Patents

Literature

640 results about "Trailing arm" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A trailing-arm suspension, sometimes referred as trailing-link is a vehicle suspension design in which one or more arms (or "links") are connected between (and perpendicular to and forward of) the axle and a pivot point (located on the chassis of a motor vehicle). It is typically used on the rear axle of a motor vehicle. A leading arm, as used on the Citroën 2CV and the M422 Mighty Mite, has an arm connected between (and perpendicular to, and to the rear of) the axle and the chassis. It is used on the front axle.

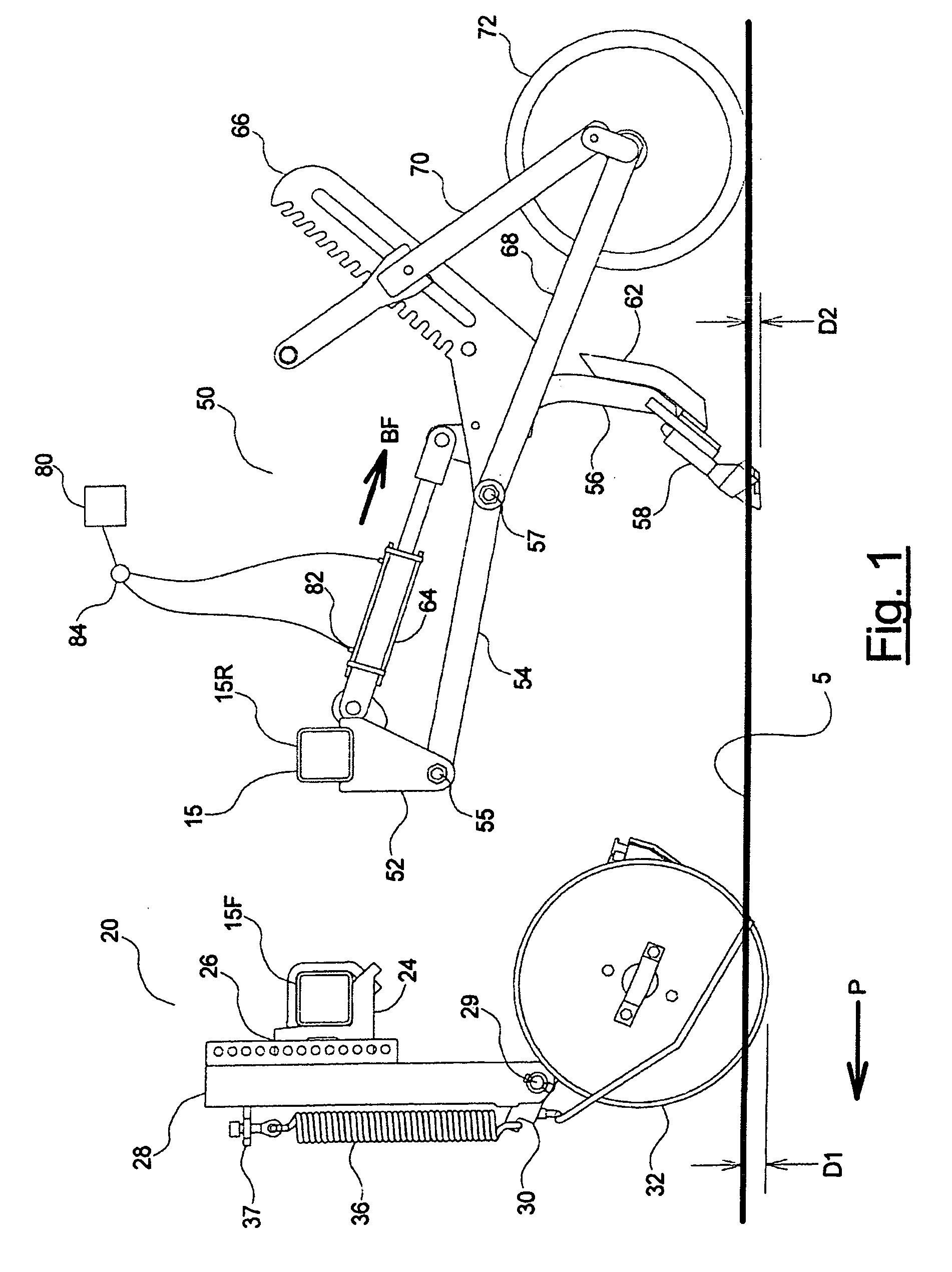

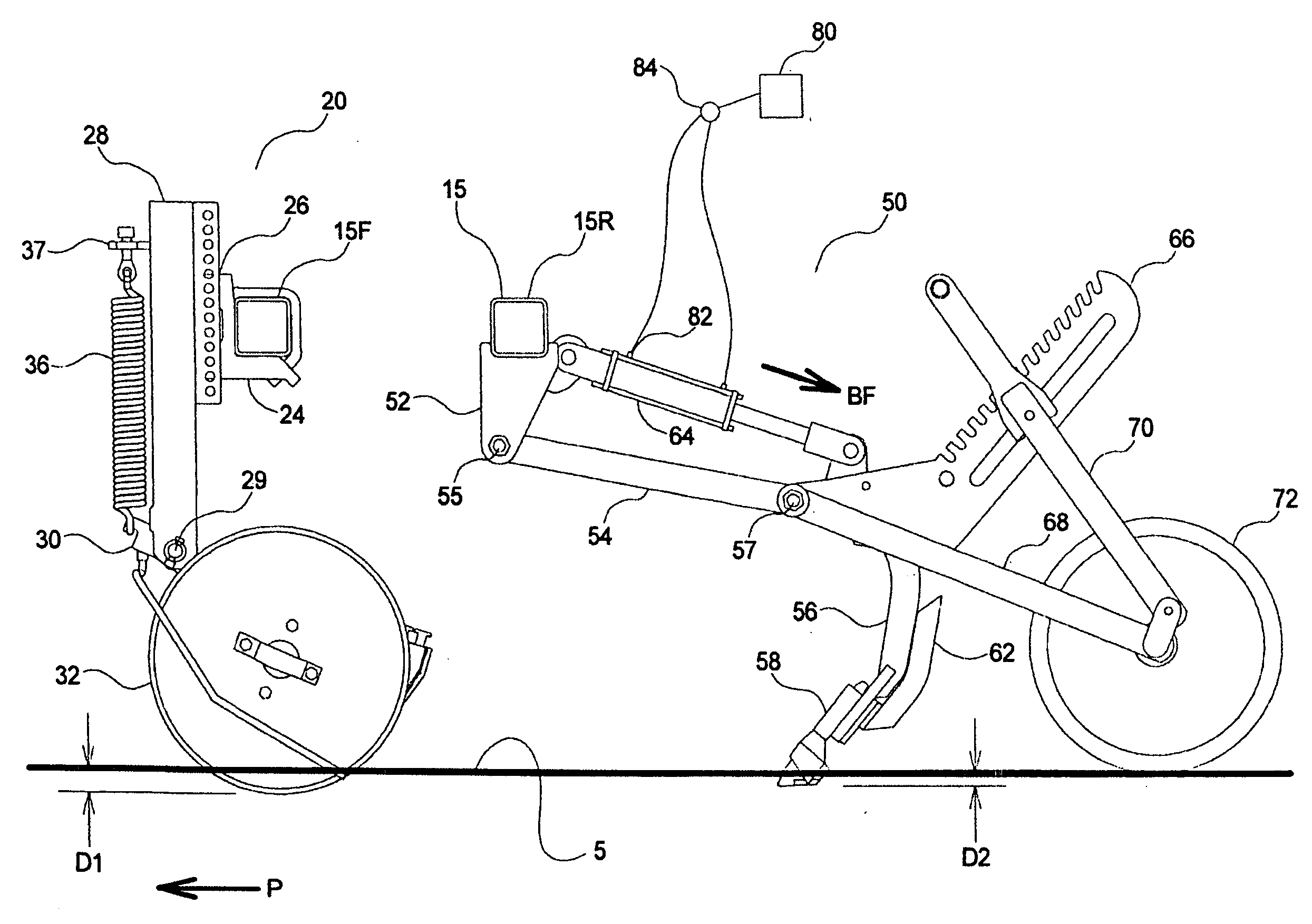

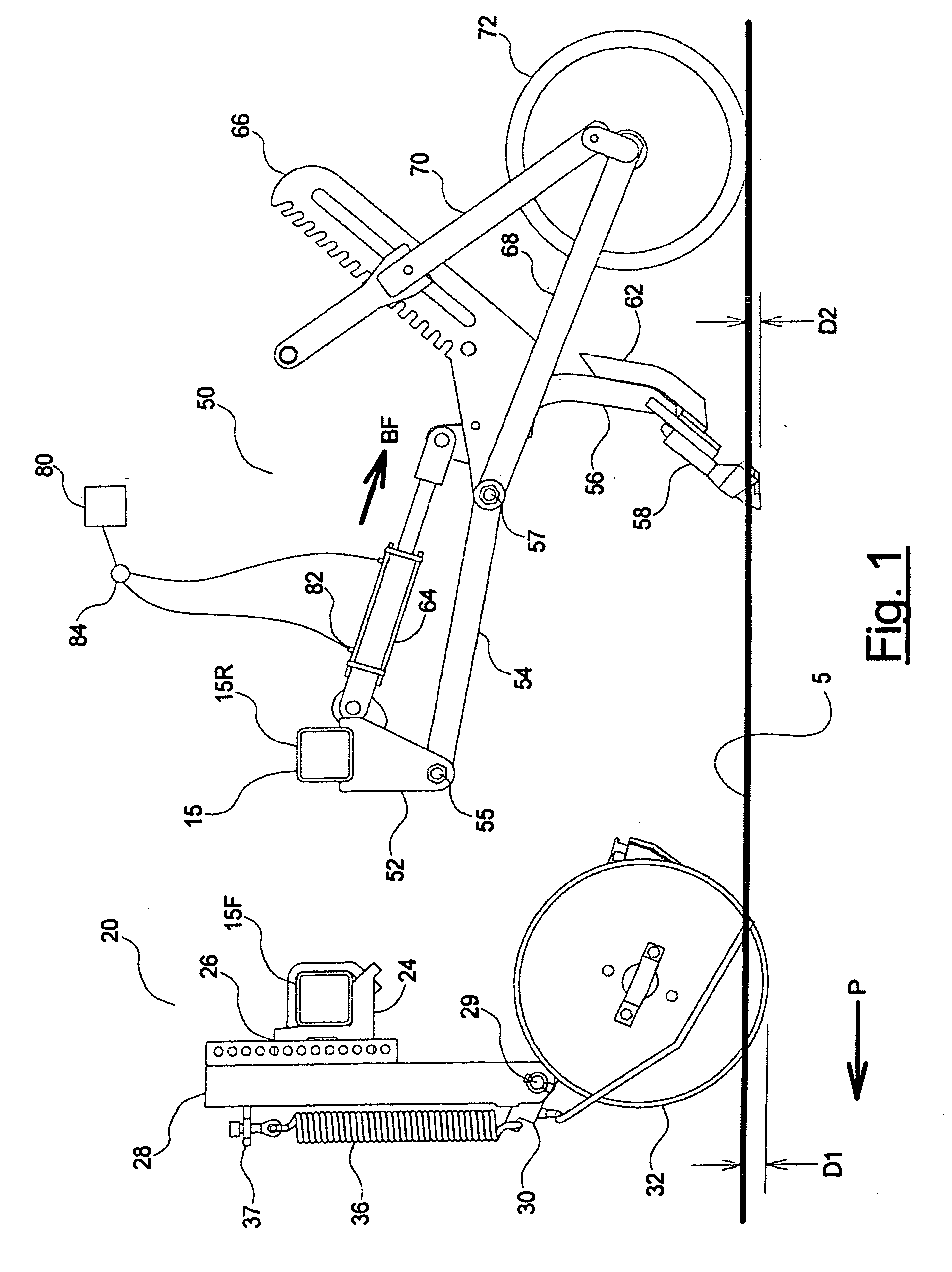

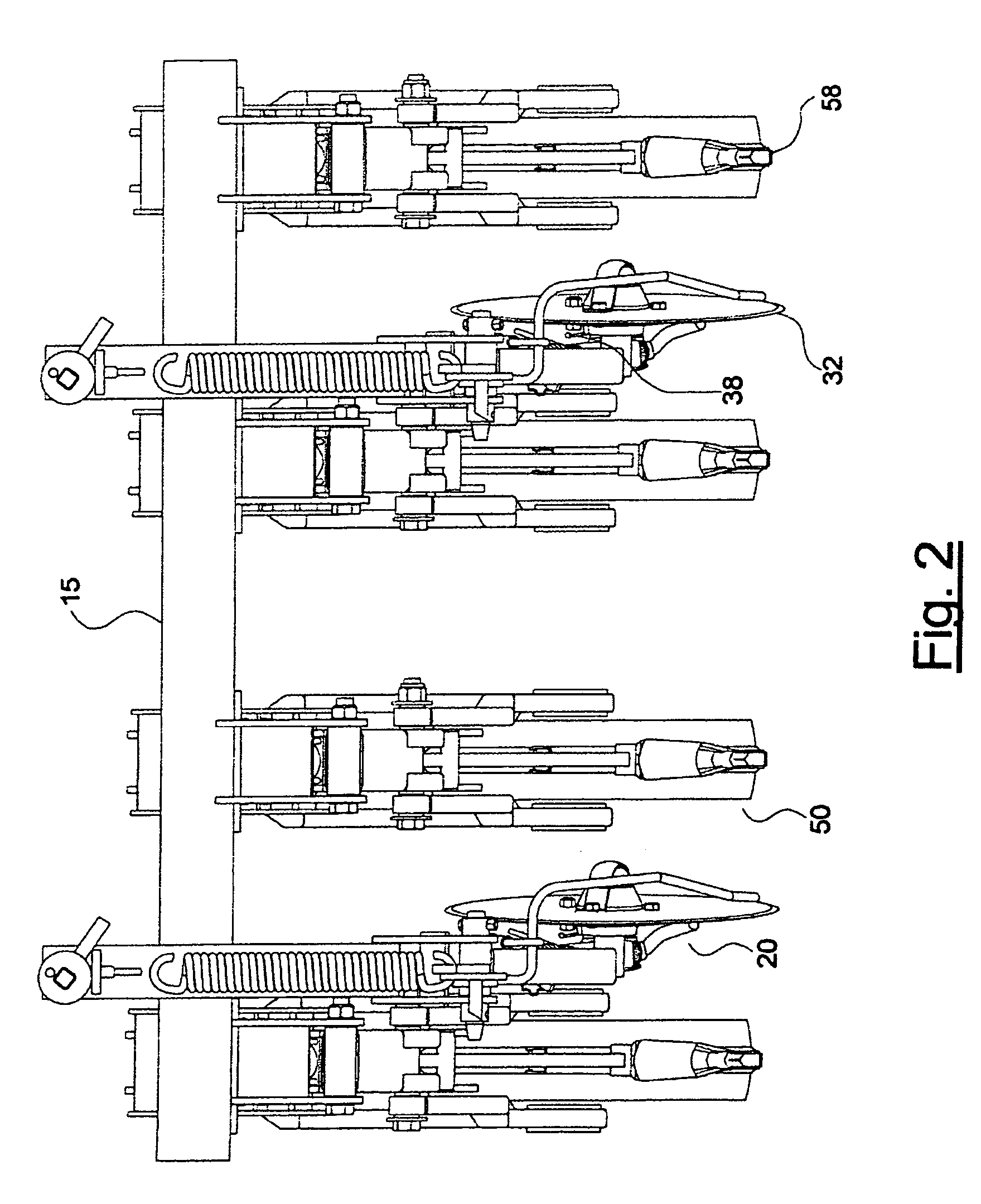

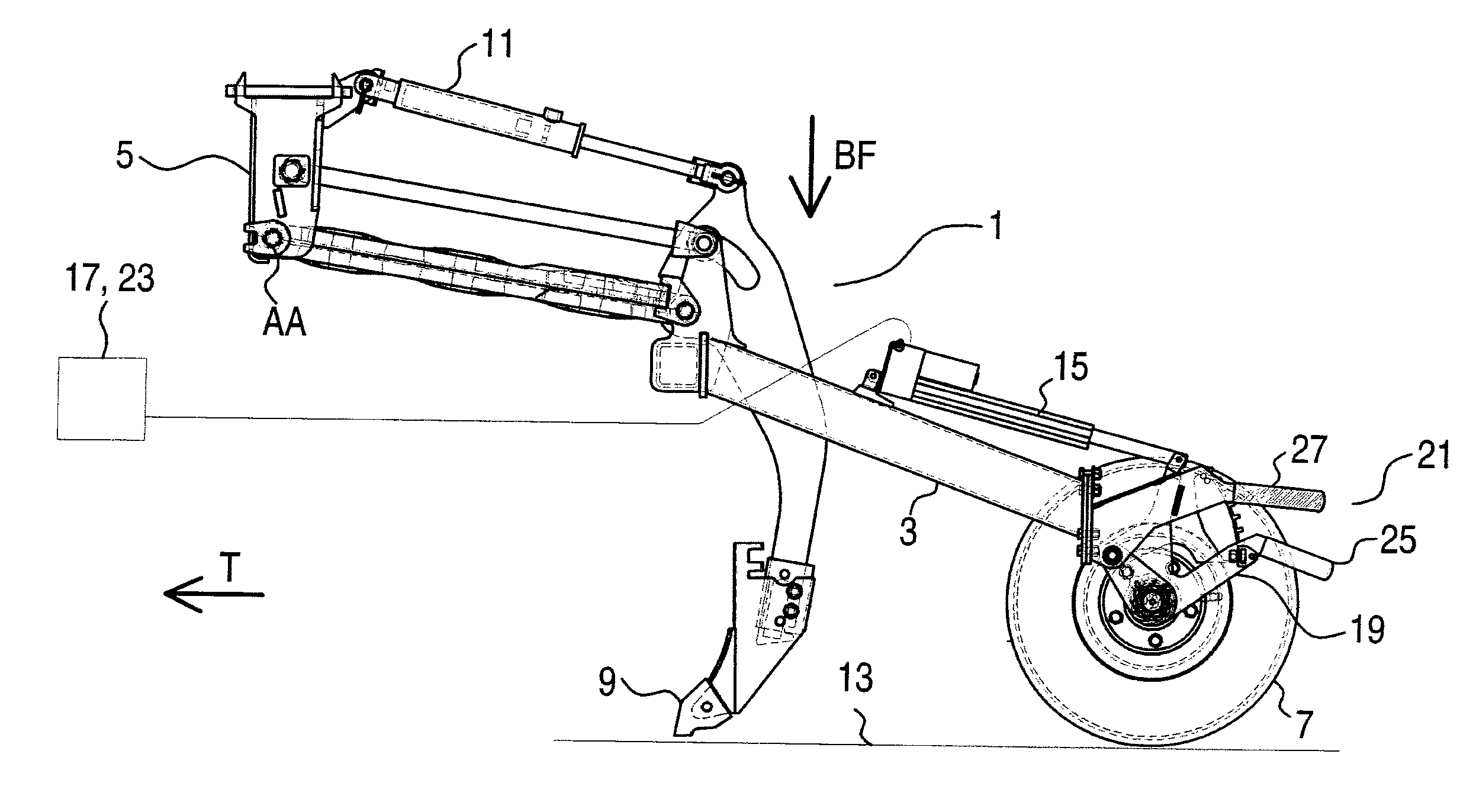

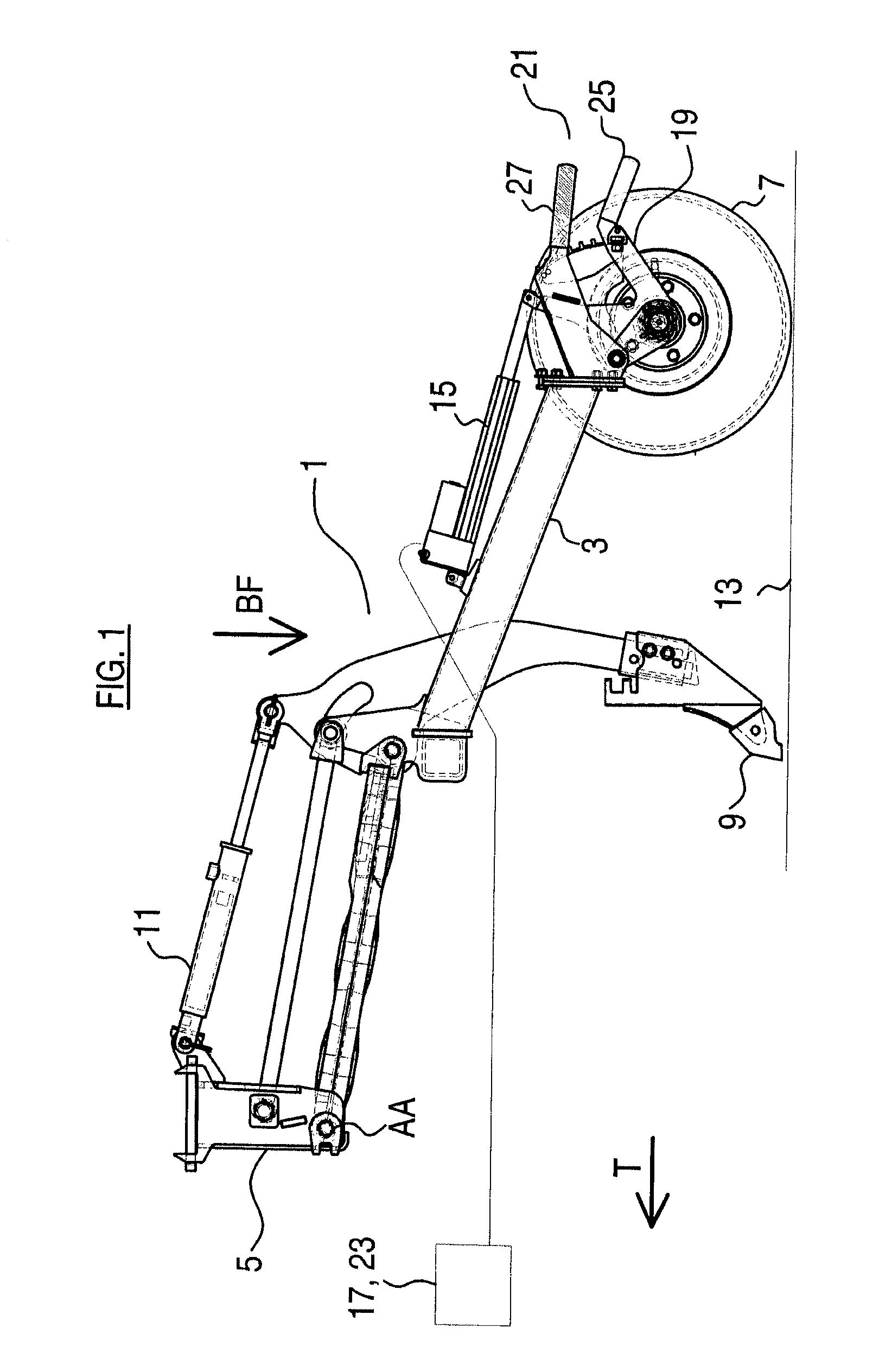

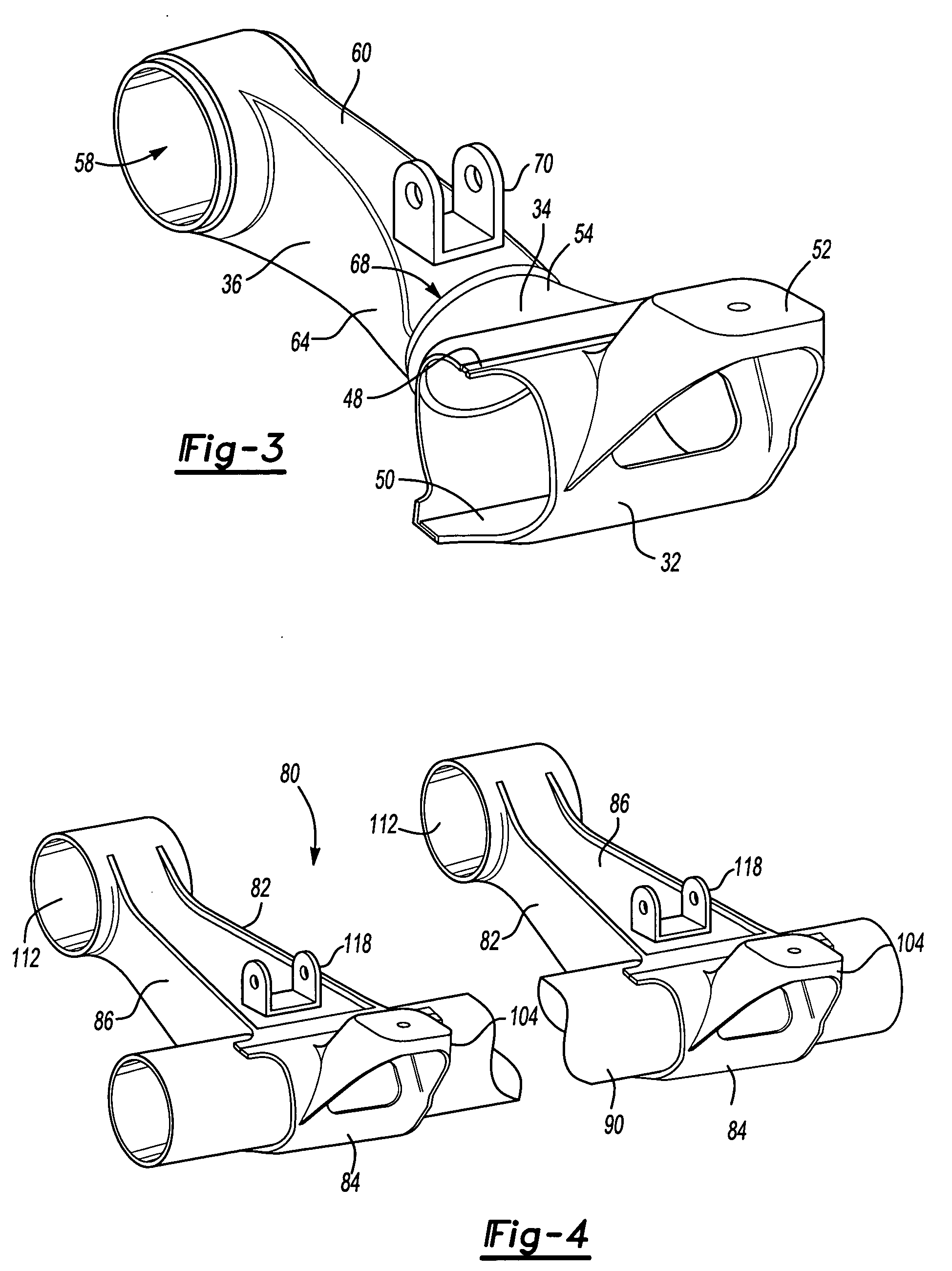

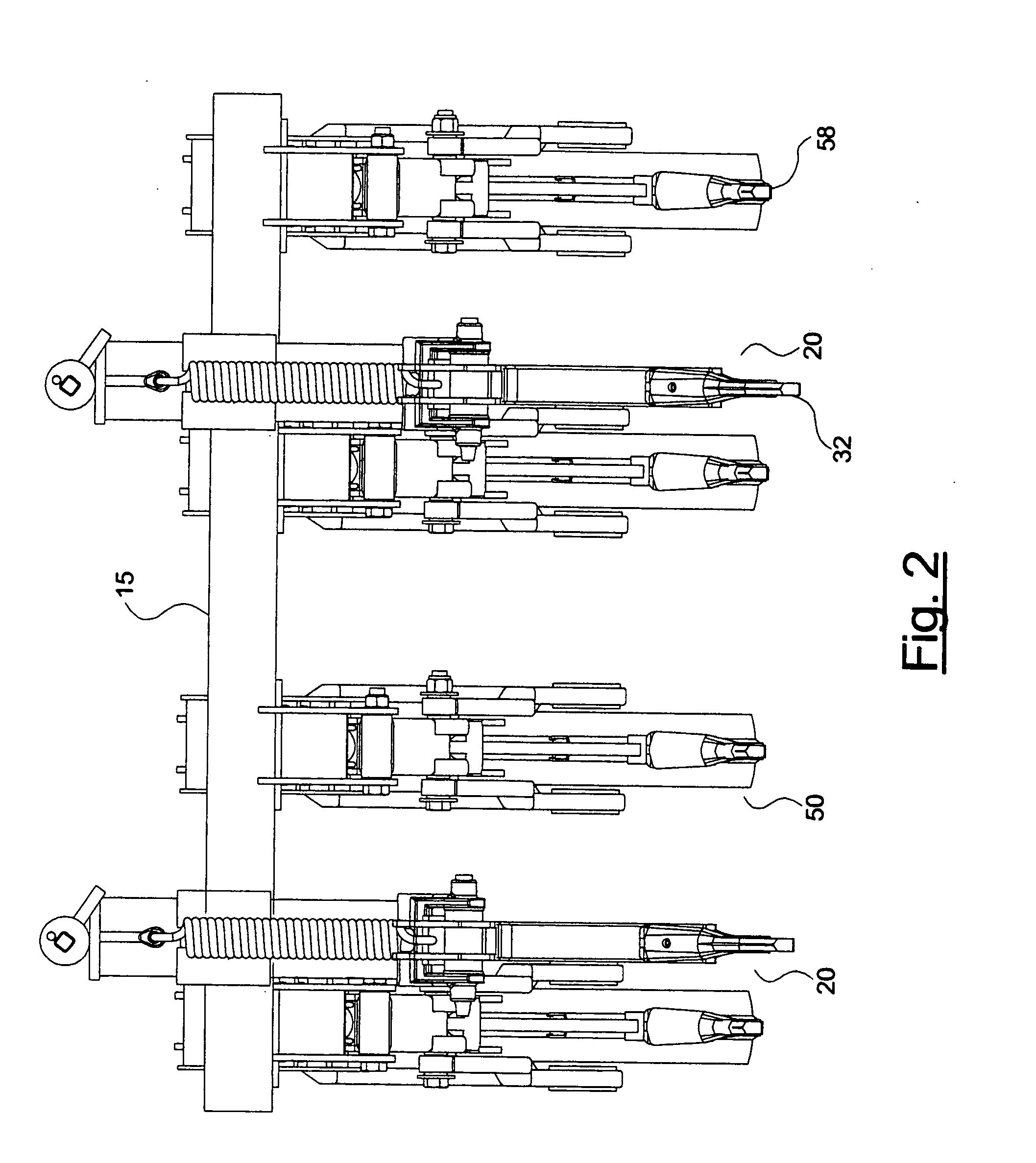

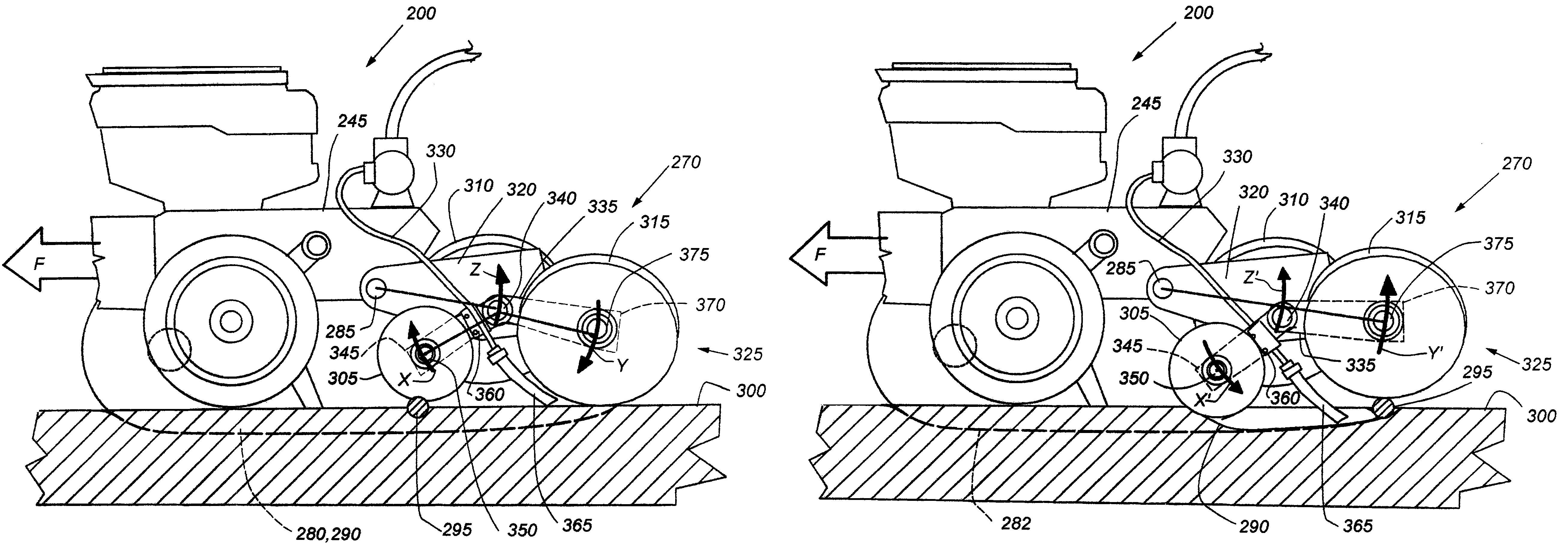

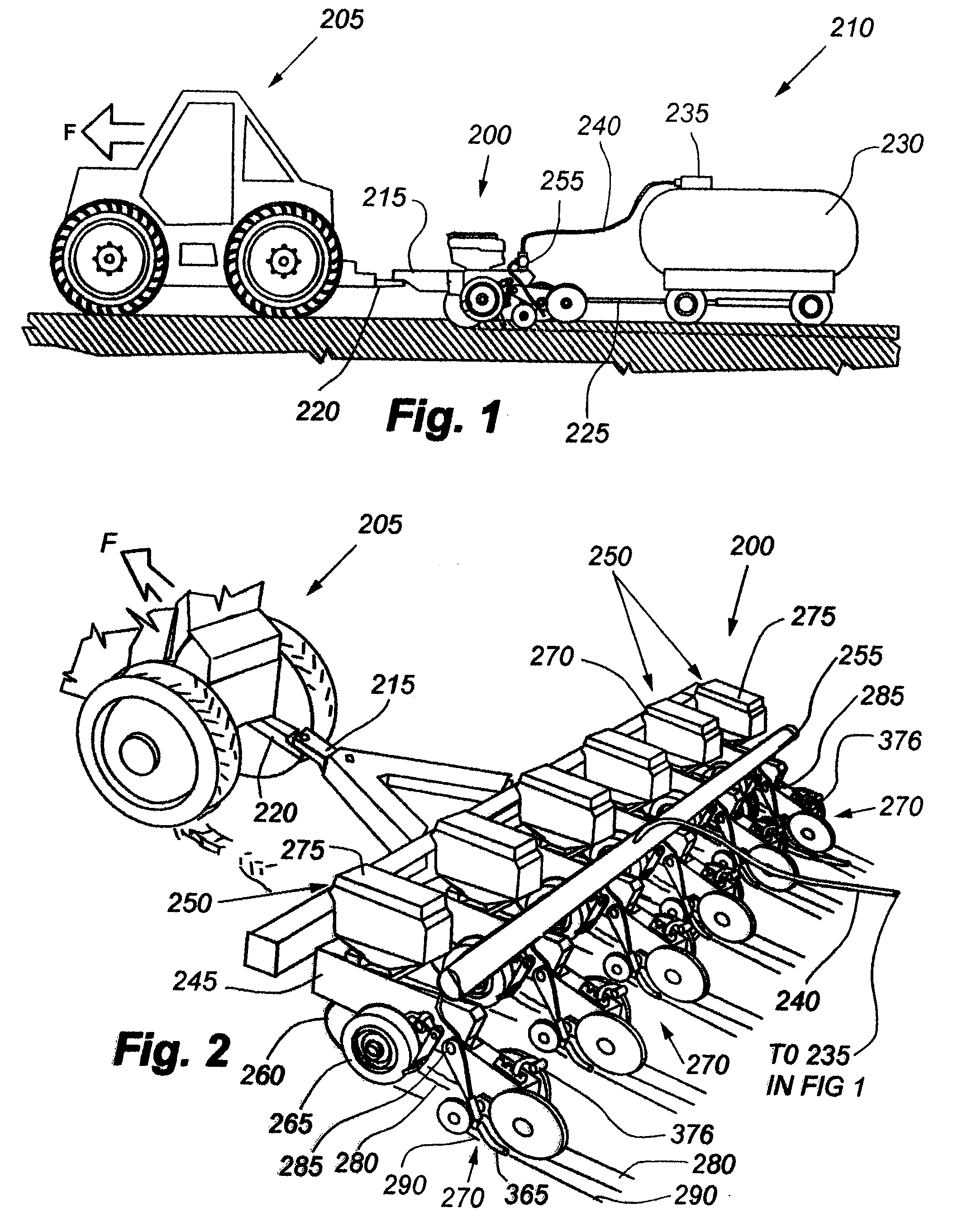

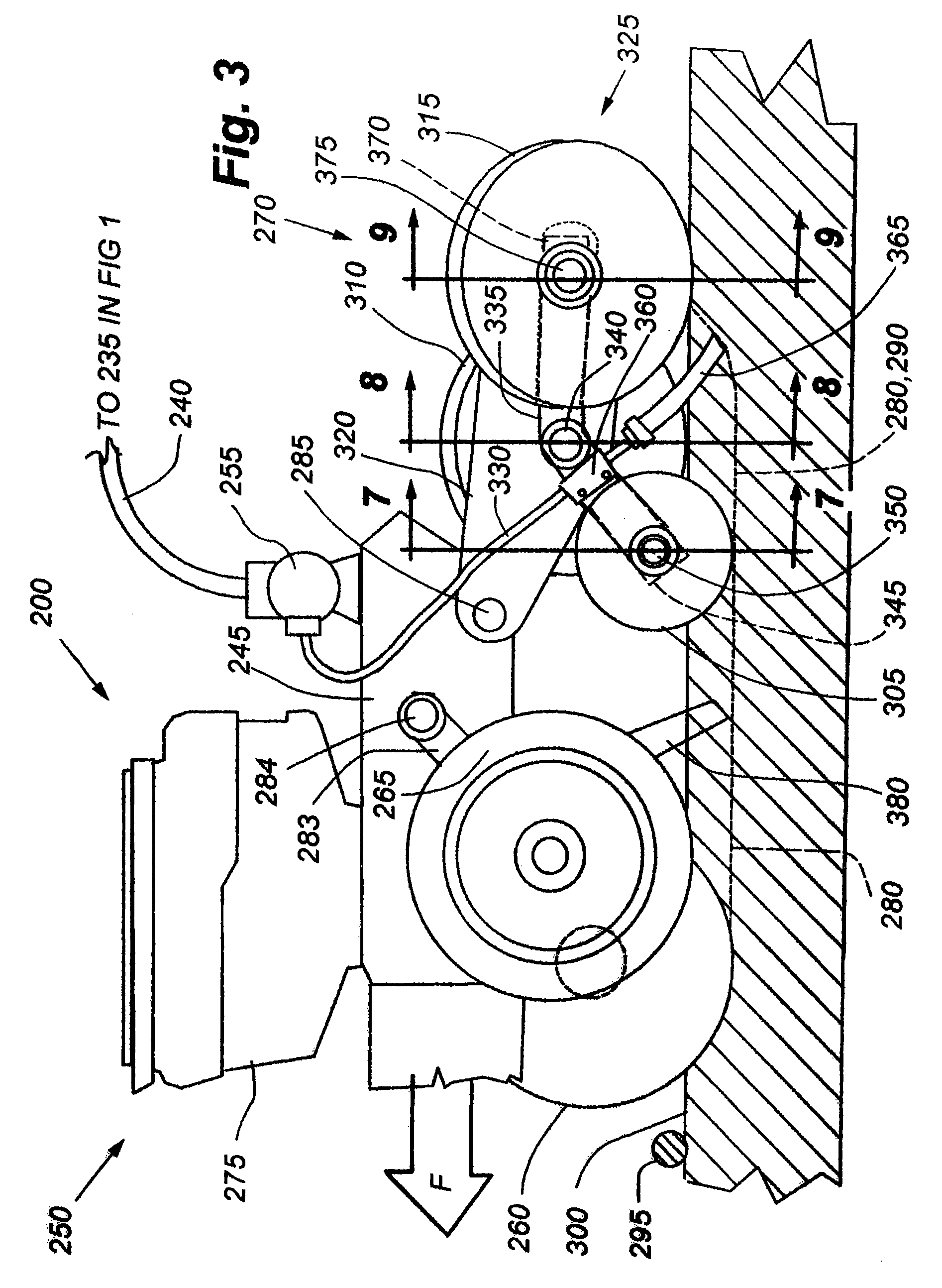

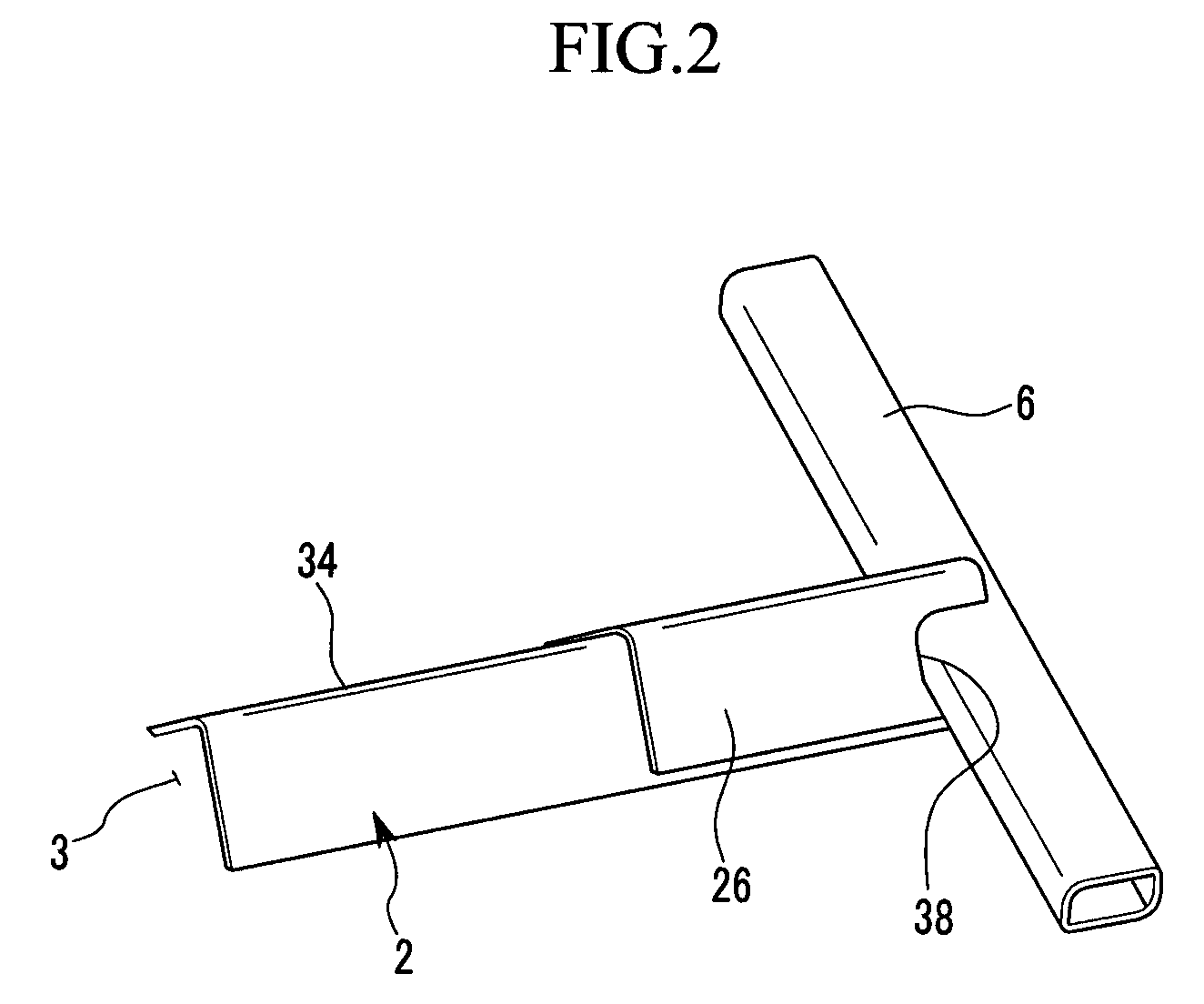

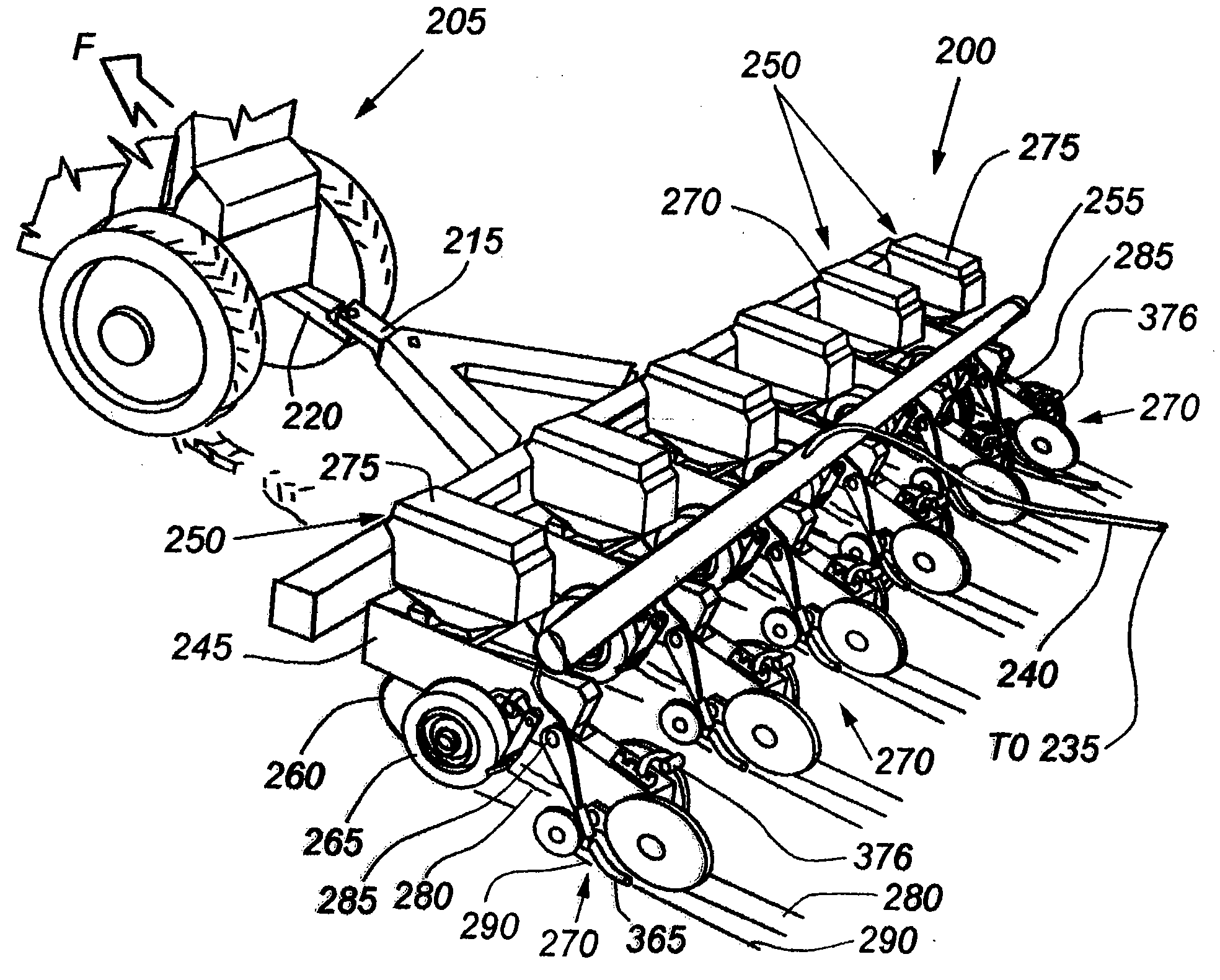

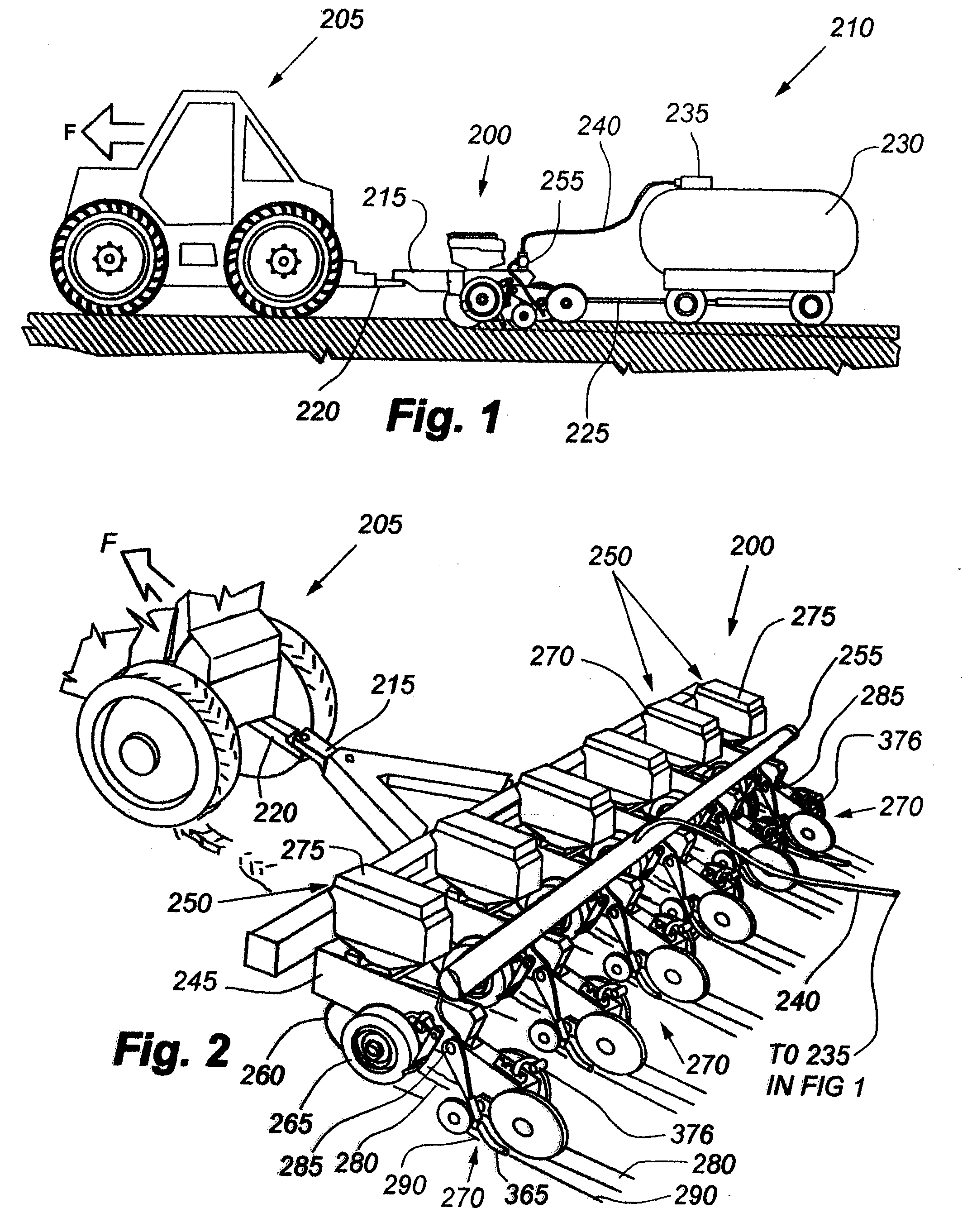

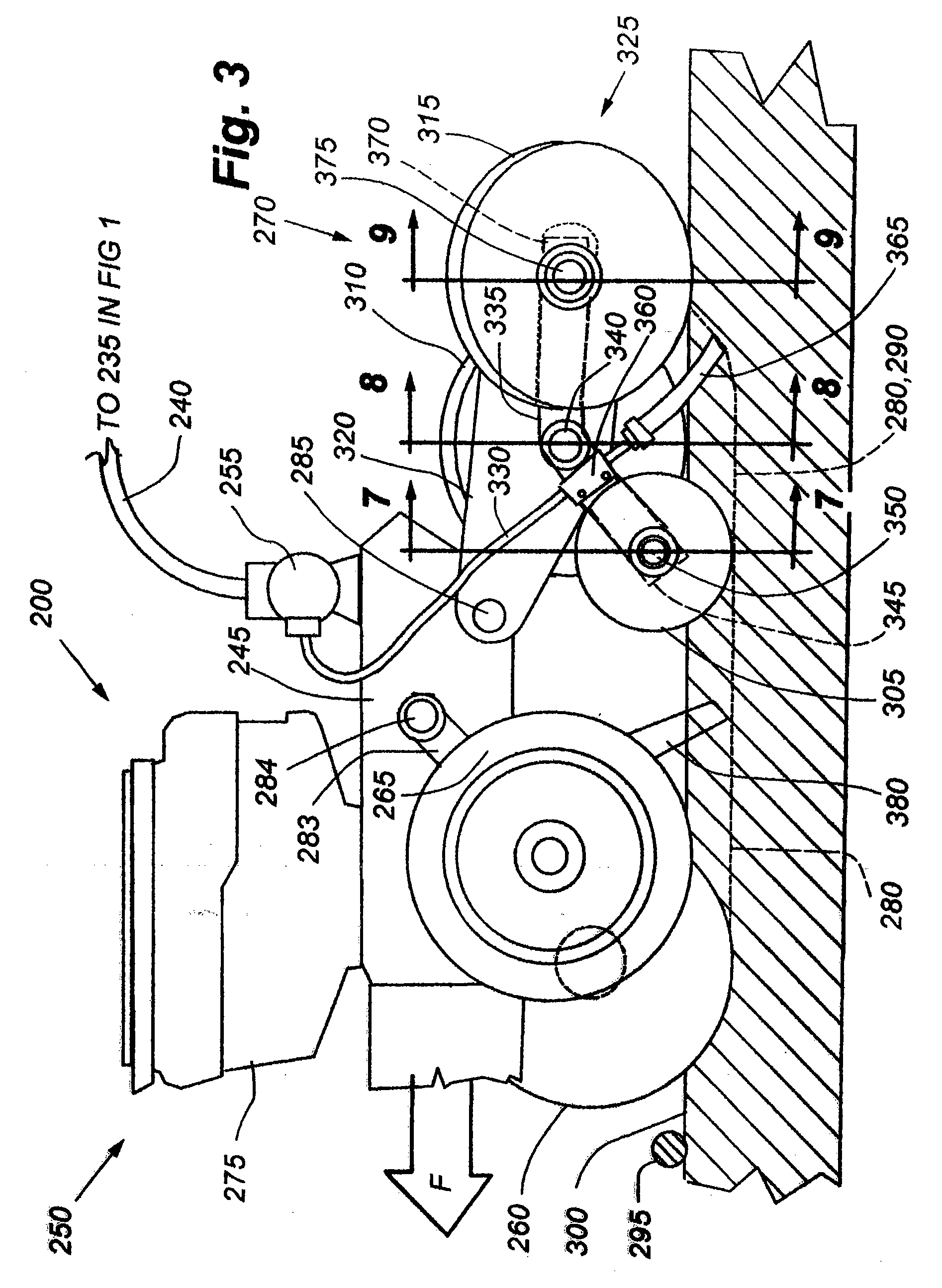

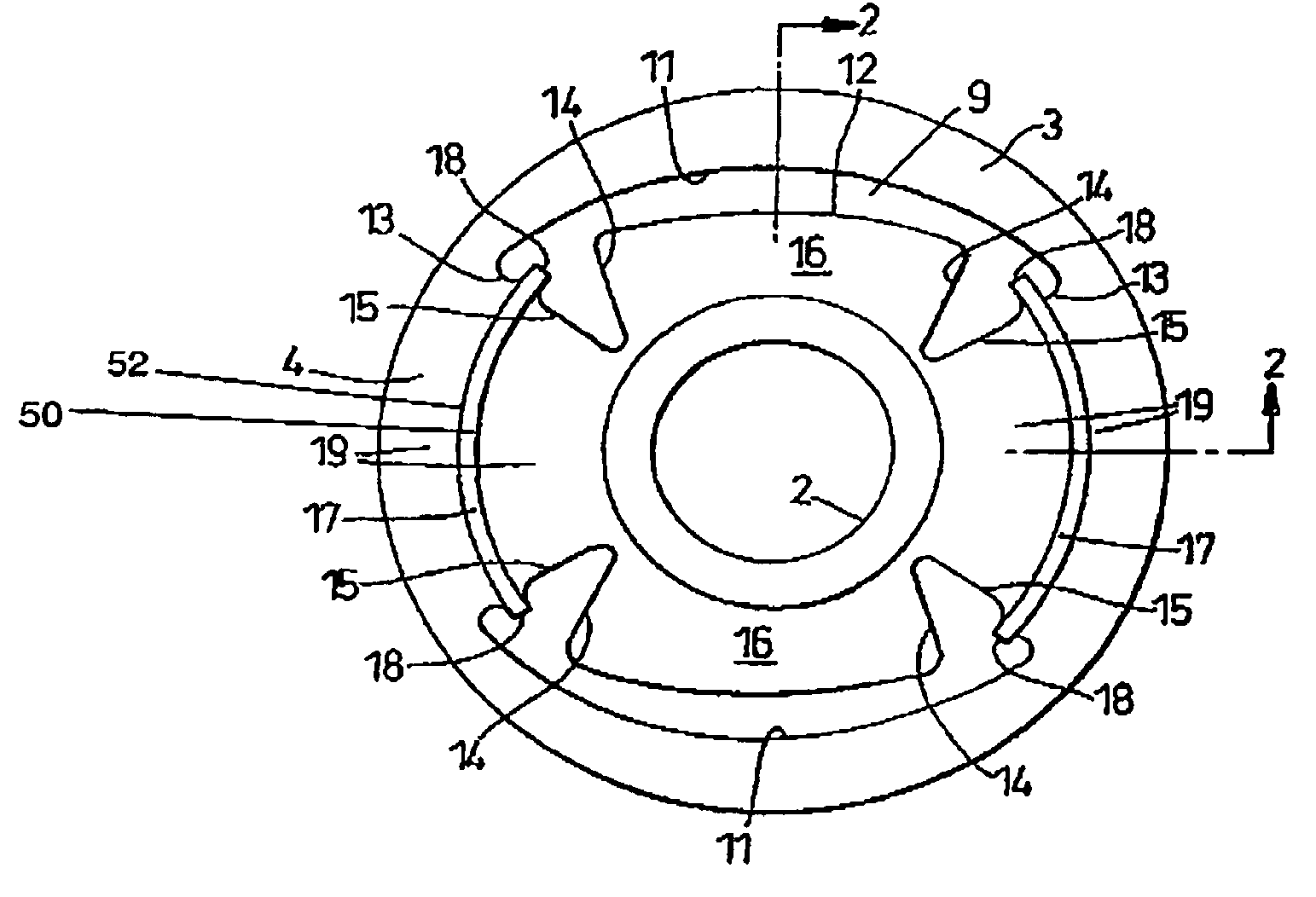

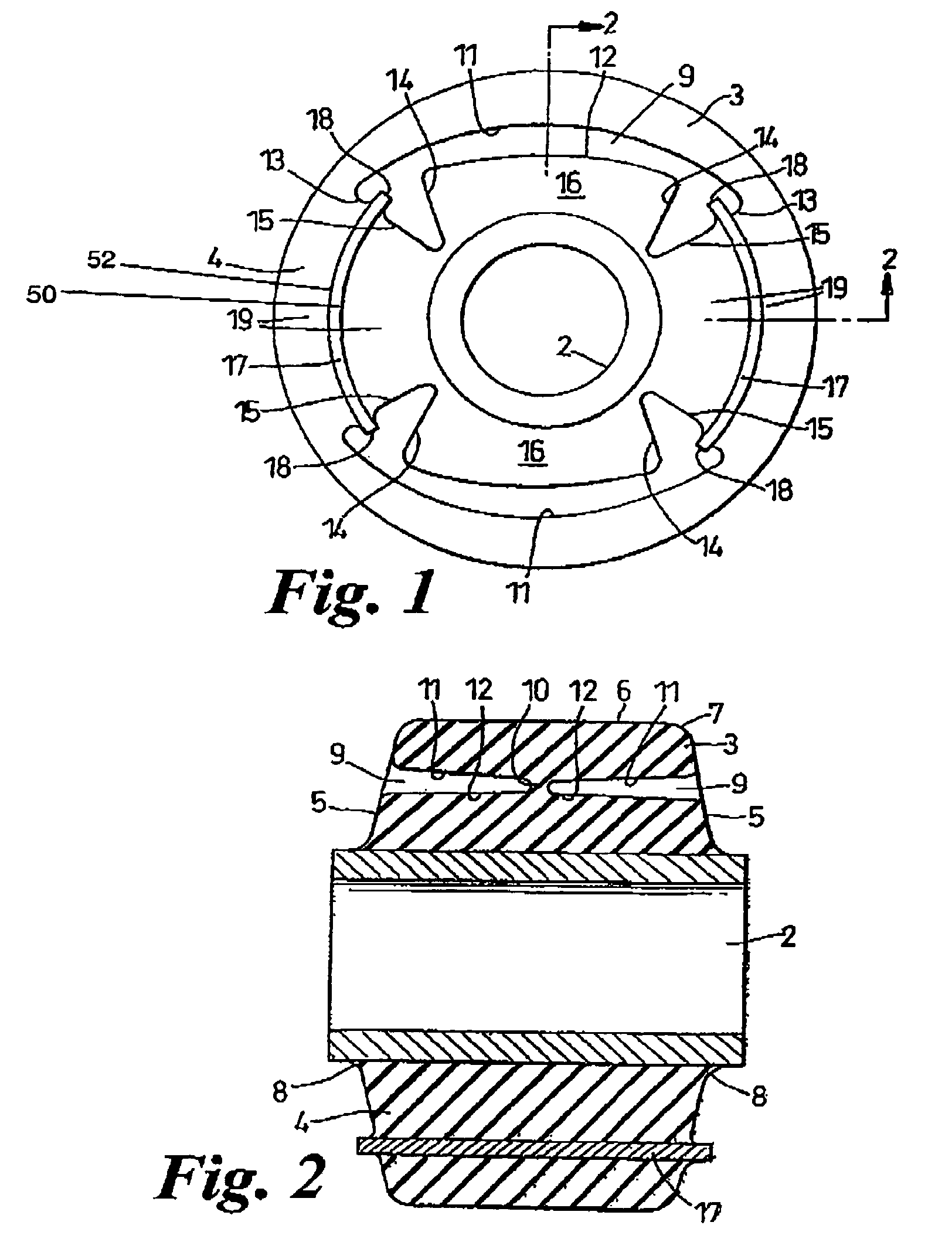

Method and apparatus of agricultural field seeding

ActiveUS7159523B2Accurate conditionImprove consistencyFertiliser distributersPotato plantersTrailing armEngineering

A seeding and fertilizing apparatus comprises a plurality of seed assemblies each comprising a trailing arm pivotally connected at a front end thereof to the frame and a packer wheel rotatably attached to rear end thereof. A seed knife is attached to the trailing arm ahead of the packer wheel which rolls along the seed furrow created by the knife. A vertical position of the knife with respect to the packer wheel is adjustable, and a bias device is operative to exert a downward bias force on the trailing arm. A plurality of fertilizer assemblies each comprises a fertilizer disc rotatably mounted to the frame such that a vertical position of the disc with respect to the implement frame is adjustable. The seed assemblies and fertilizer assemblies are oriented laterally such that each fertilizer furrow is located between adjacent seed furrows.

Owner:BOURGAULT INDS

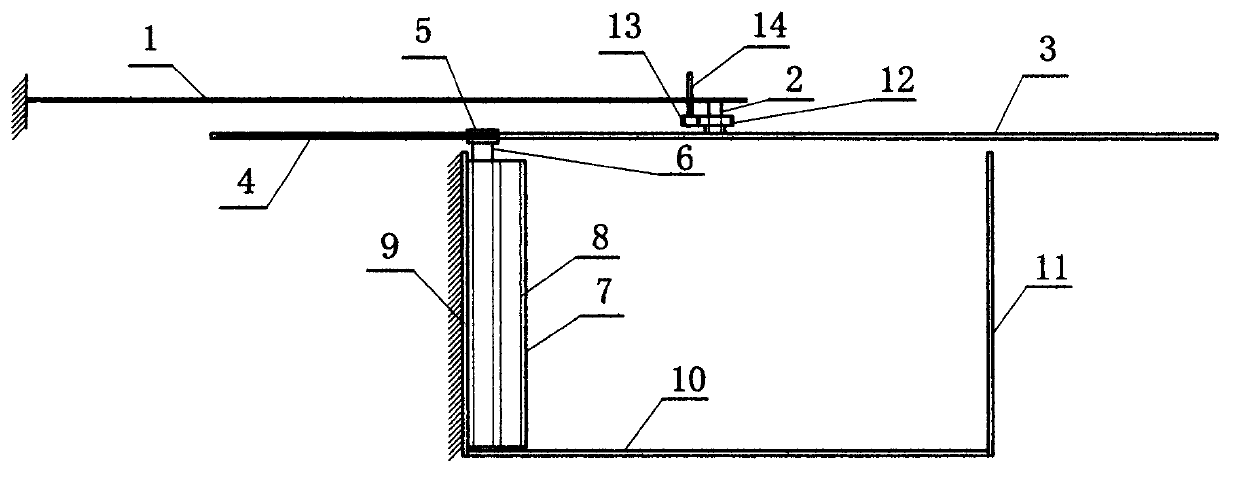

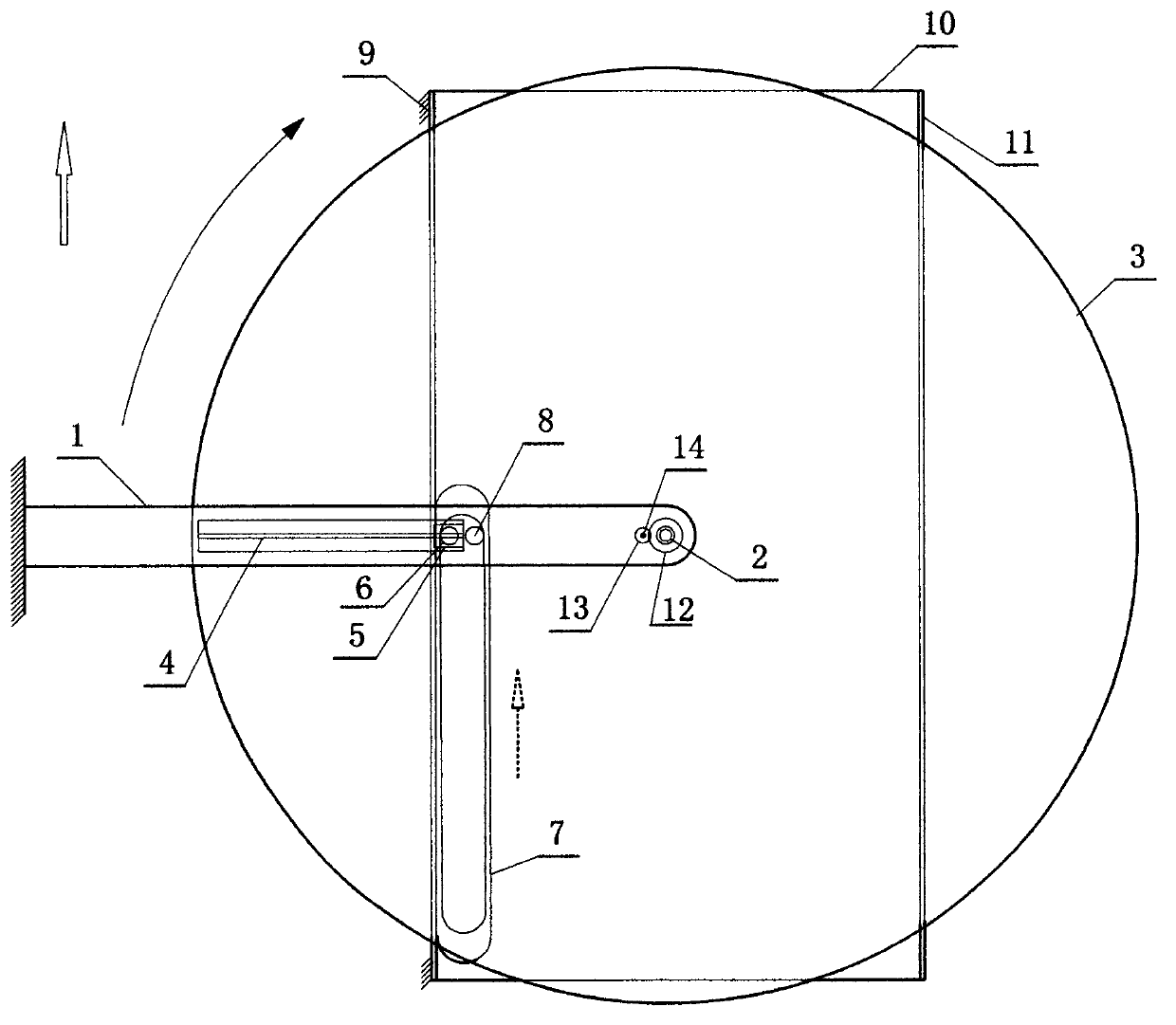

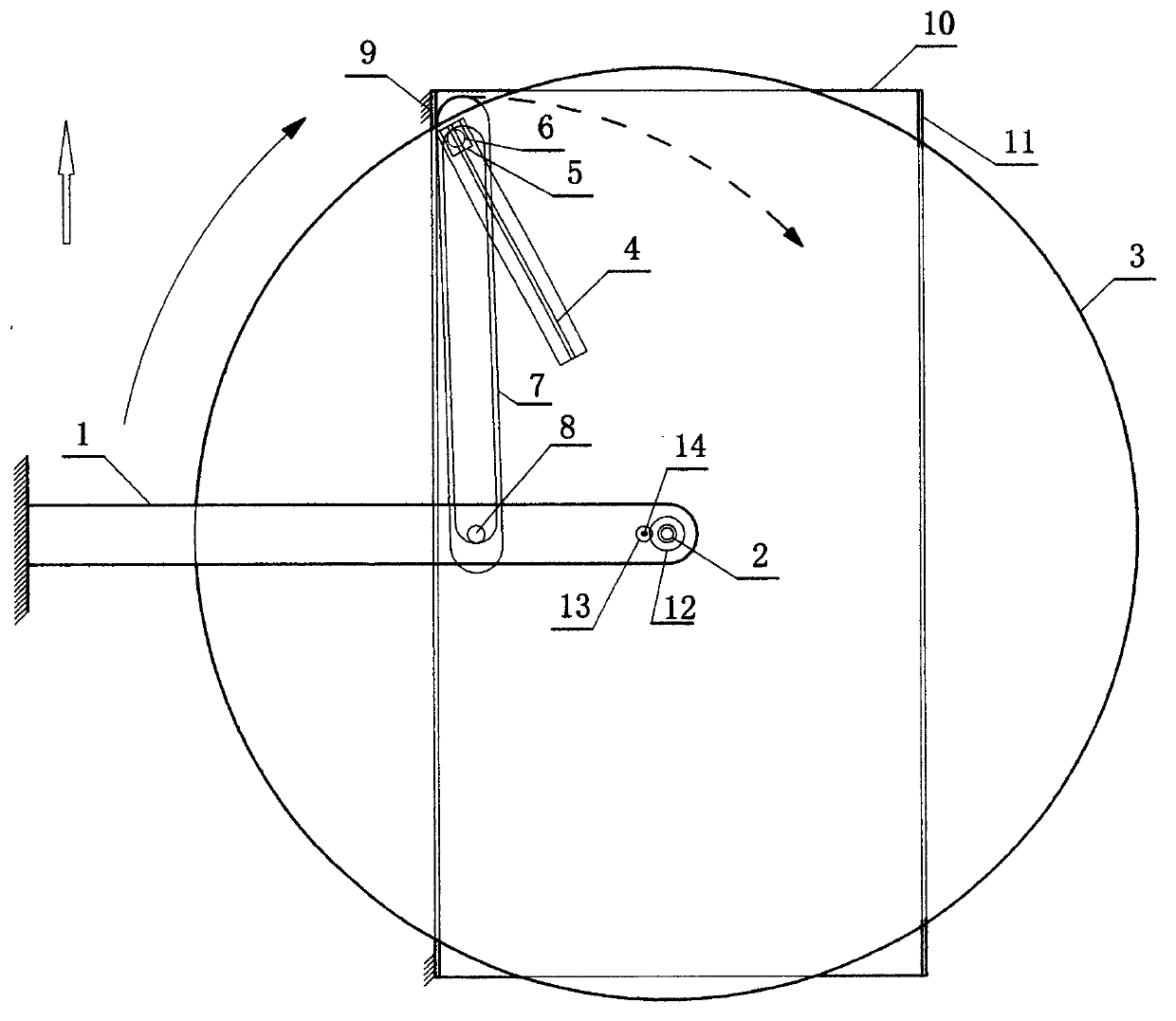

Annular flat plate paddle ship propulsion device

ActiveCN103121501AImprove mobilityThrust inefficiencyPropulsive elements of rotary typeRear quarterTrailing arm

