Patents

Literature

530results about How to "Achieve tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

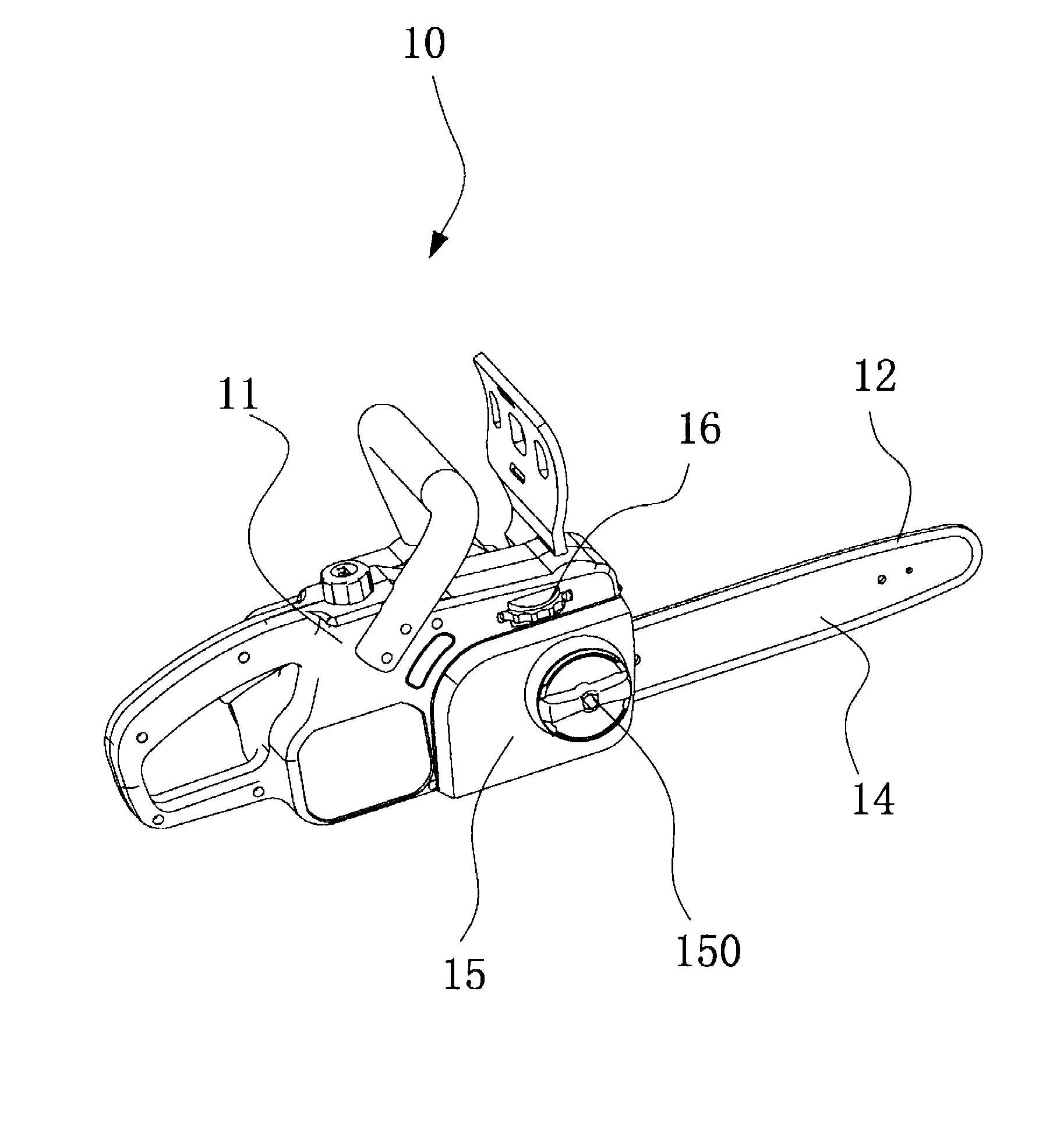

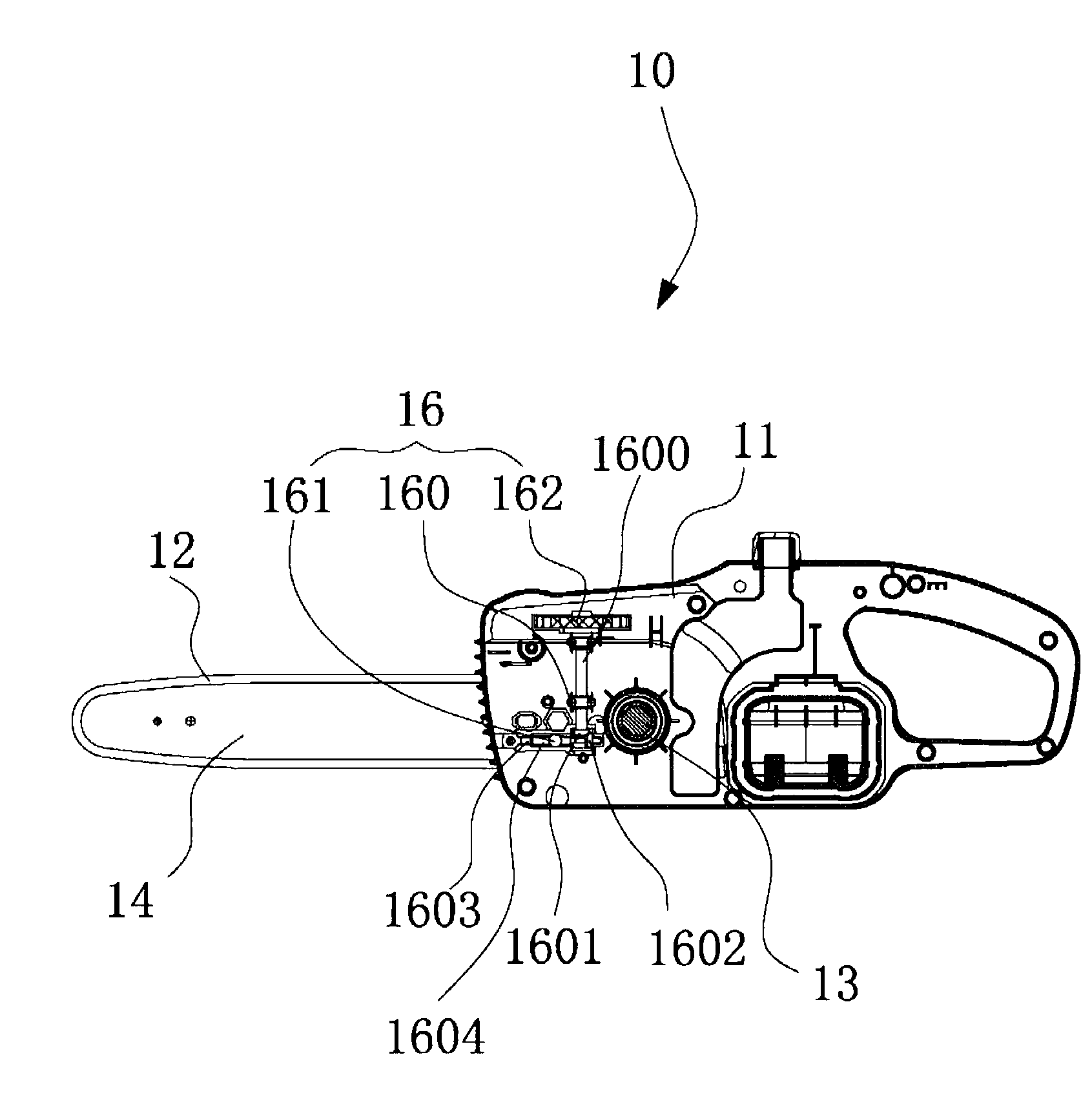

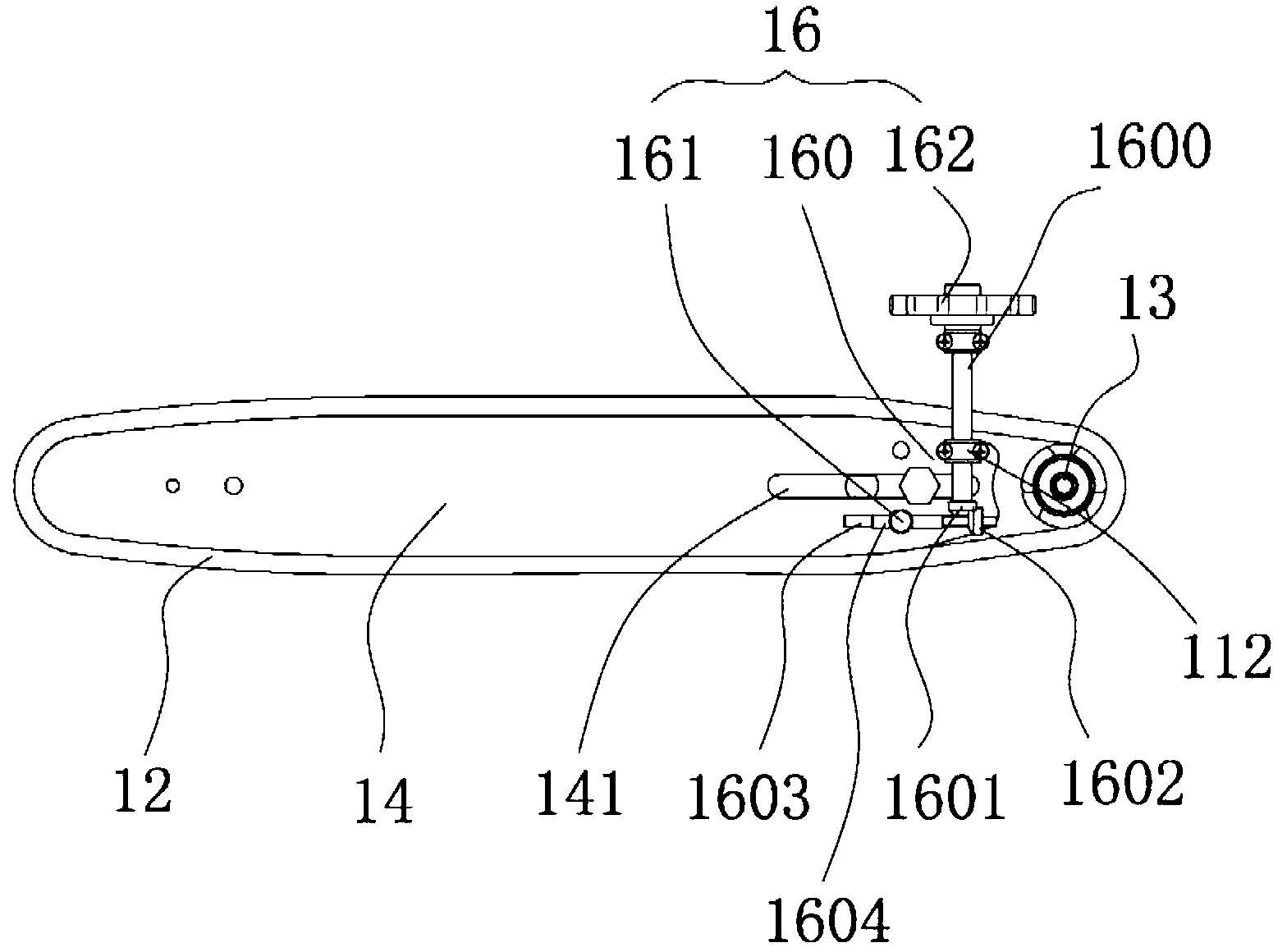

Chain saw

Owner:NANJING CHERVON IND

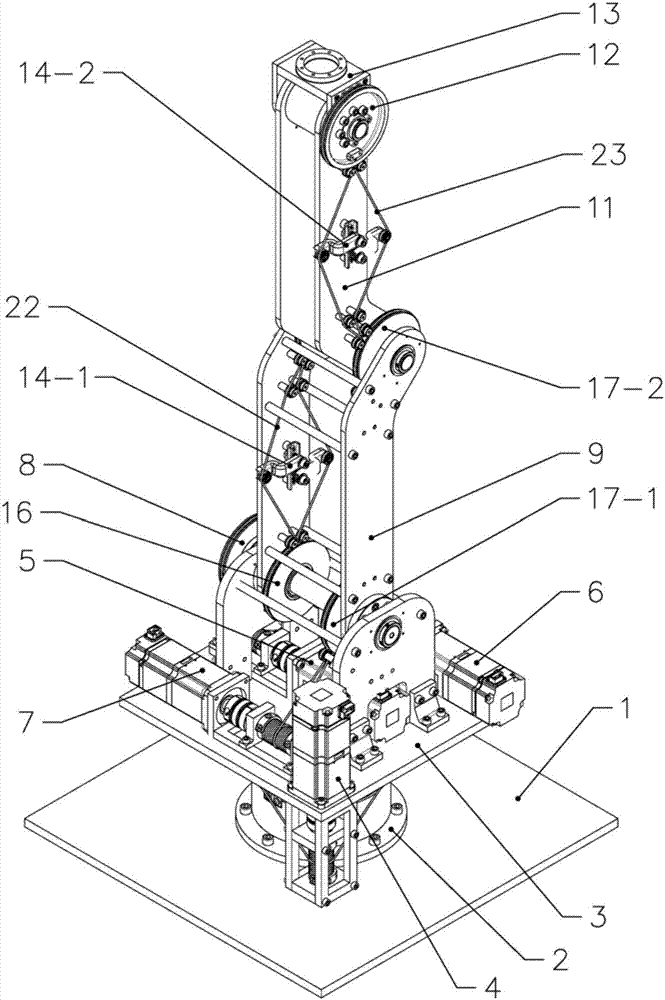

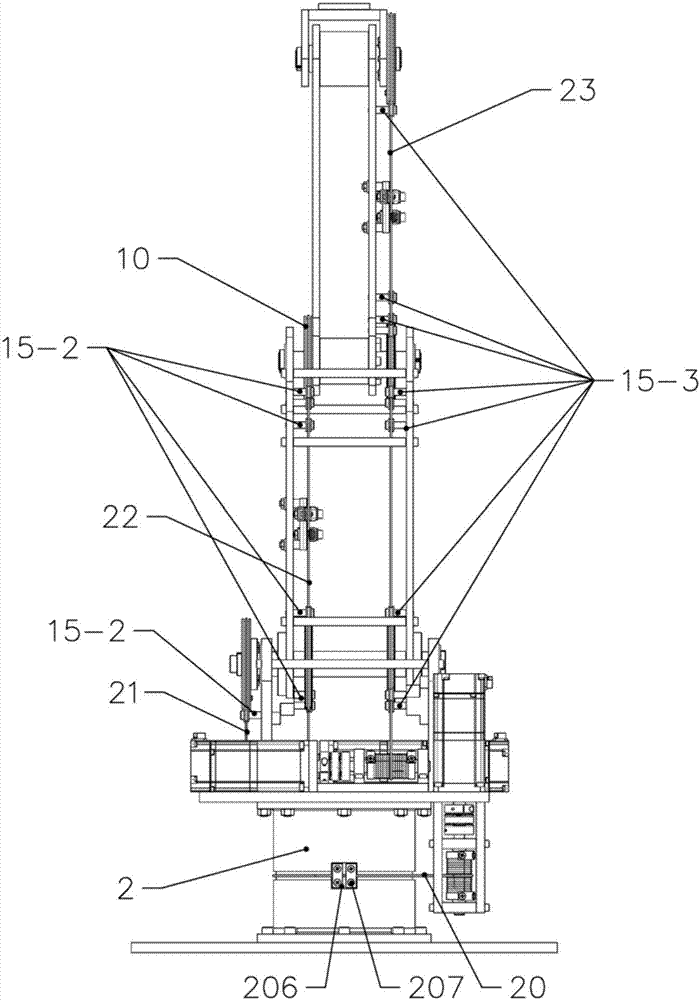

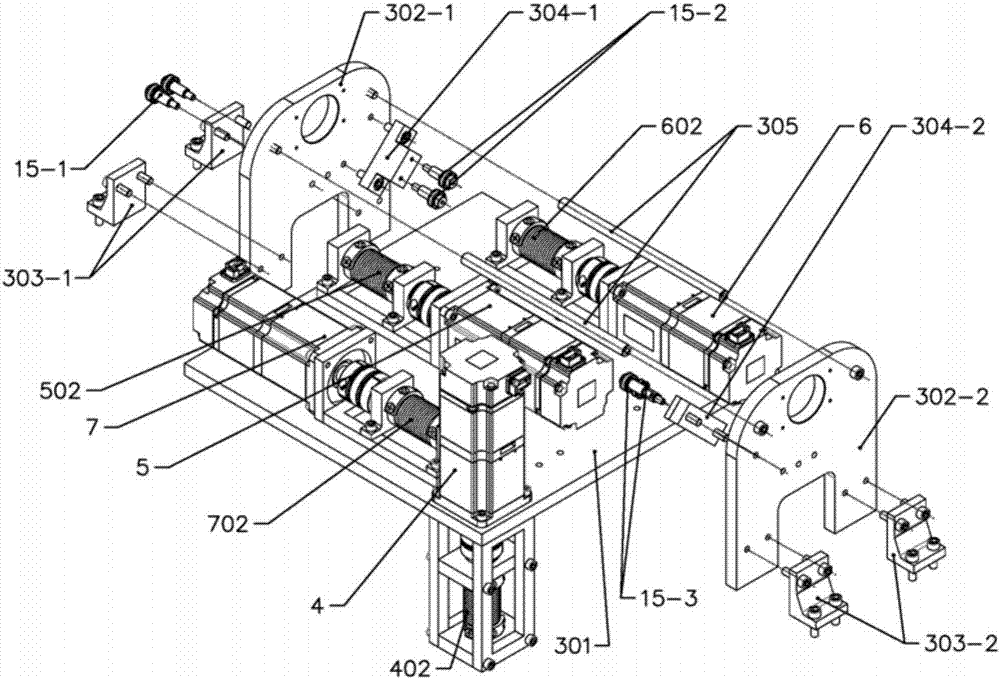

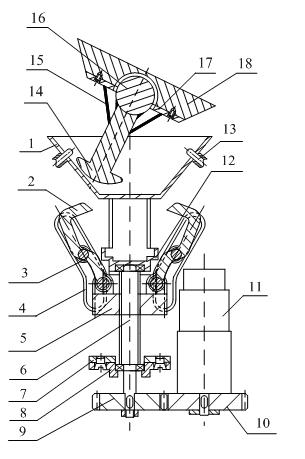

Rope-driven multi-degree-of-freedom series manipulator and driving method thereof

ActiveCN107253182AReduce size and massReduce loadProgramme-controlled manipulatorDrive wheelControl engineering

The invention discloses a rope-driven multi-degree-of-freedom series manipulator and a driving method thereof, and belongs to the field of manipulators. The rope-driven manipulator comprises a base, a waist joint unit, a waist platform, a large arm unit, a small arm unit, a tail end platform unit and the like. One ends of steel wire ropes are fixed to driven wheels at joints, the other ends of the steel wire ropes are fixed to a driving unit winch at the waist platform, so that the driving force is transferred from the winch at the waist platform to the driven wheels at the joints at the rear end by means of the ropes and accordingly drives the joint units to conduct rotation movement around joint shafts correspondingly. The joint driving ropes are guided by guide pulleys and bypass the joint shafts at the front end sequentially, by arranging the specified diameters of shaft guide wheels, a driving method is built, thus any joint at the front end of the manipulator rotates while the posture of the tail end of the manipulator remains unchanged relative to the world coordinate system. The buffer effect of making contact of the manipulator with the environment is increased through the flexibility of the ropes, and the rope-driven multi-degree-of-freedom series manipulator is especially suitable for occasions with the high requirements for the interaction safety of the manipulator, people and the environment.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

