Patents

Literature

7837 results about "Brake pad" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

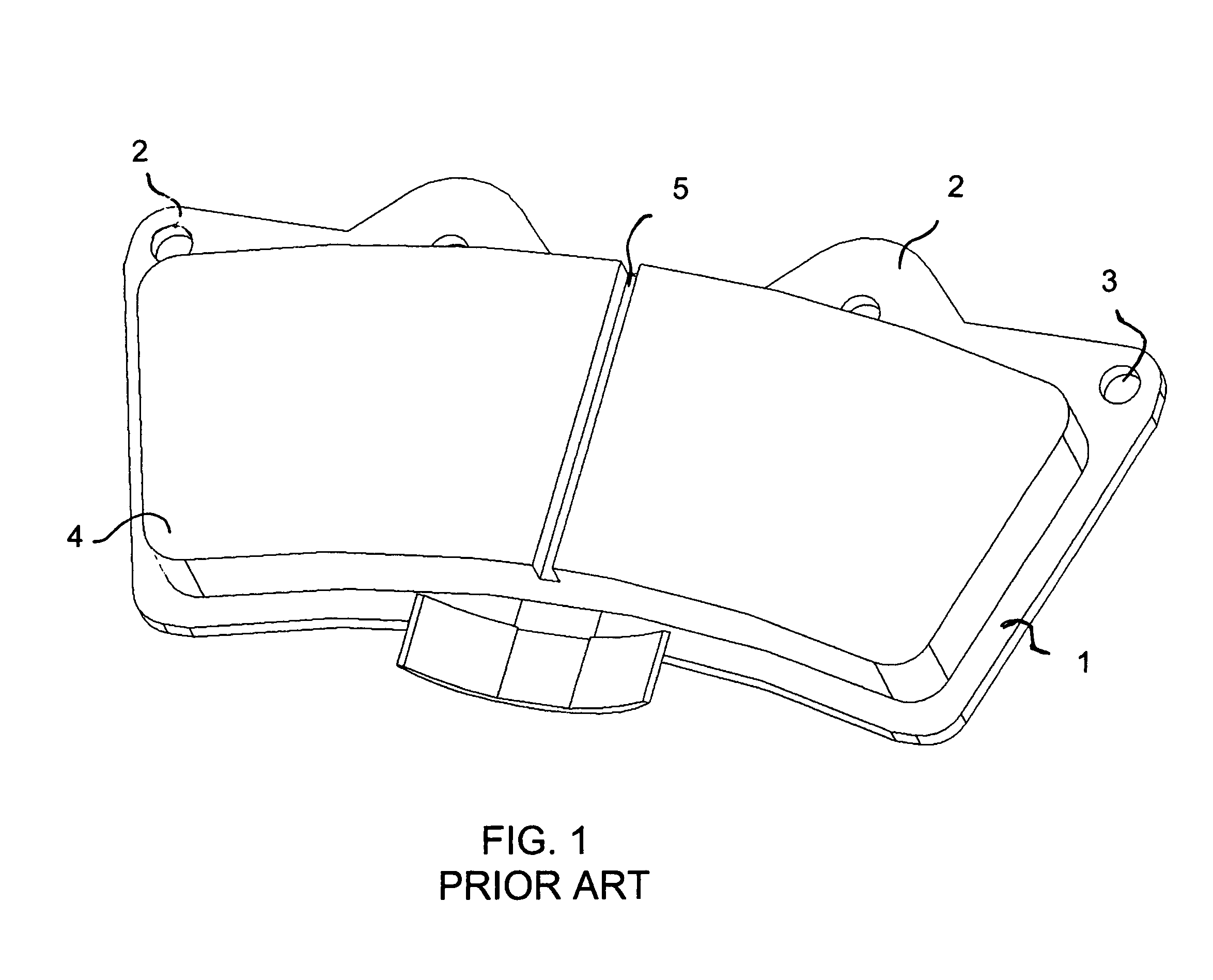

Brake pads are a component of disc brakes used in automotive and other applications. Brake pads are composed of steel backing plates with friction material bound to the surface that faces the disc brake rotor.

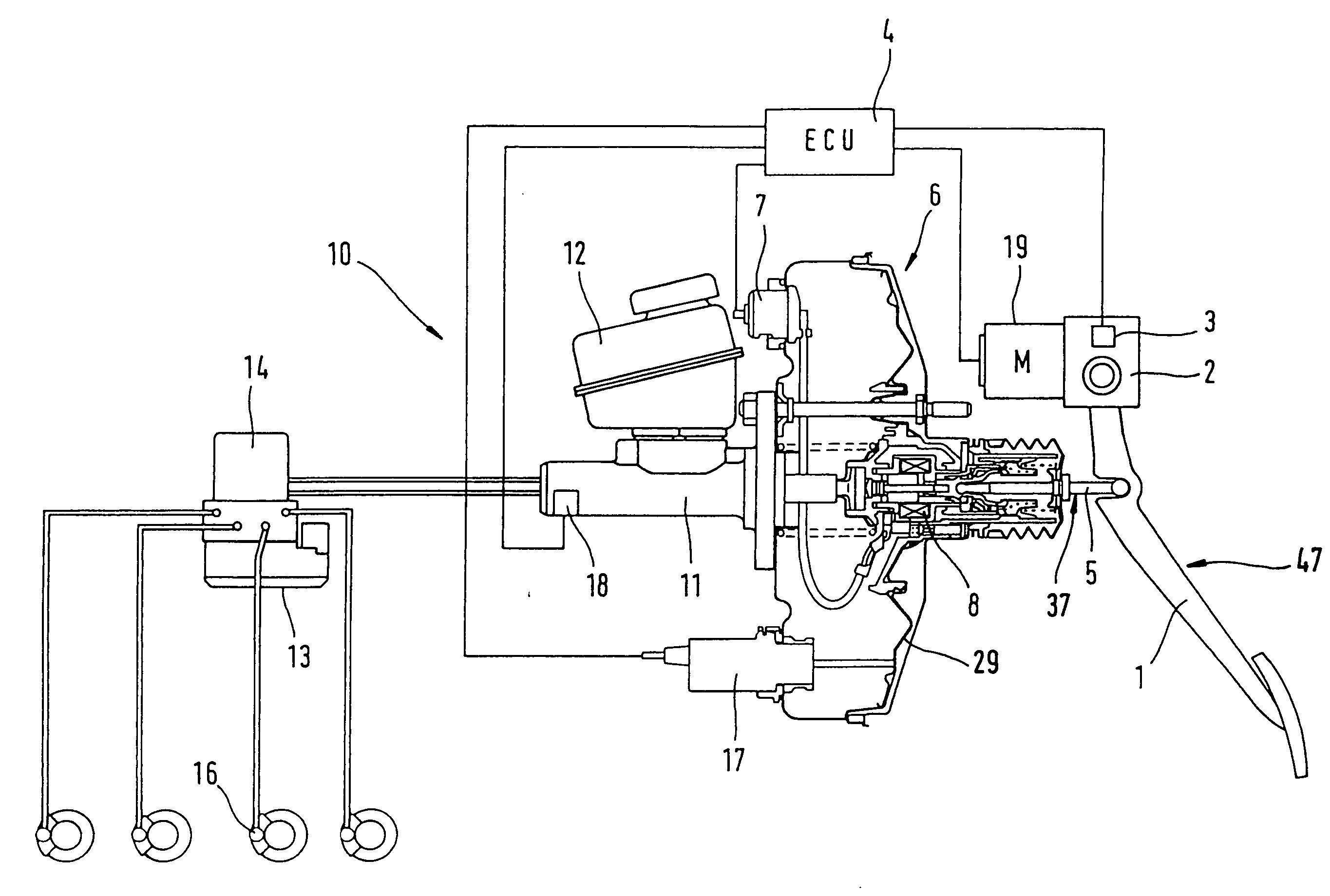

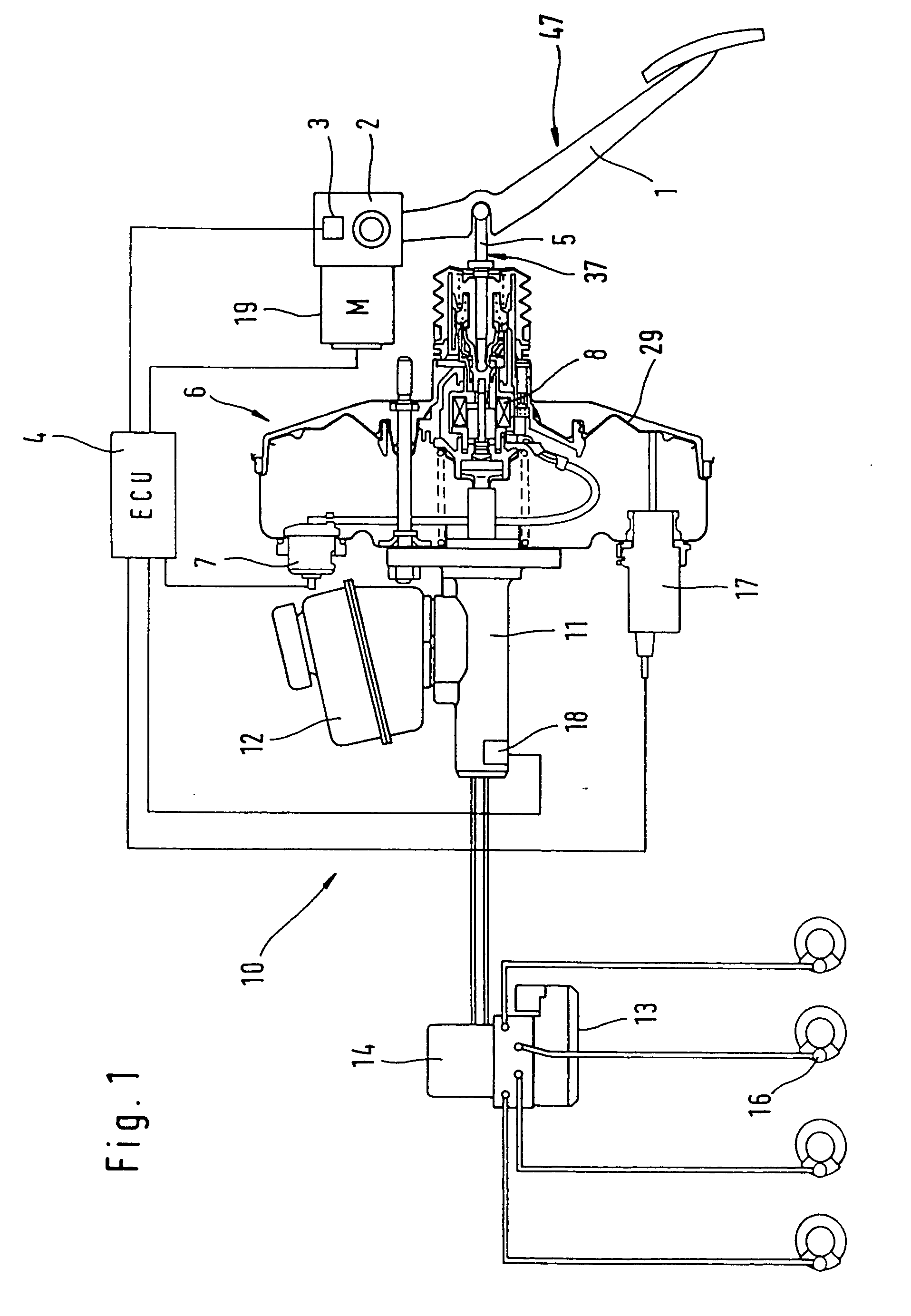

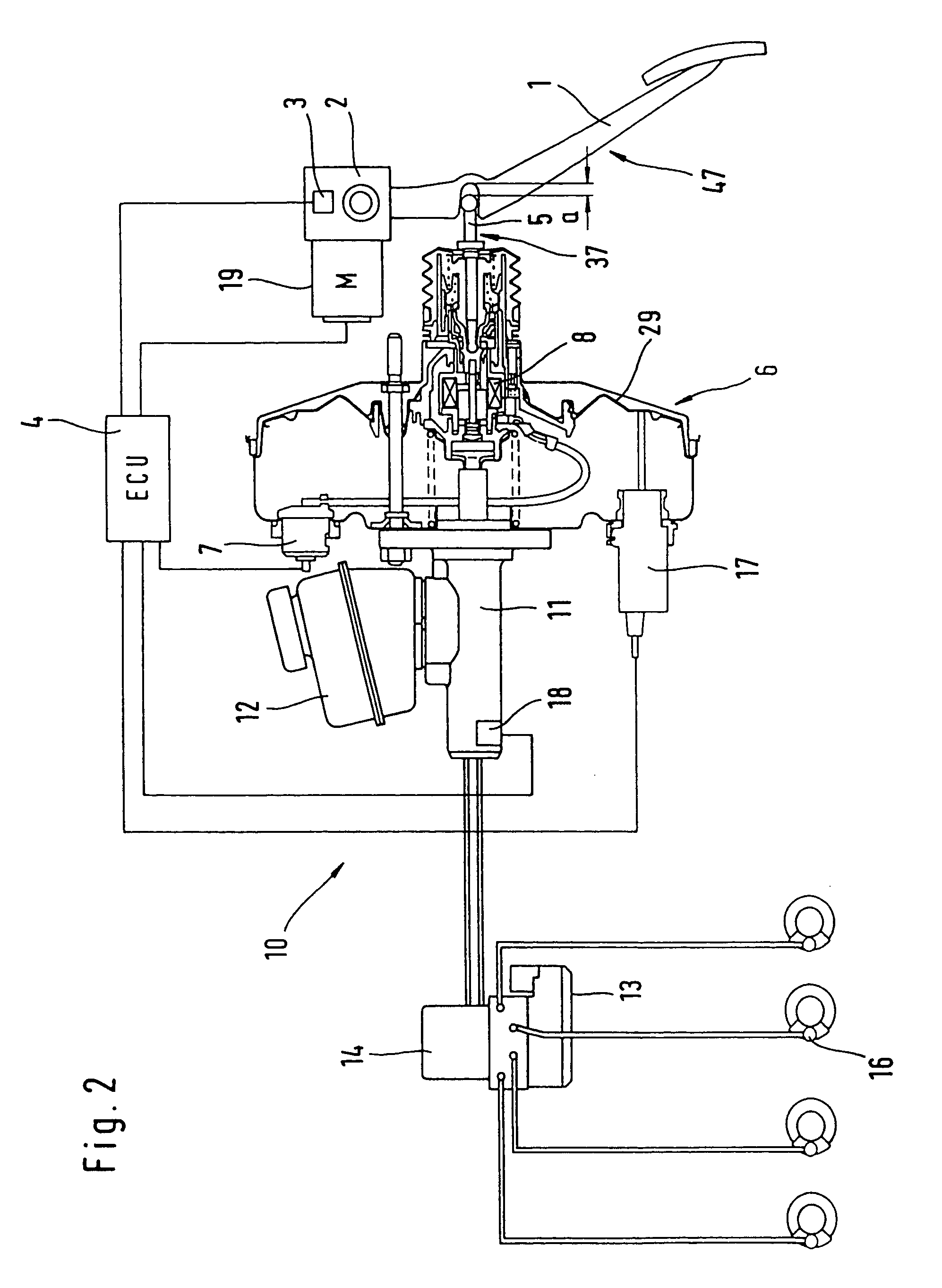

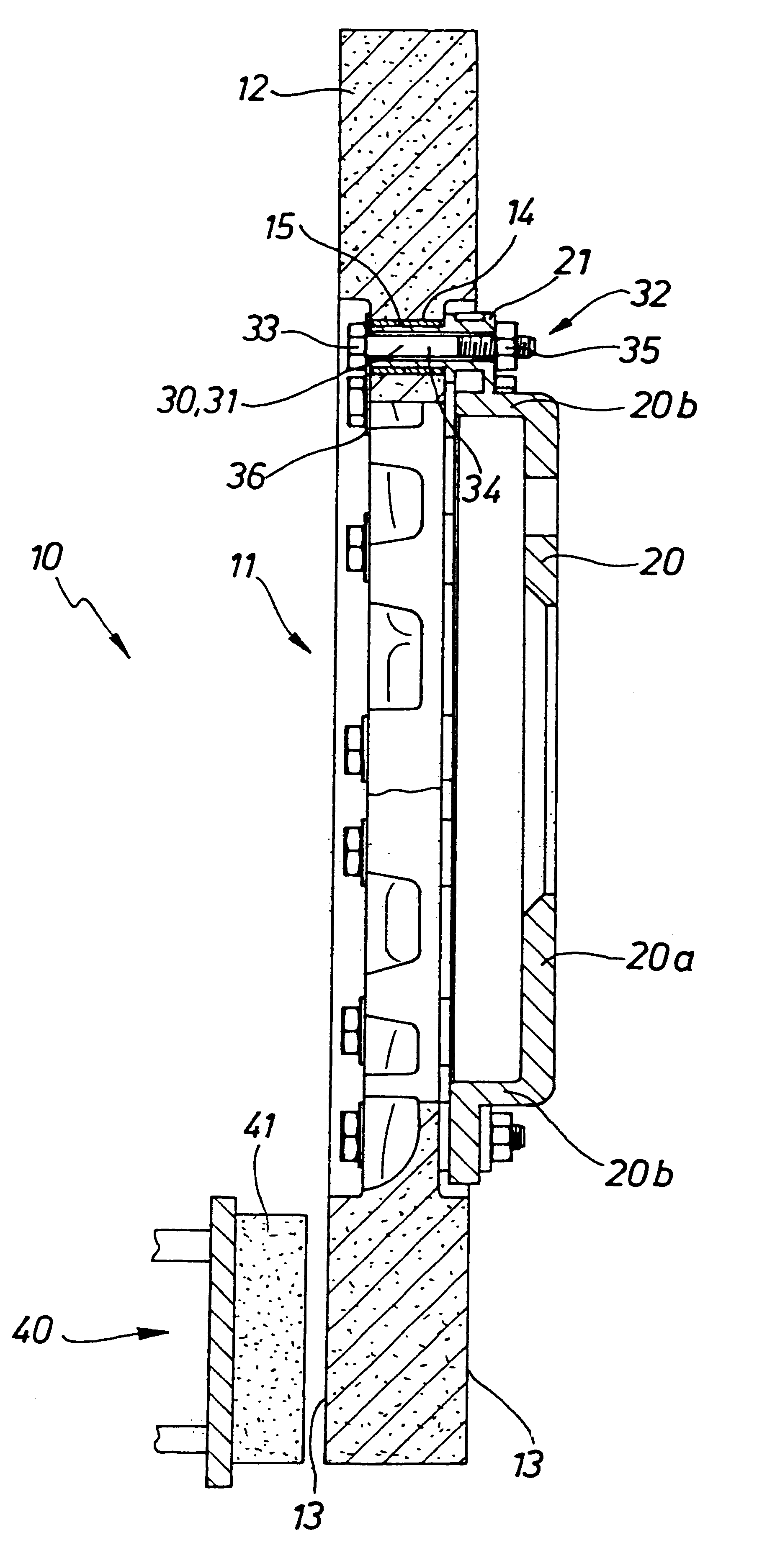

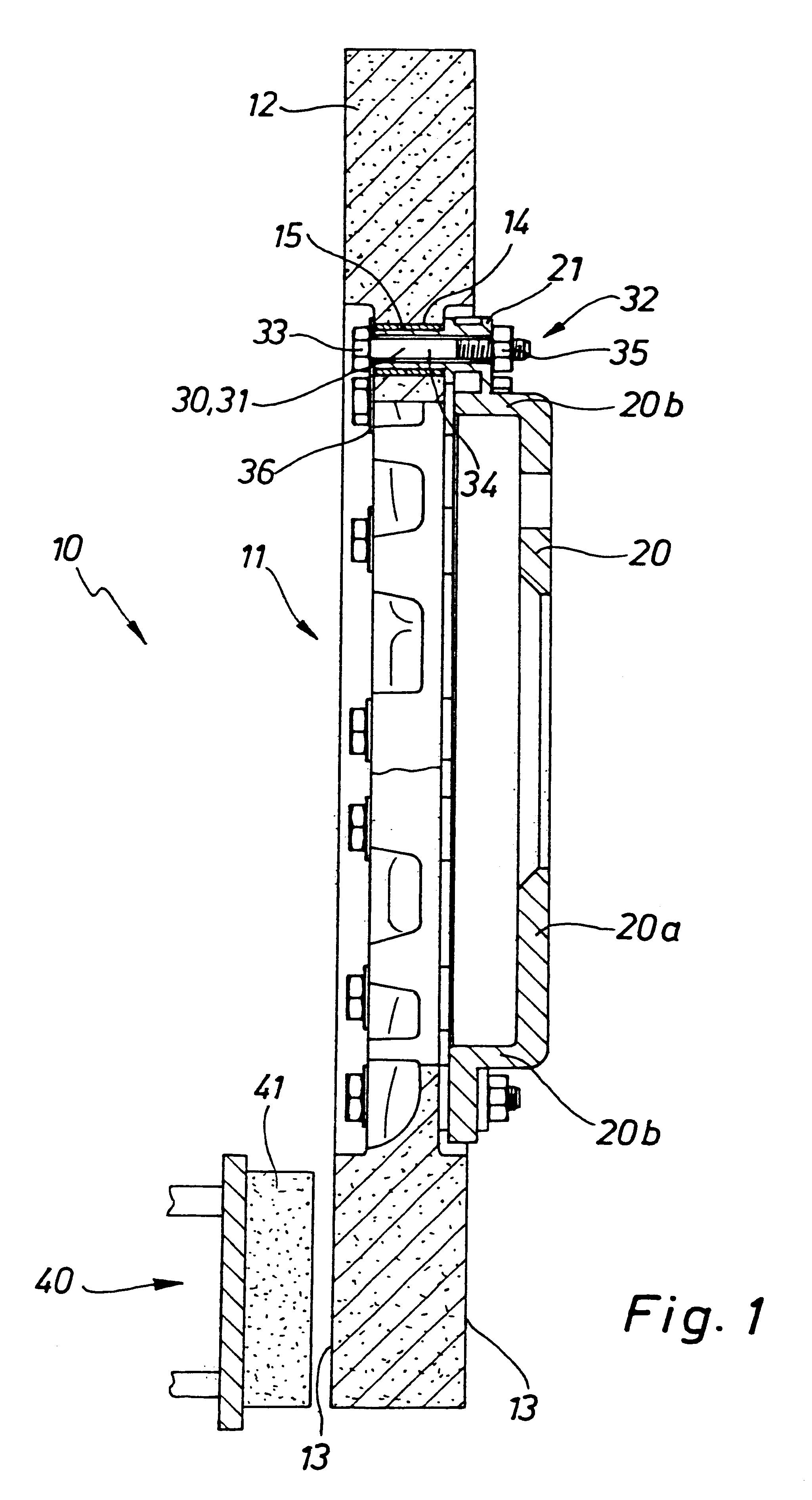

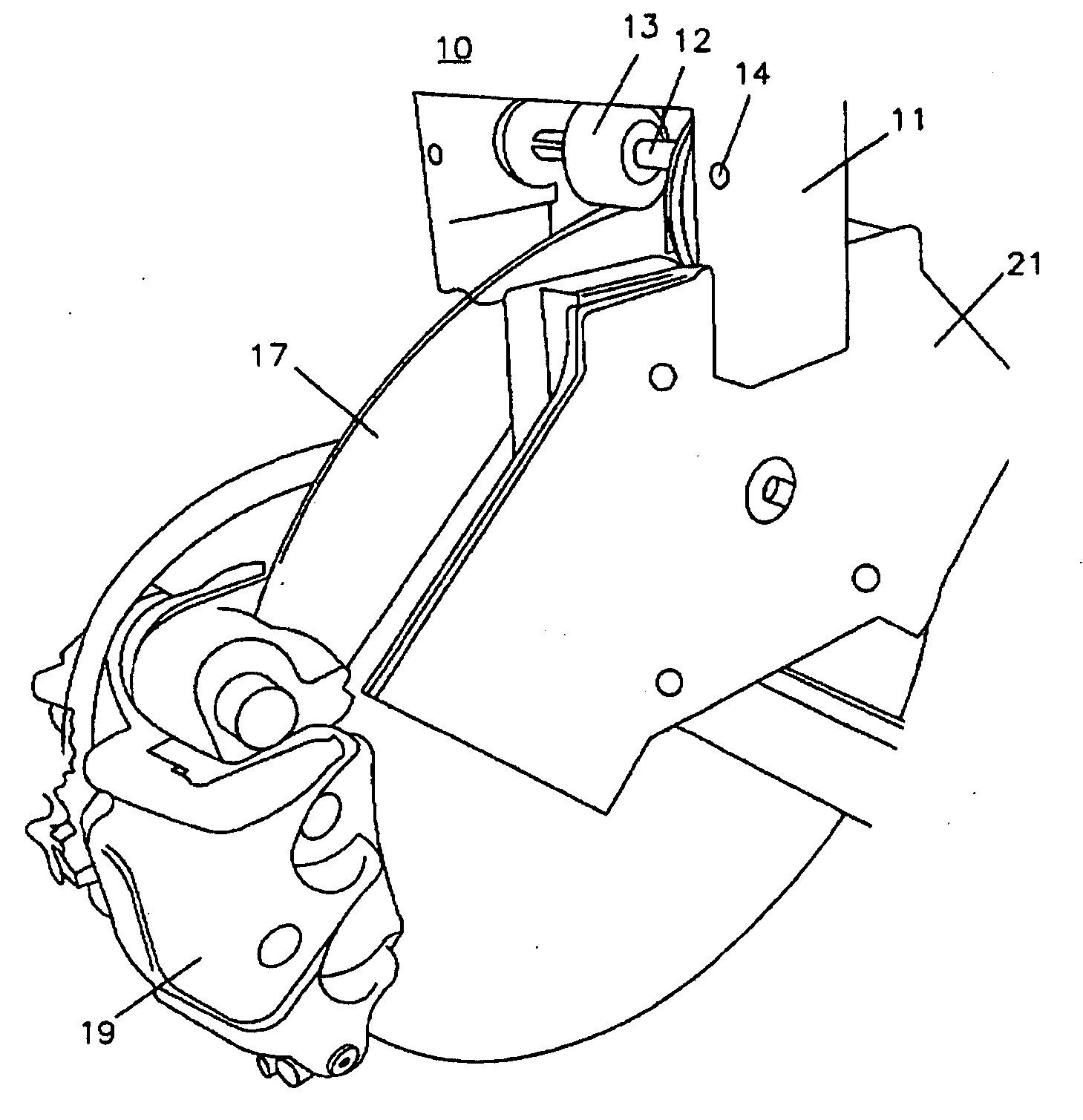

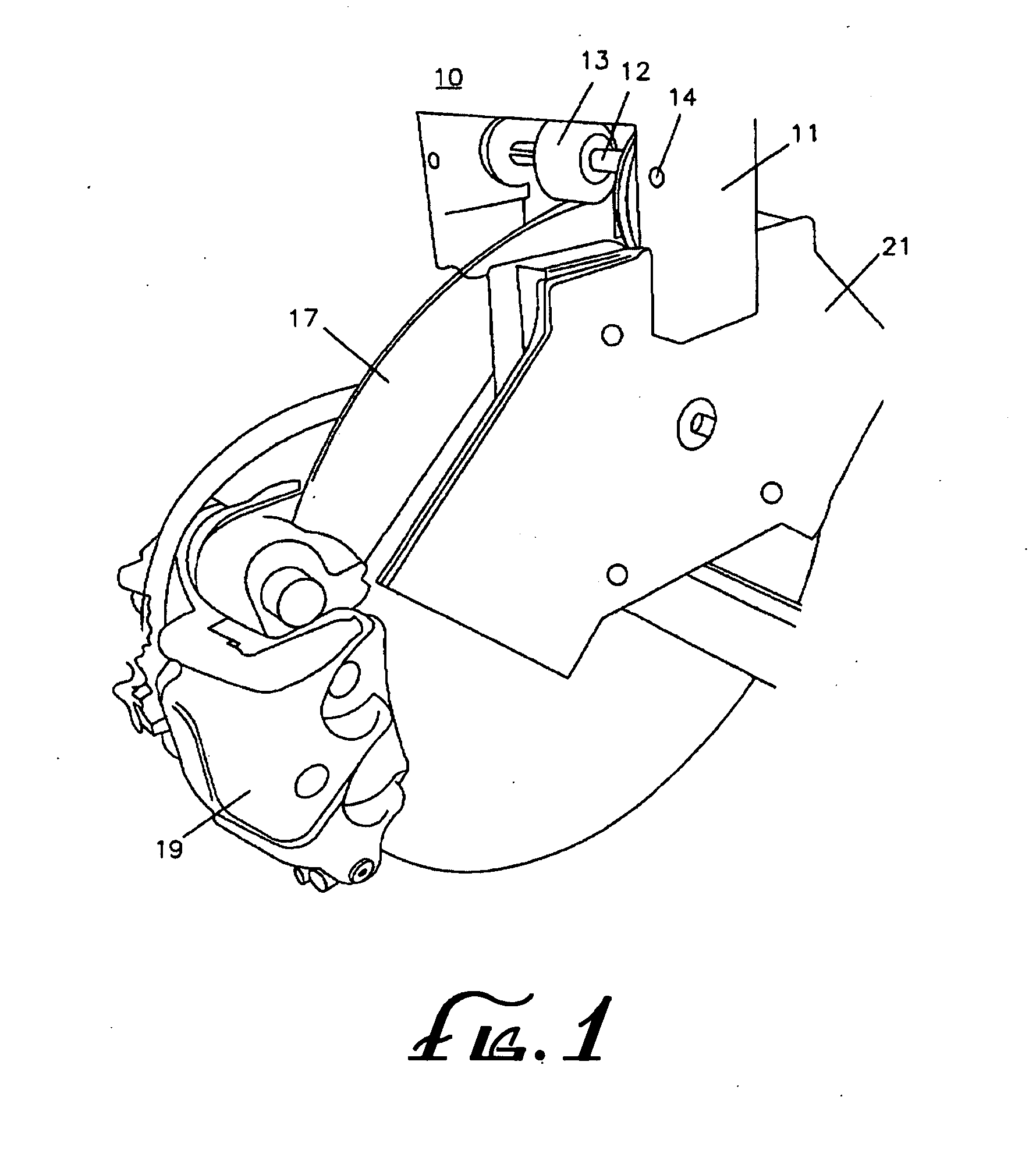

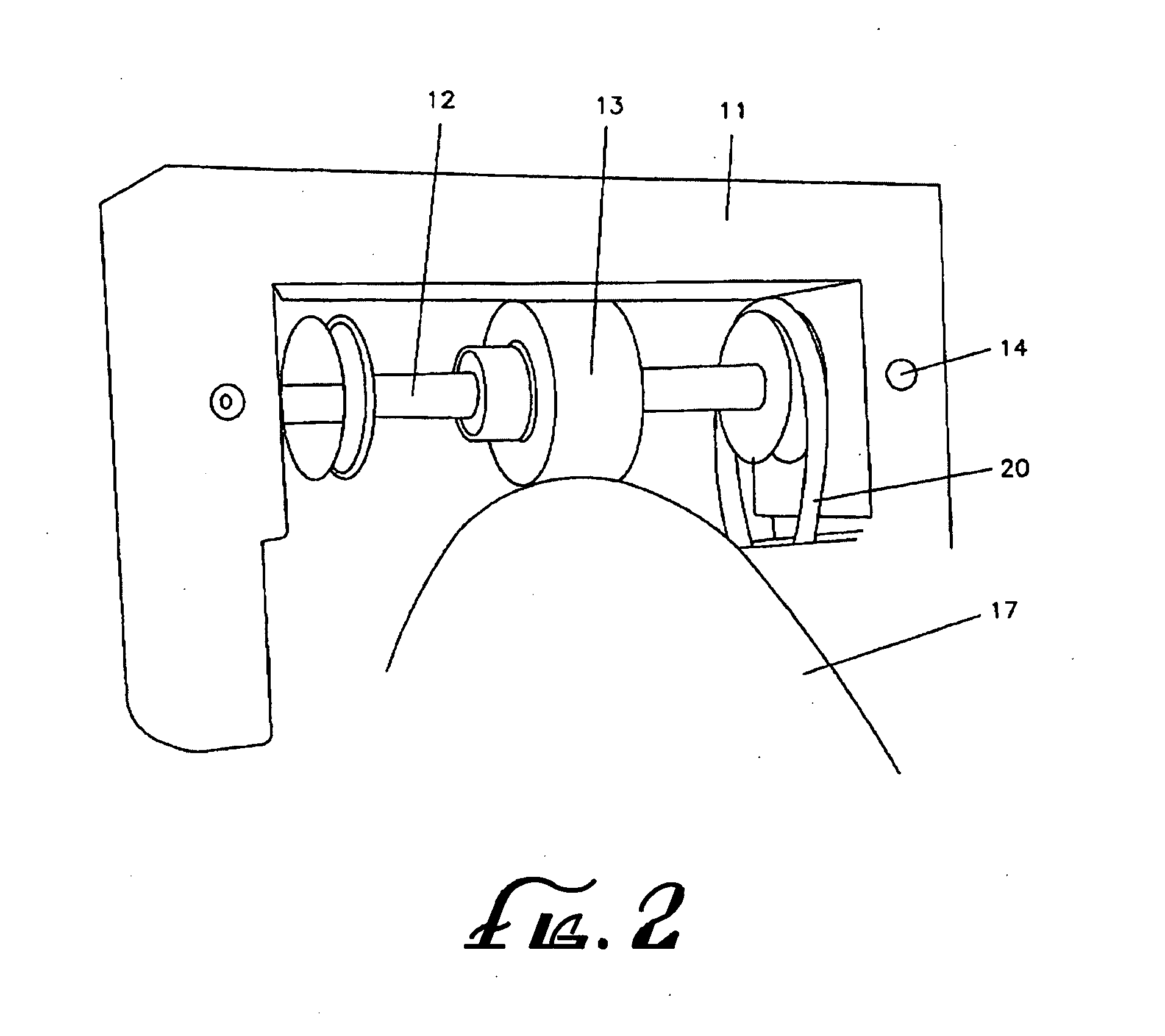

Brake by-wire actuator

InactiveUS20060163941A1High brake pressureReduce tractionBraking action transmissionFoot actuated initiationsMobile vehicleDistributor

The present invention relates to a brake-by-wire actuator for actuating the brake system of a motor vehicle, comprising a simulator which can be acted upon by a brake pedal, with a signal of an actuation sensor being sent to an electronic control unit which controls a pressure source in response to the signal of the actuation sensor, and wherein an output of the pressure source is connected to a distributor device for the brake force and actuates individual wheel brakes of the vehicle, also comprising means for enabling actuation of the brakes by muscular power within a fallback mode. In order to provide an improved fallback mode in a brake-by-wire actuator, according to the invention, a lost travel is provided between a first actuation component such as a brake pedal in particular or a component articulated at the brake pedal and an actuation component that is connected downstream in the flux of force, in particular an input member, in order to uncouple the first actuation component mechanically from the reactions of force of the motor vehicle brake system in the by-wire mode.

Owner:CONTINENTAL TEVES AG & CO OHG

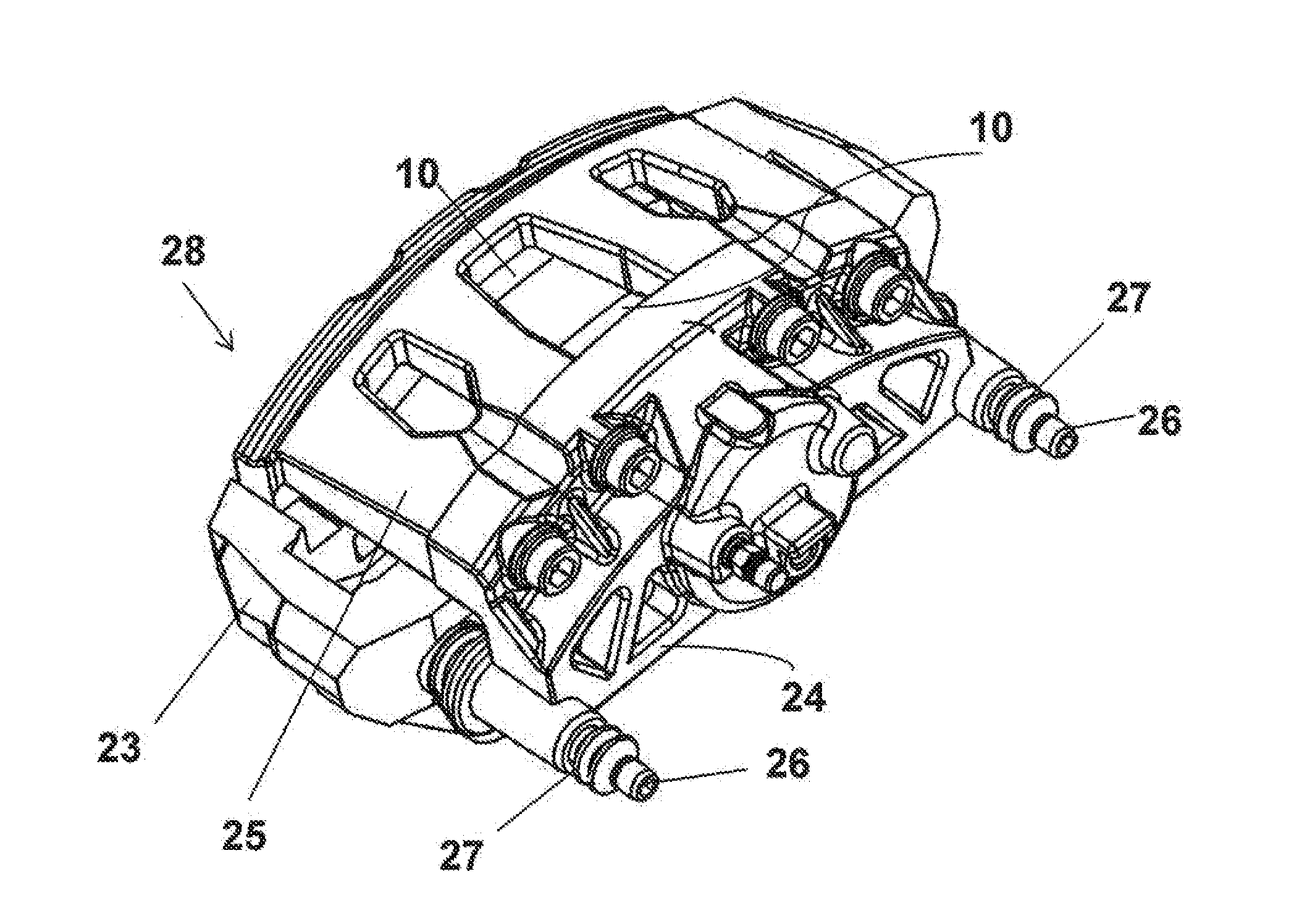

Brake unit

InactiveUS6302246B1Prolong lifeImprove flatnessBraking element arrangementsNoise/vibration controlEngineeringCeramic metal

A brake unit comprising at least one brake and at least one brake pad having at least one friction lining is described. The brake has a disk brake with a brake rotor made of a ceramic-metal composite (CMC) whose outer surface or surfaces at least partially form a friction surface for the at least one friction lining, and a disk brake cup that is mounted on the disk brake by way of one or more mounting elements. The friction surface of the disk brake has a hardness of approximately 1600 to 2500 HV, and the at least one friction lining has a coefficient of friction of approximately 0.3 to 0.5. The disk brake cup and / or the mounting elements form a corrosion-inhibiting attachment to the disk brake. The brake unit can be operated in corrosion-free fashion over a service life of at least approximately eight to 10 years or approximately 200,000 to 300,000 km.

Owner:FRENI BREMBO SPA

Method for preparing C/SiC composite material through low-cost fused silicon impregnation method

The invention relates to a method for preparing a C / SiC composite material through a low-cost fused silicon impregnation method, which comprises the following steps: performing calcining pretreatment on a carbon felt or graphite felt at 400-600 temperature; immersing the pretreated carbon felt or graphite felt in a melamine and boric acid solution, thus coating a boron nitride protective layer; immersing in a carbon / silicon carbide slurry water solution, performing impregnation to ensure that pores of the carbon felt or graphite felt are fully filled with carbon / silicon carbide, placing in a sintering furnace, and performing primary fused silicon impregnation treatment at 1600-1800 DEG C; immersing in liquid phenolic resin, and performing carbonization treatment under the protection of an inert atmosphere at 800-1000 DEG C to ensure that all the resin is carbonized; and finally, performing secondary fused silicon impregnation treatment to ensure that carbon produced by carbonization of the resin totally reacts with silicon to generate silicon carbide, thus obtaining the C / SiC composite material. The obtained C / SiC composite material is high in density, low in air pore and free silicon content, and favorable in material strength, toughness and frictional wear performance, and can be used for manufacturing of brake pads.

