Patents

Literature

50 results about "Floorcovering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

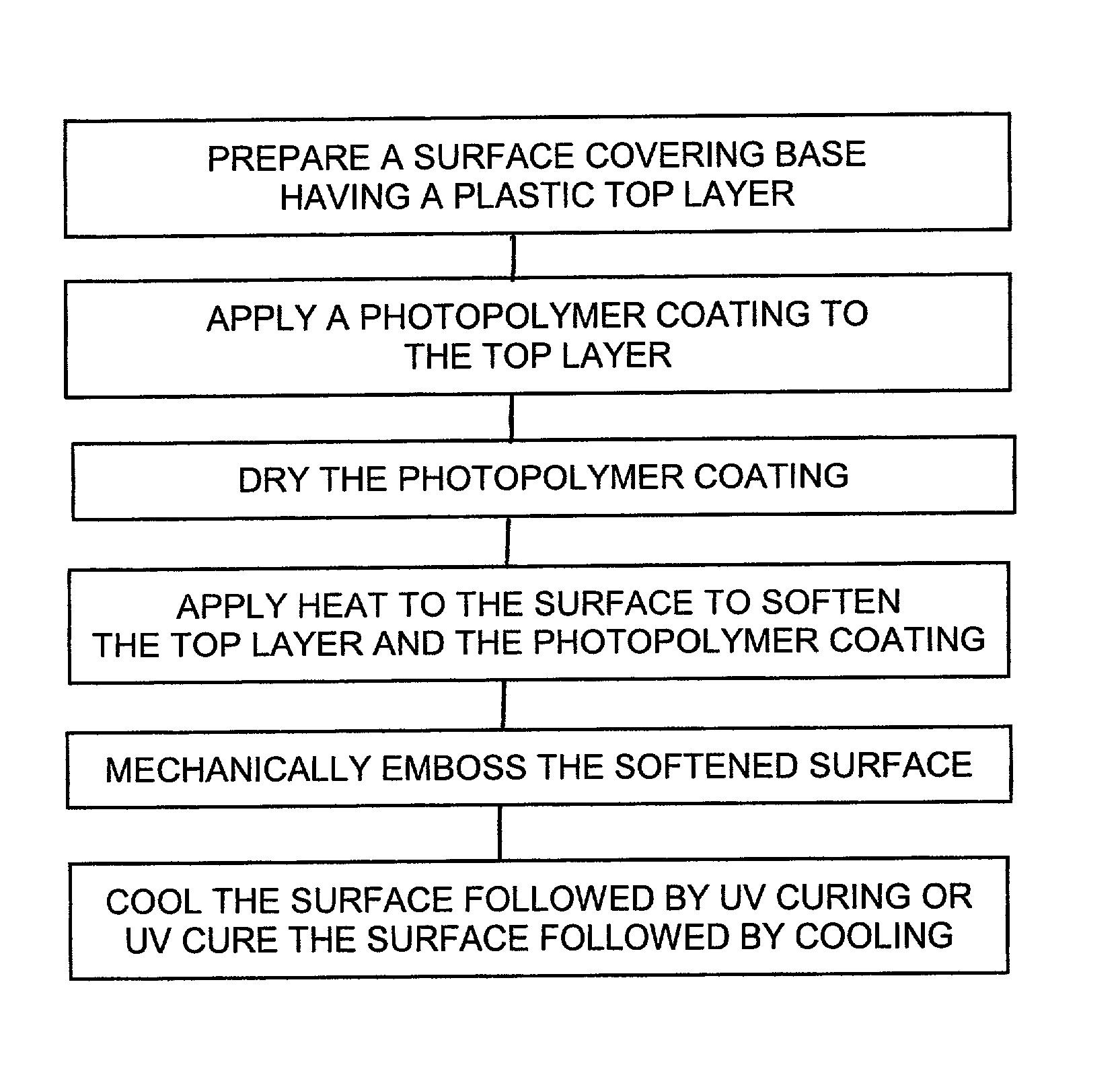

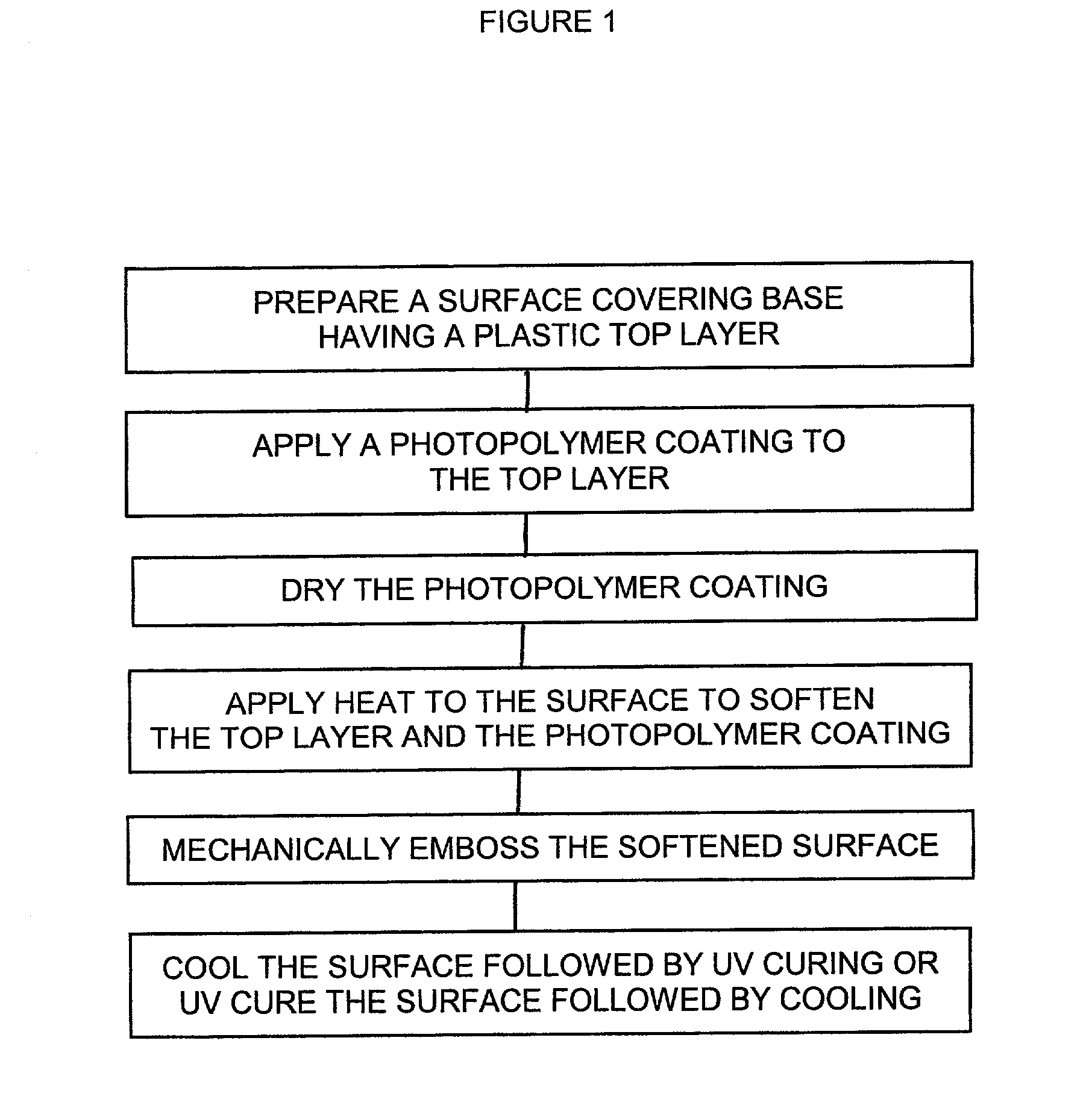

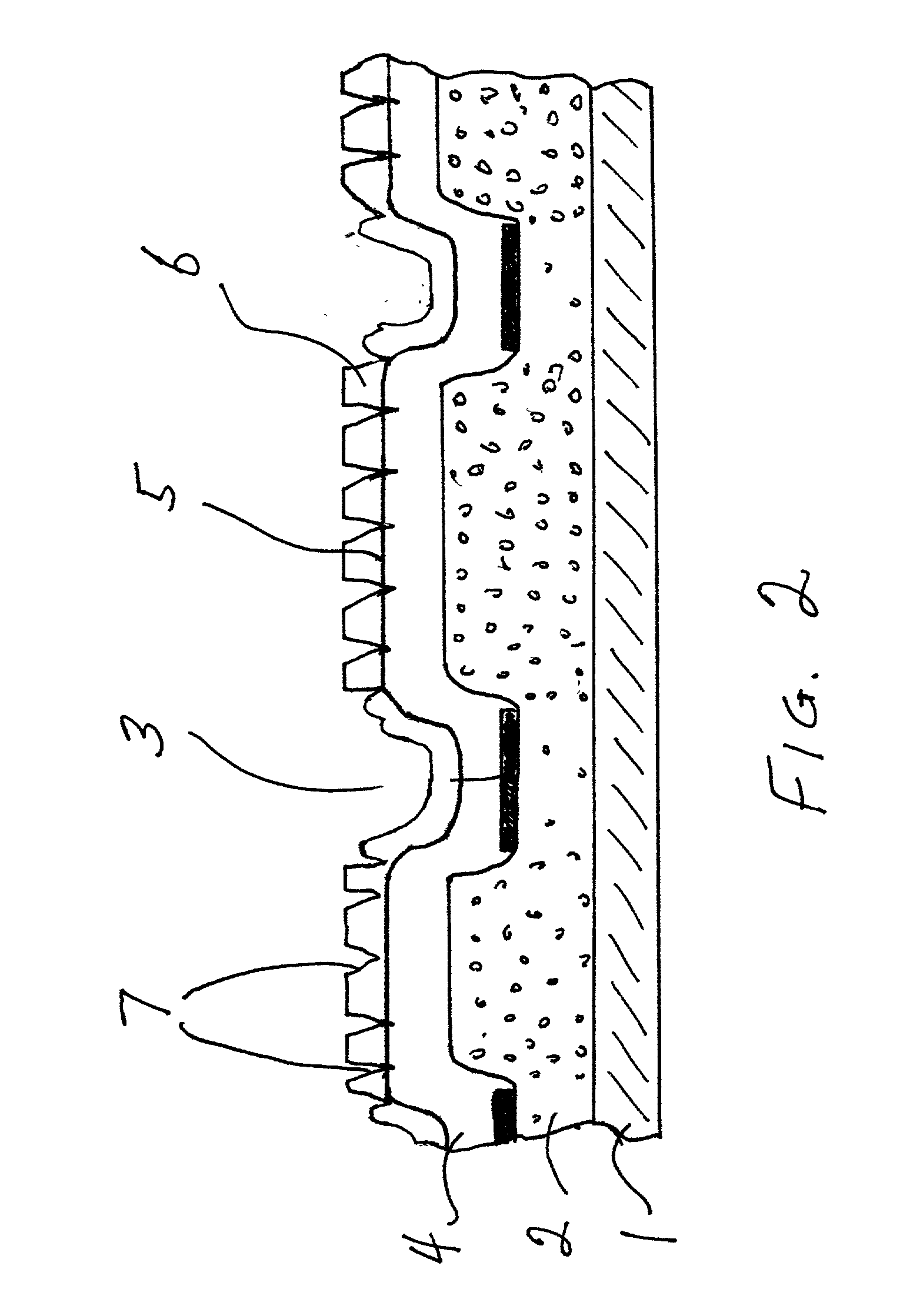

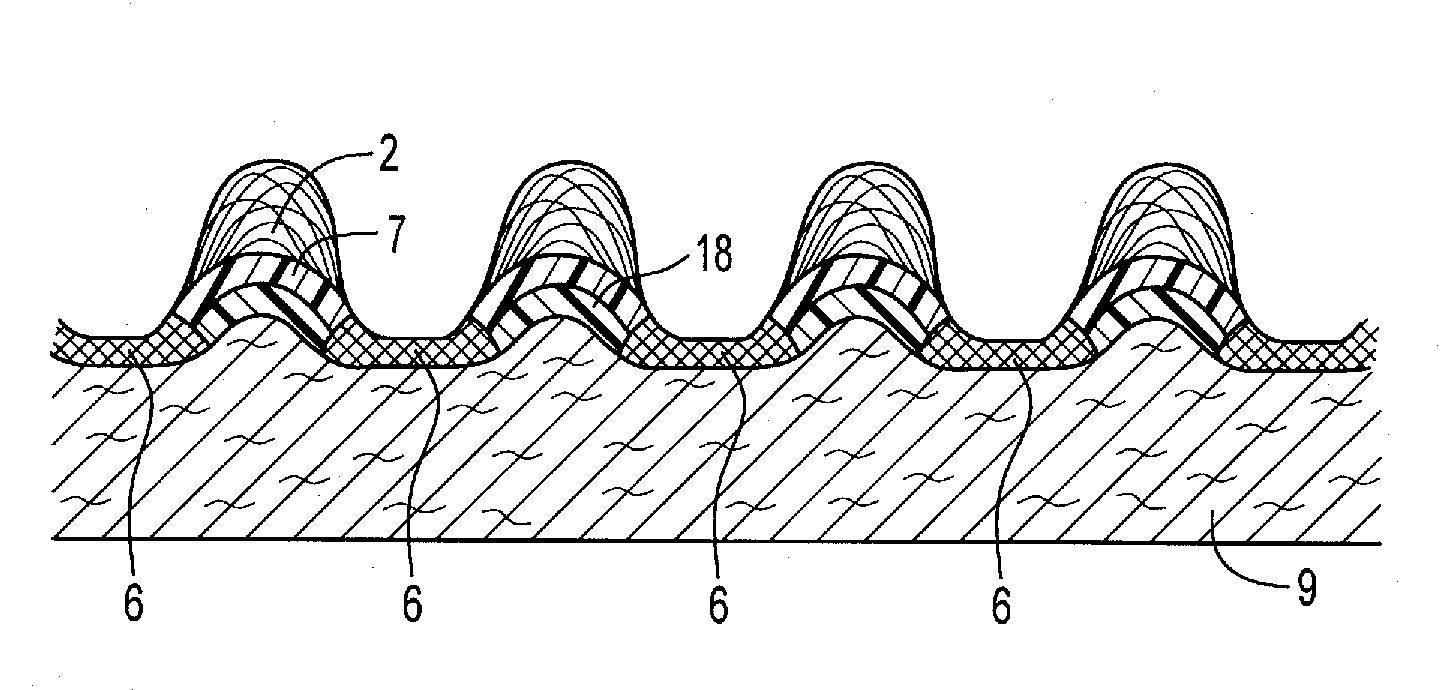

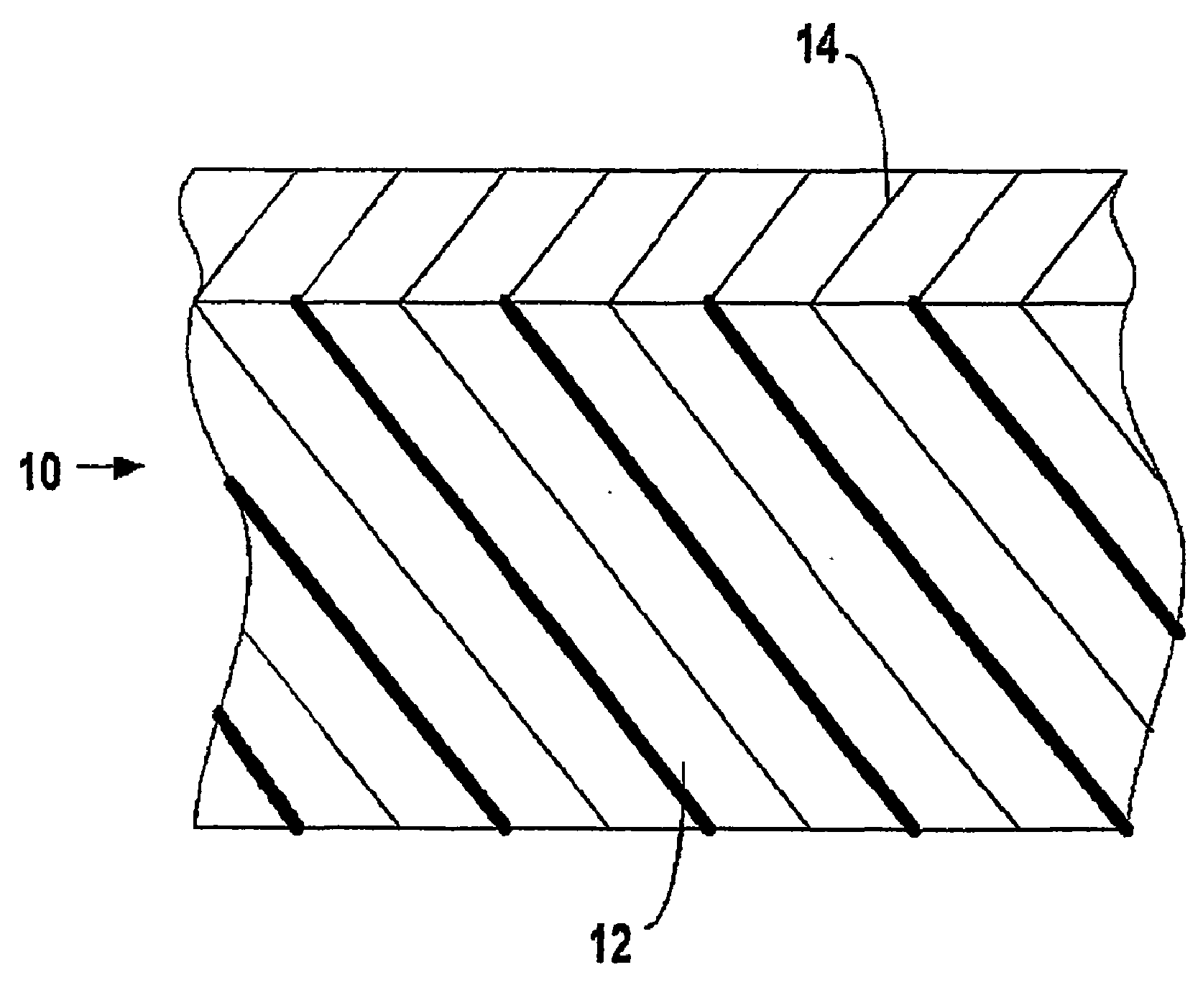

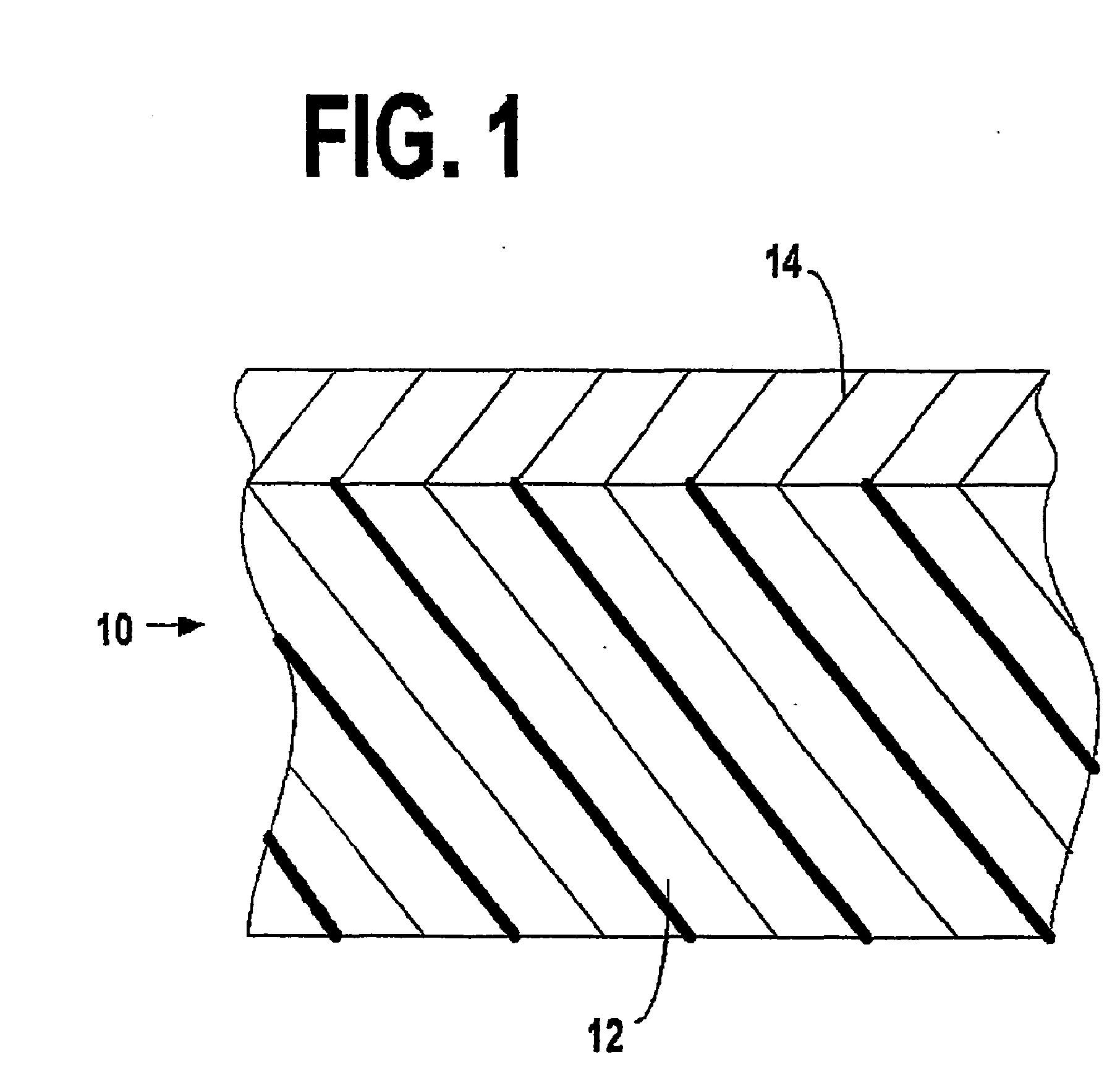

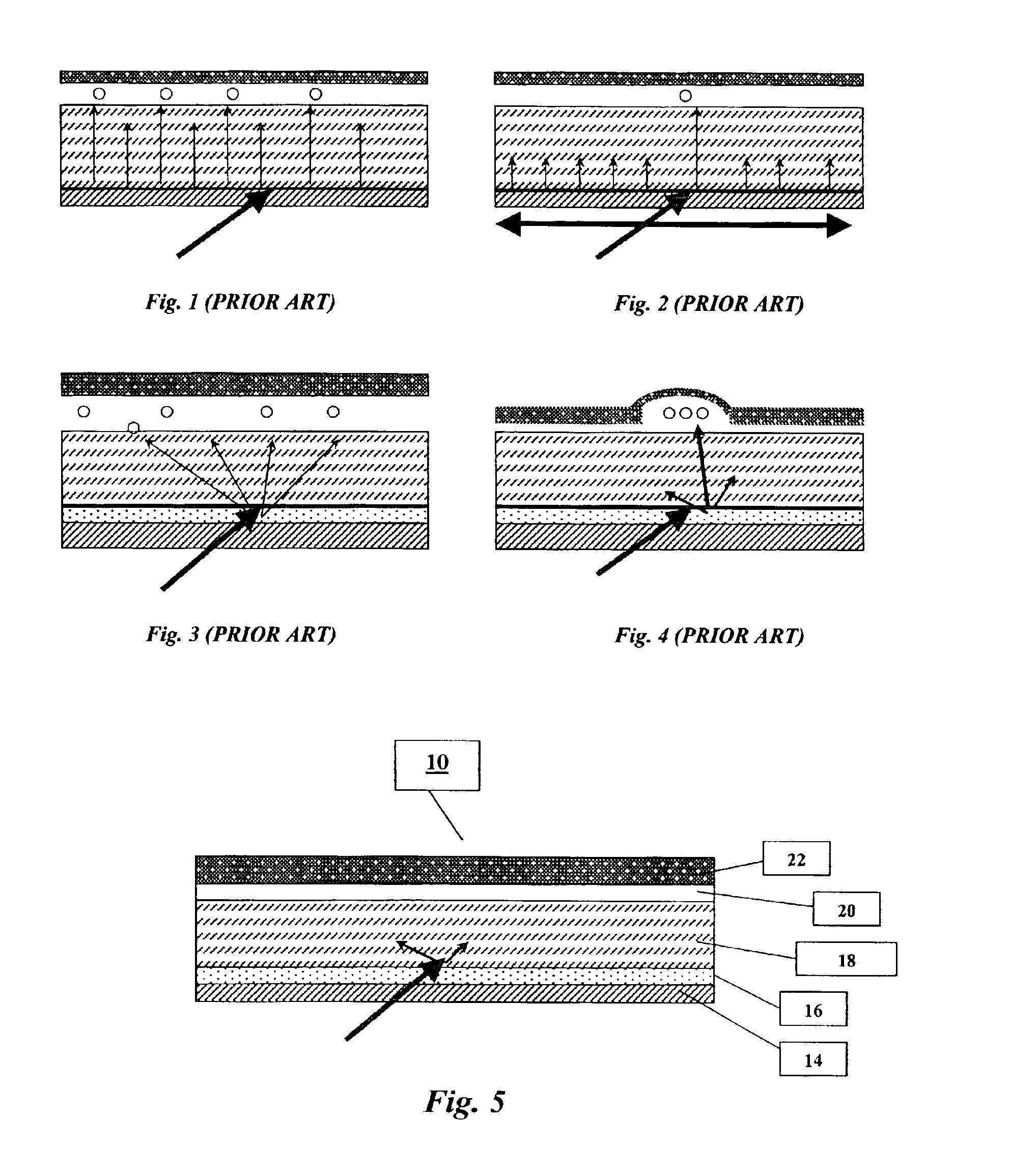

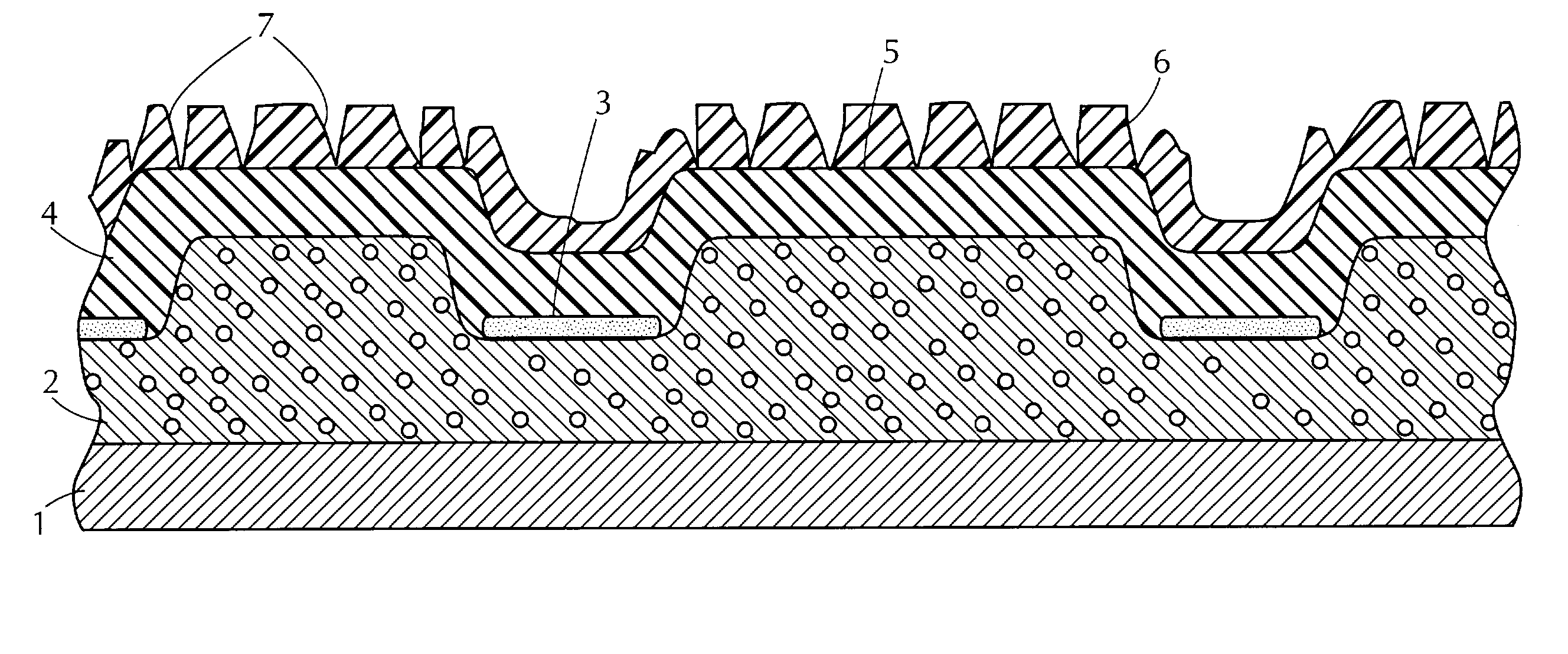

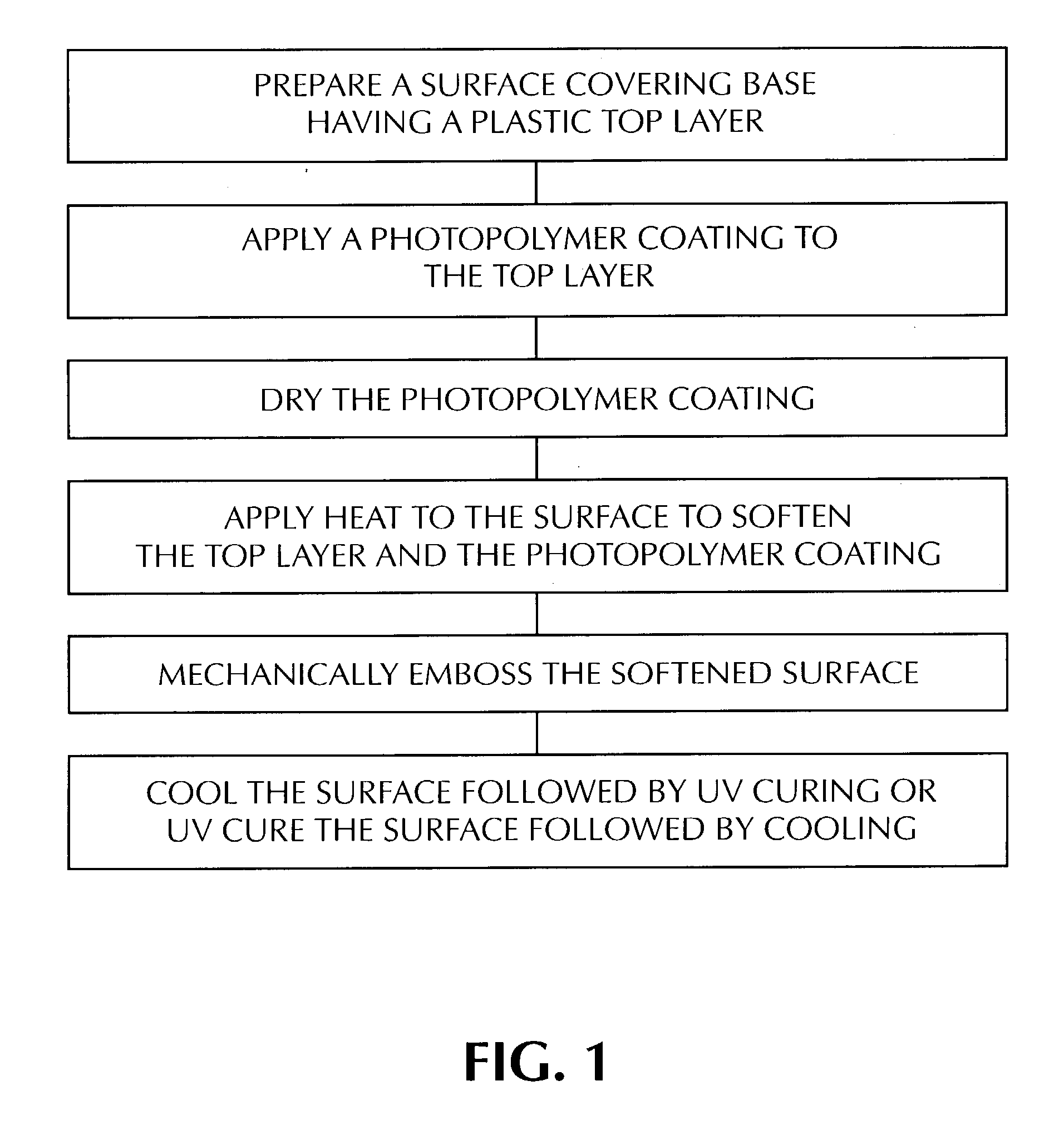

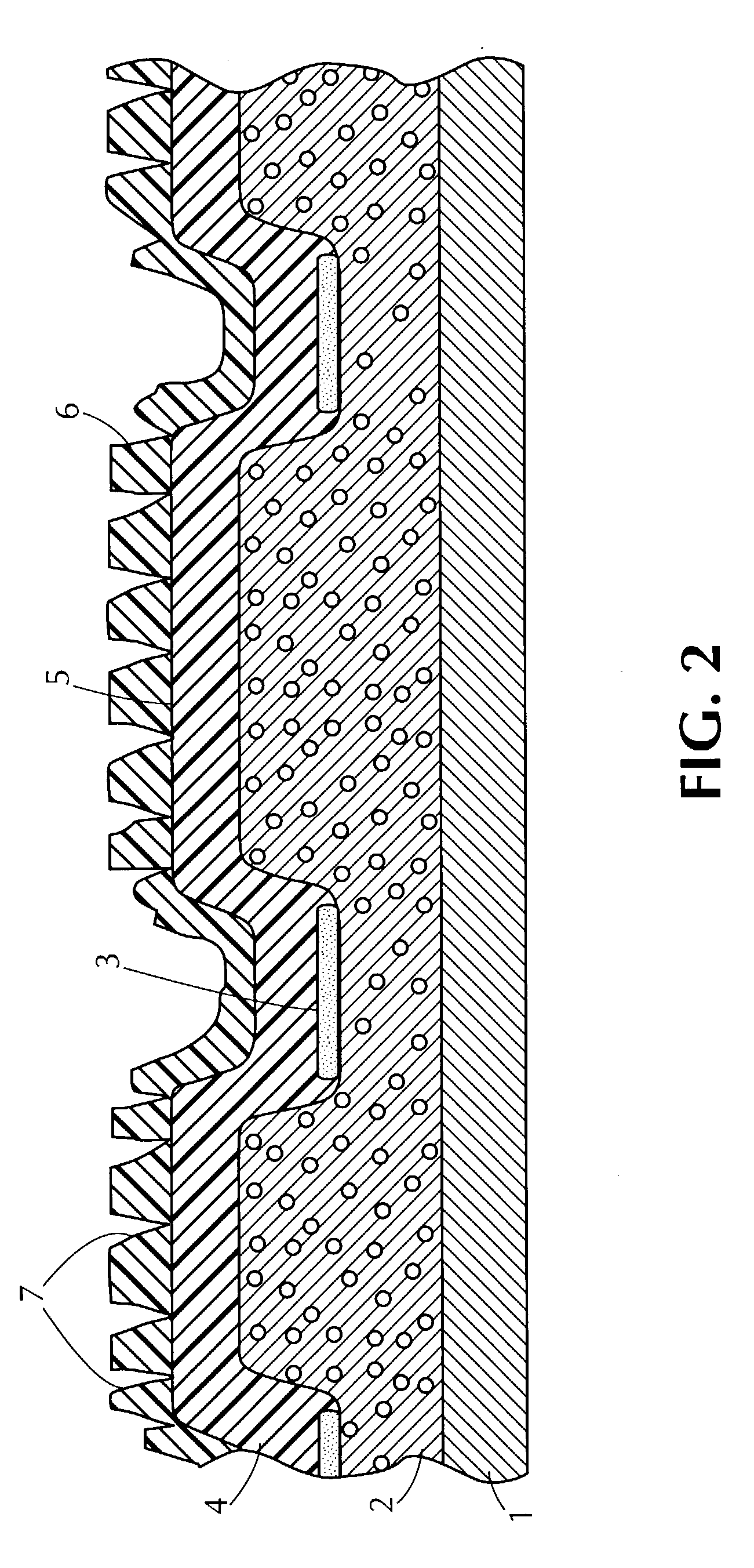

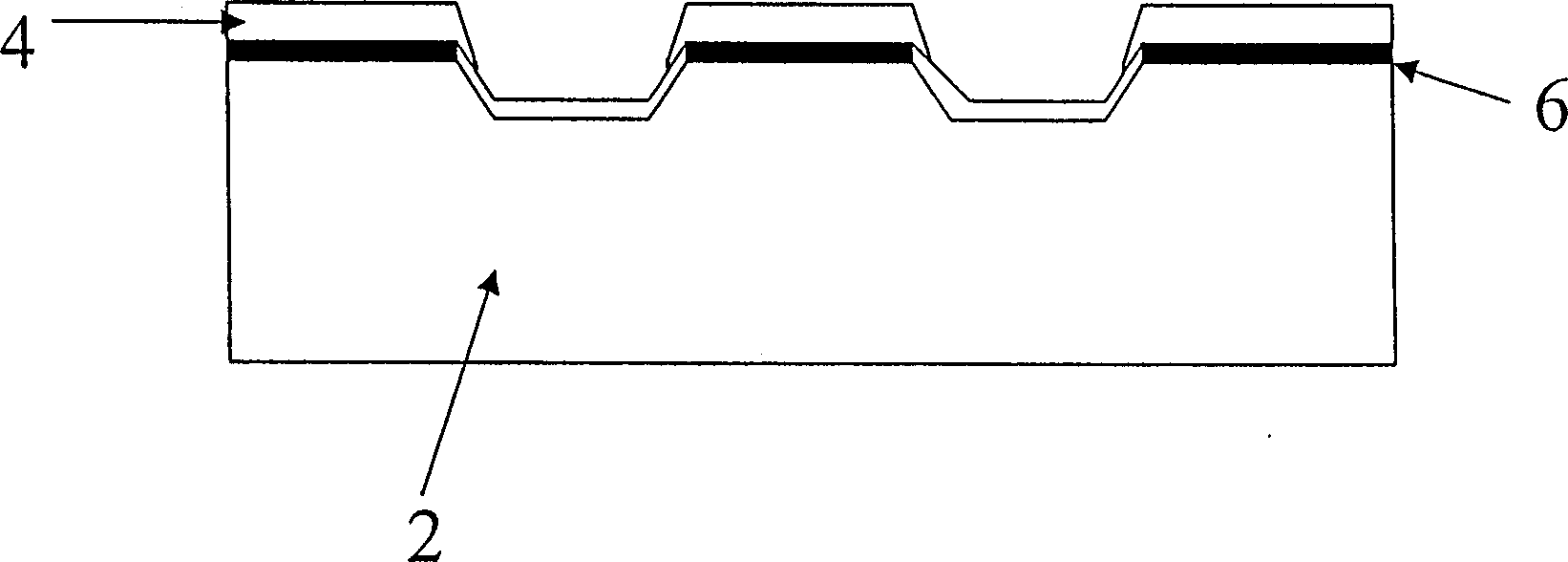

Polyurethane coated resilient surface covering having improved fidelity of texture and process of manufacture

Mechanically embossed resilient surface coverings having superior textural fidelity are prepared by mechanically embossing a polyurethane coated floorcovering before the polyurethane is cured. The mechanical embossing is conducted when the polyurethane is dry and the underlying plastic layer and the polyurethane are softened by heating. After the mechanical embossing step, the polyurethane is cured using ultraviolet (UV) light. The product can be cooled before or after UV curing. The invention is applicable to a variety of resilient surface covering products including floor and wall coverings which otherwise have a wearlayer which can be softened by heating. This includes surface coverings having the full range of decorative effects available in the art, including surface coverings which also have been, for example, chemically embossed, mechanically embossed, chemically and mechanically embossed or not embossed at all prior to application of the process of the invention.

Owner:TARKETT INC +1

Foamable compositions which comprise isononyl benzoate

InactiveUS20050049341A1High viscosityIncrease shear rateSynthetic resin layered productsAbsorbent padsFloorcoveringPlasticizer

Compositions for producing foamed products which comprise a chlorinated polymer such as PVC and at least one isomeric nonyl benzoate as a plasticizer, the use of these compositions, and products produced therefrom including PVC-containing floorcoverings, synthetic leather, and wallcoverings.

Owner:EVONIK OXENO GMBH (DE)