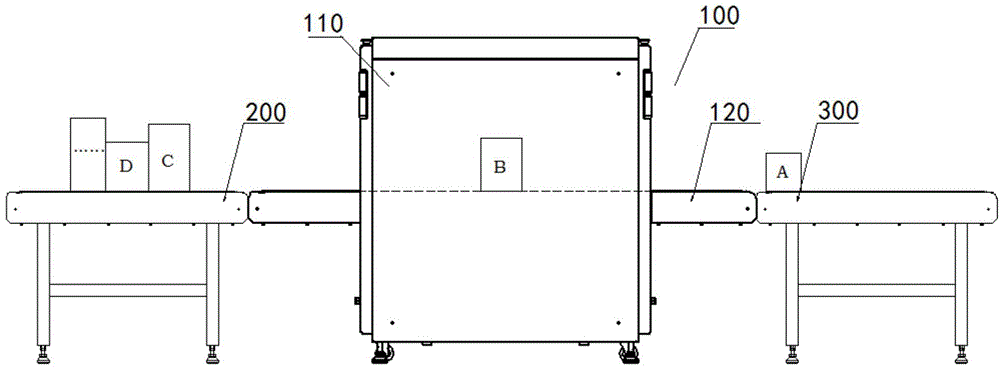

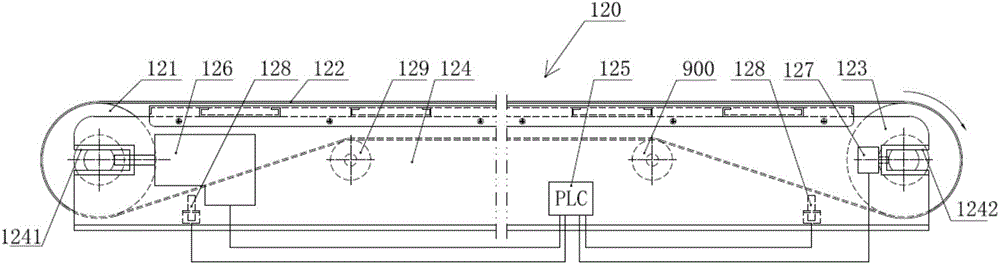

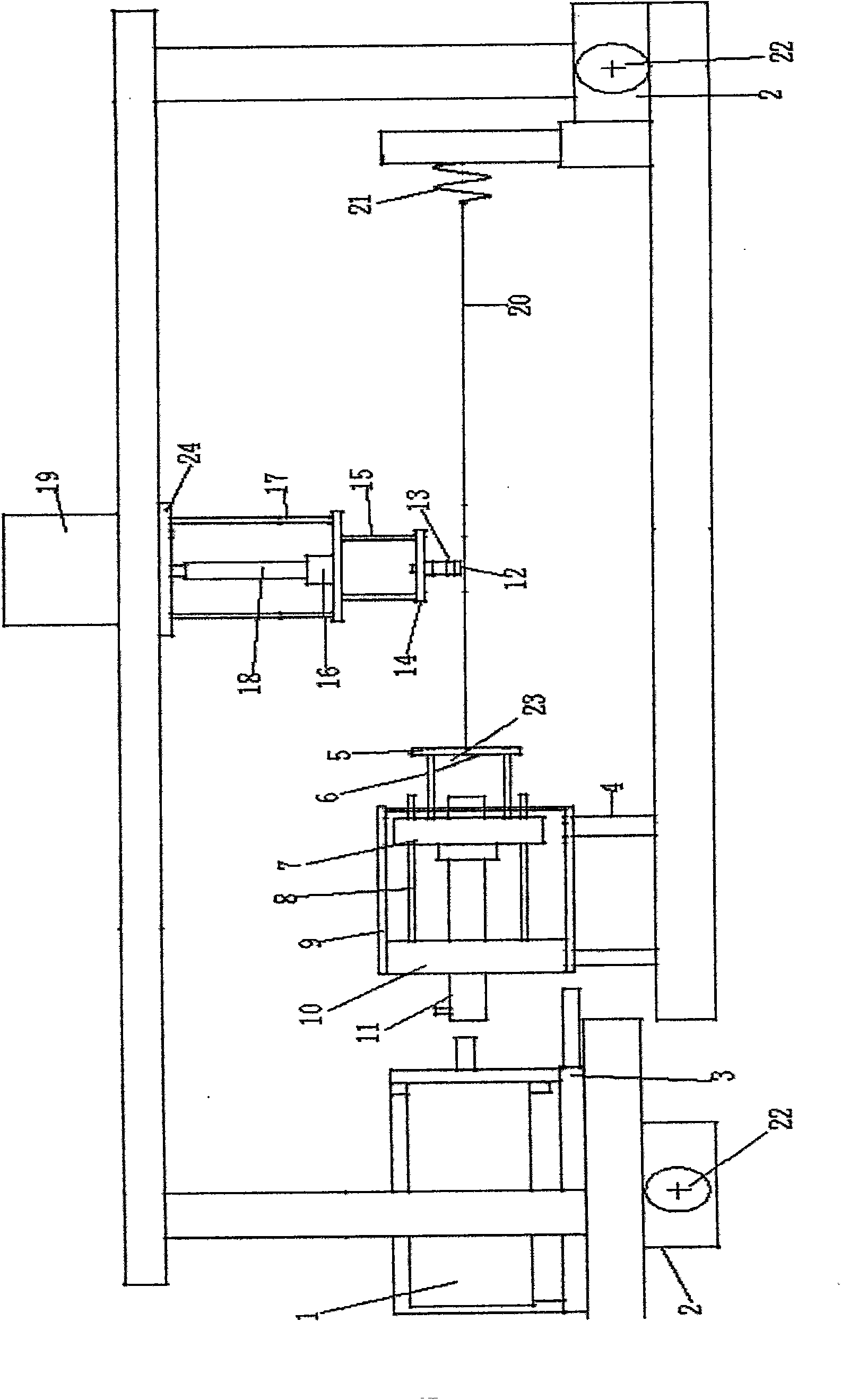

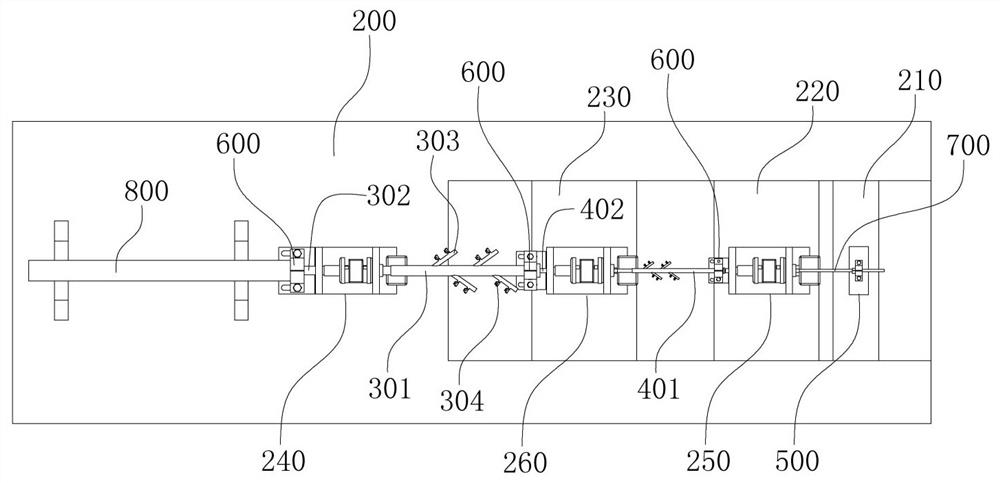

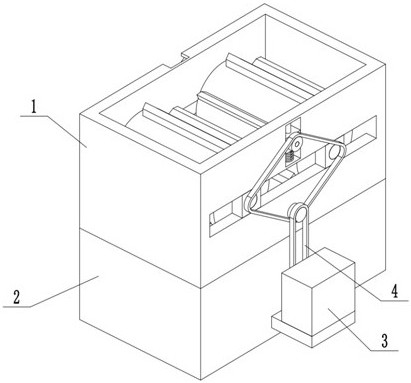

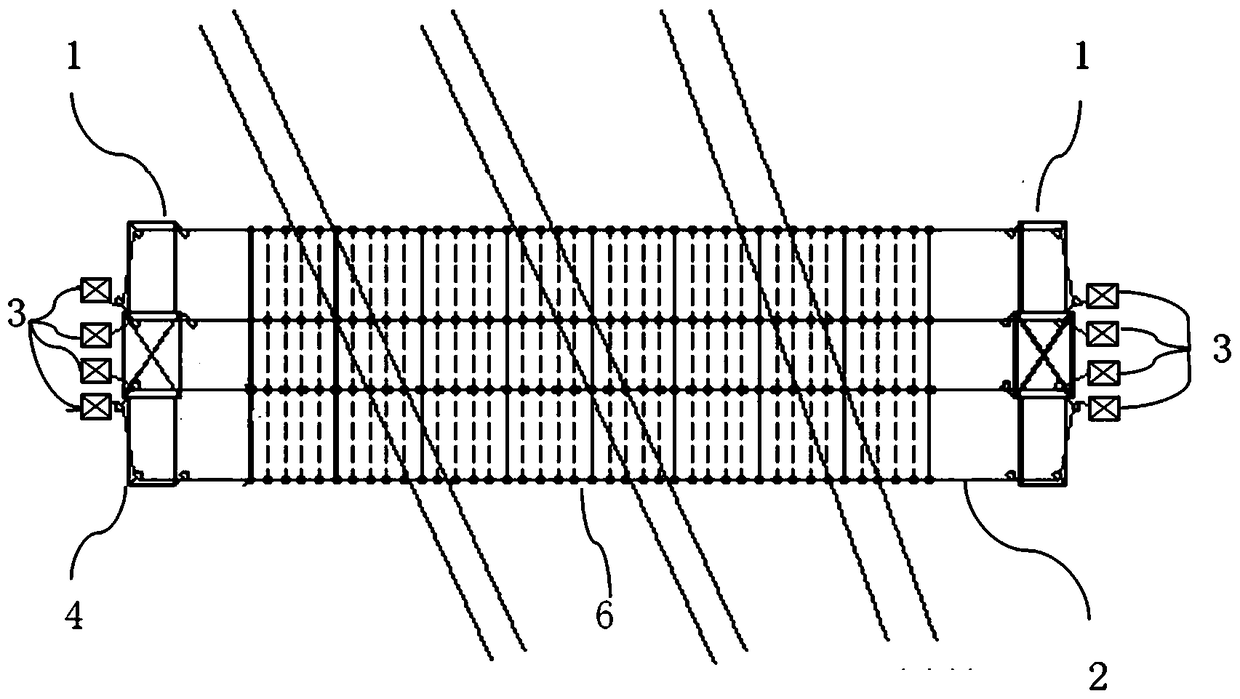

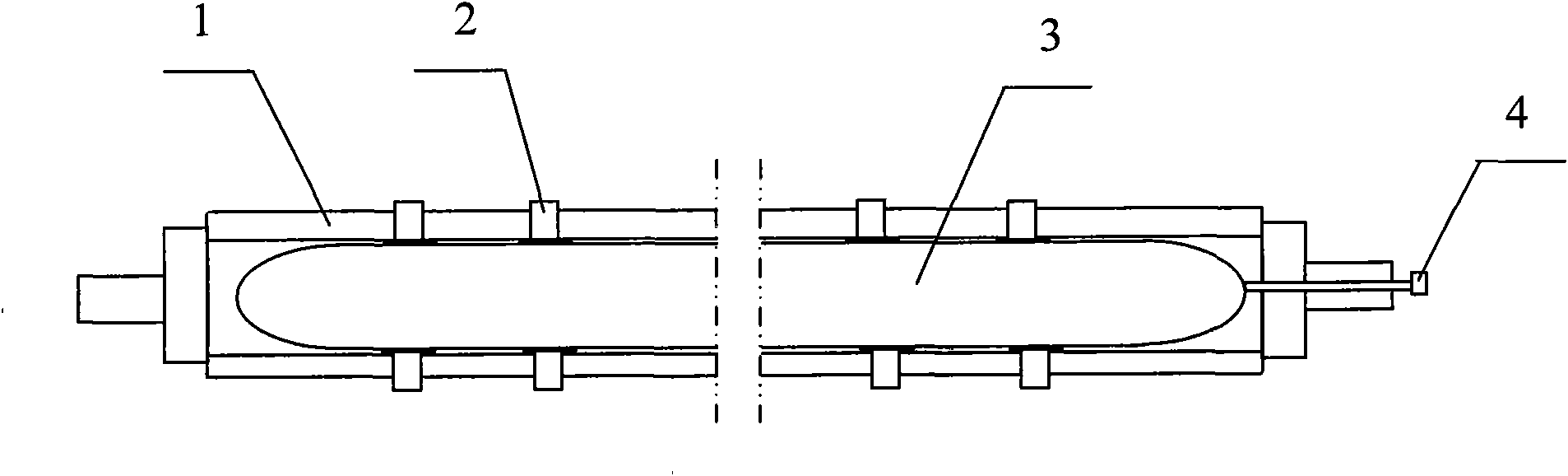

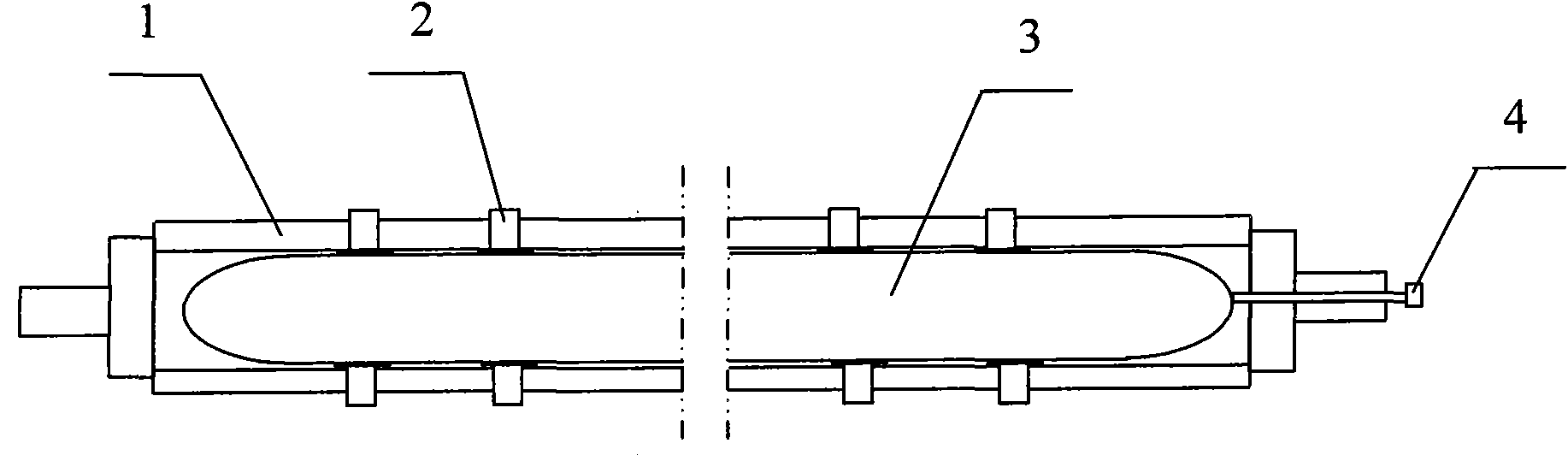

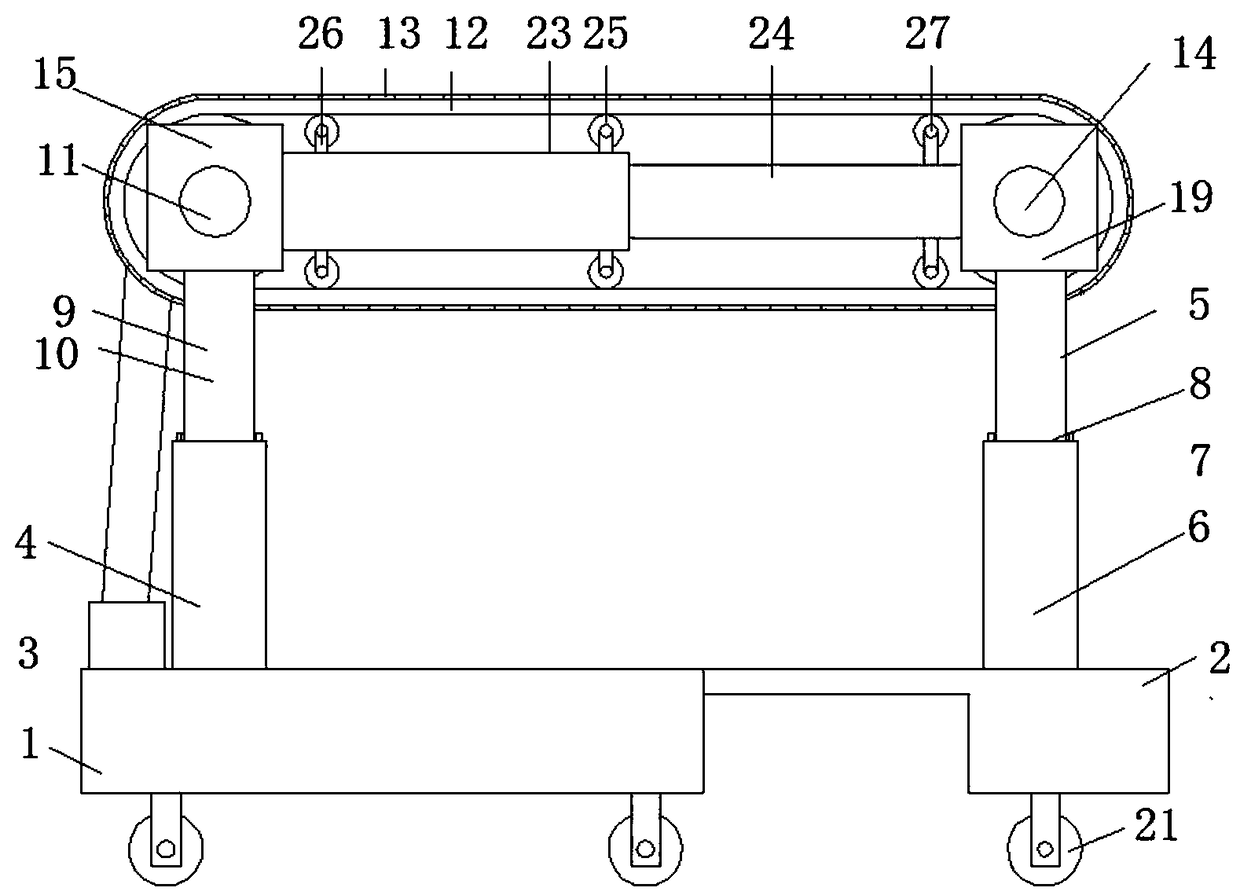

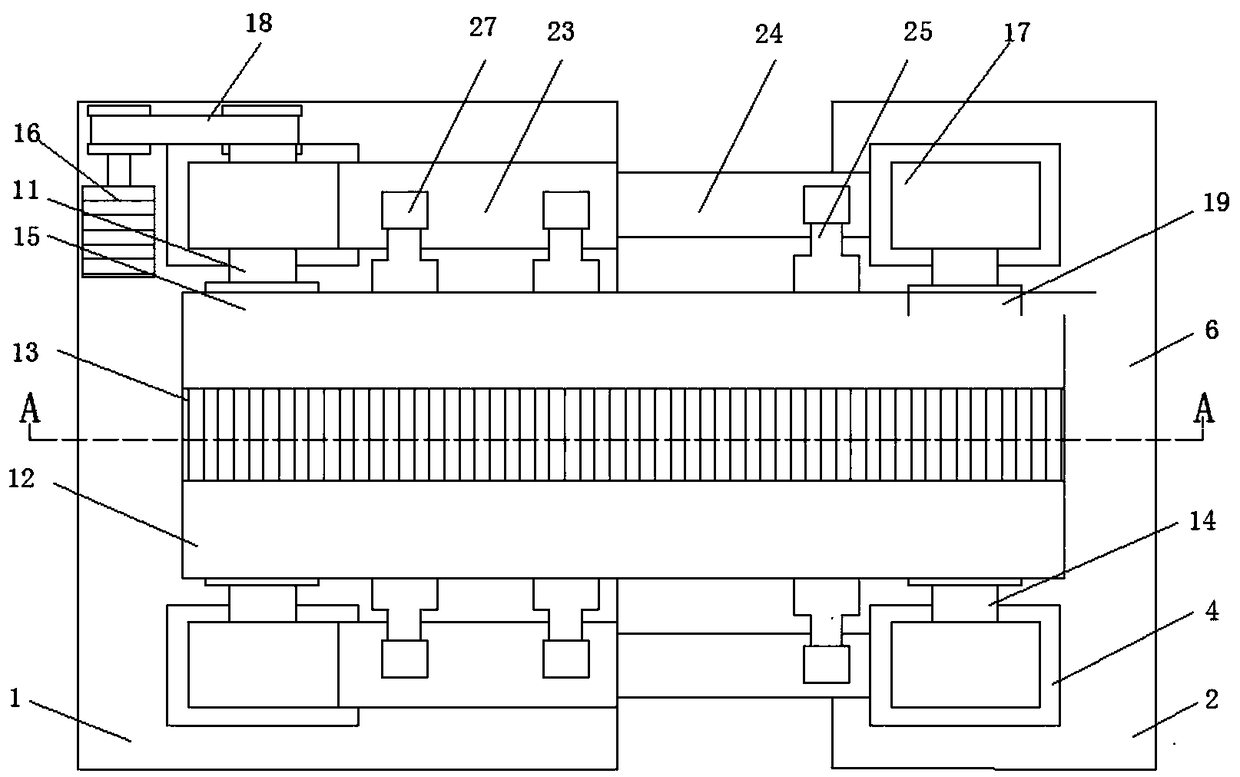

Differential conveying security check system

ActiveCN104536055AOvercome the stacking defectEasy to checkNuclear radiation detectionButt jointEngineering

The invention discloses a differential conveying security check system which comprises a security check machine and a power conveying device. The power conveying device is in butt joint with the inlet of a belt conveyor. The power conveying device and the belt conveyor are located on the same horizontal plane and identical in conveying direction. The conveying linear speed of the power conveying device is smaller than that of the belt conveyor. Luggage parcels are conveyed to the belt conveyor through the power conveying device. The belt conveyor quickly increases the distances between the adjacent luggage parcels. The differential conveying security check system can quickly increase the distances between the luggage parcels which are compactly stacked in the prior art, and the luggage parcels enter a detector as a queue at certain intervals one by one, so that the defect that in the conveying process of an existing security check machine, luggage parcels are stacked is overcome, image uniformity of luggage parcels which pass through the security check machine each time is guaranteed, the check leakage phenomenon is effectively avoided, and the abnormal luggage parcels can be conveniently checked.

Owner:SHANGHAI RAYS ELECTRONICS SCI & TECH

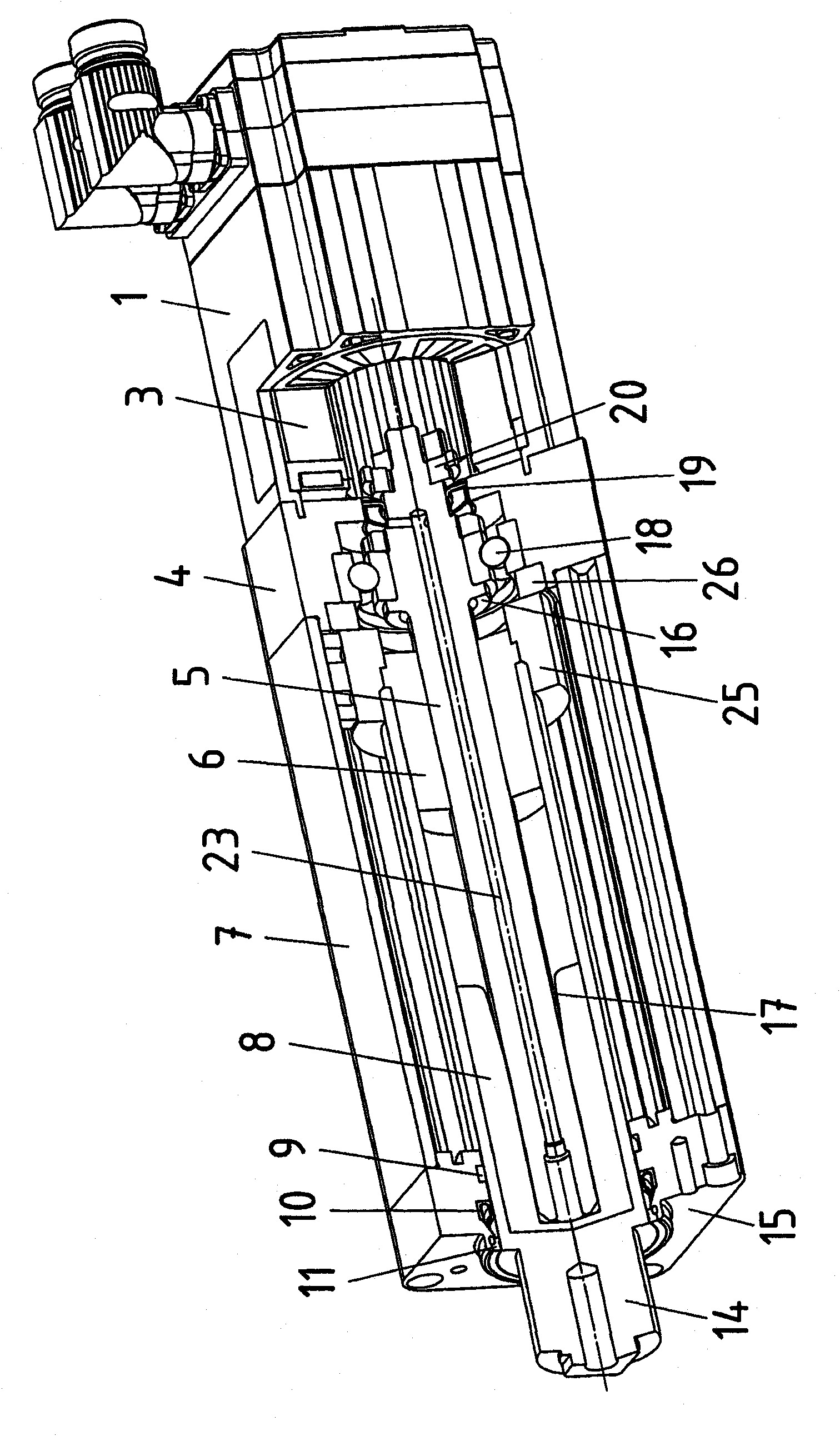

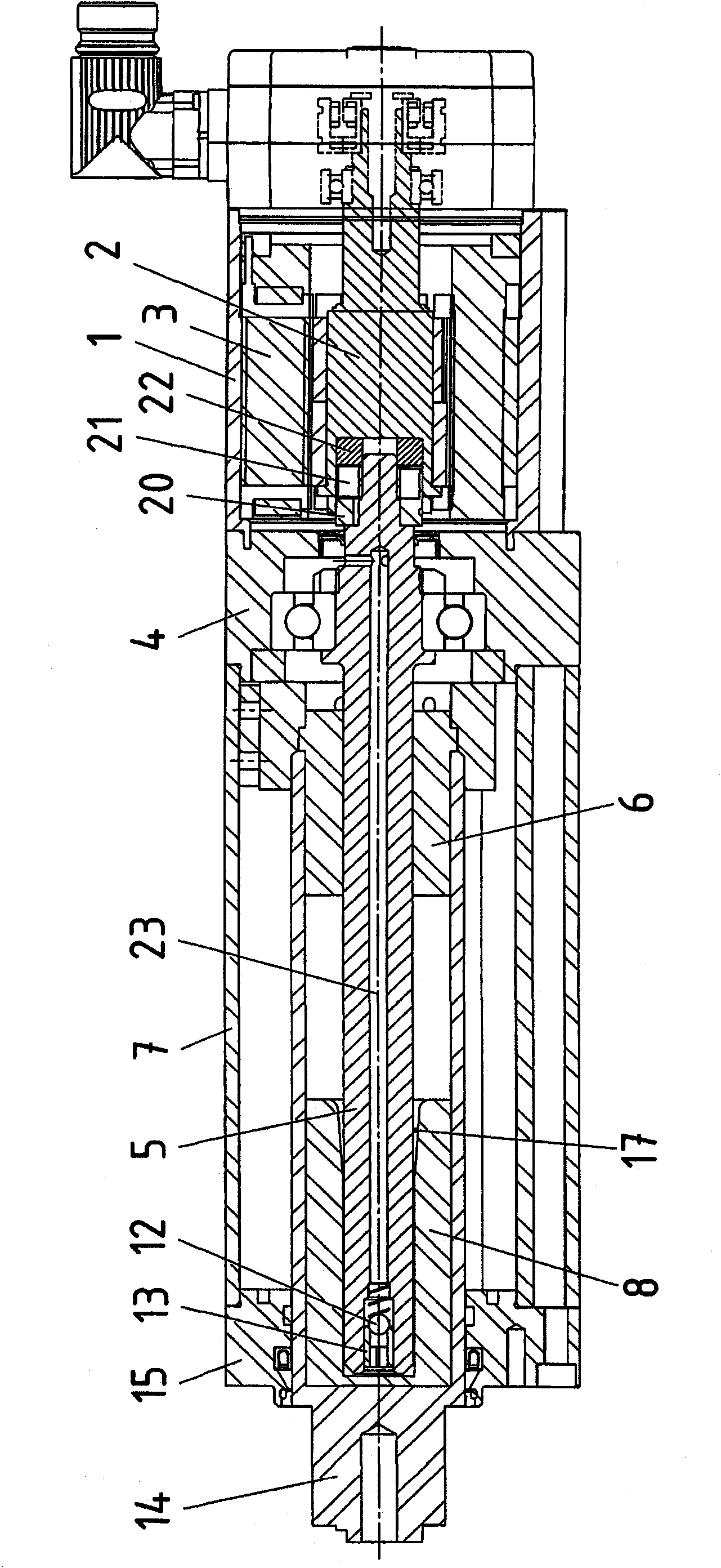

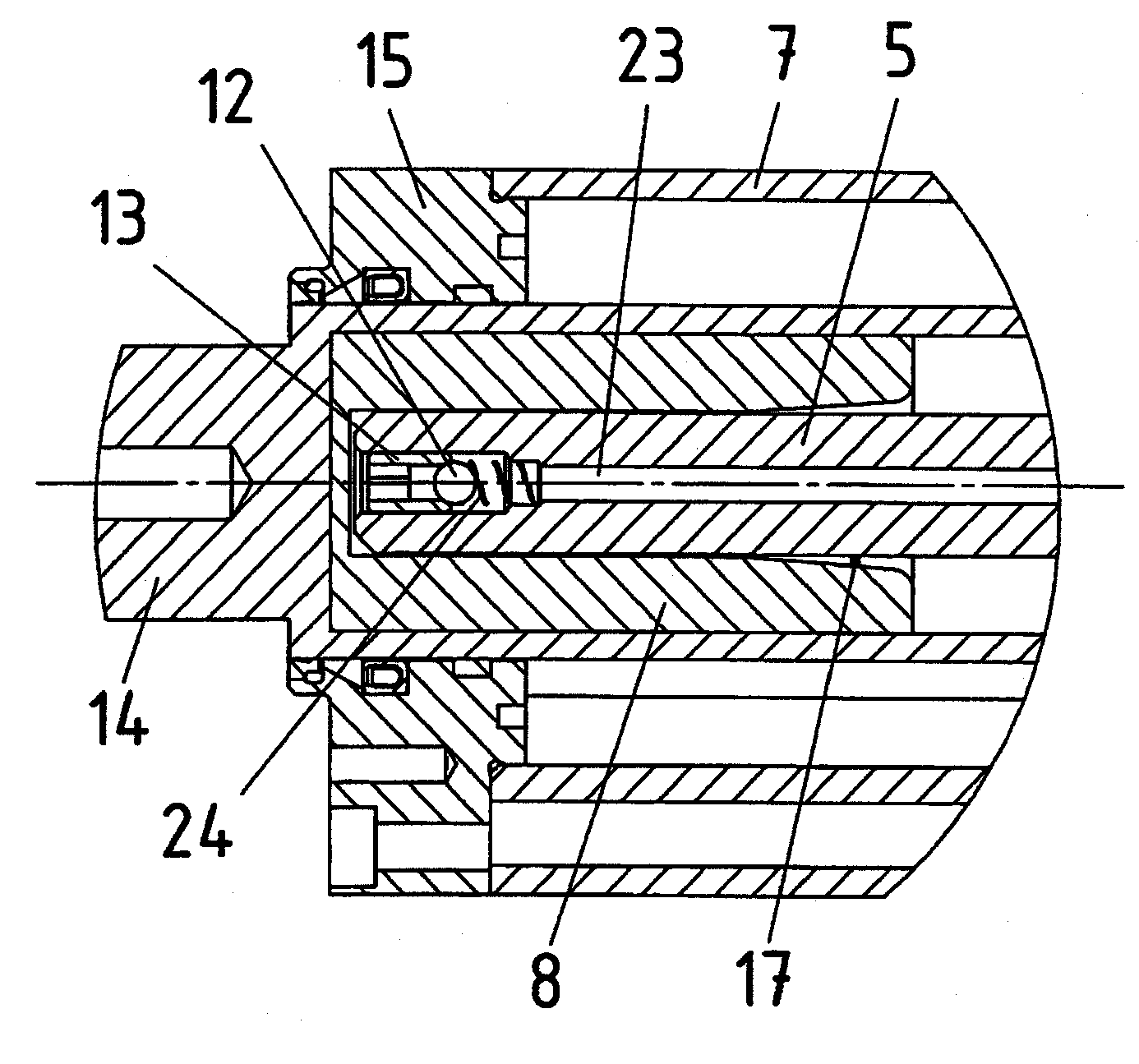

Spindle motor

The invention relates to a spindle motor, comprising an electric motor having a rotor connected to a threaded spindle, the thread of which is engaged with a thread of a spindle nut connected to a piston rod, wherein the spindle nut, along with the piston rod, is axially guided in a housing part, a guide part is connected to the spindle nut and piston rod for axially guiding the same, and wherein the threaded spindle is mounted by means of a bearing in the housing part or in a second housing part connected to the first housing part, a cooling channel being configured in the housing part, in particular a cooling channel which extends in the circumferential direction.

