Patents

Literature

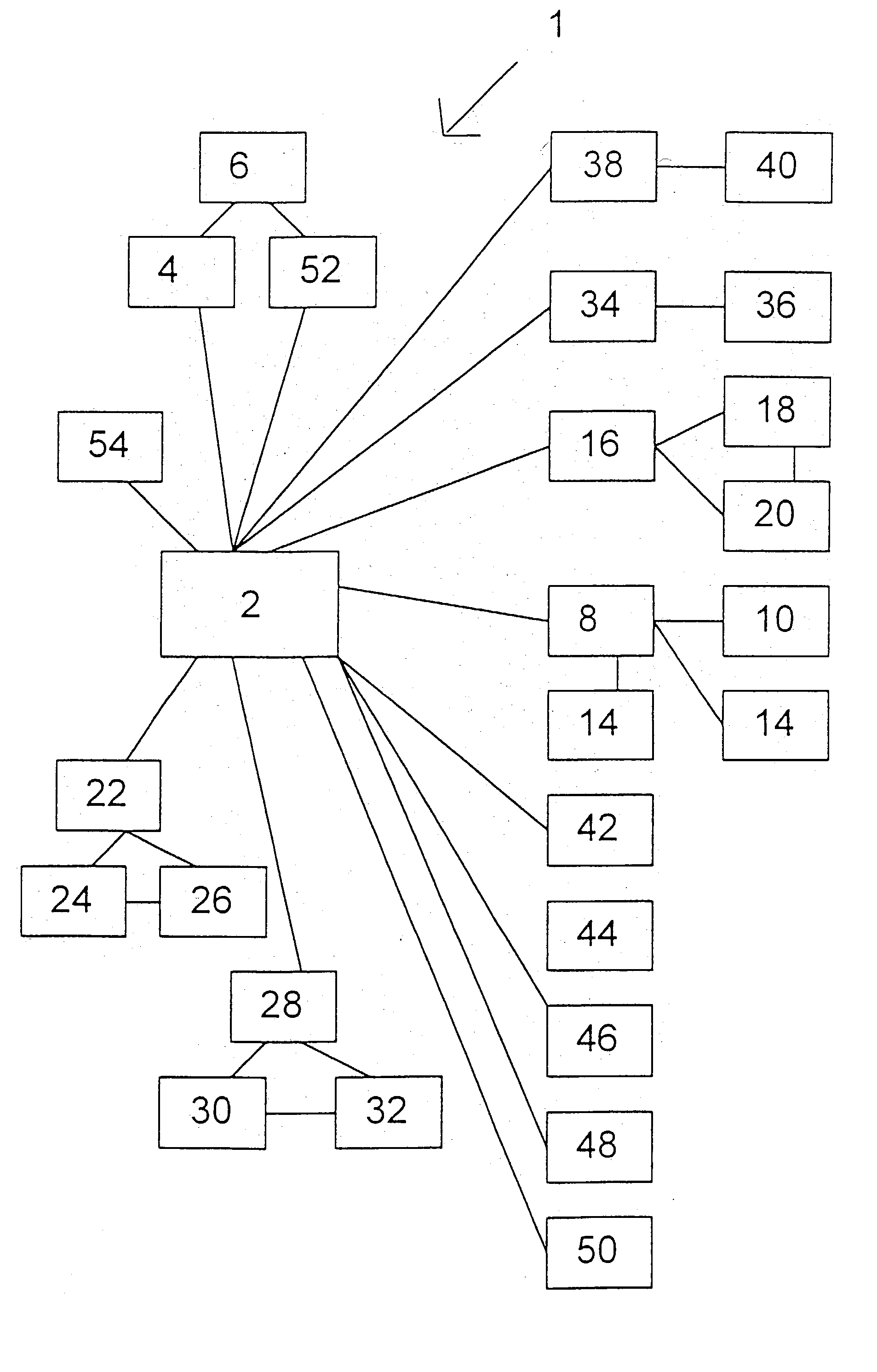

506 results about "Braking equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

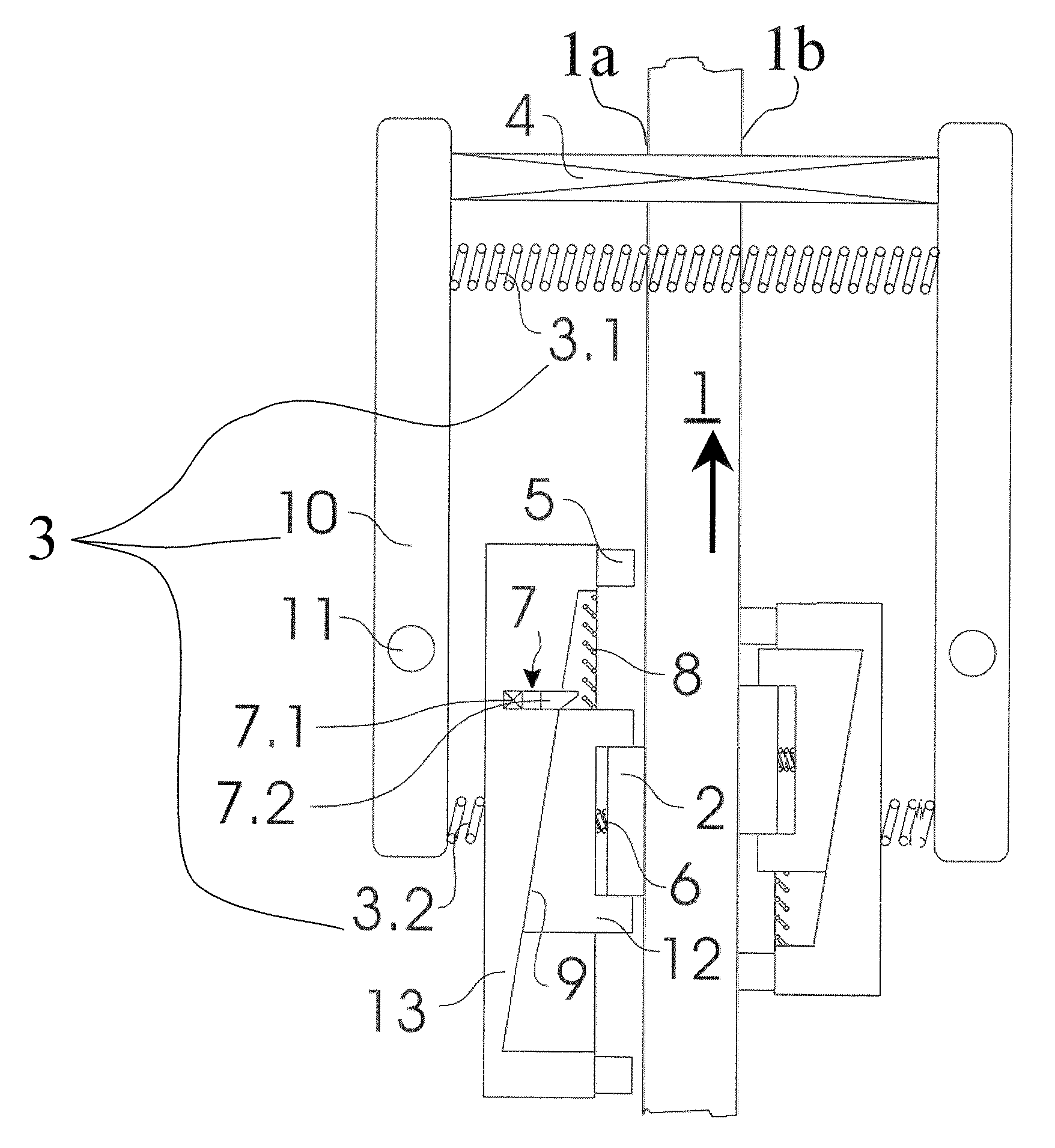

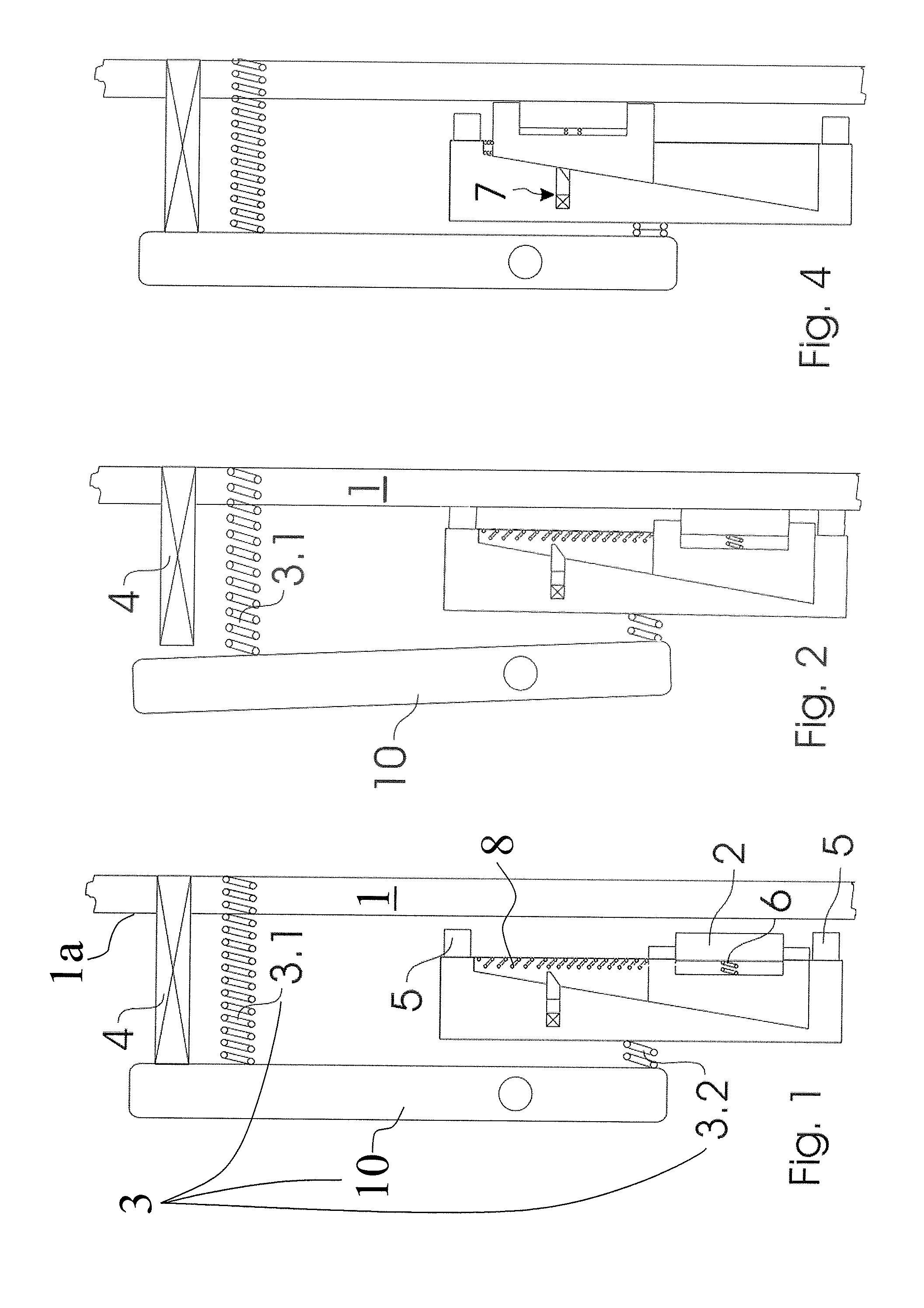

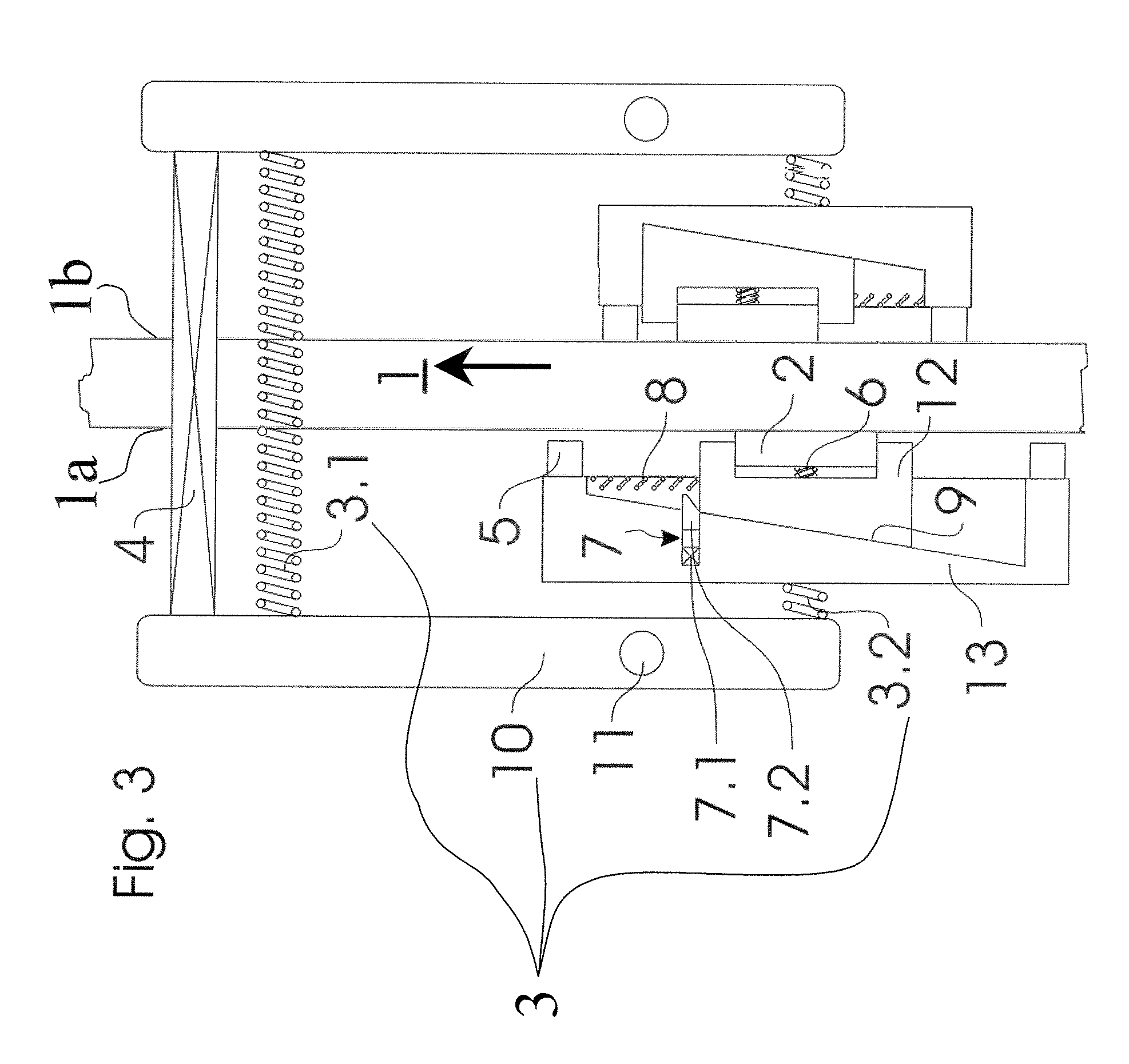

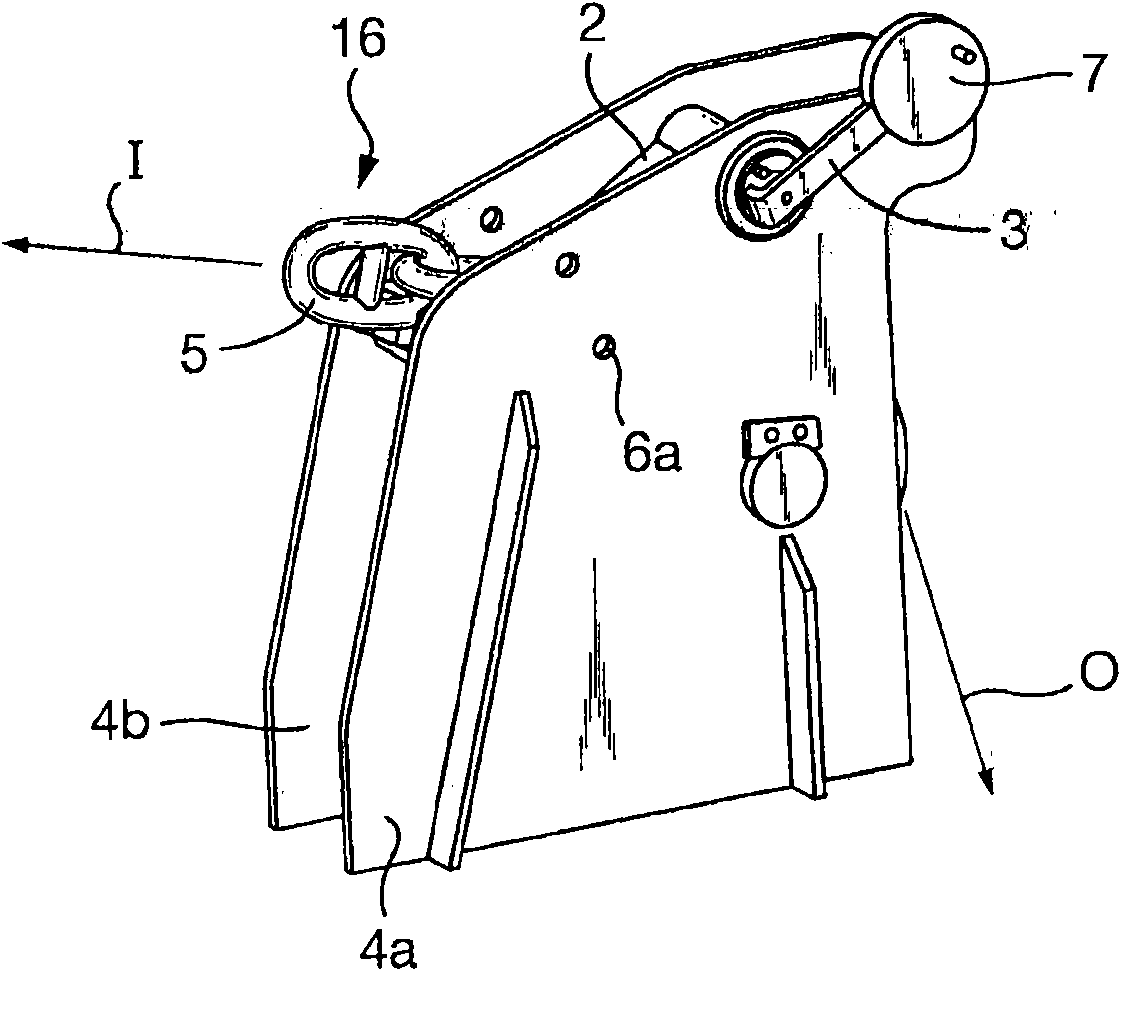

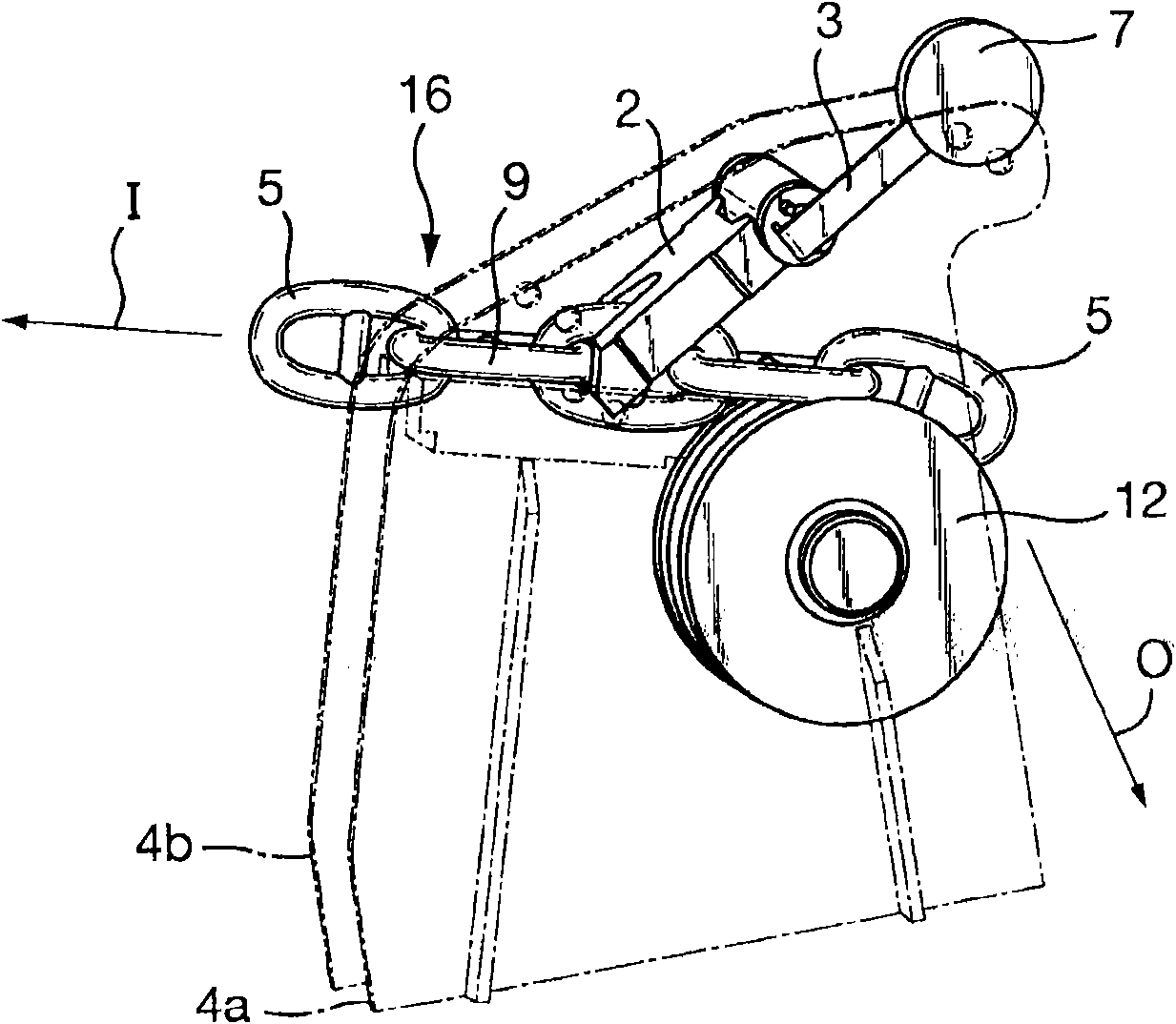

Brake equipment for holding and braking an elevator car in an elevator installation and a method of holding and braking an elevator installation

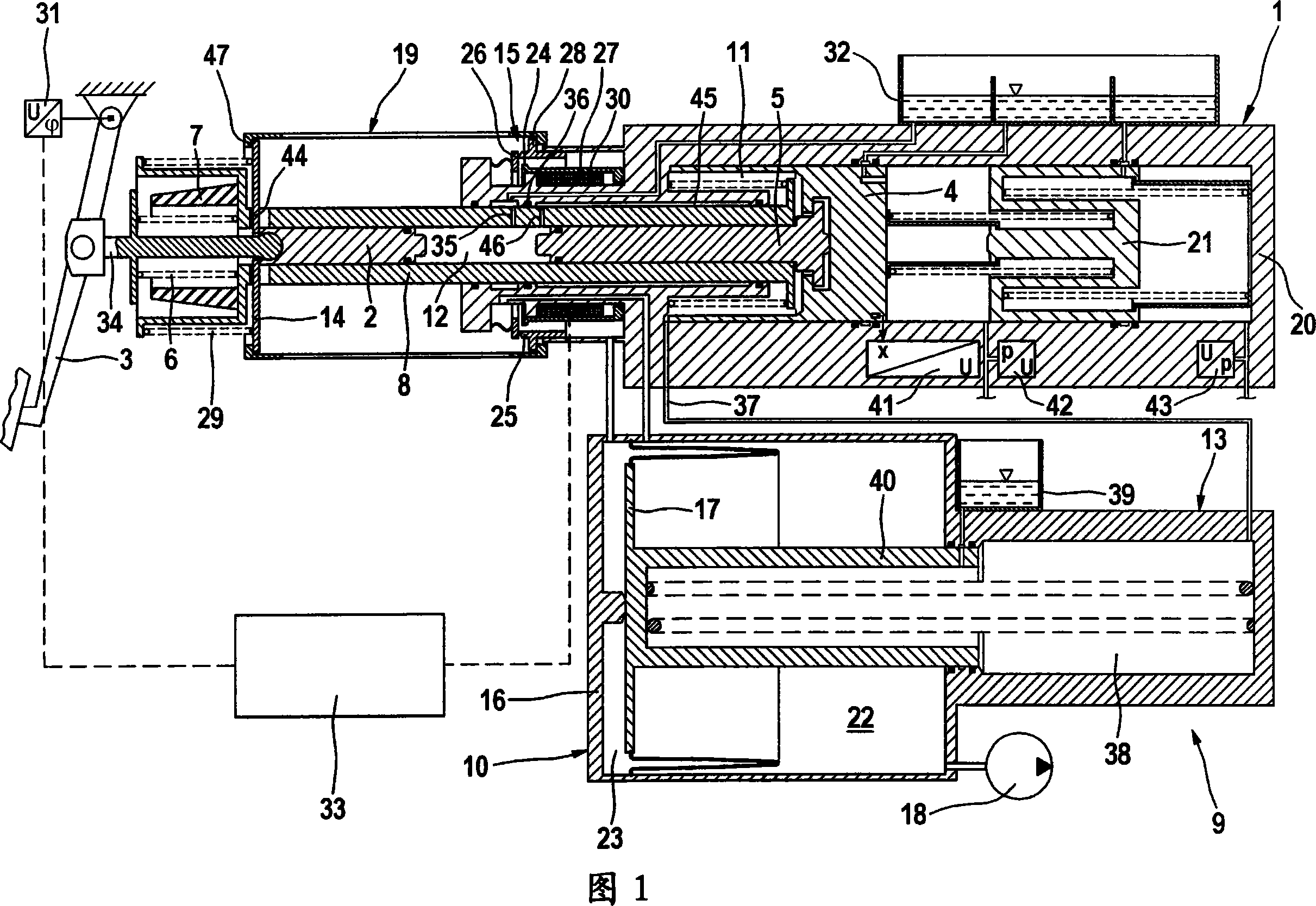

Brake equipment for holding and braking an elevator car in an elevator installation, which is arranged to be movable along a brake track in two directions of travel, includes a mount with a brake lining which automatically adjusts under friction couple with the brake track on movement of the elevator car relative to the rail and in that case tightens a first tightening means, which can be released by an actuator. The first tightening means tightens the mount together with the brake lining against the brake track by a biasing force. The brake equipment produces, with unmoved brake equipment and an unreleased state of the actuator, a holding force acting in both directions of travel. The holding force is determined substantially by the biasing force acting on the mount.

Owner:INVENTIO AG

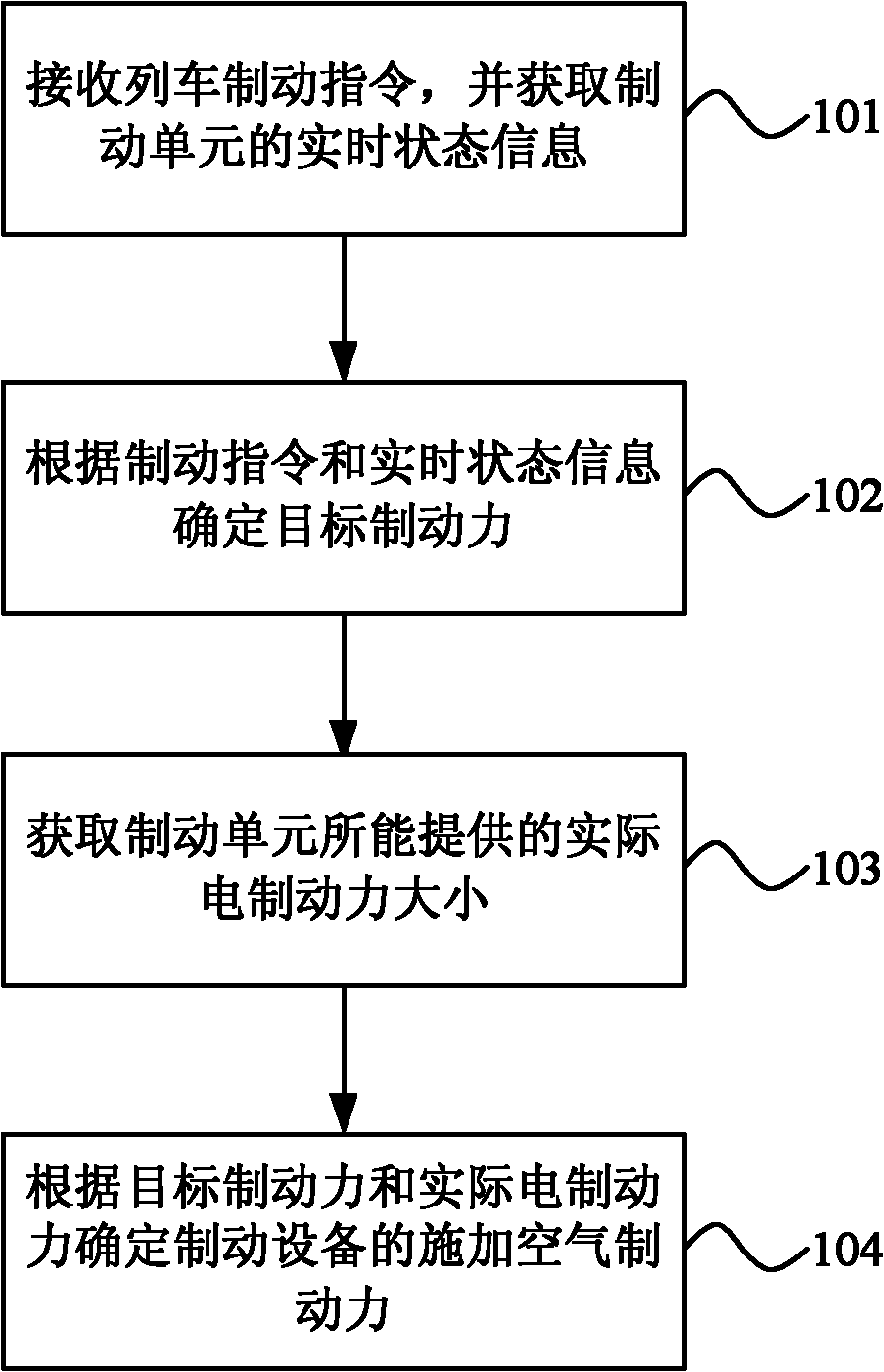

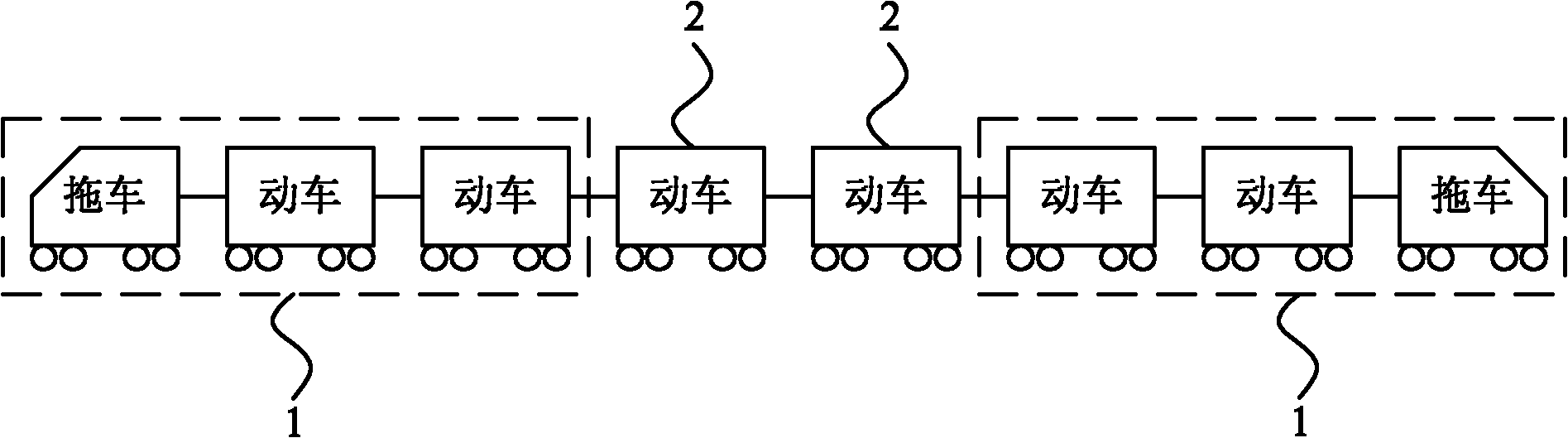

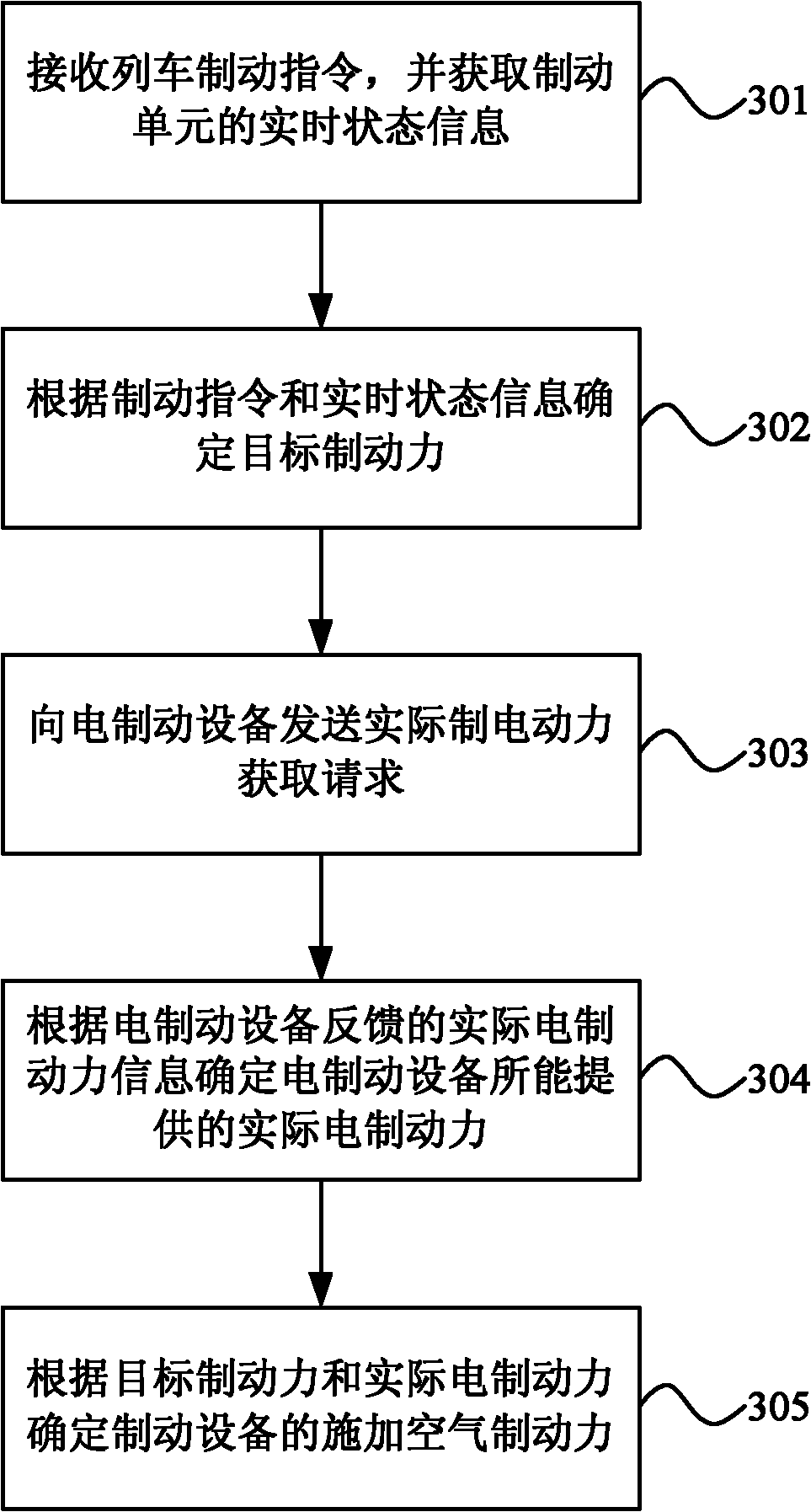

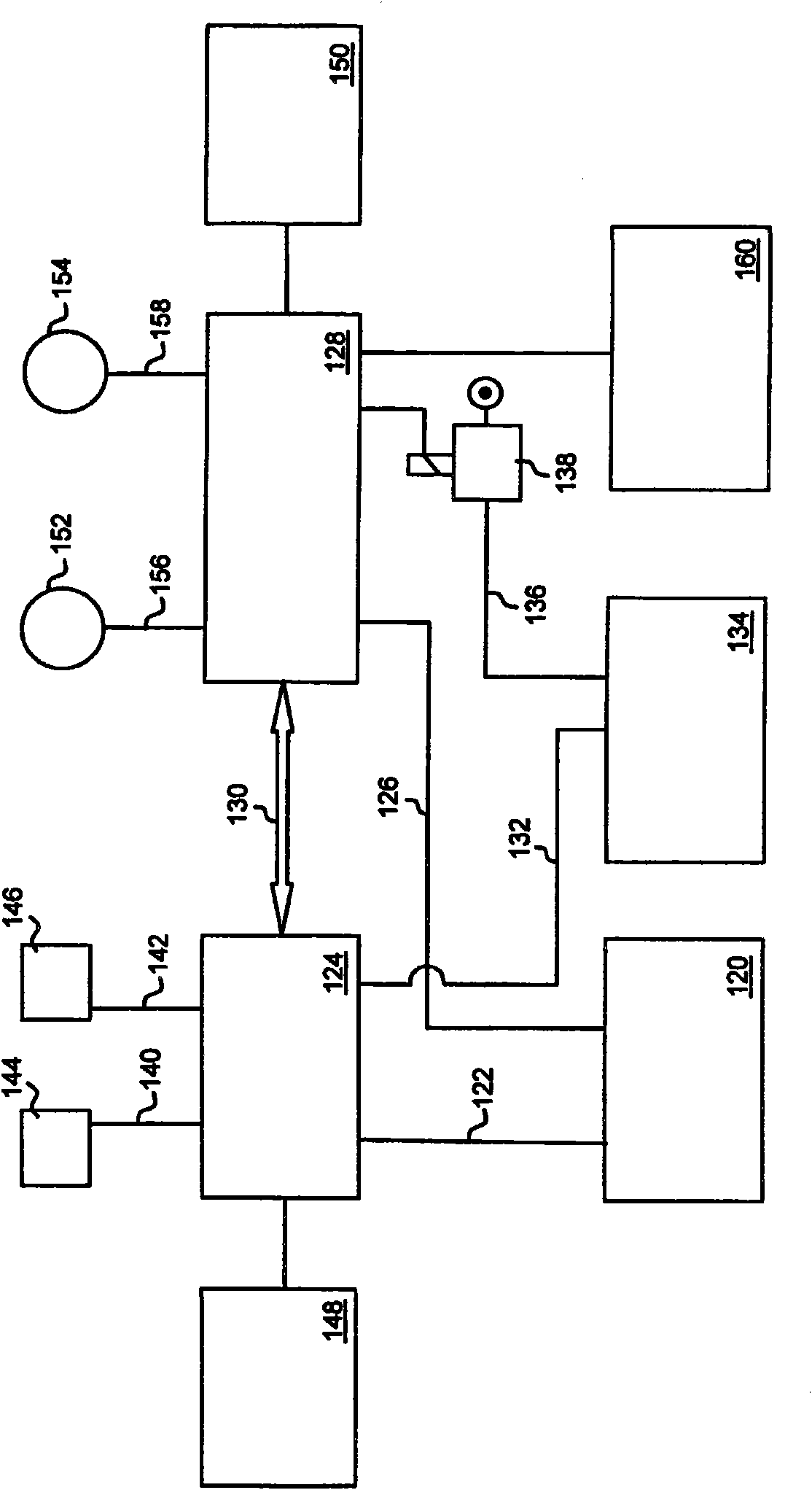

Method and system for braking high-speed train and brake control device

ActiveCN102602386AControl braking distanceImprove braking efficiencyBraking action transmissionRailway braking systemsElectricityBraking distance

The invention provides a method for braking a high-speed train, a system for braking the high-speed train, and a brake control device. The method for braking the high-speed train comprises the steps of: receiving a train braking instruction, and acquiring real-time state information of a braking unit; determining target brake force according to the braking instruction and the real-time state information; acquiring the actual electric braking force provided by the braking unit; and determining the air braking force exerted by braking equipment according to the target braking force and the actual electric braking force. According to the method for braking the high-speed train, the system for braking the high-speed train and the brake control device, the braking force can be determined according to the real-time sate of the braking unit of the train; the braking force can be reasonably distributed according to the actual conditions of an electric braking device and an air braking device, thus, the braking distance of the high-speed train can be effectively controlled; the braking efficiency can be improved; and the energy can be effectively saved.