Owner:山东宝纳新材料有限公司

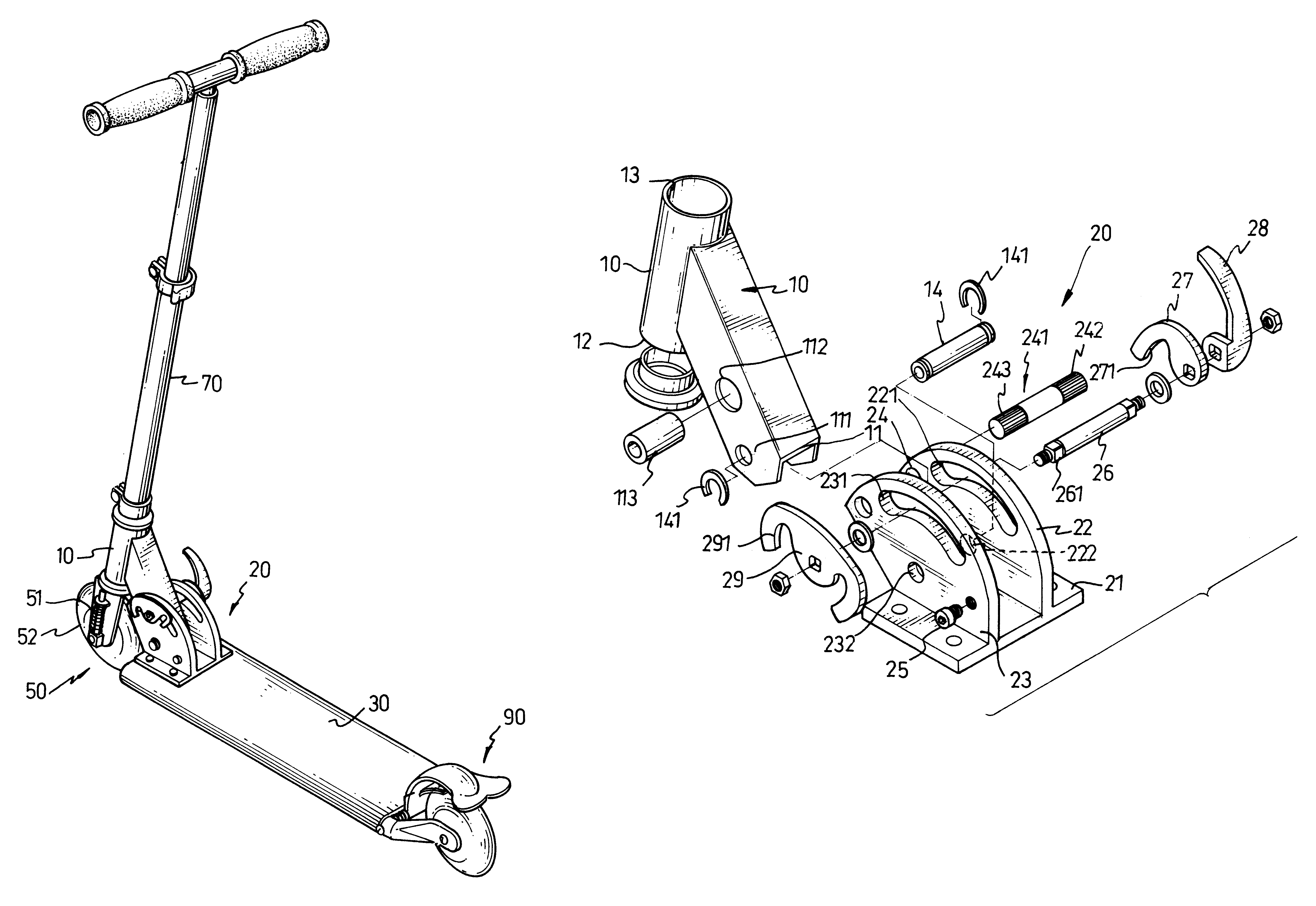

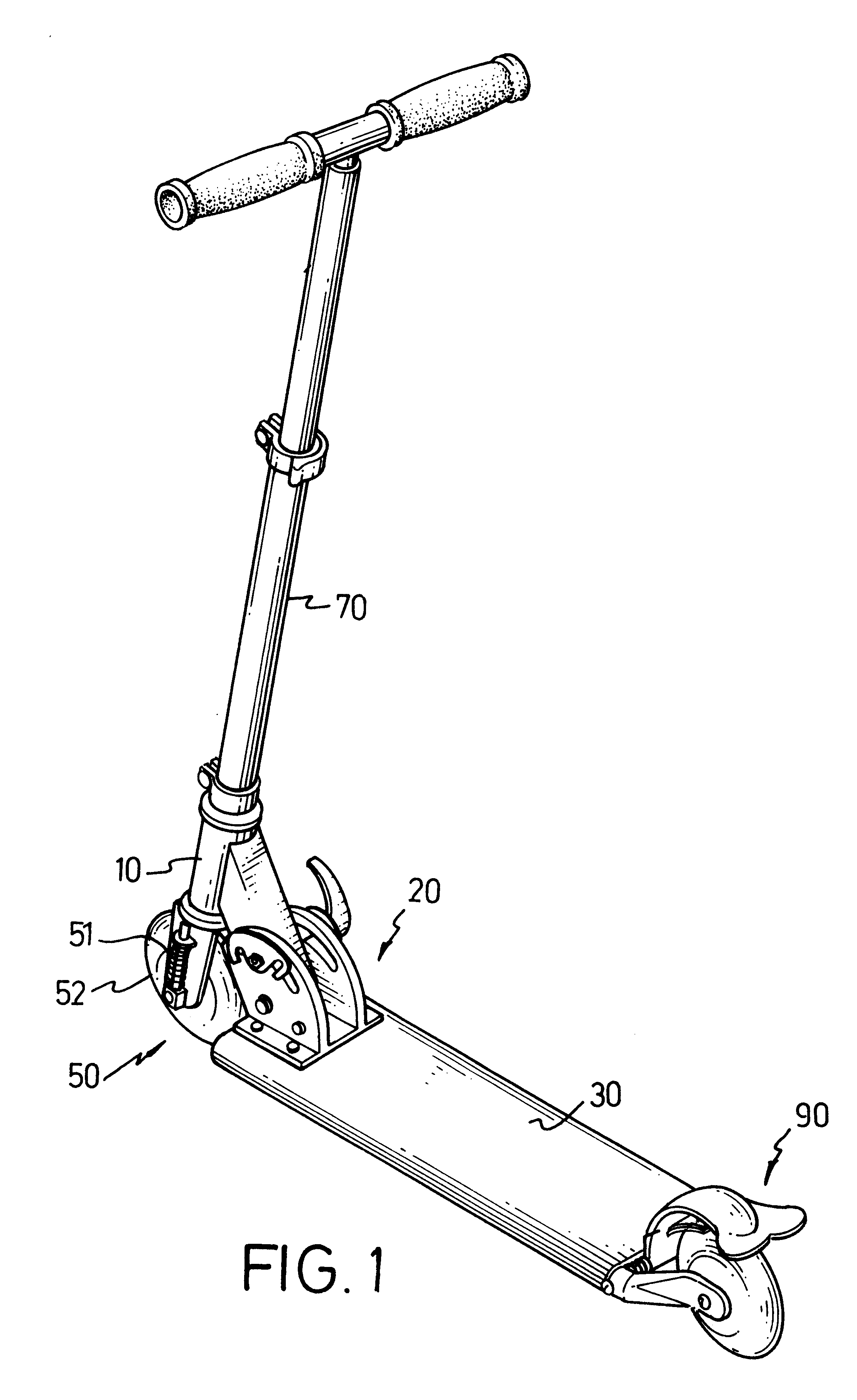

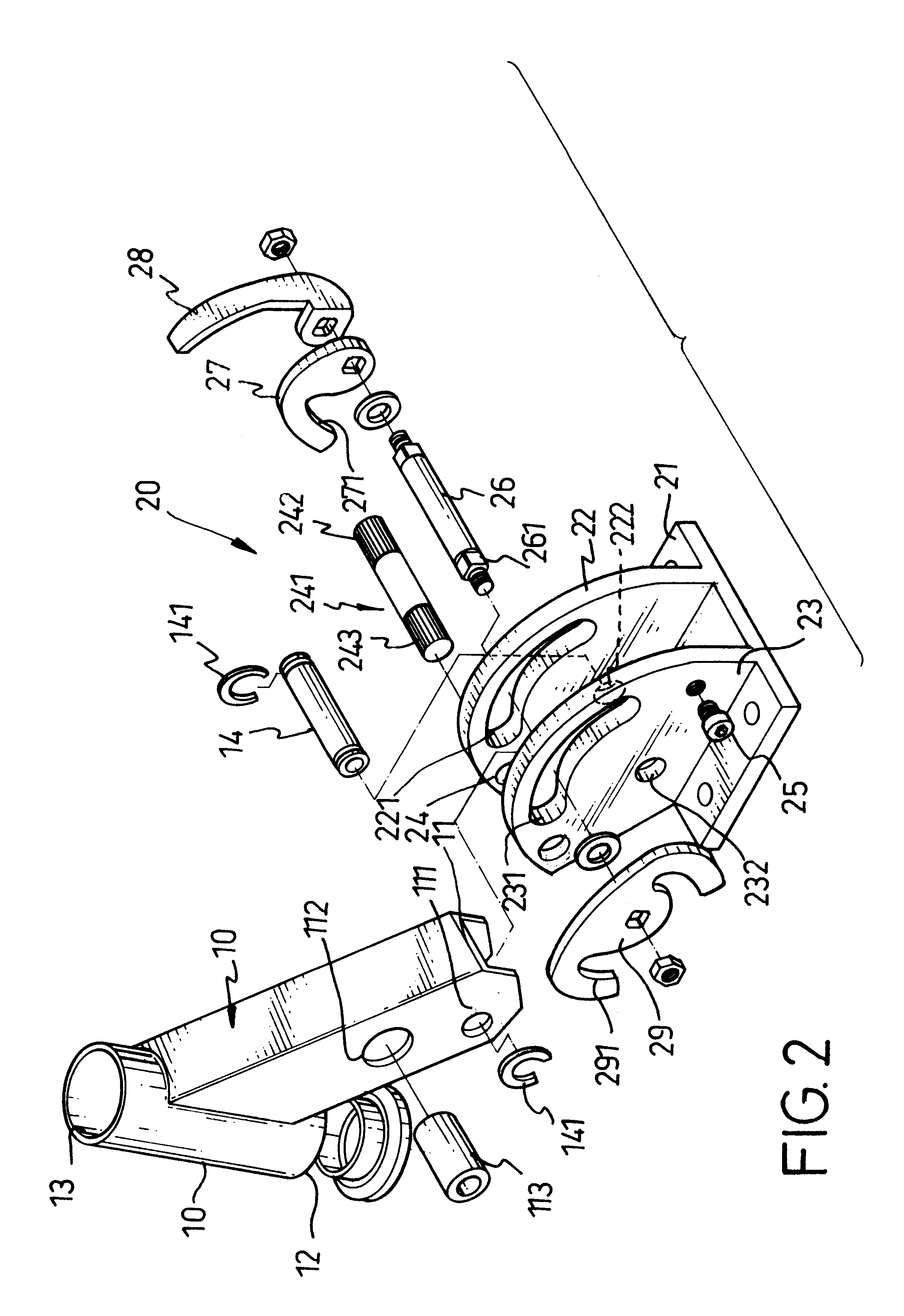

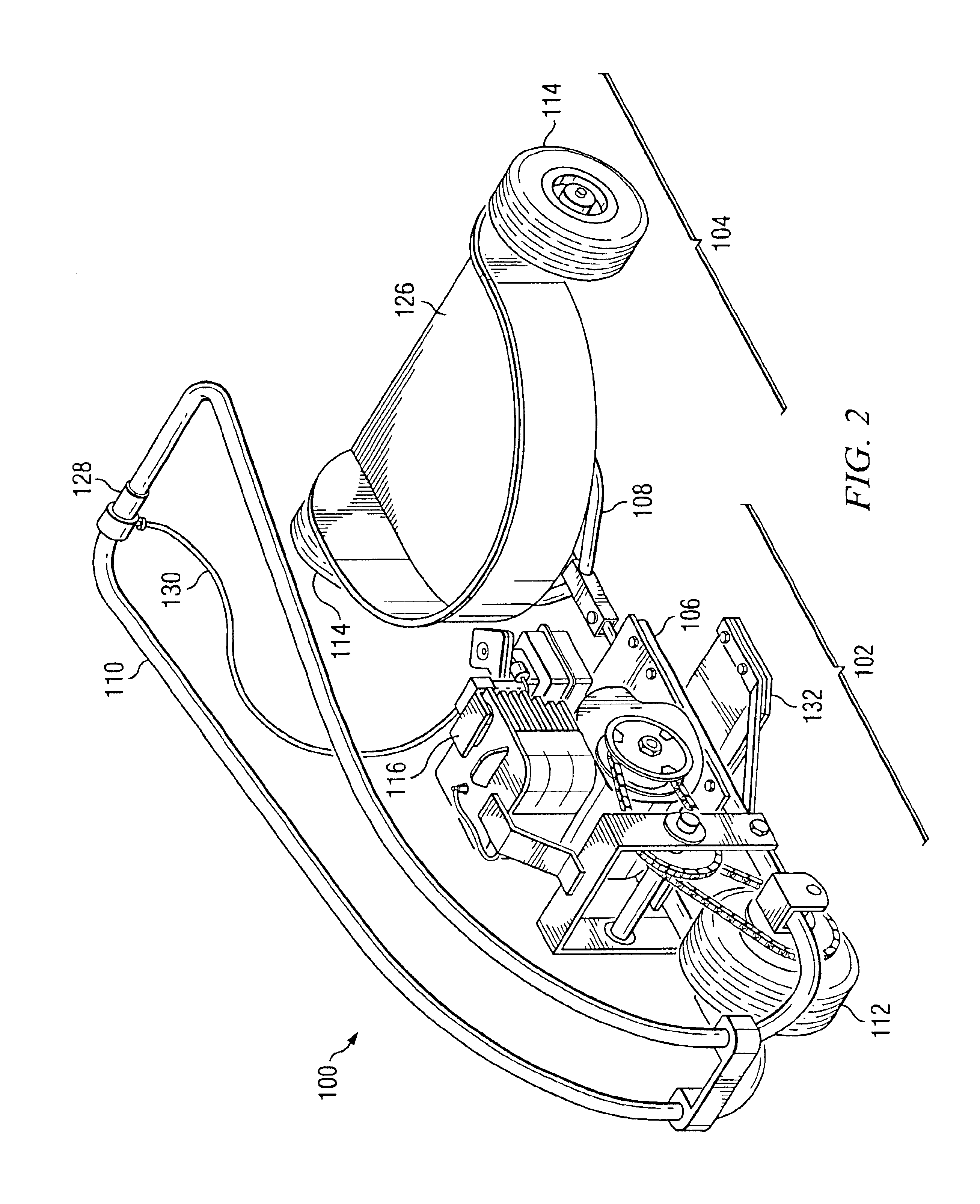

Foldable scooter with head tube assembly, brake and suspension

A foldable scooter has a head tube pivot assembly having a seat with two wings, a head tube with a push bar, a lever and a rocker. The head tube is able to be pivotally received between the wings. The lever, the push bar and the rocker are simultaneously moveable relative to the head tube, such that a hook on the push bar is able to detachably engage with one end of a limit pin to release or secure the head tube. A front wheel suspension spring is provided on both sides of the front wheel to function as a damper to smooth the ride. A brake assembly is provided on the rear wheel. The brake assembly has a fender with a brake pad securely attached thereto such that the friction between the brake pad and the rear wheel enhances the braking effect to the scooter.

Owner:CHEN CHIH LIANG

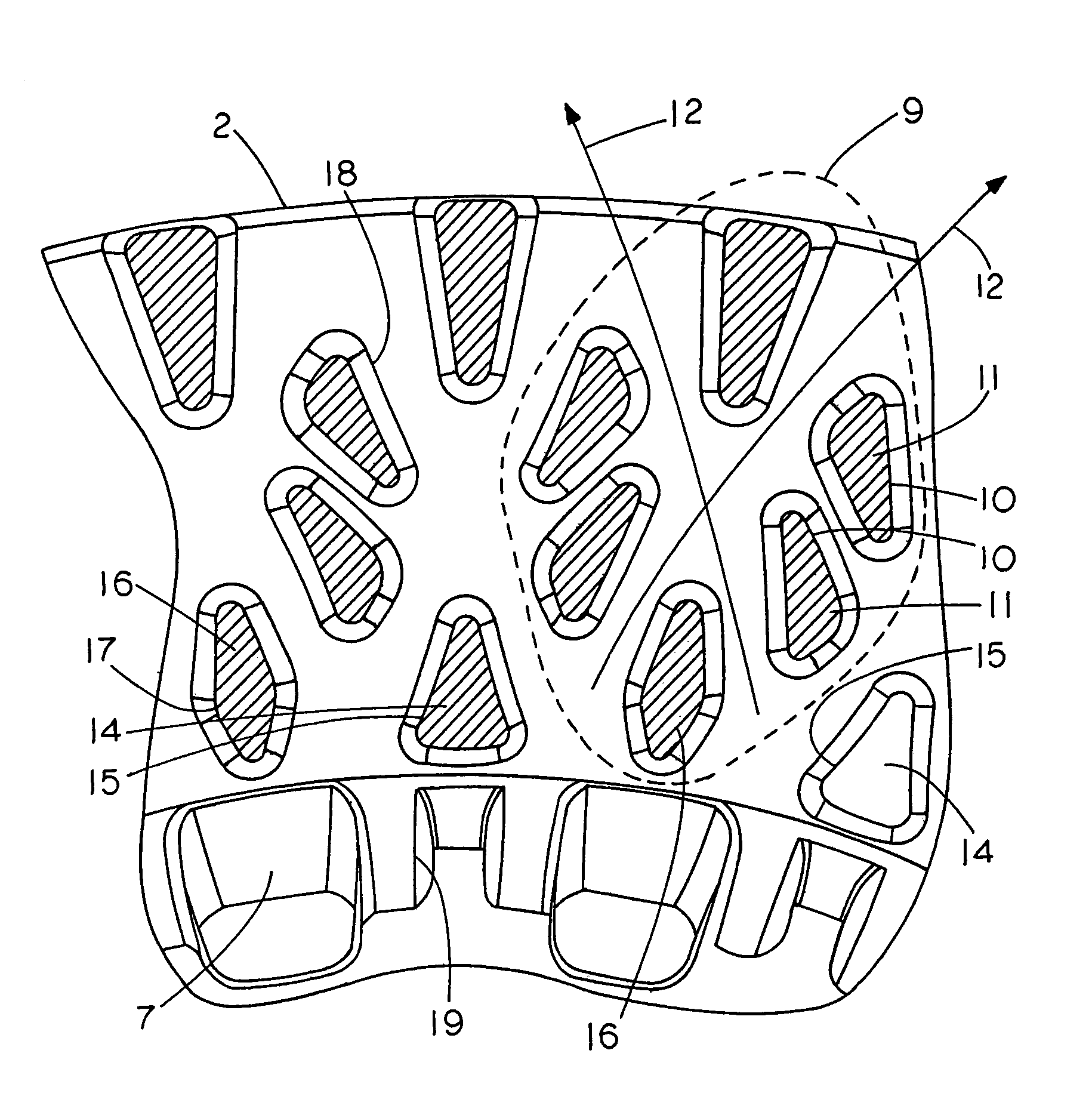

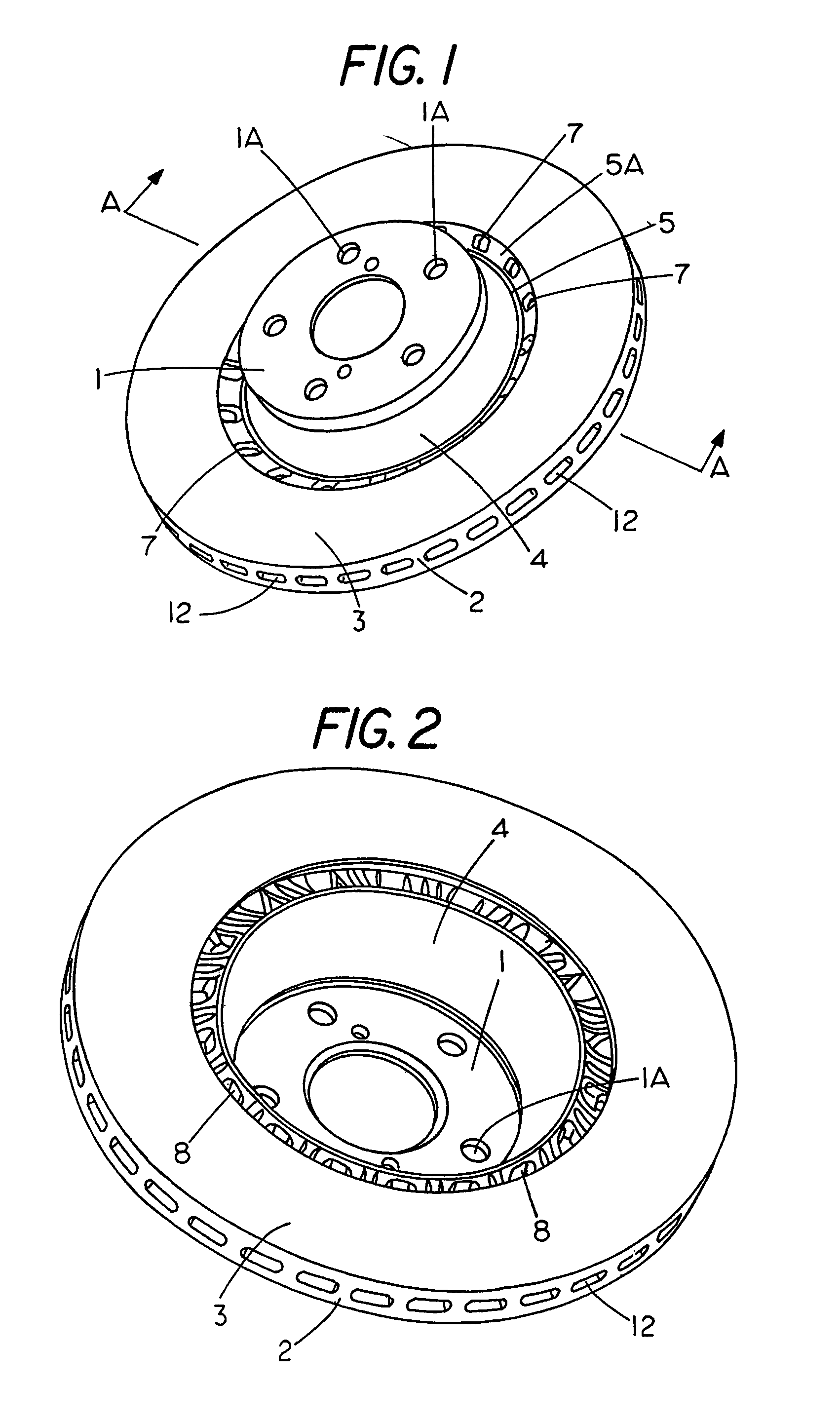

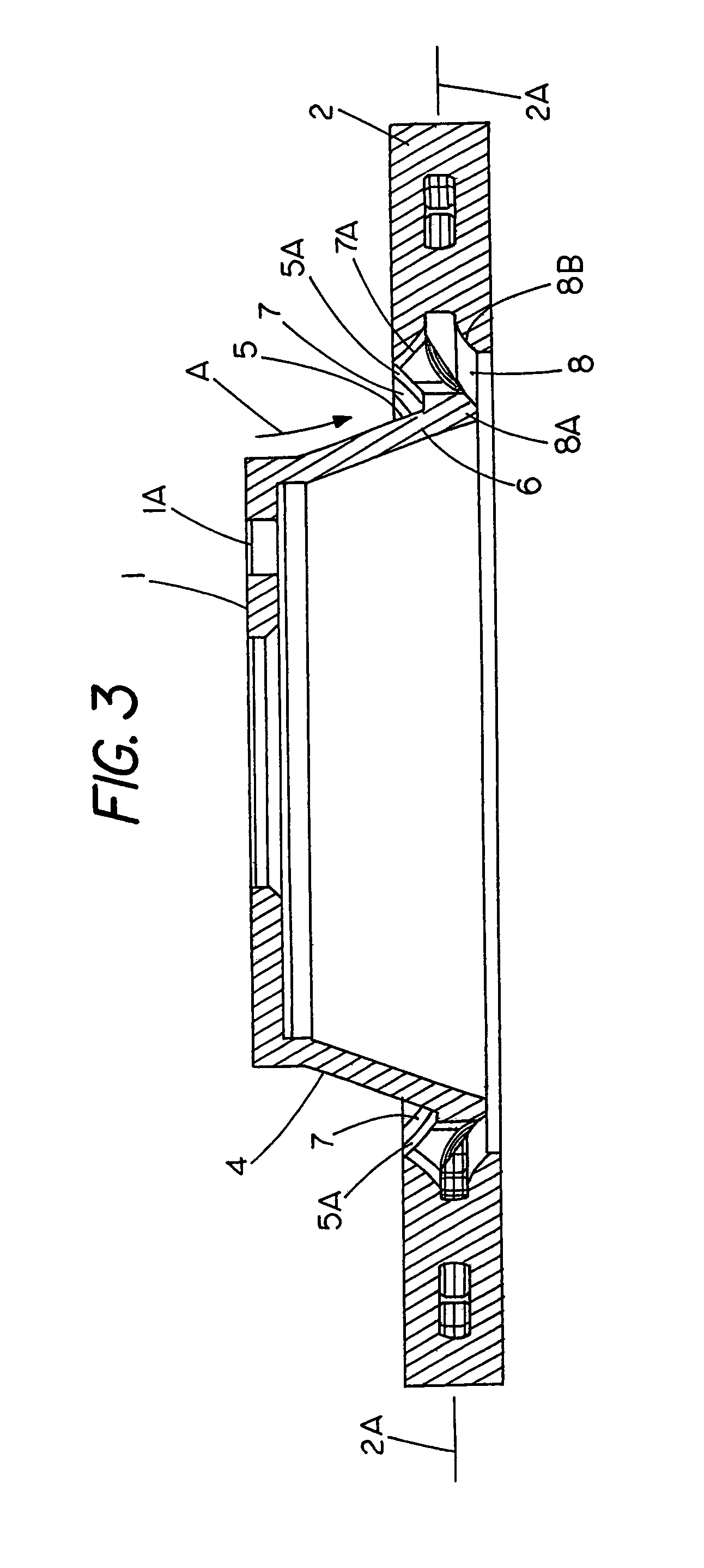

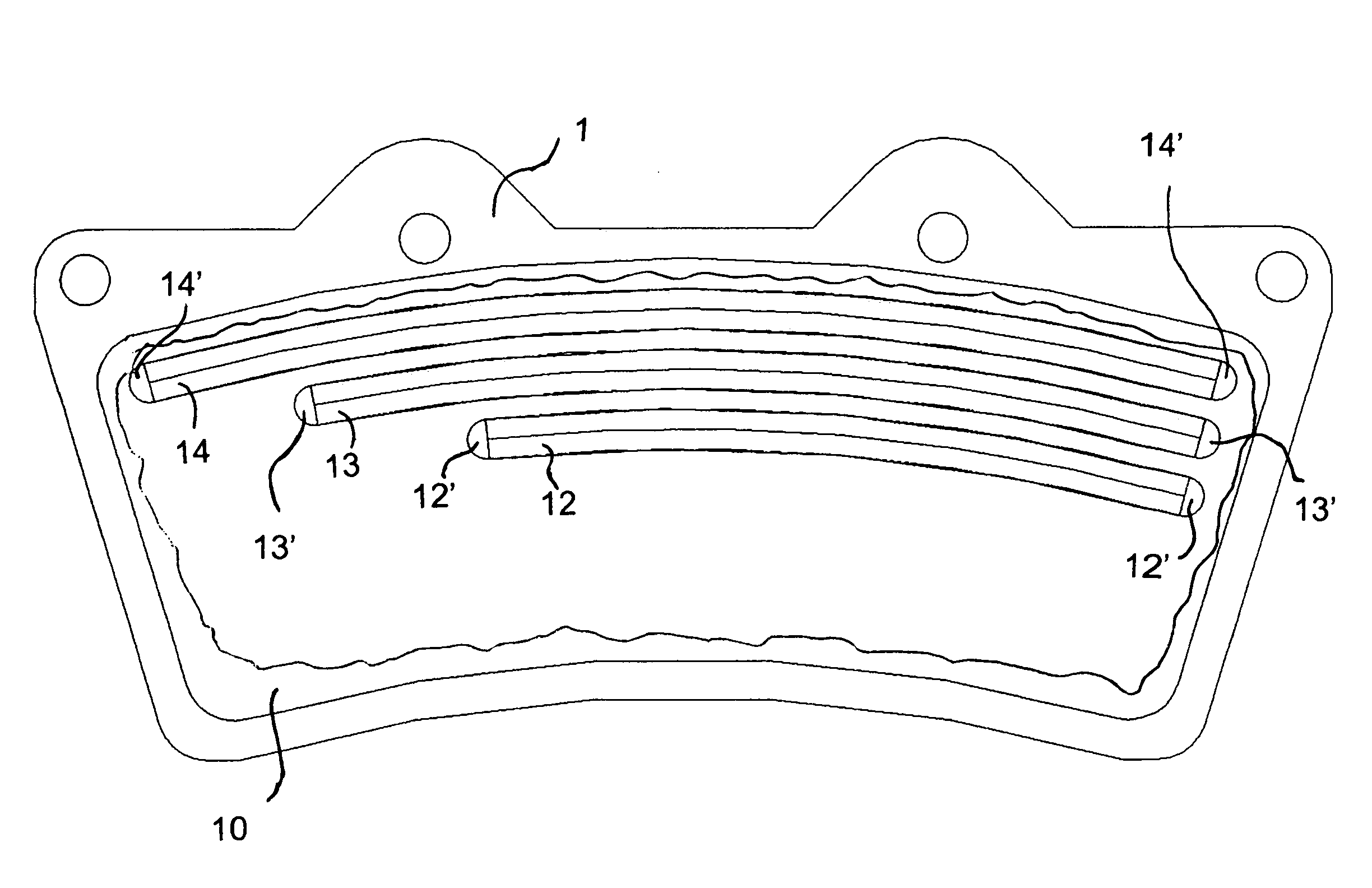

Self-ventilating disc brake rotor

There is a brake disc rotor having a central hub (1) co-axial with surrounding rings (2) which form brake bands (3) for engagement with brake pads. The rings (3) are supported in a spaced apart parallel configuration with channels (12) therebetween whereby in use of the rotor cooling air is drawn in through vent openings formed around the inner periphery of the rings (3) and then radially outwardly through the channels (12) as the rotor turns. The vent openings include inlet vent ports (7) on the outboard side of the rotor.