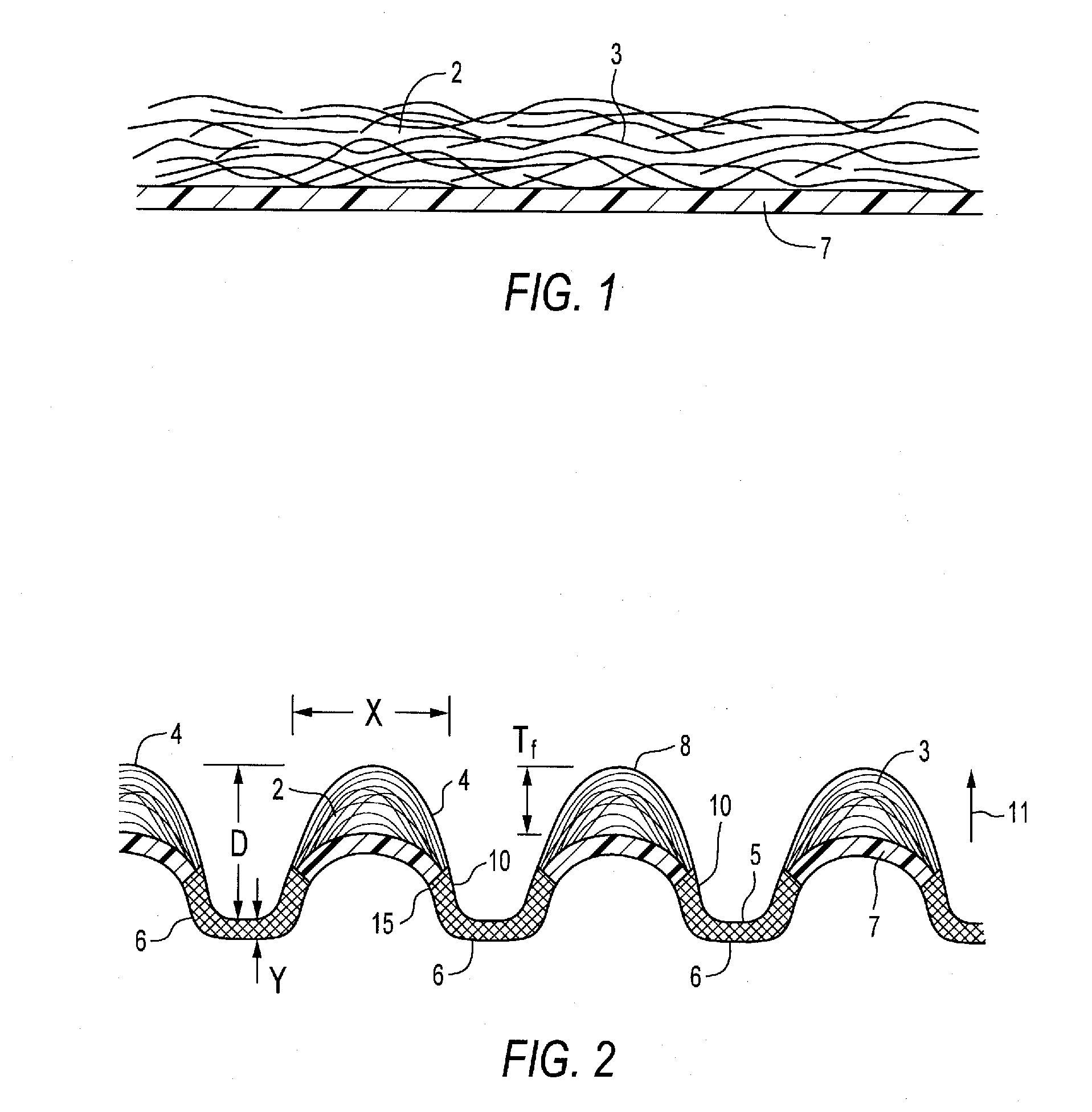

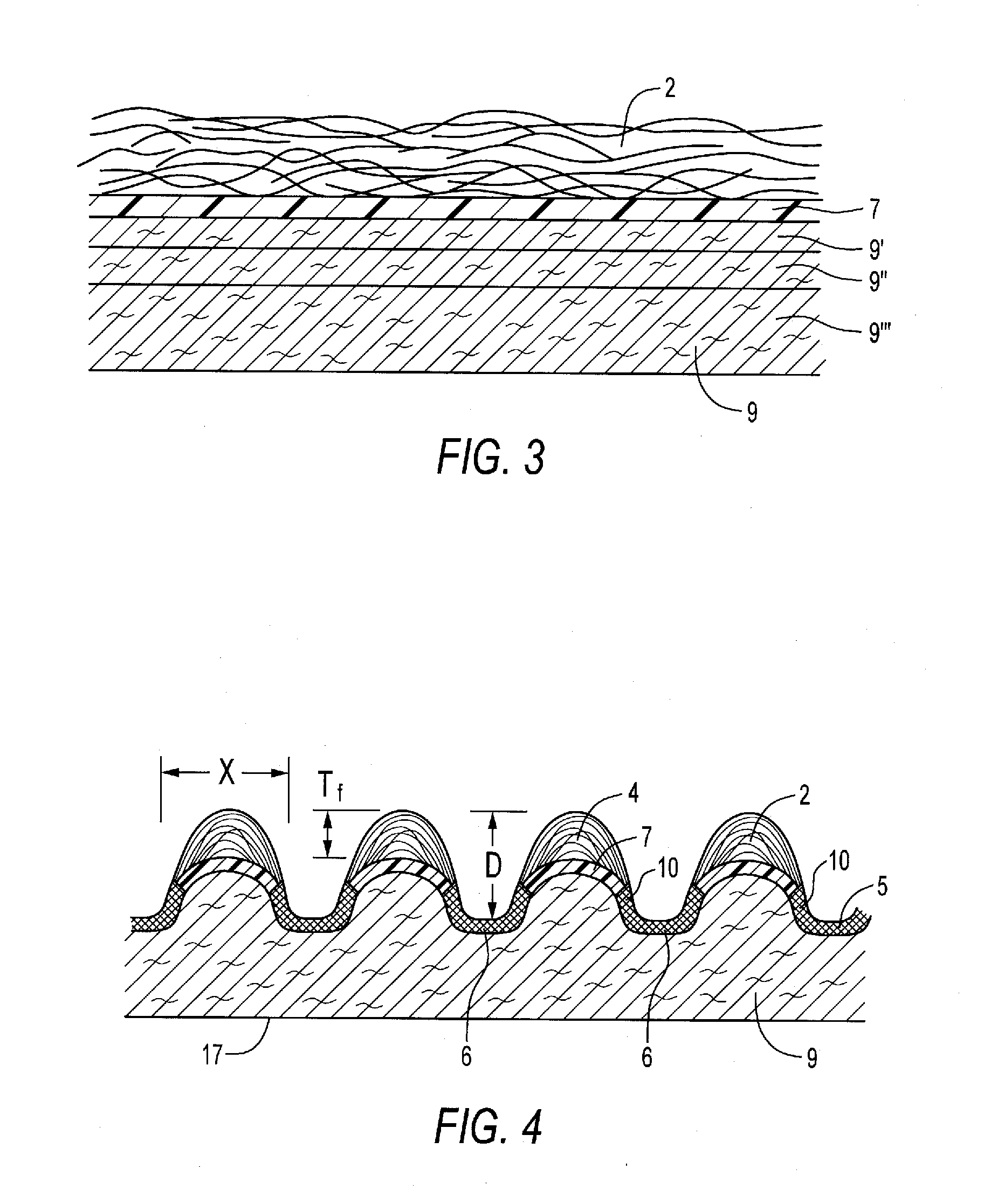

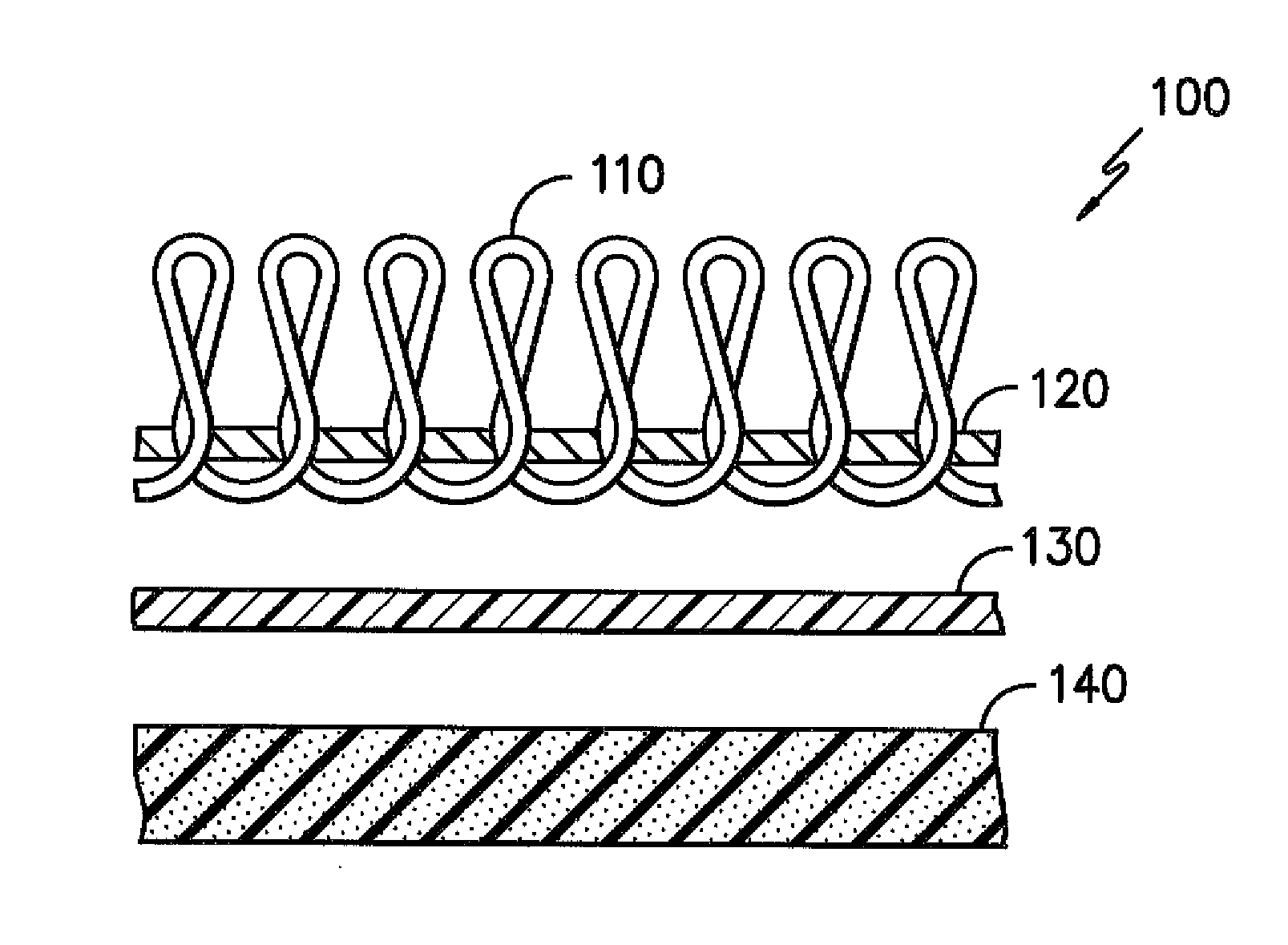

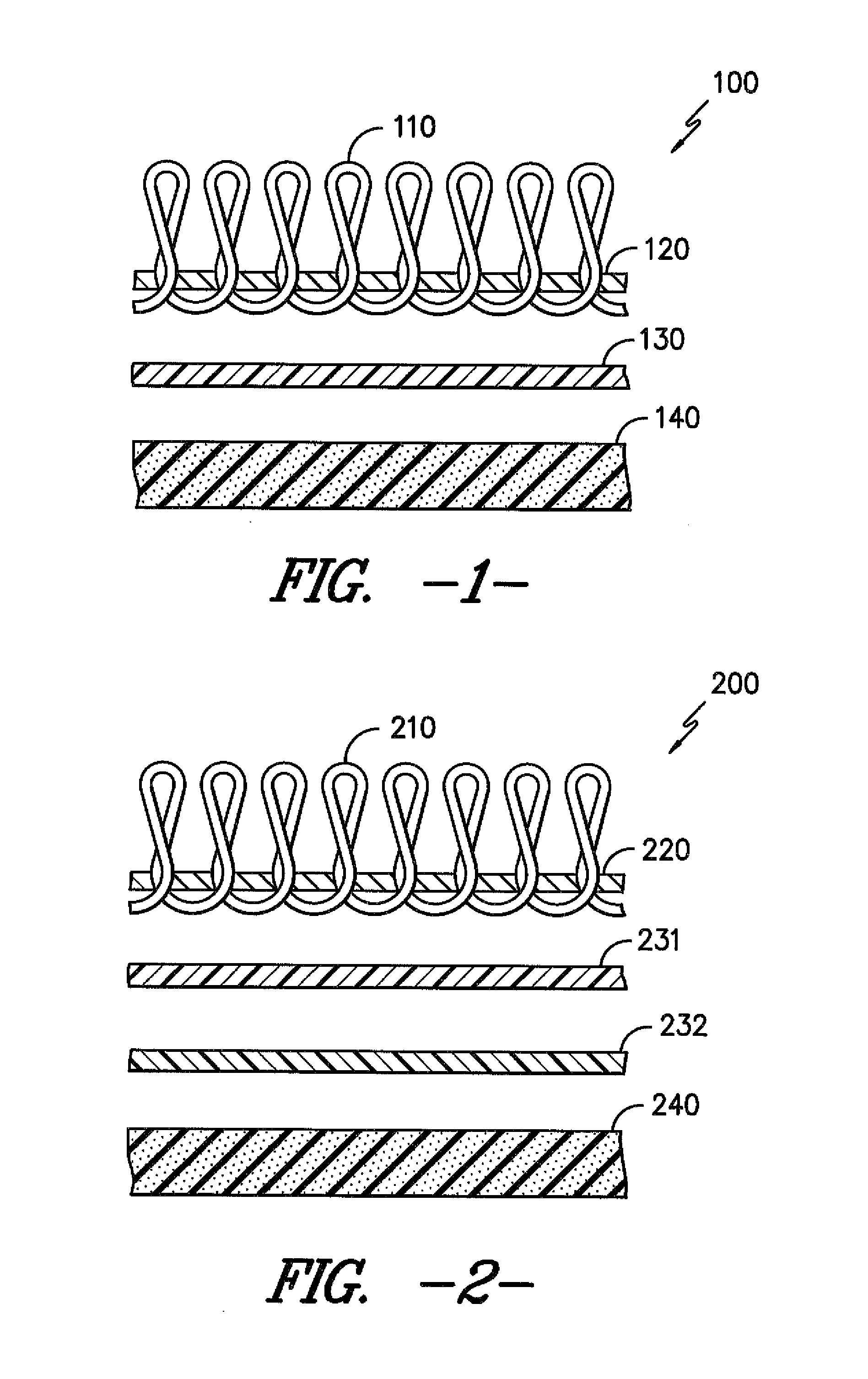

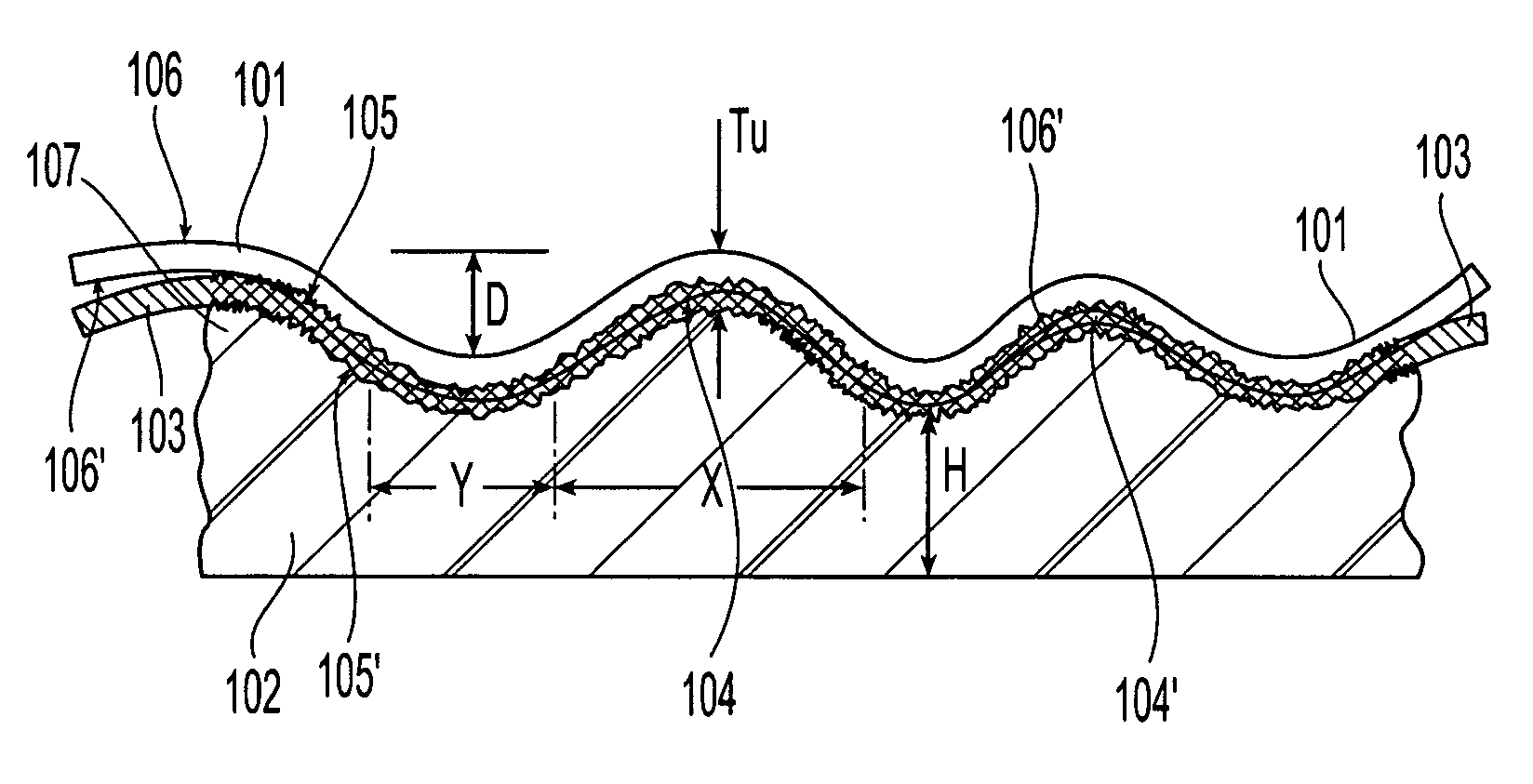

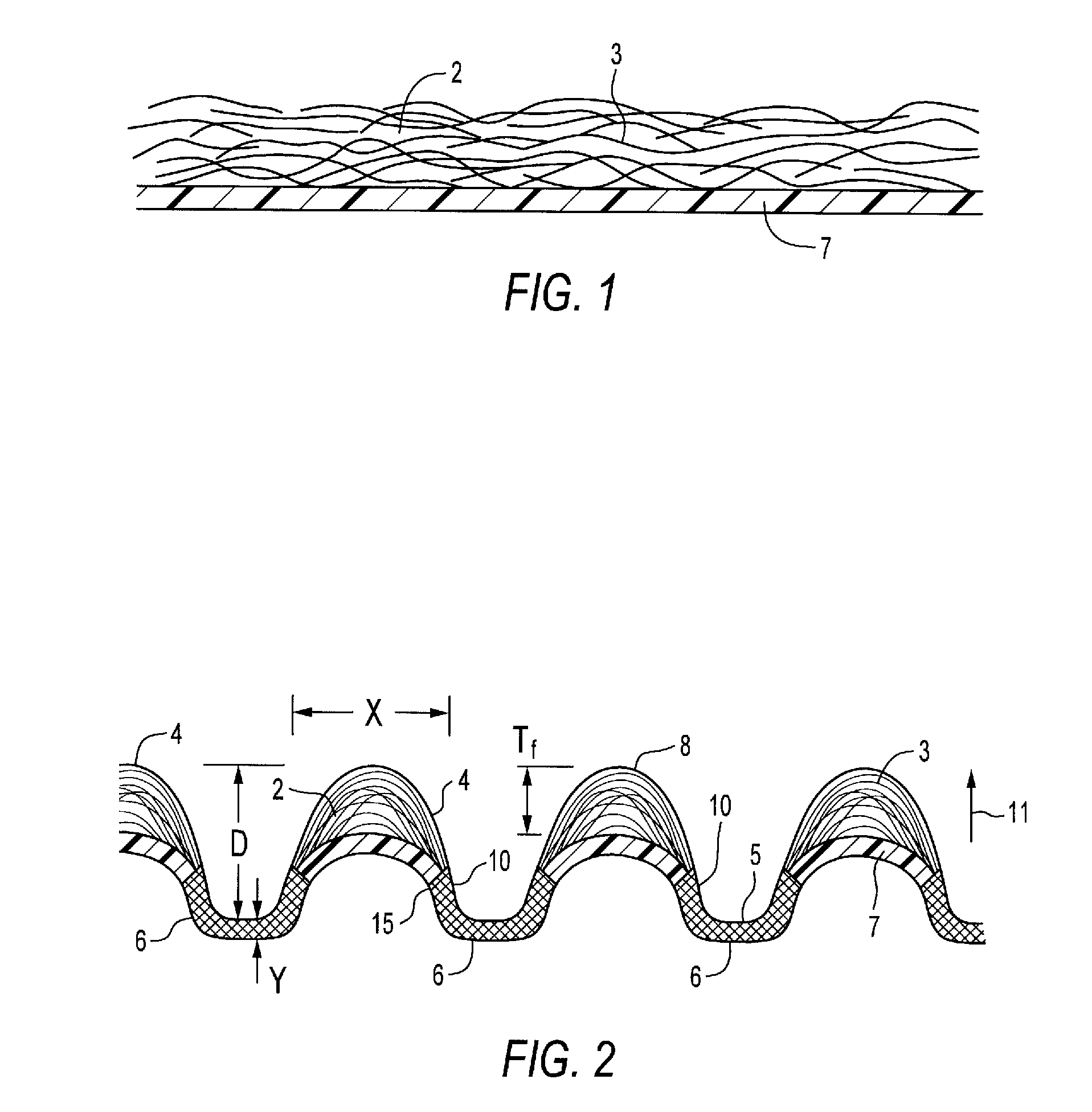

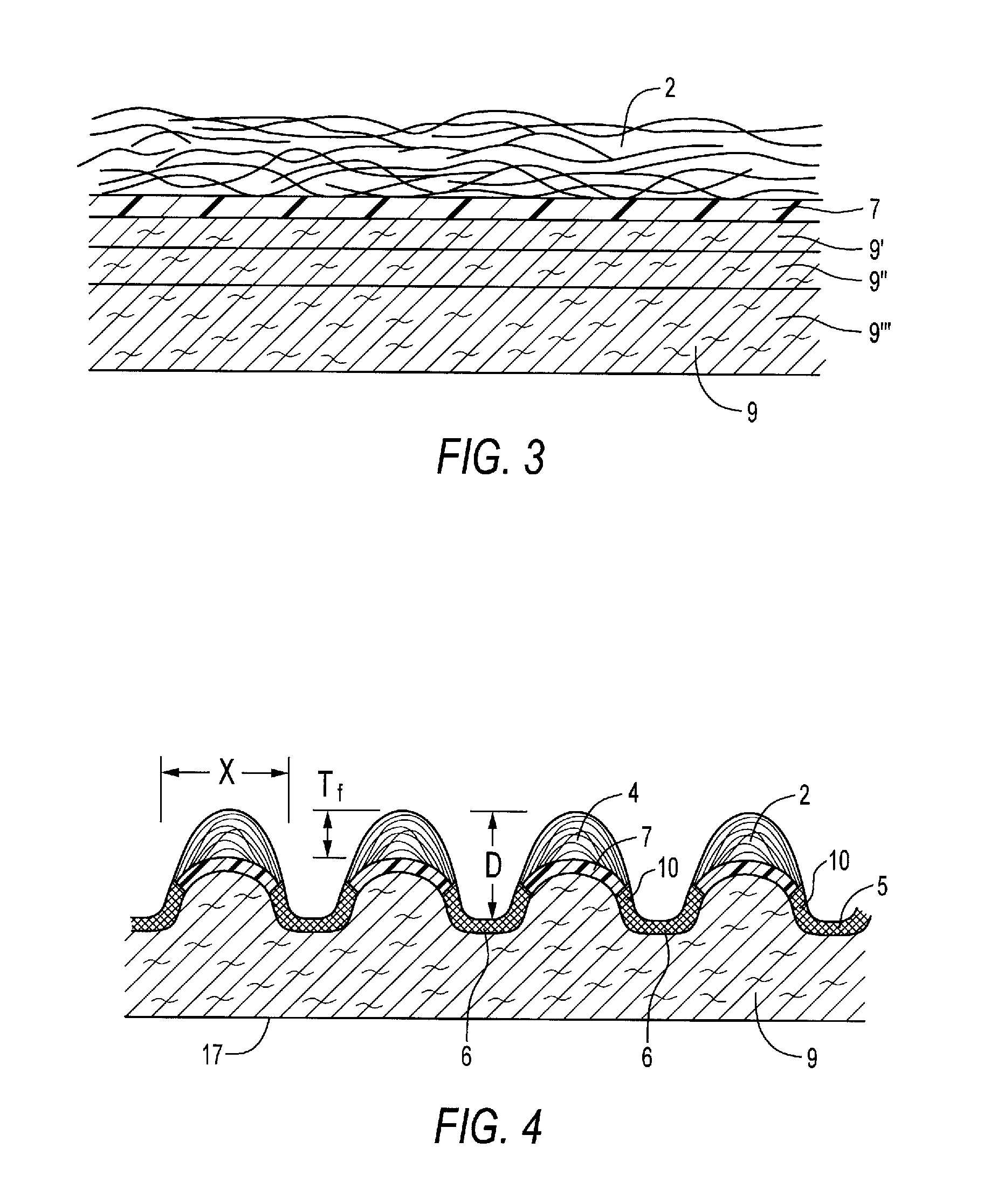

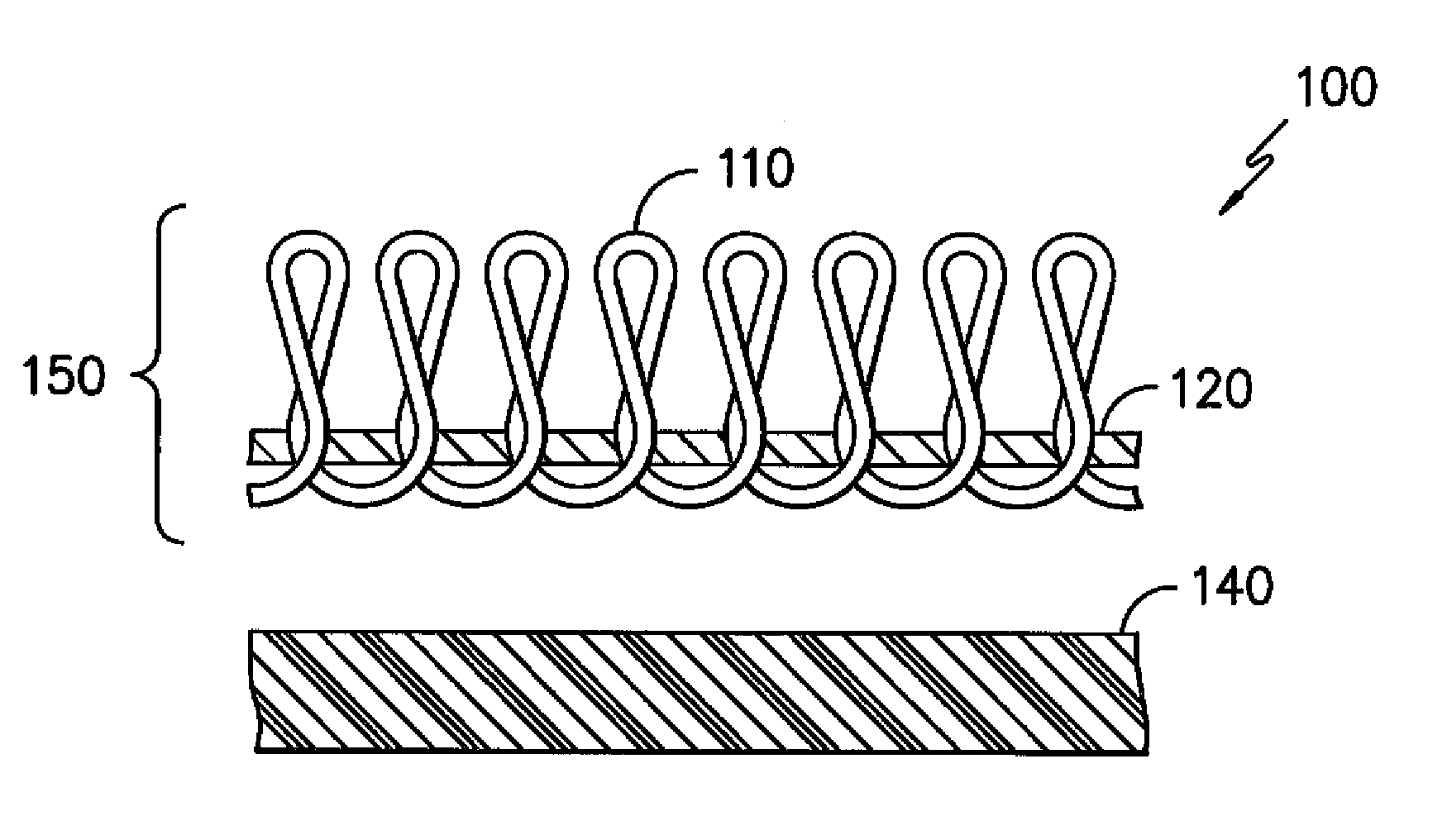

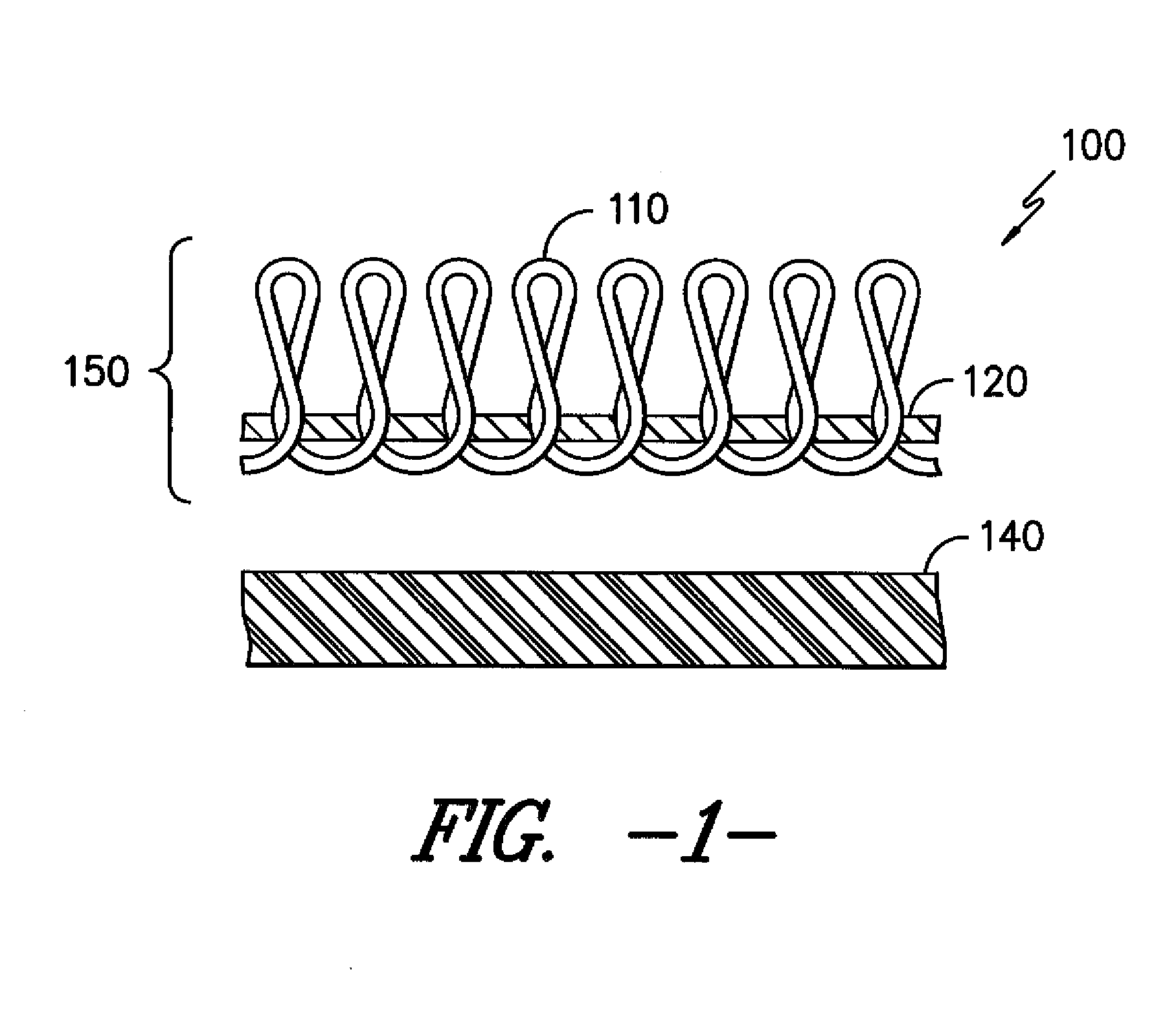

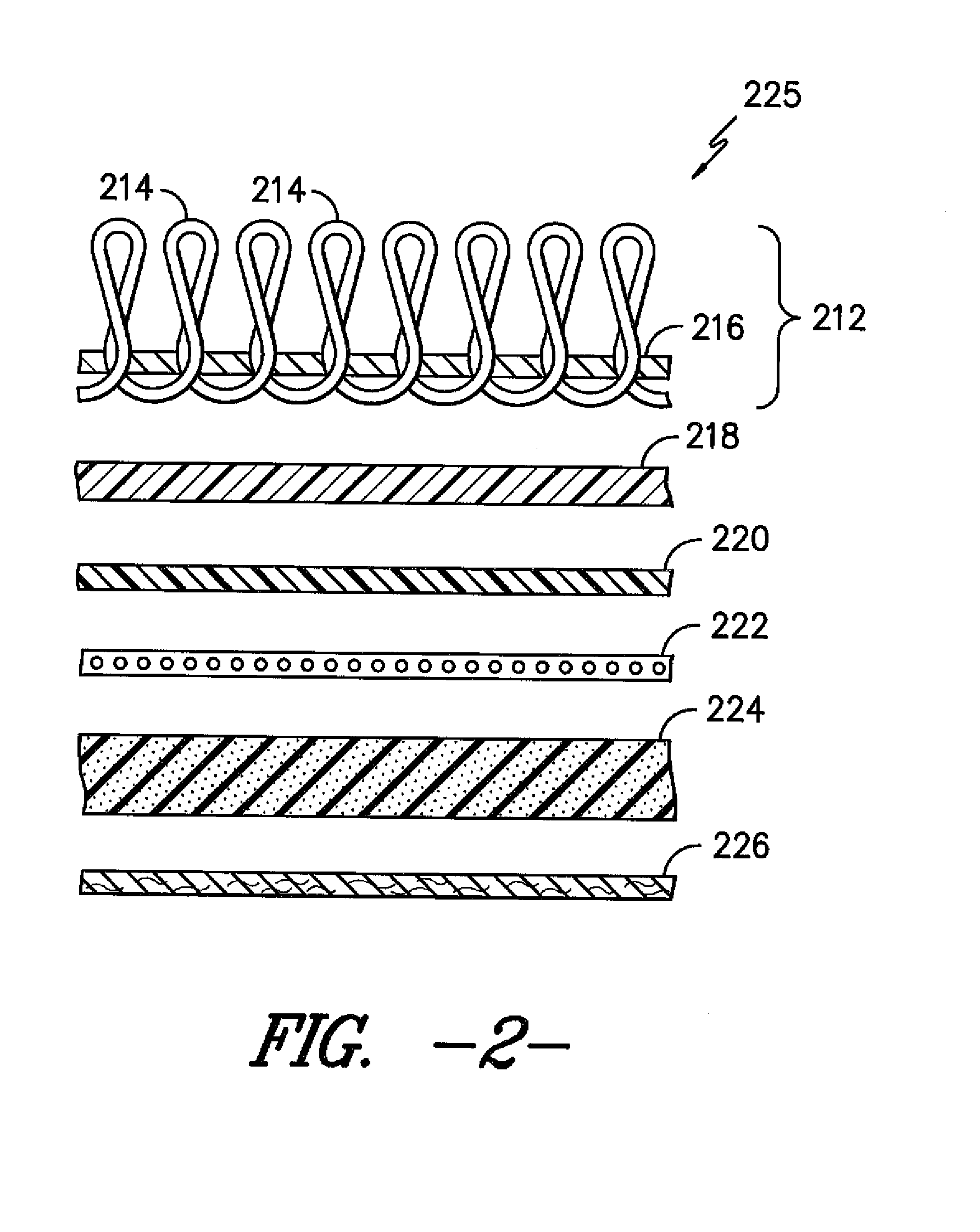

