Patents

Literature

5602results about "Fertiliser distributers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

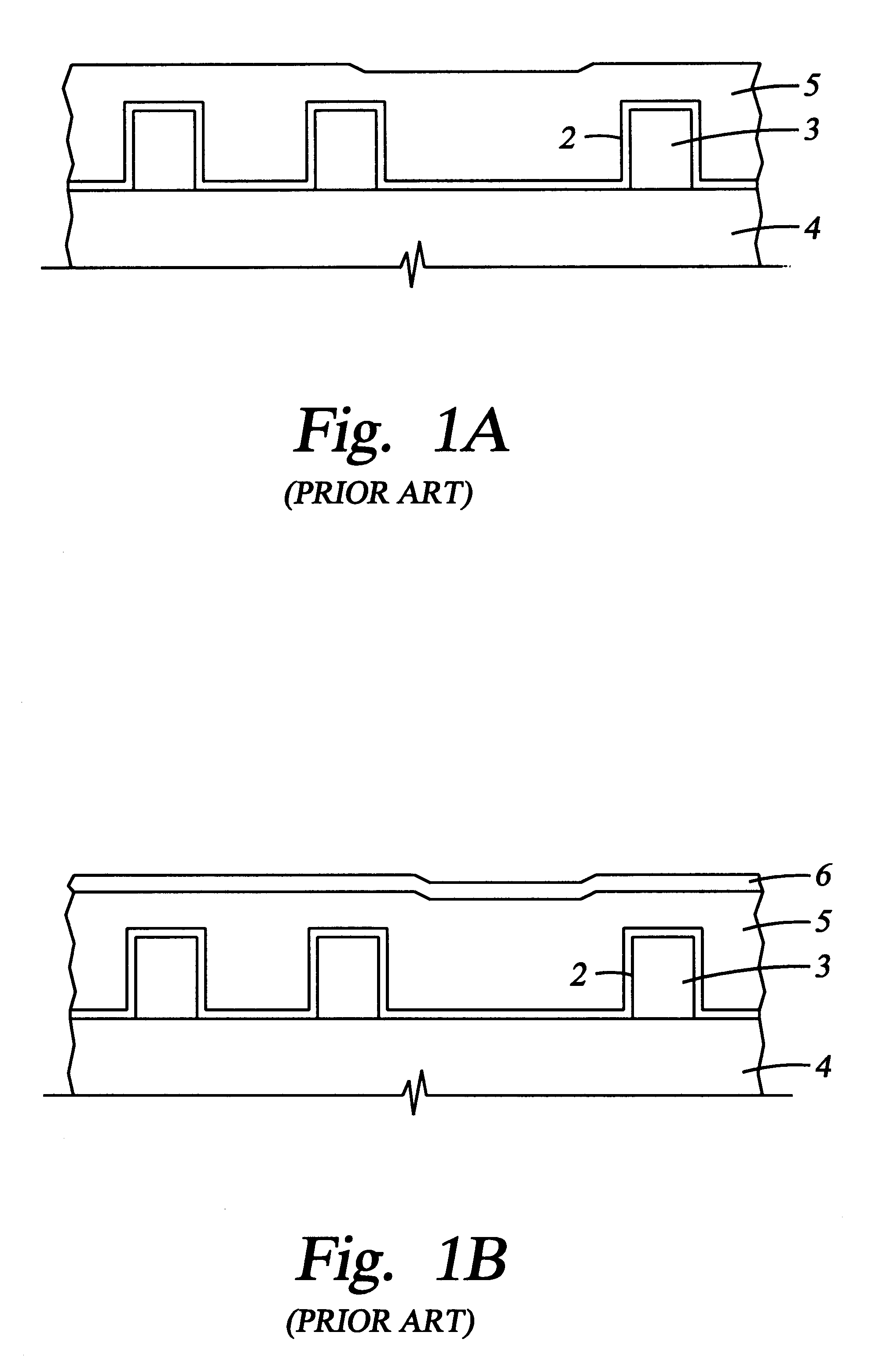

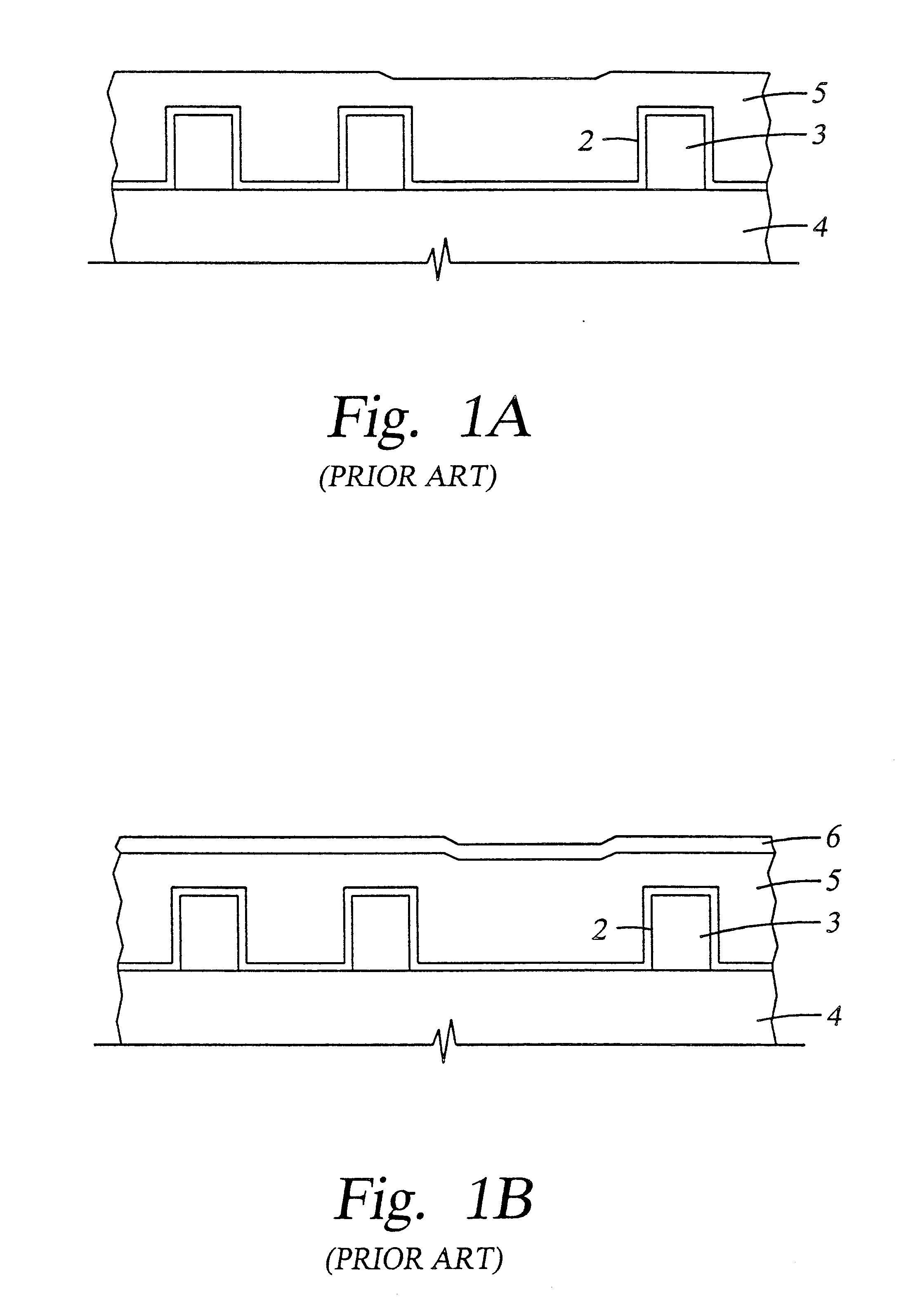

Integrated low K dielectrics and etch stops

InactiveUS6340435B1Decorative surface effectsSemiconductor/solid-state device detailsHydrogenFluorocarbon

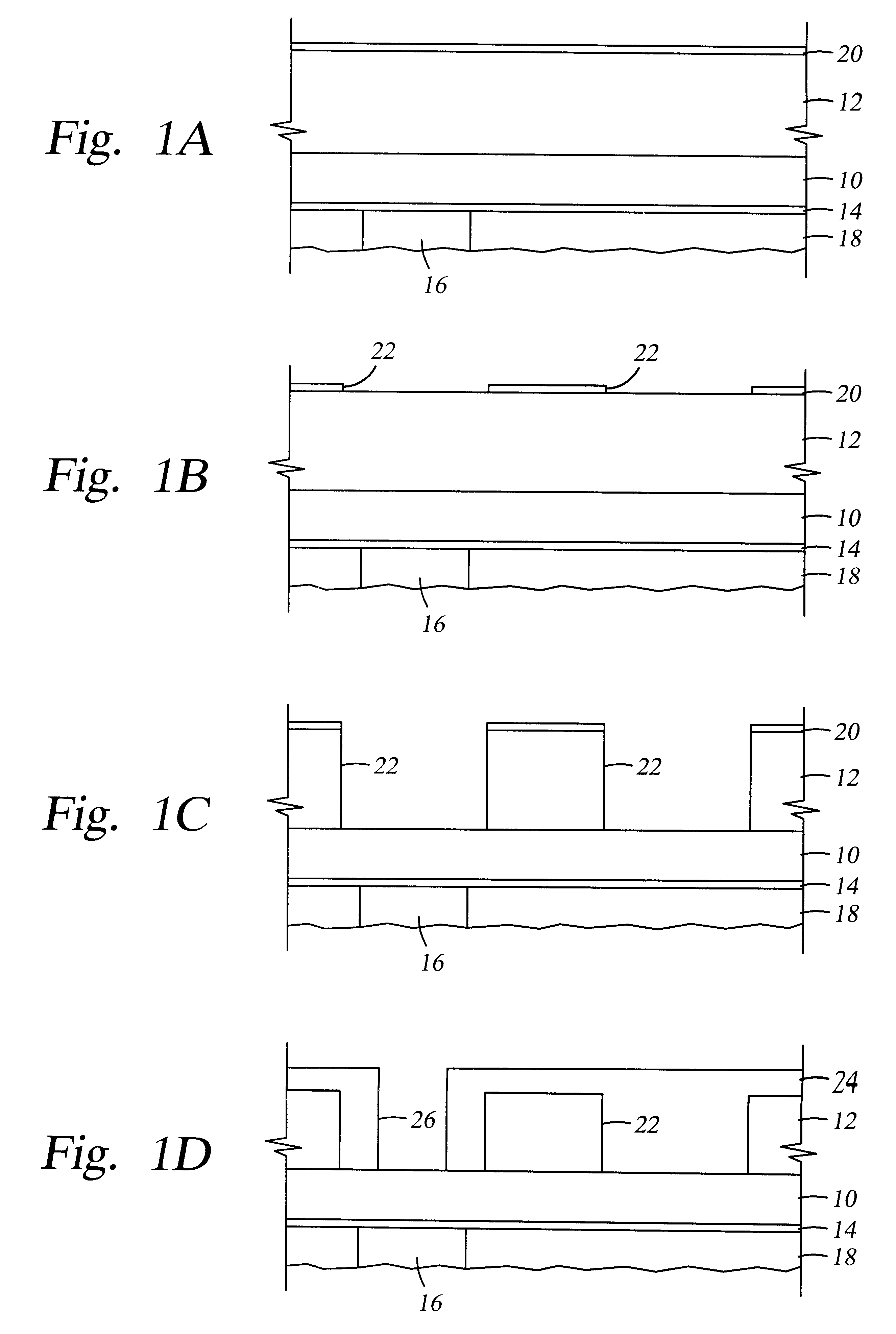

A method of depositing and etching dielectric layers having low dielectric constants and etch rates that vary by at least 3:1 for formation of horizontal interconnects. The amount of carbon or hydrogen in the dielectric layer is varied by changes in deposition conditions to provide low k dielectric layers that can replace etch stop layers or conventional dielectric layers in damascene applications. A dual damascene structure having two or more dielectric layers with dielectric constants lower than about 4 can be deposited in a single reactor and then etched to form vertical and horizontal interconnects by varying the concentration of a carbon:oxygen gas such as carbon monoxide. The etch gases for forming vertical interconnects preferably comprises CO and a fluorocarbon, and CO is preferably excluded from etch gases for forming horizontal interconnects.

Owner:APPLIED MATERIALS INC

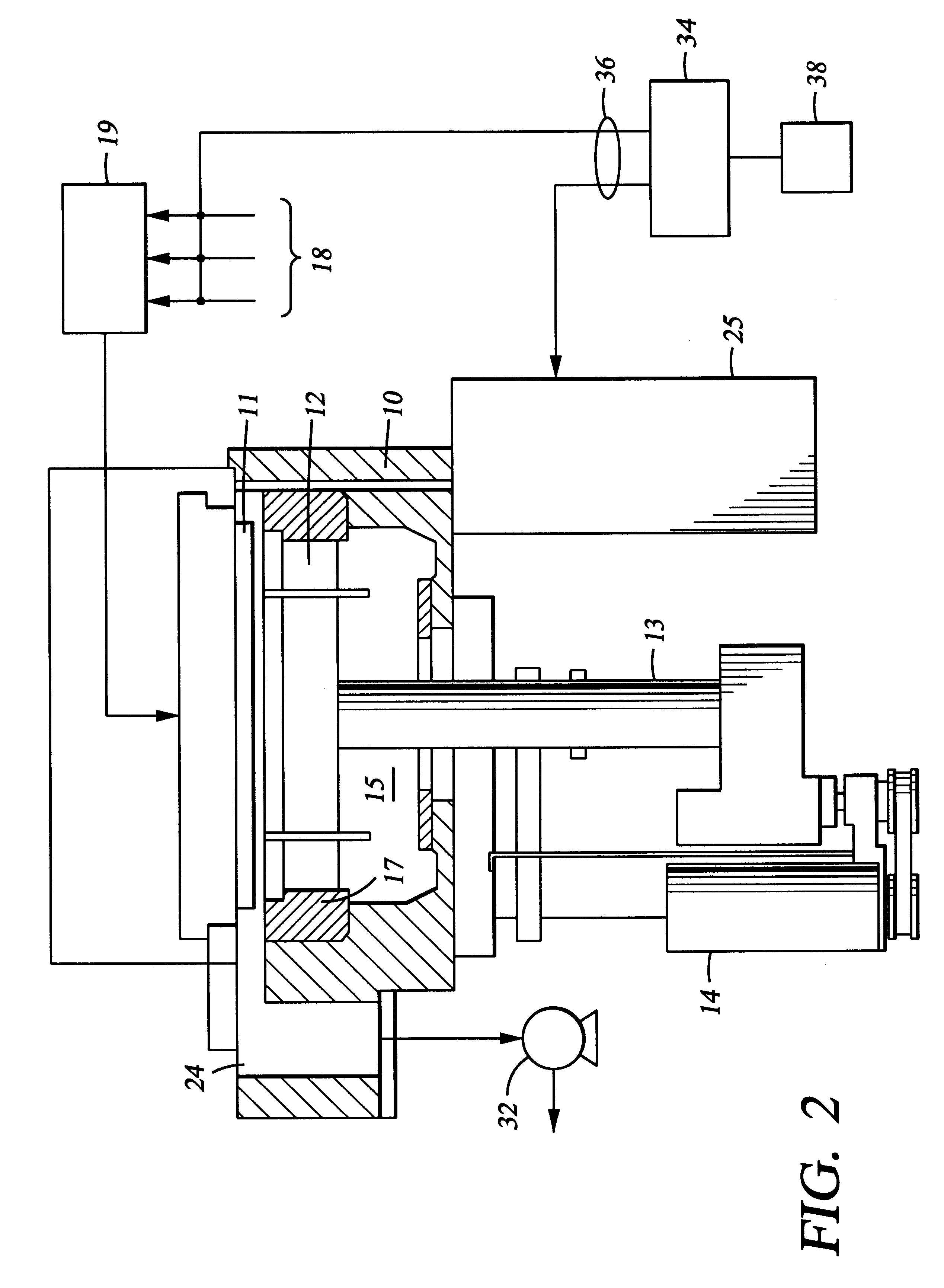

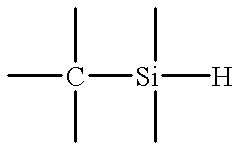

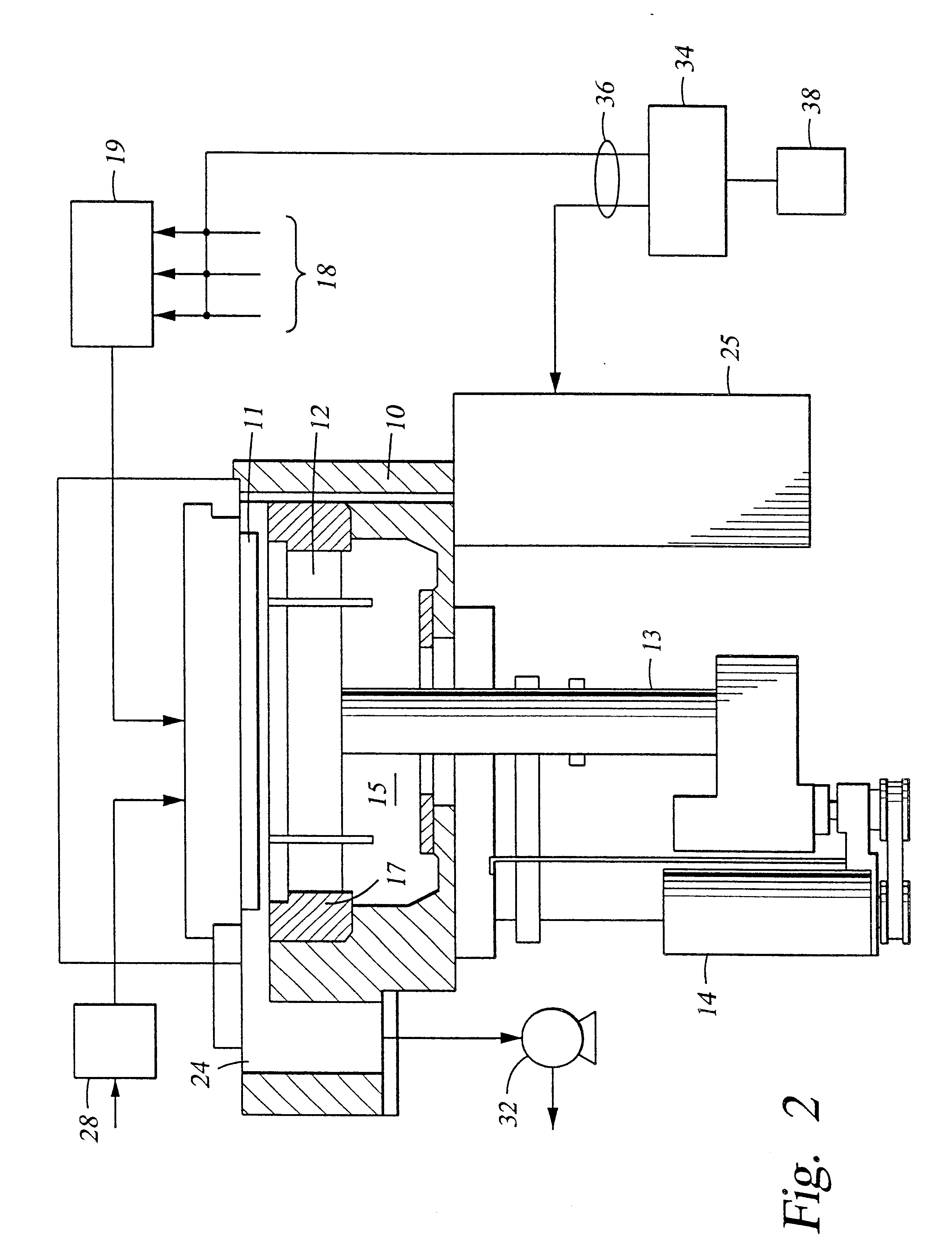

CVD plasma assisted low dielectric constant films

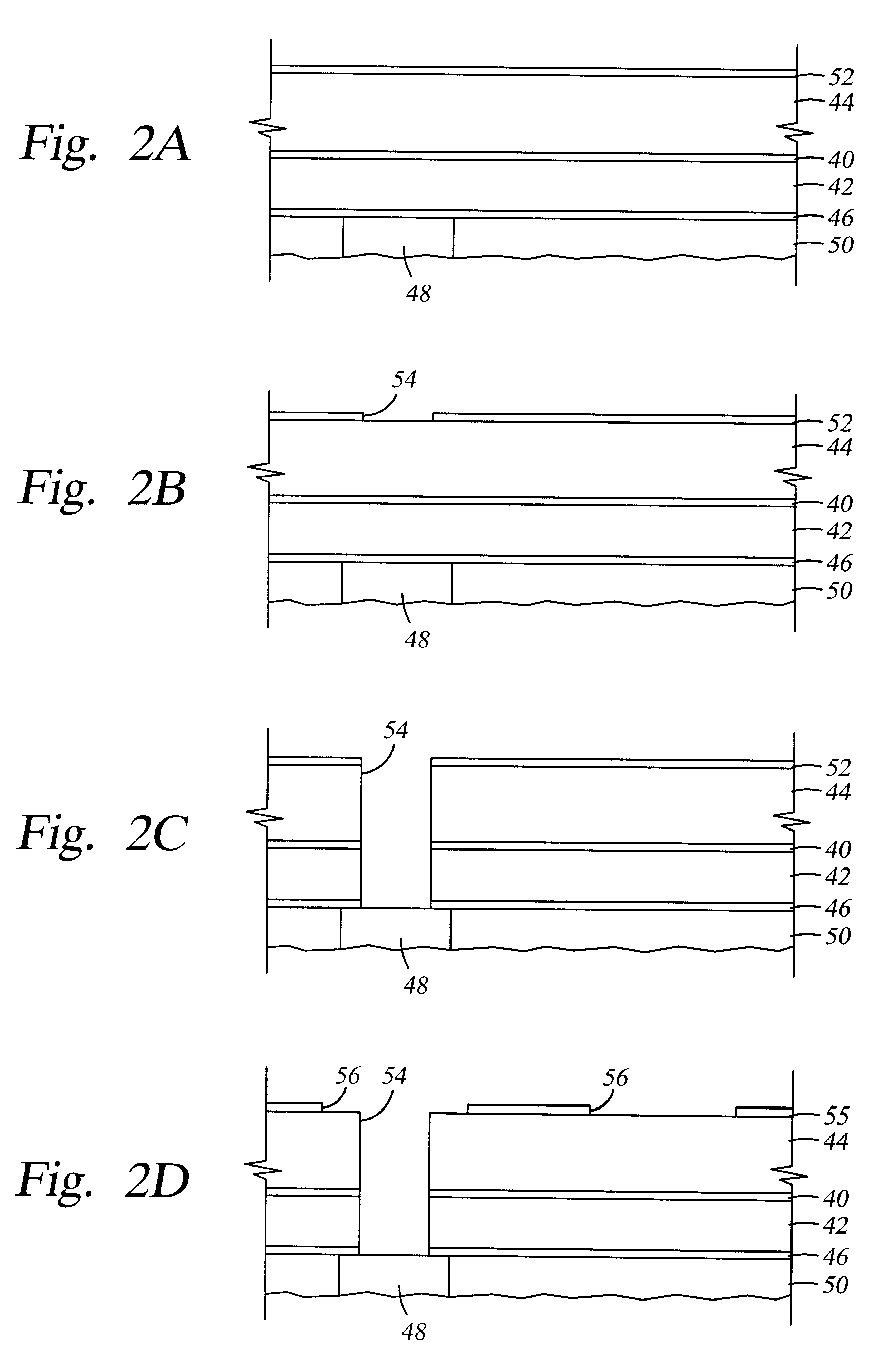

A method and apparatus for depositing a low dielectric constant film by reaction of an organosilane or organosiloxane compound and an oxidizing gas at a low RF power level from 10-250 W. The oxidized organosilane or organosiloxane film has good barrier properties for use as a liner or cap layer adjacent other dielectric layers. The oxidized organosilane or organosiloxane film may also be used as an etch stop or an intermetal dielectric layer for fabricating dual damascene structures. The oxidized organosilane or organosiloxane films also provide excellent adhesion between different dielectric layers. A preferred oxidized organosilane film is produced by reaction of methylsilane, CH3SiH3, or dimethylsilane, (CH3)2SiH2, and nitrous oxide, N2O, at an RF power level from about 10 to 200 W or a pulsed RF power level from about 20 to 250 W during 10-30% of the duty cycle.

