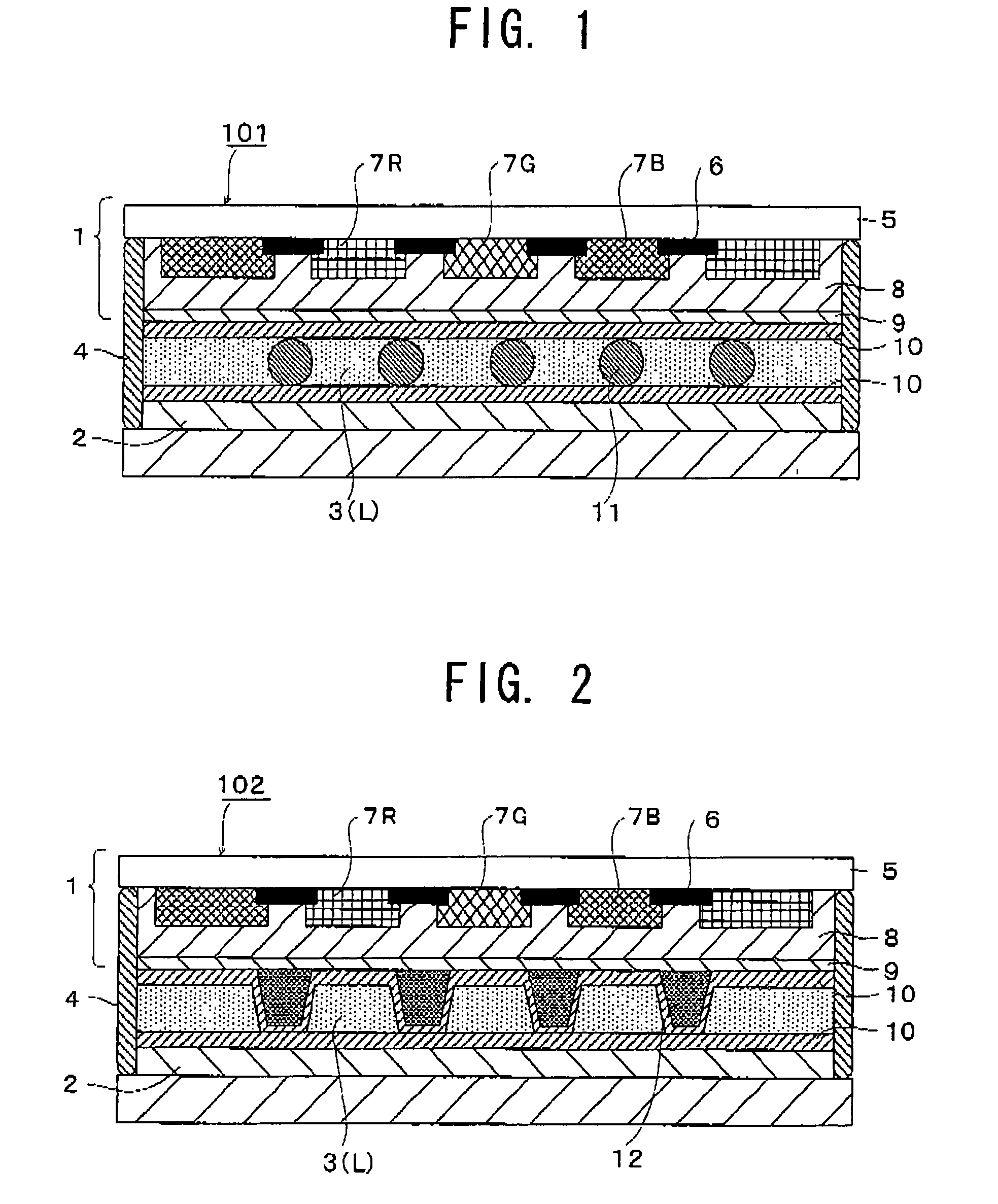

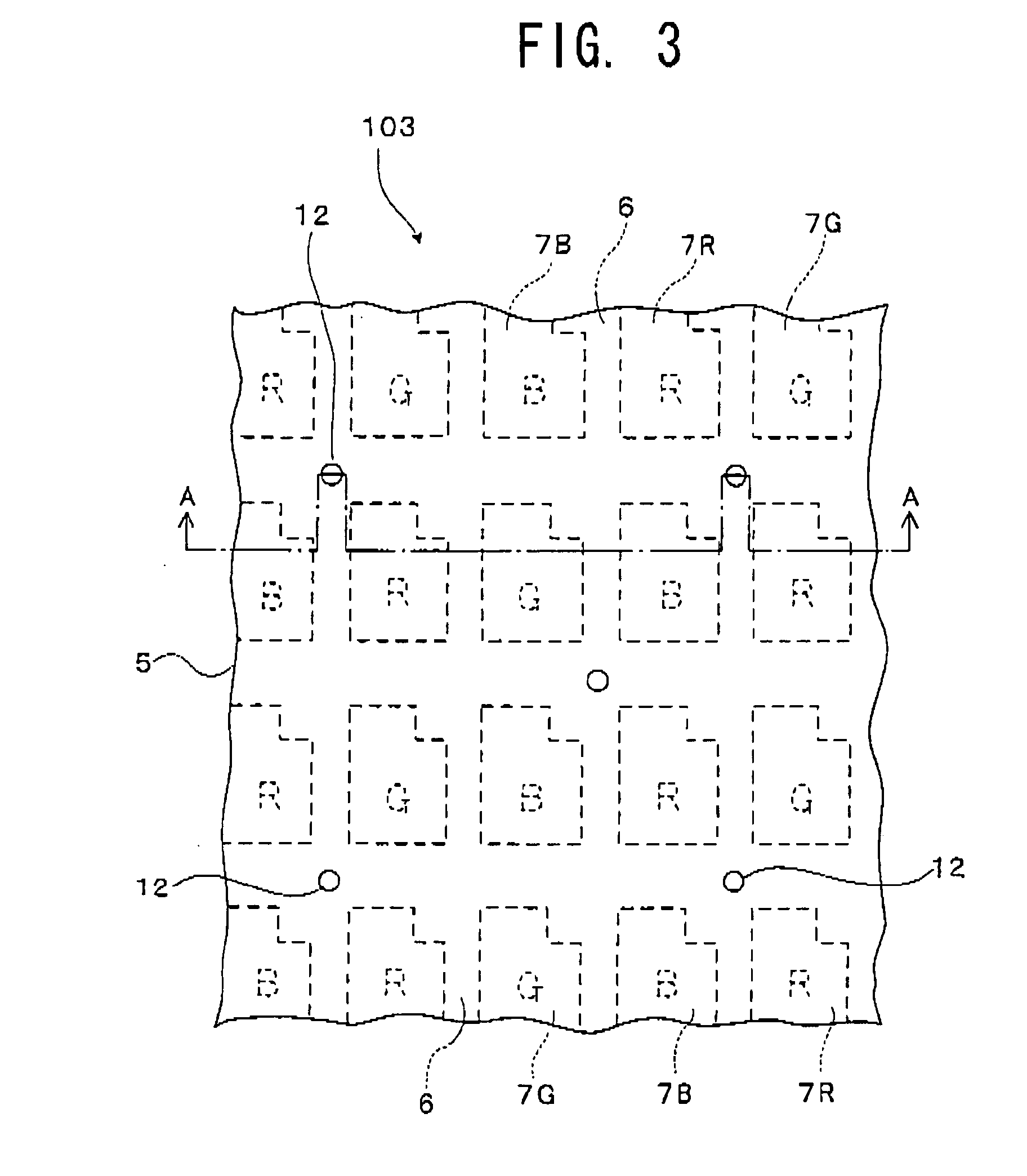

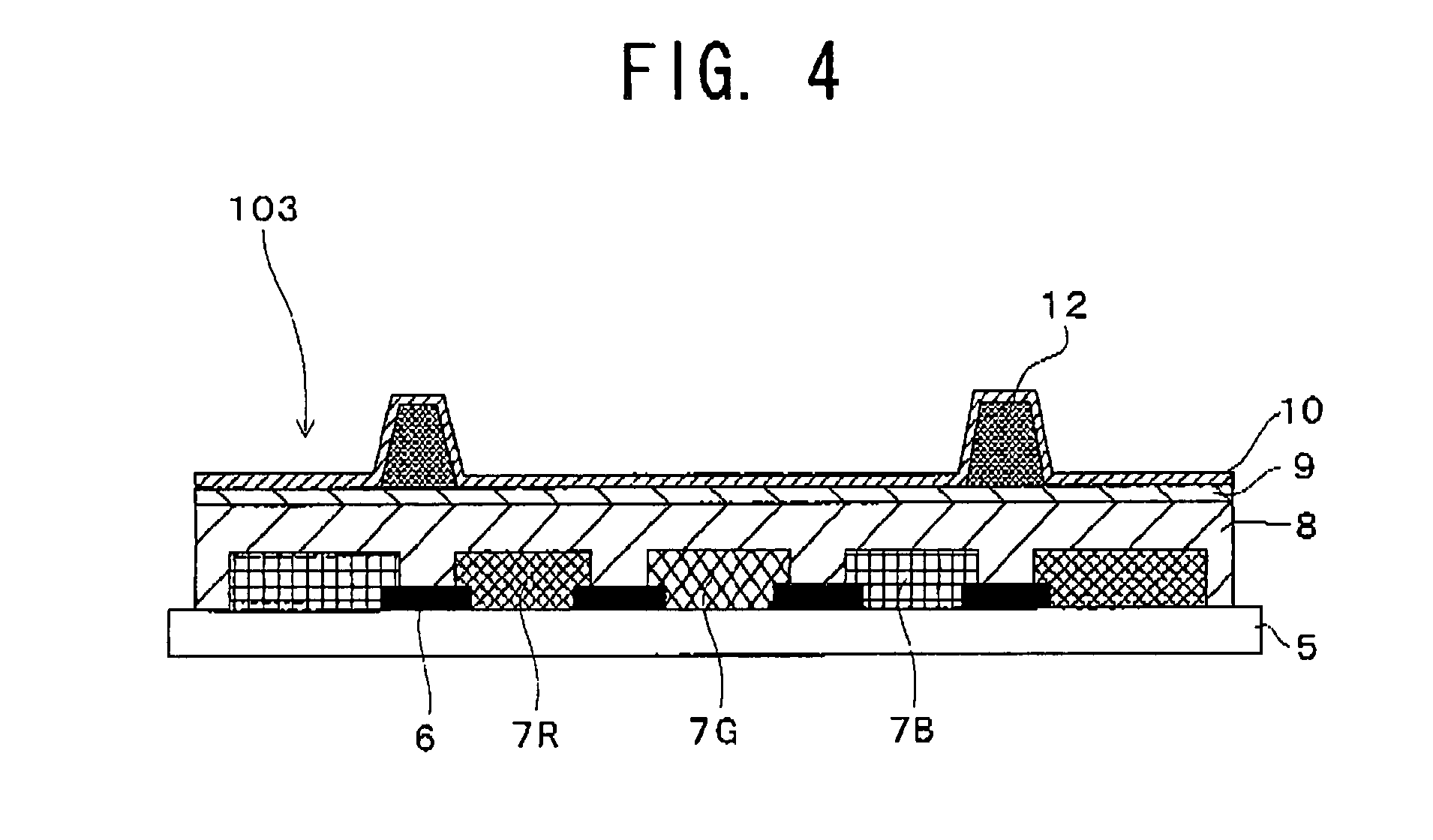

Curable resin composition, photosensitive pattern-forming curable resin composition,color filter, substrate for liquid crystalline panel, and liquid crystalline panel

InactiveUS20060229376A1High exposure sensitivityGood developing propertiesLiquid crystal compositionsPhotosensitive materialsLiquid crystallineTectorial membrane

There are provided: a curable resin composition having a high exposure sensitivity and a good developing property, and thereby capable of forming an accurate and precise pattern; a liquid crystal panel substrate on which a protective film for covering a color layer or spacers for a liquid crystal layer, by using the curable resin composition, hardly causing a color irregularity and contrast irregularity; and a liquid crystal panel using the liquid crystal panel substrate and having a superior display quality. The curable resin composition of the present invention comprises: a copolymer (a) having a molecular structure in which a constitutional unit including an acidic functional unit and a constitutional unit including a photocurable functional group are linked at least; a photopolymnerization initiator (b) having a tertiary amine structure; and a photocurable compound (c) having at least one acidic functional group and at least three photocurable functional groups.

