Patents

Literature

2399results about "Braking discs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

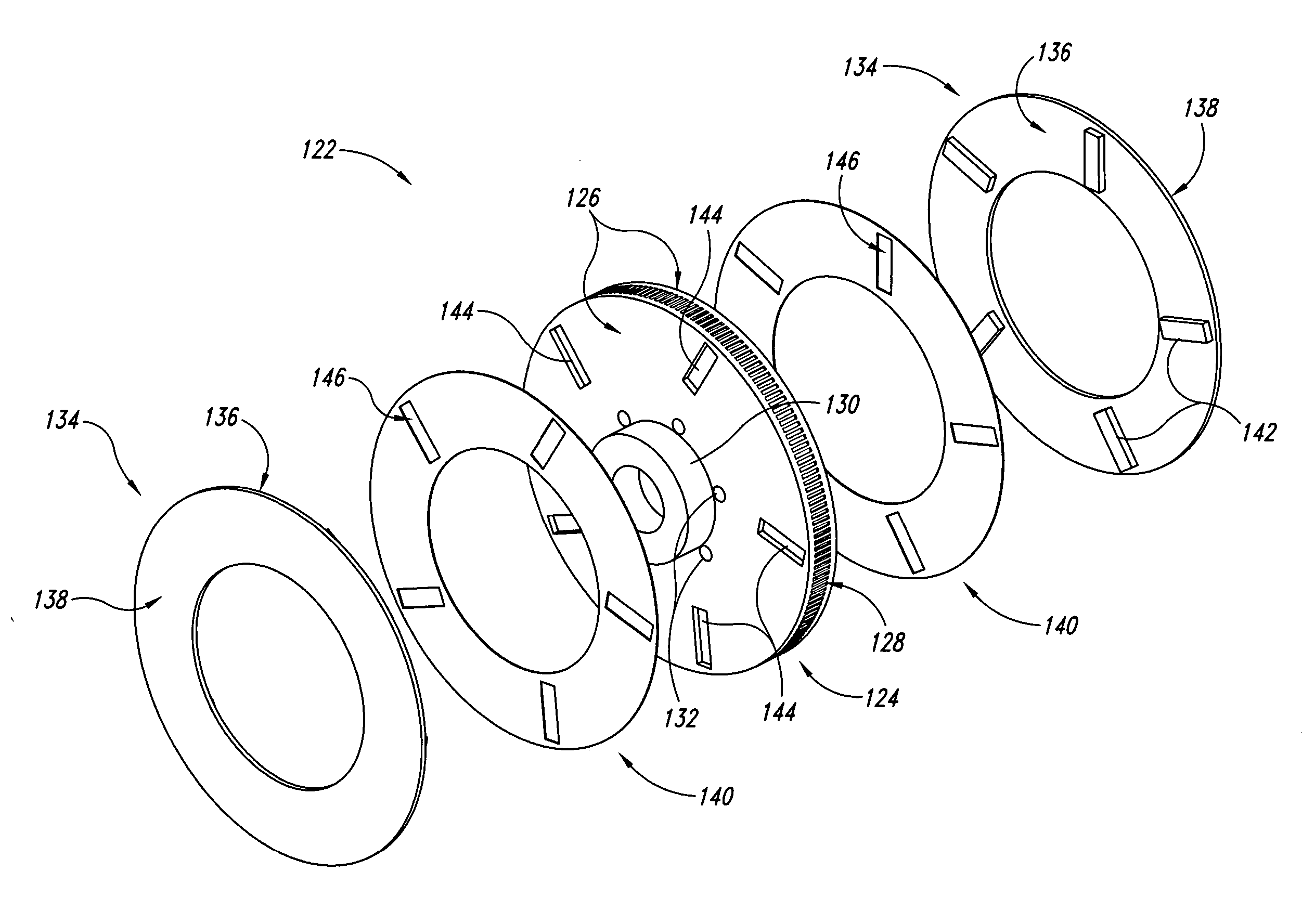

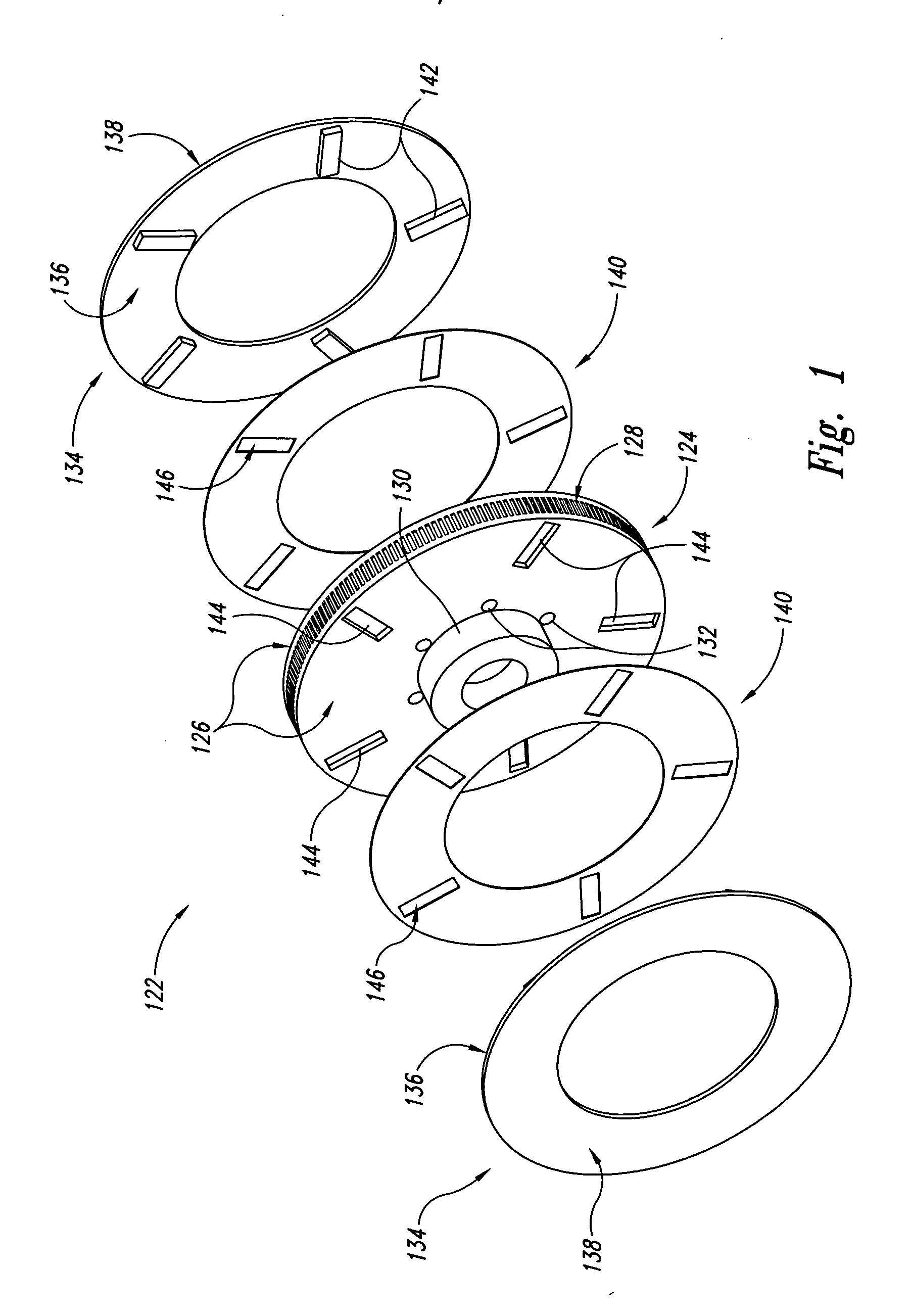

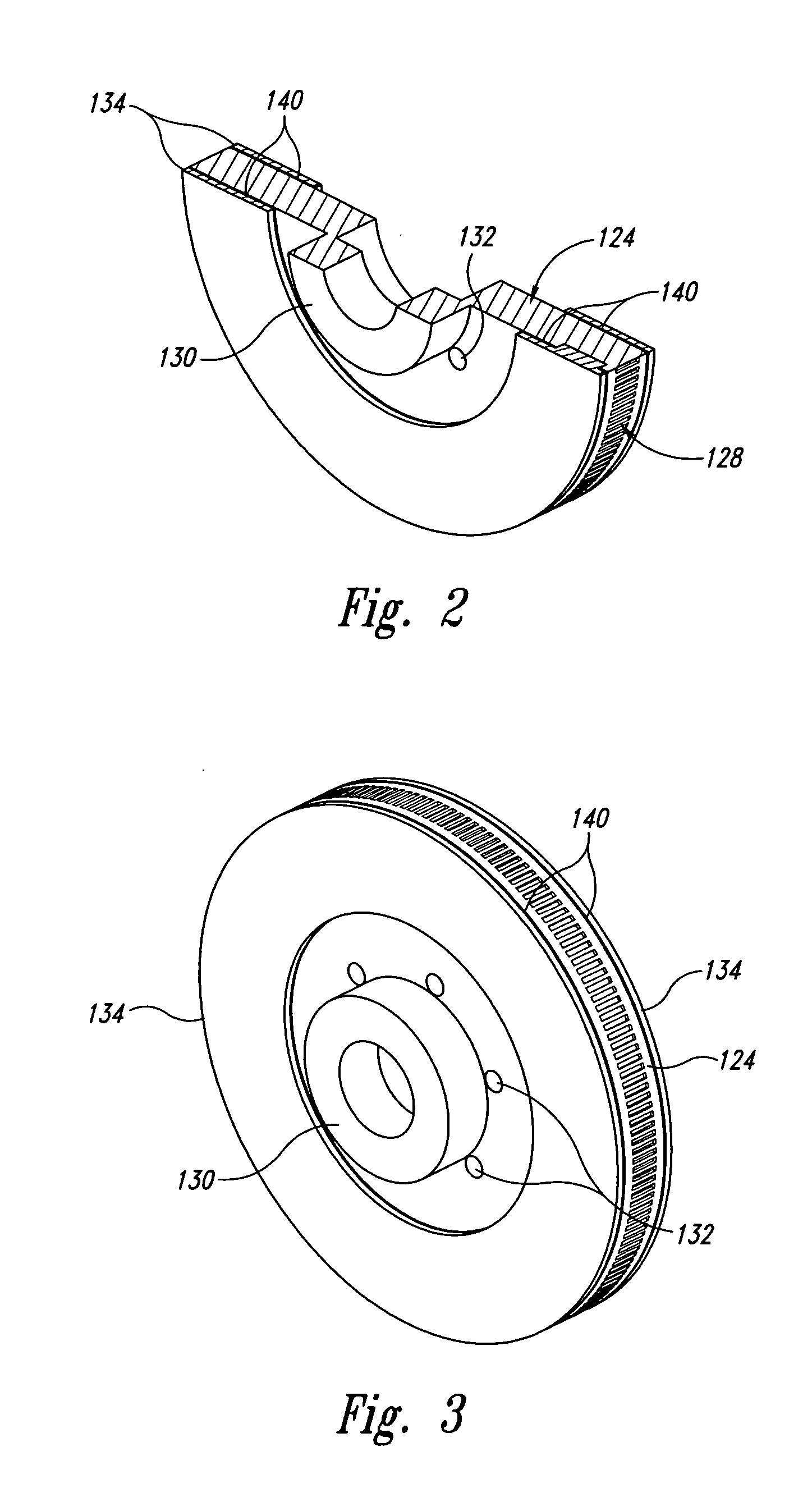

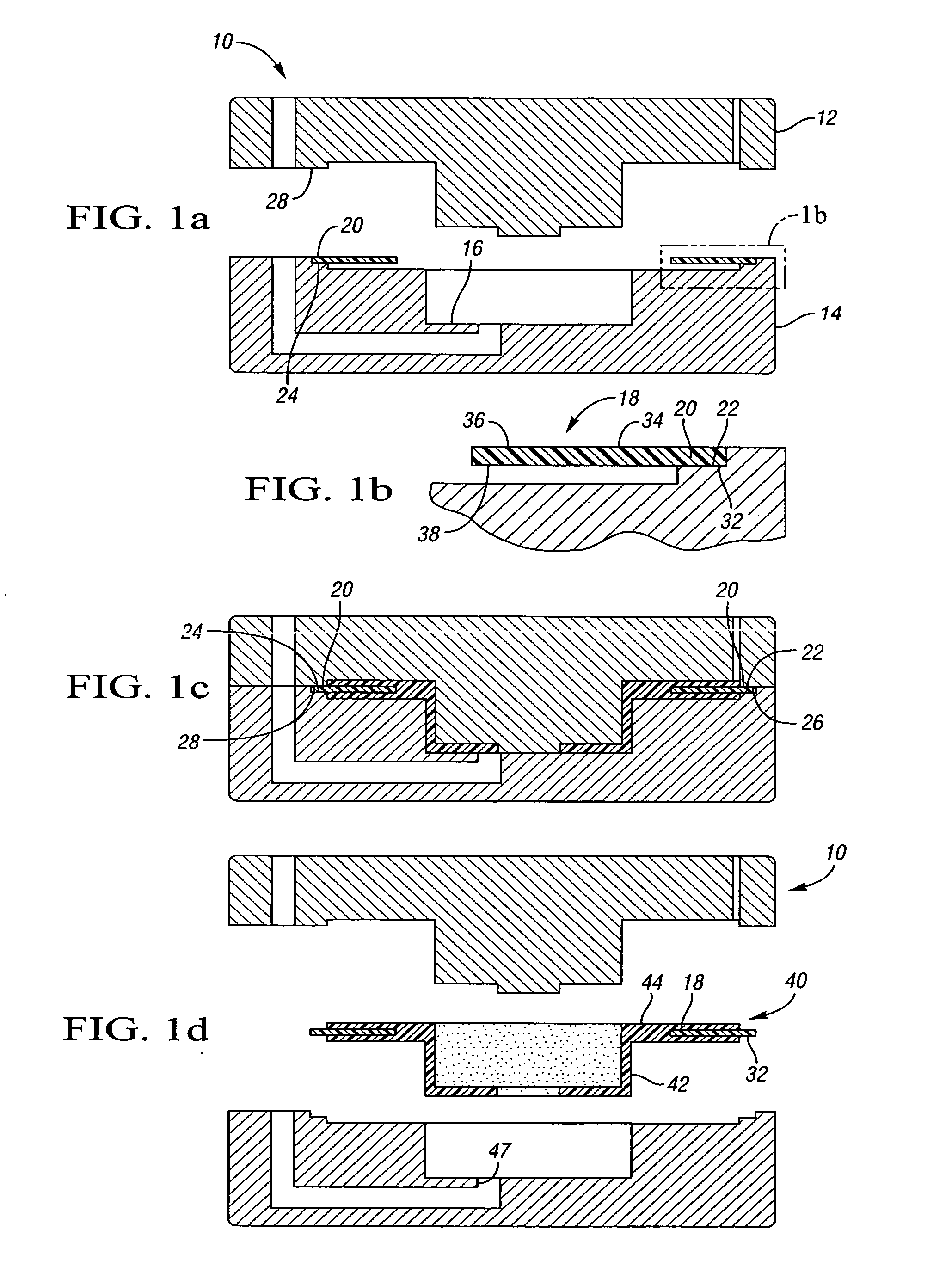

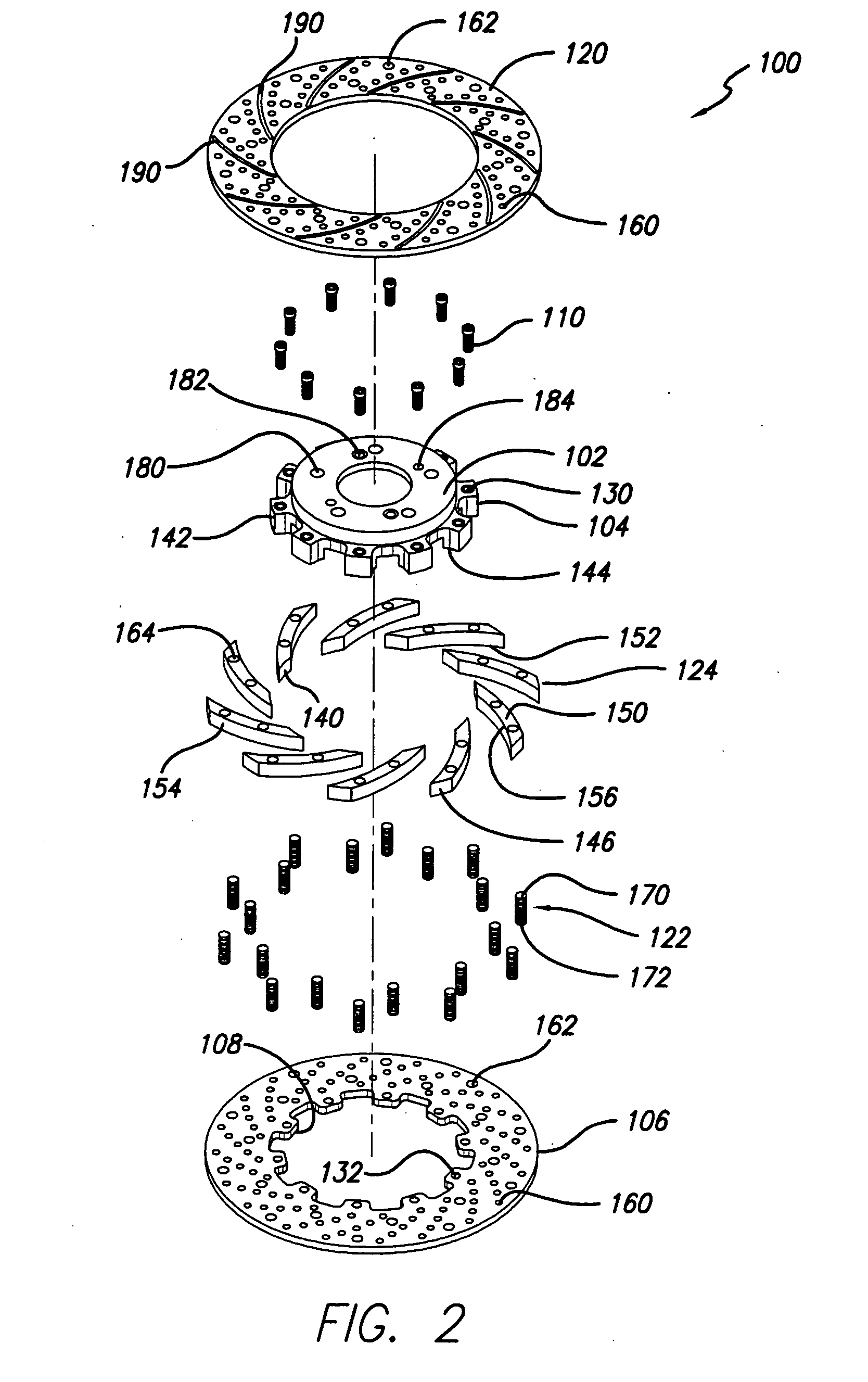

Disc brake rotor assembly and method for producing same

InactiveUS20050183909A1Improve thermal conductivityOptimize acoustic frequency transferBraking element arrangementsNoise/vibration controlAdhesiveMetal alloy

Novel composite disc brake rotor assemblies are provided, along with novel and efficient methods for manufacturing them. Preferably, the rotor assemblies comprise annular wear plates formed of particle reinforced aluminum-based metal matrix composite (MMC), ceramic matrix composite (CMC), or of ‘carbon graphite foam.’ The wear plates, made of a first material, are attached to annular surfaces of a central rotor, made of a second material, by fusing bonding layers between the wear plates and the rotor surfaces. The bonding layers are comprised of at least one of a metal alloy having a melting temperature lower than that of either the first or second materials, and a high-temperature adhesive. Preferably, the wear plates comprise projections that are positioned within adjacent receiving recesses in the center rotor. The bonding layers and projections enhance thermal and acoustical transference between the wear plates and the center rotor section. Carbon graphite foam provides for substantially enhanced heat transference. Use of the fusable binding layer, or adhesive provides for an efficient, low cost method of manufacturing for composite disc brake rotor assemblies.

Owner:BENMAXX

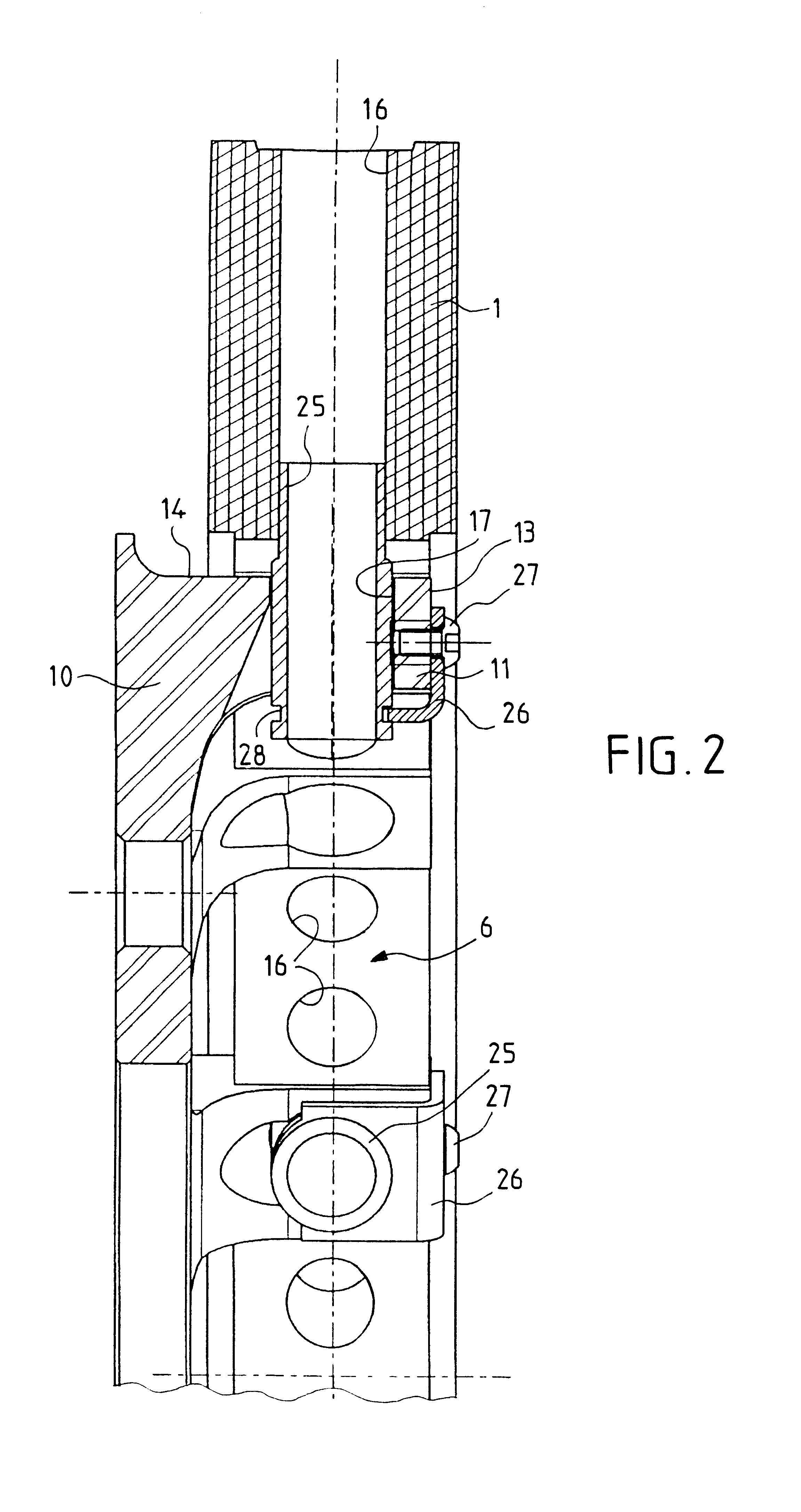

Brake unit

InactiveUS6302246B1Prolong lifeImprove flatnessBraking element arrangementsNoise/vibration controlEngineeringCeramic metal

A brake unit comprising at least one brake and at least one brake pad having at least one friction lining is described. The brake has a disk brake with a brake rotor made of a ceramic-metal composite (CMC) whose outer surface or surfaces at least partially form a friction surface for the at least one friction lining, and a disk brake cup that is mounted on the disk brake by way of one or more mounting elements. The friction surface of the disk brake has a hardness of approximately 1600 to 2500 HV, and the at least one friction lining has a coefficient of friction of approximately 0.3 to 0.5. The disk brake cup and / or the mounting elements form a corrosion-inhibiting attachment to the disk brake. The brake unit can be operated in corrosion-free fashion over a service life of at least approximately eight to 10 years or approximately 200,000 to 300,000 km.

