Patents

Literature

696 results about "Normal force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In mechanics, the normal force Fₙ is the component of a contact force that is perpendicular to the surface that an object contacts. For example, the surface of a floor or table that prevents an object from falling. In this instance normal is used in the geometric sense and means perpendicular, as opposed the common language use of normal meaning common or expected. For example, a person standing still on flat ground is supported by a ground reaction force that consists of only a normal force.

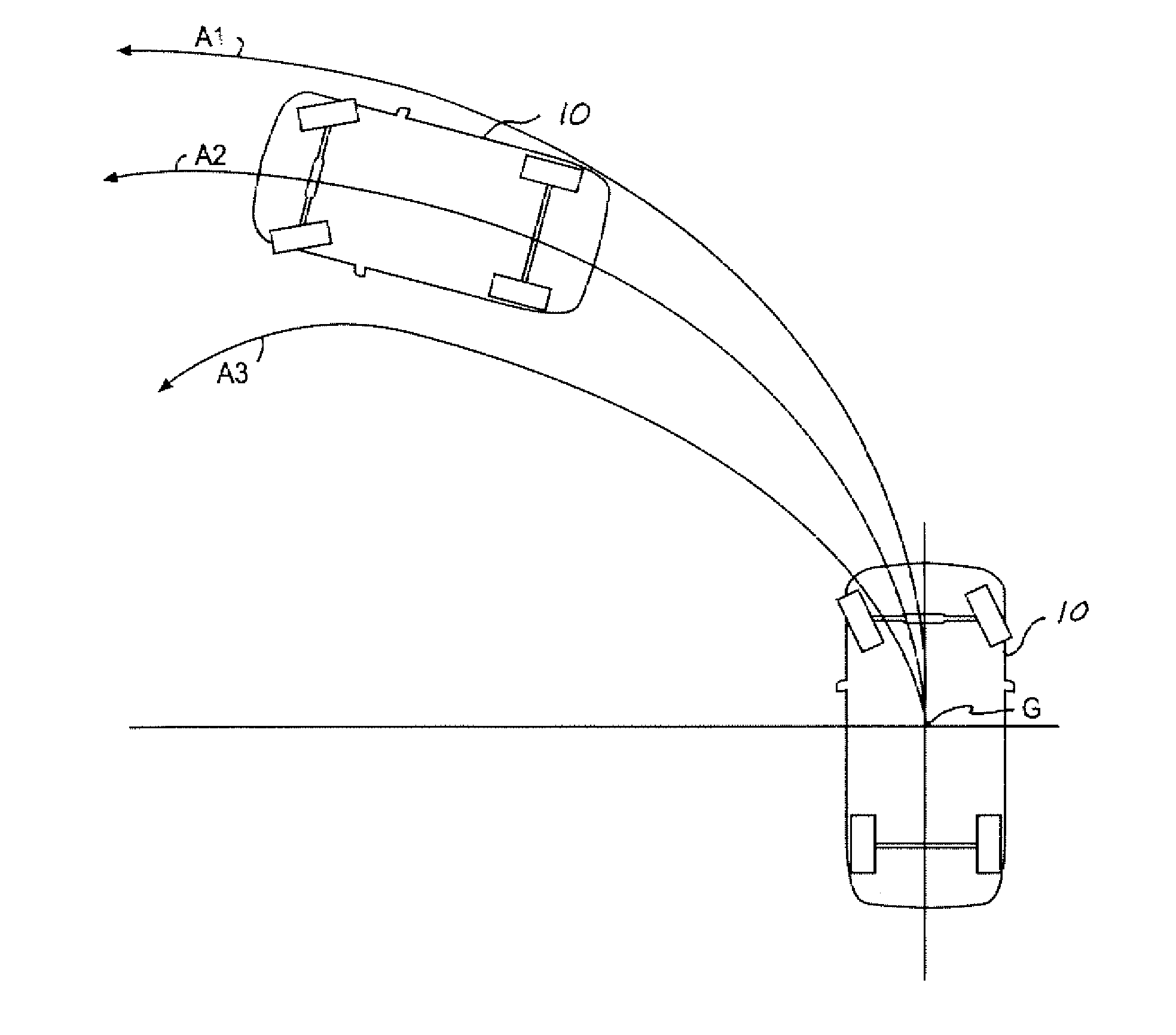

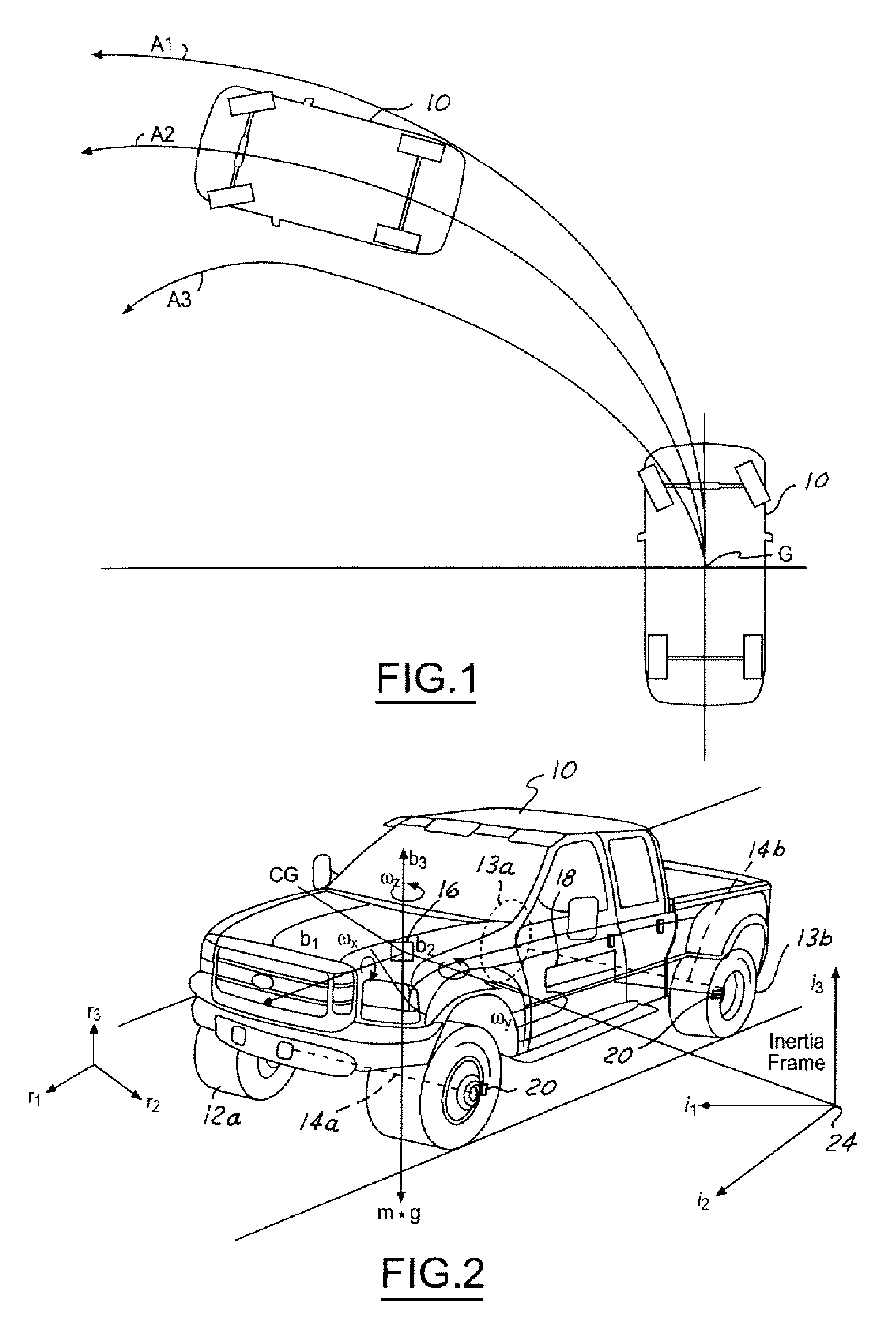

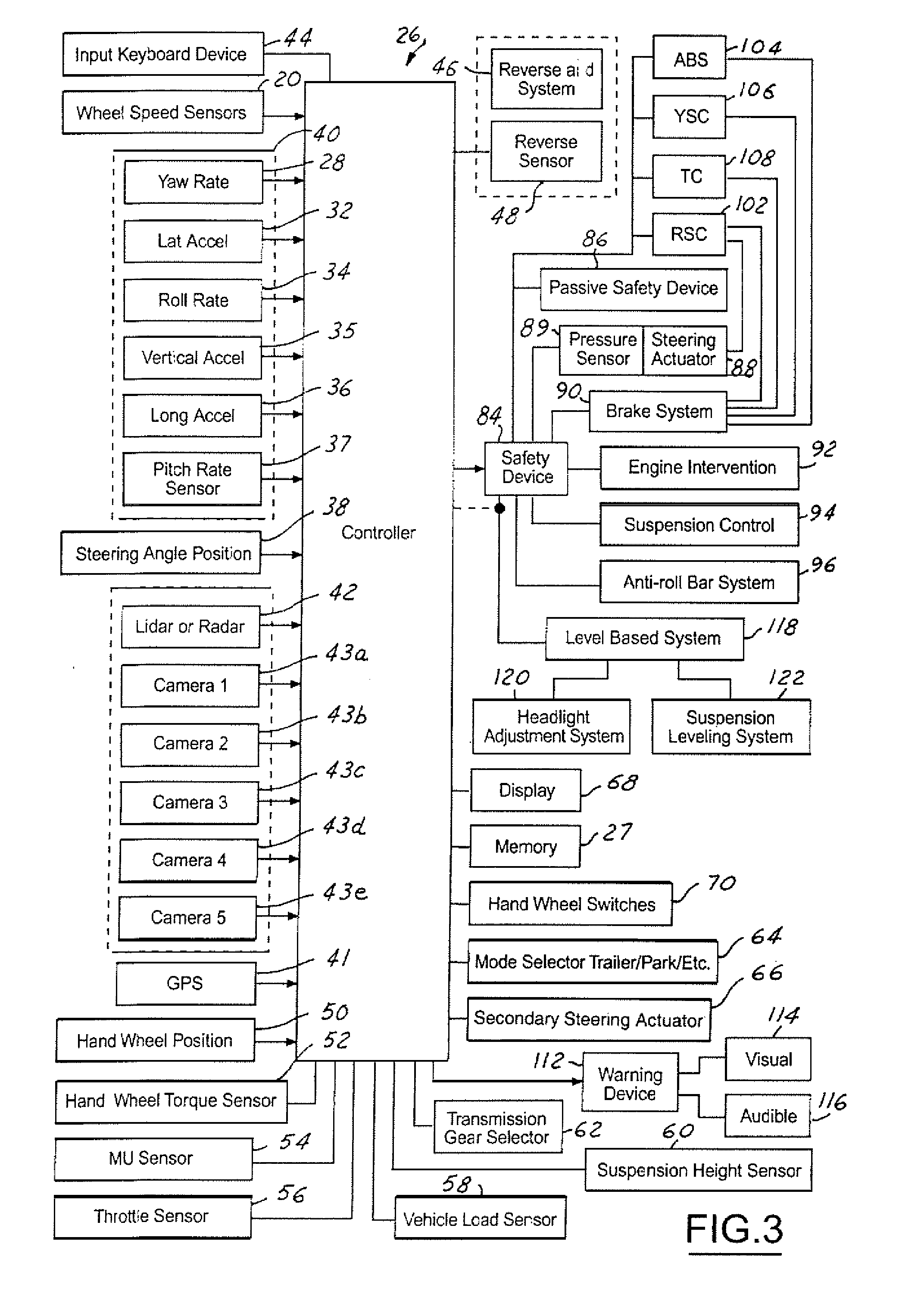

Method and apparatus for controlling an automotive vehicle using brake-steer and normal load adjustment

InactiveUS20050206231A1Good effectIncrease speedSteering partsResilient suspensionsNormal loadMotorized vehicle

A method of controlling an automotive vehicle includes detecting a parking mode and applying brake-steer to a first wheel to reduce the turning radius of the vehicle. Simultaneously, the normal force on a wheel can be increased by adjusting a chassis control mechanism such as a controlled suspension.

Owner:FORD GLOBAL TECH LLC

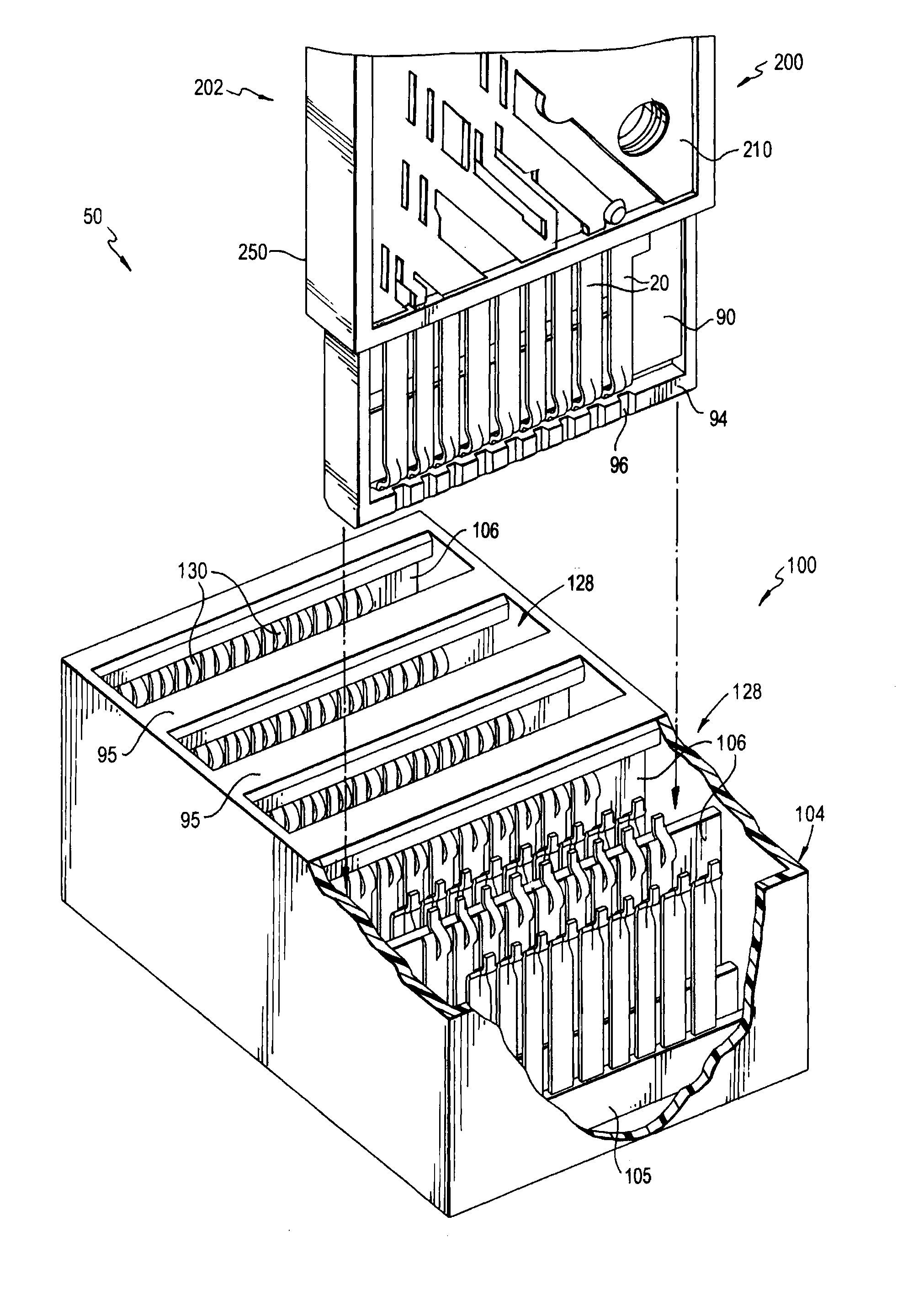

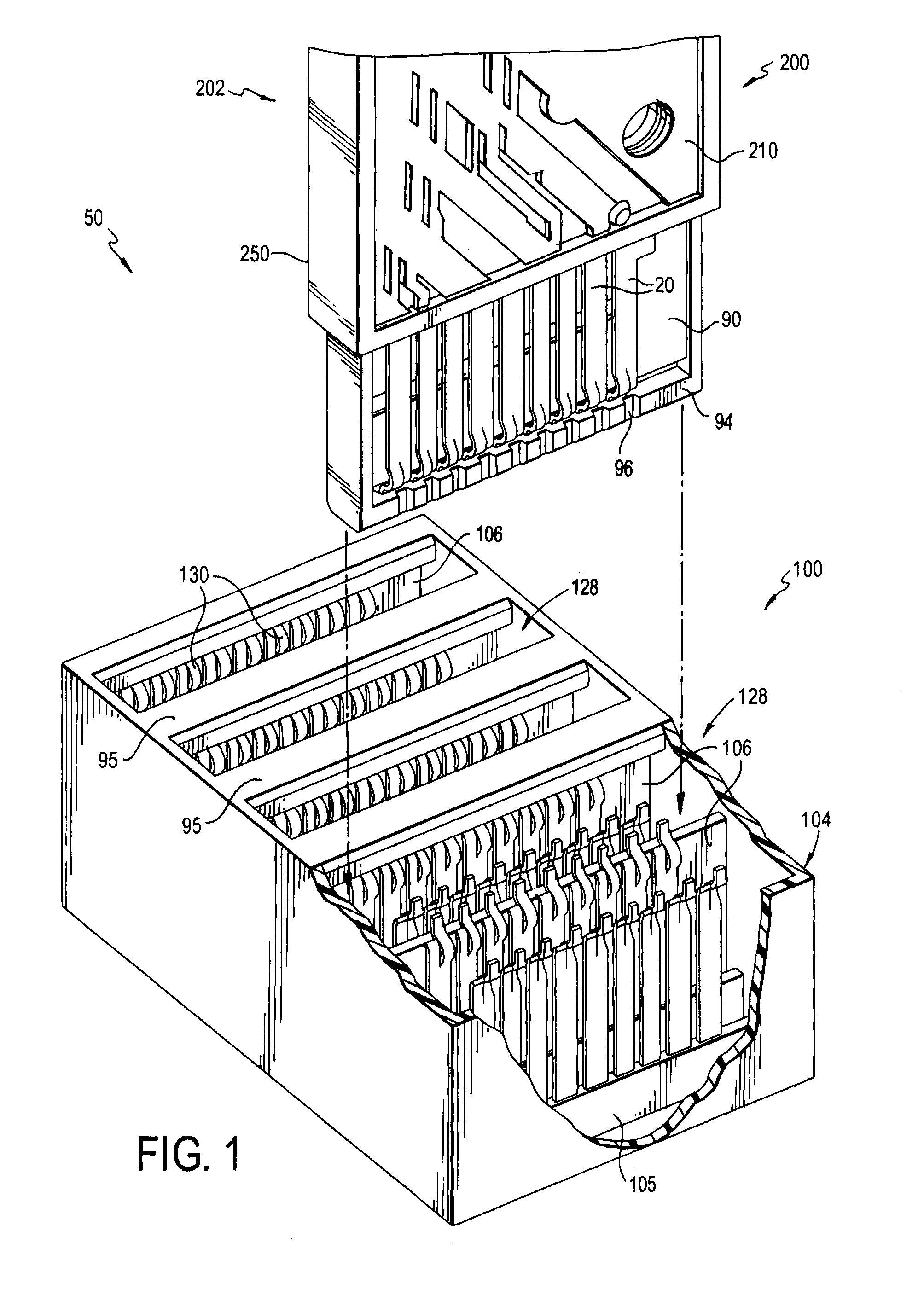

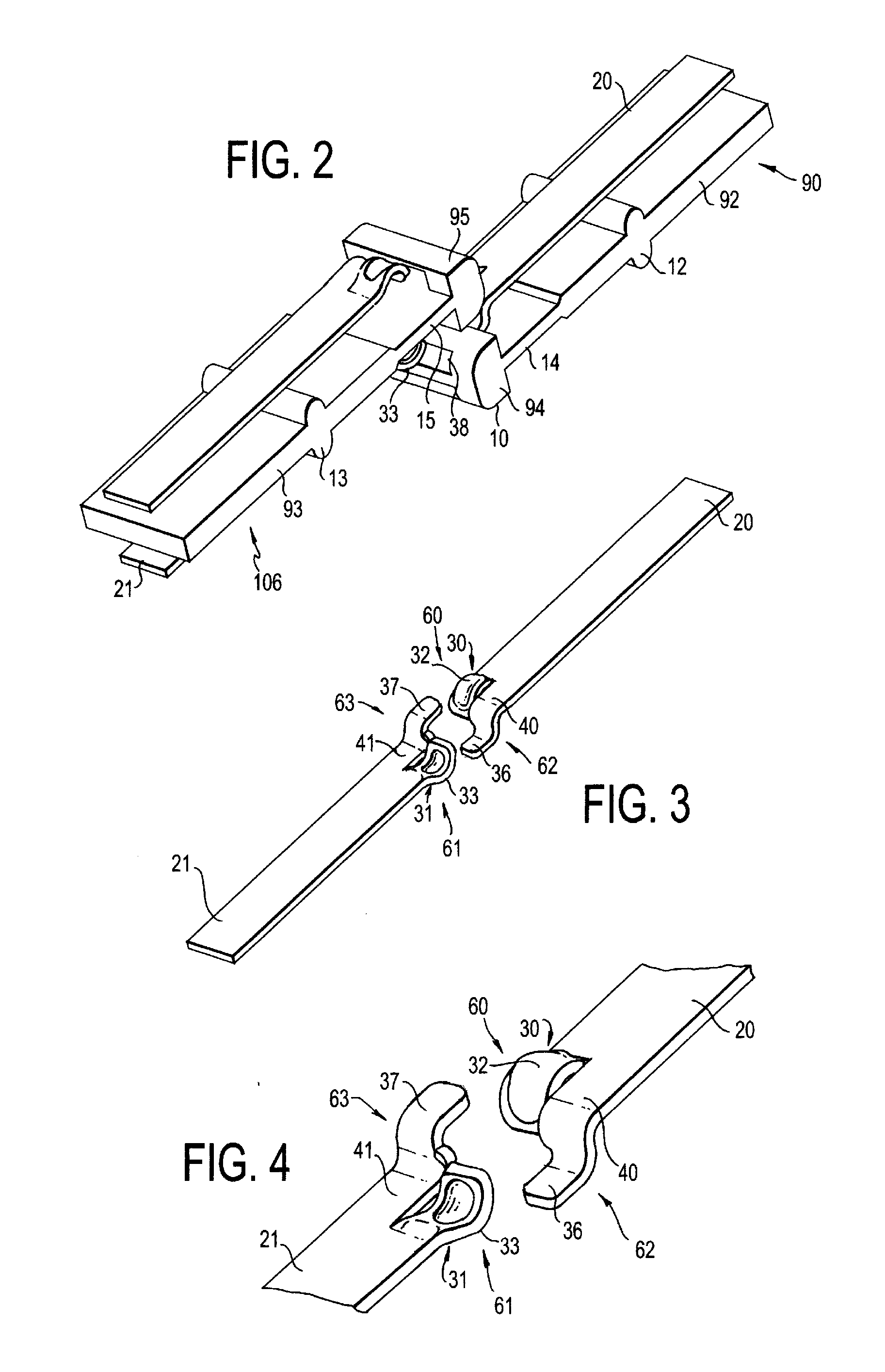

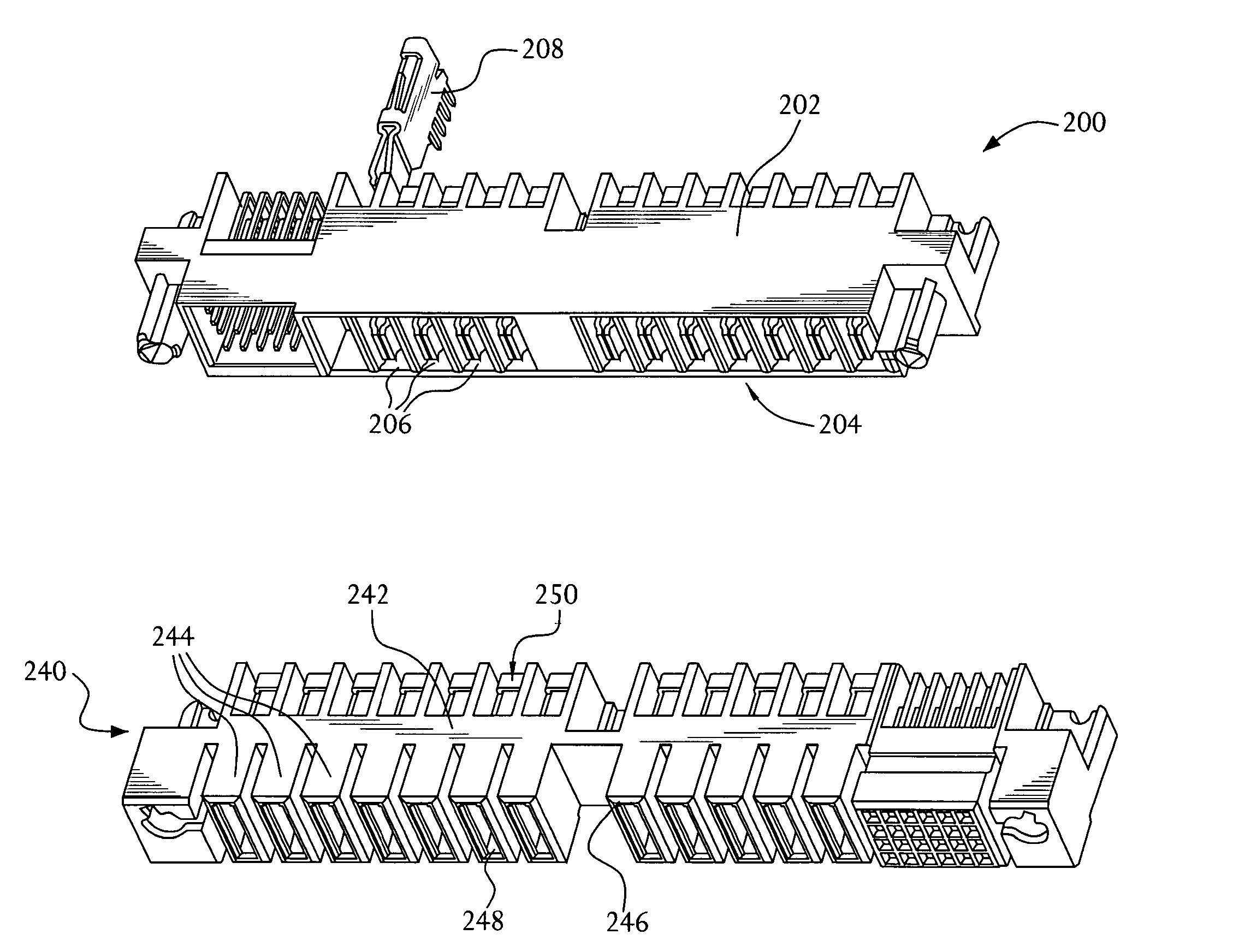

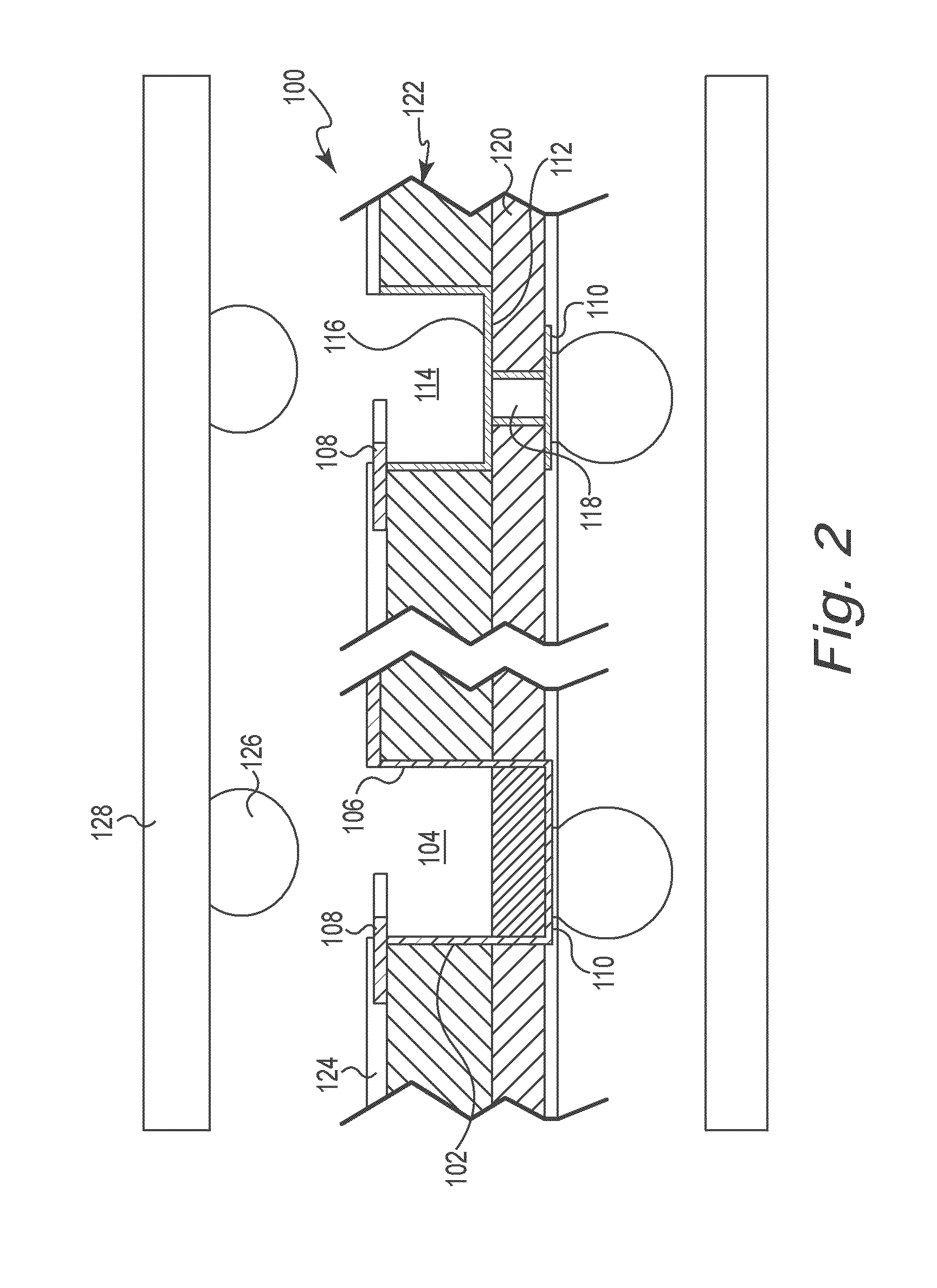

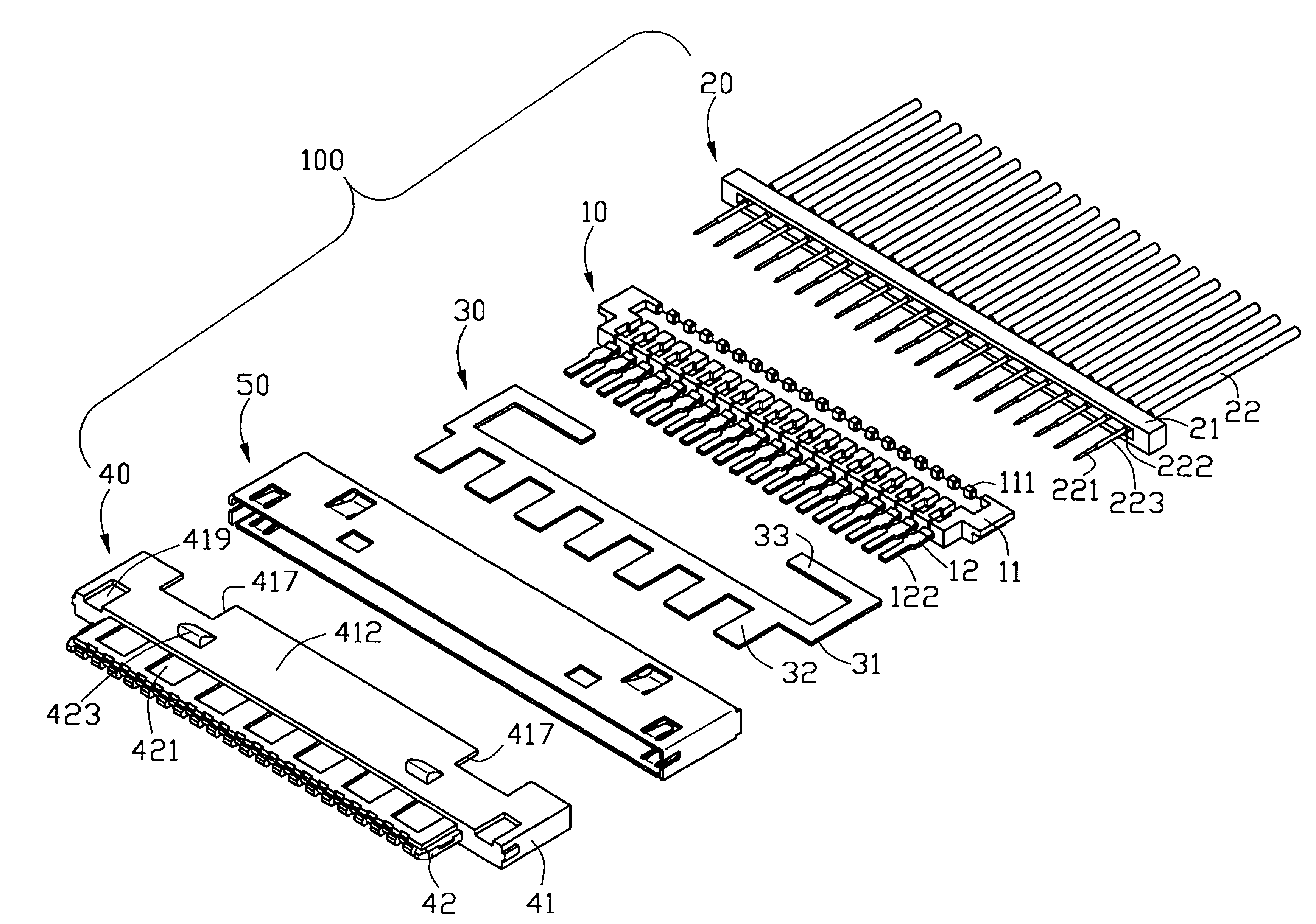

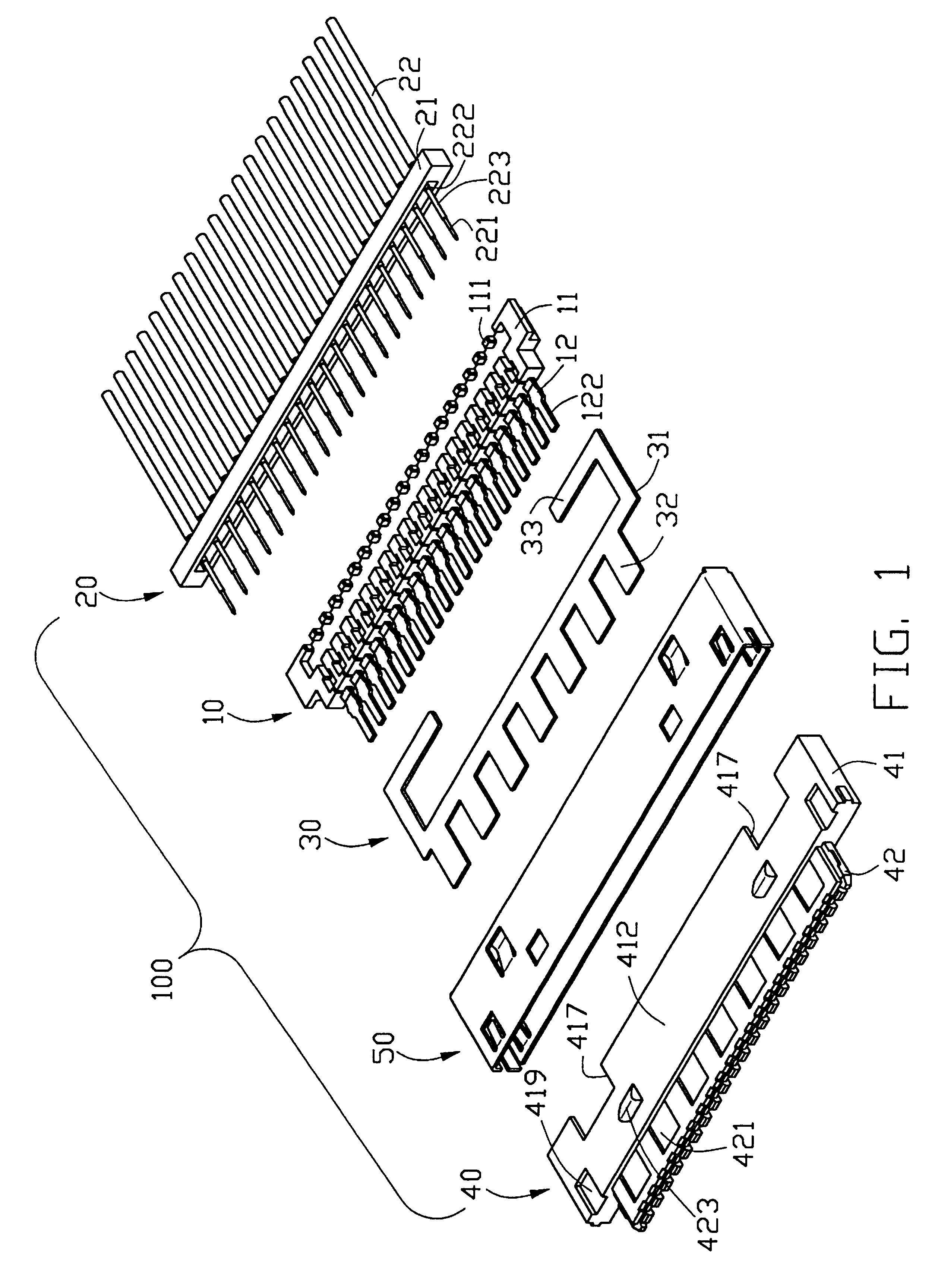

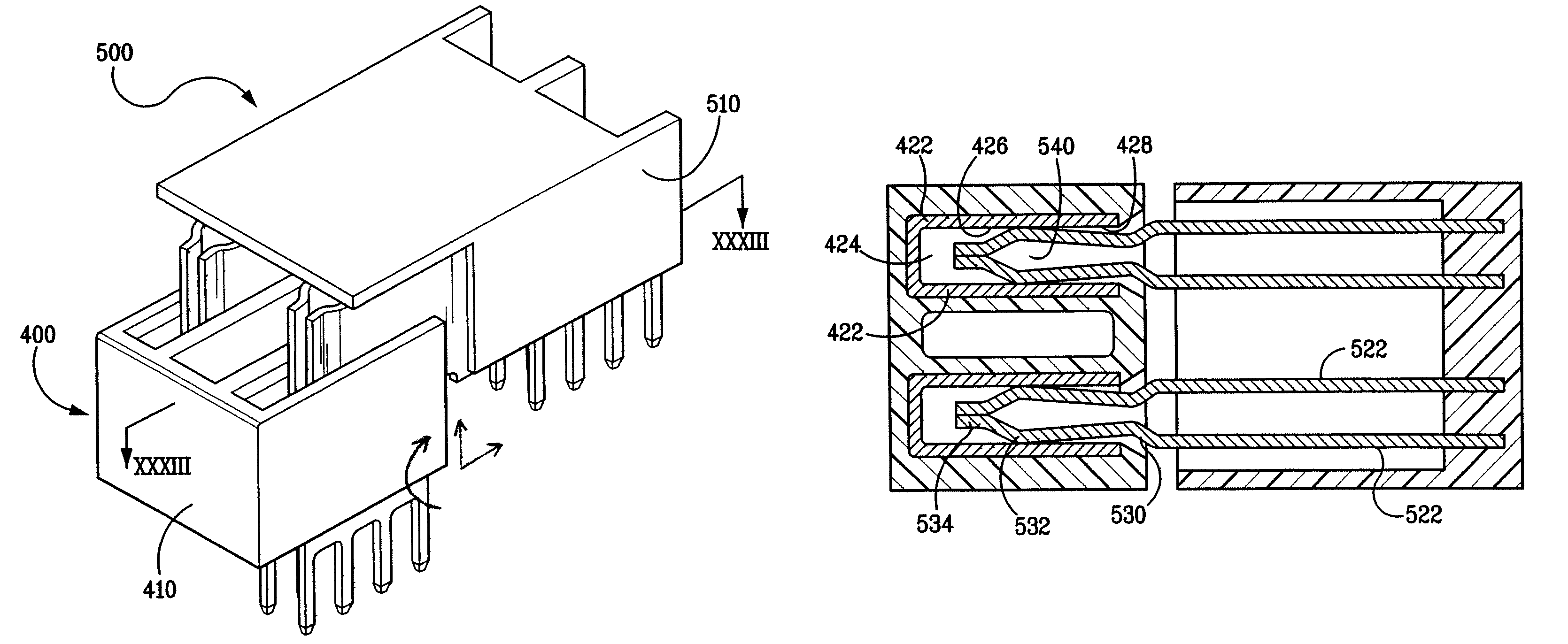

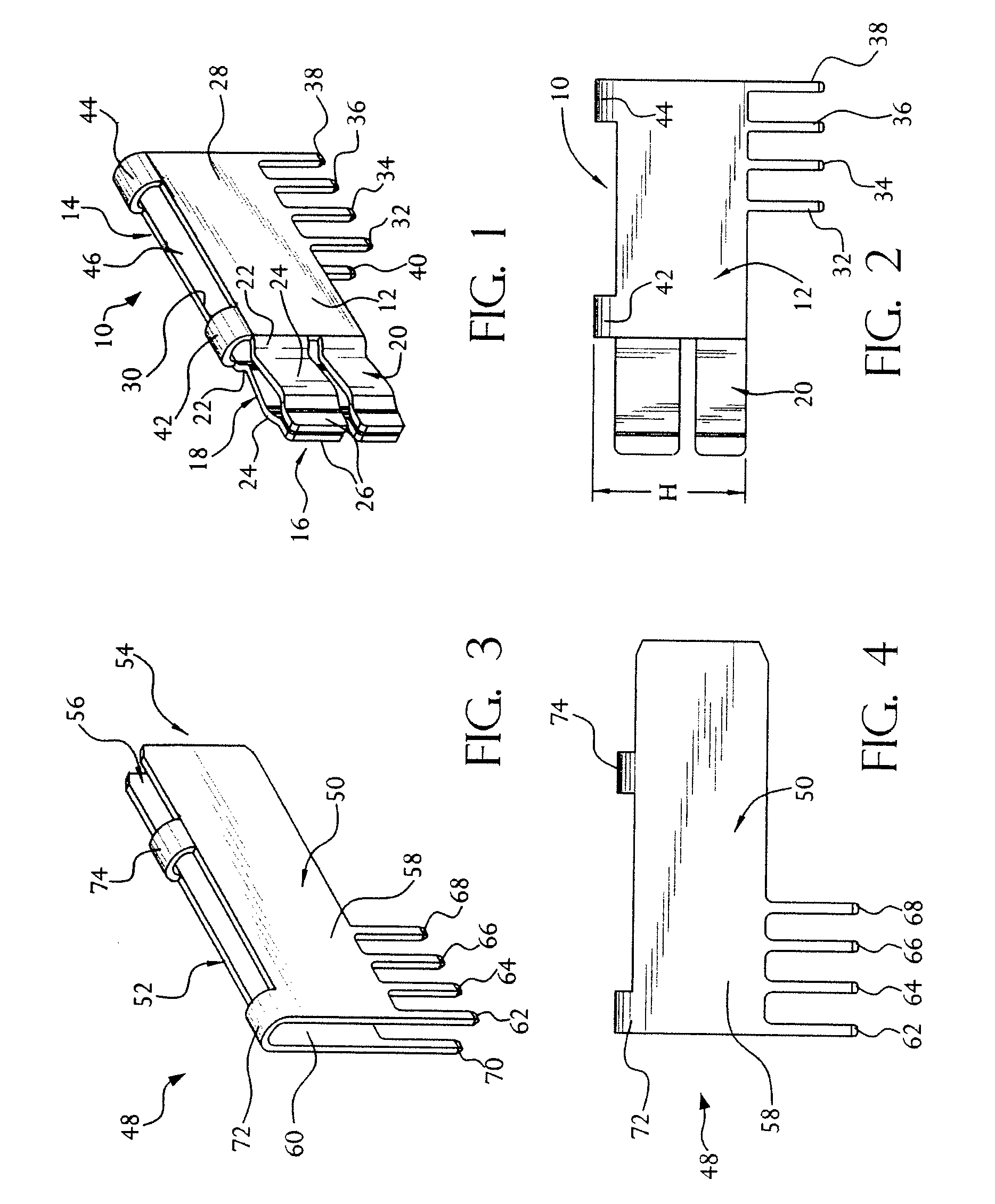

Multi-stage beam contacts

ActiveUS20120196482A1Low initial insertion forceFirmly connectedEngagement/disengagement of coupling partsElectric discharge tubesElectrical connectorNormal force

An electrical connector has a first wafer having a first housing with a first plurality of contact beams extending from the first housing in a first plane. A second wafer has a second housing with a second plurality of contact beams extending from said second housing in a second plane substantially parallel to the first plane. A dividing panel member extends from the insulative housing between the first plurality of contact beams and the second plurality of contact beams. Each of the contact beams extending from the wafer pair is configured to mate with a corresponding backplane contact in a backplane connector. The contact beams extending from the wafer pair and the backplane contacts are configured such that each pair of corresponding contacts includes a first contact point and a second contact point. When the wafer pair is fully received by the backplane connector, contact between the contact beam and the backplane contact is maintained at both the first and second contact points. Each of the contact beams includes a pivot member configured such that the electrical connector has a low initial insertion force, but a high normal force when fully mated with the backplane connector.