Owner:CHINA RAILWAYS CORPORATION +1

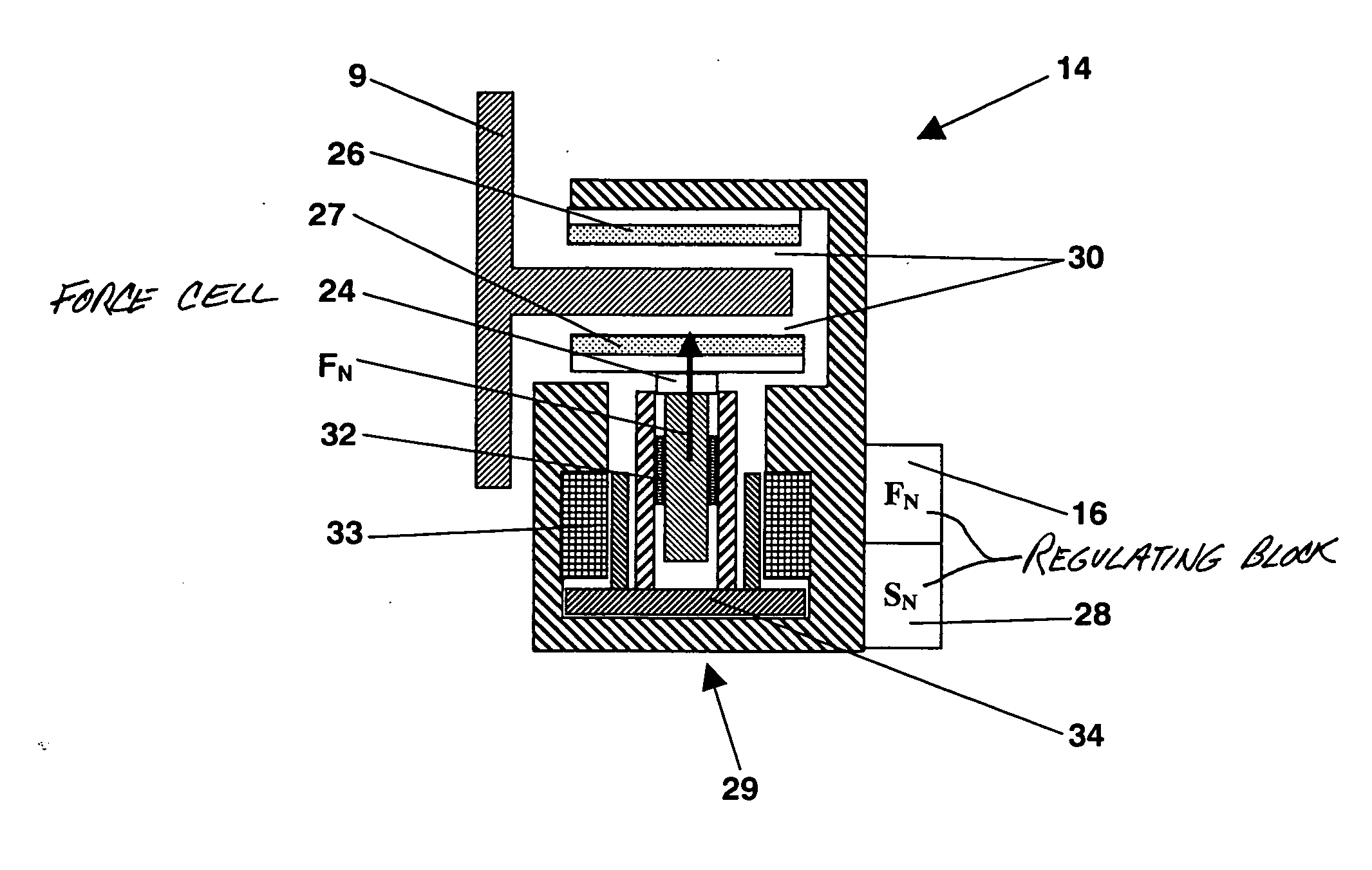

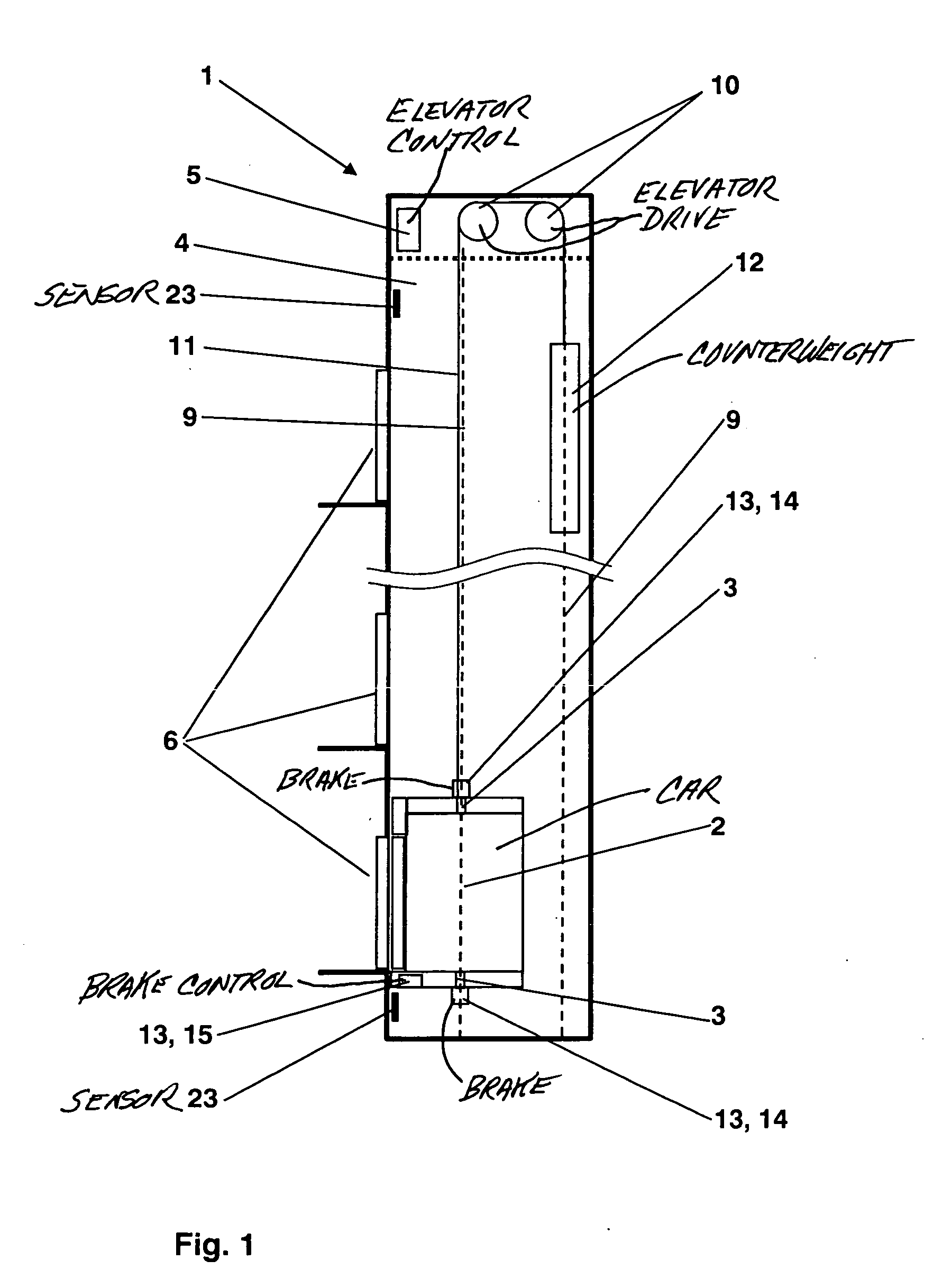

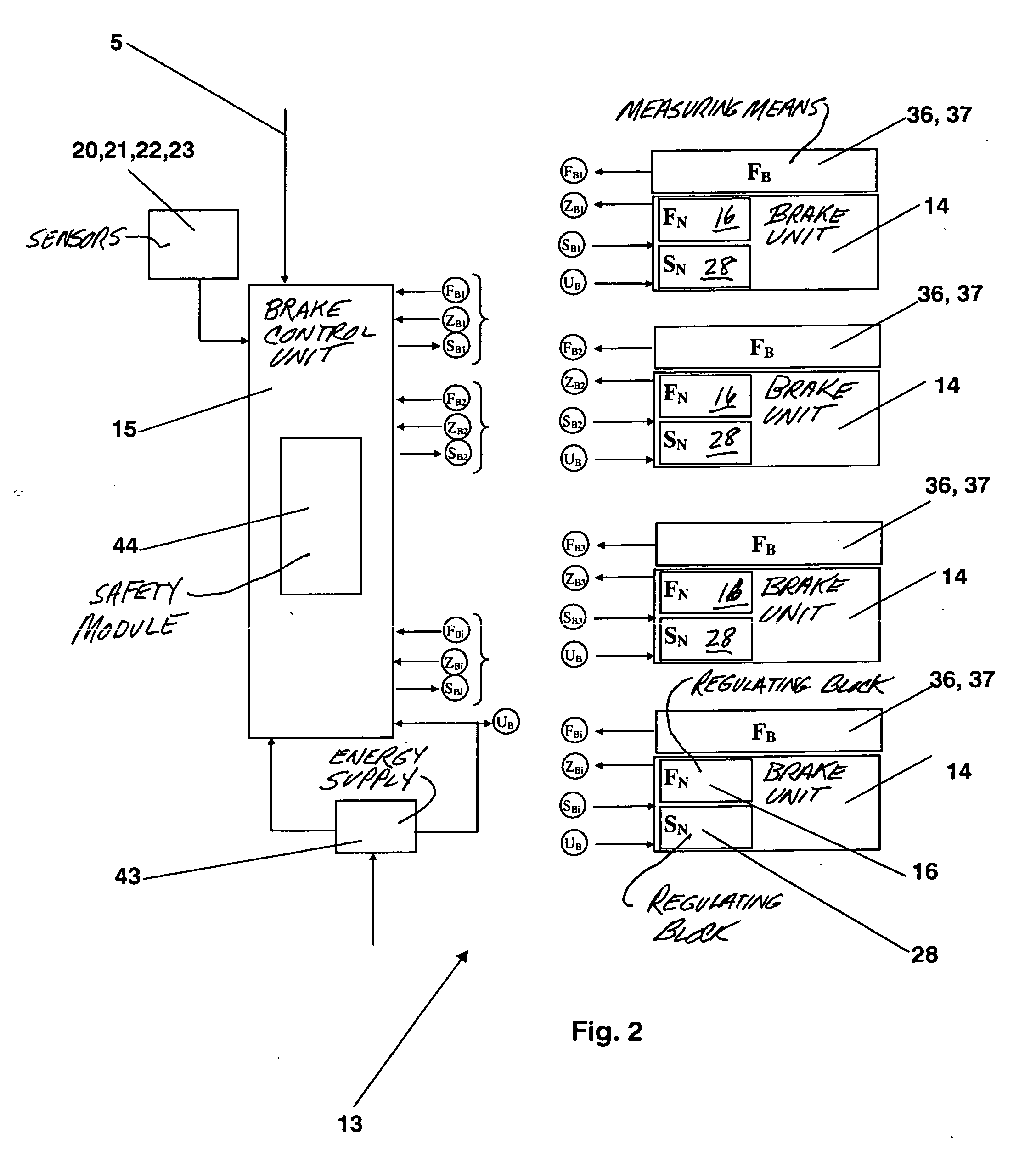

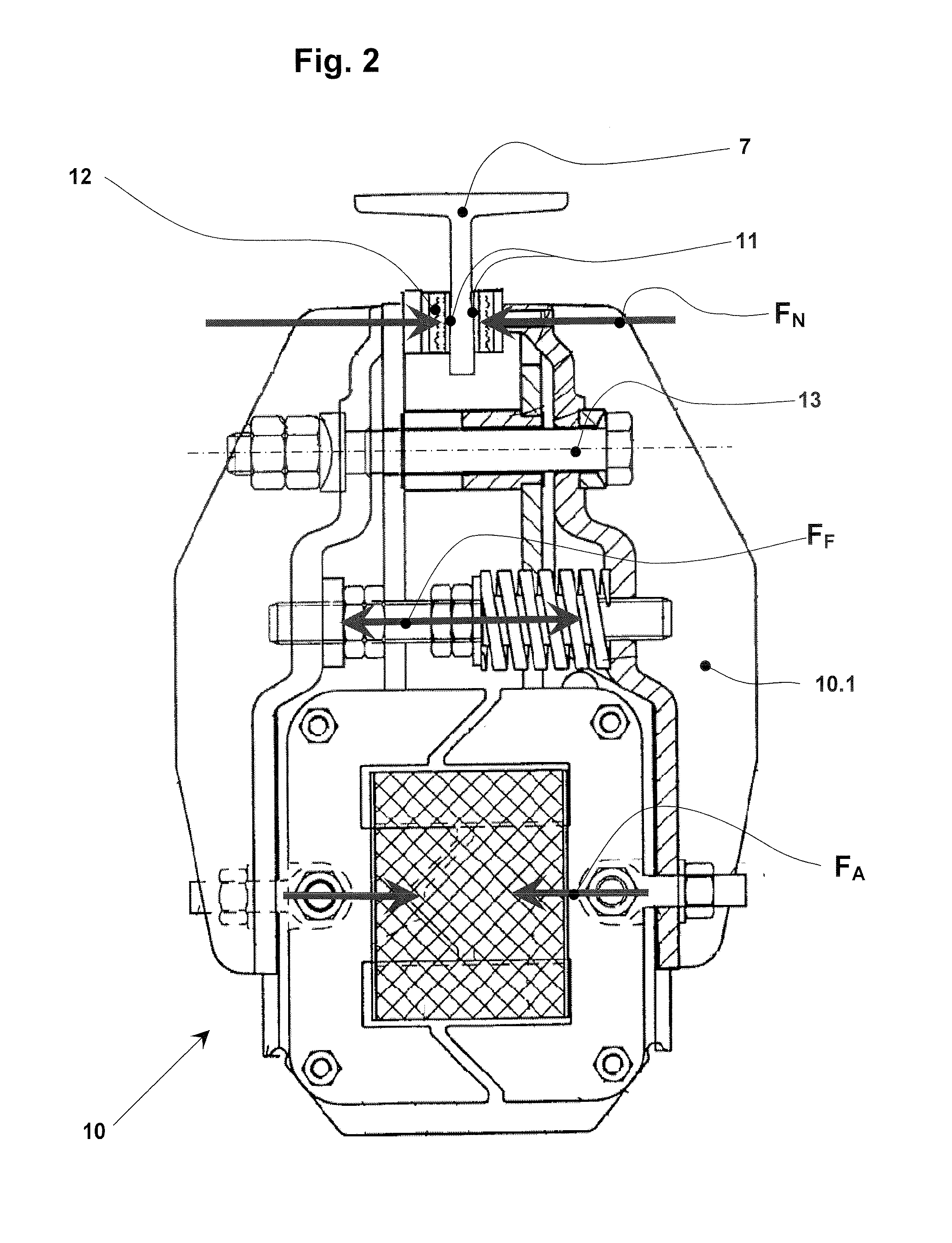

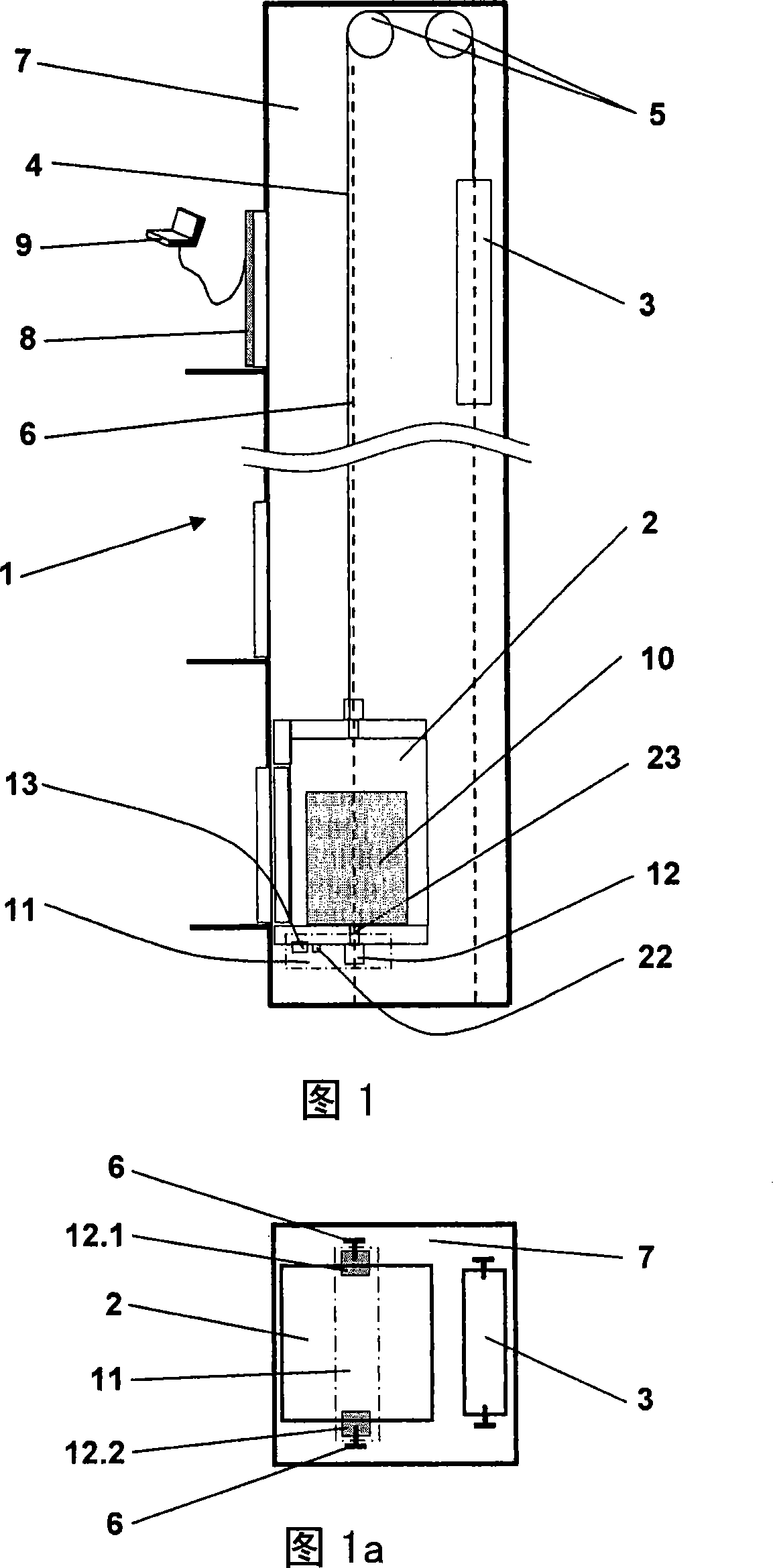

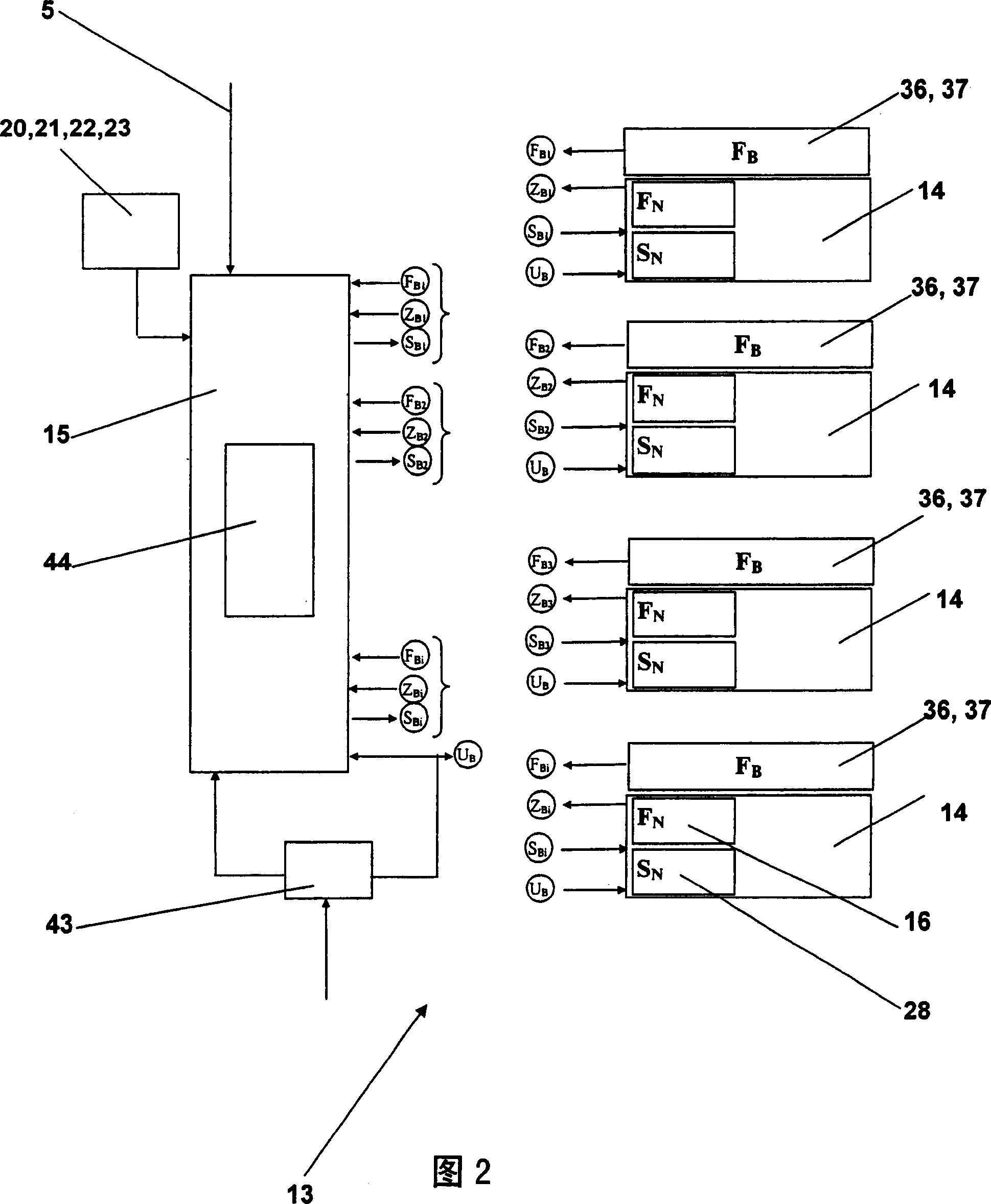

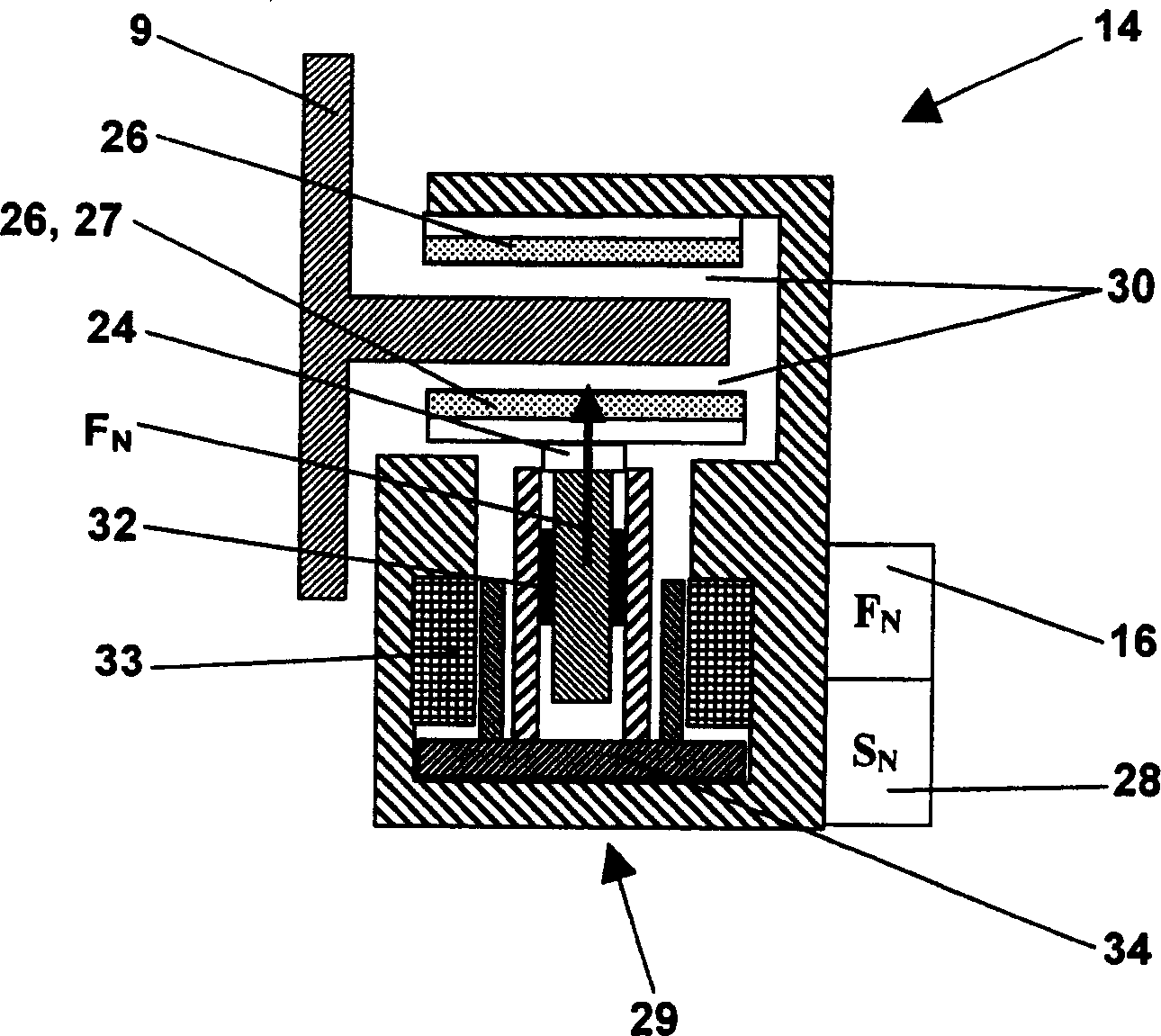

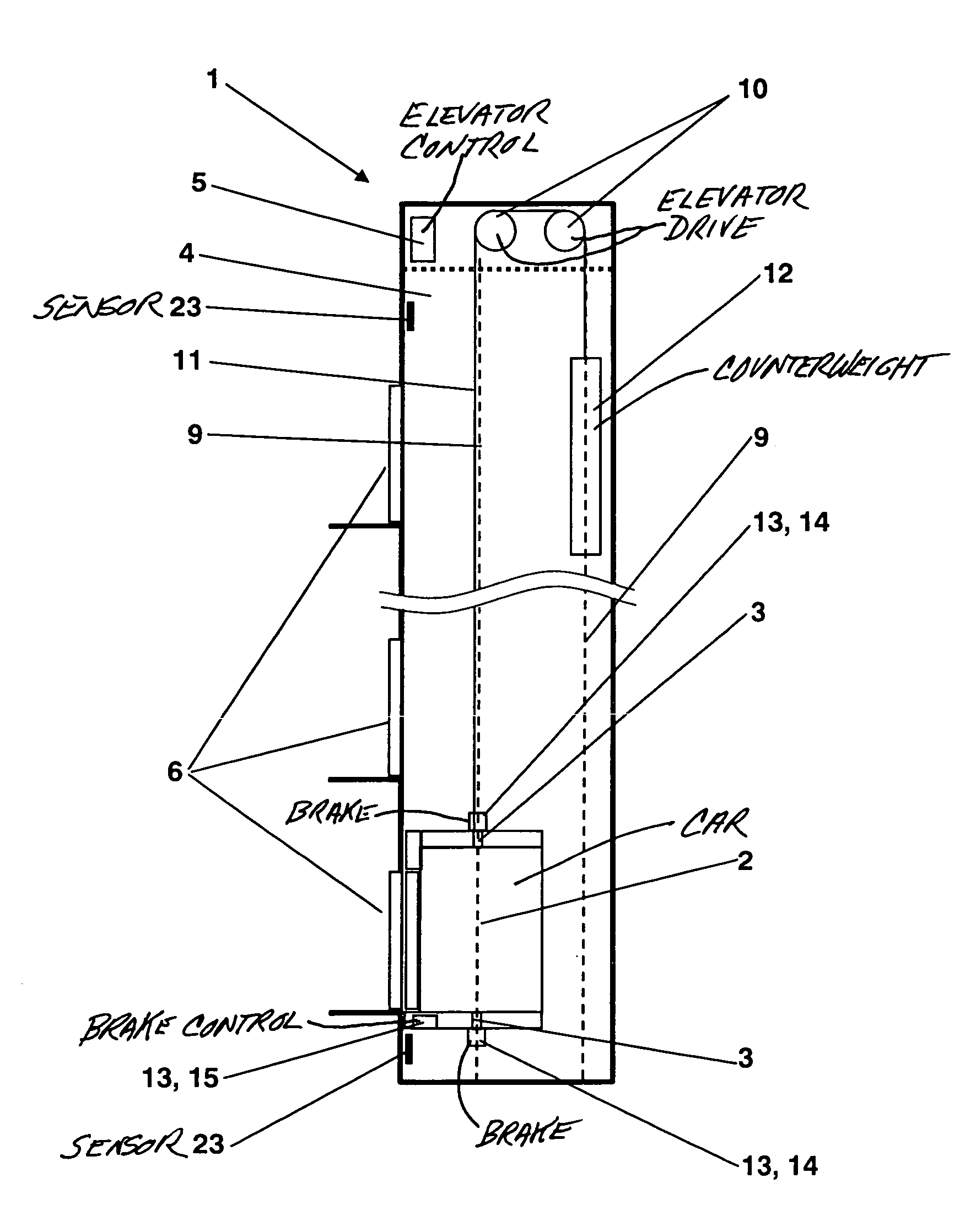

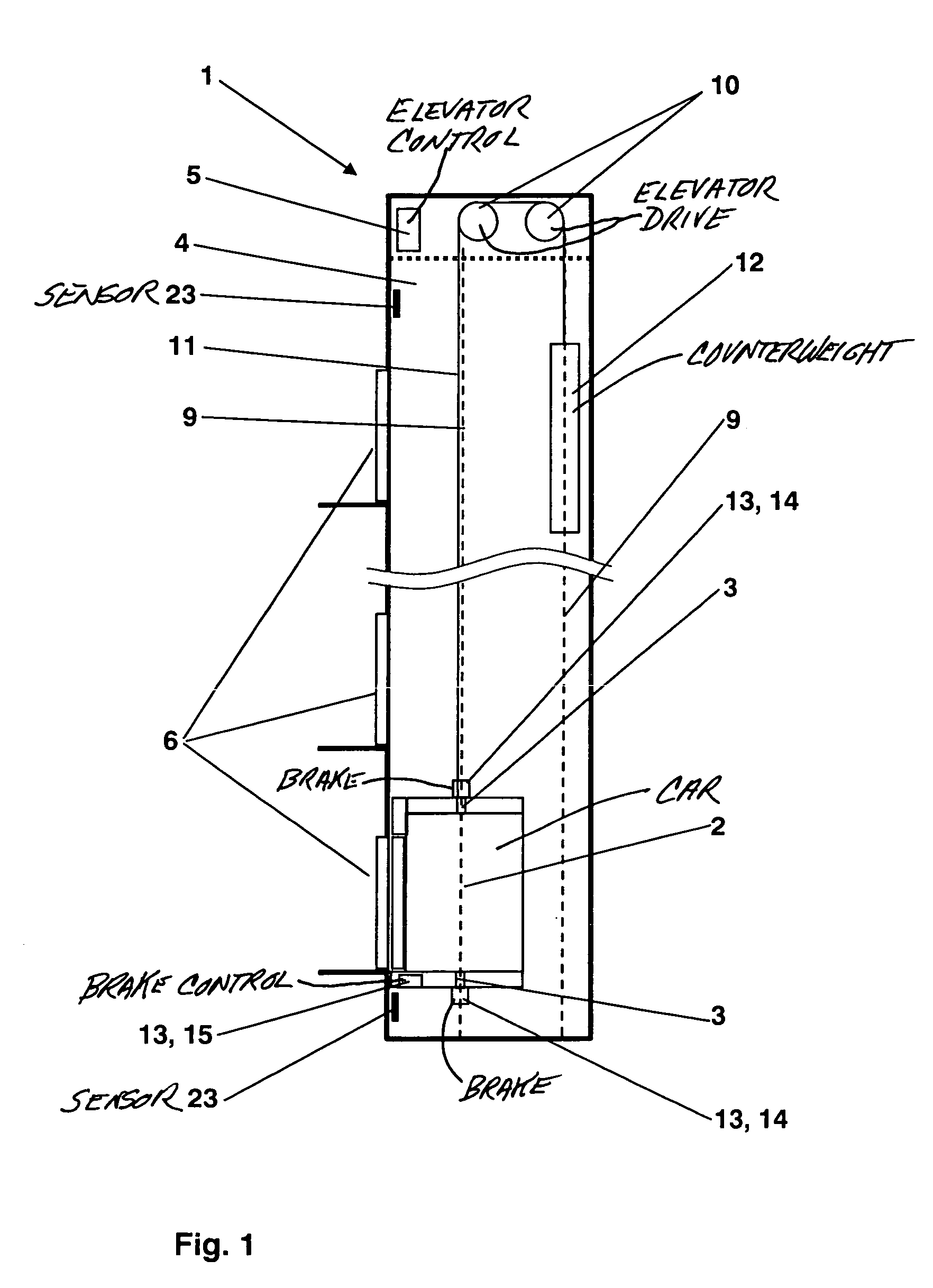

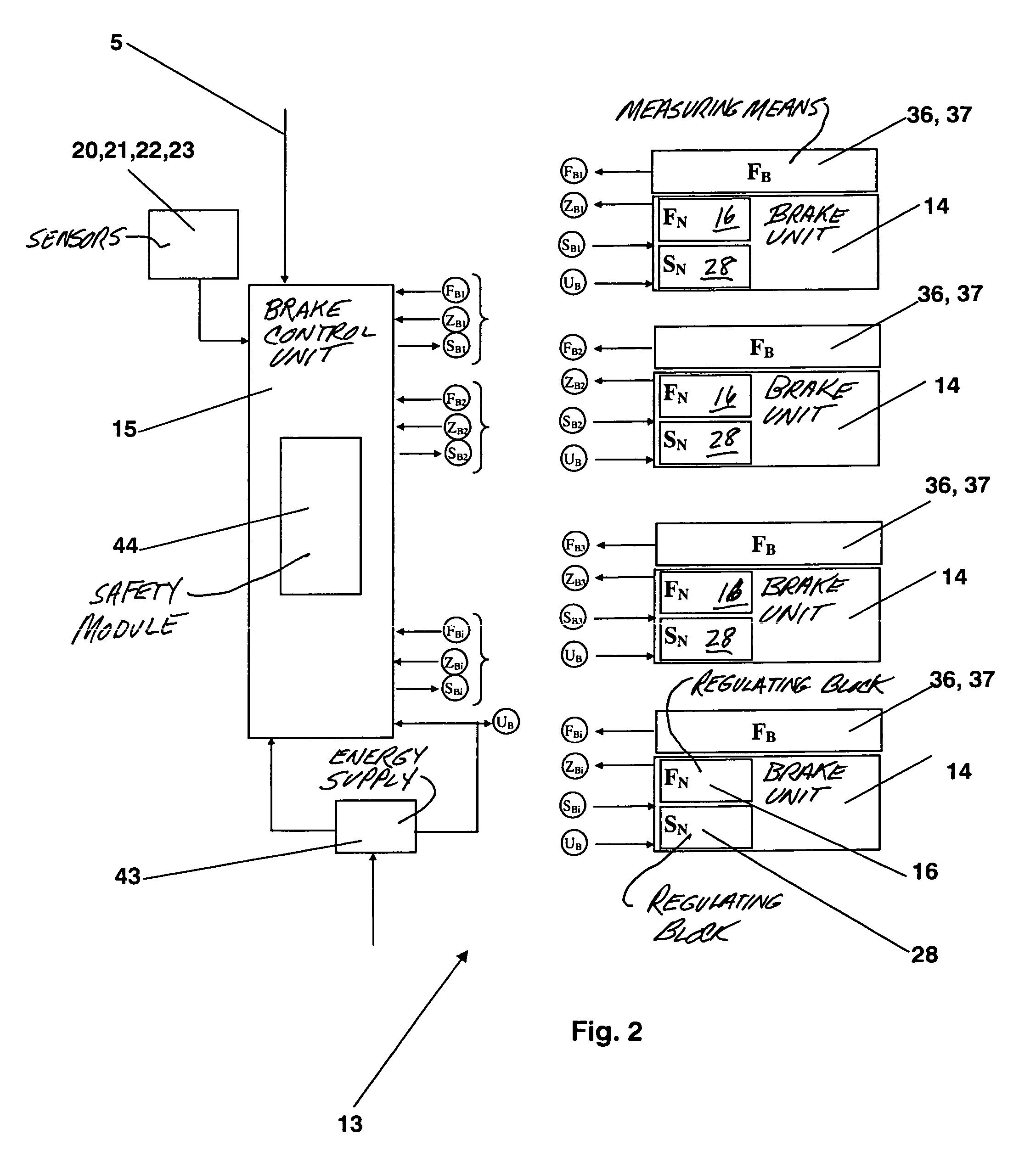

Elevator installation with a braking device and method for braking and holding an elevator installation