Owner:DAI NIPPON PRINTING CO LTD

Coating material containing POSS acrylate copolymer and preparing method

The invention relates to a manufacturing method for coat material containing POSS acrylate copolymer. It takes free radical copolymerized to acr monomer and other acr monomer, and uses as modifier adding into the base compounding of UV coat, after taking UV solidification the coat material of high rigidity would be gained. The constituent includes 40-55% light-cured resin, 5-20% active modifier, 20-45% spike, 1-10% photoinitiator, 2-10% anti-foam additive. The rigidity of coat could reach to 6H, and the shrinkage ratio could reach 2%.

Owner:XIAMEN UNIV

Ultraviolet curing paint and preparation method and application thereof

ActiveCN102070981AHigh hardnessImprove wear resistancePolyurea/polyurethane coatingsPolyether coatingsPolyesterPliability

The invention discloses an ultraviolet (UV) curing paint and a preparation method and application thereof. The preparation method comprises the following steps: weighting modified SiO2 sol to place in a container, adding water-soluble UV-cured resin, solvent and additive in turn, stirring for 10min, then adding photoinitiator, and stirring for 5min to obtain the UV curing paint, wherein the contents of the water-soluble UV-cured resin, the solvent, the additive and the photoinitiator are 10-60%, 7-33%, 0.1% and 2% respectively. The UV curing paint prepared by the method of the invention has the advantages of inorganic materials such as high hardness, high wear resistance, scratch resistance and good thermal stability and also has the advantages of organic materials such as adhesivity and relative flexibility; and the UV curing paint is suitable to be used as the protective coatings on the surfaces of all kinds of optical plastic products such as polyester which contains polycarbonate, polymethylmethacrylate, polyethylene terephthalate (PET) and the like. By adopting the UV curing paint of the invention, the defects of the existing UV curing paint in the aspects of hardness, wear resistance, scratch resistance and light transmittance, can be overcomed to a certain extent.