Owner:SEW-EURODRIVE GMBH & CO KG

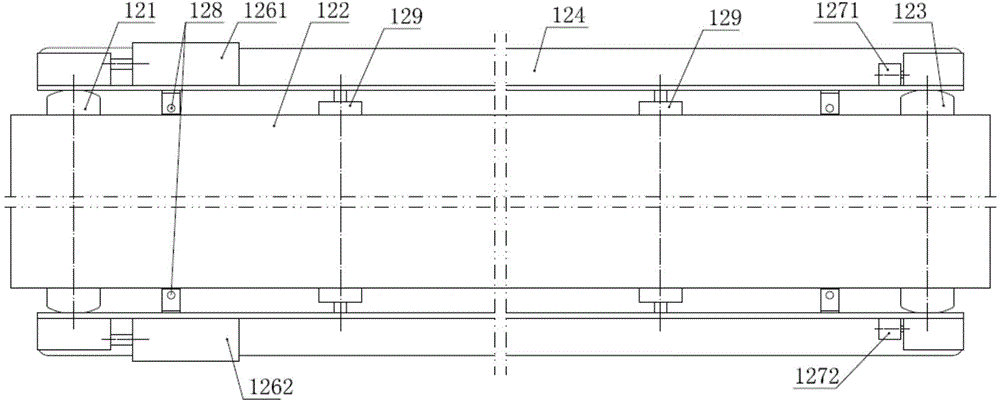

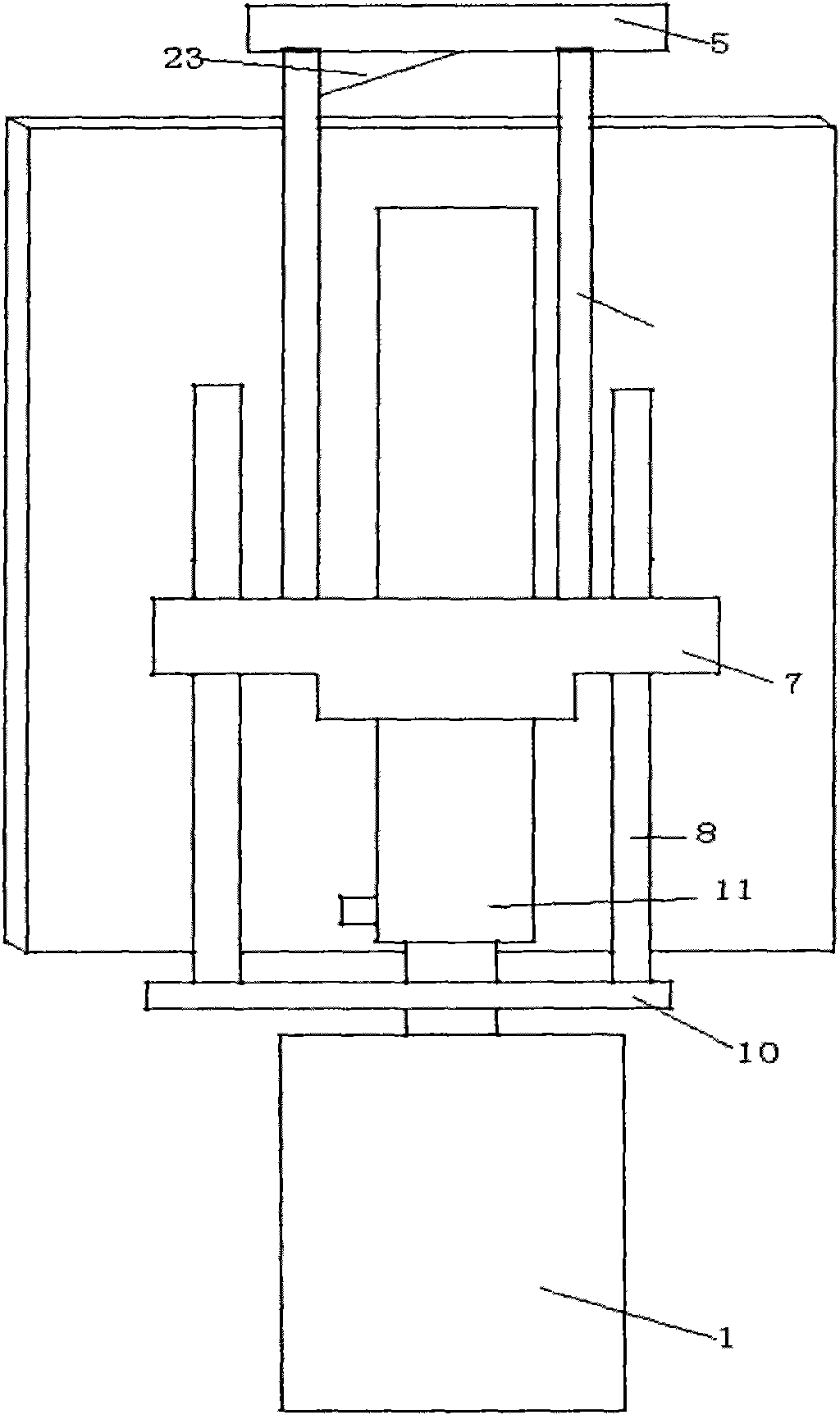

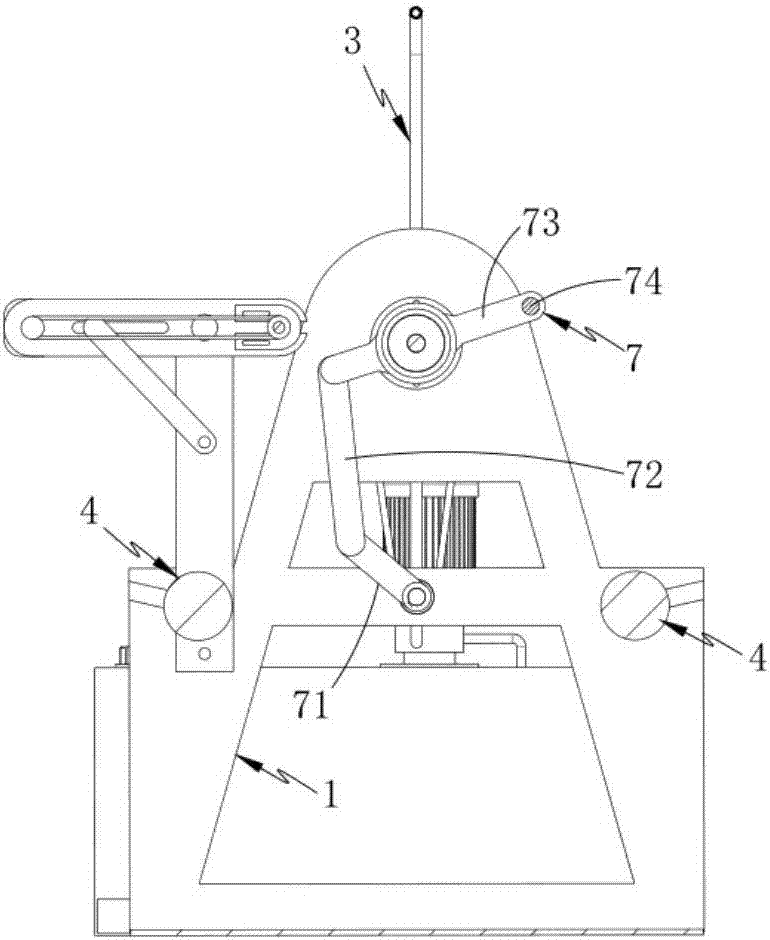

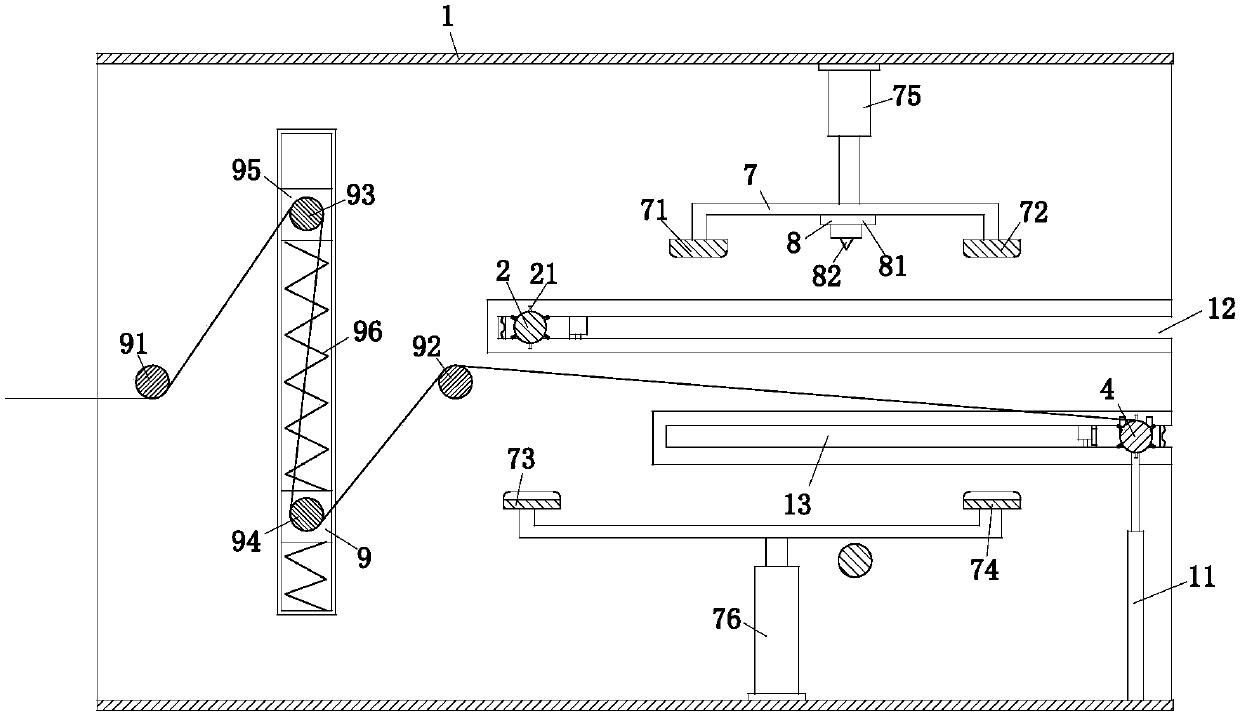

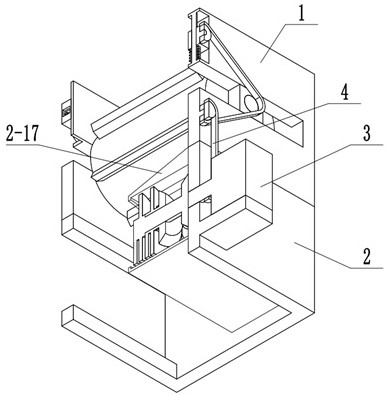

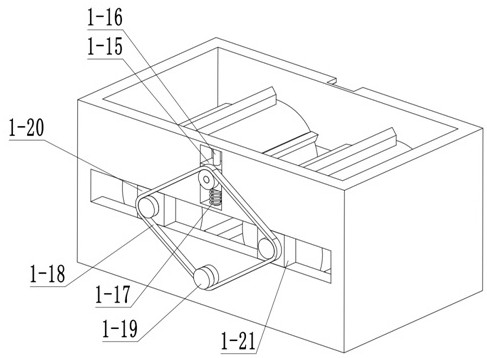

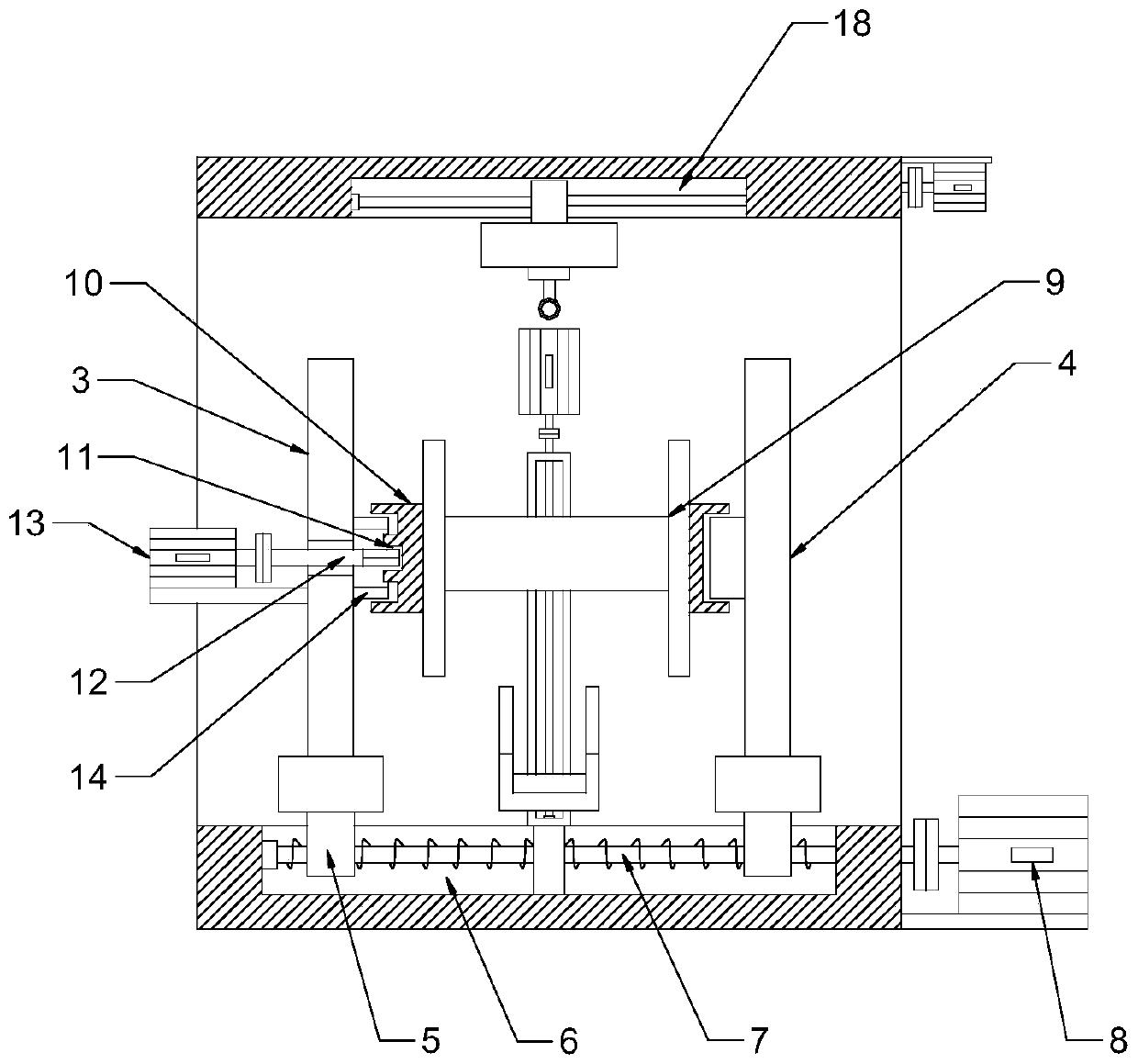

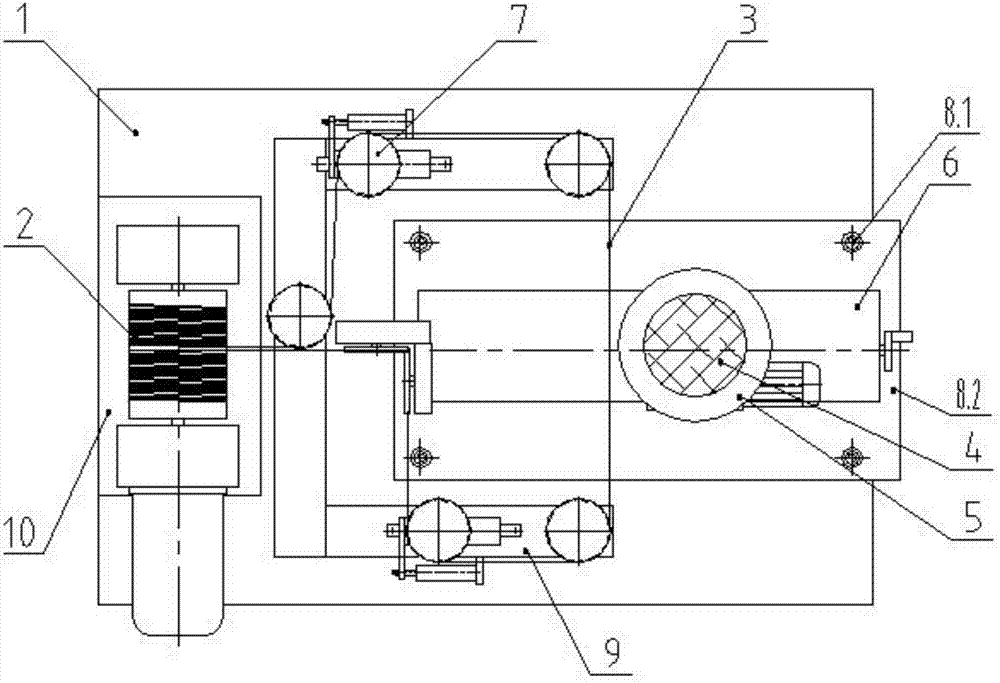

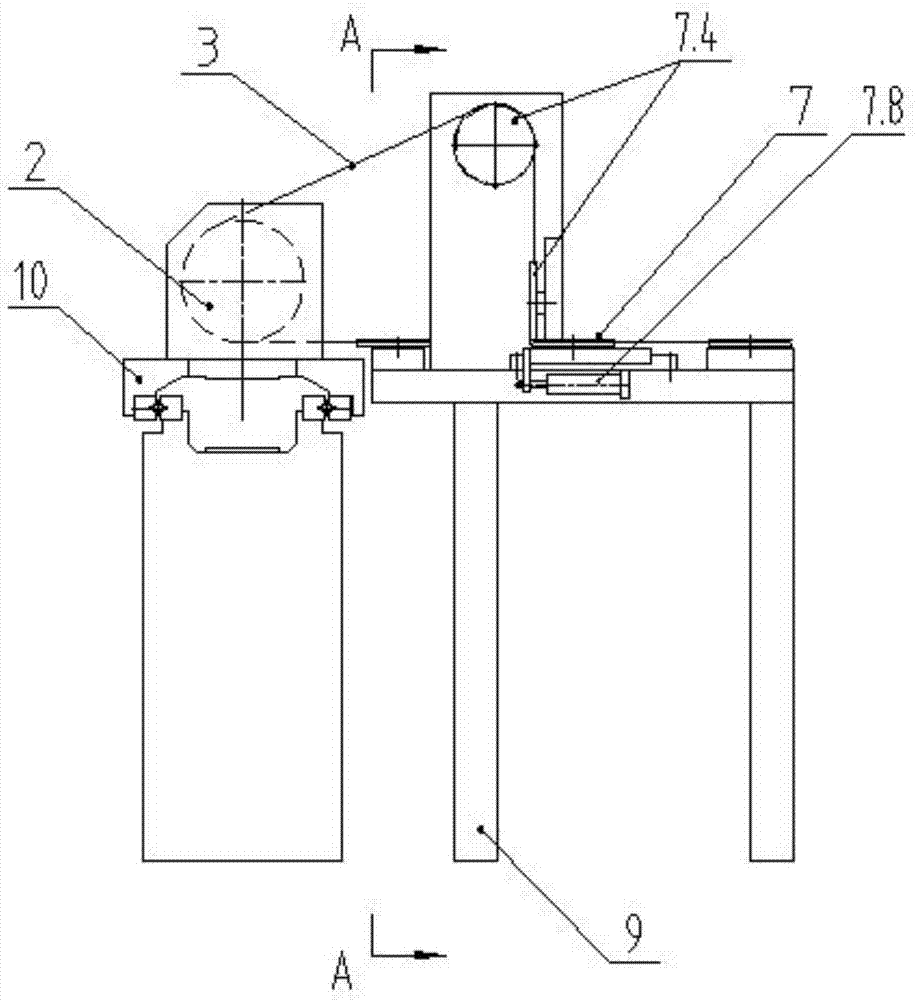

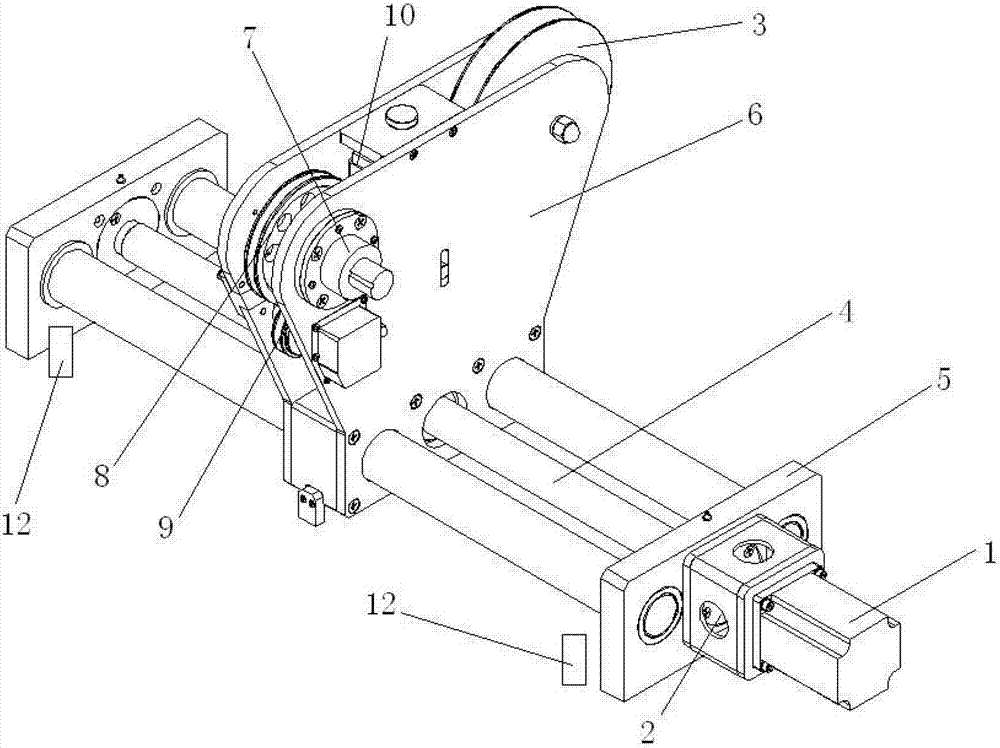

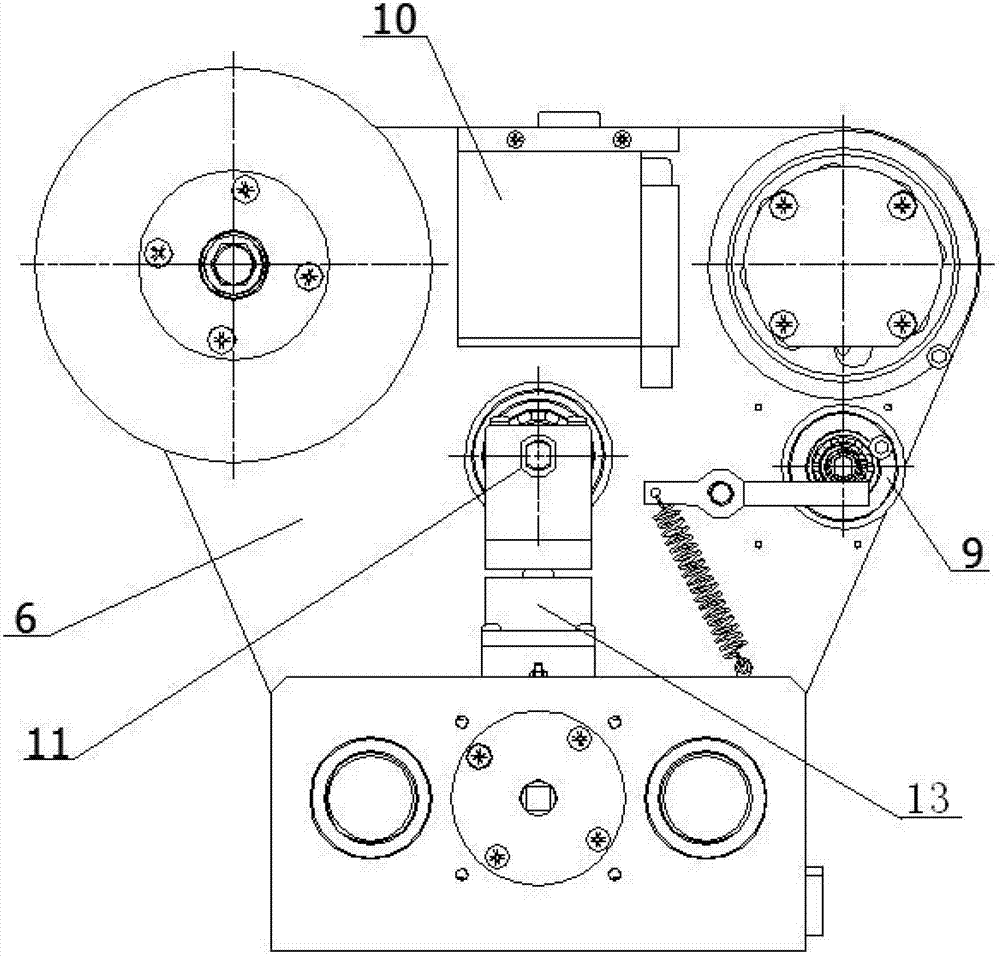

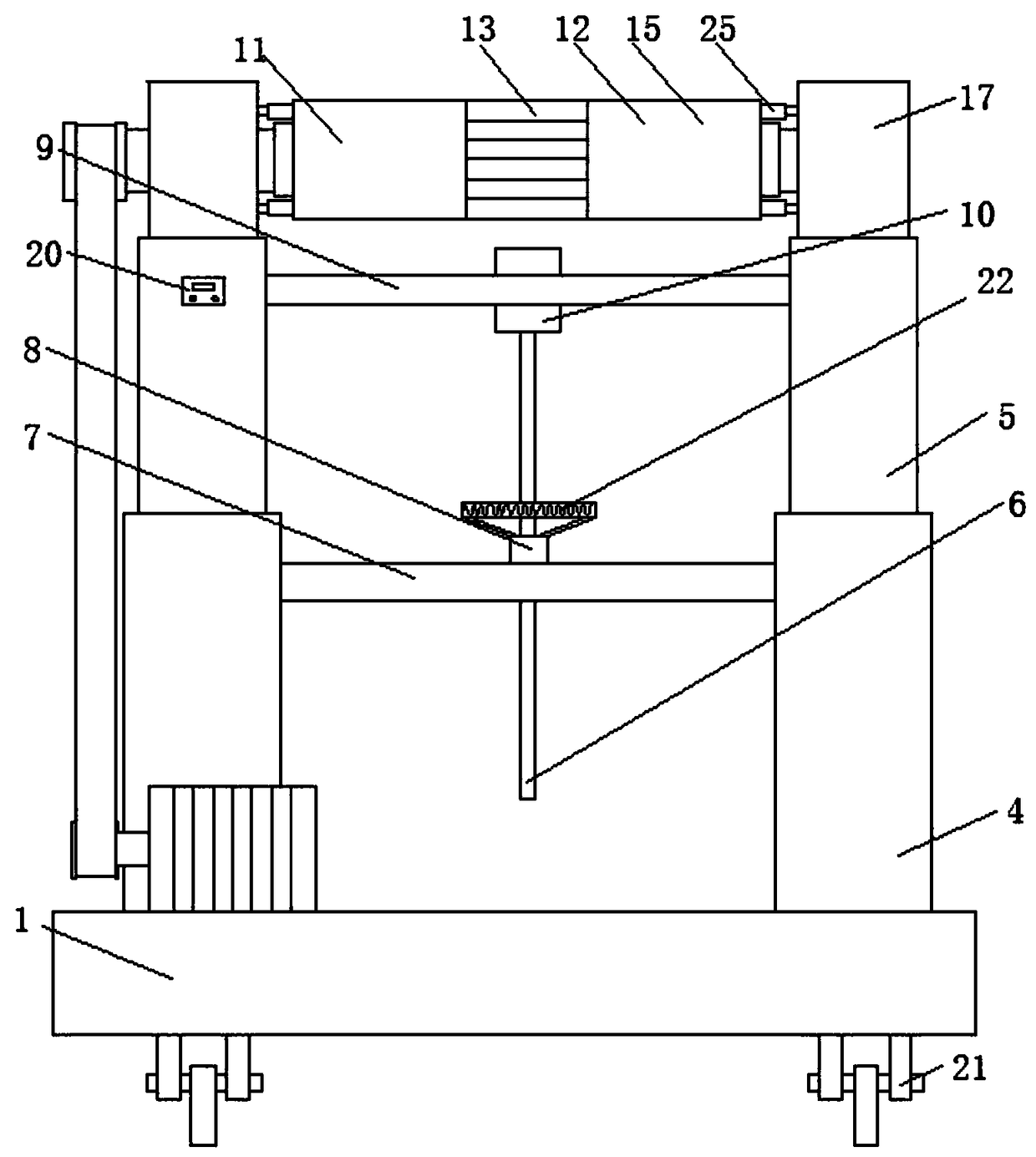

Cutting wire tensity and temperature measurement and control device for EPS (Expanded Poly Styrol) slab cutting machine

InactiveCN102366963AAchieve tensionImprove cut qualityMetal working apparatusTemperature controlOptical axis

The invention provides a cutting wire tensity and temperature measurement and control device for an EPS (Expanded Poly Styrol) slab cutting machine, belonging to the field of machining. The cutting wire tensity and temperature measurement and control device is used in non-manual installation regulation and temperature control of cutting wires for solving the problems of large installation error and human injury due to broken wires. The cutting wire tensity and temperature measurement and control device for the EPS slab cutting machine is composed of a cutting wire set tension automatic maintaining and adjusting mechanical traction mechanism, a cutting wire tension sensor, a cutting wire temperature sensor, a control traction mechanism and a cutting wire working temperature control circuit. The cutting wire set tension automatic maintaining and adjusting mechanical traction mechanism is composed of a step motor, a supporting plate, a lead screw, a movable disk, an optical axis and a wire hanging plate; and the tension sensor comprises a step motor, a lead screw, a movable disk, an optical axis, a pressure sensor, an F contactor and a PT100 temperature sensor installed at one side of a cutting wire of the traction mechanism. The invention has the advantages of automatically maintaining the cutting wire tension and the cutting wire working temperature and adjusting errors to maintain the cutting wire at the optimal working state, improving the cutting quality of EPS slabs and eliminating potential safety hazards caused by manual installation.

Owner:JILIN AGRICULTURAL UNIV

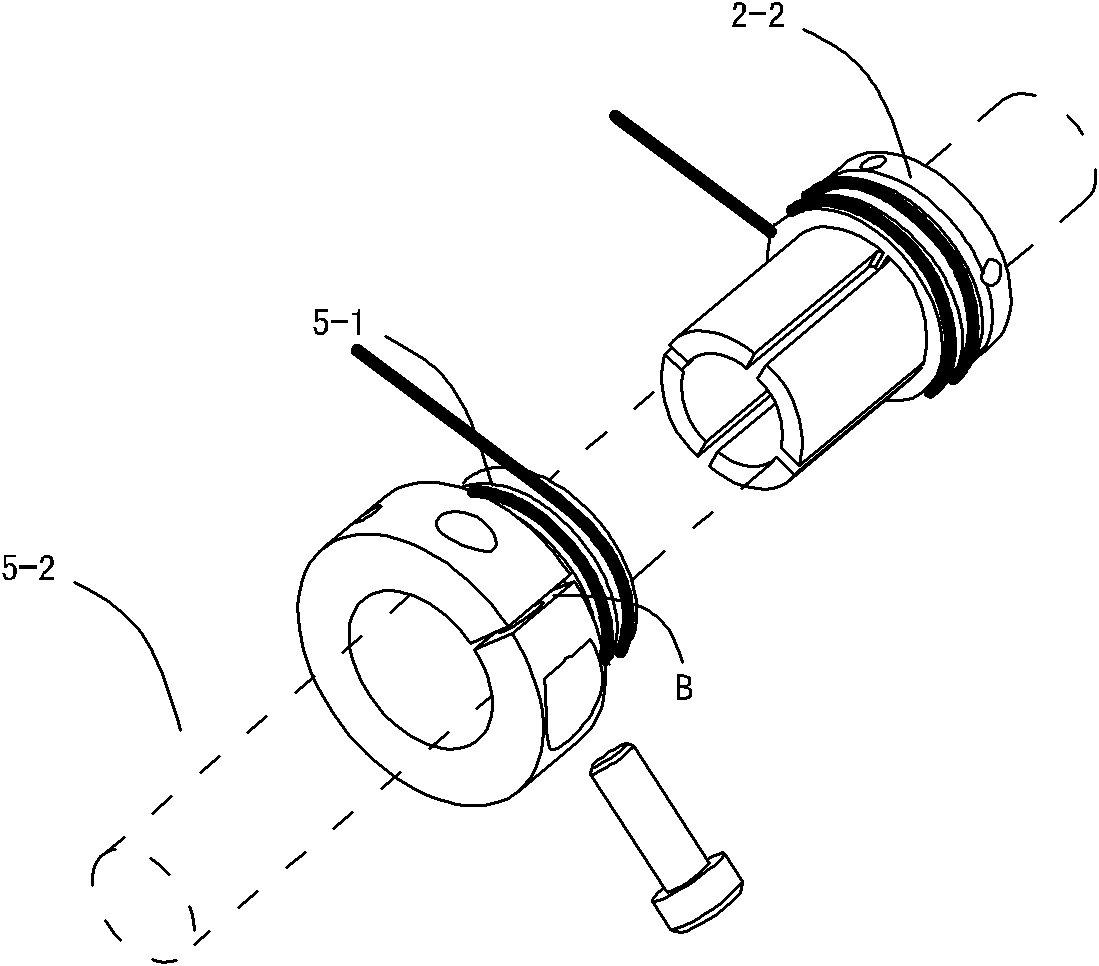

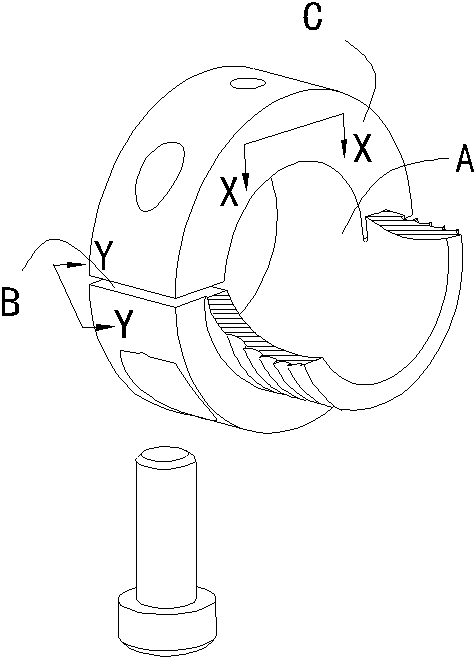

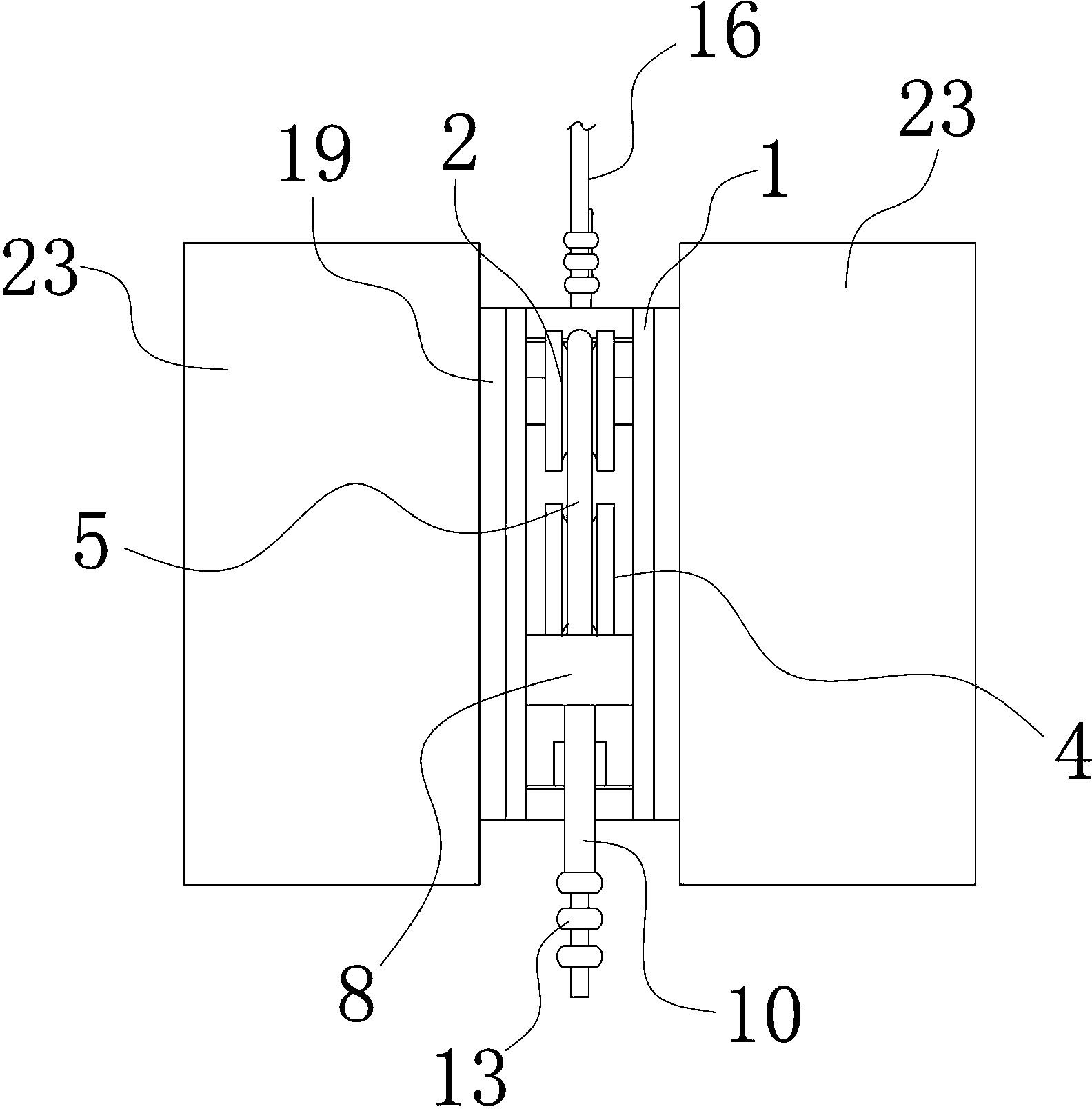

Wire fixing mechanism for wire transmission system

The invention discloses a wire fixing mechanism for a wire transmission system, which comprises an outer wire fixing wheel on which a shaft hole is formed, an inner wire fixing wheel on which a shaft hole is formed and of which the bottom is provided with a smooth shaft section and a wire fixing wheel locking block, wherein a plurality of grooves are formed on the side wall of the smooth shaft section of the inner wire fixing wheel along the axial direction of the side wall; the inner and outer wire fixing wheels are provided with wire grooves; the smooth shaft section of the inner wire fixing wheel is inserted into the shaft hole of the outer wire fixing wheel and is in clearance fit with the shaft hole of the outer wire fixing wheel; the wire fixing wheel locking block is connected withthe lower part of the outer wire fixing wheel through a connecting screw; and the smooth shaft section of the inner wire fixing wheel can be clasped on a rotating shaft arranged in the shaft hole of the inner wire fixing wheel through the wire fixing wheel locking block. Due to the adoption of the mechanism, a closed loop steel wire rope can be reliably tensioned during transmission, the condition that the wire transmission system is always in a tensioning state during operation is ensured, the wire transmission system can be adjusted and calibrated during operation, and transmission accuracyis ensured.