Owner:APPLIED MATERIALS INC

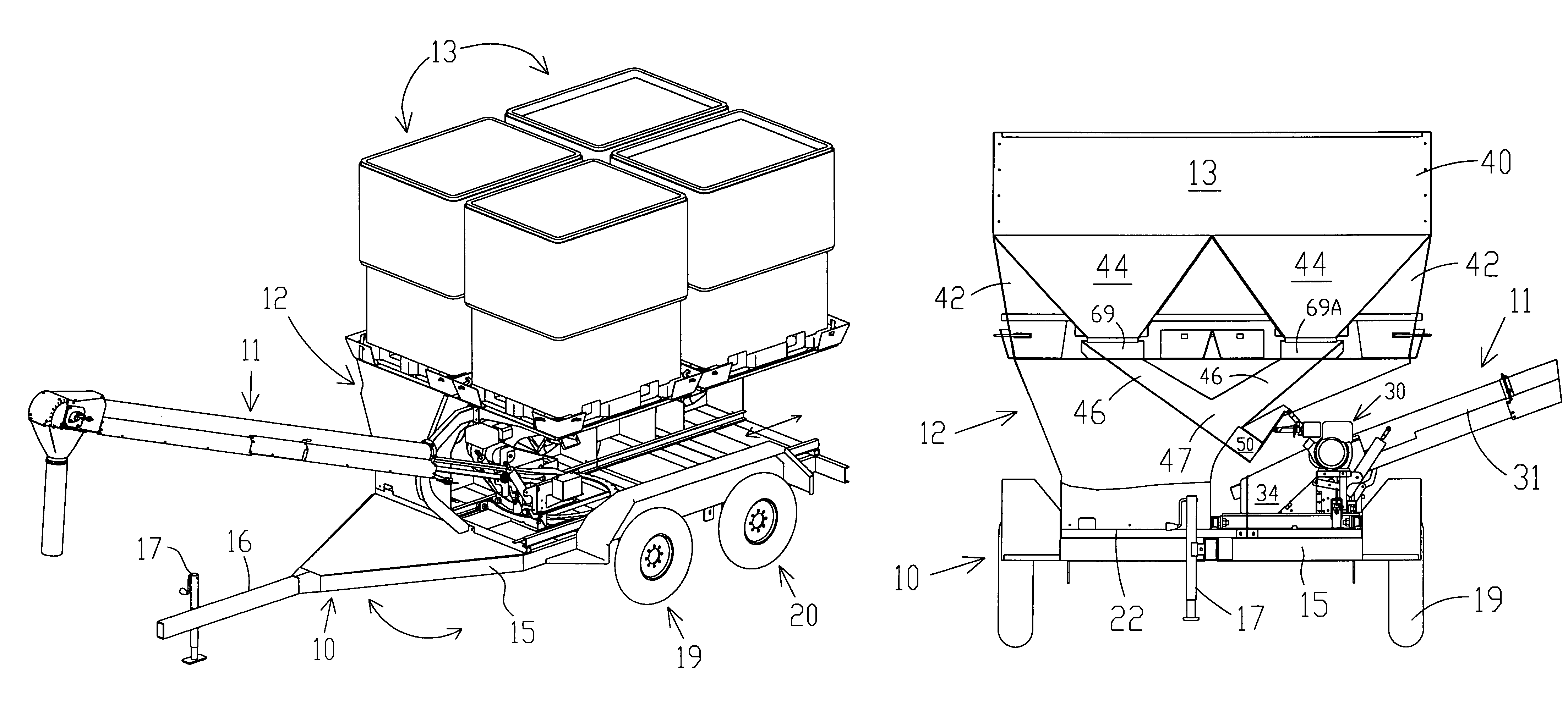

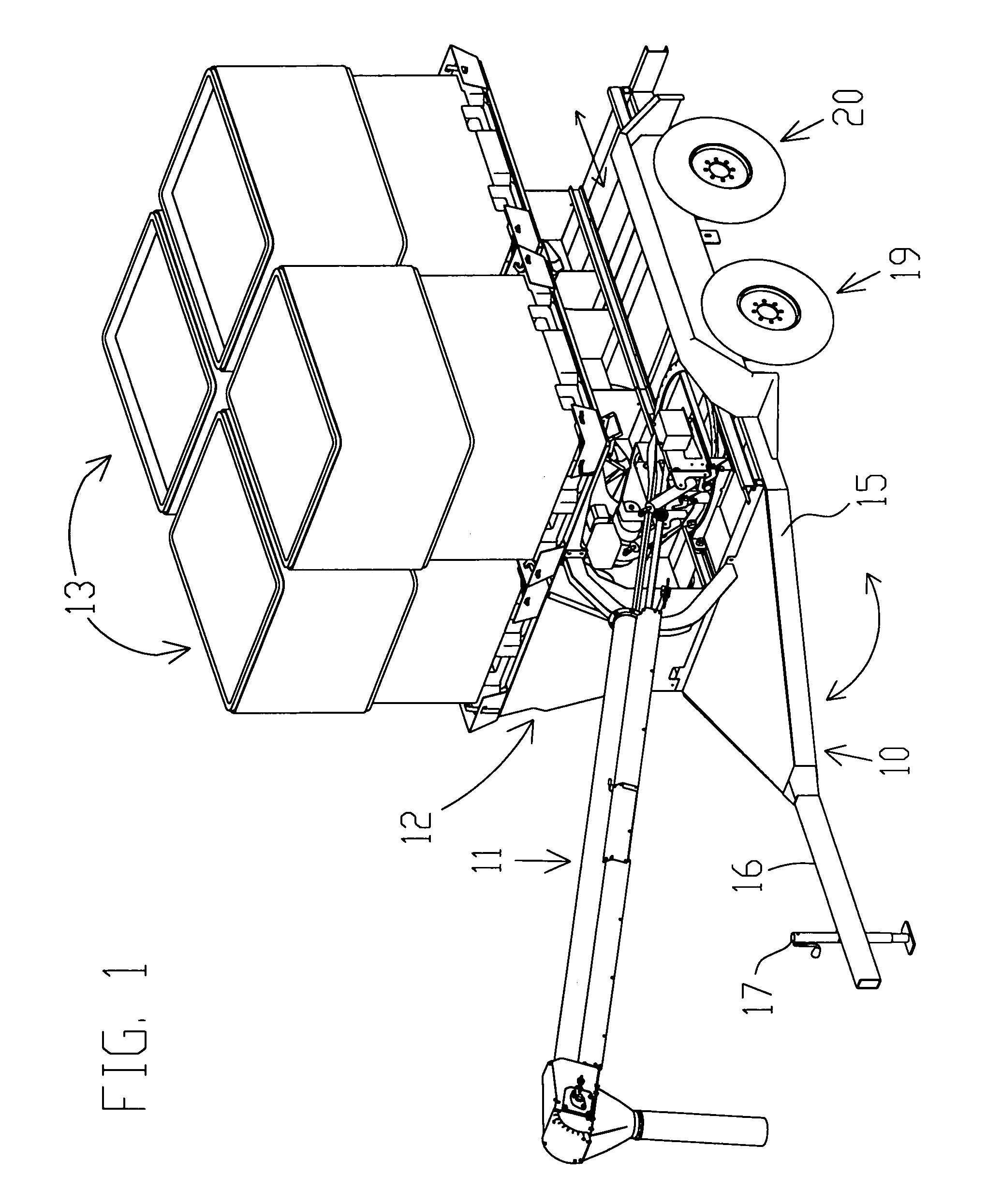

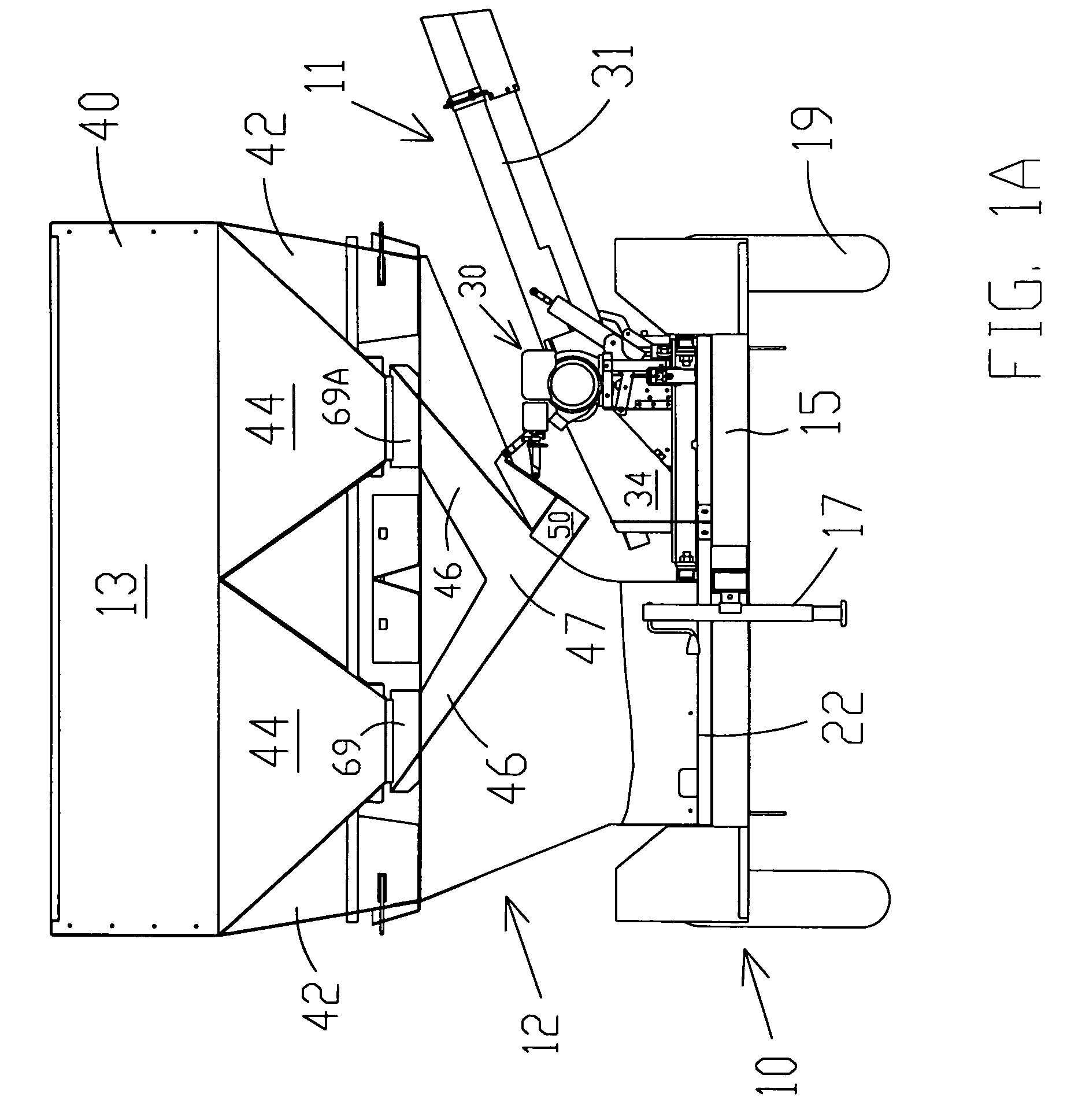

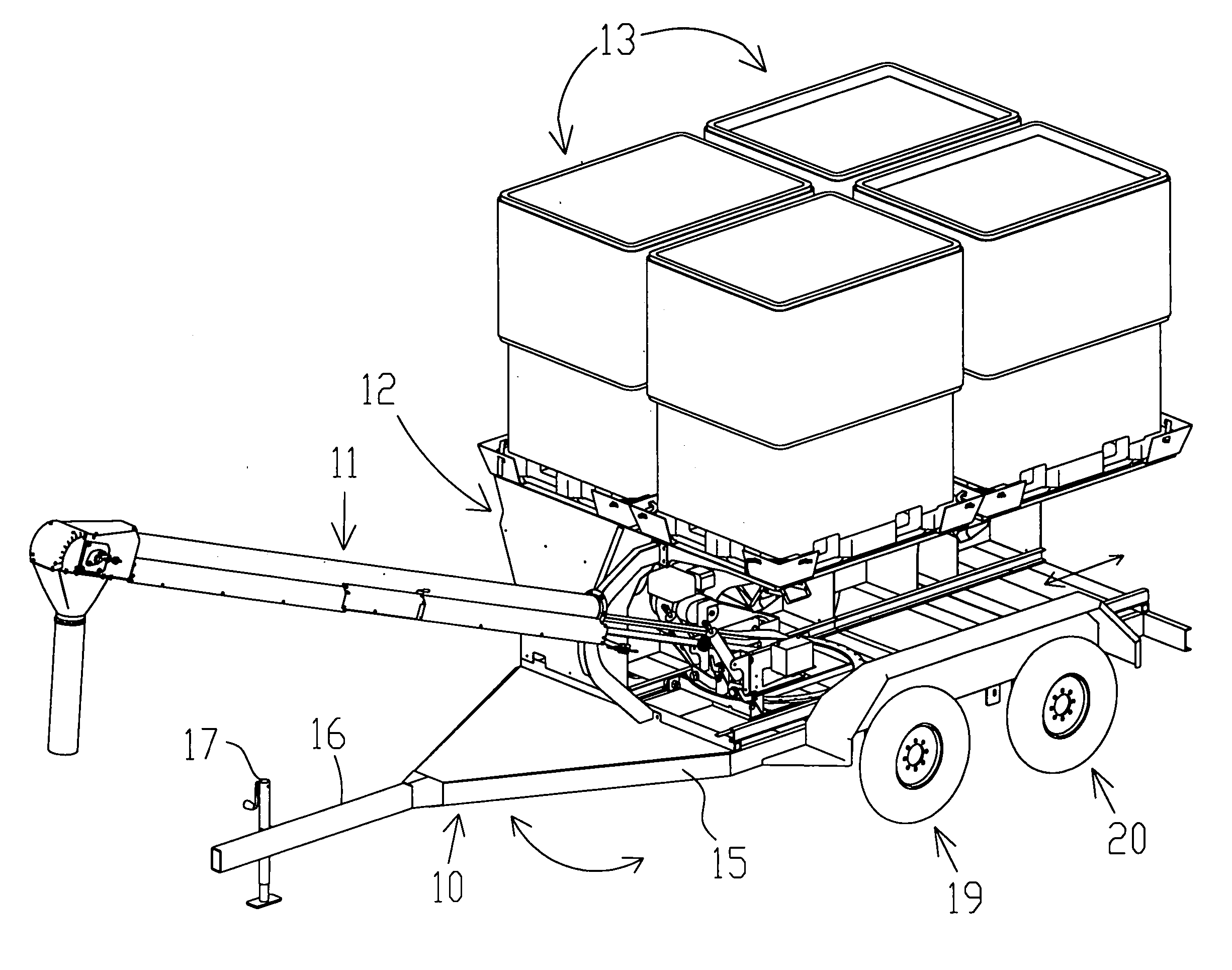

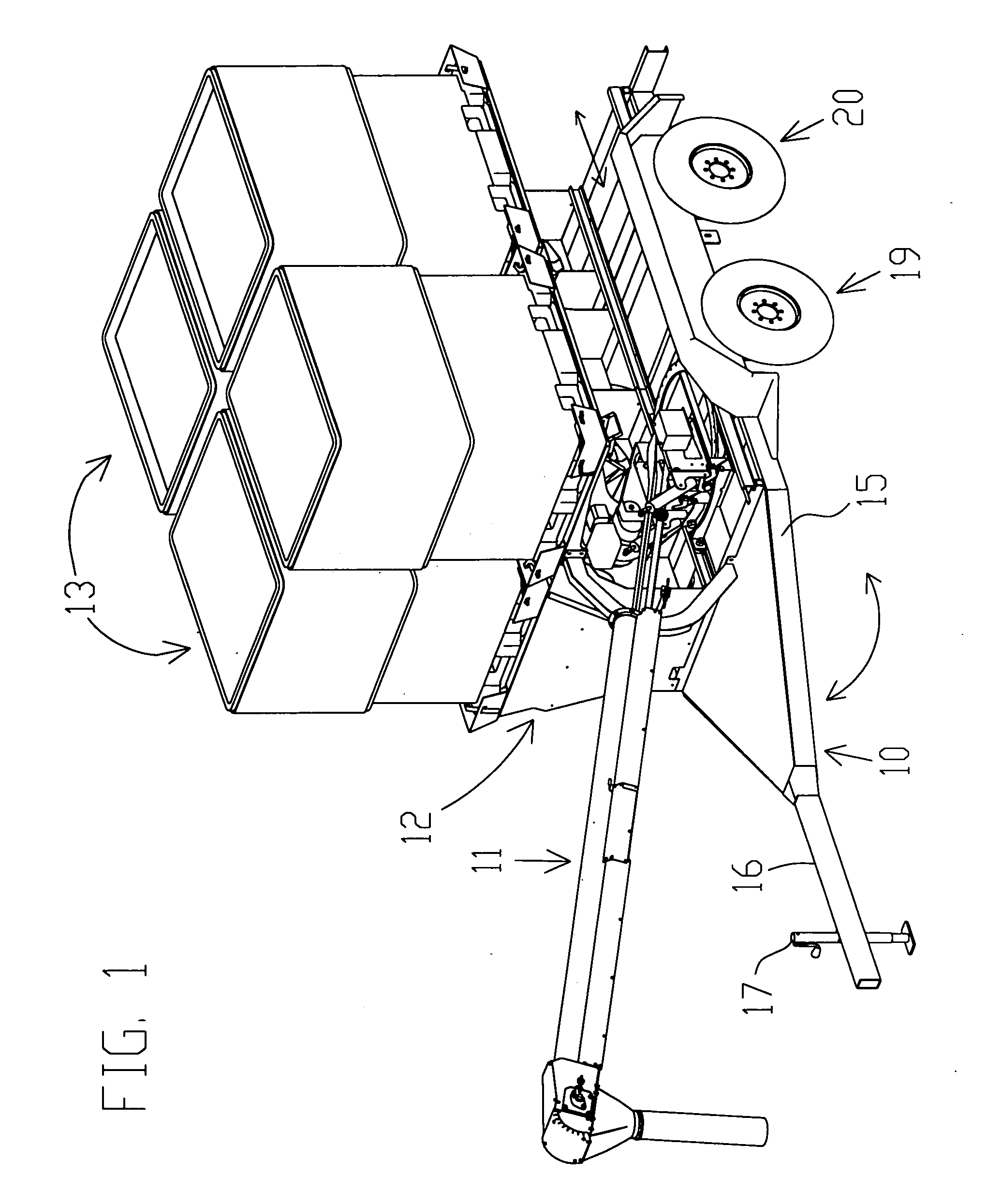

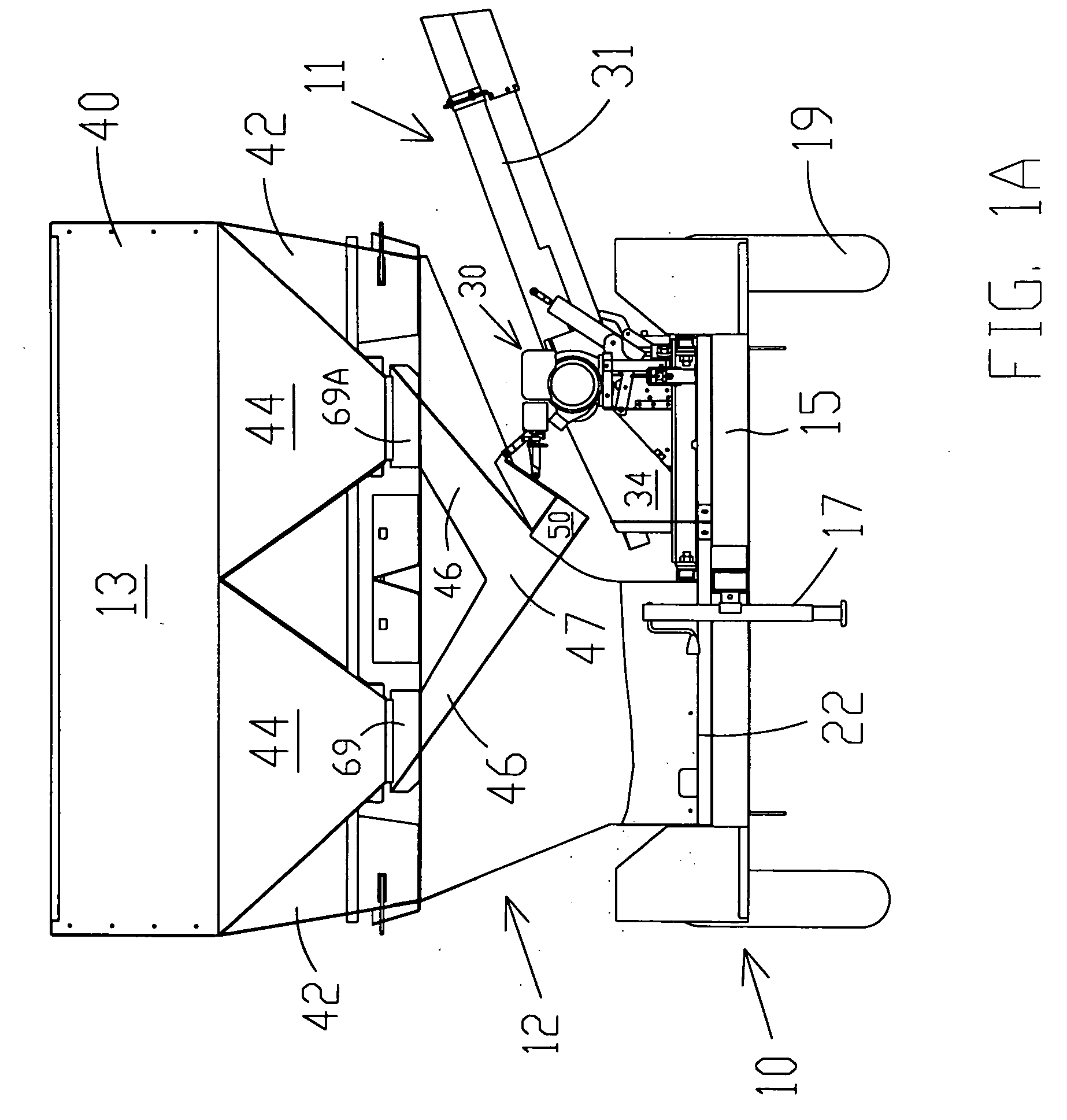

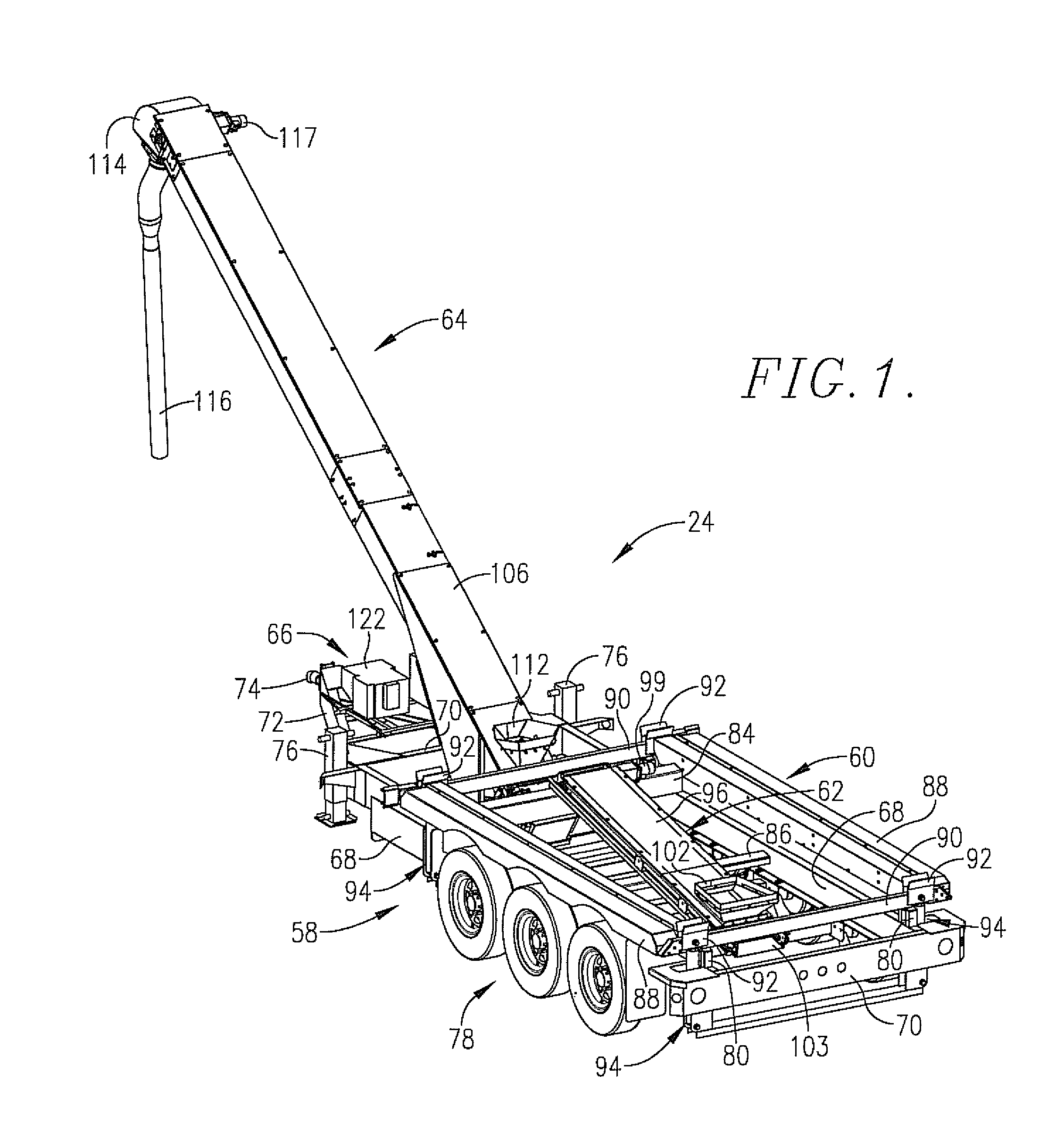

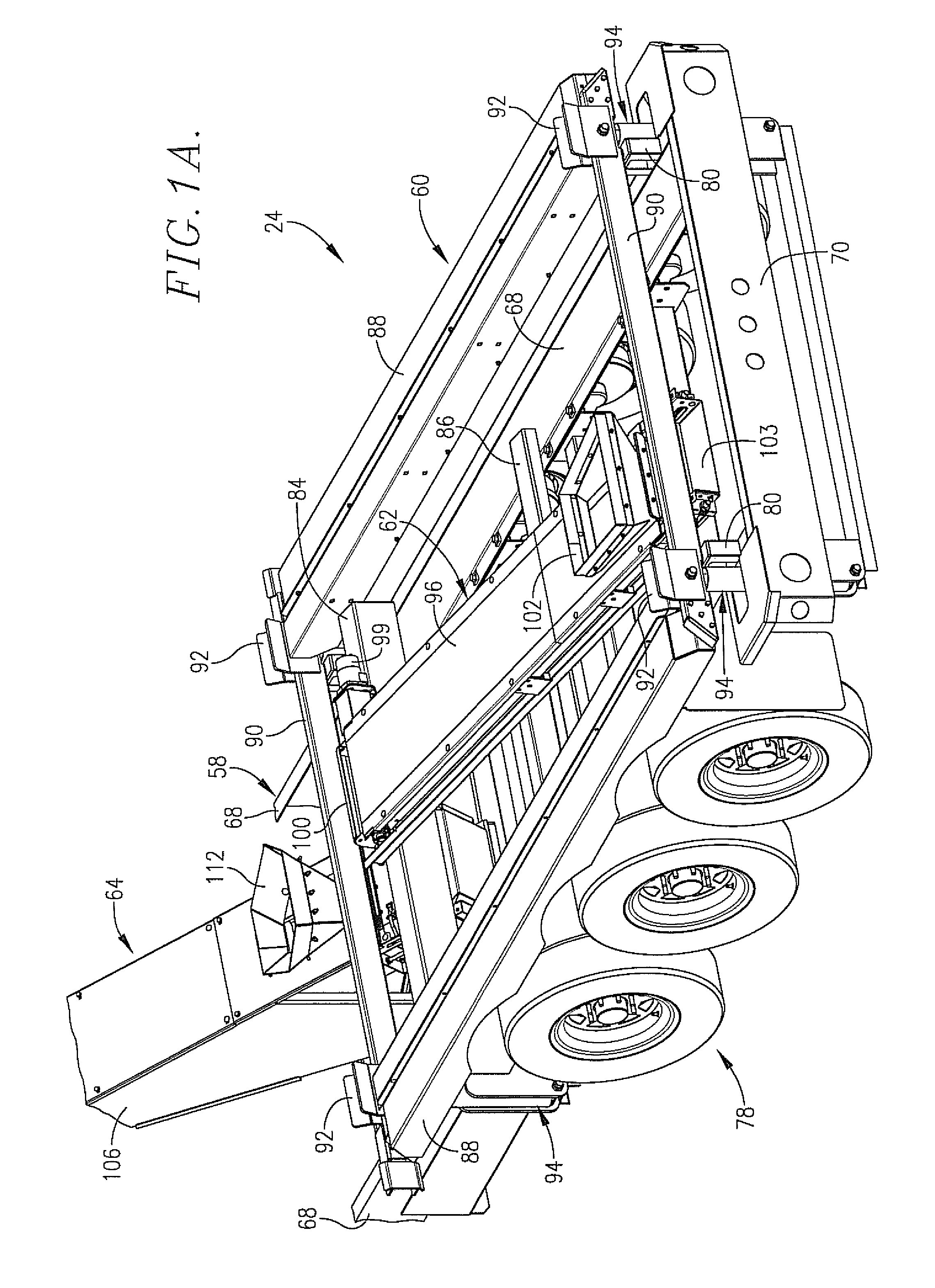

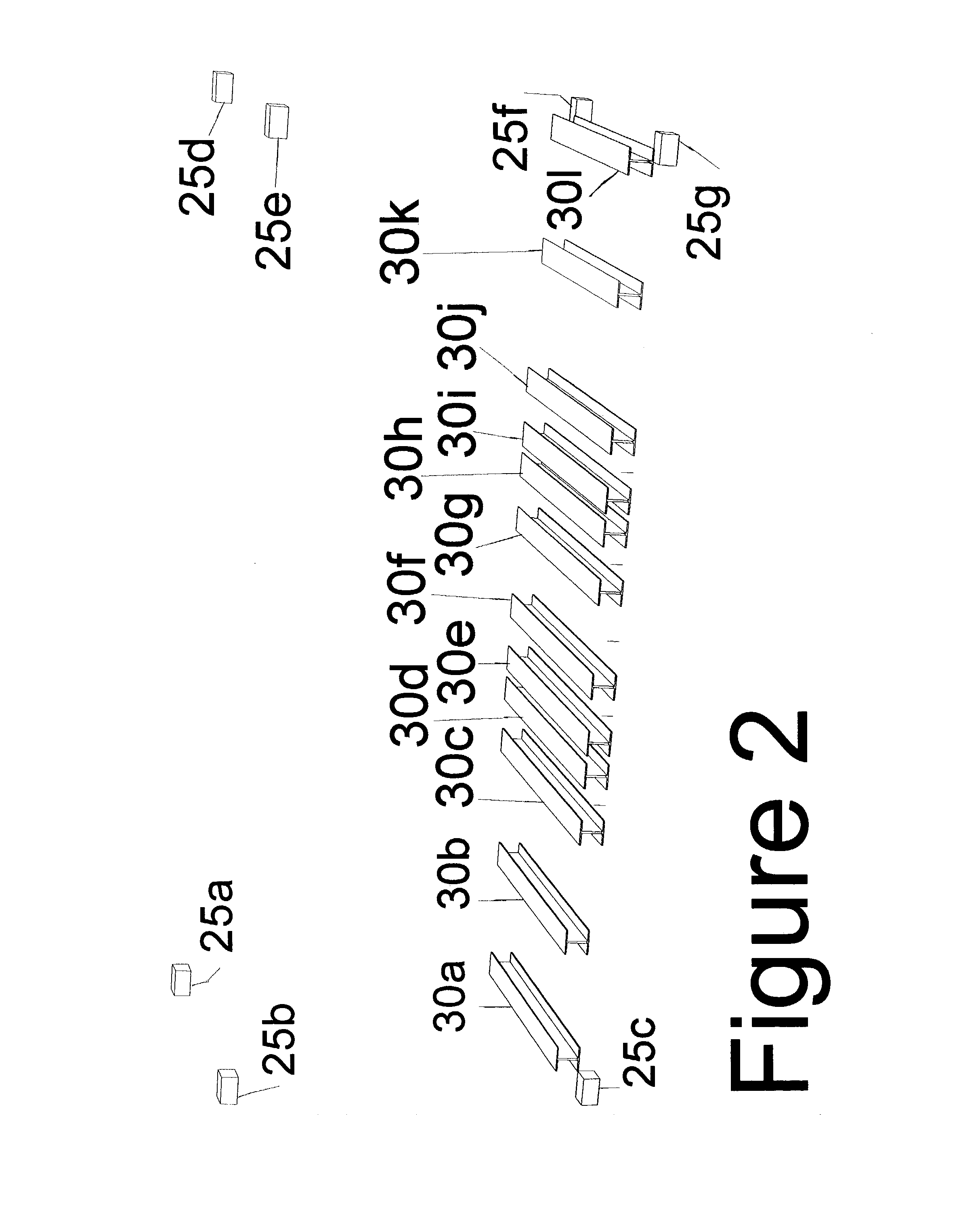

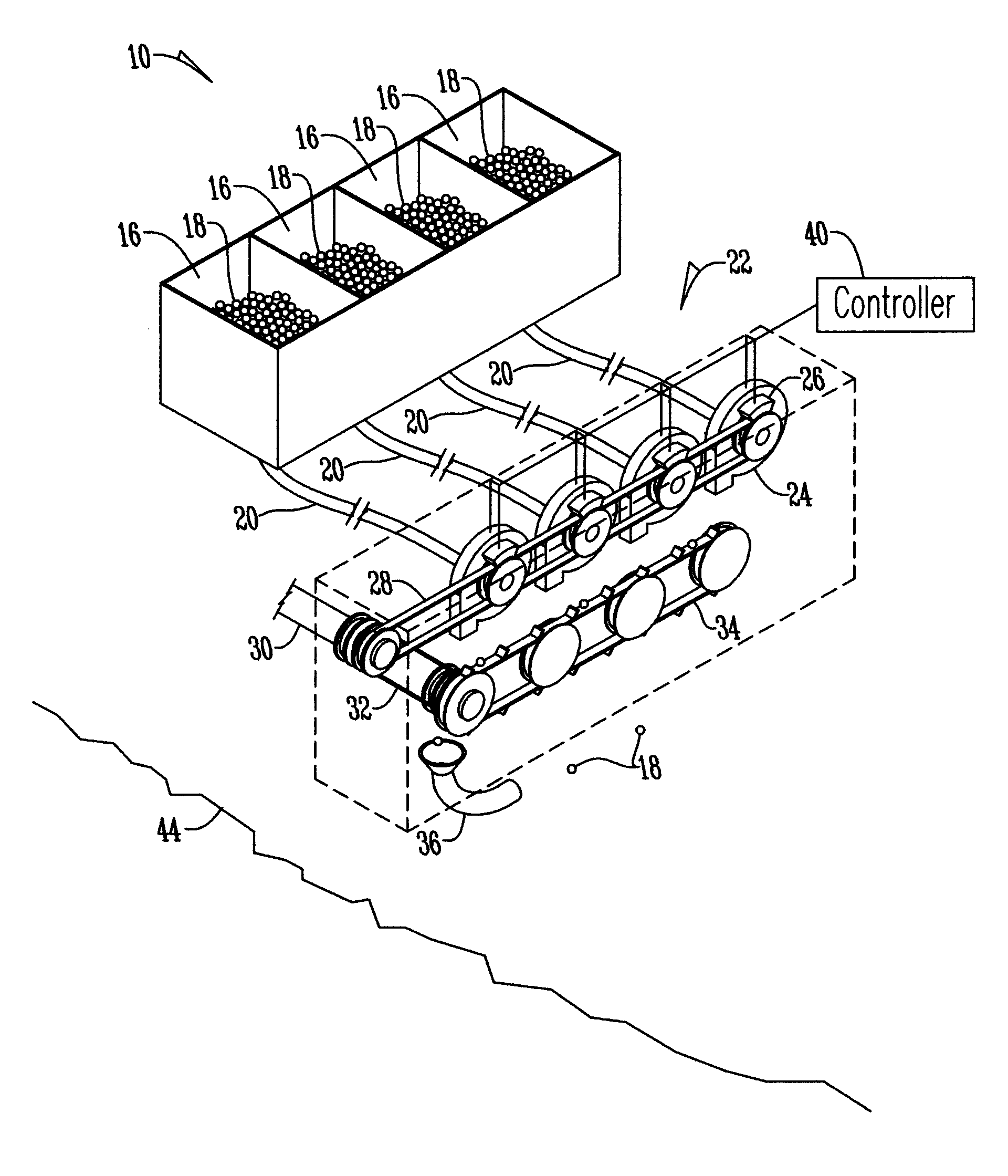

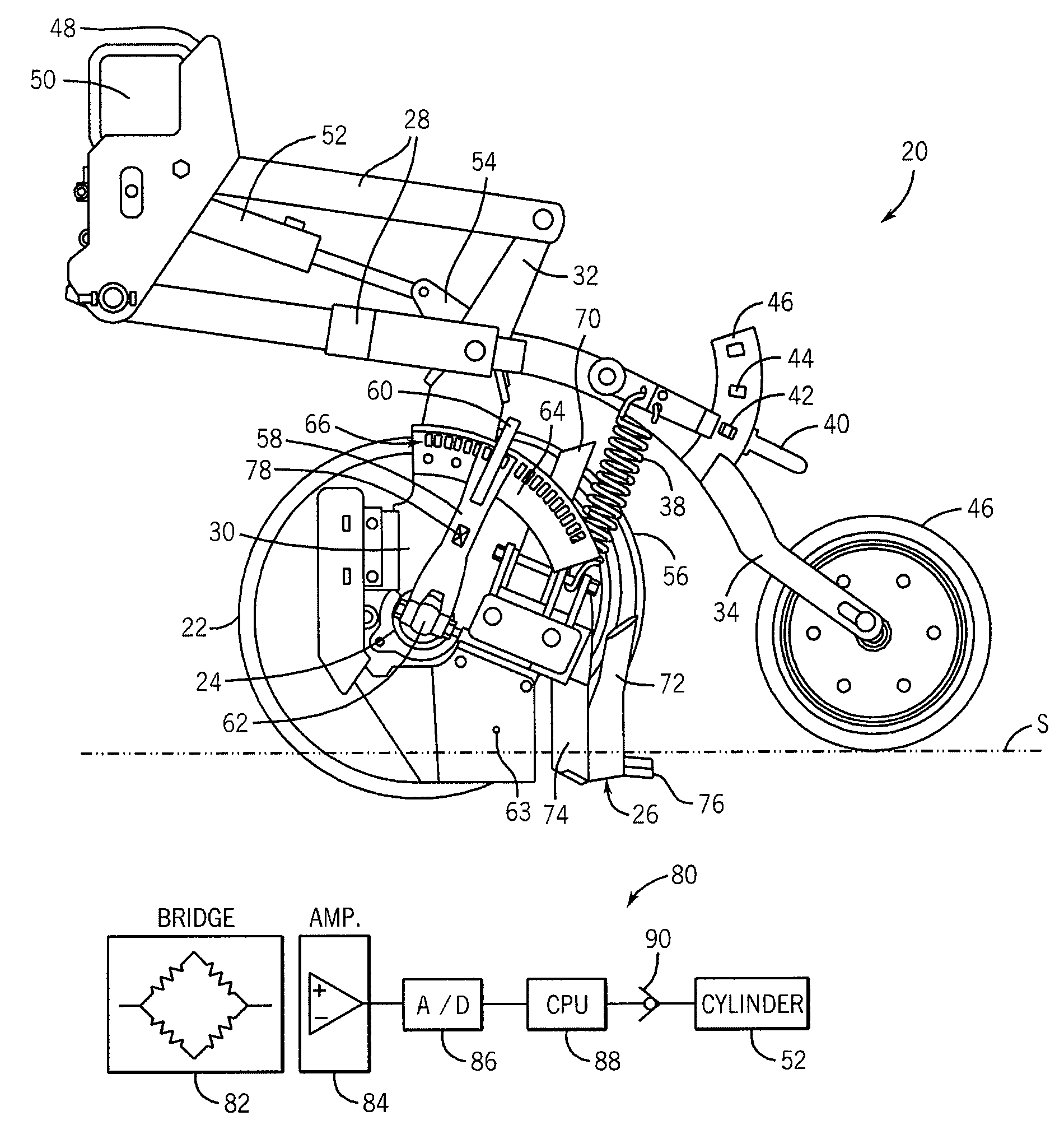

Agricultural seed tender with modular storage containers

ActiveUS7500817B2Improve economyIncrease storage capacityConveyorsMovable measuring chambersComputer moduleEngineering

Owner:MERIDIAN MFG

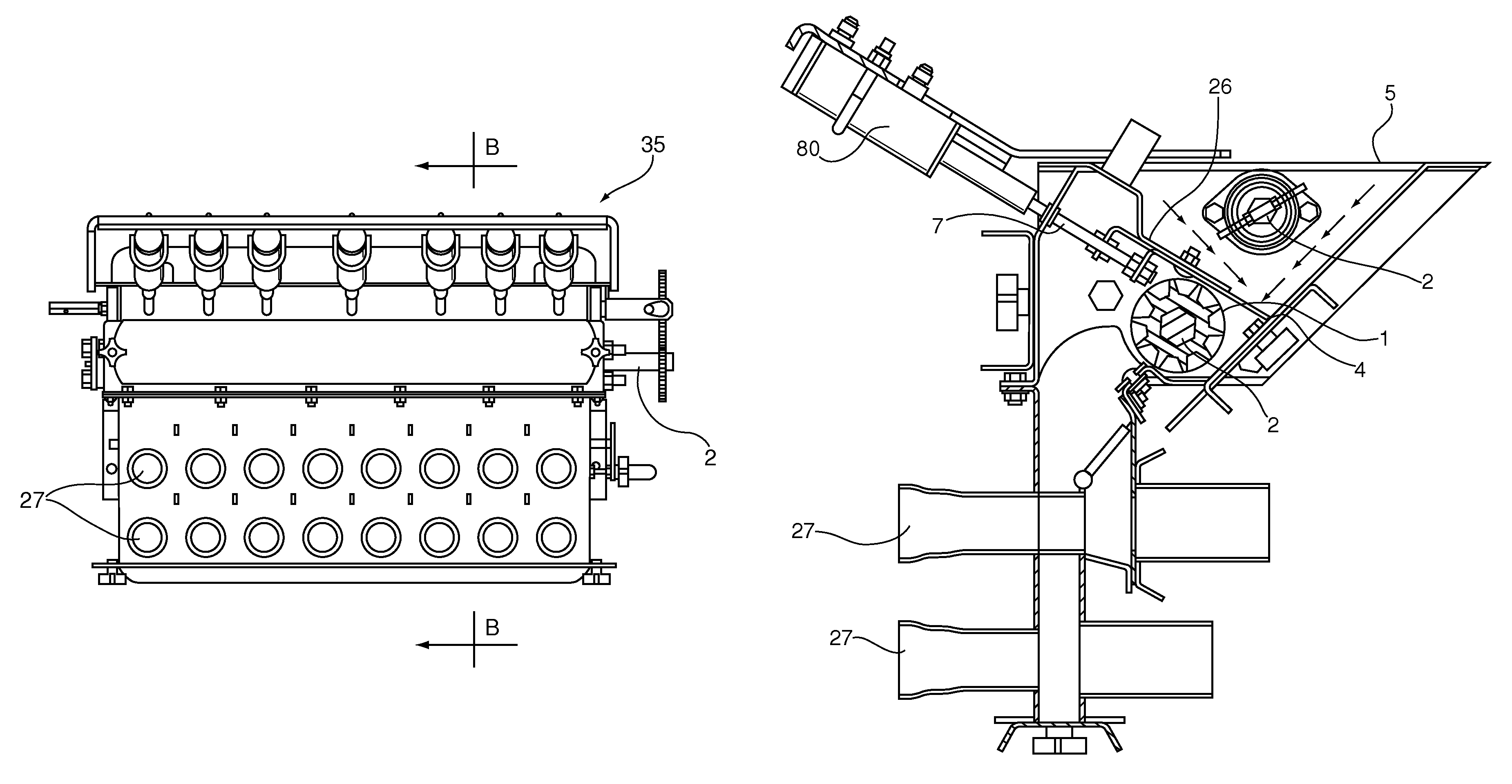

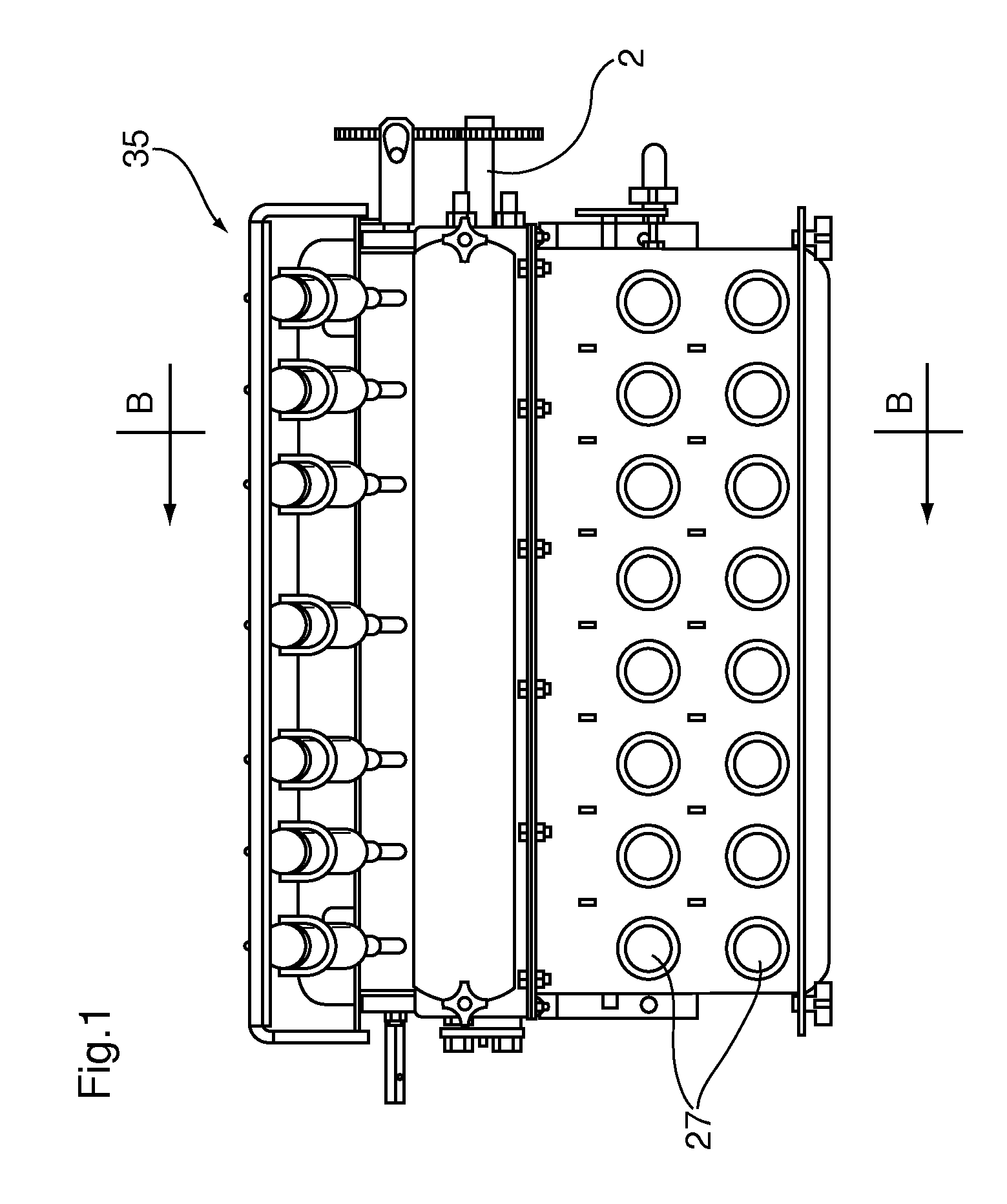

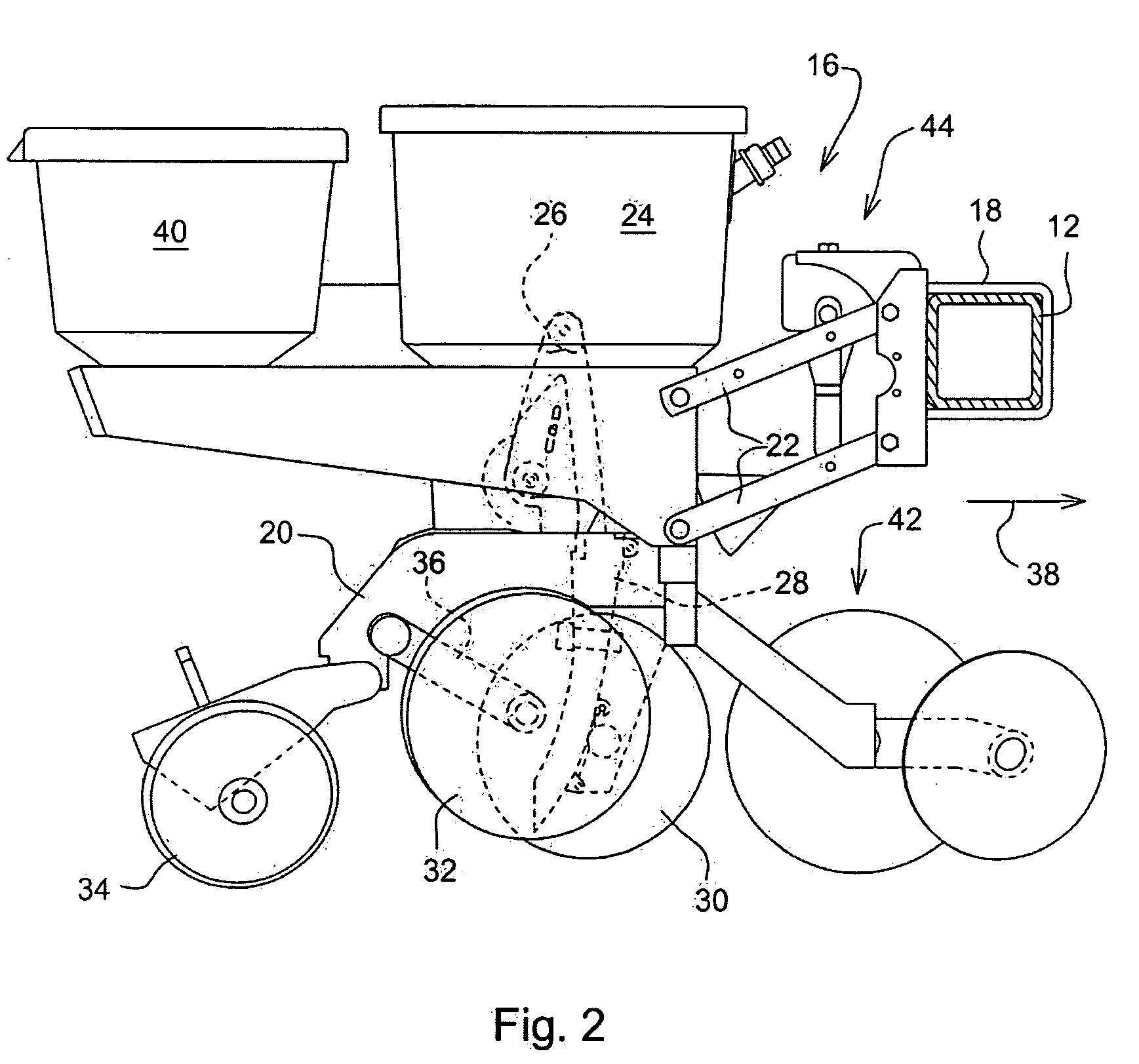

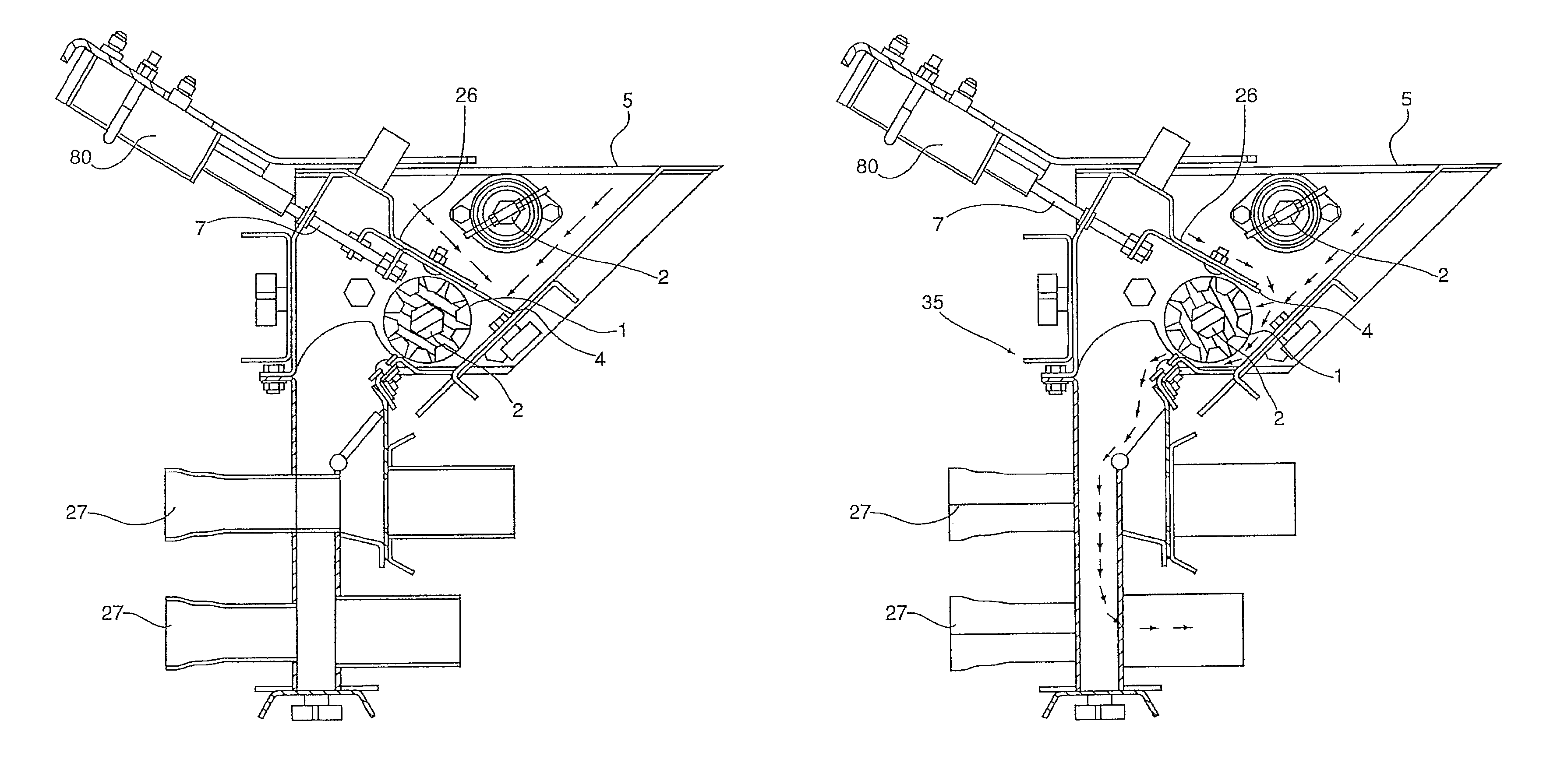

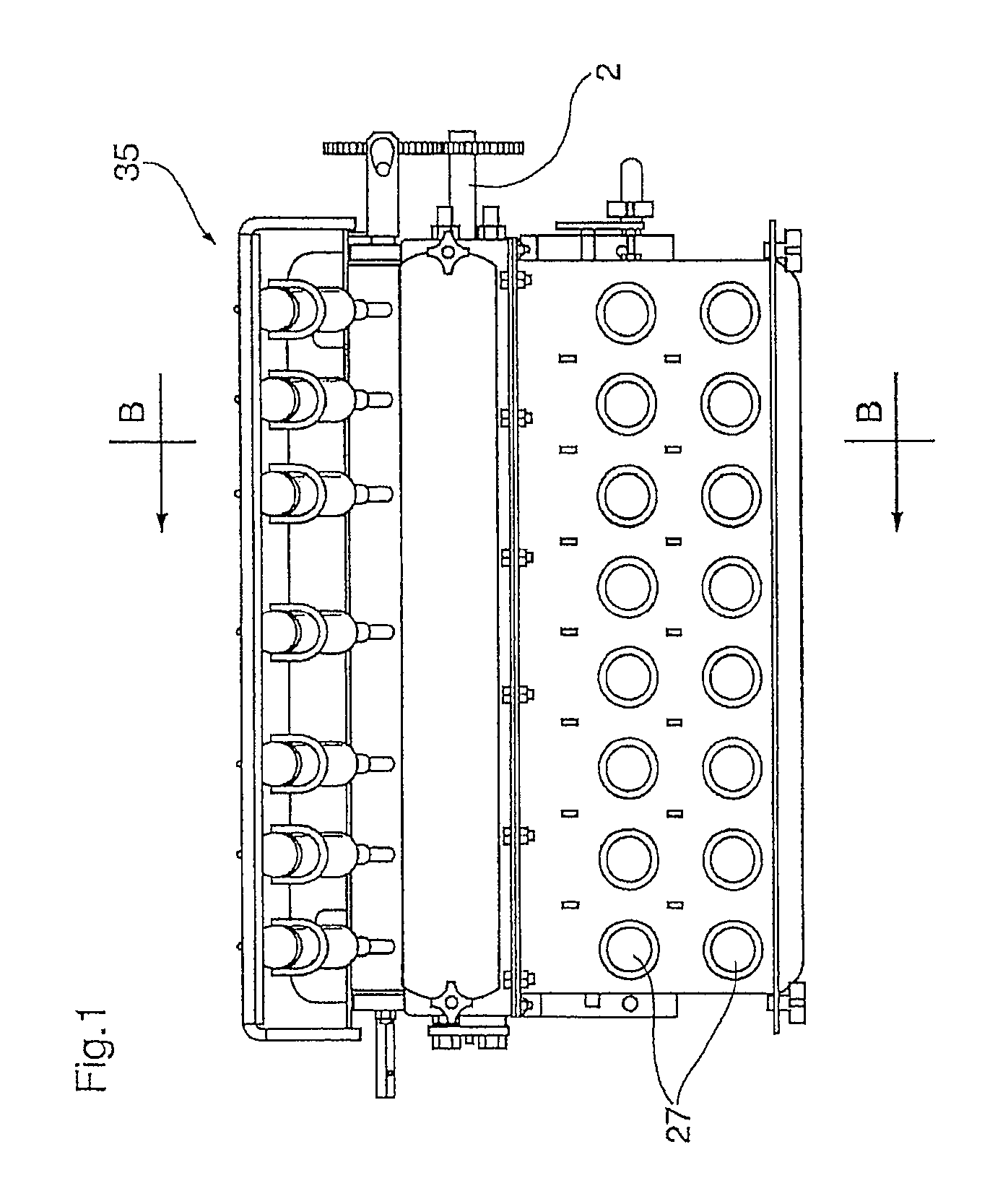

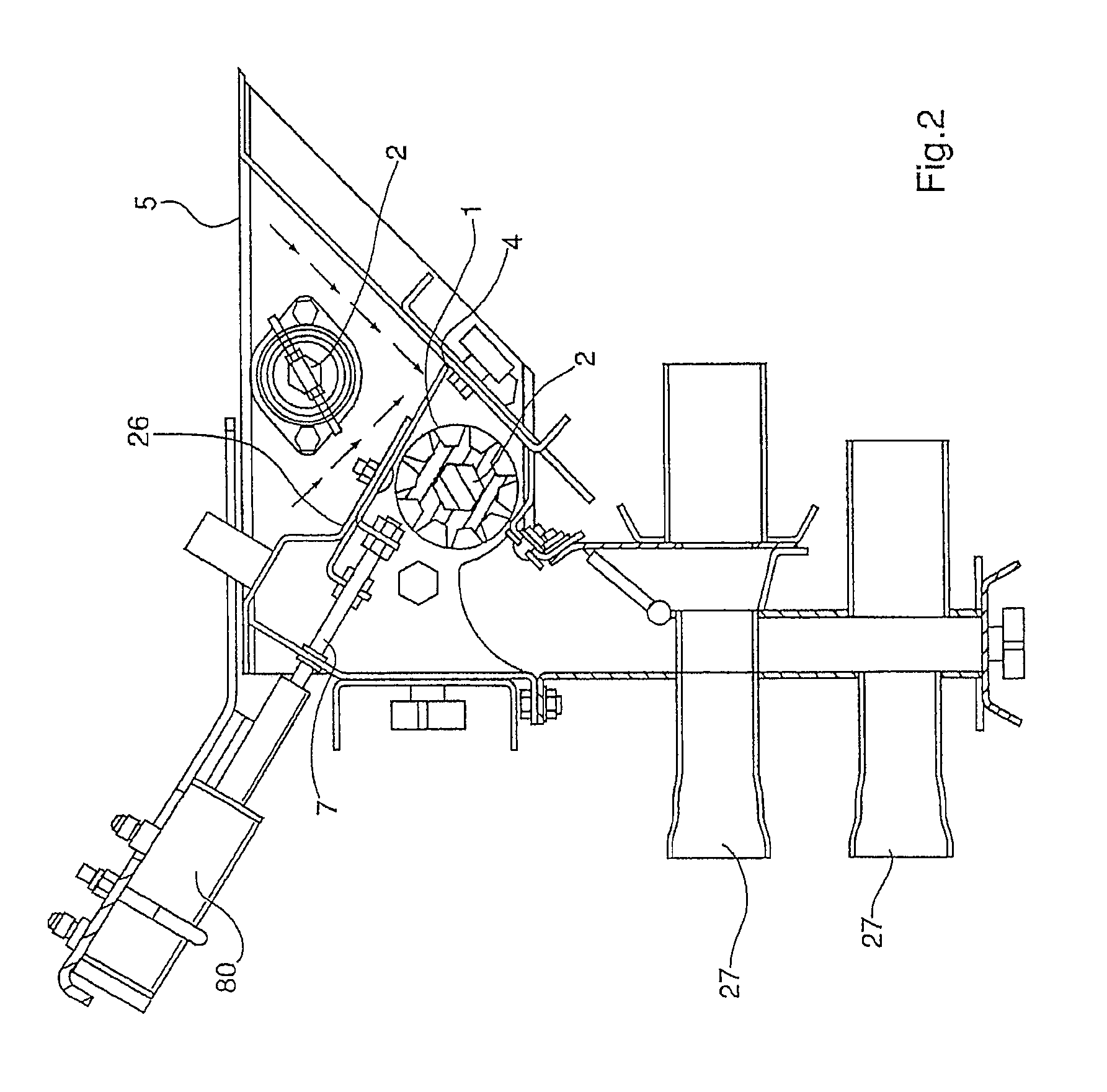

Air seeder/fertilizer apparatus having metering means and distribution manifold with selectively openable ports

A seeding apparatus having a distribution manifold with selectively openable outlet ports thereon, to permit or stop delivery of seed or fertilizer to soil A meter device, responsive to both the number of selected open ports and the speed of the apparatus over the ground, is provided to regulate supply of seed / fertilizer to a distribution manifold. The distribution manifold has a plurality of outlet ports spaced about a periphery of such manifold, each outlet port having a valve to allow opening and closing of individual outlet ports. Soil engaging members on such apparatus are individually raisable from an lowered operative position to a raised inoperative position, and when moved to such inoperative position, valve associated with an outlet port for providing seed and / or fertilizer to such soil engaging member is closed to prevent supply to the associated soil engaging member.

