Patents

Literature

23040 results about "Rolling chassis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A rolling chassis is the chassis without bodywork of a self-propelled motor vehicle; car or truck, bus or other commercial vehicle, assembled with its final engine and drivetrain, able to move under its own power .

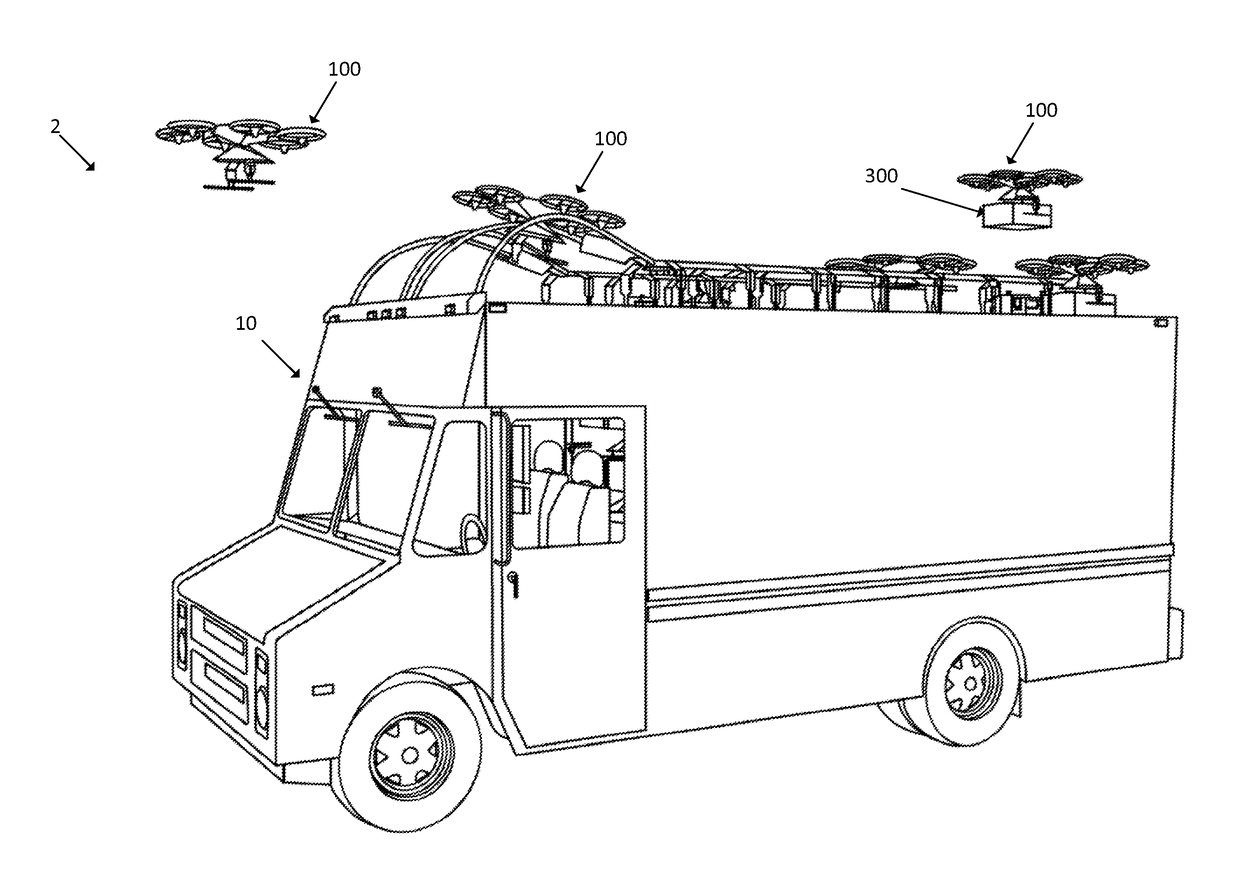

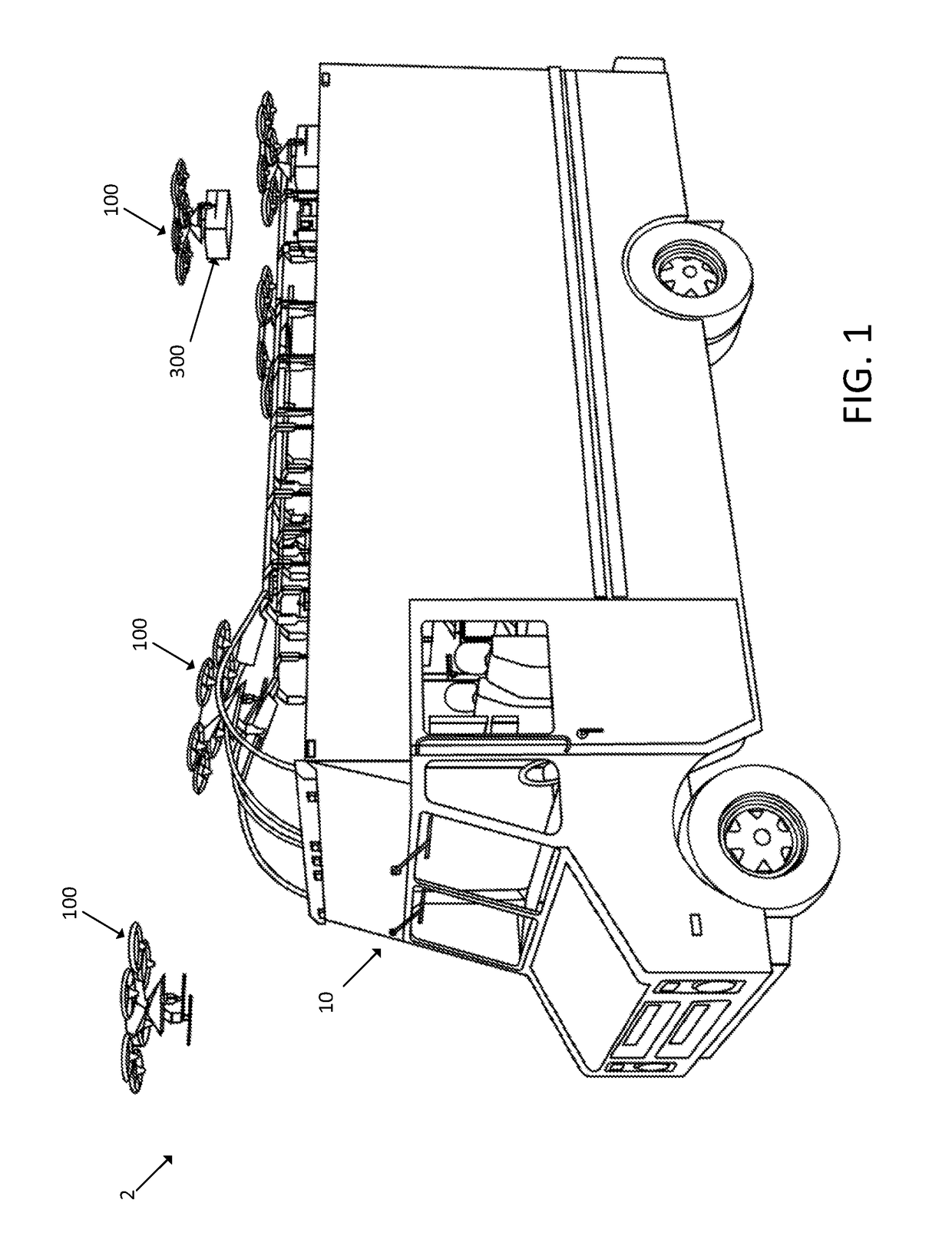

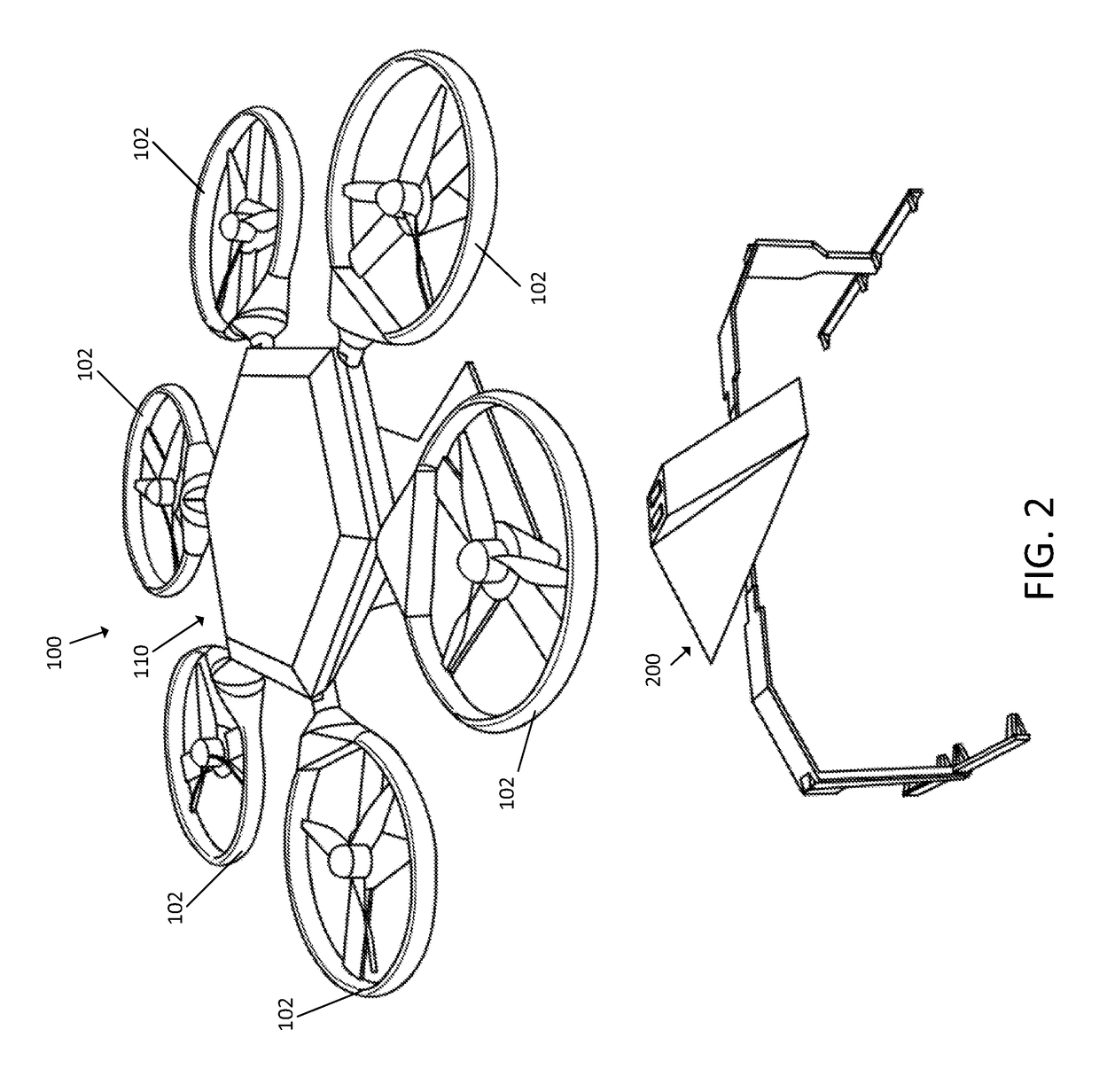

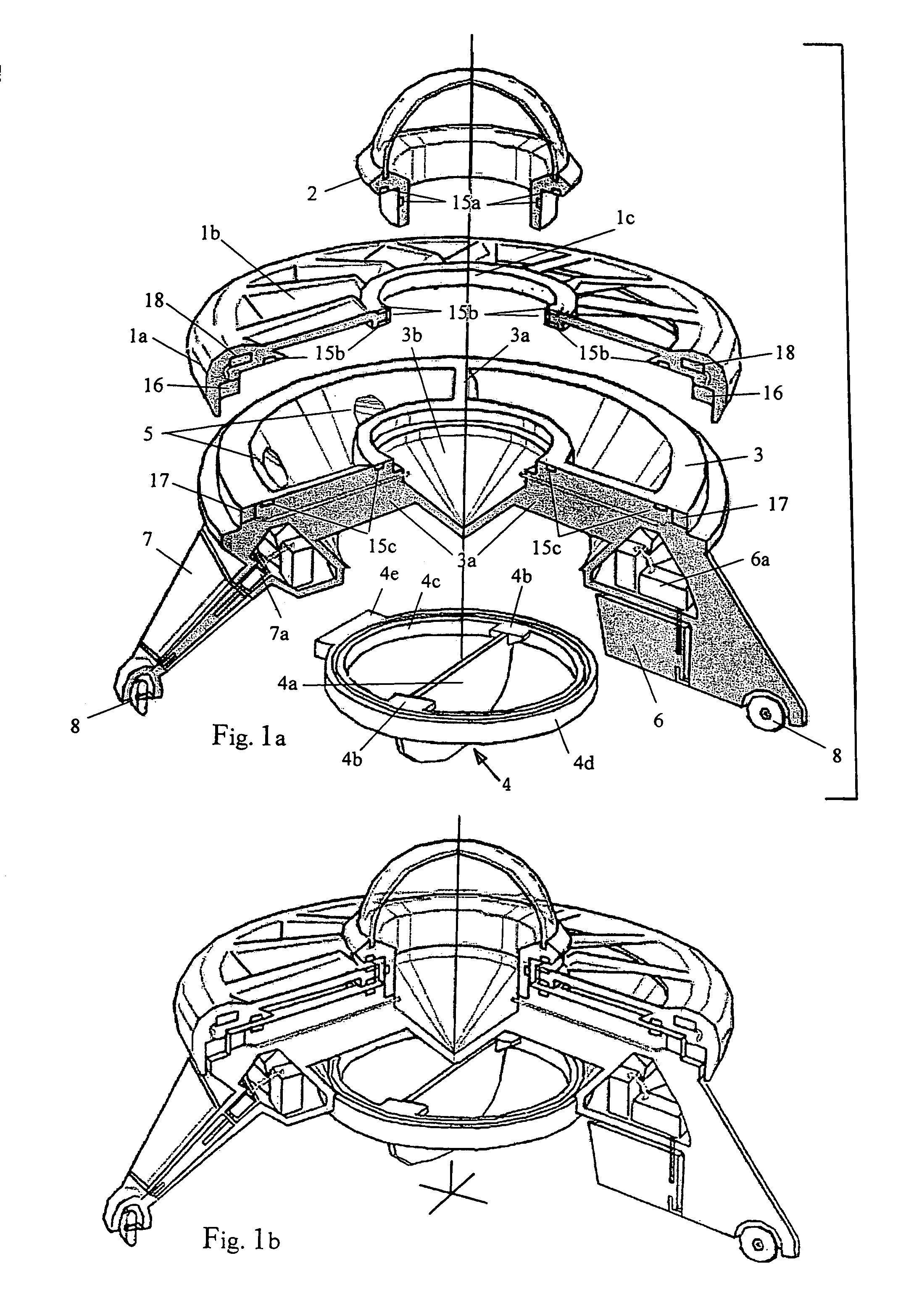

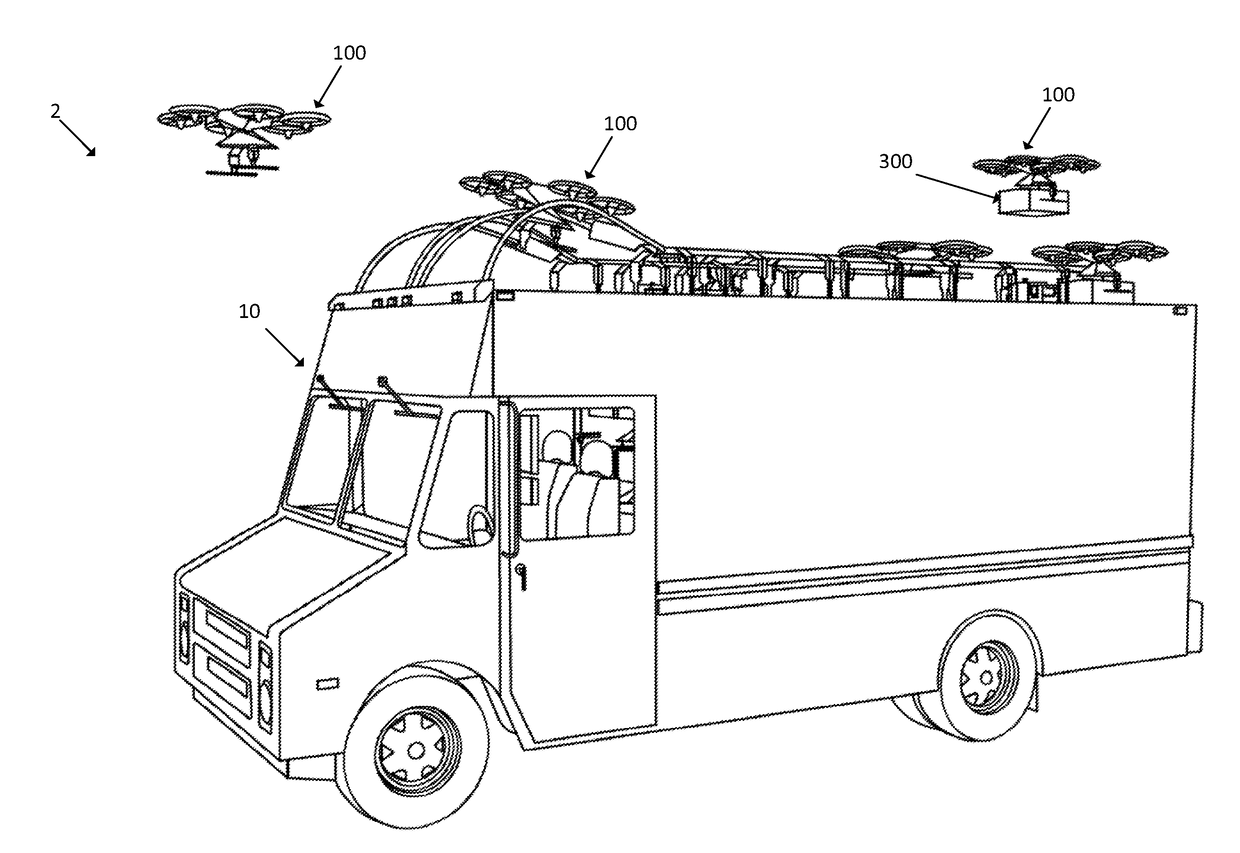

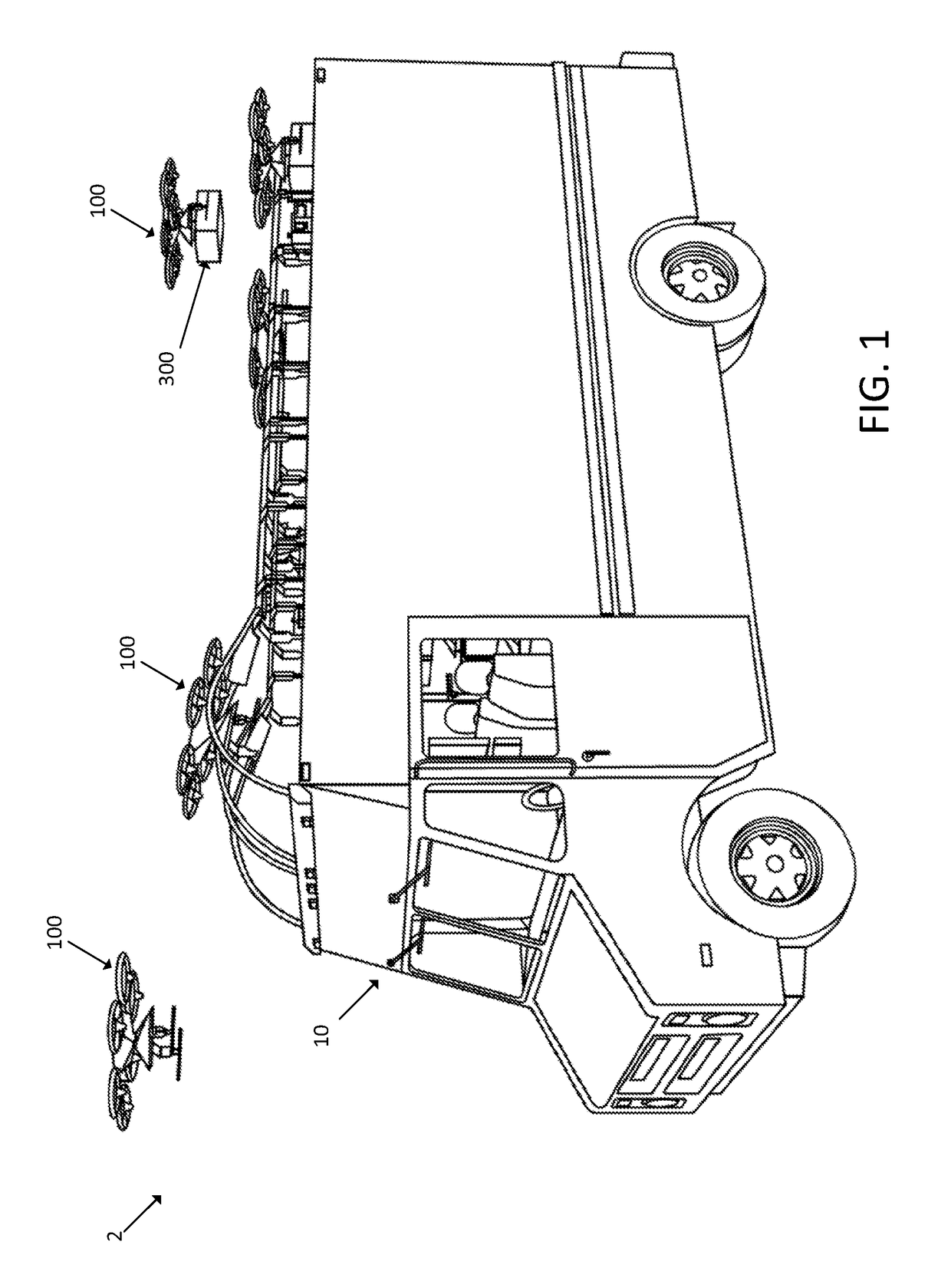

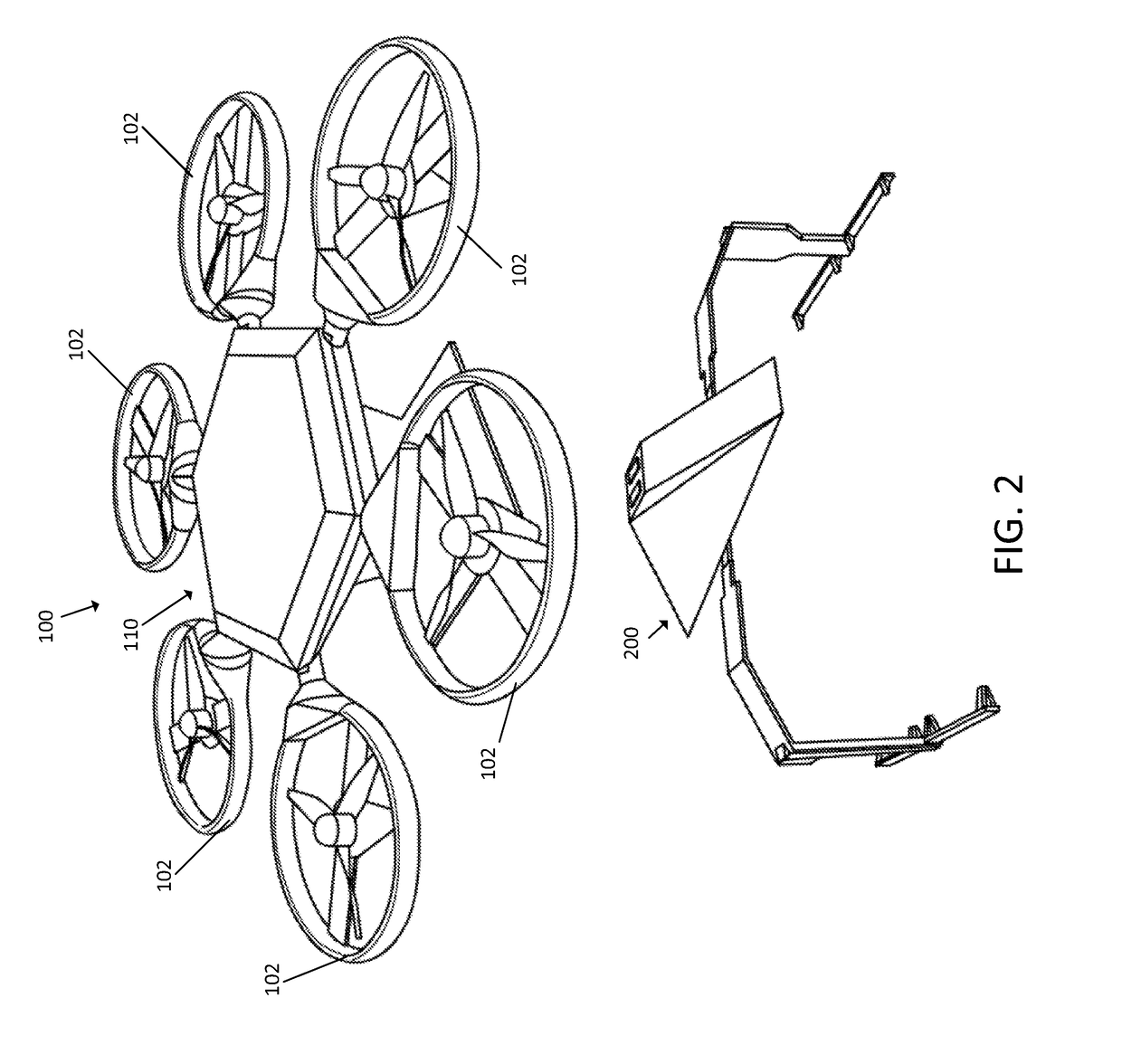

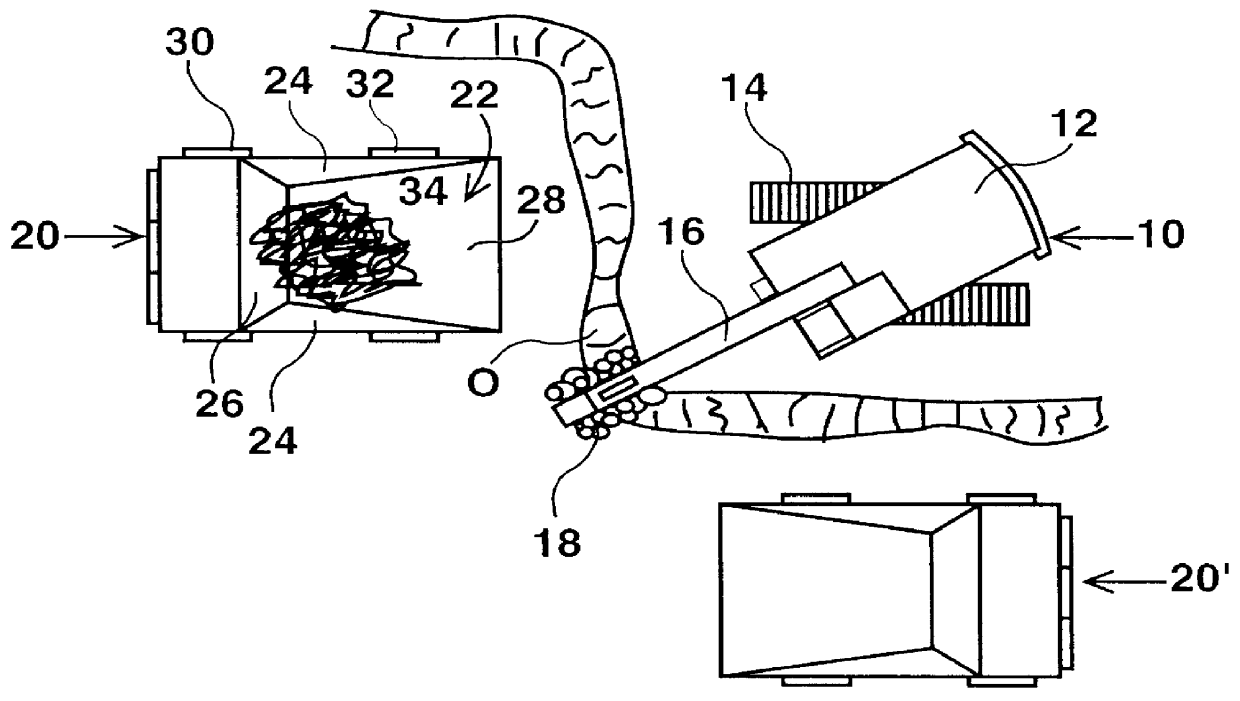

Unmanned aerial vehicle including a removable parcel carrier

ActiveUS20170313421A1Reduce the required powerArresting gearLaunching/towing gearUncrewed vehicleCarrier system

Systems and methods include UAVs that serve to assist carrier personnel by reducing the physical demands of the transportation and delivery process. A UAV generally includes a UAV chassis including an upper portion, a plurality of propulsion members configured to provide lift to the UAV chassis, and a parcel carrier configured for being selectively coupled to and removed from the UAV chassis. UAV support mechanisms are utilized to load and unload parcel carriers to the UAV chassis, and the UAV lands on and takes off from the UAV support mechanism to deliver parcels to a serviceable point. The UAV includes computing entities that interface with different systems and computing entities to send and receive various types of information.

Owner:UNITED PARCEL SERVICE OF AMERICAN INC

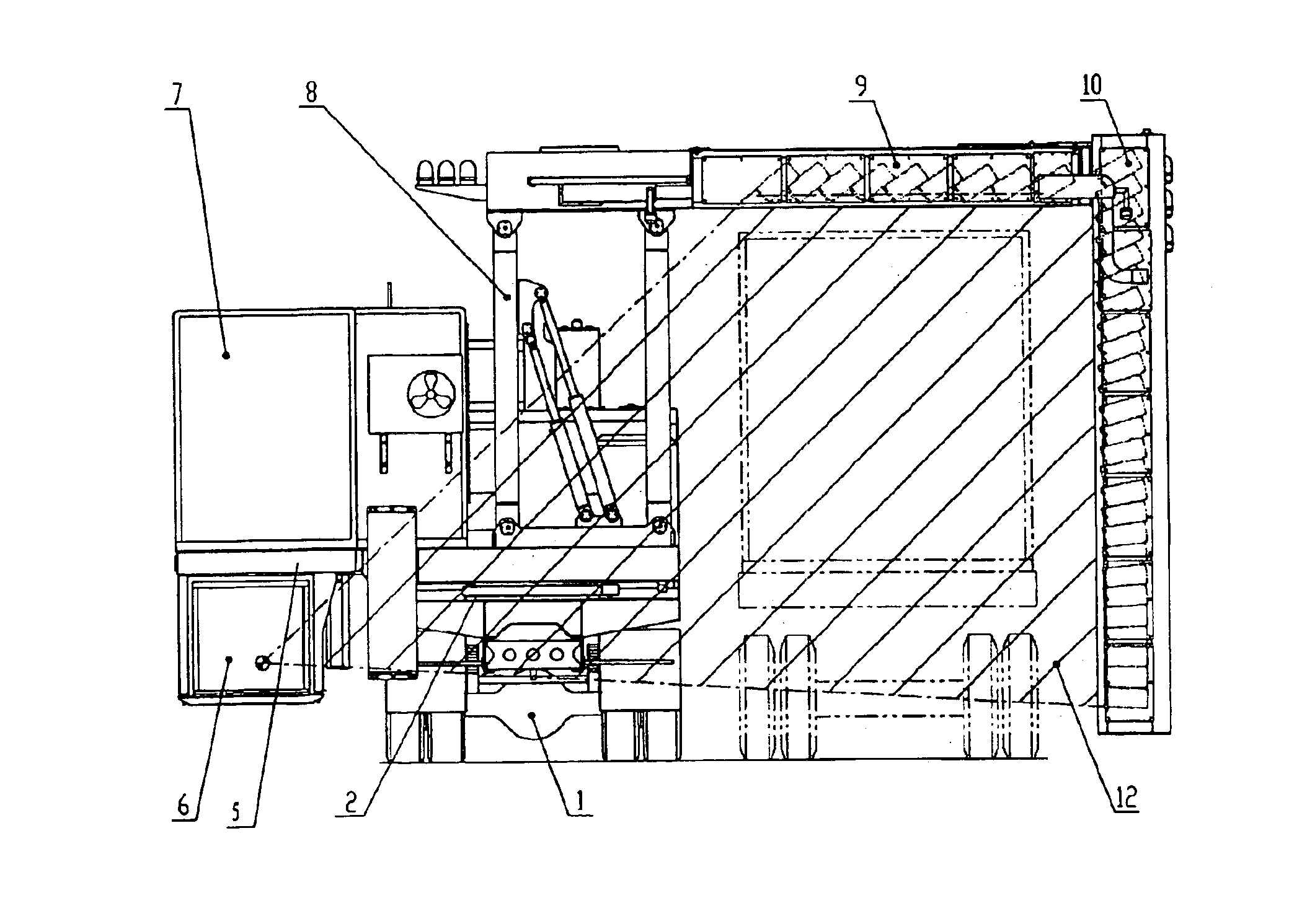

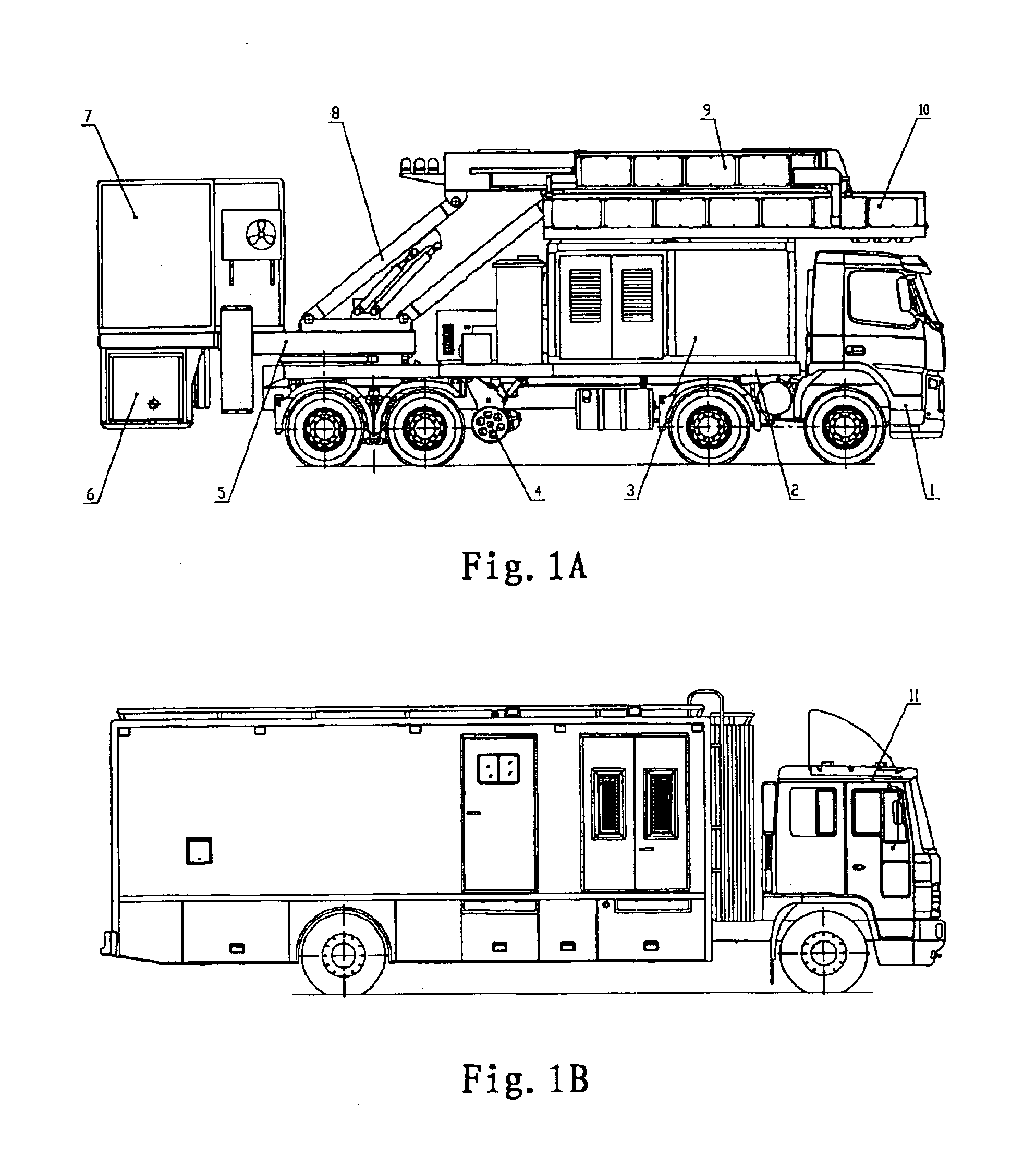

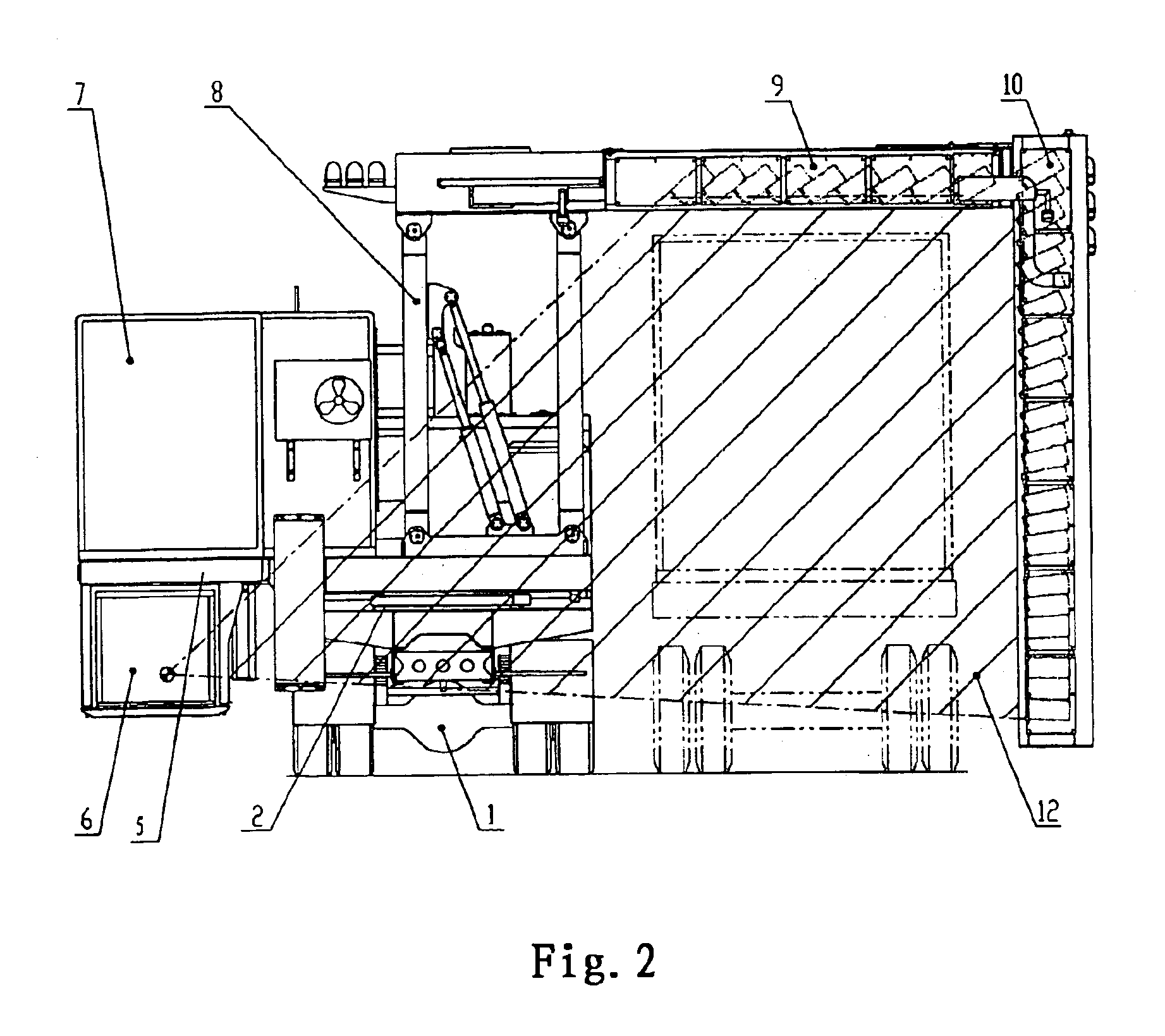

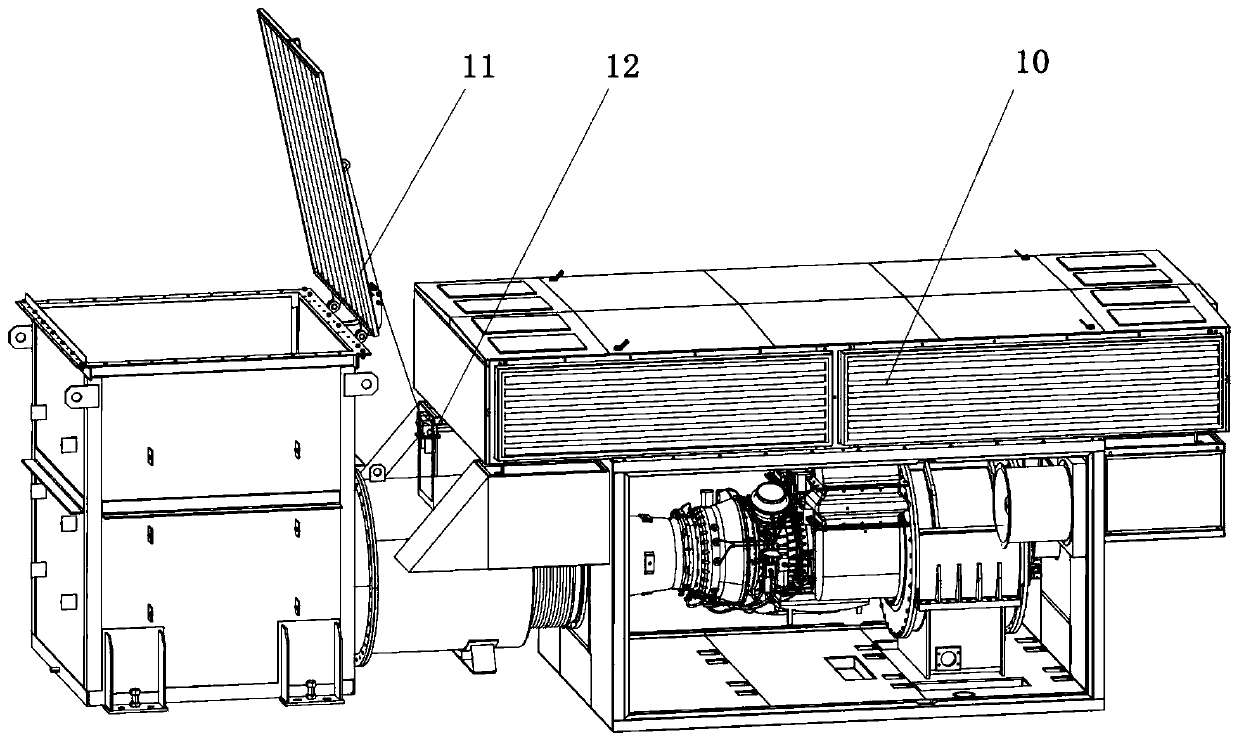

Vehicle-carried mobile container inspection apparatus

ActiveUS6920197B2Wide cross-sectionLower levelItem transportation vehiclesX-ray apparatusIn vehicleComputer module

A vehicle-carried mobile container inspection apparatus characterized in that the mobile container inspection apparatus comprises a first box-shaped cabin arranged in the front portion of the chassis and provided with a workroom accommodating a scan control module, an image acquisition module and an operation / inspection module; and a second box-shaped cabin and a third box-shaped cabin both arranged on the rear portion of the rotatable platform, in which the second box-shaped cabin is arranged on the top of the third box-shaped cabin, the control unit of the radiation source is accommodated in the second box-shaped cabin, the third box-shaped cabin is arranged under the rotatable platform, the radiation source is arranged in the third box-shaped cabin, the level of the radiation source from which the X-ray beam emit is arranged below the level of the chassis, the scanning vehicle is provided with a driving means to smoothly move the scanning vehicle the rotatable platform is provided with a rotatably driving means, when inspecting a container, the rotatable platform is driven to turn 90 degrees, and the second arm turns into its vertical gesture, so that a portal-shaped frame is formed by means of the parallelogrammical bracket, the first arm and the second arm. The mobile inspection container apparatus is capable of inspecting as broad area as to reach the vehicle chassis. The apparatus comprises two vehicles, in which usually the both vehicles are used, while only one vehicle is used for fulfilling the inspection work in emergency.