Owner:SHANDONG WEIGAO SURGICAL ROBOT CO LTD

High quality spinning dyeing mechanism

InactiveCN107034606AImprove flatnessReduce pulling forceTextile treatment by spraying/projectingTextile treatment carriersAgricultural engineeringTextile dyeing

The invention relates to a high-quality textile dyeing mechanism, which includes a frame, a transmission roller rotatably mounted on the frame, a spraying and dyeing assembly fixedly arranged above the transmission roller, and a rotatively mounted frame located on both sides of the transmission roller The cloth guide roller and the driving assembly that drives the transmission roller to carry out gray cloth transmission also include a smear assembly that is located on one side of the transmission roller and moves along its outer circumference. The first connecting rod connected to the driving assembly, the second connecting rod connected to the other end of the first connecting rod in rotation, the third connecting rod connected to the second connecting rod at one end and installed on the second connecting rod The smearing roller at the other end of the three connecting rods; the greige cloth is pre-dyed, dyed and polished, and then reciprocated on the conveying roller by the smearing roller to achieve wrinkle removal, color fixation and uniform dyeing of the greige cloth. The technical problems of uneven dyeing and easy fading in the background technology.

Owner:CHANGXING COUNTY DAWEI TEXTILE CO LTD

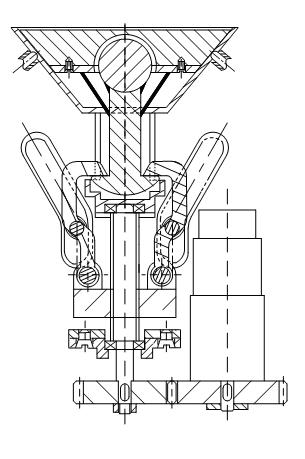

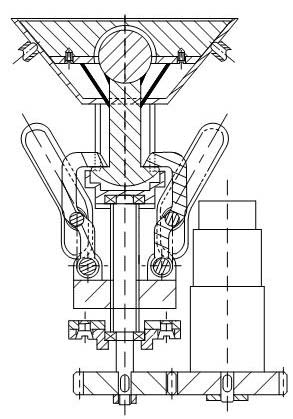

Adaptive butt-joint locking and releasing mechanical structure of combinable movable robot

The invention relates to an adaptive butt-joint locking and releasing mechanical structure of a combinable movable robot, comprising a butt junction and a butt-joint seat, wherein the butt junction is provided with a contact with a flange; and the butt-joint seat is provided with a cone-bowl-shaped butt-joint accommodation hole and two straining hooks which are opened and closed relative to each other. The contact of the butt junction can be inserted into the butt-joint seat by the guidance of the butt-joint accommodation hole of the butt-joint seat and fastened by the straining hooks, so as to realize the butt joint. The mechanical structure related by the invention can be used for improving the butt-joint feasibility of the combinable movable robot under unstructured environments and enhancing the adaptive butt-joint ability of the butt-joint gesture change between two movable robots, and has the advantages of convenience for locking and releasing, and reliability.

Owner:SHANGHAI UNIV

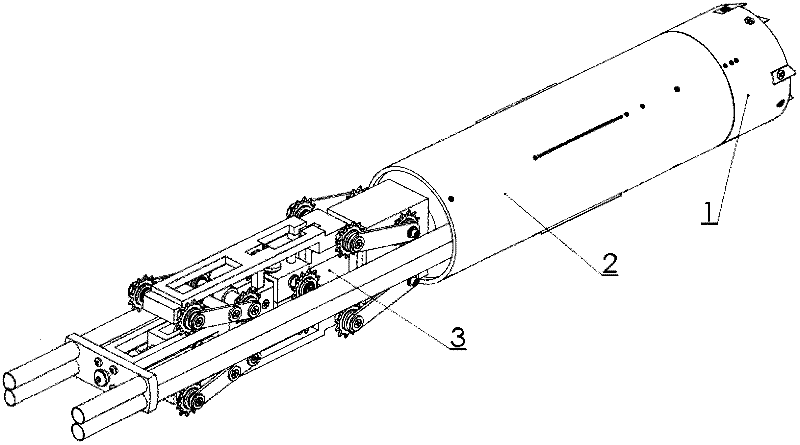

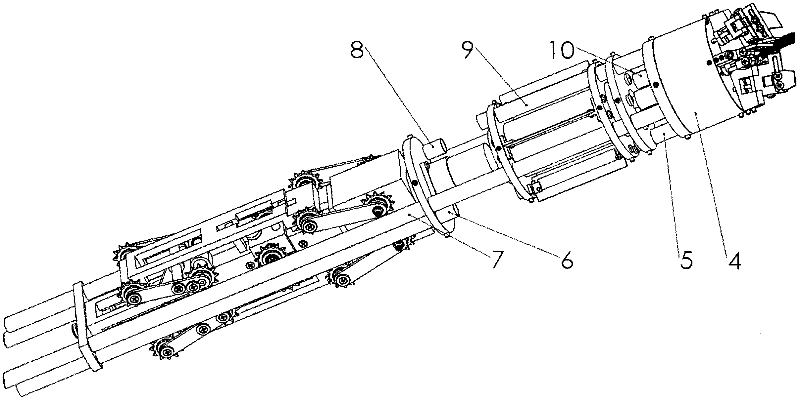

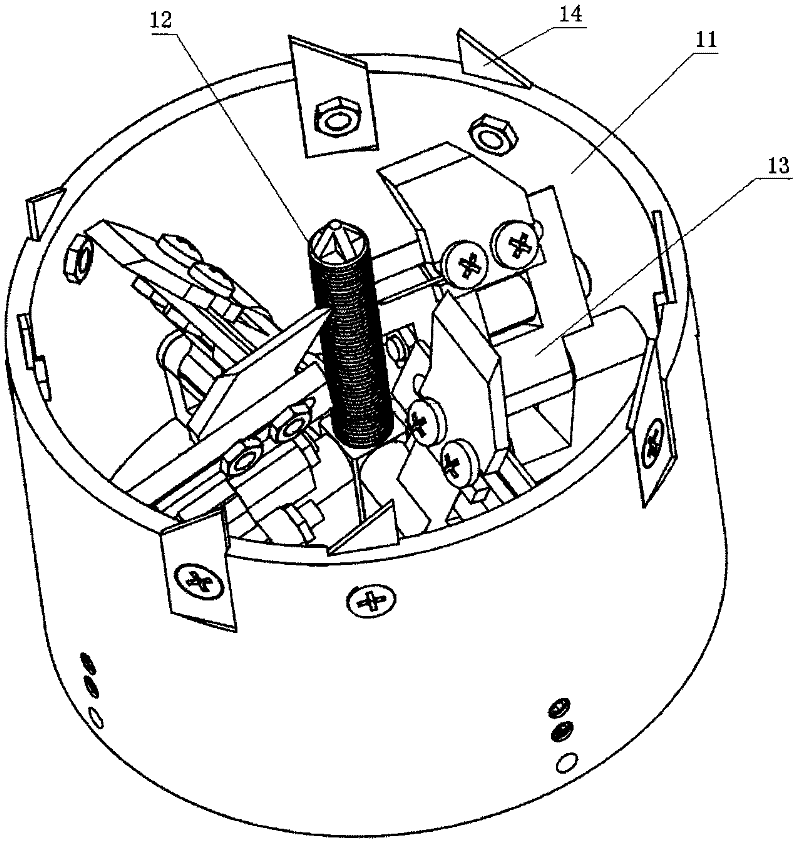

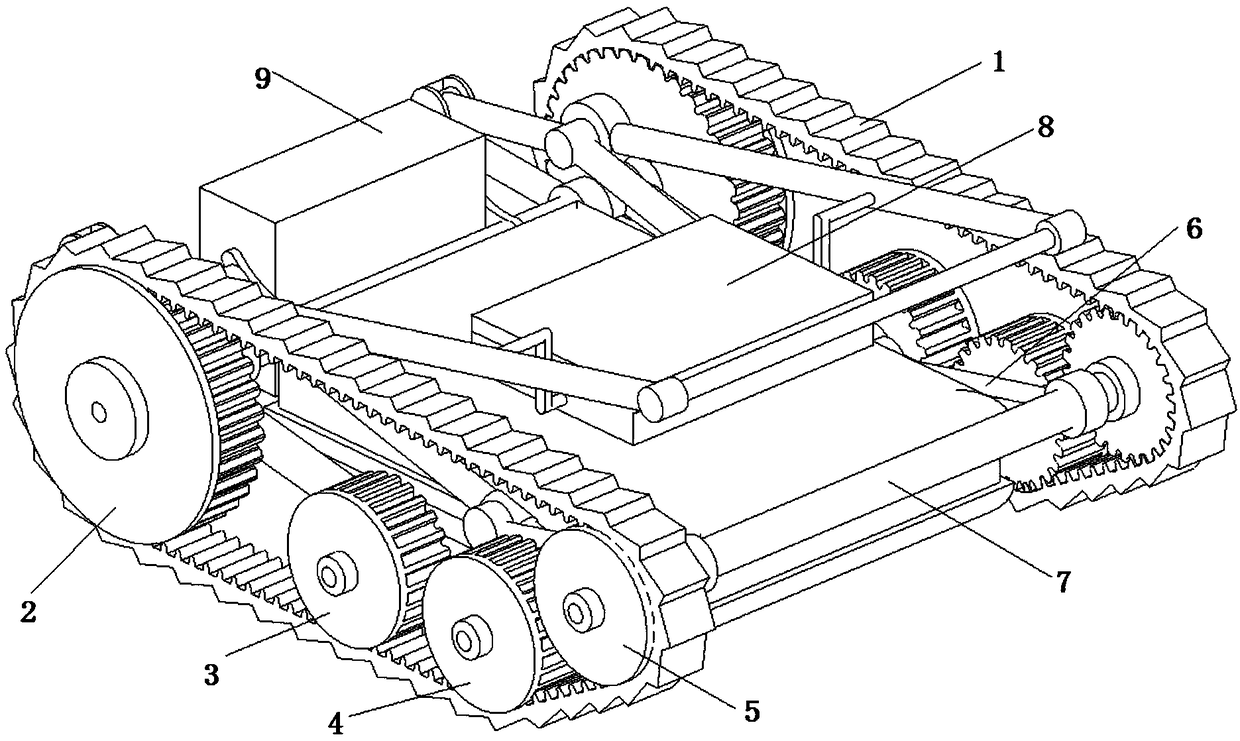

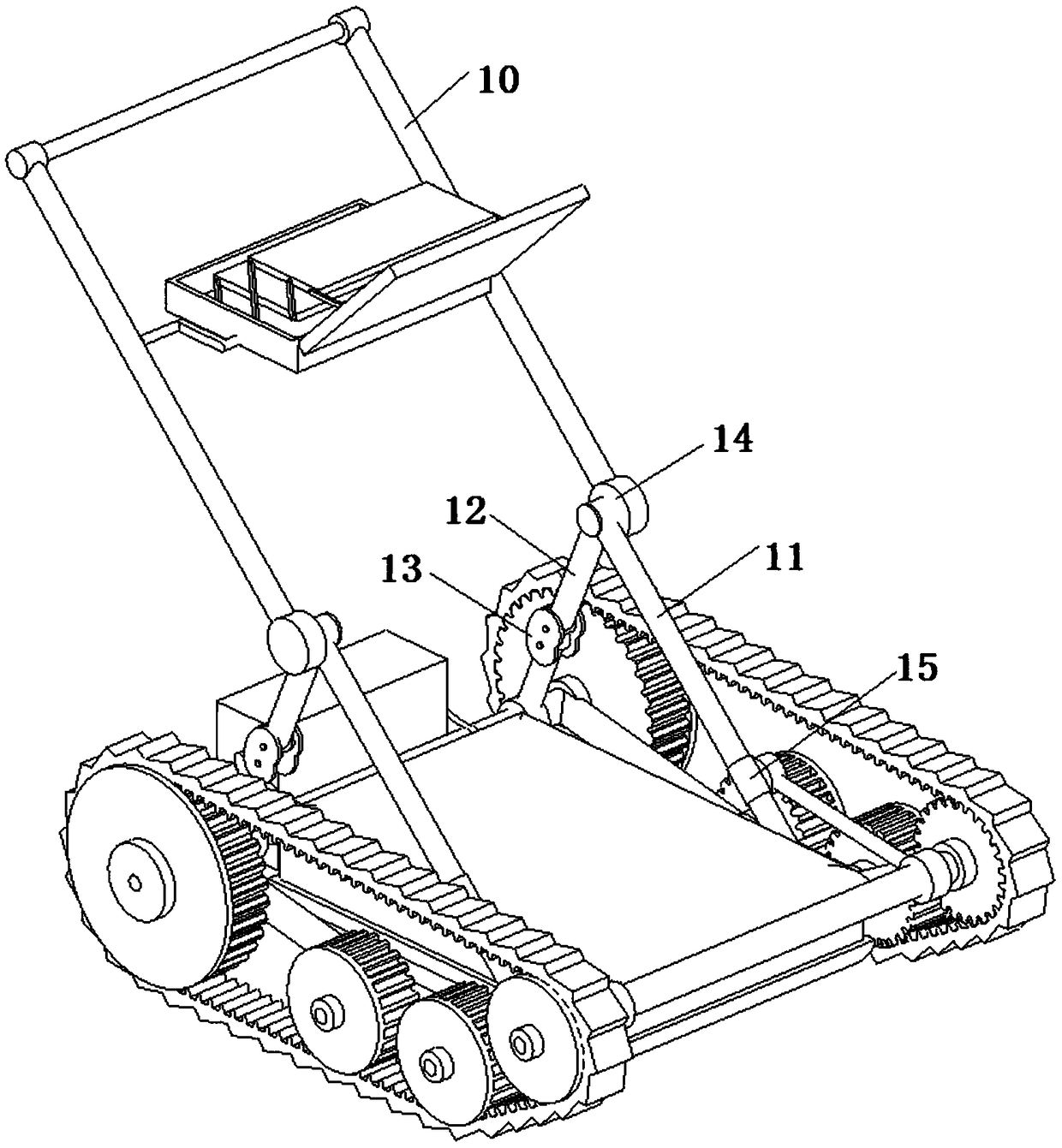

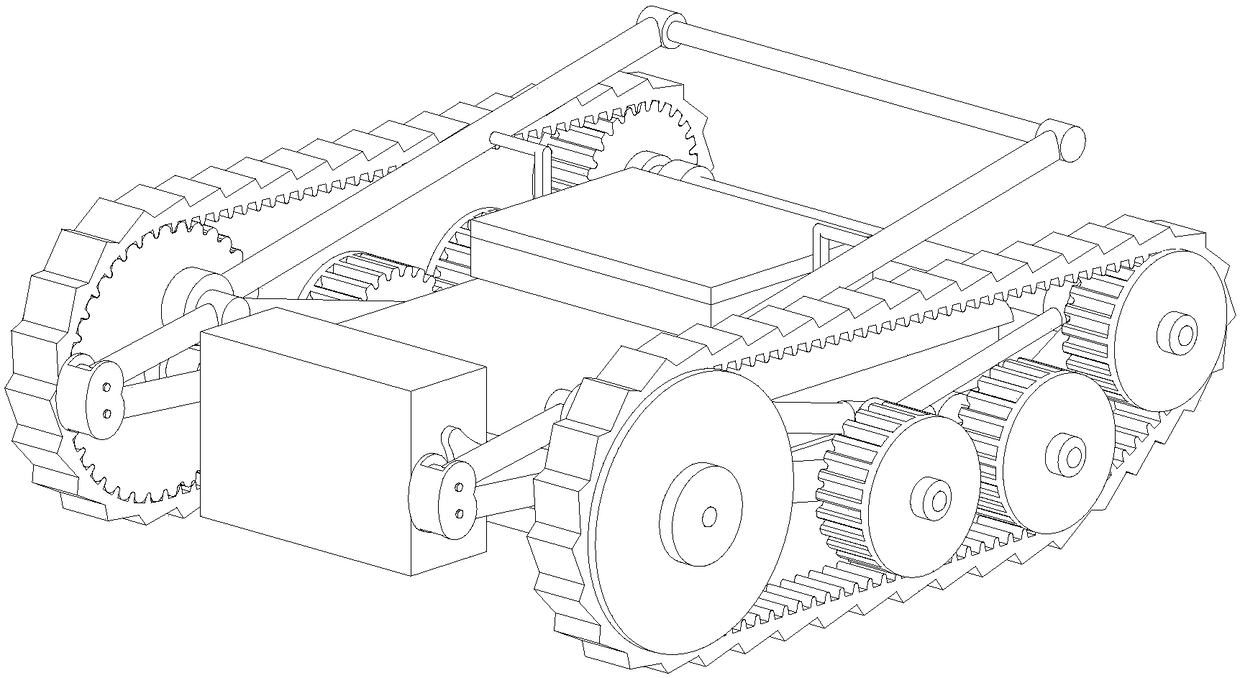

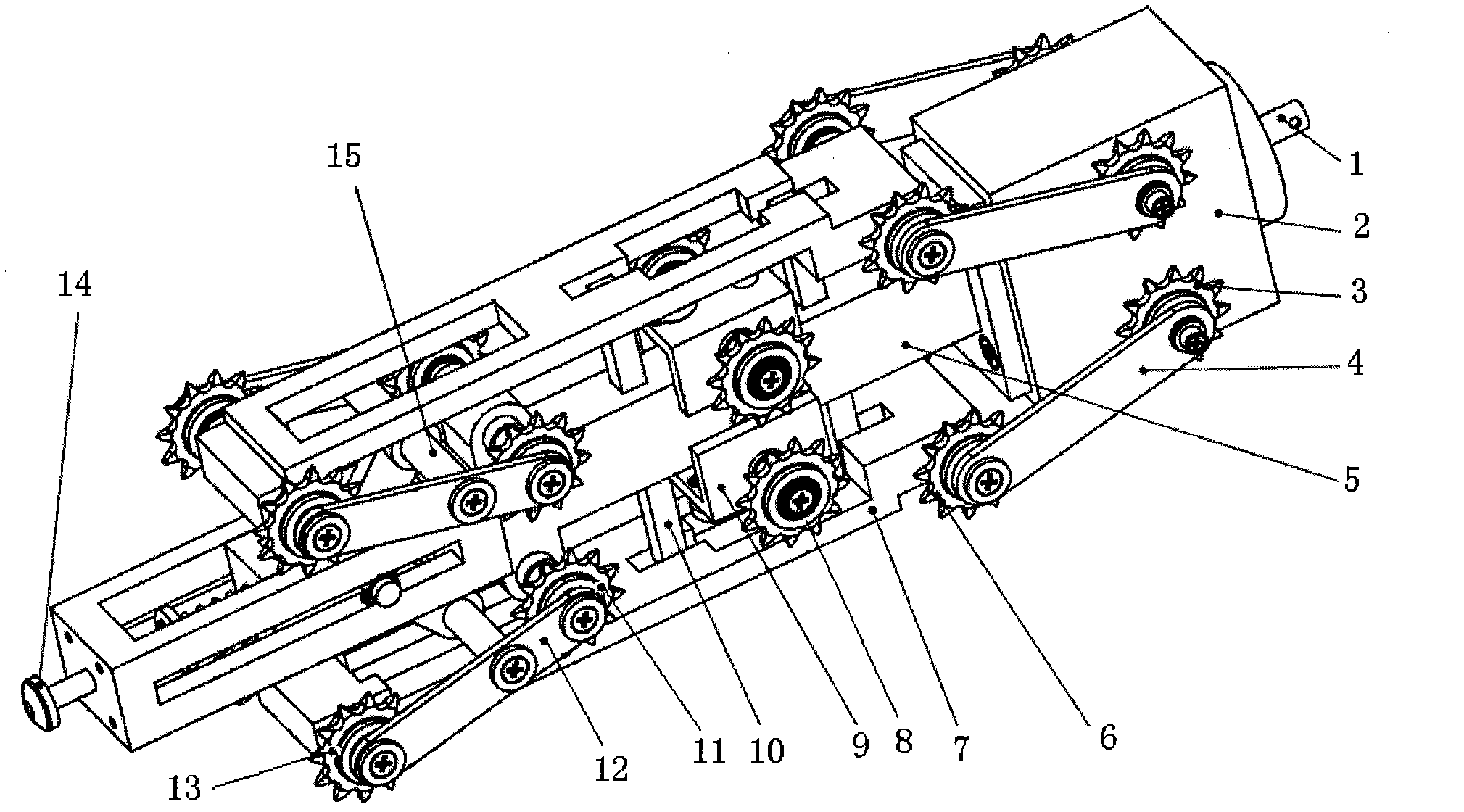

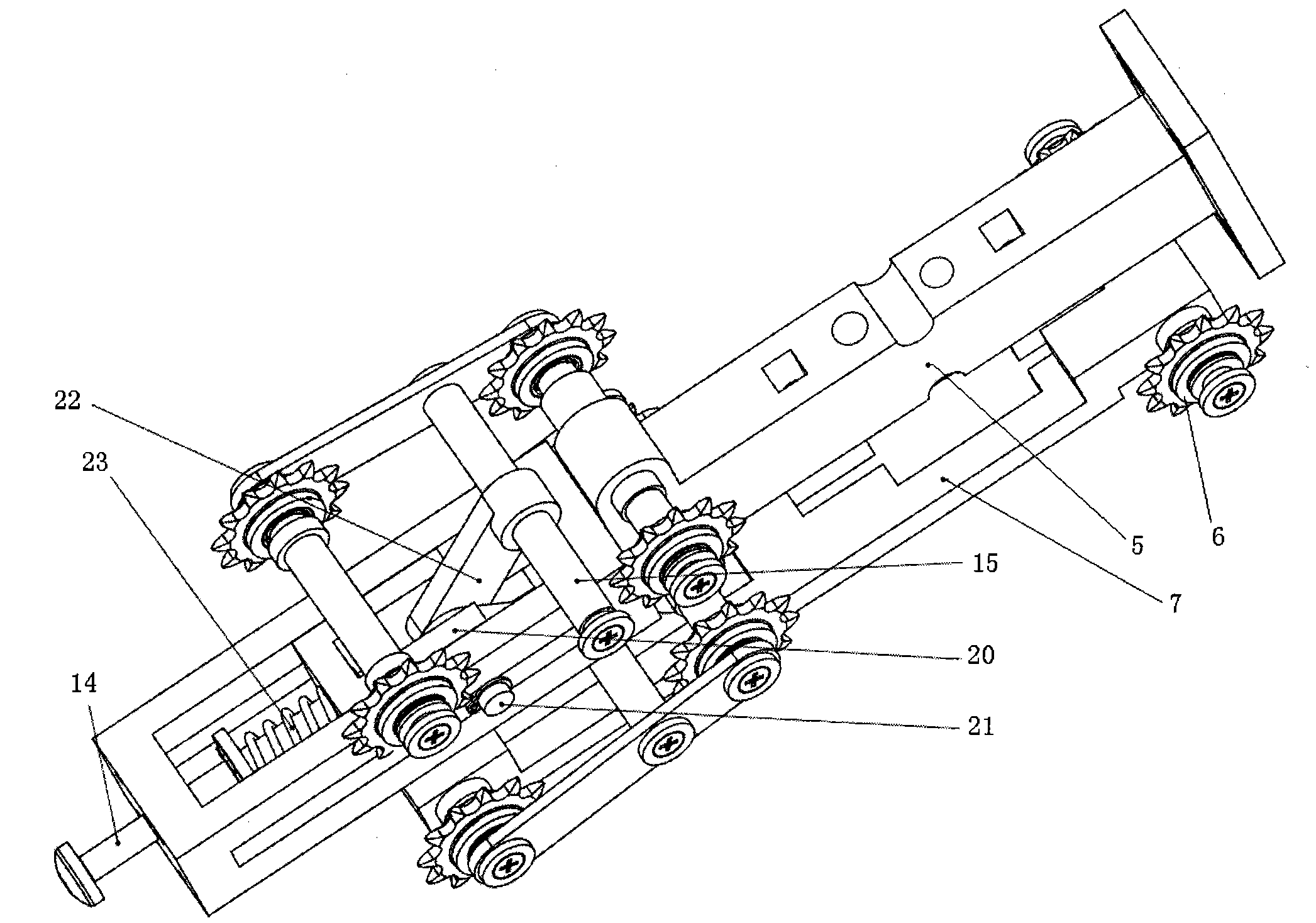

Self-traveling mini underground pipeline tunneling machine

The invention provides a self-traveling mini underground pipeline tunneling machine. According to the invention, the radial positions and the cutting angles of cutter blades in a cutter head mechanism are adjustable, and the cutter blades are spirally arranged, so as to reduce the size of the cutting edge of each cutter blade and reduce the requirement for power; and the individual groups of adjustable cutter holders and fixed cutter holders are subjected to the same stresses, so as to keep the overall stress in balance, provide an axial advancing force during cutting and benefit the axial advancement of the cutter head. Besides, according to the characteristics of different soil, the cutting angles of the cutter blades are adjusted to reduce the cutting resistance, reduce the wear of thecutter, ensure the mobility of the cut soil body and increase the service life of the cutter head. A chain tension mechanism is arranged inside a traveling mechanism to tension chains. Parallel frames are moved in parallel by using a regulating mechanism, so as to achieve the function of automatically controlling the distance between two parallel frames according to the degree of looseness of thesoil and ensure the chains to be in contact with the soil all the time. Accessory chains are adopted to ensure the chains to be in effective contact with the soil during the motion, so as to produce enough advancing force.

Owner:深圳市瀚德智能机器人有限公司

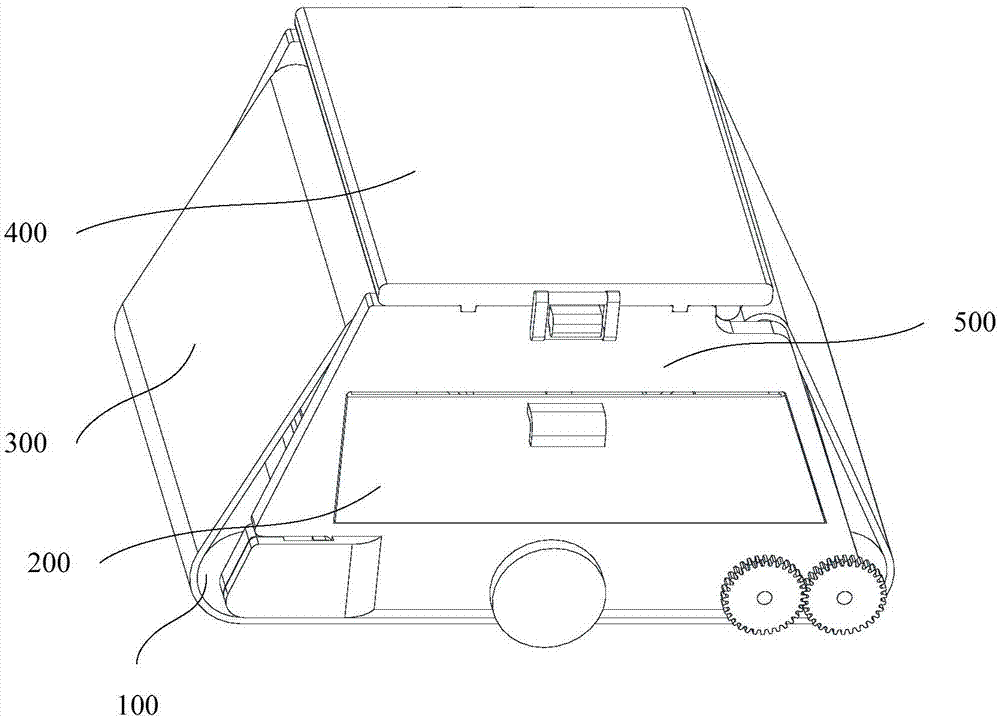

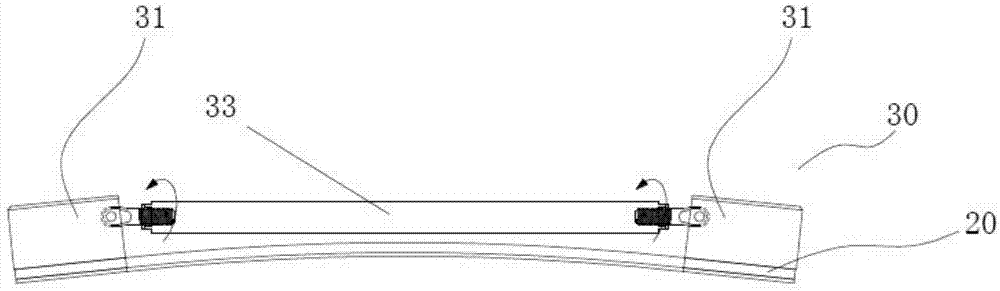

Floor-mopping cloth tensioning mechanism and floor mopping machine

InactiveCN107348913AAchieve tensionIncrease frictionCarpet cleanersFloor cleanersReciprocating motionTextile

The invention provides a floor-mopping cloth tensioning mechanism and a floor mopping machine. The floor-mopping cloth tensioning mechanism is applied to the floor mopping machine. The floor mopping machine includes floor mopping cloth and a machine body, the floor-mopping cloth tensioning mechanism is arranged on the machine body, and the floor-mopping cloth tensioning mechanism and the machine body are both sleeved with the floor mopping cloth; the floor-mopping cloth tensioning mechanism includes a fixing frame, a tensioning wheel and an elastic part, wherein the fixing frame is arranged on the machine body and can do reciprocating motion, the tensioning wheel is mounted on the fixing frame and can rotate around the fixing frame, and the elastic part is arranged on the machine body and faces one side of the fixing frame; under a working condition, the fixing frame compresses the elastic part, the floor mopping cloth is subjected to counter-acting force of the elastic part on the fixing frame and keeps tensioned. By the adoption of the floor-mopping cloth tensioning mechanism, the floor mopping cloth can have enough tensioning force, it is ensured that enough friction is generated between the floor mopping cloth and the floor, and the cleaning effect of the floor mopping machine is improved; meanwhile, even though slightly shaped or lengthened, the floor mopping cloth can be compensated through the floor-mopping cloth tensioning mechanism so that normal word cannot be influenced, and the user experience is improved.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