Owner:DISC BRAKES AUSTRALIA

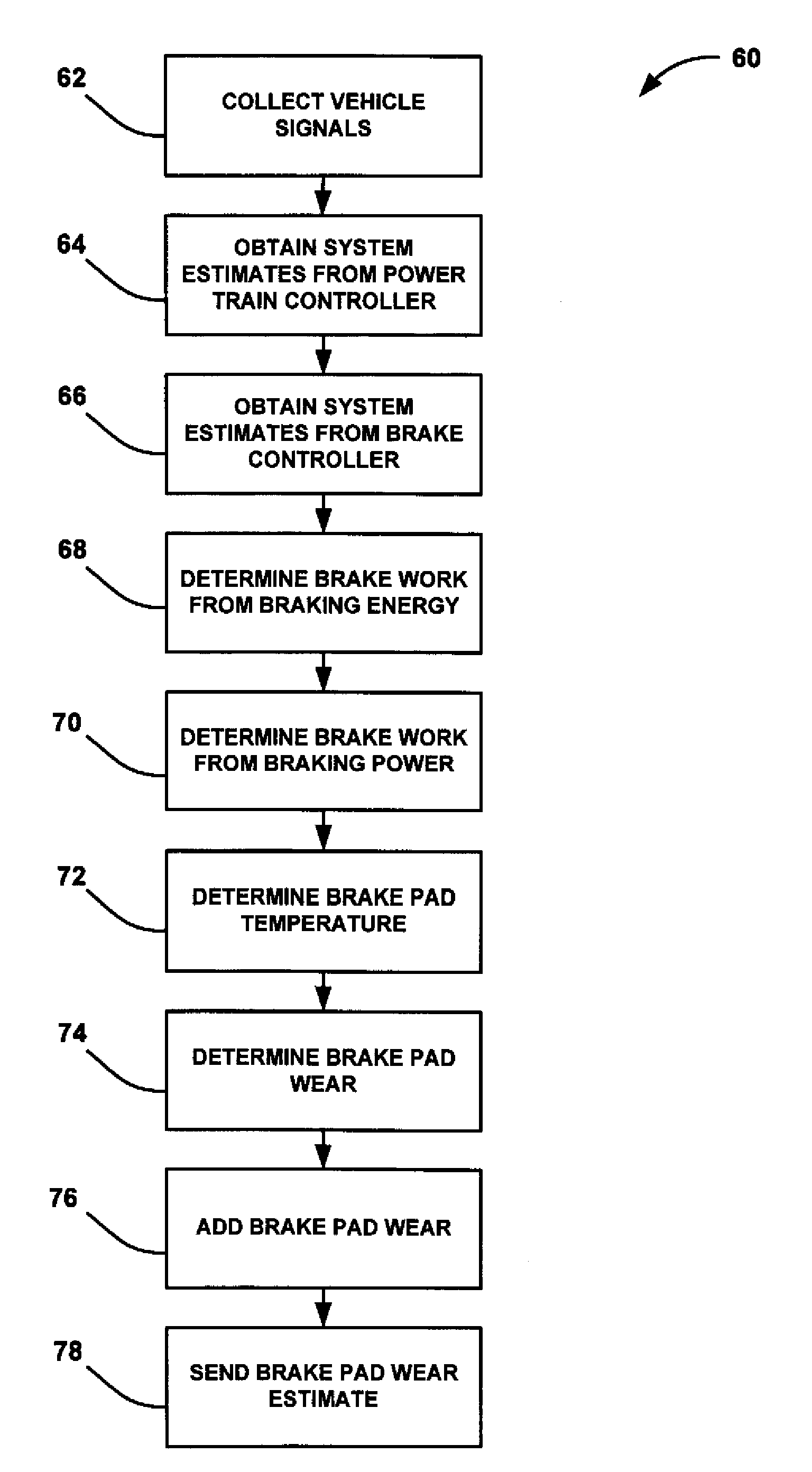

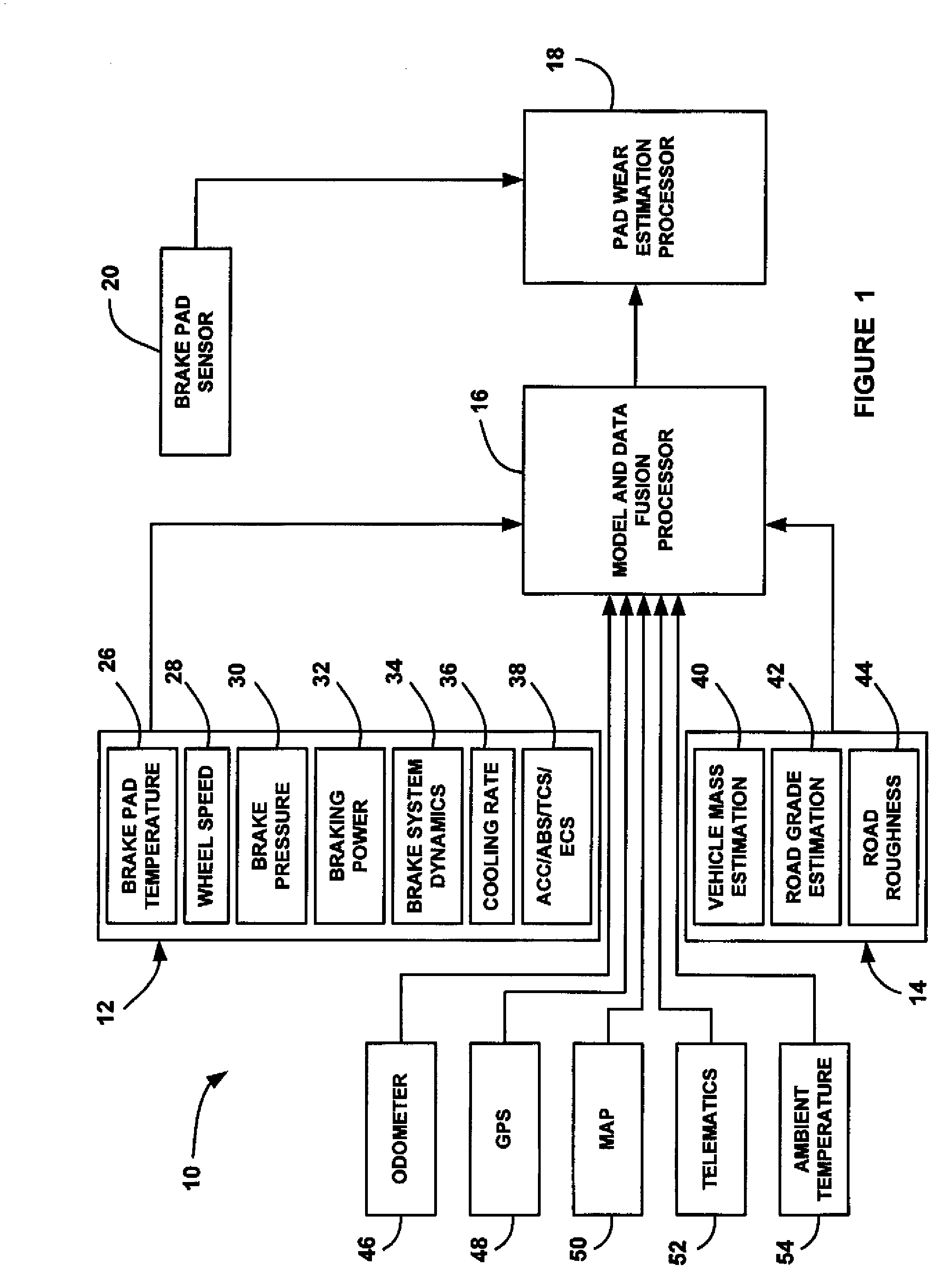

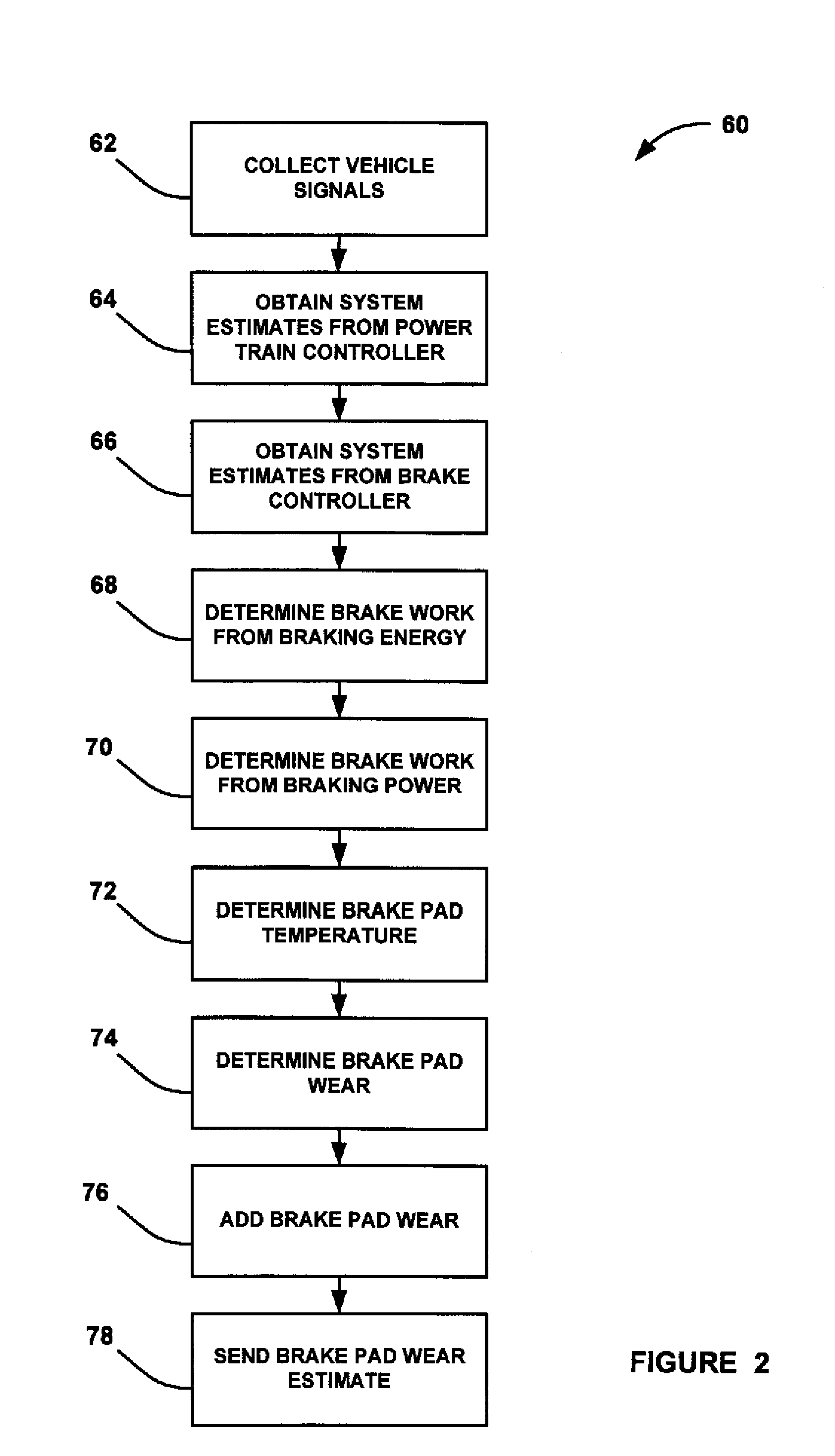

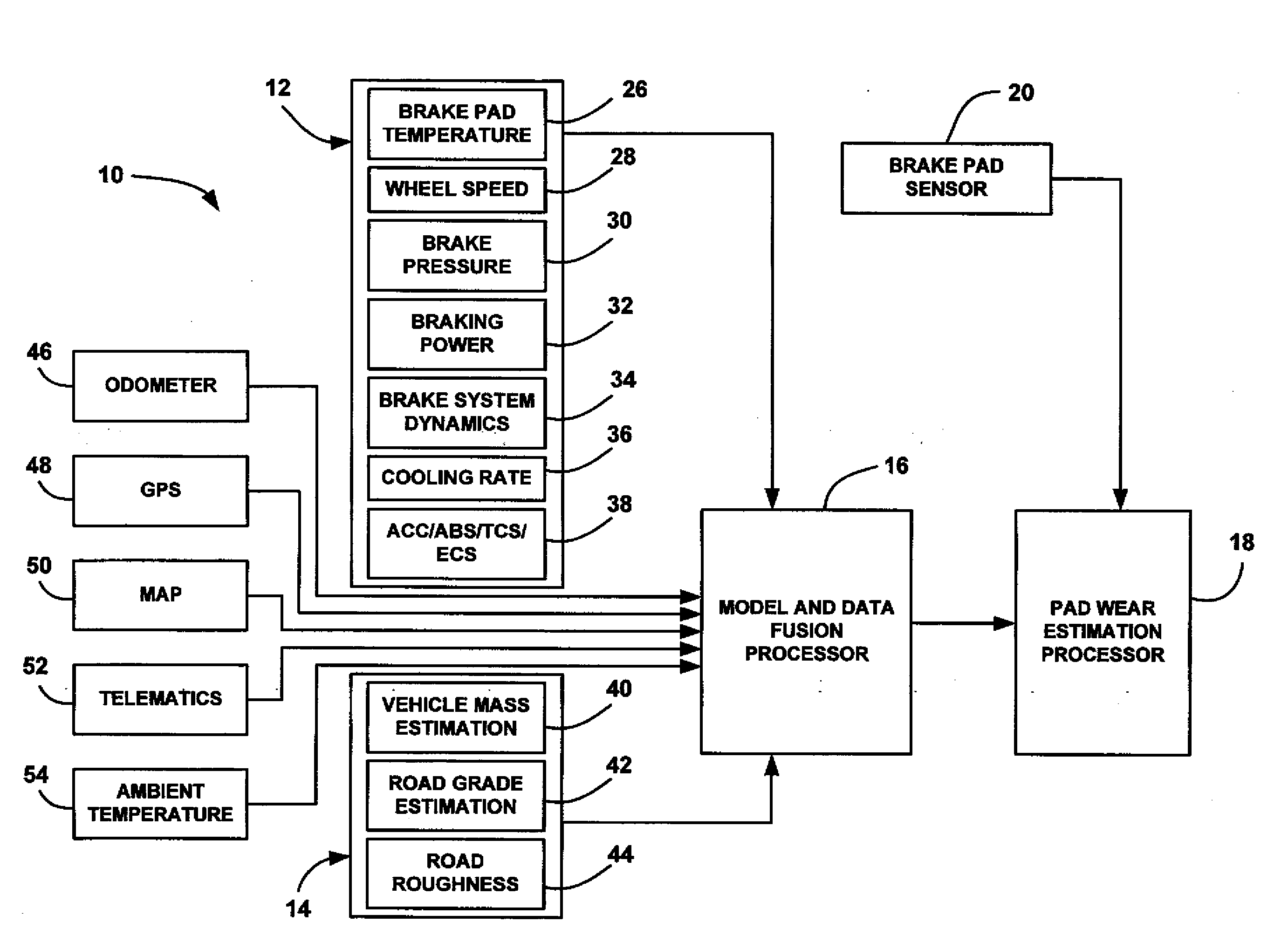

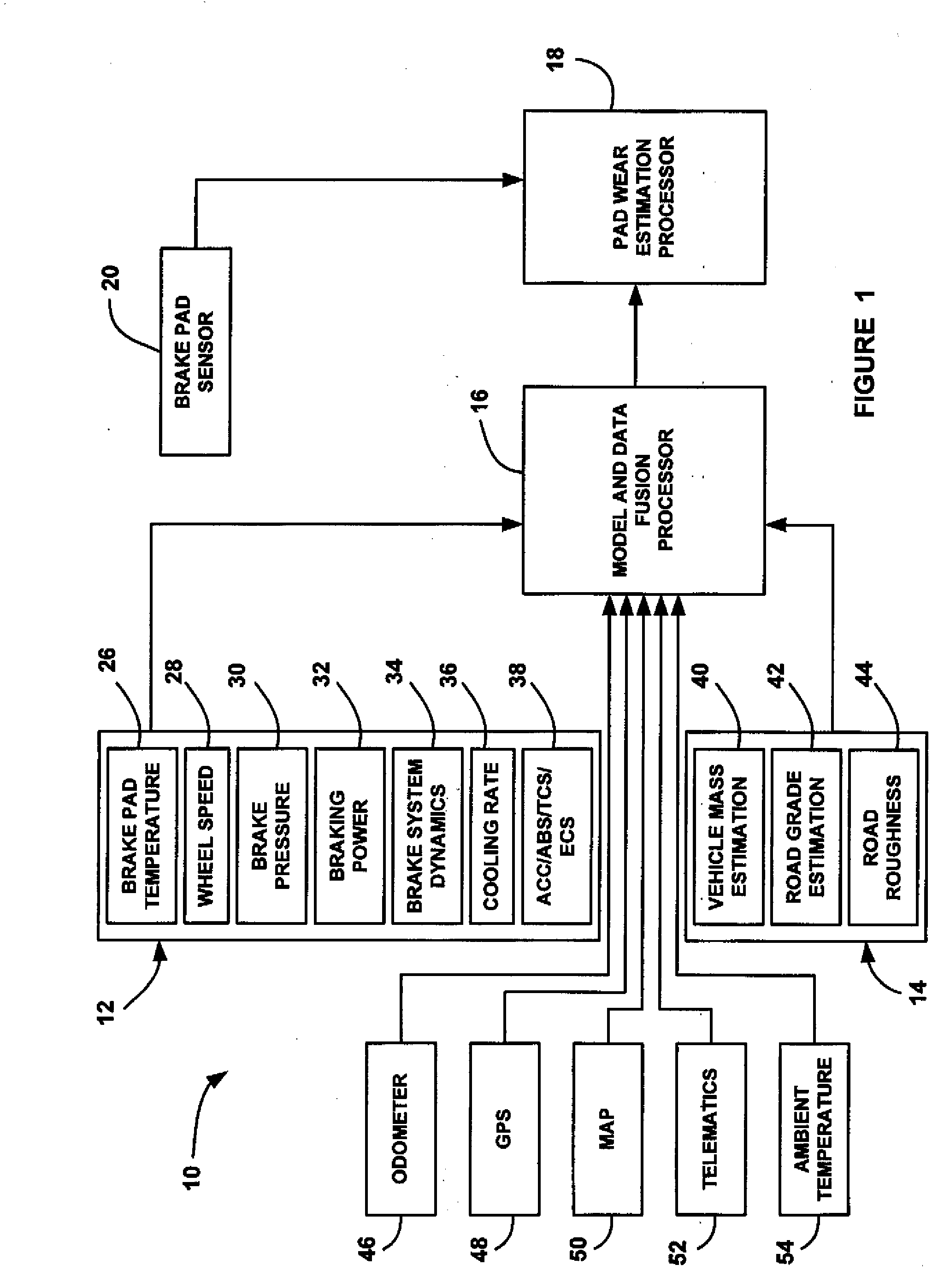

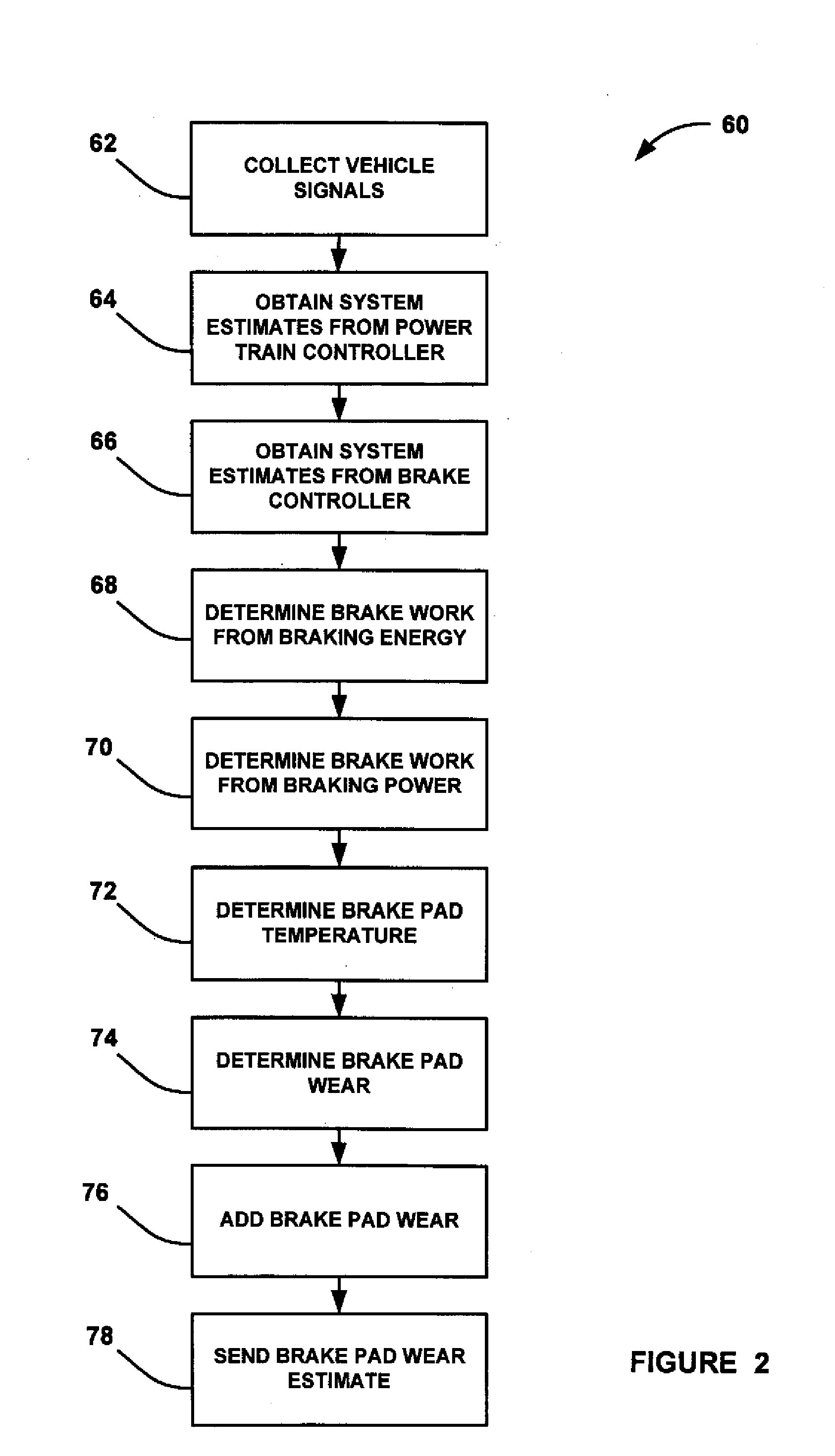

Brake pad prognosis system

A method for providing an estimate of brake pad thickness. The method employs fusion of sensors, if used, and driver brake modeling to predict the vehicle brake pad life. An algorithm is employed that uses various inputs, such as brake pad friction material properties, brake pad cooling rate, brake temperature, vehicle mass, road grade, weight distribution, brake pressure, brake energy, braking power, etc. to provide the estimation. The method calculates brake work using total work minus losses, such as aerodynamic drag resistance, engine braking and / or braking power as braking torque times velocity divided by rolling resistance to determine the brake rotor and lining temperature. The method then uses the brake temperature to determine the brake pad wear, where the wear is accumulated for each braking event. A brake pad sensor can be included to provide one or more indications of brake pad thickness from which the estimation can be revised.

Owner:GM GLOBAL TECH OPERATIONS LLC

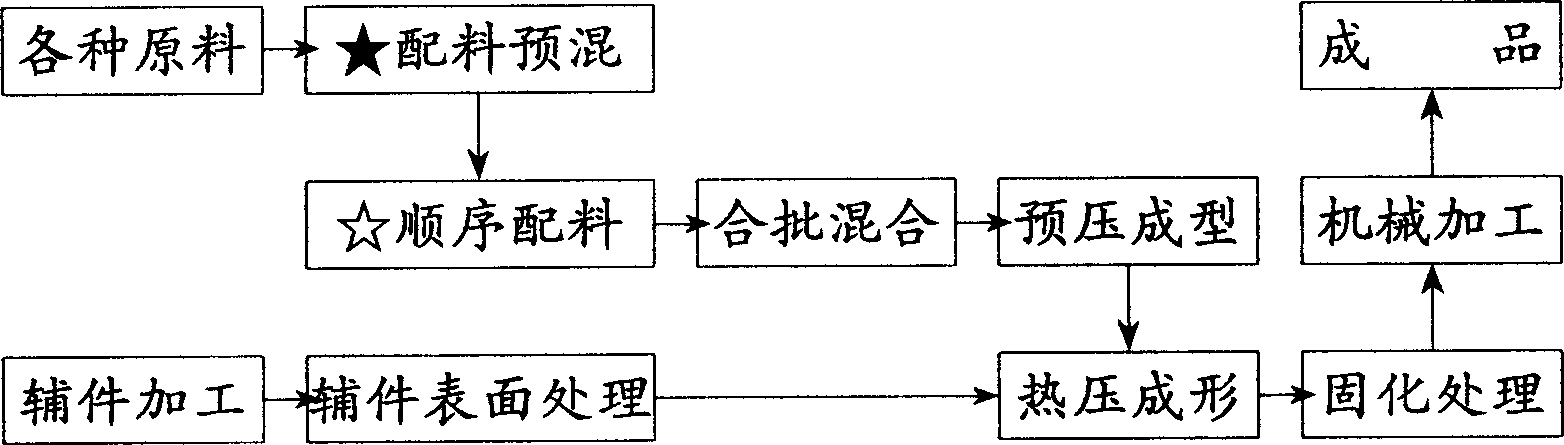

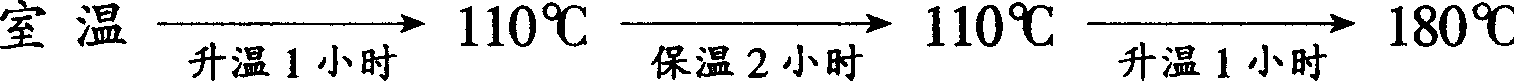

Environment-protection type high-performance automobile braking piece and making method

InactiveCN1814657AIncrease frictionOvercoming high temperature recession defectsFriction liningFiberAdhesive

This invention relates to a preparation technology for producing special products with plastic substances characterizing in mixing an adhesive agent, strengthened fibers, a regulator for friction performance and inorganic fillers in good match to process the surfaces of them with an anti-high temperature coupler to be hot-pressed to a format to get a high performance car brake plate of environmental protection, which replaces that made of asbestos fiber and overcomes the shortcoming of declining at high temperature of the asbestos car brake plates.

Owner:CENT SOUTH UNIV +1

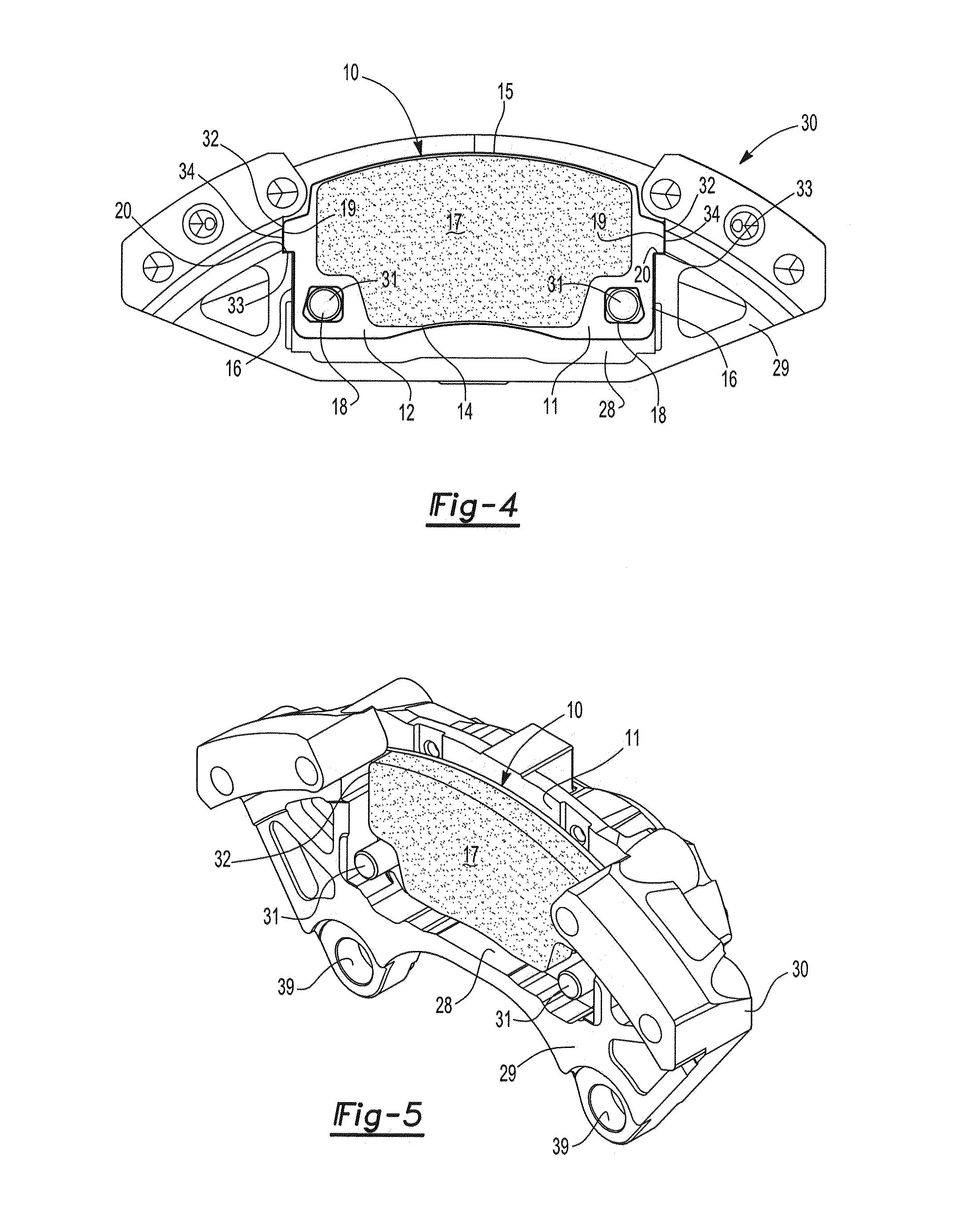

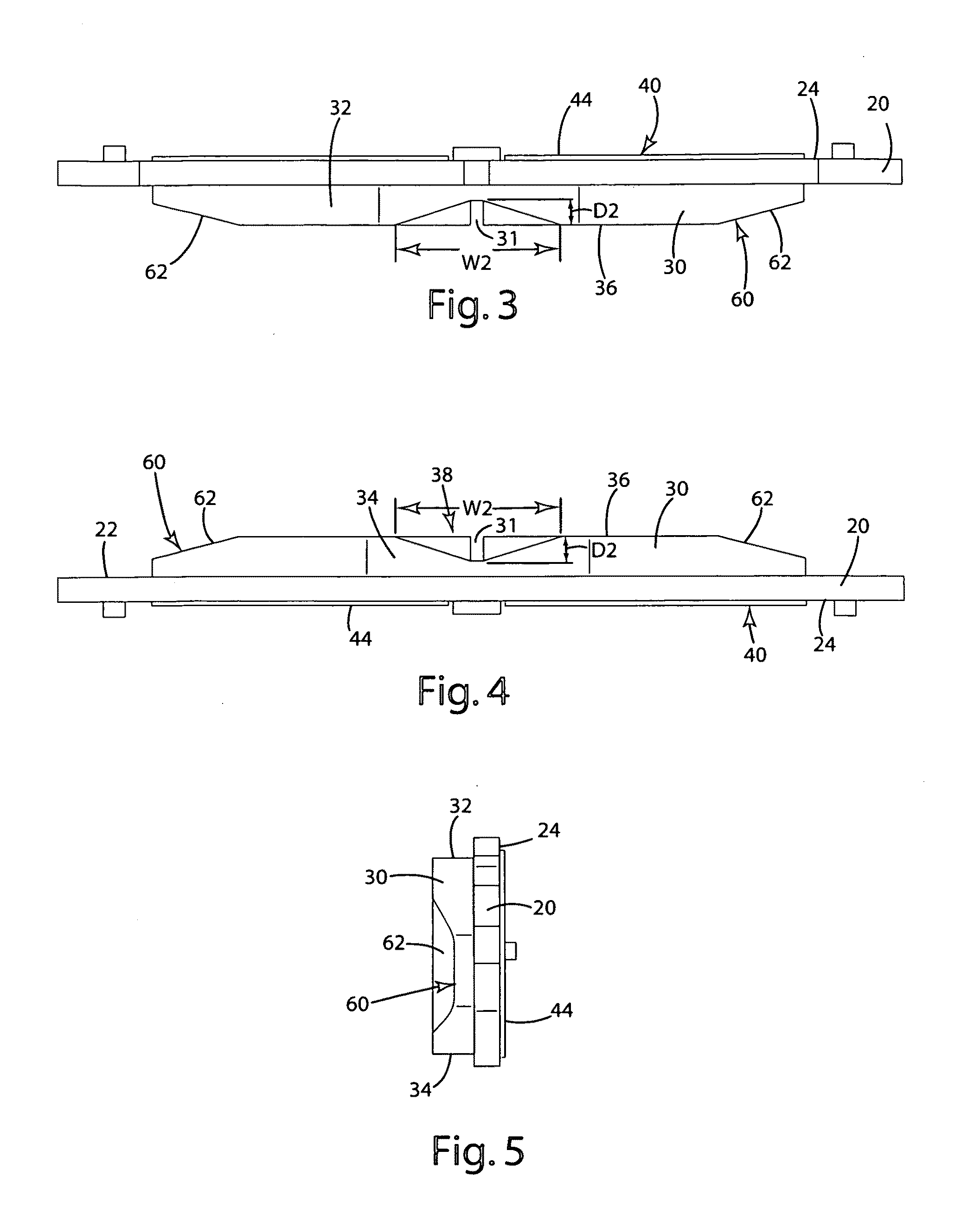

Pad retaining clips

A brake caliper mounting clip is disposed between a brake caliper having a brake pad channel and a brake pad having an edge member. The edge member moves in the brake pad channel between a rotor gap and a caliper housing. The clip further comprises a pad holding portion slidingly engaged with the edge member and having a plurality of pad retaining members. The pad retaining members are connected to the pad holding portion and disposed between the edge member and the rotor gap. The plurality of the pad retaining members is further configured to prevent the brake pad from falling into the rotor gap. Additionally the edge member of the brake pad and the plurality of pad retaining members are configured to prevent improper installation of the brake pads in the caliper.

Owner:AKEBONO BRAKE

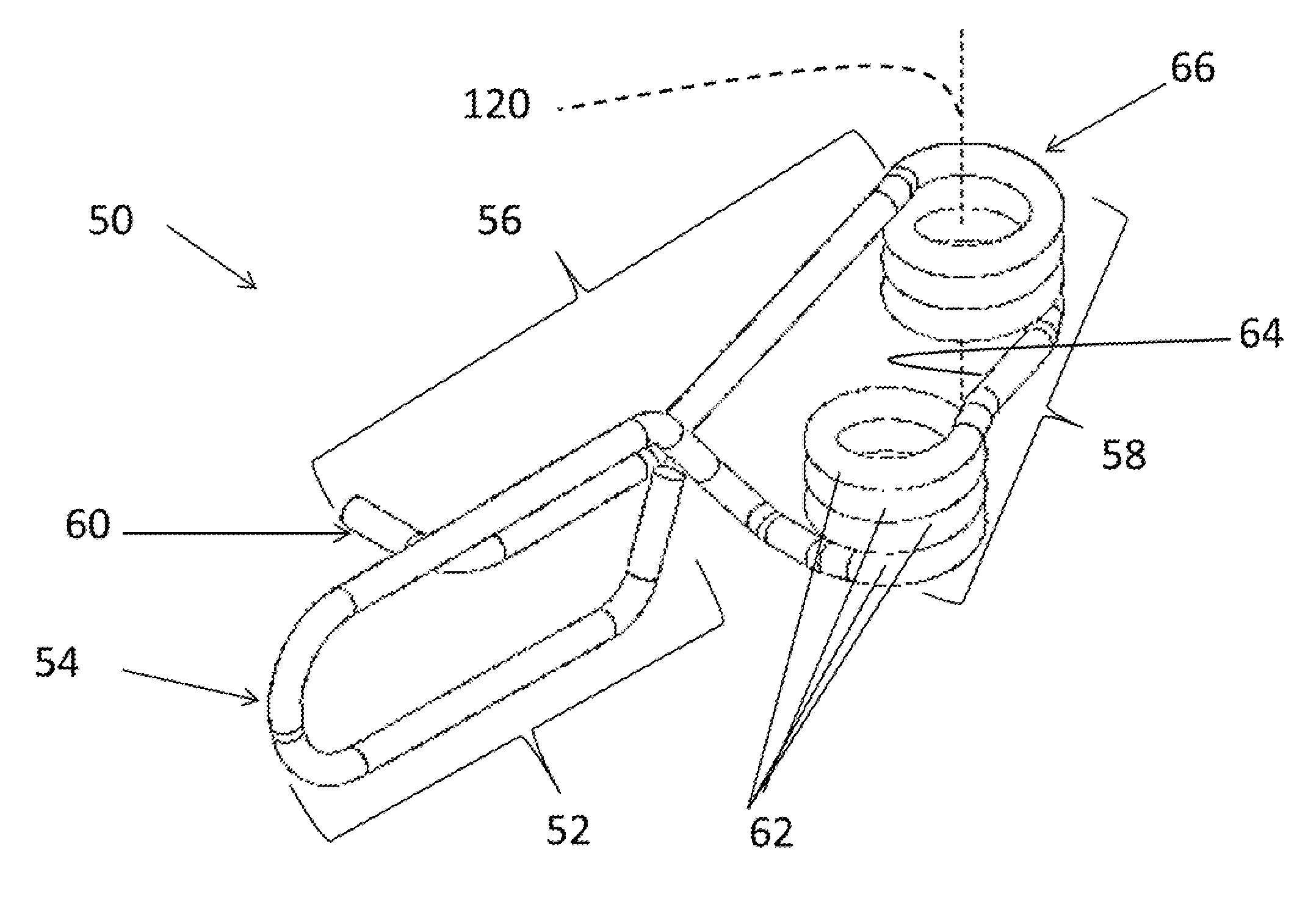

Coiled spreader spring

InactiveUS20140339026A1Movement is minimized and eliminatedMinimizes and eliminates DVT growthAxially engaging brakesBraking elementsEngineeringMechanical engineering

A spreader spring comprising: (a) a locking arm that connects the spreader spring to a brake component; (b) a retraction arm; and (c) a bias device located between the locking arm and the retraction arm; wherein the bias device includes six helical loops or more that store energy during a brake apply and once the brake apply is complete assist in retracting a brake pad.

Owner:AKEBONO BRAKE

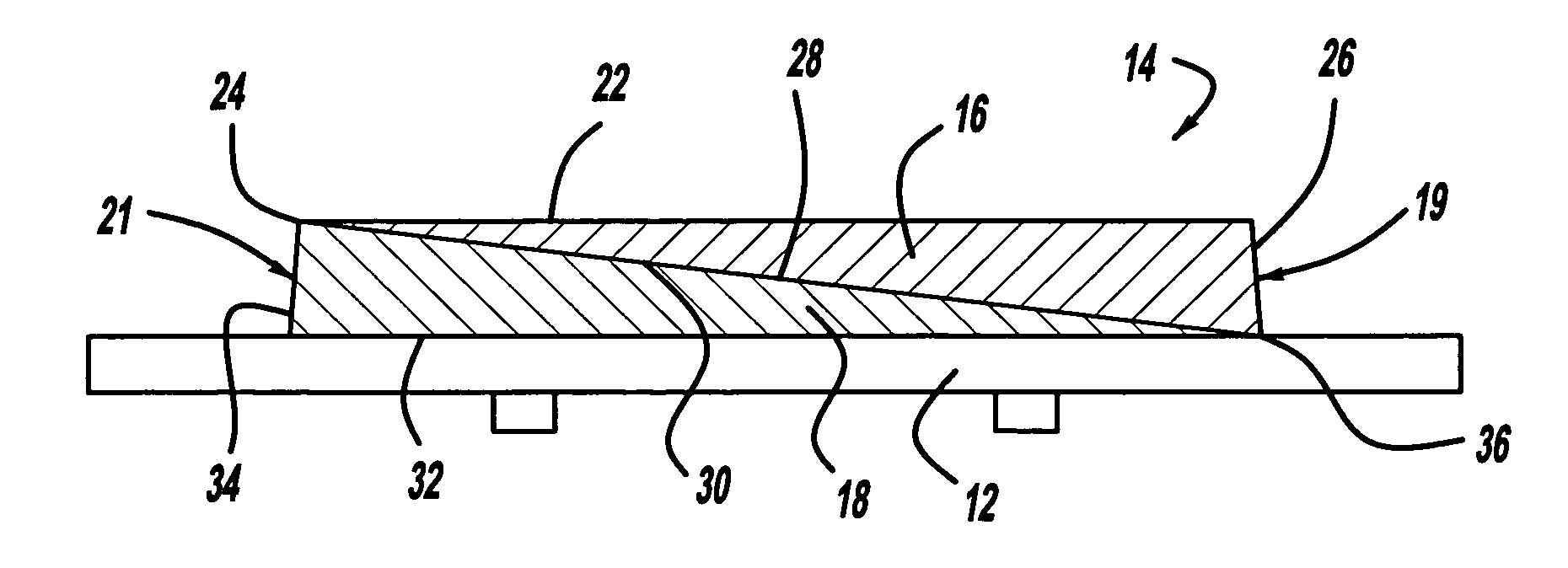

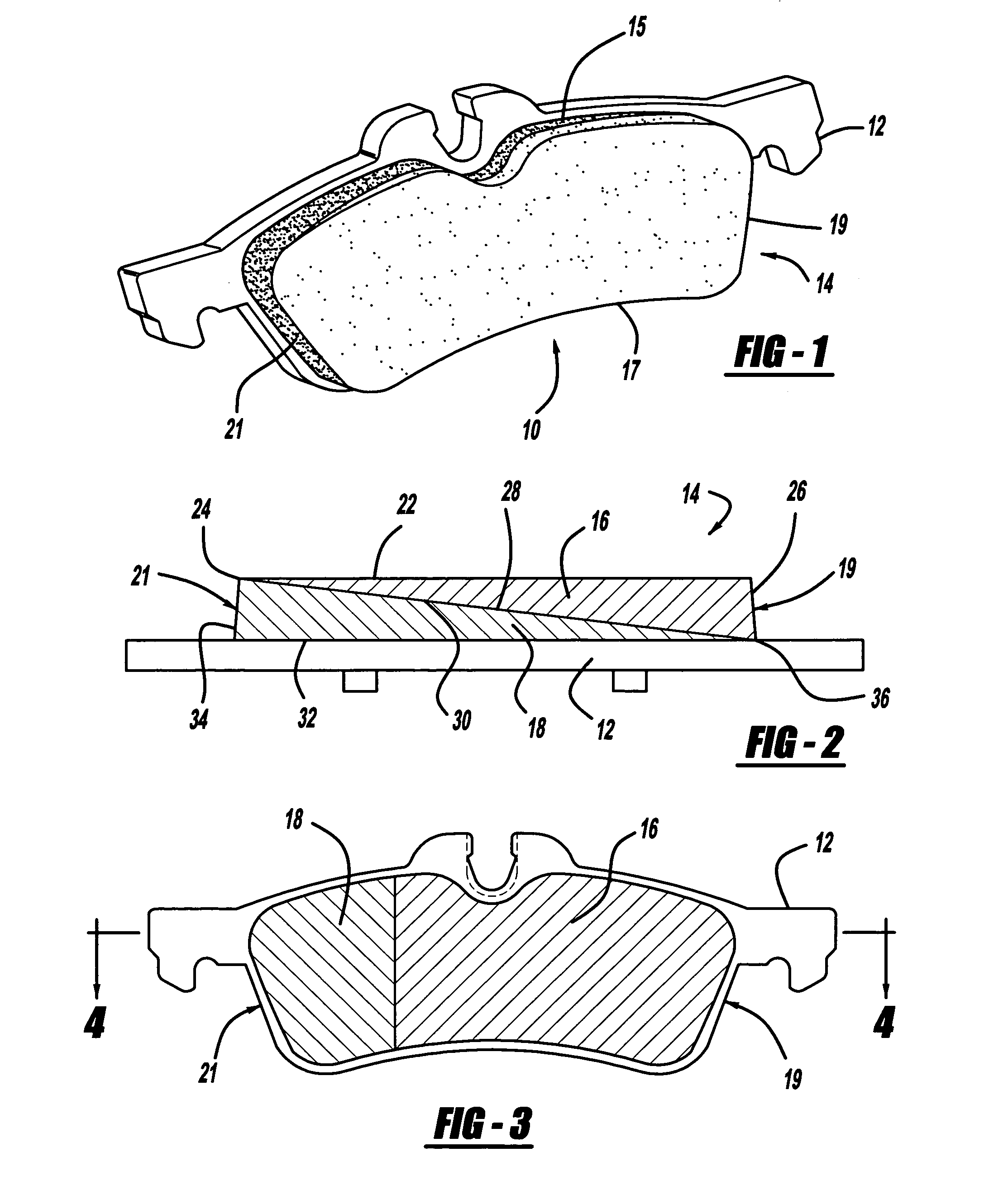

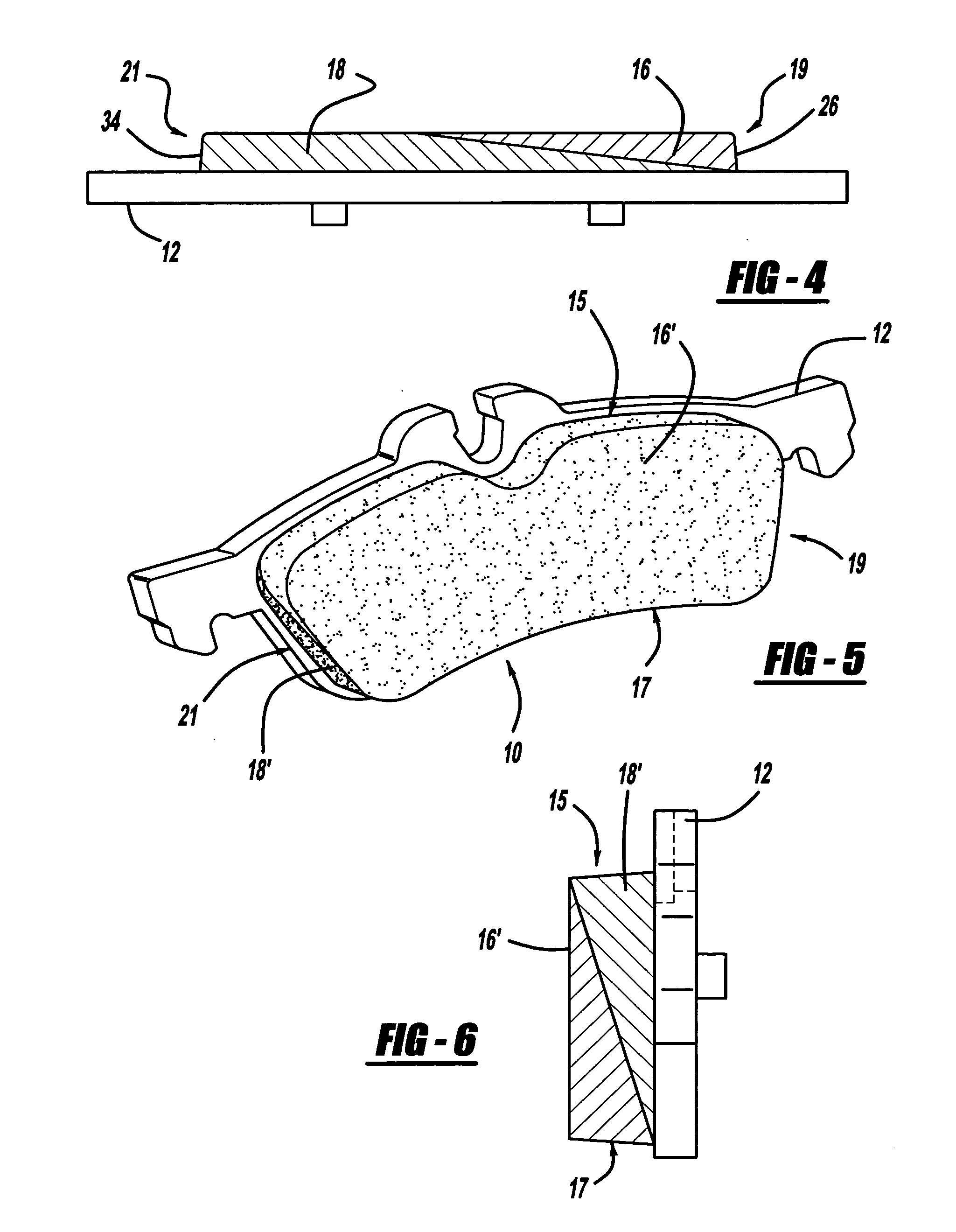

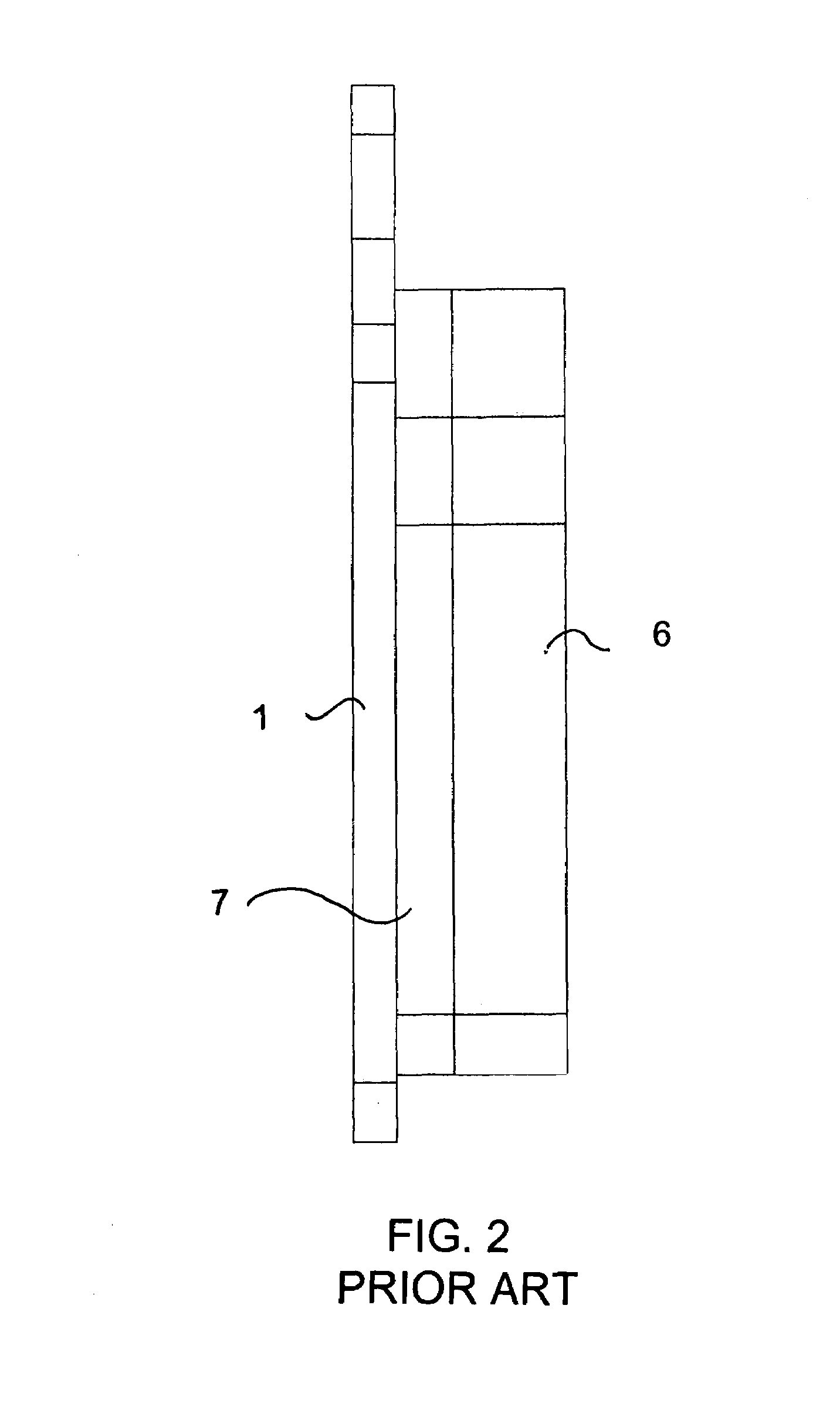

Multiple layer friction material brake pad

A brake pad has a backing plate and a friction pad. The friction pad is provided with a plurality of layers. Each layer is formed from a desired material such that at least two layers are formed from different materials. A first layer of said plurality of layers is adapted to contact a brake rotor. A second layer is covered by the first layer. At least one of said first and second layers has a tapered thickness from one edge of the friction pad to the other edge. As the first layer wears, the second layer gradually transitions into contact with the brake rotor.