Owner:AMPHENOL CORP

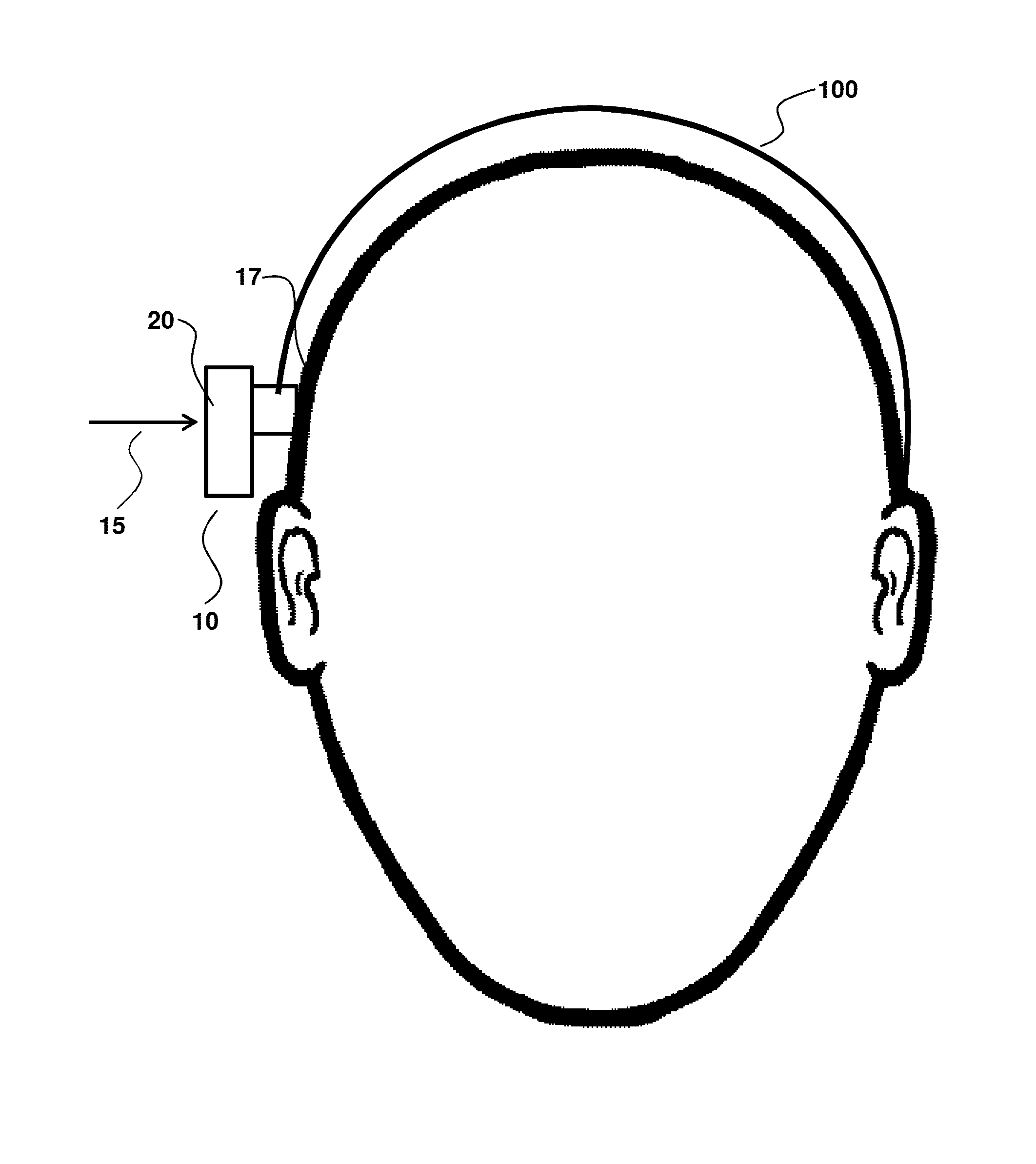

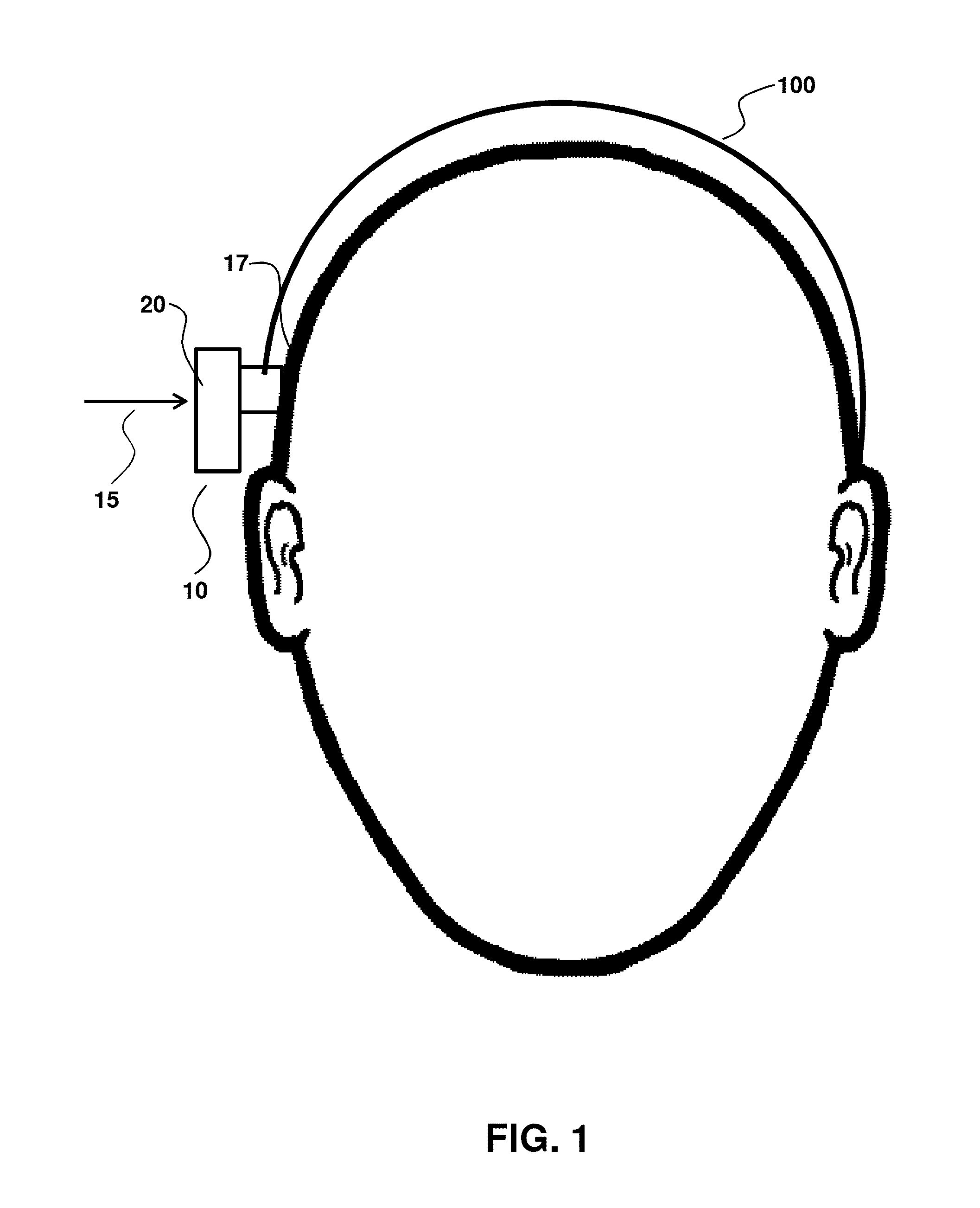

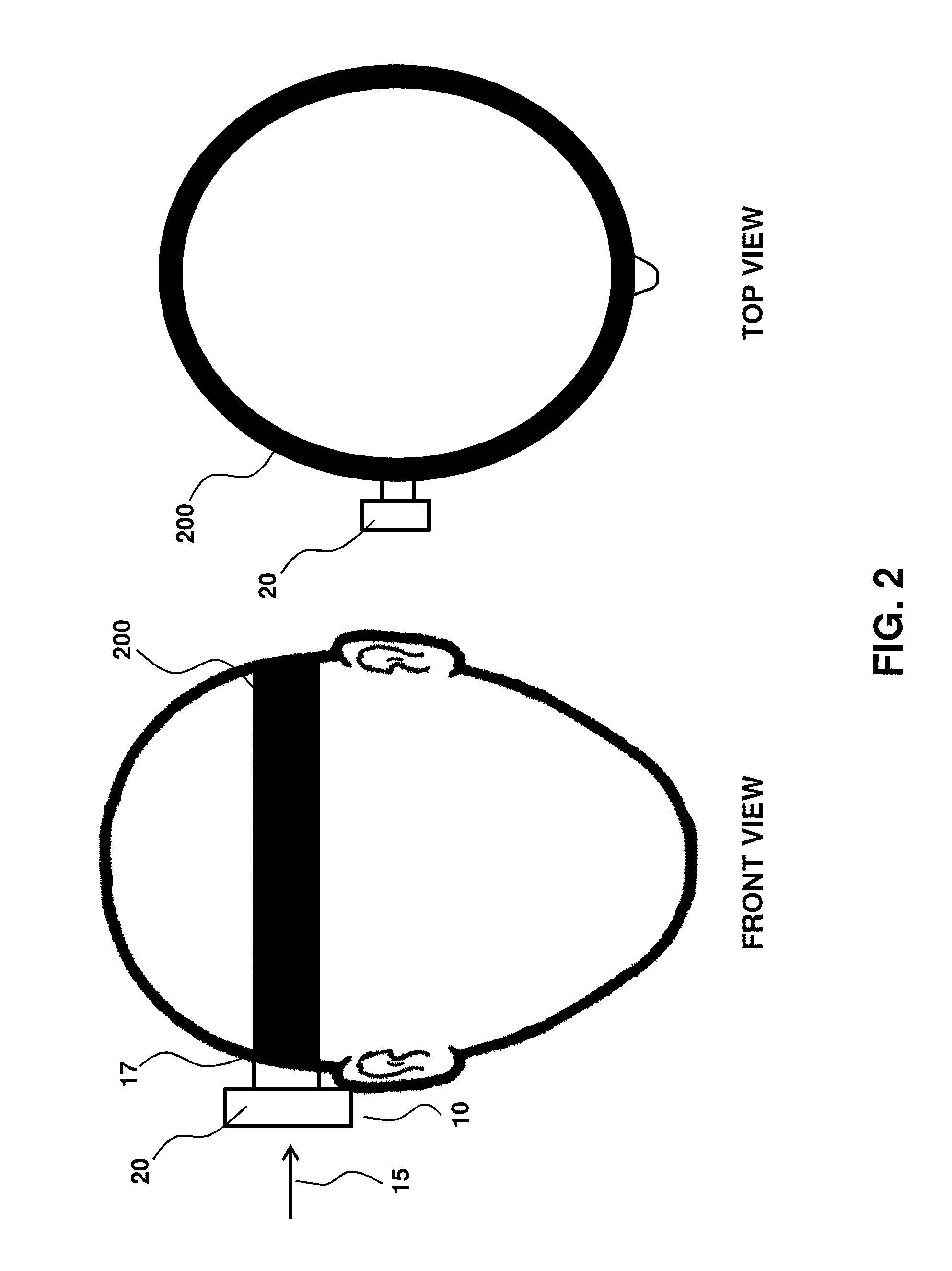

Adhesive Bone Conduction Hearing Device

ActiveUS20140064533A1Improved physical contactImprove vibration transmissionBone conduction transducer hearing devicesHearing aids mounting/interconnectionForce generationEngineering

Provided are bone conducting hearing devices having a normal force that secures the device to a user. A removable adhesive anchor secures an external component of the bone conducting hearing device to the user and provides reliable connecting that is comfortable, such as by a substantially uniform force generation over the contact area between the device and the user. Because the adhesive anchor is removable, a user can readily and reliably remove the device or connect the device, as desired. Also provide are methods of connecting any of the bone conducting hearing devices provided herein to a user, including the mastoid process of the user.