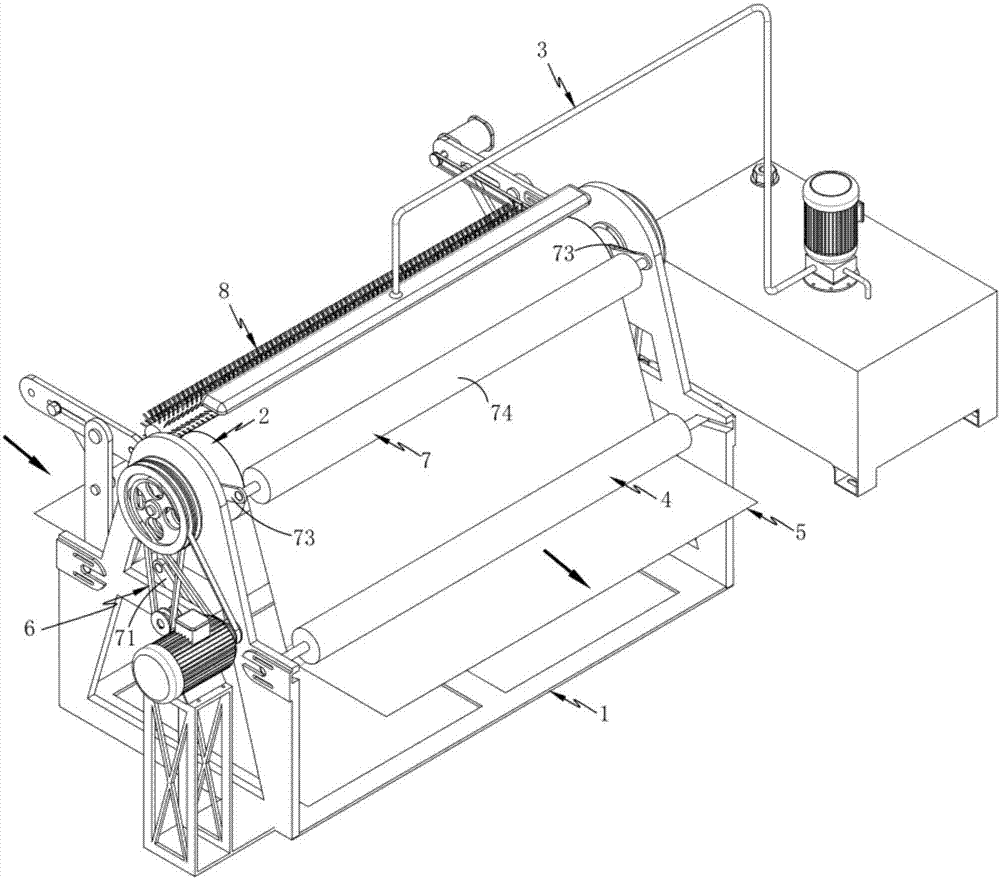

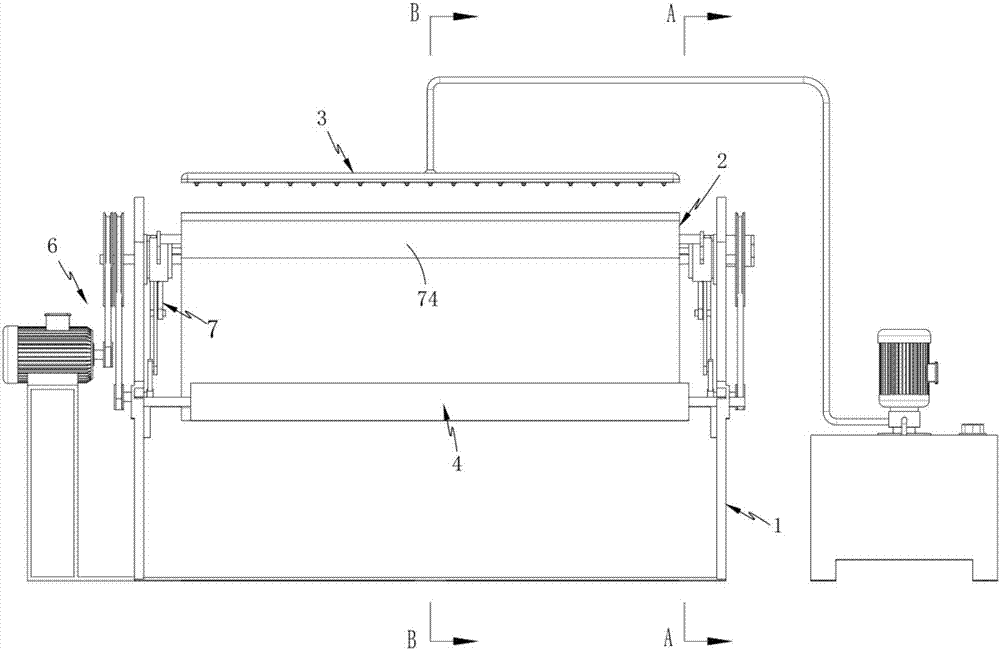

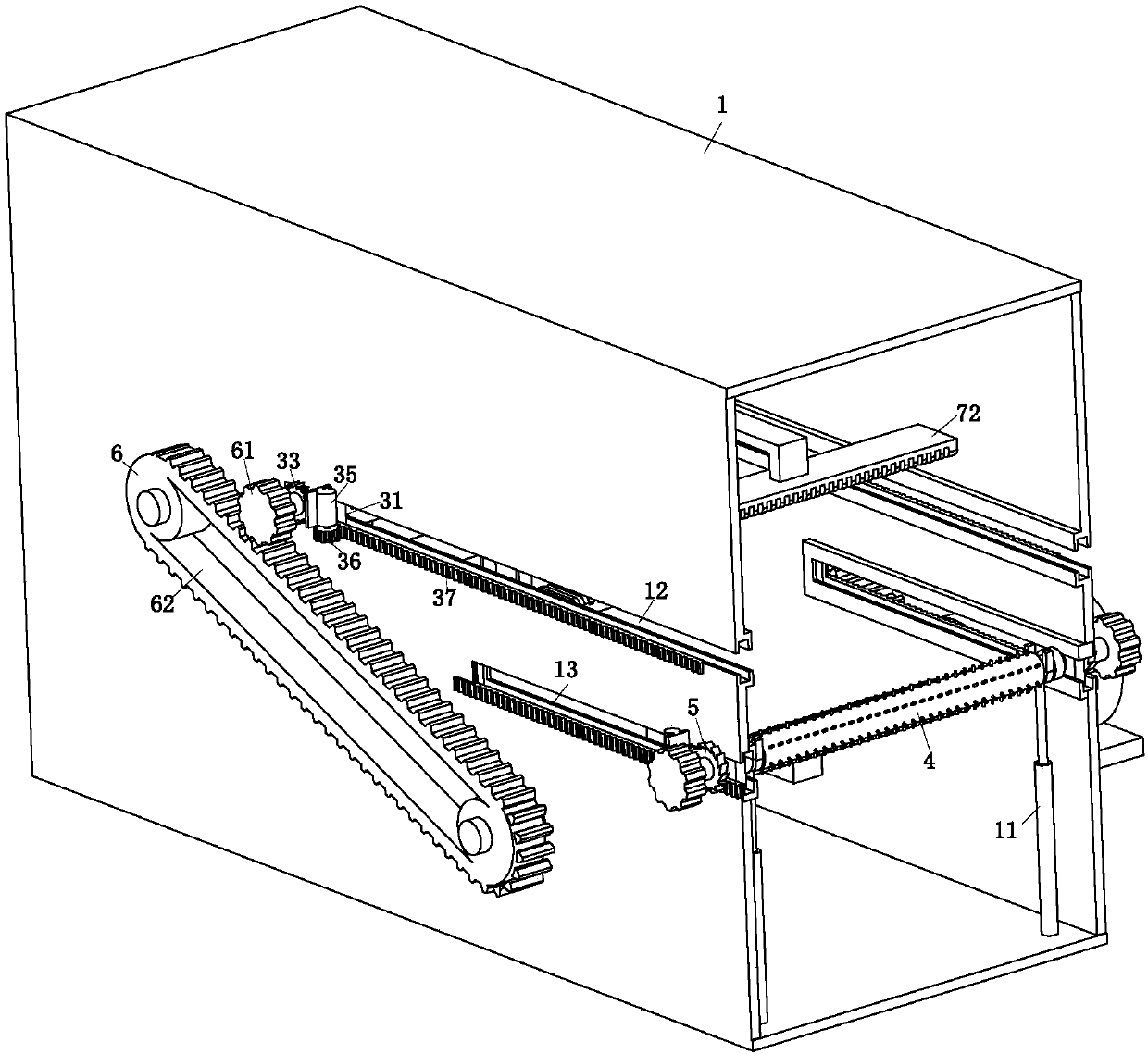

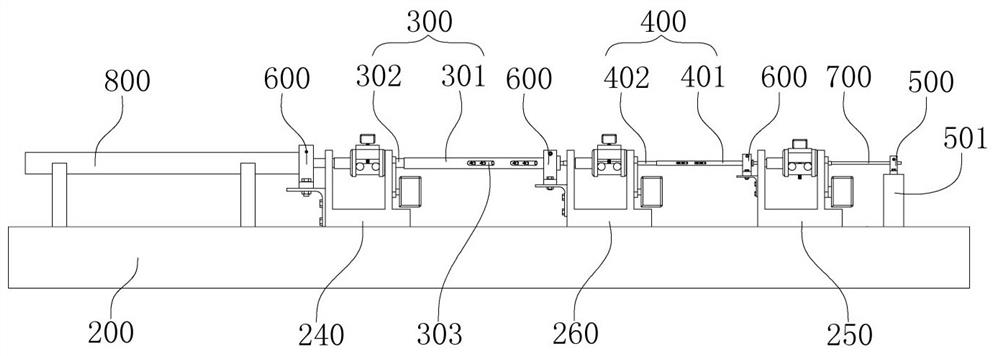

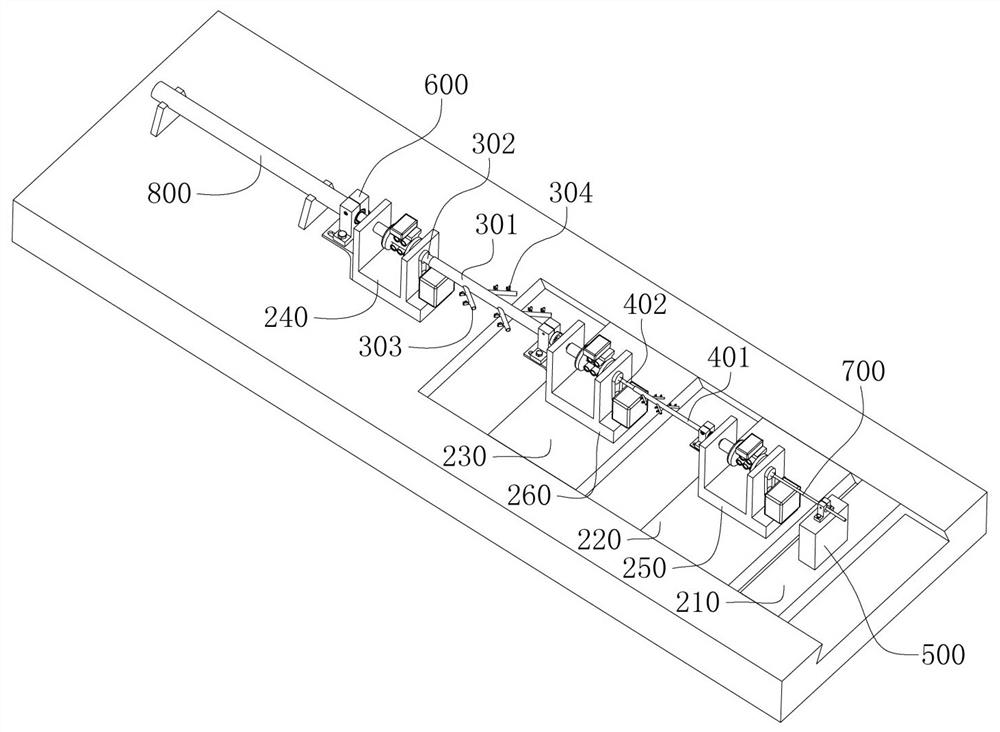

Continuous rolling-up device for textile fabrics

ActiveCN107618911AAchieve continuous windingAchieve tensionWebs handlingEngineeringContinuous rolling

The invention relates to the field of textile machinery equipment, in particular to a continuous rolling-up device for textile fabrics. An upper sliding groove and a lower sliding groove are formed inthe front side wall and the rear side wall of a machine body; an upper rolling shaft can slide in the upper sliding groove through an upper connecting module; a lower rolling shaft can slide in the lower sliding groove through a lower connecting module; a driving module synchronously drives the upper rolling shaft and the lower rolling shaft from the front side and the rear side of the machine body; a clamping module is used for clamping the textile fabrics; a cutting module is mounted on the clamping module and is used for cutting the textile fabrics after being clamped; and an adjusting module is located at the left end of the machine body and is used for adjusting the tension degree of the textile fabrics and temporally storing the textile fabrics when the textile fabrics are cut. Thecontinuous rolling-up device can conduct continuous rolling-up of the textile fabrics without stopping, and the production speed of the textile fabrics can be effectively improved.

Owner:佛山市汇科纺织有限公司

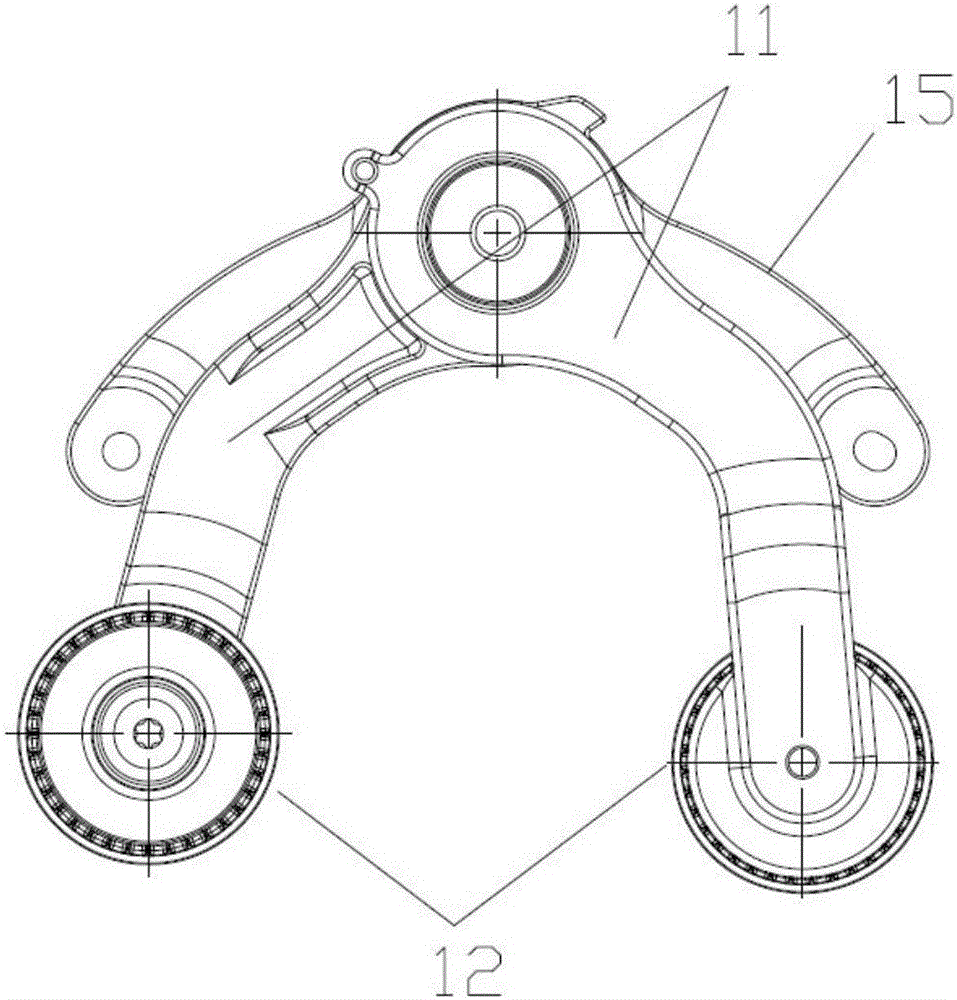

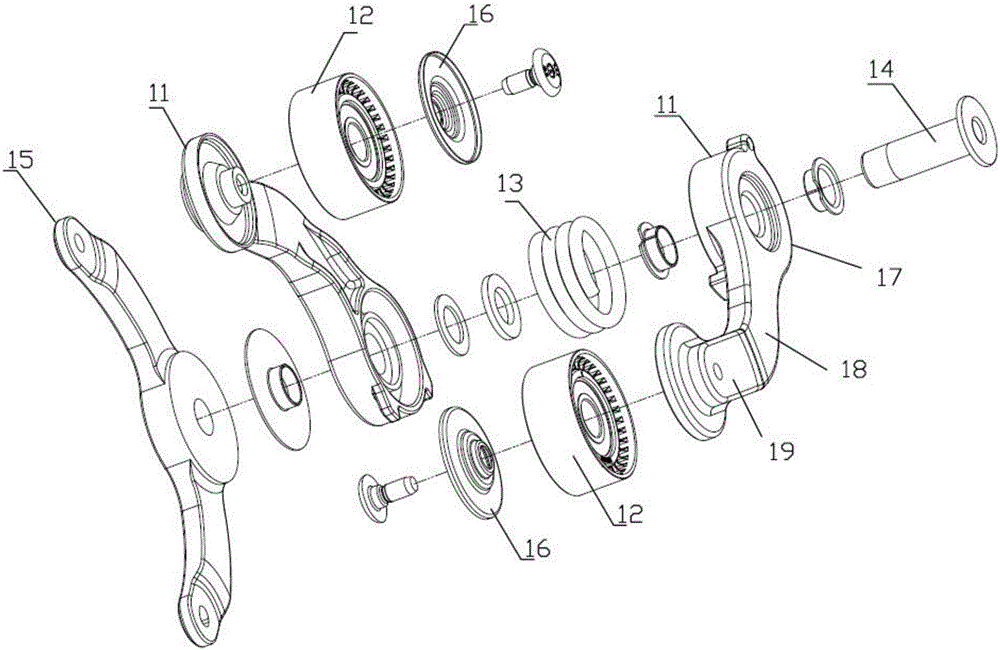

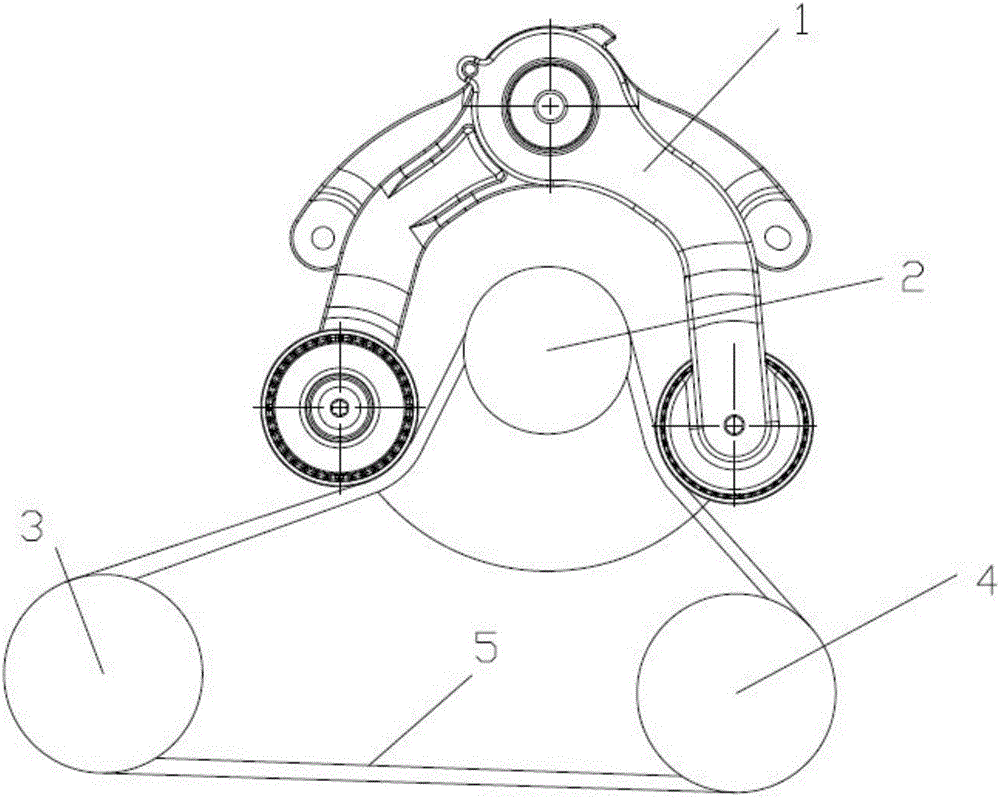

Two-way tensioner applied to BSG wheel system and vehicle engine system

The invention discloses a two-way tensioner applied to a BSG wheel system, and is suitable for a hybrid power engine. The tensioner adopts two tensioner arms arranged in a swing manner, and the internals are connected through a torsion spring to generate elastic tension to realize tensioning of two edges of a motor so as to adapt to interchange of elastic edges of transmission belts on the left and right two sides of the motor due to different working states; and the tensioner is fast in response, is convenient for quick start and stop of the engine, and prevents accidents. The two-way tensioner is compact in structure, convenient for installation and low in control mounting requirements.

Owner:LITENS AUTOMOTIVE PARTS (SUZHOU) CO LTD

Balance weight body with self-tensioning effect

ActiveCN104355211AThere will be no slipping and idling phenomenonGuaranteed stabilityMine liftsEngineeringPulley

The invention relates to a balance weight body with a self-tensioning effect. The balance weight body comprises two parallel fixing plates, a rack and metal balance weights, wherein the fixing plates are fixedly connected through two horizontal fixing rods; the rack is arranged between the fixing plates; the balance weights are fixed on the fixing plates; the rack comprises two clamping plates; a first long slotted hole and a second slotted hole, which penetrate through the front parts and the rear parts of the clamping plates are formed in the clamping plates; the two fixing rods are arranged in the first long slotted hole and the second slotted hole respectively; the rack further comprises a first fixed pulley, a second fixed pulley, a movable pulley and a connecting wire rope; the first fixed pulley and the second fixed pulley are fixed between the two clamping plates; the two ends of the connecting wire rope are connected with the fixing rods respectively; the top of the rack is fixedly connected with an upper wire rope; the movable pulley is fixedly connected with a lower wire rope. Since the distance between the nodes of the upper wire rope and the lower wire rope of the balance weight body provided by the invention can be adjusted freely within a certain range, a hanging wire rope can be kept tight, a traction wheel is free from the phenomena of slipping and idle rotation during working, and the working stability of the whole traction mechanism is guaranteed.