Owner:AKEBONO CORP (NORTH AMERICA)

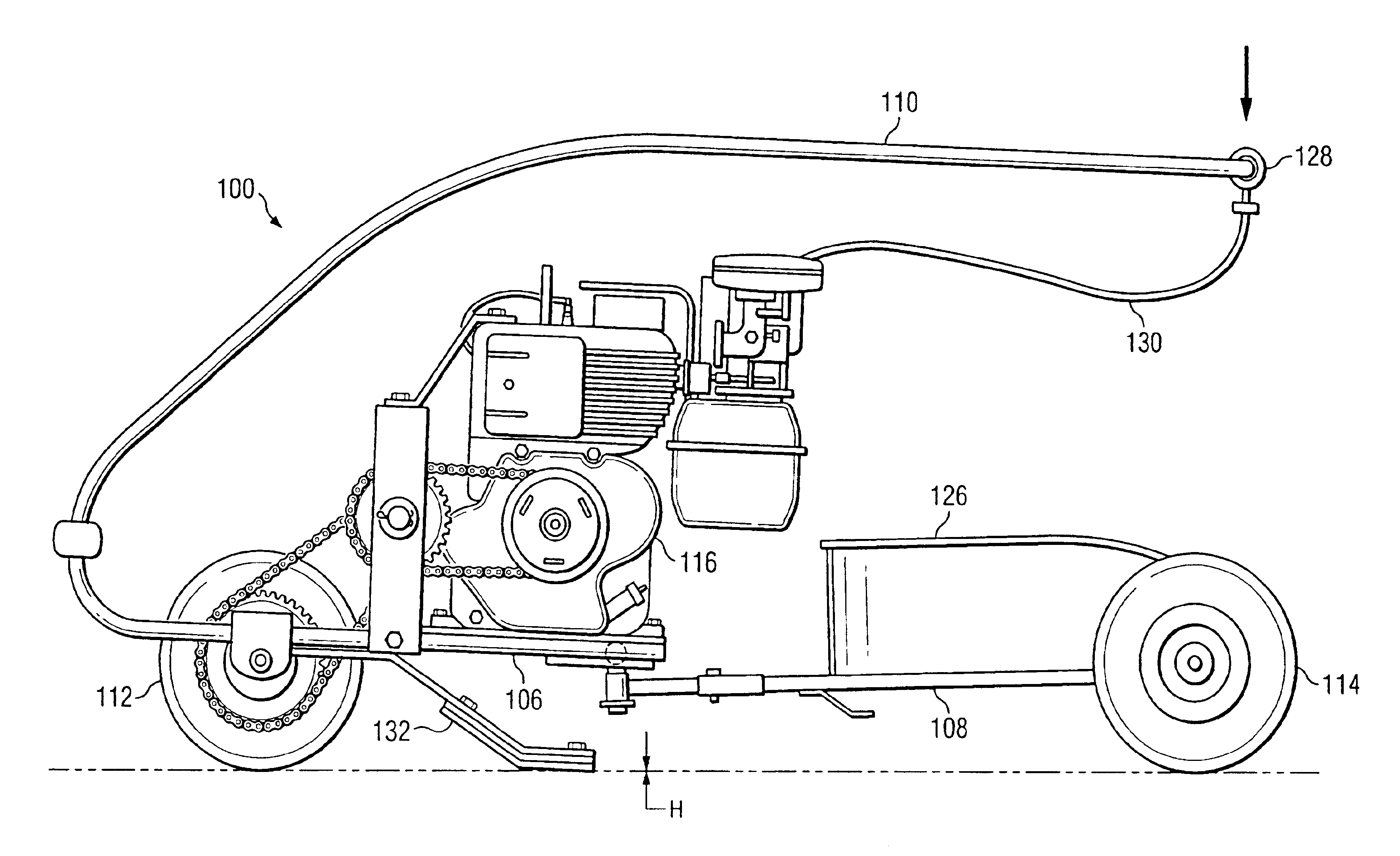

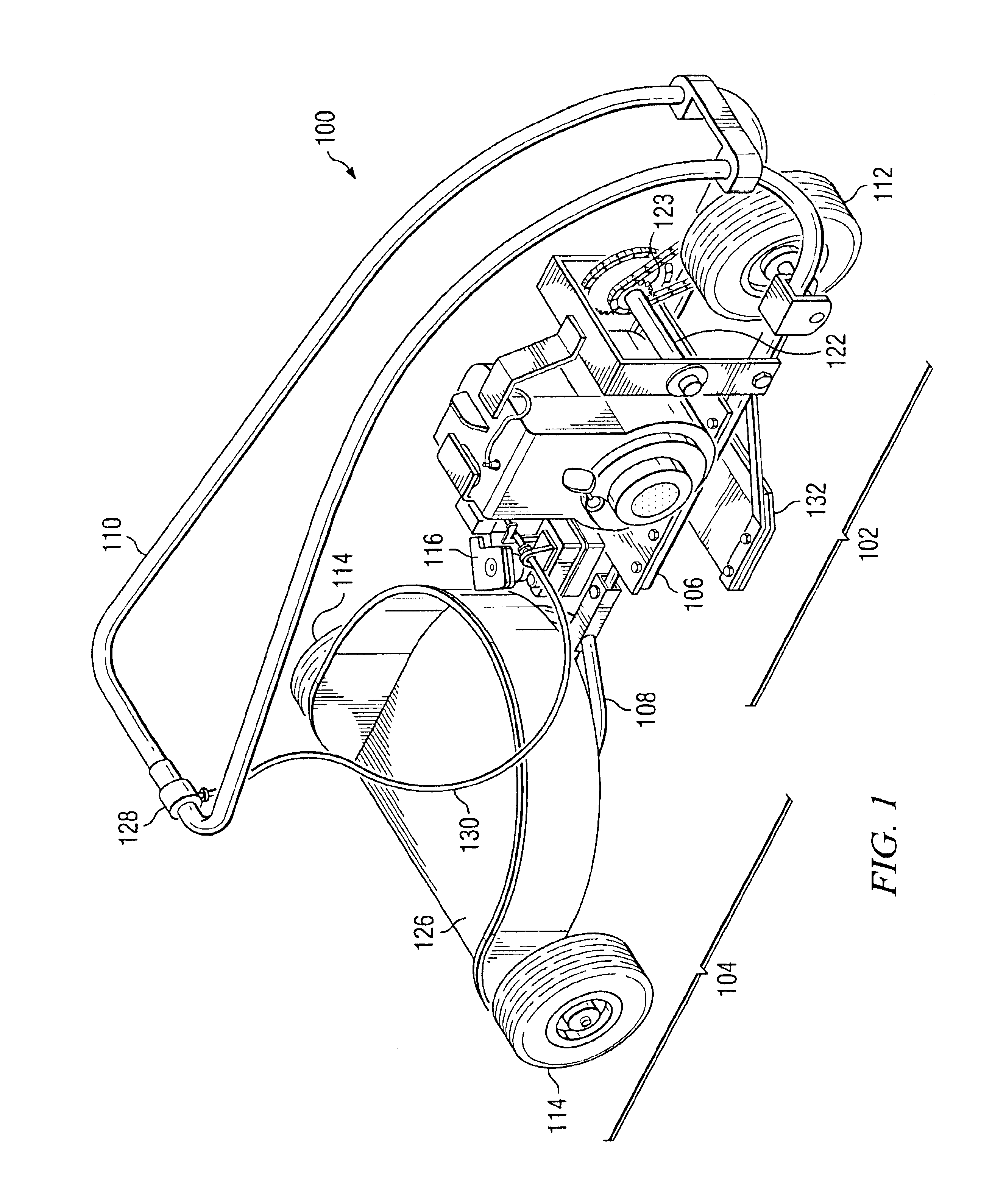

Motorized chariot

A vehicle incorporating a power unit having a front portion, a rear portion and a power source. A drive wheel, disposed in the front of the power unit, is connected to the power source. A brake pad is connected to the power unit beneath the power source and a handle bar extends back from the power unit. The vehicle includes a trailer unit, disposed behind the power unit, having two trailer wheels, disposed on opposite sides of the trailer unit. A connecting joint, connecting the power unit to the trailer unit, allows the power unit and trailer unit to move with respect to one another about the horizontal pitch axis and / or vertical yaw axis.

Owner:TROLL DONALD E

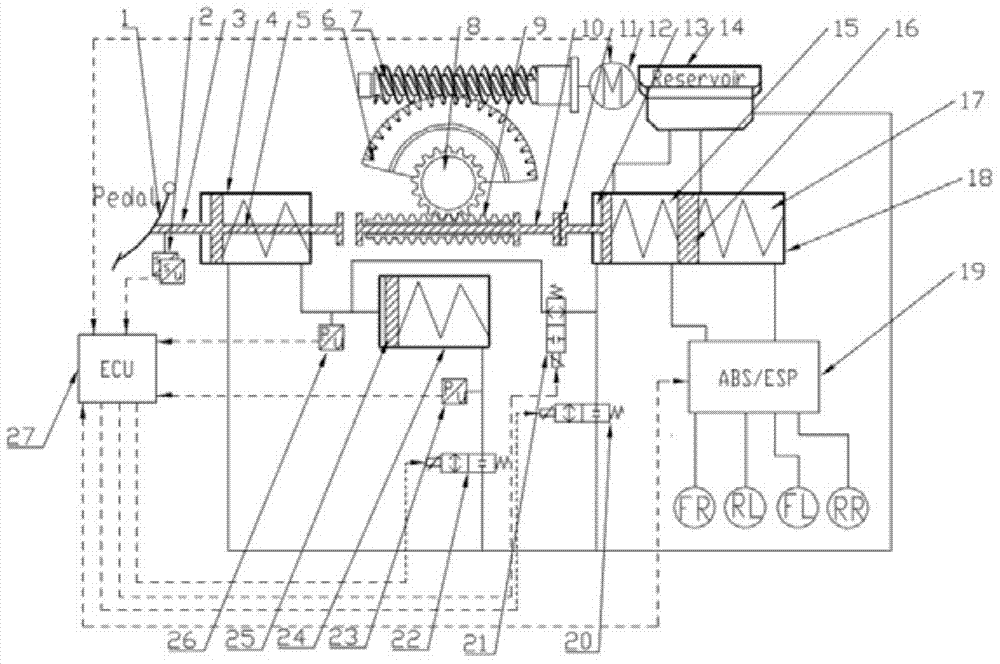

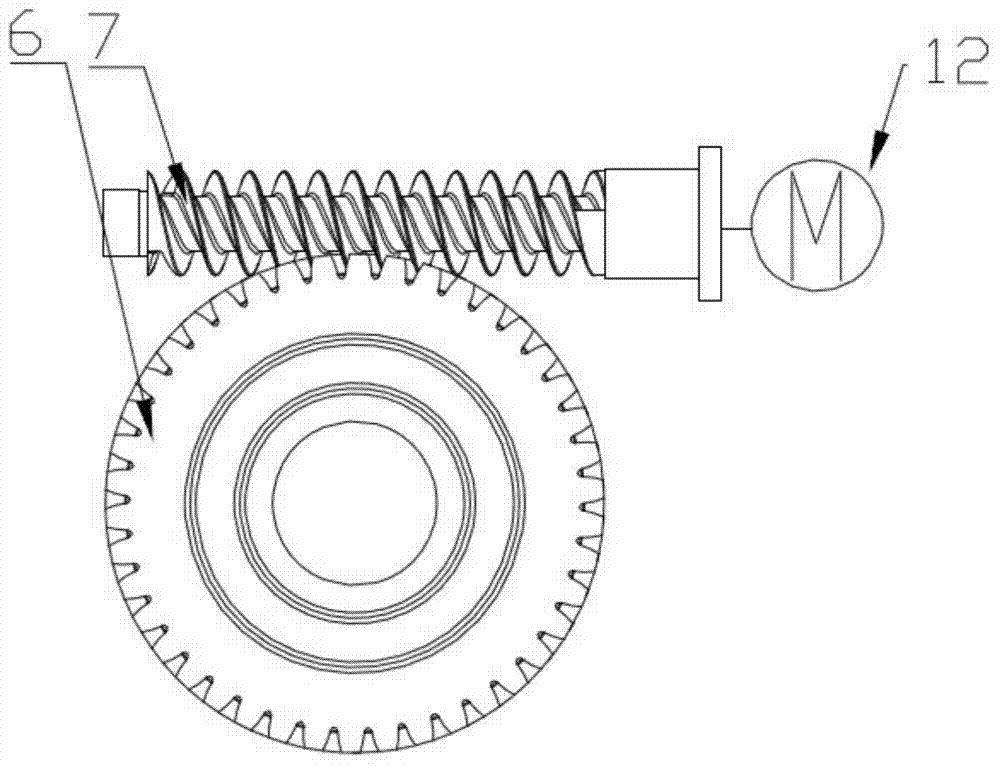

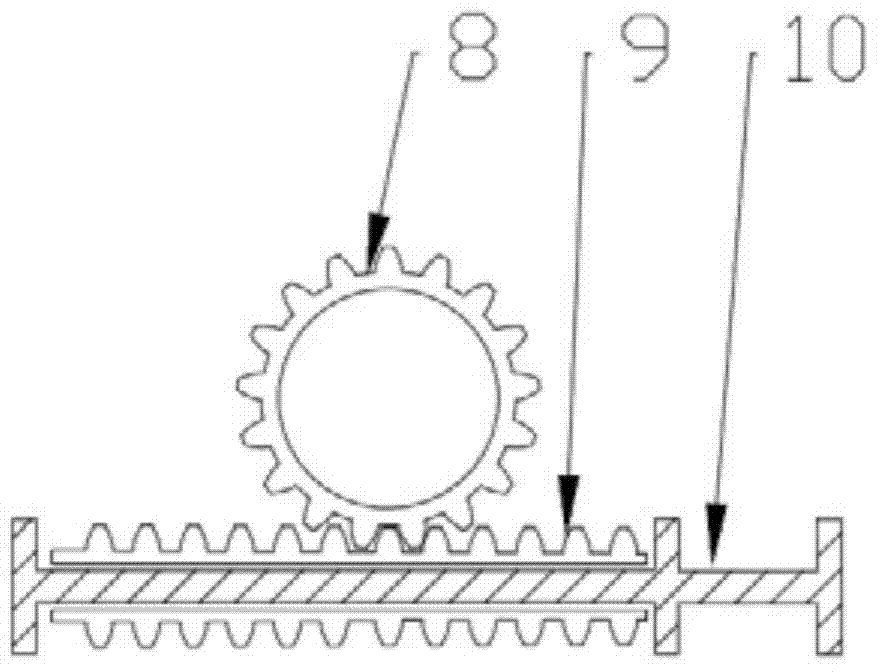

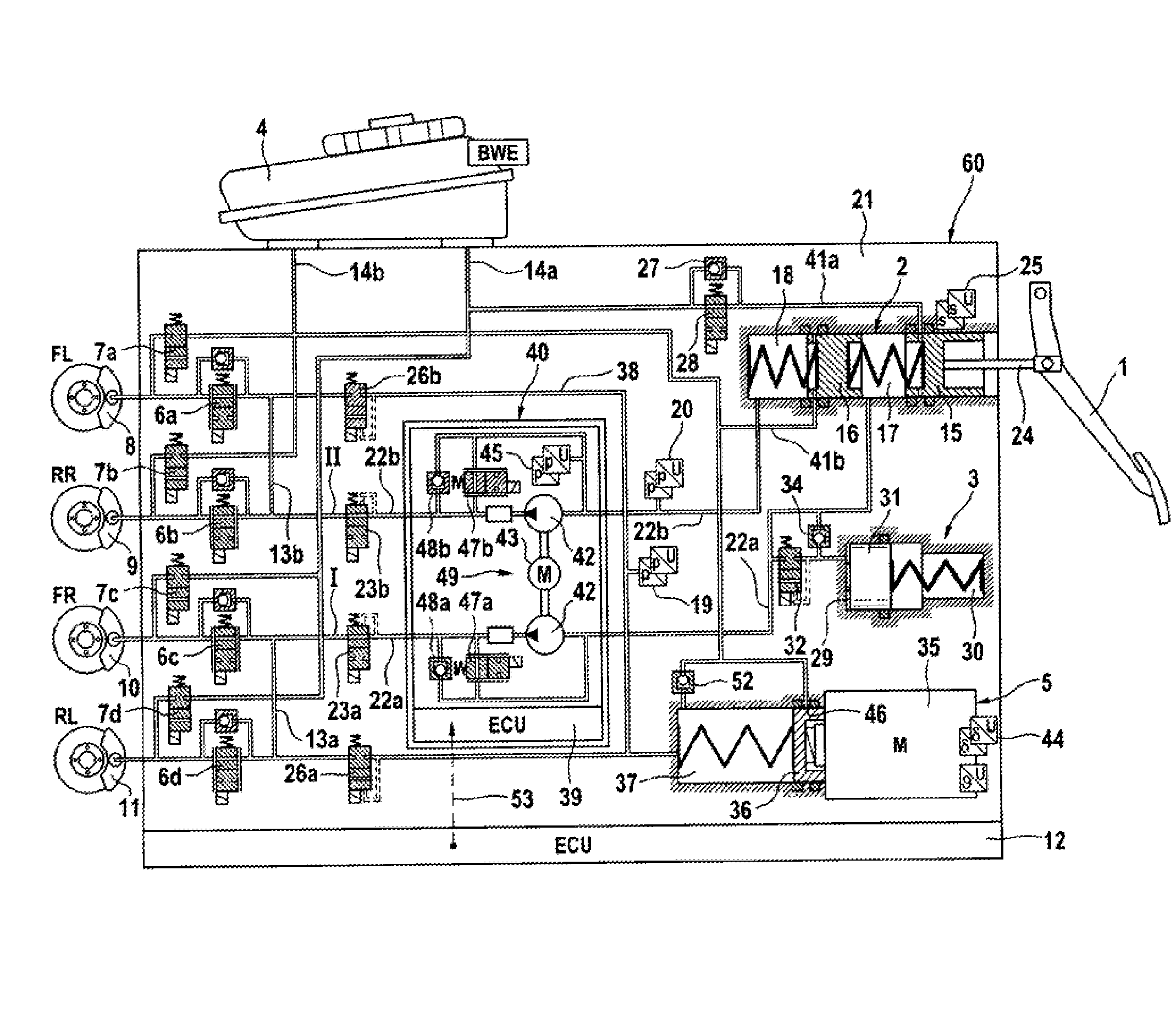

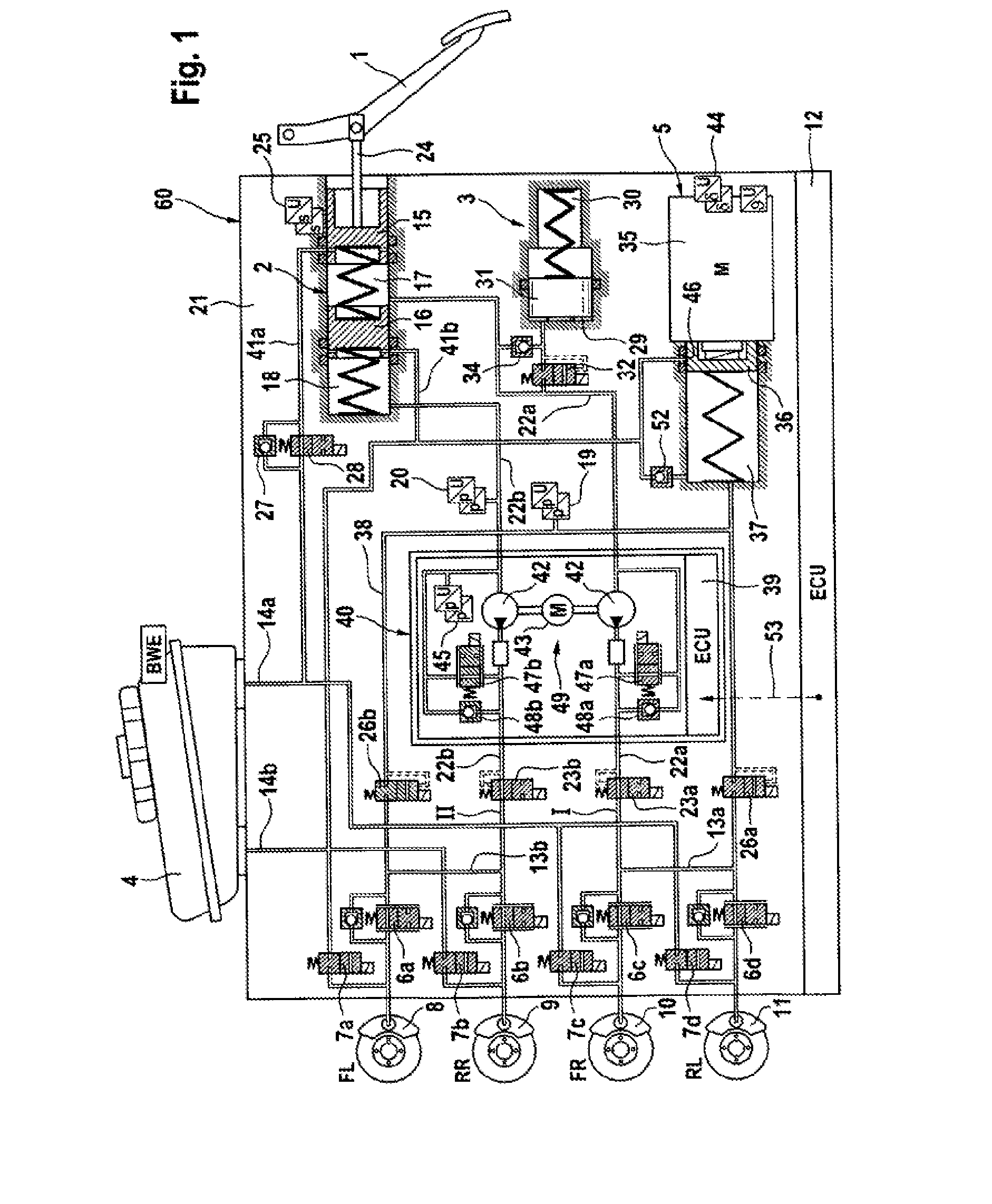

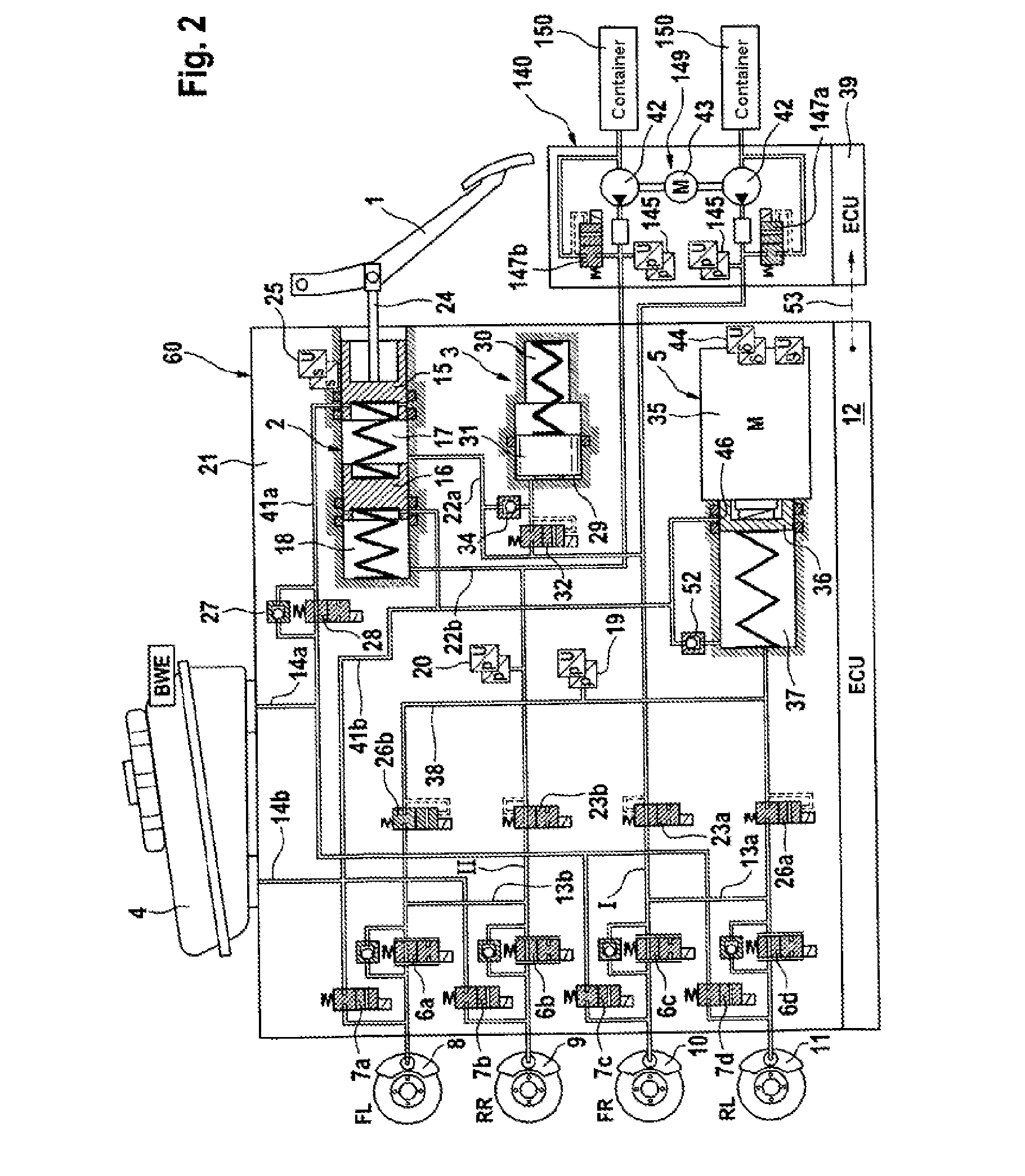

Motor-driven electronic hydraulic braking system

ActiveCN103754210AQuick responsePrecise control of hydraulic braking forceBraking action transmissionSystems designLinear control

A motor-driven electronic hydraulic braking system comprises a brake pedal, a pedal displacement sensor, a secondary master cylinder, a pedal simulator pressure sensor, a pedal simulator, pedal simulator solenoid valves, a push rod, an electrically-controlled linear movement module, a brake master cylinder and an ABS / ESP (anti-skid brake system / electronic stability program) module. The electrically-controlled linear movement module drives the push rod to move by means of driving a movement regulating mechanism through a motor, the motor is controlled through a displacement signal, and linear control on braking pressure is realized. The brake master cylinder passes the ABS / ESP module to be hydraulically coupled with vehicle wheel brakes. The ABS / ESP module can passively regulate pressure transmitted from the master cylinder to the wheel brakes, and can actively regulate the pressure of the brake of each wheel. The motor-driven electronic hydraulic braking system has the advantages of rapid response, accurate control on brake fluid pressure, capabilities of well simulating brake pedal feeling of a driver and maximally recovering braking energy, and the like; meanwhile, the system is designed with a dual failure protection mode, thereby having high safety and reliability.

Owner:上海同驭汽车科技有限公司

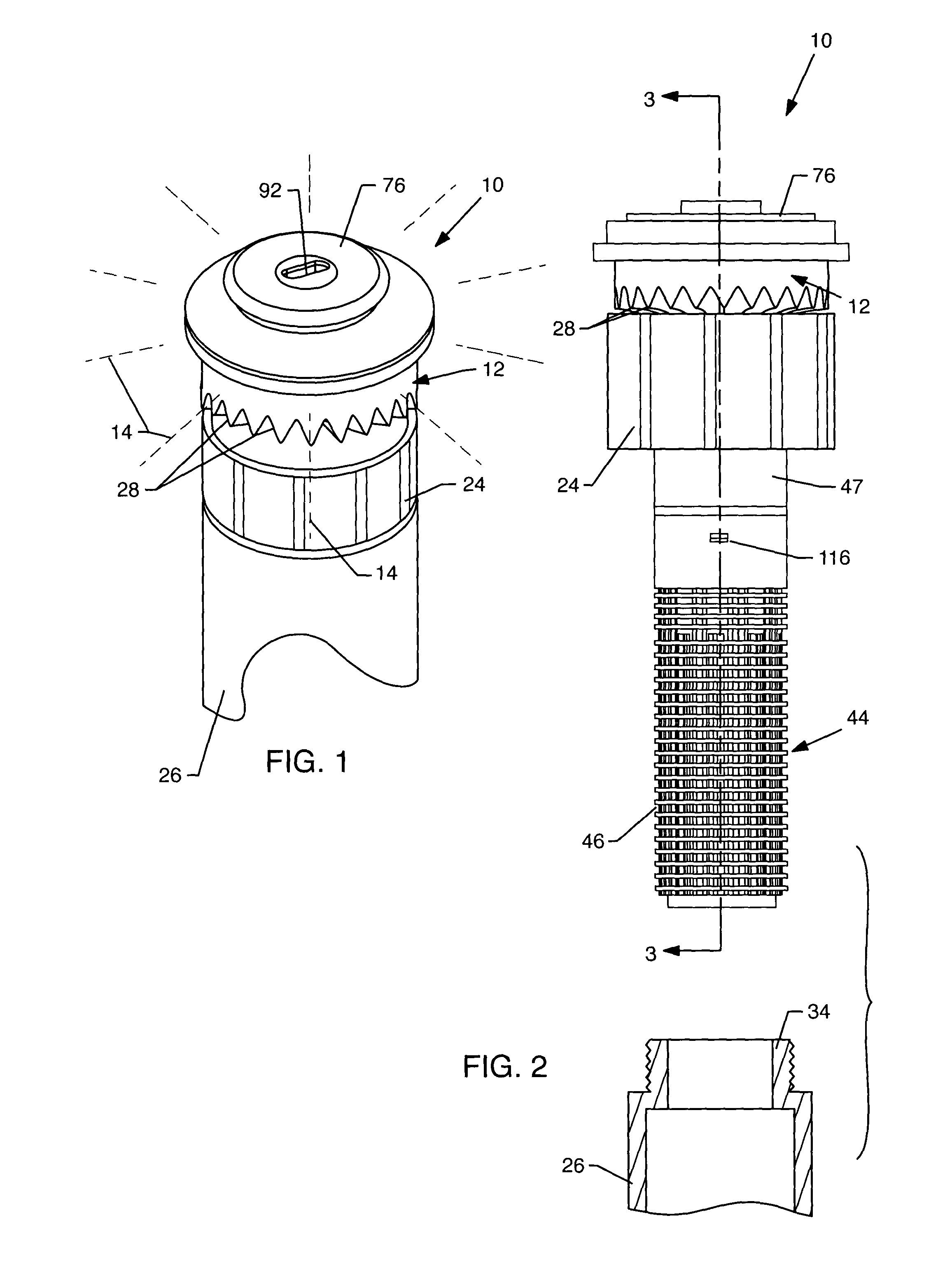

Rotating stream sprinkler with ball drive

A rotating stream sprinkler of the type having a rotatable vaned deflector for stepwise sweeping of relatively small water streams over surrounding terrain to irrigate adjacent vegetation. The sprinkler includes a turbine driven ball drive rotor having at least one drive ball carried by centrifugal force into repetitious impact engagement with one or more raised anvils on the deflector for incrementally displacing the deflector in a succession of small rotational steps. A speed control brake includes a brake pad interposed between a friction surface on the deflector and a nonrotating brake disk to provide a variable friction force to maintain deflector rotation substantially constant within a range of normal water supply pressures and flow rates.