The invention provides an annular flat plate paddle ship propulsion device and relates to the ship machinery technical field. The annular flat plate paddle ship propulsion device comprises a trailing arm, a rotary table shaft, a rotary table, a guide rail, a sliding block, a drag bar, a flat plate paddle, a paddle shaft, a guide plate, a base board, a side board, a driven gear, a driving gear and a power shaft, wherein the upper end and the lower end of the rotary table shaft are respectively connected with the right end of the trailing arm and the center of the rotary table; the guide plate, the base board and the side board surround to form a U-shaped groove which is placed below the rotary table; the flat plate paddle, the paddle shaft and the drag bar are vertically arranged in the U-shaped groove; power is transmitted to the rotary table through gears and then transmitted to the drag bar through the guide rail and the sliding block, and the drag bar drives the annular flat plate paddle to paddle and generate thrust. Due to limiting of the guide plate, the annular flat plate paddle moves ahead in a similar to a straight line mode after turning half circle. The annular flat plate paddle ship propulsion device is simple in structure, high in efficiency, and can be used as a thrust device for a ship and a ship model.

Owner:珠海杰腾造船有限公司

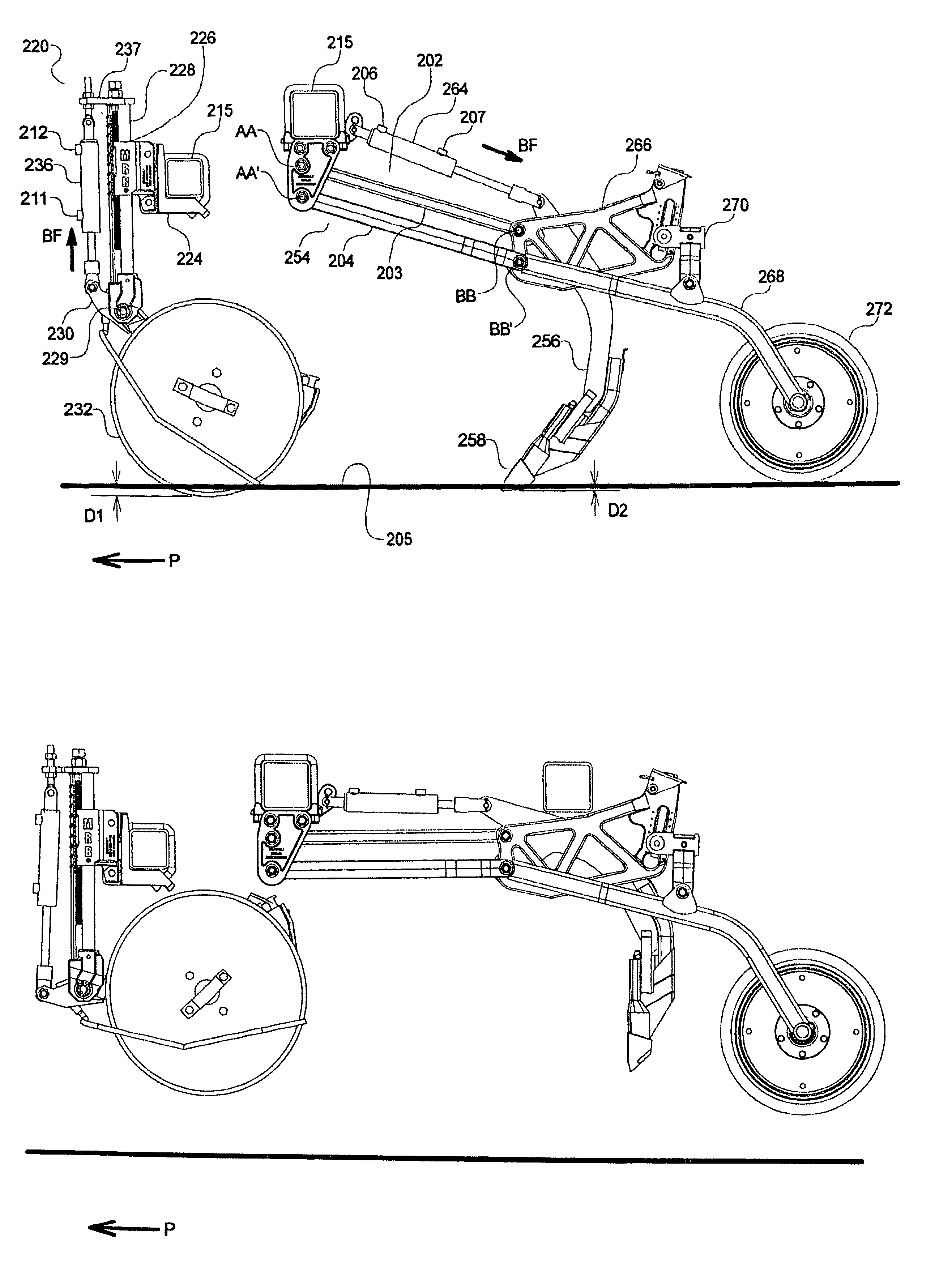

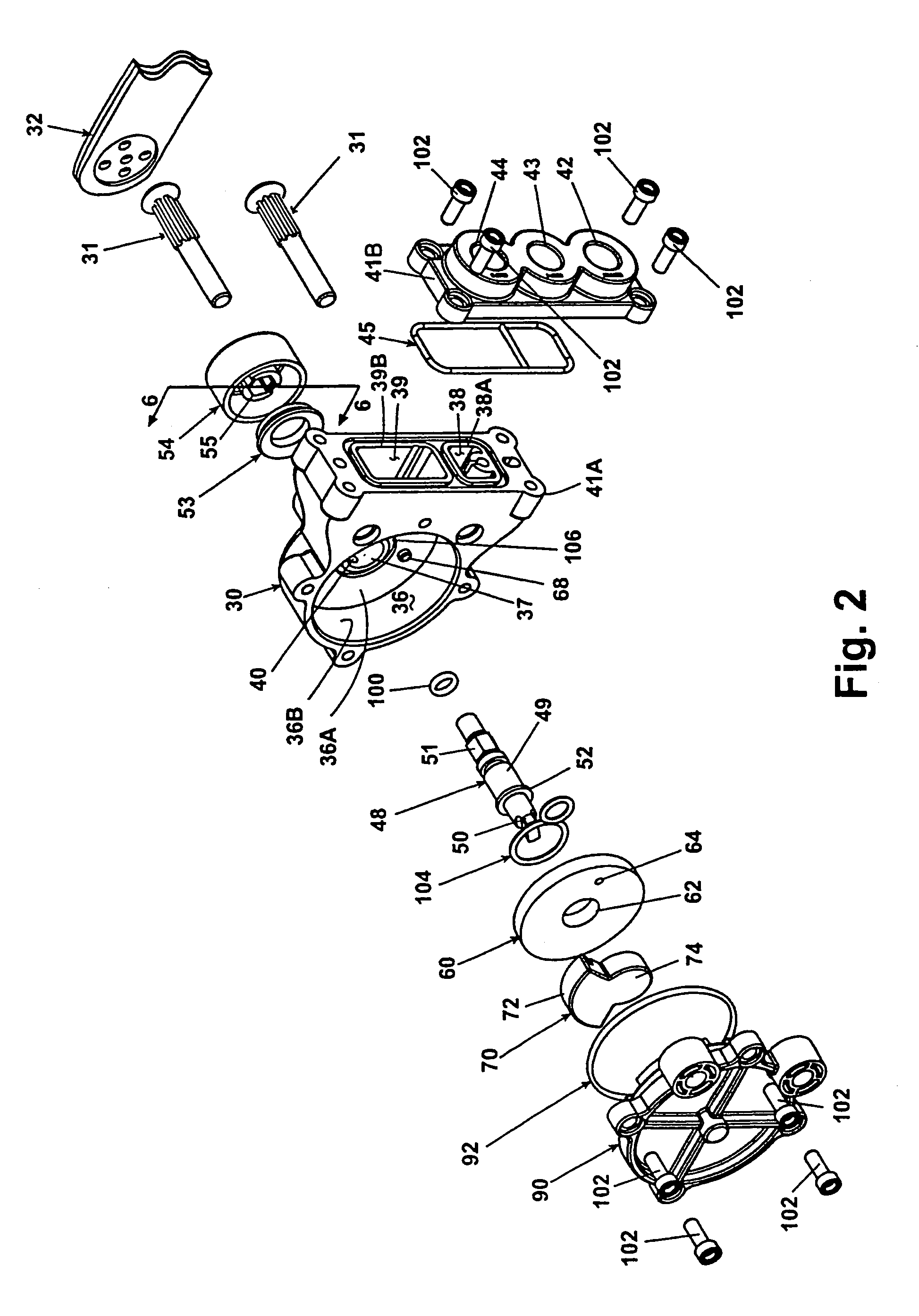

Method and apparatus of agricultural field seeding

ActiveUS20060162632A1Accurate conditionImprove consistencyFertiliser distributersPotato plantersTrailing armEngineering

A seeding and fertilizing apparatus comprises a plurality of seed assemblies each comprising a trailing arm pivotally connected at a front end thereof to the frame and a packer wheel rotatably attached to rear end thereof. A seed knife is attached to the trailing arm ahead of the packer wheel which rolls along the seed furrow created by the knife. A vertical position of the knife with respect to the packer wheel is adjustable, and a bias device is operative to exert a downward bias force on the trailing arm. A plurality of fertilizer assemblies each comprises a fertilizer disc rotatably mounted to the frame such that a vertical position of the disc with respect to the implement frame is adjustable. The seed assemblies and fertilizer assemblies are oriented laterally such that each fertilizer furrow is located between adjacent seed furrows.

Owner:BOURGAULT INDS

Suspension trailing arm

A cast or forged suspension trailing arm for suspending a heavy vehicle chassis from a beam-type axle includes an integral axle locating feature.