Owner:FRENI BREMBO SPA

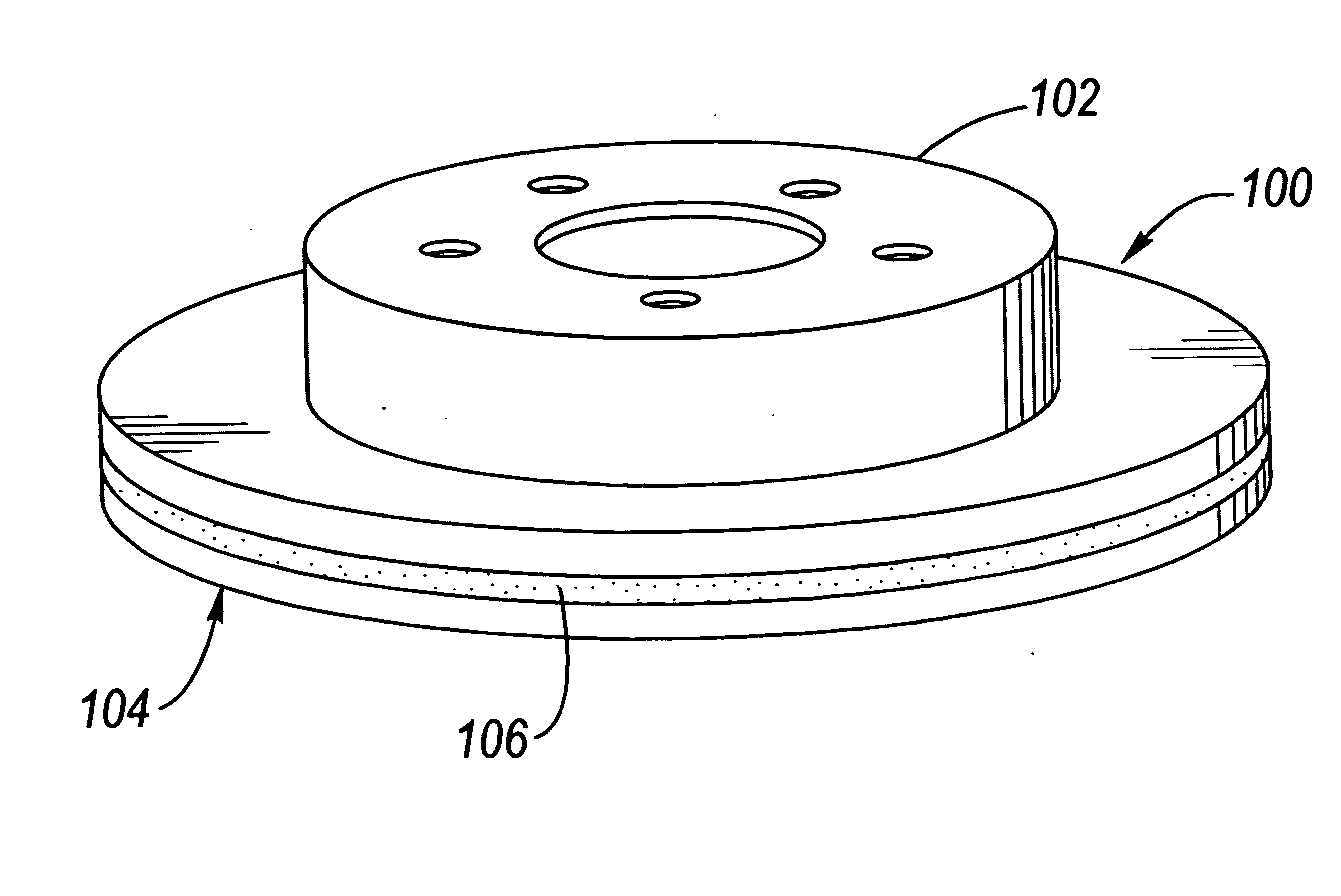

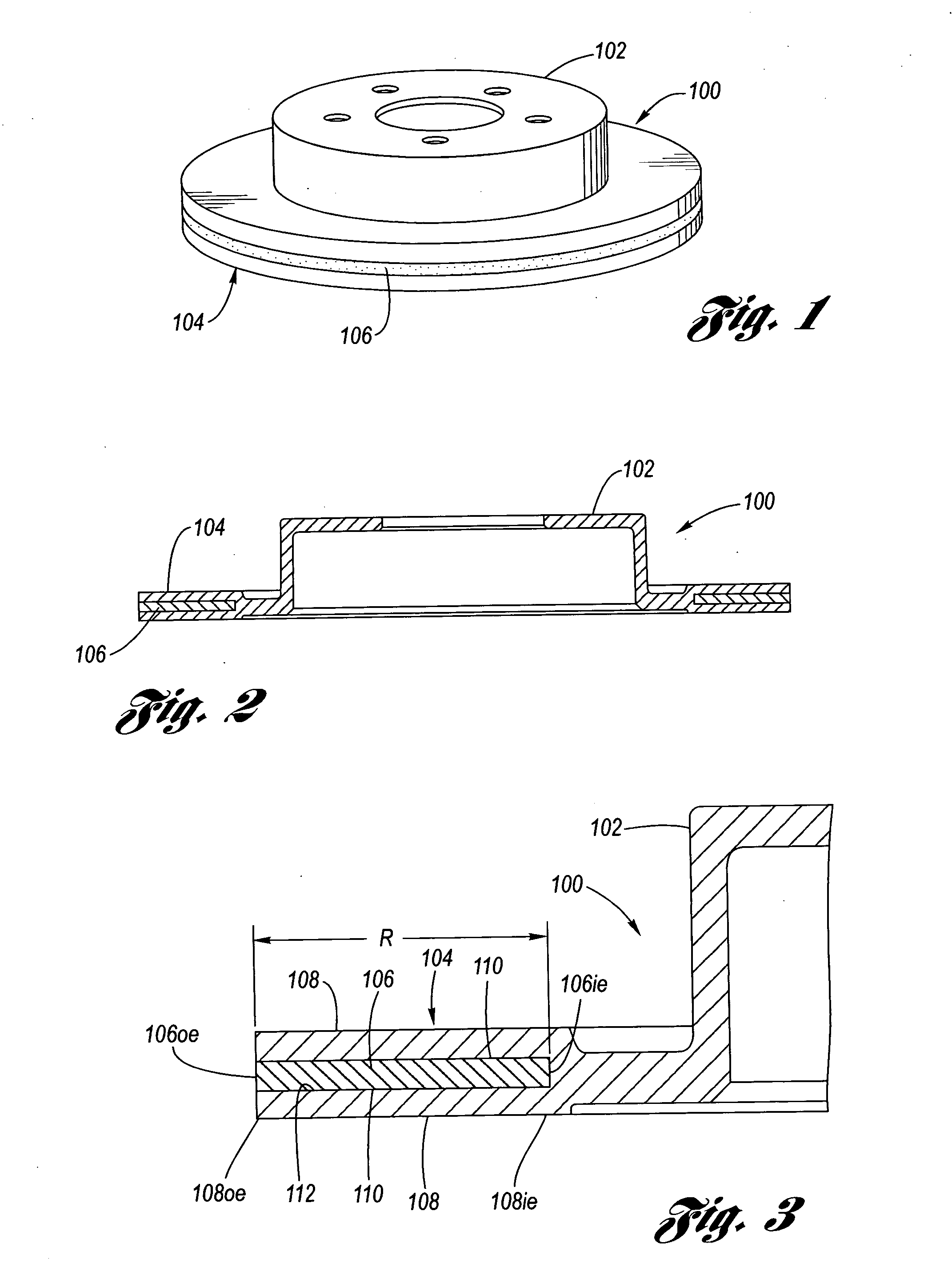

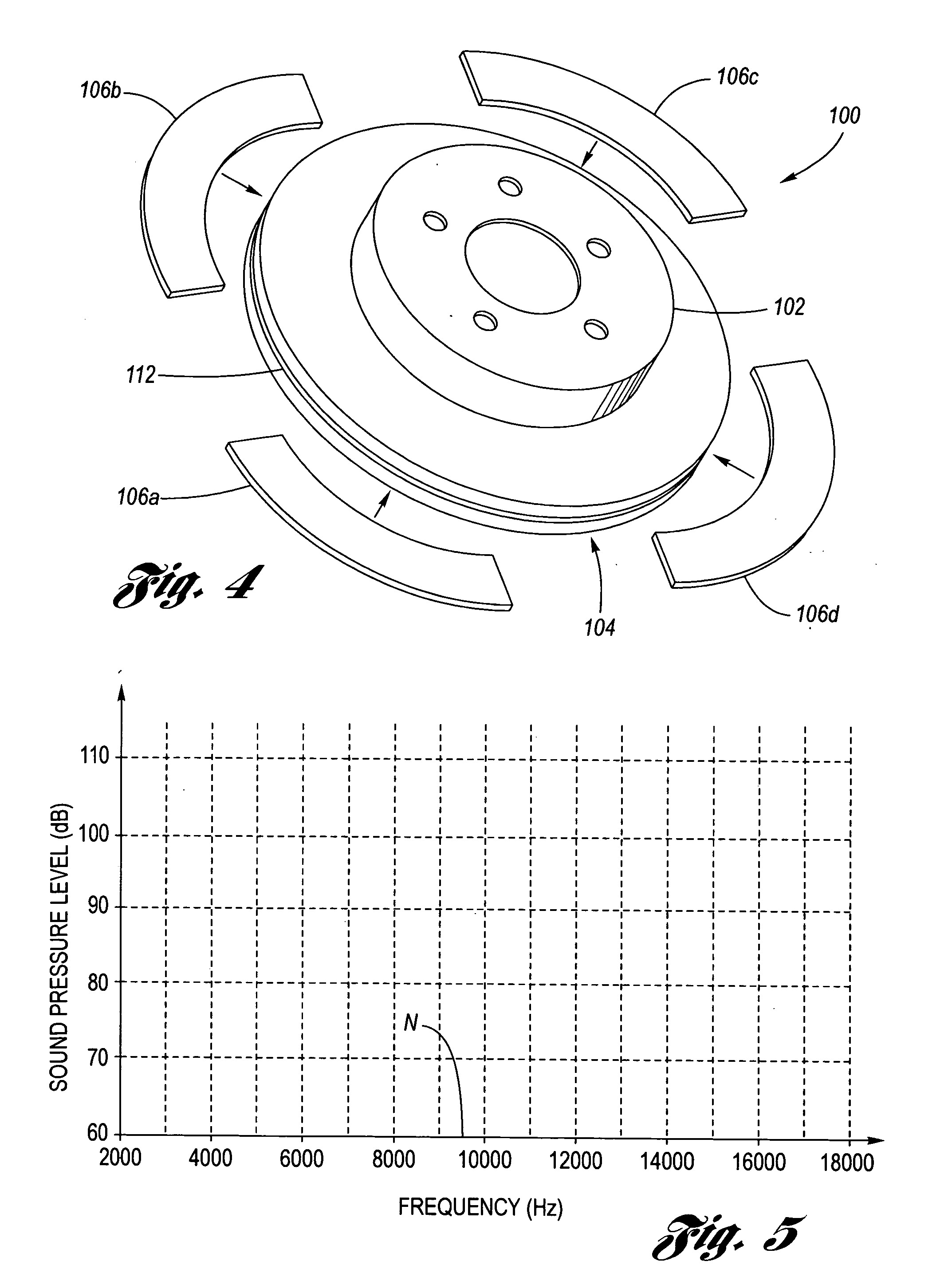

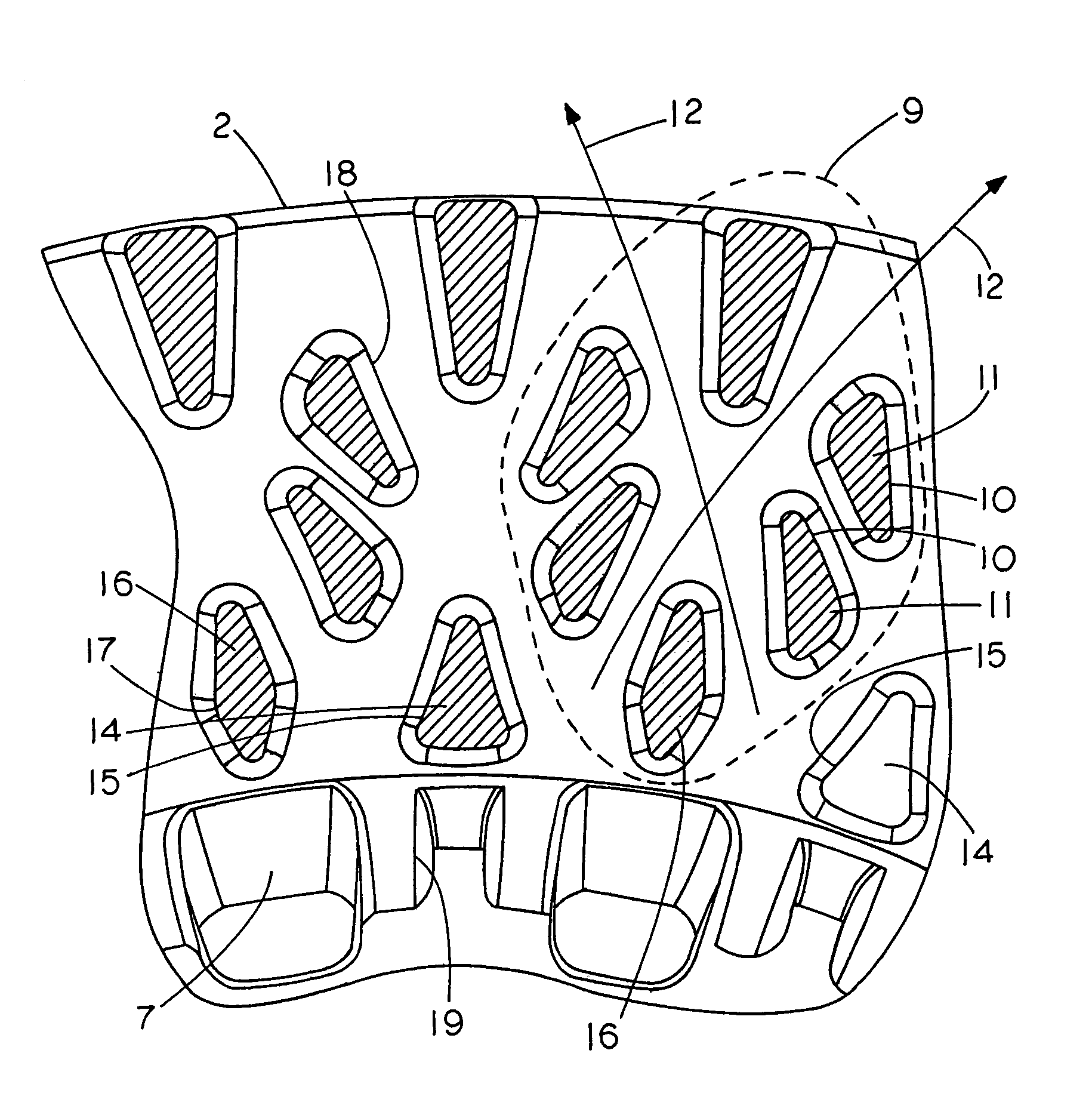

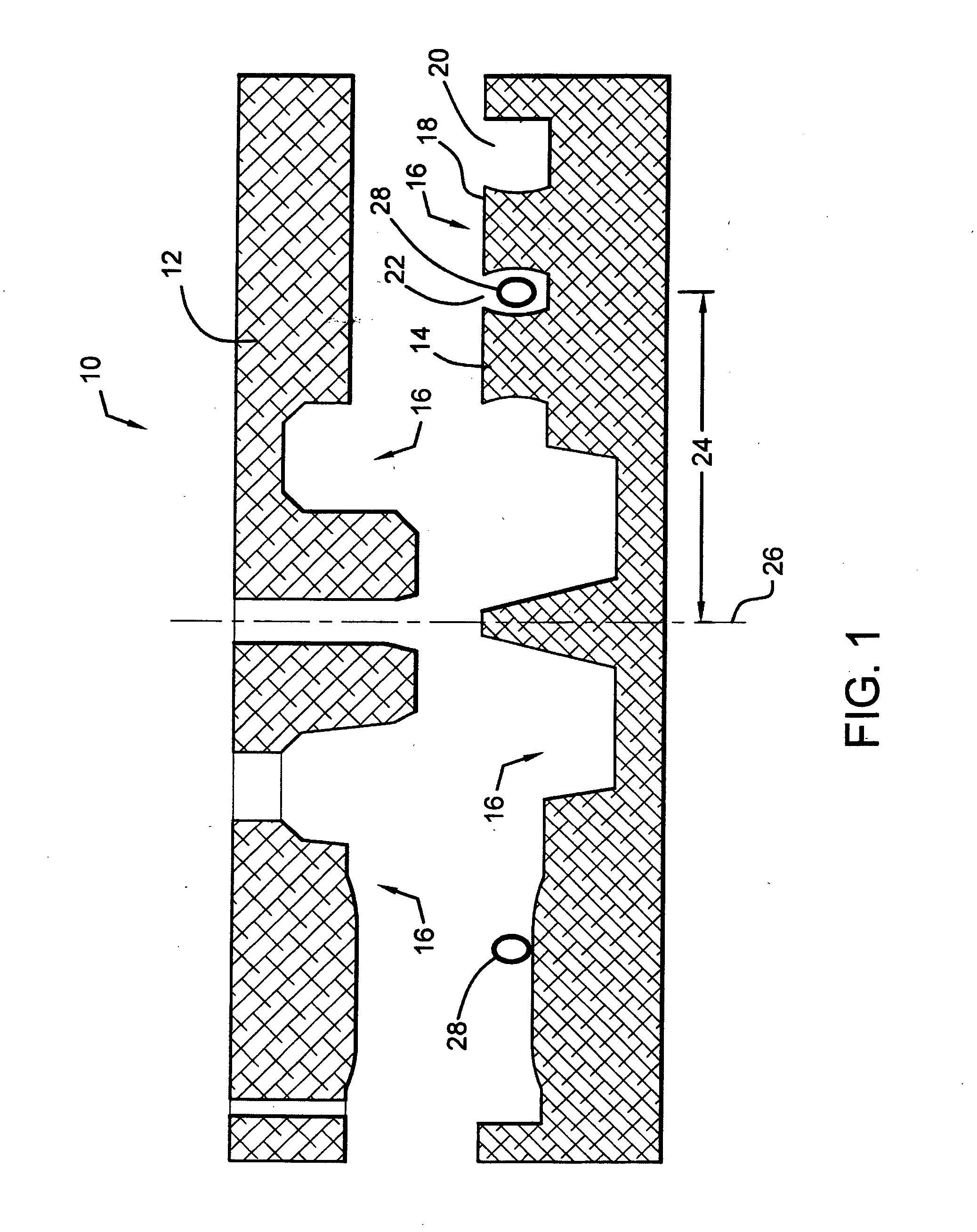

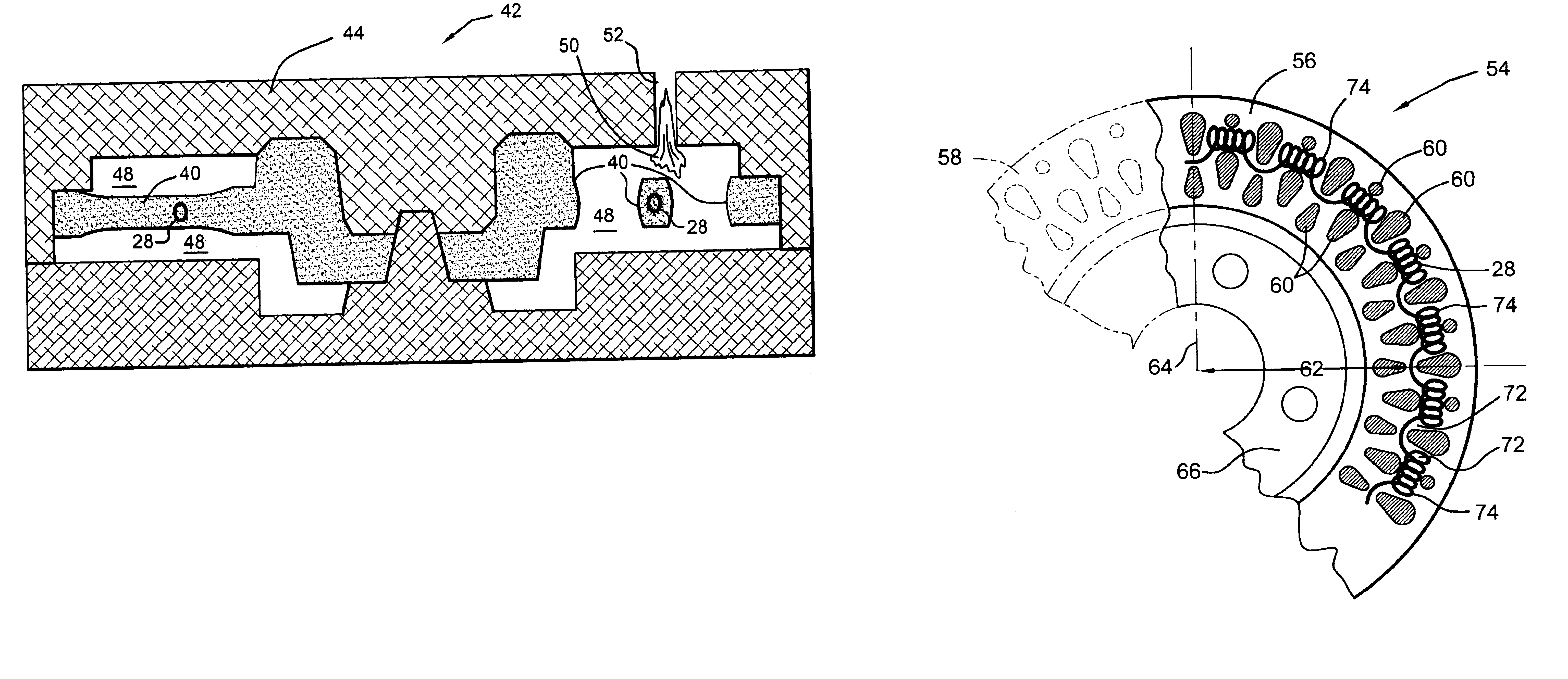

Coulomb friction damped disc brake rotors

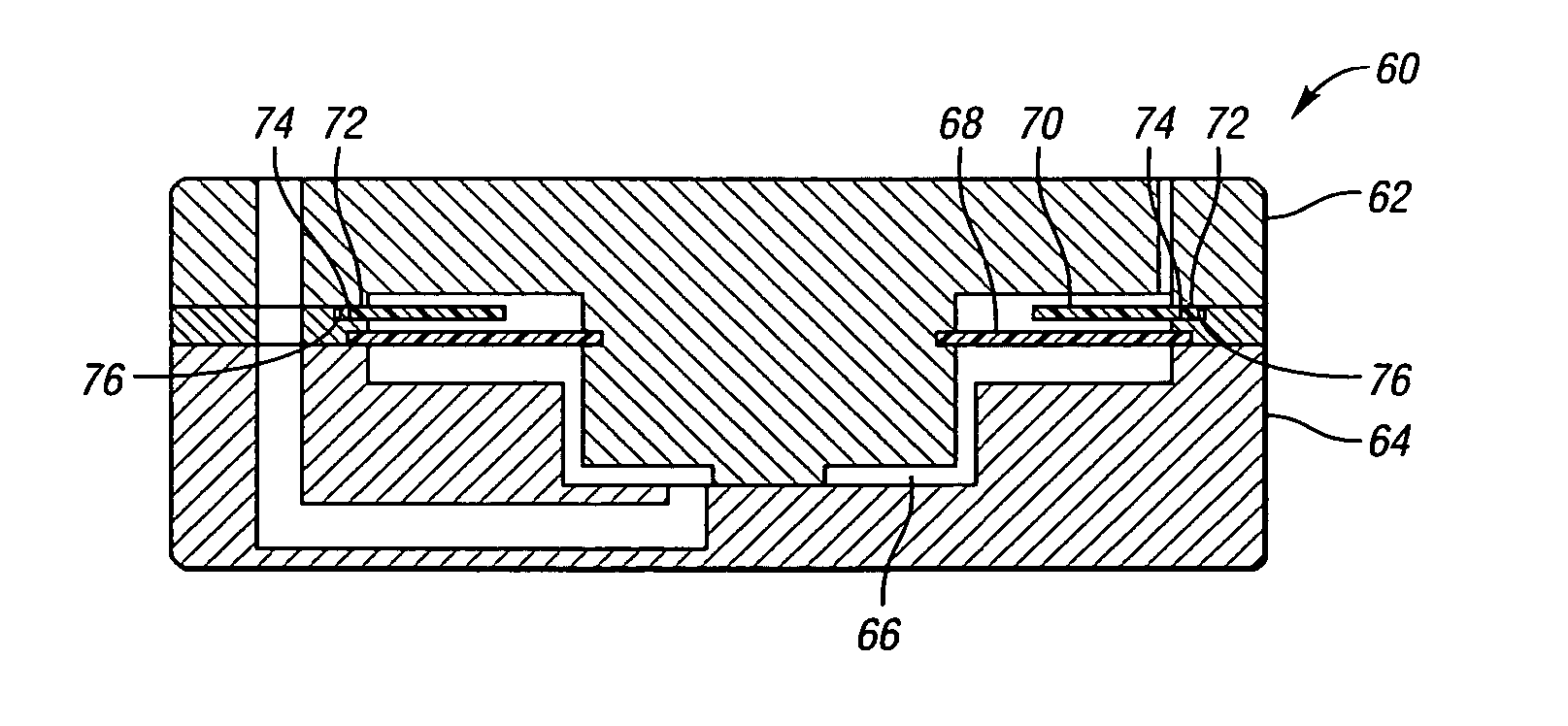

InactiveUS20060076200A1Average thicknessSmall thicknessNoise/vibration controlBraking discsEngineeringMechanical engineering

A Coulomb friction damped disc brake rotor, wherein damping is provided Coulomb friction in generally coextensive relation with the braking surfaces of the one or more rotor cheeks. The Coulomb friction damped disc brake rotor has at least one interfacial boundary formed in at least one rotor cheek disposed in generally coextensive relation to the braking surface thereof. The interfacial boundary provides a mechanically distinguishable surface boundary between two surfaces which are in mutual contact such that a state of Coulomb friction exists therebetween.

Owner:GM GLOBAL TECH OPERATIONS LLC

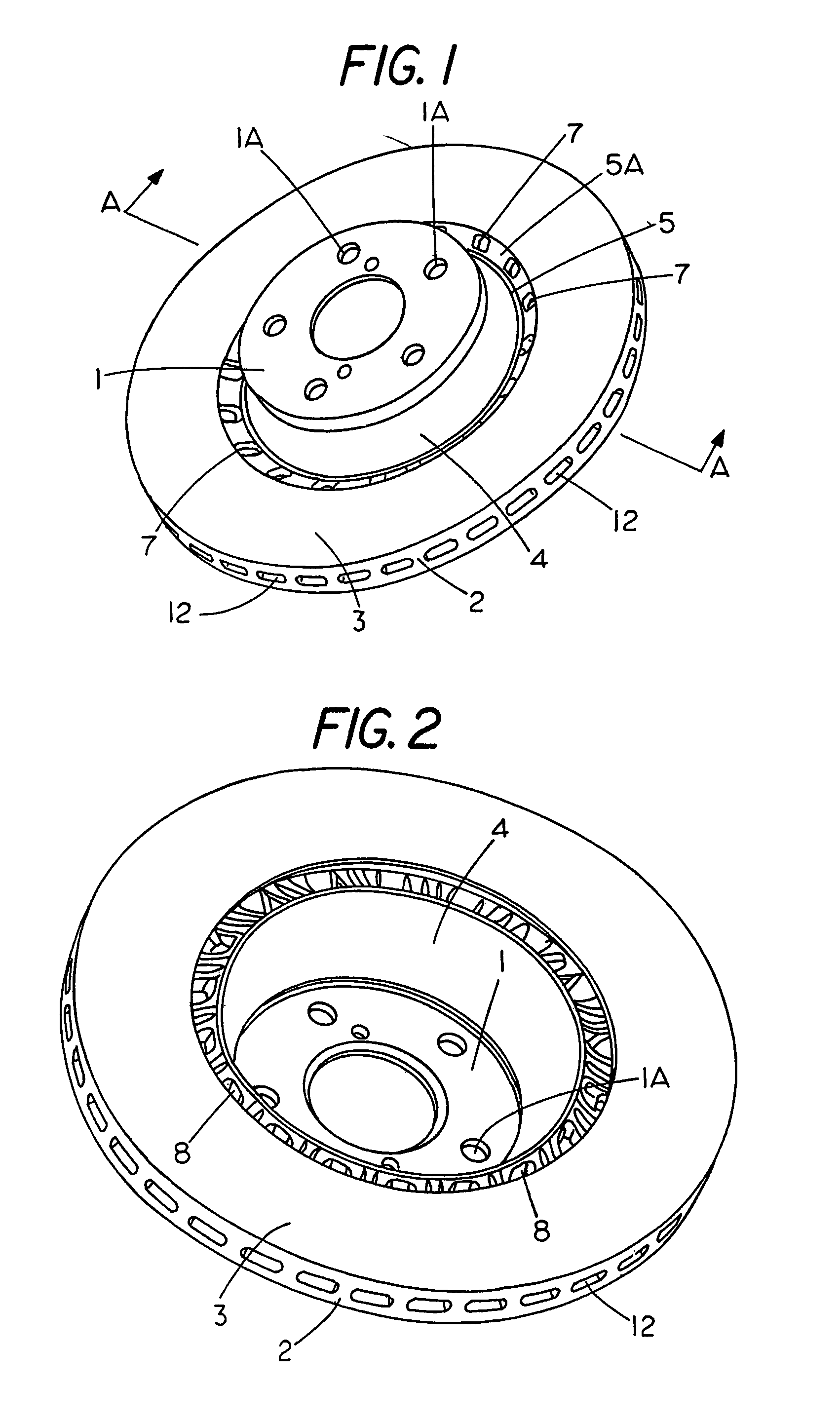

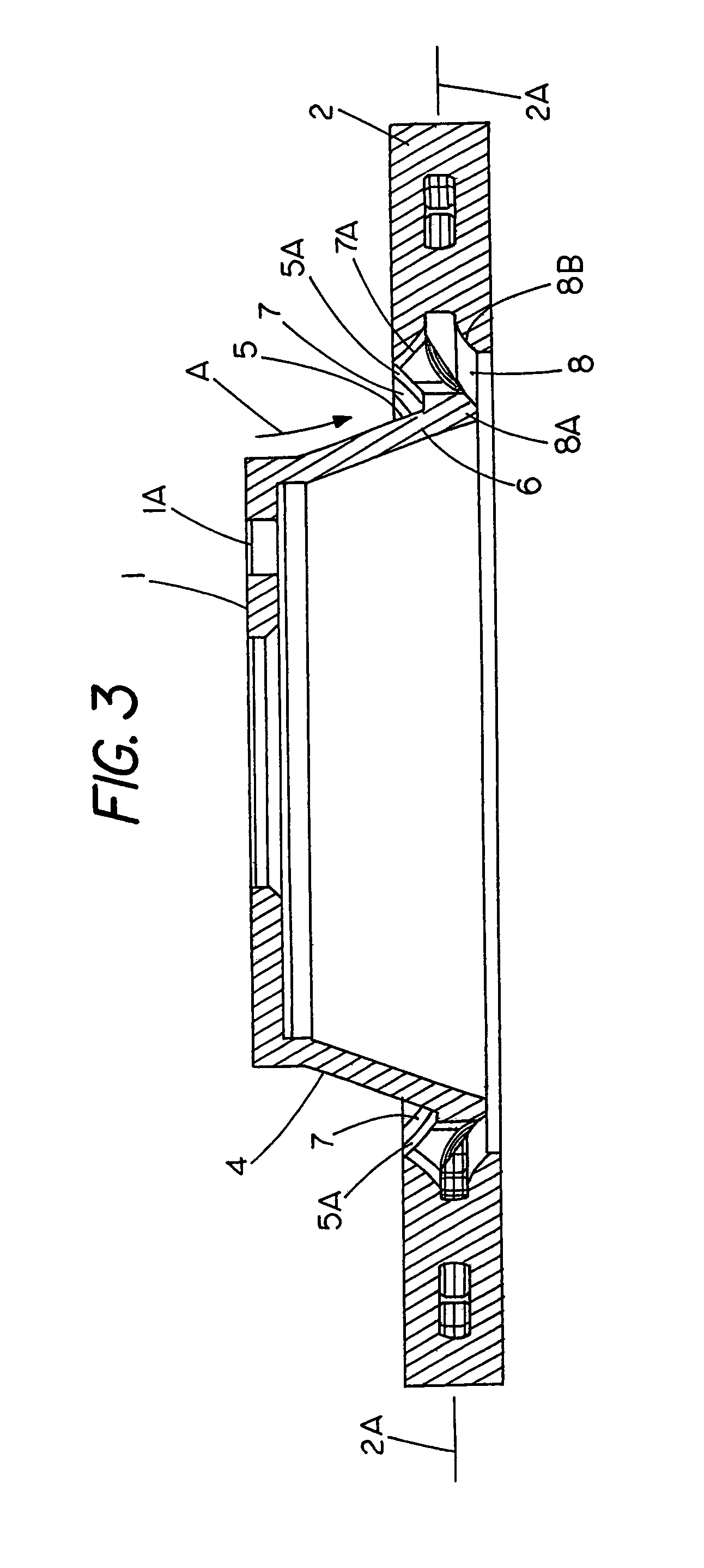

Self-ventilating disc brake rotor

There is a brake disc rotor having a central hub (1) co-axial with surrounding rings (2) which form brake bands (3) for engagement with brake pads. The rings (3) are supported in a spaced apart parallel configuration with channels (12) therebetween whereby in use of the rotor cooling air is drawn in through vent openings formed around the inner periphery of the rings (3) and then radially outwardly through the channels (12) as the rotor turns. The vent openings include inlet vent ports (7) on the outboard side of the rotor.

