Adjustable adaptive traveling mechanism in pipeline

A walking mechanism and self-adaptive technology, applied in the direction of pipe components, mechanical equipment, pipes/pipe joints/pipe fittings, etc., can solve problems such as difficulty in adapting to the complex environment of pipeline engineering and poor self-adaptive ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] This embodiment is a traveling mechanism used in underground micro-pipeline excavation construction. Driven by a motor, the traveling mechanism moves forward to push the front cutter head to carry out pipeline excavation. The diameter of the pipeline is 20cm, and the pipeline laying environment is a soil environment.

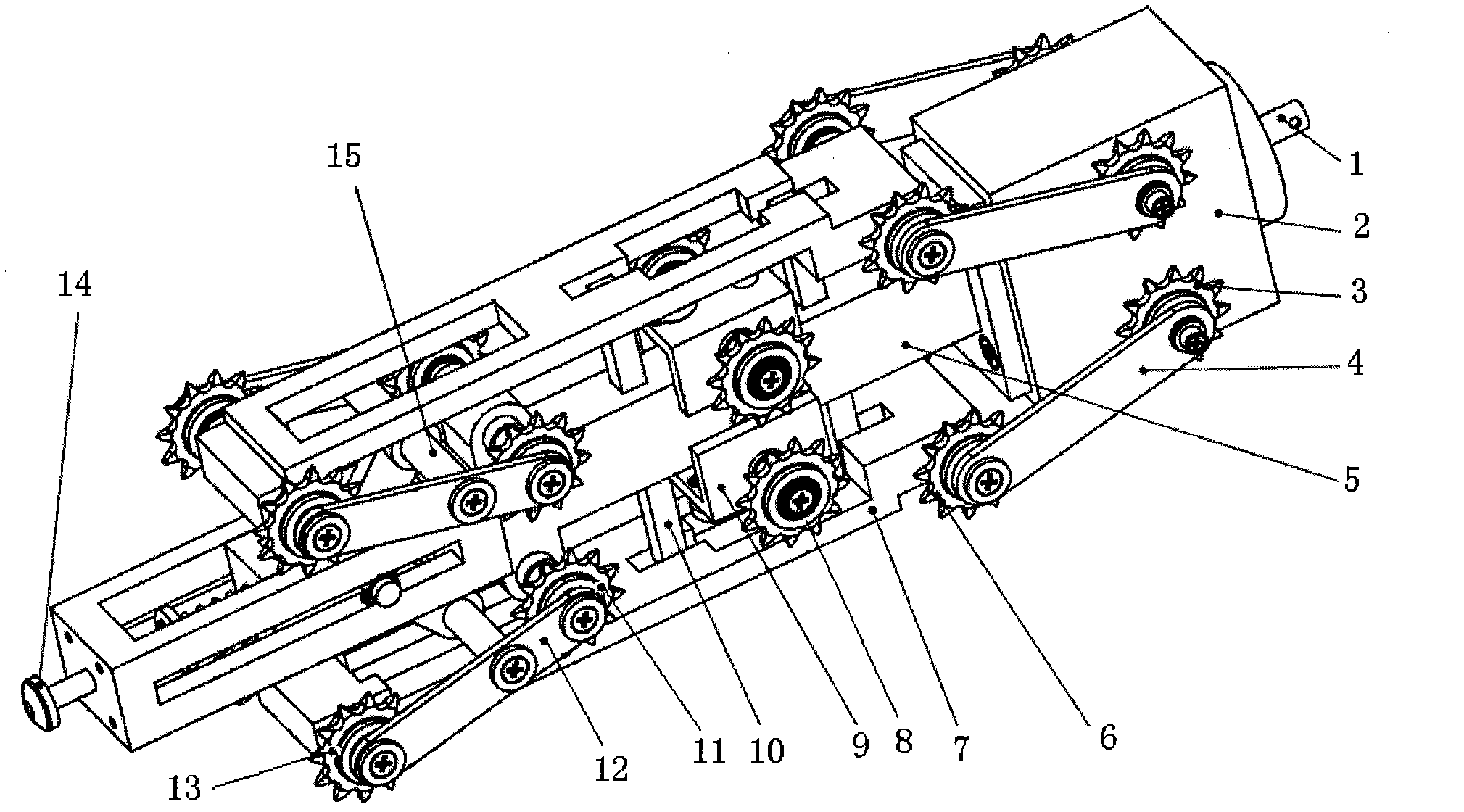

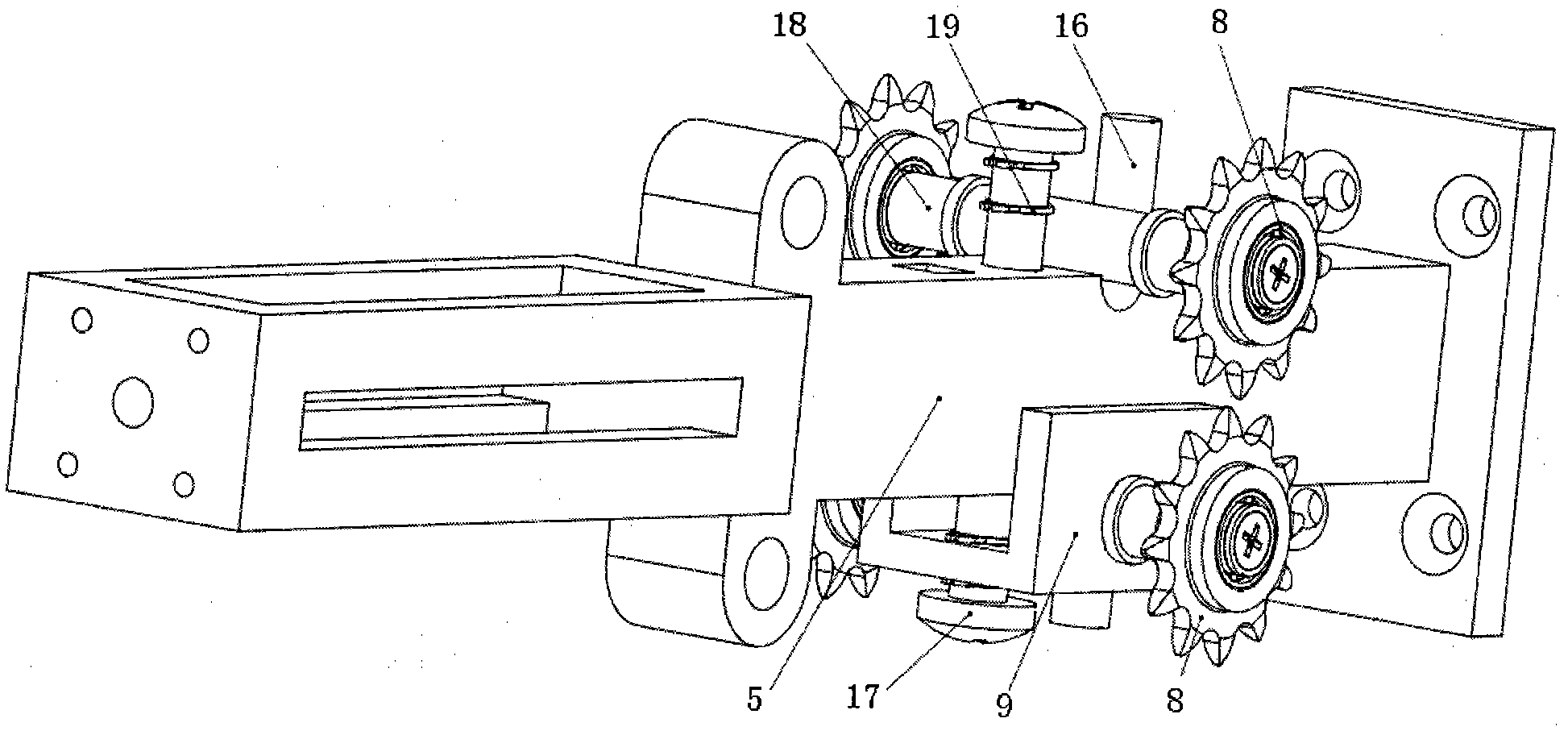

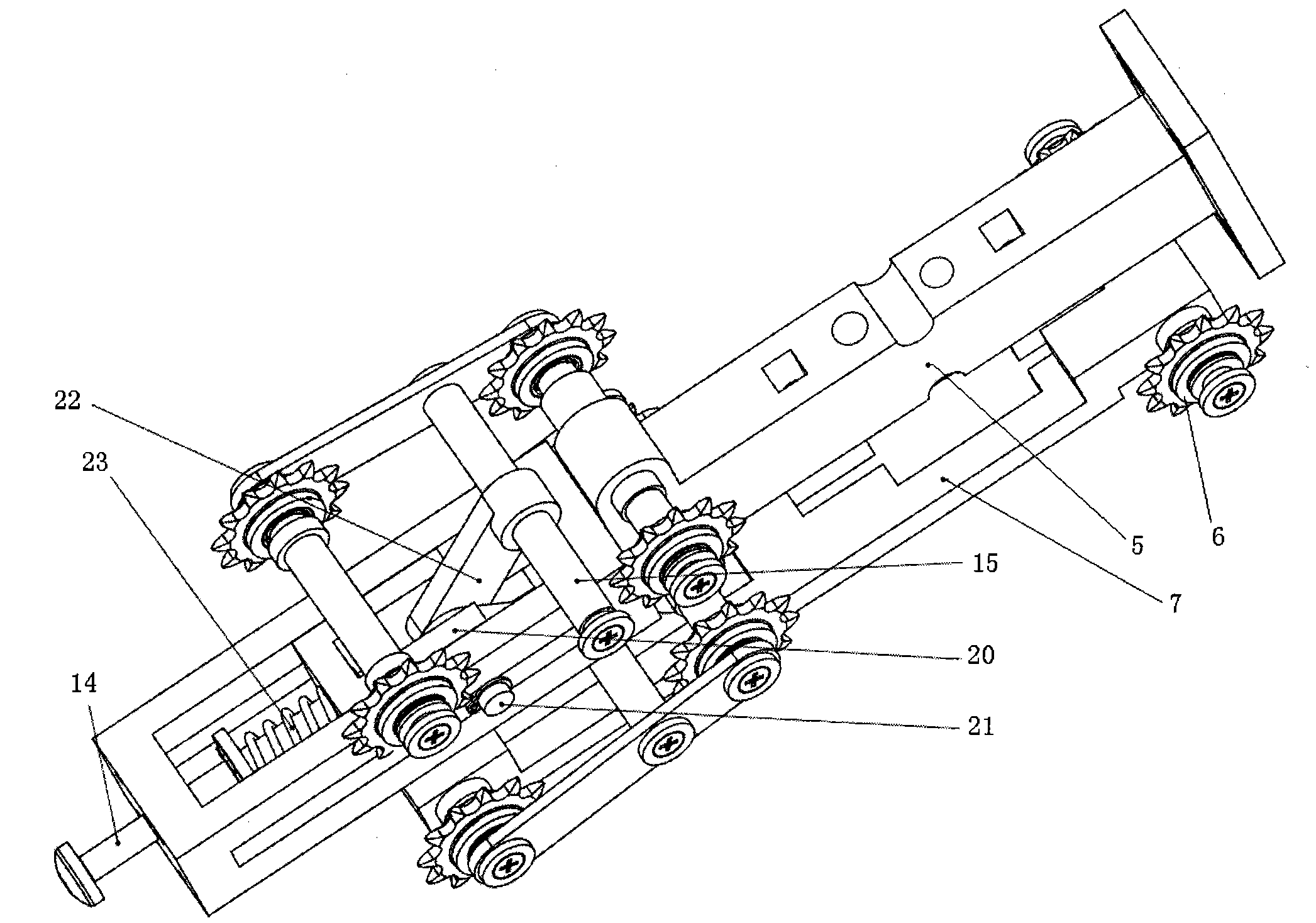

[0026] Refer to attached figure 1 , this embodiment includes a power mechanism, a support bracket 5 and a transmission adjustment mechanism.

[0027] The power mechanism includes RV reducer 2 and 4 driving sprockets 3. The RV reducer 2 is connected to the external power input shaft 1. The power input shaft 1 is the power input of the external motor. The 4 driving sprockets 3 are respectively fixed on the RV reducer 2 The two ends of the two power output shafts are connected with the key of the power output shaft, the power output shaft is perpendicular to the power input shaft, and the two power output shafts are symmetrically placed one up and one down, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com