Owner:MERITOR HEAVY VEHICLE SYST

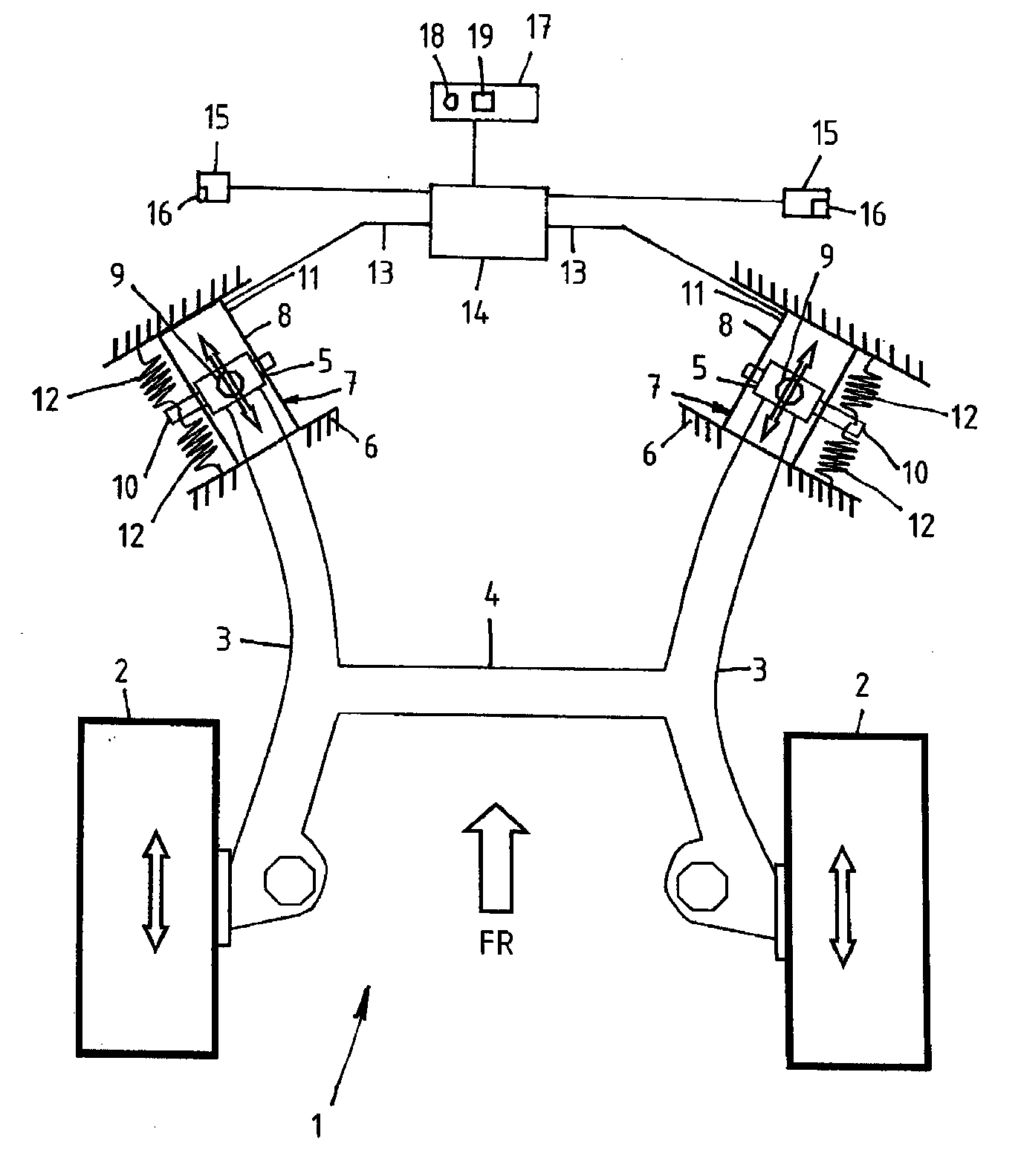

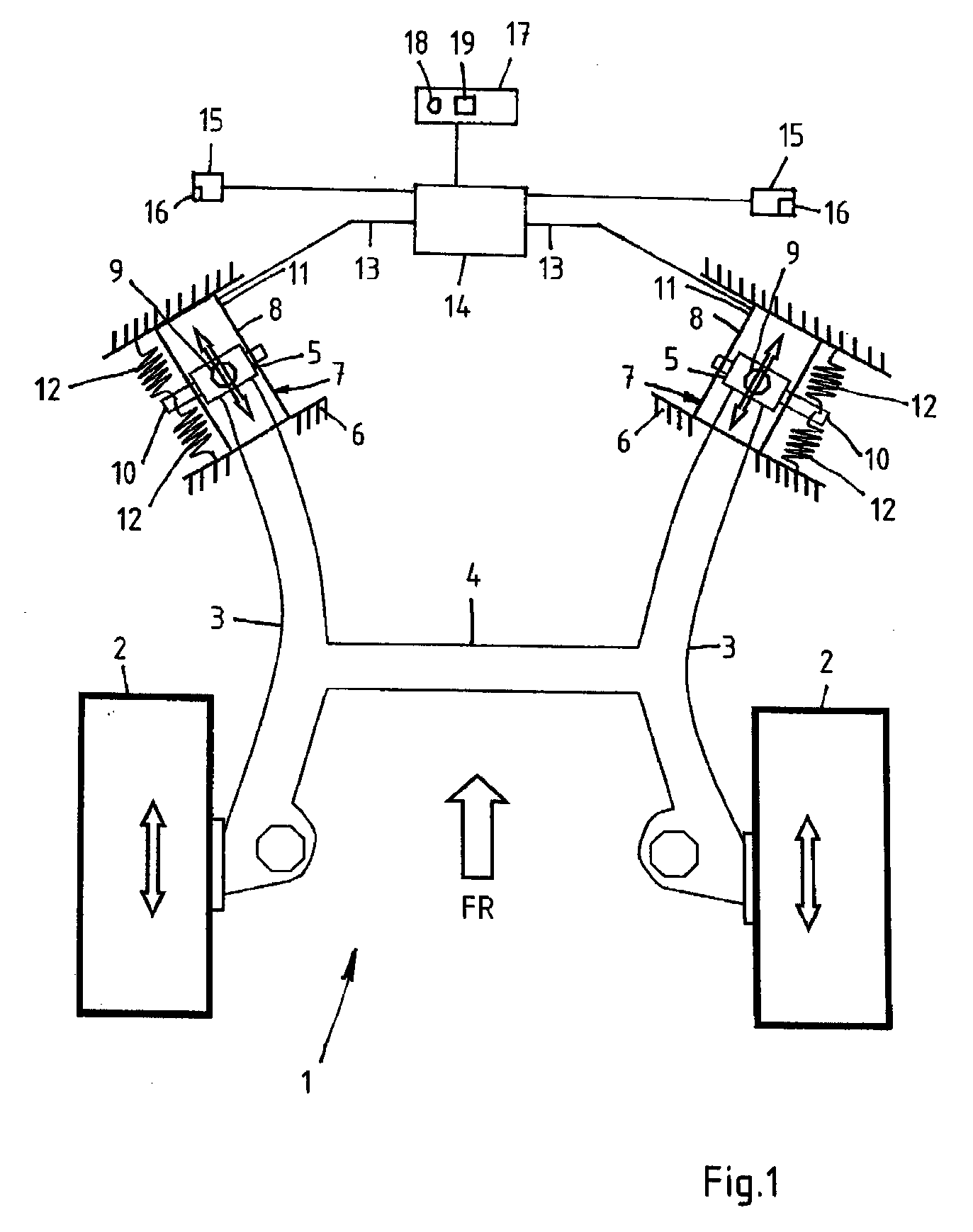

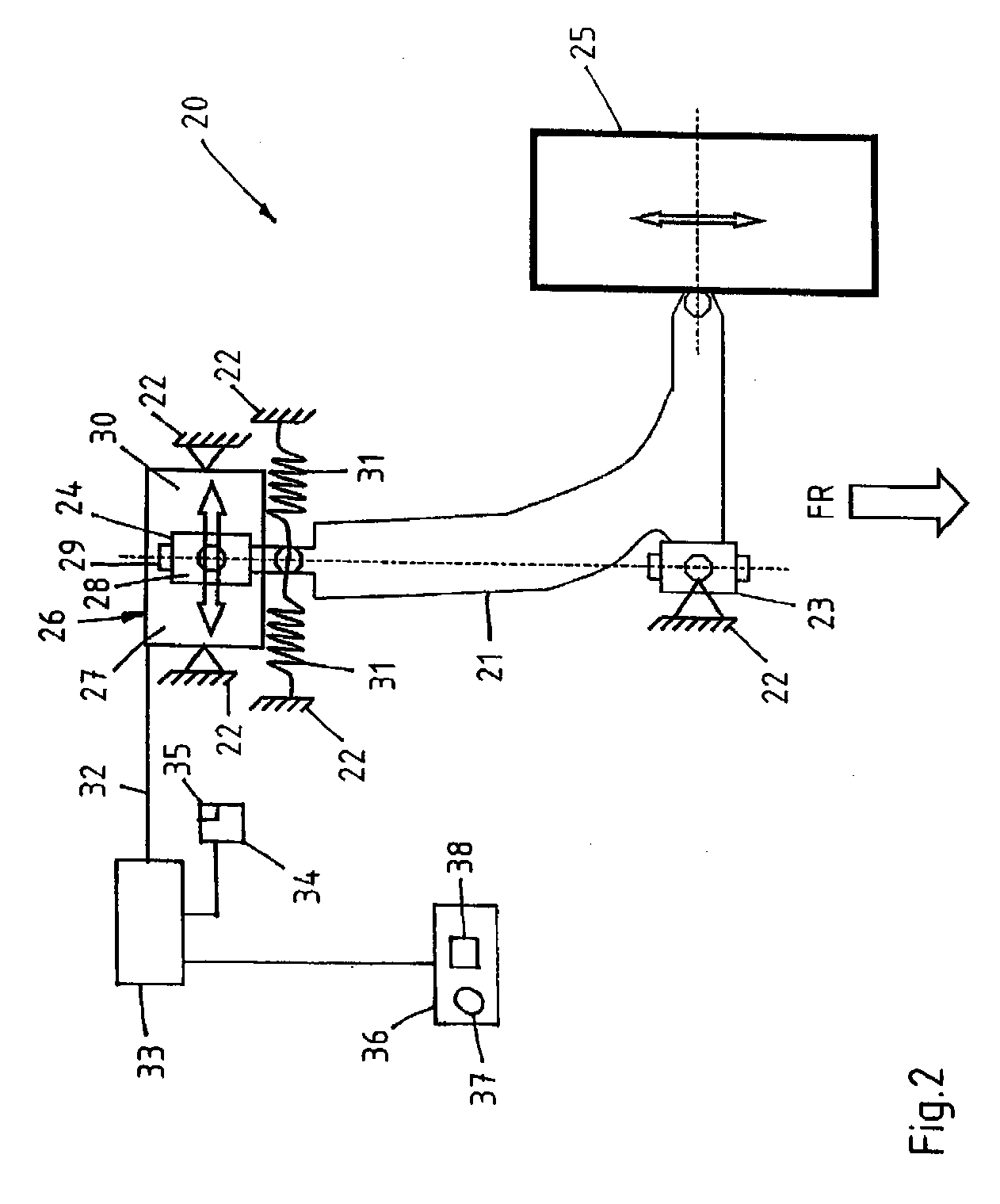

Wheel guidance

InactiveUS20060273530A1Limit on characteristicEffectively neutralizeSteering partsInterconnection systemsTrailing armLinear motor

A wheel guidance includes at least one bearing for articulation of a trailing arm or wishbone to a vehicle body. Oscillations caused during travel are detected by a sensor and superimposed by a compensation oscillation generated by a controller in combination with linear motors to provide oscillation damping.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

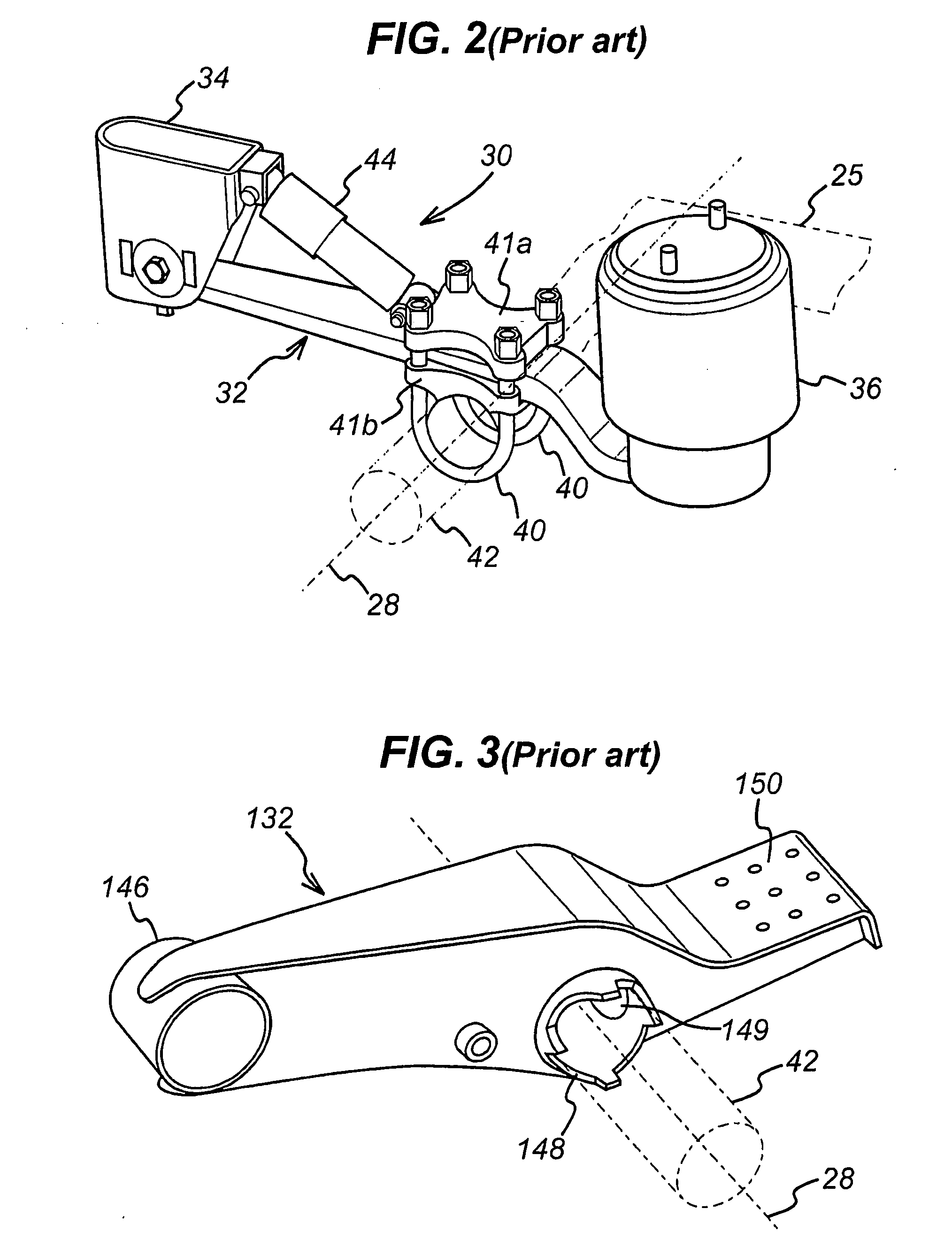

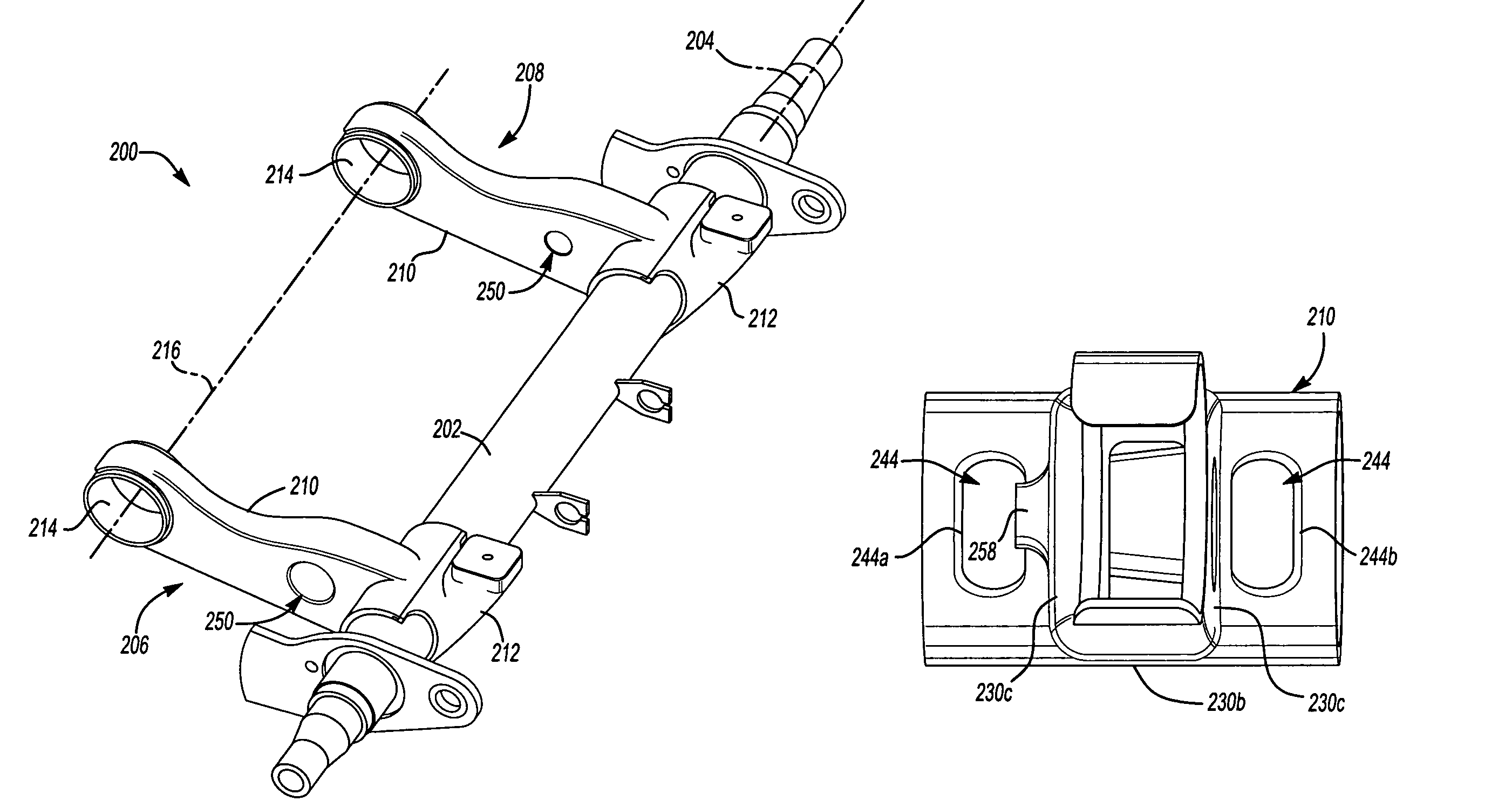

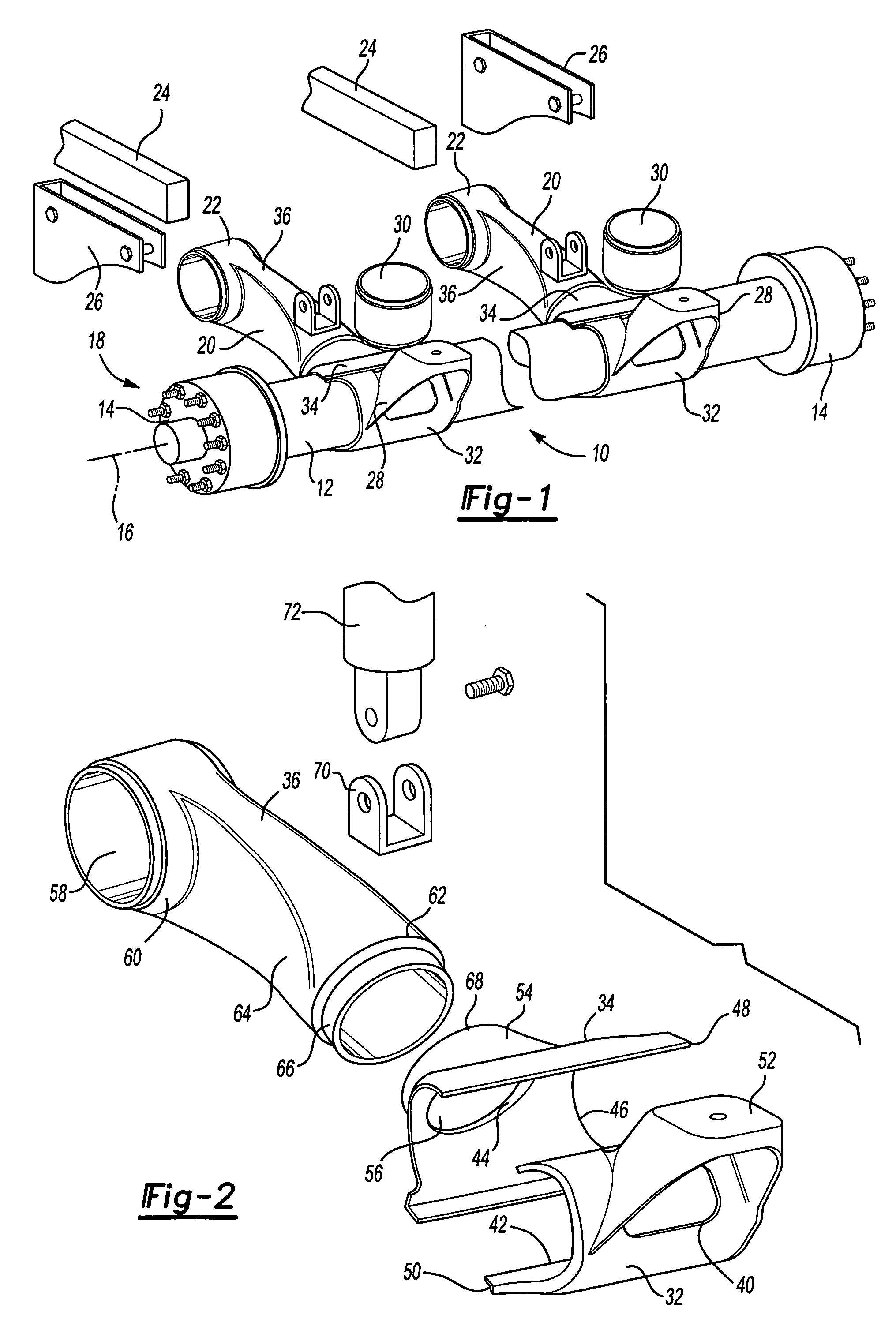

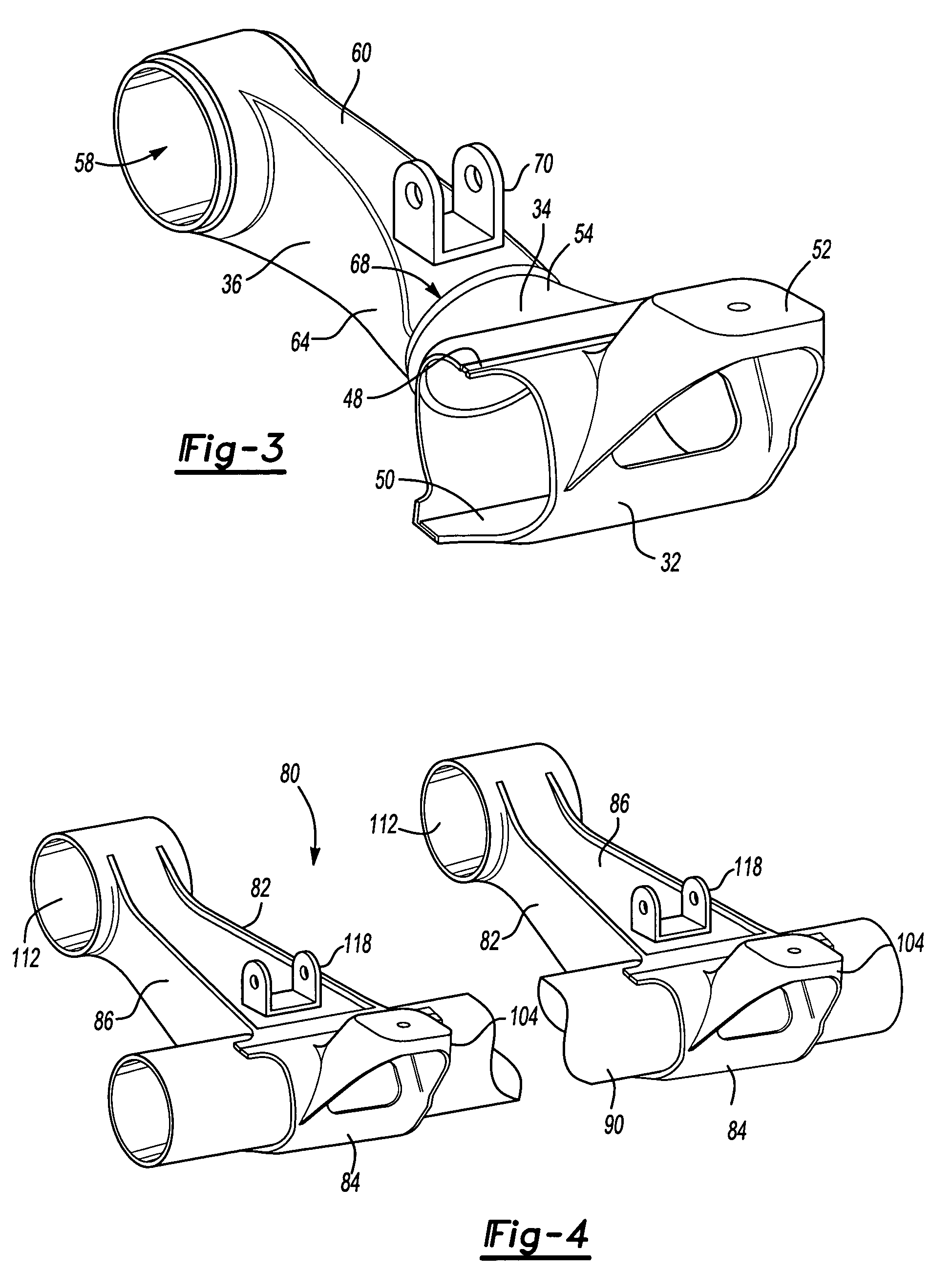

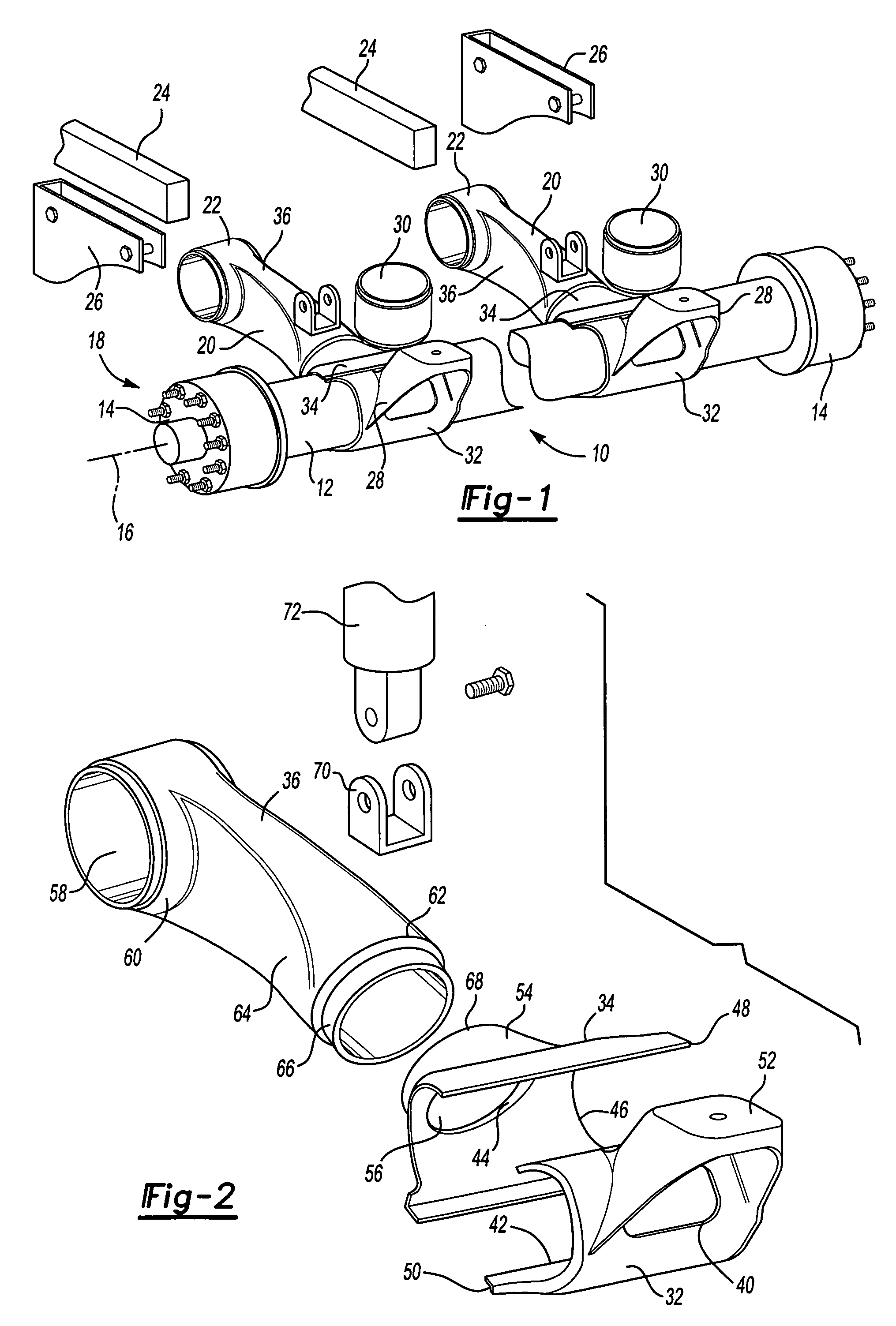

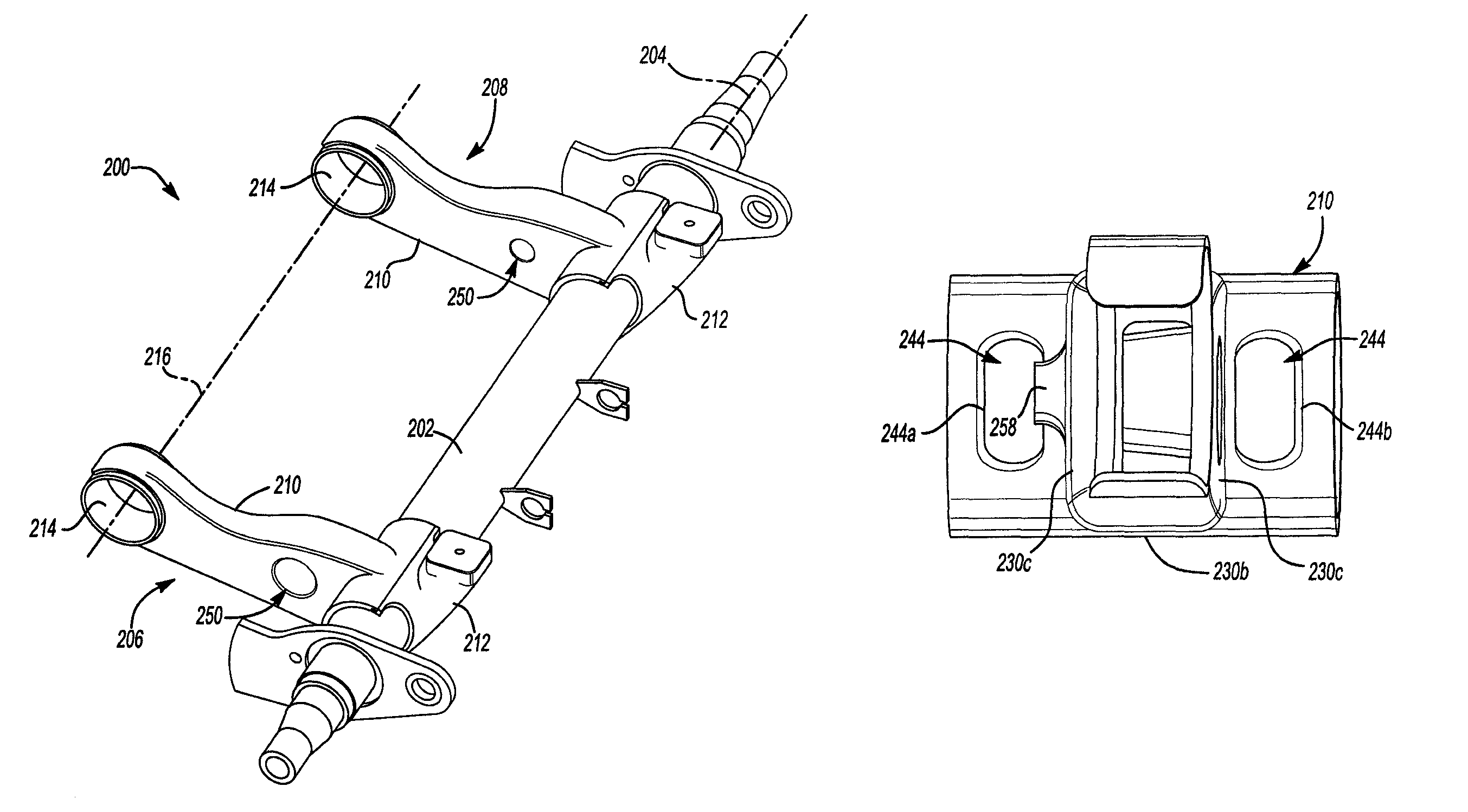

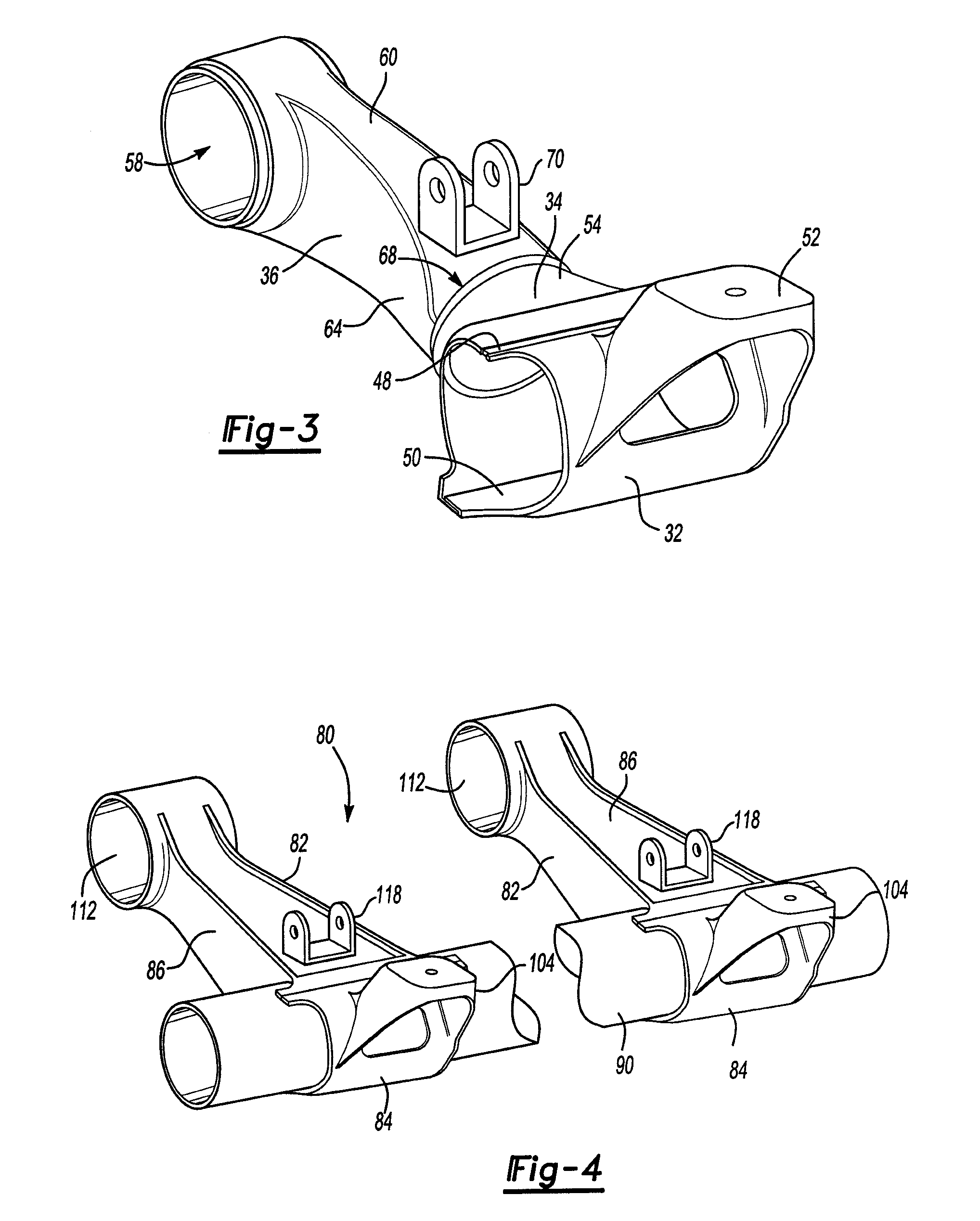

Cast trailing arm assembly for trailer suspension

A trailing arm assembly for a suspension includes at least first and second cast components. The first and second cast components are welded to each other to substantially surround an outer perimeter of an axle member. The first cast component is then welded to one side of the axle member at a first weld and the second cast component is welded to an opposite side of the axle member at a second weld. A bushing tube is then welded to one of the first and second cast components and is subsequently attached to a vehicle frame member. The first weld area comprises a pair of laterally spaced window welds and the second weld area comprises a single window weld.

Owner:ARVINMERITOR TECH

Cambering vehicle

A cambering vehicle includes a front column, left and a right trailing arms each having a front portion pivotally attached to either the front column or a bracket attached thereto by a pivot axle which is preferably inclined relative to the bracket or the front column. A detachable latching device may be used to detachably latch the bracket, if so provided, and thus the trailing arms to the front column at the working position. The bracket and thus the trailing arm may be rotated relative to the front column to the folding position when the detachably latching device releases the bracket relative to the front column. The cambering vehicle may also include a link connect the trailing arms independent of the front column, and a braking mechanism to inhibit forward movement of the cambering vehicle.

Owner:PRODS OF TOMORROW

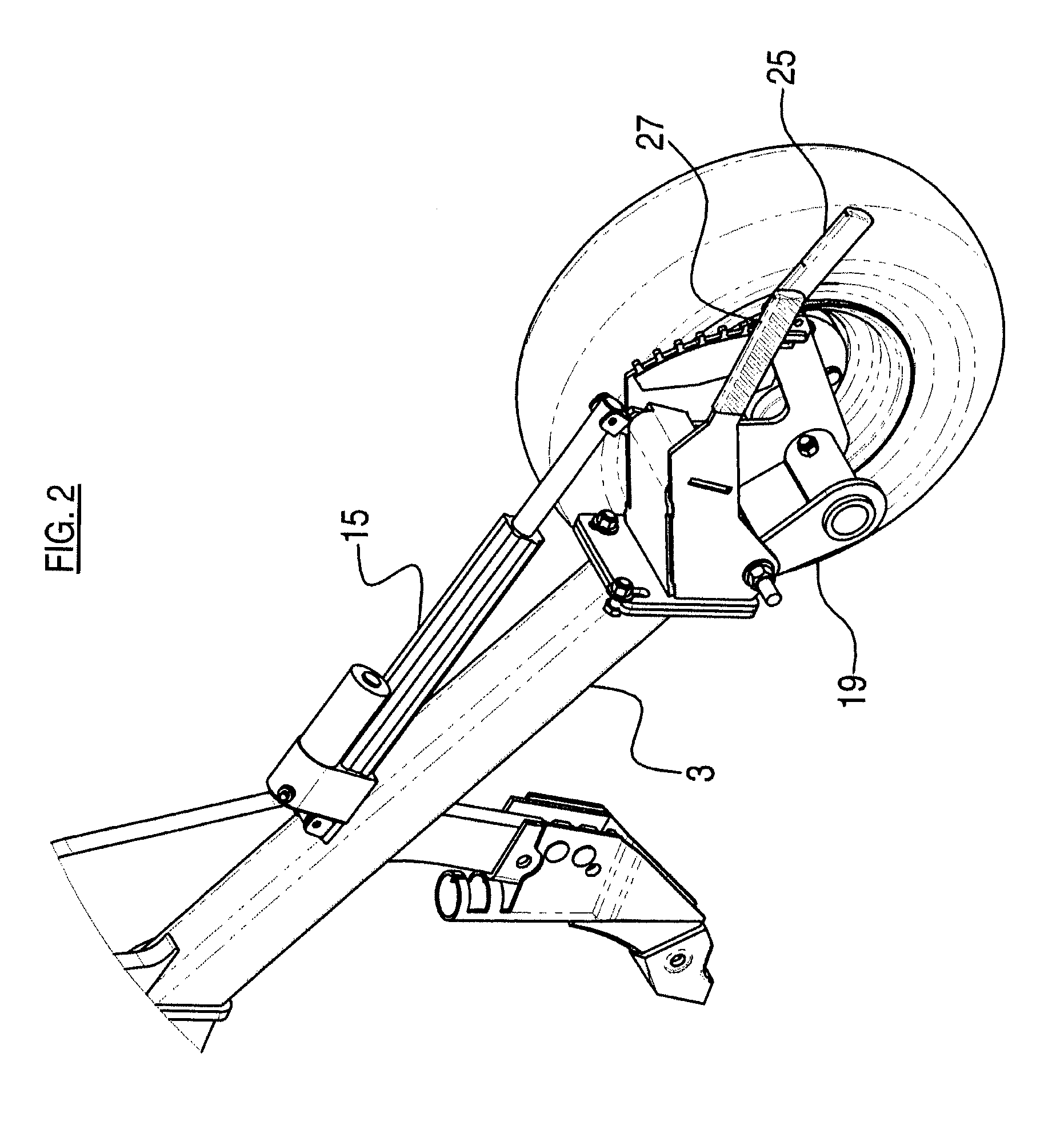

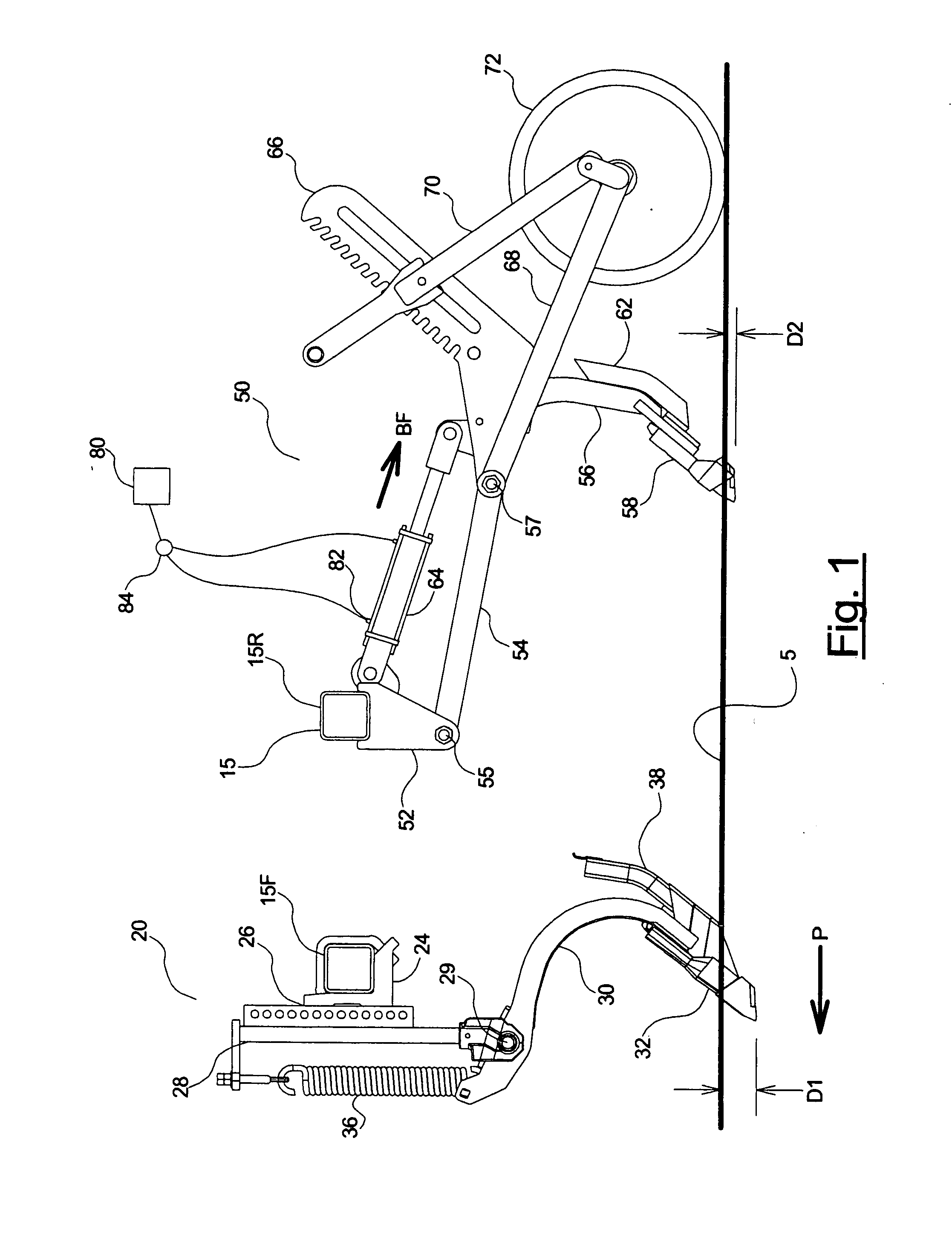

Depth Adjustment of Trailing Arm Furrow Openers

A furrow opener apparatus has a trailing arm pivotally attached to a seeding implement and extending rearward. A packer wheel is rotatably mounted at a rear end of the trailing arm, and a furrow opener is mounted to the trailing arm forward of, and in alignment with, the packer wheel. A bias element exerts a downward bias force forcing the packer wheel downward against the ground. An actuator is operative to move the packer wheel up and down through a range from a lowest vertical position with respect to the furrow opener to a highest vertical position with respect to the furrow opener. A remote control is operative to activate the actuator from the towing vehicle, and a microprocessor is programmed to adjust all furrow openers on the seeding implement by an equal amount when desired.