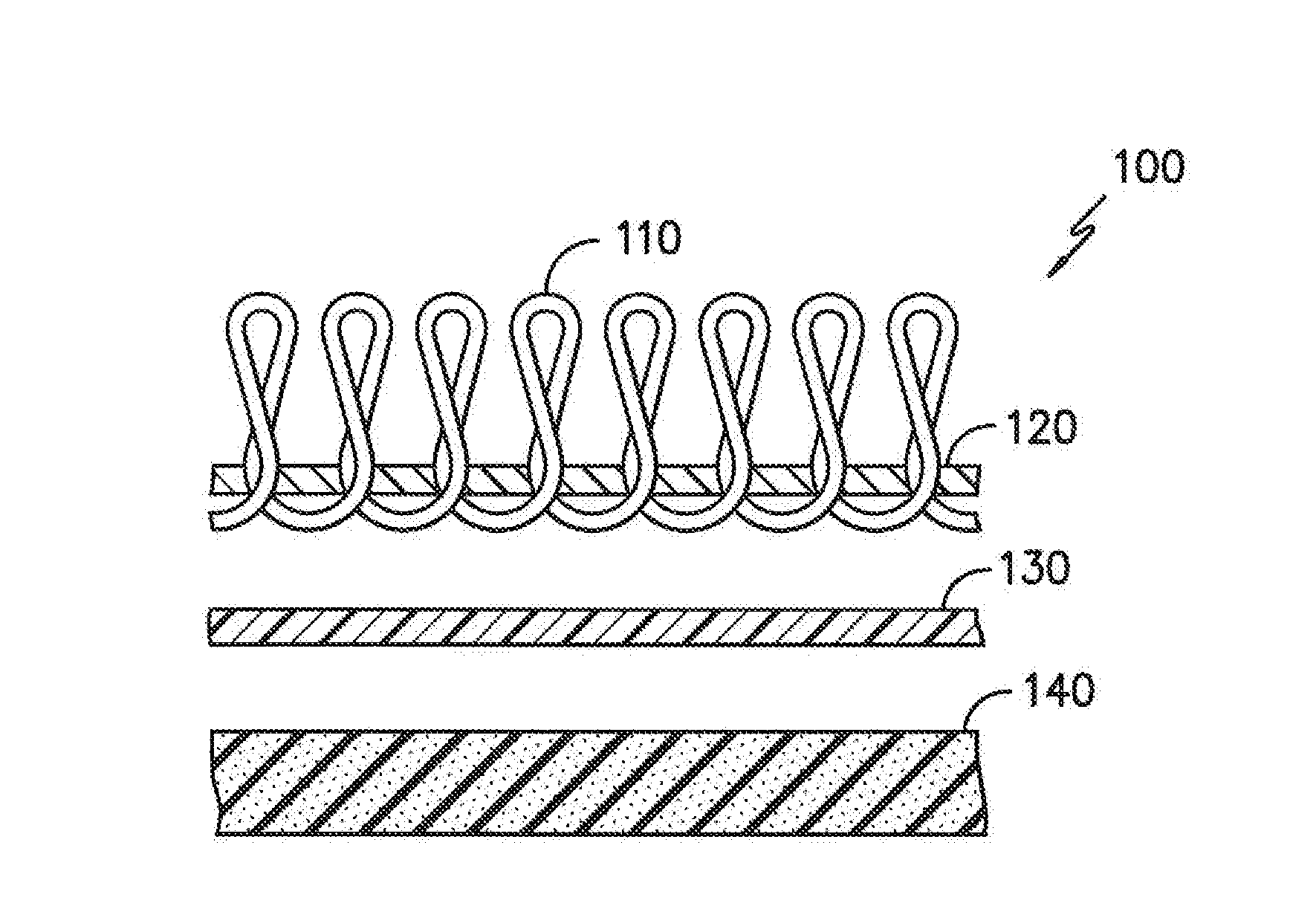

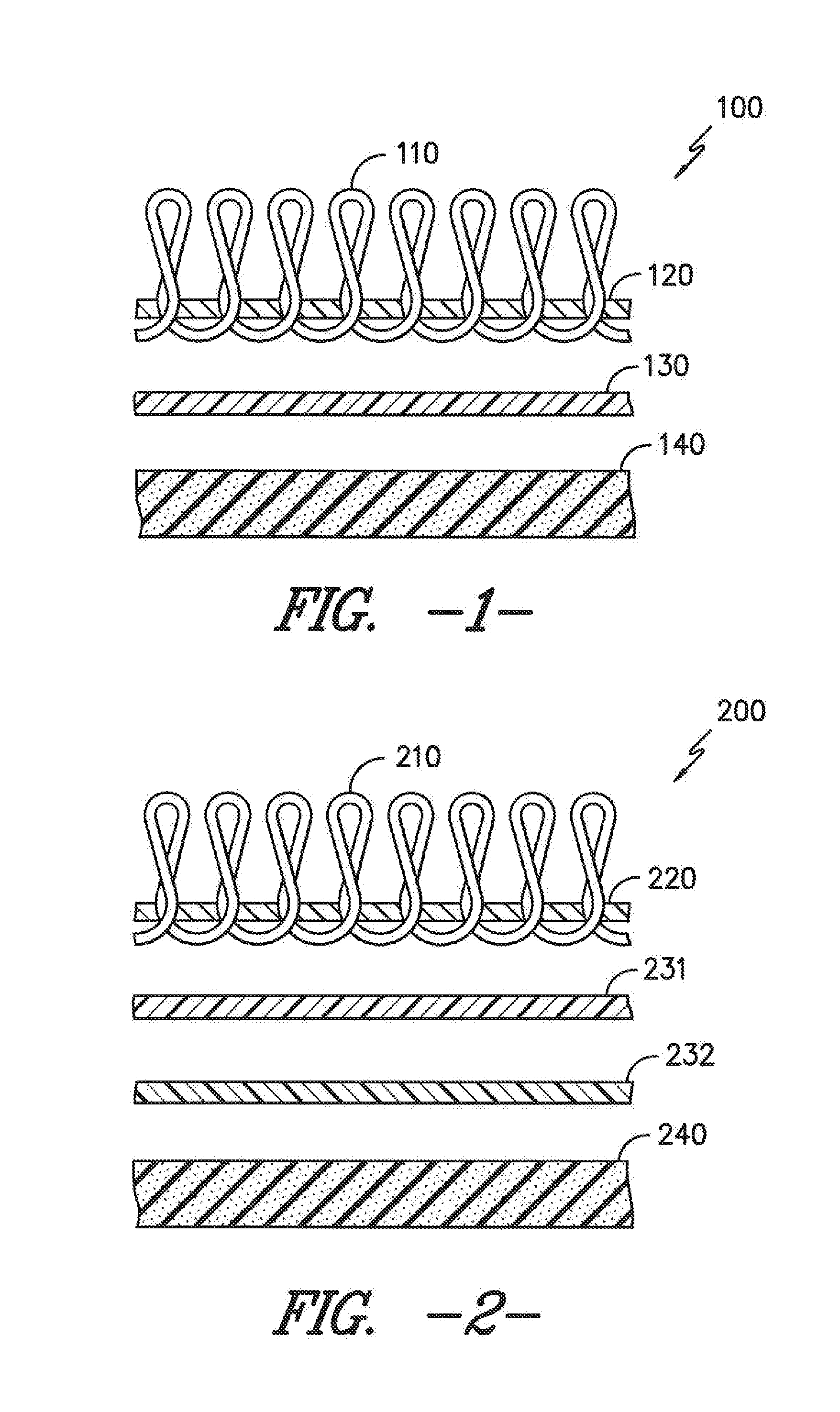

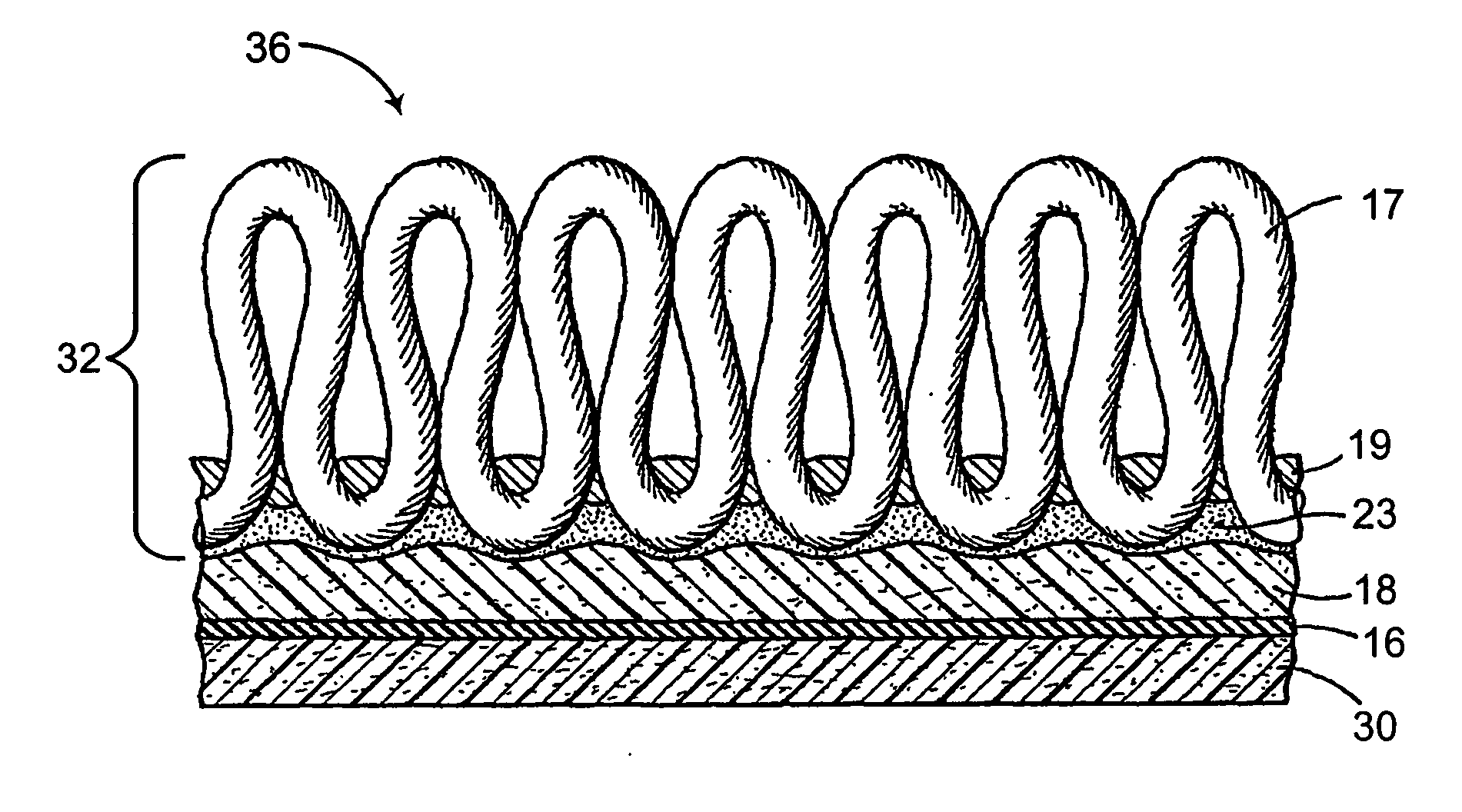

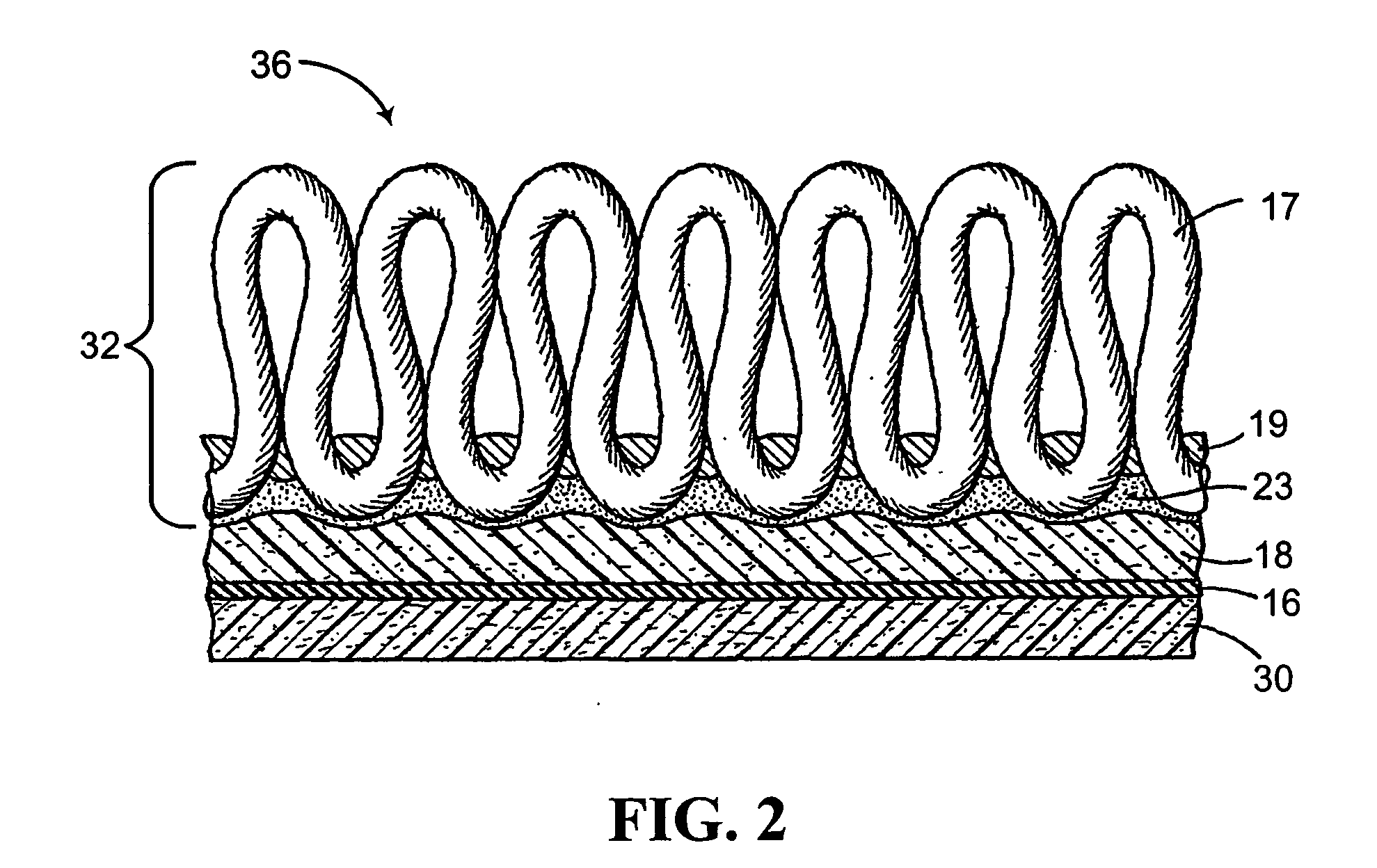

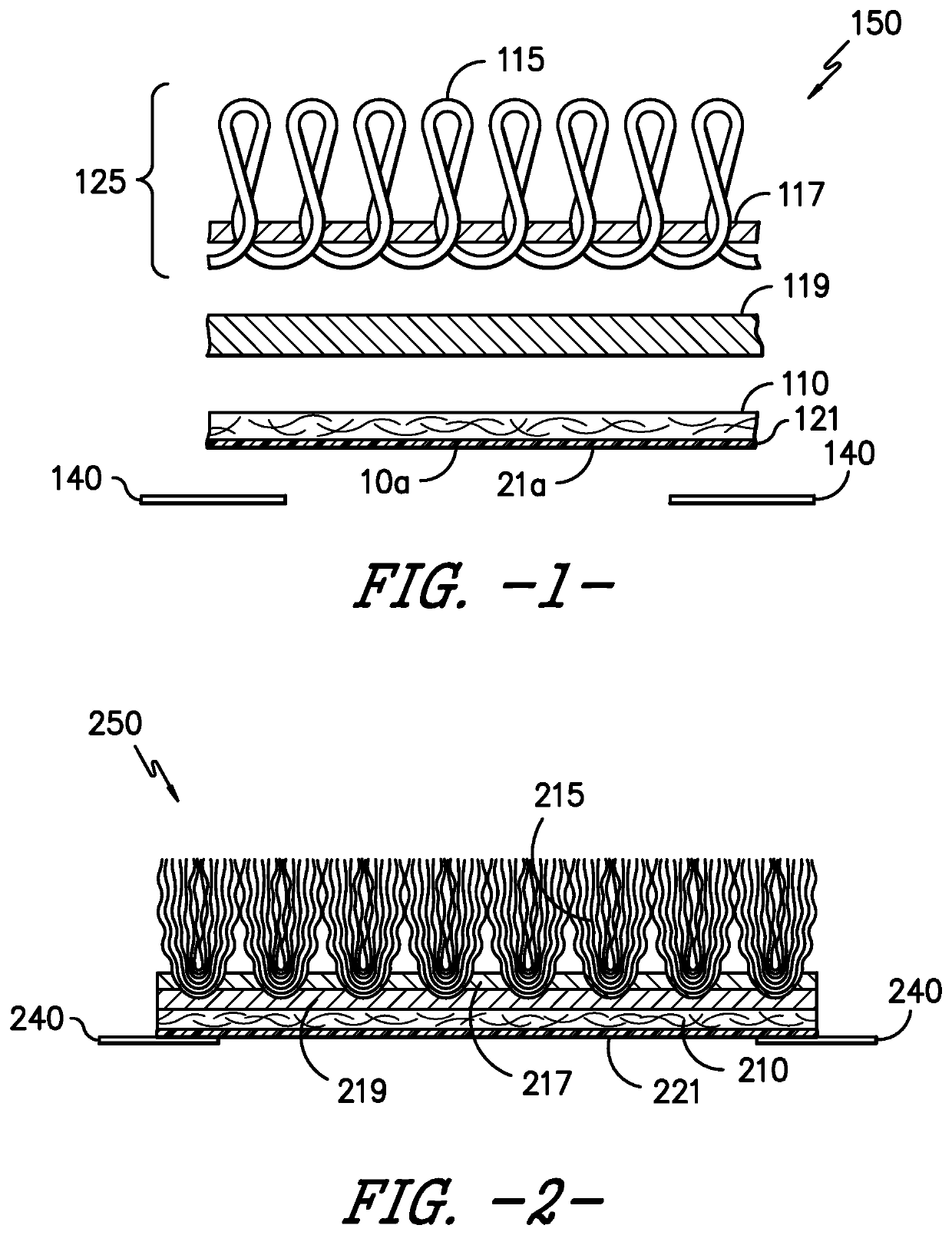

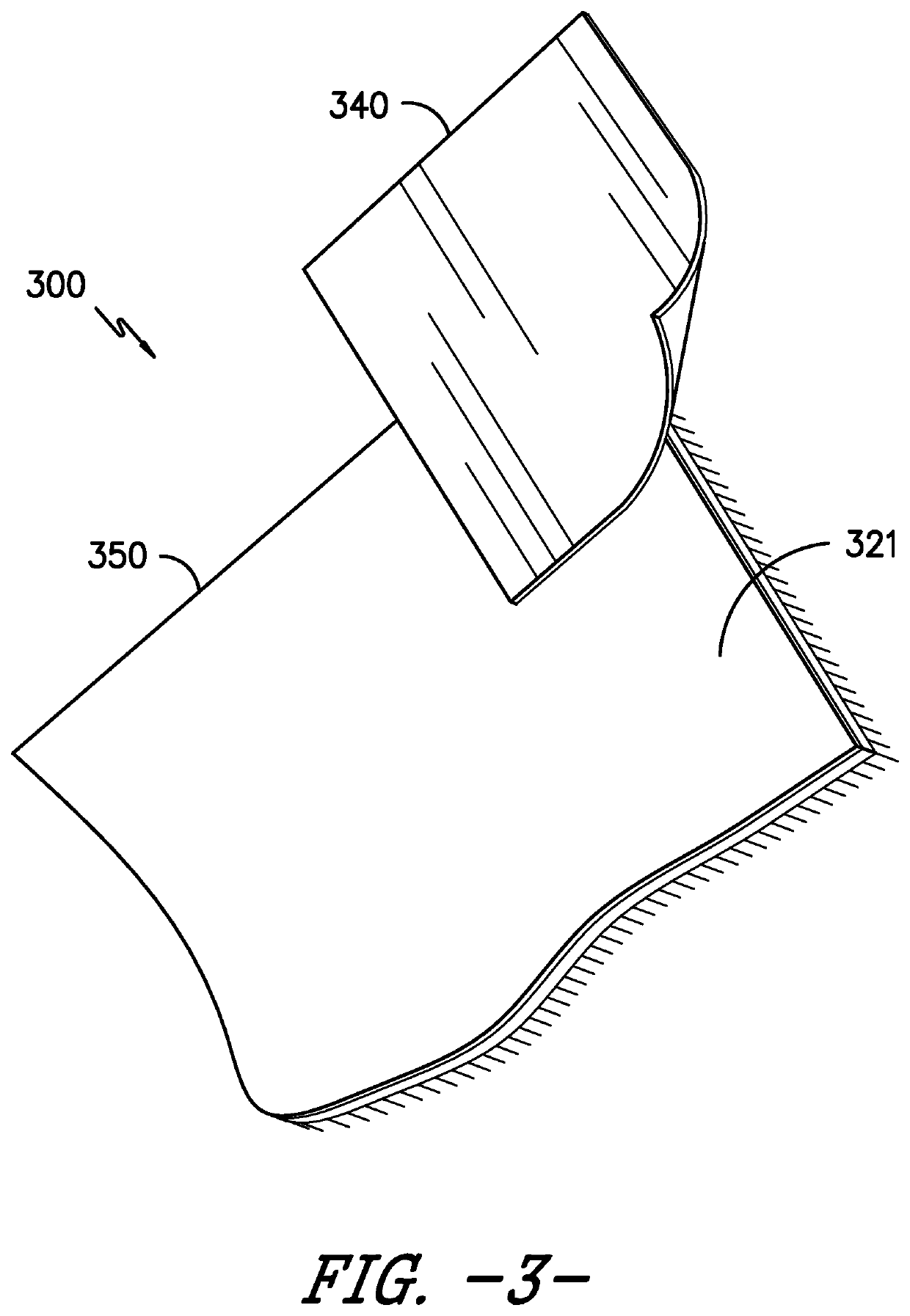

Spring-like Textured Composite Floorcovering

InactiveUS20090047465A1Maintain good propertiesDegree of reductionCovering/liningsSynthetic resin layered productsFloorcoveringFiber