Owner:ONE PASS IMPLEMENTS

Agricultural seed tender with modular storage containers

ActiveUS20060180062A1Improve economyImprove stabilityConveyorsMovable measuring chambersEngineeringAdemetionine

A trailer having support wheels and a frame adapted to be hitched to a truck, includes a support track extending longitudinally for supporting an unload conveyor. The conveyor is mounted by a turret to the support track and, thus, to the trailer frame, permitting the turret to move in a fore-to-aft direction, as well as to rotate about the vertical for about 180°, providing flexibility in use as well as transport and storage. A support module, carrying at least one storage container is mounted on the trailer frame. The storage containers may be provided in a number of different sizes and they may be arranged in various configurations suiting the user's needs. The turret is positioned along the track beneath a desired seed container, which may then be unloaded by the conveyor to fill a planter seed box or grain drill, or for other seed handling applications.

Owner:MERIDIAN MFG

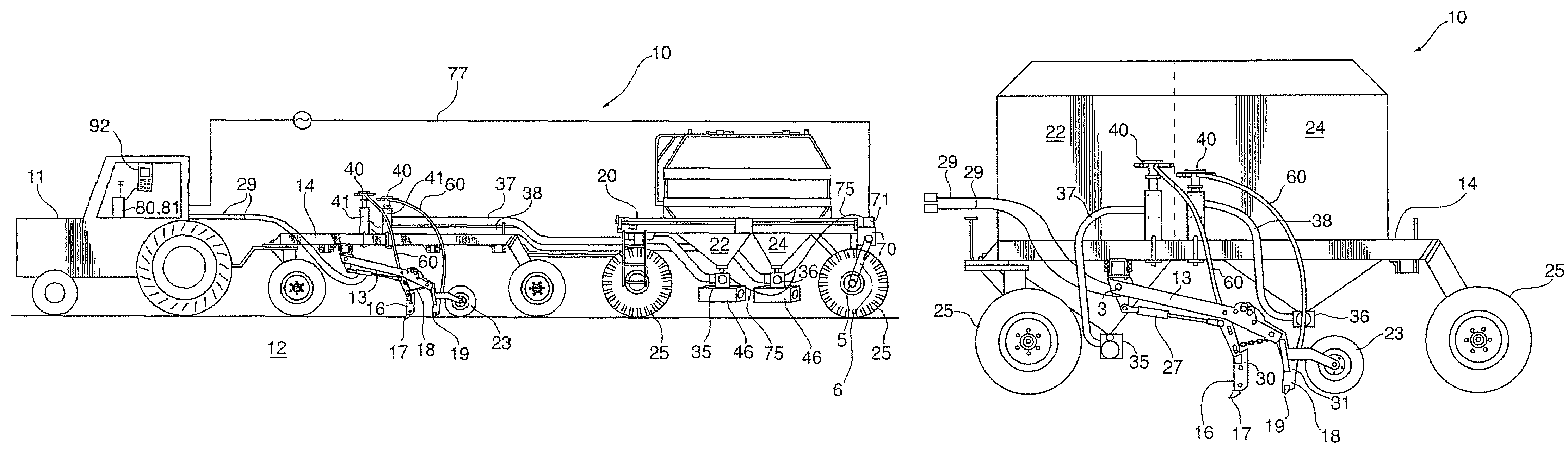

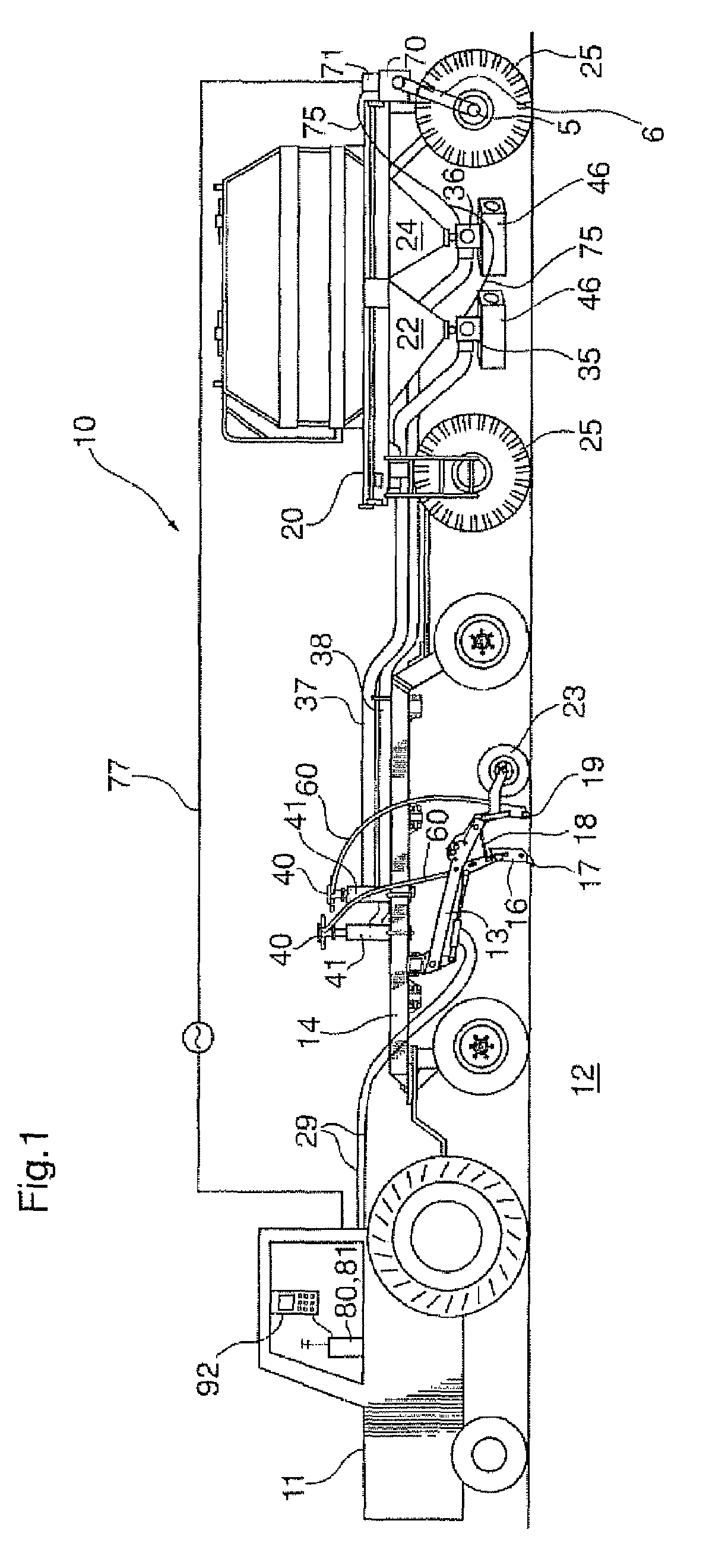

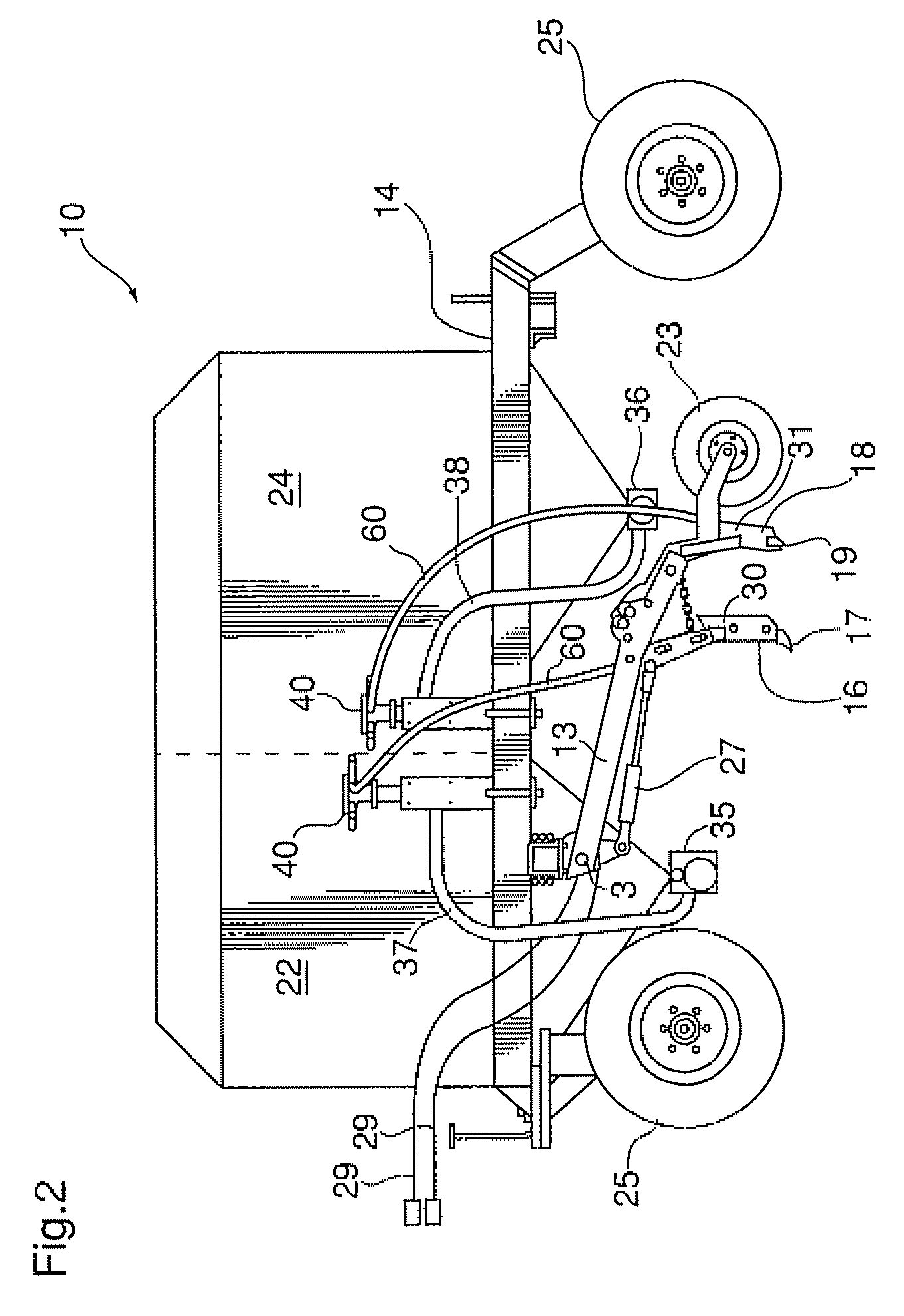

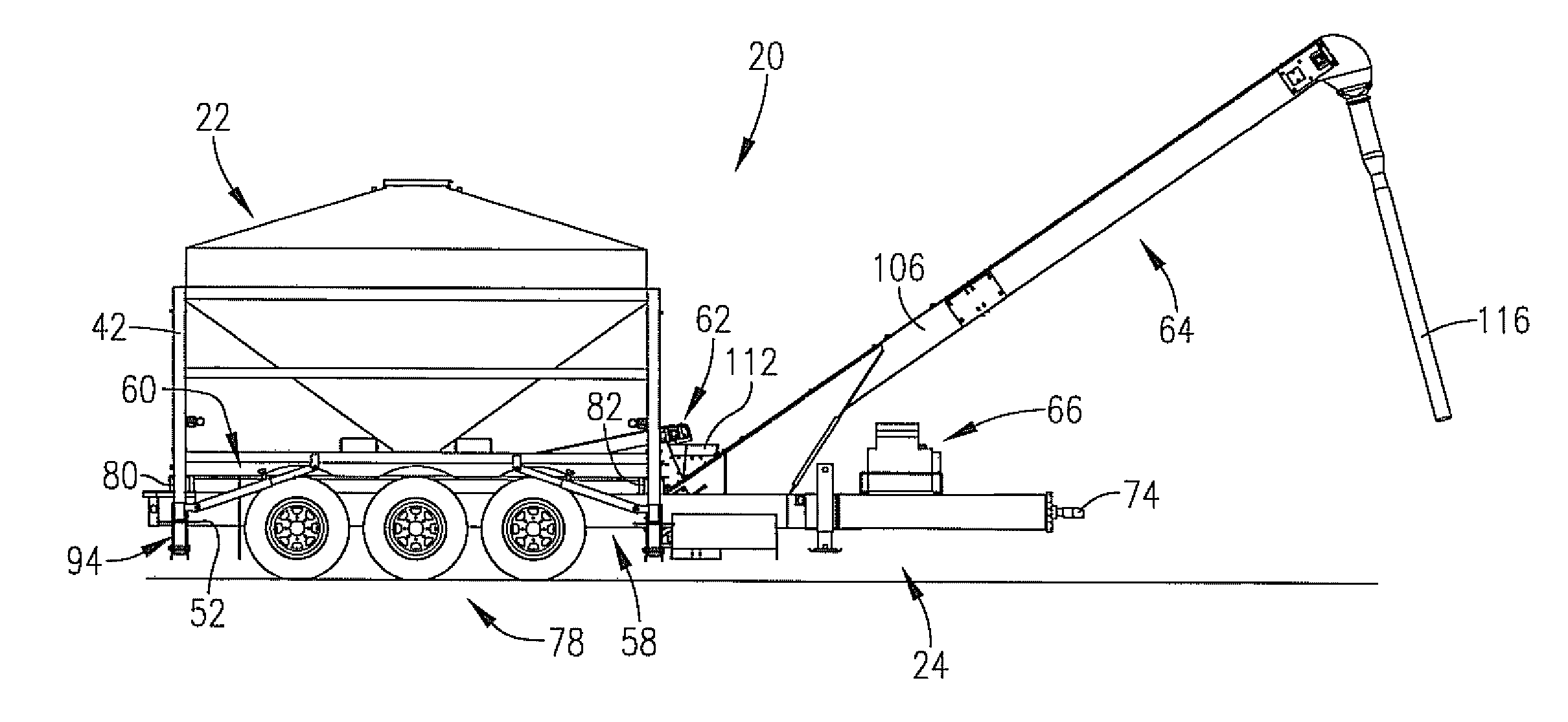

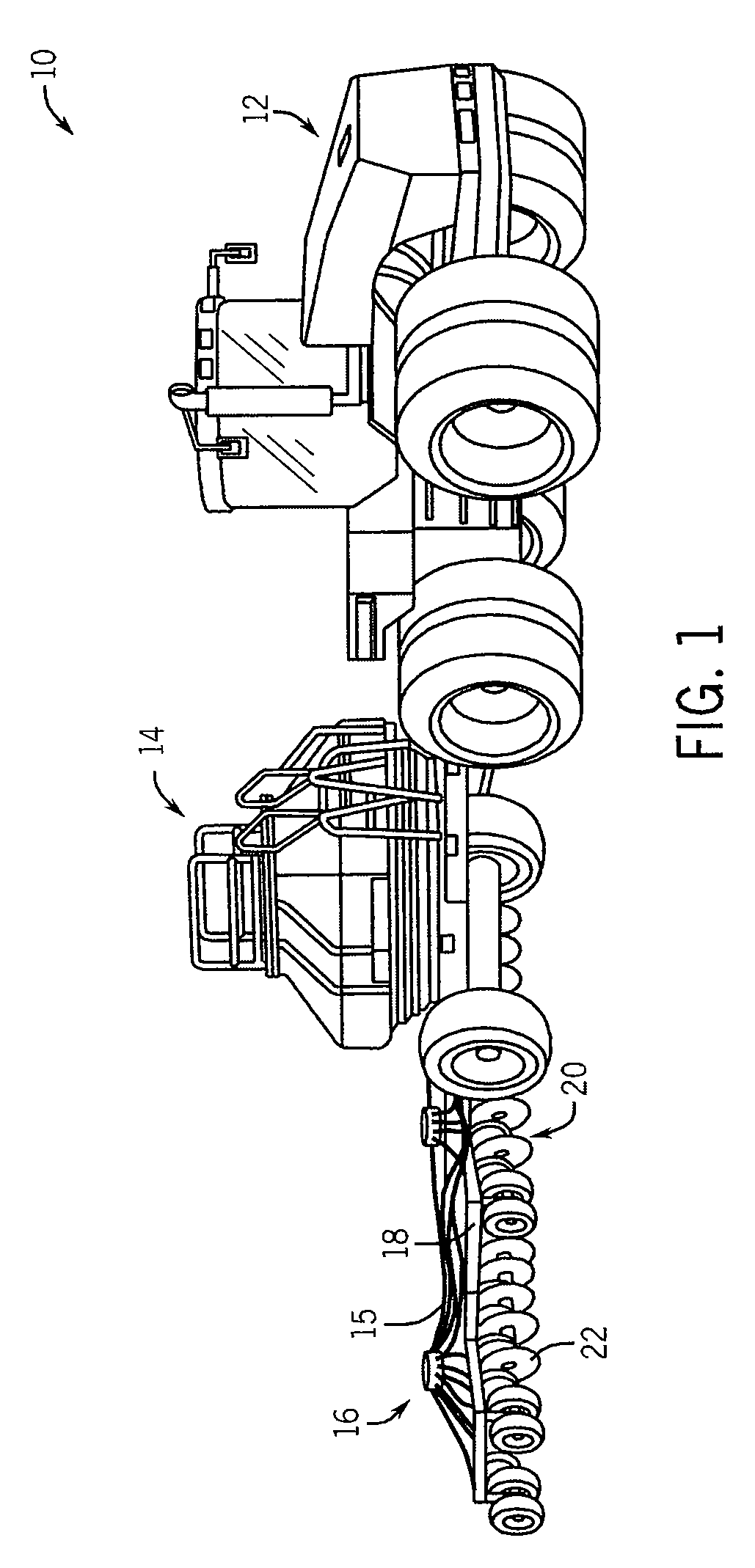

Bulk seed handling system

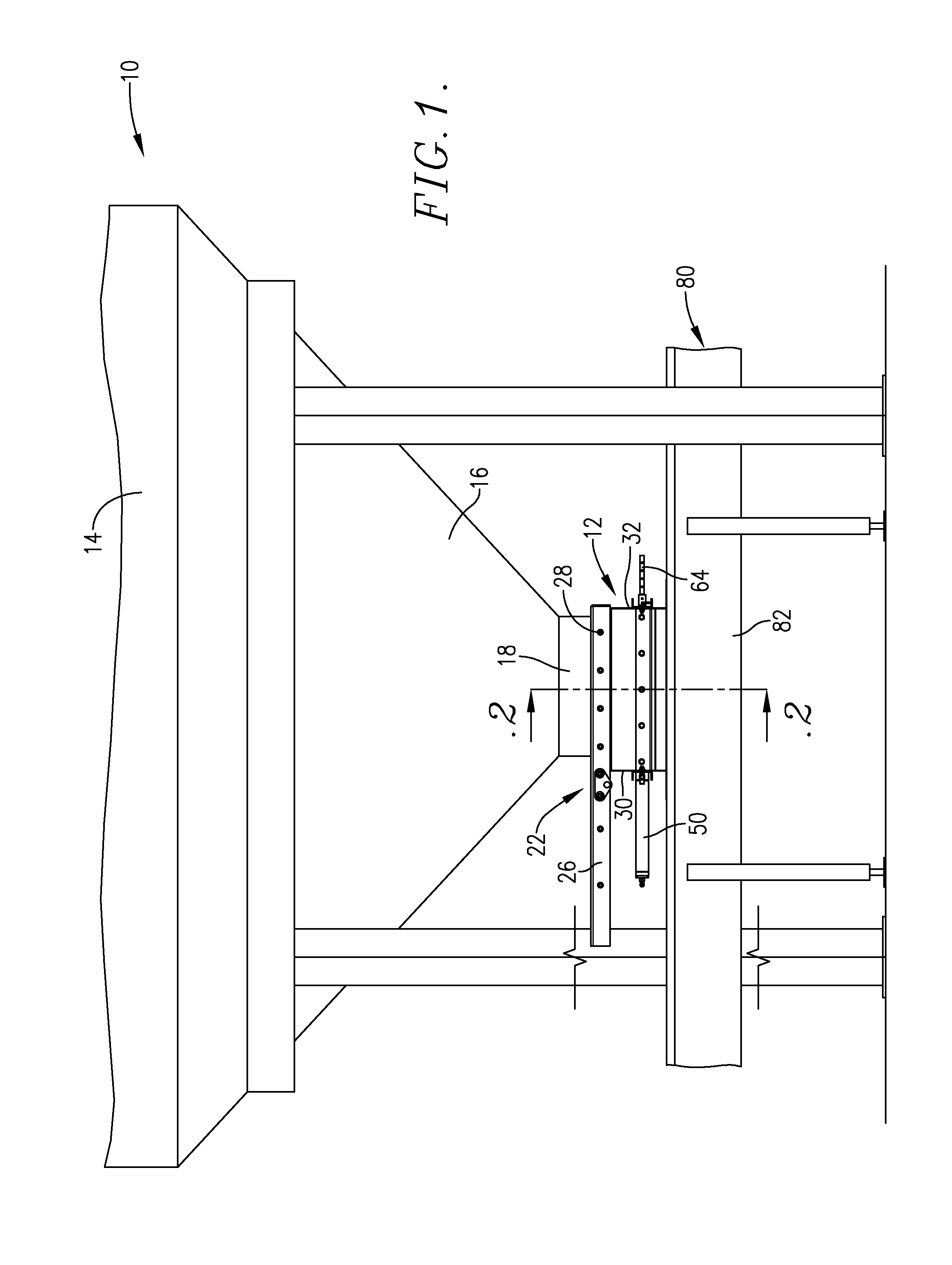

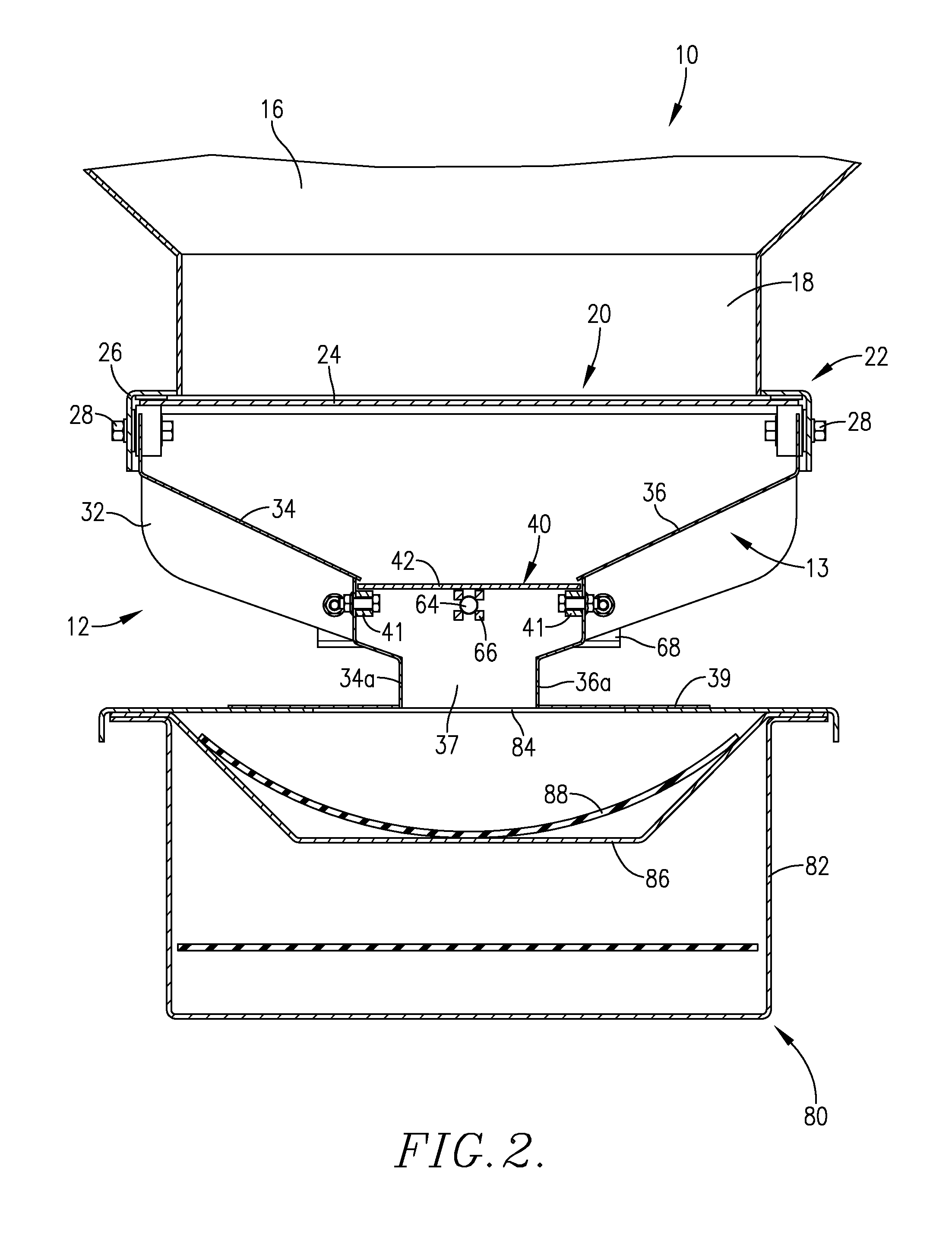

InactiveUS8573917B2Facilitates transfer and handlingEasy to handleConveyorsFertiliser distributersEngineeringHandling system

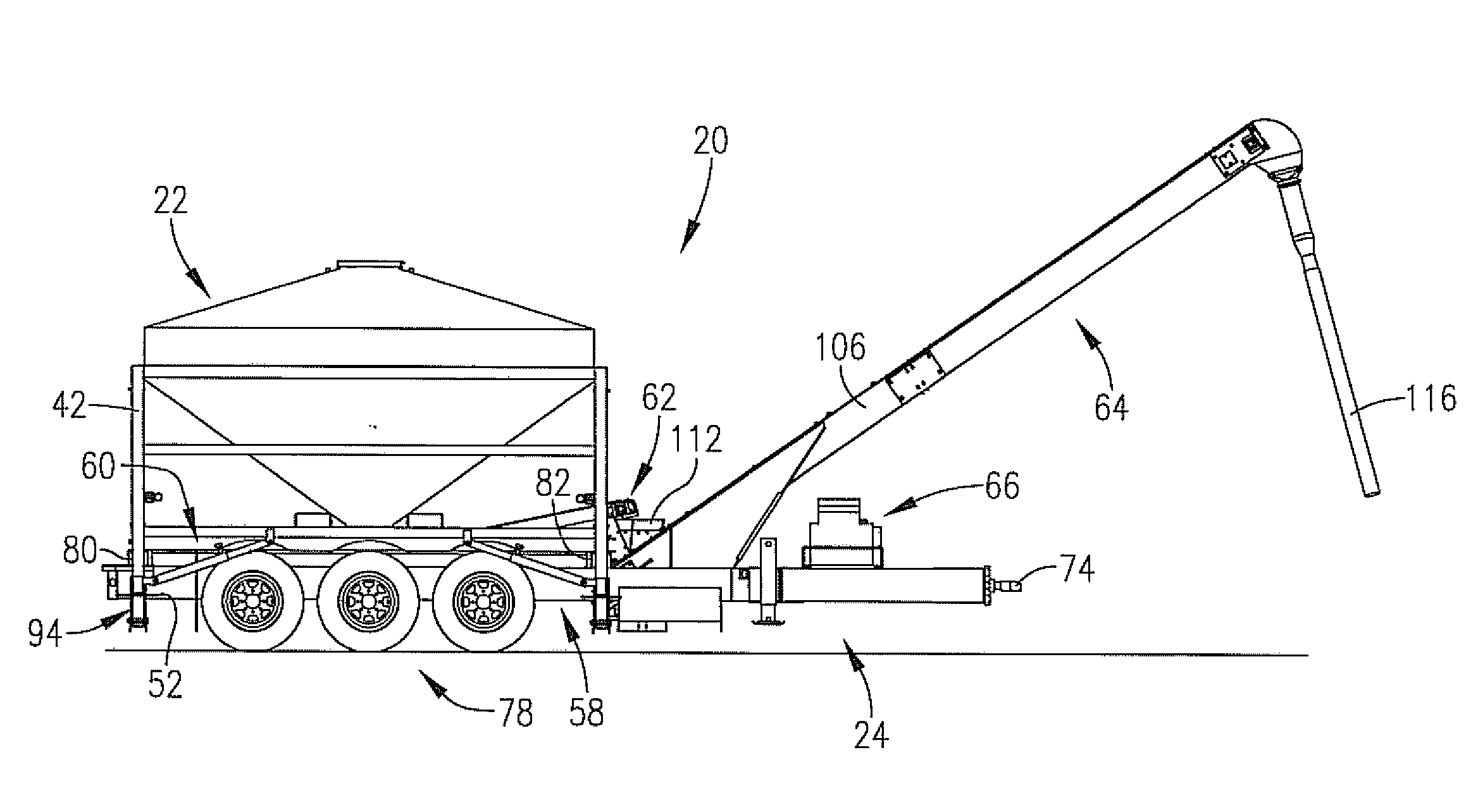

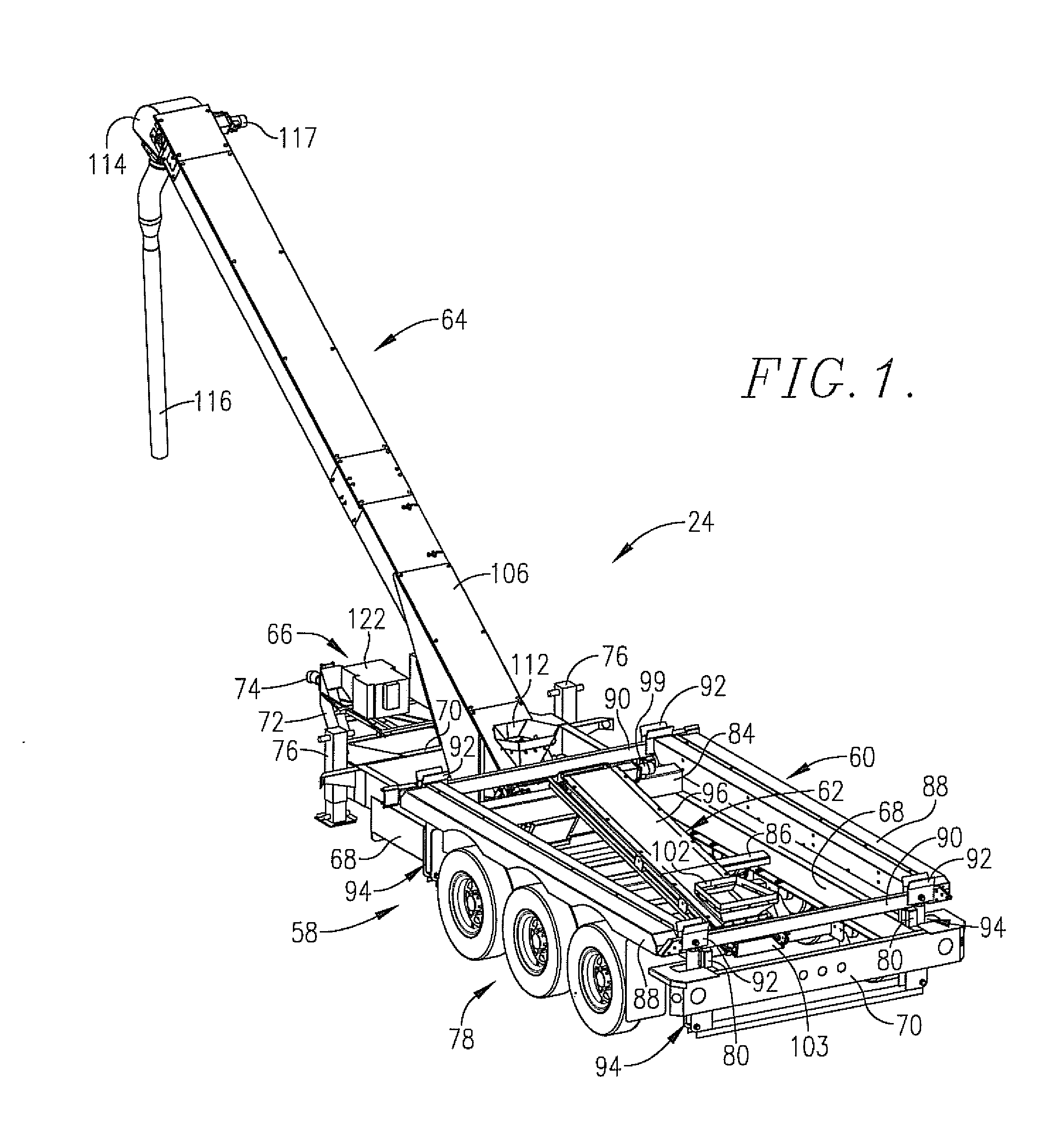

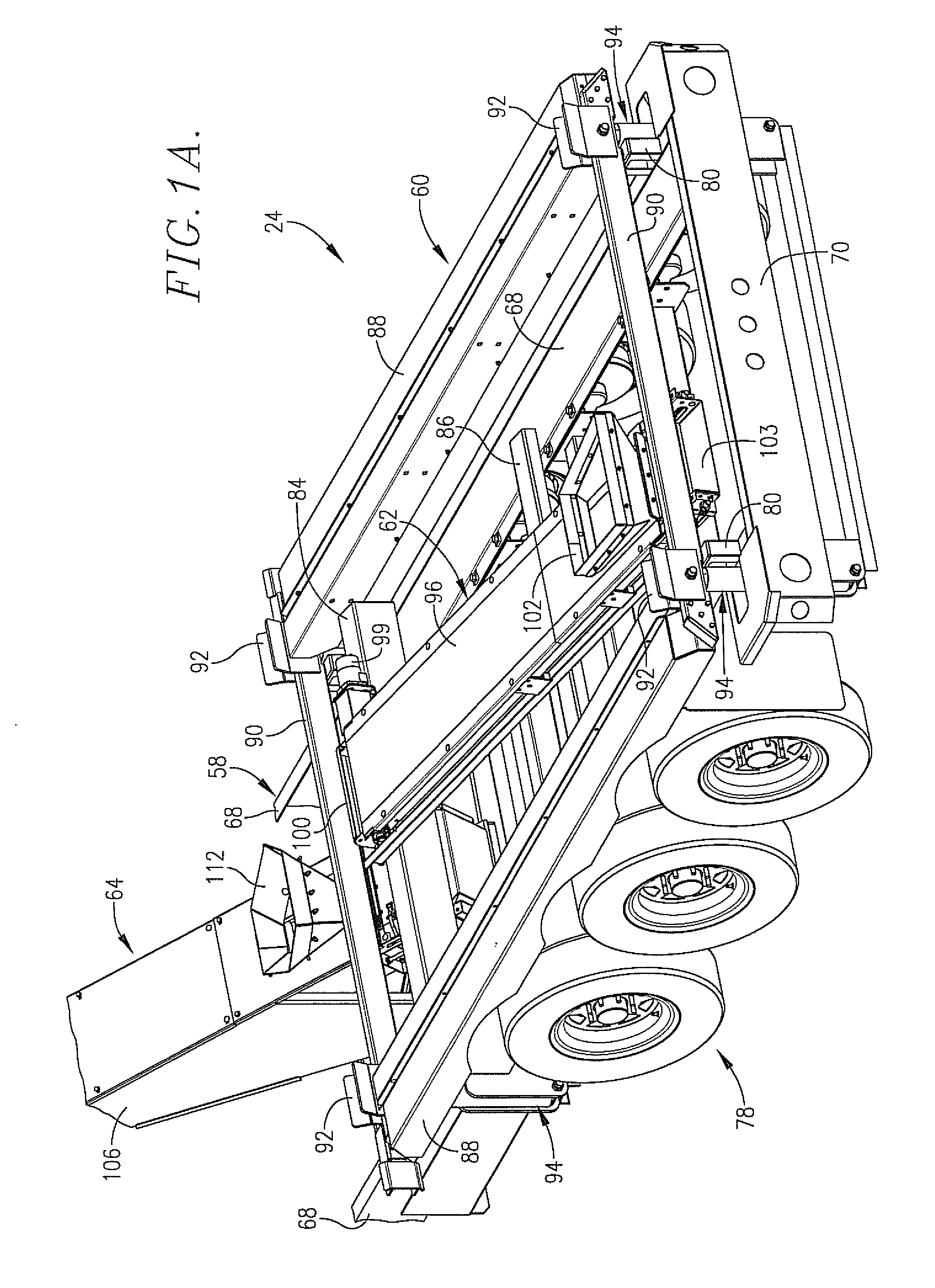

A bulk seed handling system (20) is provided to facilitate seed transfer from a distributor to a farm and then to a planter or the like. The handling system (20) includes one or more upright bin assemblies (22) adapted to be moved in a filled condition, and a trailer (24) designed to move the bin assembly (22) and unload seed therefrom. The bin assembly (22) includes a seed bin (26) having a lower unload opening (34) and supported by a frame assembly (38) including telescopic legs (50) shiftable between a retractable travel position and an extended bin support position. The trailer (24) includes a lift frame (60) operable to engage and elevate the bin assembly (22) for travel with the legs (50) thereof in a retracted position, and a seed-conveying arrangement including an intermediate conveyor (62) and a delivery conveyor (64). At an unloading site, the intermediate conveyor (62) is shifted to an unloading position in communication with the bin unload opening (34) and the delivery conveyor (64) in order to transfer seed from the bin.

Owner:USC

Intermodal bulk dry particulate cargo container and method

A method for loading and unloading of dry bulk freight containers vertically, and a device in the form of an improved intermodal dry bulk freight container for vertical loading and unloading. Standardized corner locks may be used and dimensions may be selected so as to provide a standardized cargo container.The present invention teaches that an intermodal dry bulk freight container may be loaded in either the customary horizontal orientation of such devices, or in a vertical orientation in which one end is opened and elevated. In particular, however, such a container may advantageously be emptied by elevating it into the vertical orientation. The method of the invention is thus to provide only a single hopper and yet allow one hopper to empty the entire container, as well as providing a more efficient gravity feed of bulk cargo as it is off loaded.The present invention furthermore teaches an intermodal dry bulk freight container suitable for this method of operation. In the presently preferred embodiment, the container is loaded conventionally via hatches on the top of the container when it is in a horizontal orientation, but is unloaded via a single hopper located at the lower end when the container is raised into the vertical orientation.