Owner:GUANGZHOU HUMAN CHEM

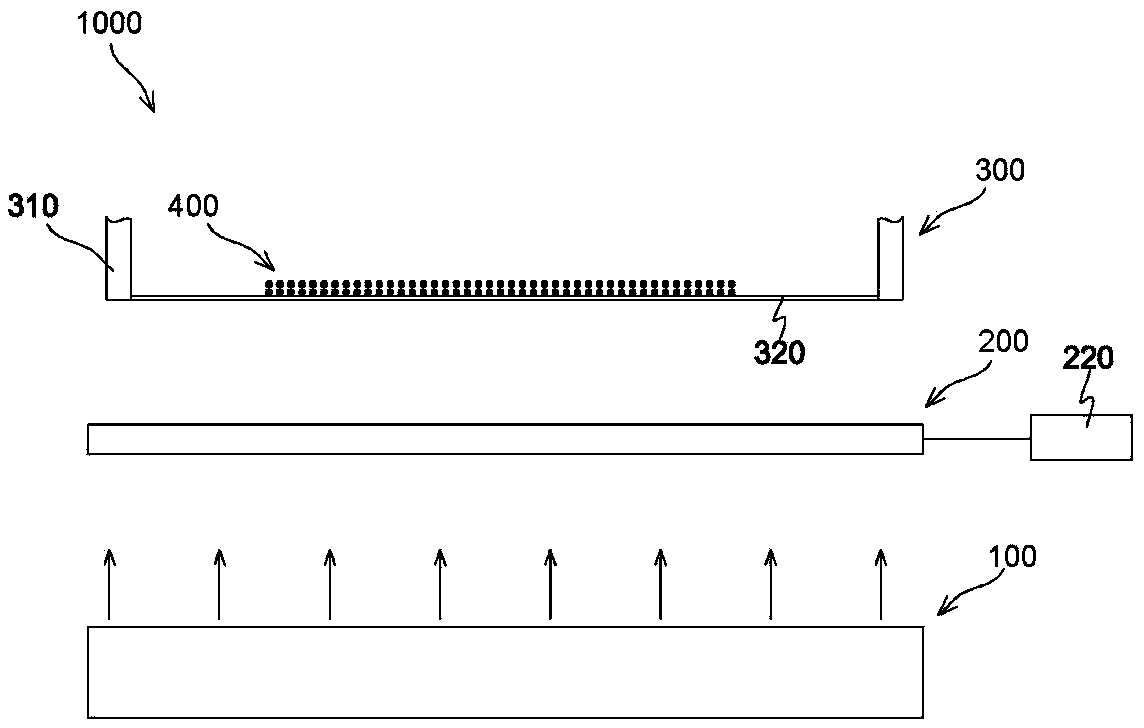

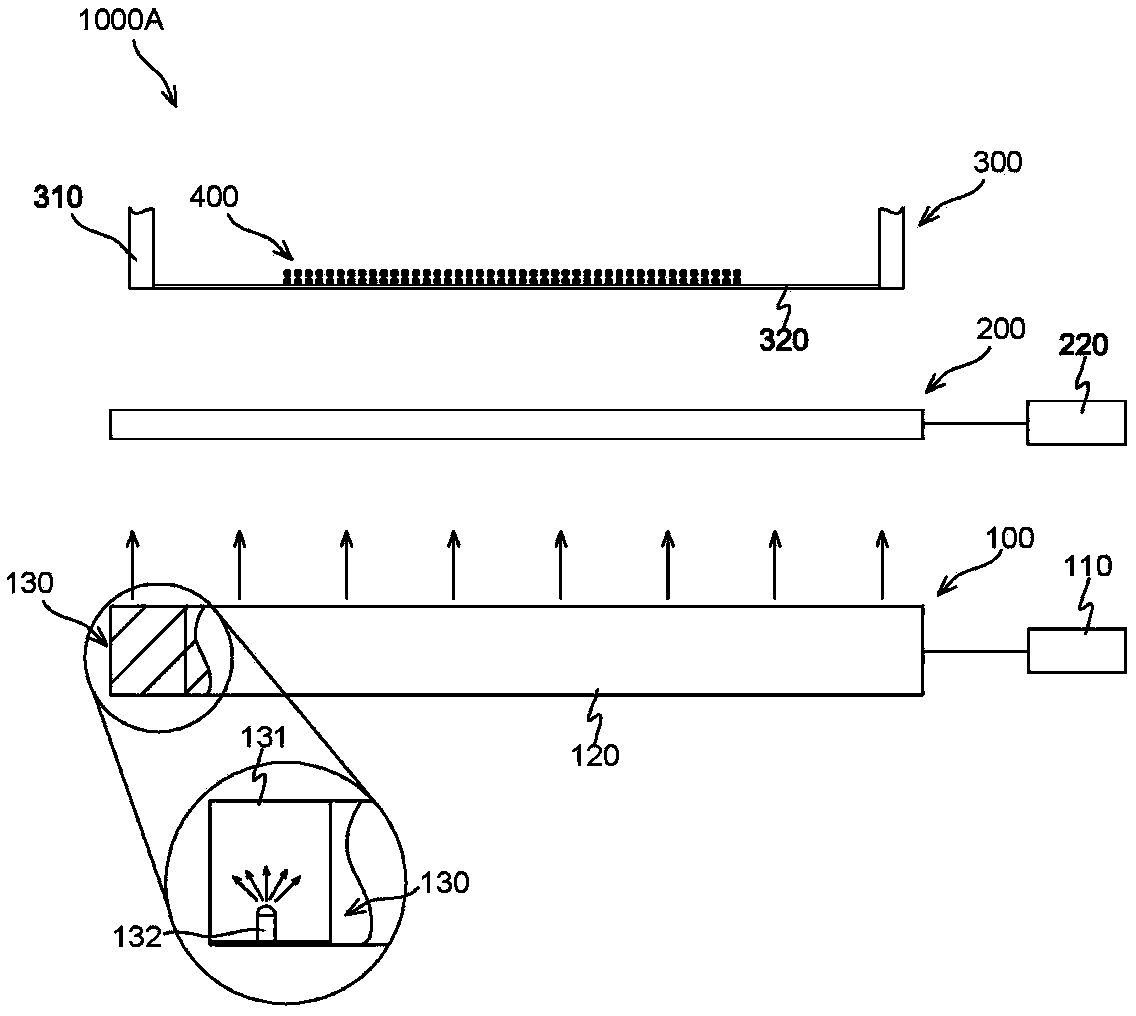

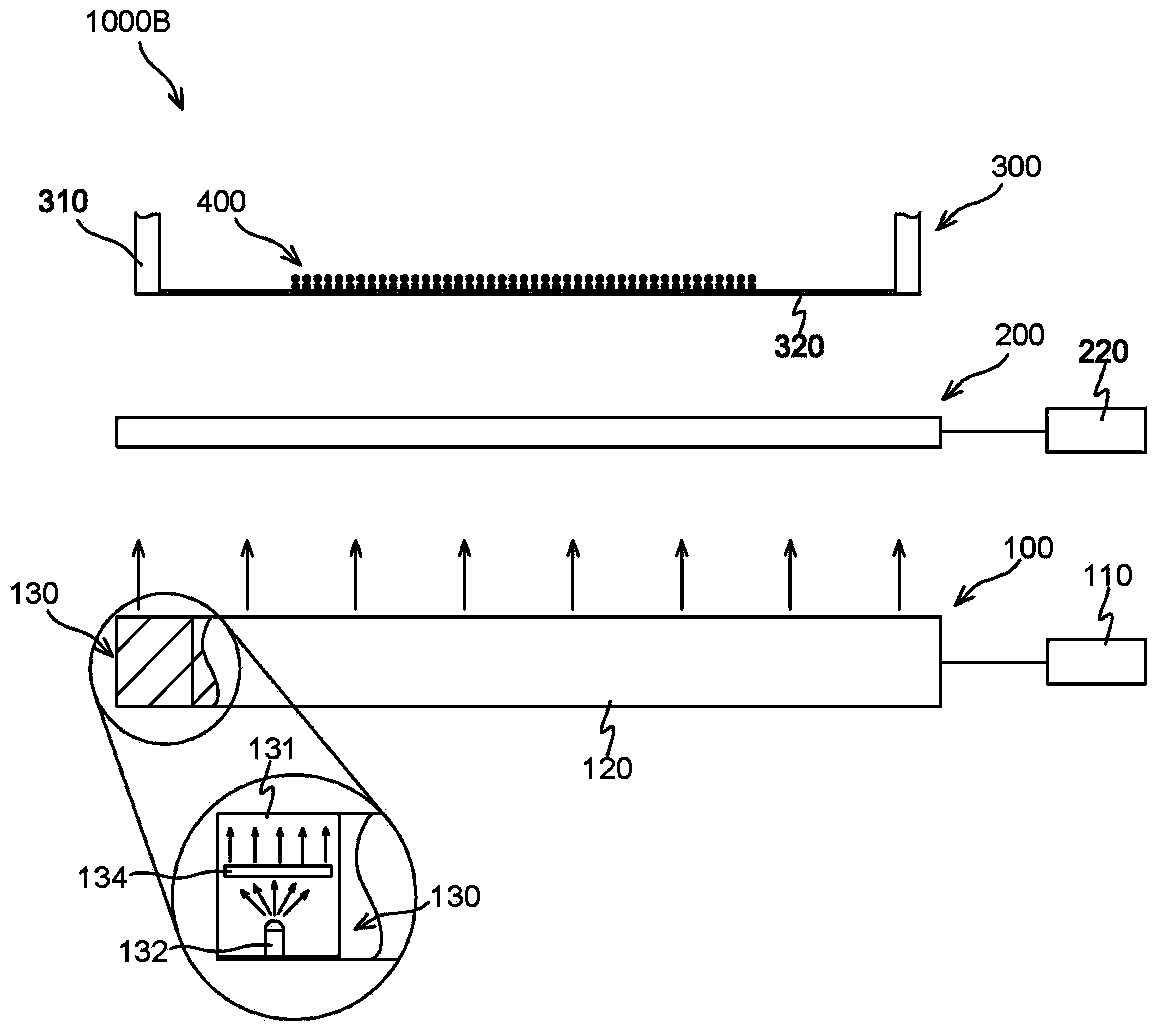

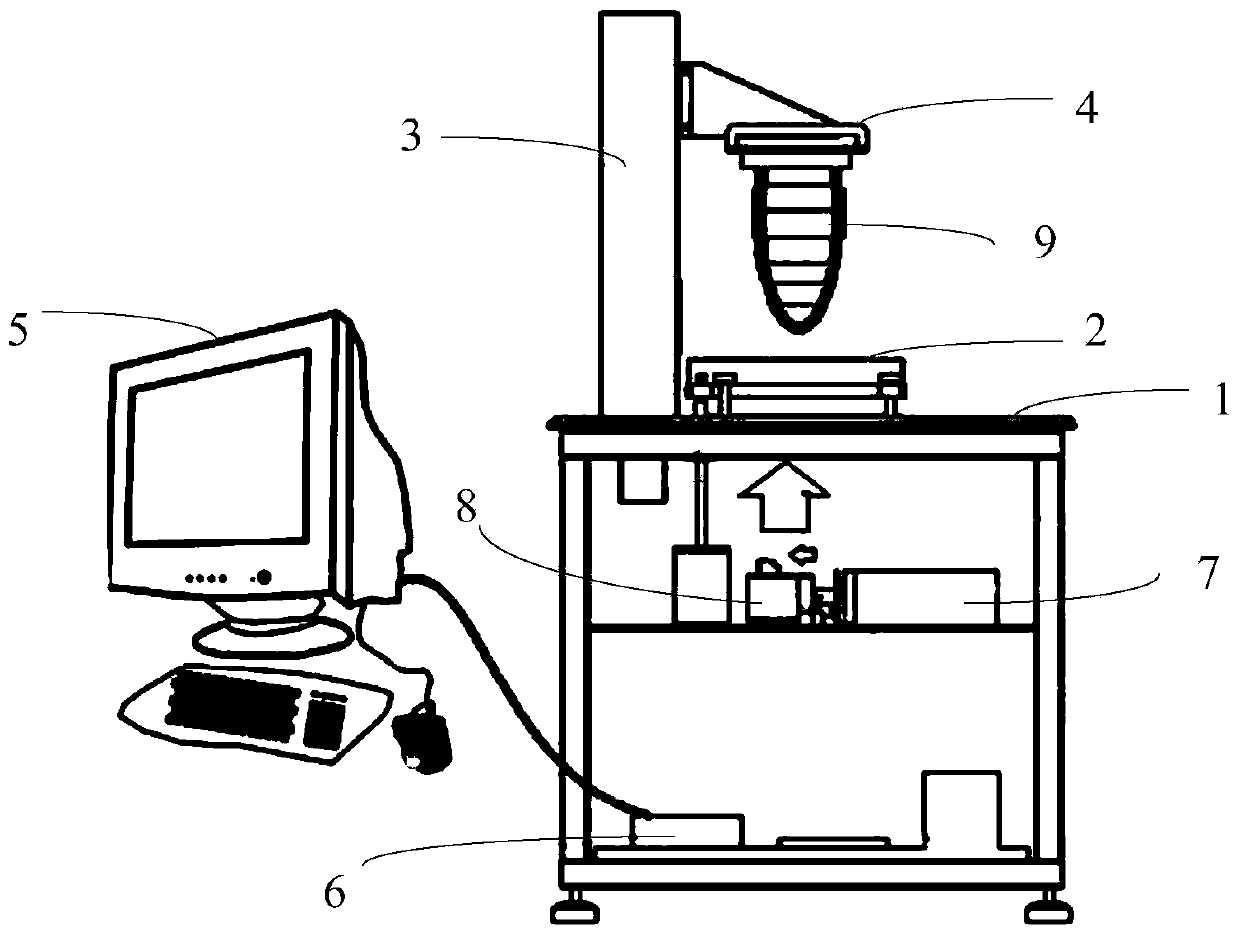

Light-cured rapid forming device and method

InactiveCN103895231APrevent curingUniform lightAdditive manufacturing apparatus3D object support structuresEngineeringLight transmission

The invention discloses a light-cured rapid forming device and method. The light-cured rapid forming device (1000) comprises a bearing body (300) used for bearing photosensitive resin (400), an imaging part (200) used for showing a two-dimensional image in a light transmission mode and a light source device (100) used for sending light which penetrates through a region corresponding to the two-dimensional image to enable the photosensitive resin to carry out photopolymerization reaction for curing forming, wherein the imaging part (200) is arranged between the light source device (100) and the bearing body (300), and the light source device (100) is a surface light source. With the adoption of the light-cured rapid forming device and method, the light source device is the surface light source, and the light sent by the light source device uniformly penetrates through the region corresponding to the two-dimensional image to enable the photosensitive resin to carry out the photopolymerization reaction for curing forming, so that the photosensitive resin which do not need to be cured can be effectively prevented from curing.

Owner:刘彦君 +1

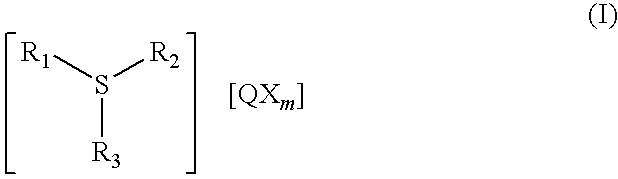

Antimony-free photocurable resin composition and three dimensional article

ActiveUS20100015408A1Fast curingLiquid surface applicatorsOrganic chemistryInvestment castingActive component

The present invention provides a low viscosity photocurable composition including (i) a cationically curable component (ii) a free radically active component (iii) an antimony-free cationic photoinitiator (v) a free radical photoinitiator, and (vi) a toughening agent. The photocurable composition can be cured using rapid prototyping techniques to form three-dimensional articles which can be used in various aerospace and investment casting applications.

Owner:3D SYST INC

Ultraviolet curing coating for preventing static on plastic surface and method for preparing the same

InactiveCN101423675ALight weightGood electrical conductivityElectrically-conductive paintsSolventPhotoinitiator

The invention relates to an ultraviolet photo-cured coating for the electrostatic prevention of the surface of plastic and a preparation method thereof, in particular to a photo-cured coating containing conductive powder of a metal oxide system or composite conductive powder. The coating comprises the following compositions in weight percent: 30 to 70 percent of oligomer, 25 to 65 percent of active thinner, 0.5 to 10 percent of light evocating agent, 5 to 40 percent of conductive powder, 0.2 to 8 percent of additive and 0 to 50 percent of solvent. As the added conductive powder of the metal oxide system and the composite conductive powder is white or light color, the prepared photo-cured has the characteristic of easy color modulation, has lasting antistatic property, high rigidity and wearing resistance, can be used for electrostatic prevention of the surface of electronic equipment, plastic vessel, shell of an electric appliance, office supplies, sports equipment and other plastic products.