Owner:BOURGAULT INDS

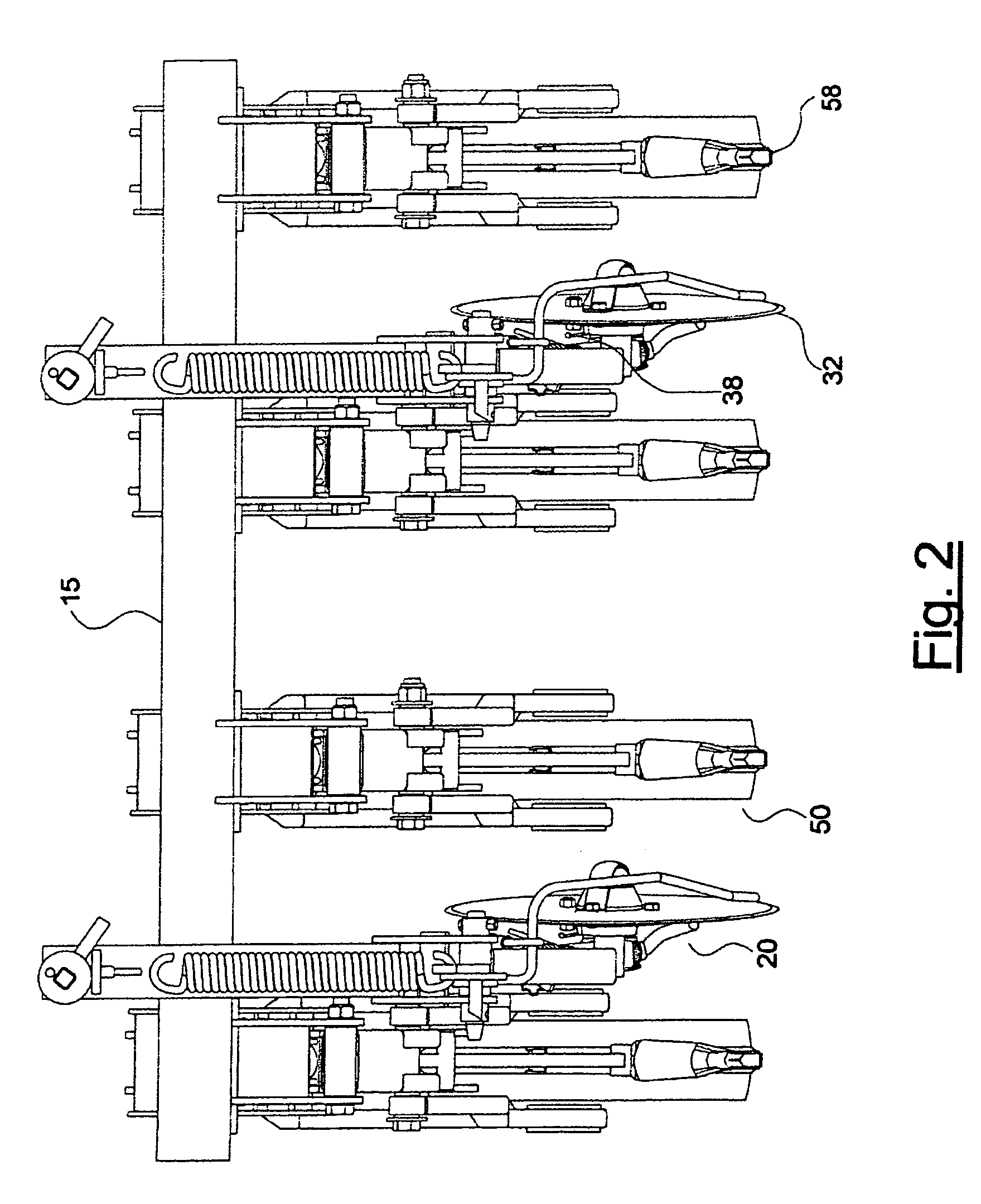

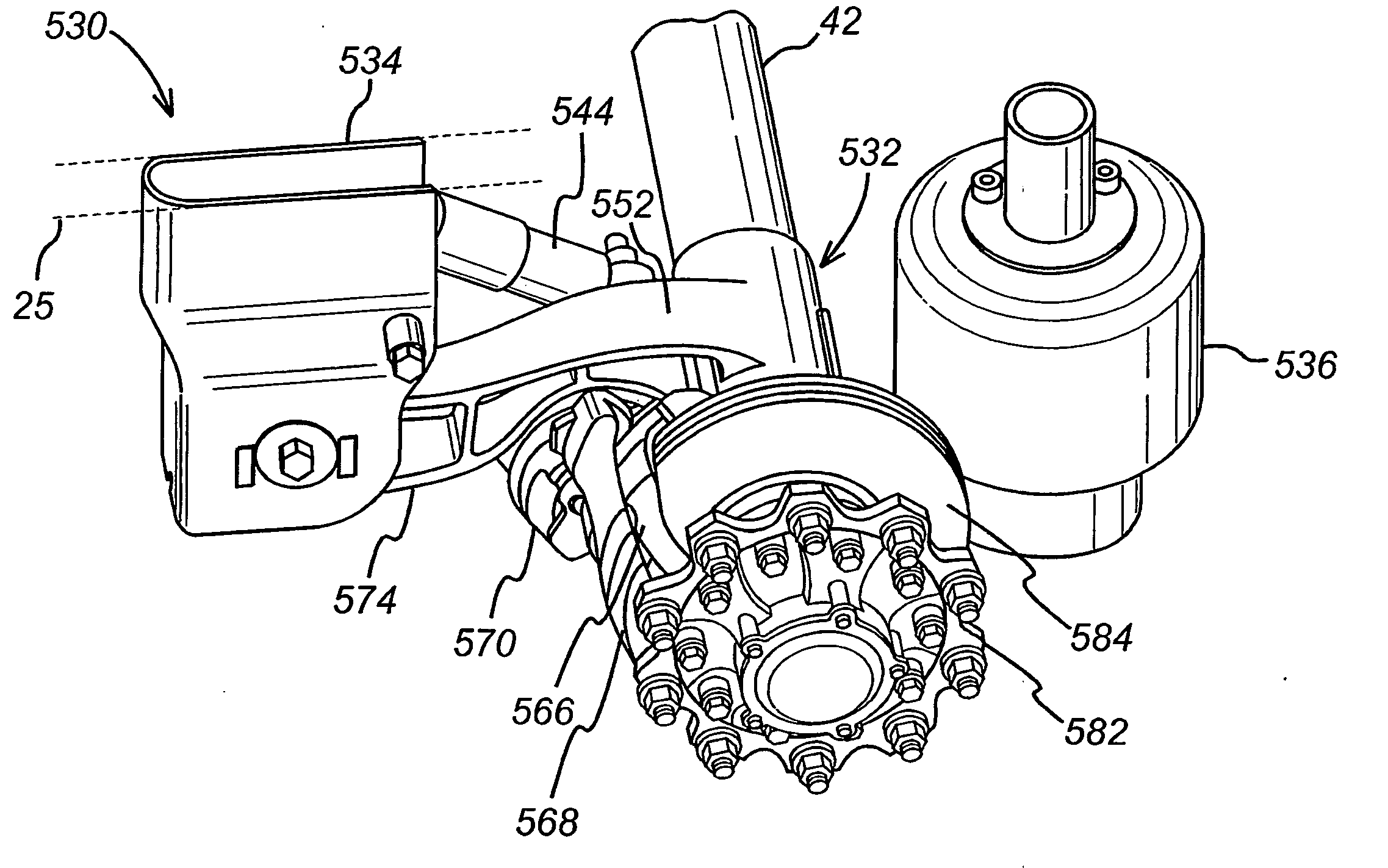

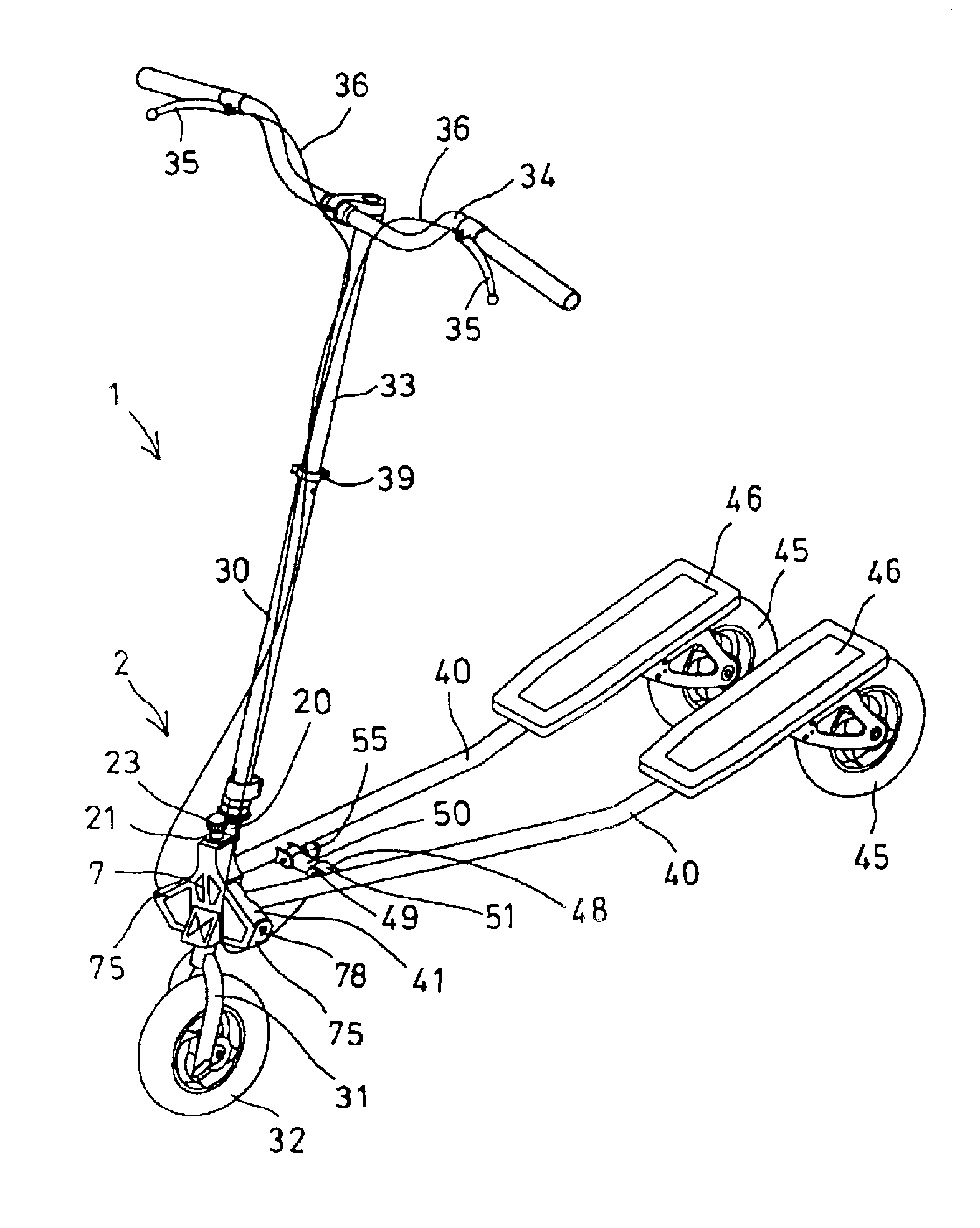

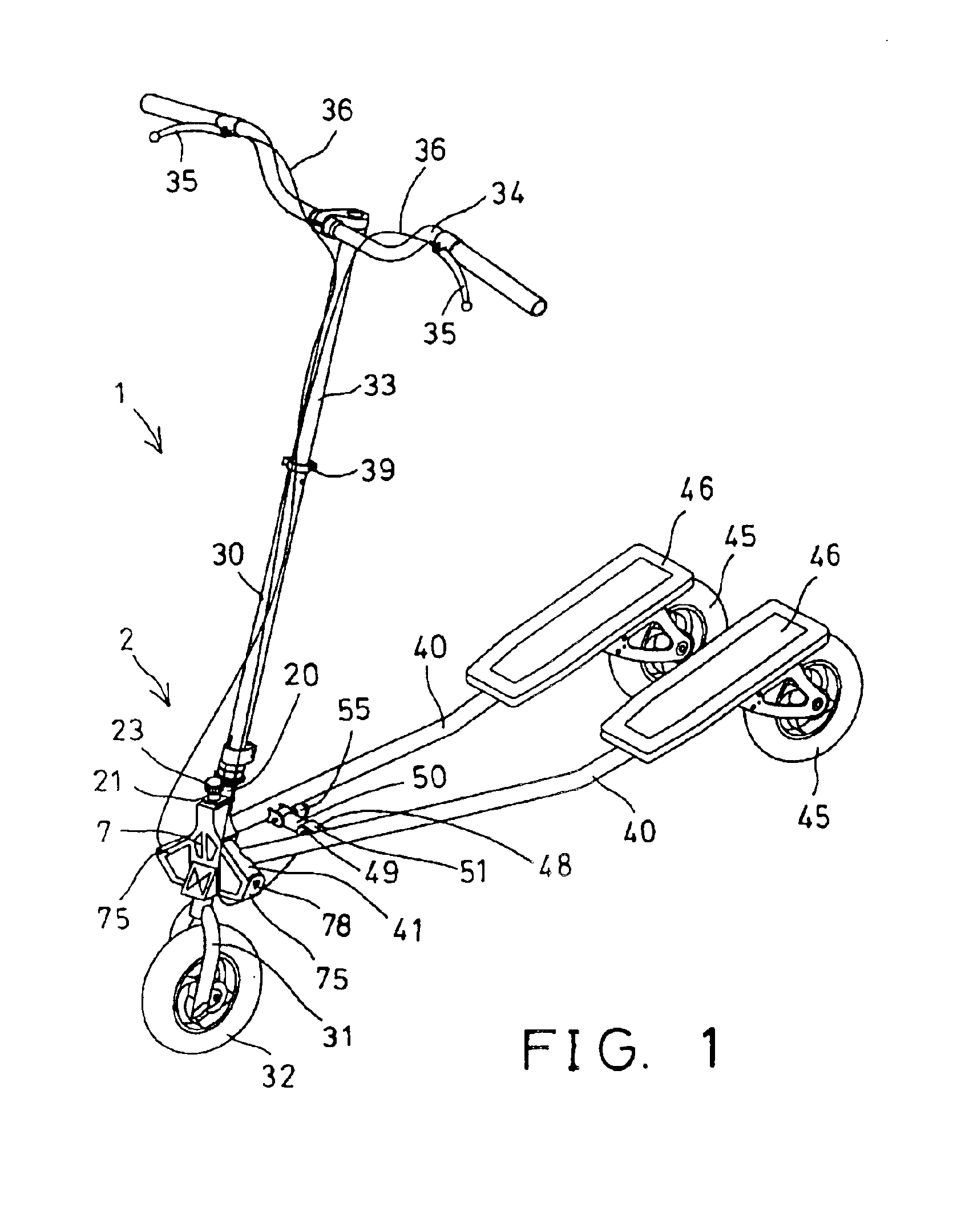

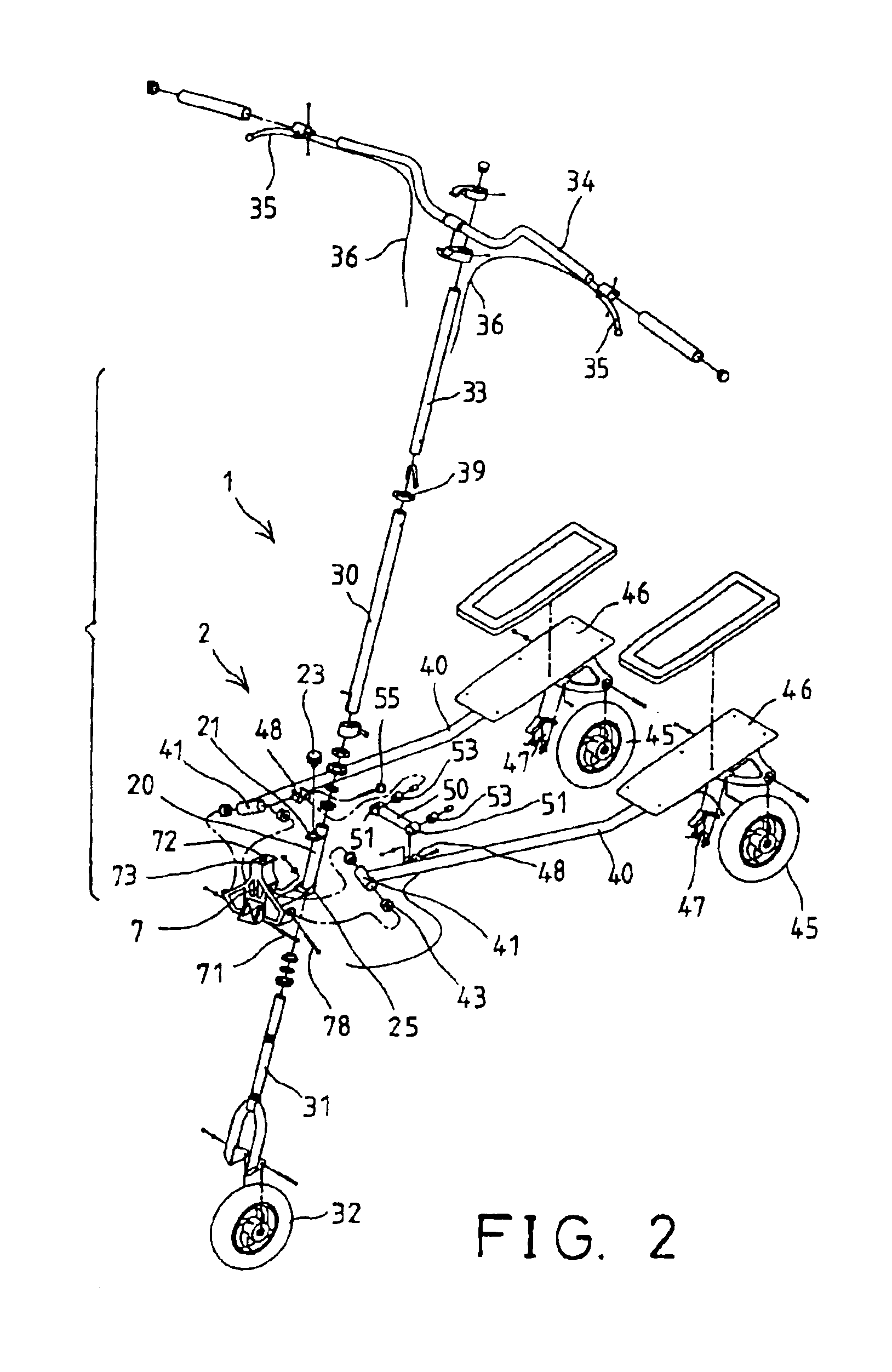

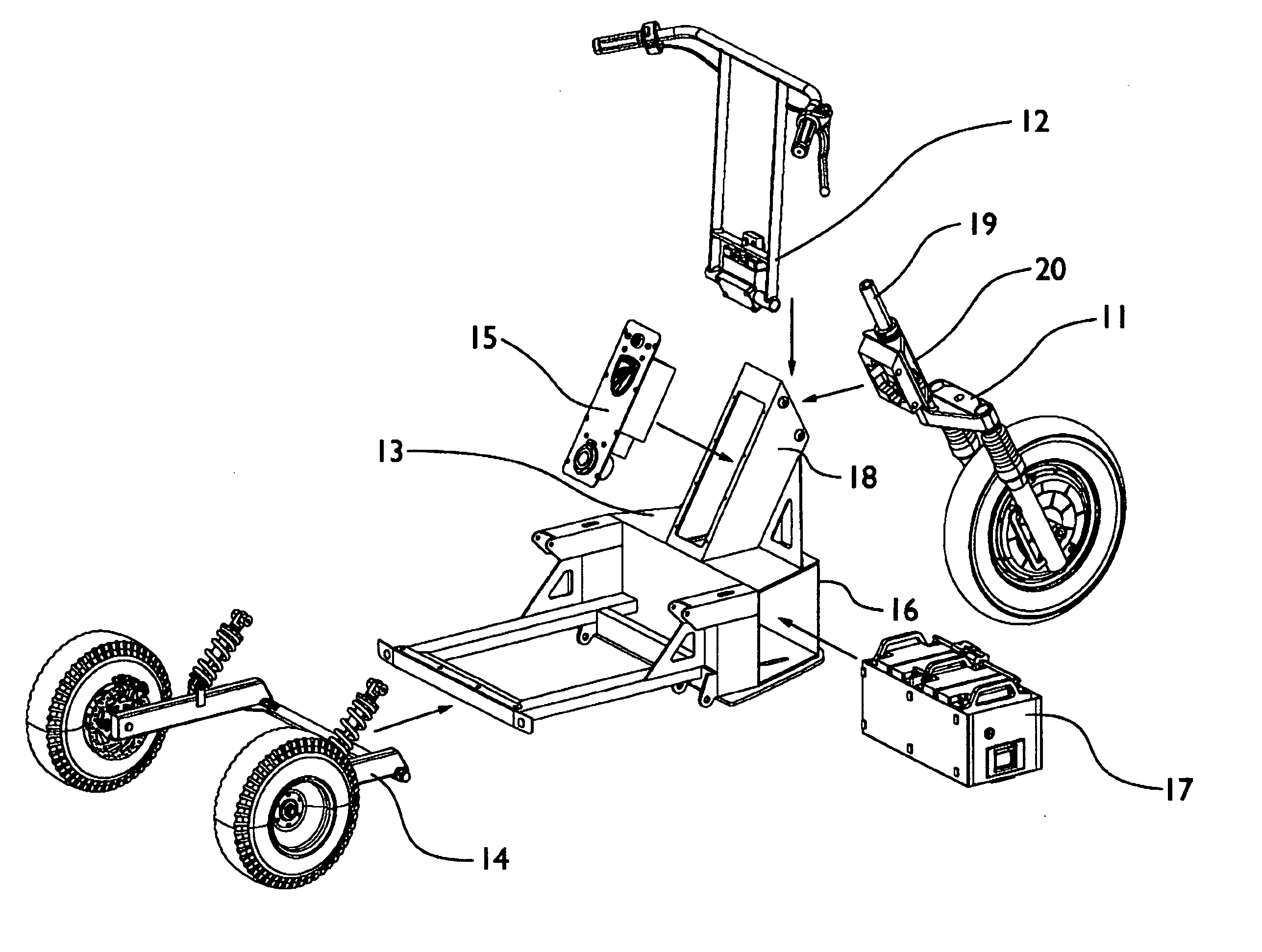

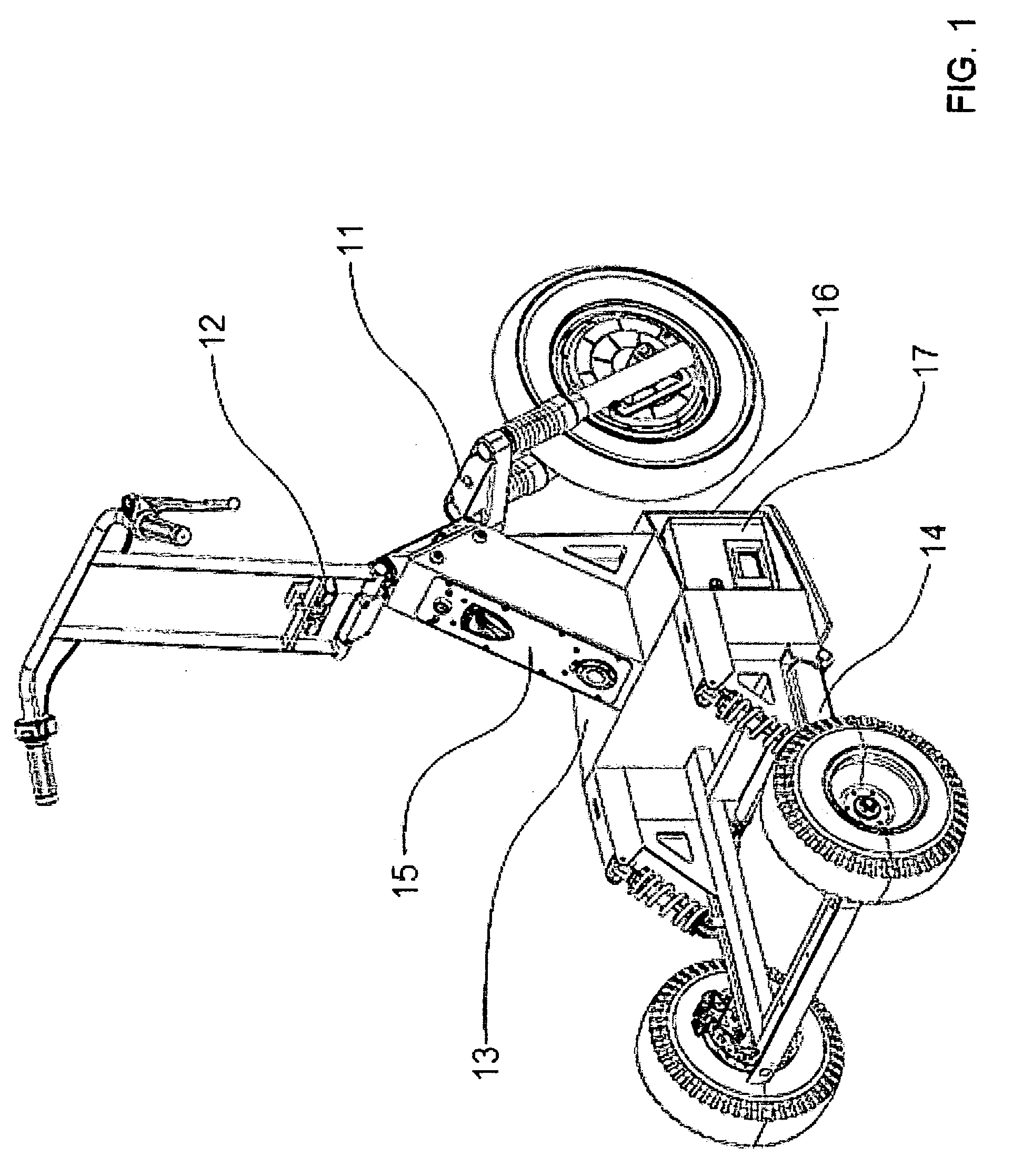

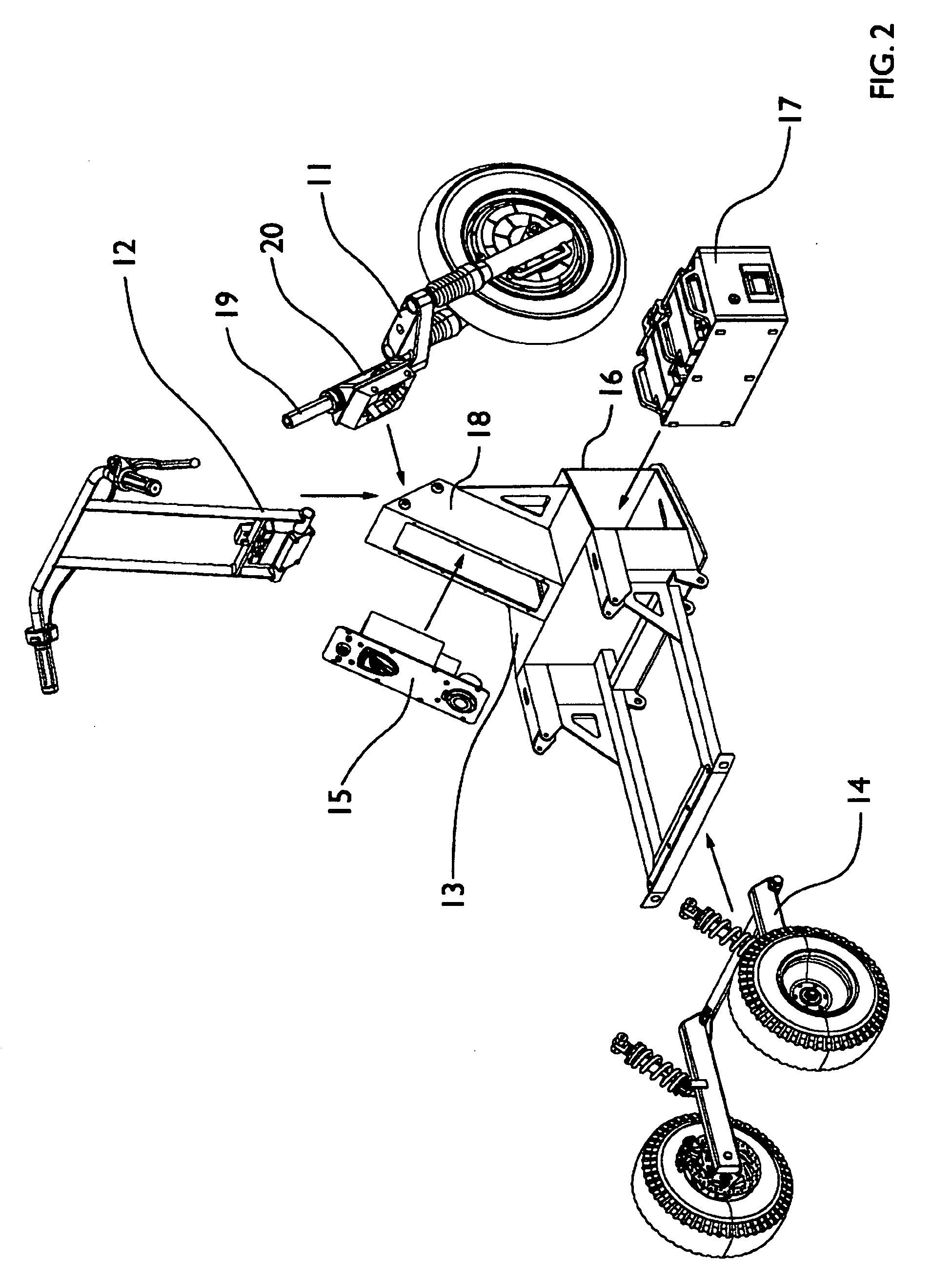

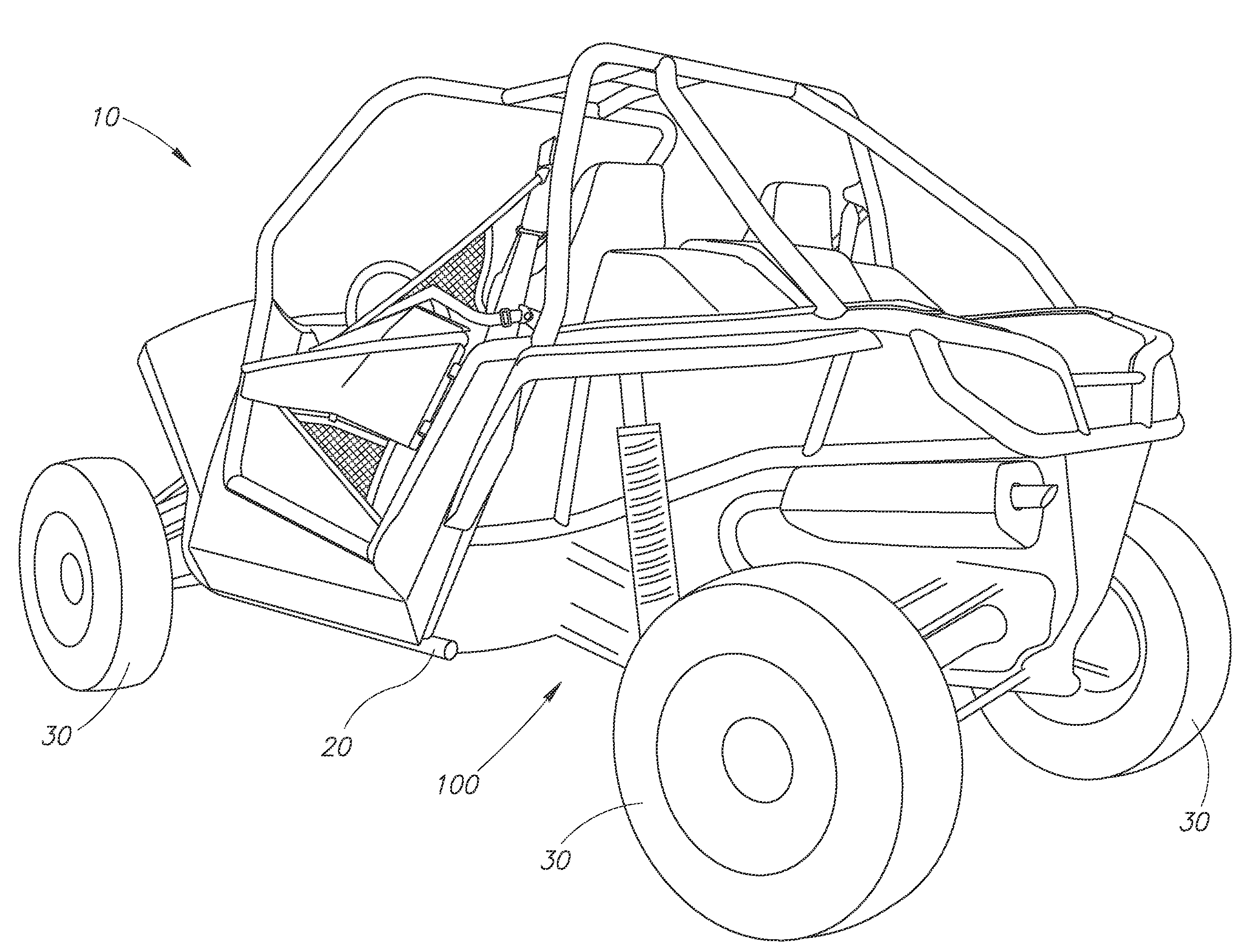

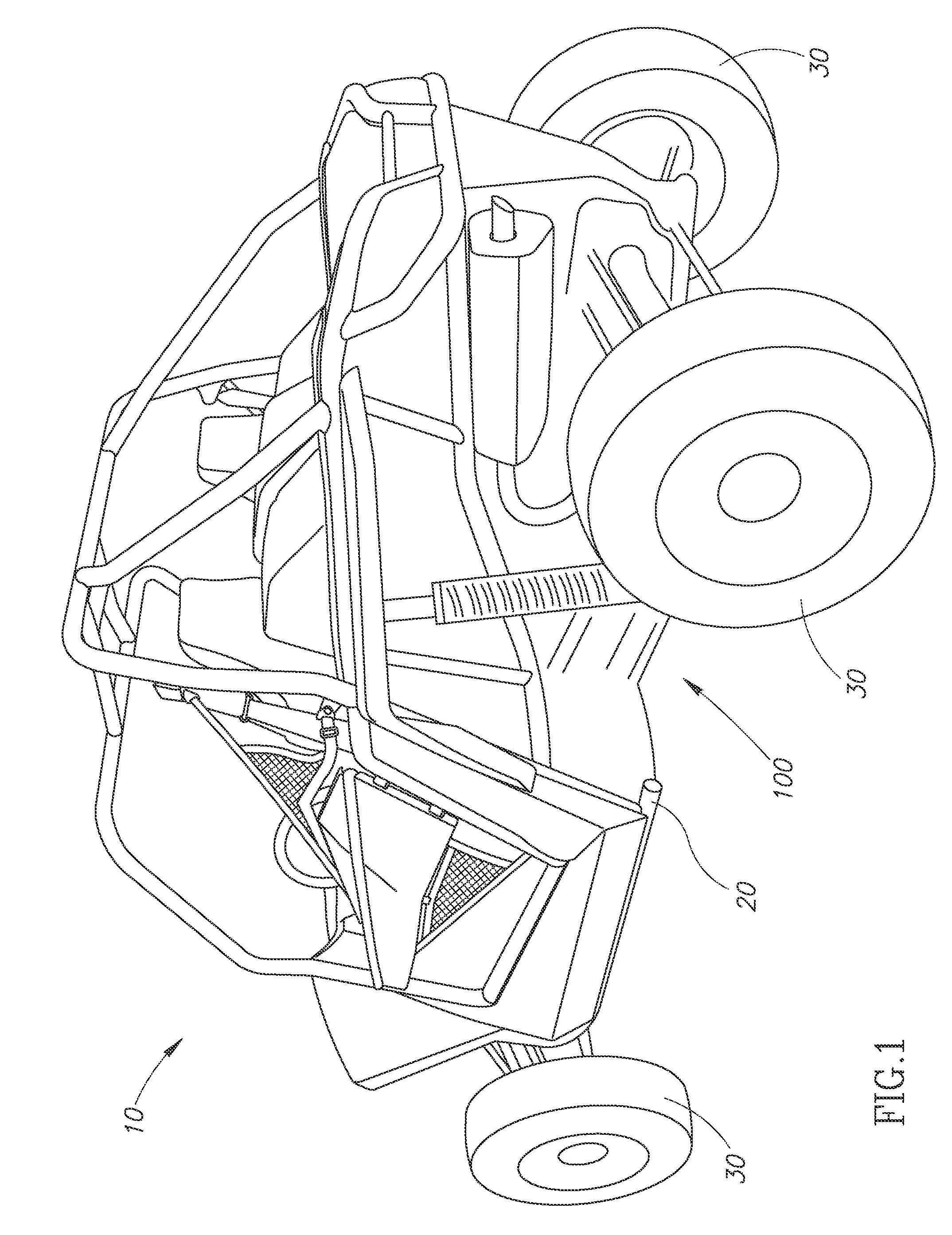

3-Wheeled stand-up personal mobility vehicle and components therein

InactiveUS20090255747A1Less likely to tip overReduce fatigueMechanical apparatusElectric propulsion mountingTrailing armTraction system

An electric vehicle with a modular frame that includes a main chassis with a rider platform (standing position), front fork / wheel assembly, handlebar assembly, and rear trailing arm assembly with left and right rear wheels. The front fork assembly bolts to the main chassis. The handlebar assembly fastens to the pivoting steer tube of the front fork assembly. The trailing arm assembly bolts to the main chassis and pivots to provide rear suspension for the vehicle. The trailing arm includes a stabilizer bar connecting the right and left trailing arms. Electronics enclosures are integral to the main chassis and are structural members of the vehicle. The battery pack can be installed or removed from the main chassis with a hand-activated latch. The electronics plate contains traction system electronics and is removable from the main chassis. The handle bar assembly includes a folding mechanism.

Owner:RIDE VEHICLES

Cast trailing arm assembly for trailer suspension

InactiveUS20060033304A1Less componentsLess-expensive and time-consume to assembleInterconnection systemsResilient suspensionsTrailing armVehicle frame

A trailing arm assembly for a suspension includes at least first and second cast components. The first and second cast components are welded to each other to substantially surround an outer perimeter of an axle member. The first cast component is then welded to one side of the axle member at a first weld and the second cast component is welded to an opposite side of the axle member at a second weld. A bushing tube is then welded to one of the first and second cast components and is subsequently attached to a vehicle frame member. The first weld area comprises a pair of laterally spaced window welds and the second weld area comprises a single window weld.

Owner:ARVINMERITOR TECH

Seeder with trailing arm and hoe-type mid row bander

A seeding and fertilizing apparatus comprises a plurality of seed assemblies each comprising a trailing arm pivotally connected at a front end thereof to the frame and a packer wheel rotatably attached to rear end thereof. A seed furrow opener is attached to the trailing arm ahead of the packer wheel which rolls along the seed furrow created by the opener. A vertical position of the seed furrow opener with respect to the packer wheel is adjustable, and a bias device is operative to exert a downward bias force on the trailing arm. A plurality of fertilizer assemblies each comprises a fertilizer knife mounted to the frame such that a vertical position of the fertilizer knife with respect to the implement frame is adjustable. The seed assemblies and fertilizer assemblies are oriented laterally such that each fertilizer furrow is located between adjacent seed furrows.