Owner:DISC BRAKES AUSTRALIA

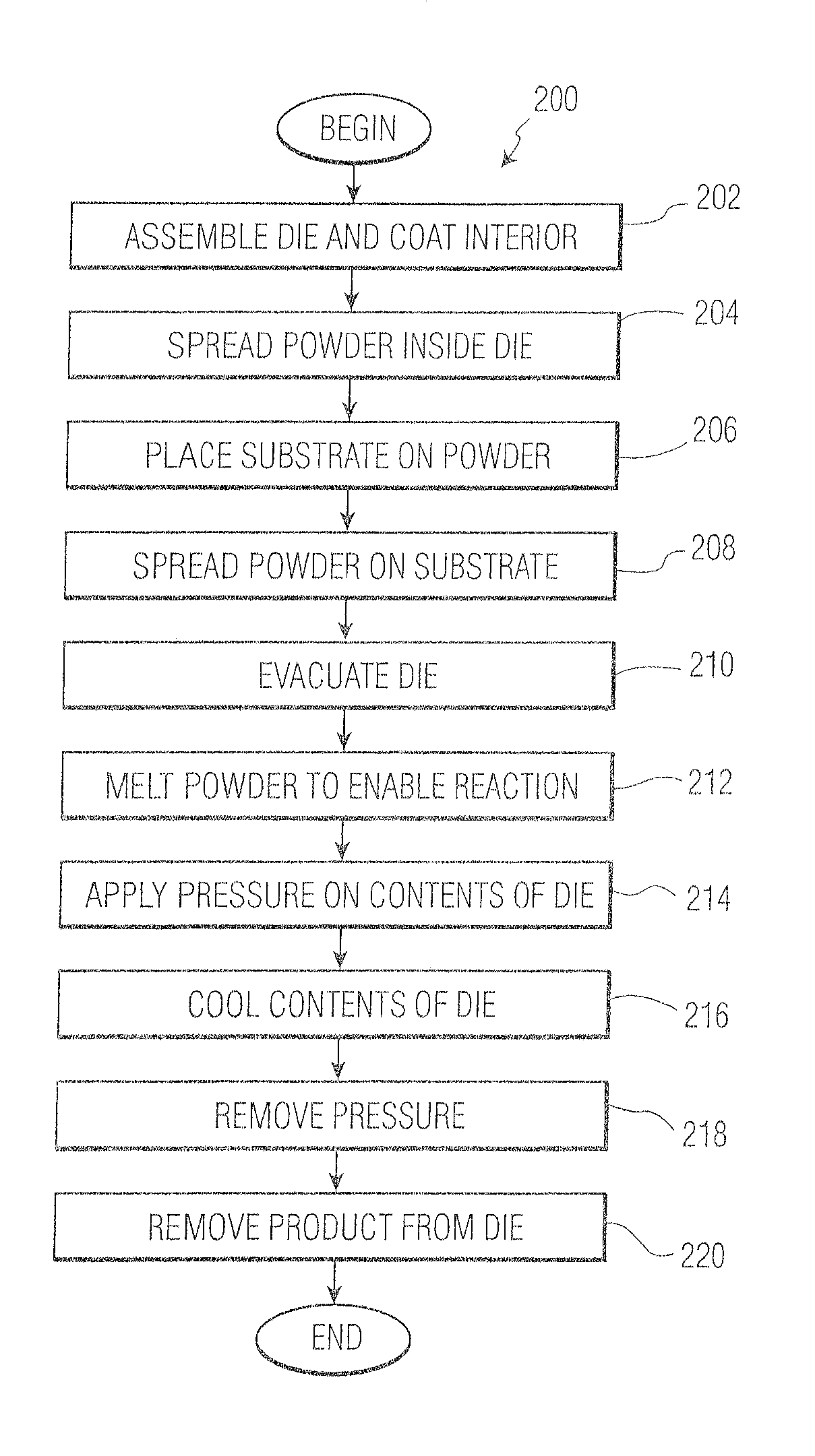

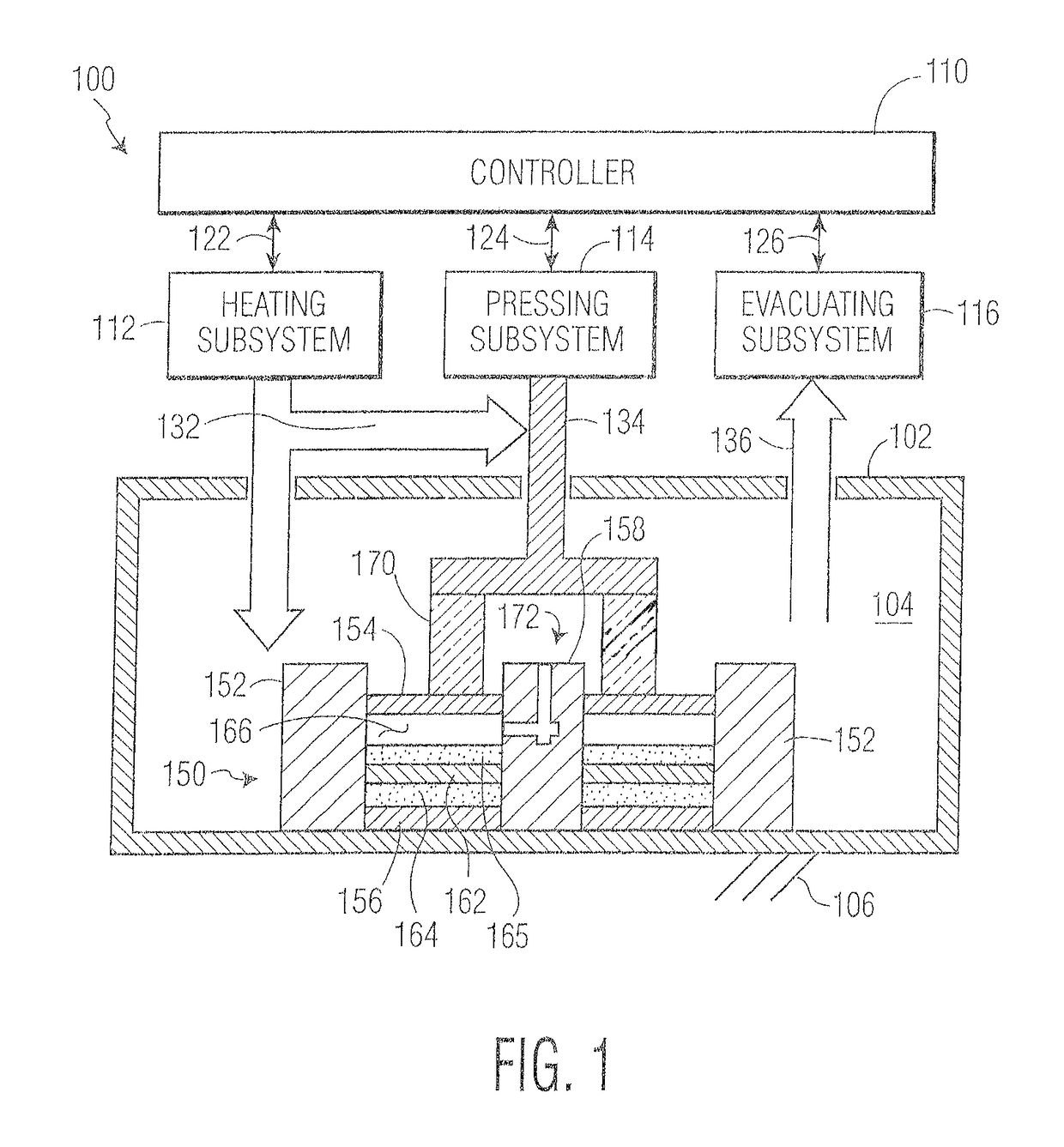

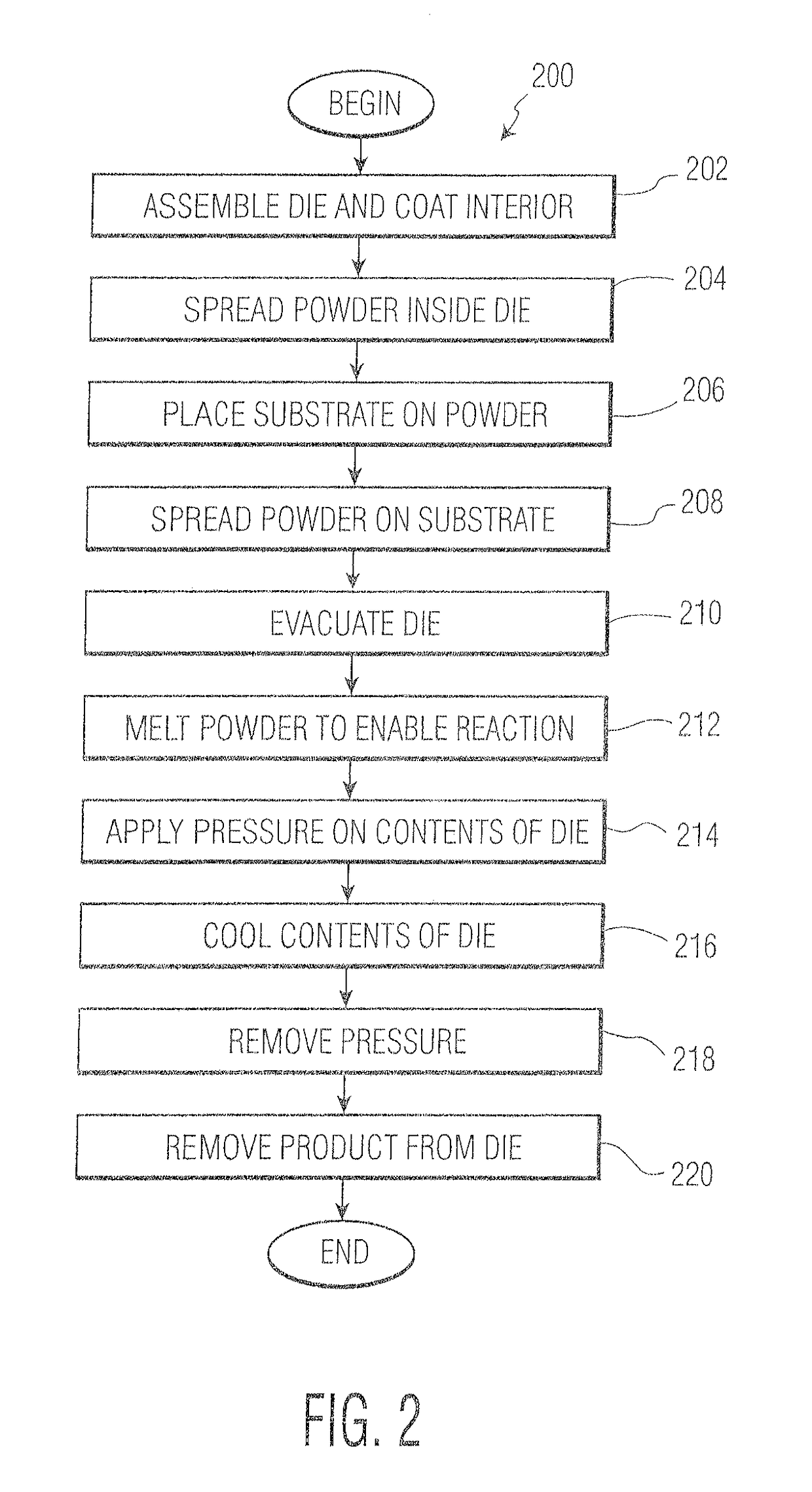

Systems and methods for forming a layer onto a surface of a solid substrate and products formed thereby

InactiveUS9933031B2Increase capacityImprove the overall coefficientBlade accessoriesBraking discsMetal matrix compositeSolid substrate

A method for forming a vehicular brake rotor involving loading a shaped metal substrate with a mixture of metal alloying components and ceramic particles in a dieheating the contents of the die while applying pressure to melt at least one of the metal components of the alloying mixture whereby to densify the contents of the die and form a ceramic particle-containing metal matrix composite coating on the metallic substrate; and cooling the resulting coated product.

Owner:ATS MER LLC

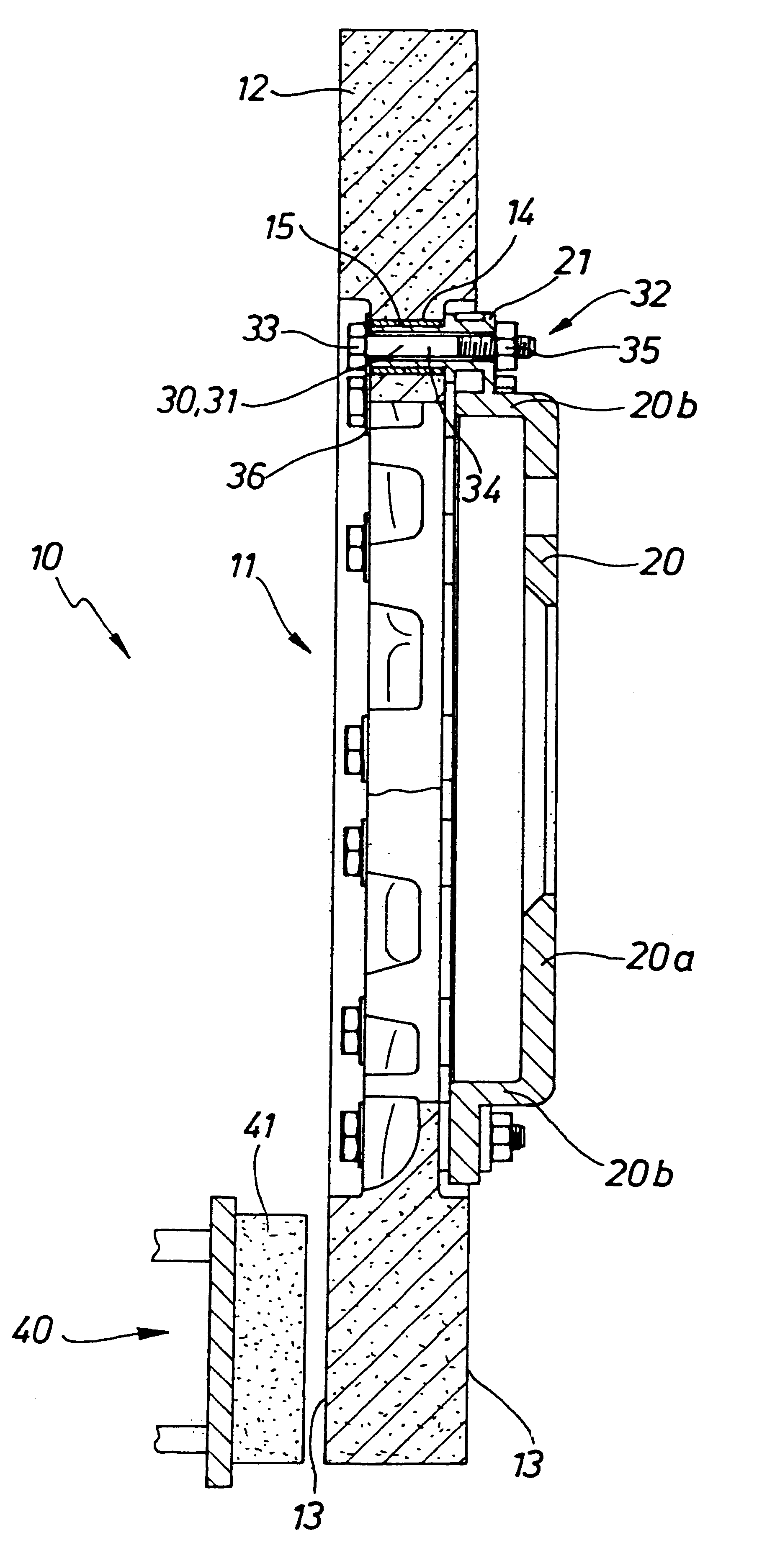

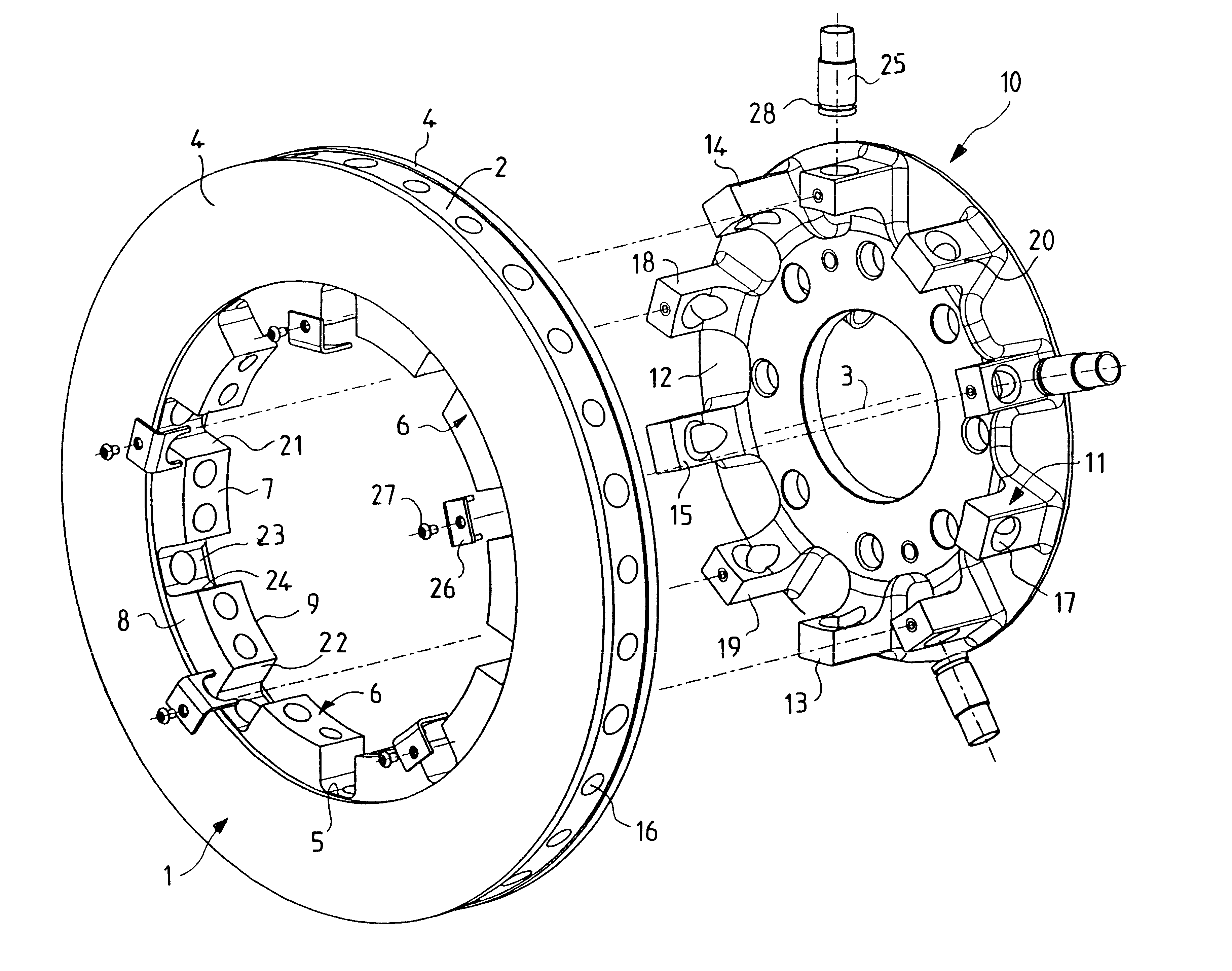

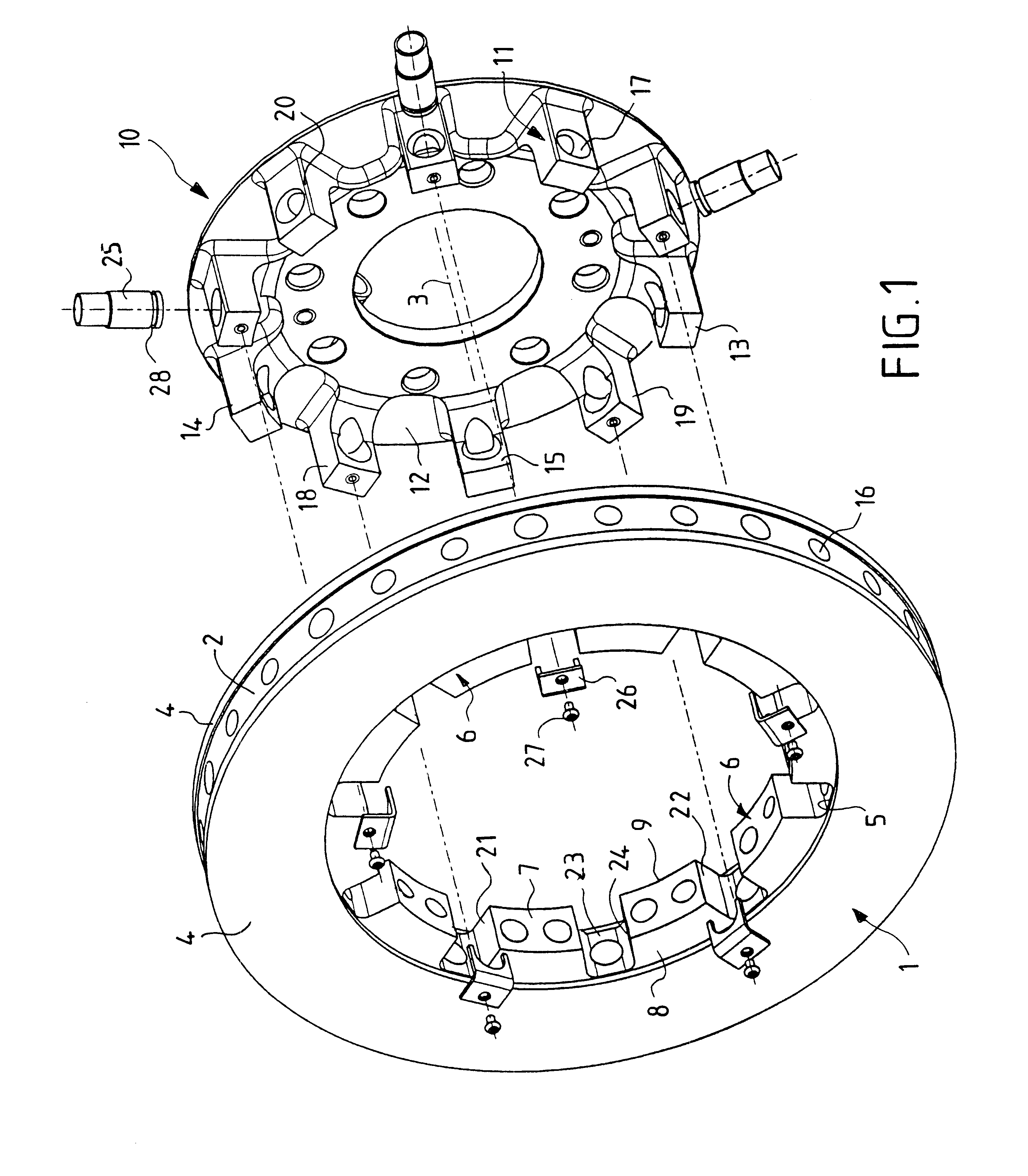

Device for fixing a ventilated brake disk axially on the hub of a motor vehicle wheel

InactiveUS6446765B1Easy to controlHigh speed usBraking element arrangementsAxially engaging brakesEngineeringMechanical engineering

An axial fixing device for axially fixing an annular brake disk on a wheel hub of a motor vehicle, the annular brake disk having the same axis of rotation as the hub and including radial ventilation ducts regularly distributed about its periphery. According to the invention, the hub has axial guide pieces in relief, or "lugs", for co-operating with fluting in an inner peripheral edge of the disk to center the disk, to lock it angularly, and to guide it axially relative to the hub, each lug of the hub having a radial through channel for co-operating with a corresponding ventilation duct of the disk, and the disk is held axially in the hub with play by axial holding means disposed between the disk and the hub.

Owner:MESSIER BUGATTI INC

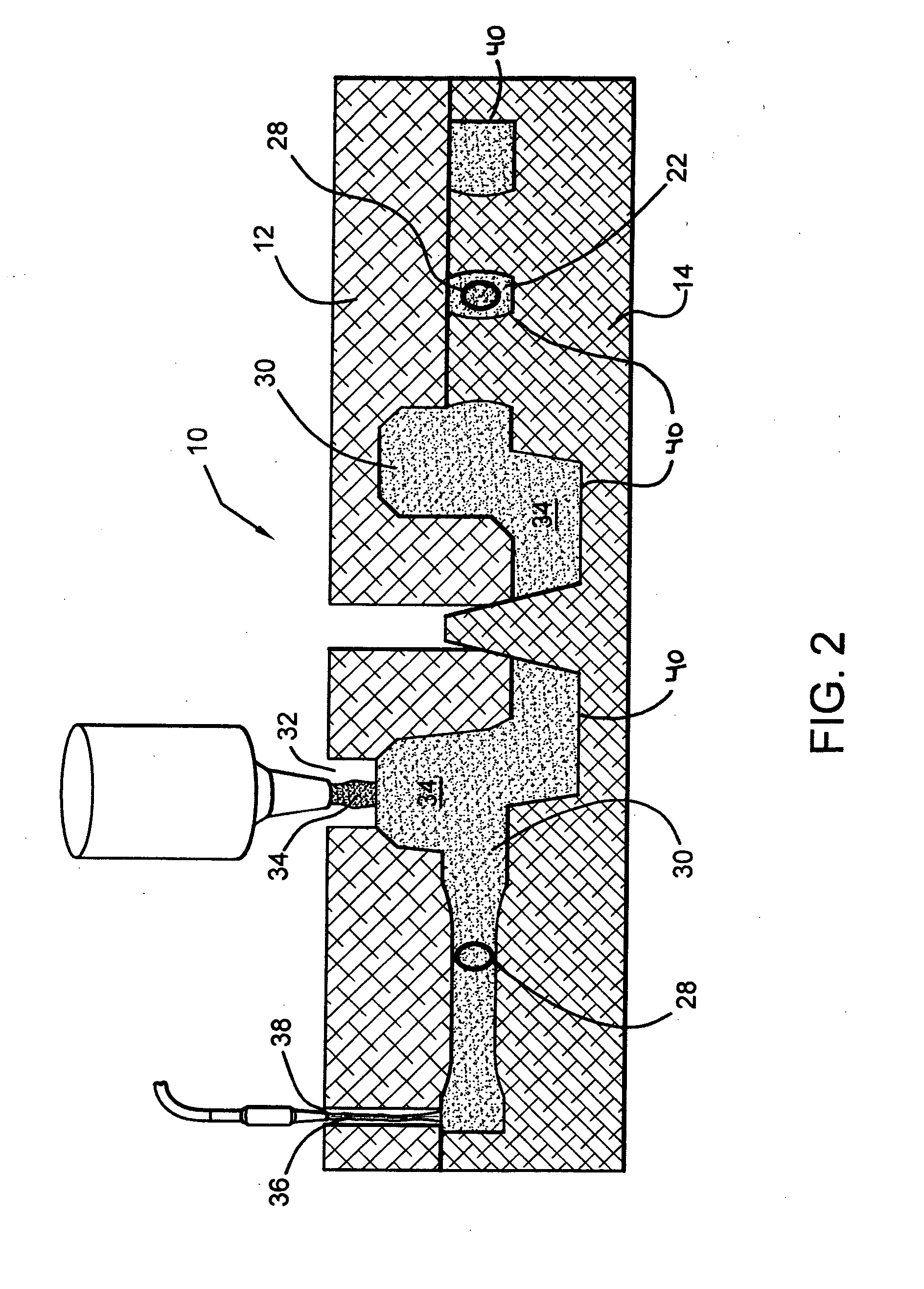

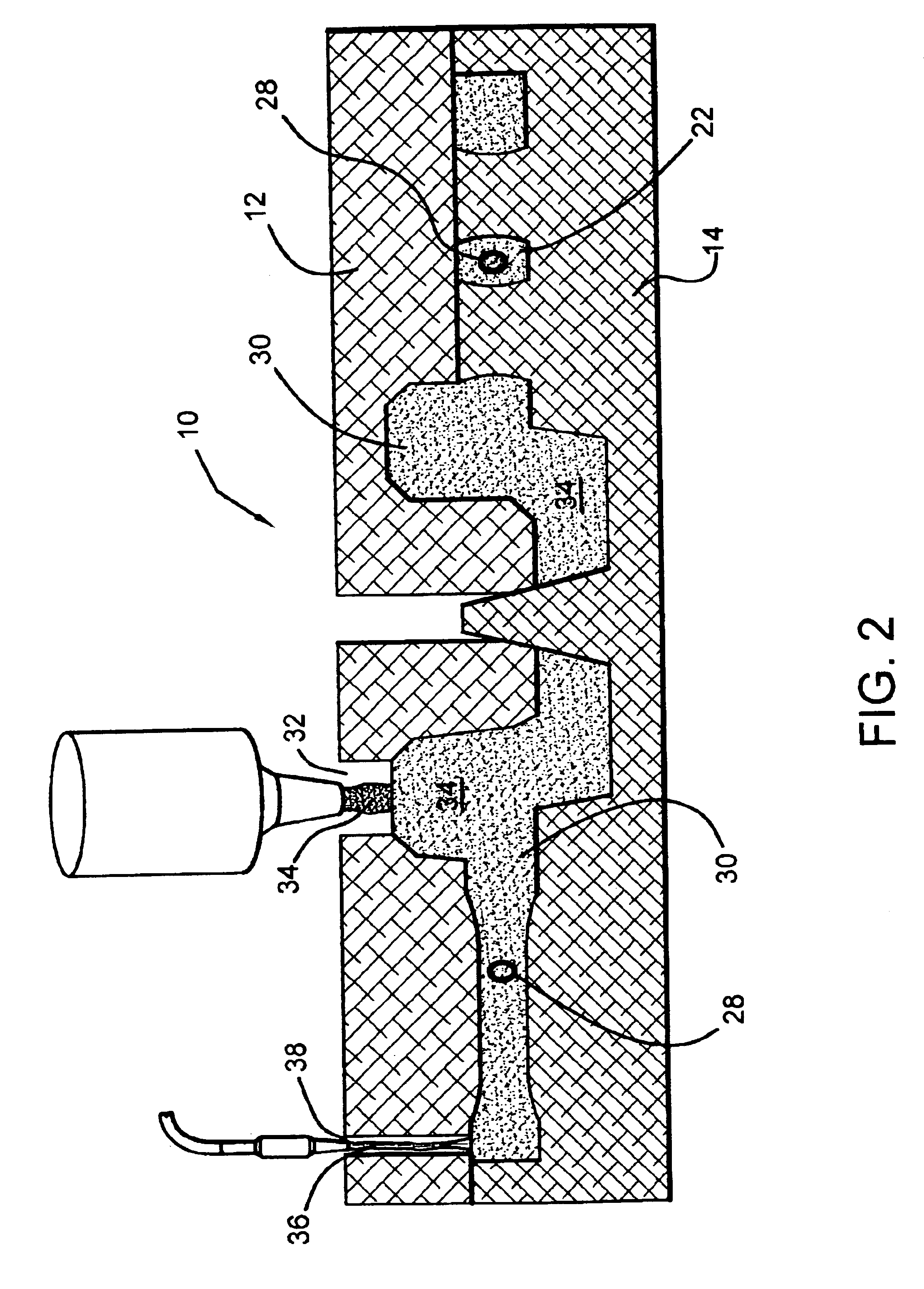

Bi-metal disc brake rotor and method of manufacturing

InactiveUS20070062768A1Avoid problemsImprove bindingNoise/vibration controlMetal rolling stand detailsCeramic coatingMaterials science

The invention provides a method for manufacturing a friction damped disc brake rotor, including the steps of: (A) providing a ceramic coating on an insert, wherein the insert has a body with tabs extending therefrom to hold the insert in a desired position within a mold; (B) washing the ceramic coating off of the tabs; (C) positioning the insert into the mold; and (D) casting a rotor cheek of the disc brake rotor in the mold around the insert such that a portion of each tab is bonded with the rotor cheek, and such that the coating is substantially non-bonded with the rotor cheek so that the coating provides a proper interfacial boundary between the body and the cheek for damping, and the at least partial bonding of each tab with the rotor cheek prevents corrosion-causing exterior elements from reaching the interfacial boundary when the friction damped disc brake rotor is in use.