Owner:SICHUAN UNIV

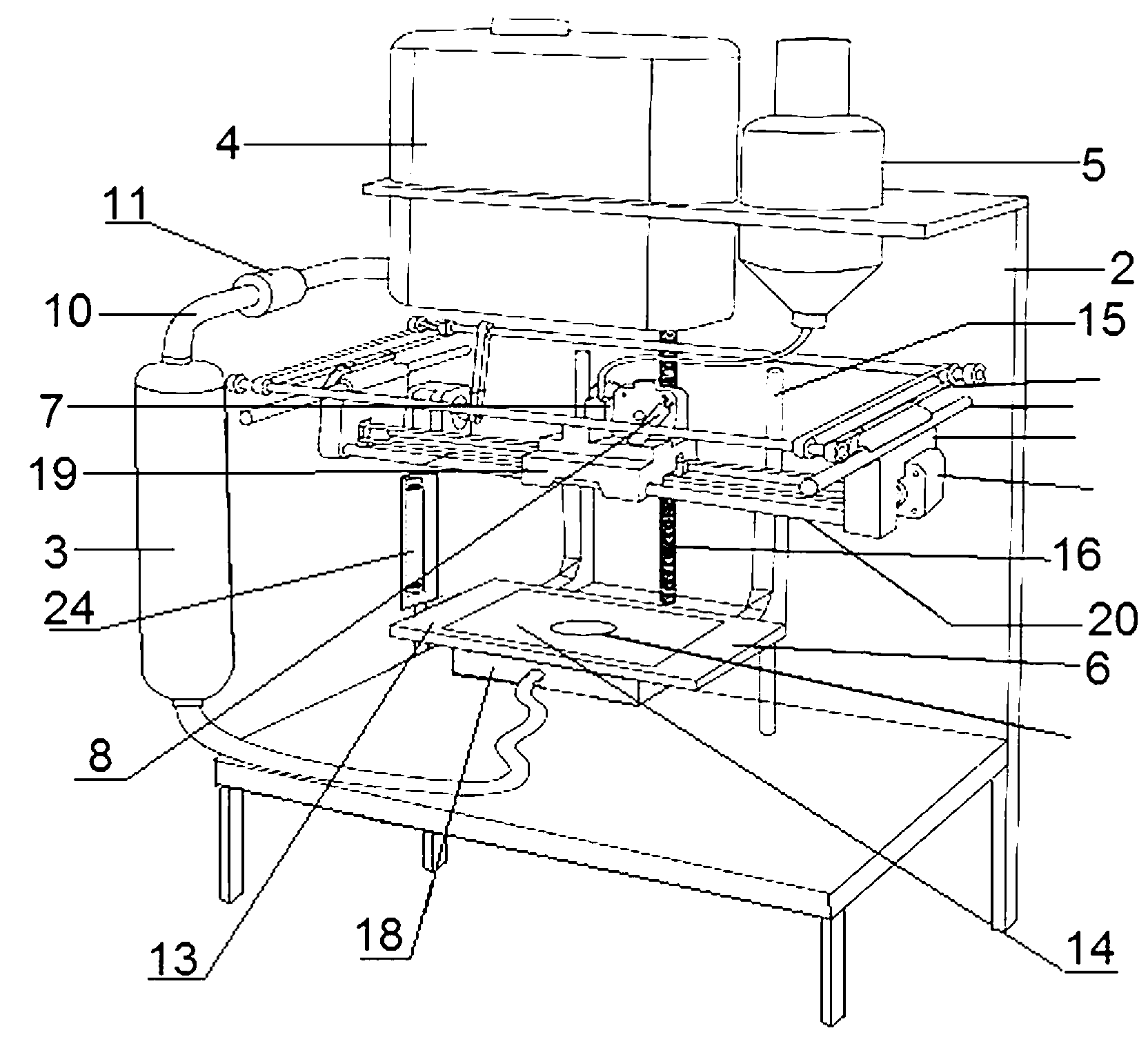

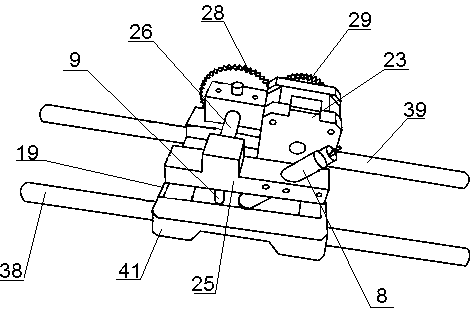

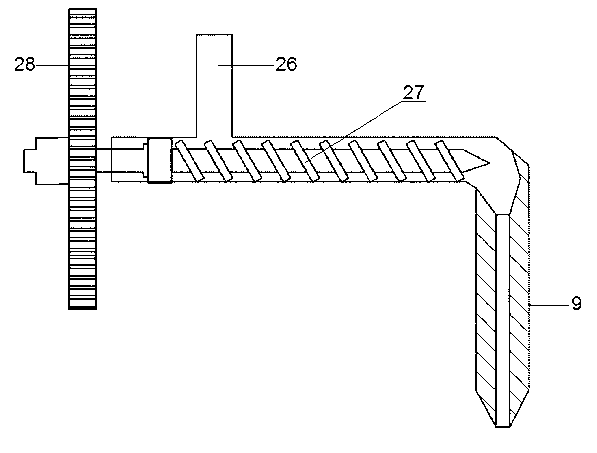

3D printer

The invention discloses a 3D (three dimensional) printer, which comprises a frame, a liquid storage pot with an upper end opening, as well as a first resin cylinder, a second resin cylinder, a lifting platform, a line extrusion device and an ultraviolet (UV) light point light source arranged on the frame. The first resin cylinder is loaded with liquid UV light cured resin, and the second resin cylinder is loaded with paste UV light cured resin. The lower part of the second resin cylinder is communicated with the line extrusion device that is provided with a nozzle, and the irradiation position of the UV light point source is located below the nozzle. The lifting platform includes a flat plate provided with a through hole in the middle part, the upper surface of the flat plate is provided with a metal net, and the flat plate is in sliding connection with two guide pillars on the frame. The lower part of the liquid storage pot is communicated with an upper end opened liquid storage box arranged on the flat plate lower surface through a duct. The 3D printer provided in the invention has high printing efficiency, and while ensuring the printing efficiency, it also can guarantee that the printed object has high density and is difficult to damage.