Owner:TSINGHUA UNIV +1

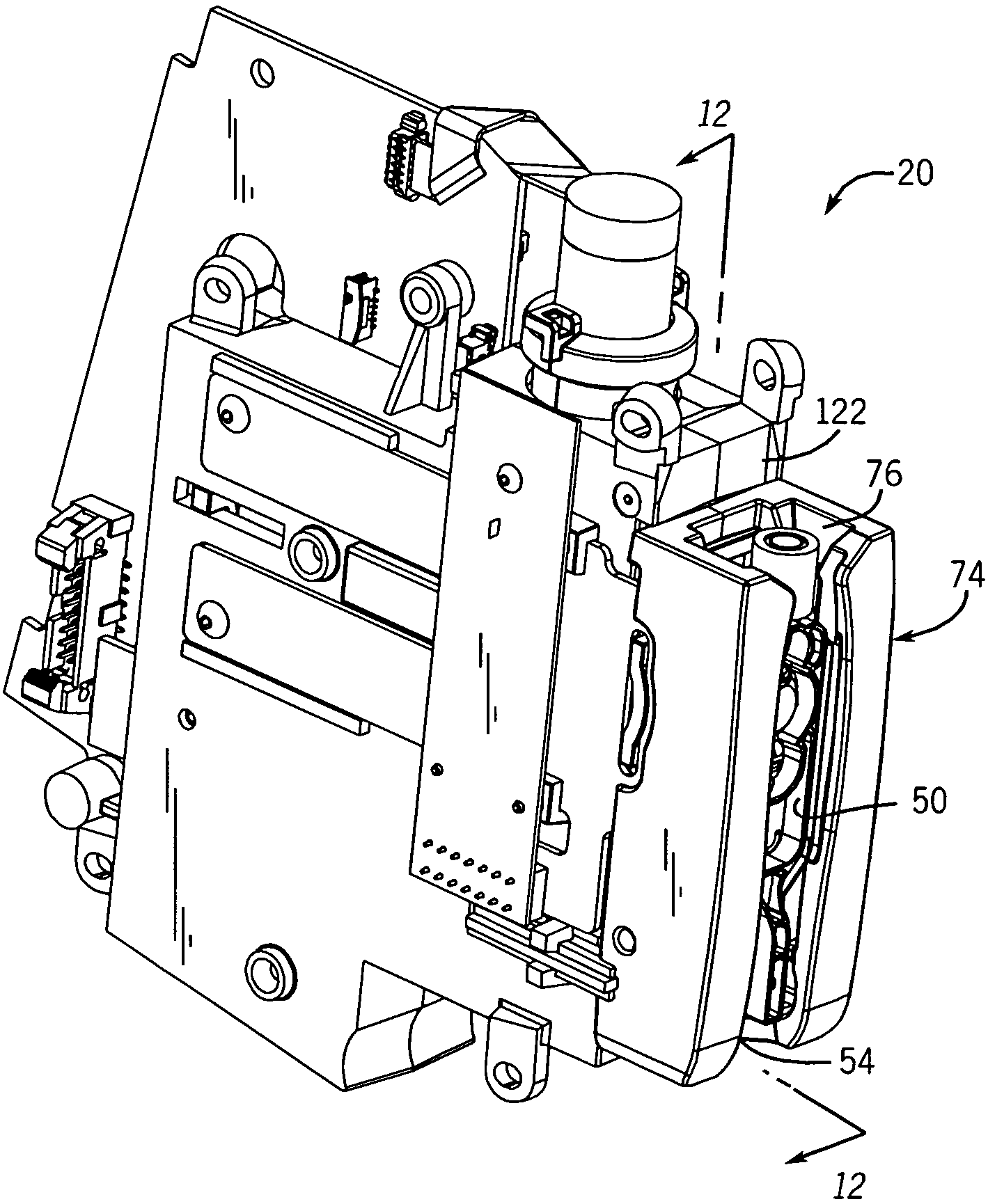

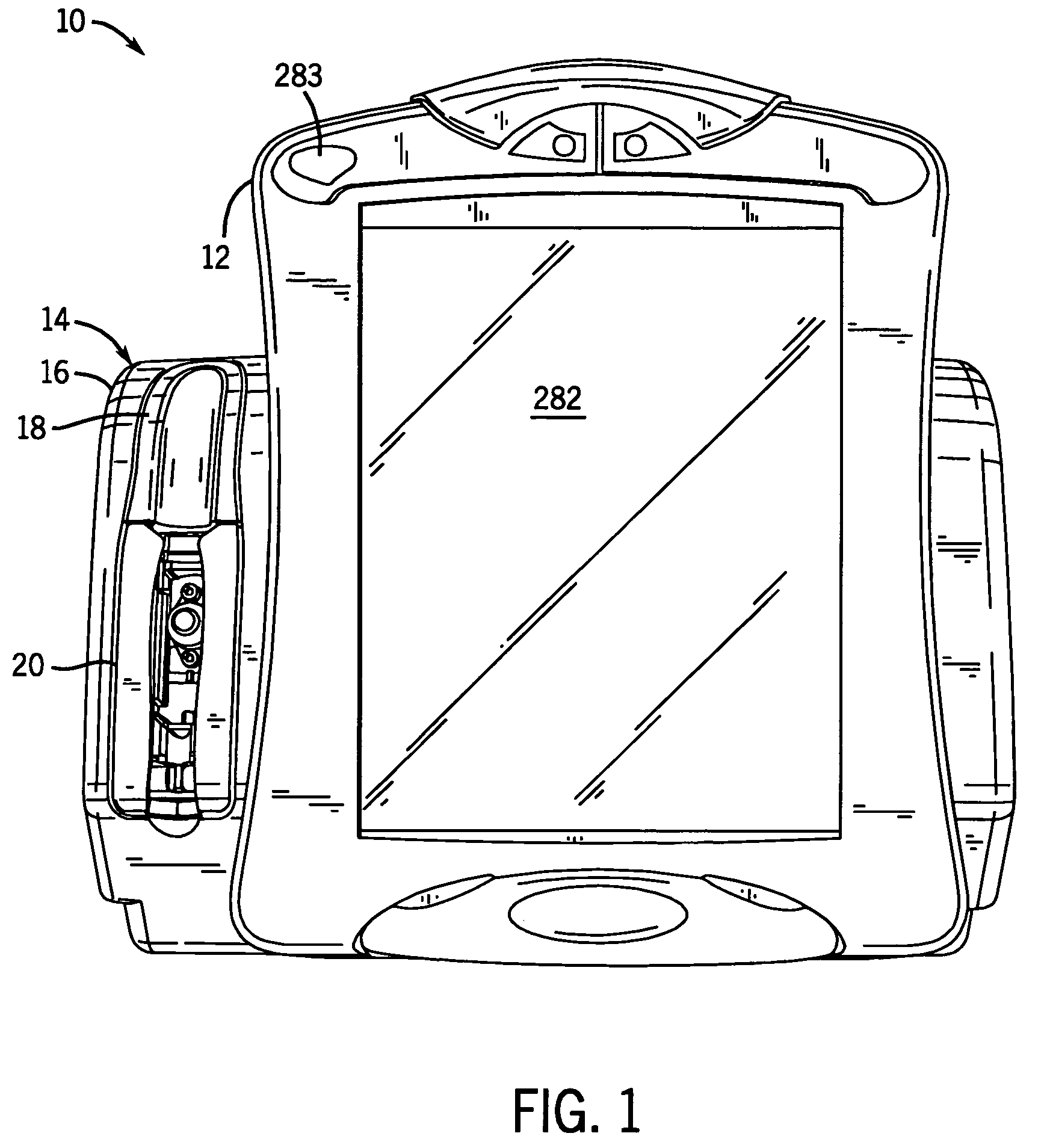

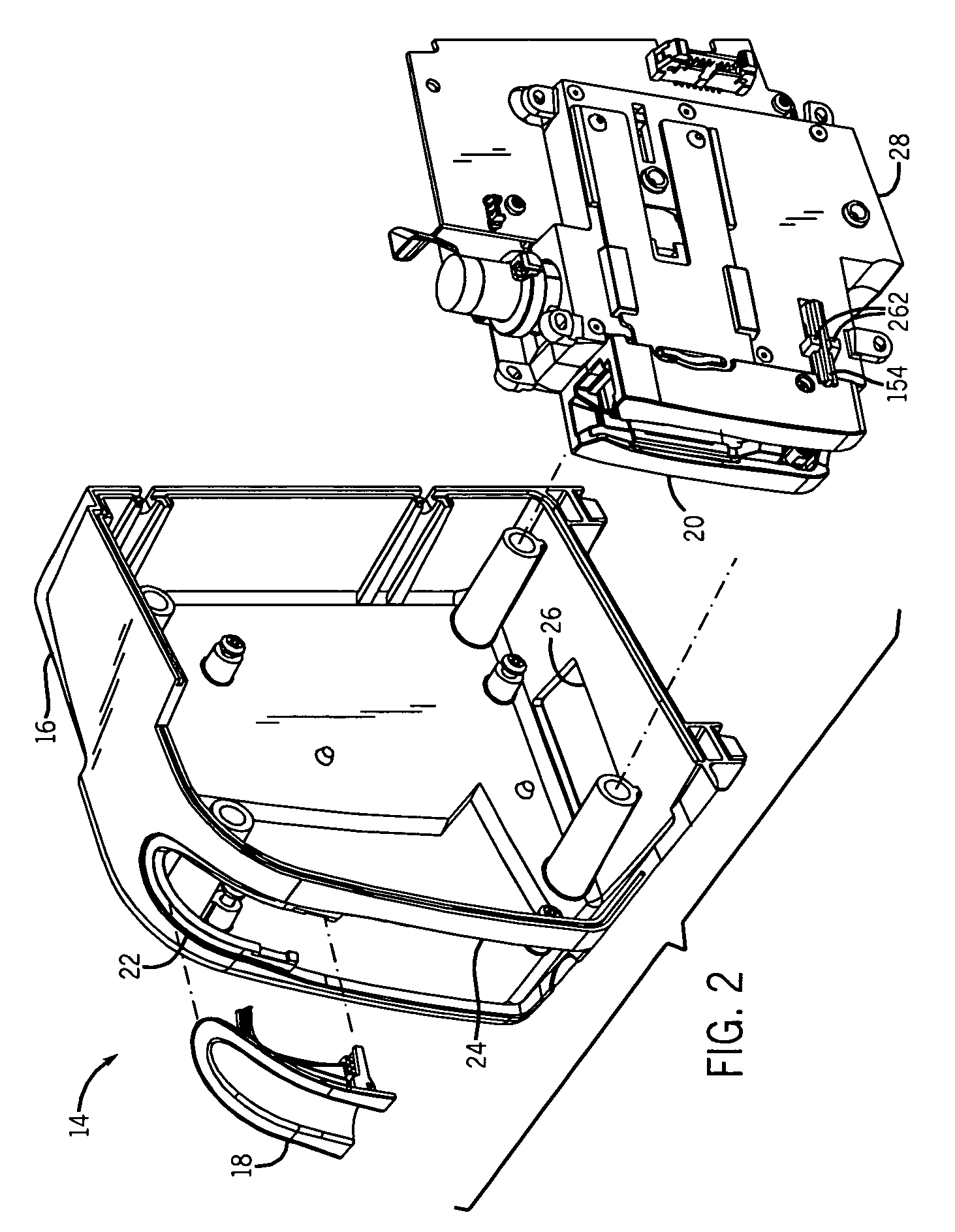

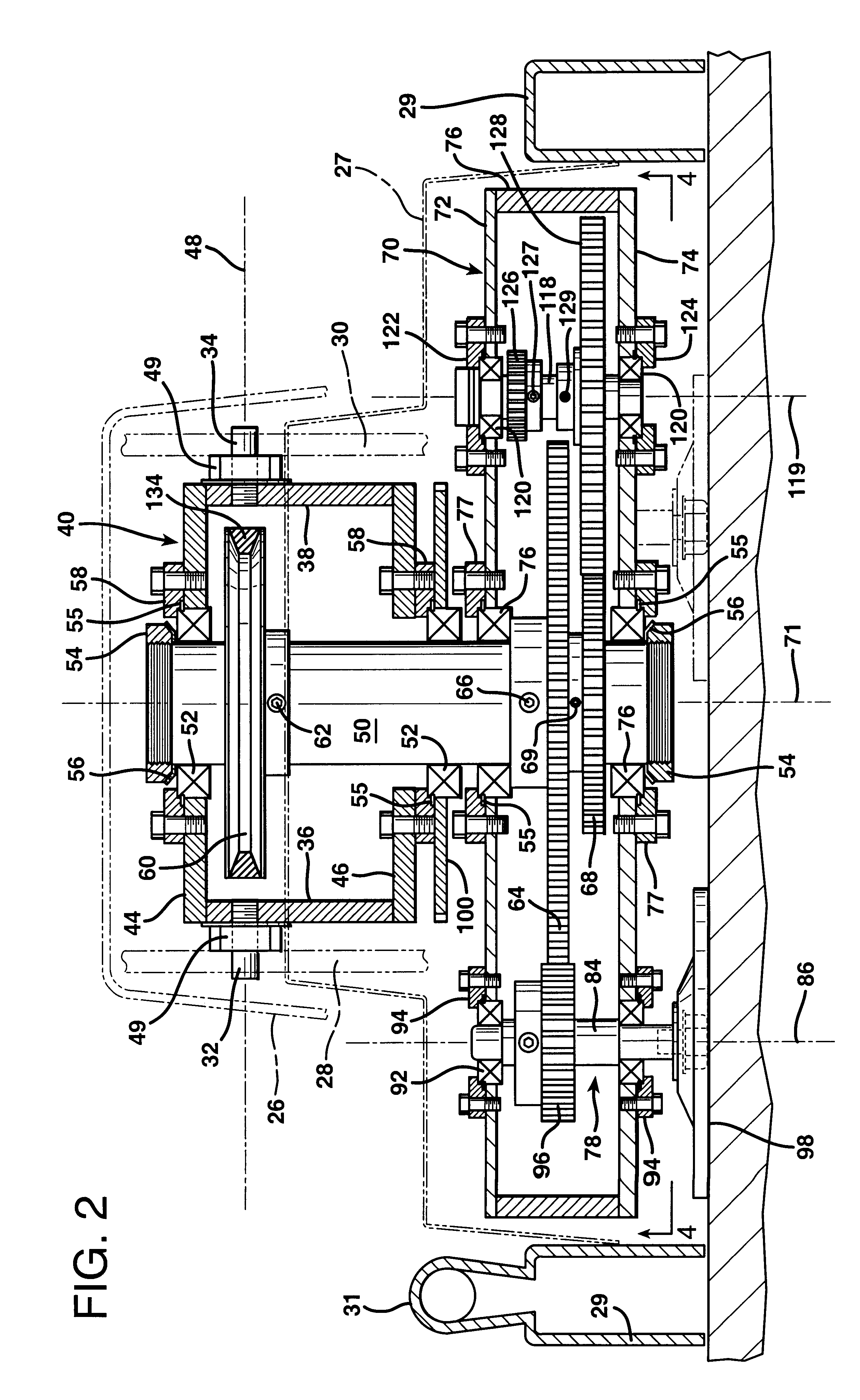

Fluid delivery device identification and loading system

A medical pump includes a chassis having a fixed seat, and a main carriage having a carriage footing for receiving a fluid delivery device and restricting its movement. An actuator automatically moves the main carriage between open and closed positions to engage the fluid delivery device to the seat. The seat establishes the position of both the main carriage and fluid delivery device in the closed position. The actuator is connected to the main carriage by a rear carriage assembly having a manual release element for disengaging the actuator from rear carriage assembly and thereby from the main carriage. A processing unit detects jam conditions by processing carriage position data and electrical load data from the actuator.

Owner:ICU MEDICAL INC

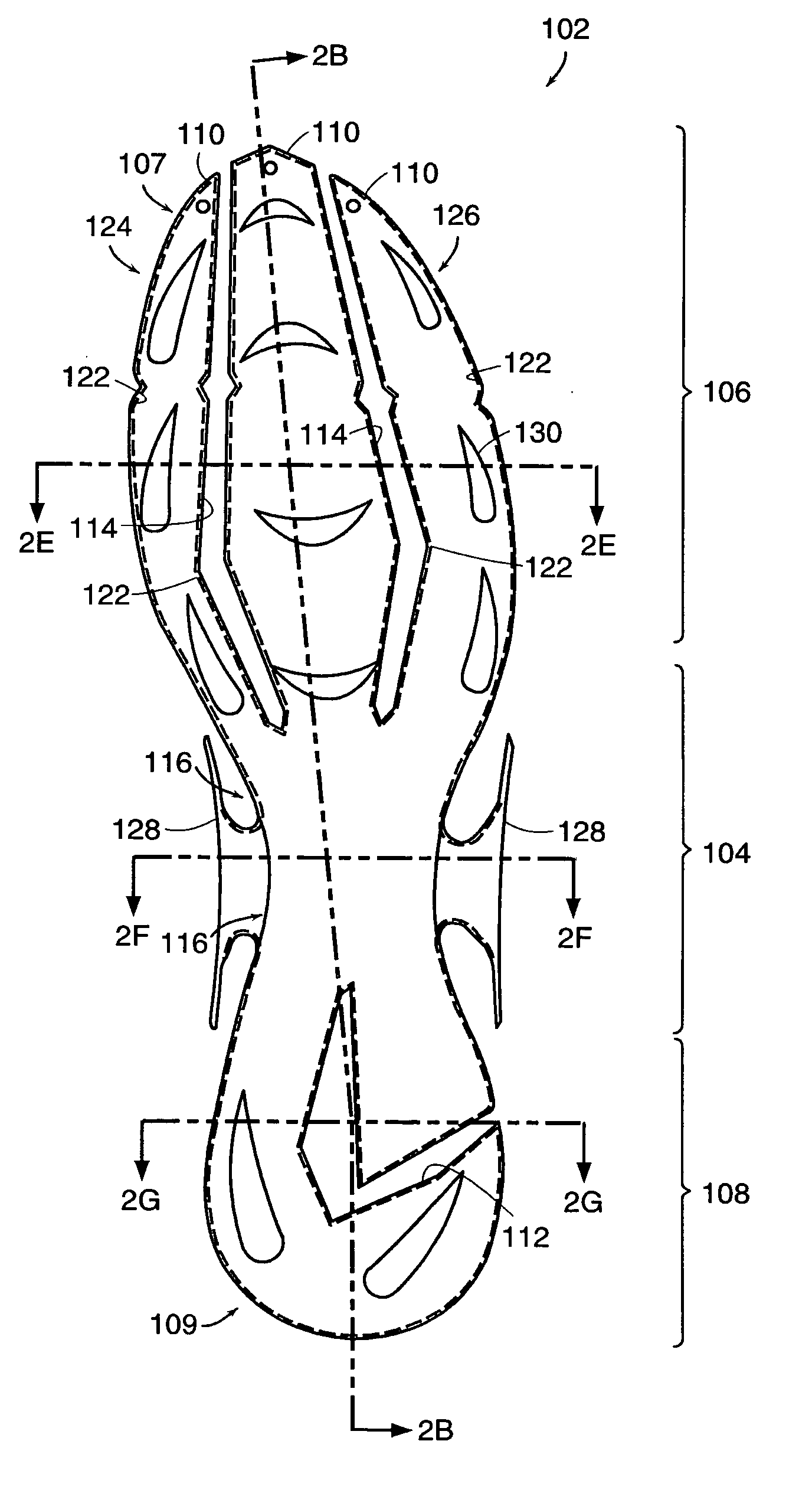

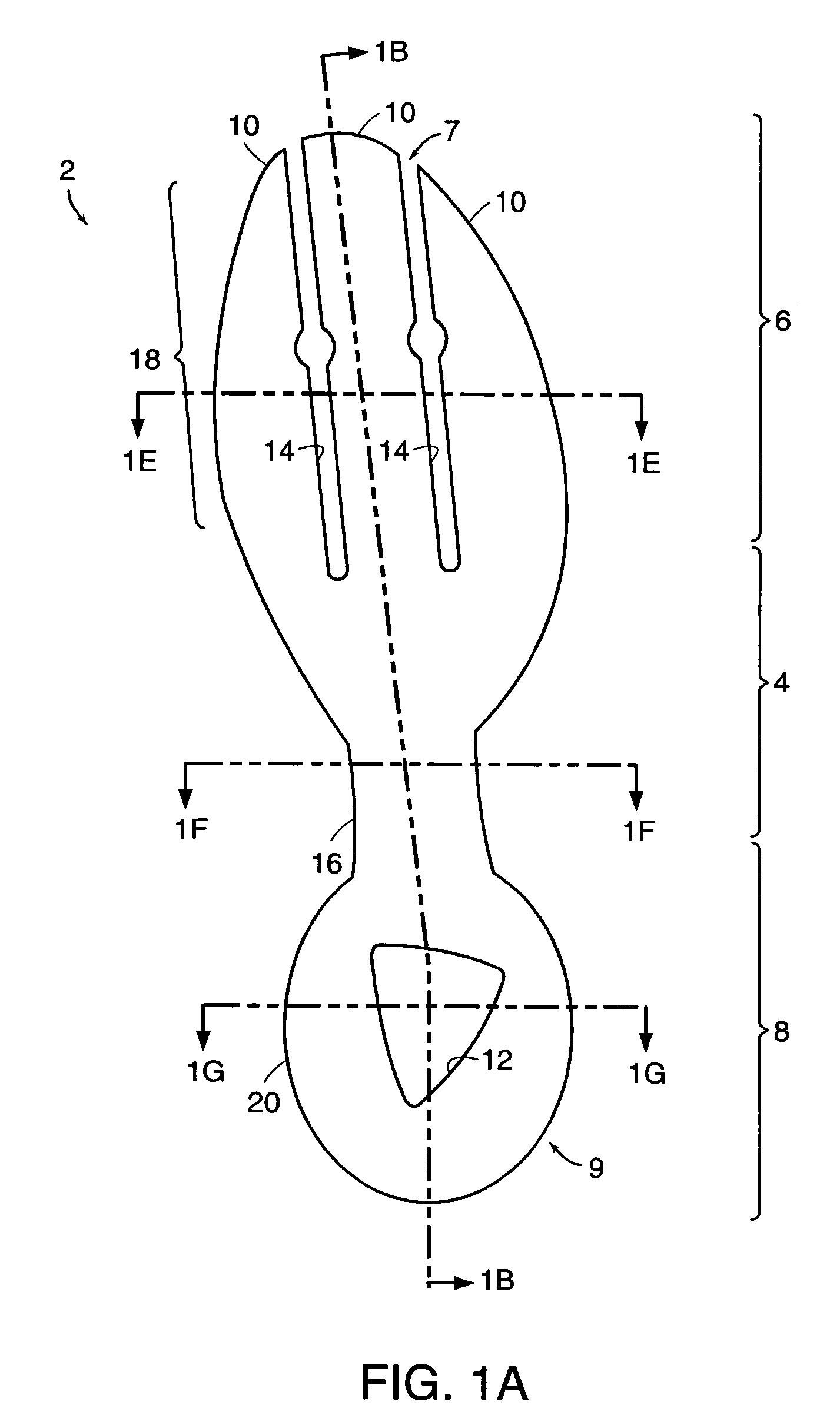

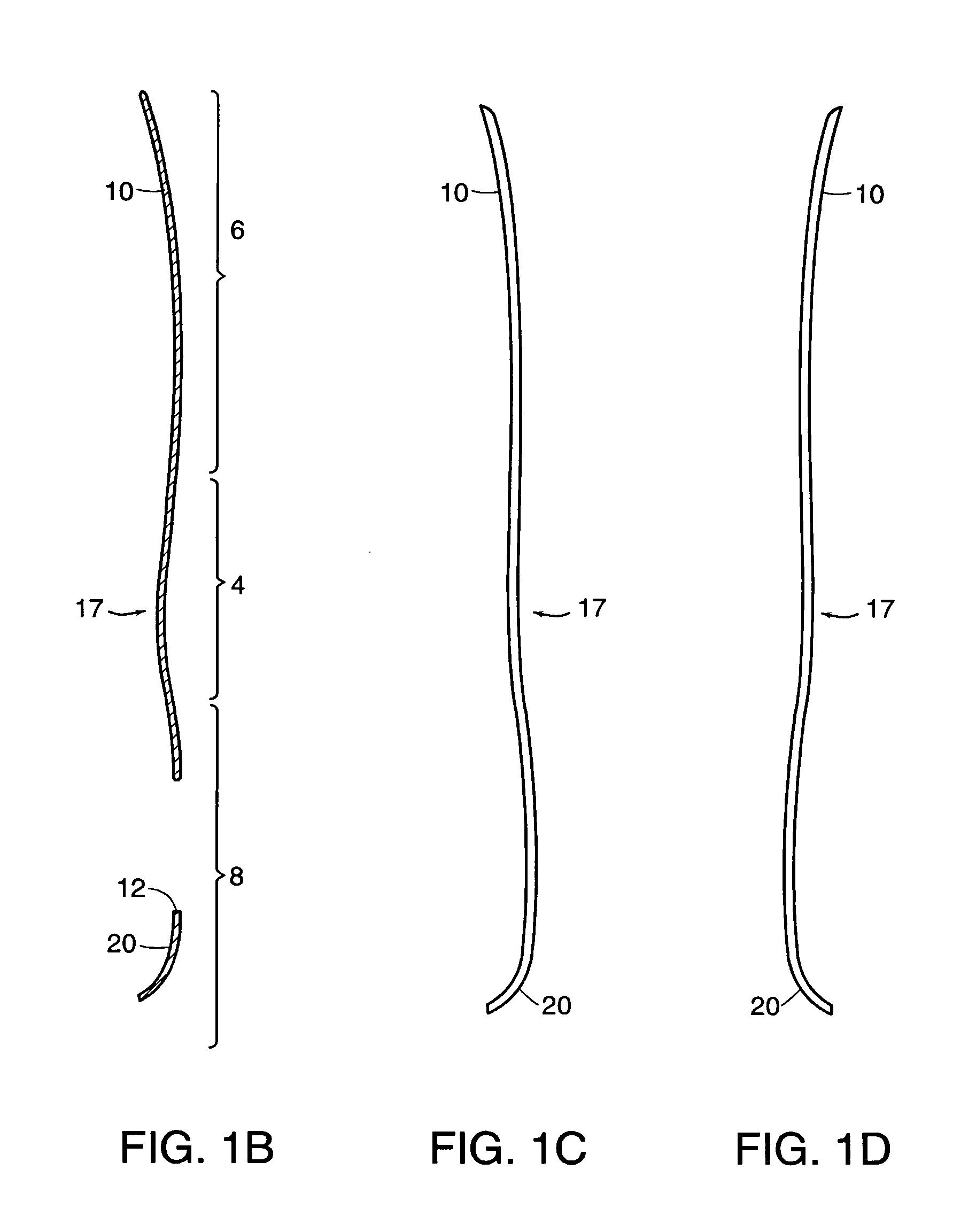

Chassis construction for an article of footwear

InactiveUS6954998B1Enhance performanceEffective power transferSolesUpperEngineeringMechanical engineering