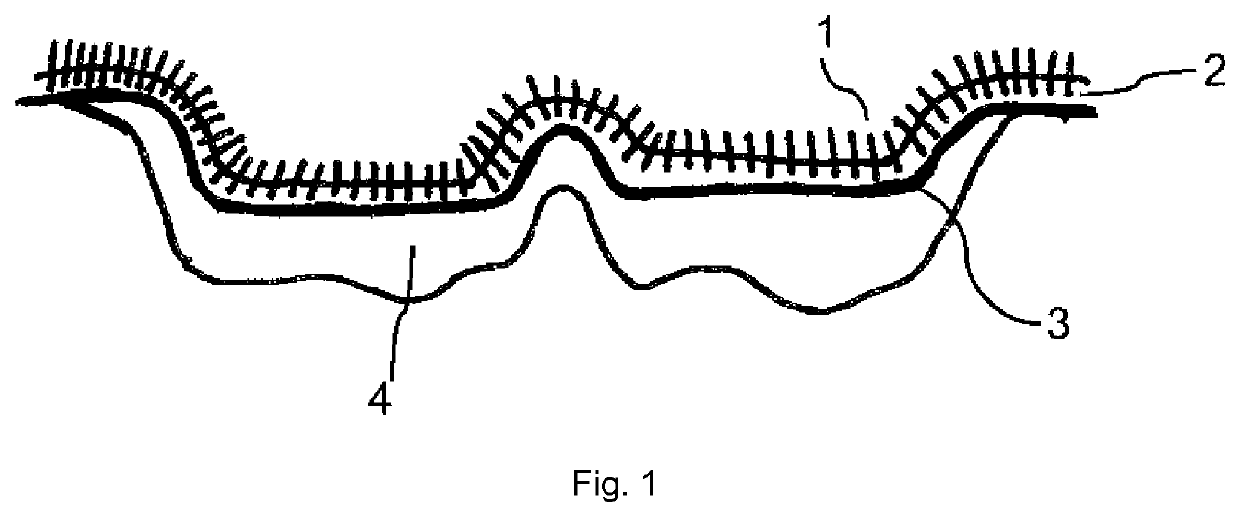

The present invention concerns a textured floorcovering composite comprising a highly conformable fibrous outer layer 101 and an optional porous and resilient backing layer 102 that are continually, contiguously, or continuously attached to an activated adhesive layer 103 along a three-dimensional, undulating interface. The undulations correspond to depressed and elevated areas on the surface of the composite. Such a composite can be fabricated if its precursor is subjected to heat and pressure for a finite length time, provided that the applied pressure is relatively low, preferably under about 200 psi. The textured composite can be used as a floorcovering that advantageously resists warping and remains insensitive to variations in ambient temperature and humidity, including exposure to water.

Owner:J&J FLOORING GRP LLC

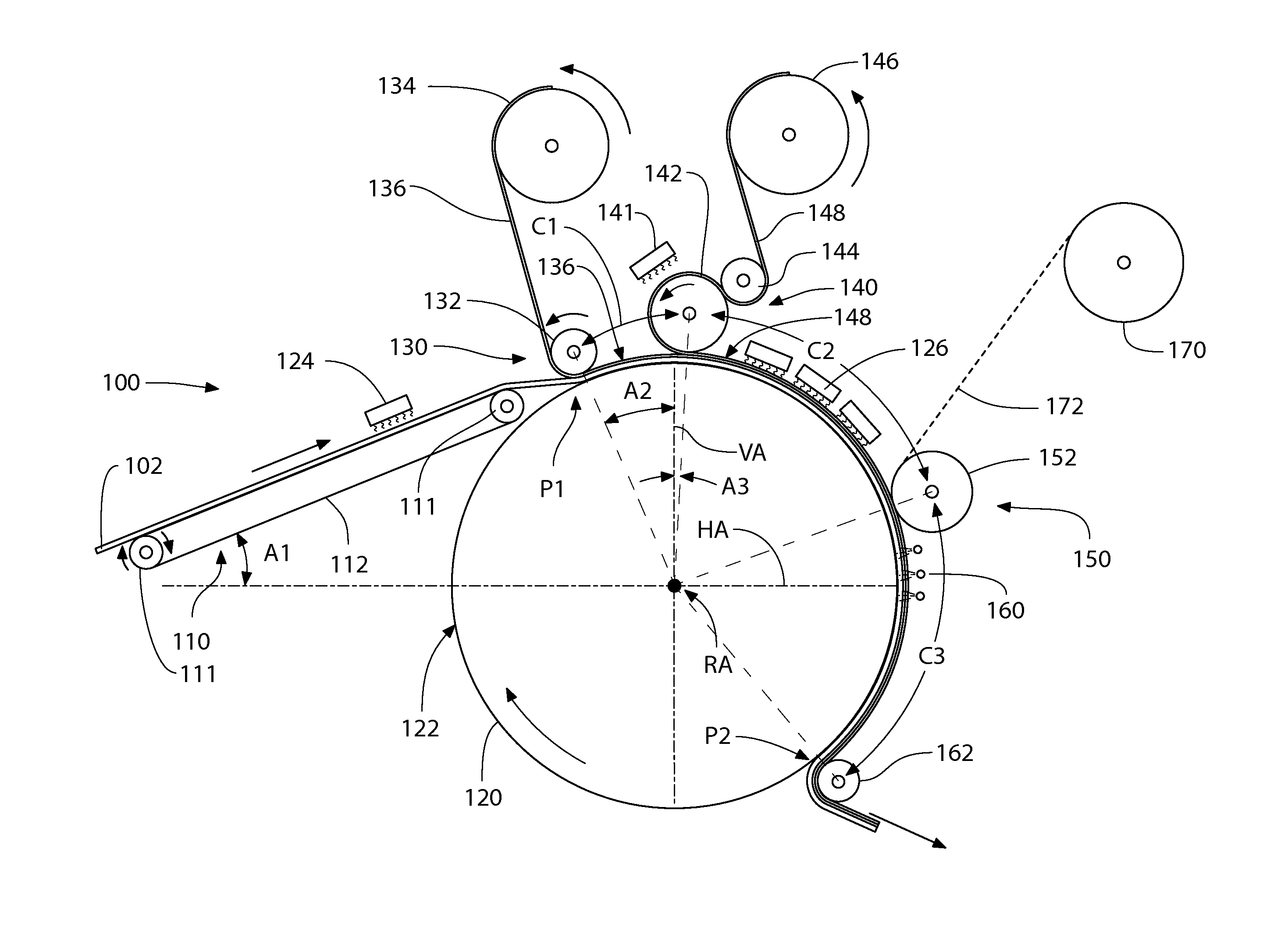

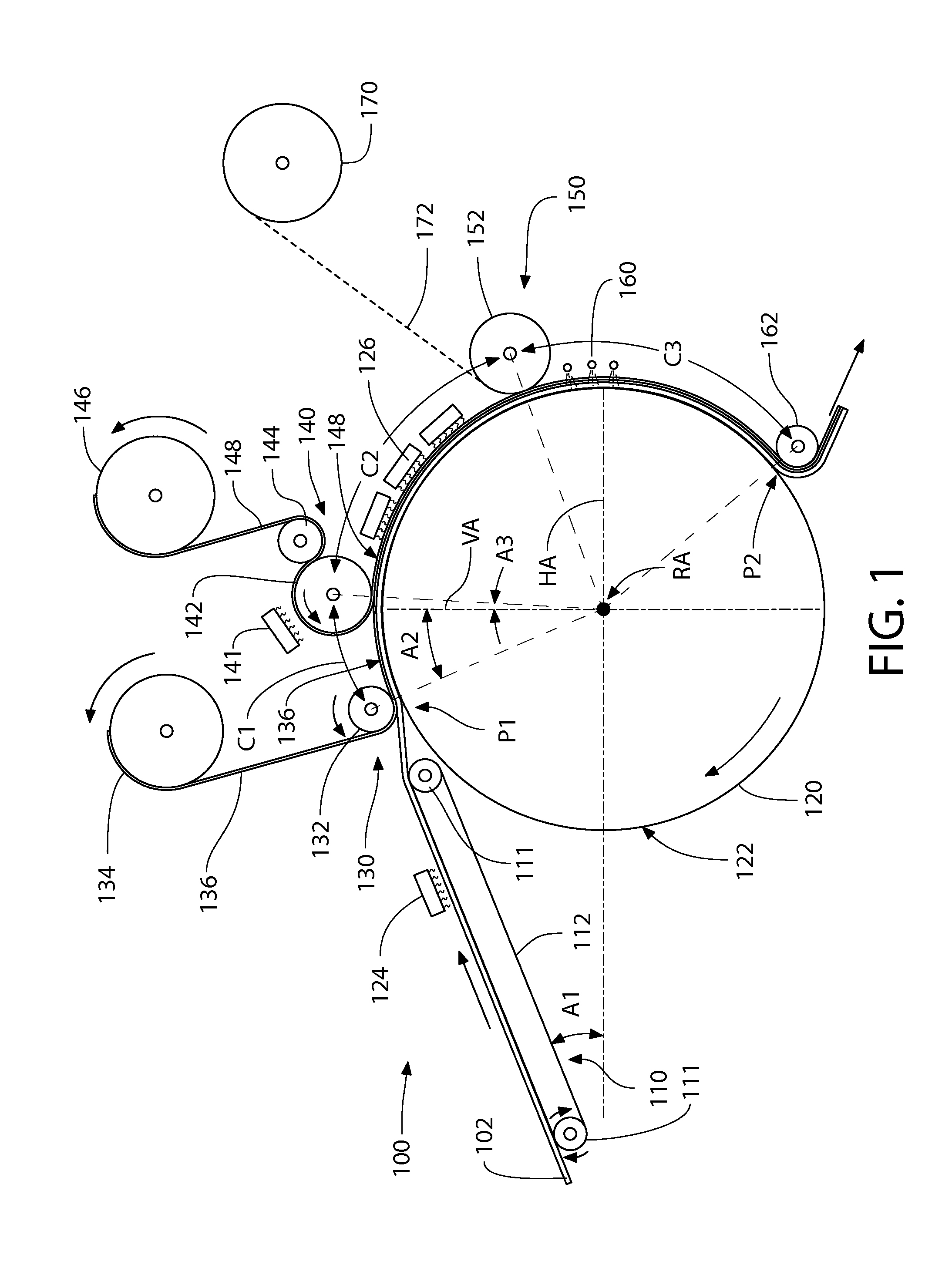

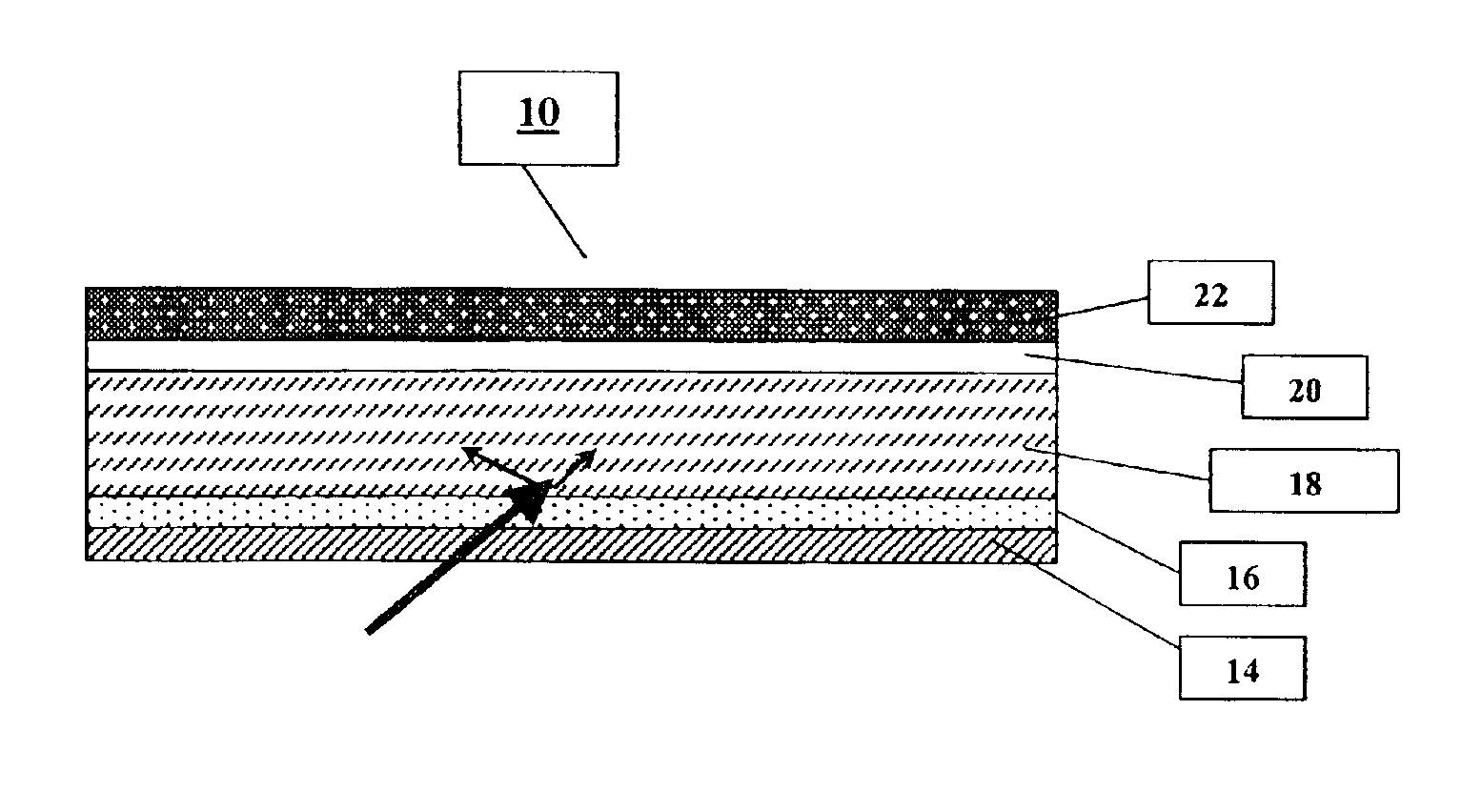

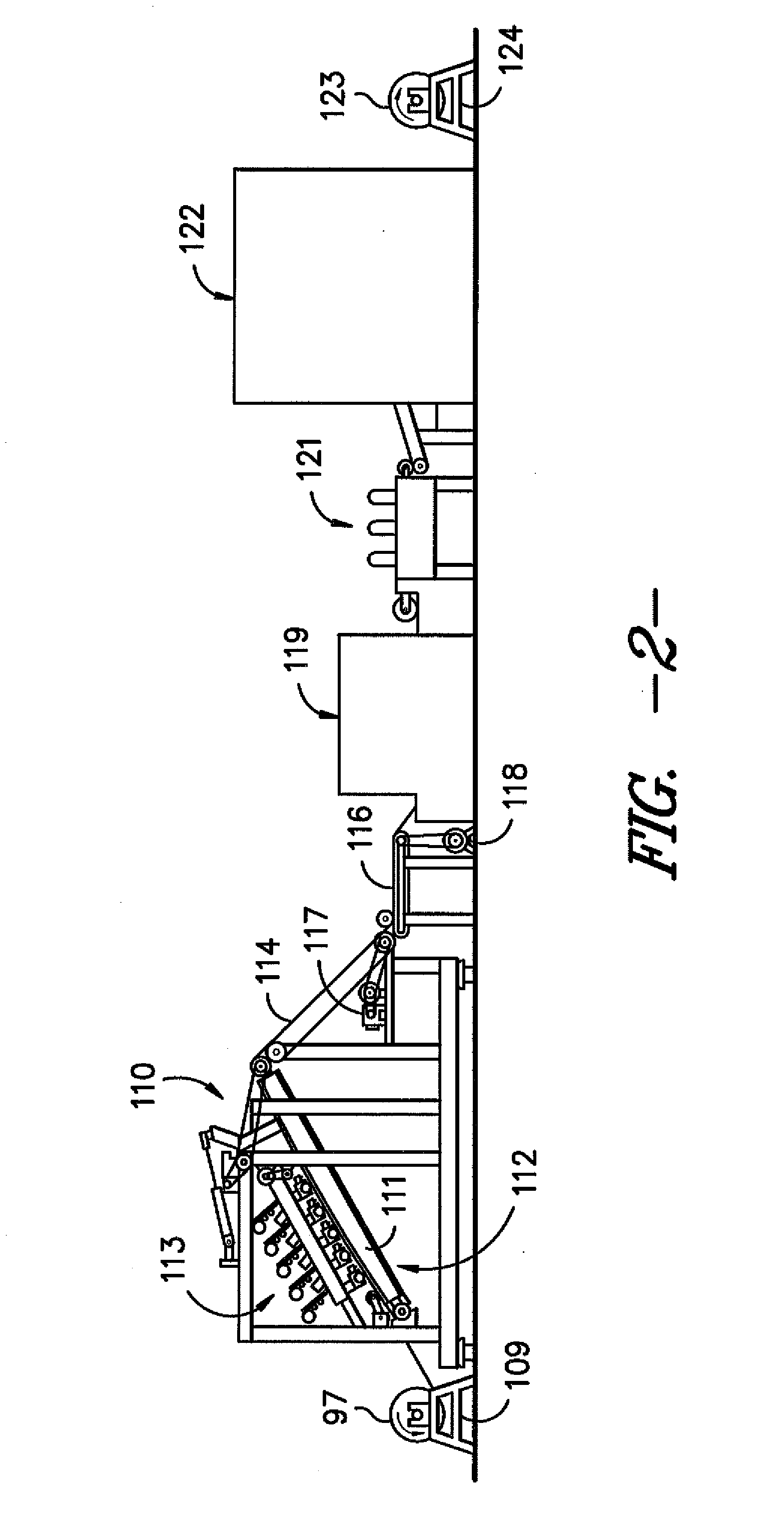

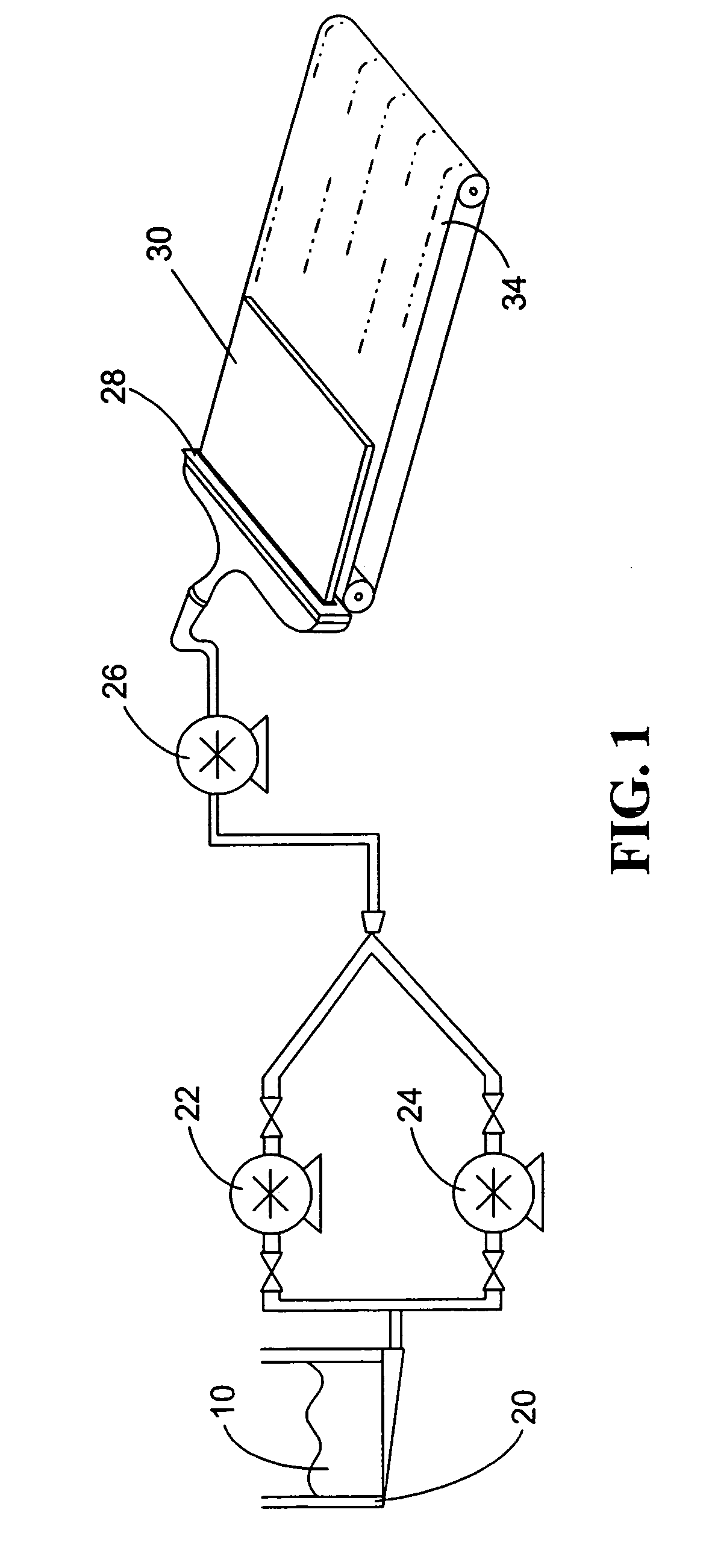

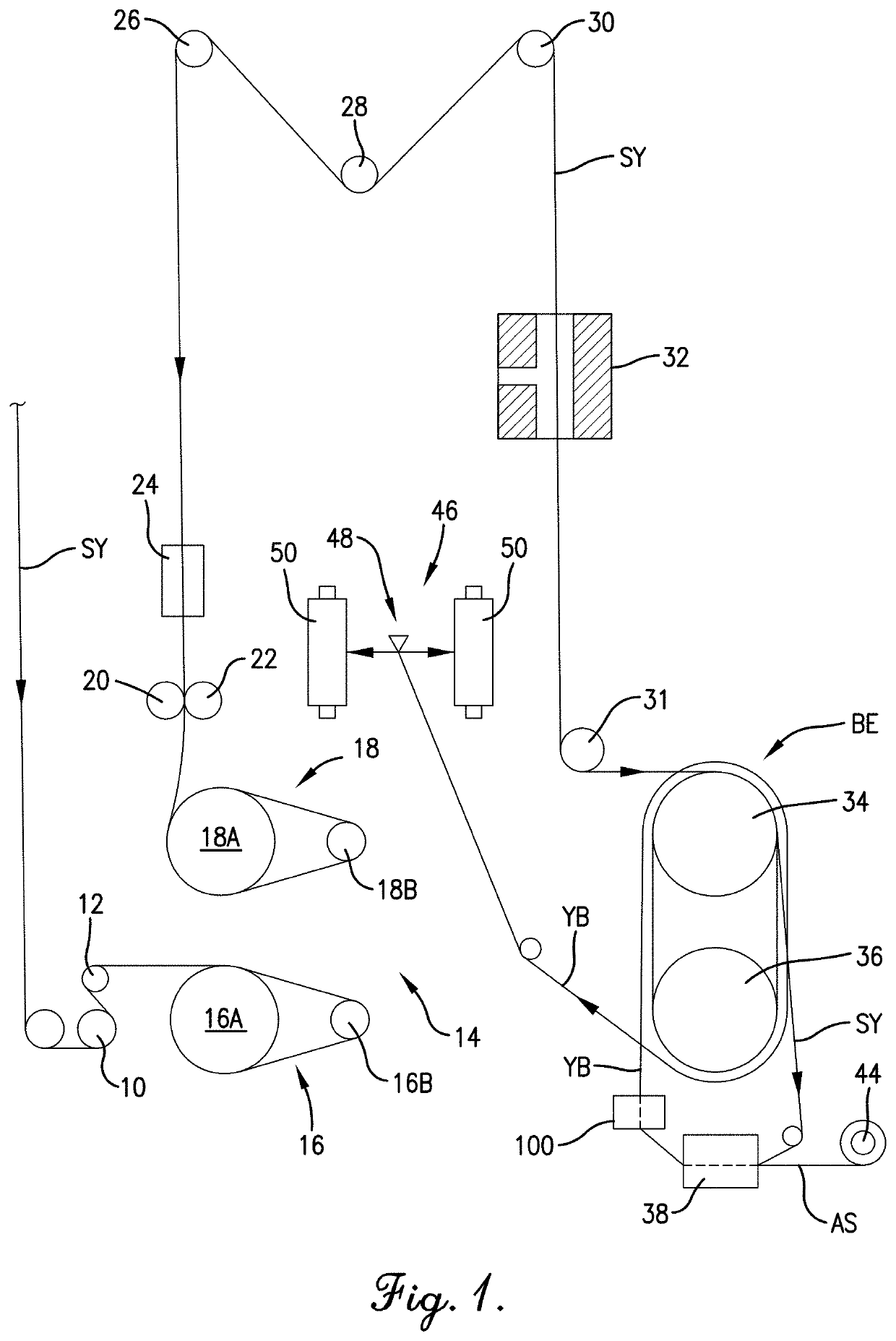

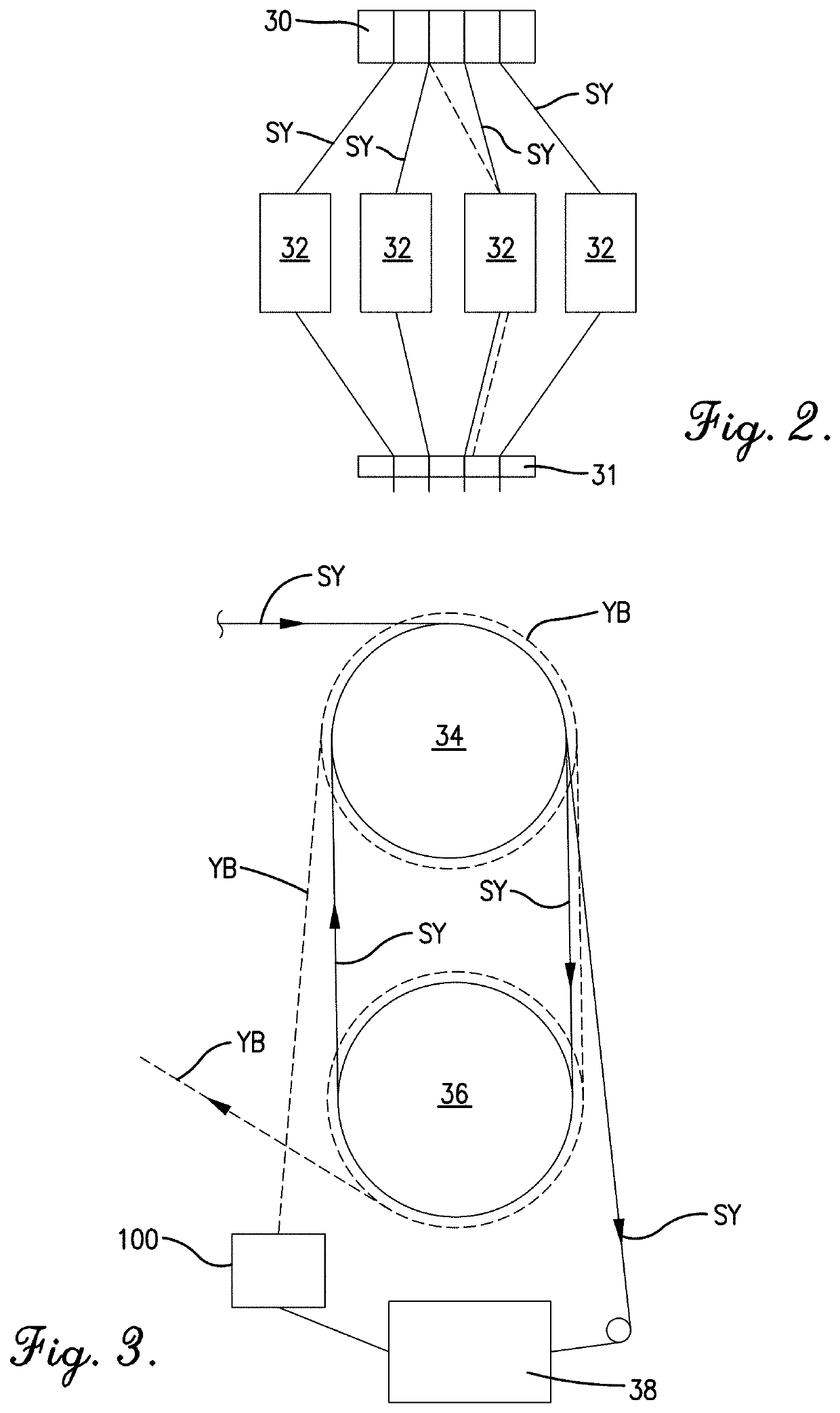

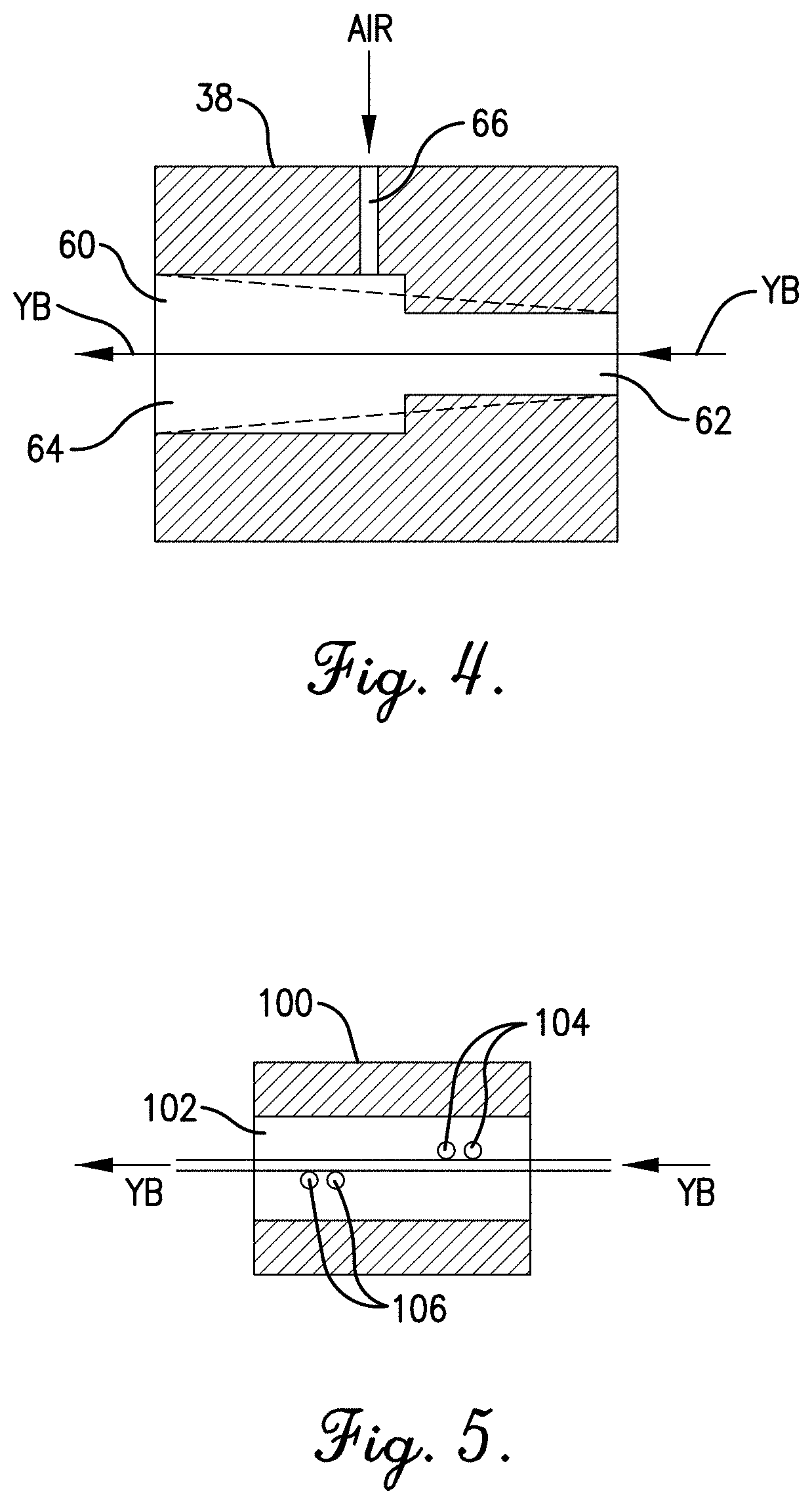

Continuous floor product forming system and process

InactiveUS20150165748A1Improve adhesionEasy to shapeAdhesive processesMechanical working/deformationFloorcoveringPolymer science

A process for forming laminated floor covering product having a relatively thick wear layer. In one embodiment, the process includes heating a base layer sheet which may comprise a plastic material to a first temperature, preheating a wear layer film to a second temperature, and laminating the wear layer film onto the base layer sheet at a first laminating station to form a flooring laminate. The wear layer may be rigid vinyl film (RVF). The foregoing process may be use for producing luxury vinyl tile (LVT). In some embodiments, the process includes embossing the flooring laminate at a second laminating station after the laminating step. In laminate constructions using a RVF wear layer, the process may include heating the flooring laminate to a third temperature between the first and second laminating stations prior to embossing to improve embossing depth.

