Patents

Literature

5073results about "Supporting frames" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

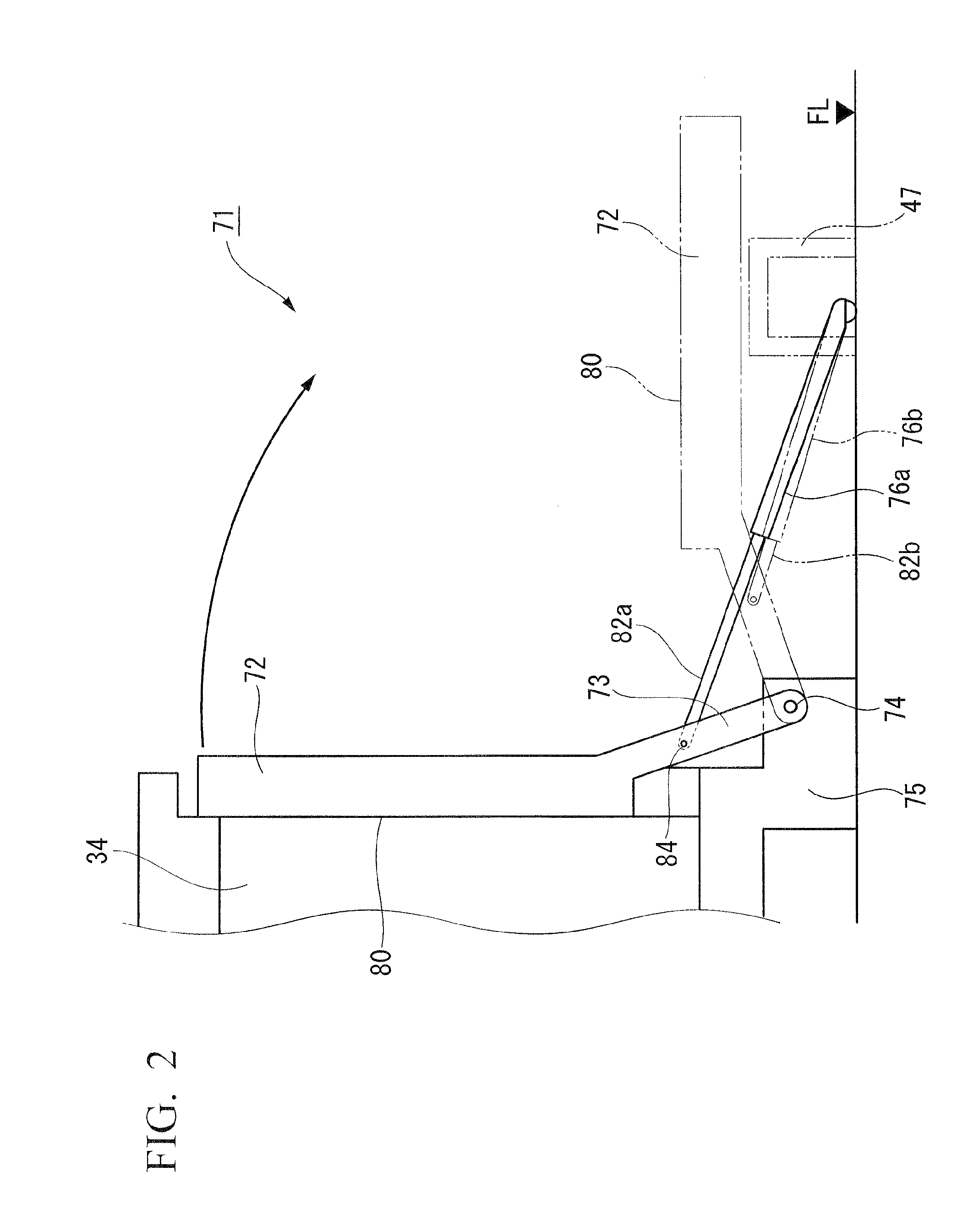

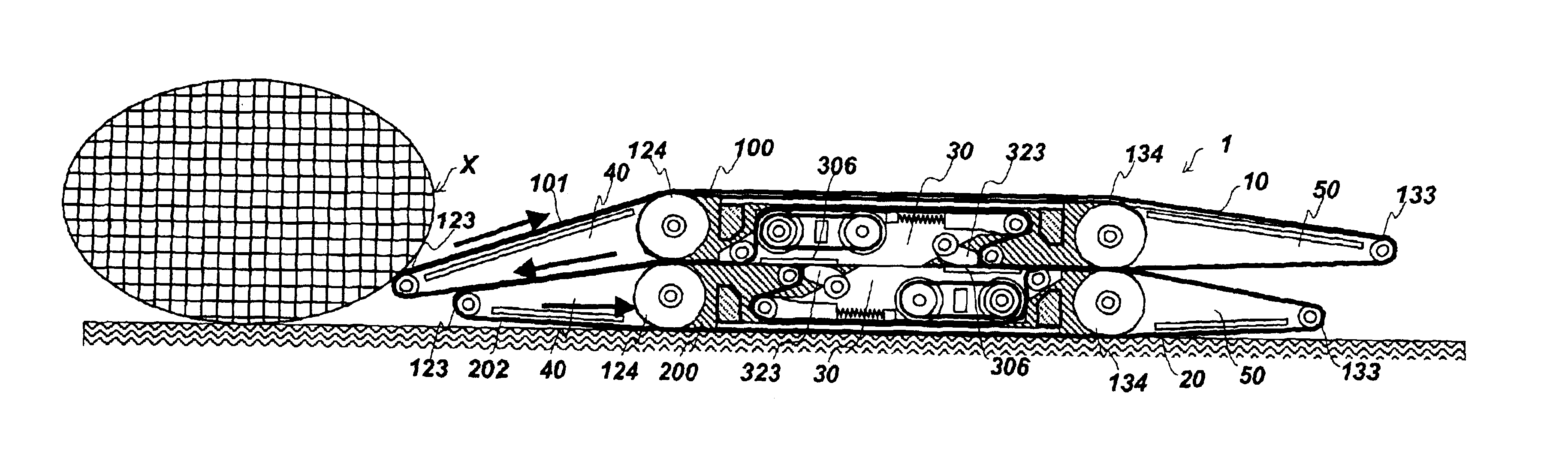

Conveyor and deposition apparatus, and maintenance method thereof

ActiveUS20100126415A1Installation area of the deposition apparatus small and narrowLiquid surface applicatorsConveyorsTransfer systemEngineering

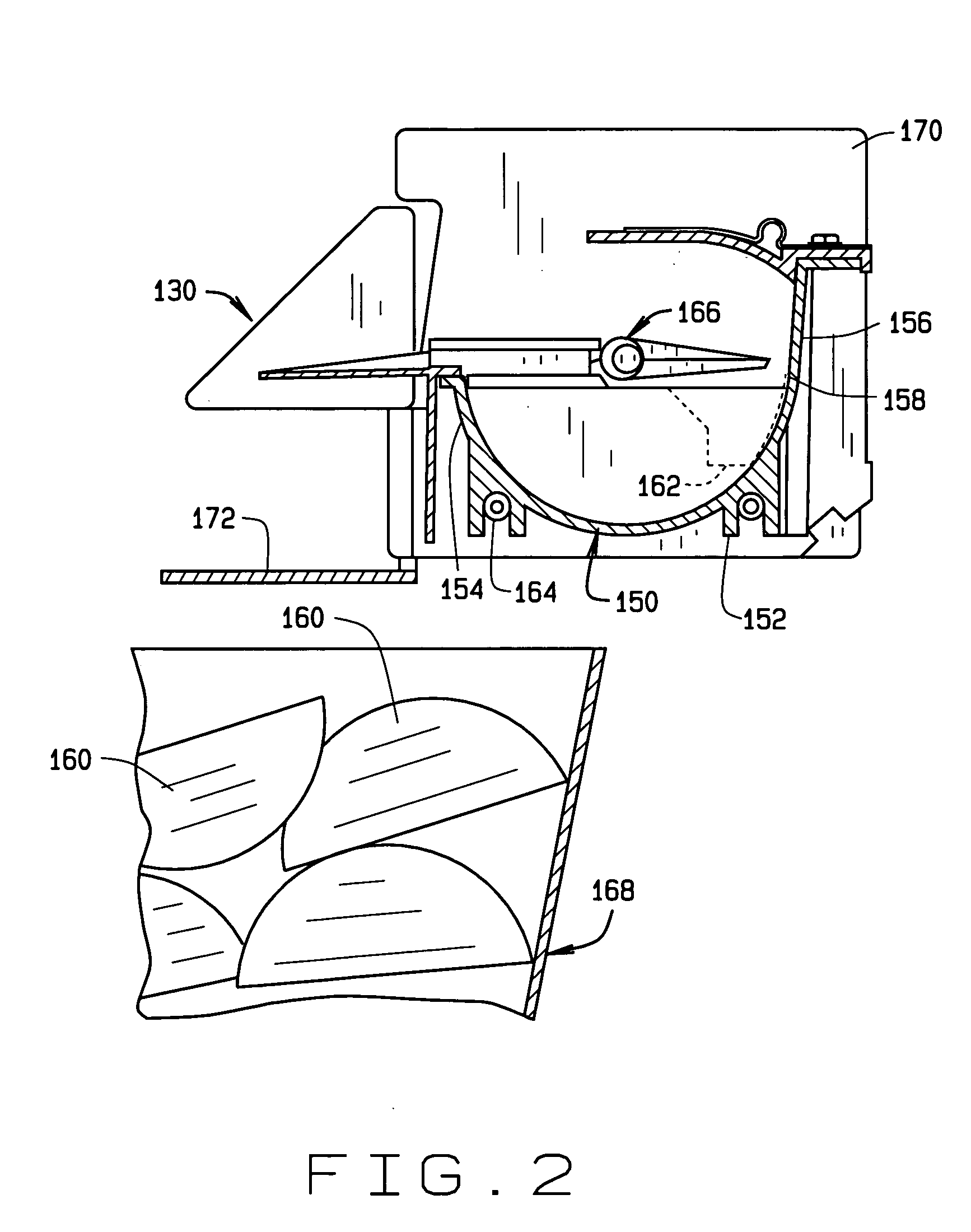

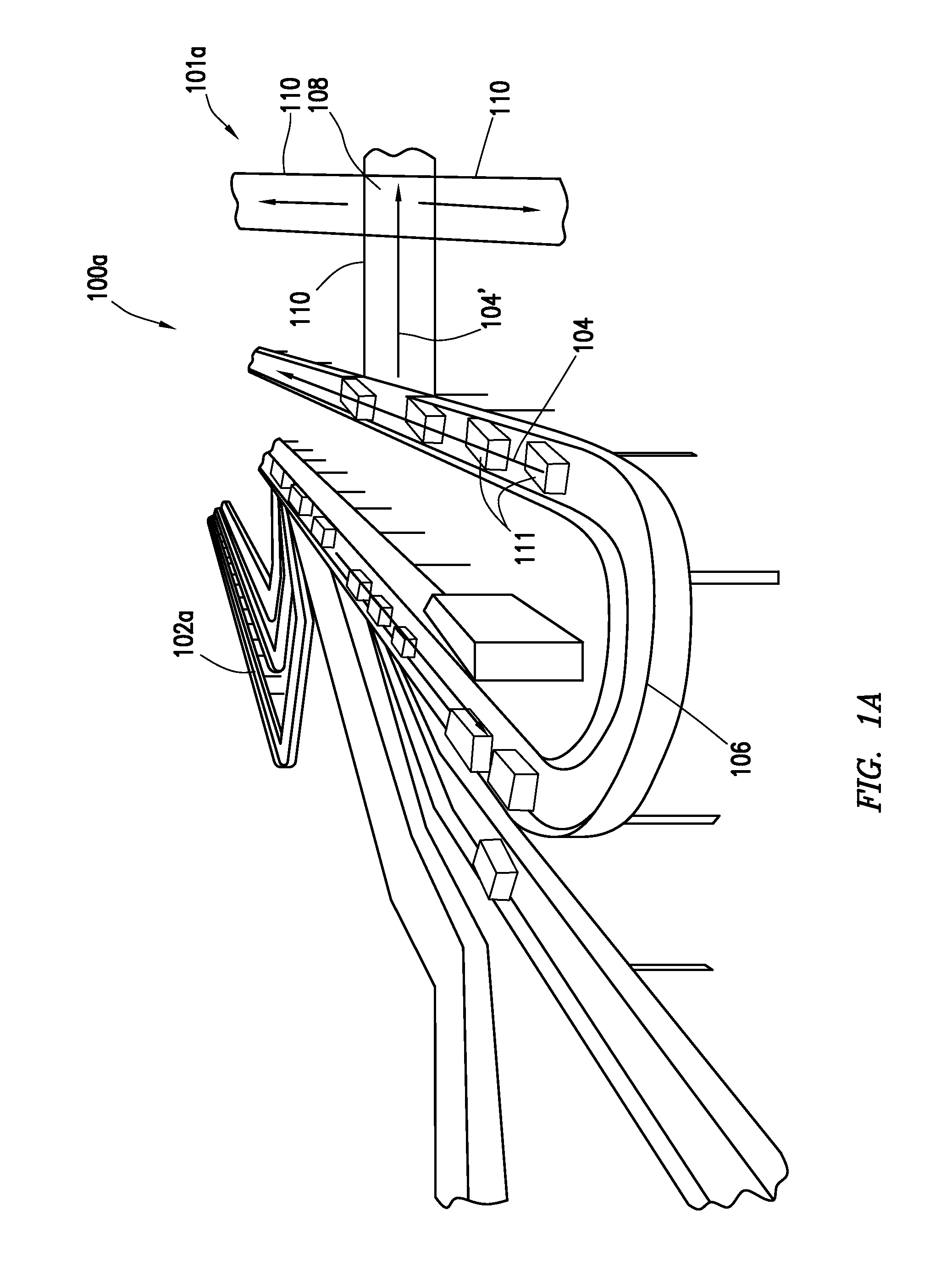

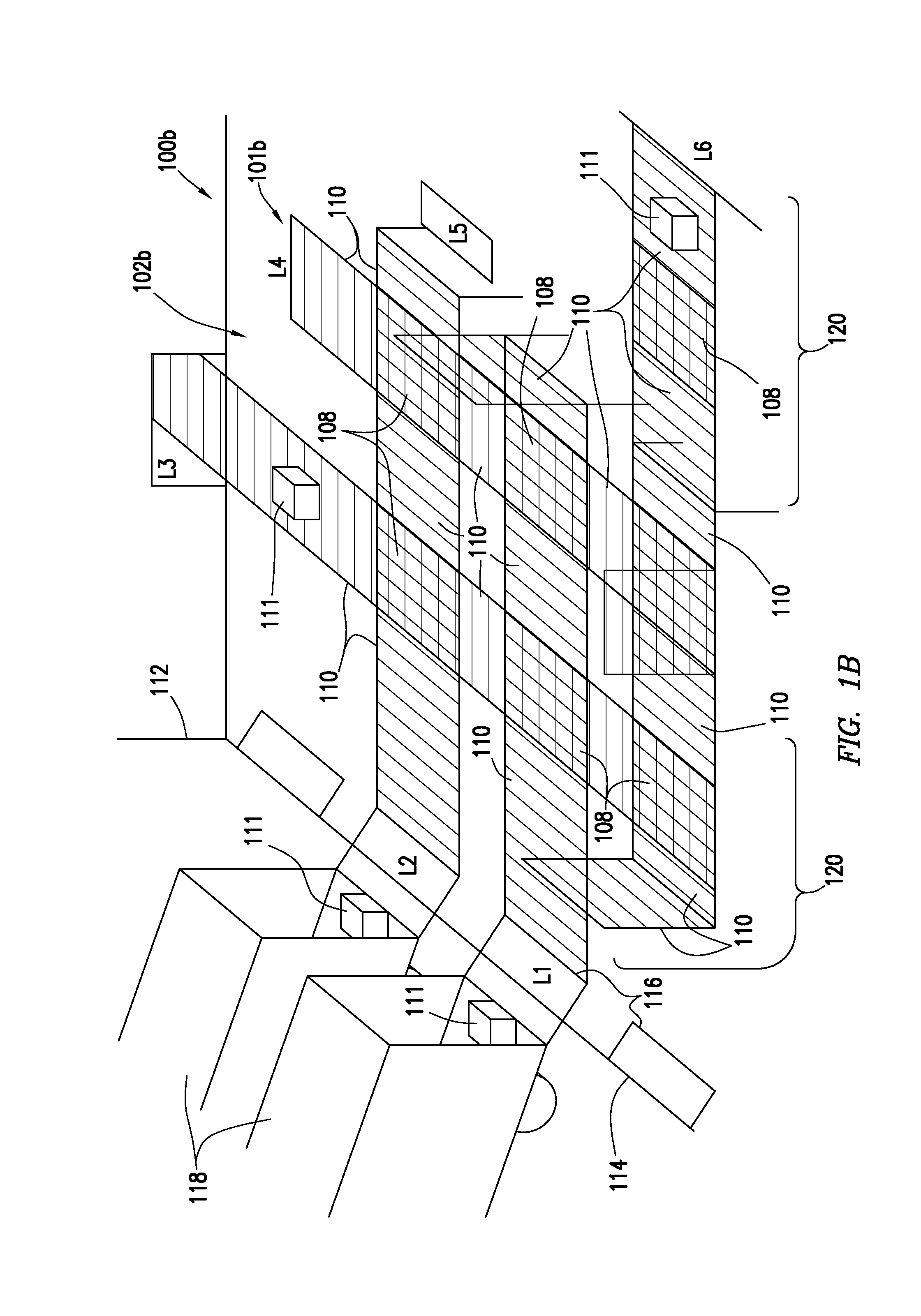

A conveyor and a deposition apparatus, and a maintenance method thereof are disclosed. The conveyor includes a frame; a lower support mechanism for supporting a carrier on which is longitudinally mounted a substrate and for transferring the carrier; and an upper support mechanism for supporting the carrier, in which the frame comprises a lower frame and an upper frame, and in which the lower support mechanism is provided on the lower frame and the upper support mechanism is provided on the upper frame, the upper frame and the lower frame being configured to be separately movable. Therefore, with the rotational movement of the upper frame, it is possible to arrange a cathode member in a space formed above the lower frame. This can make the spacing between the deposition treatment passage and the carrier transfer passage small. As a result, it is possible to make an inner court of the deposition apparatus narrow. Therefore, in the conveyor capable of transferring a carrier and in the deposition apparatus including the conveyor and further including a vacuum treatment apparatus and a transfer system, it is possible to make the installation area thereof small and narrow.

Owner:ULVAC INC

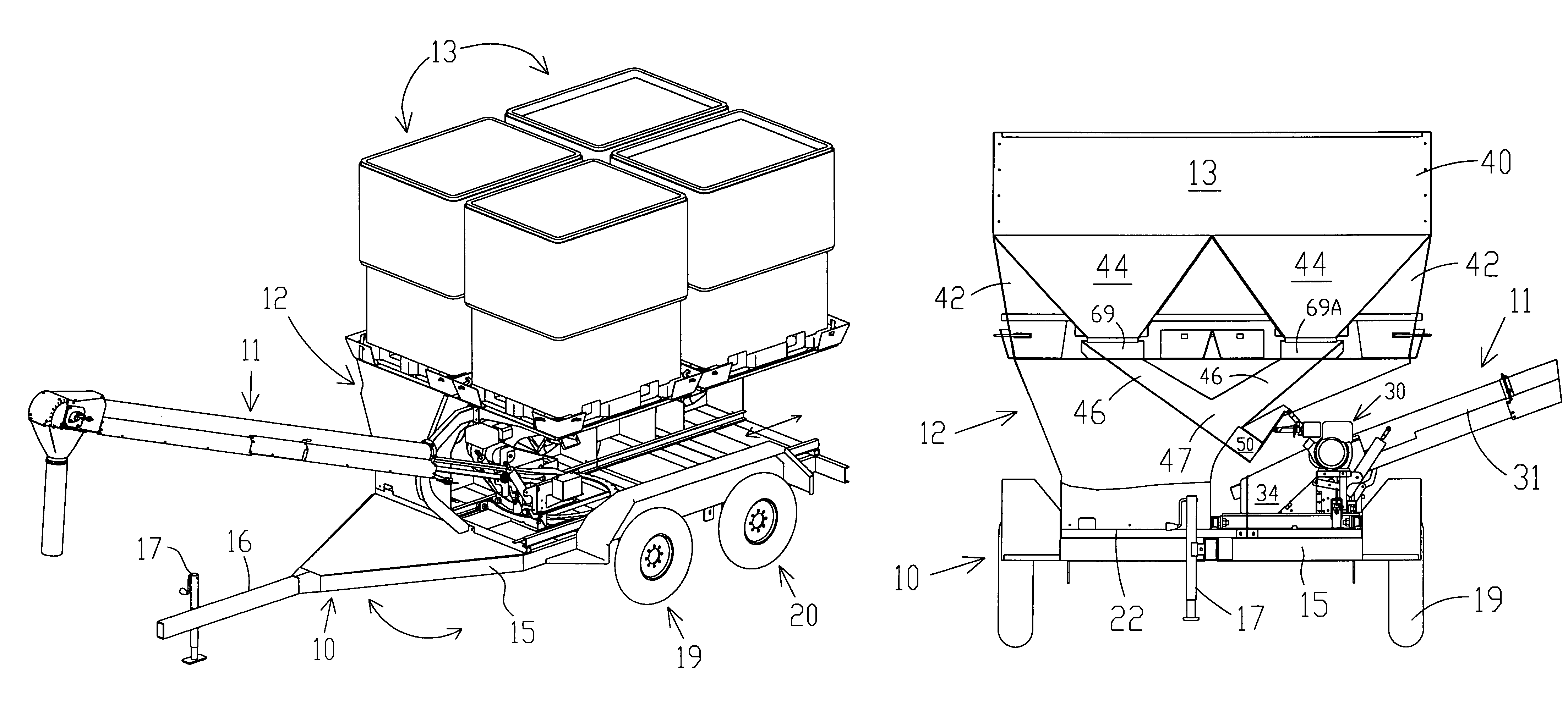

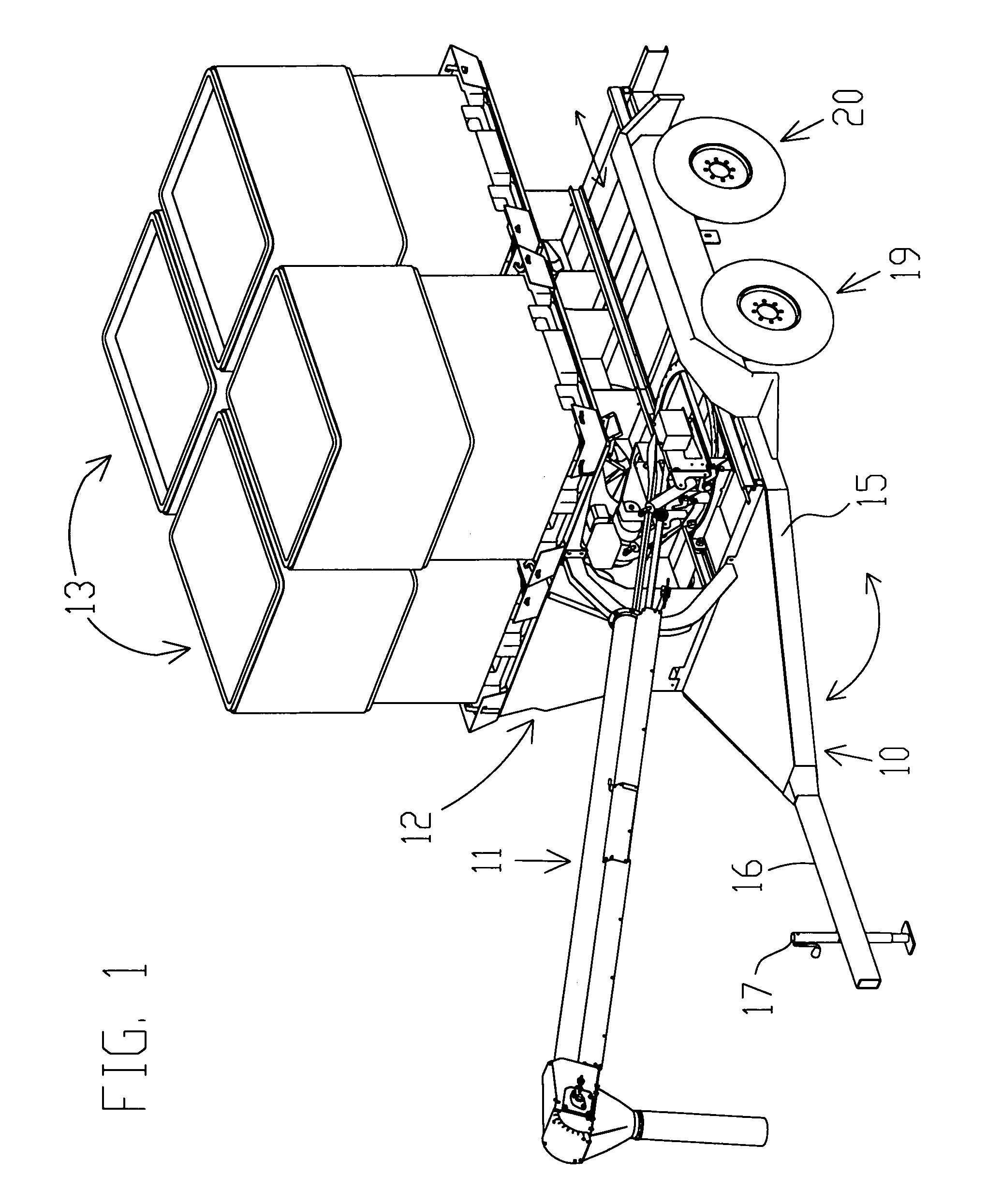

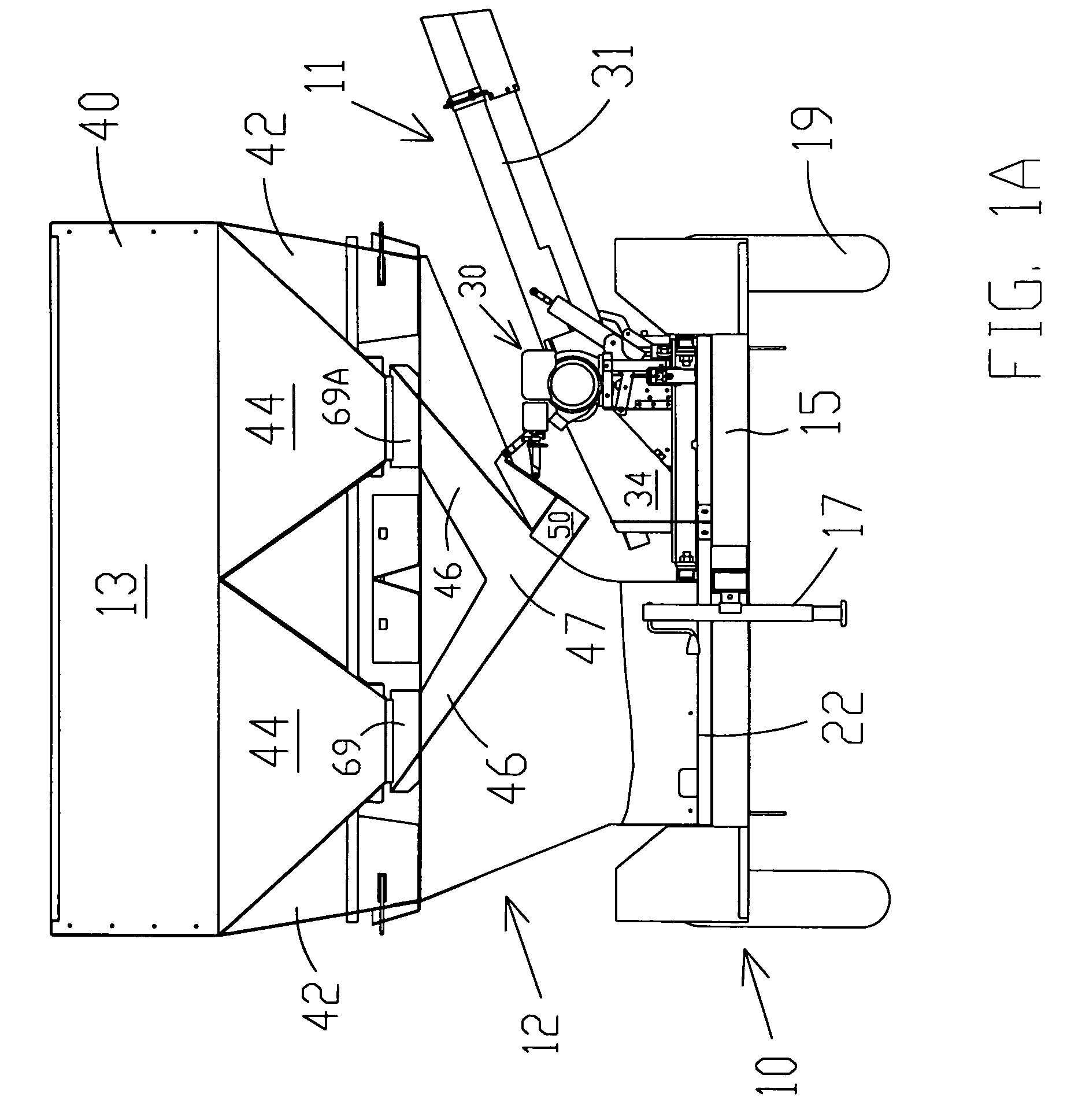

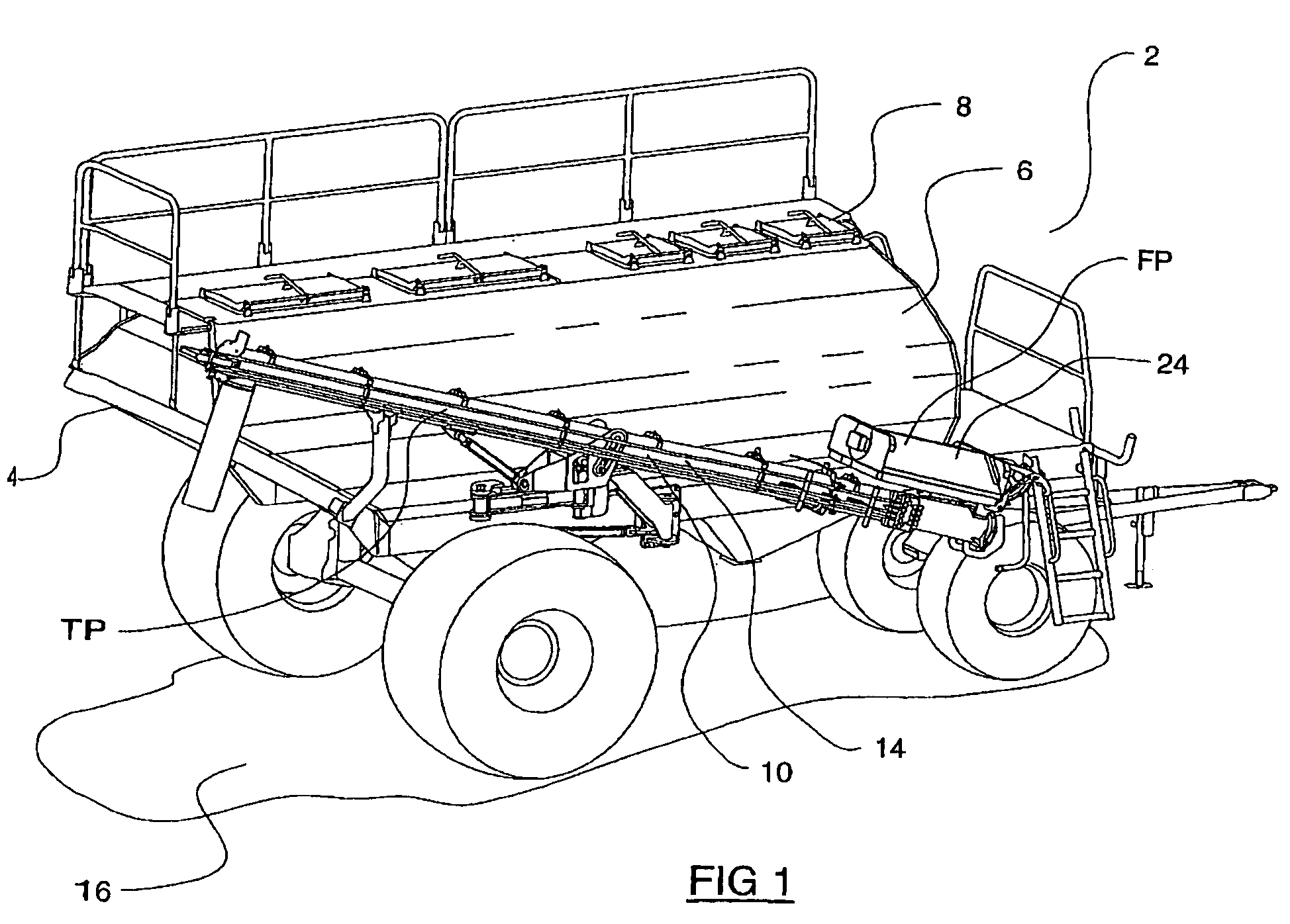

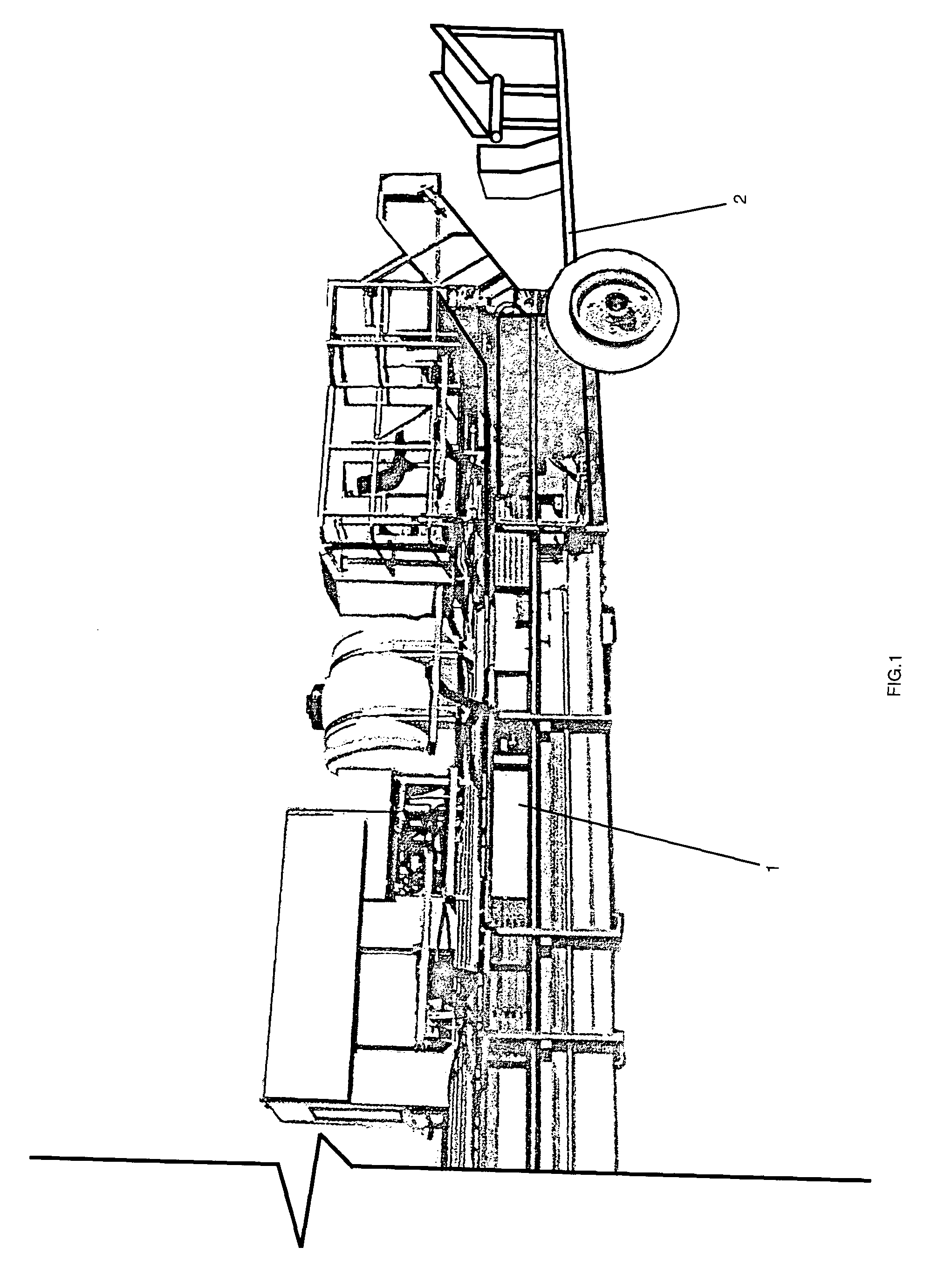

Agricultural seed tender with modular storage containers

ActiveUS7500817B2Improve economyIncrease storage capacityConveyorsMovable measuring chambersComputer moduleEngineering