Owner:ADIDAS

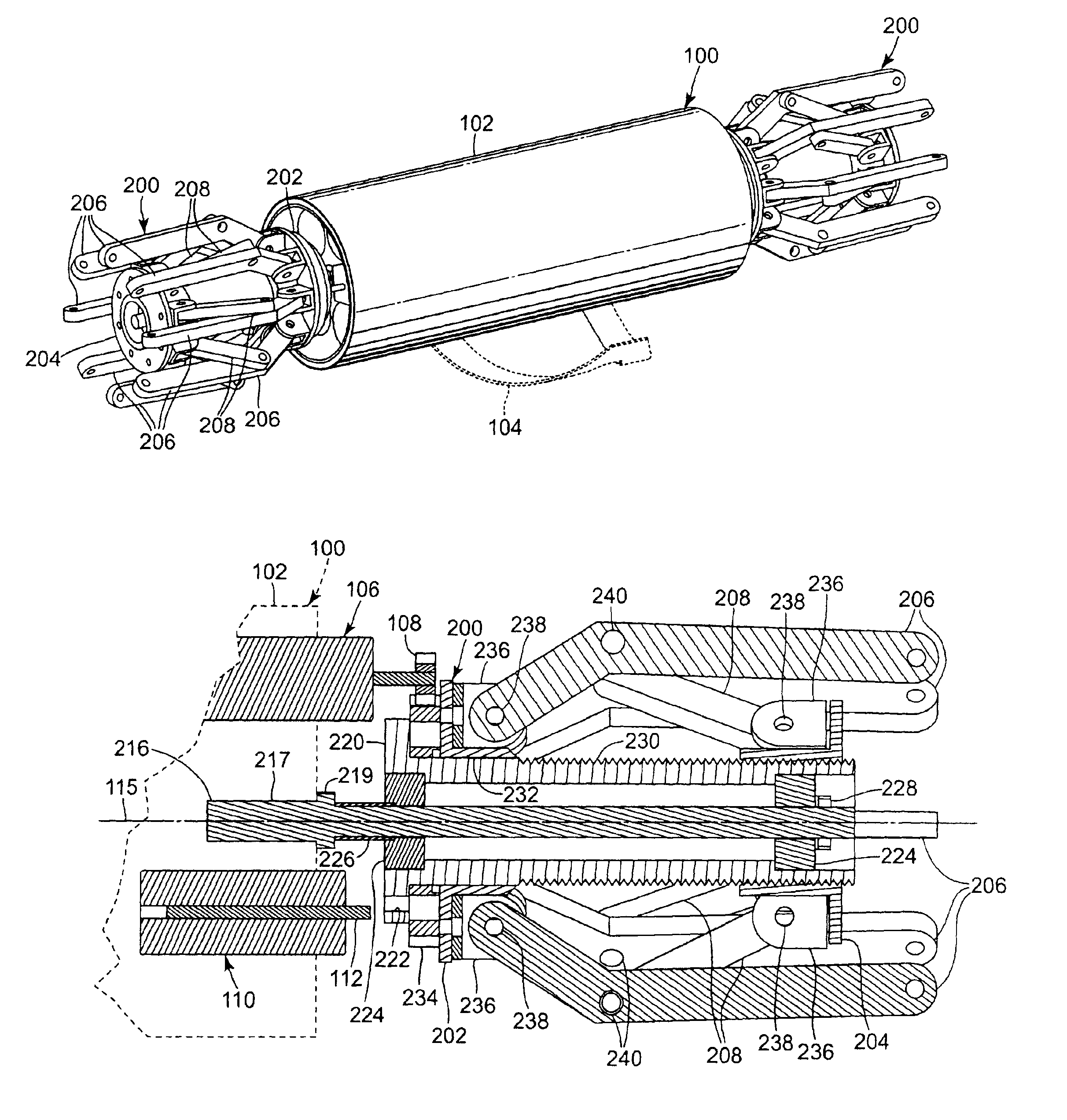

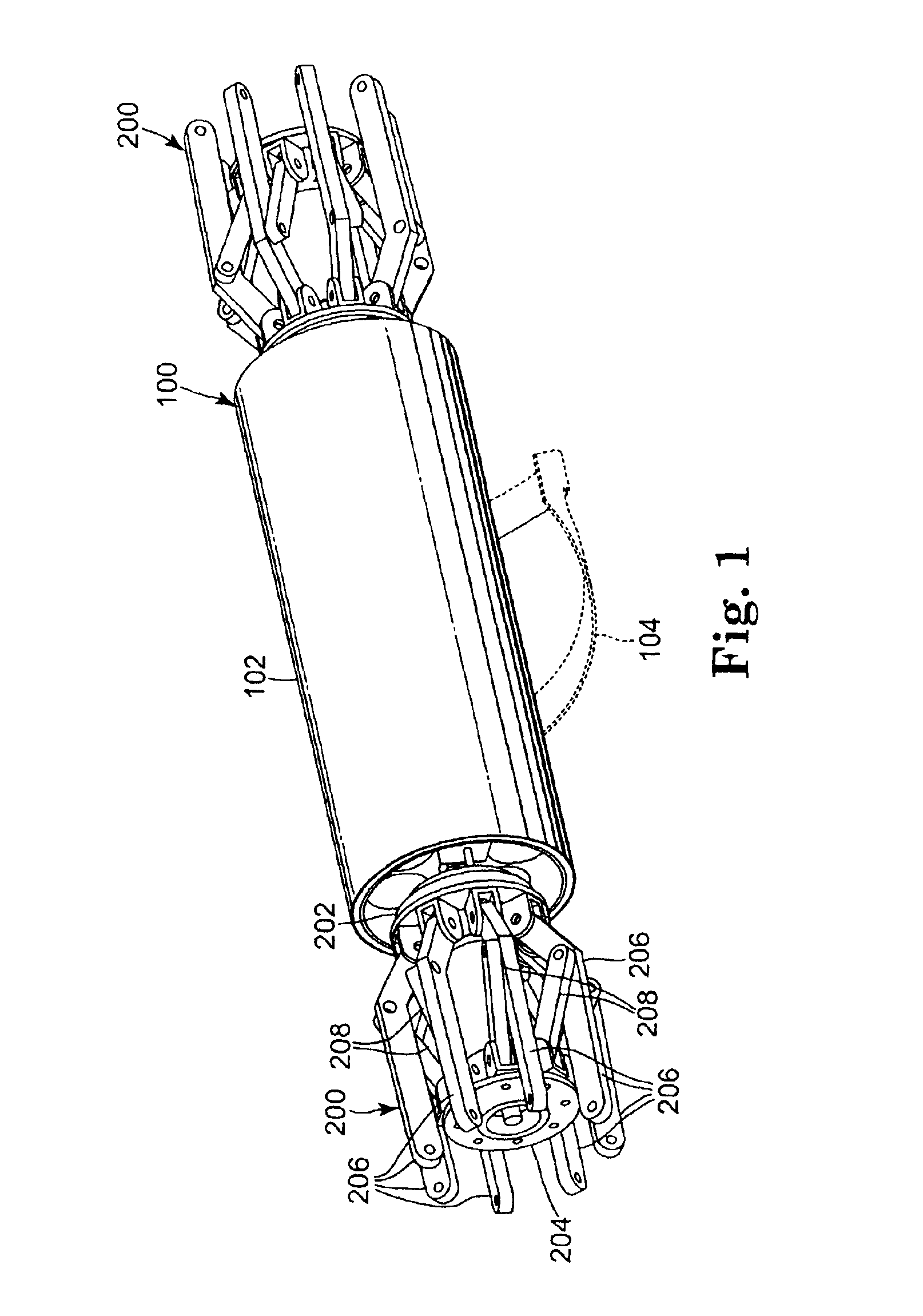

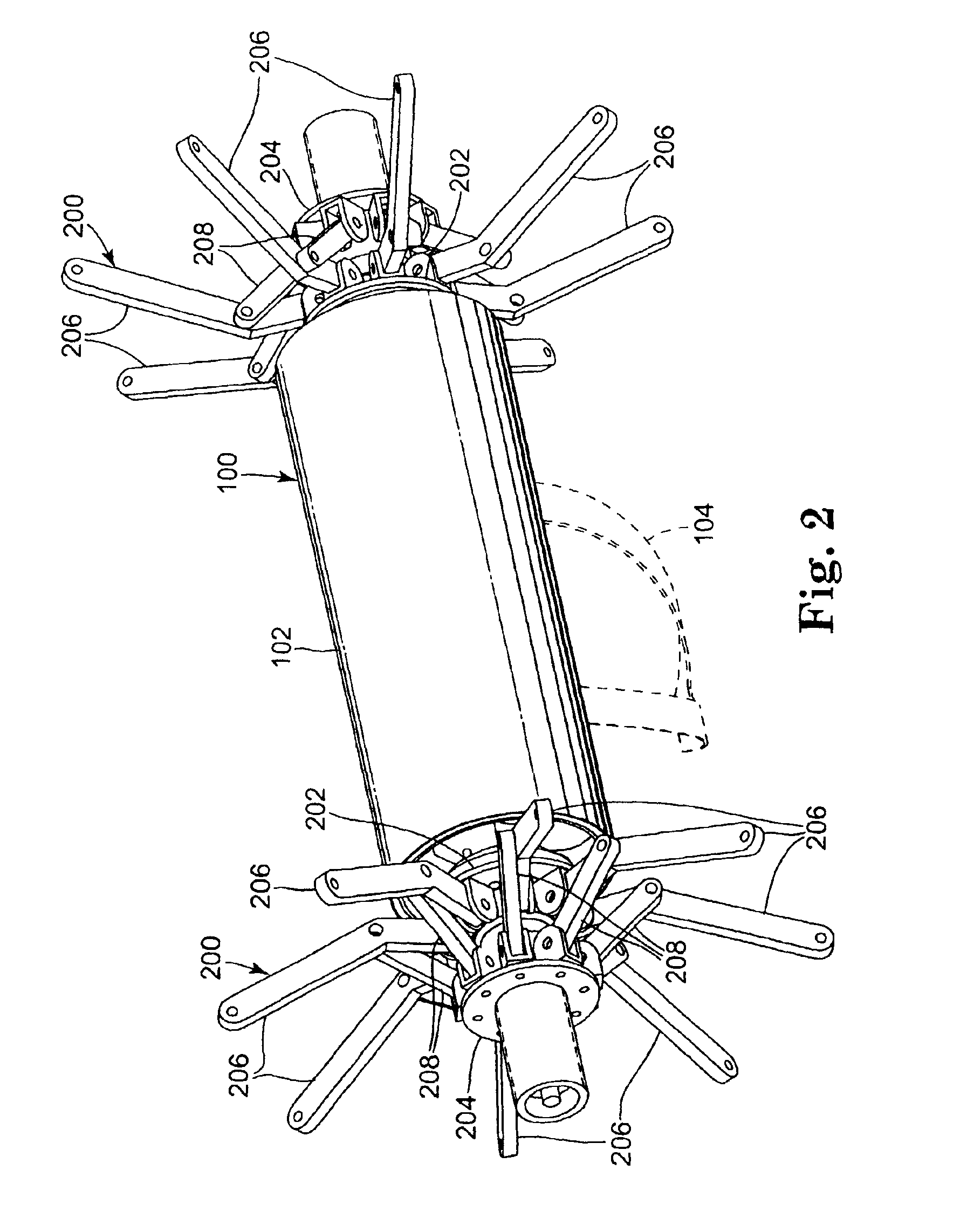

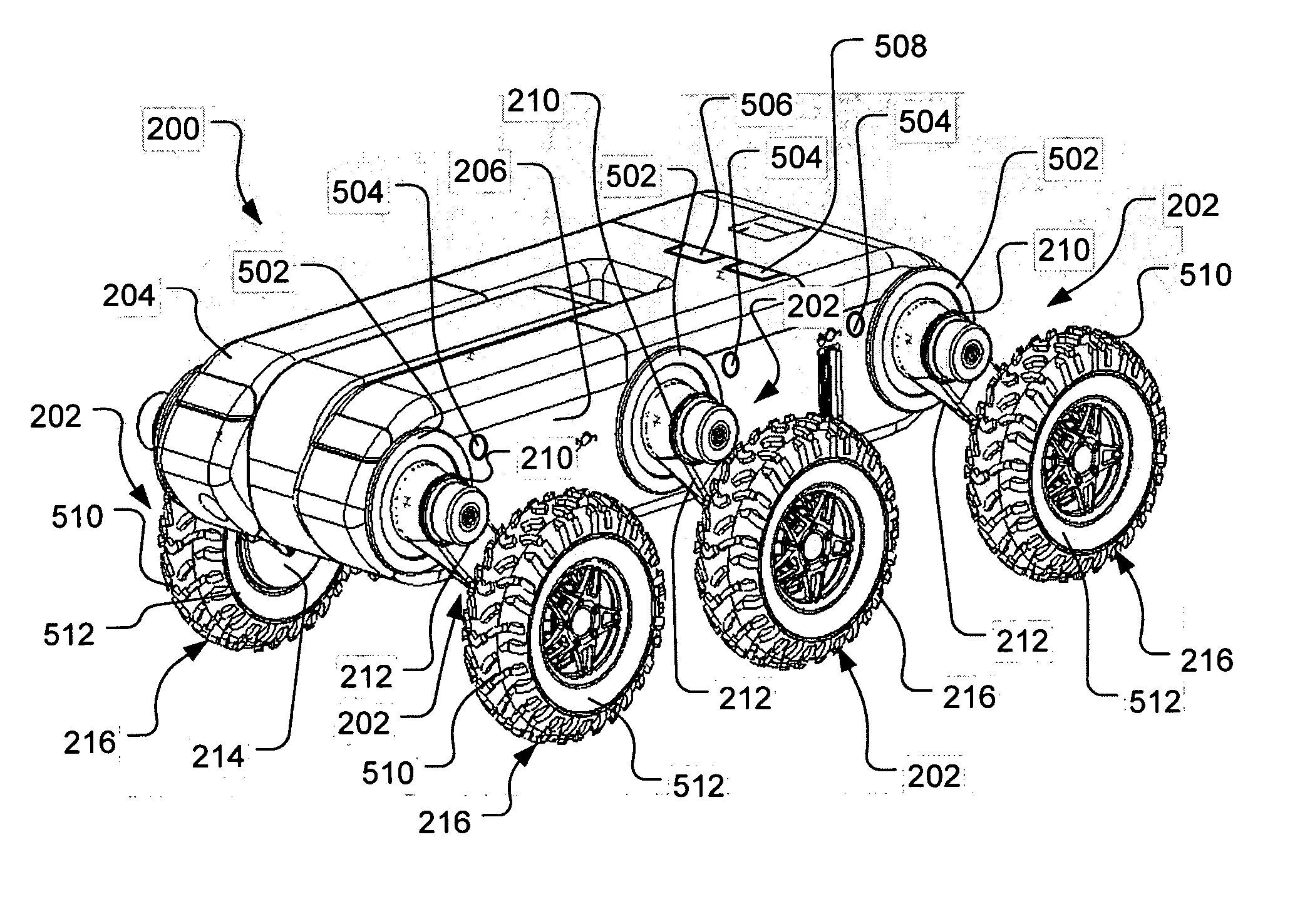

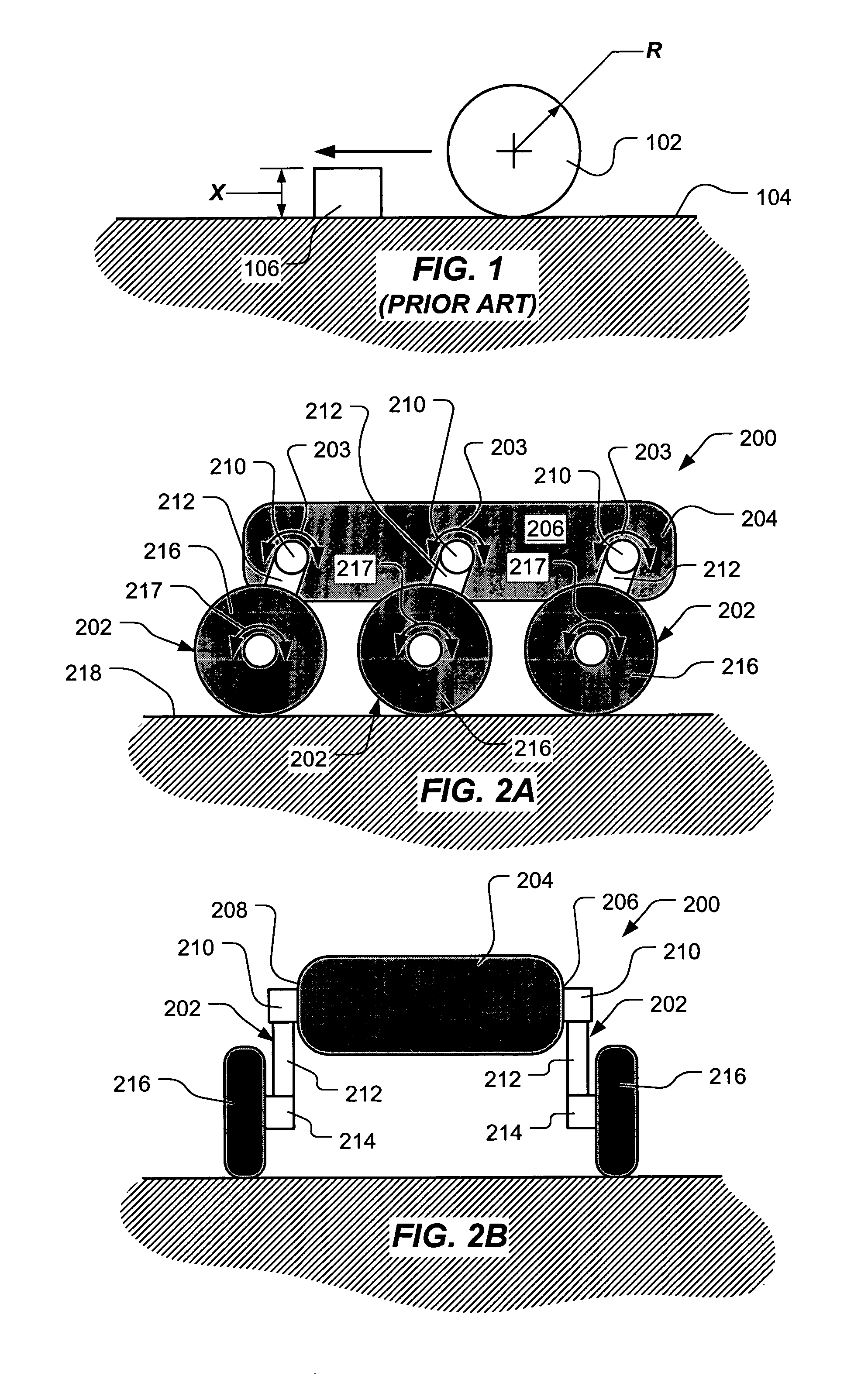

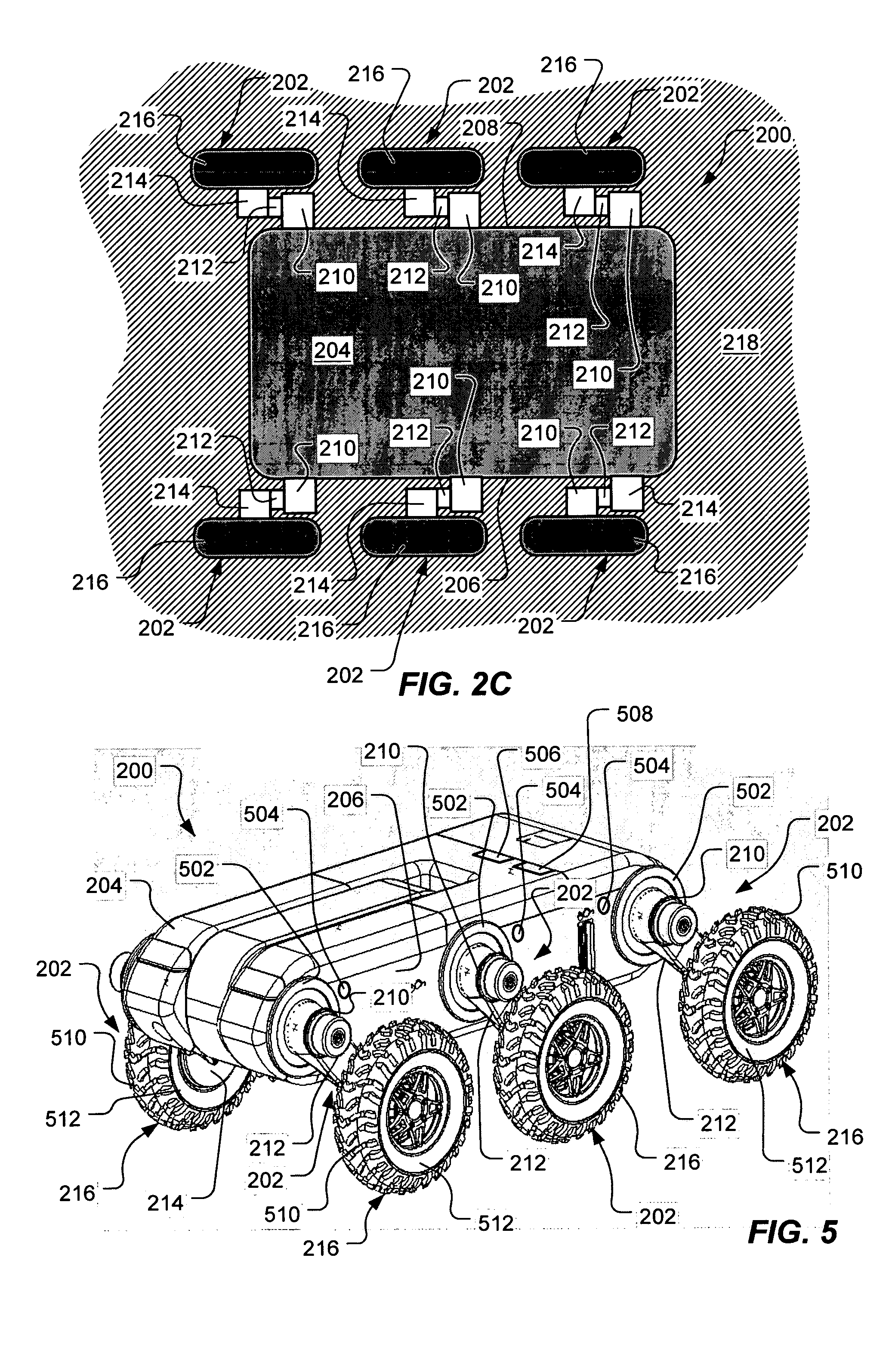

Adjustable diameter wheel assembly, and methods and vehicles using same

A powered wheel assembly, and method and ground-engaging vehicle (e.g., a robotic vehicle) using the same, are provided. The vehicle incorporates at least one of the wheel assemblies on its chassis body. In addition to its ability to propel the vehicle across a surface, the wheel assembly is reconfigurable between a retracted configuration, wherein the wheel assembly has a first rolling diameter, and an expanded configuration, wherein the wheel assembly has a second rolling diameter greater than the first rolling diameter. A drive motor assembly may both rotate the wheel assembly, e.g., propel the vehicle across a surface, and selectively actuate the wheel assembly from the first rolling diameter to the second rolling diameter, or to any intermediate rolling diameter.

Owner:MINNESOTA RGT UNIV OF A CORP OF MN

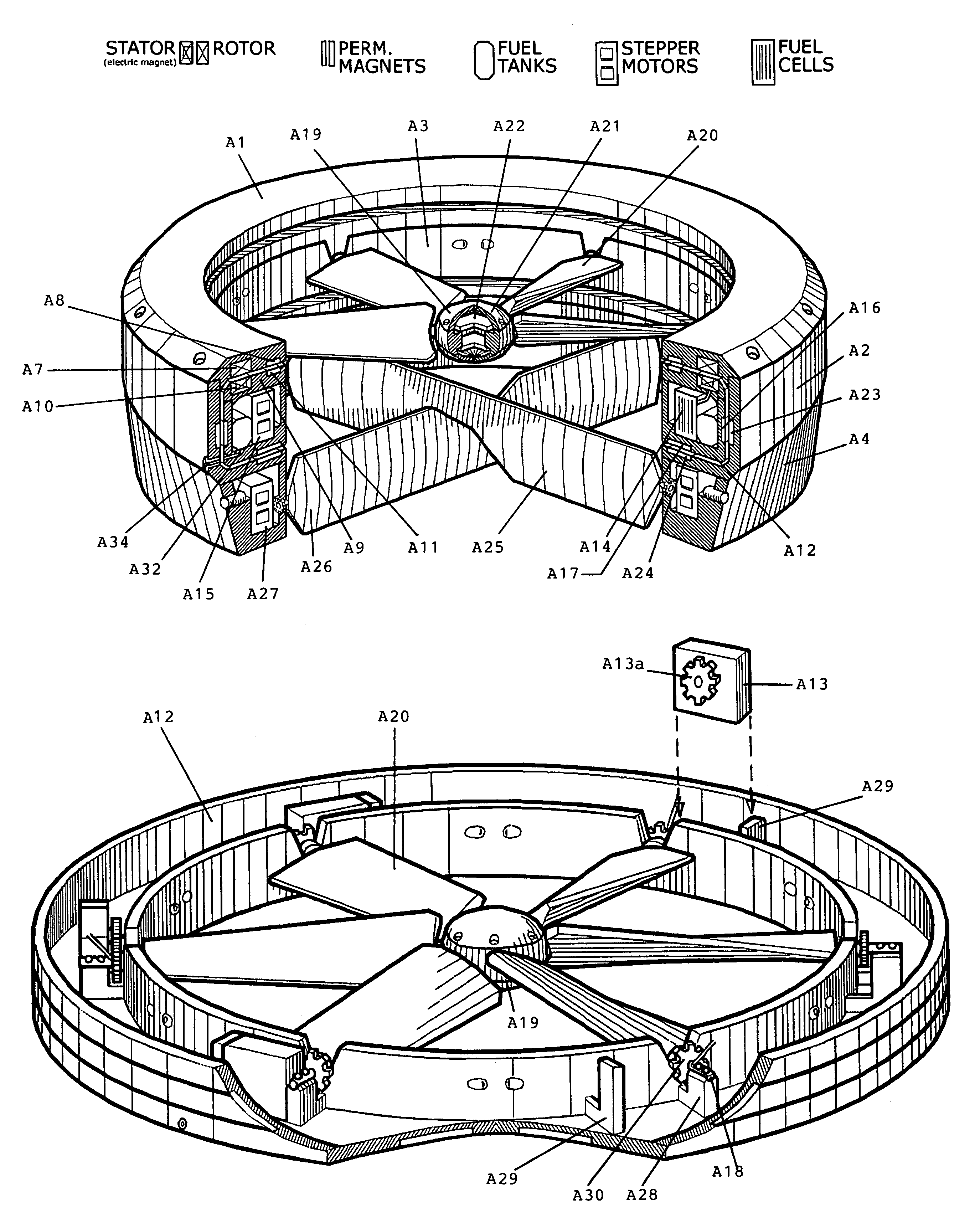

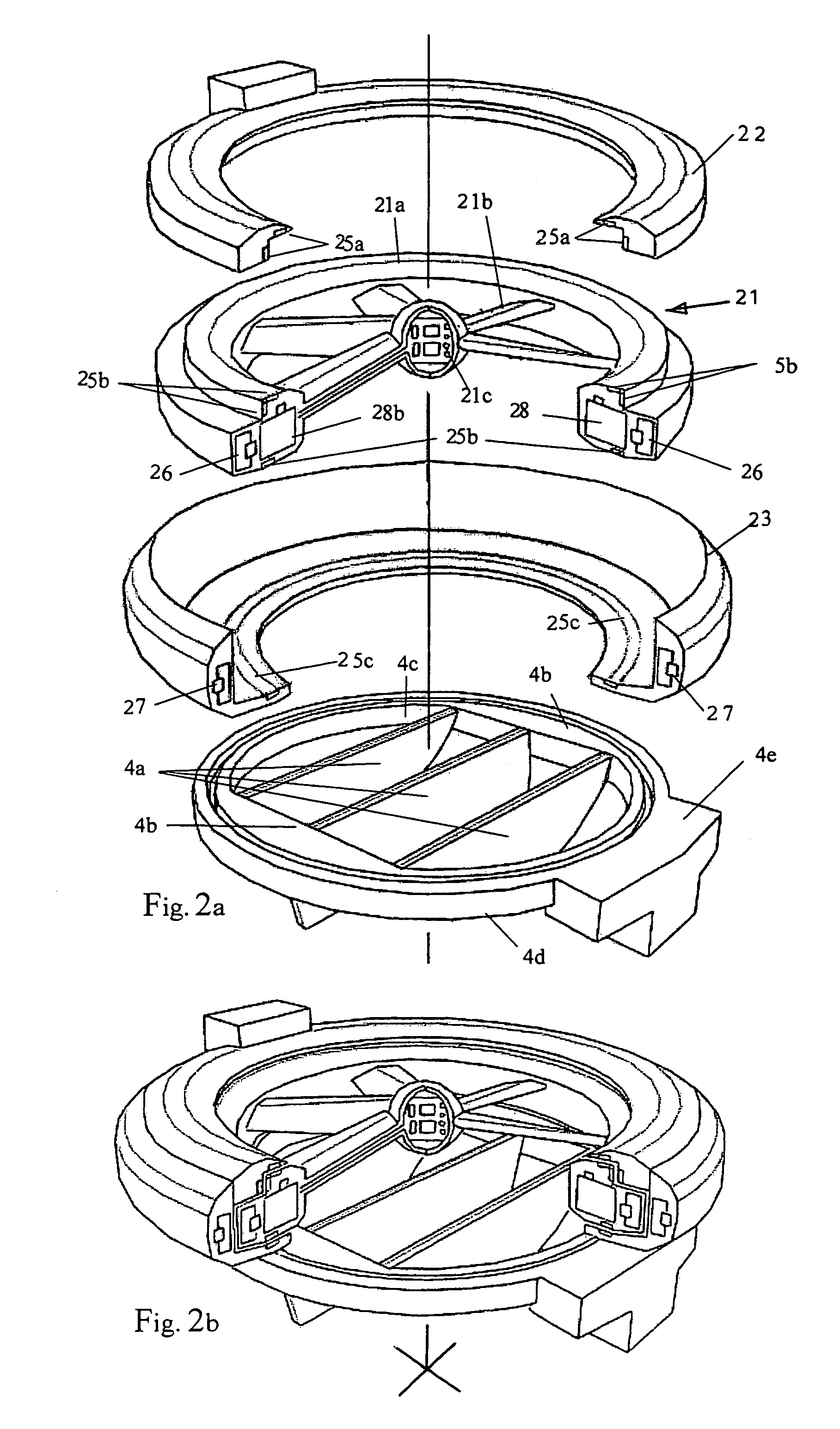

Quiet vertical takeoff and landing aircraft using ducted, magnetic induction air-impeller rotors

InactiveUS7032861B2Improve performanceImprove stabilityAircraft navigation controlUnmanned aerial vehiclesFlight control modesRudder

A hover aircraft employs an air impeller engine having an air channel duct and a rotor with outer ends of its blades fixed to an annular impeller disk that is driven by magnetic induction elements arrayed in the air channel duct. The air-impeller engine is arranged vertically in the aircraft frame to provide vertical thrust for vertical takeoff and landing. Preferably, the air-impeller engine employs dual, coaxial, contra-rotating rotors for increased thrust and gyroscopic stability. An air vane assembly directs a portion of the air thrust output at a desired angle to provide a horizontal thrust component for flight maneuvering or translation movement. The aircraft can employ a single engine in an annular fuselage, two engines on a longitudinal fuselage chassis, three engines in a triangular arrangement for forward flight stability, or other multiple engine arrangements in a symmetric, balanced configuration. Other flight control mechanisms may be employed, including side winglets, an overhead wing, and / or air rudders or flaps. An integrated flight control system can be used to operate the various flight control mechanisms. Electric power is supplied to the magnetic induction drives by high-capacity lightweight batteries or fuel cells. The hover aircraft is especially well suited for applications requiring VTOL deployment, hover operation for quiet surveillance, maneuvering in close air spaces, and long duration flights for continuous surveillance of ground targets and important facilities requiring constant monitoring.

Owner:SANDERS JR JOHN K +3

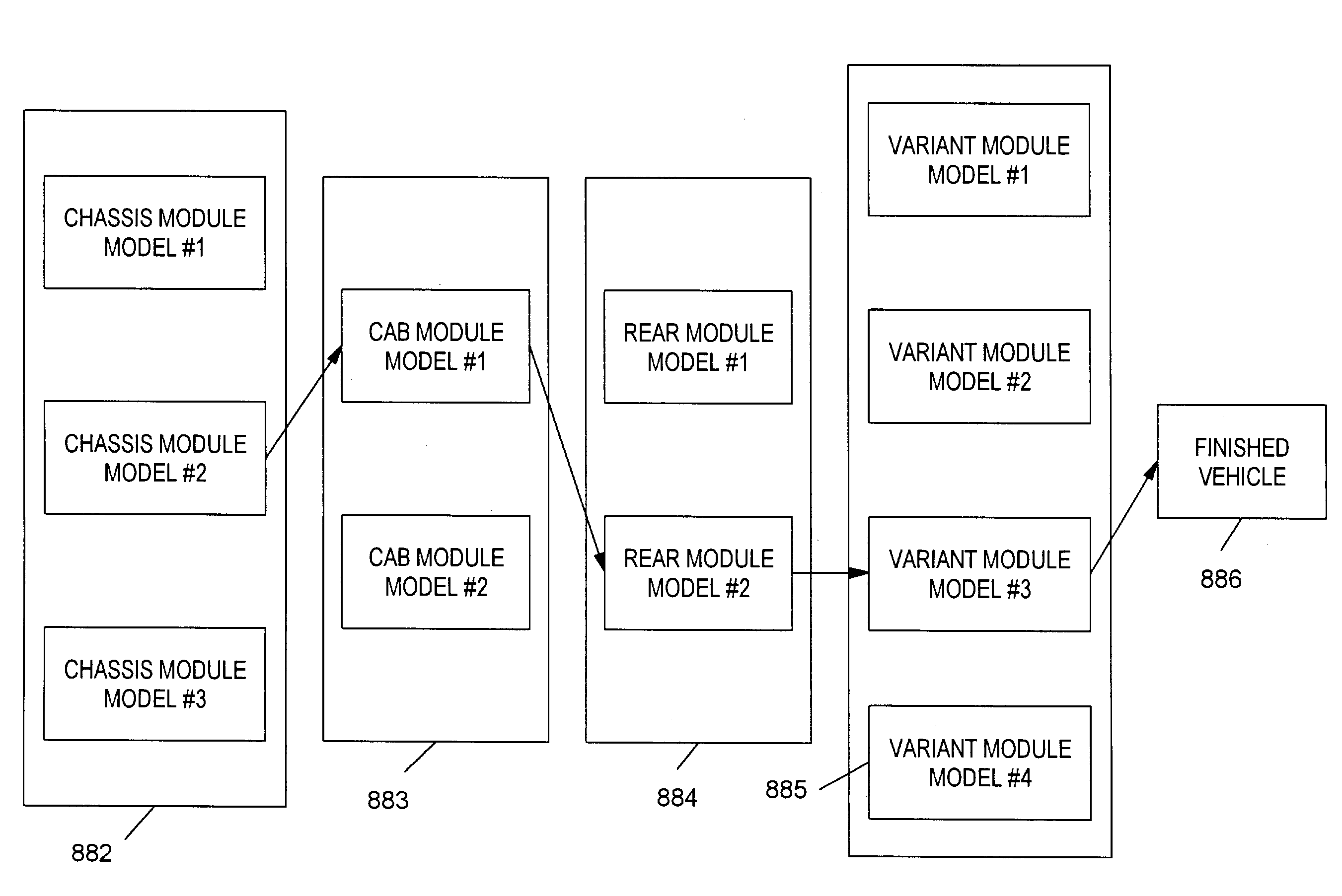

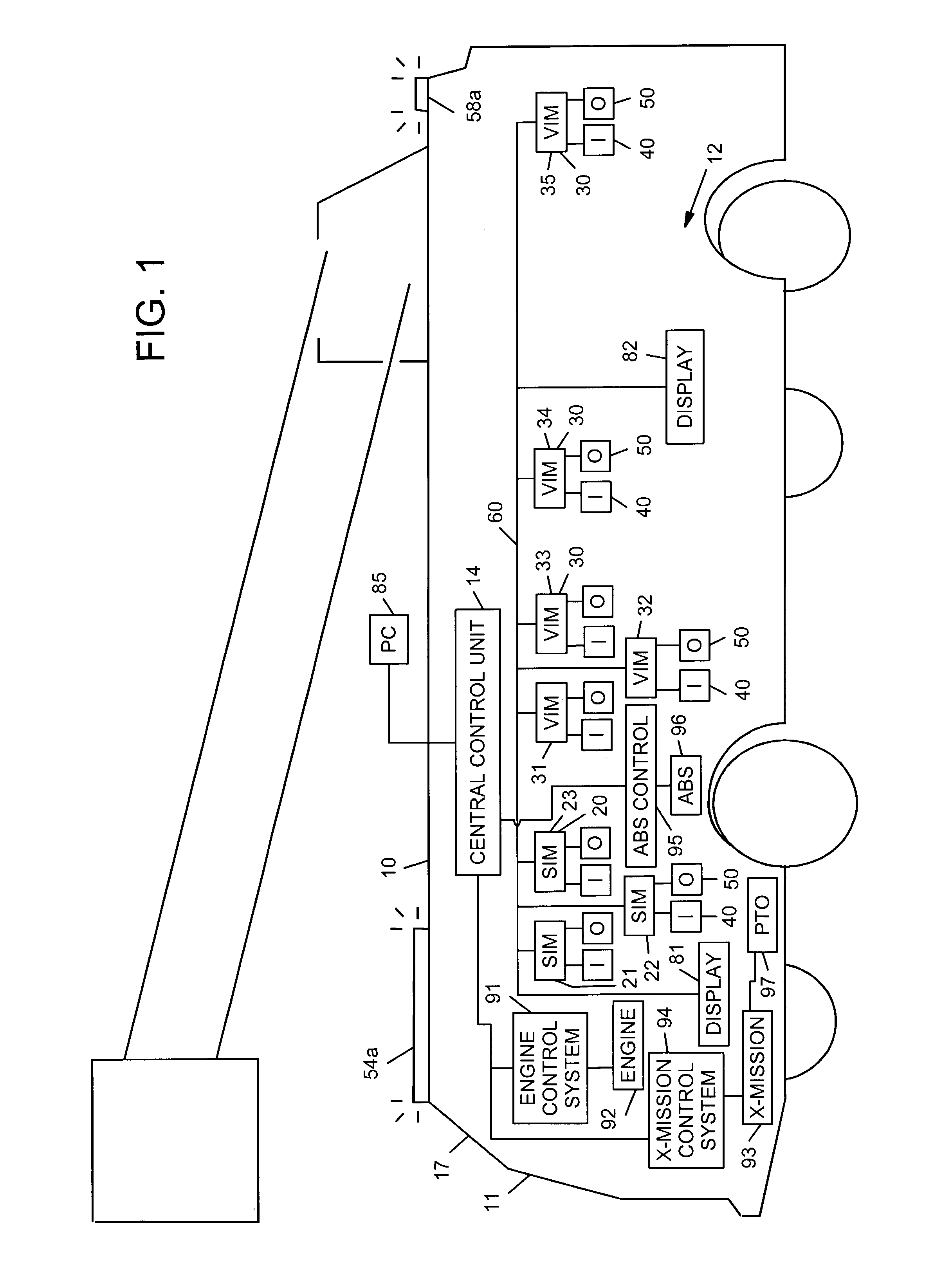

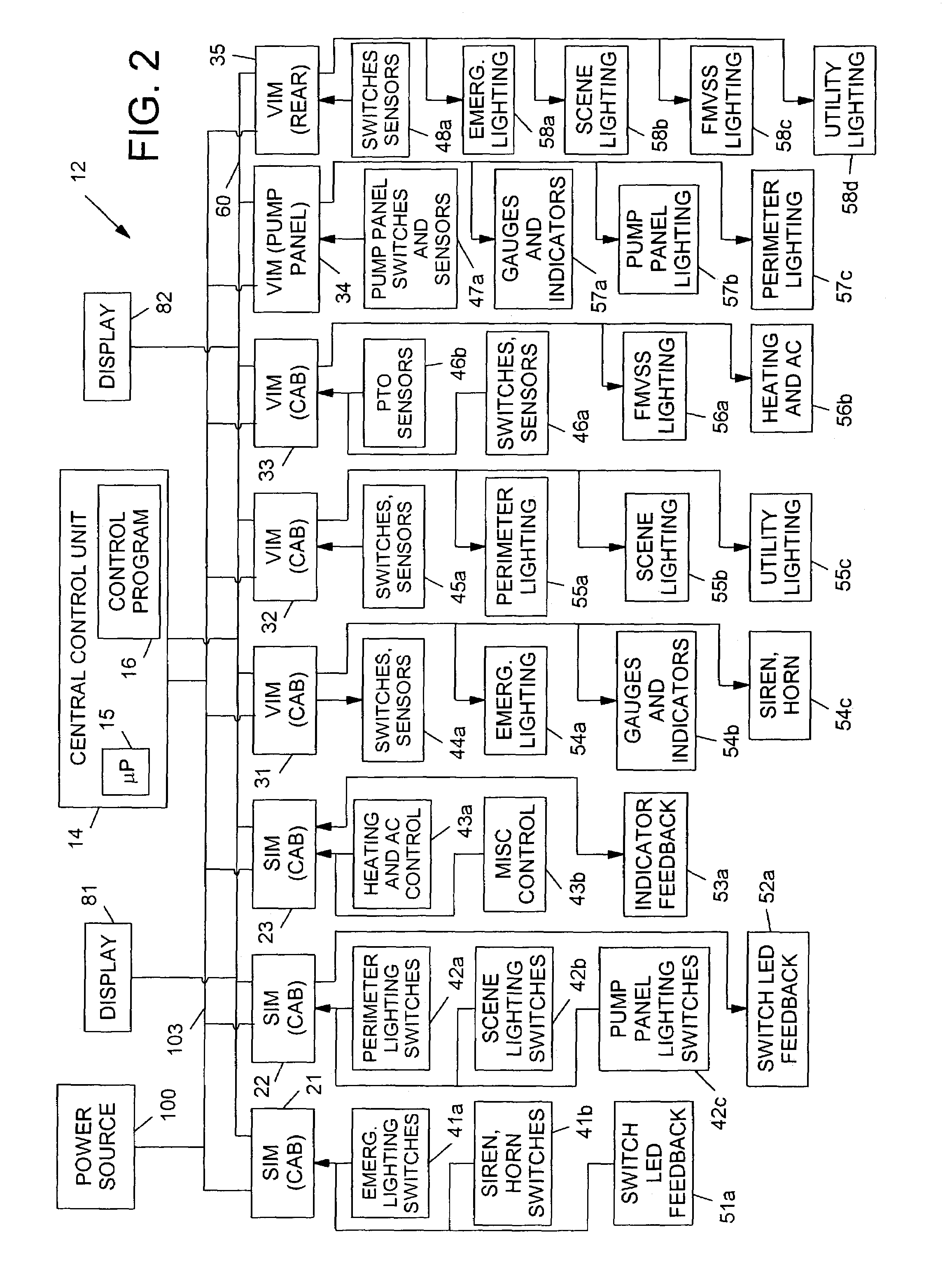

Control system and method for an equipment service vehicle

An aircraft rescue fire fighting vehicle comprises a chassis module, a cab module, and a control system. The control system further comprises a plurality of input devices, a plurality of output devices, a plurality of interface modules, and a communication network. The plurality of interface modules is distributed throughout the fire fighting vehicle and are coupled to each other by way of the communication network. The plurality of interface modules are each coupled to the plurality of input devices and output devices. The plurality of interface modules are operative to control the output devices based on input status information from the plurality of input devices. Some of the plurality of interface modules are mounted on the chassis module and other ones of the plurality of interface modules are mounted on the cab module. The cab module is mounted on top of the chassis and is modular in construction such that the cab module is mounted on top of the chassis module as a substantially complete stand-alone unit.