Owner:AFI LICENSING

Resilient Floor Surface

InactiveUS20080104914A1Easy to installEasy maintenanceFloorsSynthetic resin layered productsEngineeringSynthetic rubber

A resilient floor surface for indoor and outdoor, residential, commercial and sporting applications includes a resilient underpad formed of expanded polypropylene product (“EPP”) and suitable for being laid down directly on the ground or other subfloor surface in a floating arrangement not requiring securing to the ground or other subfloor surface, and a floor covering material applied upon the resilient underpad as a covering for the resilient underpad. The surface covering is of the type suitable for floor surfacings, sport playing surfacings and decorative and sports surface coatings, and is selected from hardwood flooring, synthetic rubber and / or plastic flooring tiles and panels, rubber flooring tiles and panels, laminated wood flooring, residential and commercial carpets, crumb rubber surface coatings, EPDM (ethylene-propylene terpolymer) surface coatings, polyurethane surface coatings and any other suitable coatings. The resulting floor surface is shock-absorbing, sound and heat insulating, waterproof, lightweight, and durable, and is less expensive and easier to install than other flooring systems, due to the elimination of the multiple components required in prior flooring systems.

Owner:LEMIEUX ALAIN

Recyclable Single Polymer Floorcovering Article

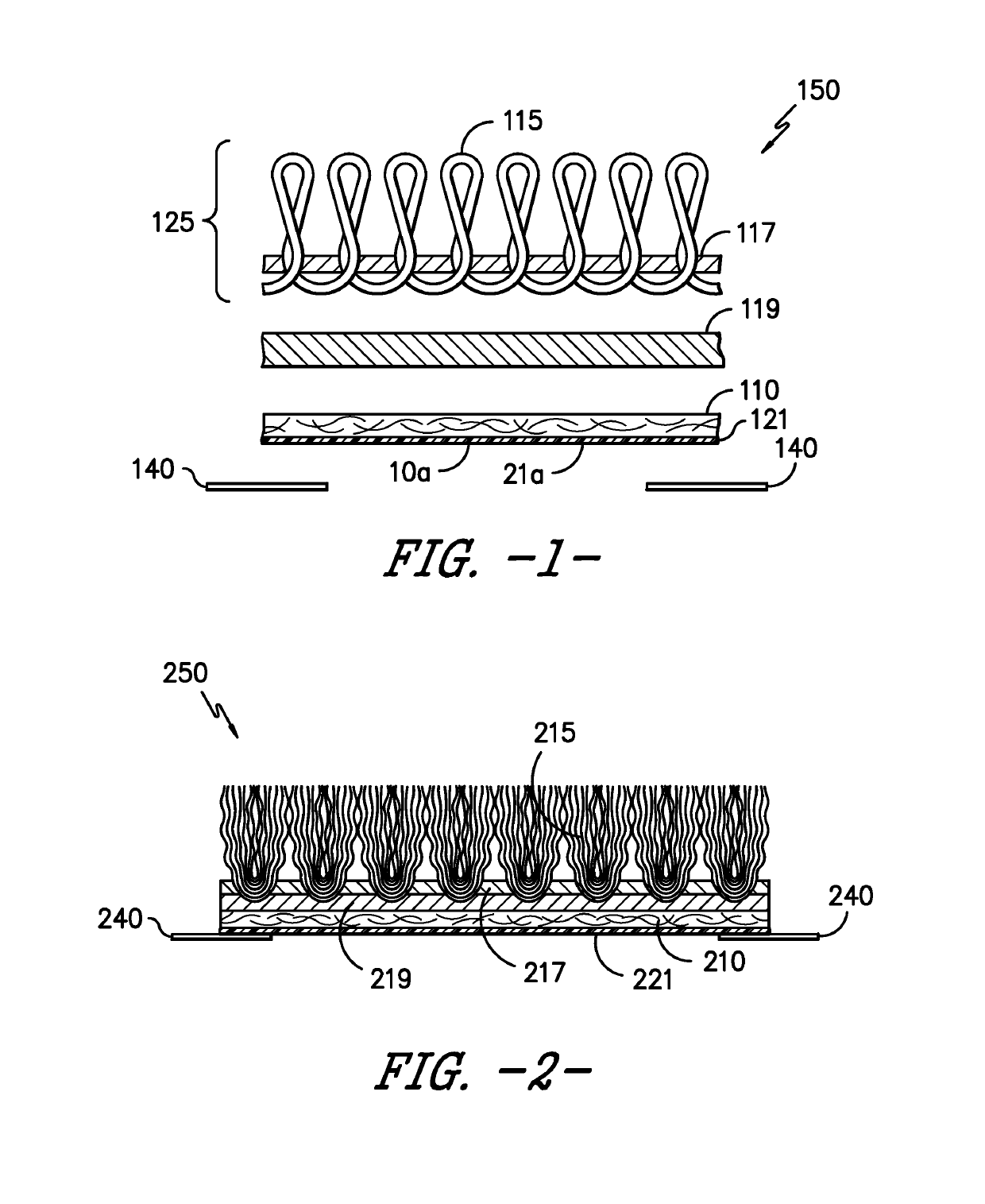

This invention relates to tufted floorcovering articles, including carpet tiles and broadloom carpet. In particular, this invention relates to tufted floorcovering articles made from the family of polymers known as polyester. Specifically, this invention relates to tufted carpet tile products made from polyester. The polyester carpet tiles meet commercial performance specifications and are fully end-of-life recyclable.

Owner:MILLIKEN & CO

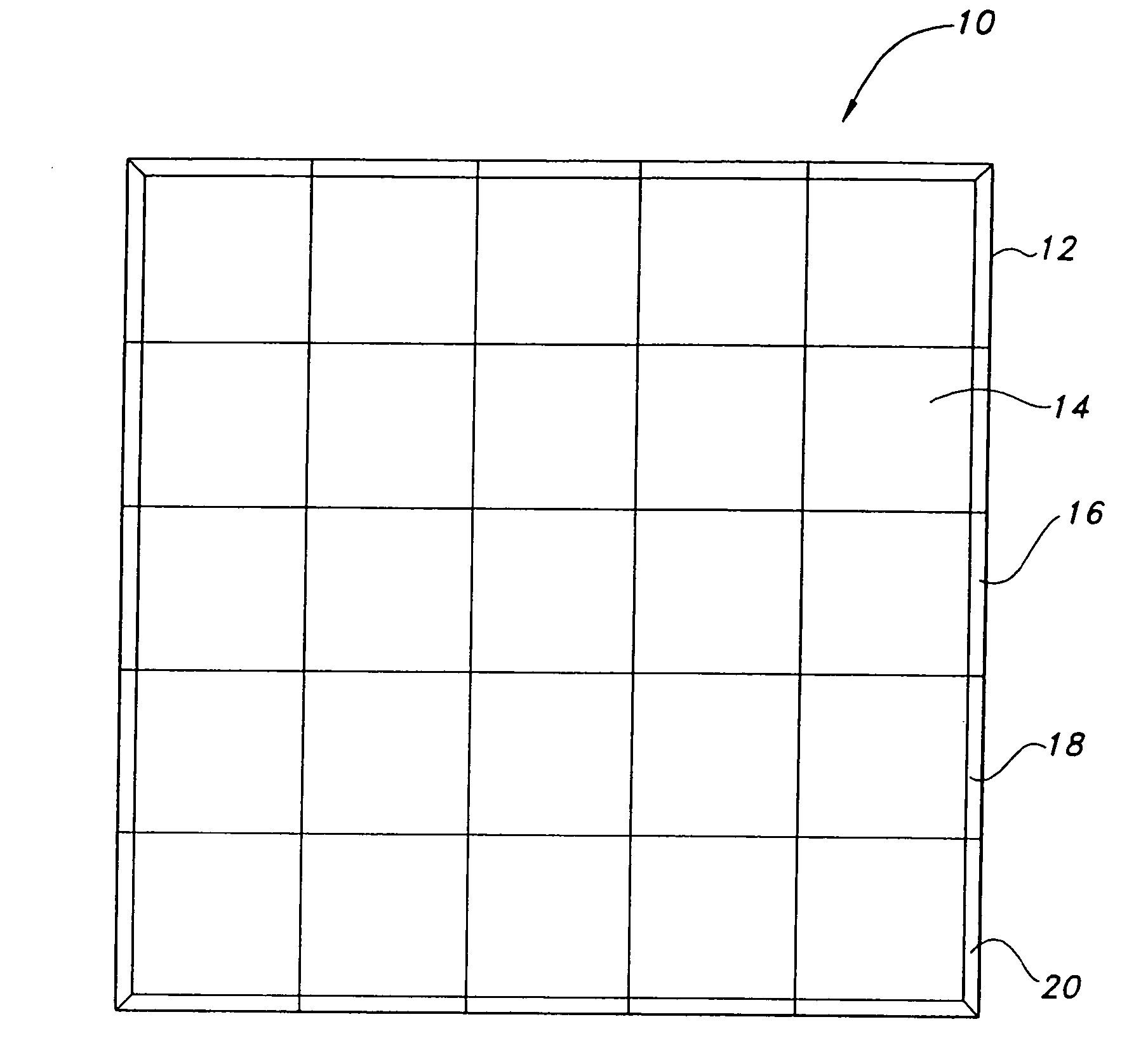

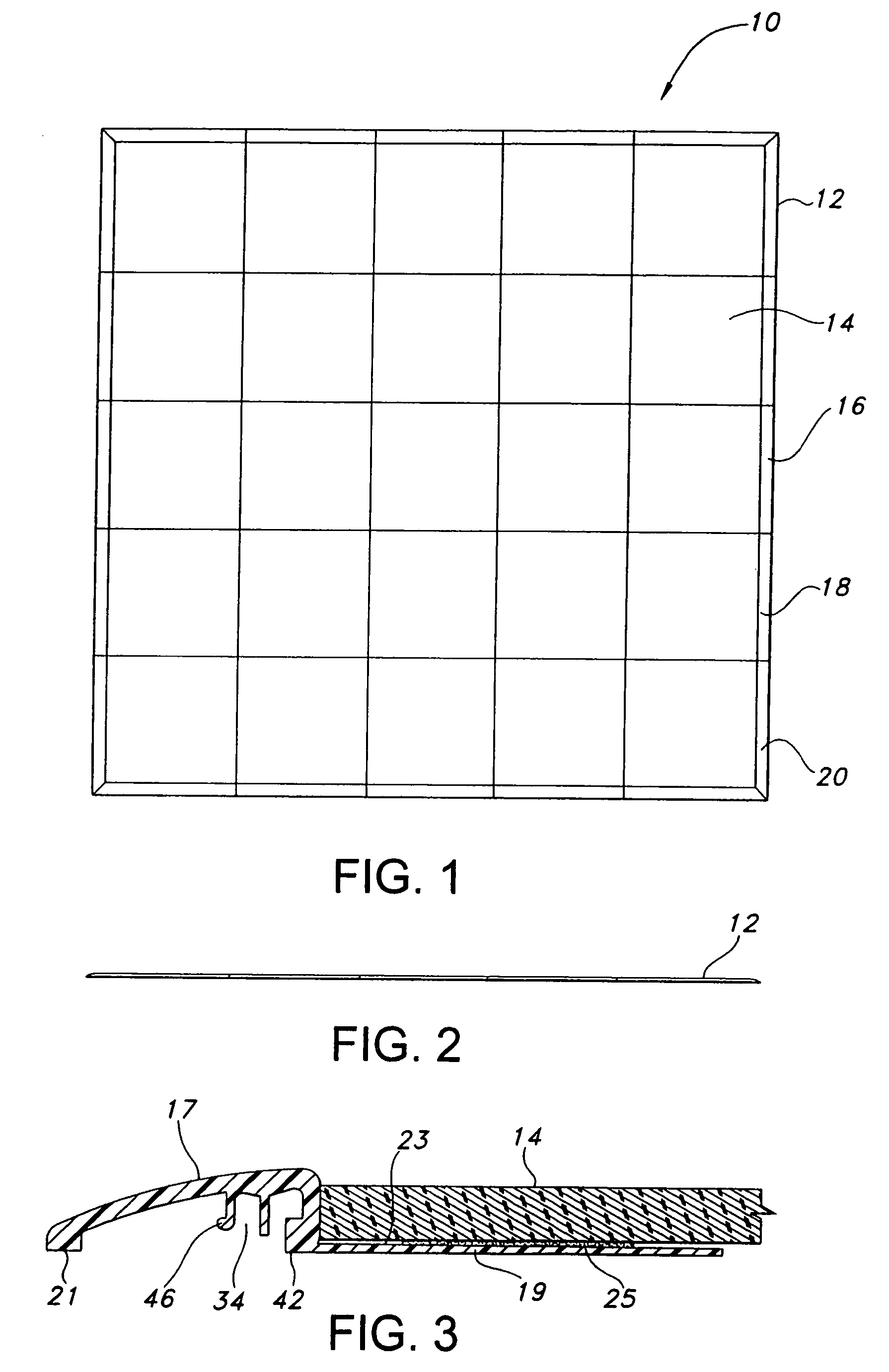

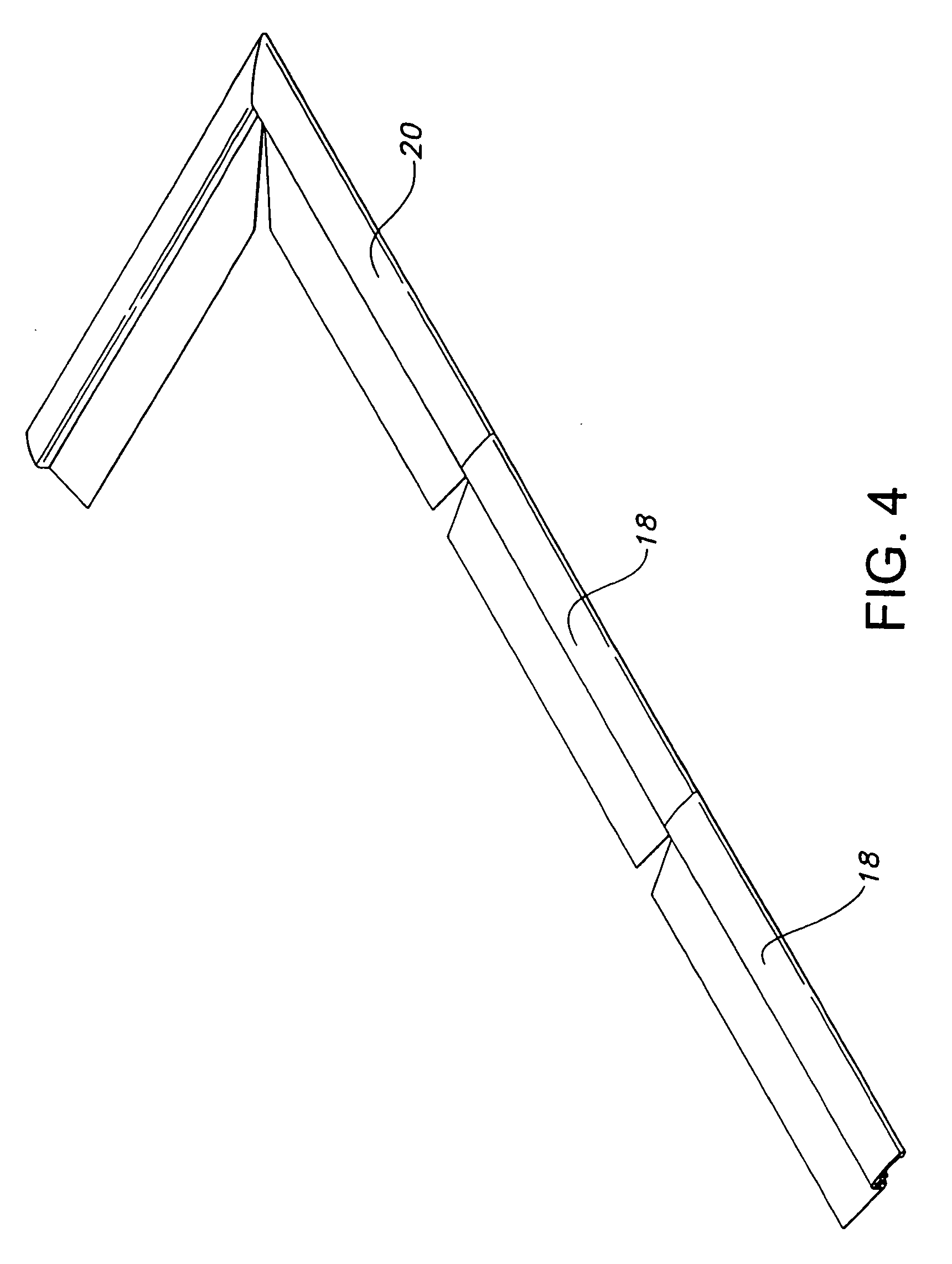

Modular frame area floor covering

InactiveUS20060010804A1Minimal investment of laborMinimal investment of timeTreadsCarpet fastenersEngineeringMechanical engineering

A flooring system including a modular frame surrounding modular floor covering units. Frame members attach easily to one another, providing stability to the flooring system and ease of installation.

Owner:GRAY KEITH N +2

Avoiding cracking and curling in concrete flooring upon which water-based adhesives are employed

The invention provides a method for making a concrete floor slab using sub-grade waterproofing in a manner that favors the use of water-based adhesives for affixing floor covering materials. The method comprises casting a hydratable cementitious composition onto a flooring membrane, the composition having a shrinkage reduction admixture and a water:cementitious binder ratio sufficiently low that substantially all of the water moisture is retained in the hydration reaction, and achieving a fully adhered bond with the flooring membrane.

Owner:GCP APPL TECH INC

Spring-like textured composite floorcovering

InactiveUS8216659B2Degree of reductionSacrificing durabilityCovering/liningsSynthetic resin layered productsFloorcoveringFiber

Owner:J&J FLOORING GRP LLC

Polyurethane coated resilient surface covering having improved fidelity of texture and process of manufacture

Owner:TARKETT INC

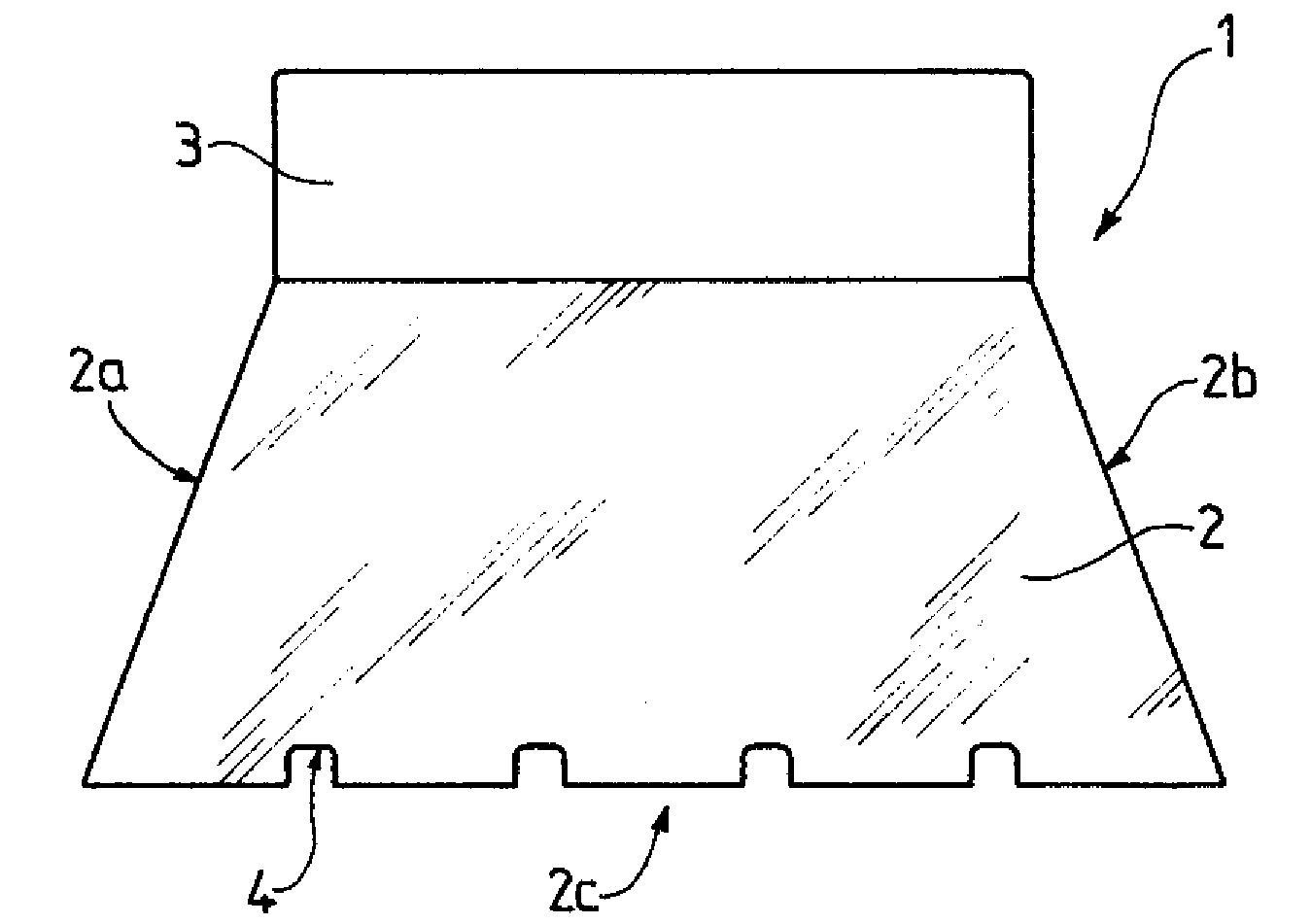

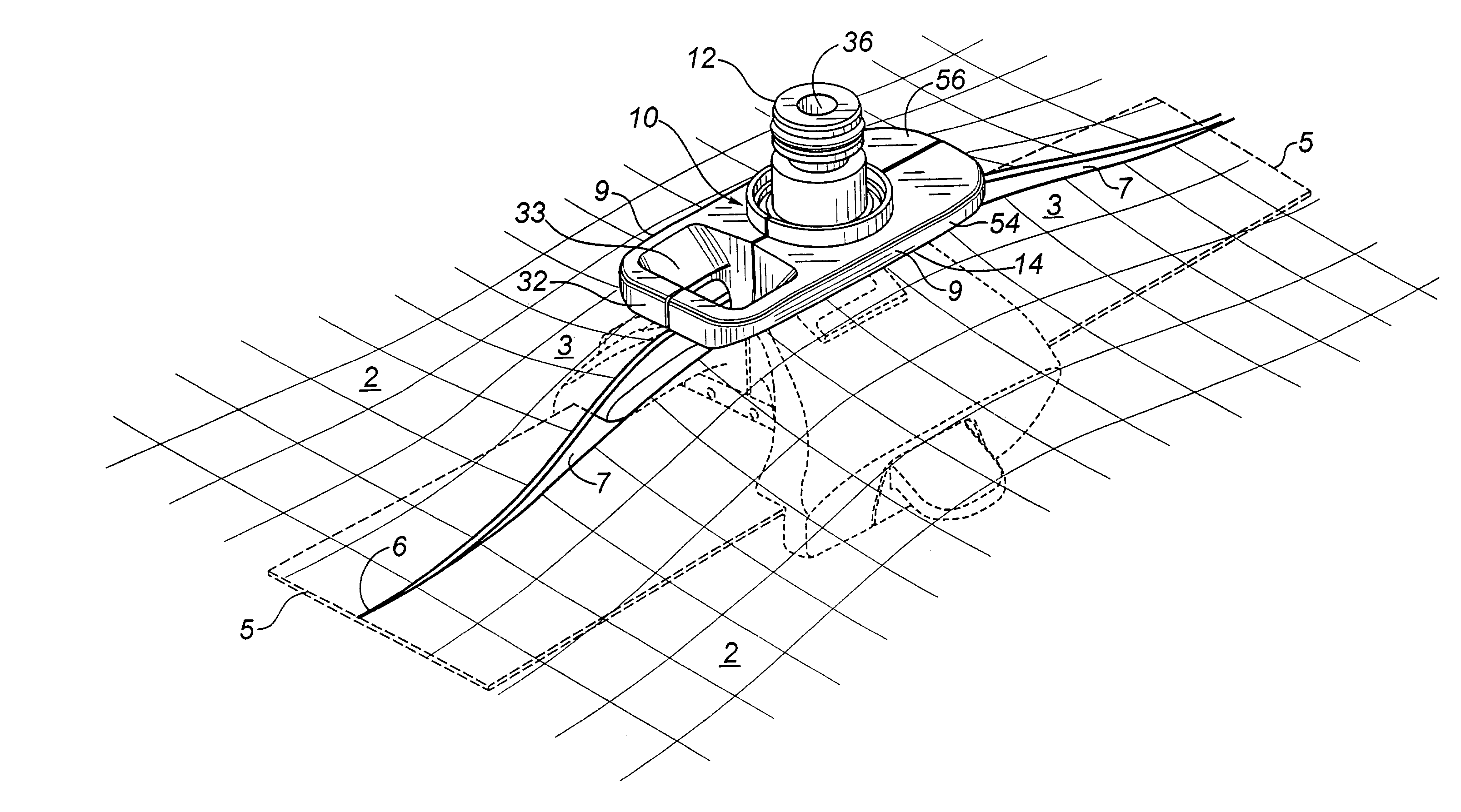

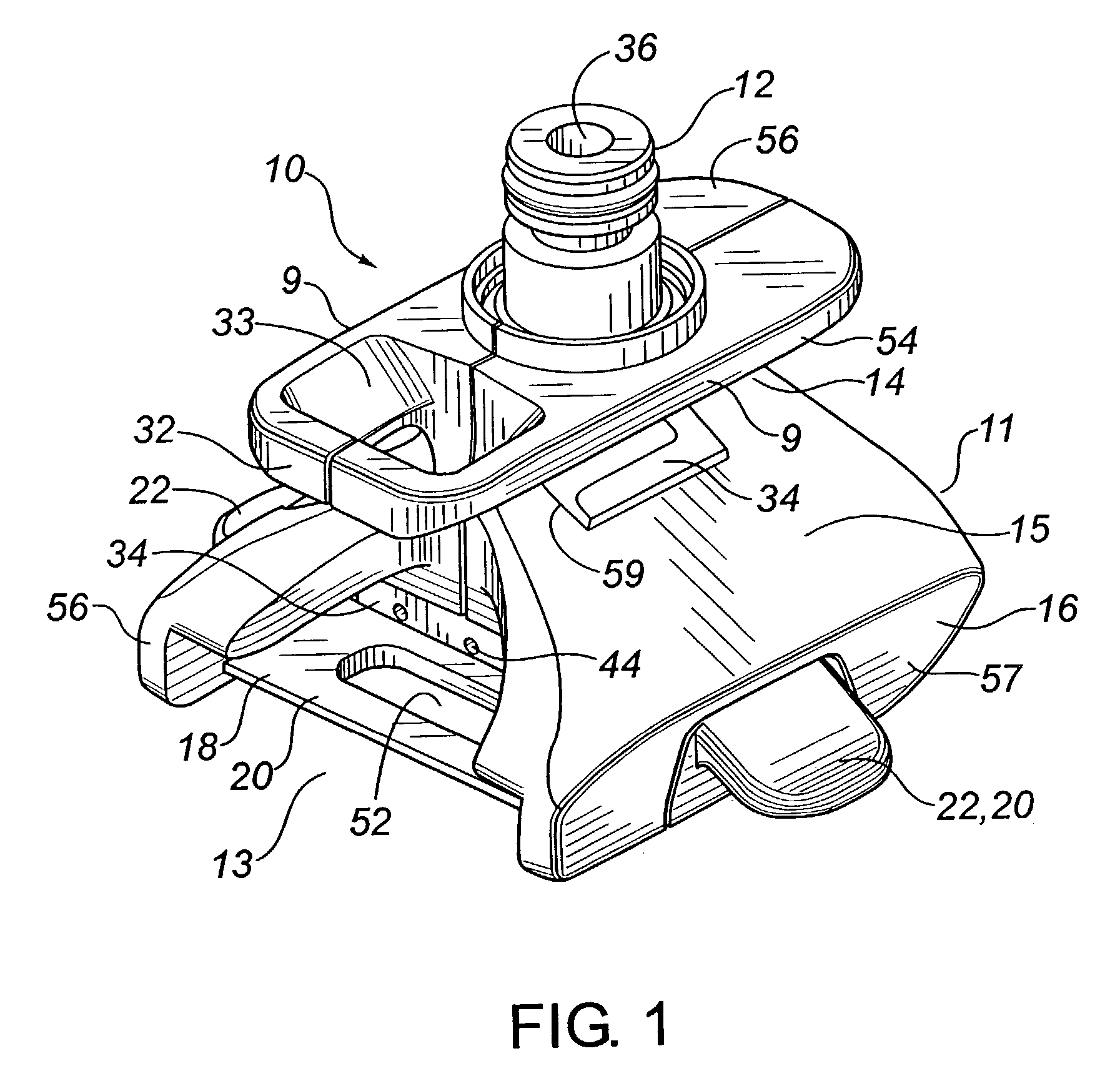

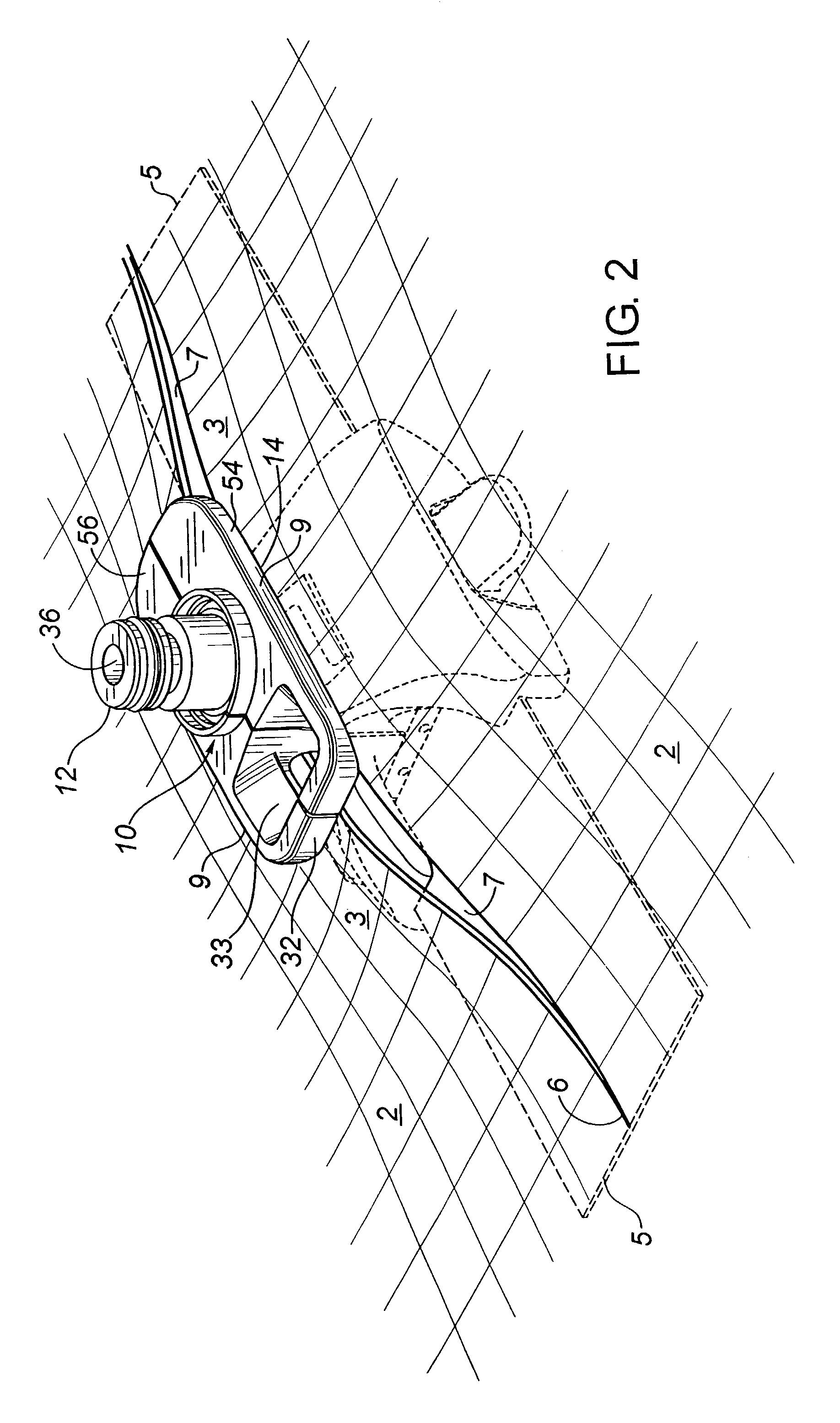

Notched spatula applicator and adhesive composition for laying parquet

InactiveUS20090044364A1Acceptable mechanical stabilityImprove acoustic propertiesLiquid surface applicatorsBuilding constructionsFloorcoveringEngineering