Owner:RAIN BIRD CORP

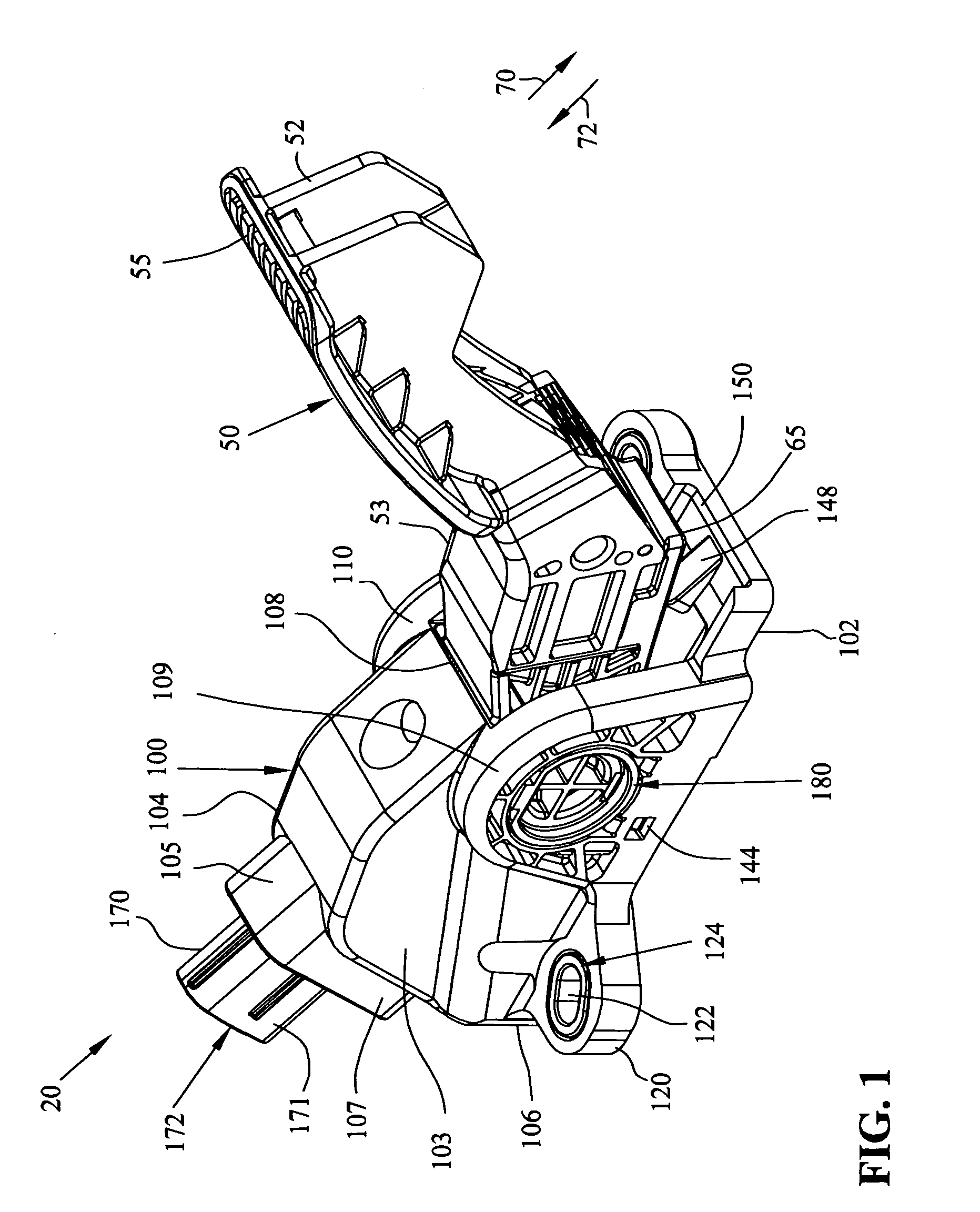

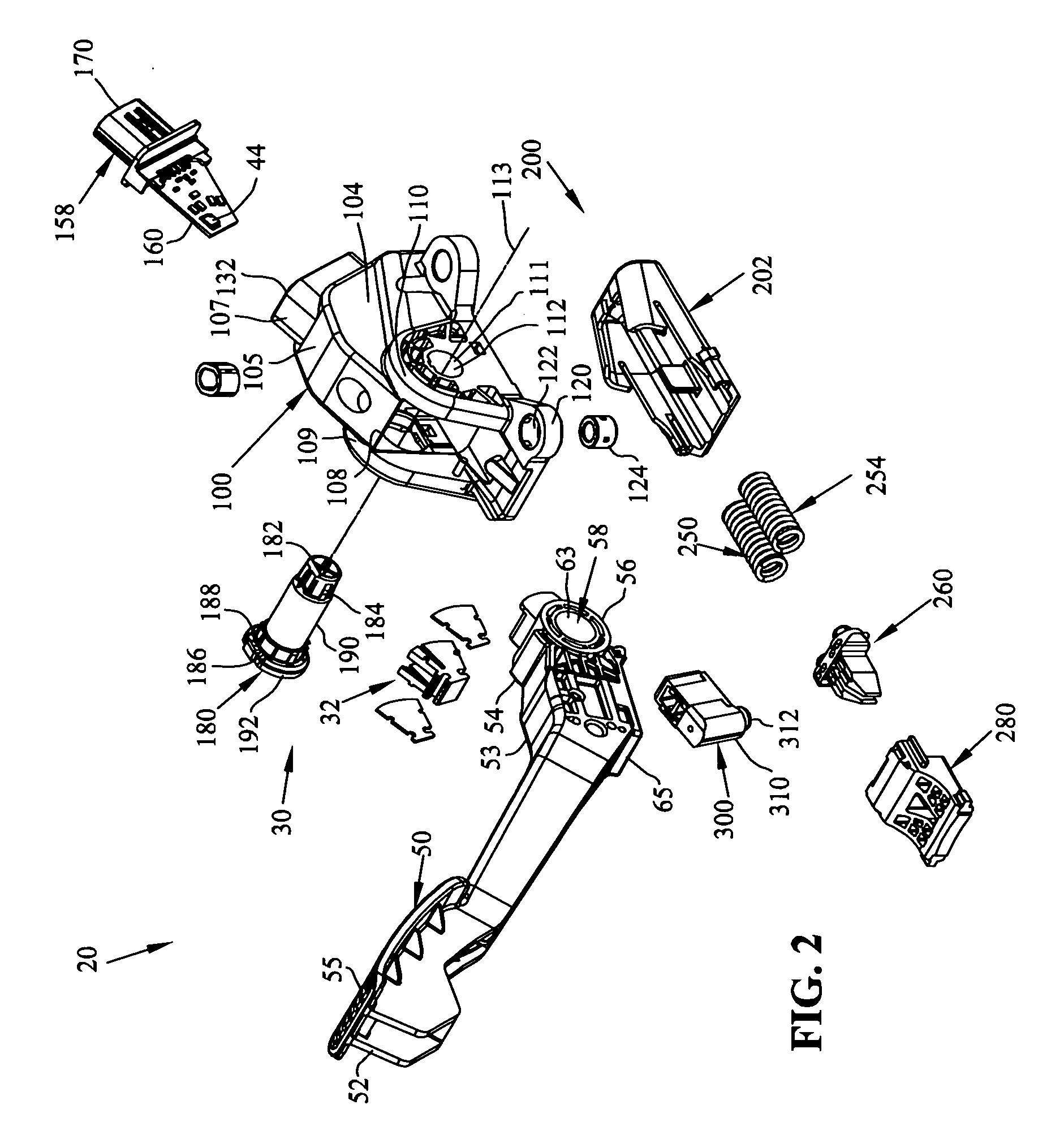

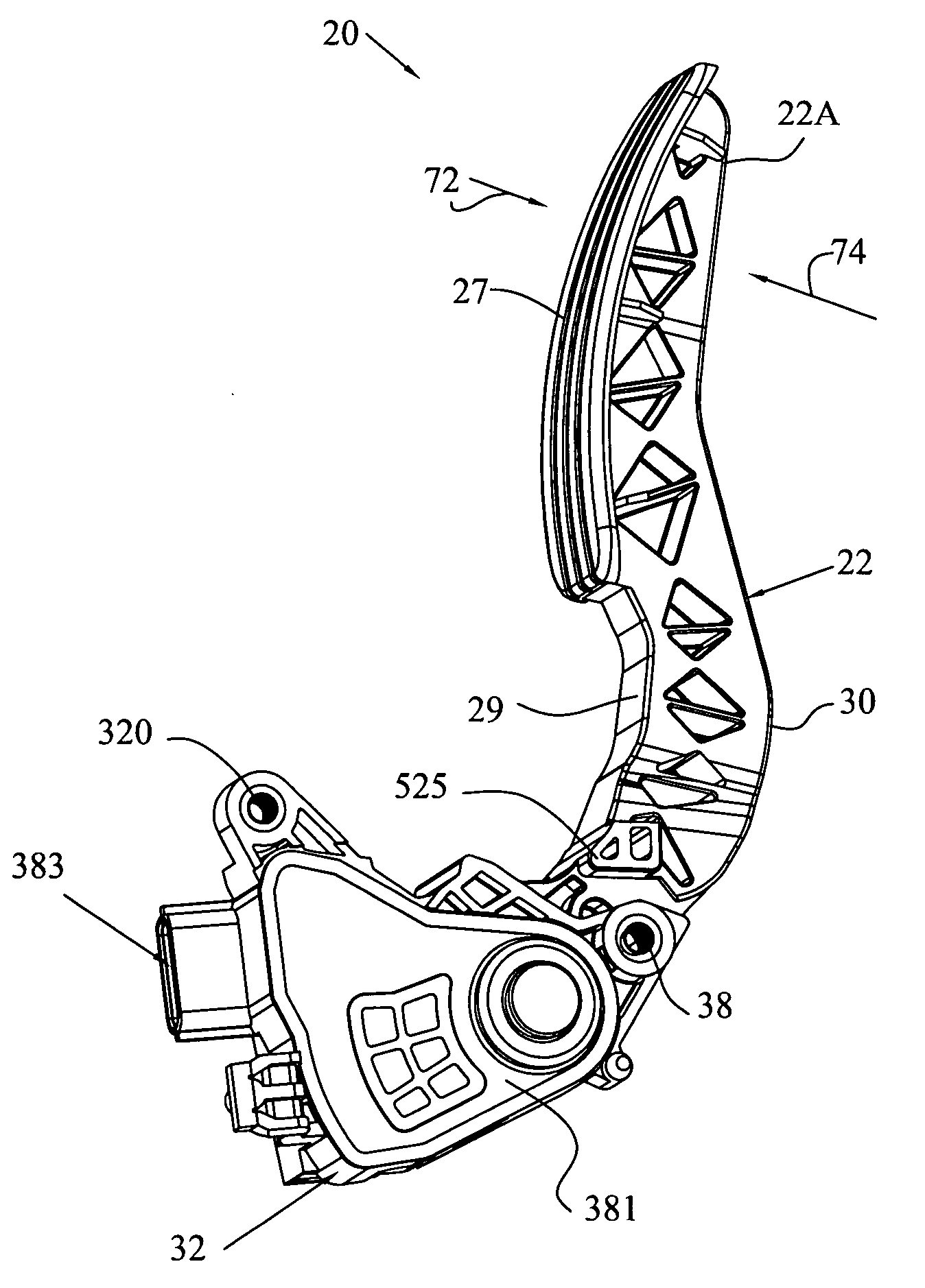

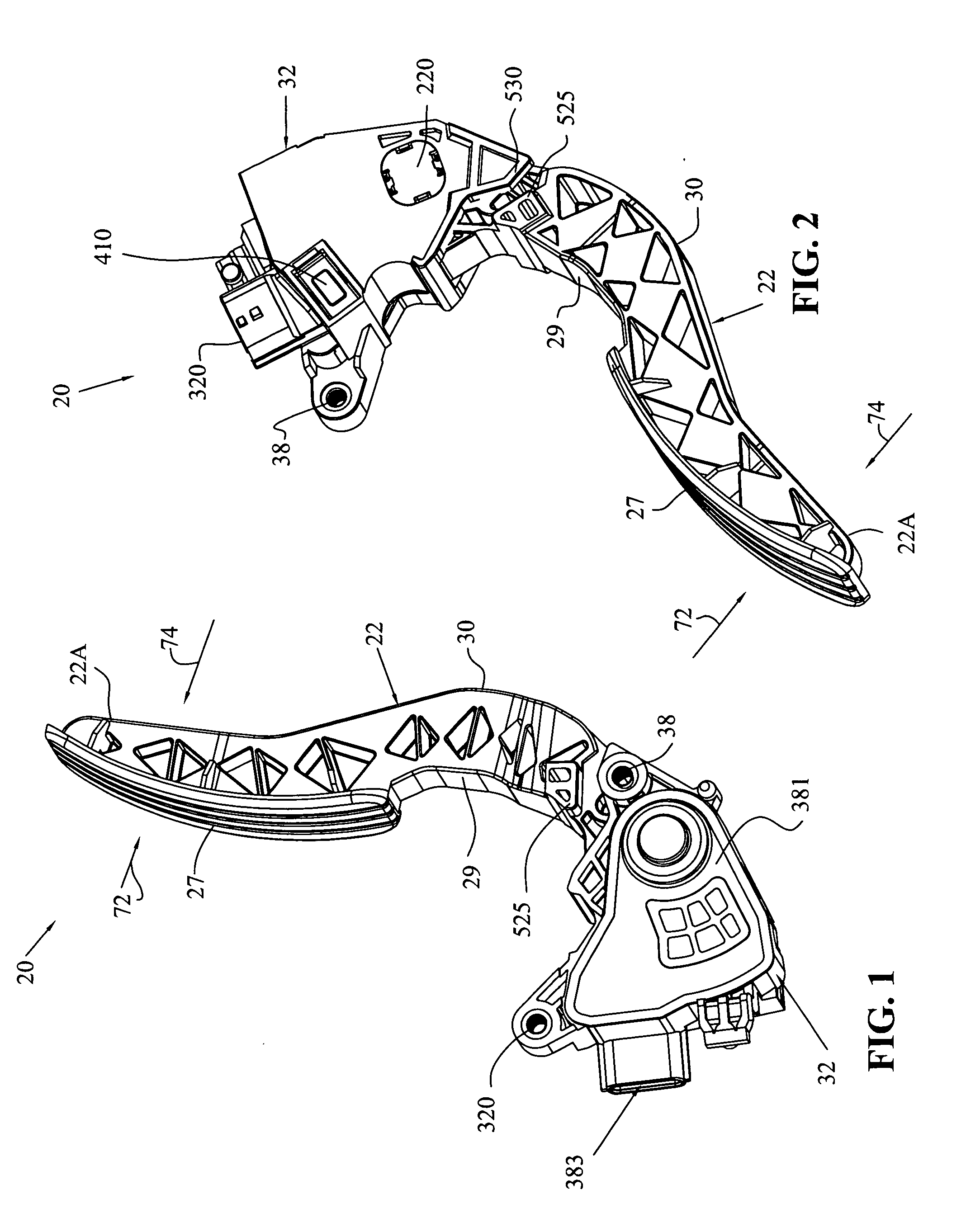

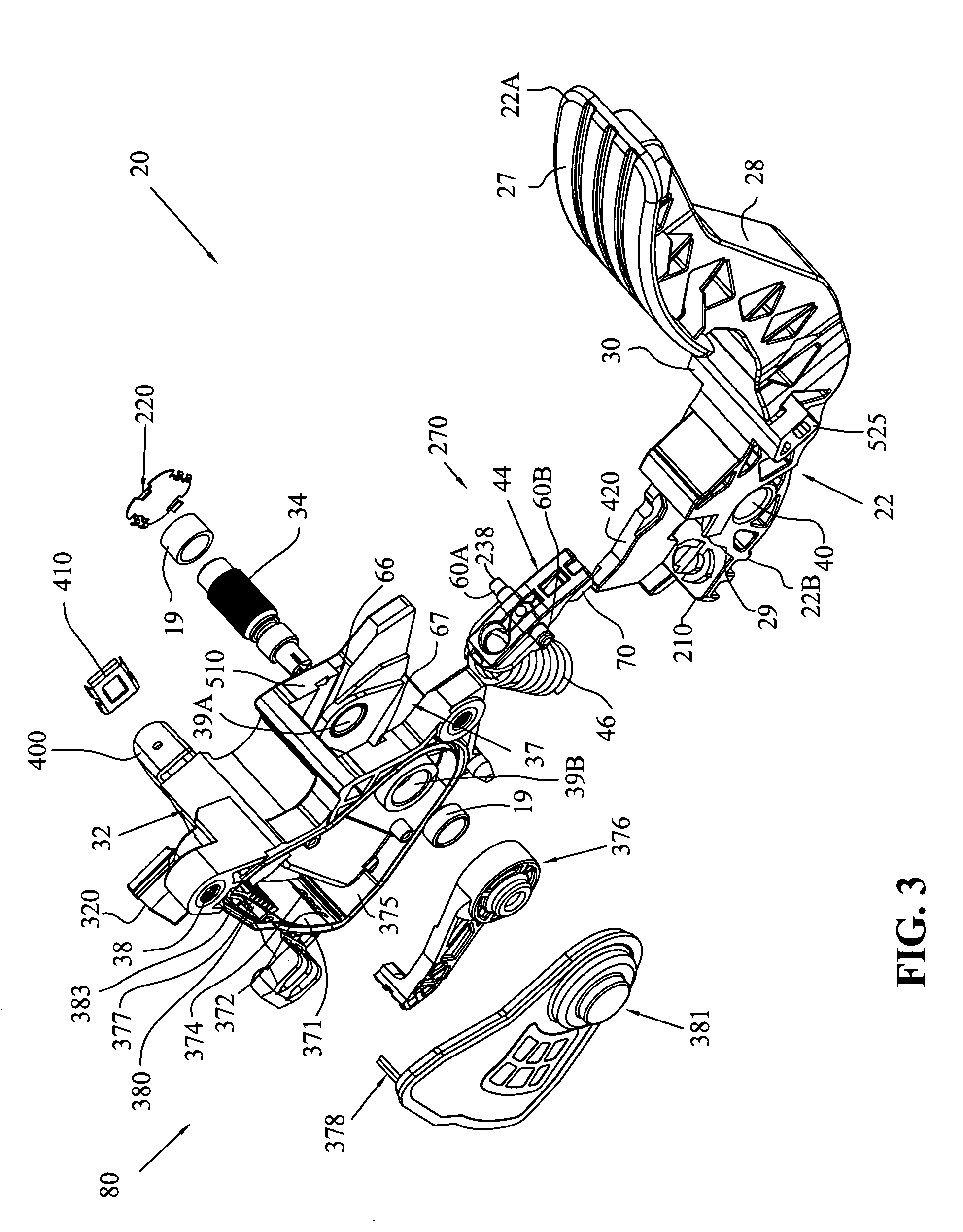

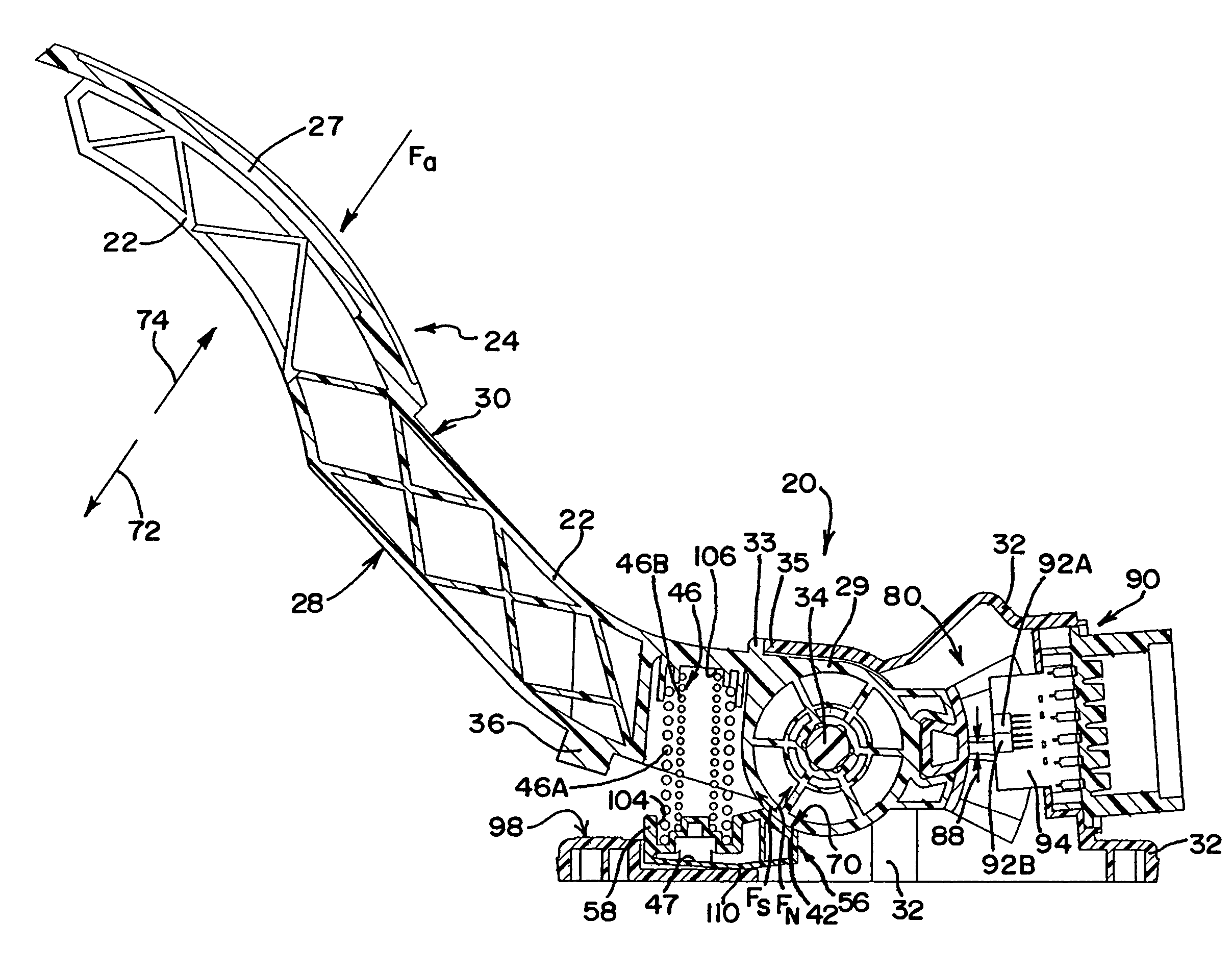

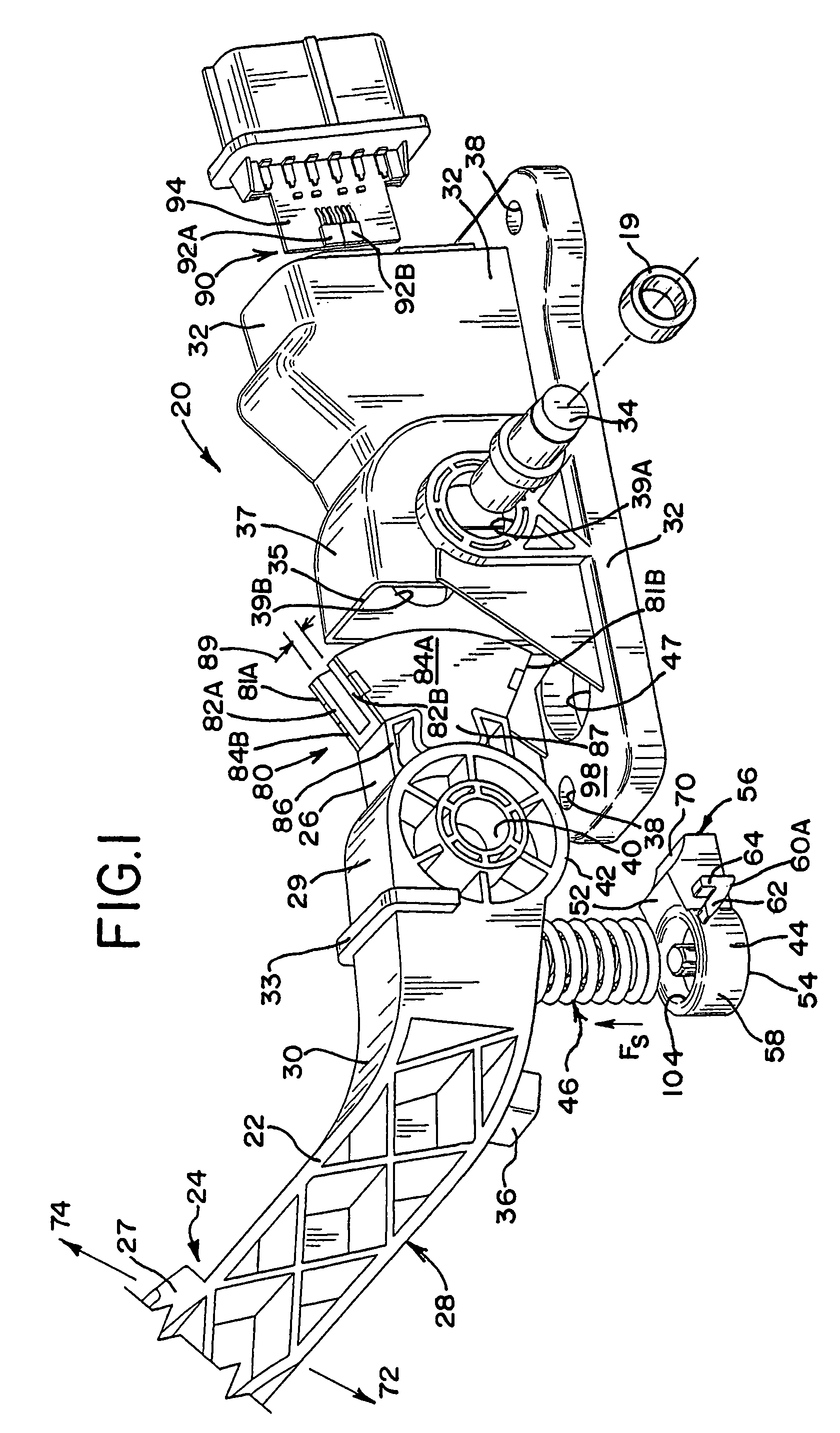

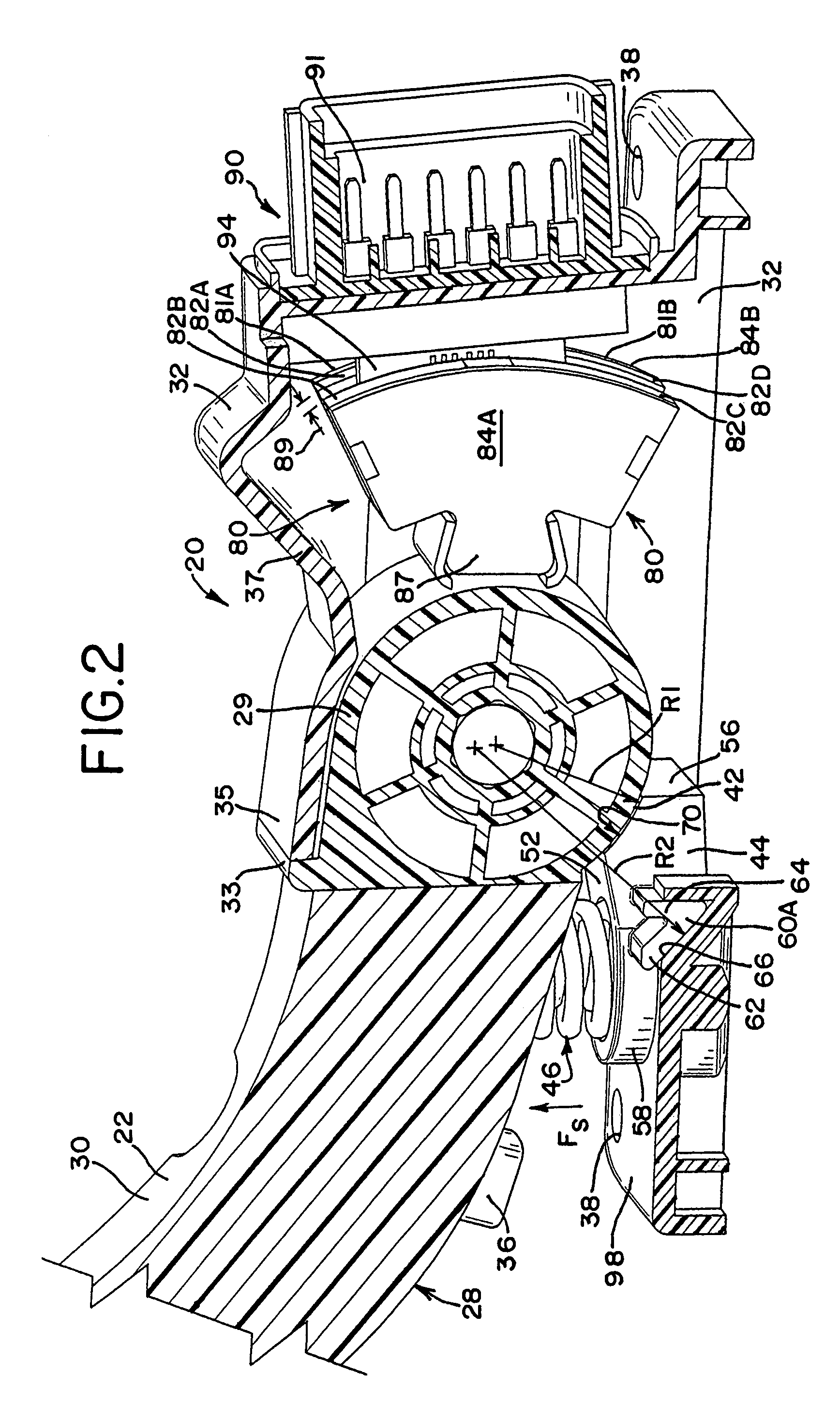

Accelerator pedal for a vehicle

A pedal assembly for a vehicle including a pedal housing and a pedal arm coupled to the housing. A friction generating assembly associated with the housing includes at least an actuator which is engaged by the pedal arm, a brake pad engaged by the actuator, and springs which engage against the brake pad. Arms on the brake pad are adapted to engage with either an interior central wall or interior peripheral wall of the friction generating assembly. In one embodiment, the friction generating assembly defines a separate module which is snap fitted into a cavity defined in the pedal housing. A magnet is coupled to the pedal arm. A sensor is coupled to the pedal housing and positioned in proximity to the magnet. The sensor is responsive to movement of the magnet to generate an electrical signal that is representative of the position of the pedal arm.

Owner:CTS CORP ELKHART

Brake System for Motor Vehicles. and Method for Operating the Brake System

A motor vehicle brake system actuated in brake-by-wire and fallback operating modes, having a brake master cylinder, brake circuits, a pressure medium storage vessel, a brake pedal, a separating valve for separating the brake circuit into a first section connected to the separating valve the master cylinder, and a second section connected to the separating valve and the wheel brakes. A first pressure provision device has a piston actuated by an actuator, a simulation device connected by a simulator release valve to the master cylinder for a pleasant brake pedal feel in the brake-by-wire operating mode. A first electronic control and regulating unit actuates the first pressure provision device, the separating valves and the simulator release valve. A second pressure provision device has a suction connector and a pressure connector per brake circuit being connected to the inlet of the separating valve.

Owner:CONTINENTAL TEVES AG & CO OHG

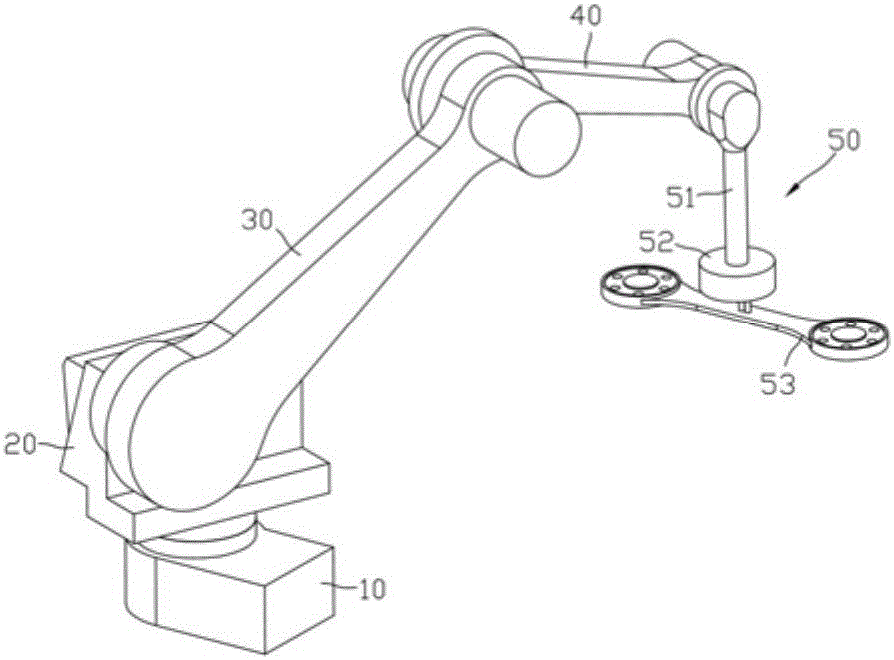

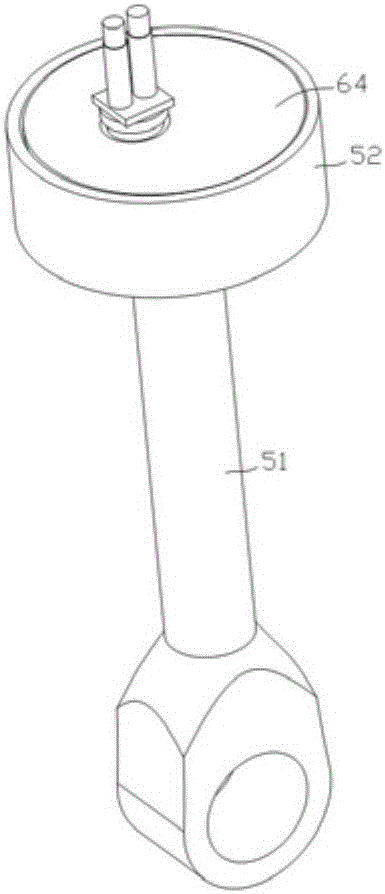

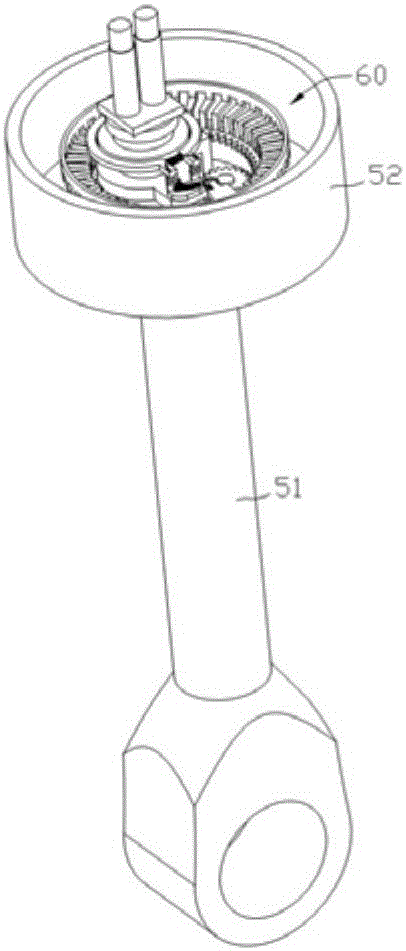

Robot provided with rotation actuation tail end

The invention relates to a robot provided with a rotation actuation tail end. The rotation actuation tail end of the robot is driven by a driving mechanism. The driving mechanism comprises a base plate, a rotation base pivoted to the base plate and an internal gear provided with a section of teeth. In the normal state, the section of teeth of the internal gear does not make contact with a gear of the rotation base, and a brake pad stops the rotation base. During operation, the rotating internal gear drives the rotation base to rotate by a preset angle through the section of teeth, and when the rotation base rotates, an unlocking device on the internal gear relieves braking of the brake pad on the rotation base. The rotation actuation tail end is fixedly connected with the rotation base, so that the rotation actuation tail end rotates by a certain angle each time, and the technical problem that the rotation angle of rotation actuation tail ends of robots in the prior art is inaccurate is solved.

Owner:聊城市洛盏新材料科技有限公司

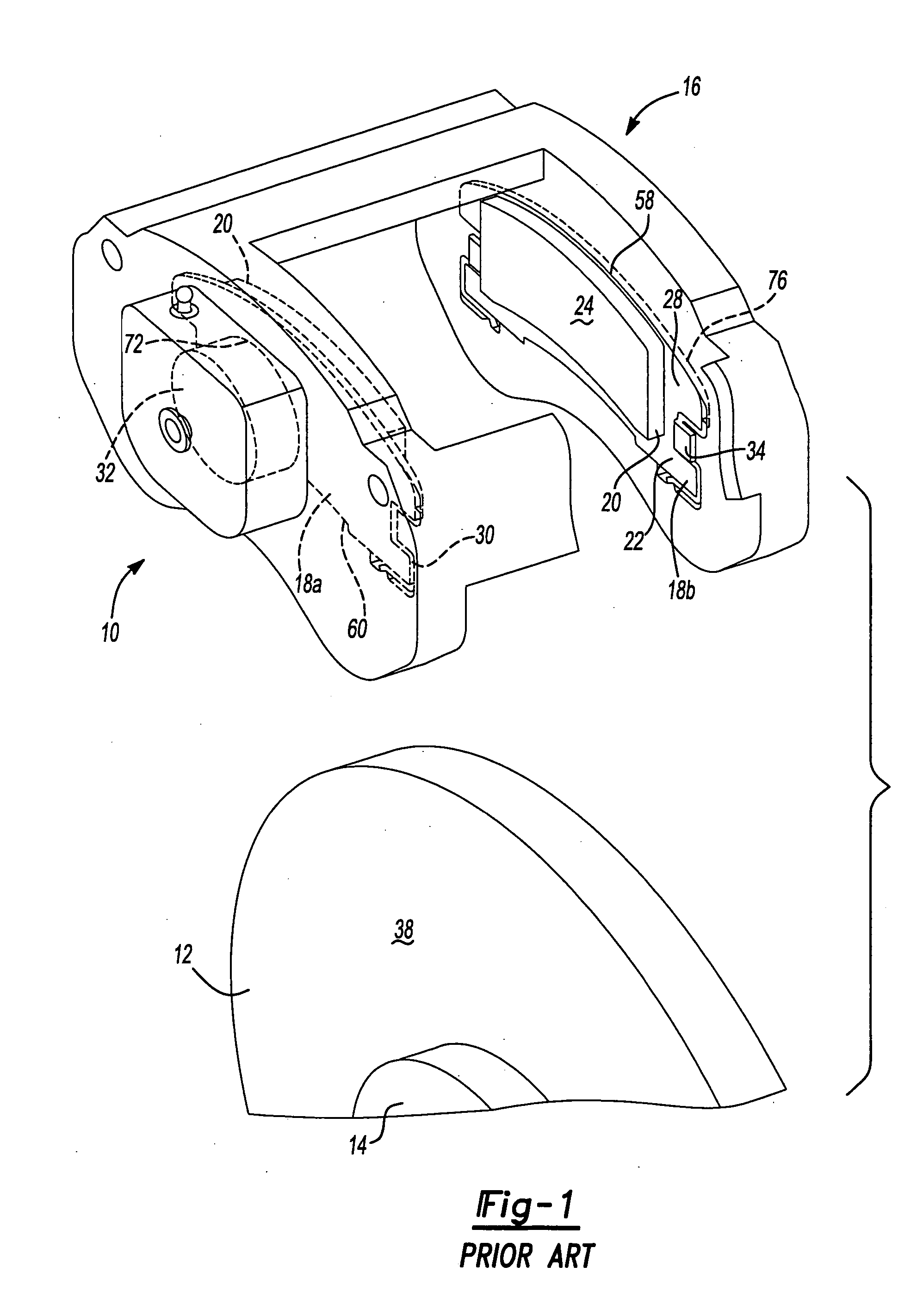

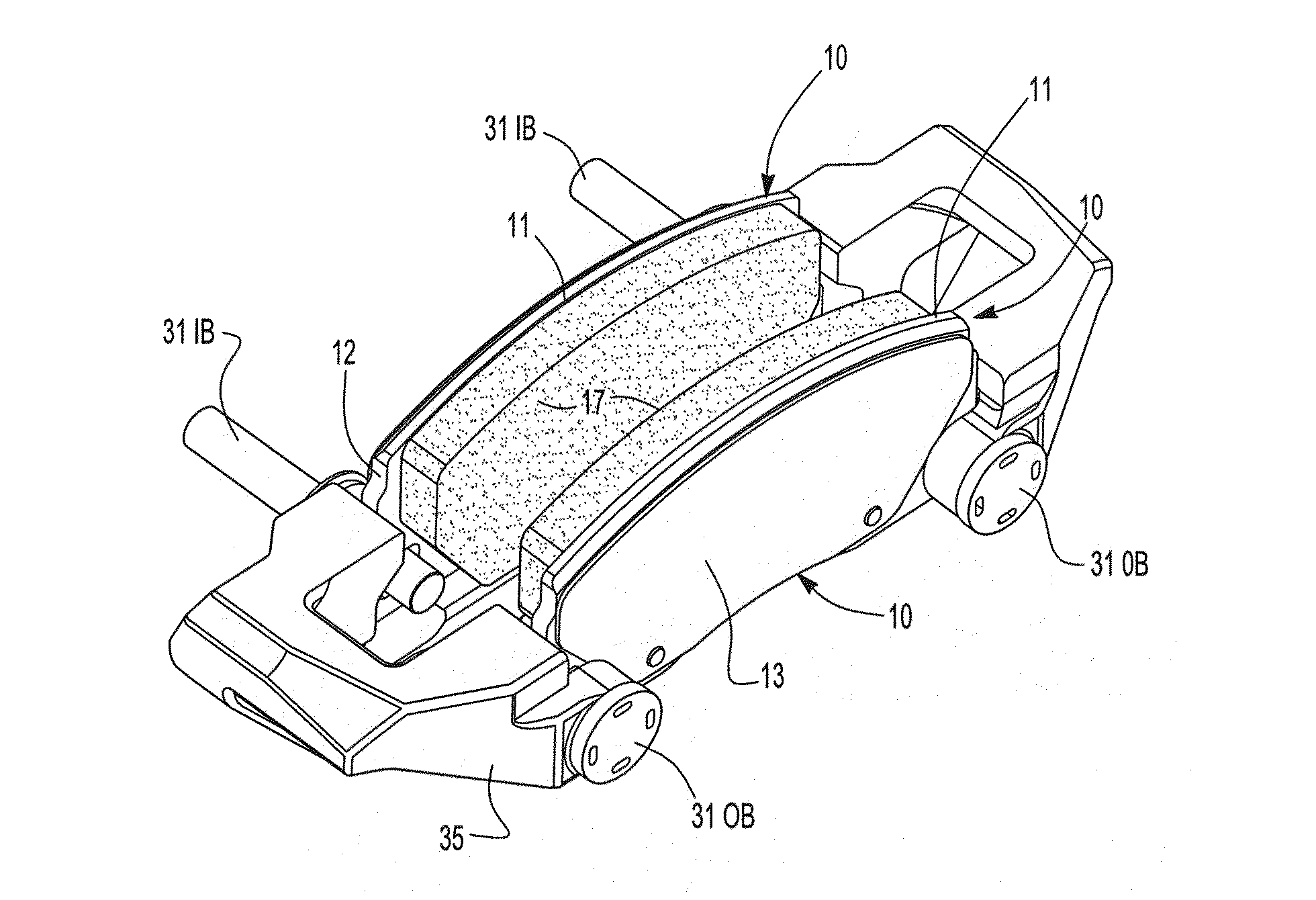

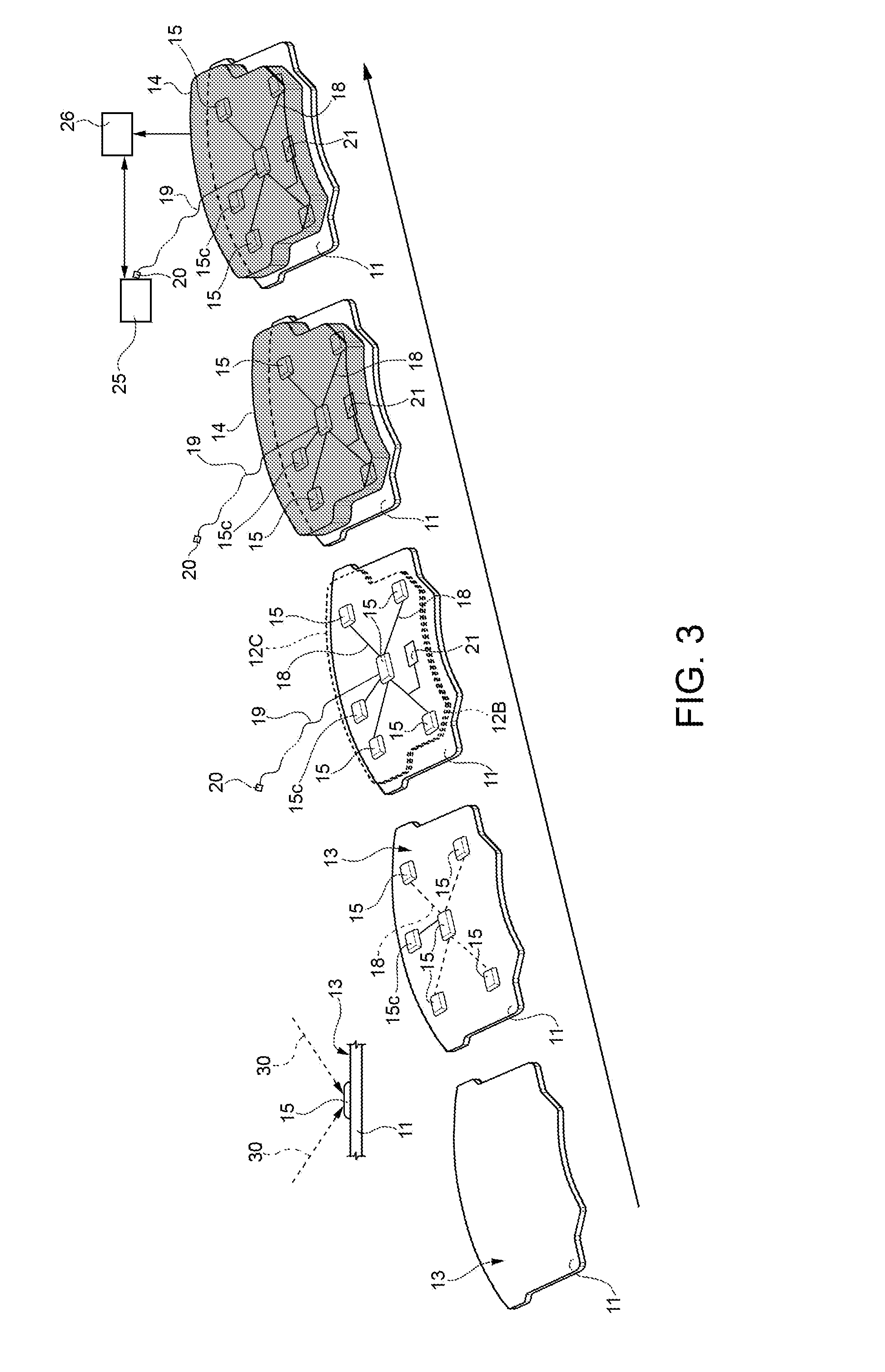

Brake systems, caliper assemblies and pads incorporating differential abutments

InactiveUS20120043168A1Transmission of forceImprove NVH performanceMechanically actuated brakesBraking membersPush pullEngineering

The present invention is directed to a unique solution for caliper assemblies, brake pads utilized in such caliper assemblies, support structures utilized in caliper assemblies and disc brake systems containing such caliper assemblies which utilize push pull or pull push abutment designs.

