Flexible material floor and floor drain combination process and product

A flexible material and flooring technology, applied in waterway systems, buildings, water supply devices, etc., can solve the problems of poor antibacterial effect and achieve the effect of improving antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

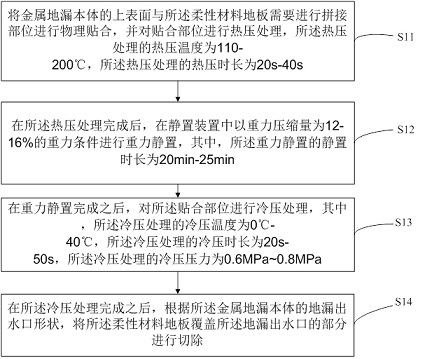

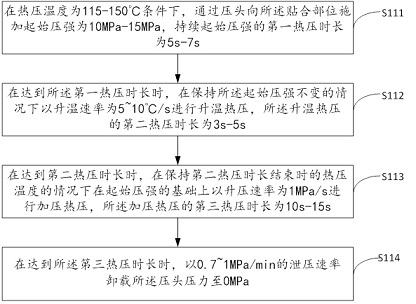

[0027] Example 1: Physically attach the upper surface of the metal floor drain body to the part that needs to be spliced on the flexible material floor. Under the condition of a hot pressing temperature of 200° C., an initial pressure of 10 MPa is applied to the bonding part by an indenter, and the first hot pressing duration for lasting the initial pressure is 5 s.

[0028] When the first hot-pressing time reaches 5s, while keeping the initial pressure of 10MPa unchanged, the heating and hot-pressing is performed at a heating rate of 5°C / s, and the second hot-pressing time of the heating-up and hot pressing is 5s .

[0029] When the second hot-pressing time period is reached, pressurization is performed at a pressure increase rate of 0.1 MPa / s on the basis of the initial pressure while maintaining the hot-pressing temperature at the end of the second hot-pressing time period. Hot pressing, the third hot pressing duration of the pressurized hot pressing is 15s;

Embodiment 2

[0030] In Example 2, the upper surface of the metal floor drain body is physically attached to the part where the flexible material floor needs to be spliced. Under the condition of a hot pressing temperature of 115° C., an initial pressure of 15 MPa is applied to the bonding part by an indenter, and the first hot pressing duration for continuing the initial pressure is 7 s.

[0031] When the first hot-pressing time reaches 7s, while keeping the initial pressure of 15MPa unchanged, the heating and hot-pressing is performed at a heating rate of 10°C / s, and the second hot-pressing time of the heating-up and hot pressing is 5s .

[0032] When the second hot pressing time reaches 5s, while maintaining the hot pressing temperature of 185°C at the end of the second hot pressing time, on the basis of the initial pressure, the pressure increase rate is 0.1 MPa / s carry out pressurization and hot pressing, and the third hot pressing duration of the pressurization and hot pressing is 1...

Embodiment 3

[0033] In Example 3, the upper surface of the metal floor drain body is physically attached to the part that needs to be spliced on the flexible material floor. Under the condition of a hot pressing temperature of 150° C., an initial pressure of 12 MPa is applied to the bonding part by an indenter, and the first hot pressing duration for continuing the initial pressure is 6 s.

[0034] When the first hot pressing duration is reached, the heating and hot pressing is performed at a heating rate of 7° C. / s while keeping the initial pressure unchanged, and the second heating pressing duration of the heating and hot pressing is 5 s.

[0035] When the second hot-pressing time period is reached, pressurization is performed at a pressure increase rate of 0.1 MPa / s on the basis of the initial pressure while maintaining the hot-pressing temperature at the end of the second hot-pressing time period. Hot pressing, the third hot pressing duration of the pressurized hot pressing is 14s; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com