Patents

Literature

906 results about "Brake lining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Brake linings are the consumable surfaces in brake systems, such as drum brakes and disc brakes used in transport vehicles.

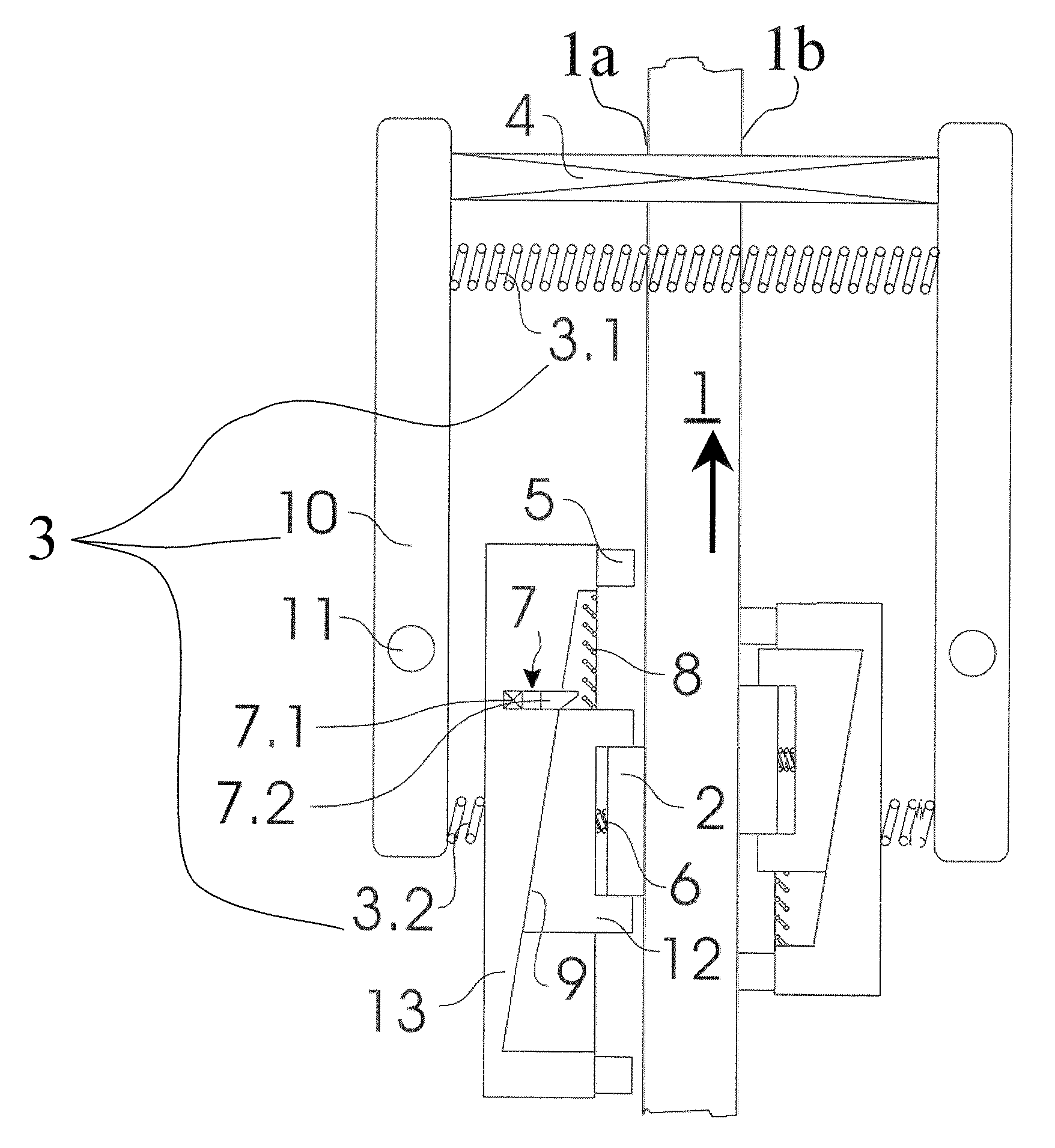

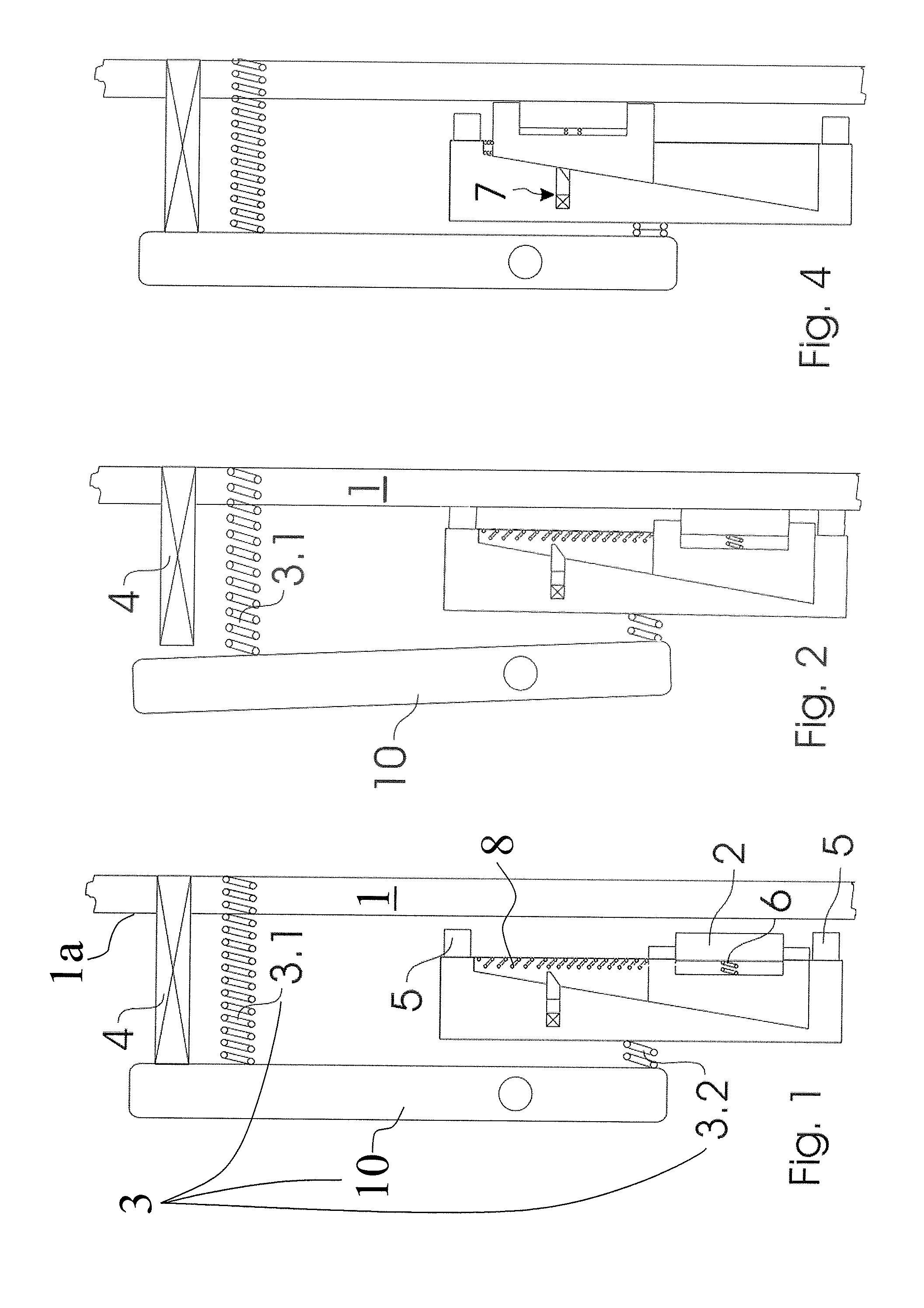

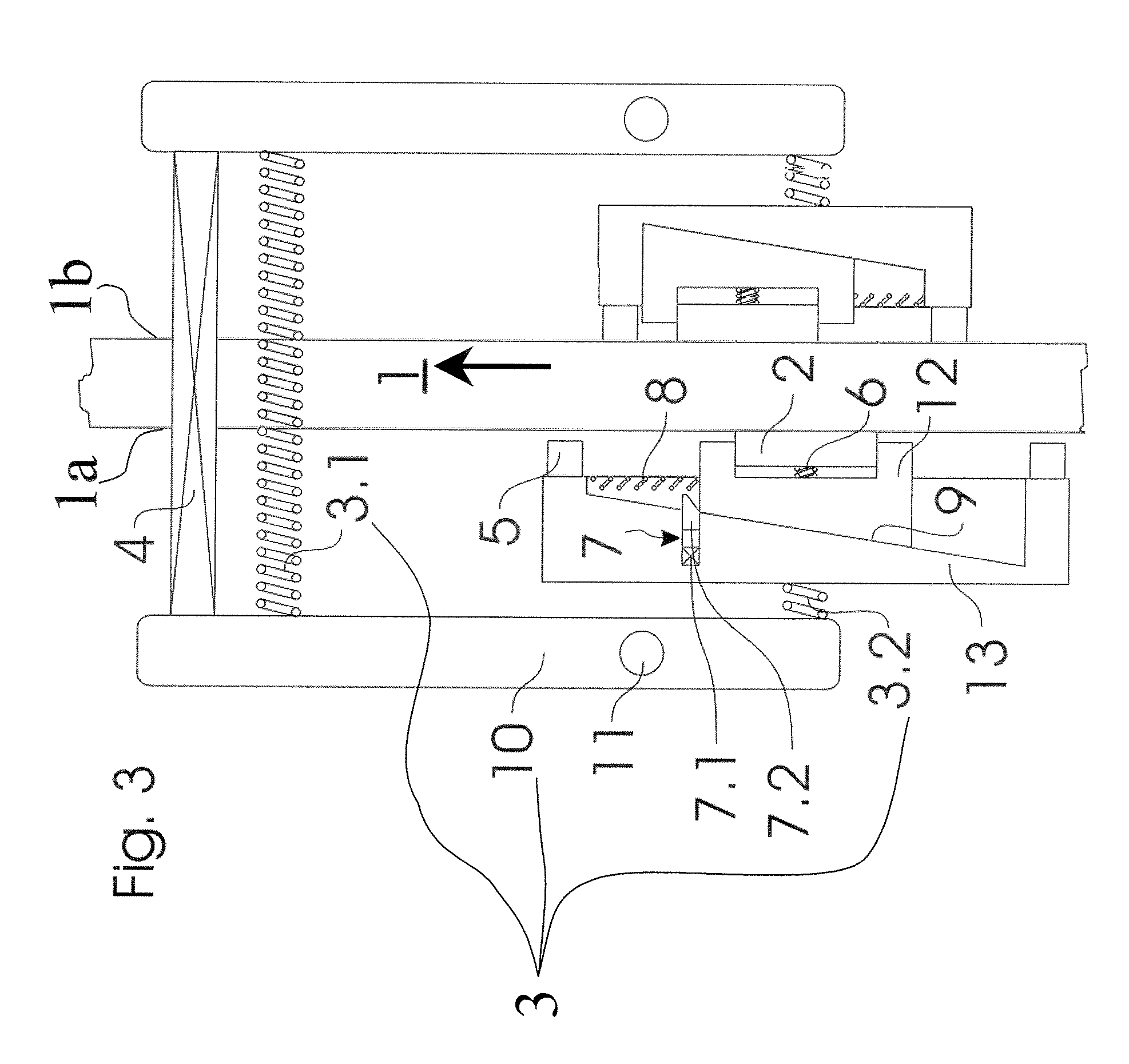

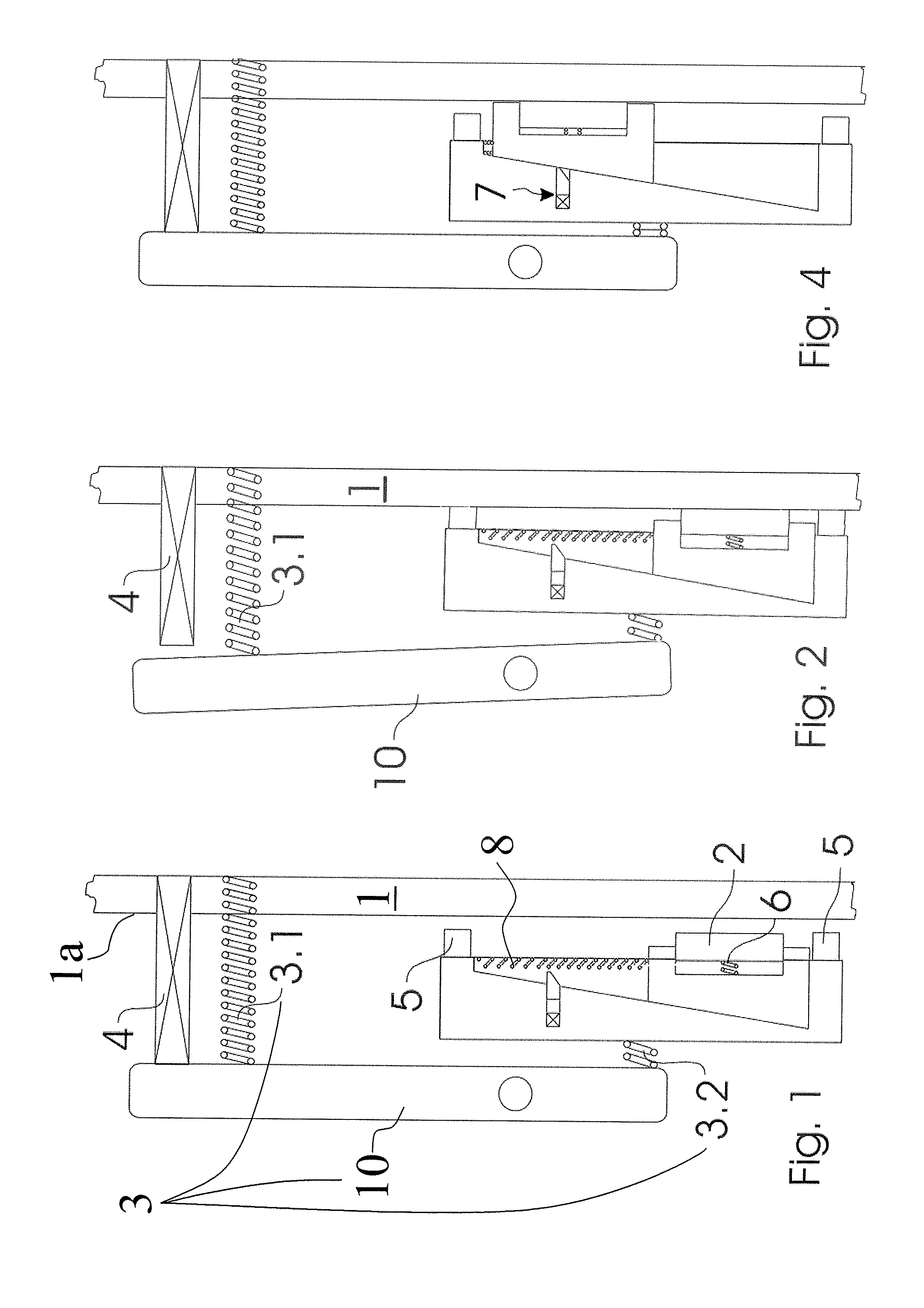

Brake equipment for holding and braking an elevator car in an elevator installation and a method of holding and braking an elevator installation

Brake equipment for holding and braking an elevator car in an elevator installation, which is arranged to be movable along a brake track in two directions of travel, includes a mount with a brake lining which automatically adjusts under friction couple with the brake track on movement of the elevator car relative to the rail and in that case tightens a first tightening means, which can be released by an actuator. The first tightening means tightens the mount together with the brake lining against the brake track by a biasing force. The brake equipment produces, with unmoved brake equipment and an unreleased state of the actuator, a holding force acting in both directions of travel. The holding force is determined substantially by the biasing force acting on the mount.

