Rolling device for lining cloth production

A technology of winding device and interlining, which is applied in the direction of winding strips, transportation and packaging, and thin material processing, can solve the problems of high labor intensity, reduced work efficiency, inconvenient fixing and disassembly, etc. High fixing reliability and manpower saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

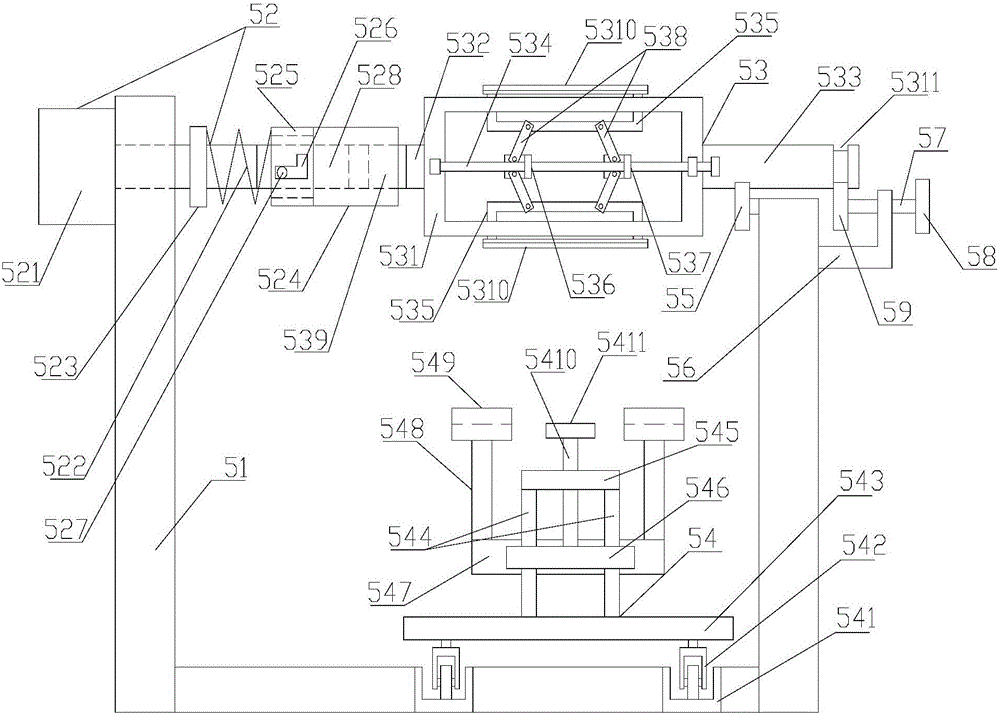

[0015] refer to figure 1 , a winding device for interlining production in the present invention, including a frame body 51, a transmission mechanism 52, a reel 53 and a blanking mechanism 54, a transmission mechanism 52 is provided on the front column of the frame body 51, and one end of the reel 53 It is detachably connected with the transmission mechanism 52, and the other end rests on the rear column of the frame body 51. A blanking mechanism 54 is provided between the front column and the rear column of the frame body 51. The transmission mechanism 52 includes a motor 521, a spring 522, blocking body 523, sleeve body 524, locking body 525, card slot 526 and card body 527, the rear end of the rotating shaft of the motor 521 is provided with an insertion part 528, and the insertion part 528 is sleeved with Sleeve body 524, the front end of described sleeve body 524 is provided with the locking body 525 that rotatably connects, and the rotating shaft of described motor 521 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com