ActiveUS20060180406A1Low powerSmall additional weightBraking action transmissionFilament handlingEnergy supplyNormal force

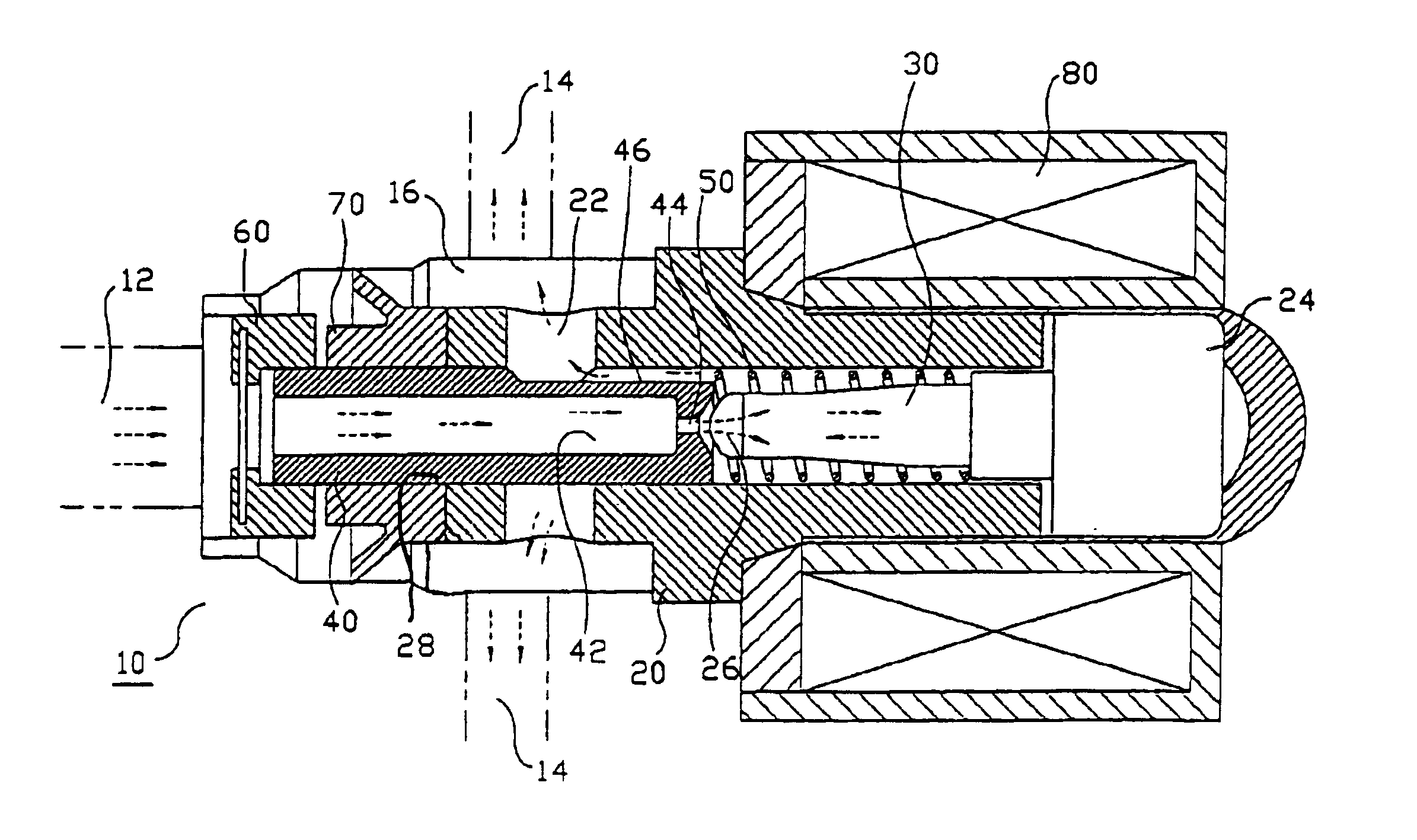

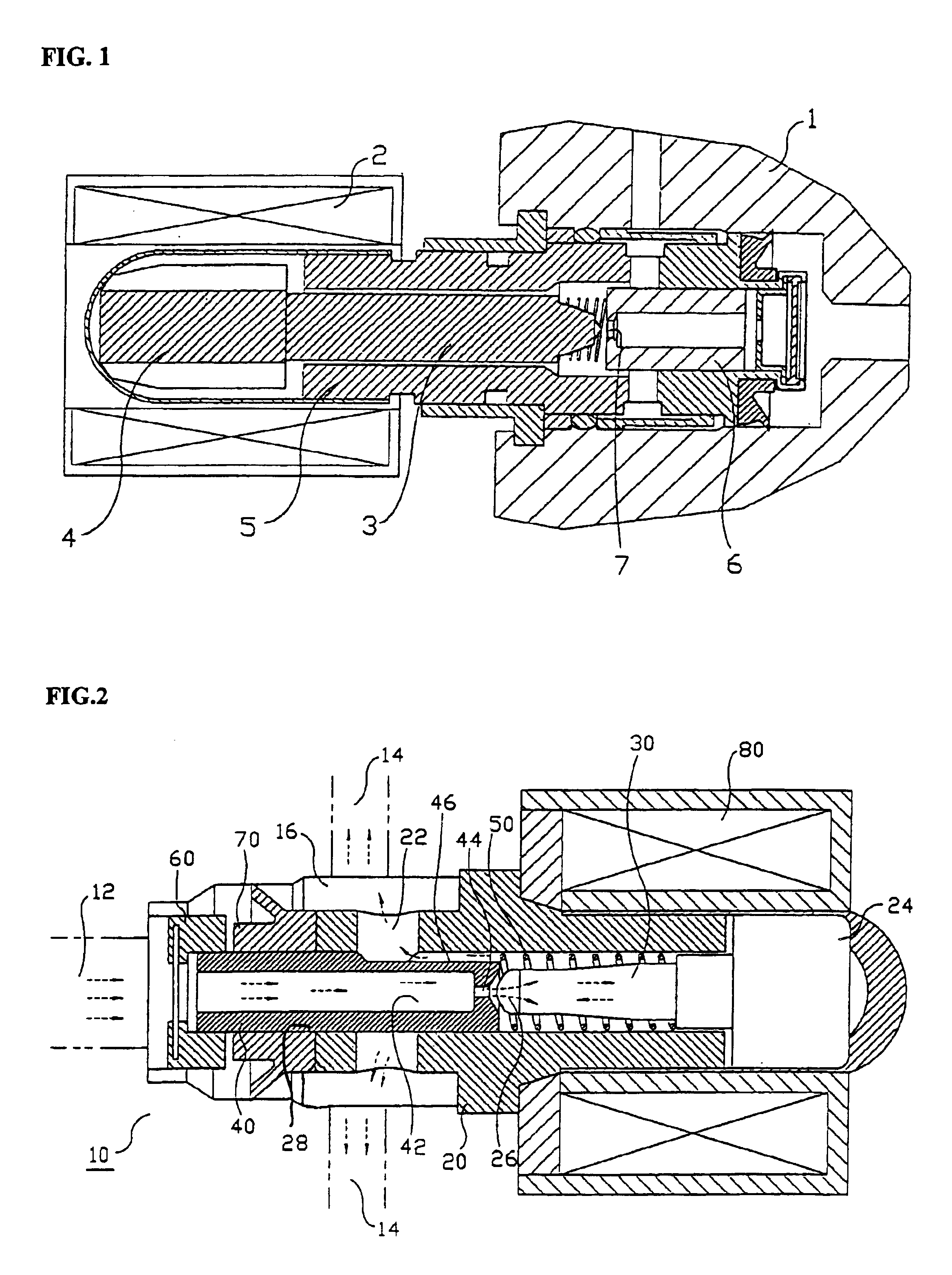

An elevator installation has braking equipment for braking and holding an elevator car which moves in vertical direction within guide tracks or rails. The braking equipment consists of at least two brake units each comprising a normal force regulation device that sets a normal force (FN) in correspondence with a normal force value determined by a brake control unit and / or a locking device that locks the brake unit in a set braking position and which preferably maintains the set braking position in the case of an interrupted energy supply. The braking equipment provides a gentle braking or holding of the elevator car, which corresponds with the operational state of the elevator installation, with a low energy requirement.

Owner:INVENTIO AG

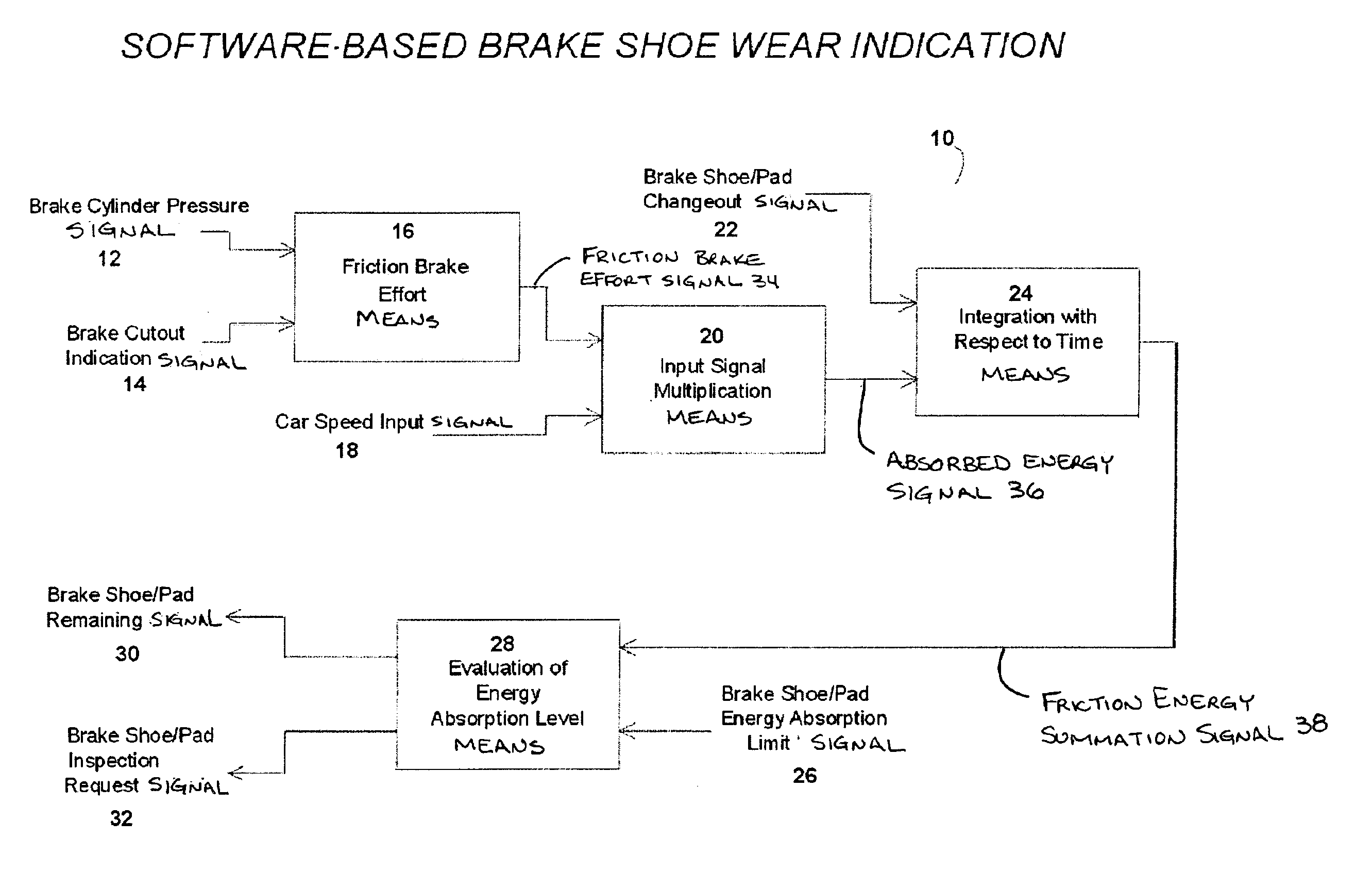

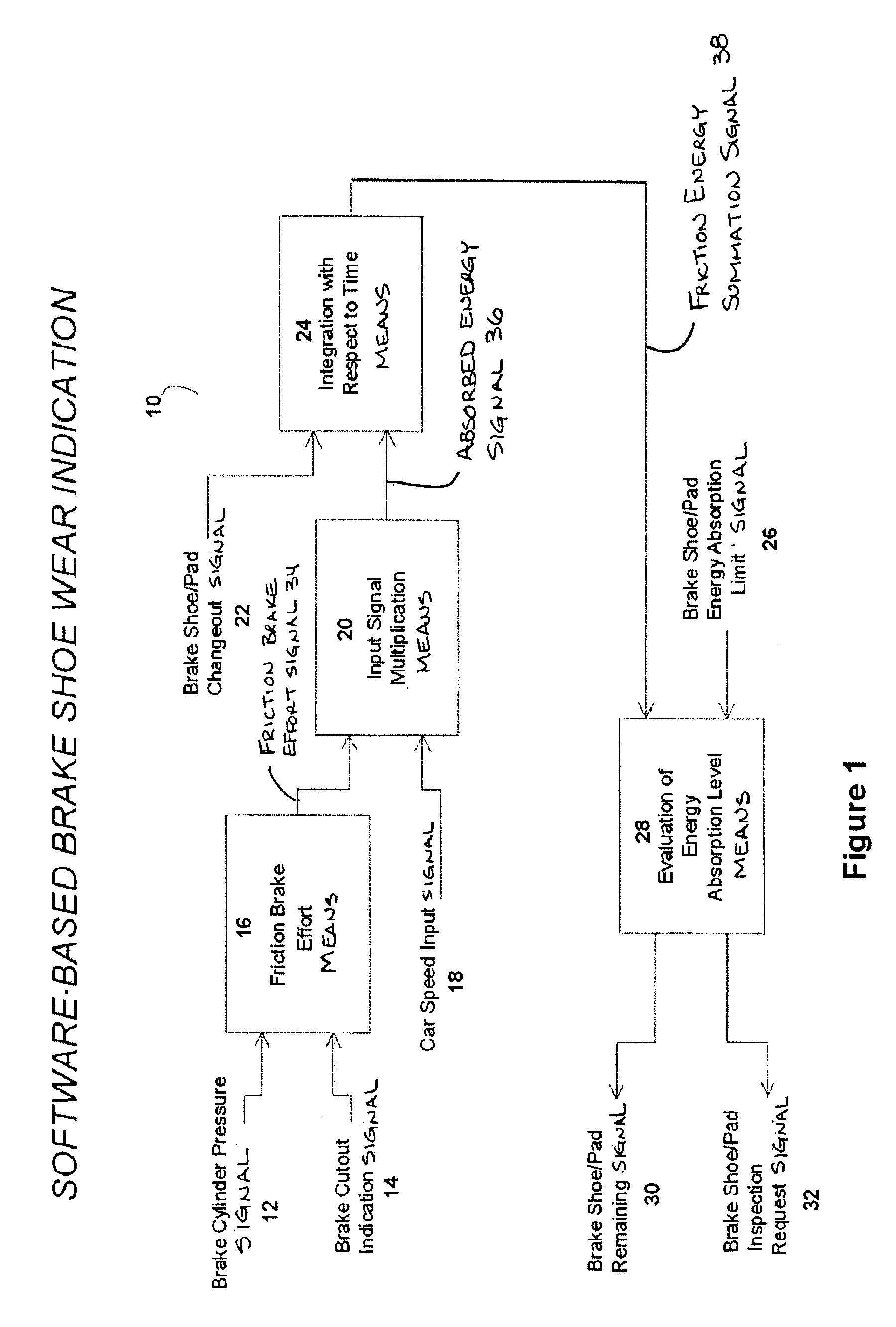

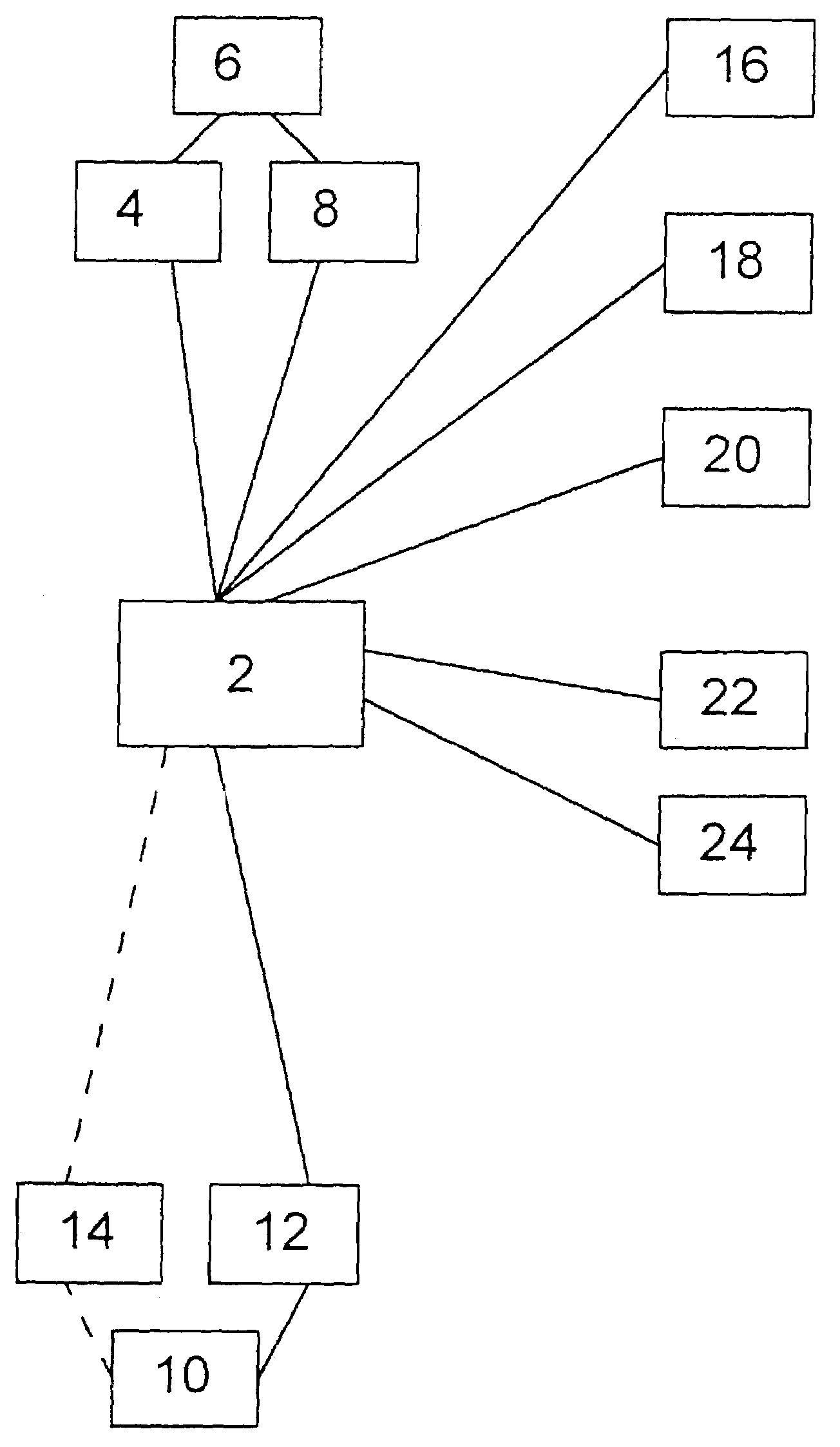

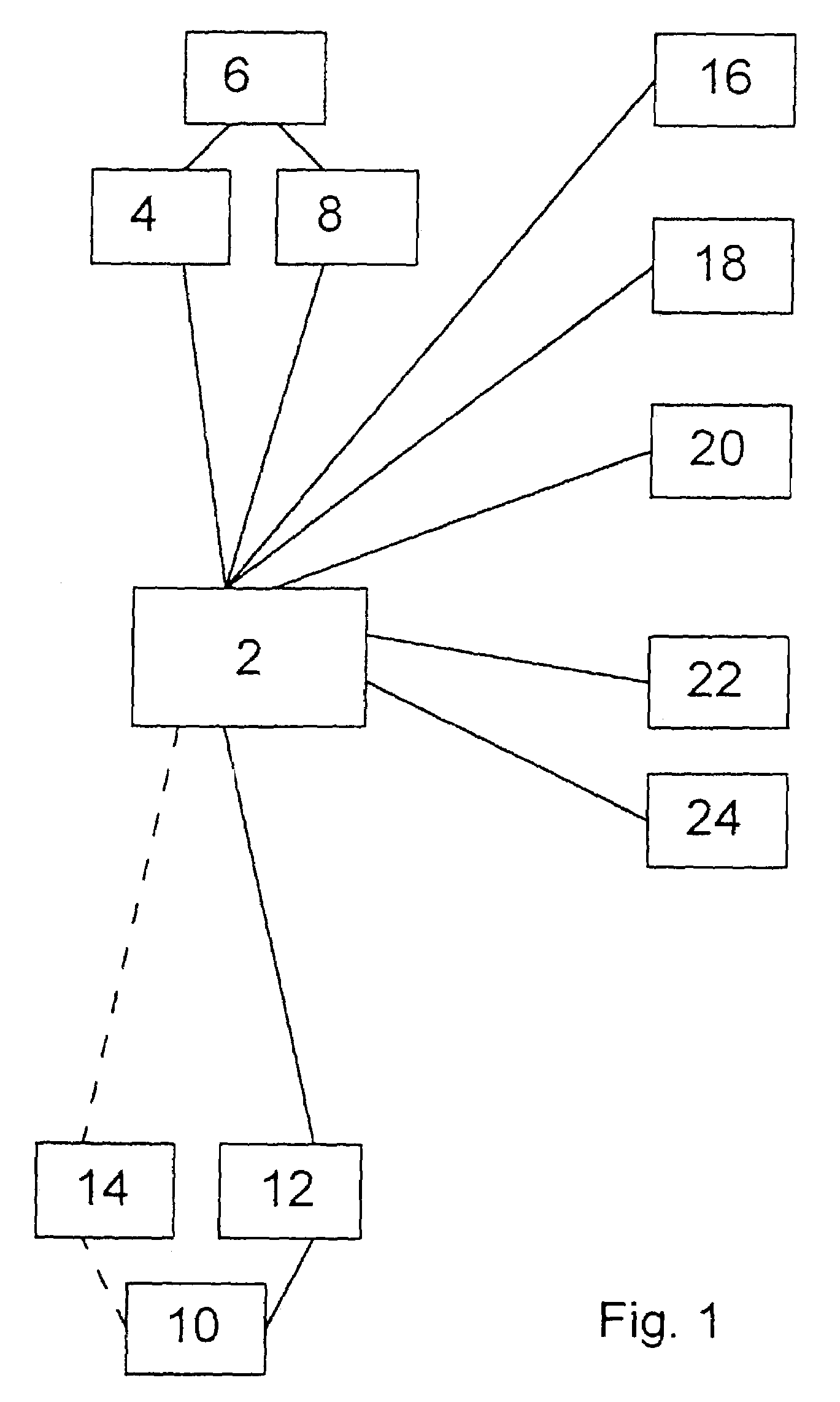

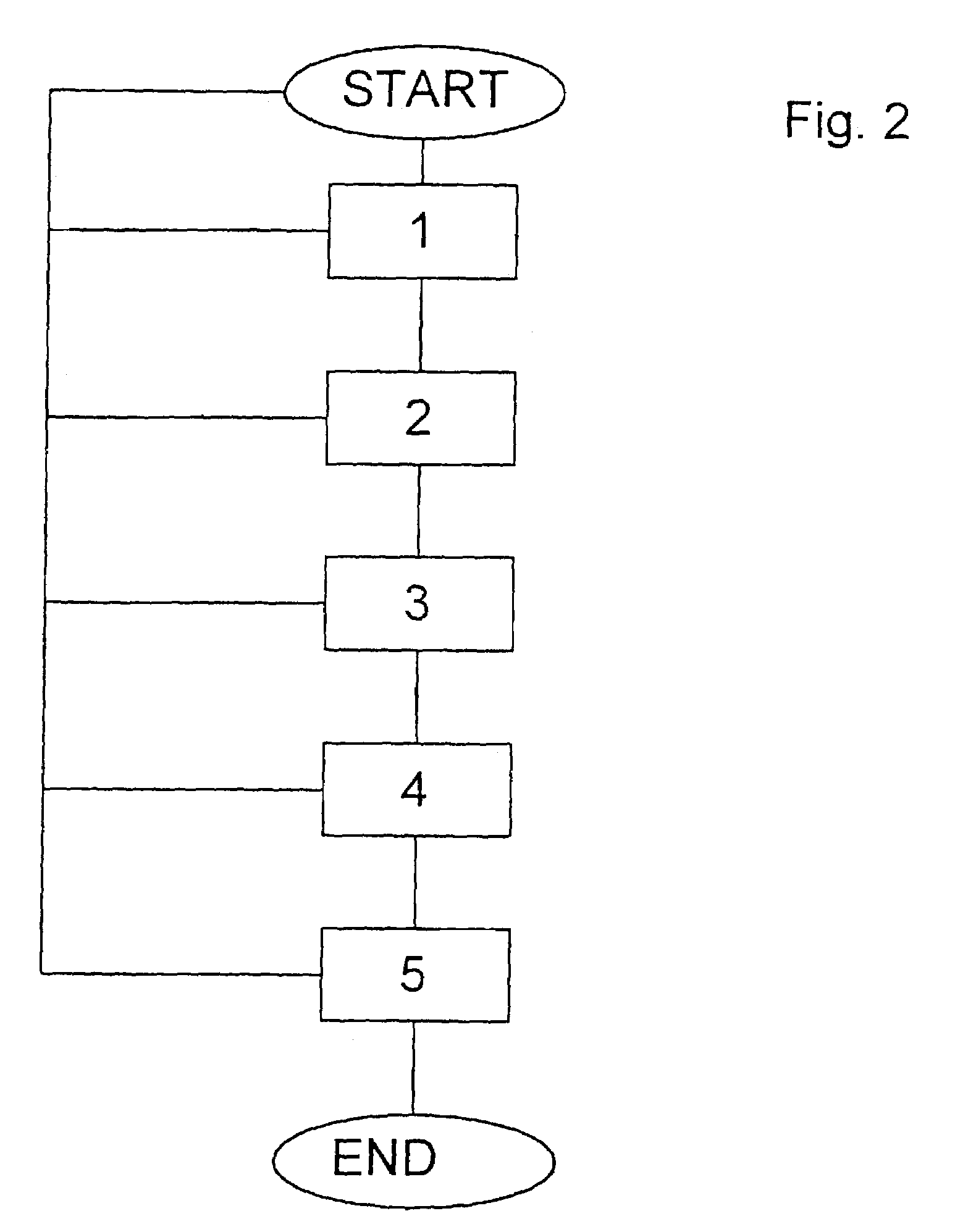

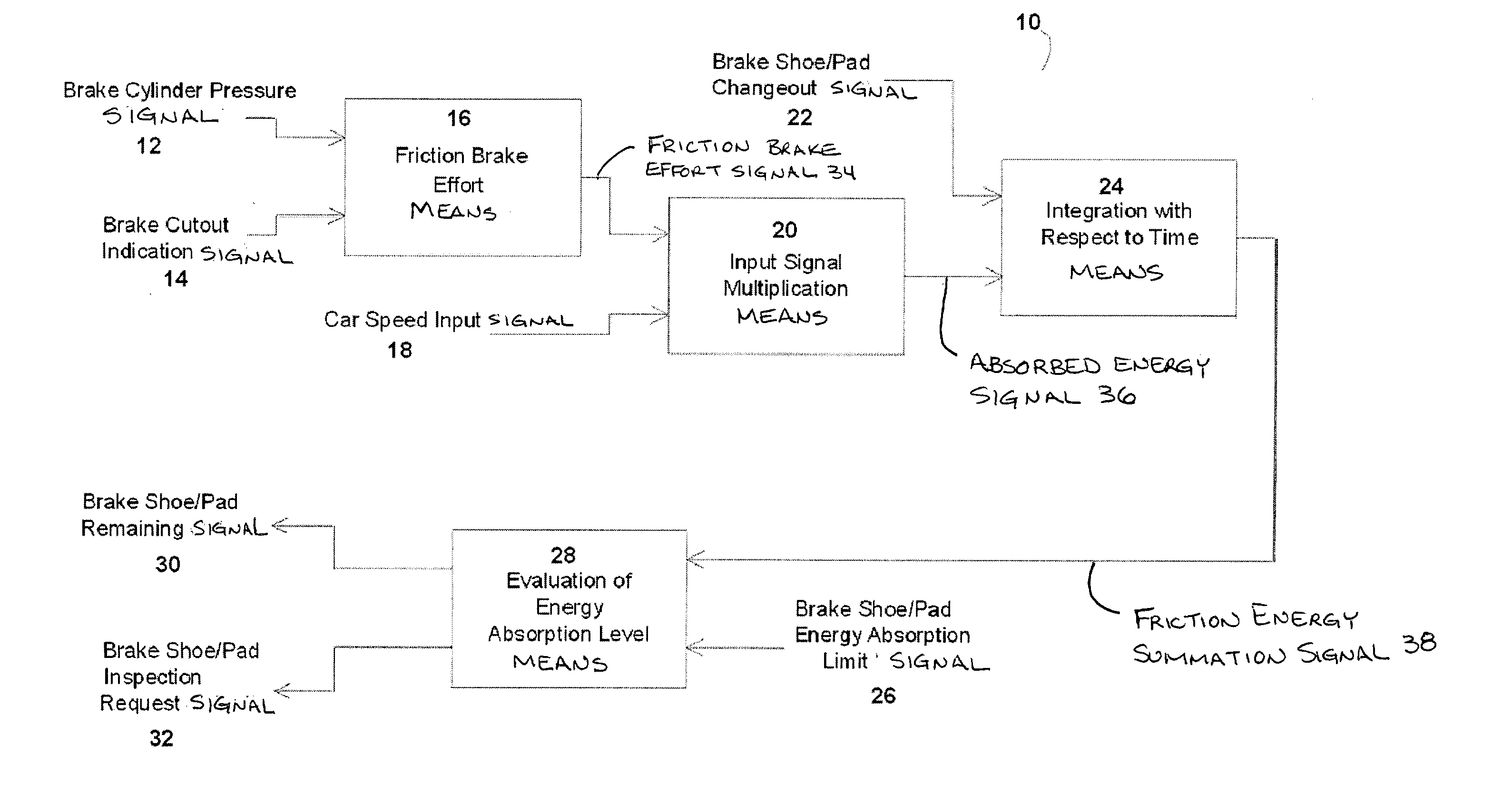

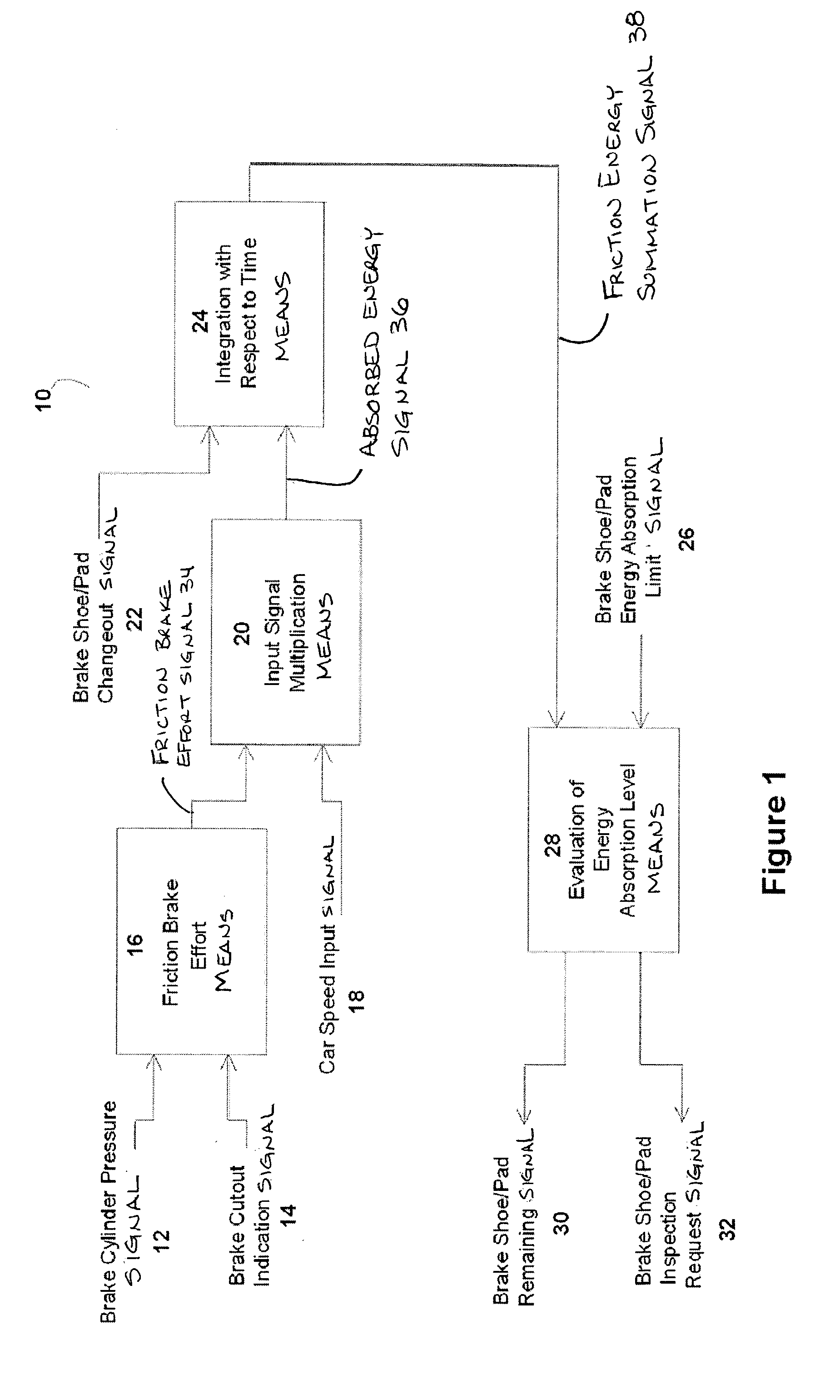

Software based brake shoe wear determination

InactiveUS6847869B2Reduce harmReduce amount of friction brake effort suppliedVehicle testingRegistering/indicating working of vehiclesEngineeringEnergy supply