Owner:AKEBONO CORP (NORTH AMERICA)

Brake pad with wear indicator

InactiveUS7424936B2Simple and reliable and effectiveBrake typesFriction liningMechanical engineeringBrake pad

A brake pad includes a backing plate and a friction material layer attached to the backing plate. At least one inner layer is disposed within the friction material layer. The inner layer has a color different than the friction material layer.

Owner:MCCLELLAN WILLIAM THOMAS

Brake Pad Prognosis System

A method for providing an estimate of brake pad thickness. The method employs fusion of sensors, if used, and driver brake modeling to predict the vehicle brake pad life. An algorithm is employed that uses various inputs, such as brake pad friction material properties, brake pad cooling rate, brake temperature, vehicle mass, road grade, weight distribution, brake pressure, brake energy, braking power, etc. to provide the estimation. The method calculates brake work using total work minus losses, such as aerodynamic drag resistance, engine braking and / or braking power as braking torque times velocity divided by rolling resistance to determine the brake rotor and lining temperature. The method then uses the brake temperature to determine the brake pad wear, where the wear is accumulated for each braking event. A brake pad sensor can be included to provide one or more indications of brake pad thickness from which the estimation can be revised.

Owner:GM GLOBAL TECH OPERATIONS LLC

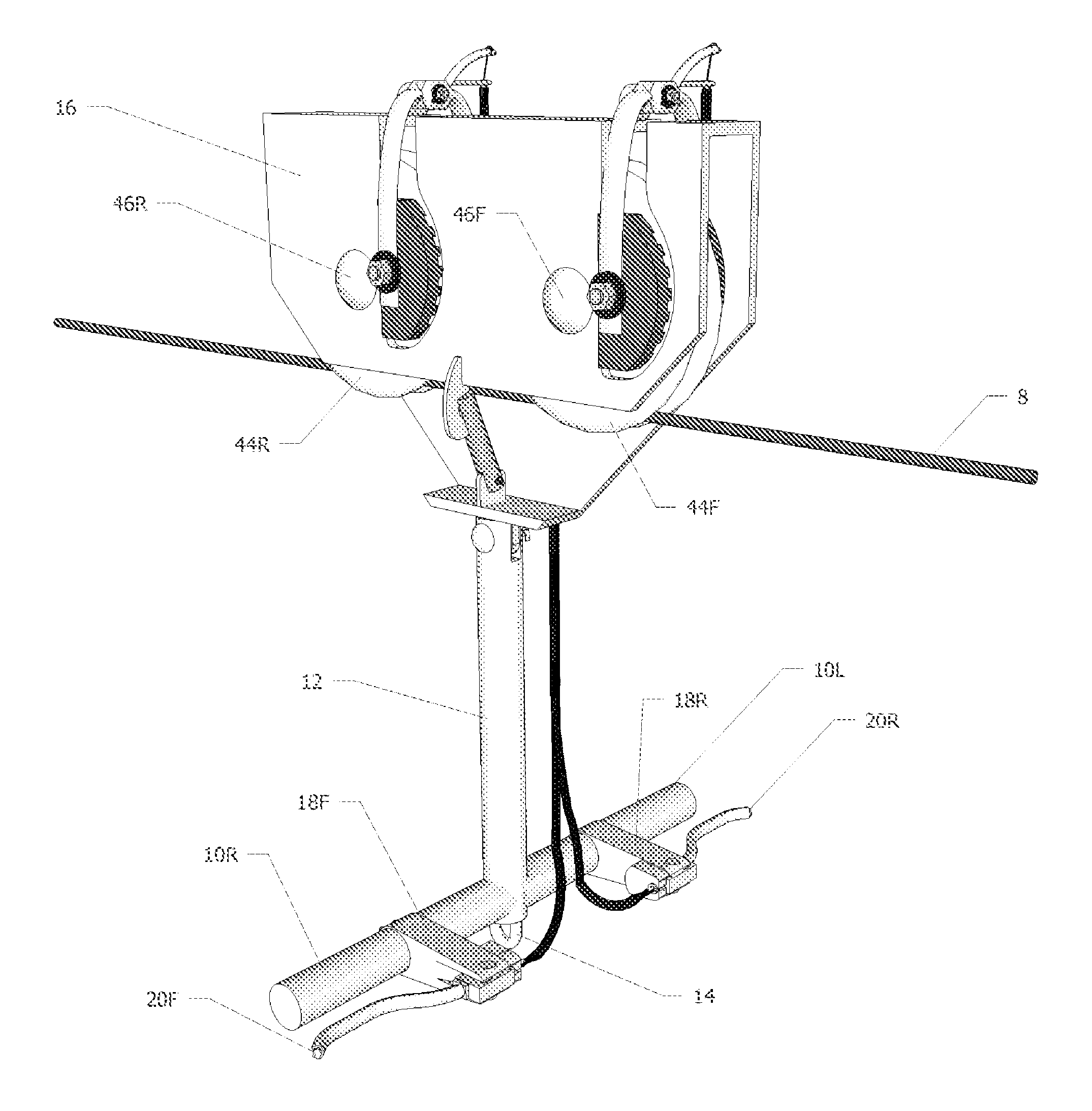

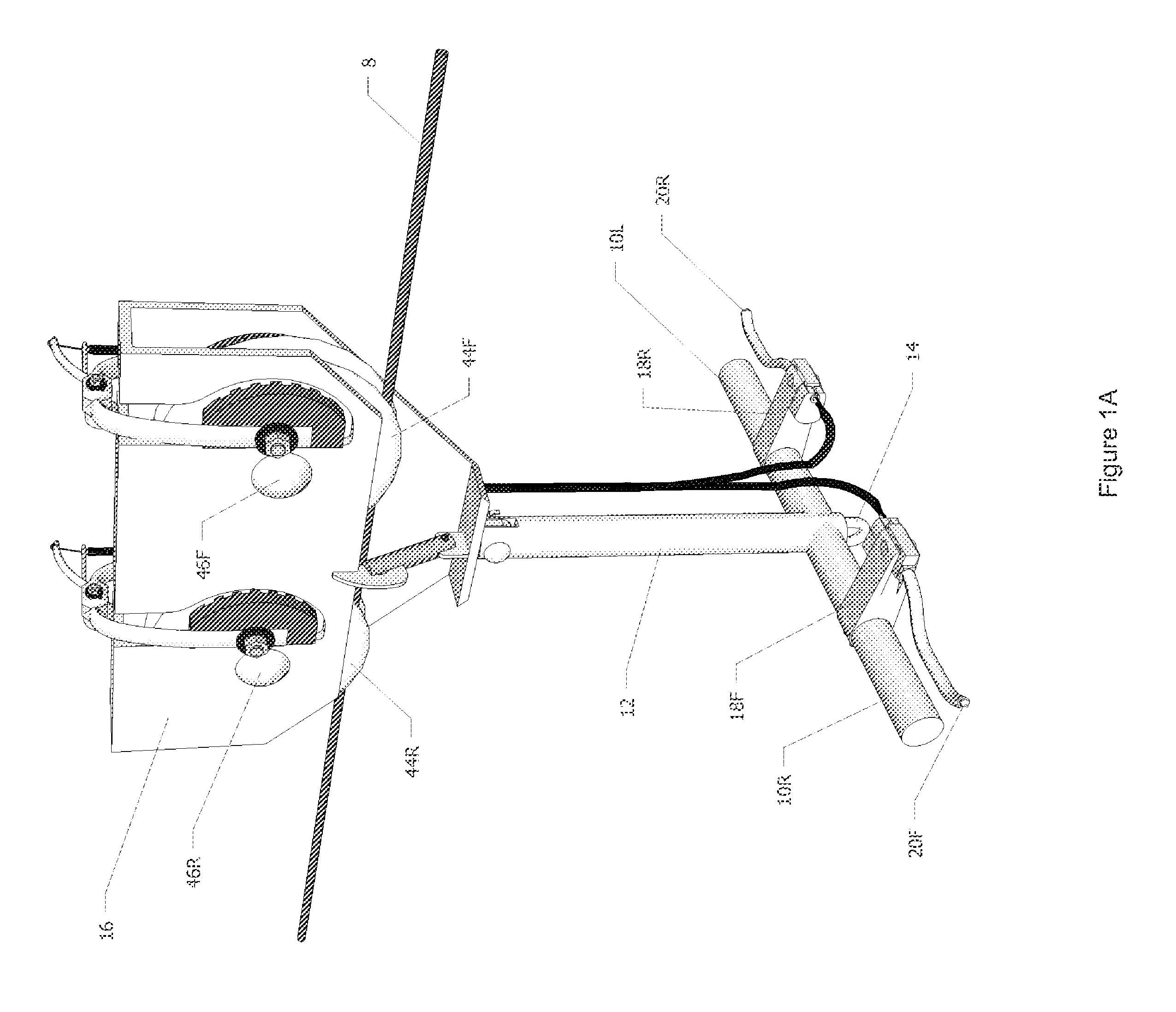

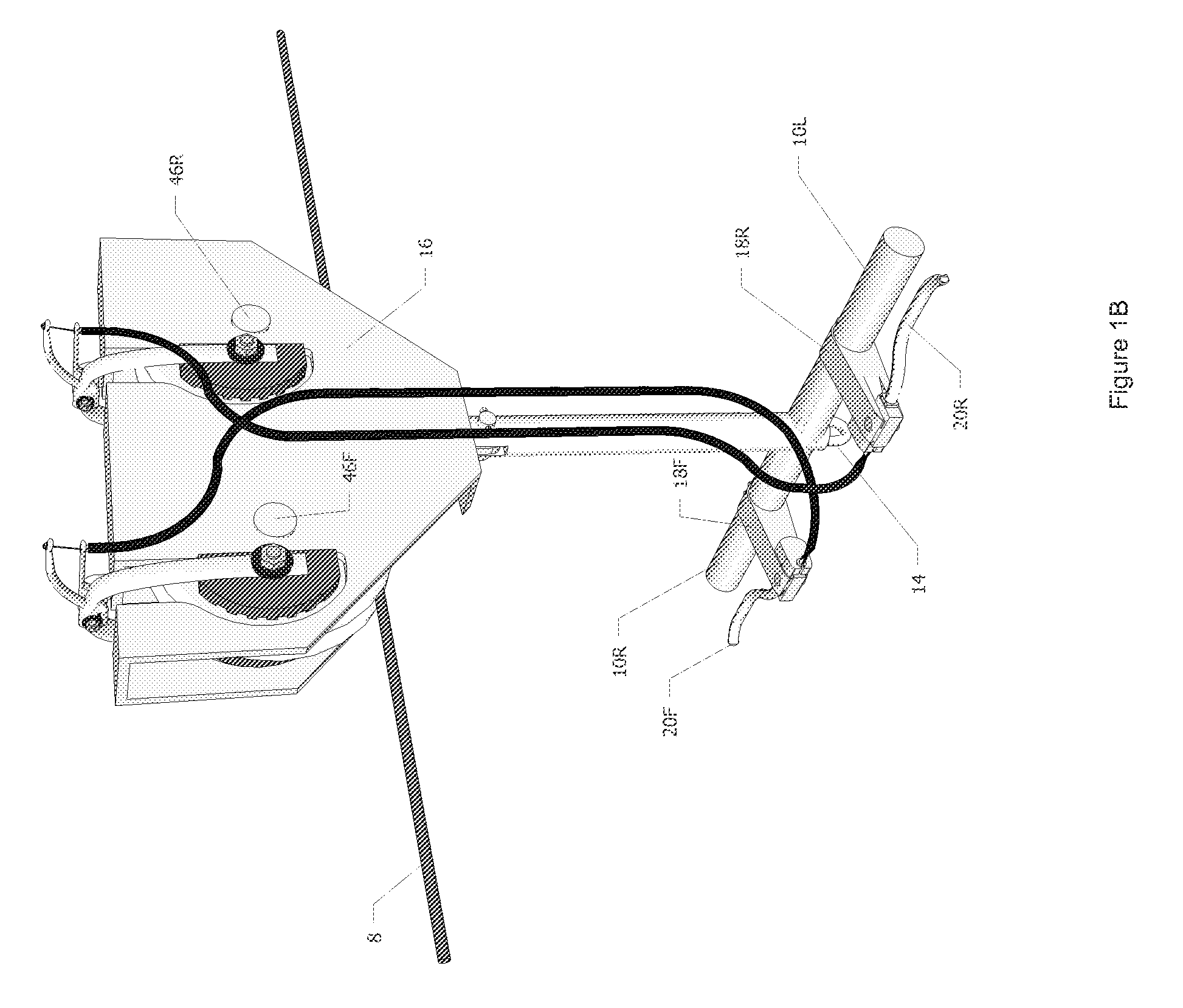

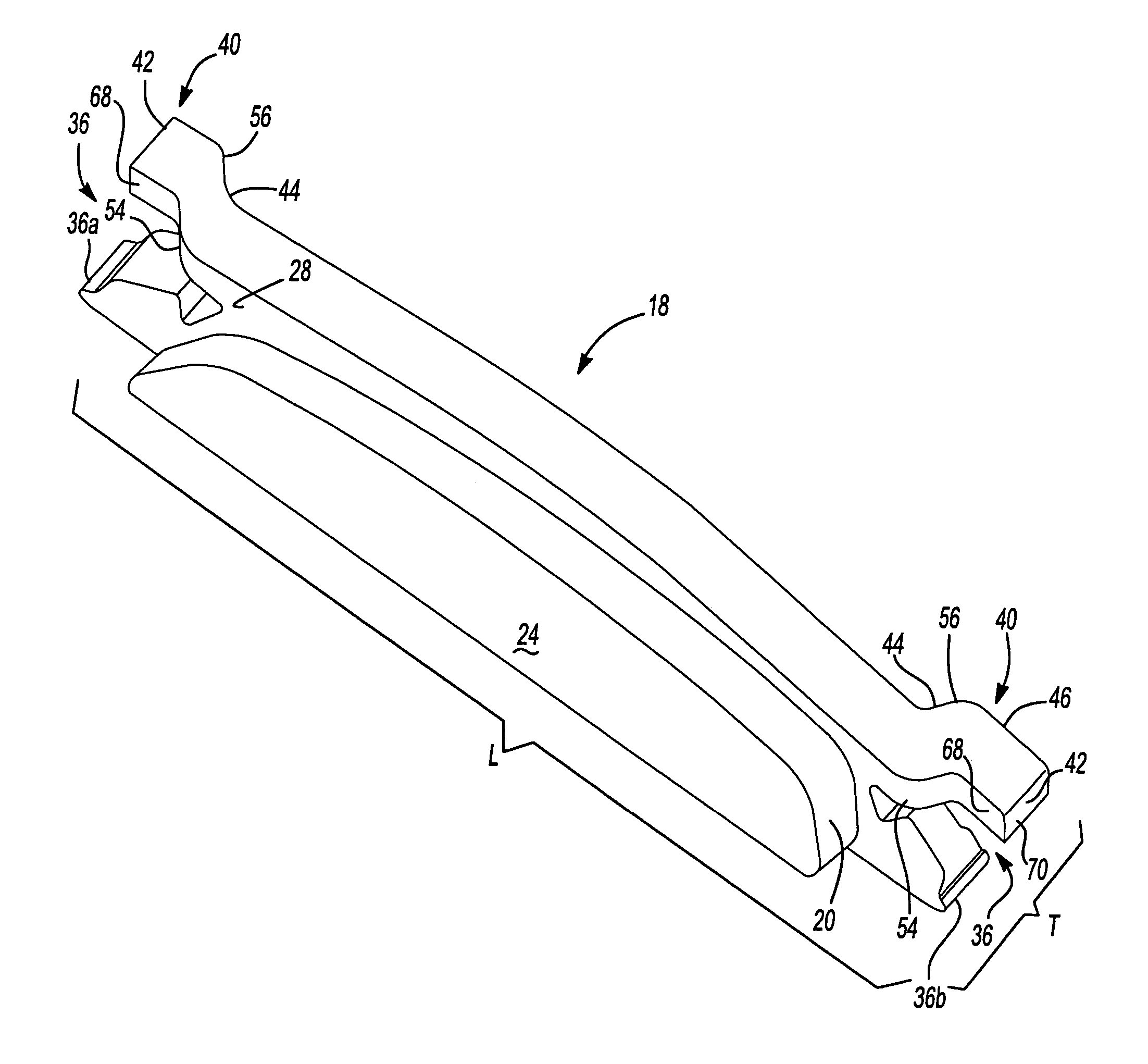

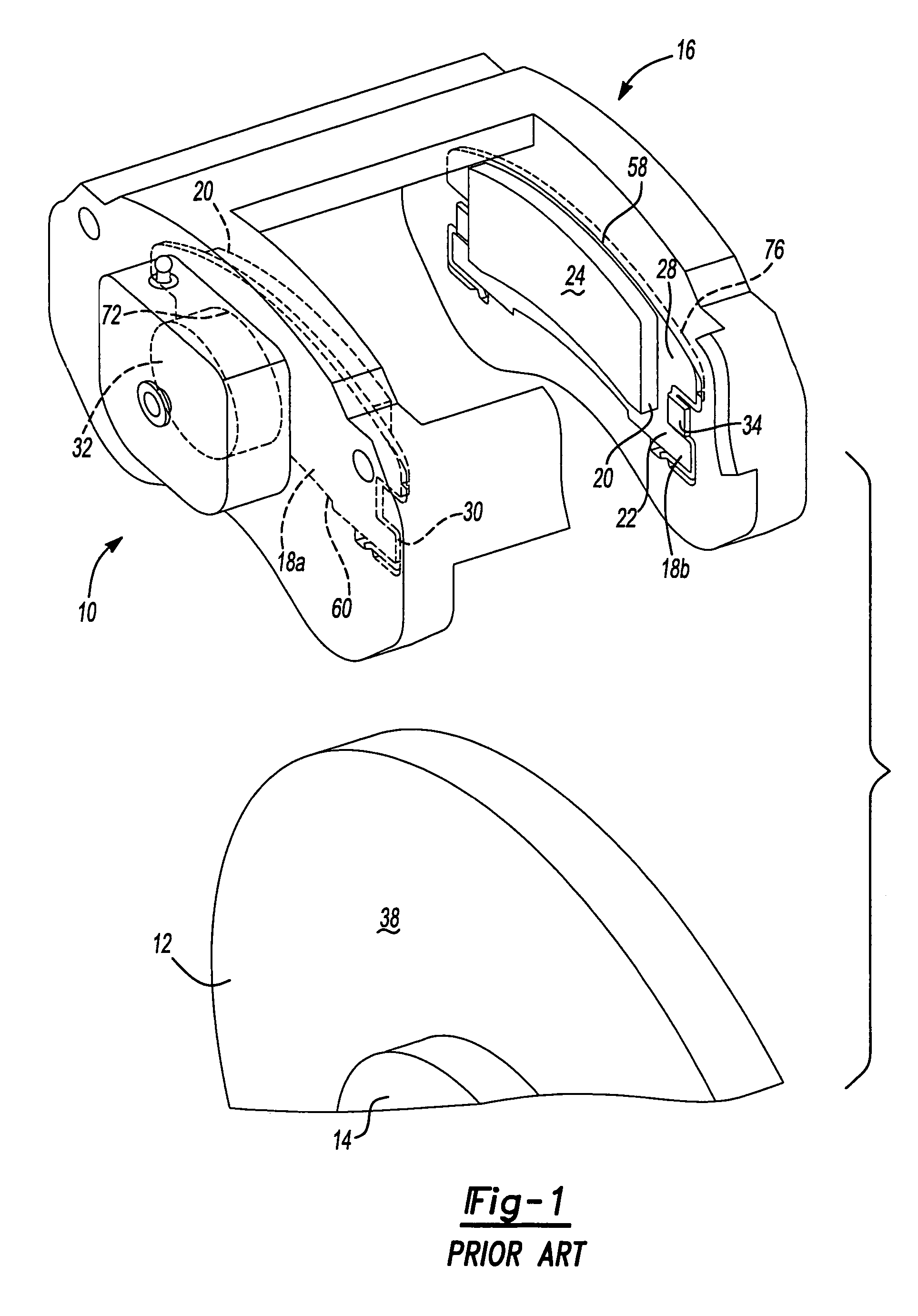

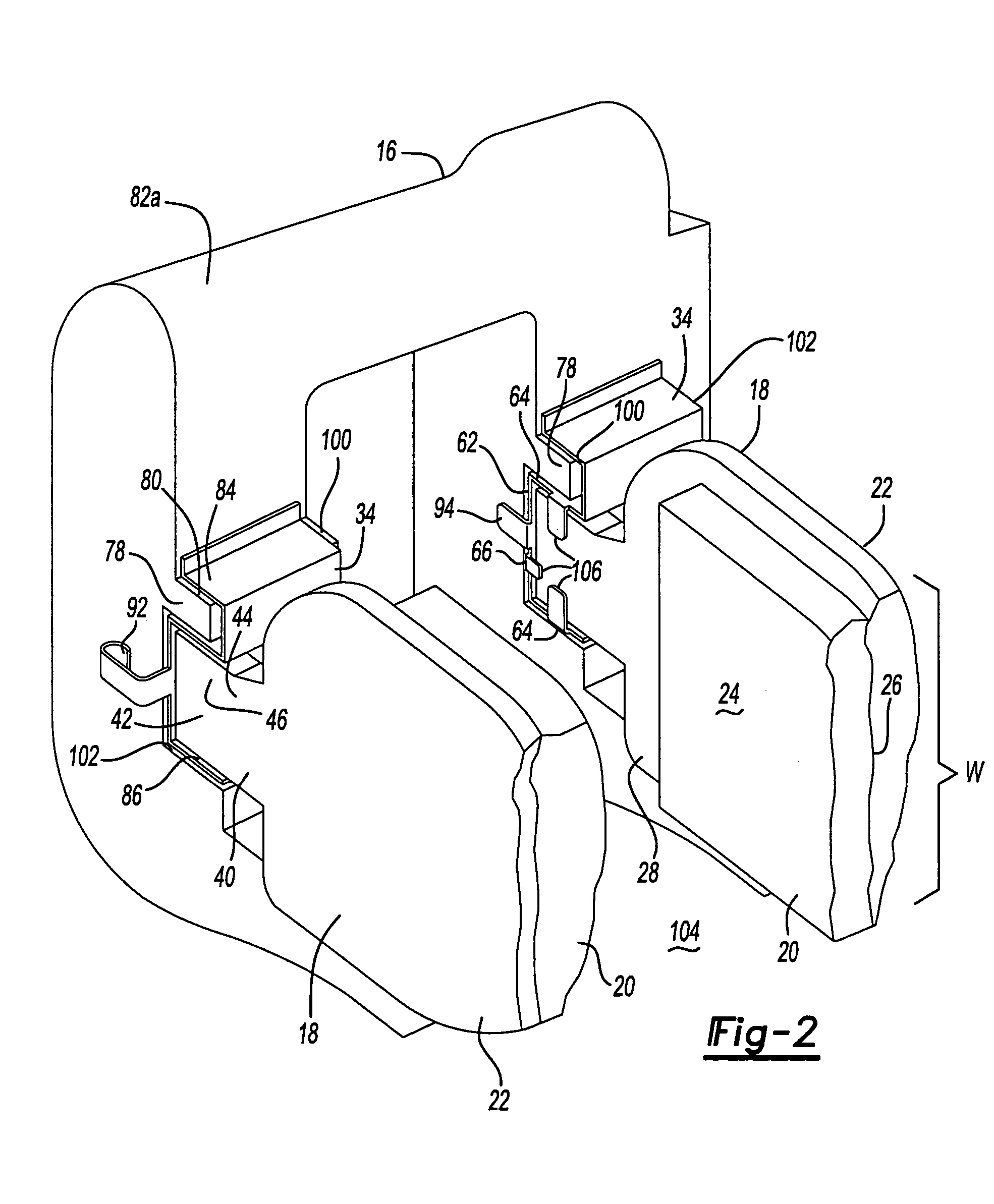

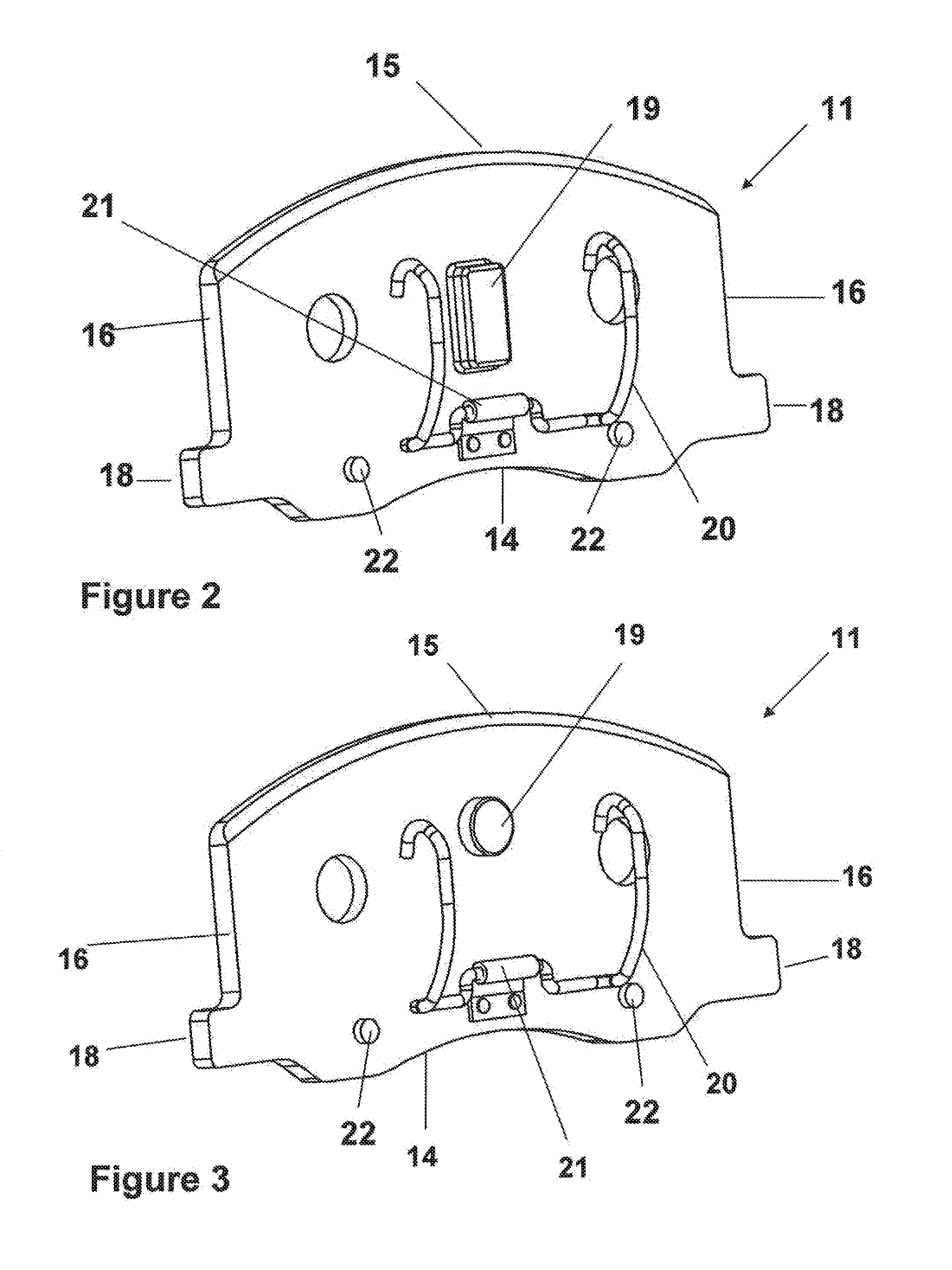

Rider controlled zip line trolley brake

An improved zip line trolley allowing a rider control of his or her speed while traversing along a suspended cable (8) as seen in FIGS. 1A and 1B. The trolley comprises front and rear pulleys (44F) and (44R) conjoined via pulley housing (16) with left and right horizontal handles (10L) and (10R) attached to vertical shaft (12). Front and rear hand brake levers (20F) and (20R) are mounted onto left and right horizontal handles (10L) and (10R). When front and rear hand brake levers (20F) and (20R) are squeezed by the rider, they create a constricting force on front left and right calipers (32FL) and (32FR) along with rear left and right calipers (32RL) and (32RR) of FIGS. 2A and 3A. Thus, friction is applied to front and rear pulleys (44F) and (44R) via front left and right brake pads (34FL) and (34FR) along with rear left and right brake pads (34RL) and (34RR). This frictional force slows the rider's speed to his or her desired rate and brings the rider to a safe stop at a precise location along suspended cable (8).

Owner:BRANNAN KENTON MICHAEL

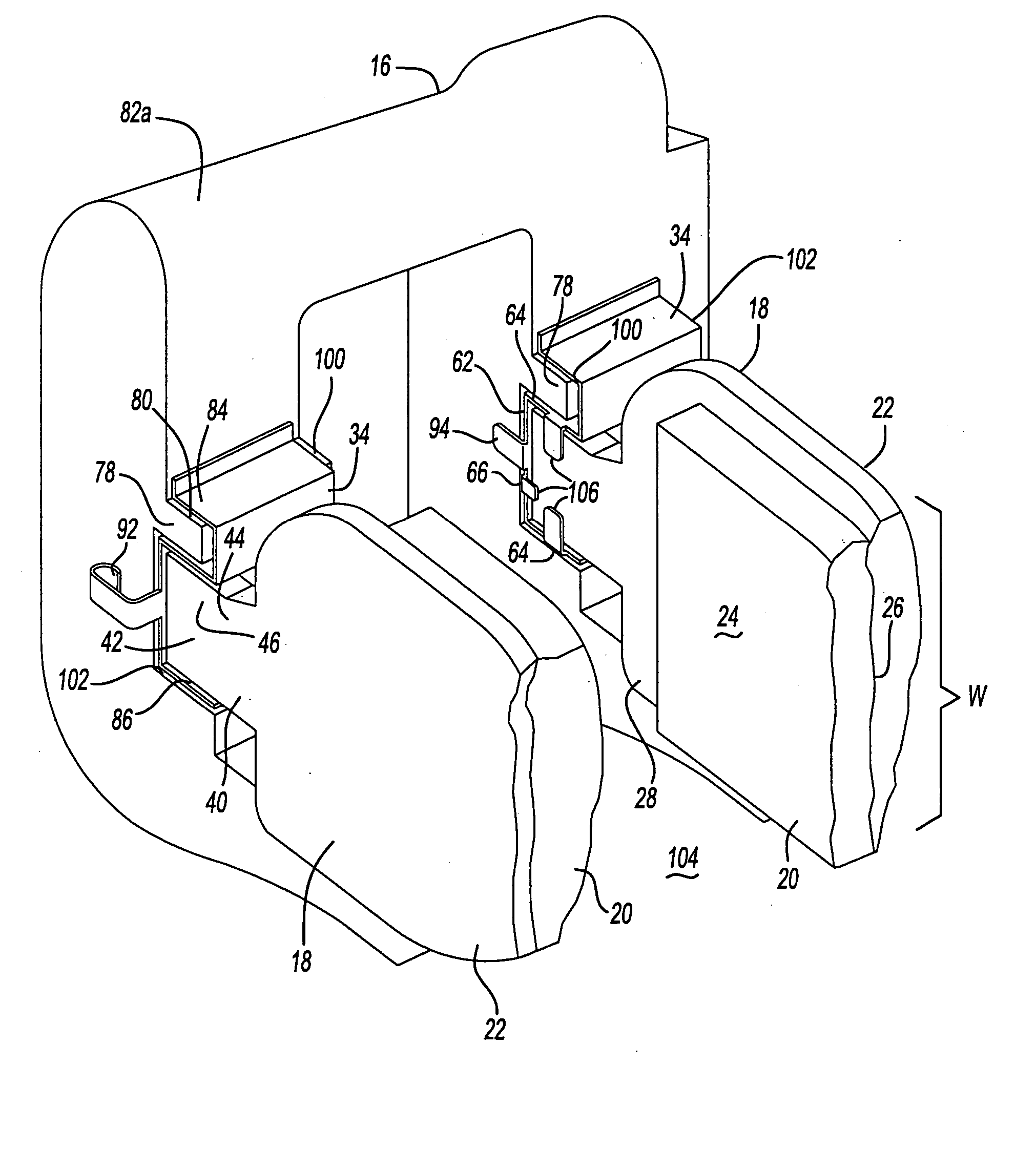

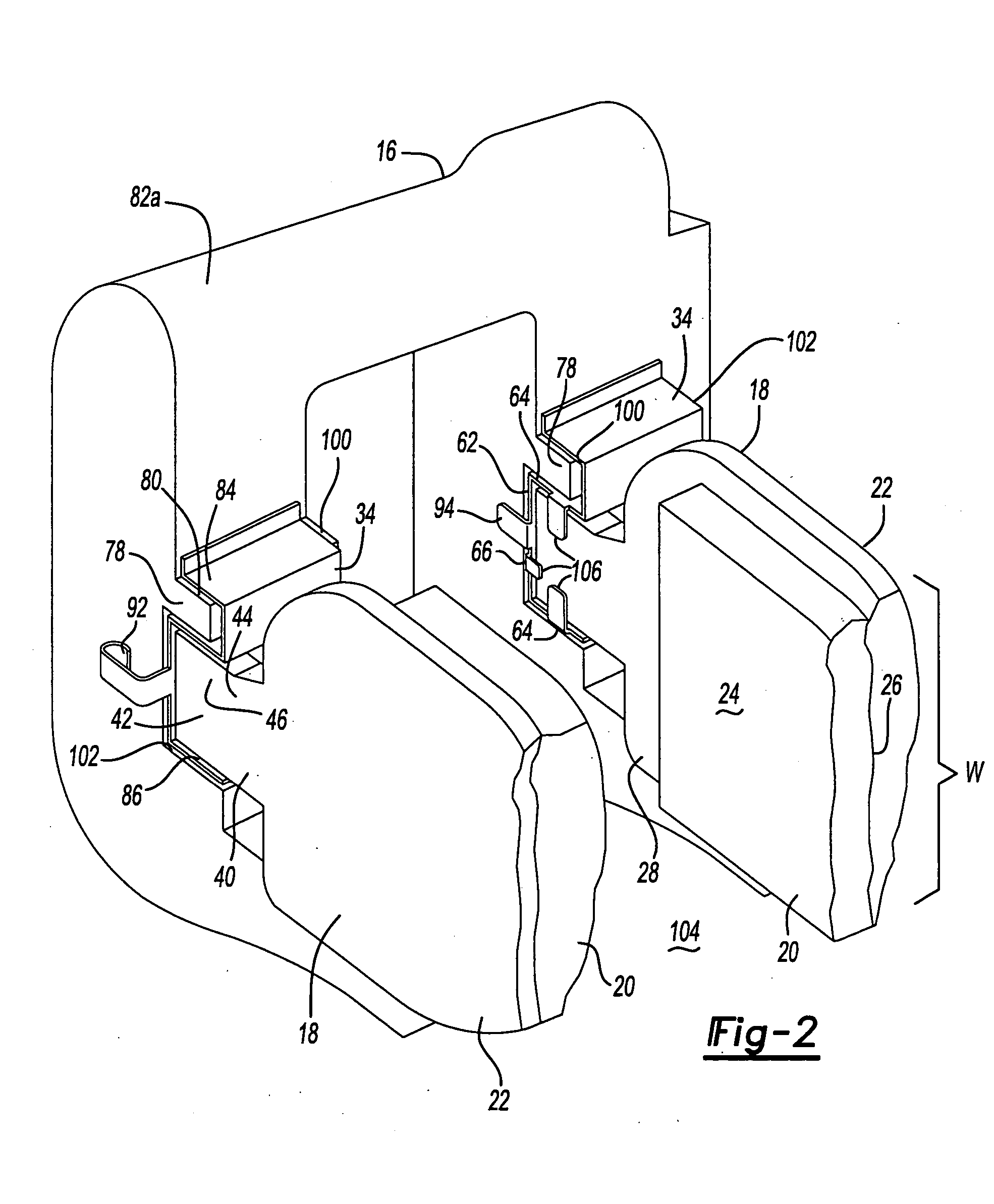

Pad retaining clips

A brake caliper mounting clip is disposed between a brake caliper having a brake pad channel and a brake pad having an edge member. The edge member moves in the brake pad channel between a rotor gap and a caliper housing. The clip further comprises a pad holding portion slidingly engaged with the edge member and having a plurality of pad retaining members. The pad retaining members are connected to the pad holding portion and disposed between the edge member and the rotor gap. The plurality of the pad retaining members is further configured to prevent the brake pad from falling into the rotor gap. Additionally the edge member of the brake pad and the plurality of pad retaining members are configured to prevent improper installation of the brake pads in the caliper.