Owner:LE ROY CURTIS W

Plasma processes for depositing low dielectric constant films

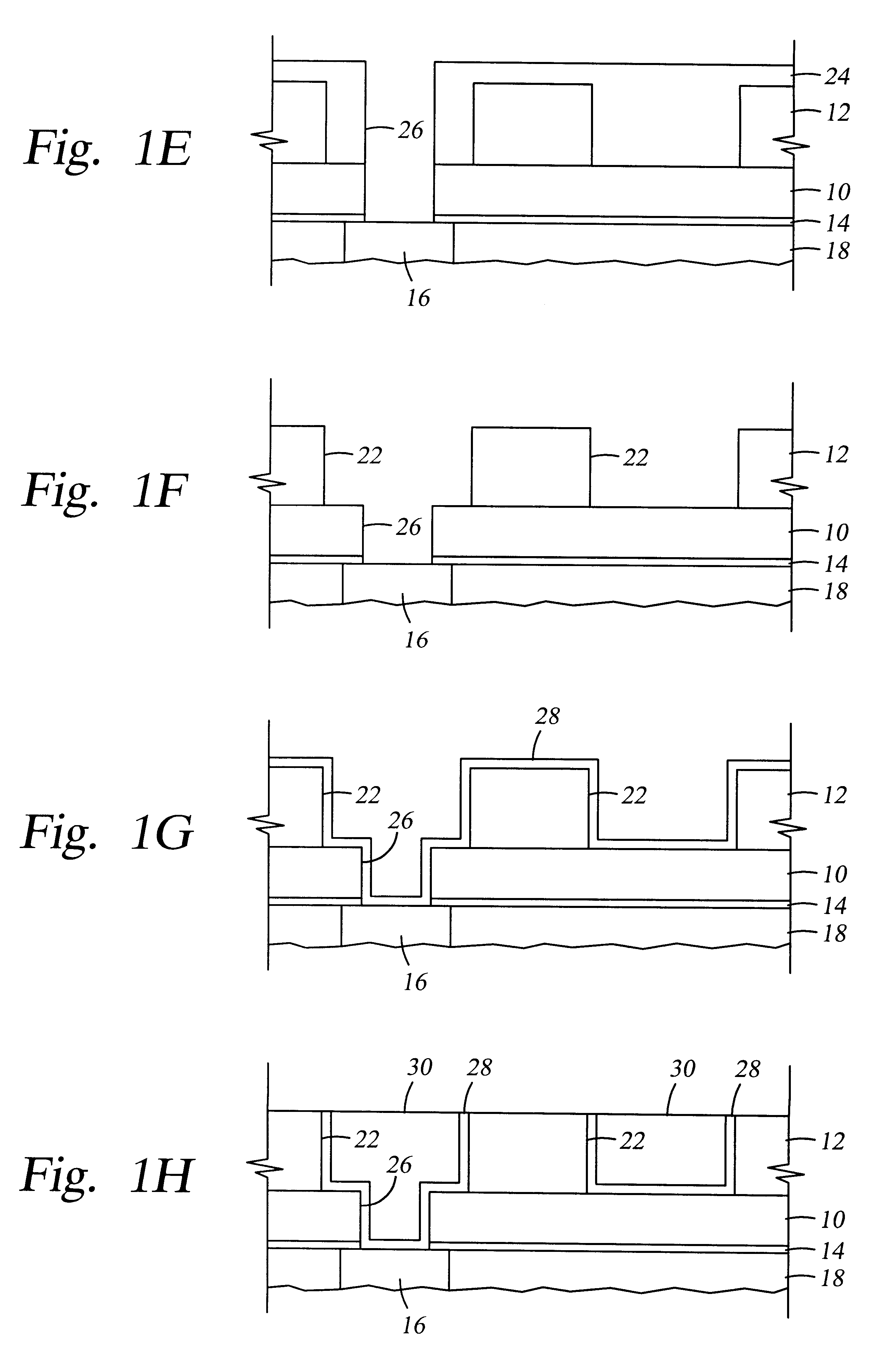

A method and apparatus for depositing a low dielectric constant film by reaction of an organosilicon compound and an oxidizing gas at a constant RF power level from about 10W to about 200W or a pulsed RF power level from about 20W to about 500W. Dissociation of the oxidizing gas can be increased prior to mixing with the organosilicon compound, preferably within a separate microwave chamber, to assist in controlling the carbon content of the deposited film. The oxidized organosilane or organosiloxane film has good barrier properties for use as a liner or cap layer adjacent other dielectric layers. The oxidized organosilane or organosiloxane film may also be used as an etch stop and an intermetal dielectric layer for fabricating dual damascene structures. The oxidized organosilane or organosiloxane films also provide excellent adhesion between different dielectric layers. A preferred oxidized organosilane film is produced by reaction of methylsilane, CH3SiH3, dimethylsilane, (CH3)2SiH2, or 1,1,3,3-tetramethyl-disiloxane, (CH3)2-SiH-O-SiH-(CH3)2, and nitrous oxide, N2O, at a constant RF power level from about 10W to about 150W, or a pulsed RF power level from about 20W to about 250W during 10% to 30% of the duty cycle.

Owner:APPLIED MATERIALS INC

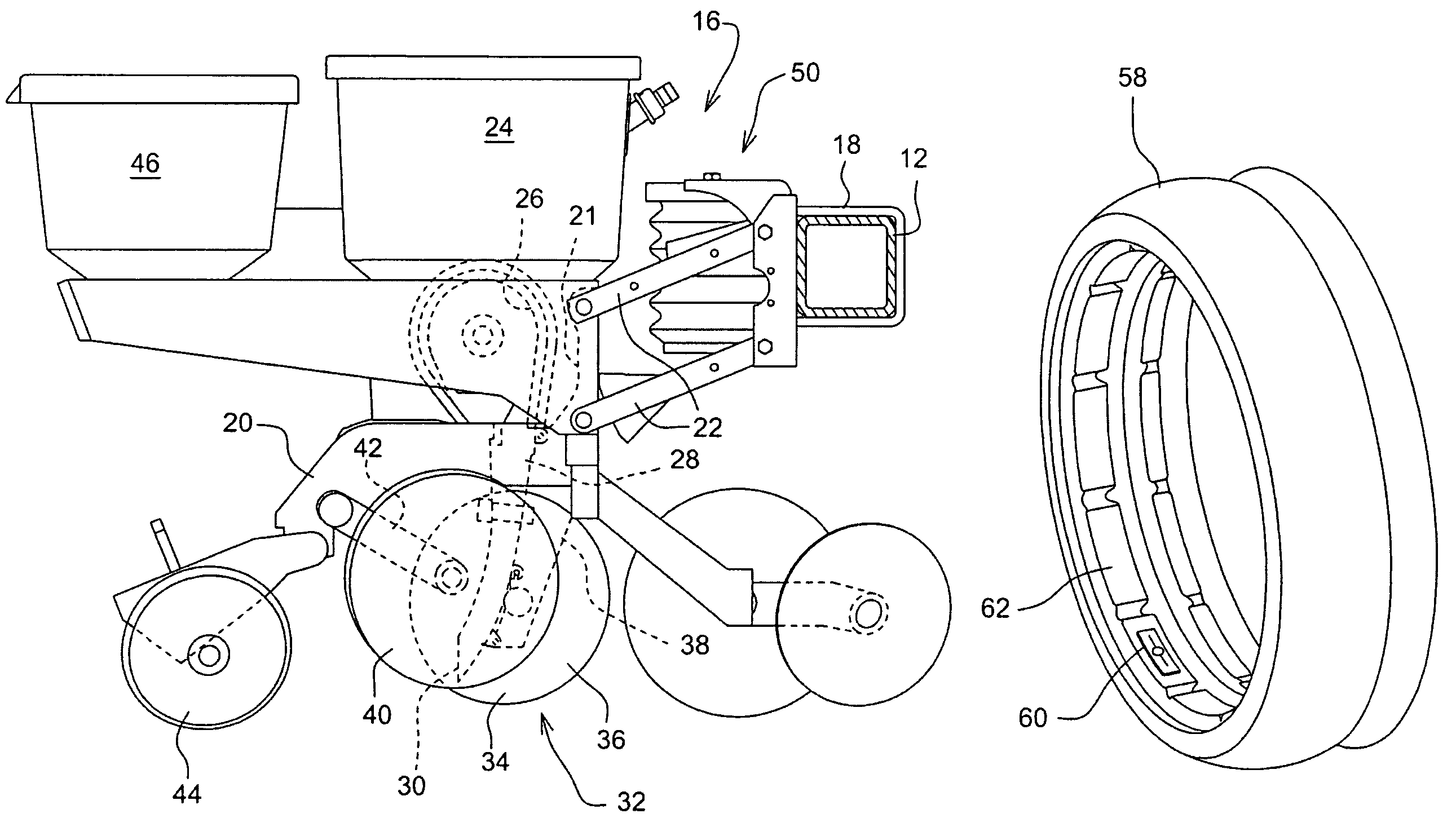

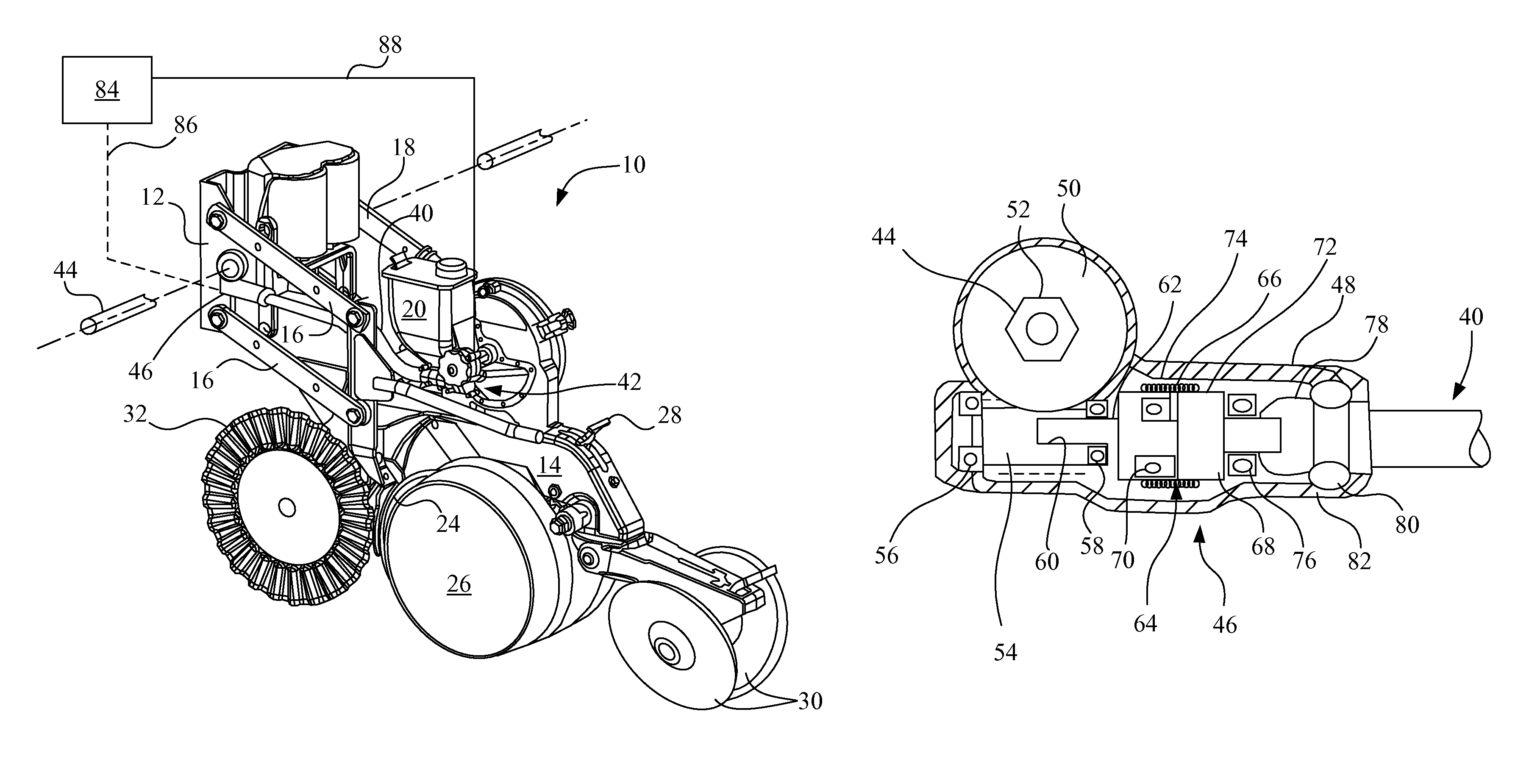

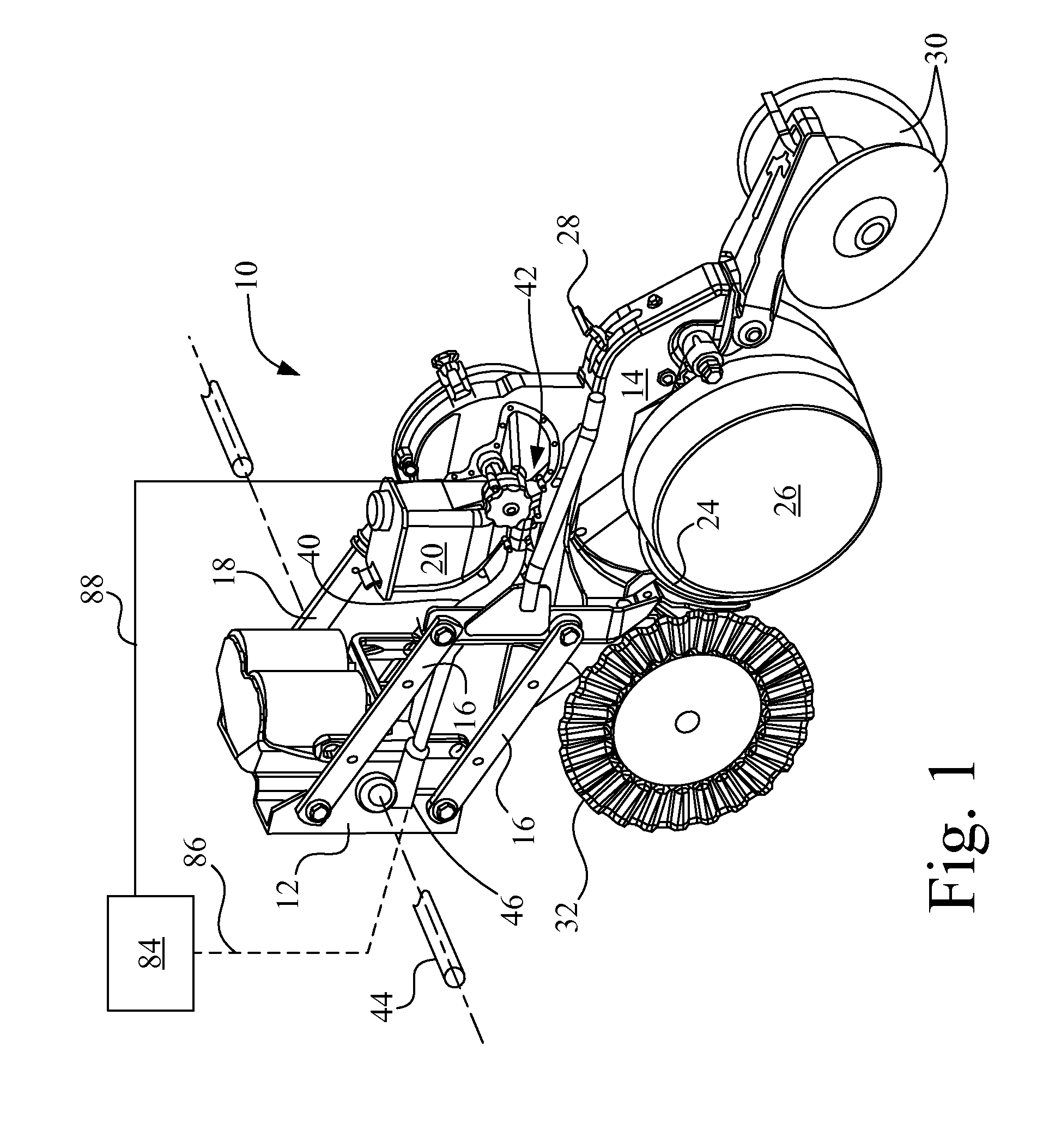

Pressure sensing system for a planter

A pressure sensing system for a seeding machine such as a planter to measure the down force on a planter row unit uses a wireless pressure sensor embedded in a load carrying wheel of the row unit. In a preferred embodiment, the pressure sensor is a passive piezoelectric pressure sensor that is a transmitter only, transmitting both pressure and RFID the information that identifies the particular sensor. Multiple sensors may be employed in each wheel and sensors may be employed in more than one wheel of the row unit, such as the gauge wheels on opposite sides of the trench opening disks. The sensors may be made of a PVDF, a known piezoelectric material. A wireless receiver is located on the planter frame or could be located elsewhere to receive the signals from the pressure sensor. A controller determines from the signal, any change in down force and commands the change to a down force generator on the row unit.

Owner:DEERE & CO

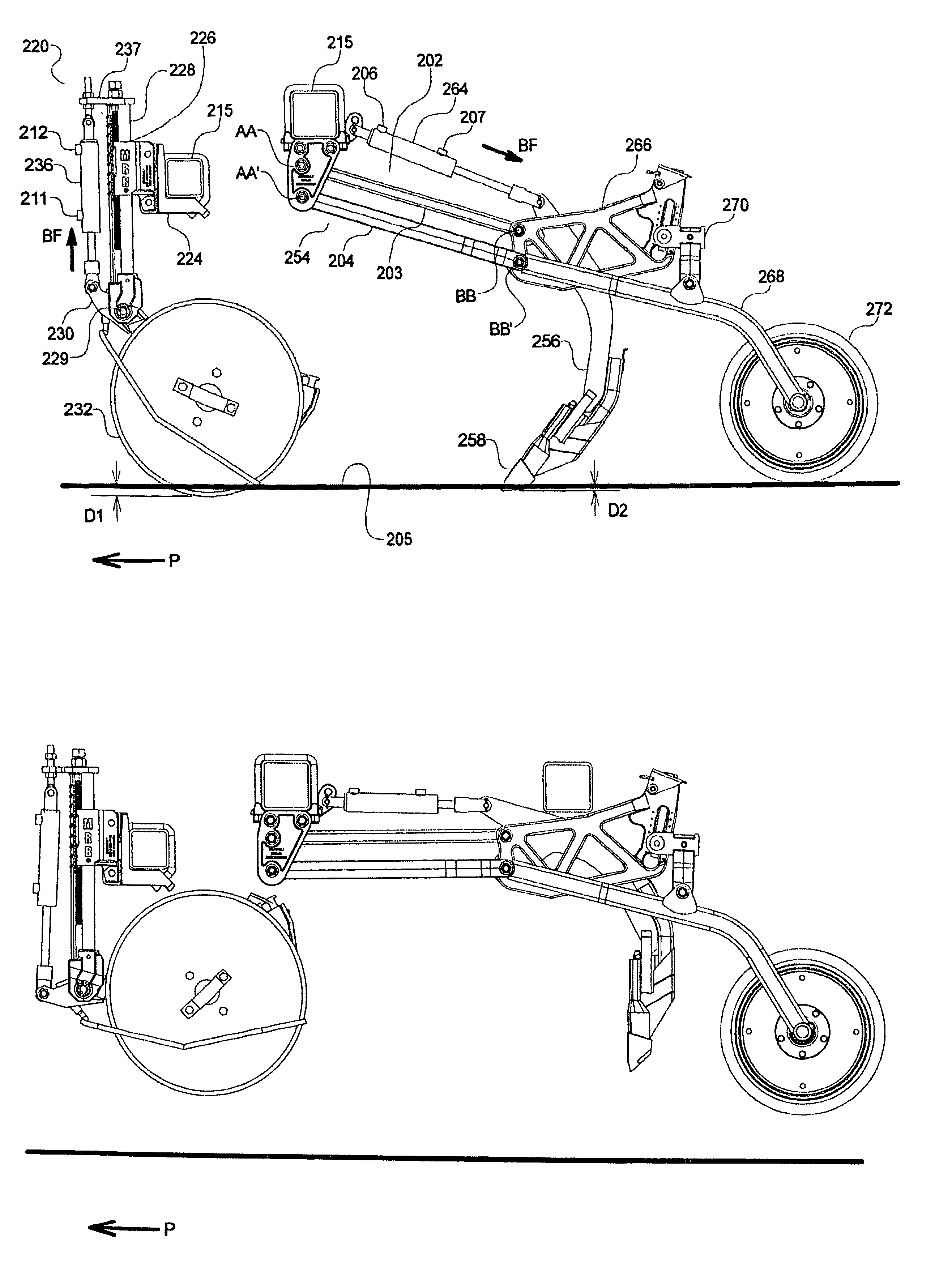

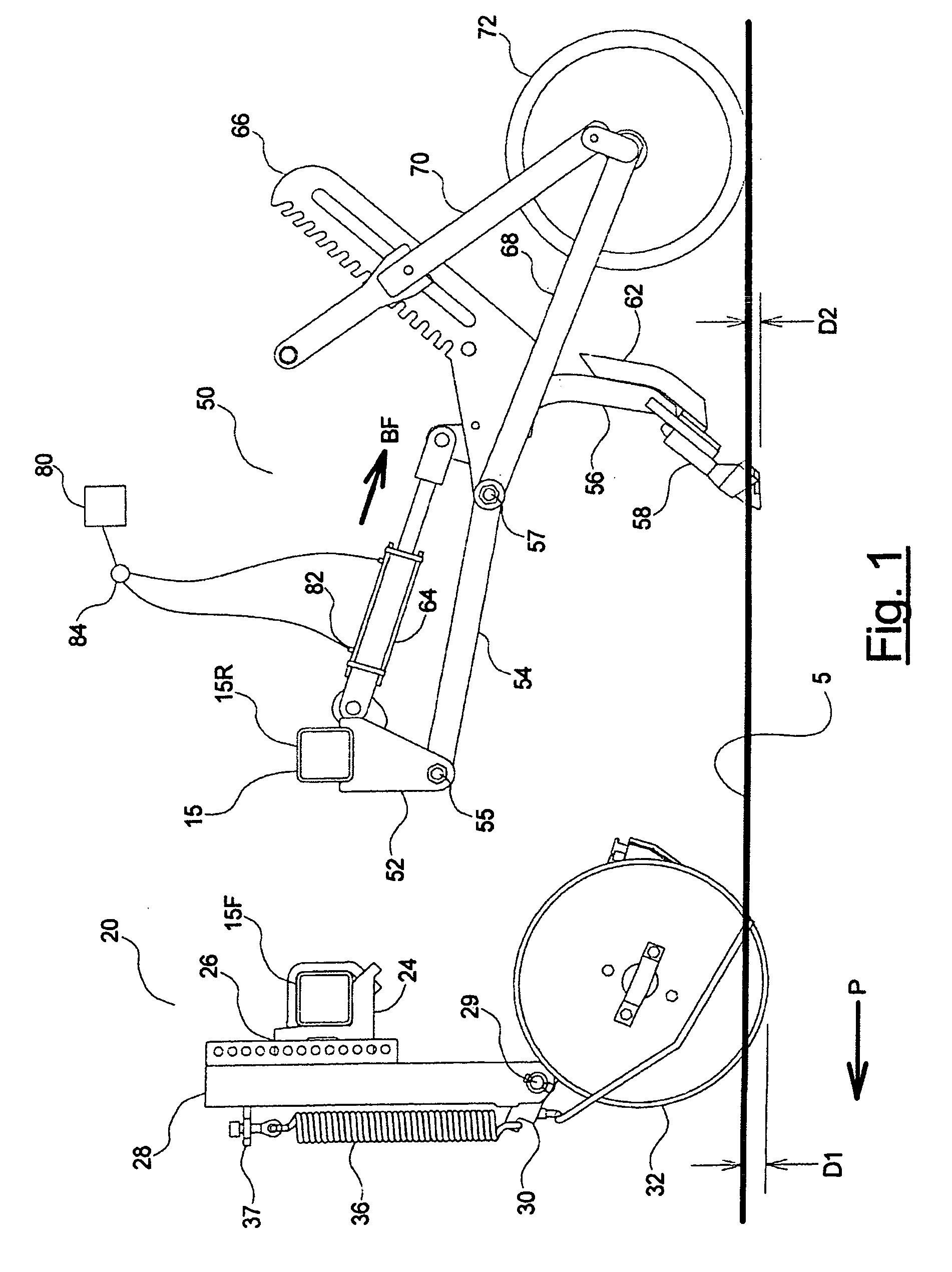

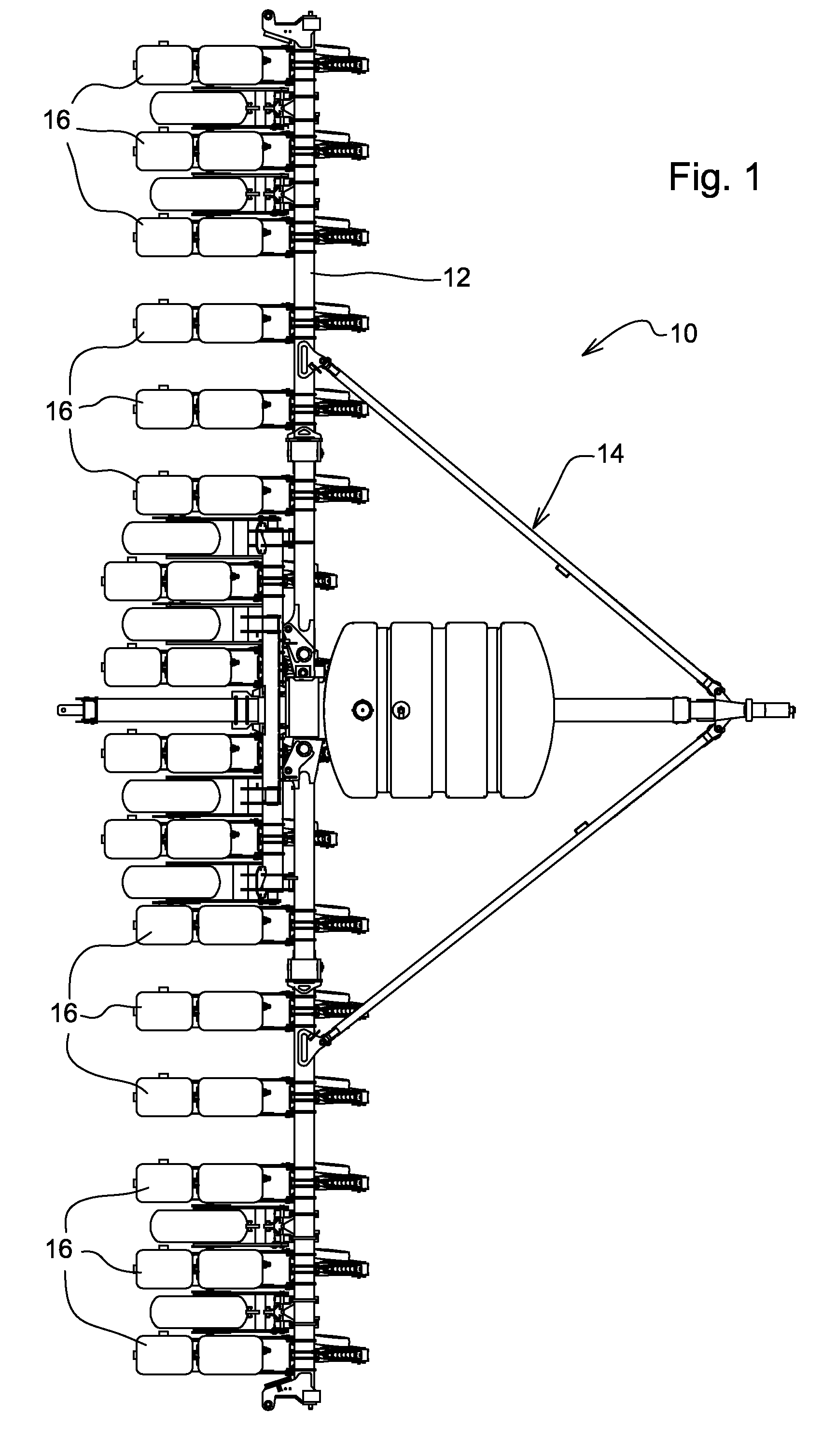

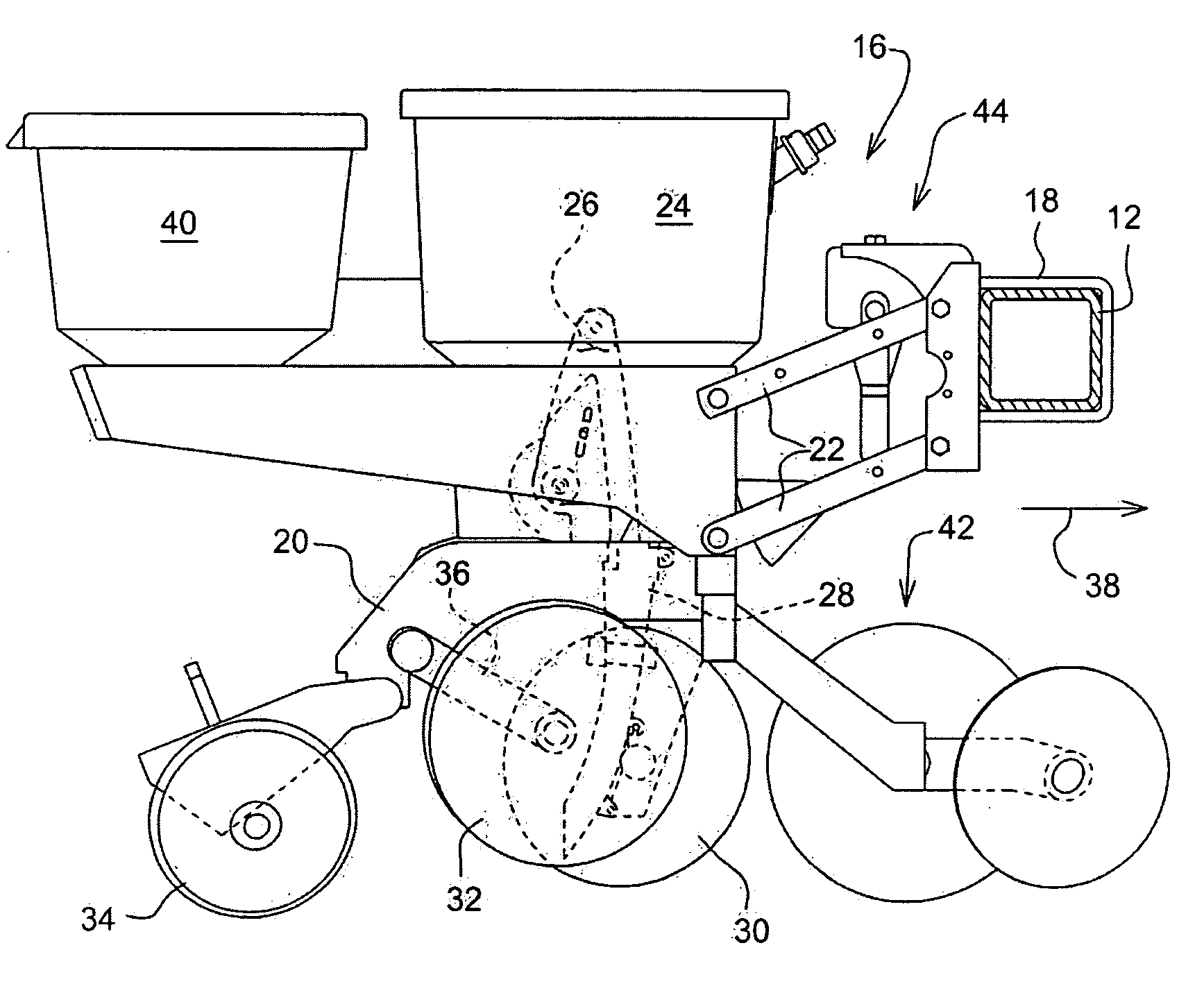

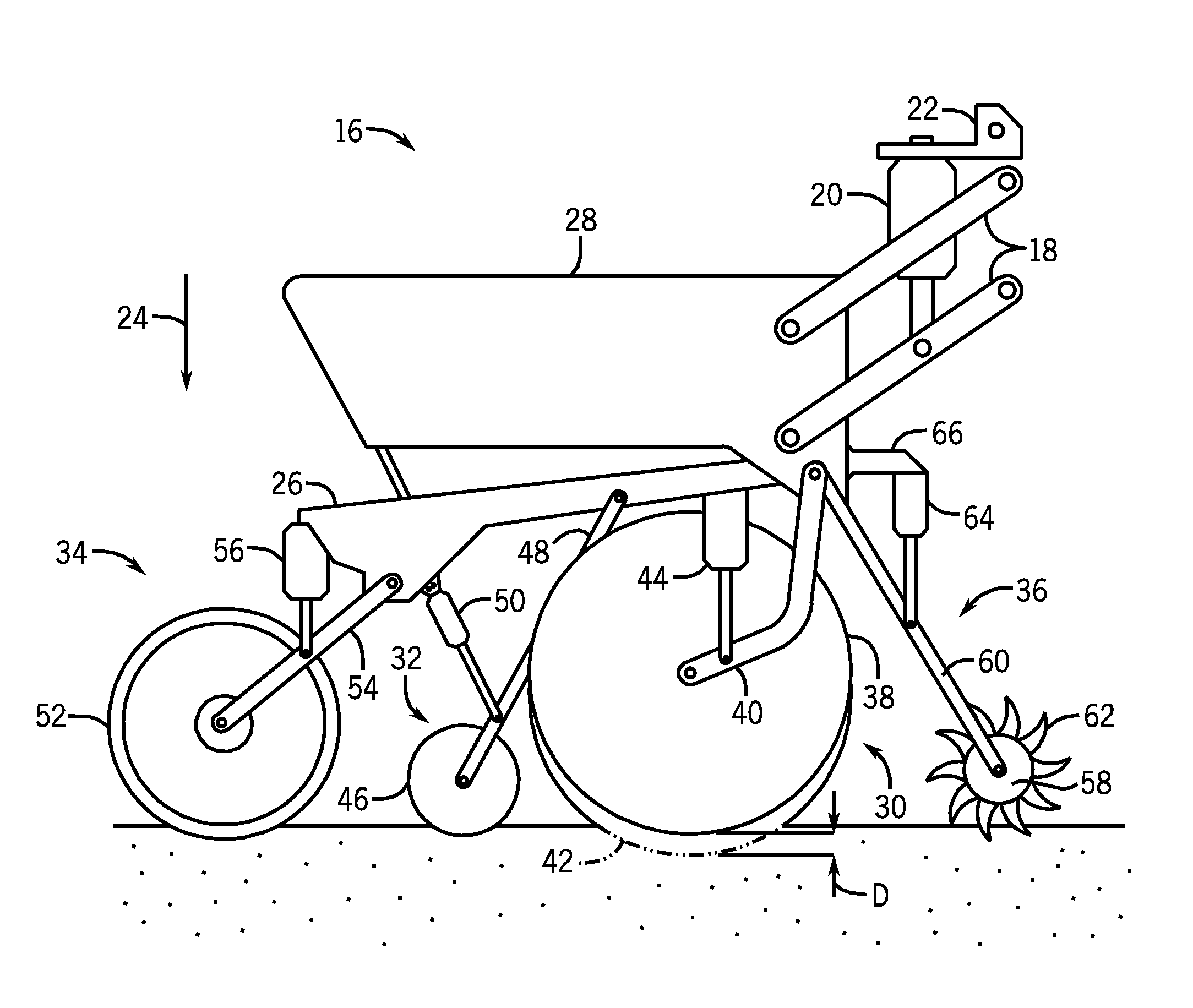

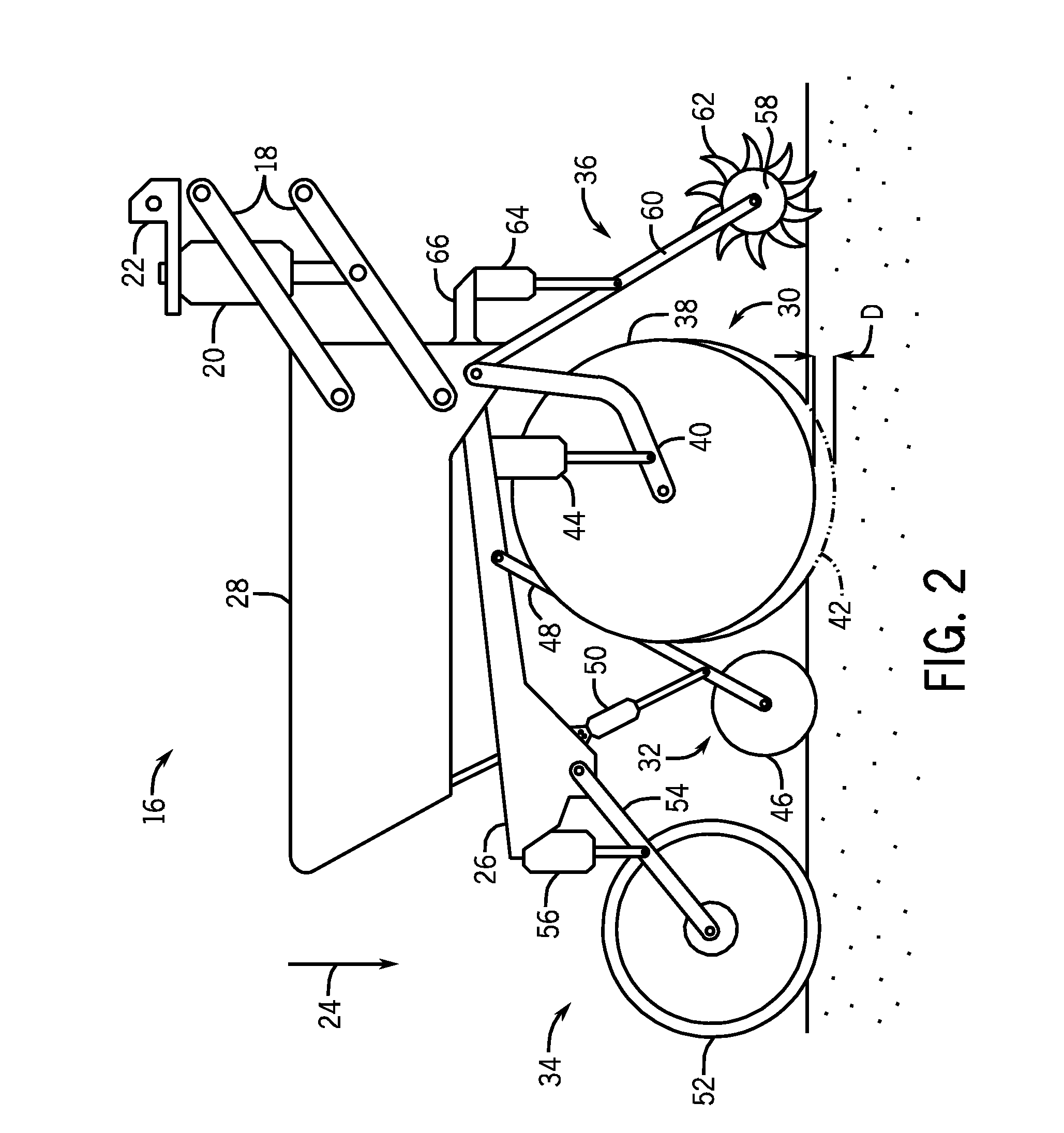

Method and apparatus of agricultural field seeding

ActiveUS7159523B2Accurate conditionImprove consistencyFertiliser distributersPotato plantersTrailing armEngineering

A seeding and fertilizing apparatus comprises a plurality of seed assemblies each comprising a trailing arm pivotally connected at a front end thereof to the frame and a packer wheel rotatably attached to rear end thereof. A seed knife is attached to the trailing arm ahead of the packer wheel which rolls along the seed furrow created by the knife. A vertical position of the knife with respect to the packer wheel is adjustable, and a bias device is operative to exert a downward bias force on the trailing arm. A plurality of fertilizer assemblies each comprises a fertilizer disc rotatably mounted to the frame such that a vertical position of the disc with respect to the implement frame is adjustable. The seed assemblies and fertilizer assemblies are oriented laterally such that each fertilizer furrow is located between adjacent seed furrows.