Owner:WESTINGHOUSE AIR BRAKE TECH CORP

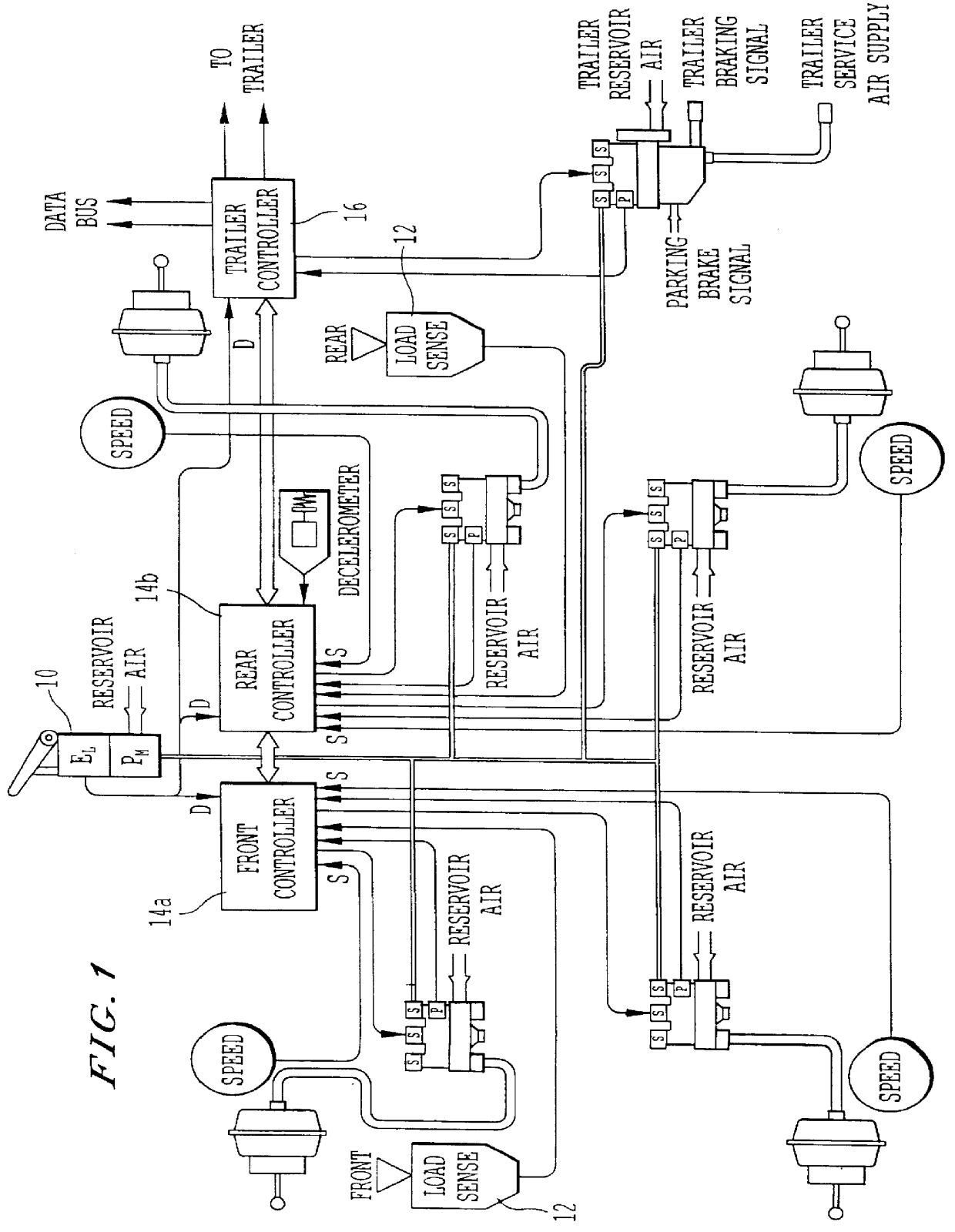

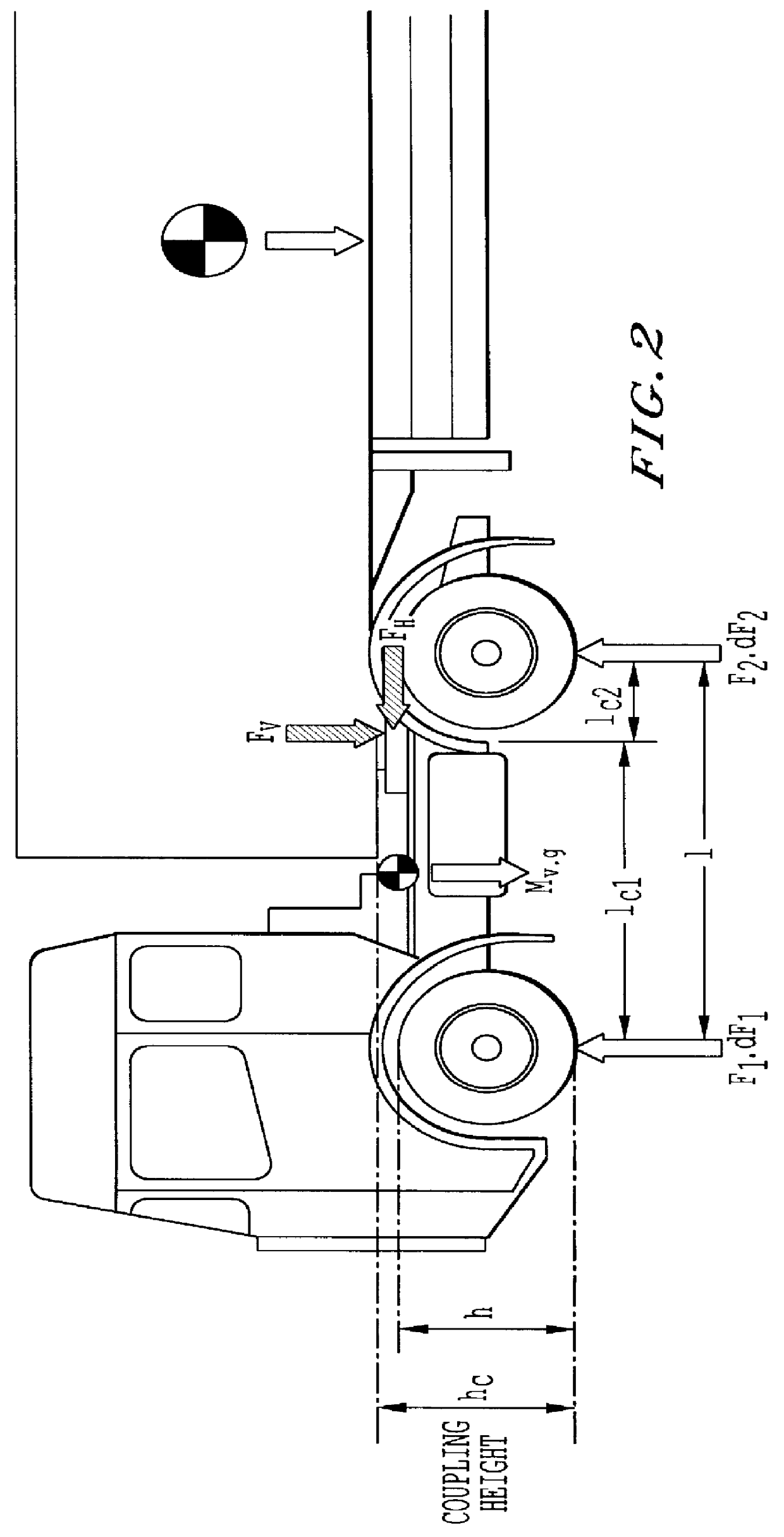

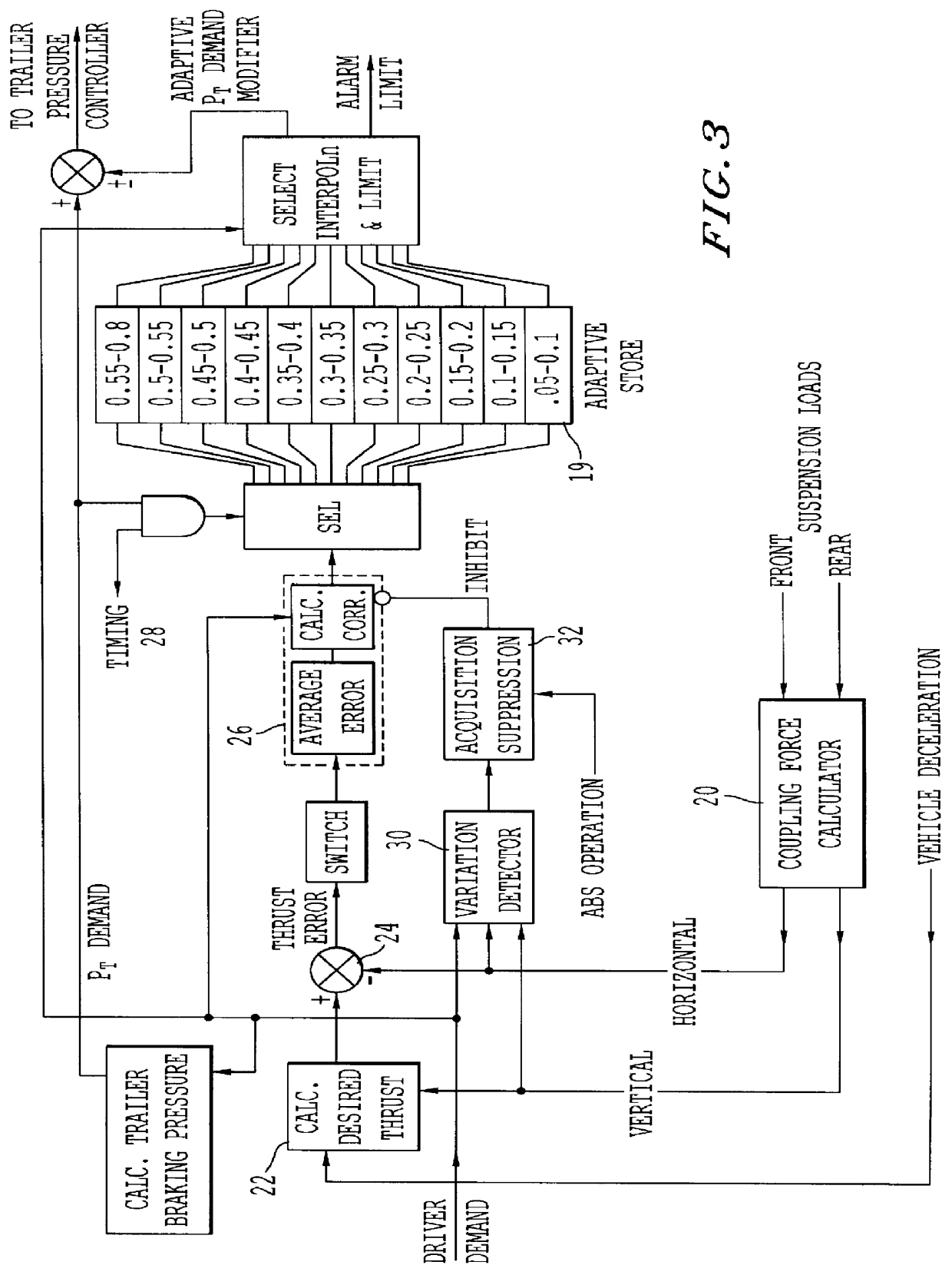

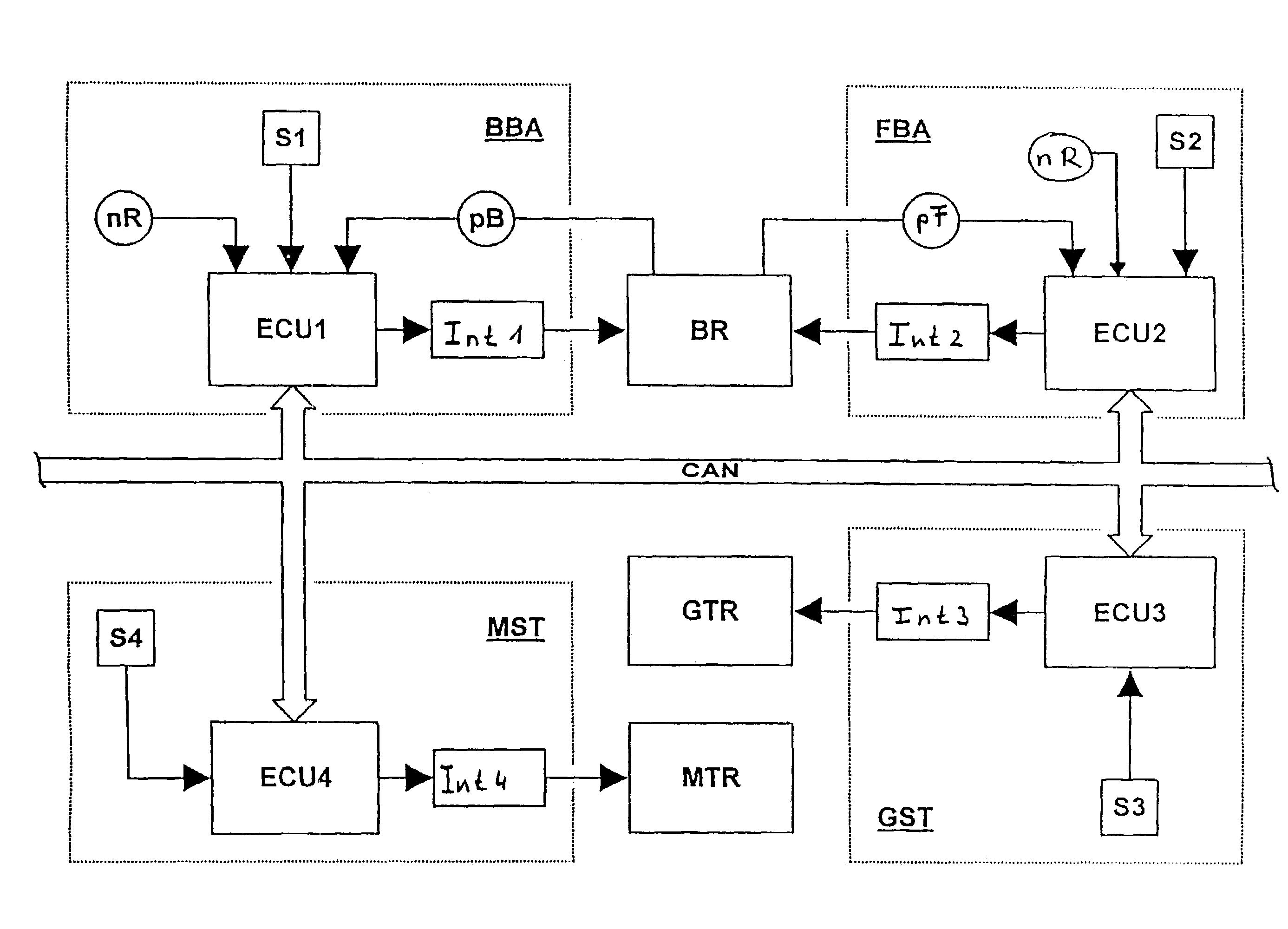

Electronic braking system for road vehicles operating with a trailer

PCT No. PCT / GB96 / 02888 Sec. 371 Date Jun. 5, 1998 Sec. 102(e) Date Jun. 5, 1998 PCT Filed Nov. 22, 1996 PCT Pub. No. WO97 / 19843 PCT Pub. Date Jun. 5, 1997An electronic braking system for trailers. A control system is incorporated into the braking equipment of a towing vehicle to provide a trailer braking command signal. This signal is regulated so as to balance the braking between the towing vehicle and the trailer through the assessment of forces in the coupling between the two vehicles. The assessment is made indirectly and is calculated from forces measured in the suspension components of at least two axles of the towing vehicle and the changes occurring therein during braking.

Owner:MERITOR AUTOMOTIVE INC

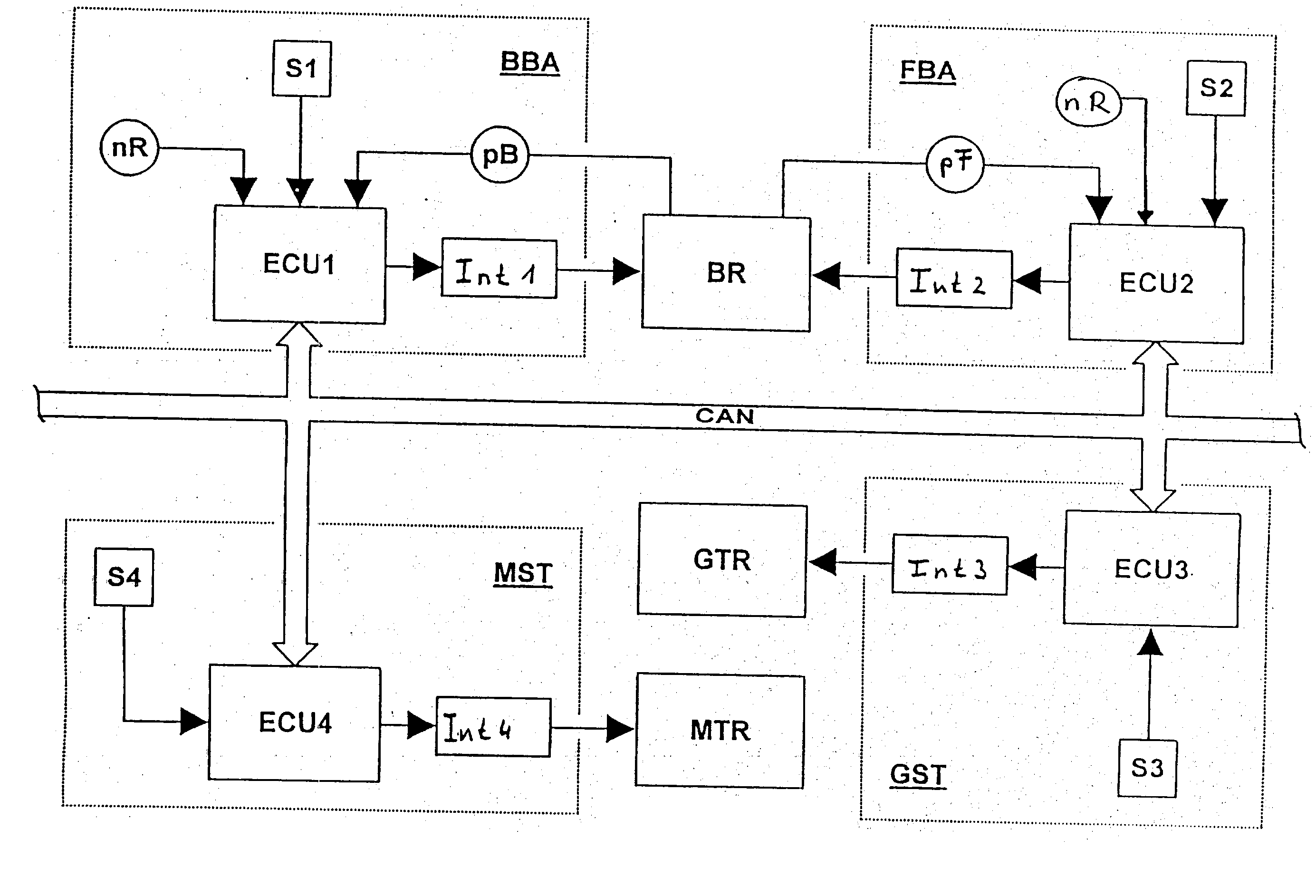

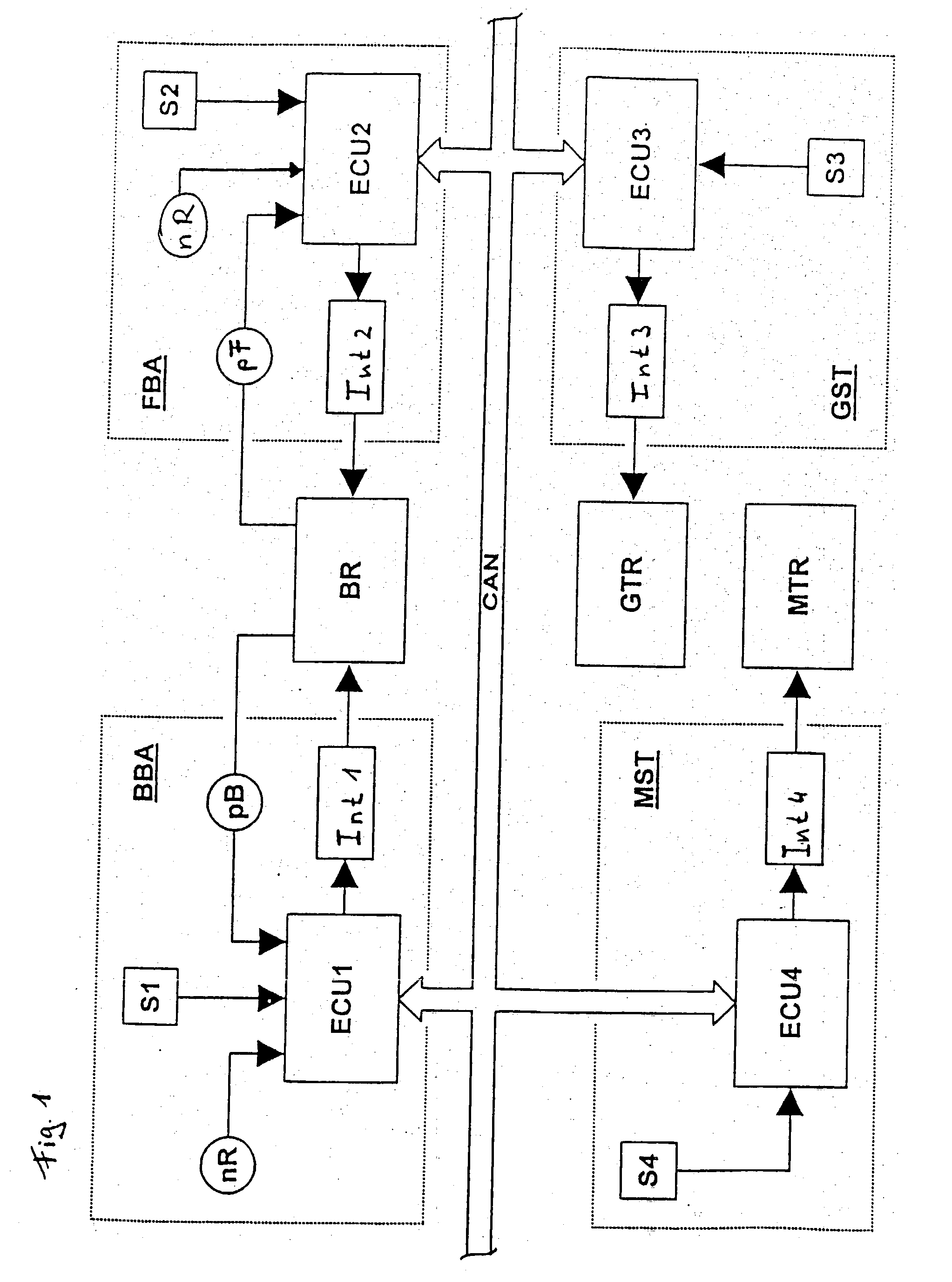

Method and system for controlling brake equipment which can be activated when a motor vehicle is stationary

The present invention provides a method and a system for controlling a braking equipment of a motor vehicle in order to activate the braking equipment at a standstill of the motor vehicle such that braking forces are built up which are necessary to keep the motor vehicle in a state of standstill. To this end it is established on the basis of vehicle movements whether the vehicle is at a standstill. If vehicle movements are detected that cannot occur during driving modes of the motor vehicle, the motor vehicle is in a state of standstill. Subsequently, the braking equipment, and in particular a holding brake mechanism included in the braking equipment, are activated. In order to provide braking forces keeping the motor vehicle at a standstill also when it is on a slope, the braking equipment, and in particular the holding brake mechanism, are controlled in response of the vehicle inclination present in the state of standstill.

Owner:LUCAS AUTOMOTIVE GMBH

Anti-lock brake equipment solenoid valve

InactiveUS6918570B2Improve the preparation effectSpeed up the flowOperating means/releasing devices for valvesApplication and release valvesPower flowSolenoid valve

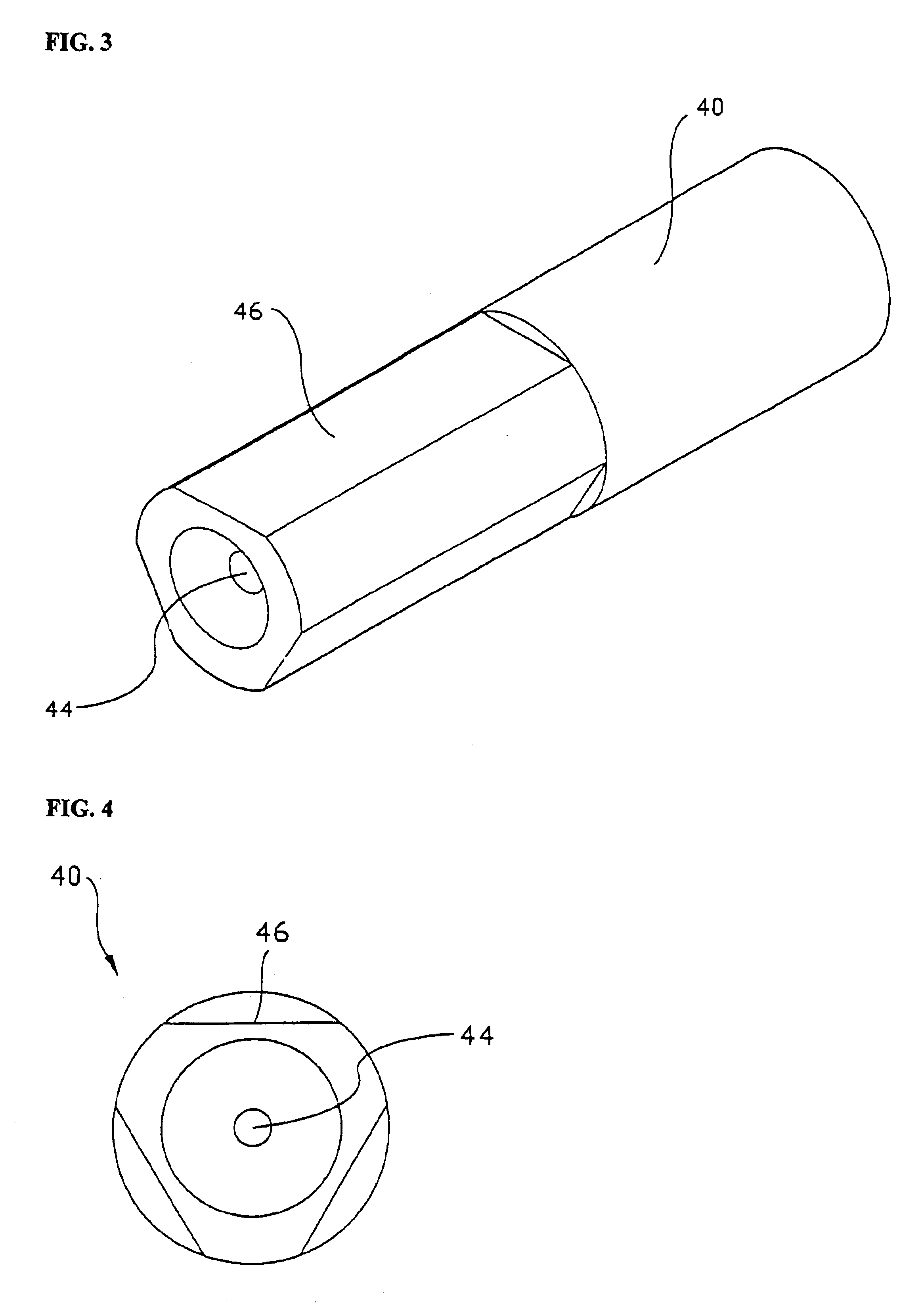

A hydraulic control valve for an Anti-lock Braking System (ABS) includes a modulator block having at least a housing, an inlet port, a receiving unit, and an outlet port. The housing is coupled to at least a plunger, an armature, and a coil body. The housing also has a coupling hole to receive a valve seat. Upon application of a current, a coil generates a magnetic field causing a plunger coupled with the armature to perform a reciprocating motion in which a projection of the plunger moves in contact with and separates from an aperture in the valve seat to adjust fluid flow. The hydraulic control valve also comprises fluid flow paths, provided in a space between the valve seat and the housing, which communicate with an outlet port. The hydraulic control valve accommodates at least a filter and a seal cup on the outer periphery of the valve seat.

Owner:HYUNDAI MOBIS CO LTD

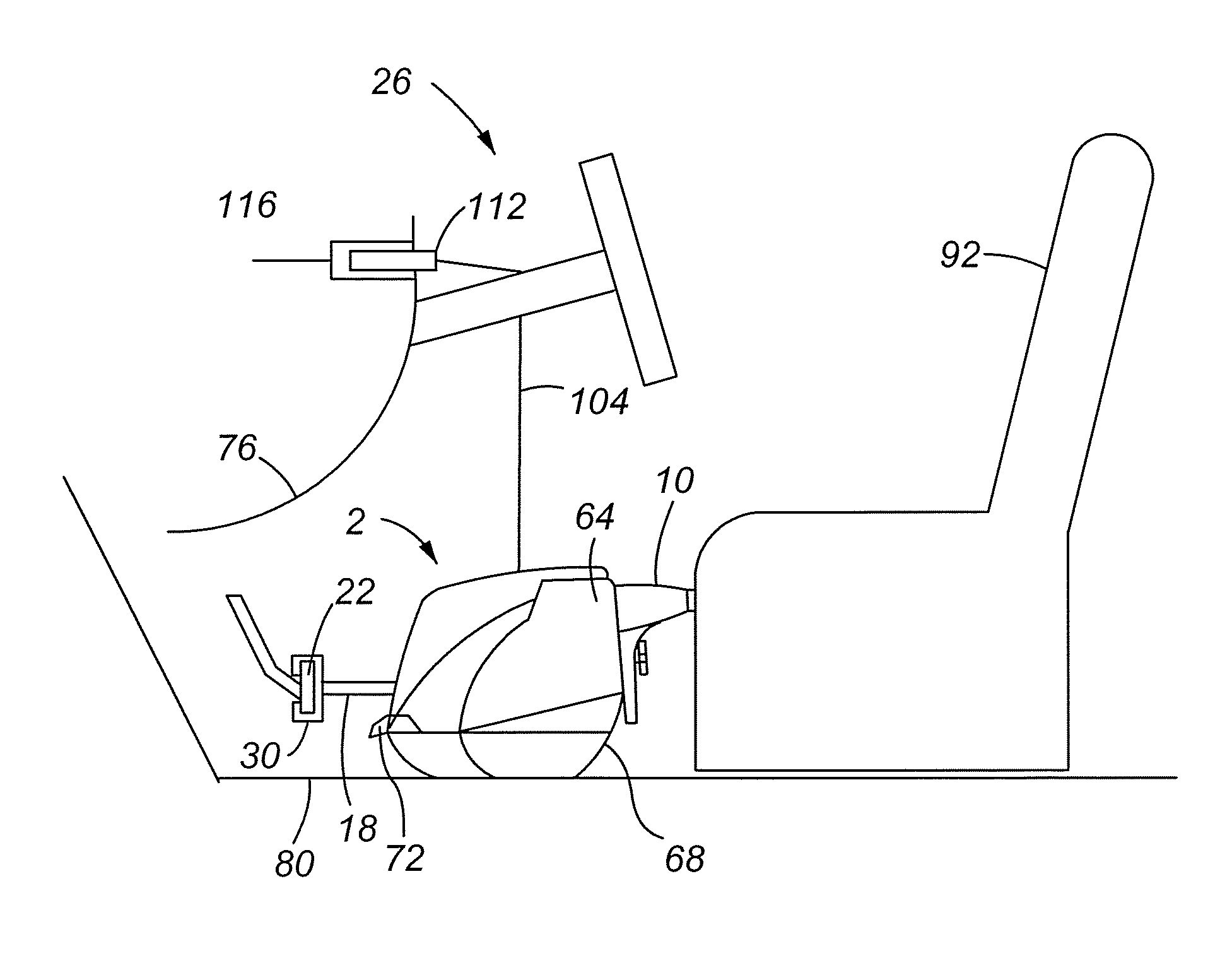

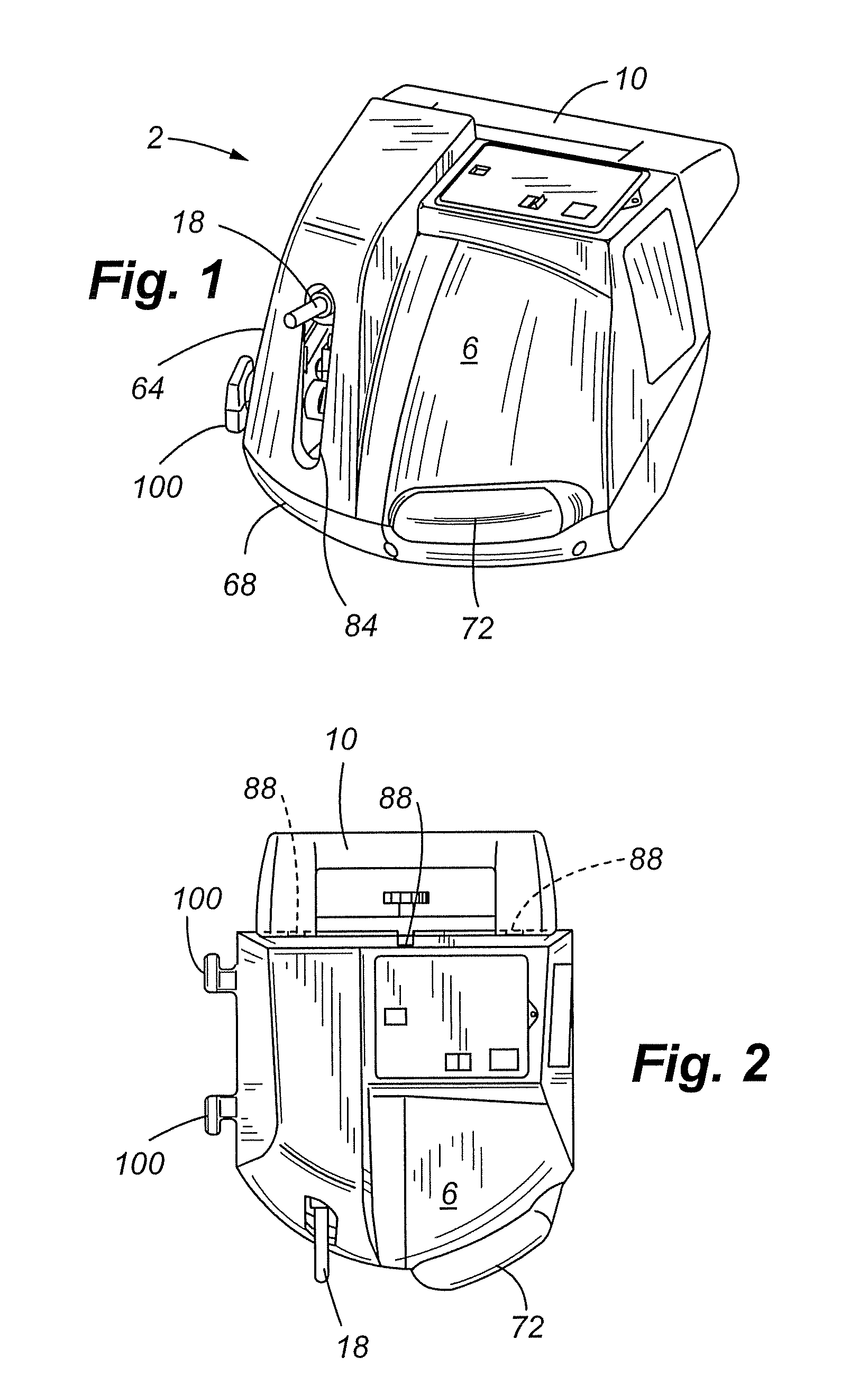

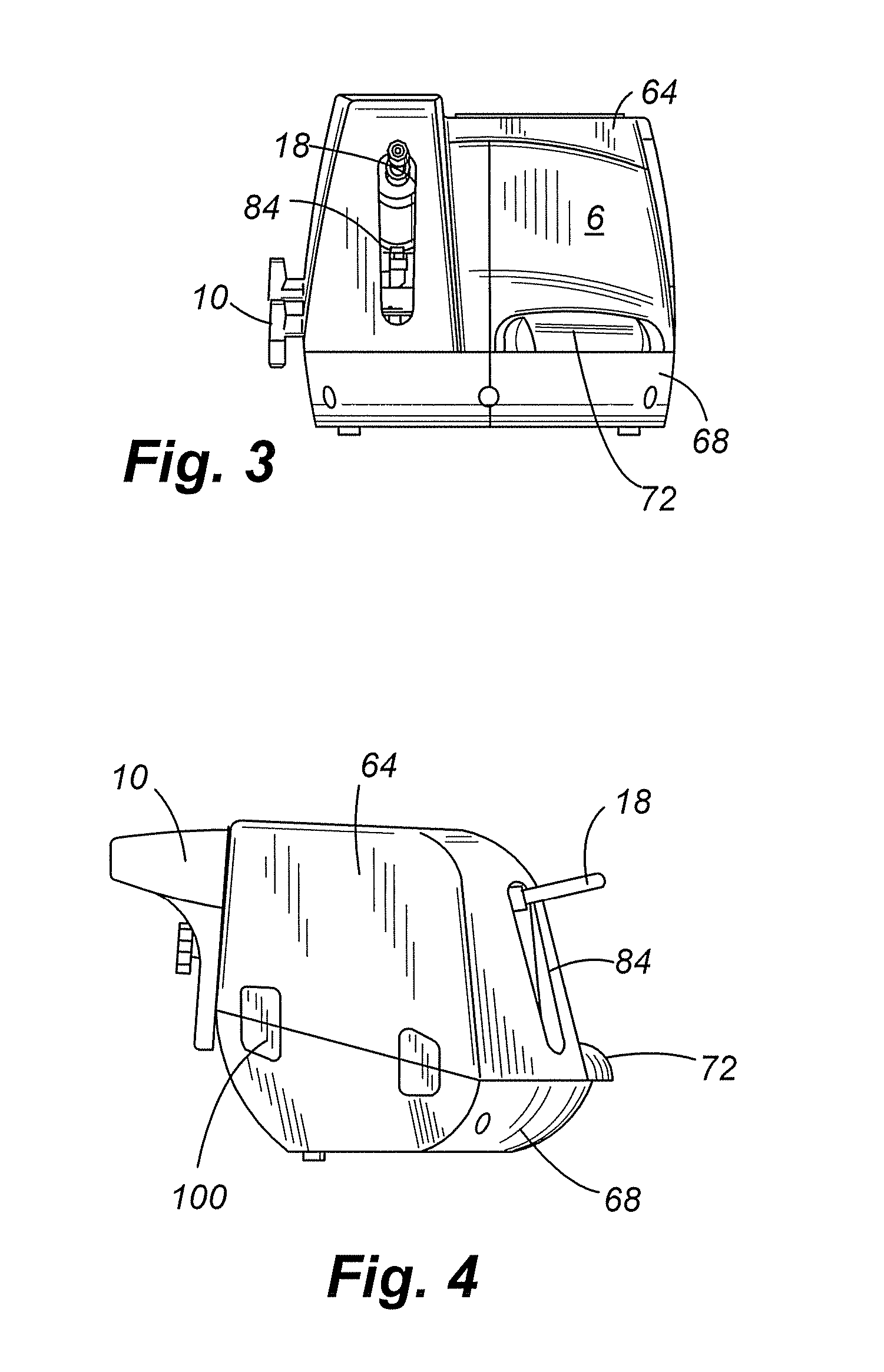

Towed vehicle braking apparatus

ActiveUS8430458B2Reduce needCost prohibitiveAnalogue computers for trafficFoot actuated initiationsRemote controlBraking system

An auxiliary braking system and method of controlling the braking a towed vehicle is provided that includes a remote control that is in selective communication with an auxiliary braking unit positioned in a towing vehicle. More specifically, it is often desirable for the operator of the towing vehicle to assess the performance of the auxiliary braking apparatus positioned in a towed vehicle. In addition, it is often advantageous for the operator to perform real time adjustments to the performance parameters of the auxiliary braking apparatus positioned in the towing vehicle without having to cease driving and physically access the auxiliary braking device.