Owner:SOPHONO

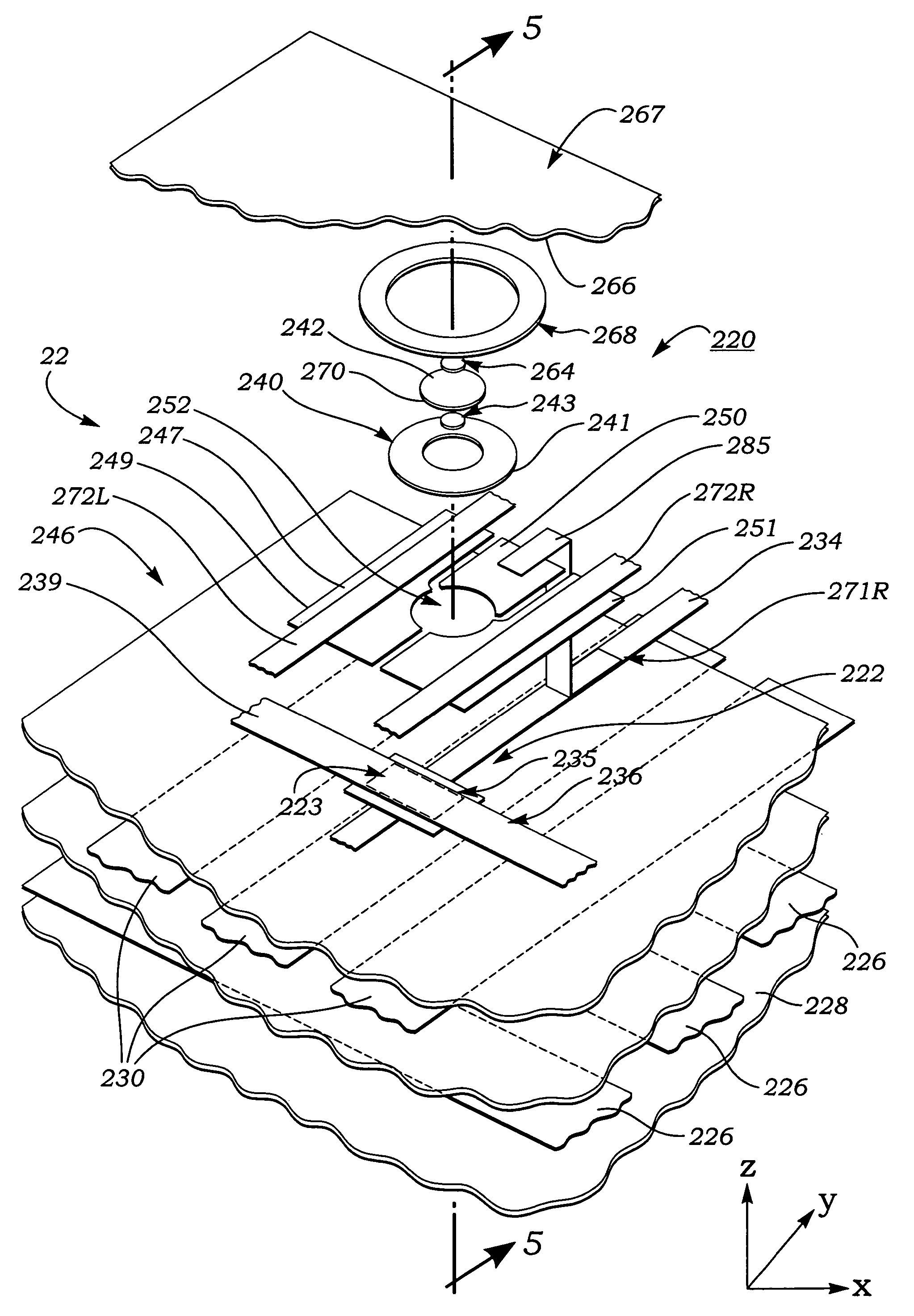

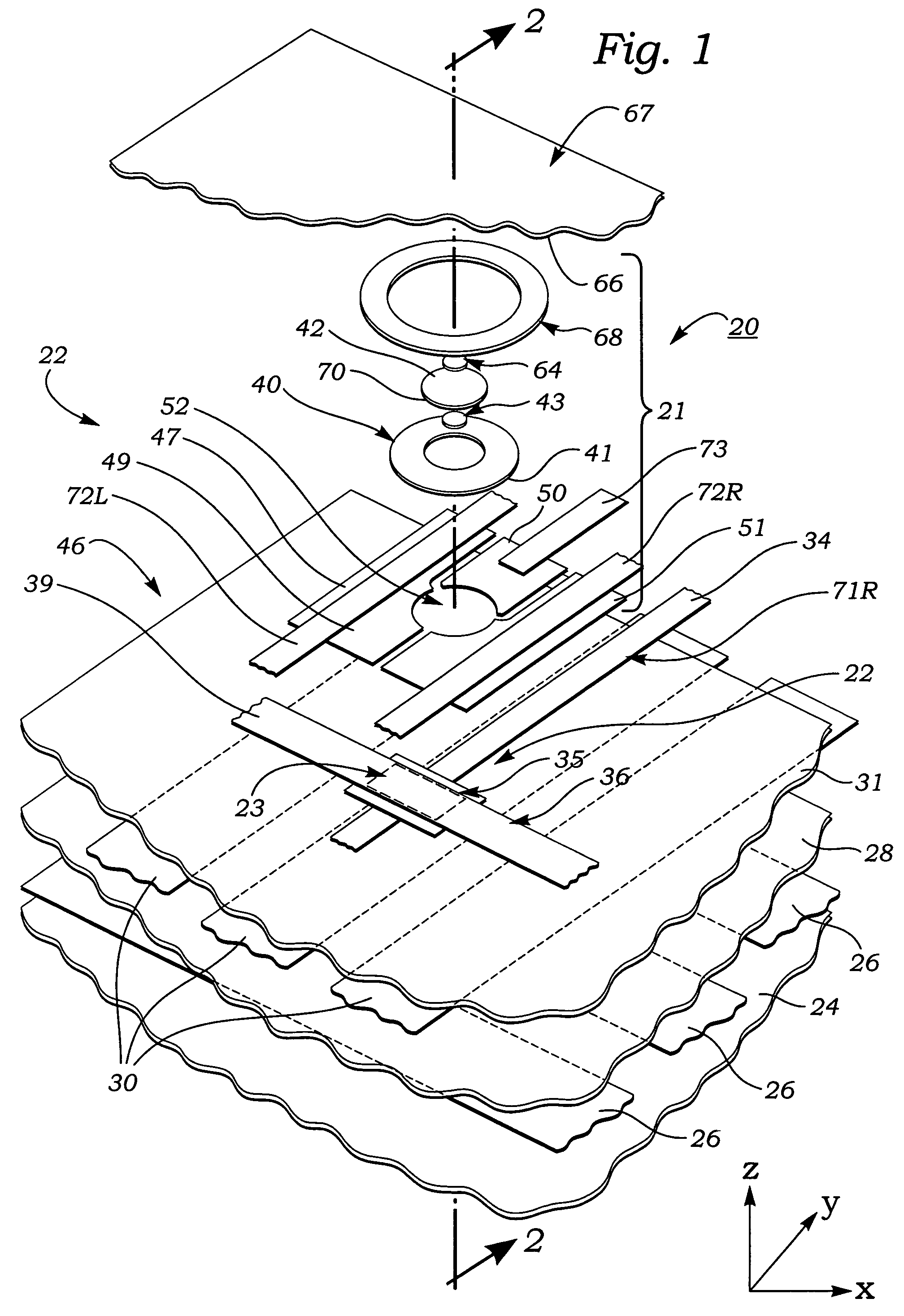

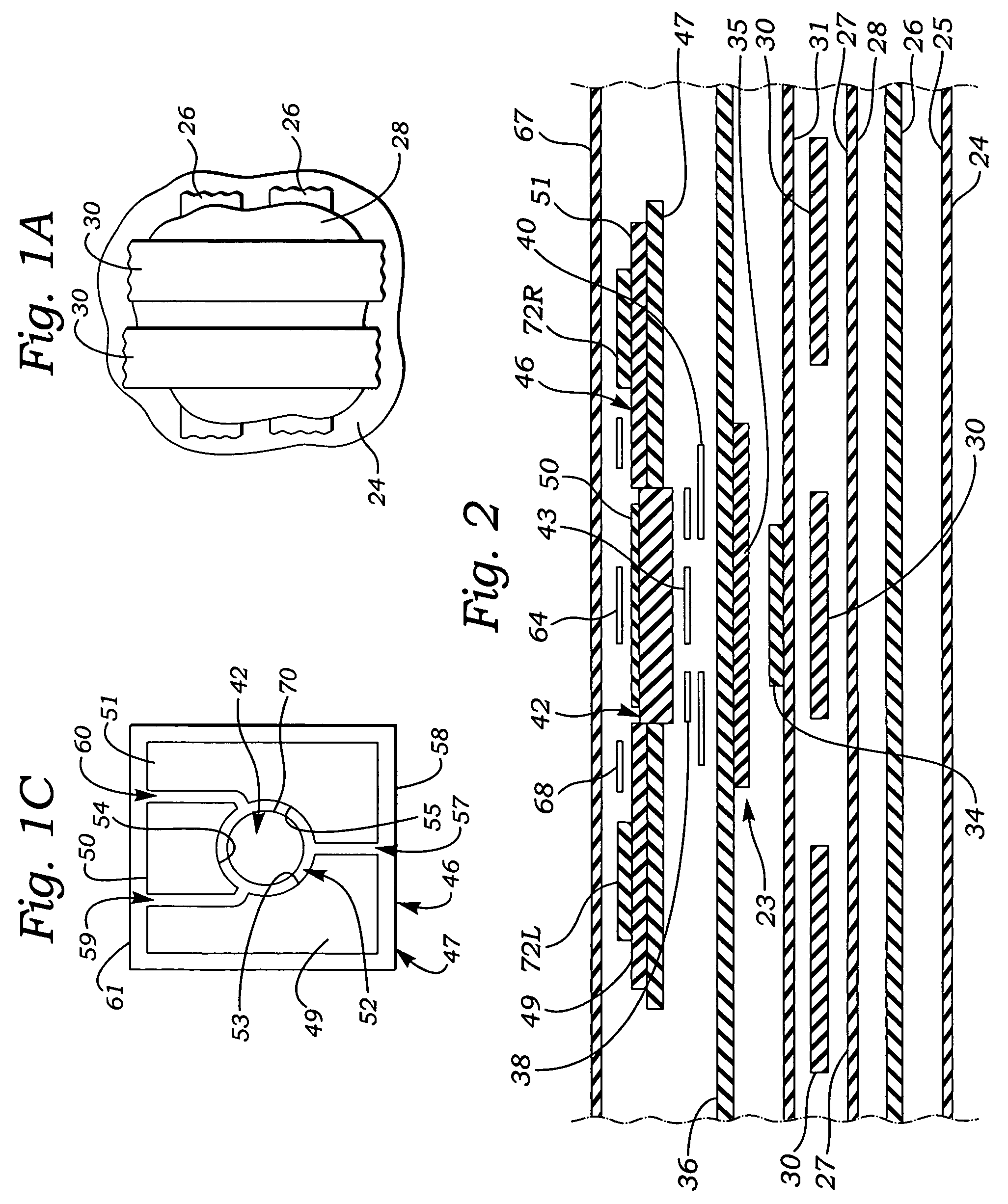

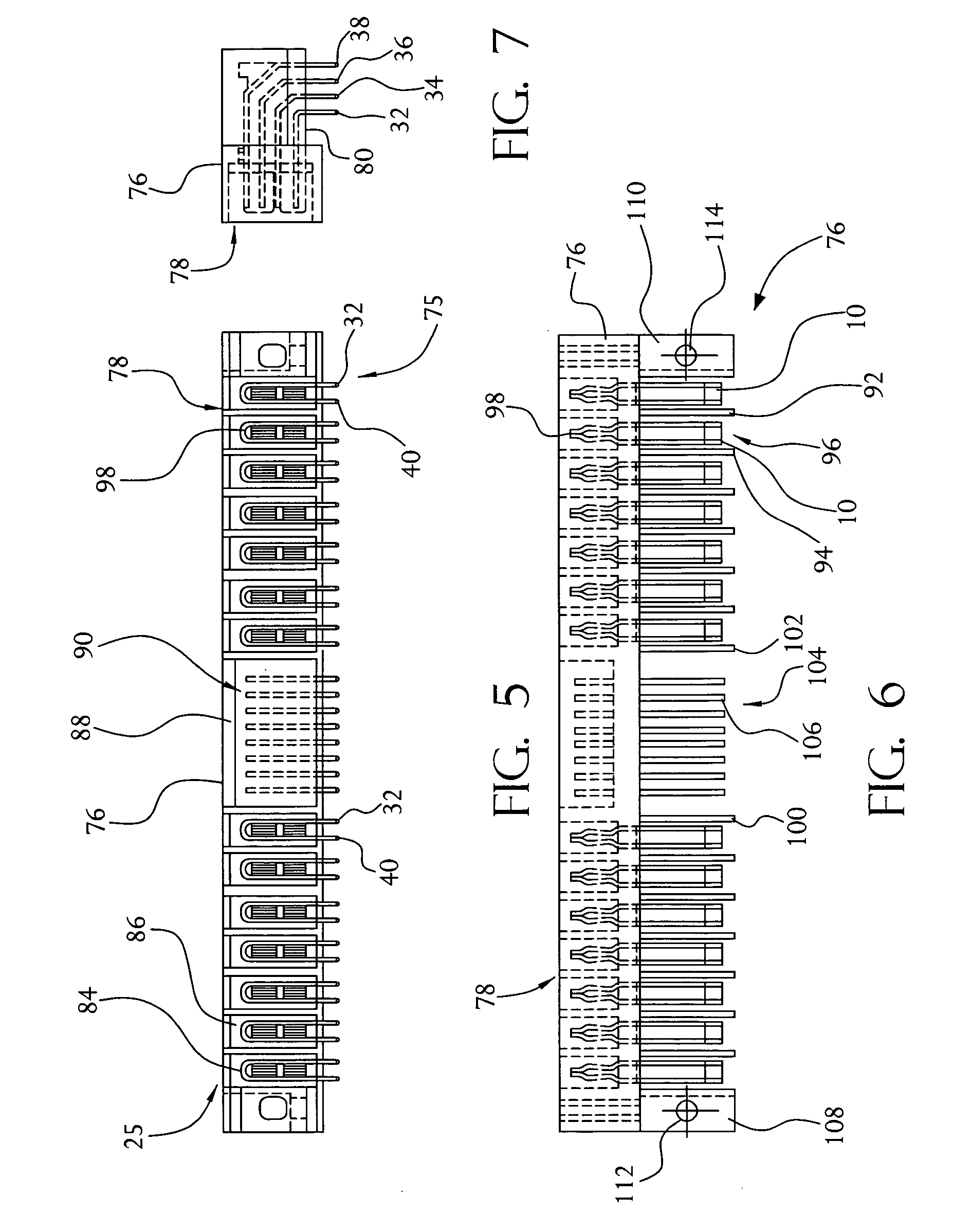

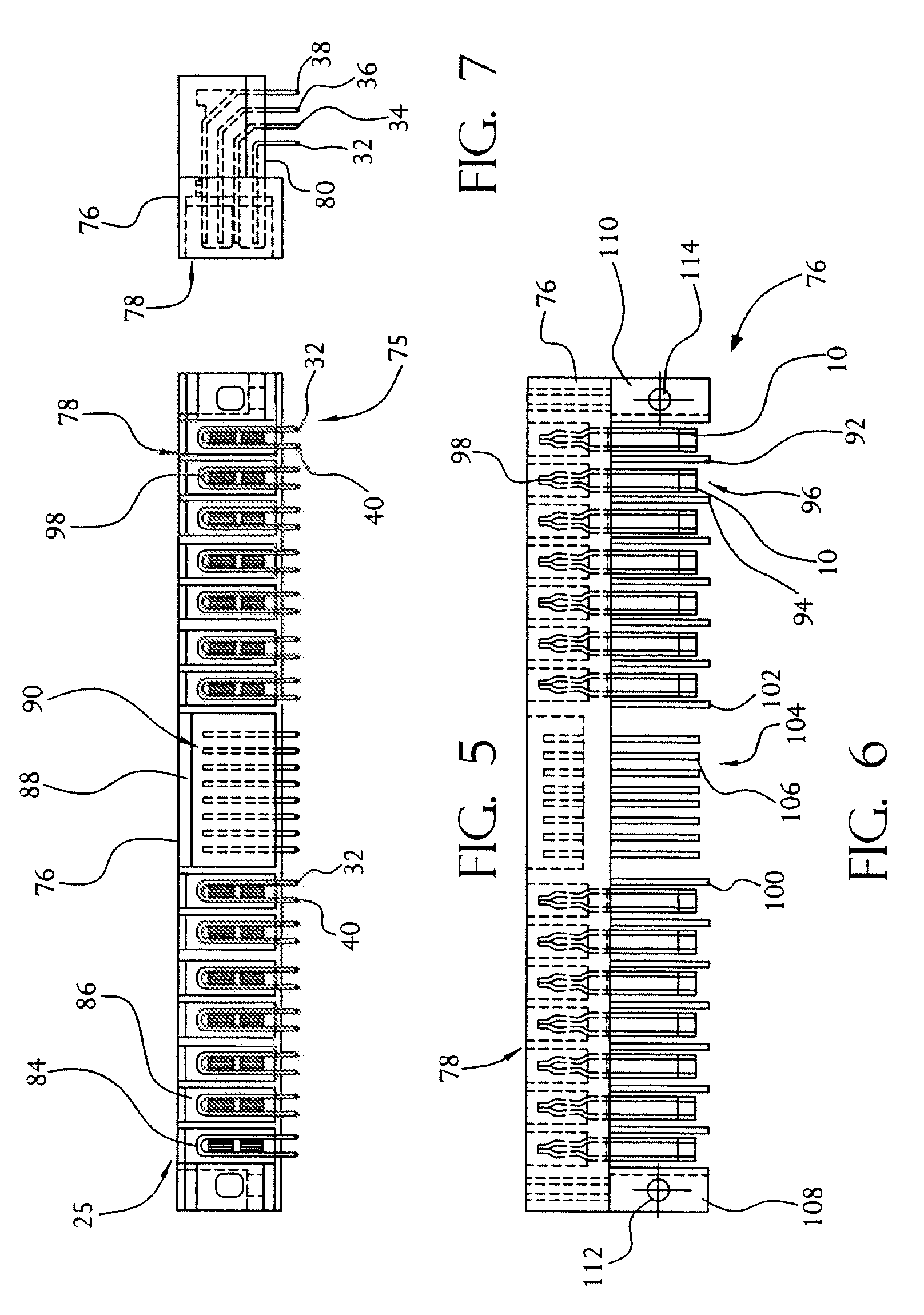

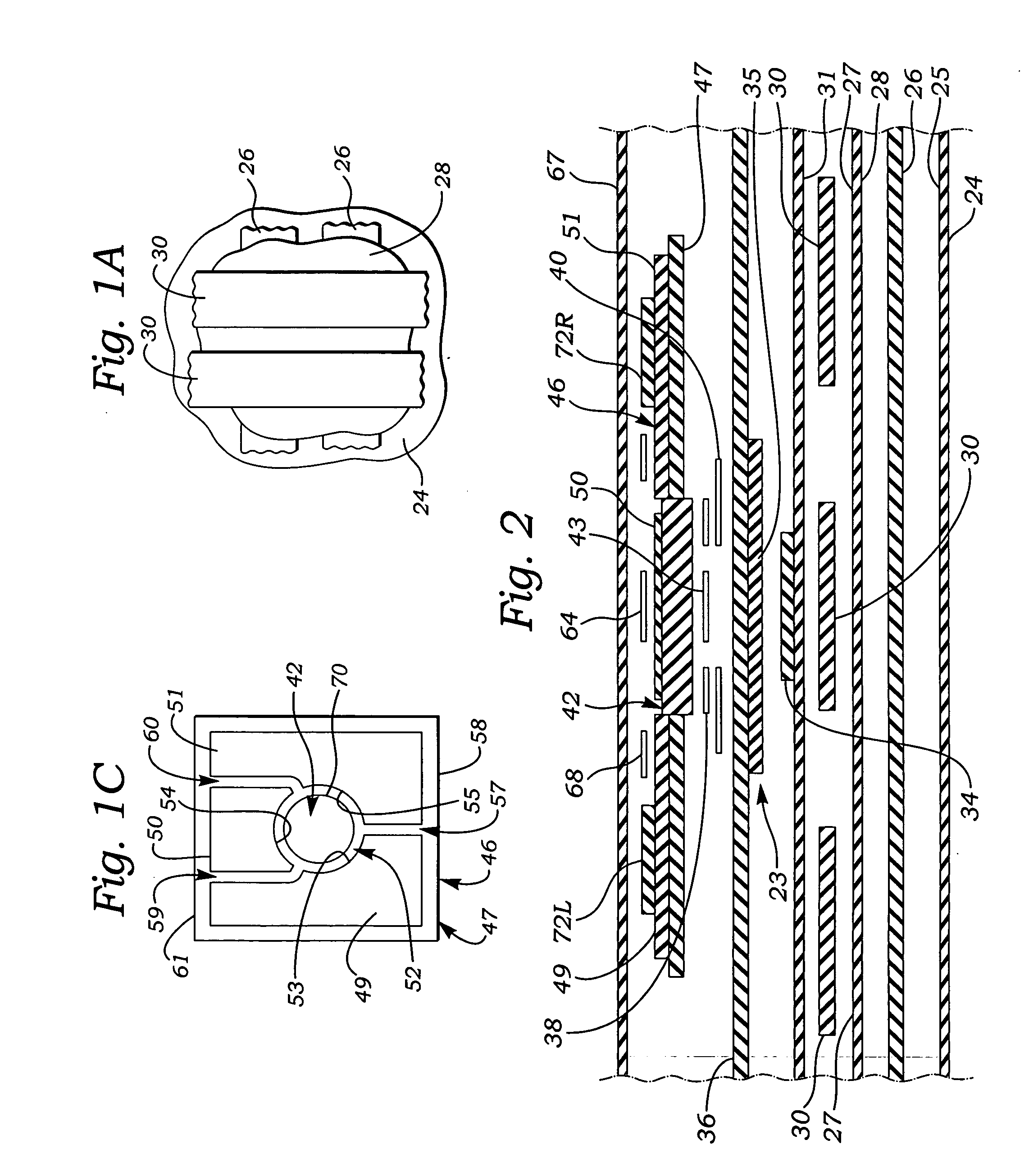

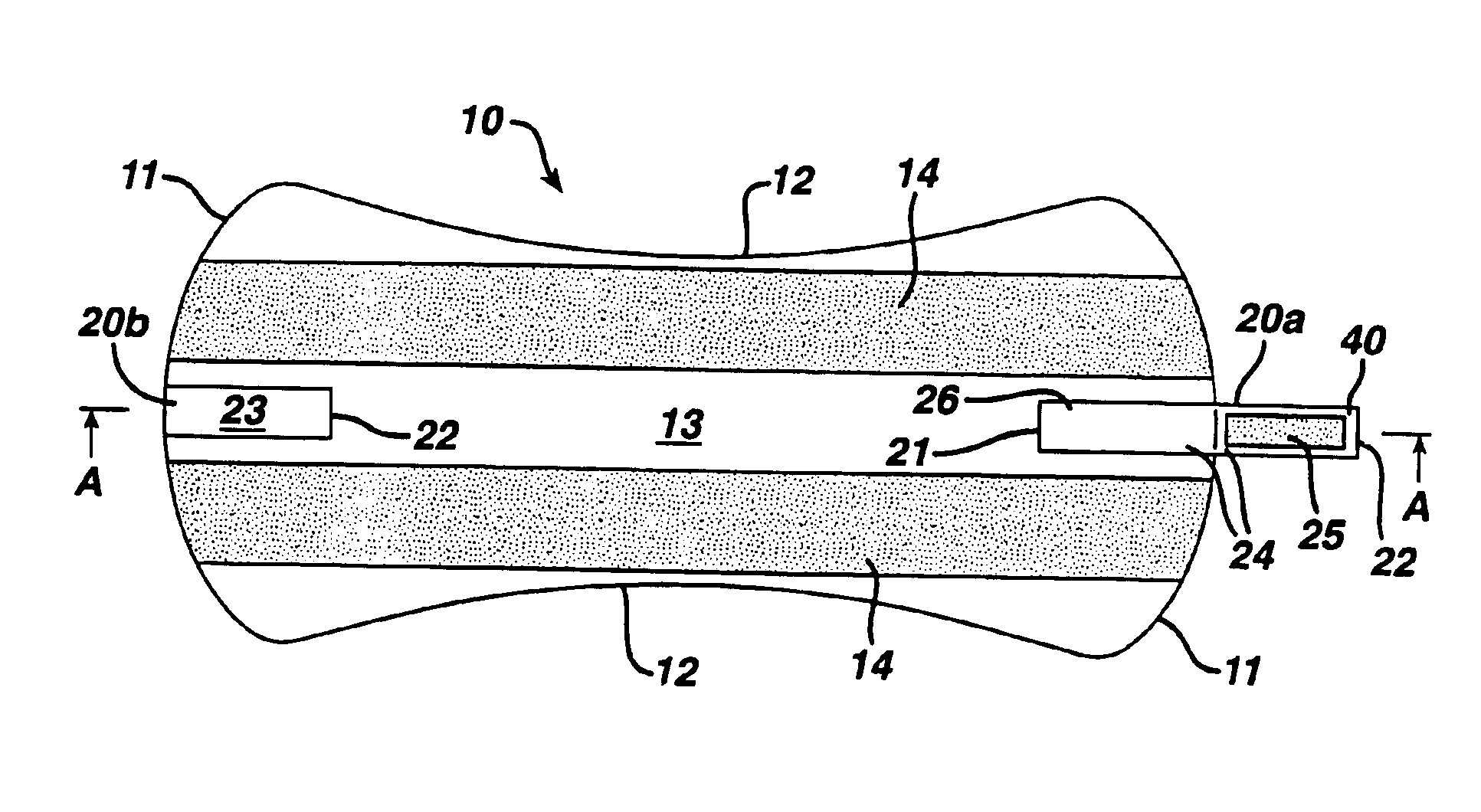

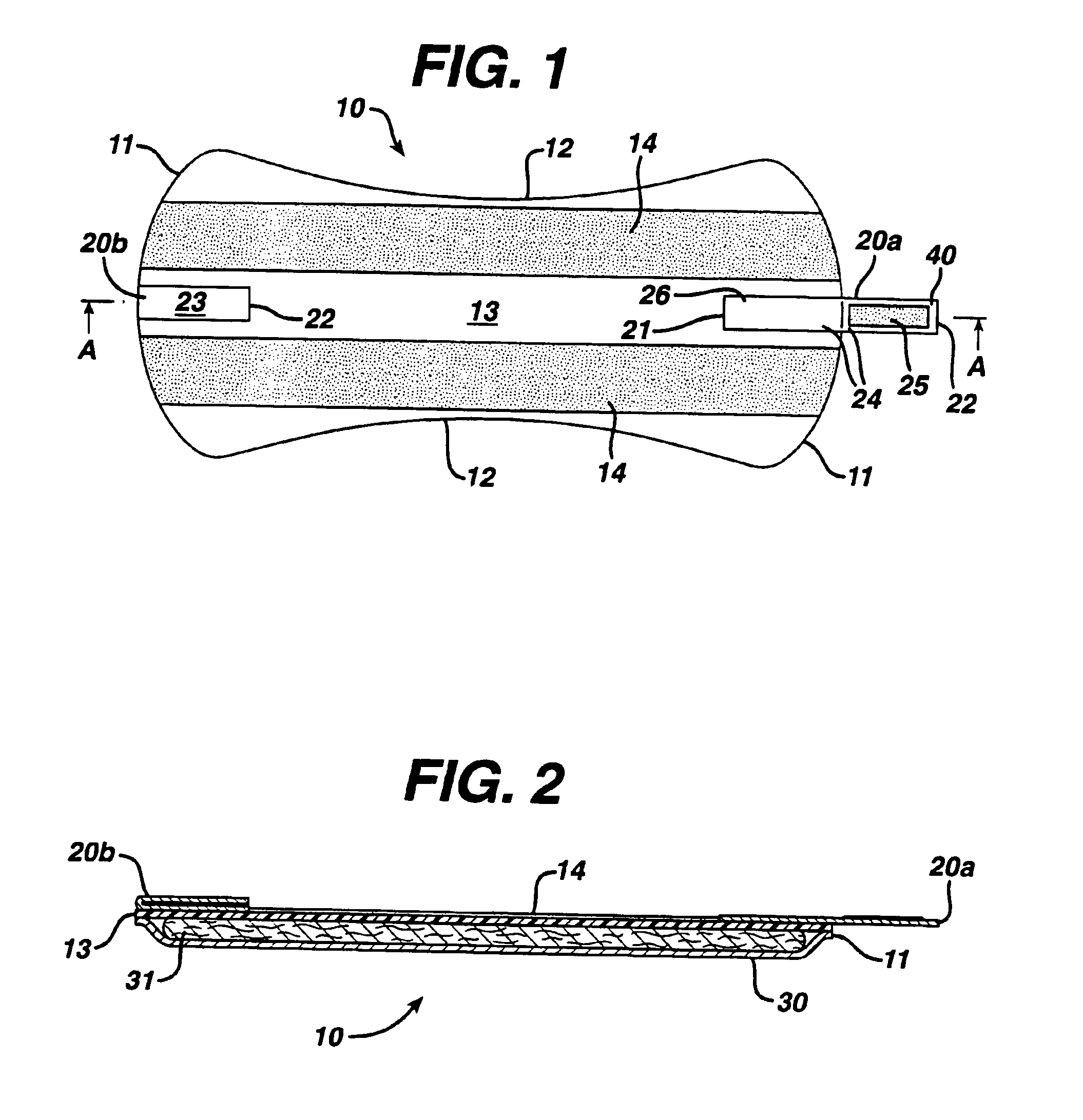

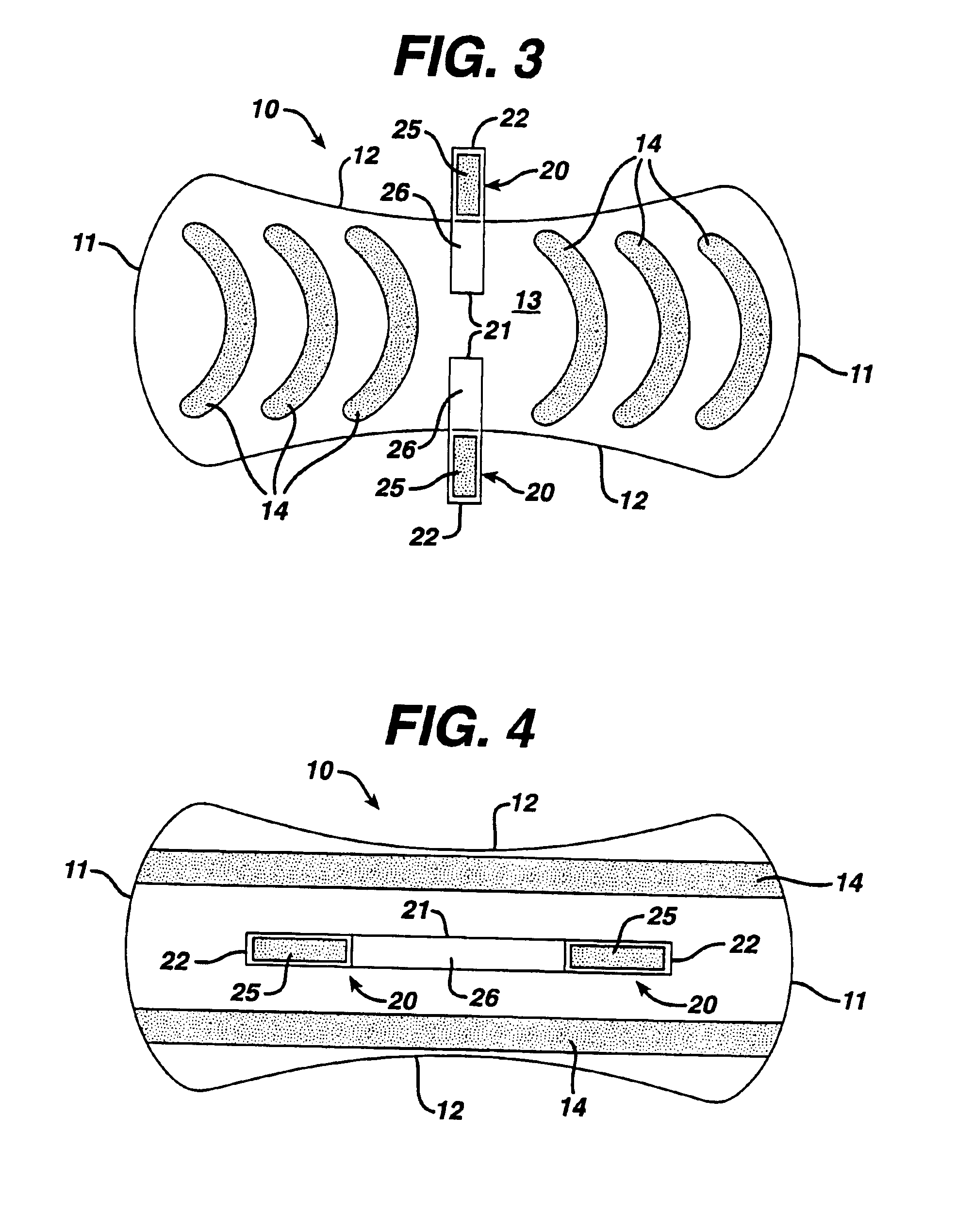

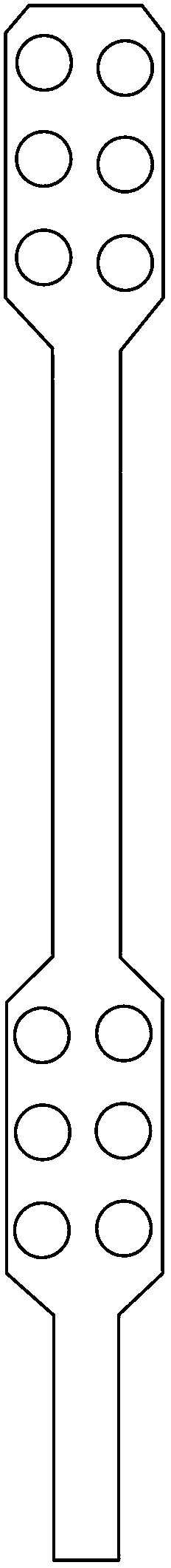

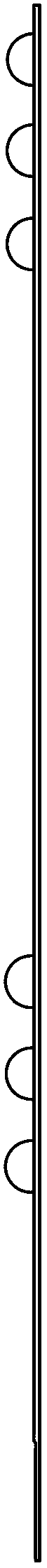

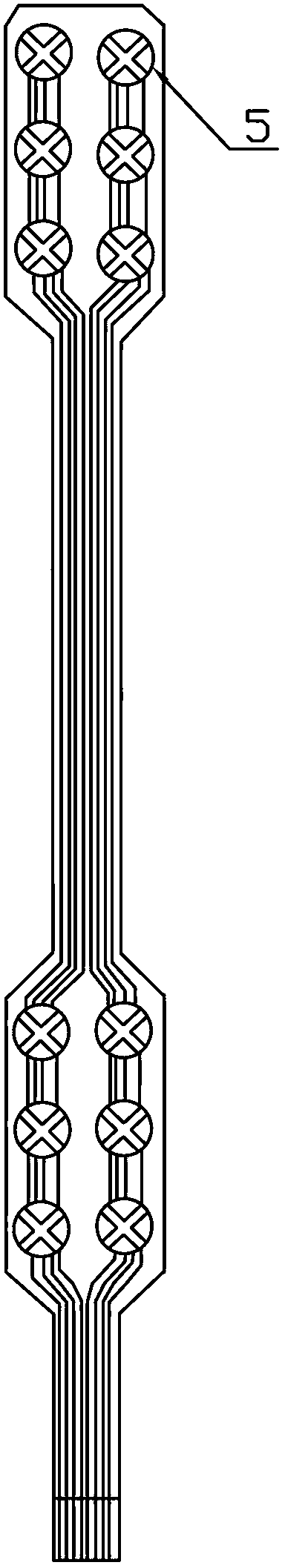

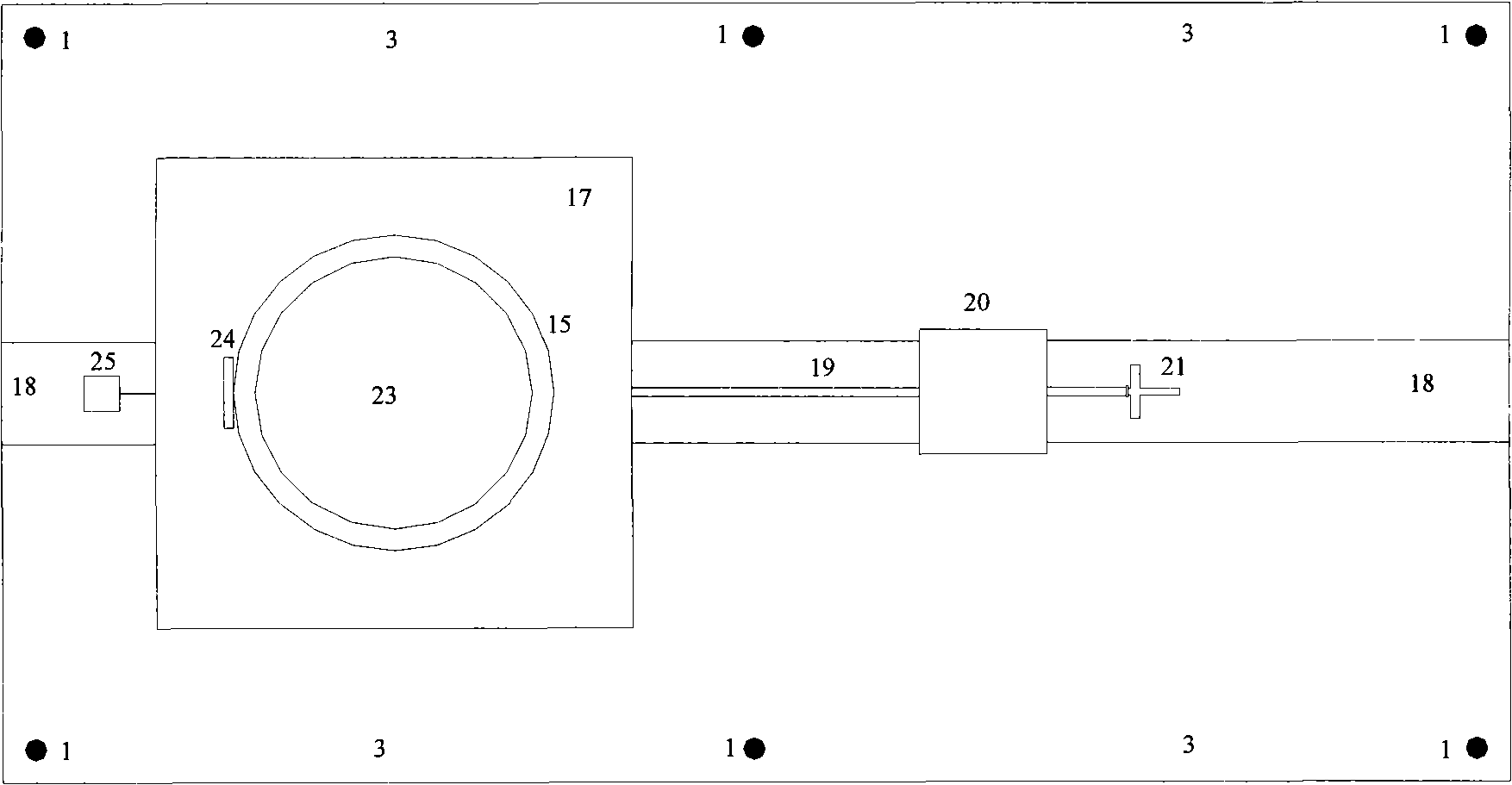

Normal force gradient/shear force sensors and method of measuring internal biological tissue stress

InactiveUS7201063B2Small sizeStretchable conformabilityForce measurementDiagnostic recording/measuringSensor arrayElectrical conductor

A normal force gradient / shear force sensor device and measurement method for measuring internal stresses in tissues of a person supported by a chair or bed includes a planar matrix array of peripheral normal force sensors radially spaced from central shear force sensors, comprising an electrically conductive disk located within a circular opening bordered by circumferentially spaced apart electrodes. The disk and electrodes are located between upper and lower cover sheets made of a stretchable material such as polyurethane; one cover sheet is adhered to the disk and the other sheet is adhered to a support sheet for the electrodes. Motion between the cover sheets in response to shear forces exerted on the array causes the disk to press more or less tightly against the electrodes varying electrical conductance between the disk and electrodes proportionally to the magnitude and direction of the shear force. Each normal force sensor includes an electrically conductive film pressed between row and column conductors. Measurements of conductance values of pairs of sensor, which vary proportionally to normal forces exerted on the sensor, are used to calculate a gradient vector of normal forces exerted by a body part on the sensor array, which is combined with the shear force vectors in an algorithm to calculate internal reaction shear forces, e.g., on flesh near a bony prominence.

Owner:VISTA MEDICAL

Power connector

Owner:FCI AMERICAS TECH LLC

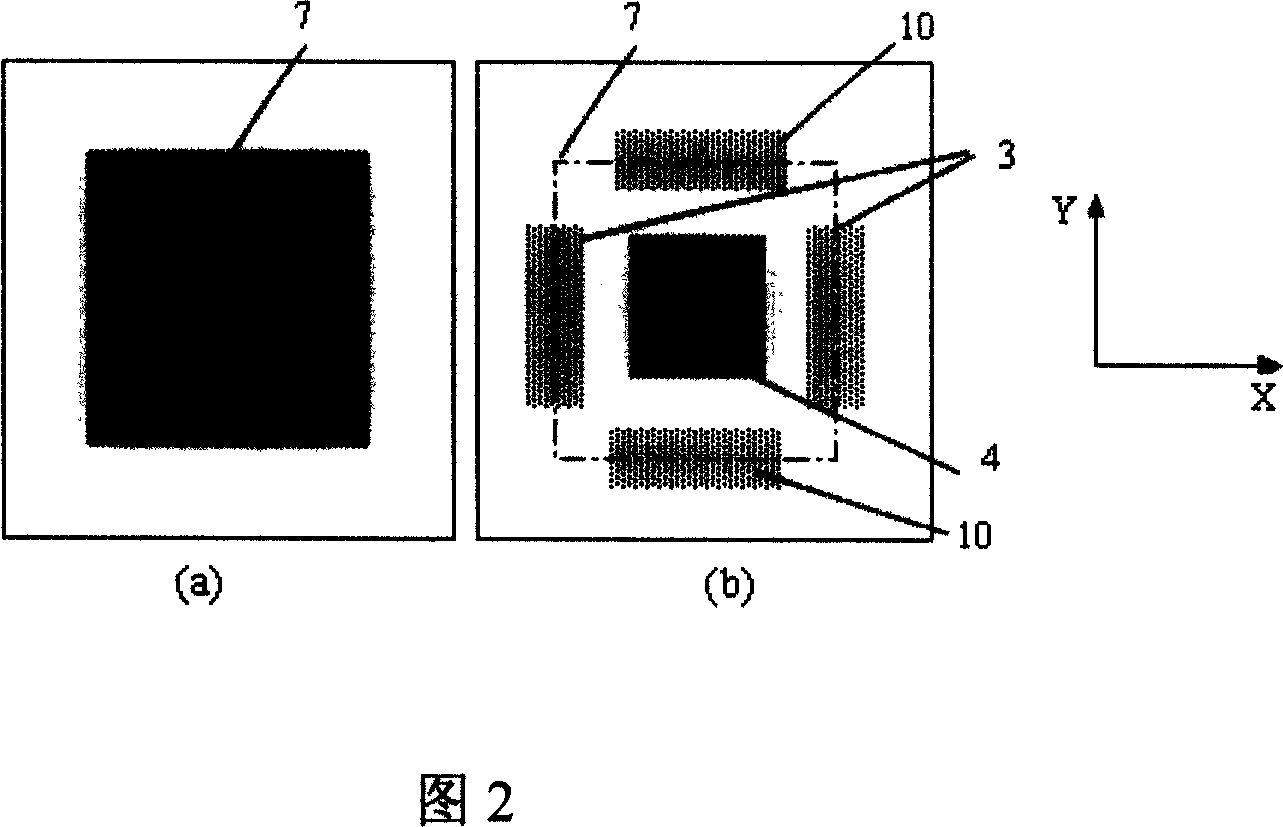

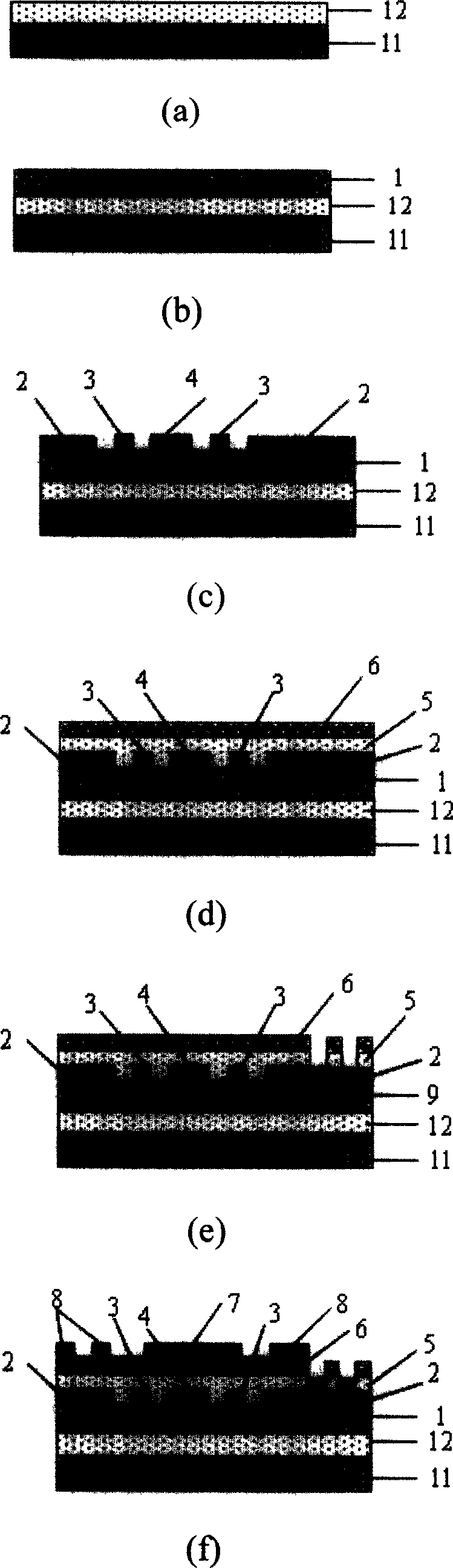

Flexible capacitance type touch sensor production method

InactiveCN101059380ALow costImprove yieldSemi-permeable membranesForce measurementElectricitySensor array

The invention relates to a method for producing flexible capacitor touch sensor, characterized in composed of middle layer preparation of PDMS, preparation of flexible PI substrate, graph metal sensitive electrode and relative electric connection, preparation of a first high-elasticity dielectric layer PDMS and a second flexible dielectric layer PI, graph metal drive electrode and relative electric connection, graph a top flexible insulation protective layer PI, separation of the flexible capacitor touch sensor. The invention optimizes and combines techniques, to realize the compatibility of organic flexible material PDMS, PI and traditional MEMS technique. And the capacitor touch sensor has compact structure, high mechanical strength, and high flexibility, while the product can contact the surface with any curvature to sense the volumes of normal force and tangent force, and be applied for the production of flexile capacitor touch sensor array.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

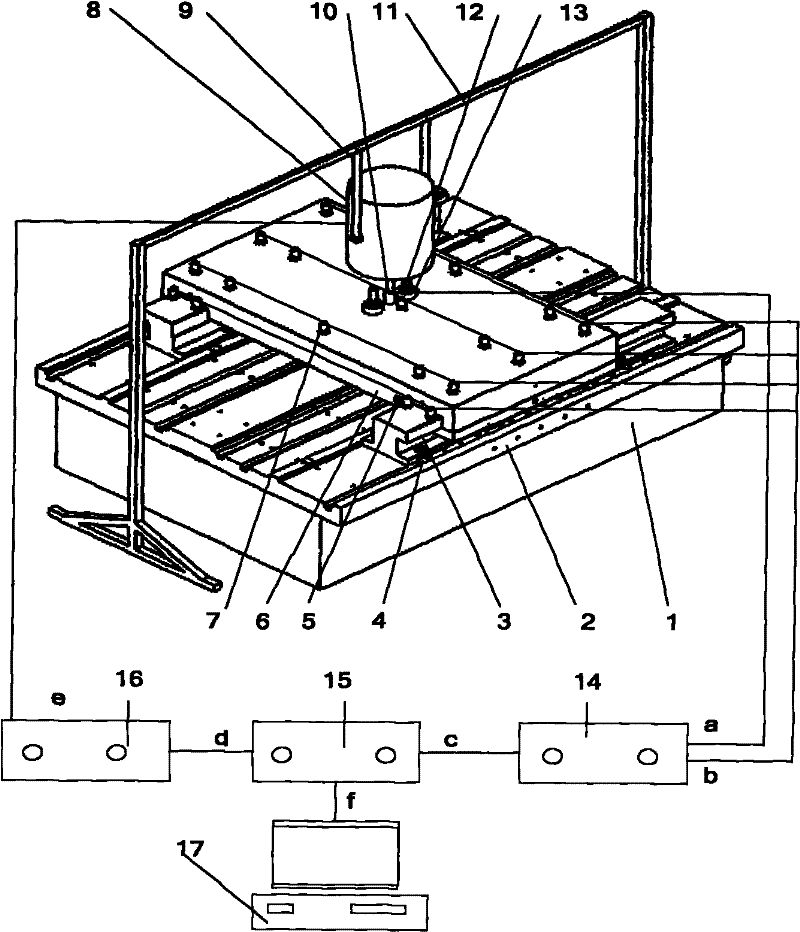

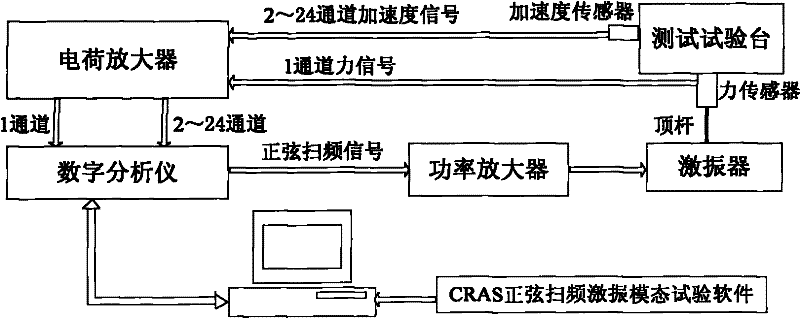

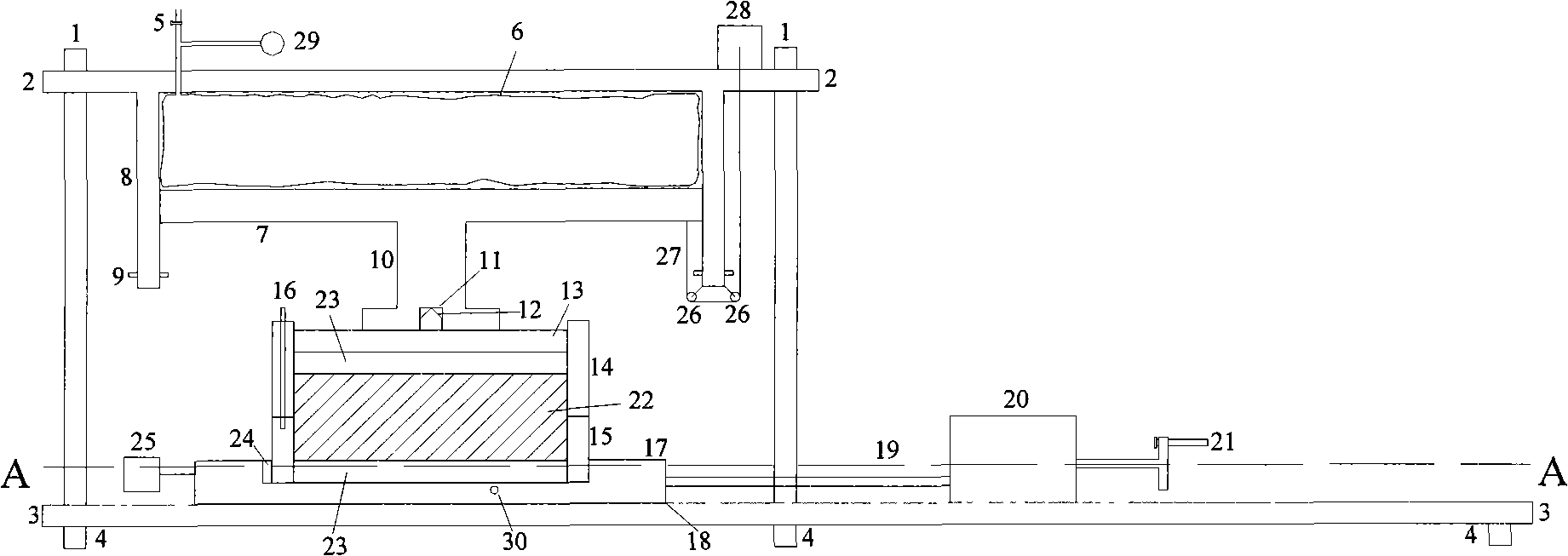

Dynamic characteristic parameter test device and method of sliding guide rail junction surface

InactiveCN102183363AAccurate acquisitionImprove accuracyMachine part testingVibration testingData acquisitionEngineering

The invention relates to a dynamic characteristic parameter test device of a sliding guide rail junction surface, which can be simplified into a single degree of freedom system. The device comprises a base, an installation platform, a fixed guide rail, a wedge-shaped block, an inlaid strip, a sliding block, a plurality of piezoelectric type acceleration sensors, a vibration exciter, an elastic rope, an impedance head, a stand, a normal force applying bolt, a rubber ring, a charge amplifier, a data acquisition unit, a power amplifier and an electronic computer. Compared with the prior art, thedynamic characteristic parameter test device has the advantages that: the structure is compact, the test principle is distinct, dynamic characteristic parameters of the junction surface under different load states can be measured by adjusting the pretightening force of a normal force applying bolt, the vibration exciting force direction passes through the gravity of the sliding block during measurement so that vibration signals of the sliding block and the base can be measured simultaneously, the influence of the vibration signals of the base is eliminated when a frequency response function of a system is calculated, and the characteristics of high efficiency, high stability and high precision are achieved.

Owner:NANJING UNIV OF SCI & TECH

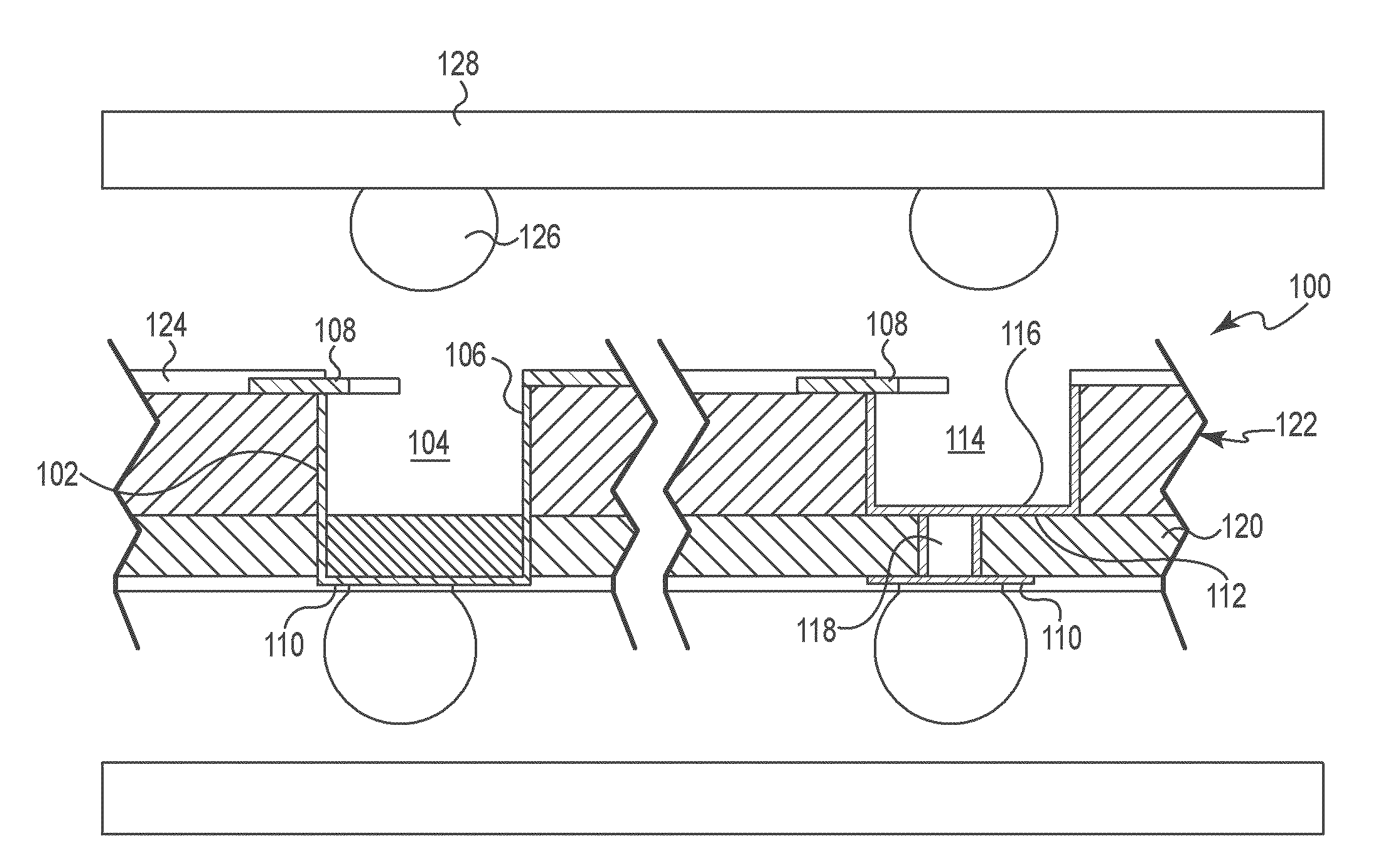

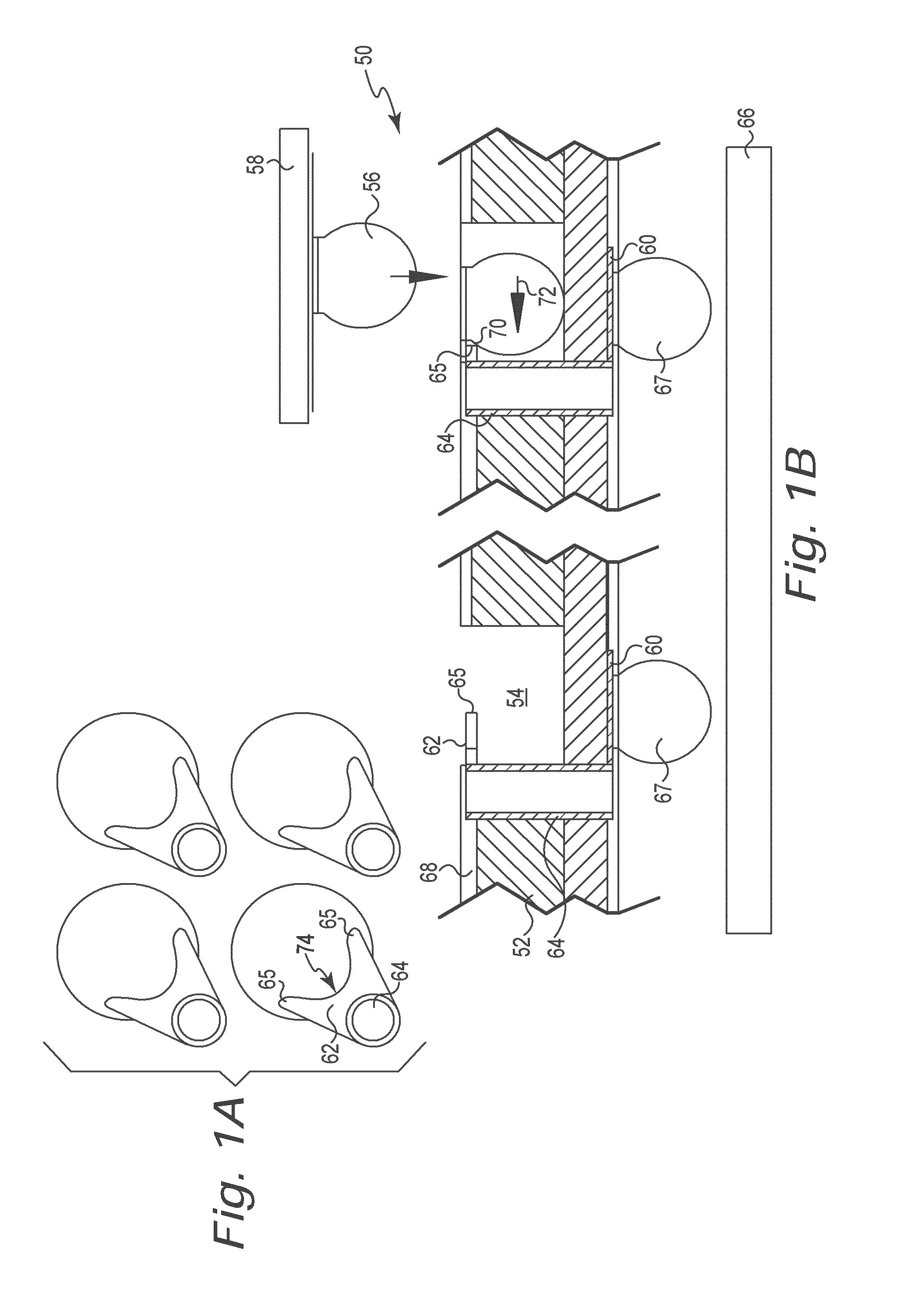

High performance surface mount electrical interconnect with external biased normal force loading

ActiveUS20120244728A1Low enough forceEasy to disassembleCoupling device connectionsContact member manufacturingContact padSurface mounting

A surface mount electrical interconnect adapted to provide an interface between solder balls on a BGA device and a PCB. A socket substrate is provided with a first surface, a second surface, and a plurality of openings sized and configured to receive the solder balls on the BGA device. A plurality of electrically conductive contact tabs are attached to the socket substrate so that contact tips on the contact tabs extend into the openings. The contact tips electrically couple with the BGA device when the solder balls are positioned in the openings. Vias electrically couple the contact tabs to contact pads located proximate the second surface of the socket substrate. Solder balls are bonded to the contact pads to electrically and mechanically couple the electrical interconnect to the PCB.