Owner:王景保

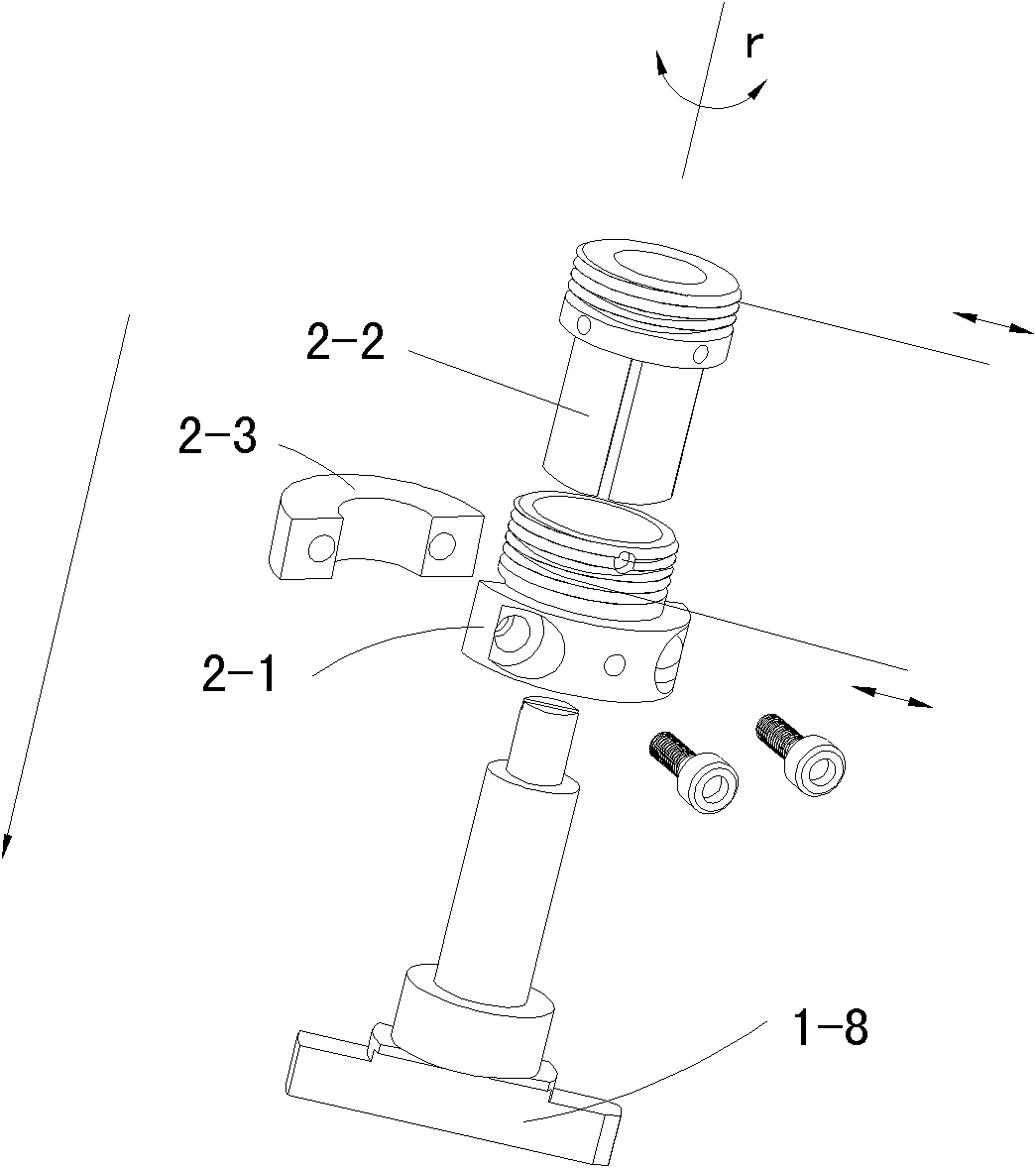

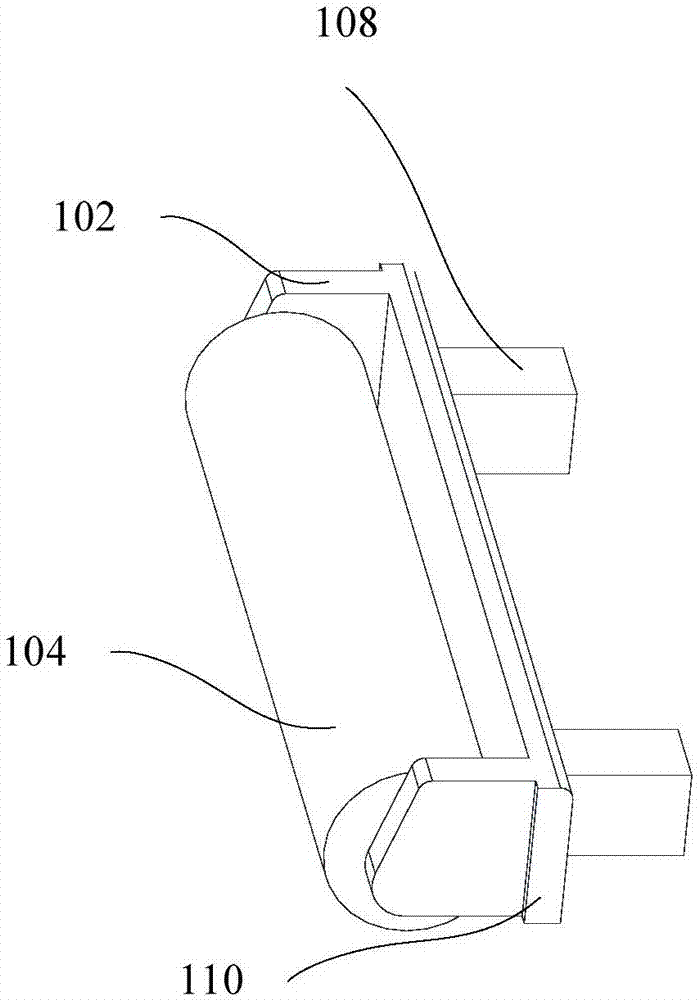

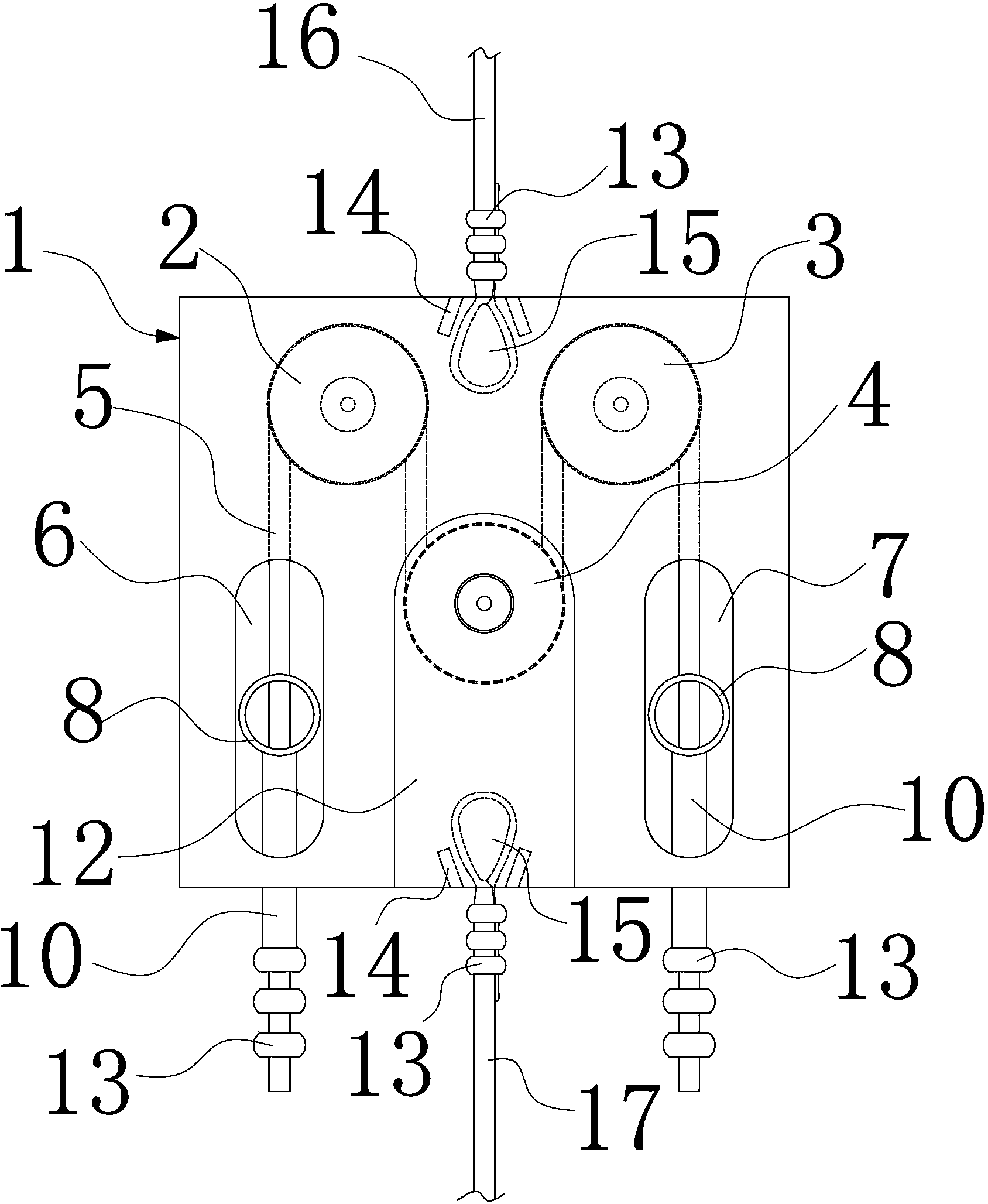

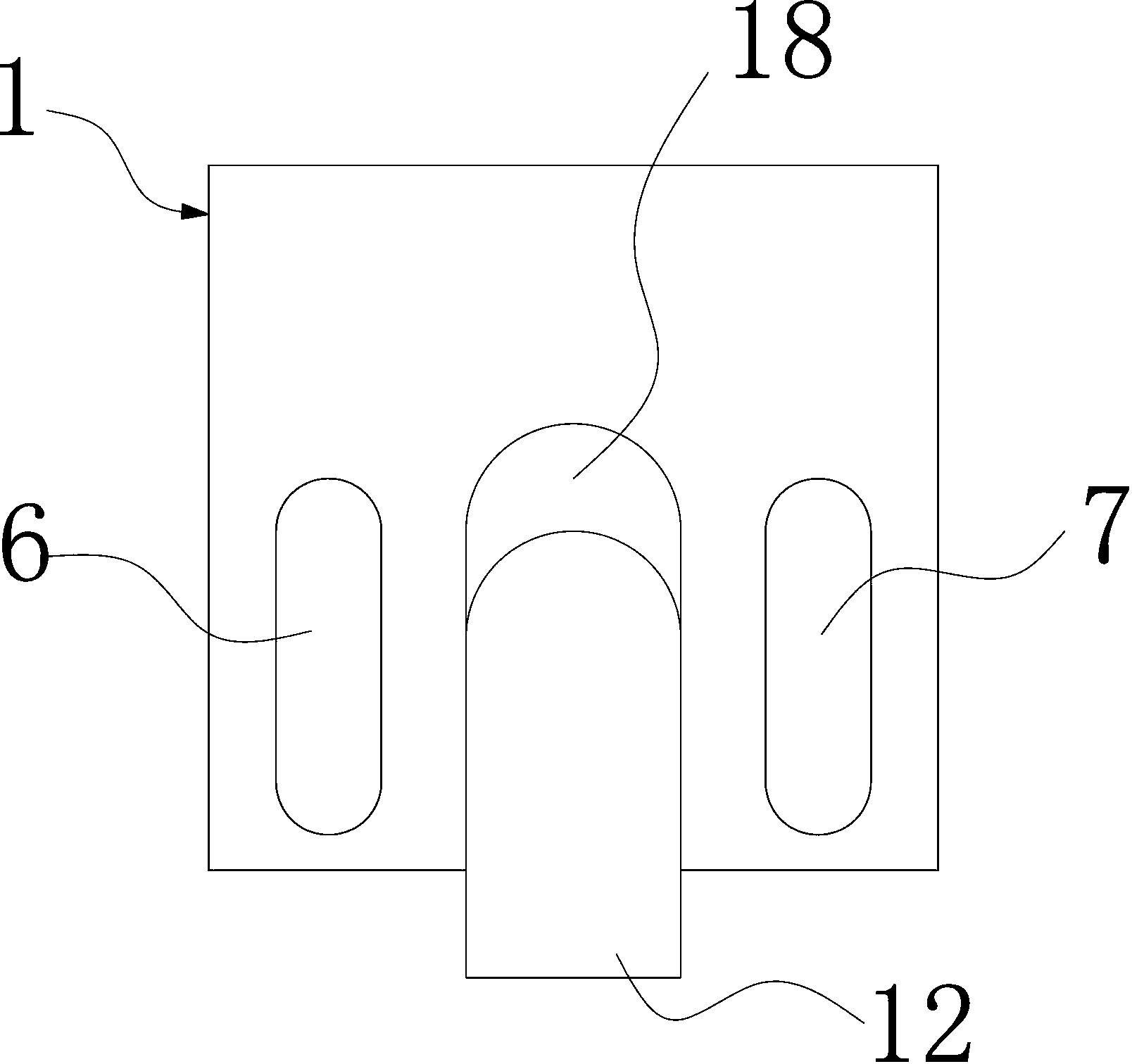

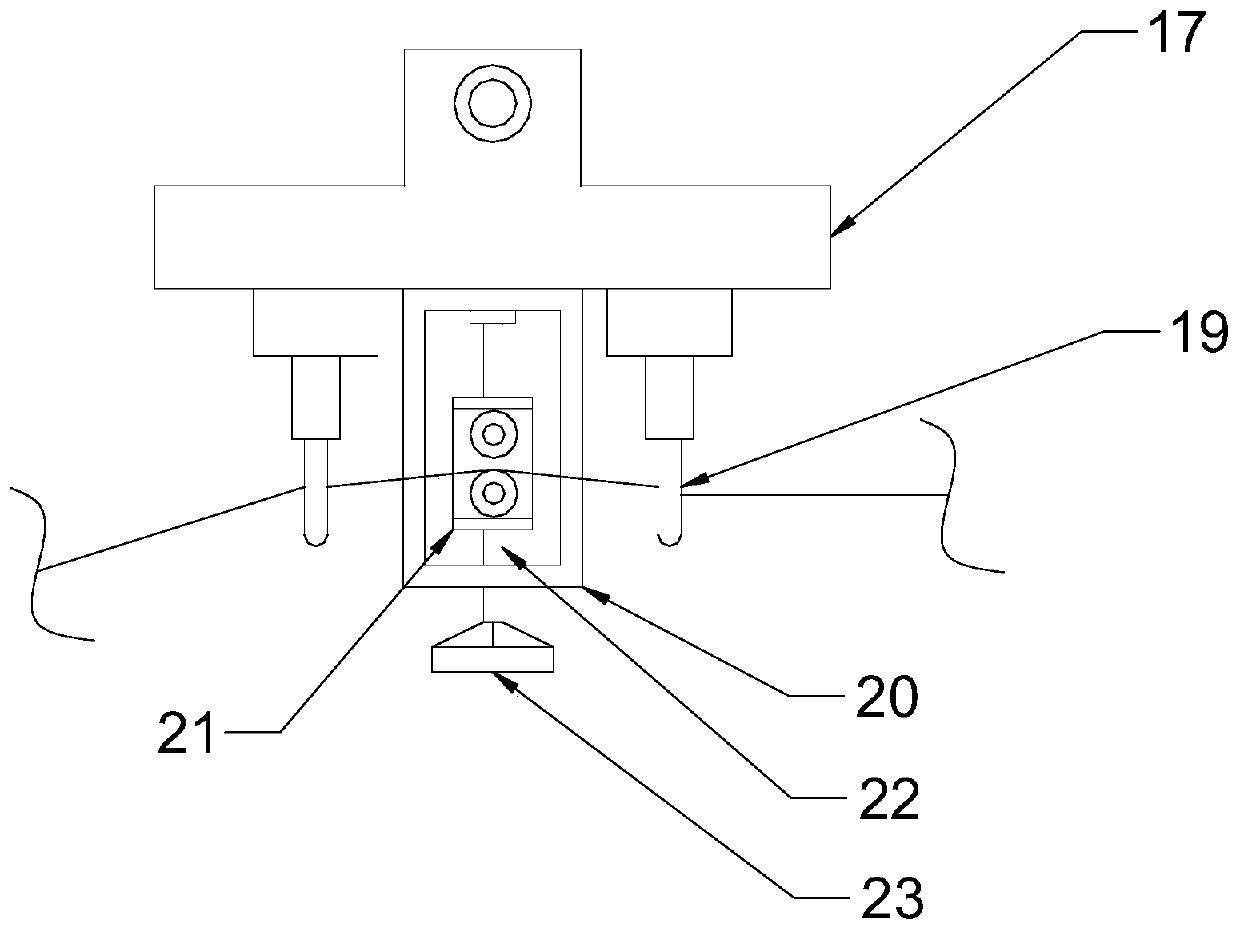

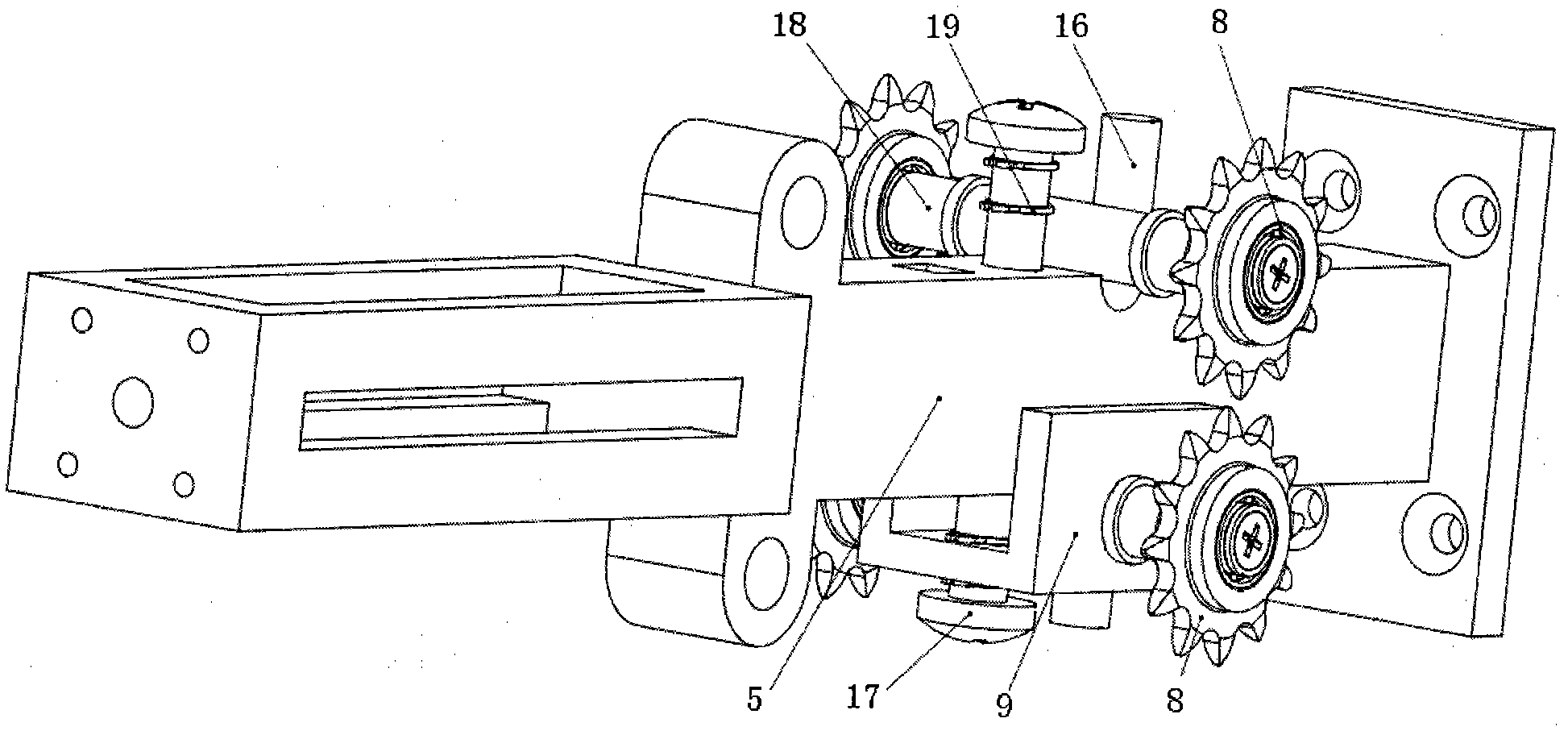

Rotary pushing device and interventional operation robot

The invention belongs to the technical field of medical equipment. The invention discloses a rotary pushing device for controlling a catheter or a guide wire and comprises a base, a rotary table, a pushing unit and a pushing driving part, the rotary table is arranged on the base through two hollow pivot shafts, and a rotary driving part for driving the rotary table to rotate is arranged on the base; the pushing unit is arranged on the rotary table, the pushing unit comprises an upper pushing roller and a lower pushing roller which are correspondingly arranged up and down, and at least part of the upper pushing roller and the lower pushing roller are arranged up and down in a staggered mode; and the pushing driving part drives the pushing unit to act. The invention further discloses an interventional surgical robot. Stable pushing of the guide wires or the catheters can be effectively improved, the product structure is simplified, modularization of the rotary pushing device is achieved, assembling is more convenient, tensioning of the guide wires or the catheters can be achieved through a new transmission mode, the accuracy of surgical actions is guaranteed, and practicability is higher.

Owner:王利

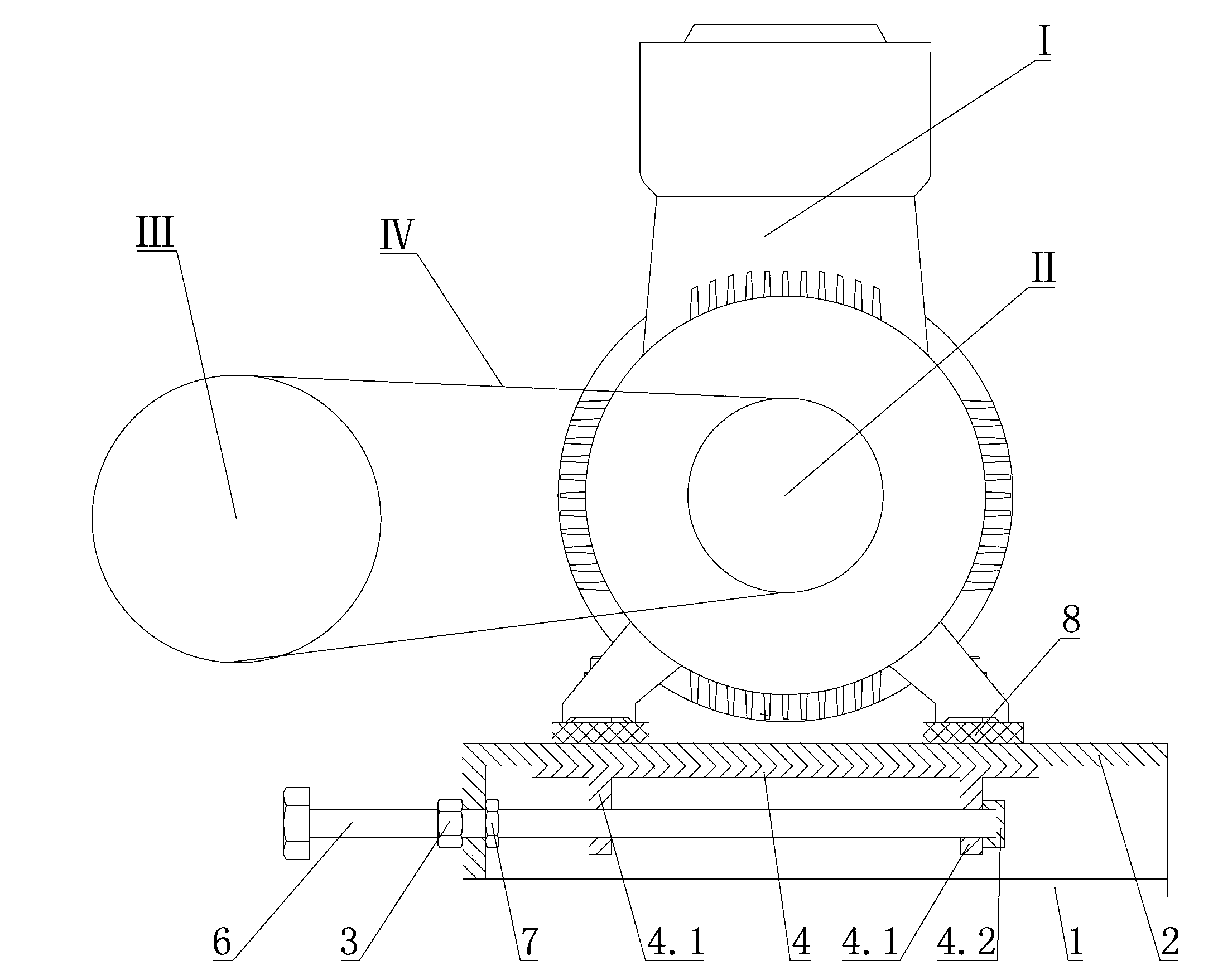

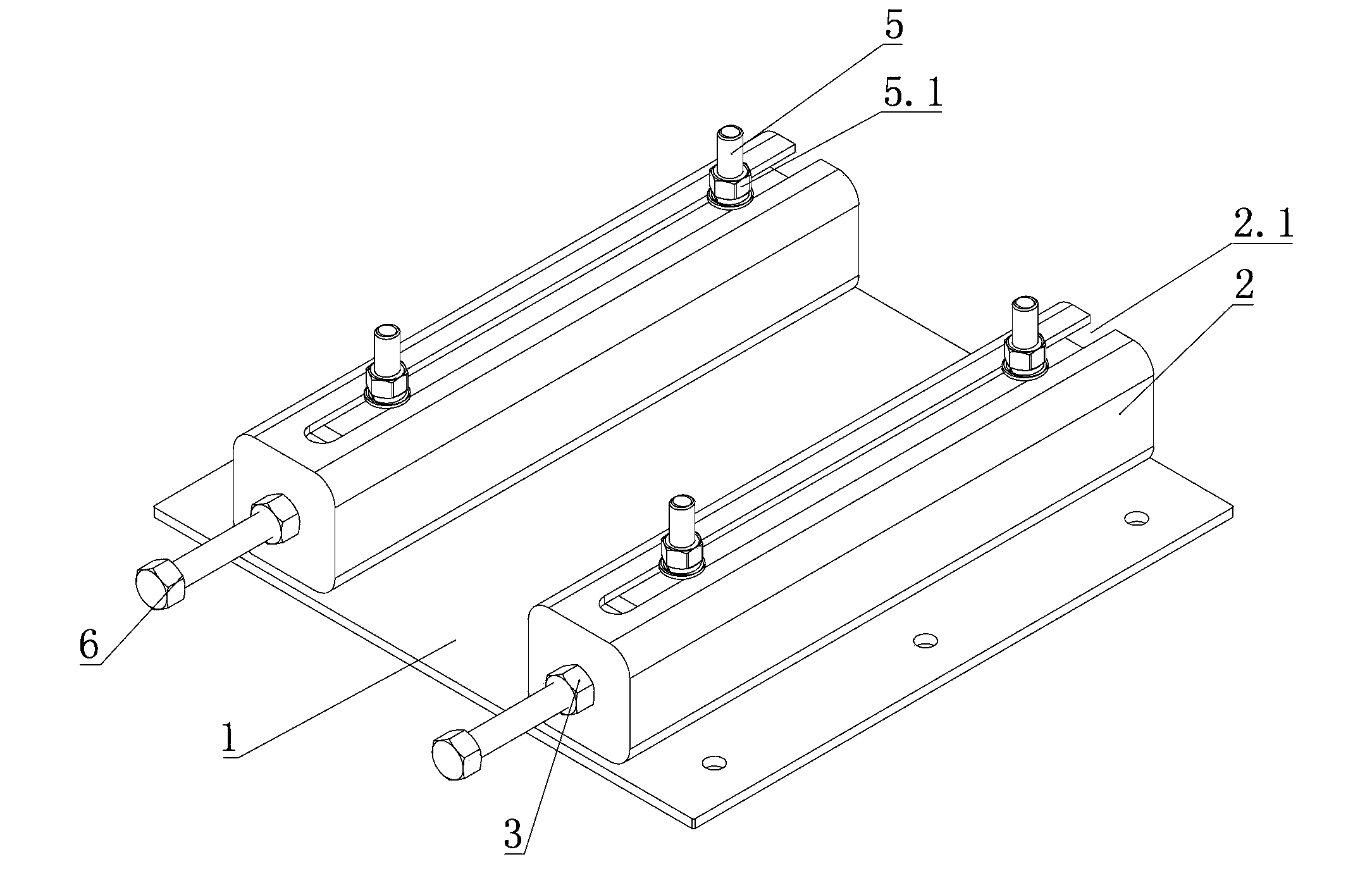

Adjustable motor cabinet

The invention relates to an adjustable motor cabinet. The adjustable motor cabinet comprises a base. An installing plate and the base are fixed. A fixed guide rail body is arranged above the installing plate, a line-shaped groove is formed in the top of the fixed guide rail body, a through hole is formed in one side of a shell, the outer side of the side of the shell is fixedly connected with a sliding retaining nut, and the other side of the shell is open. A pi-shaped sliding plate assembly is hoisted inside the fixed guide rail body through motor set bolts arranged above the sliding plate assembly. Through holes are formed in lifting lugs of a sliding plate, a limiting block is arranged outside one lifting lug, and internal threads are arranged in the limiting block. An adjusting screw rod penetrates through the sliding retaining nut and the through holes, and the top of the adjusting screw rod makes contact with the limiting block. The adjusting screw rod is rotated to make the sliding plate assembly move towards one side, a belt can be tensioned without adjusting the motor set bolts, and the adjustable motor cabinet is convenient to use; meanwhile a complex tensioning wheel structure does not need to be installed, the structure is simple, and the installing space requirement is low.

Owner:WUHAN QIDAKANG ENVIRONMENTAL PROTECTION TECH CO LTD

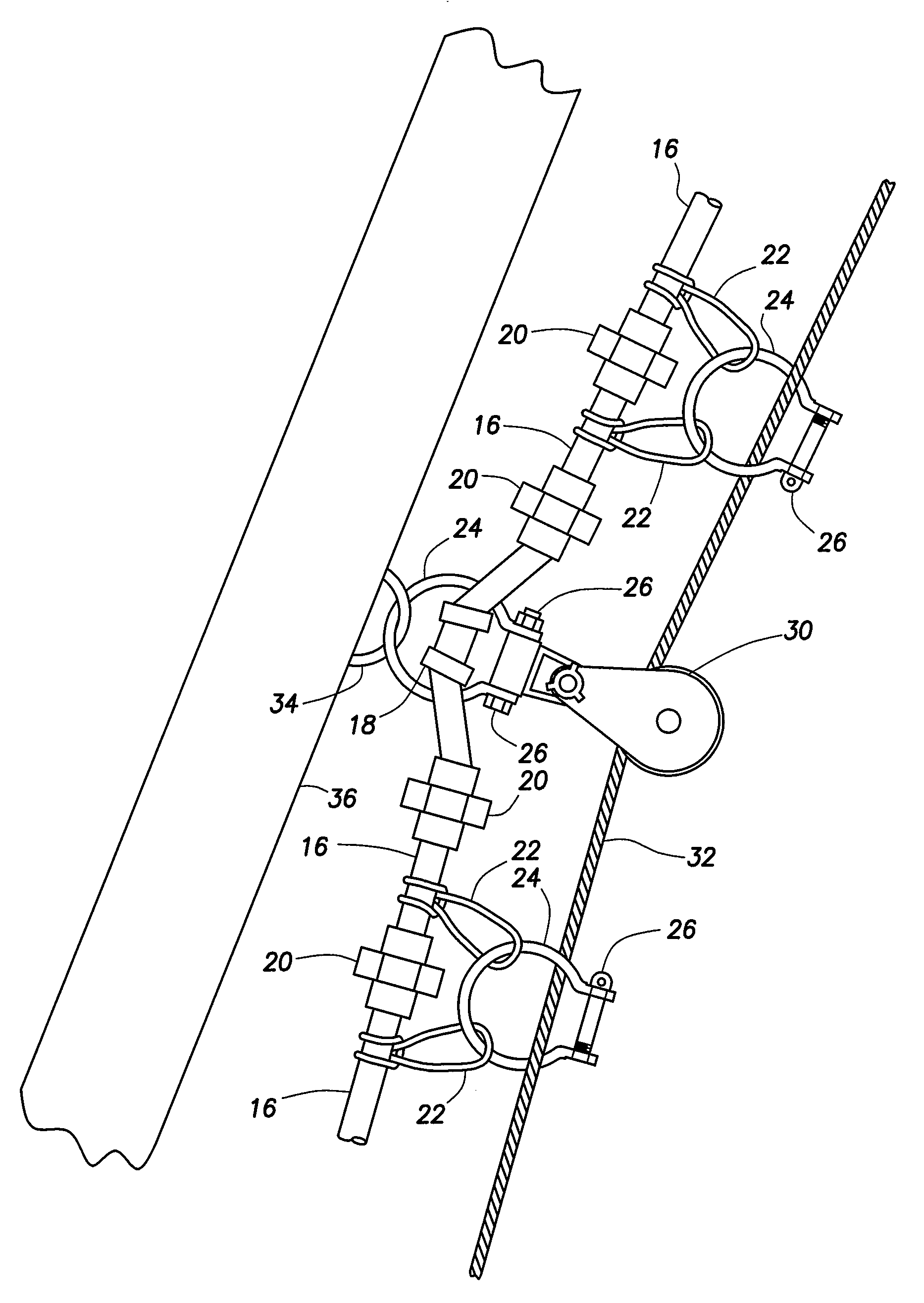

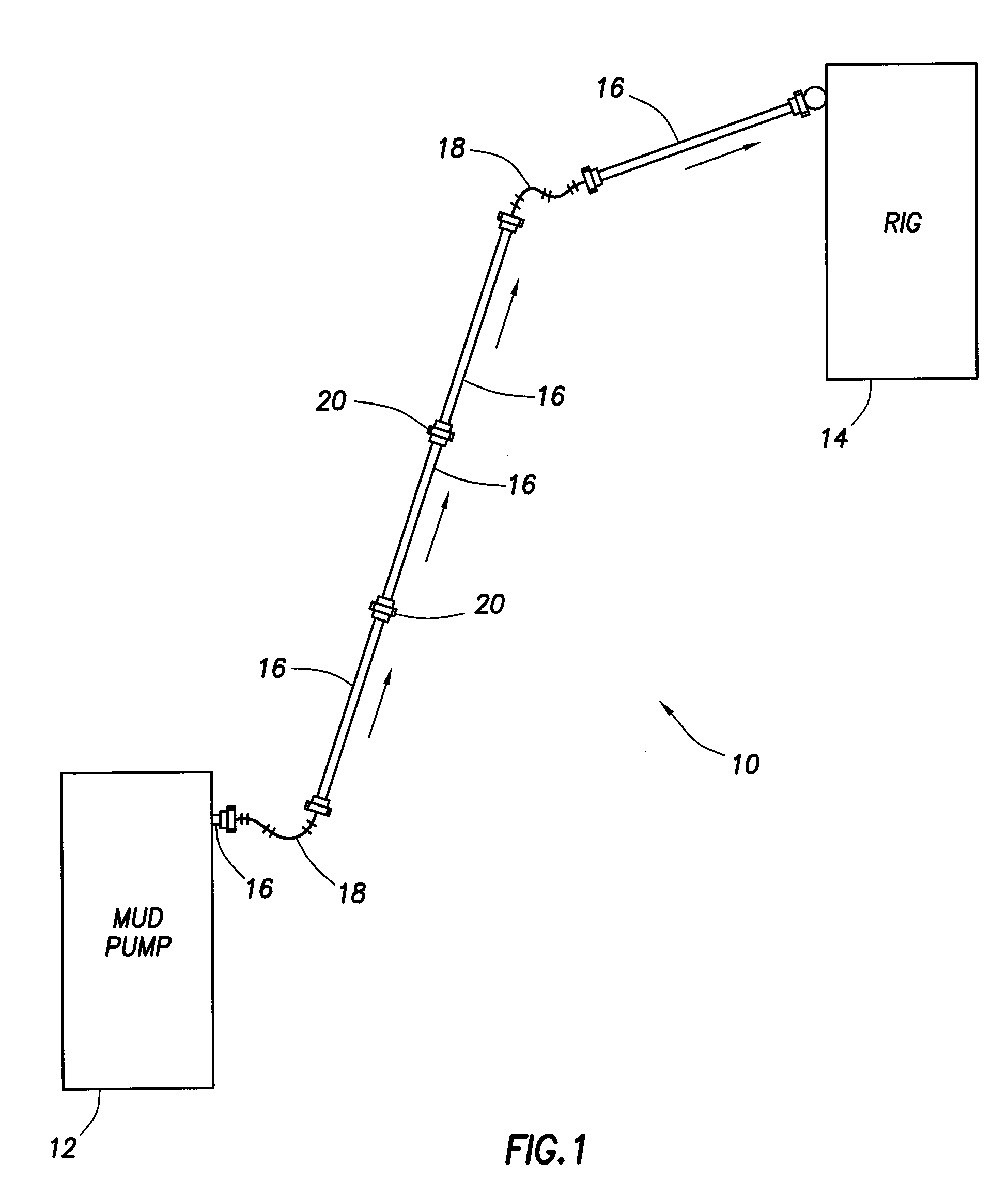

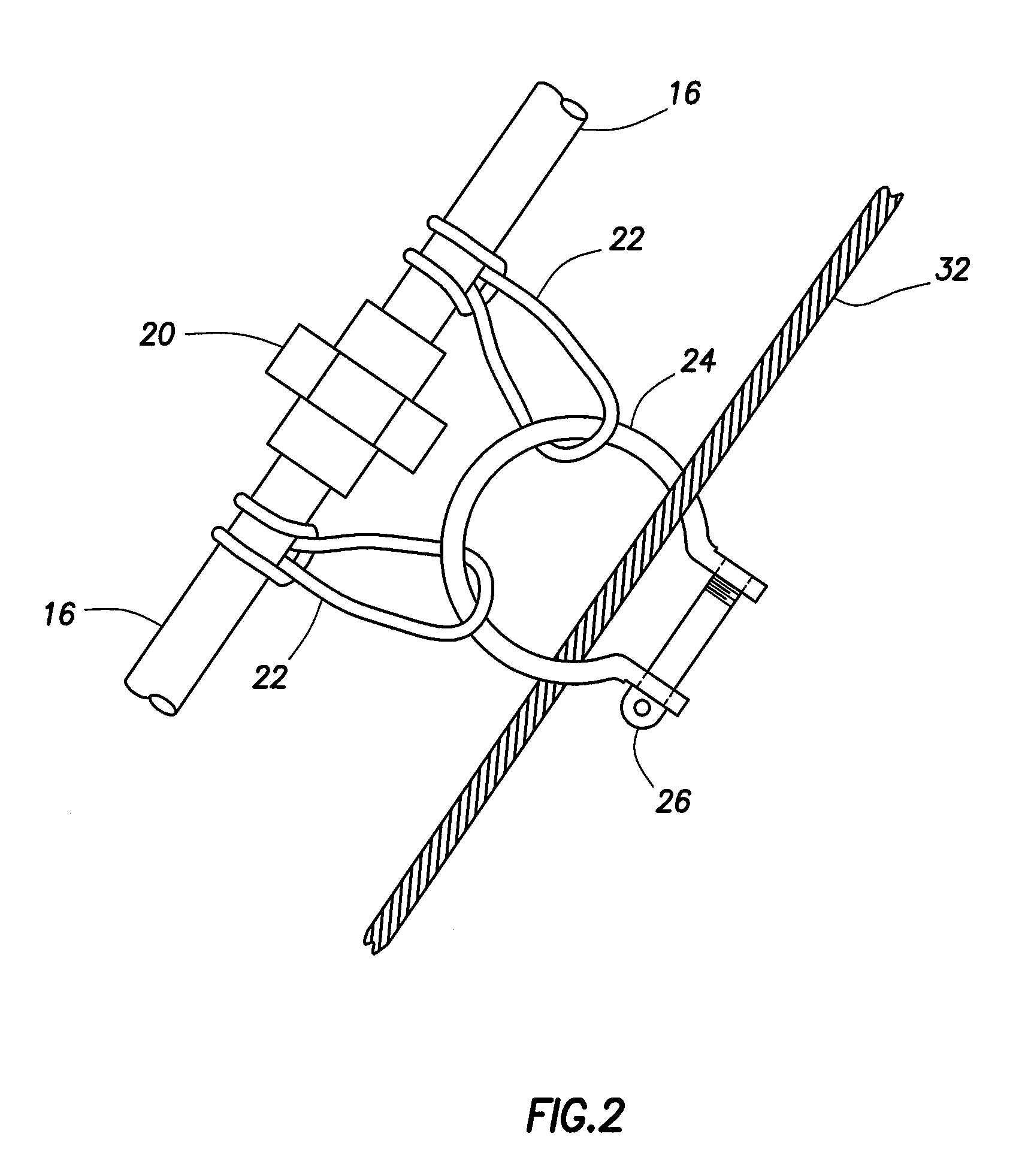

Pump Iron Restraint System

A pump iron restraint system is disclosed in which a fastening system is coupled to successive pump iron joints and a wireline is threaded through the fastening system. The fastening system may comprise a pair of endless flat straps, each of which is coupled to one of the pump iron joints. The eyes of the endless flat straps are placed around the interior arch of the screw pin shackle. A wireline is placed through the spaced formed by the screw pin and the screw pin shackle. The wireline is secured at the well site so that the wireline is taut.

