Powder metallurgy iron-based high-speed brake pad

A powder metallurgy, iron-based technology, applied in the field of powder metallurgy iron-based high-speed brake pads, can solve the problems of increasing brake disc and brake block wear, high temperature, reducing powder metallurgy friction area, etc., to improve service performance and service life , smooth and effective braking, and the effect of improving braking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

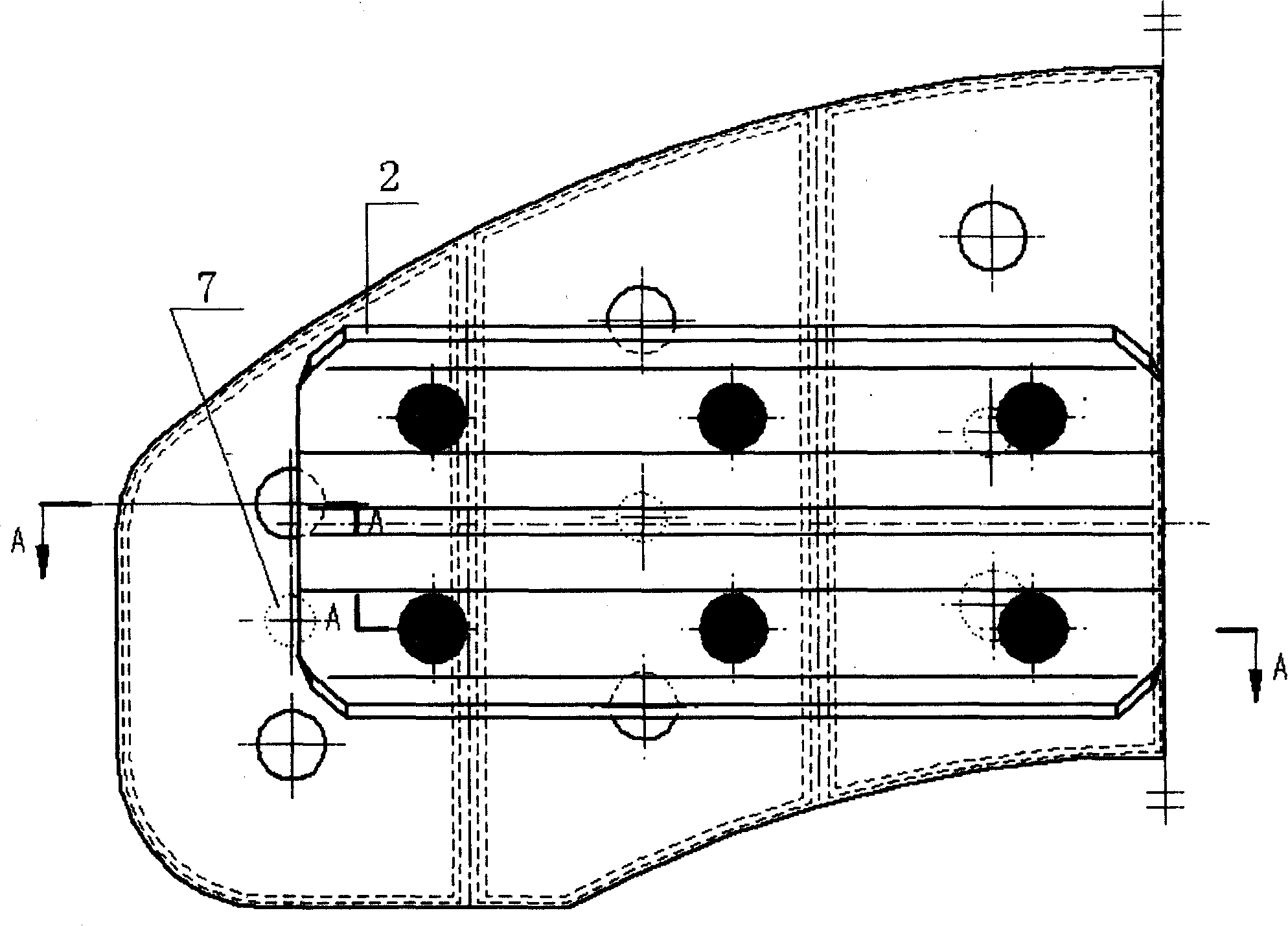

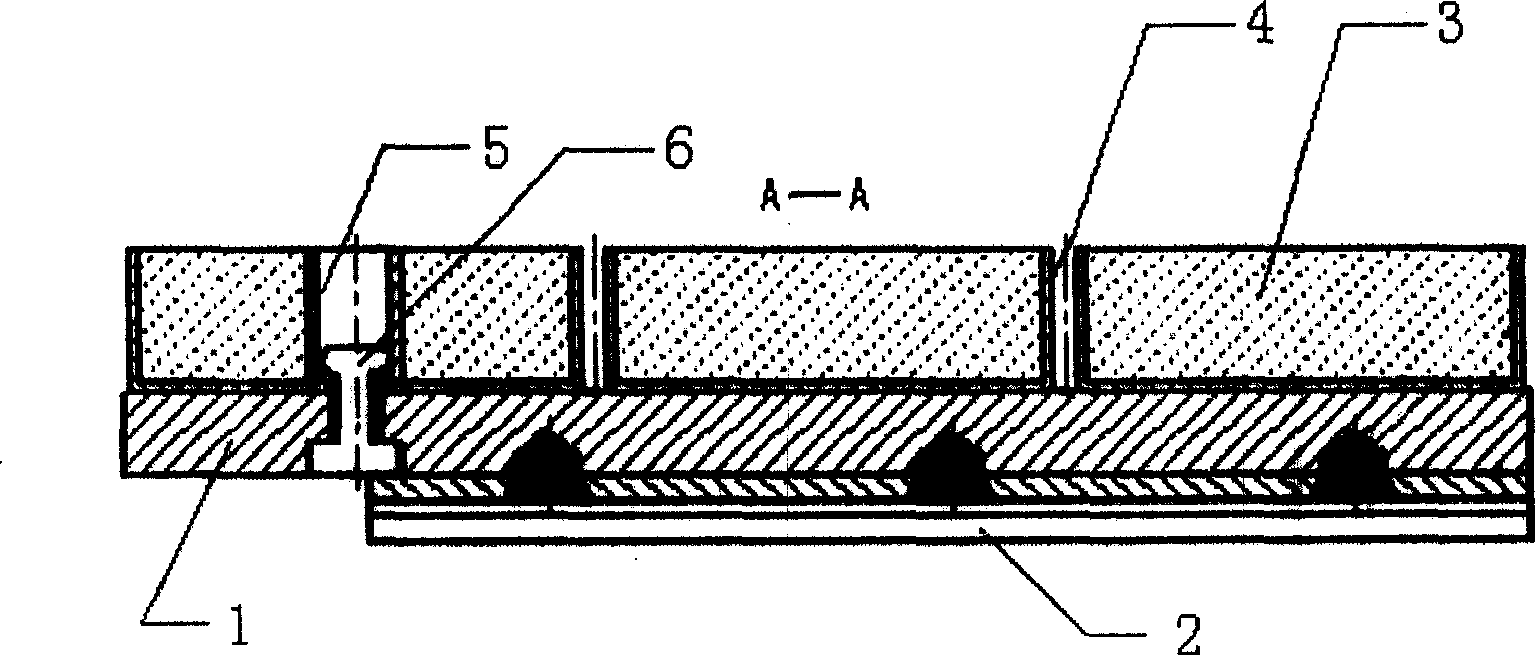