Owner:HSIO TECH

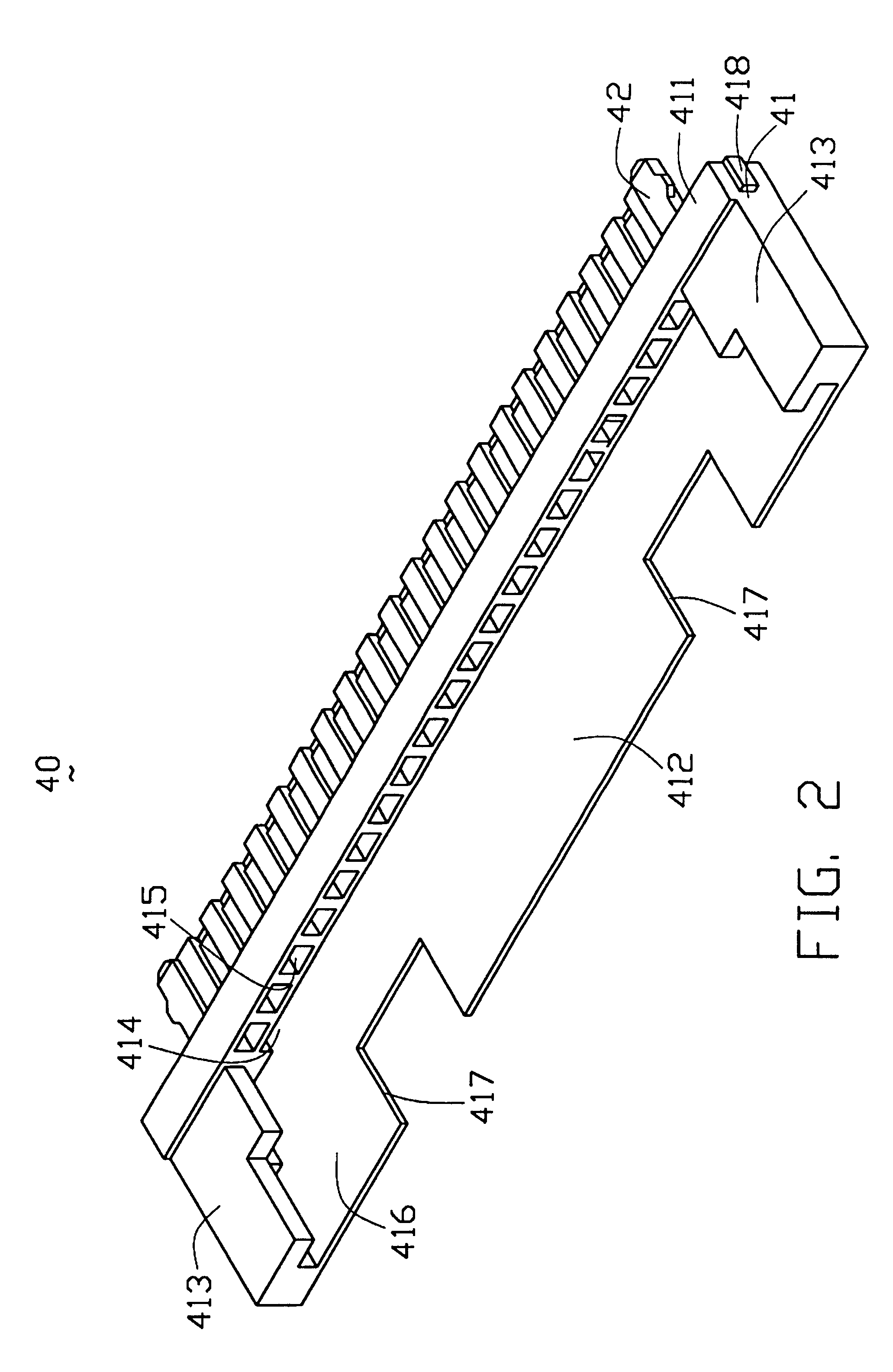

Low profile mini coaxial cable connector

InactiveUS6305978B1Electrically conductive connectionsCoupling protective earth/shielding arrangementsCoaxial cableEngineering

A low profile mini coaxial cable connector 100 includes a contact set 10, a cable set 20, a grounding plate 30 a dielectric housing 40 and a metal shell 50. The contact set 10, the cable set 20 and the grounding plate 30 are fixedly accommodated in the housing 40 and the metal shell 50 encloses the housing 40. The metal shell 50 has two grounding tabs 513 electrically contacting the grounding plate 30. The metal shell 50 has an upper flap 51, a lower flap 52 and two side flaps 54, which extend from the upper flap 51 and which do not engage with but whose lower edges 541 are flush with side edges 523 of the lower flap 52. The housing 40 forms two buds 418 on two side surfaces thereof and each of the two side flaps 54 of the metal shell 50 defines a notch 517 which fixedly engages with a corresponding bud 418 of the housing 40 thereby reliably maintaining the metal shell 50 on the housing 40 and developing adequate normal force between the grounding tabs 513 and the grounding plate 30.

Owner:HON HAI PRECISION IND CO LTD

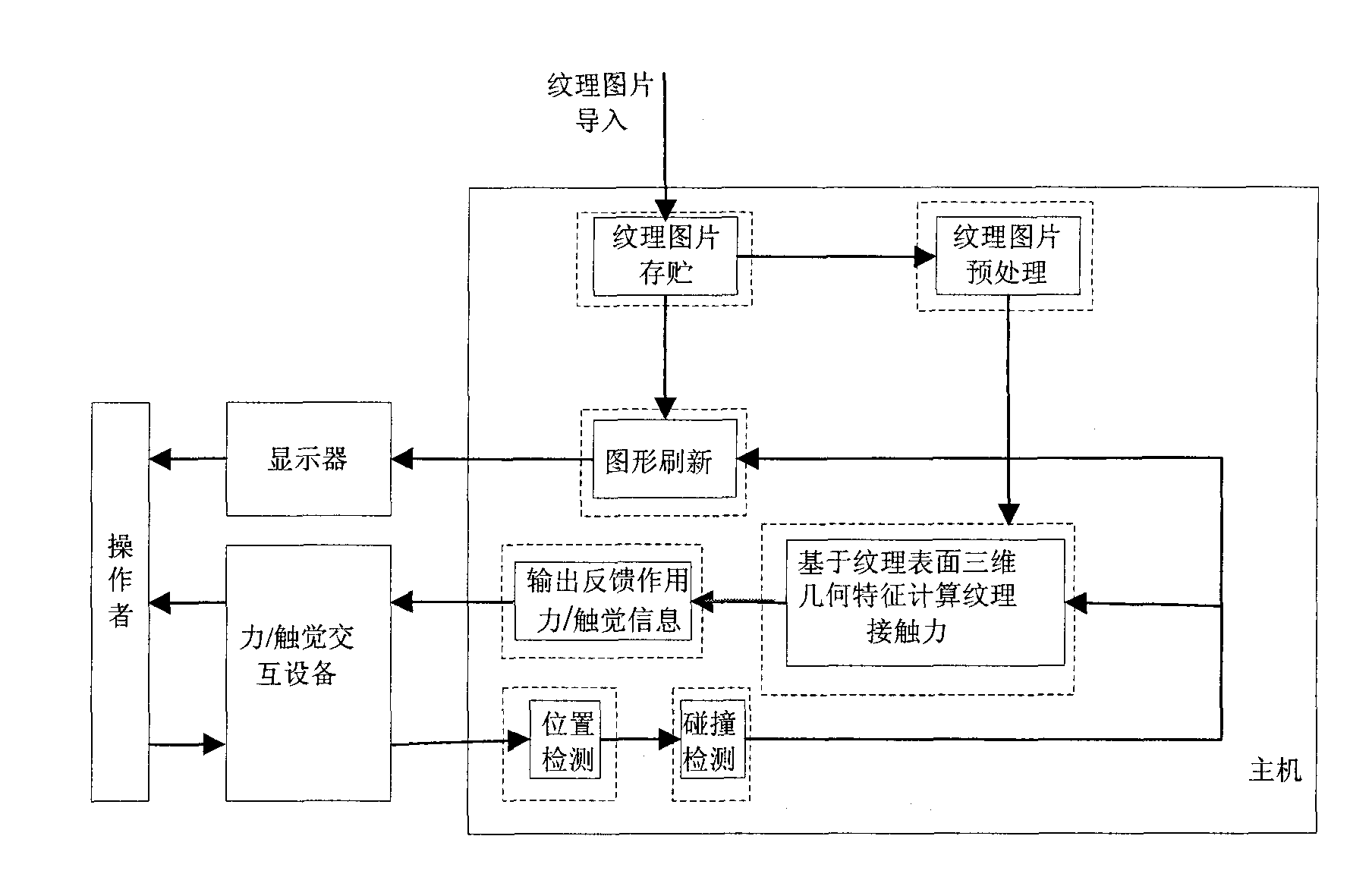

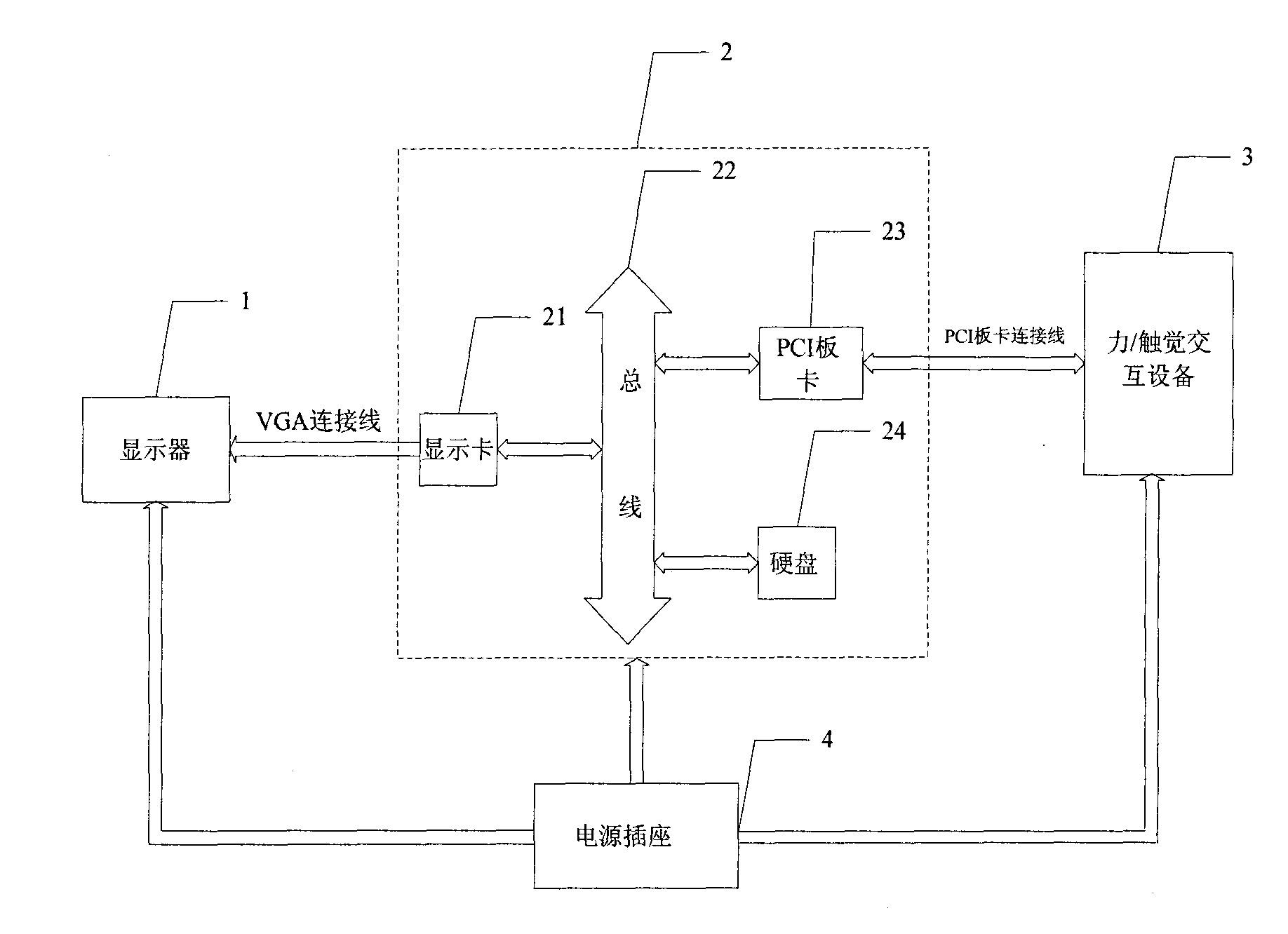

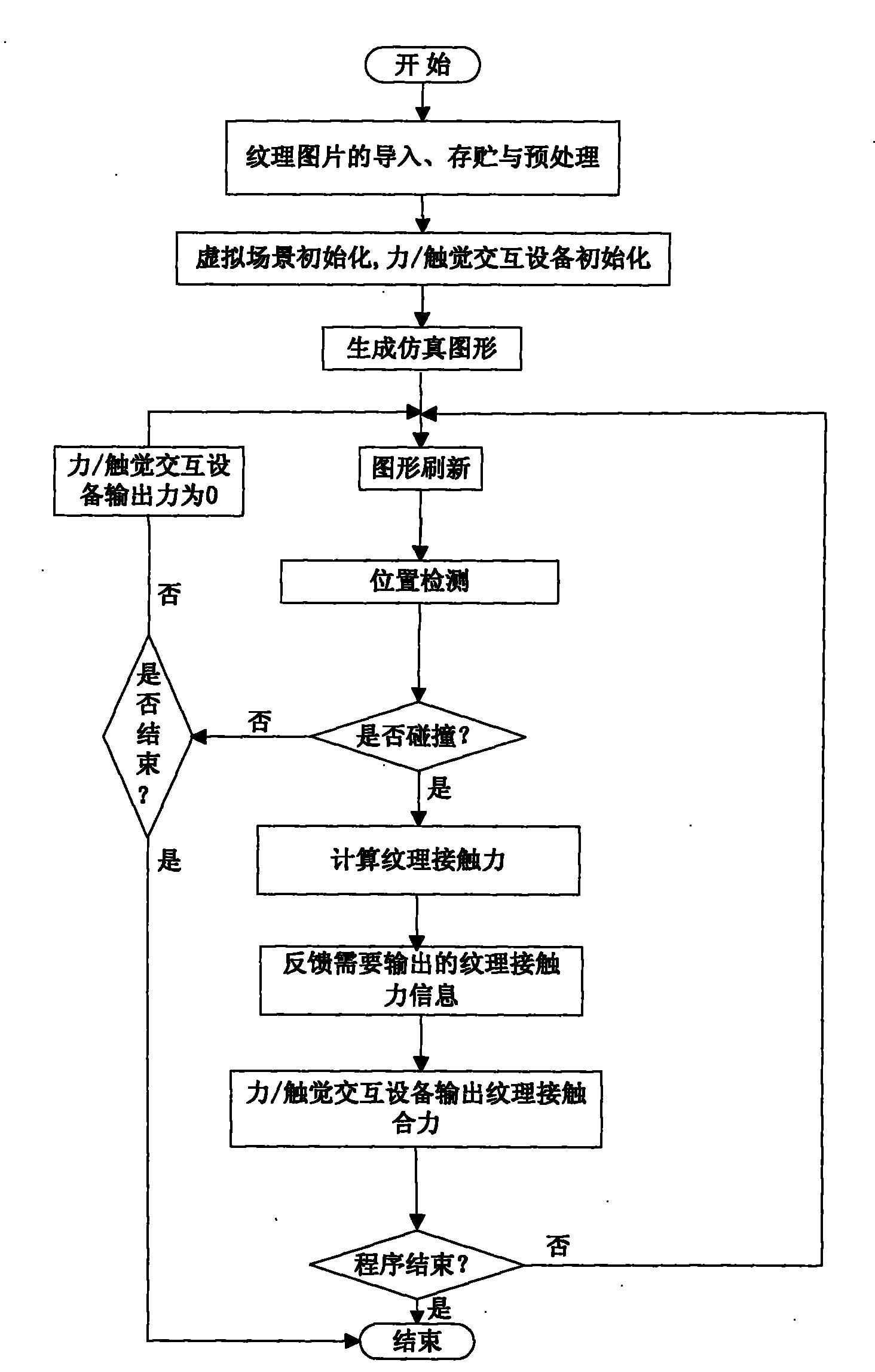

Image texture tactile representation system based on force/haptic interaction equipment

ActiveCN101819462AImprove realismImprove stabilityInput/output for user-computer interactionGraph readingInteraction systemsImaging processing

The invention discloses an image texture tactile representation system based on force / haptic interaction equipment for virtual reality human-computer interaction, which is characterized in that when the virtual proxy of the force / haptic interaction equipment slides on a texture surface of a virtual object in a virtual environment, the surface height of the object texture corresponding to the contact point and a coefficient of kinetic friction for reflecting the rough degree of the contact point are firstly obtained on the basis of an image processing method, a continuous normal contact force model reflecting the concave-convex degree of the contact point and a tangential friction model reflecting the rough degree of the contact point are respectively established, and finally the texture contact force is fed back to an operator in real time through the force / haptic interaction equipment so as to realize the force haptic express and reappear when fingers slide over the surface texture of the virtual object. The feedback continuous change normal force not only enables the human-computer interaction to be more real, but also enables an interaction system to be more stable, and the feedback friction related to the rough degree of the contact point also further enhances the sense of reality when the texture reappears.

Owner:NANTONG MINGXIN CHEM +1

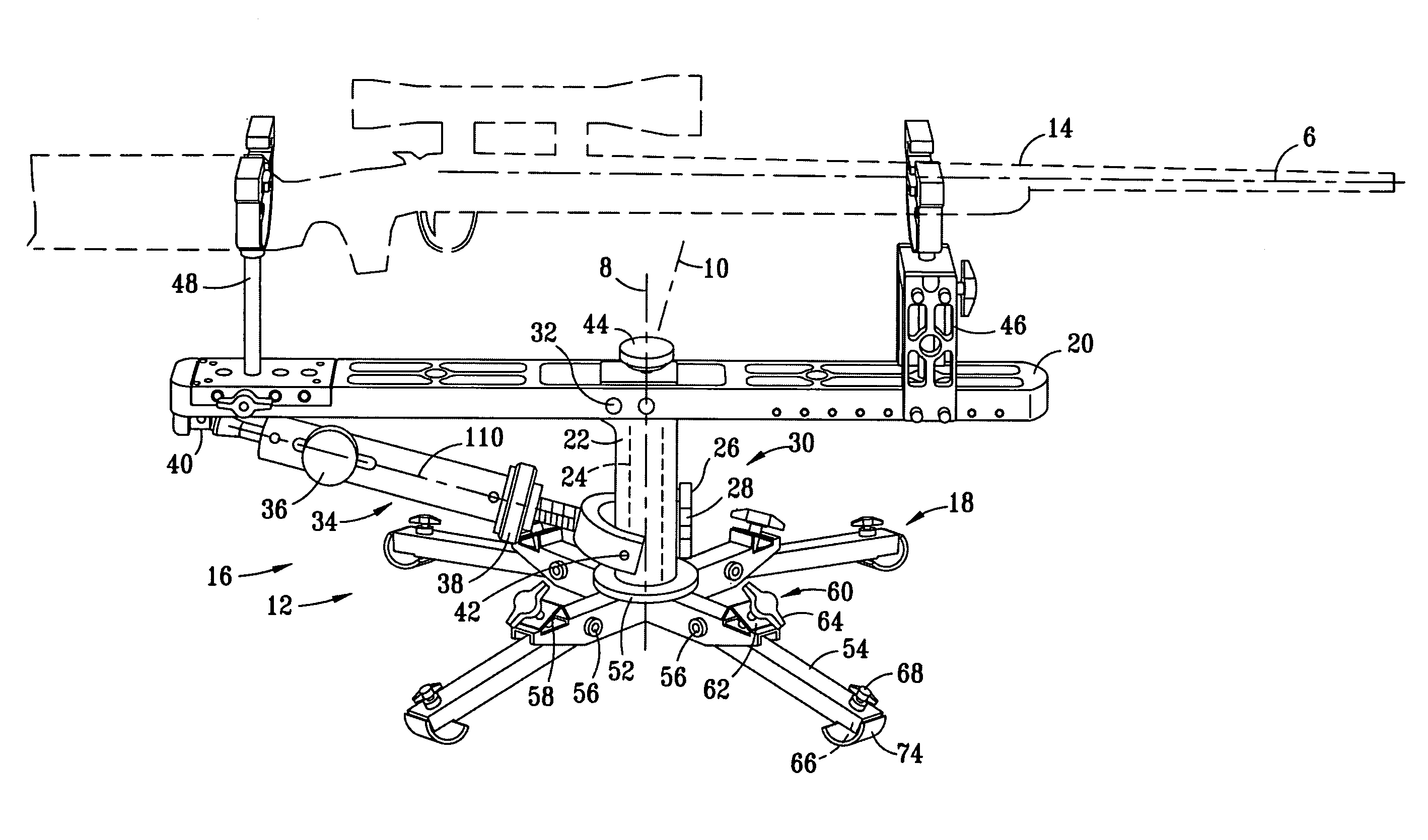

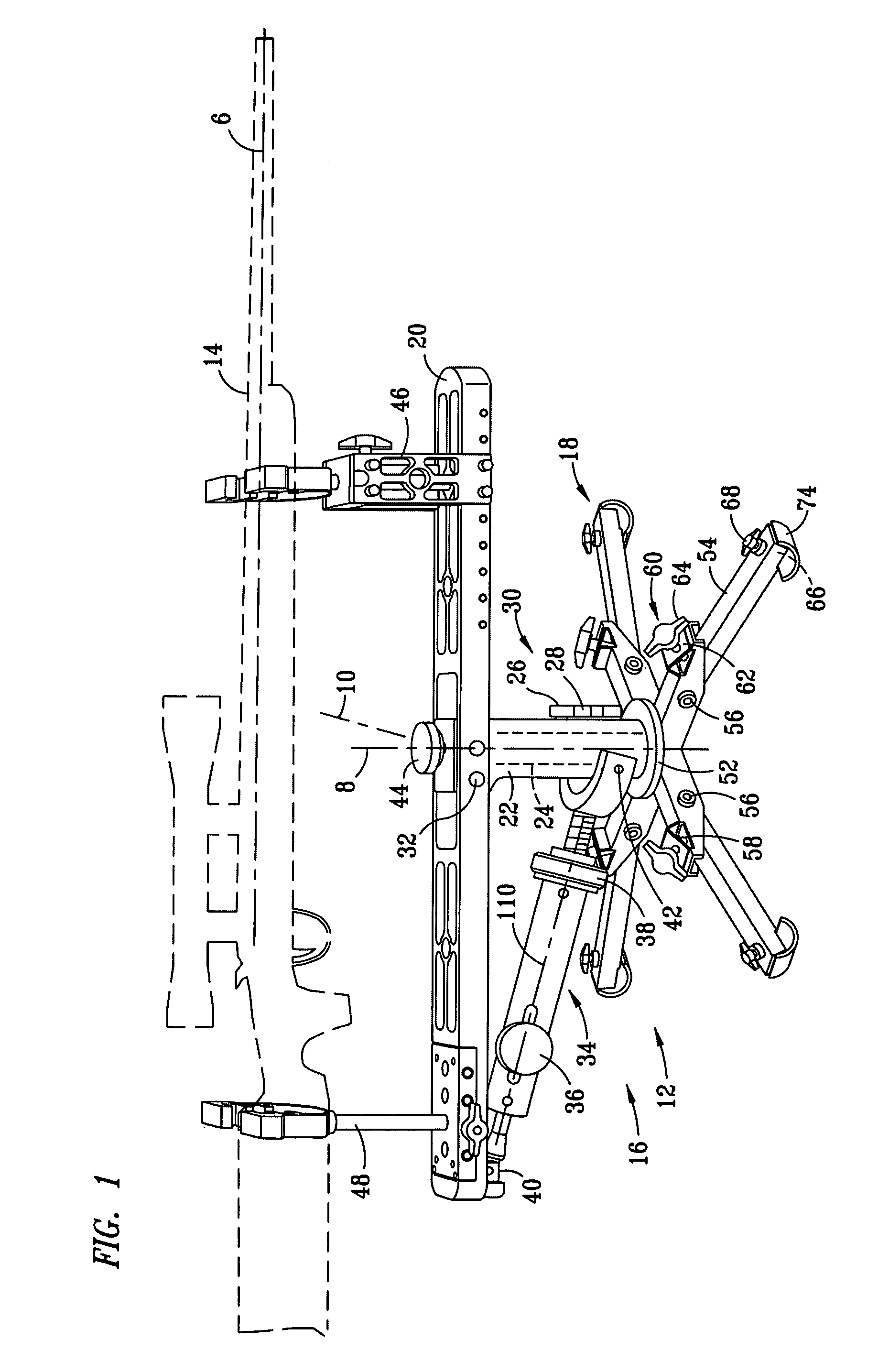

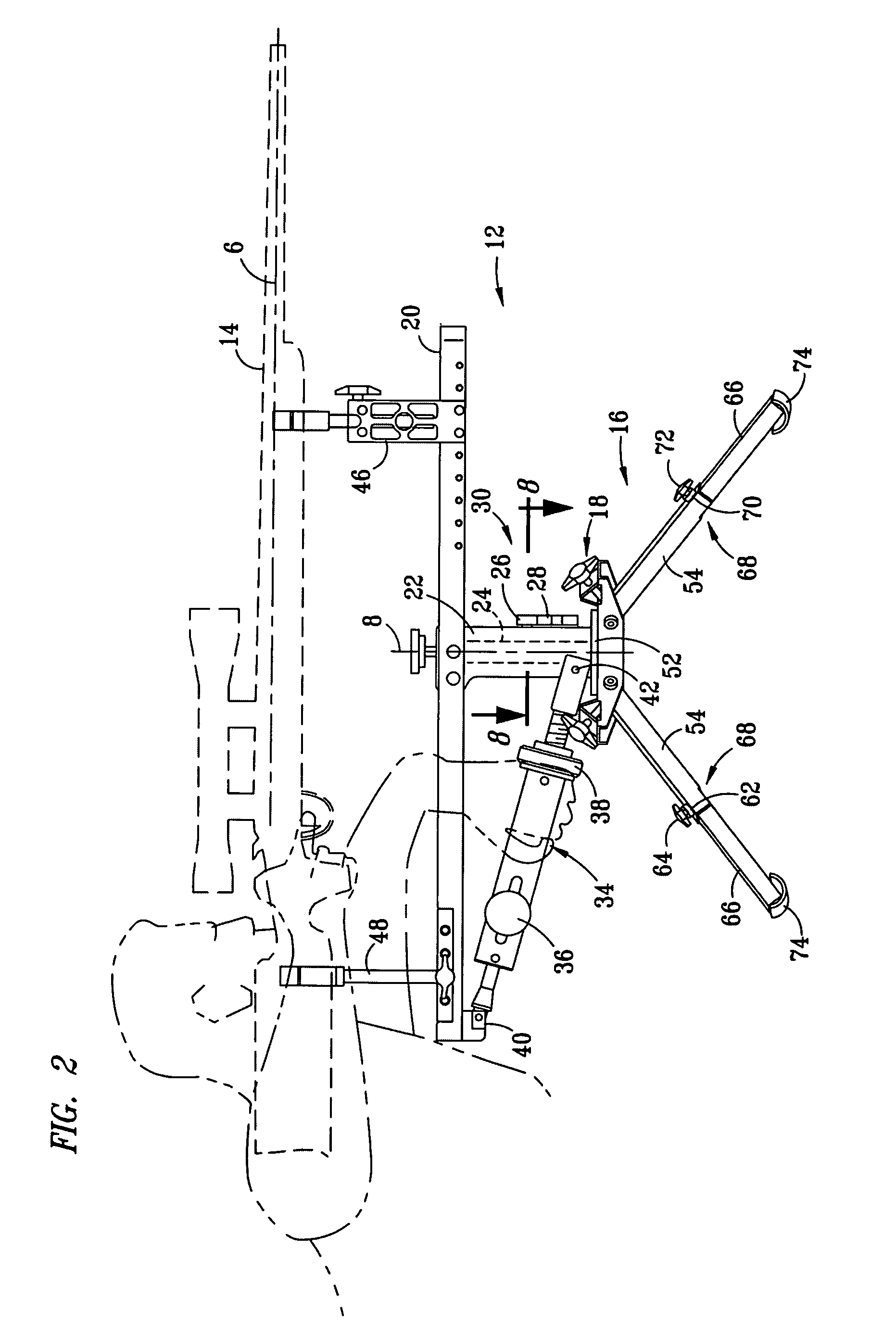

Precision tactical mount

A precision tactical mount (12) includes a horizontal controller (30) and a vertical controller (34) for determining azimuth angles and elevation angles for a sight line of the precision tactical mount (12). The horizontal controller (30) and the vertical controller (34) have friction blocks (102, 114, 196) which engage mating friction surfaces with selectable forces for providing specific resistance against azimuth and elevation angular movement, without requiring separate mechanisms for locking the tactical mount (12) in selected positions. The friction blocks (102, 114 and 196) are preferably formed of softer materials than the mating friction surfaces to conform to the shape of the mating friction surfaces with increased normal forces, providing varying surface areas. The vertical controller (34) includes a course threaded screw member (142) mounted at an angle to a centerline (6) of the precision tactical mount (12) to provide fine control adjustment for elevation.

Owner:BLACK ROBERT O

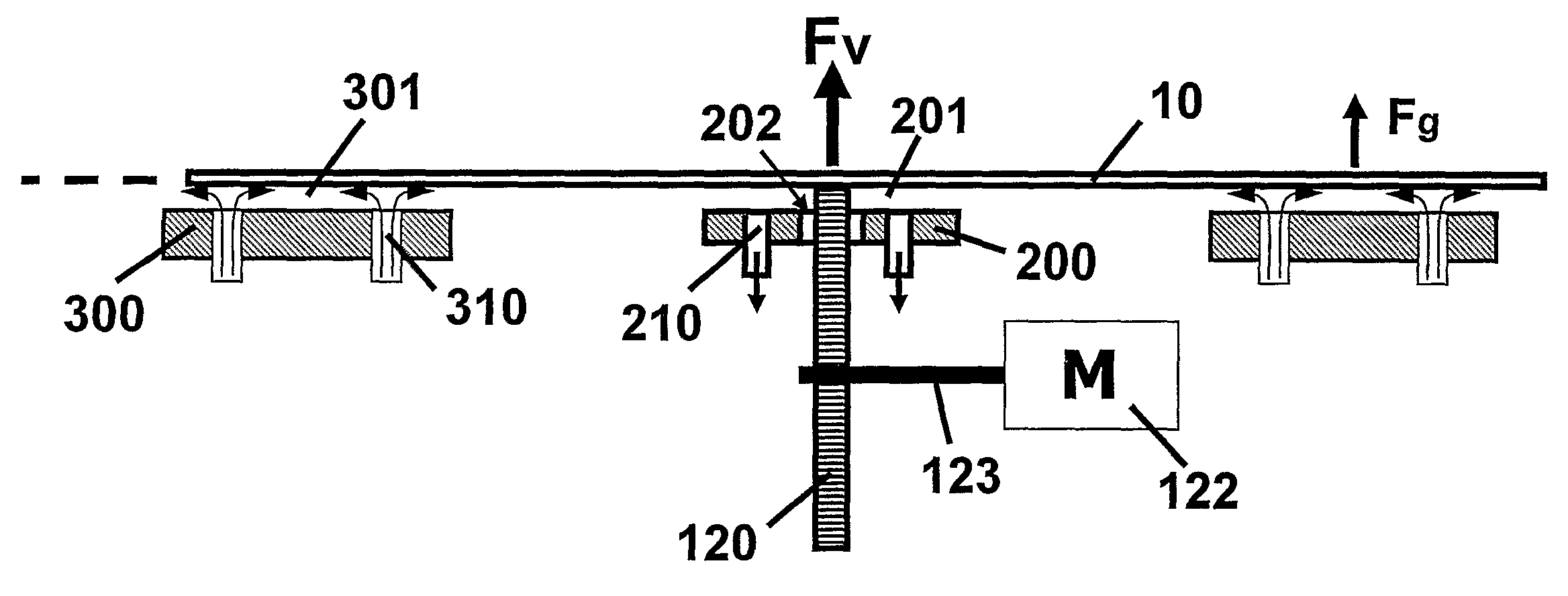

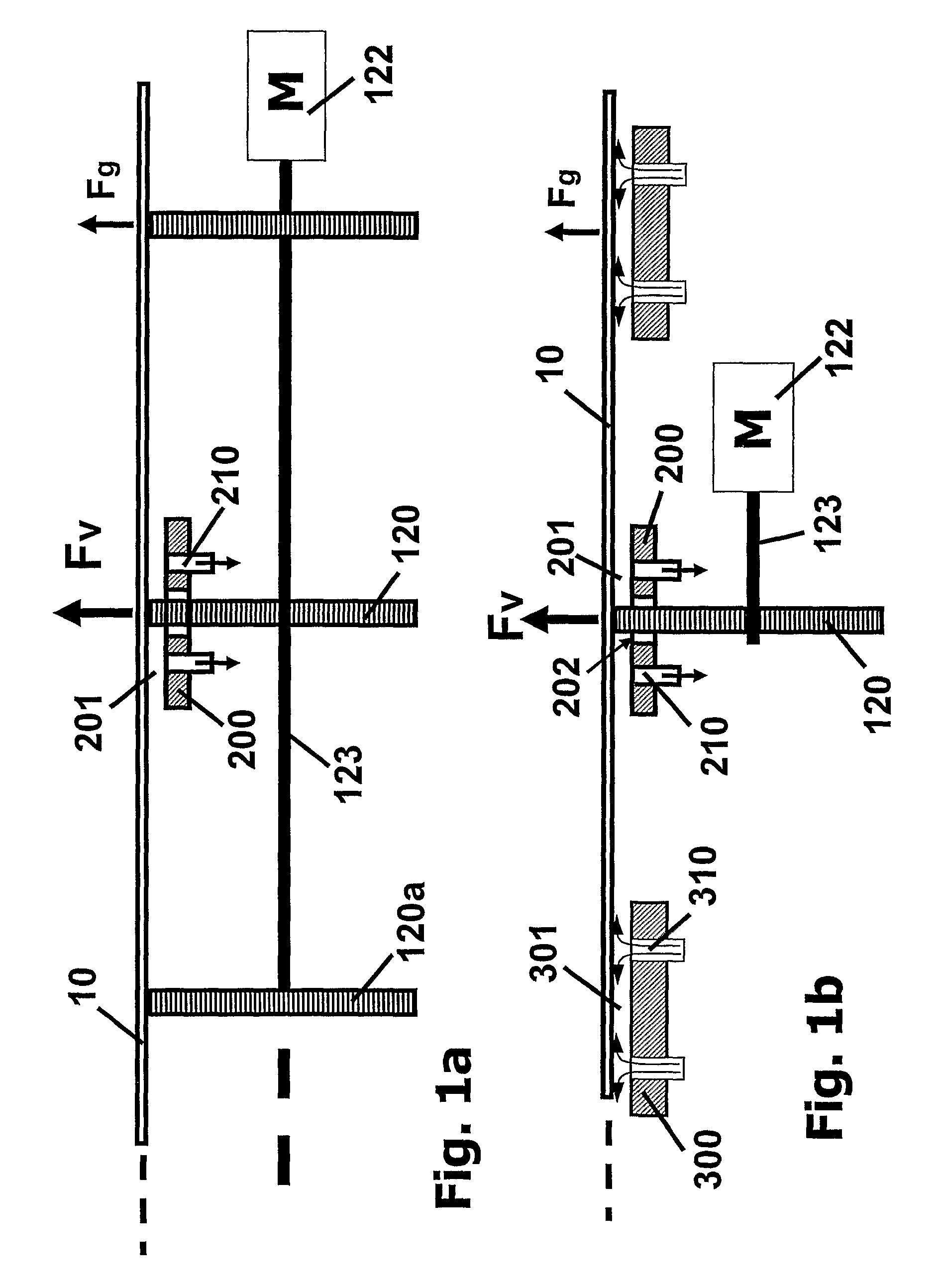

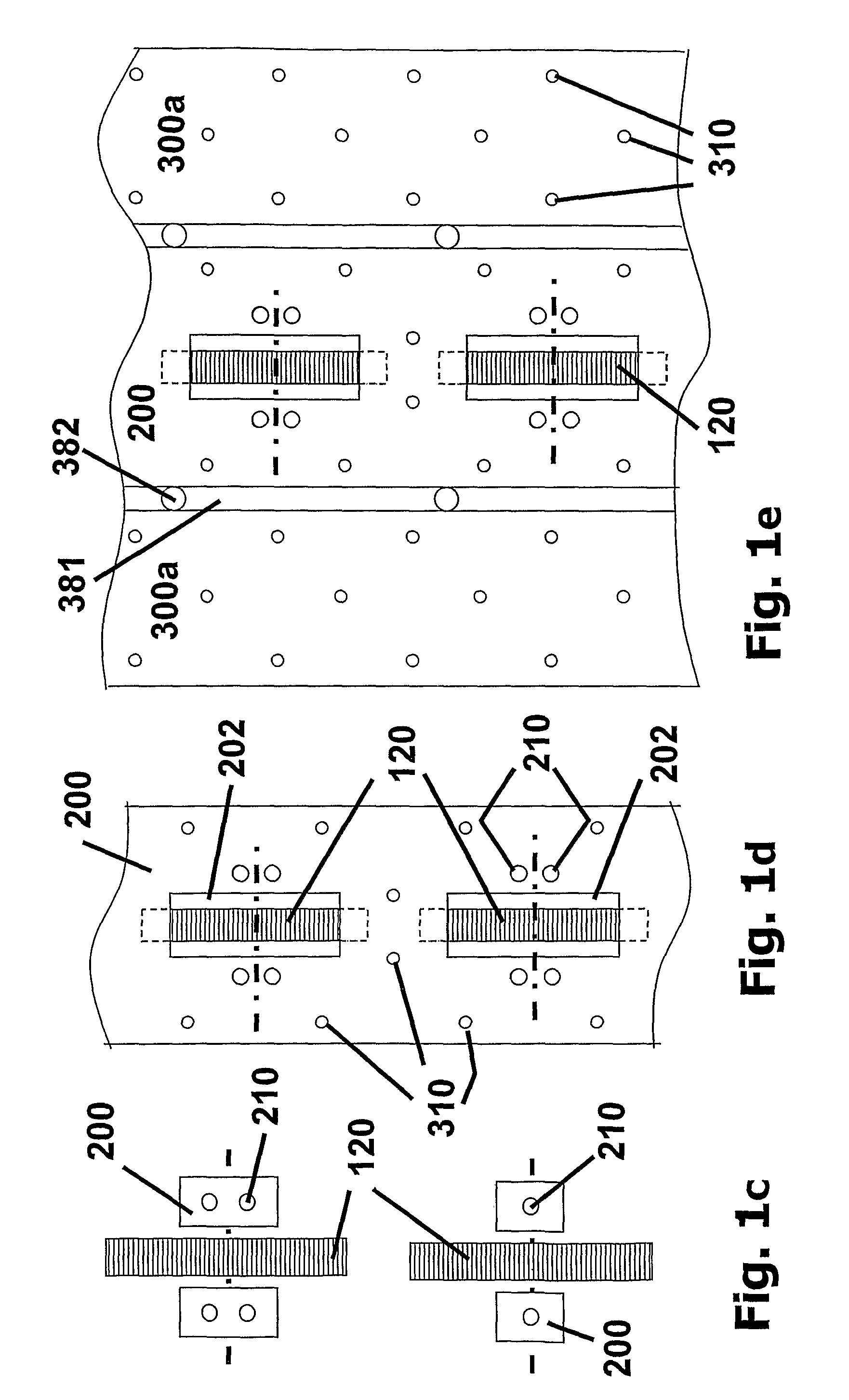

System and method for enhancing conveying performance of conveyors

ActiveUS7857121B2Semiconductor/solid-state device manufacturingManual conveyance devicesDrive wheelEngineering

A system and method for conveying and for accurately handling a generally flat object employing a plurality of support elements. The system comprises: a plurality of vacuum preload drive wheels arranged in one or more drive units, each drive unit comprising at least one vacuum preload drive wheel; one or more vacuum ports located on one or more counter plates adjacent each of the vacuum preload drive wheels, for applying induced holding down forces on the object. The vacuum ports of each drive unit are fluidically connected to a main vacuum pipe with controllable valve to a vacuum source. When the main vacuum pipe is connected to a vacuum source the normal force between the object and the vacuum preload drive wheels is increased and accordingly the lateral drive force is increased.