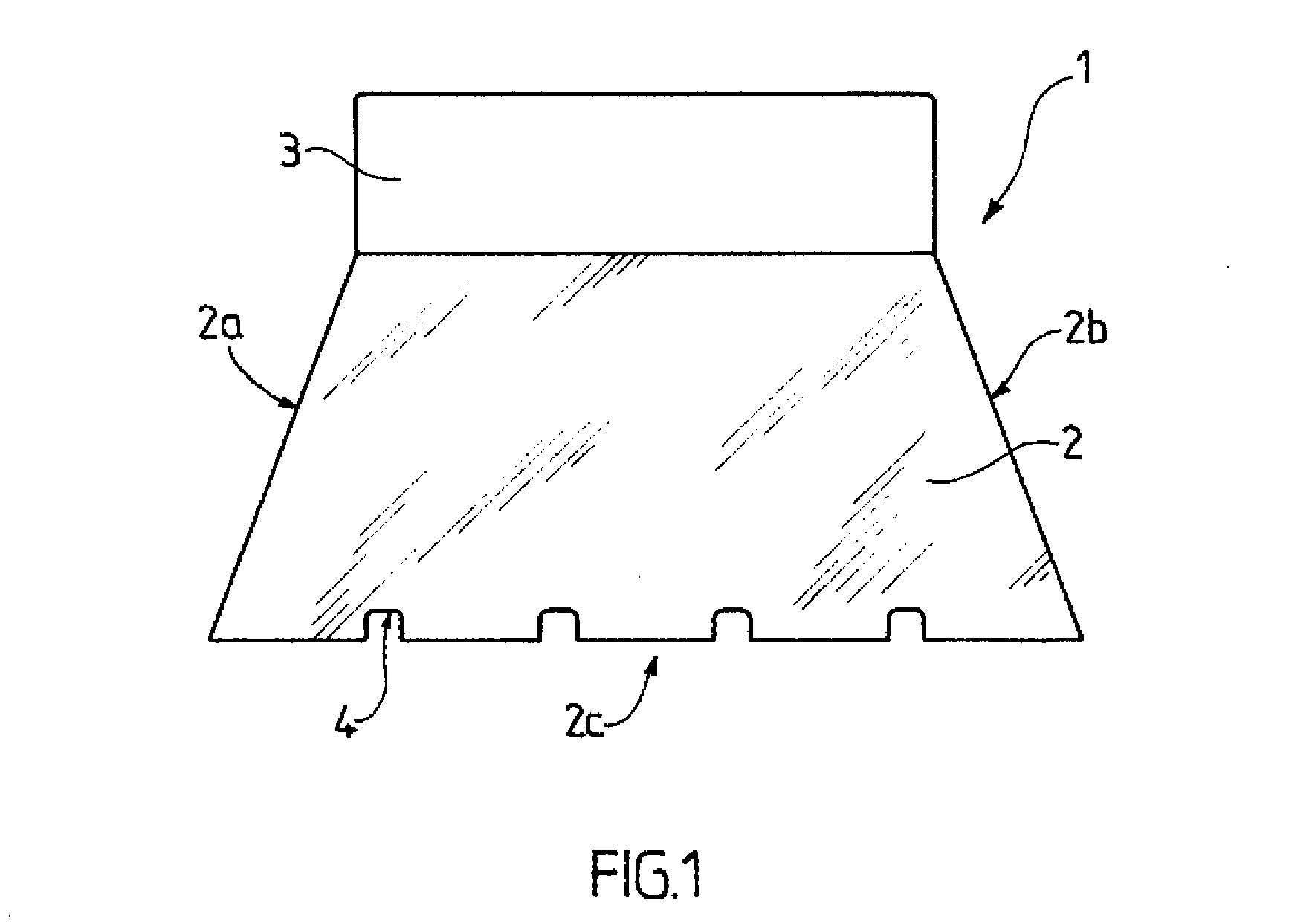

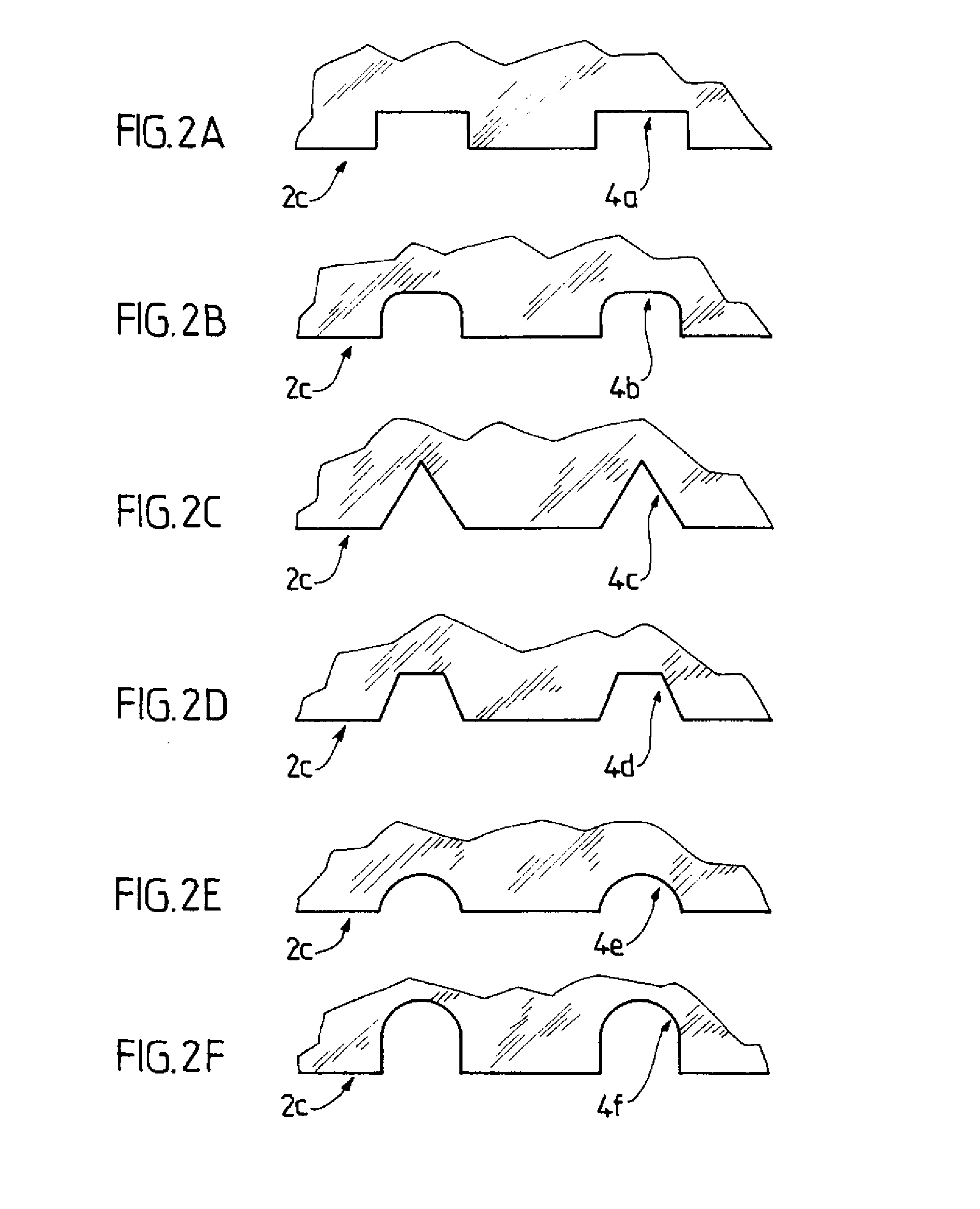

The invention relates to a notched spatula applicator (1) including gripping means (3) connected to a spatula (2) of which the straight working edge (2c) is equipped with a plurality of notches (4) that are identical and evenly spaced apart by a distance between 35 and 50 mm, the width of said notches being between 9 and 18 mm and their height between 8 and 20 mm.The invention also relates to a process for laying, by bonding, rigid floorcoverings, especially parquet, which uses said applicator and an adhesive composition comprising from 0.2 to 5 wt % of substantially spherical particles of a material for which the substantially identical diameter may range from 1 to 7 mm.The invention finally relates to the adhesive composition used in said process.

Owner:BOSTIK SA

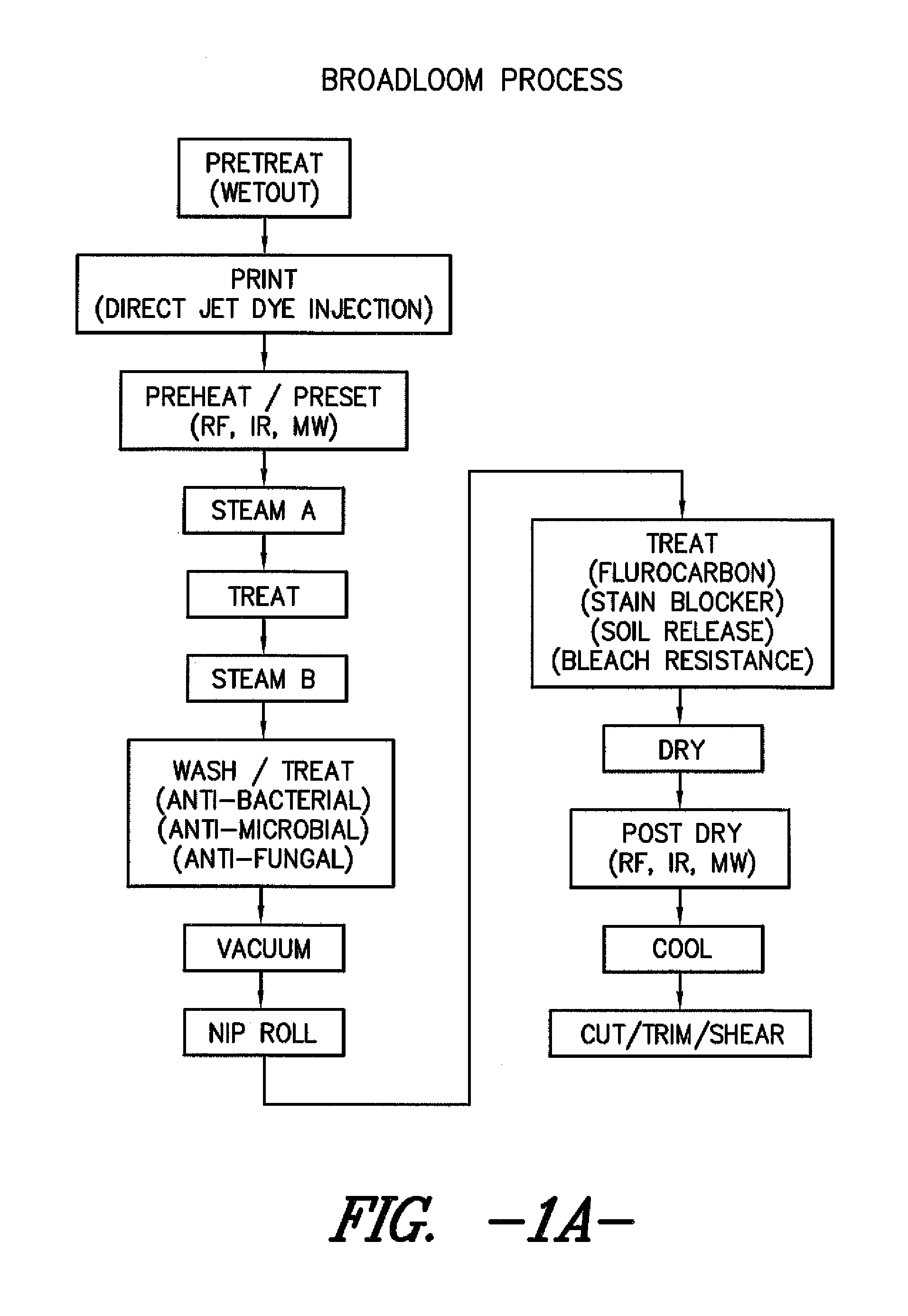

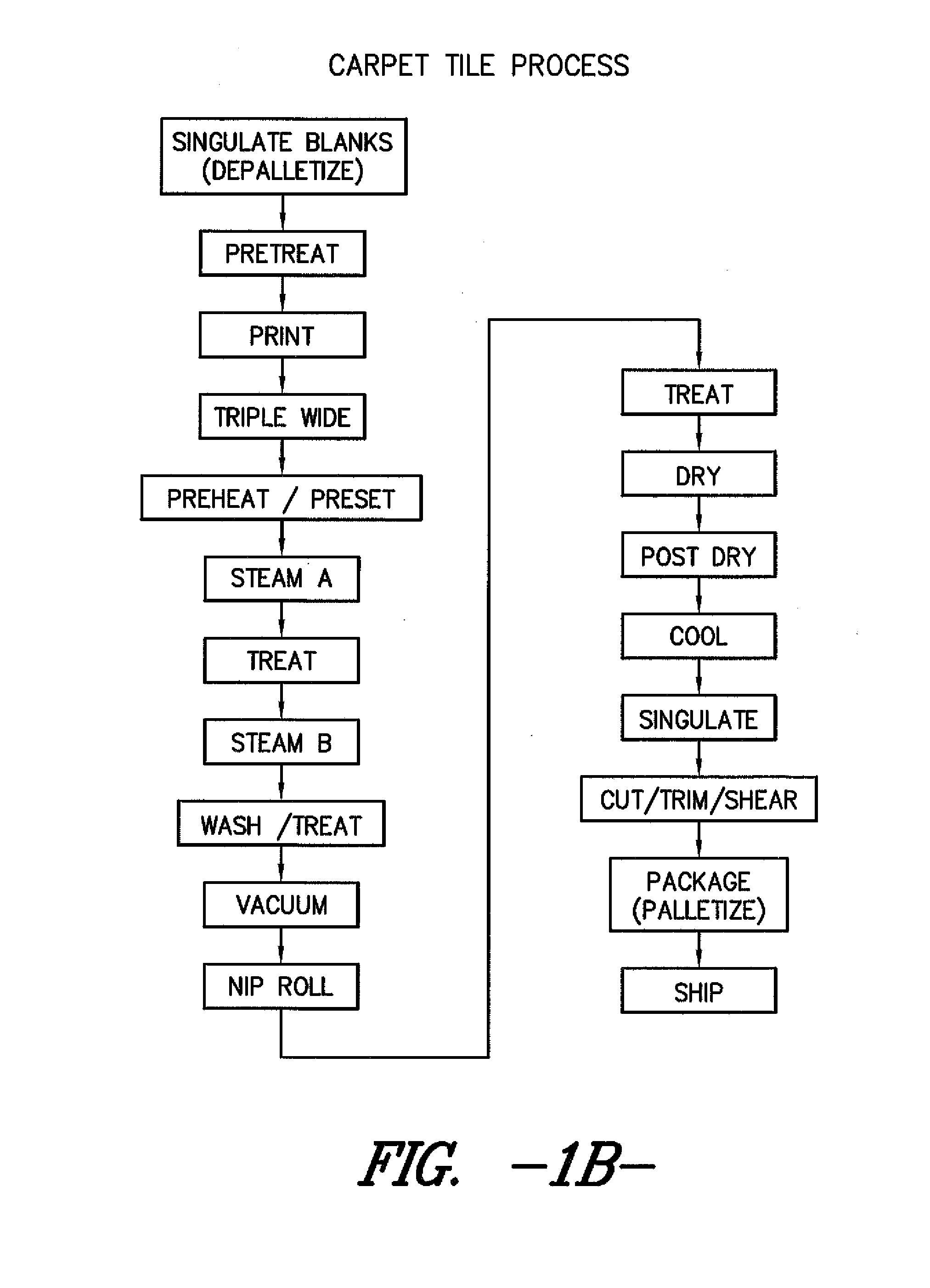

Printed Textile Substrate and Process for Making

InactiveUS20140212618A1Evenly distributedAvoid contactLayered productsDyeing processFloorcoveringOne pass

This invention relates to a printed textile substrate, such as a floorcovering article, and a process for making a printed textile substrate. The printed textile substrate contains areas of low viscosity printing ink and high viscosity printing ink. The process for making the textile substrate includes a one pass manufacturing step that results in a textile substrate having areas of low viscosity and high viscosity printing inks.