Owner:INVENTIO AG

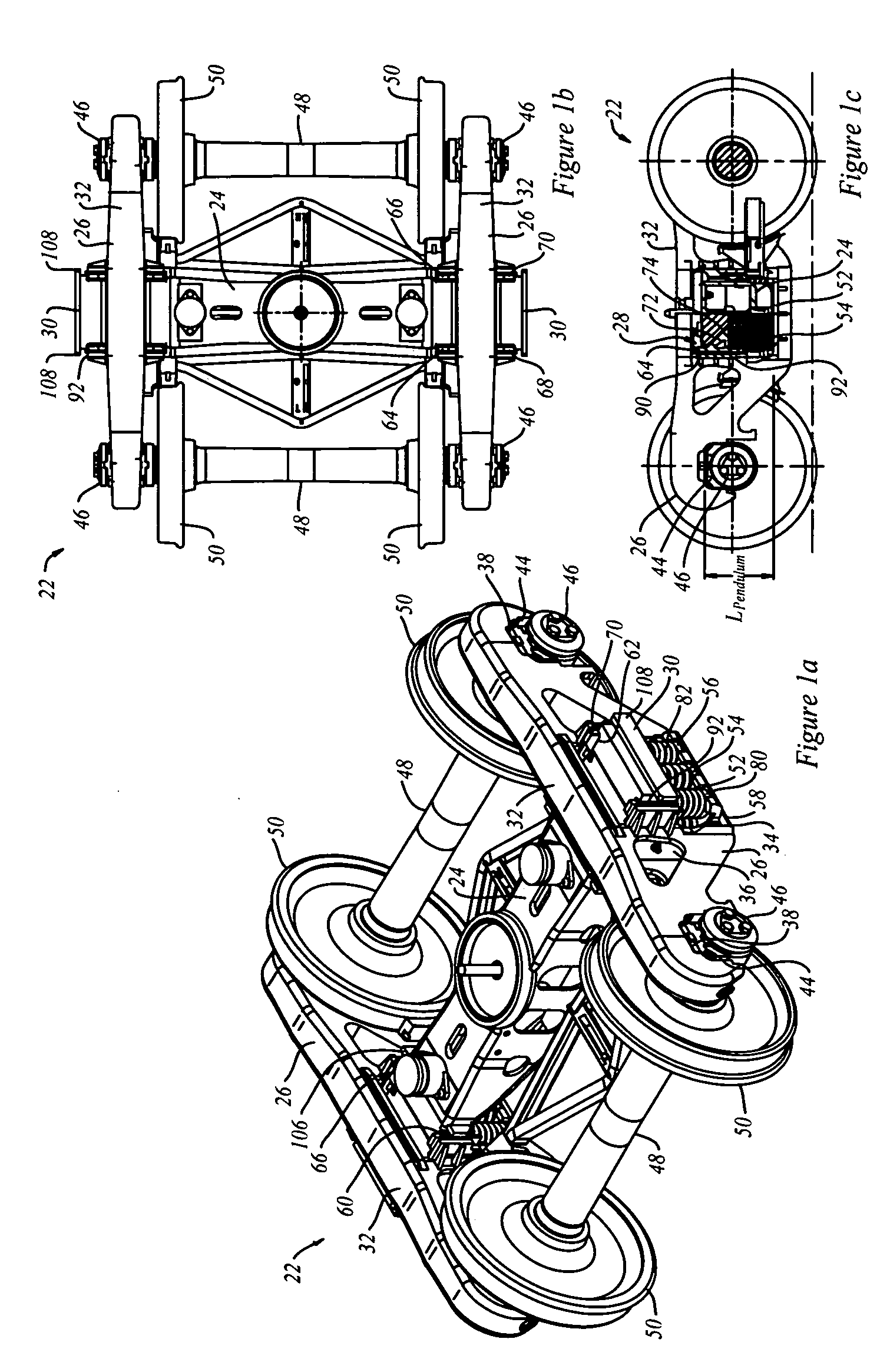

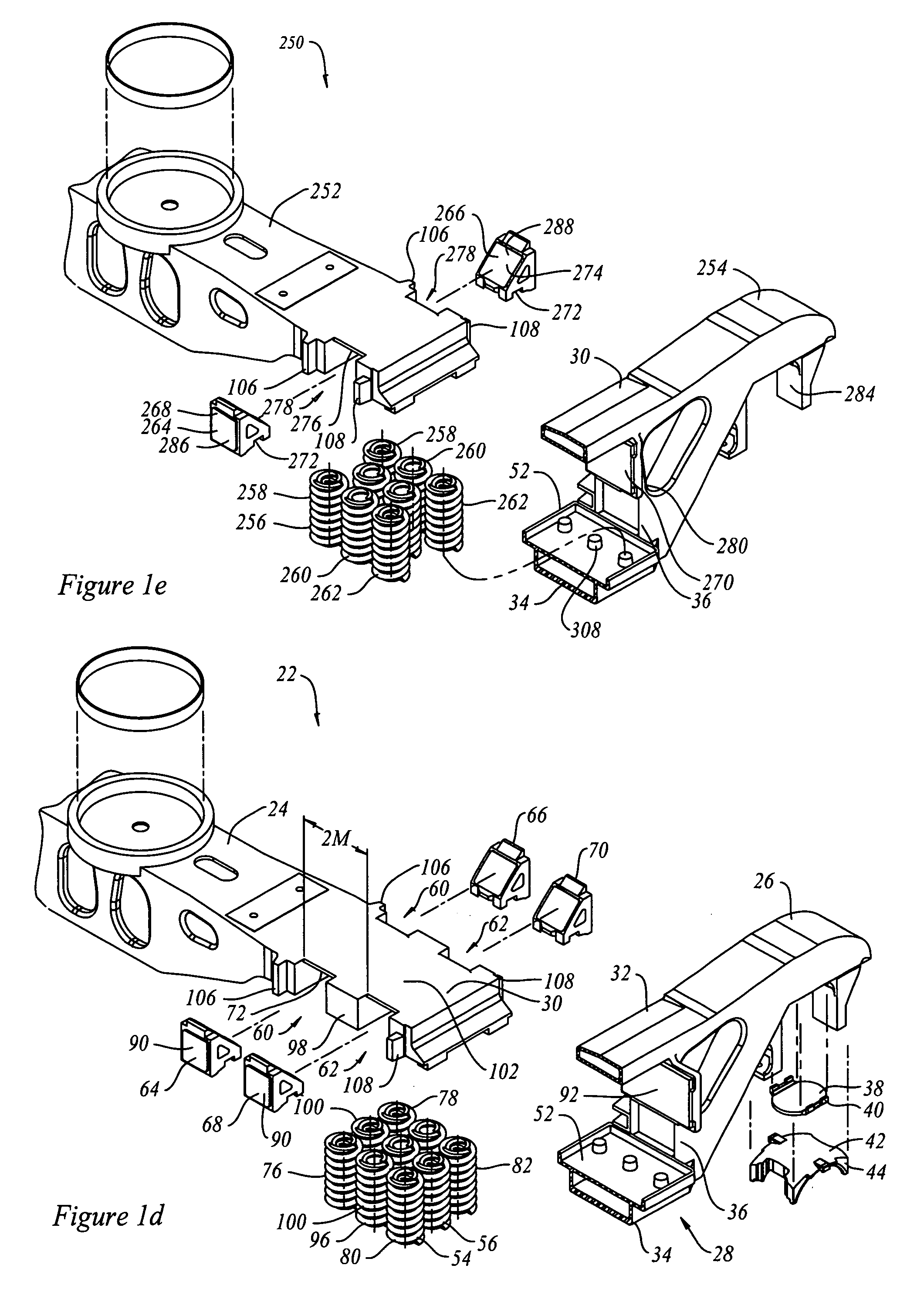

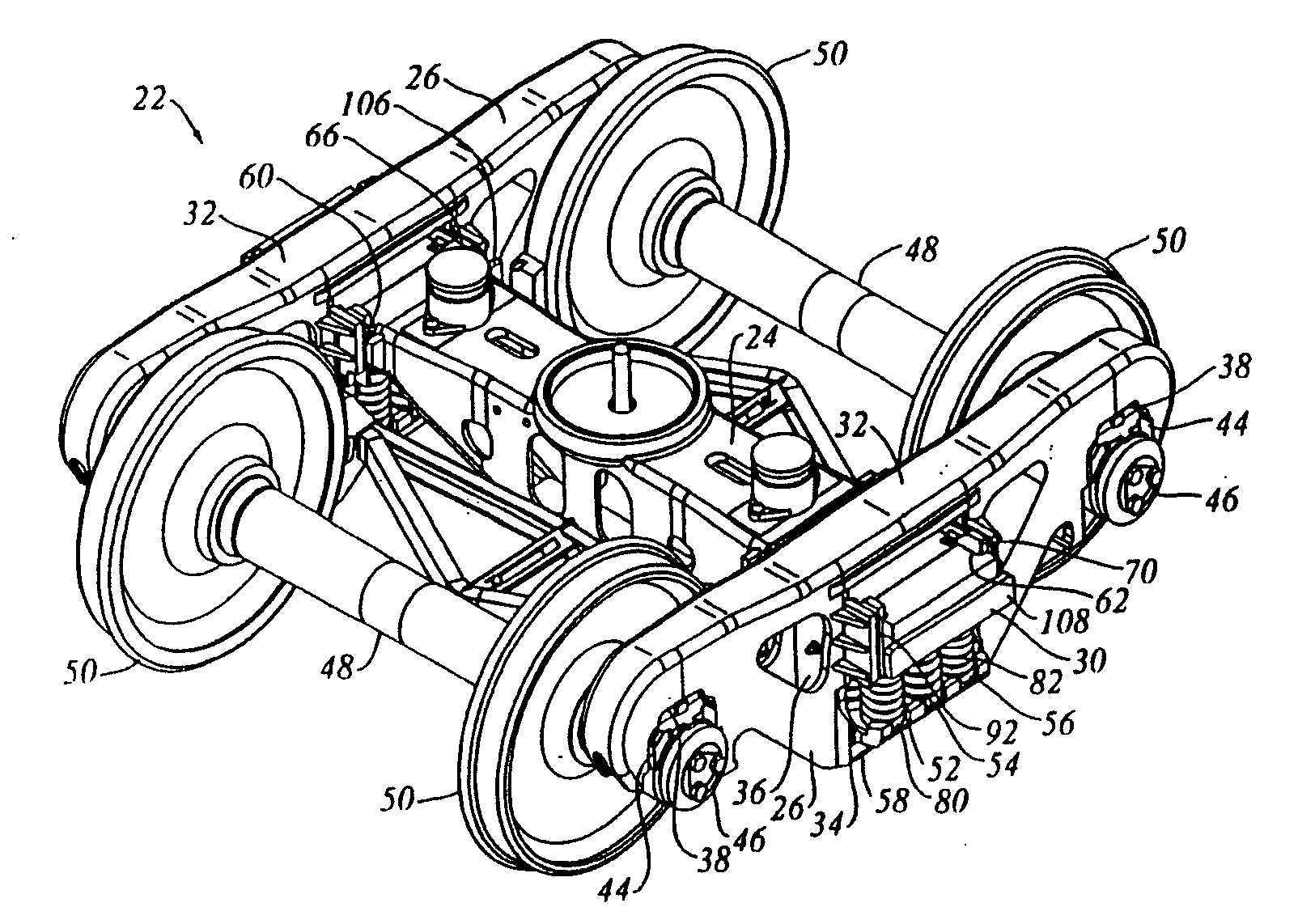

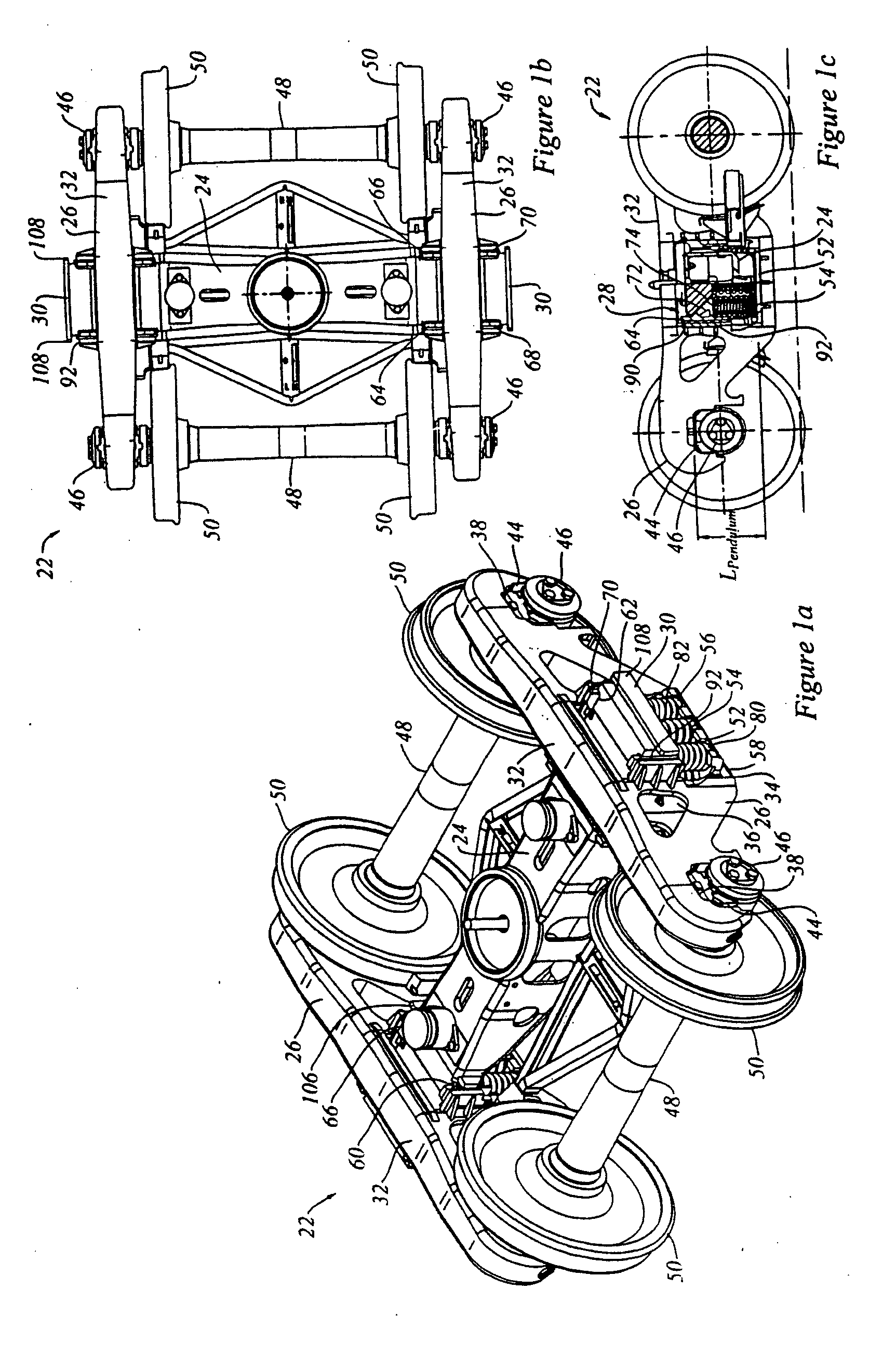

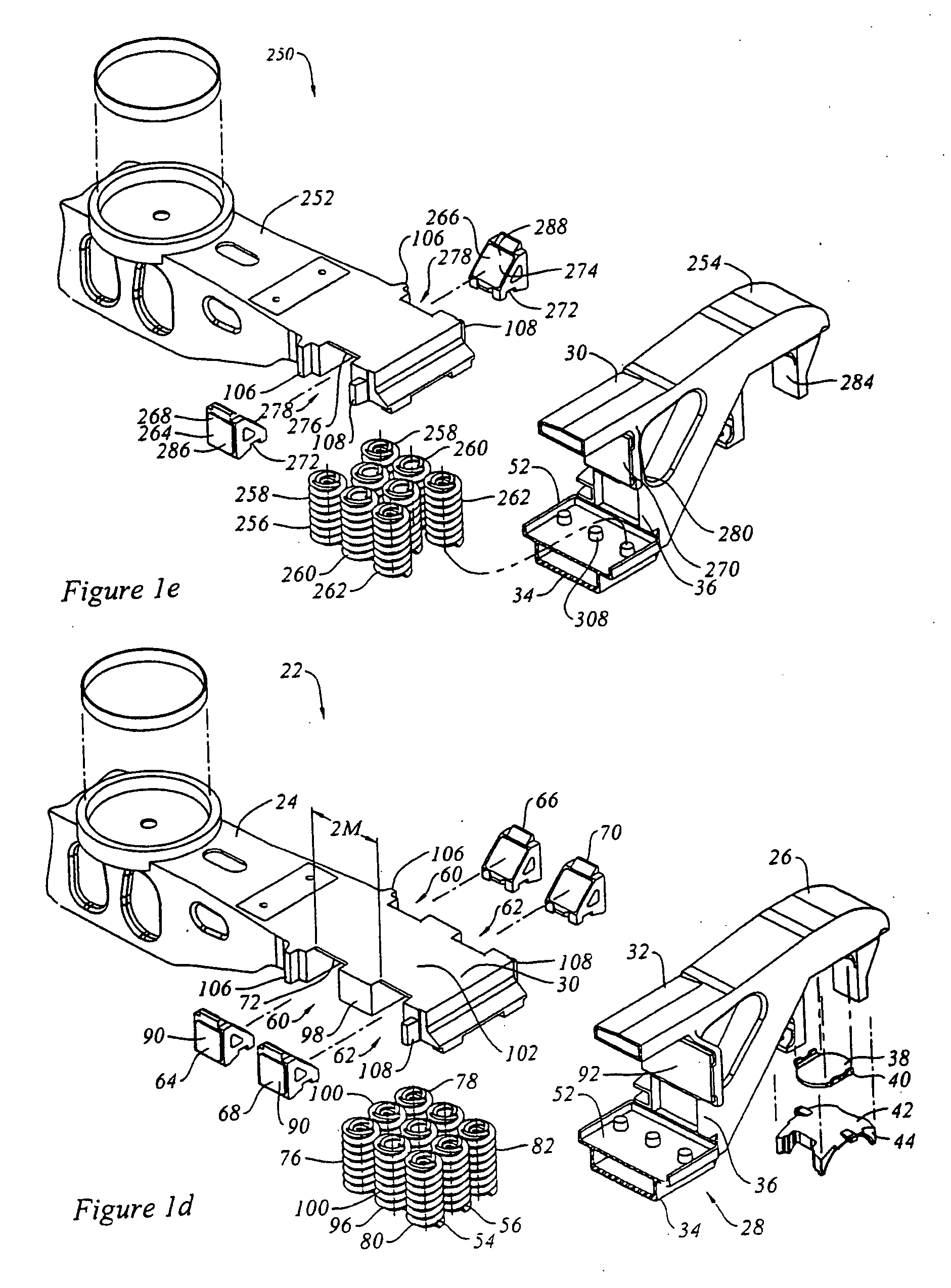

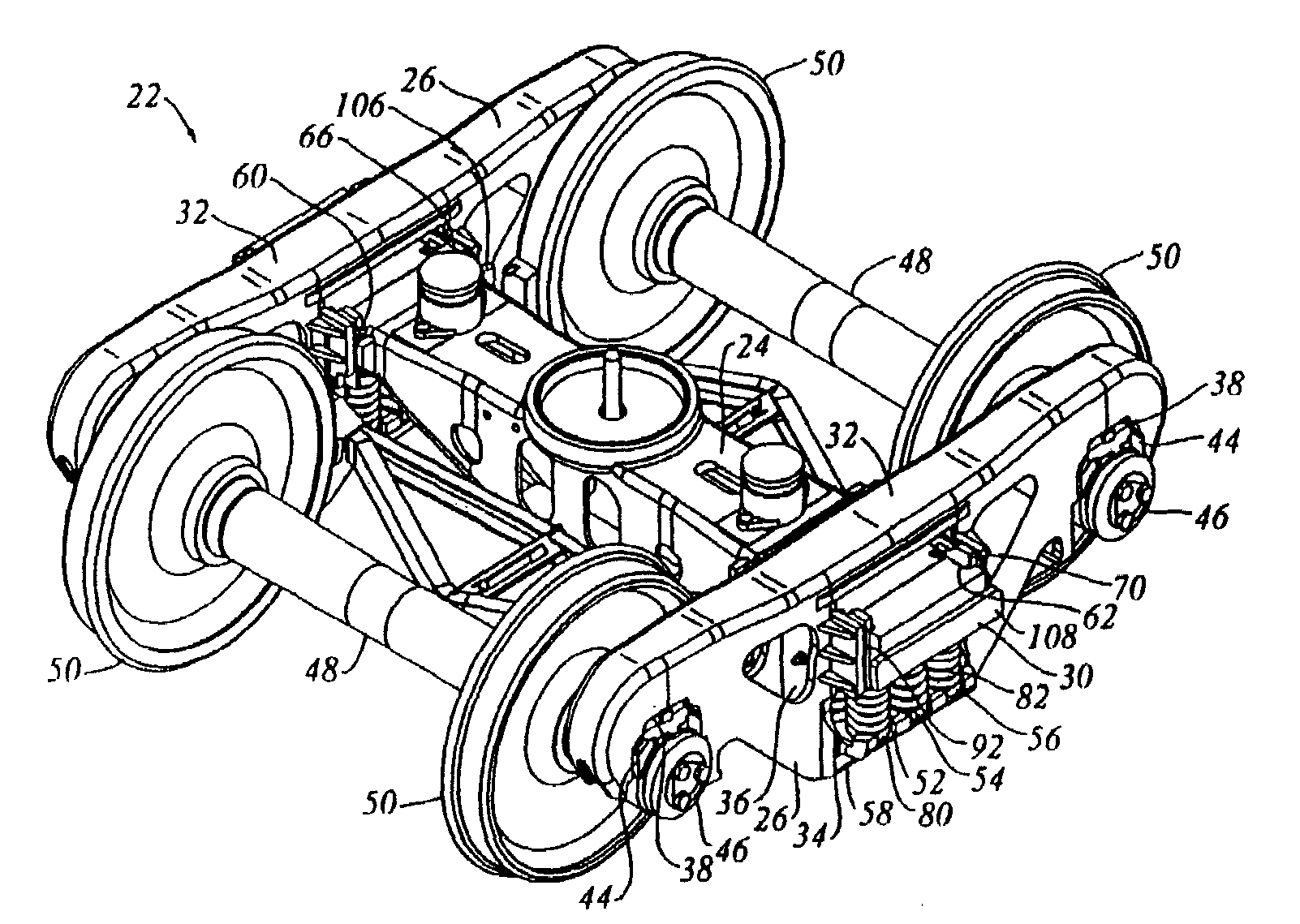

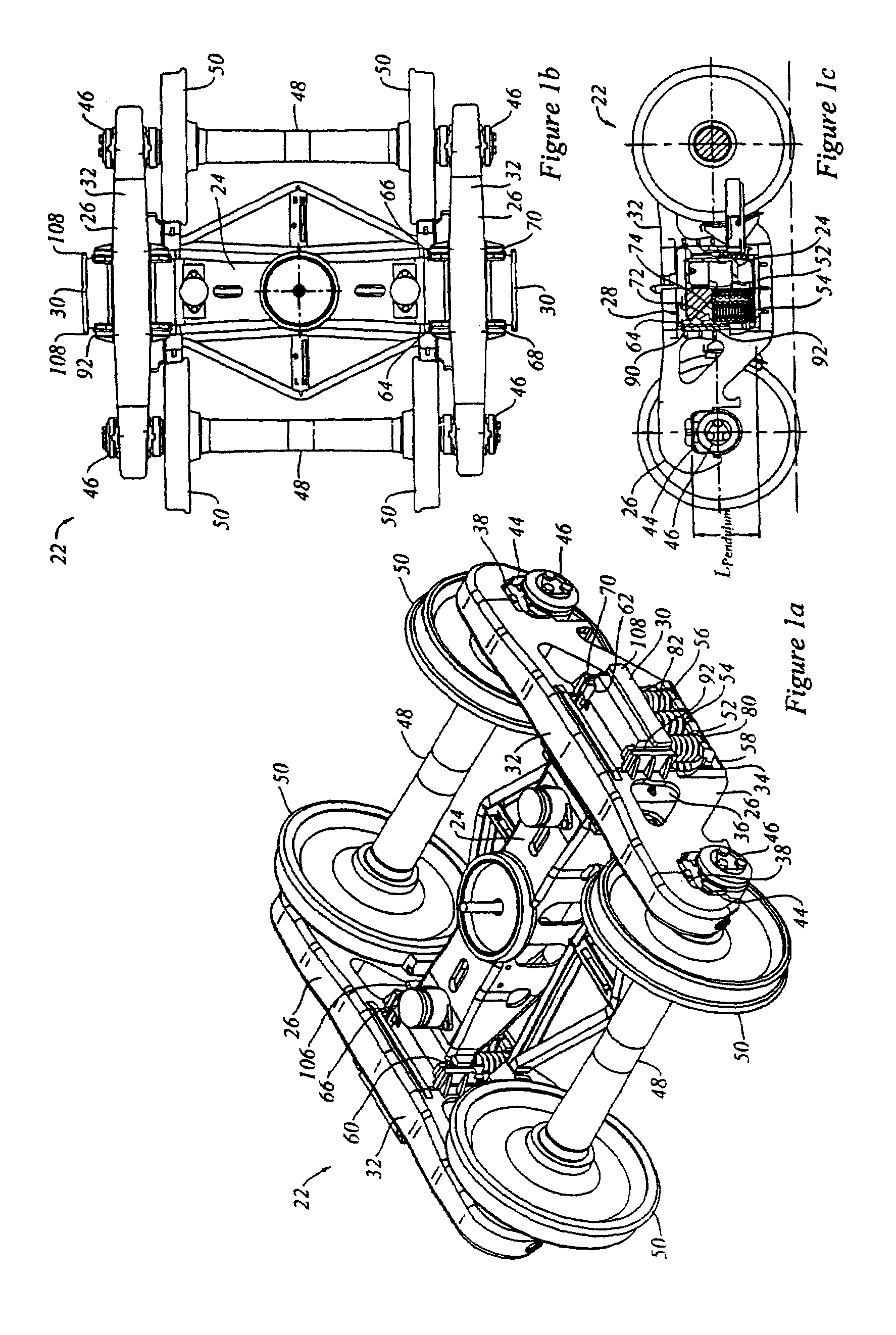

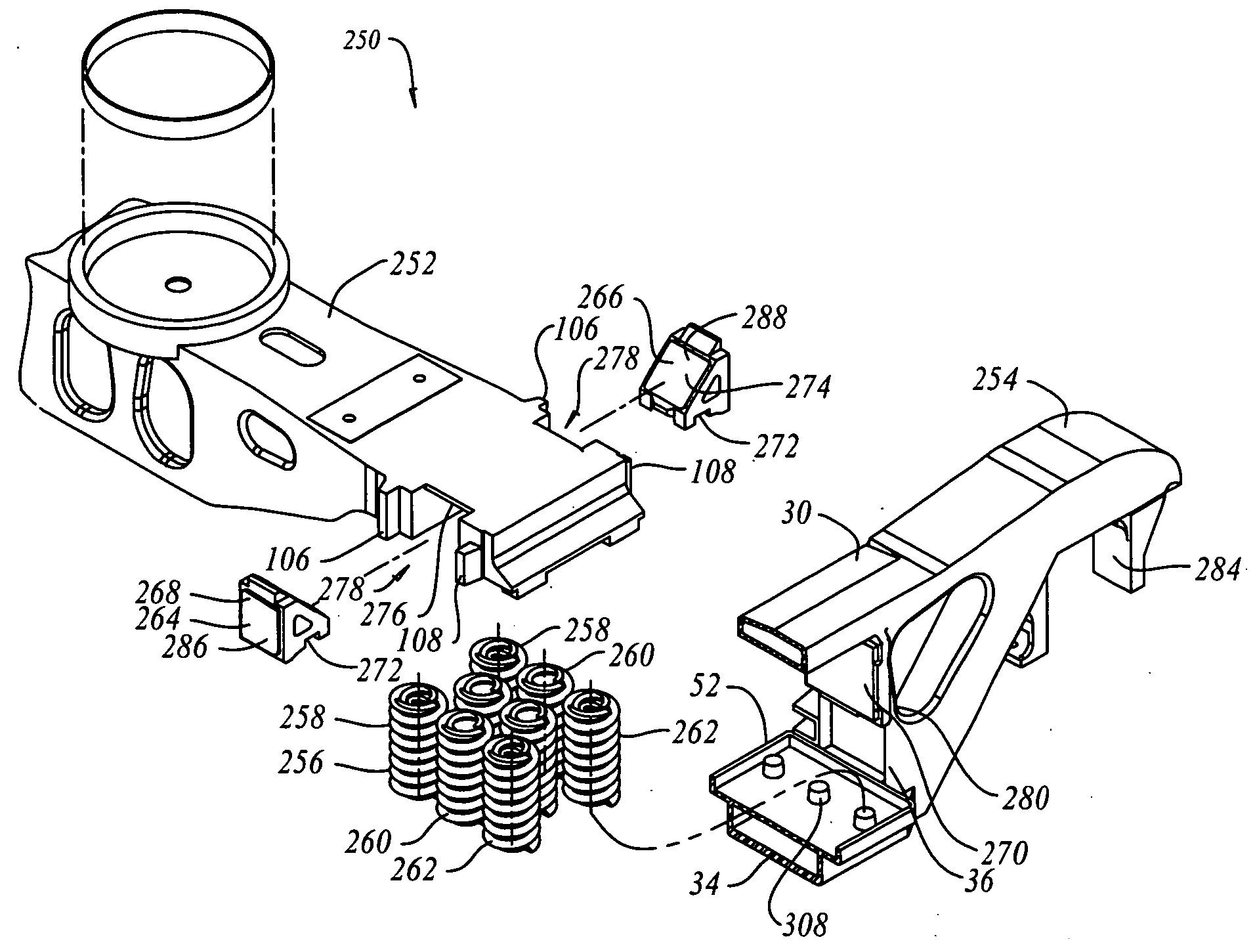

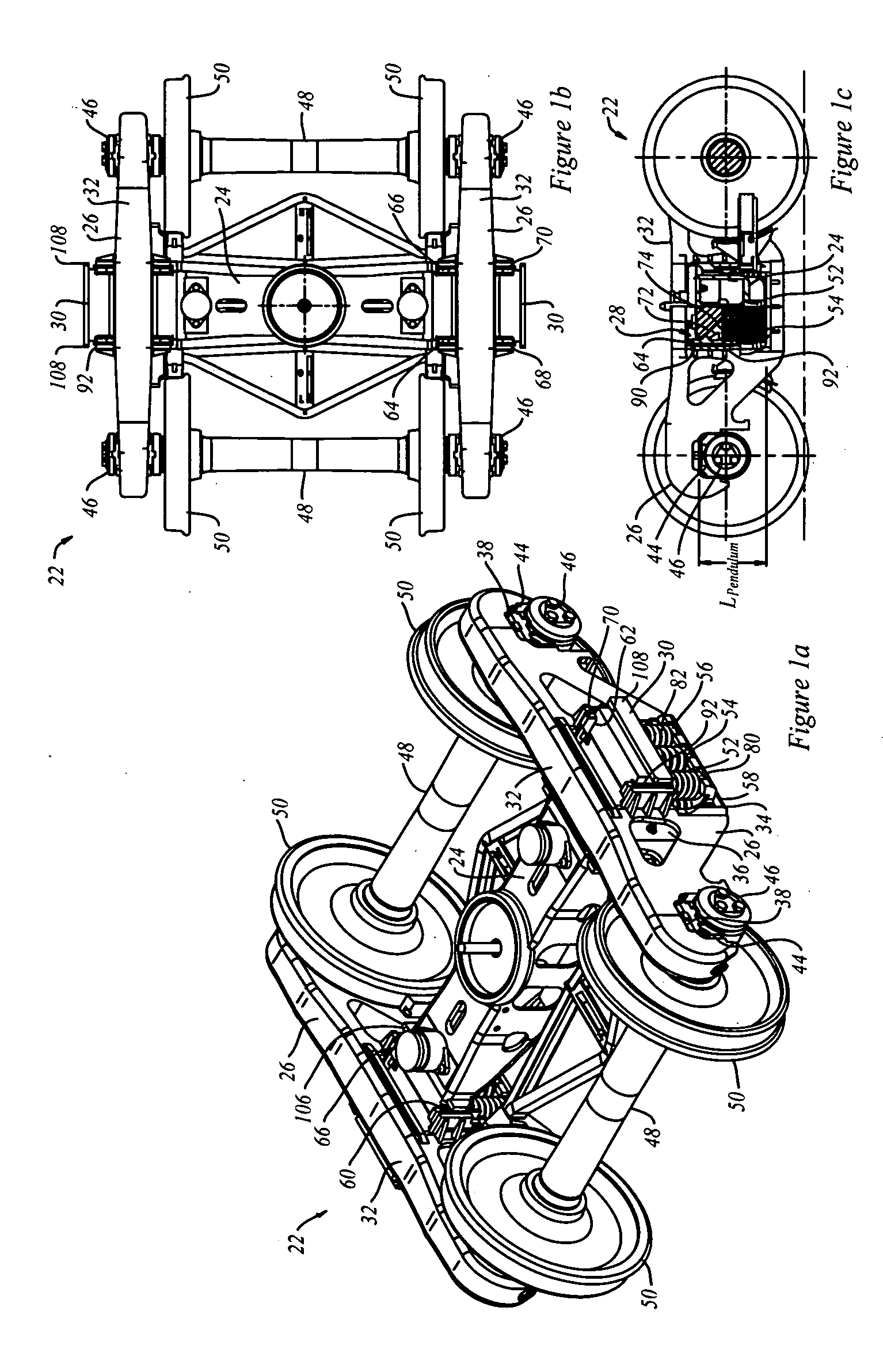

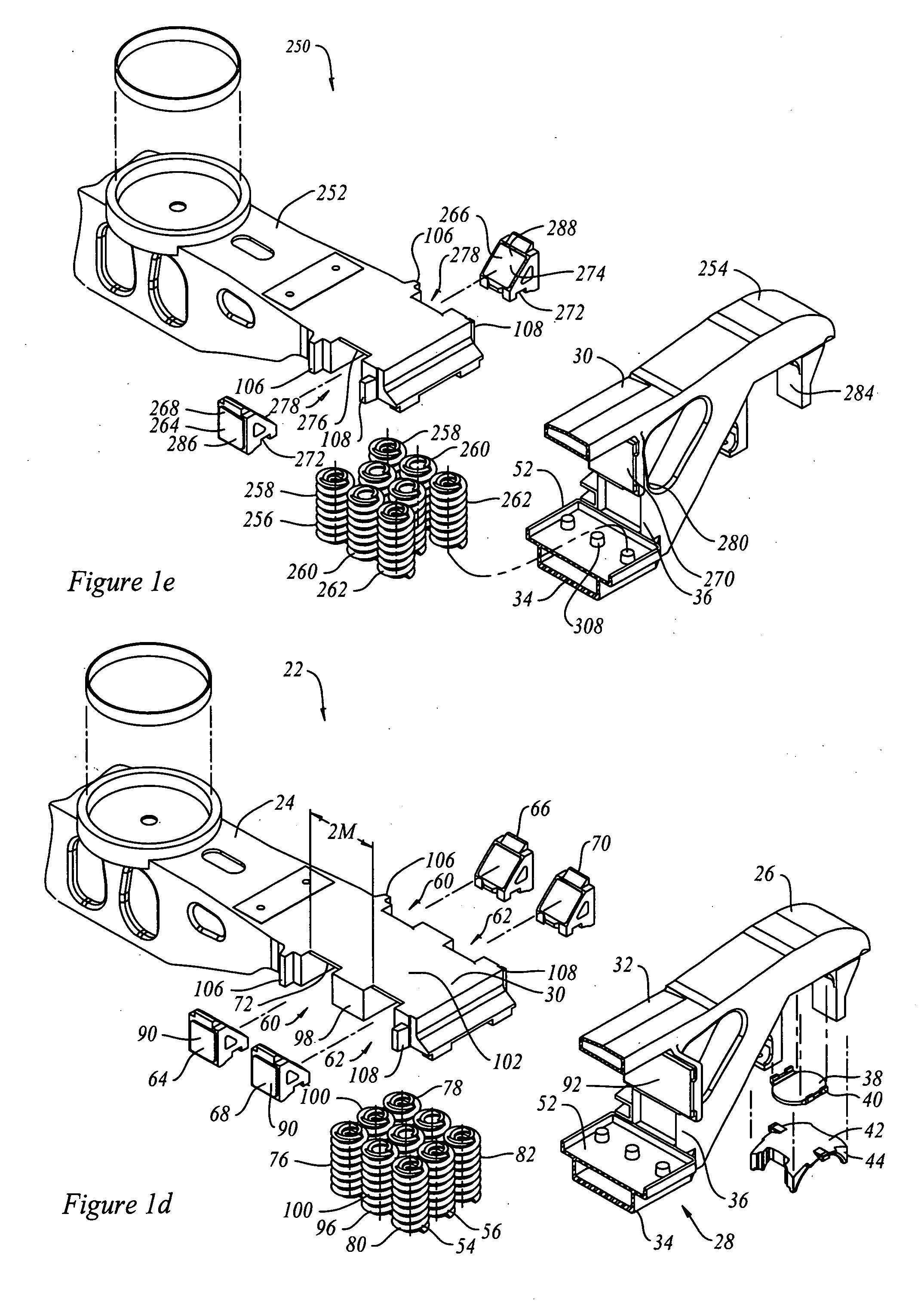

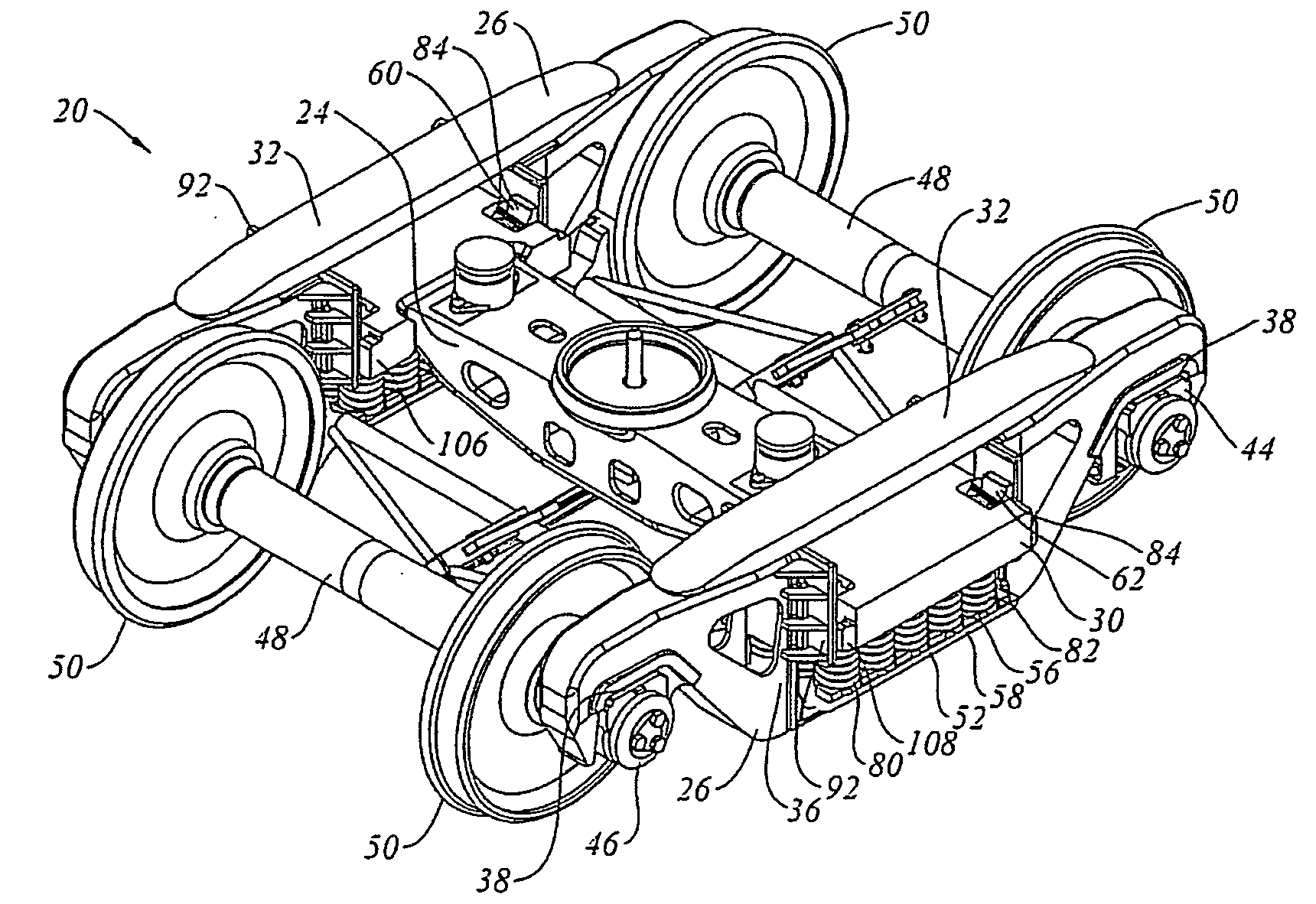

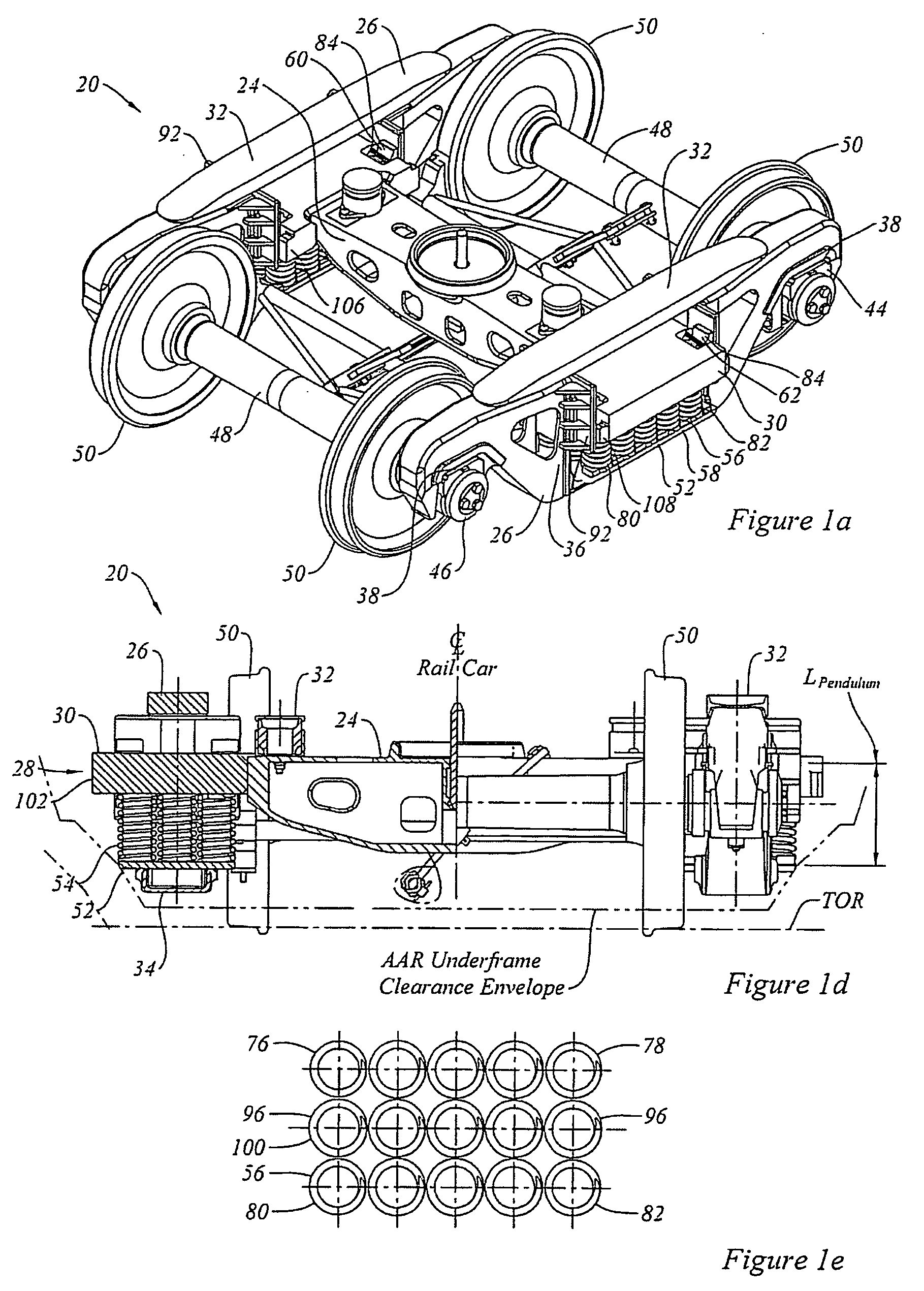

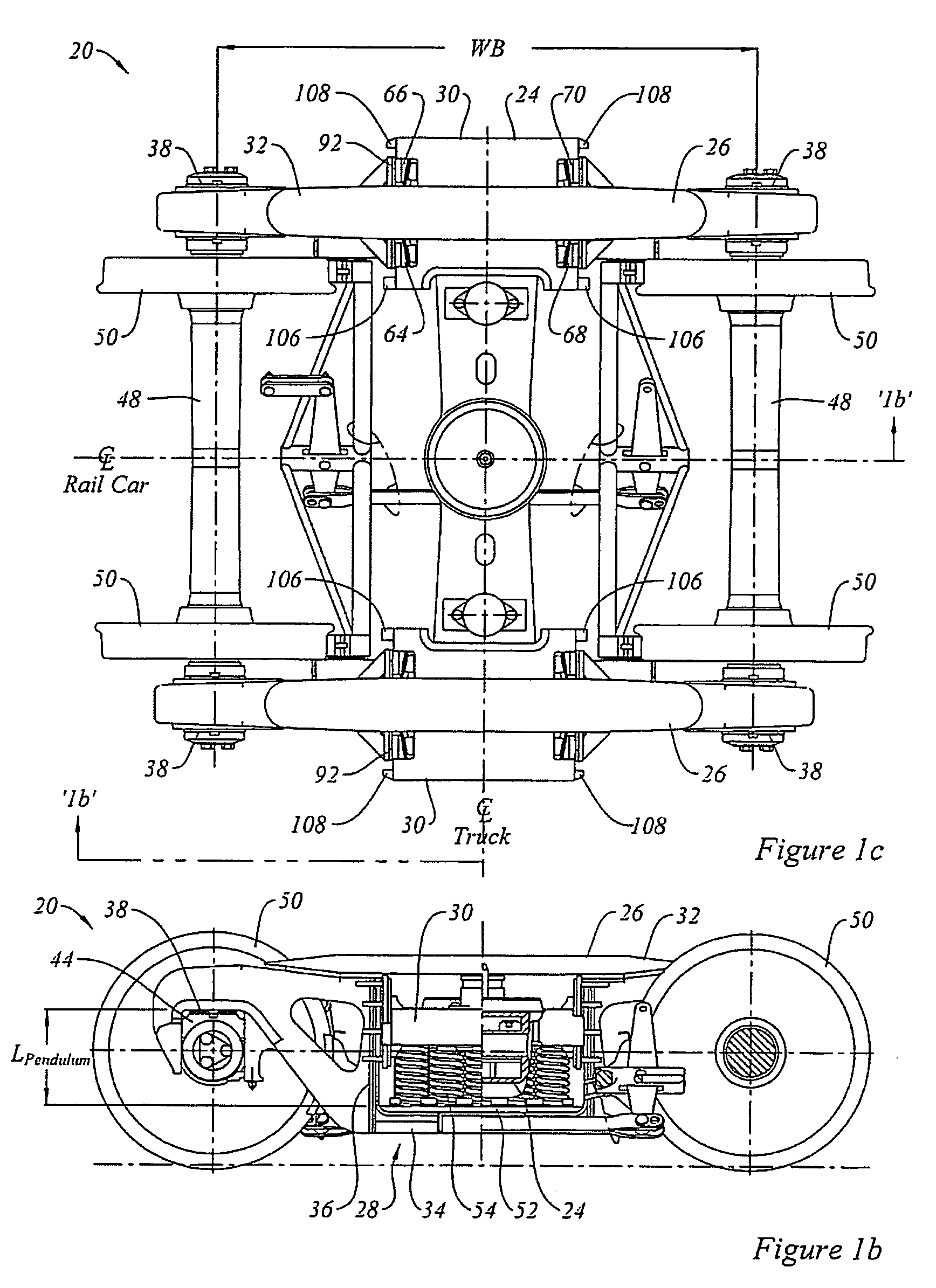

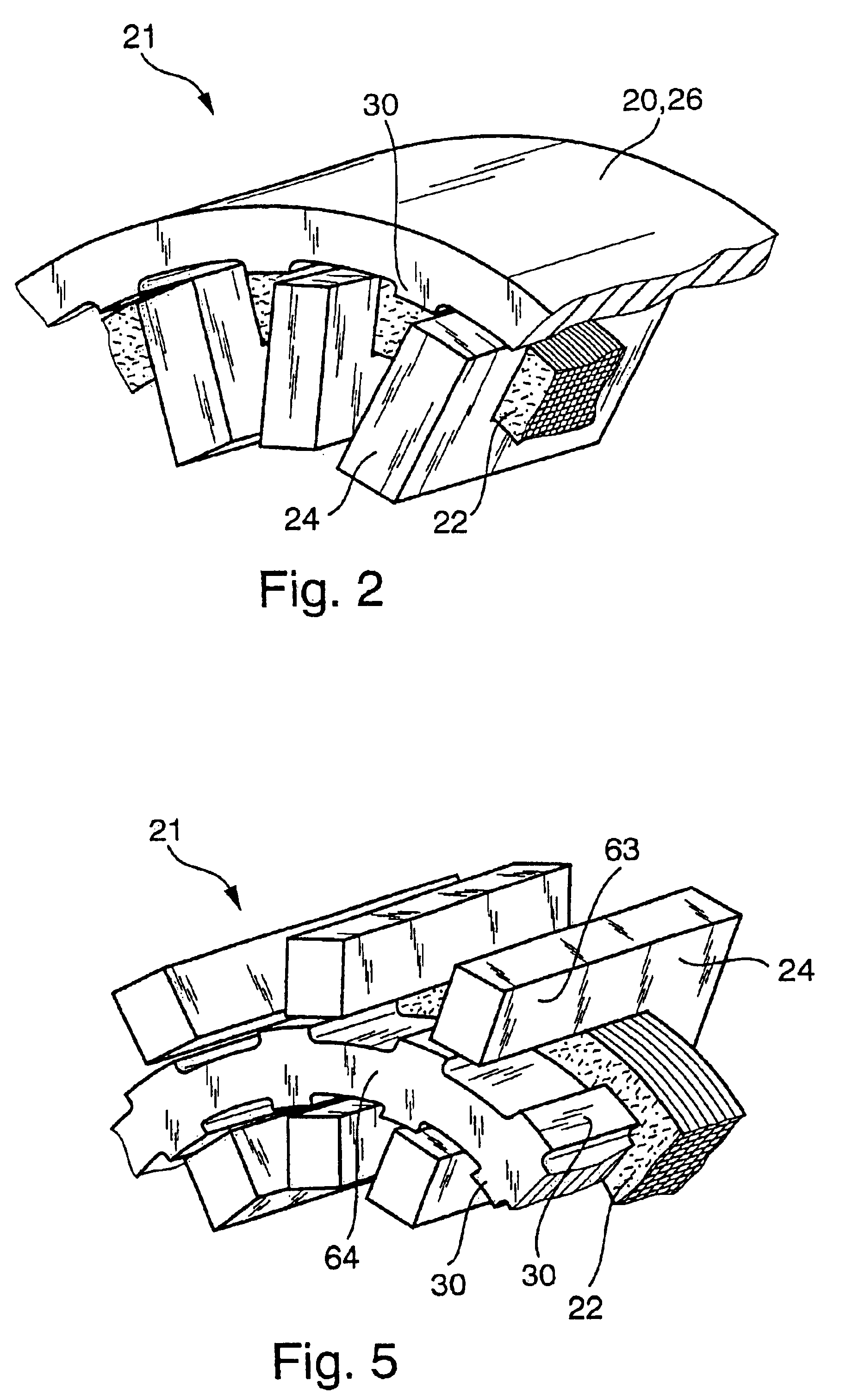

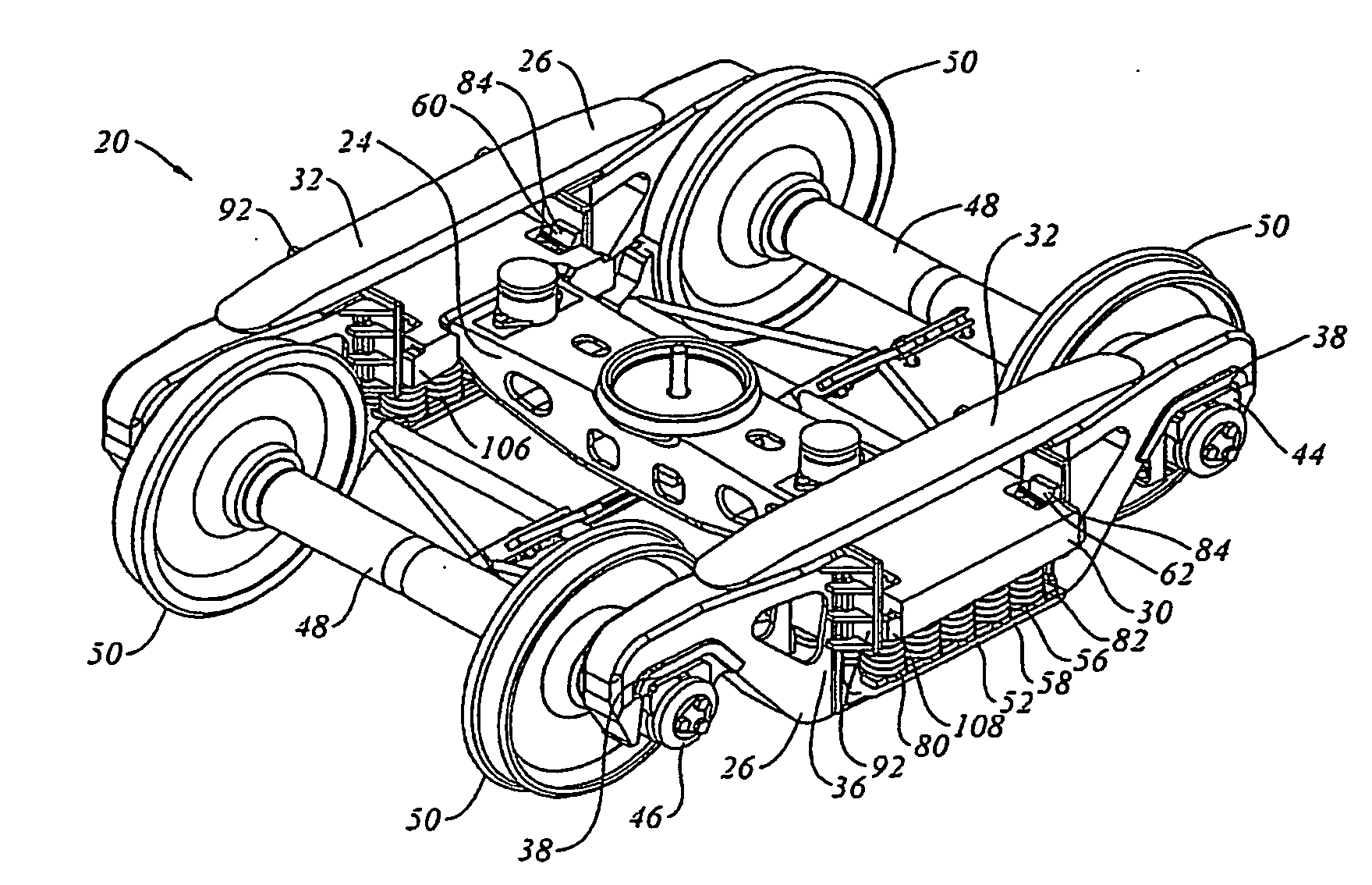

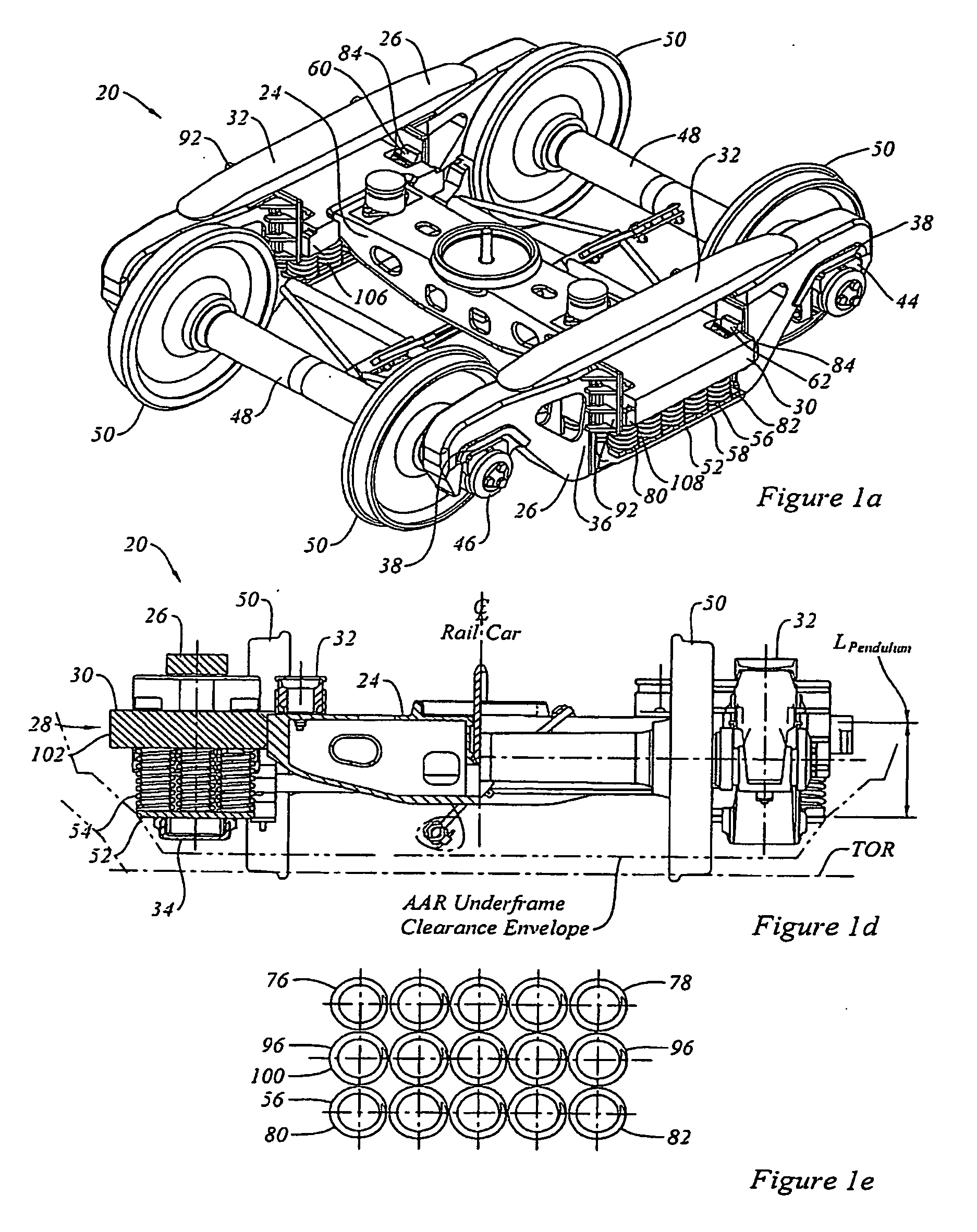

Rail road car truck and fittings therefor

A rail road freight car truck has a truck bolster and a pair of side frames, the truck bolster being mounted transversely relative to the side frames. The mounting interface between the ends of the axles and the sideframe pedestals allows lateral rocking motion of the sideframes in the manner of a swing motion truck. The lateral swinging motion is combined with a longitudinal self steering capability. The self steering capability may be obtained by use of a longitudinally oriented rocker that may tend to permit resistance to deflection that is proportional to the weight carried across the interface. The truck may have auxiliary centering elements mounted in the pedestal seats, and those auxiliary centering elements may be made of resilient elastomeric material. The truck may also have friction dampers that have a disinclination to stick-slip behaviour. The friction dampers may be provided with brake linings, or similar features, on the face engaging the sideframe columns, on the slope face, or both. The friction dampers may operate to yield upward and downward friction forces that are not overly unequal. The friction dampers may be mounted in a four-cornered arrangement at each end of the truck bolster. The spring groups may include sub-groups of springs of different heights.