Owner:OSHKOSH CORPORATION

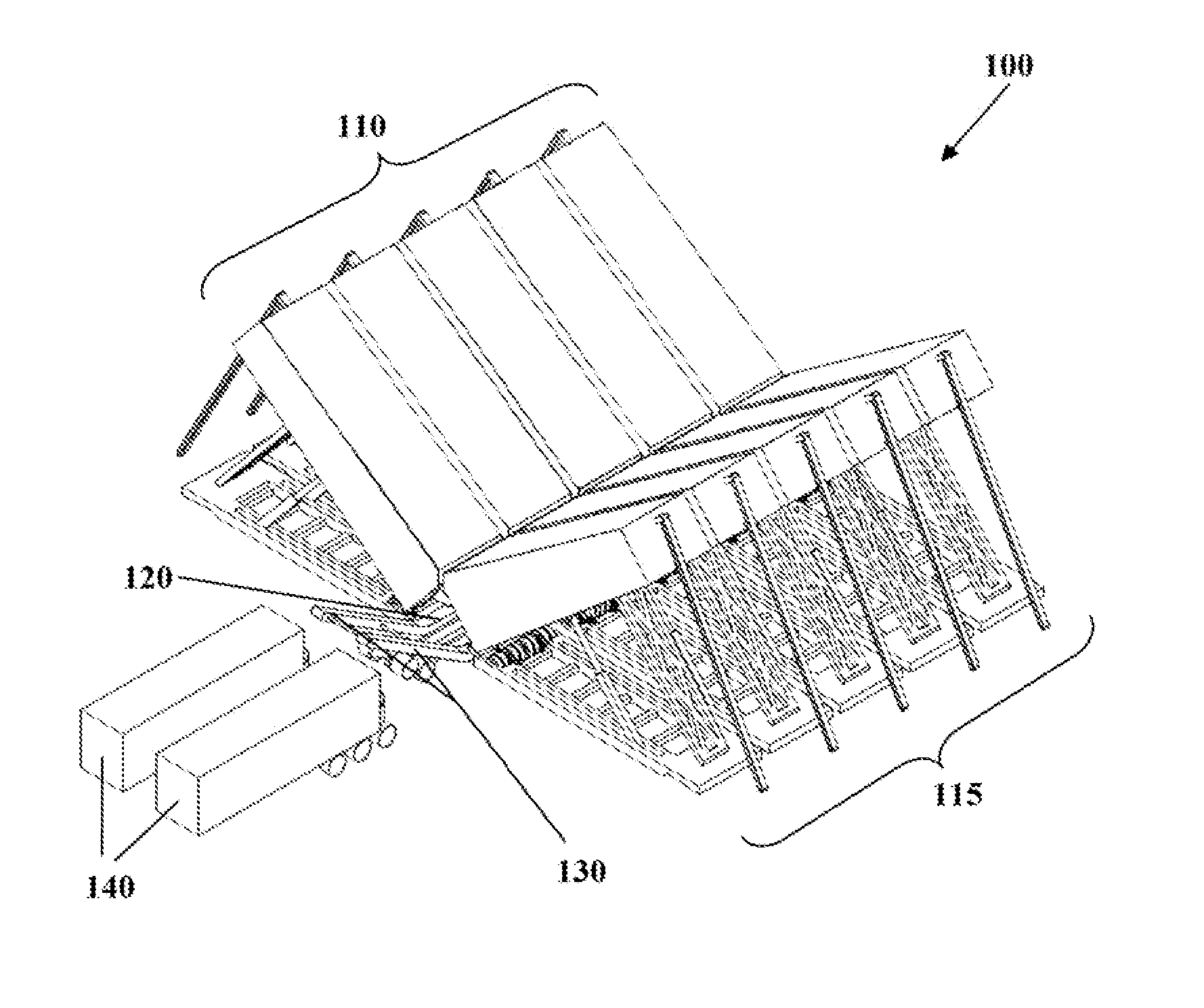

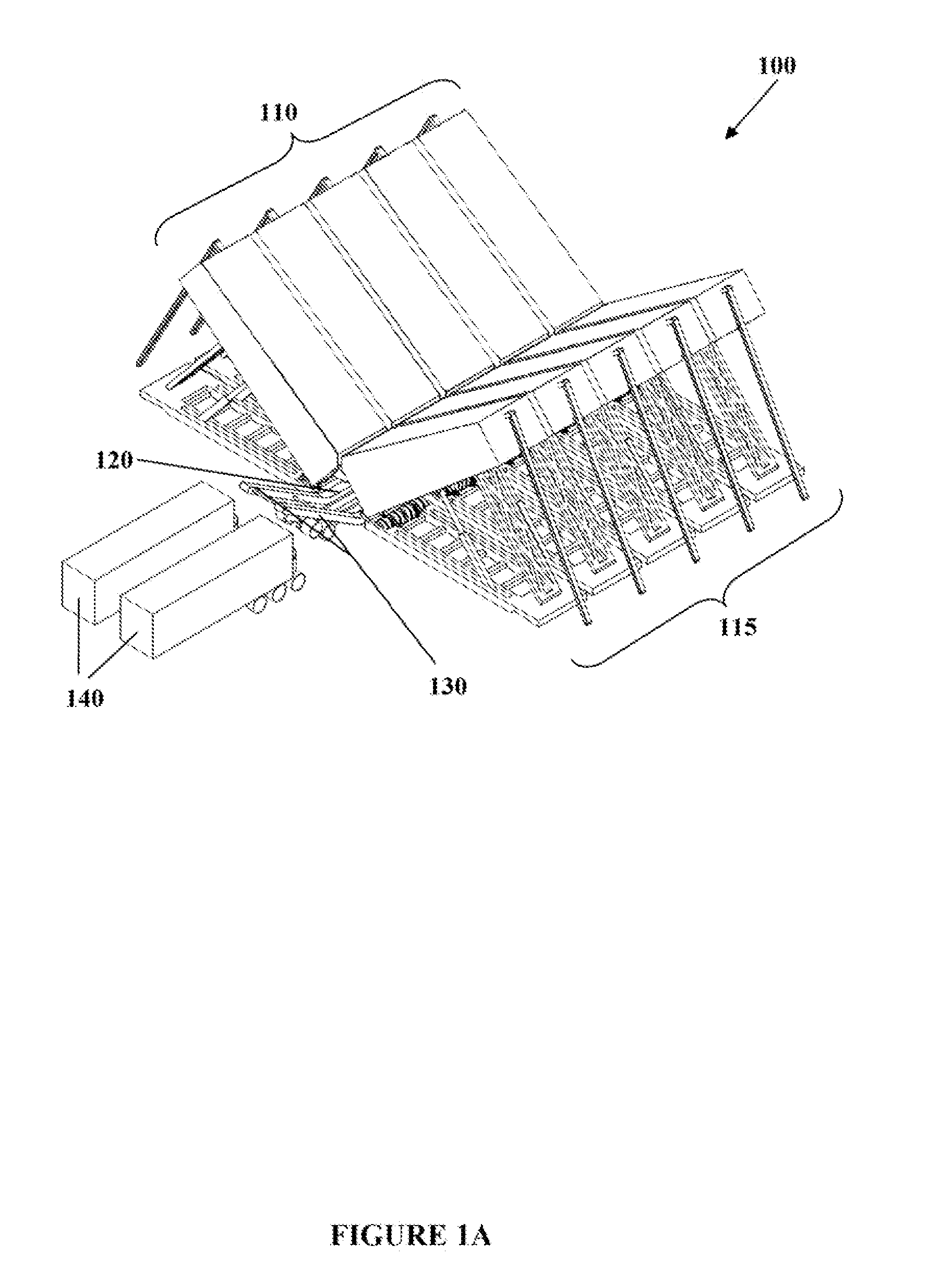

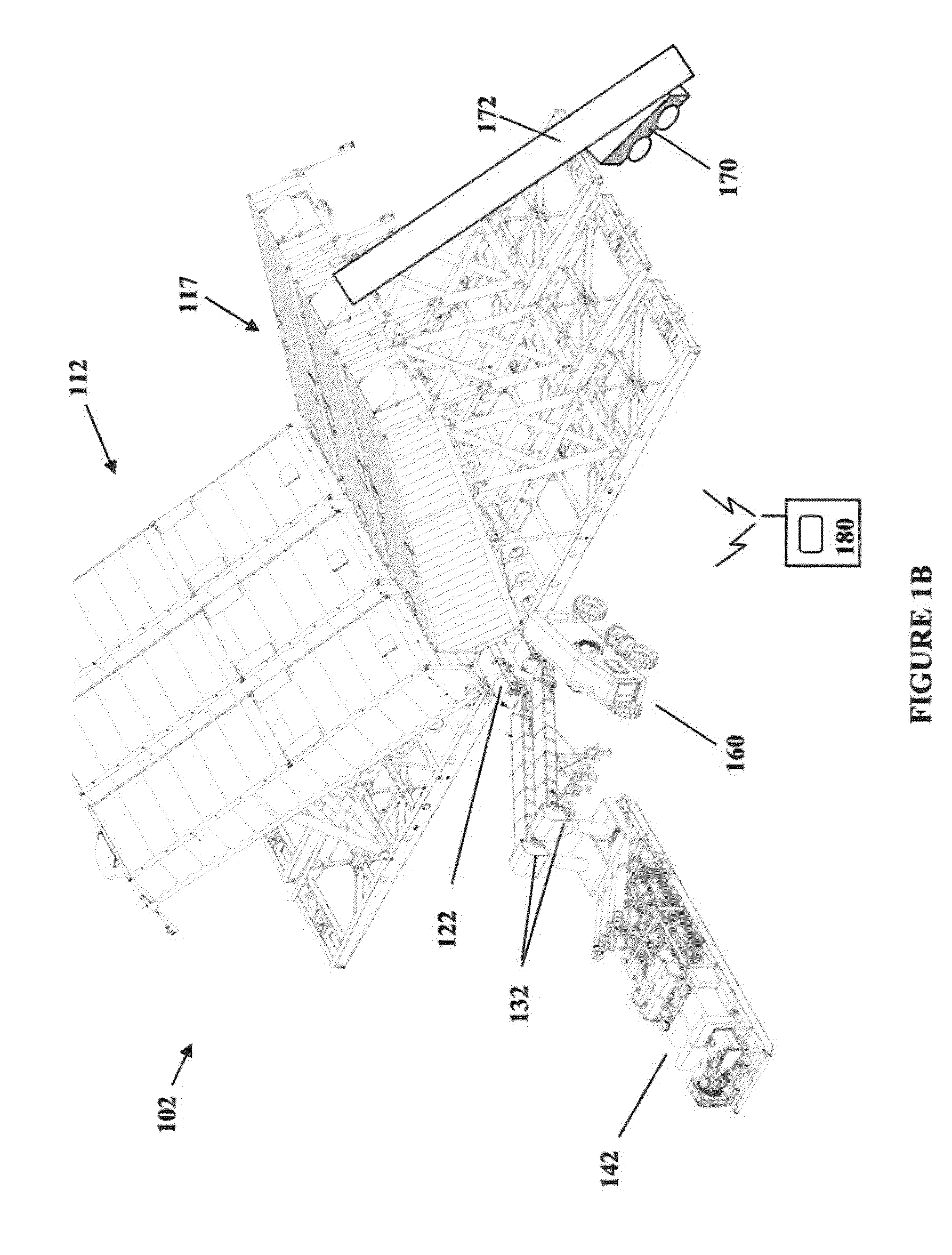

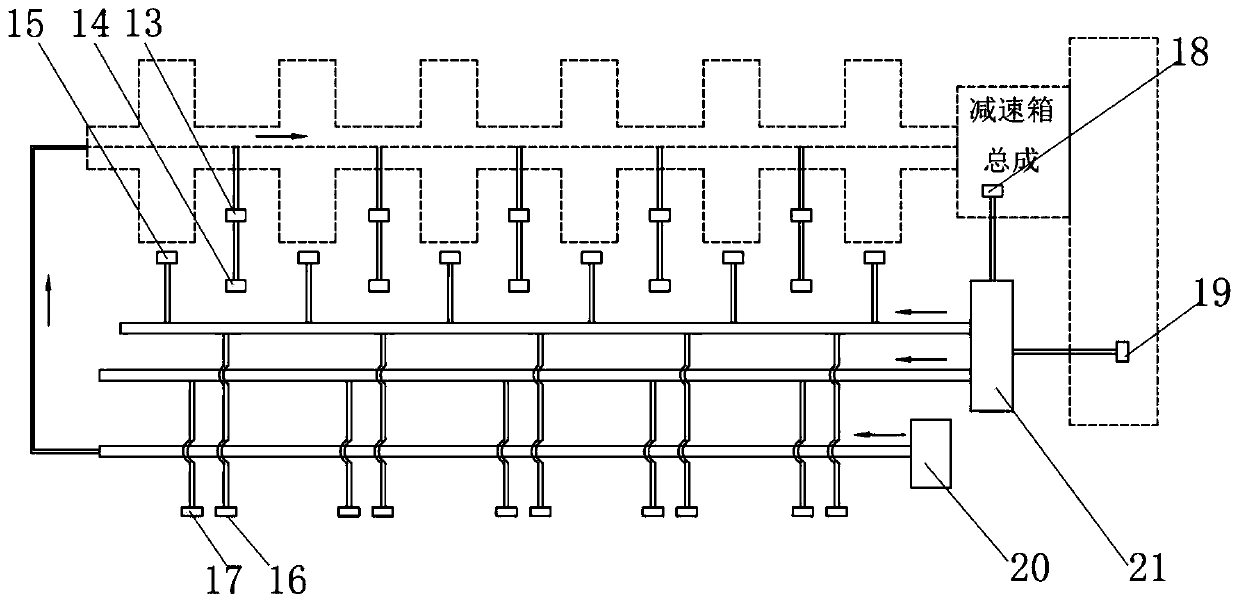

Mobile Material Handling and Metering System

ActiveUS20120219391A1Convenient for centralized processingEasy remote controlLarge containersRefuse transferringWell drillingRemote control

A method and system for handling granular material, such as proppant used in hydraulic fracturing in well drilling, is provided. In an operational configuration, a delivery module having conveyors receives and conveys granular material to a delivery location, and one or more mobile storage modules receive, hold and dispense granular material downward to the delivery module. The mobile storage modules comprise a raised, angular container portion for holding granular material. Each mobile storage module may comprise a rock-over chassis for support against ground. A remote control module provides centralized, remote control of the system. Mobile support unit modules may also be provided as a remotely controlled vehicle capable of providing power, control, heating, and the like to other modules. Mobile in-feed elevator modules may also be provided as a remotely controlled vehicle for feeding granular material to mobile storage modules. In a transportation configuration, each module is separately transportable.

Owner:CONTINENTAL INTERMODAL GRP TRUCKING LLC

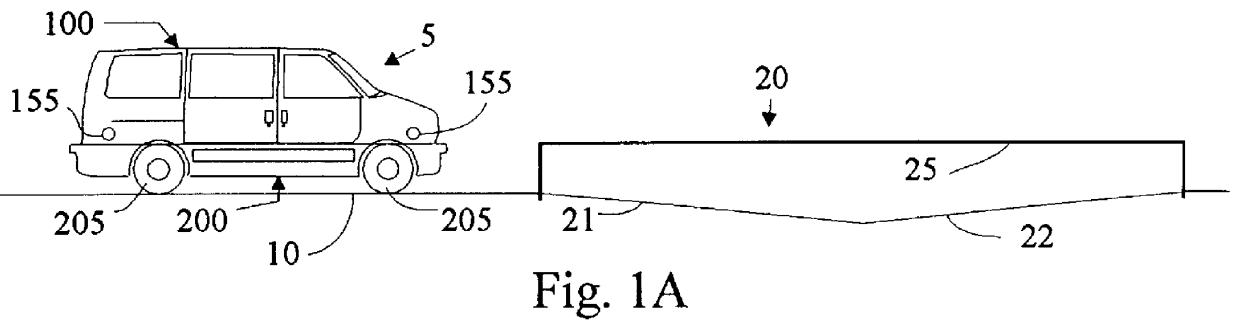

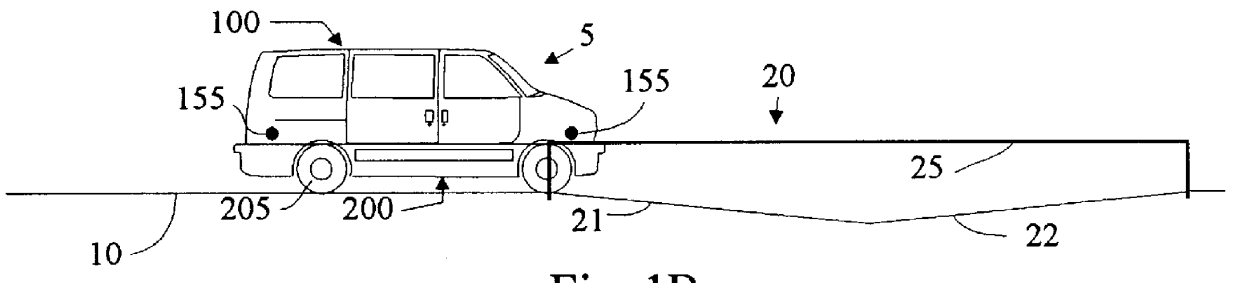

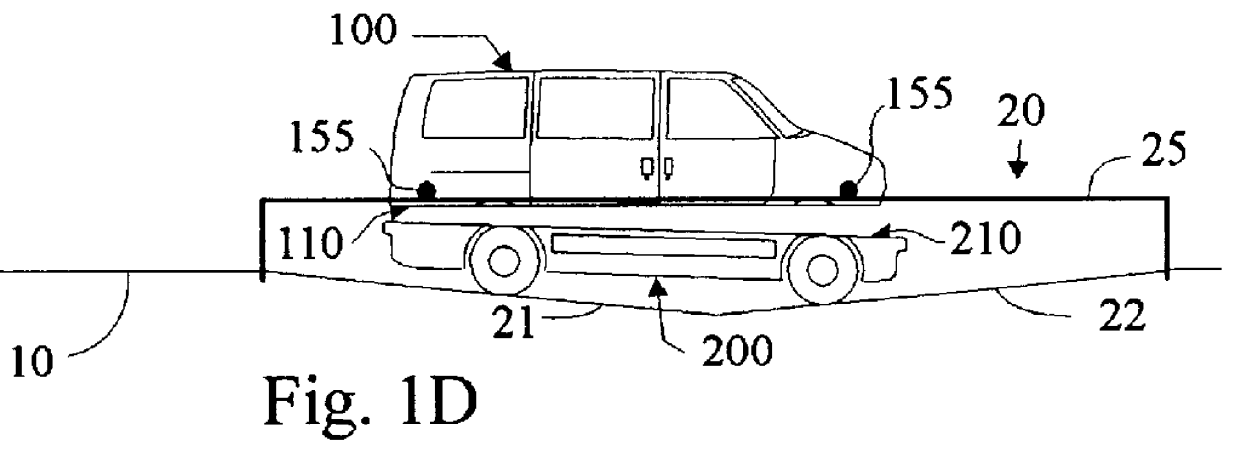

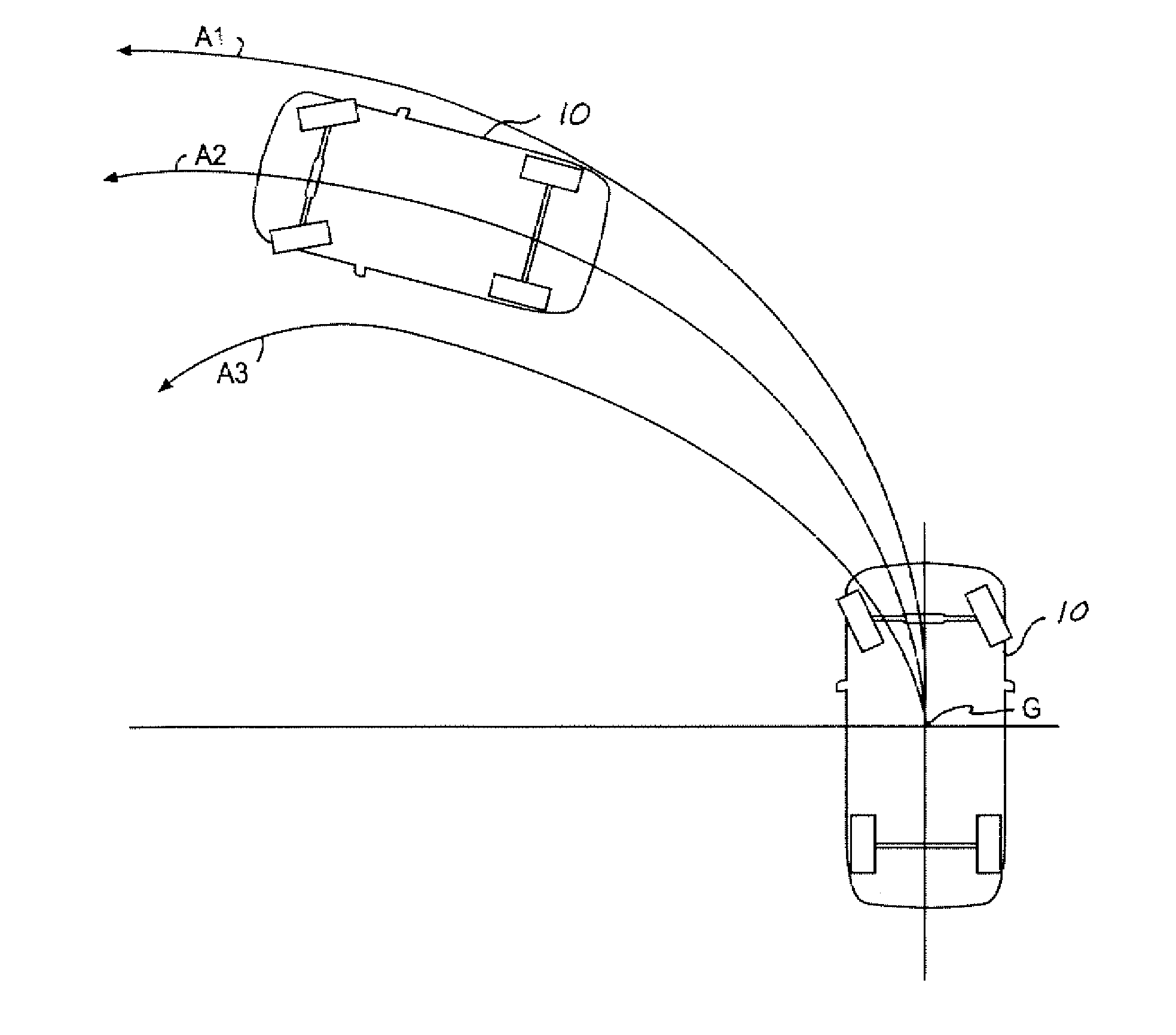

Modular vehicle construction and transportation system

A modular vehicle comprises a preassembled undercarriage module, a preassembled overcarriage module, and coupling means for releasably coupling the overcarriage module to the undercarriage module. The undercarriage module includes wheels for permitting travel of the vehicle on a travelling surface, means for holding a power source for supplying operating power to the vehicle, and means for directing controlled motive power from the power source to at least one of the wheels. The overcarriage module includes control means linkable with the undercarriage module for controlling operation of the vehicle. When the power source associated with a first undercarriage module is in need of maintenance service, there is provided a method of handling an overcarriage module coupled to the first undercarriage module comprising the steps of decoupling and separating the two modules; then releasably coupling the overcarriage module to a second one of such undercarriage modules, the associated power source of the second undercarriage module not being in need of maintenance service; then operating the overcarriage module and the second undercarriage module together as a vehicle while providing the maintenance service required by the power source of the first undercarriage module.

Owner:GED PATENTS

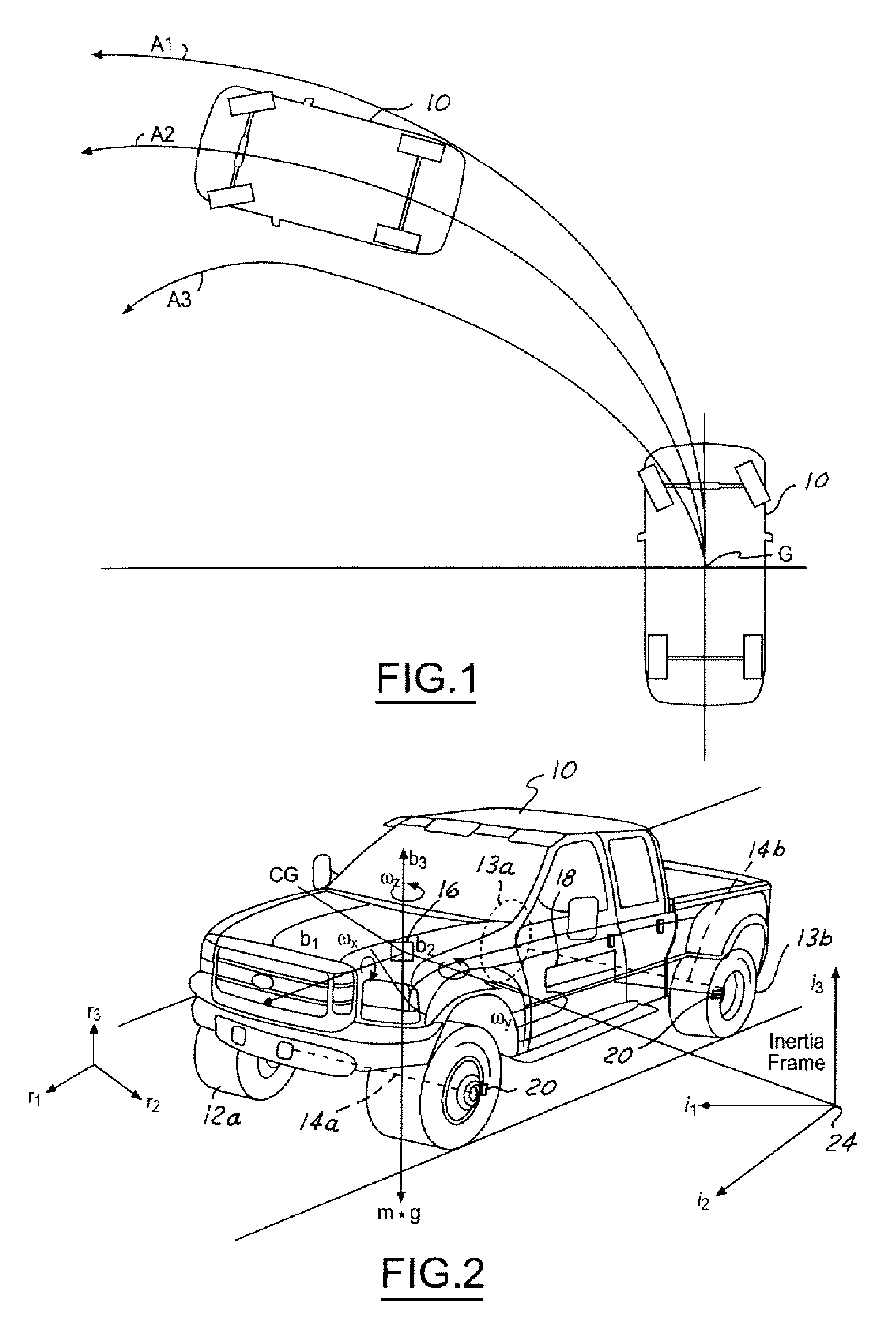

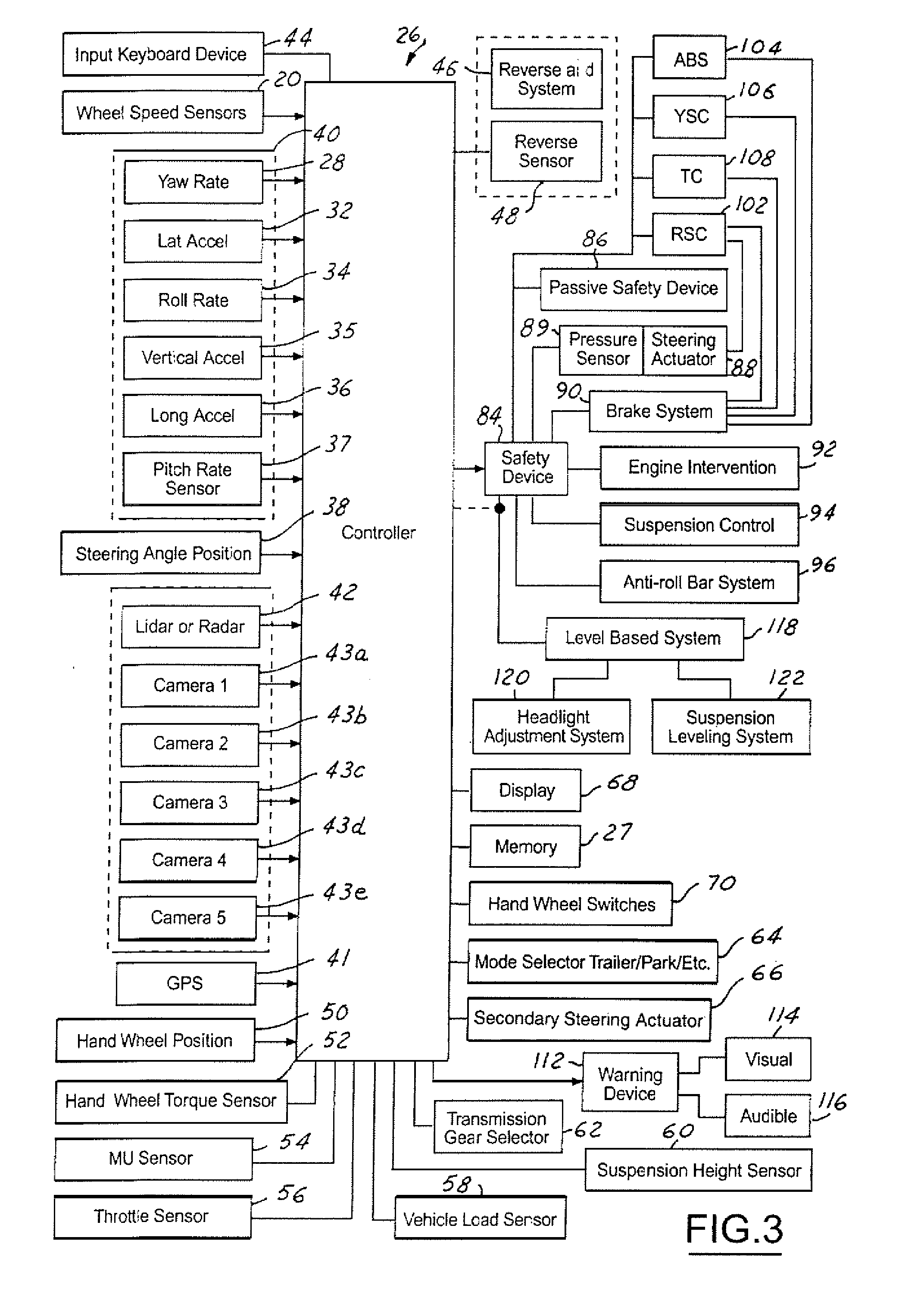

Method and apparatus for controlling an automotive vehicle using brake-steer and normal load adjustment

InactiveUS20050206231A1Good effectIncrease speedSteering partsResilient suspensionsNormal loadMotorized vehicle

A method of controlling an automotive vehicle includes detecting a parking mode and applying brake-steer to a first wheel to reduce the turning radius of the vehicle. Simultaneously, the normal force on a wheel can be increased by adjusting a chassis control mechanism such as a controlled suspension.

Owner:FORD GLOBAL TECH LLC

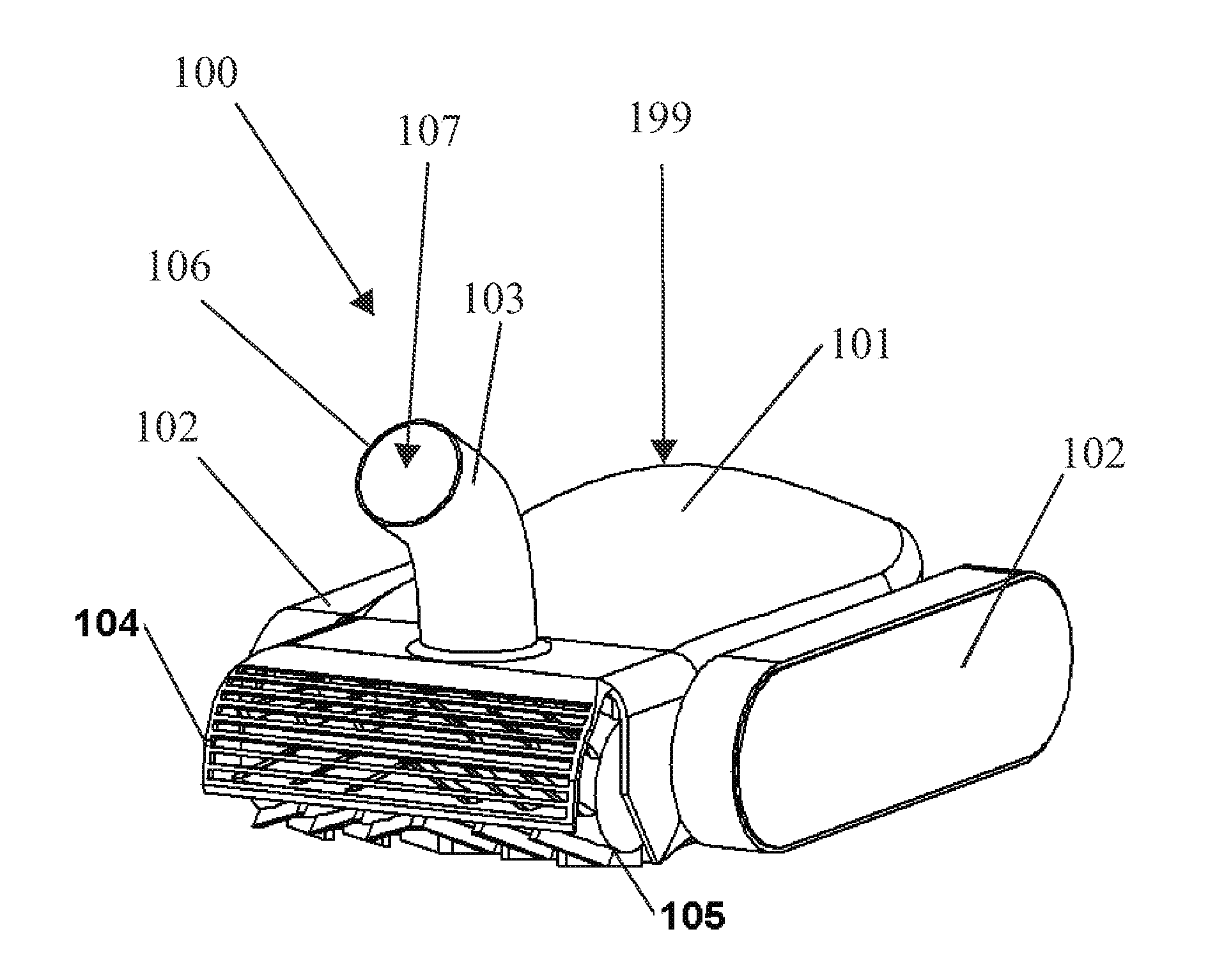

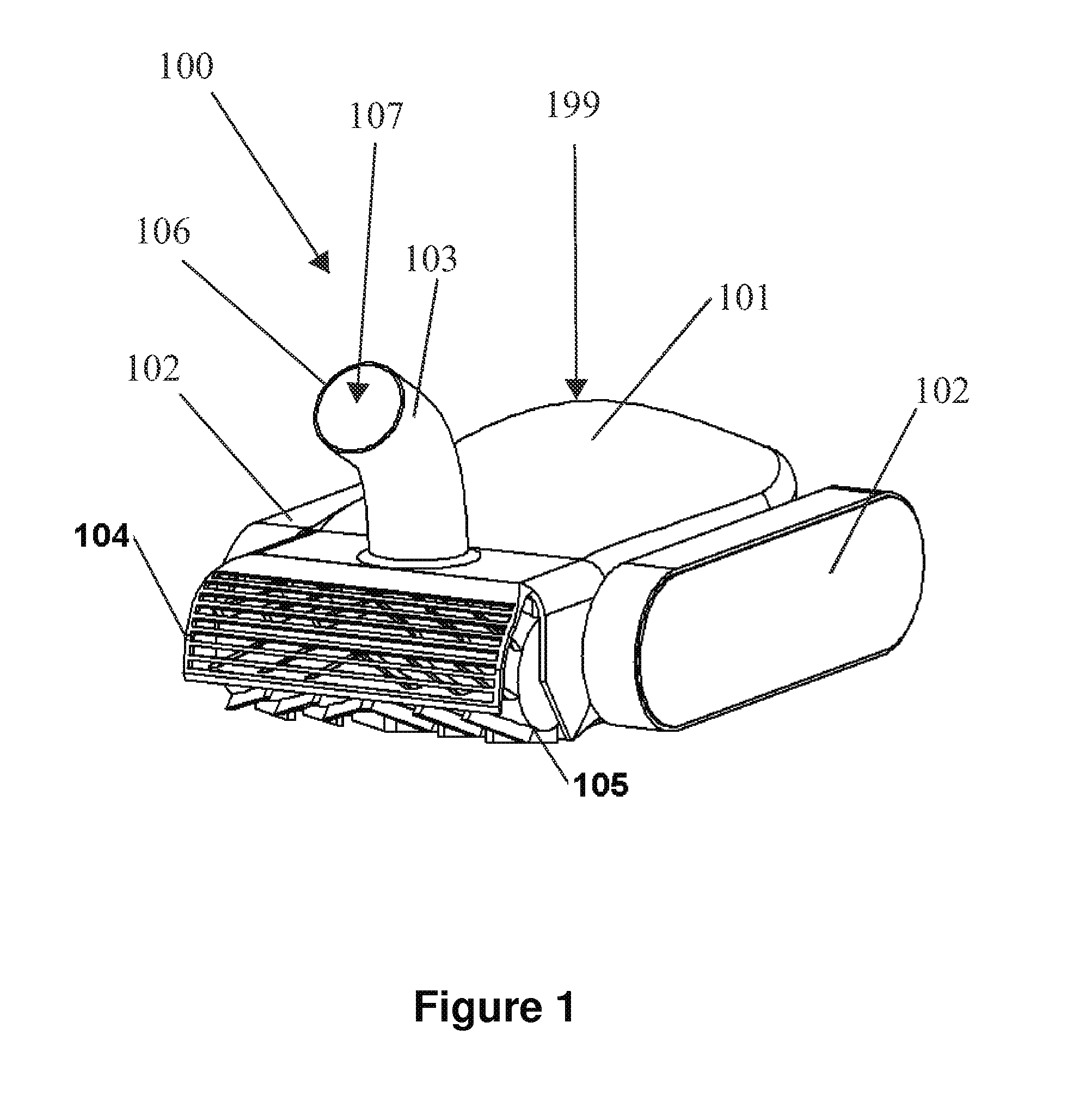

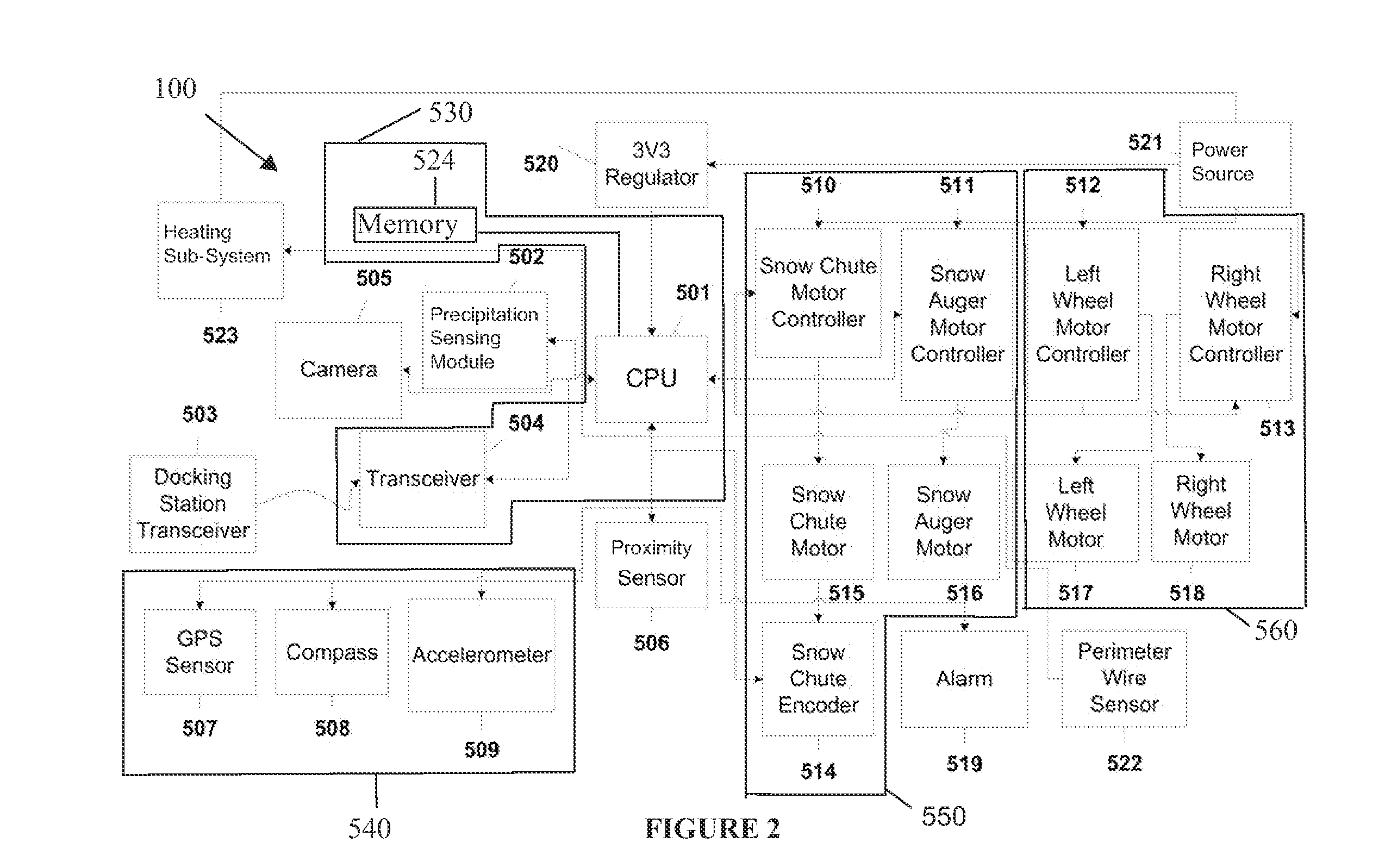

Autonomous robot apparatus and method for controlling the same

ActiveUS20140180478A1Programme controlProgramme-controlled manipulatorControl engineeringProcess engineering

An autonomous robot apparatus that is activated to perform a work routine upon detecting the accumulation of precipitation. In one aspect, the invention can be an autonomous robot apparatus comprising: a chassis; a plurality of wheels mounted to the chassis; a drive system mounted to the chassis and operably coupled to the plurality of wheels; a control module operably coupled to the drive system; a precipitation sensing module comprising an accumulation level sensor configured to generate and transmit, to the control module, a first signal upon a predetermined initial accumulation level being detected; and the control module configured to activate the autonomous robot apparatus to perform a first instance of a work routine upon receipt of the first signal.