Owner:MILLIKEN & CO

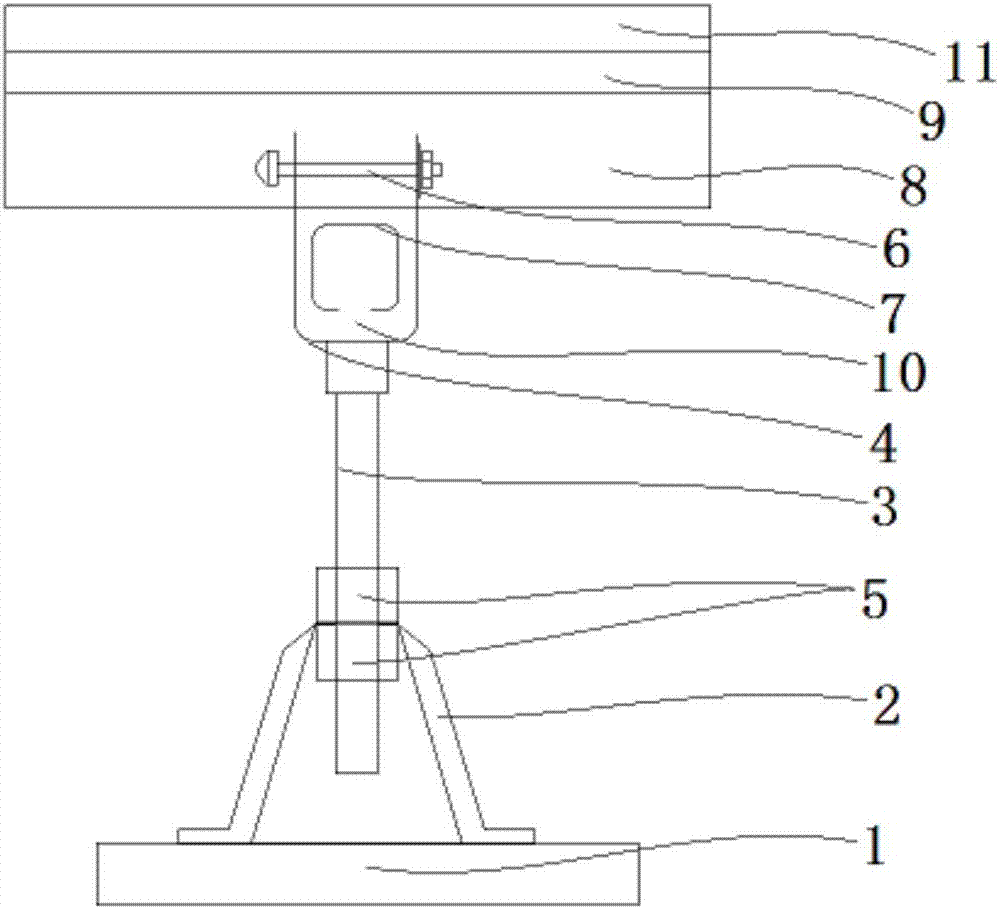

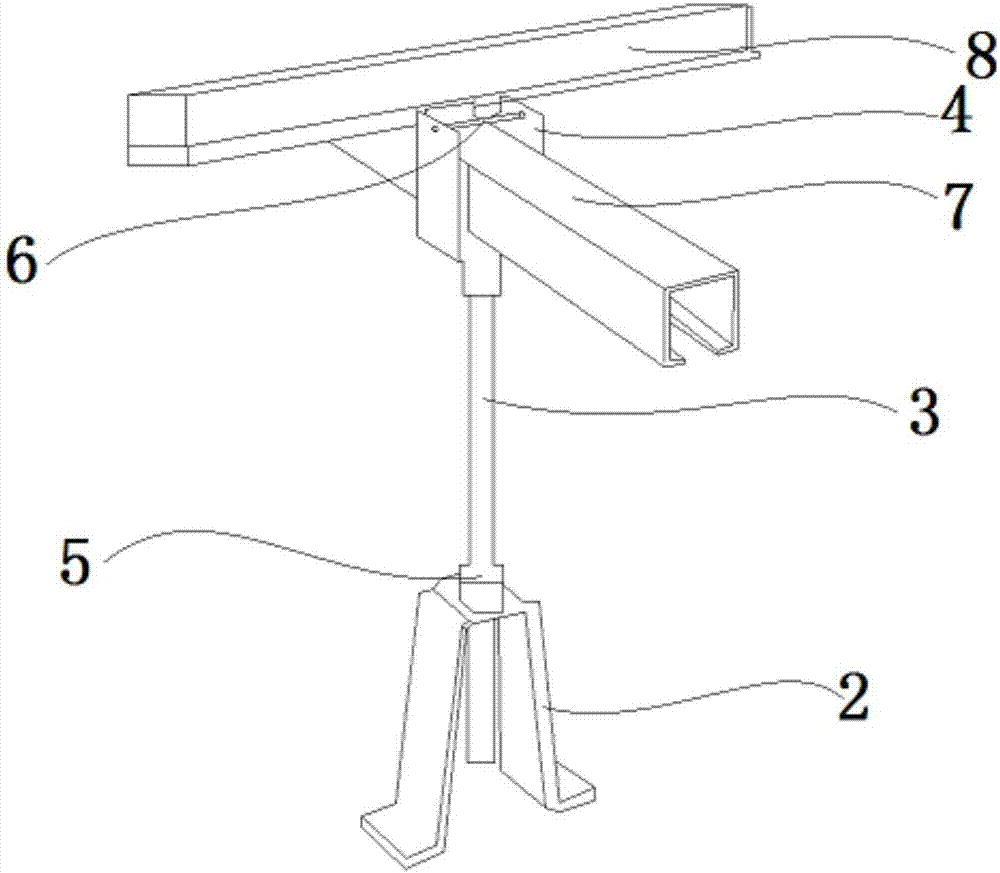

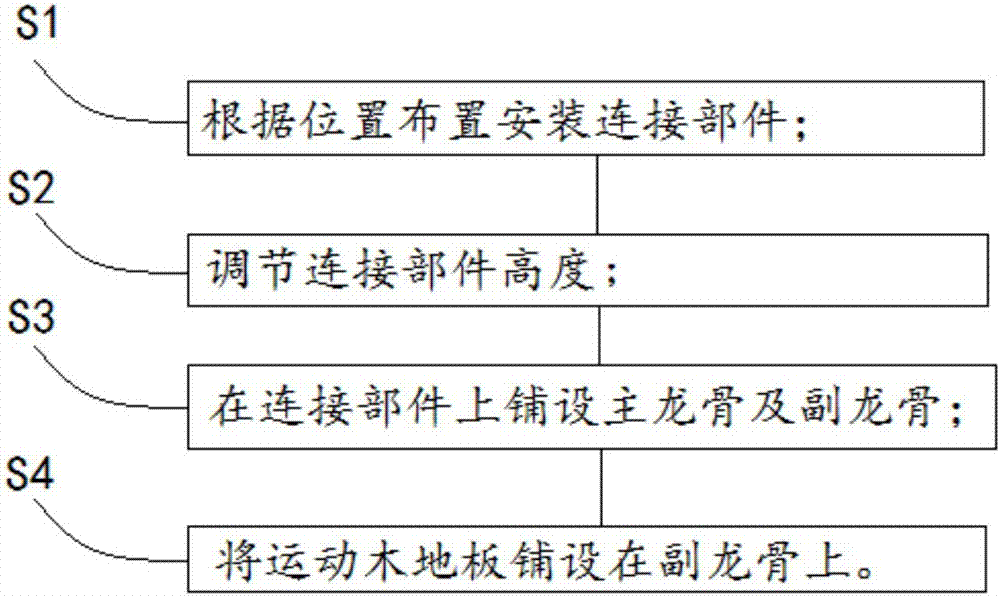

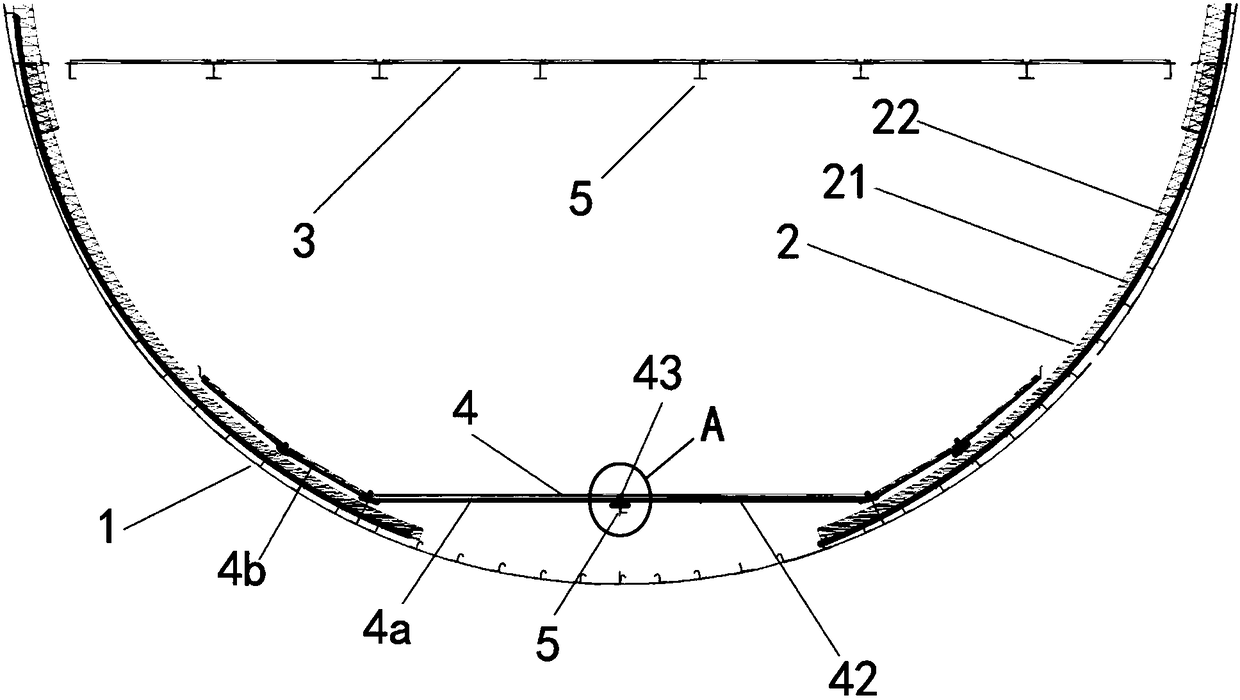

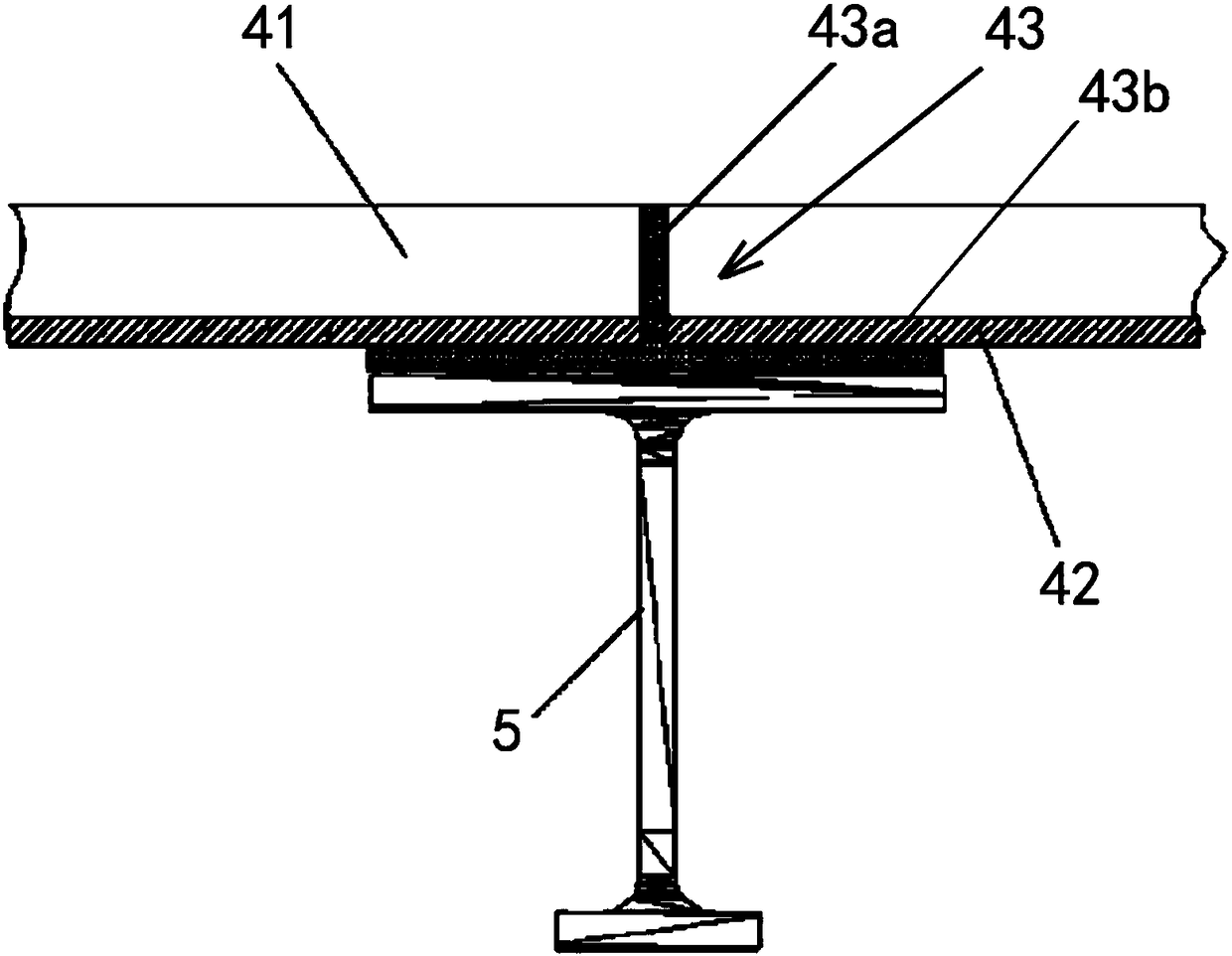

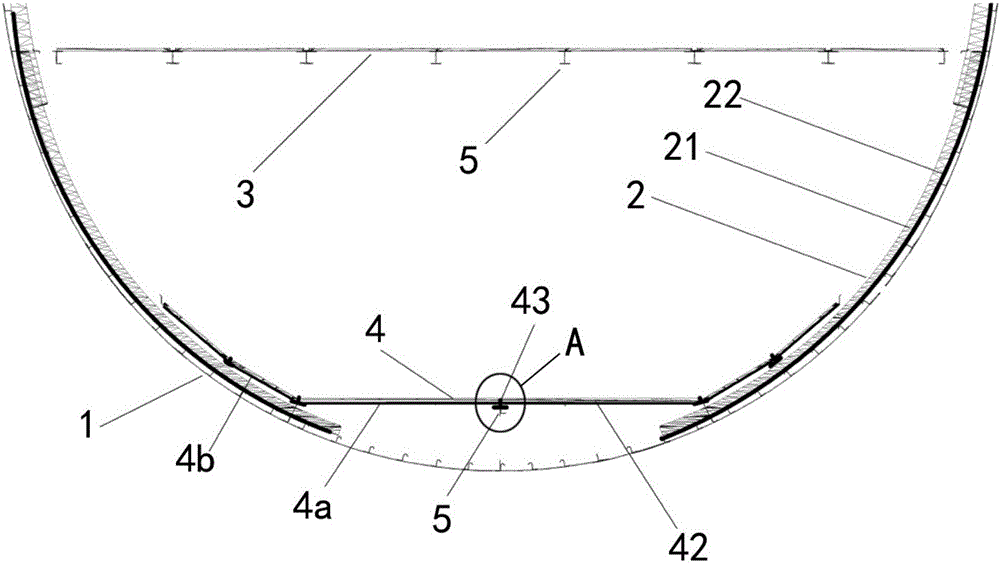

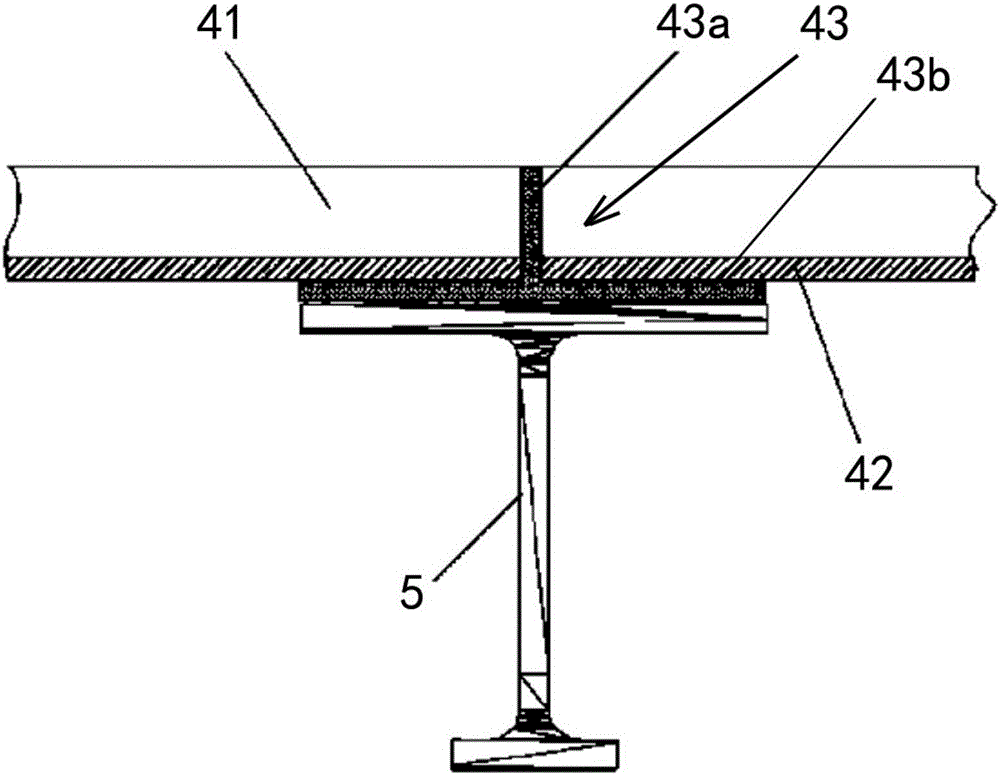

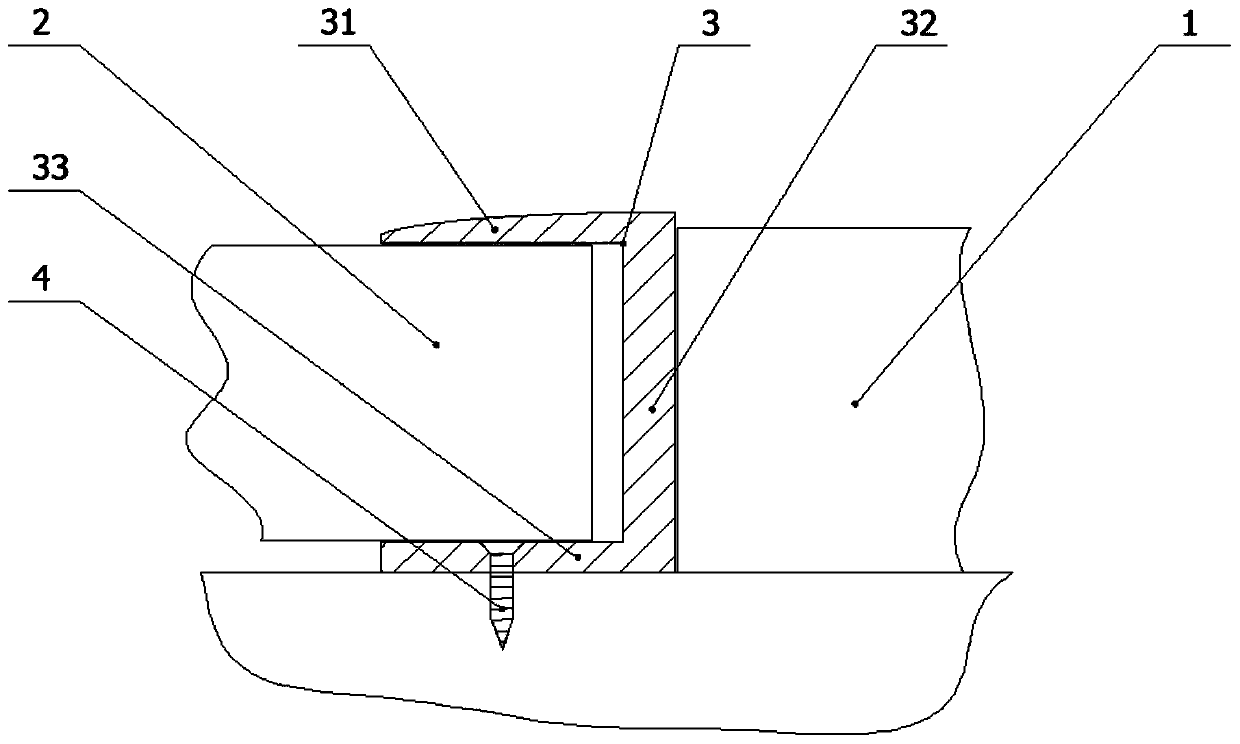

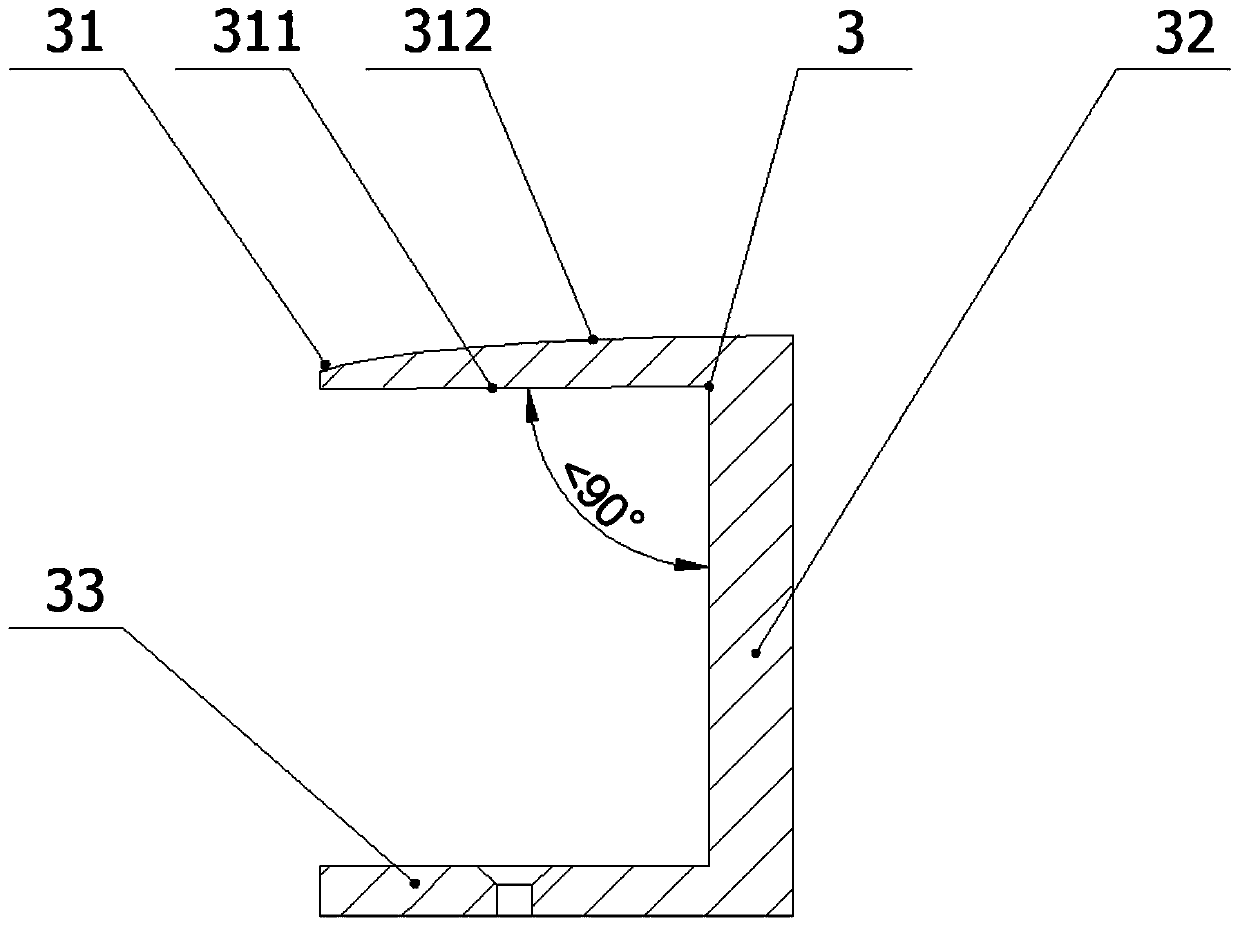

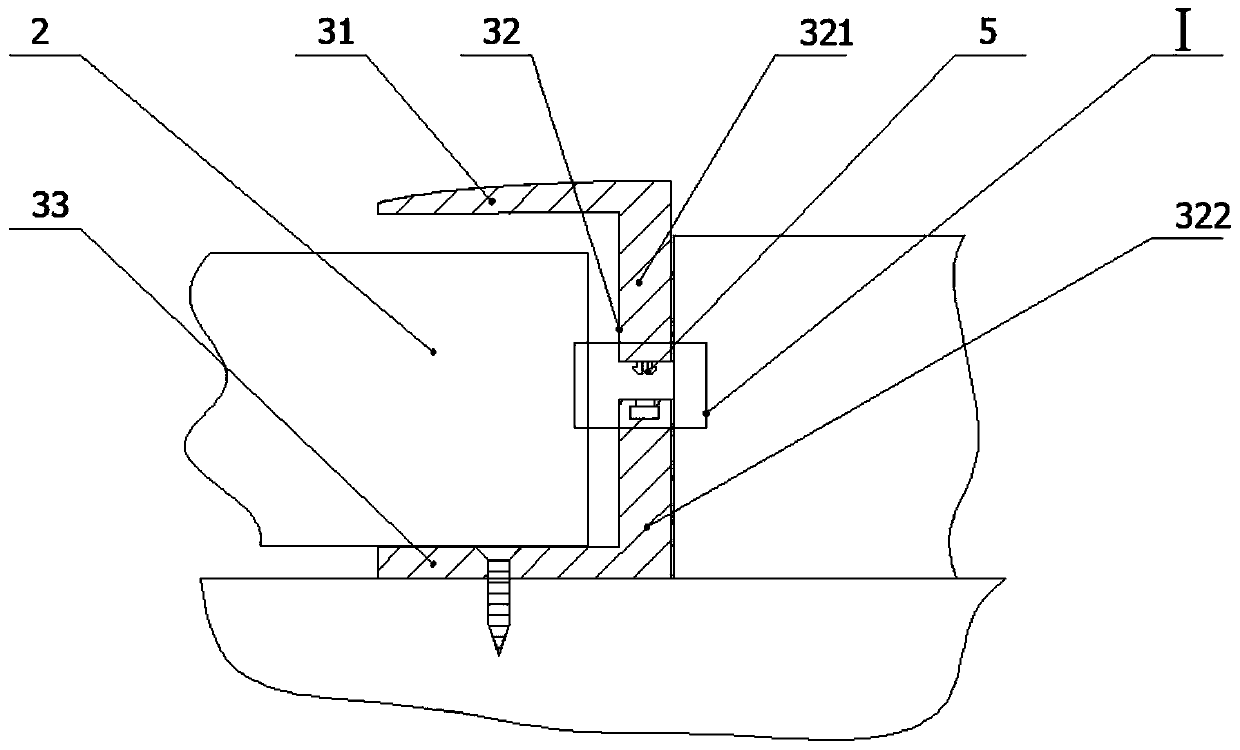

Combination type sports floor

The invention relates to the field of floors, in particular to a combination type sports floor. The combination type sports floor comprises at least one set of floor units. Each floor unit comprises a connecting part with the adjustable height, a keel assembly and a sports wood floor. Each connecting part is arranged between the ground and the corresponding keel assembly. Each connecting part is detachably connected with the ground and the corresponding keel assembly. The sports wood floors are laid at the upper parts of the keel assemblies. The sports wood floors are fixedly connected with the keel assemblies. During installing, the ground is fixed firstly, the connecting parts are installed on the ground, the connecting parts are adjusted according to the depth of a foundation, then the keel assemblies are installed on the connecting parts, and after the connecting parts are adjusted well, finally, the sports wood floors cover and are installed on the keel assemblies; and because the height of the connecting parts is adjustable, the height can be adjusted freely, the height of the connecting parts is not influenced by the depth of the foundation of a stadium and not in conflict with other projects and does not need ground leveling before construction, and the working time and the labor force are saved greatly.

Owner:钱浩

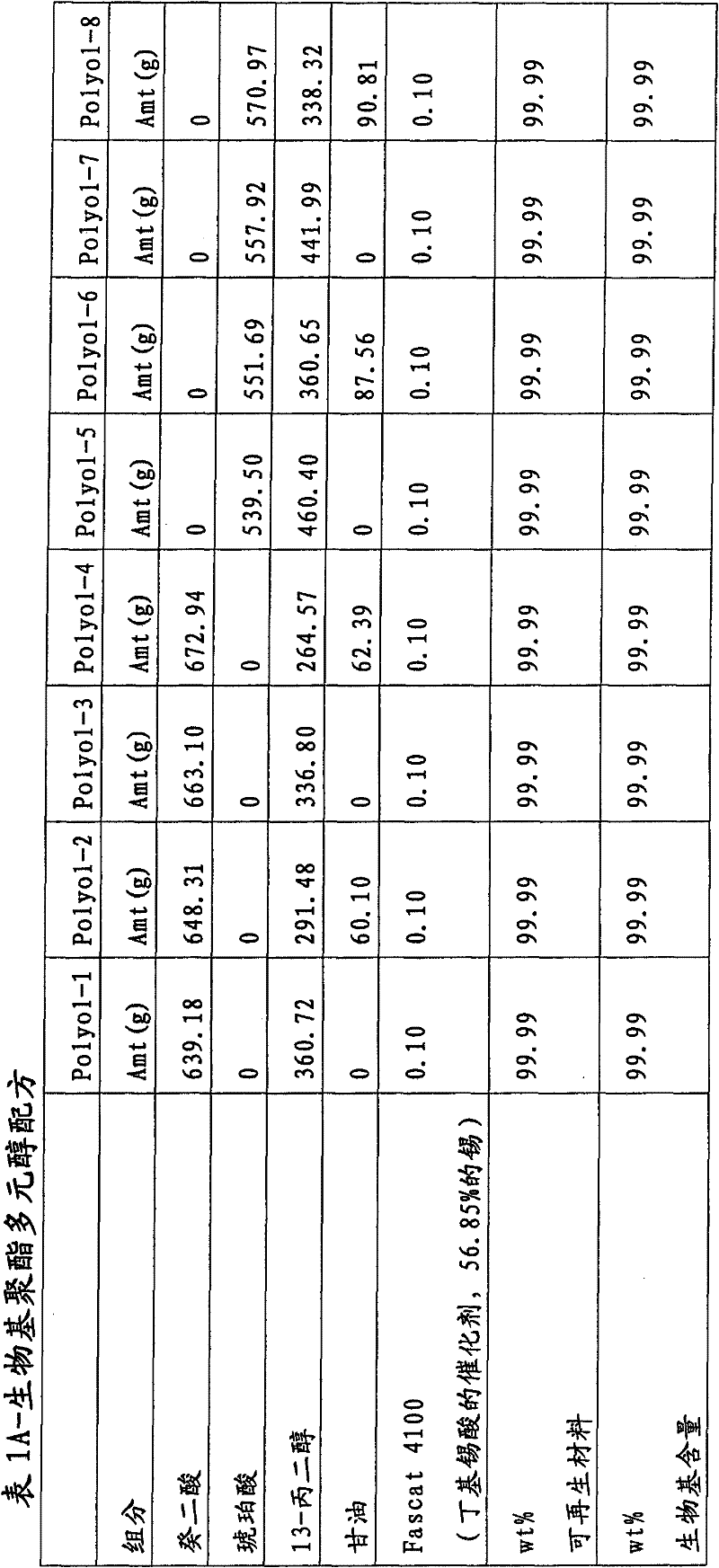

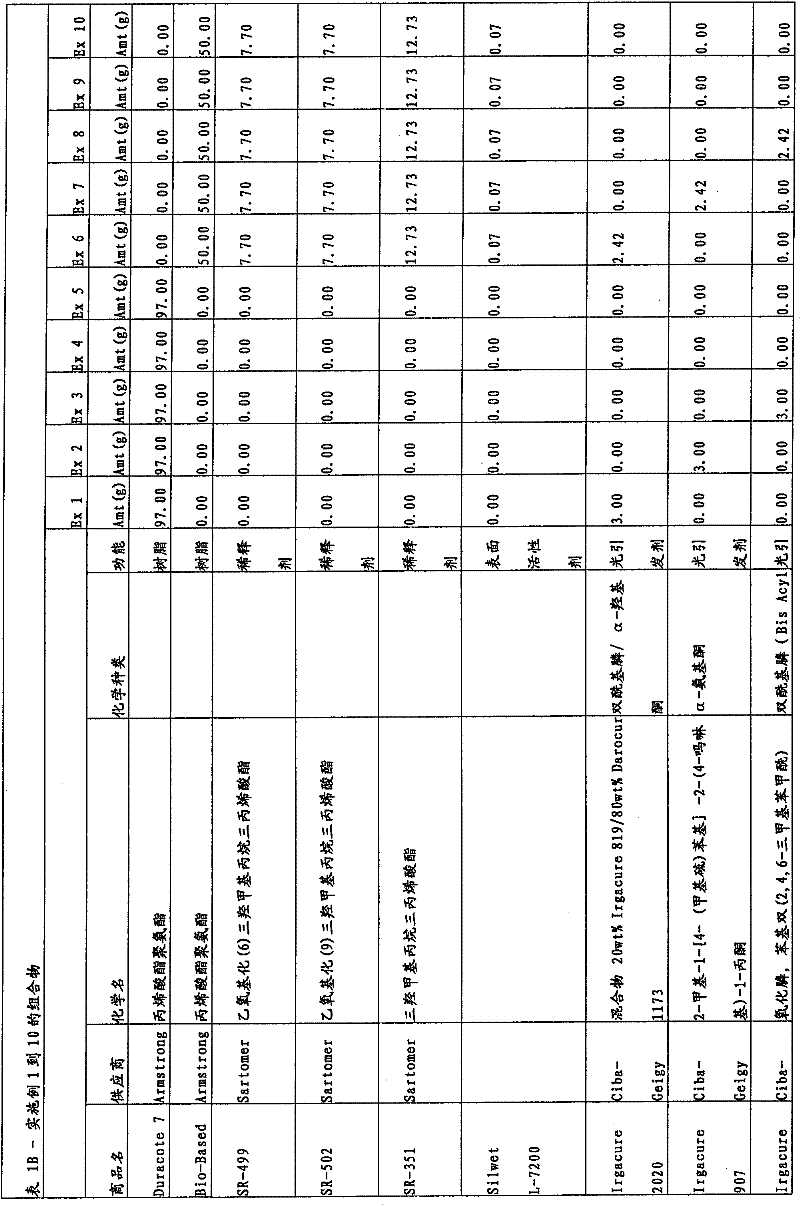

Uvv curable coating compositions and method for coating flooring and other substrates with same

InactiveCN102459381AWon't absorbHigh glossPretreated surfacesPolyether coatingsCoated surfaceFloorcovering

A floor covering includes a wear layer including a resin and a photoinitiator in which the composition of the wear layer is curable by radiation having the strongest wavelength in the UW range of 400 to 450 nm. The gloss of the wear layer can be controlled by controlling the amount of flatting agent in the composition applied to the surface, the amount of power applied to the surface coated with the composition or the temperature of the surface coated with the composition when the coated surface is subjected to the UW radiation.

Owner:ARMSTRONG WORLD IND INC

Washable Carpet Tile

This invention relates to tufted floorcovering articles that are washable in commercial, industrial, and / or residential washing machines. In particular, this invention relates to modular carpet tiles that are constructed in such a way as to withstand exposure to at least one wash cycle in an automatic washing machine. The carpet tiles are designed to be soiled, washed, and re-used, thereby providing ideal end-use applications such as entryway floorcovering articles. A further advantage includes the ability to print advertising logos on the carpet tiles and easily change out the advertising logos as desired. Both features of the carpet tile of the present invention are achievable, at least in part, because the surface of the tile that contacts the floor does not require any type of adhesive in order to use the carpet tile for its intended function.

Owner:MILLIKEN & CO

Colored radiation solidifed wearing-resistant layer

InactiveCN1358810ALamination ancillary operationsDecorative surface effectsWear resistantOptoelectronics

A method and composition for providing a colored high performance wear surface for floor coverings is disclosed. Specifically, the floor covering includes a substrate and a high performance layer comprising a radiation cured pigmented composition. The exposed surface of the floor covering has a stain resistance of less than about 150 Delta E units. A pigmented high performance wear layer can be added in register with a printed design on the substrate or in register with an embossed texture of the substrate. Additionally, a high performance topcoat wear layer may be added. The pigmented high performance layer may include a nacreous pigment.

Owner:ARMSTRONG WORLD INDUSTRIES

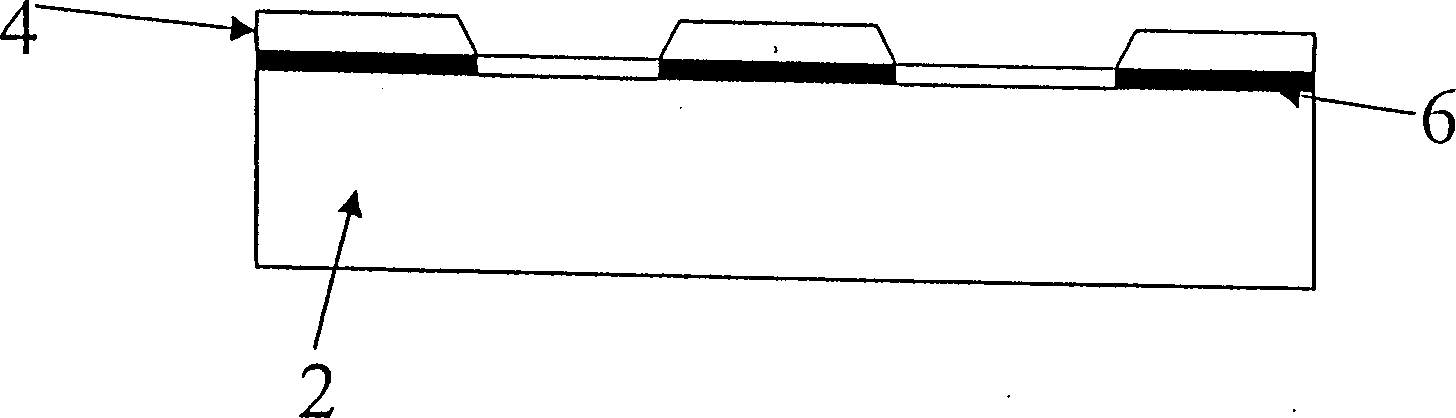

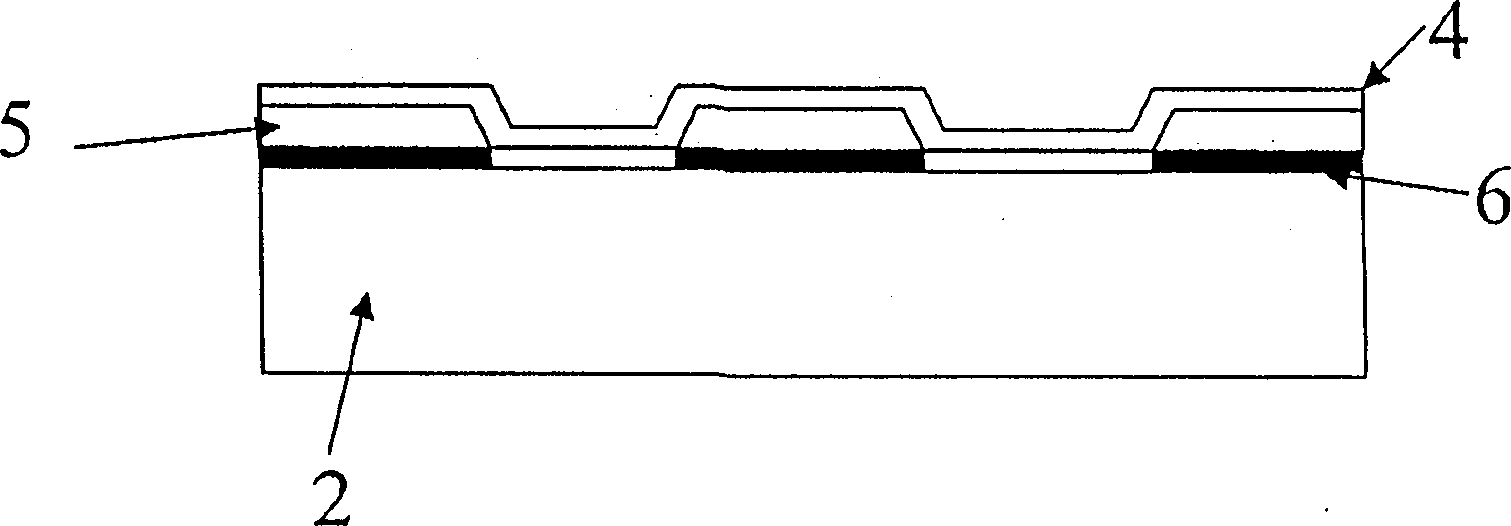

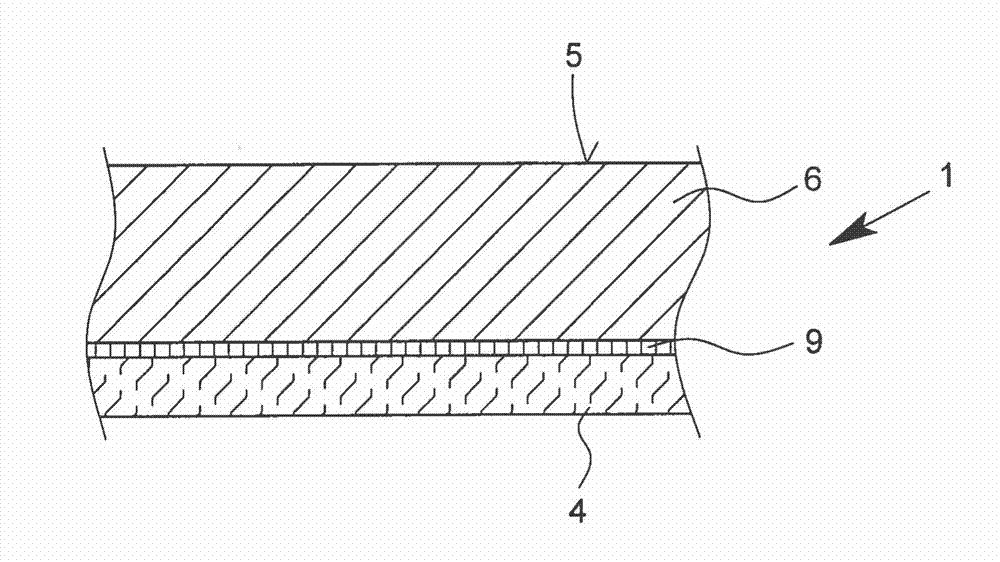

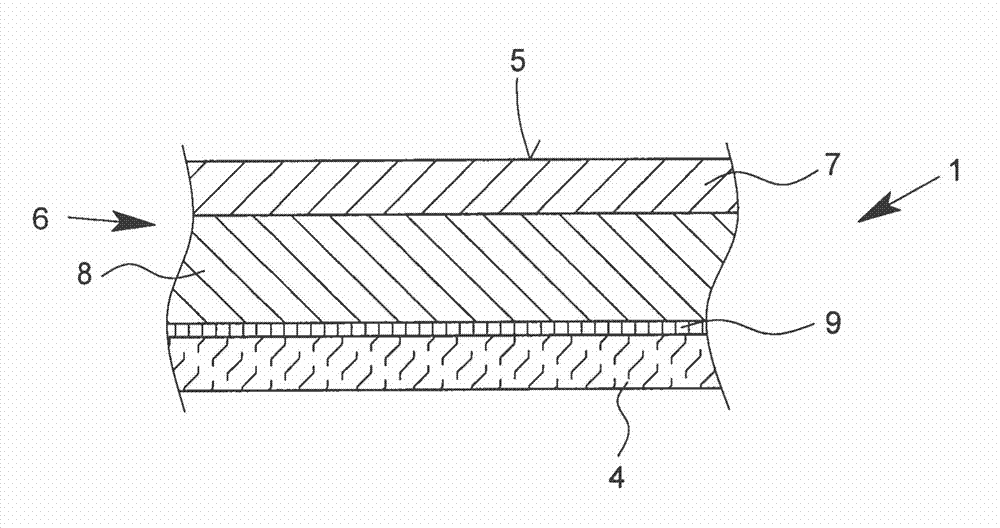

Cover layer with outside film layer of an elastic plastic

A cover layer (1) for a panel (3) which has a panel base body (2), such as a floor covering panel, wall panel or ceiling sheathing panel and / or furniture component panel, building panel, covering panel or dry finish panel and / or as a facade element, panel element or board element, trimming plate or the like, the cover layer (1) having a paper layer (4) and a film layer (6) of elastic plastic which forms the outside (5) of the cover layer (1). The paper layer (4) is made as a preimpregnate which has already been partially impregnated during paper manufacture or as paper, especially decorative paper, which has been partially impregnated after paper manufacture and before joining to the paper layer (4).

Owner:MONDI GRONAU +1

Recyclable Single Polymer Floorcovering Article

This invention relates to tufted floorcovering articles, including carpet tiles and broadloom carpet. In particular, this invention relates to tufted floorcovering articles made from the family of polymers known as polyester. Specifically, this invention relates to tufted carpet tile products made from polyester. The polyester carpet tiles meet commercial performance specifications and are fully end-of-life recyclable.