Owner:GM GLOBAL TECH OPERATIONS LLC

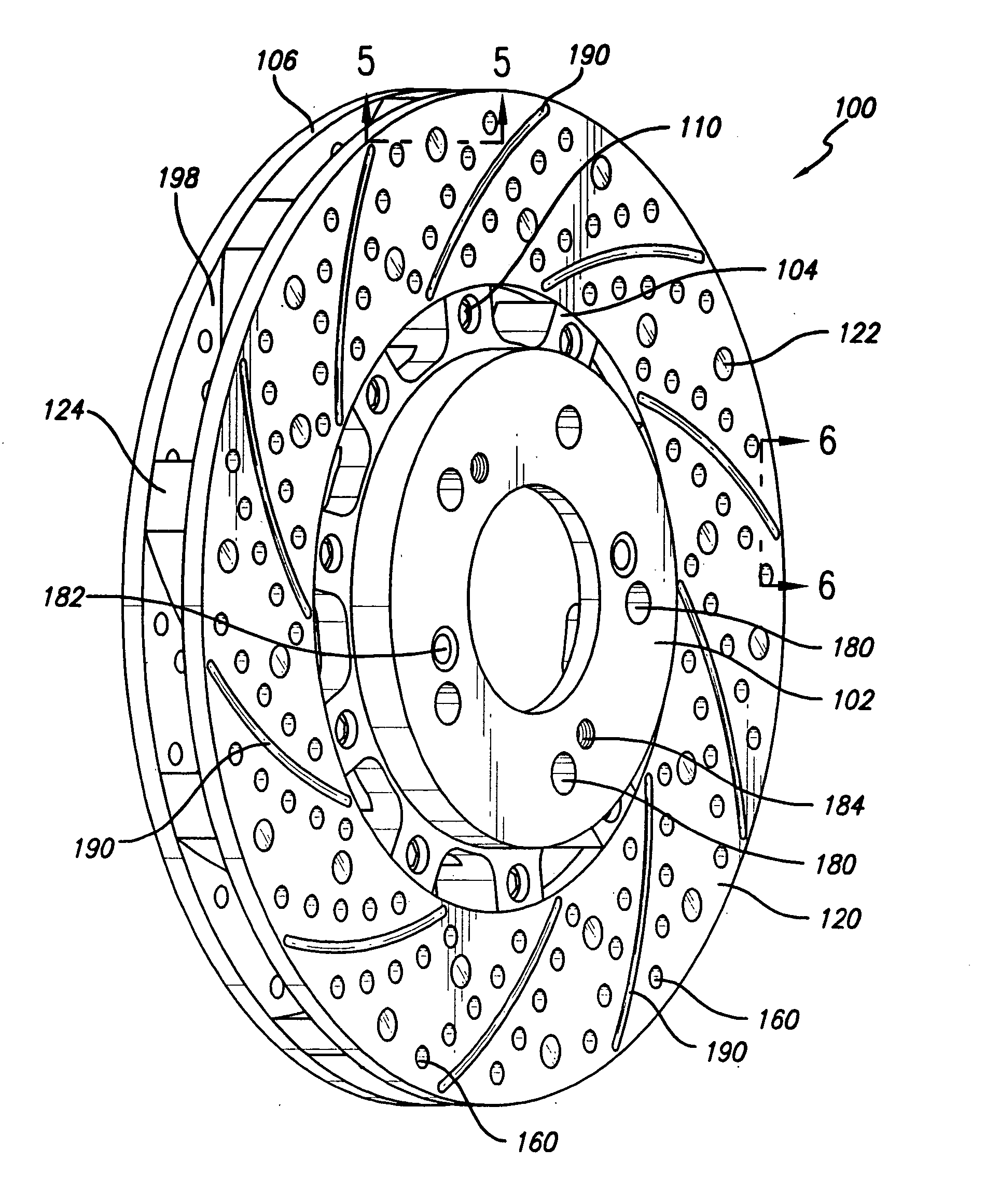

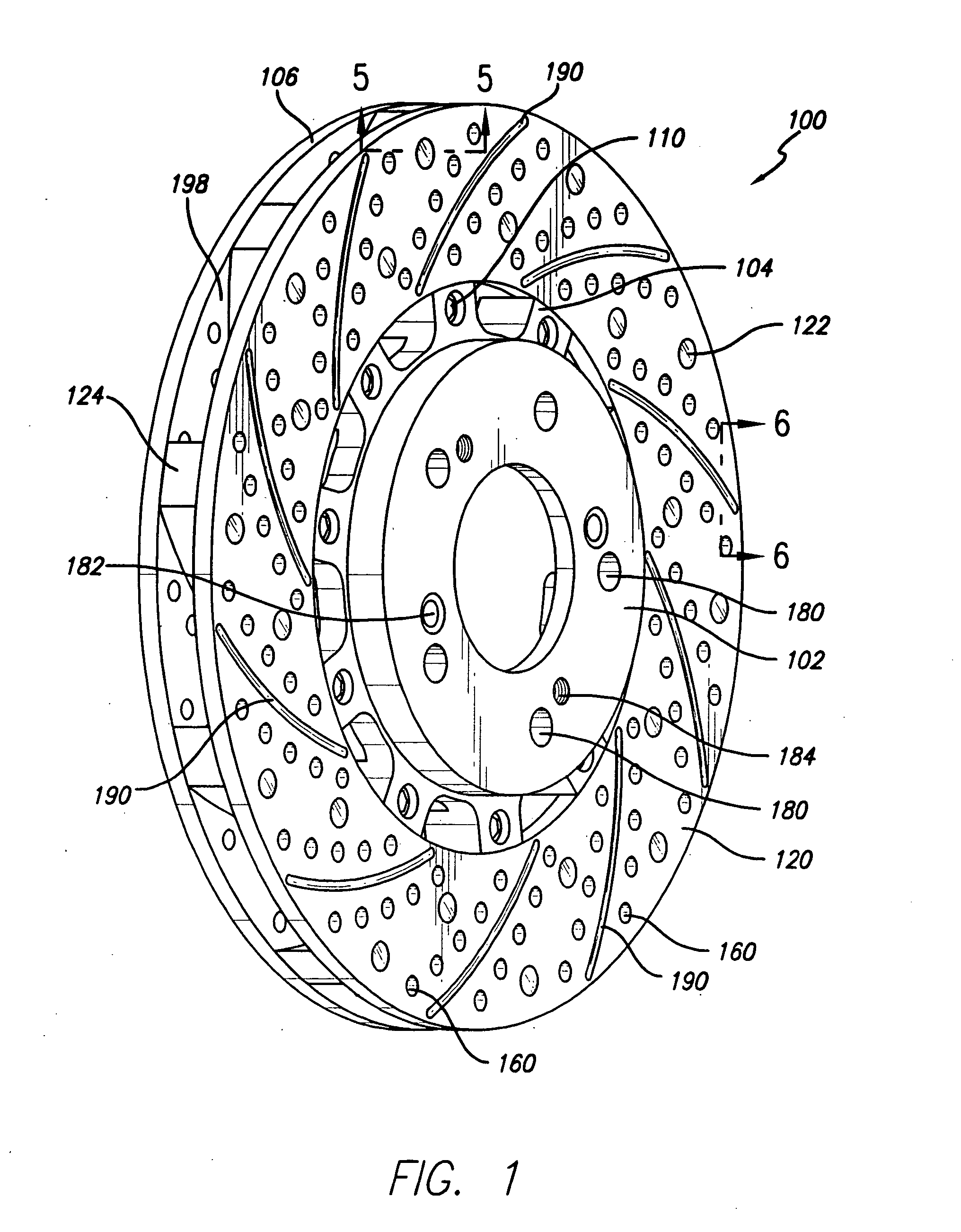

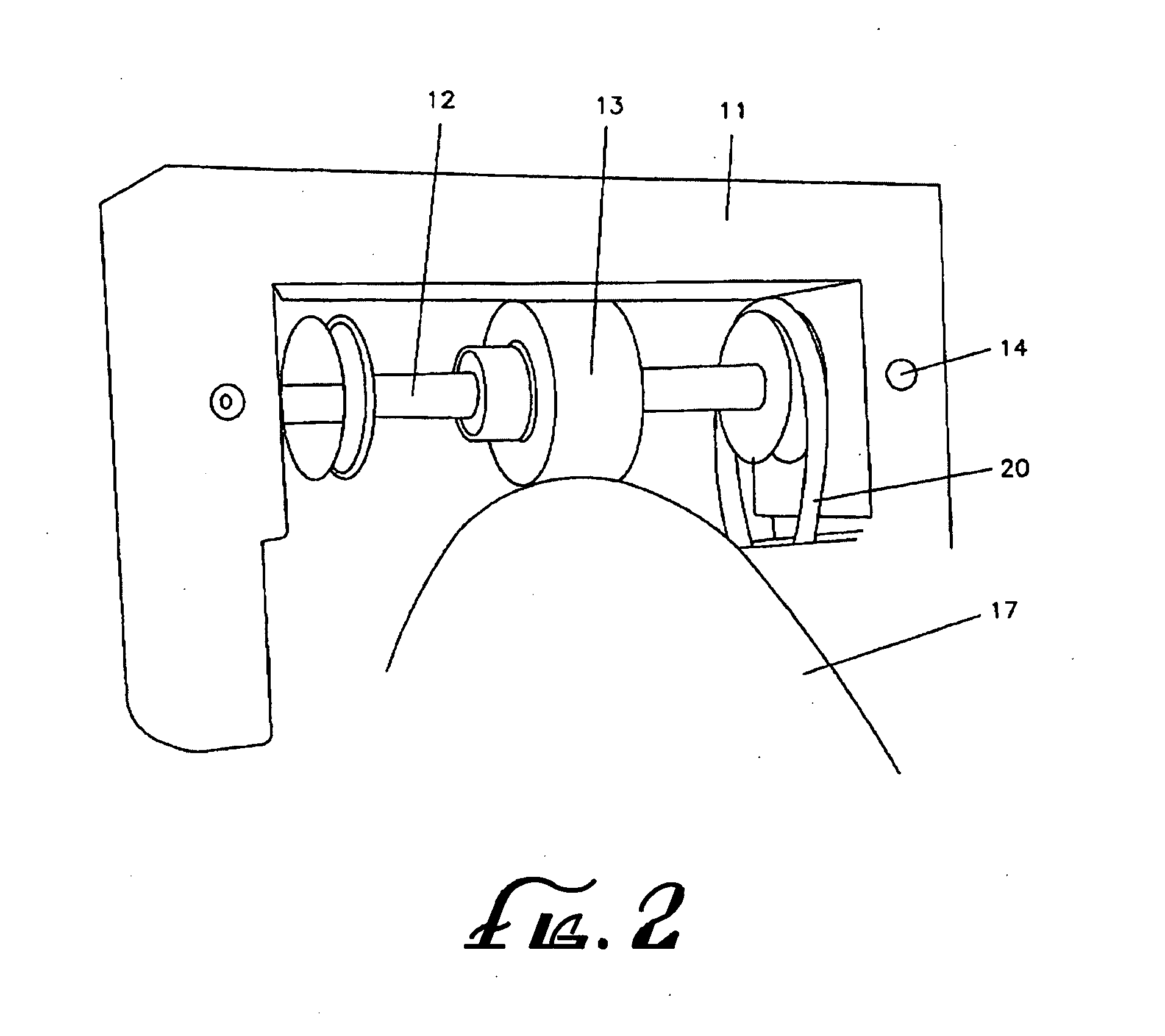

Air-cooled brake rotor system

InactiveUS20070181390A1Easy to replaceImprove cooling effectBraking discsFriction liningDisc brakeEngineering

An air-cooled brake rotor system defining an inter-rotor disk slot through which spacers in the form of turbine or fan vanes propel air when the brake rotor system is turned. An inner disk brake rotor plate is attached to a hub which in turn may be attached to an axle on a vehicle such as an automobile. Pins having ends of opposite threading are used to connect the inner rotor to the outer rotor. The outer rotor is spaced apart from the inner rotor by means of spacers which are shaped to propel air through the slots defined between the two rotors. The spacers are also configured so that compression of the two rotors by a caliper system always serves to have a spacer beneath the area engaged by the brake pad to provide mechanical support for the rotor system. Each rotor generally has defined in it venting holes and inscribed debris-channeling slots in an arcuate, volute, or turbinate manner. An enhanced braking system experiencing lower heat retention is thereby attained.