Owner:COREFLOW SCI SOLUTIONS

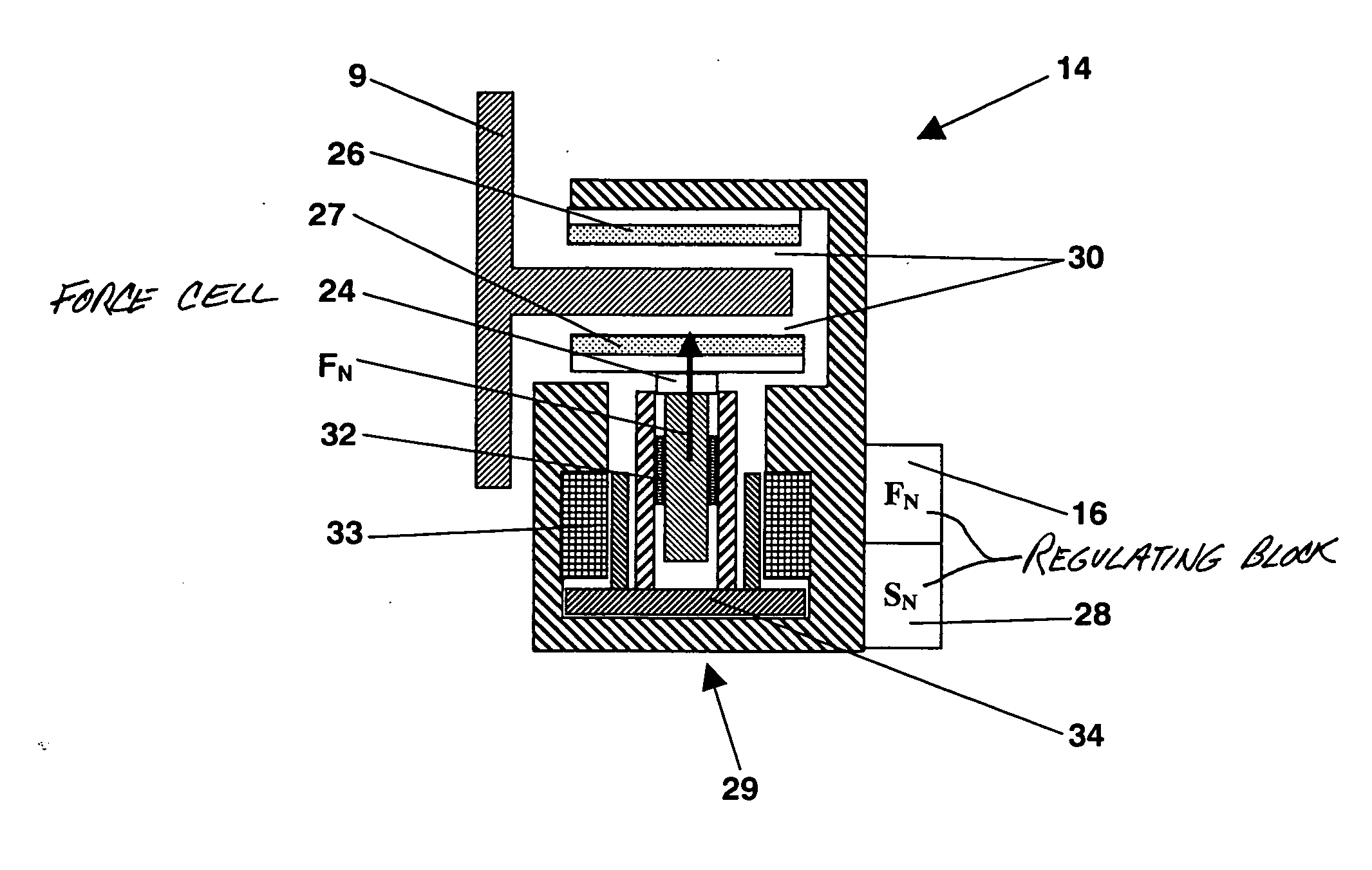

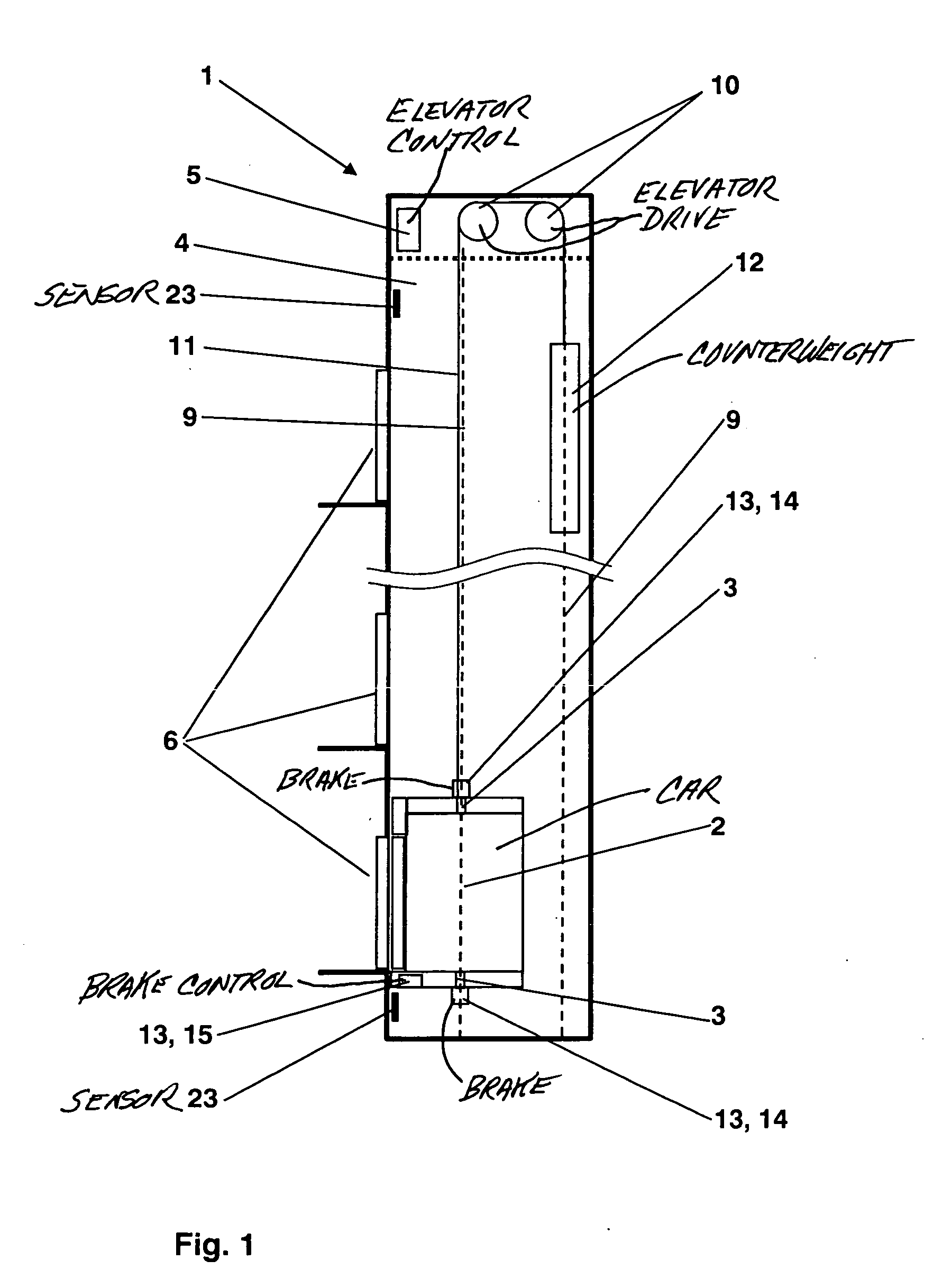

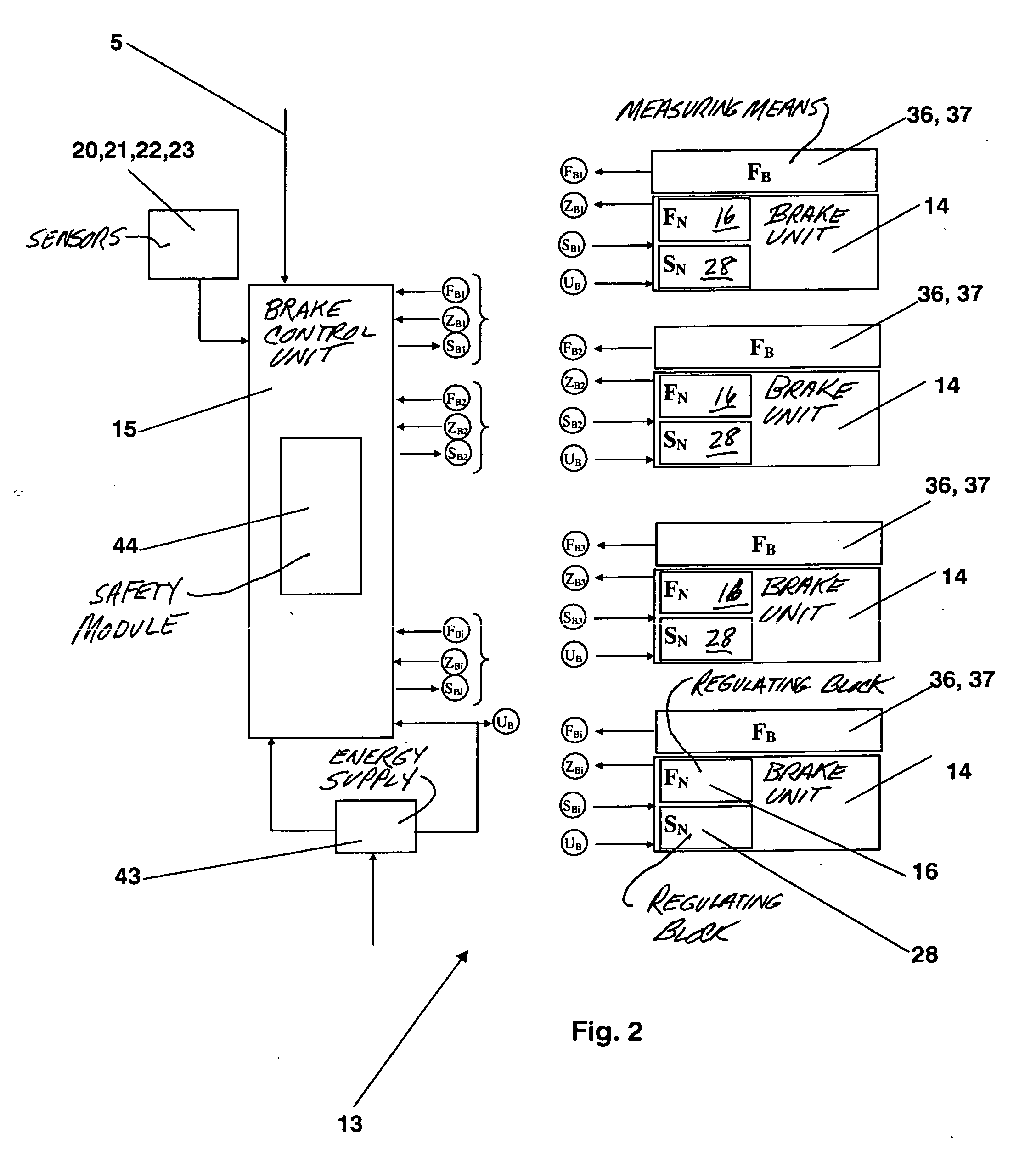

Elevator installation with a braking device and method for braking and holding an elevator installation

ActiveUS20060180406A1Low powerSmall additional weightBraking action transmissionFilament handlingEnergy supplyNormal force

An elevator installation has braking equipment for braking and holding an elevator car which moves in vertical direction within guide tracks or rails. The braking equipment consists of at least two brake units each comprising a normal force regulation device that sets a normal force (FN) in correspondence with a normal force value determined by a brake control unit and / or a locking device that locks the brake unit in a set braking position and which preferably maintains the set braking position in the case of an interrupted energy supply. The braking equipment provides a gentle braking or holding of the elevator car, which corresponds with the operational state of the elevator installation, with a low energy requirement.

Owner:INVENTIO AG

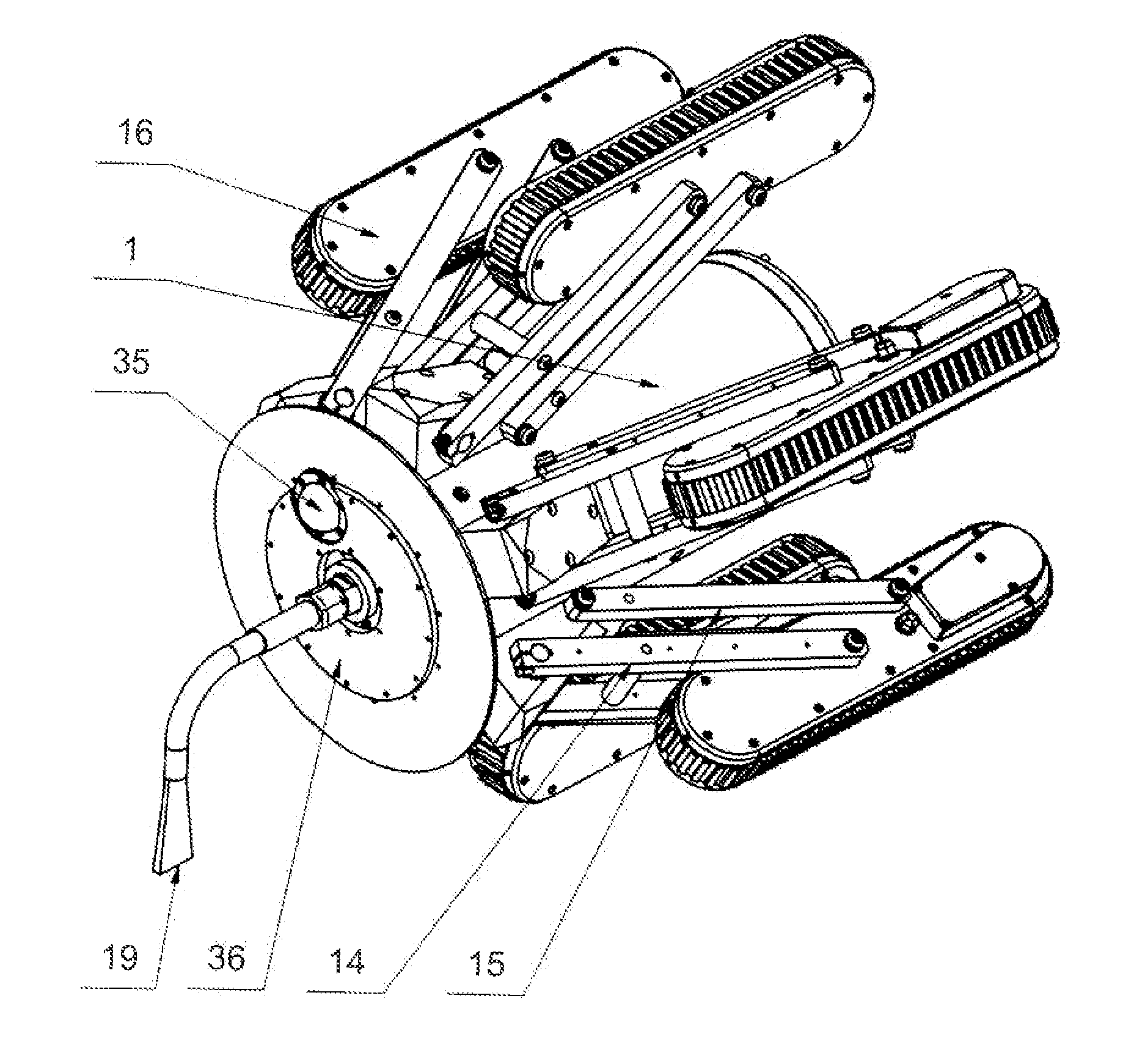

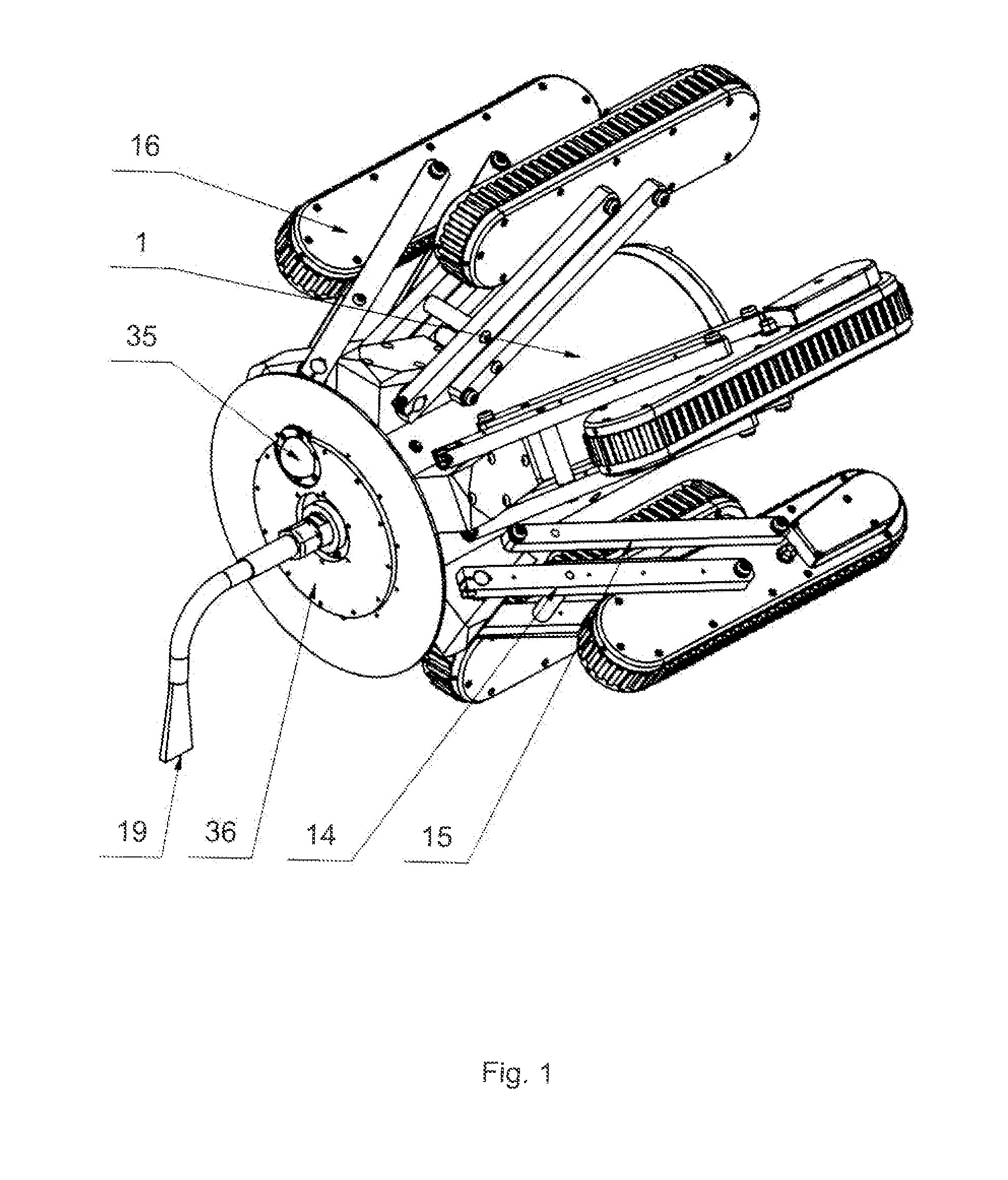

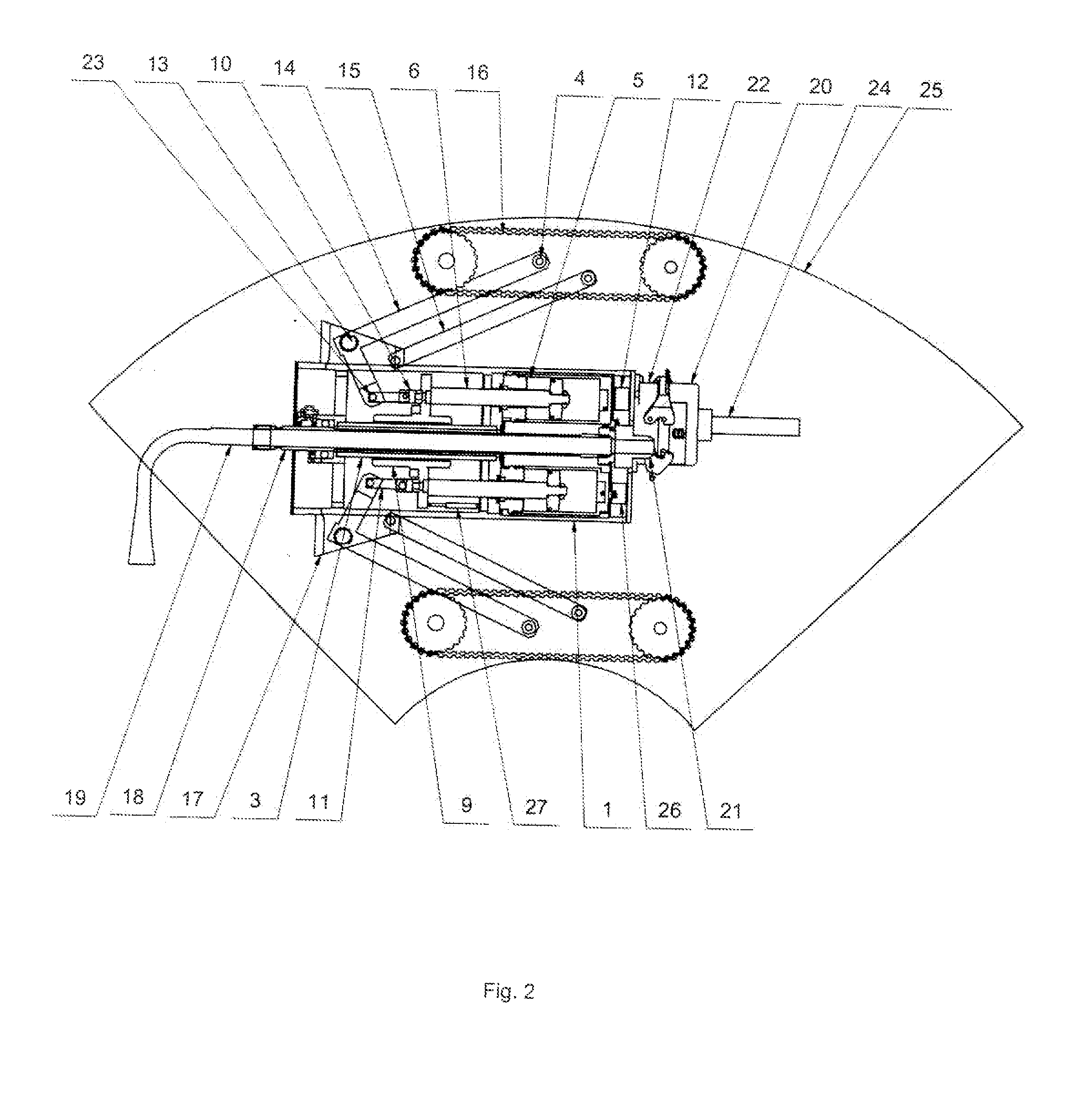

Robot for cleaning and inspection of conduits and its control unit

ActiveUS20120197440A1Small diameterEasy to controlProgramme controlComputer controlEngineeringControl theory

A robot for cleaning and inspecting conduits has a synchronizing mechanism, which extends all driving units simultaneously and with a constant normal force applied to the conduit wall. The robot may be equipped with adapters for conduits with rectangular cross section, and with extension bars for conduits with large diameters. Further, the robot may be equipped with sensors monitoring the robot status, these include a sensor of the synchronizing mechanism position, inclinometer and gyroscope. Data from these sensors may be displayed on a monitor. The movement of the robot inside the conduit and therefore the speed of individual tracks is controlled by the operator by three control elements: direction of turning, diameter of bend and speed of motion. The robot is also able to travel backwards inside the conduit automatically based on stored information about forward movement.

Owner:JETTYROBOT SRO +1

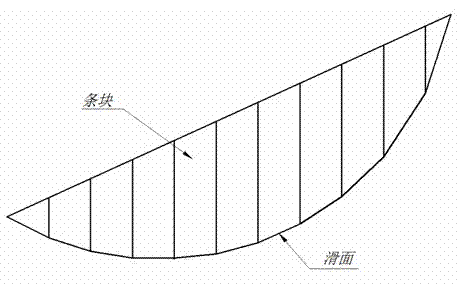

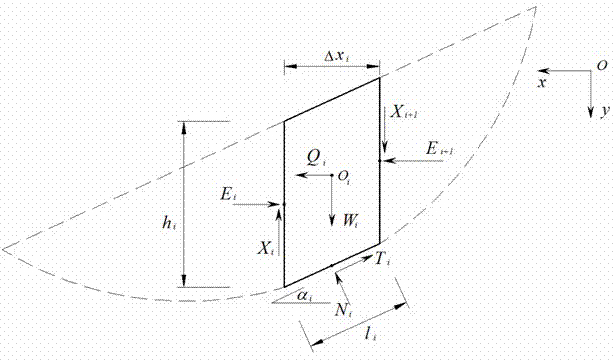

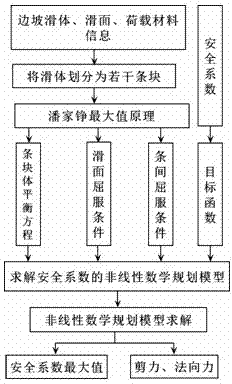

Slope stability analysis slice method based on global optimization

ActiveCN103485353AImprove securityMethod concept is clearExcavationsSlope stability analysisGlobal optimization

The invention discloses a slope stability analysis slice method based on global optimization and belongs to the field of slope stability analysis. The method includes that a slope slip mass is divided into vertical strip blocks or inclined strip blocks, acting force (including normal force and shearing force) on the bottom faces of the strip blocks and acting force (including normal force and shearing force) between the strip blocks are utilized as unknown variables, stable safety coefficient of the slope is utilized as a target function, and a balance equation of the strip blocks, the yield condition of the bottom slip face of the strips blocks, the yield condition of contact face between the strip blocks and other constraint conditions are combined to build a nonlinear mathematical planning model for slope stability analysis, and an optimization algorithm is utilized to solve the global optimum maximum stable safety coefficient. By means of the method, the performance that the slope safety coefficient has a floor solution can be achieved. The method has the advantages of being clear in conception, high in calculation accuracy and the like and can be applied to stability analysis of soil slopes or rock slopes.