Owner:AKEBONO BRAKE

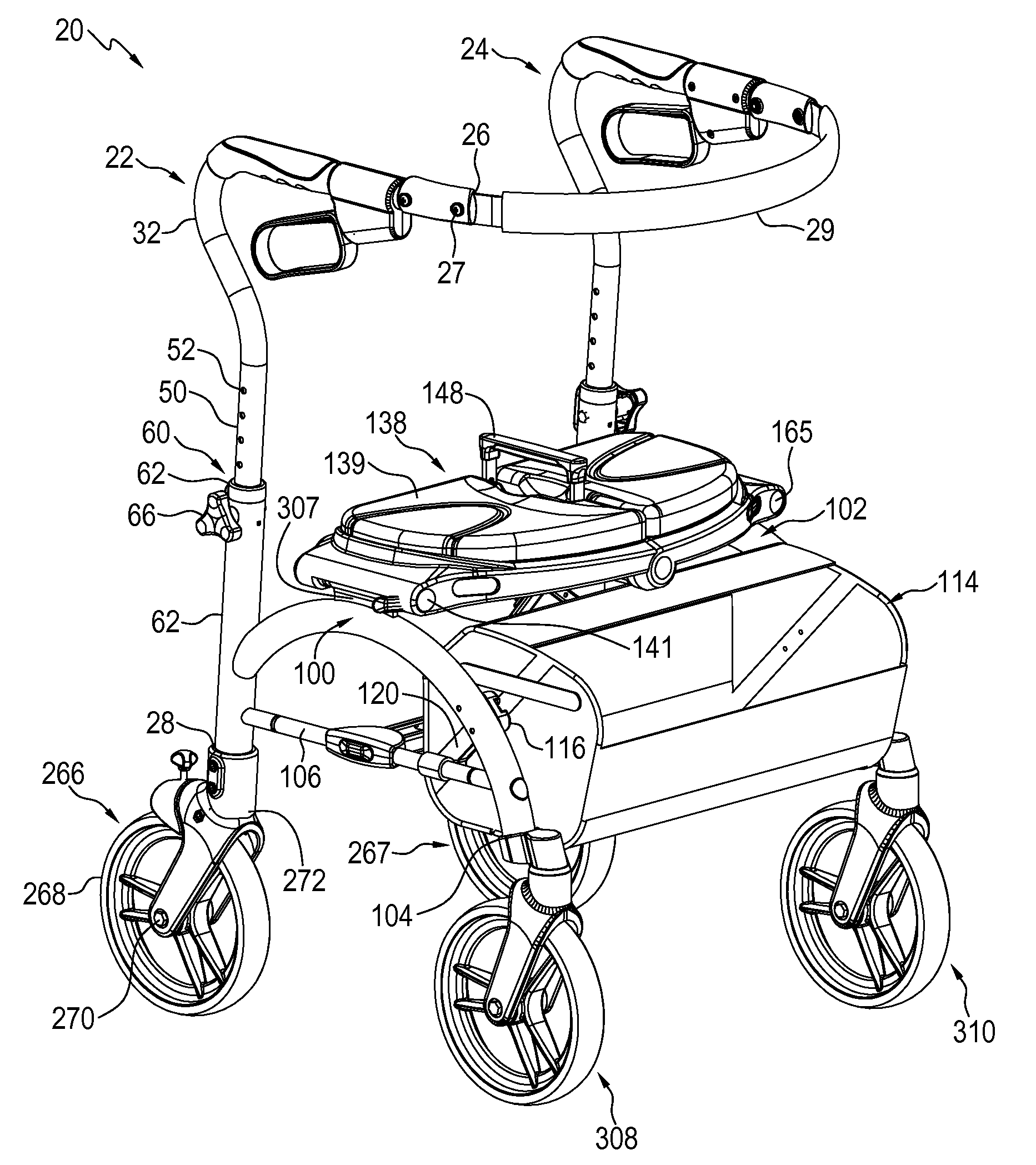

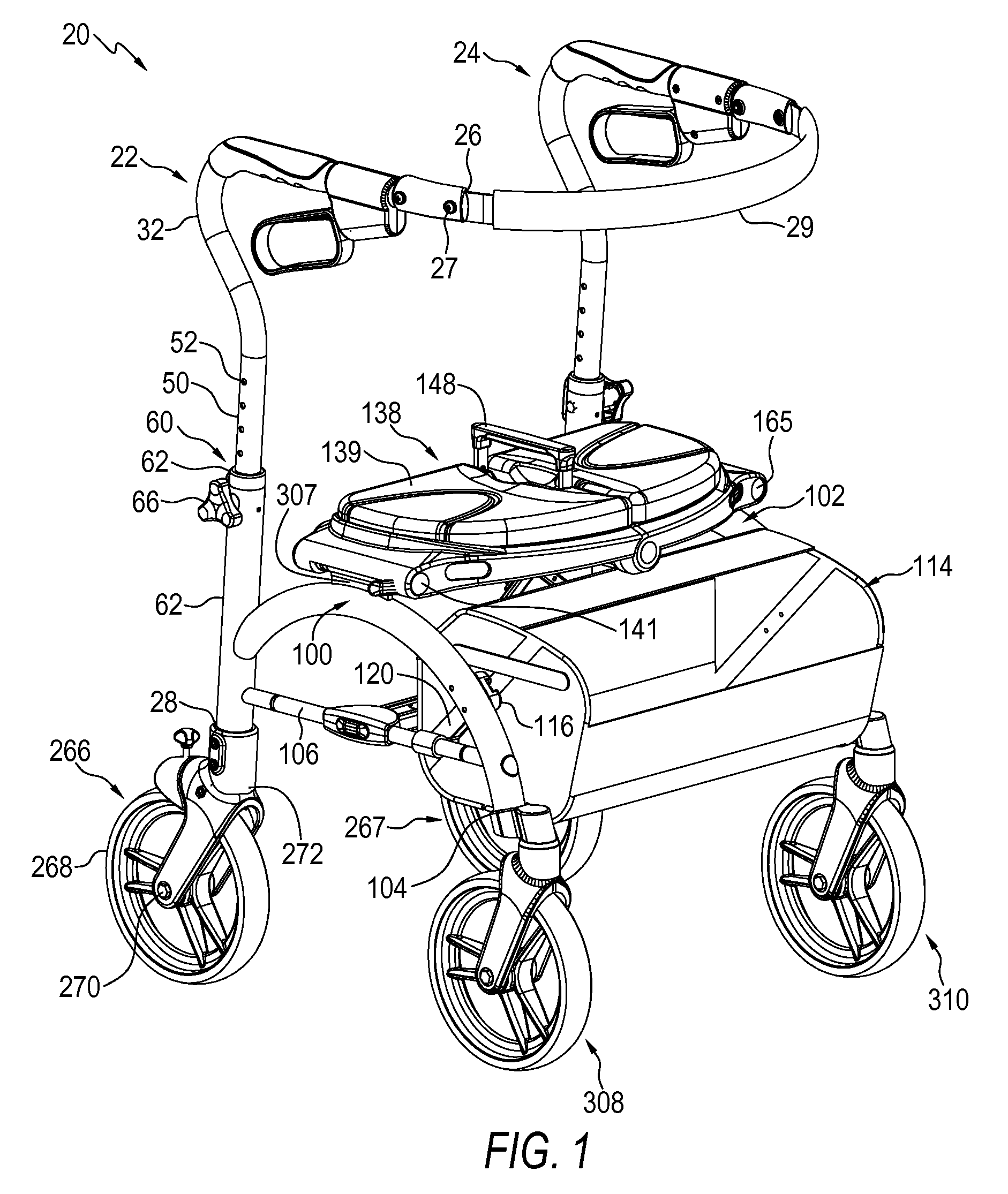

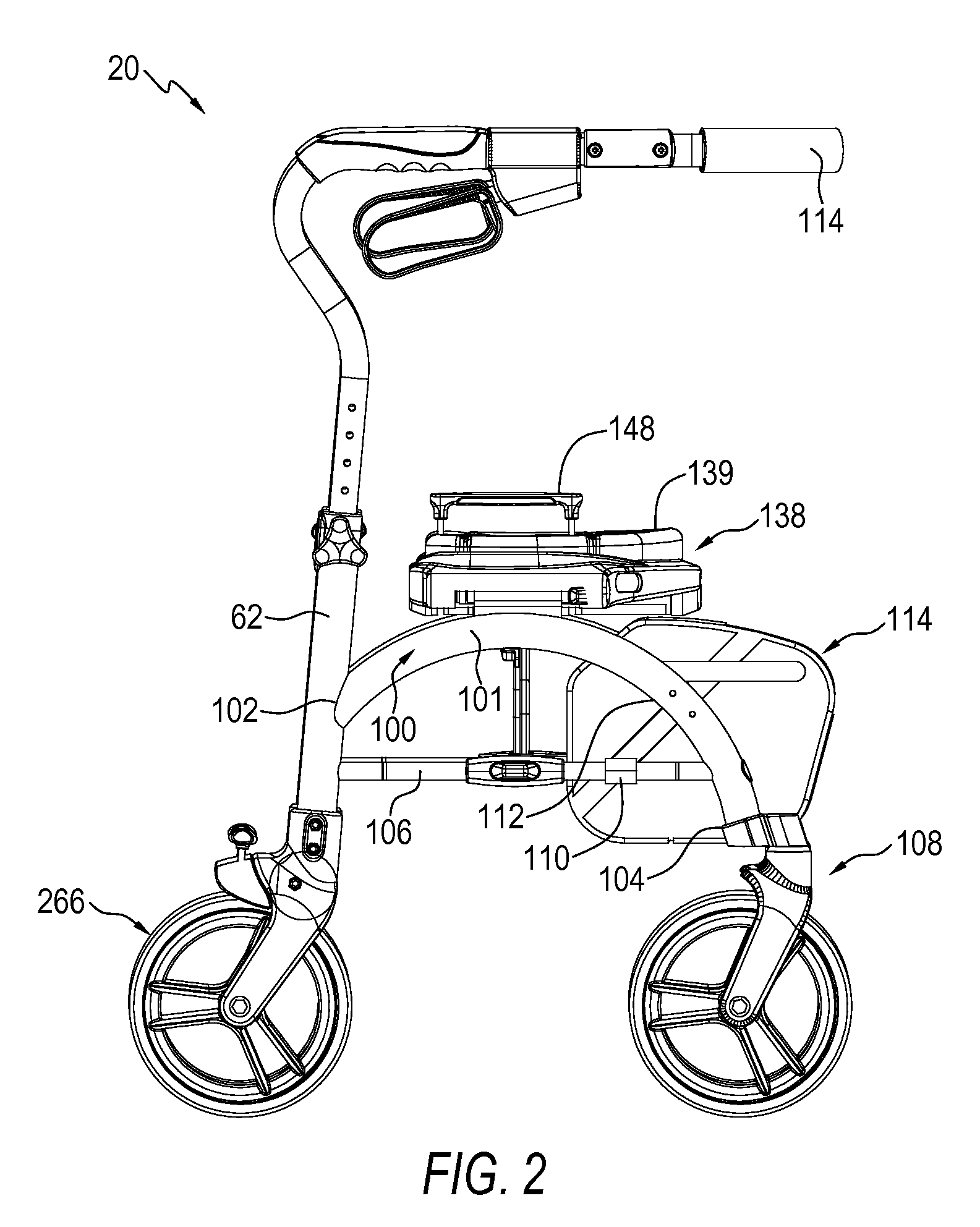

Foldable walker apparatus

ActiveUS20100083994A1Minimize the numberOptimizing robustnessWalking sticksCarriage/perambulator accessoriesEngineeringBrake pad

A foldable walker apparatus includes a pair of spaced-apart inner frame members of two parts each hinged together, with a pair of link members diagonally extending therebetween. Each link has a bend extending upwardly and outwardly. The walker has support members that are arc-shaped with a seat extending between their apexes. A collapsible basket is provided with two end members each having a rigid peripheral portion connecting the frame members and a basket member of flexible fabric extending therebetween. A self-adjusting brake rod is provided with a gripping member spring-biased to remain free of the brake rod until the gripping member is operatively actuated to engage and thereby actuate the brake rod. A brake housing fully extends around a brake pad mechanism, including a means for connecting and adjusting the corresponding brake pad, to at least the outer periphery of one of the wheels for fully protecting the brake pad mechanism.

Owner:EVOLUTION TECH

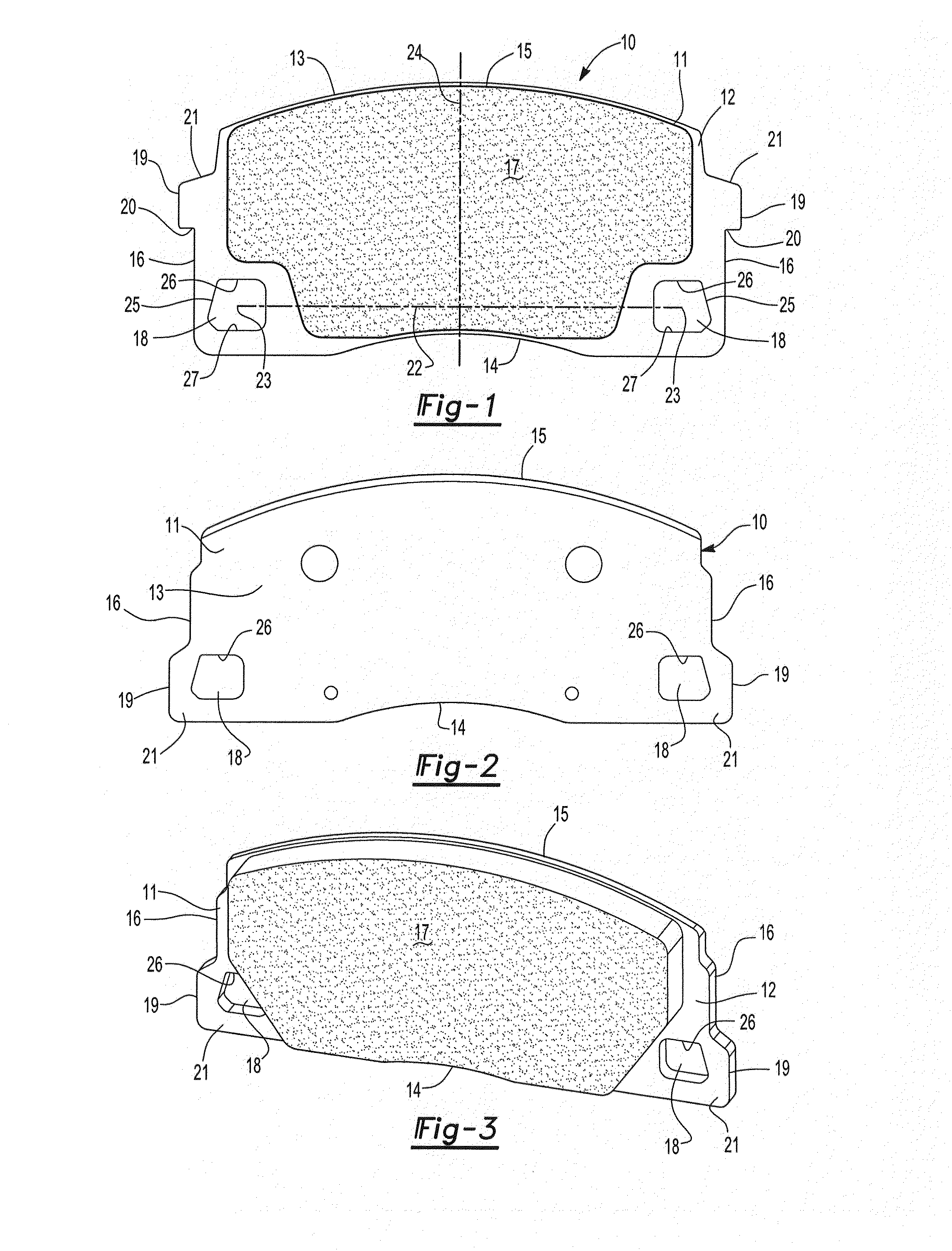

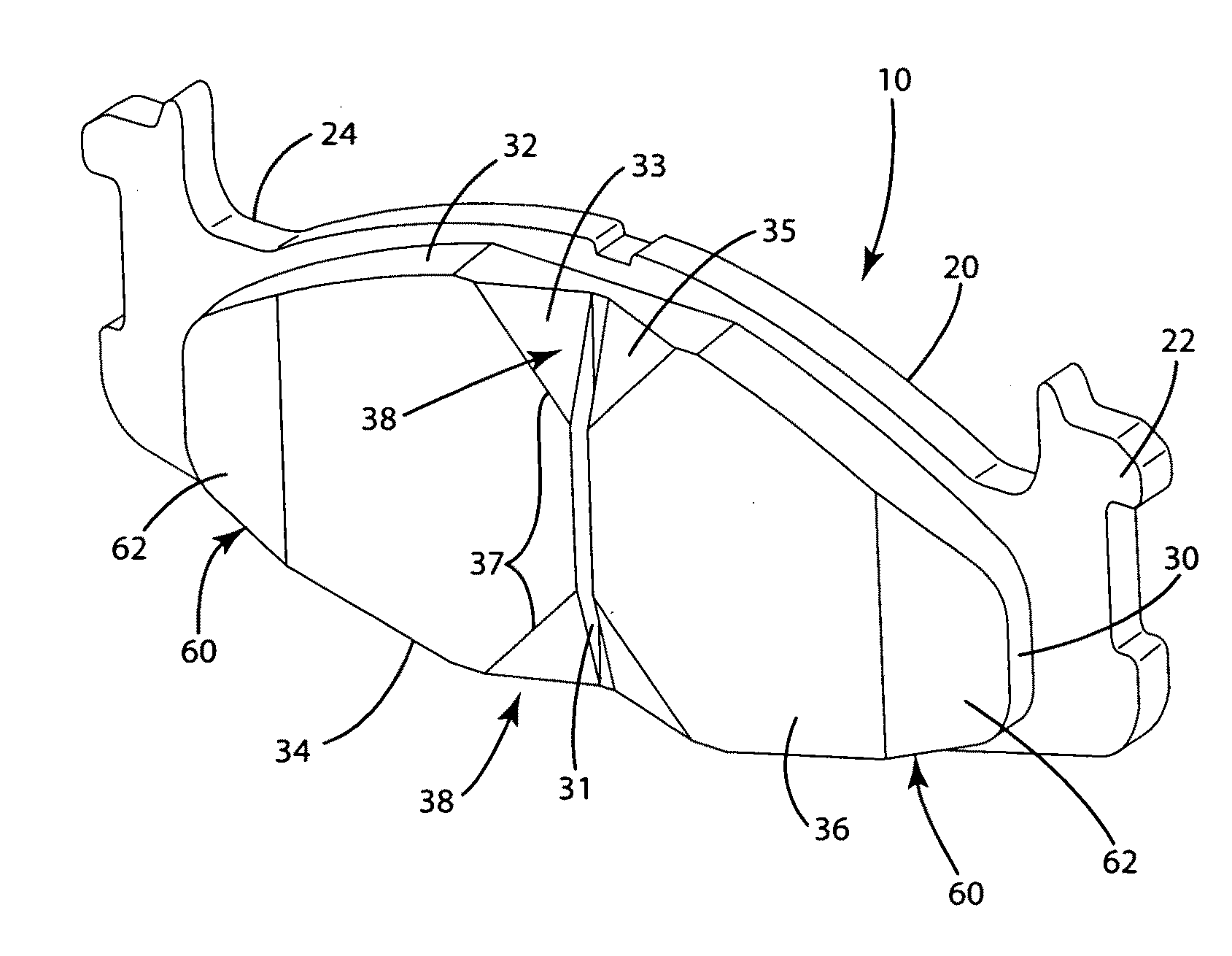

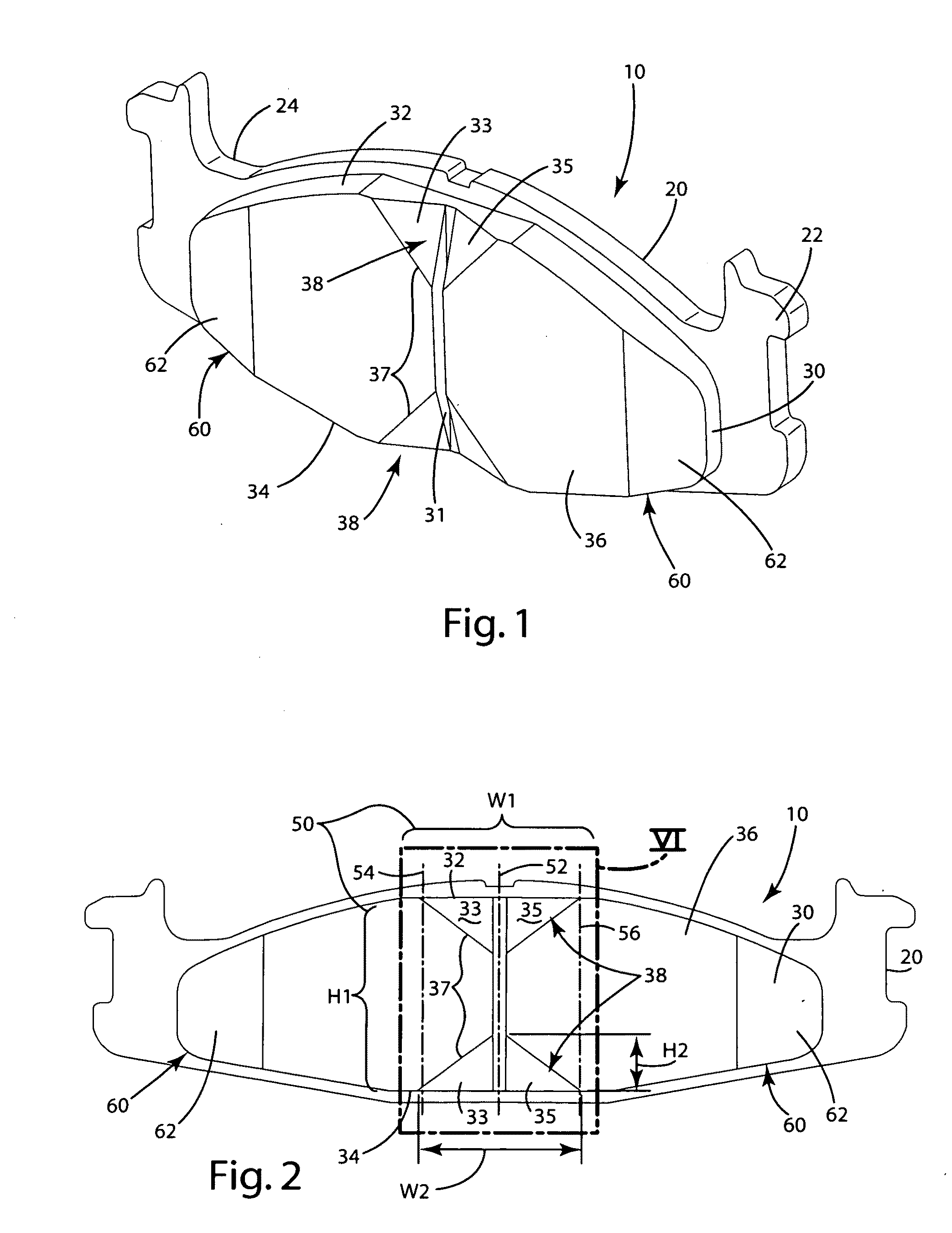

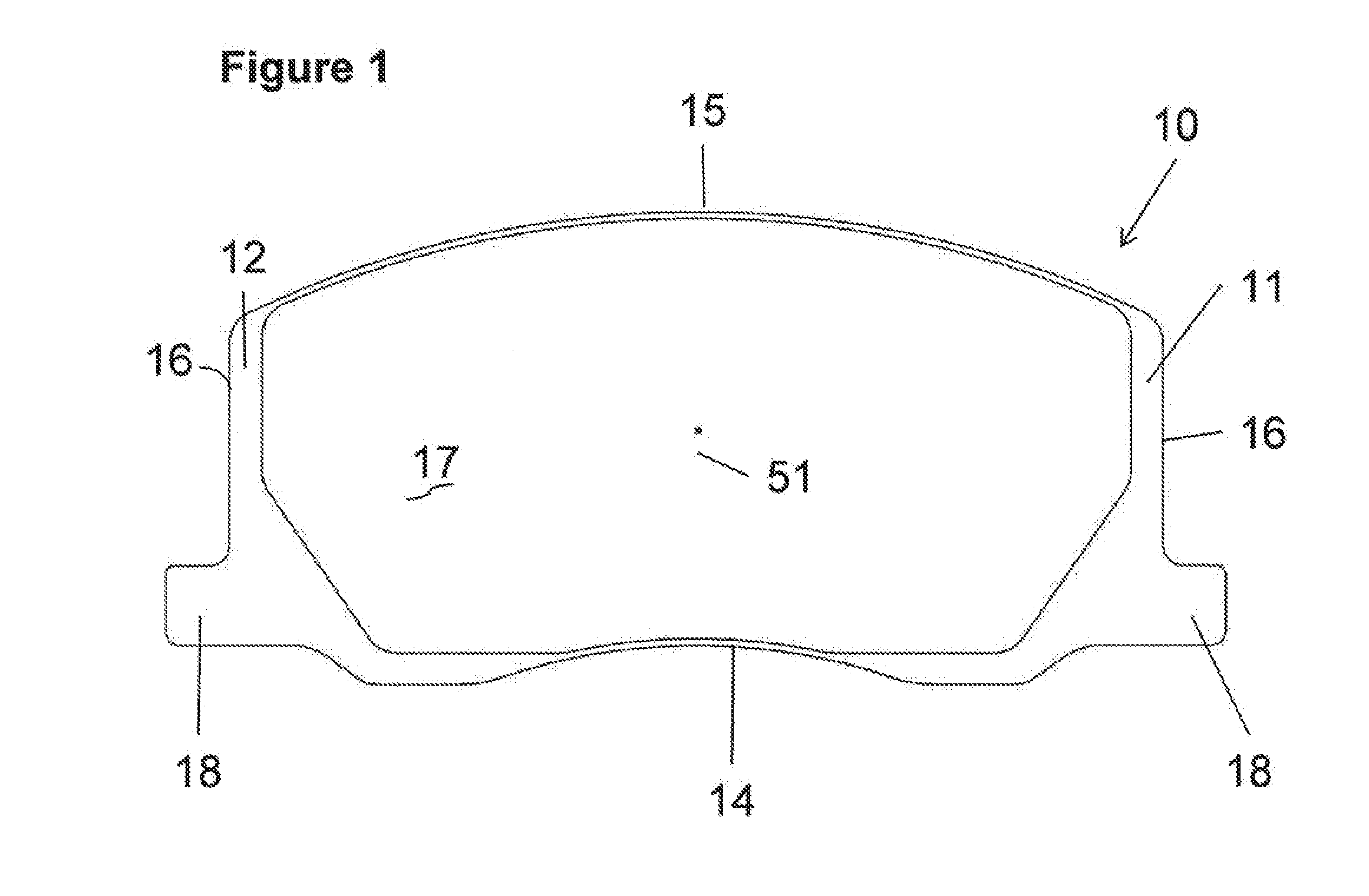

Brake Pad

The subject invention generally relates to a disc brake pad which has reduced brake squeal in response to a braking event by the incorporation of a relieved portion to the center section of a friction pad along an outer edge or inner edge thereof, or along both edges. The invention is a disc brake pad which includes a backing plate and friction pad attached to the backing plate.

Owner:FEDERAL MOGUL PROD US LLC

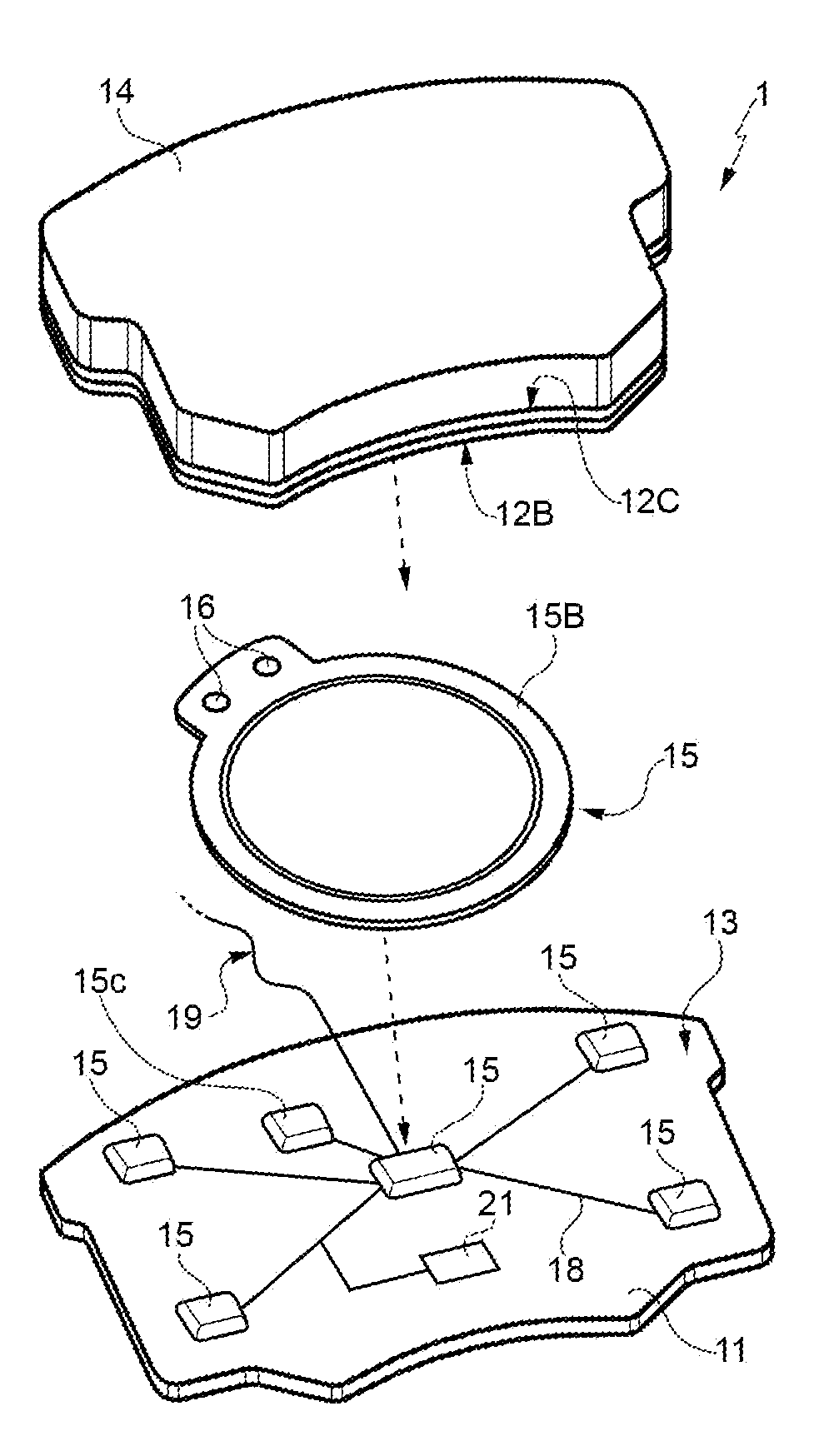

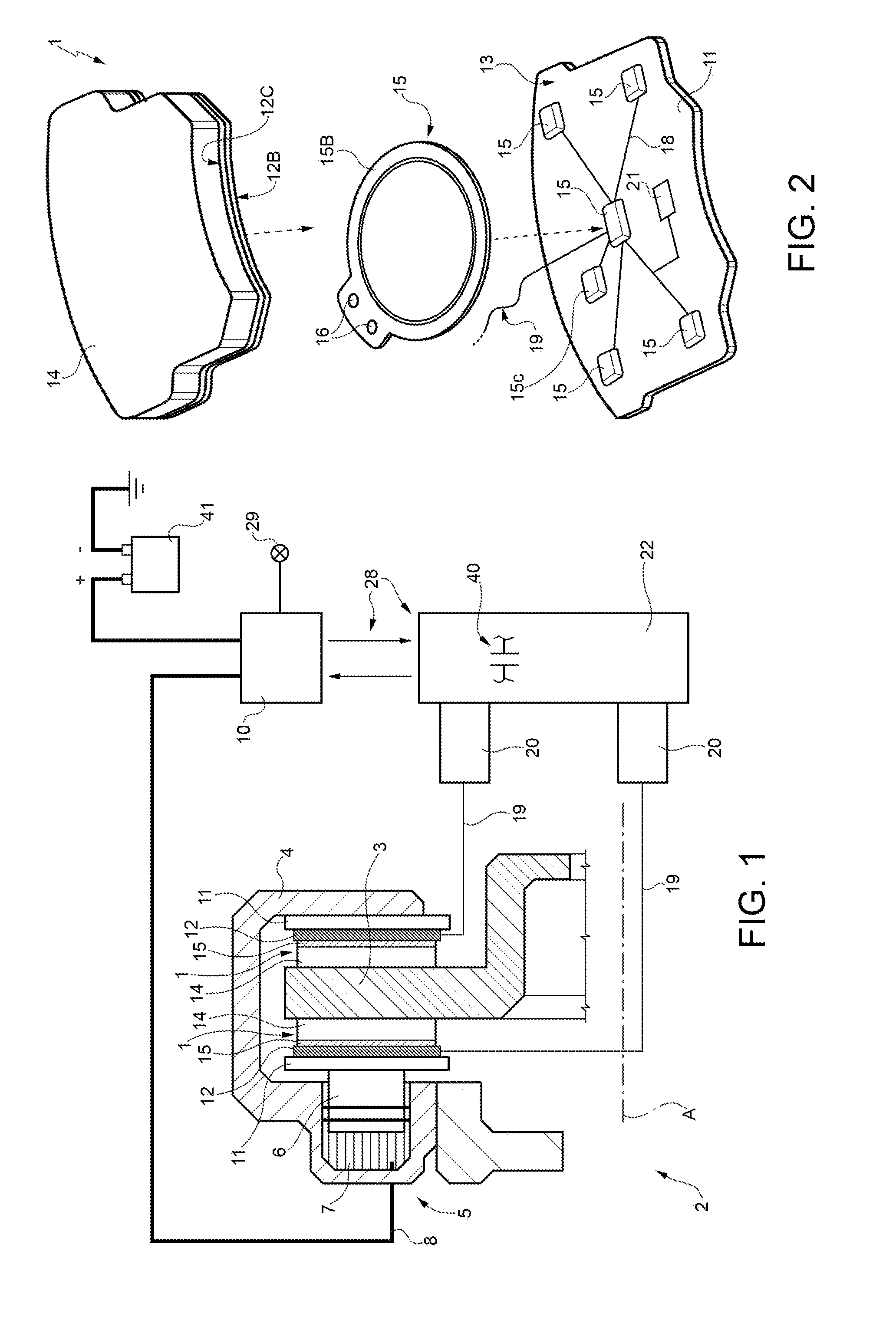

Method for manufacturing a braking element with integrated sensor, in particular a brake pad, brake pad with integrated sensor, vehicle braking system and associated method

ActiveUS20140311833A1Significant energy savingAvoid spendingPiezoelectric/electrostrictive device manufacture/assemblyNoise/vibration controlElectricityPotential difference

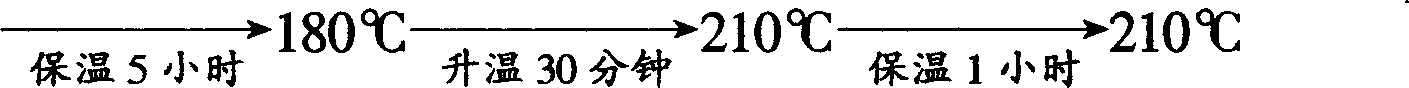

A method in which at least one piezoceramic sensor, which converts every mechanical force to which it is subjected into an electrical signal and having a Curie temperature higher than 200° C., is solidarized directly onto the surface of a metal support element of a vehicle braking element, which during use faces a vehicle element to be braked. While in contact with such a surface, an electrical circuit is implemented that picks up and eventually processes the electrical signal, the electrical circuit being connected with a connector integrated with the metal support element. An electrically insulating layer sandwiches the at least one piezoceramic sensor and the electrical circuit, and a block of friction material with an underlying damping layer is formed upon the electrically insulating layer. After forming the block of friction material, the piezoceramic sensor is polarized by applying a predetermined potential difference thereto by means of the connector.

Owner:ITT ITAL SRL

Accelerator pedal for a vehicle

A pedal assembly that provides a hysteresis in pedal force-response upon actuation is provided. The pedal assembly includes a housing and a pedal arm that has an end. The end has a rotatable drum that defines a braking surface. The pedal arm is rotatably mounted to the housing. A lever extends from the second end. A brake pad is retained by the housing and has a contact surface that is substantially complementary to the braking surface. The brake pad is adapted to be engaged with the braking surface. A bias spring device is situated between the lever and the brake pad for urging the contact surface of the brake pad into frictional engagement with the braking surface of the drum. A sensor is coupled to the pedal arm to sense the position of the pedal arm.

Owner:CTS CORP ELKHART

Disc brake assembly

A disc brake assembly includes a rotor, a caliper, brake pads and an optional filter. The optional filter can be disposed within a shroud which covers at least about 70% of the distal side periphery on at least one of the two sides of the rotor. The disc brake also includes an impeller or other means for providing air flow to the disc brake assembly. The impeller can be provided by the rotor itself or it can be provided by a separate component which is powered either directly or indirectly by the rotor.