Owner:KORM KEVIN

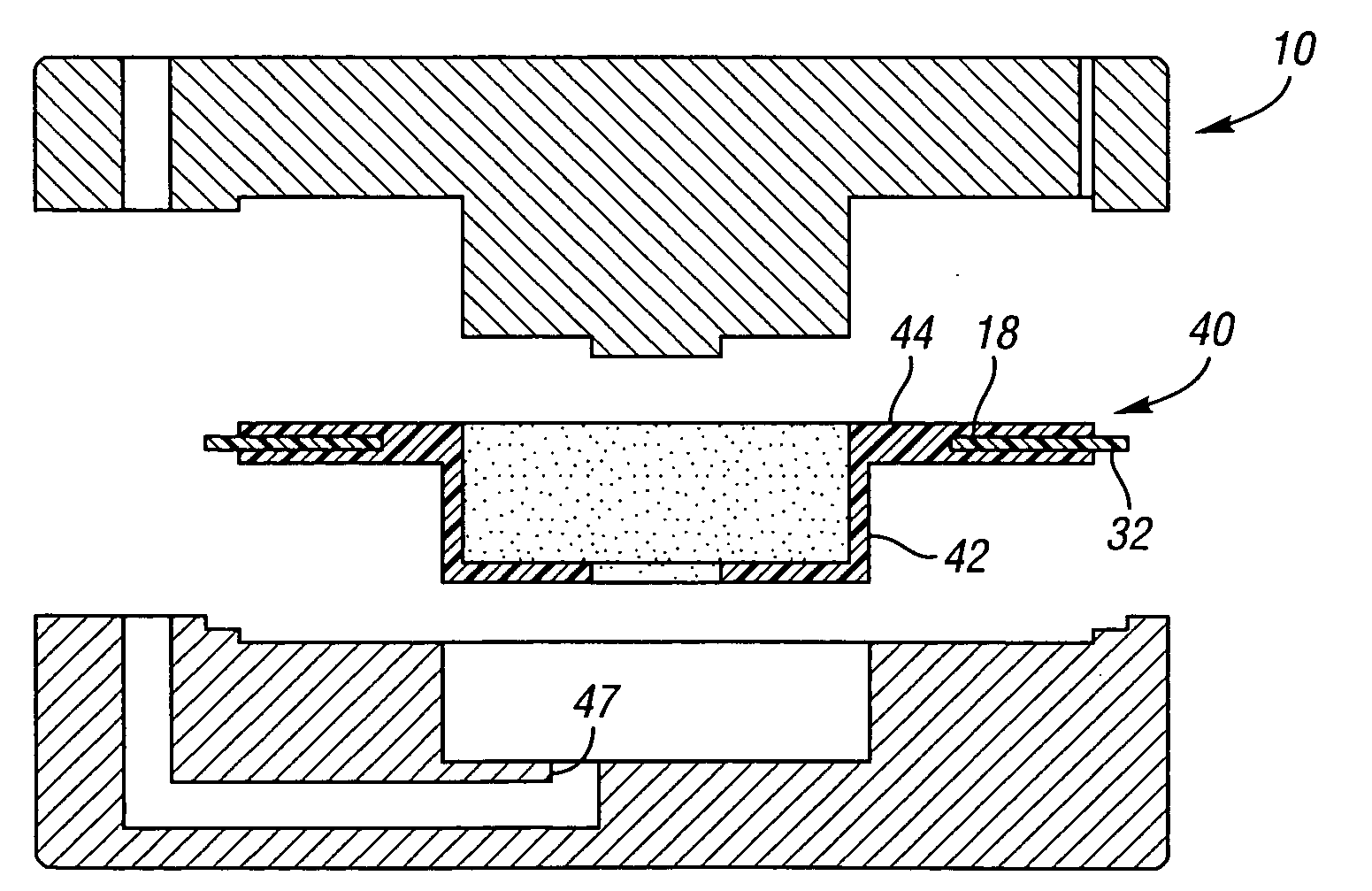

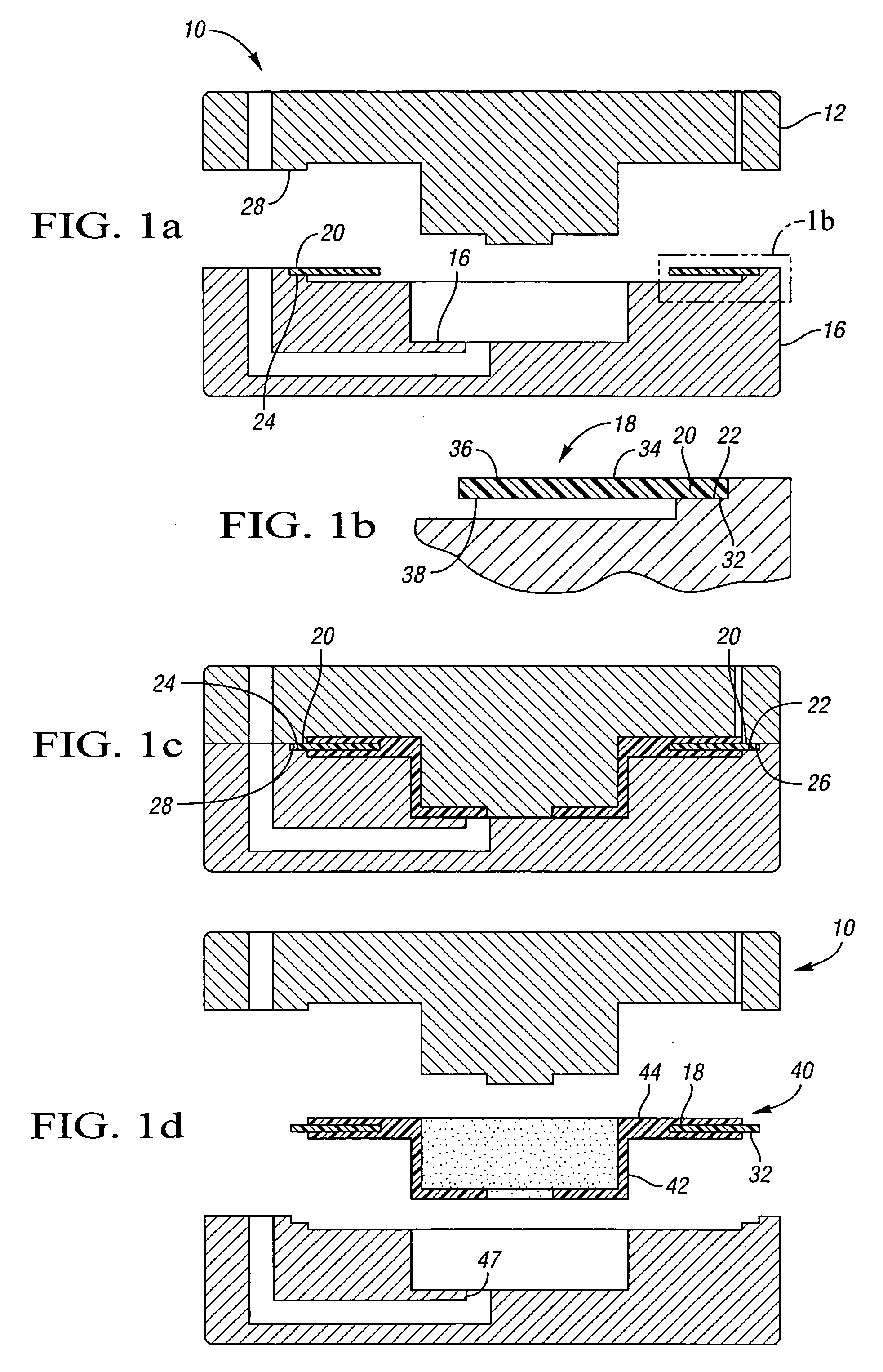

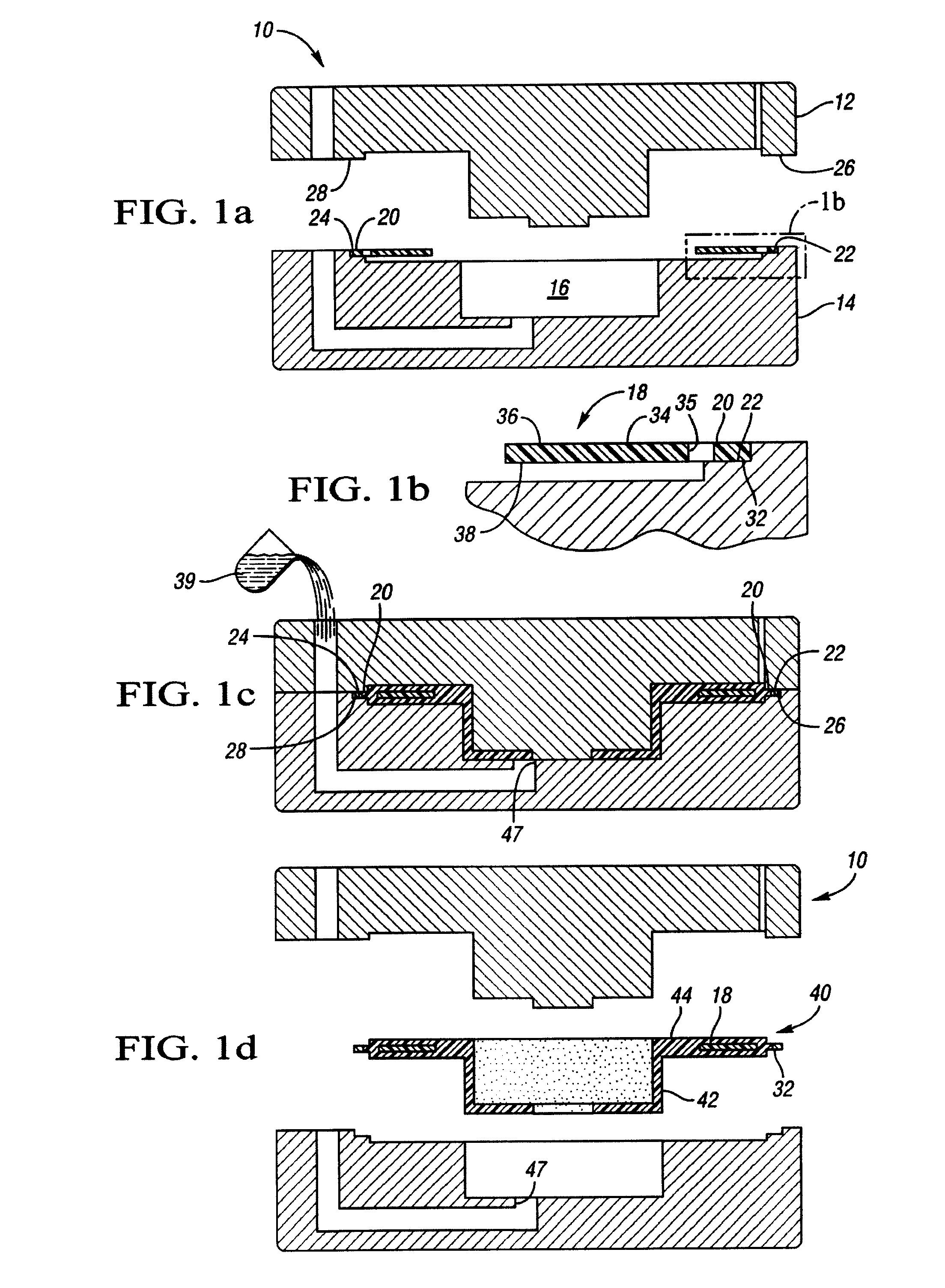

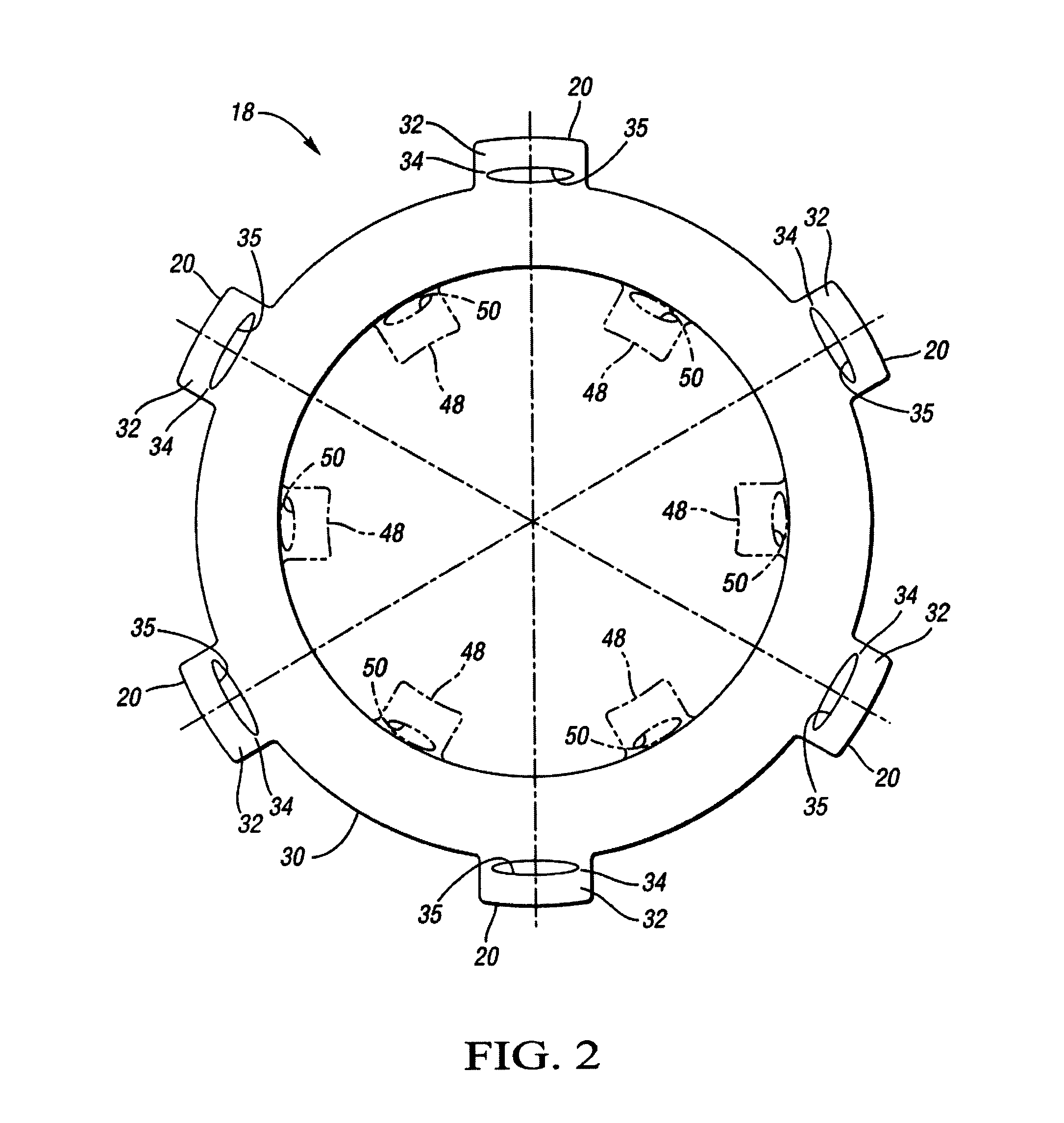

Method and apparatus for forming a part with dampener

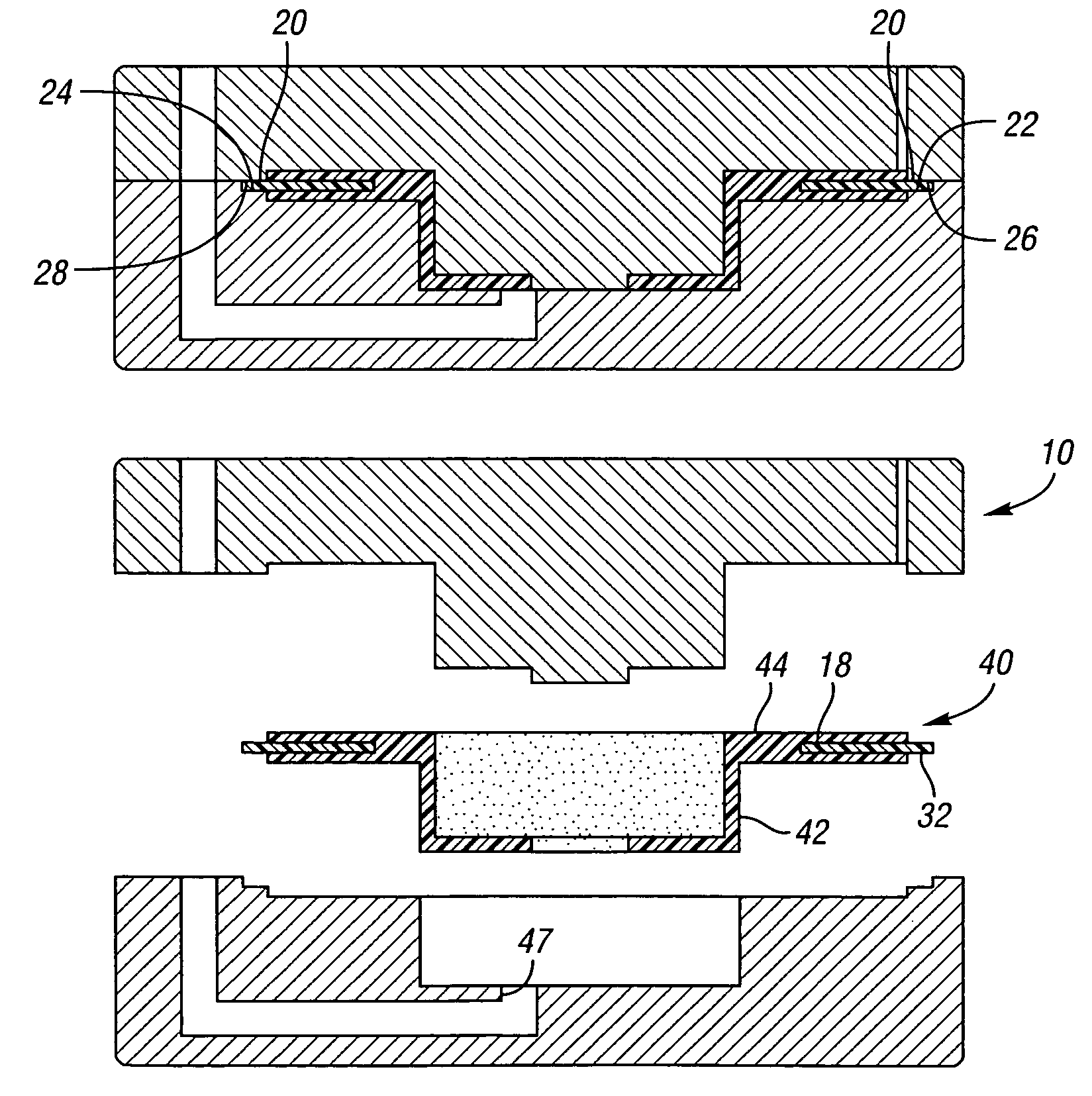

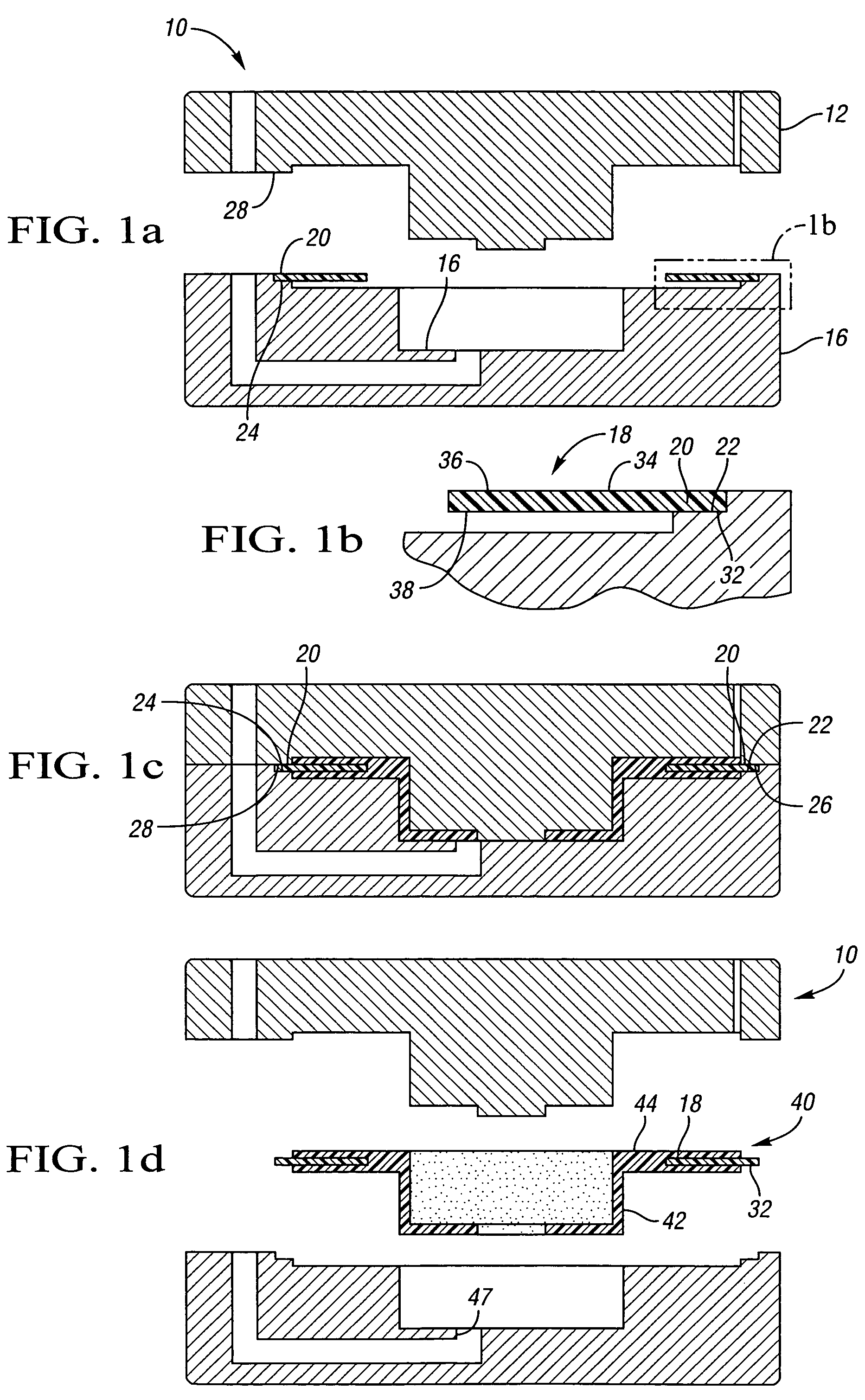

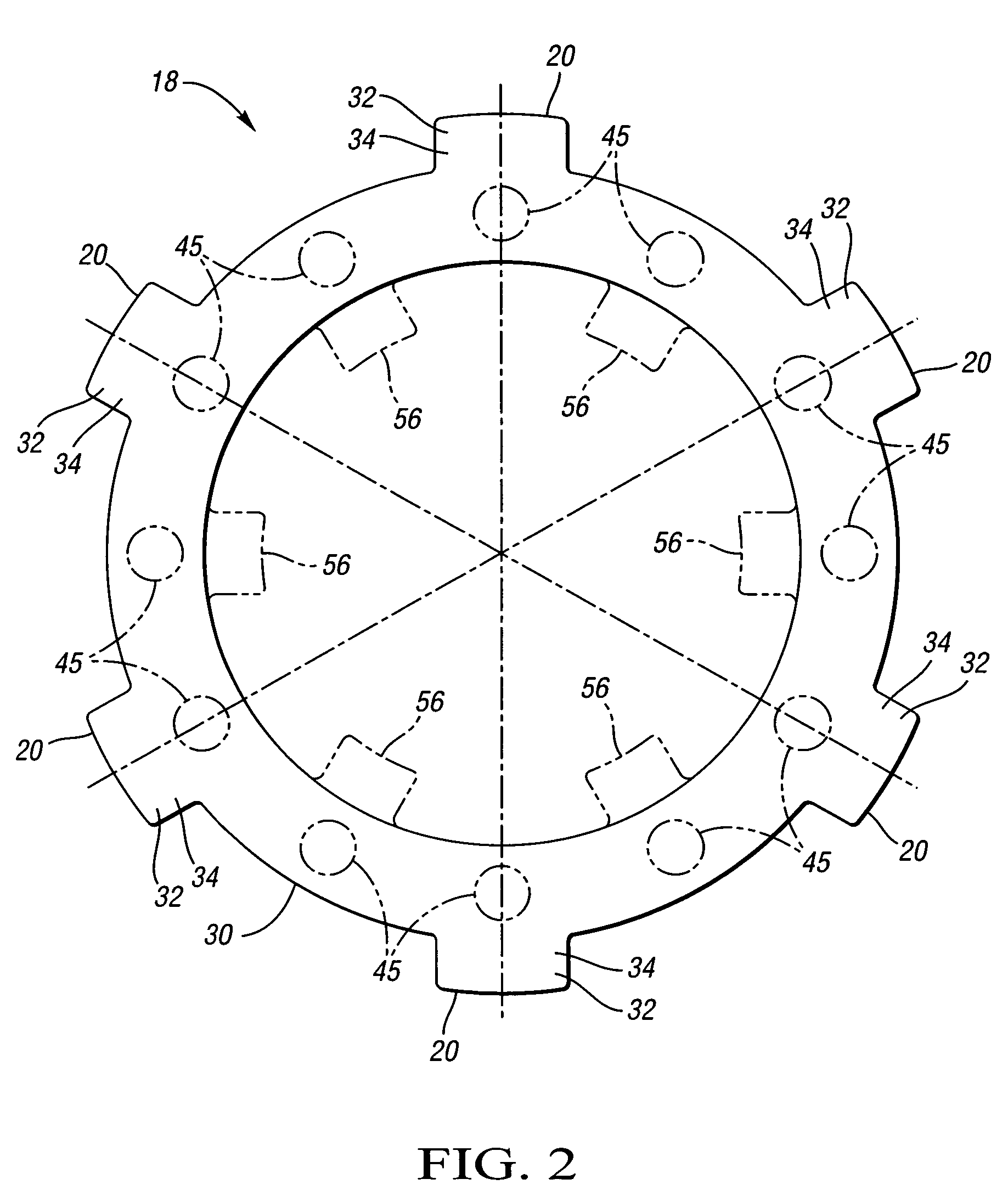

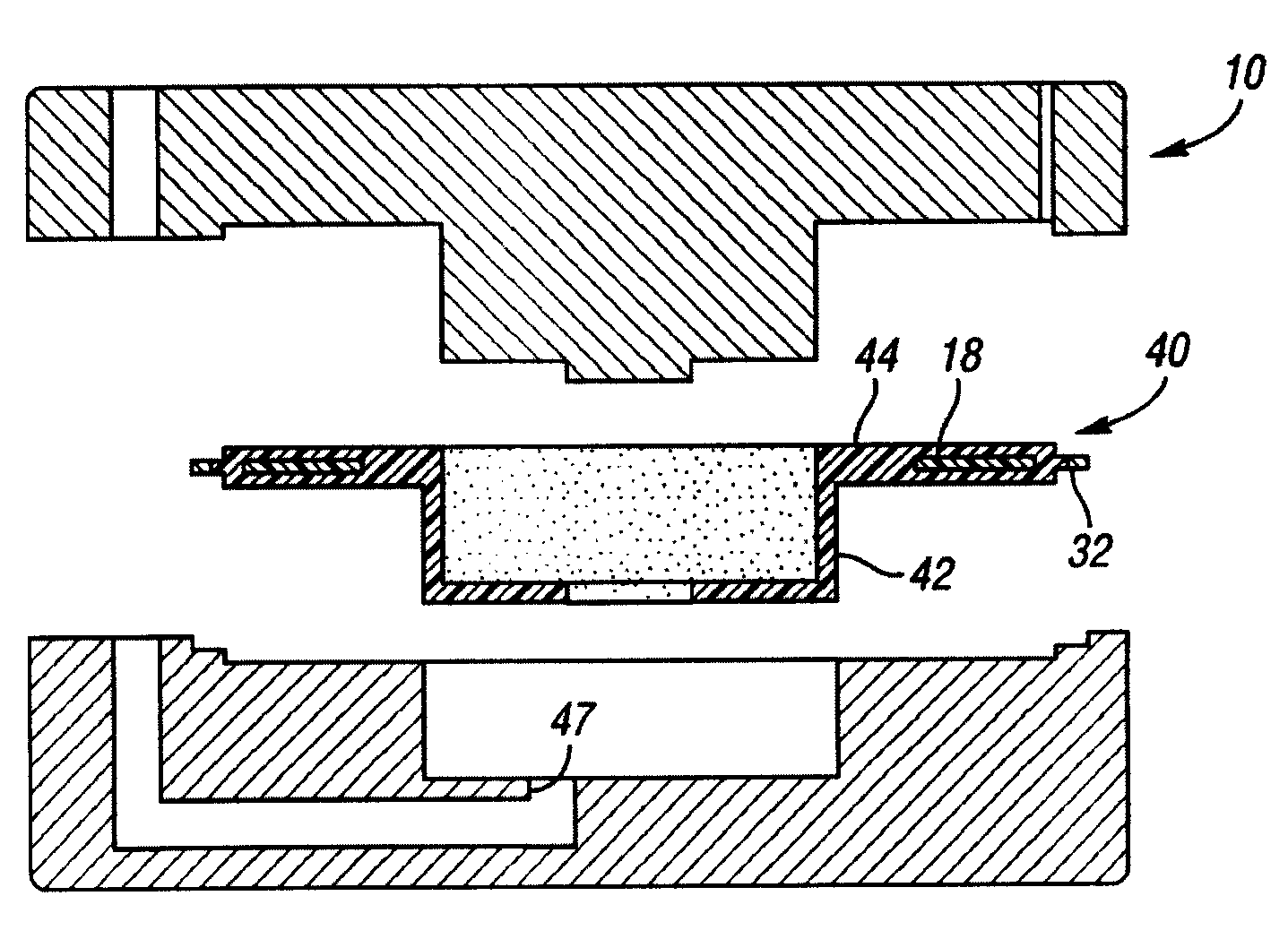

InactiveUS20050011628A1Effectively and efficiently constructedDampening structureNoise/vibration controlFoundry mouldsMaterials scienceShock absorber

Owner:FRENI BREMBO SPA

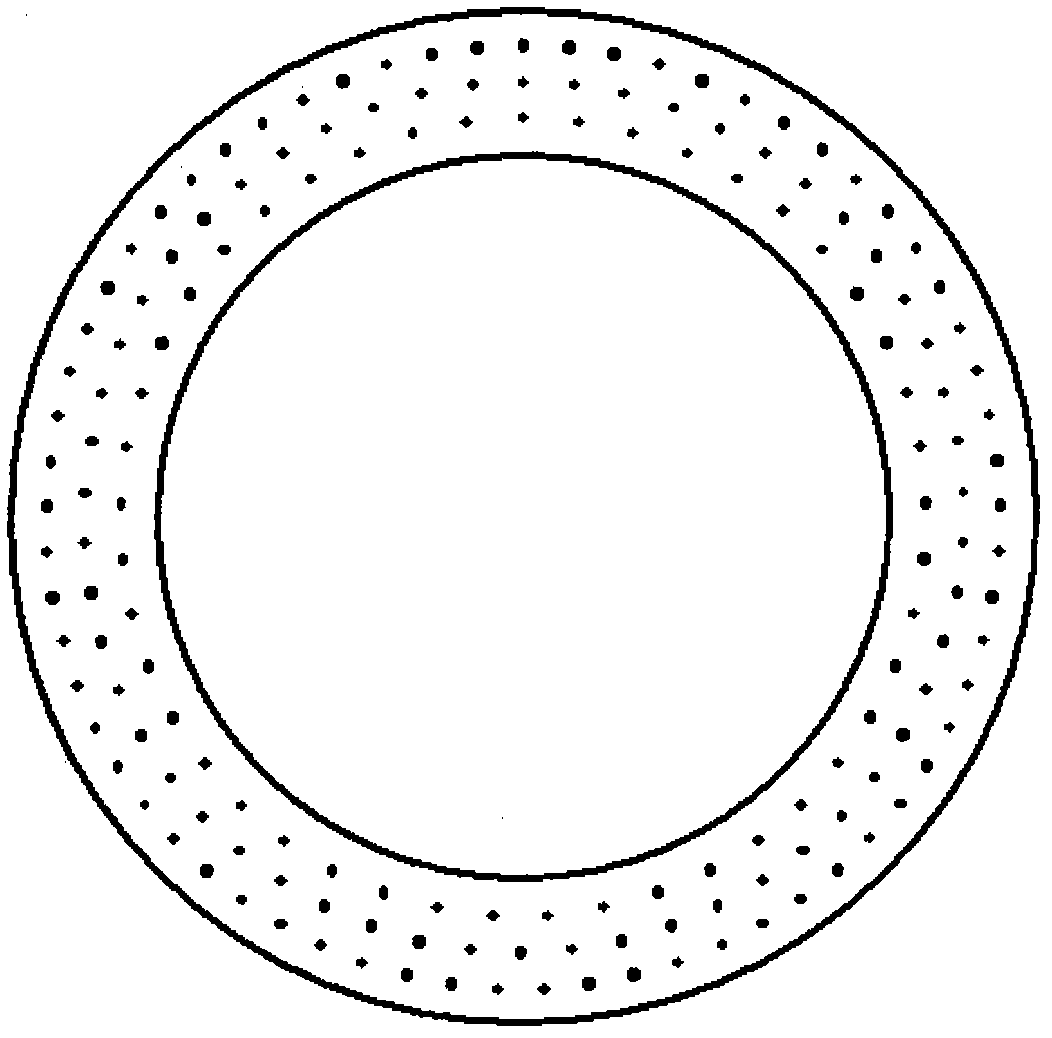

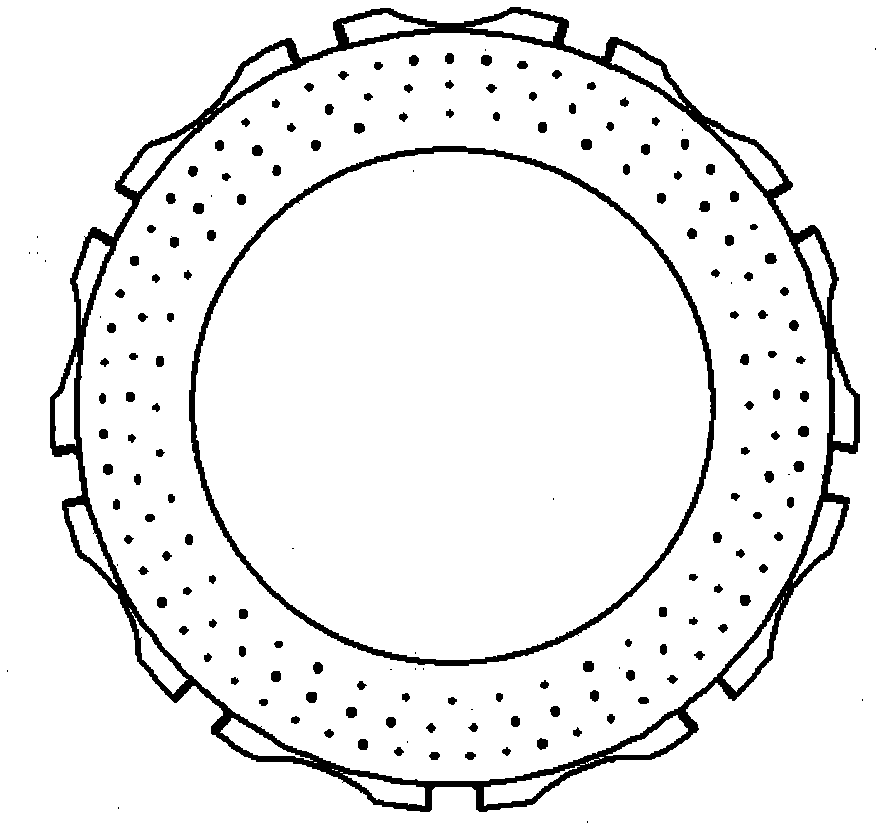

Brake rotor with ceramic matrix composite friction surface plates

The disclosure relates to structures and a method for providing an air cooled rotor with ceramic-metal composite friction surface plates, and in particular to a brake rotor including a rotor hat; a ventilation disc having a plurality of cooling vanes extending therefrom; a ceramic matrix composite (CMC) friction surface plate on each side of the ventilation disc; and a fastener for holding the CMC friction surface plates and the ventilation disc to the rotor hat.