Owner:MERIDIAN MFG

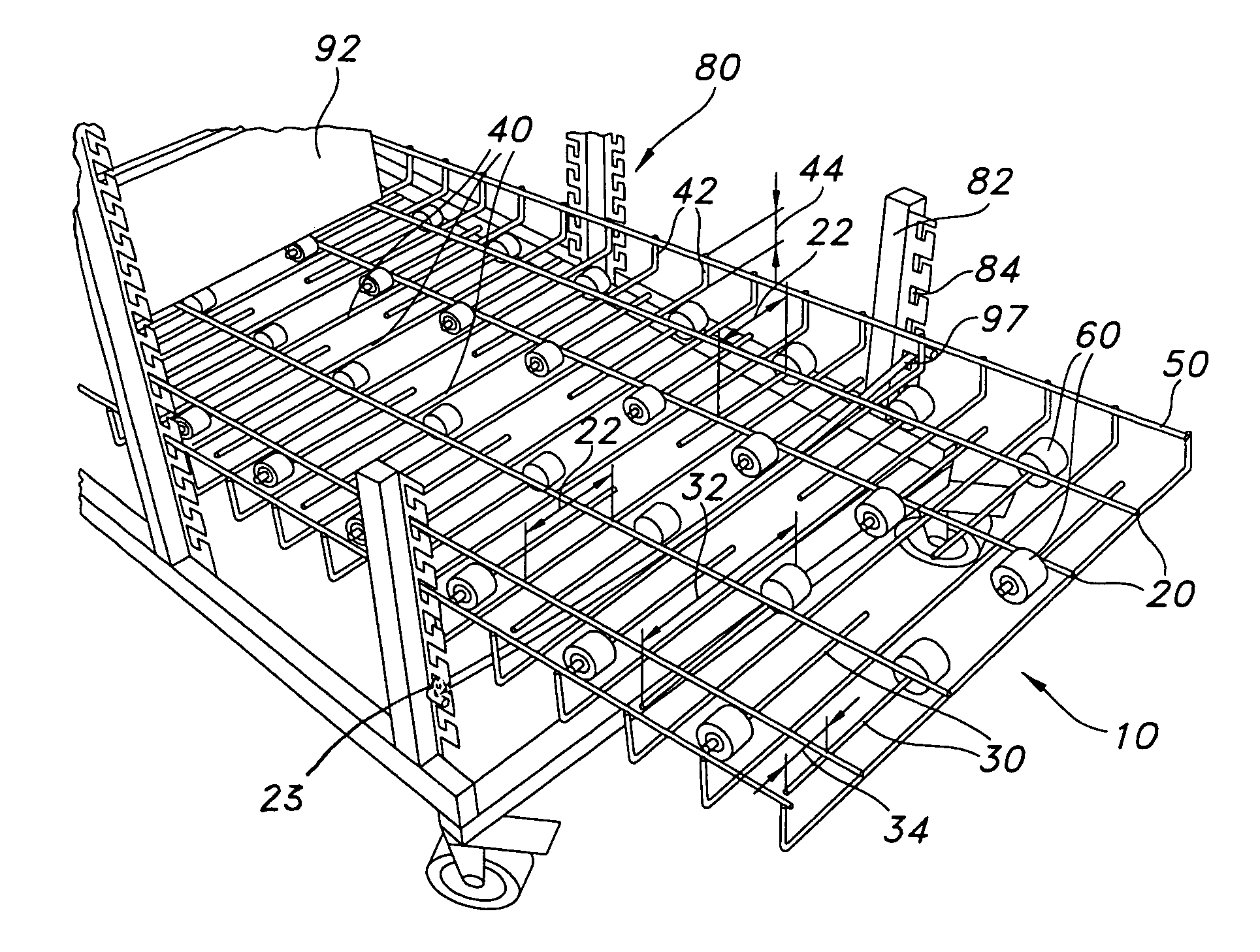

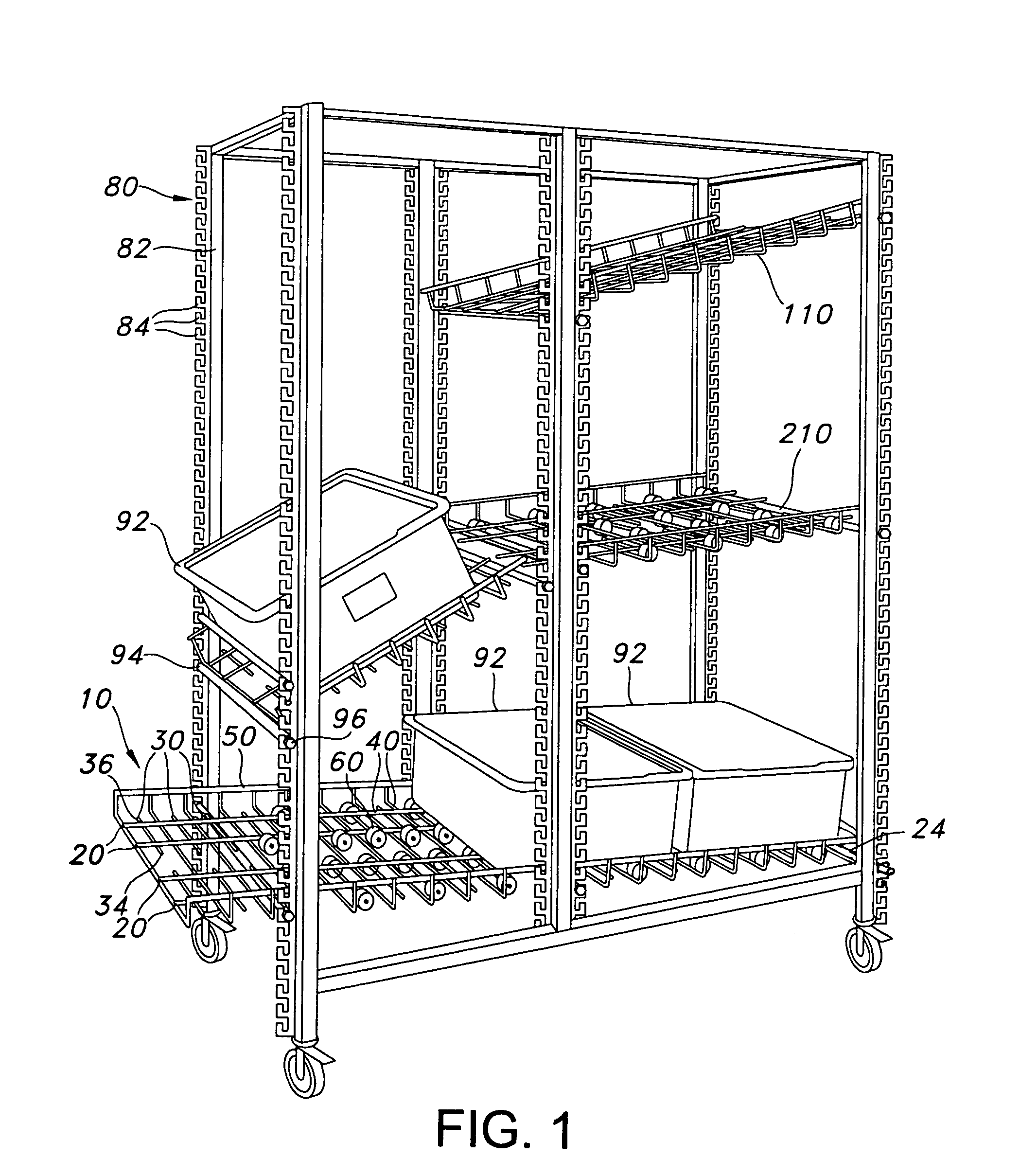

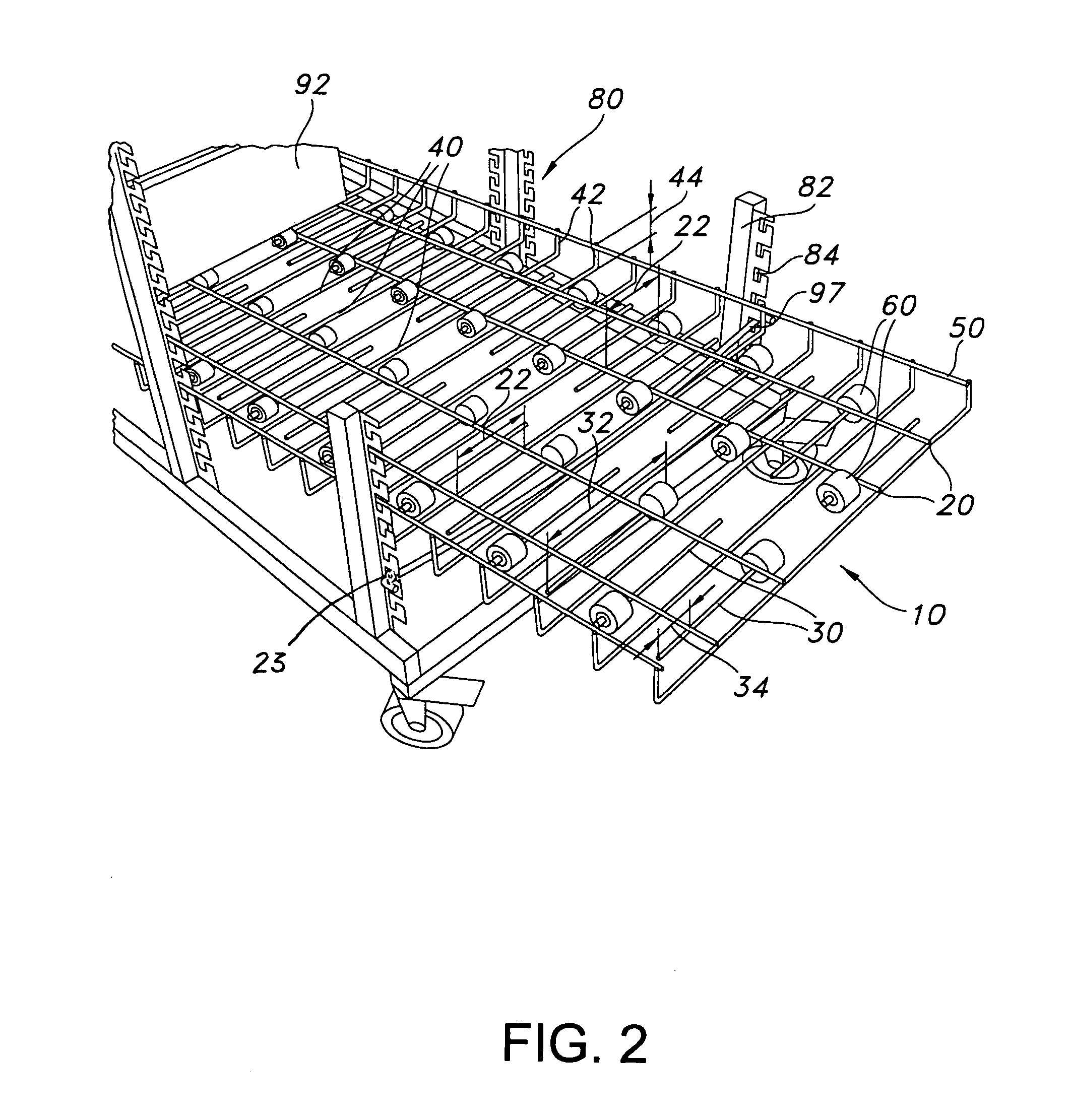

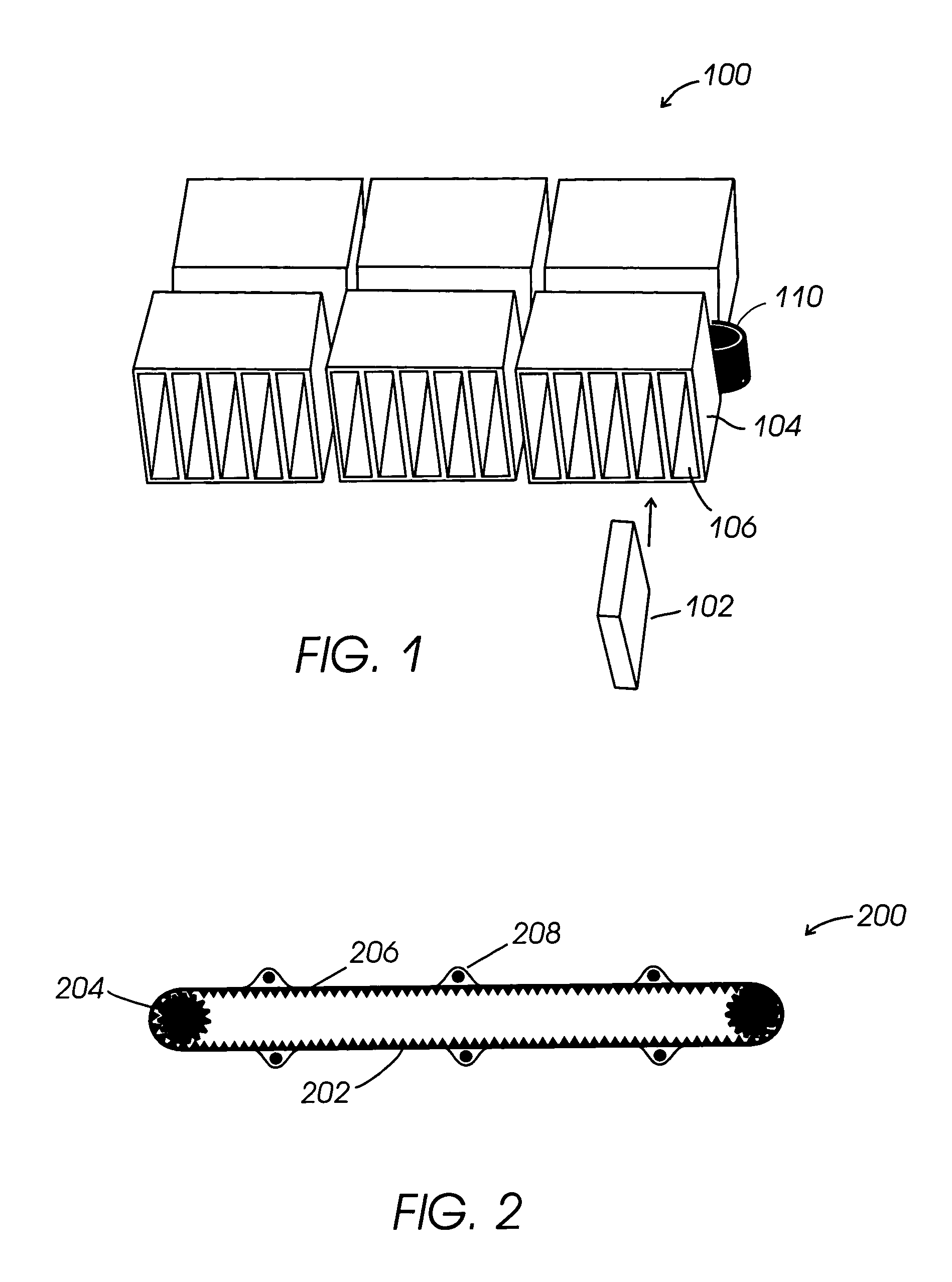

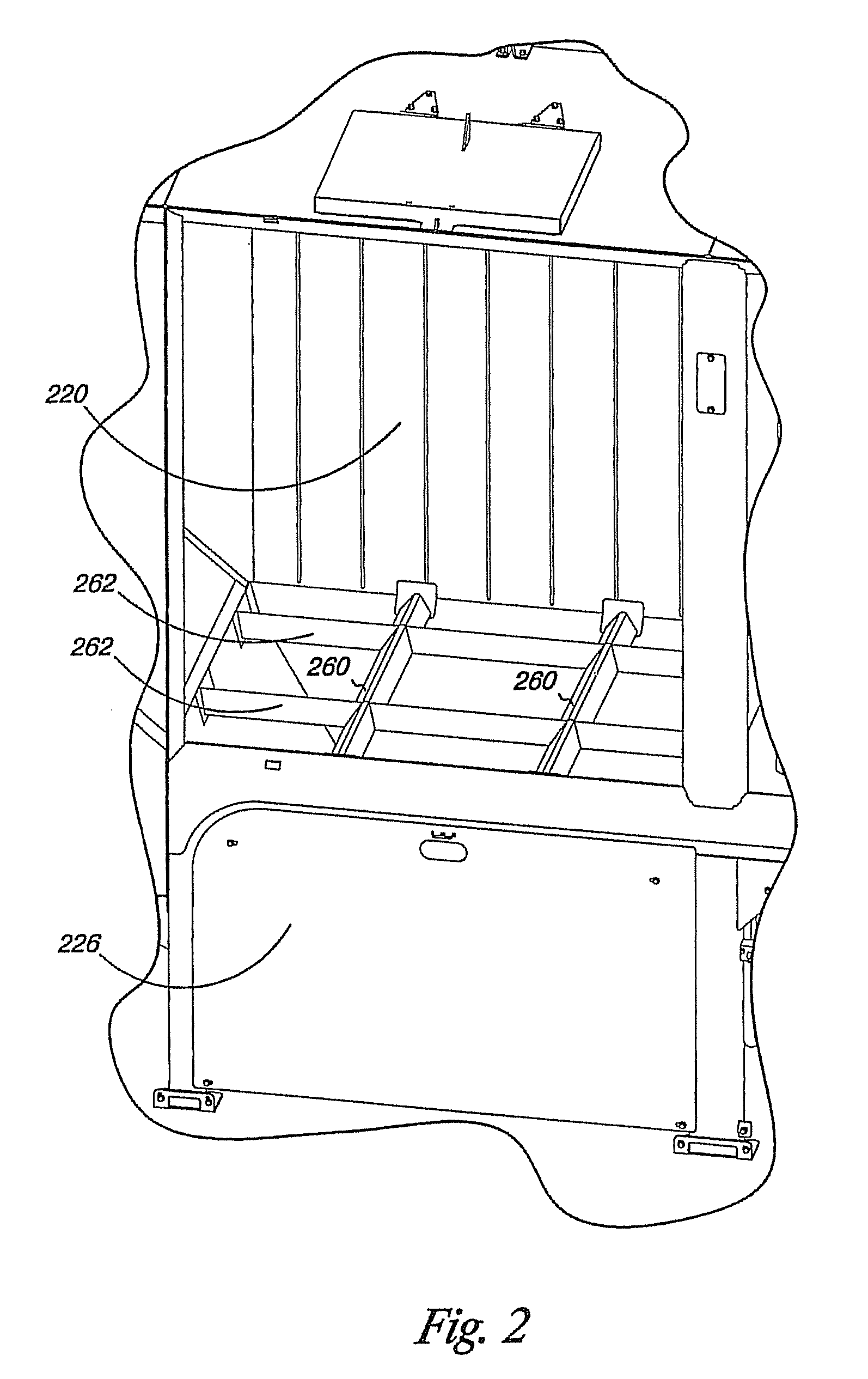

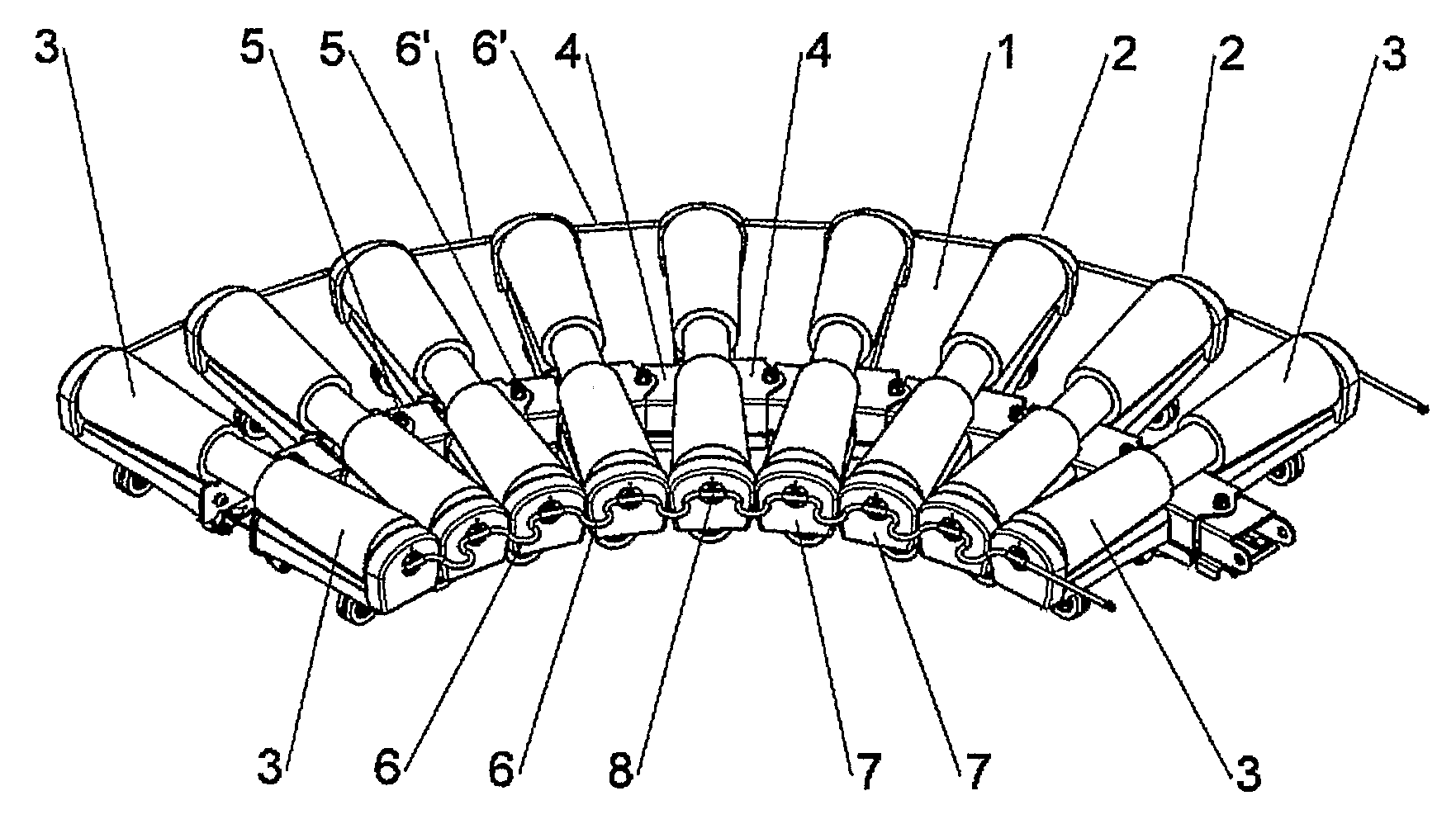

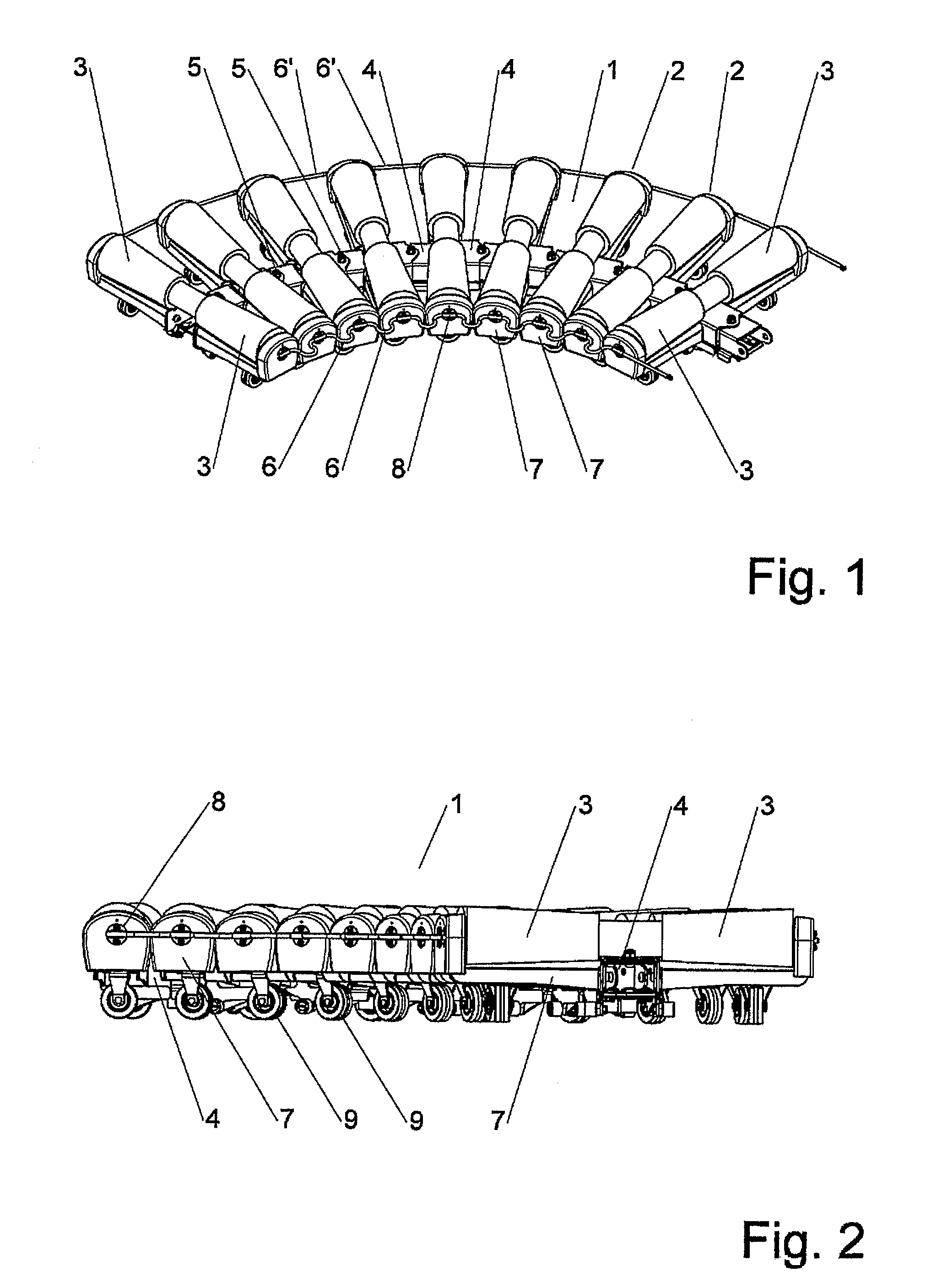

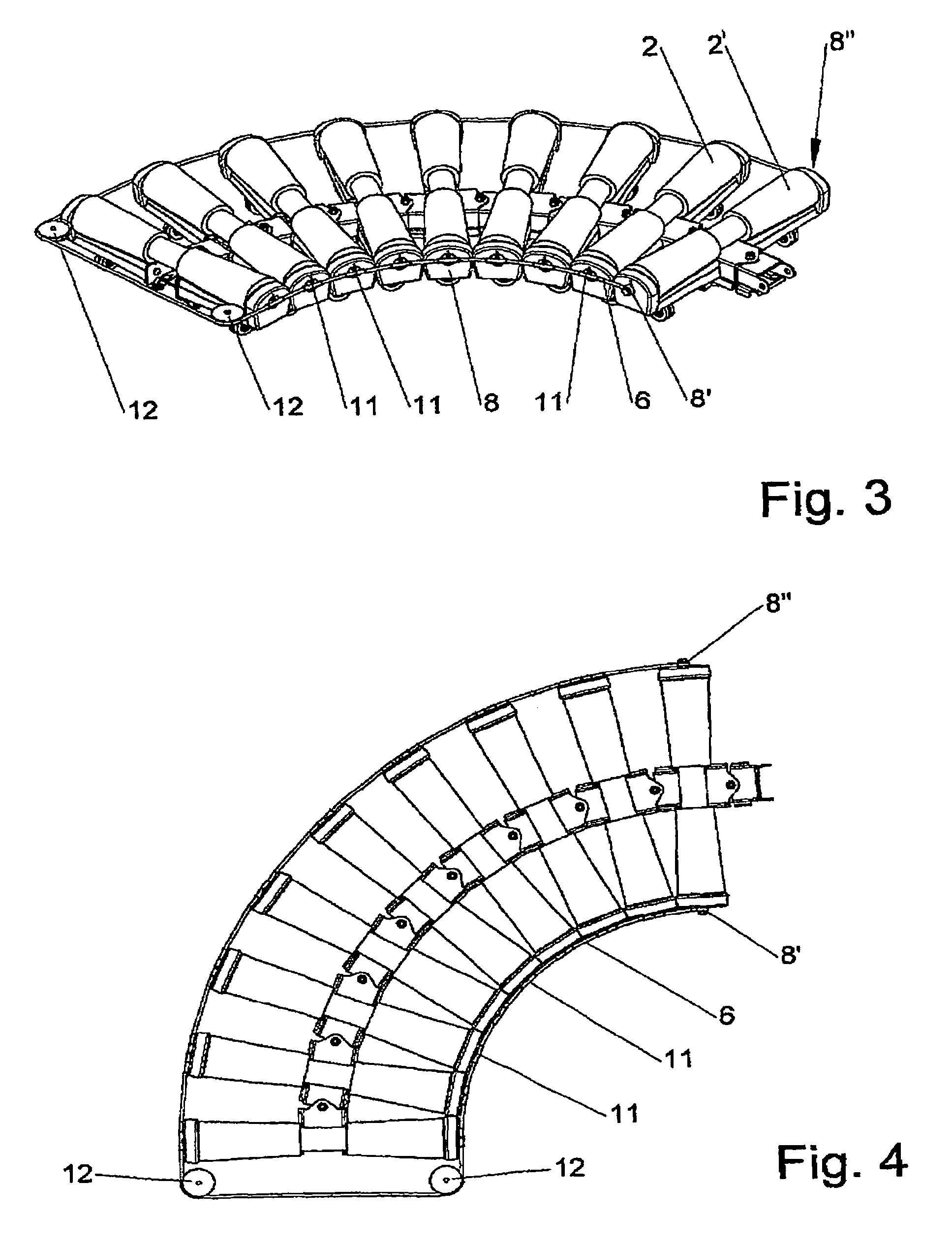

Flow rack

InactiveUS6948900B1Easy to assembleEasy to replaceShow cabinetsSupporting partsFree rotationEngineering

A wire flow rack system including a longitudinal wire, a roller wire, a roller and an optional cap. The roller wire is joined with and transverse to the longitudinal wire and includes an unsupported free end that projects beyond the longitudinal wire. The roller defines an axial bore, and is positioned on the free end so that the it is free to rotate about the roller wire. A end element, for example, a cap, can be joined with the free end to prevent the roller from disengaging the free end. The cap can be friction fit with the free end and easily, manually replaceable relative to the free end, without the use of tools.