Owner:NATIONAL STEEL CAR

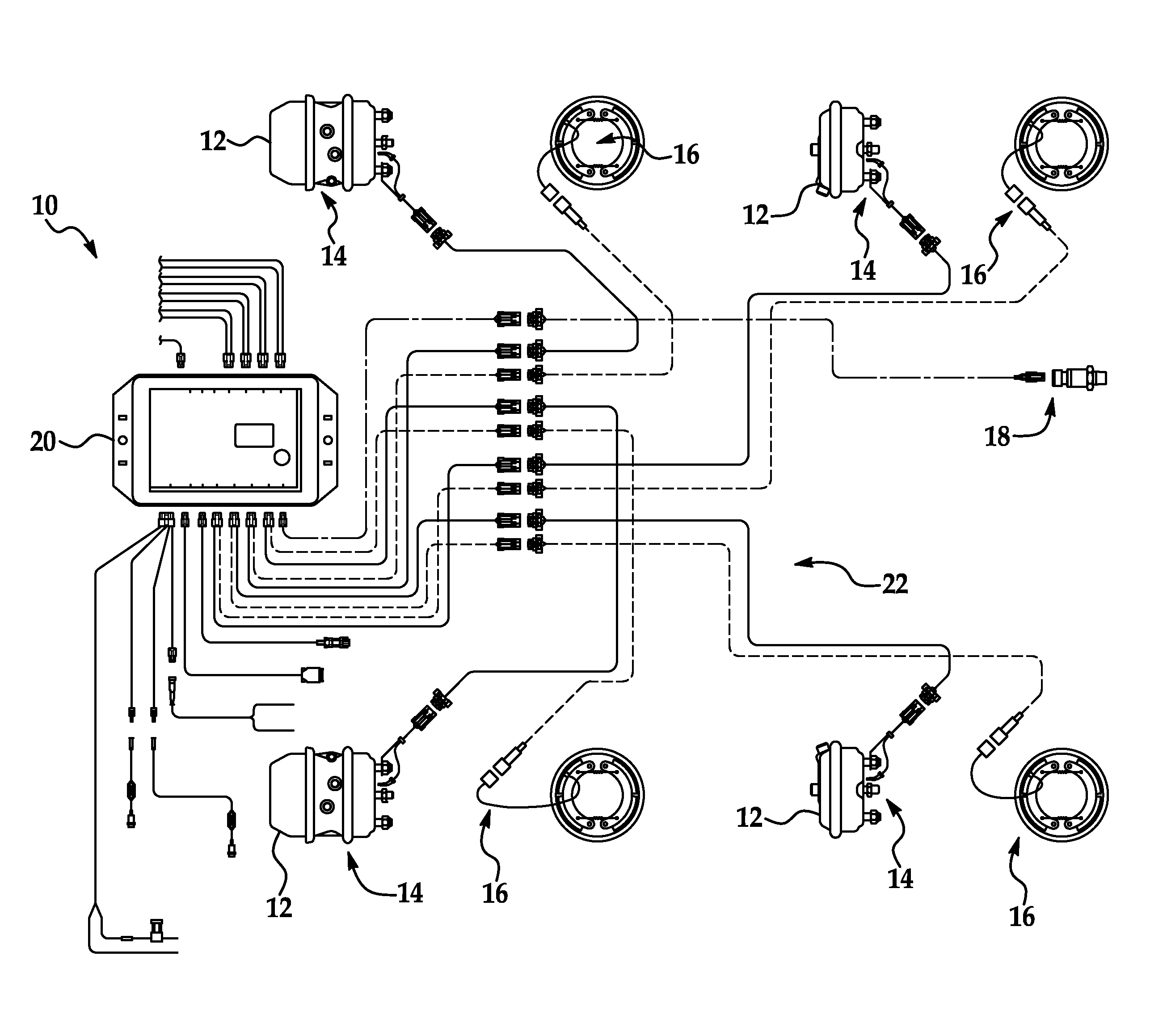

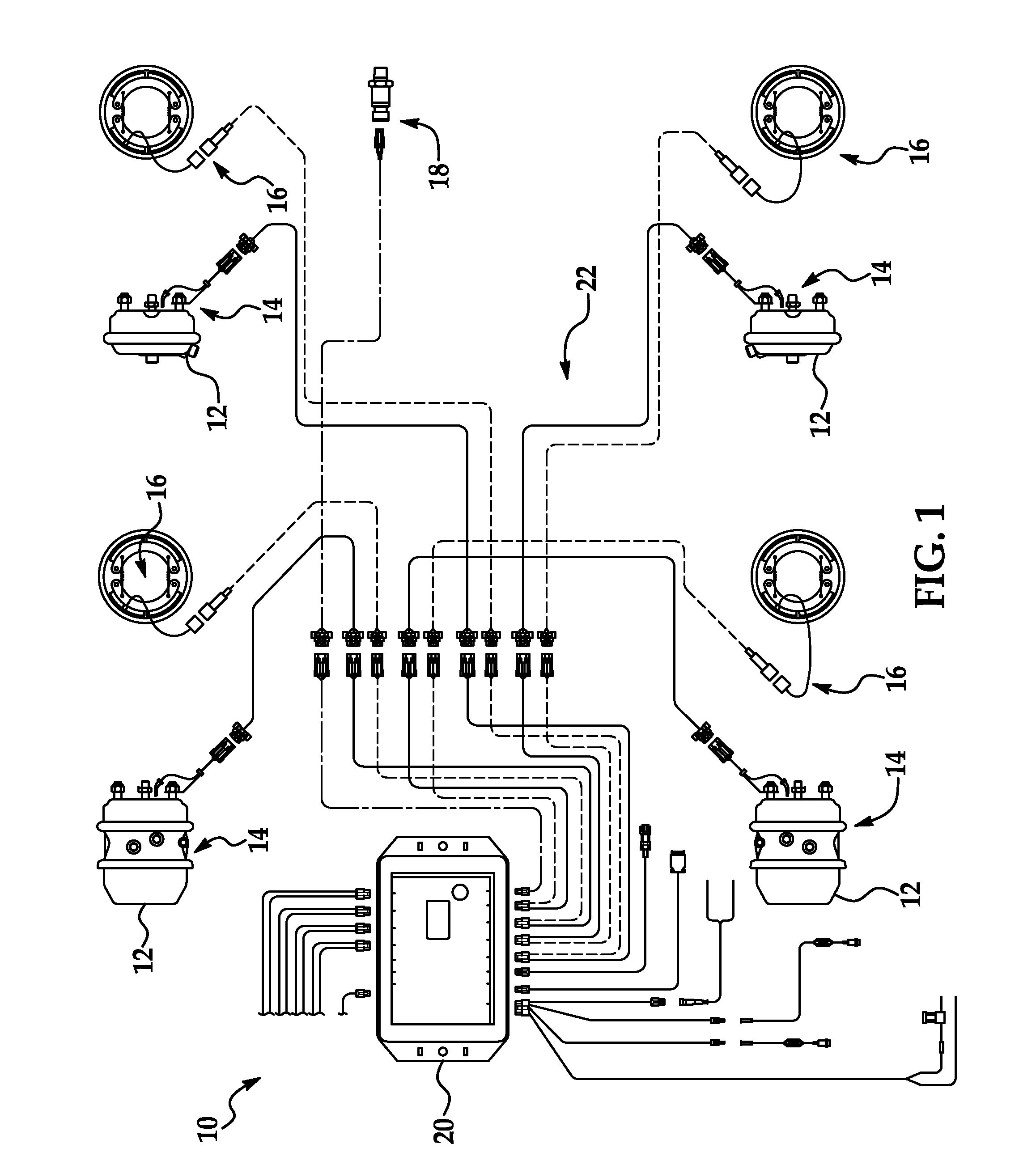

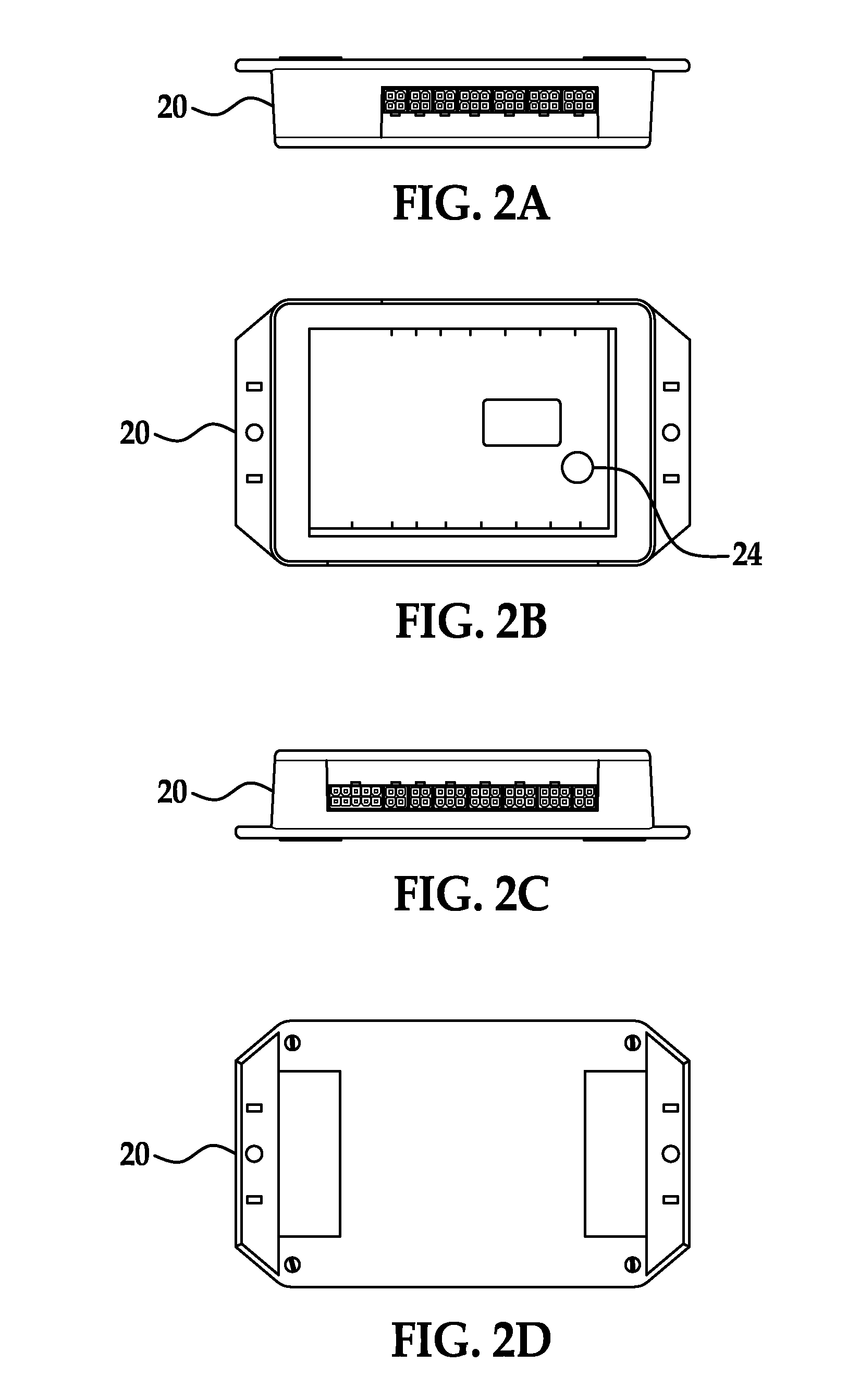

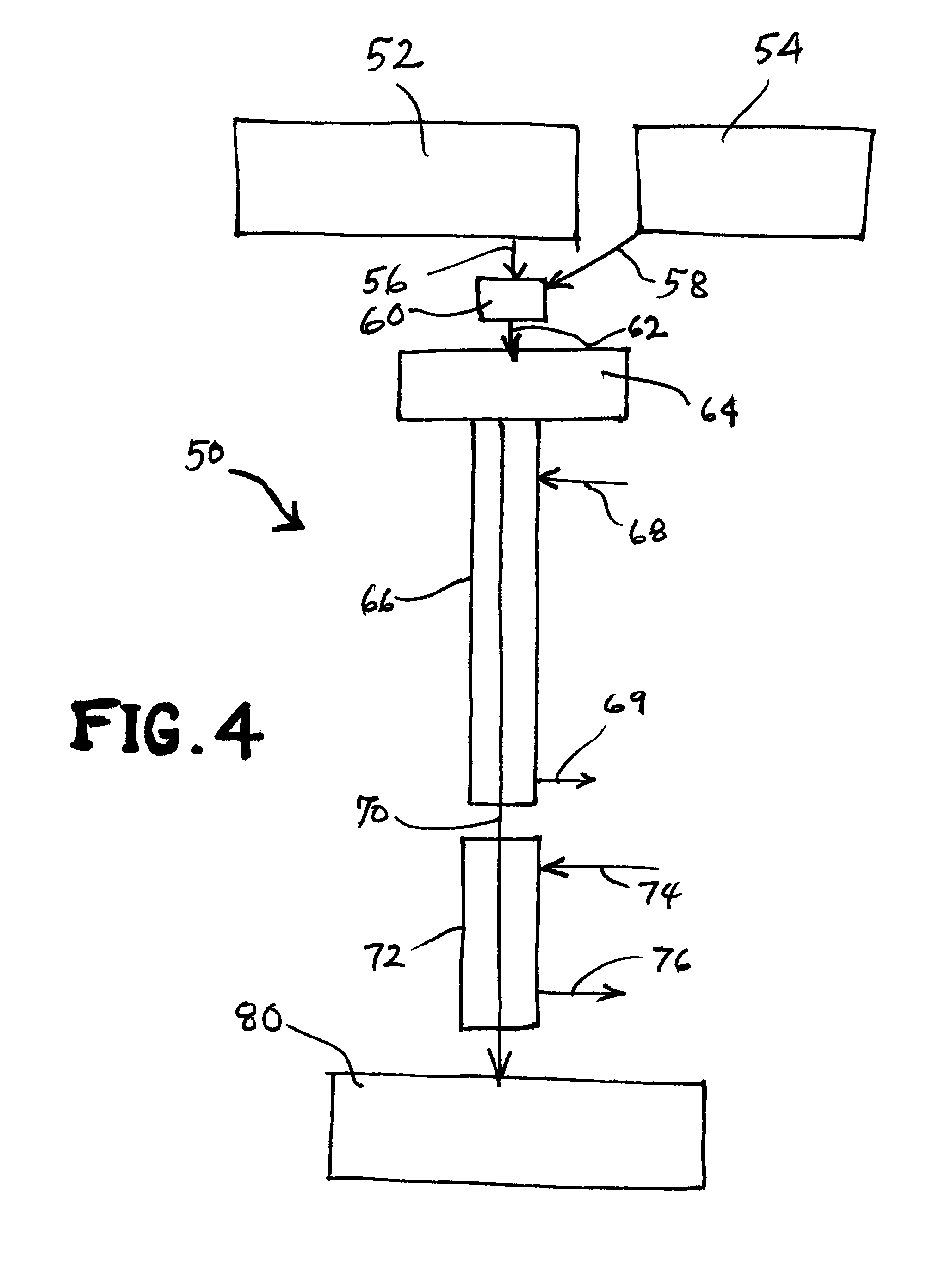

Brake monitoring system and method

ActiveUS20100188203A1Vehicle speed is limitedVehicle testingRegistering/indicating working of vehiclesMonitoring systemActuator

A brake monitoring system and method for a vehicle having multiple axles and a plurality of brake actuators and an engine control module, each brake actuator being associated with one of the axle. The system include sensors for measuring, in real-time, brake pressure and brake lining wear, and generating first and second signals. The first and second signals are received and stored in a chassis communications module. The chassis communications module detects fault condition of the brakes as a function of the first and / or second signals and for recording the fault condition, the fault condition being one of a brake monitor warning and a brake lining warning and provides an indication of status via warning lights.

Owner:INDIAN HEAD INDUSTRIES INC

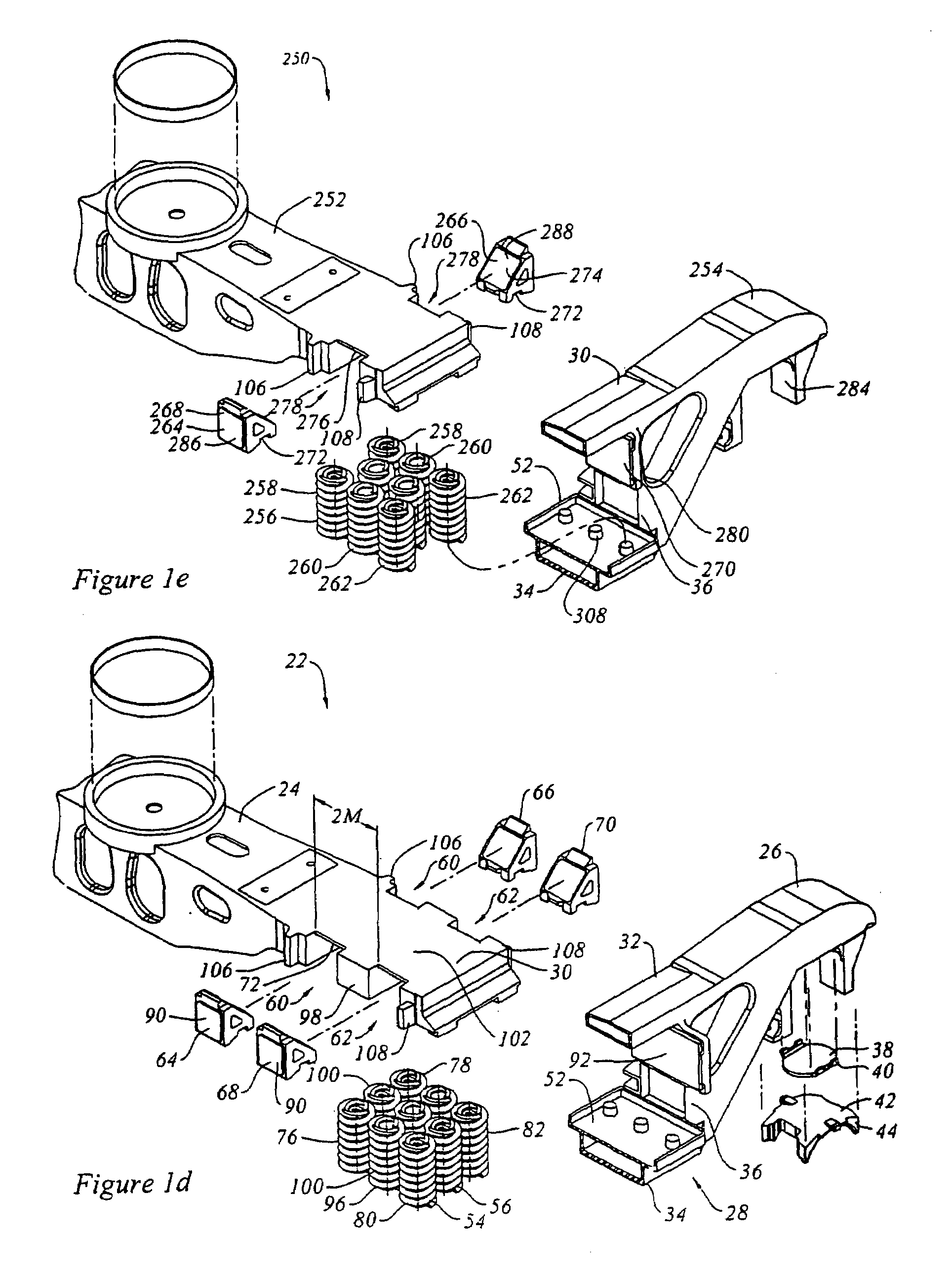

Rail road car truck and bolster therefor

ActiveUS20060117985A1Precise positioningAvoid misdirectionUnderframesPassenger carriagesBogieEngineering

A rail road freight car truck has a truck bolster and a pair of side frames, the truck bolster being mounted transversely relative to the side frames. The mounting interface between the ends of the axles and the sideframe pedestals allows lateral rocking motion of the sideframes in the manner of a swing motion truck. The lateral swinging motion is combined with a longitudinal self steering capability. The self steering capability may be obtained by use of a longitudinally oriented rocker that may tend to permit resistance to deflection that is proportional to the weight carried across the interface. The truck may have auxiliary centering elements mounted in the pedestal seats, and those auxiliary centering elements may be made of resilient elastomeric material. The truck may also have friction dampers that have a disinclination to stick-slip behaviour. The friction dampers may be provided with brake linings, or similar features, on the face engaging the sideframe columns, on the slope face, or both. The friction dampers may operate to yield upward and downward friction forces that are not overly unequal. The friction dampers may be mounted in a four-cornered arrangement at each end of the truck bolster. The spring groups may include sub-groups of springs of different heights.

Owner:NATIONAL STEEL CAR

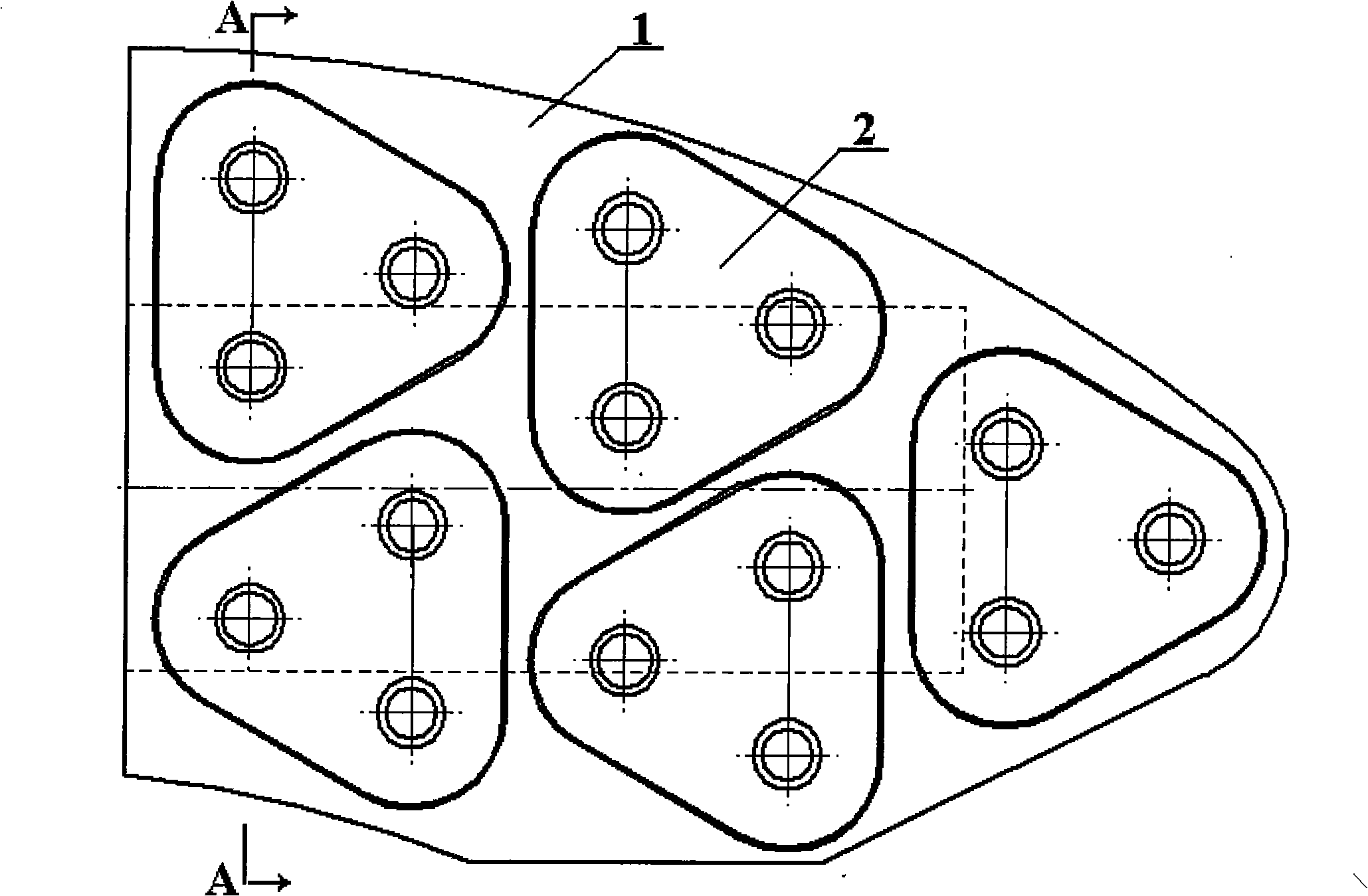

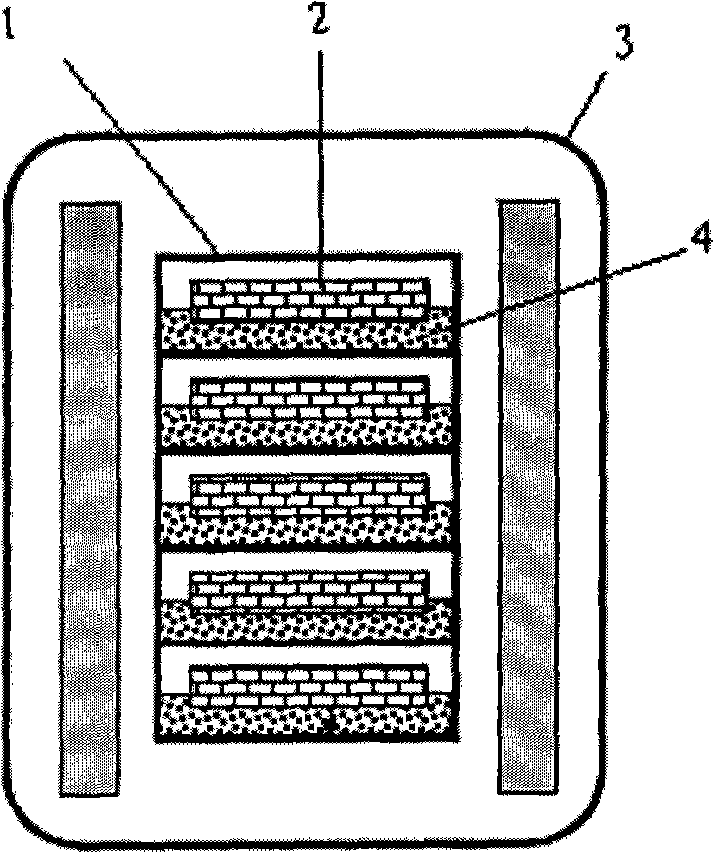

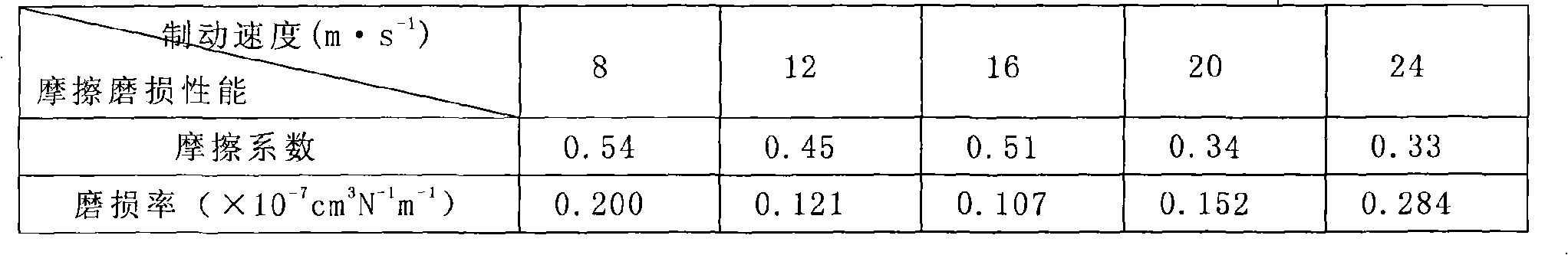

Copper-based powder metallurgy high speed brake lining

InactiveCN101493127AComply with work performance requirementsEffect of small friction propertiesBraking membersFriction liningBoron nitrideSilicon dioxide

The invention provides a copper based powder metallurgy high speed brake lining, which comprises a steel backing, a brake block, a framework, a spring washer and a swollen tail block. In the course of braking, the brake lining has smaller abrasion loss and can effectively prevent the edge dropping, angle dropping and camber wear of the brake block. The brake block uses copper based powder metallurgy friction material; copper powder, iron powder, tin powder, chromium powder, titanium powder, nickel powder, bismuth meal, graphite, boron nitride, aluminum oxide, silicon dioxide, zirconite and the like are well blended according to the proportion, stamped and sintered on the framework after cold pressing. The copper based powder metallurgy high speed brake lining has the characteristics of high mechanical strength, good thermal conduction, good thermal stability, strong heat-resistant fade performance, long service life, small abrasion on a retarding disc and stable friction performance and the like, and can effectively control very high way trains with 200-300km / h per hour.