Owner:FUTUREGEN TECH INC

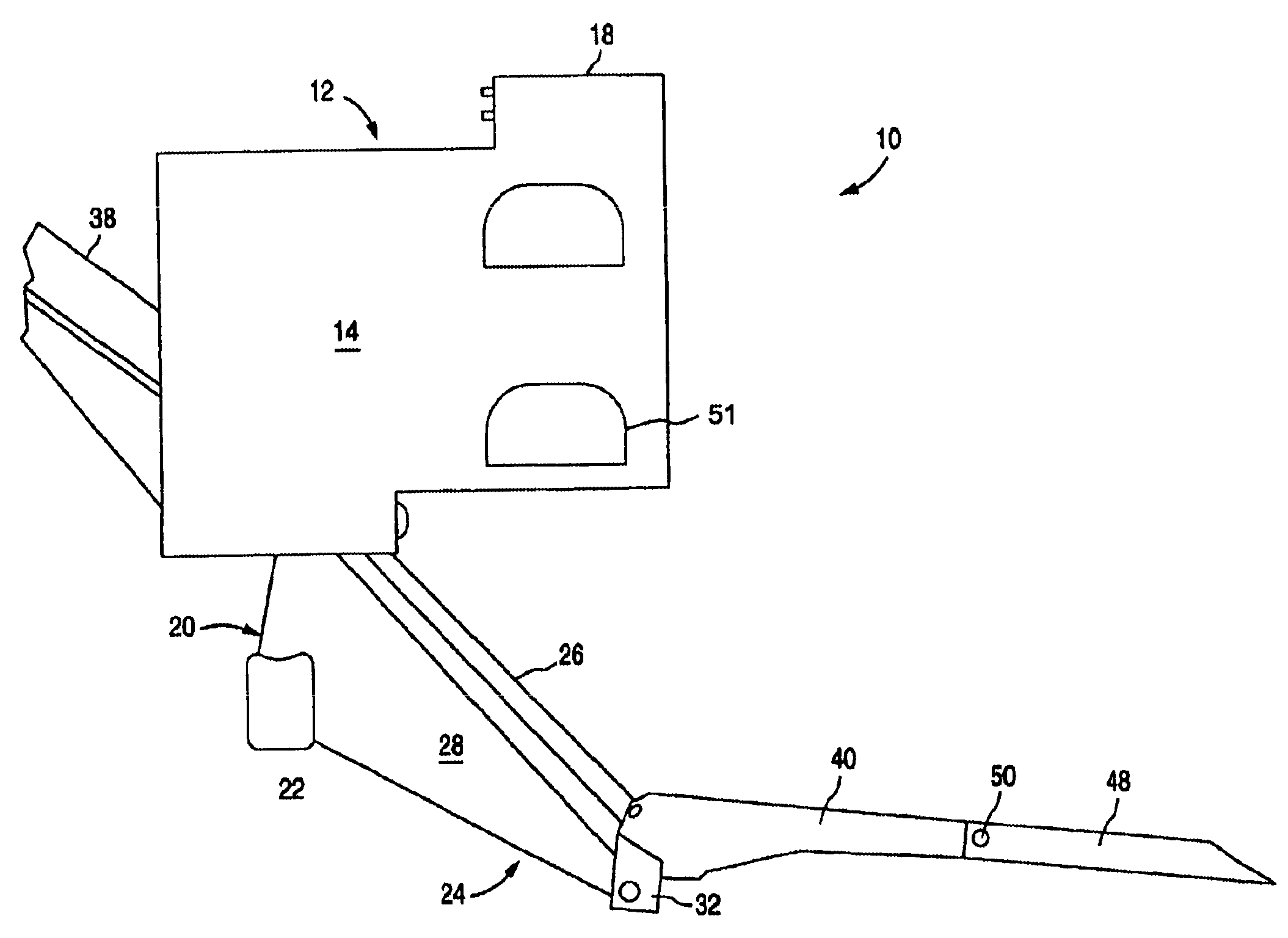

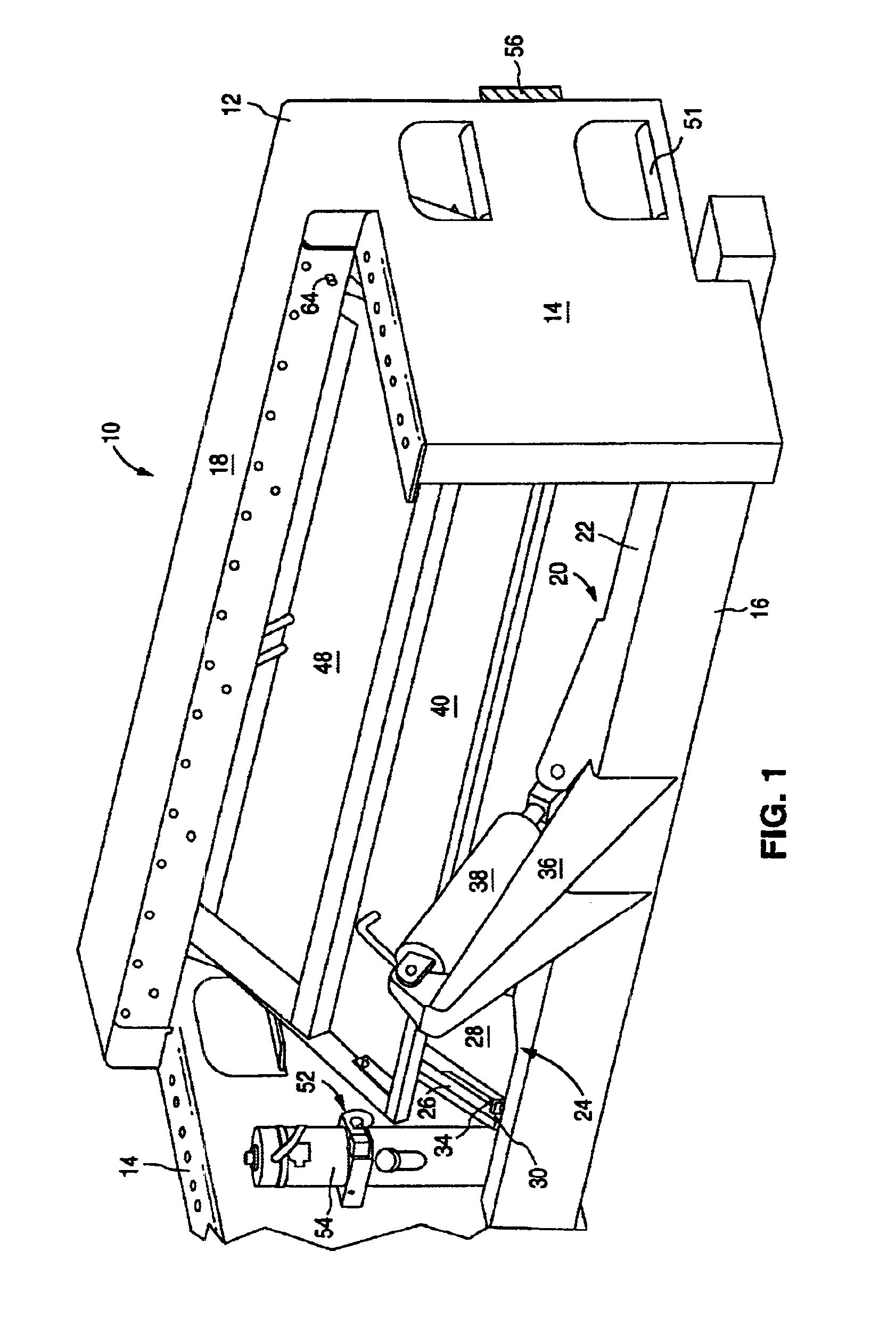

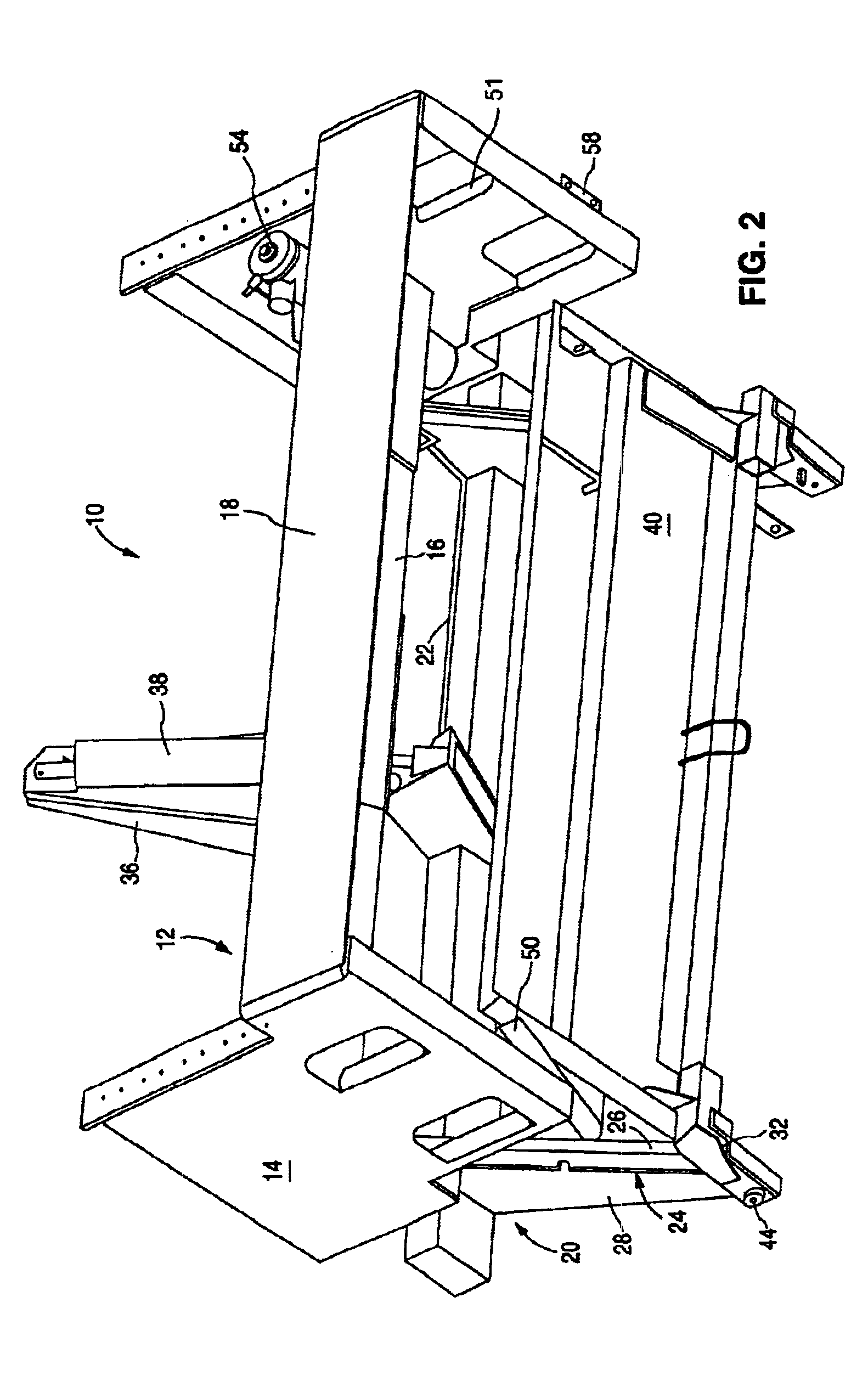

Unitary liftgate

InactiveUS6948903B2Less timeVehicle with raised loading platformRefuse receptaclesEngineeringCantilever

The invention is a unitary cantilever liftgate that attaches to the vehicle body instead of the vehicle chassis. The liftgate may be fully assembled and tested prior to installation on the vehicle body. This greatly reduces installation time while improving performance and reliability. Various features such as steps, bumpers and brackets are integrated into the liftgate. Further, the liftgate is preferably configured so that multiple units can be stacked together for shipping and ease of unloading and loading. The stackability of the liftgates simplifies storing as well, by removing the necessity of storing several components separately.

Owner:MAXON LIFE

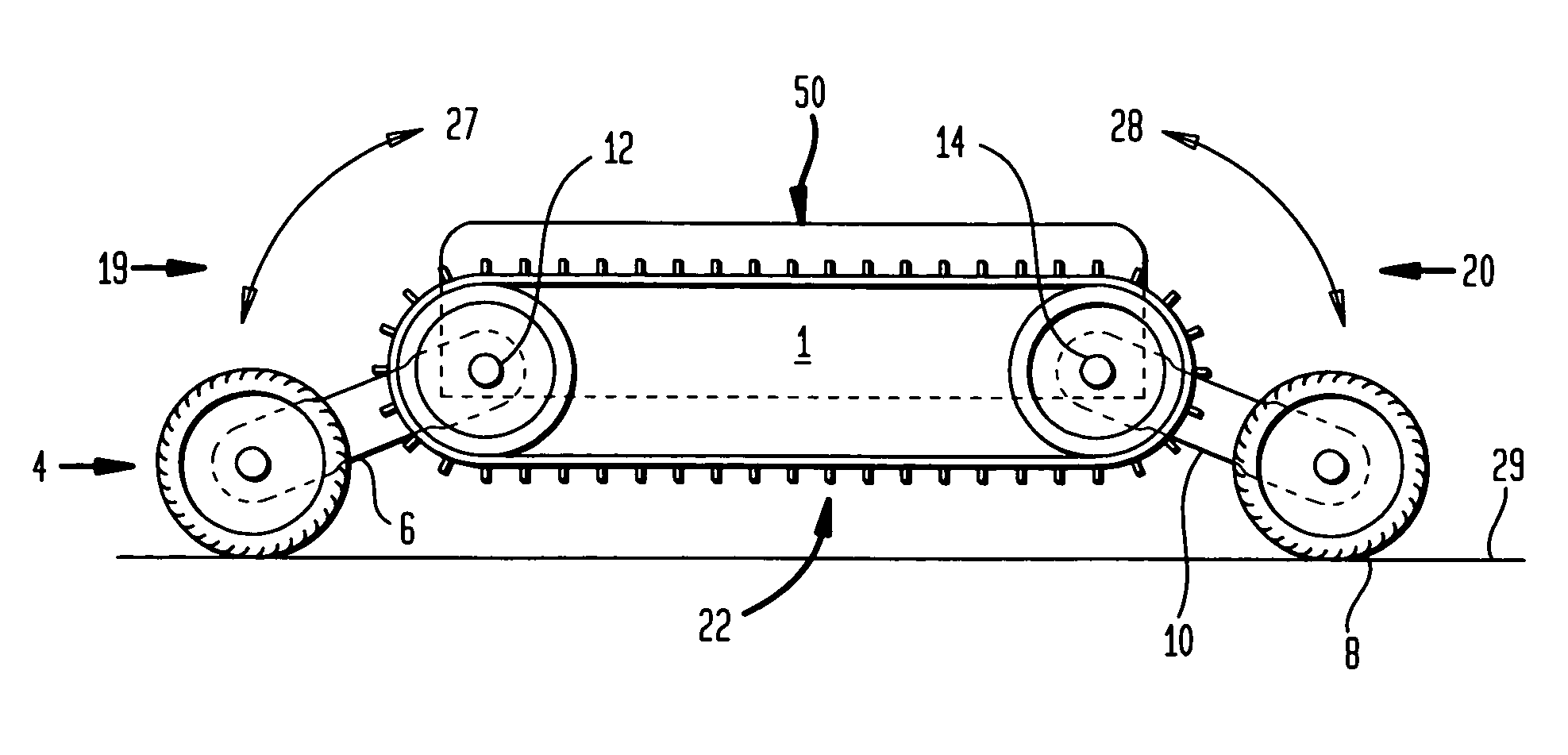

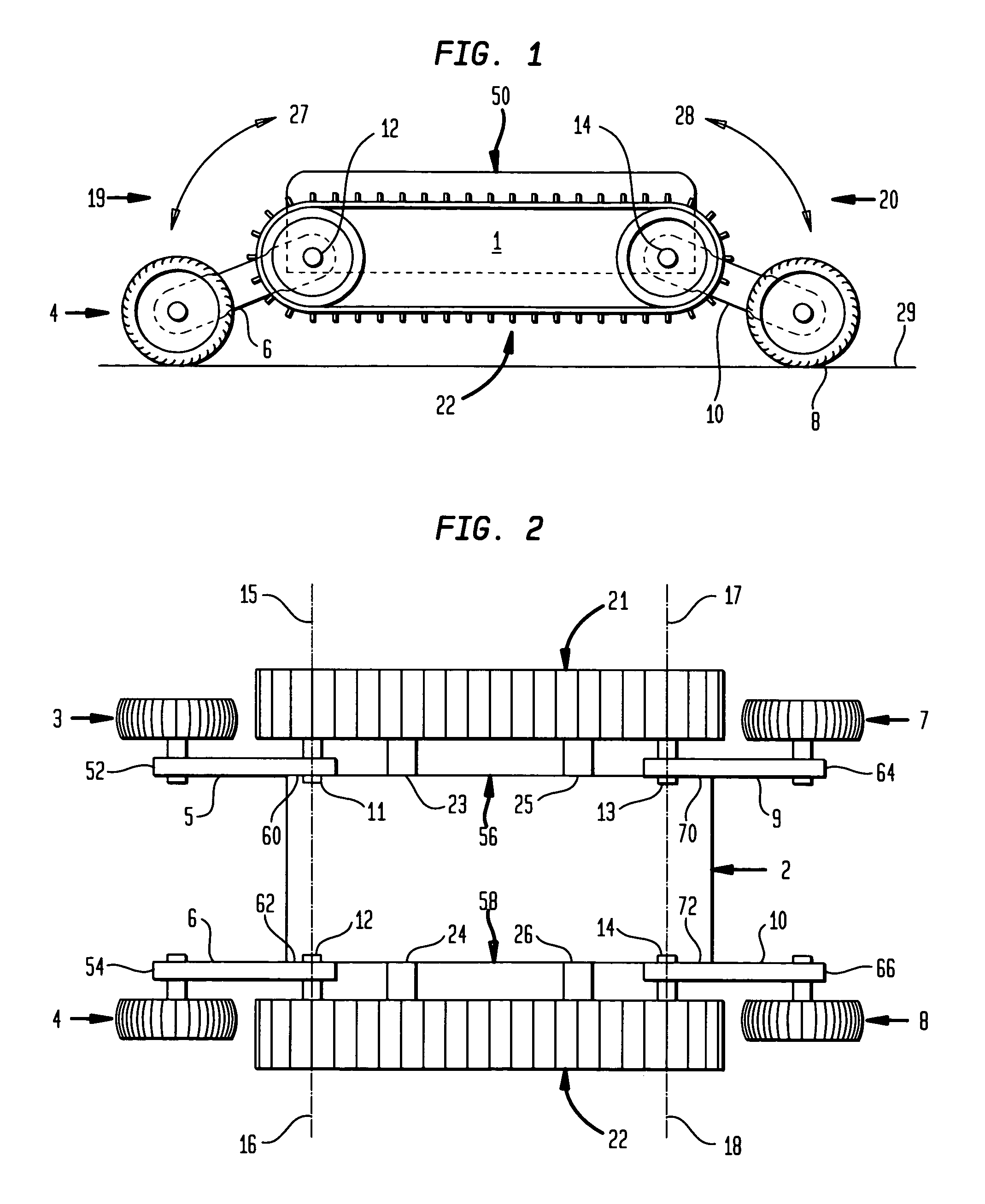

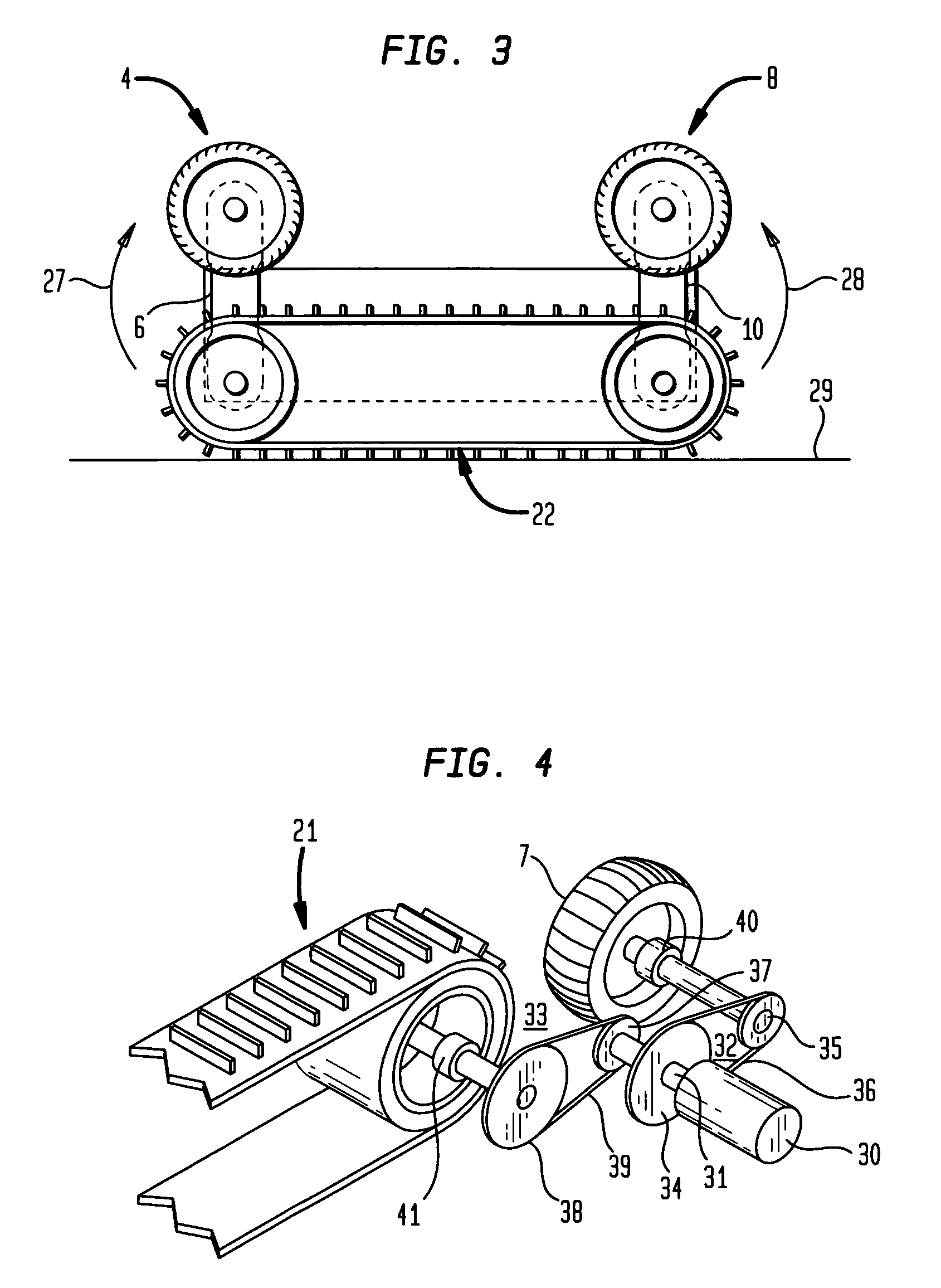

High mobility vehicle

InactiveUS7475745B1Reduces rolling lossExtended service lifeEndless track vehiclesManipulatorDrive wheelGear wheel

An embodiment of a high-mobility vehicle comprises a vehicle body, a track assembly attached to the vehicle body, arms pivotally attached to the vehicle body, and trackless drive wheels mounted on distal ends of the arms. Another embodiment of a high-mobility vehicle comprises a vehicle chassis, right and left drive motors attached to the vehicle chassis, right and left power transmission mechanisms having high torque and low torque sets of gears, track assemblies coupled to the high torque sets of gears, and trackless drive wheels coupled to the low torque sets of gears.

Owner:DEROOS BRADLEY G

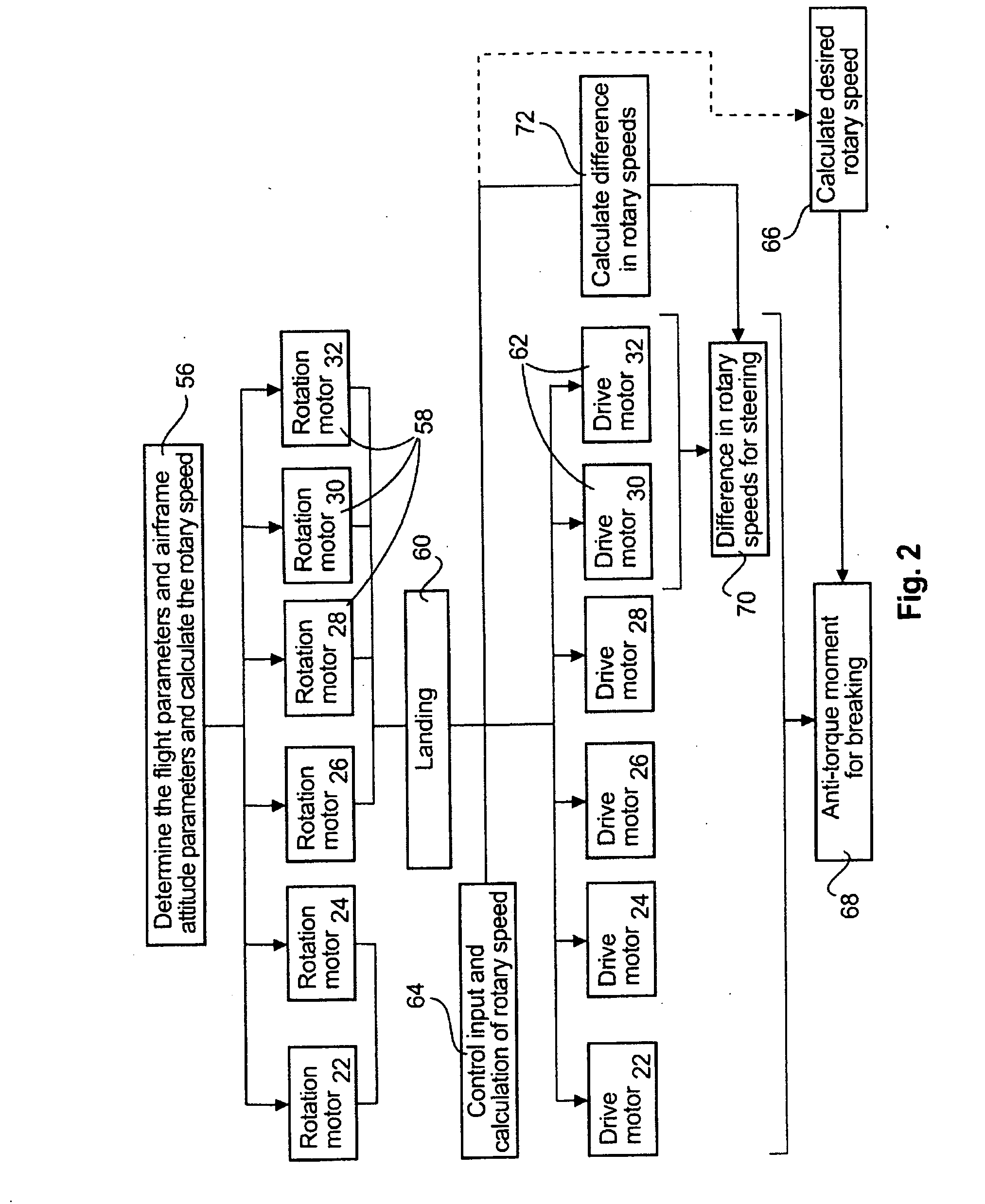

Methods for landing an unmanned aerial vehicle

ActiveUS20170316701A1Reduce the required powerArresting gearLaunching/towing gearUncrewed vehicleChassis

Systems and methods include UAVs that serve to assist carrier personnel by reducing the physical demands of the transportation and delivery process. A UAV generally includes a UAV chassis including an upper portion, a plurality of propulsion members configured to provide lift to the UAV chassis, and a parcel carrier configured for being selectively coupled to and removed from the UAV chassis. UAV support mechanisms are utilized to load and unload parcel carriers to the UAV chassis, and the UAV lands on and takes off from the UAV support mechanism to deliver parcels to a serviceable point. The UAV includes computing entities that interface with different systems and computing entities to send and receive various types of information.

Owner:UNITED PARCEL SERVICE OF AMERICAN INC

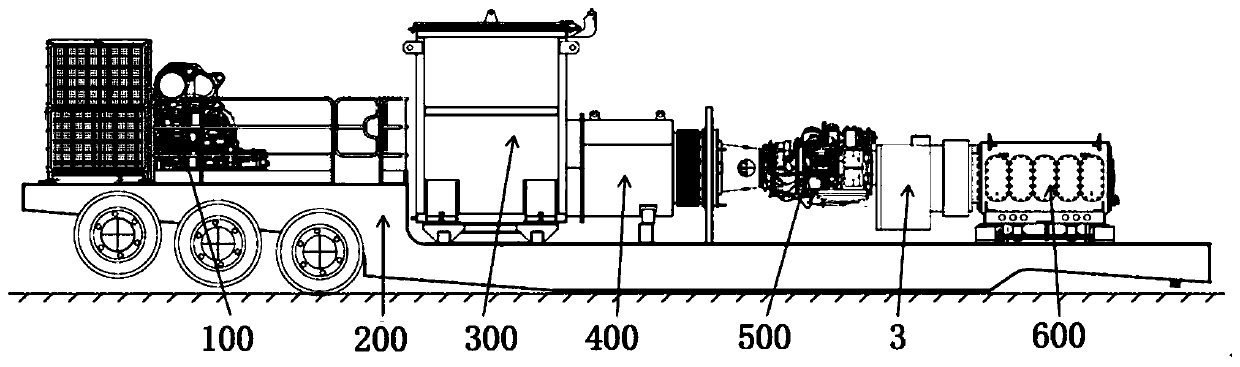

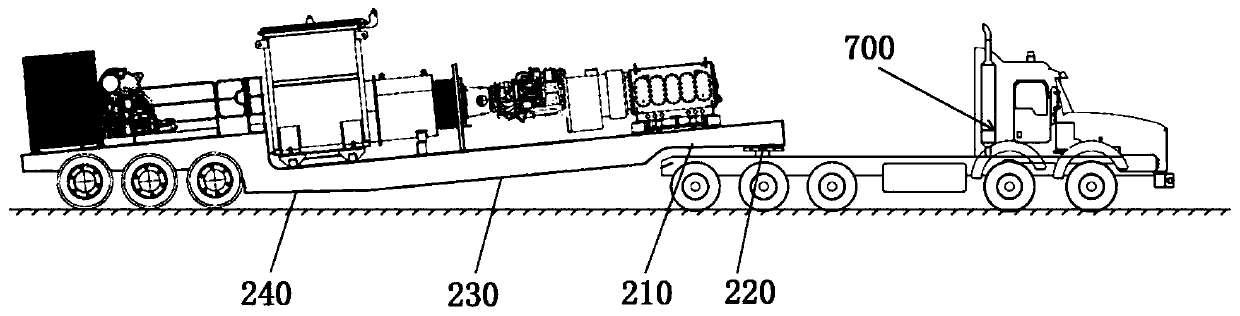

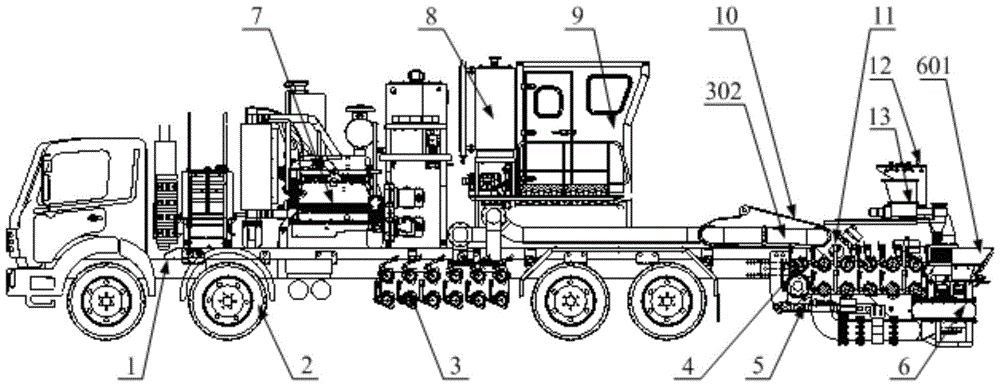

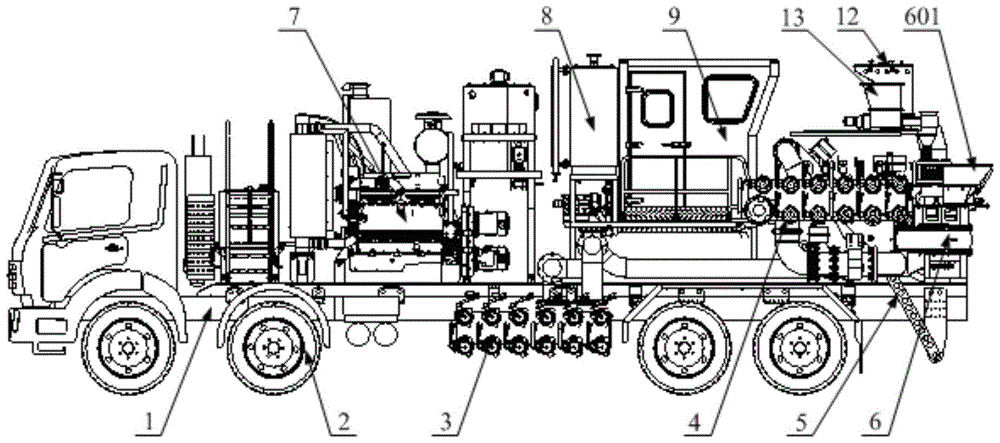

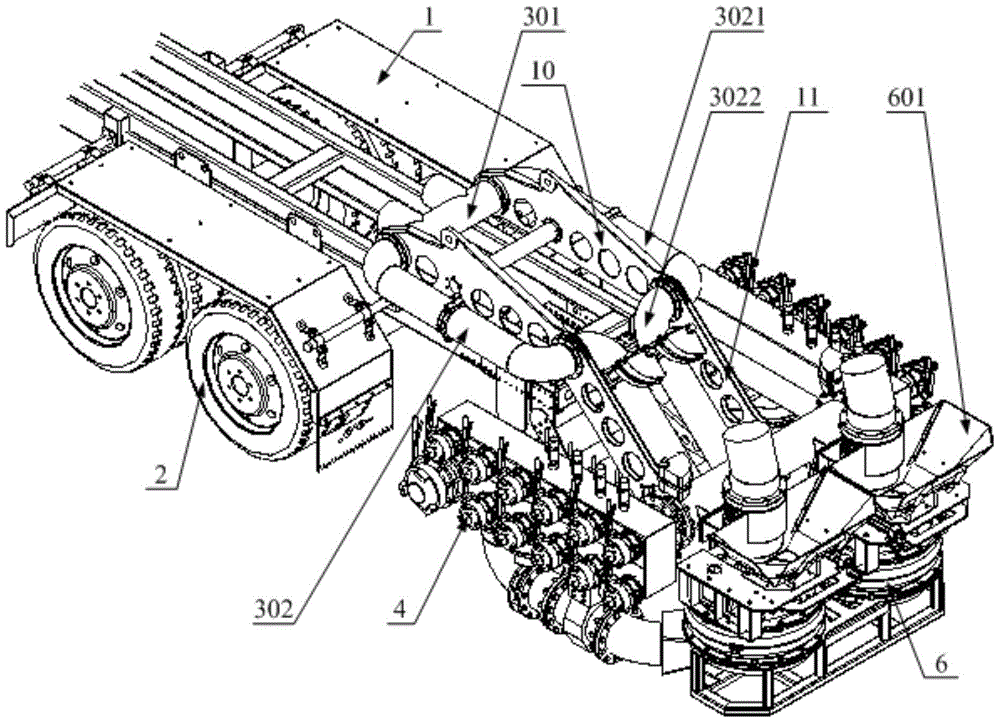

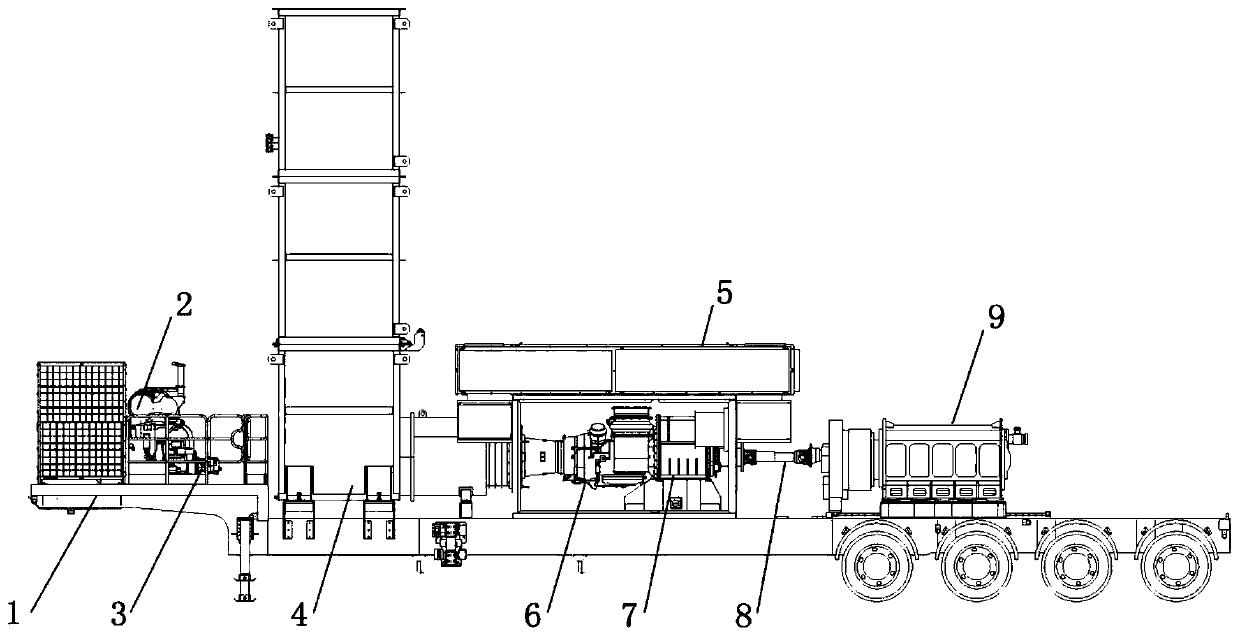

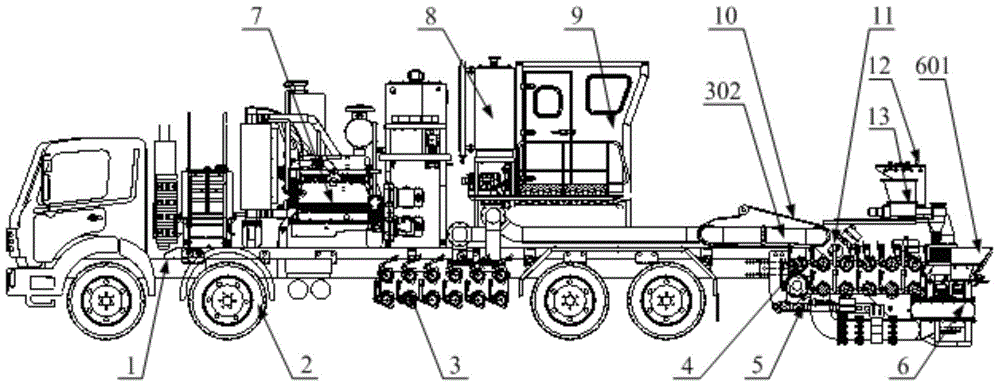

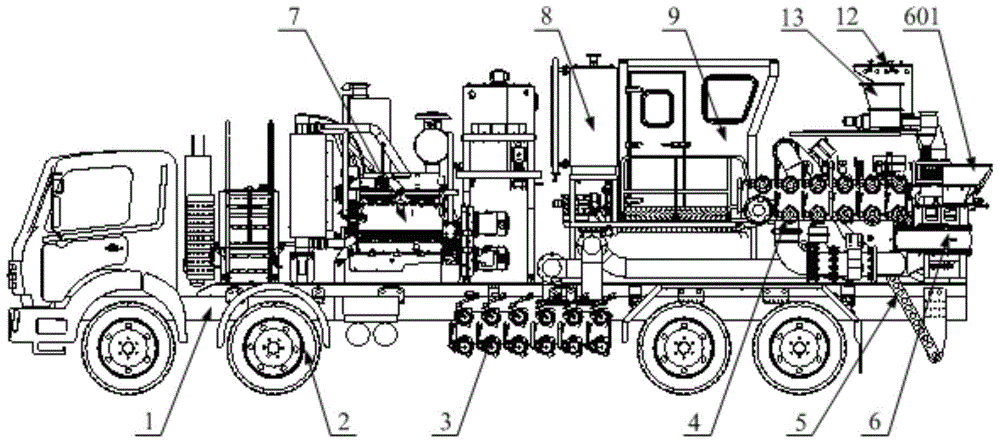

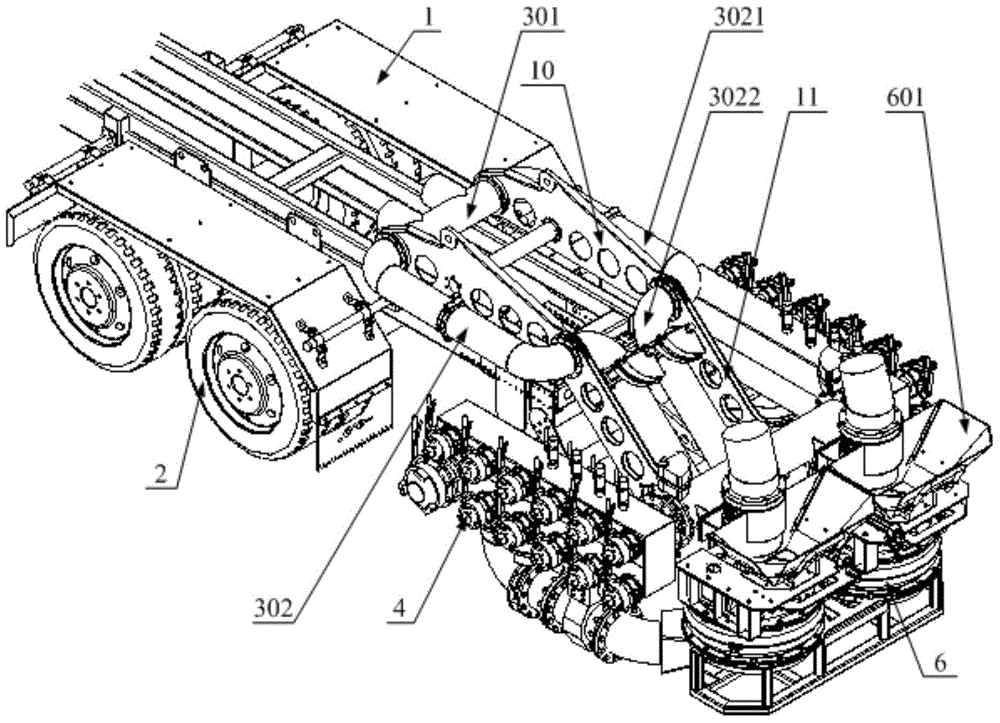

Semitrailer-mounted turbine fracturing equipment

PendingCN110485984AReduce weightLower center of gravityPositive displacement pump componentsFlexible member pumpsOperational costsGravity center

The invention discloses semitrailer-mounted turbine fracturing equipment. Straight-line connection and special chassis design of the whole equipment can double reduce center of gravity of the equipment, stability and safety are better ensured, the structure is simpler, the investment cost and the operation cost are lowered, risks of the whole breakdown of fracturing sites are reduced, transmissionis better, and the semitrailer-mounted turbine fracturing equipment is suitable for continuous operation working conditions with long time and large load. By improving a plunger pump, optimization ofrotating center distances of a crank throw and a crankshaft makes rated power input of the crank throw and the crankshaft increase to 5000-7000 hp, optimization of the transmission ratio of an integrated reduction gearbox on the plunger pump makes the maximum input speed of the integrated reduction gearbox reach 16000 rpm, and ultra-high speed enables reduction gearboxes to be directly connectedwith a turbine engine so as to the solve the problems that turbine fracturing equipment slows down depending on the two reduction gearboxes, and weight of the whole semitrailer is reduced, and boundary dimension of the semitrailer-mounted turbine fracturing equipment is reduced.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

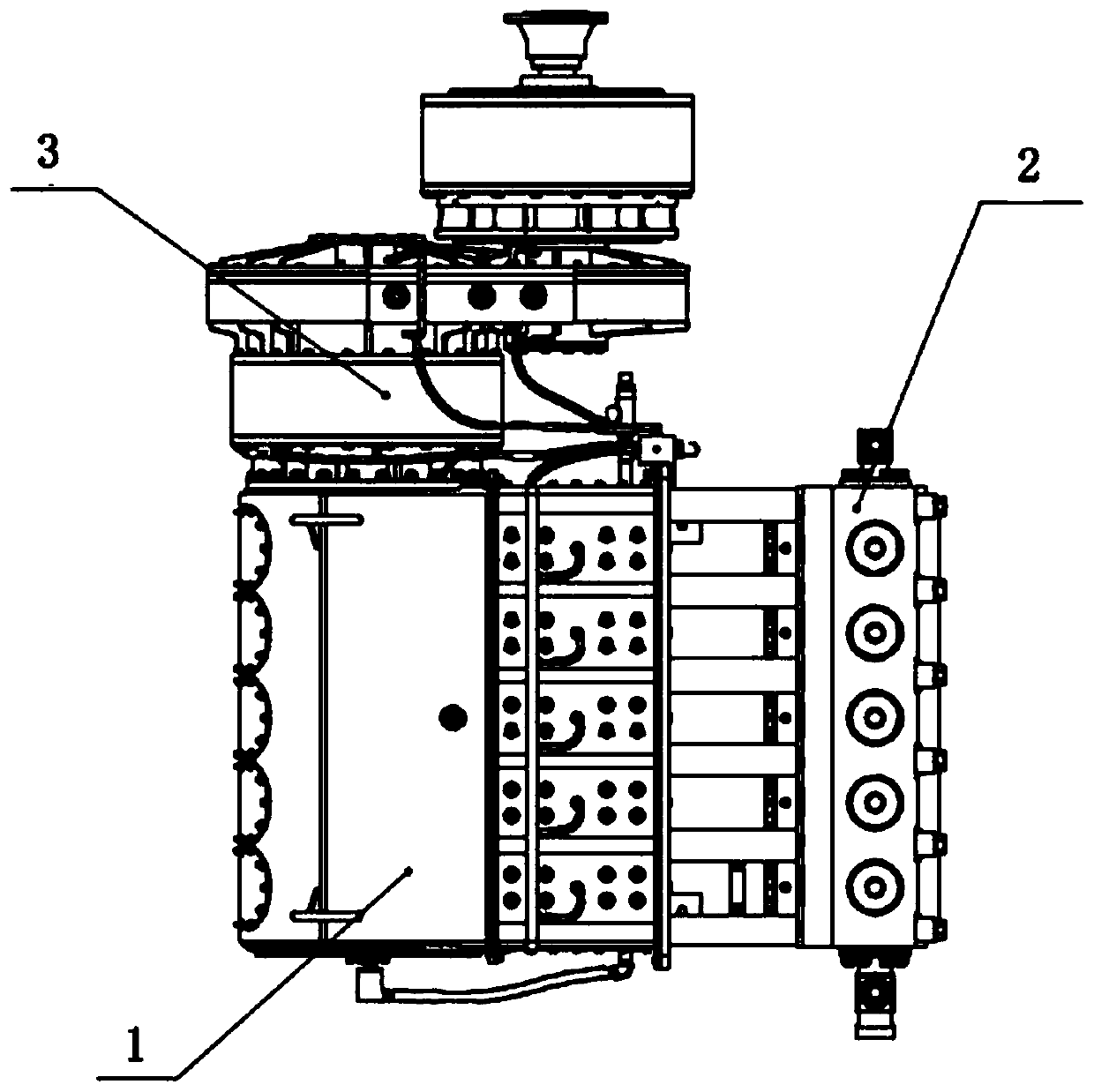

A kind of fracturing sand mixer

ActiveCN104563994BLower the altitudeReduce the overall heightFluid removalGround contactFracturing fluid

The invention provides a fracturing blender truck. The fracturing blender truck comprises a chassis, a sand blending device, a four-connecting-rod mechanism and a power system. The sand blending device is arranged above the chassis and provided with a sand blender, and a closed-type mixing pump serves as the sand blender. The four-connecting-rod mechanism is capable of driving the sand blending device to move to enable a base of the closed-type mixing pump to contact with the ground, a first connecting rod and a third connecting rod of the four-connecting-rod mechanism are arranged on the chassis rotatably, and the sand blending device is arranged on a second connecting rod of the four-connecting-rod mechanism. The power system arranged on the chassis is connected with the first connecting rod and drives the four-connecting-rod mechanism to rotate to enable the closed-type mixing pump to contact with the ground. The fracturing blender truck has the advantages that the closed-type mixing pump serves as the sand blender, and the second connecting rod of the four-connecting-rod mechanism is used for bearing the sand blending device to enable the base of the closed-type mixing pump to be capable of contacting with the ground, so that the height of the closed-type mixing pump is decreased, suction capacity of the closed-type mixing pump is improved, a great quantity of fracturing fluid can be guided out, delivery capacity of the fracturing blender truck is increased, and the requirements on large-scale fracturing operation can be met.