Owner:LIFE TIME SYST

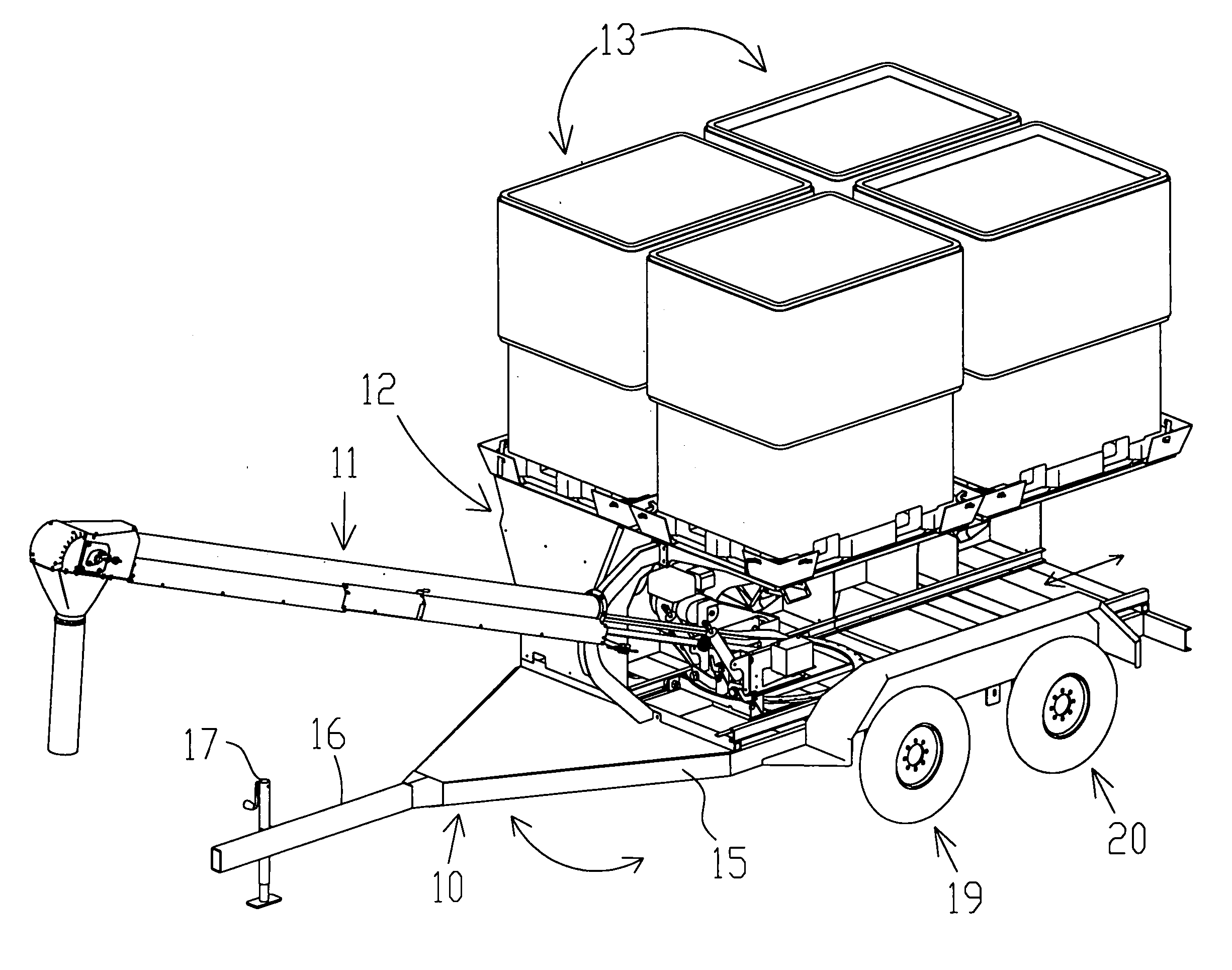

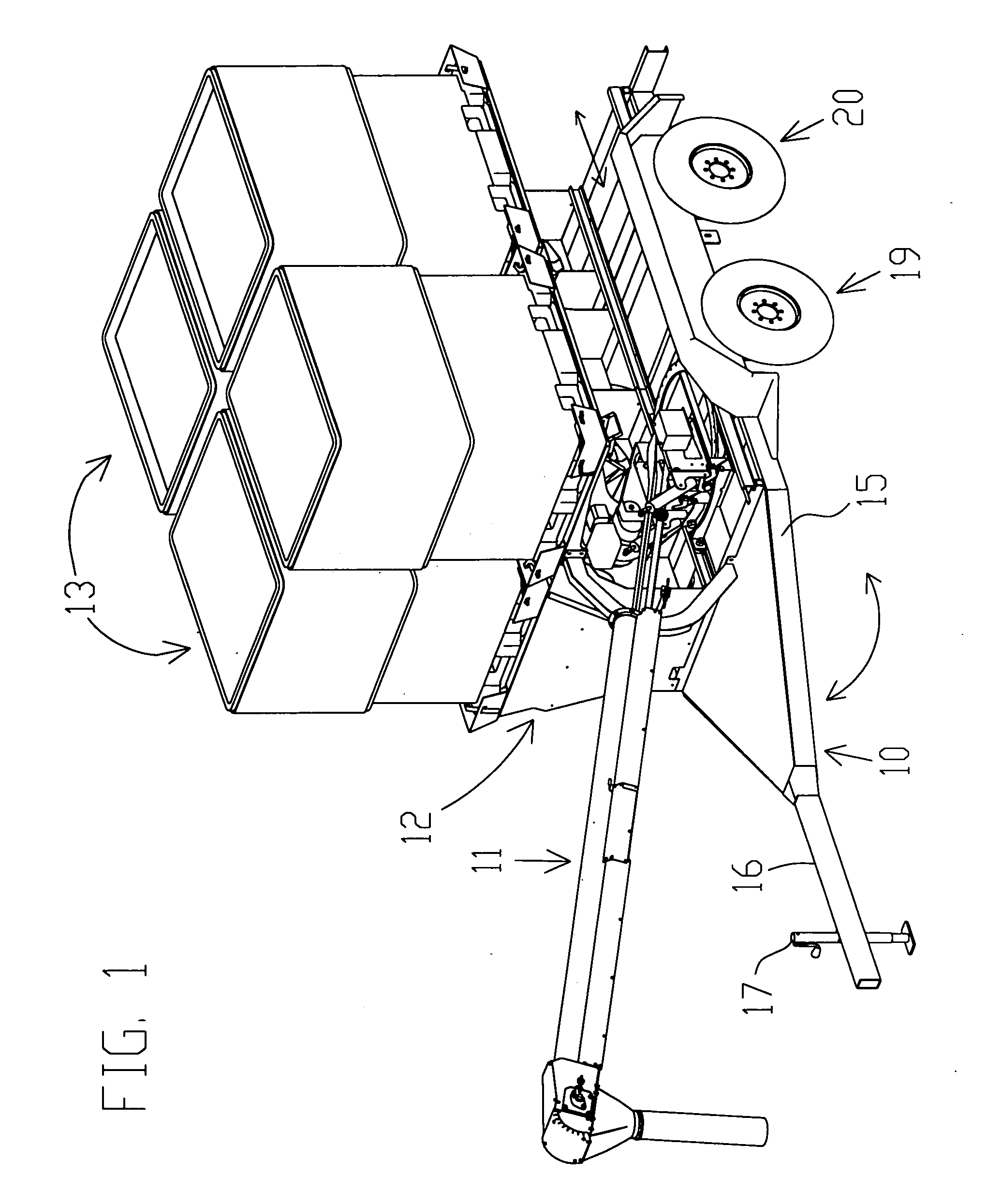

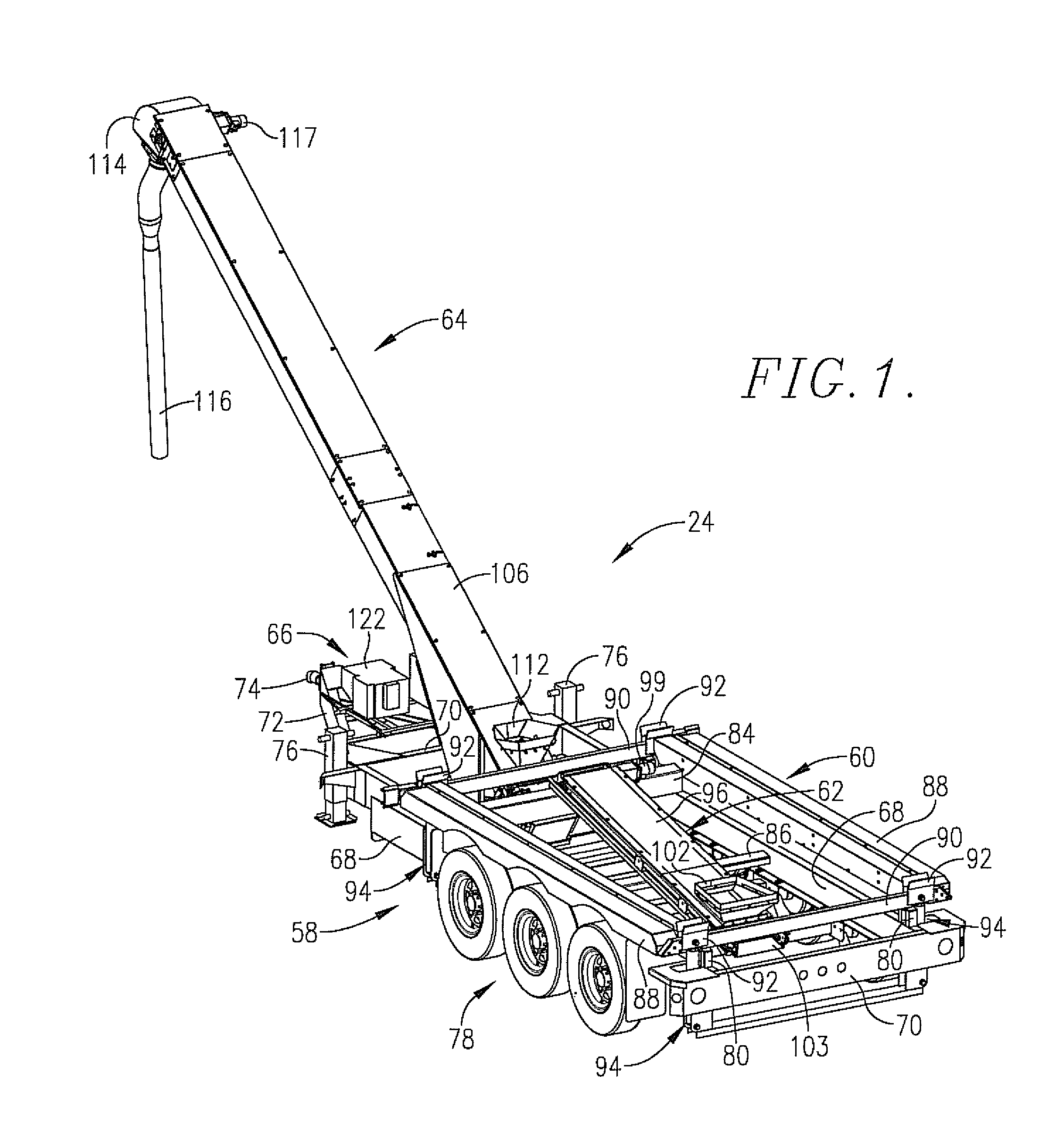

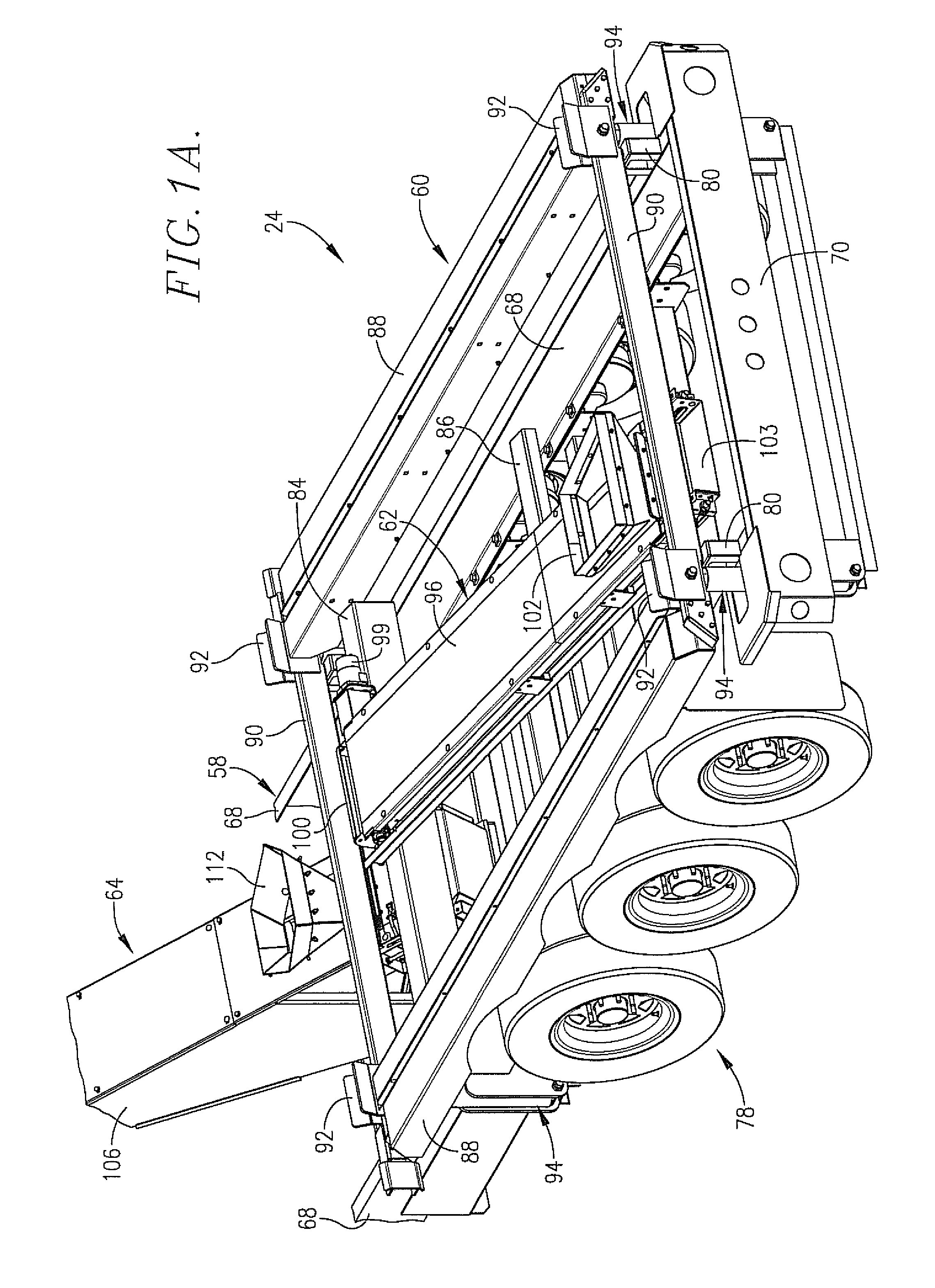

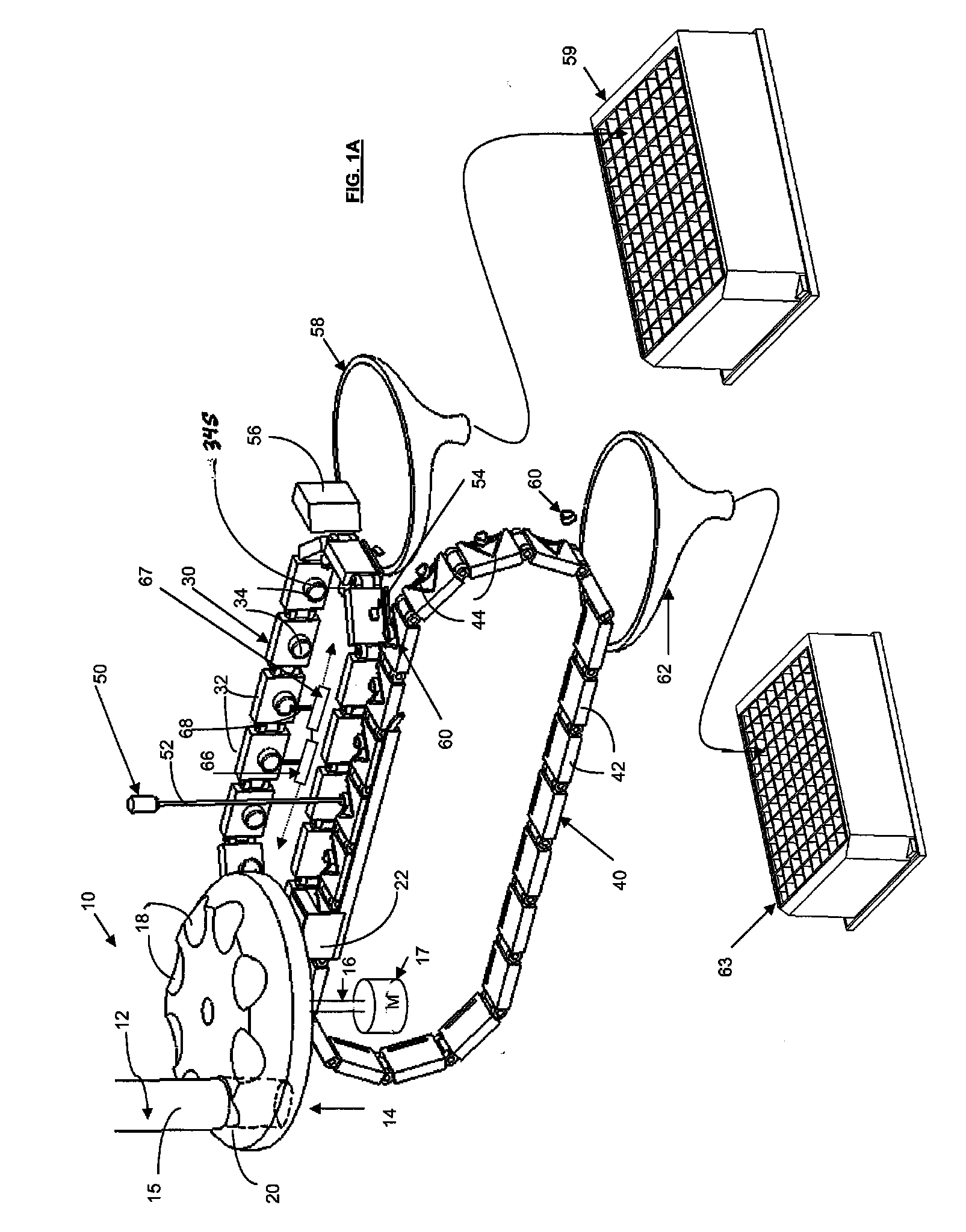

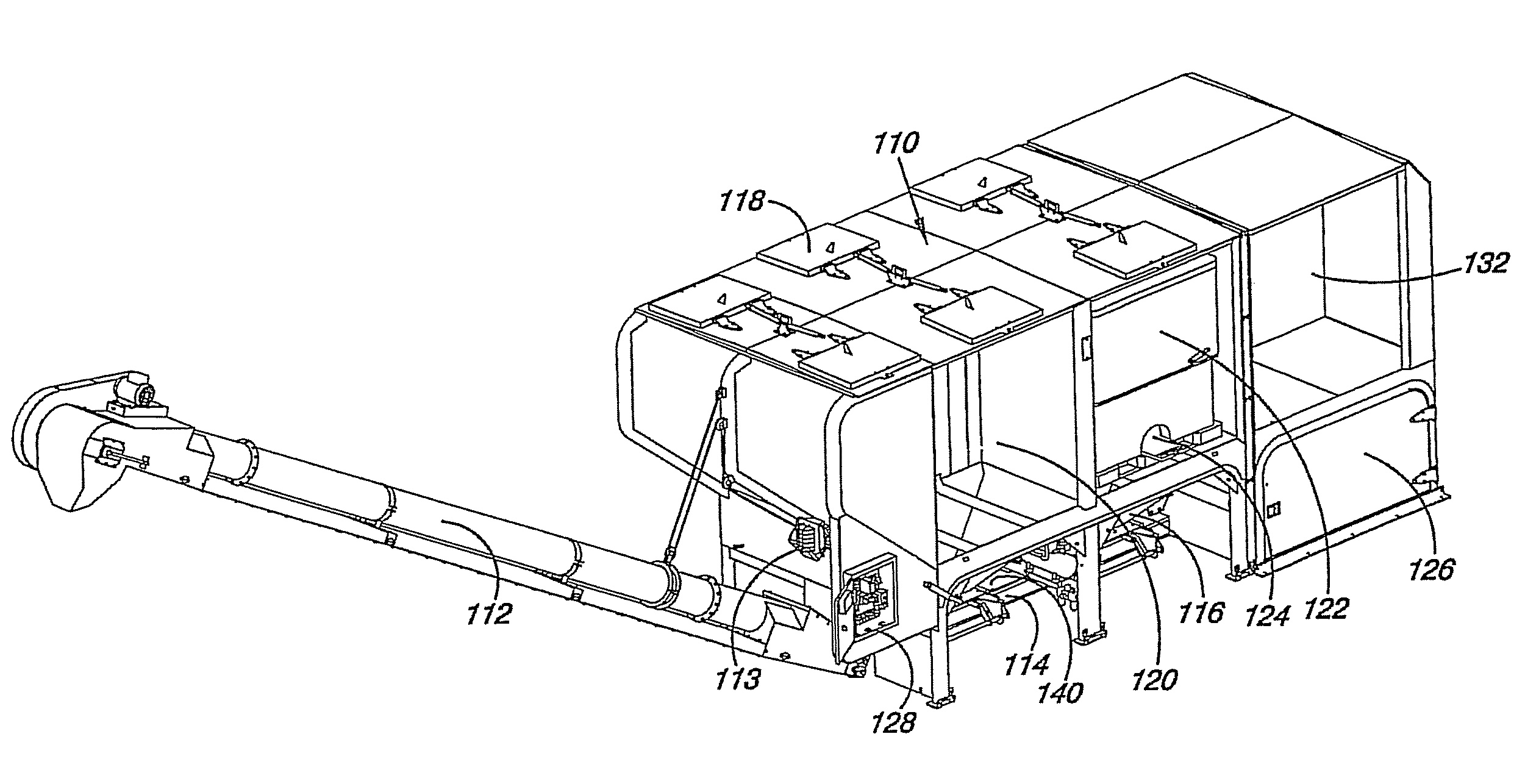

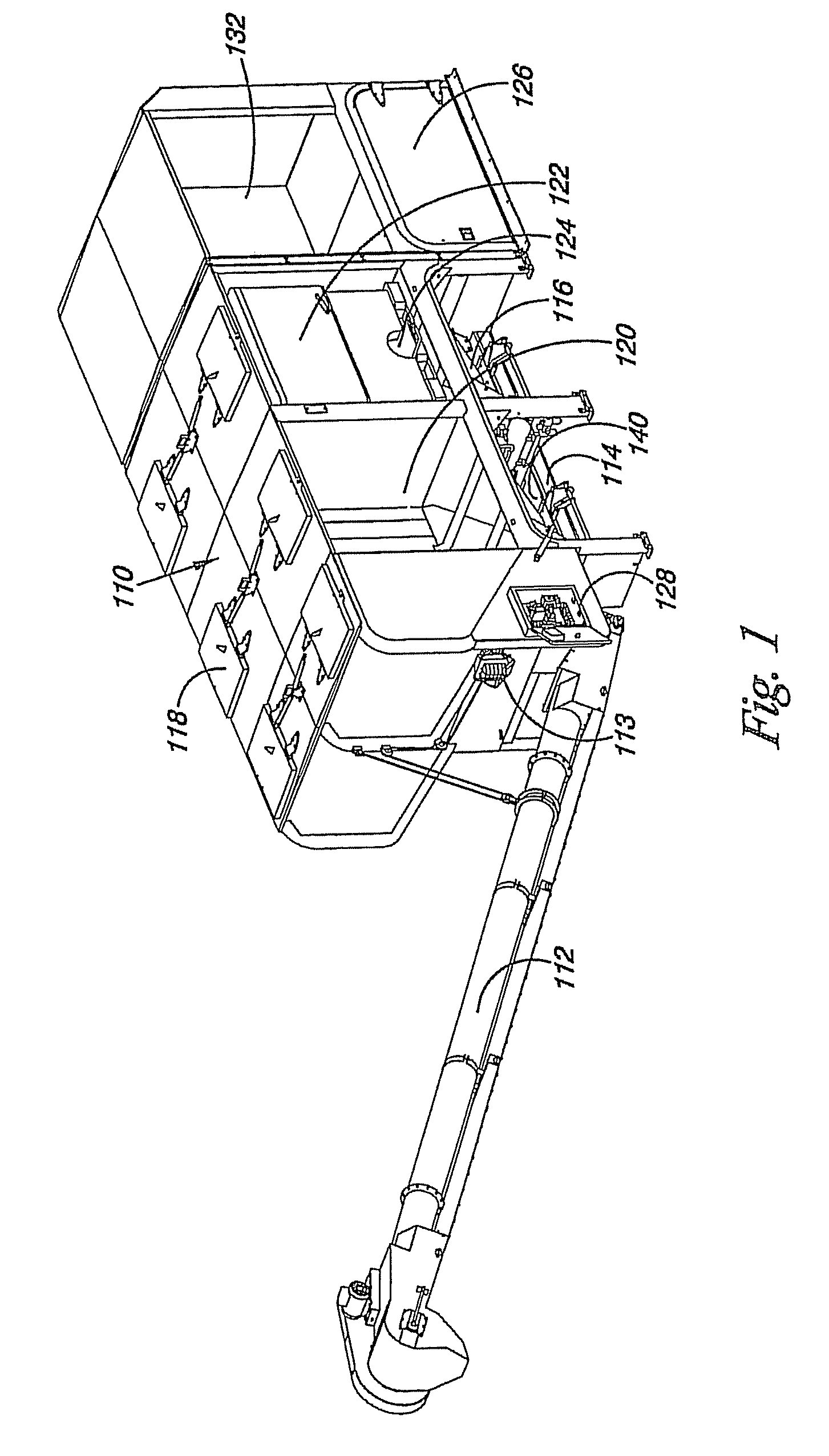

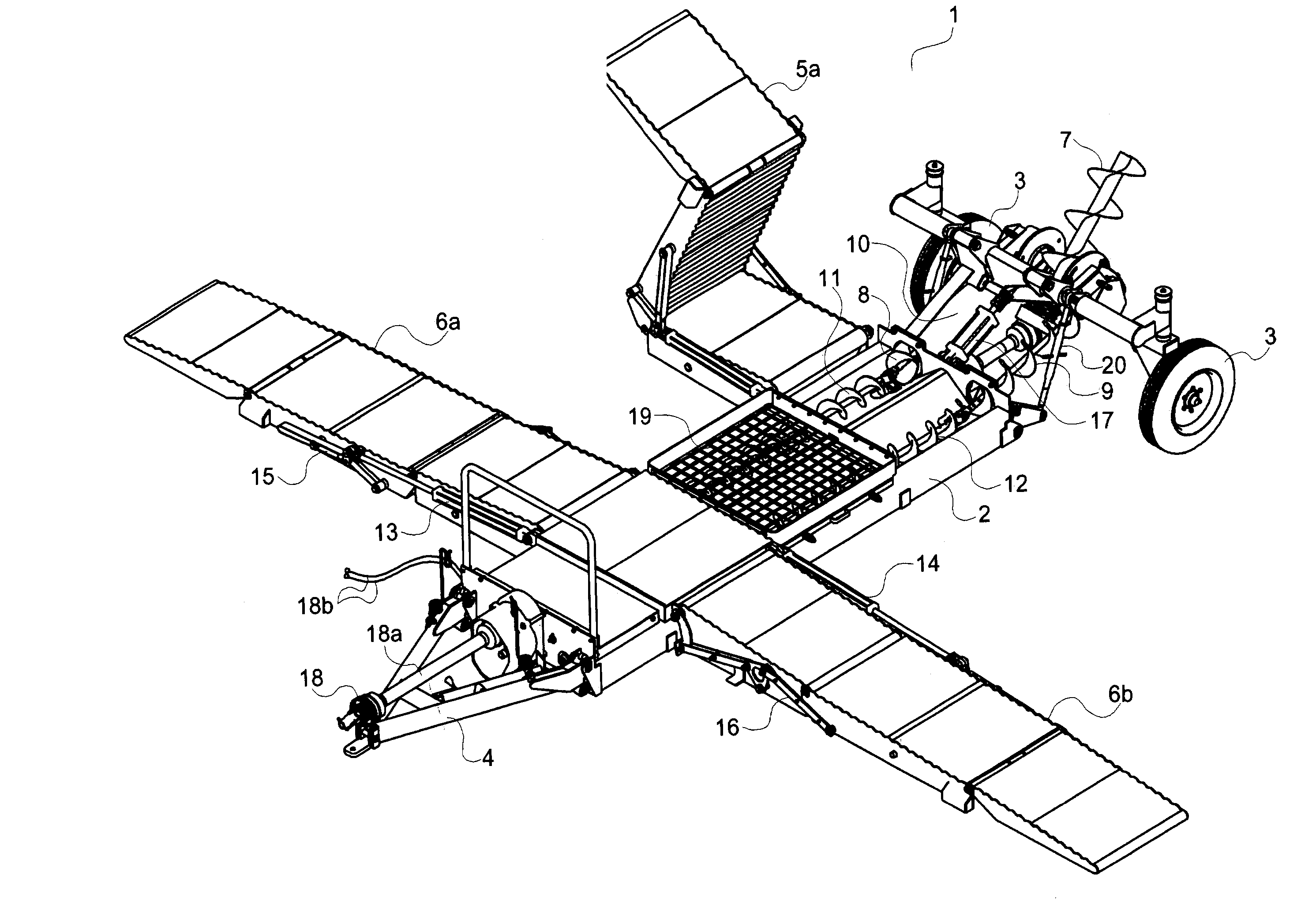

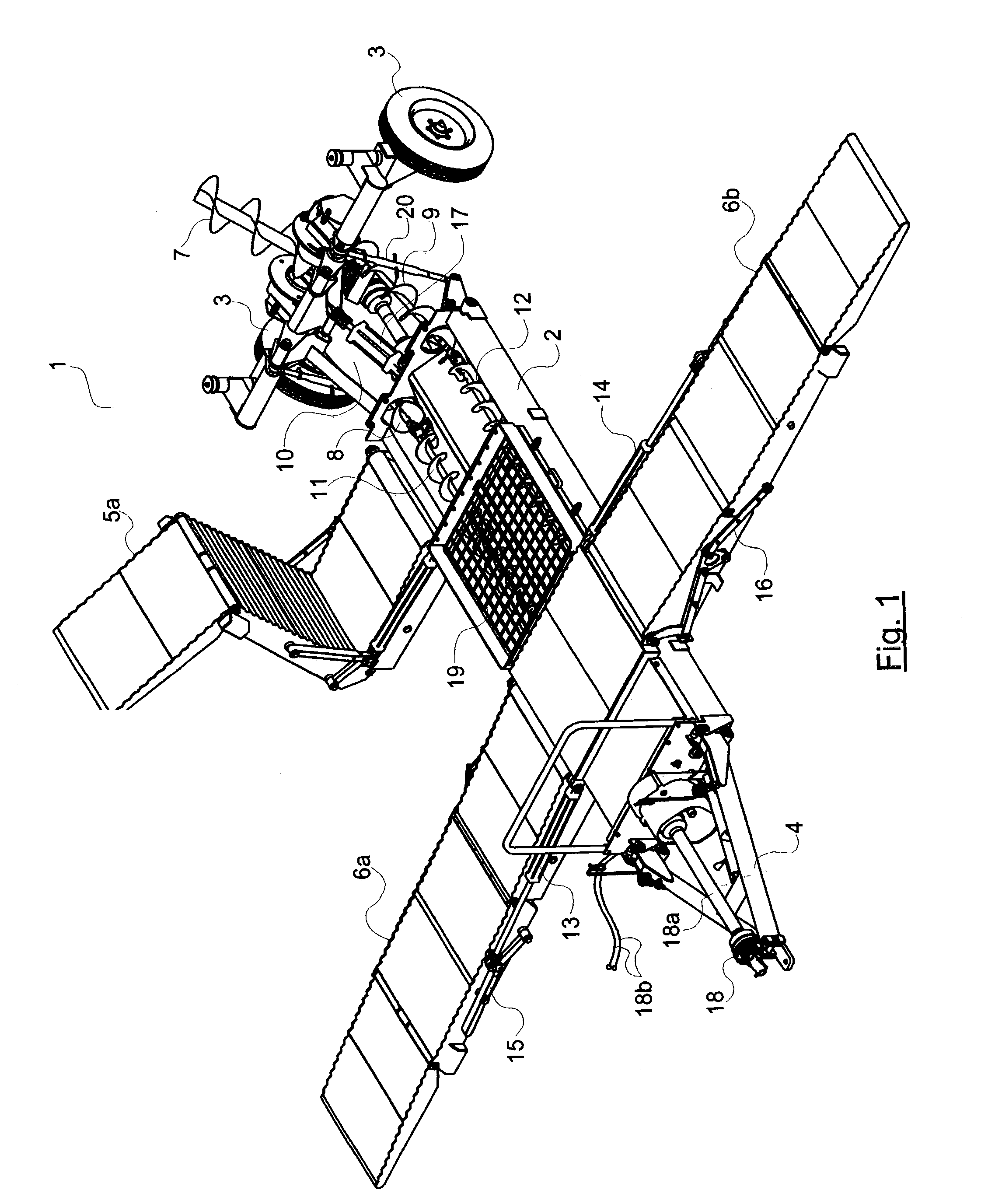

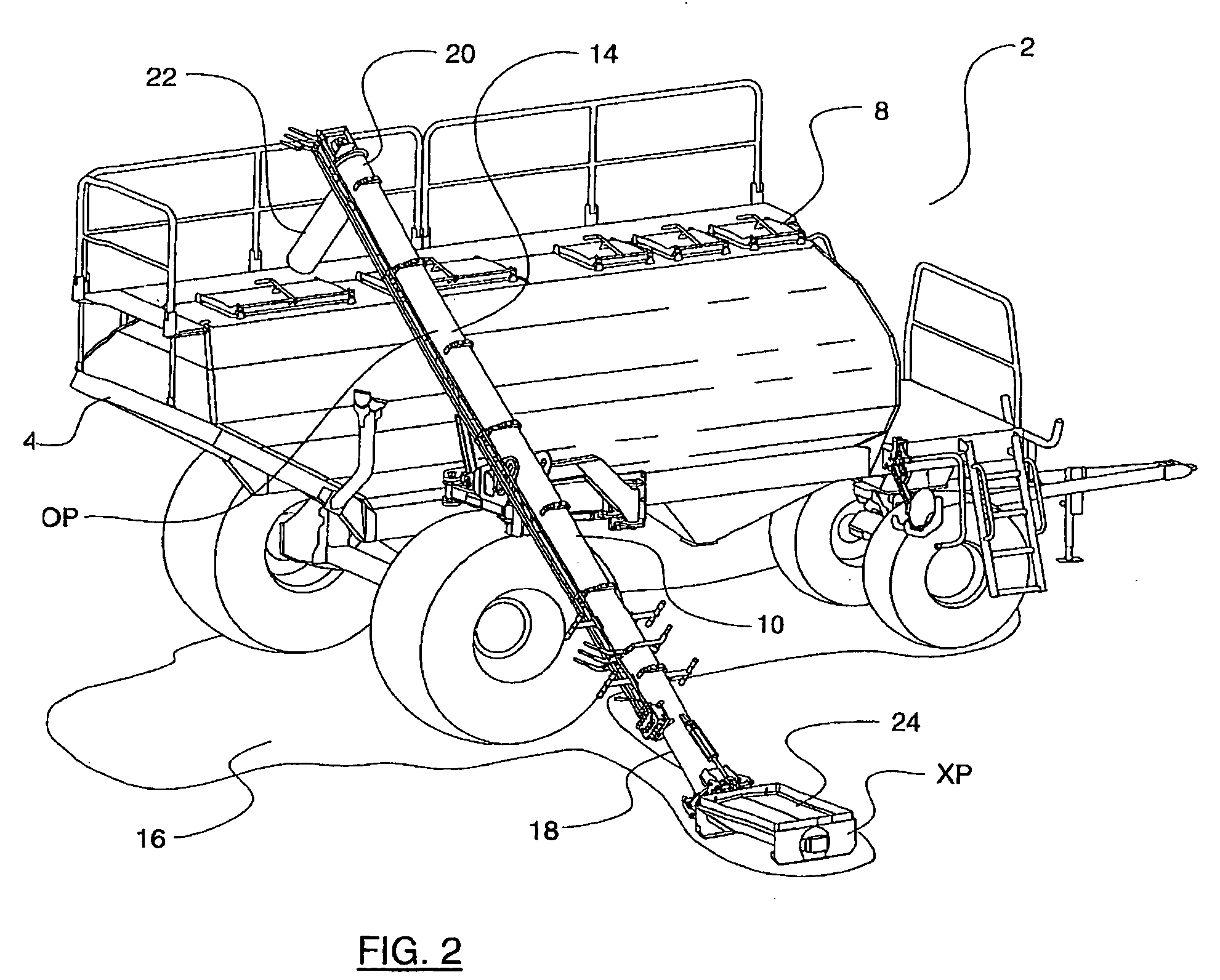

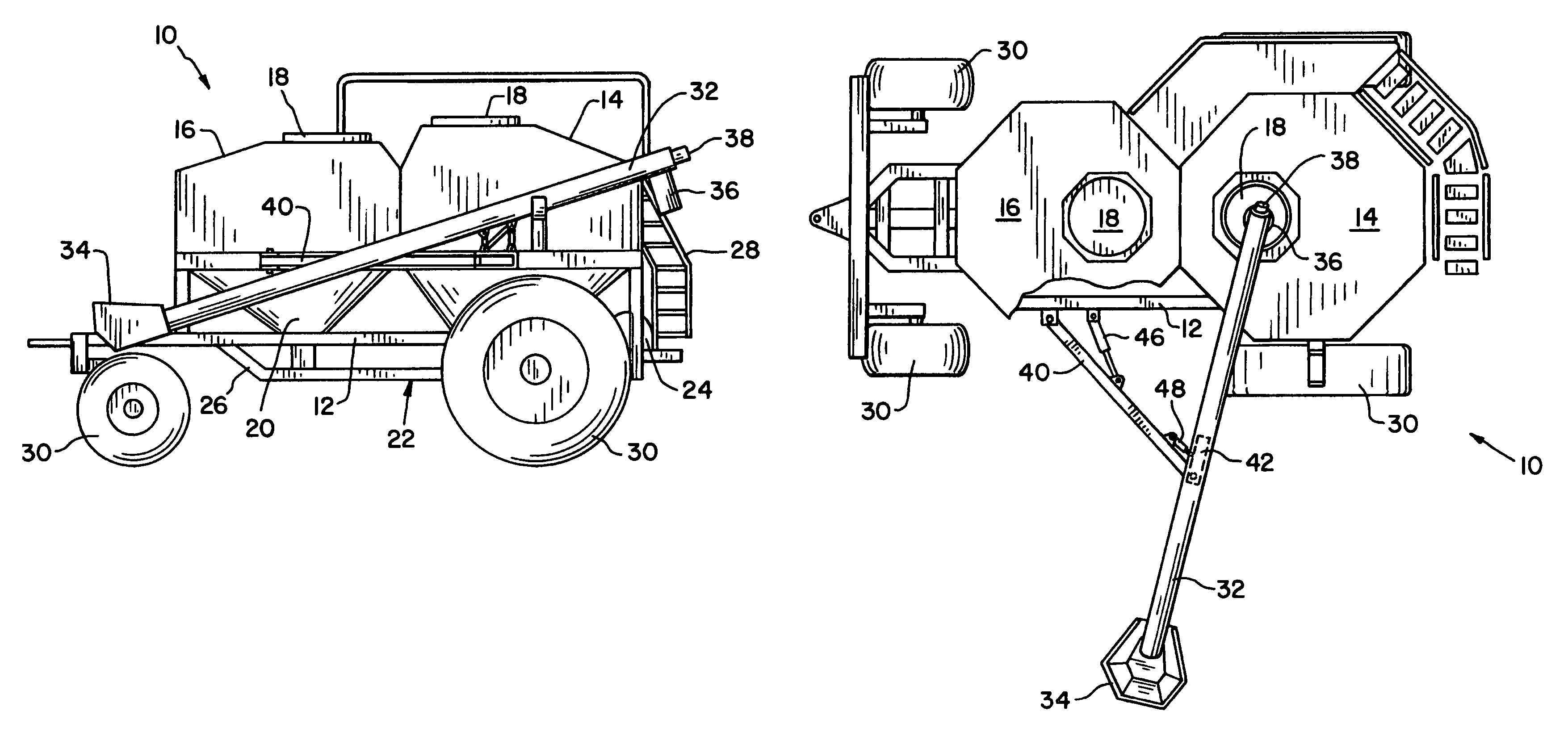

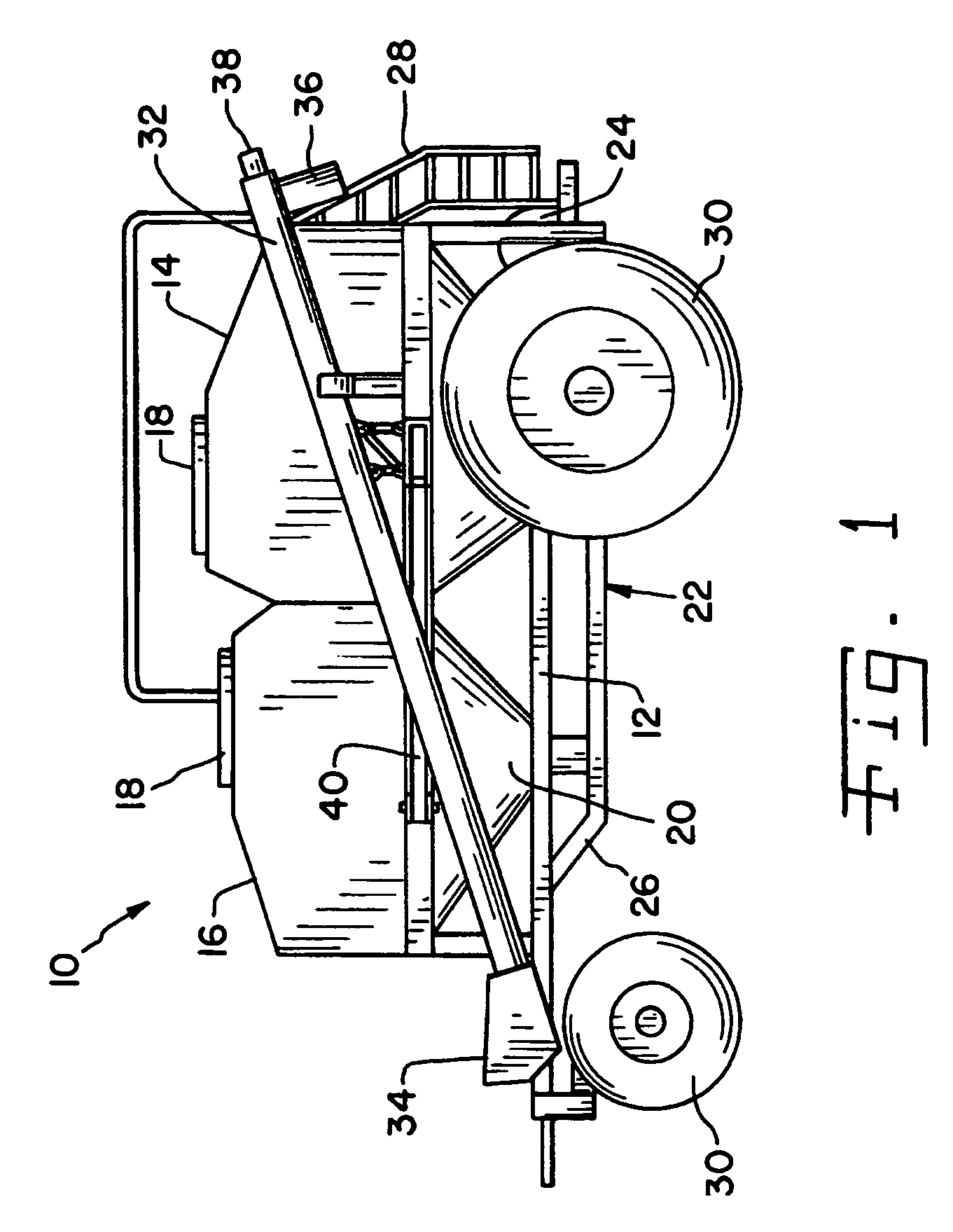

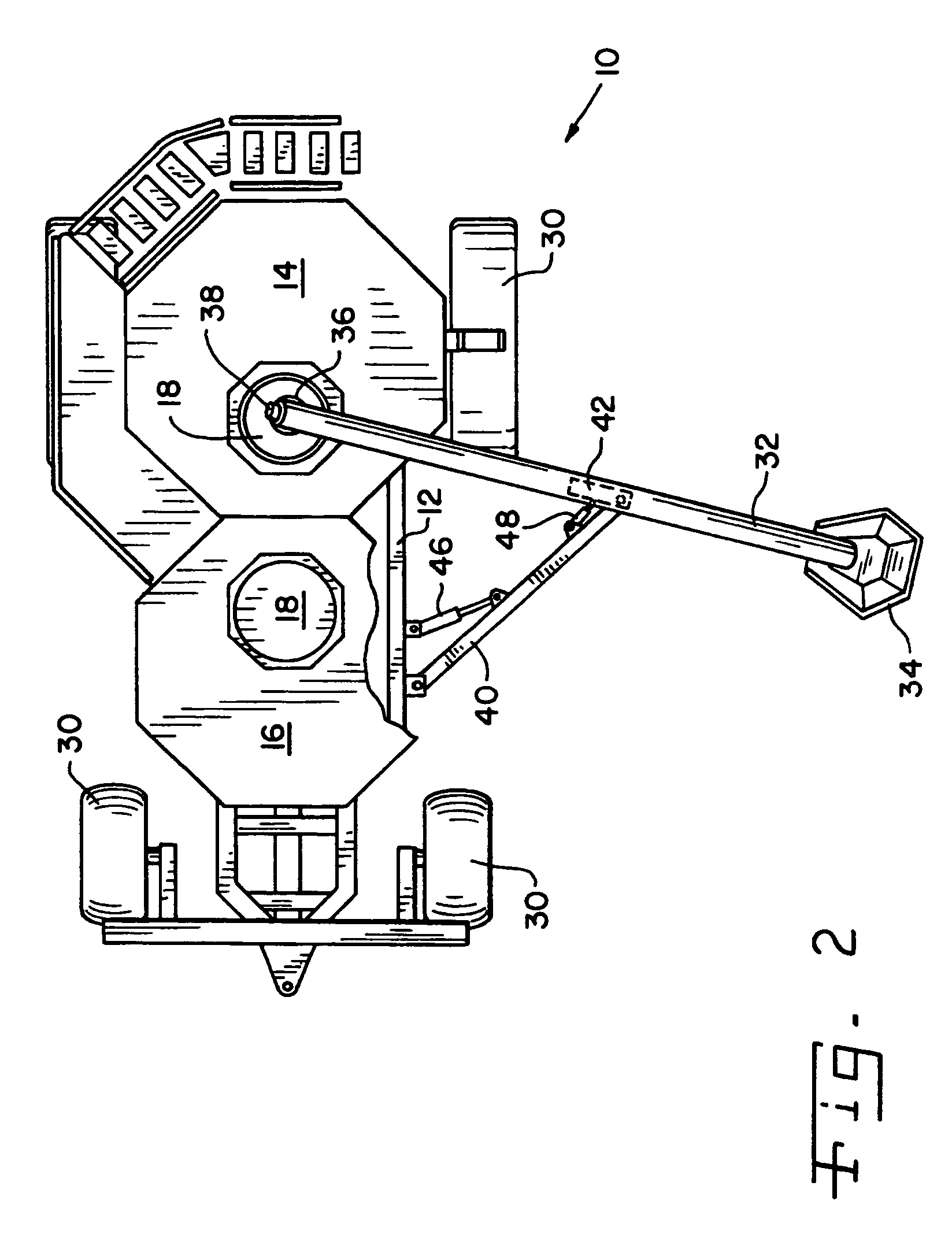

Agricultural seed tender with modular storage containers

ActiveUS20060180062A1Improve economyImprove stabilityConveyorsMovable measuring chambersEngineeringAdemetionine

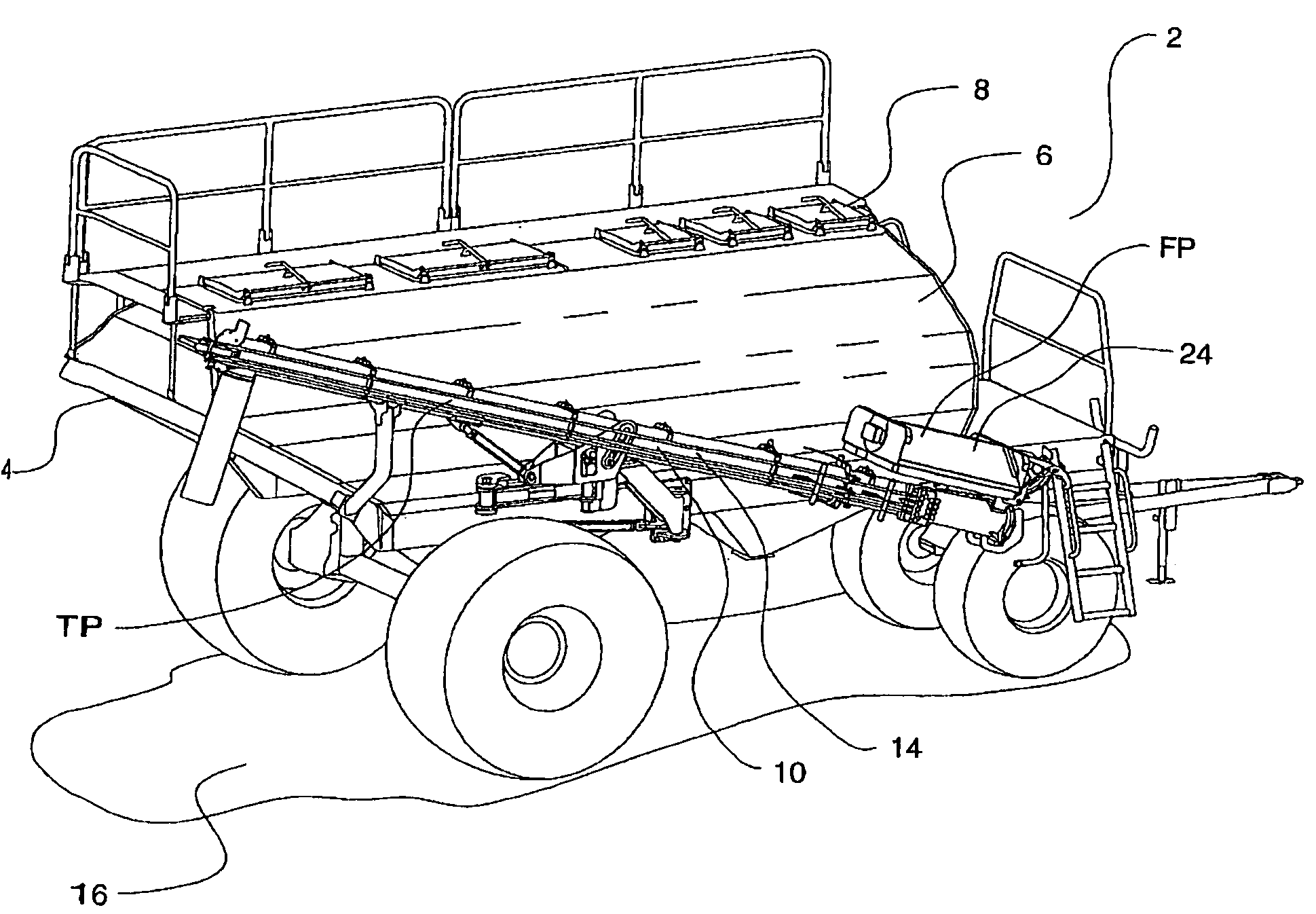

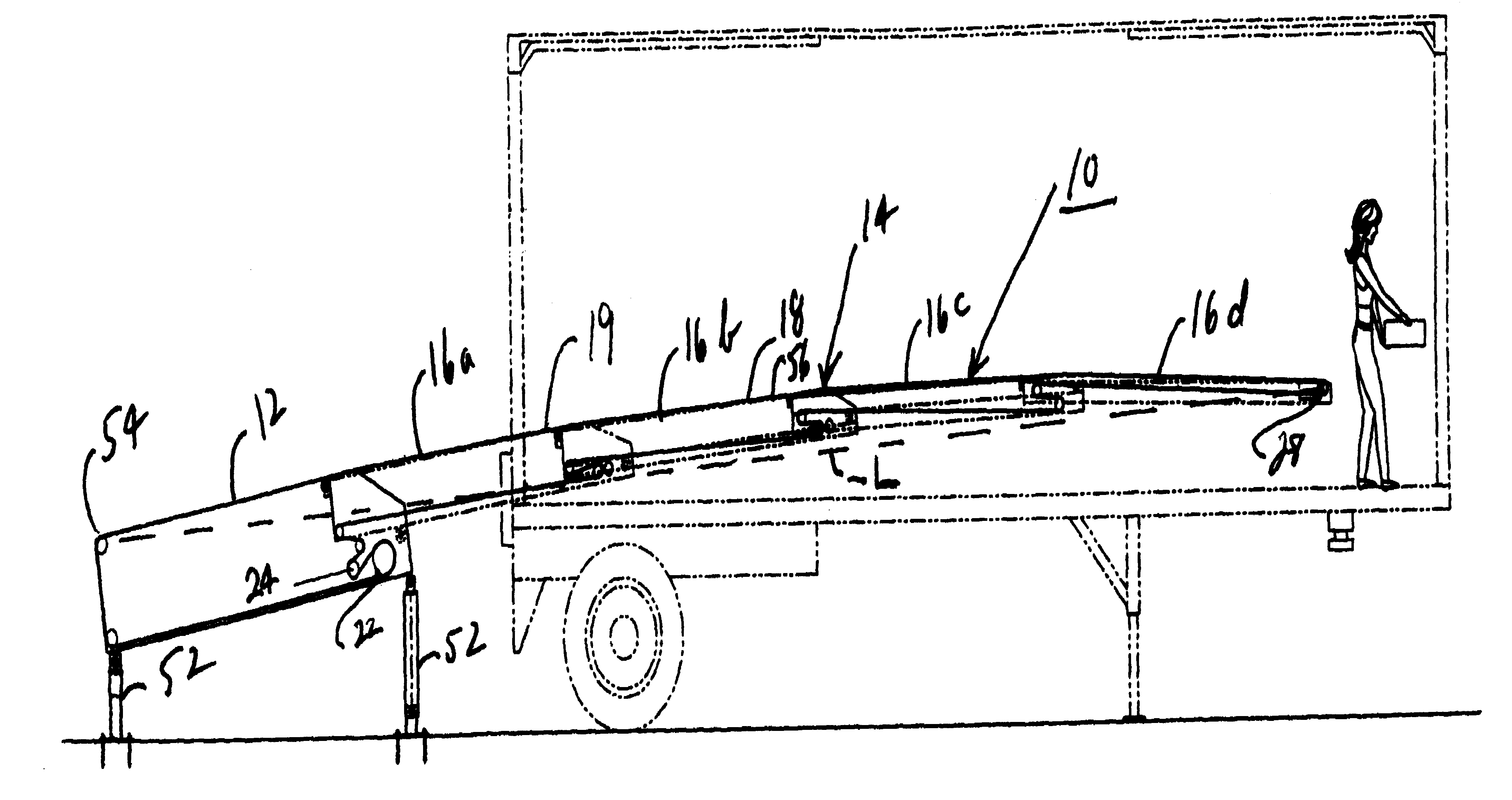

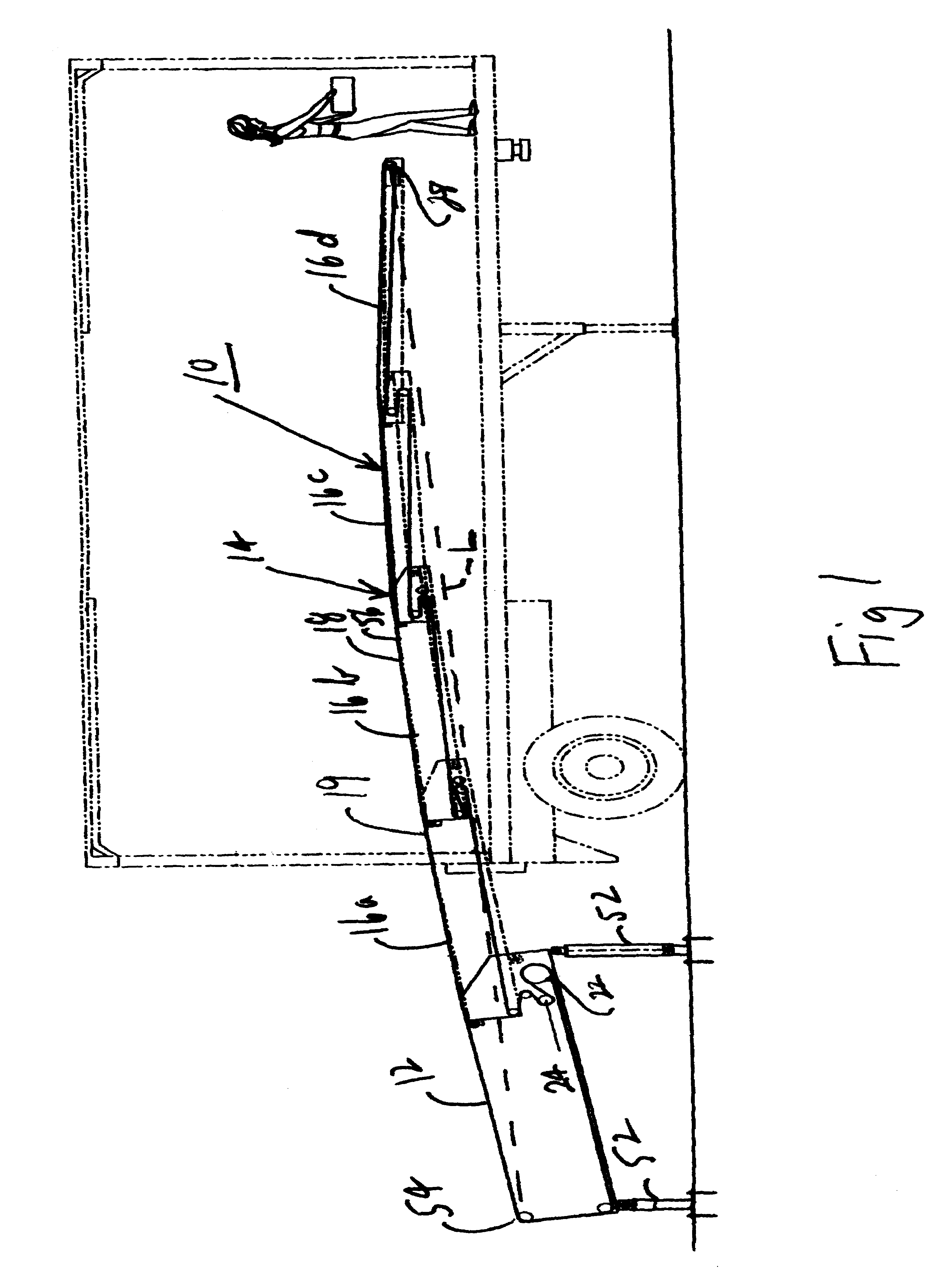

A trailer having support wheels and a frame adapted to be hitched to a truck, includes a support track extending longitudinally for supporting an unload conveyor. The conveyor is mounted by a turret to the support track and, thus, to the trailer frame, permitting the turret to move in a fore-to-aft direction, as well as to rotate about the vertical for about 180°, providing flexibility in use as well as transport and storage. A support module, carrying at least one storage container is mounted on the trailer frame. The storage containers may be provided in a number of different sizes and they may be arranged in various configurations suiting the user's needs. The turret is positioned along the track beneath a desired seed container, which may then be unloaded by the conveyor to fill a planter seed box or grain drill, or for other seed handling applications.