Owner:温州启龙电子科技有限公司

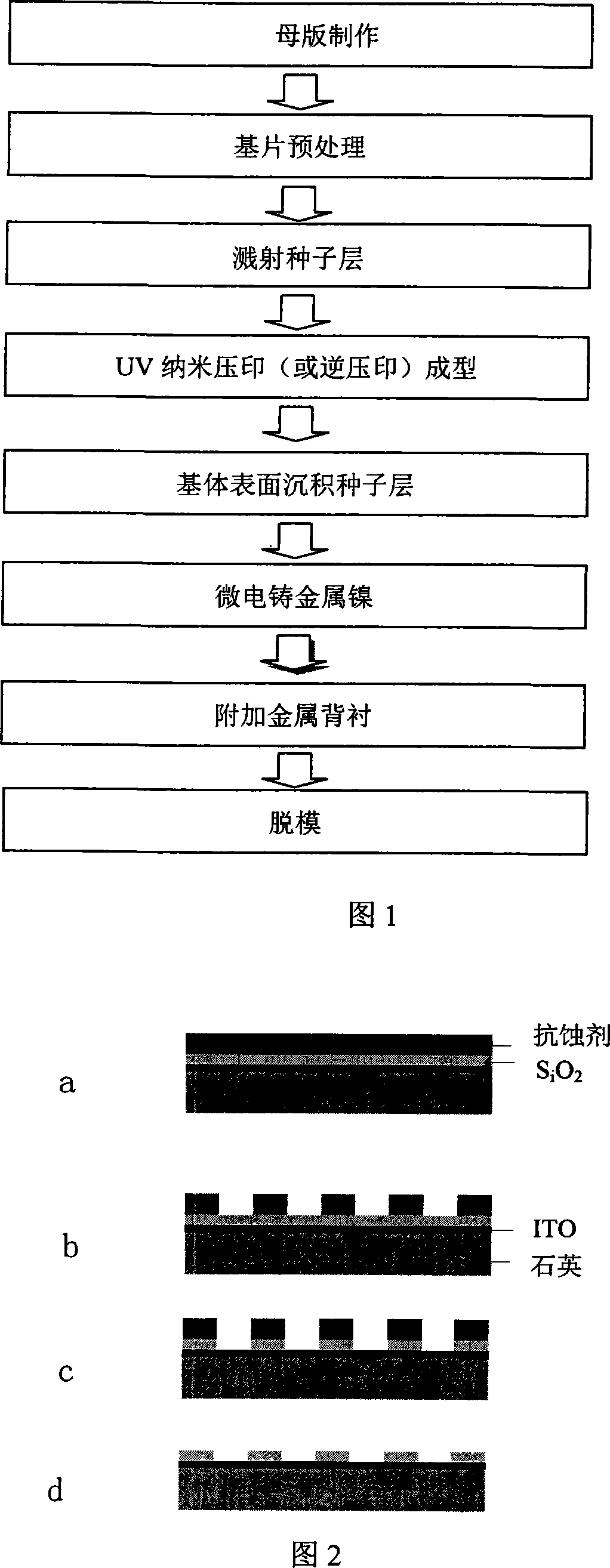

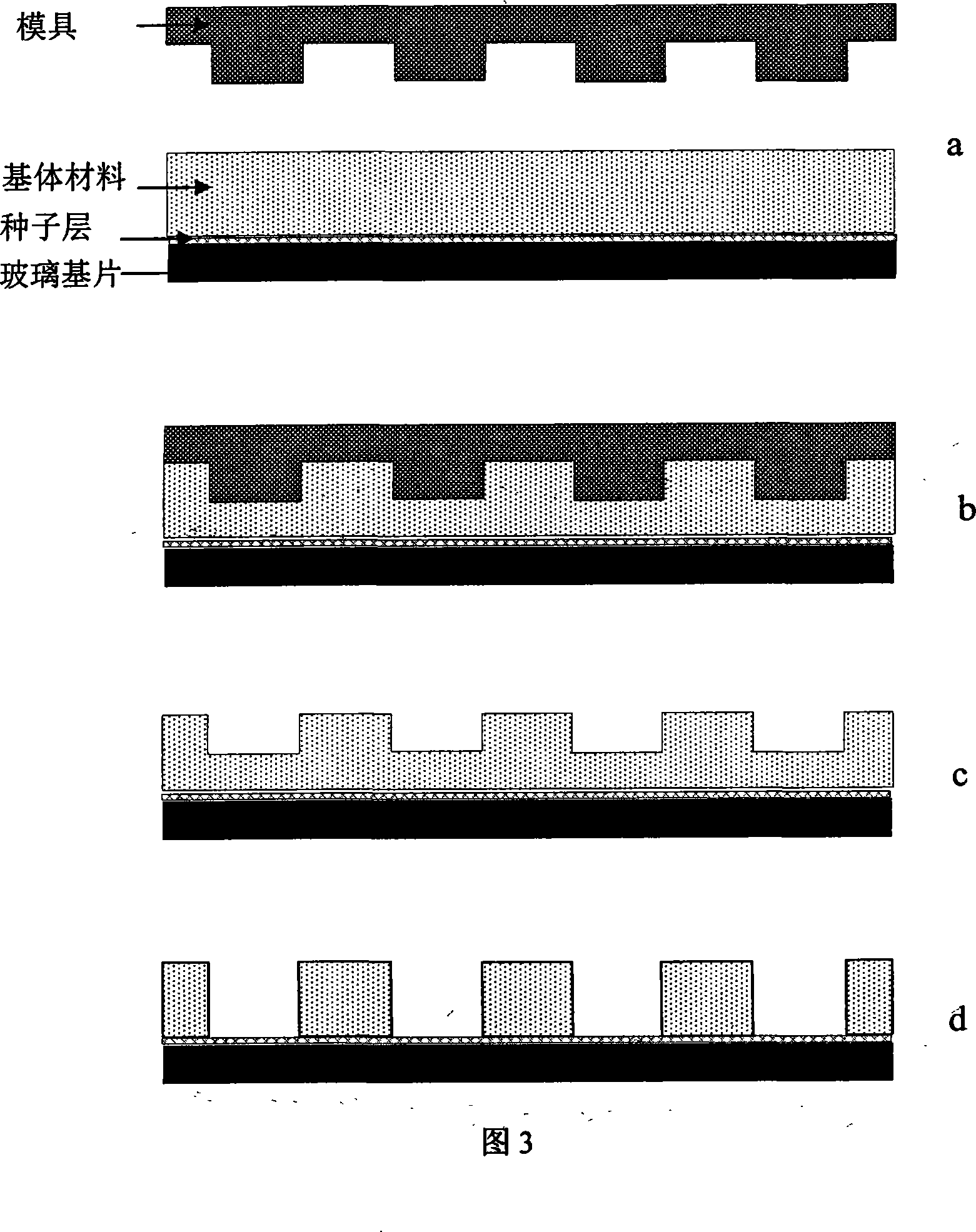

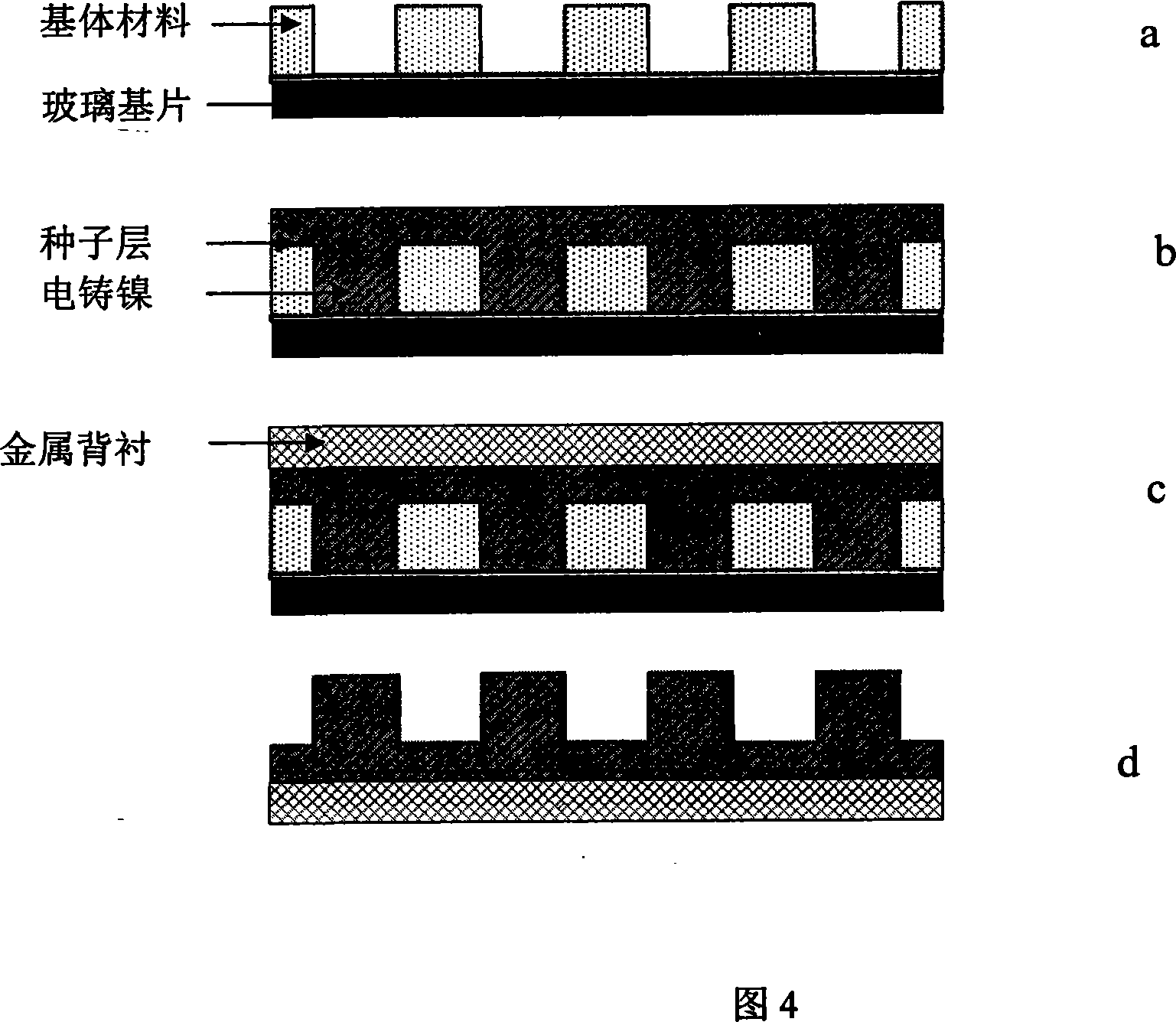

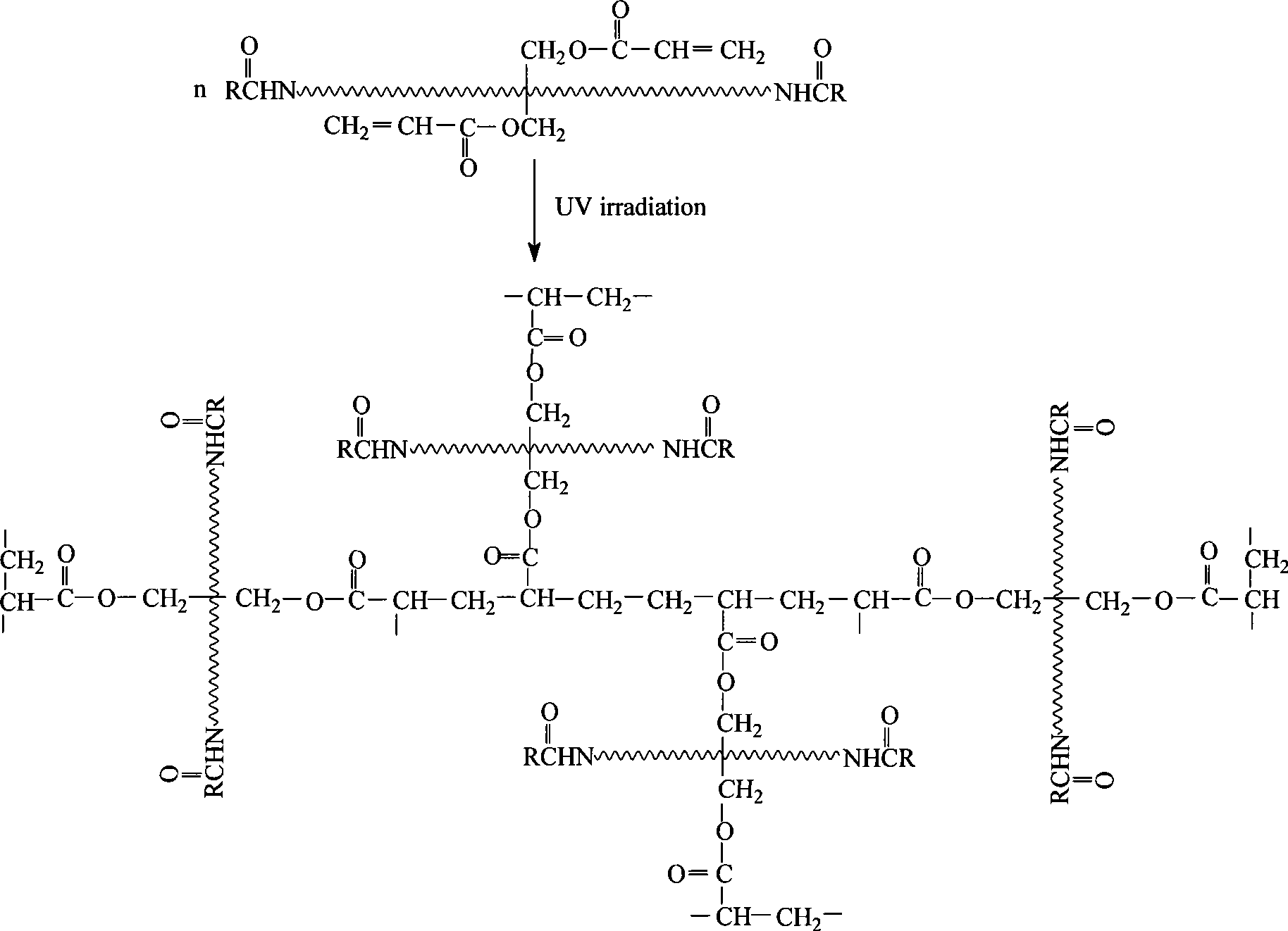

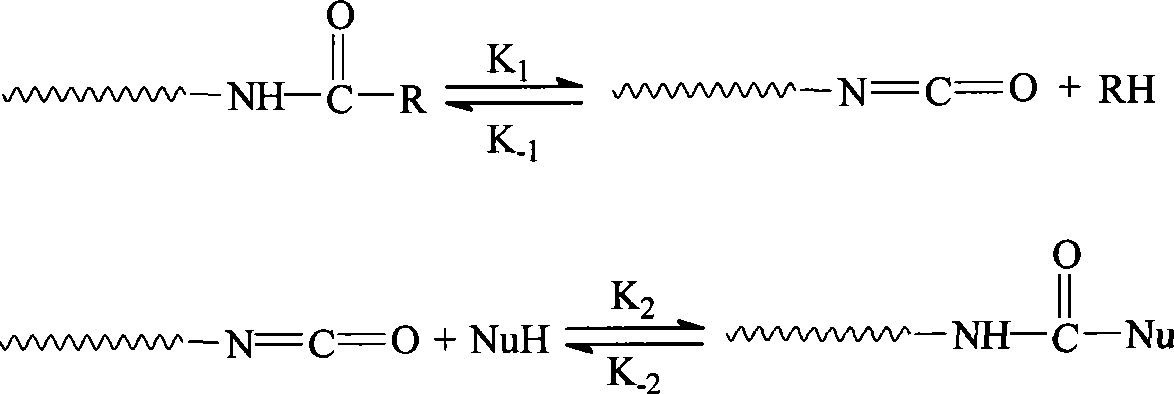

Minitype metal nickel mould producing method

InactiveCN101205054ASimple preparation processReduce manufacturing costDecorative surface effectsChemical vapor deposition coatingUltravioletElectron

The invention discloses a method for making a micro metal nickel mold. By adopting ultraviolet nano-imprint lithography and micro electroforming composite technology, the invention comprises the following basic technique flow: (1) a mother blank is lithographed by electron direct lithographing and dry etching; (2) a piece of glass taken as a substrate is cleaned and baked, with surface pretreated; (3) a Cr / Cu electroforming seed layer with a thickness of 90-110nm is sputtered on the glass substrate; (4) by taking the mother blank made by the step (1) as an imprint plate, a mold cavity microstructure is copied on ultraviolet organic light-cured substrate material by using a UV nano-imprint lithography technique; (5) a Cr / Cu or Au / Ti electroforming seed layer with a thickness of 8-12nm is deposited on the substrate material; (6) nickel with a depositional thickness of 300-500Mum is electroformed on the seed layer of the substrate material; (7) a metal backing is added; (8) after knockout, the metal nickel mold is obtained. The method has the advantages of low producing cost, simple technique and high producing effect, and can realize batch fabrication of submicron and nano-micro metal nickel mold with low cost.

Owner:SHANDONG UNIV

Sealed UV curable aqueous polyurethane resin and preparation method thereof

InactiveCN101381446AGood storage stabilityHigh hardnessPolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsSide chainAdhesive

The invention discloses closed type ultraviolet light solidifying waterborne polyurethane resin and a method for preparing the same. The polyurethane resin and the method are characterized in that the double bond of acrylic ester is introduced to the side chain of the polyurethane by utilizing a chain extender mode, and an end NCO group is sealed and protected by a sealer; and the side chain of a molecular chain of the obtained product has the double bond of an acrylic ester group, wherein the double bond is capable of ultraviolet light solidifying, and the end of a molecular main chain of the product has an unsealable sealer group. The polyurethane resin has the advantages of good storage stability and high hardness after solidification, and further improves the solidifying degree and the adhesive force of a solidifying film and is applied to the coating of workpiece shadow areas, thicker coatings and three-dimensional parts which are hard to penetrate by ultraviolet light. Because the resin coating film is subjected to triple solidification of natural drying solidification, ultraviolet solidification and unsealing-hot solidification, the resin coating film has the advantages of high solidifying degree, high hardness and high adhesive force of base materials. The product of the invention is obviously environmental friendly, and can be widely applied in fields of thick coatings of various base materials and an adhesive.