Owner:YANTAI JEREH OILFIELD SERVICES GROUP

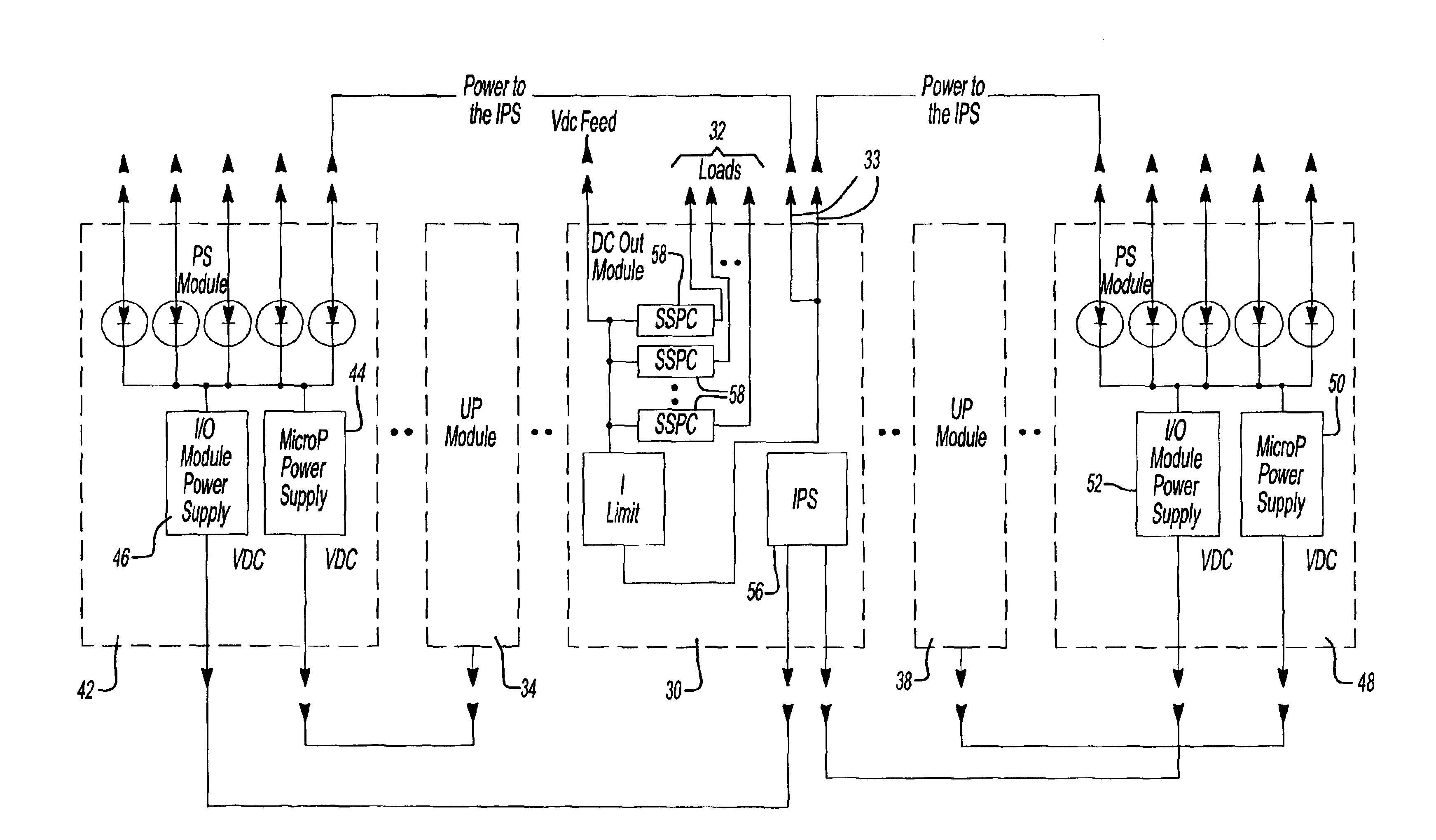

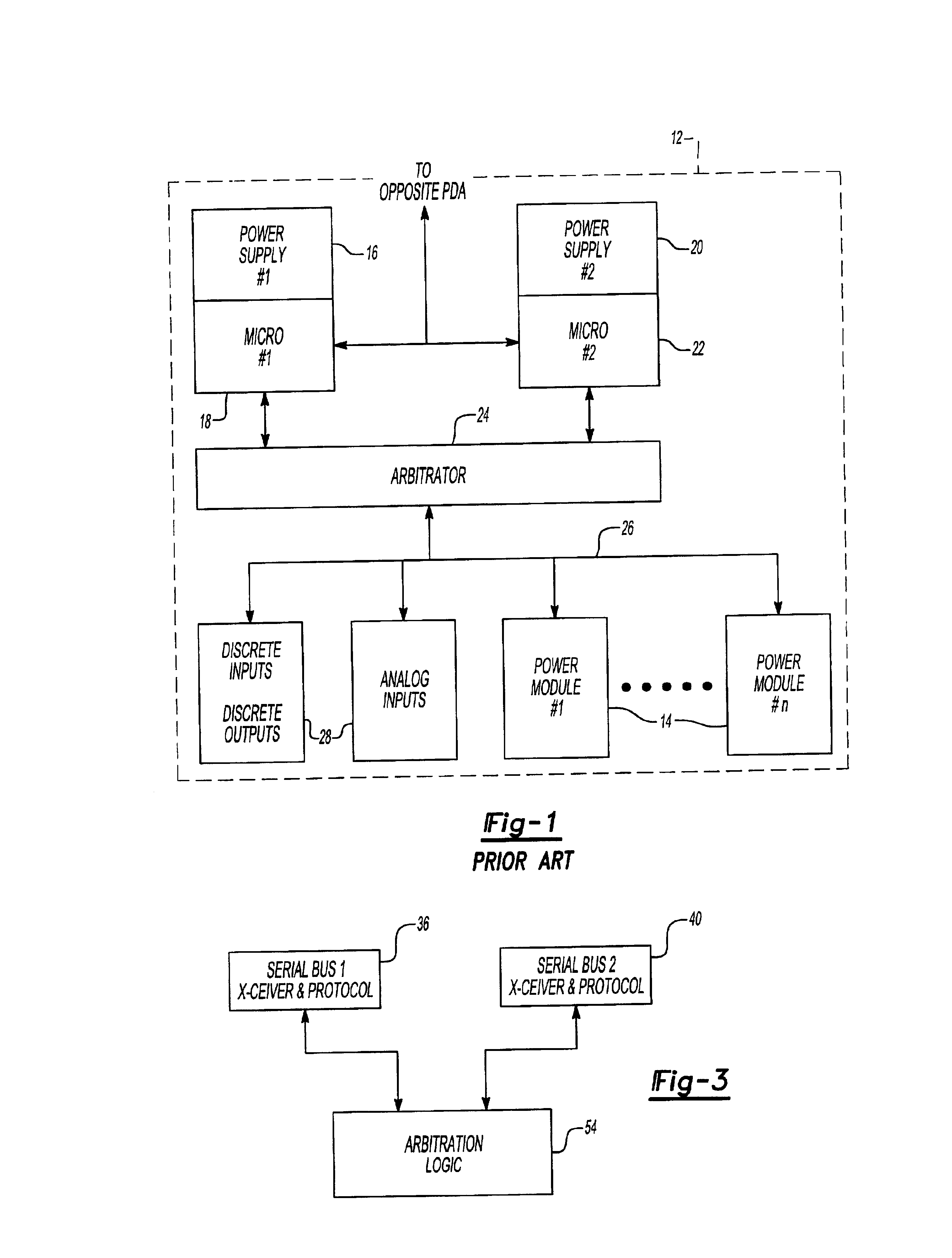

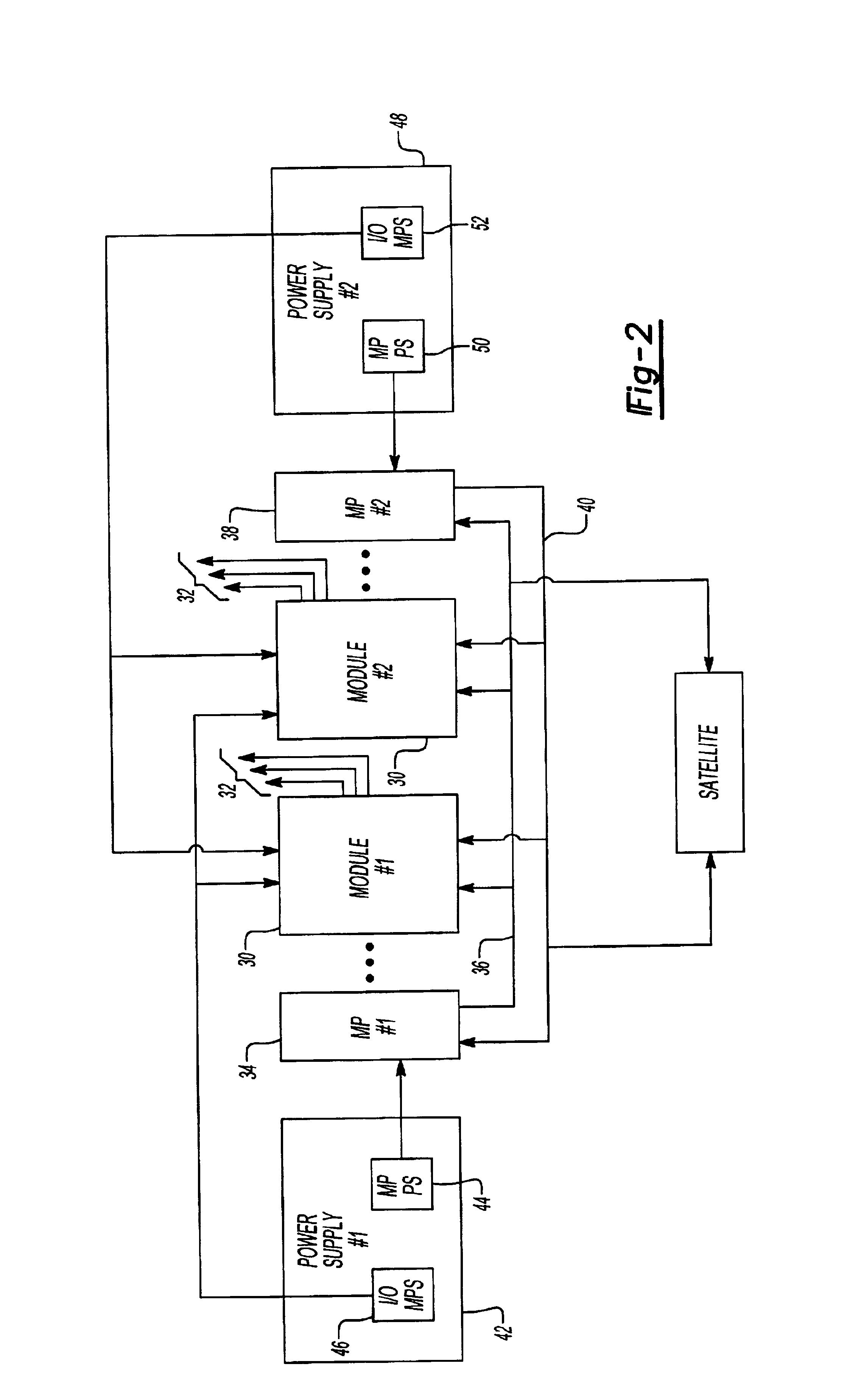

Power distribution assembly with redundant architecture

InactiveUS6856045B1Reduce the impactReduce impactBatteries circuit arrangementsVolume/mass flow measurementTemperature controlControl system

A power distribution assembly (PDA) includes a plurality of power modules that are installed within a chassis that is mounted to a vehicle, such as an aircraft. The power modules are used to control aircraft systems such as braking, navigation, or temperature control systems. The PDA includes first and second microprocessors that have separate serial busses that are in communication with each of the power modules. A first power supply powers the first microprocessor and each of the power modules and a second power supply powers the second microprocessor and each of the power modules independently from the first power supply. Additionally the first and second microprocessors communicate with each other via both serial busses to determine which microprocessor is in active control and which microprocessor is on standby in addition to monitoring the health of the other microprocessor. The microprocessors can be used to provide command signals to satellite power distribution assemblies having satellite power modules for controlling additional aircraft systems. This configuration allows smaller satellite power distribution assemblies to be incorporated into the aircraft, which facilitates installation and provides more flexibility.

Owner:HAMILTON SUNDSTRAND CORP

Continuous large-power turbine fracturing equipment

PendingCN111206992AStable and efficient transmissionStable working platformPositive displacement pump componentsGear lubrication/coolingDrive shaftControl engineering

The invention discloses continuous large-power turbine fracturing equipment. The large-power turbine fracturing equipment comprises a turbine engine, a reduction box, a transmission shaft and a plunger pump, wherein the turbine engine and the reduction box are arranged on the same straight line; the reduction box is connected to the plunger pump through a transmission shaft; and an angle of the transmission shaft ranges from 2 degrees to 4 degrees. The continuous large-power turbine fracturing equipment has the beneficial effects that: a chassis T1 material is selected, so that a stable working platform is provided for the equipment; the turbine engine and the reduction box are on the same straight line, the transmission shaft is arranged between the reduction box and the plunger pump, andthe angle of the transmission shaft ranges from 2 degrees to 4 degrees, so that stable and efficient transmission of the turbine engine is guaranteed, and a fault occurrence rate is reduced; a lubricating system driven by an auxiliary power system guarantees that the turbine engine, the reduction box and the plunger pump work under a proper environment; dual lubricating systems guarantee that theplunger pump realizes continuous operation under power of 5000 HP or higher; and the technical means finally can meet continuous large-power operation requirements of the fracturing equipment.

Owner:美国杰瑞国际有限公司

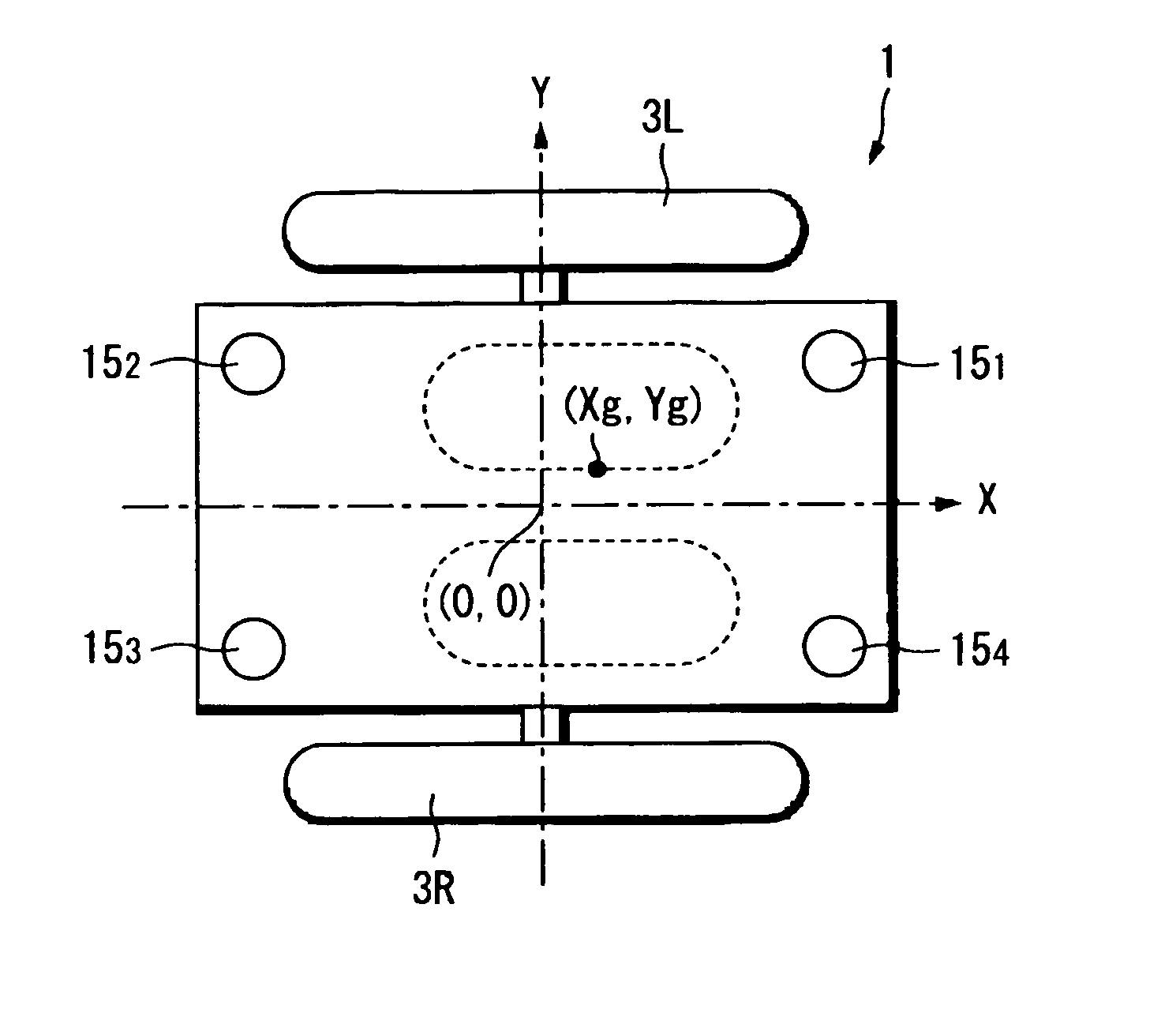

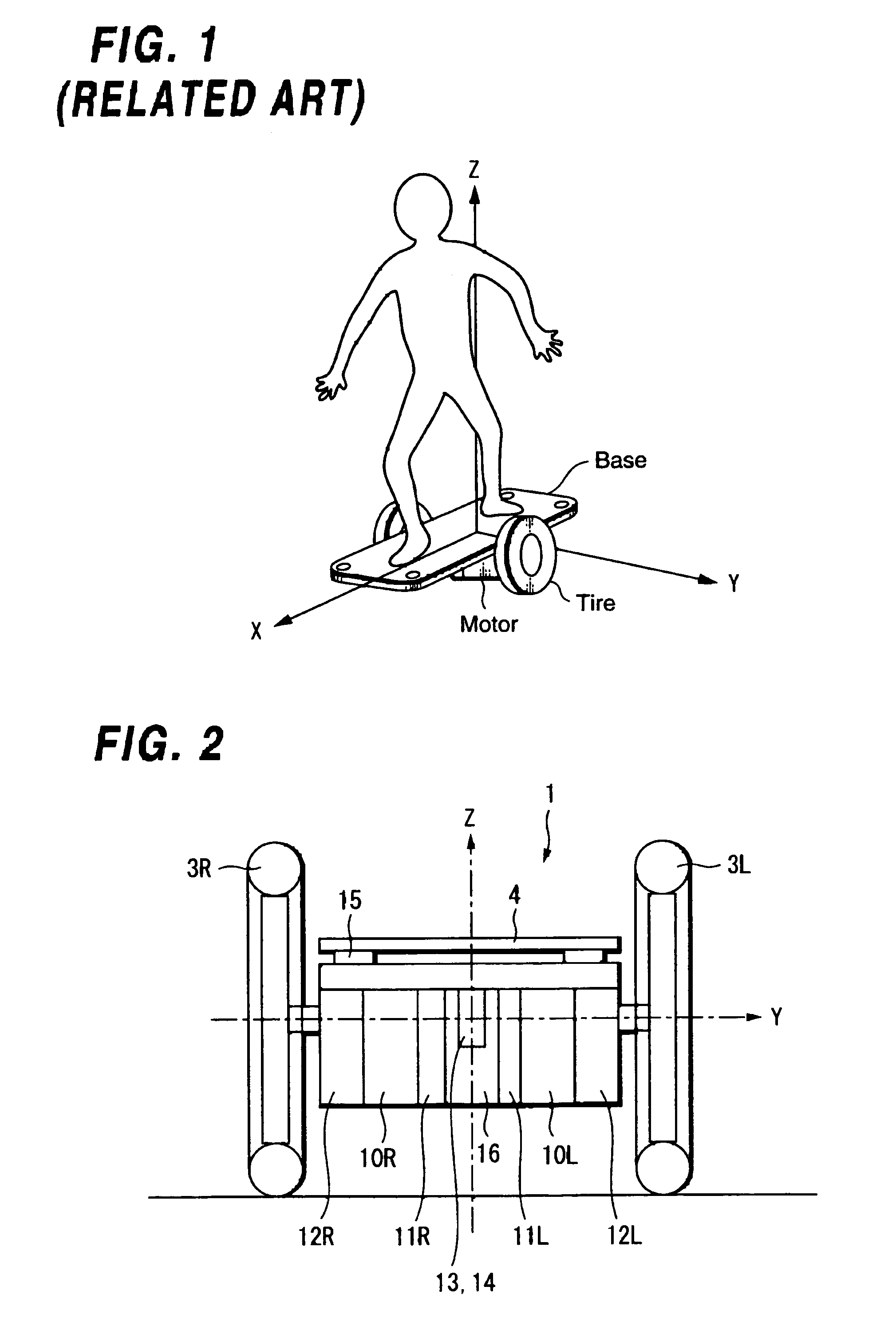

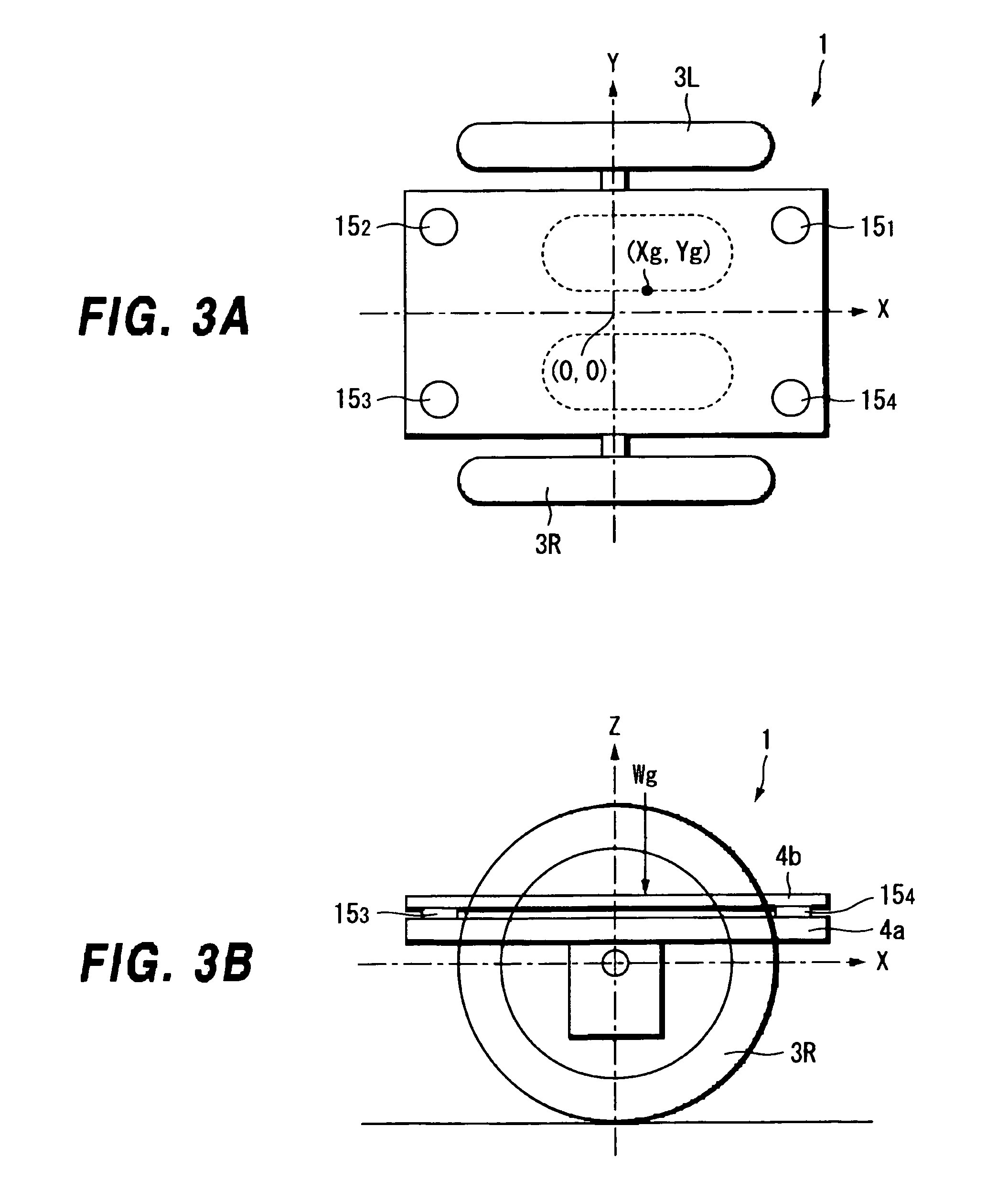

Traveling apparatus and method for controlling thereof

InactiveUS7363993B2Reduce the average velocityLanding safetySpeed controllerElectric devicesRotation velocityRolling chassis

A traveling apparatus suitable for use in a two-wheeled traveling vehicle on which a man rides, and a method for controlling thereof, are provided. An abrupt turn, which can make a rider fall down, is prevented, and stable traveling is obtained without fail. Specifically, the apparatus and method efficiently charge regenerative energy that is generated when decelerating or traveling on a downward slope. The apparatus and method include motors for driving a plurality of wheels independently, a chassis for connecting the plurality of wheels, in which sensors for detecting a shift of barycenter of a rider are provided, and a controller for restricting a rotational velocity of each of the plurality of wheels to a predetermined limited value, wherein turning is performed in accordance with the shift of a barycentric position.

Owner:TOYOTA JIDOSHA KK

Fracturing blender truck

ActiveCN104563994ALower the altitudeReduce the overall heightFluid removalGround contactFracturing fluid

The invention provides a fracturing blender truck. The fracturing blender truck comprises a chassis, a sand blending device, a four-connecting-rod mechanism and a power system. The sand blending device is arranged above the chassis and provided with a sand blender, and a closed-type mixing pump serves as the sand blender. The four-connecting-rod mechanism is capable of driving the sand blending device to move to enable a base of the closed-type mixing pump to contact with the ground, a first connecting rod and a third connecting rod of the four-connecting-rod mechanism are arranged on the chassis rotatably, and the sand blending device is arranged on a second connecting rod of the four-connecting-rod mechanism. The power system arranged on the chassis is connected with the first connecting rod and drives the four-connecting-rod mechanism to rotate to enable the closed-type mixing pump to contact with the ground. The fracturing blender truck has the advantages that the closed-type mixing pump serves as the sand blender, and the second connecting rod of the four-connecting-rod mechanism is used for bearing the sand blending device to enable the base of the closed-type mixing pump to be capable of contacting with the ground, so that the height of the closed-type mixing pump is decreased, suction capacity of the closed-type mixing pump is improved, a great quantity of fracturing fluid can be guided out, delivery capacity of the fracturing blender truck is increased, and the requirements on large-scale fracturing operation can be met.