Owner:PENNY TECH S A R L

Decoration garbage treatment equipment

ActiveCN112121906AShatter Effect AdjustmentAchieve positioningGearingGrain treatmentsElectric machineryStructural engineering

The invention relates to the field of decoration garbage, in particular to decoration garbage treatment equipment. The equipment can adjust a smashing degree of the decoration garbage according to anactual situation. The equipment comprises a smashing assembly, a separating assembly, an input motor and a connecting belt, wherein a first rectangular sliding block and a second rectangular sliding block are driven by a first hinge connecting rod and a second hinge connecting rod to relatively slide in a first rectangular sliding groove respectively, then a distance between the first rectangularsliding block and the second rectangular sliding block is changed, and then a distance between a first smashing roller and a second smashing roller is changed, so that the specification of a decoration garbage fragment capable of being adapted to a space between the first smashing roller and the second smashing roller is changed, and the adjustment of a decoration garbage smashing effect is achieved. Through matched connection of a first inner end clamp and a first clamping groove, positioning of a sliding position of a driving slider on an outer frame is achieved, and then control over the decoration garbage smashing degree through adjustment is achieved.

Owner:上海筱启新能源科技集团有限公司

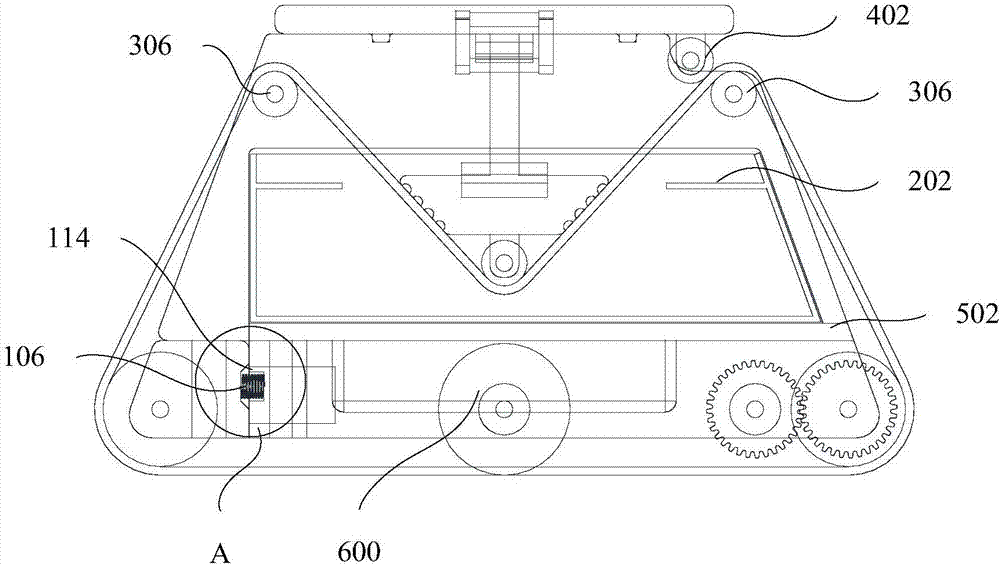

Folding geological radar detecting trolley

The invention discloses a folding geological radar detecting trolley which is composed of a vehicle frame system, a driving system, a folding system, a power supply box and an intensive equipment box.The driving system and the folding system are both mounted on the vehicle frame system, the power supply box is mounted on one side of the vehicle frame system, and the intensive equipment box is mounted on the folding system. The intensive equipment box can be placed in a vehicle frame, and the folding system is small in occupied space and is overturned flexibly; when a space is narrow, geological parameters of the narrow space are detected by deformation folding, the normal operation on various road conditions are achieved by hand pushing or folding deformation, and the work efficiency is ensured. A vehicle-mounted connecting front bumper is mounted at the front end of the vehicle frame to protect the vehicle frame and a vehicle-mounted radar detection device from impact. The intensiveequipment box is of a multi-layer structure, can accommodate a plurality of pieces of inspection equipment in intensive design, and can effectively protect key control devices such as display screensand control buttons.

Owner:北京市政路桥锐诚科技有限公司

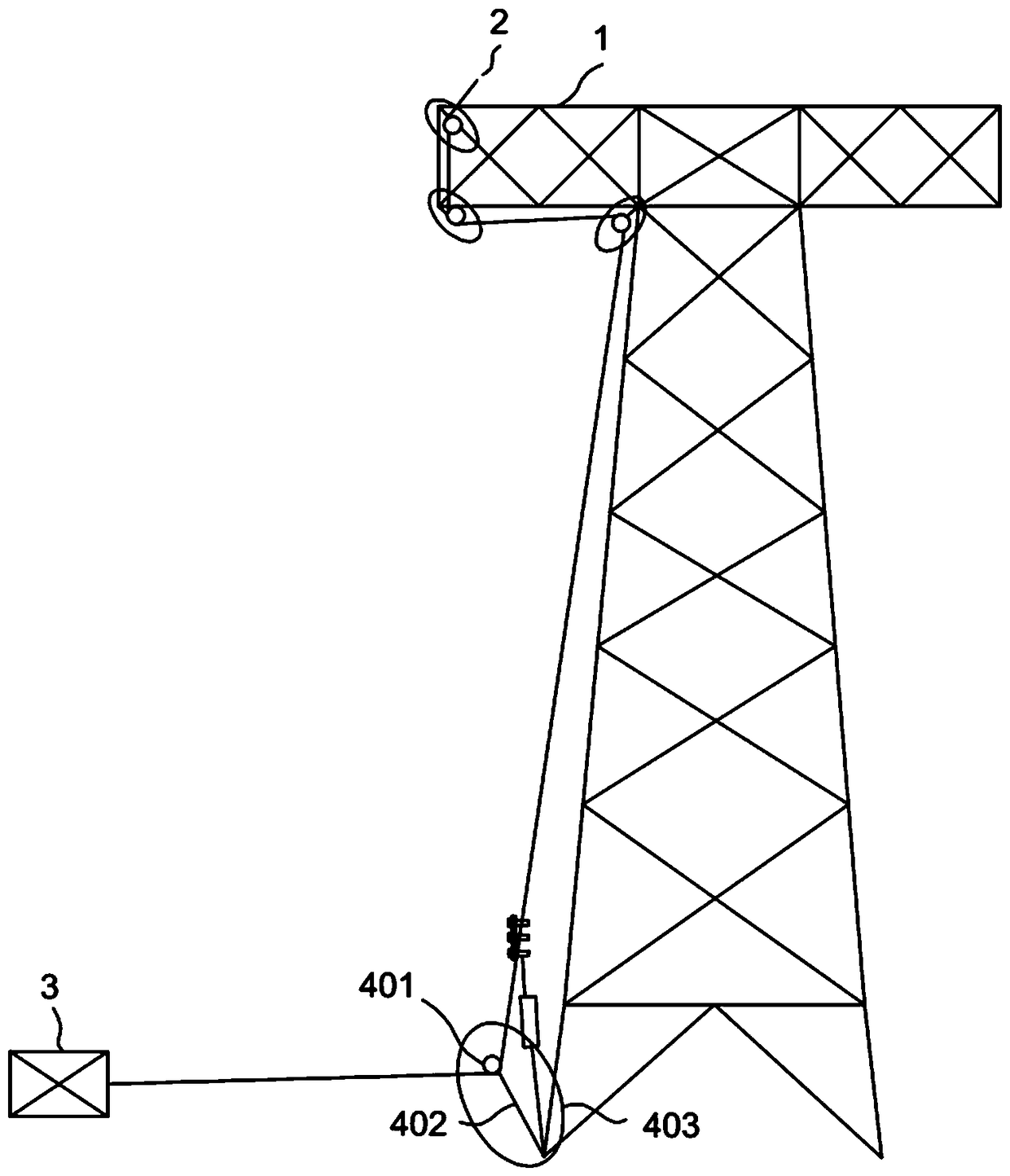

Net blocking system for crossing power line by using auxiliary cross arms and mounting and dismounting method of net blocking system

PendingCN108512115AEasy to install and disassembleSolve the problem that it is impossible to set up the reverse side landing cableApparatus for overhead lines/cablesStop timeEngineering

The invention discloses a net blocking system for crossing a power line by using auxiliary cross arms, and relates to the field of construction of power transmission line projects. An existing crossing mode is very hard to implement and difficult to perform. The net blocking system comprises the auxiliary cross arms arranged on iron towers on two sides of the power line, steel wire rope main cables, a main cable fixing device and a blocking net, wherein the auxiliary cross arms are symmetrically and detachably arranged on two sides of the iron towers; the steel wire rope main cables are detachably fixed on the auxiliary cross arms and the iron towers through the main cable fixing device; the blocking net is arranged on the steel wire rope main cables; the steel wire rope main cables and the blocking net are located above the power line. The net blocking system disclosed by the invention is convenient to mount and dismount; under the condition that the allowable maximum single lateral horizontal tension of the auxiliary cross arms can bear the tension of the blocking net, backside ground stay wires of the auxiliary cross arms and the iron towers can be canceled; the problem that thebackside ground stay wires cannot be erected due to mountain steepness is solved; by adoption of a high-altitude net blocking mode, the net blocking is easier and more convenient, and the time can besaved; the accompanying stop time of a power line below is shortened; and the overall construction cost of the net blocking system is reduced.

Owner:浙江省送变电工程有限公司 +4

Method for processing yarn-dyed four-side stretch fabric garment

ActiveCN109097974AClear organizationImprove cohesionLiquid/gas/vapor removalBiochemical treatment with enzymes/microorganismsYarnEngineering

The invention discloses a method for processing a yarn-dyed four-side stretch fabric garment. The method comprises the following steps: (a) alkali soaking; (b) biological enzyme polishing; (c) dyeing;(d) air drying; (e) sizing; (f) weaving; (g) desizing; (h) scouring and bleaching; (i) padding; (j) drying; (k) finishing; and (l) pre-shrinking. The method is simple in process, saves energy and reduces consumption and is easy to control, and an obtained fabric is soft and comfortable in touch and has a fine and soft gloss, good non-ironing property, anti-wrinkle performance and anti-pilling performance and dimensional stability.

Owner:盛泰智造集团股份有限公司

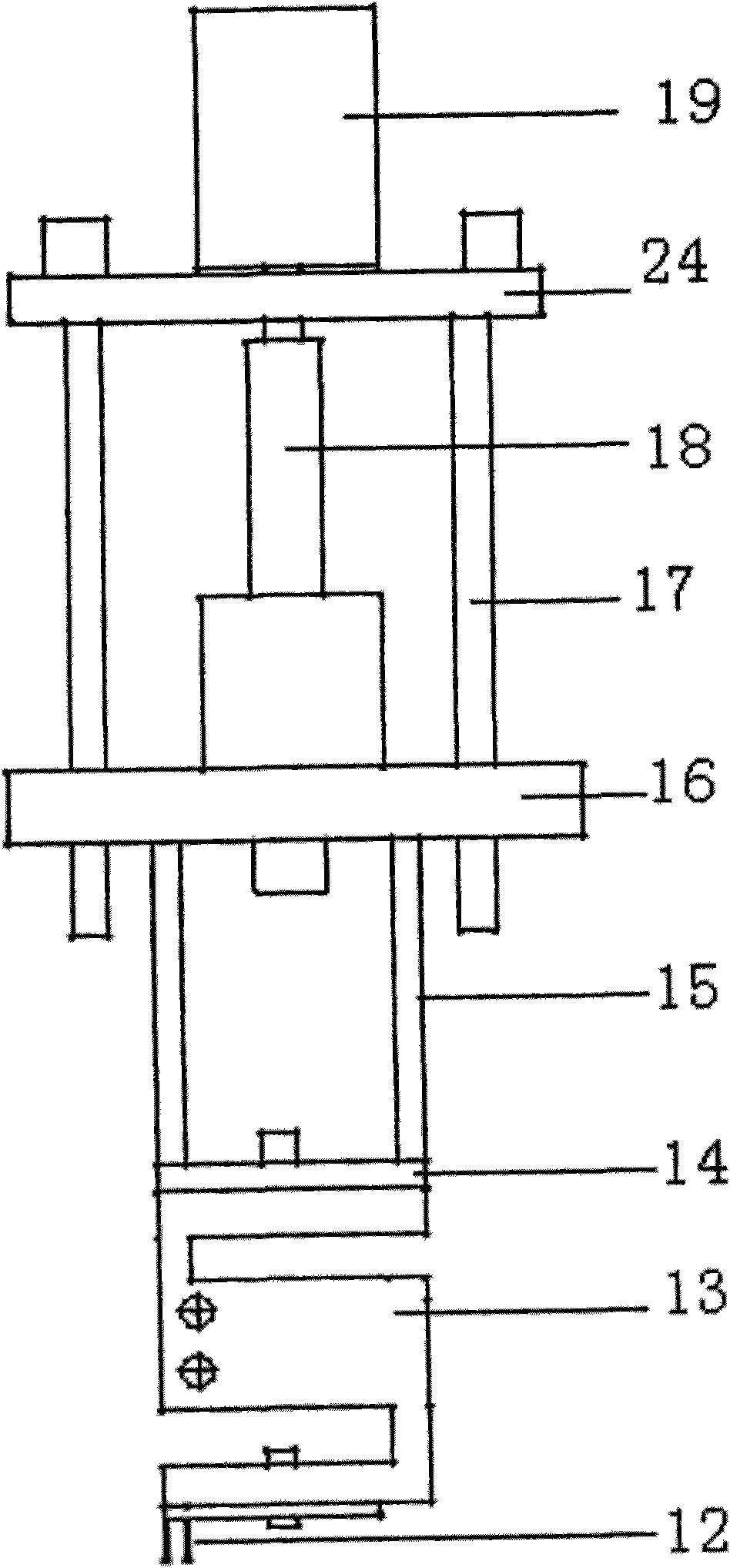

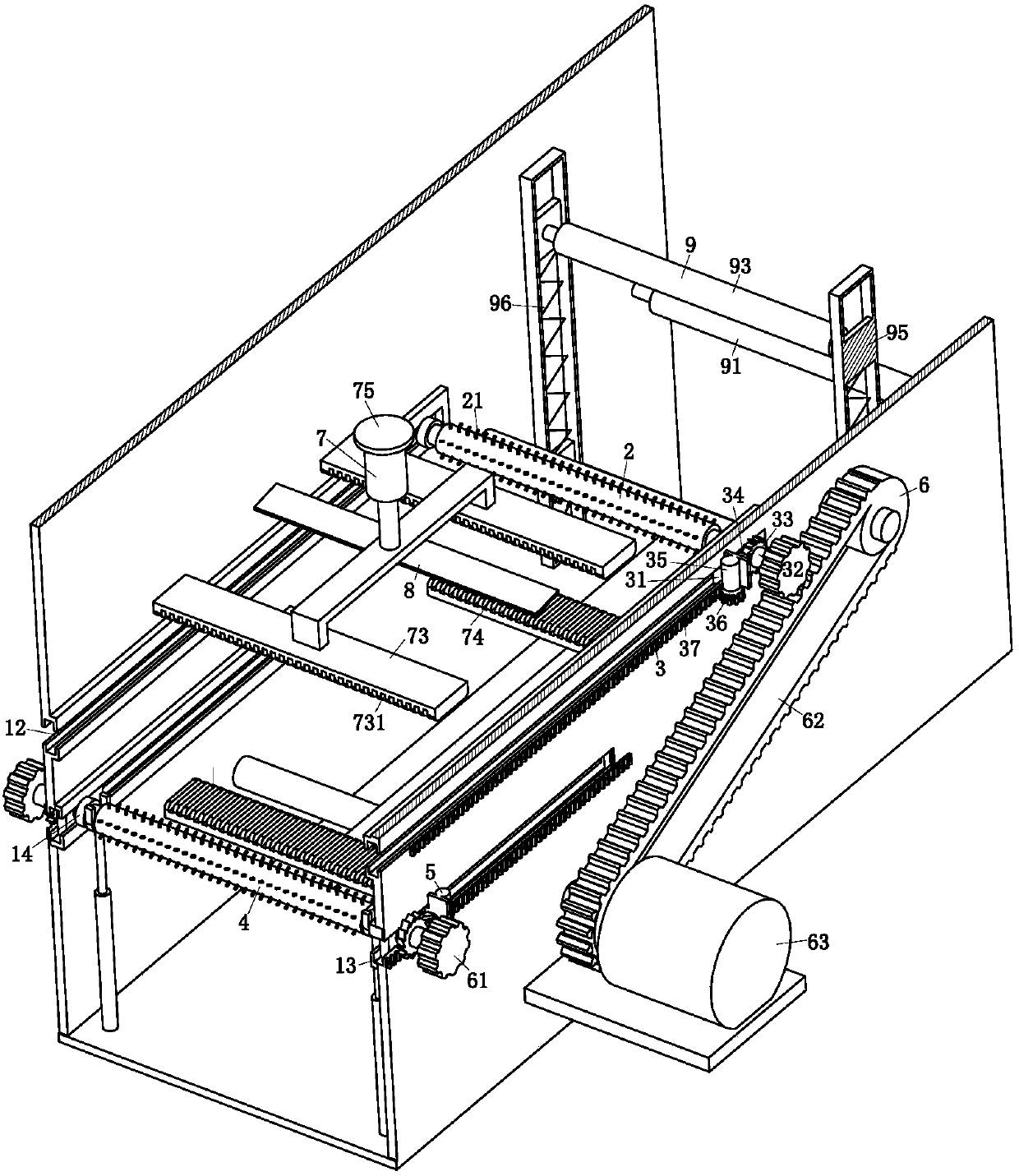

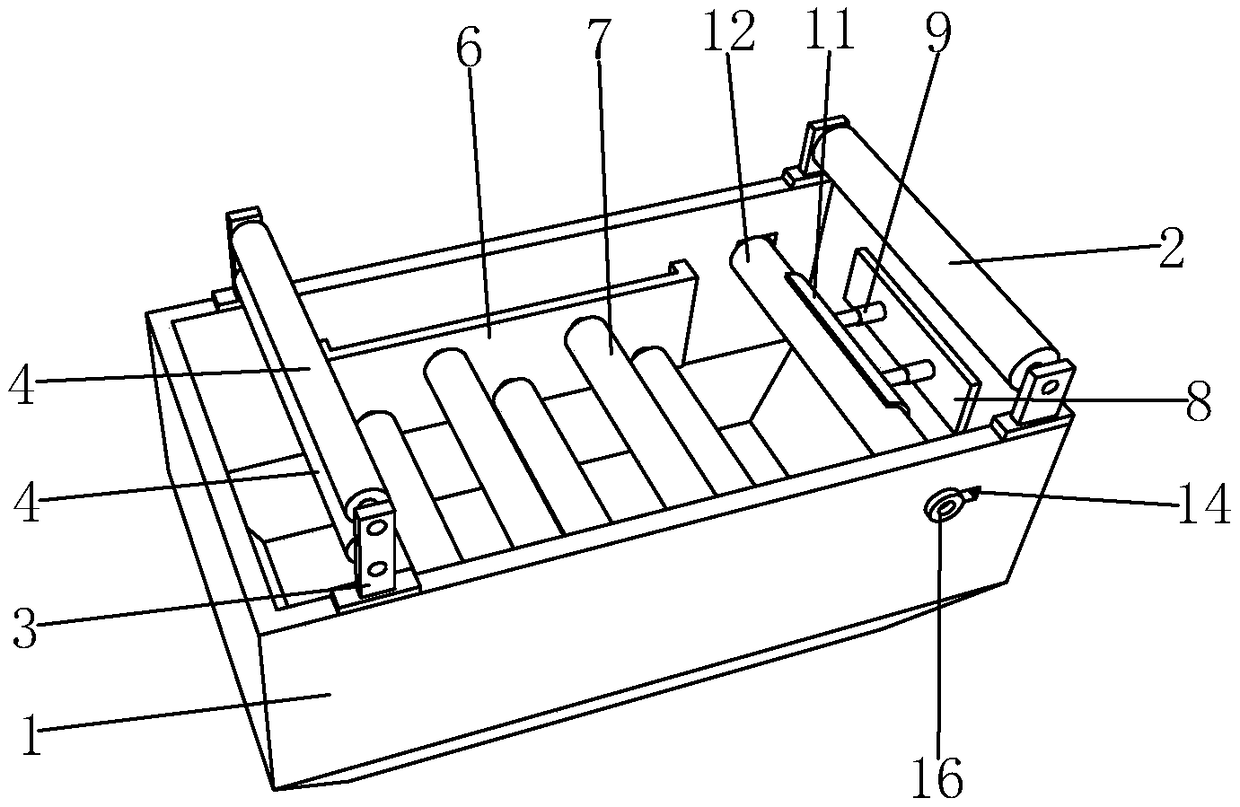

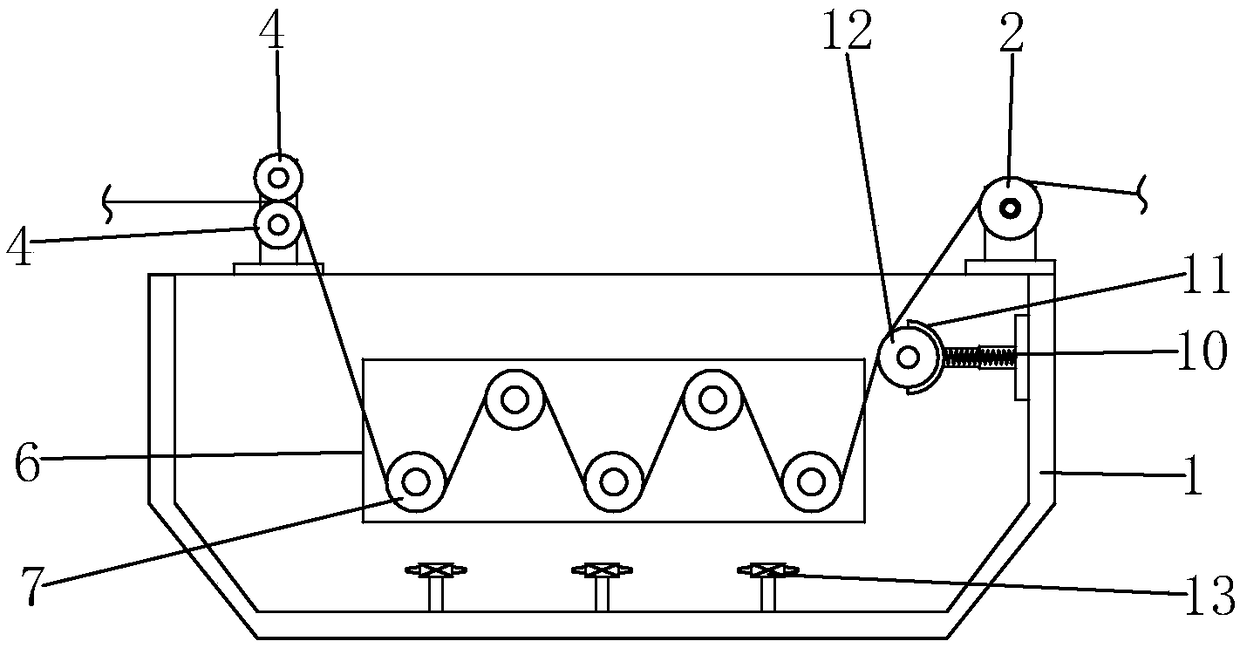

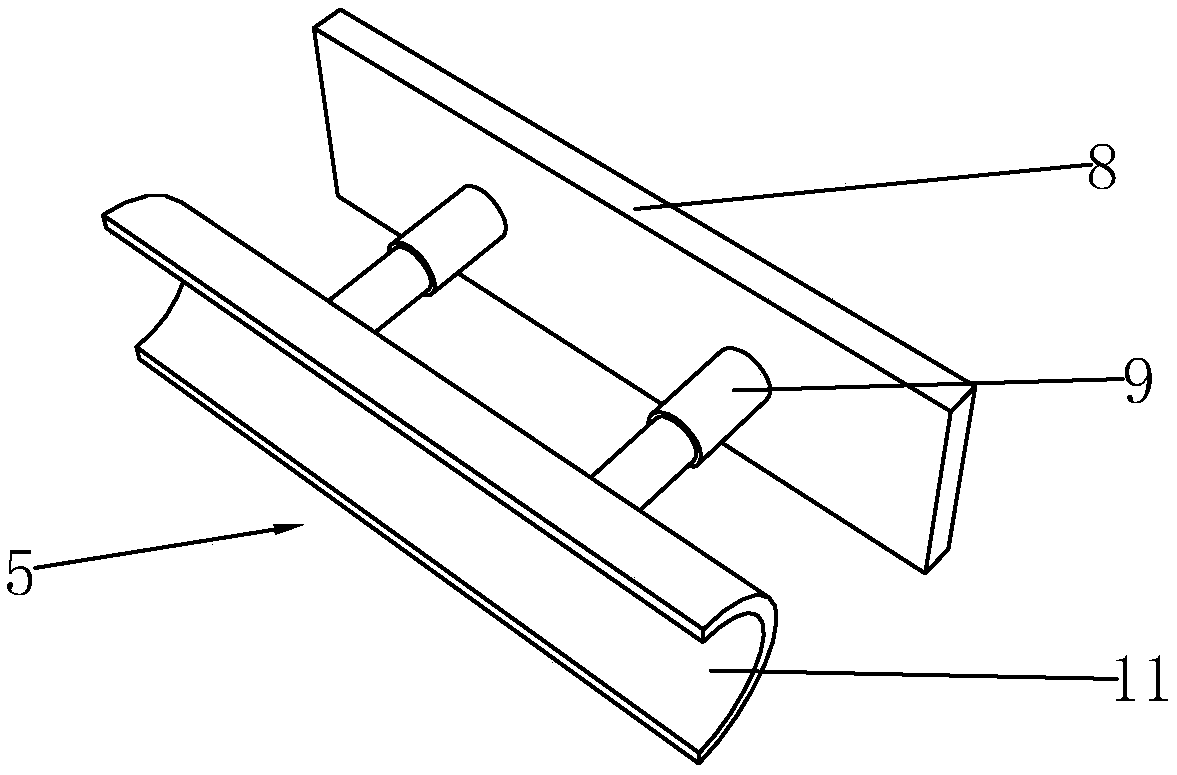

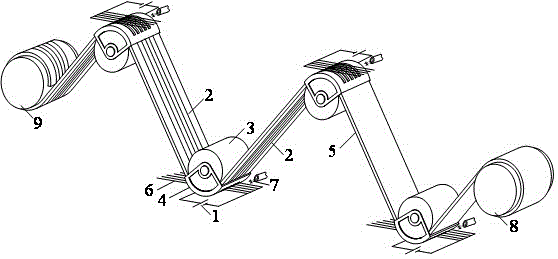

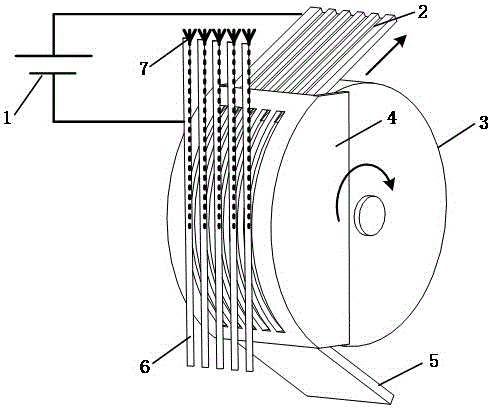

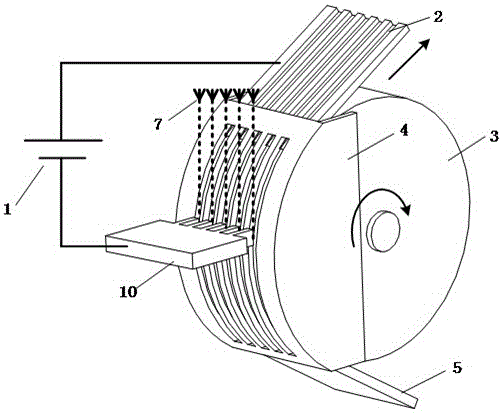

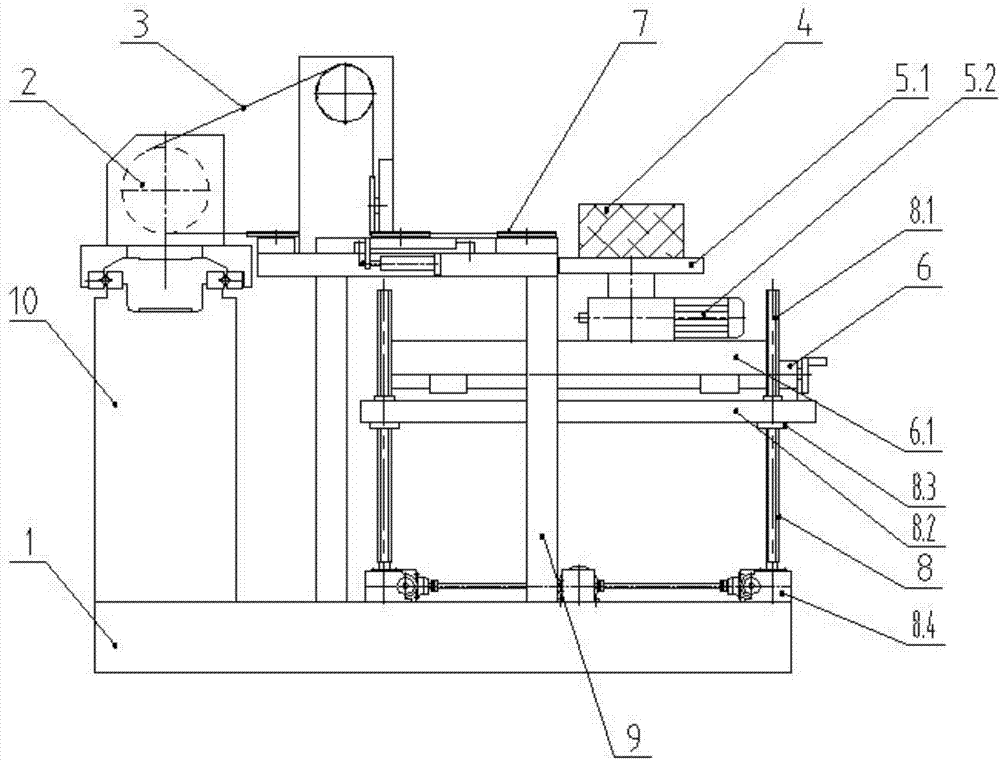

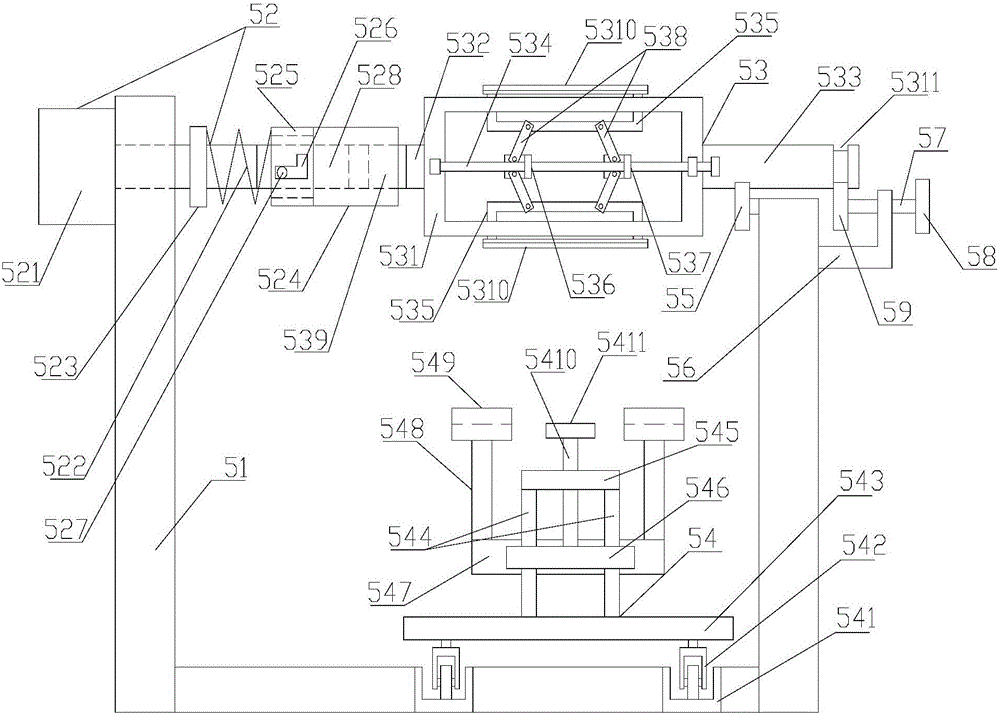

System and method for continuous electrolysis processing of microgroove groups of flexible metal sheet

ActiveCN106270841AImprove processing efficiencyRealize one-time processing and moldingElectrochemical machining apparatusElectricityElectrolysis

The invention relates to a system and a method for continuous electrolysis processing of microgroove groups of a flexible metal sheet, and belongs to the technical field of electrolysis processing. The system comprises a flexible metal sheet workpiece conveying system, an electrolysis processing tool electrode system, a processing power source, an electrolyte circulating system, and an electrolysis processing machine tool. The method comprises the following steps of during processing, firstly, clamping the flexible metal sheet, enabling the flexible metal sheet to penetrate between a plurality of support rollers and an arc-shaped masking plate, and enabling the inner and outer surfaces to tightly attach with the corresponding support rollers and the arc-shaped masking plate; according to the structure and size of each microgroove group, selecting a tool electrode, and completing the clamping; flushing electrolyte, feeding each tool electrode along the radial direction of the corresponding support roller, and processing a groove structure in the surface of the flexile metal sheet; processing to the specified depth, enabling a driving wheel to continuously rotate, and driving the flexible metal sheet to slowly slide along the tangential direction of each roller, so as to complete the continuous processing of the microgroove groups of the flexible metal sheet. The system and the method have the advantages that the tool electrodes can be synchronously performed with auxiliary movement, and the updating of electrolyte and the discharging of electrolysis products are promoted.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Varnished wire pulling and winding device

The invention discloses a varnished wire pulling and winding device which comprises a base, an installing frame and winding rolls. The installing frame is fixedly connected with the base and extends forwards. A rotating guide ring is arranged at the front end of the installing frame. A pulling guide mechanism is arranged on the inner side of the rotating guide ring. By arranging a first supportingplate, a second supporting plate and a bi-directional screw rod, the first supporting plate and the second supporting plate are arranged symmetrically, and the distance between the supporting platesis adjusted to adapt to installing of the winding rolls of different specifications; by arranging an elevating frame and a vertical screw rod drive mechanism, the winding rolls can be assembled and disassembled in a labor-saving manner; and by arranging the pulling guide mechanism comprising a tension mechanism and a fixing guide ring, tensioning and pulling winding of varnish wires can be achieved, uniform and closeness of the varnish wire winding rolls are ensured, and the winding roll quality is improved.