Owner:贵州新安航空机械有限责任公司

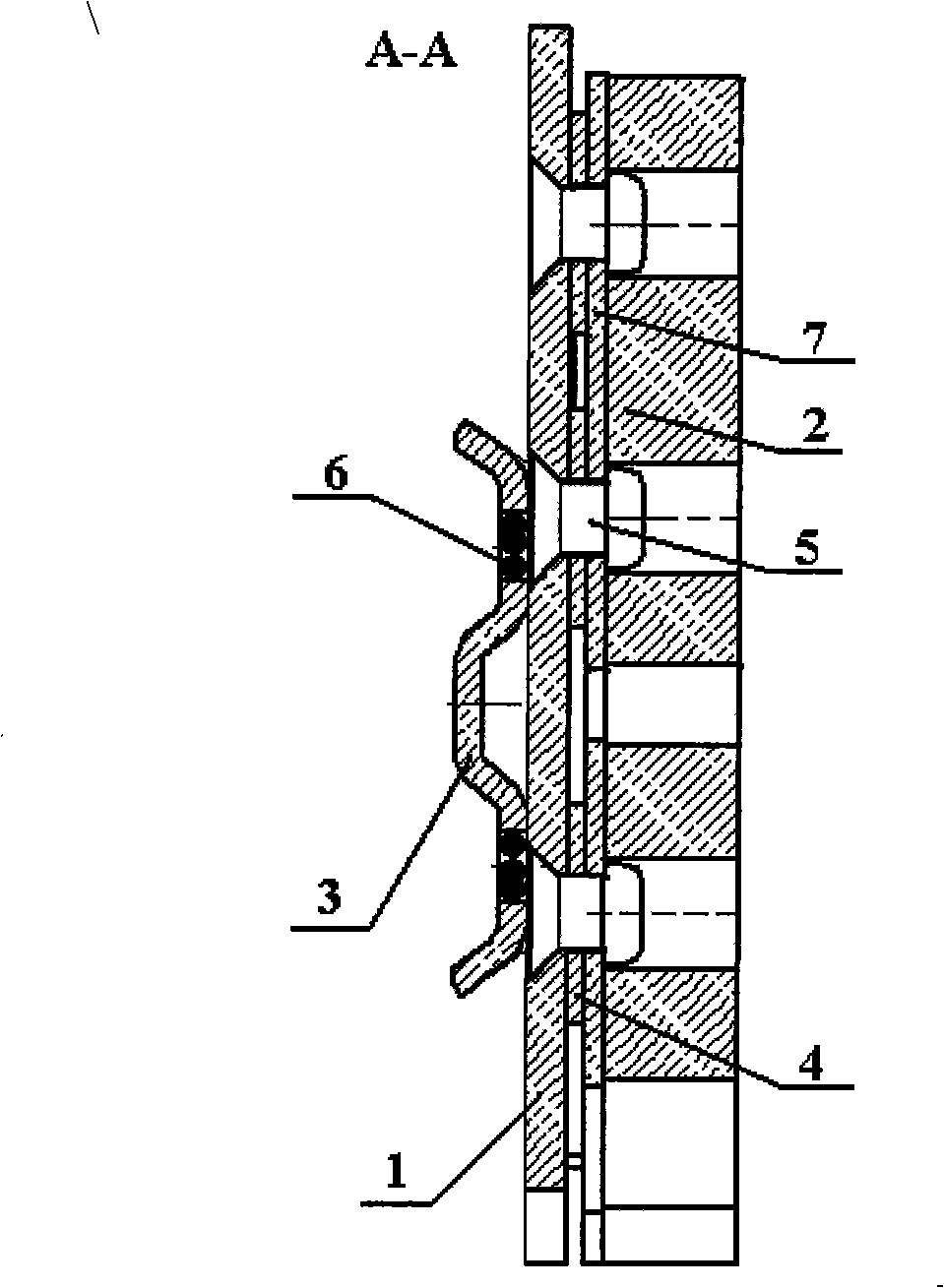

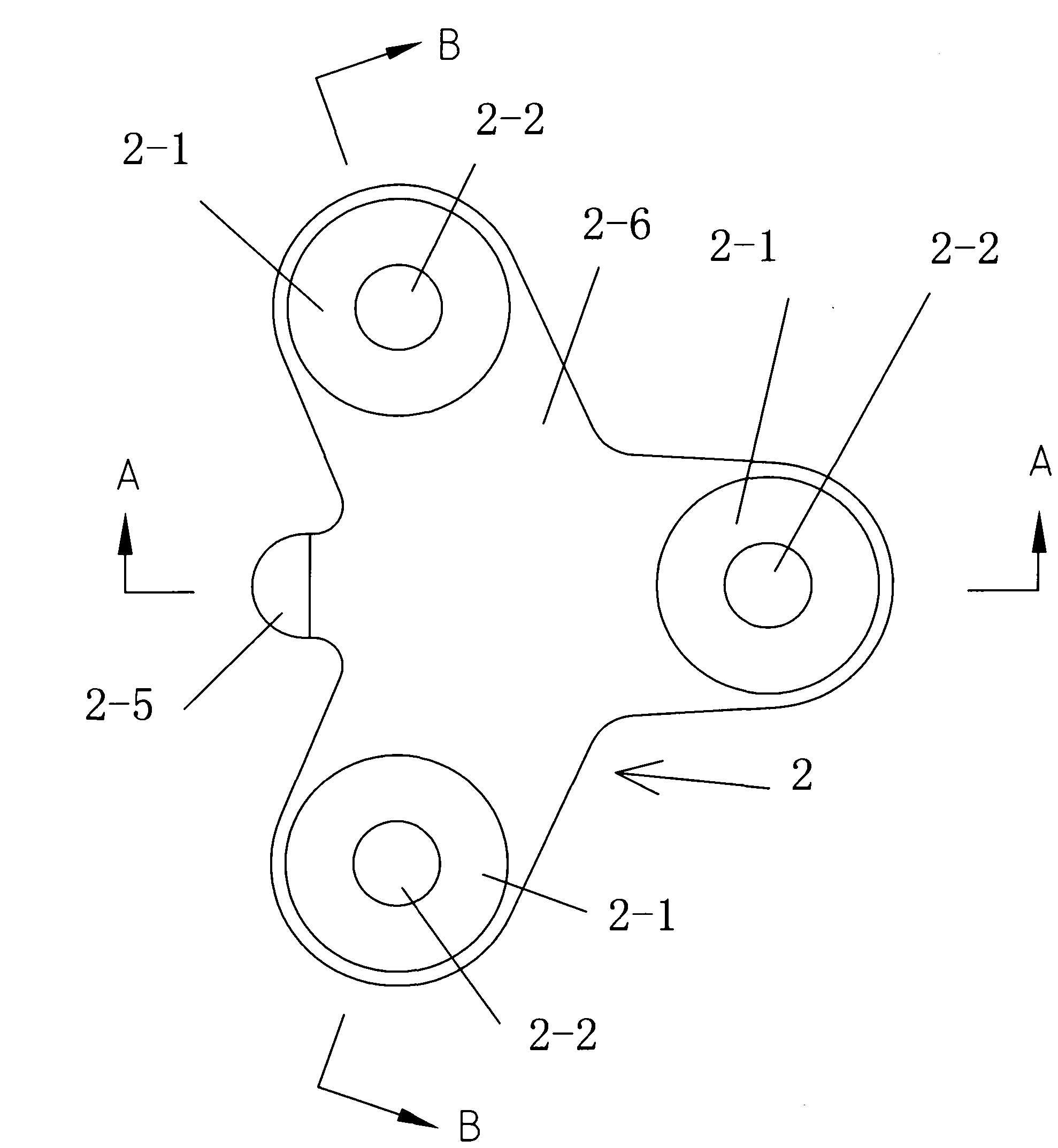

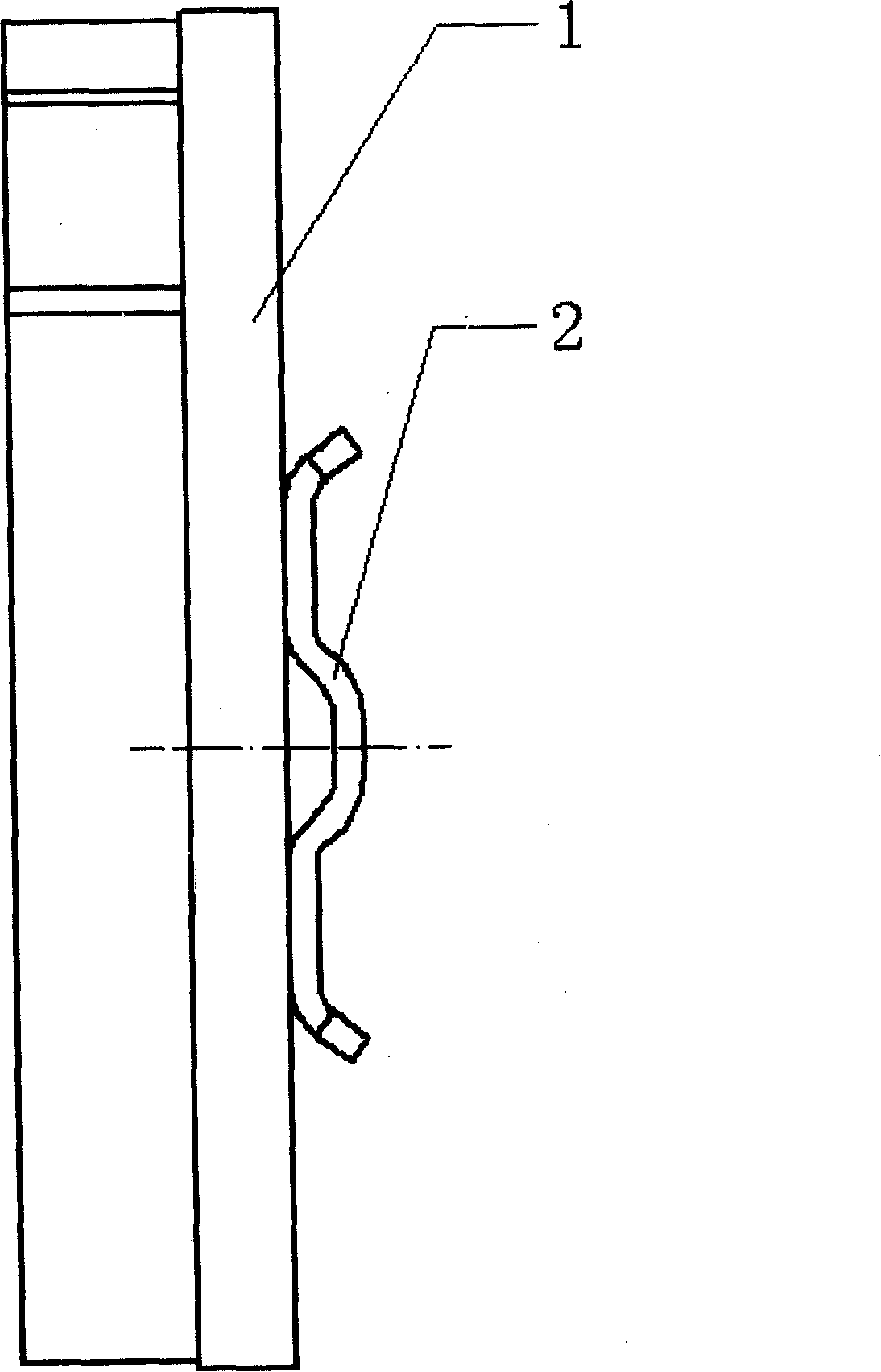

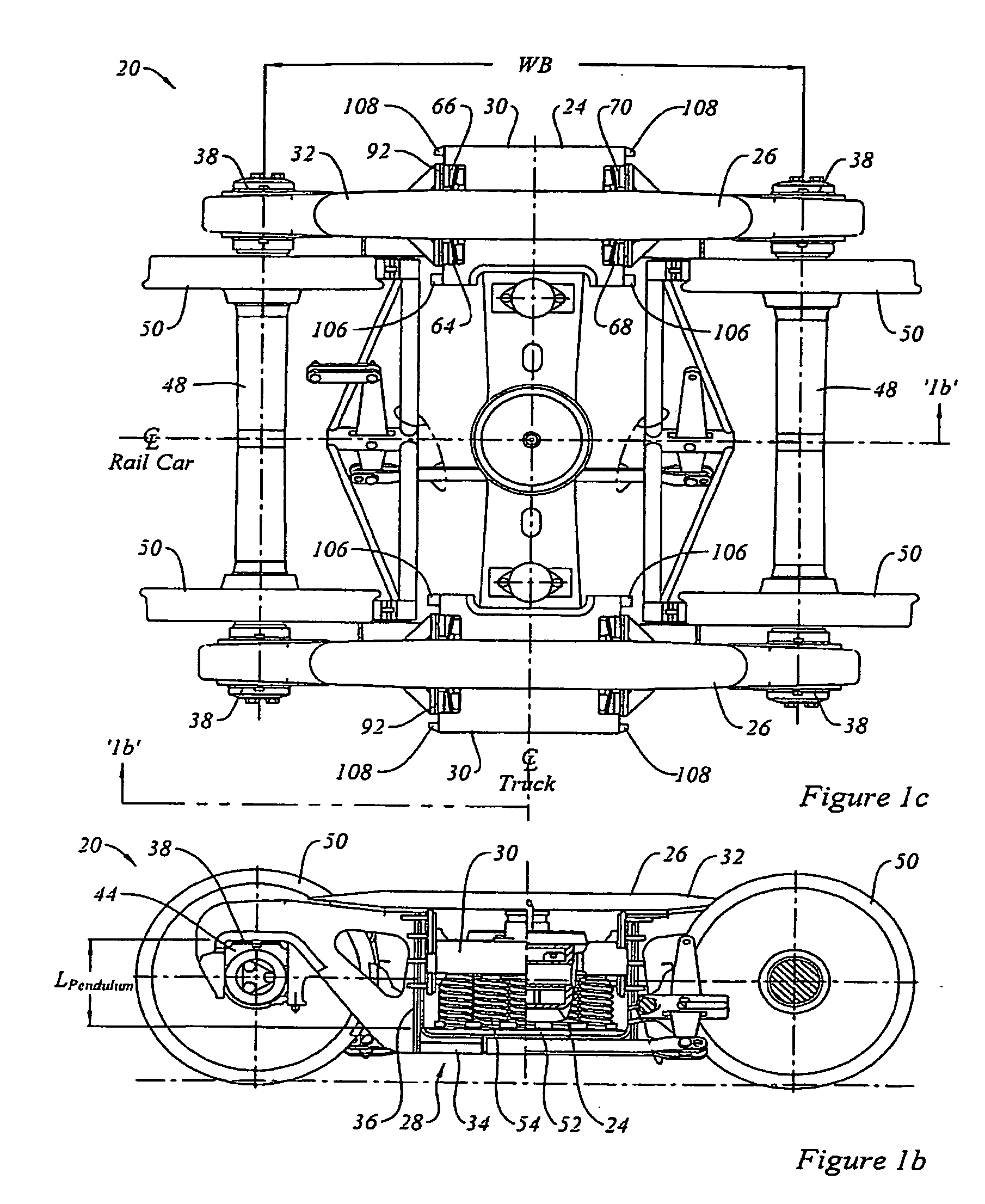

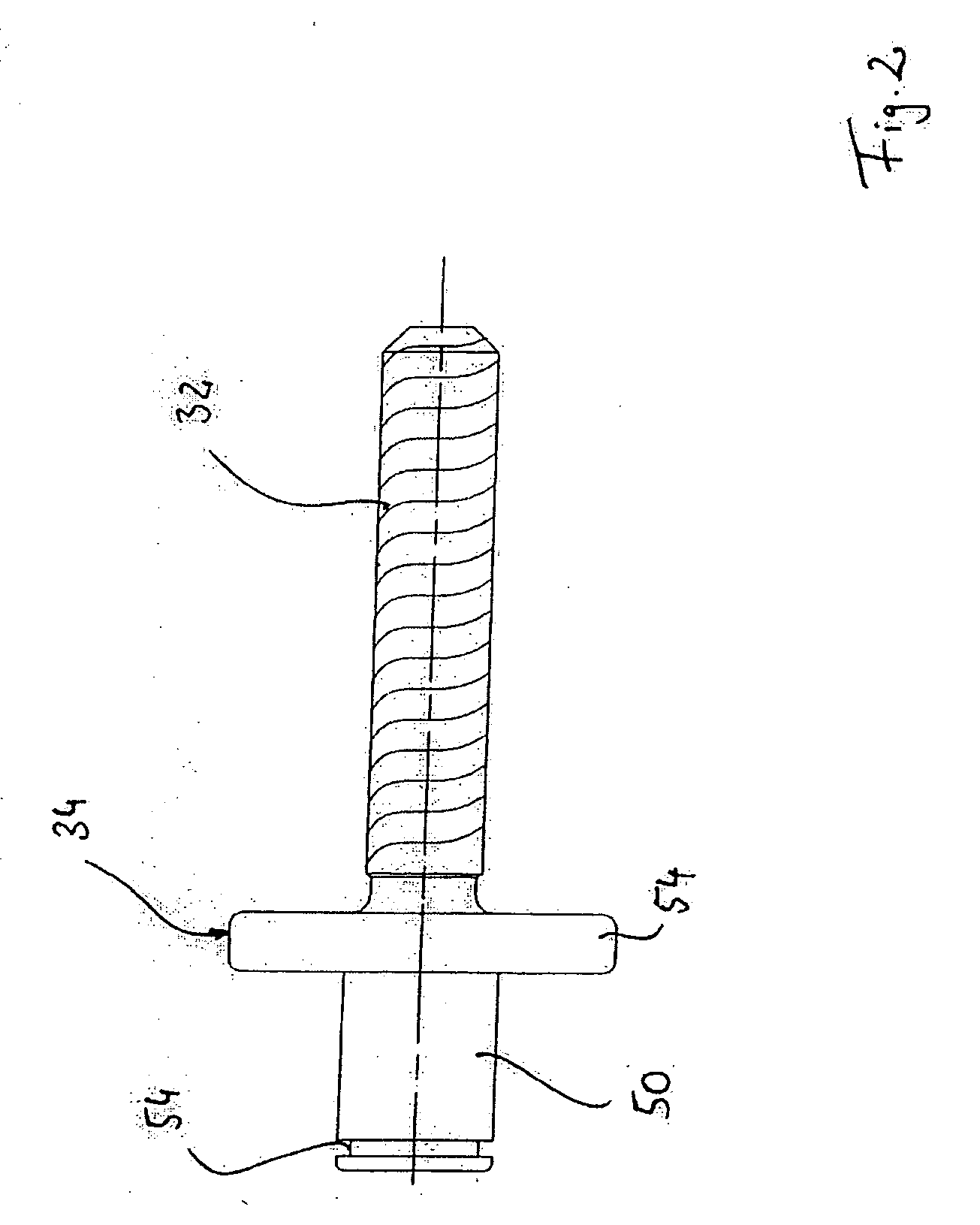

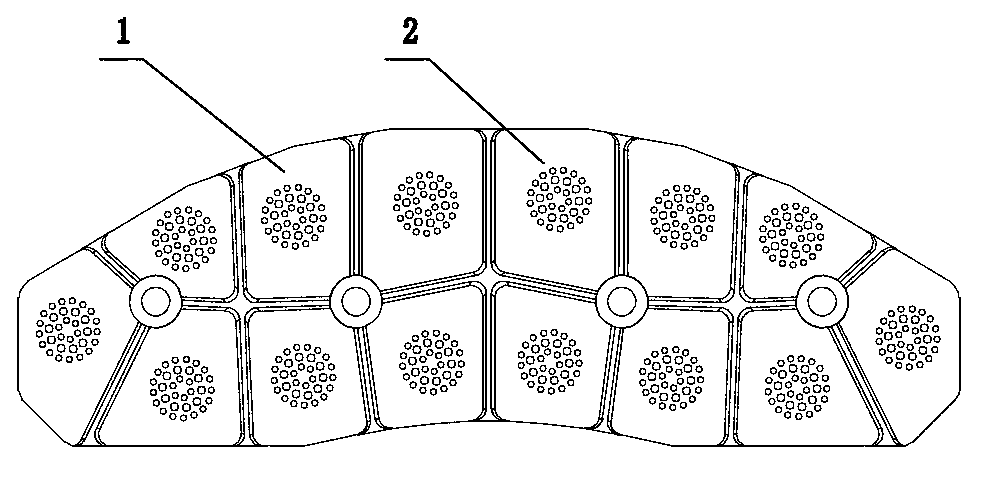

Train brake lining with adjuster

The invention discloses a train brake lining with an adjuster, comprising an installation plate, an adjuster, friction blocks and a spring retainer ring, wherein the adjuster comprise an installation lug boss and an adjuster positioning convex pin, a tail connection shaft for the friction blocks passes through a through hole on the adjuster and a friction block installation hole on the installation plate, and the end part of the tail connection shaft is elastically connected with the installation plate through the spring retainer ring; in the friction blocks, first friction blocks are hexagon bodies, second friction bodies are pentagon bodies, one face of five side faces of each second friction block, facing the outside of the installation plate, is a cambered face, the second friction blocks are arranged along the periphery of the front side of the installation plate and surround the first friction blocks in the middle, or the second friction blocks are distributed along the inner and outer arc edges of the front side of the installation plate in two rows and sandwich the first friction blocks. The train brake lining with the adjuster can improve an effective friction area during working and effectively decrease the occurrence of the phenomena of cracking, falling, defecting, performance declination and the like of the friction blocks, and has strong heat dissipation capability.

Owner:CRRC CHANGZHOU TECH MARK IND CO LTD +1

Rail road car truck and bolster therefor

ActiveUS7631603B2Precise positioningAvoid misdirectionUnderframesPassenger carriagesEngineeringRotational degrees of freedom

Owner:NATIONAL STEEL CAR

Vitreous carbon composite and method of making and using same

A reinforced vitreous carbon composite suitable for use in the formation of wear-resistant assemblies, such as joint prosthetic devices, bearings, current collectors, sealing components, brake linings, electrical motor brushes, and other tribological products. The reinforced composite is formed by impregnating a metal reinforcement structure with a furfuryl alcohol resin, and polymerizing the resin while thermally managing the polymerization process, to produce a poly(furfuryl) alcohol continuous phase that is isotropic, homogeneous and essentially completely void-free, e.g., in a bulk composite form having dimensions greater than 25 millimeters in each of the x, y and z directions thereof.

Owner:CARBON CERAMICS CO LLC

Rail road car truck and fittings therefor

A rail road freight car truck has a truck bolster and a pair of side frames, the truck bolster being mounted transversely relative to the side frames. The mounting interface between the ends of the axles and the sideframe pedestals allows lateral rocking motion of the sideframes in the manner of a swing motion truck. The lateral swinging motion is combined with a longitudinal self steering capability. The self steering capability may be obtained by use of a longitudinally oriented rocker that may tend to permit resistance to deflection that is proportional to the weight carried across the interface. The truck may have auxiliary centering elements mounted in the pedestal seats, and those auxiliary centering elements may be made of resilient elastomeric material. The truck may also have friction dampers that have a disinclination to stick-slip behaviour. The friction dampers may be provided with brake linings, or similar features, on the face engaging the sideframe columns, on the slope face, or both. The friction dampers may operate to yield upward and downward friction forces that are not overly unequal. The friction dampers may be mounted in a four-cornered arrangement at each end of the truck bolster. The spring groups may include sub-groups of springs of different heights.

Owner:NATIONAL STEEL CAR

Charcoal/pottery brake lining manufacturing method for industrial brake

InactiveCN101493126AReduce processing intensityIncrease coefficient of frictionFriction liningGas phaseLow density

The invention discloses a method for manufacturing carbon / ceramic braking linings used in an industrial brake, which comprises the following steps: carbon fiber performs are prepared by a needle method; low-density C / C composite material is prepared by a chemical gas permeation method after the carbon fiber performs are treated in high temperature; the C / C composite material is treated in high temperature, machined and then the molten silicon infiltration is carried out on the C / C material in a high temperature vacuum furnace; Sic is formed by the Si and C reaction to prepare C / C-SiC baking material; and finally after the C / C-SiC baking material is machined, the C / C-SiC baking material is riveted with the steel backing by a rivet in a cold way to prepare the needed C / C-SiC baking material used in an industrial brake. The carbon / ceramic braking lining manufactured by the method has higher mechanical property and excellent frictional wear performance and is used in the industrial brake.

Owner:CENT SOUTH UNIV

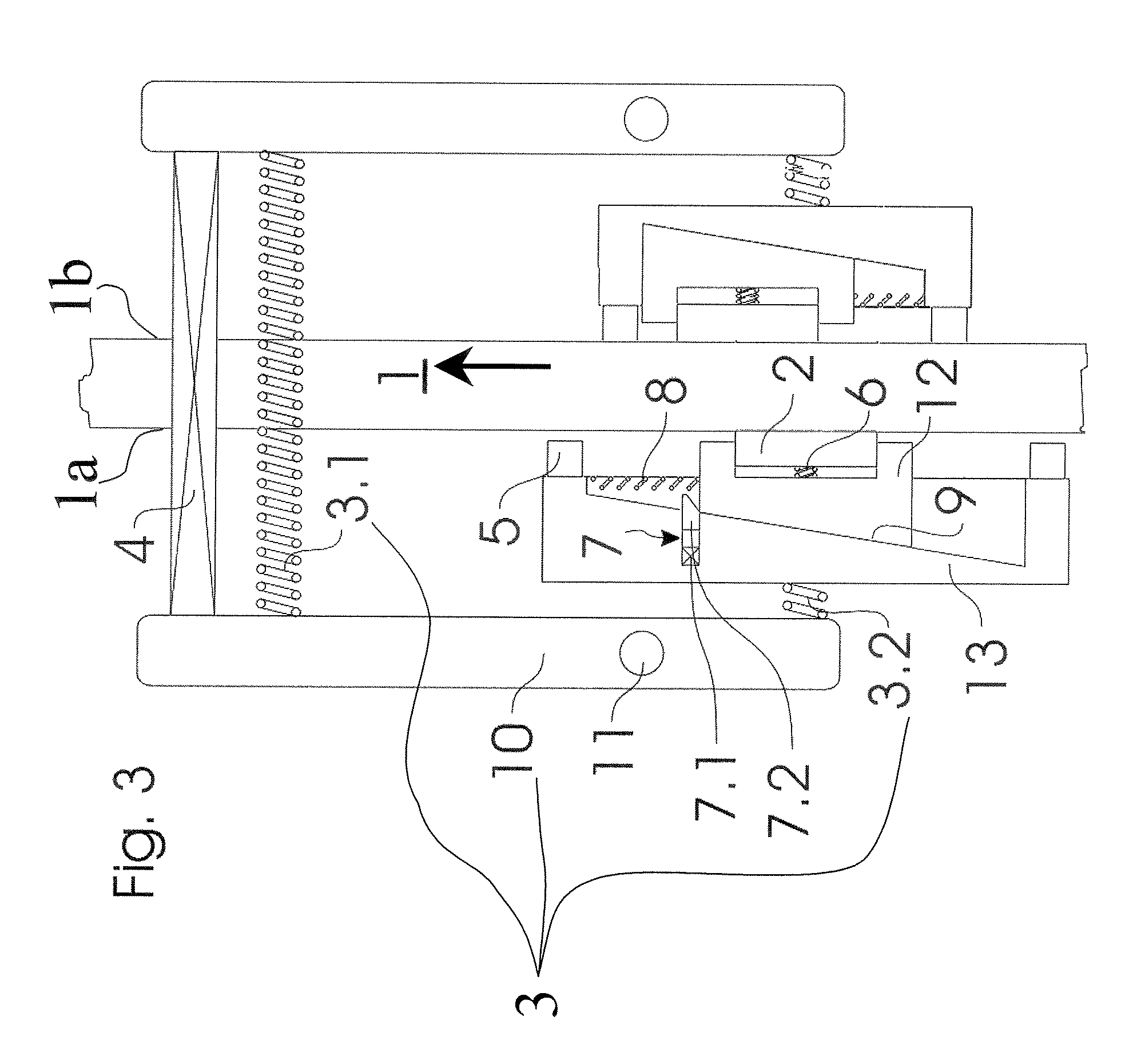

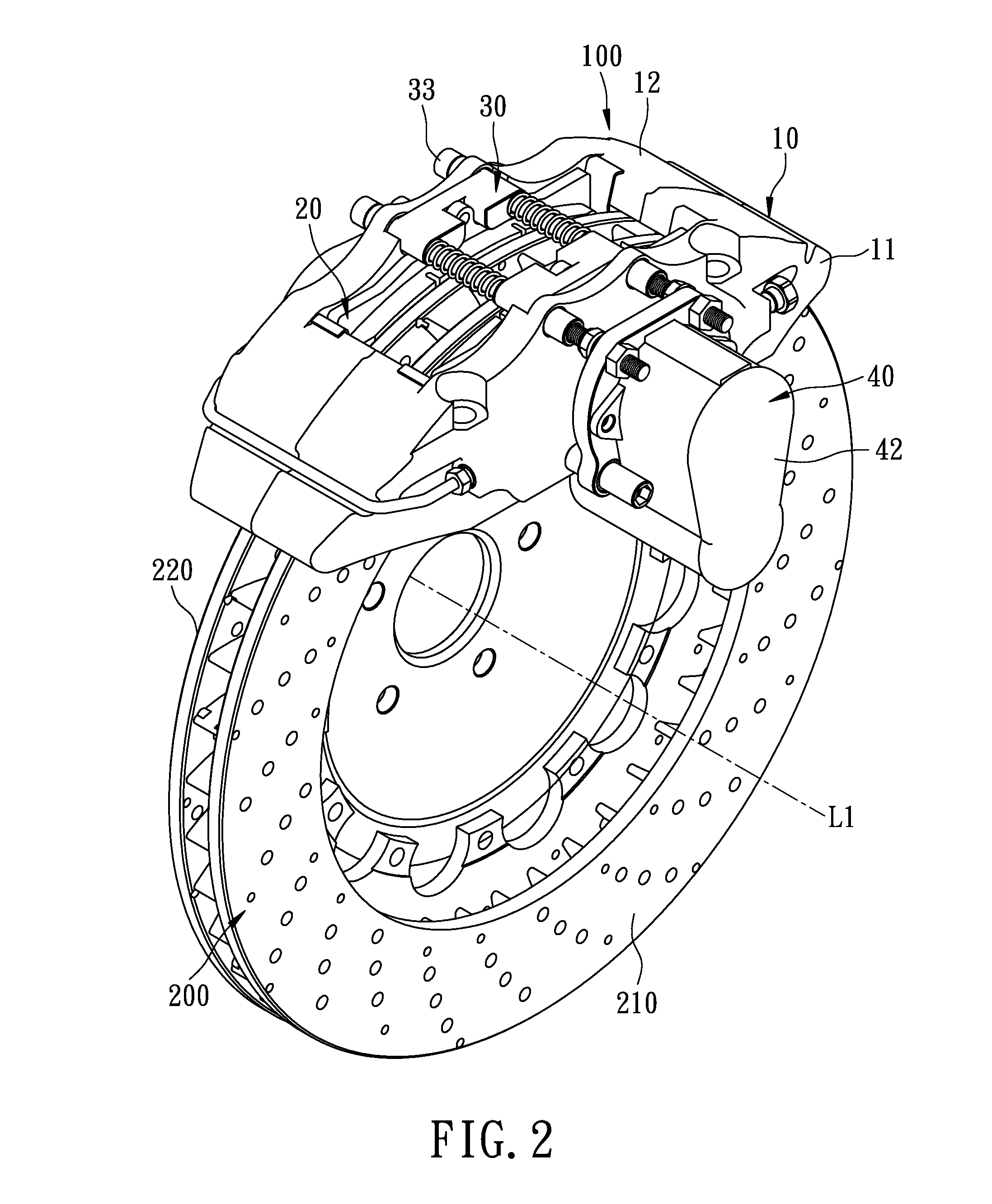

Disk Brake

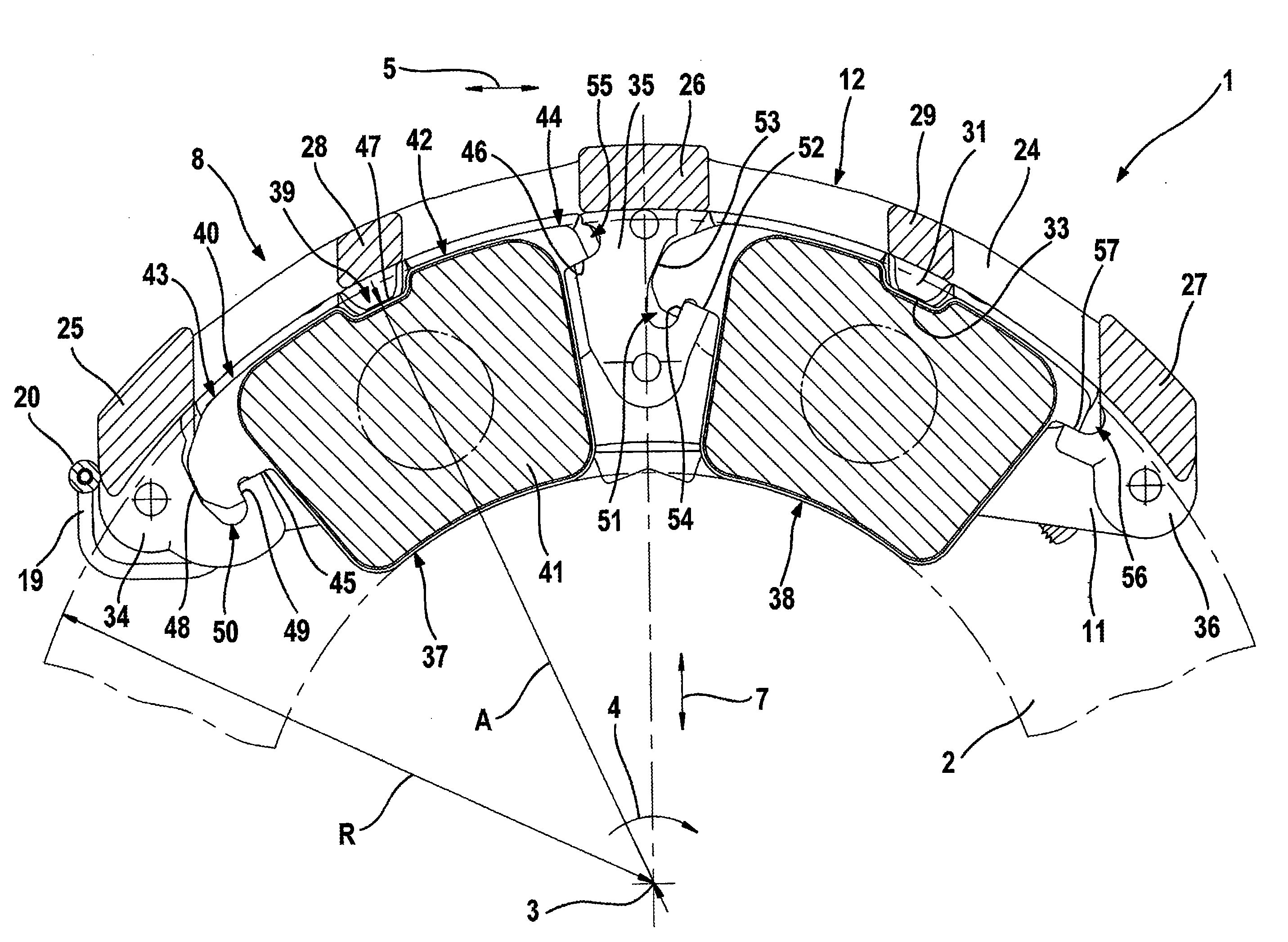

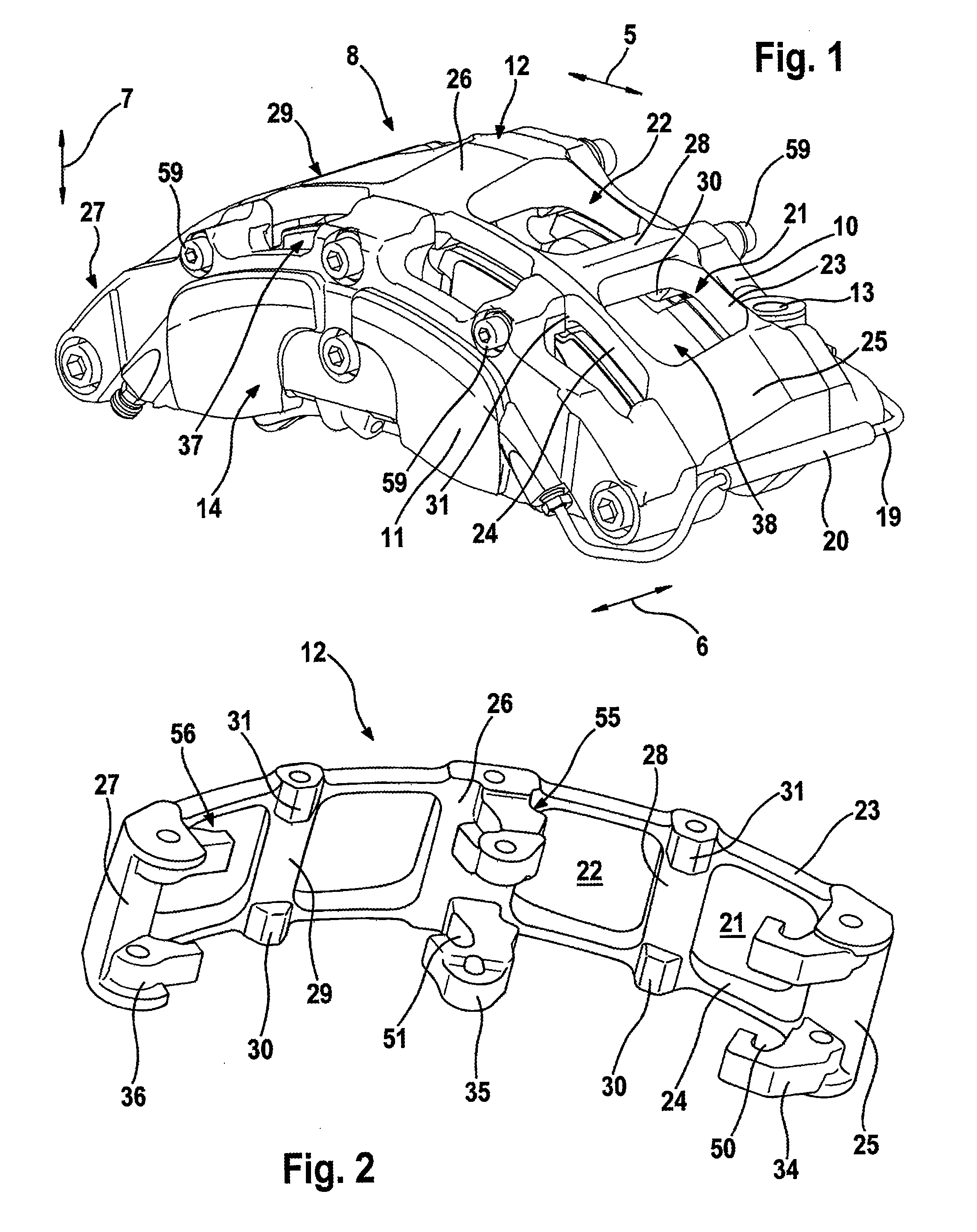

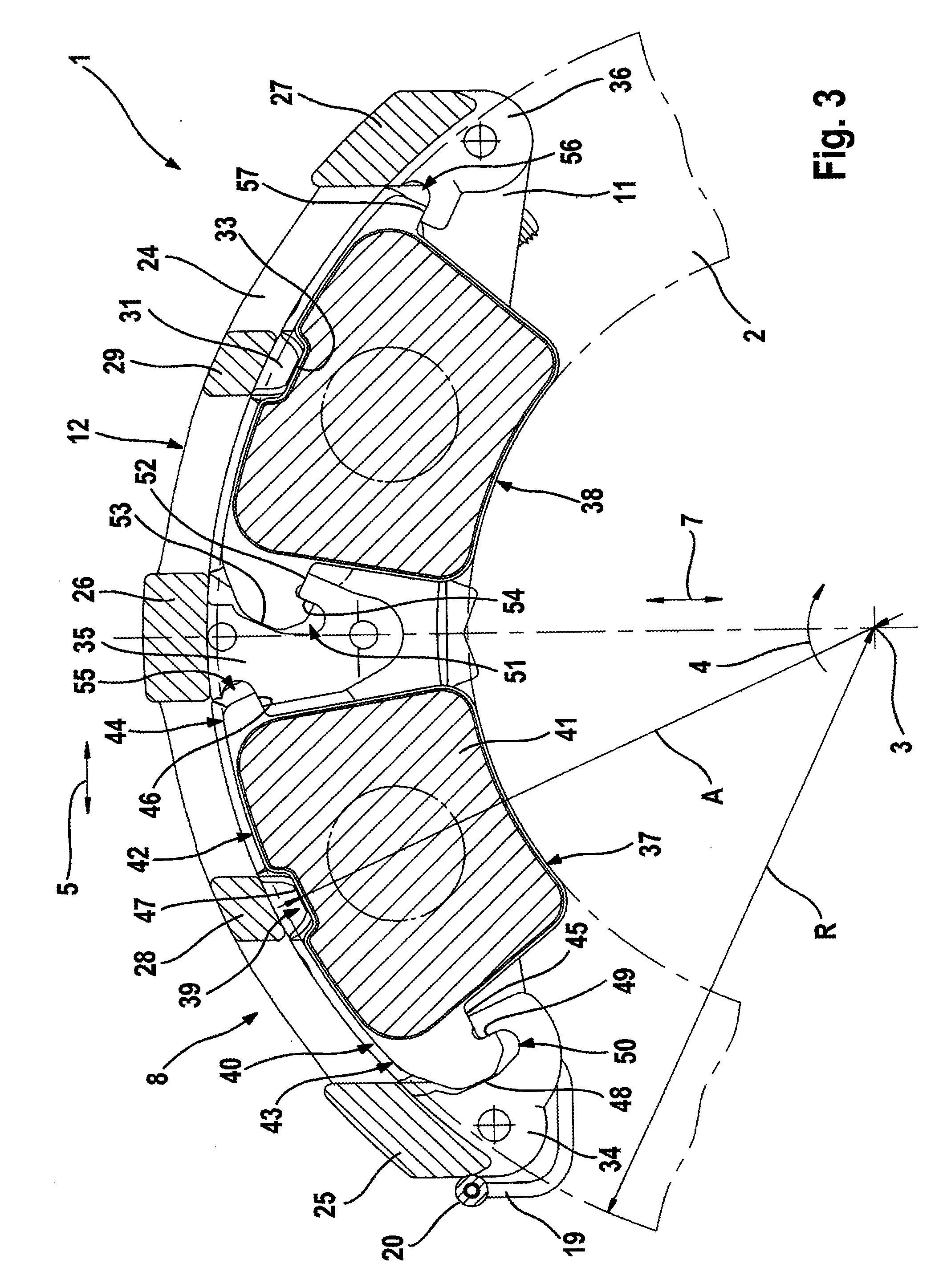

InactiveUS20090236187A1Good componentReduce thermal stressAxially engaging brakesBraking membersCalipersBrake lining

A disk brake having a brake caliper, which engages axially in a U shape around a rotatable brake disk is provided. The disk brake includes a caliper bridge, two caliper limbs and at least one actuating device. At least one brake lining is mounted in an axially movable fashion in the brake caliper. The caliper bridge has, in the peripheral direction, at least three substantially axially extending supports, wherein two of the supports are embodied as a main support and one support is embodied as a central support. These supports connect the two caliper limbs and in the process form two windows and axially project beyond the brake disk. The central support projects both beyond the brake disk and beyond the brake lining in the axial direction.