Owner:MERIDIAN MFG

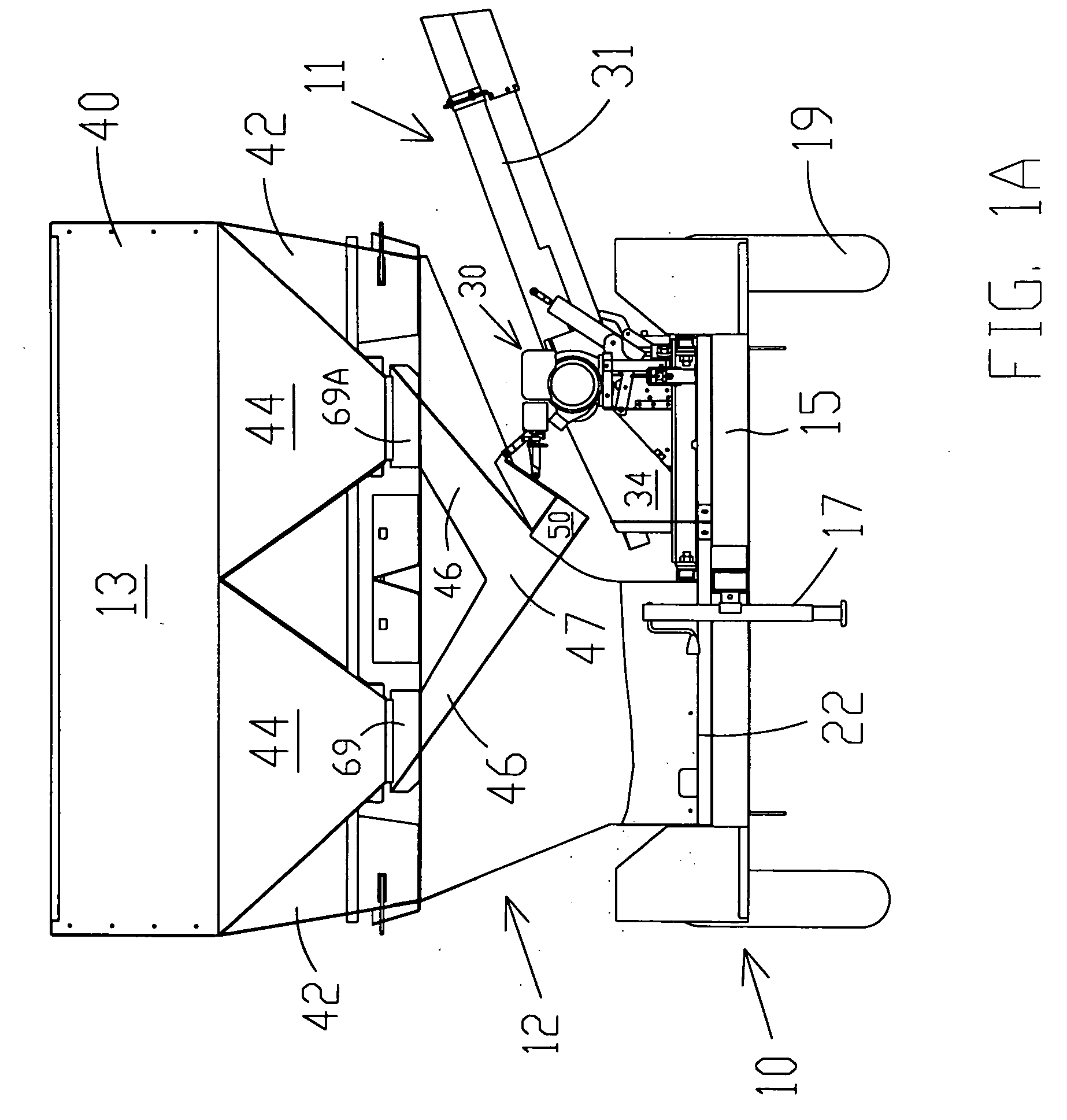

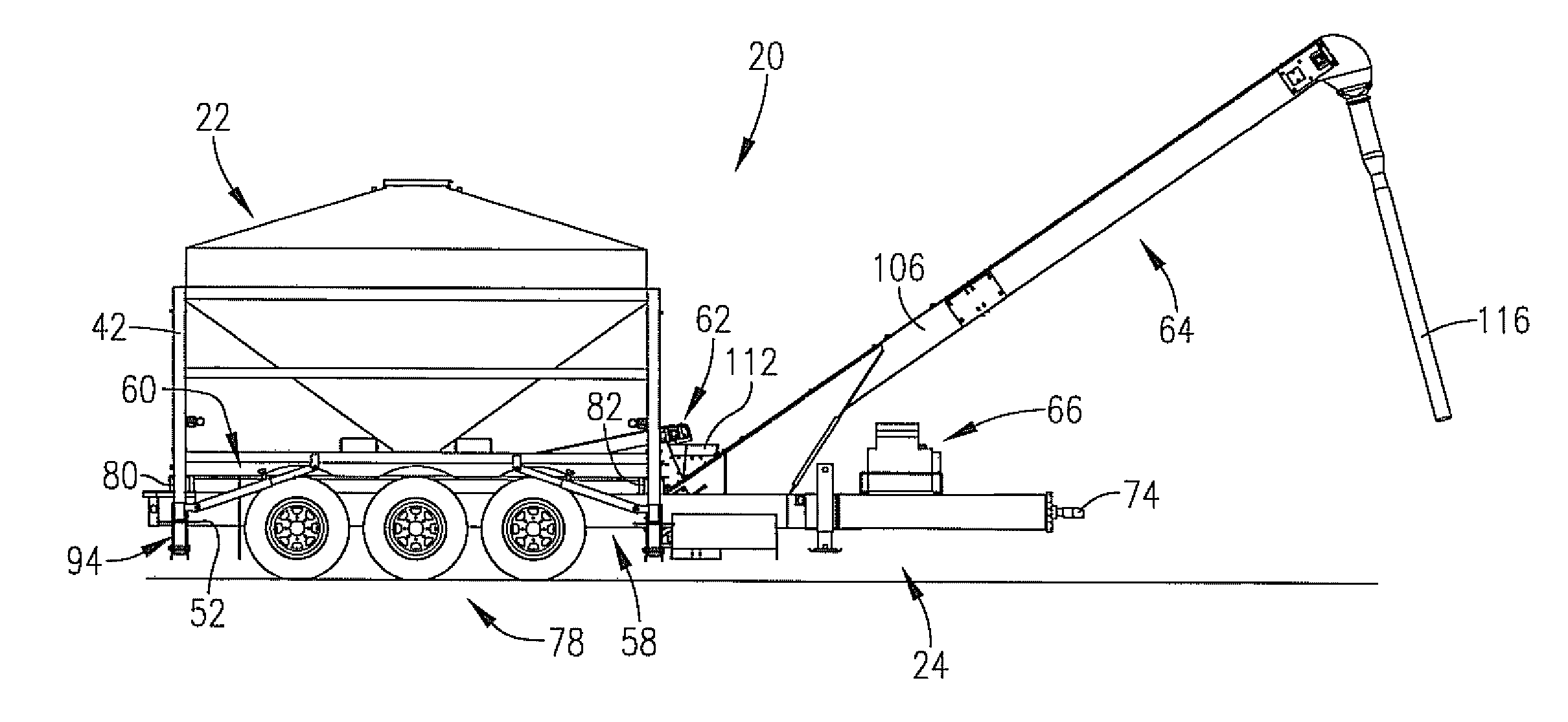

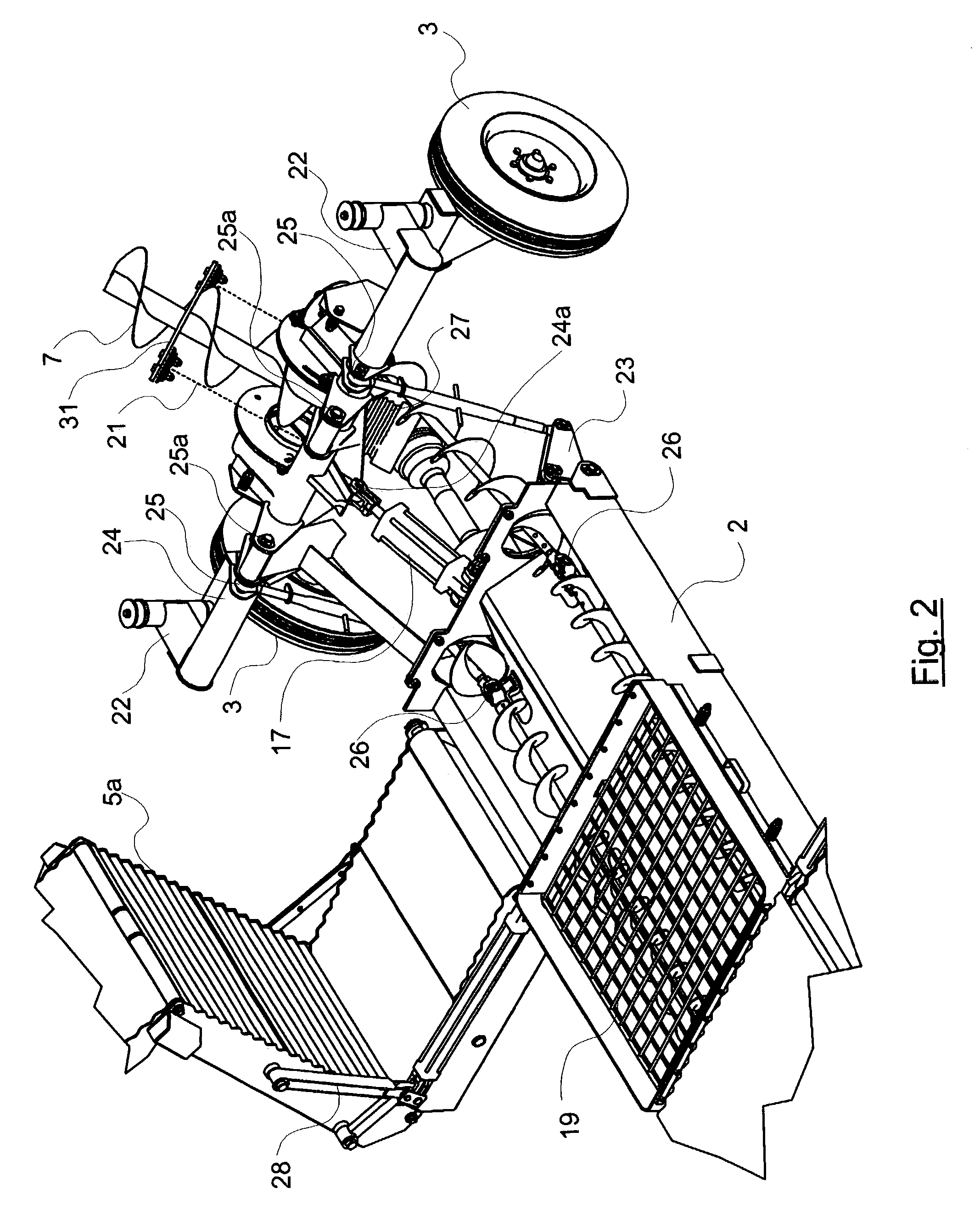

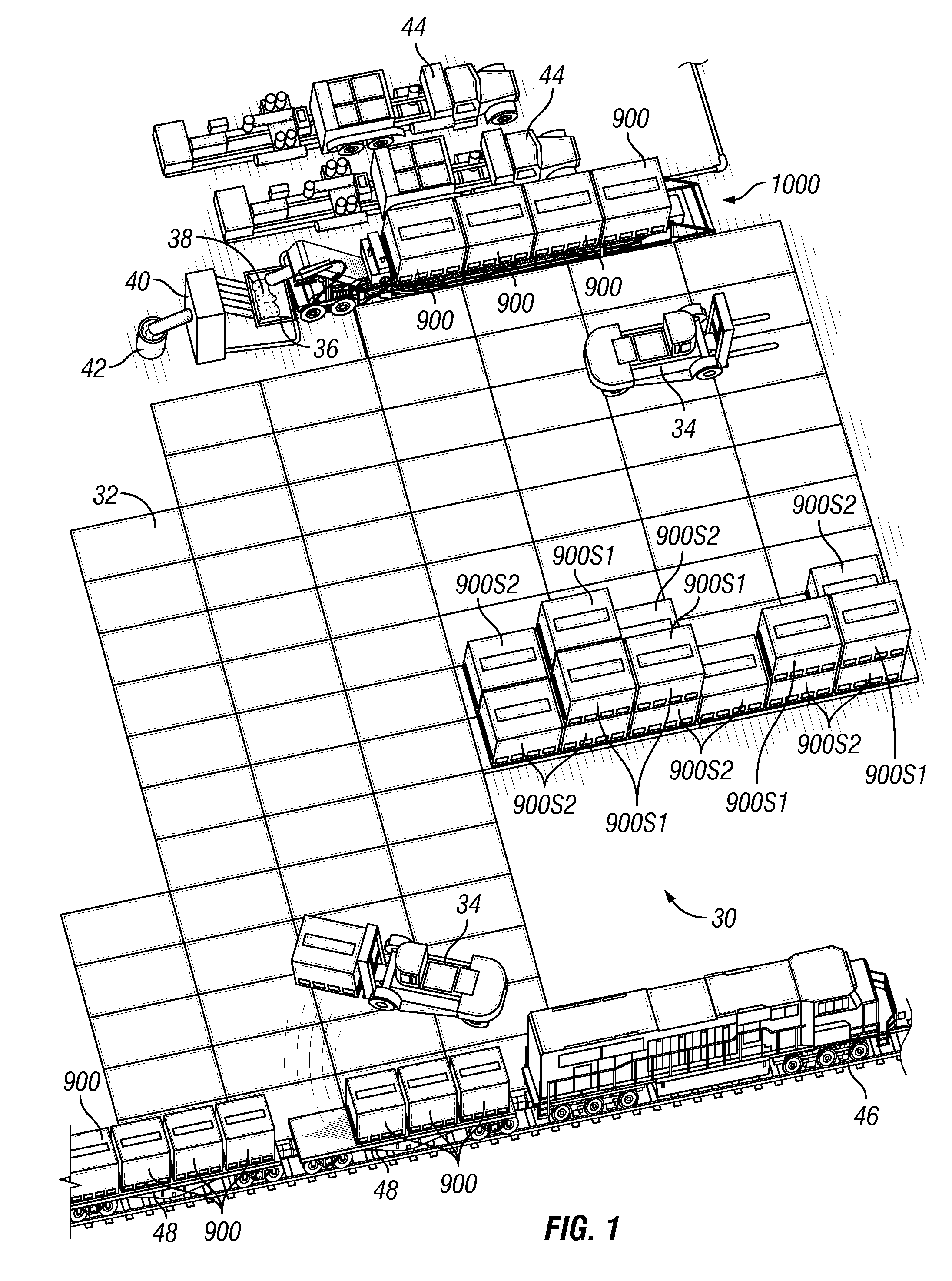

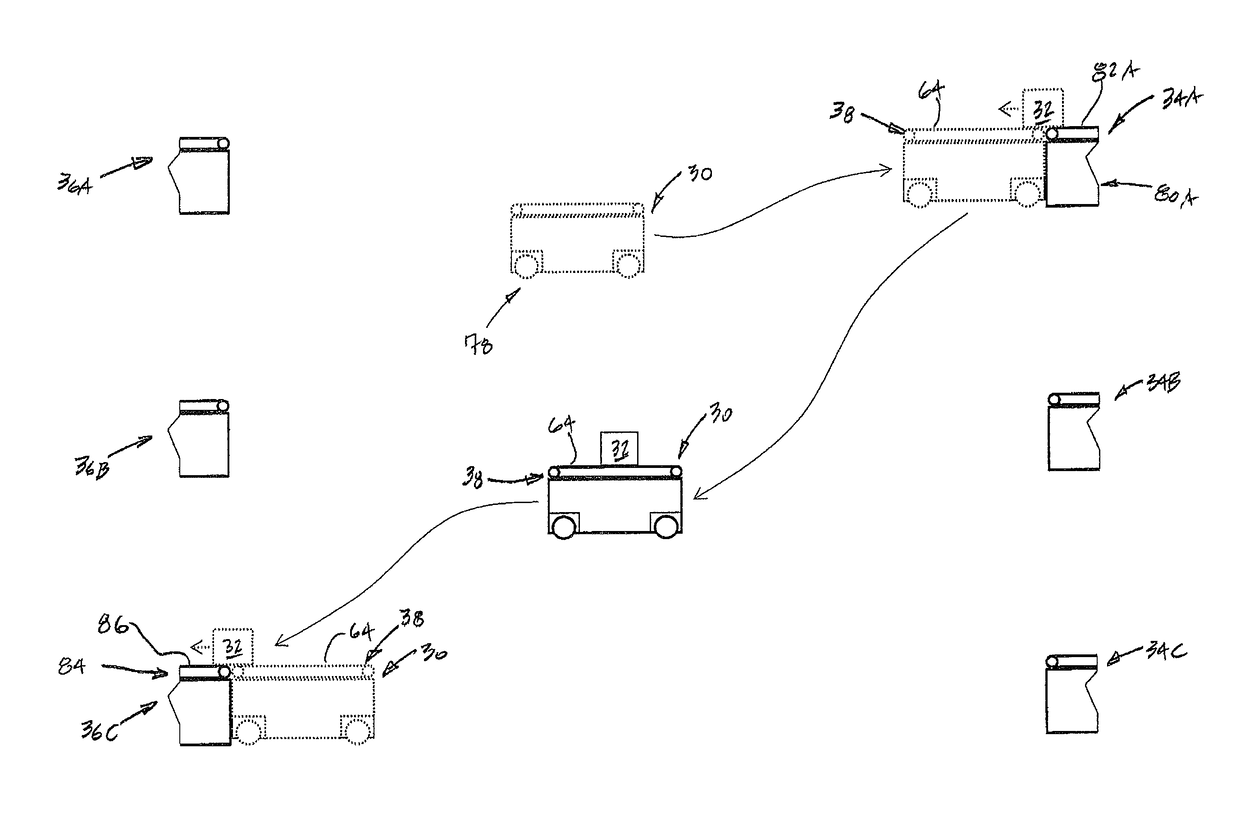

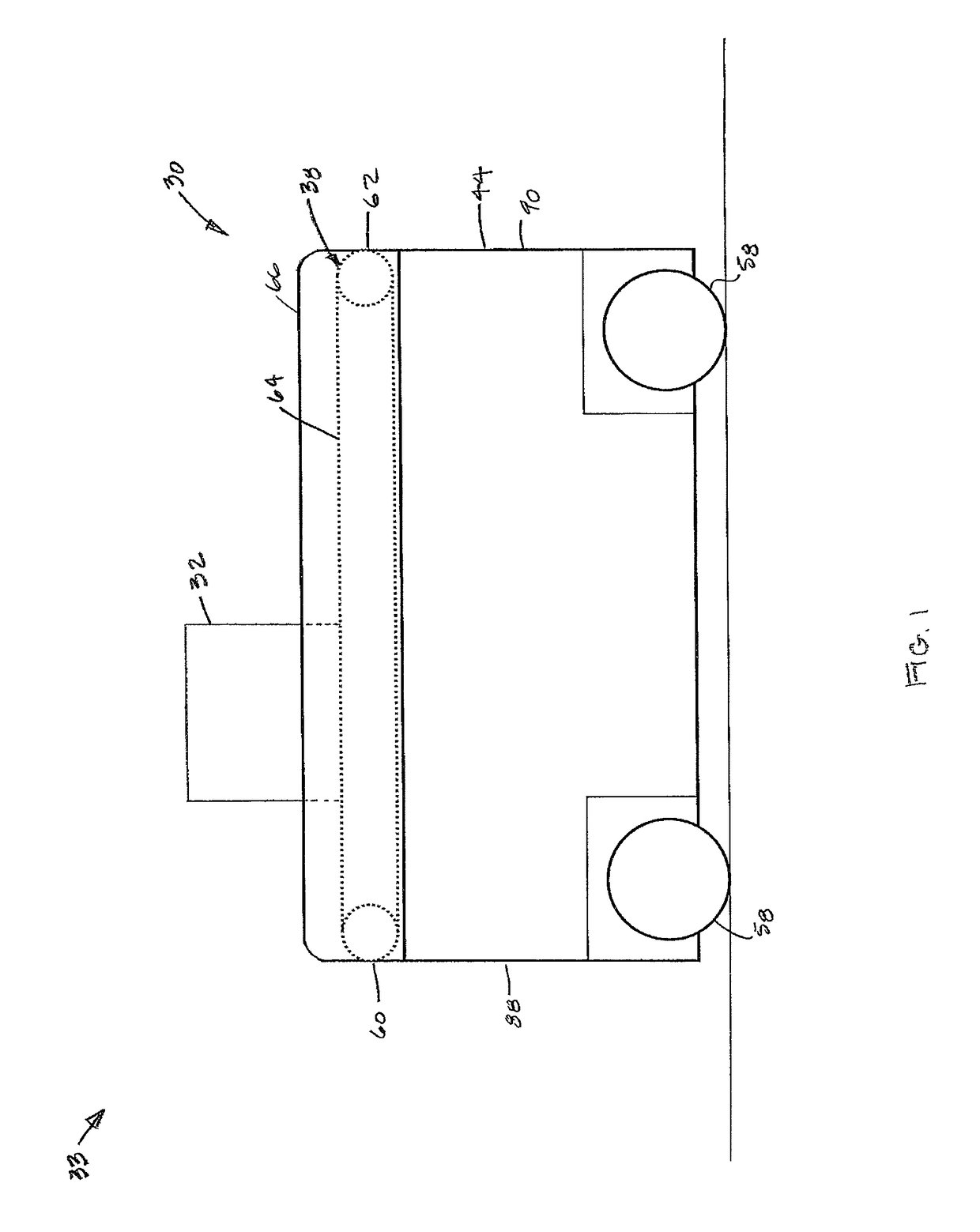

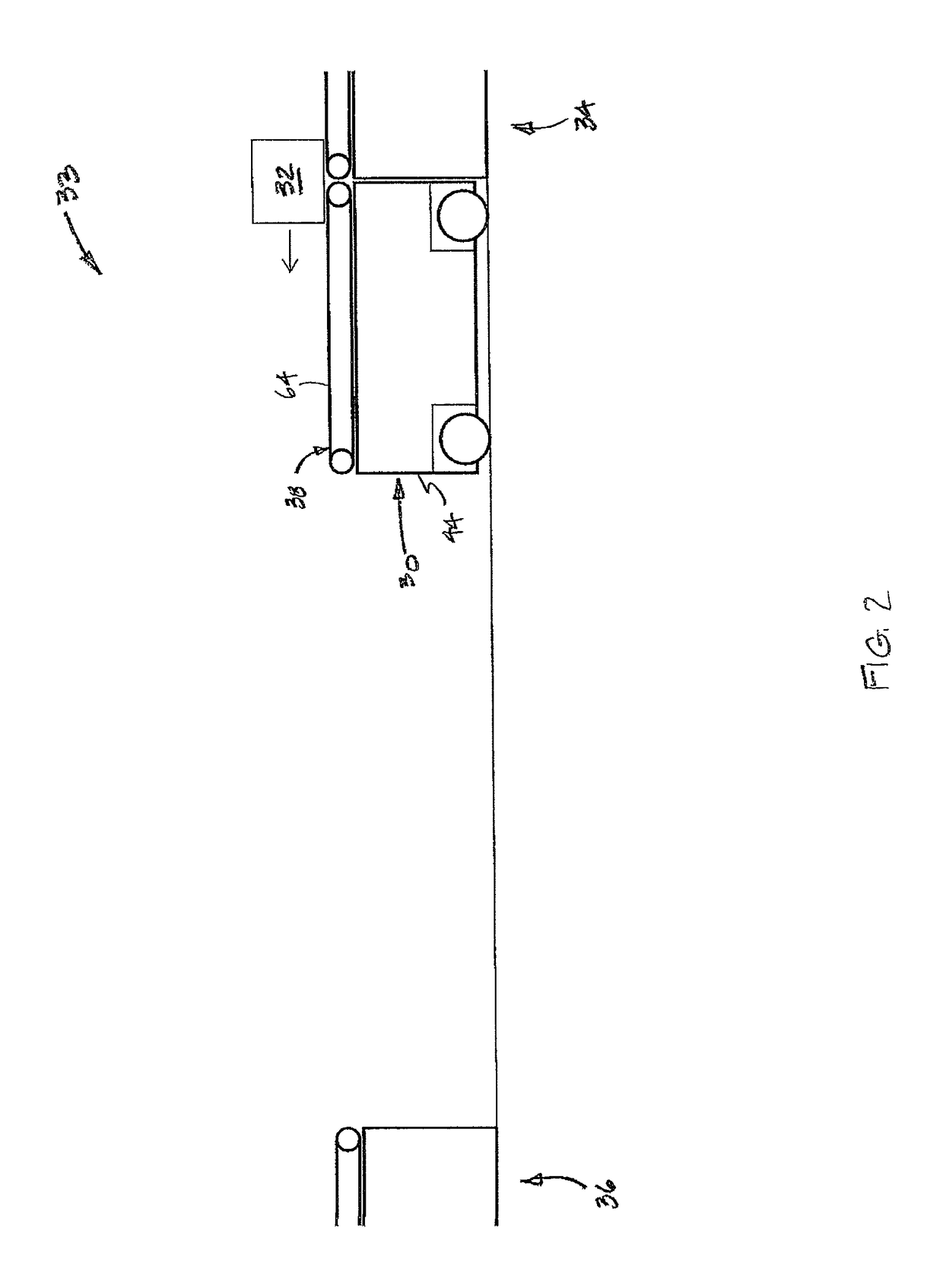

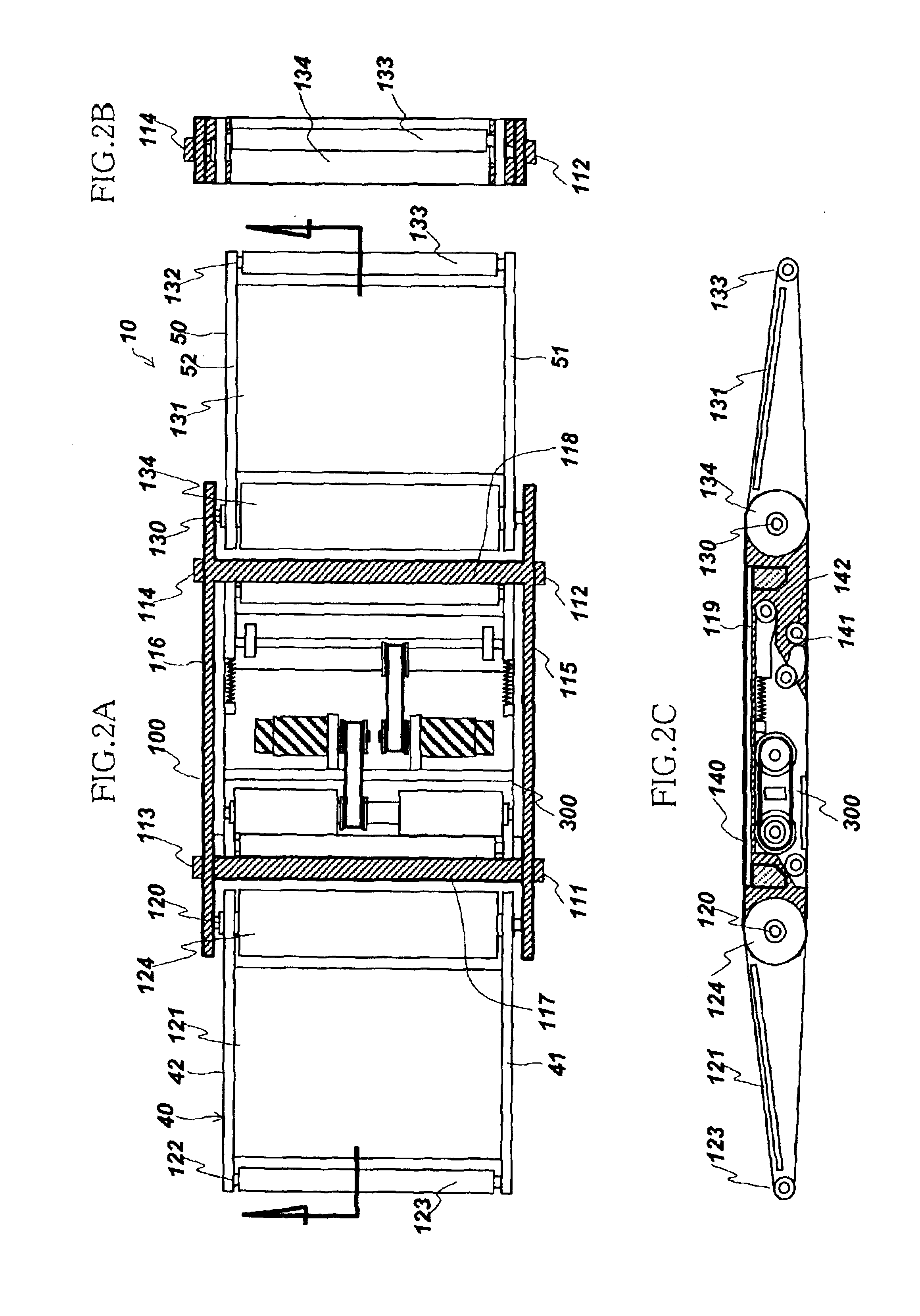

Bulk seed handling system

InactiveUS8573917B2Facilitates transfer and handlingEasy to handleConveyorsFertiliser distributersEngineeringHandling system

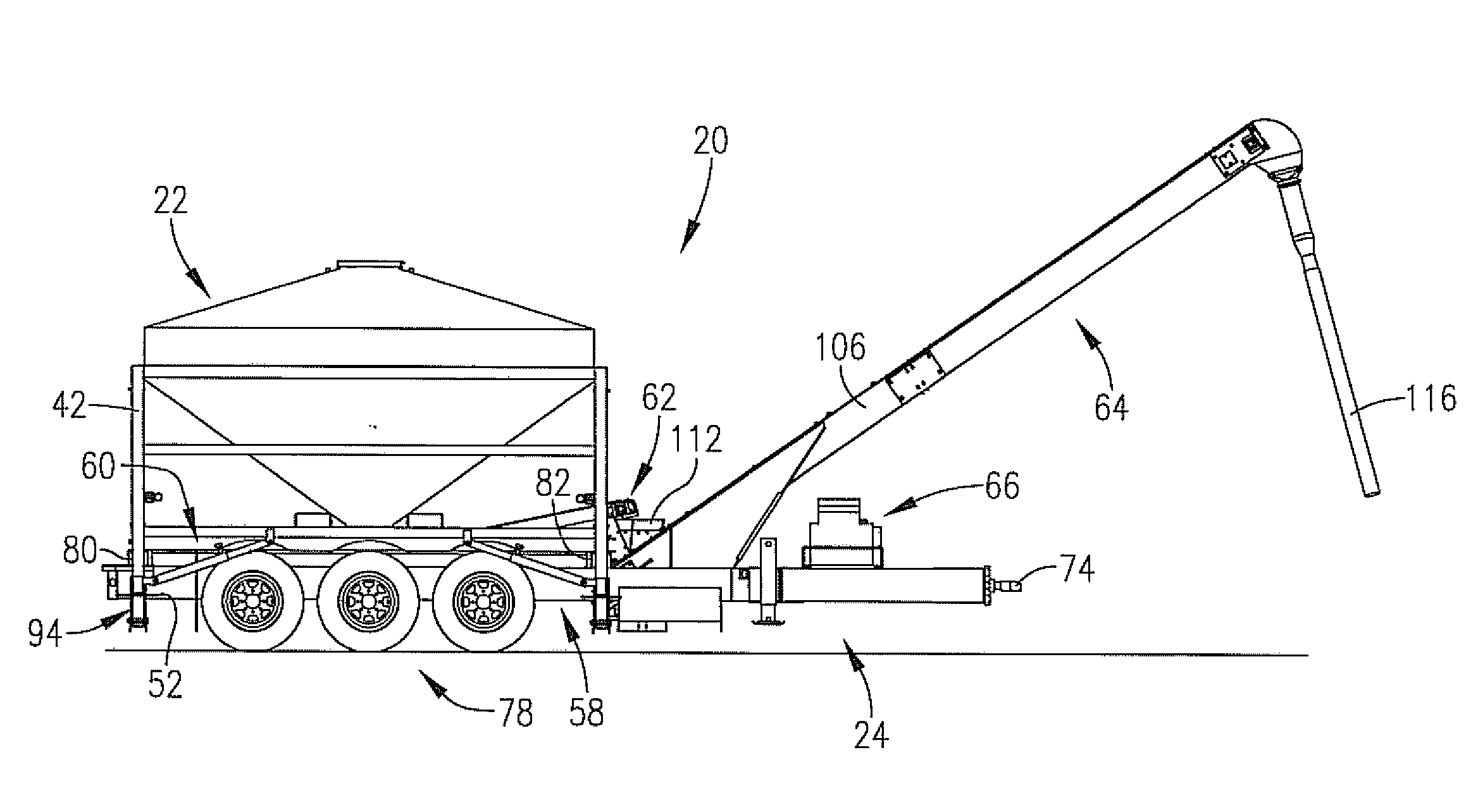

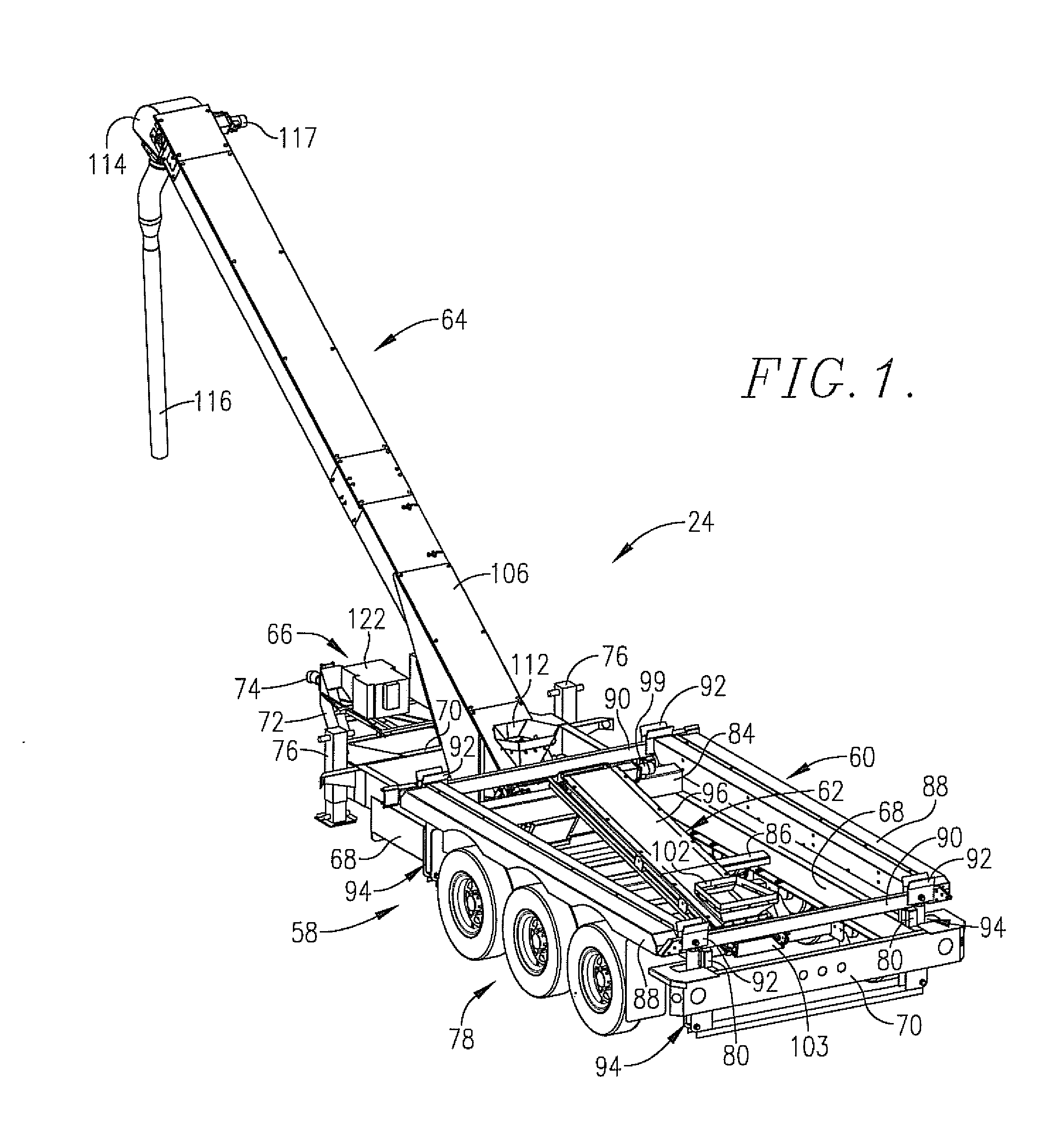

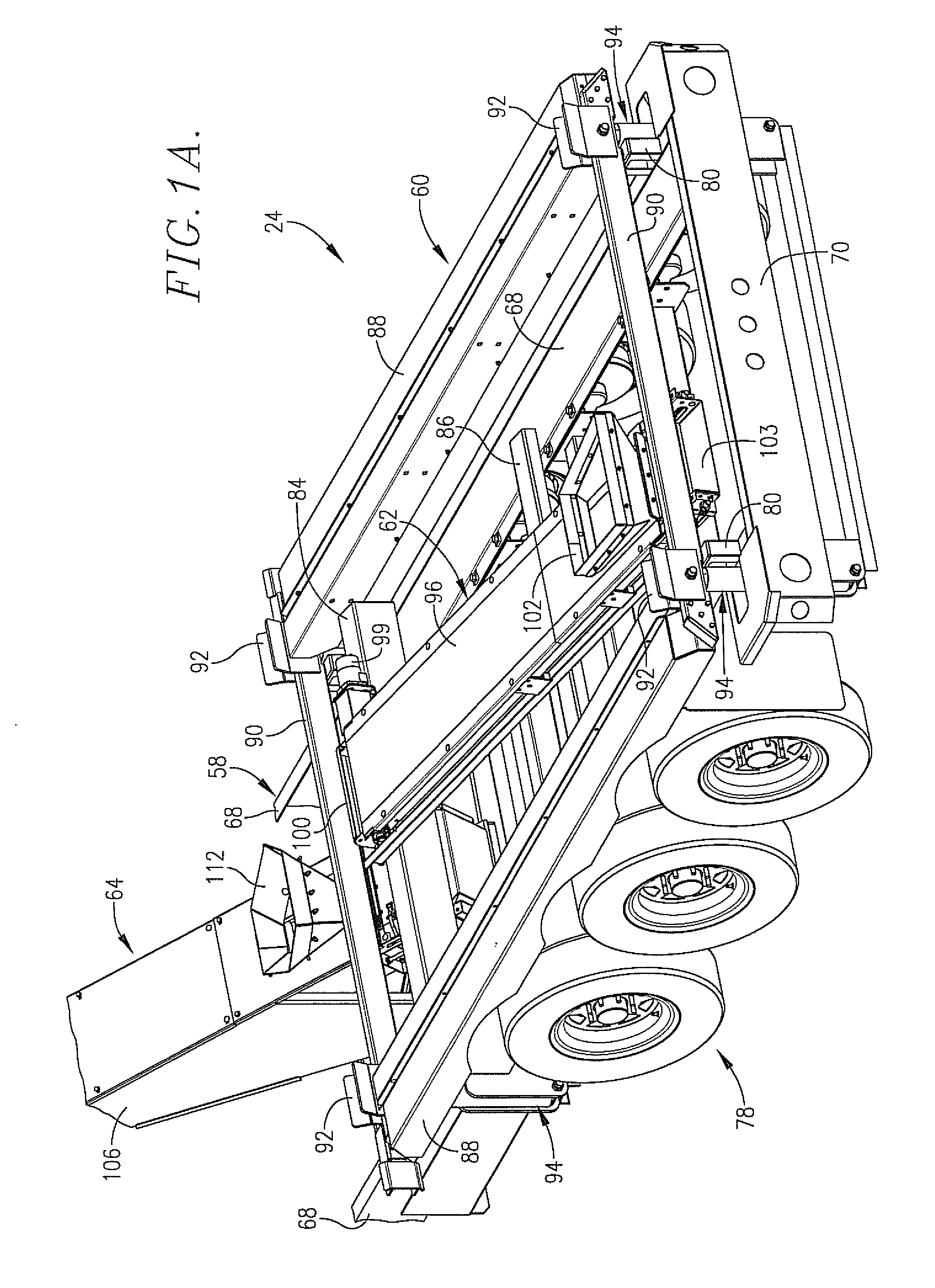

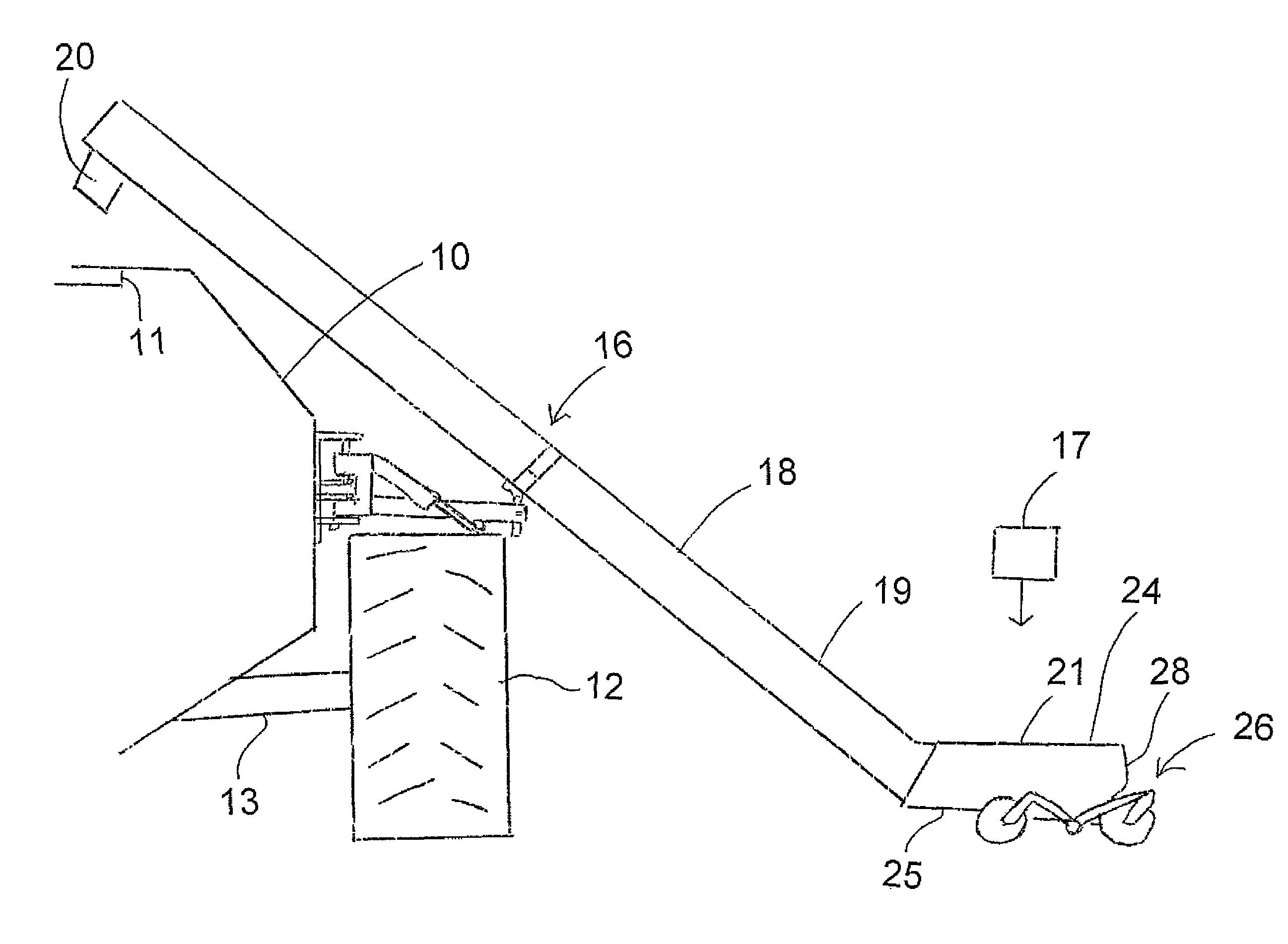

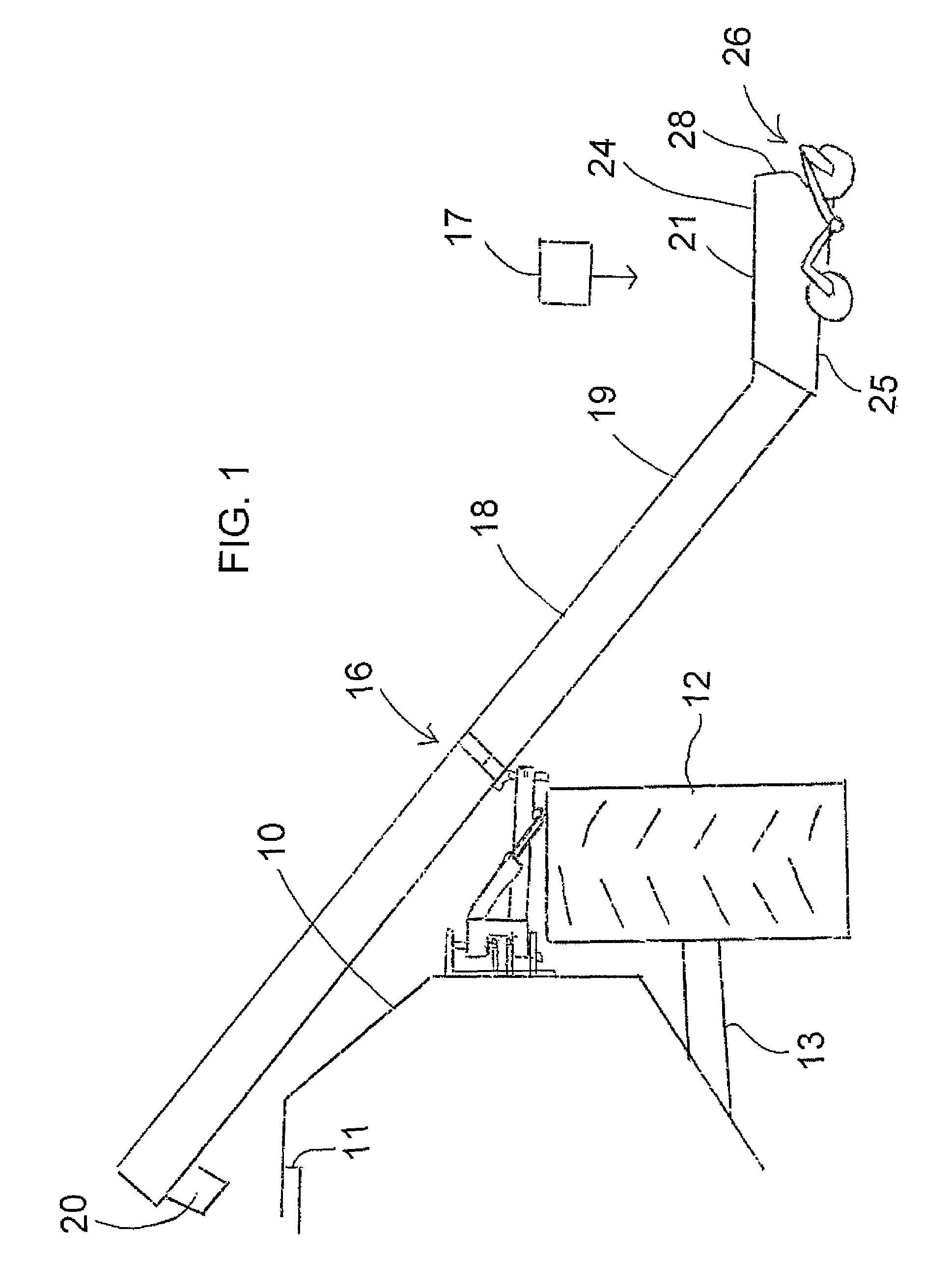

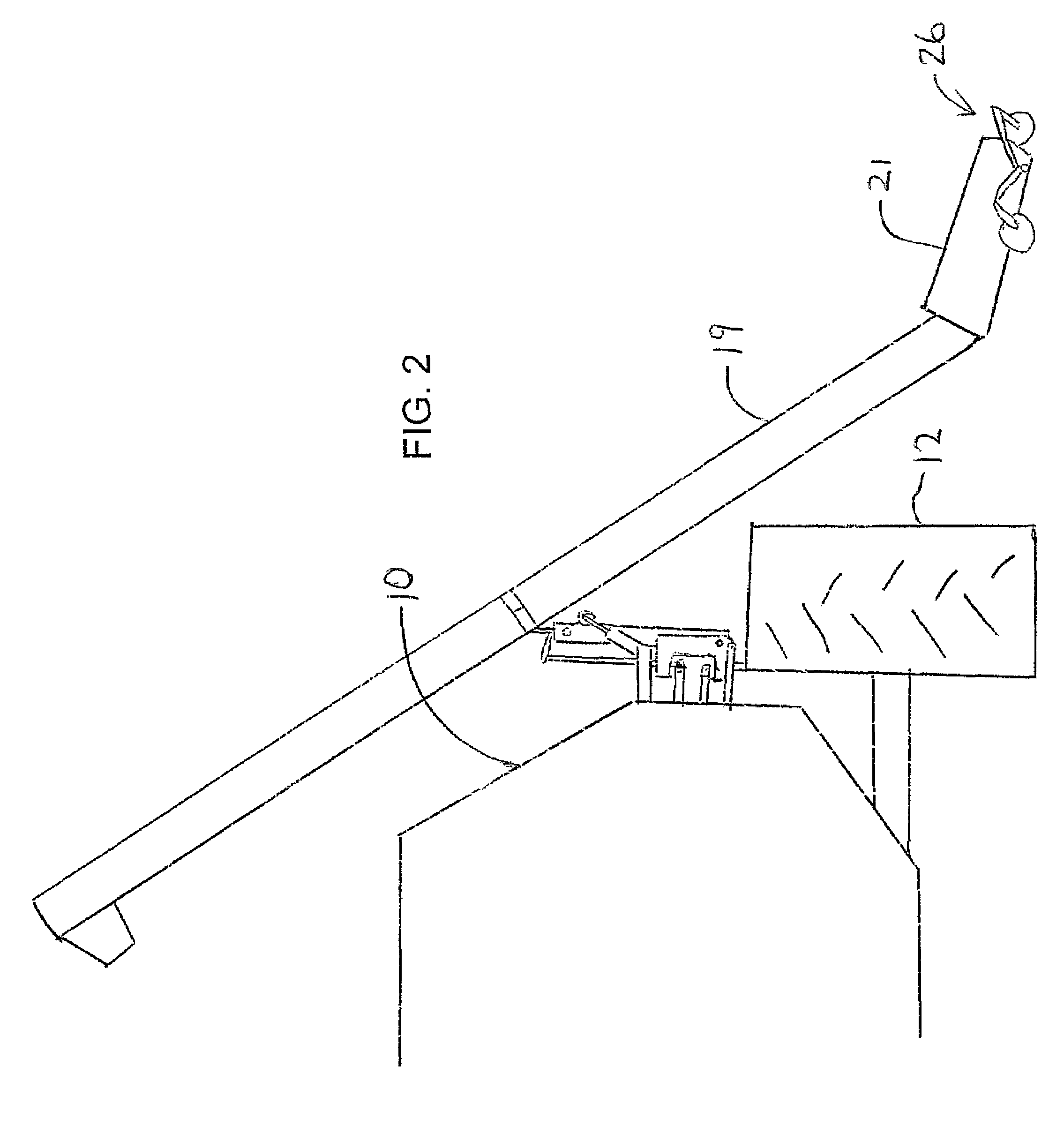

A bulk seed handling system (20) is provided to facilitate seed transfer from a distributor to a farm and then to a planter or the like. The handling system (20) includes one or more upright bin assemblies (22) adapted to be moved in a filled condition, and a trailer (24) designed to move the bin assembly (22) and unload seed therefrom. The bin assembly (22) includes a seed bin (26) having a lower unload opening (34) and supported by a frame assembly (38) including telescopic legs (50) shiftable between a retractable travel position and an extended bin support position. The trailer (24) includes a lift frame (60) operable to engage and elevate the bin assembly (22) for travel with the legs (50) thereof in a retracted position, and a seed-conveying arrangement including an intermediate conveyor (62) and a delivery conveyor (64). At an unloading site, the intermediate conveyor (62) is shifted to an unloading position in communication with the bin unload opening (34) and the delivery conveyor (64) in order to transfer seed from the bin.