Owner:BOURGAULT INDS

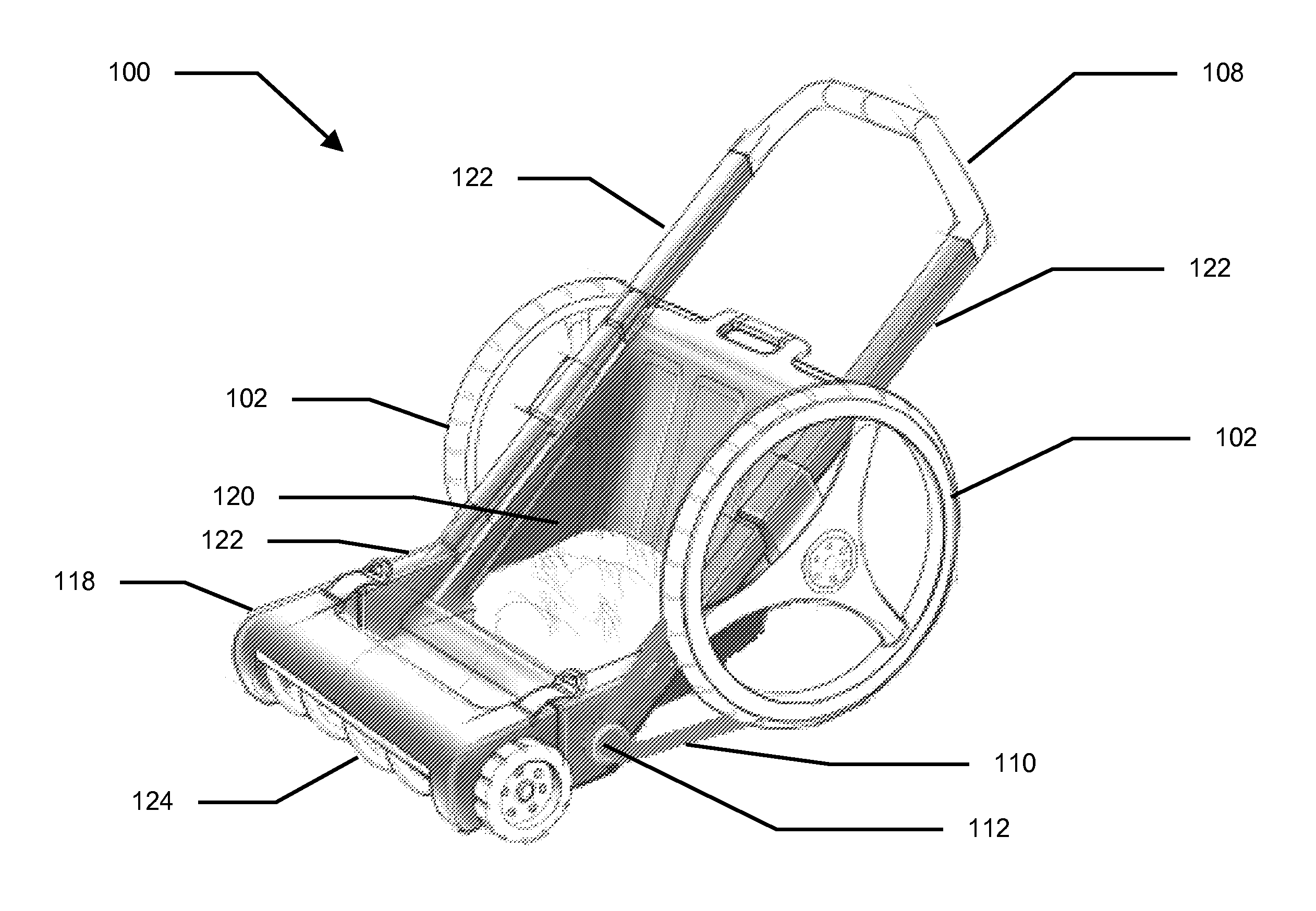

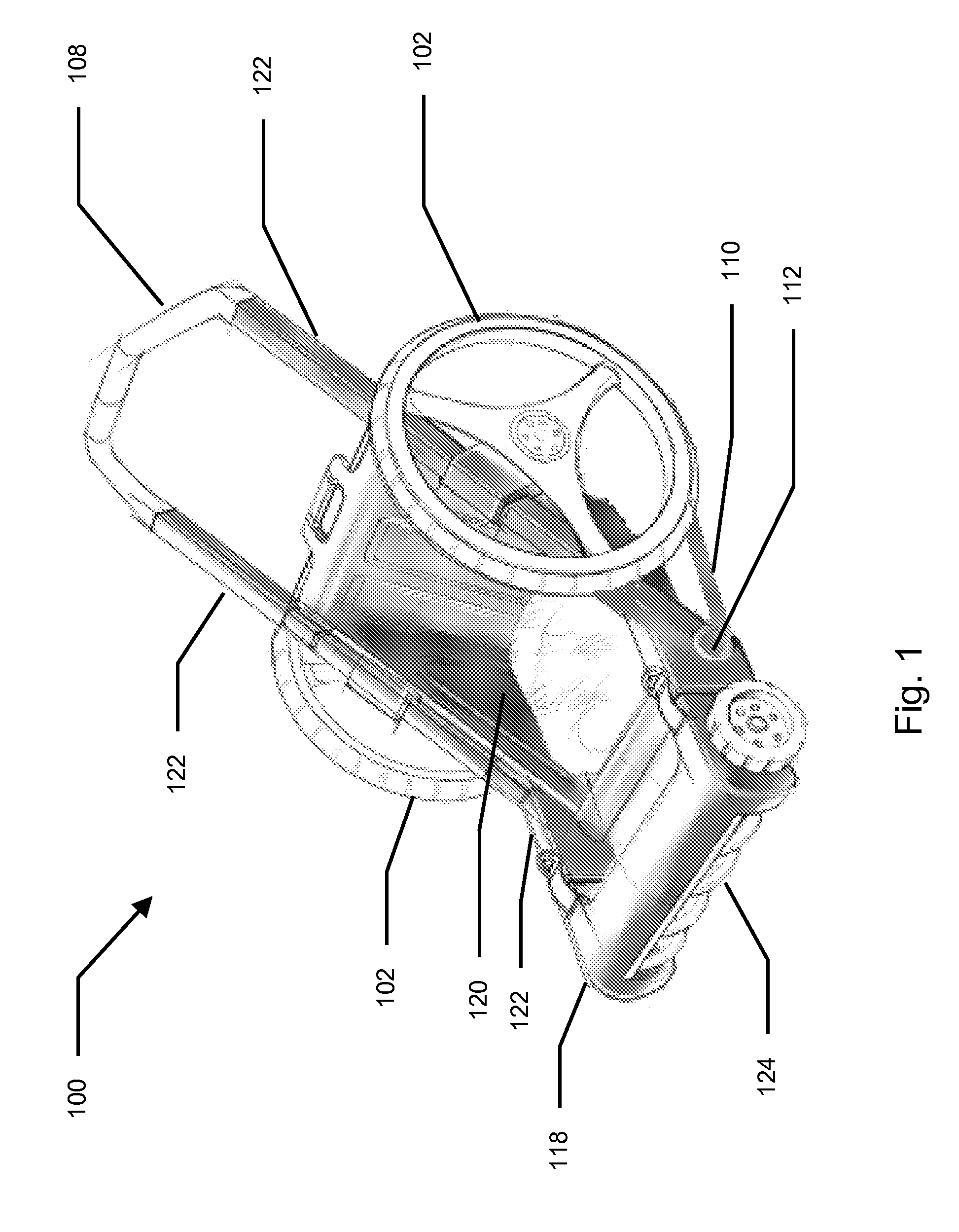

Modular landscaper

InactiveUS20080105445A1Fast spinReduce exerciseAgricultural machinesHops/wine cultivationModularityRotational energy

A modular landscaper uses oversized wheels to generate torque for turning one or more of several interchangeable modular landscape maintenance attachments. The landscaper provides a handle configured in relationship to the landscaper frame to allow an adult to normally walk behind the landscaper while applying a forward force by pushing on the handle that results in the wheels of the landscaper rolling along a landscape maintenance surface and generating torque that is transferred through a drive train to the one or more attached landscaping maintenance attachments. A drive train uses the rotational energy of the wheels to increase the operator pushing force to operate the maintenance attachment. Interchangeable attachments facilitate using the landscaper for a wide variety of landscaping maintenance tasks.

Owner:UMAGINATION LABS

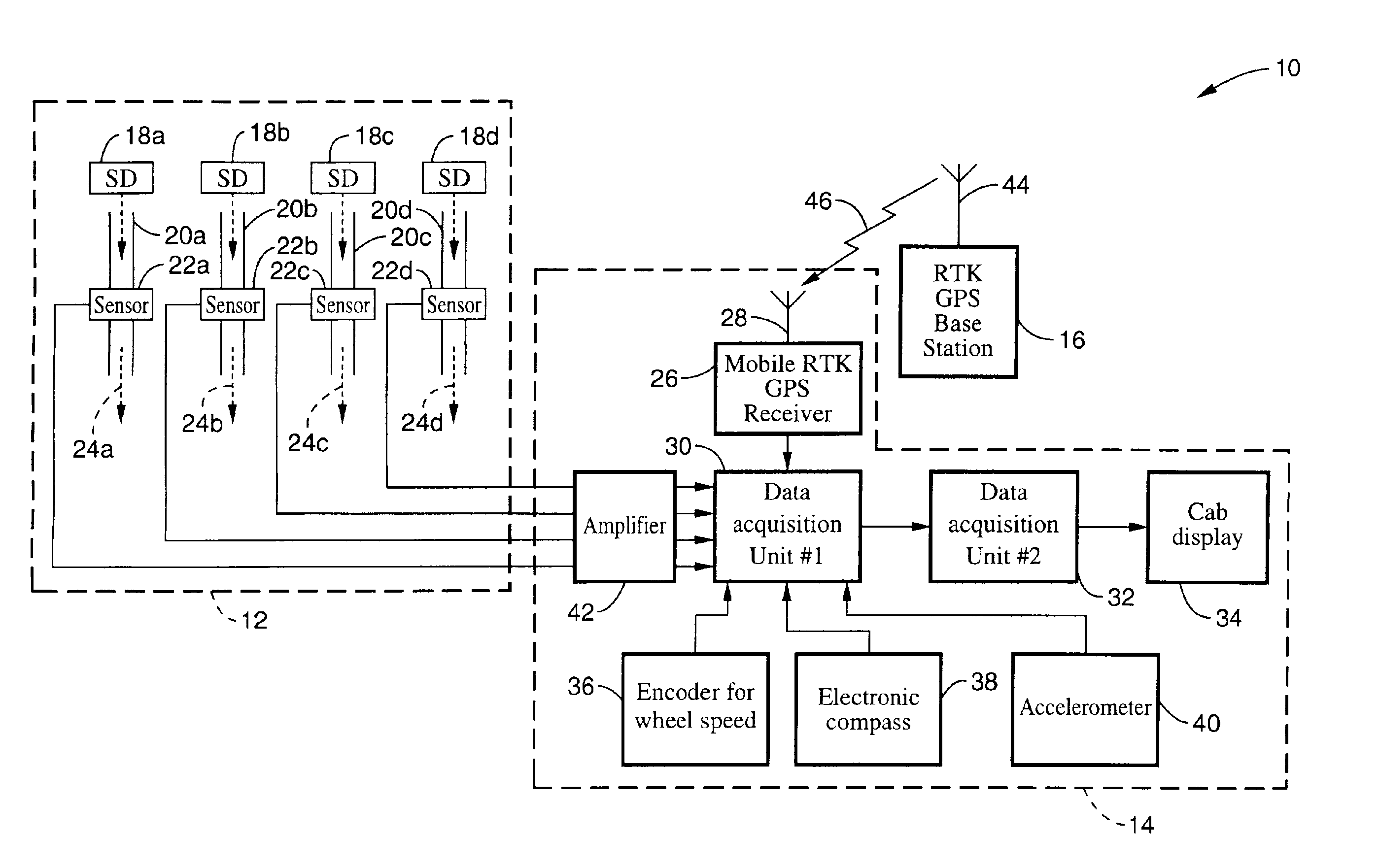

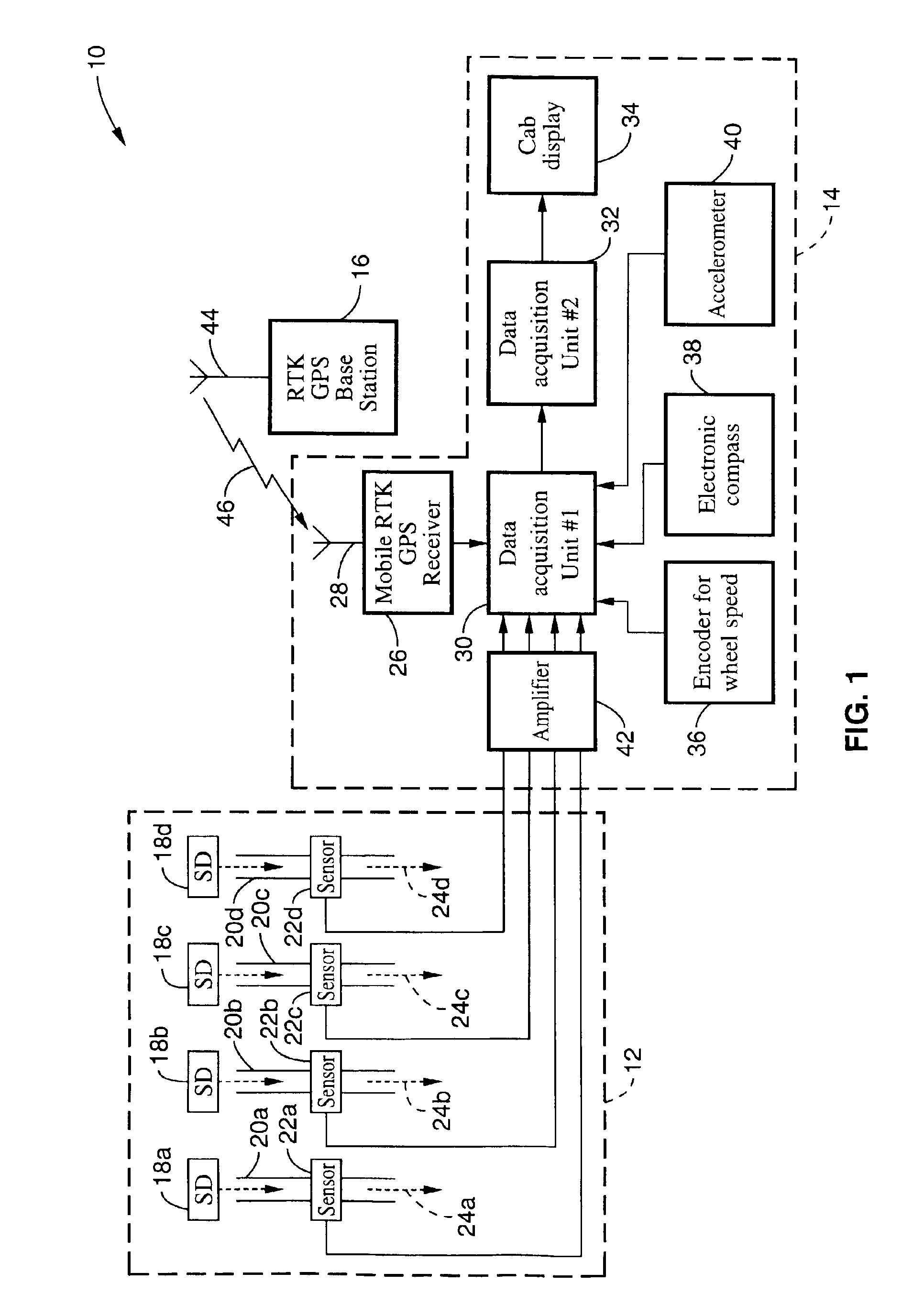

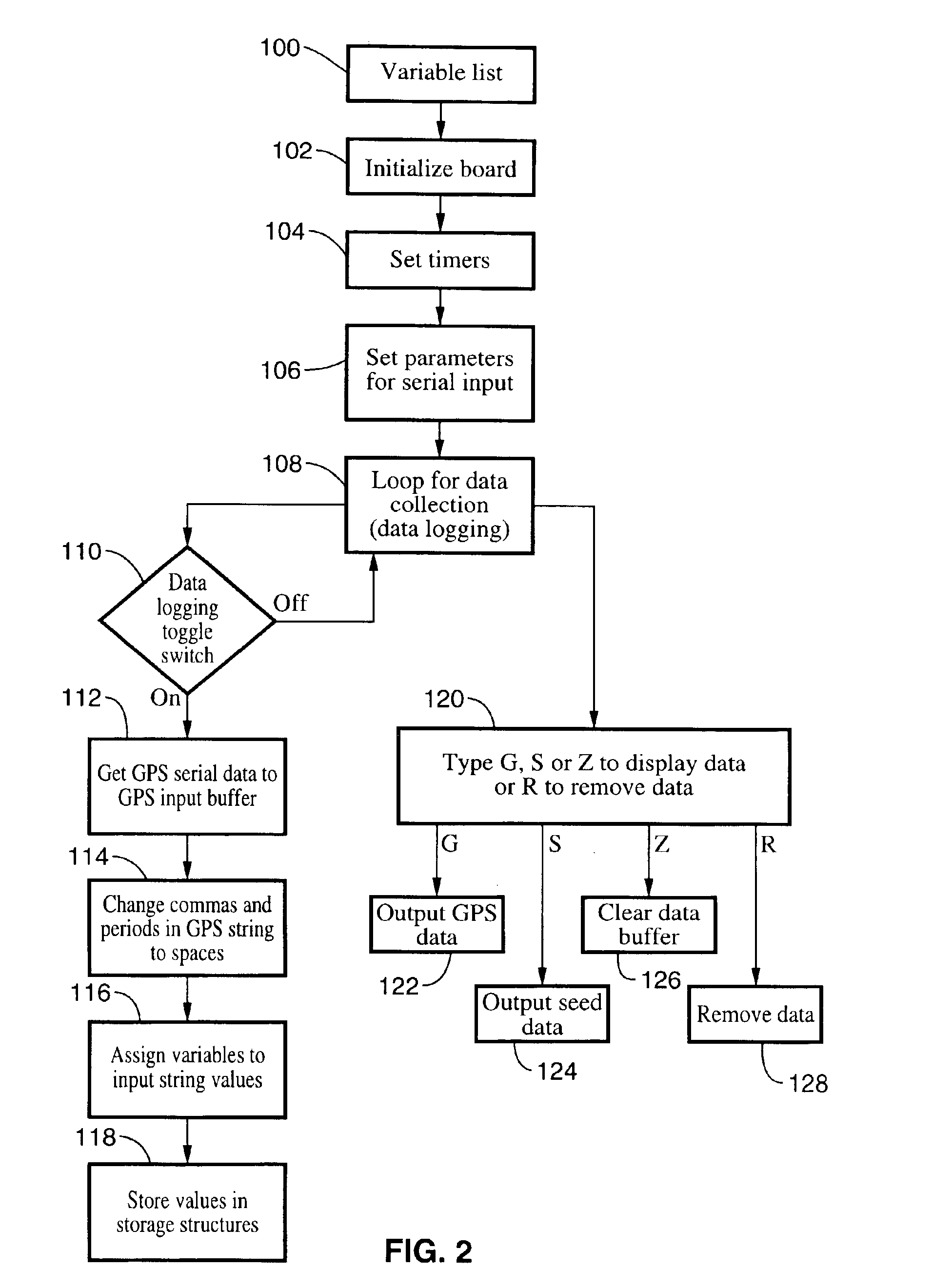

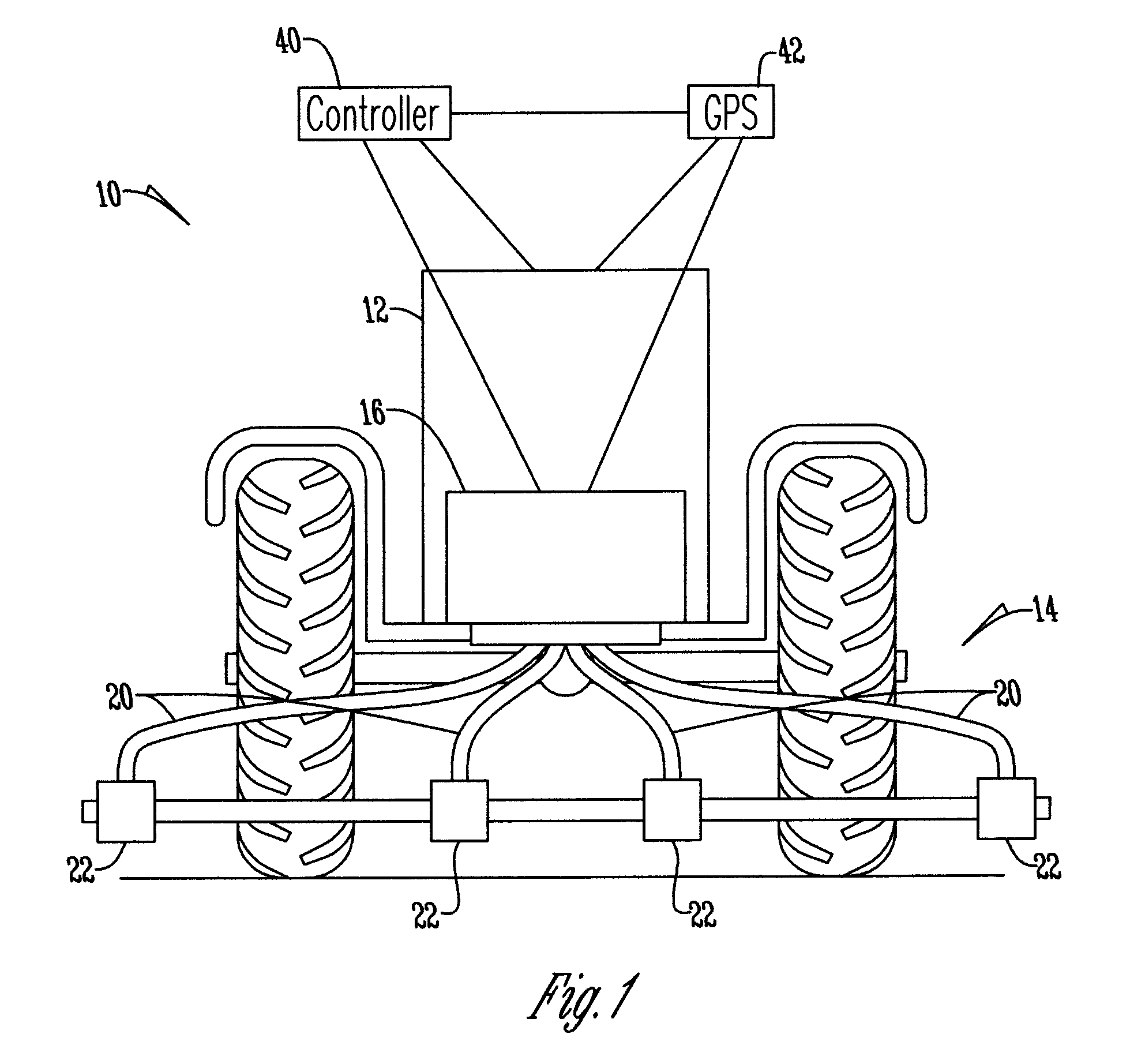

Method and apparatus for ultra precise GPS-based mapping of seeds or vegetation during planting

InactiveUS6941225B2Application can be controlledLow costMowersFertiliser distributersVegetationGps receiver

An ultra precise seed planter apparatus and method for generating a centimeter accuracy map of the location of seeds or vegetation as they are planted from an agricultural planting machine. The apparatus is fitted with a GPS receiver feeding a data logger, and optical sensors that are placed adjacent seed or vegetation dispenser. The data logger monitors GPS time and UTM coordinates, as well as the optical sensors. Ground speed and azimuth are also monitored. The seeds or vegetation are time-tagged as they are dispensed, and software is used to process the dispensing time and GPS location data and estimate the exact coordinates of each seed or plant and its distance from adjacent seeds or plants. As a result, a precise planting map is generated. The invention may also be used to determine the location to dispense seeds or vegetation, and activating the dispenser when that location is reached.

Owner:RGT UNIV OF CALIFORNIA

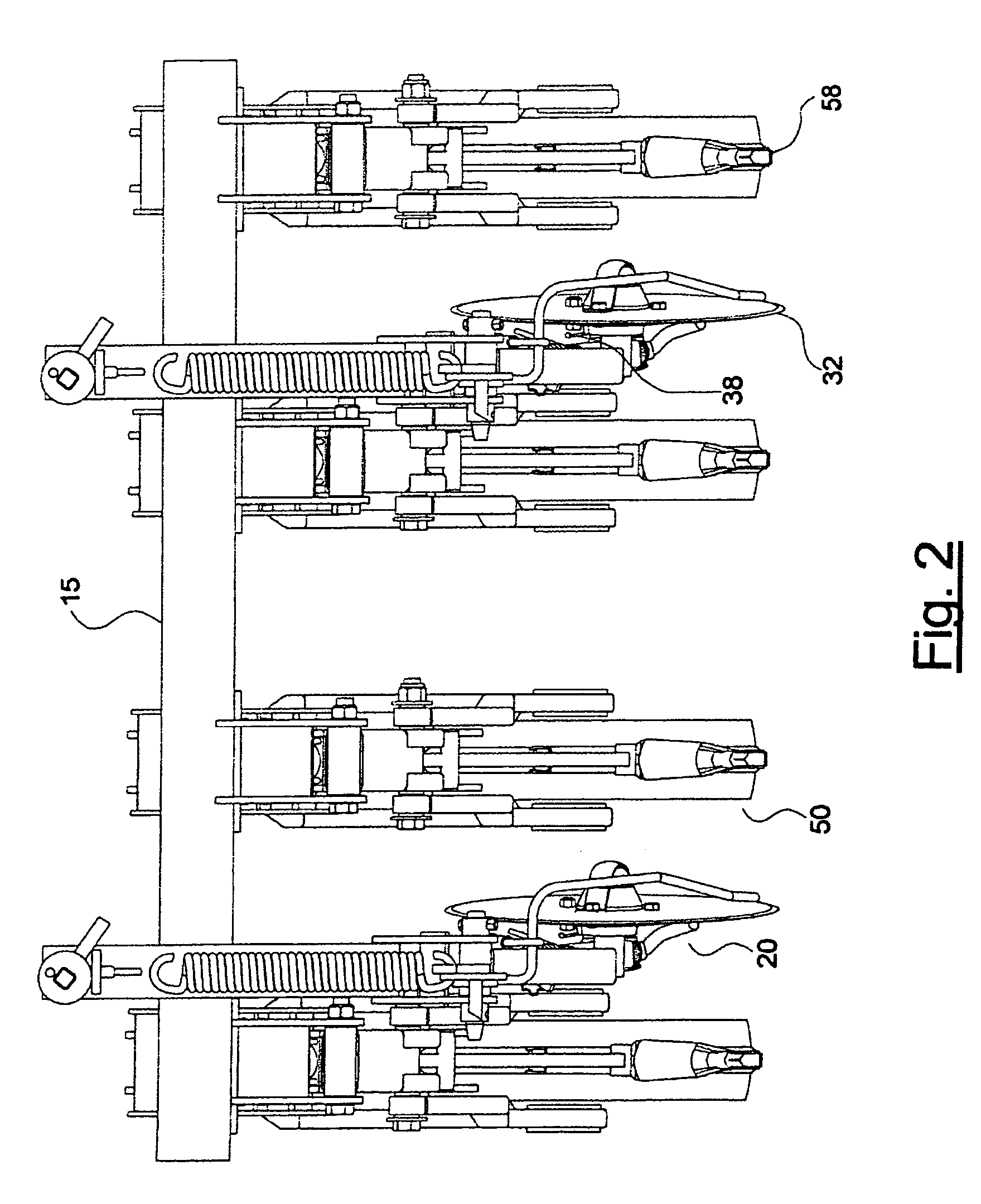

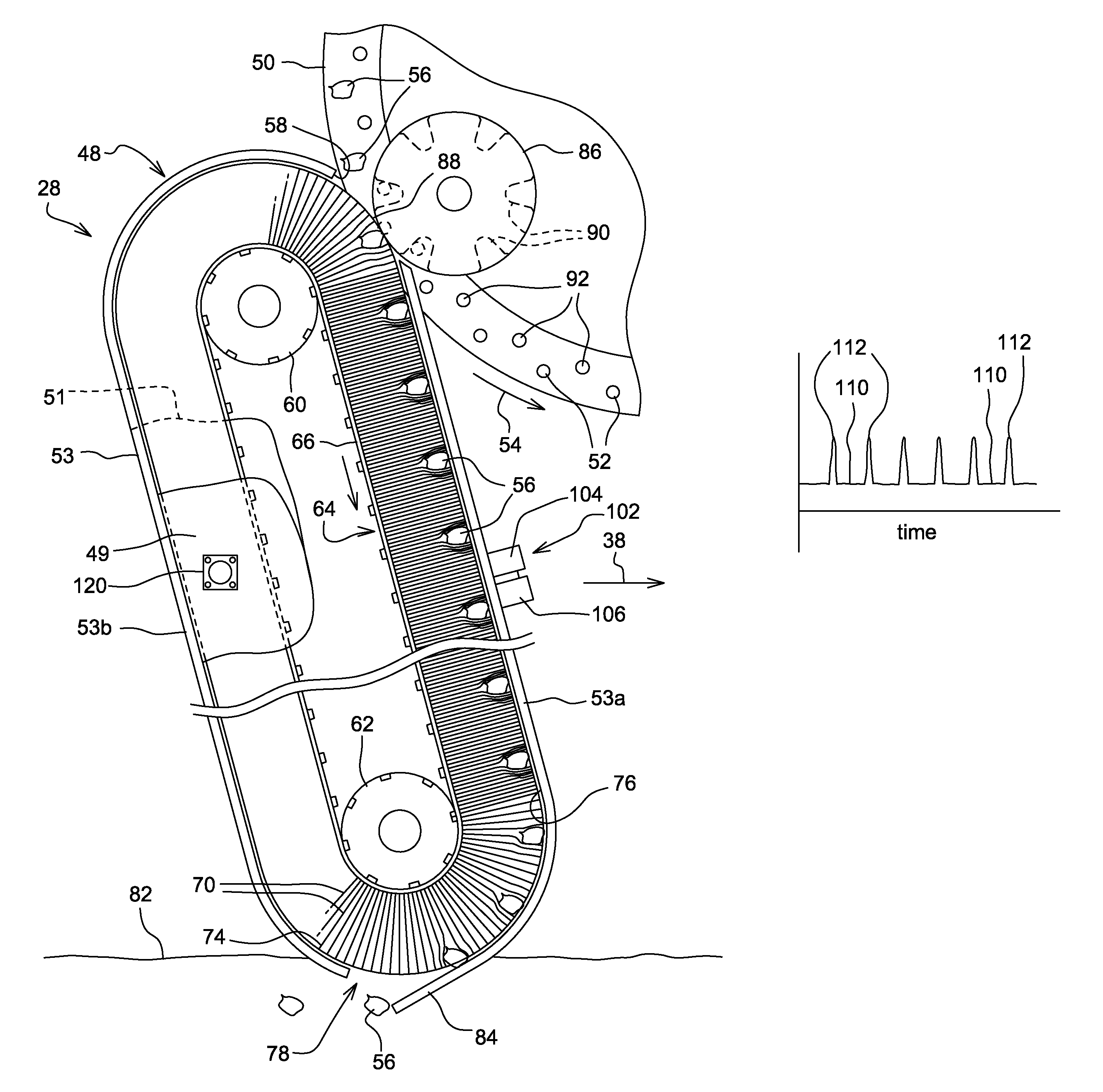

Bulk seed handling system

InactiveUS20100040446A1Easy transferEasy to handleConveyorsFertiliser distributersEngineeringHandling system

A bulk seed handling system (20) is provided to facilitate seed transfer from a distributor to a farm and then to a planter or the like. The handling system (20) includes one or more upright bin assemblies (22) adapted to be moved in a filled condition, and a trailer (24) designed to move the bin assembly (22) and unload seed therefrom. The bin assembly (22) includes a seed bin (26) having a lower unload opening (34) and supported by a frame assembly (38) including telescopic legs (50) shiftable between a retractable travel position and an extended bin support position. The trailer (24) includes a lift frame (60) operable to engage and elevate the bin assembly (22) for travel with the legs (50) thereof in a retracted position, and a seed-conveying arrangement including an intermediate conveyor (62) and a delivery conveyor (64). At an unloading site, the intermediate conveyor (62) is shifted to an unloading position in communication with the bin unload opening (34) and the delivery conveyor (64) in order to transfer seed from the bin.

Owner:USC

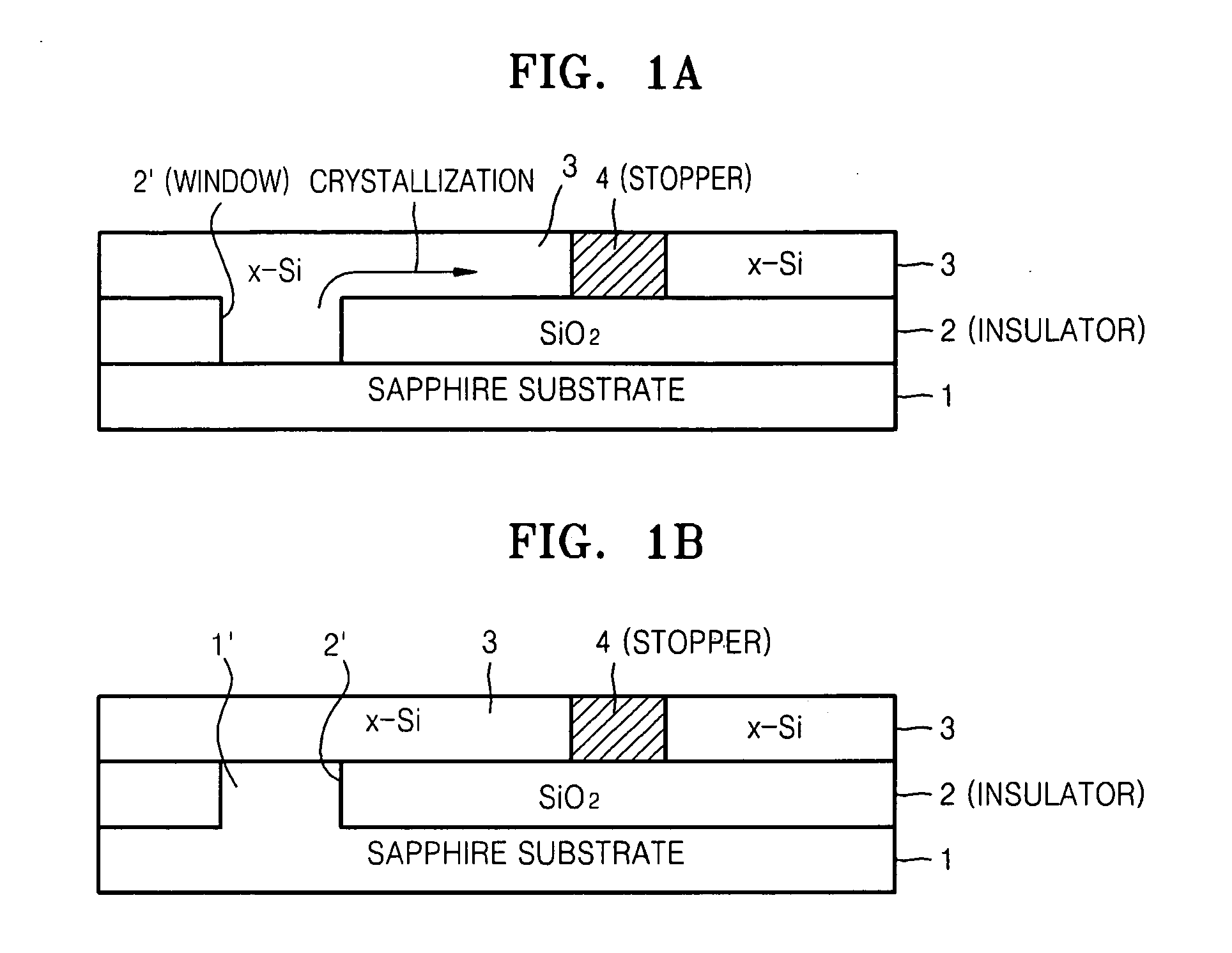

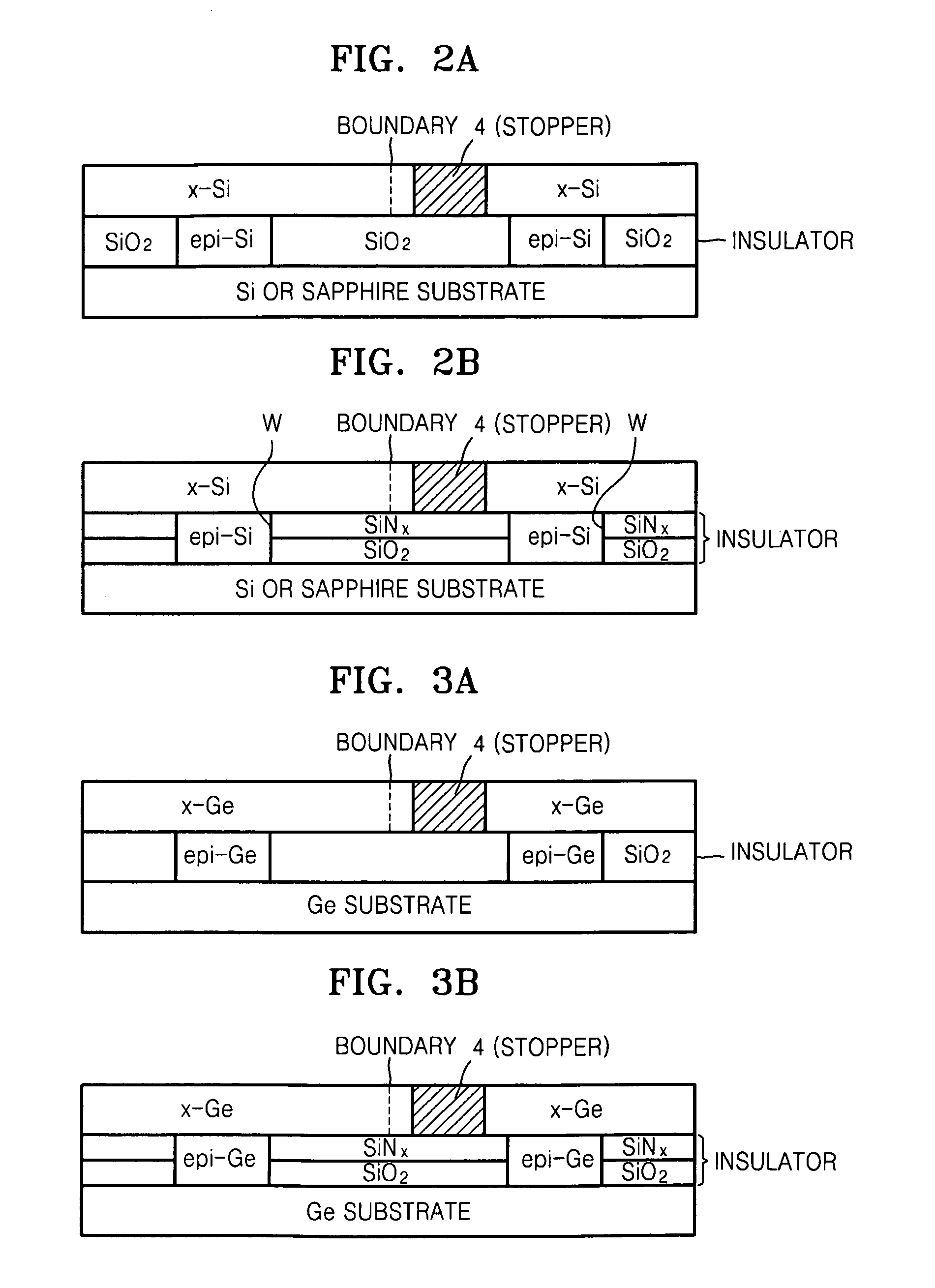

Crystal substrates and methods of fabricating the same

InactiveUS20070187668A1Thickness is easy to controlSpadesPolycrystalline material growthSingle crystal substrateOptoelectronics

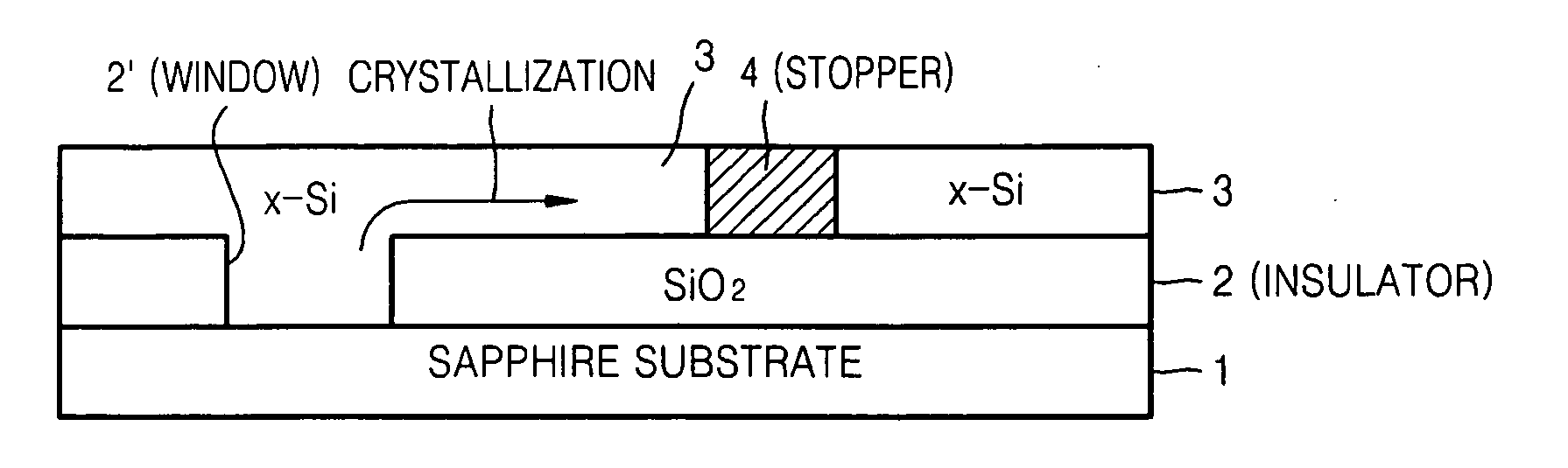

A single crystal substrate and method of fabricating the same are provided. The single crystal substrate includes an insulator having a window exposing a portion of a substrate, a selective epitaxial growth layer formed on the portion of the substrate exposed through the window and a single crystalline layer formed on the insulator and the selective epitaxial growth layer using the selective epitaxial growth layer as an epitaxial seed layer.

Owner:SAMSUNG ELECTRONICS CO LTD

Seed delivery apparatus with sensor and moving member to capture and move seed to a lower outlet opening

A seed delivery apparatus has a moving member that captures and entraps the seed from the seed meter and physically moves the seed from the meter to the lower outlet opening. In so doing, the seed engages and travels along an interior surface of the seed delivery apparatus. A seed sensor is mounted on the housing wall such that the seed passes directly in front of the sensor. The sensor has both the light emitting devices and the photo-sensitive elements on the same wall of the delivery apparatus, or on two opposed walls. The moving member prevents ambient light, dust and dirt from entering the housing and impacting the sensor output signal.