Owner:STARFIRE SYST

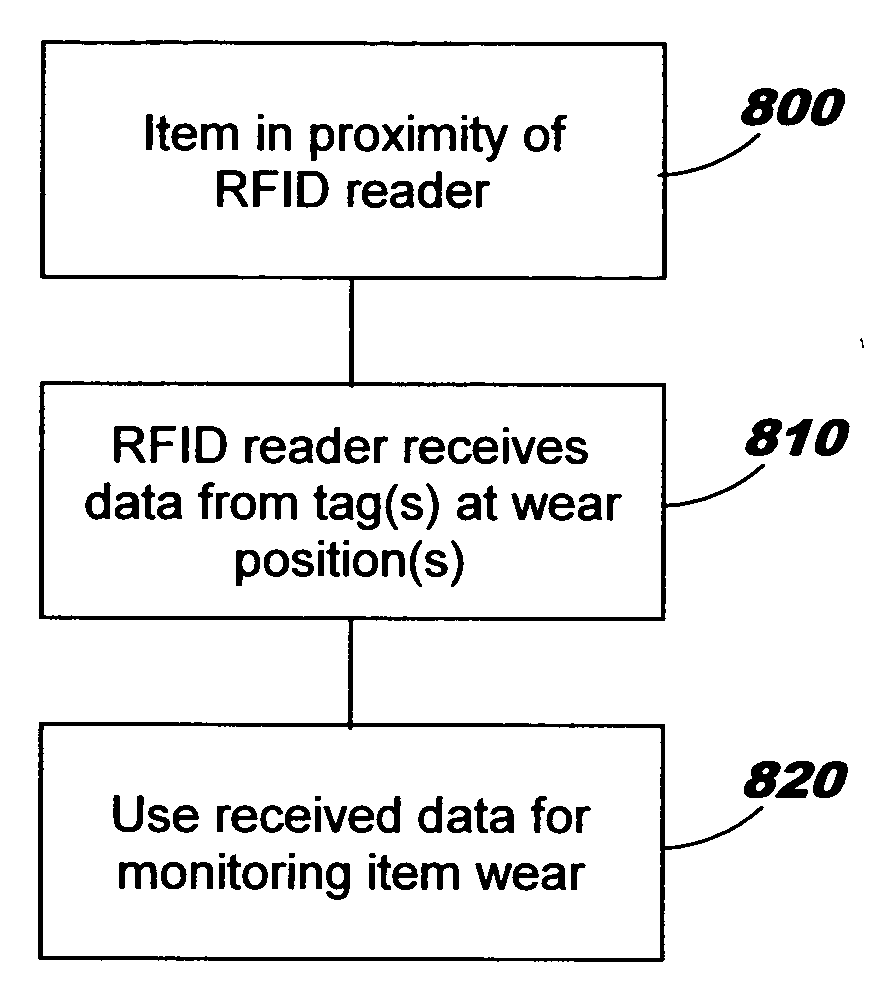

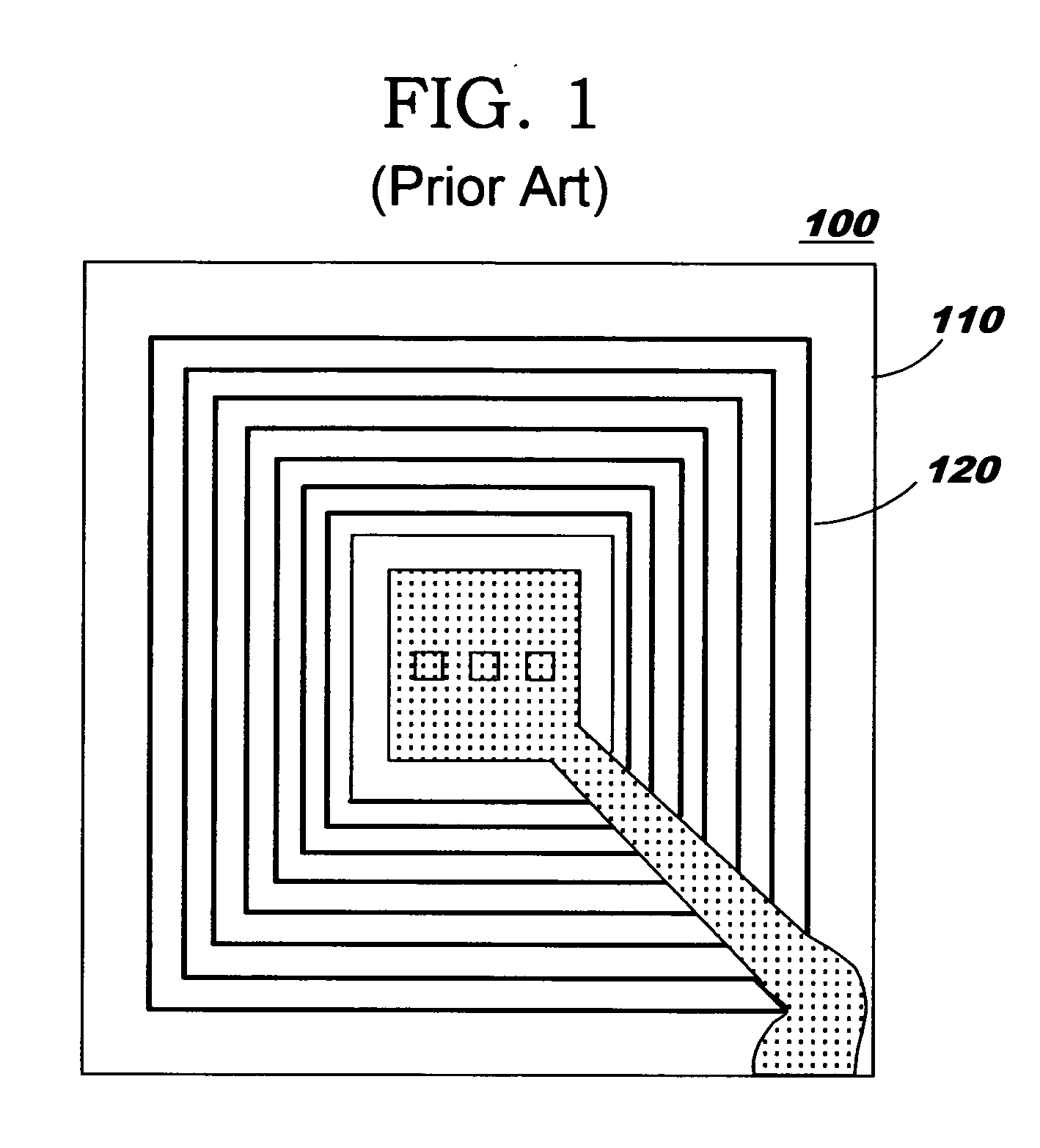

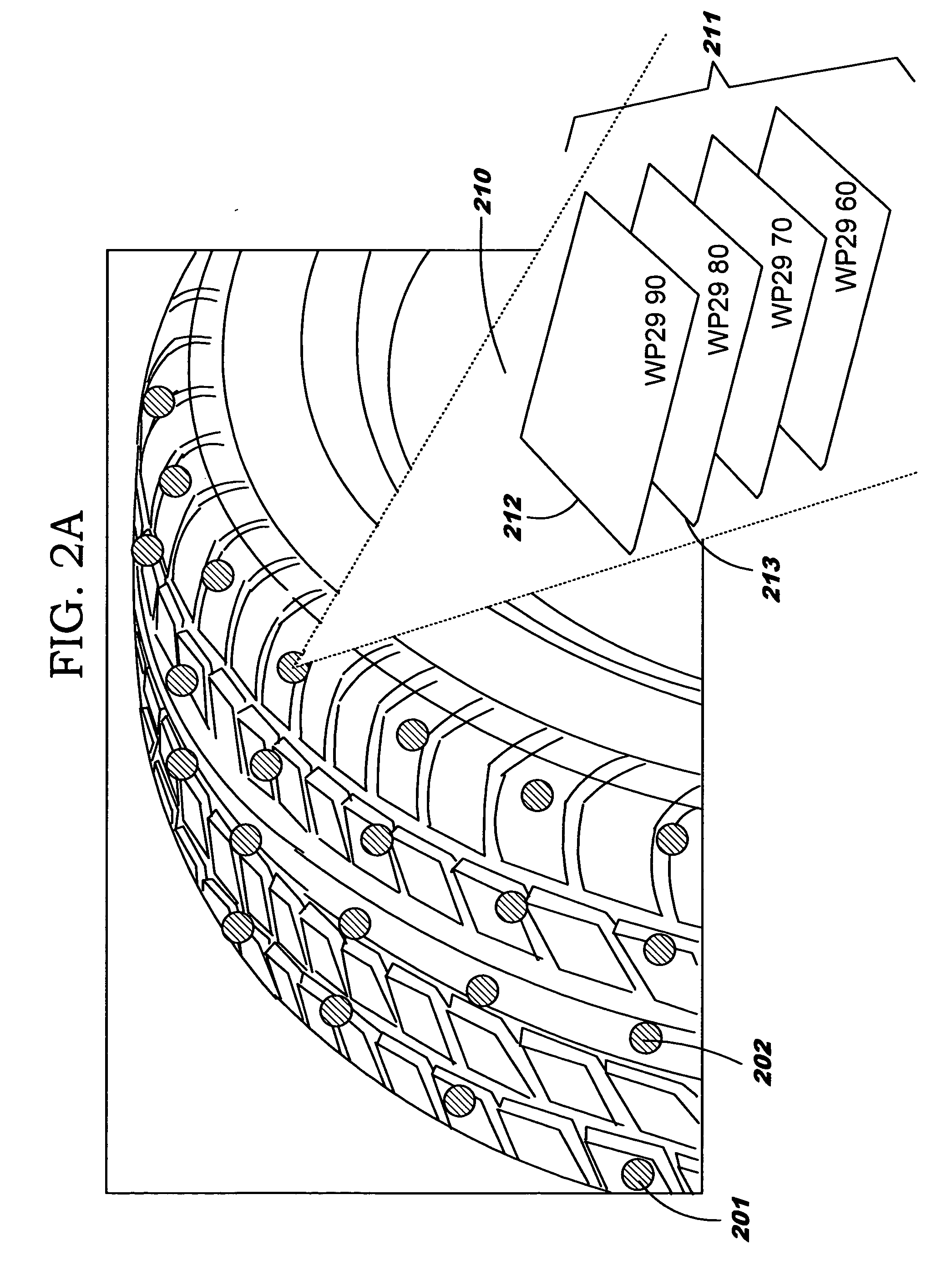

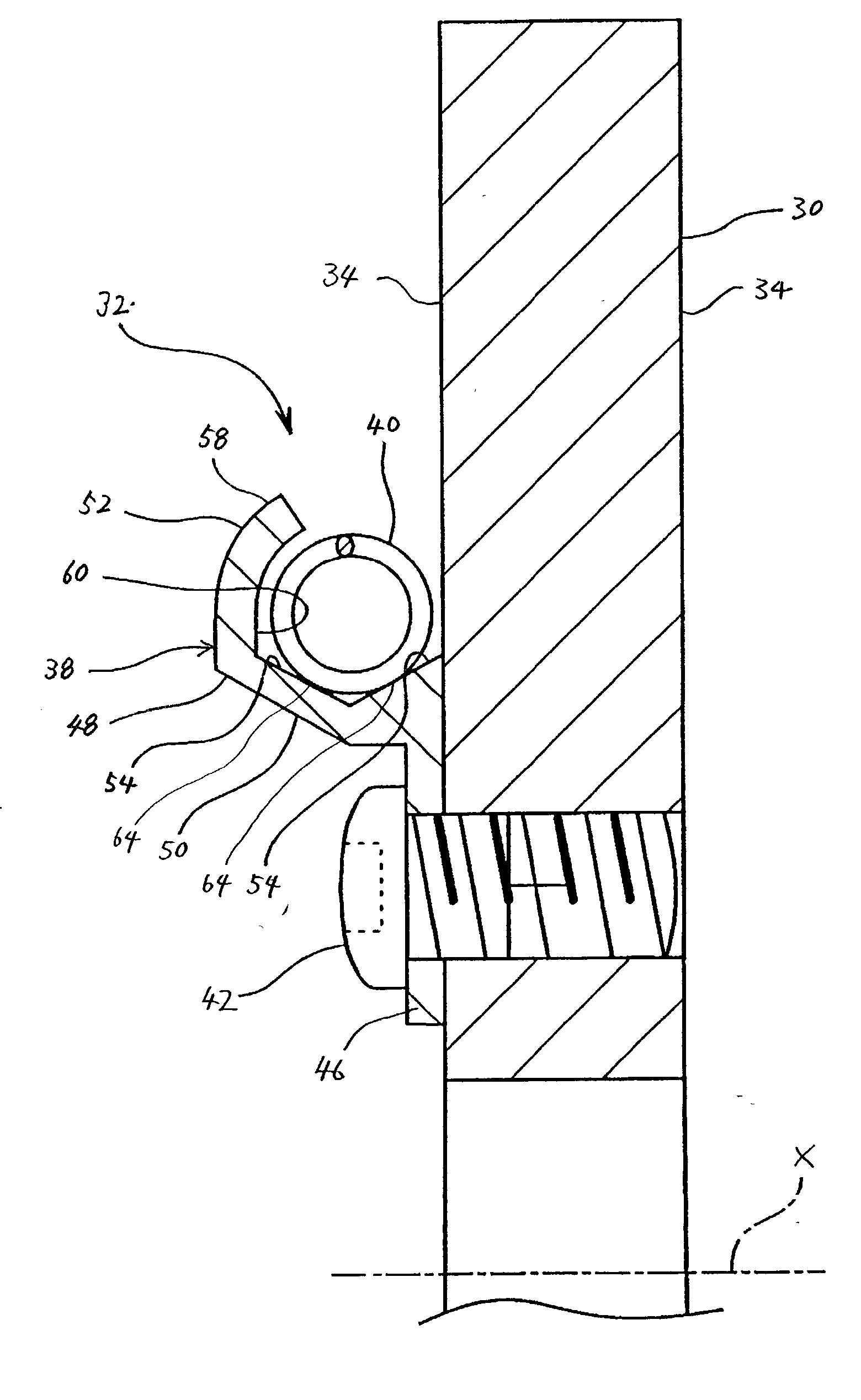

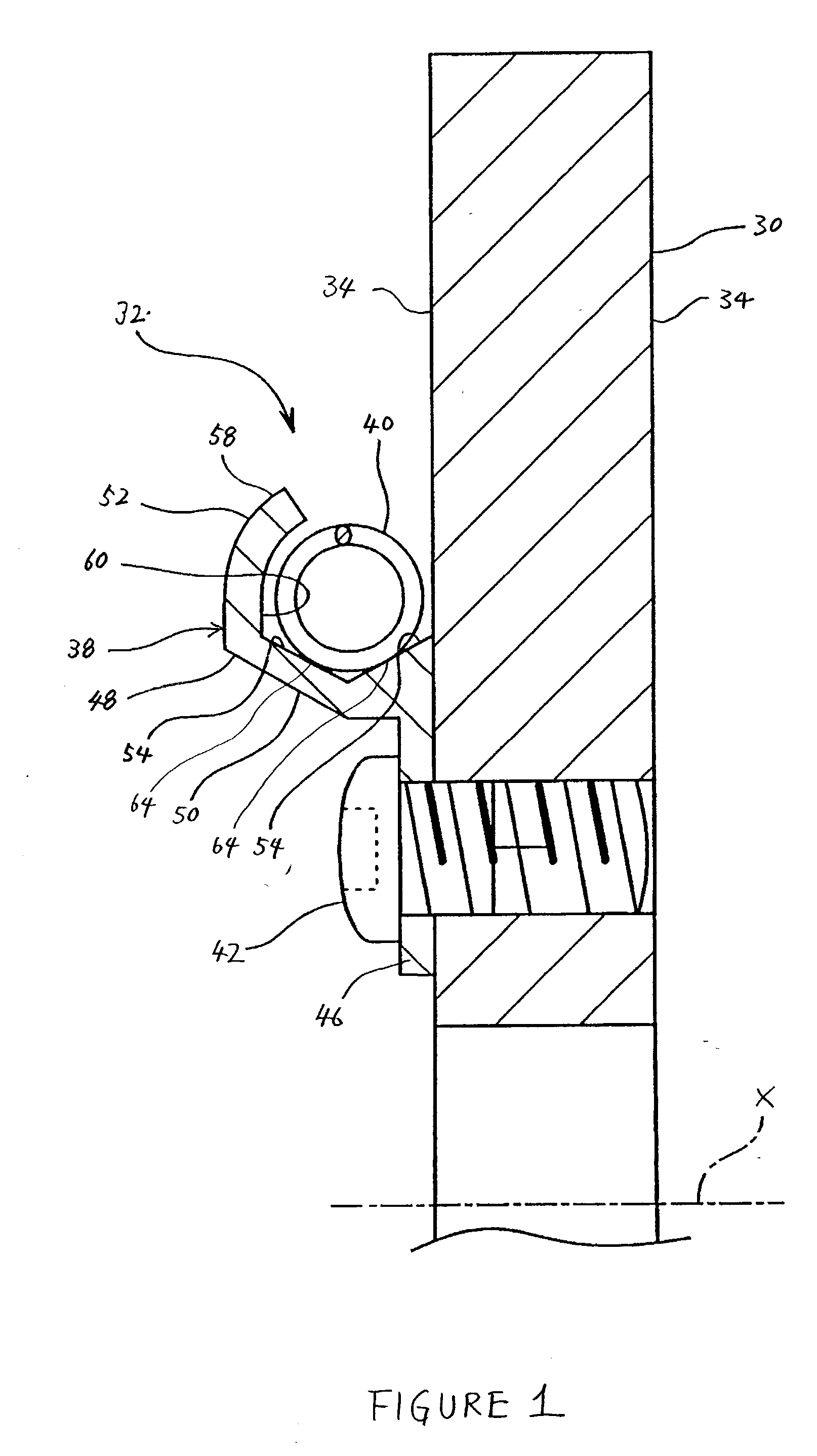

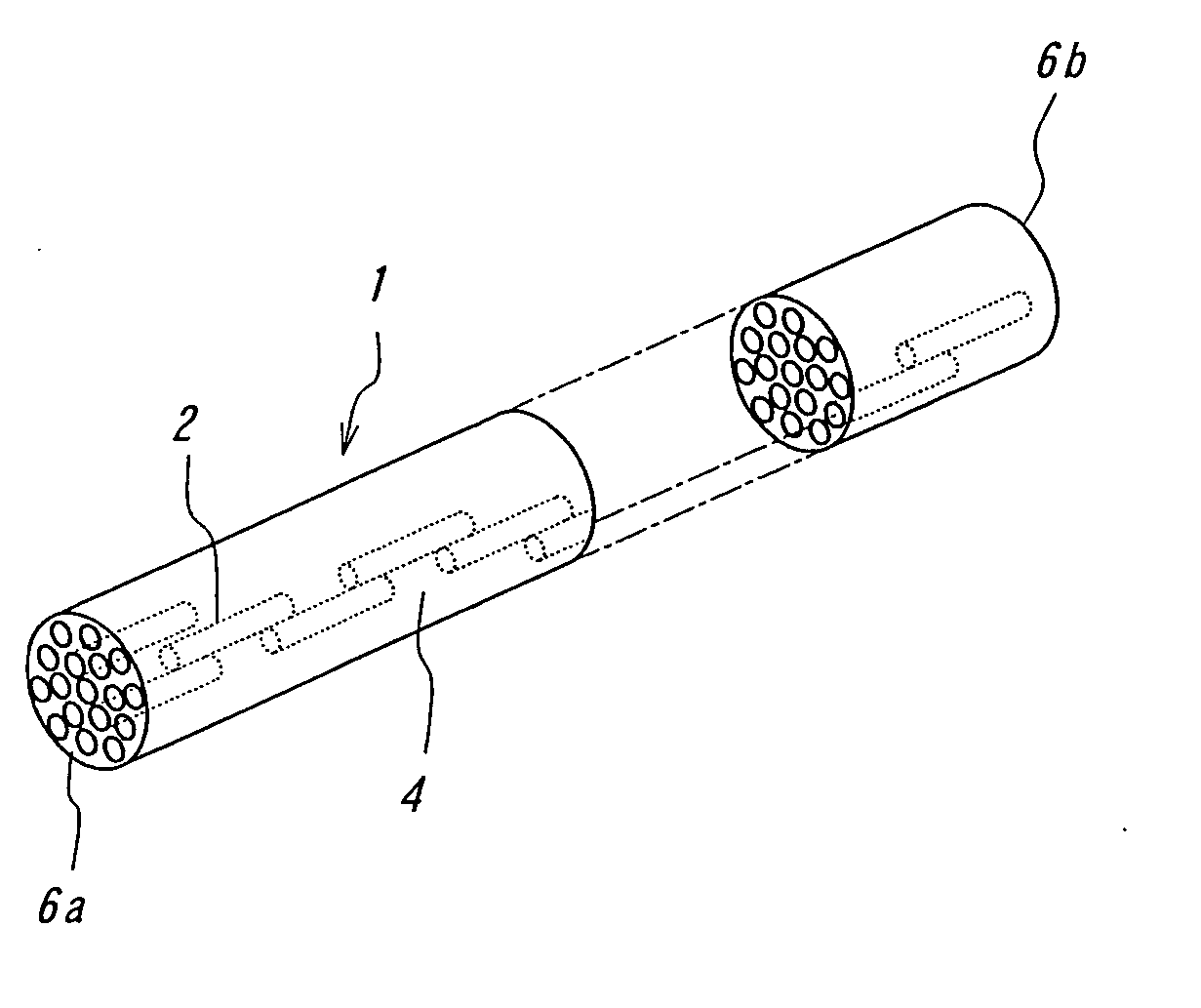

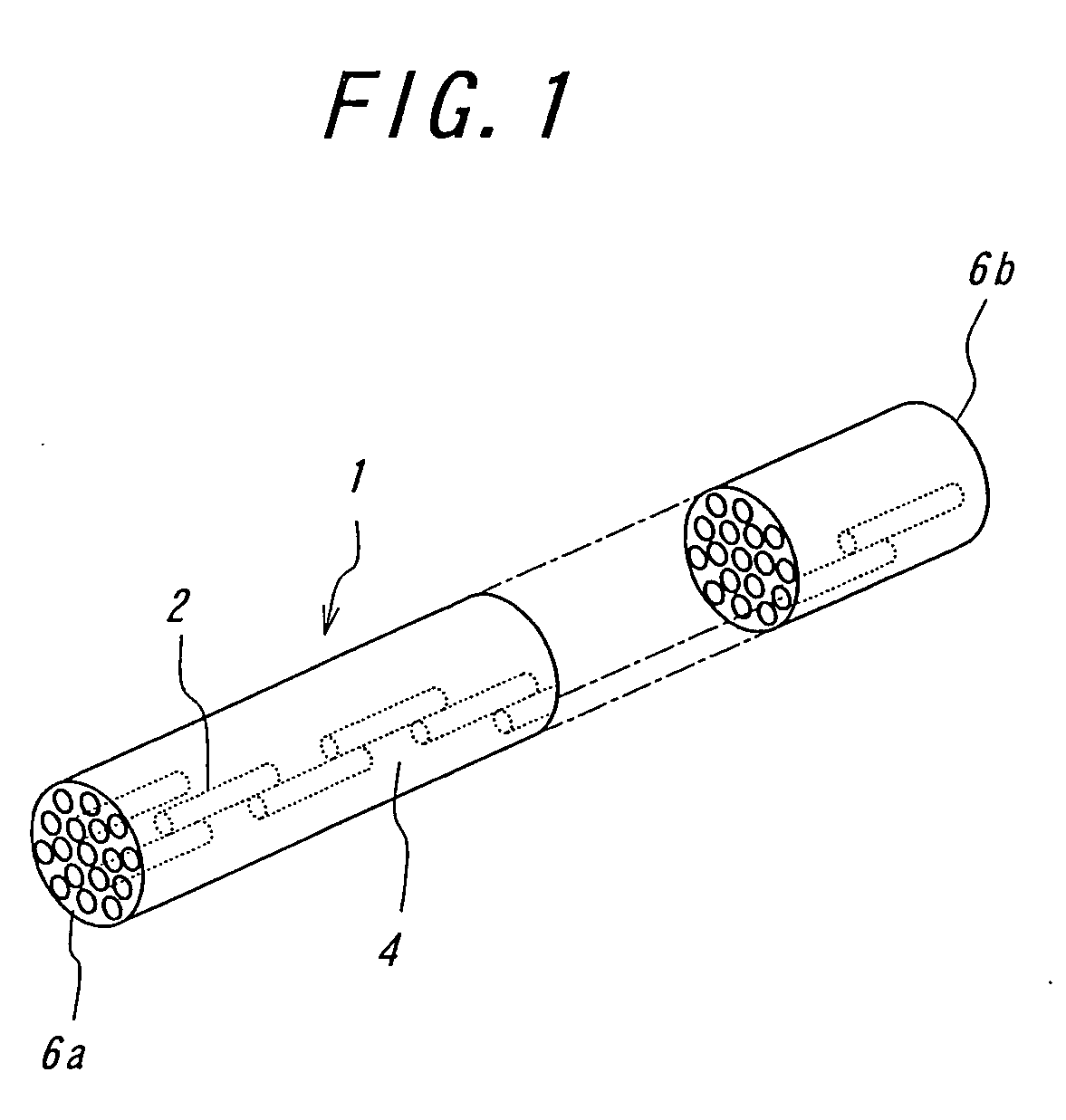

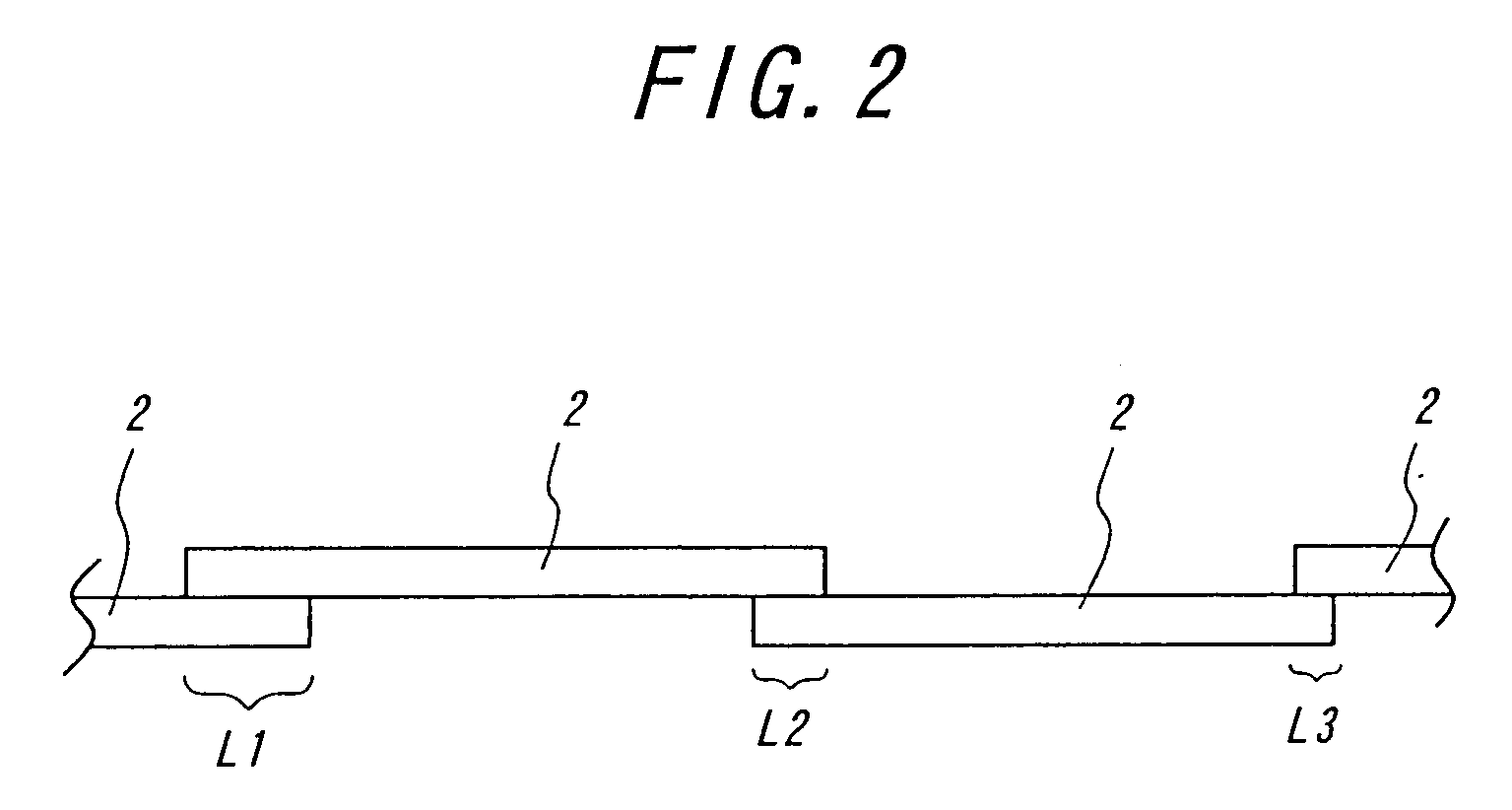

Detecting wear through use of information-transmitting devices

InactiveUS20060273148A1Digital data processing detailsBraking discsEngineeringTransmission equipment

Detecting wear through use of information-transmitting devices. At least one information-transmitting wireless device is provided for each of one or more wear positions of an item, wherein each of the devices is adapted for transmitting information to a reader, such that each of the devices can transmit information usable for detecting wear of the item as the item wears. When using a plurality of devices for a particular wear position, the devices may be stacked or placed in a depth-wise, end-to-end arrangement. As another alternative, a single device having a plurality of separable areas may be provided for each of one or more wear positions. As yet another alternative, a single device may be provided for each of one or more wear positions such that its failure to transmit indicates wear at the corresponding wear position. An information-transmitting device may become damaged or missing, due to item wear, and an RFID reader may therefore be unable to scan (i.e.., receive data from) the device.