Owner:CONTINENTAL TEVES AG & CO OHG

Disk type brake lining of cars and its preparing method

InactiveCN1431408AStable coefficient of frictionModerate thermal conductivityFriction liningFiberBrake lining

The percentage of each component weight for a vehicle disk brake gasket is: carbon fiber 0-16; steel fiber 5-25; organic fiber 0.5-8, mineral fiber 3-20; friction performance adjuster 37-60; COPNA resin 4-16; phenolic resin 0-8. Its preparation applies a dry technology to weigh, mix and stir matters in certain proportion then to be dried and moulded by chill-pressure, heat-pressure and after heatprocess mechanical process, polish, spraying paint, and packaging to become product with the advantage of no noise, no vibration, no scuffing the opposite side when braking.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Rail road car truck

A rail road freight car truck has a truck bolster and a pair of side frames, the truck bolster being mounted transversely relative to the side frames. The mounting interface between the ends of the axles and the sideframe pedestals allows lateral rocking motion of the sideframes in the manner of a swing motion truck. The lateral swinging motion is combined with a longitudinal self steering capability. The self steering capability may be obtained by use of a longitudinally oriented rocker that may tend to permit resistance to self steering that is proportional to the weight carried across the interface. The trucks may have auxiliary centering elements mounted in the pedestal seats, and those auxiliary centering elements may be made of resilient elastomeric material. The truck may also have friction dampers that have a disinclination to stick-slip behaviour. The friction dampers may be provided with brake linings, or similar features, on the face engaging the sideframe columns, on the slope face, or both.

Owner:NATIONAL STEEL CAR

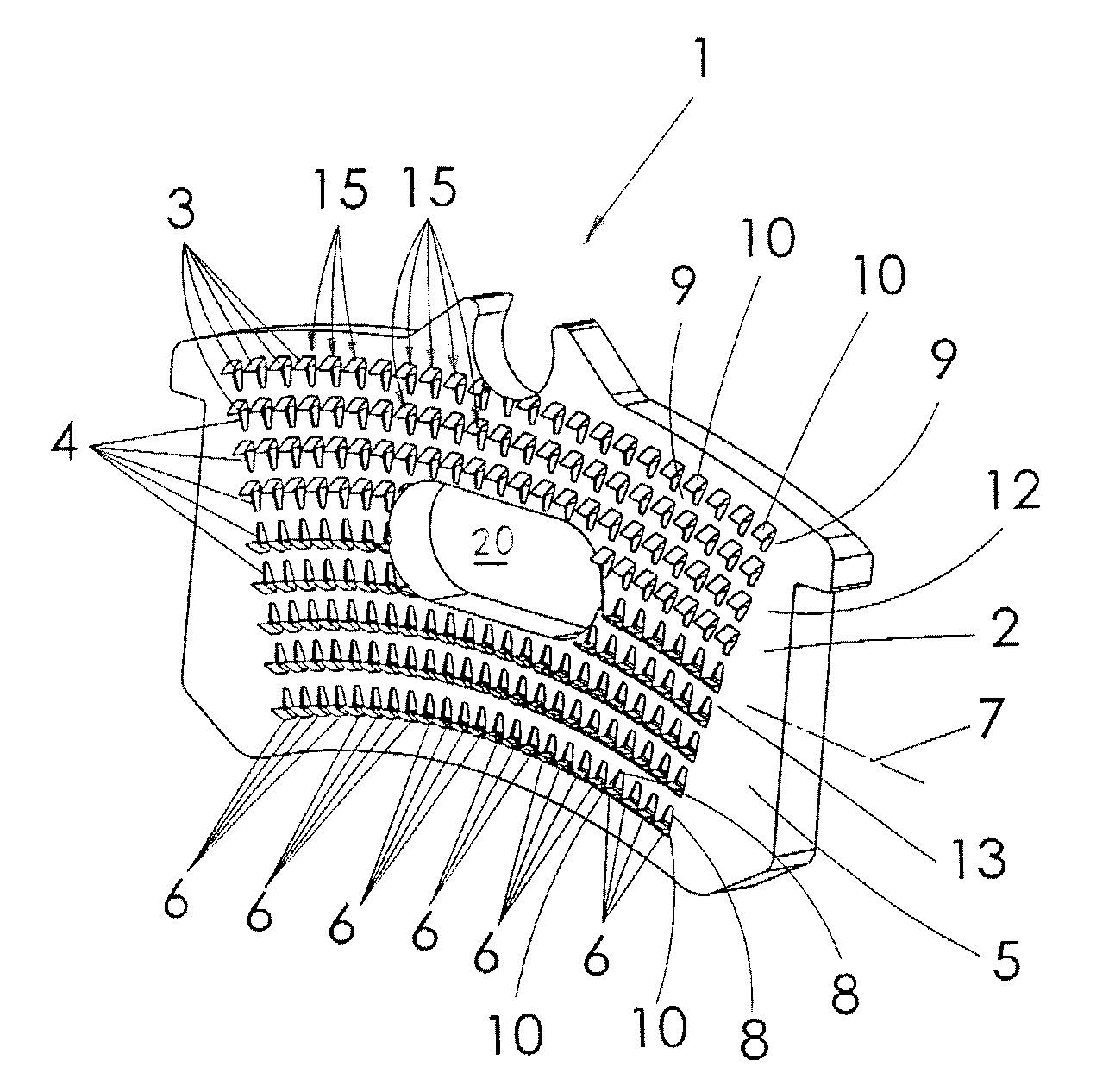

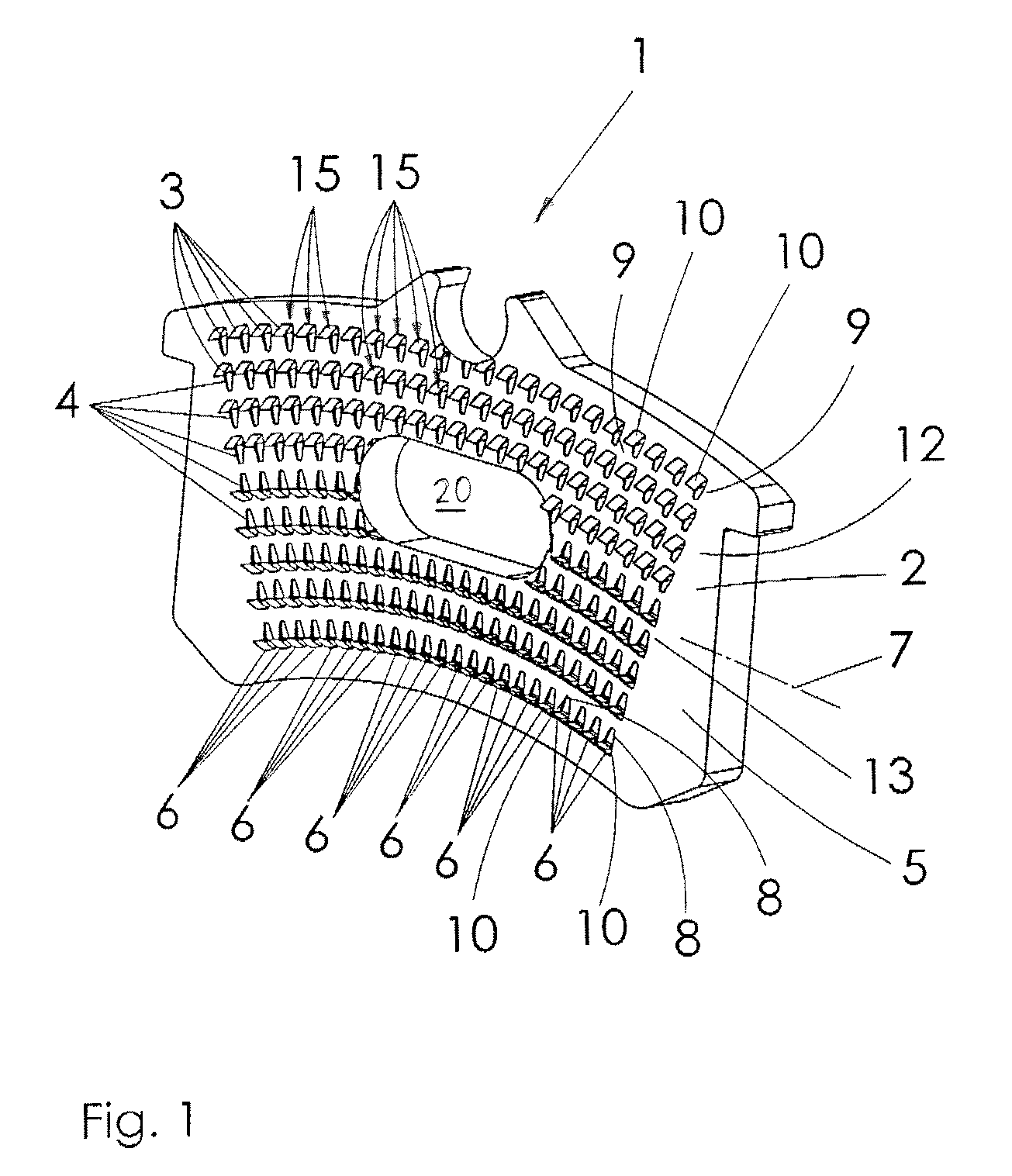

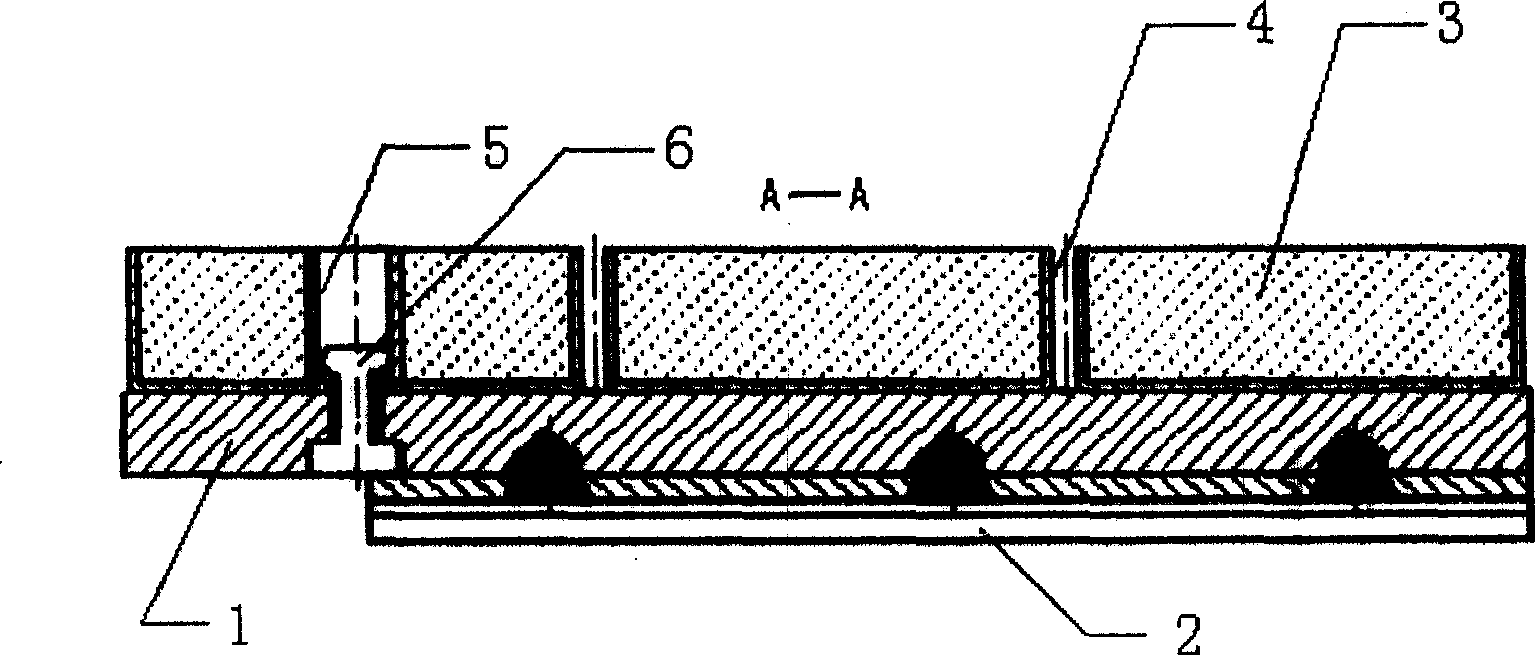

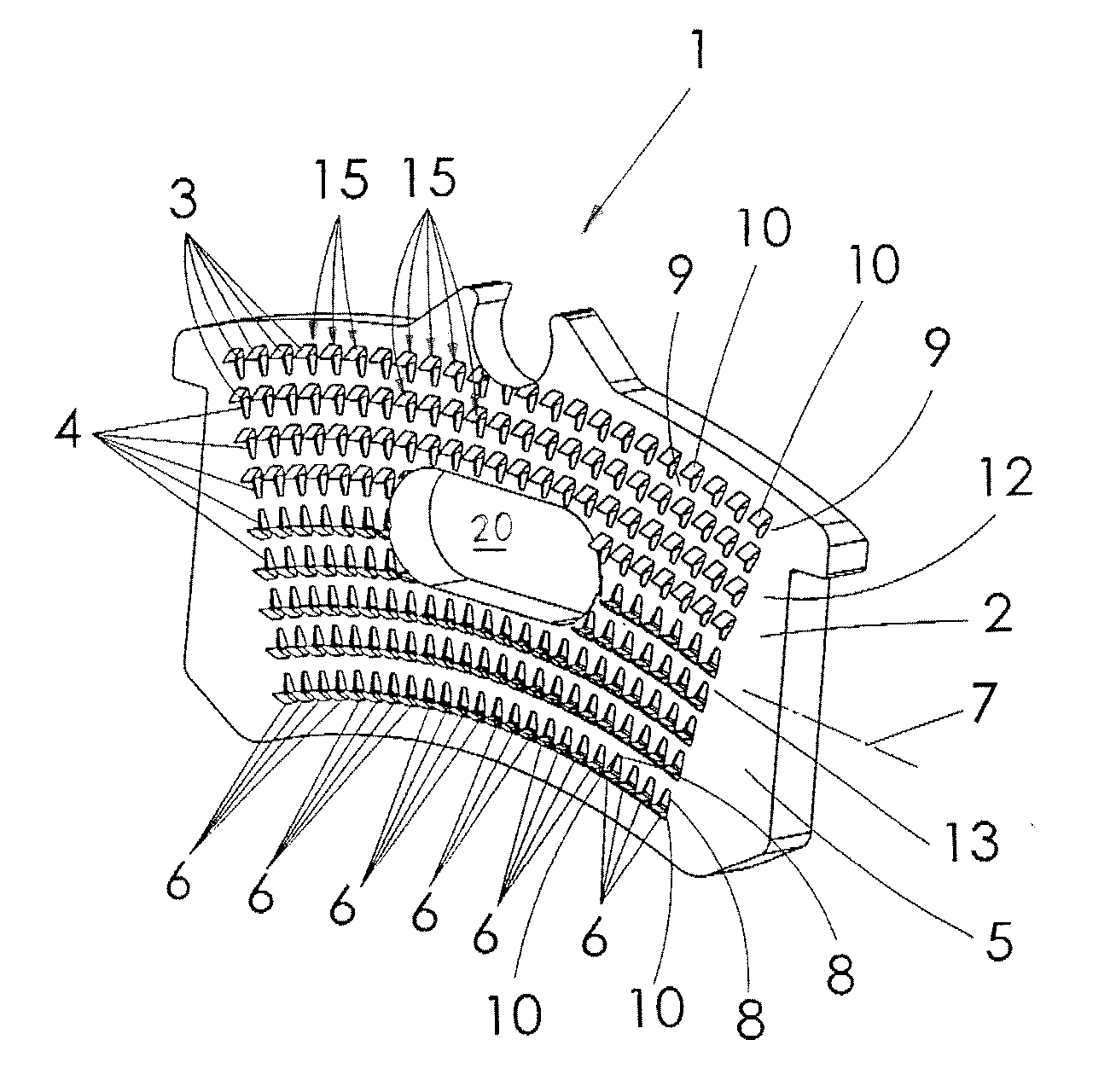

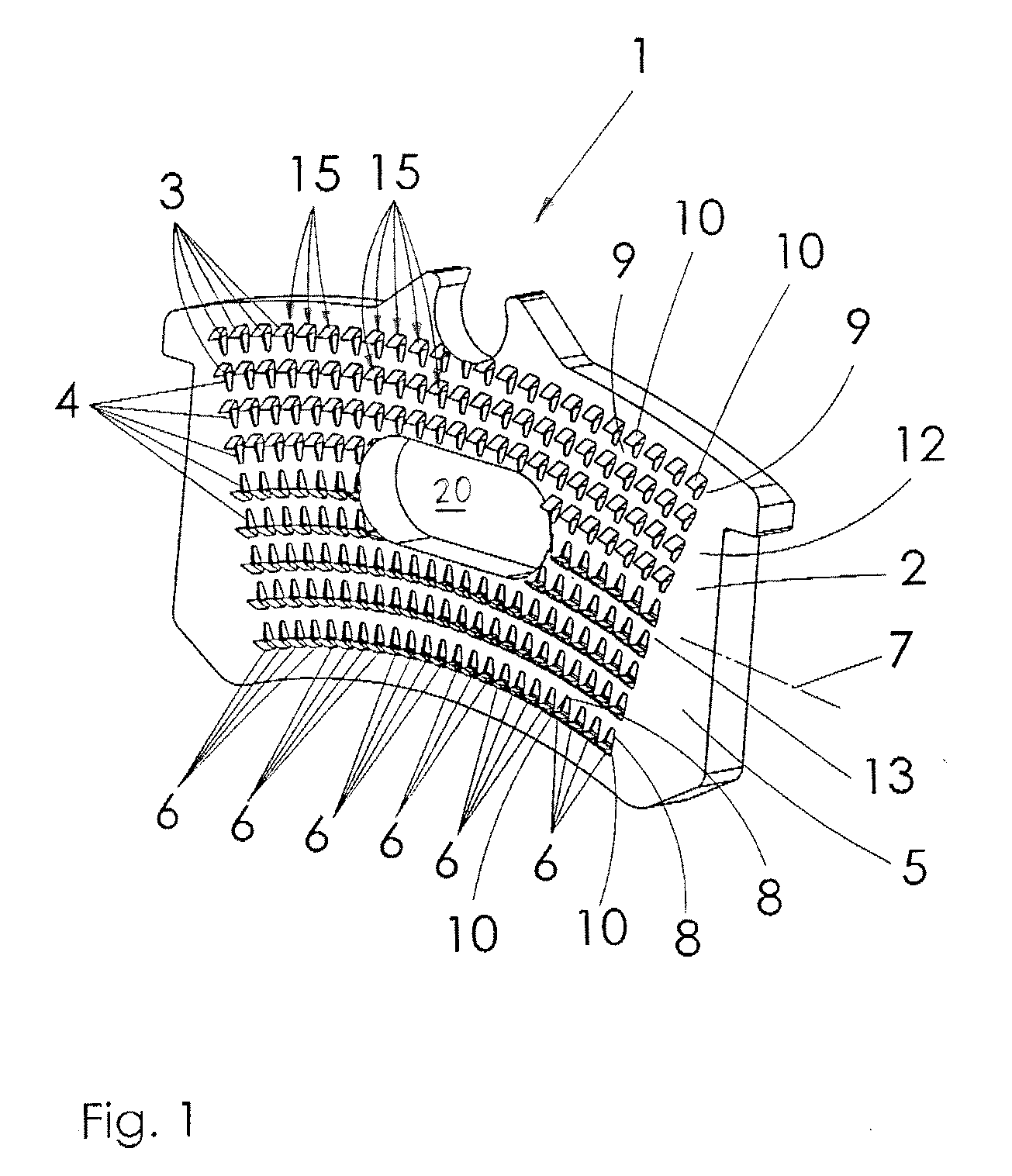

Brake plate

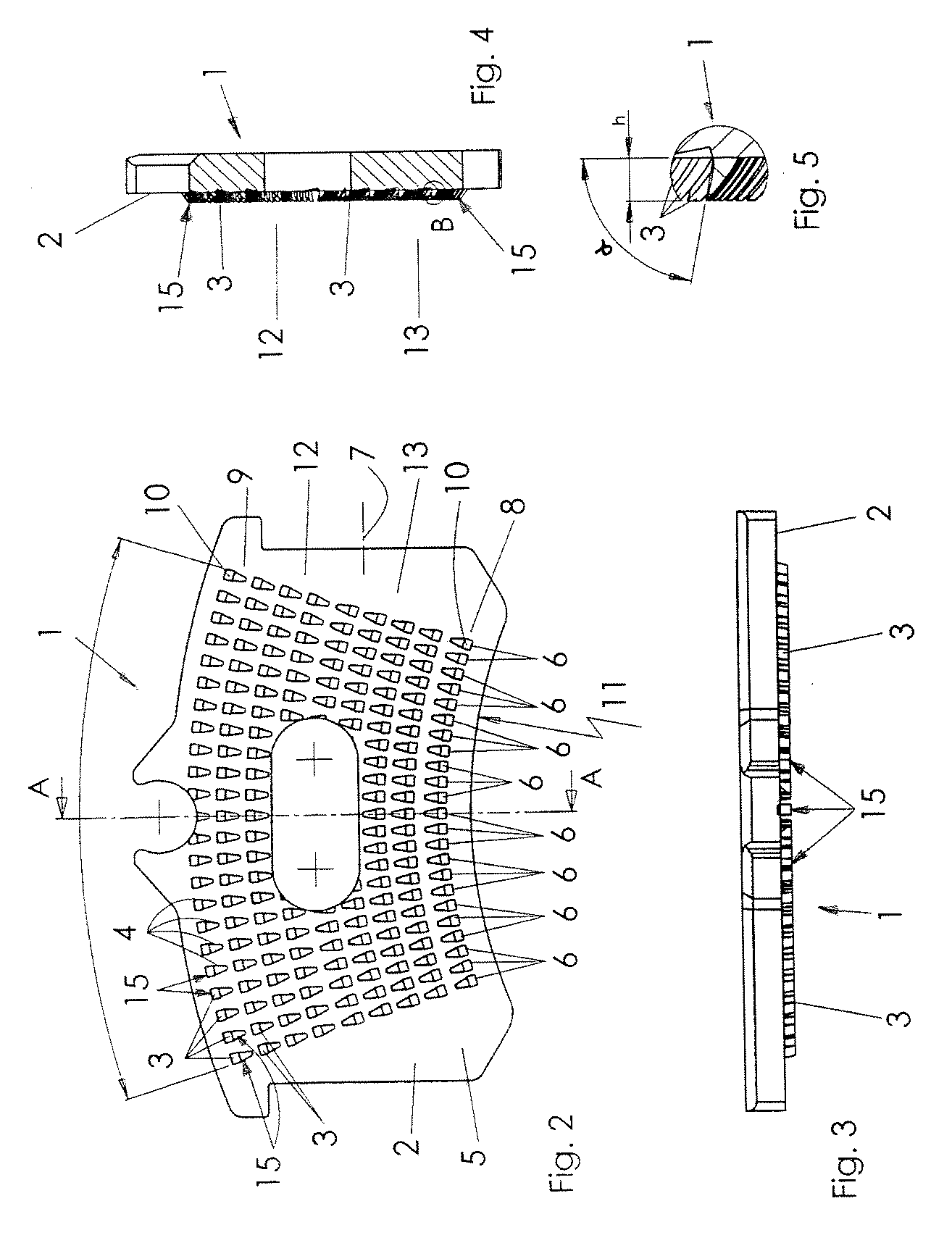

InactiveUS7686142B2Improve stressLarge braking forceMetal-working apparatusBraking membersEngineeringBrake lining

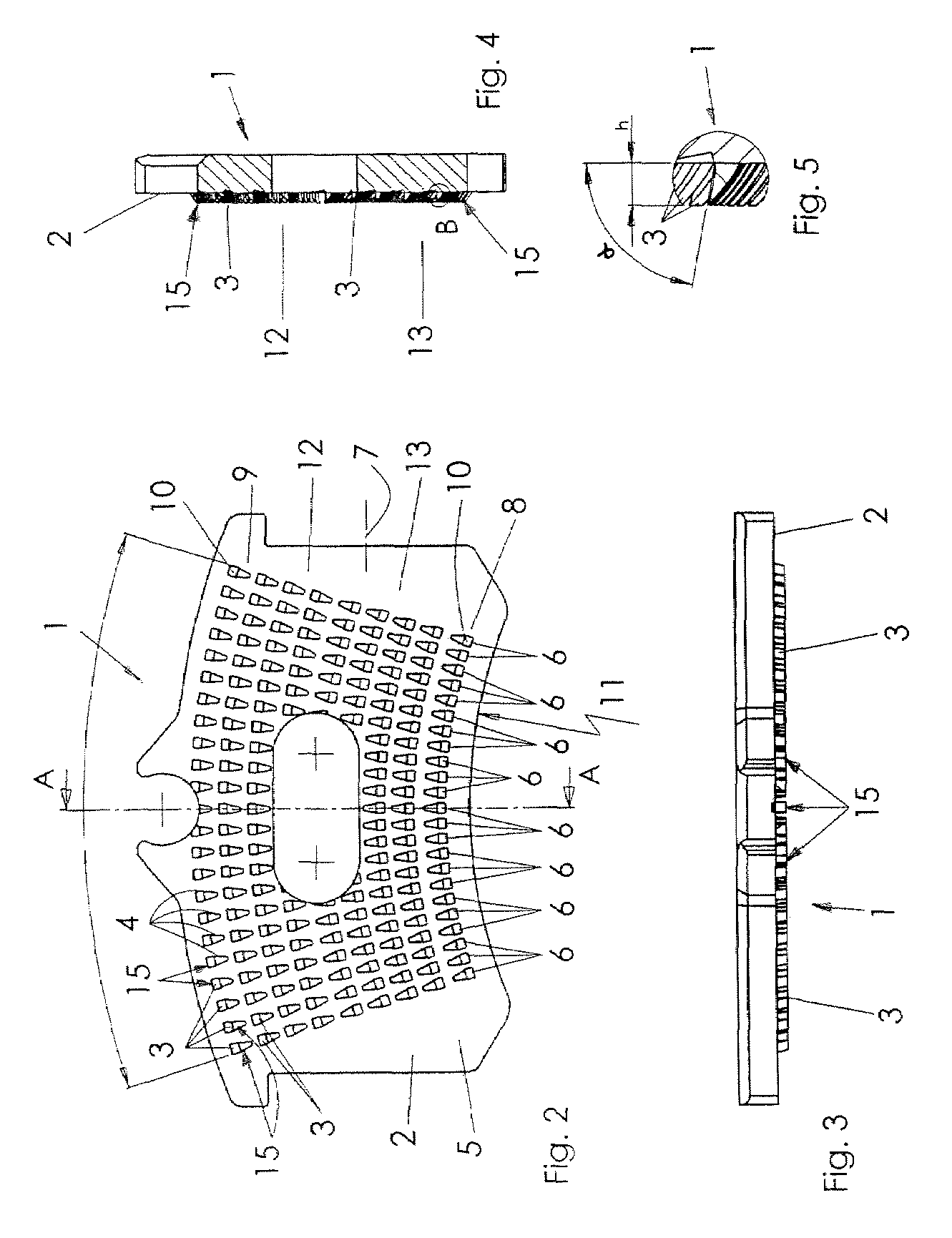

The invention relates to a brake lining carrier plate 1 to hold a friction lining, especially for installation into a vehicle brake system, with holding structures 15, 16 for the friction lining arranged in rows 6 on the lining side 2, whereby each holding structure 15, 16 has a protrusion 3 and a depression 4, whereby the protrusion 3 is made when the depression 4 is formed in the surface 5 through the displacement of material. Said protrusion 3 engages with the friction lining. The holding structures 15, 16 in the rows 6 are arranged in such a way that there is a protrusion 10 at the beginning 8 and at the end 9 of each row 6. In one embodiment, the rows 6 run essentially crosswise to the longitudinal axis 7 of the brake lining carrier plate 1.

Owner:AML LANXIDE EURO

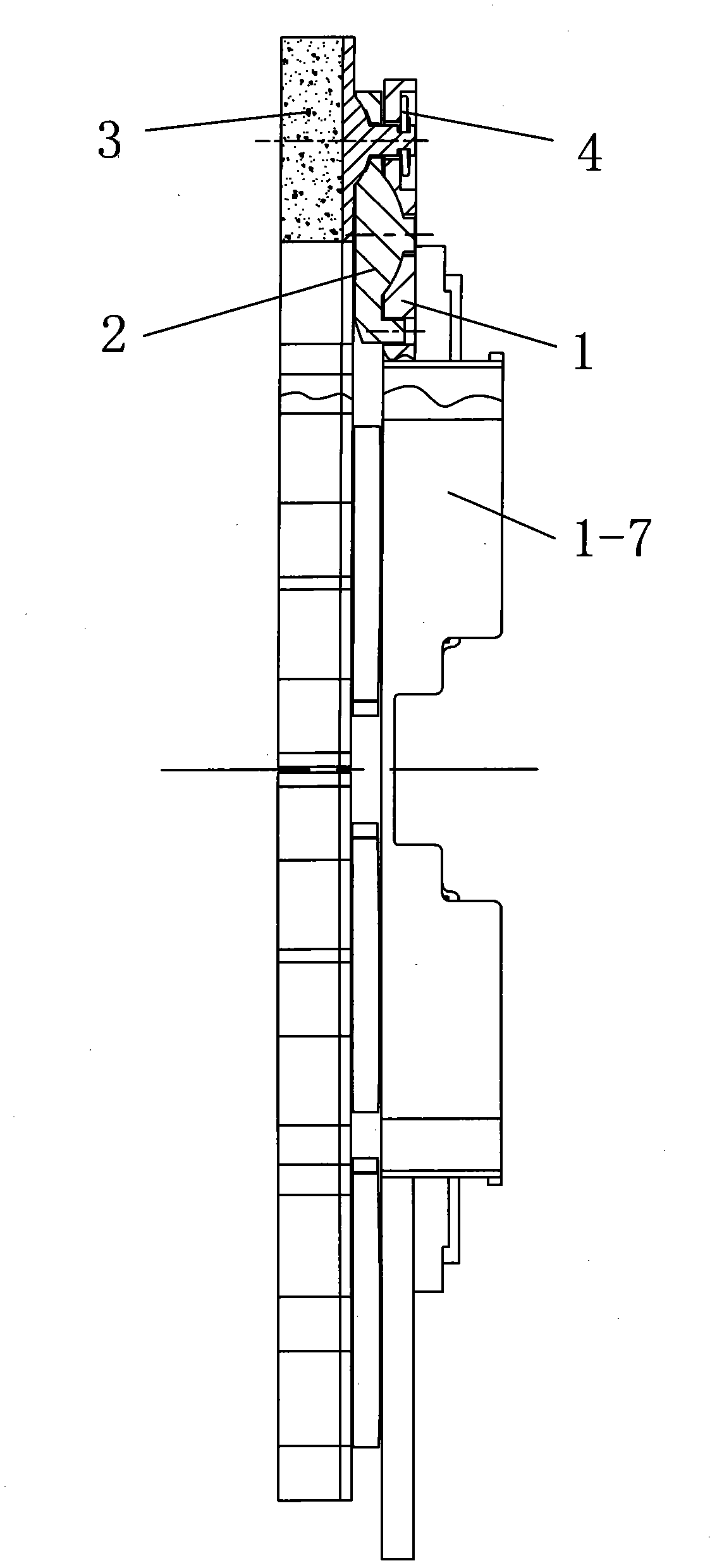

Vehicle brake, in particular caliper brake

InactiveCN101273213AEasy to removeGuaranteed forceBrake actuating mechanismsActuatorsSelf lockingCalipers

