Bendable LED (light emitting diode) module, circular LED module and wavy LED module

An LED module, wave-shaped technology, applied in the field of display equipment, can solve the problems of high production cost, poor applicability, heavy weight, etc., and achieve the effects of reduced production cost, good display effect, and reduced weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

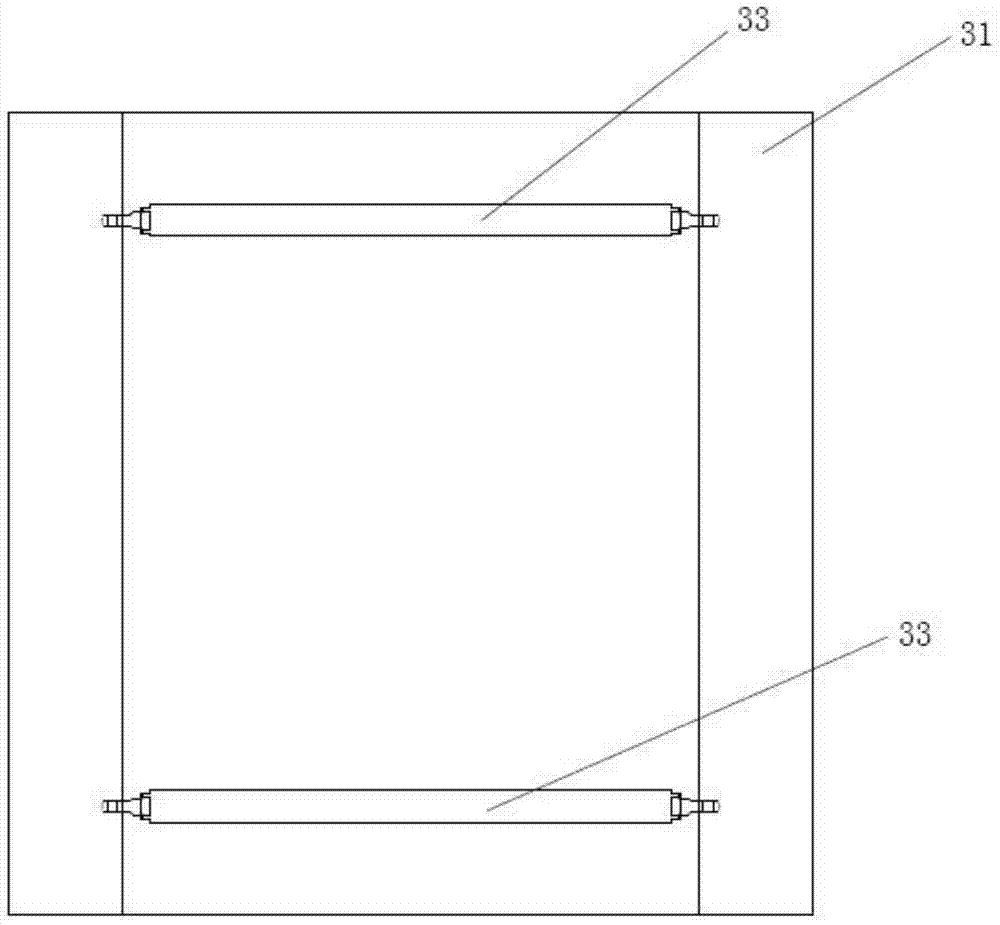

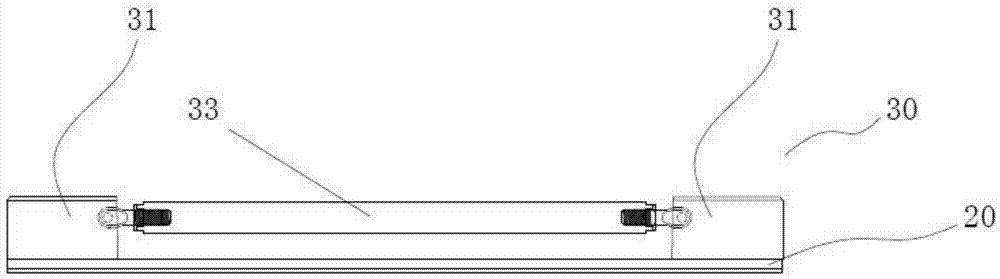

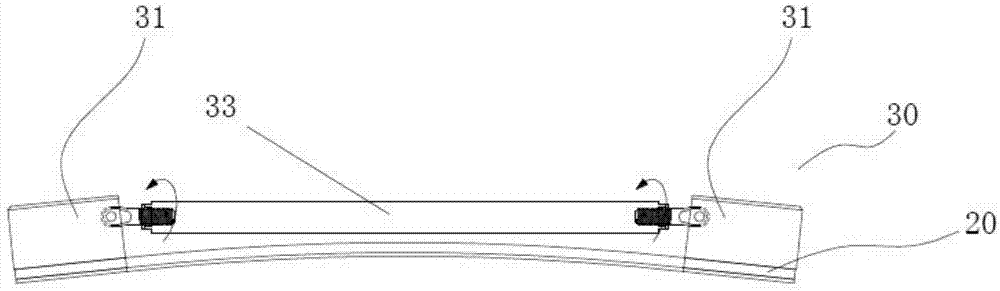

[0036] see Figure 1-4 , a bendable LED module, comprising: an elastic component layer 20 as an installation base, the elastic component layer 20 is installed with several light-emitting components, acting on the adjustment part 30 on the back of the elastic component layer 20, the adjustment part 30 The two sides of the elastic component layer 20 are supported or tensioned, so that the elastic component layer 20 is bent in an inner arc or an outer arc. The elastic component layer 20 is a material suitable for rebounding after bending deformation, so that the carbon fiber layer does not have large gaps or gaps between the light-emitting components after bending deformation, so that the display effect is better.

[0037] The bendable LED module of this embodiment has three usage states, wherein when the adjustment part 30 does not regulate the elastic member layer 20, the elastic member layer 20 is in the shape of a flat plate, which is suitable for transportation or storage; ...

Embodiment 2

[0046] This embodiment provides a circular LED module using the bendable LED module in Embodiment 1, see Figure 7 , the circular LED module is surrounded by a number of bendable LED modules with curved outer arcs, and the adjacent fixed blocks 31 of the adjacent bendable LED modules are screwed together, obviously the adjacent The connection method between the two fixing blocks 31 is not limited to screw connection, for example, bonding, riveting, inlaying and the like may also be used.

Embodiment 3

[0048] This embodiment provides a wave-shaped LED module using the bendable LED module in Embodiment 1, see Figure 8 , the wave-shaped LED module is composed of one / several bendable LED modules with curved inner arcs and one / several bendable LED modules with curved outer arcs, and the adjacent bendable LED modules The adjacent fixing blocks 31 of the module are screwed, obviously, the connection method between two adjacent fixing blocks 31 is not limited to screw connection, for example, bonding, riveting, inlaying, etc. can also be used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com