Owner:GELB JOSEPH

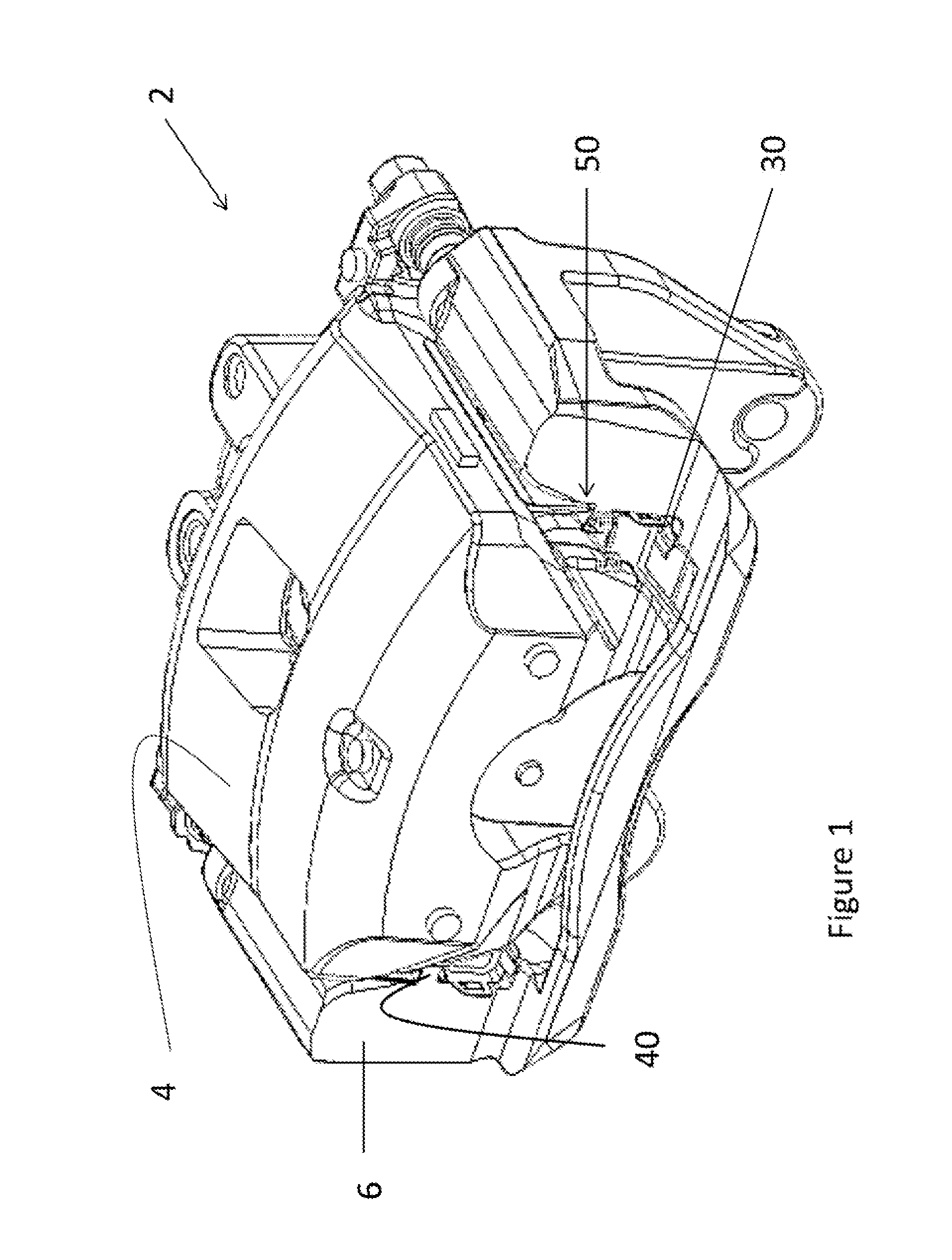

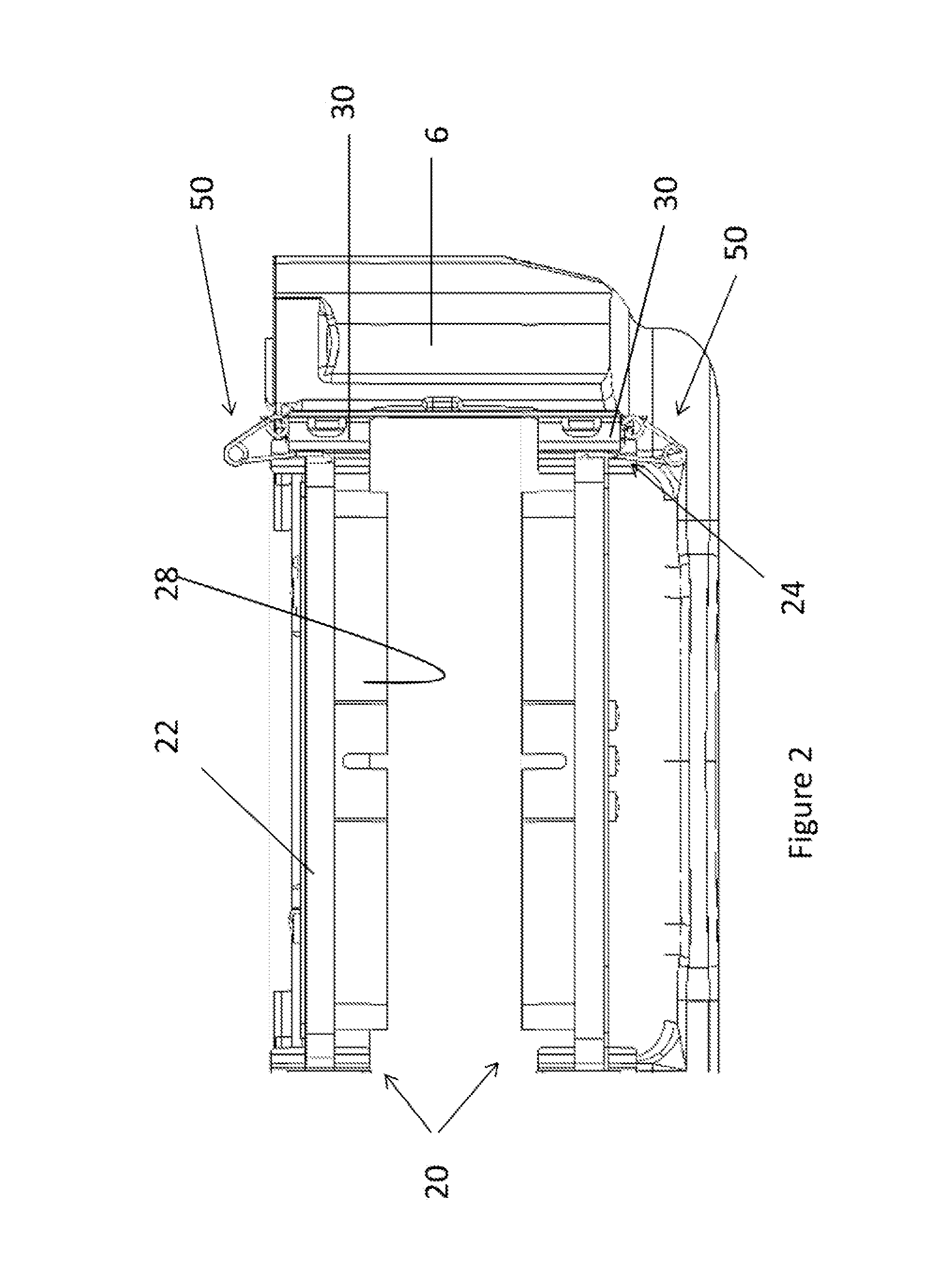

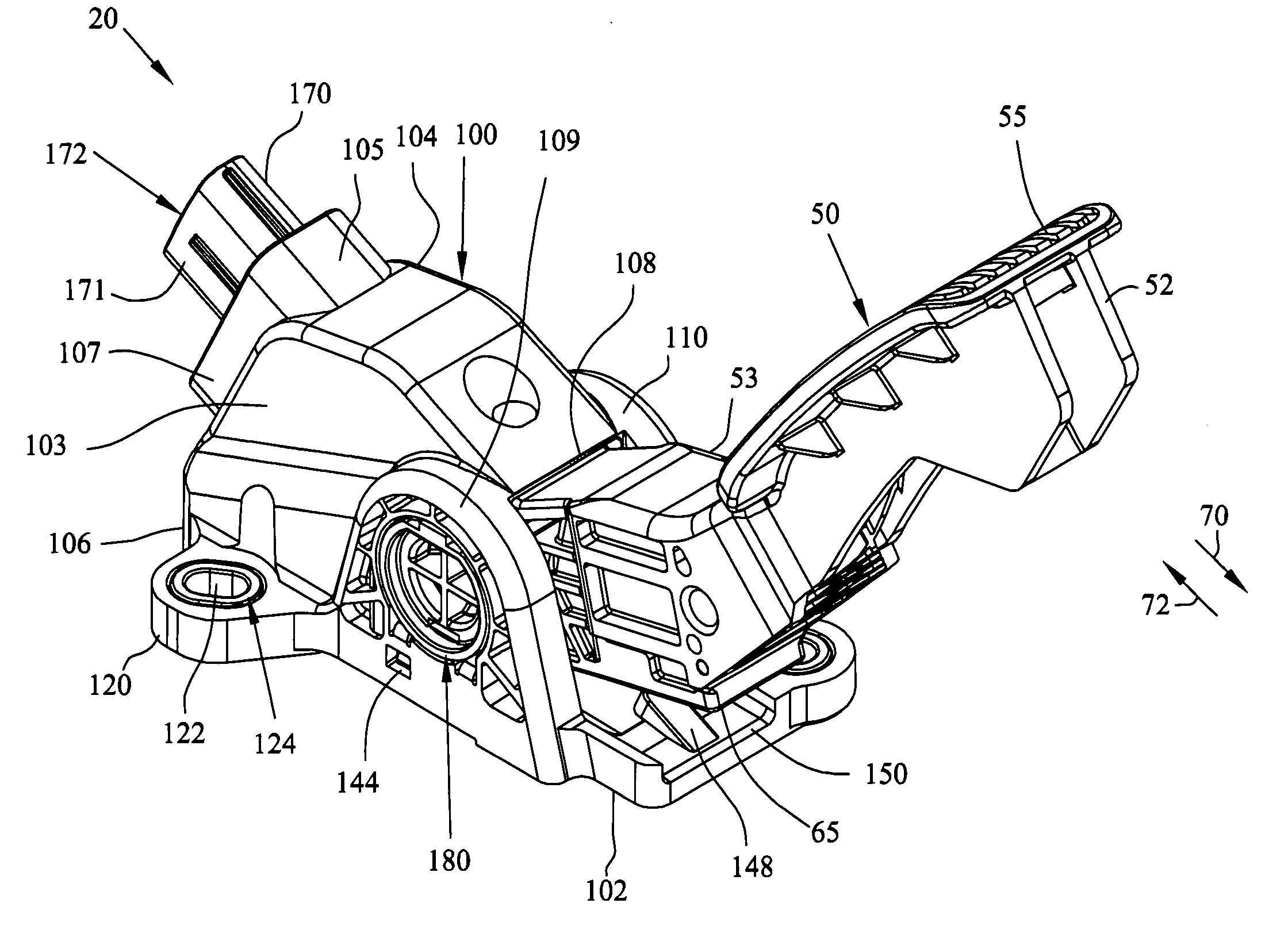

Caliper assembly for disc brake system

InactiveUS20120085597A1Improve NVH performanceImprove component performanceMechanically actuated brakesSlack adjustersEngineeringCalipers

A caliper assembly comprising: a brake pad comprising a carrier plate having two opposing faces and a top edge a bottom edge and two opposing side edges, wherein on one face is friction material and on the opposing face is a projection adapted to seat in a matched hole or recess in a caliper body, the two opposing side edges each having an ear which is adapted to seat in pad locator indentations in a support structure; a support structure comprising a recess for housing at least one brake pad and at least two pad locator indentations adapted for receiving the ears located on the two opposing sides of the brake pad and at least two caliper body locator indentations for seating two ears defined by the caliper body; and a caliper body having a hole or recess adapted for seating the projection on the opposing face of the brake pad and having two ears on each opposing side which are adapted to seat in the caliper body locator indentations of the support structure; wherein the ears of the brake pad are seated in the pad locator indentations of the support structure, the projection on the opposing face of the brake pad is seated in the hole or recess located in the caliper body, and a clip which engages the opposing face of the brake pad and the caliper body and holds the brake pad in position with respect to the caliper body and the ears of the caliper body are seated in the caliper body locator indentations in the support structure.

Owner:AKEBONO BRAKE

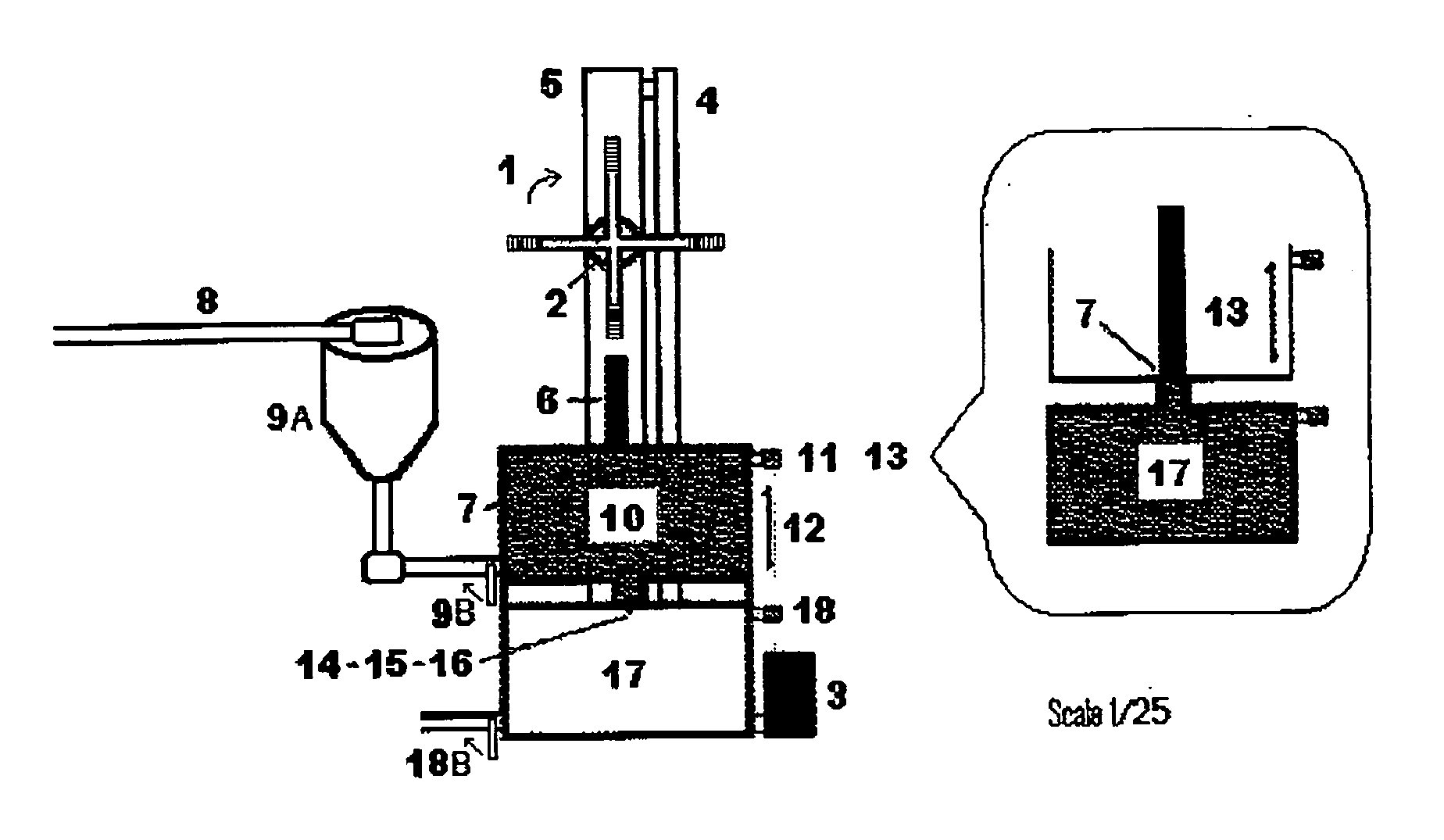

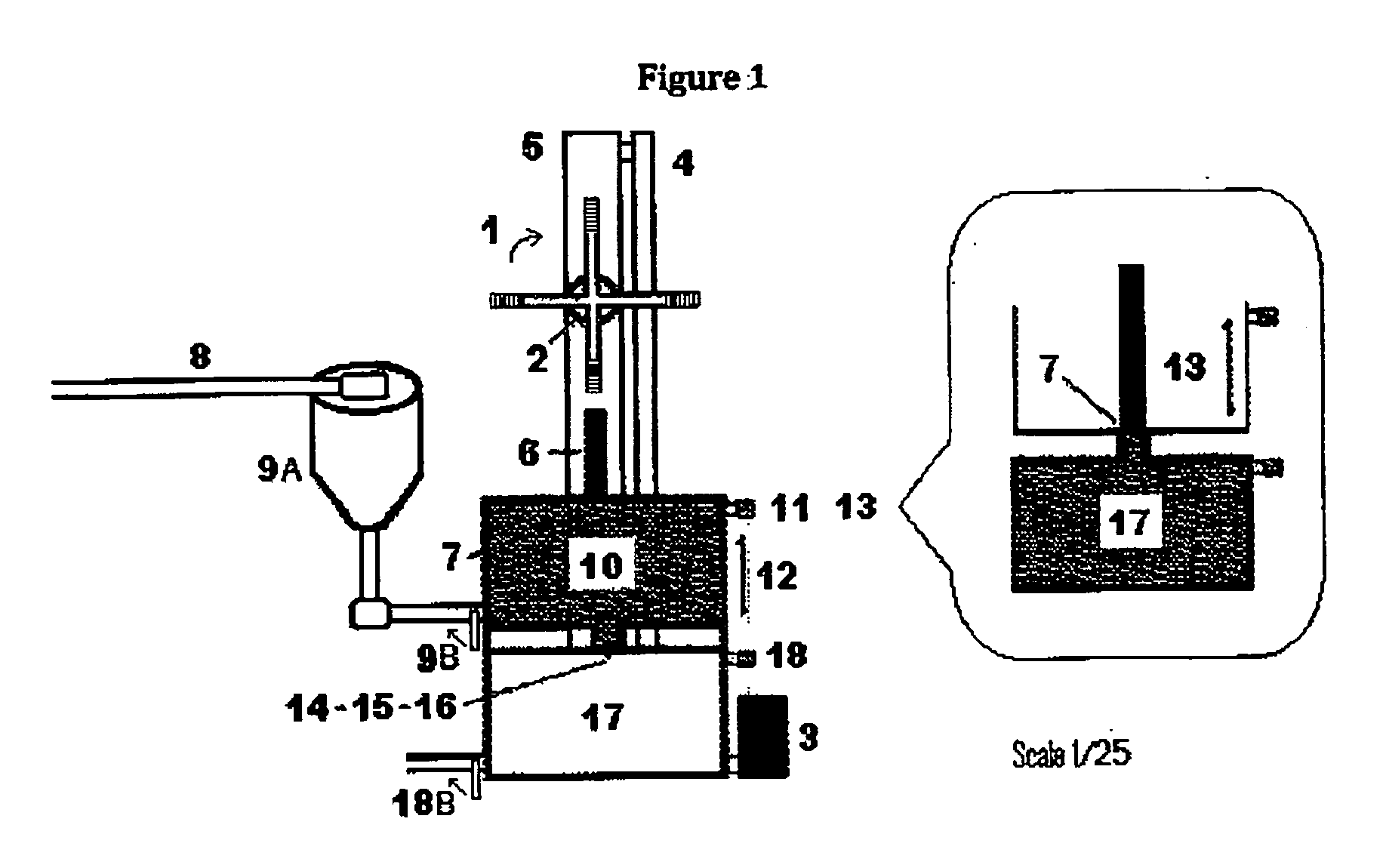

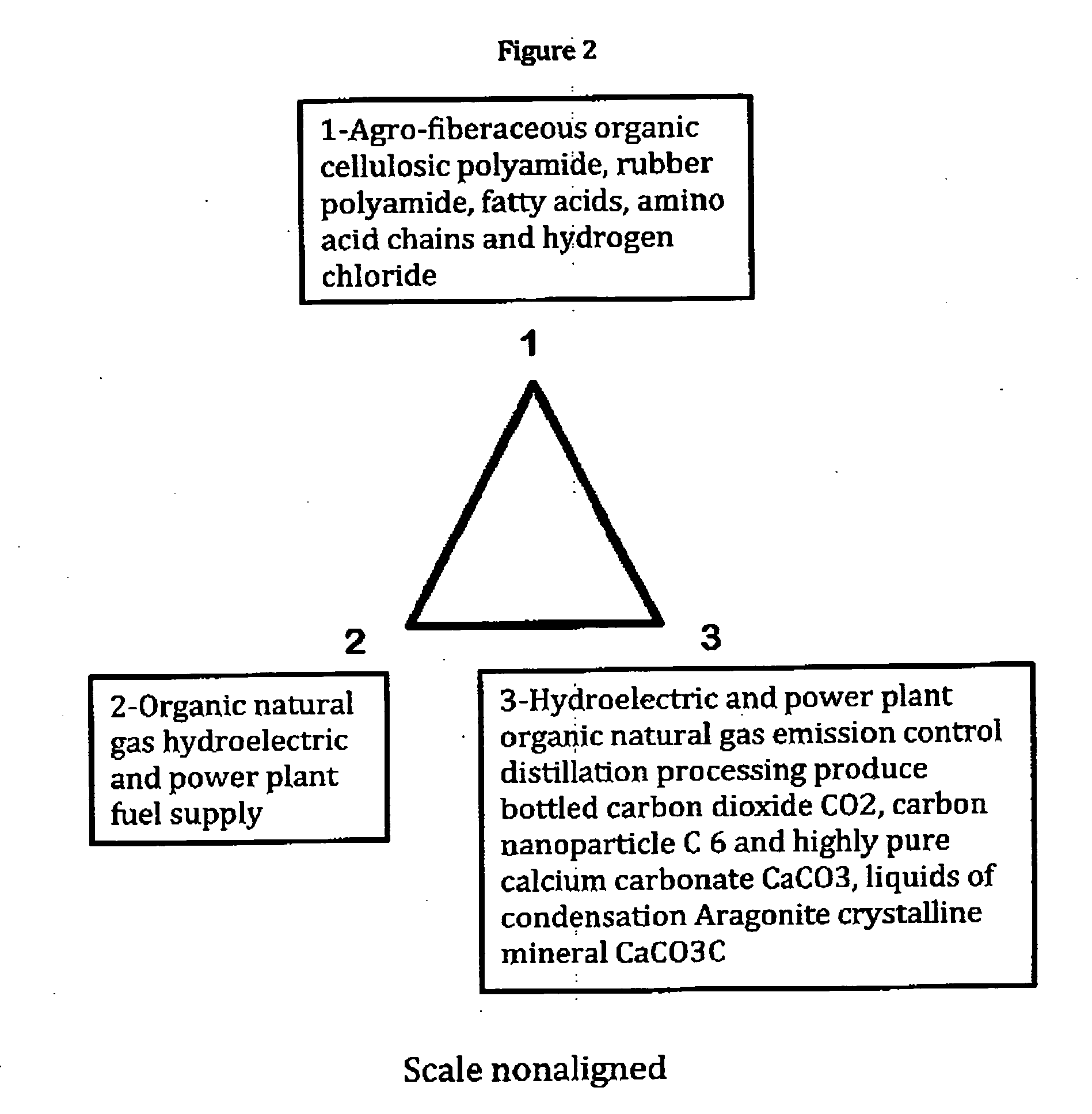

Non ionic/electrolyte, liquid/gaseous, mechanically refined/nanoparticle dispersion Building Materials/High Wear-Heat Resistant Part Brushes, Windings, Battery Cells, Brake Pads, Die Cast Molding, Refrigeration, Polarized/Integrated Optical, Spectrometric Processors, Central Processor Unit Processors, Electronic Storage Media, Analogous Series/Parallel Circuit Generators/Transceivers, Particulate Matter PM Carbonaceous-Polyamide, Crystalline Silica, and Cellulosic Filament Extraction/Miners Suit

InactiveUS20140178513A1High wear-heat resistant partAuxillary shaping apparatusShaping pressTransceiverTransformer

The variable hydraulic press and distillation reservoir process scientific formula non ionic or electrolyte mechanically refined and nanoparticle dispersion preform slurry extrusion with or without ionic suspension Preform slurry high wear-heat resistant parts electronic composite coils, windings, annealing, drawn, spun, coils, windings, wire, woven textile mesh, shielding, parts brushes, inductors, antinode couplers, electric rheostats, starters, motors, alternators, generators, ionic suspension enhanced composite coils, composite windings, spun wound coils and windings beryllium Be4, magnesium Mg12, copper Cu29 and carbon nanofoam C6, electronic parts capacitors, ionic suspension circuit battery cells, electronic parts rheostats, resistors, transformers, transducers, rectifiers, power supplies, or heat sinks Preform slurry high wear-heat resistant parts aerospace, automotive, and transportation brake calipers, rotors, pads, and bushings Preform slurry non ionic or electrolyte mechanically refined and nanoparticle high wear-heat resistant parts precision casting molds 2.5 phase die cast molding Building Materials fine concrete, mortar, brick, and tiles.

Owner:MATTHEWS ROBERT RICHARD

Accelerator pedal for motorized vehicle

An accelerator pedal assembly that provides a hysteresis in pedal force-response upon actuation is provided. The accelerator pedal assembly includes a housing, an elongated pedal arm terminating at one end in a rotatable drum defining a curved braking surface, a brake pad having a curved contact surface substantially complementary to the braking surface and a bias spring device operably situated between the pedal arm and the brake pad. The pedal arm is rotatably mounted to the housing such that the curved braking surface rotates as the pedal moves. The brake pad defines a primary pivot axis and is pivotably mounted for frictional engagement with the braking surface. The bias spring serves to urge the contact surface of the brake pad into frictional engagement with the braking surface of the drum.

Owner:CTS CORP ELKHART

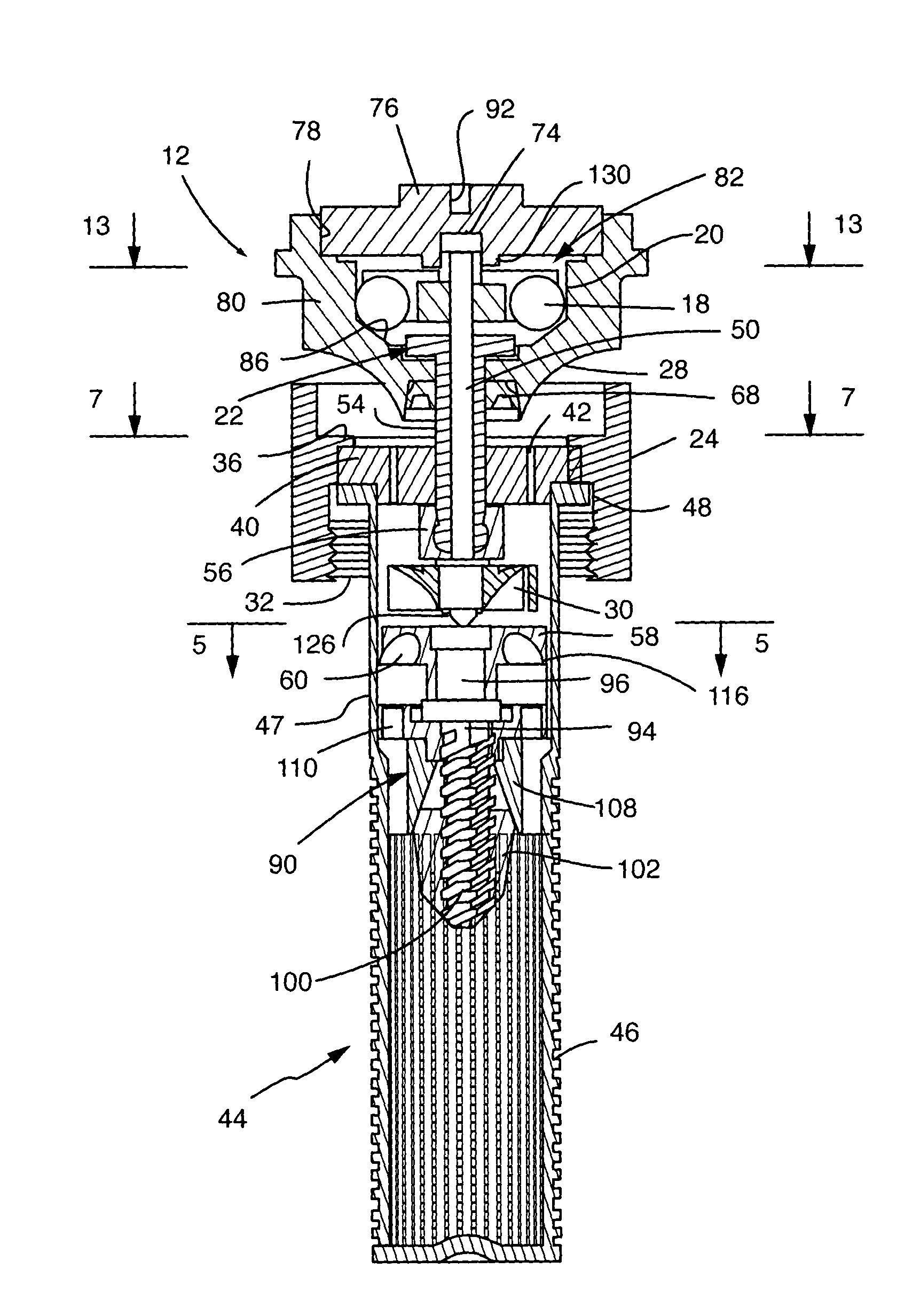

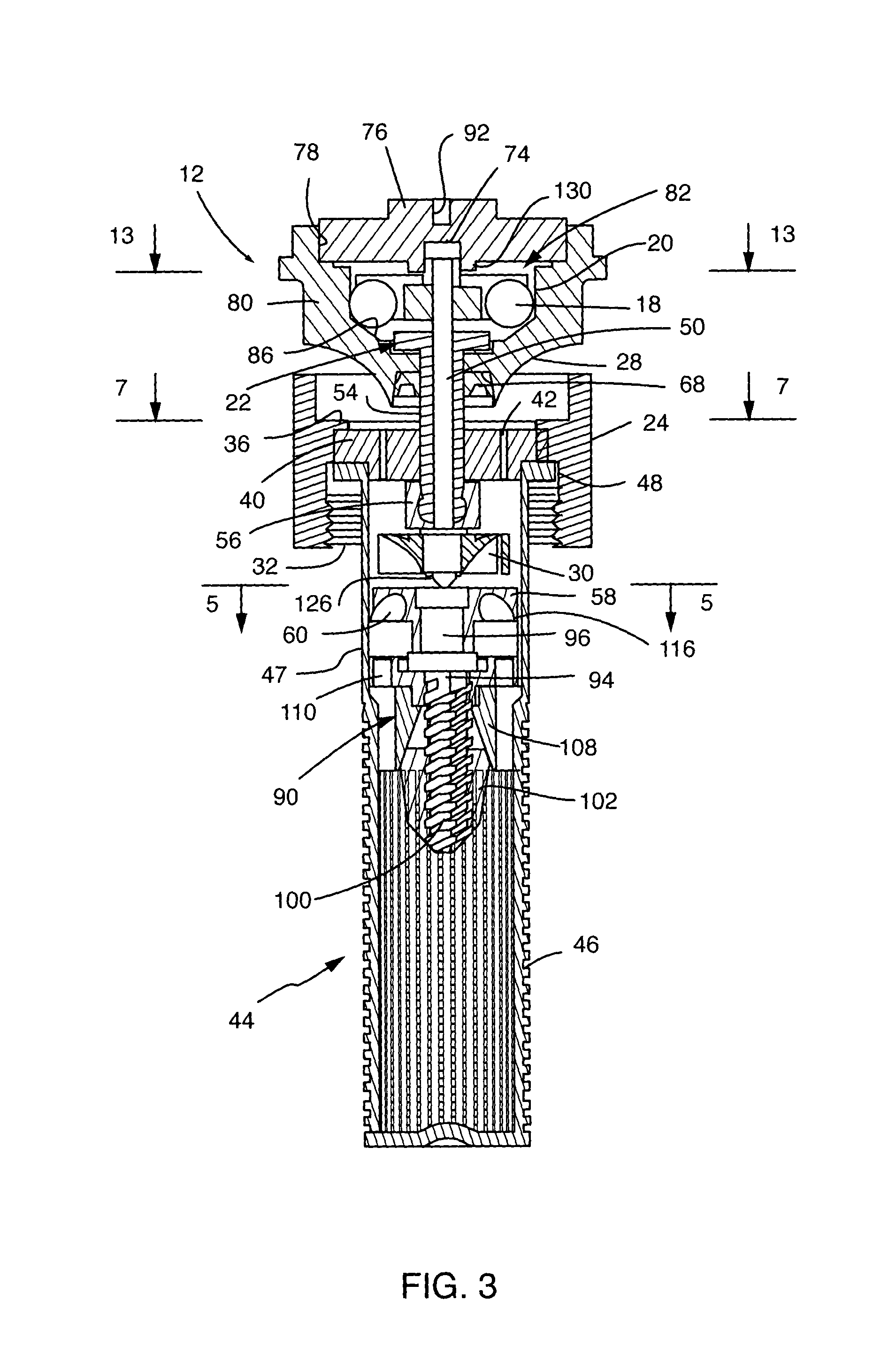

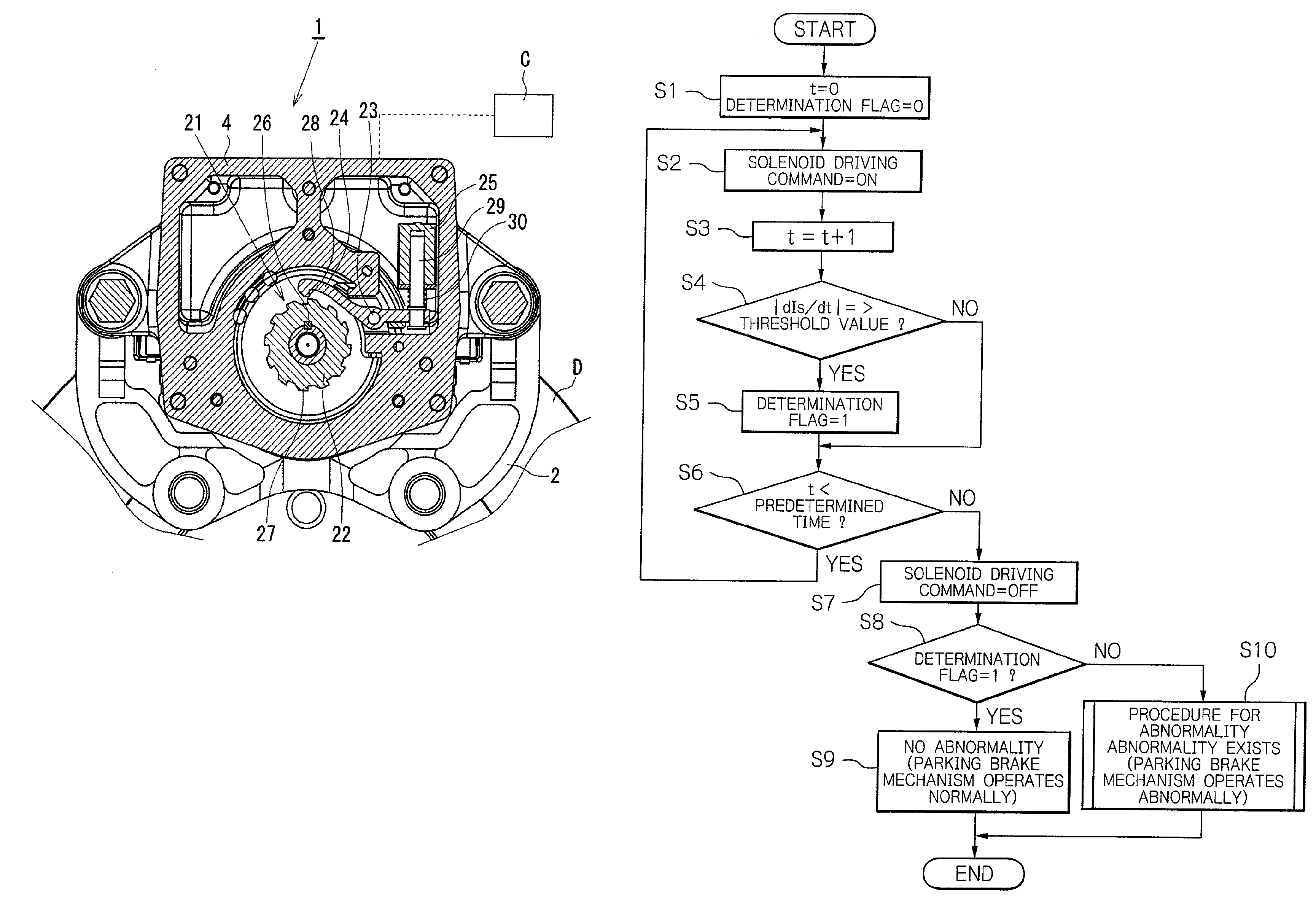

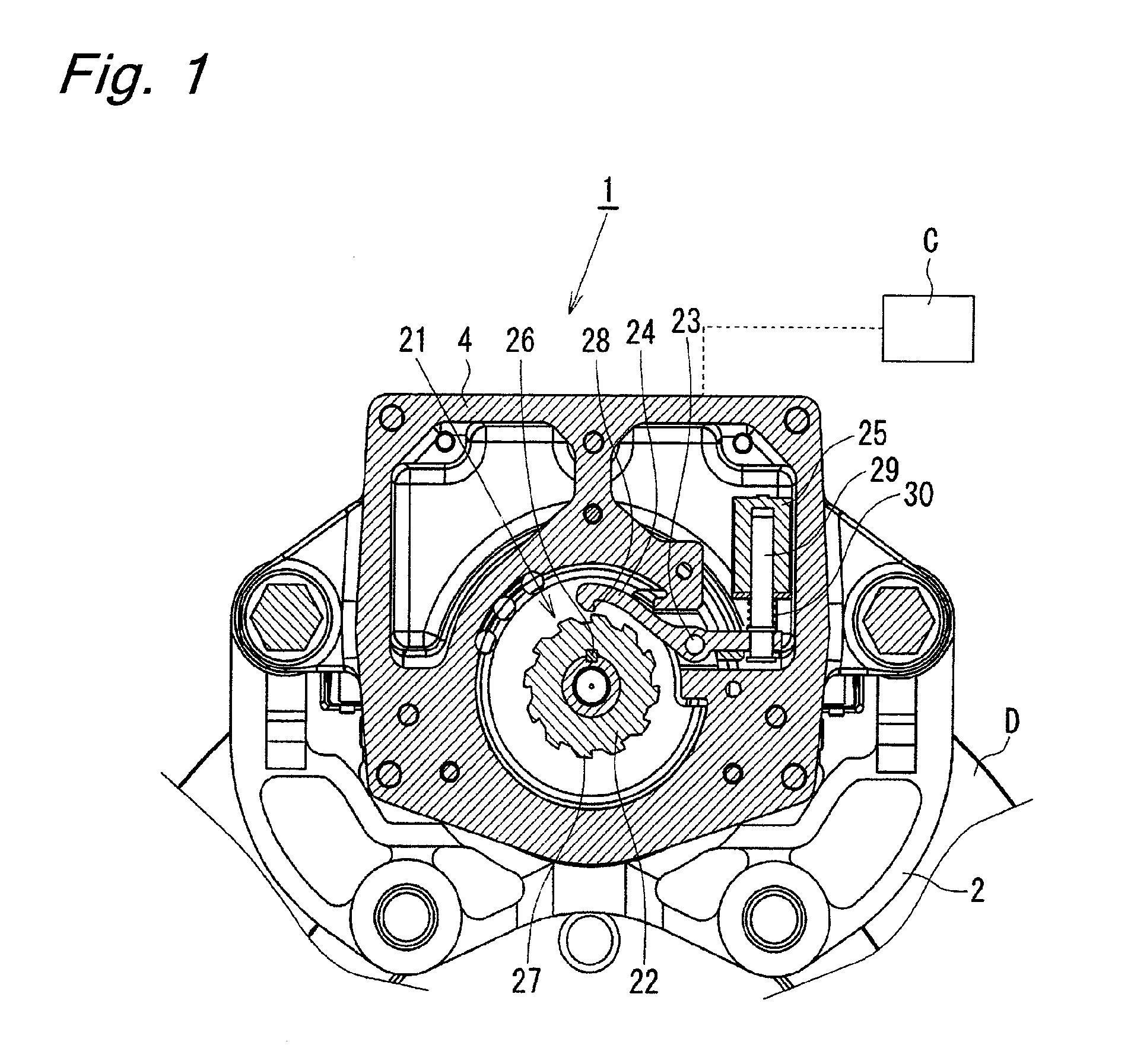

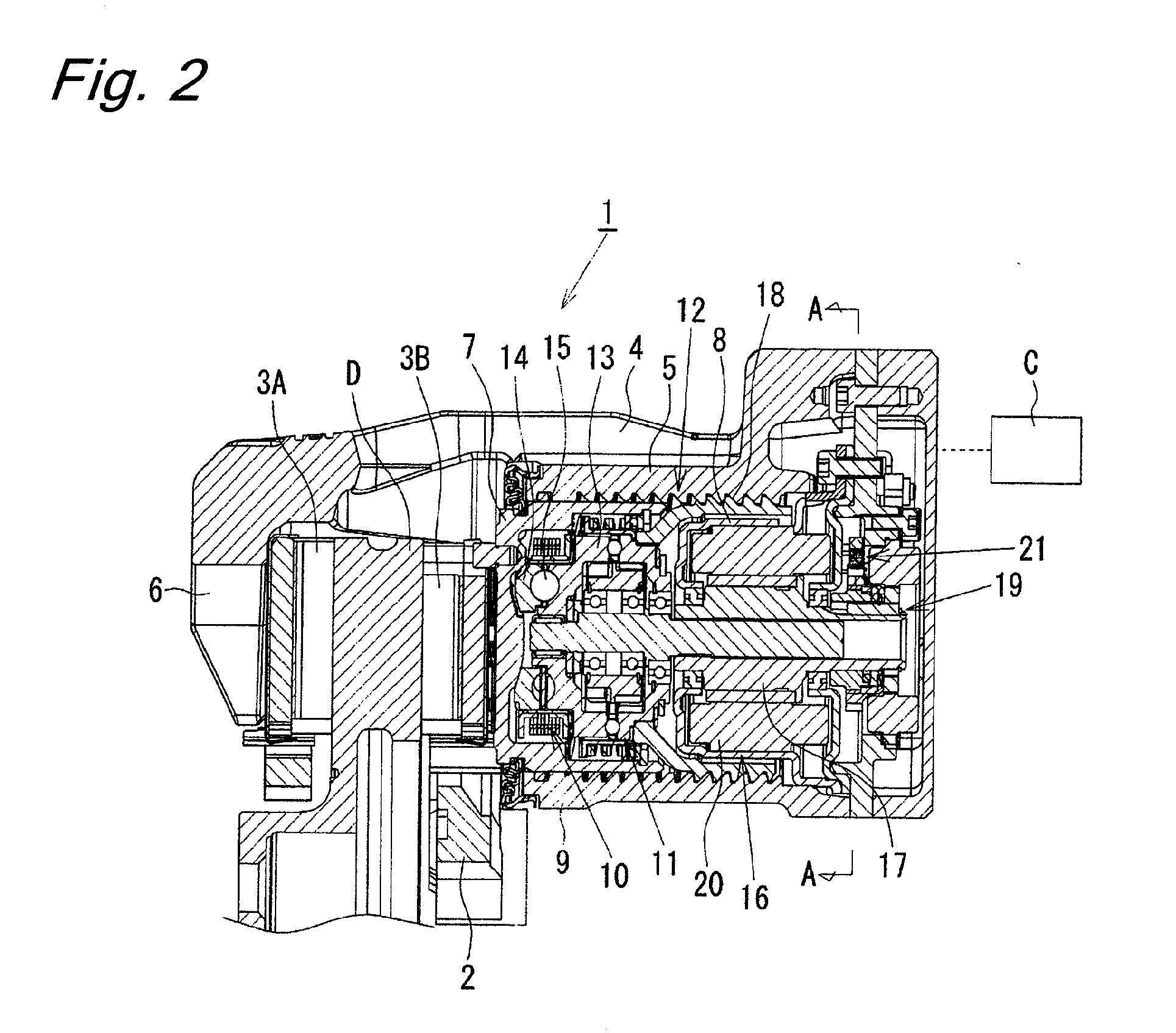

Electric disk brake

An object of the present invention is to provide an electric disk brake capable of determining an abnormality of a parking brake mechanism while the parking brake mechanism is in operation. A brake force is generated in the following manner. A rotation of an electric motor is slowed down by a differential speed reducing mechanism, and is converted into a linear motion by a ball ramp mechanism so as to advance a piston, which then presses a brake pad against a disk rotor to generate a brake force. A parking brake mechanism can lock a rotation of a rotor of the electric motor and maintain a braked state by rotating an engagement pawl through a plunger of a solenoid and causing the engagement pawl to be engaged with a ratchet wheel coupled to the rotor of the electric motor. A play is provided at a coupling portion of the engagement pawl and the plunger. The play enables the plunger to move within the range of the play while the engagement pawl is engaged with the ratchet wheel, thereby enabling determination whether the parking brake mechanism operates normally or abnormally based on whether the plunger moves or not upon application of an electric current to the solenoid while the parking brake mechanism is in an actuated state.

Owner:HITACHI ASTEMO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com