Owner:UNIV OF SCI & TECH OF CHINA +1

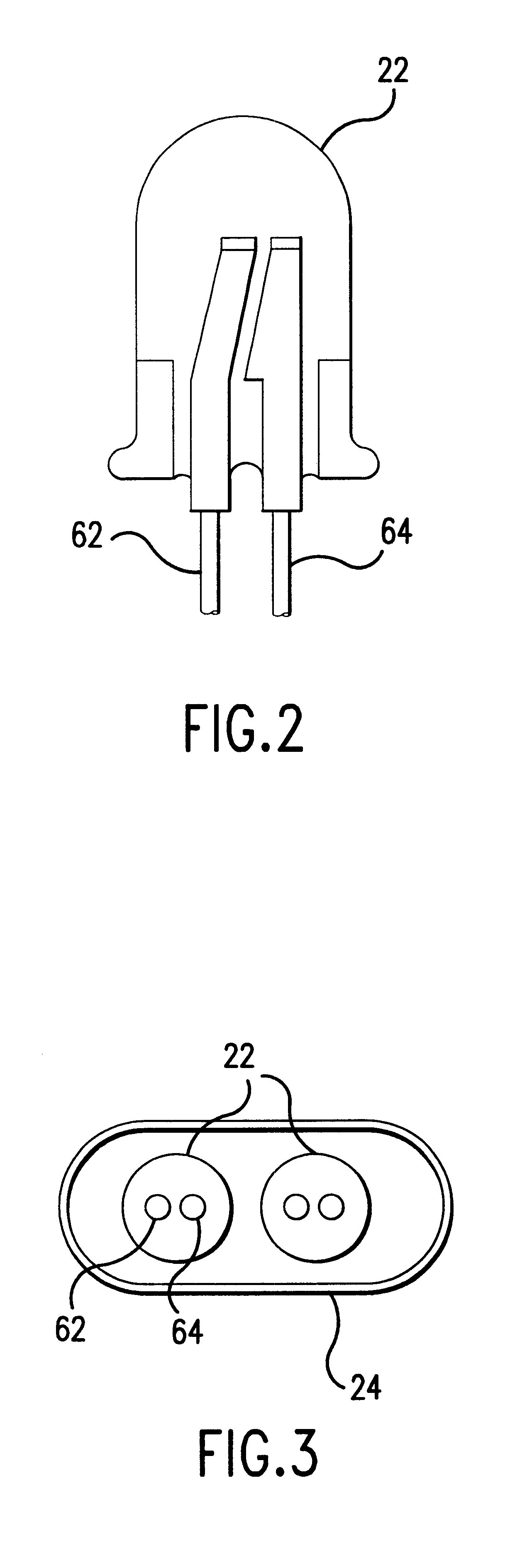

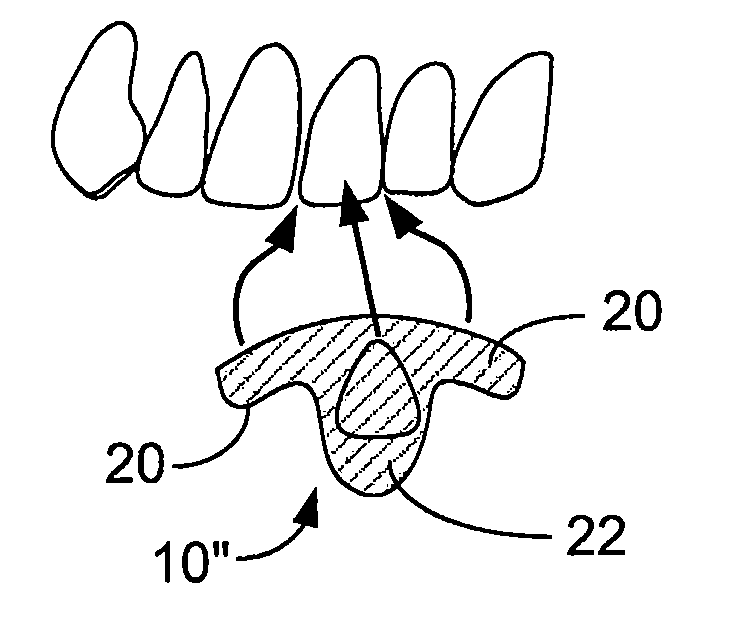

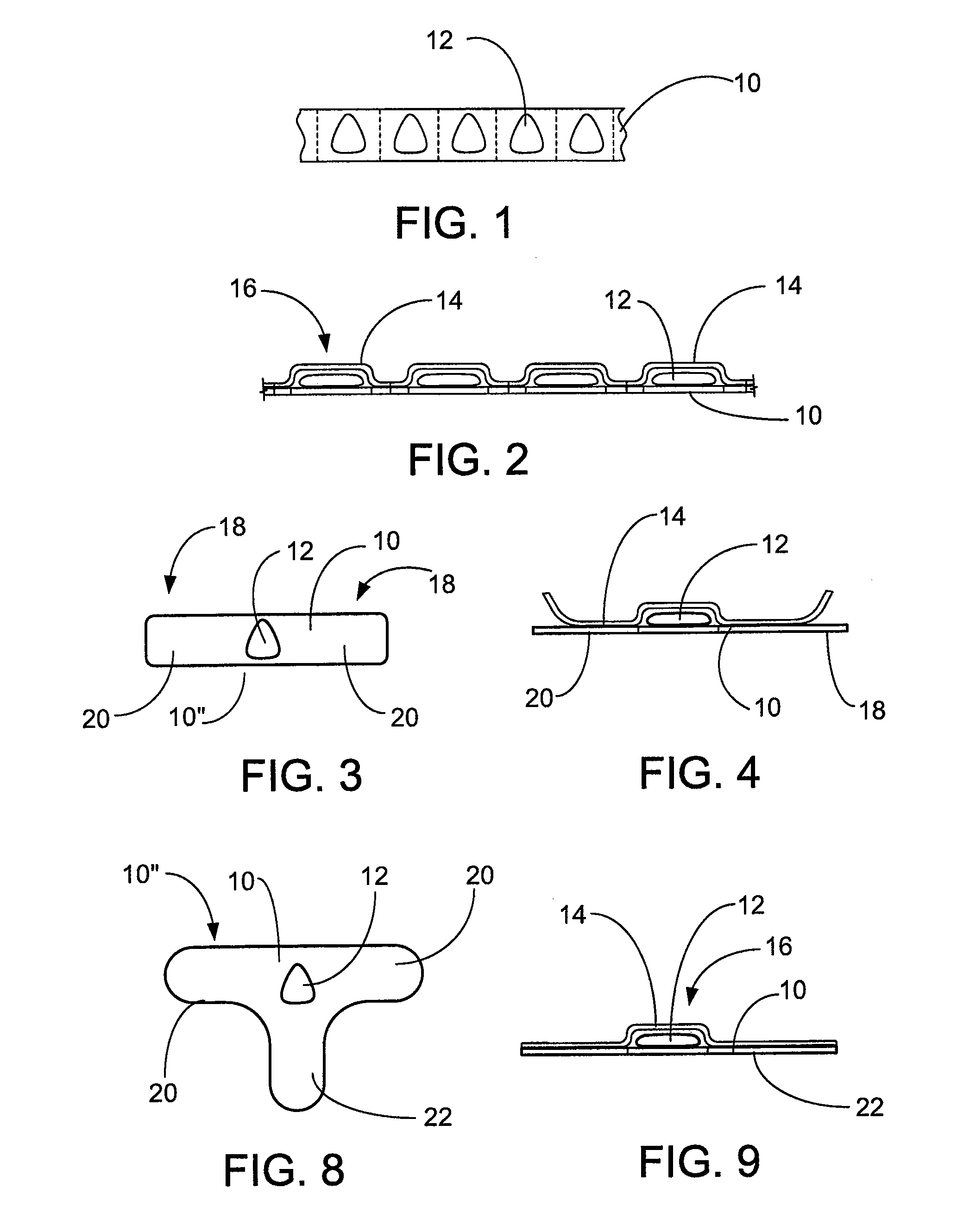

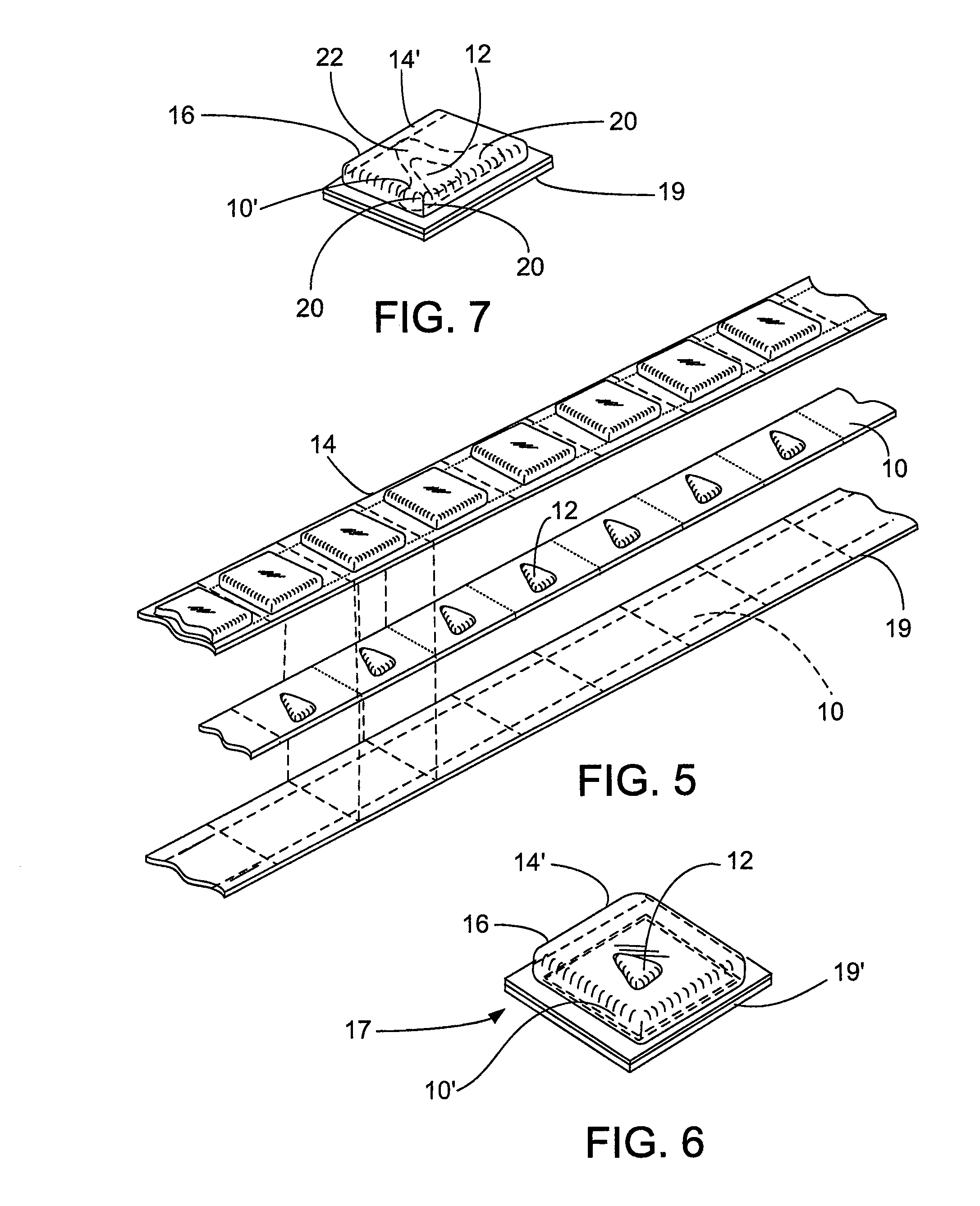

Dental composite delivery system

InactiveUS8197252B1Easy to pasteAvoid excessive accumulationDam holdersTooth clampsDental compositePolymer thin films

A packaged unit of composite for performing an aesthetic restoration. The unit is mounted on a polymeric film carrier material and is covered and sealed with the same or otherwise suitable covering film. The carrier film may be an elongated strip containing serially placed units of composite, each readily separable from the strip for individual usage. This packaging is in light restrictive outer packaging since the preferred unit of composite is of a light-cured material such as bis-GMA. In preferred packaging, the unit dose is singular and applicable to the tooth surface with the film carrier which is adapted with tabs to facilitate handling and the draping or damming of the subject tooth from adjacent teeth to facilitate application of the composite. The composite is then worked, i.e., formed on the tooth with the film intermediate the composite and the customary forming tools. In preferred embodiments, the single unit packaging of composite is mounted on a clear carrier film which includes embrasure tabs for selective insertion in the embrasure between the teeth, and in a further preferred embodiment, the carrier film includes an incisal tab to cover the incisal edge of the tooth. The clear carrier is contained in further outer packaging which limits actinic radiation from reaching the composite.