Owner:KUNMING UNIV OF SCI & TECH

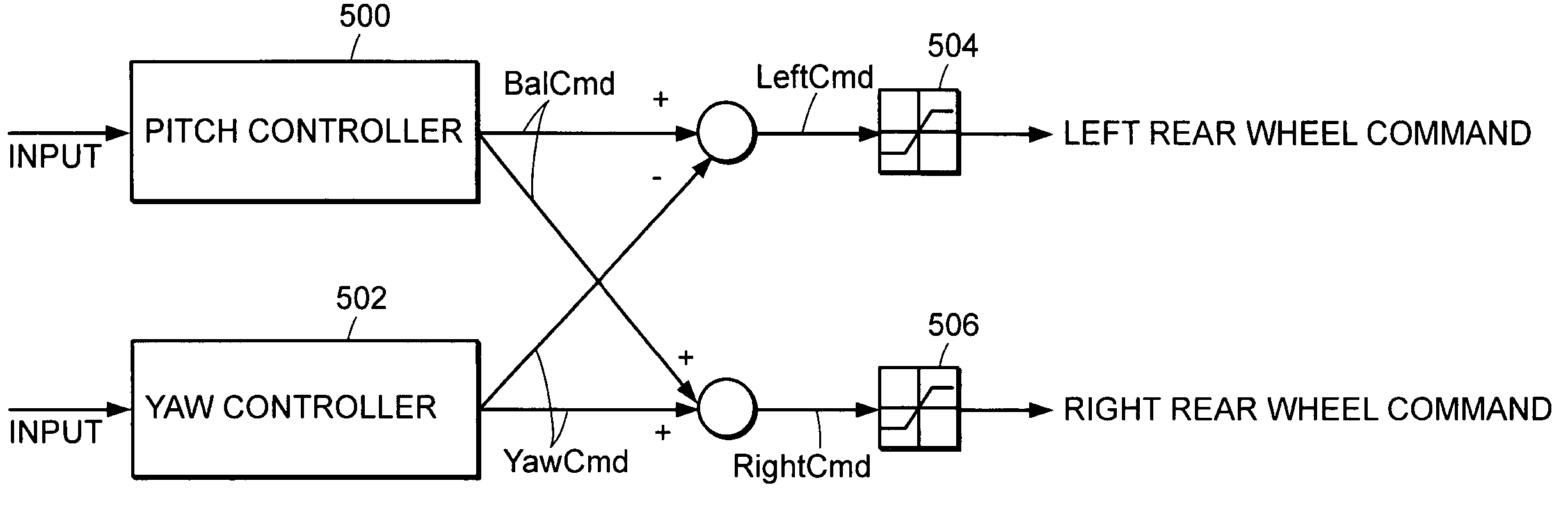

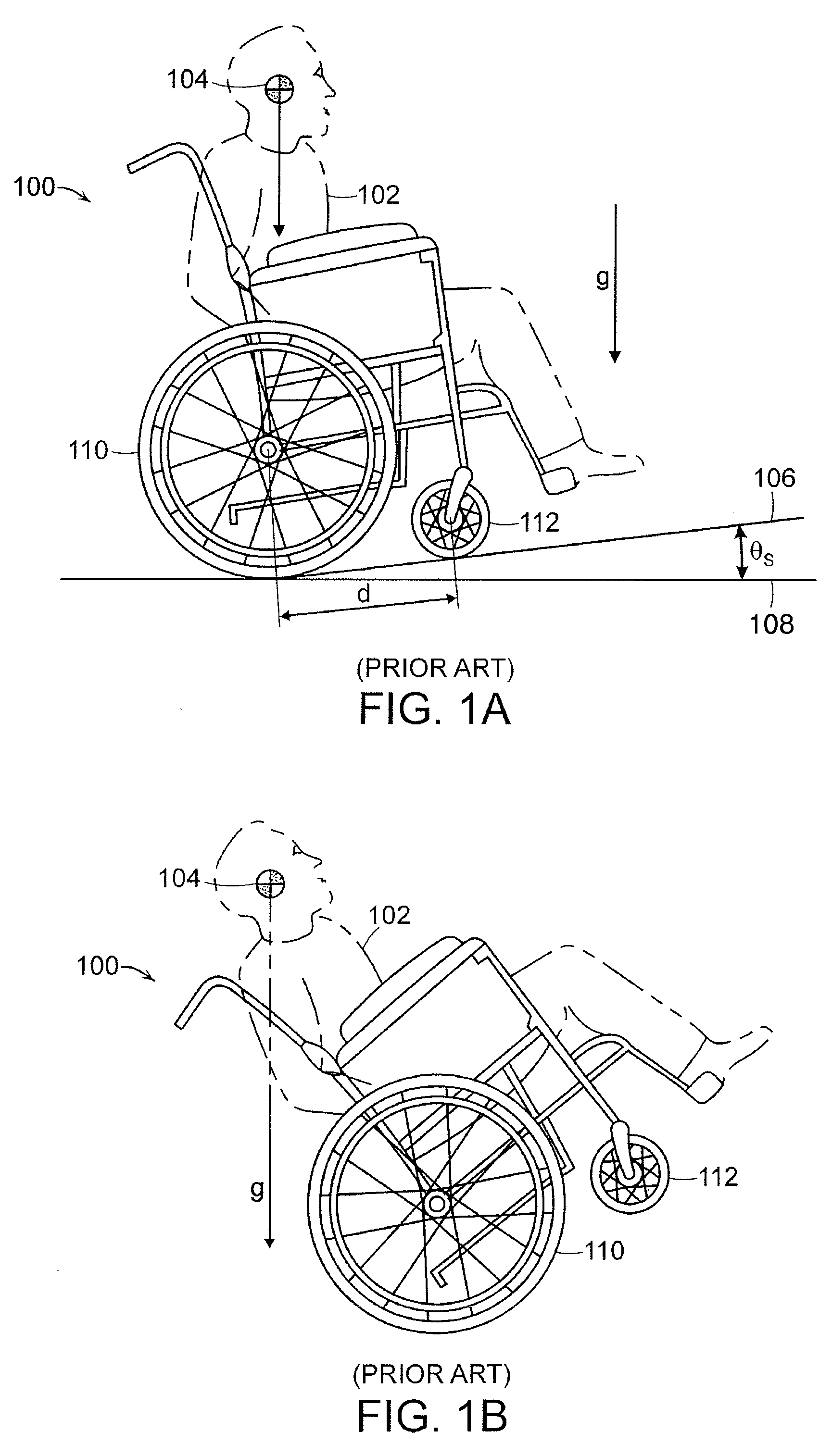

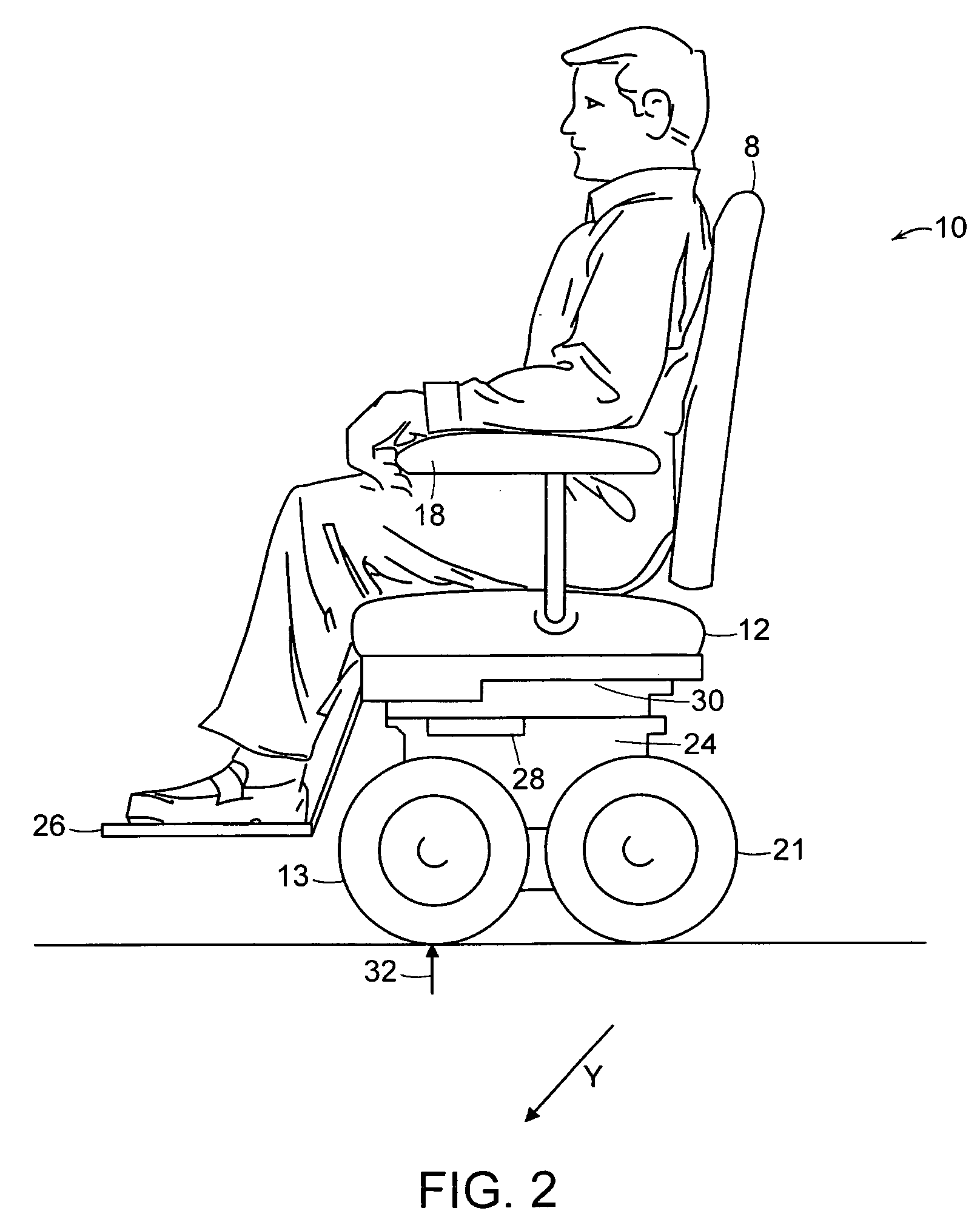

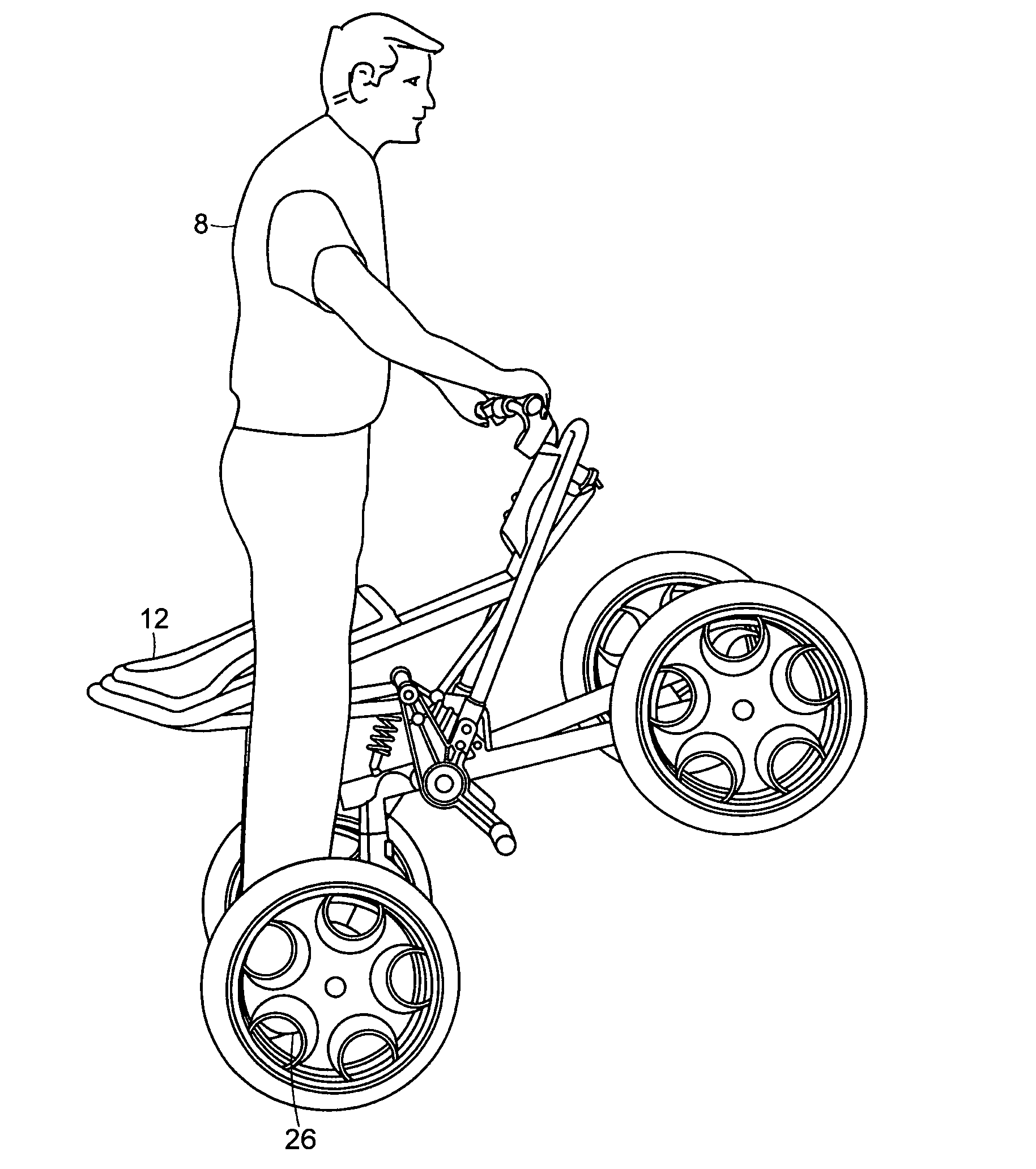

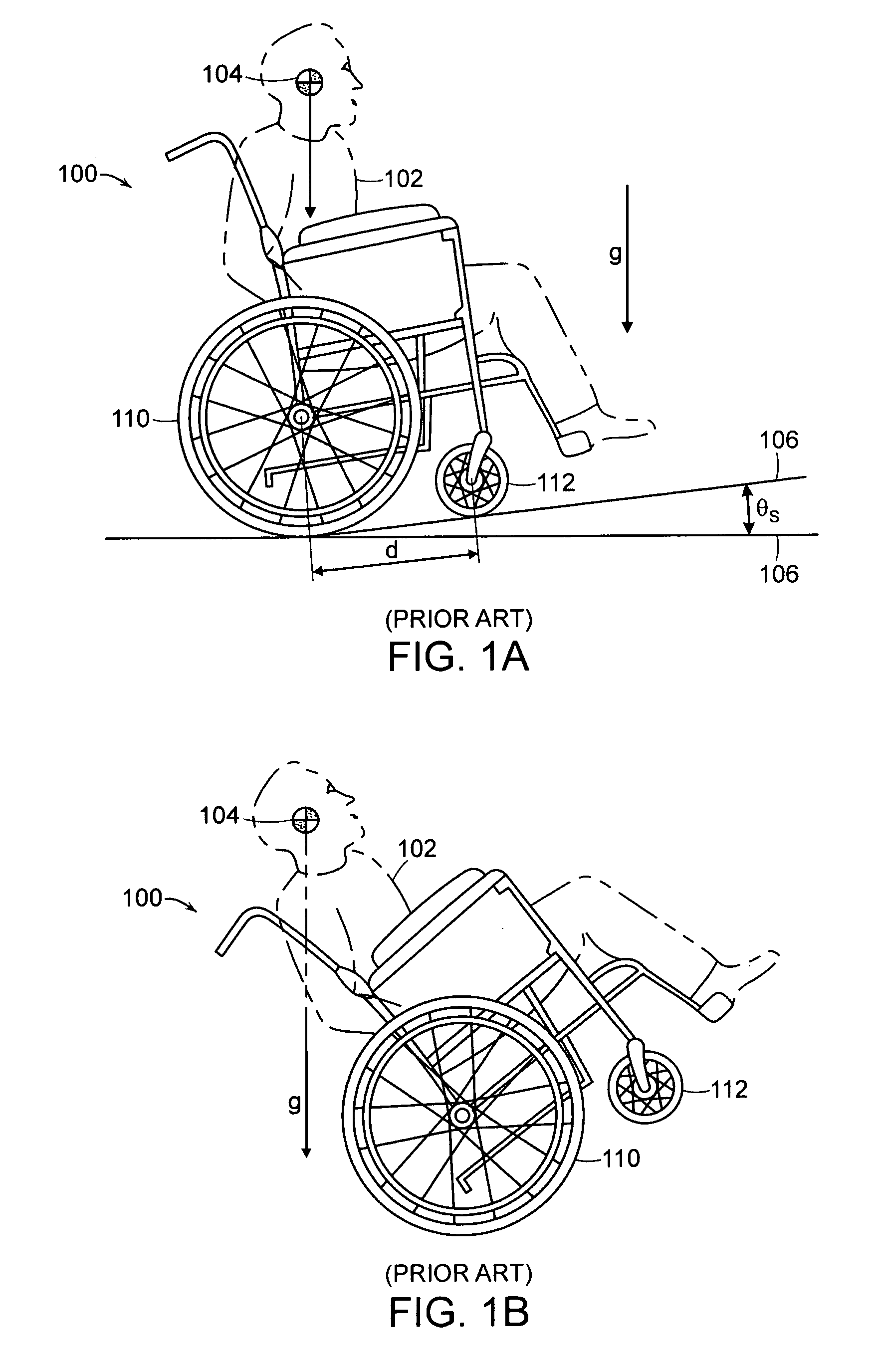

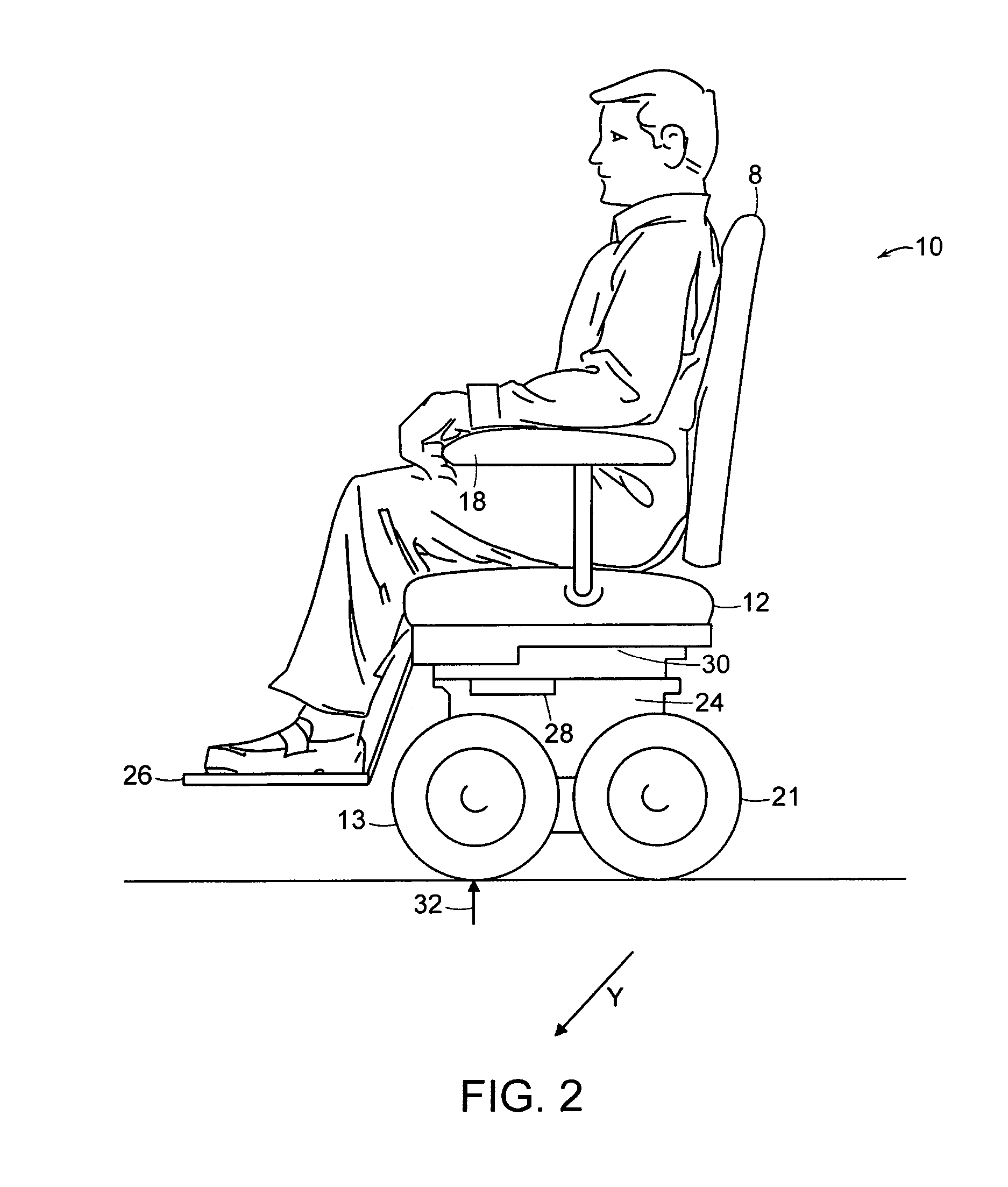

Vehicle control by pitch modulation

A method for fore-aft stabilization of a vehicle for motion in a specified direction over an underlying surface. The vehicle has at least one forward wheel and at least one aft wheel, and the forward wheel is characterized by a force normal to the instantaneous direction of motion of the vehicle. A motor actuator drives each aft wheel, and a controller governs the motor actuator or motor actuators in such a manner as to dynamically stabilize the vehicle, according to a uniform control law, when the forward wheel is in contact with the underlying surface or not. A torque is applied to the aft wheel on the basis of vehicle pitch or the force on the forward wheel normal to the direction of motion. Additionally, a periodic rotational modulation may be applied to the aft wheel, and a stabilizing torque provided based on a detected response, either of vehicle pitch or of normal force on the front wheel. Left and right motor actuators may independently control left and right aft wheels to continue turns as governed by user steering, whether or not forward wheels are in contact with the ground.

Owner:DEKA PROD LLP

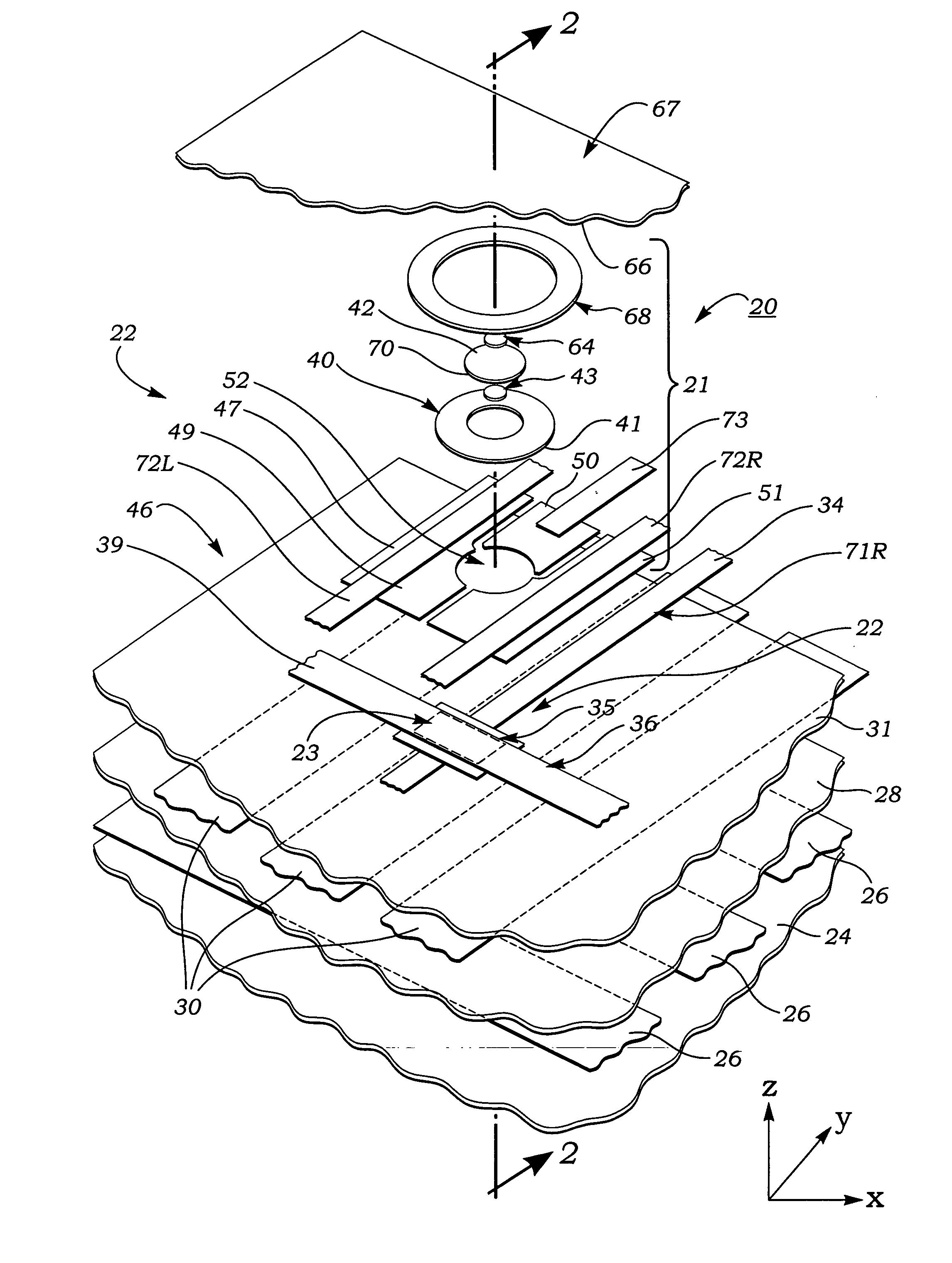

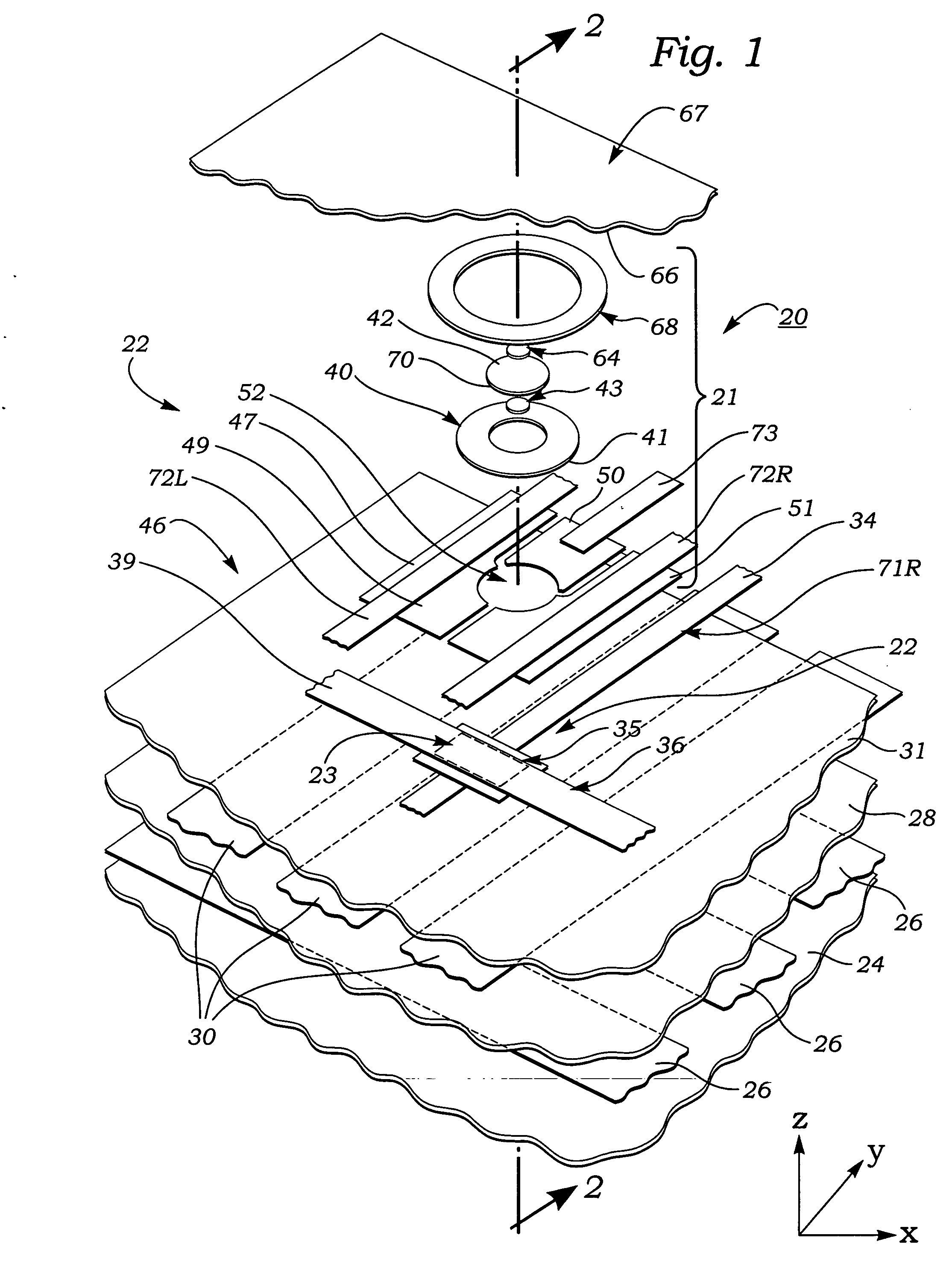

Capacitive Force/Torque Sensor

ActiveUS20180073942A1Force measurementApparatus for force/torque/work measurementElastomerCapacitance

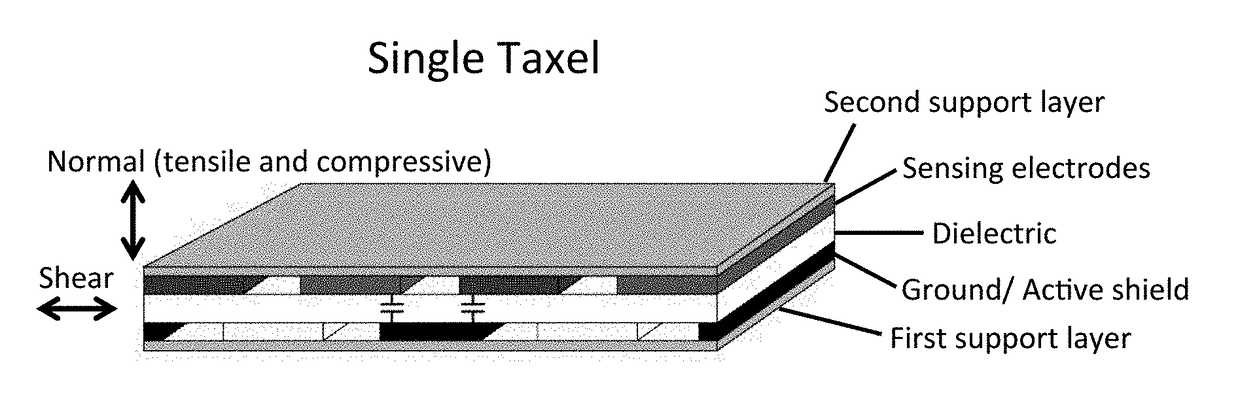

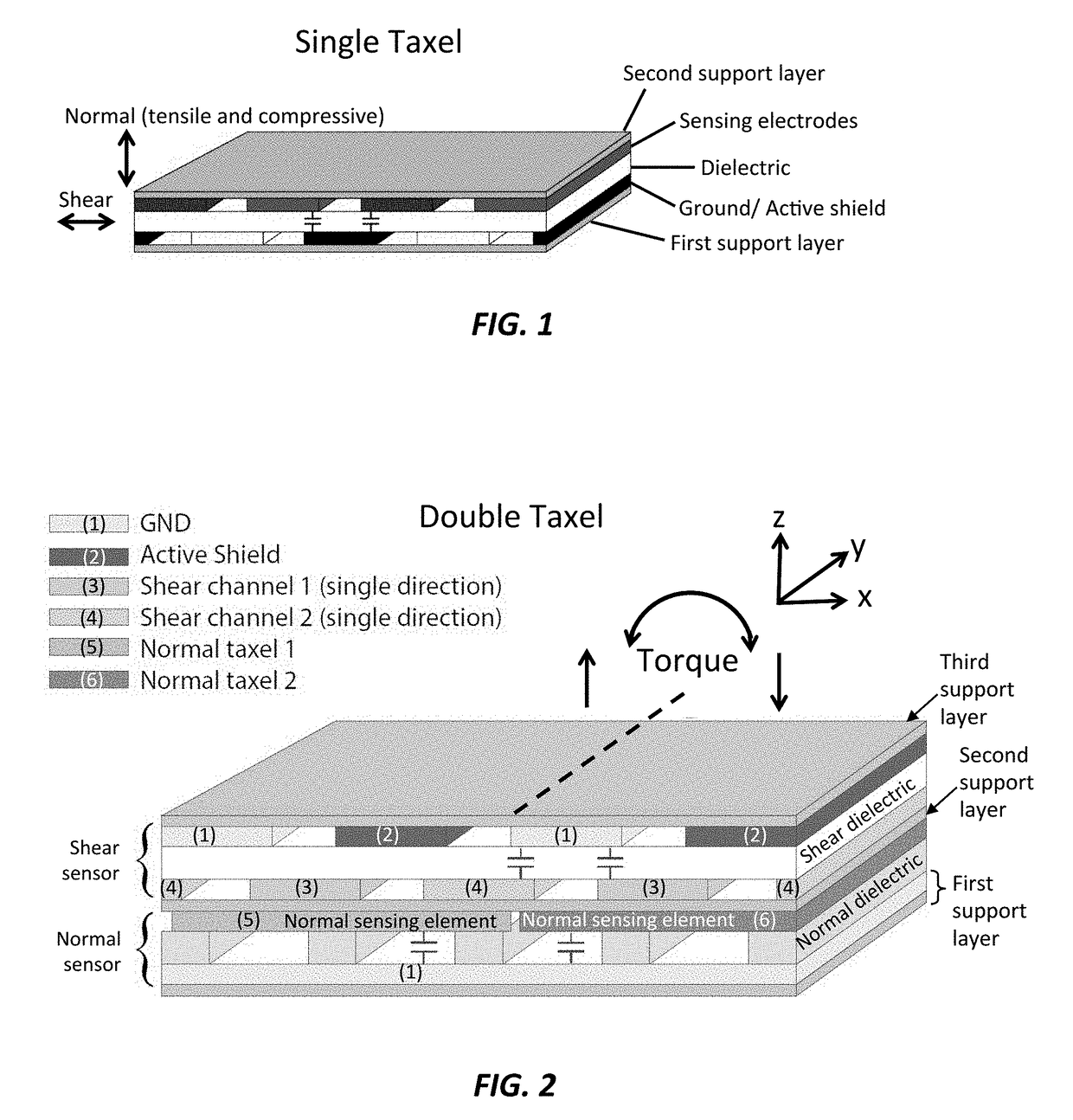

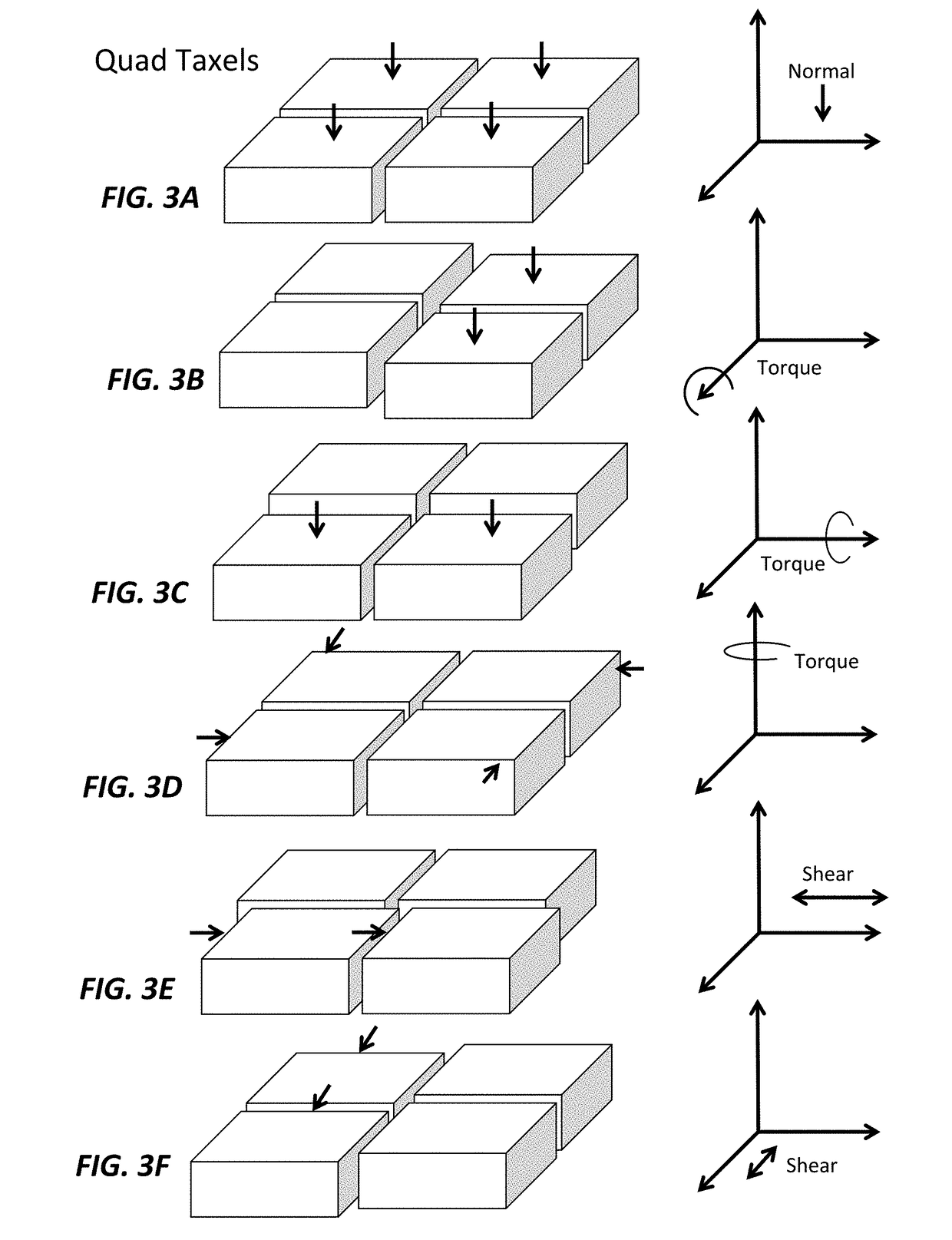

A capacitive force sensor is provided that includes a first support layer and a second support layer, a dielectric layer disposed between the first support layer and the second support layer, where the dielectric layer is a non-conductive elastomer that is incompressible in the a normal direction and deflects in a shear direction, a layer of parallel conductive traces disposed between and bonded to the dielectric layer and the first support layer, and a conductive layer of parallel shear channel traces having at least two distinct channels disposed between and bonded to the dielectric layer and the second support layer, where the parallel conductive traces and the parallel shear channel traces are locally parallel to each other and provide capacitive shear force measurement sensitivity while rejecting normal forces, where the normal force measurement is decoupled from the shear force measurement.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Electrical power connector

Owner:FCI AMERICAS TECH LLC

Normal force gradient/shear force sensors and method of measuring internal biological tissue stress

InactiveUS20050241409A1Small sizeEffective friction forceForce measurementDiagnostic recording/measuringSensor arrayElectrical conductor

A normal force gradient / shear force sensor device and measurement method for measuring internal stresses in tissues of a person supported by a chair or bed includes a planar matrix array of peripheral normal force sensors radially spaced from central shear force sensors, comprising an electrically conductive disk located within a circular opening bordered by circumferentially spaced apart electrodes. The disk and electrodes are located between upper and lower cover sheets made of a stretchable material such as polyurethane; one cover sheet is adhered to the disk and the other sheet is adhered to a support sheet for the electrodes. Motion between the cover sheets in response to shear forces exerted on the array causes the disk to press more or less tightly against the electrodes varying electrical conductance between the disk and electrodes proportionally to the magnitude and direction of the shear force. Each normal force sensor includes an electrically conductive film pressed between row and column conductors. Measurements of conductance values of pairs of sensor, which vary proportionally to normal forces exerted on the sensor, are used to calculate a gradient vector of normal forces exerted by a body part on the sensor array, which is combined with the shear force vectors in an algorithm to calculate internal reaction shear forces, e.g., on flesh near a bony prominence.

Owner:VISTA MEDICAL

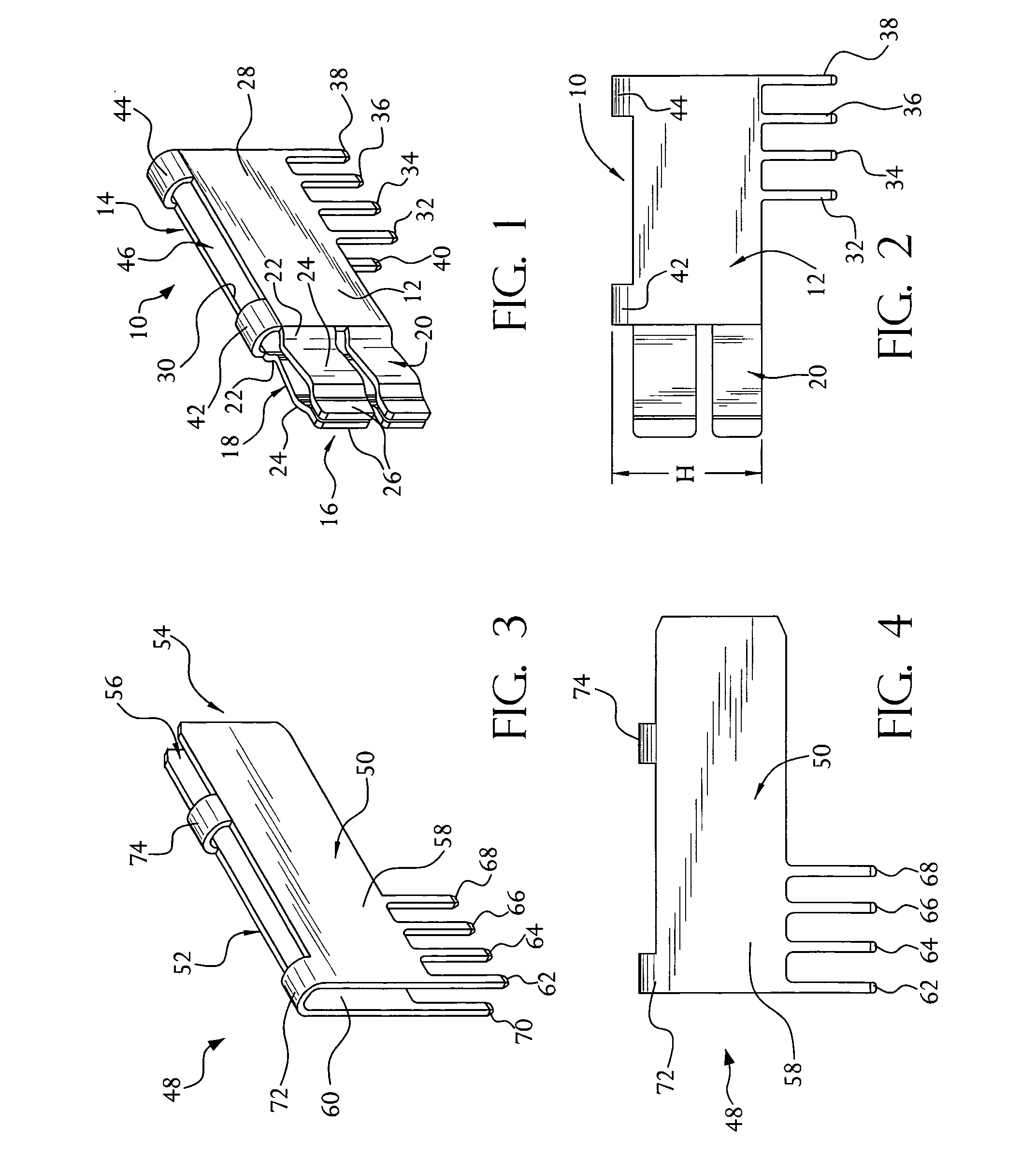

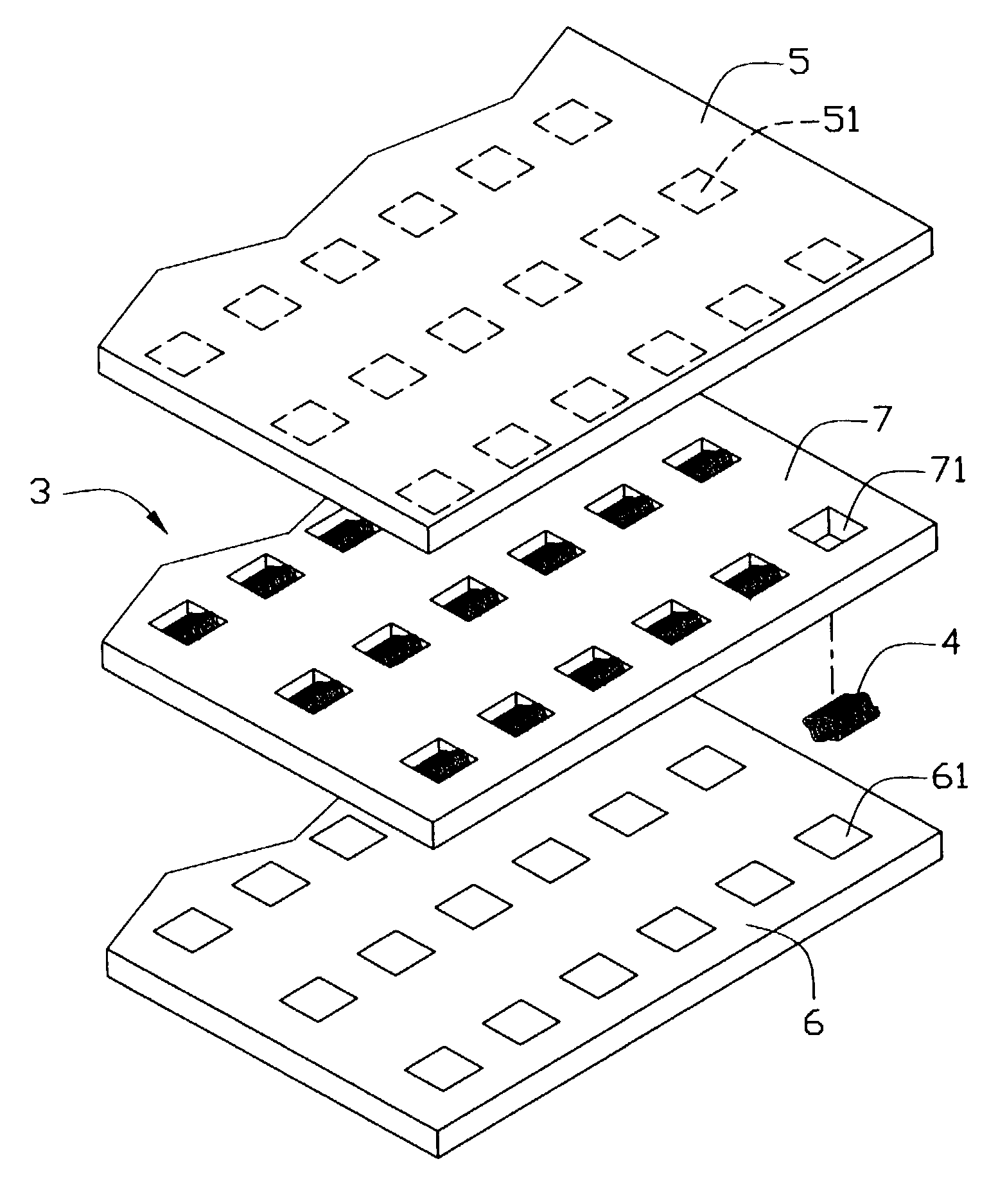

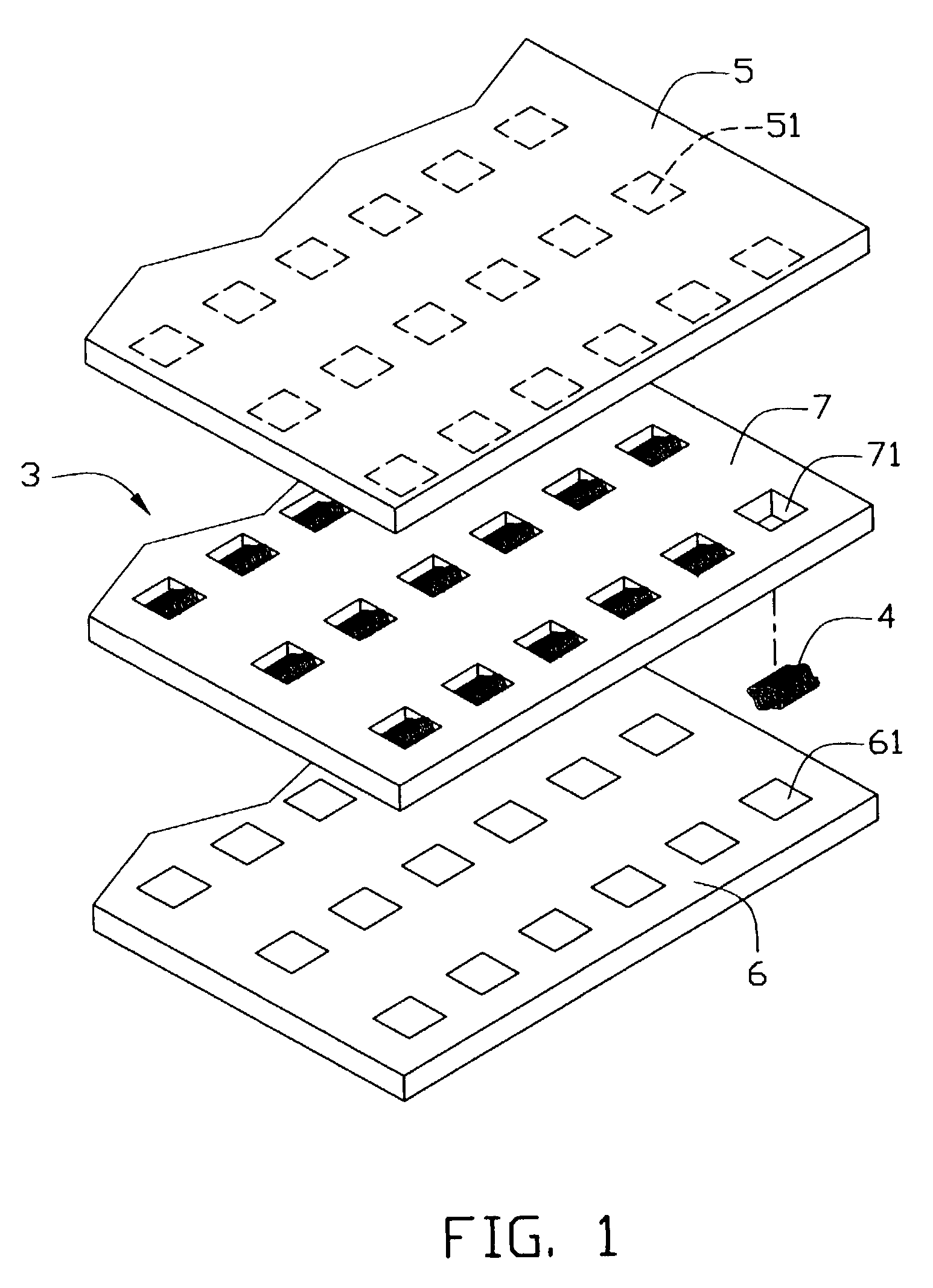

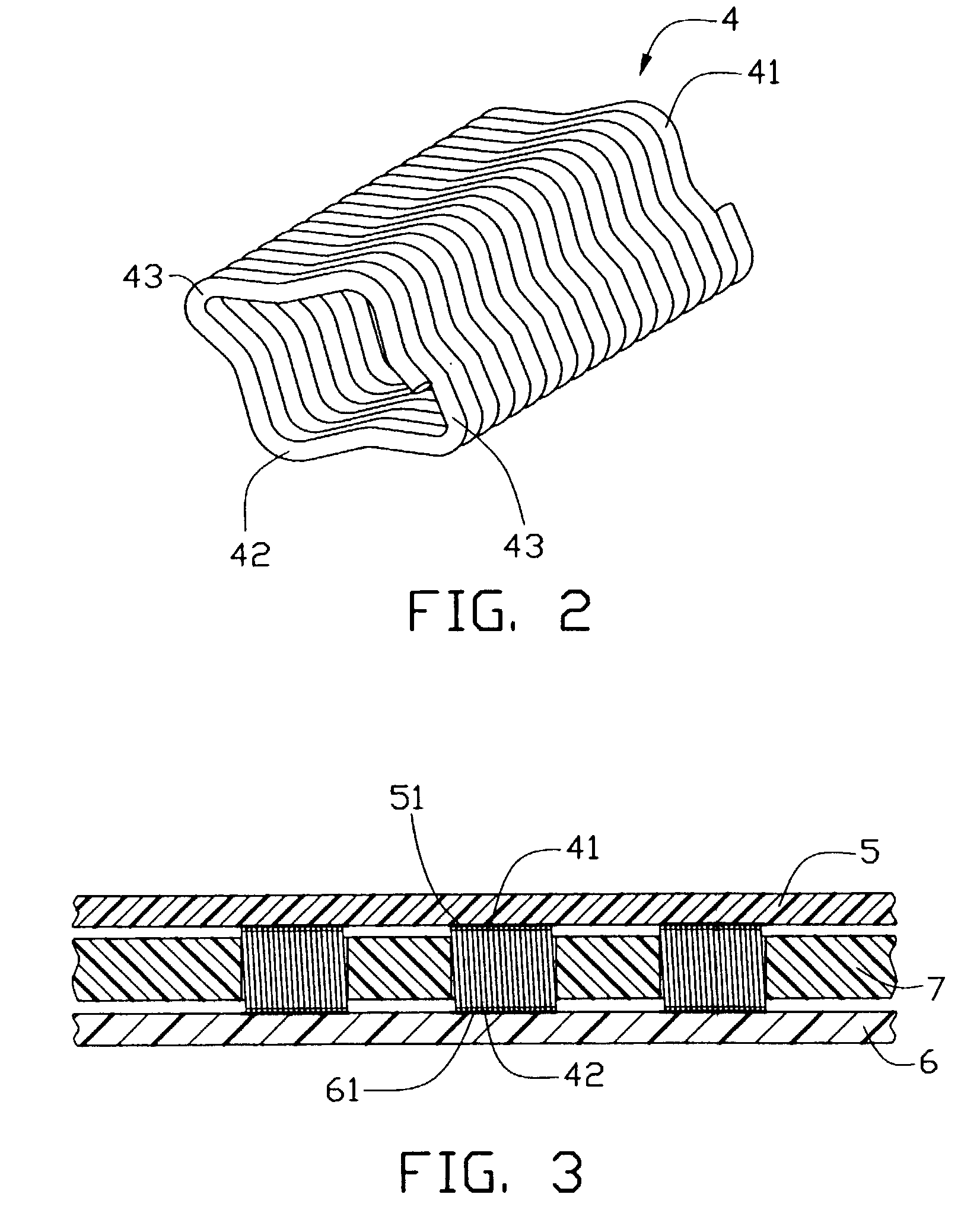

Land grid array connector with canted electrical terminals

InactiveUS20040002234A1Coupling contact membersElectrical connection printed elementsElectricityCoil spring

An electrical connector (3) for electrical interconnection of a pair of circuit substrates (5, 6) includes a carrier plate (7) defining a plurality of openings (71) retaining electrical terminals (4) therein. The openings correspond to circuit pads (51, 61) on the circuit substrates. Each terminal generally has a canted coil spring configuration. Each loop of the canted coil spring configuration has curved contact portions (41, 42) for bearing against corresponding circuit pads, engaging portions (43) for engaging side walls of the carrier plate at a corresponding opening, and connection portions interconnecting the curved contact portions and the engaging portions. Radiuses of curvature of the curved contact portions are less than radiuses of curvature of the connection portions of each loop. Each loop closely abuts an adjacent loop of the terminal. Relatively large contact normal force is thus attained when the curved contact portions bear against the corresponding circuit pads.