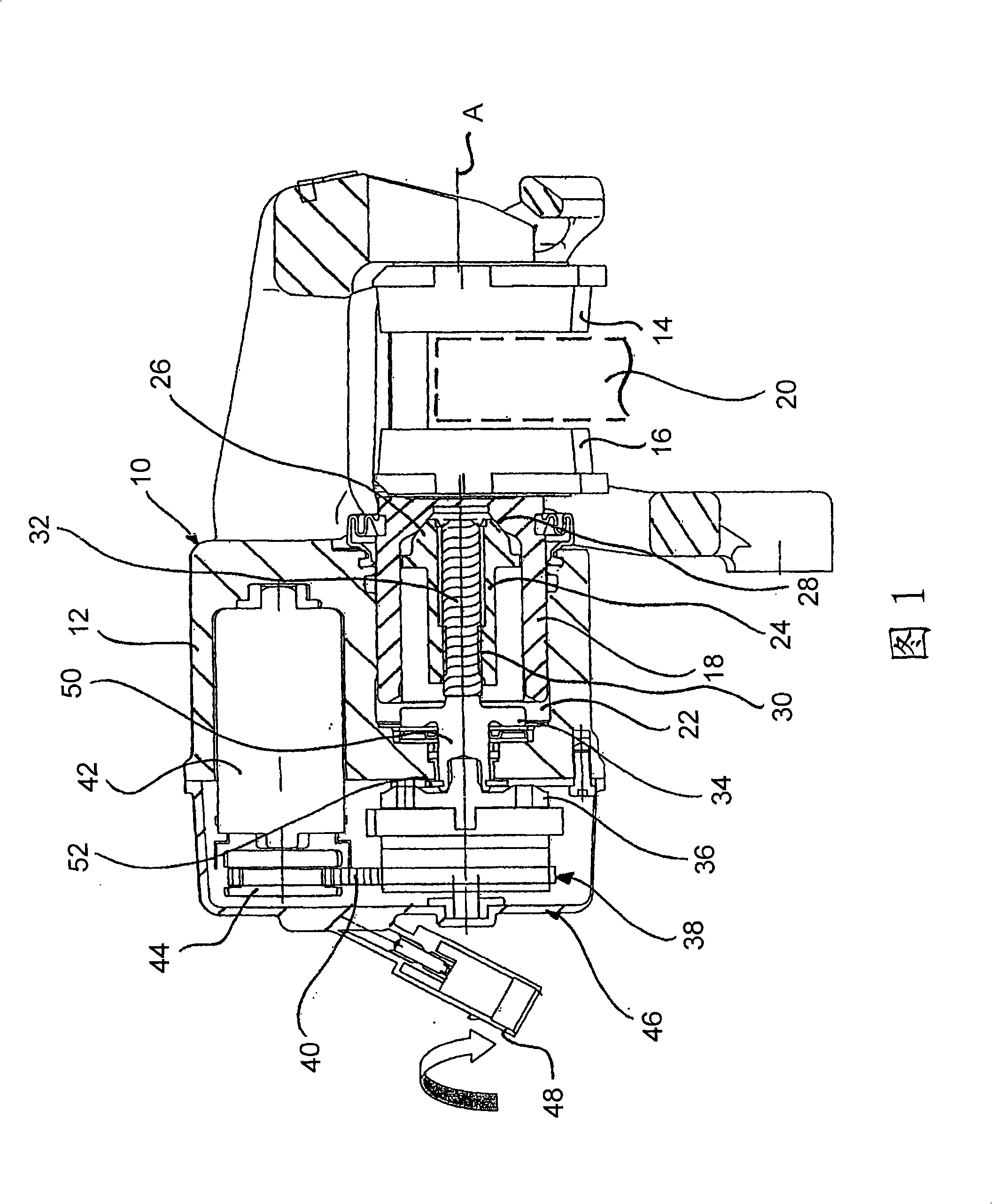

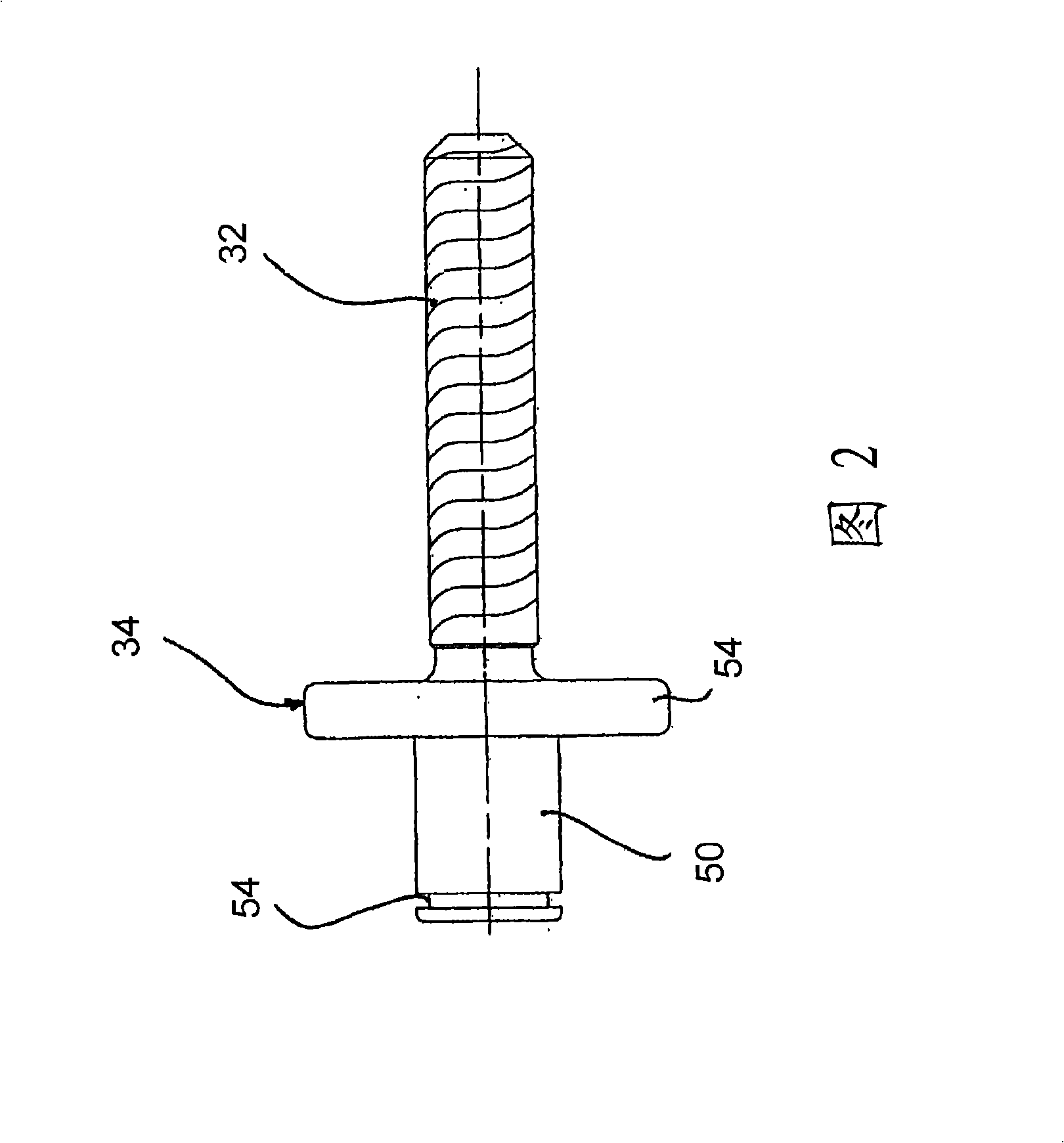

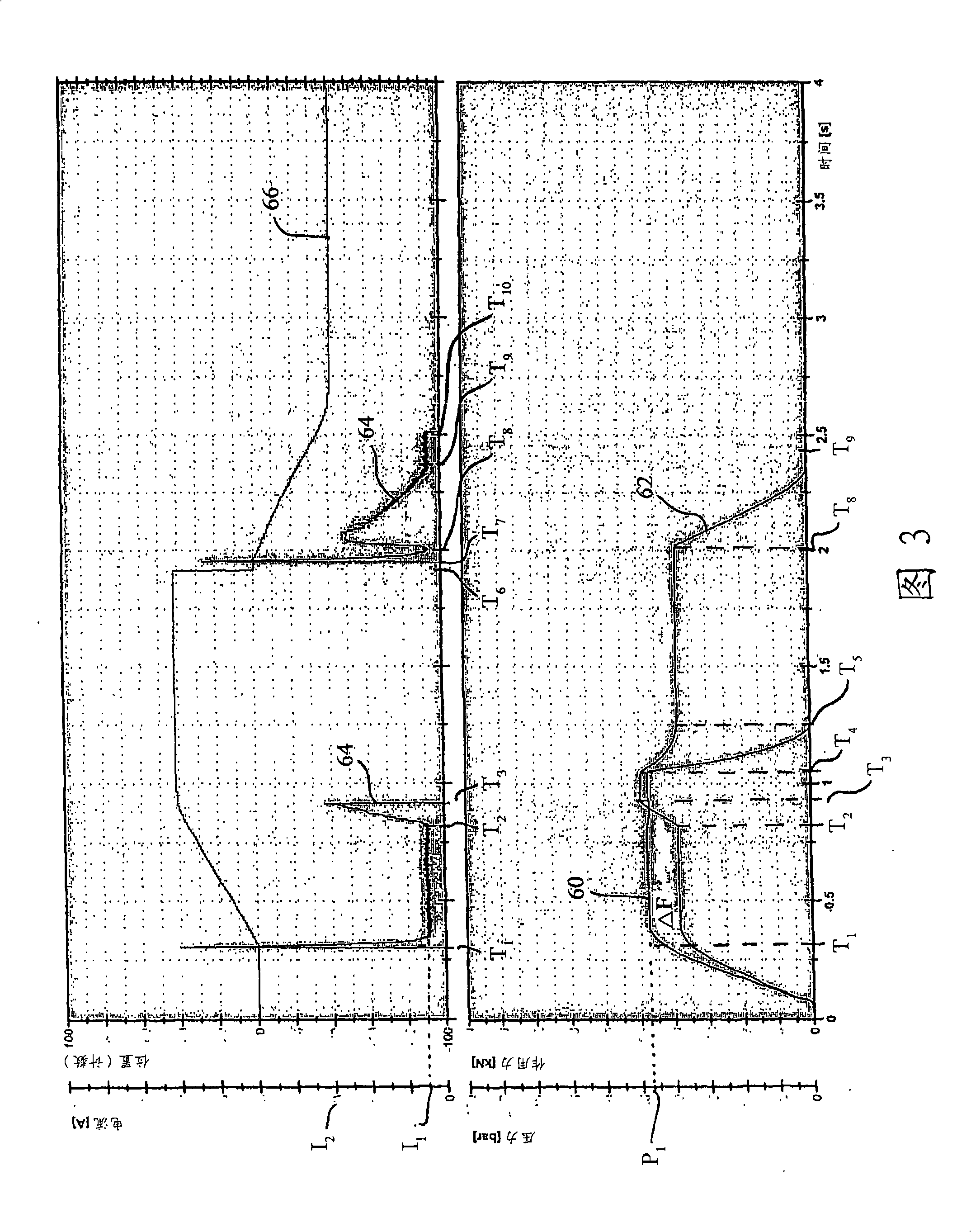

The invention relates to a vehicle brake (10), in particular caliper brake, having a housing (12), having a brake piston (18), which is held in the housing (12) and is linearly displaceable relative thereto, for displacing a brake lining (16), and having a mechanical actuator arrangement for displacing the brake piston (18), wherein the brake piston (18) in the housing (12) can be displaced by filling a hydraulic chamber (22) via a hydraulic brake circuit, and wherein the mechanical actuator arrangement has a threaded spindle (32) which is rotatably mounted in the housing (12) and can be driven in rotation, wherein the brake piston (18) can be displaced linearly relative to the housing (12) as a result of a rotary movement of the threaded spindle (32).; In said vehicle brake, it is provided according to the invention that the threaded spindle (32) is provided with a multiple-start self-locking thread with n flights, wherein the number n and the thread pitch are selected such that the thread is close to the self-locking limit.

Owner:LUCAS AUTOMOTIVE GMBH

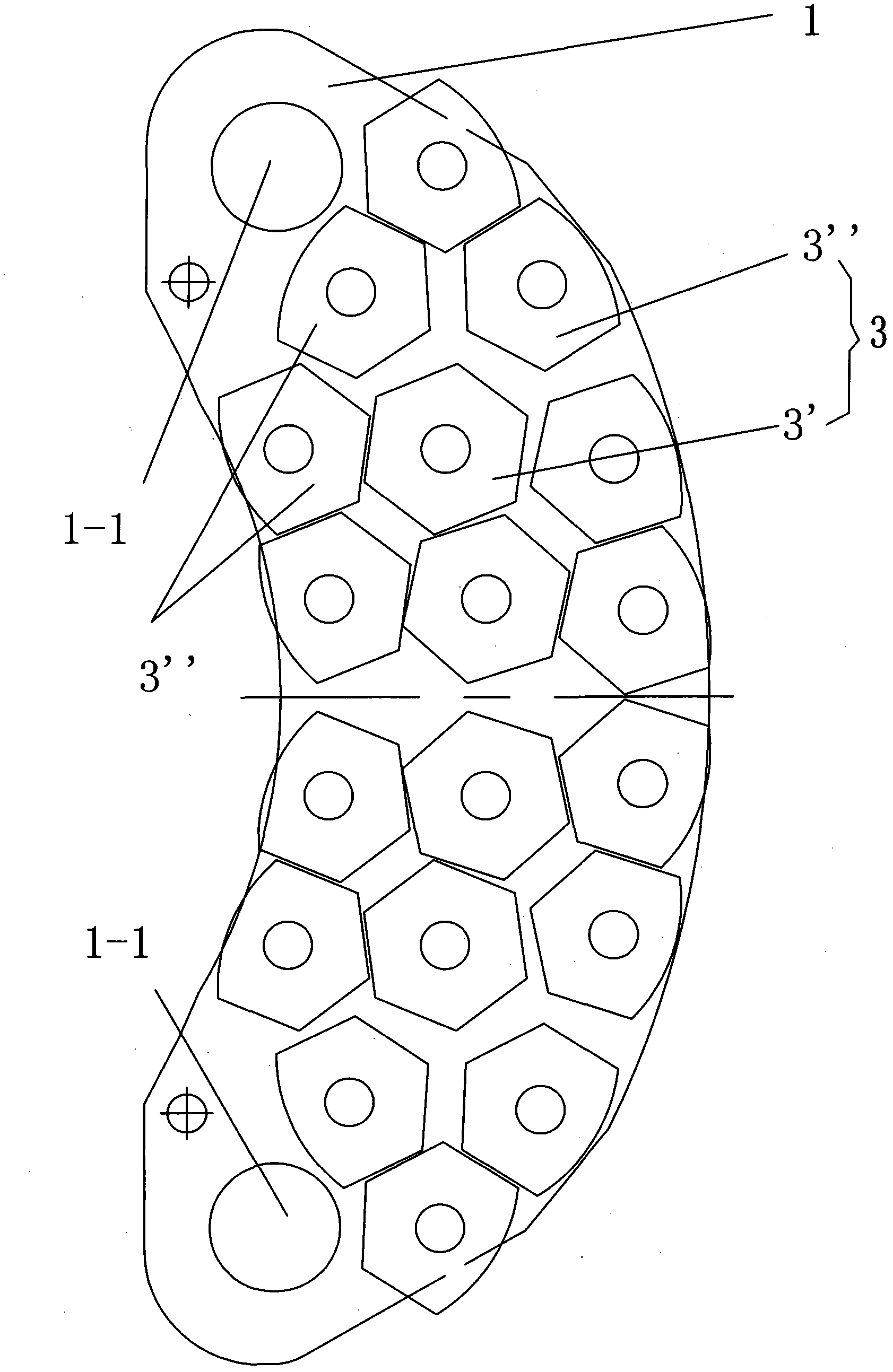

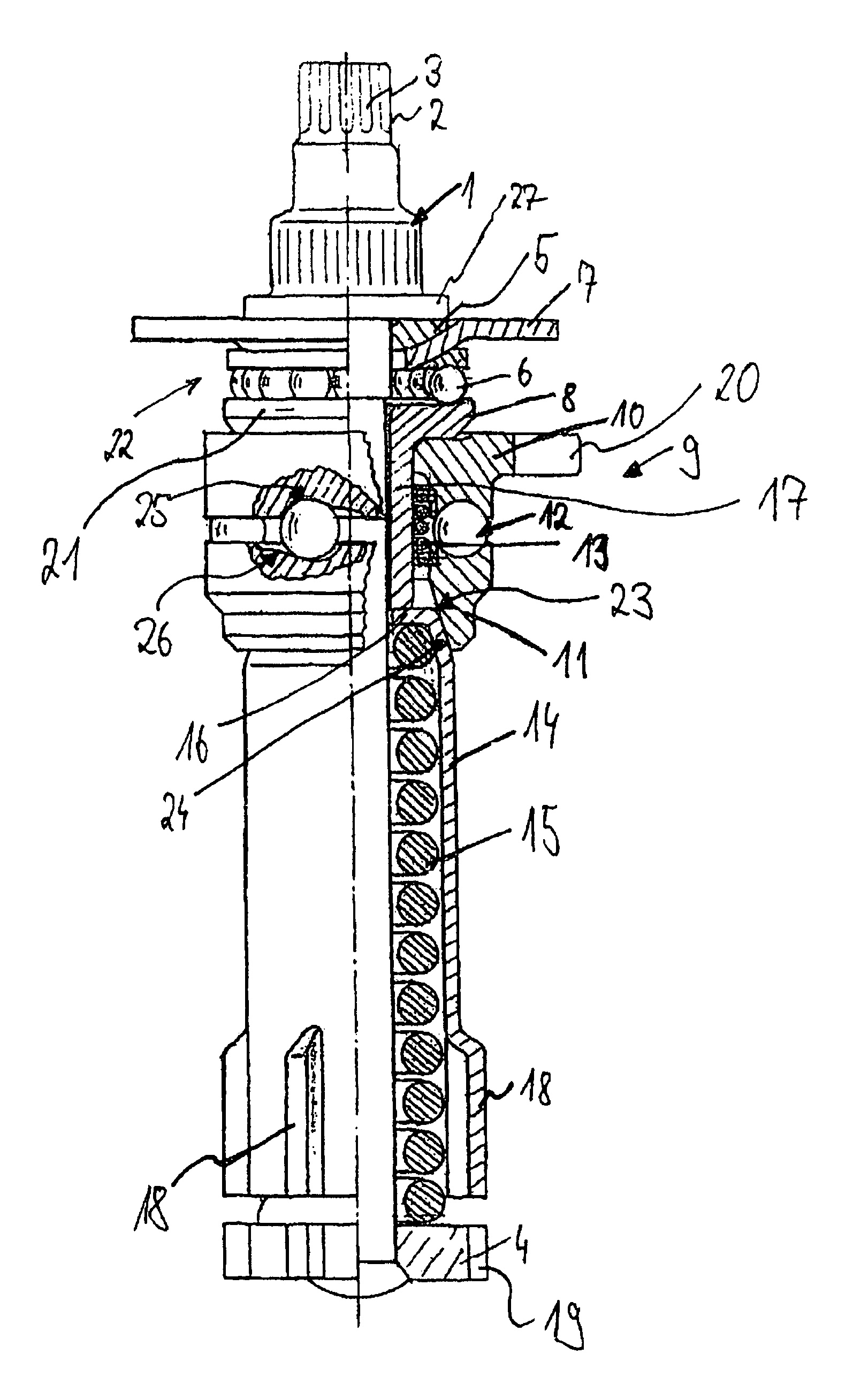

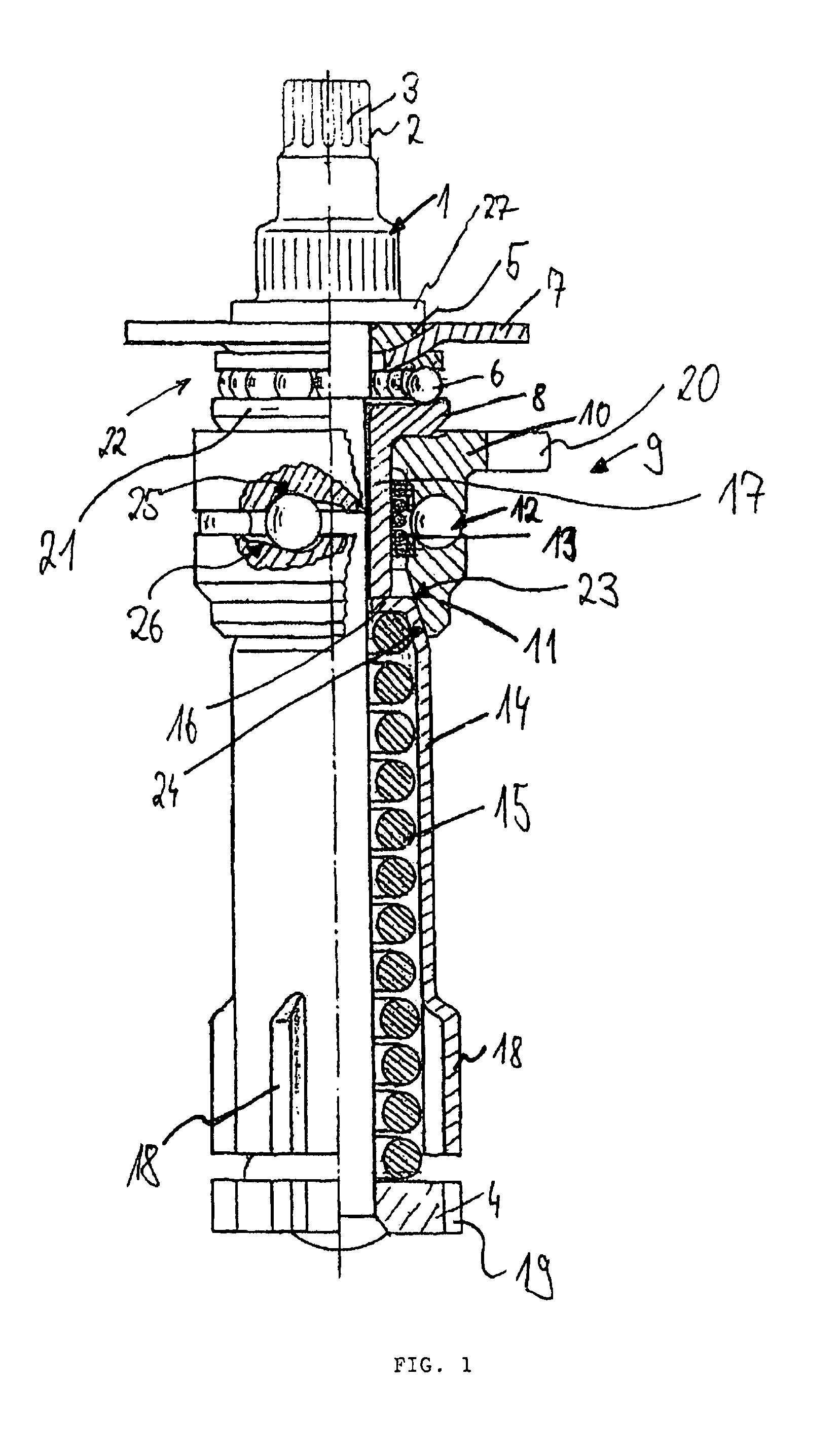

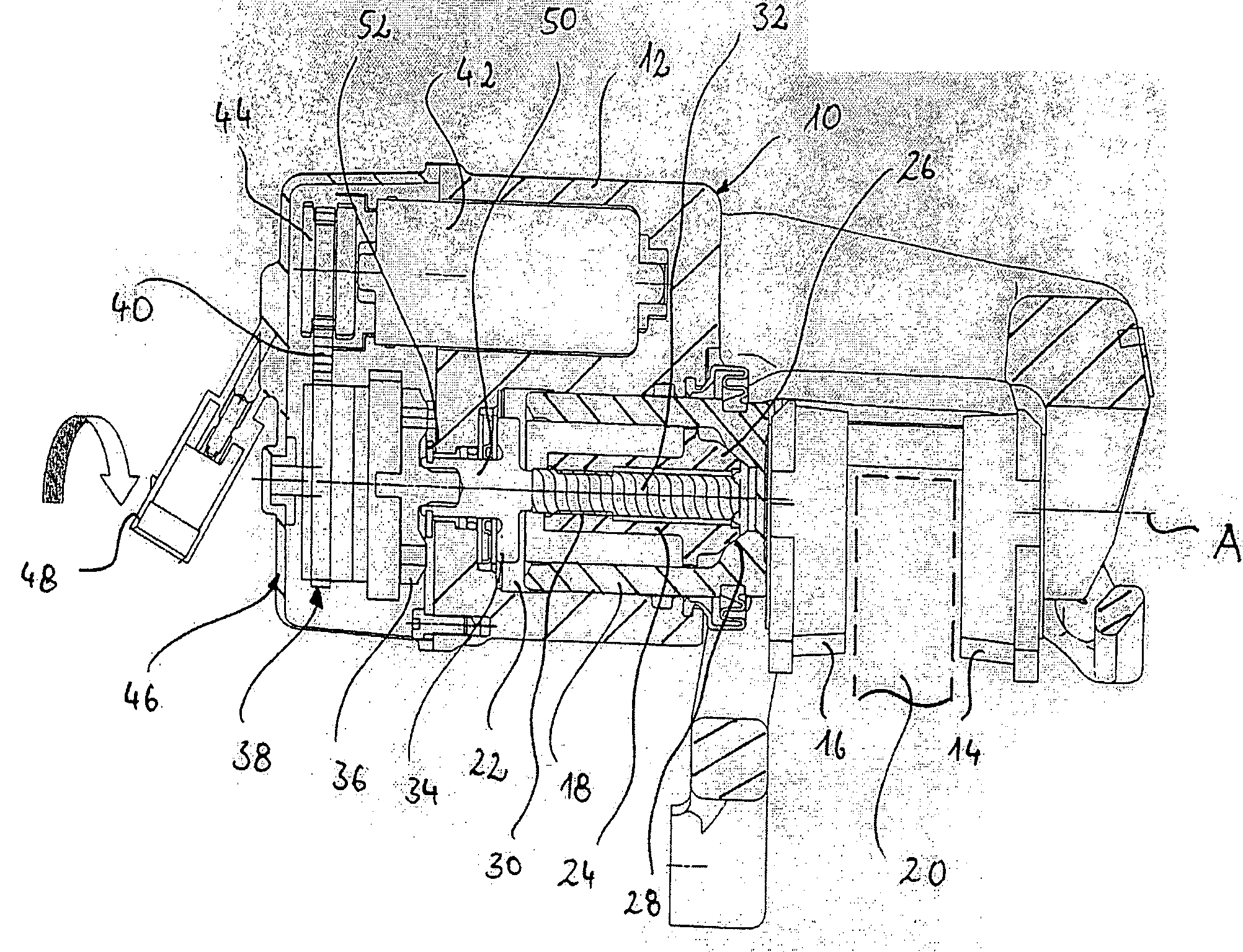

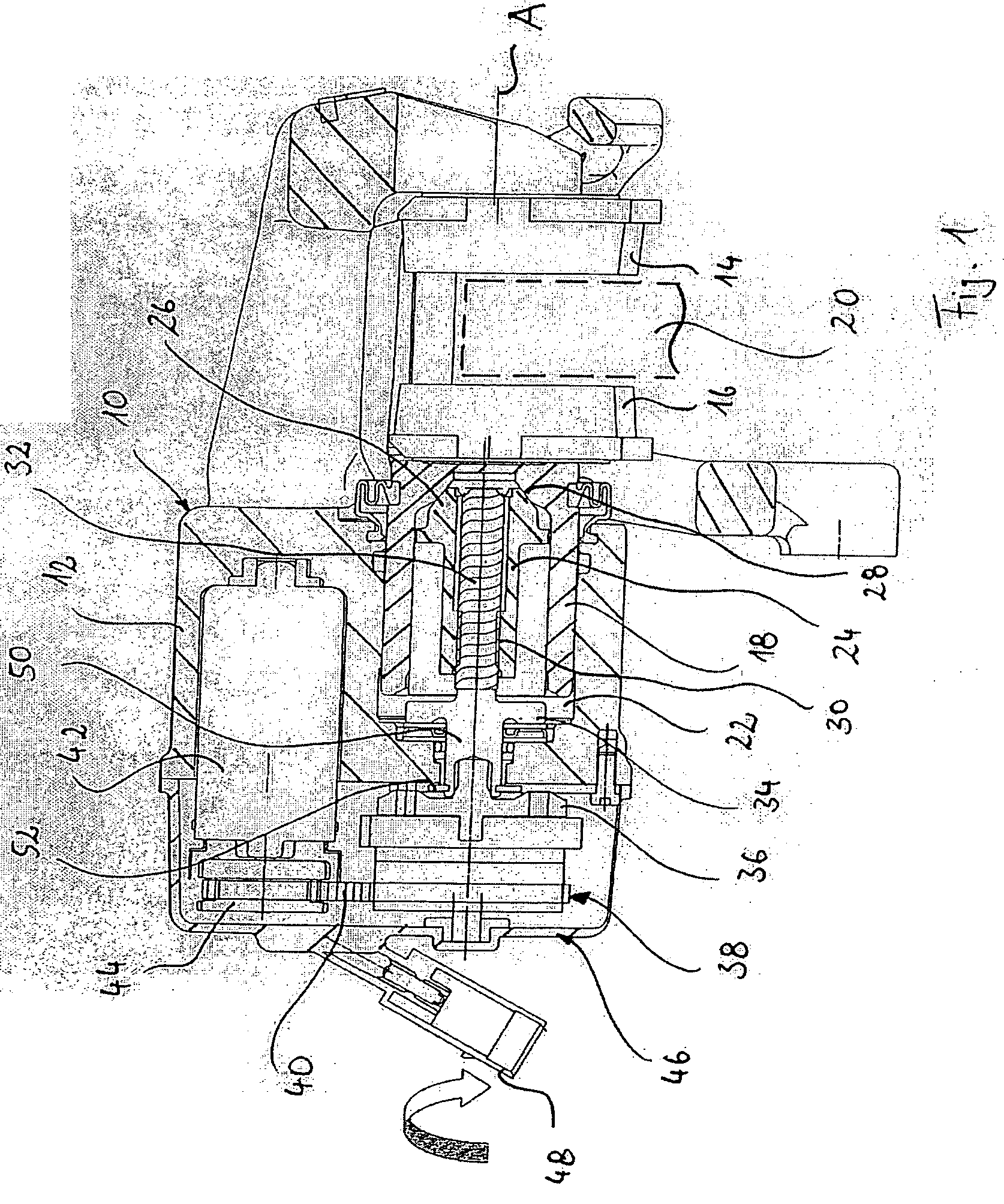

Adjusting device for a pneumatic disc brake

InactiveUS7926626B2InexpensivelyLow processing expenditureMechanically actuated brakesBrake actuating mechanismsCouplingEngineering

An adjusting device for adjusting the wear of the friction surface on the brake lining and brake disc of a pneumatic disc brake having a clamping device that is actuated by a rotary lever is provided. The device preferably can be inserted into a rotary spindle of the disc brake. An anti-friction body is positioned on both axial sides of a drive element, with the one bodies being a ramp coupling with a freewheeling function. The ramp coupling has coupling bushes and clamping balls, and the coupling bush on the driven side being supported on a spring sleeve. A conical seat is configured between the coupling bush and the sprung sleeve cooperates with the ramp coupling to preclude locking of the coupling bushes.

Owner:KNORR-BREMSE SYST FUER NUTZFAHRZEUGE GMBH

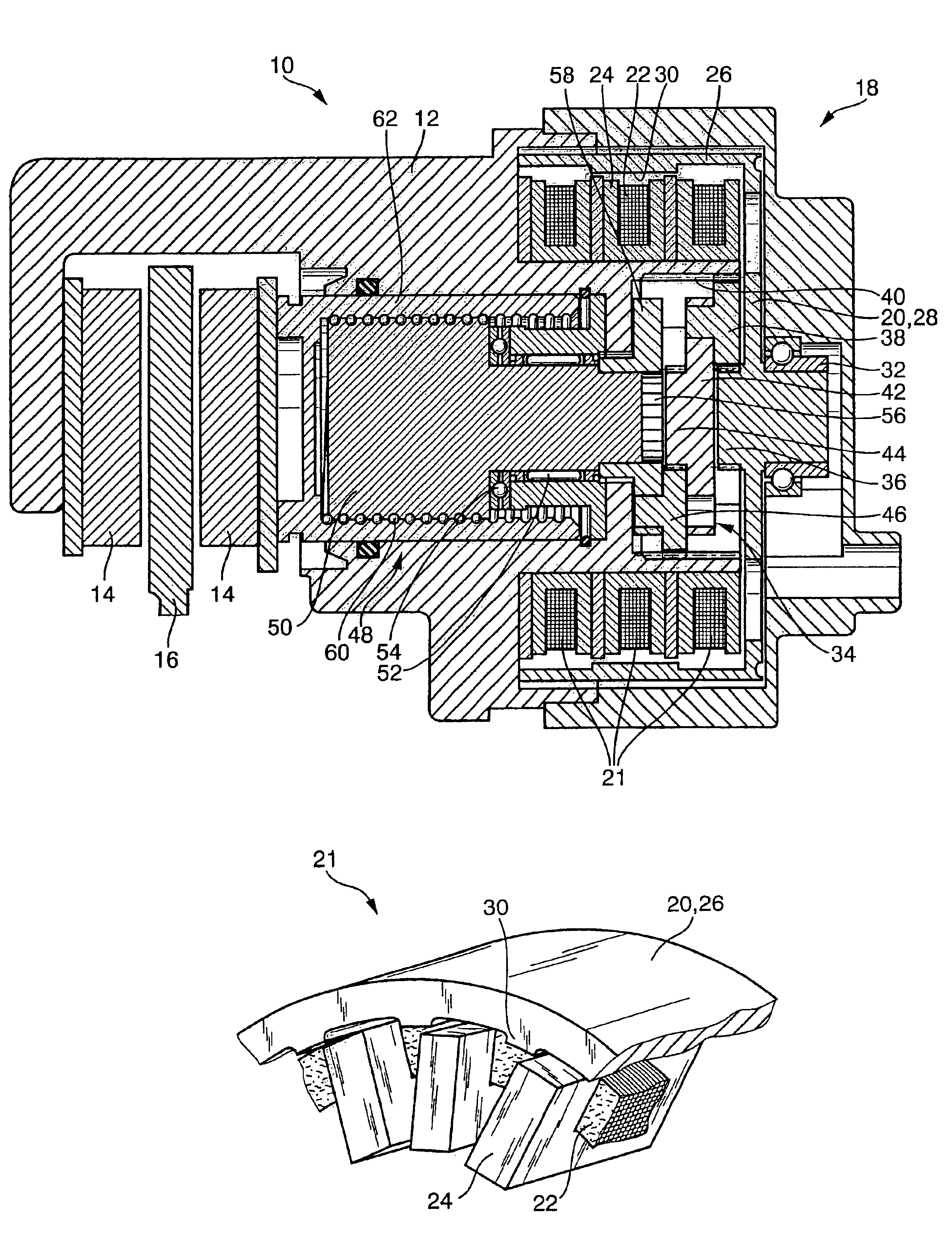

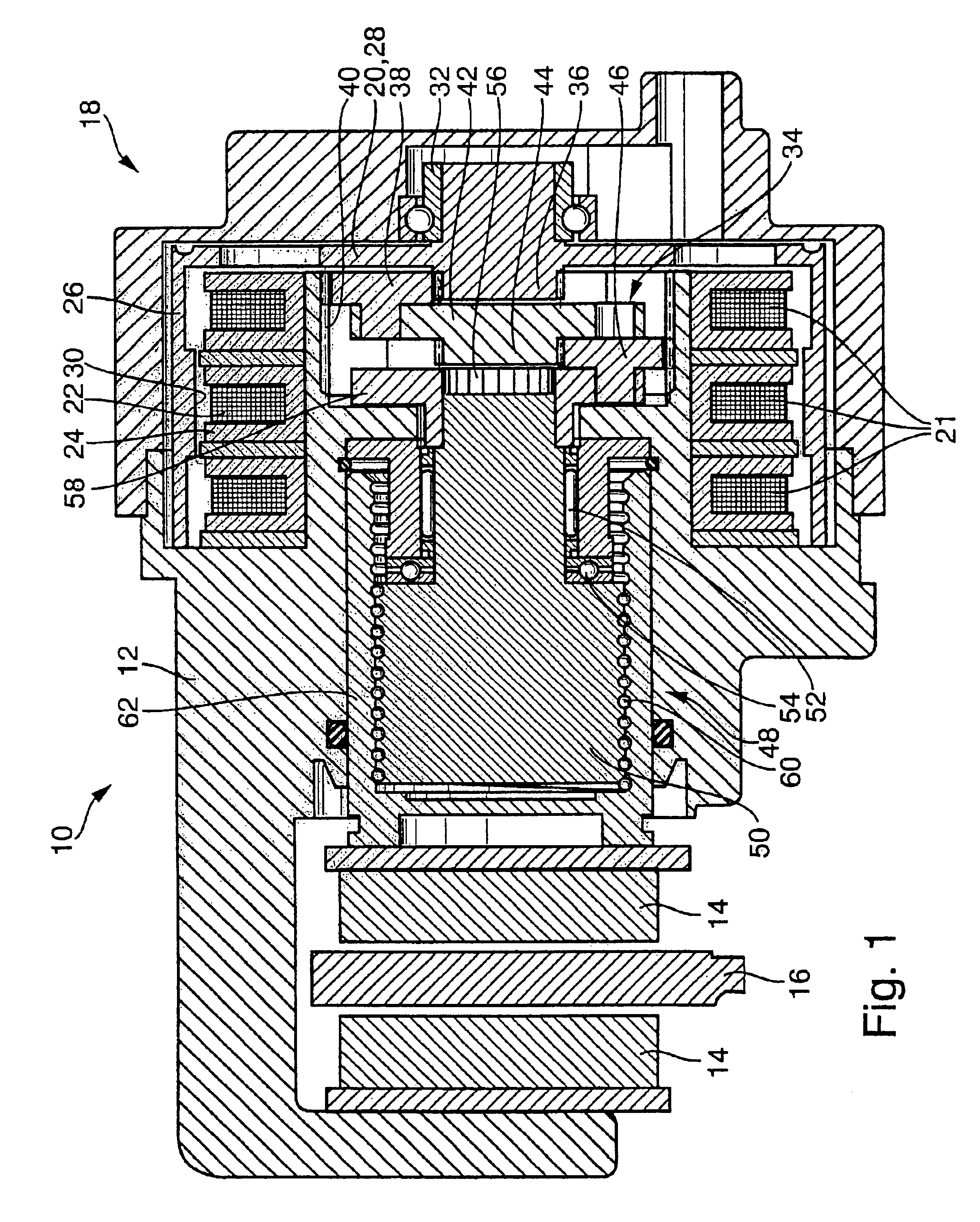

Electromechanical wheel brake device

InactiveUS6806602B2Improve power densityInterrupt supplyDynamo-electric brakes/clutchesBraking action transmissionTransverse fluxBall screw

The invention relates to an electromechanical wheel brake device, with an electric motor that can press a frictional brake lining against a brake body (brake disk) by a reduction gear (planetary gear) and a rotation / translation conversion gear (ball screw). The invention proposes embodying the electric motor as a transverse flux motor with three phase windings; each phrase winding has a circular, annular excitation winding that is disposed inside U-shaped yokes, which are distributed over the circumference of the excitation winding. This embodiment of the electric motor permits a compact design of the electric motor in an annular, hollow shaft design so that the reduction gear and the rotation / translation conversion gear can be disposed at least partially inside the electric motor.