Owner:YANTAI JEREH OILFIELD SERVICES GROUP

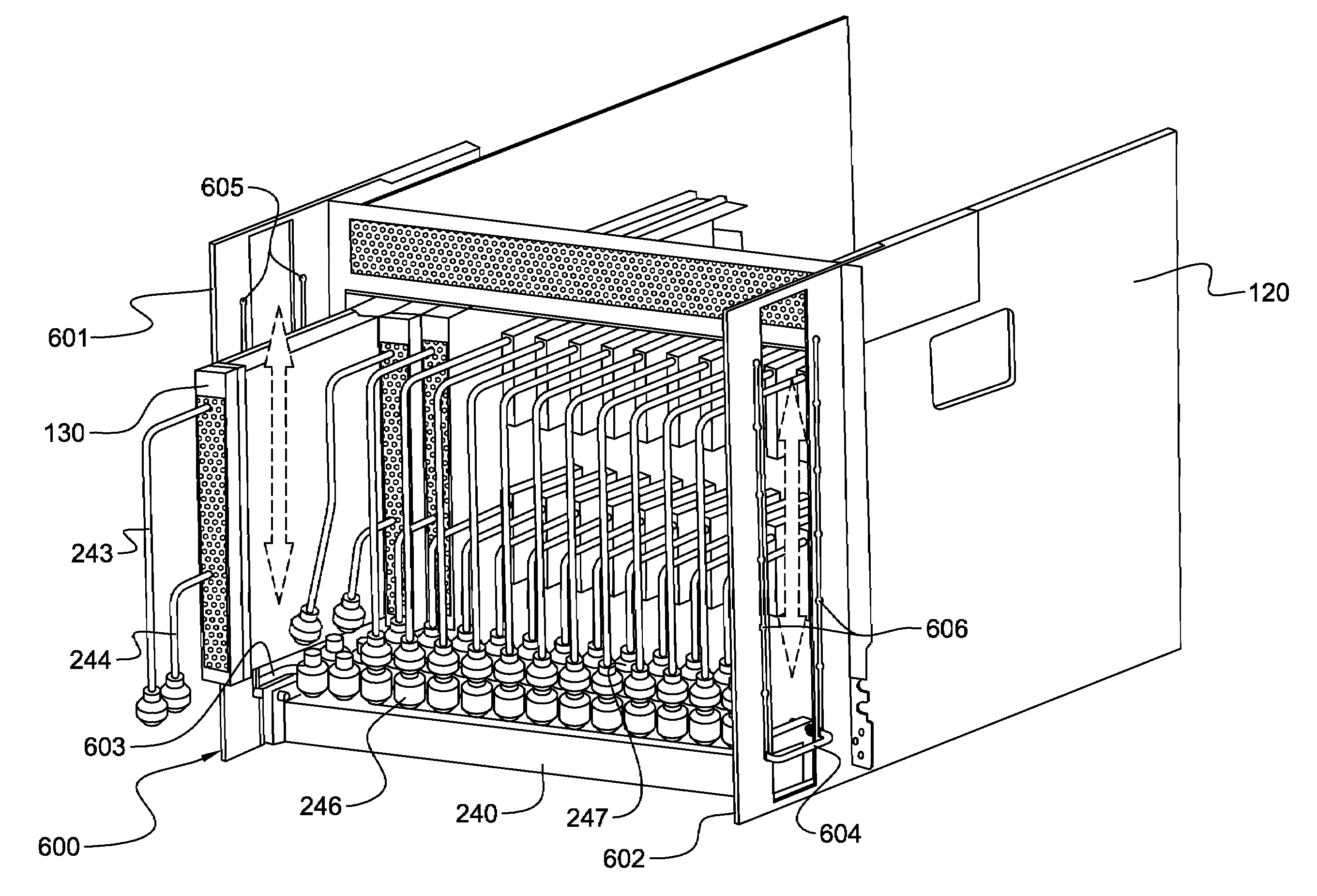

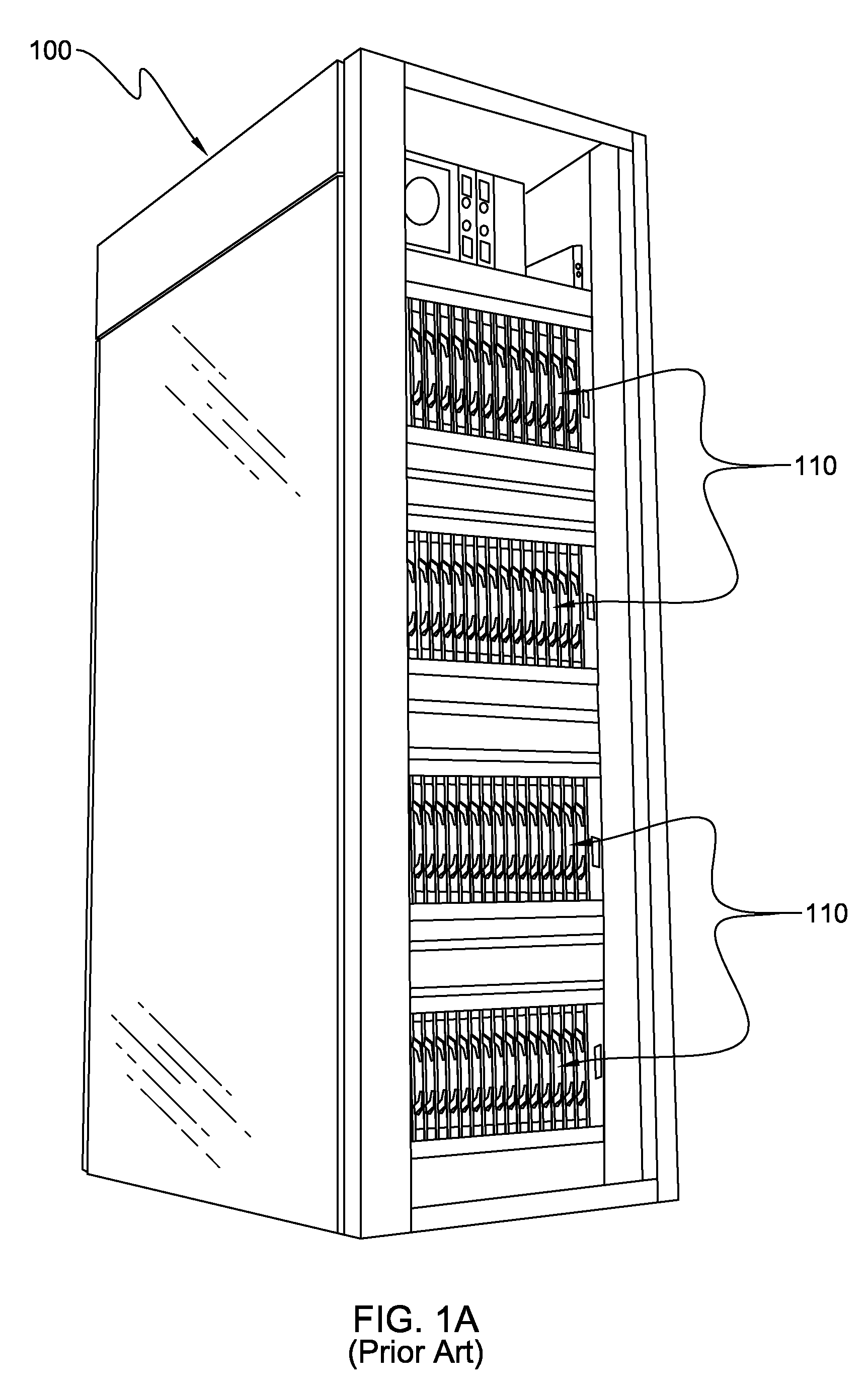

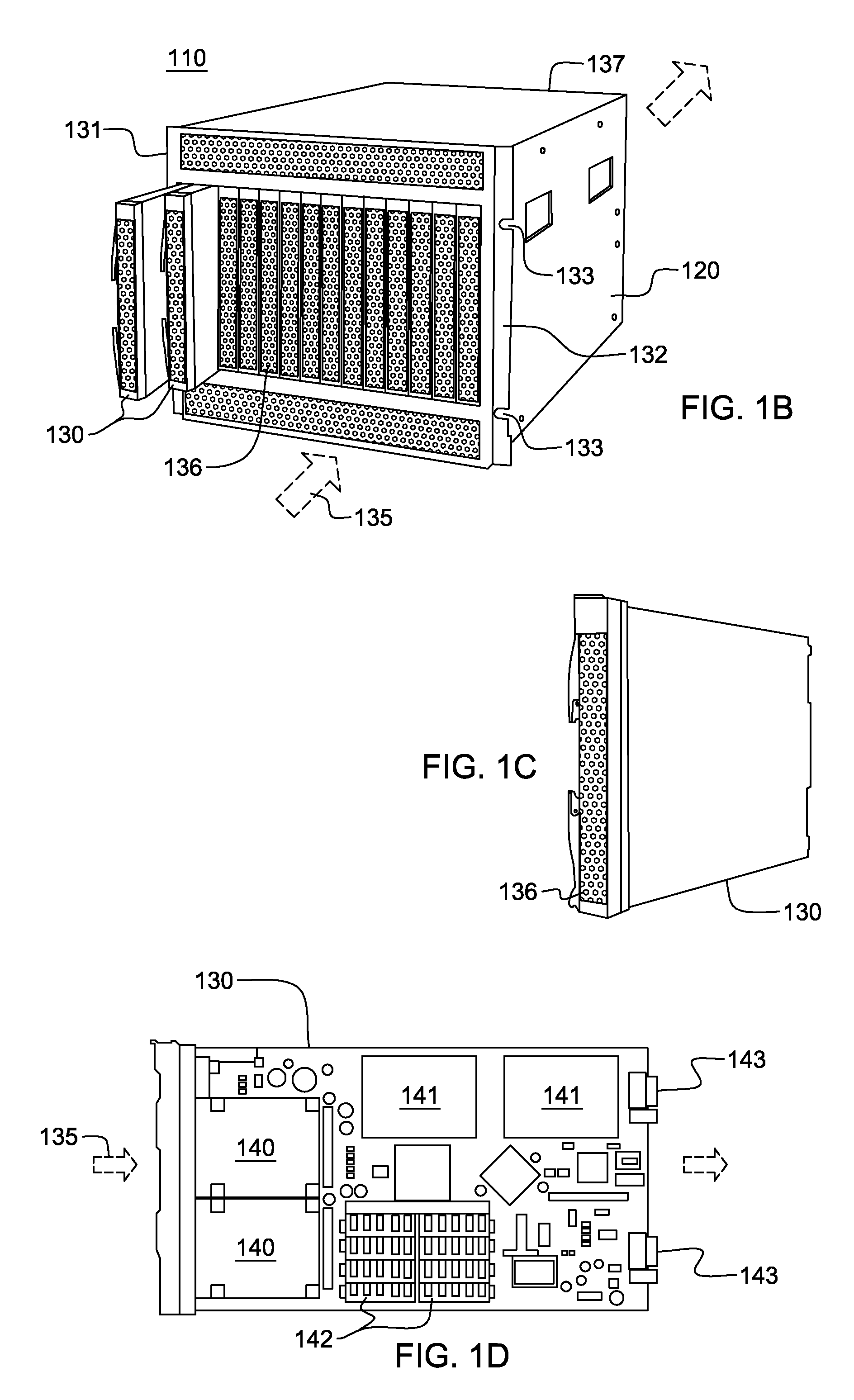

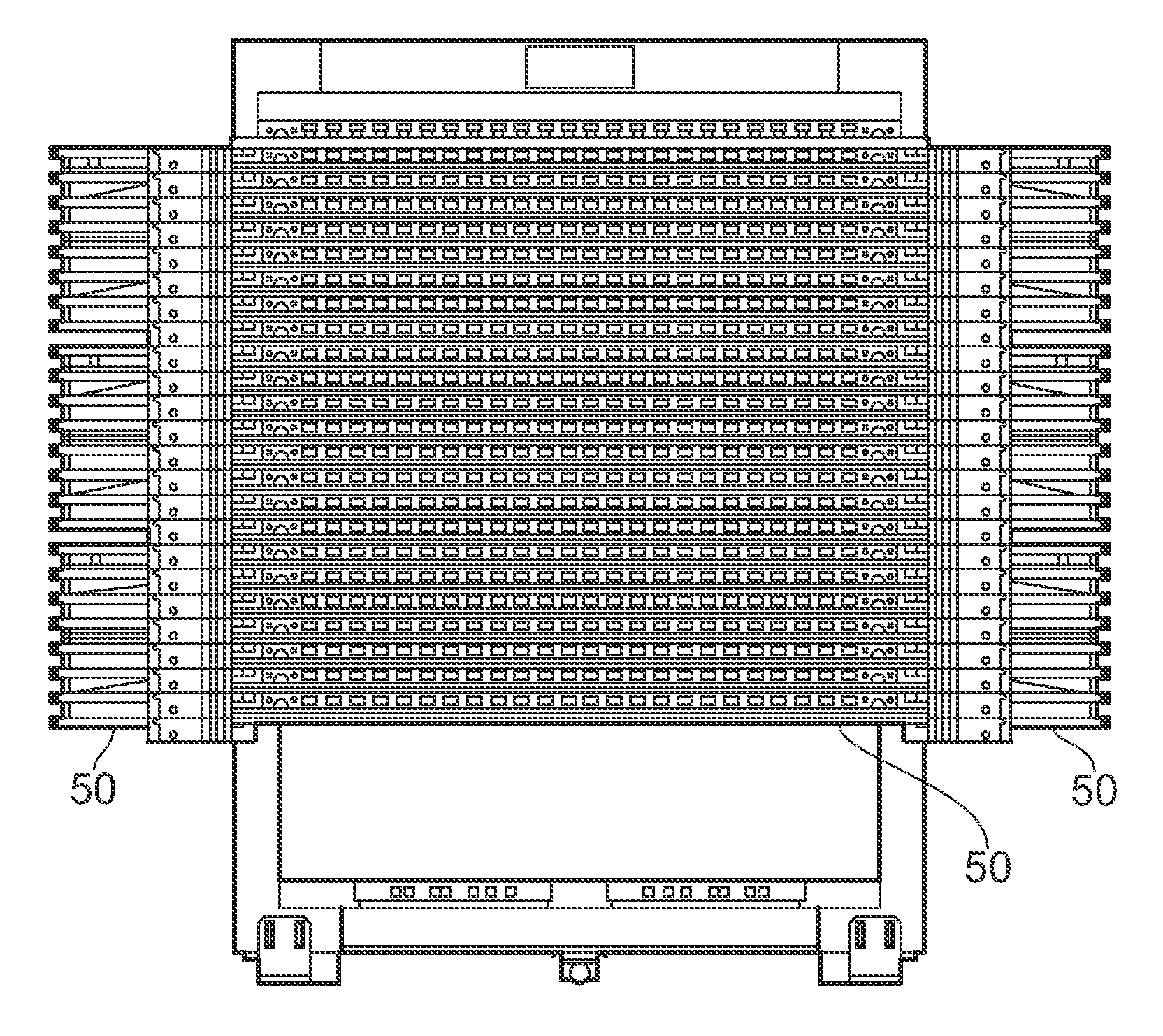

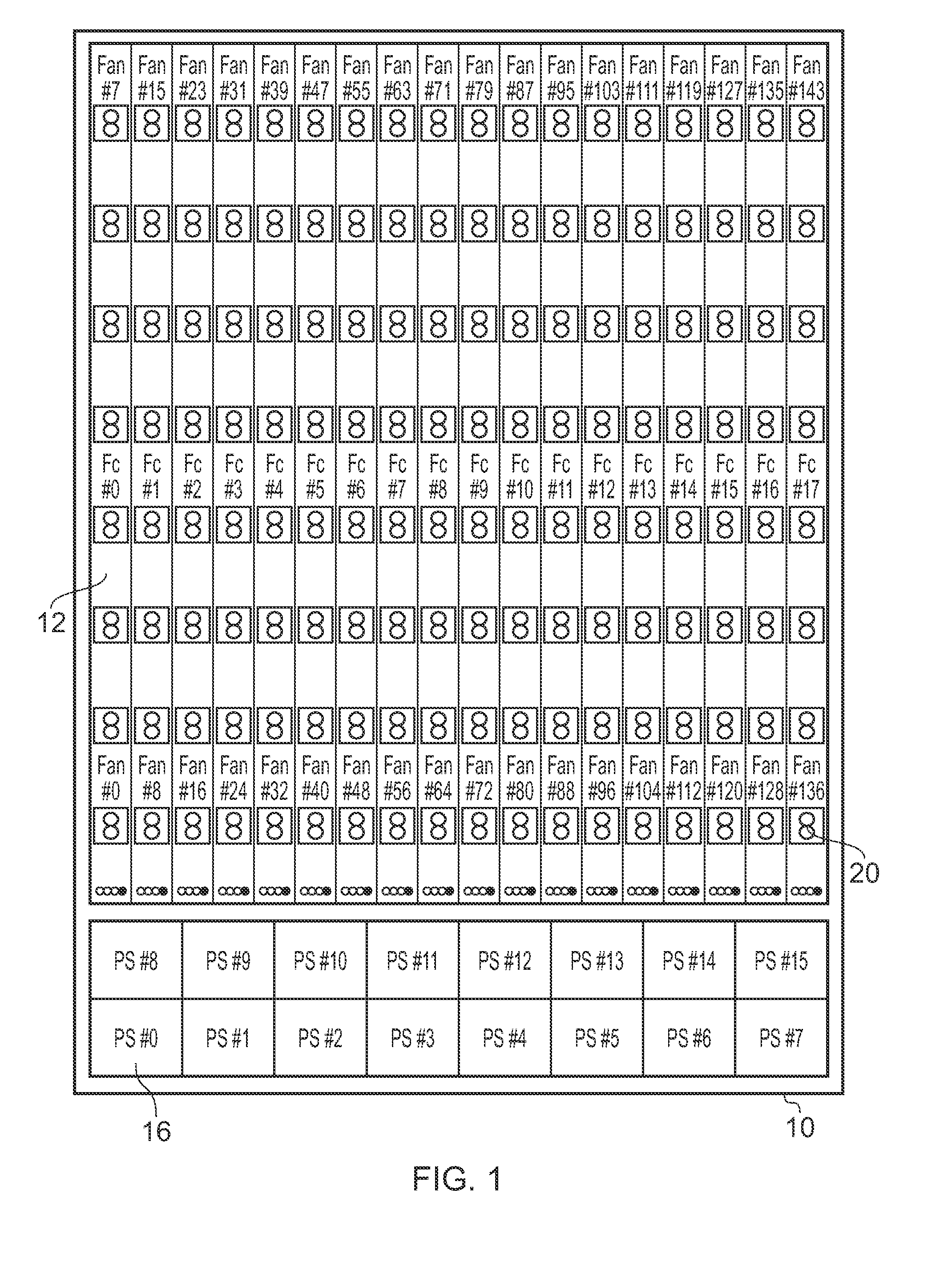

Liquid cooling apparatus and method for facilitating cooling of an electronics system

InactiveUS7639499B1Easy accessOvercomes shortcomingDomestic cooling apparatusSemiconductor/solid-state device detailsElectronic systemsInlet manifold

Apparatus and method are provided for facilitating liquid cooling one or more components of an electronic subsystem chassis disposed within an electronics rack. The apparatus includes a rack-level coolant manifold assembly and at least one movable chassis-level manifold subassembly. The rack-level coolant manifold assembly includes a rack-level inlet manifold and a rack-level outlet manifold, and each movable chassis-level manifold subassembly includes a chassis-level coolant inlet manifold coupled in fluid communication with the rack-level inlet manifold, and a chassis-level coolant outlet manifold coupled in fluid communication with the rack-level outlet manifold. The chassis-level manifold subassembly is slidably coupled to the electronics rack to facilitate access to one or more removable components of the electronic subsystem chassis. In one embodiment, the electronics subsystem chassis is a multi-blade center system having multiple removable blades, each blade being an electronics subsystem.

Owner:IBM CORP

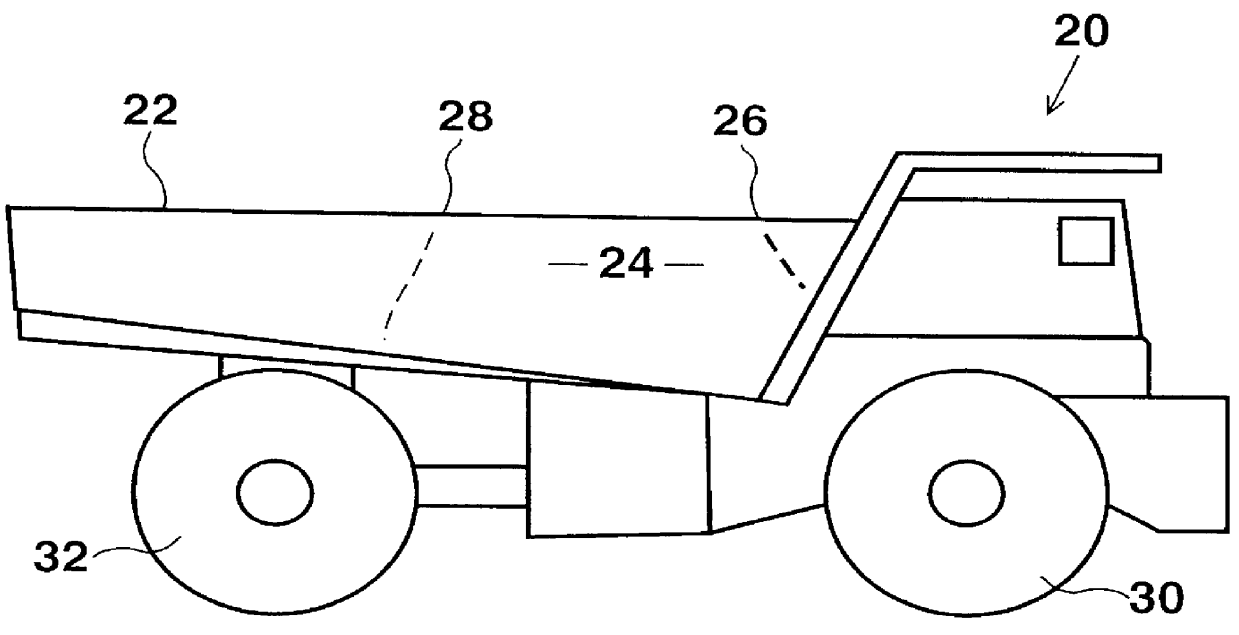

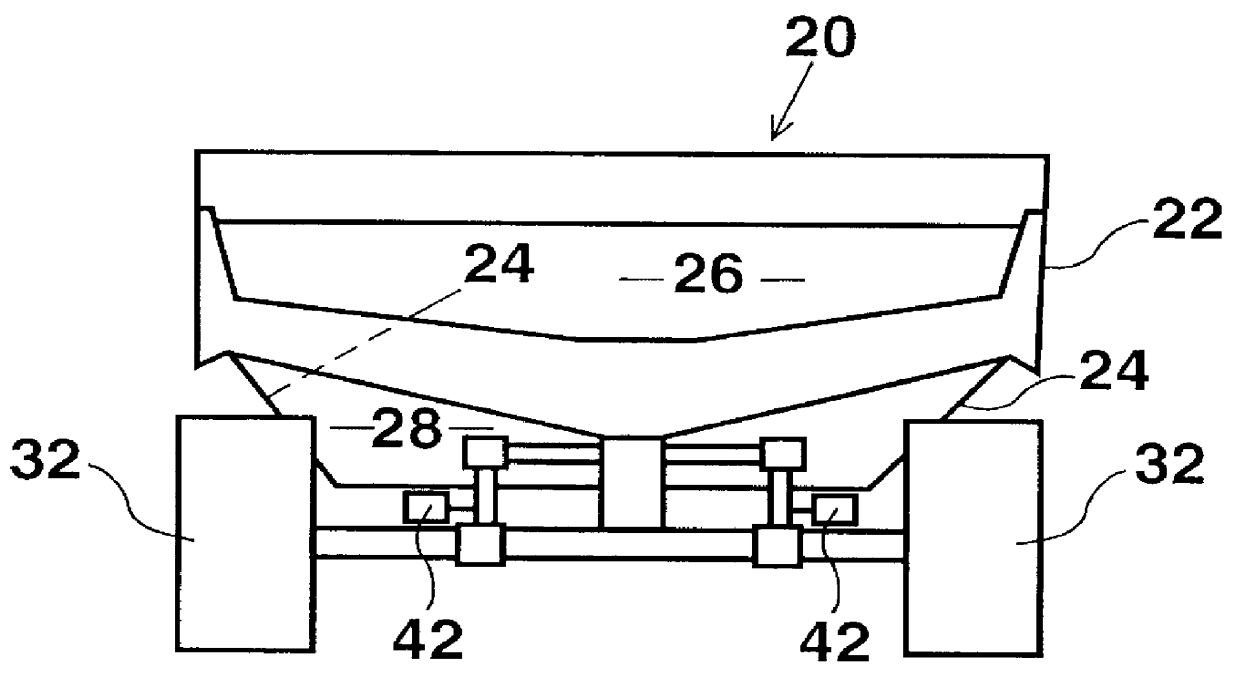

Load distribution system for haulage trucks

InactiveUS6157889AMechanical machines/dredgersMeasurement arrangements for variableAutomated algorithmEngineering

Weight sensors coupled to the bed of a conventional haulage truck measure the weight applied to each tire strut as the truck is being loaded. Based on the weight applied to each strut, the exact position of the center of gravity of the load in the truck's bed is calculated and displayed on a monitor relative to a target position deemed optimal for uniform weight distribution. Based on this information, the operator of the loading machine can complete the loading operation in such a way as to shift the center of gravity toward the chosen target position. In another embodiment of the invention, an automated algorithm calculates and displays where the next bucket load should be dropped, based on its approximate weight, in order to shift the center of gravity toward the target location.

Owner:MODULAR MINING SYSTEMS

Switch chassis

InactiveUS20080112133A1Simple designImproved electrical signal characteristicOrthogonal PCBs mountingPrinted circuit manufactureEngineeringMulti path

A switch chassis includes a plane having pass-through vias. An array of connector pairs is provided. A connector pair includes a first multi-path connector on first side of the plane and a second multi-path connector on the second side of the plane interconnected through the pass-through vias in the plane. Fabric cards can be connected to respective columns of first connectors and line cards can be connected respective rows of second connectors of the connector pairs to orient the fabric and lines cards orthogonally with respect to each other.

Owner:SUN MICROSYSTEMS INC

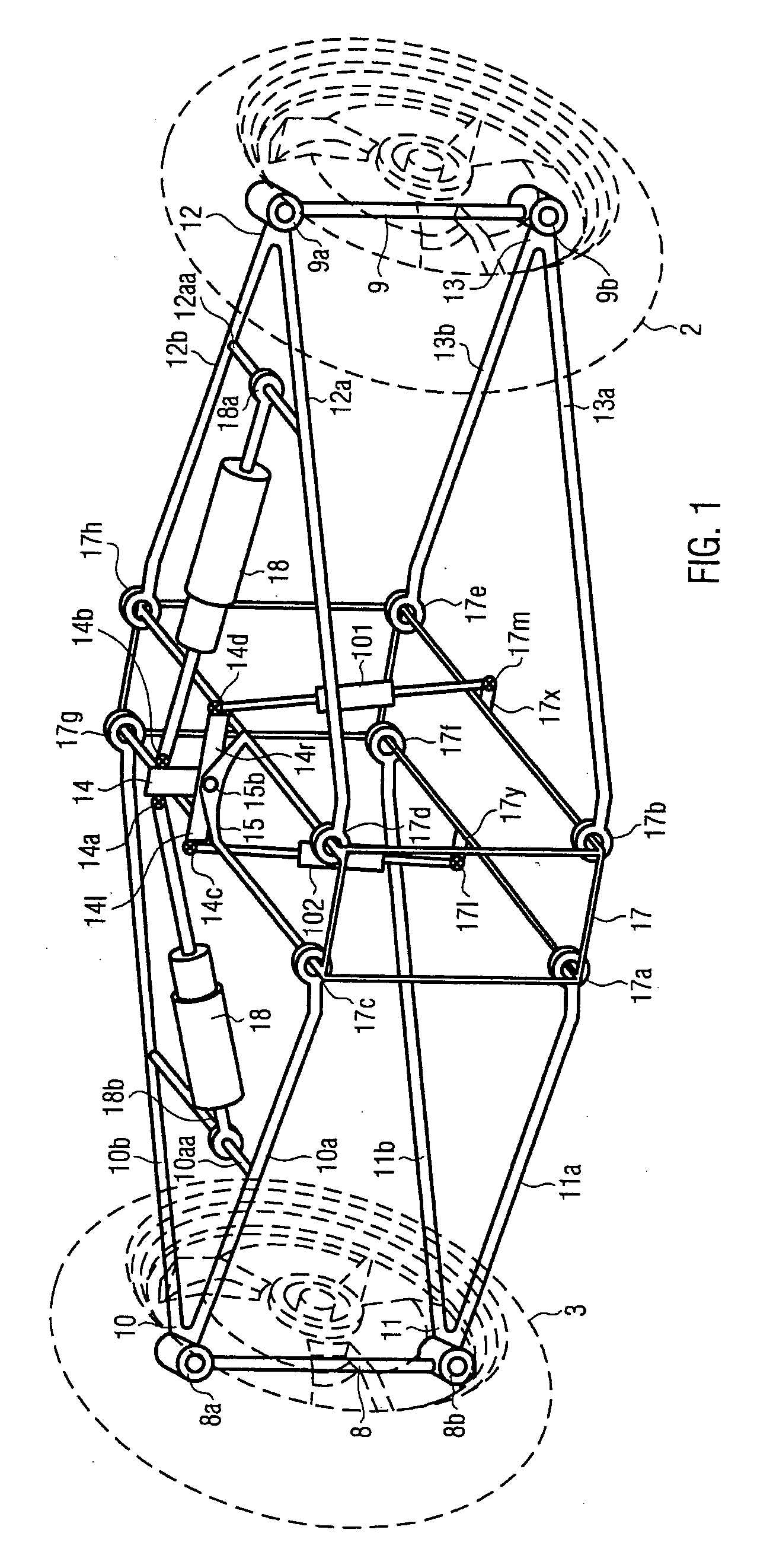

Vehicle having an articulated suspension and method of using same

InactiveUS20050023052A1Braking element arrangementsExtraterrestrial carsRolling chassisAutomotive engineering

A vehicle includes a chassis and a plurality of wheel assemblies articulated with the chassis, each of the plurality of wheel assemblies comprising a rotatable wheel spaced away from the chassis. A vehicle includes a chassis and an articulated suspension system mounted to the chassis. A method includes comprising articulating at least one of a plurality of wheel assemblies with a chassis, each of the wheel assemblies including a rotatable wheel spaced apart from the chassis. A vehicle includes a chassis and articulatable means for rolling the chassis along a path.

Owner:LOCKHEED MARTIN CORP

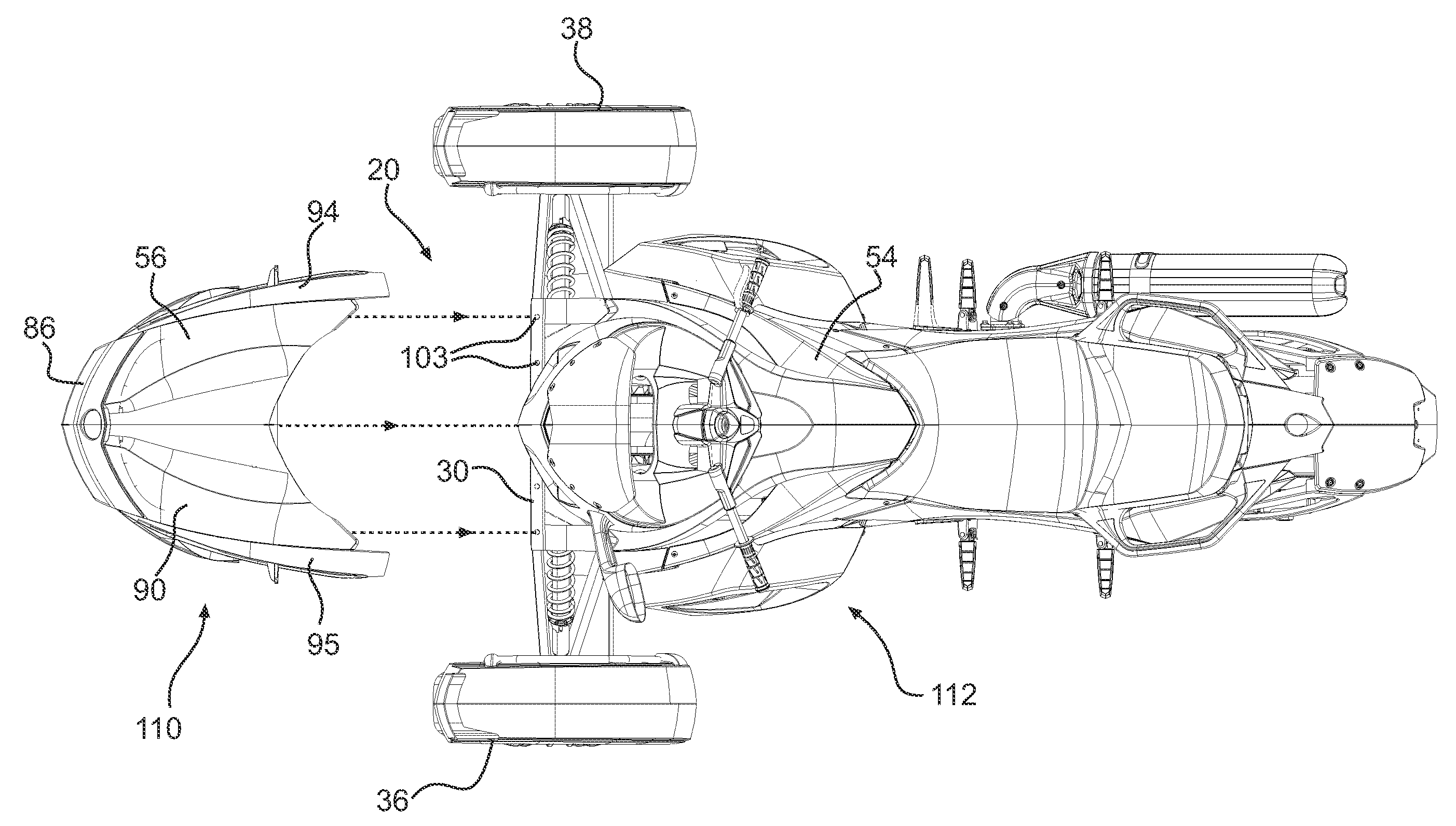

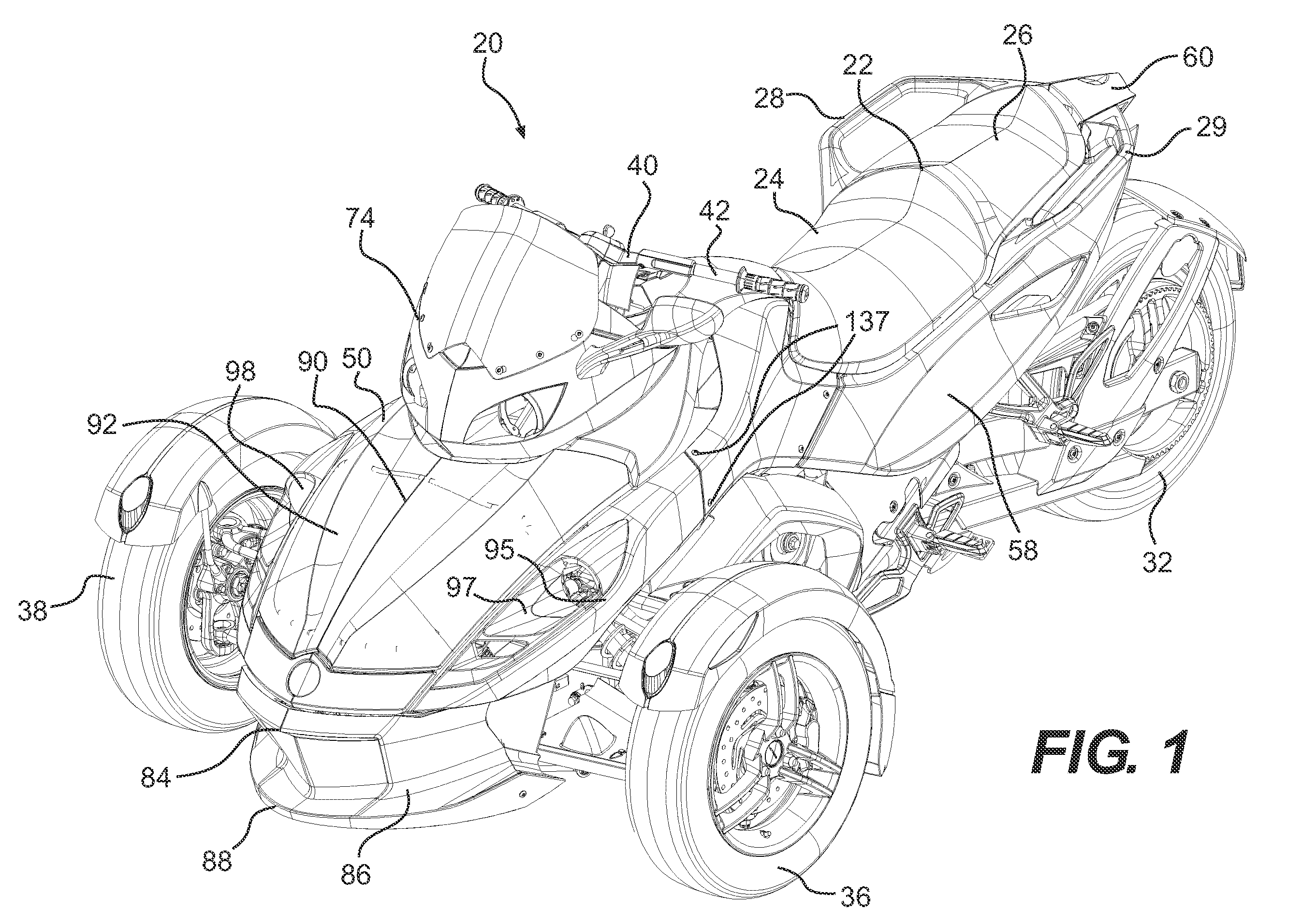

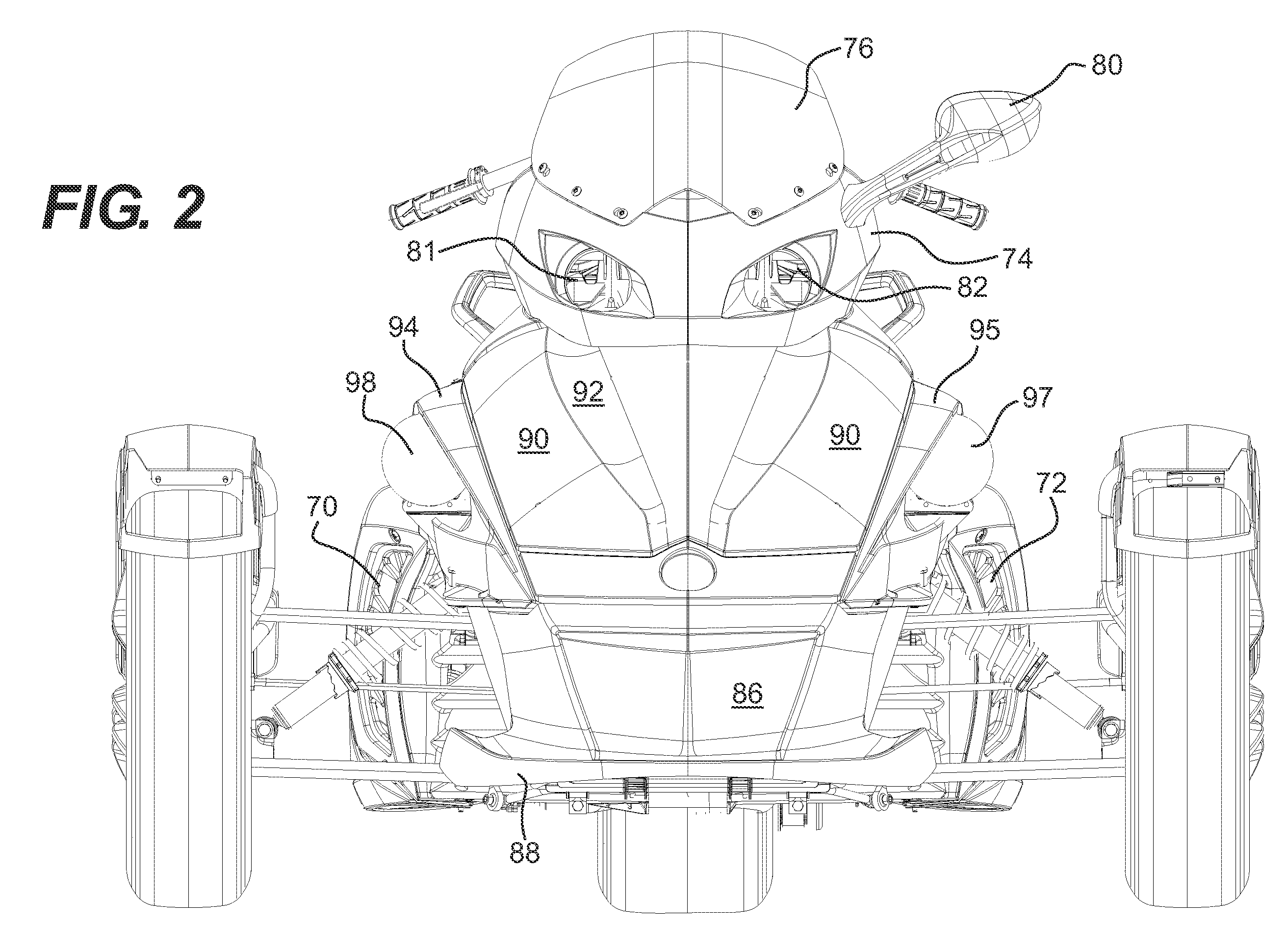

Three-Wheel Vehicle

An three-wheel vehicle including a modular front structure having a storage compartment therein. The modular front structure is adapted to be mounted onto the chassis of the three-wheel vehicle and to support bodywork elements thereby providing ease of assembly of the vehicle and ease of disassembly for packaging the vehicle.

Owner:BOMBARDIER RECREATIONAL PROD INC

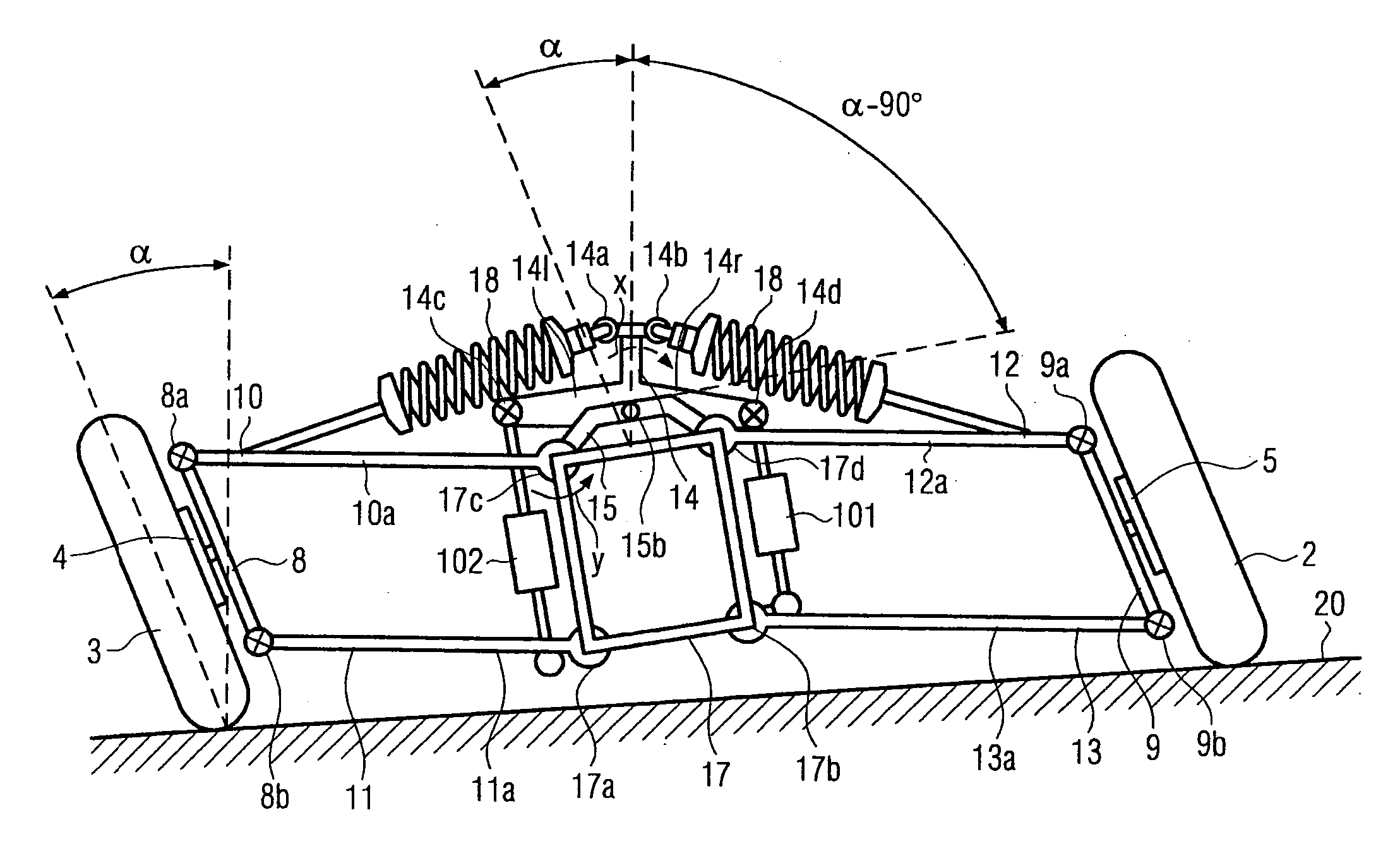

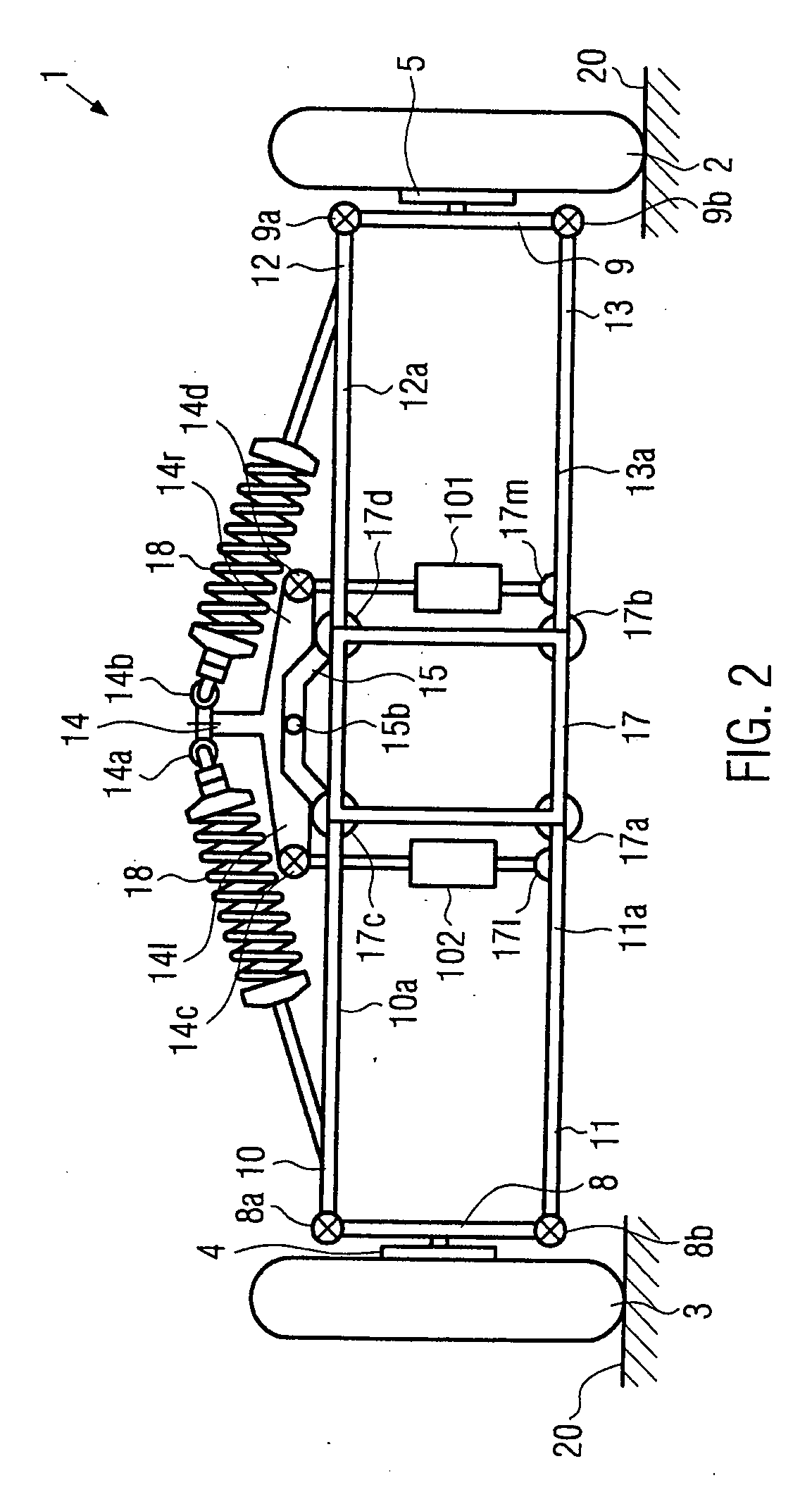

Suspension tilting module for a wheeled vehicle and a wheeled vehicle equipped with said suspension tilting module

A tilting suspension system is provided for two wheels (2, 3) of a vehicle (200) disposed on a common axle with the module comprising a rigid frame (17) adapted to be firmly fixed to the chassis of the vehicle so as to be tilted together with the whole vehicle and a tilting arm (14) pivotally linked to the rigid frame. The tilting of the rigid frame is obtained as a result of the counter torque arising when activating hydraulic actuating means (101, 102) pivotally interposed between the tilting arm (14) and the rigid frame (17), with the tilting arm being pivotally connected to shock absorbers (18). The tilting module further comprises suspension arms (10, 11, 12, 13) pivotally connected to the rigid frame, with the suspension arms supporting, in cooperation with supporting uprights, the two wheels thus allowing both tilting and steering of the two wheels. The hydraulic actuating means (101, 102) are actuated by a hydraulic pump (112) driven by an electric motor (108).