Owner:HON HAI PRECISION IND CO LTD

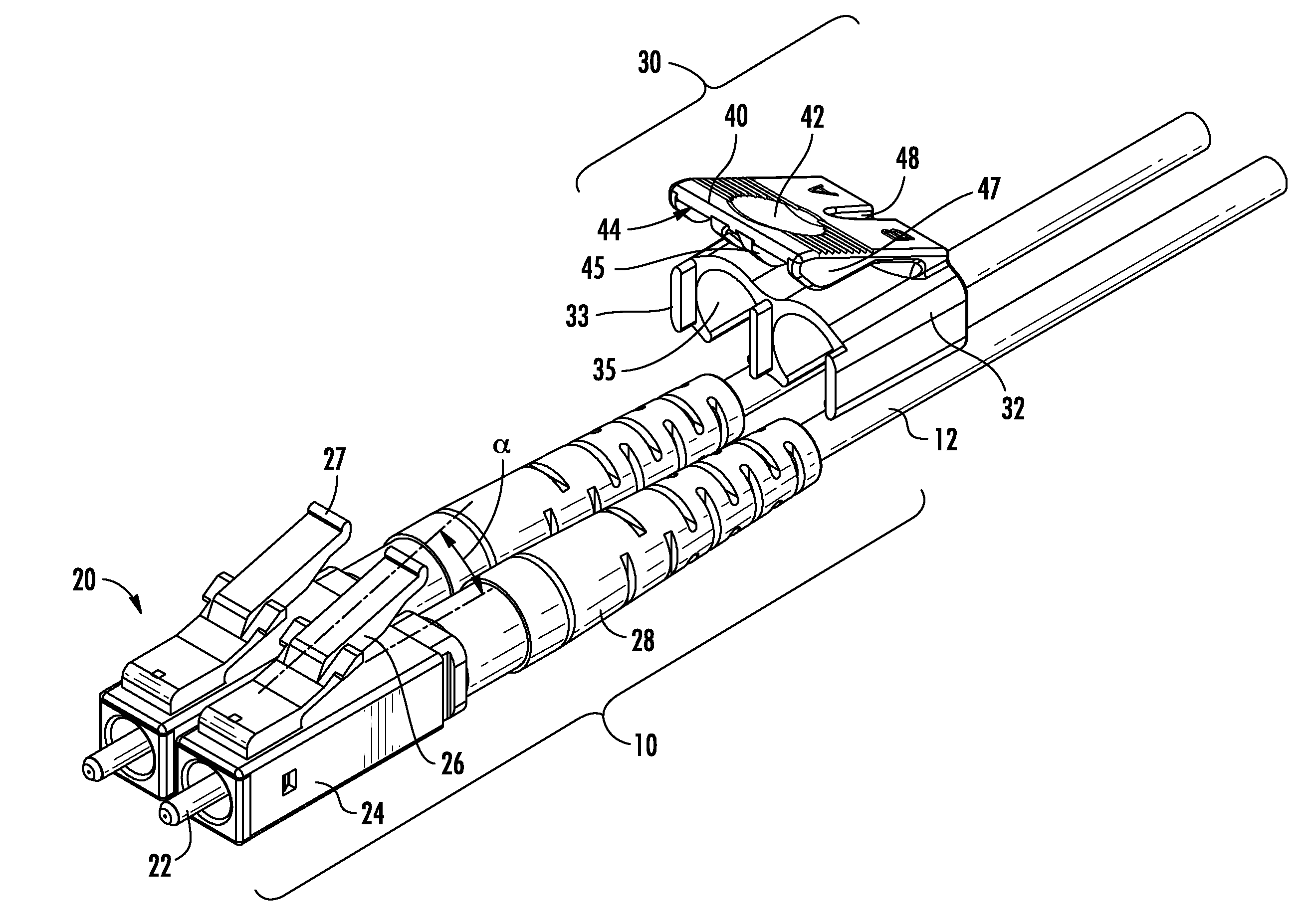

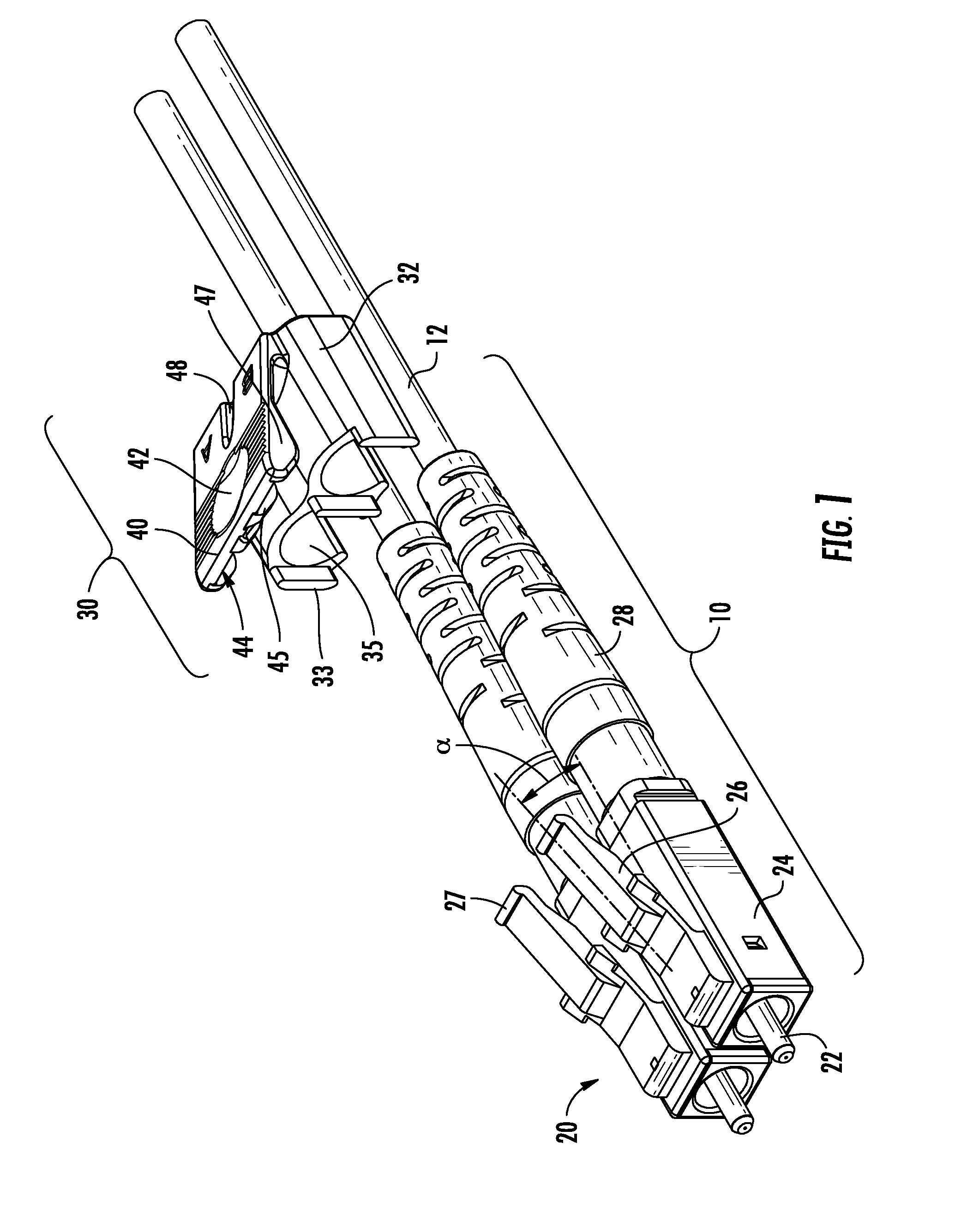

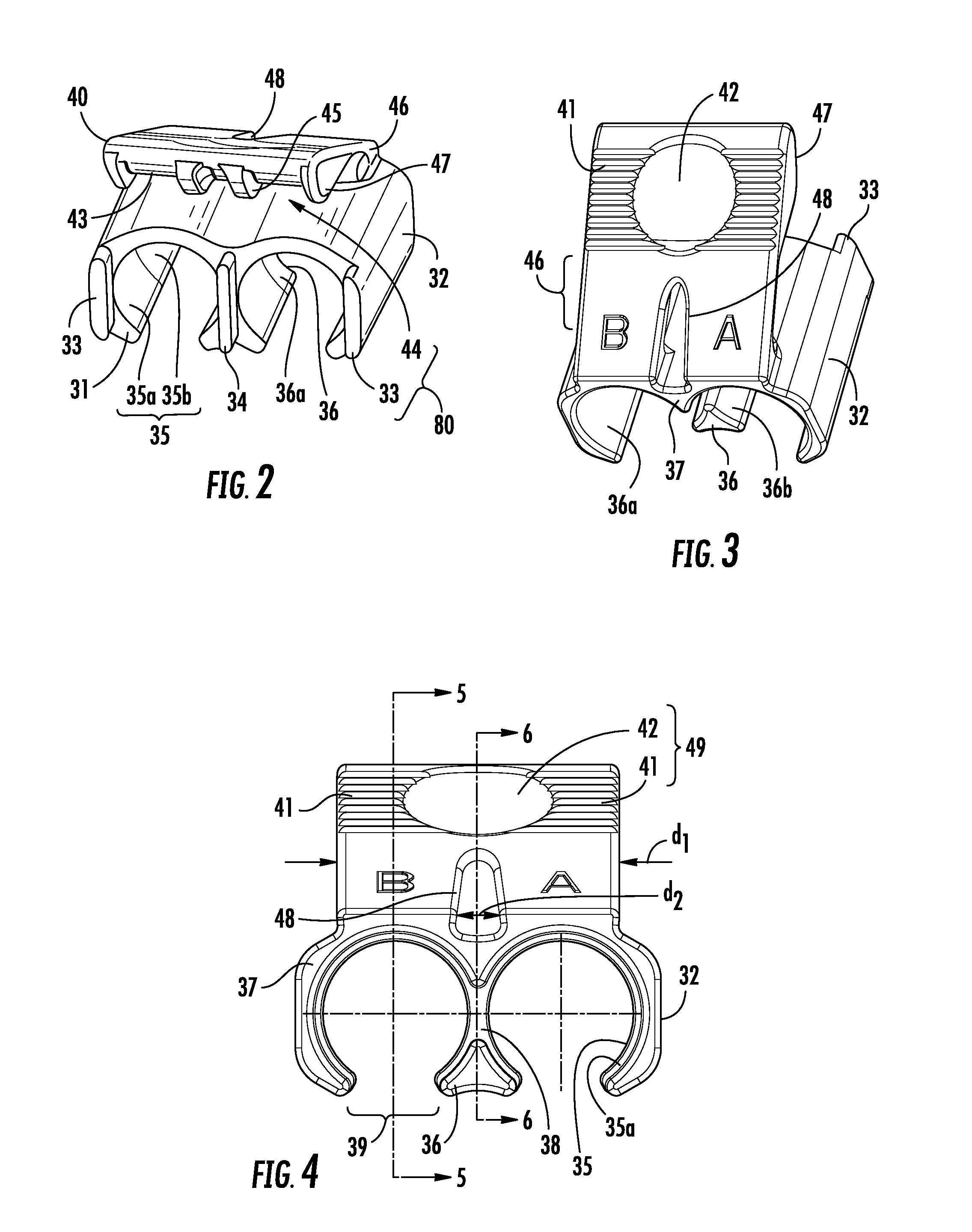

Fiber Optic Connector Assembly and Methods Therefor

A fiber optic connector assembly includes two connectors on fiber optic cables joined together by a clip having a trigger arm and a clip body. The trigger arm extends from the clip body at a shallow angle. The shallow angle of the trigger arm effectively reduces an amount of normal force required to activate latch mechanisms on the connectors. The clip is sandwiched between a connector housing and a boot, inhibiting the clip from axially translating relative to the connector assembly. The clip further includes an anti-rotation system to inhibit rotation of the connector assembly relative to the clip.

Owner:CORNING CABLE SYST LLC

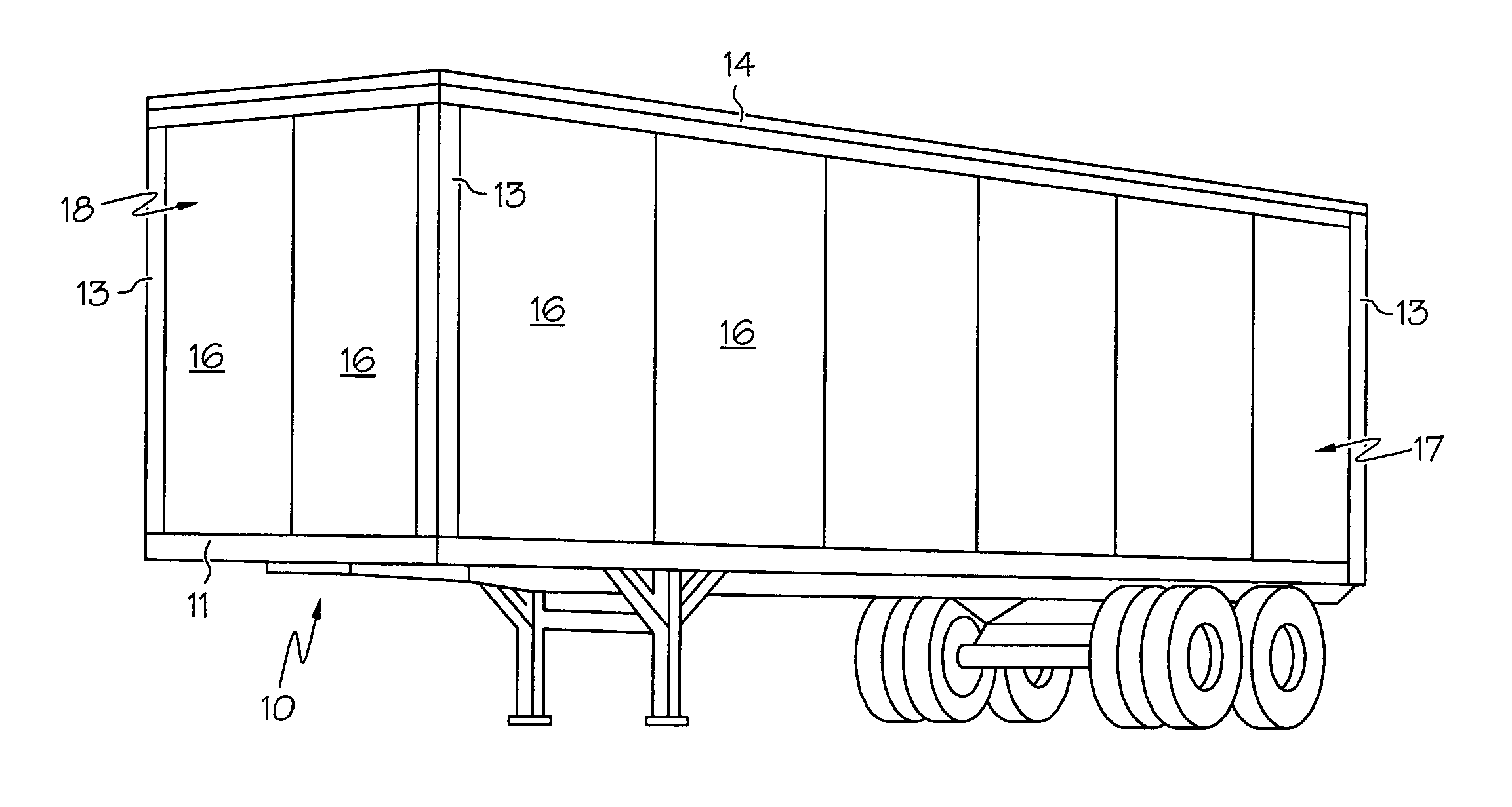

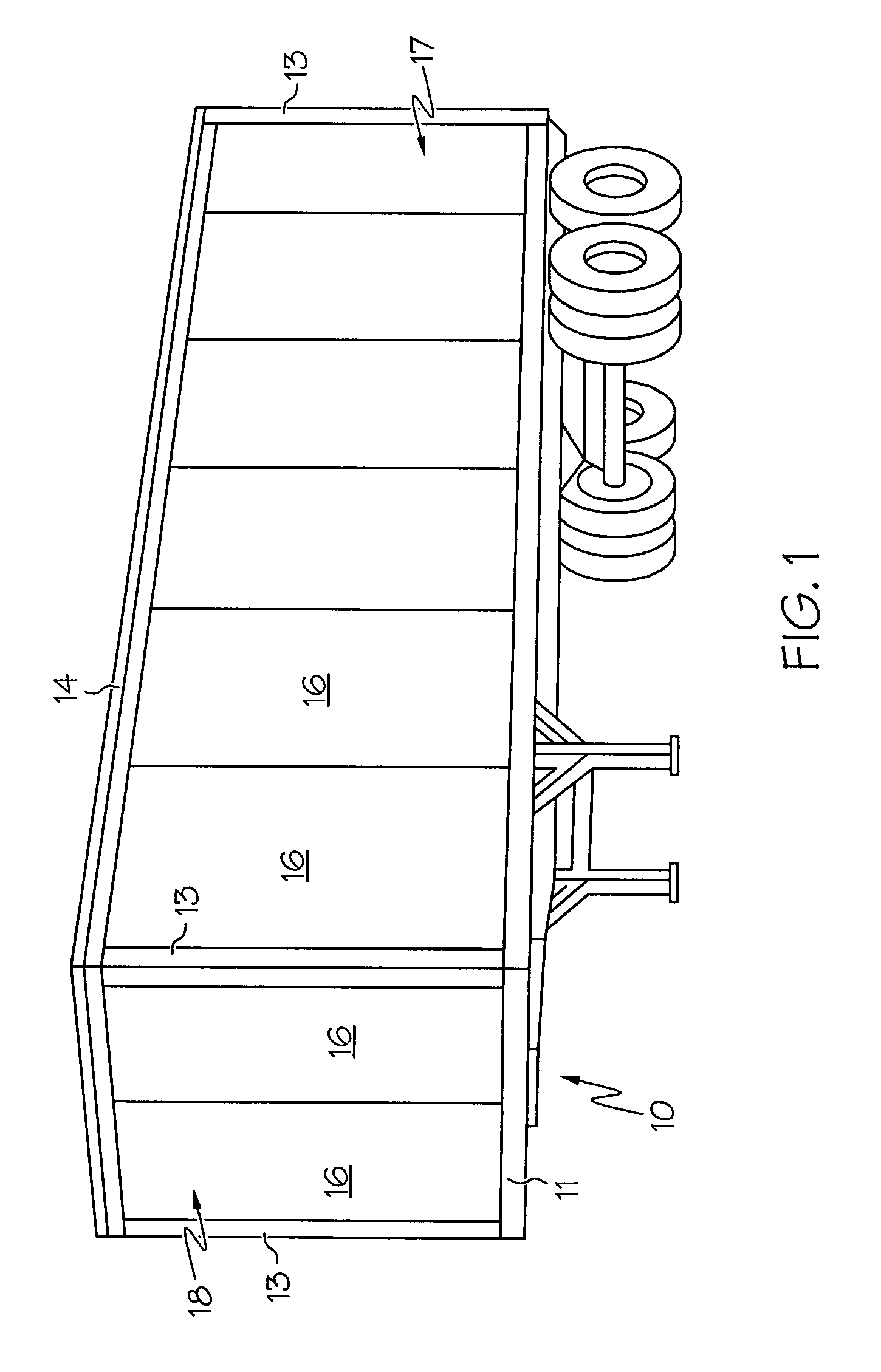

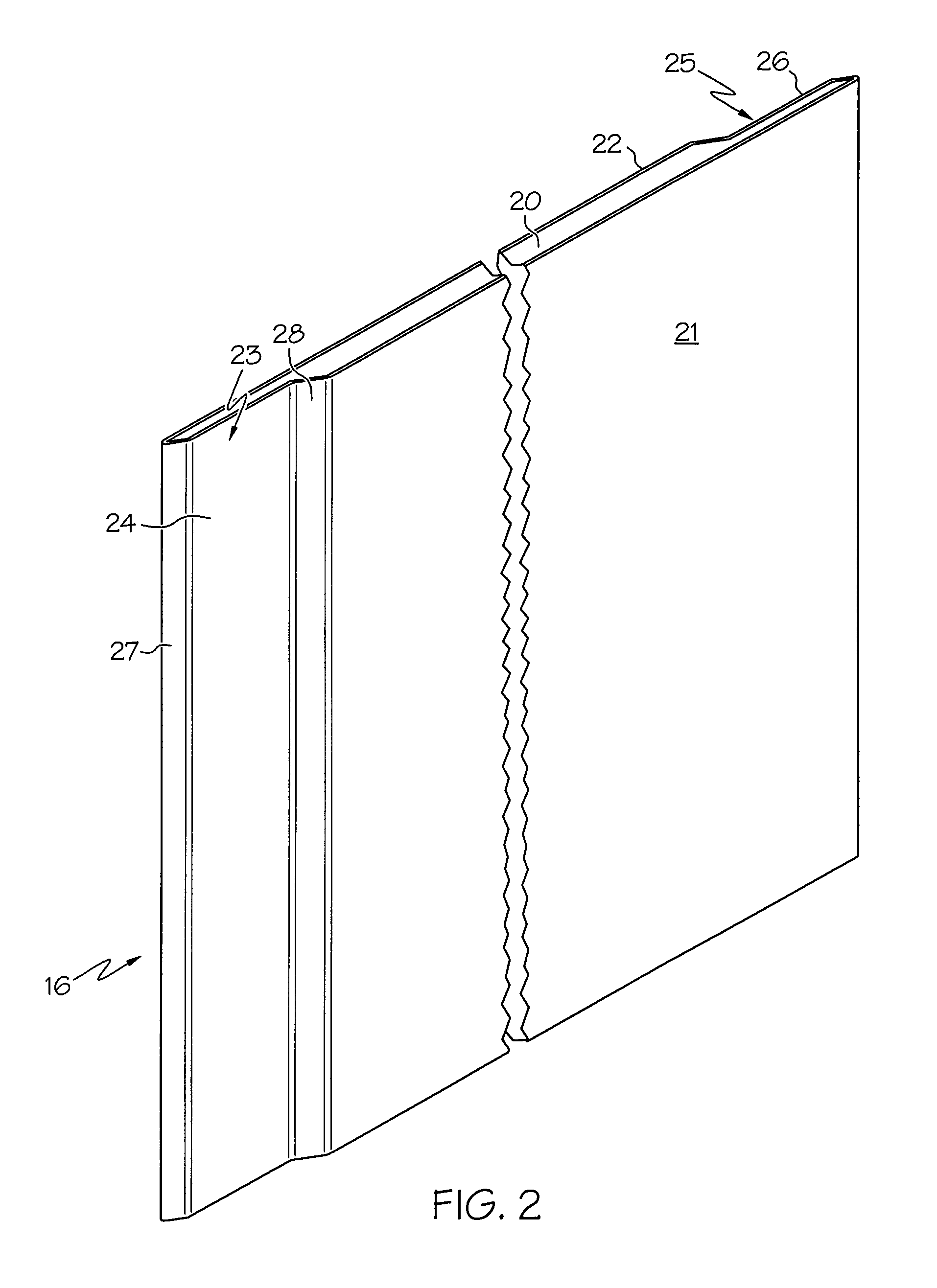

Panels for a walled enclosure

Panels of the invention are used to form large capacity enclosure sidewalls. Trailers, trucks and cargo vans are examples of such enclosures. Intermediate framing support is not needed. Each panel has a polymeric core with a first metal cladding and a second metal cladding. The core has opposed longitudinal configured ends, each of which has a stepped shoulder which extends the length of the panel. The metal claddings follow the contour of the stepped shoulder. The stepped shoulders are offset from the first face of the core approximately one-half the thickness of the panel. In assembling a walled enclosure sidewall, the panels are positioned so that adjacent stepped shoulders mate together to create a flush face surface. Joining means are used in the stepped shoulder areas to permanently join together adjacent panels. The joint formed by the attachment has a total of four metal cladding layers and two interposed polymeric cores to give the joint sufficient rigidity for the sidewall to withstand normal forces during use.

Owner:GEROME PERRY

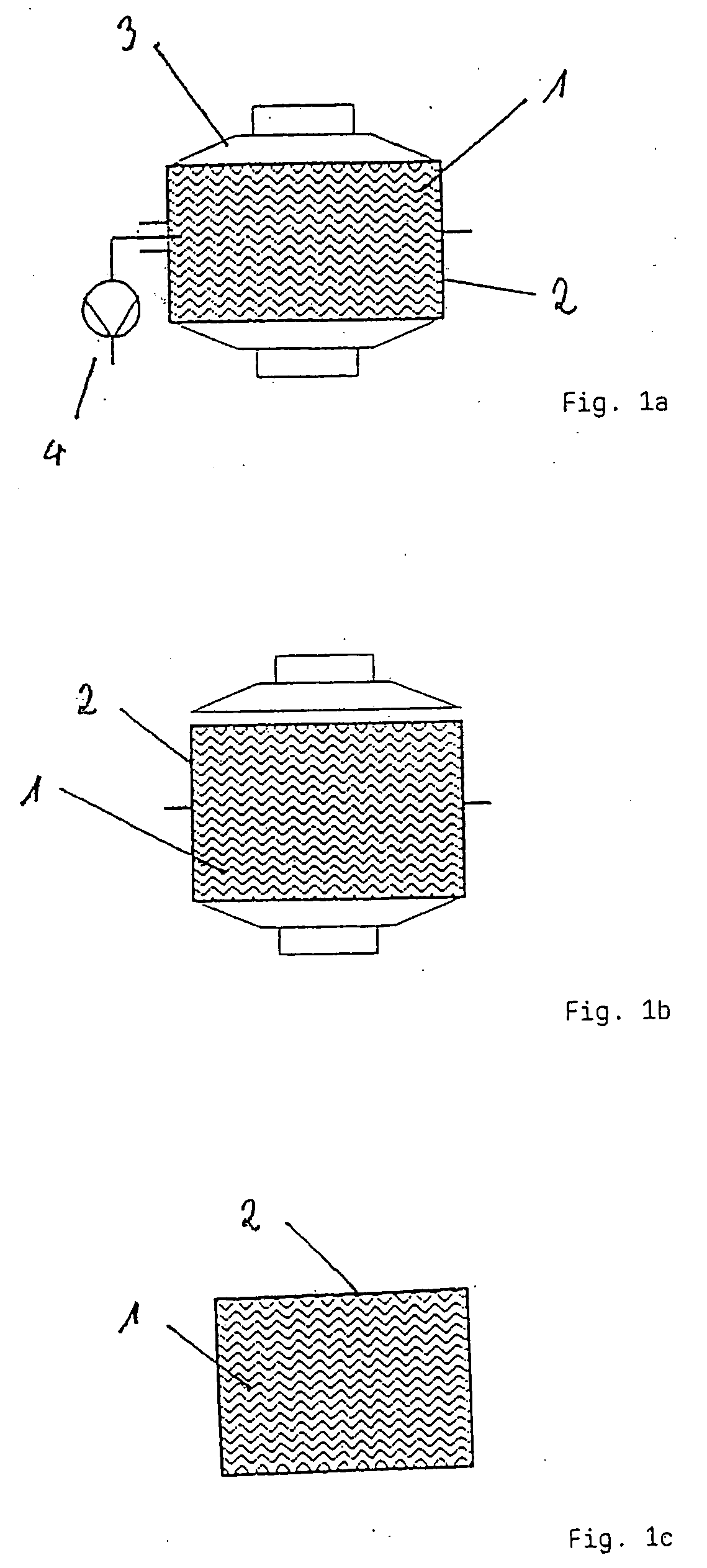

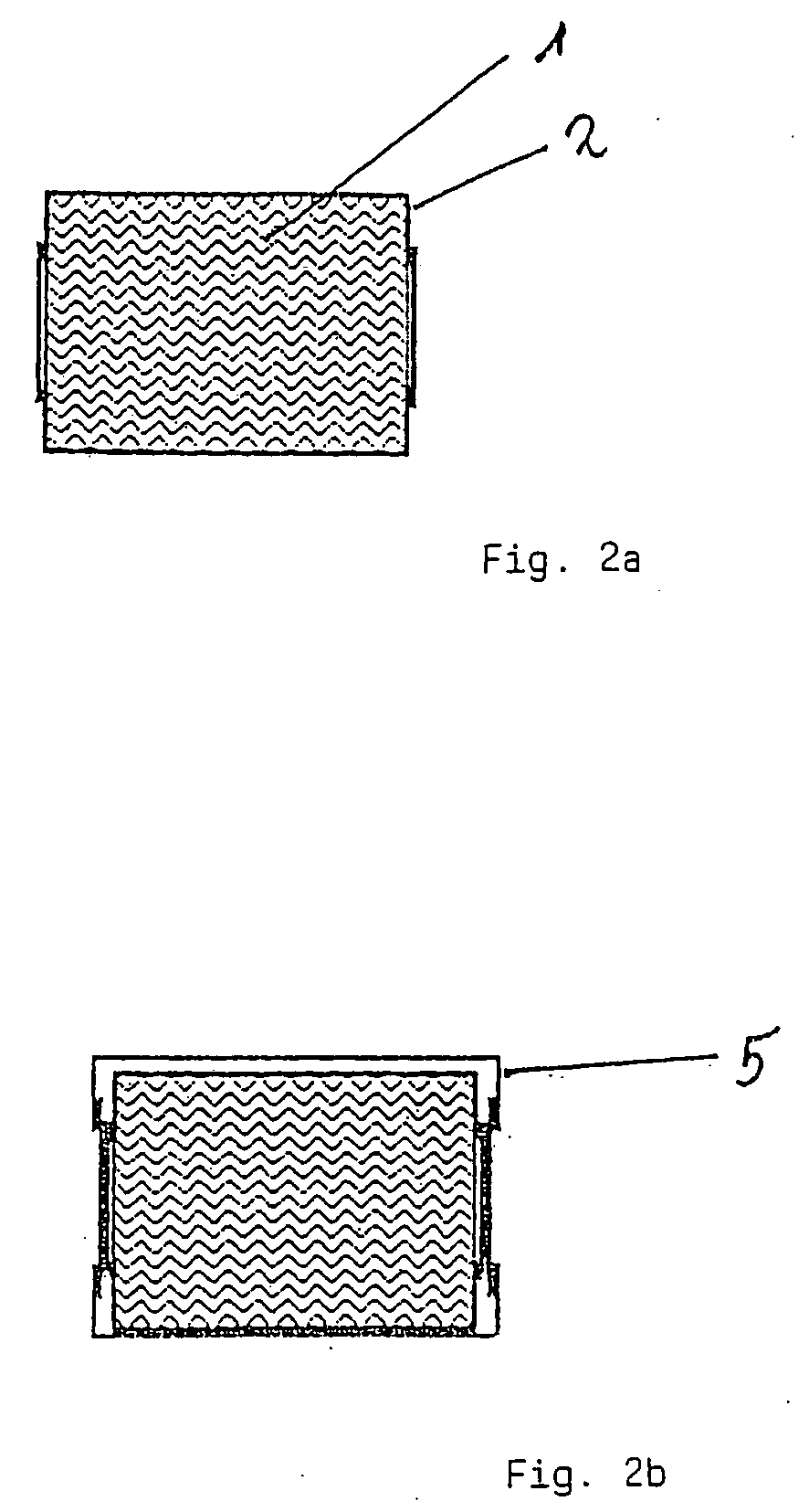

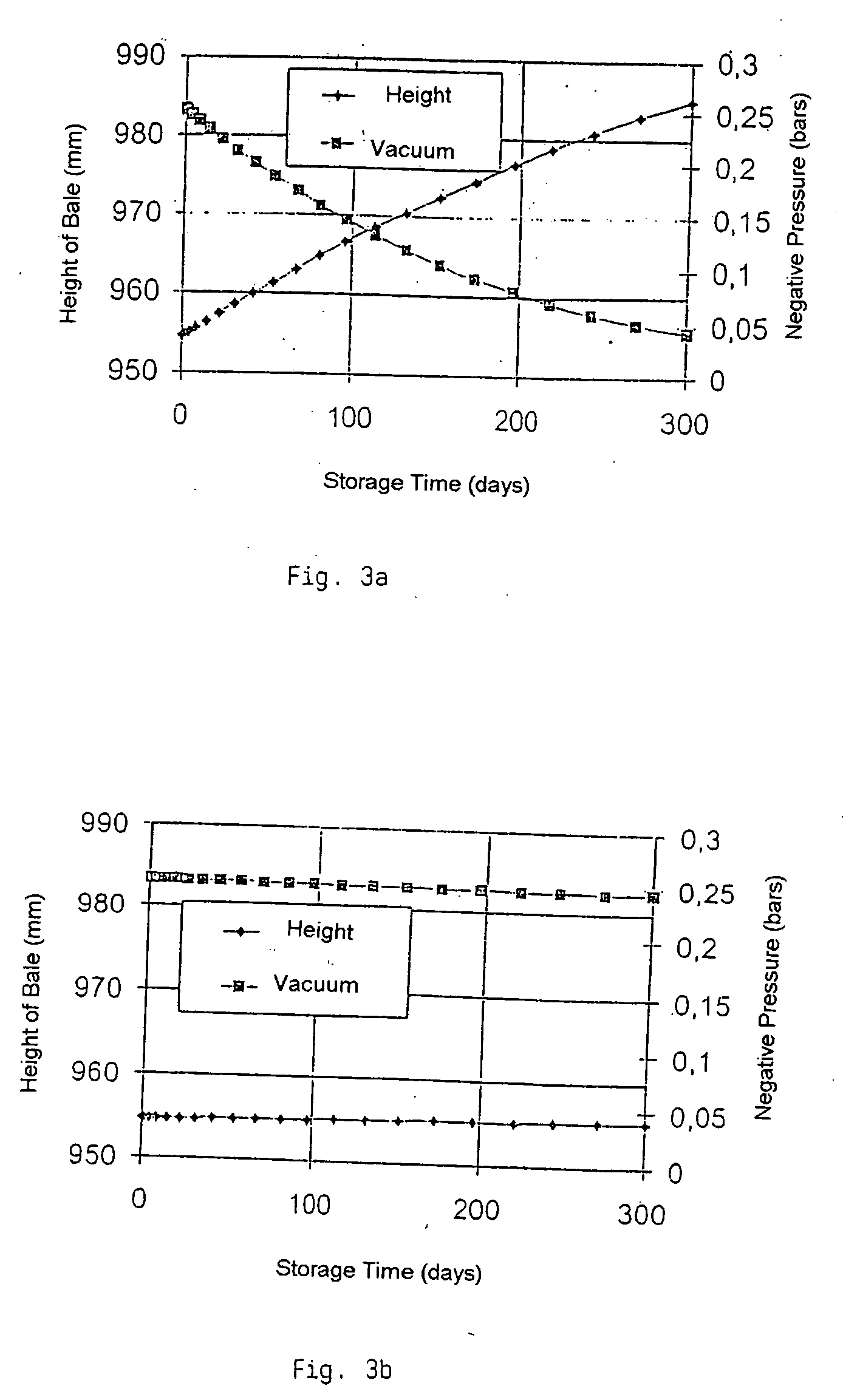

Highly compressed filter tow bales and process for their production

ActiveUS20050161358A1Reduce compressive loadPaper/cardboard wound articlesFilament handlingInternal pressureMechanical engineering

Disclosed is a packed, highly compressed cuboid-shaped filter tow bale, the top side and bottom side of which are free from noisome curvatures or constructions. The bale is characterized by the fact that (a) the bale has a packing density of at least 300 kg / m3, (b) the bale is entirely wrapped in an elastic packaging material which is provided with one or several convectively airtight connections, and (c) the upper side and lower side of the bale are substantially planar such that a flat plate which fully covers the bale can be pressed onto the upper side of the bale via a centrally effective normal force of 100 N and at least 90 percent of the surface of the upper side of the bale, which lies within the largest rectangle that can be inscribed by vertically projecting the bale onto the pressed plate, has a maximum distance of about 40 mm from the flat plate when the unopened bale is placed on a horizontal plane. A particularly suitable method for producing said bale comprises the following steps: (a) filter tow is supplied in a compressed form; (b) the compressed filter tow is enveloped in a wrapping; (c) the wrapping is closed in an airtight manner; and (d) the wrapped bale is relieved of the load. The wrapping of such a bale is largely prevented from bursting as a result of the prevailing internal pressure. The inventive bale has an ideal cuboid shape such that curvatures negatively affecting the bale during transport, or constructions hampering the behavior of the filter tow, are largely prevented from occurring.