Owner:ROBERT BOSCH GMBH

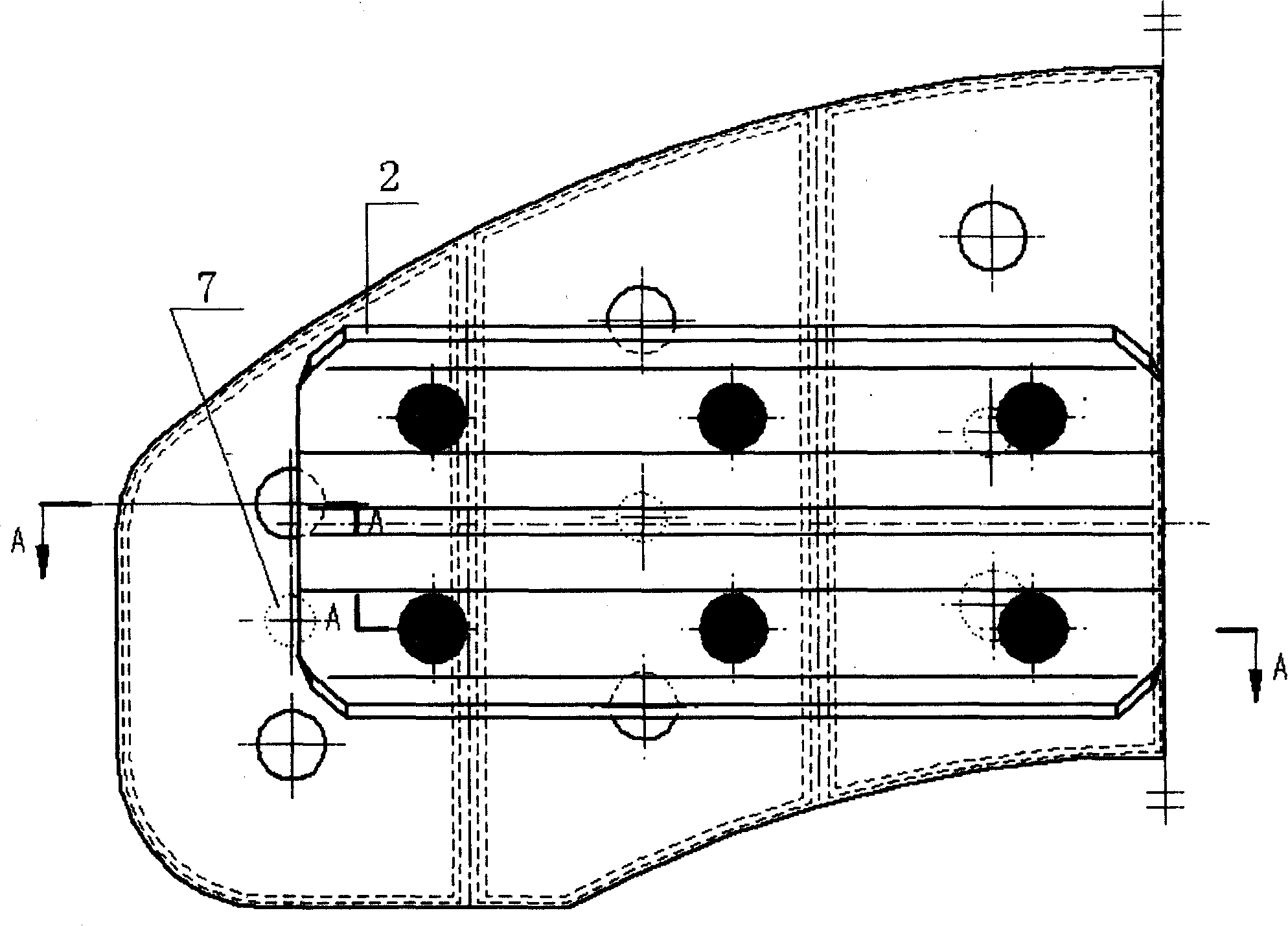

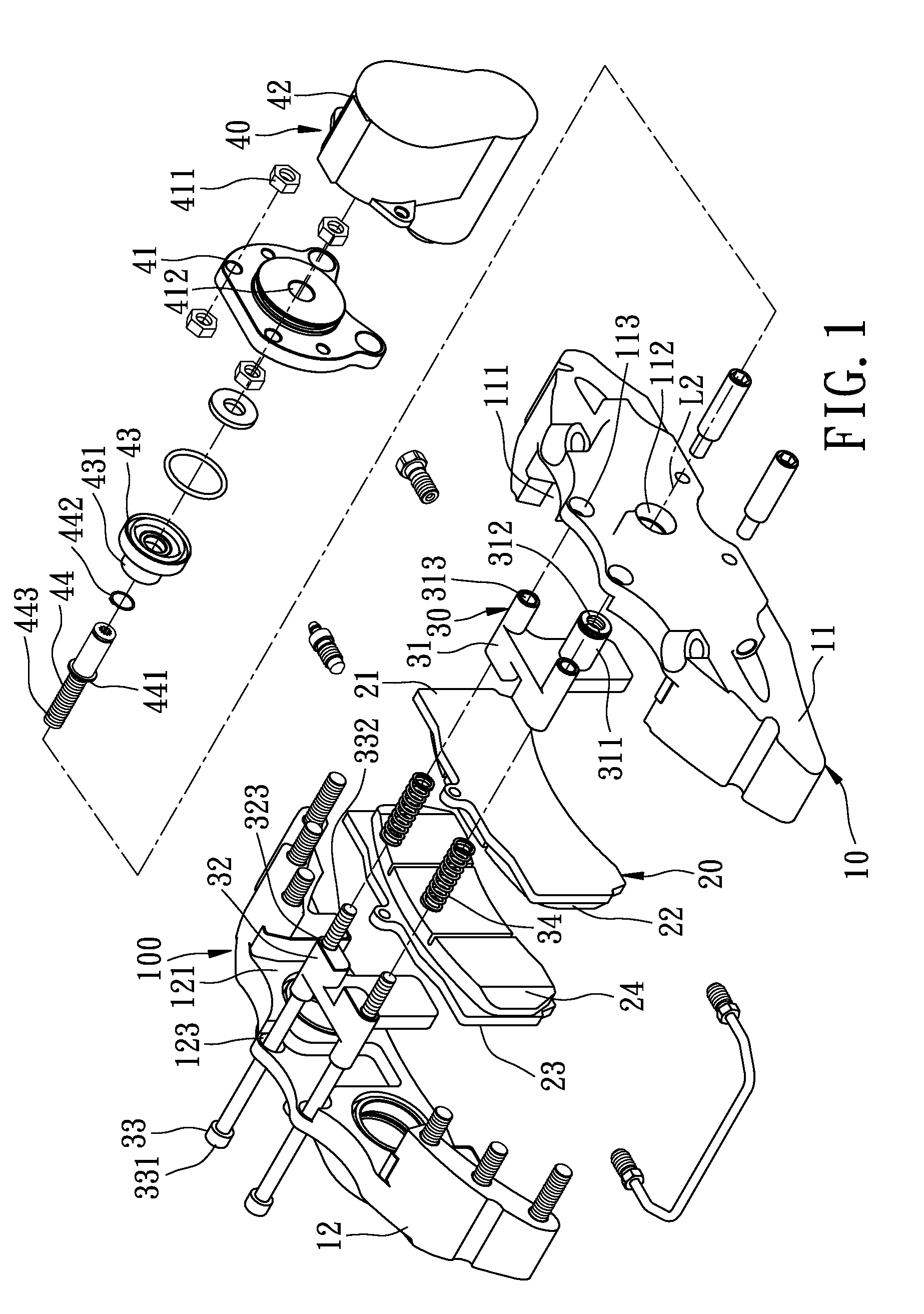

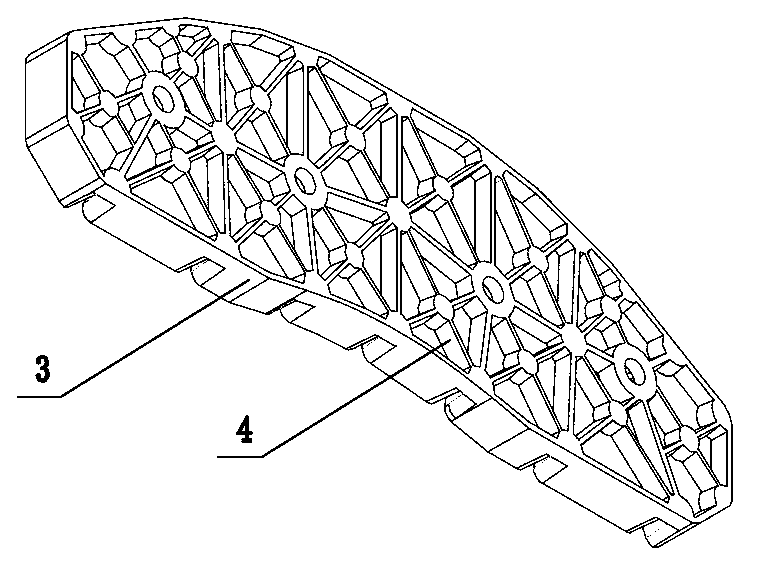

Powder metallurgy iron-based high-speed brake pad

The invention relates to a powder metallurgy iron-base high-speed brake lining, composed of a brake shoe back (1), a dovetail block (2), a friction block (3) and a serging vessel (4) linked with a rivet (6) through a rivet seat (5), wherein, the friction block (3) adopts a vessel serging structure and powder metallurgy iron-base friction materials and is formed by chill pressing and compression sintering. The invention is characterized by reliable structure, stable drag friction performance, low surface temperature rise, small relative dispersion and good wearing resistance, etc., and is suited to starting or towing a car on a railway with speed at or below 300km / h.

Owner:贵州新安航空机械有限责任公司

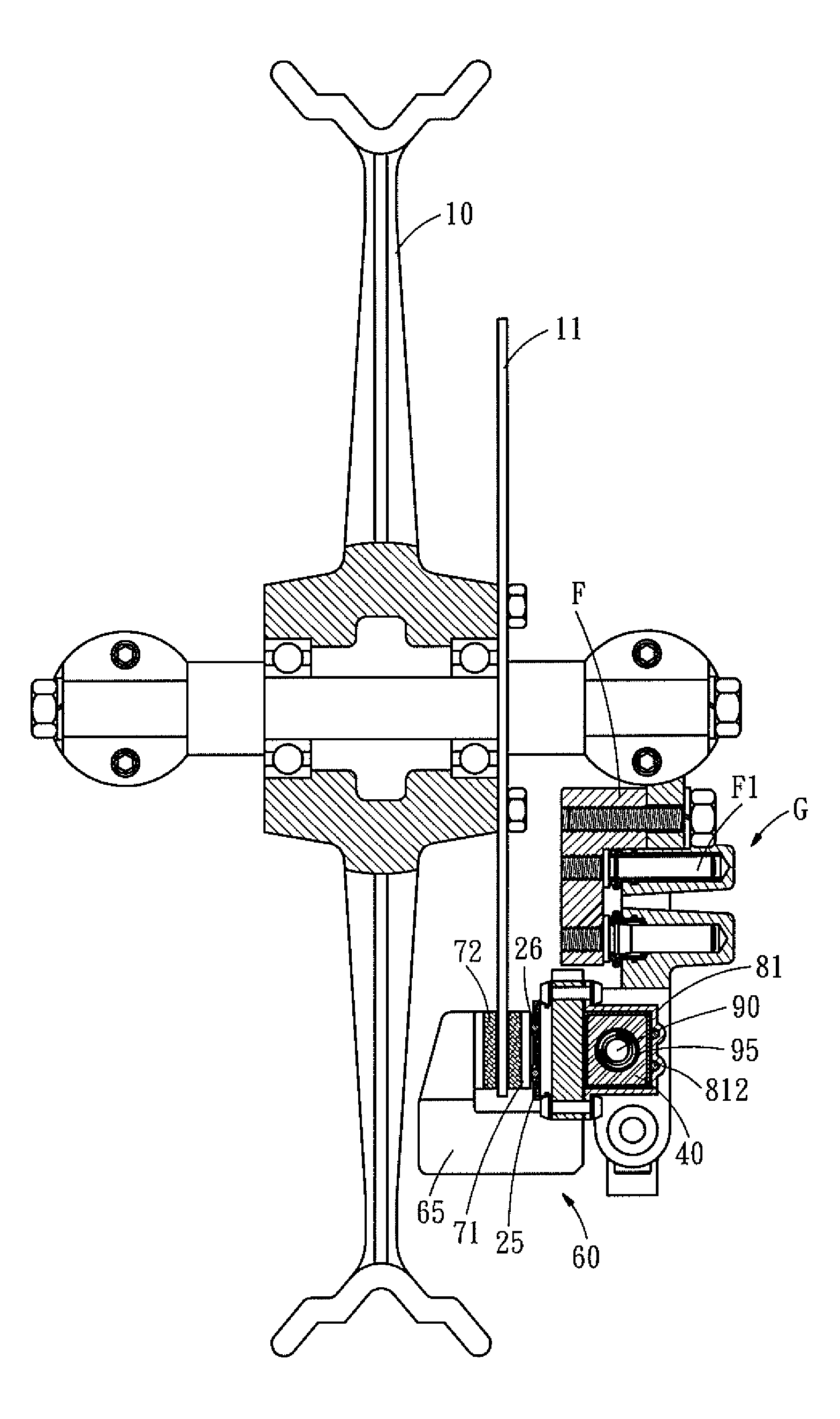

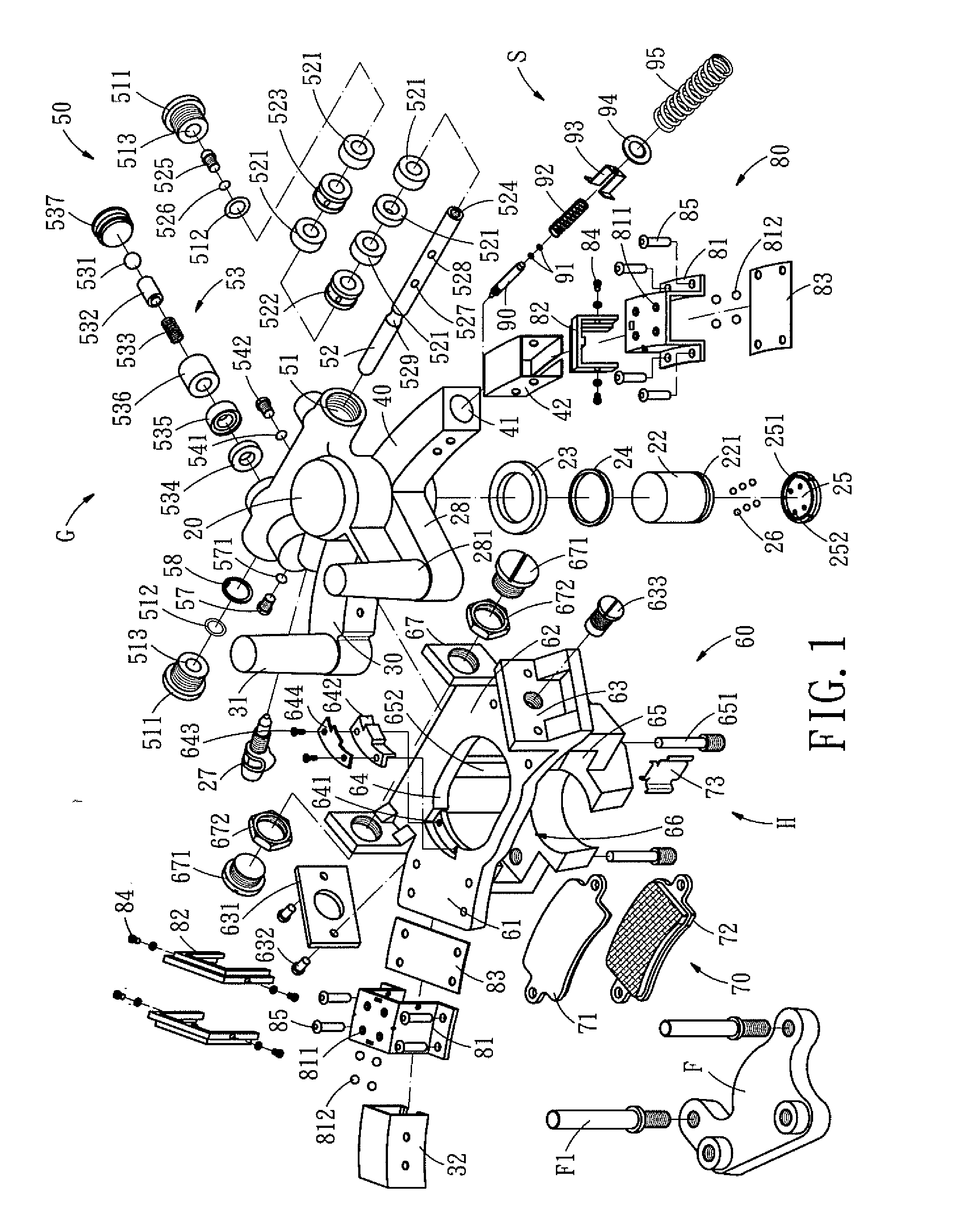

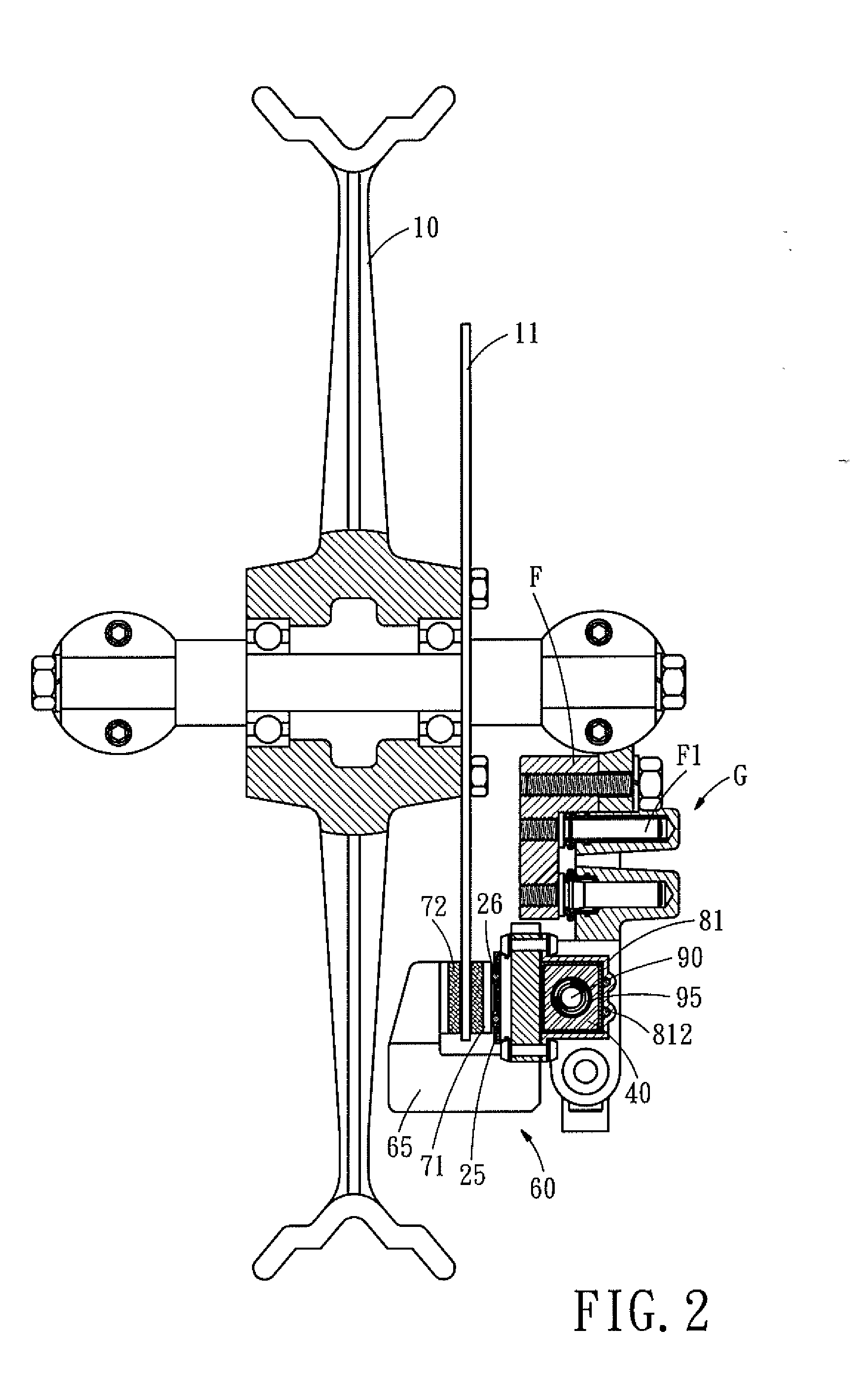

Hydraulic Disc Brake Device

InactiveUS20070251771A1Economical and low costBraking element arrangementsAxially engaging brakesEngineeringBrake lining

A hydraulic disc brake device comprises: a base assembly mounted on a vehicle, a sliding assembly slideably mounted on the base assembly, a return spring disposed between the base assembly and the sliding assembly, a brake lining assembly, a control valve assembly disposed on the oil pressure system. hydraulic disc brake system that has an antilock effect. The hydraulic disc brake is low cost and has an antilock function.

Owner:HUANG TAN CHENG

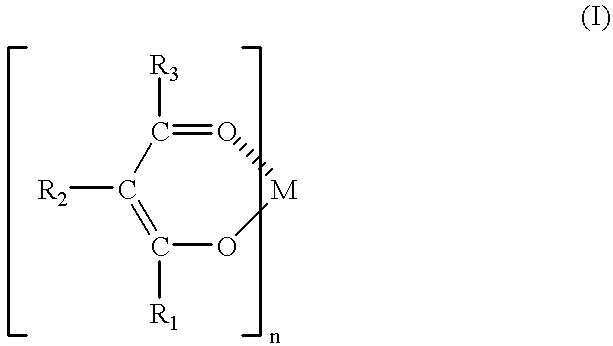

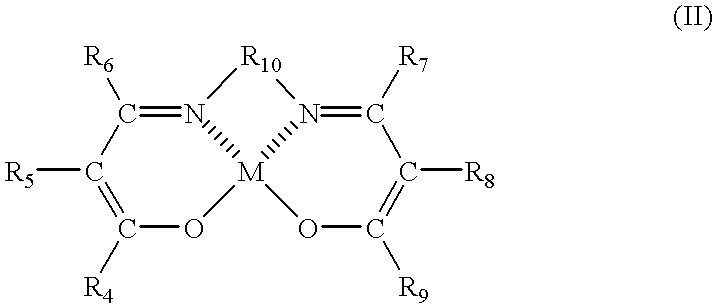

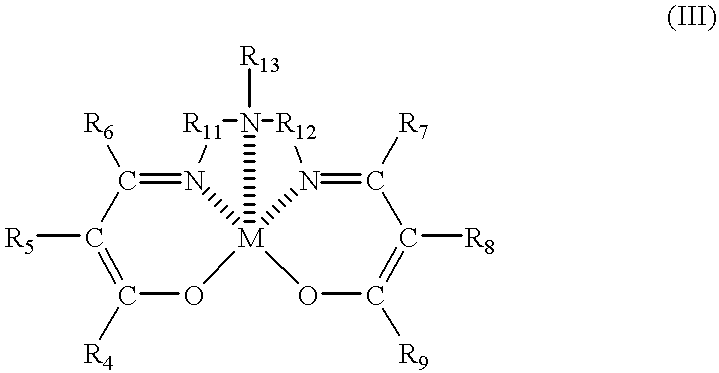

Resin composition and process for producing the same

A curable resin composition, which comprises a resin formed, in the presence of a transition metal complex, by polymerizing an oxidative-polymerizable compound that contains a phenol-compound-containing vegetable oil. A method for producing a curable resin composition comprising a resin formed, in the presence of a catalyst, by polymerizing an oxidative-polymerizable compound that contains a phenol-compound-containing vegetable oil, wherein the catalyst is a transition metal complex. The curable resin composition is useful as a raw material for a urushi-like coating, a friction material, a brake lining material, a brake pad material, a material for forming a coating film, a compound for a recording material, a raw material for an ink, a raw material for a coating,.a raw material for a adhesive, a raw material for an epoxy resin, a raw material for a photoresist or antioxidant, and a starting material for a functional polymer.

Owner:TOYO INK SC HOLD CO LTD +1

Brake plate

InactiveUS20060180414A1Improve stressLarge braking forceMetal-working apparatusBraking membersEngineeringBrake lining

The invention relates to a brake lining carrier plate 1 to hold a friction lining, especially for installation into a vehicle brake system, with holding structures 15, 16 for the friction lining arranged in rows 6 on the lining side 2, whereby each holding structure 15, 16 has a protrusion 3 and a depression 4, whereby the protrusion 3 is made when the depression 4 is formed in the surface 5 through the displacement of material. Said protrusion 3 engages with the friction lining. The holding structures 15, 16 in the rows 6 are arranged in such a way that there is a protrusion 10 at the beginning 8 and at the end 9 of each row 6. In one embodiment, the rows 6 run essentially crosswise to the longitudinal axis 7 of the brake lining carrier plate 1.