Owner:USC

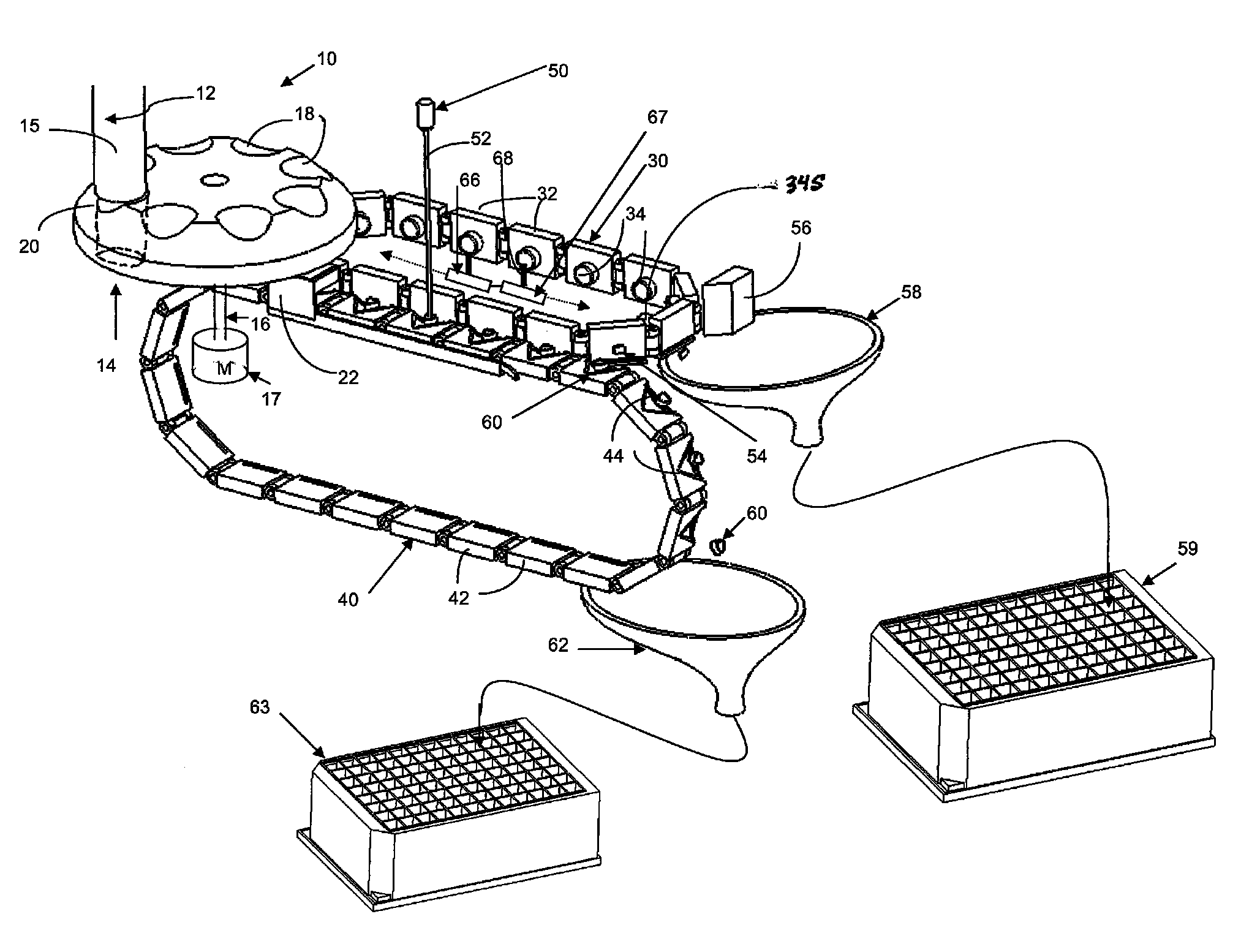

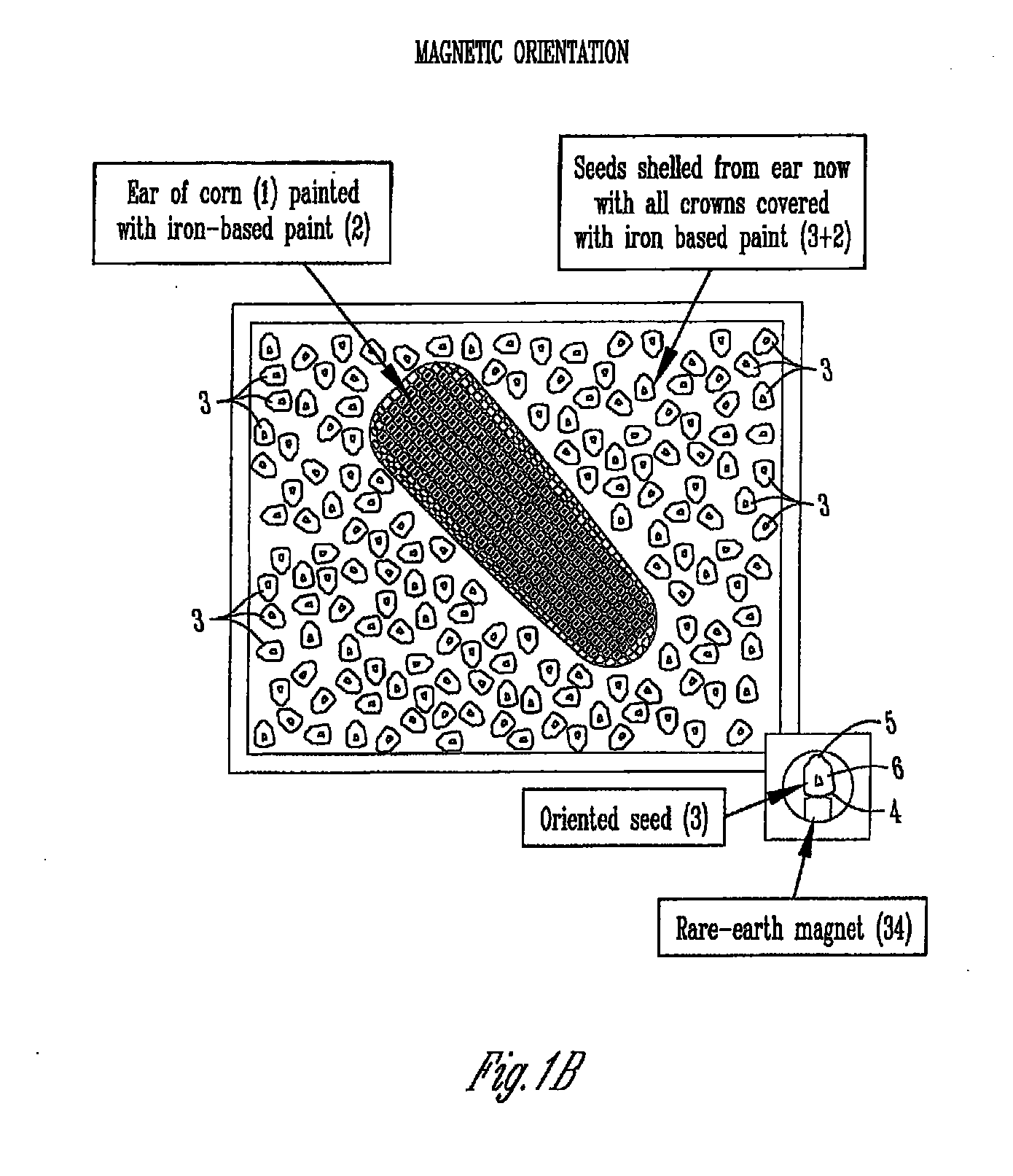

Apparatus, method and system for handling, positioning, and/or automatically orienting objects

InactiveUS20080131254A1Avoid small quantitiesMaximum flexibilityWithdrawing sample devicesPreparing sample for investigationEngineeringComputer vision

A method and apparatus for automatic positioning and / or orientation of an object. The method includes applying a substance or component to an object, or takes advantage of a substance or component already on or associated with an object. The substance or component has a characteristic that can be utilized to automatically attract the substance or component. That characteristic is used to position, move, and / or orient the object automatically, without requiring manual handling. The object can then be further processed or handled. In one embodiment, the substance or component is a magnetically active substance or component. The attraction can be actuated by a magnet.

Owner:PIONEER HI BRED INT INC

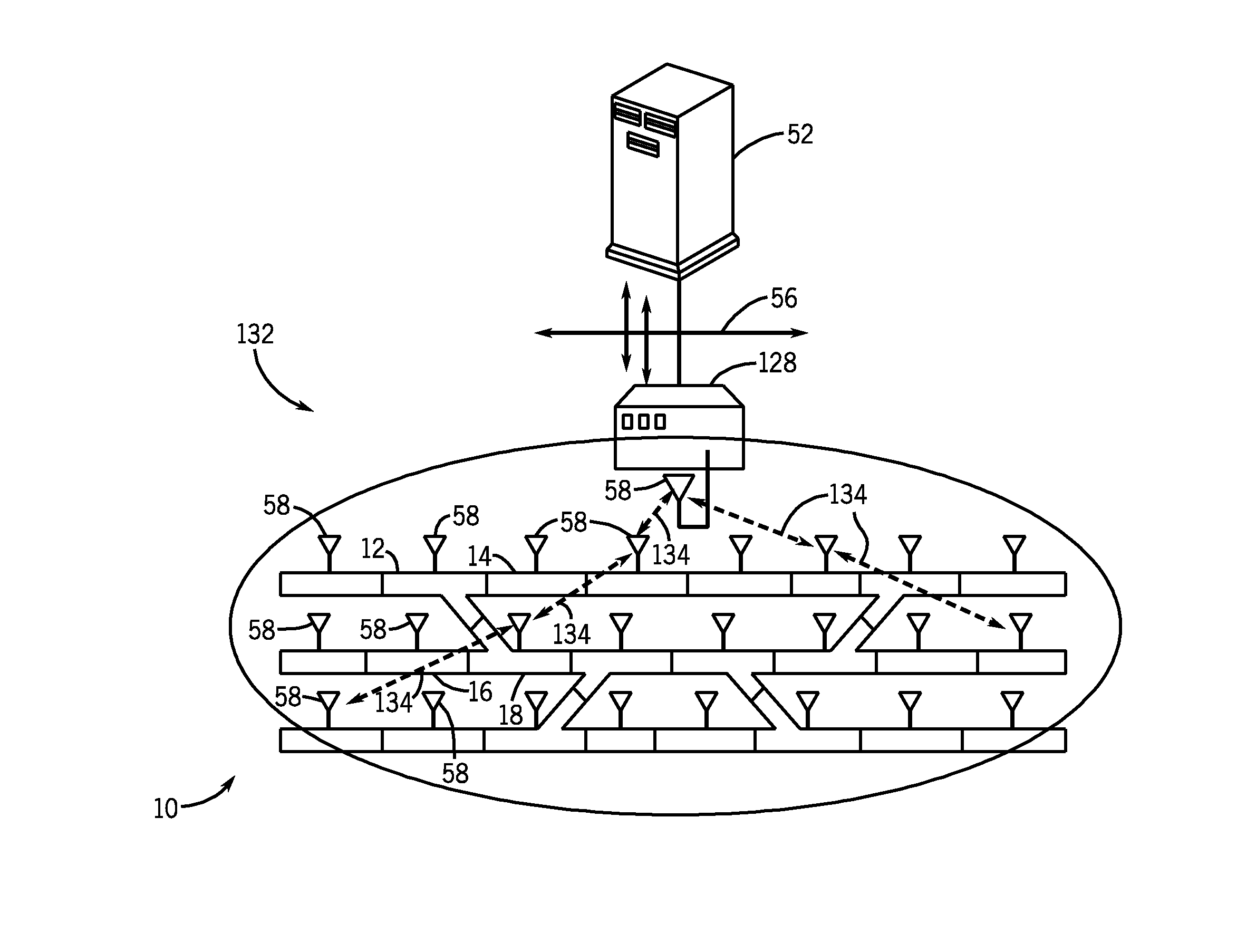

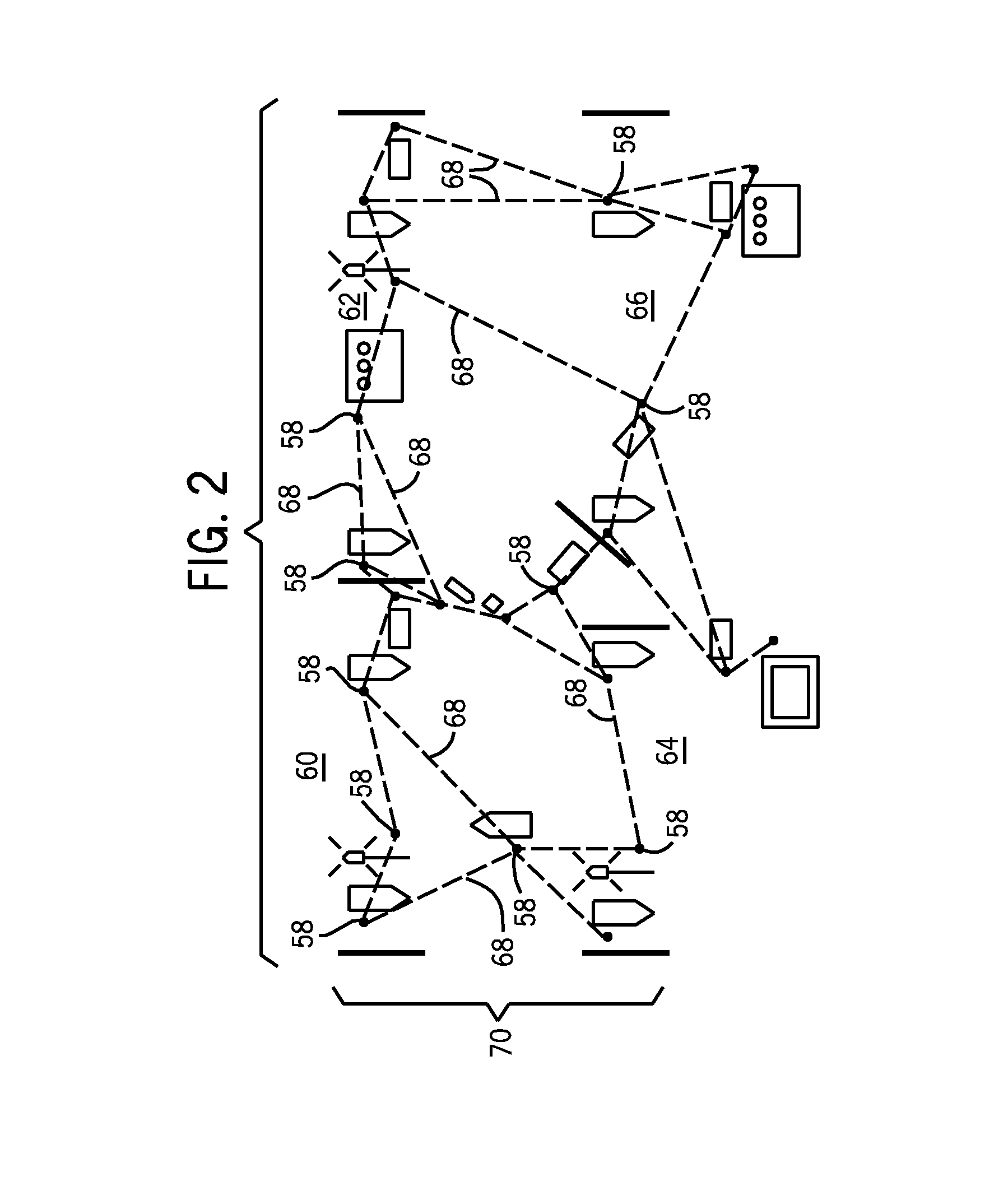

Modular wireless conveyor interconnection method and system

ActiveUS20090084657A1Control devices for conveyorsMultiple digital computer combinationsElectrical batteryComputer module

A modular conveyor system is disclosed in which components of each conveyor module is designed for wireless mesh communication. The communications may be within a module or between modules. Certain of the components may be powered by battery, such that the components may be completely wireless. The network may be entirely self-configuring such that the modules may be assembled and the network established in a straightforward manner.

Owner:ROCKWELL AUTOMATION TECH

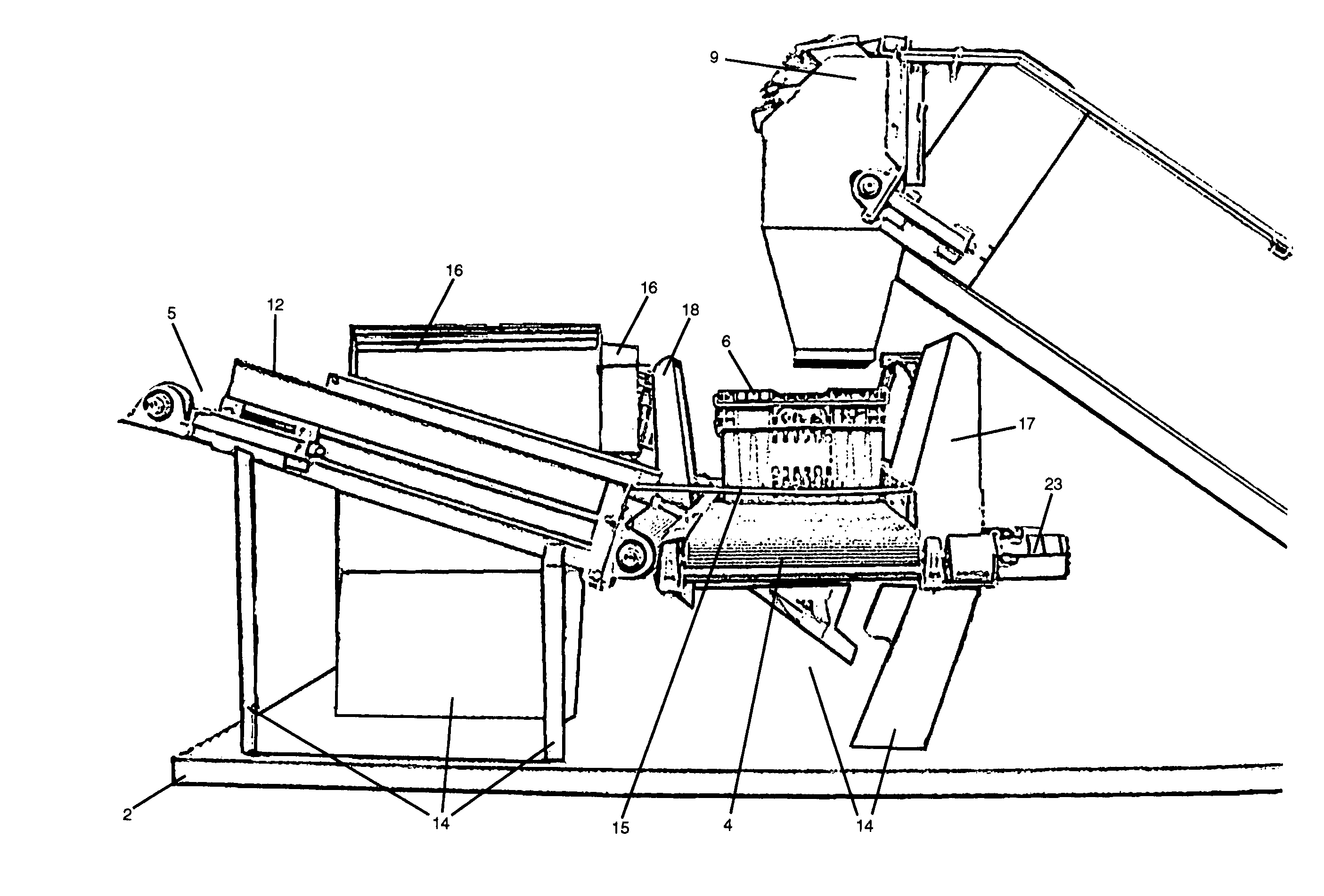

Bulk Material Container and Container Discharging Apparatus

A bulk material container suitable for handling with a pallet mover includes a hopper portion which tapers downwardly to a discharge gate which is in an upright orientation offset to one side of the container. When several containers are supported on a flat deck vehicle or trailer, the gates of all of the containers can be oriented to discharge to the sides of the deck. A discharge apparatus supported on the deck comprises a track supporting a discharge conveyor for displacement along the sides of the deck such that an inlet hopper of the conveyor can be aligned with respective ones of the side discharging gates of the containers supported on the deck.

Owner:REDEKOP JOHAN

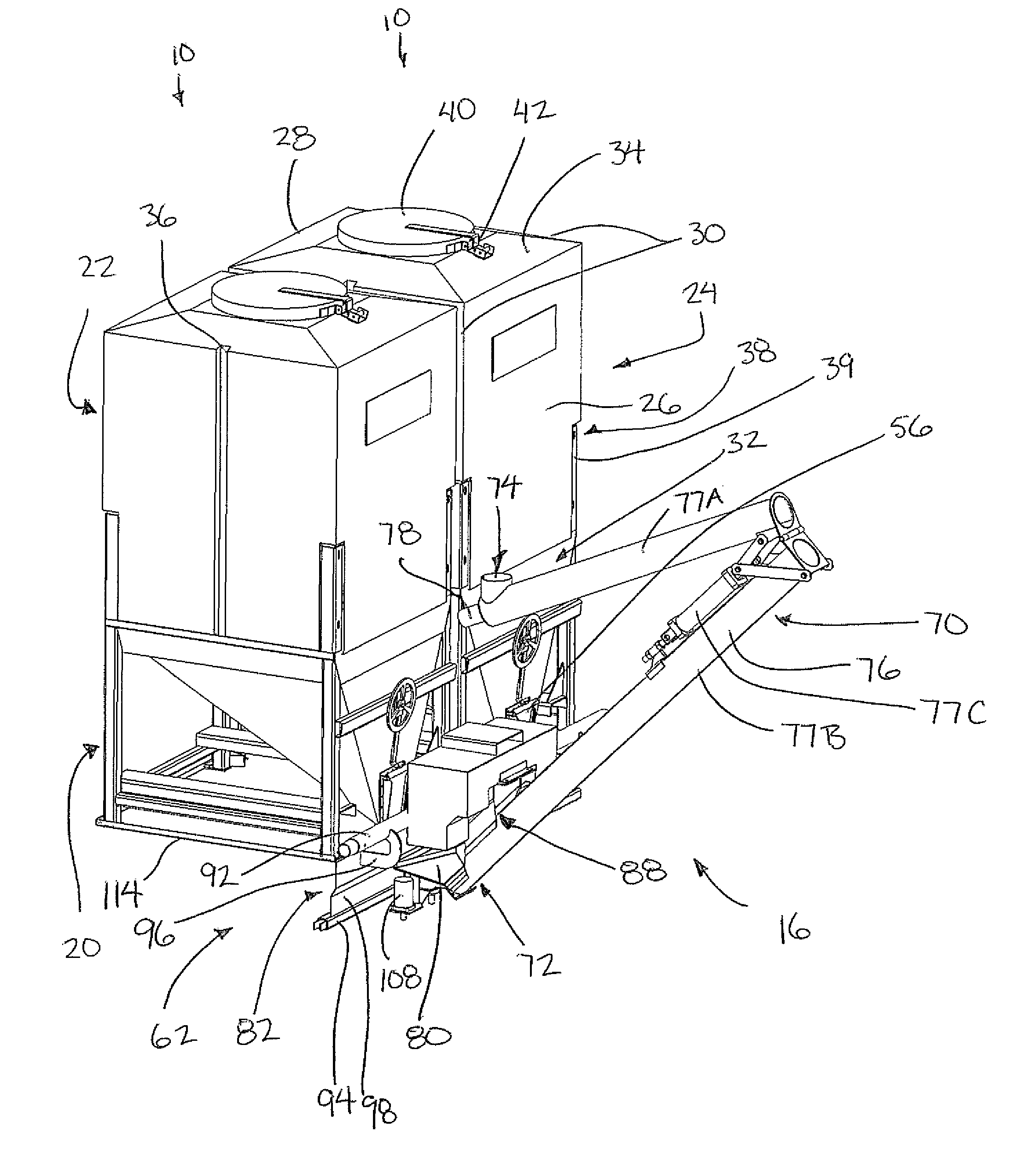

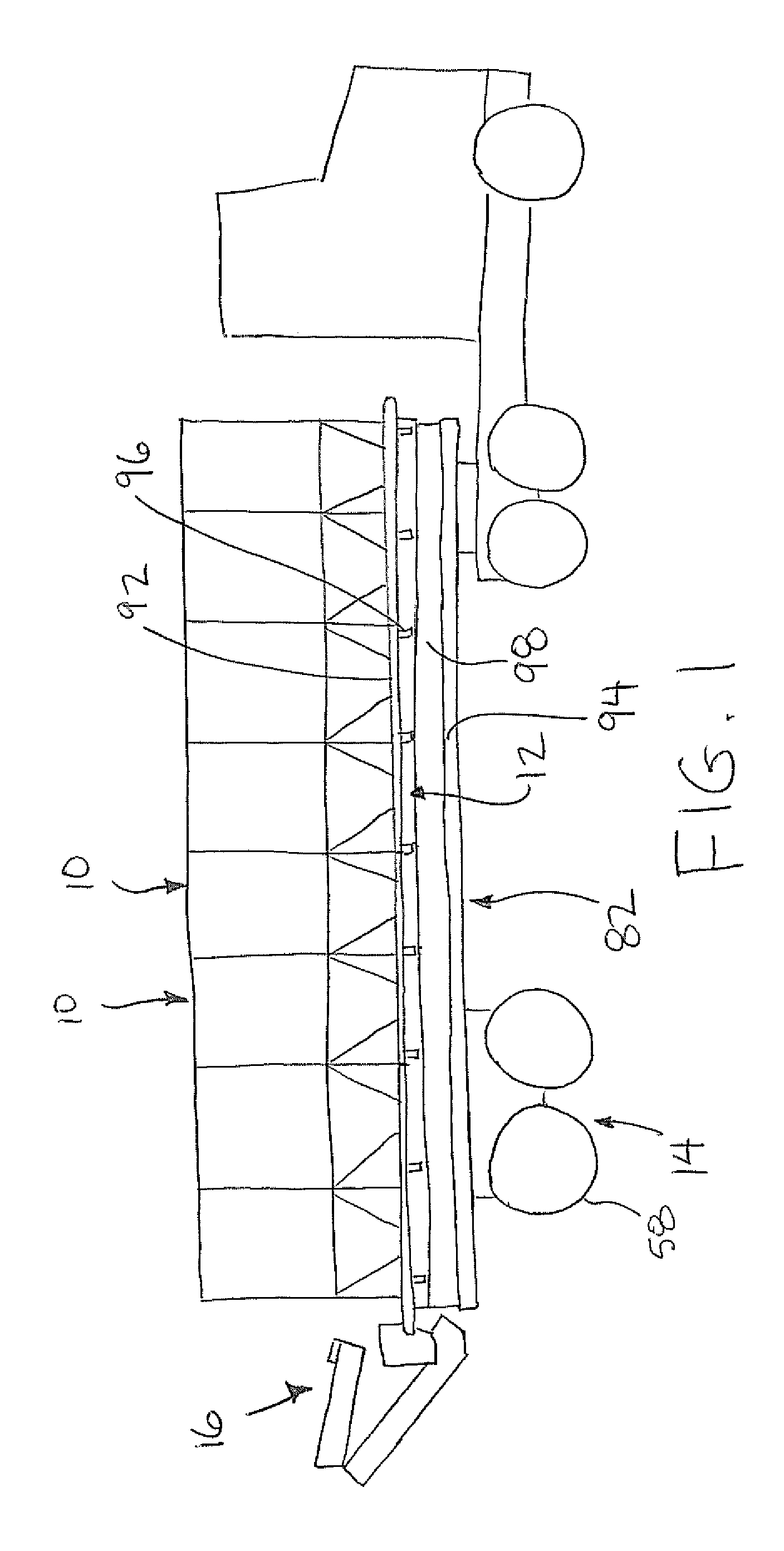

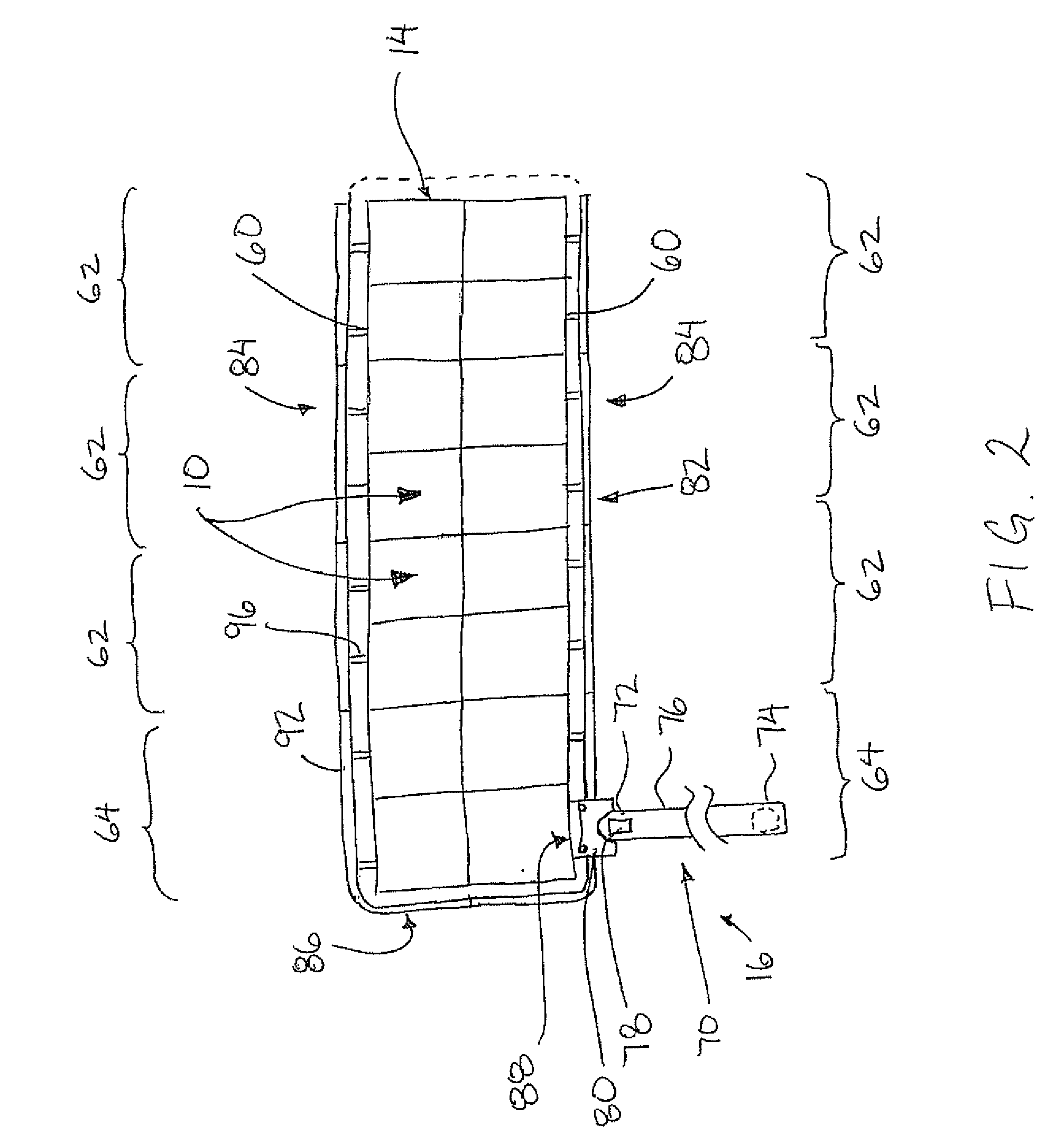

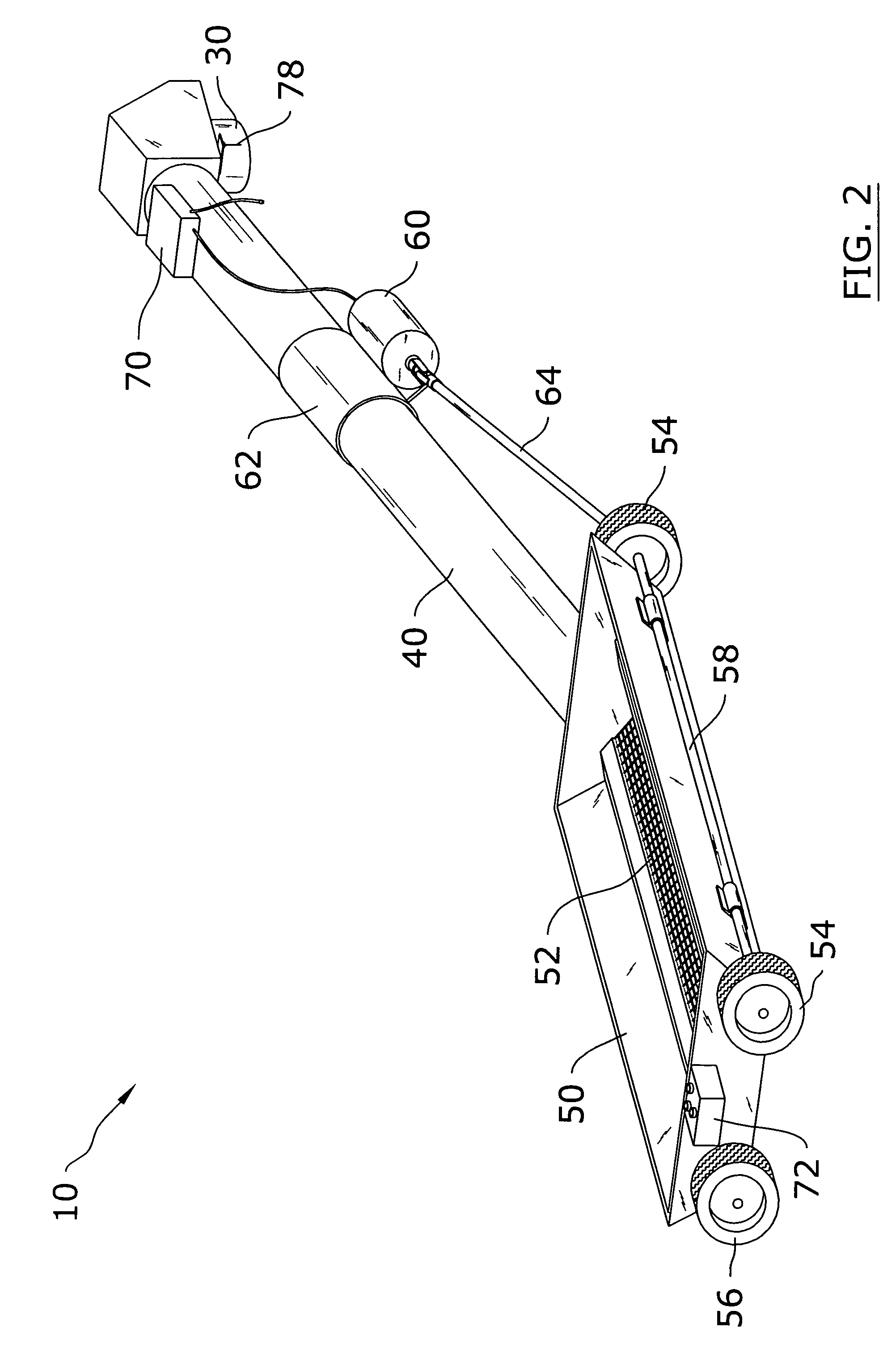

Bulk seed handling system

InactiveUS20100040446A1Easy transferEasy to handleConveyorsFertiliser distributersEngineeringHandling system

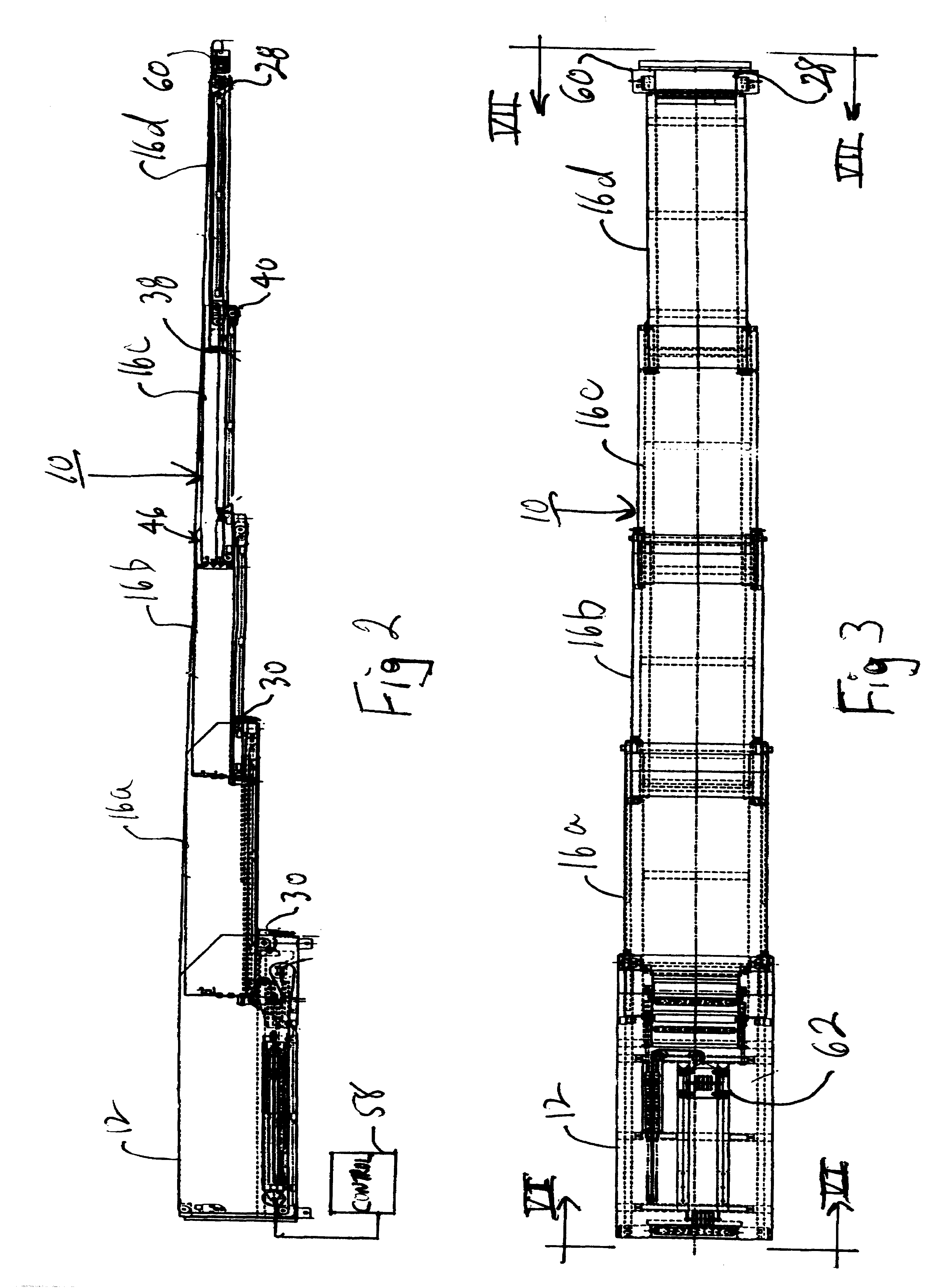

A bulk seed handling system (20) is provided to facilitate seed transfer from a distributor to a farm and then to a planter or the like. The handling system (20) includes one or more upright bin assemblies (22) adapted to be moved in a filled condition, and a trailer (24) designed to move the bin assembly (22) and unload seed therefrom. The bin assembly (22) includes a seed bin (26) having a lower unload opening (34) and supported by a frame assembly (38) including telescopic legs (50) shiftable between a retractable travel position and an extended bin support position. The trailer (24) includes a lift frame (60) operable to engage and elevate the bin assembly (22) for travel with the legs (50) thereof in a retracted position, and a seed-conveying arrangement including an intermediate conveyor (62) and a delivery conveyor (64). At an unloading site, the intermediate conveyor (62) is shifted to an unloading position in communication with the bin unload opening (34) and the delivery conveyor (64) in order to transfer seed from the bin.