Owner:BOURGAULT INDS

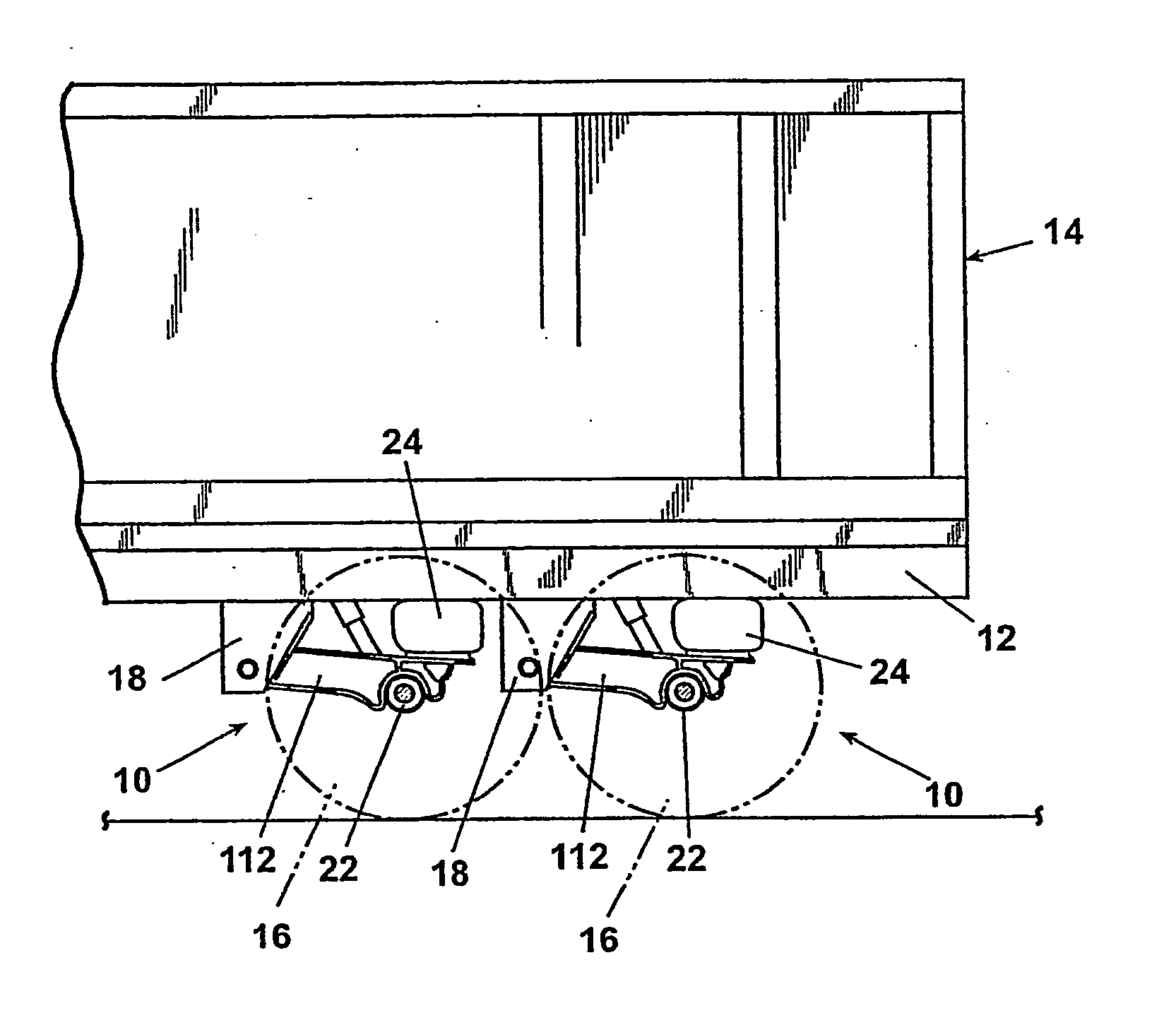

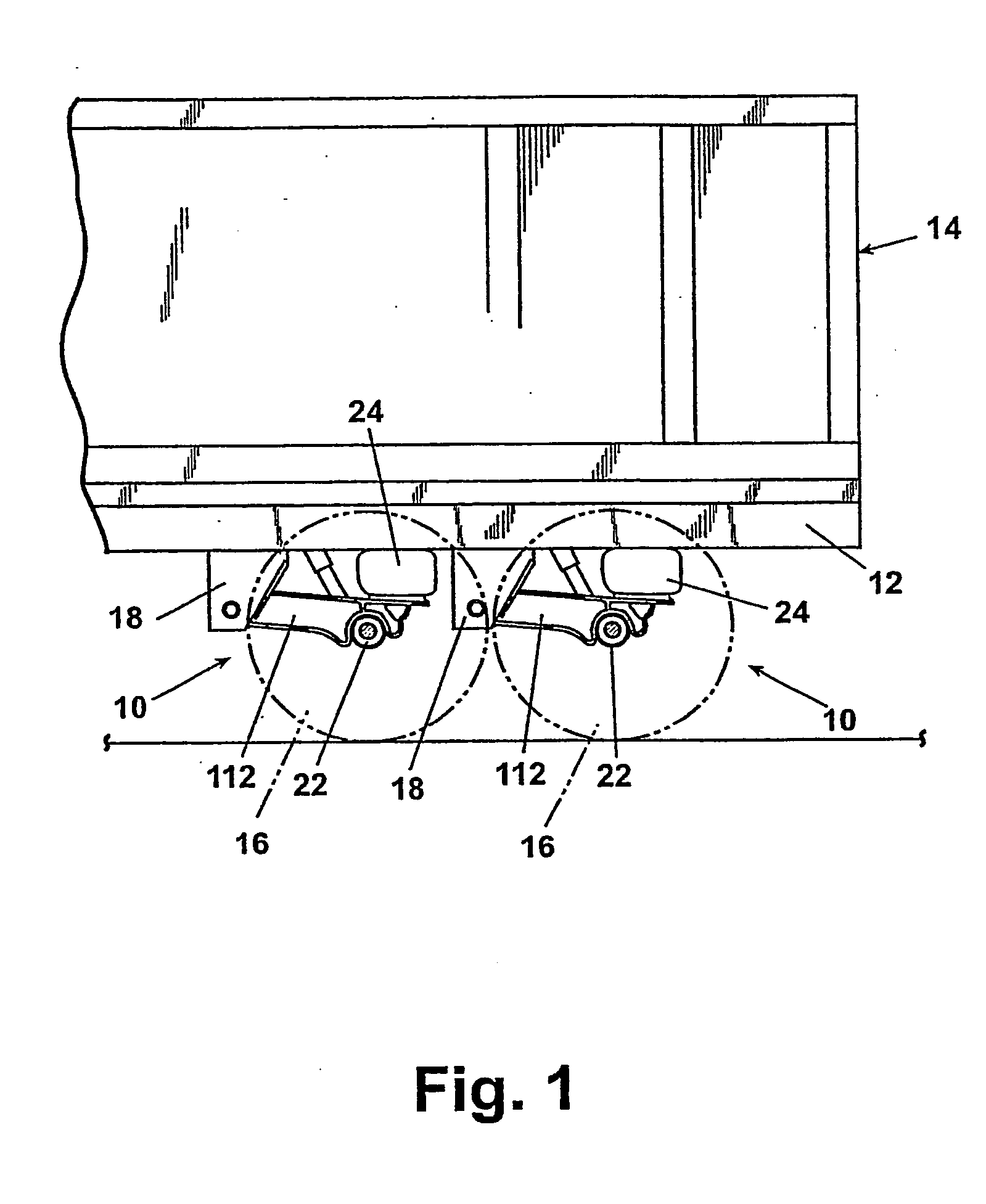

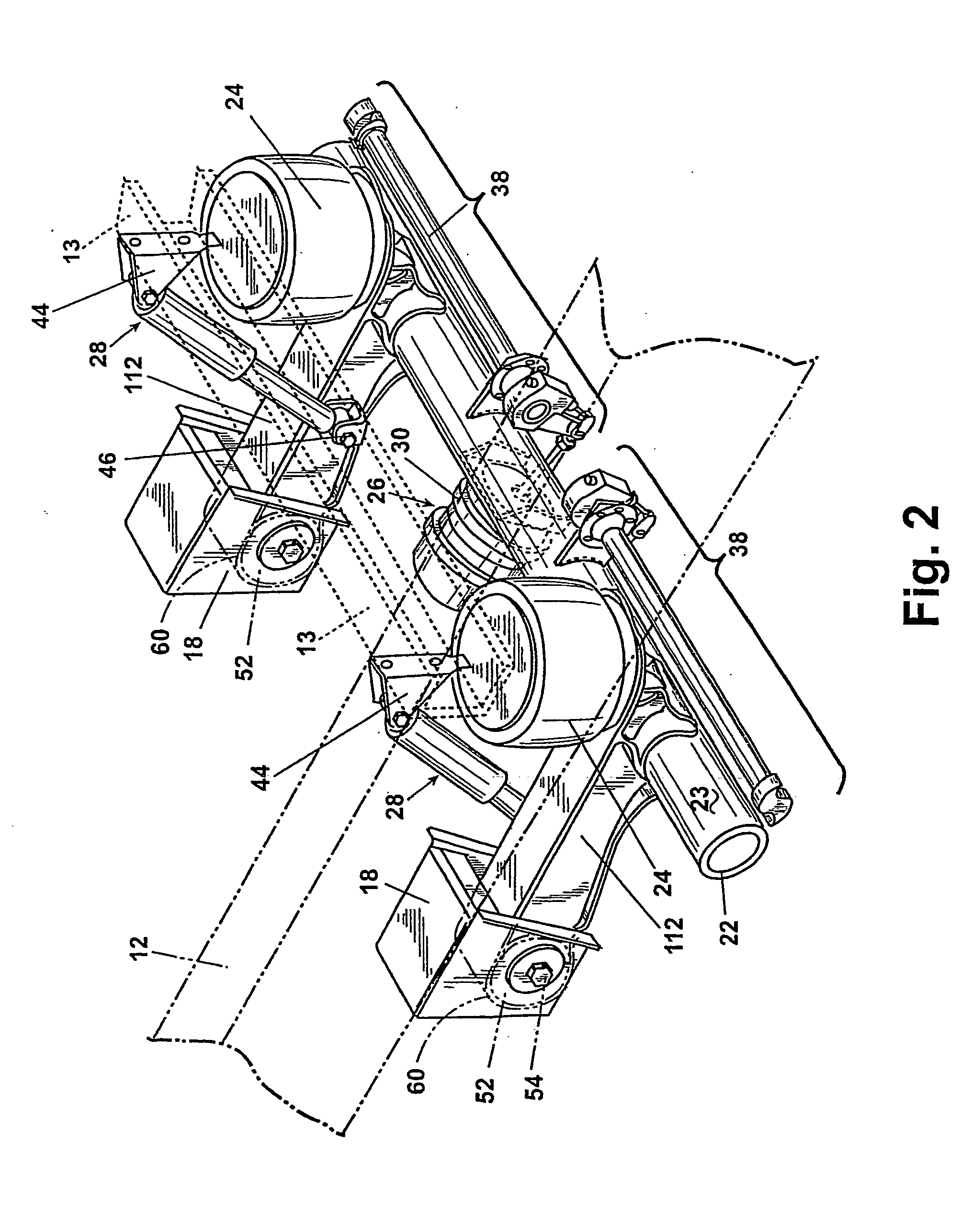

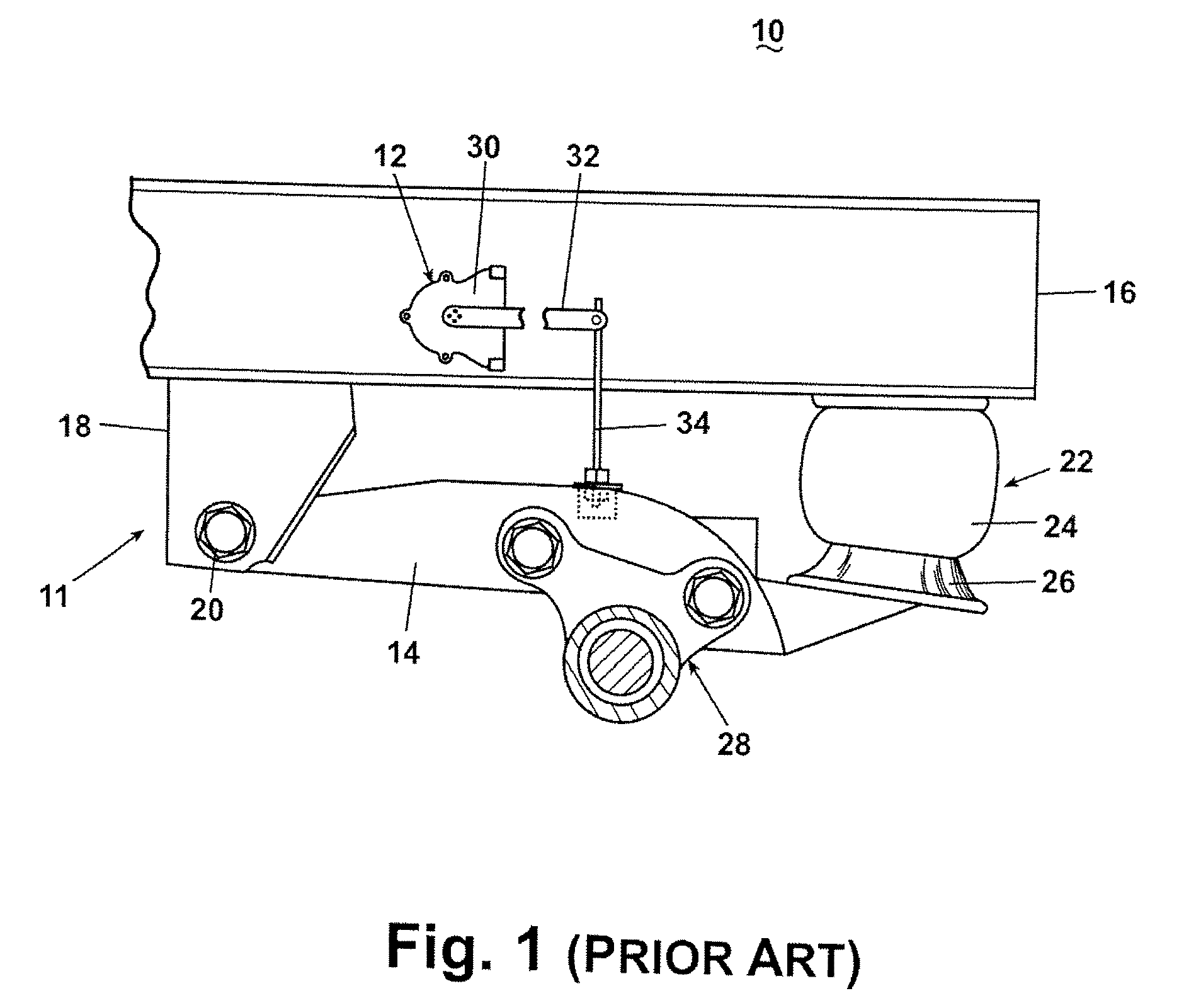

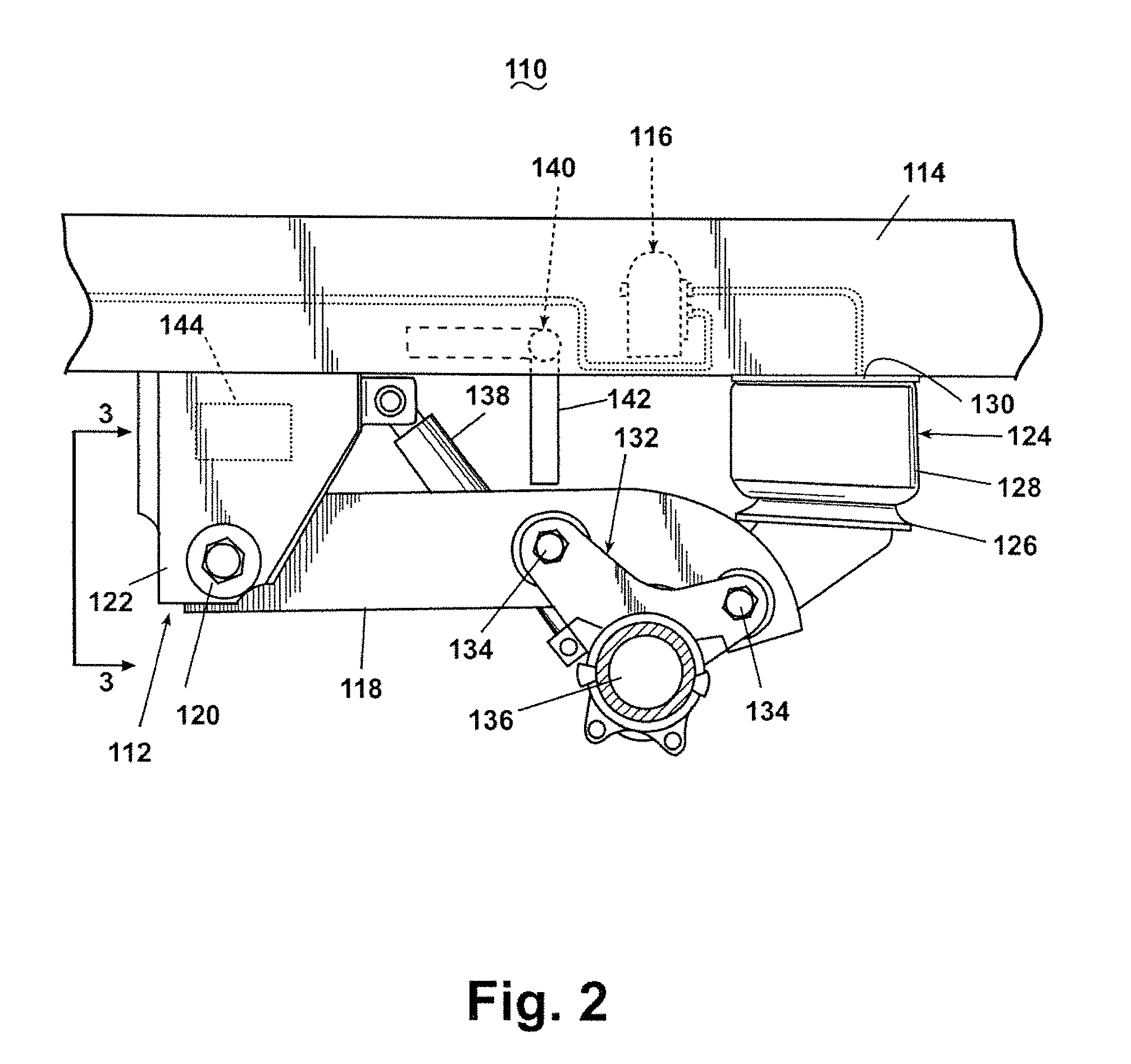

Trailing arm suspension with optimized i-beam

InactiveUS20050051986A1Economizing costEconomizing weightRigid suspensionsResilient suspensionsTrailing armEngineering

A suspension system includes a pair of trailing arms (112) extending between frame brackets (18) and a wheel-carrying axle (22). Each trailing arm (112) comrises an I-beam portion having a web section and first and second flanges, wherein the thickness of at least one of the flanges vaires along a length thereof. The trailing arms (112) are welded directly to the axle (22).

Owner:THE HOLLAND GROUP

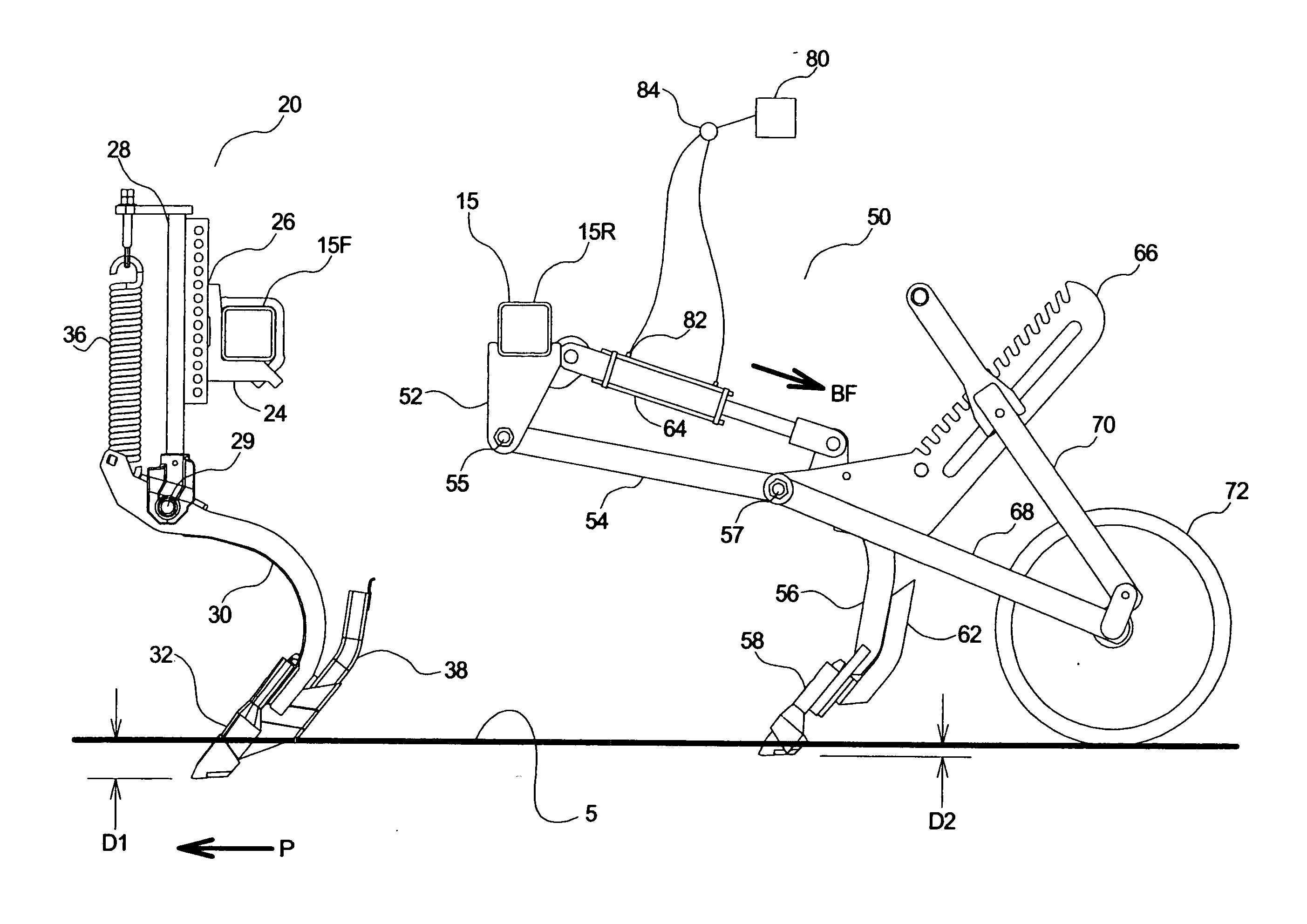

Seed planter with equalizer assembly

Disclosed herein is an agriculture planter. The planter may include a planter frame, a seed hopper and a trailing arm assembly. The planter frame may include a hitch tongue extending forwardly from the planter frame. The planter frame supports the seed hopper. The a trailing arm assembly is vertically pivotally coupled to a rear portion of the planter frame, extends rearward from the planter frame and includes a trailing arm frame and a lever arm vertically pivotally coupled to the trailing arm frame by a pivot point. The lever arm includes a leading end, a trailing end, a middle portion, a furrow opener disc and a first furrow closer wheel. The disc is rotatably mounted to the lever arm near the leading end. The first wheel is rotatably mounted to the lever arm near the trailing end. The middle portion is pivotably coupled to the pivot point.

Owner:SCHAFFERT MFG

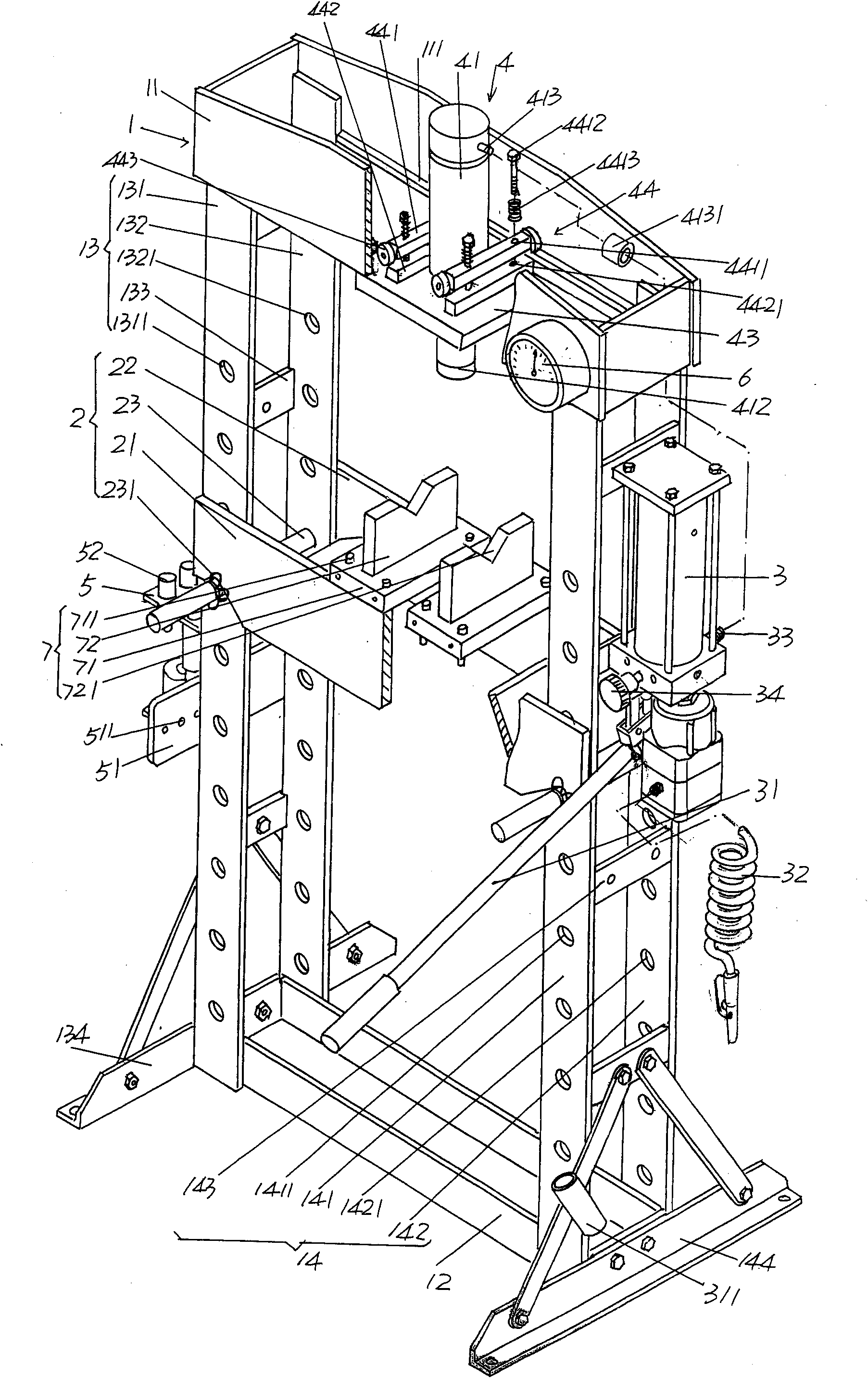

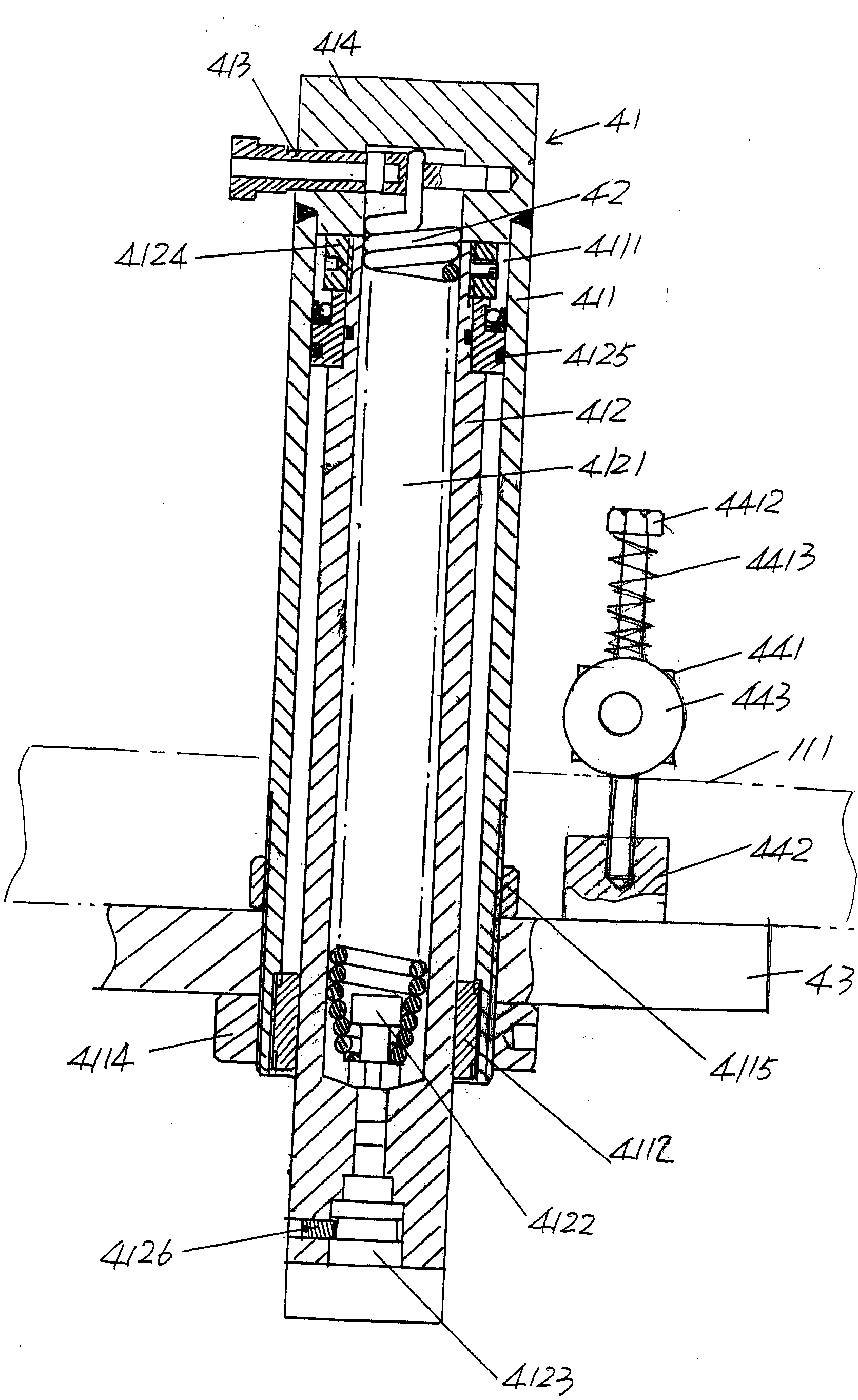

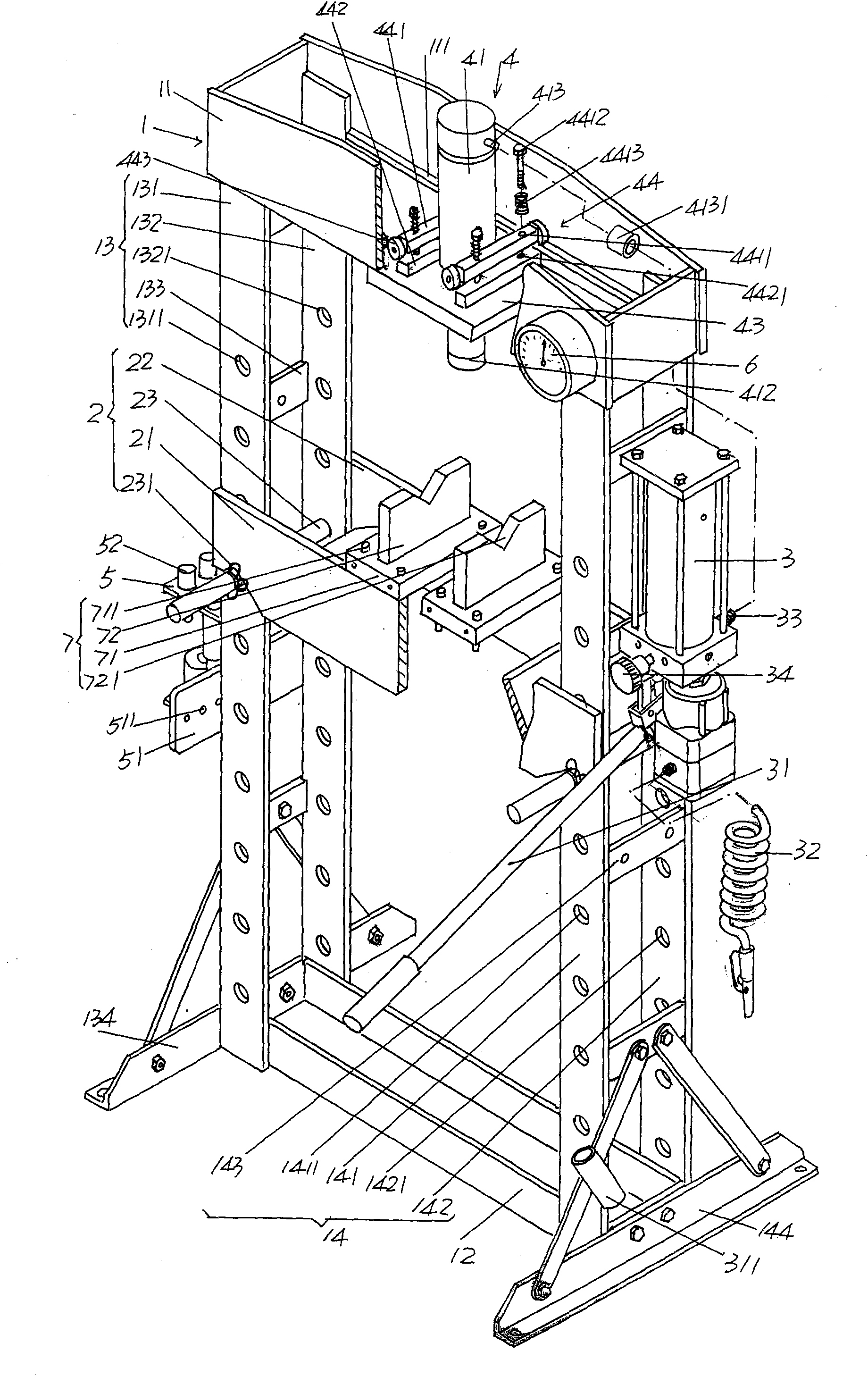

Jack hydraulic press

The invention discloses a jack hydraulic press, which belongs to the technical field of presses, and comprises a machine frame comprised of an upper beam, a lower beam, first and second trailing arms which are connected between the upper beam and the lower beam and longitudinally parallel to each other, a work rest arranged at the first trailing arm and the second trailing arm and corresponding to the space between the upper beam and the lower beam, a jack body arranged on the outer side of the first trailing arm or the second trailing arm, and an under-thrust device arranged at the upper beam and connected with a hydraulic circuit of the jack body. The jack hydraulic press is characterized in that: the upper beam is in a square structure which is closed on four sides and hollow along the up-and-down direction, the inner walls of a pair of wall bodies along the length direction of the upper beam are fixedly provided with a guide rail respectively, two guide rails are parallel to each other, and the under-thrust device is slipperily arranged on the guide rails. The jack hydraulic press has the advantages of saving operational labor, achieving high adaptability and reducing the labor intensity of the operator.

Owner:CHANGSHU TONGRUN AUTO ACCESSORY

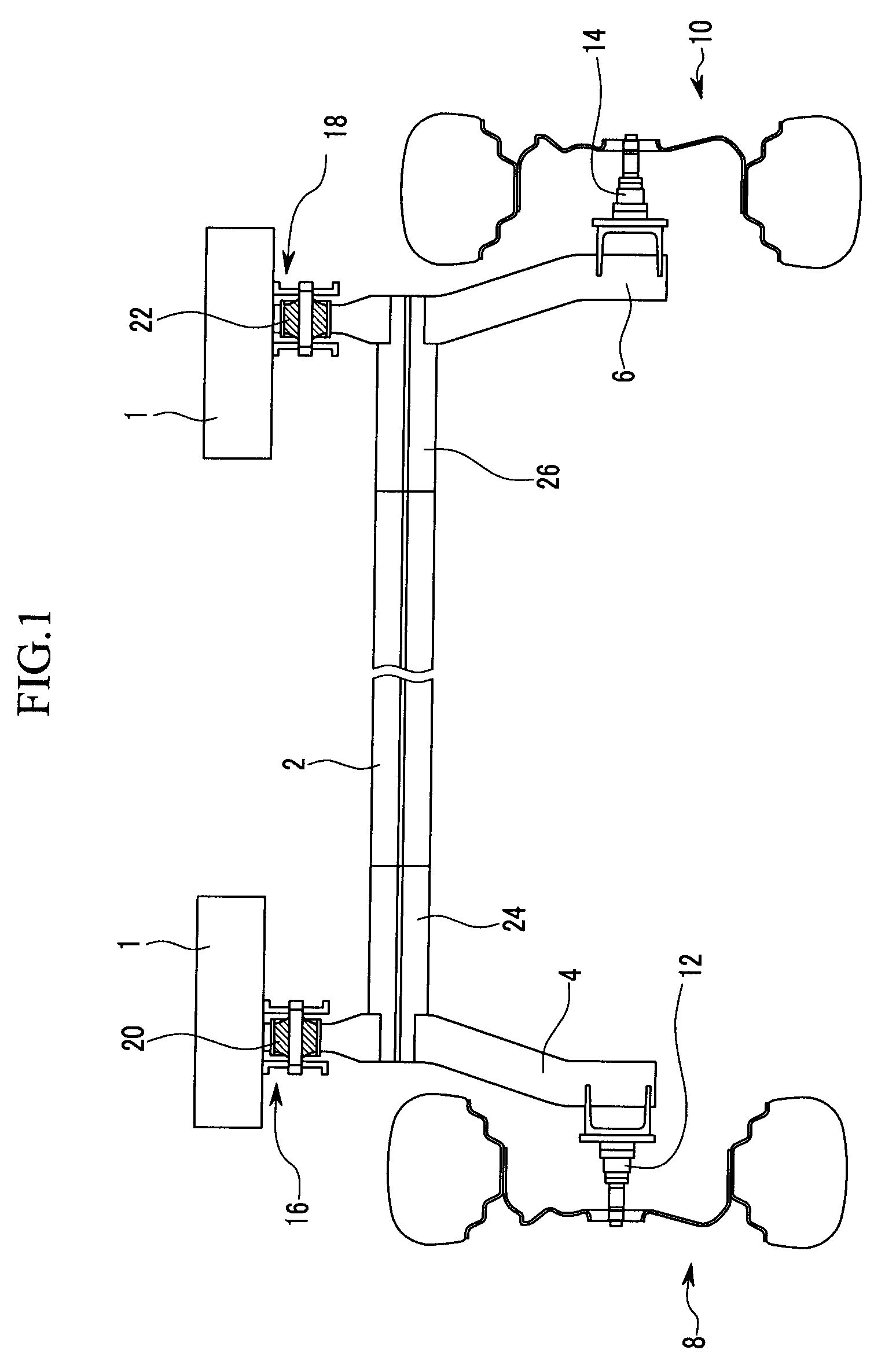

Suspension System for Vehicle

InactiveUS20100059959A1Improve rigidityInterconnection systemsResilient suspensionsTrailing armVehicle suspension system

A suspension system for a vehicle may include a torsion beam disposed along width direction of the vehicle and including an attaching portion formed to an end portion thereof, a trailing arm disposed to the attaching portion of the torsion beam and aligned along length direction of the vehicle, wherein one end portion of the trailing arm is coupled to a wheel and the other end portion of the trailing arm is connected to a vehicle body, and a stiffener connecting the attaching portion of the torsion beam and the trailing arm disposed between the stiffener and the attaching portion of the torsion beam.