Owner:AML LANXIDE EURO

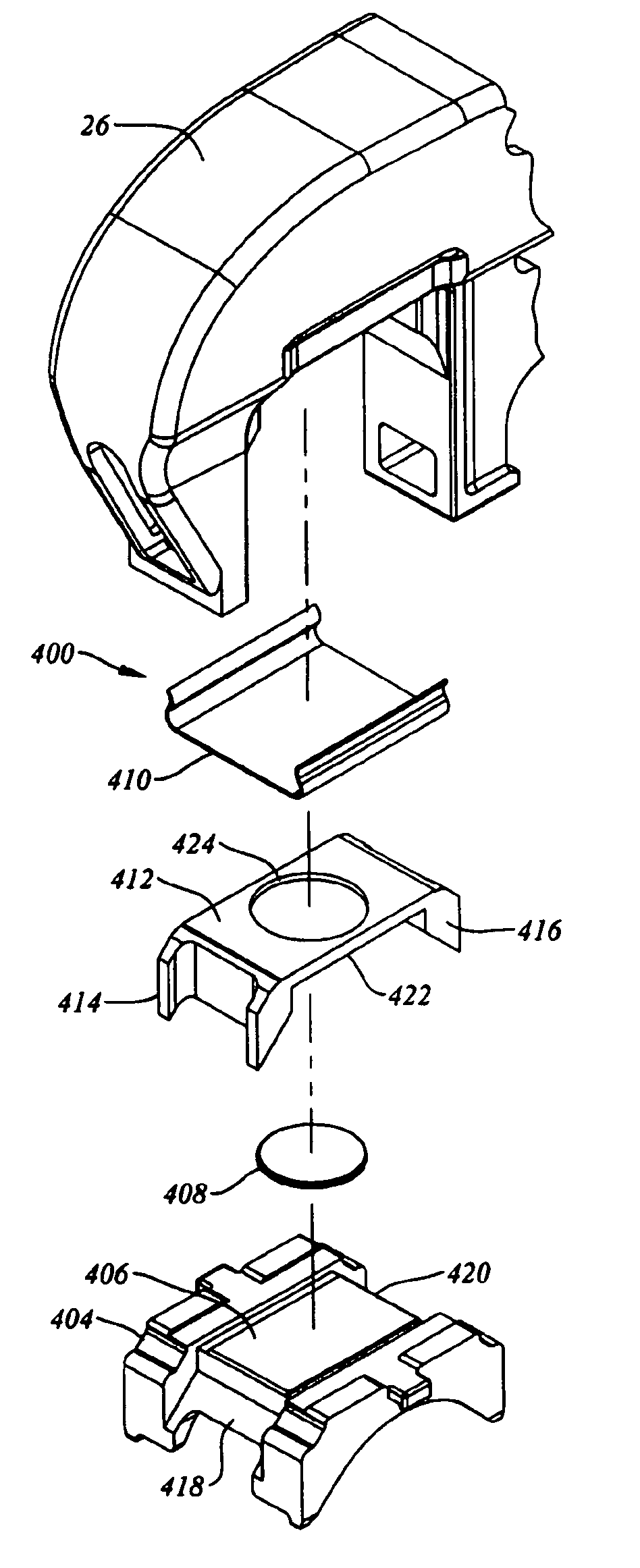

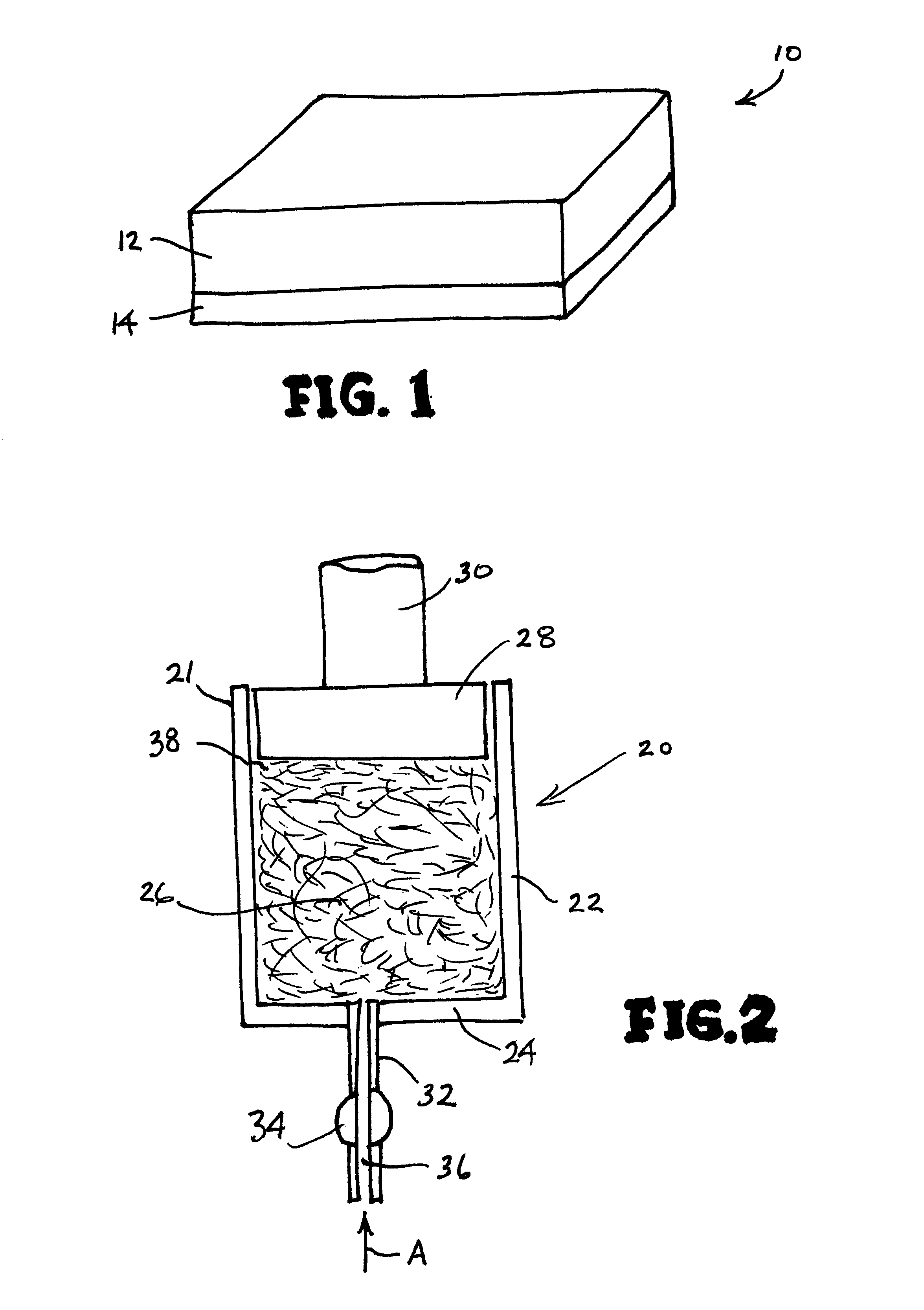

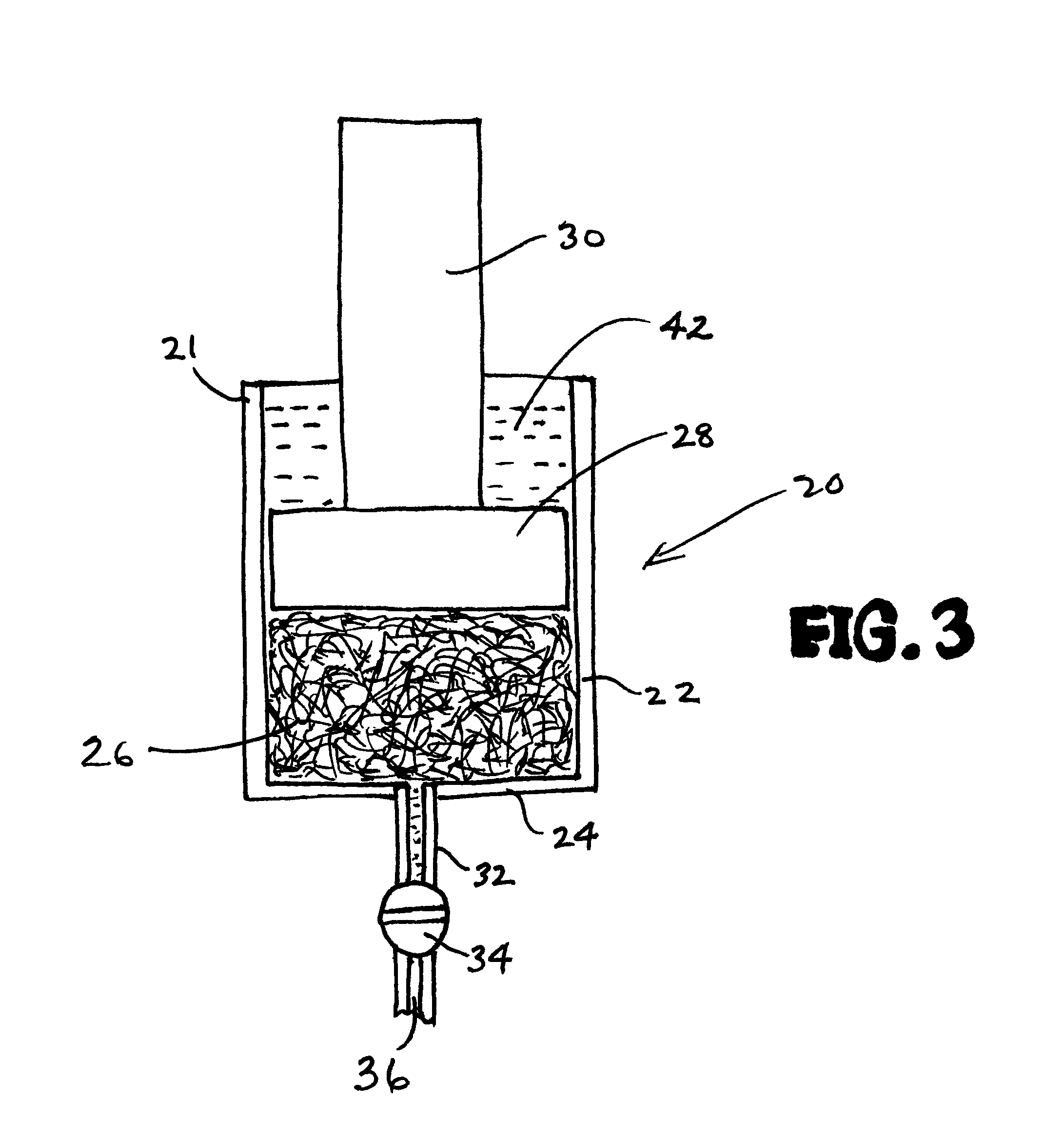

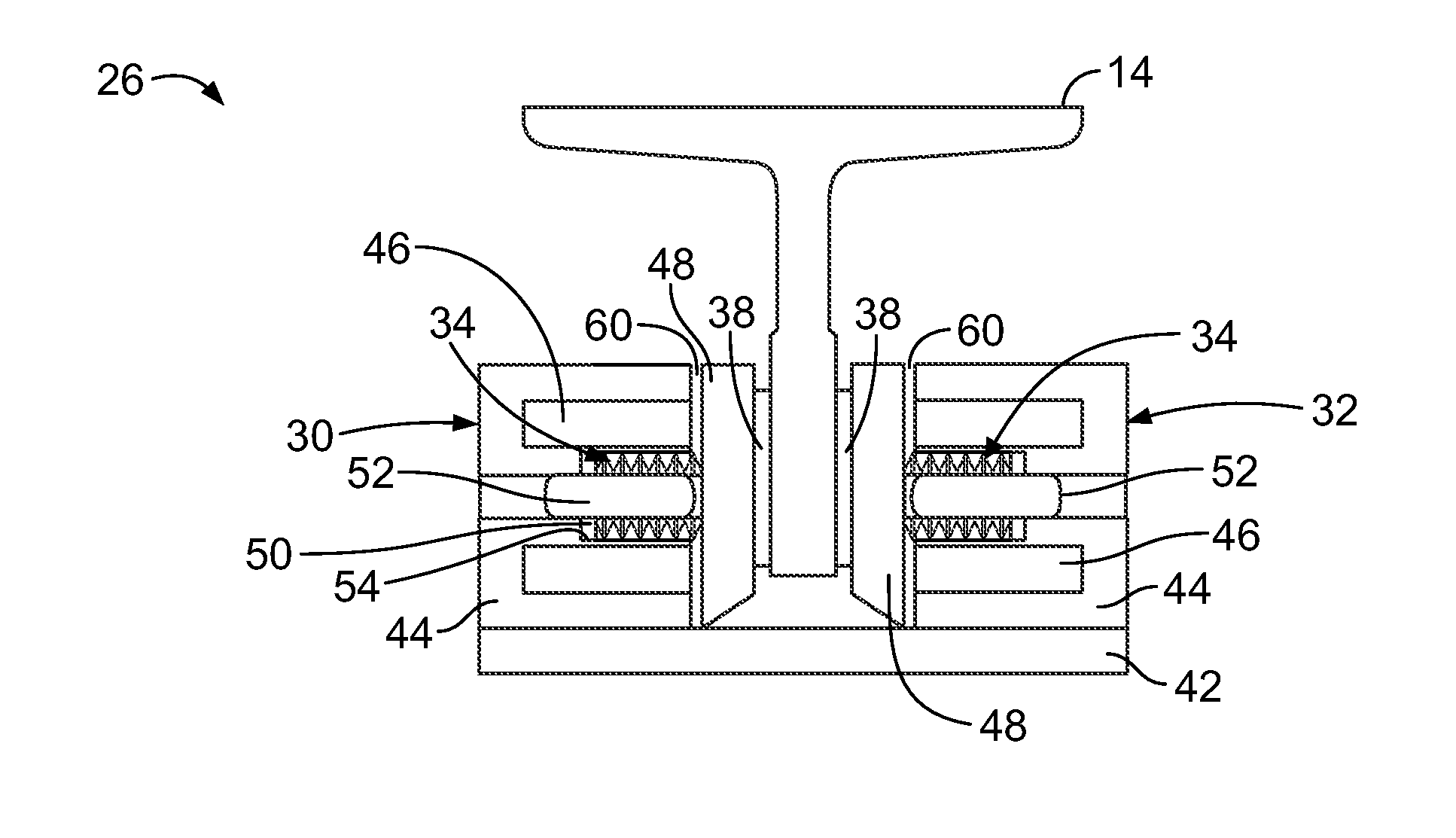

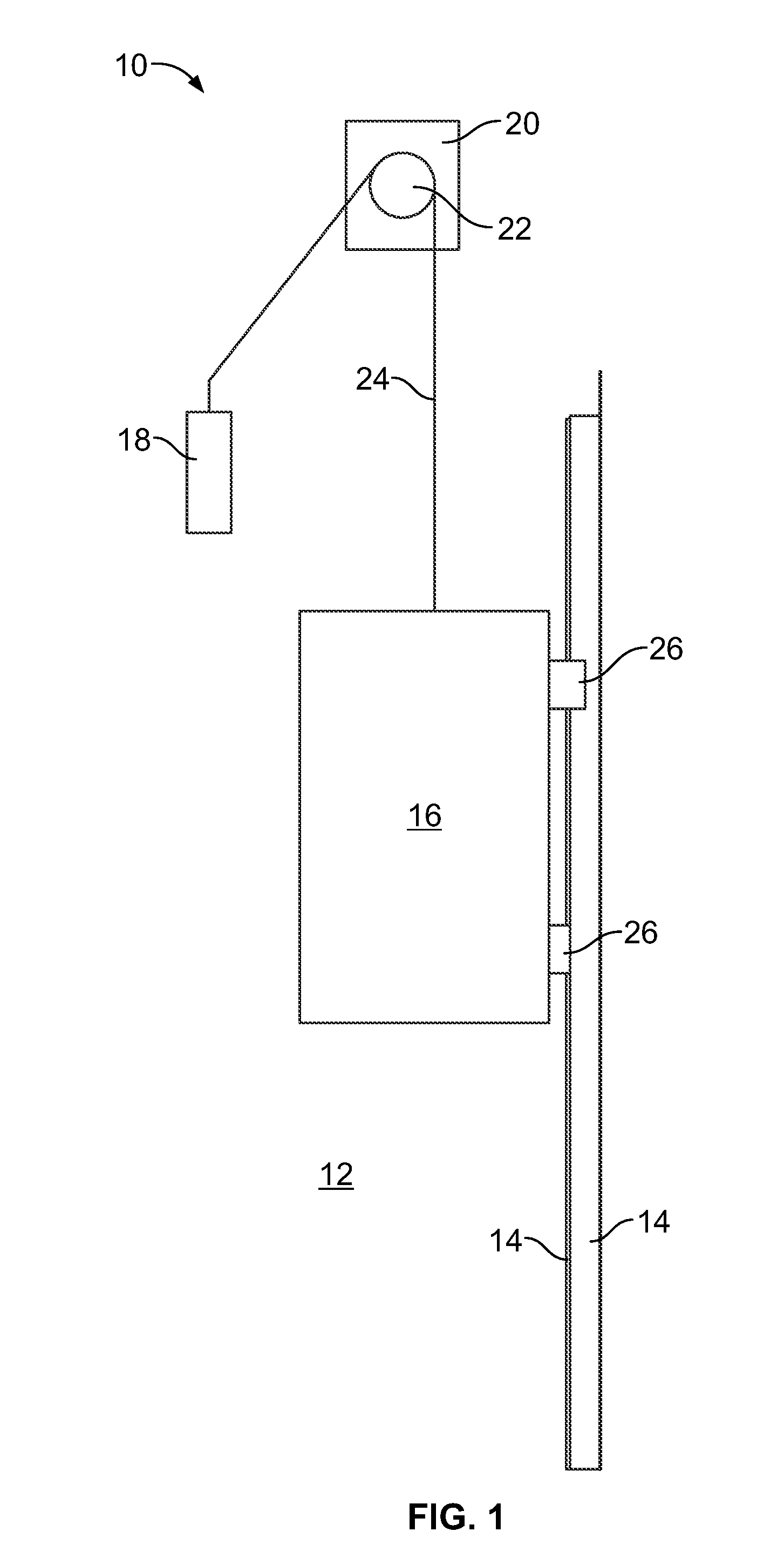

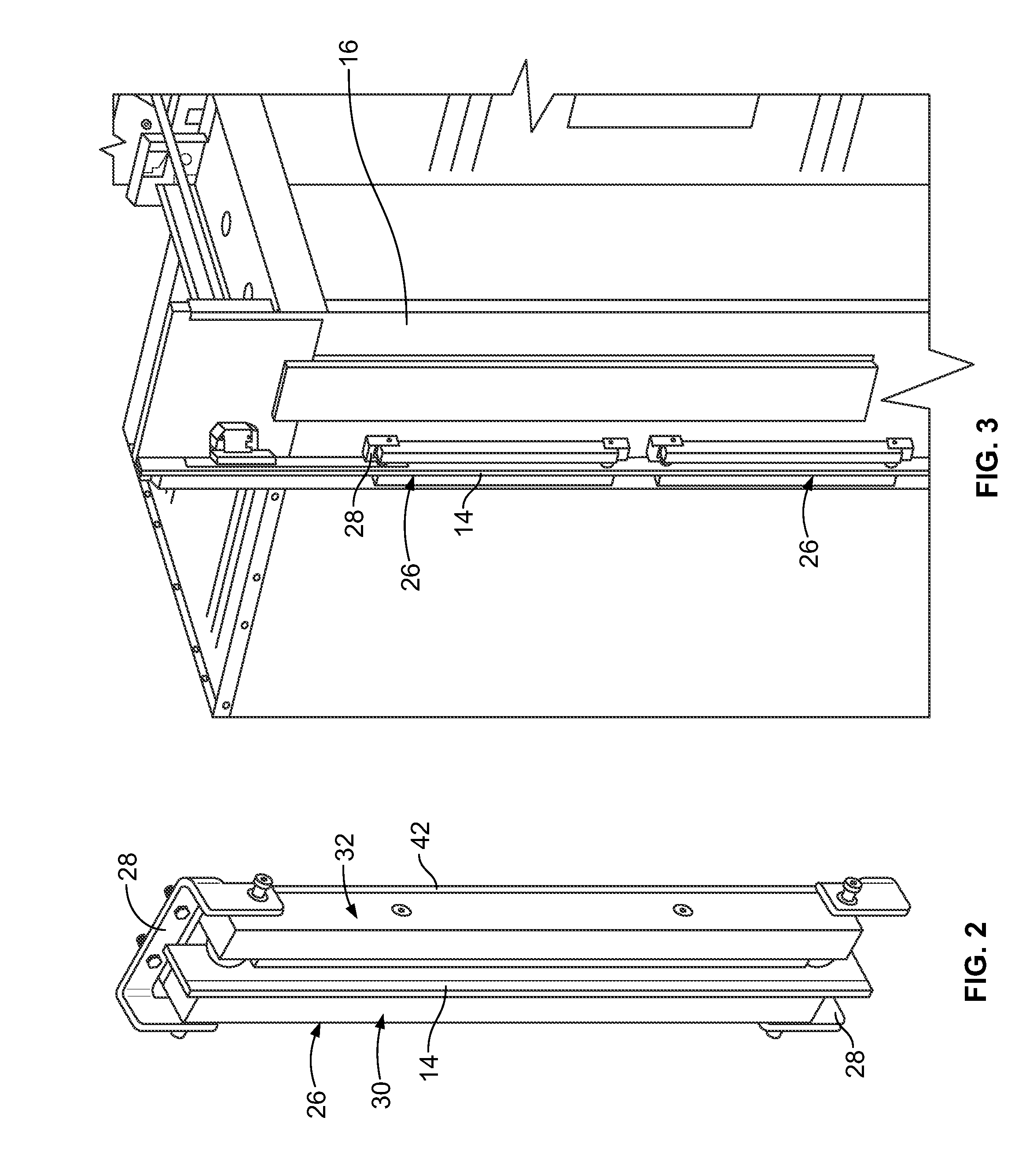

Elevator brake

A brake (26) for an elevator system (10) and method of using the brake (26) is disclosed. The brake (26) may comprise first and second brake linings (38) configured to be frictionally engageable with a rail (14) of the elevator system (10), a first biasing member (34) configured to urge the first brake lining (38) to engage the rail (14), and a first actuator (30) configured to move the first brake lining (38) to disengage the rail (14) when the first actuator (30) is energized. The brake (26) may be configured to be mounted on an elevator car (16) of the elevator system (10).

Owner:OTIS ELEVATOR CO

Rail road car truck

Owner:NATIONAL STEEL CAR

Brake equipment for holding and braking an elevator car in an elevator installation and a method of holding and braking an elevator installation

Brake equipment for holding and braking an elevator car in an elevator installation, which is arranged to be movable along a brake track in two directions of travel, includes a mount with a brake lining which automatically adjusts under friction couple with the brake track on movement of the elevator car relative to the rail and in that case tightens a first tightening means, which can be released by an actuator. The first tightening means tightens the mount together with the brake lining against the brake track by a biasing force. The brake equipment produces, with unmoved brake equipment and an unreleased state of the actuator, a holding force acting in both directions of travel. The holding force is determined substantially by the biasing force acting on the mount.

Owner:INVENTIO AG

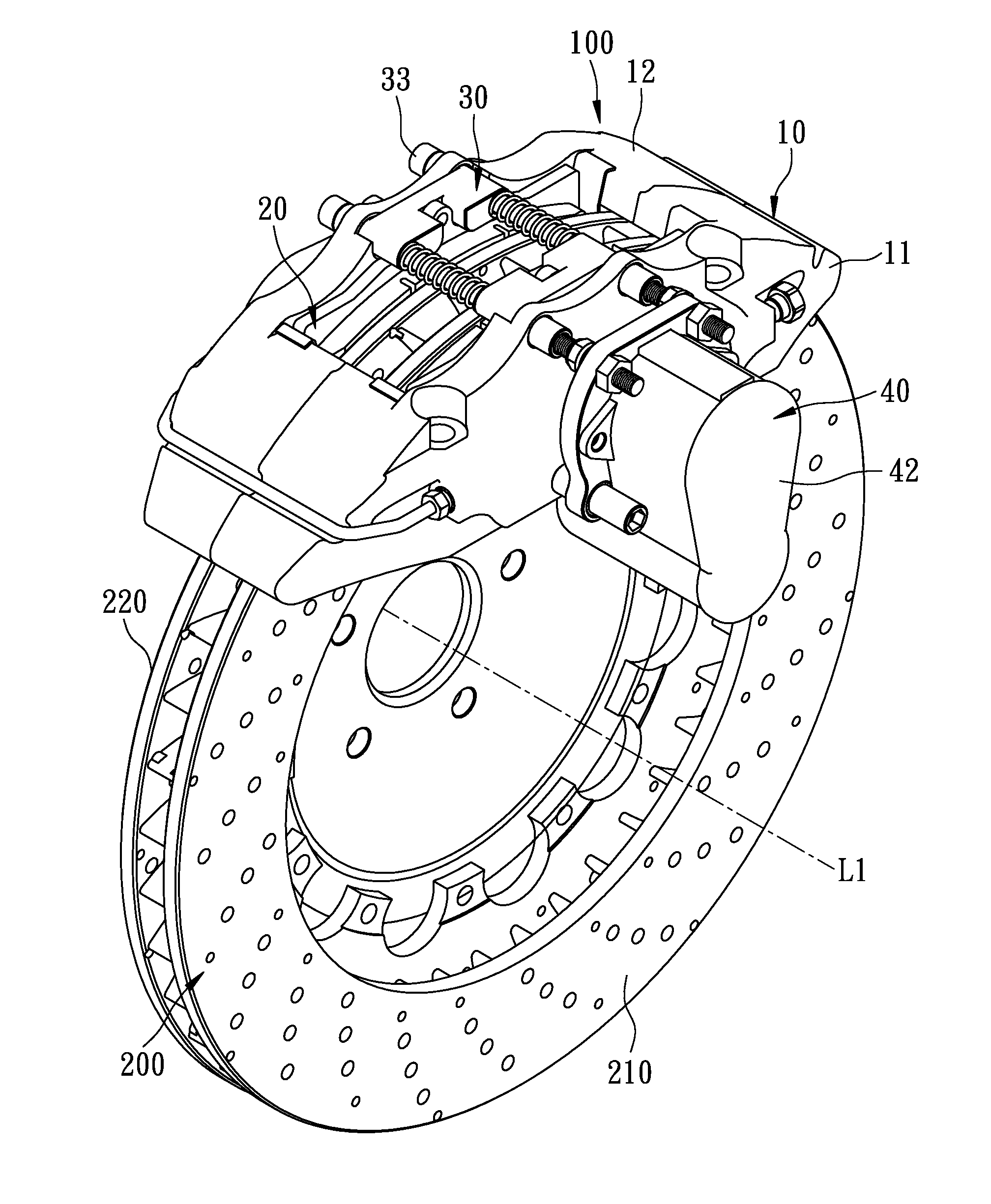

Electric parking caliper

InactiveUS20150001010A1Easy to operateSimple structureBraking element arrangementsAxially engaging brakesEngineeringCalipers

An electric parking caliper is adapted to connect with a brake disk. The brake disk has first and second side surfaces perpendicular to an axis. The electric parking caliper includes first and second brake linings, first and second driving members movable along a central line parallel to the axis, a plurality of driving rods connected between the first and second driving members and parallel to the axis, and an actuating shaft. The actuating shaft is movable for driving movement of the first driving member along the central line so as to move the first brake lining toward or away from the first end surface, and for activating the driving rods to move the second driving member along the central line so as to move the second brake lining toward or away from the second end surface.

Owner:LIAO CHIH HSIEN

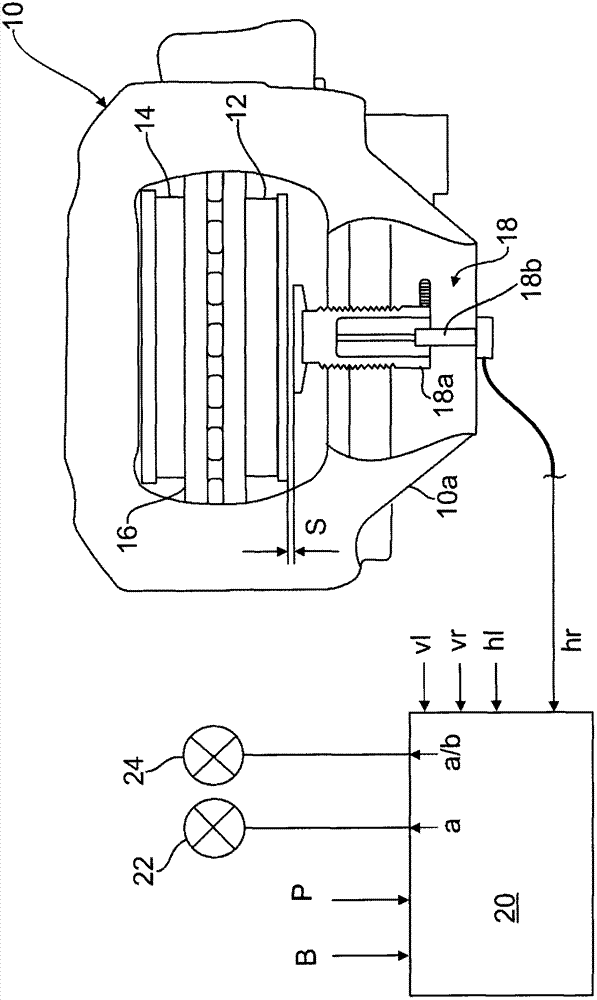

Method and device for monitoring brake lining wear and air clearance of an operating brake in motor vehicles

InactiveCN102777520AImprove operational safetyLow priorityAxially engaging brakesActuatorsTransducerControl theory

The invention refers to a method and device for monitoring brake lining wear and air clearance of an operating brake in motor vehicles, especially in commercial vehicles. Each wheel brake is provided with at least one displacement transducer which marks brake lining wear and air gap of service brake by means of an evaluation unit. A warning indicator is activated, when the detected air gap is larger or smaller than the predetermined air gap. According to the utility model, the displacement transducer and the evaluation unit are designed to obtain a current gap as an actual gap according to evaluation of signal difference of the displacement transducer under the case of controlling or not controlling the brake so as to obtain each difference between a gap and a rated gap, wherein the warning signal is activated when limits obtained by a specified rated gap exceed or the gaps is too large accordingly and when limits obtained by a specified rated gap is lower or the gaps is too small or no gap exists accordingly.

Owner:MAN NUTZFAHRZEUGE AG

Vehicle Brake, In Particular Caliper Brake

InactiveUS20090133975A1Realized very quicklyReleaseAxially engaging brakesBrake actuating mechanismsSelf lockingCalipers

The invention relates to a vehicle brake, in particular a caliper brake, having a housing, a brake piston accommodated in and linearly displaceable relative to the housing for displacing a brake lining, and a mechanical actuator arrangement for displacing the brake piston, wherein the brake piston is displaceable in the housing by charging a hydraulic chamber by means of a hydraulic brake circuit and wherein the mechanical actuator arrangement comprises a threaded spindle, which is mounted rotatably in the housing and may be set in rotation, wherein the brake piston as a result of a rotational movement of the threaded spindle is linearly displaceable relative to the housing. In this vehicle brake, it is provided that the threaded spindle is provided with a multiple-start self-locking thread having n flights, wherein the number n and the thread lead are selected in such a way that the thread is close to the self-locking limit.

Owner:LUCAS AUTOMOTIVE GMBH

Novel brake pad material of truck

InactiveCN101555399AStable coefficient of frictionStable recovery performanceOther chemical processesFriction liningLow speedEngineering

The invention relates to a frictional material, in particular to a novel brake pad material of truck. The invention provides a novel brake pad material of a truck, wherein the novel brake pad material is used in a dry one-step hot press molding process applied to a nanocopper modified phenolic resin agglutination technology and a parent material modifying and adjusting technology. The raw material mixing ratio of the novel brake pad material is as below: 15%-20% of binder, 30%-50% of framework material, 10%-15% of friction enhancing agent, 5%-10% of anti-friction agent and 20%-30% of filling material. The binder is nanocopper modified phenolic resin, the framework material is mineral fibre and the like, the friction enhancing agent is great-hardness chromium ore power, and the like, the anti-friction agent is low-hardness graphite, and the like, the filling material is BaSO4, coarse whiting, and the like. The novel brake pad material has the advantage that a brake lining has a stable friction factor, stable recovery performance, good heat resistance, no crack performance, low speed sensitivity, good wearability and no braking noise.

Owner:SHANDONG DAWANG XINYI AUTOMOBILE FITTING

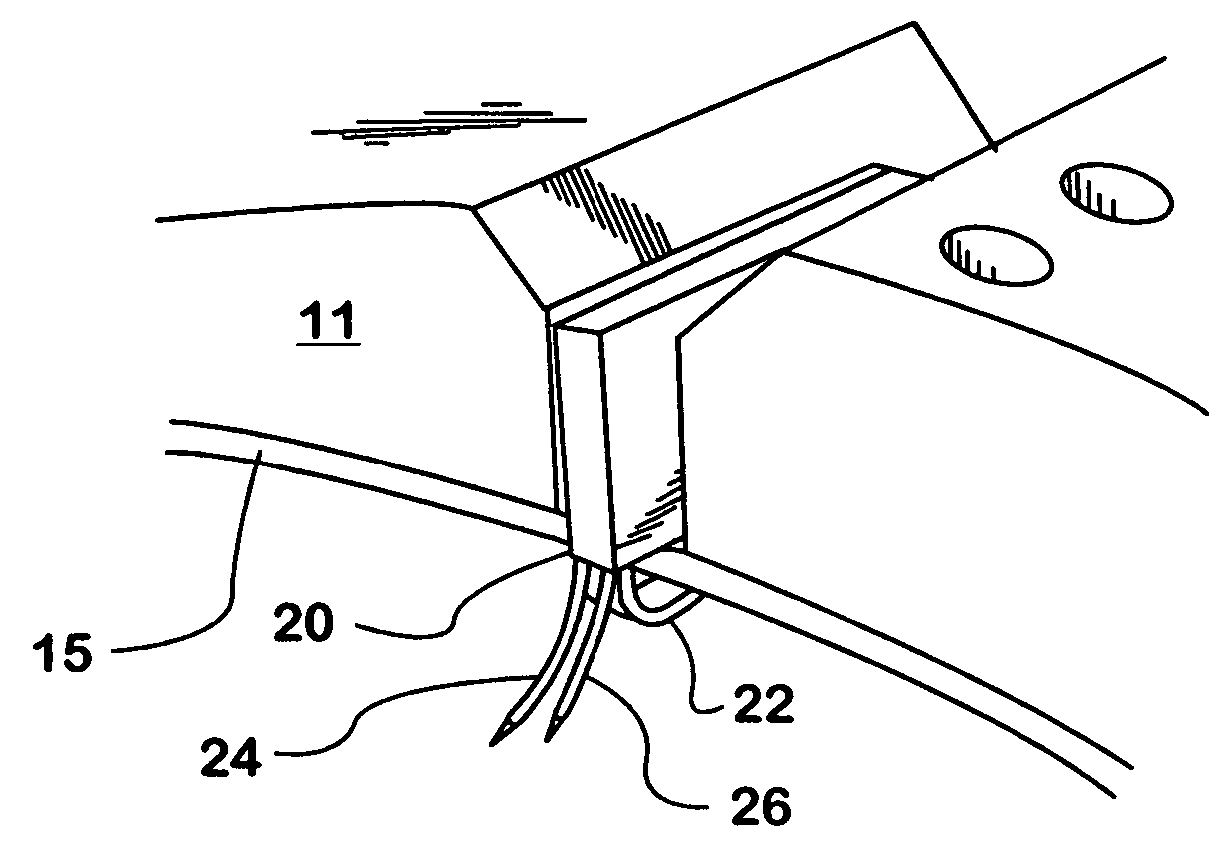

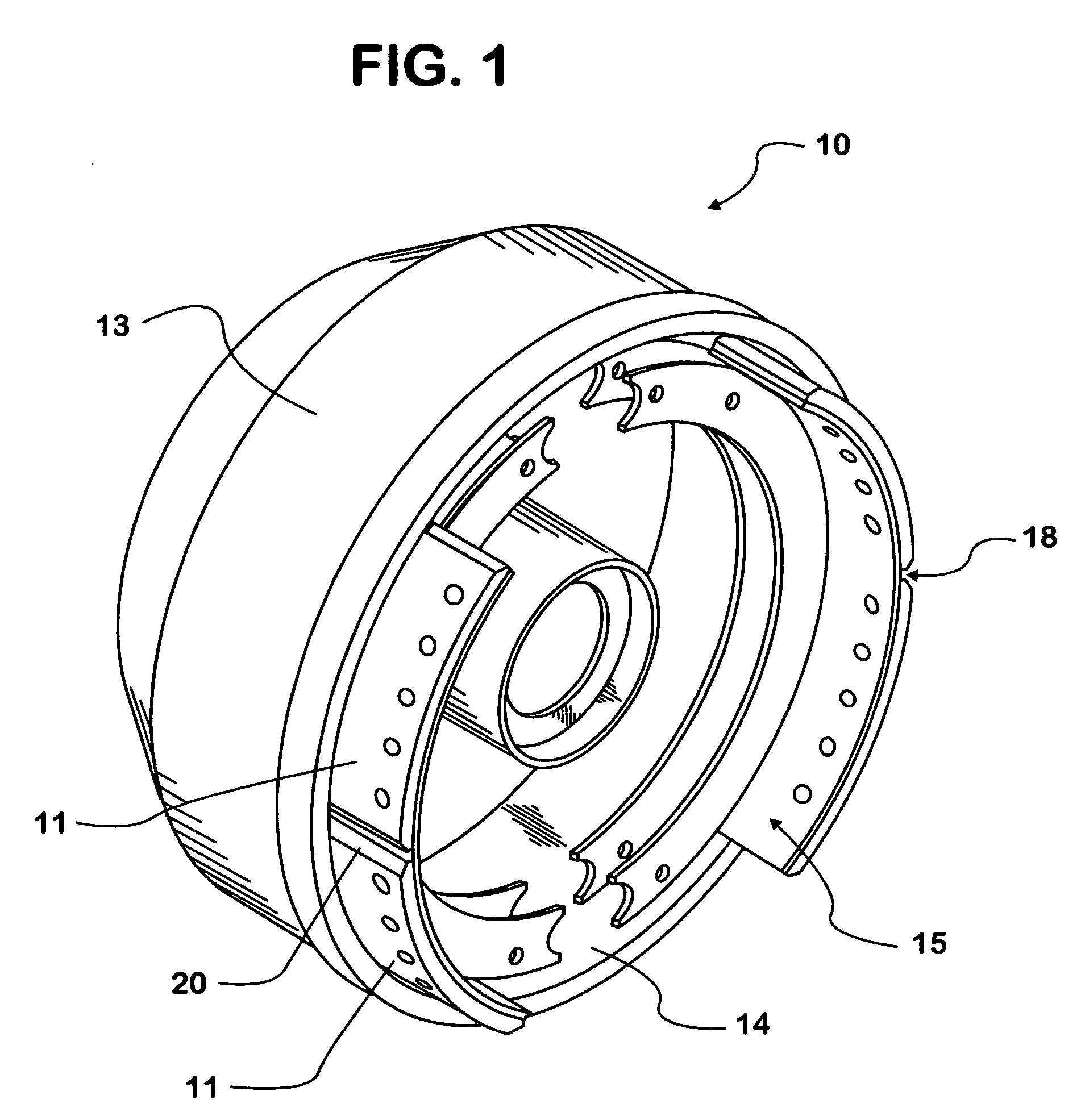

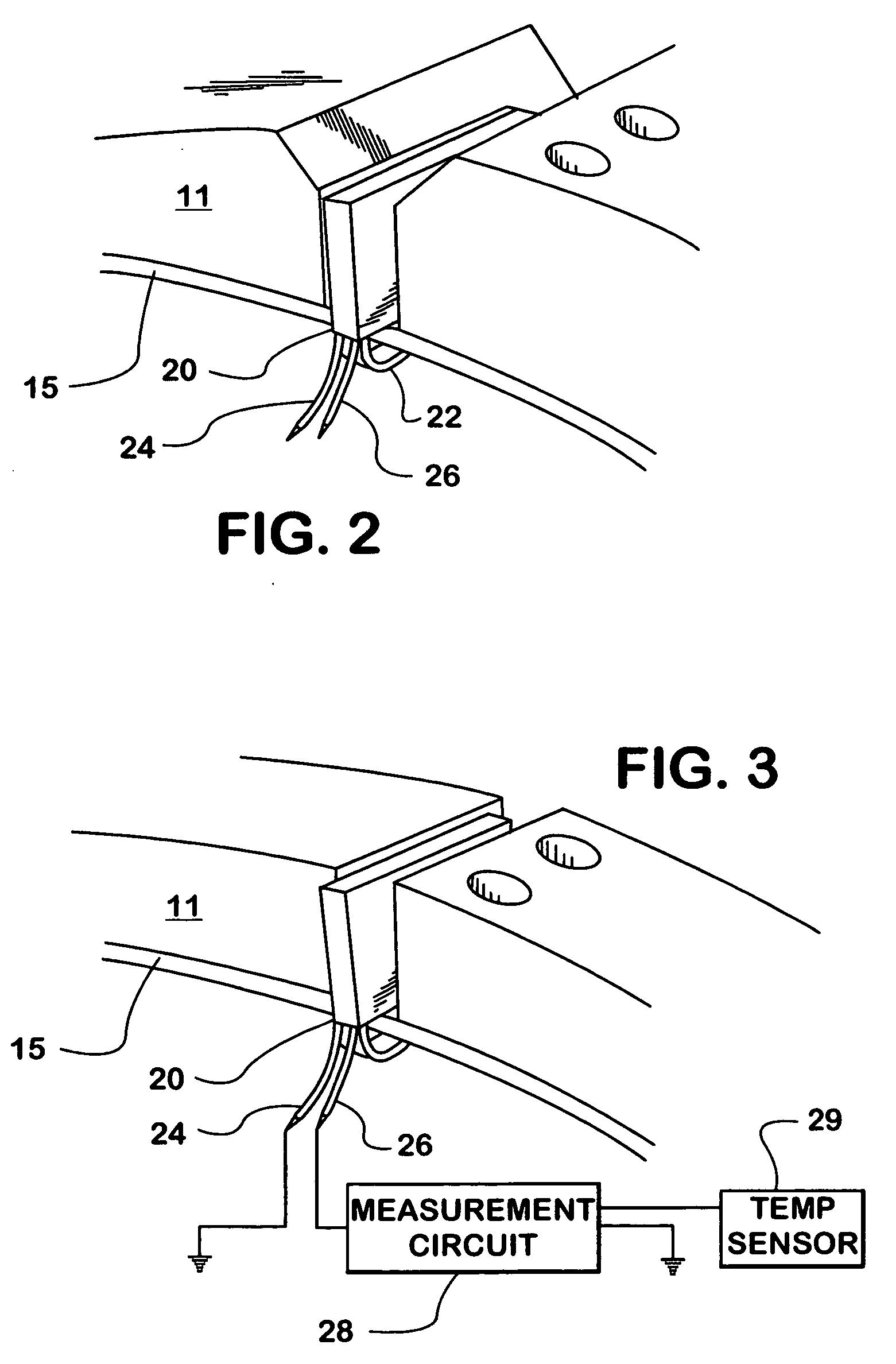

Thin film sensor for brake lining pad wear and brake temperature sensing

InactiveUS20060076196A1Improve electrical resistanceOptical signallingBrake typesThin film sensorElectrical resistance and conductance

A modular electrical resistance sensor is positionable in gaps between brake linings for a drum brake. The modular sensor is worn with the brake linings resulting in steadily increasing electrical resistance of the modular sensor. A measurement circuit associated with the modular sensor is programmed to equate electrical resistance to the degree of wear when the sensor has assumed a steady state temperature at or near the ambient temperature. Otherwise, particularly during periods of use of the brakes, resistance and the degree of wear last calculated become arguments into a function for determining brake lining temperature.

Owner:INT TRUCK INTPROP LLC

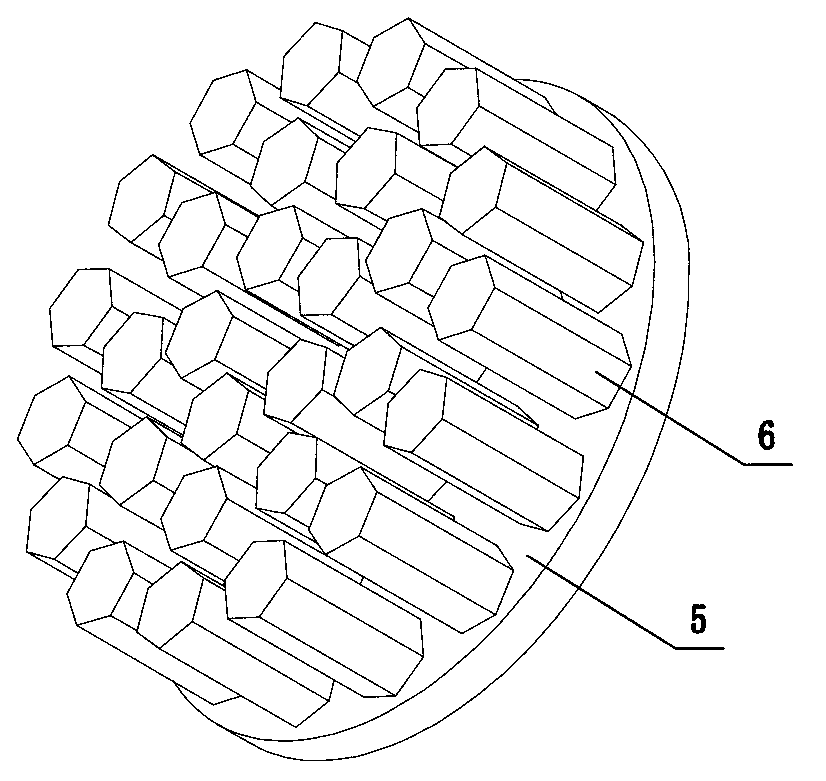

Ceramic/metal composite material brake lining for high-speed train and preparation method of ceramic/metal composite material brake lining

ActiveCN103075445AReduce movementConvenient engineering preparationBraking membersFriction liningThermal decaySlurry

The invention provides a ceramic / metal composite material brake lining for a high-speed train and a preparation method of the ceramic / metal composite material brake lining, and belongs to the technical field of high-speed brake. The existing high-speed train brake lining has the defects that the thermal stability is poor, the friction factor is low, the abrasion rate is high, the thermal decay resistance is poor, and the service life is short. The ceramic / metal composite material brake lining comprises friction blocks, a base plate and a heat radiation fin, wherein the friction blocks are made of ceramic block reinforced metal composite materials, the gap width among the friction blocks is 3 to 8mm, the ceramic block is obtained through sintering ceramic posts of a certain rule and connected ceramic biscuits of ceramic substrates connected with the ceramic posts, and the connected ceramic biscuits can be formed in modes of slurry filling, gel mold filling, molding pressing, isostatic pressing and the like. The preparation method provided by the invention comprises the following steps including ceramic block sintering, surface treatment, brake lining casting, precise processing and heat treatment. The ceramic / metal composite material brake lining has the characteristics that the thermal stability is good, the friction factor is high, the abrasion rate is low, the thermal decay resistance is good, the service life is long, and the like, and the effective braking can be realized on 380km / h high-speed trains.

Owner:浙江天乐新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com