Owner:HARRISON III LOUIE V

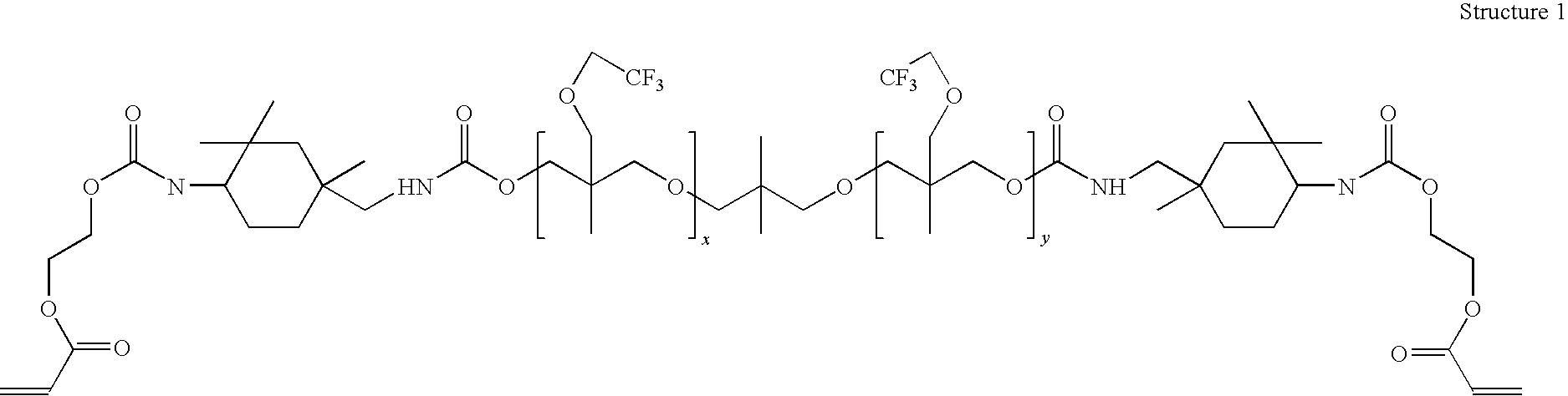

Ultra-violet light curable hot melt composition

InactiveUS6841589B2Consistency is sufficientTough physical propertiesAdditive manufacturing apparatusDuplicating/marking methodsWaxDiluent

A UV curable composition useful for three-dimensional inkjet printing comprising (i) at least one UV curable urethane (meth)acrylate resin; (ii) at least one wax; (iii) at least one (meth)acrylate diluent; (iv) at least one photoinitiator; and (v) at least one polymerization inhibitor; wherein the amount of wax (ii) is sufficient to phase change the UV curable composition after jetting.

Owner:3D SYST INC

Crystal whisker wear-resistant ultraviolet ray solidified paint and preparation process thereof

InactiveCN100999643AEasy constructionGood environmental benefitsPolyurea/polyurethane coatingsEpoxy resin coatingsWear resistantUltraviolet

The present invention is one kind of ultraviolet cured antiwear crystal whisker paint and its preparation process, and belongs to the field of light cured paint technology. The ultraviolet cured paint has crystal whisker filled to raise the antiwear performance, and consists of mainly photosensitive oligomer, active diluent, photoinitiator, crystal whisker, stuffing and assistant. It may be applied onto the surface of timber, high density board, metal, glass or ceramic to form coating with excellent performance, including high toughness and high antiwear property. In addition, the paint has no organic solvent and is environment friendly and convenient in use.

Owner:JIANGNAN UNIV

Coating material solidified by ultraviolet light and prepartion method

InactiveCN1796478AImprove wear resistanceGood flexibilityPolyurea/polyurethane coatingsPliabilityUltraviolet lights

An ultraviolet curing painting, comprising the main resin, the dilution agent and the photo-initiator, and comprising or not comprising the assistant, wherein the said main resin is a mixture of high and low degree of functionality polyurethane acrylate resins, of which the said high degree of functionality polyurethane acrylate resin is a polyurethane acrylate resin with 4-9 double carbon bonds at the end of the molecules, while the said low degree of functionality polyurethane acrylate resin is a polyurethane acrylate resin with 2-3 double carbon bonds at the end of the molecules. Compared with the present processes, the curing coat of the painting has good abrasion resistance and flexibility.

Owner:BYD CO LTD

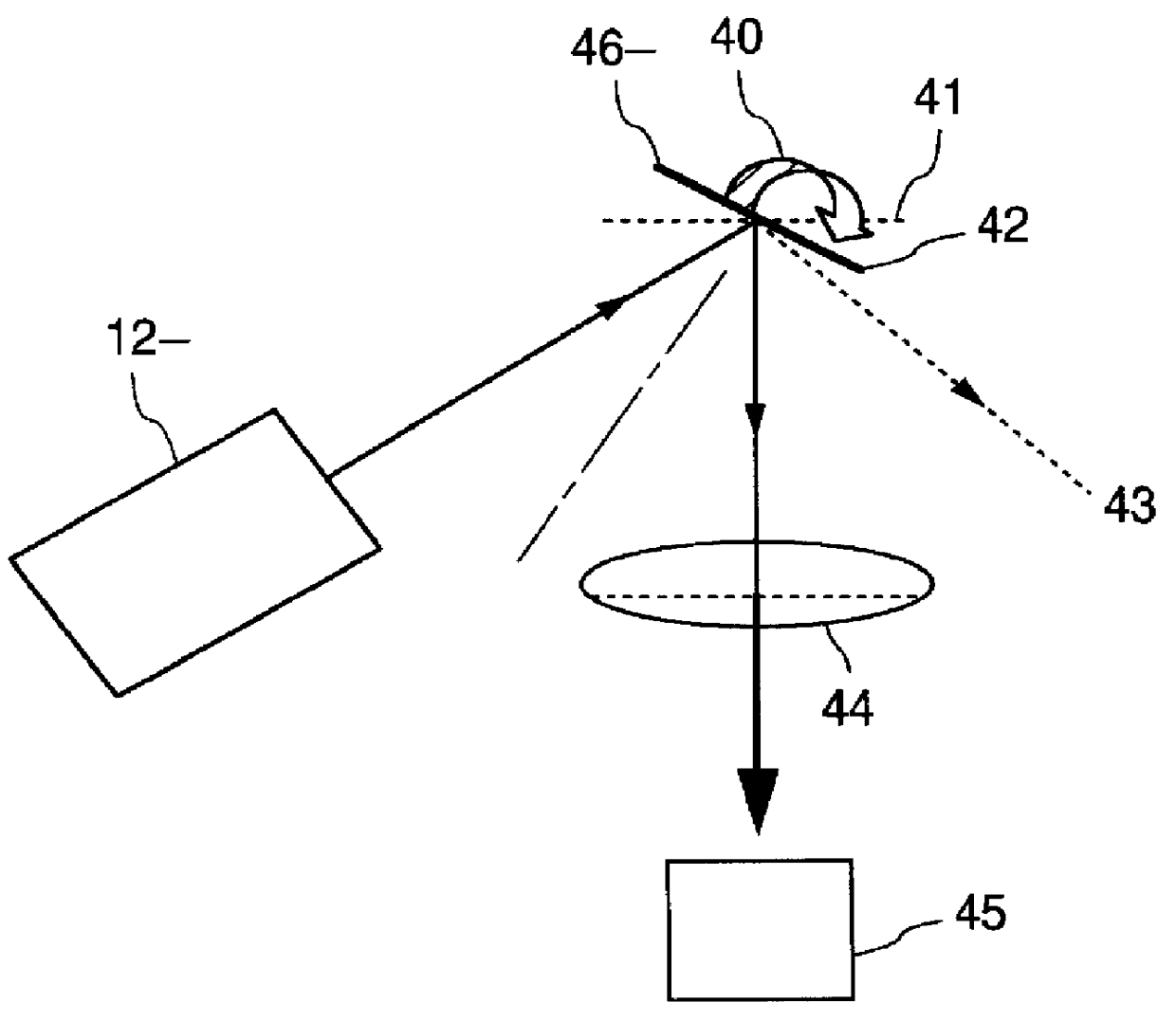

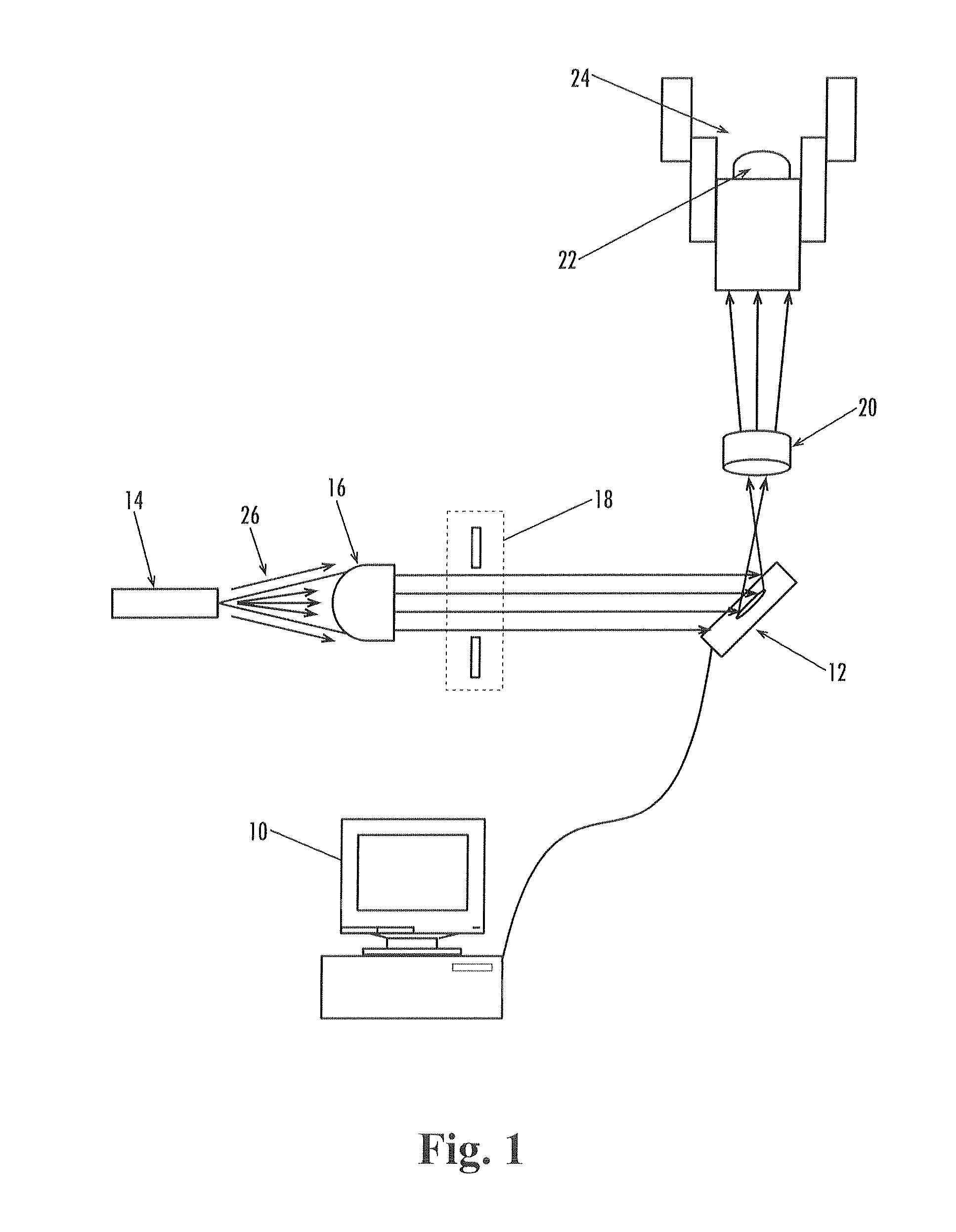

Method for Making Ophthalmic Devices Using Single Mold Stereolithography

InactiveUS20090250828A1Easy to adaptCost-effective mannerAdditive manufacturing apparatusOptical articlesMathematical modelLens materials

A method for manufacturing an ophthalmic lens comprising introducing a volume of photocurable lens material into a container, wherein said container comprises a mold surface. The method further comprises creating a digital 3-D mathematical model defining corrective needs of an eye and projecting programmed patterns of UV light through said mold via a pattern generator, wherein said programmed patterns of UV light cure said photocurable lens material into a lens shape defined by said mold surface and said digital model.