Owner:梧州市同润铜业有限公司

Inflatable paper winding shaft of high speed paper machine

The invention discloses an inflatable paper winding shaft of a high speed paper machine, and specifically provides a paper winding shaft which has the advantage of simple inflation structure and is convenient in use. The inflatable paper winding shaft comprises a hollow paper winding shaft body which is equipped with a plurality of through holes, wherein, each through hole is inlaid with an expansion block which moves along the shaft diameter direction; the shaft body is internally equipped with an inflatable airbag; and the end part of the inflatable airbag is equipped with an air nozzle which extends outside the shaft body. When in use, after the expansion block retracts into the shaft body, a paper core is easily sheathed on the paper winding shaft owing to smaller amount of gas in the inflatable airbag; the inflatable airbag is aerated via the air nozzle and then expands to extrude the expansion block so that the expansion block extends outside the through hole to be tightly connected with the paper core; and when the paper winding shaft rotates, the paper core is driven to rotate at the same time so as to realize winding. The inflatable paper winding shaft has a simple structure, and is flexible in operation and convenient in use.

Owner:天津天轻造纸机械有限公司

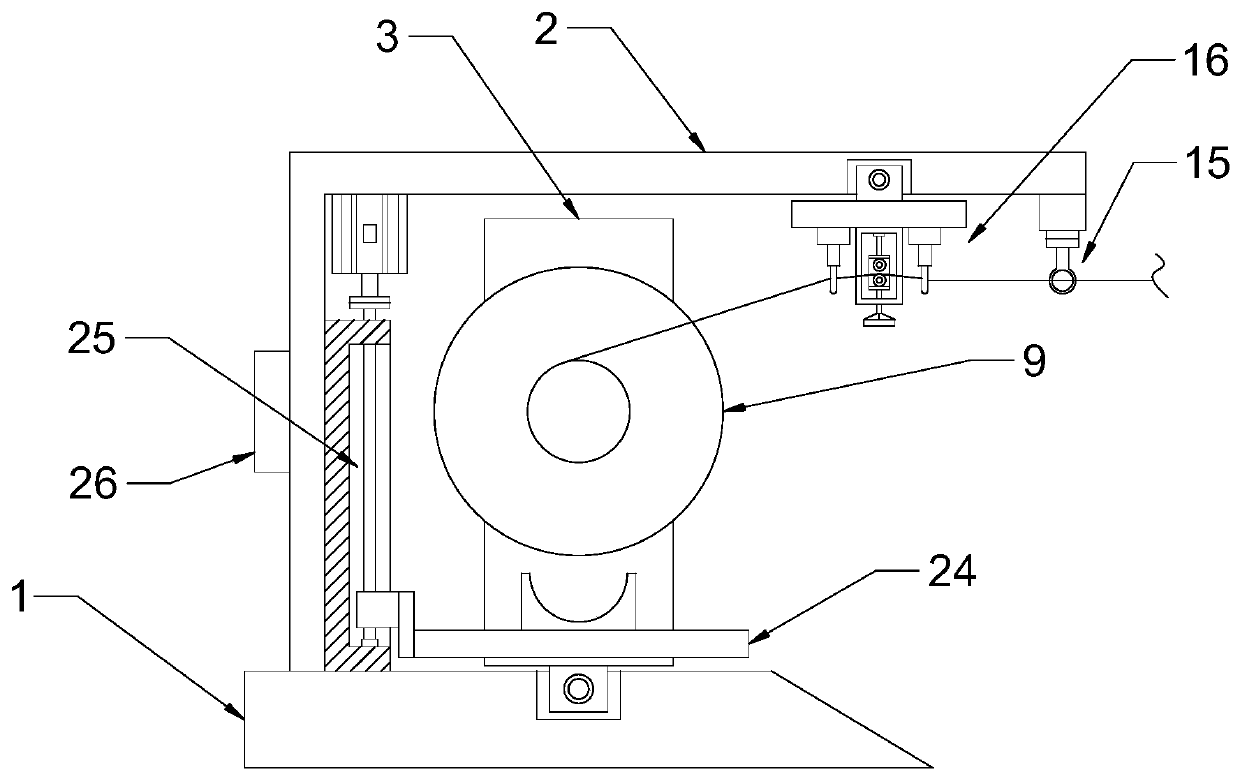

Cutting machine tool horizontally cutting sand line

InactiveCN106881773AEasy to installAchieve horizontal cuttingWorking accessoriesGrinding machinesMetallic materialsLarge size

The invention discloses a cutting machine tool horizontally cutting a sand line. The cutting machine tool comprises a base, a line storage cylinder, a line storage cylinder moving part, a sand line, a worktable assembly, a guide wheel assembly, a lifting mechanism and a guide wheel supporting frame. The central axis of the line storage cylinder is arranged levelly, and the line storage cylinder is driven by the line storage cylinder moving part to achieve transverse moving. The guide wheel assembly is arranged on the guide wheel supporting frame. The lifting mechanism is supported on the base and comprises a top plate arranged levelly above the base. The worktable assembly is supported on the upper end face of the top plate of the lifting mechanism and comprises a worktable which is located on the upper portion of the worktable assembly and can longitudinally move. The guide wheel assembly can achieve sand line horizontal cutting. Further improvement lies in that the lifting mechanism is an electric lifting mechanism. A rotating disc assembly is arranged on the upper end face of the worktable. A nylon or resin layer is arranged on the outer surface of a line storage cylinder body. Non-metallic materials with large sizes and high weights can be cut conveniently and quickly, the production efficiency is high, no stripe cutting can be achieved, and cutting precision is high.

Owner:泰州市江洲数控机床制造有限公司

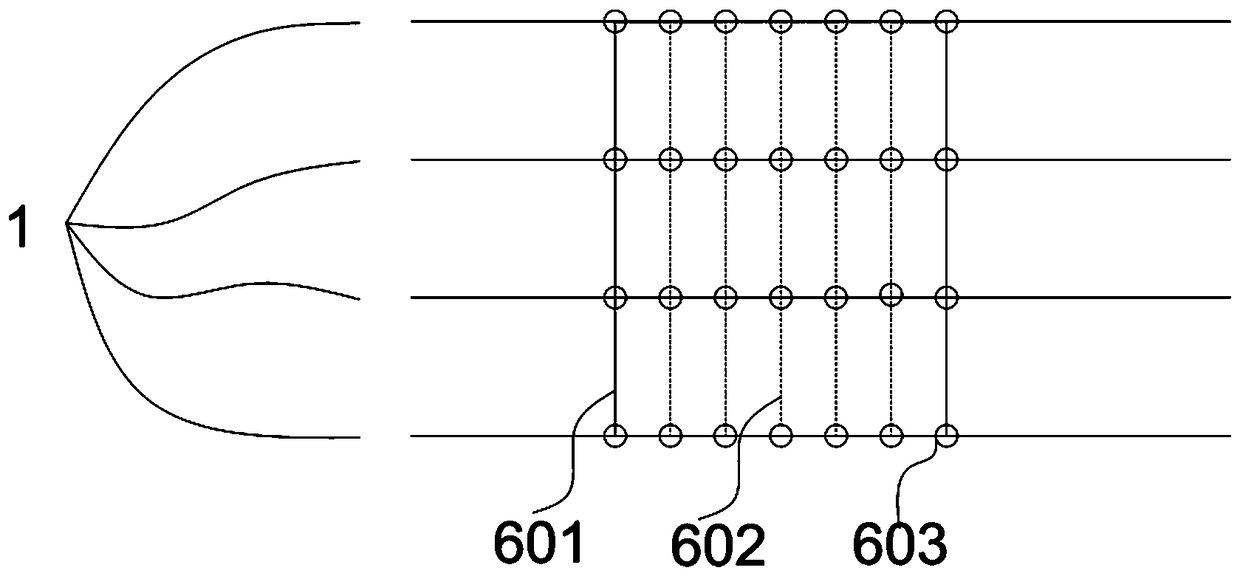

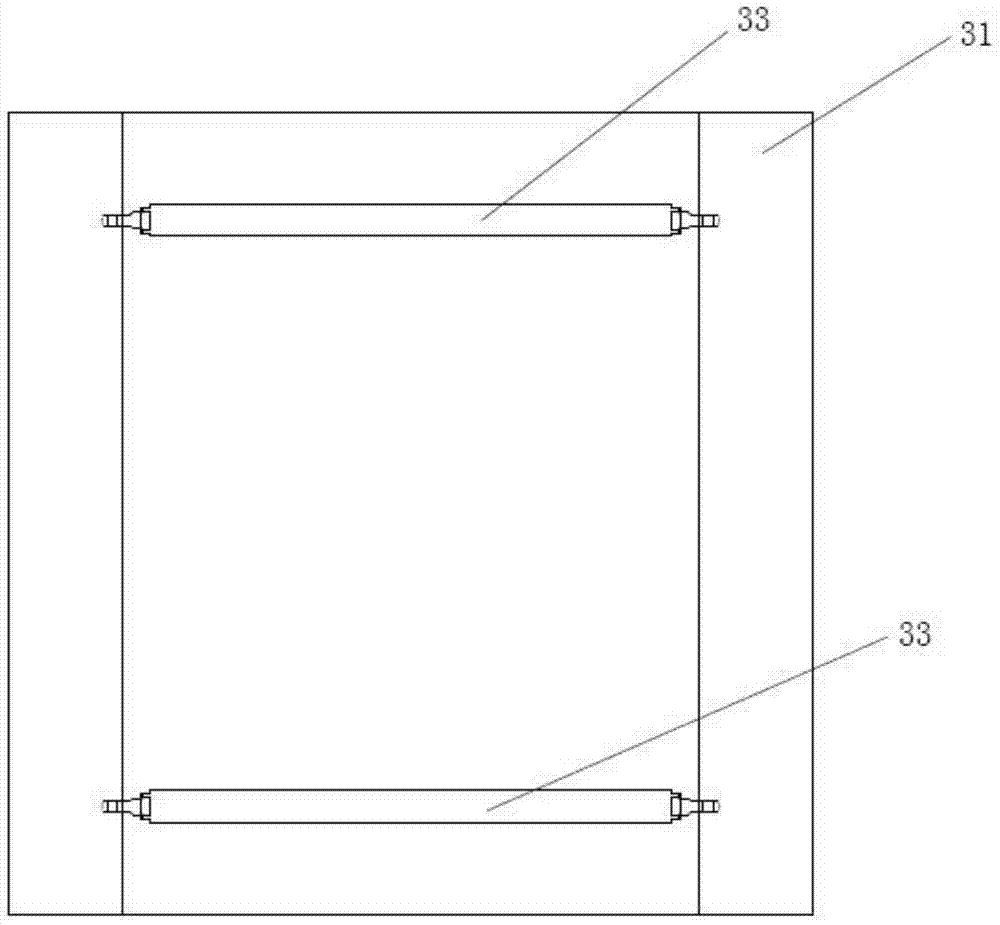

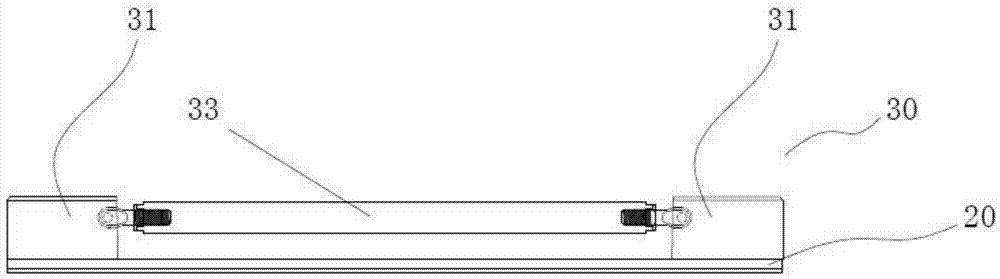

Bendable LED (light emitting diode) module, circular LED module and wavy LED module

ActiveCN104332114ANo gapsImprove the display effectElectric lightingLight fasteningsEngineeringLight-emitting diode

The invention discloses a bendable LED (light emitting diode) module, which comprises an elastic part layer (20) and an adjusting part (30), wherein a plurality of light emitting assemblies are arranged on the elastic part layer (20), the adjusting part (30) is arranged at the back part of the elastic part layer (20), and is tensioned or supported at the two sides of the elastic part layer (20), and the elastic part layer (20) is bent in an inner arc or outer arc way. The bendable LED module has the advantage that after the elastic part layer (20) is bent and deformed, a larger clearance or gap between the light emitting assemblies is avoided, so the display effect is better.

Owner:GLUX VISUAL EFFECTS TECH (SHENZHEN) CO LTD

Digital intelligent rope guiding device

The invention discloses a digital intelligent rope guiding device. The digital intelligent rope guiding device comprises a stepping motor, a shaft coupler, a lead screw, a guide wheel, a metering wheel, a rotary encoder and a machine body, wherein the stepping motor is connected with the lead screw through the shaft coupler; the machine body is arranged on the lead screw and can move leftwards and rightwards along with the lead screw; the guide wheel and the metering wheel are arranged on two top corners of the machine body in an axle center parallel mode; and the rotary encoder is connected with the metering wheel through the shaft coupler. The digital intelligent rope guiding device monitors the strength of a steel wire rope in real time, automatically lubricates the steel wire rope, improves the rope guiding reliability of the rope guiding device and avoids the disordered ropes during operation.

Owner:SUZHOU DAYI EQUIP TECH

Rolling device for lining cloth production

InactiveCN105731128AAchieve tensionImprove fixed reliabilityWebs handlingAgricultural engineeringUltimate tensile strength

Owner:长兴科恩德服装材料有限公司

Adjustable adaptive traveling mechanism in pipeline

The invention provides an adjustable adaptive traveling mechanism in a pipeline, which can be applied to various pipeline projects. In the traveling mechanism, a chain can be tensioned by arranging a chain tensioning mechanism; parallel motion of parallel brackets is realized through an adjusting mechanism; the traveling mechanism has the function that the distance between the two parallel brackets can be automatically adjusted according to looseness of soil, so that the chain is contacted with the soil all the time; and a chain with an accessory ensures that the chain is effectively contacted with the soil during movement to produce sufficient forward thrust.

Owner:JIANGSU SUNLIKE EQUIP GRP CO LTD +1

Flexible graphite anti-thunder grounding wire conveying device

InactiveCN109205228AAchieve tensionRealize up and down adjustmentConveyorsApparatus for feeding conductors/cablesGraphiteMechanical engineering

The invention discloses a flexible graphite anti-thunder grounding wire conveying device and relates to the technical field of flexible graphite anti-thunder grounding wire processing. The flexible graphite anti-thunder grounding wire conveying device comprises a left base, a right base, a supporting column I, a supporting column II, a screw rod, a first cross rod, a hand wheel, a second cross rod, a nut, a first rotary shaft, a conveyor belt, a second rotary shaft, a supporting rod I, a supporting rod II and guide rolls. The flexible graphite anti-thunder grounding wire conveying device is simple in structure, fast and convenient to operate, capable of adjusting the conveying distance through a driving device, also capable of tensioning the conveyor belt, capable of implementing up-down adjustment through the hand wheel and suitable for meeting different requirements for conveying graphite grounding wires. Meanwhile, when the conveying device is not in use, the right base can be driven to slide to the left base through the driving device. The flexible graphite anti-thunder grounding wire conveying device is small in occupied space and convenient to store and maintain.

Owner:ANHUI HUAXI ELECTRIC POWER TECH CO LTD

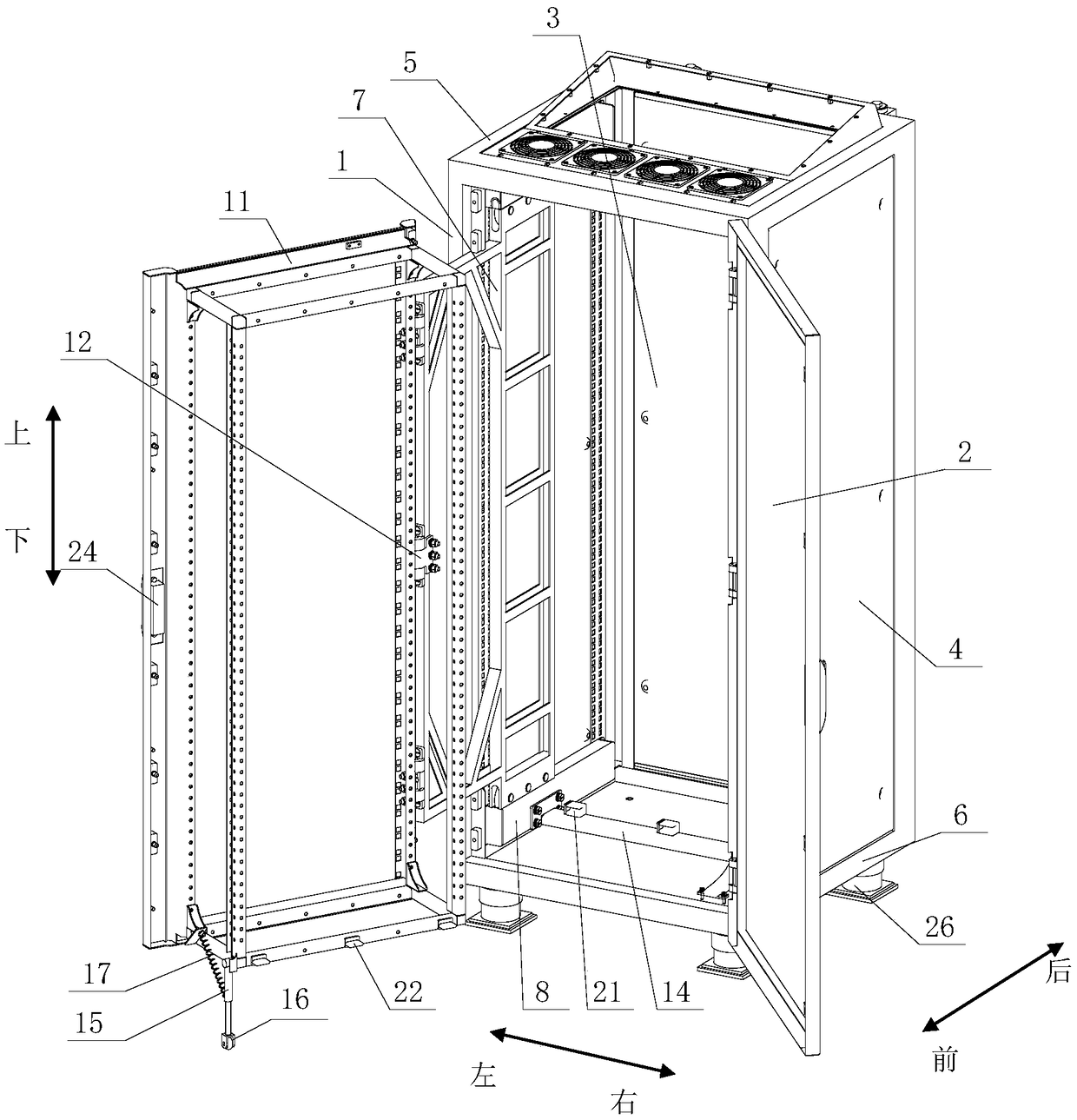

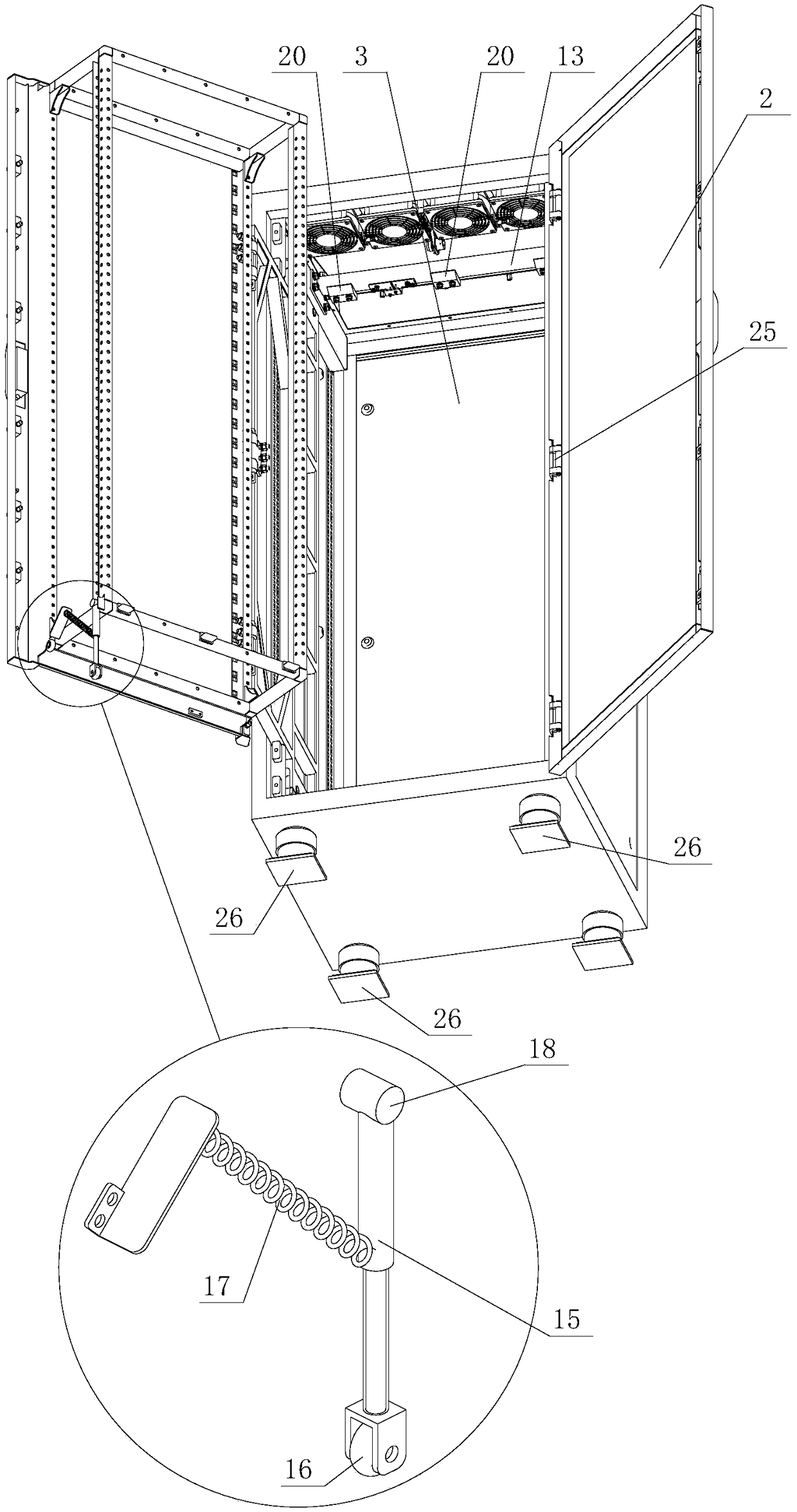

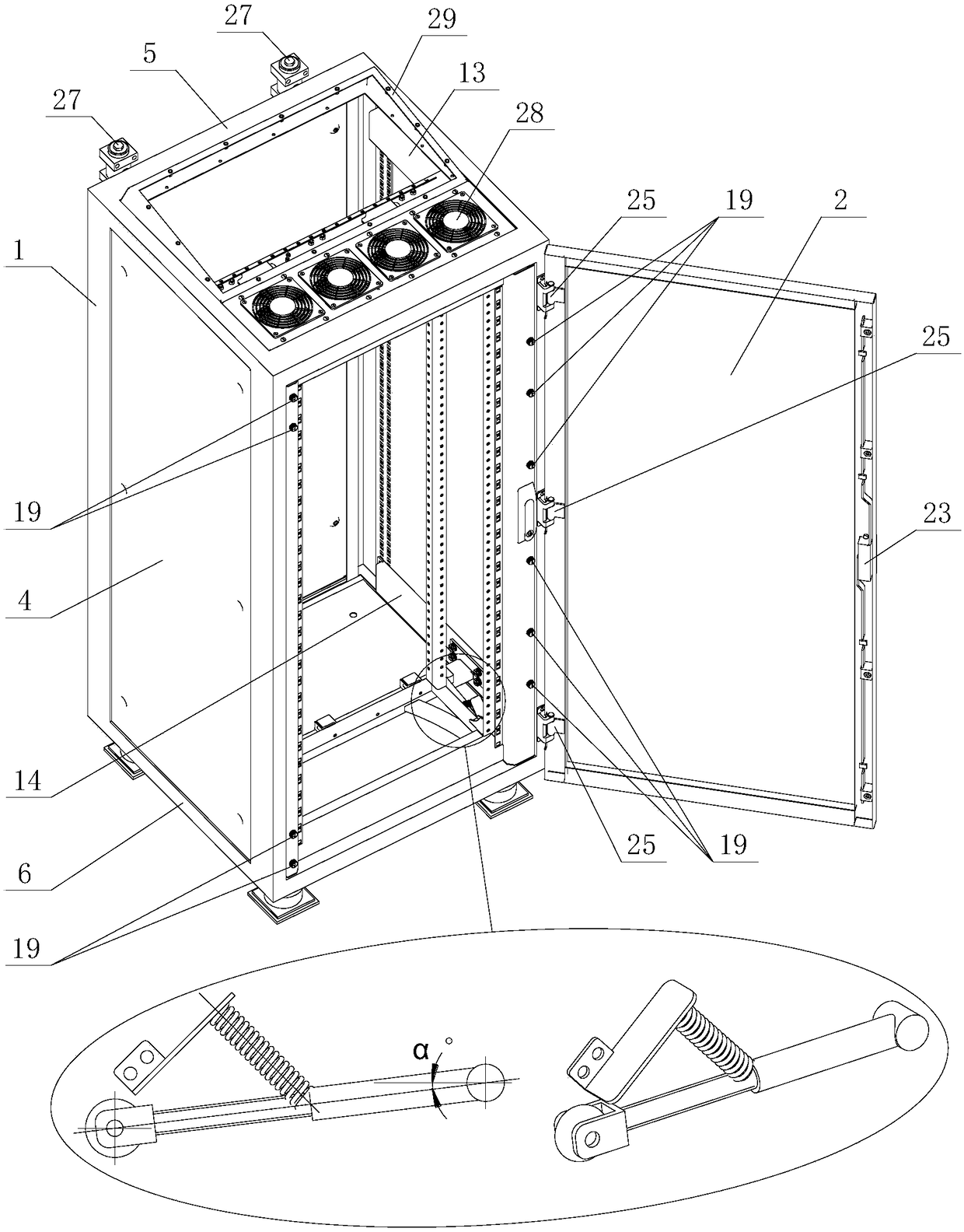

Cradle cabinet for pull-type radar electronic device

The invention relates to a cradle cabinet for a pull-type radar electronic device, comprising: a cabinet body, a sliding frame assembly, track beams and a cradle, wherein the front side of the cabinetbody is provided with an accommodating cavity with an open end, the upper and lower ends of the sliding frame assembly are respectively slidably connected with track beams, the track beams are fixedly connected to the vertical side wall of the accommodating cavity, and the cradle is hinged with the front end of the sliding frame assembly. When the sliding frame assembly slides along the track beams, the cradle may be pumped back and forth by pulling in the cabinet body and rotate around the front end of the sliding frame assembly. The invention solves the contradiction between the large cradle depth and the smaller cabinet width of the conventional rotating shaft fixed cradle cabinet, and reduces the square space occupied by the overall cabinet. The cradle motion form of the pull-type andhinge-type rotation makes the overall structure compact with no maintaining dead angle, has strong system openness, and greatly utilizes the internal space of the cabinet.

Owner:BEIJING INST OF RADIO MEASUREMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com