Owner:IBM CORP

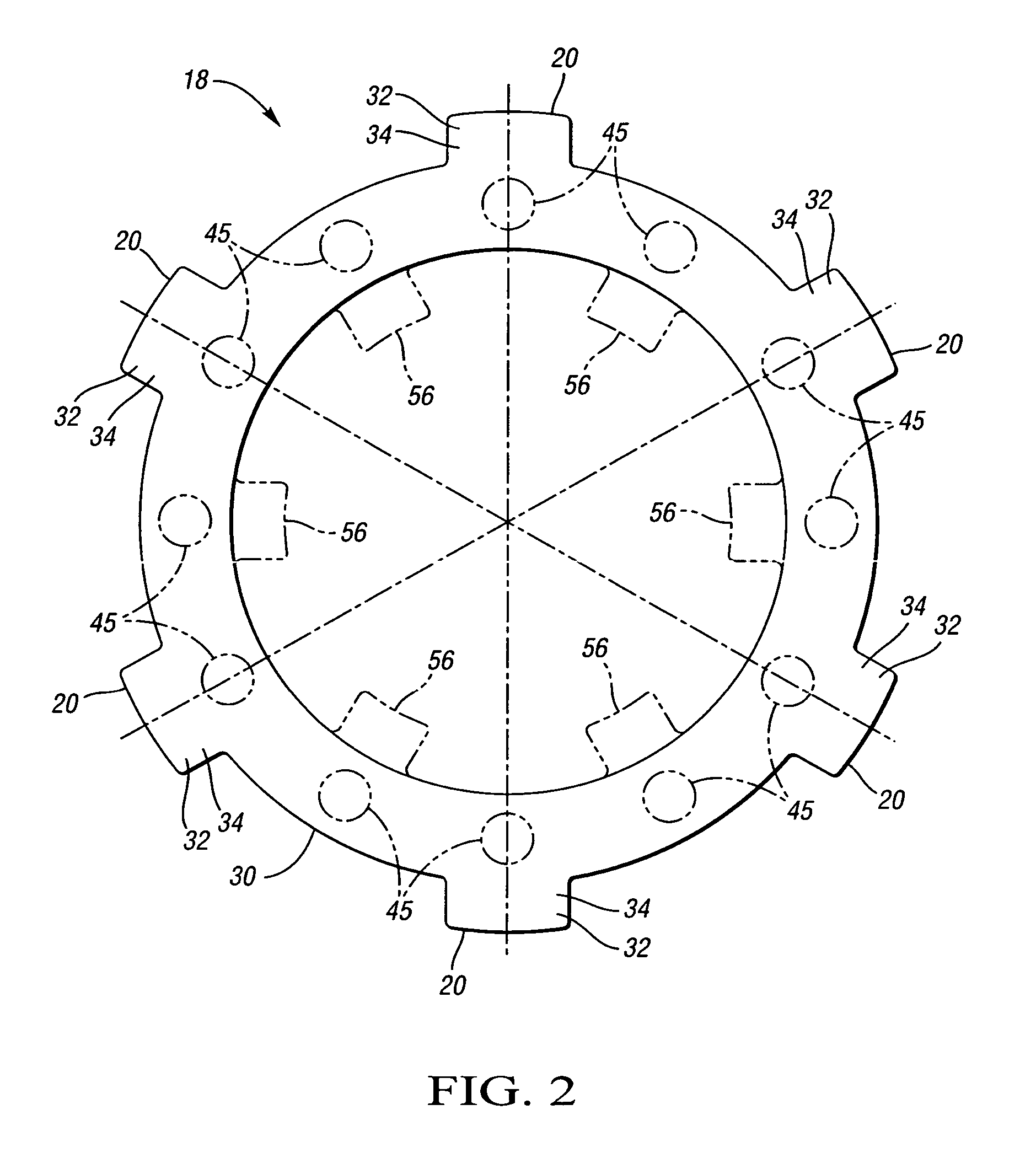

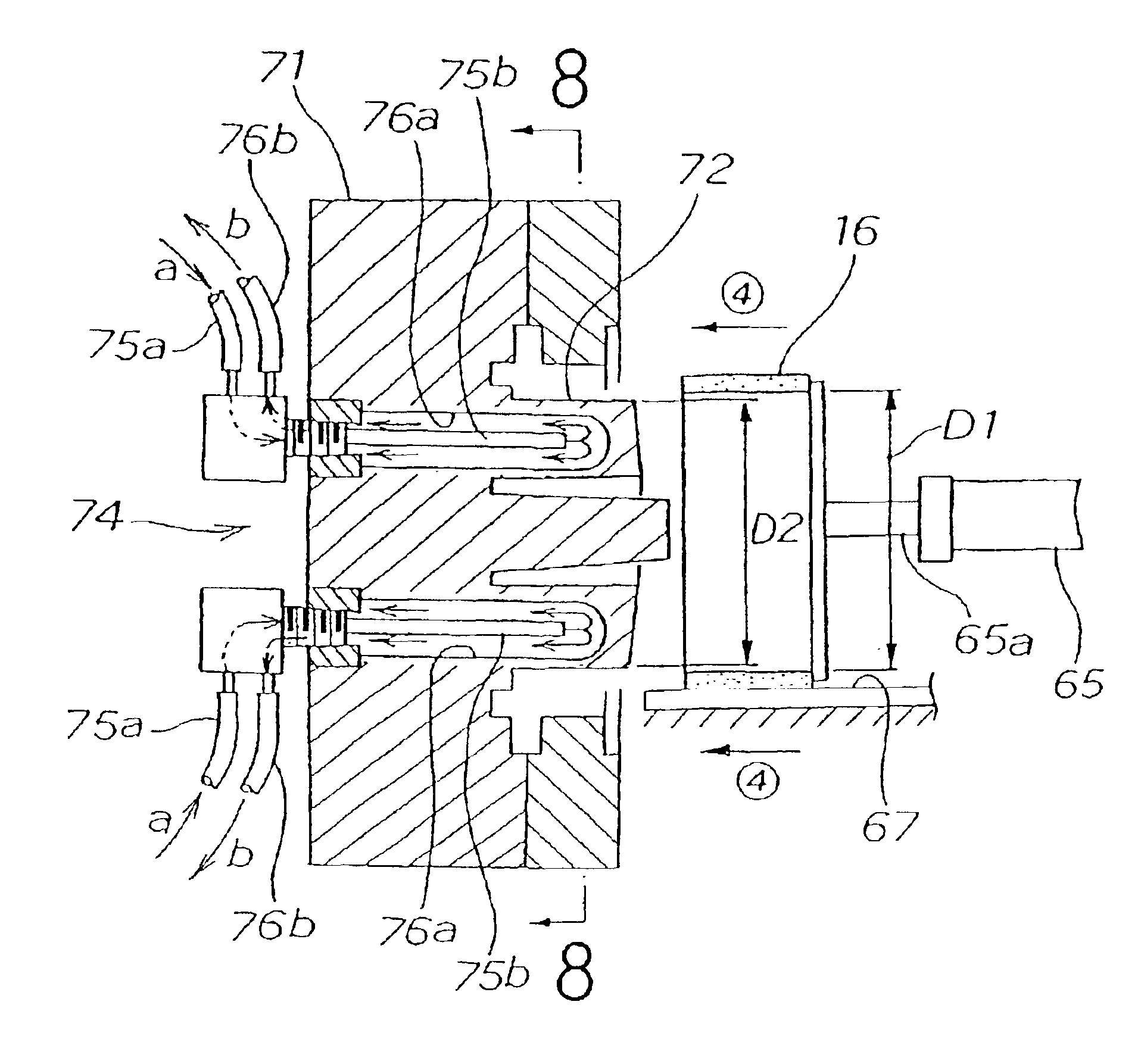

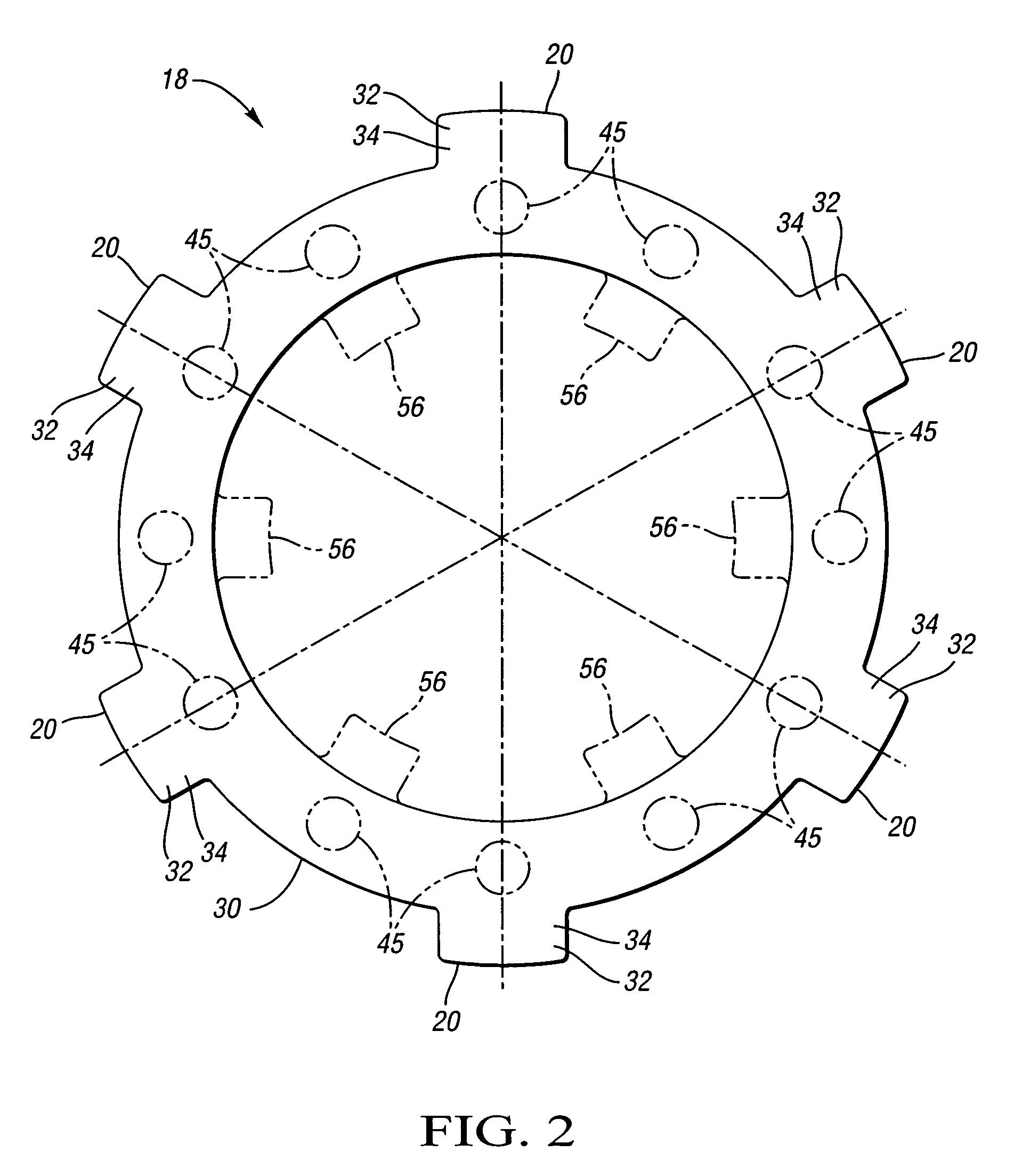

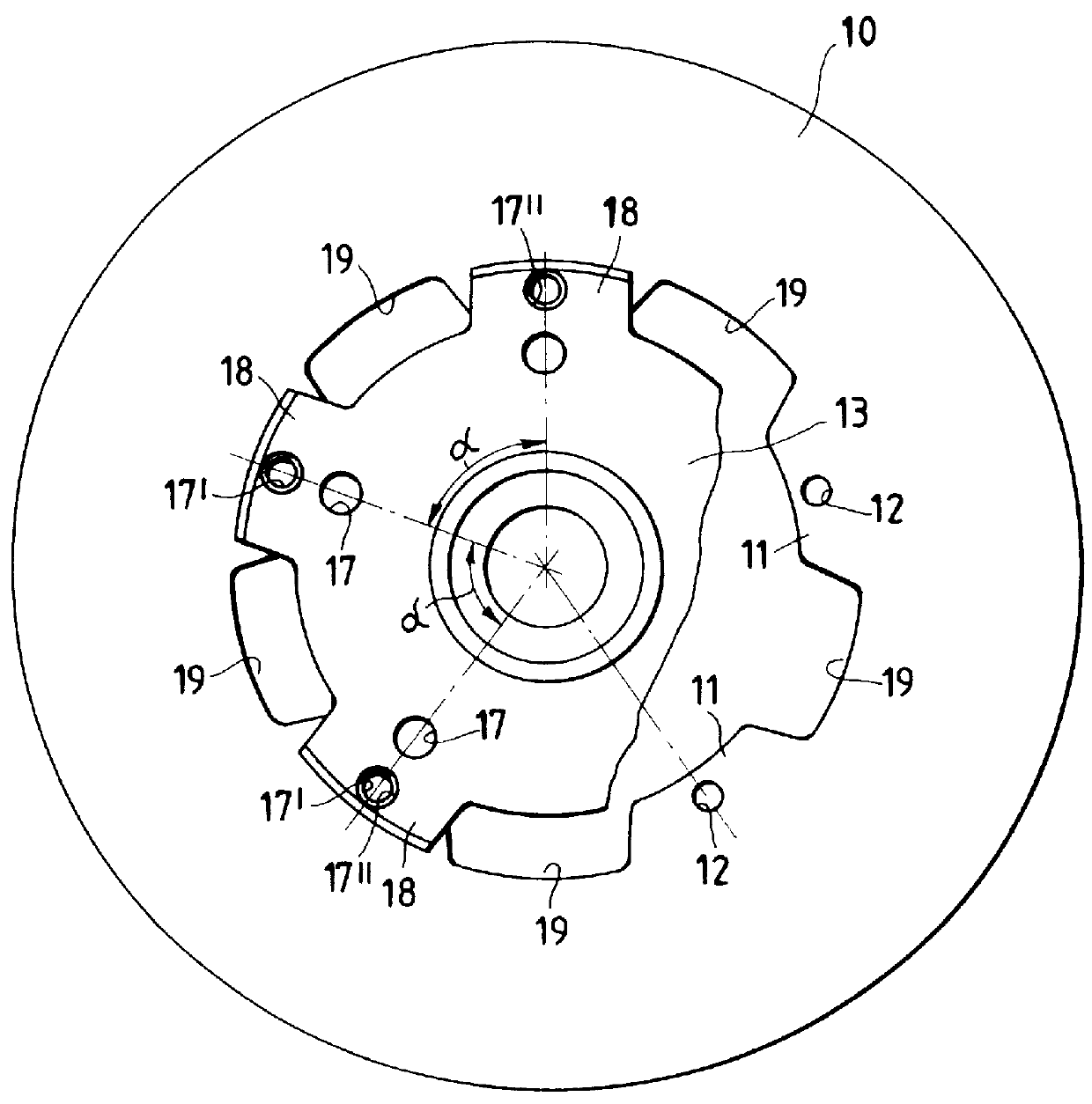

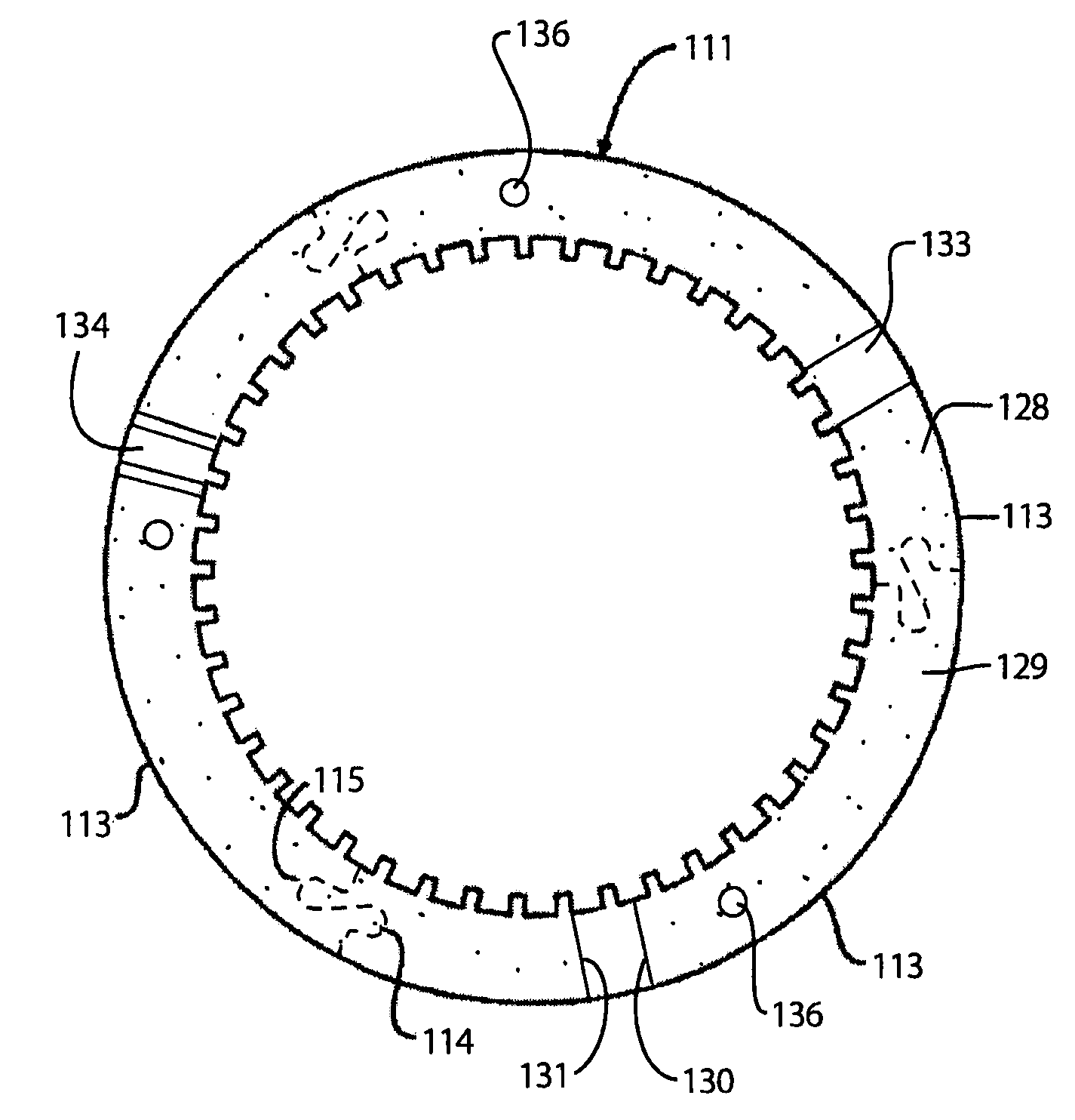

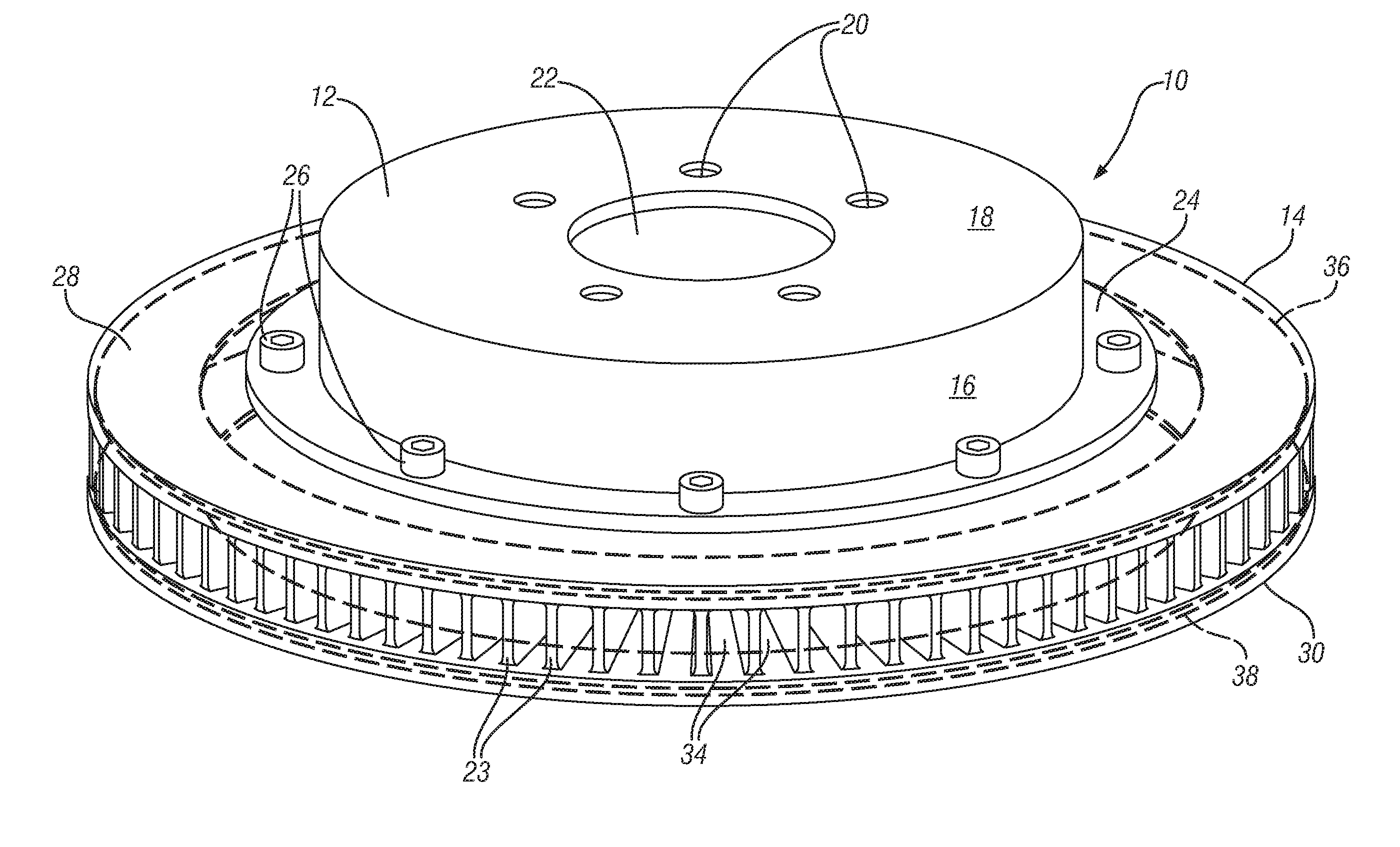

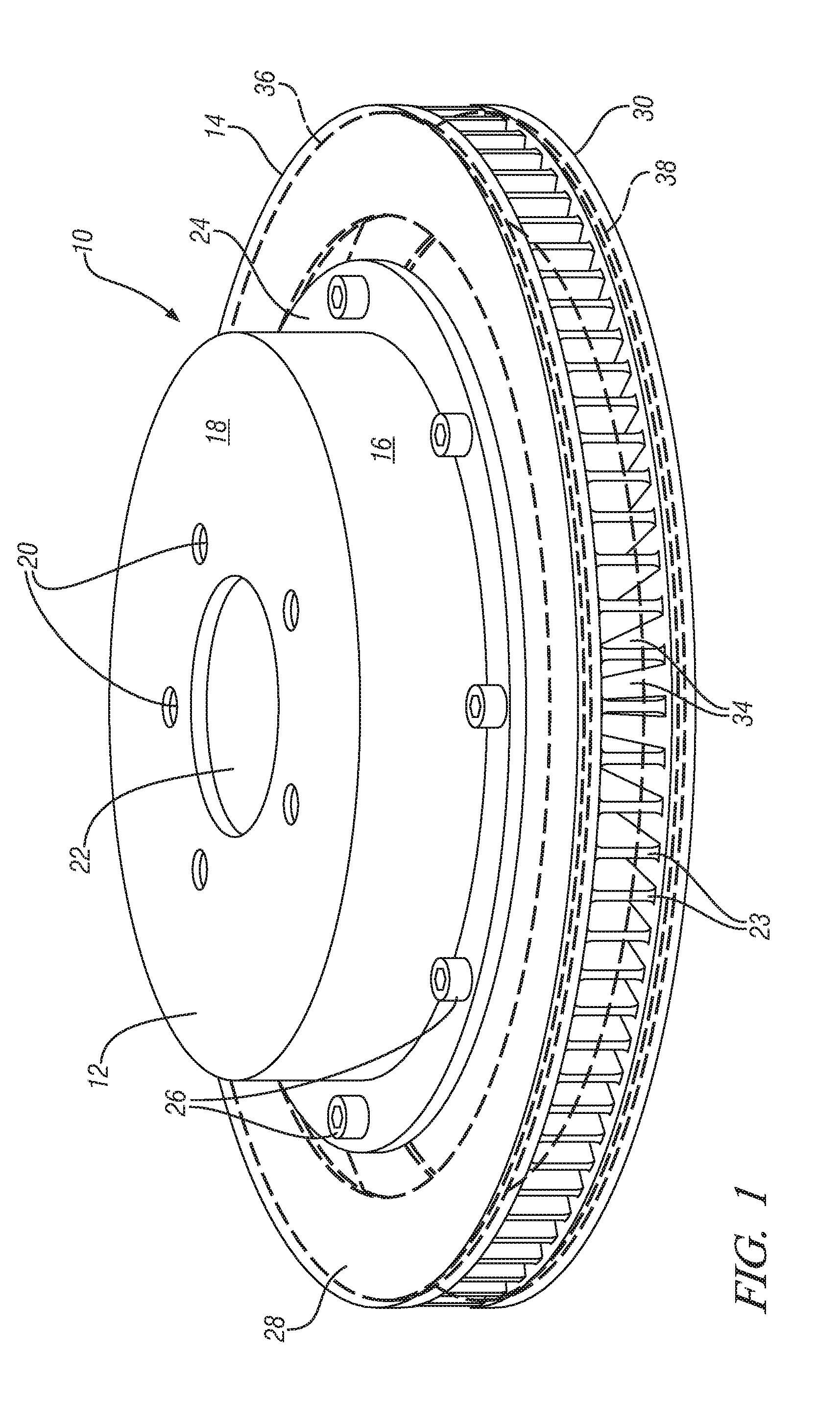

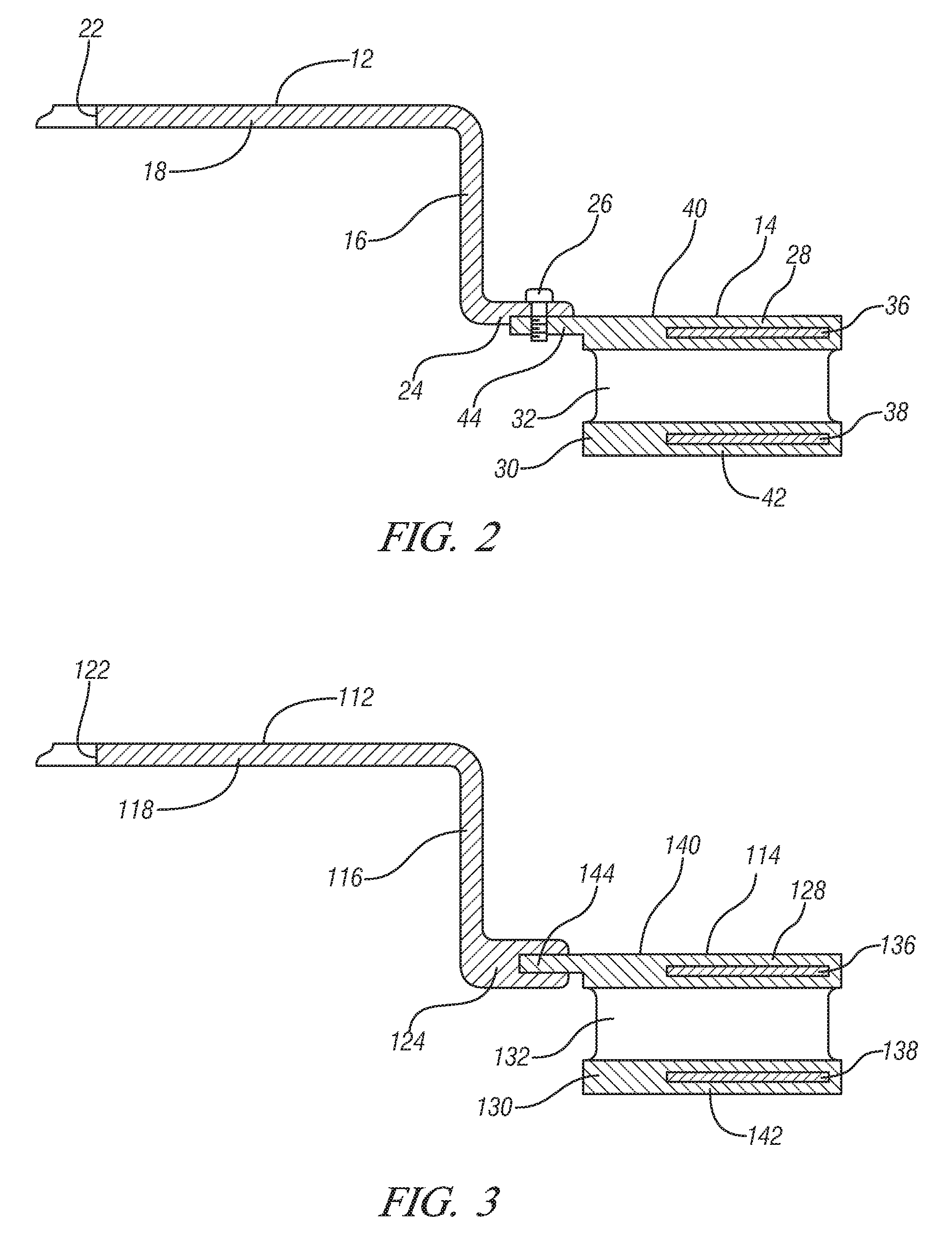

Brake rotor and abs tone ring attachment assembly that promotes in plane uniform torque transfer distribution

A brake assembly for use on vehicles includes a rotor having connection tabs and a hub having bobbins, integrally formed or separate, with the rotor connection tabs being positioned between the hub bobbins and clamped together with a top plate. An ABS tone ring is fastened to the hub and is circumscribed by the rotor. Alternatively, an ABS tone ring can be formed as part of the top plate. A spring clip can be used with the top plate to accommodate thermal expansion of the rotor and eliminate rotor rattling. Torque is transferred from the brake rotor to the hub in a common plane to prevent twisting in the fastener connection.

Owner:PERFORMANCE FRICTION

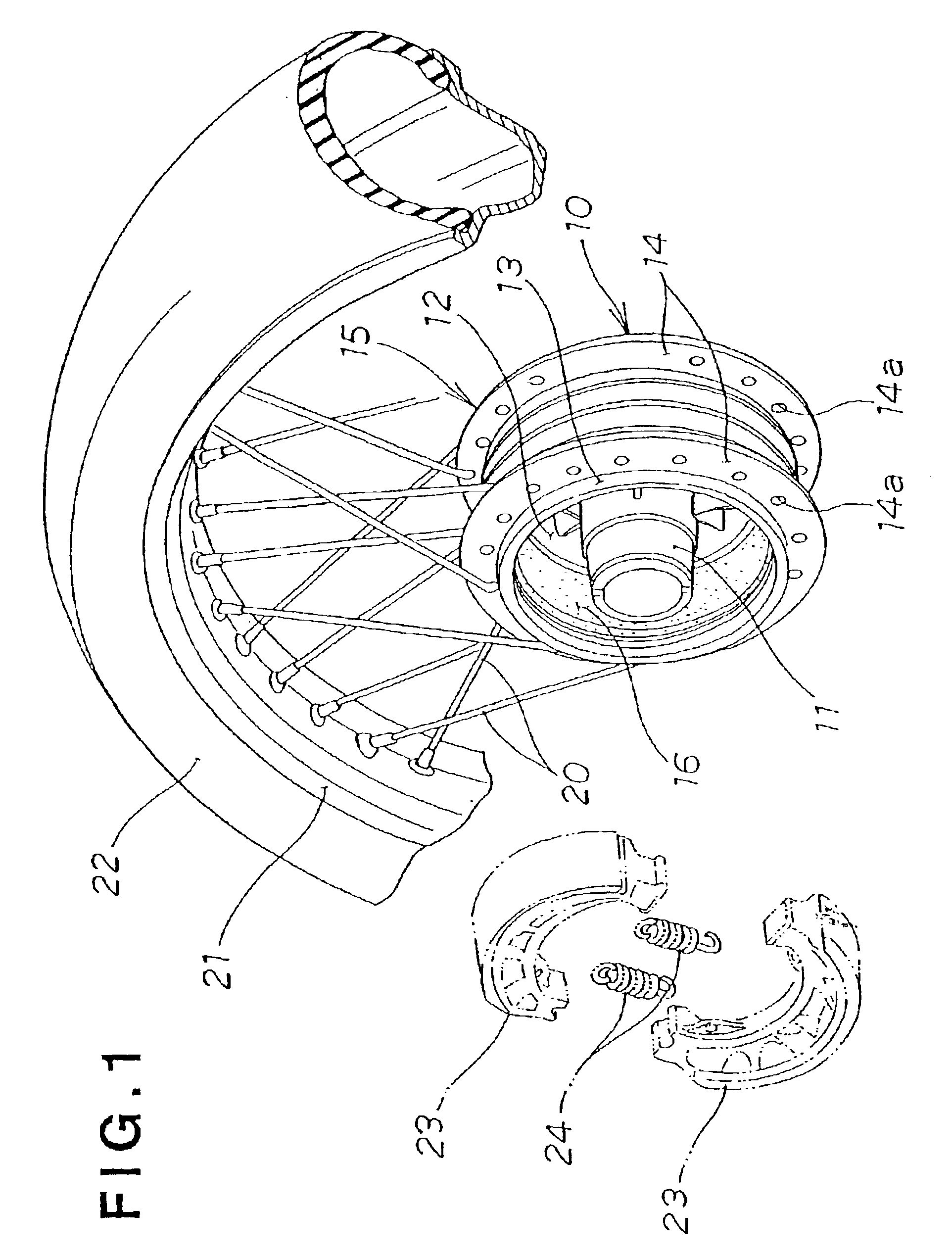

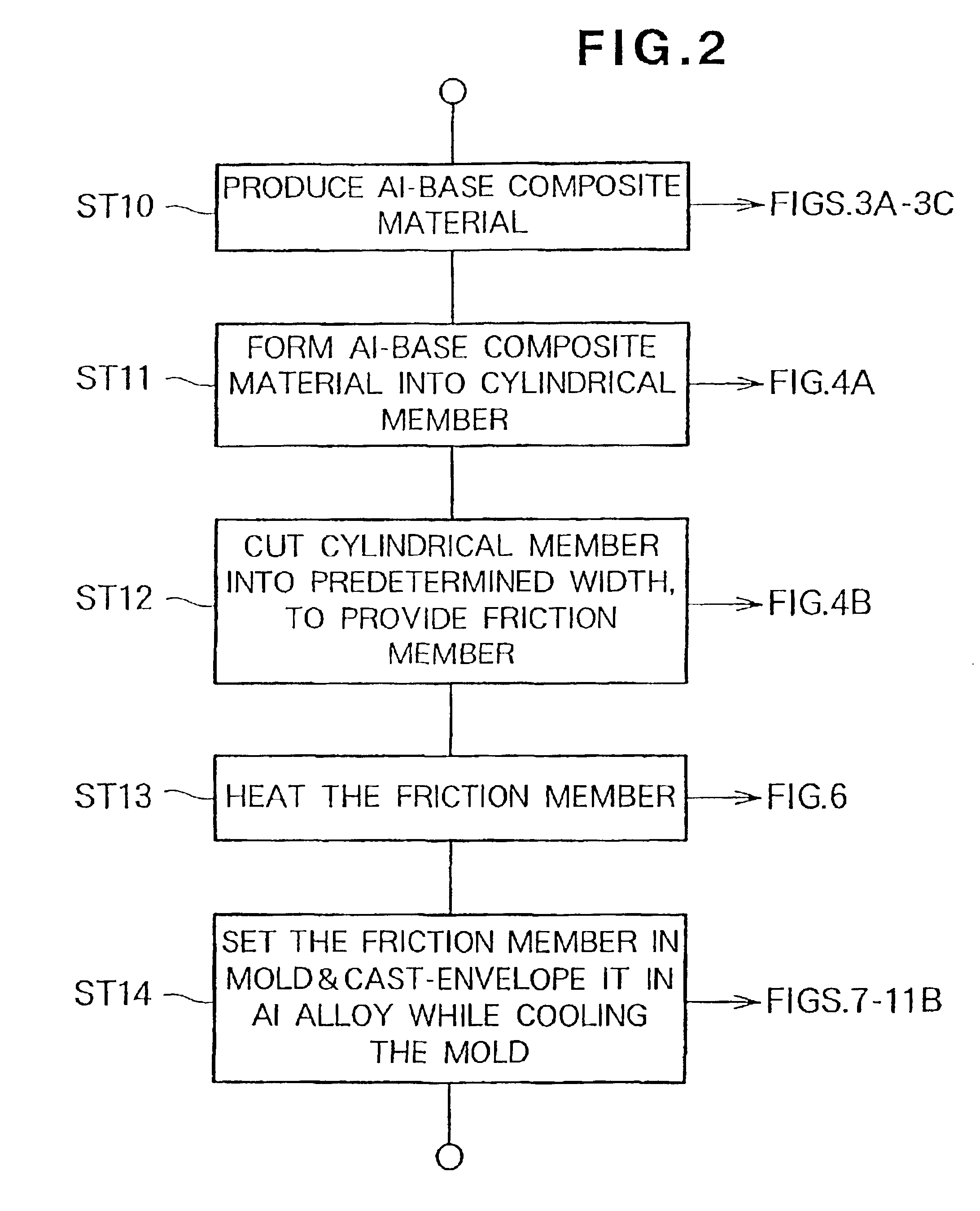

Brake drum and method for producing the same

Owner:HONDA MOTOR CO LTD

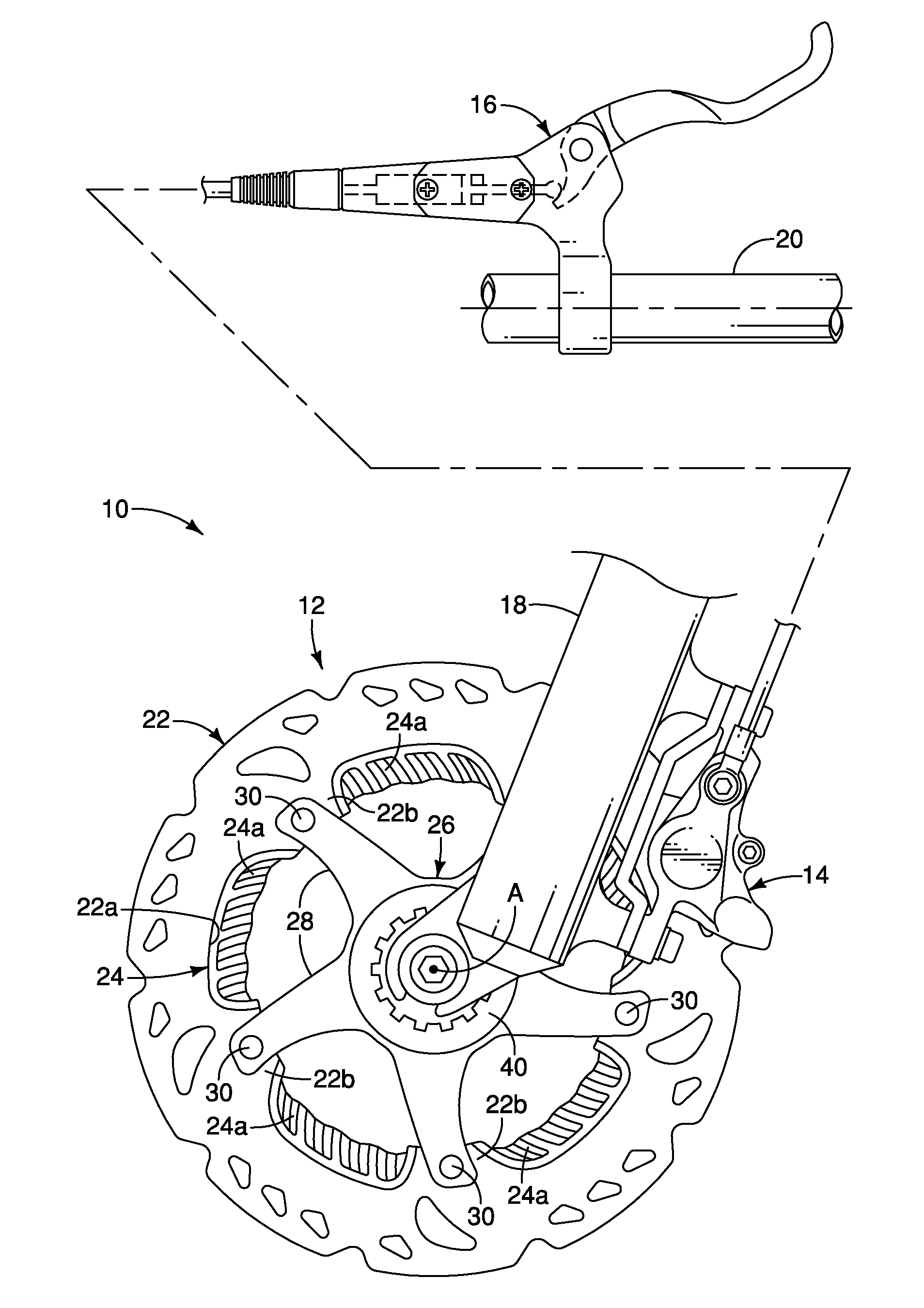

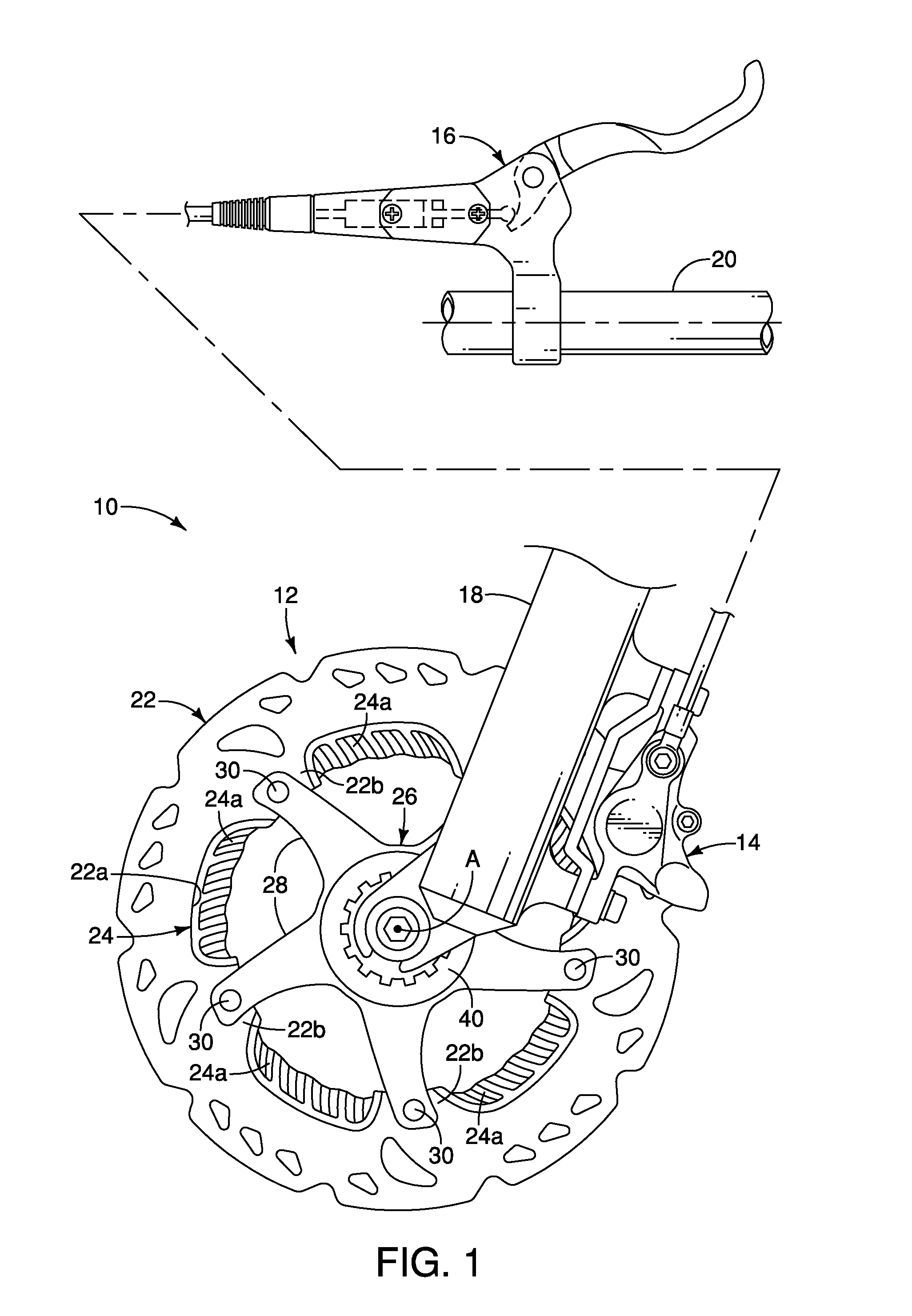

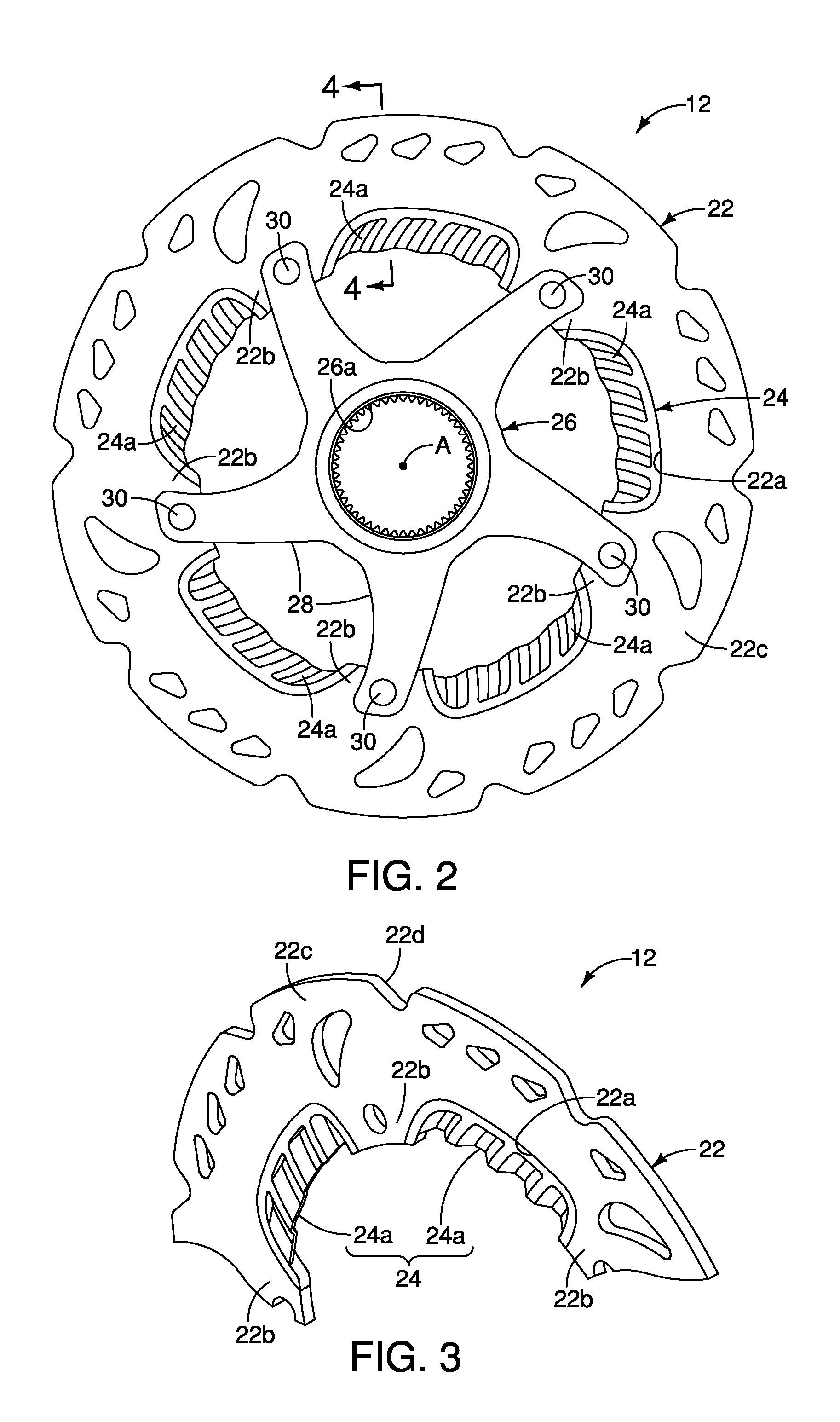

Bicycle disc brake rotor

ActiveUS20130168193A1Improve performanceEffective coolingAxially engaging brakesBraking discsEngineeringMechanical engineering

A bicycle disc brake rotor basically has an outer portion and a cooling fin. The outer portion has first and second base surfaces facing in opposite axial directions. The cooling fin is disposed radially offset from at least one of the first and second braking surfaces.