Owner:NOVARTIS AG +1

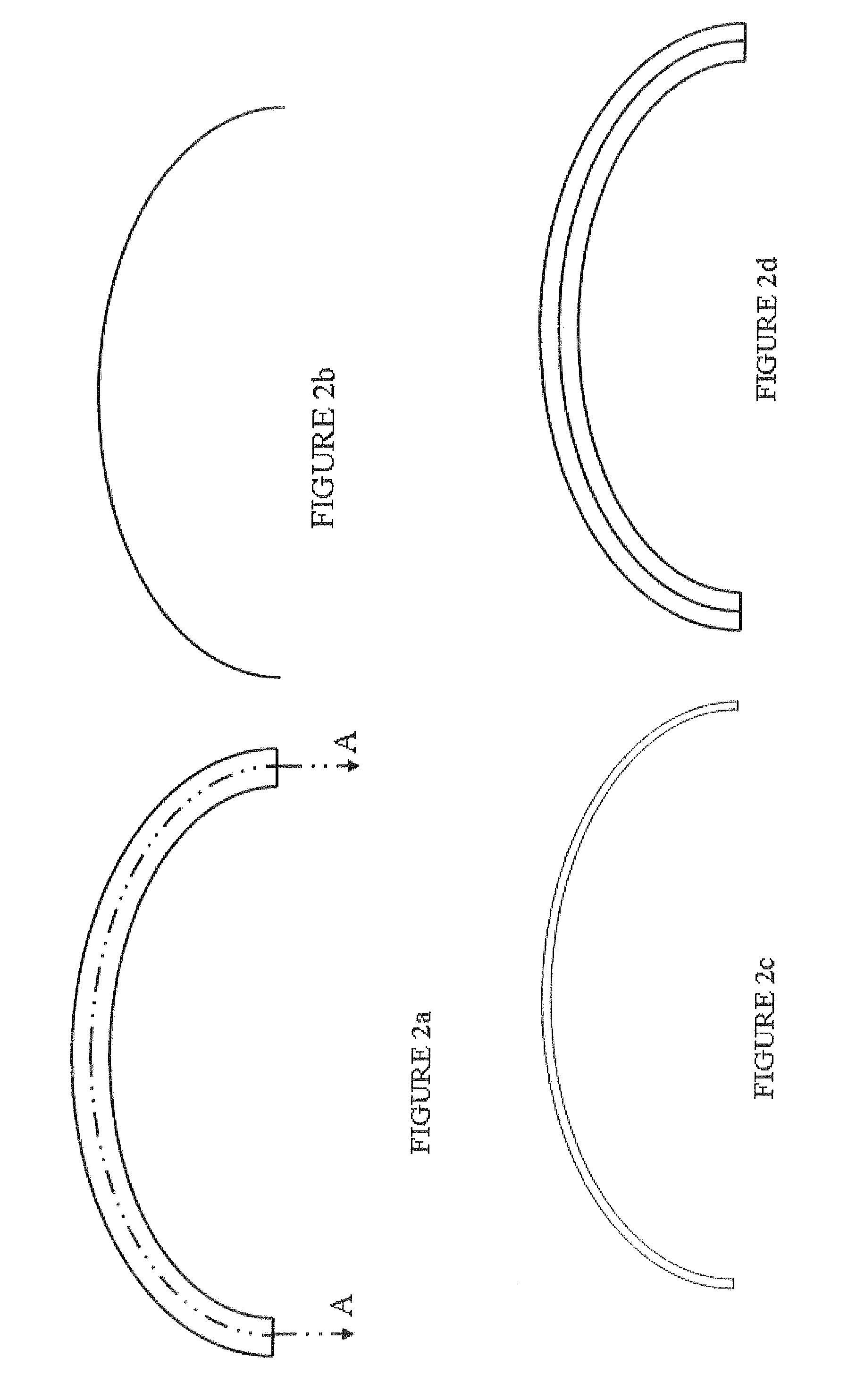

DLP principle based 3D printer

The invention discloses a DLP principle based 3D printer. The 3D printer includes: a resin tank, the bottom plate of which is light-transmitting; a vertical lifting mechanism, which is in fixed connection with a forming platform and is used for adjusting the distance between the resin tank and the forming platform; a computer, which is used for processing a three-dimensional model and segmenting the three-dimensional model into several profile graphs with certain thickness sequentially, and is connected to an electrical control device for controlling automatic lifting of the forming platform by the vertical lifting mechanism and controlling irradiation of a DLP projector on the liquid level of light-cured resin in the resin tank; and the DLP projector, which is arranged below the resin tank and is connected to the computer, and makes the graph light path of the profile graphs transmit the bottom plate of the resin tank so as to irradiate the light-cured liquid resin. According to the invention, the DLP projection technology is adopted and the light cured material forming technology is combined to form a set for system. The system has the characteristics of simple components and compact whole structure, the formed products have improved precision, the manufacturing cost is low, and the product forming speed is faster.

Owner:SHANGHAI KUNRONG IND

Transparent anti-ultraviolet heat insulating compound film and method for preparing the same

InactiveCN101323191AGood heat insulationExcellent UV absorptionSynthetic resin layered productsPretreated surfacesSurface layerAdditive ingredient

The invention relates to a transparent anti-ultraviolet heat-proof complex film with nanometer oxide and a preparation method thereof, which mainly solves technical problems of high cost, poor quality and the like that existed in the transparent film and film technique of glass surface. Technical proposal of the invention is: the transparent anti-ultraviolet heat-proof complex film, of which, the understratum is the high transparent film or glass base material, and the surface layer is the nanometer transparent heat-proof function photo-cured coating or the nanometer transparent heat-proof function pressure-sensitive adhesive; wherein, the components and parts by weight of the nanometer transparent heat-proof function photo-cured coating or the nanometer transparent heat-proof function pressure-sensitive adhesive are as follows: photo-cured resin or pressure sensitive adhesive: 50-94, nanometer powder: 3-9, surface tension accessory ingredient: 0.2-1.0, thinner: 2.0-35.0, dispersant: 0.8-5.0. The heat-proof complex film of the invention possesses not only the excellent heat isolation performance, ultraviolet radiation absorption performance, but also excellent 'penetrability'. The heat-proof complex film can be extensively used for auto windows, building windows, glass curtain walls and other occasions.

Owner:金国华

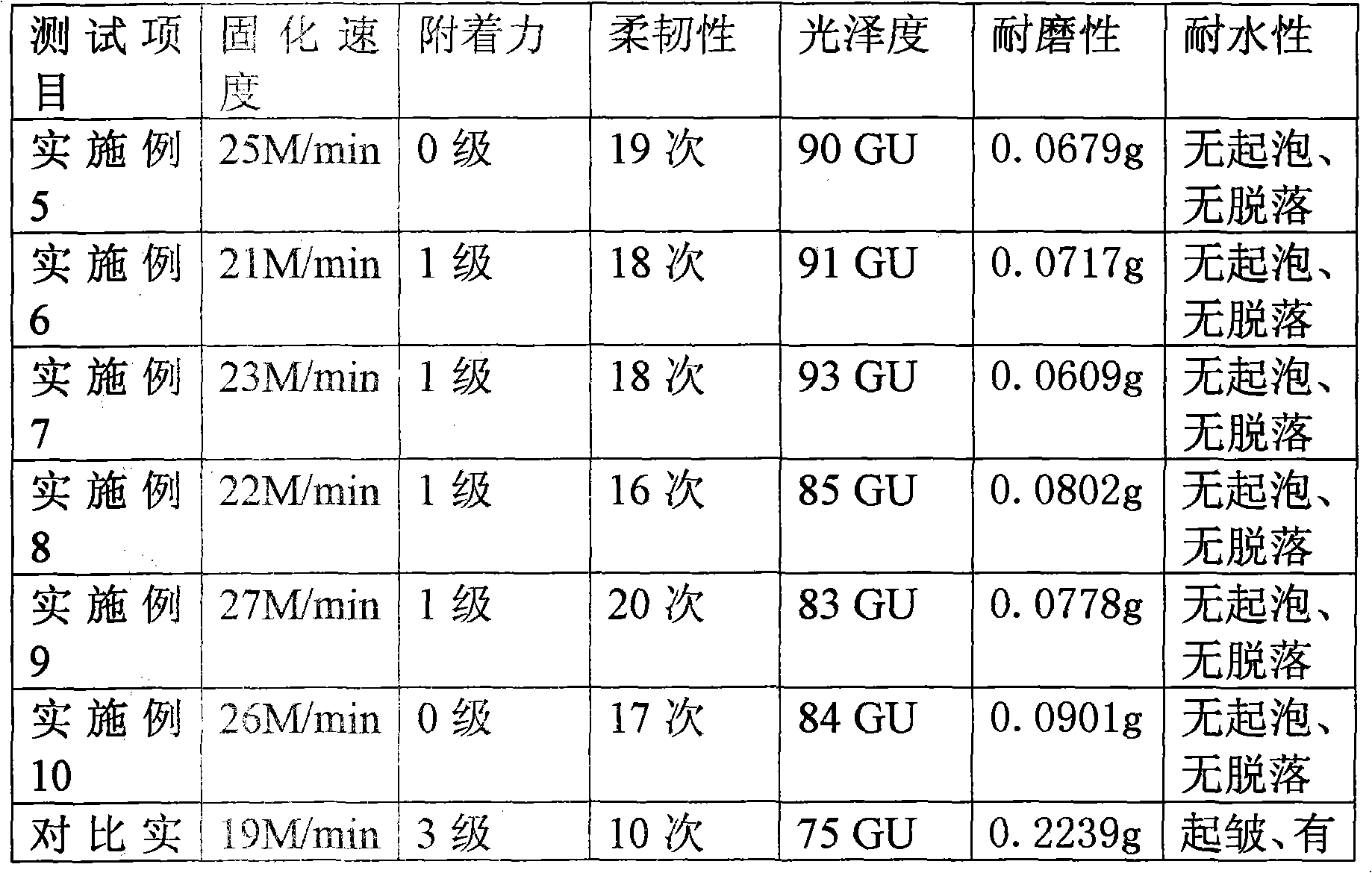

Waterborne wear-resisting ultraviolet-cured glazing oil and preparation method thereof

ActiveCN101967341AImprove wear resistanceImprove water resistancePolyurea/polyurethane coatingsEpoxyAminosilochrome

The invention provides waterborne wear-resisting ultraviolet-cured glazing oil and a preparation method thereof. Epoxy resin is subjected to ring opening by the amino of an amino siloxane coupling agent, and is subjected to polymerization with diisocyanate, a chain extender and hydroxyl acrylate to prepare modified polyurethane acrylate waterborne light-cured resin, and is stirred with various aids to obtain a target. A siloxane group is introduced into a resin main chain structure, so that the wear resistance and the water resistance of the glazing oil are improved; a dry film of the glazingoil has the 100-circle wear of less than 0.1 g, and does not foam or fall after soaking in water for 10 hours. An epoxy resin structure is introduced, so that the initial tack of the glazing oil to print ink is improved. Through small molecules and an internal crosslinker chain extender, an obtained flexible chain structure resin ensures the adhesion and the flexibility of the glazing oil on the ink, the folding number of the dry film of the glazing oil is 16 to 20, and the adhesion is 0 to 1 level. An active monomer diluent is not used, toxic and harmful substances of methylbenzene or dimethylbenzene are free, and a paint film does not have a diluent residual, and is environment-friendly.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com