Owner:HOPKINS MFG

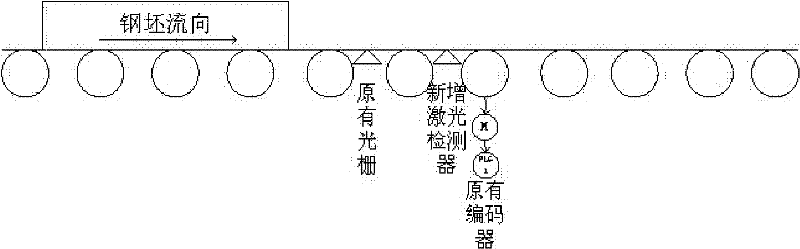

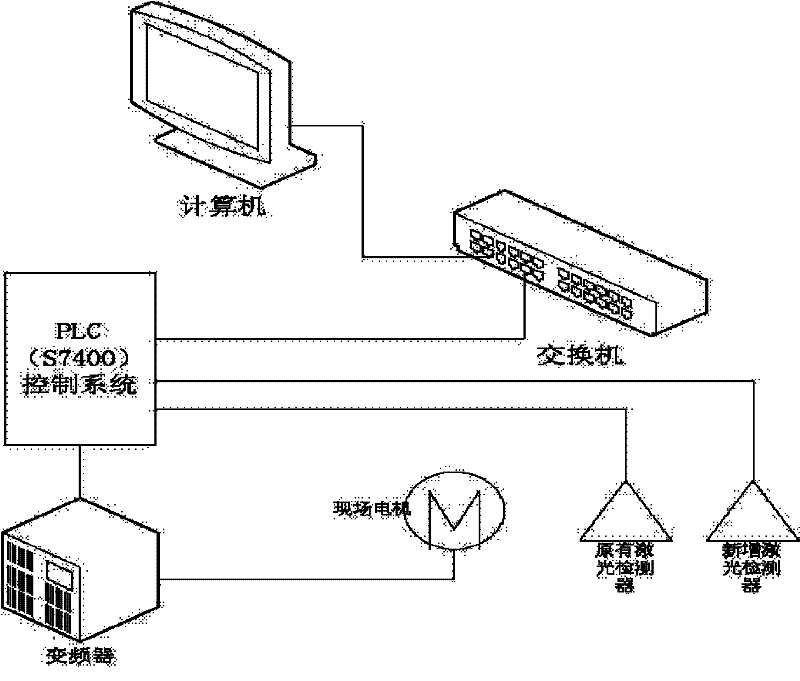

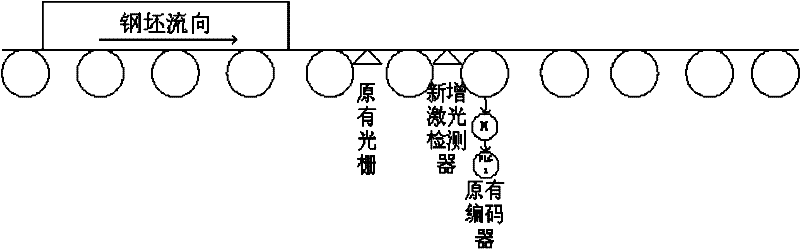

Method for realizing accurate positioning of steel billet delivered into a heating furnace

ActiveCN102230067AHigh precisionImprove stabilityFurnace typesUsing optical meansHeating furnaceMaterials science

The invention relates to the technical field of heating furnace automatic controlling, and discloses a method for realizing accurate positioning of a steel billet delivered into a heating furnace. According to the invention, logic of automatic controlling is skillfully combined with the function of a furnace roller table converter. Without external braking equipment, slipping phenomena occurred after positioning of steel billets with lengths smaller than 2700mm are avoided. With the method, accurate positioning of any sized steel billet can be realized, and slipping does not occur after positioning.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH

Brake system for a vehicle, and brake pedal device for such a brake system

ActiveCN101909953AEasy to brakePrevent rollingMechanical apparatusBraking action transmissionControl theoryParking brake

The invention relates to a braking system (16) for a vehicle (10), particularly a commercial vehicle, having an operating brake device for providing an operating brake function for braking the vehicle, and a parking brake device (92) for providing a parking brake function independently of the operating brake system. In order to improve the functionality of the braking system in case of a fault, the vehicle can be braked automatically by means of the other braking device if one of the two braking devices partially or completely fails. The invention further relates to a brake pedal device for such a braking system.

Owner:ZF CV SYST EURO BV

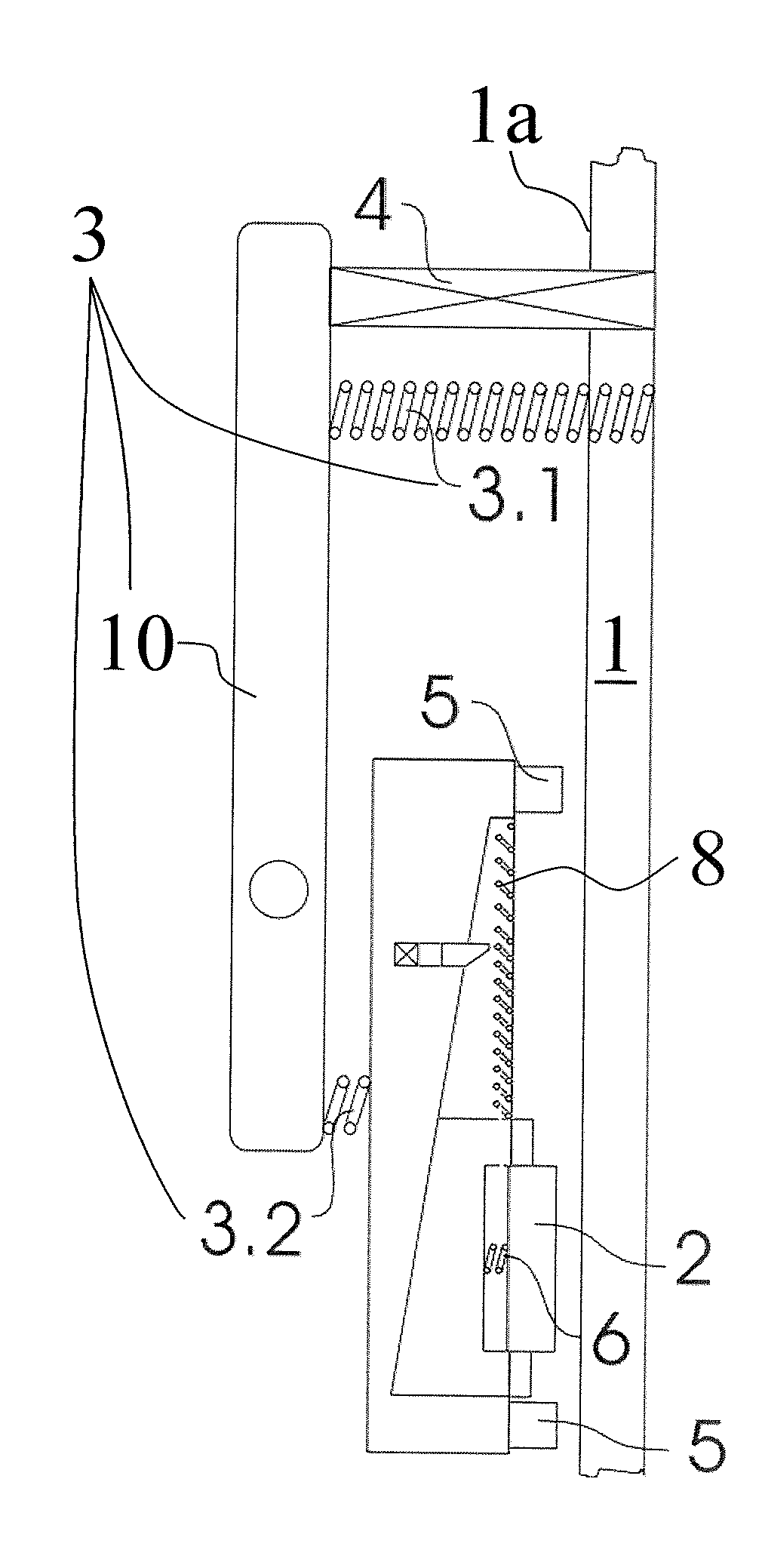

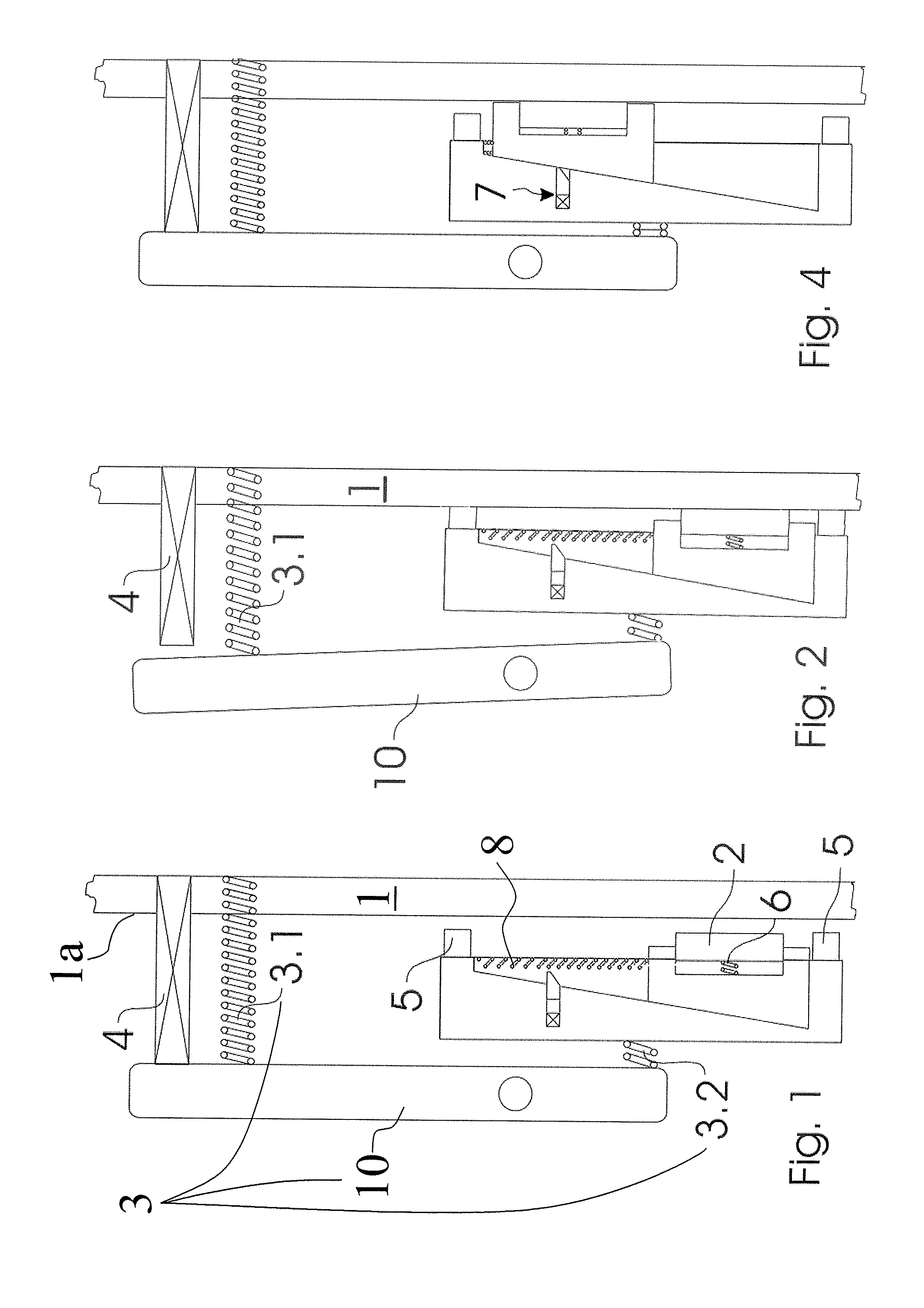

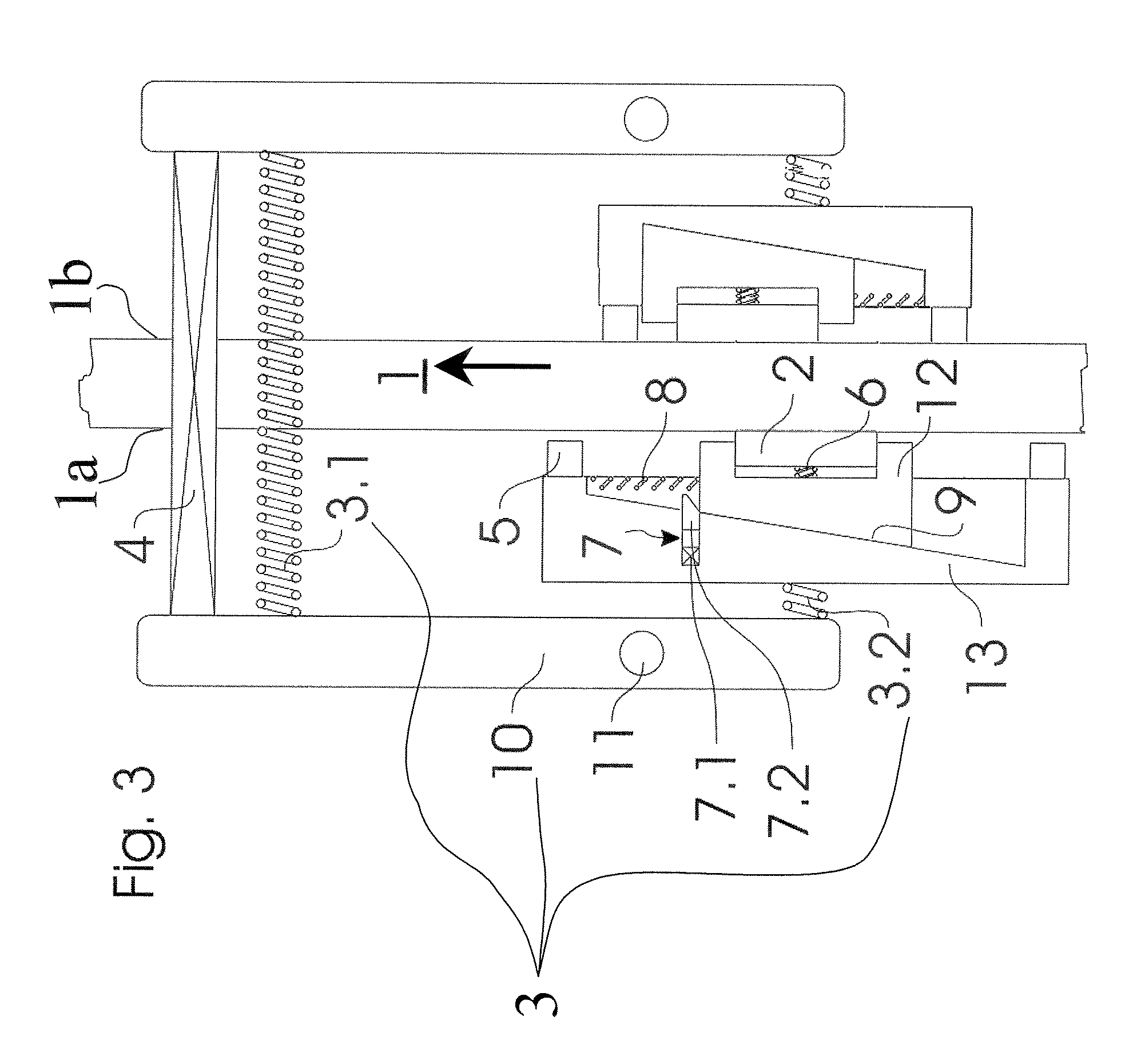

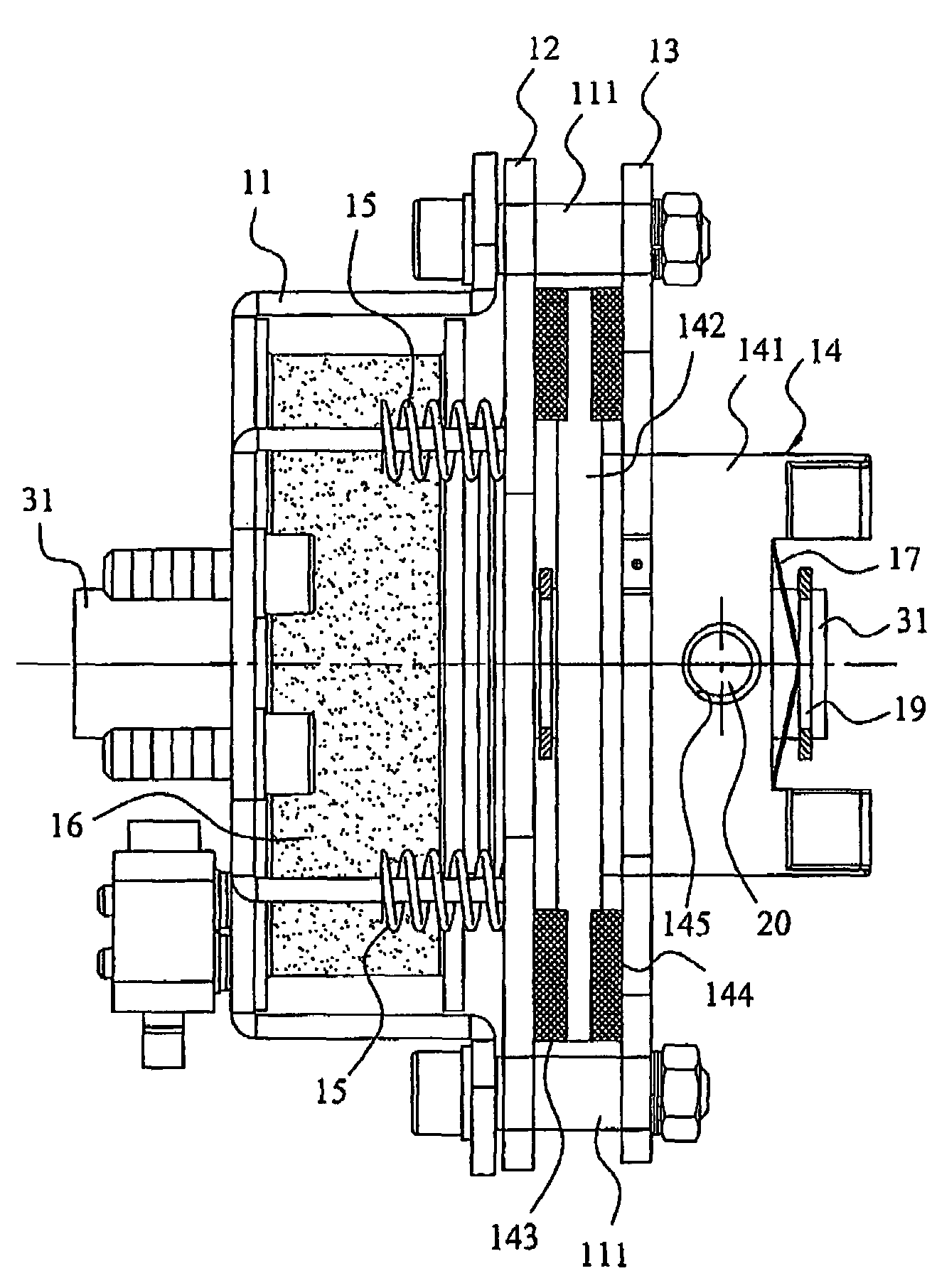

Brake equipment for holding and braking an elevator car in an elevator installation and a method of holding and braking an elevator installation

Brake equipment for holding and braking an elevator car in an elevator installation, which is arranged to be movable along a brake track in two directions of travel, includes a mount with a brake lining which automatically adjusts under friction couple with the brake track on movement of the elevator car relative to the rail and in that case tightens a first tightening means, which can be released by an actuator. The first tightening means tightens the mount together with the brake lining against the brake track by a biasing force. The brake equipment produces, with unmoved brake equipment and an unreleased state of the actuator, a holding force acting in both directions of travel. The holding force is determined substantially by the biasing force acting on the mount.

Owner:INVENTIO AG

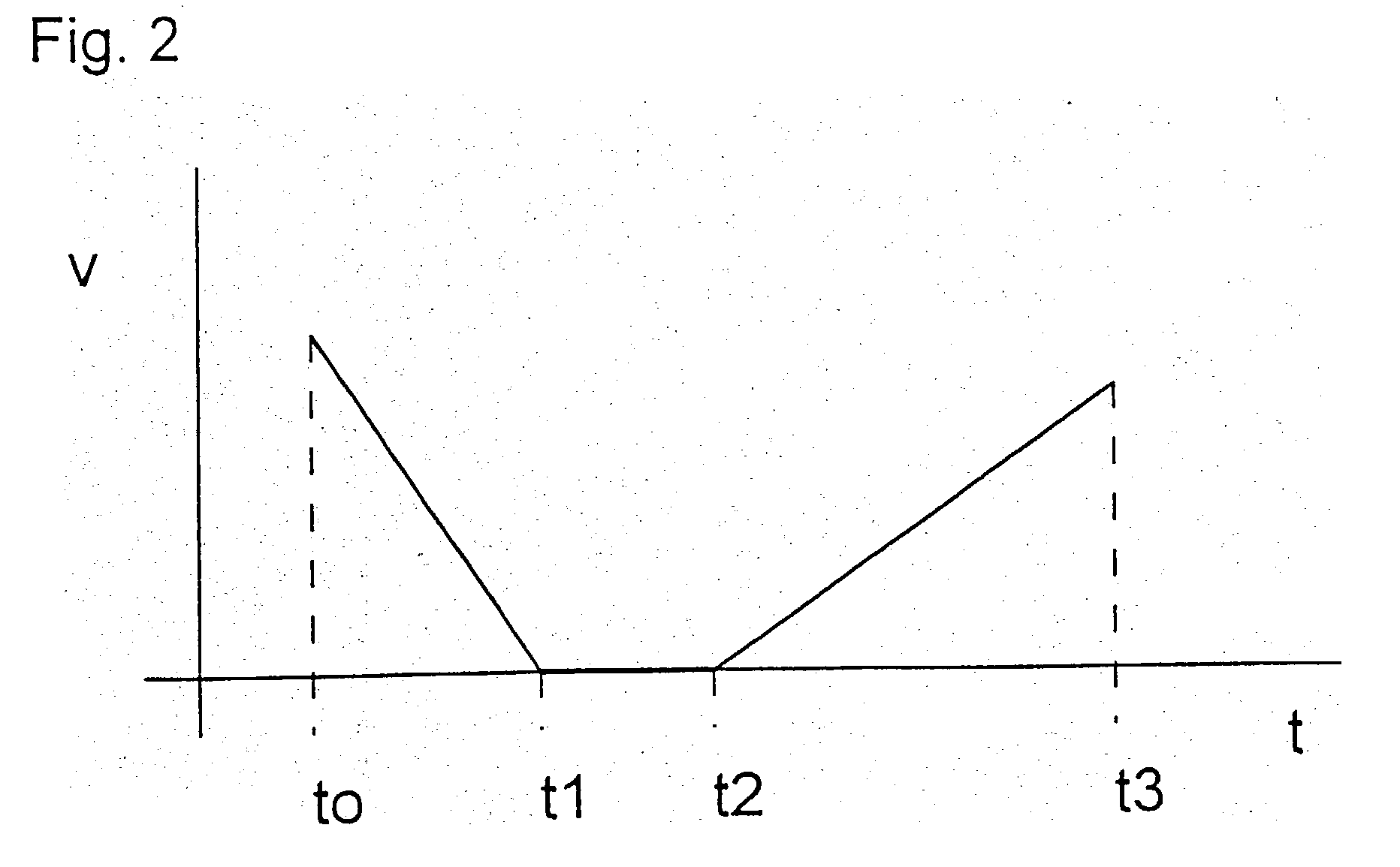

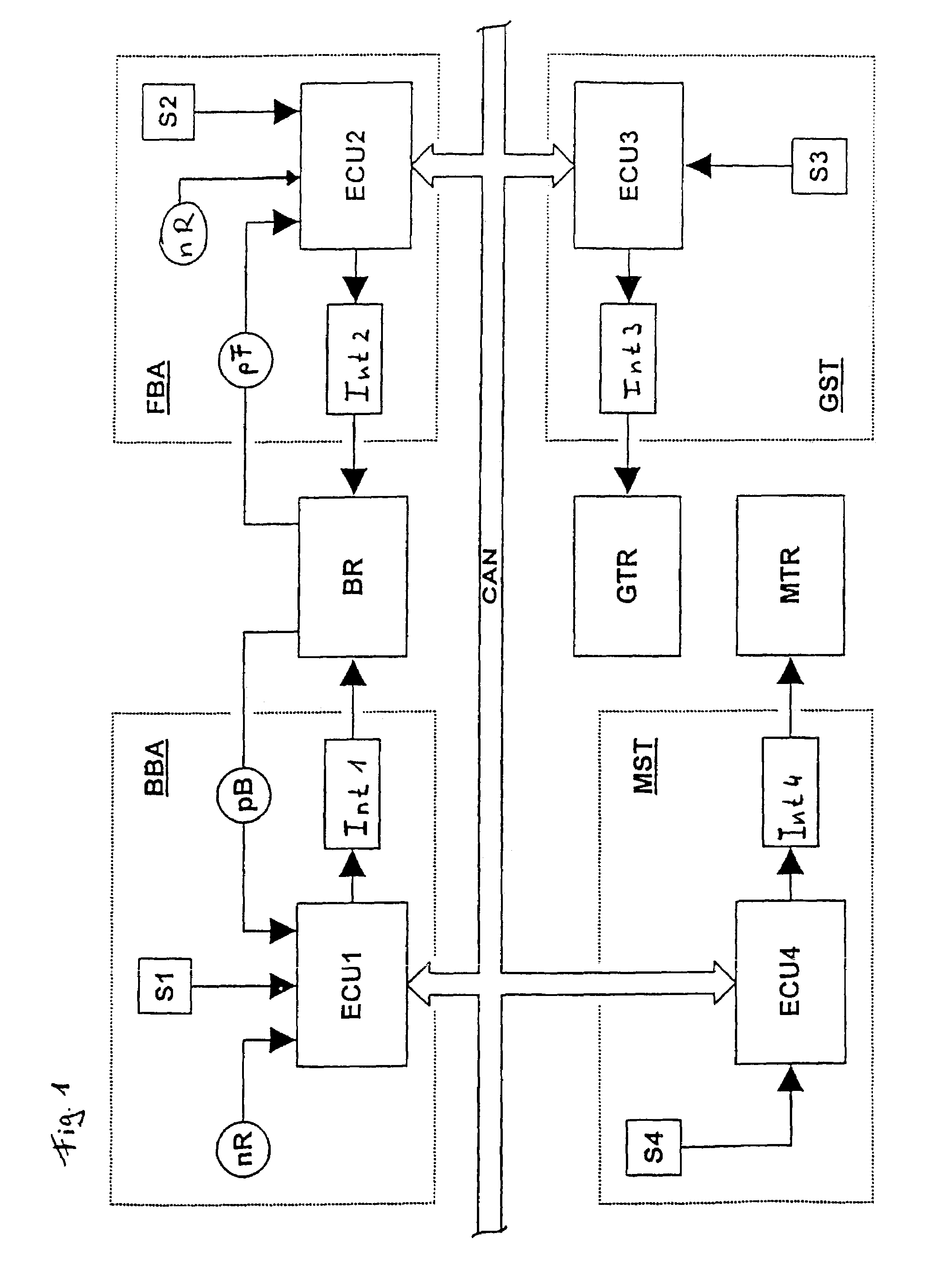

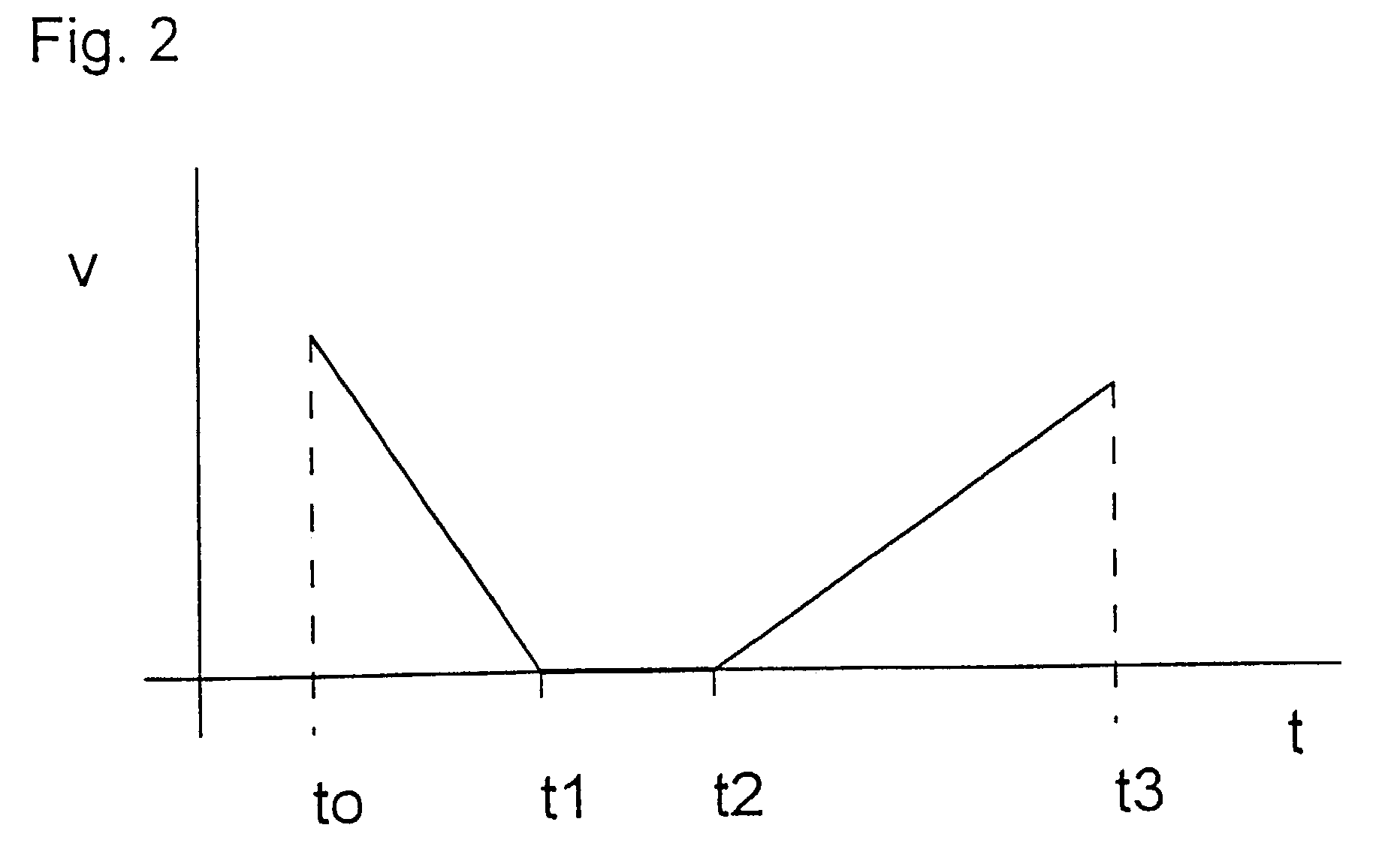

Method and device for controlling the braking equipment of a motor vehicle

InactiveUS20030227215A1Avoid disadvantagesReduce forceBraking action transmissionAutomatic initiationsMobile vehicleVehicle driving

The present invention relates to a method and a device for controlling braking equipment of a motor vehicle. Here, an operating state of a motor vehicle is determined, in which the motor vehicle is to be brought from a state, in which its speed is not zero, into a state, in which the vehicle no longer moves. If such a transition from a traveling state into a state of standstill is determined, braking equipment of the motor vehicle is controlled such that braking forces are produced, which are capable of bringing the motor vehicle into the state of standstill and / or assisting a vehicle driver in doing this. It is also possible to produce braking forces in the state of standstill, which are capable of holding the motor vehicle in the state of standstill. The present invention additionally enables to assist a vehicle driver when starting a motor vehicle. In this case, an operating state of the motor vehicle is detected in which the motor vehicle is to be brought from a state of standstill into a traveling state. If such an operating state is present, the braking equipment of the motor vehicle is controlled such that the braking forces produced by the braking equipment in the state of standstill are reduced in such a way as to allow a transition into the traveling state and / or to assist the vehicle driver in this respect.