Owner:RHODIA ACETOW AG

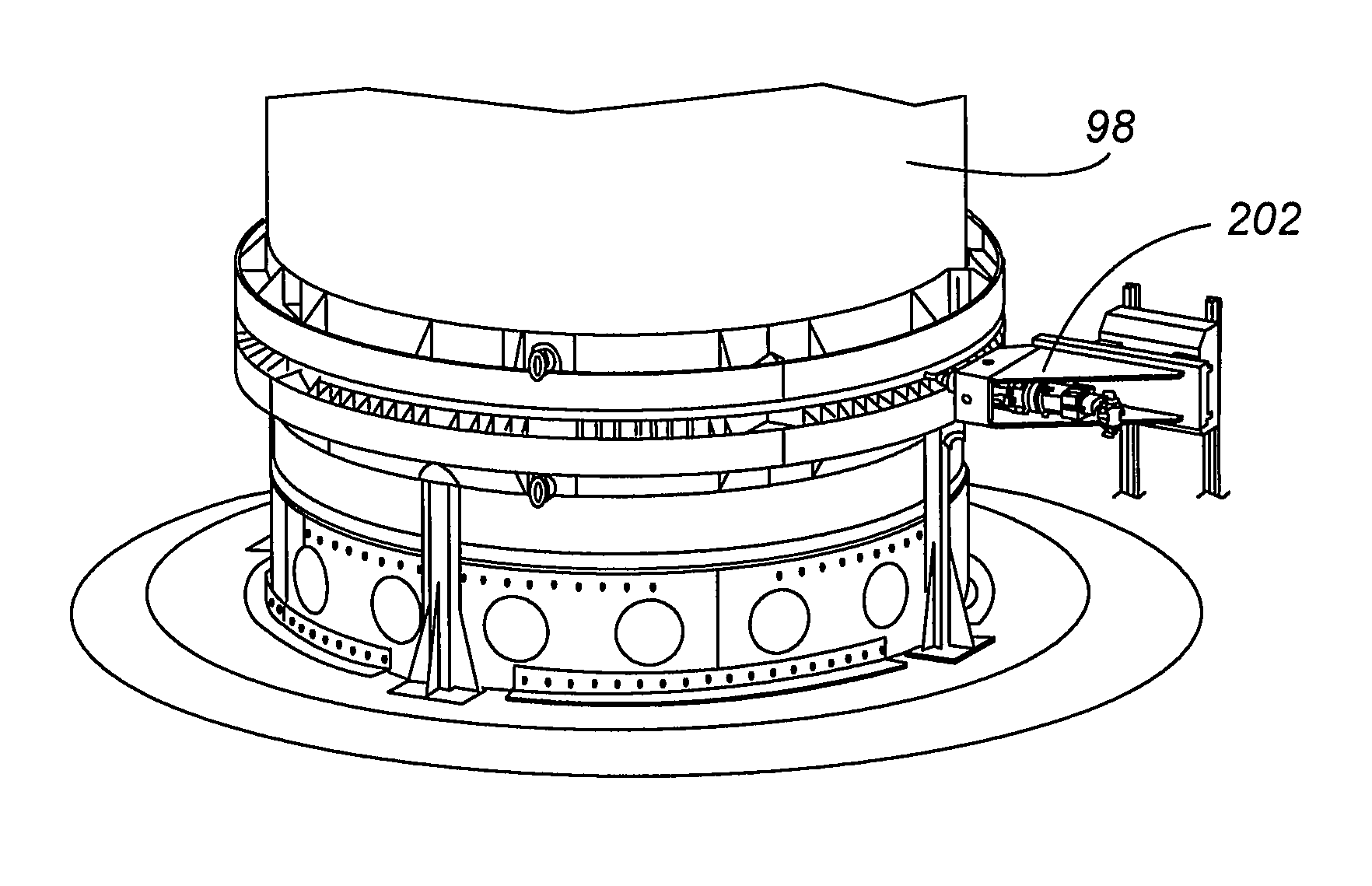

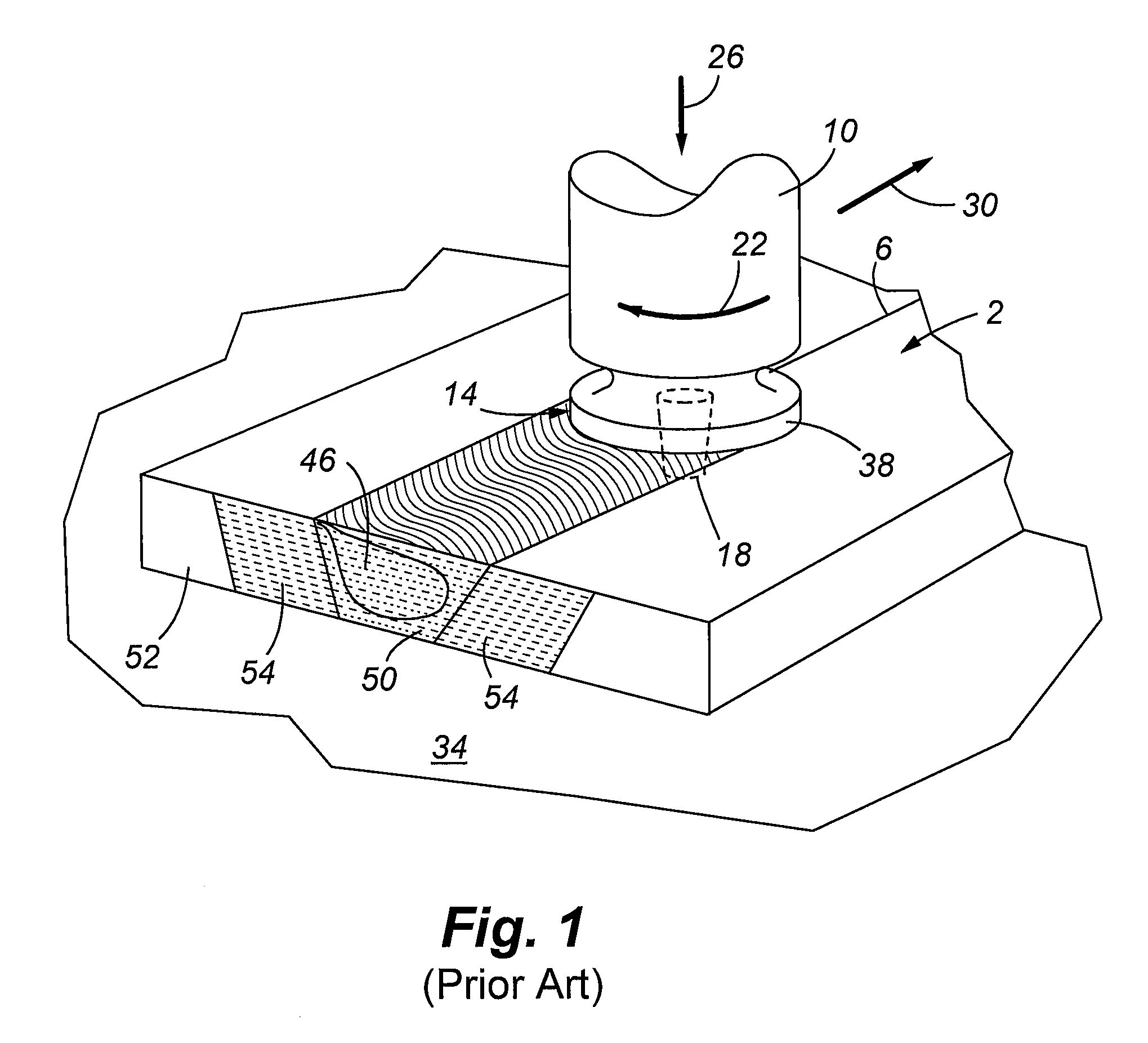

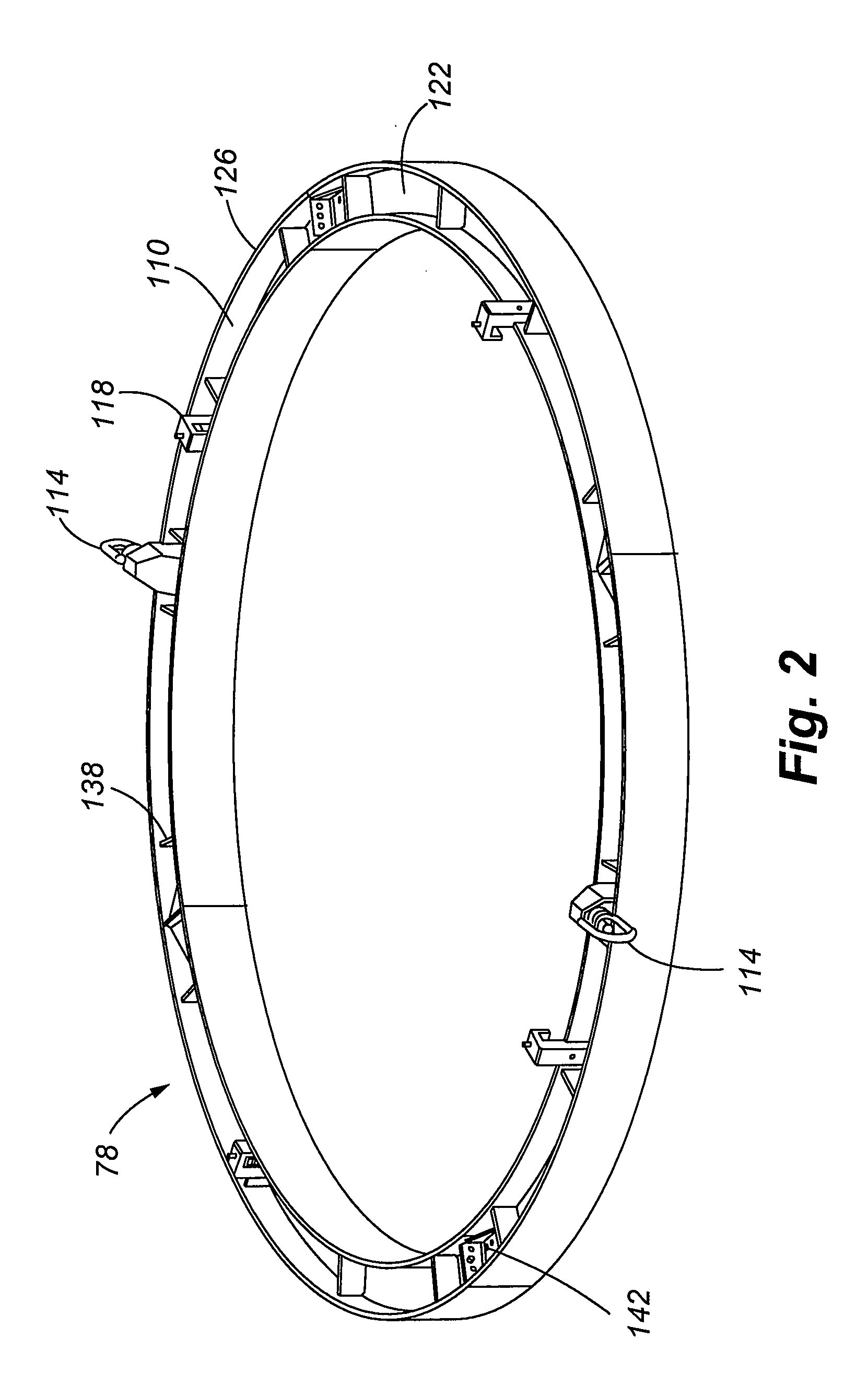

Friction stir welding apparatus, system and method

ActiveUS7866532B1Easy to useManpowerWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

A method of performing friction stir welding is provided herein. More specifically, traditional friction stir welding requires a rotatable head that is forced against a plurality of work pieces to bond the same. The rotational and normal forces generated by the friction stir welding tool are generally reacted by a backing plate, anvil, mandrel or other mechanisms, such hardware are subject to the applied forces and are often supported with additional internal supports. Conversely, a method of performing a friction stir weld is described that omits the need for such a backing member and internal supports as it is performed using a self reacting pin tool.

Owner:UNITED LAUNCH ALLIANCE

Absorbent article having a high coefficient of friction backsheet and a self-release tape tab

The present invention relates to an absorbent article for managing bodily fluids, comprising a high coefficient of friction (“COF”) backsheet and at least one tape tab extending therefrom. The tape tab comprises a minimum amount of pressure sensitive adhesive sufficient to maintain the position of the article when a user's undergarments are away from her body. When the undergarments are near her body, the high COF backsheet acts as the predominant means for maintaining the position of the article due to normal forces exerted by the user's body and undergarments. When the user wants to remove the article from her undergarments, the tape tab provides additional advantages. The user may grasp the tape tab itself for removing the article as an alternative to grasping a portion of the soiled article. In addition the soiled article may be folded or rolled up, and then held in that configuration with the tape tab, for convenient and discreet disposal.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

Vehicle control by pitch modulation

A method for fore-aft stabilization of a vehicle for motion in a specified direction over an underlying surface. The vehicle has at least one forward wheel and at least one aft wheel, and the forward wheel is characterized by a force normal to the instantaneous direction of motion of the vehicle. A motor actuator drives each aft wheel, and a controller governs the motor actuator or motor actuators in such a manner as to dynamically stabilize the vehicle, according to a uniform control law, when the forward wheel is in contact with the underlying surface or not. A torque is applied to the aft wheel on the basis of vehicle pitch or the force on the forward wheel normal to the direction of motion. Additionally, a periodic rotational modulation may be applied to the aft wheel, and a stabilizing torque provided based on a detected response, either of vehicle pitch or of normal force on the front wheel. Left and right motor actuators may independently control left and right aft wheels to continue turns as governed by user steering, whether or not forward wheels are in contact with the ground.

Owner:SEGWAY INC

Test device for dynamically measuring fretting pair frictional coefficient during fretting fatigue process and test method

ActiveCN105043976AReduce testing costsAvoid local stress concentrationsUsing mechanical meansMaterial analysisHydraulic cylinderFrictional coefficient

The invention provides a test device for dynamically measuring fretting pair frictional coefficient during the fretting fatigue process. A frictional coefficient measurement component realizes the fretting working condition and dynamically measures the frictional coefficient of a fretting pair formed by the cooperation of a fretting section and a fretting pad of a test piece during the fretting fatigue process; a normal force loading component realizes load applying in the horizontal direction; an upper-end fixing component realizes the fixing of the test piece and a clamp body; the horizontal direction loading in the fretting fatigue test is realized by adopting a hydraulic system; the loading system adopts a closed force system frame structure; the piston rods of hydraulic cylinders pushes the fretting pad to clamp a sliding block to move in a sliding groove in the clamp body; the frictional coefficient measurement component is fixed on the upper-end fixing component through a pin bolt; in the vertical direction, except the own gravity and the gravity of the hydraulic cylinder, the frictional coefficient measurement component only receives the frictional force produced due to fretting action between the test piece and the fretting pad; by adhering a strain piece to the working section of the clamp body and calibrating, dynamic monitoring of the frictional coefficient of the fretting pair during the fretting fatigue test process is realized.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

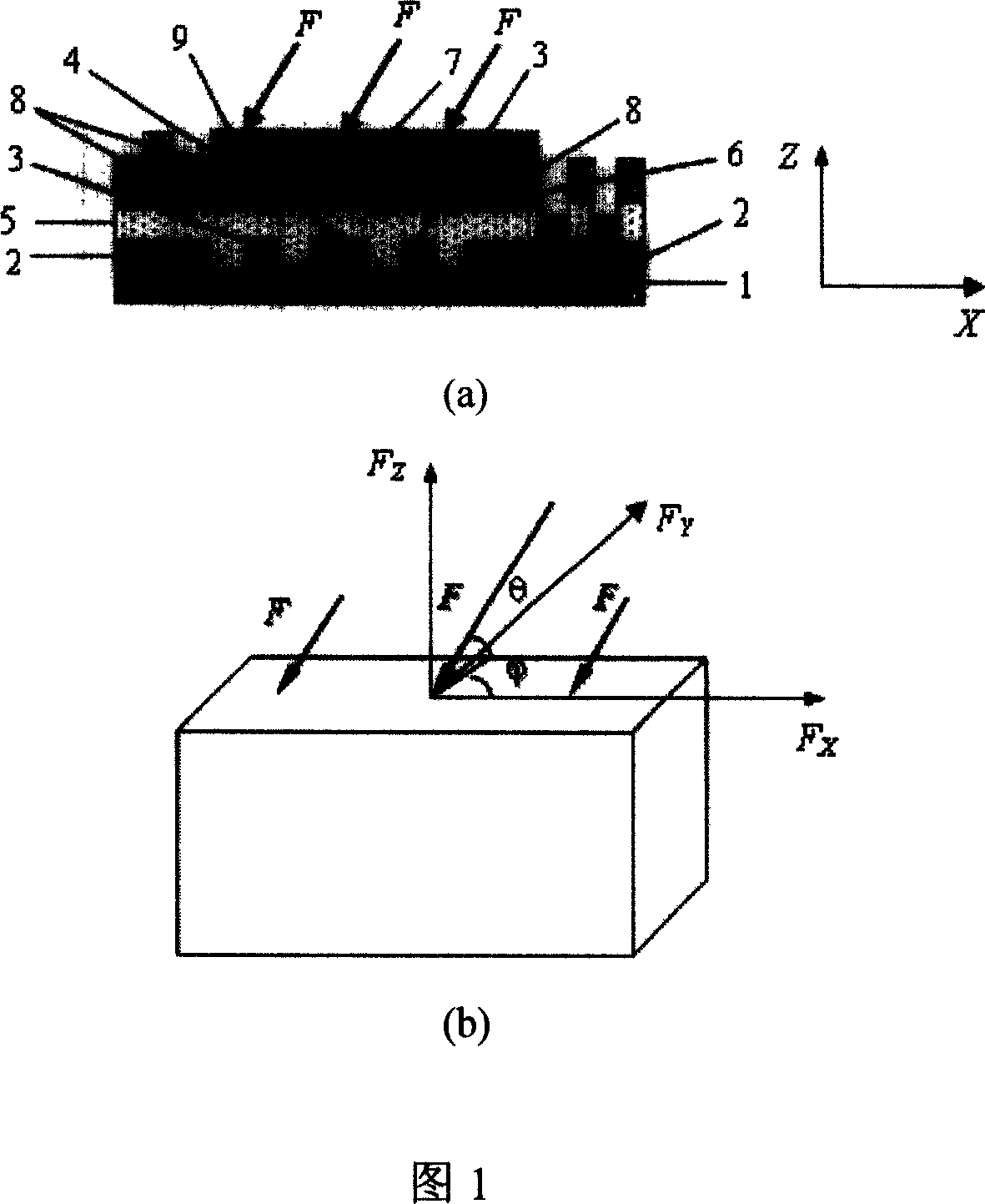

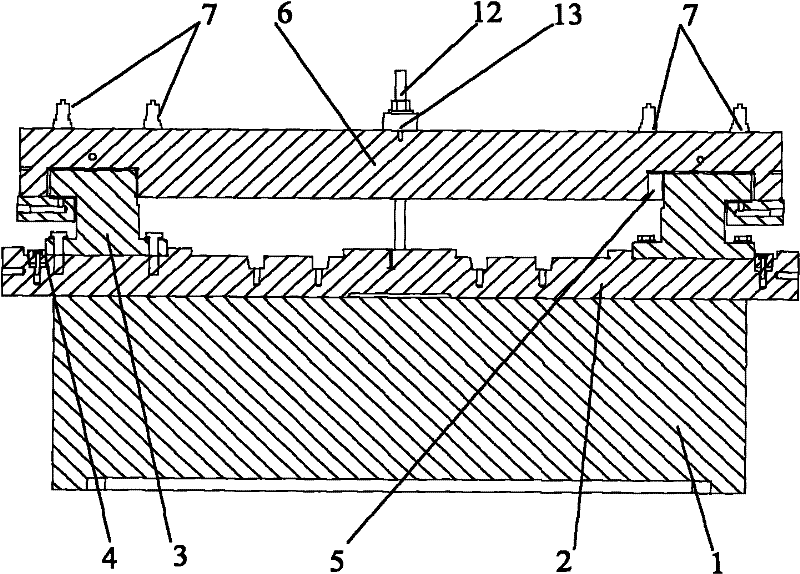

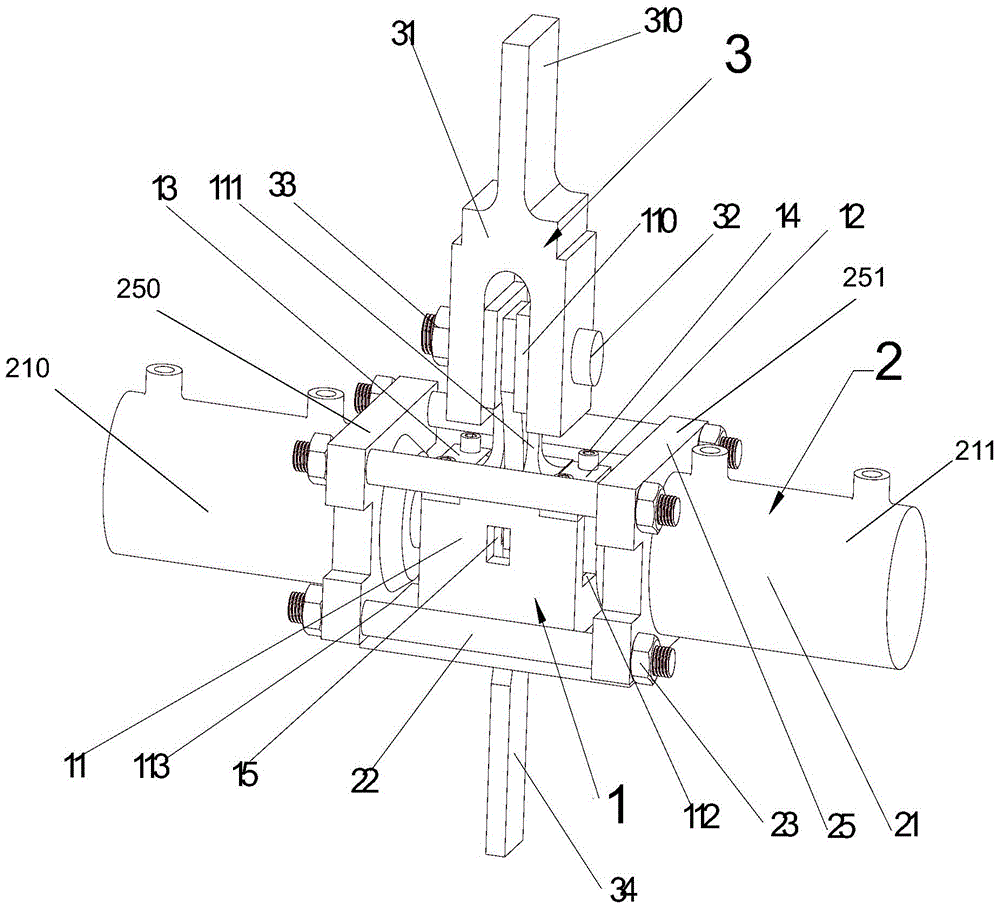

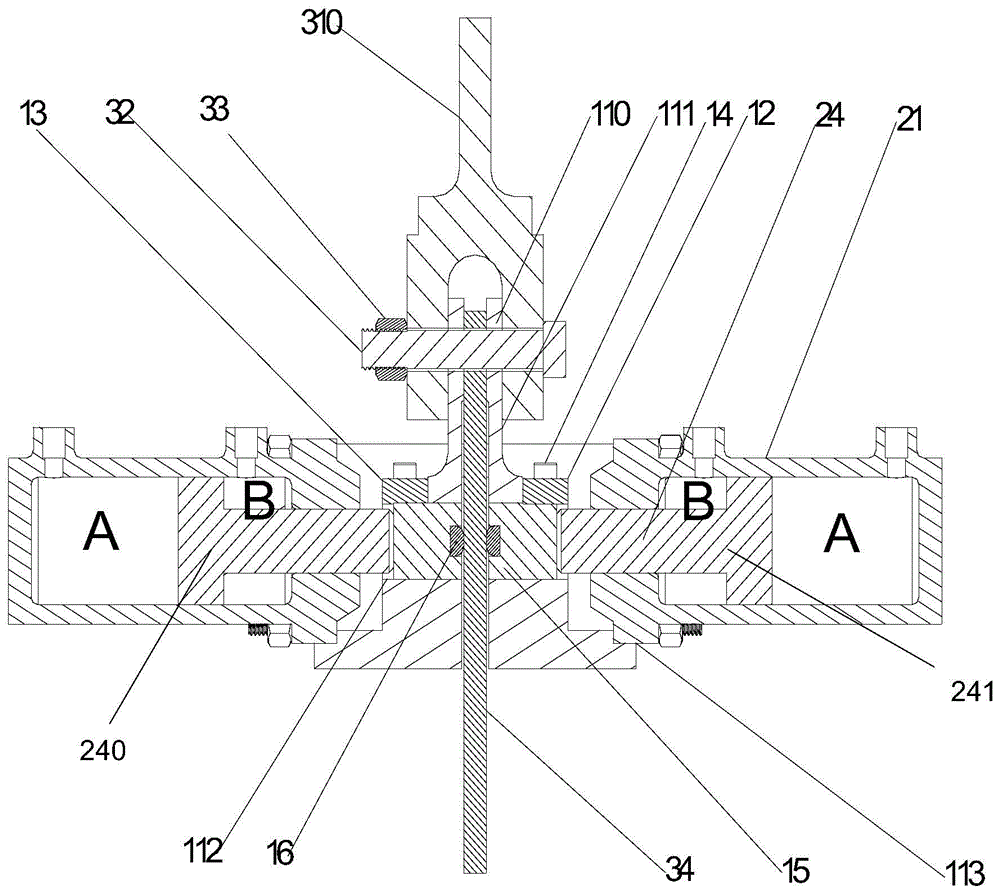

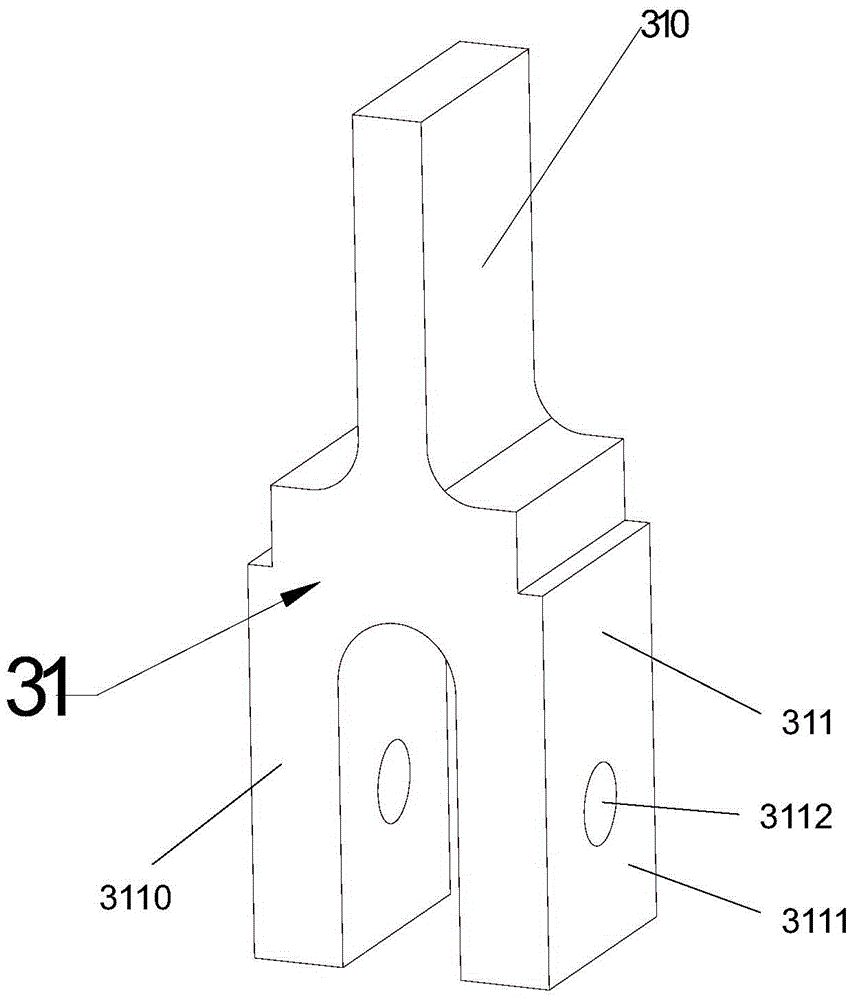

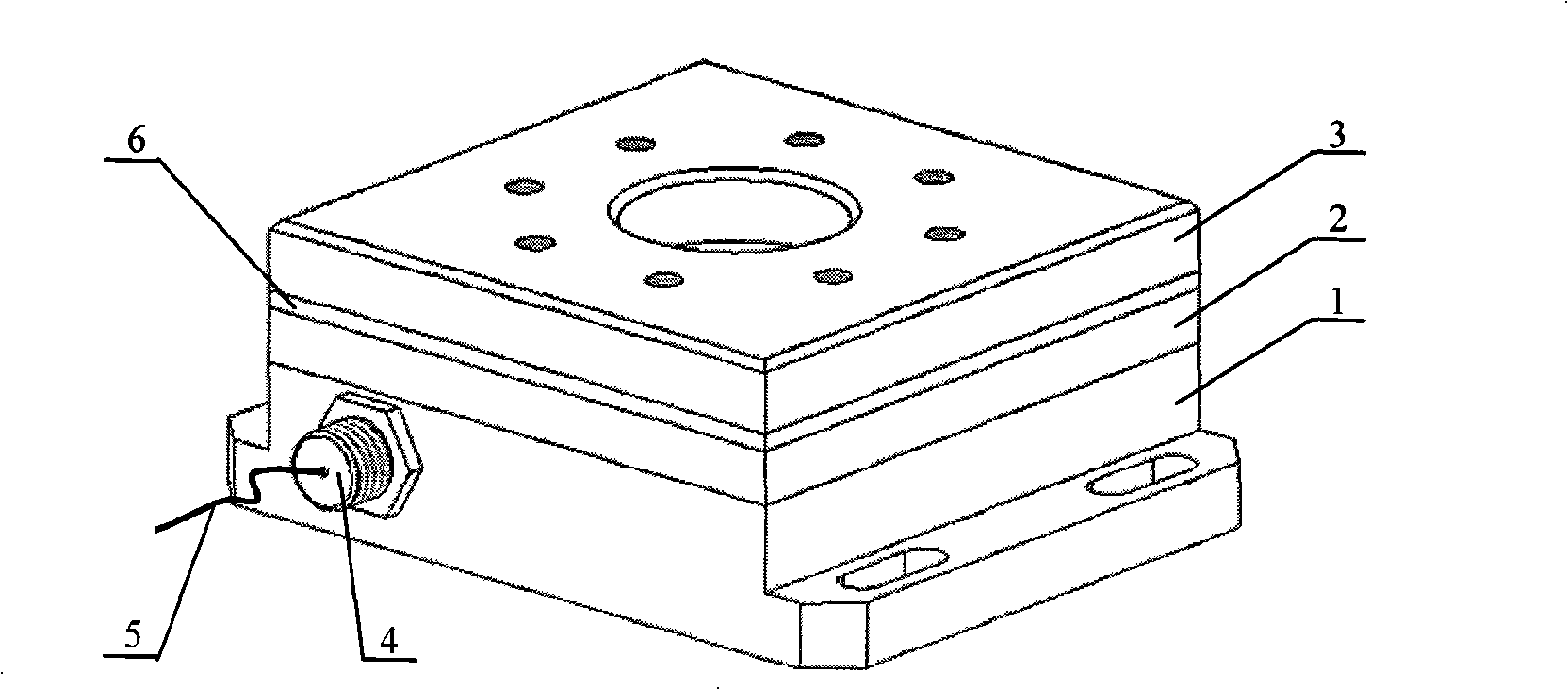

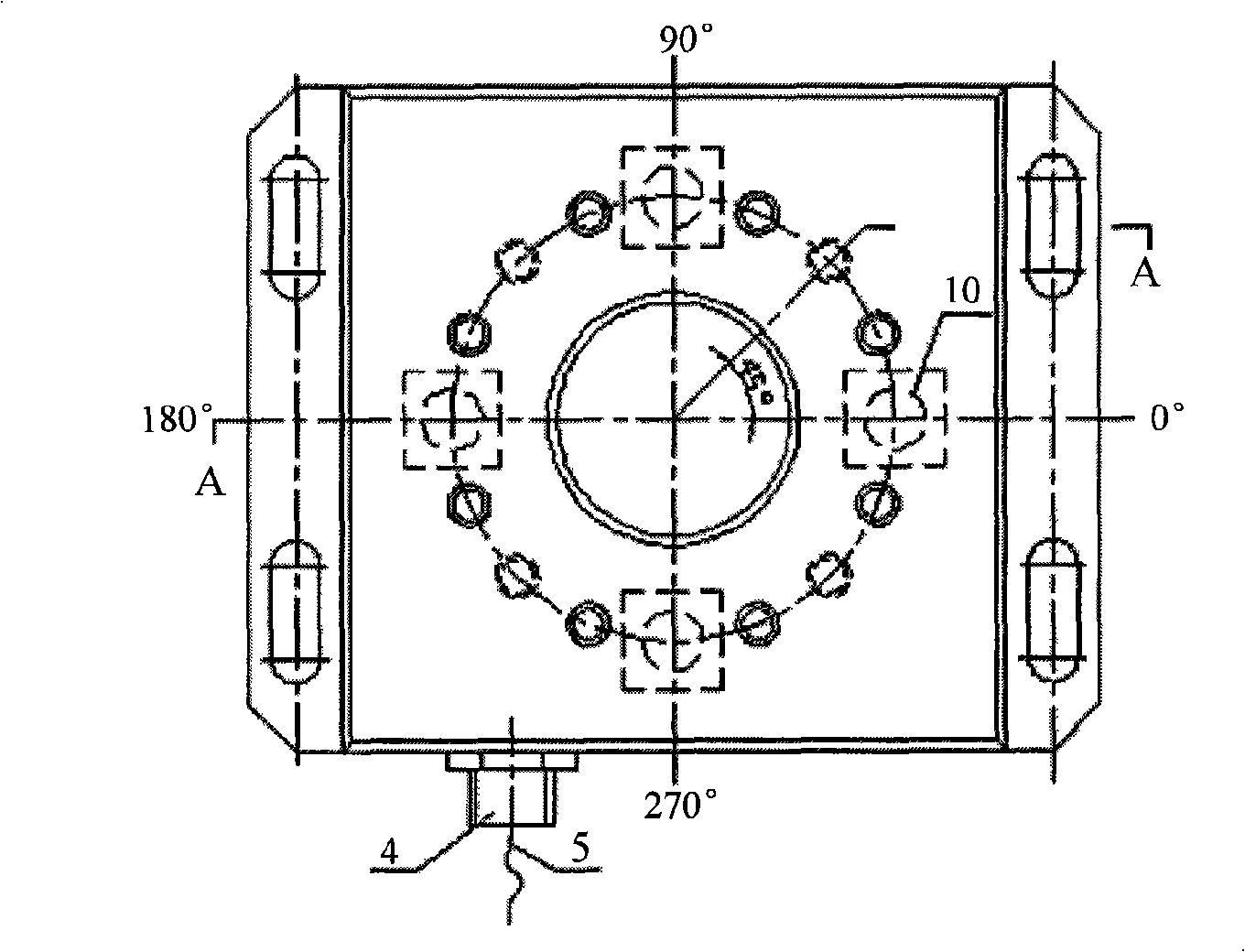

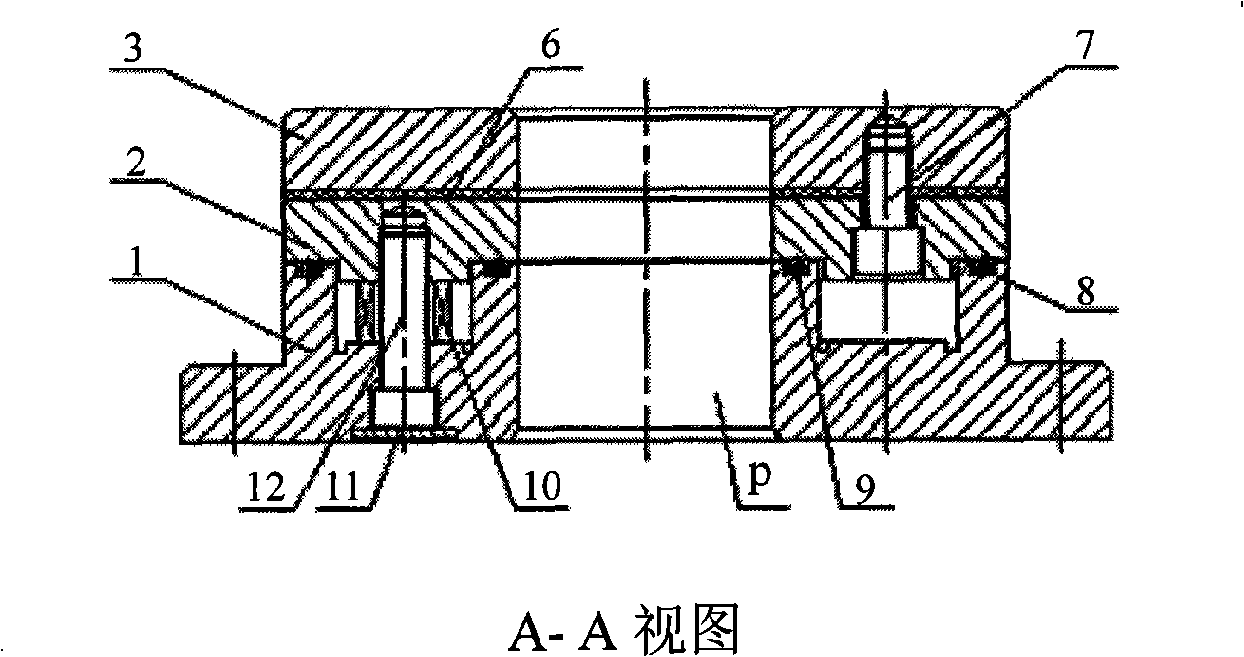

Piezoelectric-type four-dimensional cutting force-measuring platform

ActiveCN101524818AImprove featuresHigh sensitivityMeasurement/indication equipmentsPiezoelectric quartzEngineering

The invention relates to a piezoelectric-type four-dimensional cutting force-measuring platform belonging to the technical field of sensing measurement and control, in particular to a force-measuring platform for detecting normal force and torque in three directions in the cutting process. The force-measuring platform comprises a base, a middle plate, an upper plate, a lead output plug, a lead, a thermal baffle, a sealing ring, four piezoelectric quartz sensors, a protective pad and connecting screws, wherein the four piezoelectric quartz sensors in diamond arrangement between the base and the middle plate are uniformly distributed on the same circumference of the same horizontal plane. The piezoelectric-type four-dimensional cutting force-measuring platform can simultaneously measures the normal force and the torque in three directions in any cutting process, has the advantages of high sensitivity, good linearity and repeatability, little transversal interference and high measurement precision and has universality for measuring drilling, grinding, milling, lathing and planing, thereby having wide application range.

Owner:DALIAN UNIV OF TECH

Flexible three-dimensional force touch sensor of multi-fingered hands of human-simulated robot and three-dimensional force detecting system thereof

ActiveCN102706489AFlexibleBroaden applicationForce measurement using piezo-resistive materialsManipulatorTouch PerceptionQuantum channel

The invention discloses a flexible three-dimensional force touch sensor of multi-fingered hands of a human-simulated robot and a three-dimensional force detecting system, relating to the field of touch sensors of robots. The invention aims at solving the problem that more touch sensors only can acquire normal force but can not detect the normal force and the force simultaneously like the human hands. A sensor body consists of a force-transferring hemispherical layer, a flexible top-level electrode layer, a composite material QTC (Quantum Tunneling Composites) with quantum channel effect and a flexible bottom-level electrode layer which are arranged in sequence from top to bottom; a signal acquisition circuit consists of a mixed-signal array programmable on-chip system and an analog multiplex selection module; the on-chip system comprises a digital logic module, an analog digital conversion module ADC, a digital analog conversion module DAC, an analog signal register I, an analog signal register II, a voltage amplifying circuit and a multi-way switch; and the analog multiplex selection module comprises an analog multi-way switch I and an analog multi-way switch II. The invention is used for the touch sensor for detecting the three-dimensional force of the multi-fingered hands of the human-simulated robot.

Owner:HARBIN INST OF TECH

Airbag-loading potable weak and soft interlayer direct shear apparatus

InactiveCN101592575AApply evenlyContinuous and stable tangential forceMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesBall screwTangential force

The invention provides a simple, accurate and field airbag-loading potable soft and weak interlayer direct shear apparatus. In the direct shear apparatus, airbag loading is adopted to apply a normal force, and a piston system arranged on the upper part of a reaction frame can guarantee the verticality and application uniformity of the normal force when a sample produces shearing displacement; and a ball screw system applies a tangential force and linear guides under a sample seat can guarantee the horizontality of the application direction of the shearing force and the continuity and smoothness of the tangential force. A normal force applying system avoids bearing load, and airbag pressurization is accomplished by a potable pressurizing device and is high in precision, simple and easy to implement. A tangential force applying system uses a screw handle to apply force and the force application is steady and highly operable. Both the normal force applying system and the tangential force applying system are fixed, small in volume, high in reliability and convenient in on-site test. The test device can perform the quick shearing of field soft and weak interlayer and consolidated drained quick and slow shear tests and is simple, precise and high in operability.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com