Owner:DEERE & CO

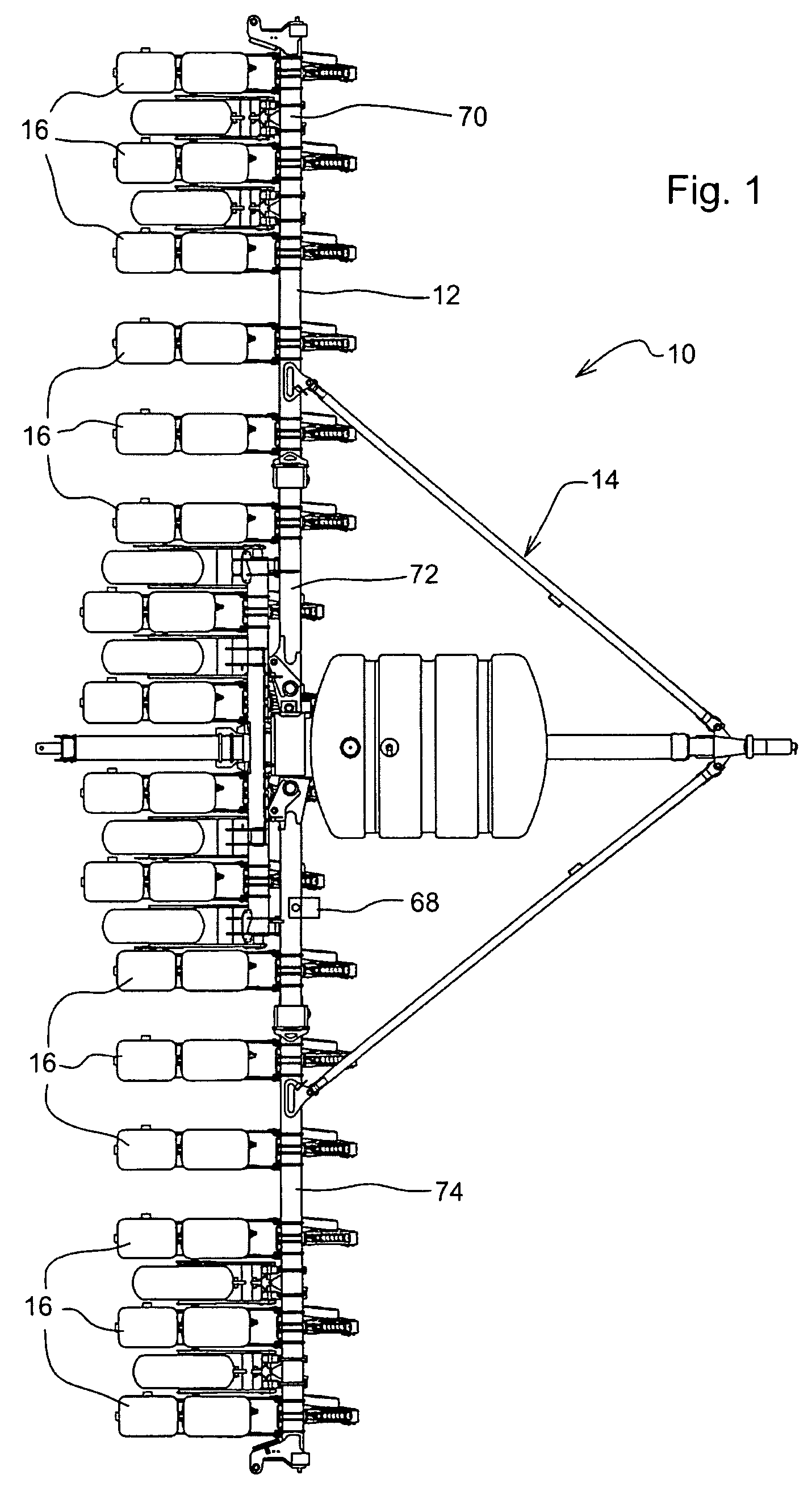

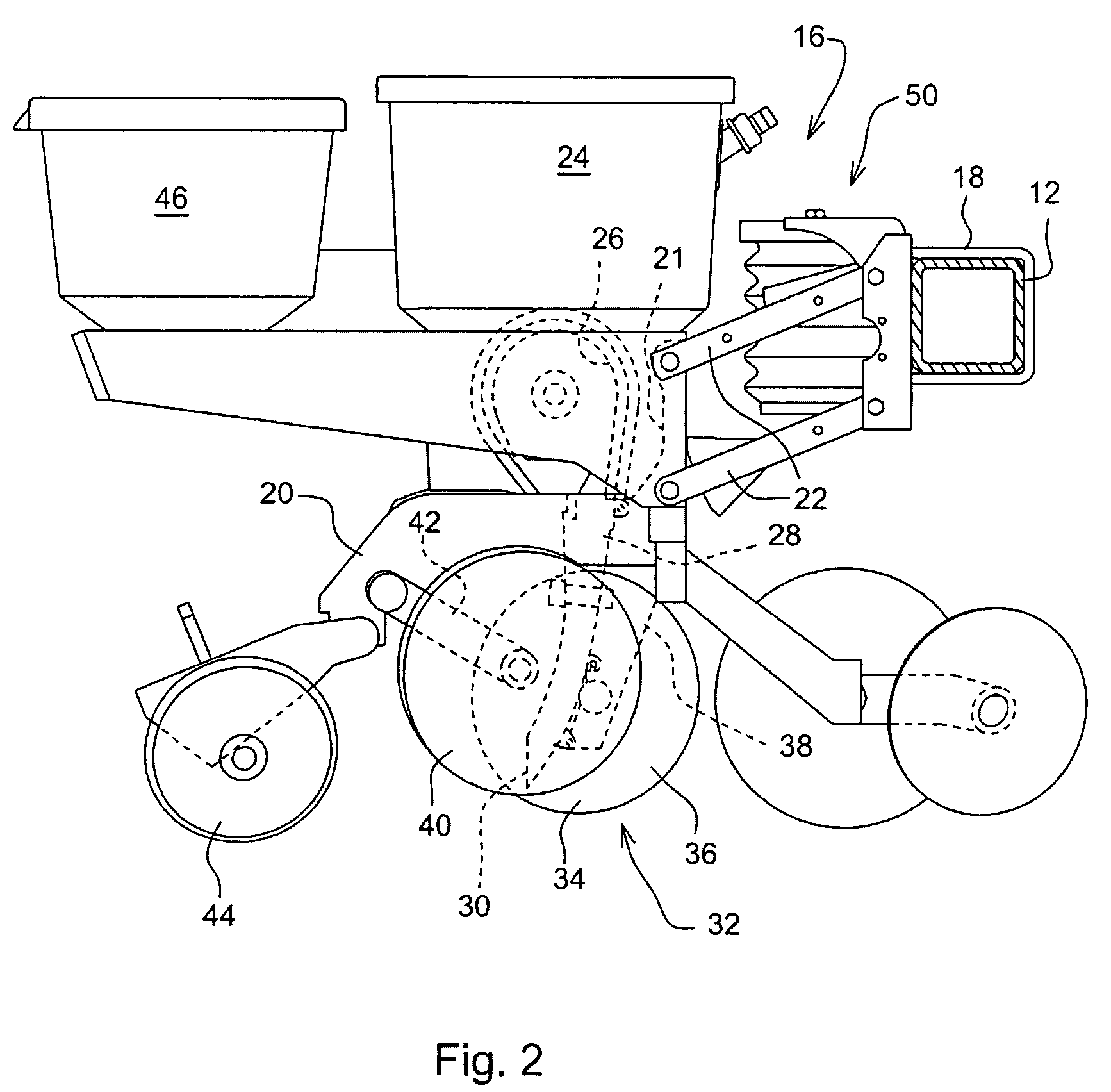

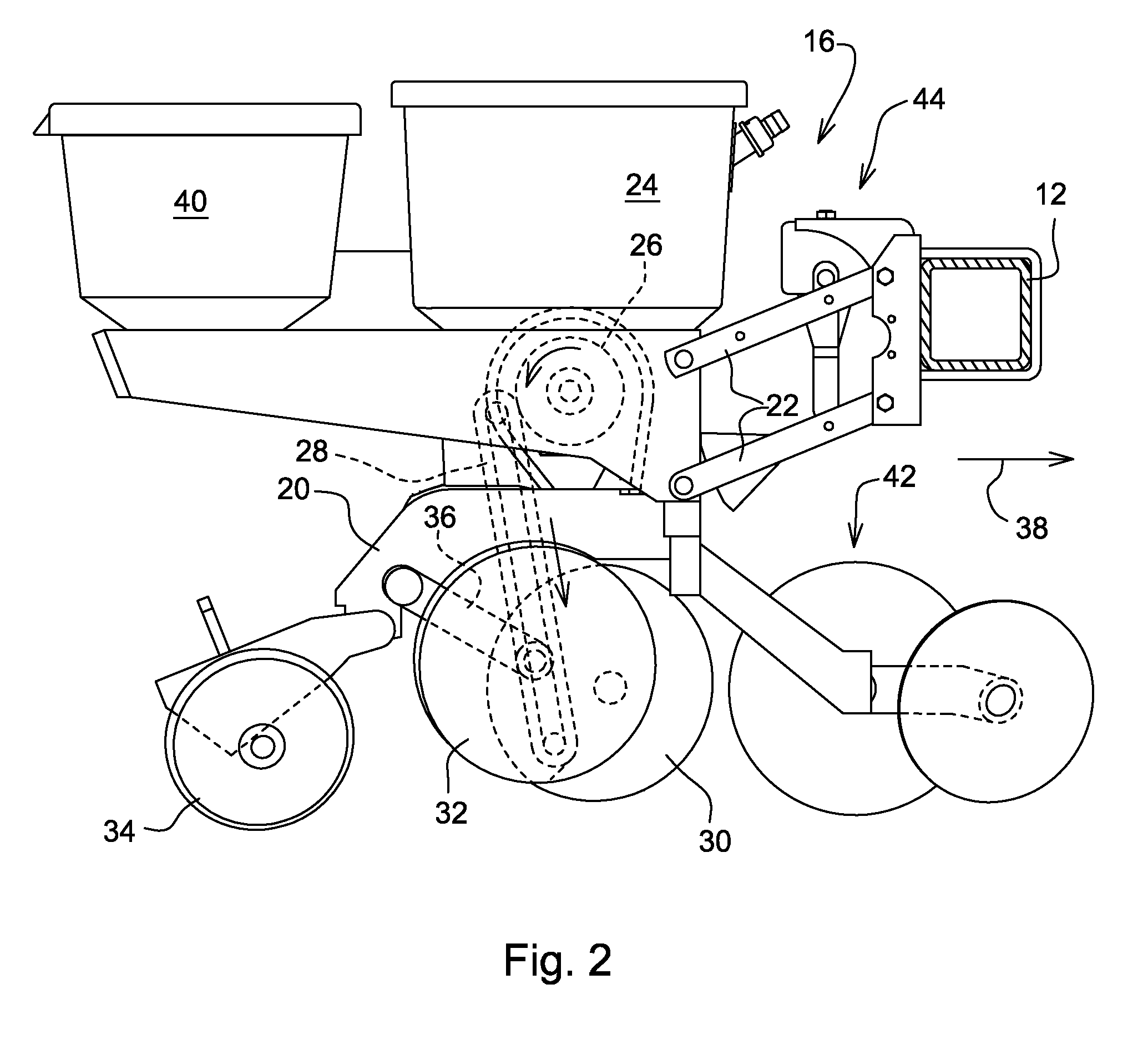

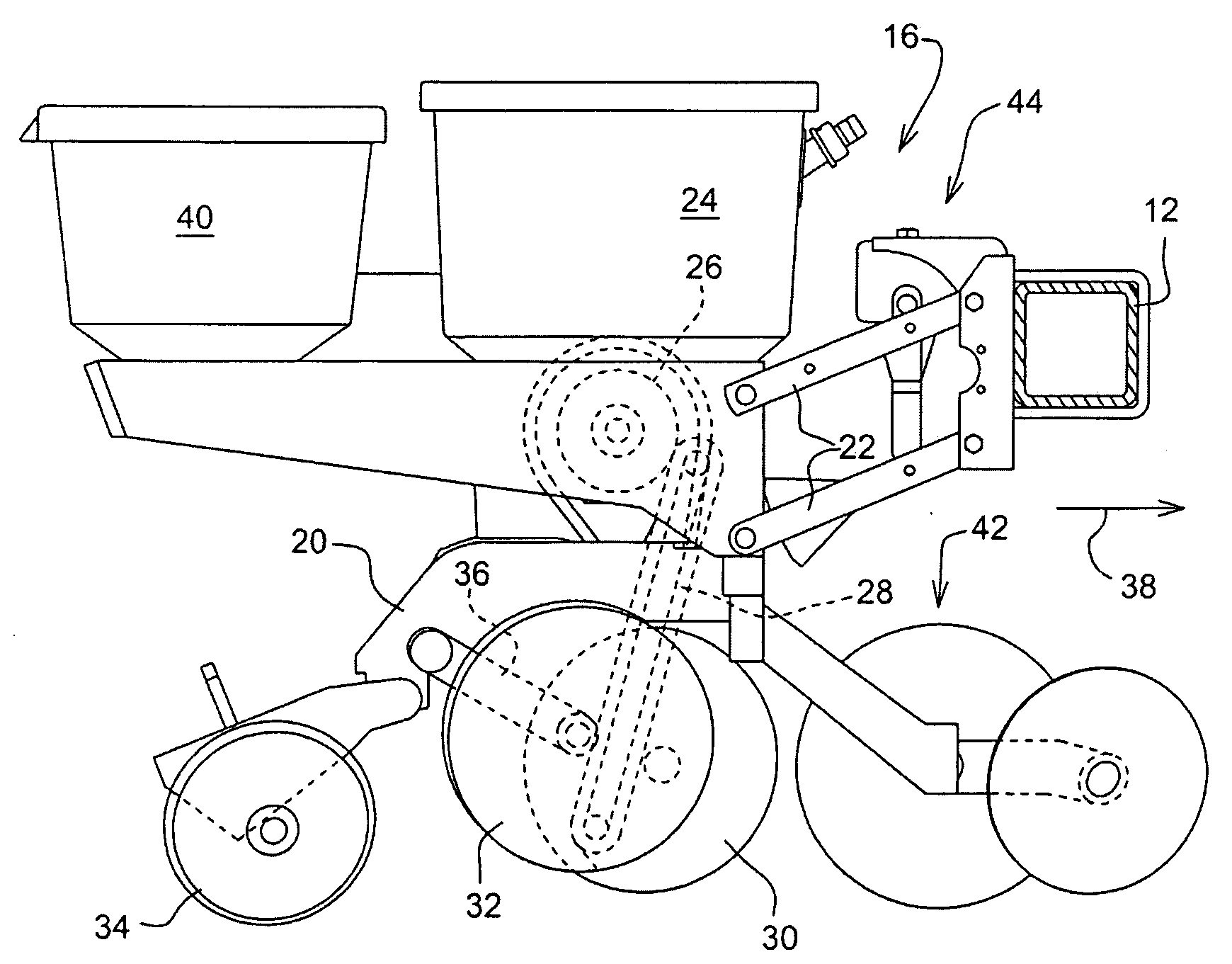

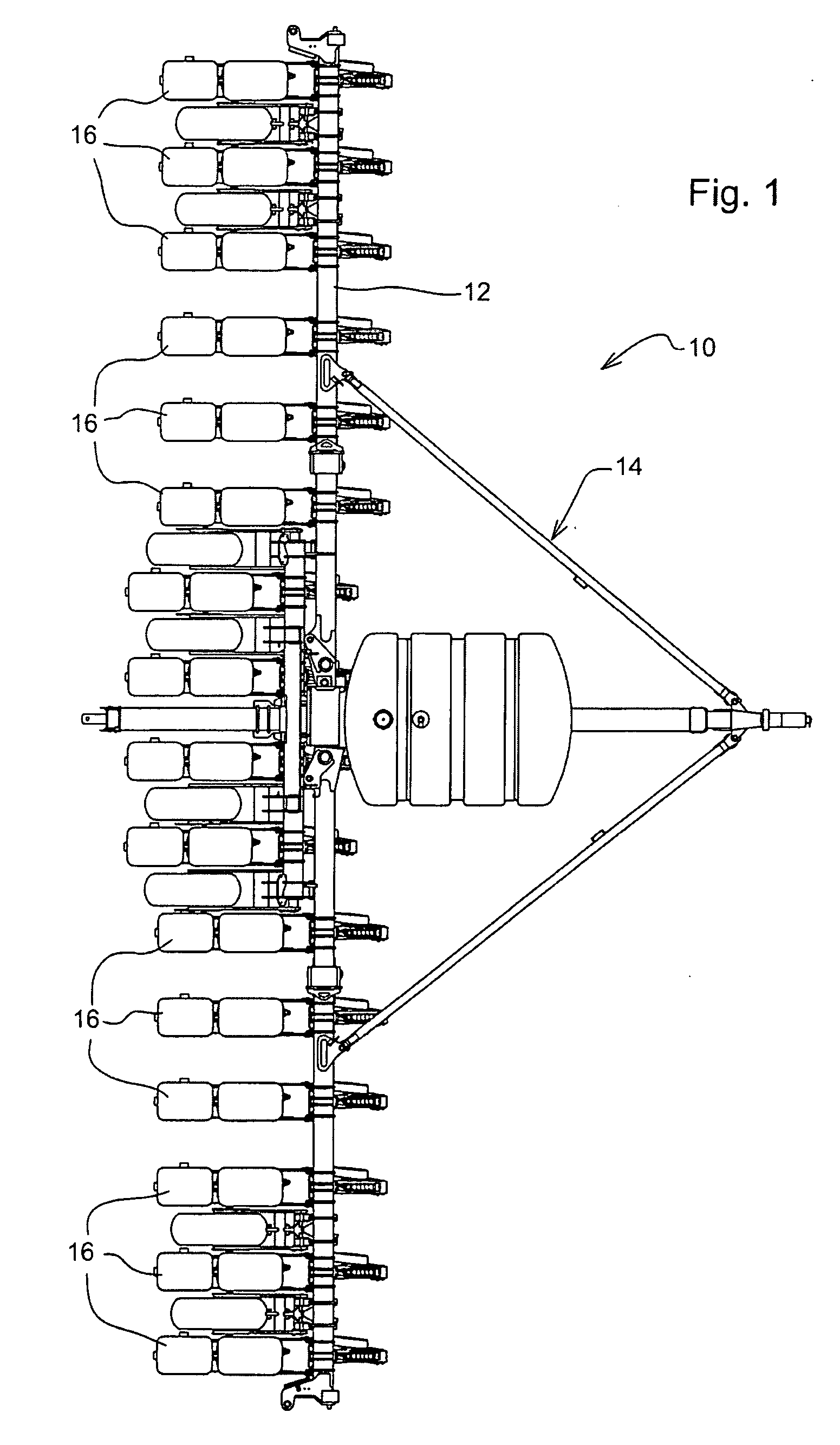

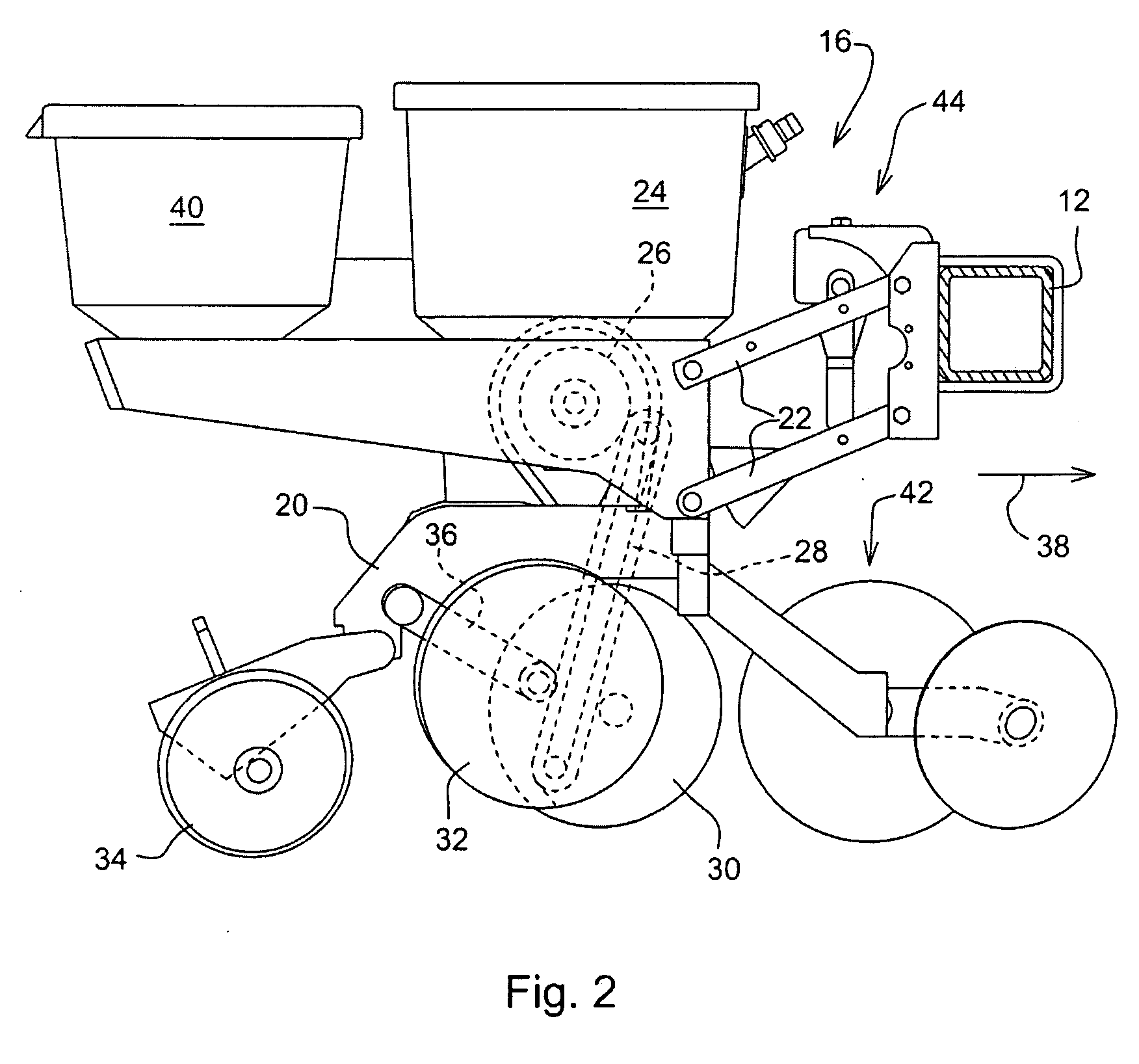

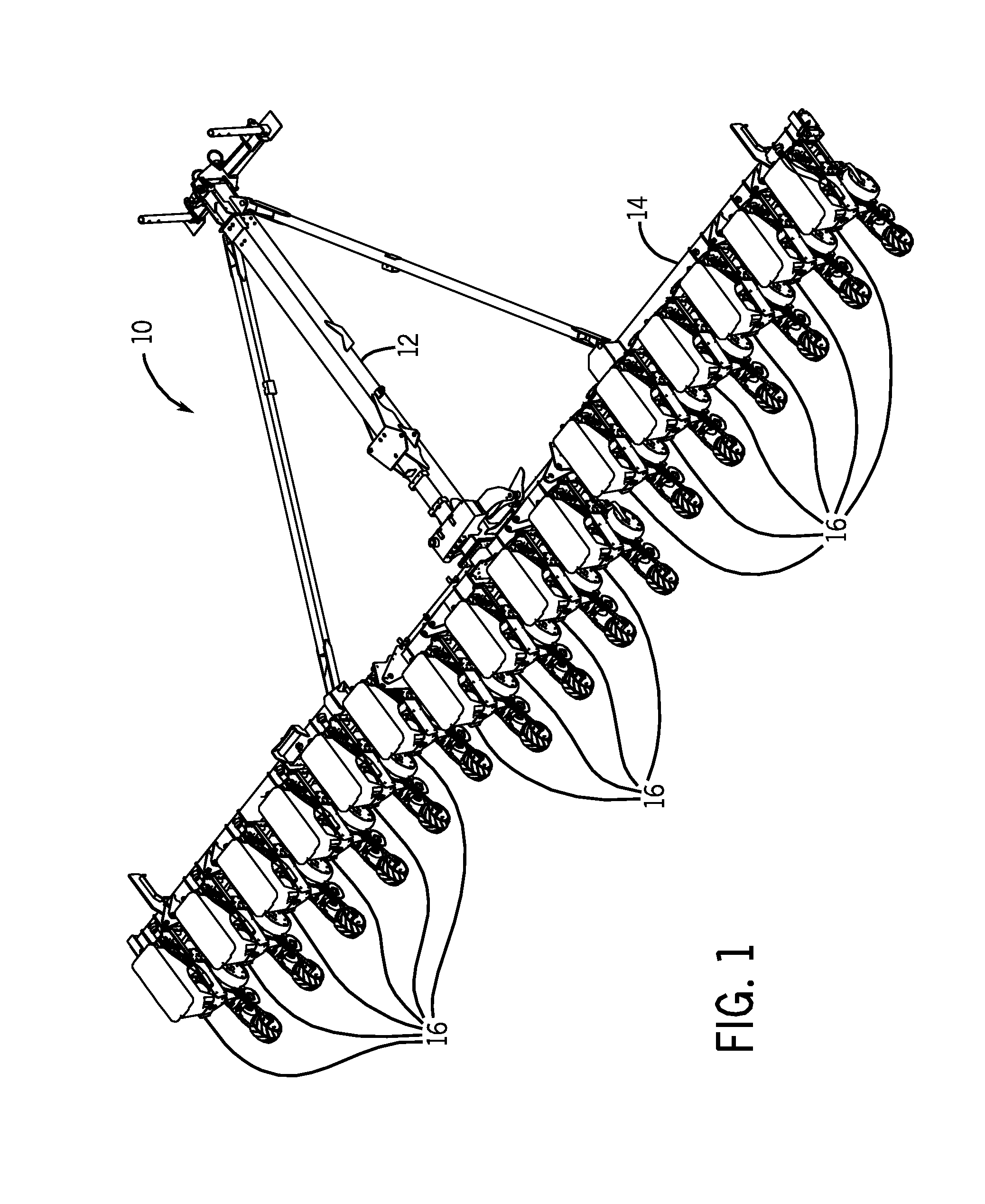

Seeding Machine With Seed Delivery System

ActiveUS20100192819A1Reduces seed spacing variabilityReduce scrollingFertiliser distributersCentrifugal wheel fertilisersEngineeringDelivery system

A seed delivery system for use in a seeding or planting machine that removes the seed from a seed meter by capturing the seed therefrom. The delivery system then moves the seed down to a lower discharge point and accelerates the seed horizontally rearward to a speed approximately equal to the forward travel speed of the seeding machine such that the seed, when discharged has a low or zero horizontal velocity relative to the ground. Rolling of the seed in the trench is thus reduced. Furthermore, as the seed only has a short drop from the outlet to the bottom of the seed trench, the seed has little vertical speed to induce bounce. The delivery system uses a brush belt to capture, move and accelerate the seed. By capturing the seed and moving it from the meter to the discharge, the seed is held in place relative to other seeds and the planter row unit. As a result, the seeds are isolated from row unit dynamics thereby maintaining seed spacing.

Owner:DEERE & CO

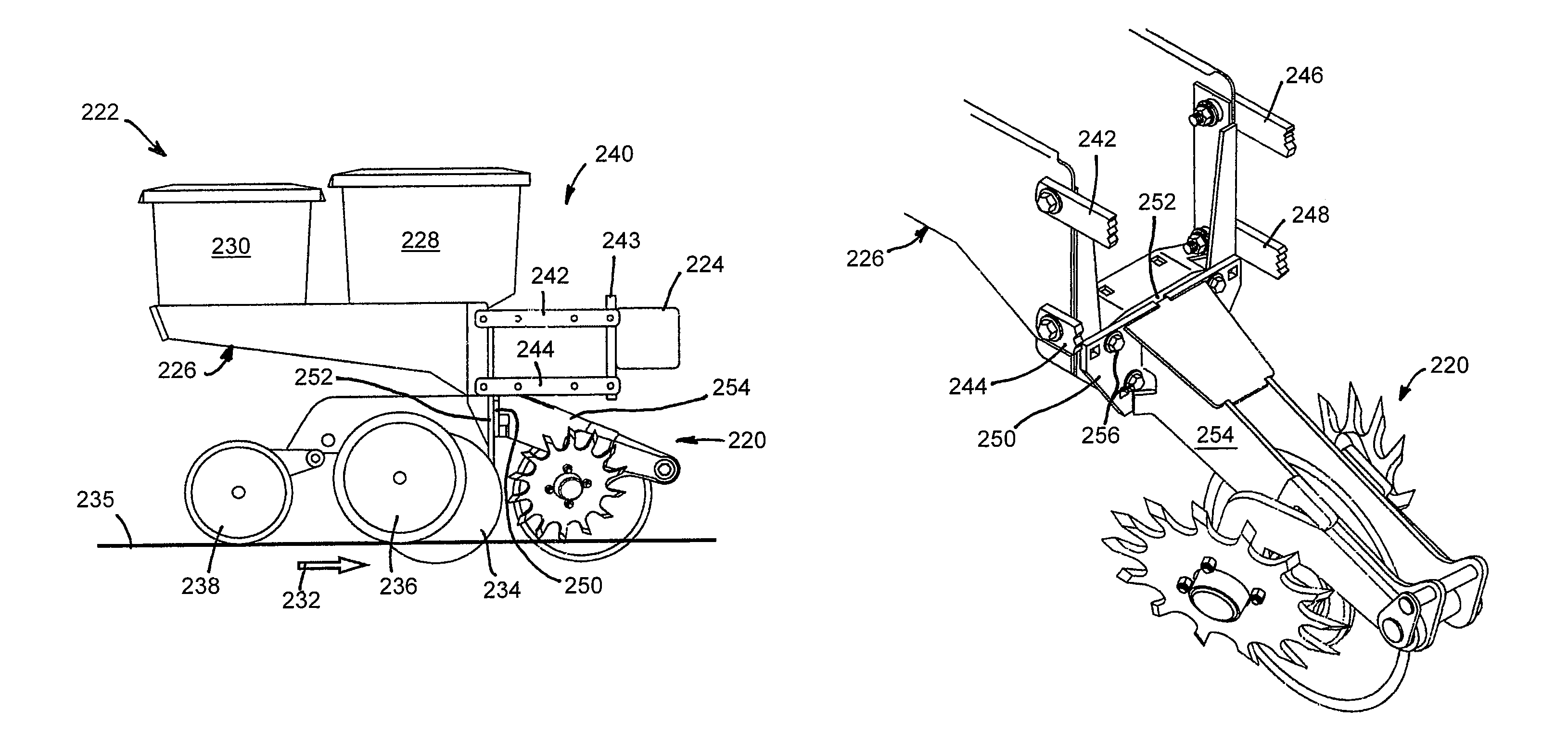

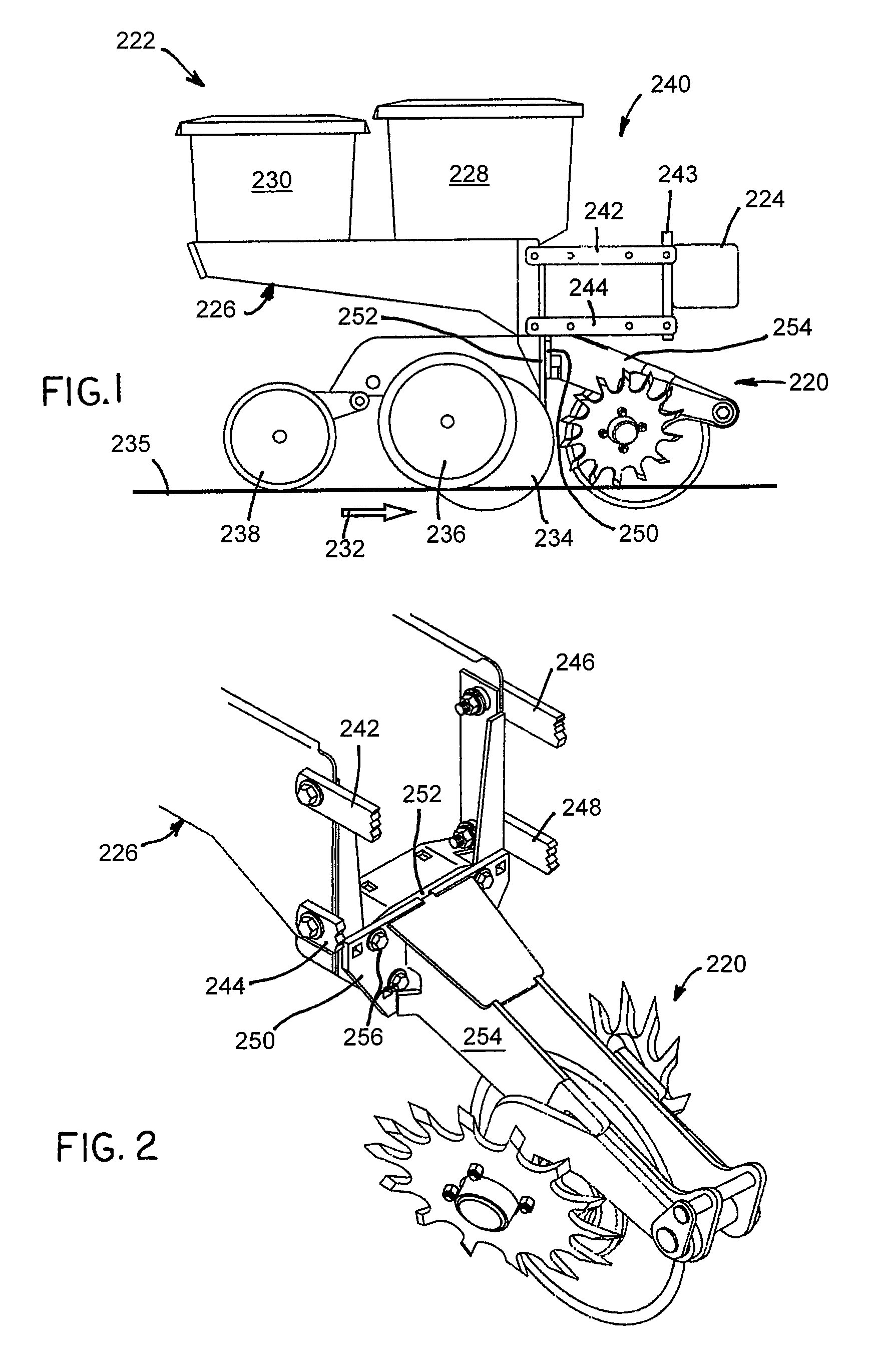

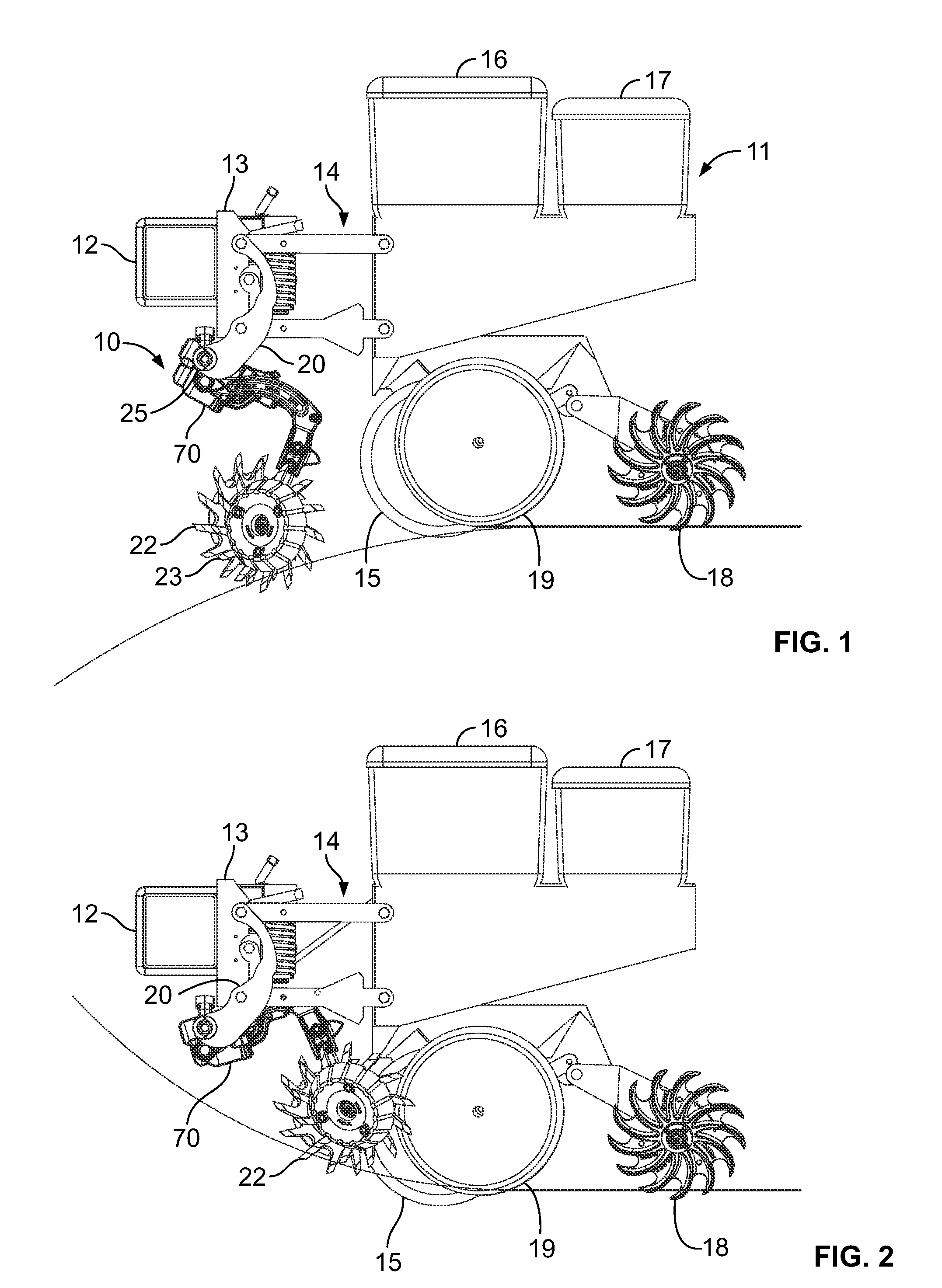

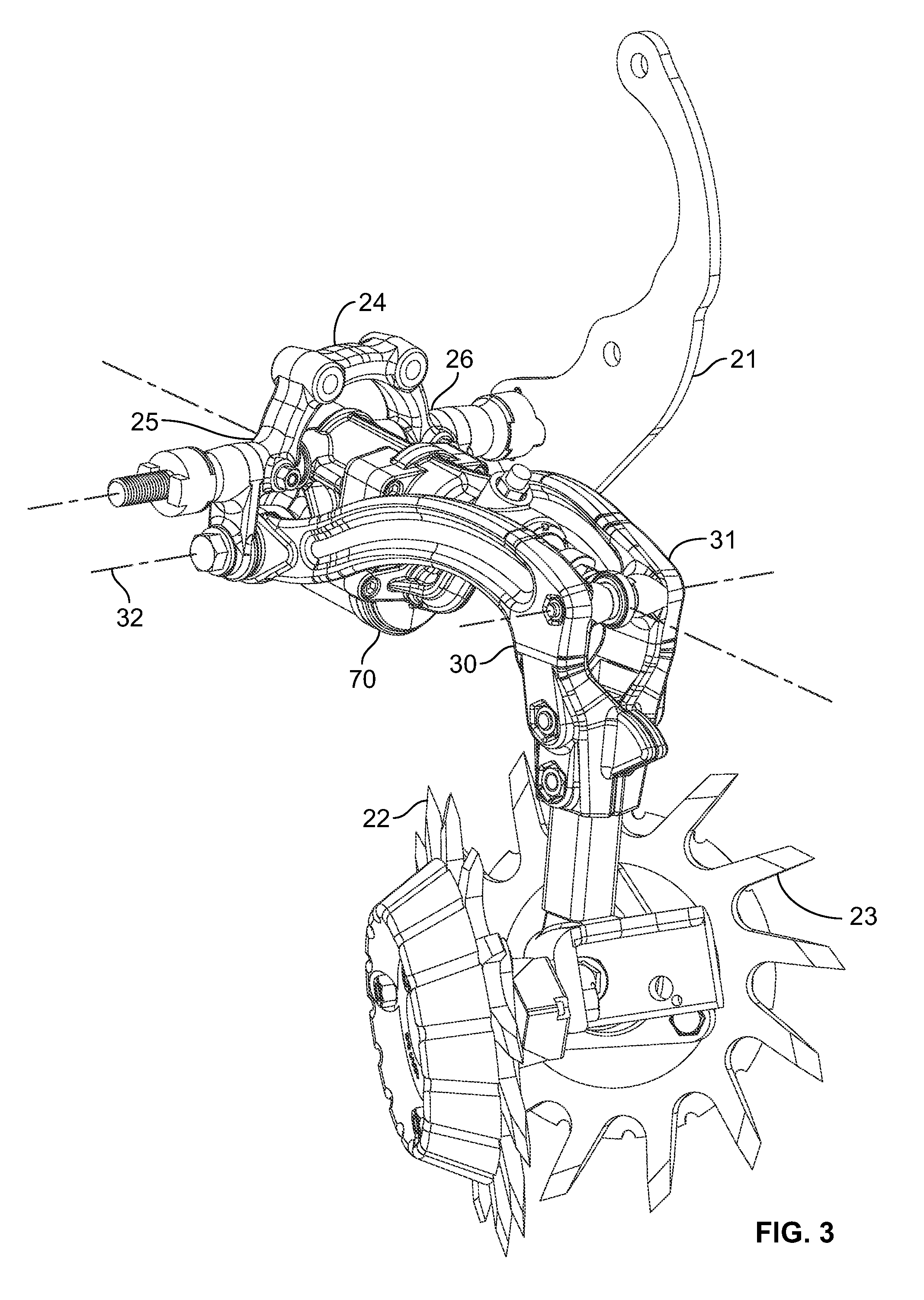

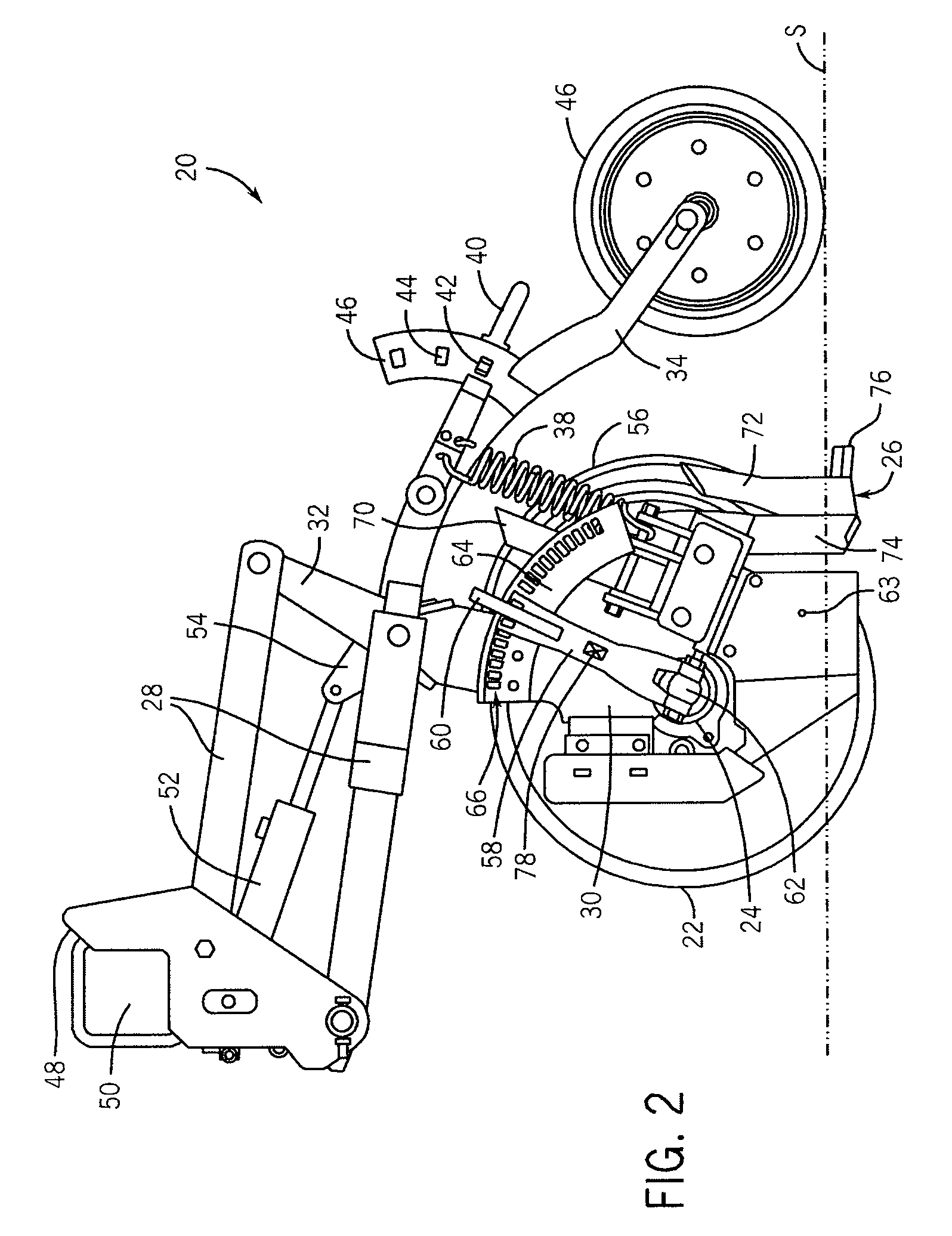

Crop residue clearing device

ActiveUS8393407B2Less susceptible to damage and destructionReduce penetrationSpadesTill seedingGear wheelCrop residue

Apparatus for clearing crop residue from a field is adapted for attachment to a tool bar of an agricultural implement or to a planter unit such that the apparatus is pulled through a field by the implement. The apparatus includes a support structure extending forward of the tool bar and at least one and preferably a pair of floating arms pivotally attached to a forward portion of the support structure and extending rearwardly, with a toothed wheel rotationally attached to an aft end of the arm(s). A coulter attached to the support structure is disposed between and extends forward of the soil-engaging toothed wheel(s) and in combination with the wheel(s) severs and removes residue in the seeding pathway. An adjustable biasing arrangement urges the toothed wheels, either in unison or independently, downwardly into engagement with the soil. Upper and lower stop limits are provided to limit vertical positioning of the toothed wheel(s).

