Flexible graphite anti-thunder grounding wire conveying device

A lightning protection grounding, flexible graphite technology, applied in conductor/cable supply devices, conveyors, conveyor objects, etc., can solve the problems of waste of space, unable to adjust the transmission distance self-sufficiently, occupying a large space, etc., to achieve convenient operation and structure. Simple, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

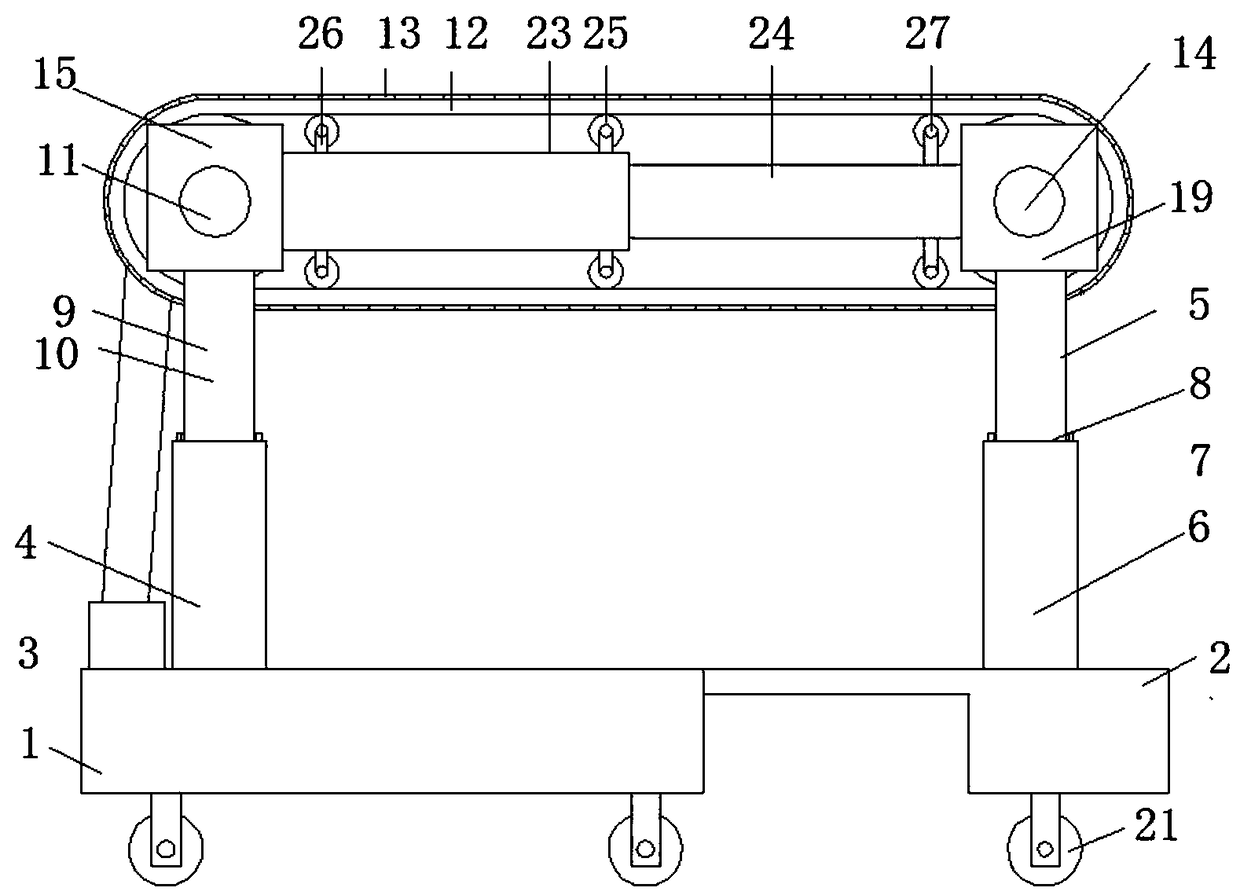

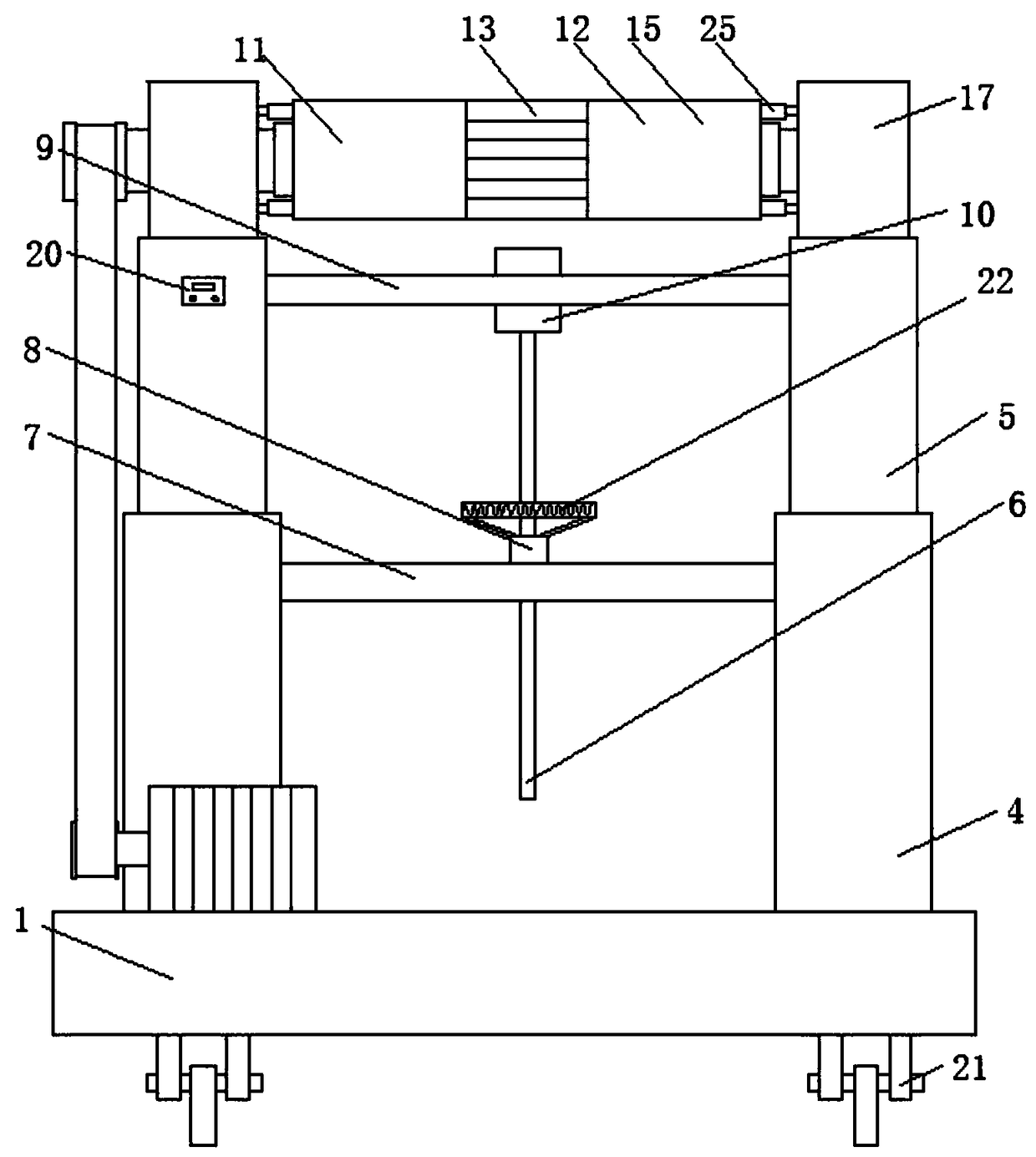

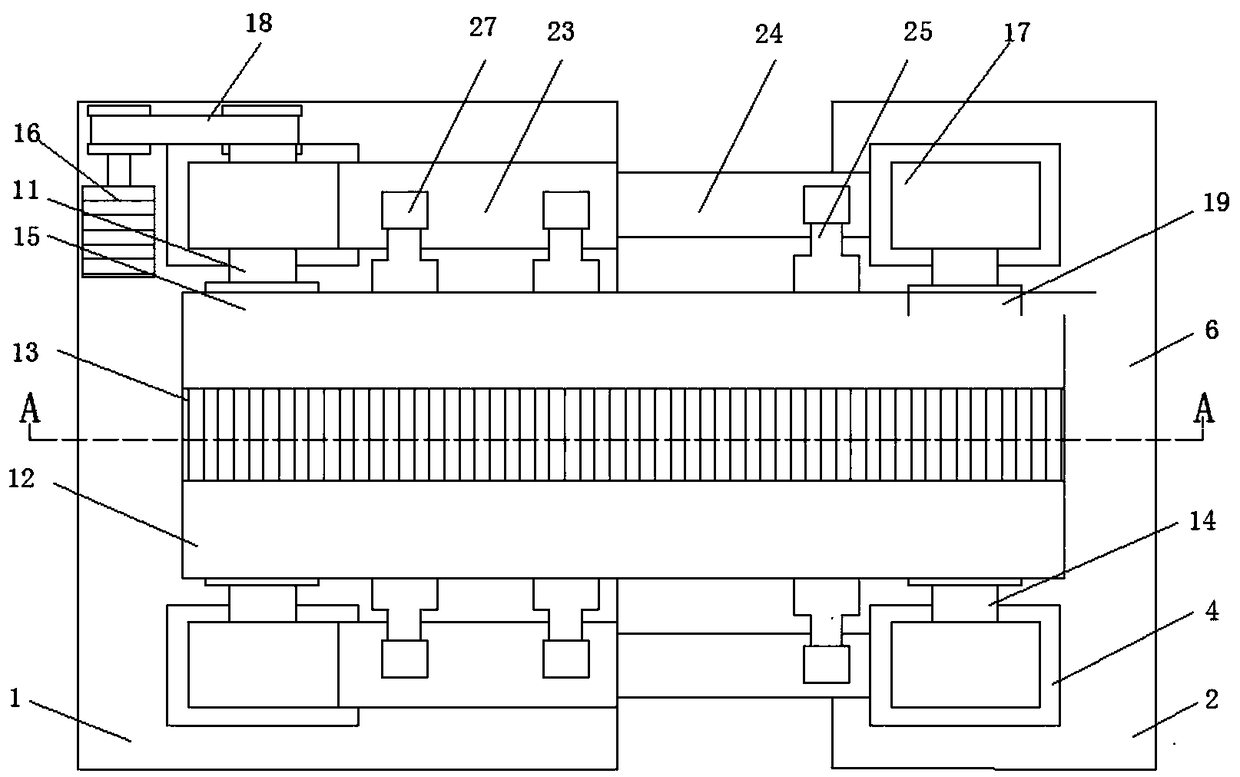

[0020] Such as Figure 1 to Figure 4 As shown, a flexible graphite lightning protection ground wire feeding device includes a left base 1, a right base 2, a support column 4, a support column 2 5, a screw 6, a first cross bar 7, a hand wheel 8, a second cross bar Rod 9, nut 10, first rotating shaft 