Owner:USC

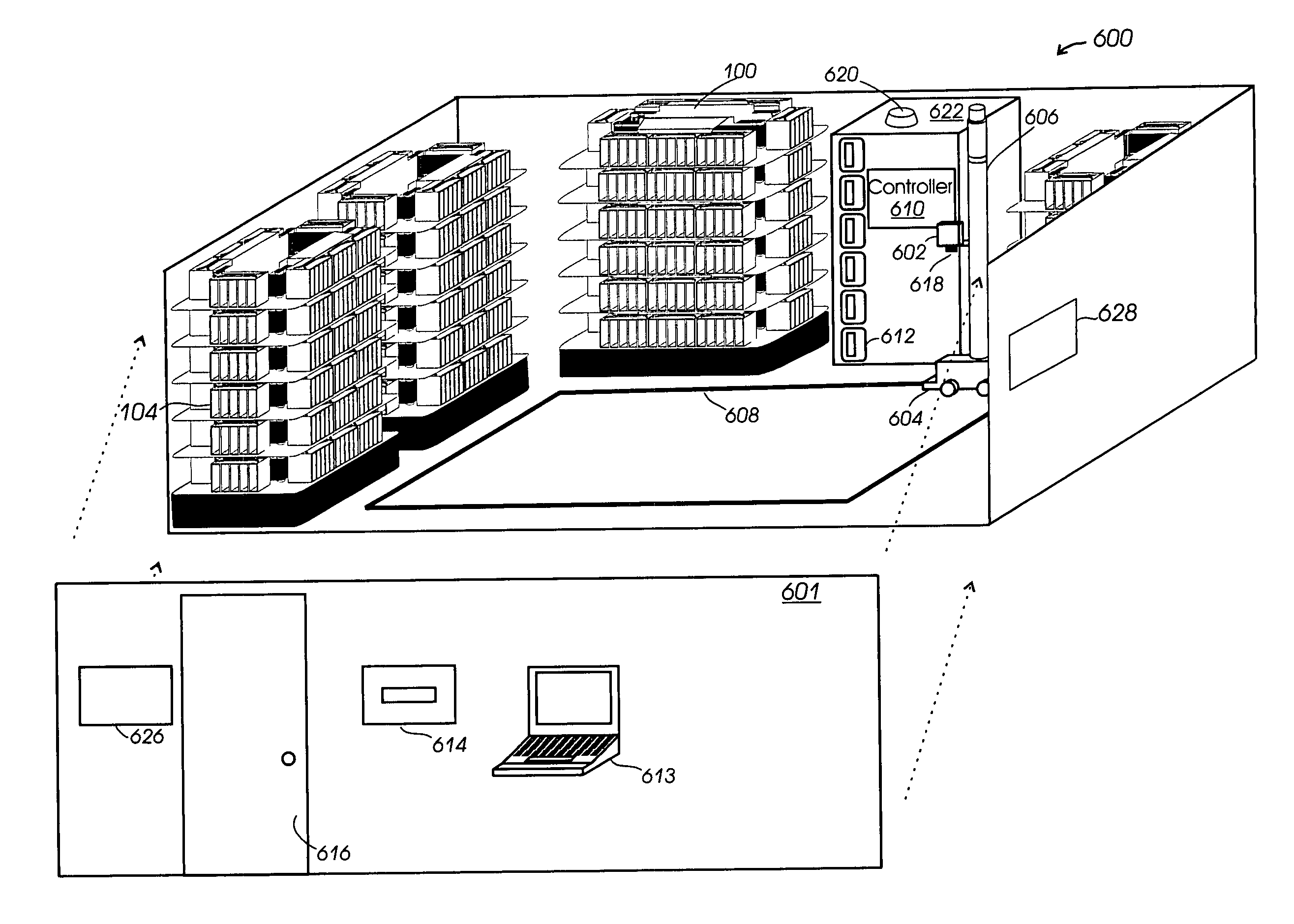

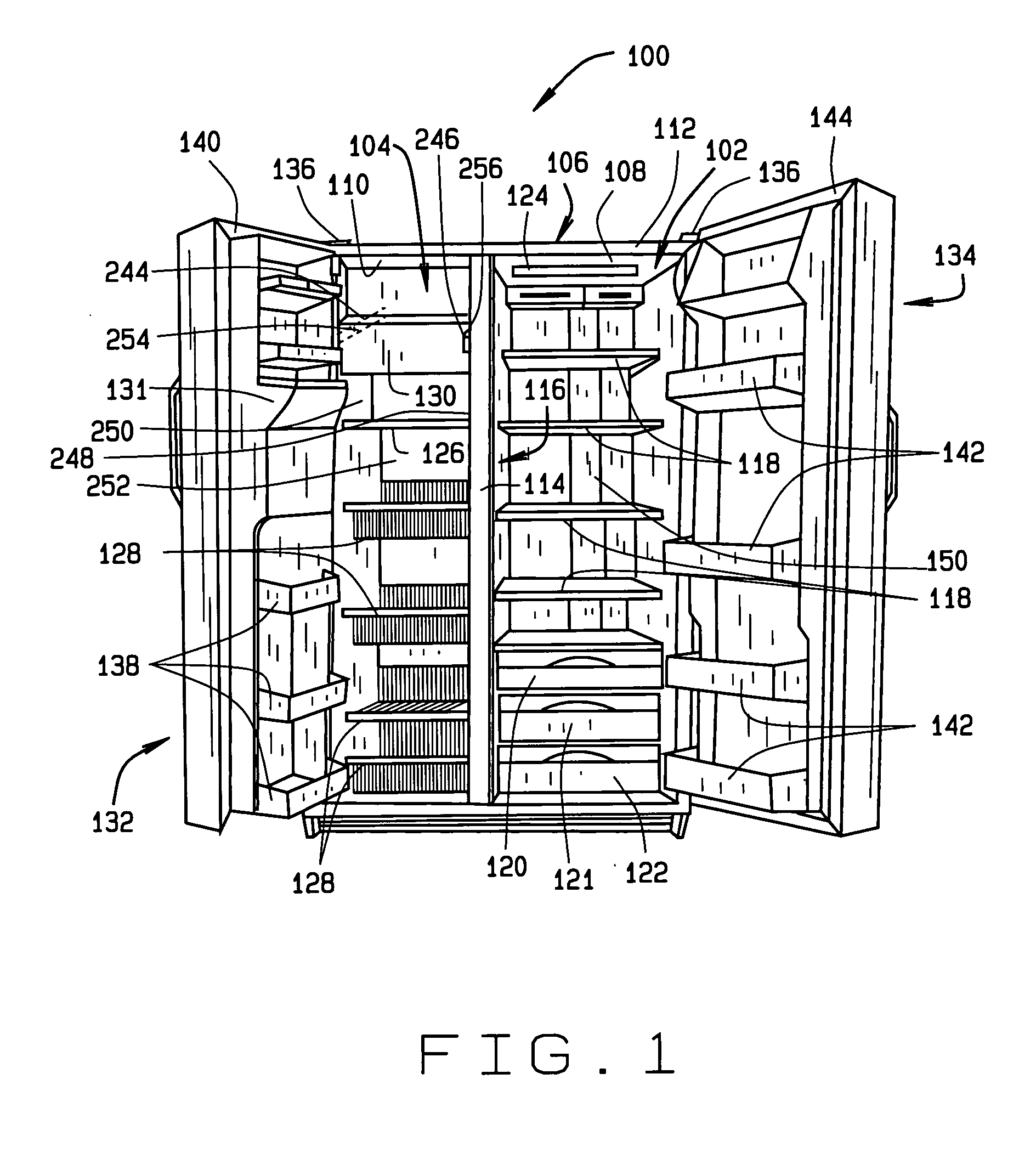

Storage system

A storage system comprises a first plurality of storage cartridges along an accessible side of a path, a second plurality of storage cartridges along a non-accessible side of the path, and a transport device to move the first and second plurality of magazines around the path. The storage system further comprises a controller that determines the location of a particular cartridge and operates the transport device to move the particular cartridge to the accessible side of the path to gain access to the particular cartridge. The controller can also be configured to re-position a movable accessor device along the accessible side of the path to access the particular cartridge. The ability to move the cartridges on both sides of the path can at least double the accessible storage capacity of the system.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

Apparatus and method for coordinating automated package and bulk dispensing

Owner:SYNGENTA PARTICIPATIONS AG

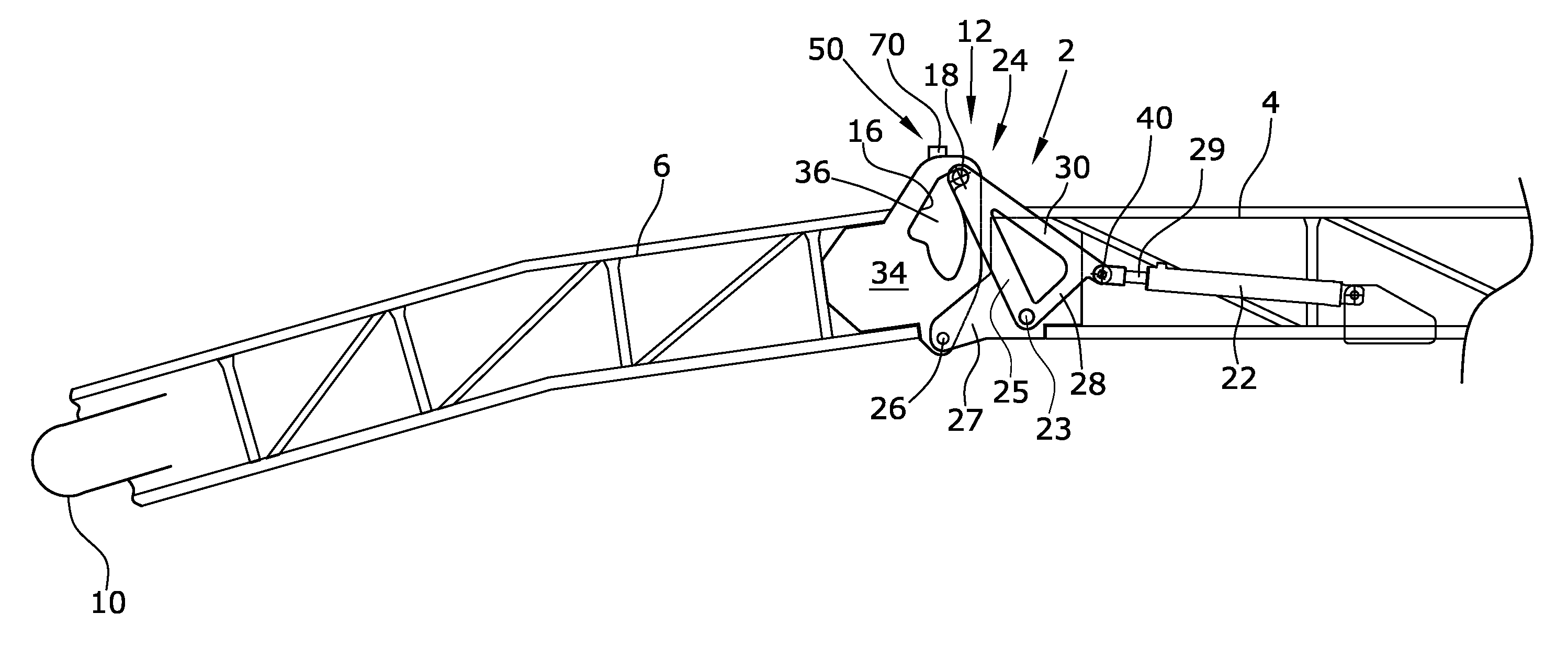

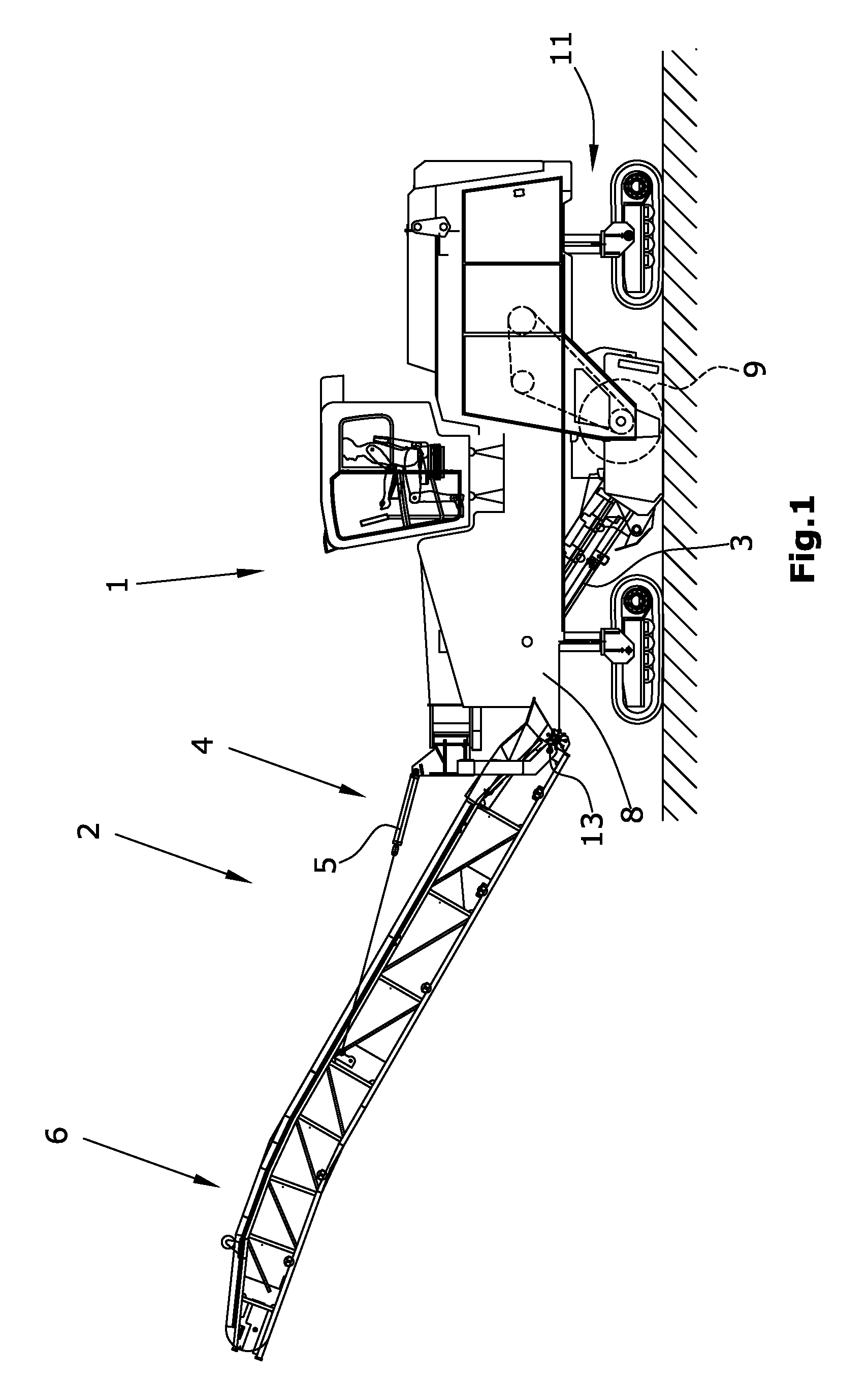

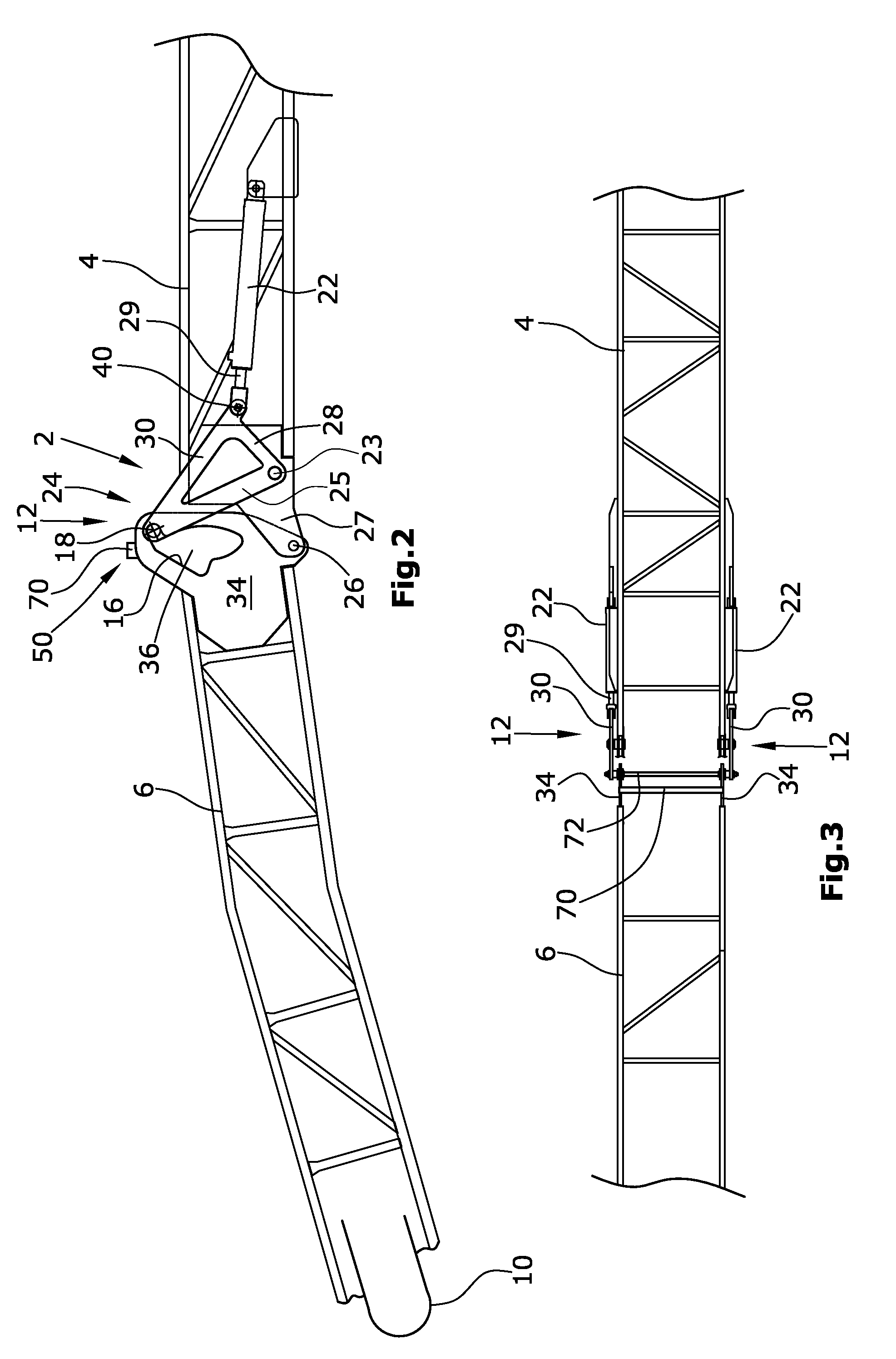

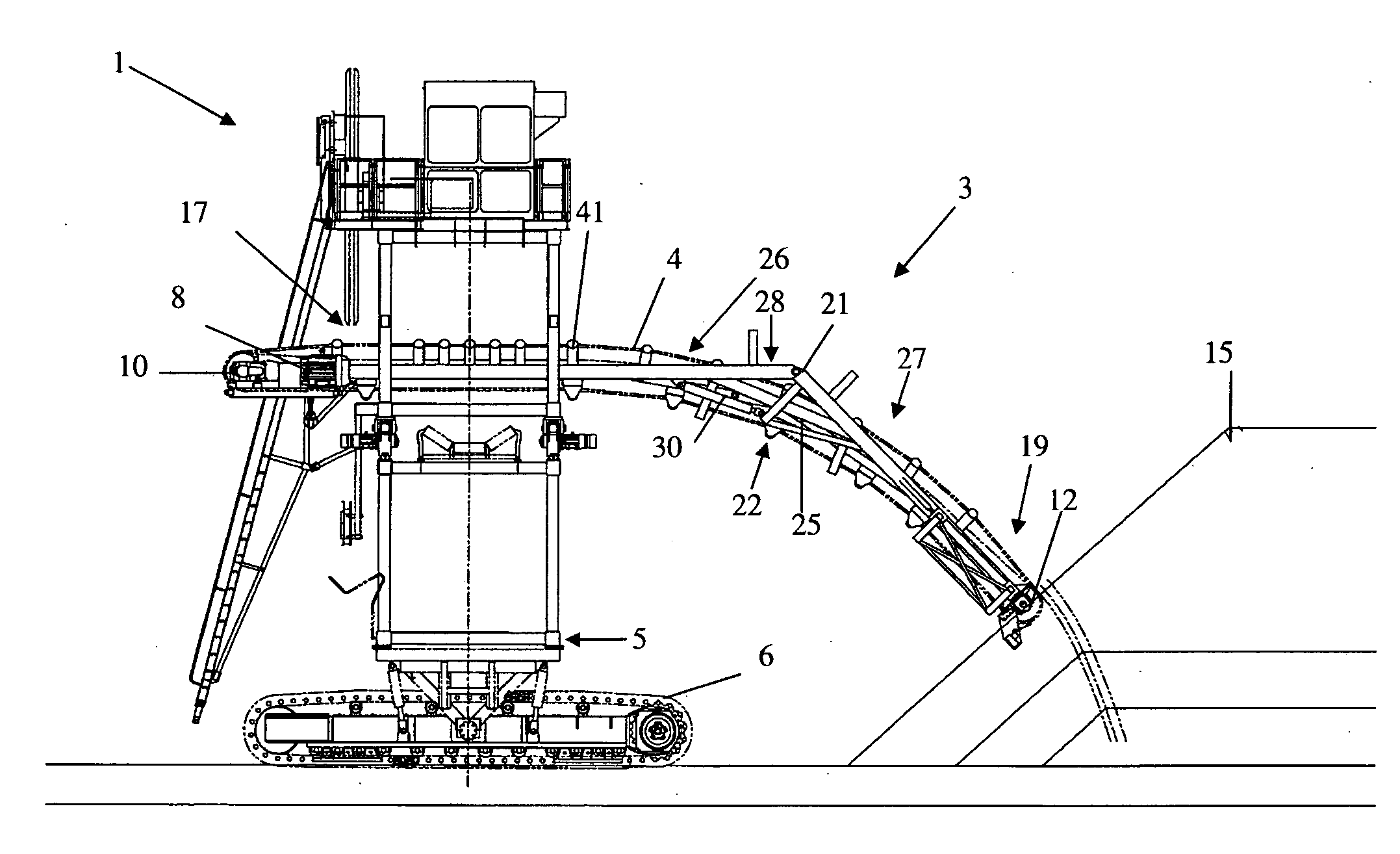

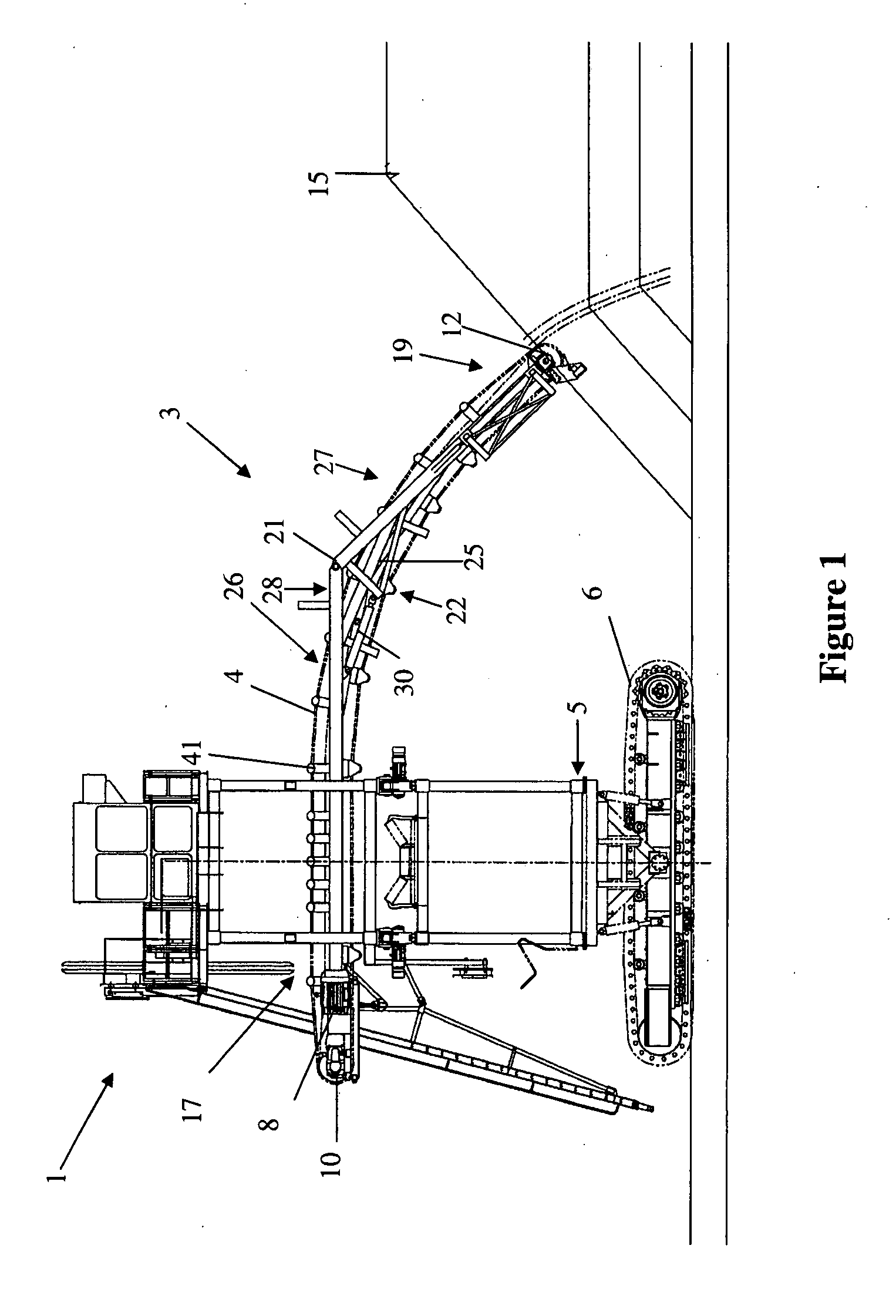

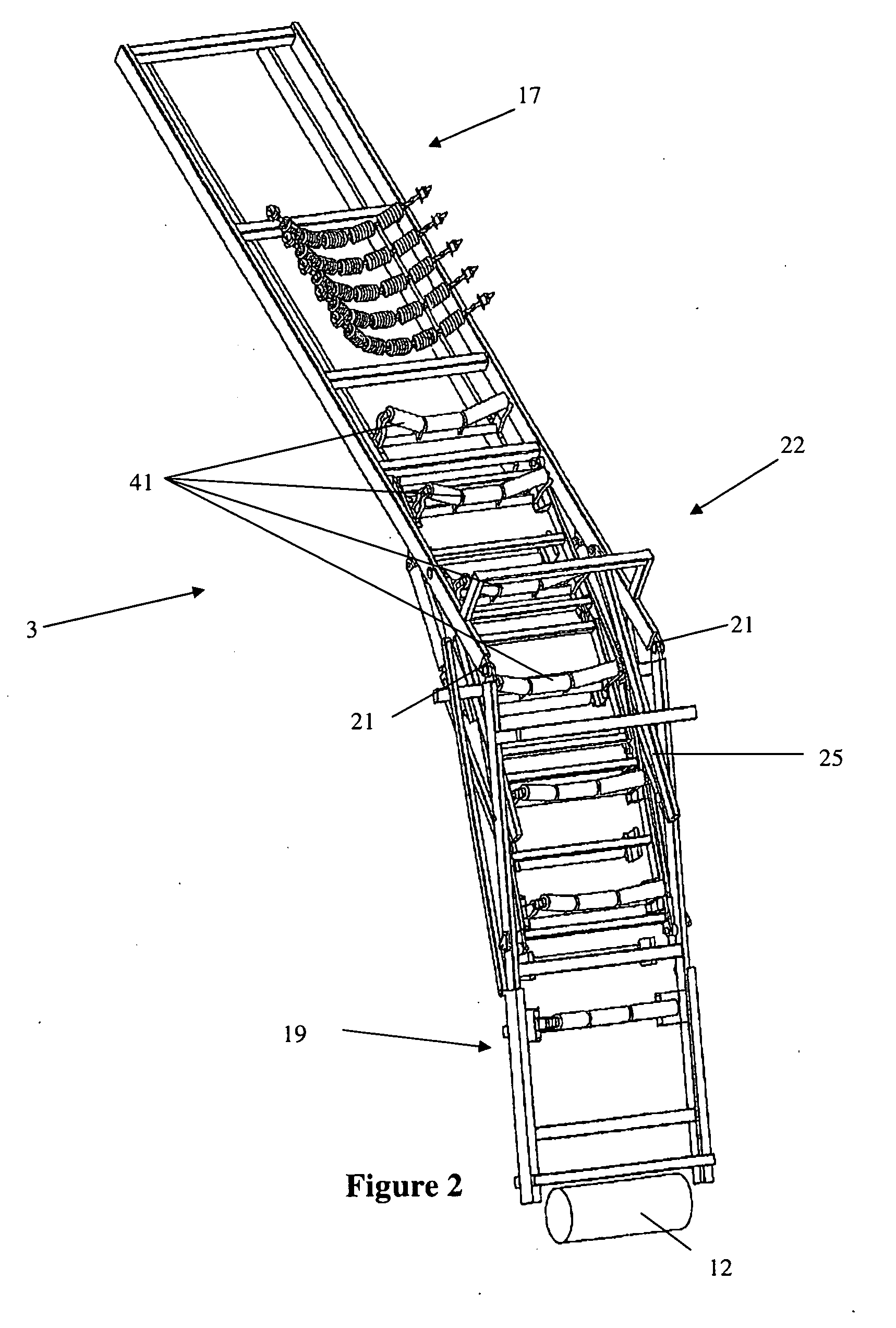

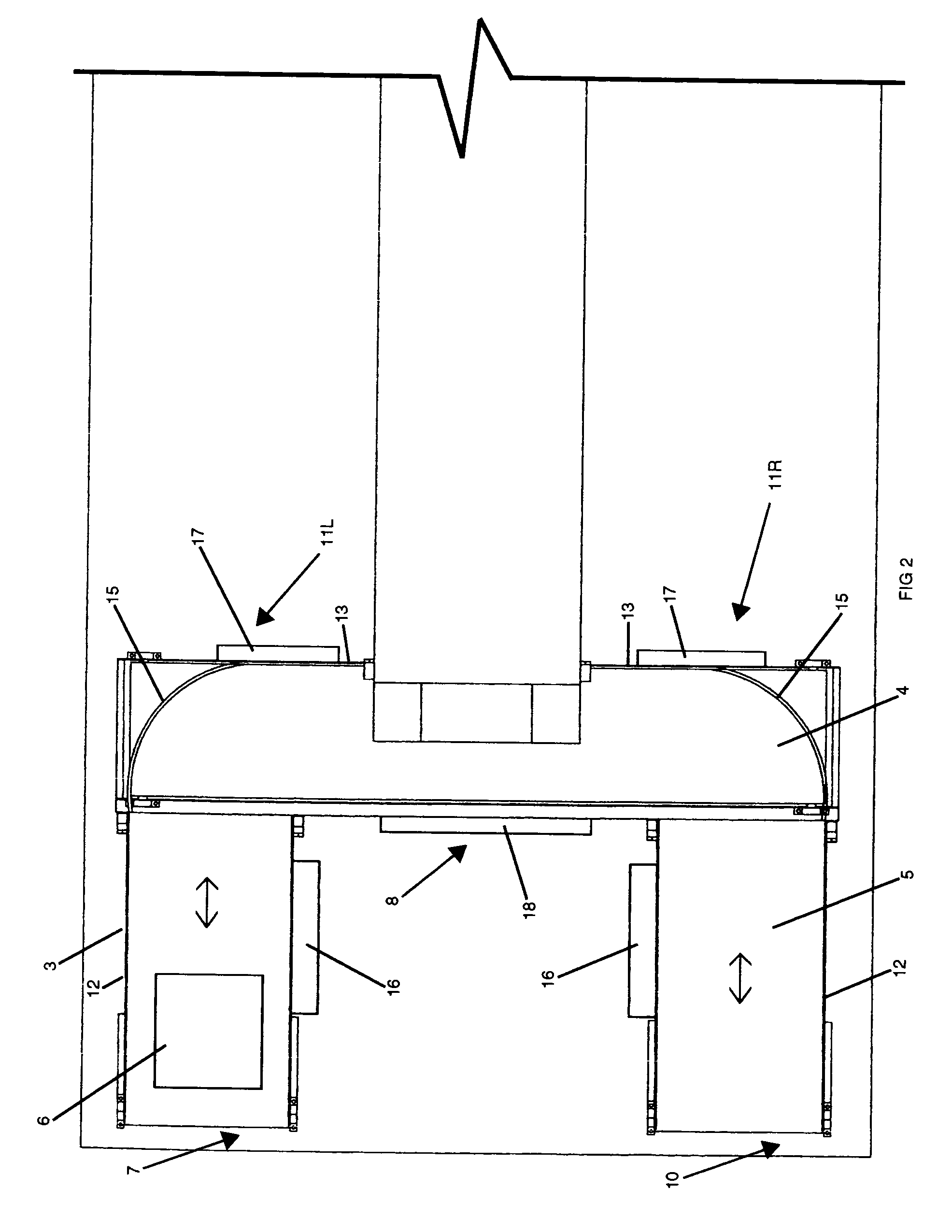

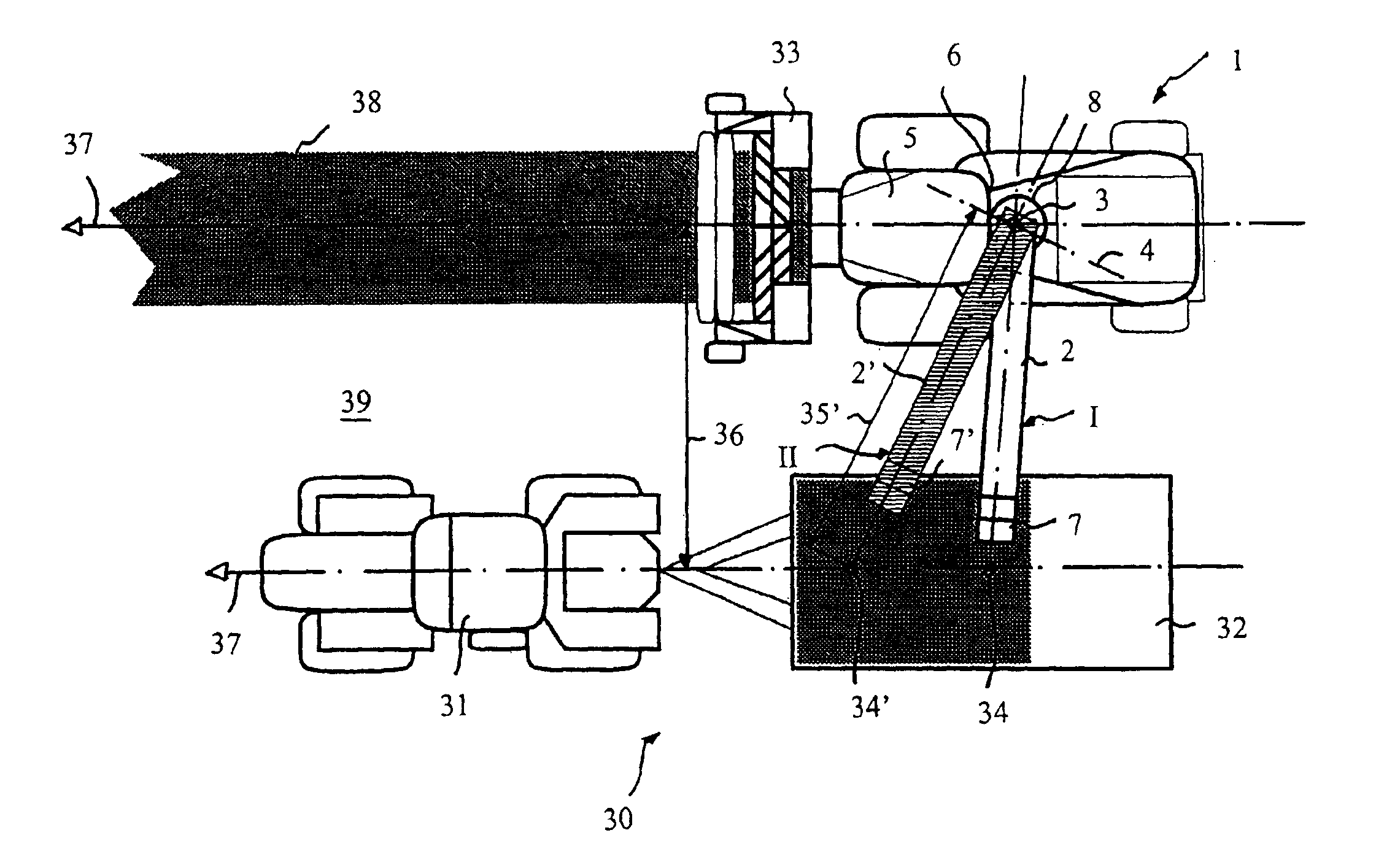

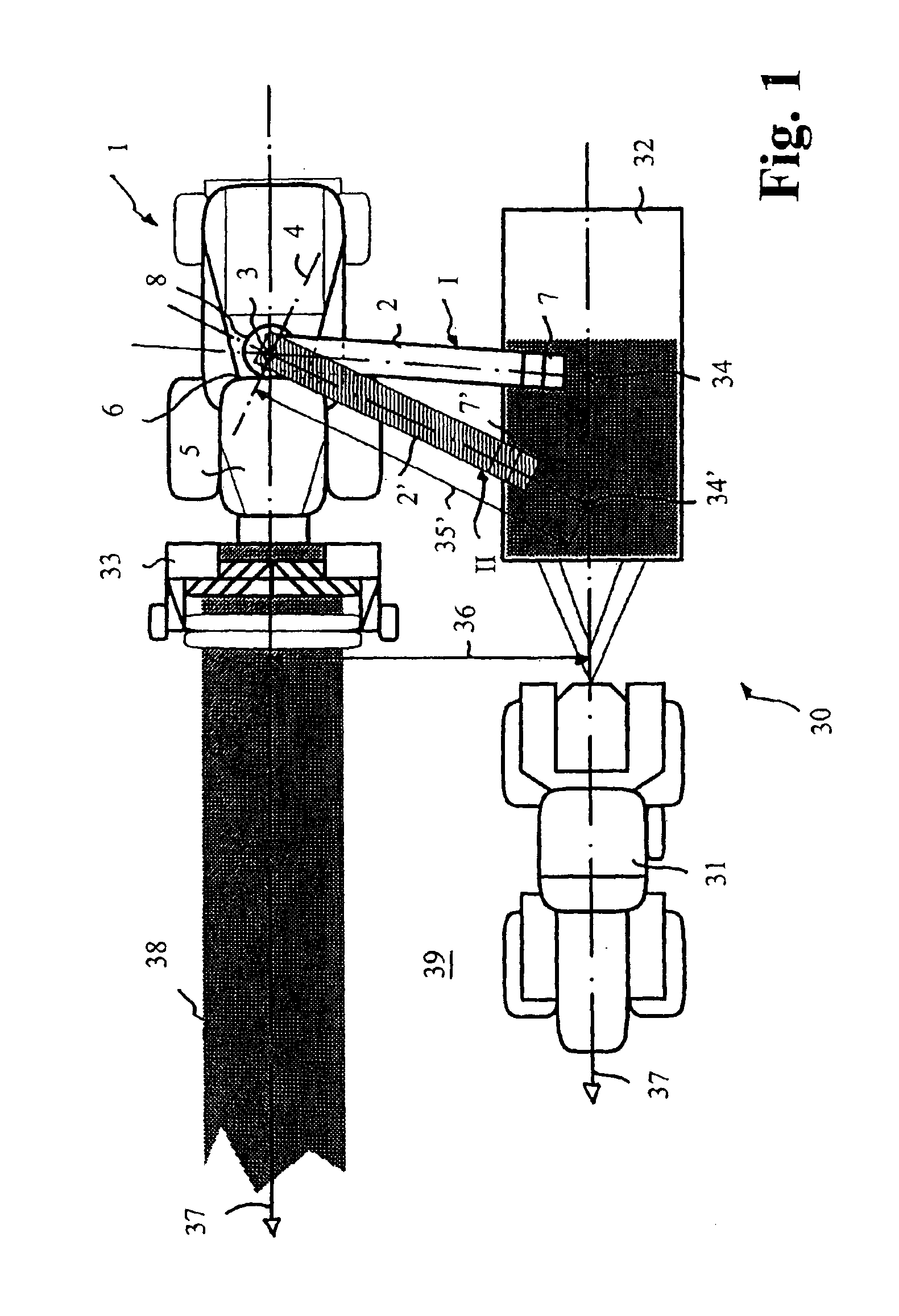

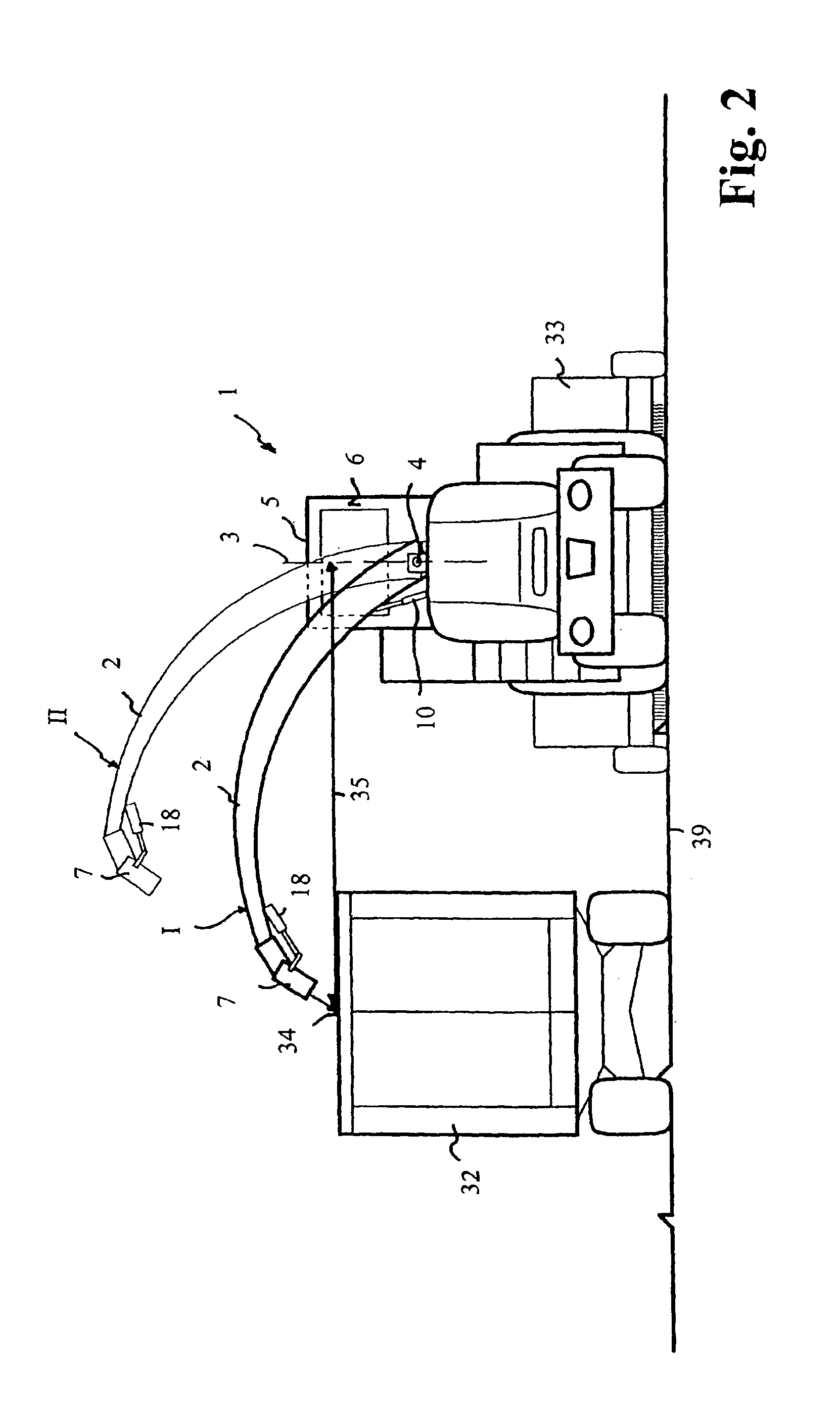

Folding transport conveyor for a construction machine, automotive construction machine, as well as method for pivoting a transport conveyor

In a folding transport conveyor (2) for a construction machine (1), with a first transport conveyor section (4) articulated at the construction machine (1), a second transport conveyor section (6) articulated at the first transport conveyor section (4) in a pivoting fashion, with a conveyor belt (10) continuously revolving around both transport conveyor sections (6), and with at least one pivoting mechanism acting between the transport conveyor sections (4, 6), it is provided that the pivoting mechanism includes a cam mechanism (12).