Owner:AG FOCUS LLC

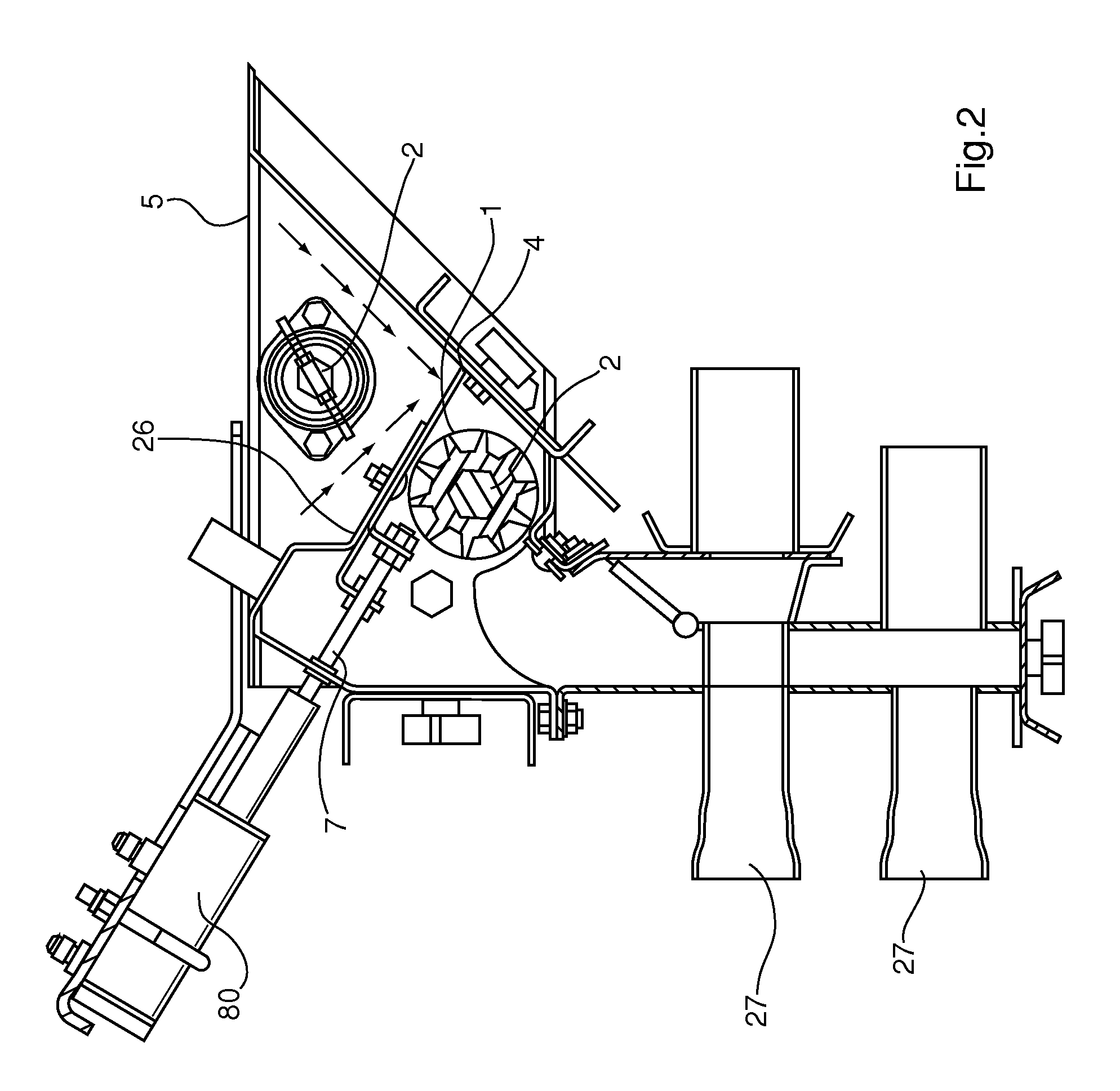

Sectional meter shut-off and agricultural implement having sectional meter shut-off

ActiveUS7690440B2Overcome problemsAvoid interferenceSpadesAnalogue computers for trafficSeederEngineering

An agricultural seeder or fertilizer having a meter device which dispenses seed or fertilizer to a plurality of ground-engaging members. The supply of metered seed or fertilizer to each of the ground-engaging members is controlled via input from a GPS / GNSS satellite navigation system to prevent the meter device delivering seed or fertilizer to selected of the ground-engaging members which would otherwise pass over soil which has been previously seeded or fertilized. Raising means, responsive to input from said GPS / GNSS satellite navigation system detecting that the device is travelling or is about to travel over areas of soil that has been previously seeded or fertilized, is further is provided to raise the selected ground-engaging members to which delivery of seed / fertilizer has been prevented in order to prevent soil which has been previously seeded or fertilized from being disturbed. A method of operating a seeder / fertilizer implement to achieve the aforesaid is further disclosed.

Owner:ONE PASS IMPLEMENTS

Differential Pressure Seed Meter With An Endless Belt Seed Transport Member

ActiveUS20100192818A1Great freedomFertiliser distributersPotato plantersSpatial OrientationsDifferential pressure

A seed meter is provided having an endless belt as a seed transport member together with a pressure differential to hold the seed onto the belt. The use of an endless belt as the seed transport member enables the spatial orientation of the seed transport member to vary from location to location along the path of the belt where different seed meter functions are performed. The belt allows greater freedom in determining the location of the seed pick-up region and the seed release or removal region beyond the constraints of a fixed diameter seed disk. The belt further allows for a narrow envelope seed meter which can cross-feed seed into a substantially vertically oriented delivery device.

Owner:DEERE & CO

Integrated clutches for a seeding machine

A seeding machine having a plurality of seed meters receiving rotary input from a common input shaft. First and second gearboxes respectively connect the common rotary input to individual seed meters. A flexible drive extends from the gearbox adjacent the common rotary input to the seed meters. Spring clutches, normally connected, are electrically actuated to disengage the drive to the individual seed meters. The clutches may be integrated in the gearbox adjacent the rotary drive or the gear box for the individual seed meters.

Owner:DEERE & CO

Method and apparatus for changing seed varieties at the row unit of a planter

A planting system for planting multiple seed varieties. The planting system includes a planter having a plurality of tanks and a plurality of row units. A plurality of seed meters are included in of the plurality of the row units. A seed transport belt is disposed below the plurality of seed meters to transport seed from each of the plurality of seed meters into a seed tube. Each of the plurality of seed meters is engaged and disengaged by a clutch, and the seed transport belt is disposed below the plurality of seed meters in an angled orientation.

Owner:KINZE MFG INC

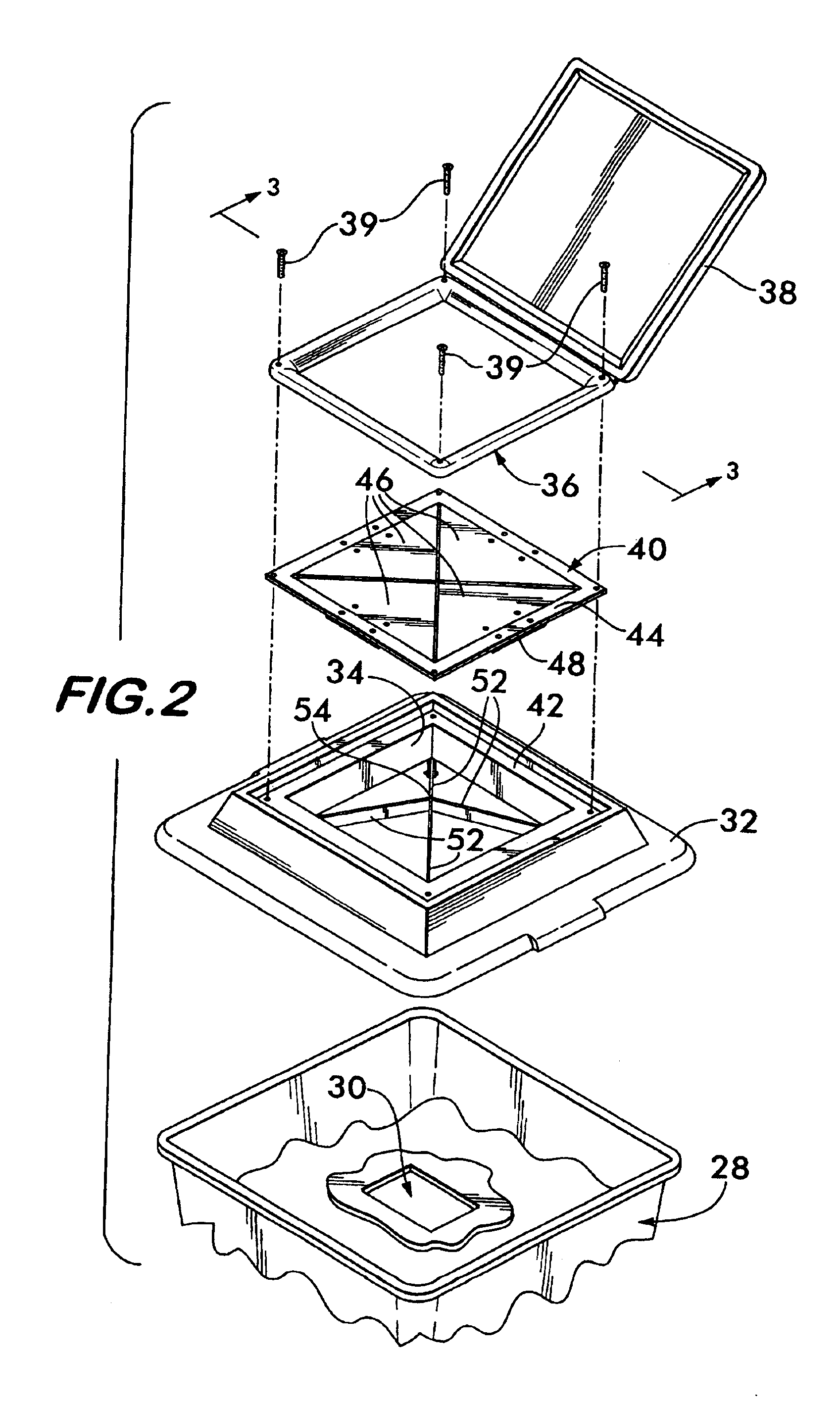

Seed metering gate assembly

Owner:RENOVATORS LLC

Packages for dispensing flowable materials and dispensing systems using such packages

A system for dispensing flowable materials from a package. The system basically comprises the package and a receiver apparatus. The receiver apparatus includes a hollow interior chamber, e.g., a hopper, a penetrating assembly e.g., plural blades, fixedly mounted with respect to the chamber, and an outlet. The package, e.g., a flexible package, has a handle and a hollow interior in which the flowable material is located and includes at least one wall portion, e.g., a bottom wall, arranged to be penetrated by the penetrating assembly, whereupon the flowable material is enabled to flow out of the package for ultimate dispensing out of an outlet of the chamber. The flexible package may include an outer carton.

Owner:FRES SYST USA

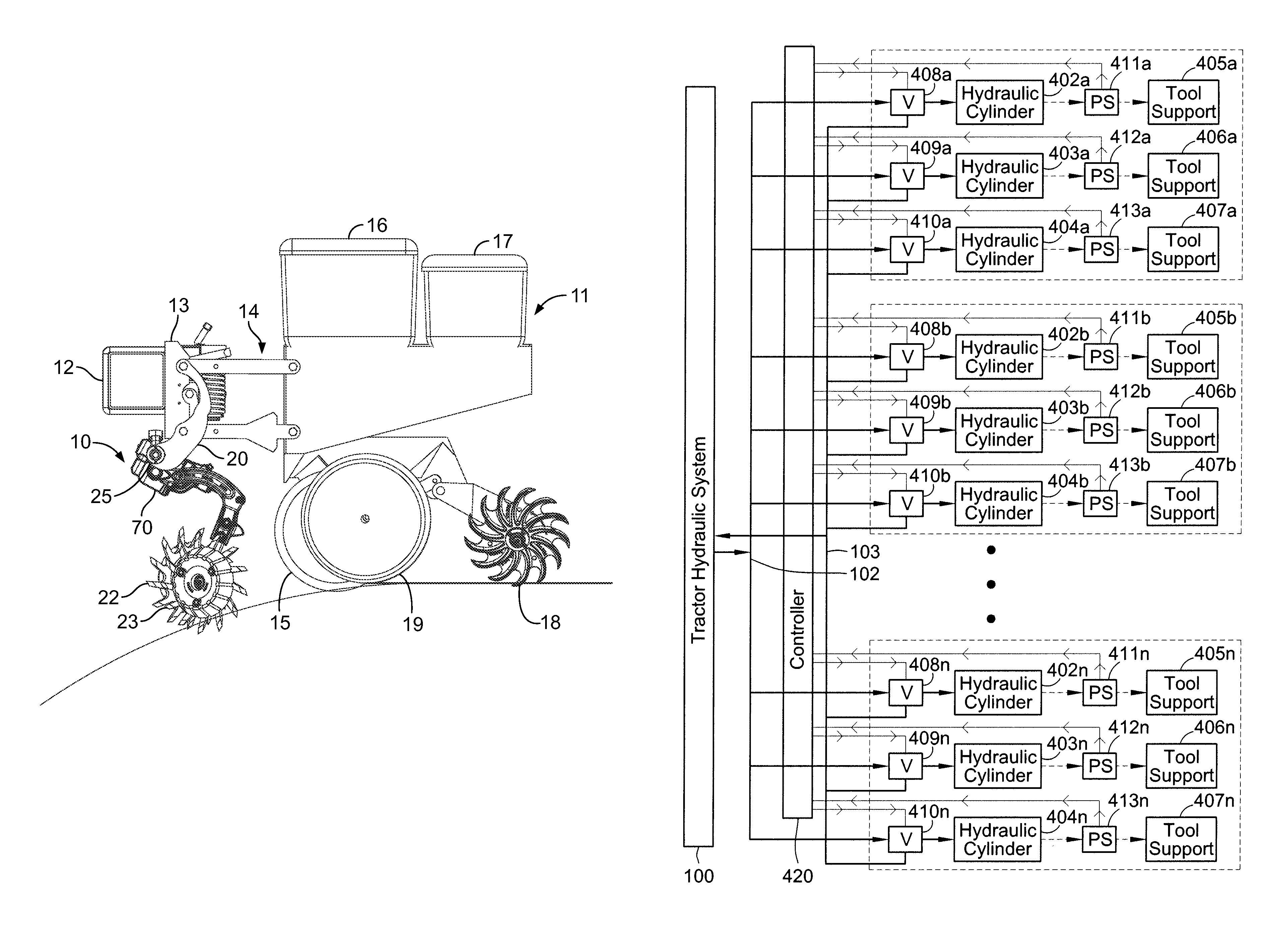

Manual backup system for controlling fluid flow to cylinders within an agricultural implement

An agricultural implement system is provided that includes a down force cylinder configured to apply a downward force to a row unit, a depth control cylinder configured to vary a penetration depth of a ground engaging tool of the row unit, a press wheel cylinder configured to vary contact force between a press wheel and a soil surface, a closing disk cylinder configured to vary contact force between a closing disk and the soil surface, a residue manager cylinder configured to vary contact force between a residue manager and the soil surface, or a combination thereof. The agricultural implement system also includes an electronic control unit configured to automatically regulate a pressure within the cylinders, and a manual backup system configured to facilitate manual pressure adjustment of the cylinders.

Owner:CNH IND AMERICA LLC

Agricultural implement with automatic down pressure control

Owner:DAWN EQUIPMENT COMPANY

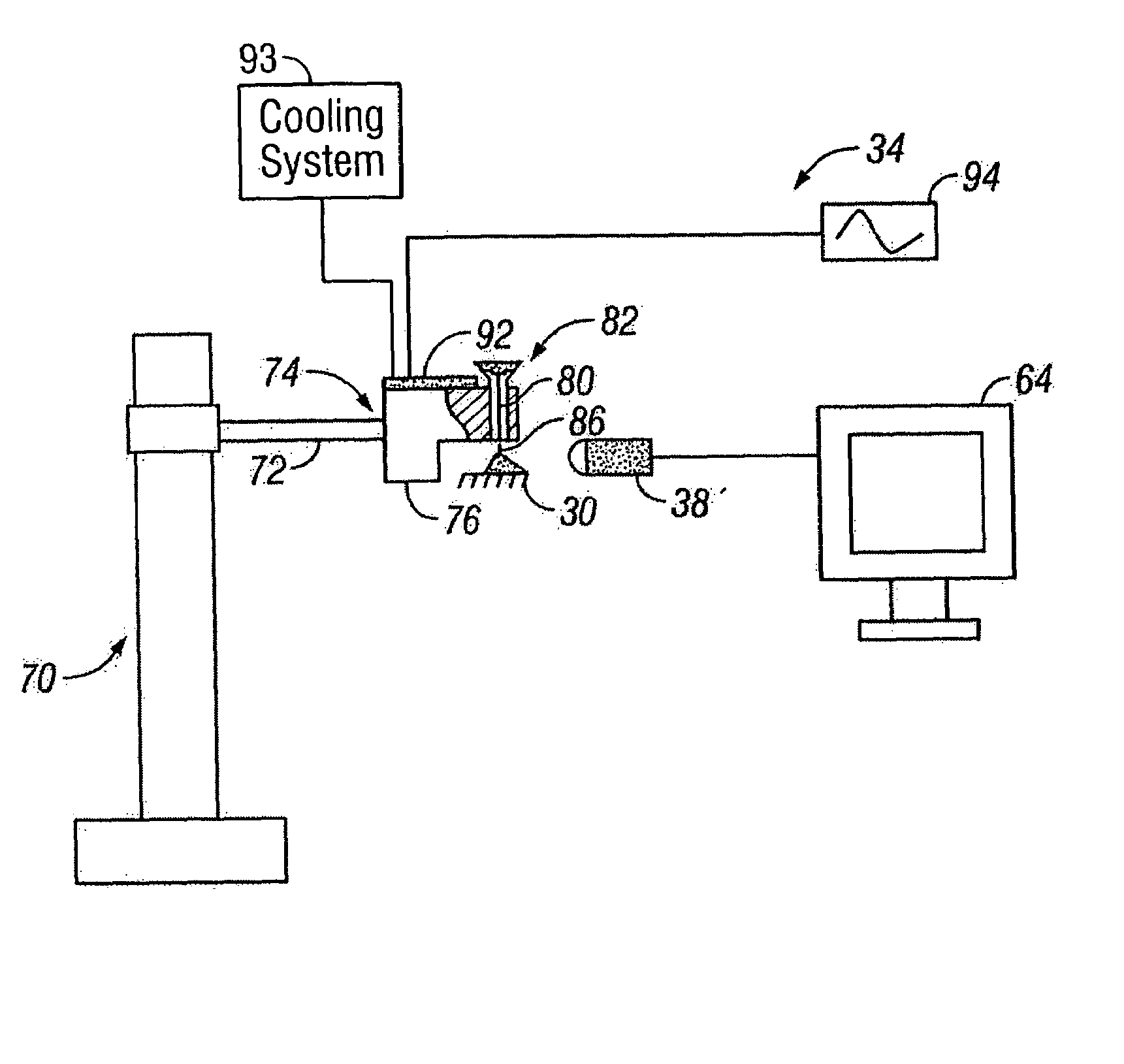

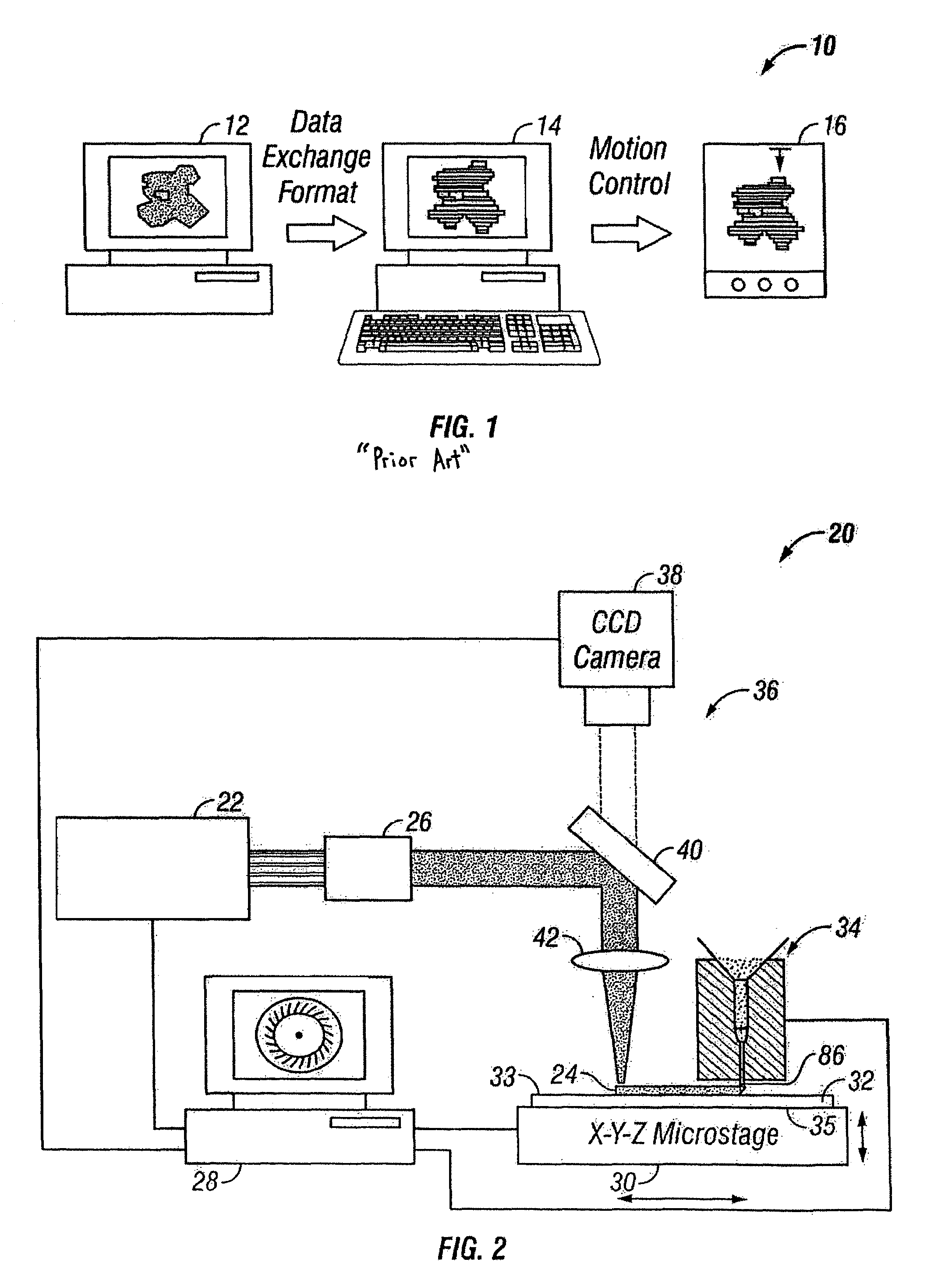

Apparatus and method of dispensing small-scale powders

InactiveUS7316748B2Facilitate depositionIncrease flow rateDispensing apparatusPretreated surfacesUltrasonic vibrationEngineering

An apparatus and method of dispensing small-scale powders for a variety of applications, including, for example, fabricating a three-dimensional heterogeneous small-scale device, includes using a feed mechanism that causes motion of the powder particles and the steps of depositing fine heterogeneous materials (such as dry powders and biological materials) towards a substrate. The depositing step preferably includes providing a feed mechanism having an input to receive the material, an output, and a source of ultrasonic vibration to impart a torsional force on the material so as to precisely discharge the material from the output. To improve particle flowability, a cooling system is provided to cool the source, generally above a threshold input voltage.

Owner:WISCONSIN ALUMNI RES FOUND

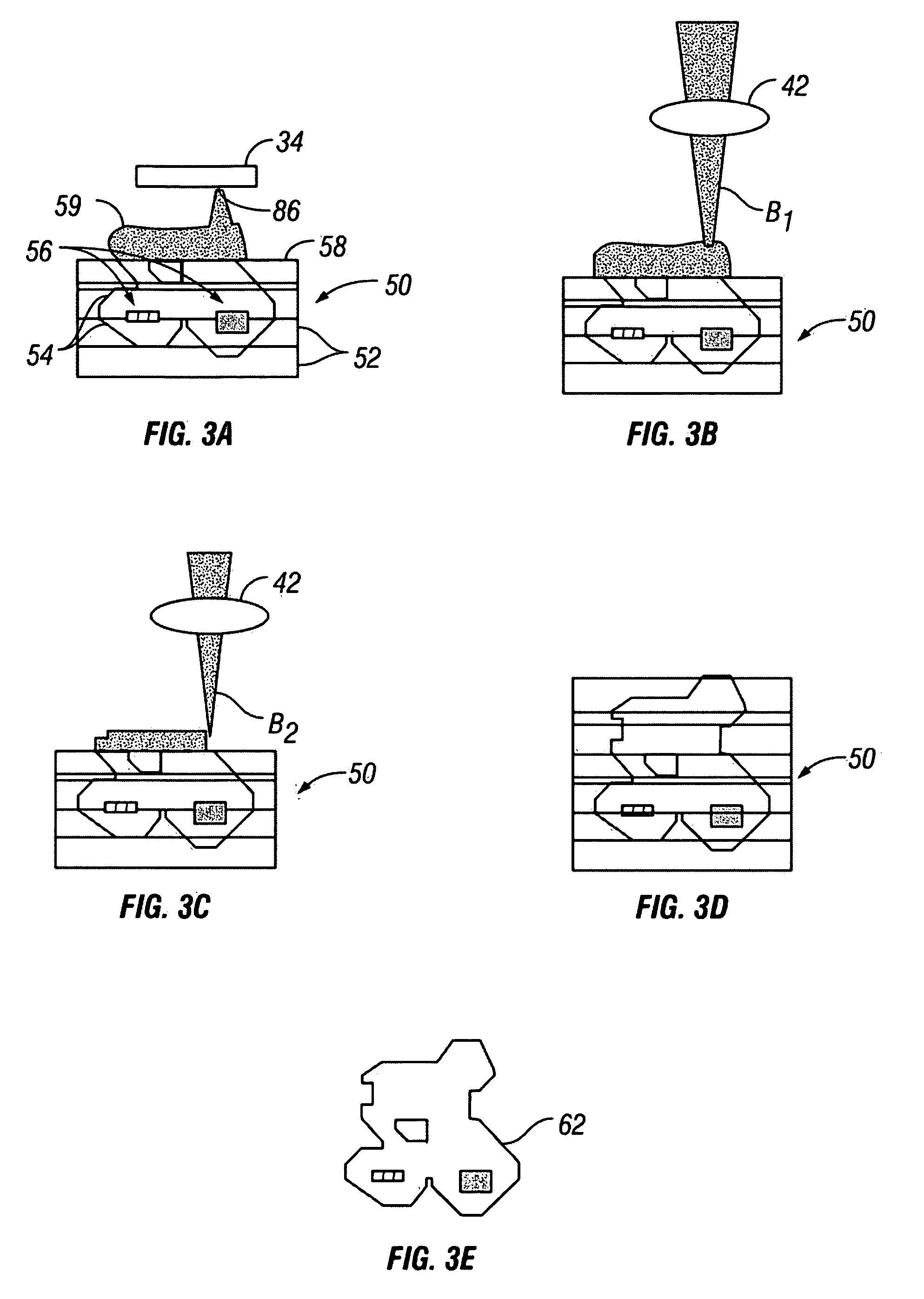

Automatic down pressure adjustment system for set of ganged disc openers

A disc opener unit for an agricultural implement has a down pressure adjustment device that automatically adjusts the amount of down pressure applied on a furrowing disc based on strain measurements taken by a strain gauge or load cell. The strain gauge, which may be mounted to an arm that is used to set the position of a depth setting gauge wheel, provides feedback to a processor that in turn controls the amount of hydraulic fluid in a hydraulic cylinder to adjust the down force applied on the disc. The amount of down pressure is therefore adjusted in substantially real-time in response to changes in field conditions, which improves furrow depth consistency and reduces wear on the gauge wheel and its components.