Owner:HYUNDAI MOTOR CO LTD +1

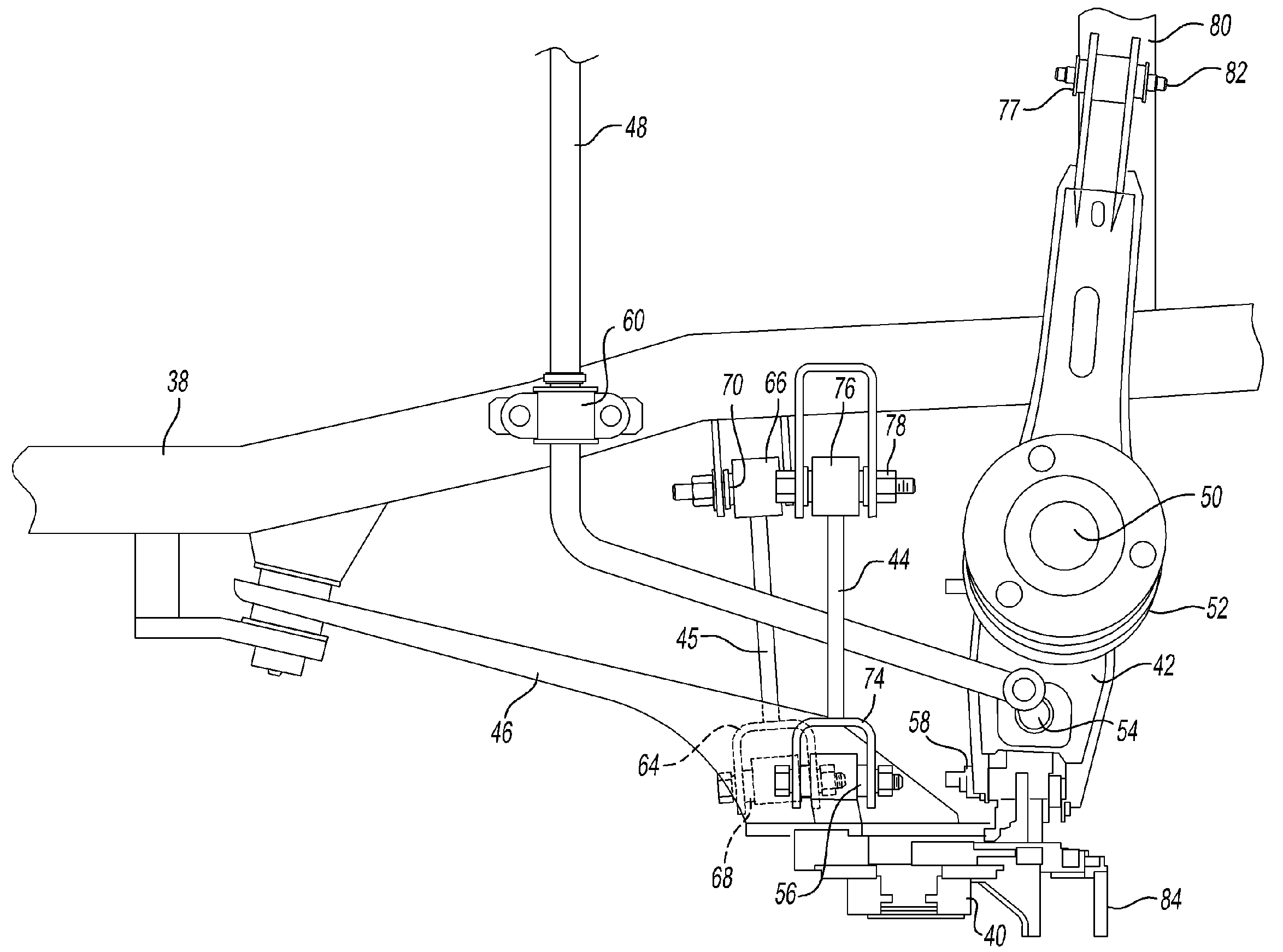

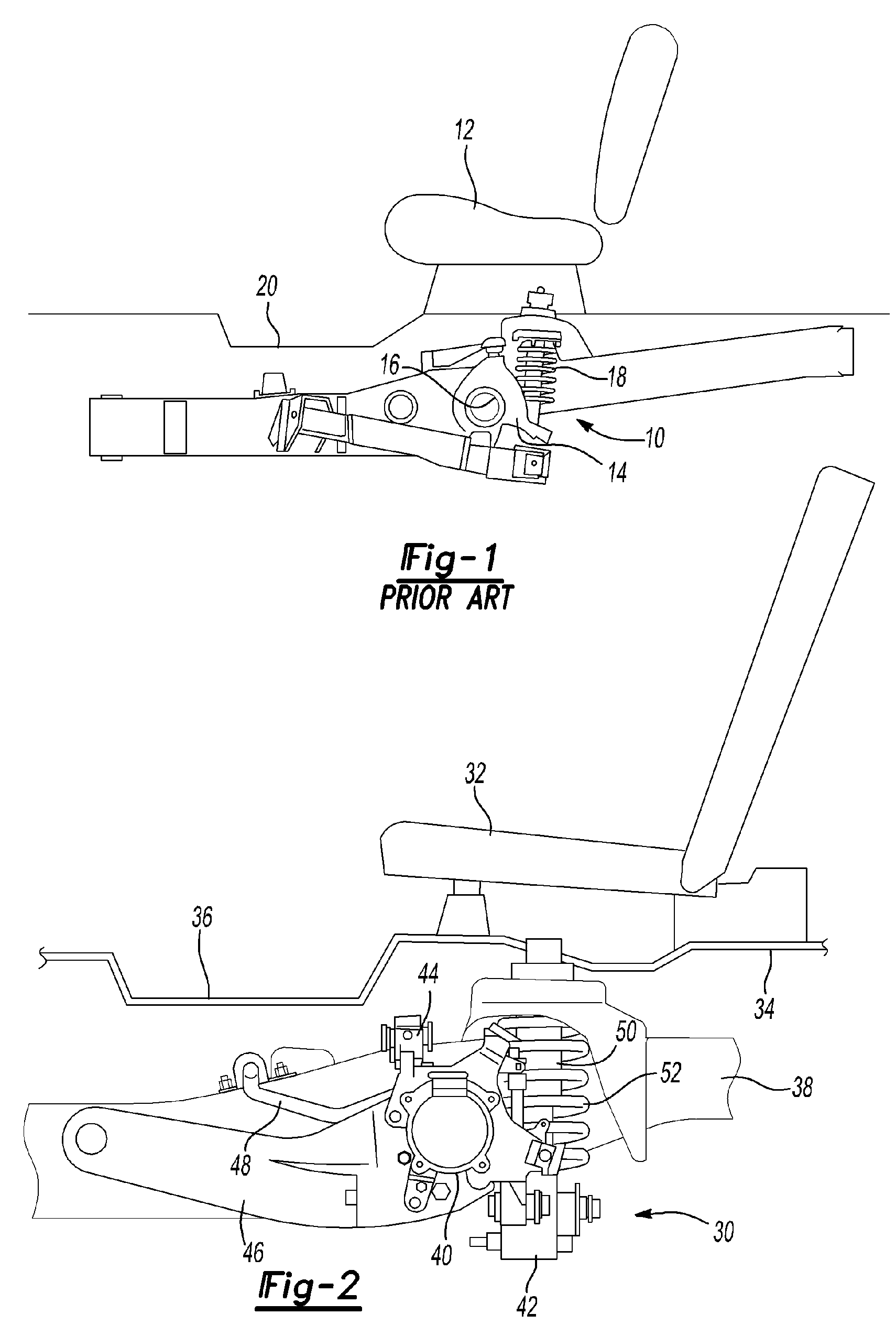

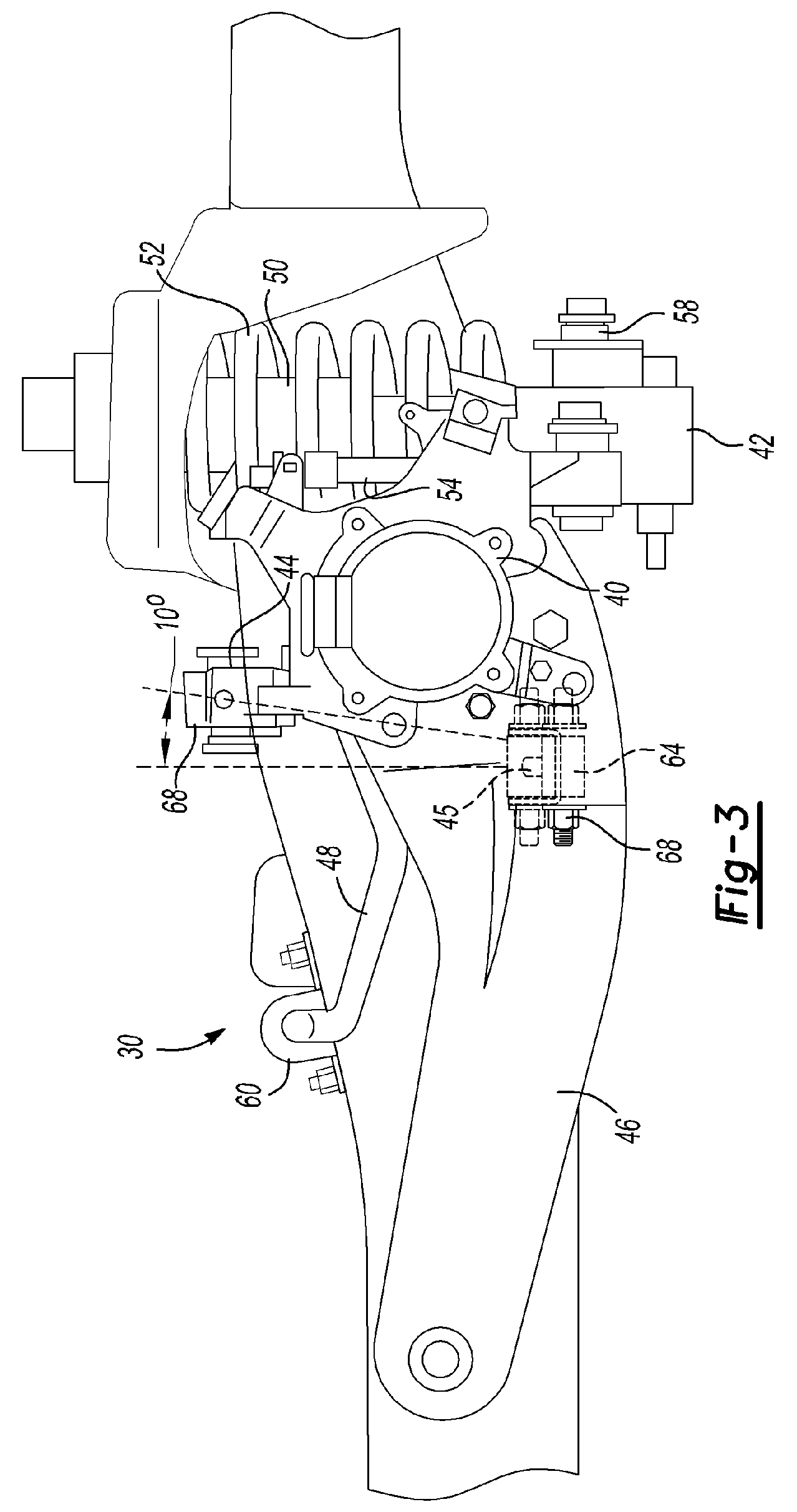

Independent rear suspension

ActiveUS7325820B2Easy to adjustReduce confusionUnderstructuresInterconnection systemsVehicle frameTrailing arm

An independent rear suspension system is provided that has a trailing arm connected between a frame rail and a wheel support knuckle. A lower control arm is connected between a frame cross member and the knuckle. The suspension system also includes an upper link that extends between the frame rail and the knuckle. The toe link and upper link are generally vertically aligned. A stabilizer bar extends between the toe link and upper link and is connected to the lower control arm outboard of the shock and spring to reduce space requirements for the suspension system forward of the wheel support knuckle. The lower control arm is elongated and attached to the frame cross member inboard of the frame rails to improve the ratio of wheel travel to shock travel.

Owner:FORD GLOBAL TECH LLC

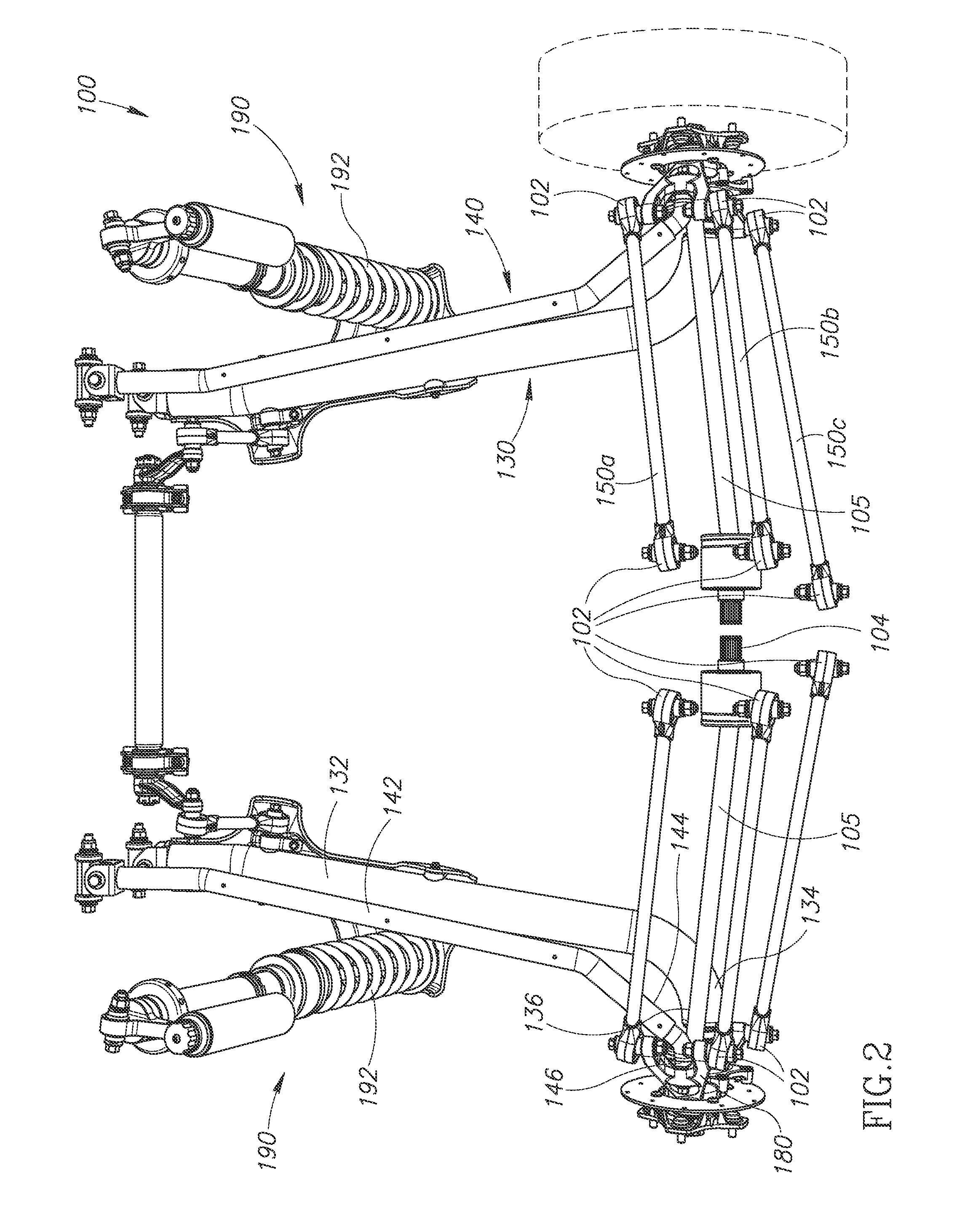

Suspension for vehicle

A suspension system for a vehicle includes two trailing arms and three lateral links to maintain a wheel in or nearly in a vertical position throughout a relatively large travel distance. The trailing arms can be an upper and a lower trailing arm that form a linkage to limit the caster movement of the wheel throughout the travel distance. The three lateral links form two linkages that maintain proper orientation of the wheel: a first linkage to limit the camber movement of the wheel, and a second linkage to limit the tracking, or toe, movement of the wheel. The trailing arms and lateral links provide a relatively large travel distance.

Owner:ARCTIC CAT

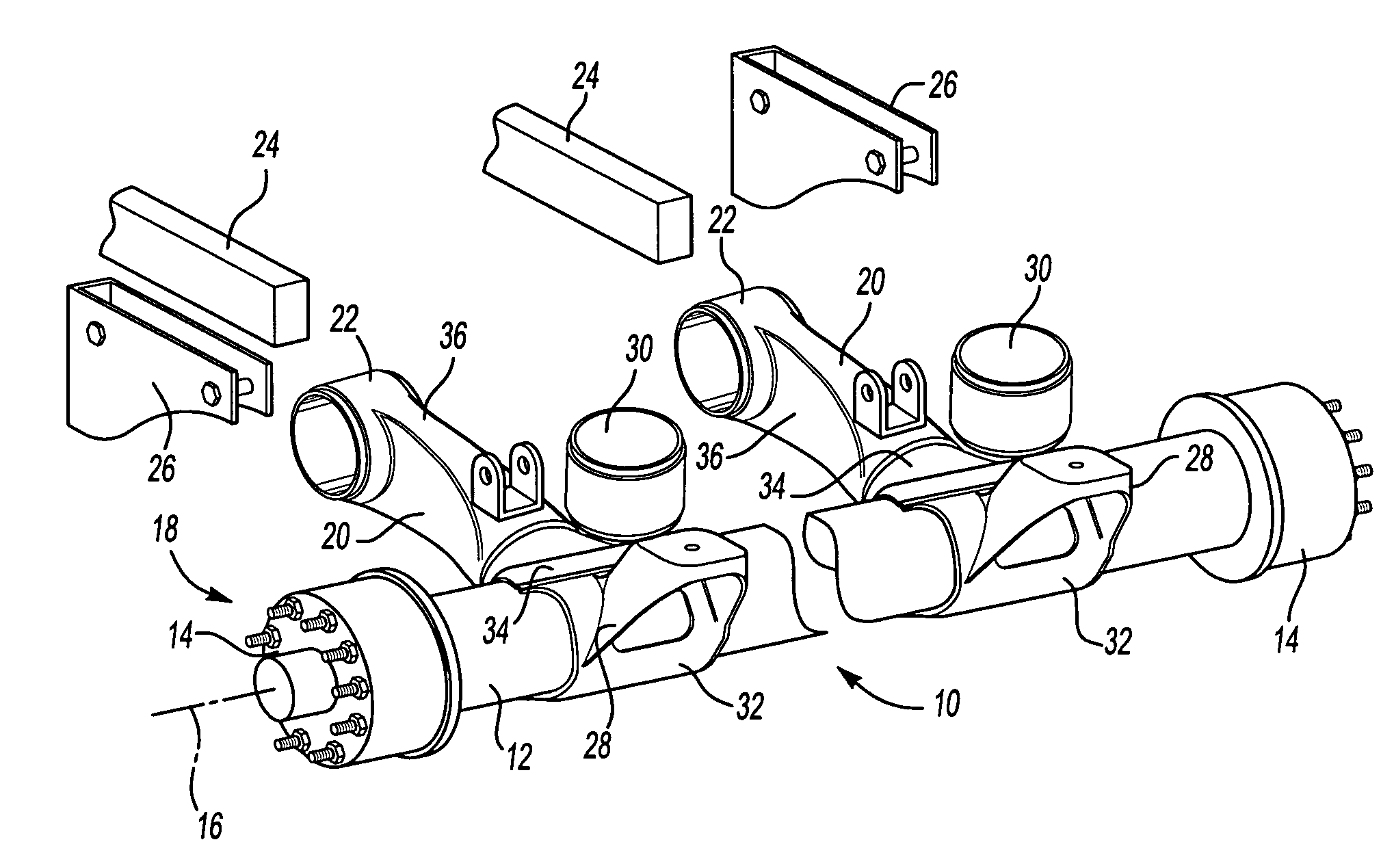

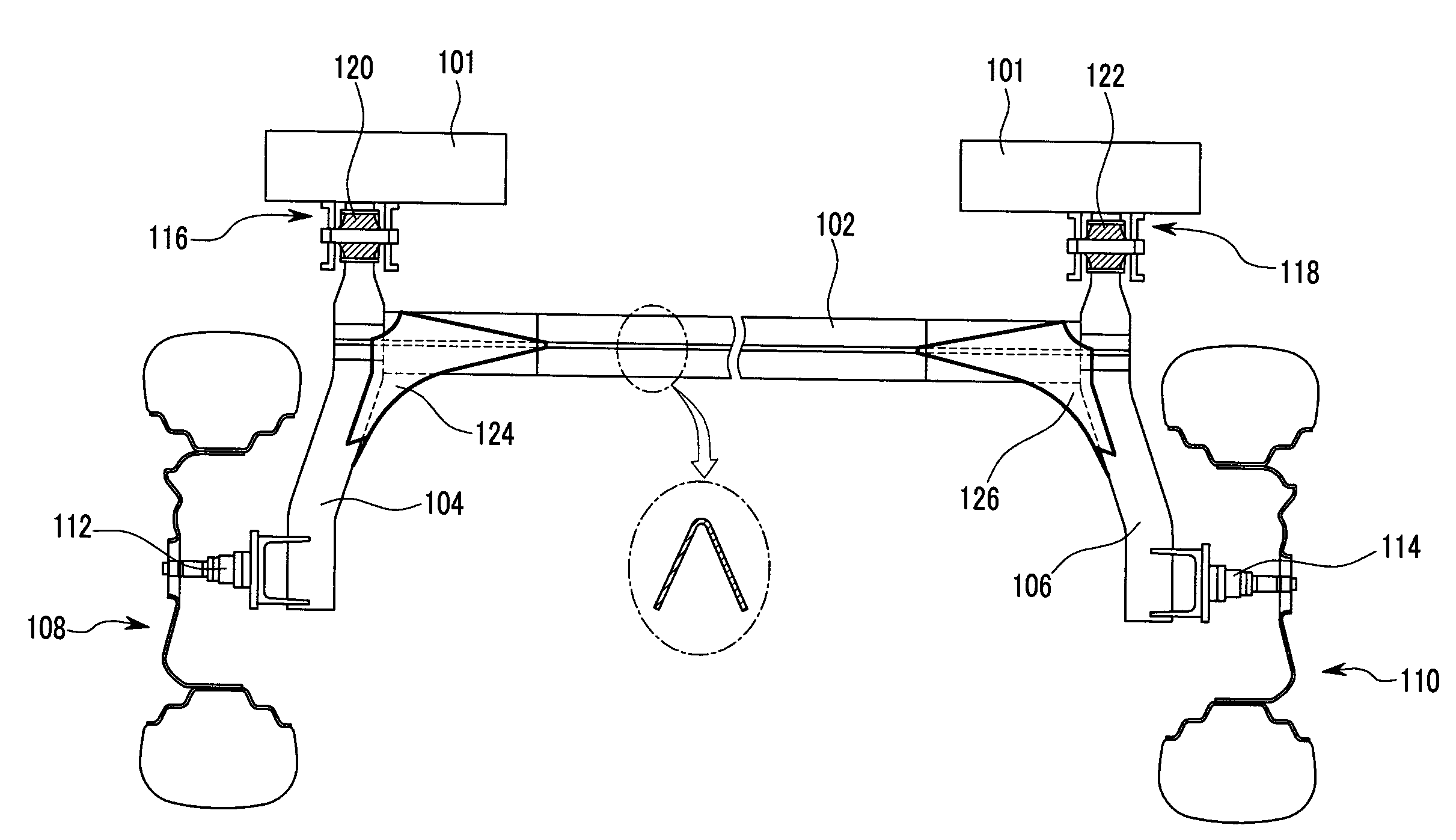

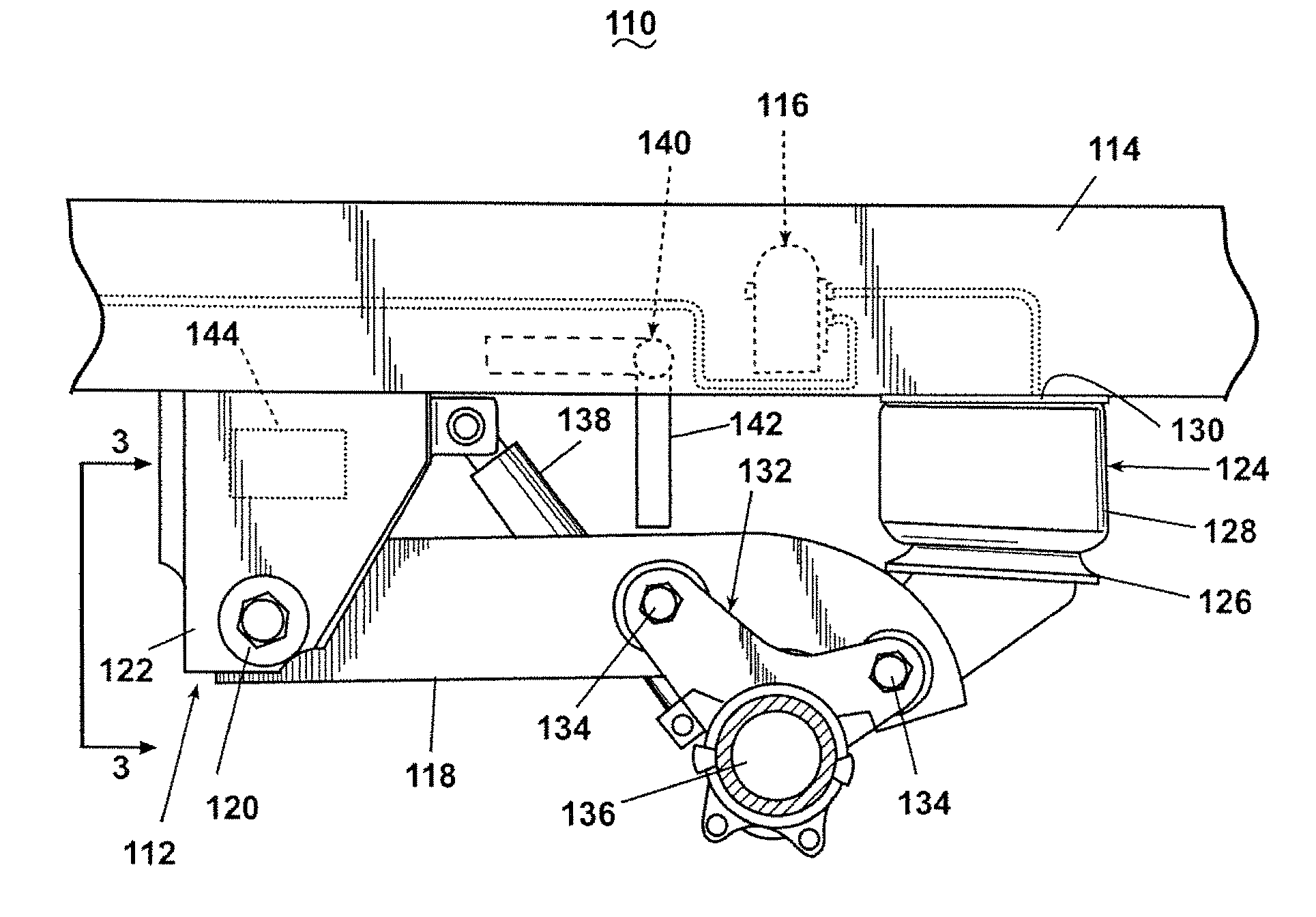

Tubular Torsion Beam for Rear Suspensions of Vehicles and Manufacturing Method Thereof

ActiveUS20100187788A1Increased durabilityImprove roll stiffnessMetal-working apparatusInterconnection systemsTrailing armEngineering

Provided is a tubular torsion beam for rear suspensions of vehicles, which is produced according to a more durable design capable of improving roll stiffness and roll strength of the tubular torsion beam. The tubular torsion beam is produced by pressure-forming a tubular steel member through hydroforming such that the tubular torsion beam has a cross-section varying along an entire length thereof, with opposite ends having a closed cross-section and mounted to respective trailing arms, a middle portion having a V-shaped open cross-section, and a transitional portion having a varying cross-section and connecting the middle portion to each of the opposite ends. During the process of manufacturing the tubular torsion beam, the opposite ends of the tubular steel member are fed using respective axial punches of a hydroforming machine, so that the opposite ends are thicker than the middle portion.

Owner:POHANG IRON & STEEL CO LTD

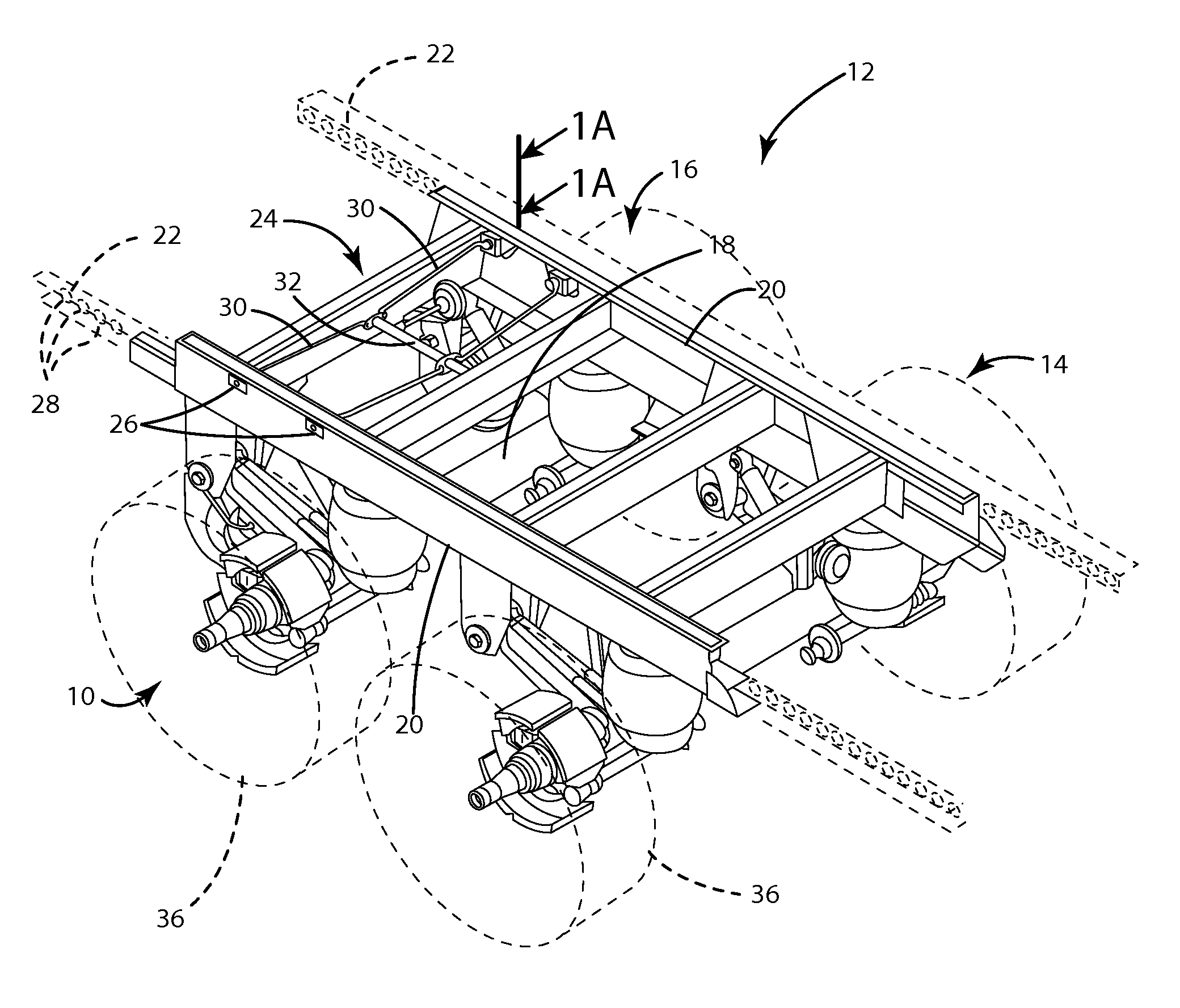

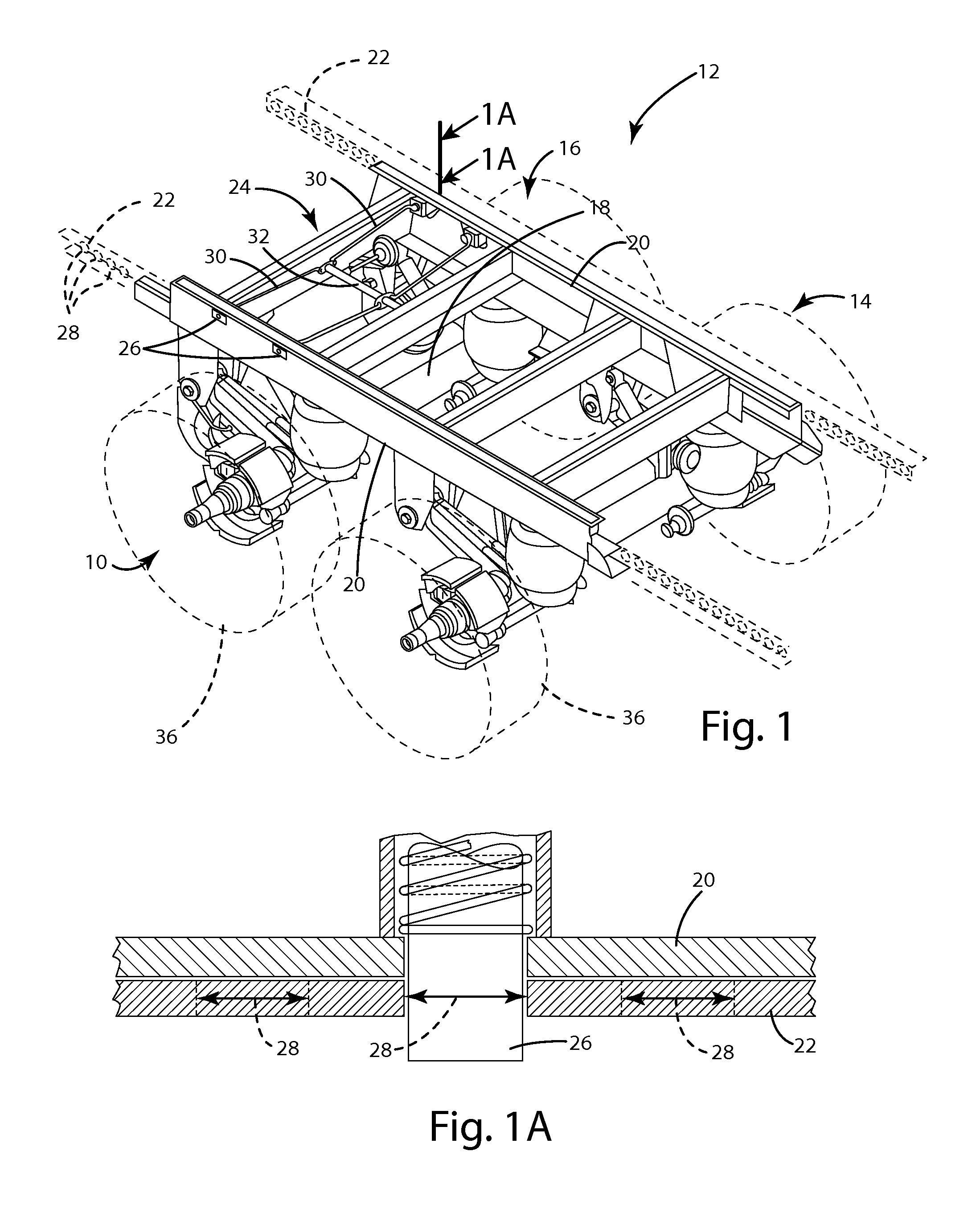

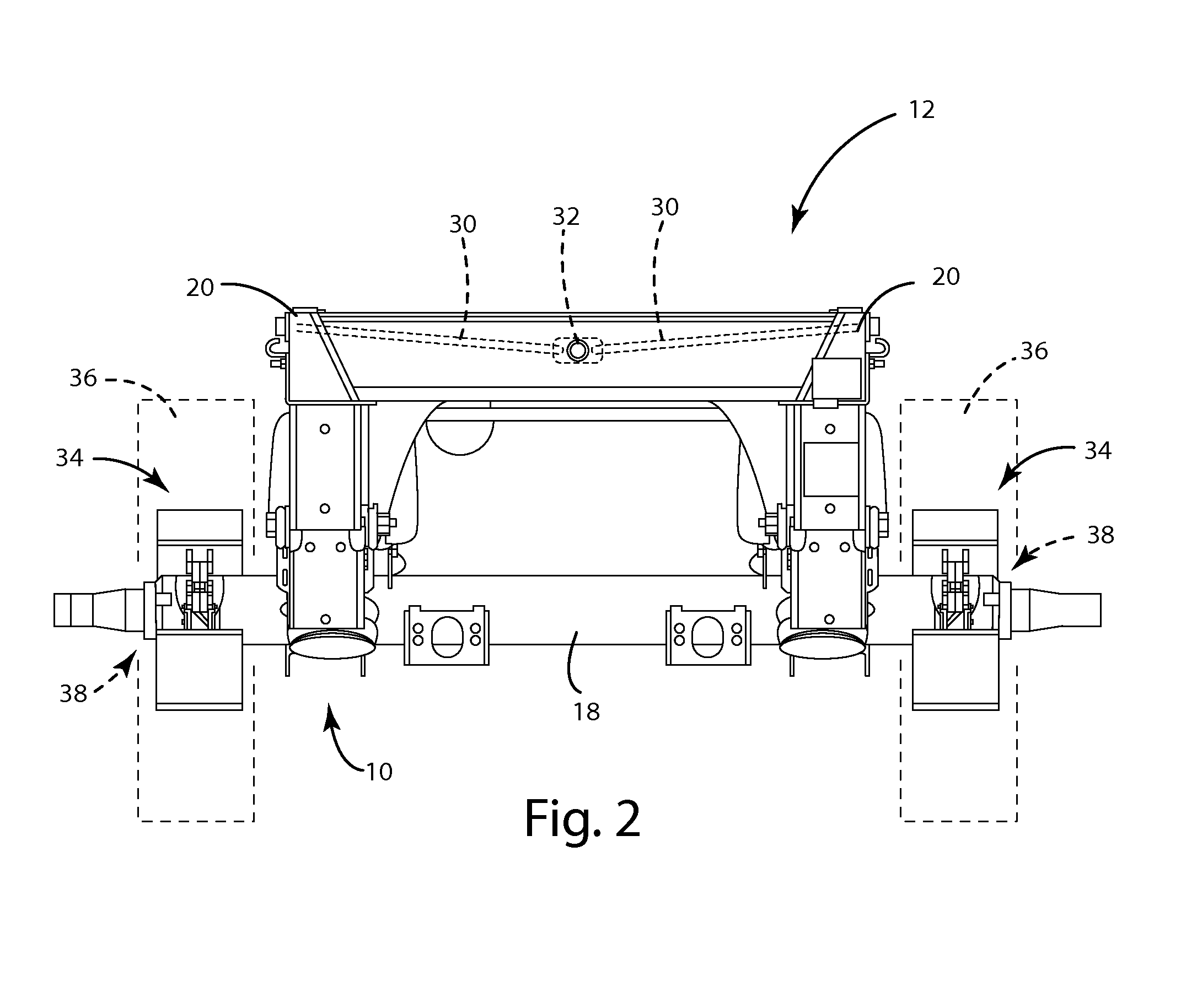

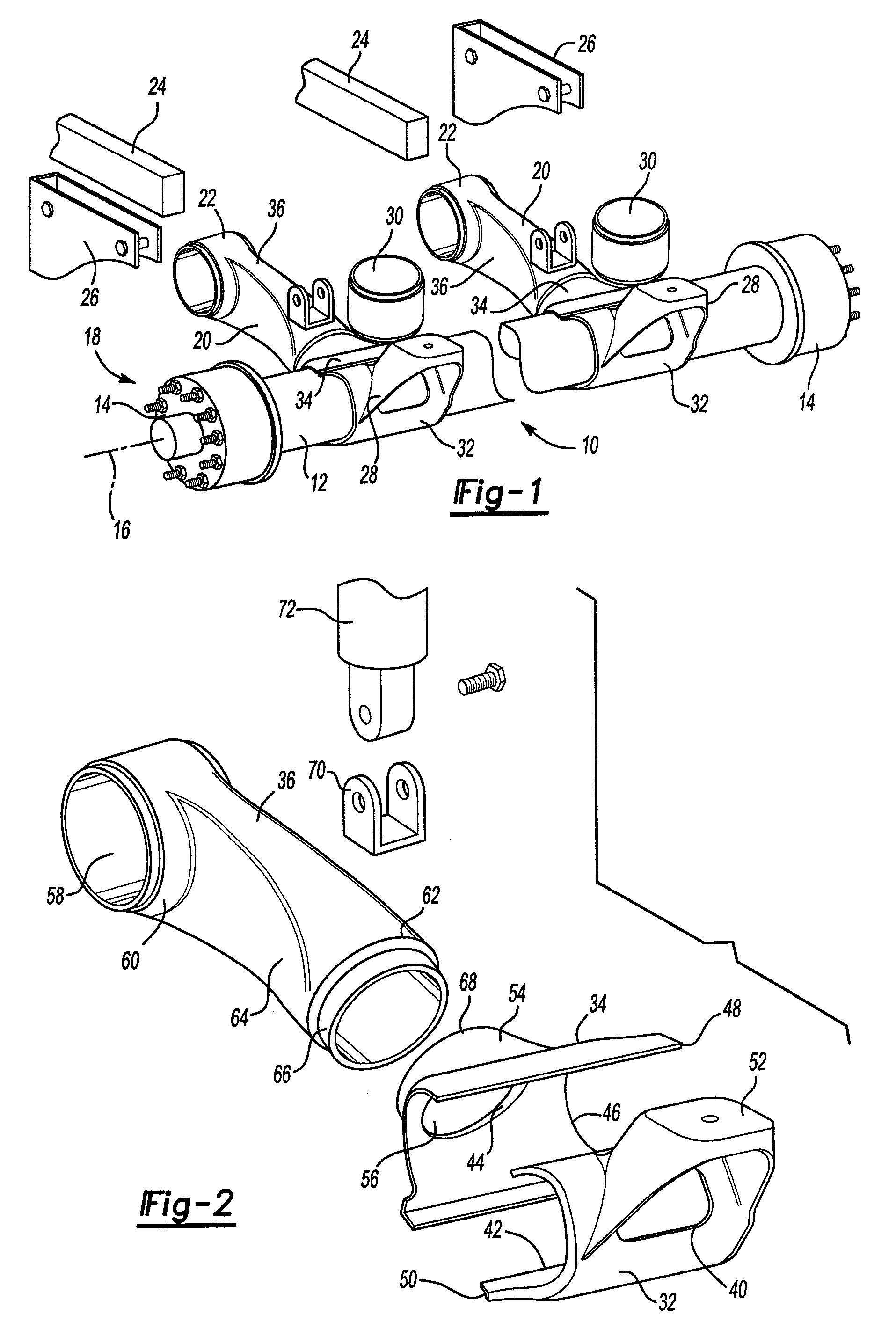

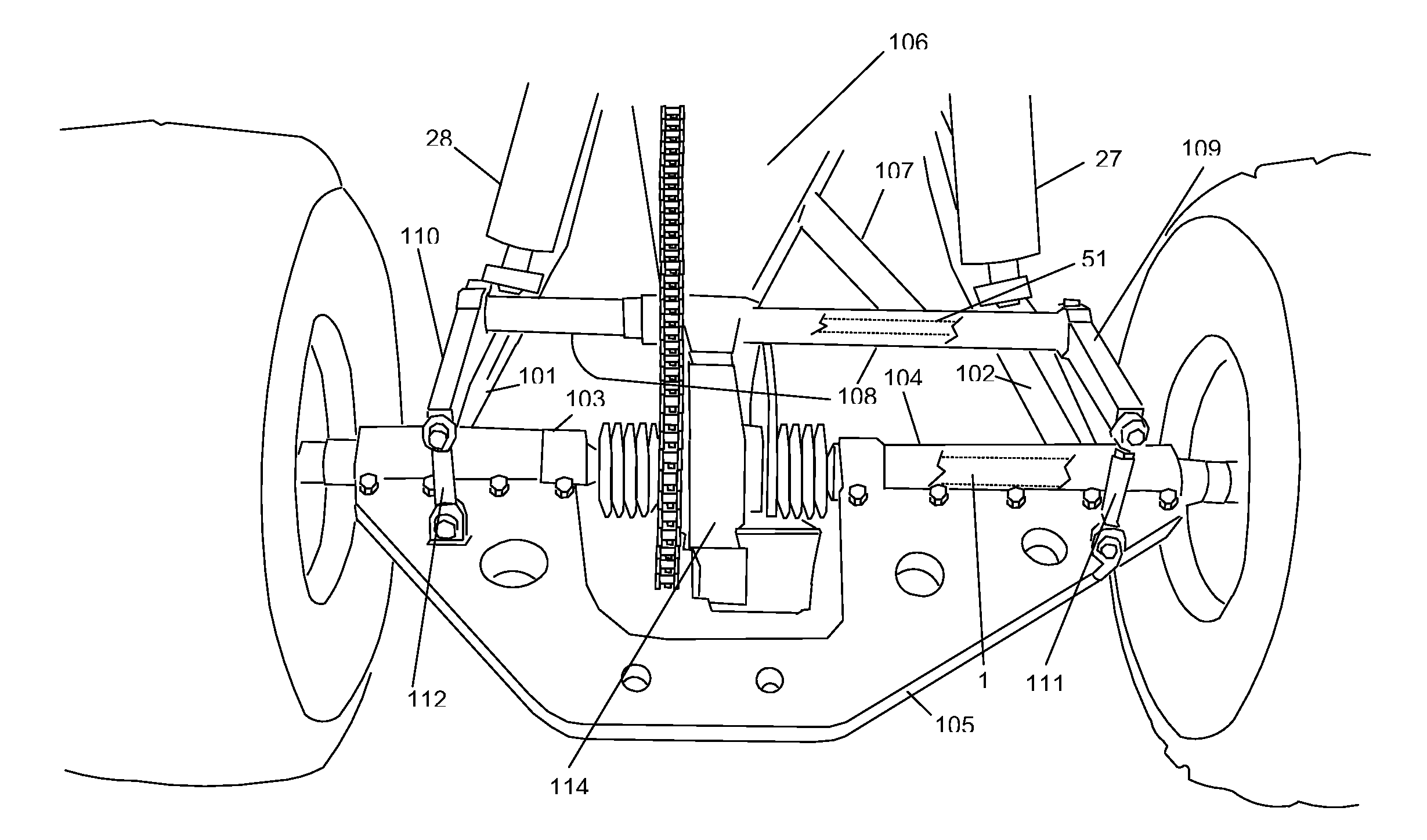

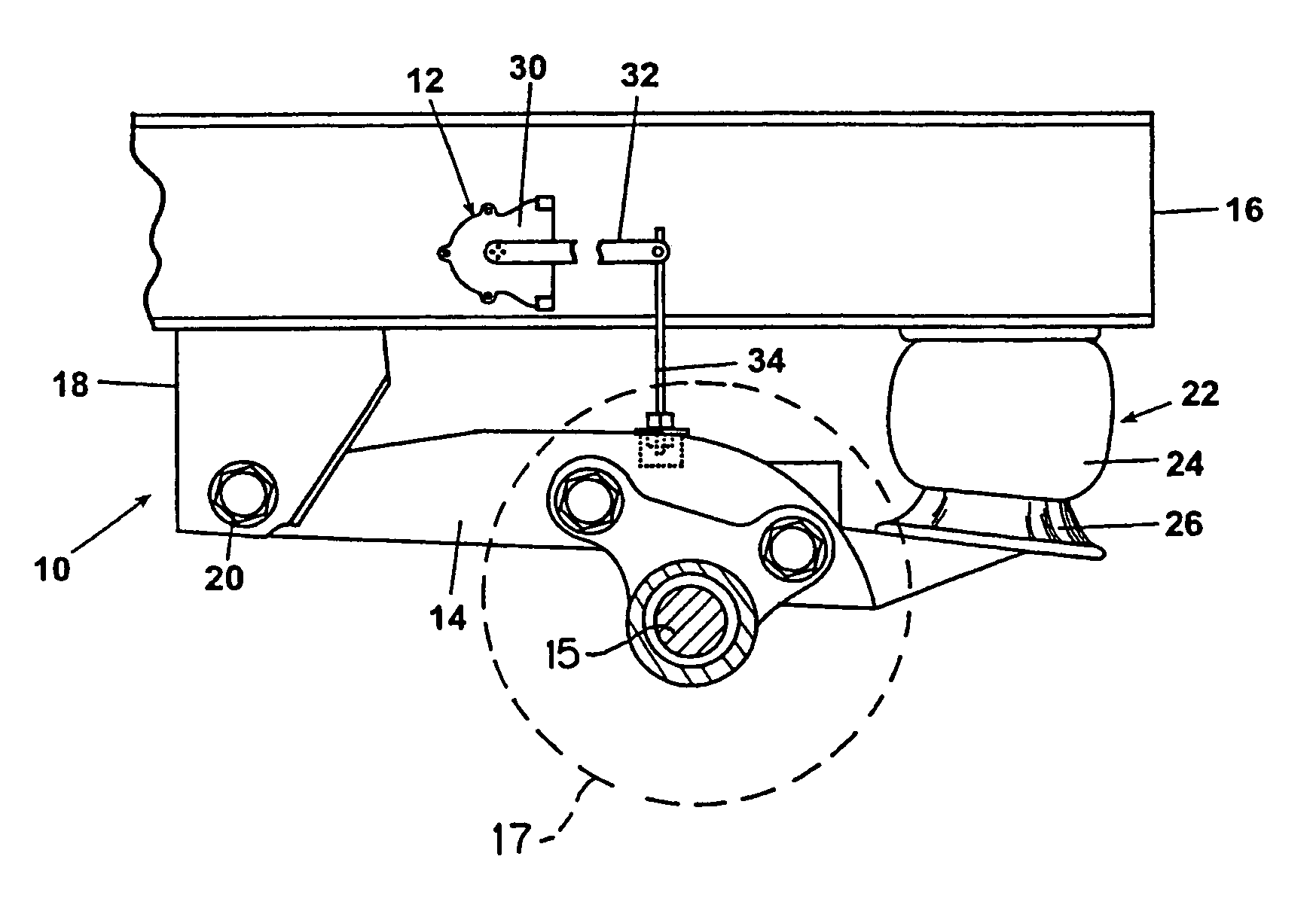

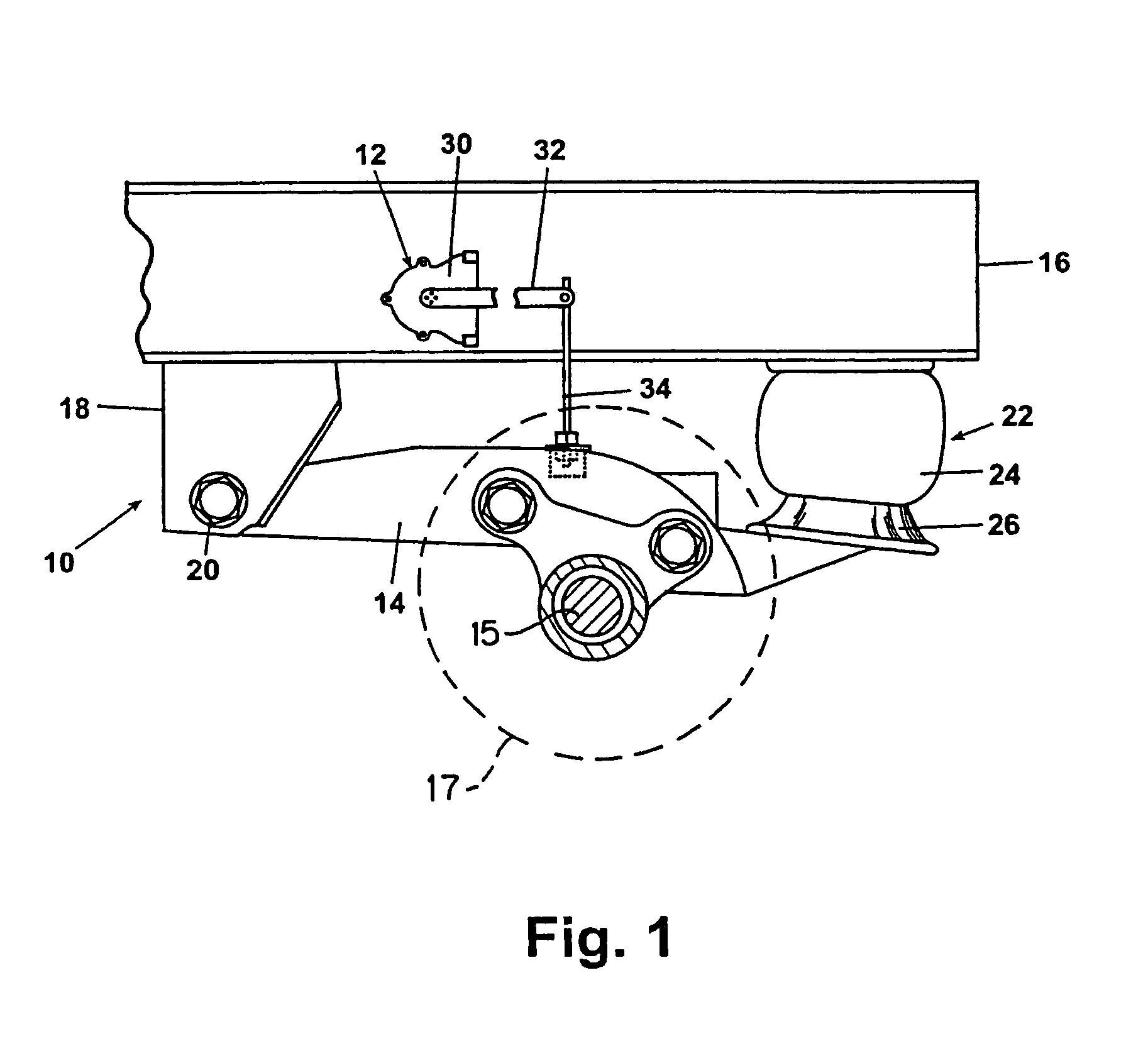

Axle lift assembly

ActiveUS8695998B1Eliminates upward forceEliminate forceResilient suspensionsPivoted suspension armsTrailing armVehicle frame

An axle lift assembly includes a beam slidably coupled with and extending on a longitudinal extent of a vehicle frame. A trailing arm has a first end pivotably coupled with the beam. An axle is rotatably coupled with an intermediate portion of the trailing arm. An air spring is disposed between a second end of the trailing arm and the beam for absorbing an upward force from the axle. A support bracket extends down from the beam proximate the first end of the trailing arm. A pneumatic actuator is disposed between the support bracket and the trailing arm for raising the axle from a deployed position to a retracted position that substantially eliminates the upward force on the air spring from the axle.