11, conveyor belt 12, second rotating shaft 14, support rod one 23, support rod two 24 and guide roller 25, the left side of described left base 1 is fixedly equipped with motor 16 and left base 1 is provided with a chute one, and a driving device is installed in the chute one, and the driving device includes a servo motor 3 and a lead screw 31, and a protrusion 32 is provided on the right base 2, and the protrusion 32 is slidably connected to the A threaded hole is provided in the chute 1 and in the protrusion 32, and the threaded hole is connected to the lead screw 31. One end of the lead screw 31 is rotatably connected to one end of the chute 1, and the other end of the lead scre...

Embodiment 2

[0024] Such as Figure 1 to Figure 4As shown, a flexible graphite lightning protection ground wire feeding device includes a left base 1, a right base 2, a support column 4, a support column 2 5, a screw 6, a first cross bar 7, a hand wheel 8, a second cross bar Rod 9, nut 10, first rotating shaft 11, conveyor belt 12, second rotating shaft 14, support rod one 23, support rod two 24 and guide roller 25, the left side of described left base 1 is fixedly equipped with motor 16 and left base 1 is provided with a chute one, and a driving device is installed in the chute one, and the driving device includes a servo motor 3 and a lead screw 31, and a protrusion 32 is provided on the right base 2, and the protrusion 32 is slidably connected to the A threaded hole is provided in the chute 1 and in the protrusion 32, and the threaded hole is connected to the lead screw 31. One end of the lead screw 31 is rotatably connected to one end of the chute 1, and the other end of the lead screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com