Owner:LUCAS AUTOMOTIVE GMBH

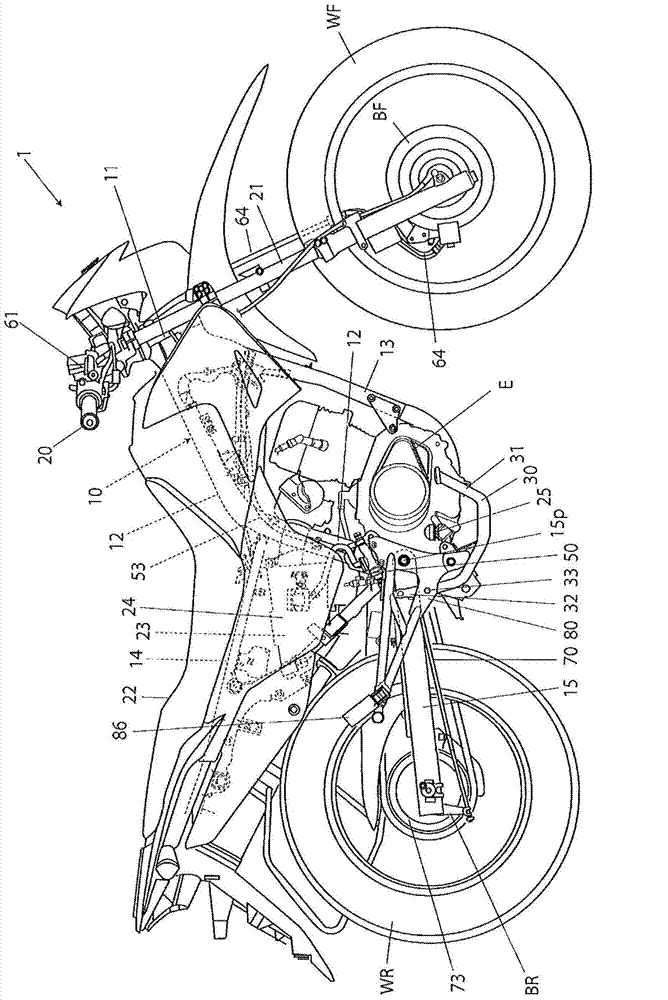

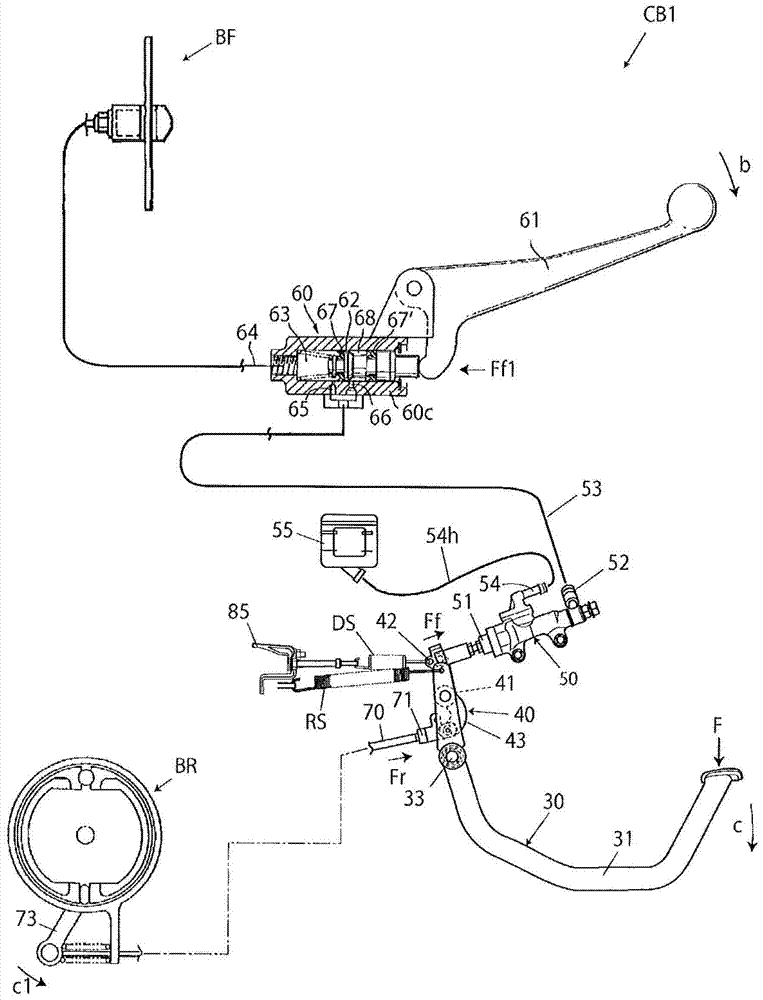

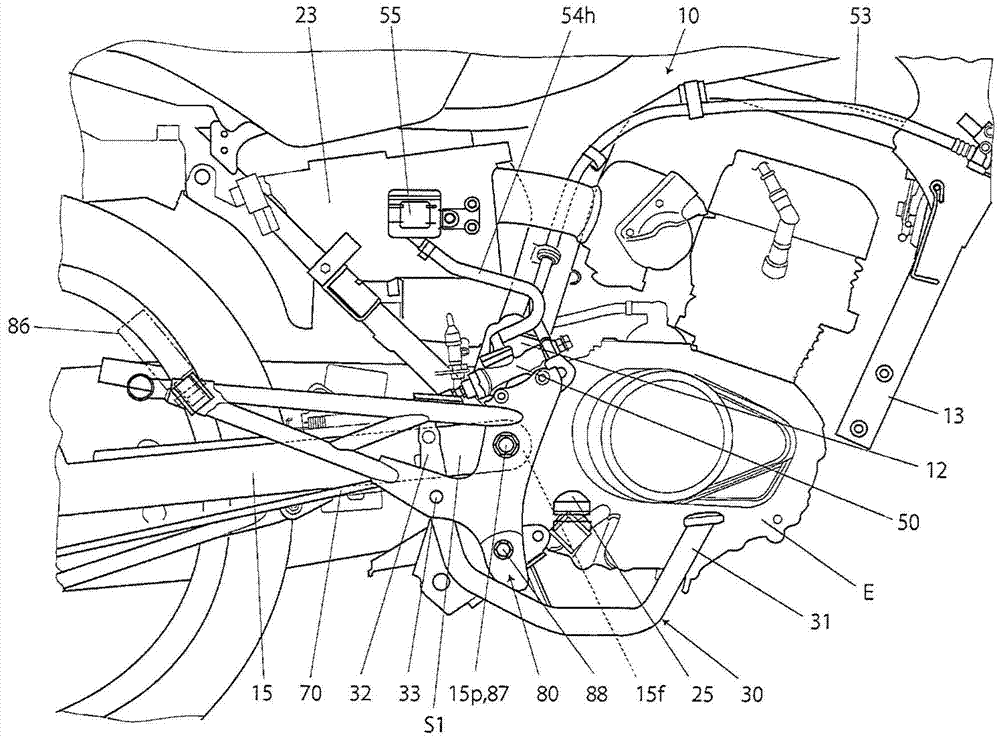

Interlocking brake equipment of saddle form vehicle

ActiveCN103693152AConfiguration impactInhibition effectCycle brakesHydraulic cylinderTransmitted power

The present invention relates to an interlocking brake equipment of a saddle form vehicle, which can properly ensure the rate of a transmitting power forced or transmitting distance of an equalizer relative to an operating force or distance of a brake pedal. The interlocking brake equipment of the saddle form vehicle includes the brake pedal (30), a pedal arm (31) that forward extends with relative to a pedal pivot (33), and a transmitting arm (32) that together rotates with the pedal arm (31) and upward extends relative to the pedal pivot (33). The interlocking brake equipment of the saddle form vehicle also includes the equalizer (40) that is connected with the transmitting arm (32) of the brake pedal (30). One end of the equalizer is connected with a rear transmitting unit (70) that transmits operating power to a rear-wheel brake (BR), the other end of the equalizer is connected with a main hydraulic cylinder (50) that receives the operating power from a front wheel brake (BF). During the observation of side-looking, a swing arm (15p) is provided in such a location: the front of the location is surrounded by a power unit (E), and the rear of the location is surrounded by the transmitting arm (32), the upward side of the location is surrounded by the main hydraulic cylinder (50) and the below side of the location is surrounded by pedal arm (31).

Owner:HONDA MOTOR CO LTD

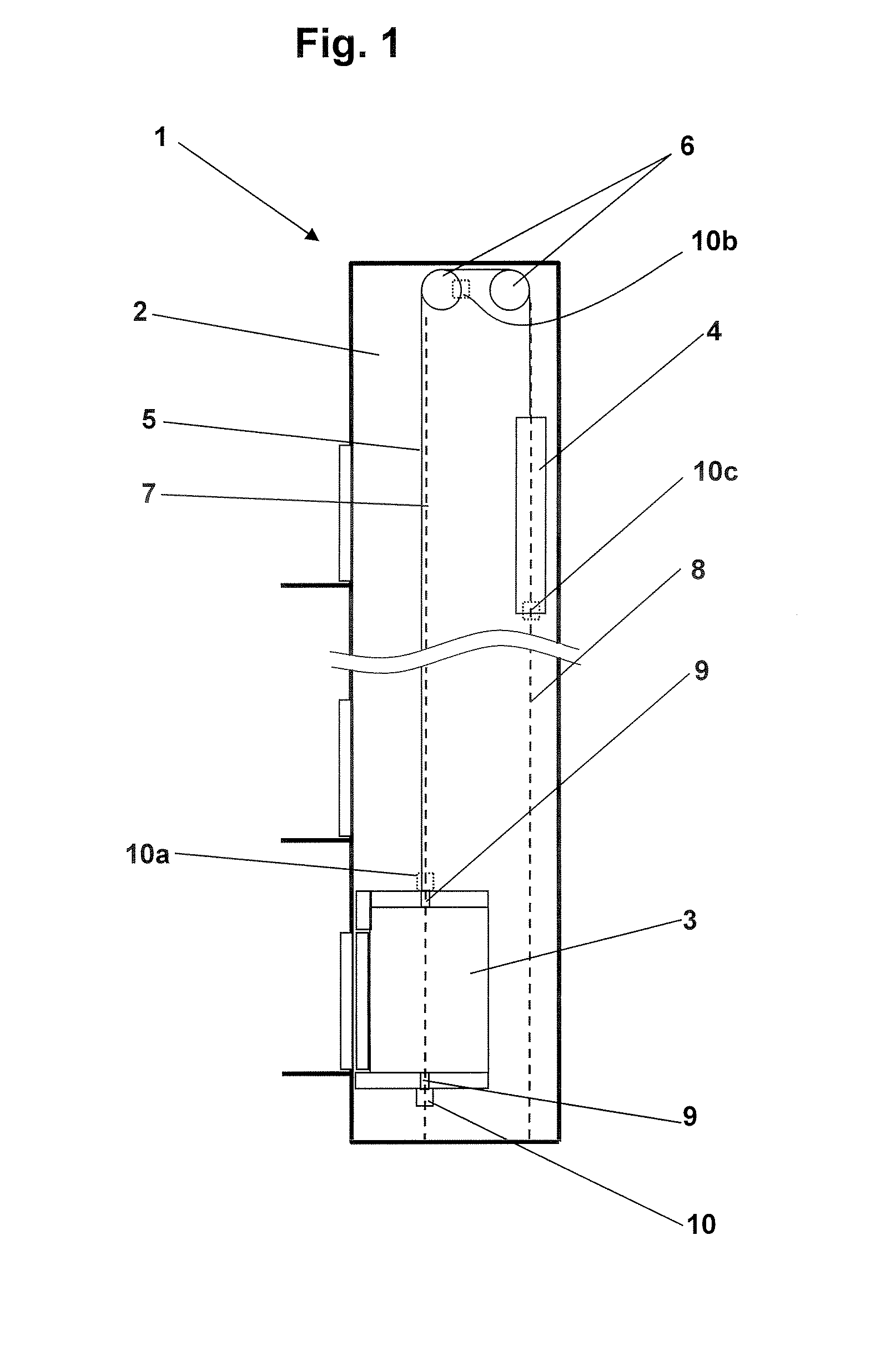

Elevator installation, a guide rail of an elevator installation, brake equipment of an elevator installation and a method for guiding, holding and braking an elevator installation

InactiveUS20080135345A1Good chemicalImprove mechanical propertiesMaterial nanotechnologyRailway system combinationsBrake liningBrake force

An elevator installation includes a guide rail and brake equipment for guiding, holding and braking the elevator installation. The brake equipment has a brake lining which co-operates with a brake surface, advantageously with the brake surface of the guide rail, for the purpose of the braking and holding. The brake surface has at least one longitudinal wedge groove or wedge elevation which is oriented in the braking direction and on which the brake lining acts in case of need. An amplification of the braking force is achieved by the longitudinal wedge groove or wedge elevation.

Owner:INVENTIO AG

Method and system for assisting the start-up of a motor vehicle

InactiveUS20030214186A1Increased damageIncreased strainAutomatic initiationsBrake typesMobile vehicleDriver/operator

The present invention provides start-up assistance for a motor vehicle having braking equipment which, in the stationary state of the mo-or vehicle, automatically or under the control of a vehicle driver summons up braking forces needed for the stationary state. To assist start-up of the motor vehicle through a reduction of the braking forces generated in the stationary state, a start-up request of a vehicle driver is determined when defined conditions, which are to be met for start-up of the motor vehicle, exist in the stationary state. Once a start-up request has been recognized, the operating state of the motor vehicle is checked until an operating state required for start-up exists. Once such an operating state is reached, the braking equipment of the motor vehicle is controlled in such a way that its braking forces generated in the stationary state are reduced to allow start-up of the vehicle.

Owner:LUCAS AUTOMOTIVE GMBH

Braking equipment for motor vehicles

The invention relates to a braking system comprising: a master cylinder (1) and a master cylinder housing (20), to which wheel-brake cylinders can be connected; a first piston (2), which is coupled to a brake pedal (3) via a pressure rod (34) that transmits actuating forces; a second piston (4), which is used to actuate the master cylinder (1); a third piston (5), which can be hydraulically actuated by the first piston (2); at least one elastic element (6, 7), which forms a pedal travel simulator and which during the brake-by-wire mode gives the vehicle driver a comforting pedal sensitivity; elements for coupling the displacement of the first (2) and the third piston (5); an intermediate chamber (11) that can be subjected to a hydraulic pressure, the influence of the latter causing a hydraulic force to act on the second (4) and third piston (5); and an electrically controlled pressure-provision module (9), which permits the intermediate chamber (11) to be filled with hydraulic fluid and to be evacuated. The aim of the invention is to assist the actuating force even when the electronic controller or the electric energy supply fails. To achieve this, the system is equipped with a fourth piston (8), which can be subjected to two opposing forces by means of the elastic element (6, 7) on the input side and the hydraulic pressure in the intermediate chamber (11) on the output side, and elements (14,19,15) that allow the pressure-provision module (9), in addition to being electrically controlled, to be controlled in accordance with the position of the fourth piston (8), obtained by the aforementioned exertion of forces.

Owner:CONTINENTAL TEVES AG & CO OHG

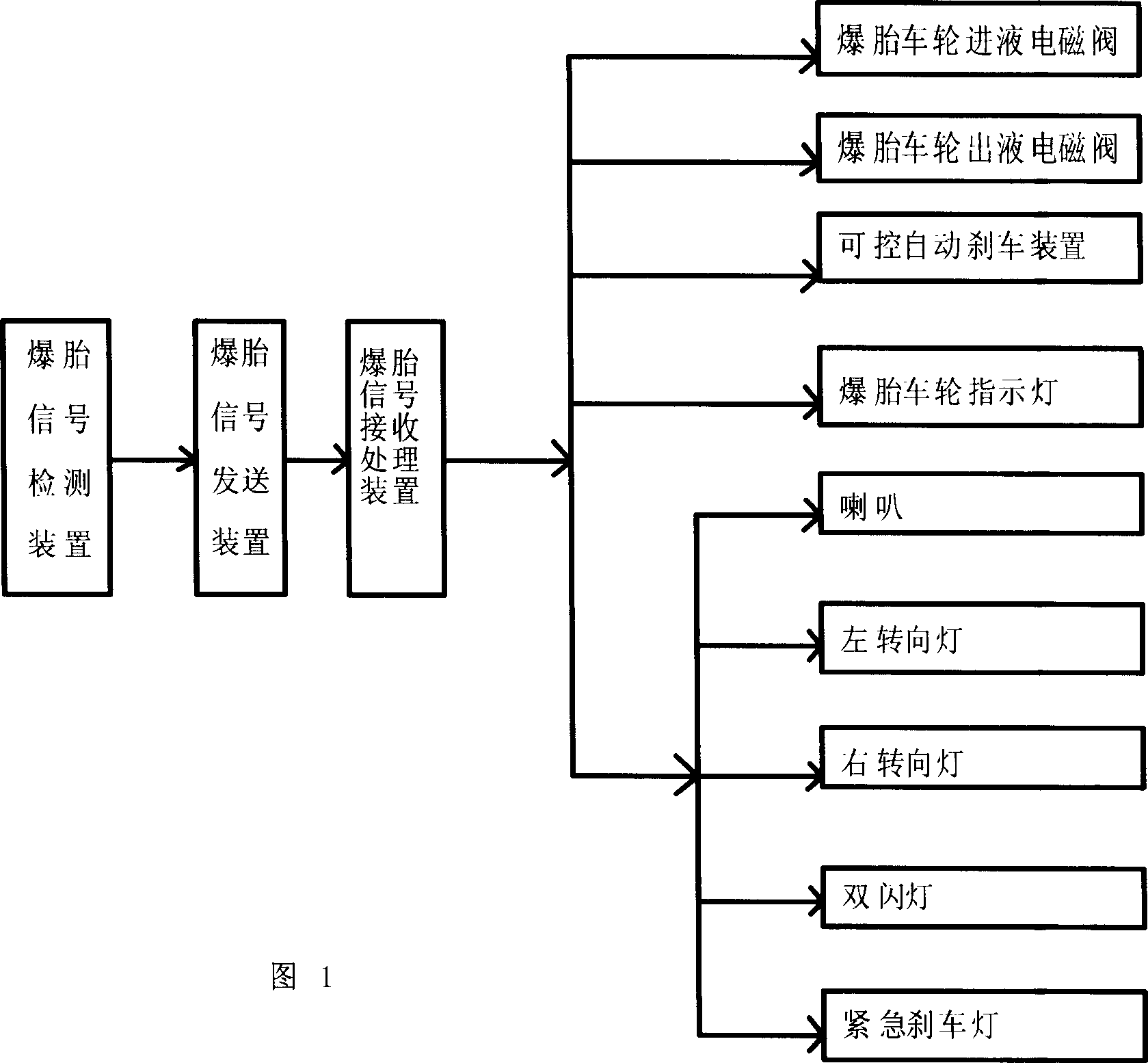

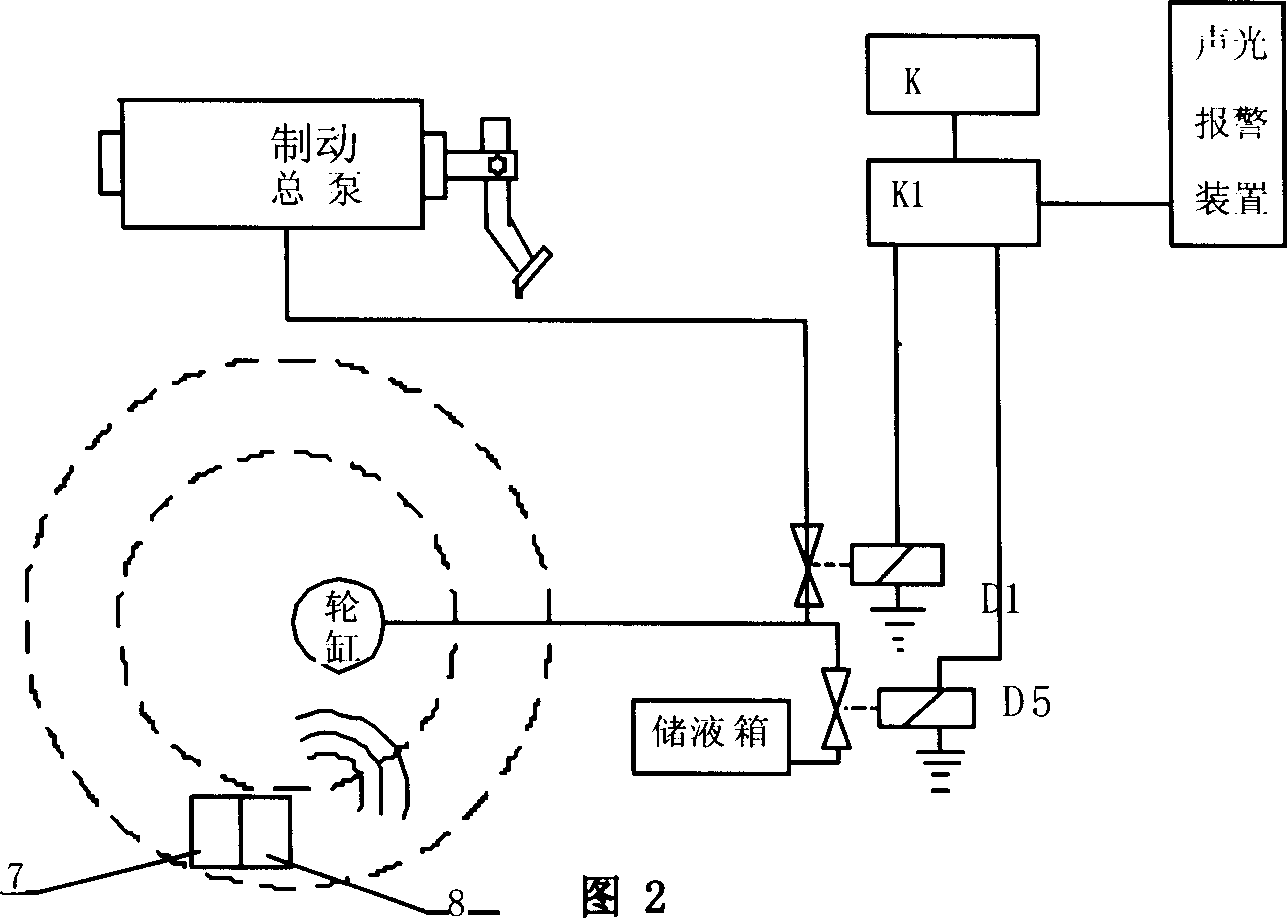

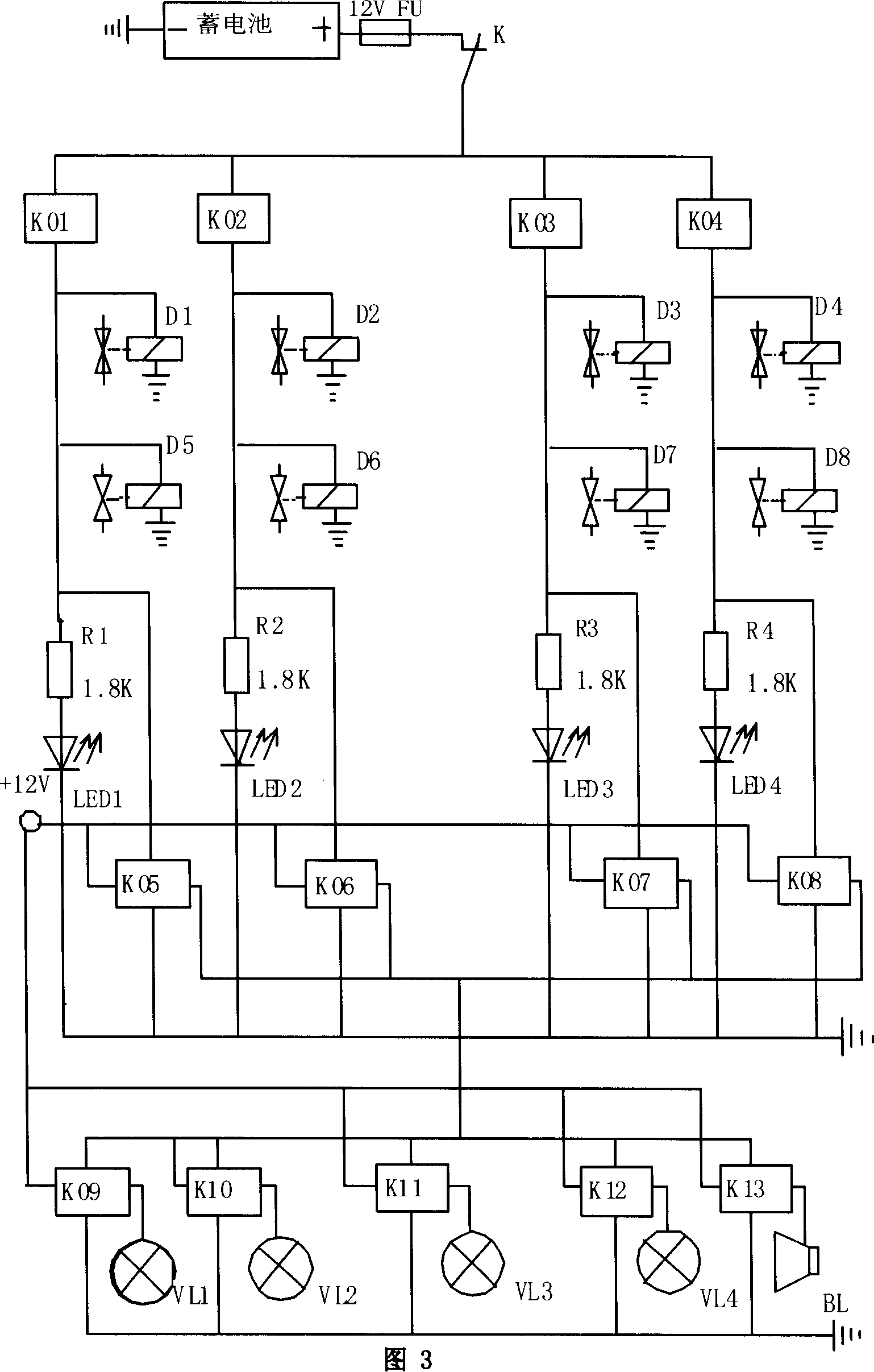

Safety tyre-burst brake deviation-rectifying system for automobile

InactiveCN101074014AAvoid the danger of blind brakingEliminate the internal force of deviationBraking systemsExhaust valveDouble flash

The invention is concerned with a safety brake error correction system when the vehicle's tire bursts. When the tire bursts, turn on the circuit to burst tire of the system by check and sending equipment and incepting and disposing equipment to burst signal, then close the liquid (gas) entering electromagnetic valve and open the liquid electromagnetic valve (exhaust valve) to break the trig pipe of burst tire and keep the brake into safety state and avoid the danger that driver stops to run in a wrong way in hurry. Control the automatic brake equipment or carry safety brake by driver will balance the huge resistance difference of tire burst among wheels. It removes the internal force when vehicle runs into a wrong way, and reminds driver by sound and light annunciator, open the left turning light, right turning light, double flash lights, emergency brake light and bugle of car to alarm cars and passerby. It relates to signal check of burst tire, sending equipment, incepting equipment, trig pipe equipment to break burst tire, controllable automatic brake equipment and sound and light alarm equipment.

Owner:杨立君

Method and system for controlling brake equipment which can be activated when a motor vehicle is stationary

Owner:LUCAS AUTOMOTIVE GMBH

Software based brake shoe wear determination

InactiveUS20040138791A1Reduce amount of friction brake effort suppliedReduce wear rateVehicle testingRegistering/indicating working of vehiclesVisual inspectionEnergy supply

By calculating the energy used by the friction brake equipment, the amount of friction brake shoe / pad wear can be monitored. As the amount of energy supplied reaches a percentage of the friction brake shoe / pad energy design limit, an indication for inspection is provided. If the supplied friction energy continues to increase beyond this point, the brake material must be replaced. The software logic limits are tunable for custom configuring by the transit authority and maintenance personnel. This invention measures the amount of friction effort supplied with respect to time and distance in a software controlled brake system. Furthermore, this invention allows the software to determine when the friction brake material must be replaced based on actual data, which simplifies the maintenance personnel operation procedures, maximizes brake material wear, and avoids costly damage from braking with worn out shoes / pads. The material life remaining for friction brakes is determined currently by a visual inspection followed by a 'best guess' as to whether the material will last until the next scheduled inspection. This invention will annunciate through the software logic program when the friction material requires inspection and replacement. Additionally, the invention provides software logic to indicate the remaining material thickness.

Owner:WESTINGHOUSE AIR BRAKE TECH CORP

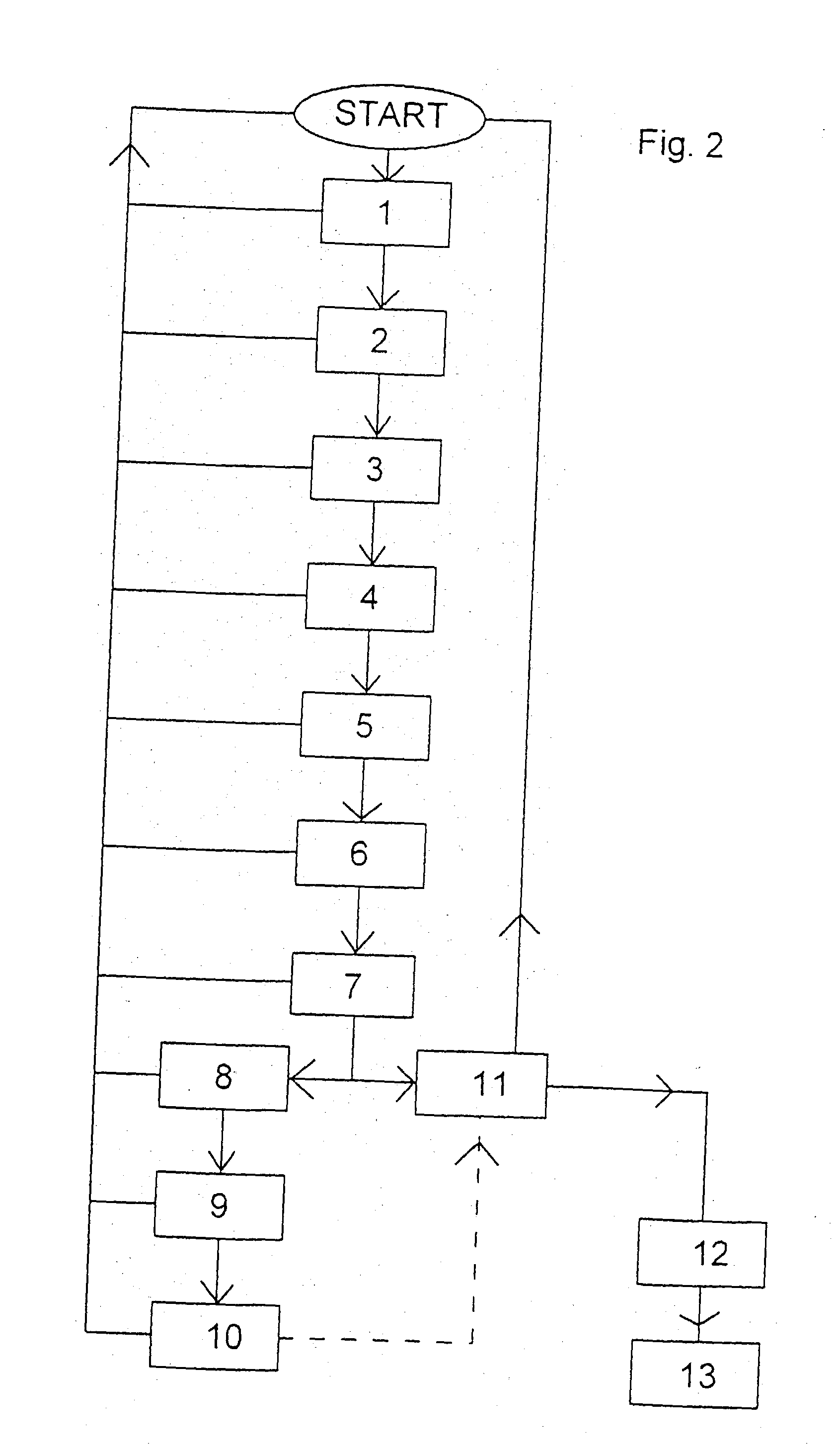

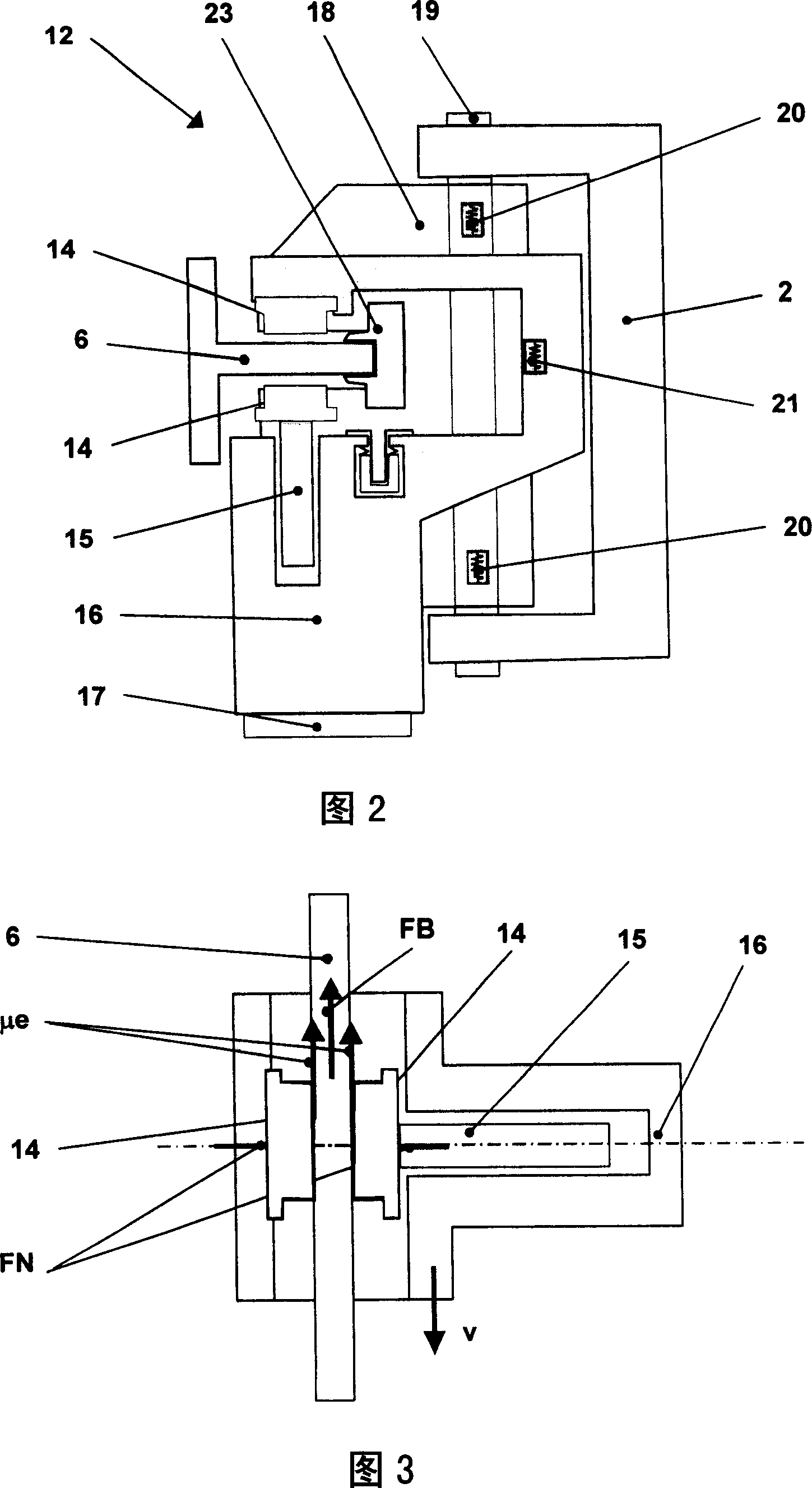

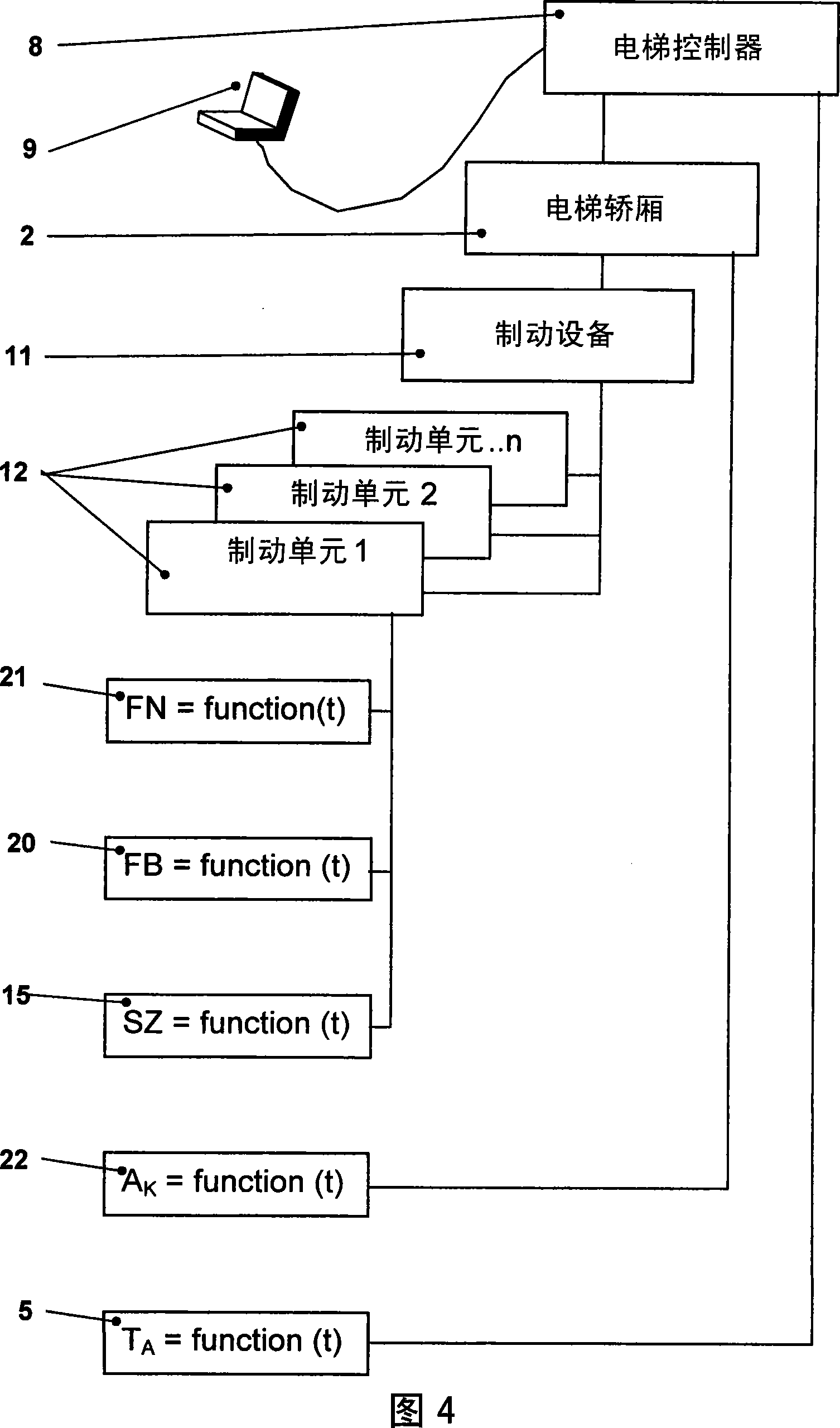

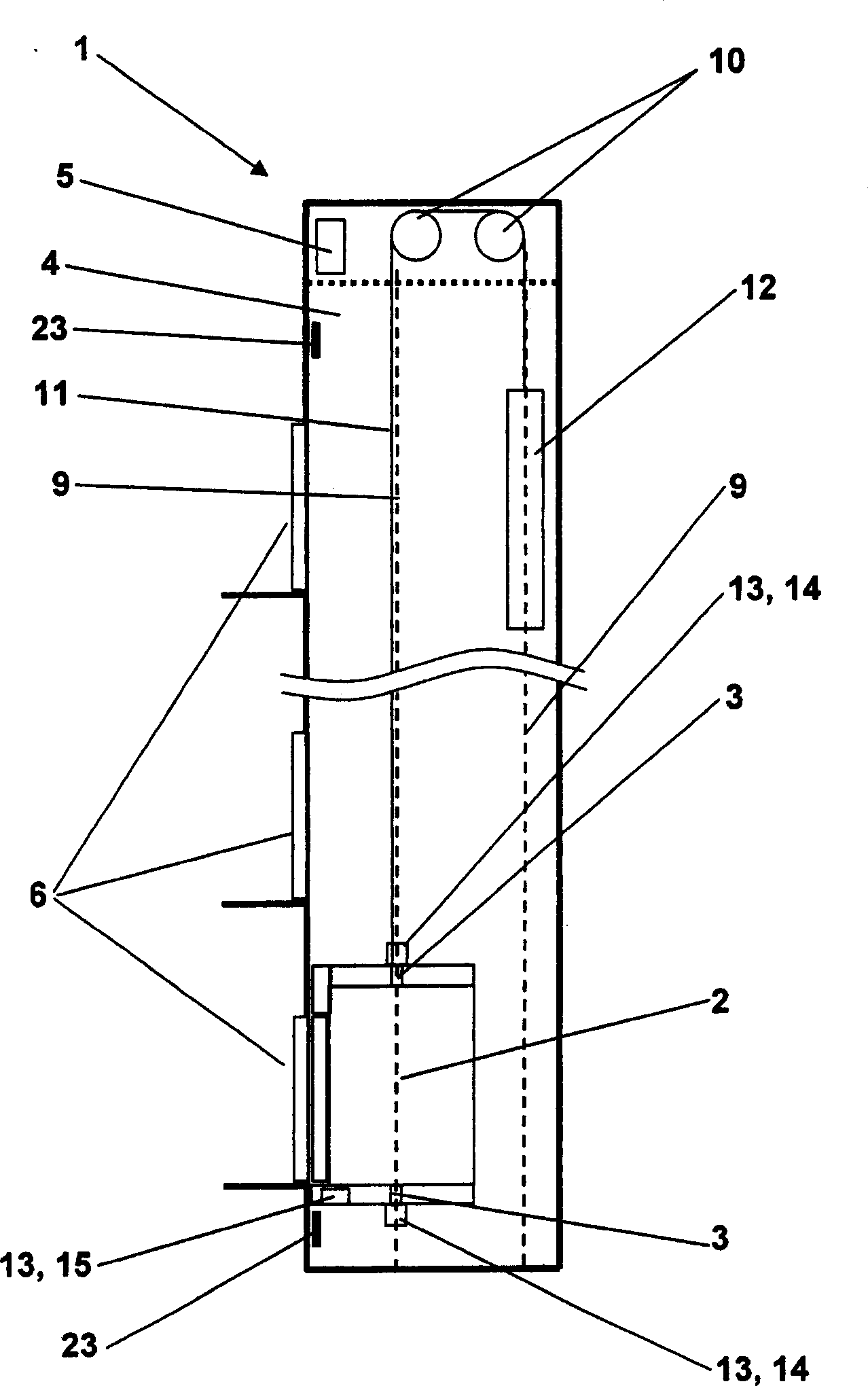

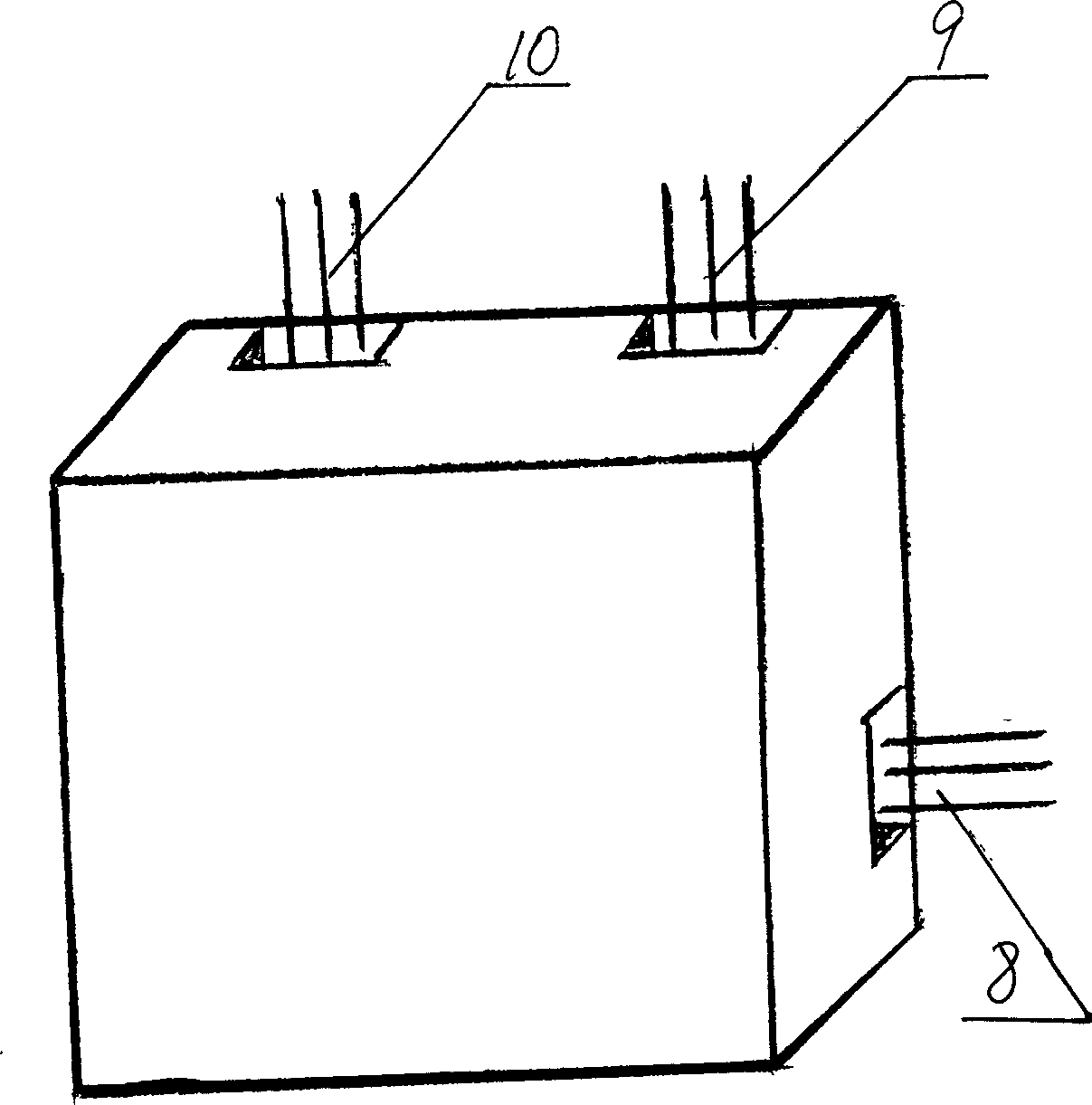

Method for testing a lift braking device, method for start-up of a lift facility and a device for carrying out start-up