Owner:CNH IND CANADA

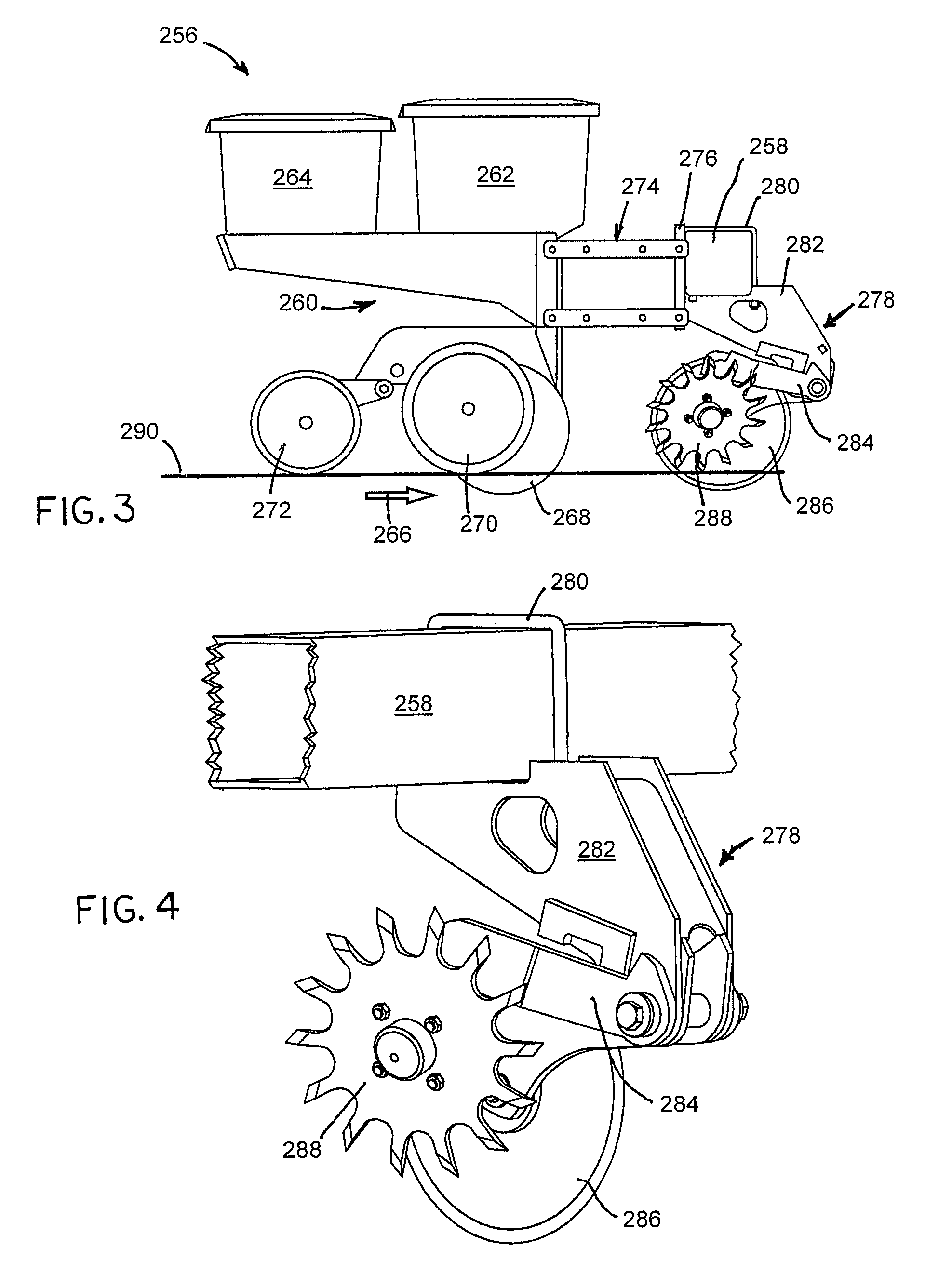

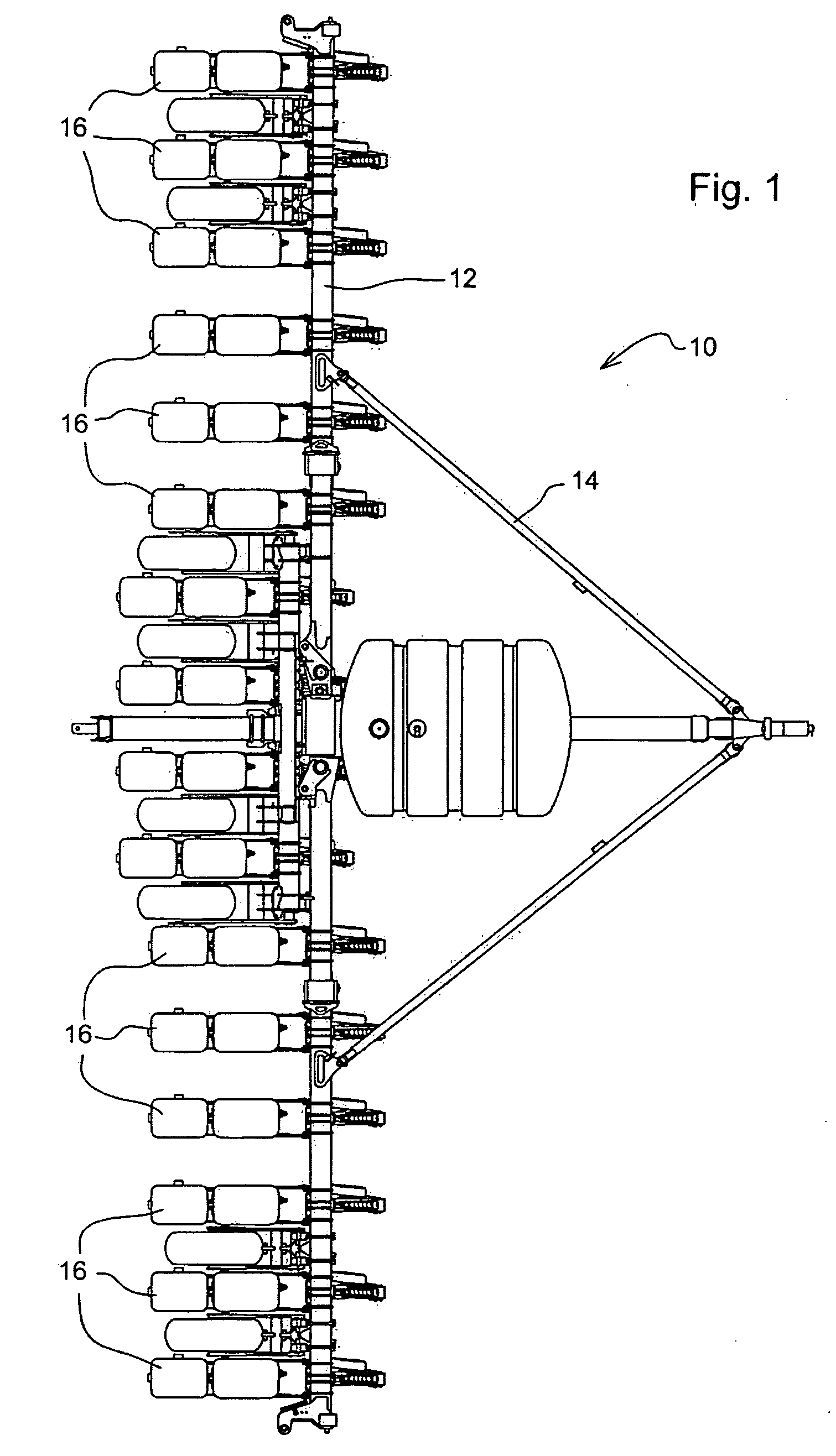

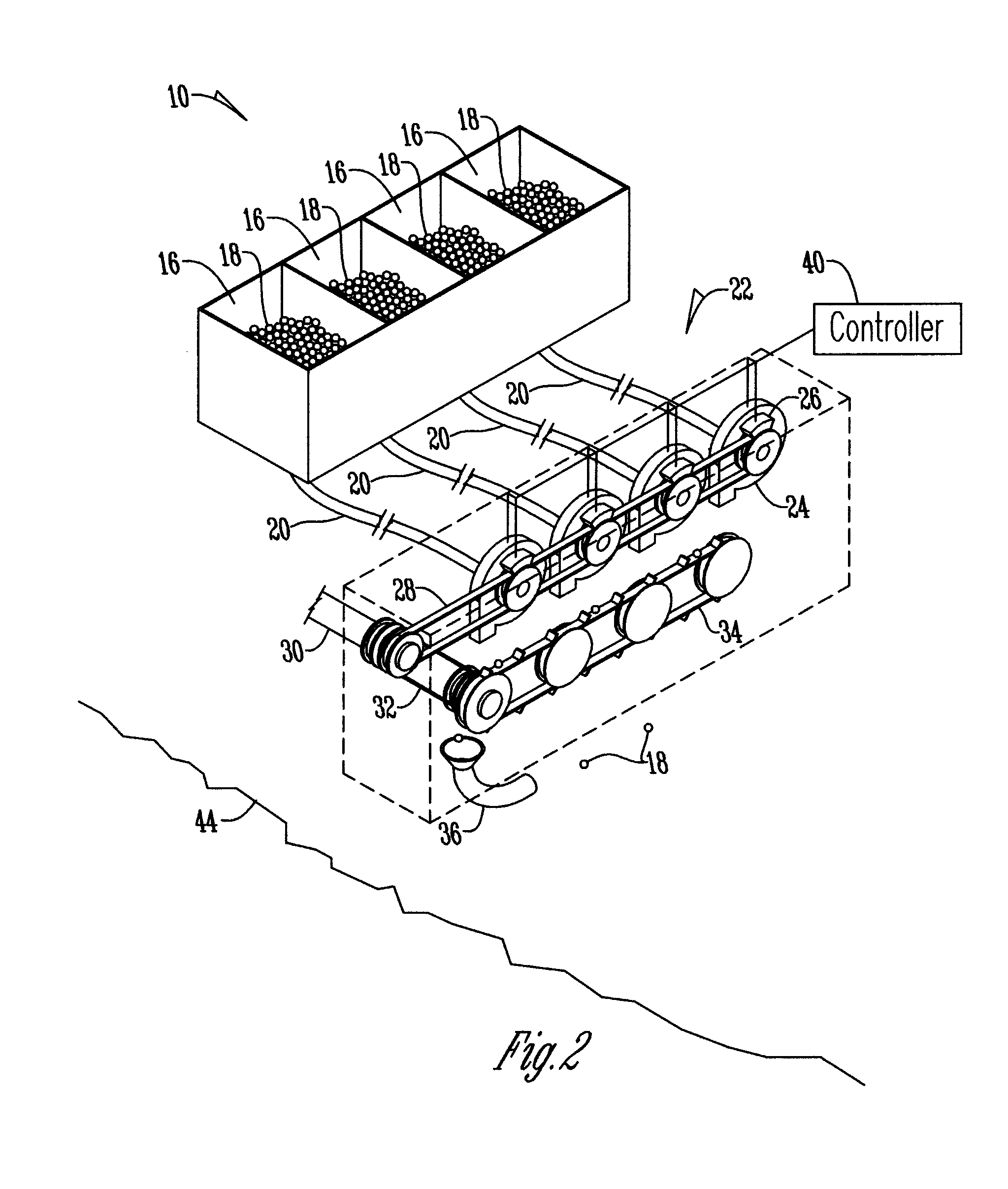

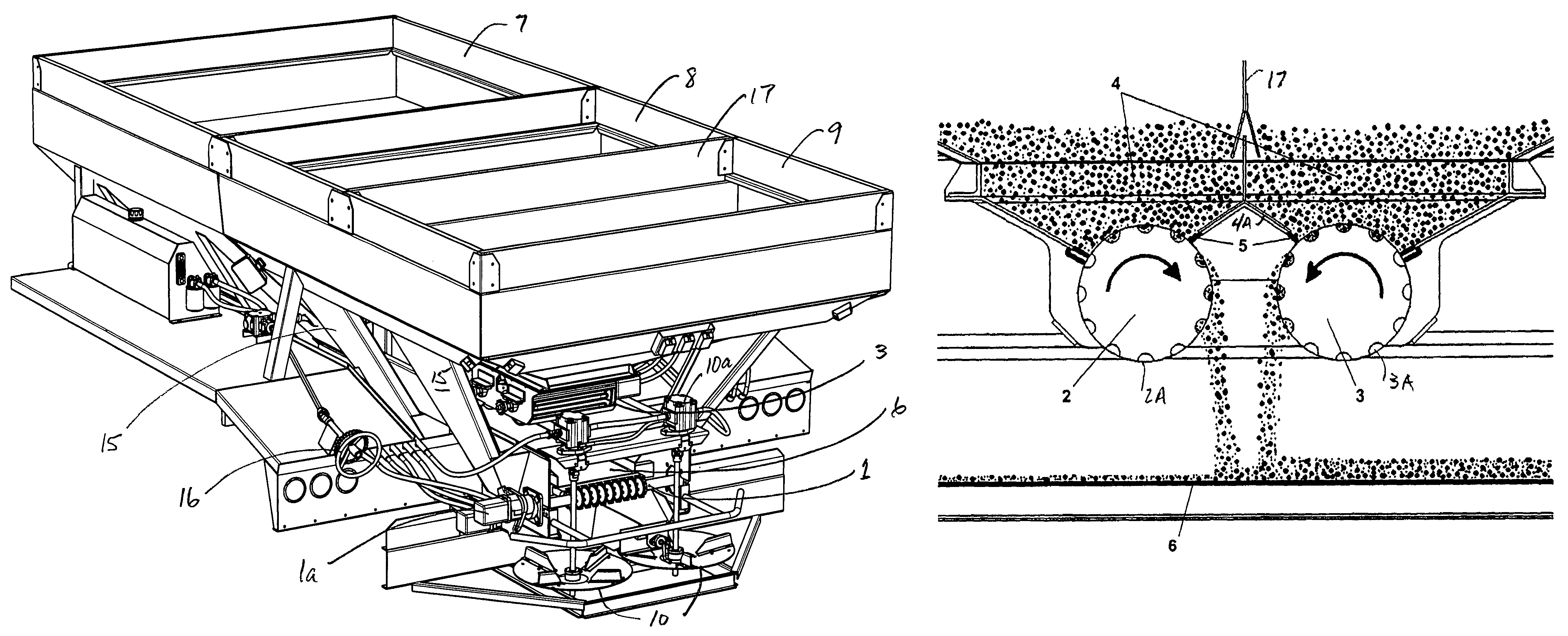

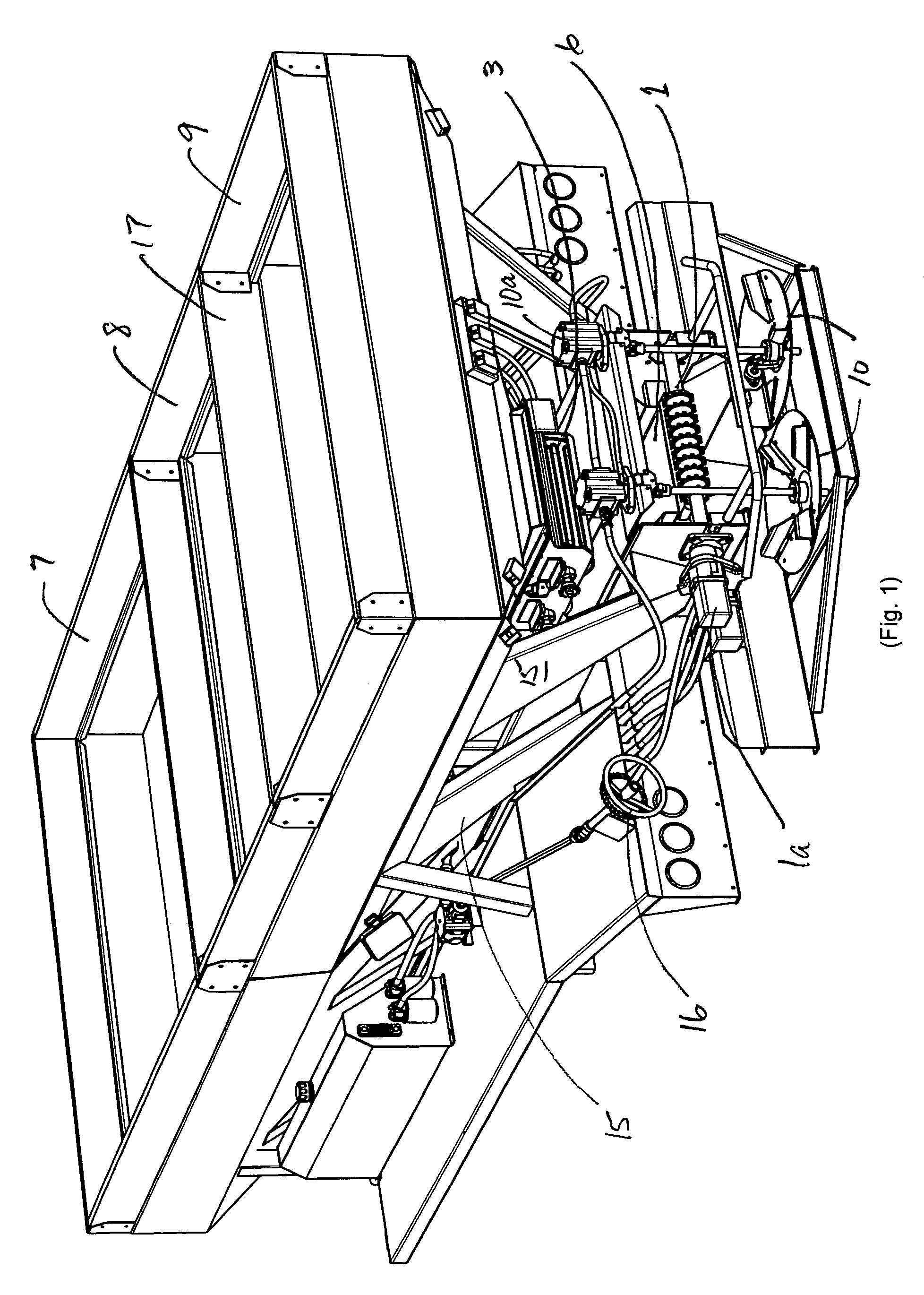

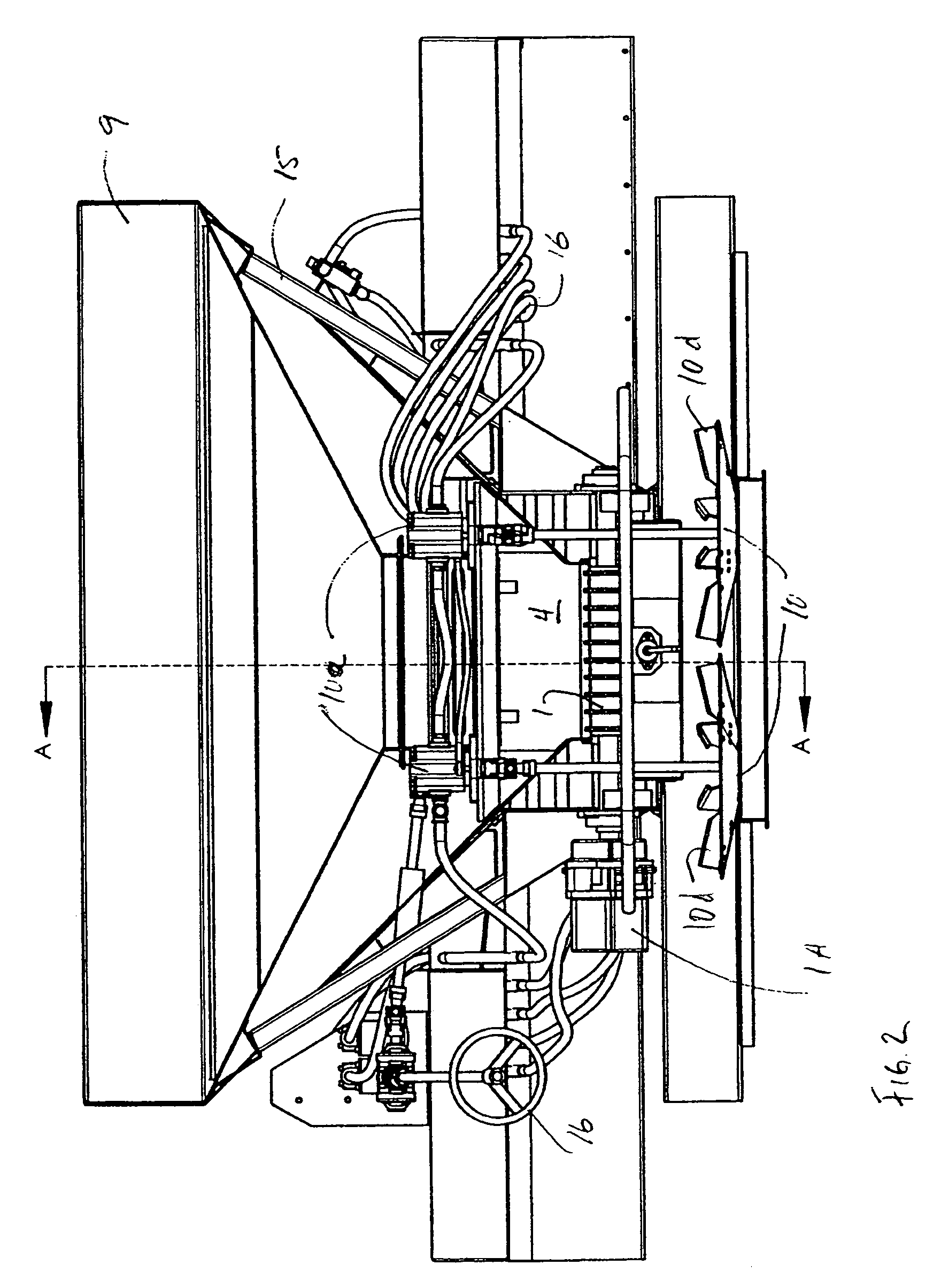

Plural bin metering system

ActiveUS7380733B2Low costLess-expensive to maintainFertiliser distributersCentrifugal wheel fertilisersOne passEngineering

A plural bin metering system for broadcasting material ingredients contained therein over a ground surface. The system includes at least two material ingredient hoppers, each of the hoppers having a material ingredient discharge port. At least one of the material ingredient hoppers includes a variably controllable metering unit associated therewith for variably controlling the discharge of material ingredients therefrom independently from the rate of discharge of material ingredients from the other material ingredient hopper. A conveyor is disposed below the hoppers for receiving material ingredients discharged from the hoppers, and a material ingredient broadcasting device disposed off of one end of the conveyor for receiving material ingredients conveyed thereon, received from the hoppers, for broadcasting the material ingredients over a ground surface. The metering unit is capable of metering material ingredients from its associated hopper at ultra low rates. In a preferred embodiment the system has three hoppers for broadcasting, for example fertilizer across a field in one pass.

Owner:SALFORD BBI

Sectional meter shut-off and agricultural implement having sectional meter shut-off

ActiveUS8141504B2Fertiliser distributersAgriculture and animal husbandary industrySeederMaterial supply

An assembly for selectively supplying particulate material to an air seeder, an agricultural implement able to selectively supply and dispense particulate material into the ground and a method of selectively dispensing particulate material into the ground are provided. The assembly has at least one supply receptacle for receiving particulate material from a source and a metering roller for supplying the material to an air seeder. The assembly is operative to selectively supply the material to the air seeder and prevent the material from being supplied to the air seeder. The implement can use the assembly to selectively supply particulate material to ground engaging openers where the particulate material will be dispensed into the ground. Particulate material can be selectively supplied to the implement when it is desired to have the particulate material dispensed into the ground and then prevented from being supplied to the implement when it is not desirable.

Owner:ONE PASS IMPLEMENTS

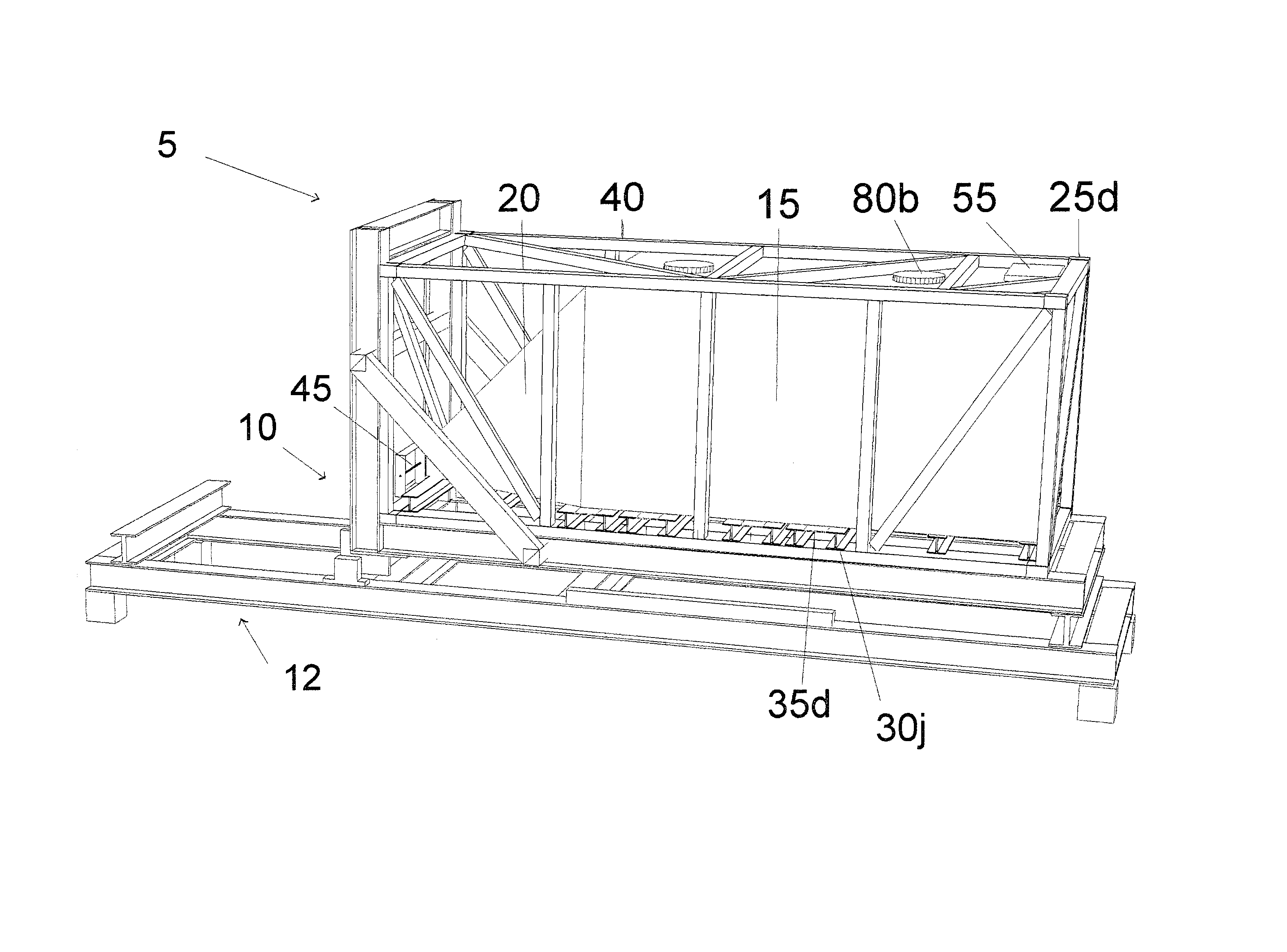

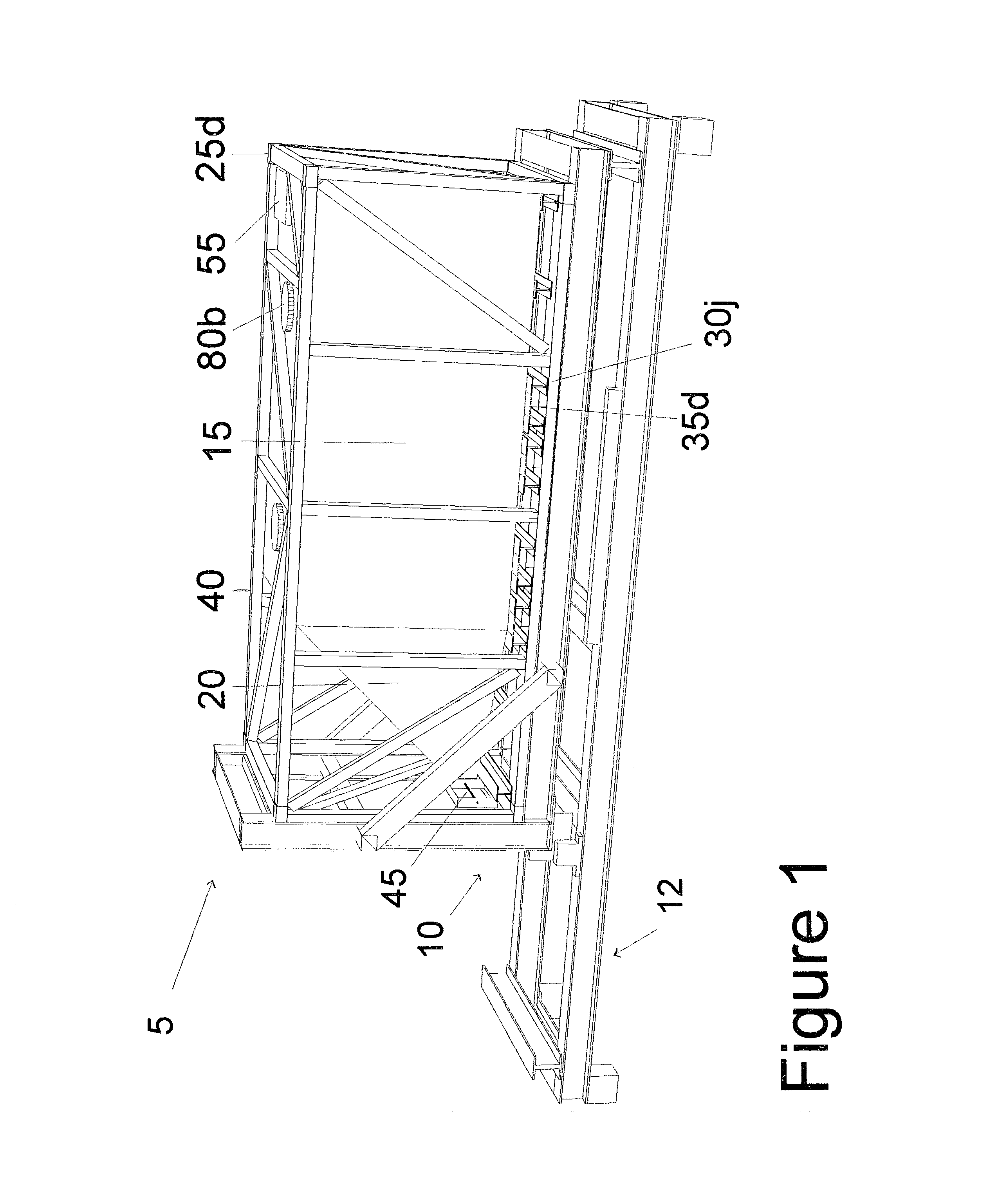

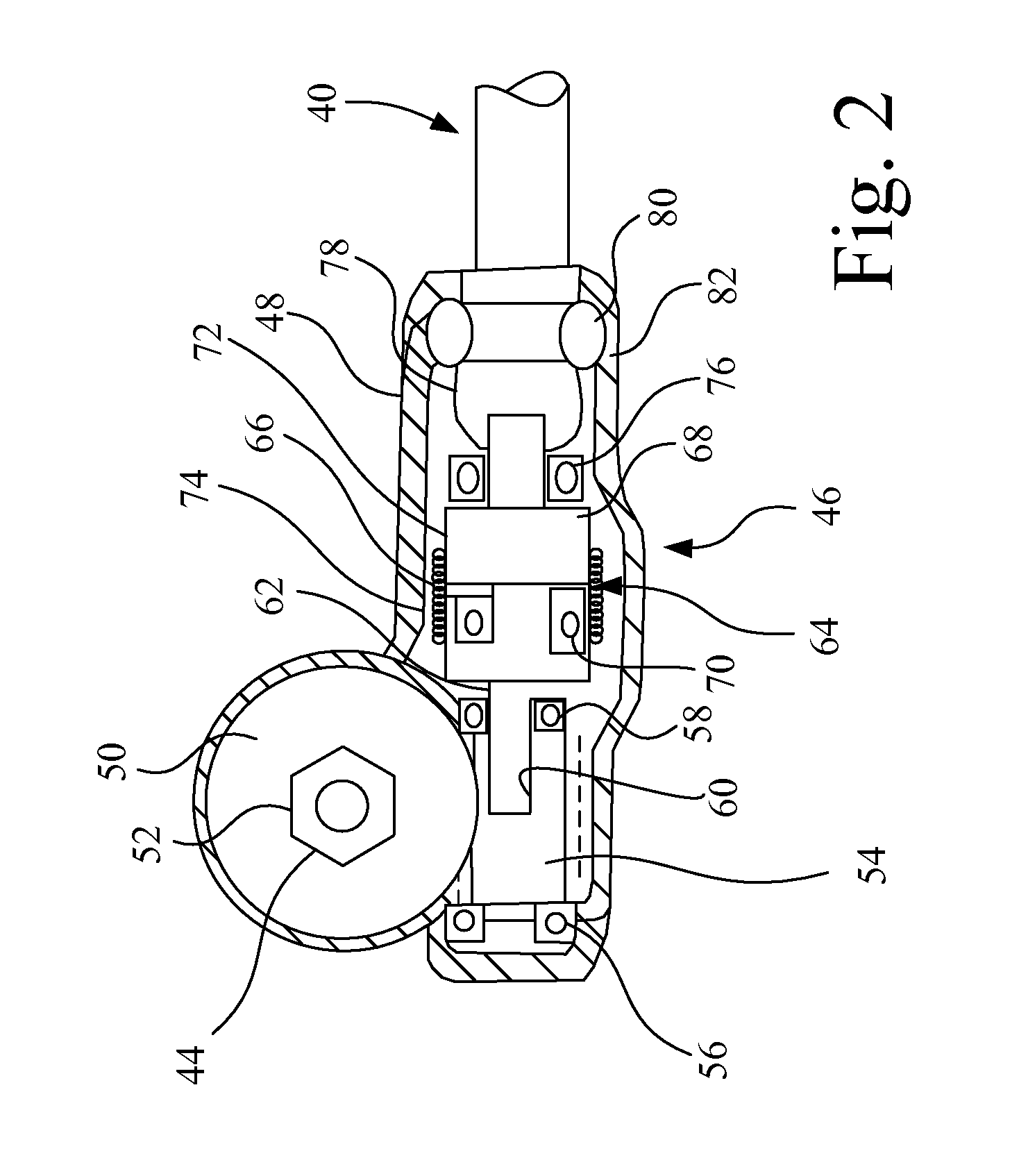

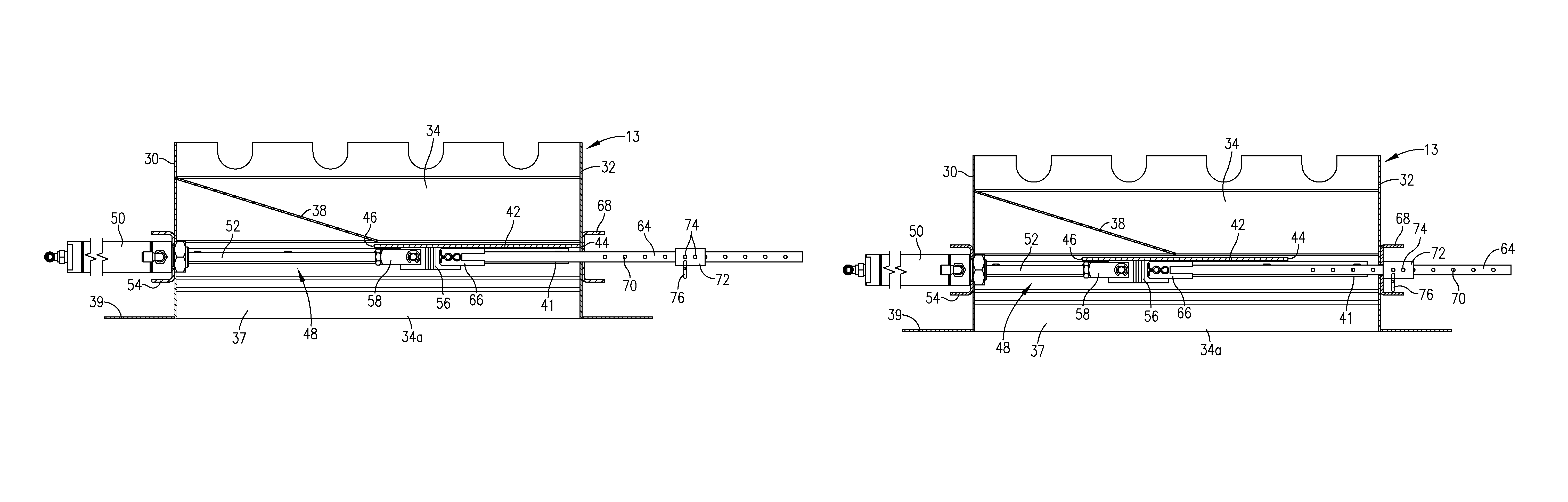

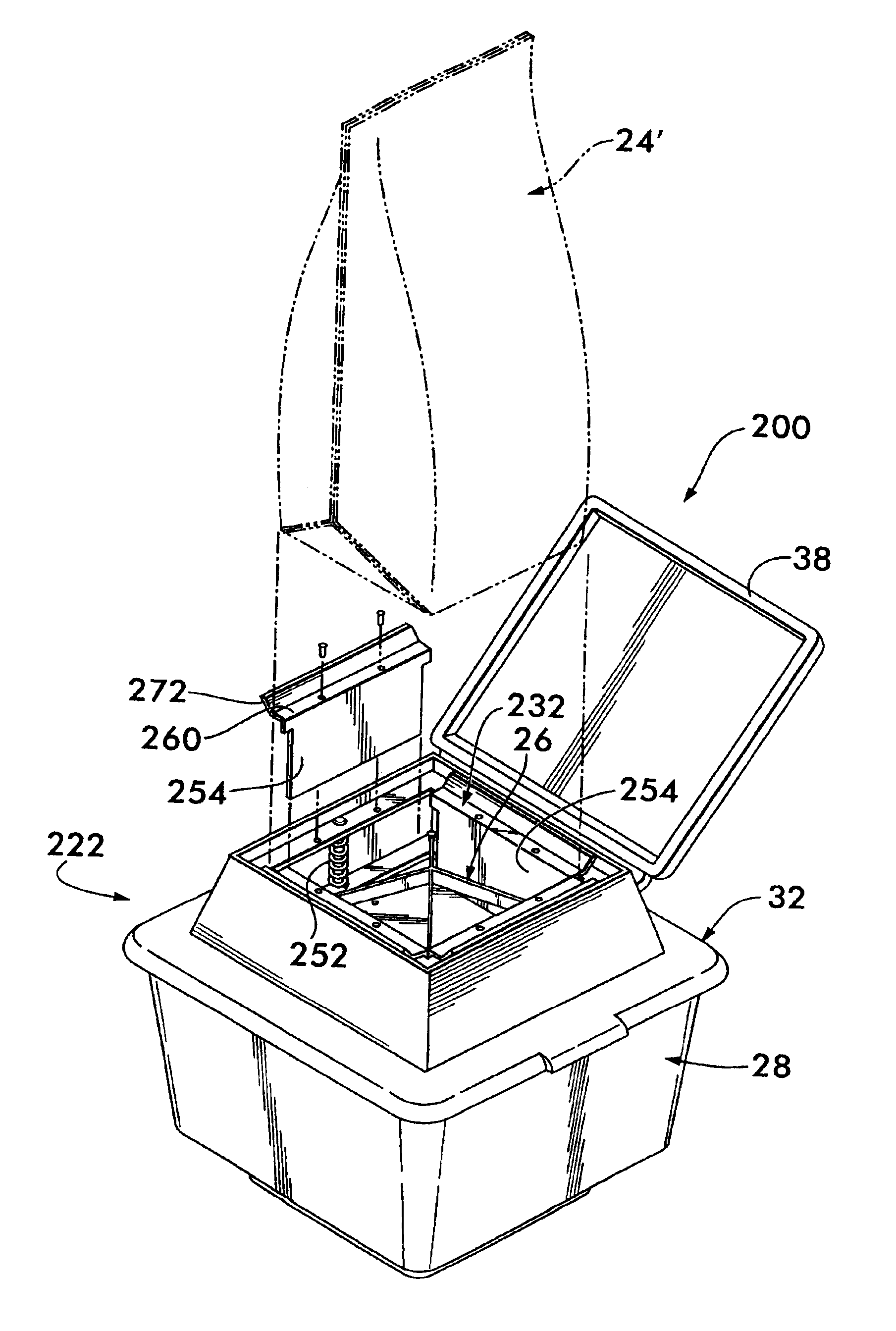

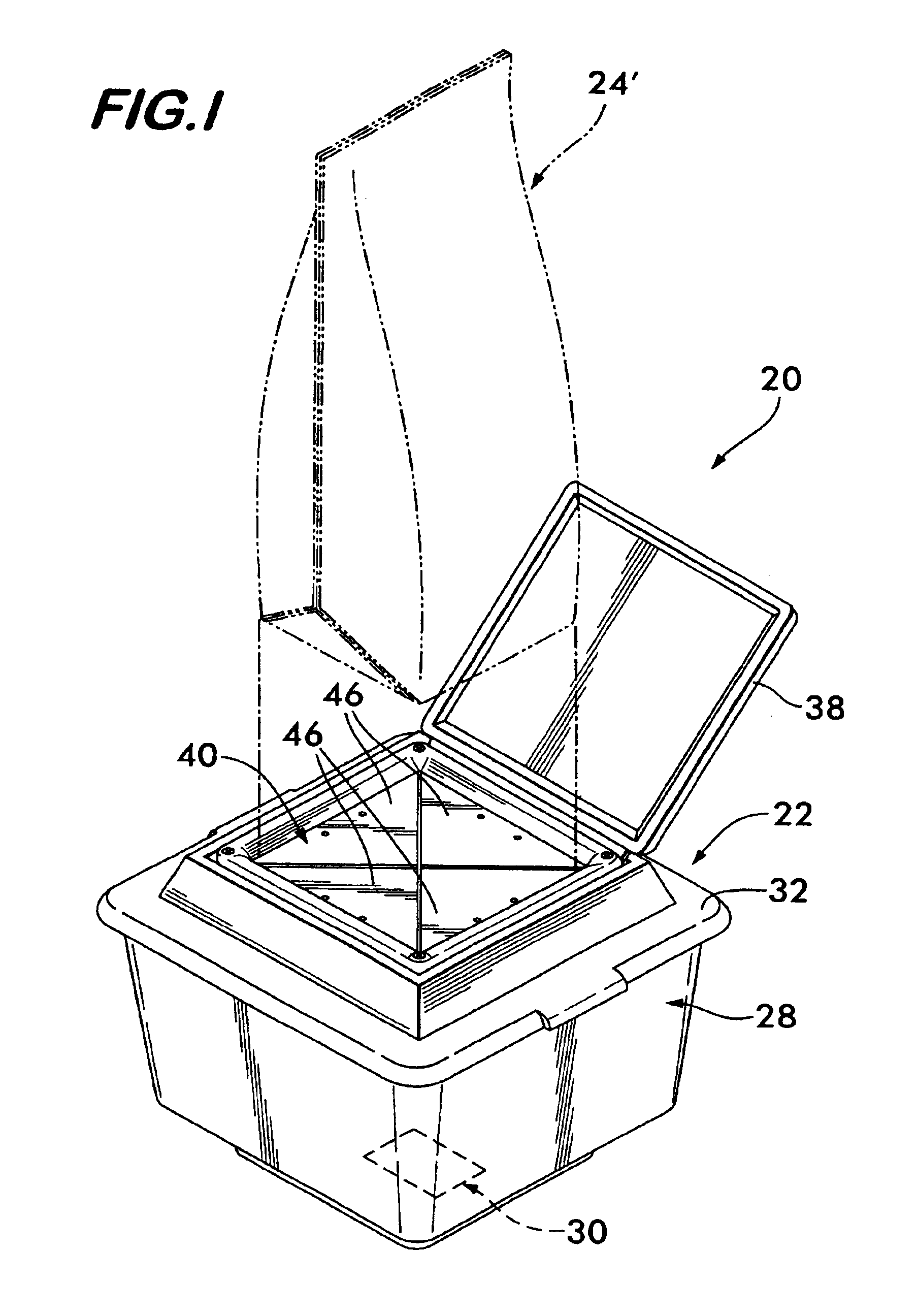

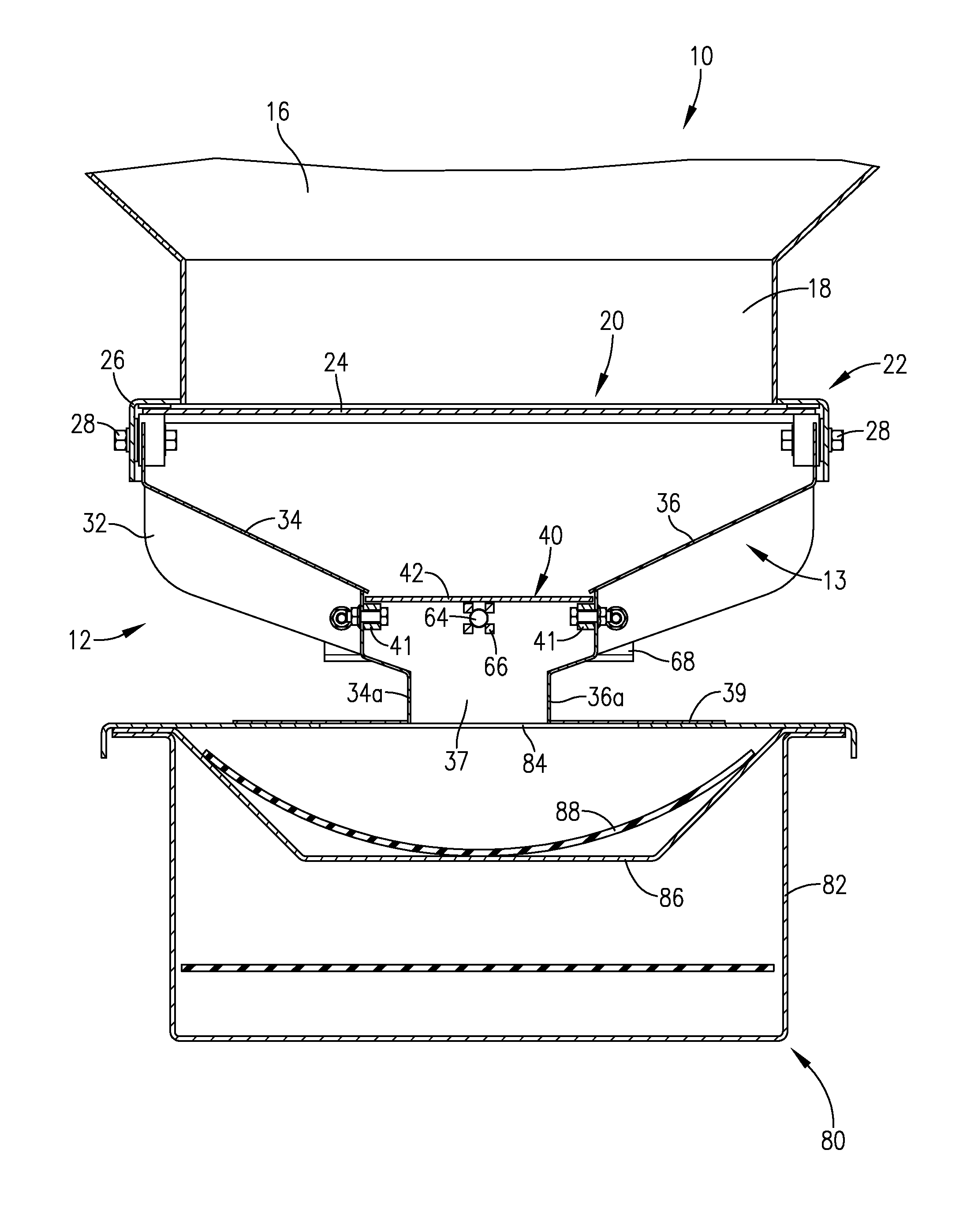

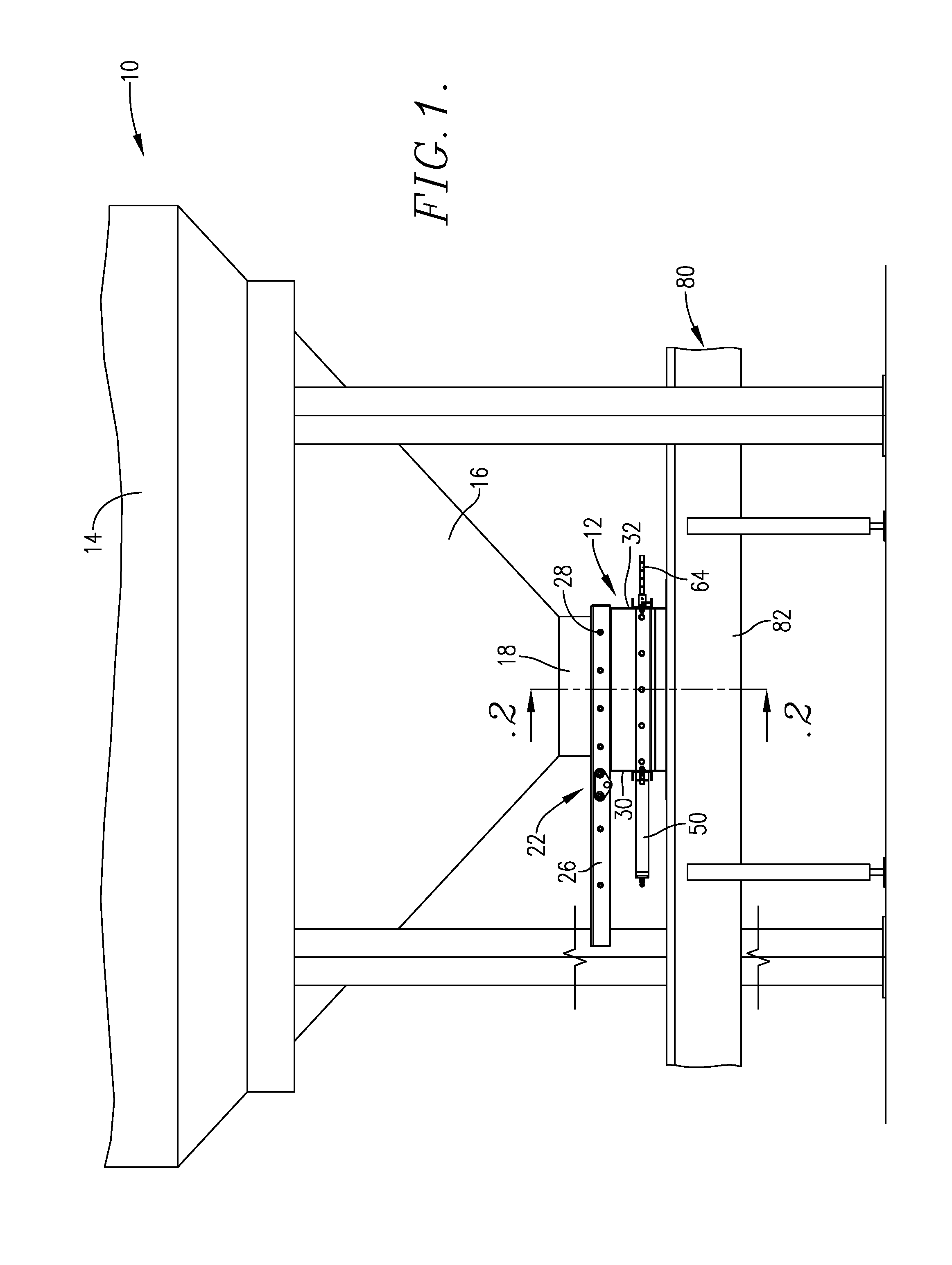

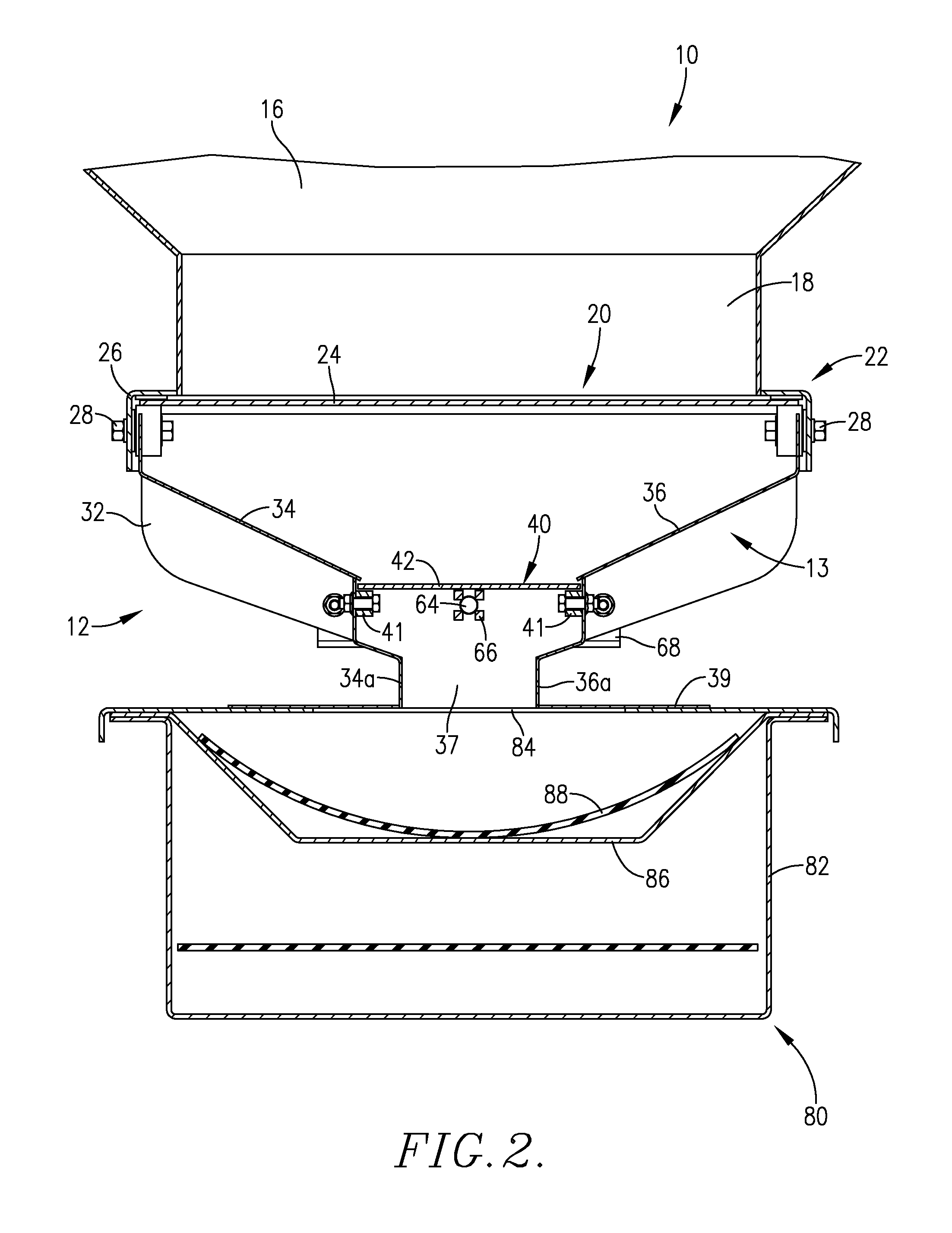

Seed metering gate assembly

A seed metering gate assembly (12) is provided for use with an upright seed bin (10) having a shiftable primary gate (24), wherein the gate assembly (12) provides an additional seed flow control function allowing more accurate dispensing of seed from the bin (10). The gate assembly (12) includes a seed hopper (13) equipped with a fore and aft-shiftable metering gate (42) movable between a closed position and an open position presenting a seed output passageway (40). Apparatus (62) is operably coupled with the gate member (42) in order to determine the travel of metering gate member between the fully closed position and a plurality of open positions presenting respective, differently sized passageways (40). The apparatus (62) preferably includes a rod (64) having a series of through openings (70) and coupled with the gate member (42), with a shiftable, motion-limiting collar (72) mounted on the rod (64) and securable at any of the openings (70) by means of clip (76). The opening movement of the rod (64) is limited by engagement between the collar (72) and a bracket (68) affixed to hopper (13).

Owner:USC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com