Owner:SAF HOLLAND INC (US)

Seed planter with equalizer assembly

Disclosed herein is an agriculture planter. The planter may include a planter frame, a seed hopper and a trailing arm assembly. The planter frame may include a hitch tongue extending forwardly from the planter frame. The planter frame supports the seed hopper. The a trailing arm assembly is vertically pivotally coupled to a rear portion of the planter frame, extends rearward from the planter frame and includes a trailing arm frame and a lever arm vertically pivotally coupled to the trailing arm frame by a pivot point. The lever arm includes a leading end, a trailing end, a middle portion, a furrow opener disc and a first furrow closer wheel. The disc is rotatably mounted to the lever arm near the leading end. The first wheel is rotatably mounted to the lever arm near the trailing end. The middle portion is pivotably coupled to the pivot point.

Owner:SCHAFFERT MFG

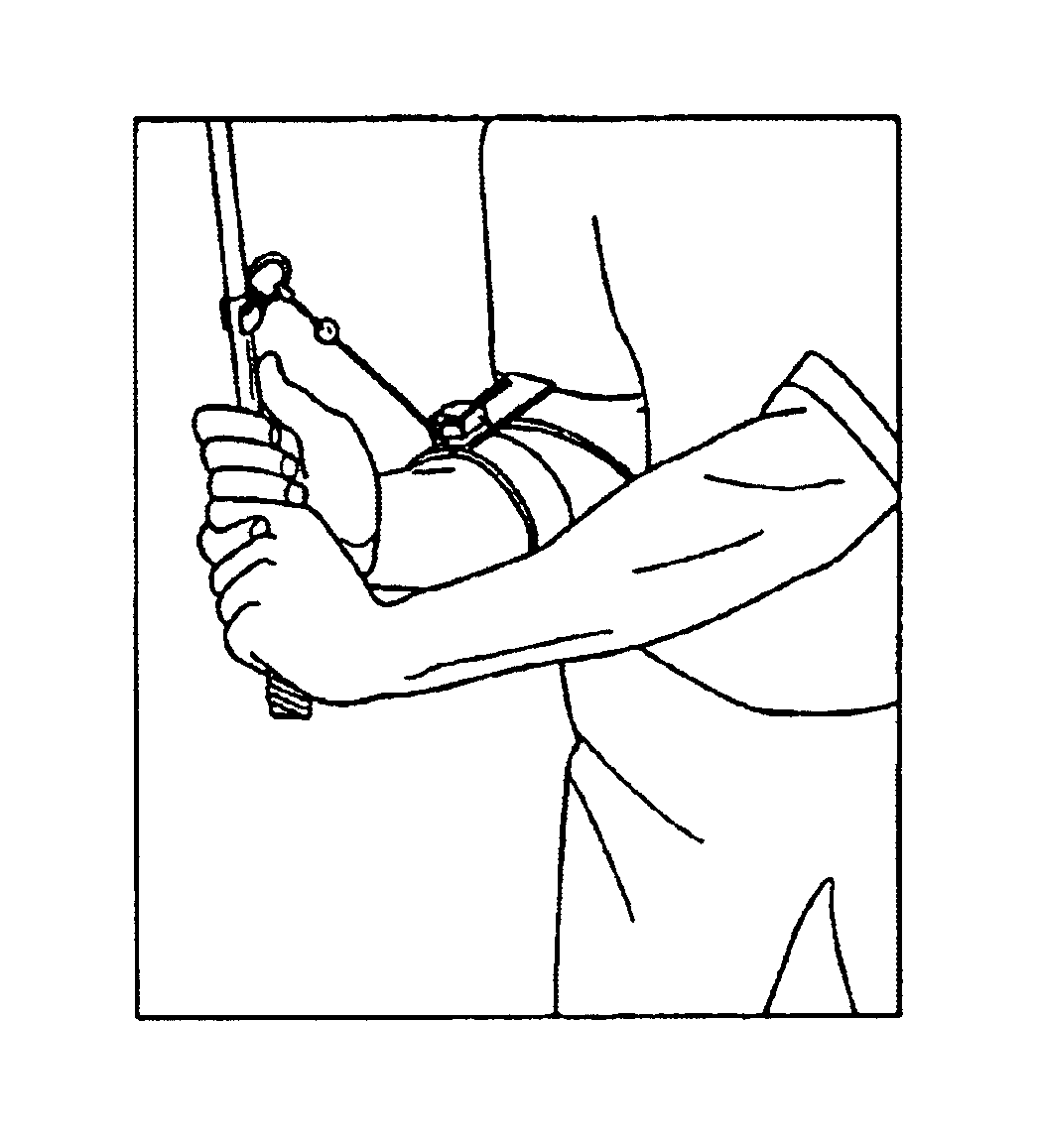

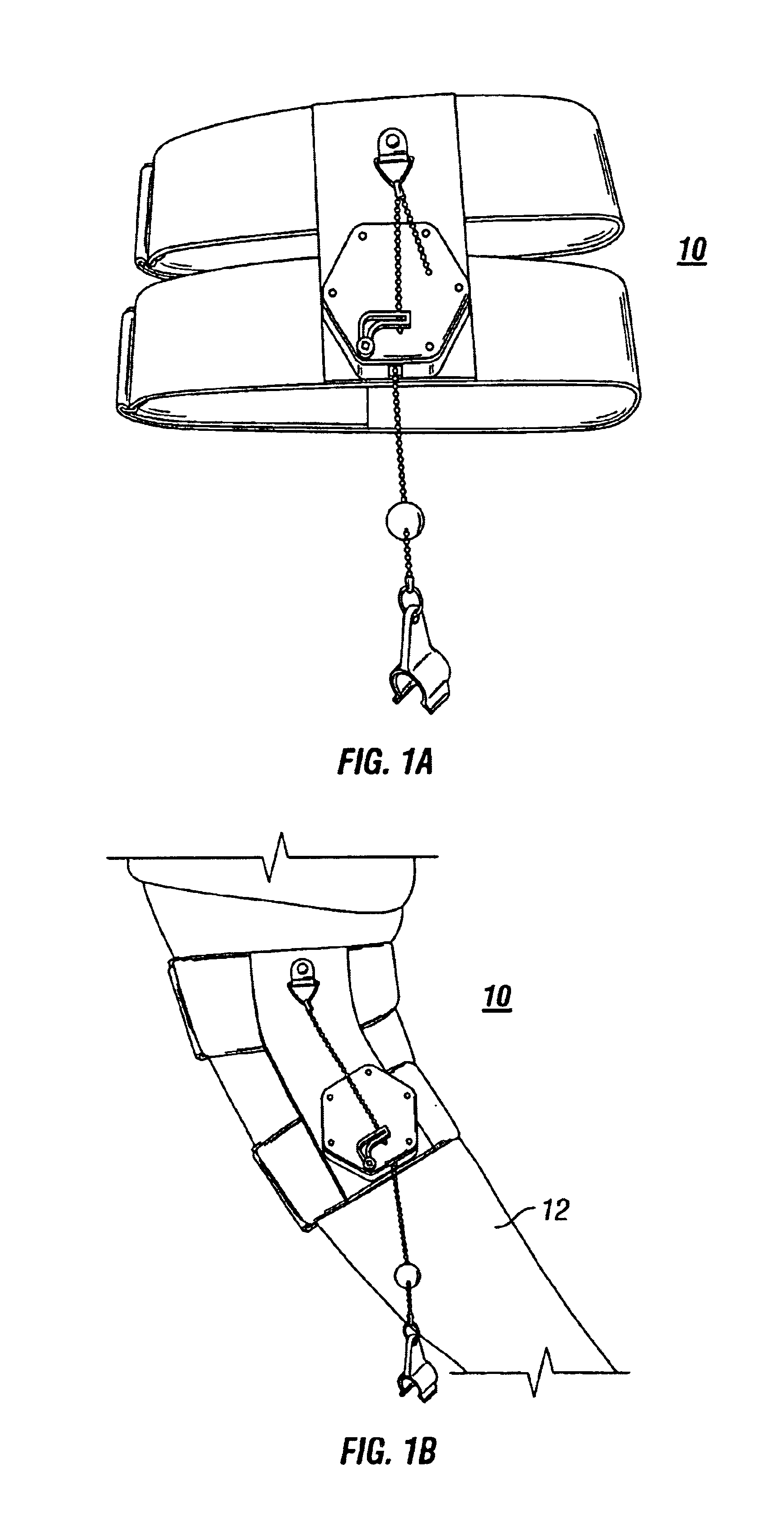

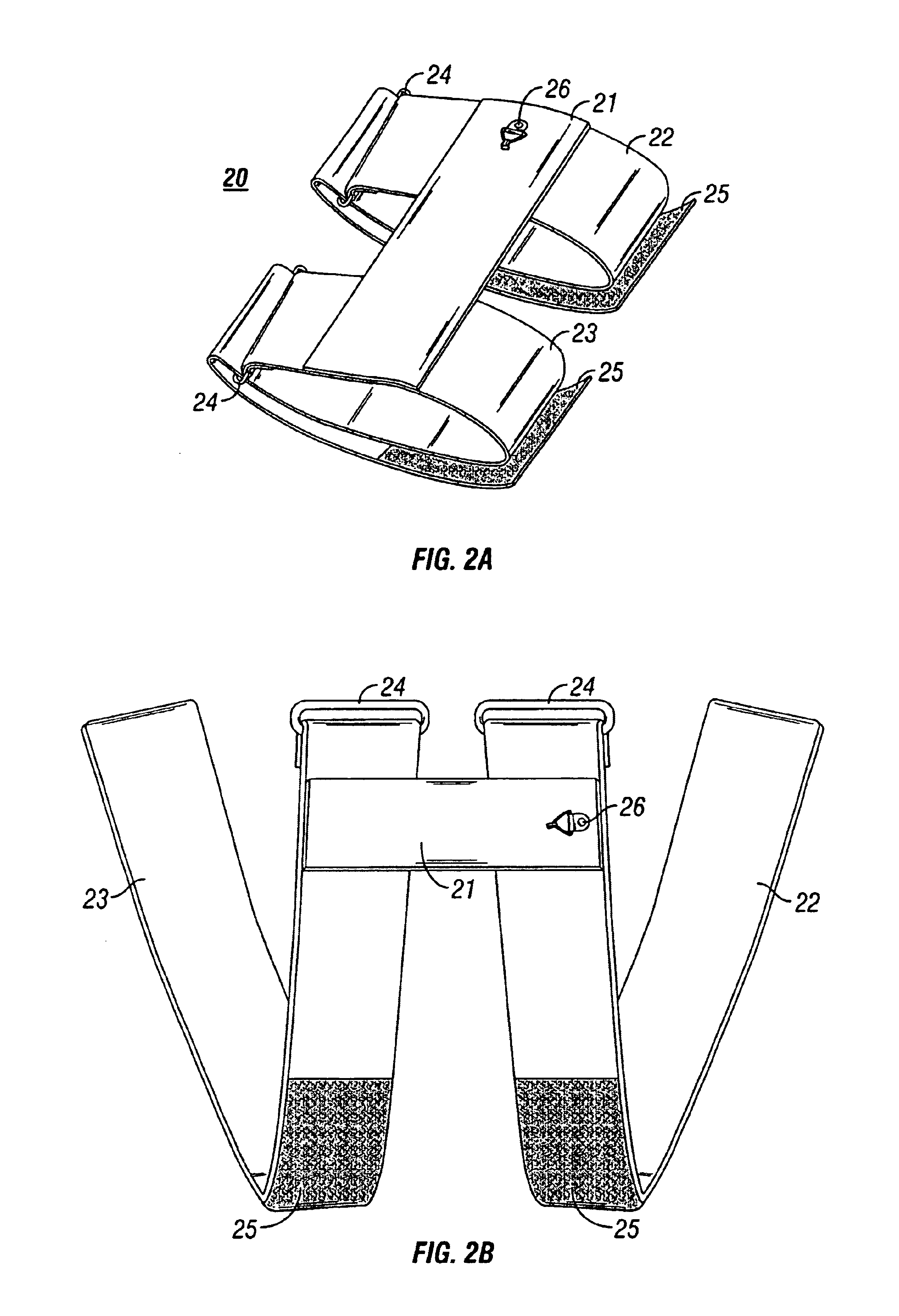

Golf swing training aid

An aid to improve a golf participant's golf swing for developing an accurate and powerful golf swing technique. The inventive device includes an arm strap assembly, a trigger assembly, a ratchet assembly and a club clip attachment. The arm strap assembly attaches to the player's trailing arm by adjustable straps. The trigger assembly includes a trigger line of fixed length and connects the arm strap to the ratchet assembly. One purpose of this component is to “trigger” the point at which the ratchet mechanism should release the ratchet line. The ratchet assembly consists of a retracting, spring-loaded release device that remains locked as long as the trigger mechanism is slack. Once the trigger mechanism exceeds a preset pull-force, the ratchet mechanism releases allowing the ratchet line connected between the ratchet assembly and the participant's golf club to extend at the appropriate position in the participant's down swing. In turn, this allows the participant to extend his trailing arm resulting in the generation of maximum force to be imparted to the golf ball at the point of impact.

Owner:HLB GOLF

Cast trailing arm assembly for trailer suspension

A trailing arm assembly for a suspension includes first and second axle wraps. The first and second axle wraps are welded to each other to substantially surround an outer perimeter of an axle member. The first axle wrap is then welded to one side of the axle member at a first weld area and the second axle wrap is welded to an opposite side of the axle member at a second weld area. The first axle wrap includes a spring seat and the second axle wrap includes an arm body with a bushing receiver portion at one arm end. A bushing tube attached to the bushing receiver portion. The first weld area comprises a single window weld and the second weld area comprises first and second window welds that are positioned on opposing sides of the arm body.

Owner:ARVINMERITOR TECH

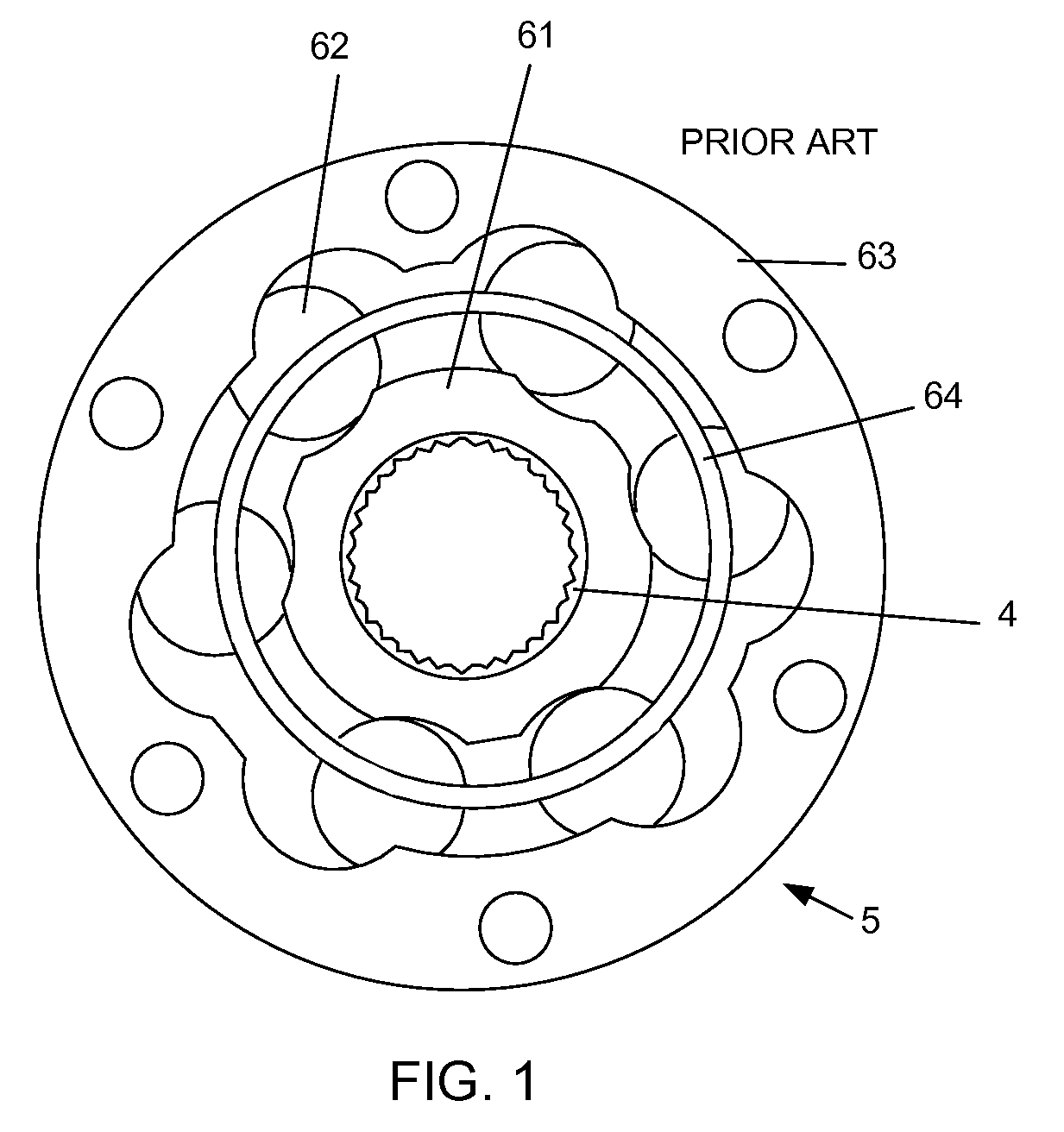

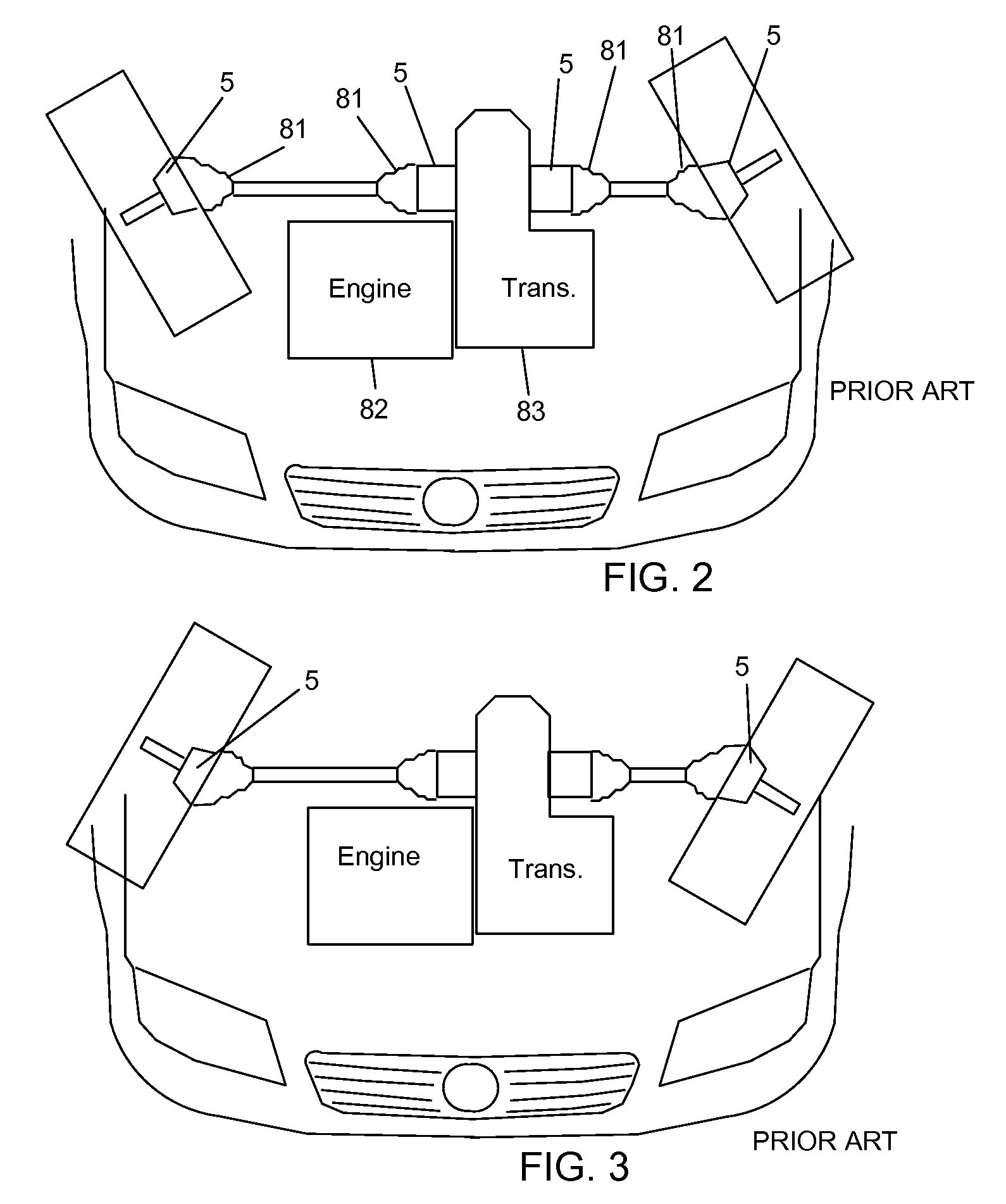

Constant velocity joint rear wheel suspension system for all-terrain vehicle

A rear suspension system for an all-terrain vehicle having a chassis and at least three wheels. Two trailing arms are pivotally connected to a chassis. Each of the trailing arms includes a drive shaft bearing. A CV joint pivot arm is pivotally connected to the chassis. A CV joint housing is connected to the CV joint pivot arm. The CV joint housing includes a CV joint bearing. A CV joint is housed inside the CV joint housing and is supported by the CV joint bearing. A drive shaft extends through the CV joint and rigidly connected to the CV joint. The drive shaft is further supported by each of the drive shaft bearings attached to the trailing arms. A shock absorption system is connected between the drive shaft and the chassis. In a preferred embodiment, a cross bar is connected between the trailing arms for stability. Also, preferably, the rear suspension system includes a sway bar and linear shock absorbers acting in combination to provide optimum suspension.