ActiveCN101092223ASafe and reliable structureAchieve rough estimateElevatorsBuilding liftsStart upBrake force

In this lift installation, lift braking equipment (11) brakes and holds a lift cage (2). The lift braking equipment (13) consists of a number of brake units (12) which when required are brought into engagement with brake tracks (6), wherein the brake unit (12) for this purpose presses at least one brake plate (14) against the brake track (6) and produces a braking force (FB). According to the invention, for checking the braking equipment (11) an effective coefficient of friction ( [mu]e), which is generated during pressing of the brake plate (14) against the brake track (6), of the brake unit is ascertained. Moreover, a placing in operation with use of this checking method is illustrated and equipment for performing this placing in operation is presented.

Owner:INVENTIO AG

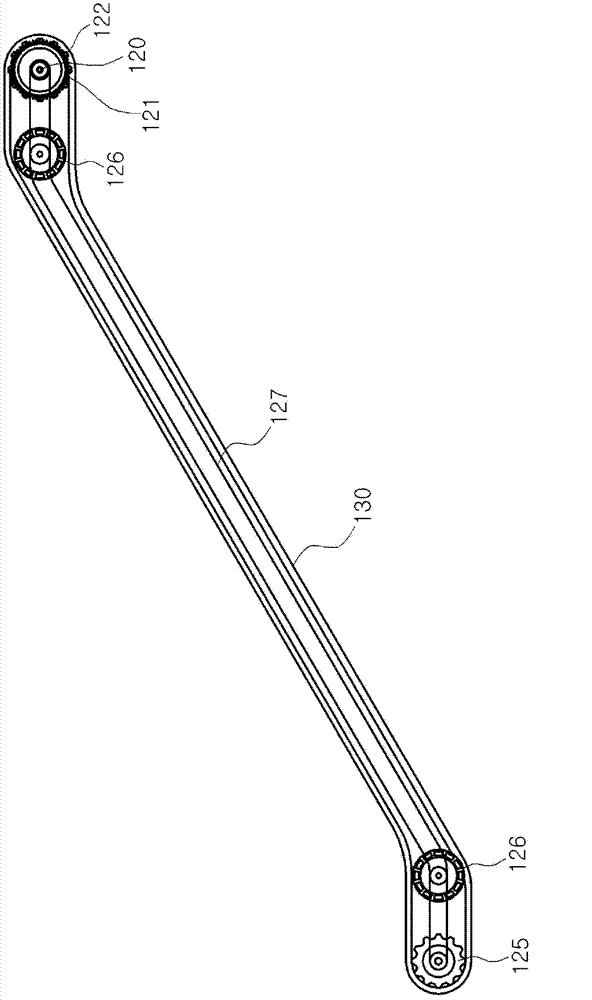

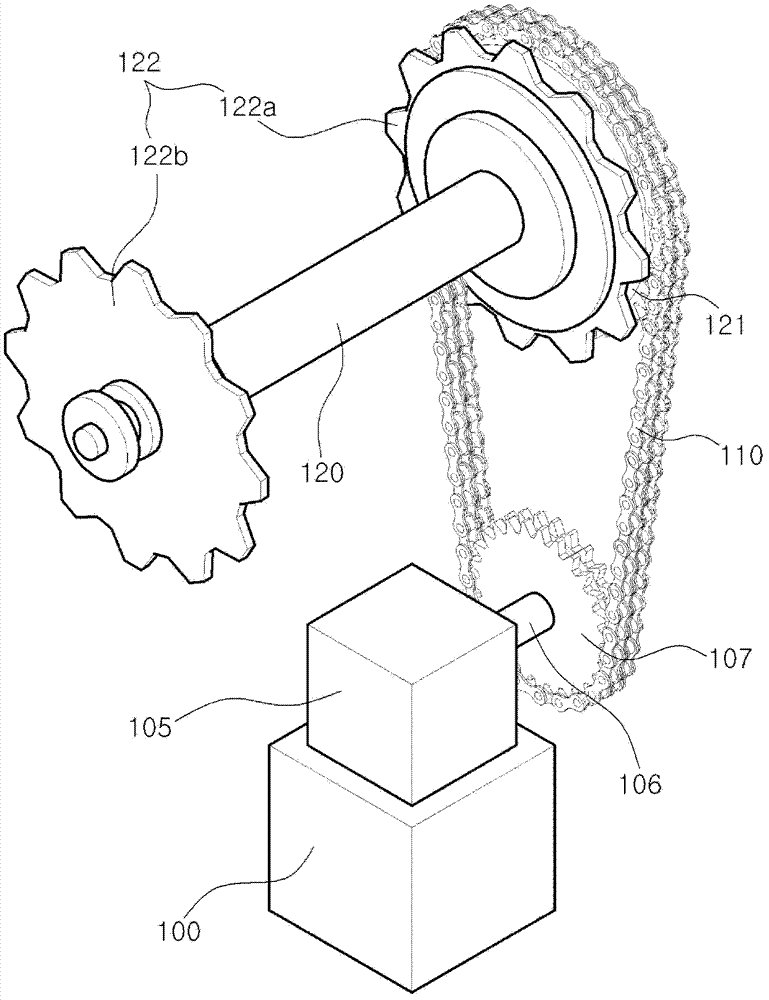

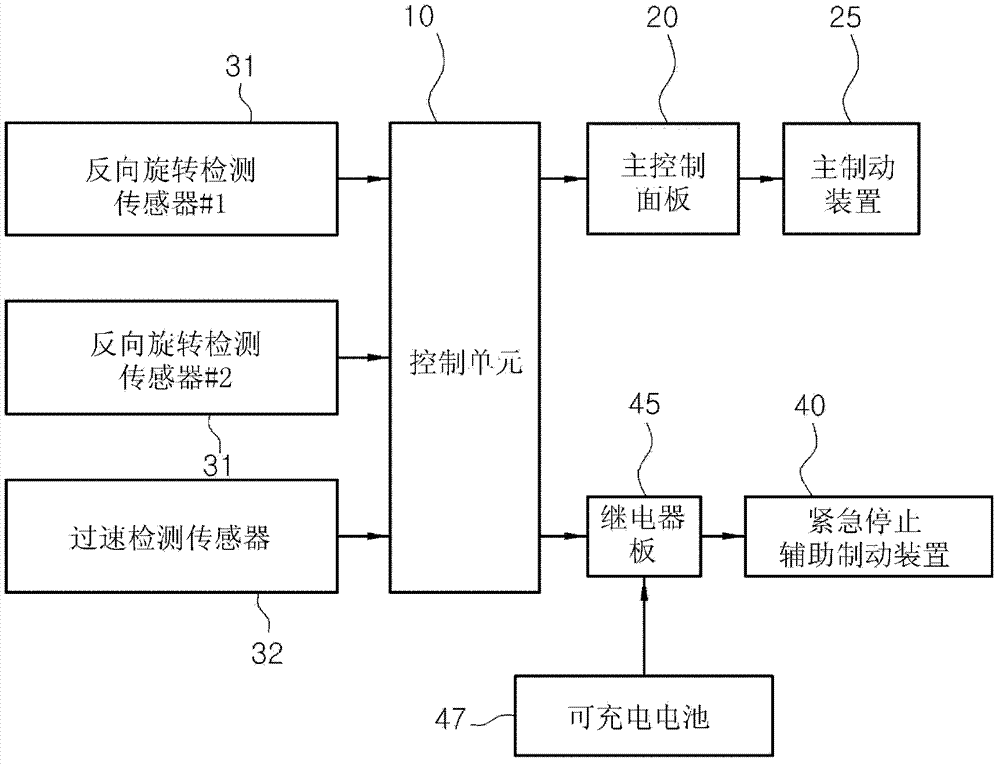

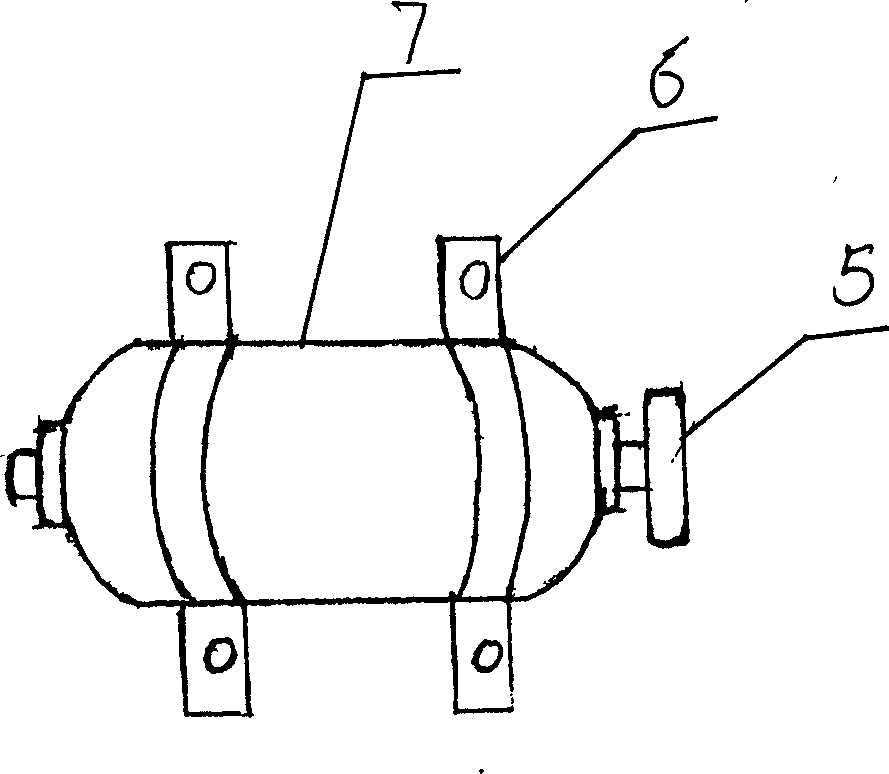

Auxiliary braking device used for preventing inverted running and overspeed of escalator

InactiveCN102849597AImprove braking effectStop spinningAxially engaging brakesBrake actuating mechanismsEngineeringDrive motor

The present invention relates to an auxiliary braking device used for preventing inverted running and overspeed of an escalator. The auxiliary braking device comprises: an escalator rotating shaft which rotates along a forward direction or a reverse direction with the help of a driving motor, so as to enable a step chain bearing escalator steps to move upwards or downwards, wherein the escalator rotating shaft has a drive chain wheel engaged with the step chain; a reverse rotation detection sensor used for detecting a rotating direction of the escalator rotating shaft; an overspeed detection sensor used for detecting a rotating speed of the escalator rotating shaft; an emergency stop auxiliary braking device used for stopping the rotation of the escalator rotating shaft; and a control unit used for controlling the emergency stop auxiliary braking device by determining occurrence of abnormal conditions based on signals supplied from the reverse rotation detection sensor and the overspeed detection sensor.

Owner:SONGSAN SPECIAL ELEVATORS

Method and device for controlling the braking equipment of a motor vehicle

InactiveUS6994407B2Reduce forceAvoid damageBraking action transmissionAutomatic initiationsMobile vehicleEngineering

The present invention relates to a method and a device for controlling braking equipment of a motor vehicle. Here, an operating state of a motor vehicle is determined, in which the motor vehicle is to be brought from a state, in which its speed is not zero, into a state, in which the vehicle no longer moves. If such a transition from a traveling state into a state of standstill is determined, braking equipment of the motor vehicle is controlled such that braking forces are produced, which are capable of bringing the motor vehicle into the state of standstill and / or assisting a vehicle driver in doing this. It is also possible to produce braking forces in the state of standstill, which are capable of holding the motor vehicle in the state of standstill. The present invention additionally enables to assist a vehicle driver when starting a motor vehicle. In this case, an operating state of the motor vehicle is detected in which the motor vehicle is to be brought from a state of standstill into a traveling state. If such an operating state is present, the braking equipment of the motor vehicle is controlled such that the braking forces produced by the braking equipment in the state of standstill are reduced in such a way as to allow a transition into the traveling state and / or to assist the vehicle driver in this respect.

Owner:LUCAS AUTOMOTIVE GMBH

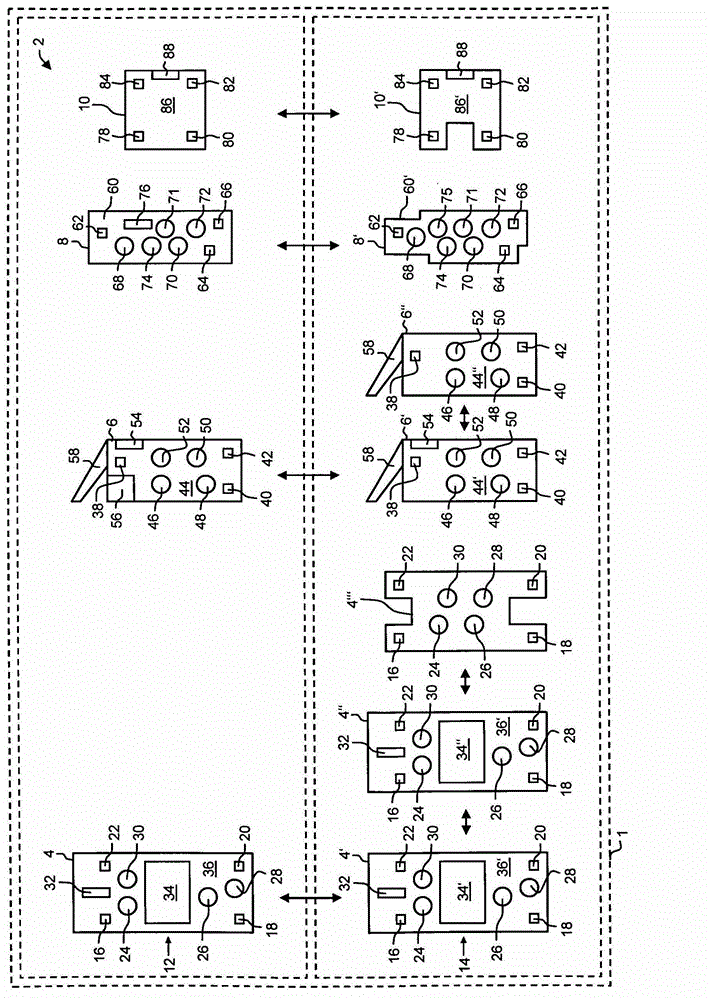

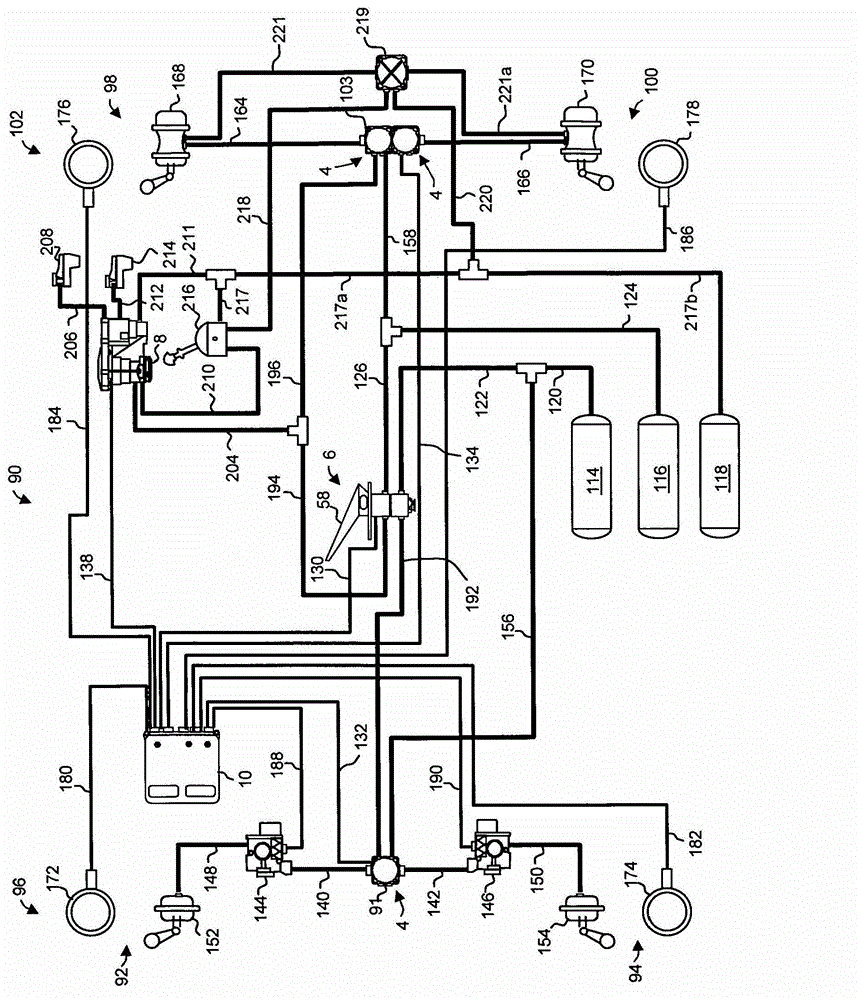

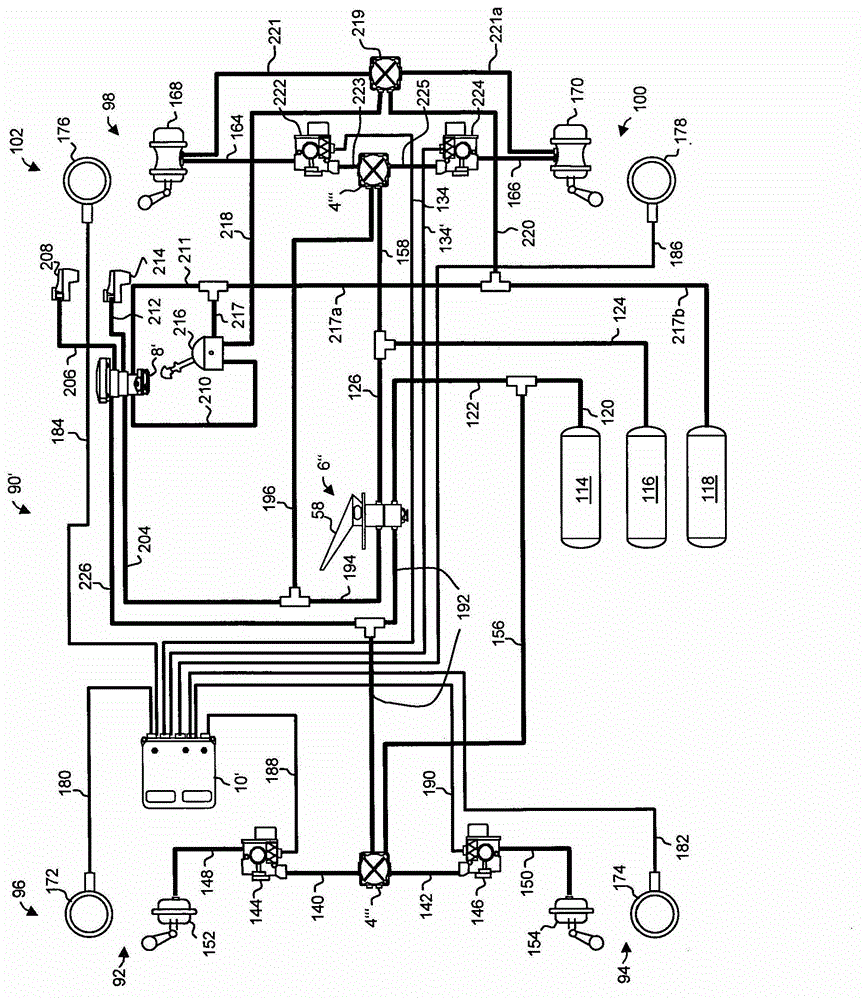

System with valve device for a pneumatically operated brake system, valve device, brake actuation device, trailer control valve device, and device for controlling for the system, brake system, vehicle, use of a component, and method for retrofitting

ActiveCN103068647ASimple technologyLow costBraking action transmissionBrake safety systemsControl mannerControl valves

The invention relates to a system (1) having at least one valve device (4, 4', 4'', 4''') for a pneumatically operated brake system (90, 90') of a vehicle, wherein the brake system (90, 90') has the valve device (4, 4', 4'', 4''') and at least one brake (92, 94, 98, 100). By means of the valve device (4, 4', 4'', 4''') a pneumatic brake pressure which can be fed to the brake is adjusted in a controlled manner. According to the invention, the system has at least two variants (12, 14) of the valve device (4, 4', 4'', 4''') which can be used alternatively in the brake system (90, 90'). Here, a first variant (12) is configured as a modulator for use in an electronically regulated embodiment of the brake system (90), and a second variant (14) is configured for use in a pneumatically controlled embodiment of the brake system (90'). However, both variants (12, 14) of the valve device (4, 4', 4'', 4''') have pneumatic interfaces (24, 26, 28, 30) and mechanical fastening points (16, 18, 20, 22) which are configured identically with respect to one another. Furthermore, the invention relates to the valve device (4, 4', 4'', 4''') for the system (1), and a brake actuation device (6, 6', 6'''), a trailer control valve device (8, 8') and a device for controlling (10, 10') in each case for this system (1). Moreover, the invention relates to a brake system (90, 90') for a vehicle with at least one replacement component (2) of the system (1), to the vehicle, the use of a component of a brake system as component (2) of the system (1), and a method for retrofitting a brake system, in which method a component of the brake system is replaced by a component (2) of the system (1) according to the invention.

Owner:ZF CV SYST EURO BV

Method for the automatic guidance, in particular parking of a motor vehicle and a driver assistance device

InactiveUS20150032323A1Safely broughtBuildBrake system interactionsBrake control systemsMobile vehicleDriver/operator

In a method for the automatic guidance, e.g., parking, of a motor vehicle, which has a driving device for driving the motor vehicle, braking equipment for braking the motor vehicle, as well as a transmission device, in a normal operation, the braking equipment carrying out automatic braking during the automatic guidance, it is provided that, when a fault of the braking equipment occurs during the automatic guidance, an emergency operation is carried out, in which the motor vehicle is braked automatically to a standstill only by using the driving device and / or the transmission device.