Owner:WIRTGEN GMBH

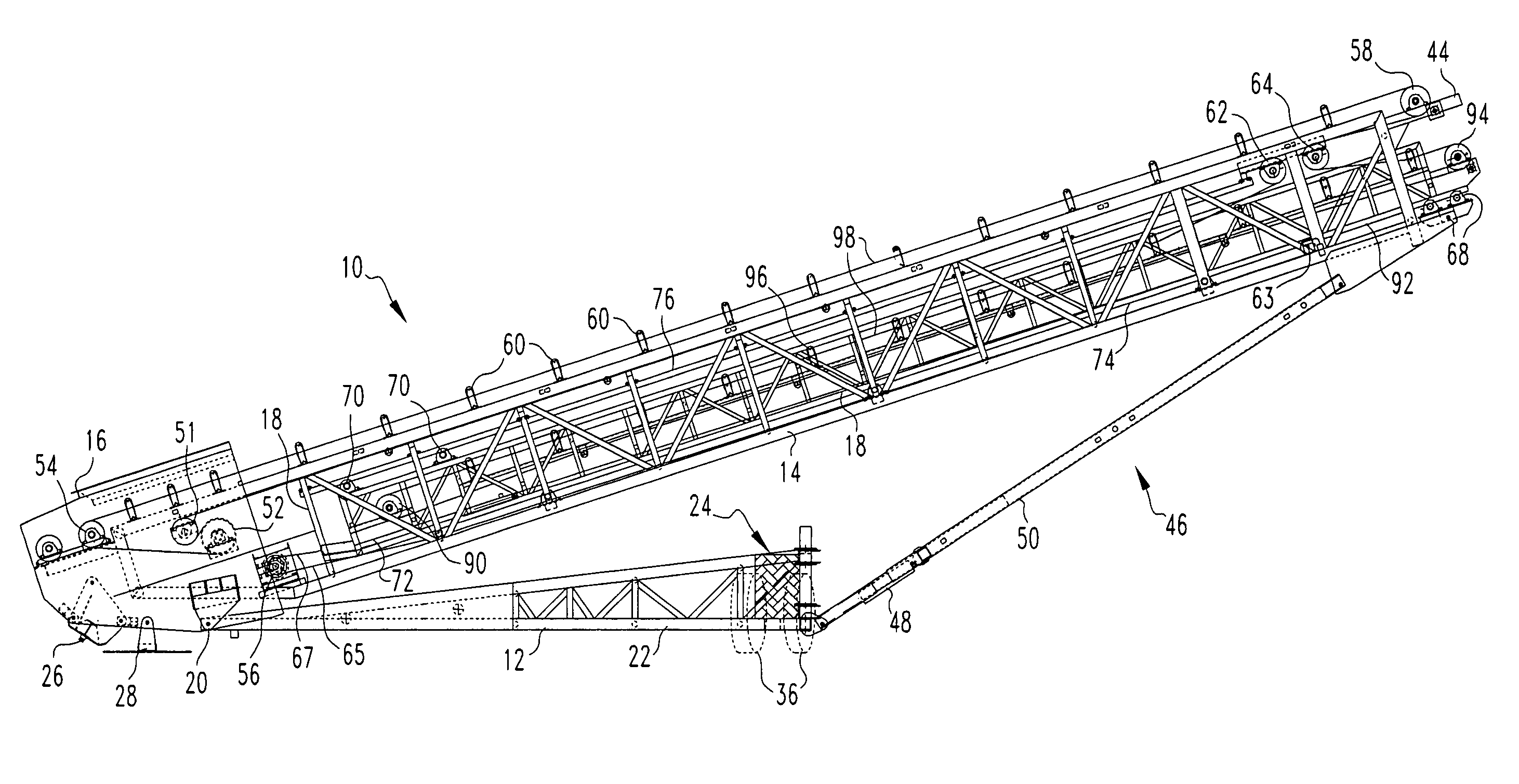

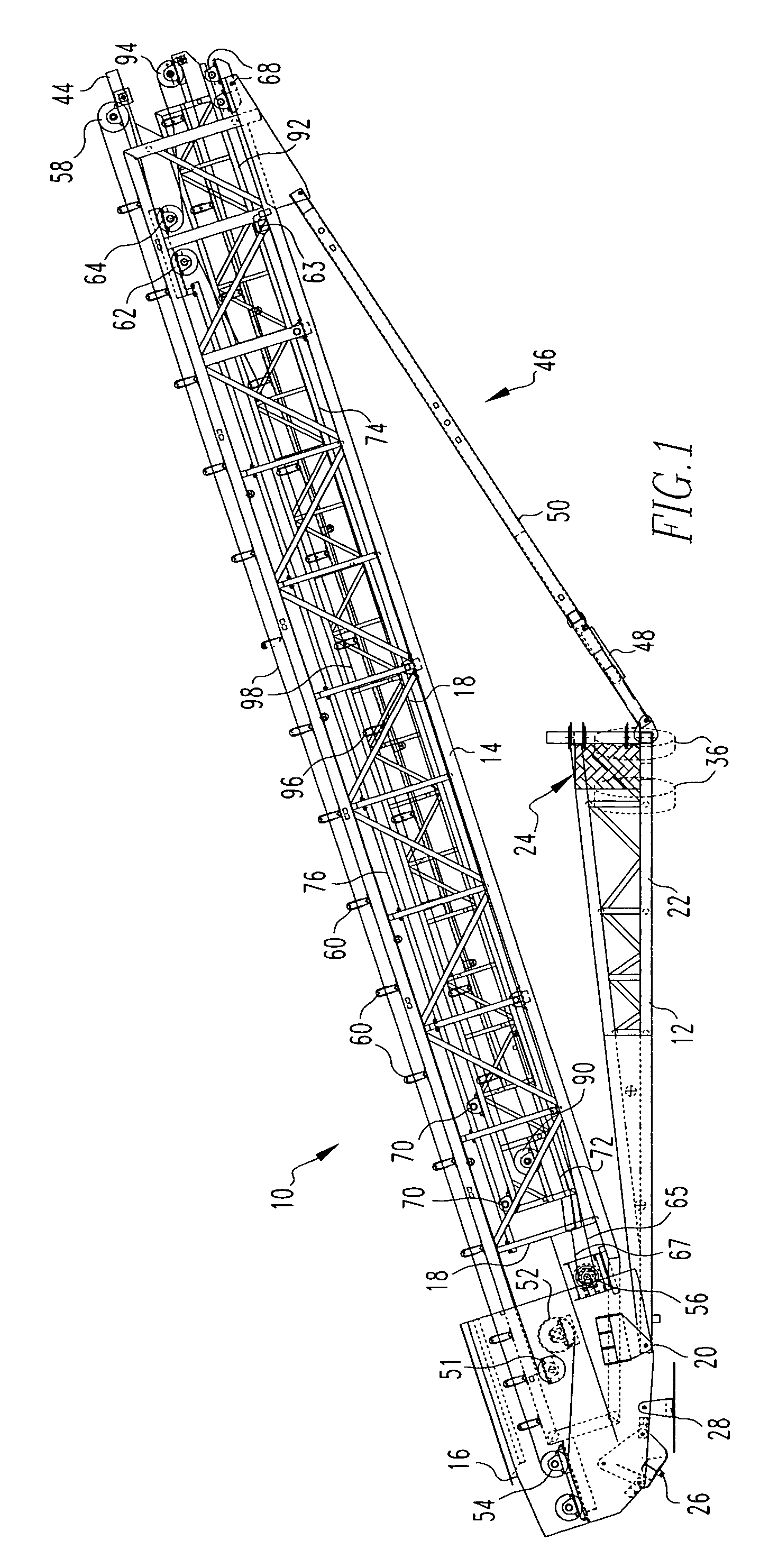

Conveyor Apparatus

A conveyor apparatus includes a tail portion connected to a head portion such that the head portion is moveable relative to the tail portion from a first position to a second position located lower than the first position. It should be appreciated that such movement of the head portion can permit the drop height of the conveyor apparatus to be adjusted. At least one frame portion is moveably positioned between the tail portion and the head portion. A stacker is also provided that includes the conveyor apparatus.

Owner:FLSMIDTH RAHCO +1

Conveyor guard

ActiveUS7530452B2Improve usability and reliabilityImprove rigidityConveyorsSupporting framesEngineeringMechanical engineering

Owner:VESTERGAARD MARTIN

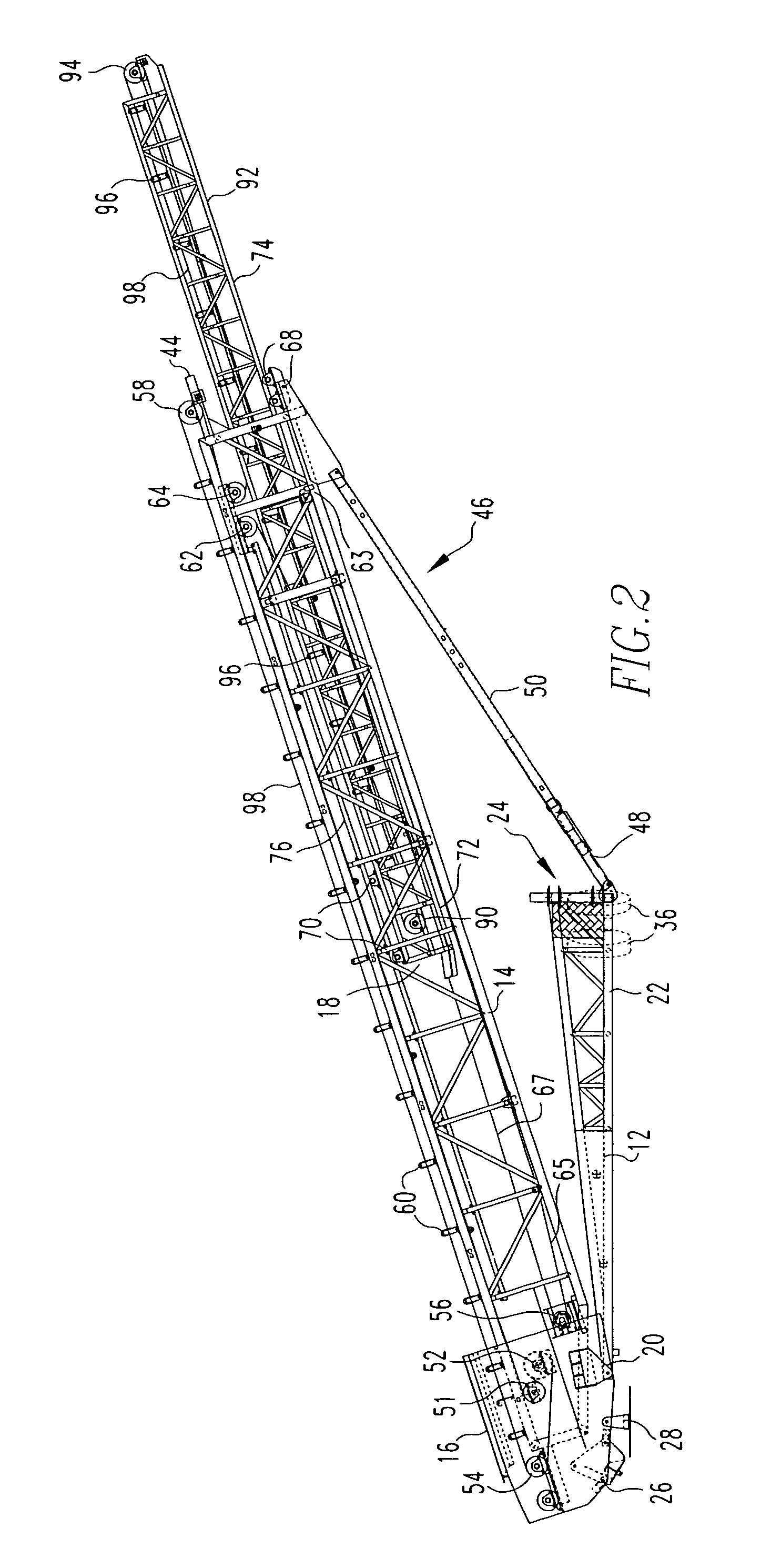

Telescoping stacking conveyor having a single conveyor belt and single drive mechanism for the belt

InactiveUS6929113B1Maximum flexibilityEasy maintenanceSupporting framesLoading/unloadingEngineeringConveyor belt

A portable radially stacking conveyor has a telescoping stinger, with the stinger and main section sharing a single conveyor belt having a single drive mechanism.

Owner:HOOVER CONVEYOR & FABTION CORP

Unloading system for particulate material

InactiveUS7090066B2Precise positioningLoadersRefuse transferringAgricultural engineeringParticulate material

This invention concerns a new grain unloading system using an integrated ramp, horizontal transfer conveyor and elevating system. The unit is towed, positioned and powered by an agricultural tractor.

Owner:BOURGAULT INDS

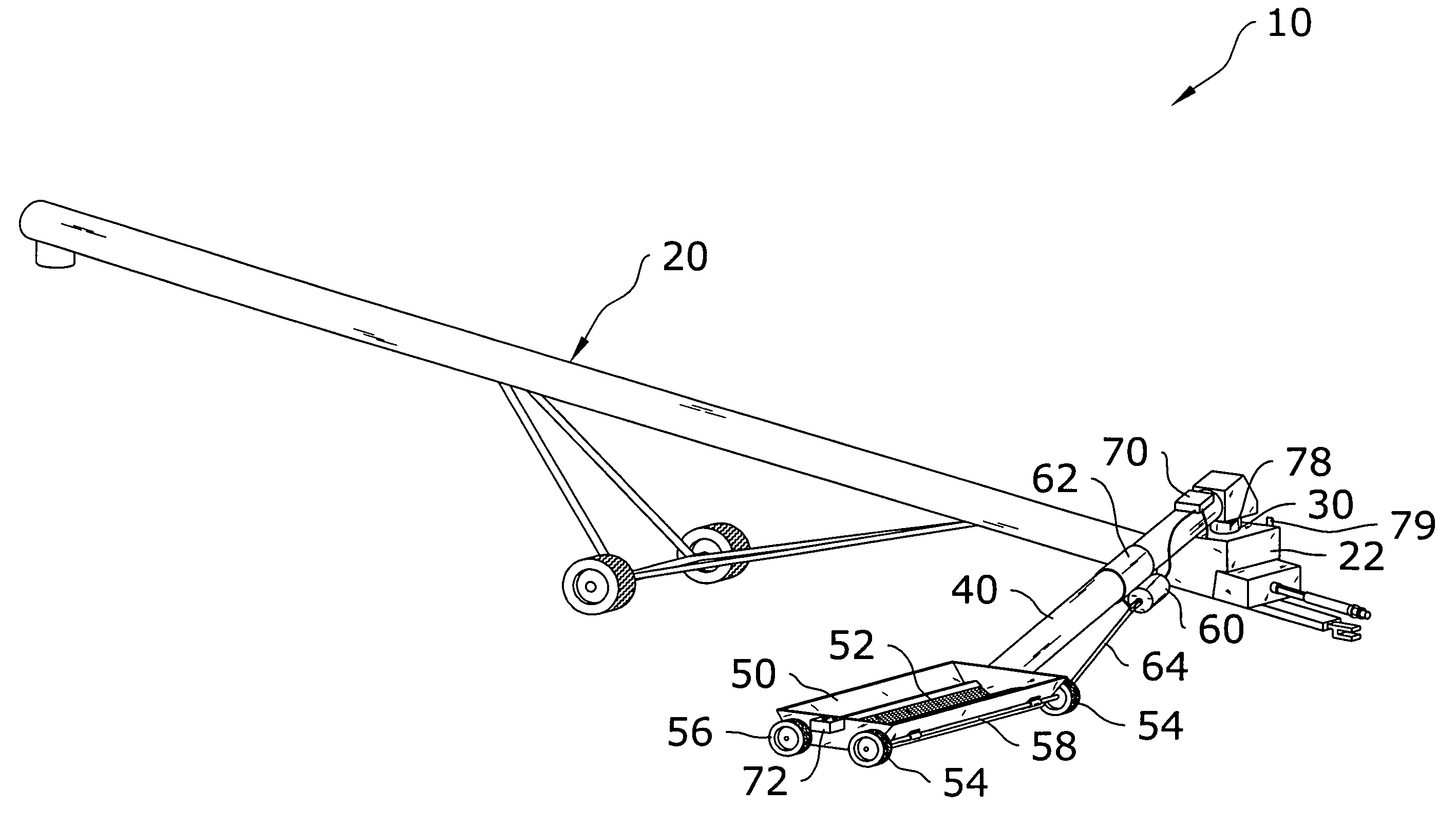

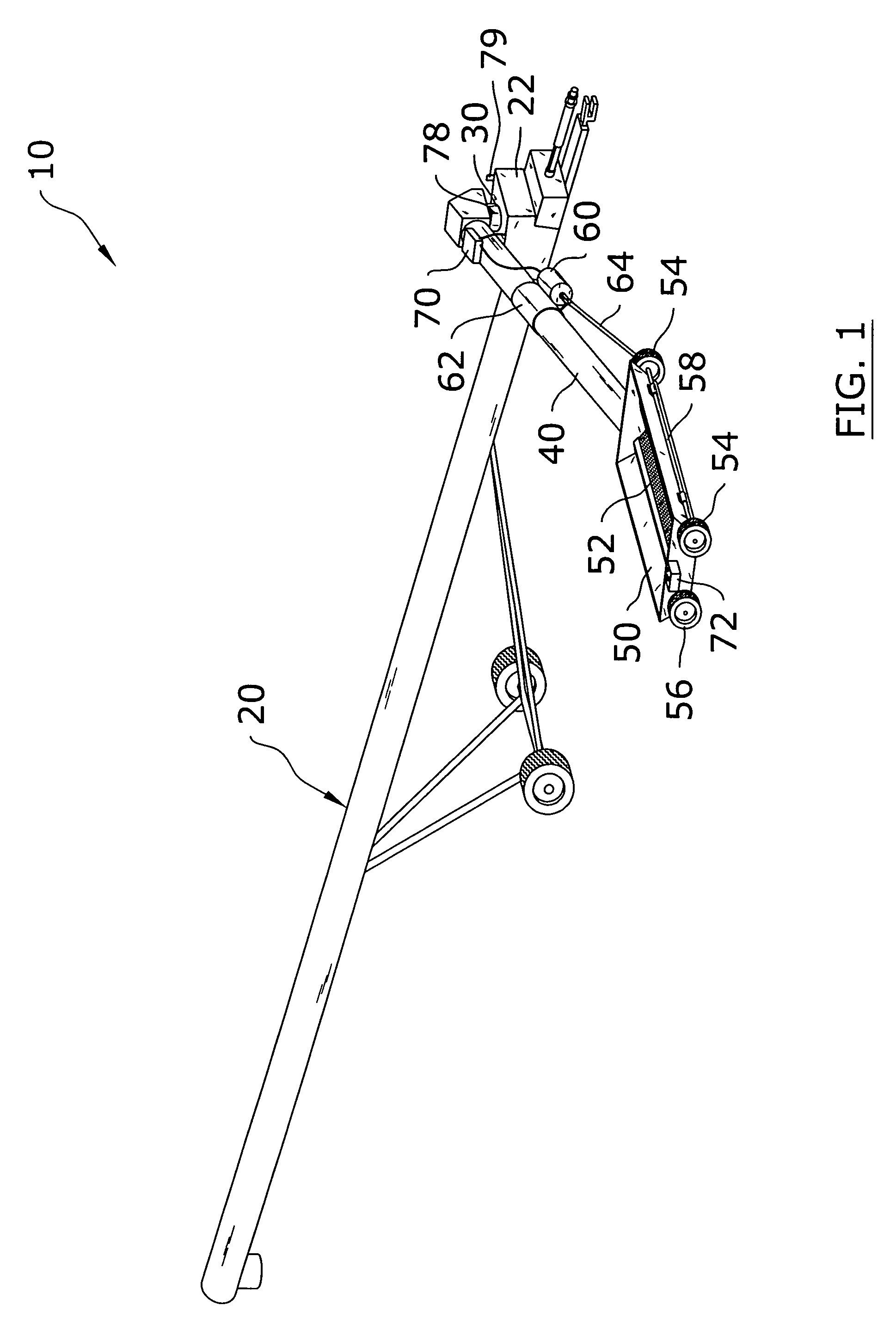

Movable conveyor for loading a container

A container for example for a seeder includes a filling conveyor mounted on one with a bottom hopper and an upper filling spout with the conveyor being movable in a direction inwardly and outwardly relative to the side of the container to different positions relative to the container for cooperation with a supply. This is achieved by mounting the conveyor on a swivel coupling at the outer end of an arm which can be raised and lowered by pivotal movement about an inner end at the container. The hopper is supported on two pairs of ground wheels, each pair being arranged on a respective side of the hopper for supporting the respective side and each pair comprising a respective one of a pair of castor wheels mounted at respective ends of a pivotal beam extending along the respective side of the hopper and pivotal about an axis transverse to the hopper.

Owner:DECKER COLONY FARMS

Loading conveyor with folding hopper for agricultural commodity carts

ActiveUS7267519B2Increase capacityShorten the lengthLoadersFertiliser distributersHydraulic cylinderEngineering

Owner:BOURGAULT INDS

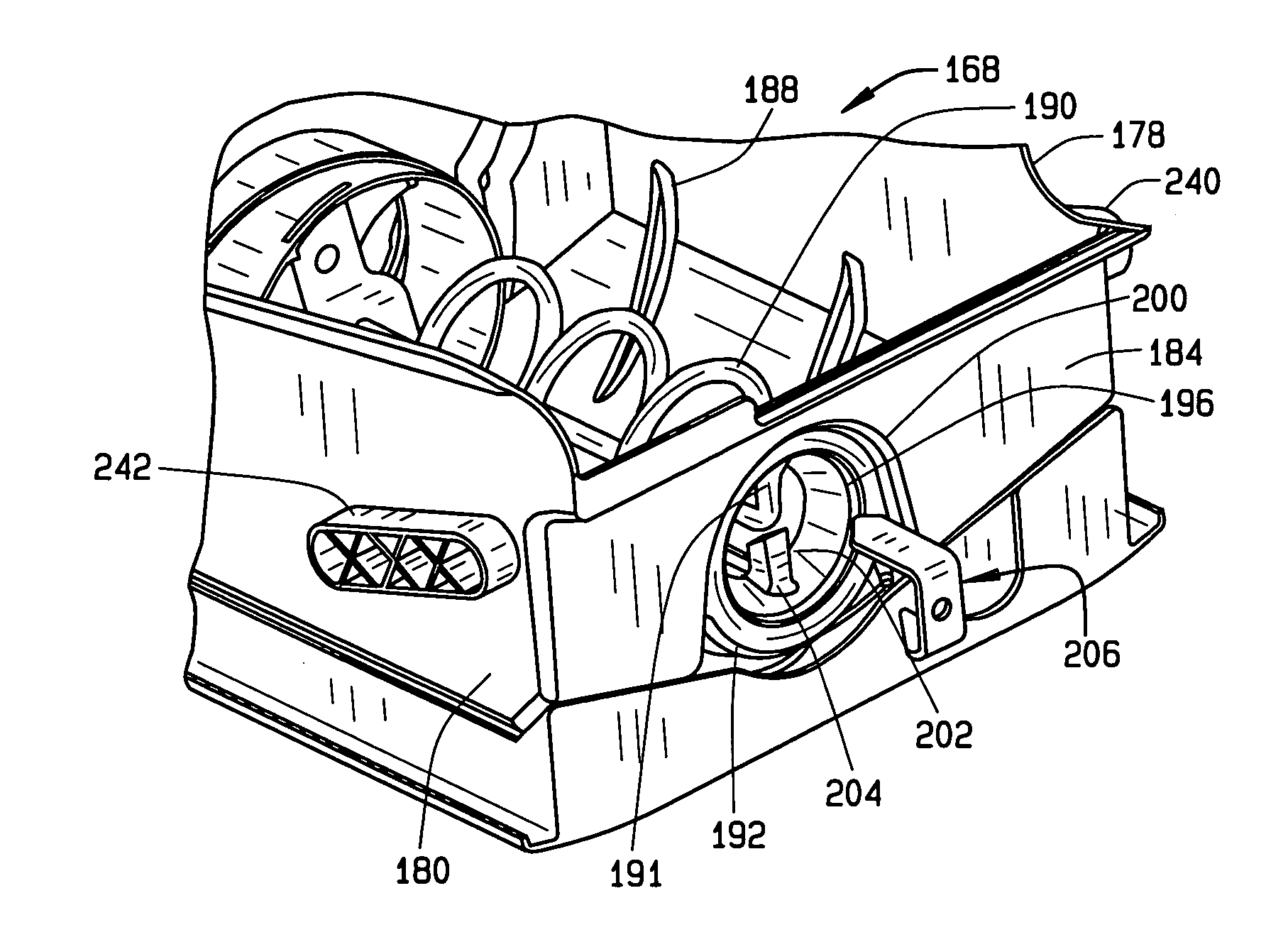

Refrigerator and ice maker apparatus

An ice maker assembly includes, in an exemplary embodiment, an ice bucket that has a bottom wall, opposing side walls extending from the bottom wall, a front wall, and a back wall. The bottom wall, side walls, front wall, and back wall define an ice collection cavity. The ice bucket also includes a plurality of ribs extending from the bottom wall into the ice collection cavity, and a rotatable auger extending between the front and back walls.

Owner:GENERAL ELECTRIC CO

Extendable belt conveyor

An extendable conveyor includes a support structure, a mechanically extendable section which is extendable along the longitudinal axis between a fully retracted position and a fully extended position, a conveyor belt reeved among the mechanically extendable section thereby defining a conveying surface and a drive. The drive is operable to drive the conveyor belt in at least one direction. The extendable section may be extended by driving the conveyor belt in one direction and retracted by driving the conveyor belt in an opposition direction. The mechanically extendable section may include a plurality of sections at least one made substantially from a unitary sheet of material.

Owner:KÖRBER SUPPLY CHAIN LLC

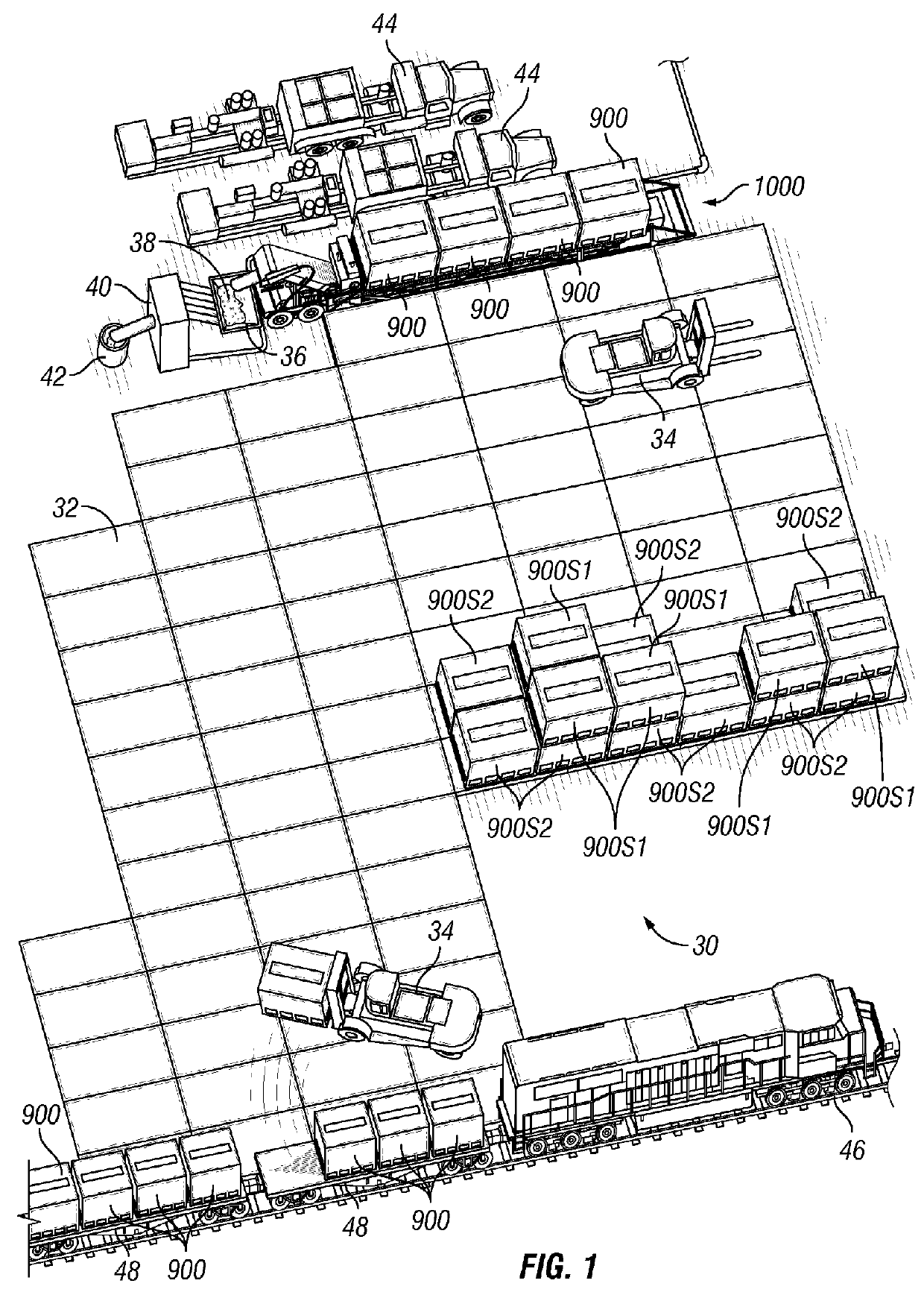

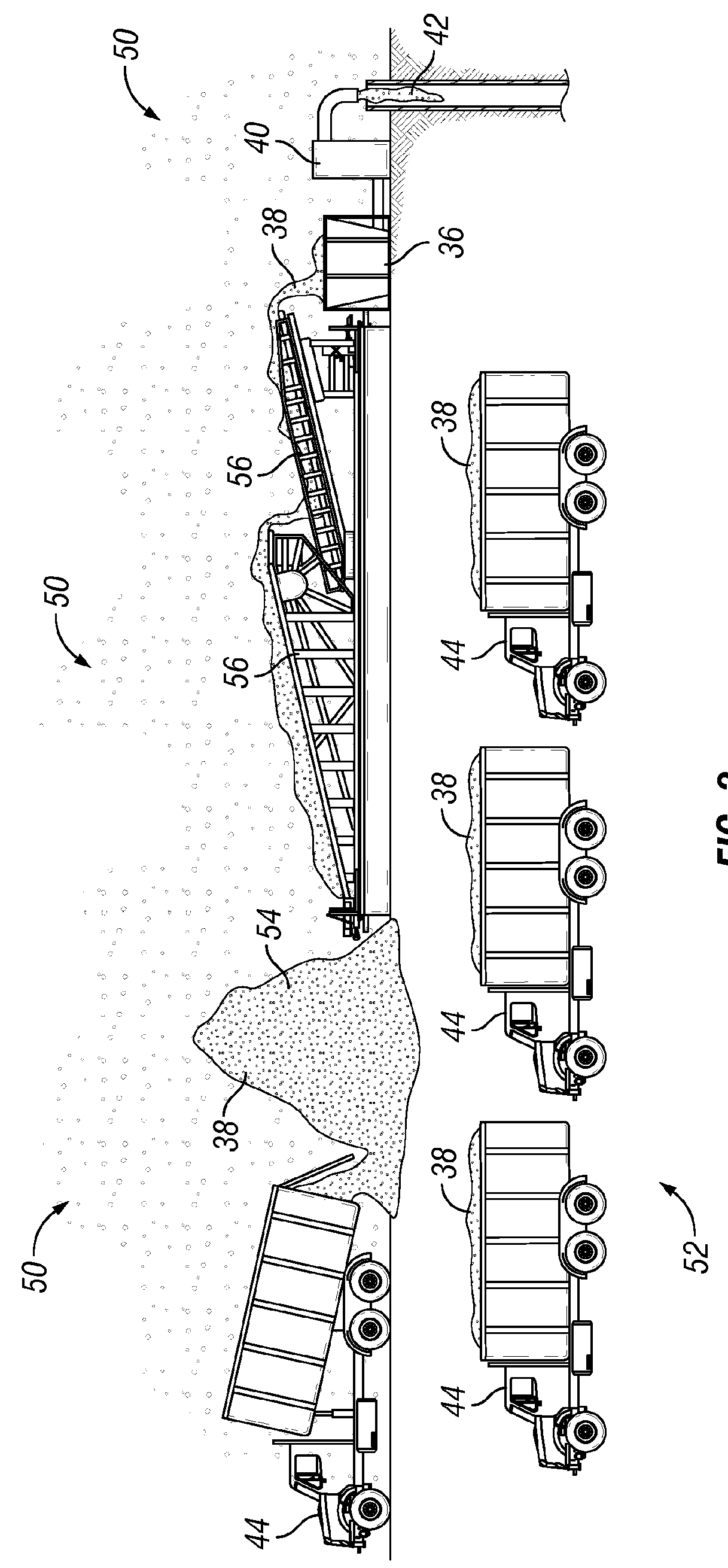

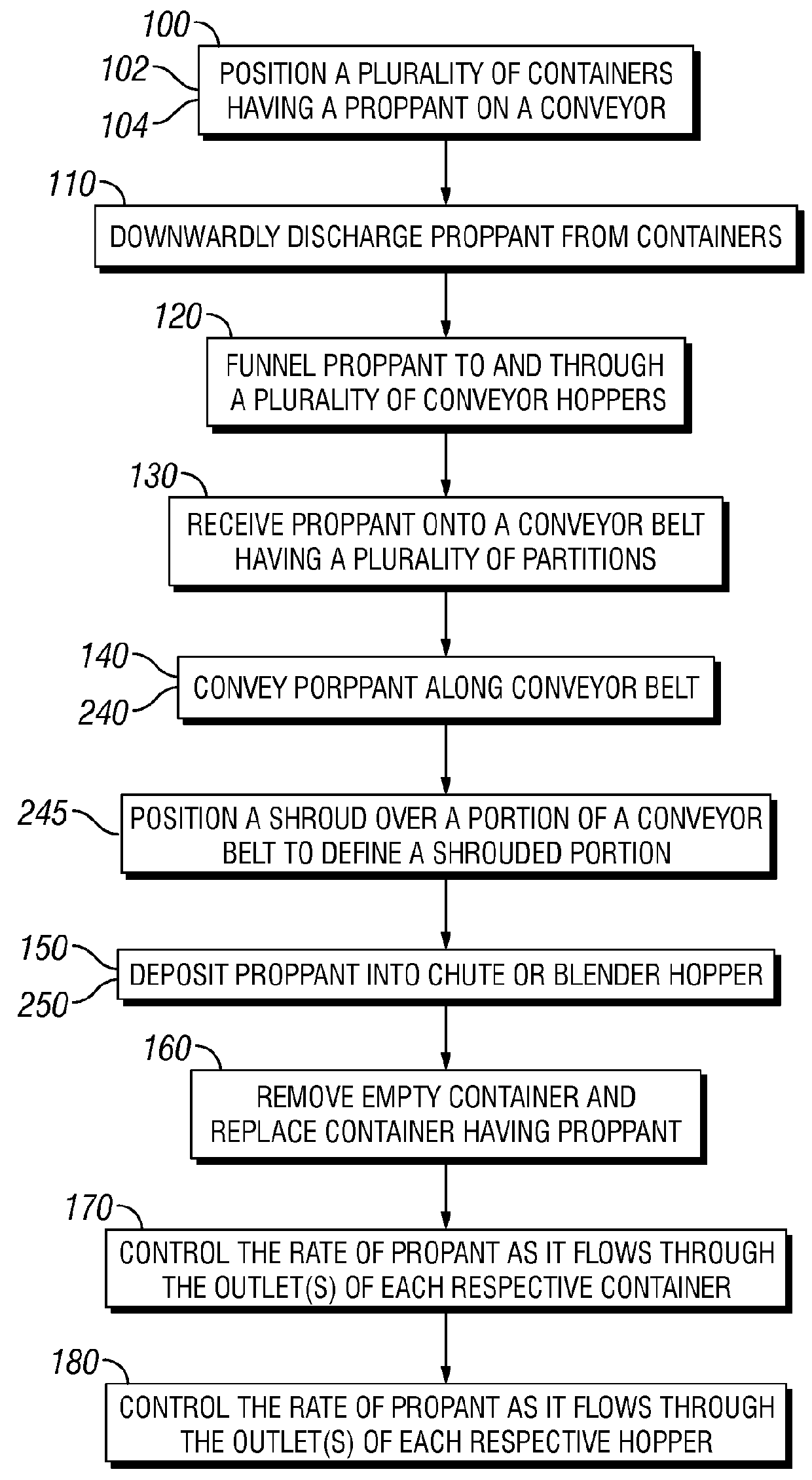

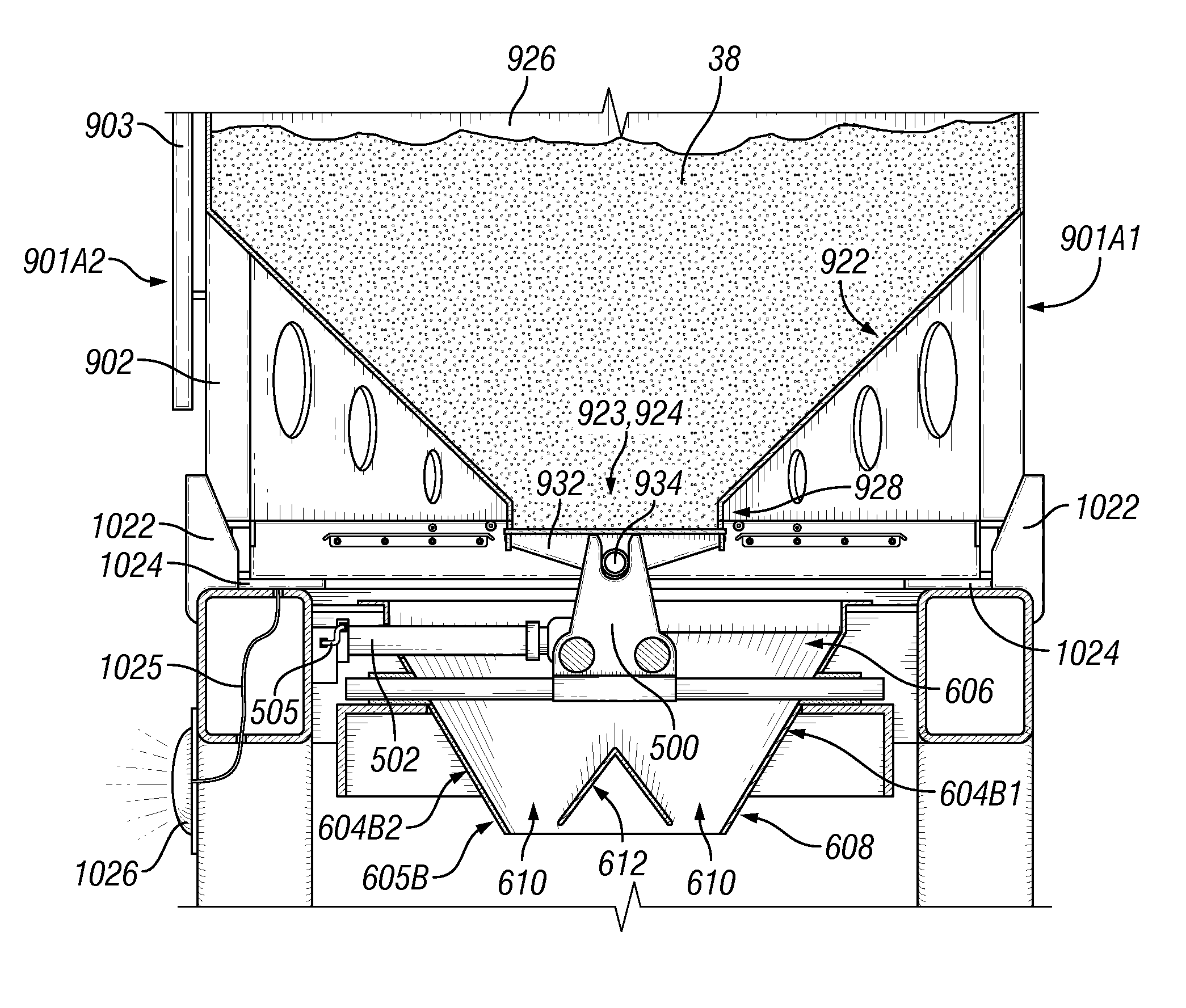

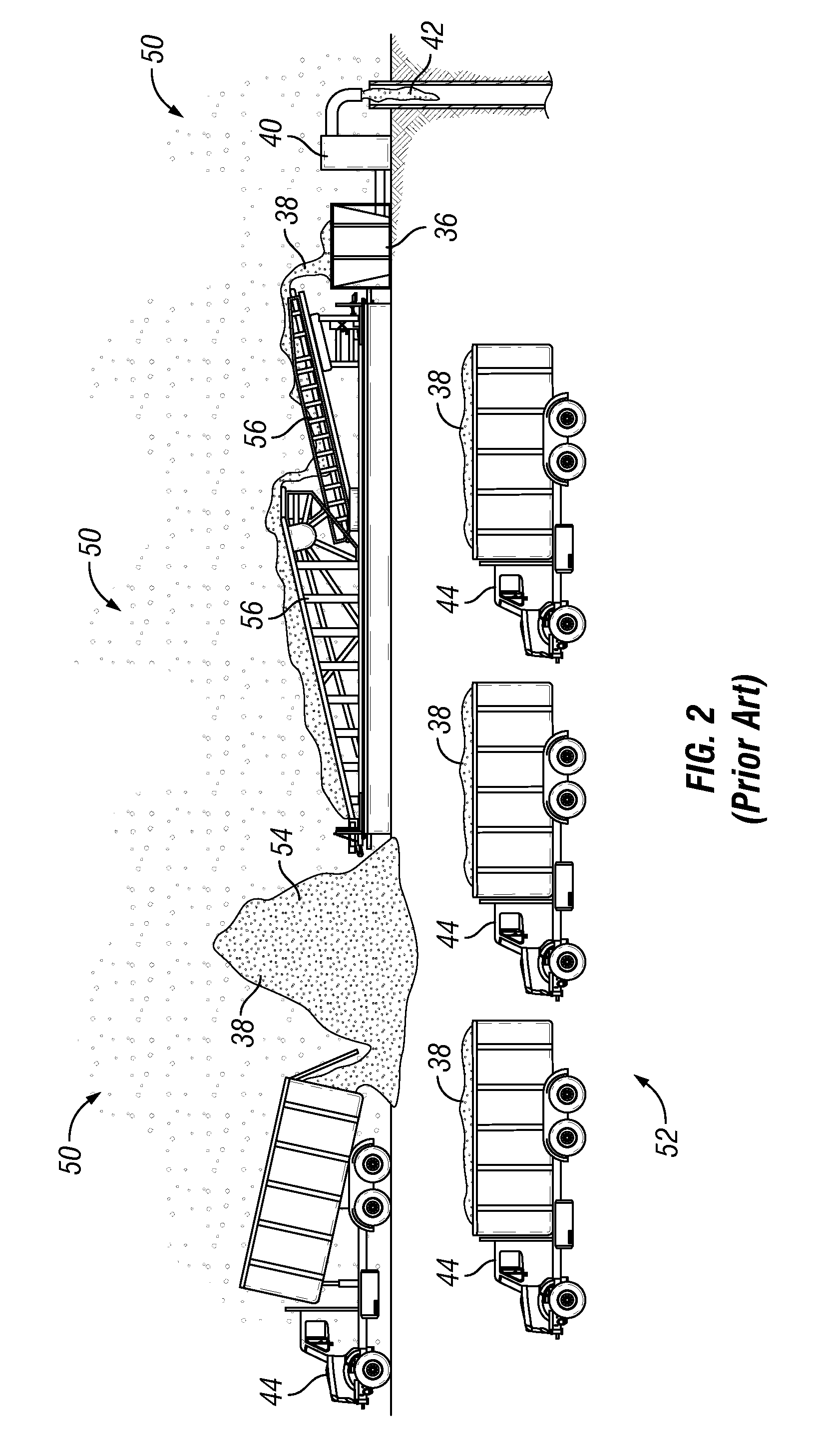

Proppant Discharge and Storage System

InactiveUS20160031658A1Reduce riskReduce productionConveyorsLarge containersEngineeringSilicon dioxide

Embodiments of methods and systems of transferring proppant for fracking, to reduce risk of production and release of silica dust at a well site are provided. An embodiment of a method can include positioning a plurality of containers each having proppant for fracking contained therein onto a conveyor at a well site, downwardly discharging proppant from each respective container of the plurality of containers, funneling proppant from the one or more outlets of each of the plurality of containers through a plurality of conveyor hoppers, receiving proppant onto the conveyor belt, conveying proppant on the conveyor to a chute, and depositing the proppant into the chute for use in a blender or other location at the well site.