Owner:STEWART CRAIG

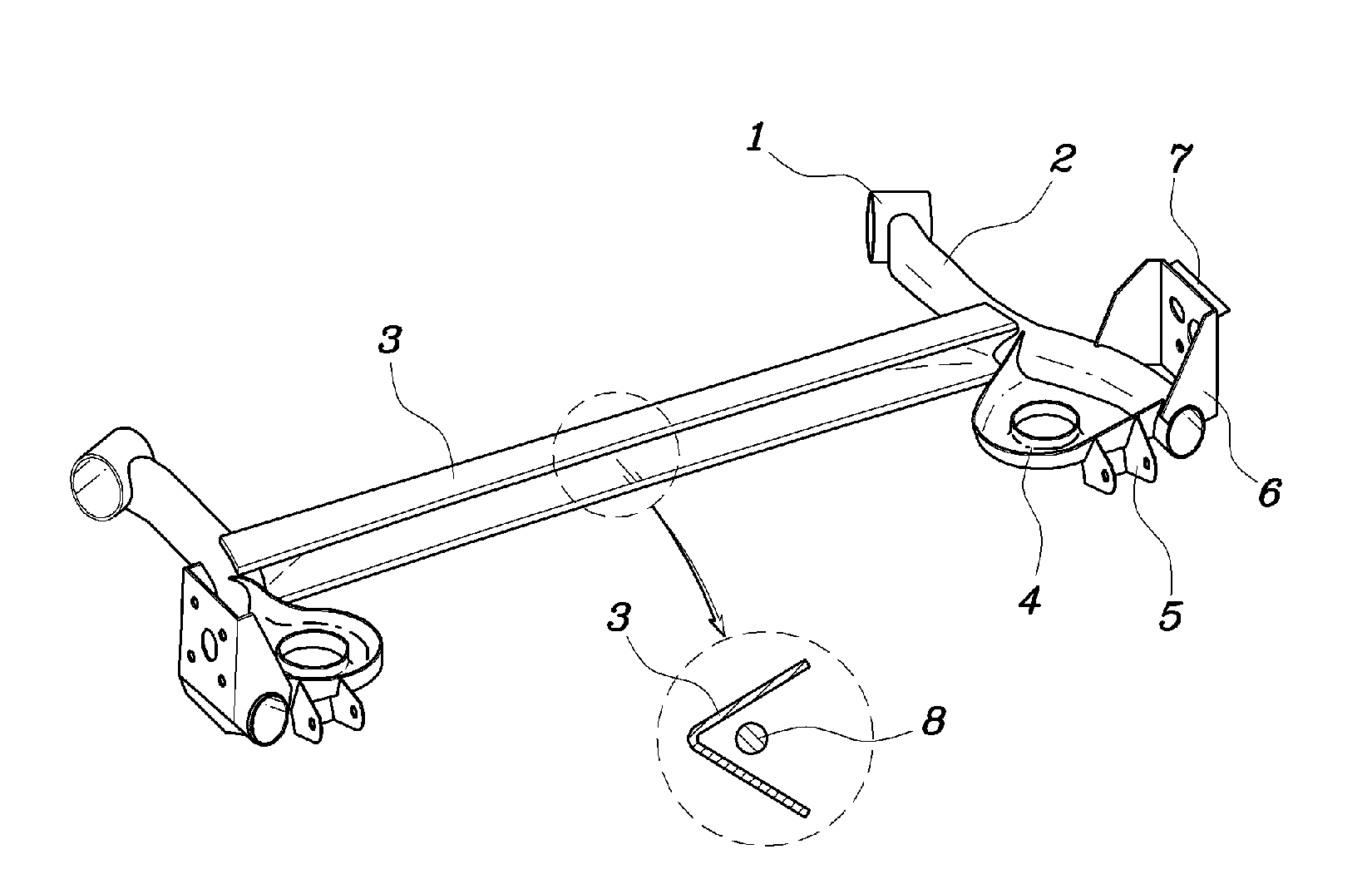

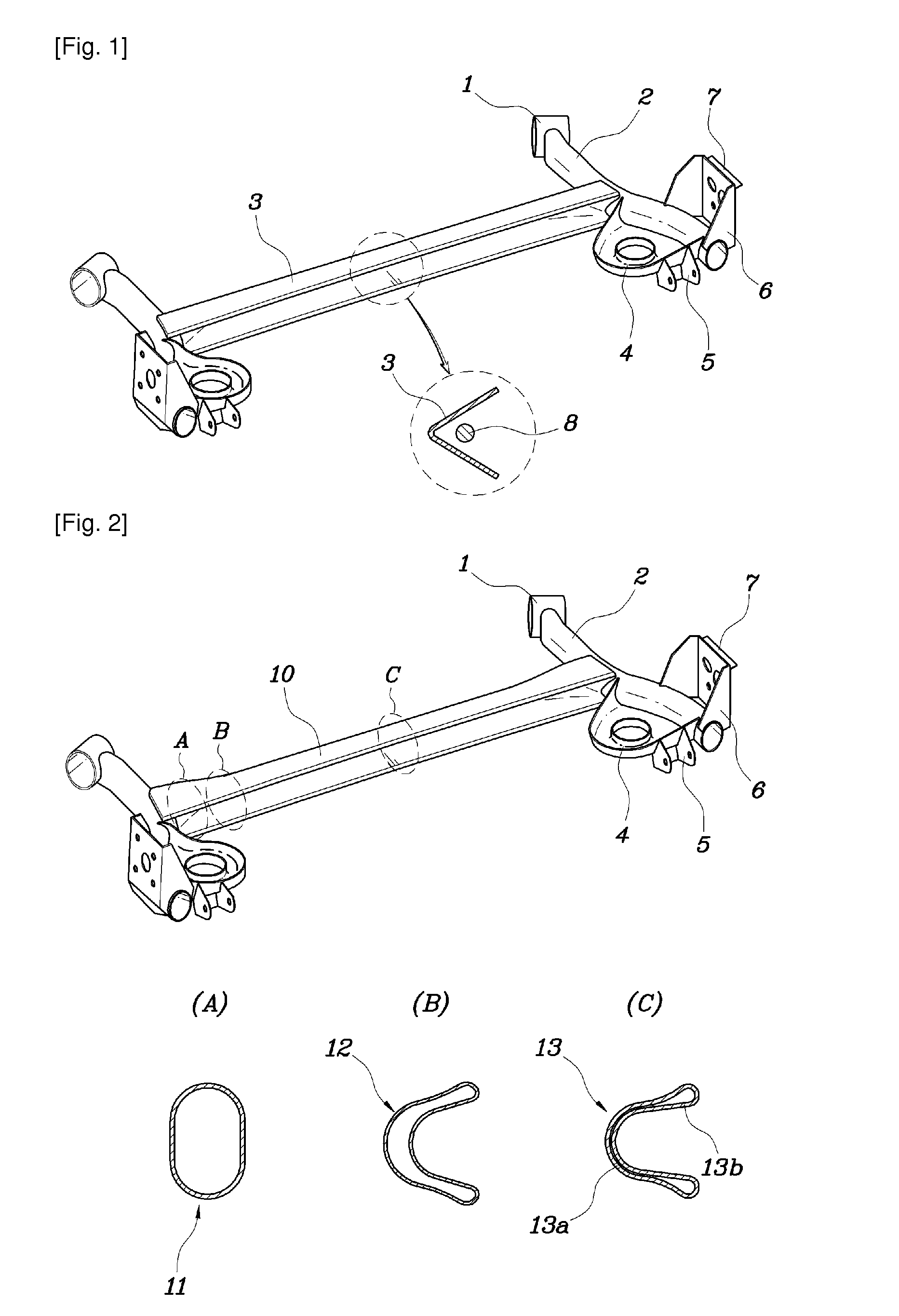

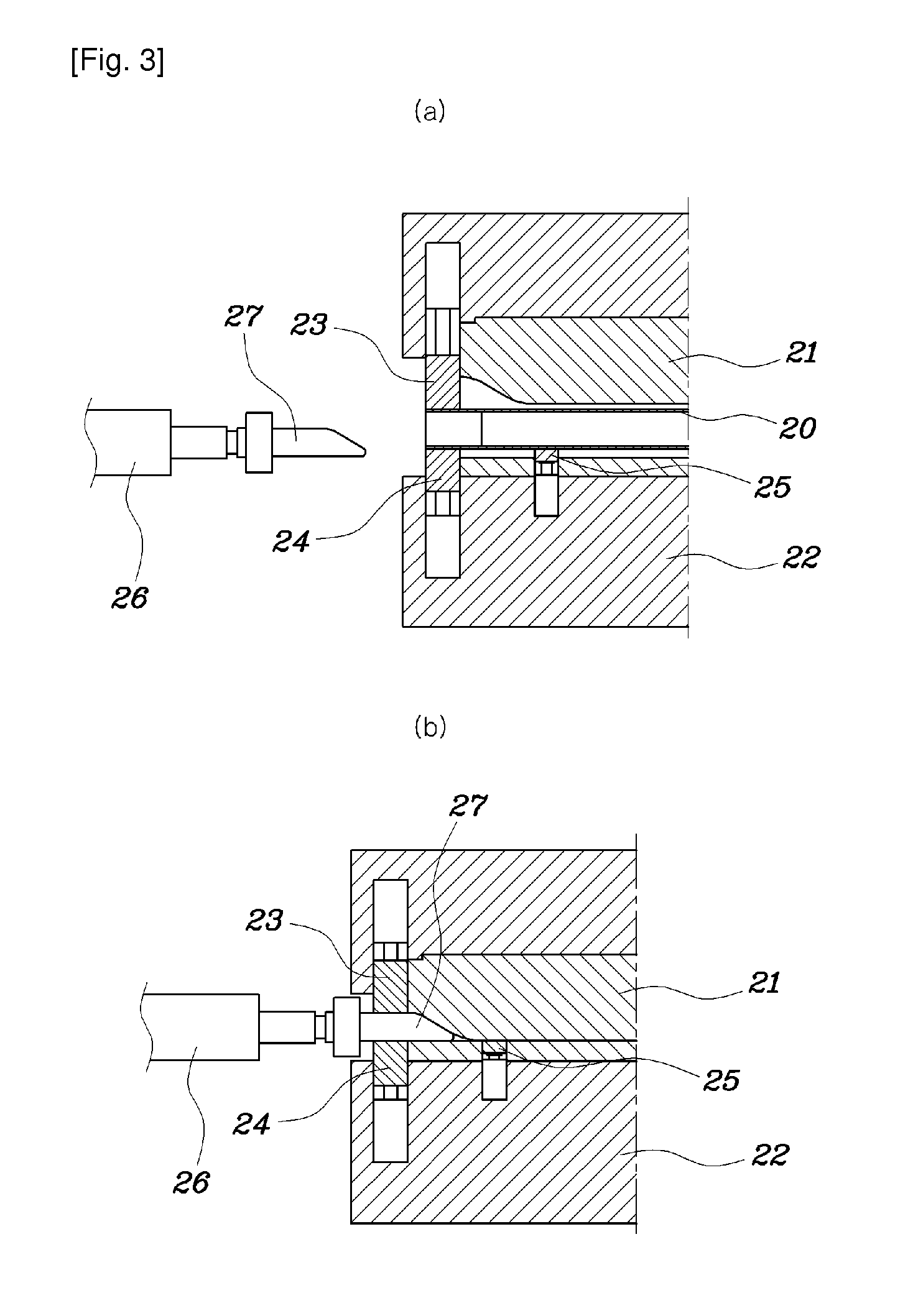

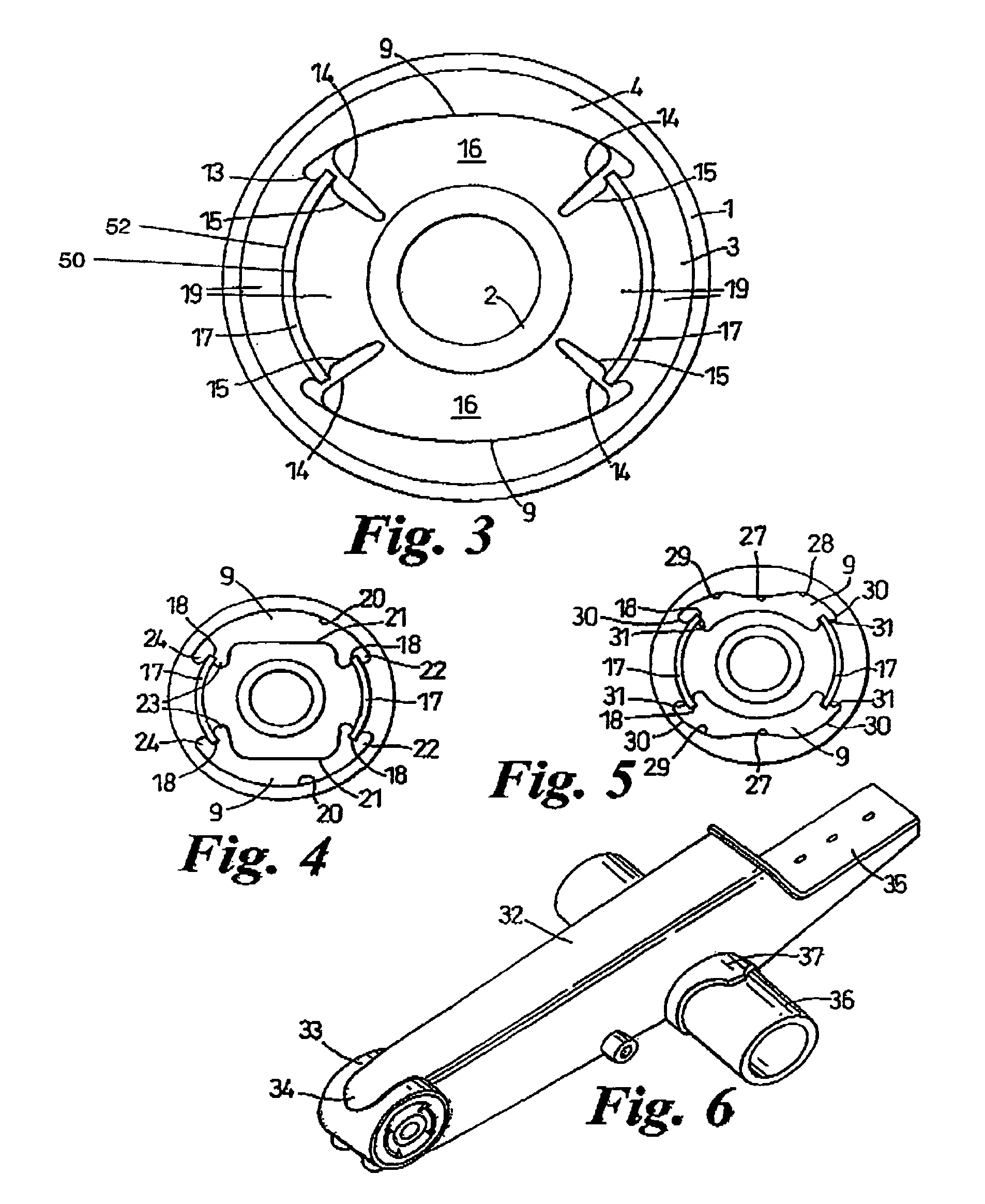

Torsion beam suspension

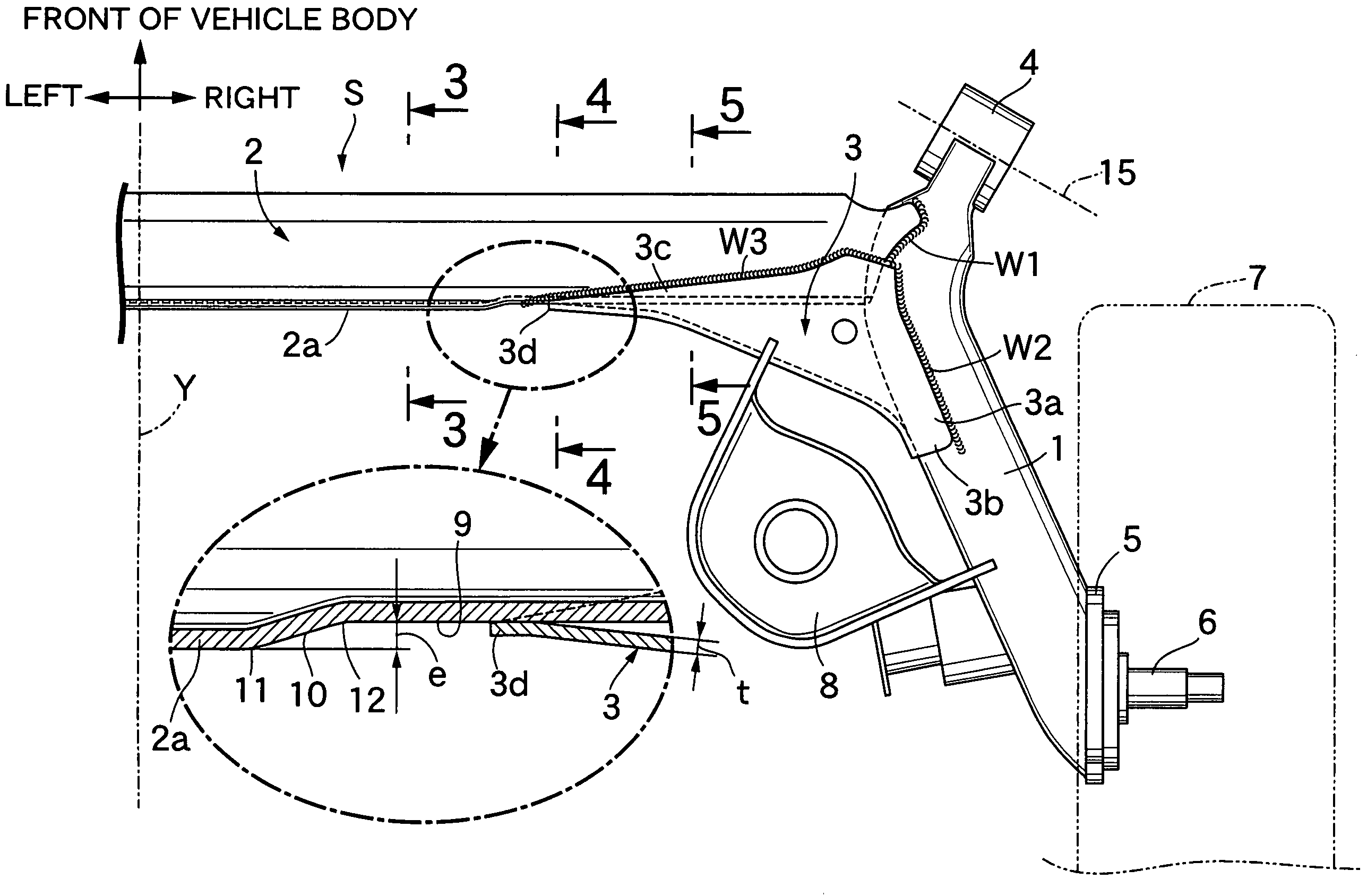

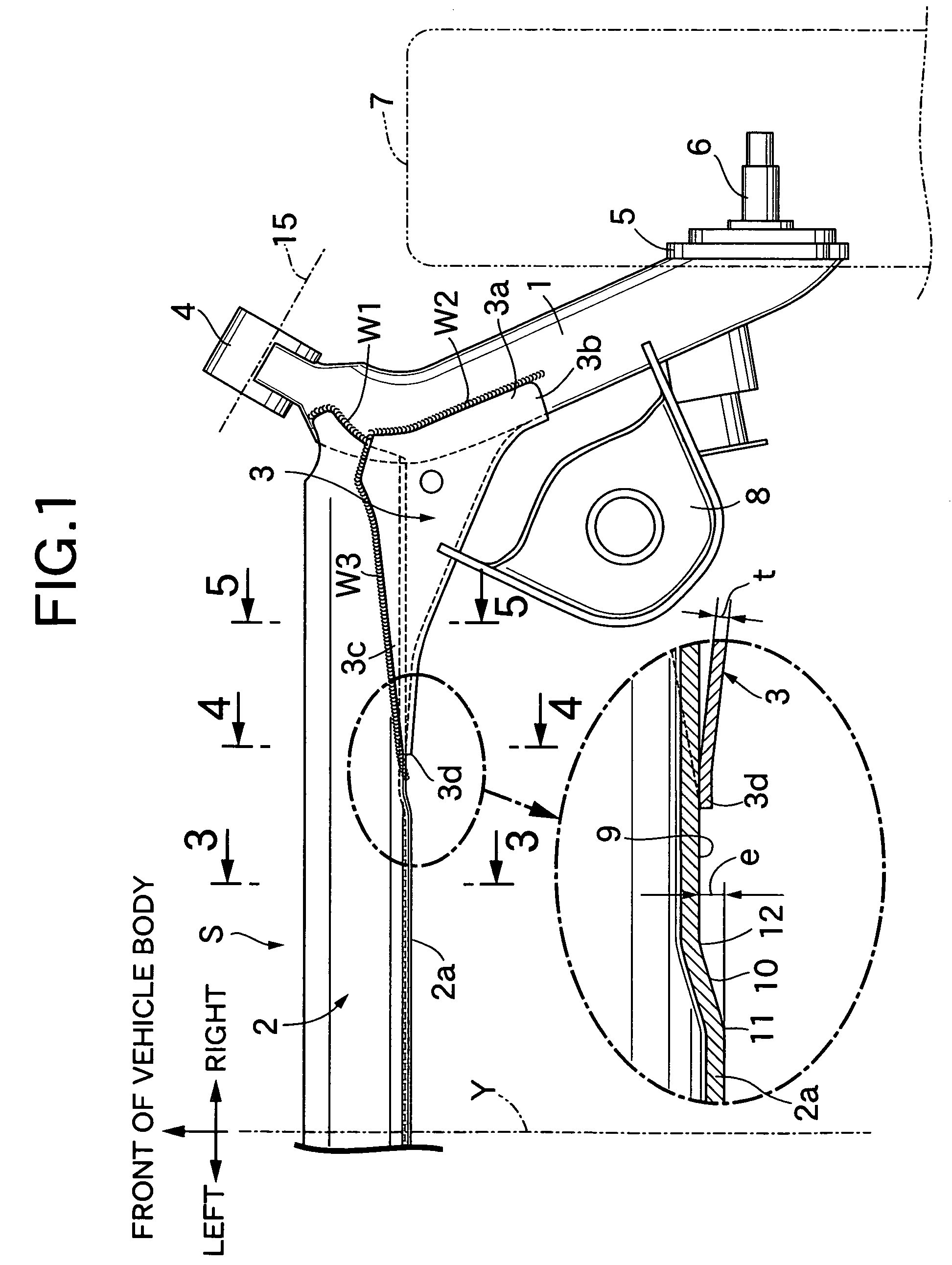

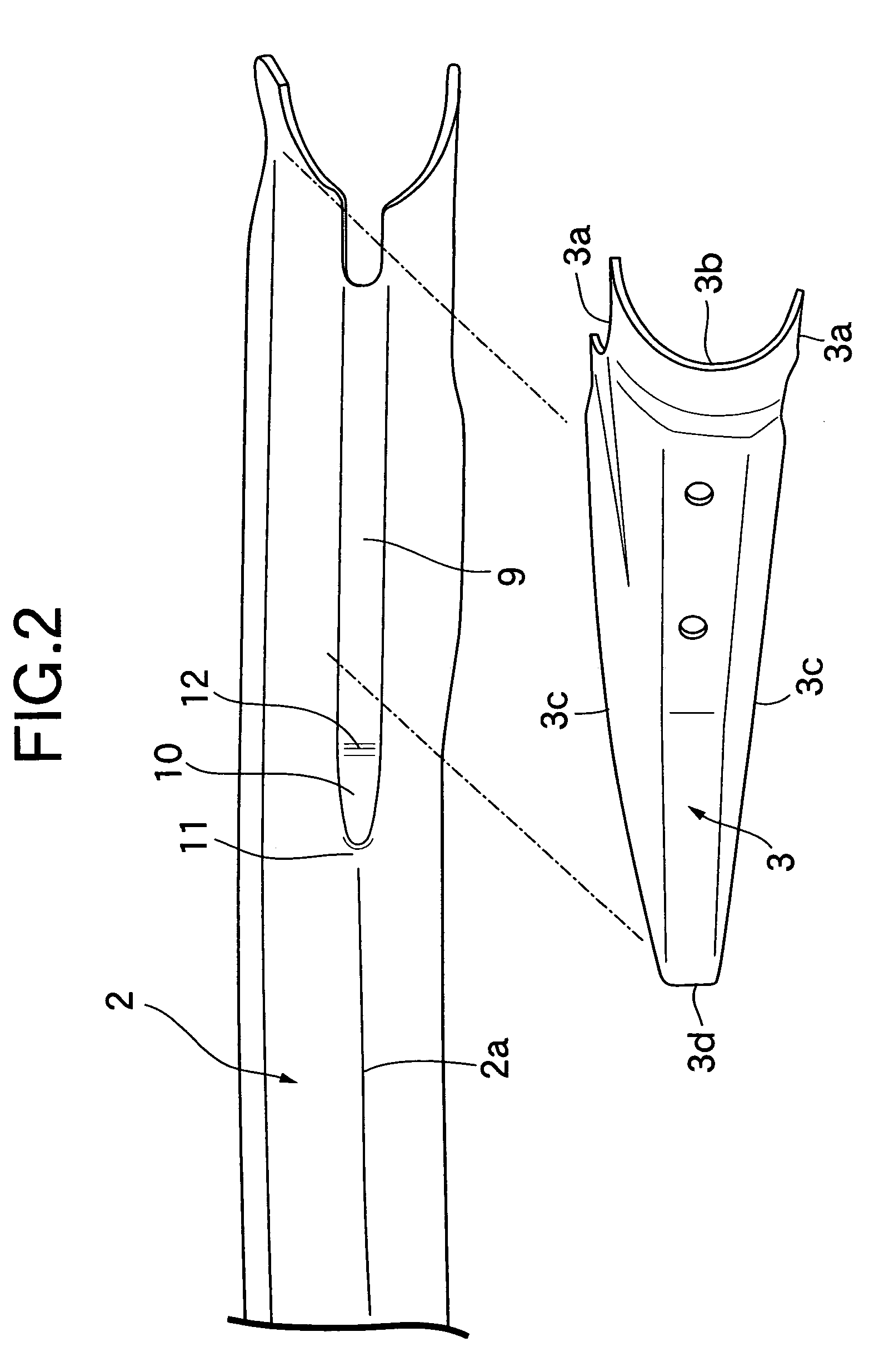

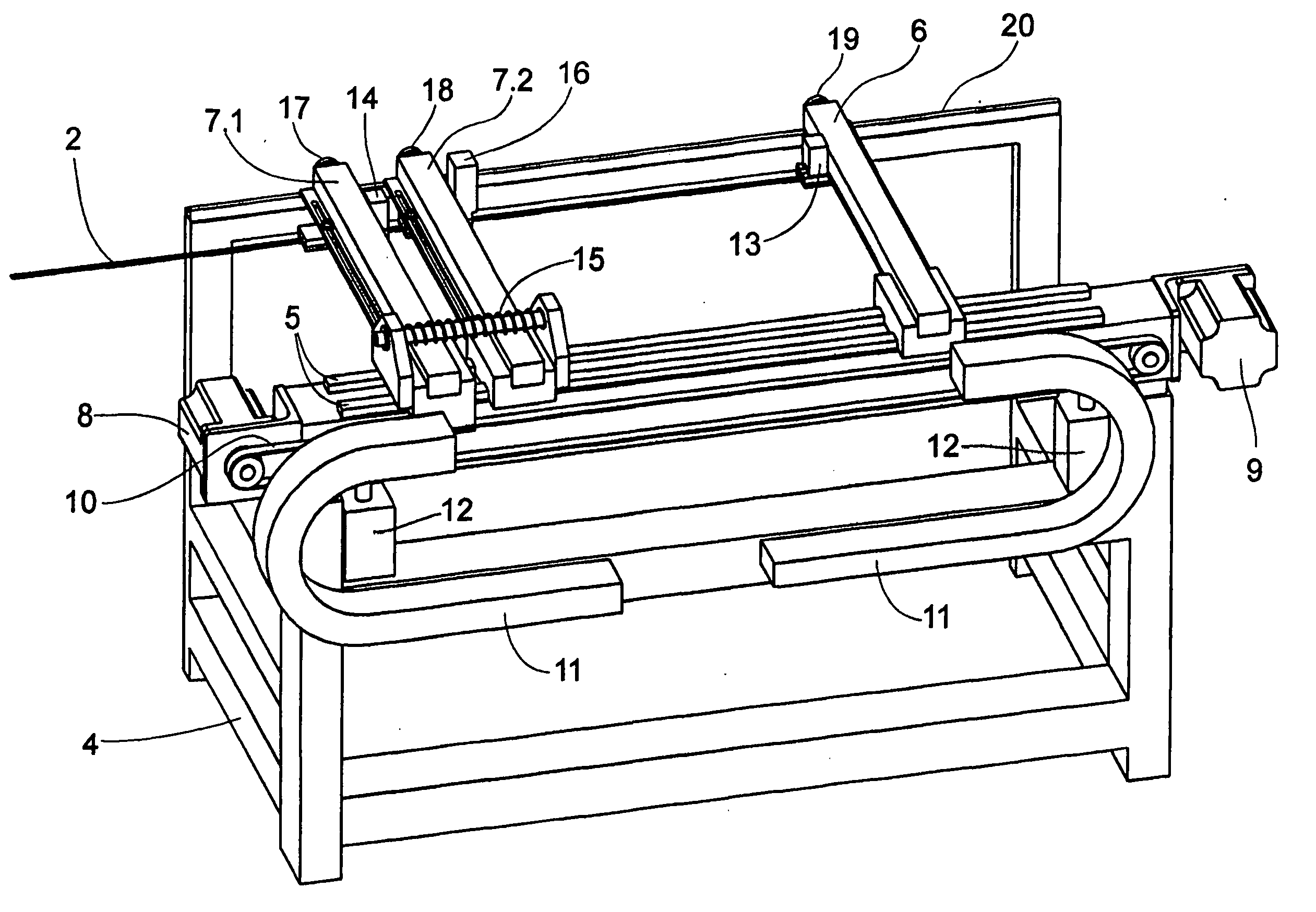

InactiveUS7284765B1Increased durabilityReduction in weight and costInterconnection systemsResilient suspensionsIn planeStress concentration

In a torsion beam suspension including: a pair of left and right trailing arms 1; a torsion beam 2 providing connection between the trailing arms 1; and gussets 3 which are U-shaped in section and substantially triangular in plane view and which are welded to inner side surfaces of connecting portions between the trailing arms 1 and the torsion beam 2, seat surfaces 9 are formed by crushing at left and right opposite end portions of a rear wall 2a of the torsion beam 2, the seat surfaces 9 being offset forward from a general outer surface of the rear wall 2a by an amount e larger than a plate thickness t of the gussets 3, and each gusset 3 includes an inner end edge portion 3d superposed on an intermediate portion in a lateral direction of the seat surface 9, and upper and lower front edge portions 3c, 3c connected by a weld W3 to upper and lower portions of an outer surface of the torsion beam 2. Thus, in the torsion beam, an abrupt increase in torsional rigidity is suppressed in the gusset inner end portion without reducing strength of the torsion beam to alleviate stress concentration, thereby providing a torsion beam suspension having a high durability.

Owner:F TECH INC

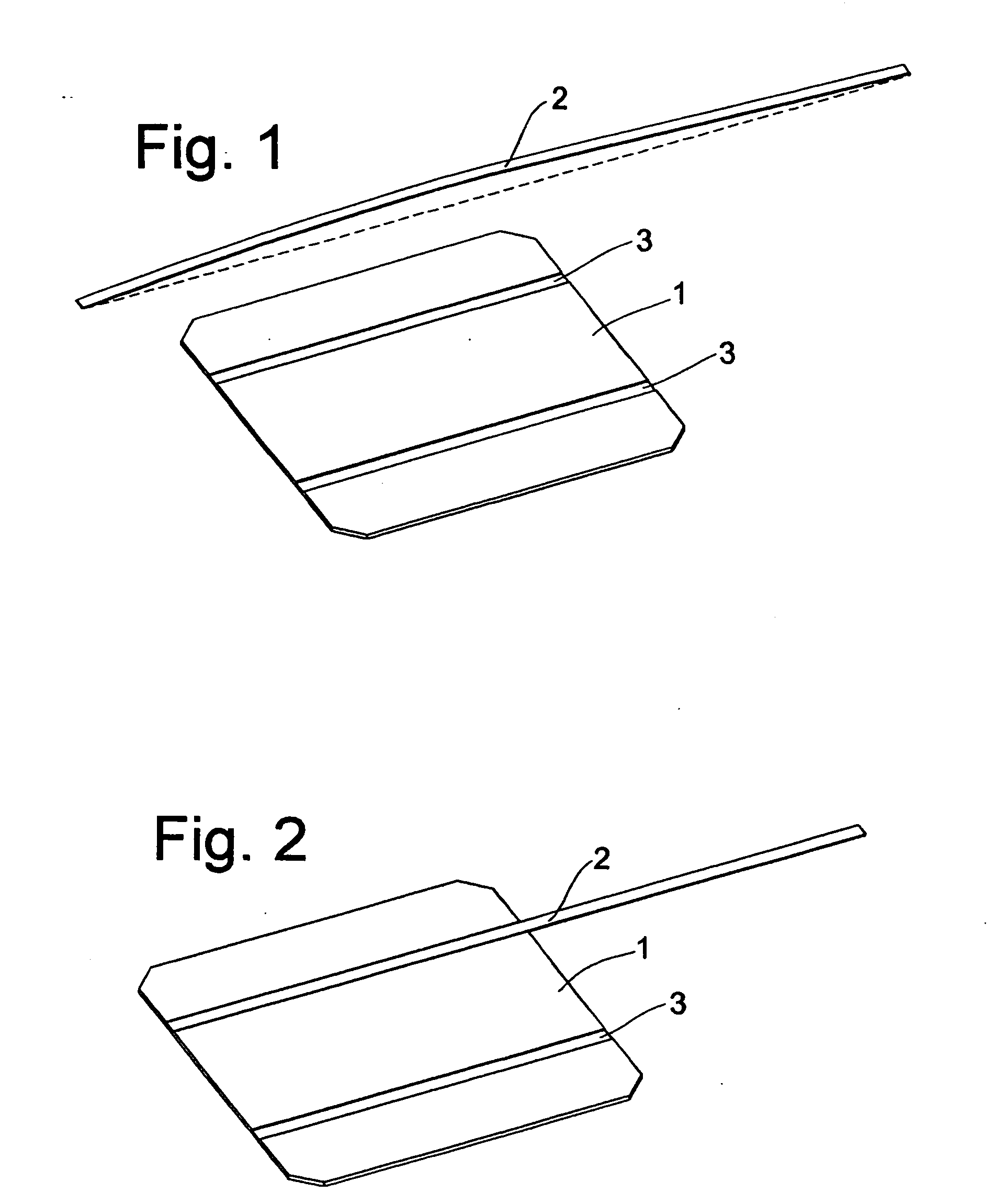

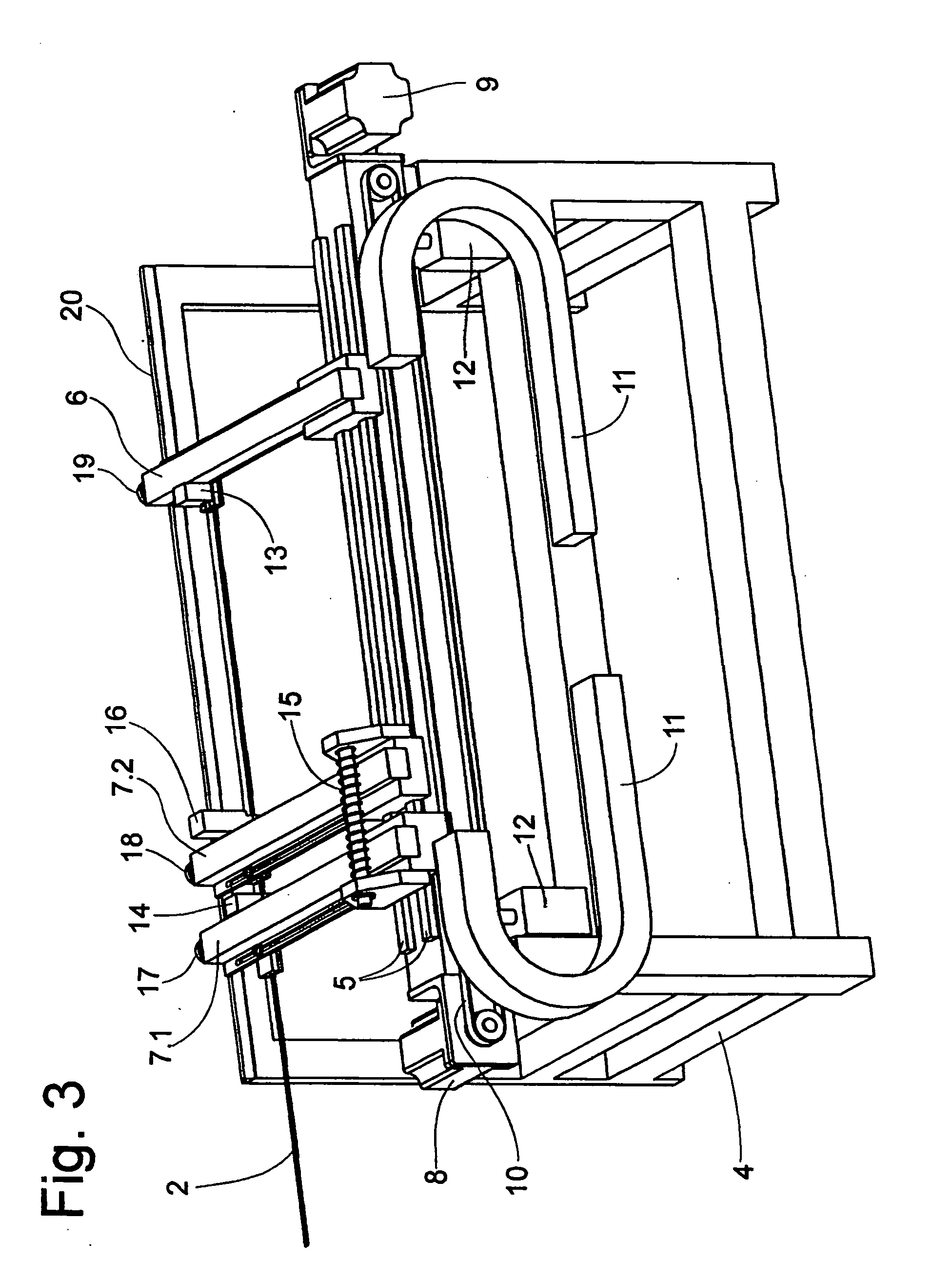

Apparatus and method for aligning and fixing ribbon on a solar cell

InactiveUS20060219352A1Avoid problemsEasy to controlMechanical working/deformationLamination ancillary operationsTrailing armEngineering

An apparatus and a method are proposed for aligning and fixing a ribbon onto the groove of a solar cell for avoiding undue stress on the ribbon as well as crystal damage of the solar cells by hardening of the ribbon. The apparatus includes a frame, a leading arm, and a trailing arm, the leading and trailing arms being movably mounted on at least one linear guide arranged on said frame. The apparatus further provides for upward and downward movement of the at least one linear guide, and a shear for cutting said ribbon. Both the leading arm and the trailing arm have a gripper for gripping the ribbon. These grippers are provided to apply a predetermined longitudinal tension to the ribbon when the leading and trailing arms are moved relative to one another.

Owner:KOMAX HOLDING

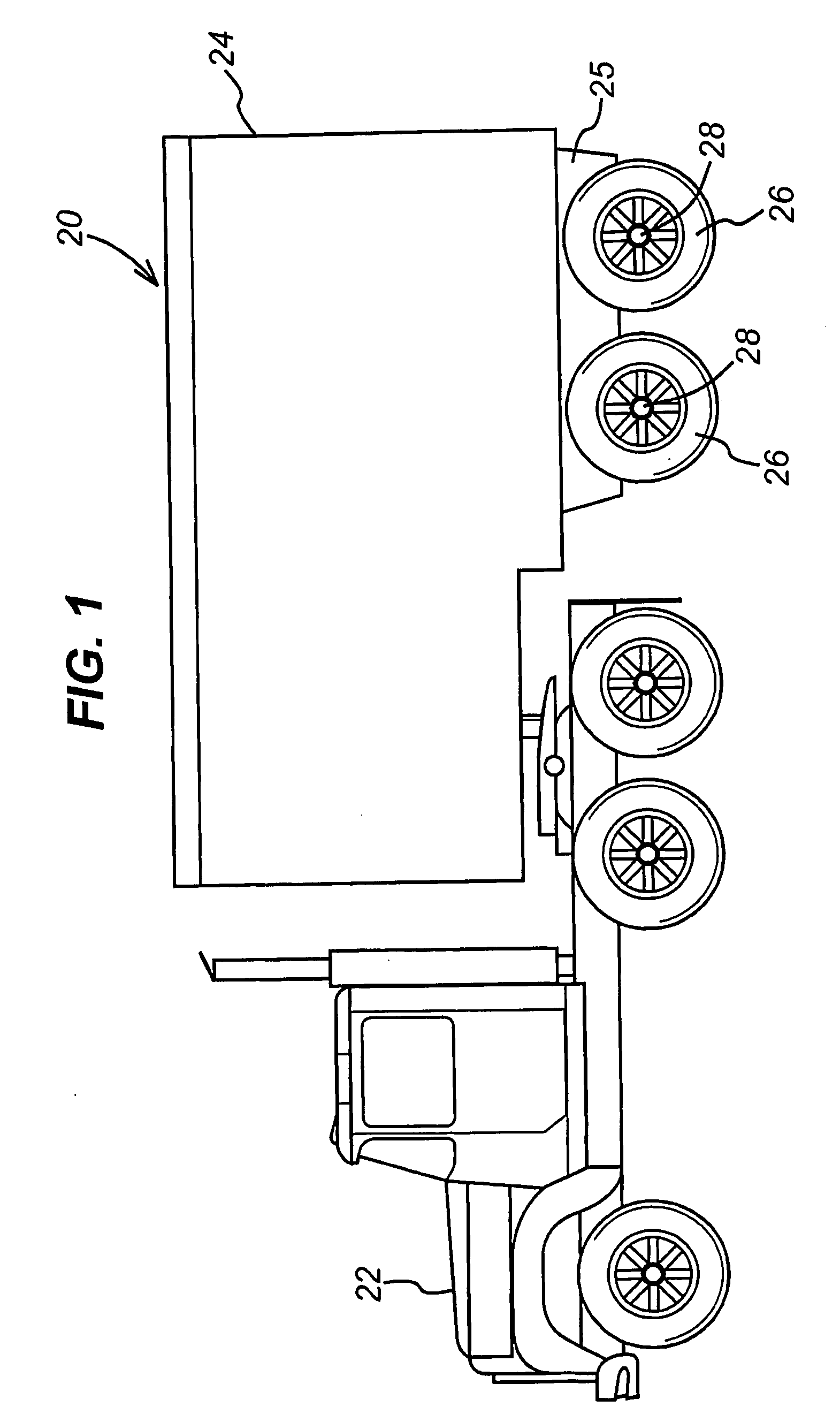

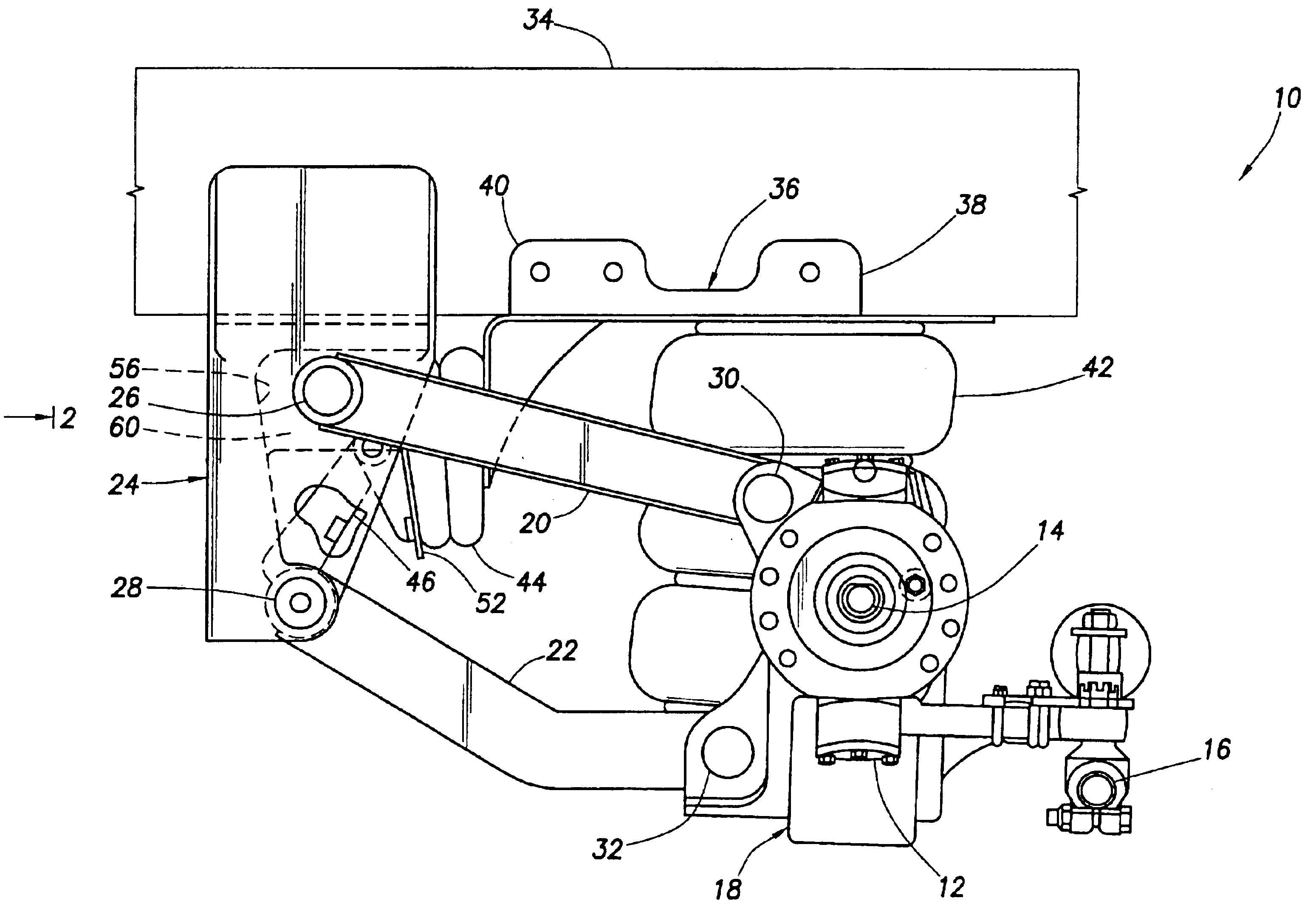

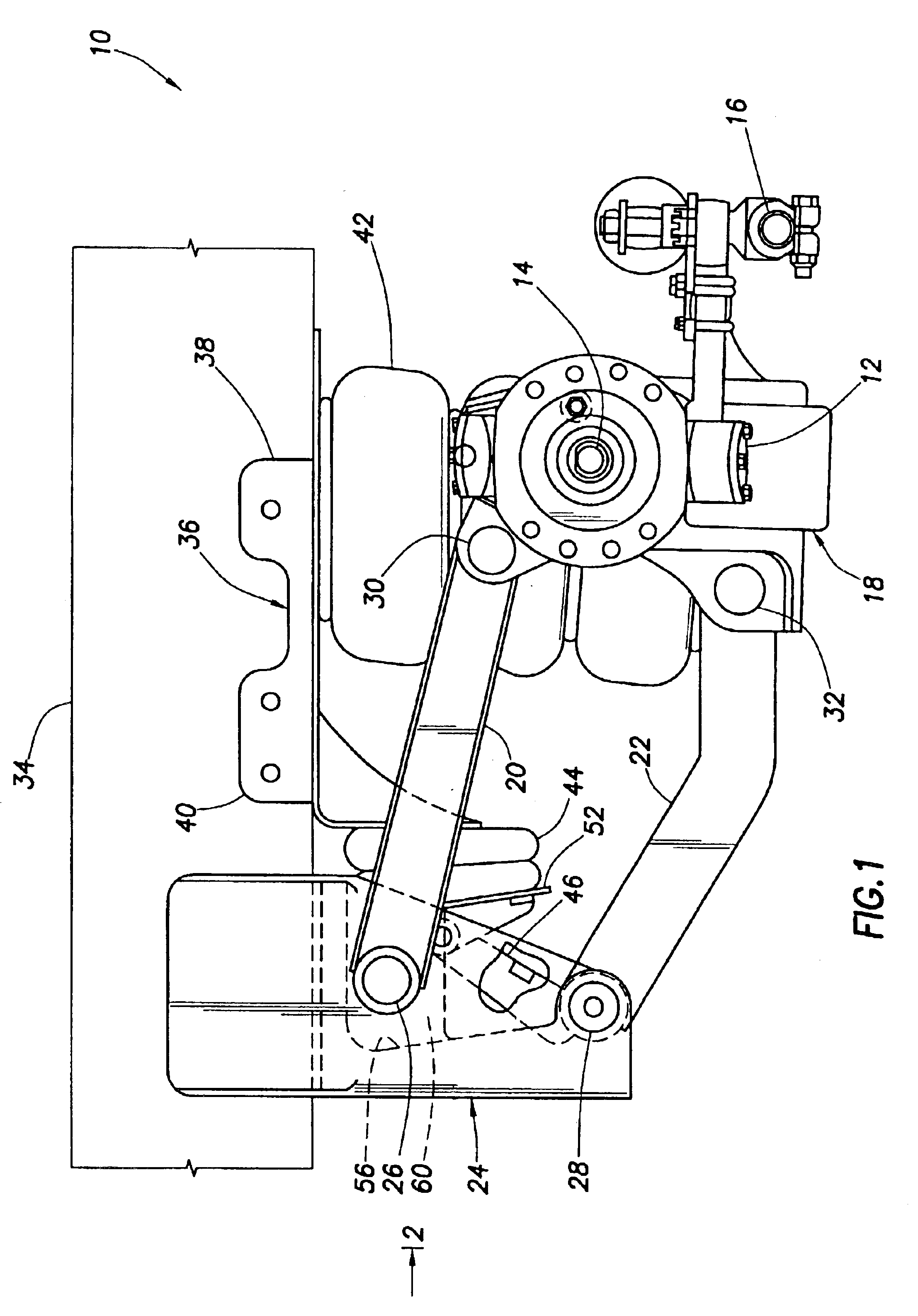

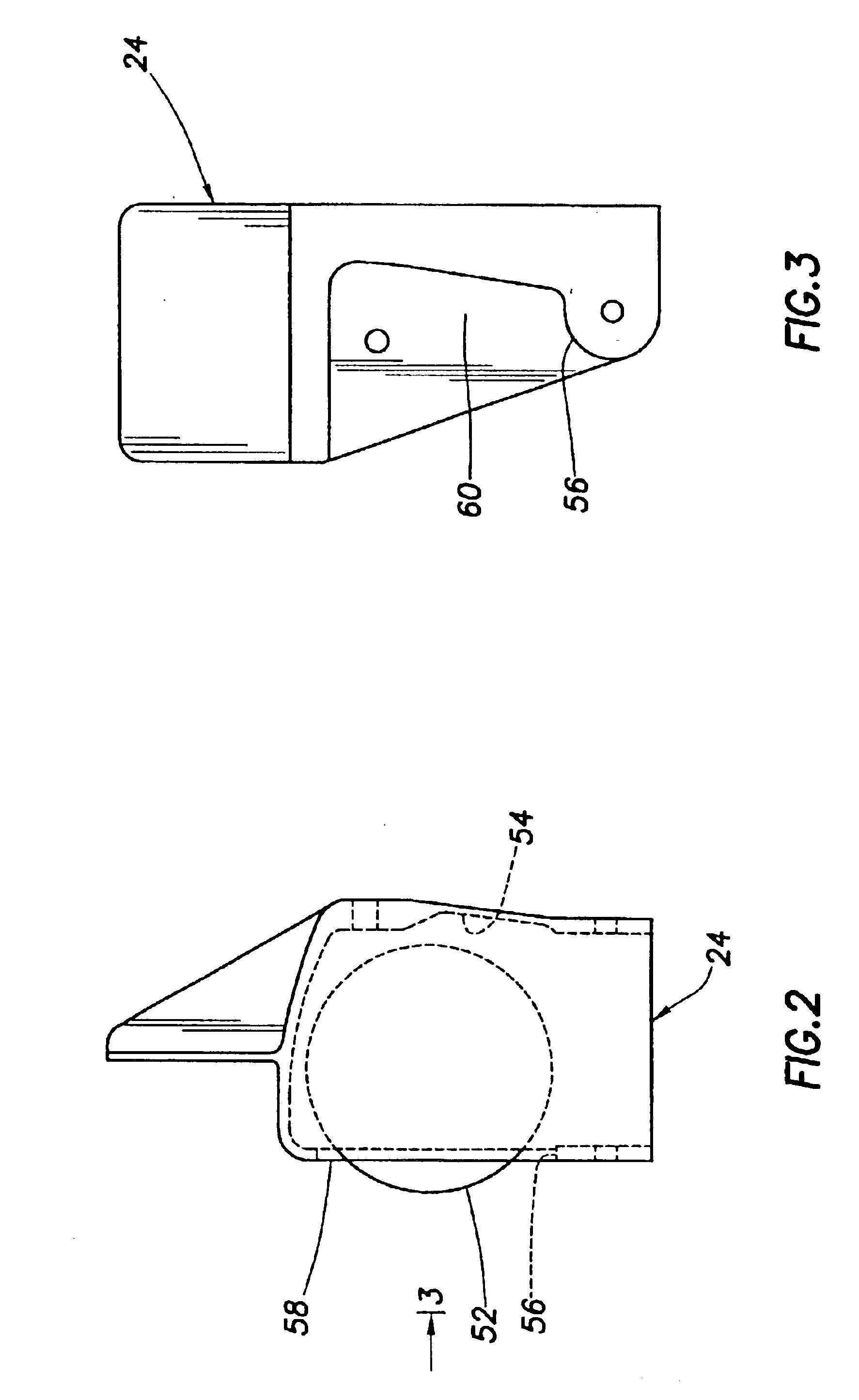

Vehicle suspension system and height control valve therefor

InactiveUS7028996B2Meet the height limit requirementsEasy to adjustServomotor componentsVehicle cleaning apparatusTrailing armVehicle frame

A height control valve for controlling the relative height between a vehicle frame and a trailing arm suspension. The height control valve comprises a housing defining an interior chamber and having an inlet port fluidly connecting to a source of pressurized air. An air spring port is provided in the housing for fluidly connecting to an air spring. Additionally, an exhaust port is provided in the housing for fluidly connecting to the atmosphere. A valve is disposed within the interior chamber and is selectively operable between a fill position, an exhaust position, and a neutral position.

Owner:HALDEX BRAKE

Lift axle suspension system

A lift axle suspension system. In a described embodiment, a lift axle suspension system includes: an axle assembly; an air spring connected between the axle assembly and a bracket attached to a vehicle frame; a trailing arm attached to the axle assembly; and a lift air spring. The lift air spring is connected between the bracket and the trailing arm, so that the axle assembly is lifted when the lift air spring is extended.

Owner:WATSON & CHALIN MFG INC

Pivot bearing

A pivot bearing used in a vehicle trailing arm suspension includes a housing, a resilient bush compressed and bonded in the housing, and a rigid axial sleeve in the bush. The bush has voids, above and below the sleeve when the pivot bearing is fitted for use and stiffening elements which extend between the voids at opposite sides of the sleeve. When the pivot bearing is in use in a vehicle trailing arm suspension, the voids increase flexibility of the bush under generally vertical loading on the pivot bearing. The stiffening elements enhance the stiffness of the bush in generally horizontal direction for improved vehicle dynamics and reduced vibration. Preferably, the stiffening elements are of plate or leaf form, are bonded to the bush, and extend arcuately about the sleeve. The voids extend partially through the axial thickness of the bush from opposite ends of the bush and generally accurately about the sleeve. The bush also has enlarged opposite circumferential end portions. The end portions extend circumferentially beyond diametrically opposite parts of the external circumference of the sleeve and are in-turned towards the sleeve. Edges of the stiffening elements extend into the opposite end portions of the voids.

Owner:MERITOR HEAVY VEHICLE SYST

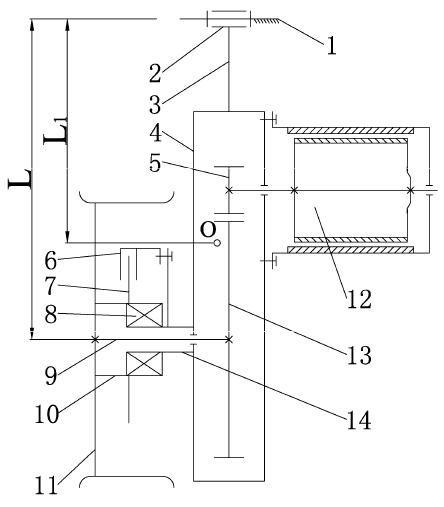

Structure and method for reducing equivalent unsprung weight of wheel-rim electrically-driven system of single trailing arm type suspension

ActiveCN102092256AHigh vibration frequencyImprove comfortResilient suspensionsControl devicesVehicle frameTrailing arm

The invention discloses a structure and method for reducing the equivalent unsprung weight of a wheel electrically-driven system of a single trailing arm type suspension, which is characterized in that an elastic rubber hinge is supported on a frame, one end of a swing arm of the single trailing arm type suspension is connected with the elastic rubber hinge, and the other end of the swing arm is connected with a reducer casing; the reducer casing is connected with a sleeve of a half axle; a motor is fixedly arranged on the reducer casing, the power output end of the motor is connected with a small gear, then the small gear is meshed with the large gear, and the large gear is connected with the sleeve of the half axle; and after the gear reducing is performed, the power is outputted to a rim by the half axle so as to drive wheels. The equivalent unsprung weight is reduced by reducing the distance between the mass centre of non-concentric parts of a wheel and a central swing axis of the single trailing arm type suspension. The structure and method disclosed by the invention have the advantages of increasing the vibration frequencies of wheels, reducing the resonance, reducing the impact and vibration from road surfaces, and improving the running smoothness of vehicles.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com