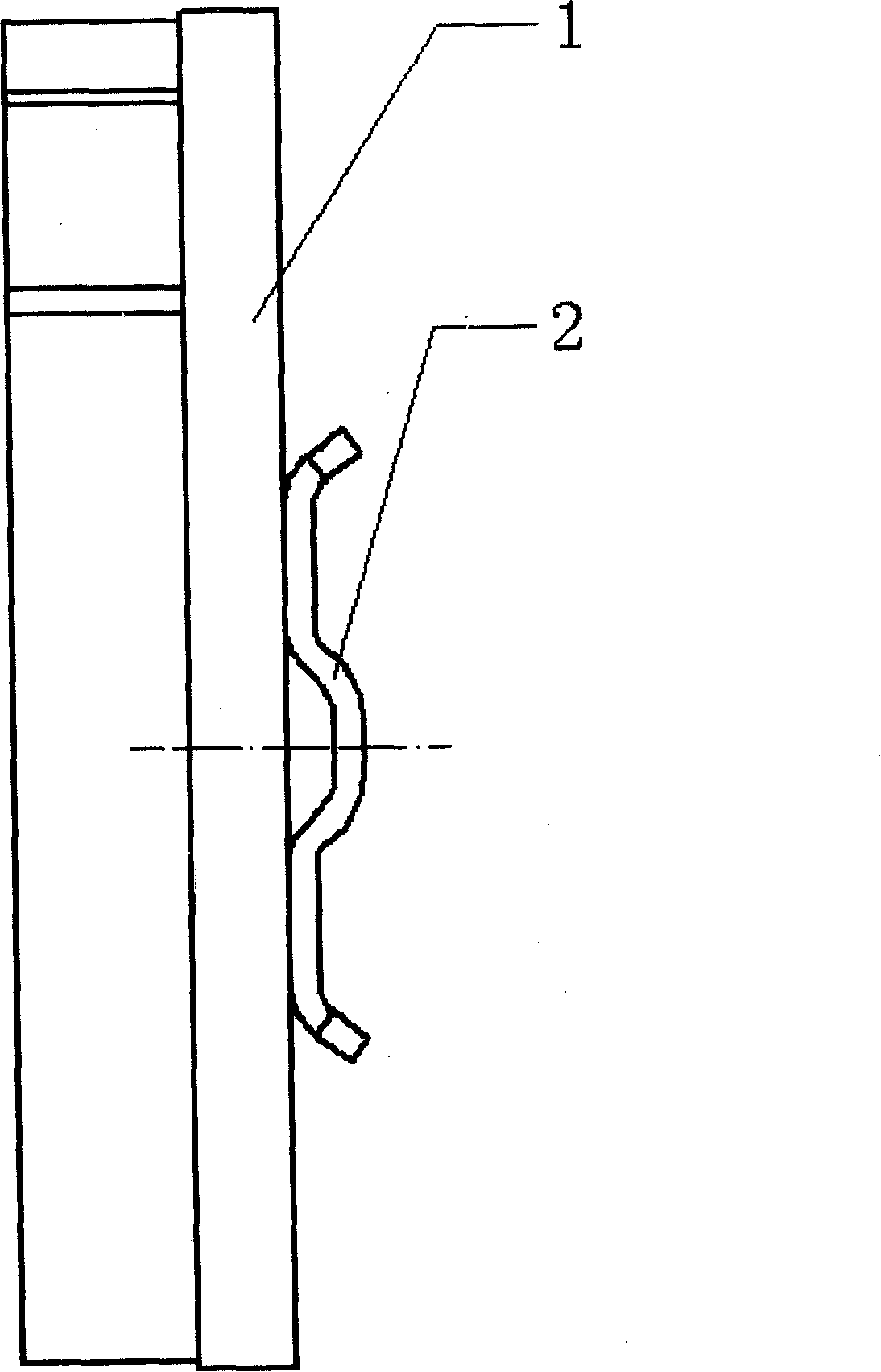

[0021] The present invention is mainly composed of a tile back 1, a dovetail block 2, a friction block 3, a hemming vessel 4 and a rivet seat 5 connected. The tile back 1 has a number of T-shaped through holes, a number of closed holes and welding holes; the friction block 3 is made of powder metallurgy materials such as iron powder and copper powder mixed evenly in proportion, cold pressed, and then pressure sintered and embedded in the edge Inside the vessel 4; the bottom of the hemming vessel 4 has several through holes and several outward bosses 7, and the hemming vessel 4 is connected to one side of the tile back 1 through the rivet seat 5, rivets 6 and bosses 7; the dovetail The block is convex in the middle, the two ends are gradually bent and concave, and the end is bent and convex again. There are 6 through holes in the concave part, and the dovetail block 2 is connected through the through holes and the welding holes on the tile back 1. Welded on the other side of ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com