Owner:SANDBOX ENTERPRISES LLC

Tote conveying apparatus and method

Owner:OSEGUERA ANTHONY DAMIAN

Methods and systems to transfer proppant for fracking with reduced risk of production and release of silica dust at a well site

ActiveUS20150360856A1Reduce riskEasy to liftPowdered material dispensingConveyorsEngineeringSilicon dioxide

Embodiments of methods and systems of transferring proppant for fracking to reduce risk of production and release of silica dust at a well site are provided. An embodiment of a method can include positioning a plurality of containers each having proppant for fracking contained therein onto a conveyor at a well site, downwardly discharging proppant from each respective container of the plurality of containers, funneling proppant from the one or more outlets of each of the plurality of containers through a plurality of conveyor hoppers, receiving proppant onto the conveyor belt, conveying proppant on the conveyor to a chute, and depositing the proppant into the chute for use in a blender or other location at the well site.

Owner:SANDBOX ENTERPRISES LLC

Mobile robot with conveyor system

ActiveUS10048697B1Programme-controlled manipulatorAutonomous decision making processControl theoryConveyor belt

A mobile robot is provided for use in an operating environment. The mobile robot may include a mobile robot base, a conveyor system and a drive system. The conveyor system may be supported by the mobile robot base. The conveyor system may include a conveyor belt configured to receive an item with the mobile robot and / or provide the item from the mobile robot. The conveyor system may be configured to support the item during movement of the mobile robot within the operating environment. The drive system may be arranged with the mobile robot base. The drive system may be configured to move the mobile robot within the operating environment and position the conveyor system such that the conveyor belt is operable to receive the item with the mobile robot and / or provide the item from the mobile robot.

Owner:VECNA TECHNOLOGIES

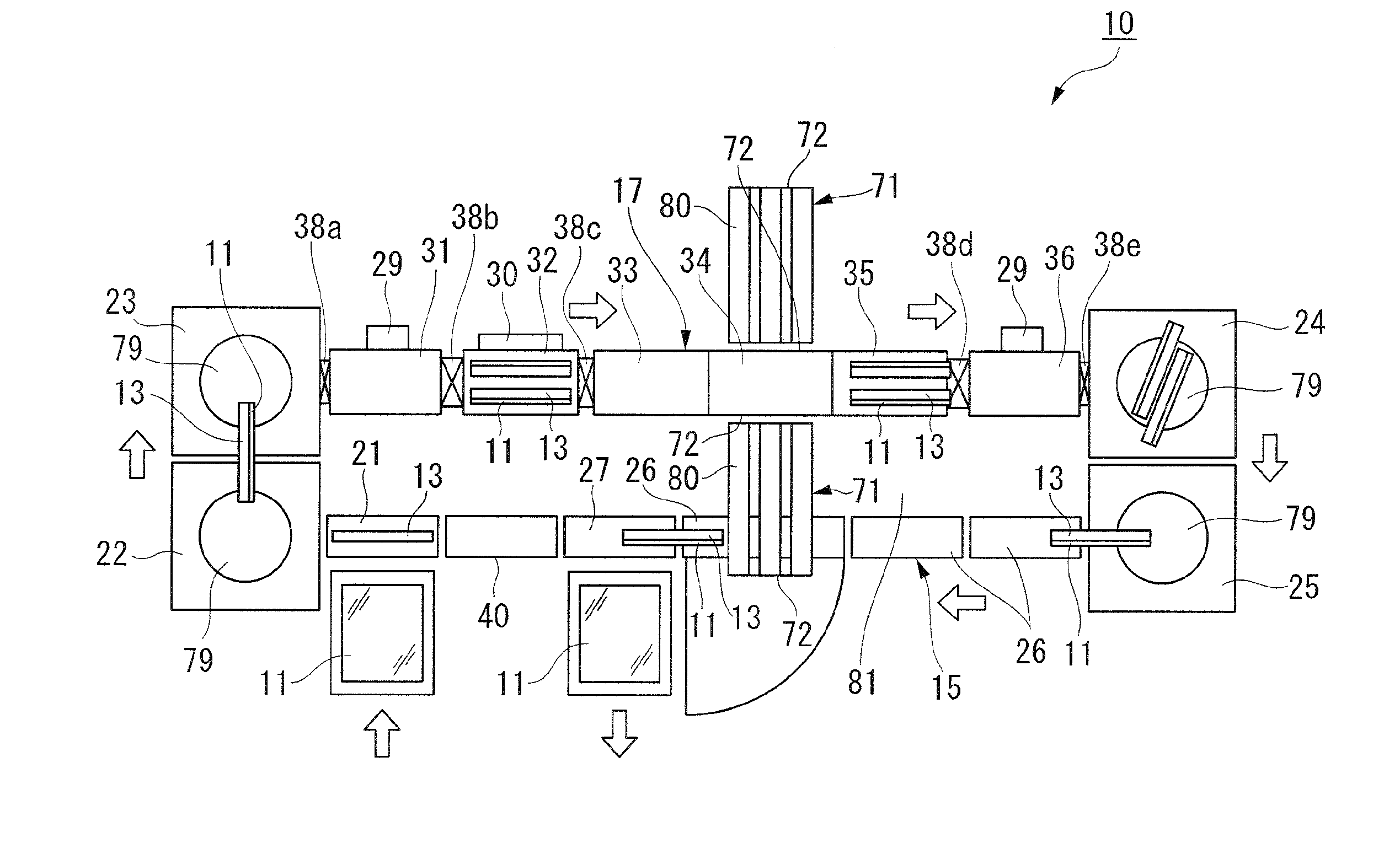

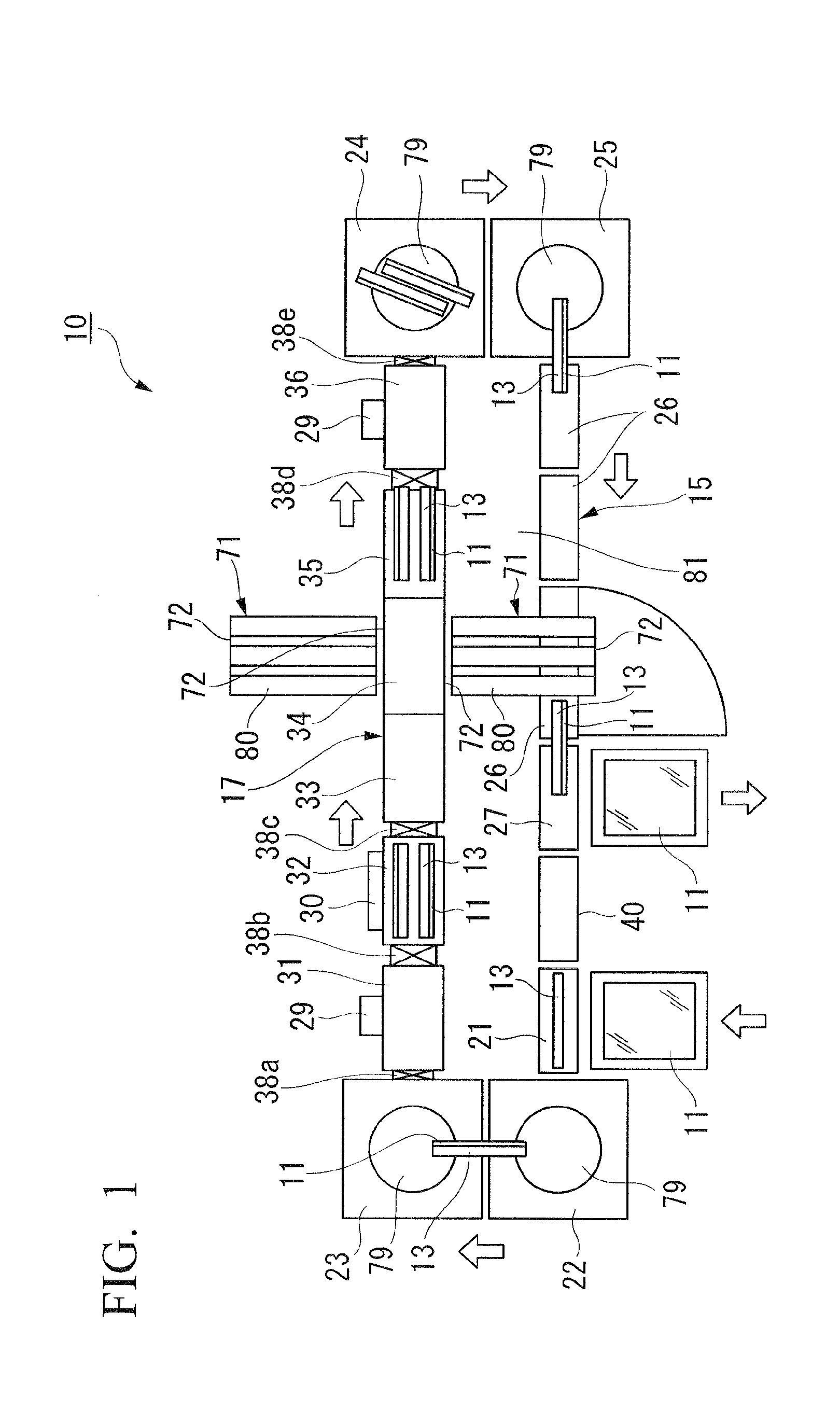

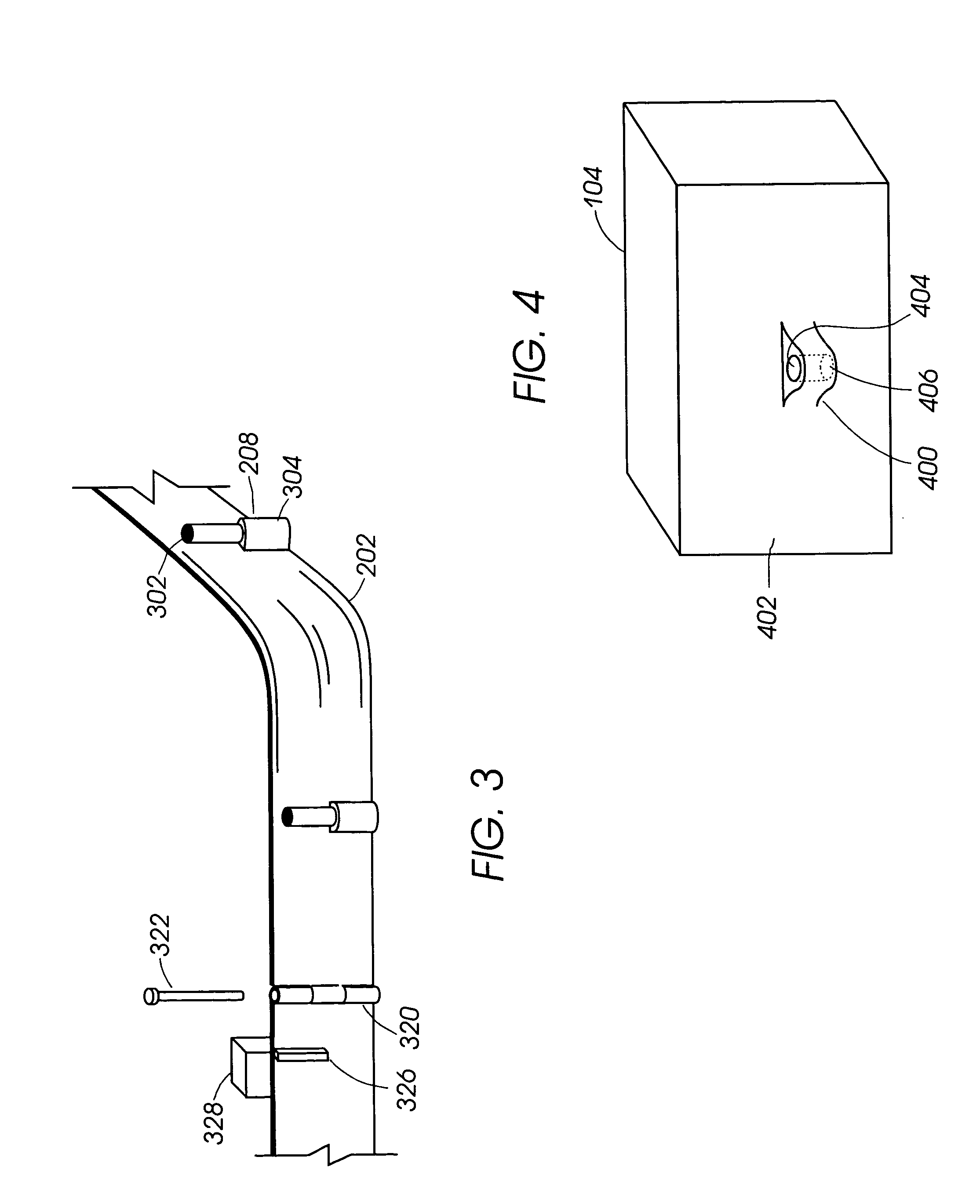

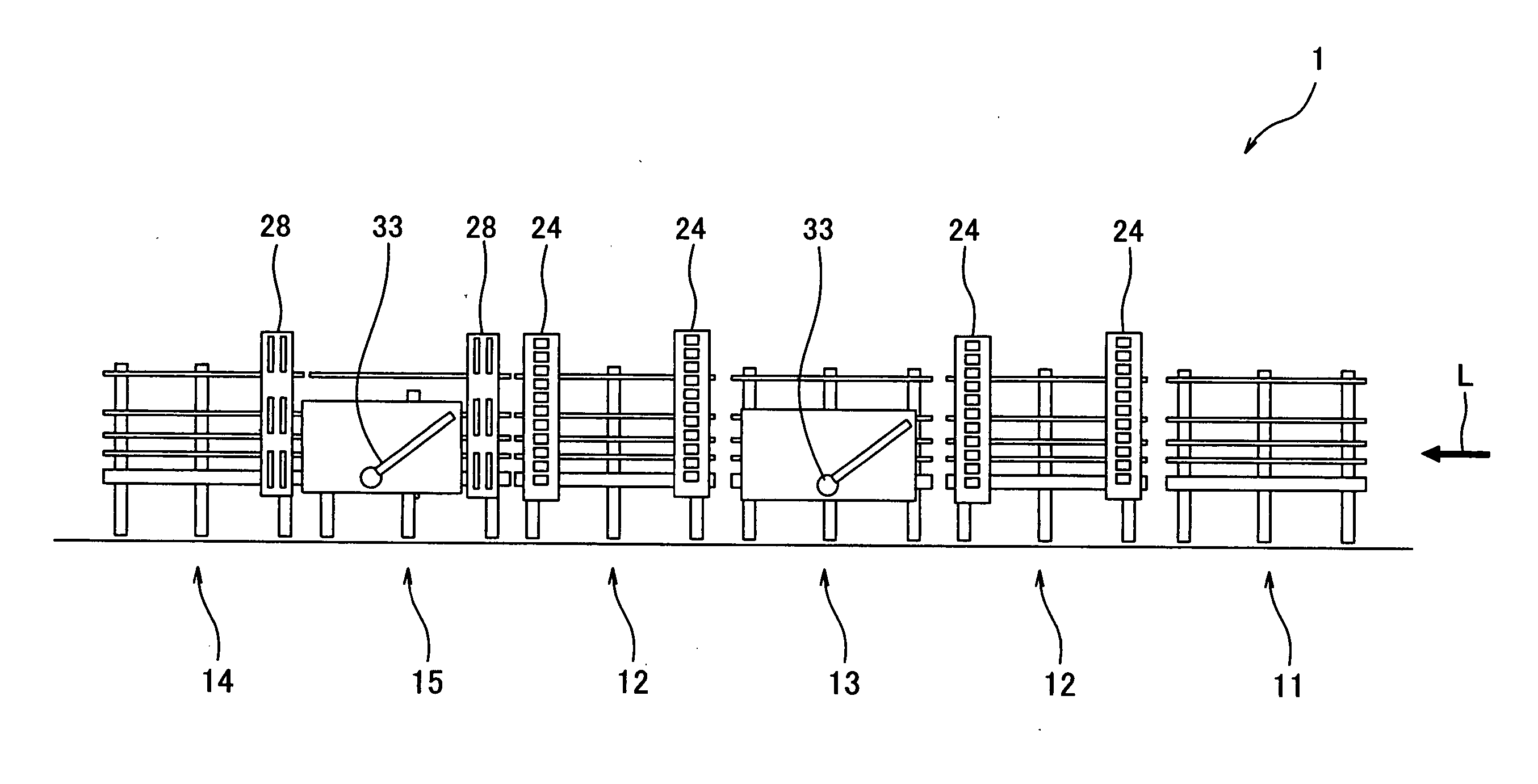

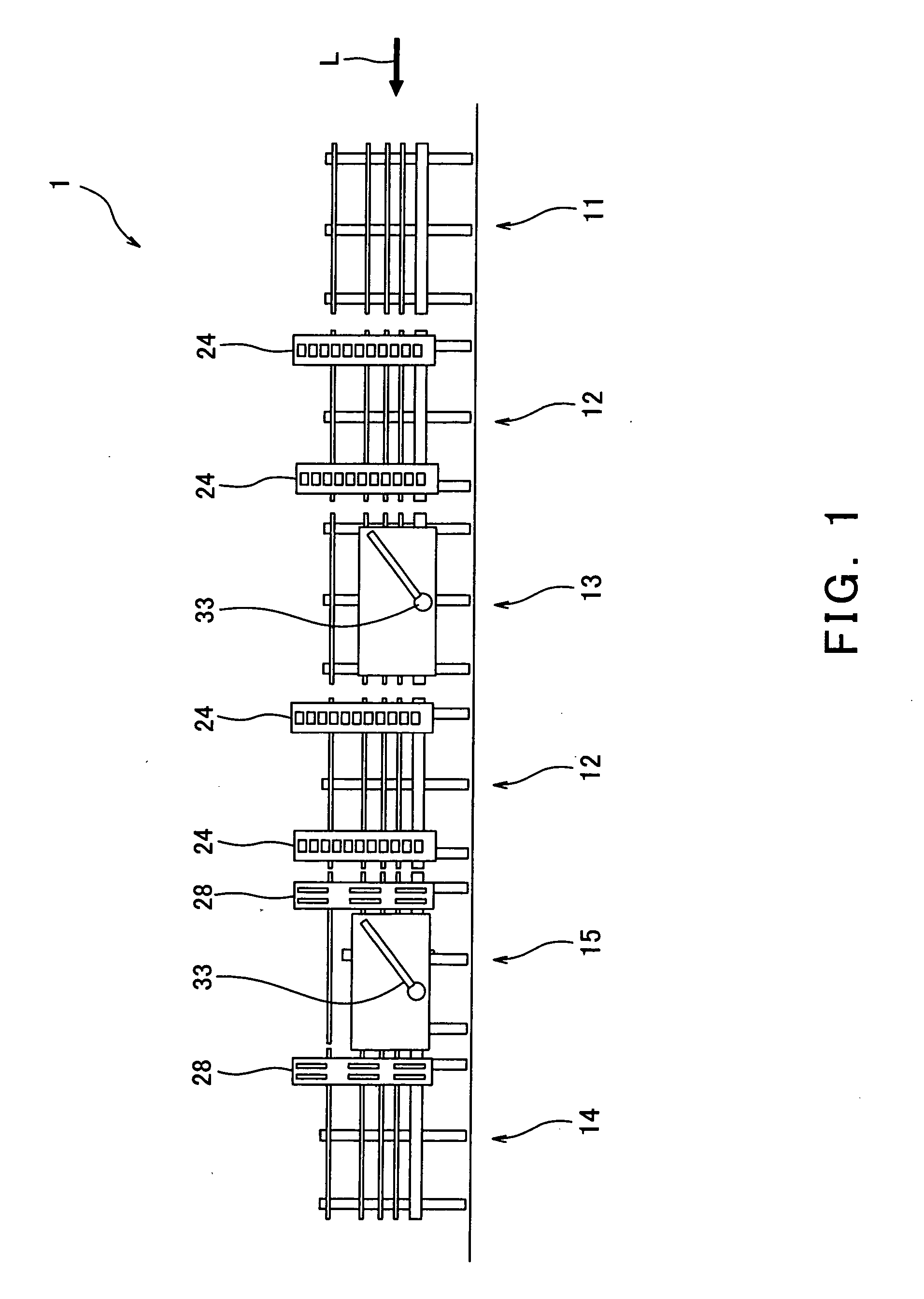

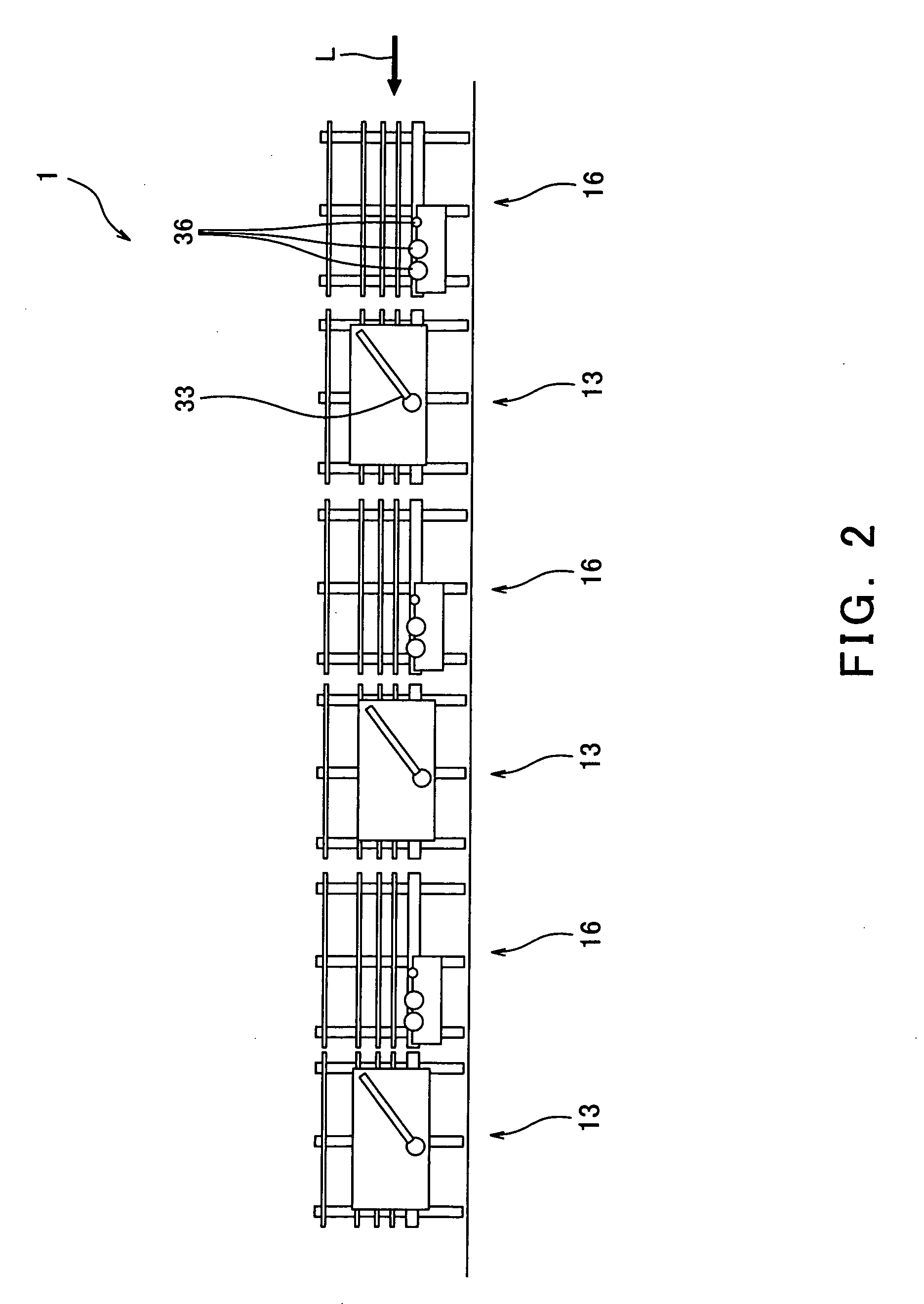

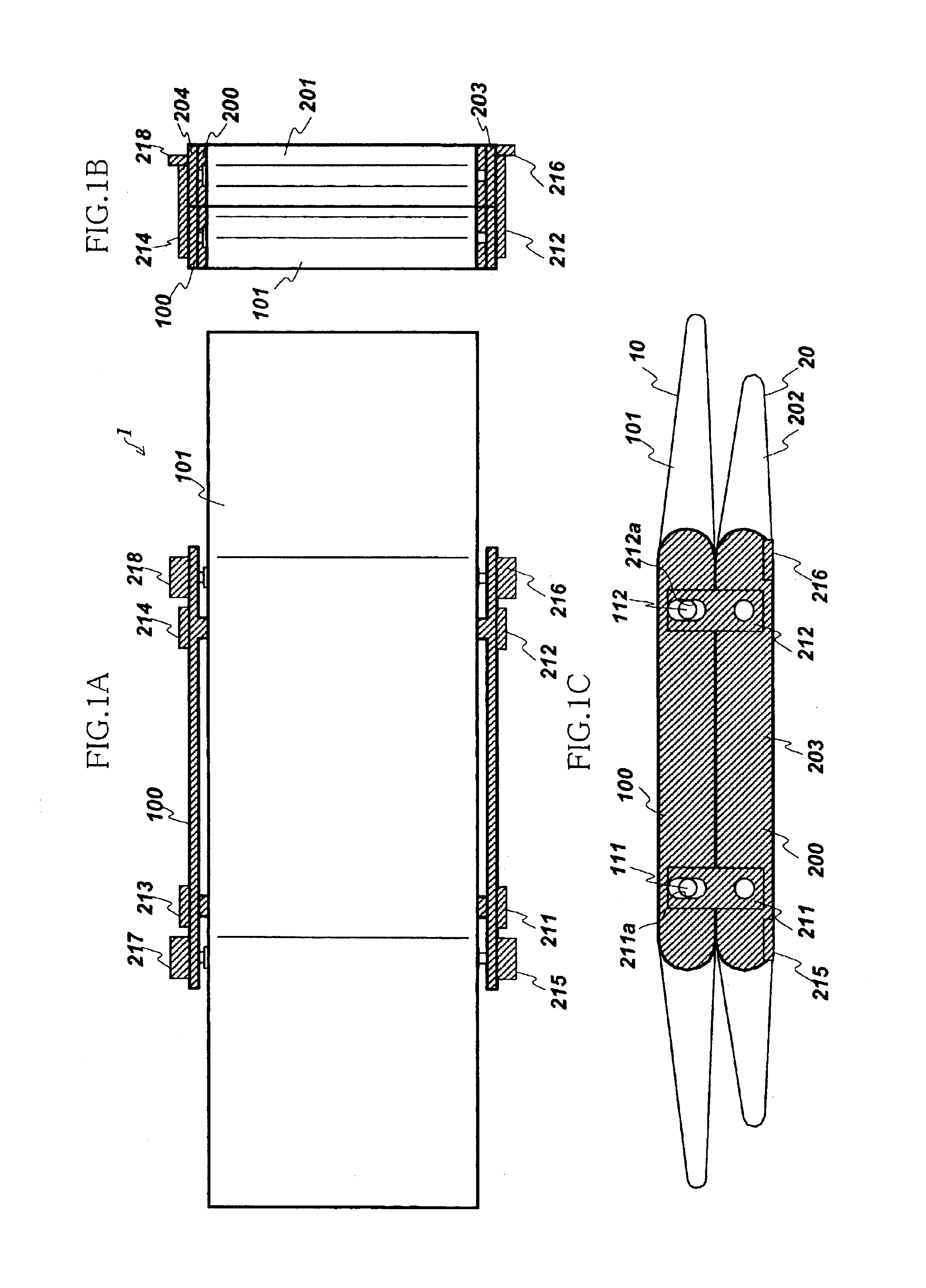

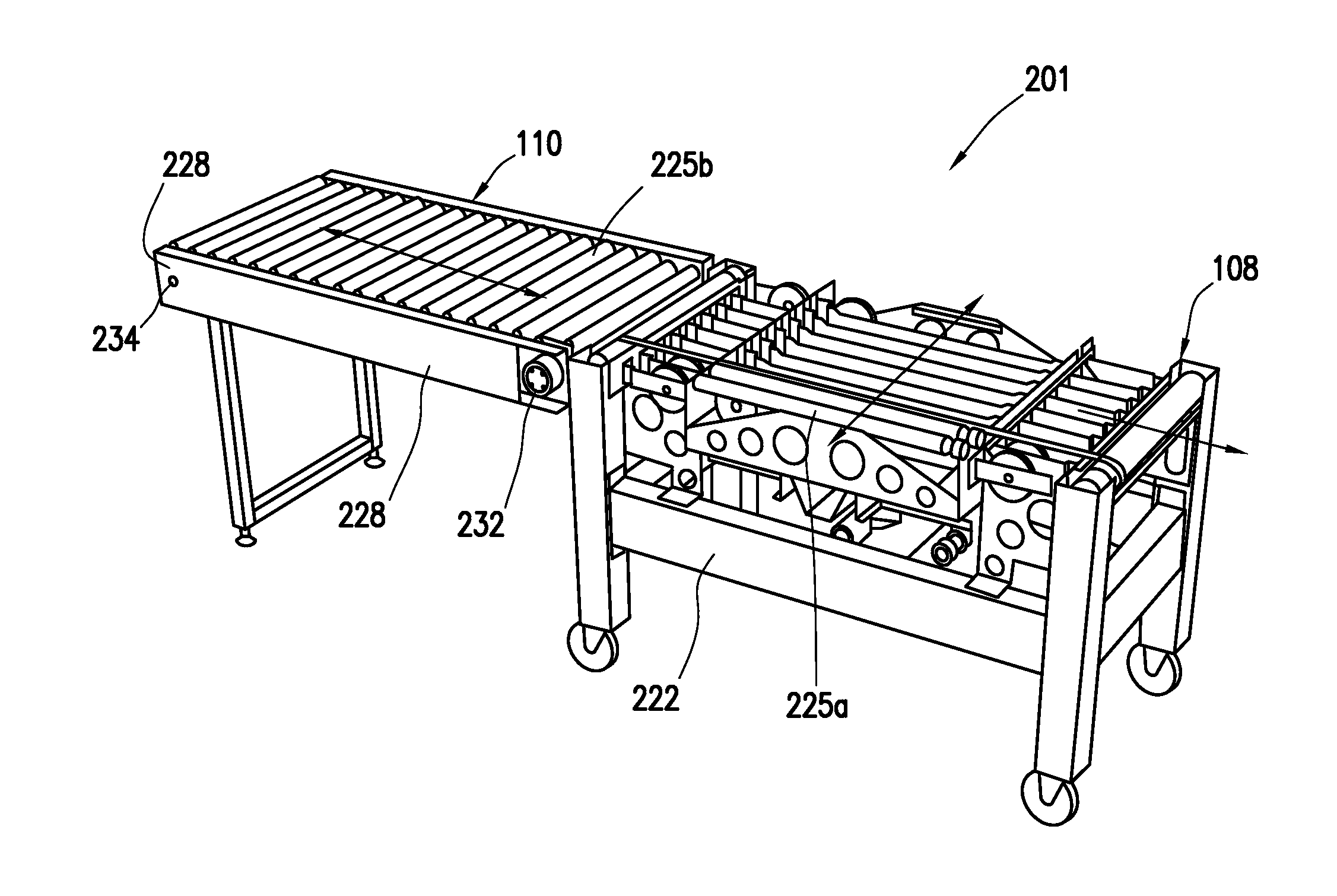

Plate Material Vertical Processing Line

ActiveUS20070271756A1Quality improvementSave installation spaceCharge manipulationSupporting framesHigh pressure waterHigh pressure

A plate material vertical processing line that is capable of subjecting large-sized and thinned glass plates to scribing, venting, etc without degrading their quality, comprises a plurality of processing devices each having a modular structure; wherein each of the processing devices includes a platform; a belt conveyor that is mounted on the platform and is configured to convey a glass plate placed in a substantially upright position while supporting a lower end of the glass plate; and a fluid guide that is mounted on the platform and is configured to apply a fluid pressure to a surface of the glass plate to support the glass plate in the substantially upright position and in a non-contact state; and wherein the processing devices include a combination of at least two processing devices selected from a scribing device, a venting device, a chamfering device, a cleaning agent washing device, a water washing device, a high-pressure water spray device, and a glass plate turn device.

Owner:KAWASAKI HEAVY IND LTD

Remote controlled swing auger system

ActiveUS7191889B1Efficiently manipulatedControl devices for conveyorsPackagingRemote controlDrive motor

A remote controlled swing auger system for efficiently manipulating a position of a swing auger. The remote controlled swing auger system includes a swing auger connectable to a main auger, a swing hopper connected to the swing auger, a plurality of front wheels and a plurality of rear wheels rotatably attached to the swing hopper, a drive motor mechanically connected to the front wheels, a control unit in communication with the drive motor, and at least one controller in communication with the control unit. The controller may be comprised of a manual controller and / or a remote controller. The user is able to pivot the swing hopper with respect to a main auger by using the remote controller while in the tractor or in a remote location away from the augers.

Owner:RUST SALES

Conveyor positioning system for an air cart in an agricultural seeder

An air cart for use in an agricultural seeder includes a frame; a material tank carried by the frame; an arm pivotally coupled with the frame; a conveyor coupled with the arm for conveying material to the tank; and a hydraulic positioning system coupled with the conveyor for automatically moving the conveyor to a selected one of a plurality of predetermined positions.

Owner:DEERE & CO

Device for controlling a forager chute

ActiveUS6932554B2Operation moreLarge rotation rangeMowersControl devices for conveyorsHorizontal axisVertical axis

A control device and corresponding method for controlling a transfer device on a harvesting machine are disclosed. The transfer device is arranged at a distance adjacent to a housing part so as to be rotatable about a vertical axis and, to alter the height setting, elevatable about a horizontal axis. The control device includes a rotation range limiting means that limits the maximum permitted pivot range of the transfer device as a function of the height setting of the transfer device.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

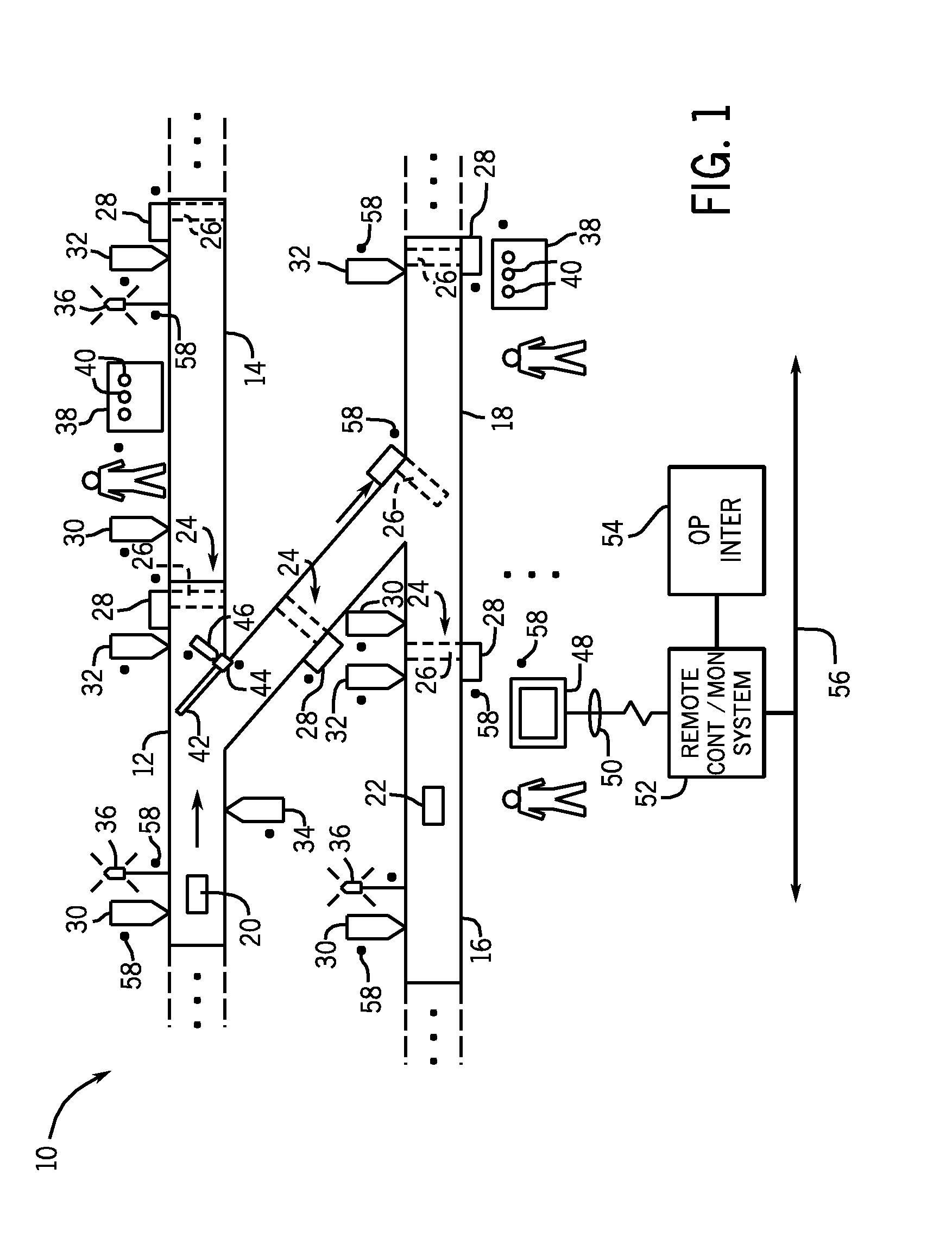

Modular handling system and method of using same

A modular handling system and method for transporting cases is disclosed. The system includes at least one mobile base including a base frame with a base diverter thereon and at least one collapsible wing. The base frame is supported by wheeled legs. The collapsible wing includes a wing frame. The wing frame is operatively connectable to the mobile base, and is supported by collapsible legs. The wing frame and the collapsible legs are movable between an operational position and a collapsed position whereby a configurable path is movably positionable about a work space. A sorting system including at least one sorter mounted to the mobile base(s) may also be provided. Each sorter is operatively connectable to the mobile bases to identify and route the cases. The sorters are interactively coupled for communication therebetween whereby the cases are selectively movable about the configurable path.

Owner:ROBOTICA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com