Owner:ROBERT BOSCH GMBH

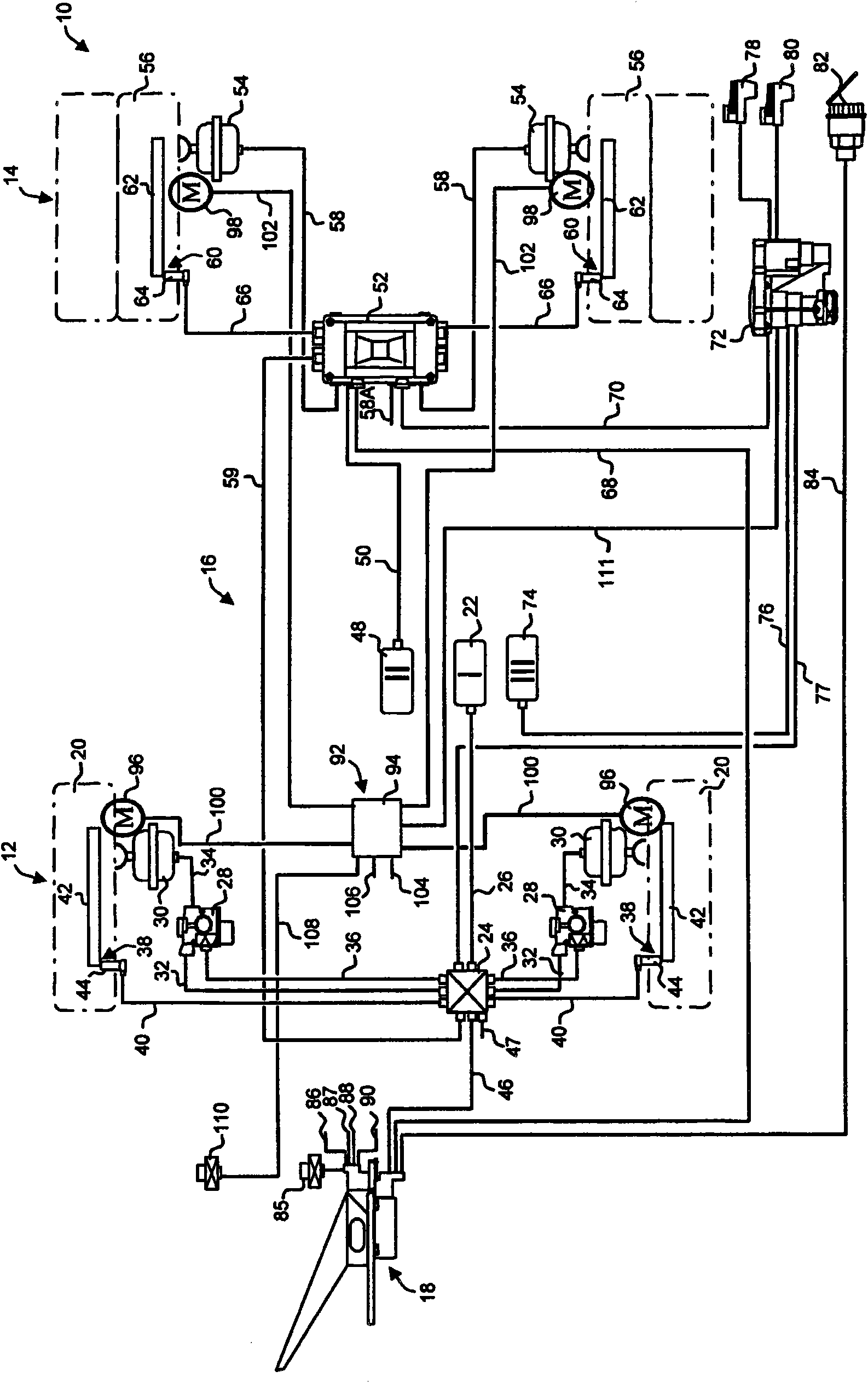

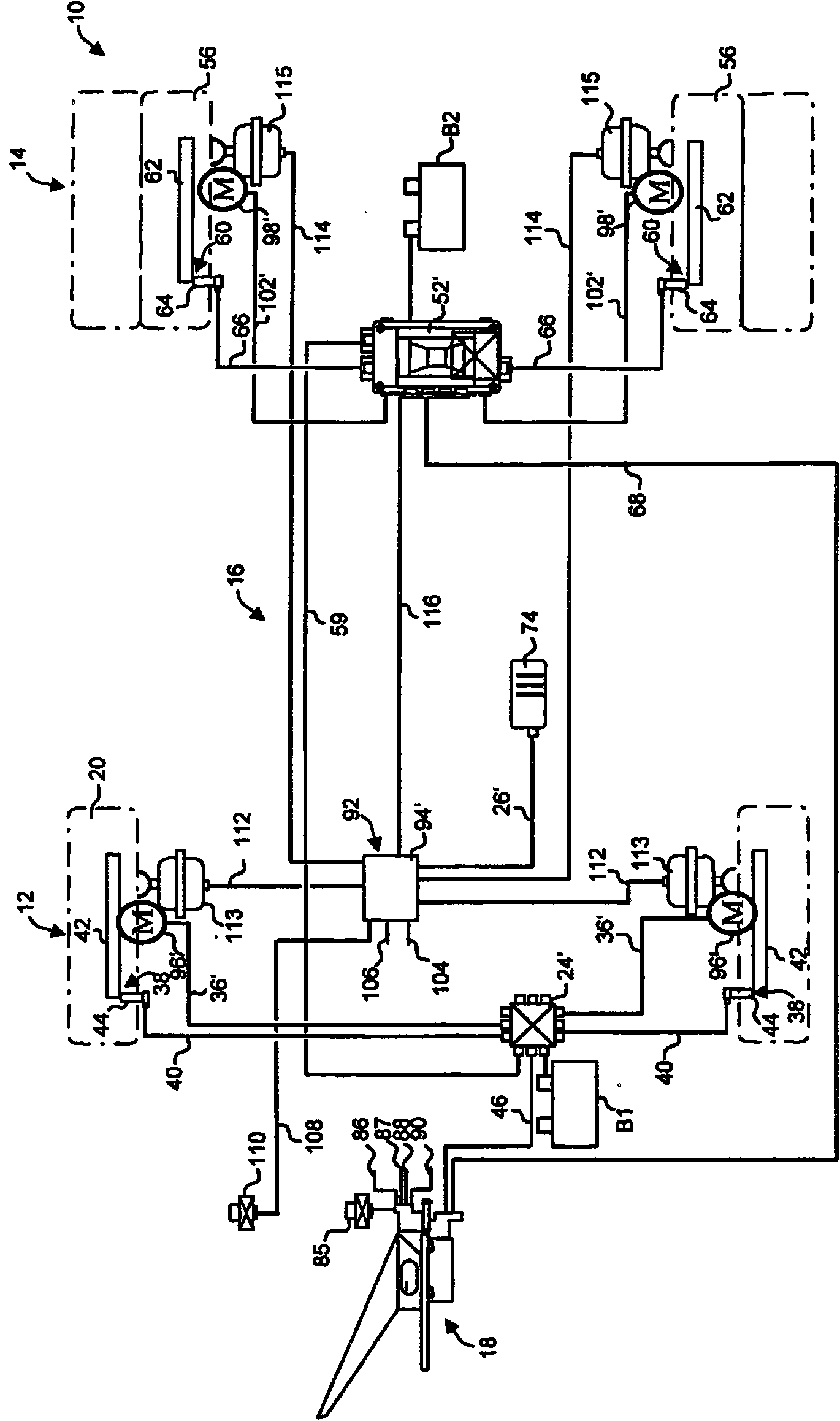

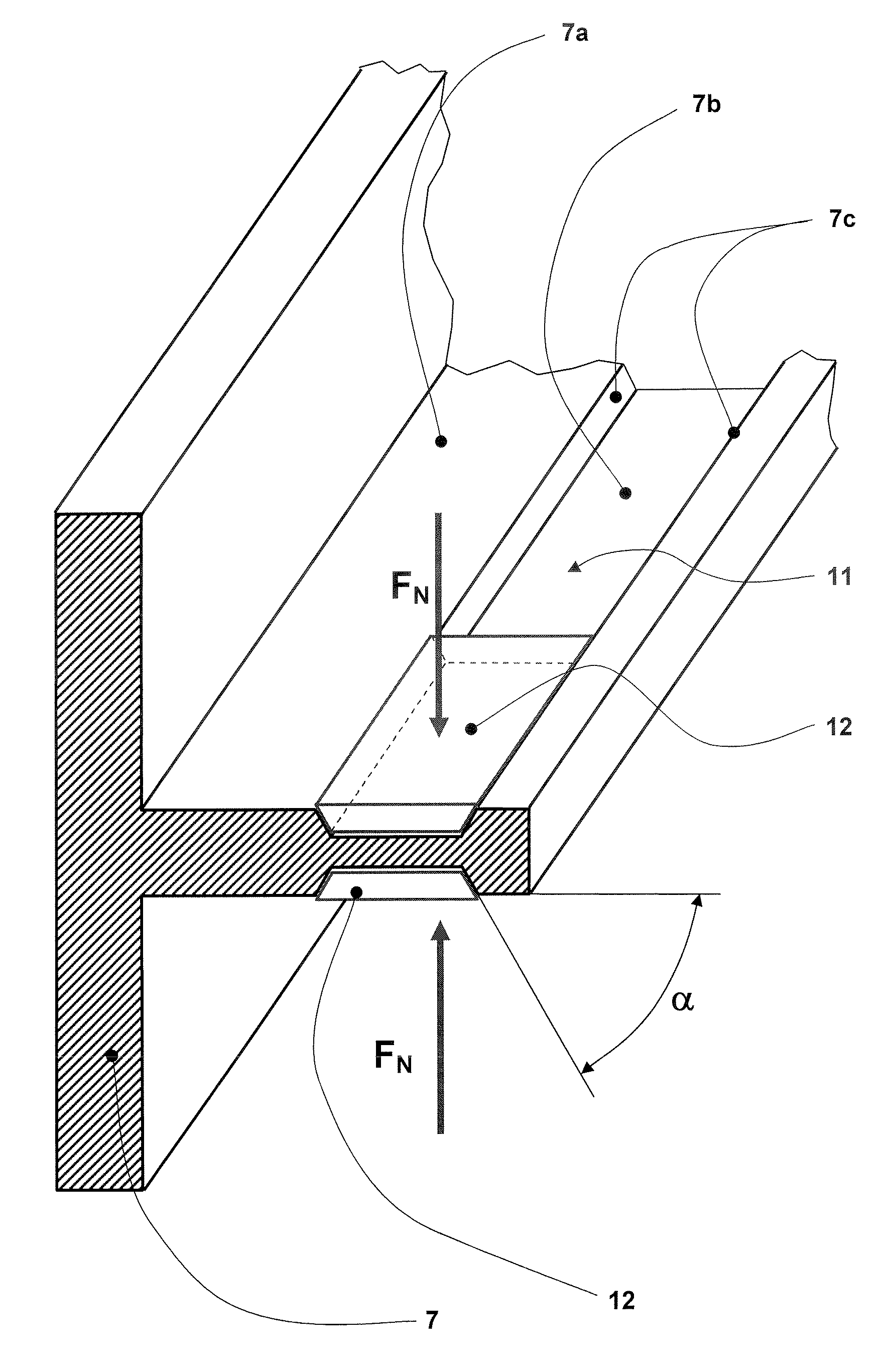

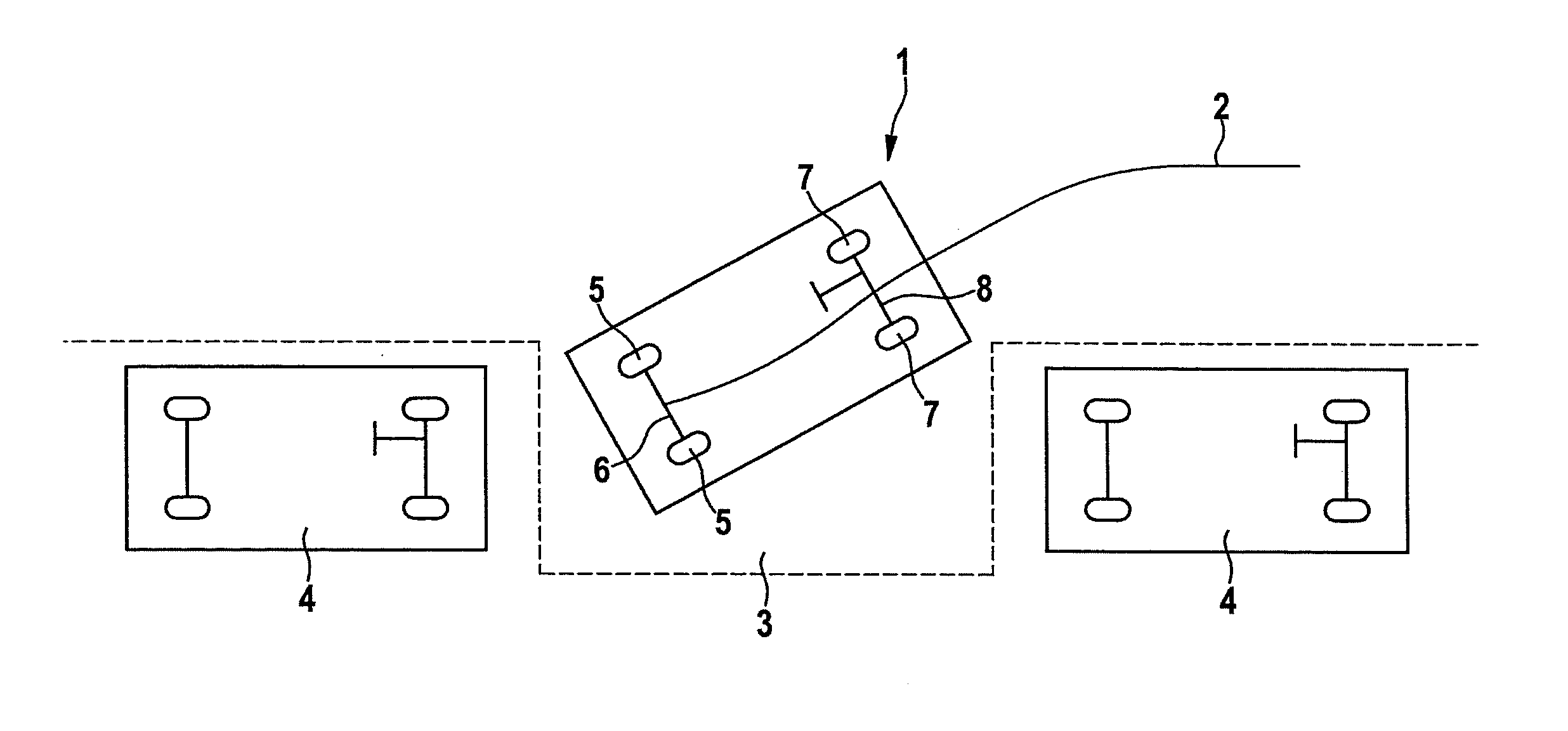

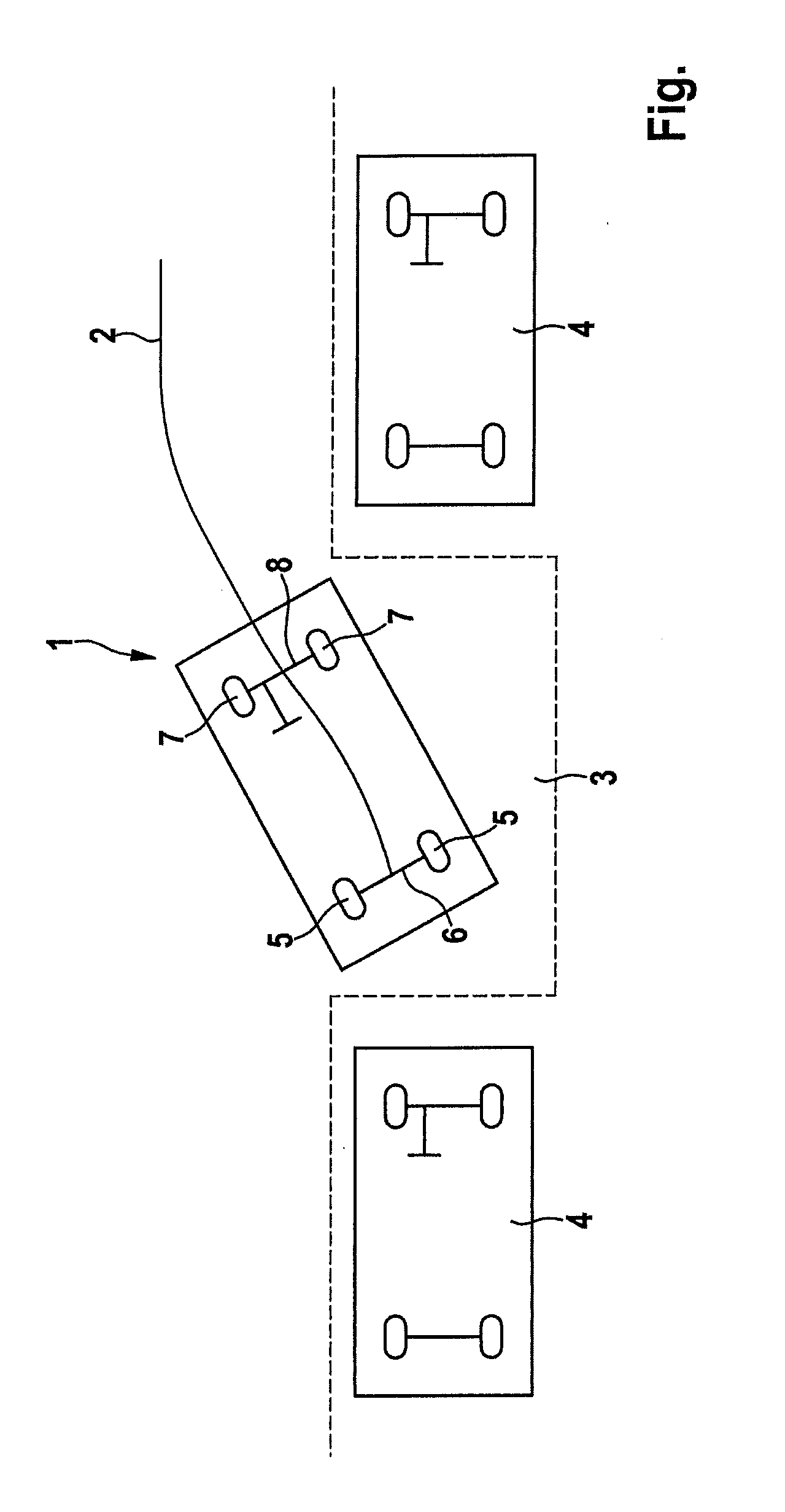

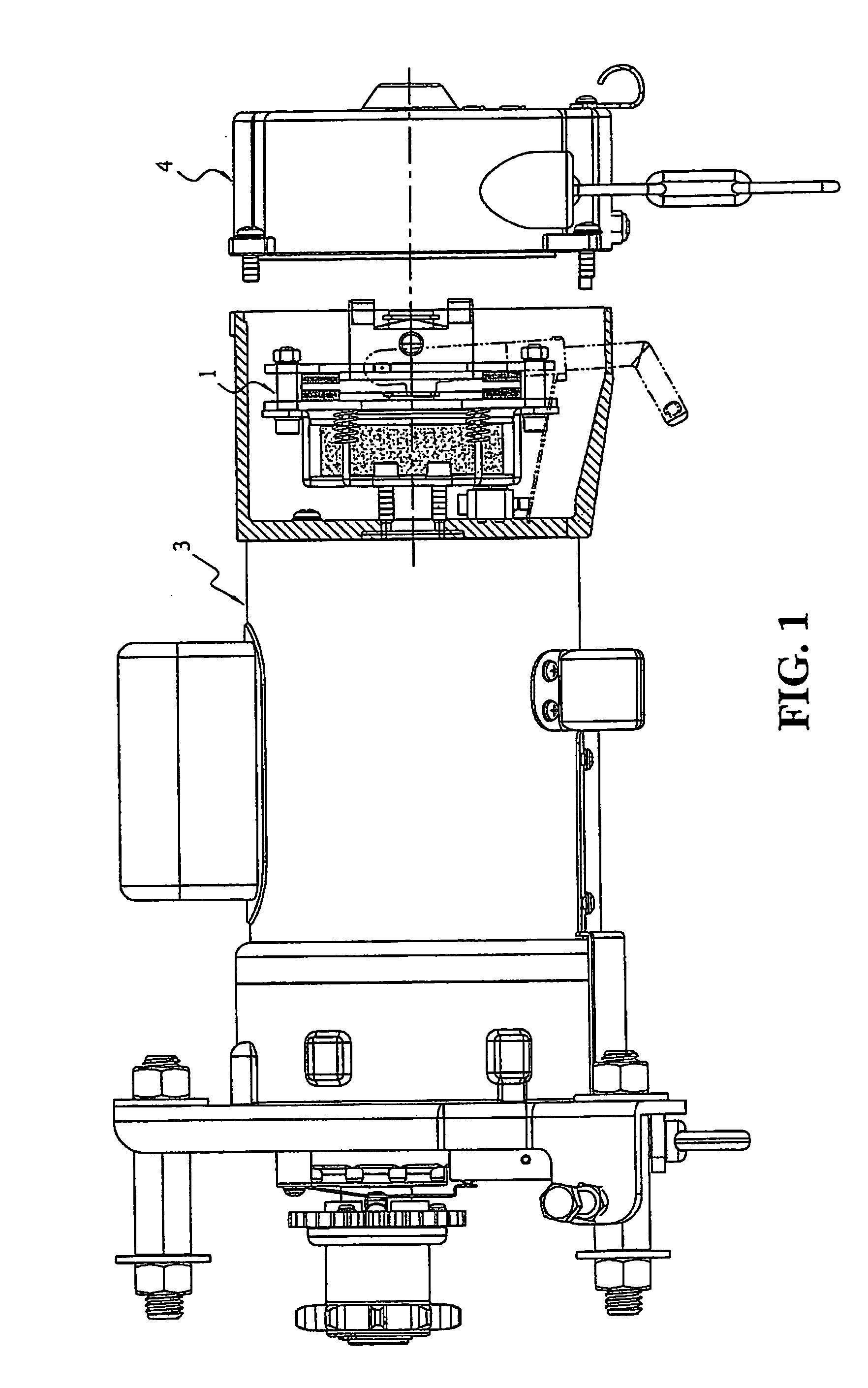

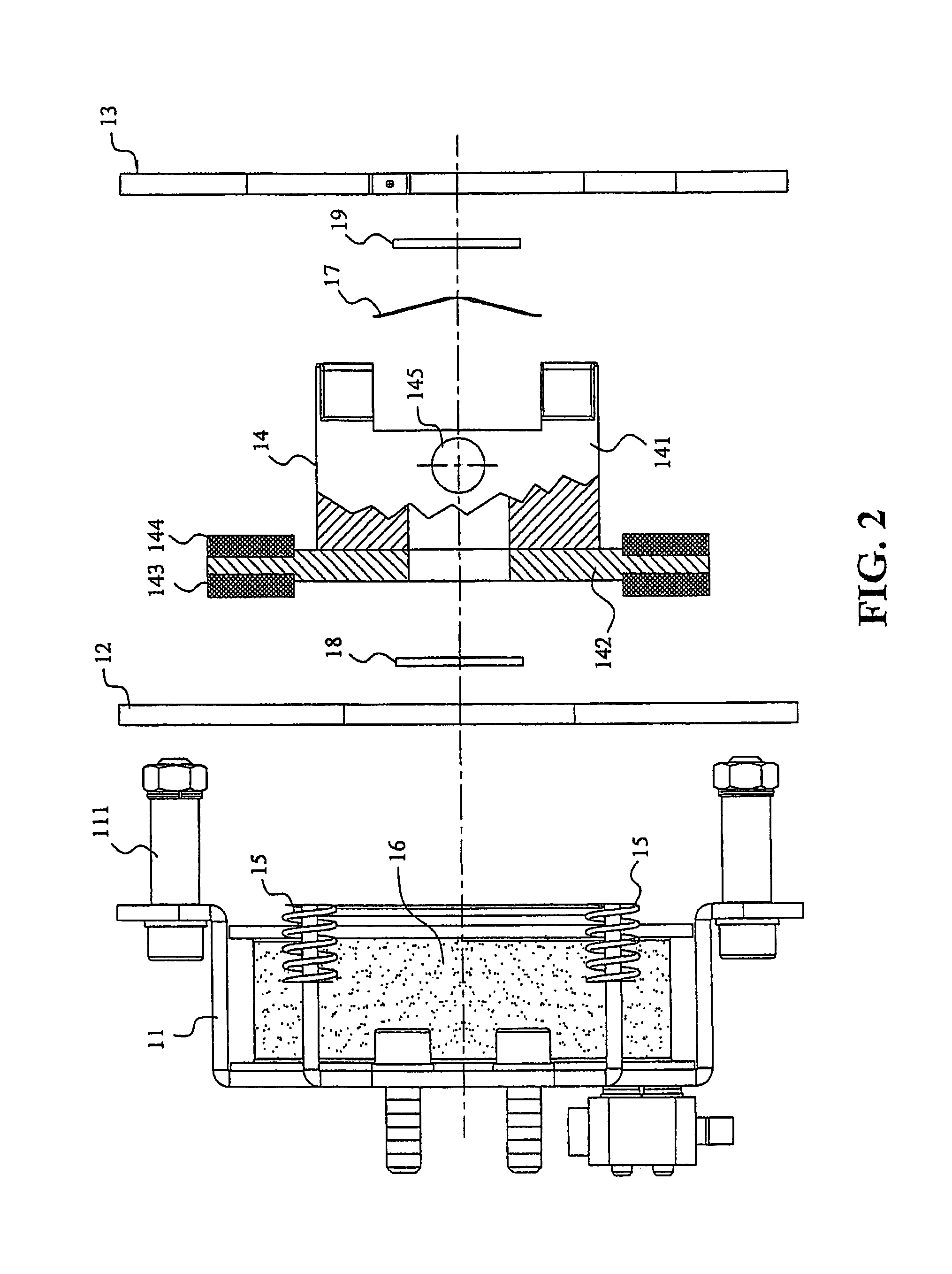

Elevator system with braking unit and method to keep the elevator stopped

InactiveCN1796261AReduce sensitivityAchieve exchangeElevatorsBuilding liftsElevator systemEnergy requirement

To provide adjustable braking equipment capable of delaying or holding according to the operating state of an elevator installation and responding in a quick and gentle mode, and to provide a method for braking and holding an elevator cage. The elevator installation is provided with the elevator cage vertically moving within guide tracks 9. The braking equipment 13 comprises at least two brake units 14. Each brake unit is provided with a normal force regulator 16 setting a normal force FNcorresponding to a normal force value determined by a brake control unit 15, and / or the brake unit comprises a locking device which locks the brake unit into a set braking position and preferably maintains the set braking position. This solution permits a gentle braking or holding of the elevator cage in low energy requirement.

Owner:INVENTIO AG

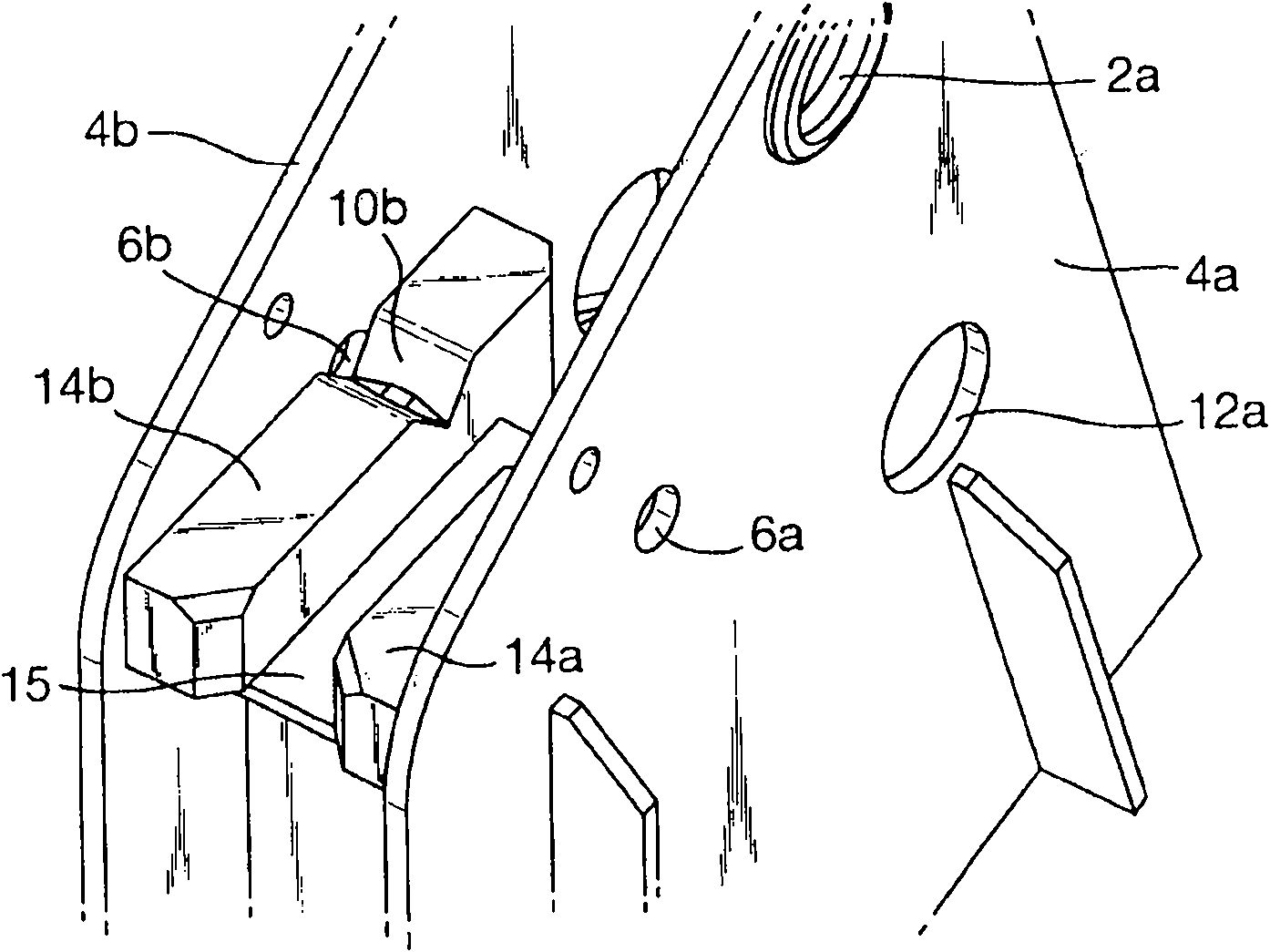

Chain brake device

The invention relates to a chain brake device, and concretely discloses a chain brake device used for an anchor chain operated by a capstan, the chain brake device comprises a guide device (14a, b, 15) used for a chain link (5, 9). A chain element (2) can perform operation at a first position in no contact with the chain link, a second position in no brake contact with the chain link, and a third position in a brake contact with the chain link. The chain element (2) further comprises at least a first adjacent device (23a, b) used for abutting against a first chain link (9), and at least a second adjacent device (19a, b) used for abutting against a corresponding static third adjacent device (10a, b) in the chain brake device.

Owner:MACGREGOR NORWAY

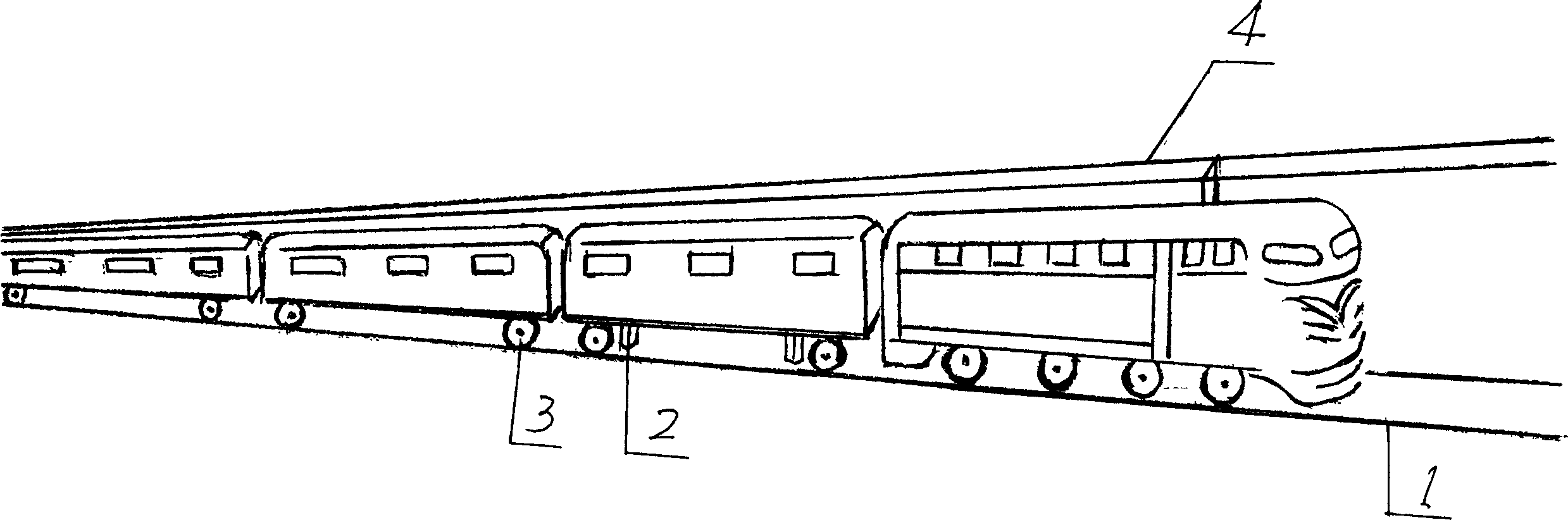

Train with electromagnetic brake device and track

InactiveCN1663863AImprove securityEnsure electricity needsTrack-braking member co-operationMagnetic tension forceDrive wheel

The invention relates to the train and the track with the electromagnetic brake equipment, which comprises the train carriages. The electric magnet of the said brake equipment has the electromagnetic coil enwound outside, one end of the magnet rigidly connects the base and the other end connects the frictional flake; the base is equipped at the bottom of the carriage motherboards; the carriage is set the battery group that connect the generator and the braking equipment; the generator wheel connects the driving wheel of the carriage shaft. The top face of the track is trapeziform structure. The train added with the electromagnetic equipment can control the current and the voltage through the distribution equipment, makes the electric magnets have different magnetic forces and has reducing and the braking functions at the same time. The generating and the charging devices are added in the carriage to ensure the electricity using demands. The trapeziform design o the top face can reduce the contacting face of the track and the wheel to the extreme extent, fall the frictional coefficient and improve the transportation performance.

Owner:李全瑞

Double-sided door braking equipment for a operator

ActiveUS7341129B2Improve braking effectIncreasing costDoor/window protective devicesBraking action transmissionBraking systemBrake pad

This invention relates to a double-sided equipment for a braking system, comprising a first braking pad, a second braking pad, a braking component, a fixing spring component, a compression spring, and an electromagnet, wherein the braking component located between the first braking pad and the second braking pad is movable along the axle of the door operator but is unrotatable with respect to the door operator axle. As a result of the compression spring, the first braking pad and the braking component will be pushed together towards the second braking pad, thereby the braking component is clamped from its two sides by the two braking pads. When the first braking pad is retracted by the electromagnet, the fixing spring enables the braking component to separate from the second braking pad, causing the braking component to be fully separated from the first and second braking pads.

Owner:HSIEH CHUNG HSIEN

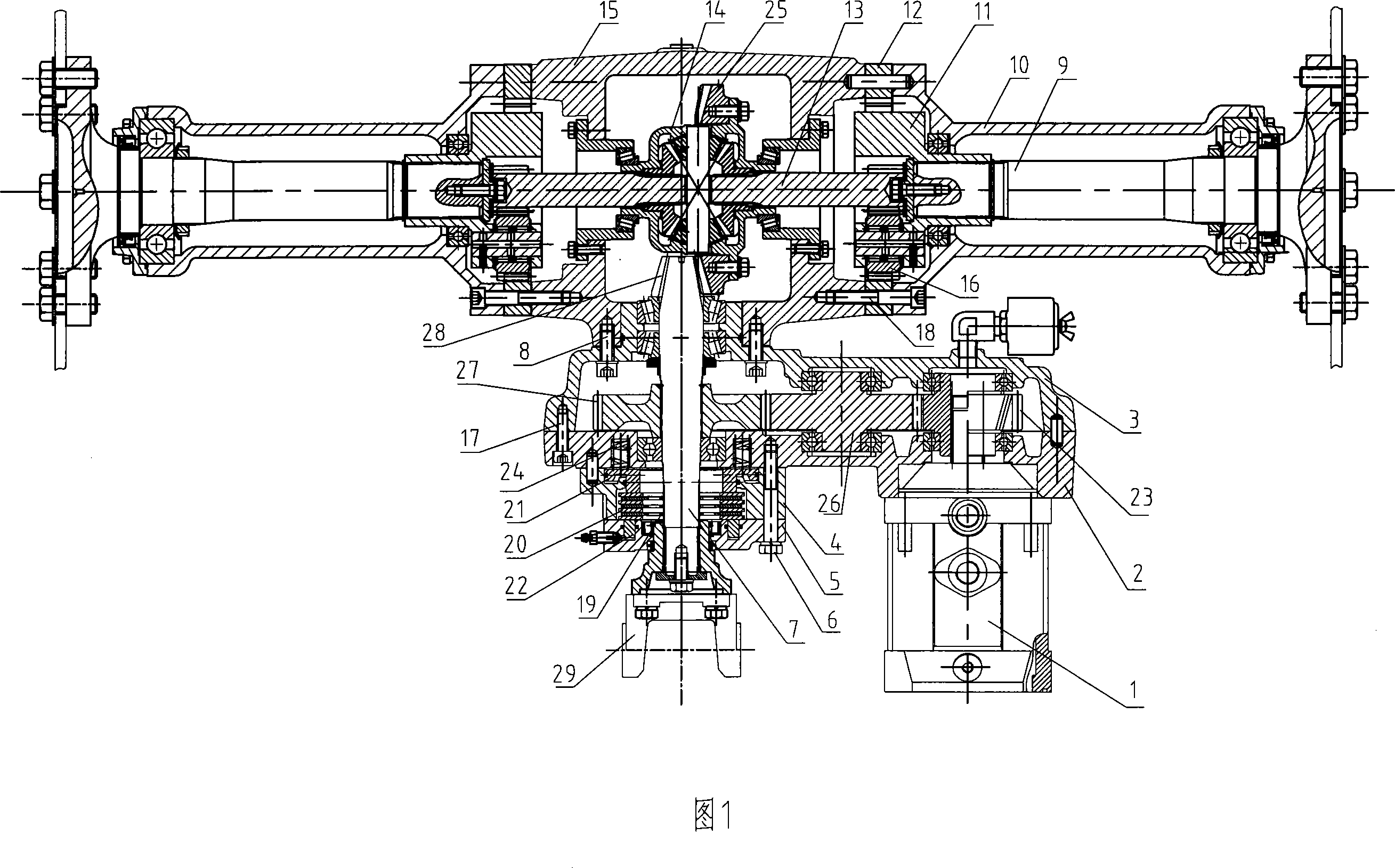

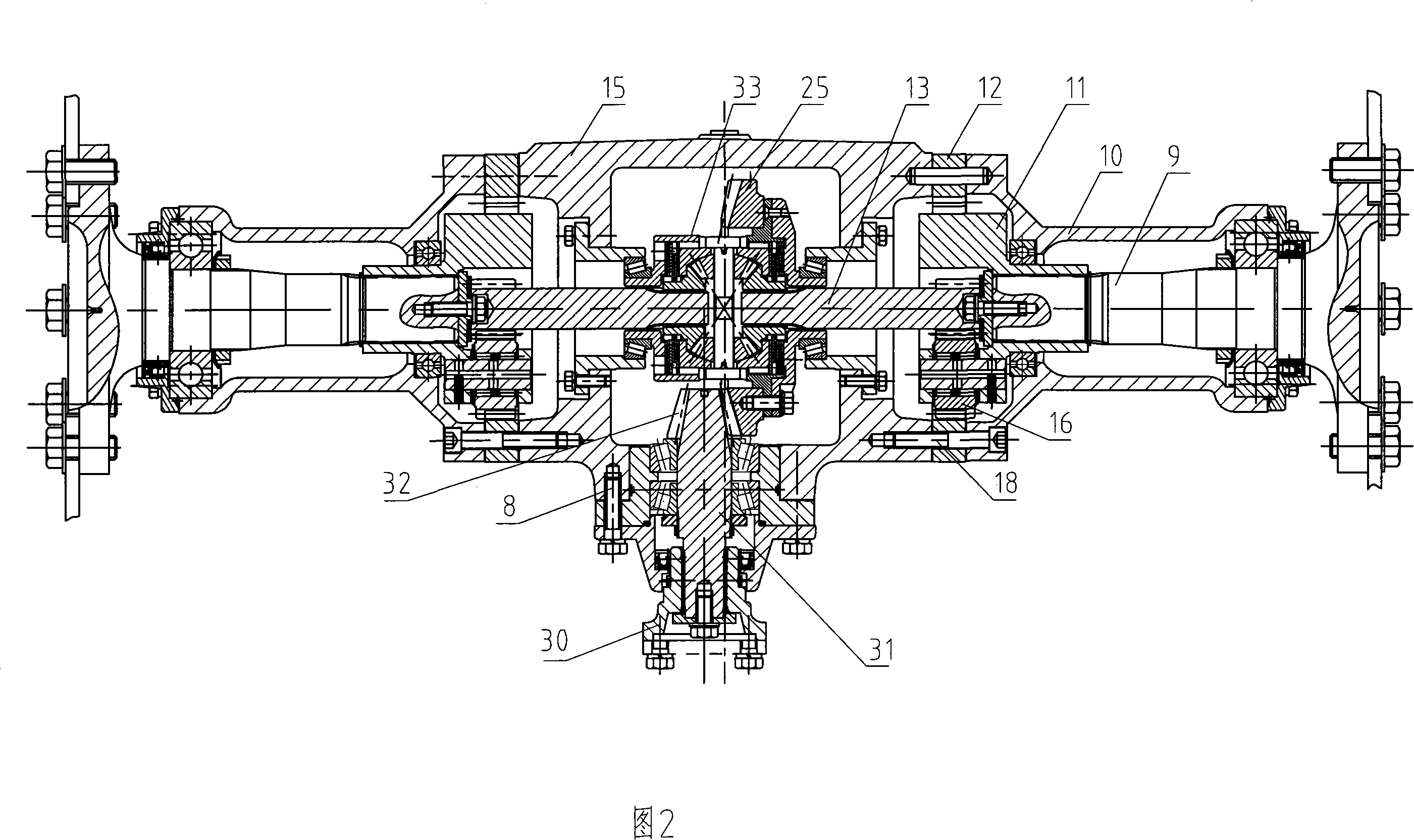

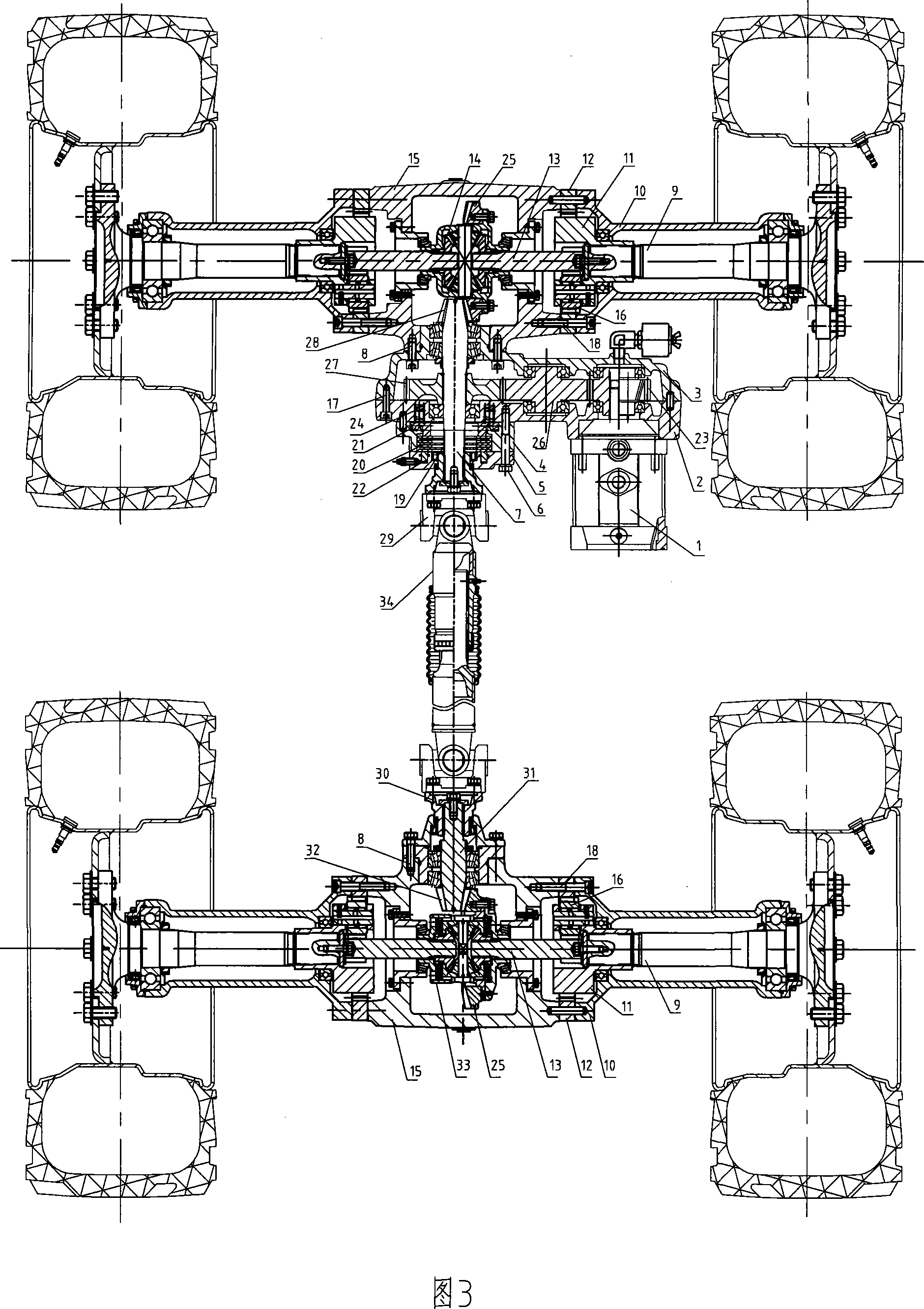

Walking and braking device for loader

InactiveCN101054059ASimple structureCompact structureBraking element arrangementsVehiclesDrive shaftGear wheel

The invention relates to the walking braking equipment of a loader, particularly to the walking braking equipment of four-wheel drive loader, which belongs to engineering machinery equipment field. The characteristic is one end of rear axle circular cone driving gear shaft is connected with rear axle circular cone driven gear, drives rear axle axletree by way of rear axle differential, another end is linked with transmission shaft subassembly, and drives front axle axletree by way of transmission shaft subassembly; a hydraulic brake is disposed on the said rear axle circular cone driving gear shaft. Invention structure is simple, compact, and is equitable; for the brake is disposed on the rear axle circular cone driving gear shaft, synchronous revolution of the front axle differential and rear axle differential is enabled; brake force for the driving mechanism can be passed through rear axle circular cone driving gear shaft when wheel loader driving or parking; the braking power is high, the manufacturing cost is low, and is convenient to repair.

Owner:WUXI KIPOR POWER CO LTD

Elevator installation with a braking device and method for braking and holding an elevator installation

ActiveUS8157061B2Low powerLittle additional weightBraking action transmissionFilament handlingEnergy supplyEnergy requirement

An elevator installation has braking equipment for braking and holding an elevator car which moves in vertical direction within guide tracks or rails. The braking equipment consists of at least two brake units each comprising a normal force regulation device that sets a normal force (FN) in correspondence with a normal force value determined by a brake control unit and / or a locking device that locks the brake unit in a set braking position and which preferably maintains the set braking position in the case of an interrupted energy supply. The braking equipment provides a gentle braking or holding of the elevator car, which corresponds with the operational state of the elevator installation, with a low energy requirement.

Owner:INVENTIO AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com