Owner:MILLIKEN & CO

Method and apparatus for seaming abutting layers of planar material

The present invention is concerned with a method and apparatus for seaming together abutting side-by-side layers of planar material with adhesive and a backing tape to form a finished seam extending along the line of abutment. The method consists of laying a backing tape underneath the line of abutment between adjacent layers of planar material, such as floorcovering, followed by dispensing an adhesive along the edges of the abutting layers while simultaneously centering the backing tape with the line of abutment and dispensing adhesive on top of the backing tape. The edges of the abutting layers are then pressed together and against the backing tape until the adhesive has at least partially set thereby forming a finished seam. The apparatus is an applicator tip comprising an upright body having a tape retaining portion for centering the backing tape, a foot portion having wedges for upraising and tilting marginal portions of the abutting layers, an ankle portion that is relatively narrow, and an upper leg portion adapted to connect with an adhesive dispenser via a swiveling elbow connection. A flow passageway extends through the elbow connection from the dispenser to a leg passageway extending from the upper leg portion, through the ankle portion, to the foot portion. The leg passageway connects with an ankle passageway that terminates in orifices on either side of the ankle portion, and with a foot passageway that terminates in orifices on the rear face of the applicator tip. Thus, adhesive injected into the applicator tip by the dispenser is discharged through the orifices on the ankle portion onto the edges of the abutting layers and is discharged through the orifices on the rear face of the foot portion onto the top surface of the backing tape as the applicator is advanced along the line of abutment between the abutting layers.

Owner:BENO J GUNDLACH

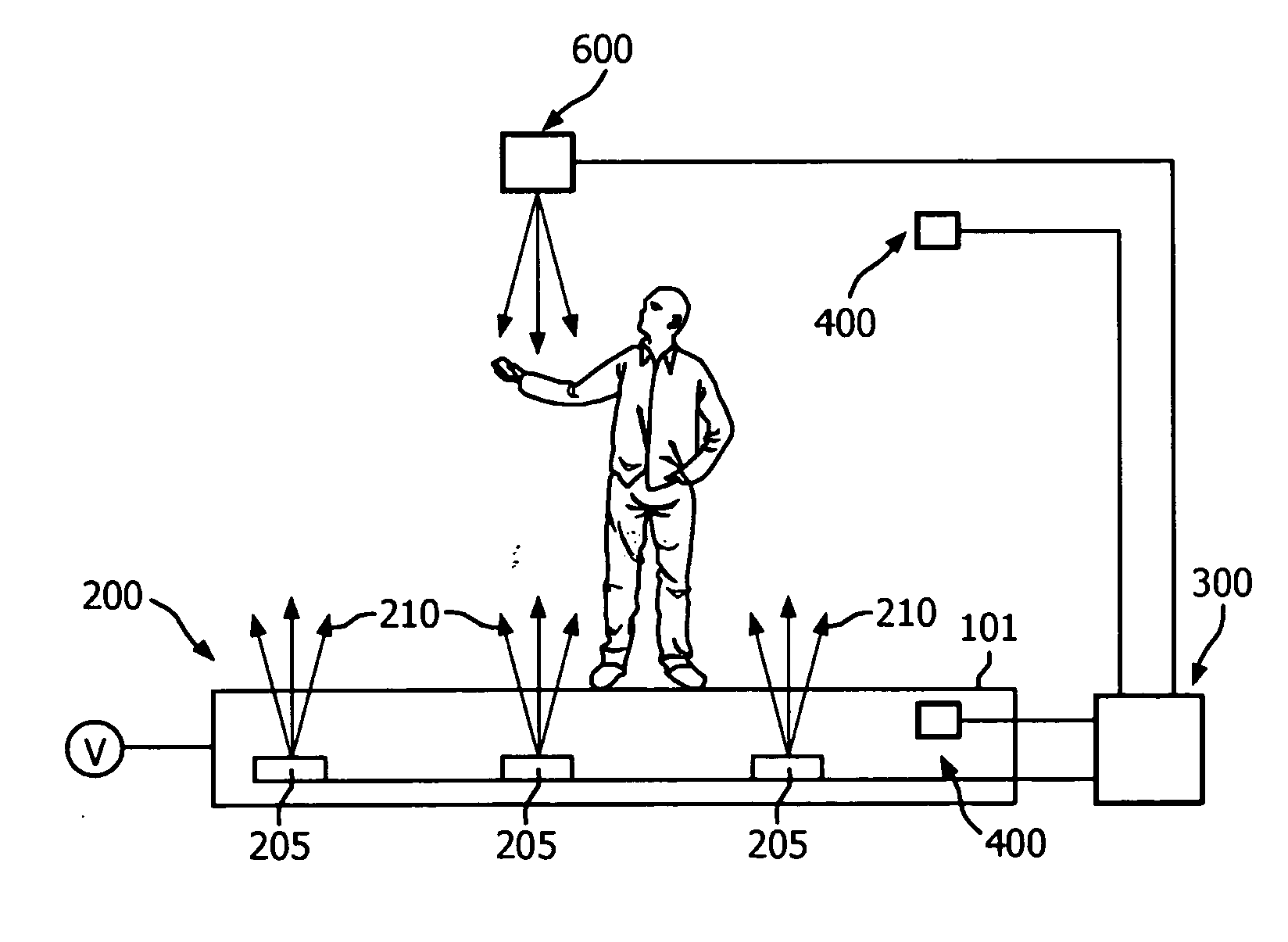

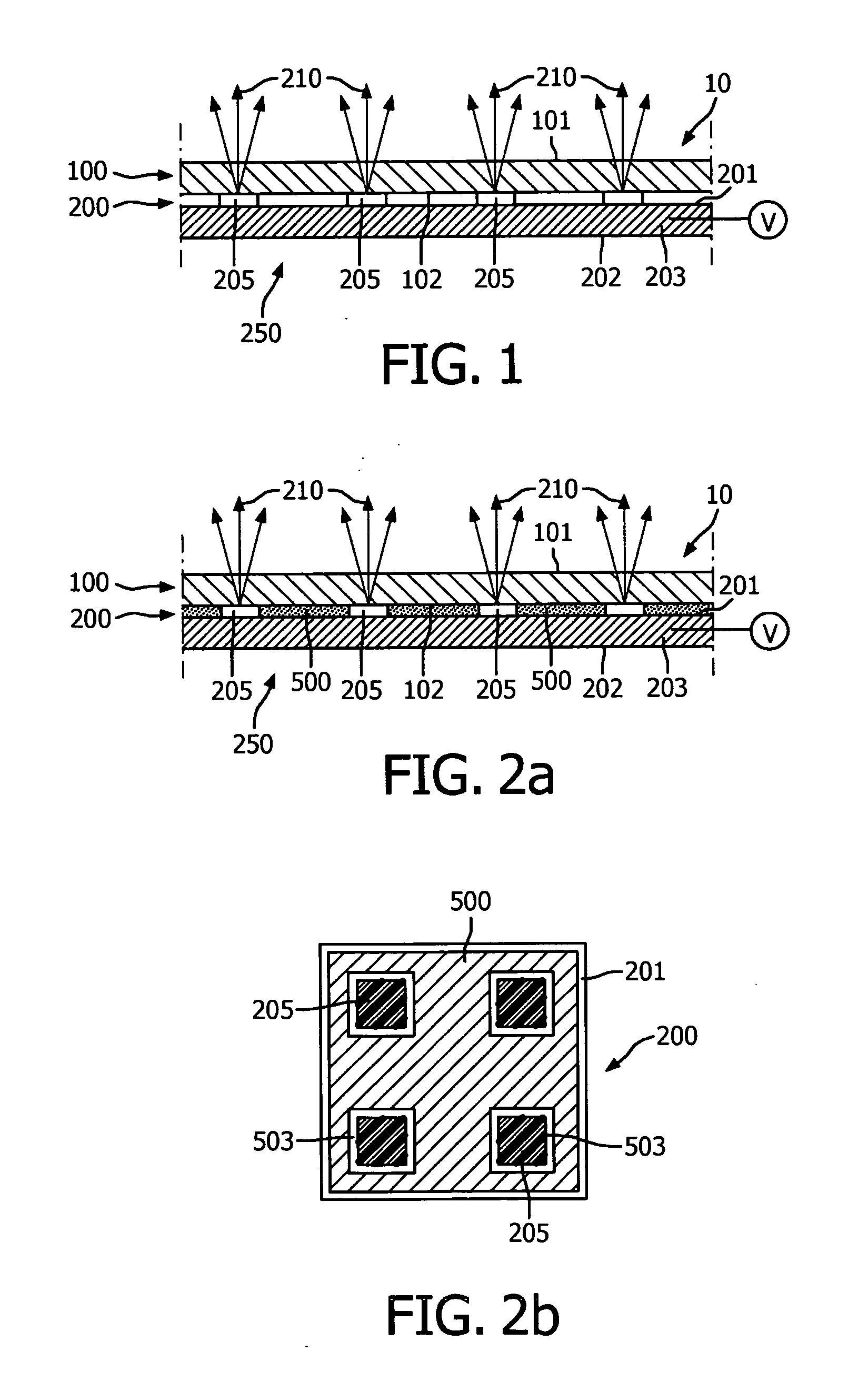

Floor covering system comprising a lighting system

ActiveUS20120201014A1Low production costProtection from damageCovering/liningsElectric circuit arrangementsFloorcoveringEngineering

The invention provides a floor covering system (10) with (a) a PVC-based floor covering (100) and (b) a lighting system (200) arranged to generate light (210). The PVC-based floor covering (100) has a user side (101) and an opposite back side (102). The lighting system (200) is arranged at the back side (102) of the PVC-based floor covering (100). The PVC-based floor covering (100) has a light transmission for light (210) generated by the lighting system (200) in the range of 0.5% to 30%, especially in the range of 1% to 20%.

Owner:SIGNIFY HLDG BV

Production of backing component for carpet products

Disclosed are plastic compositions for a carpet backing having from about 5 to about 25% by weight PVC resin, from about 5 to about 25% by weight plasticizer, and from about 50 to about 90% by weight filler. In a preferred embodiment, the plastic composition is about 15% by weight Geon-138, about 15% by weight di-isononyl phthalate, and about 70% by weight fly ash. Also disclosed are methods for forming backings for floorcoverings using the disclosed plastic compositions. In preferred embodiments, a plastic composition is applied through a slot-die directly to the underside of a carpet or alternatively onto a conveyor belt on top of which the carpet or floorcovering may be subsequently positioned.

Owner:INTERFACE INC

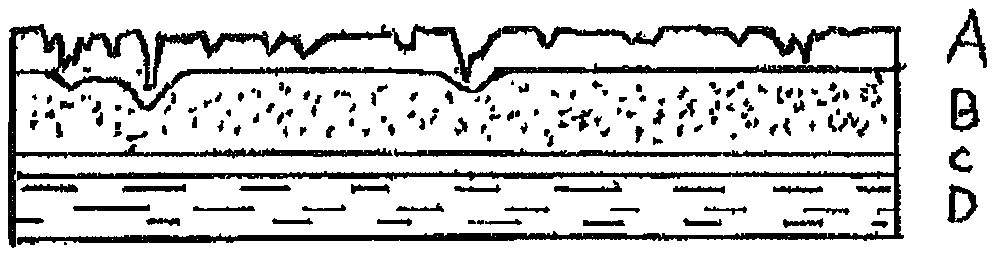

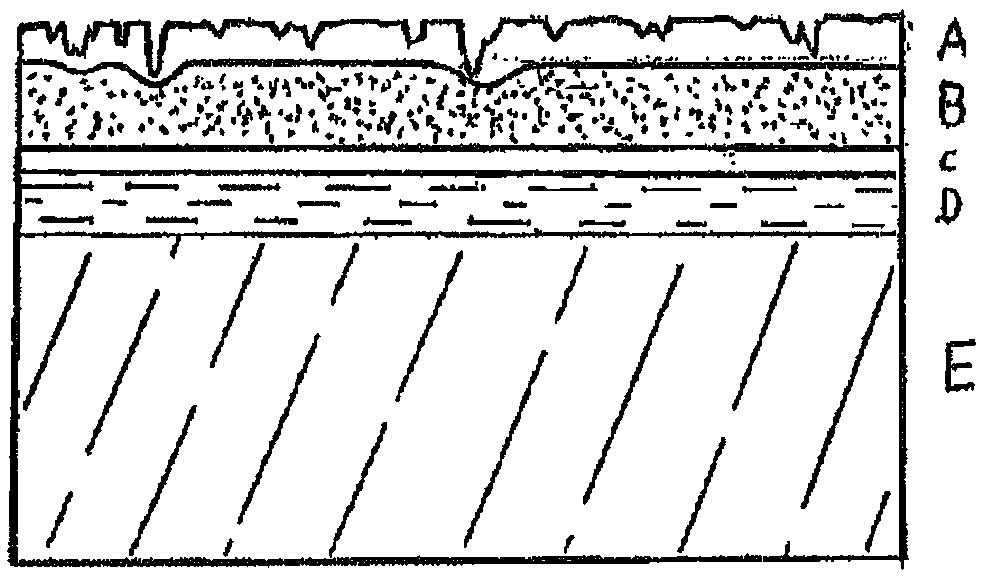

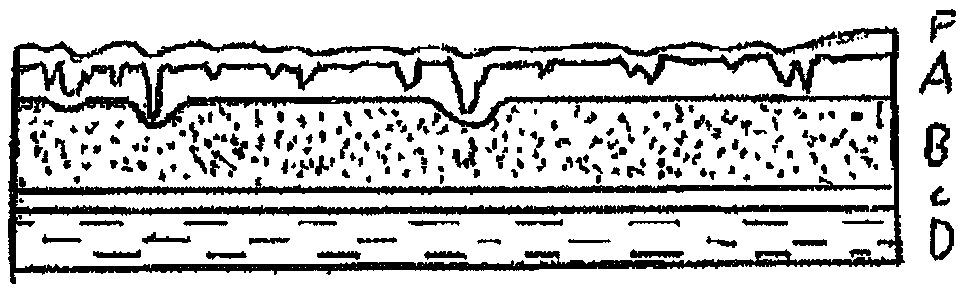

Hot-melt laminated decorative laminate

InactiveCN109070529AImprove wear resistanceIncrease flexibilityCovering/liningsSpecial ornamental structuresIonomerFloorcovering

The invention relates to a decorative laminate, in particular a structured decorative laminate, comprising at least the following layers A-B-C-D following one another directly and connected to one another in an adhering manner: A: on the visible side a functional layer comprising one or more ionomers and optionally one or more fillers and / or functional additives dispersed in the layer; B: an intermediate polymer layer comprising a mixture of 5 to 95 wt% of an extrudable ionomer, extrudable ionomer mixture or extrudable ionomer blend and 9 to 5 wt% of a polyolefin; C: adhesion promoter layer comprising one or more modified plastics for adhesion promotion; D: on the substrate side a decoration-bearing layer, characterized in that the layer composite comprising the layers A, B, and C is co-extruded and, at a temperature above the melting temperature of the layer composite, is hot-melt laminated with the decoration-bearing layer on the substrate side. The invention further relates to the use of the decorative laminate according to the invention as floorcovering, wall cladding, or furniture foil, to such floorcoverings, wall claddings, furniture foils, and to a method for producing thedecorative laminate according to the invention.

Owner:PROFOL KUNSTE

Flame-through fuselage and flame-through-resistant floor for flame-through fuselage

ActiveCN105923144BEasy to disassemble and repairReduce manufacturing costFuselage insulationAircraft floorsInsulation layerButt joint

The invention provides a flame-burning-through-resistant floor. The floor extends longitudinally and comprises a plurality of floor strips which extend longitudinally and are adjacent to one another, a plurality of flame-burning-through-resistant films covering the lower surfaces of the floor strips correspondingly, and an inverted-T-shaped firewall sealant which extends longitudinally between one pair of floor strips in butt joint. The upper portion of the firewall sealant is located between the pair of floor strips. The lower portion of the firewall sealant extends on the lower surfaces of at least one parts of the flame-burning-through-resistant films of the pair of floor strips. The invention further provides a flame-burning-through-resistant machine. The flame-burning-through-resistant machine comprises a machine body, a first floor extending longitudinally along the machine body, and a heat and sound insulation layer covering the inner surface of the machine body. The heat and sound insulation layer comprises the flame-burning-through-resistant films. The first floor comprises a horizontal floor part and extending parts which are transversely overlapped on the heat and sound insulation layer on the two sides. The flame-burning-through-resistant floor is adopted by the first floor. The heat and sound insulation layer at least extends to the position under the floor part of the first floor.

Owner:COMAC +1

Aesthetic Floor Covering System

InactiveUS20200171993A1Improve puncture resistanceHigh wear resistanceVehicle arrangementsSynthetic resin layered productsElastomerFloorcovering

Moulded floor covering system for acoustic attenuation of an automotive vehicle comprising a surface layer, a thermoplastic elastomeric base layer with a density of at least 0.5 kg / m3, and a decoupling layer, characterised in that the facing layer comprises an adhesive layer jointed to the surface of the base layer and an adherent pile of fibrous flock standing substantially on end in the adhesive forming the surface coverage.

Owner:AUTONEUM MANAGEMENT AG

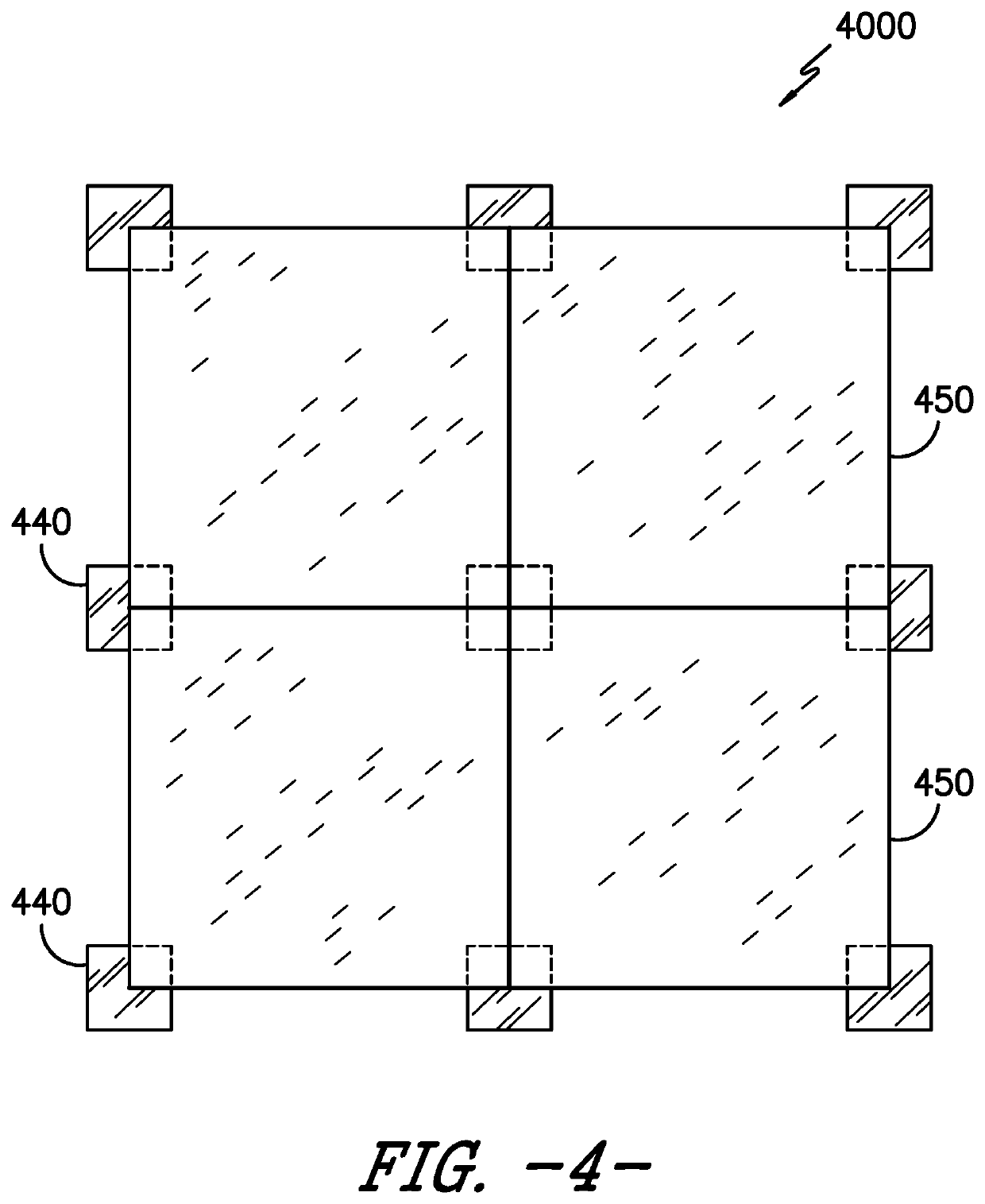

Flooring System

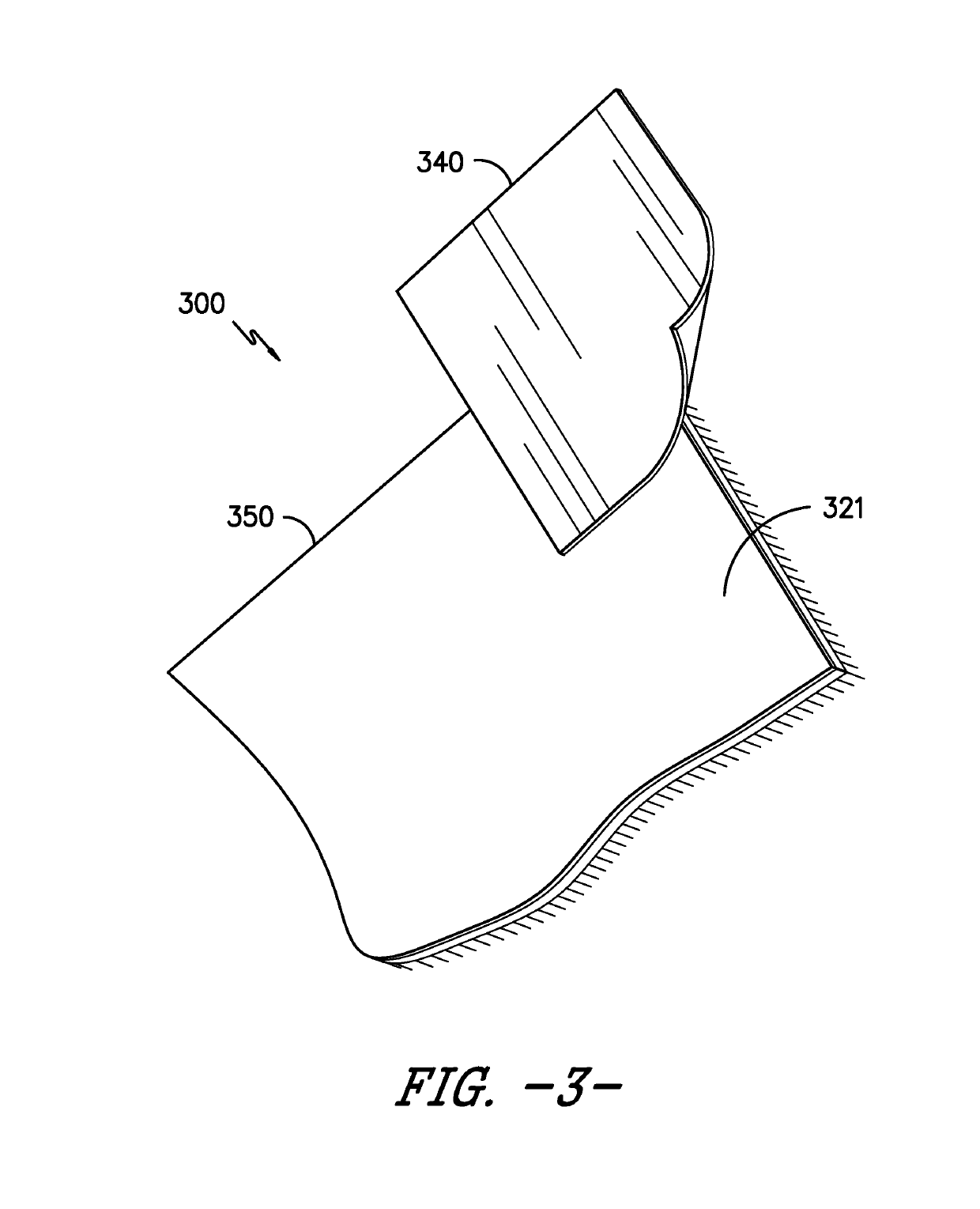

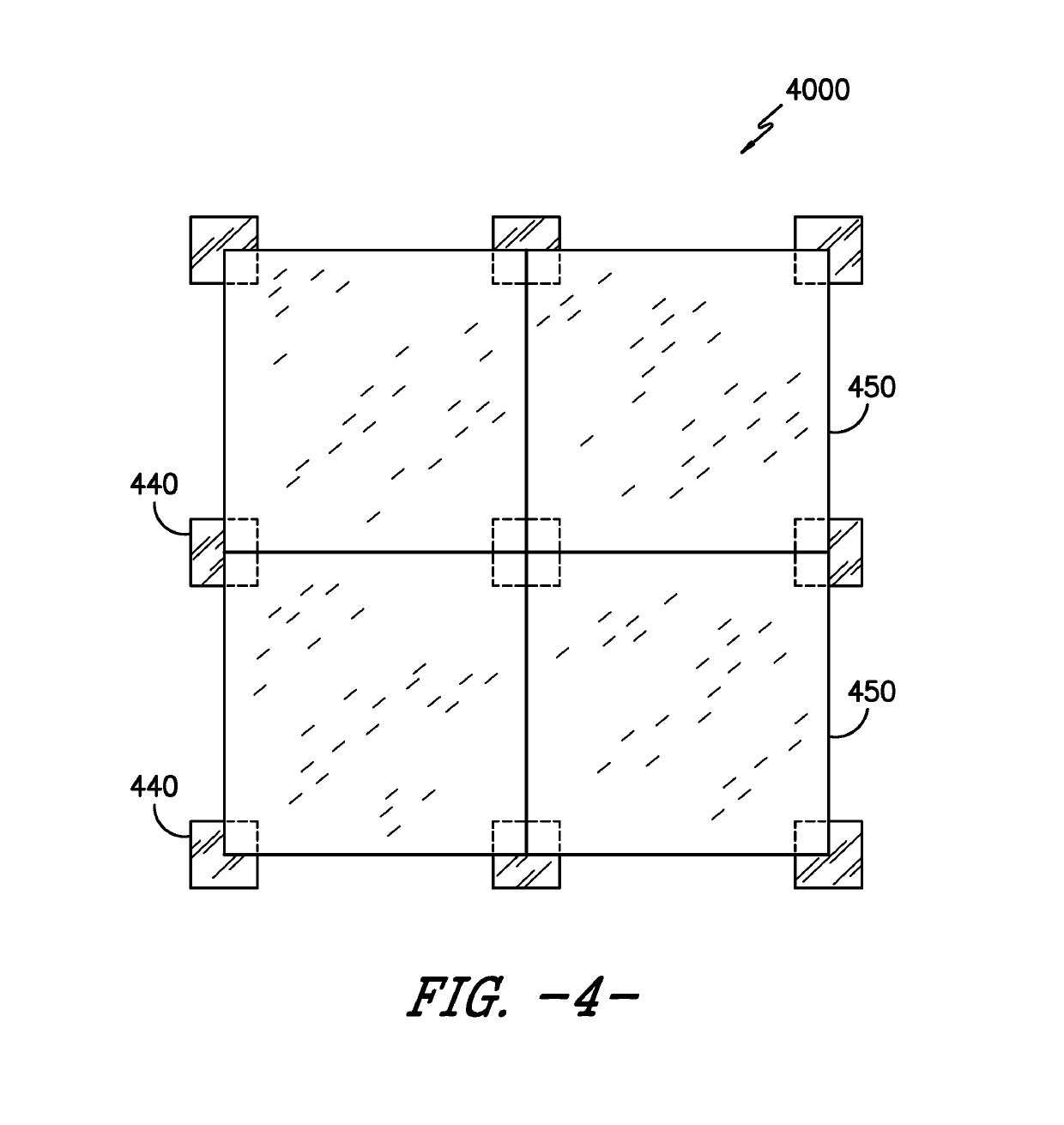

This invention relates to a method for adhering floor tiles together and the flooring system thereby created. The method utilizes individual adhesive units as fasteners for attachment of each floor tile to the next contiguous floor tile. The adhesive units are a multi-layered composite comprised of at least one adhesive layer and at least one layer of polymer film or textile substrate. When a series of floor tiles are attached to one another in this manner, a floating floorcovering article is achieved.

Owner:MILLIKEN & CO

Heathered helix yarns

A process is provided for the manufacture of an effect yarn, such as heathered helix yarns, for use in carpets, floorcoverings, and textile articles. The effect yarns contain patterned alternating sections of twisted multiple singles yarns and sections of entangled multiple singles yarns. More particularly, these effect yarns may comprise a plurality of S-direction twist sections, a plurality of Z-direction twist sections, and a plurality of non-twisted entangled sections interspersed between the S-direction twist sections and the Z-direction twist sections.

Owner:UNIVERSAL FIBERS INC

Flame-burning-through-resistant machine and flame-burning-through-resistant floor used for flame-burning-through-resistant machine

ActiveCN105923144AEasy to disassemble and repairReduce manufacturing costFuselage insulationAircraft floorsInsulation layerButt joint

The invention provides a flame-burning-through-resistant floor. The floor extends longitudinally and comprises a plurality of floor strips which extend longitudinally and are adjacent to one another, a plurality of flame-burning-through-resistant films covering the lower surfaces of the floor strips correspondingly, and an inverted-T-shaped firewall sealant which extends longitudinally between one pair of floor strips in butt joint. The upper portion of the firewall sealant is located between the pair of floor strips. The lower portion of the firewall sealant extends on the lower surfaces of at least one parts of the flame-burning-through-resistant films of the pair of floor strips. The invention further provides a flame-burning-through-resistant machine. The flame-burning-through-resistant machine comprises a machine body, a first floor extending longitudinally along the machine body, and a heat and sound insulation layer covering the inner surface of the machine body. The heat and sound insulation layer comprises the flame-burning-through-resistant films. The first floor comprises a horizontal floor part and extending parts which are transversely overlapped on the heat and sound insulation layer on the two sides. The flame-burning-through-resistant floor is adopted by the first floor. The heat and sound insulation layer at least extends to the position under the floor part of the first floor.

Owner:COMAC +1

Closing structure for joint between wood floor and stone and installation method

PendingCN111350285AImprove stabilityExtended service lifeBuilding material handlingBuilding insulationsFloorcoveringStructural engineering

Owner:GOLD MANTIS CONSTR DECORATION

Flooring system

ActiveUS10774542B2Automatic/semiautomatic turning machinesSynthetic resin layered productsFloorcoveringPolymer science

Owner:MILLIKEN & CO

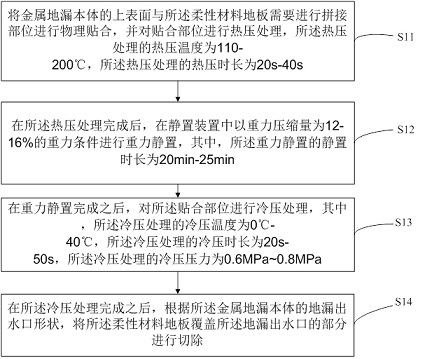

Flexible material floor and floor drain combination process and product

PendingCN114571734ANo gapsIncrease antibacterialSewerage structuresClimate change adaptationFloorcoveringStructural engineering

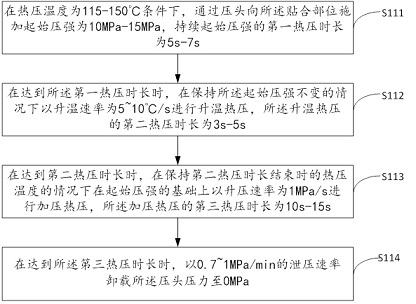

The invention provides a flexible material floor and floor drain combination process and product, and the flexible material floor and floor drain combination process comprises the following steps: physically laminating the upper surface of a metal floor drain body and a part, needing to be spliced, of a flexible material floor, and carrying out hot pressing treatment on the laminated part at the hot pressing temperature of 110-200 DEG C for 20-40 seconds; after hot pressing treatment is completed, gravity standing is carried out in a standing device under the gravity condition that the gravity compression amount is 12-16%, and the standing time of gravity standing is 20-25 min; after gravity standing is completed, cold pressing treatment is conducted on the attached portion, the cold pressing temperature ranges from 0 DEG C to 40 DEG C, the cold pressing duration ranges from 20 s to 50 s, and the cold pressing pressure ranges from 0.6 MPa to 0.8 MPa; and after cold pressing treatment is completed, the part, covering the floor drain water outlet, of the flexible material floor is cut off according to the shape of the floor drain water outlet of the metal floor drain body. The flexible material floor is naturally bent and shaped, no gap is generated, and the antibacterial effect is improved.

Owner:恳盈环保科技(上海)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com