Owner:FONDAZIONE TORINO WIRELESS

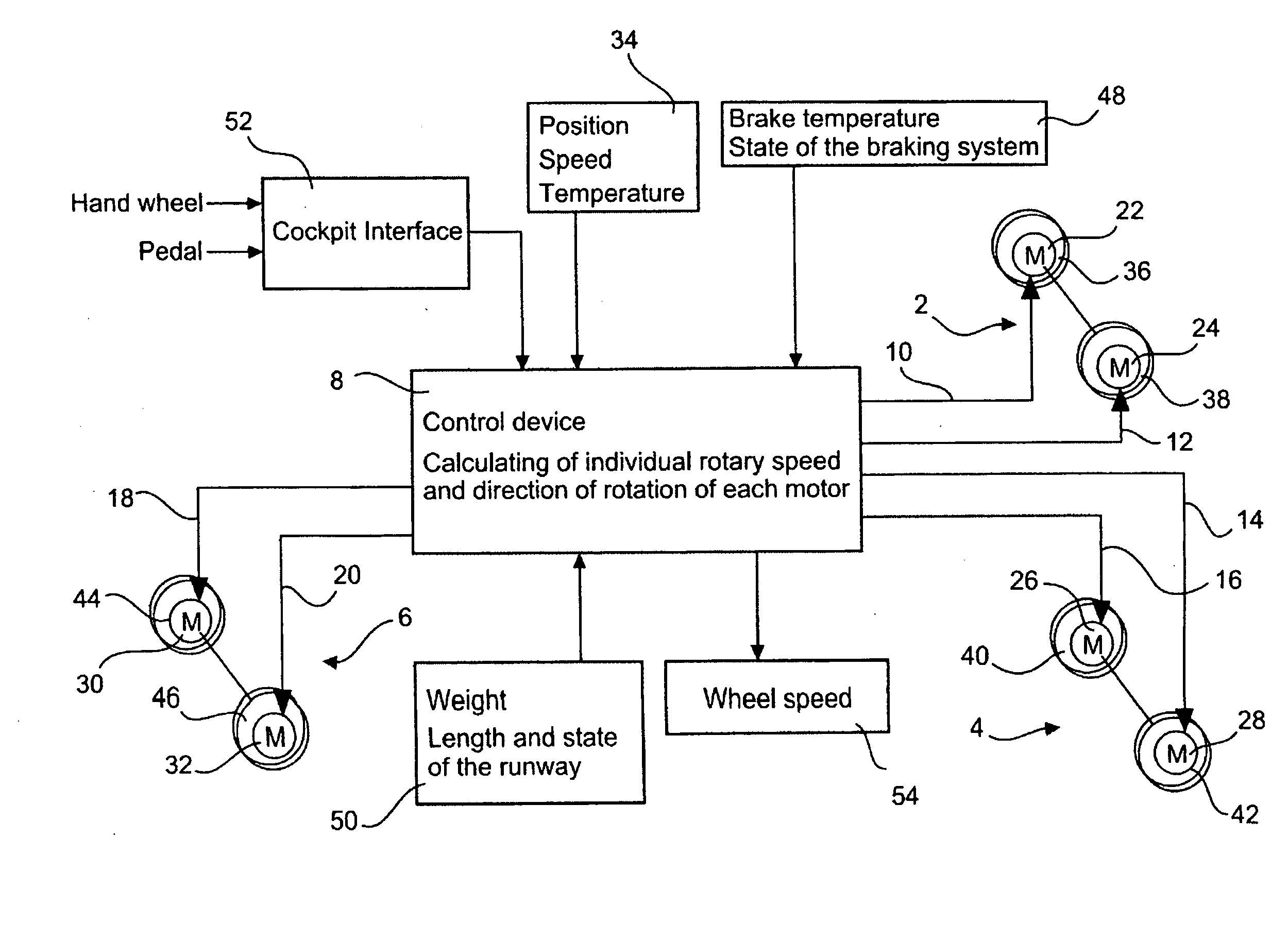

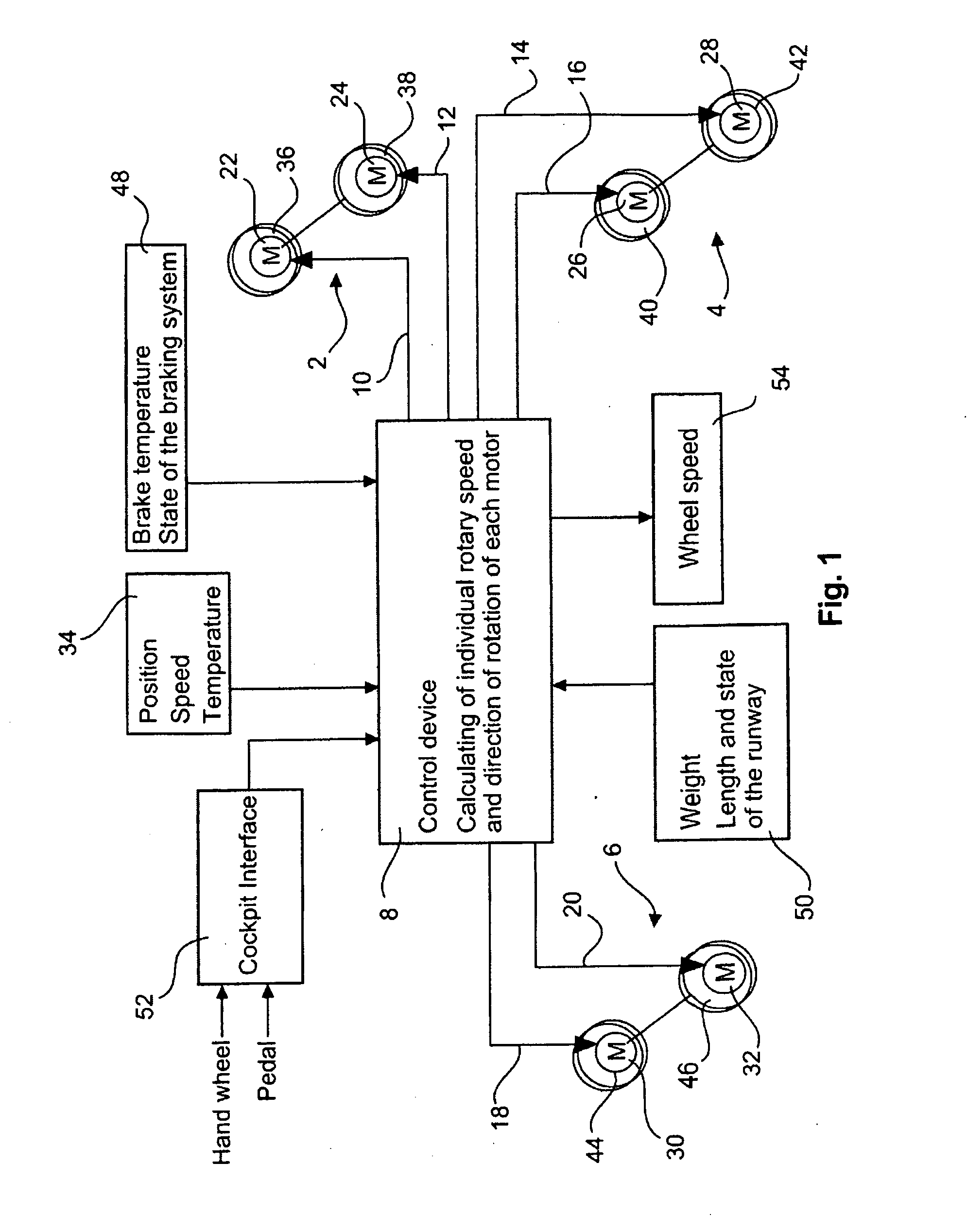

Integrated multifunctional powered wheel system for aircraft

ActiveUS20090218440A1Improve braking effectWeight increaseEnergy efficient operational measuresWheel arrangementsDrive wheelFlight vehicle

Owner:AIRBUS SAS +1

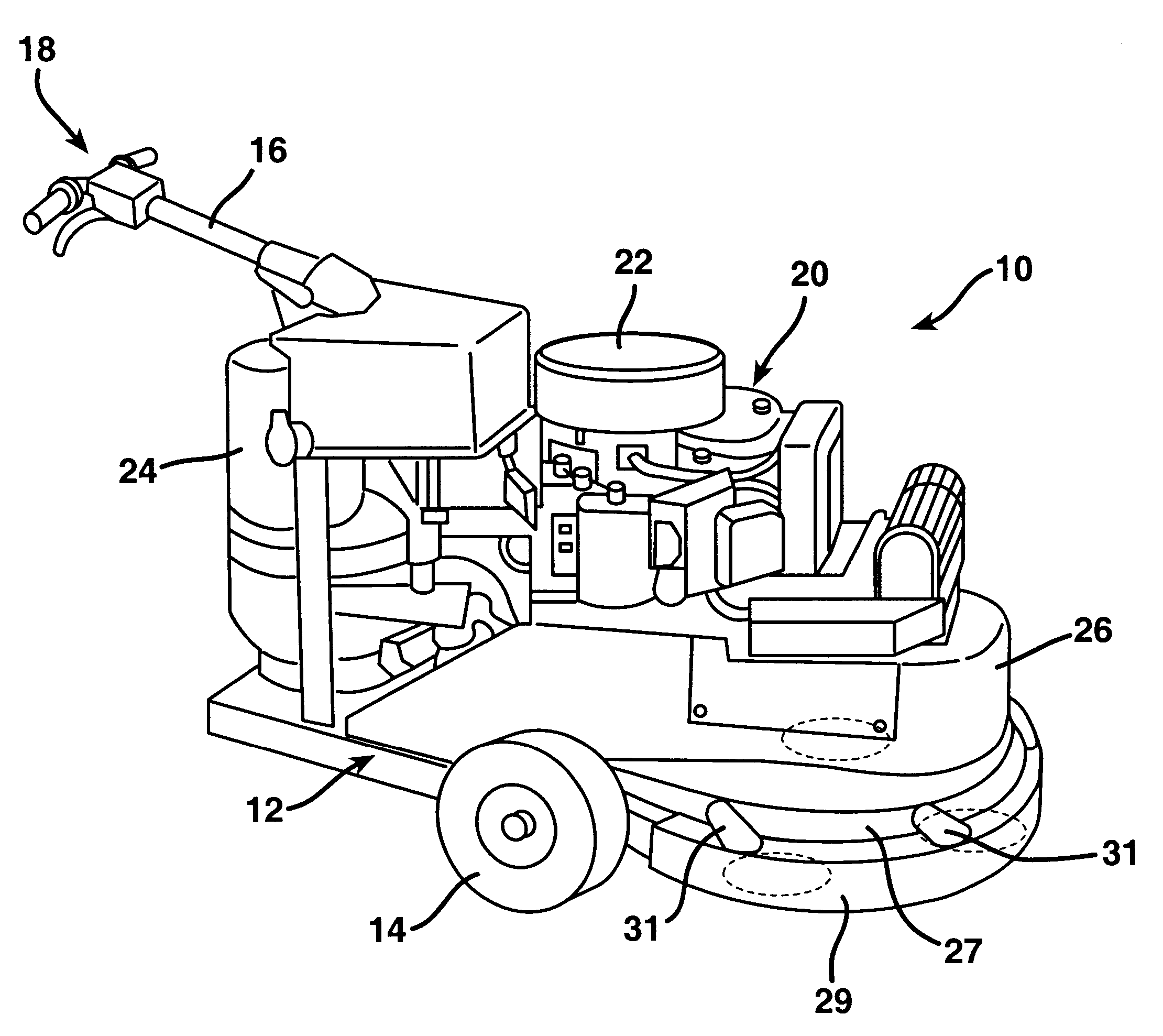

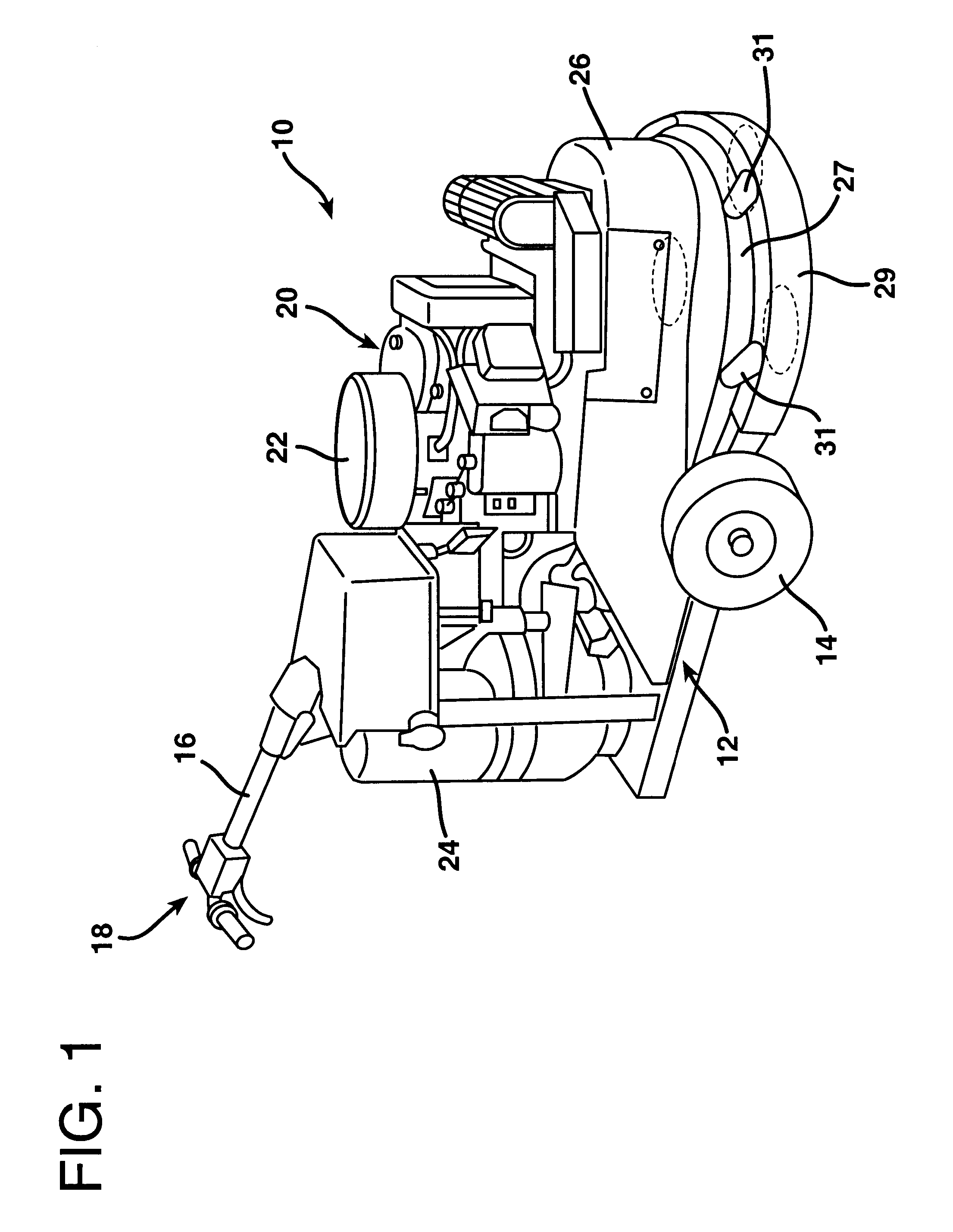

Multidisc floor grinder

A multidisc floor grinder is constructed as a wheeled device that may be moved about the floor by means of a handle. The chassis of the floor grinder supports a bearing housing on gimbals that allow the bearing housing to vary in orientation as the device is moved across an uneven floor. The gimbals are aligned to allow rotation of the bearing housing about a bearing housing axis that is parallel to the floor. The bearing housing supports a main drive shaft which extends downwardly from the bearing housing. The main drive shaft is rotatable relative to the bearing housing within its bearings. A grinder mounting frame is rotatably mounted about the main drive shaft and is supported therefrom. The grinder mounting frame is driven in rotation about the main drive shaft at a greatly reduced speed relative to the rotation of the main drive shaft. The grinder mounting frame carries a plurality of grinding elements which are also driven from the main drive shaft, but at a substantially increased speed of rotation relative thereto. The grinding elements thereby rotate not only about their own axes, but also about the axis of the main drive shaft so as to cover a relatively large floor area with relatively small grinding elements. This arrangement substantially reduces the time required to grind paint or other matter from a floor surface.

Owner:DUNCAN +1

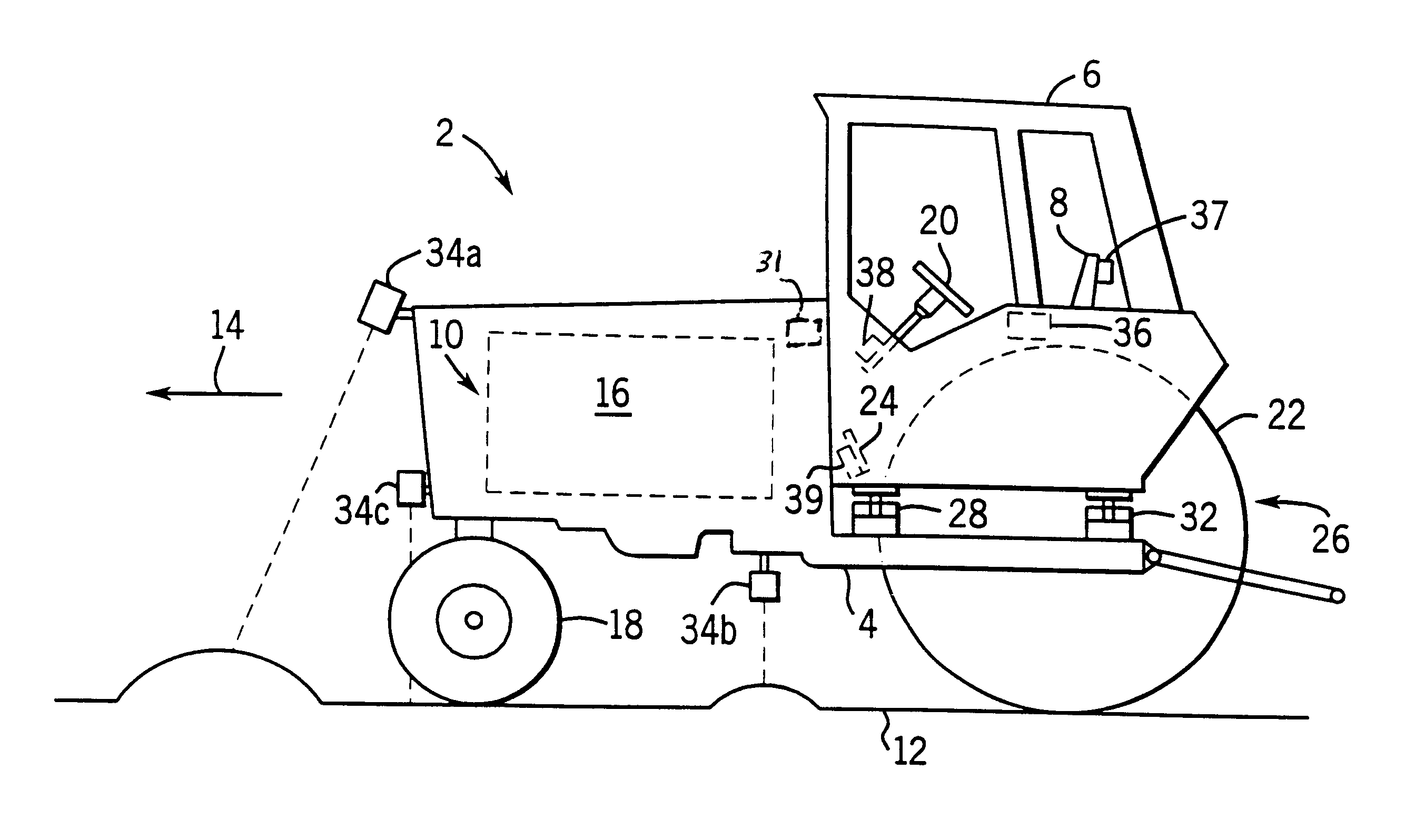

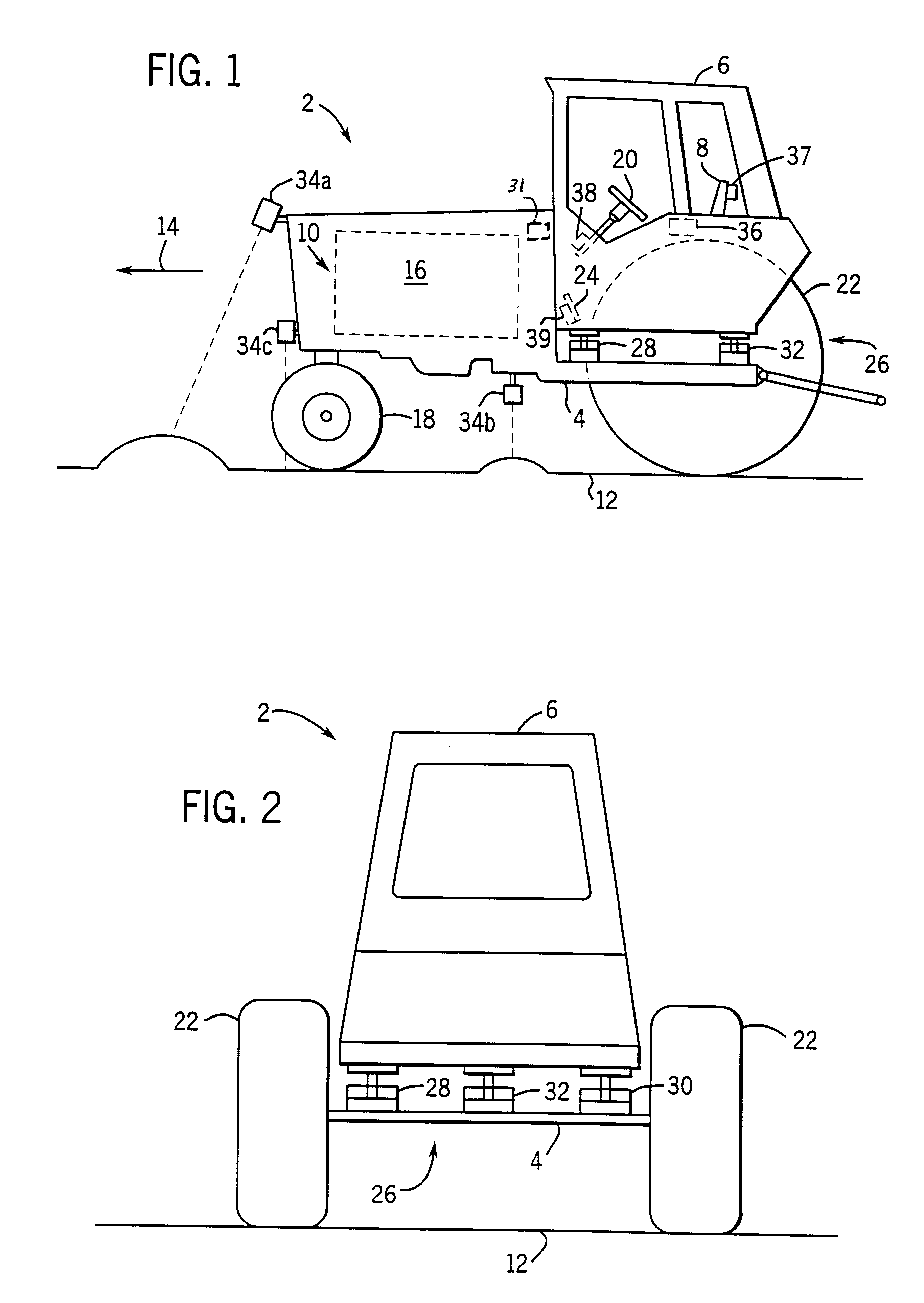

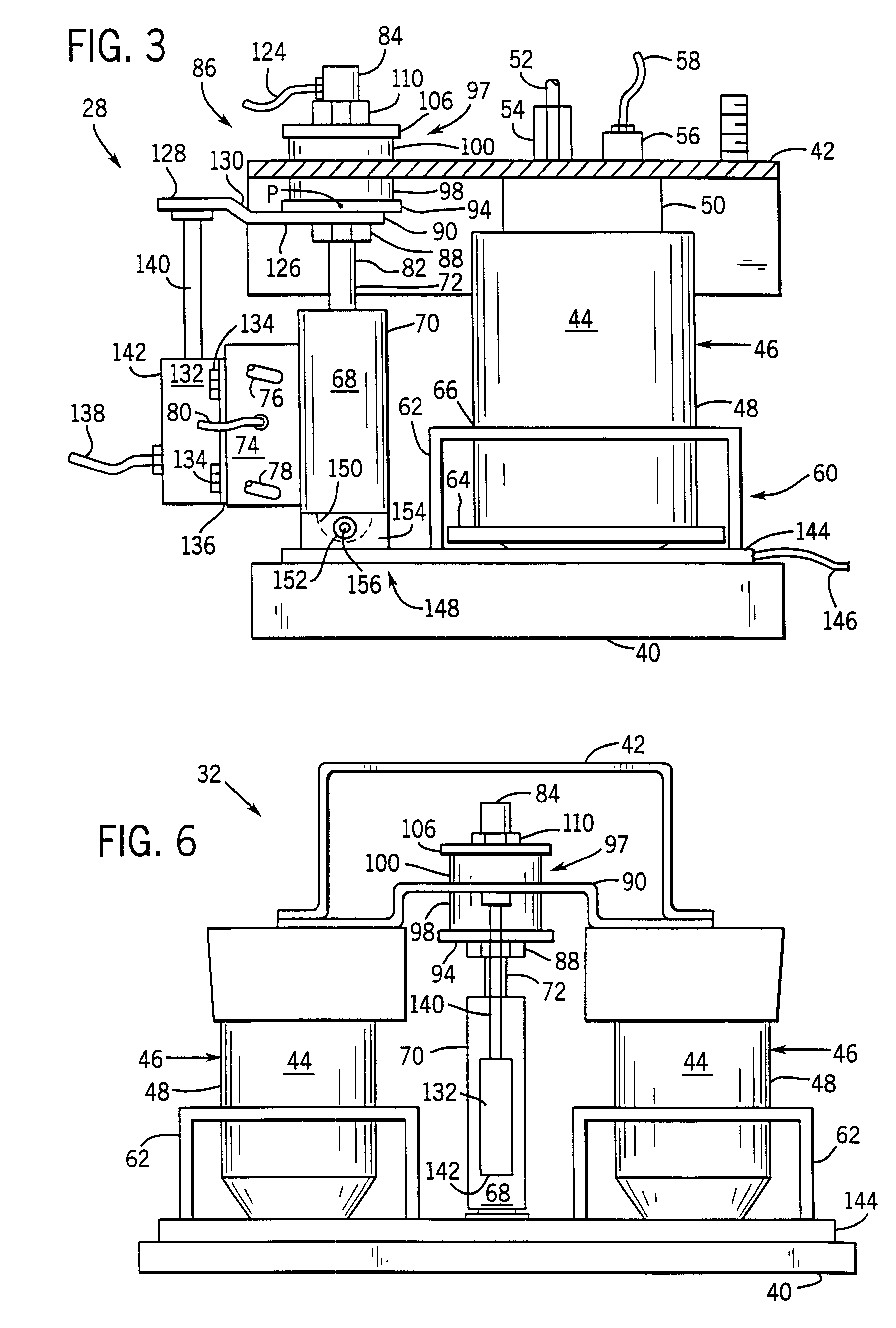

Apparatus for facilitating reduction of vibration in a work vehicle having an active CAB suspension system

InactiveUS6898501B2Reduce vibrationEar treatmentAnalogue computers for trafficEngineeringSignal processing

An apparatus and method for determining when a component of a work vehicle experiences vibration above a predetermined threshold, and responding to the vibration so that the vibration is reduced below the predetermined threshold. The apparatus, which is in a work vehicle that includes a chassis, an operator's cab and an active cab suspension system, includes a sensor that is configured to sense a quantity representative of the vibration experienced by the component of the work vehicle and to develop a first signal indicative of that quantity. The apparatus also includes a signal processor that is coupled to the sensor and is configured to develop, in response to the first signal, a second signal indicative of whether the vibration experienced by the component is above the predetermined threshold. The apparatus further includes a device that is coupled to the signal processor and, in response to the second signal, is either configured to provide an indication or configured to take an action to reduce the vibration below the predetermined threshold when the vibration is above the predetermined threshold.

Owner:BLUE LEAF I P INC +1

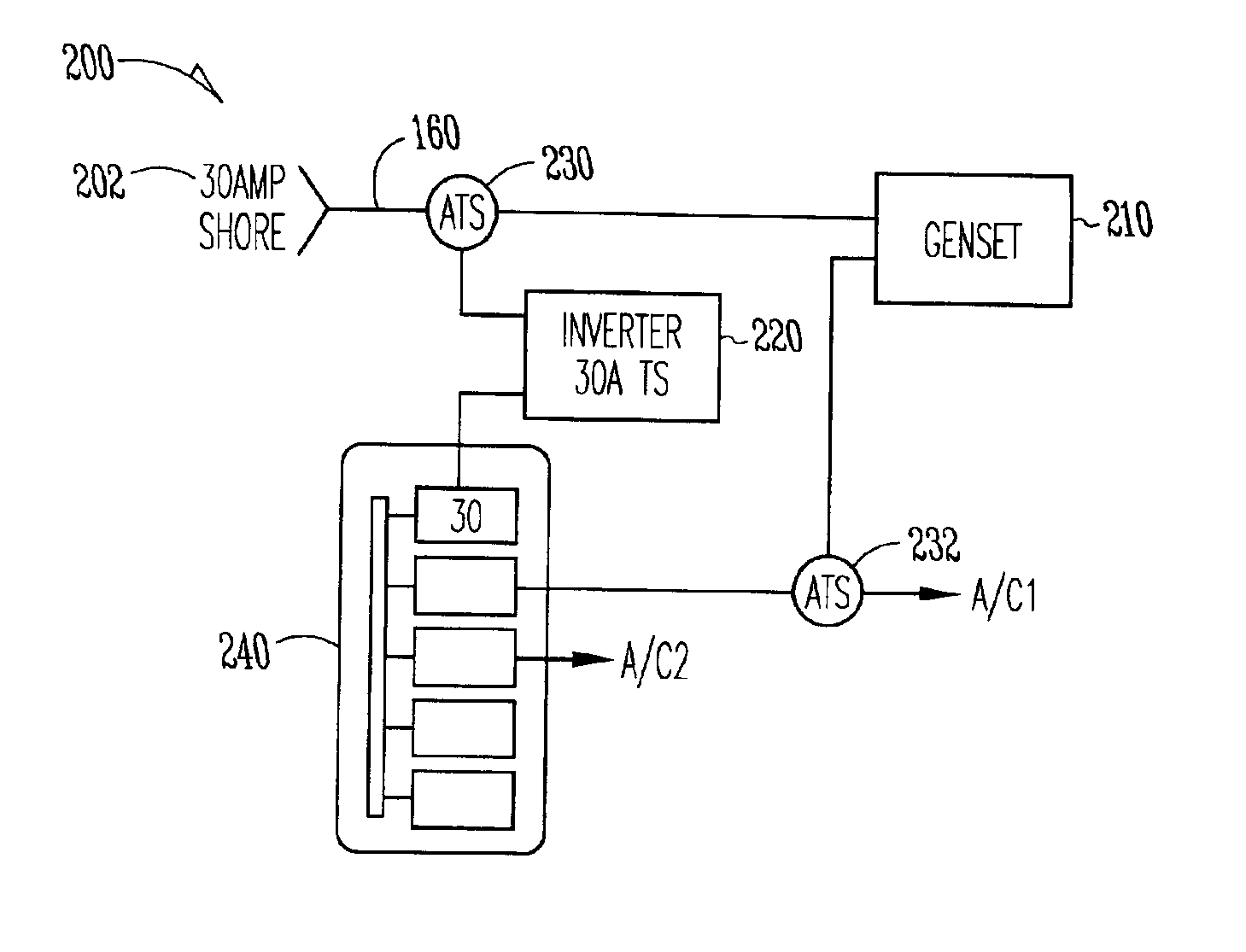

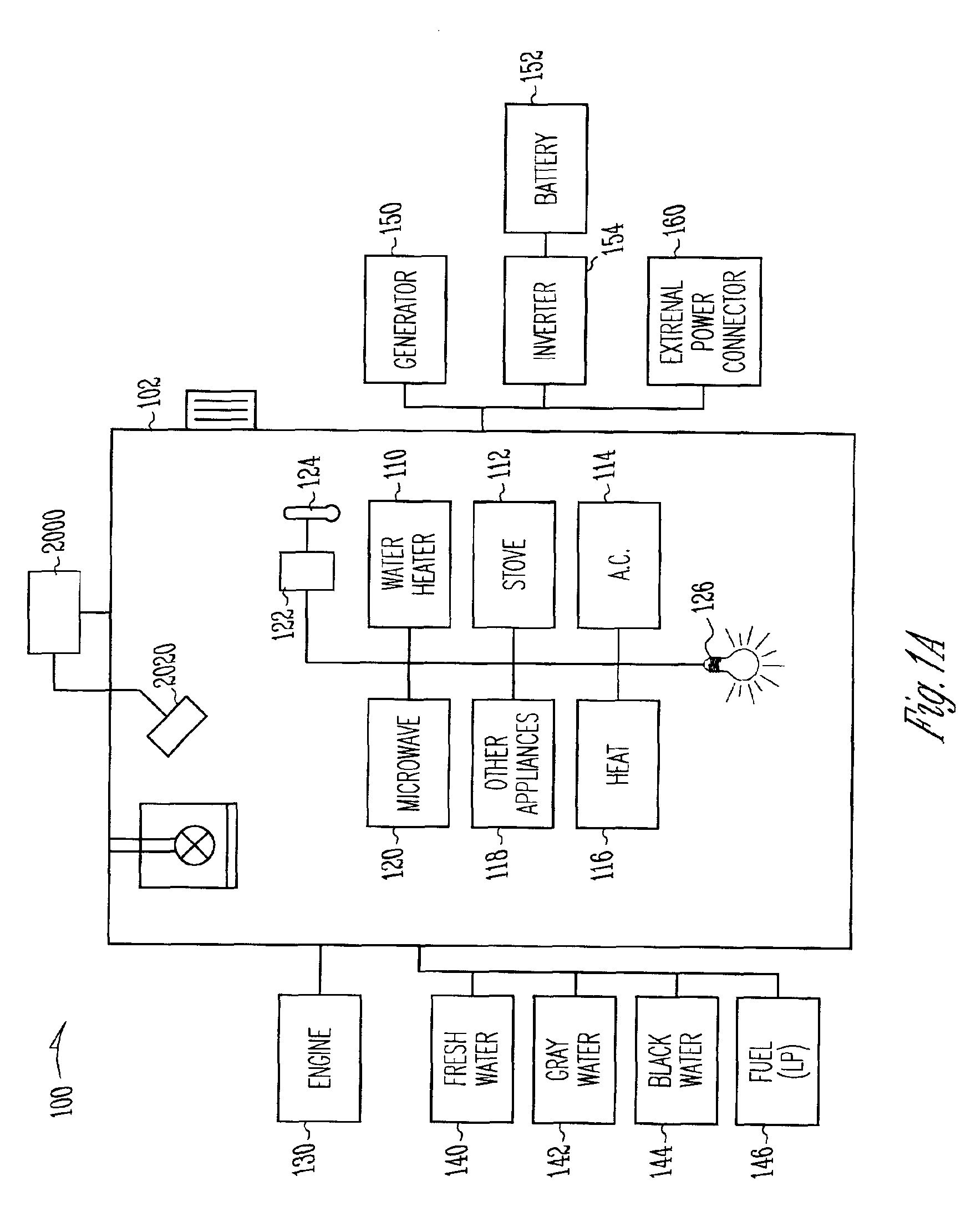

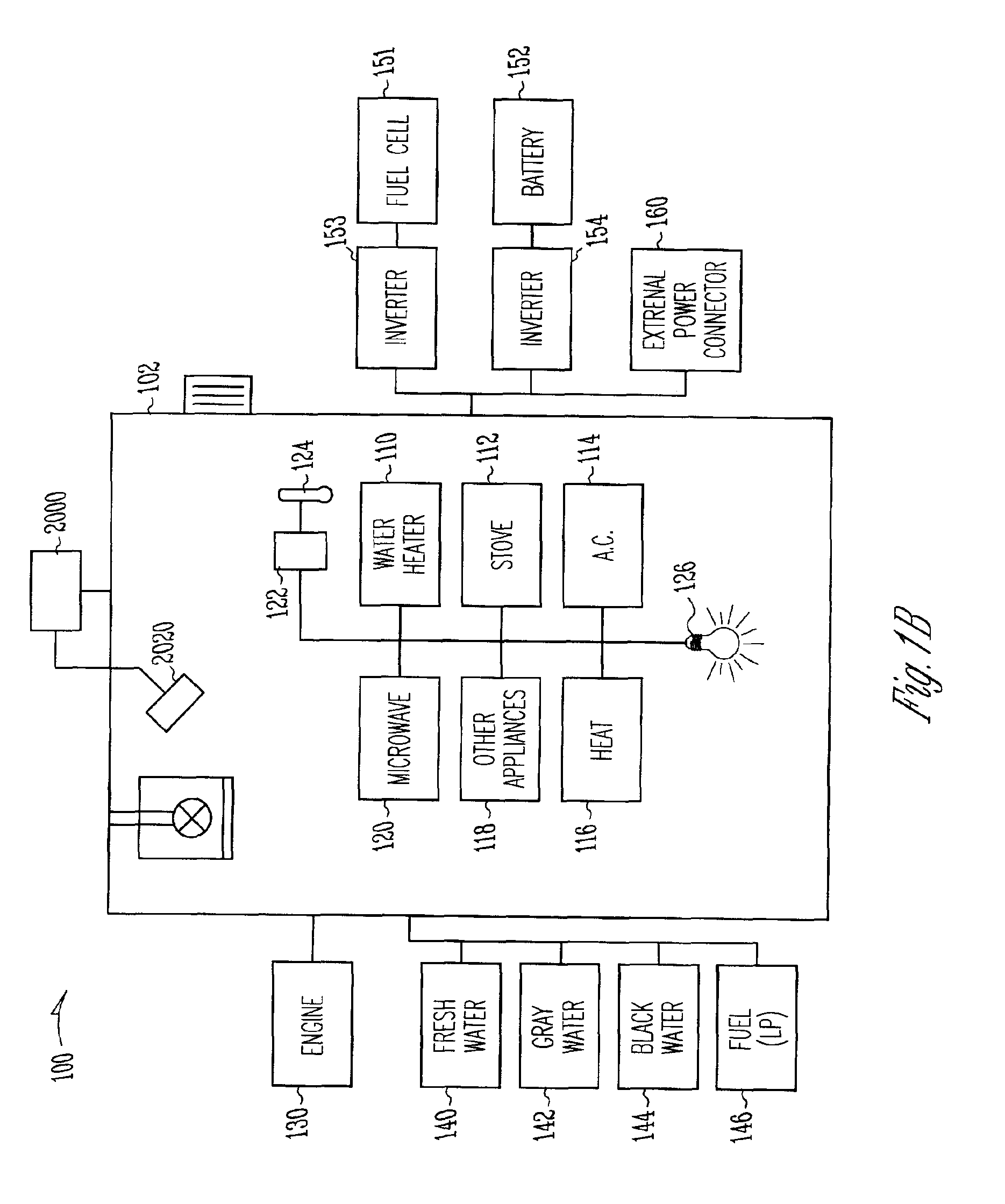

Mobile energy management system

InactiveUS6965818B2Easy to useDigital data processing detailsElectric power transfer ac networkElectricityDisplay device

A recreational vehicle includes a chassis having a living space, an electrical system for providing electrical power to the living space, an air conditioner for cooling the living space, a heater for heating the living space, and a plurality of appliances within the living space attached to the electrical system. The recreational vehicle also includes an engine for moving the recreational vehicle, a motor generator for supplying power to the recreational vehicle, a connector for connecting the electrical system of the recreational vehicle to an external power source, and a local area network system electrically connected to the air conditioner, the heater, the plurality of appliances, and the motor generator. The local area network manages the power provided to the to the electrical appliances. A display positioned within the living space shows data related to the air conditioner, the heater, the plurality of appliances, the motor generator and the engine.

Owner:ONAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com