Owner:SHIMANO INC

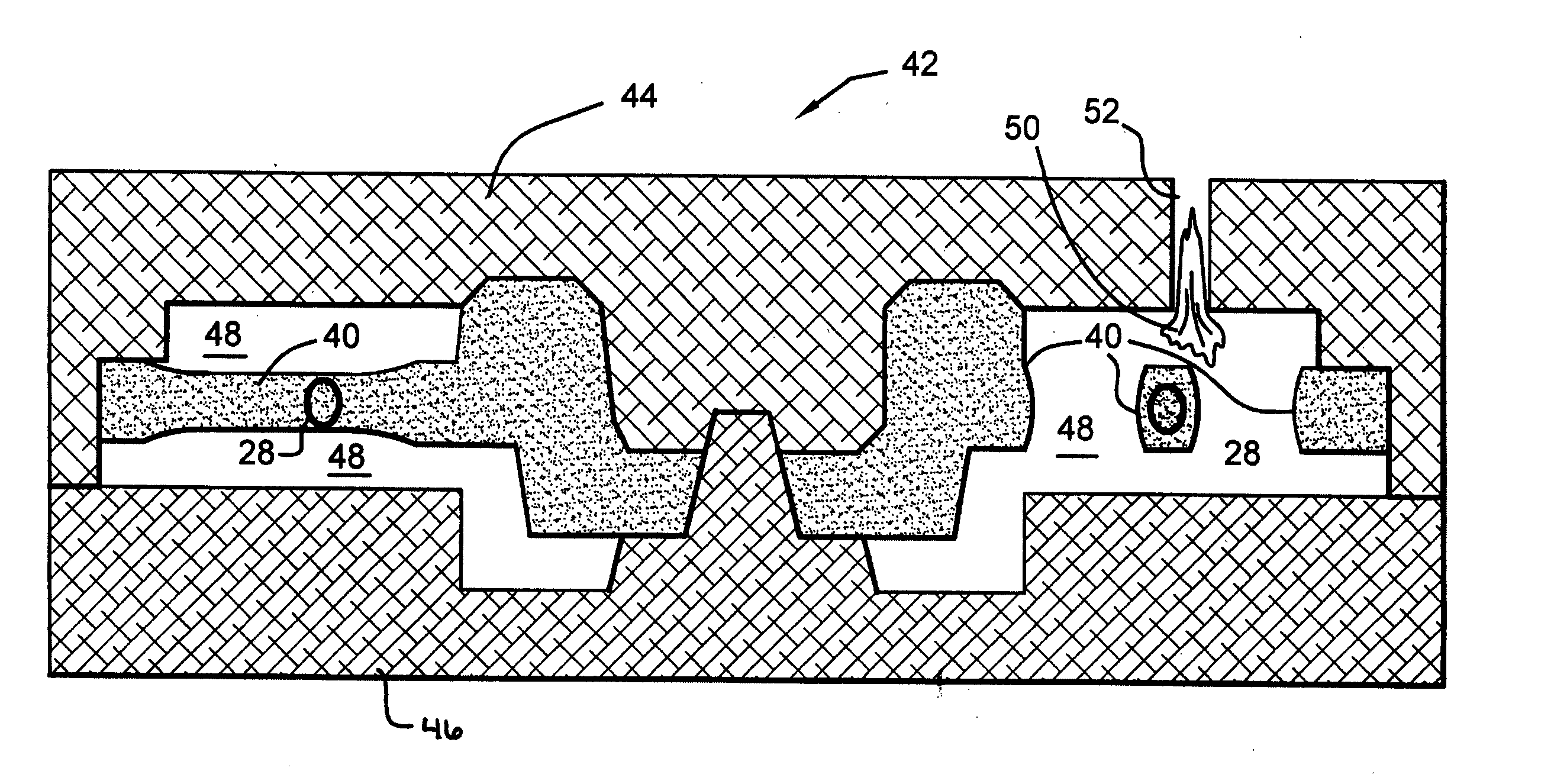

Bi-metal disc brake rotor and method of manufacturing

InactiveUS20070056815A1Avoid problemsImprove bindingMetal rolling stand detailsBraking discsMechanical engineeringMetal

The invention provides a method for manufacturing a friction damped disc brake rotor, including the steps of: (A) positioning at least one insert into a mold, wherein the insert has a body with tabs extending therefrom to hold the insert in a desired position within the mold; and (B) casting a rotor cheek of the disc brake rotor in the mold around the insert such that a portion of each tab is bonded with the rotor cheek and the body is substantially non-bonded with the rotor cheek so that the body provides a proper interfacial boundary with the cheek for damping while the bonding of the tabs with the rotor cheek prevents corrosion-causing exterior elements from reaching the interfacial boundary.

Owner:GM GLOBAL TECH OPERATIONS LLC

Bi-metal disc brake rotor and method of manufacturing

InactiveUS7775332B2Avoid problemsImprove bindingMetal rolling stand detailsBraking discsEngineeringMechanical engineering

The invention provides a method for manufacturing a friction damped disc brake rotor, including the steps of: (A) positioning at least one insert into a mold, wherein the insert has a body with tabs extending therefrom to hold the insert in a desired position within the mold; and (B) casting a rotor cheek of the disc brake rotor in the mold around the insert such that a portion of each tab is bonded with the rotor cheek and the body is substantially non-bonded with the rotor cheek so that the body provides a proper interfacial boundary with the cheek for damping while the bonding of the tabs with the rotor cheek prevents corrosion-causing exterior elements from reaching the interfacial boundary.

Owner:GM GLOBAL TECH OPERATIONS LLC

Coulomb damped disc brake rotor and method of manufacturing

InactiveUS20080099289A1Avoid bondingExternal exposure is reducedNoise/vibration controlBraking discsEngineeringMechanical engineering

The invention provides a method for manufacturing a coulomb damped disc brake rotor, including the steps of: (A) providing a mold having the general shape of the coulomb damped disc brake rotor; (B) placing a coulomb damper insert having a generally annular body and at least one tab extending generally radially from the generally annular body, wherein the at least one tab operates to locate the coulomb damper insert within the mold, and wherein the at least one tab at least partially defines an orifice with its major axis generally coincident with the periphery of the coulomb damped disc brake rotor; and (C) causing casting material to enter the mold to substantially encapsulate the coulomb damper insert with the casting material to form a rotor cheek of the coulomb damped disc brake rotor. A coulomb damper insert and coulomb damped disc brake rotor are also disclosed.

Owner:GM GLOBAL TECH OPERATIONS LLC

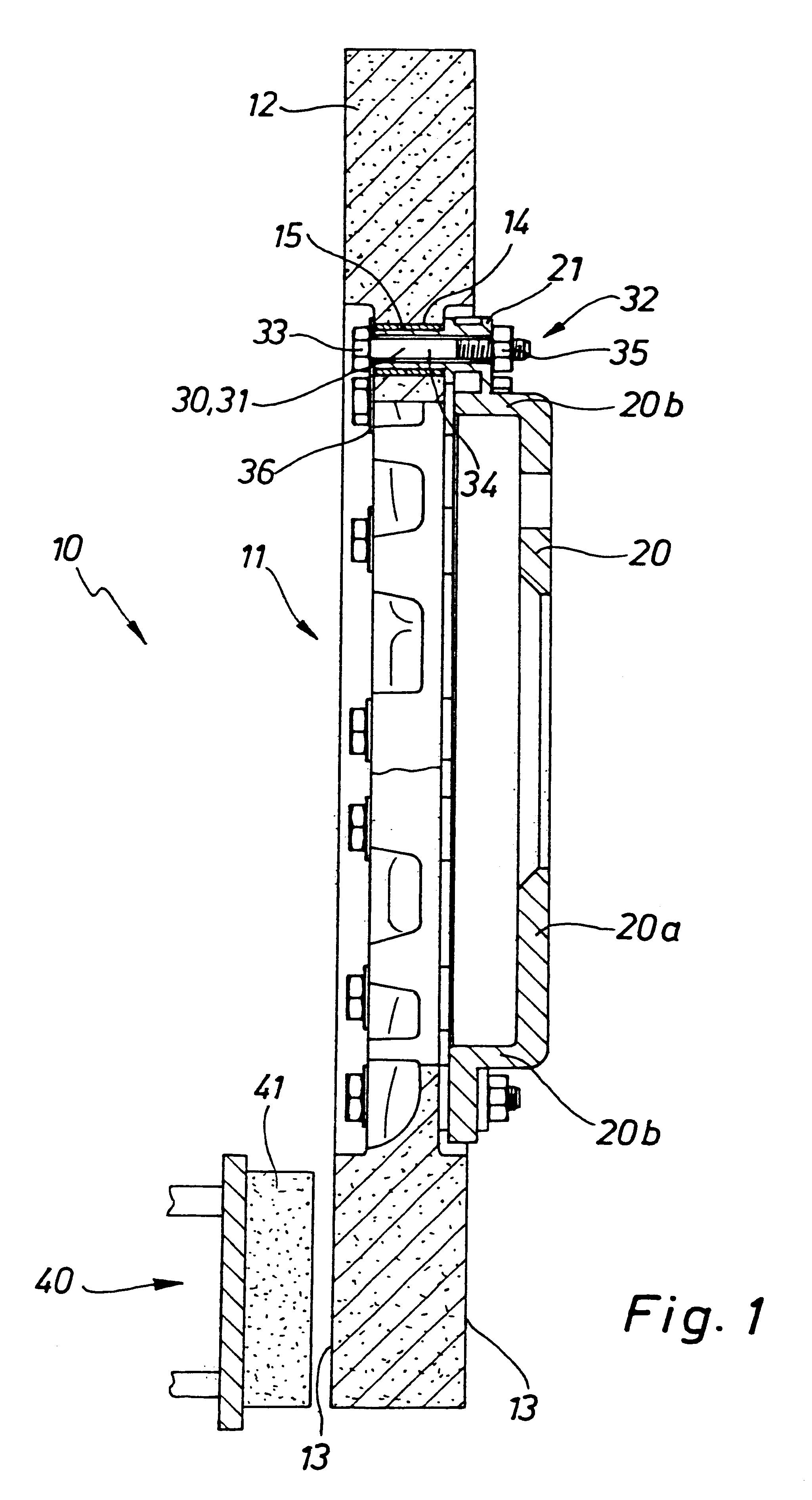

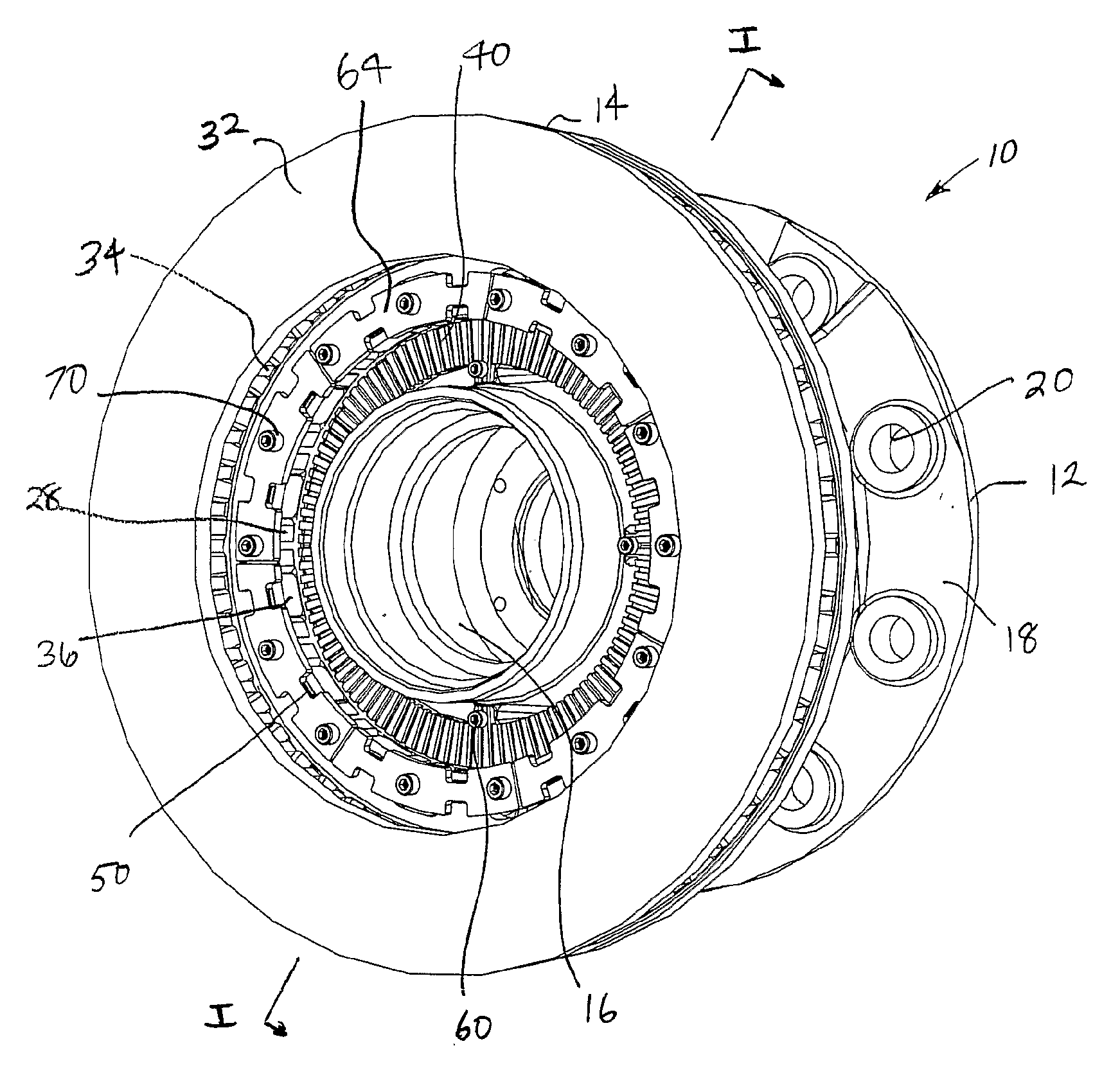

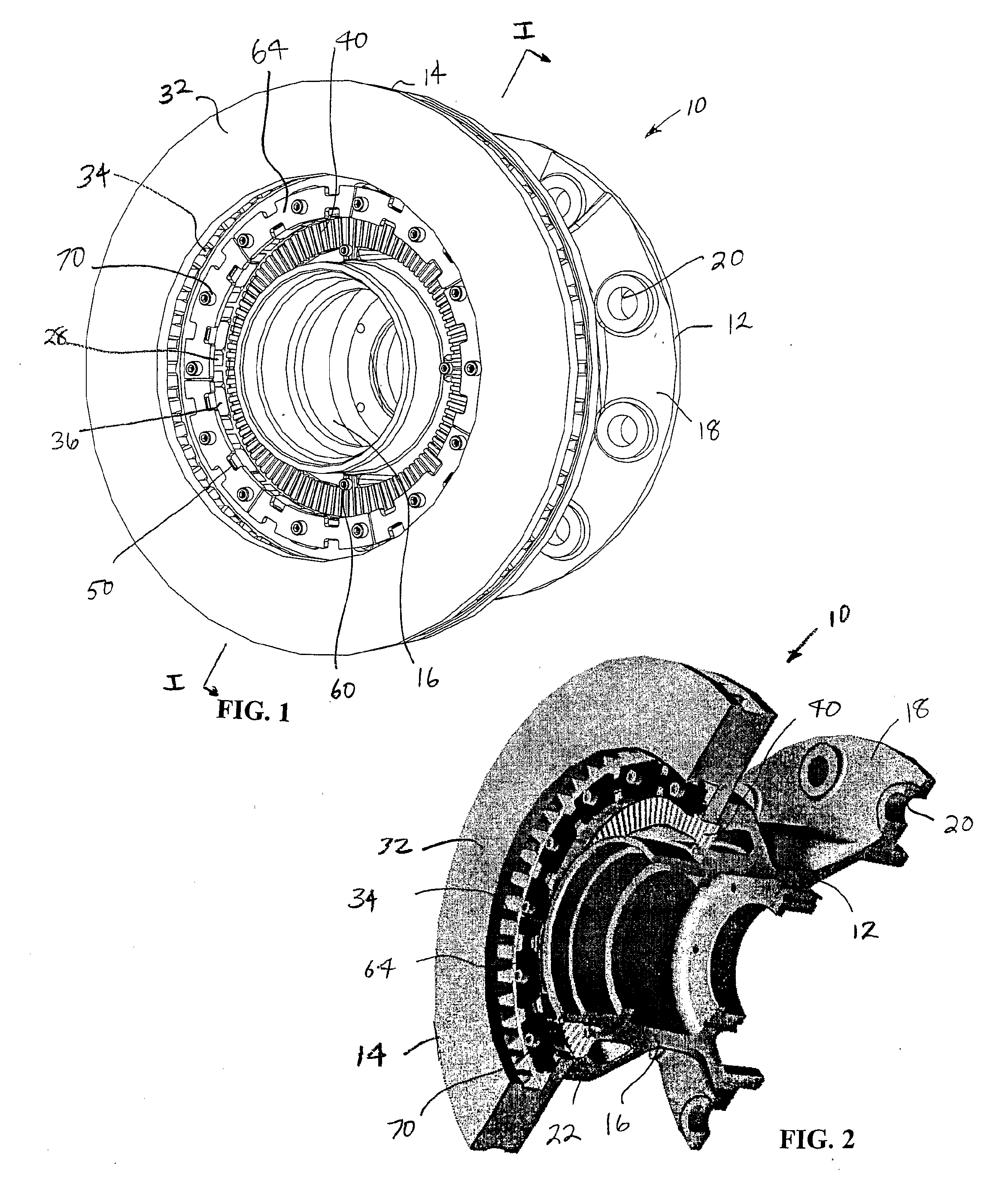

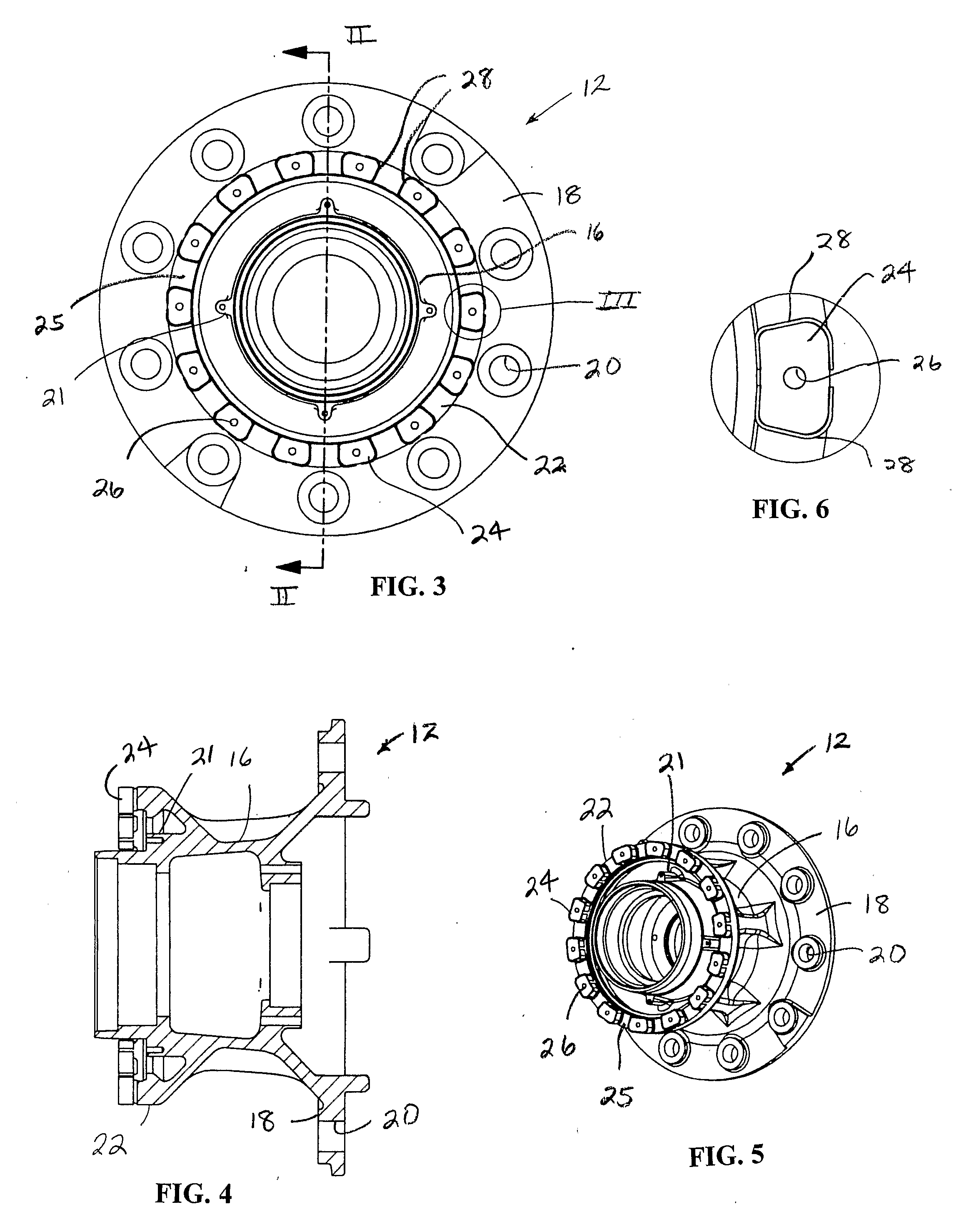

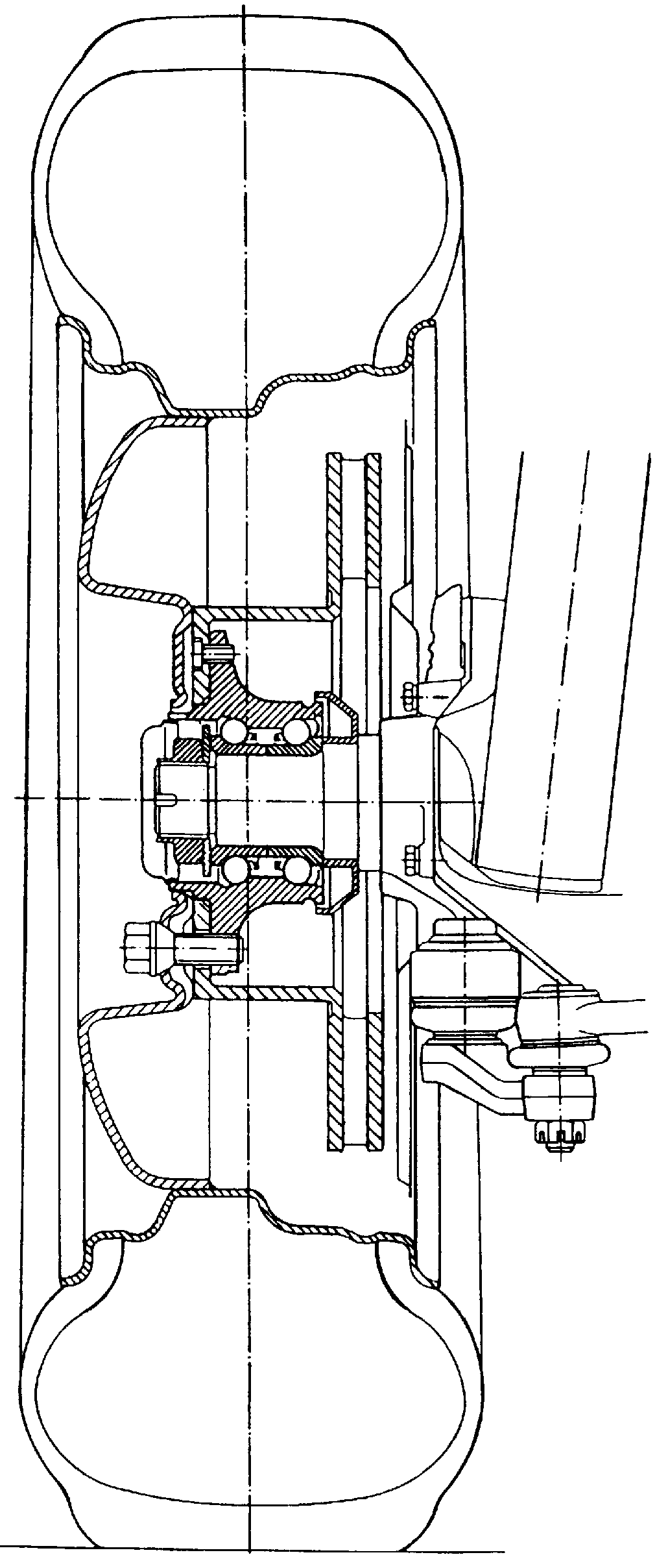

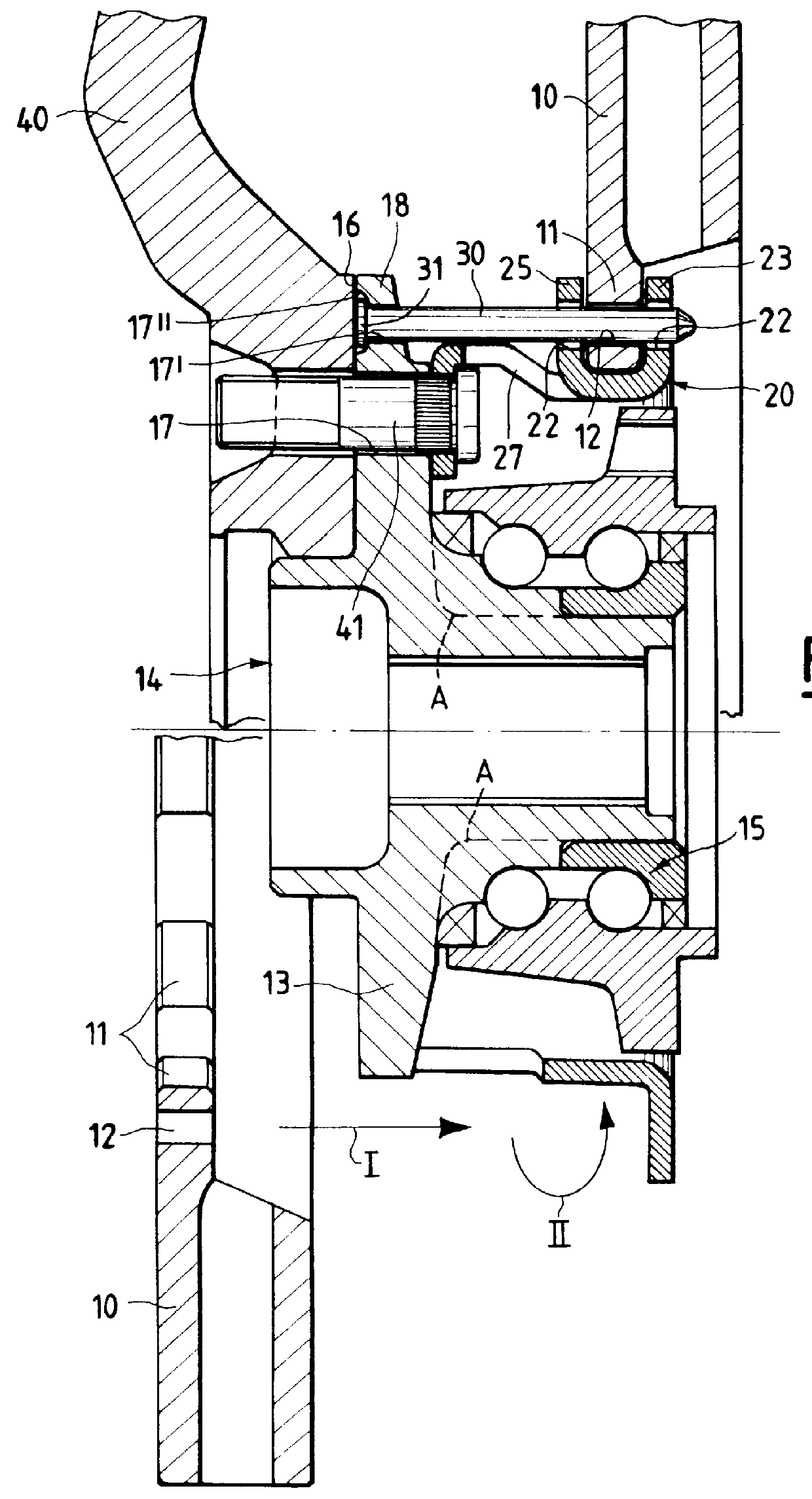

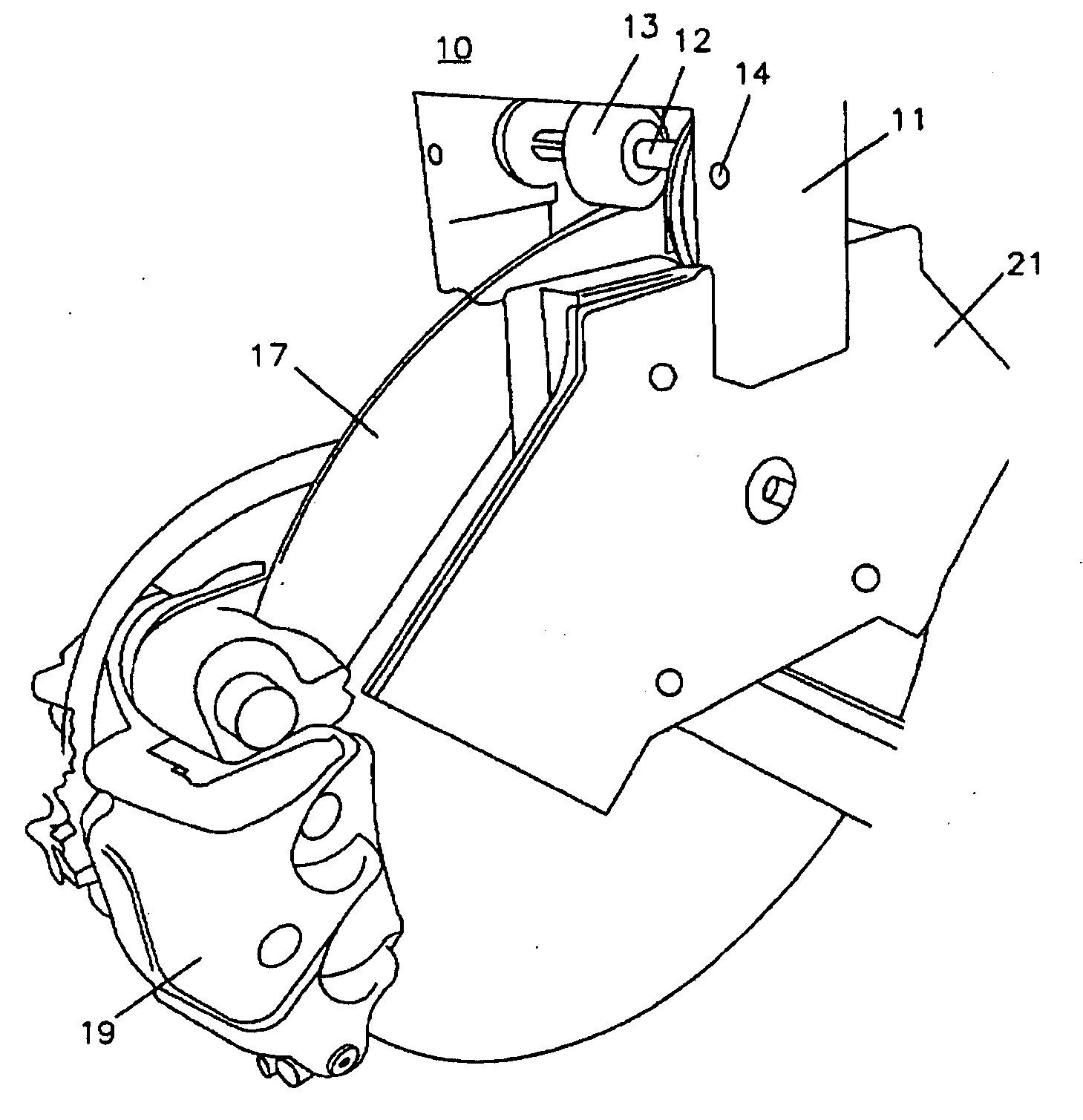

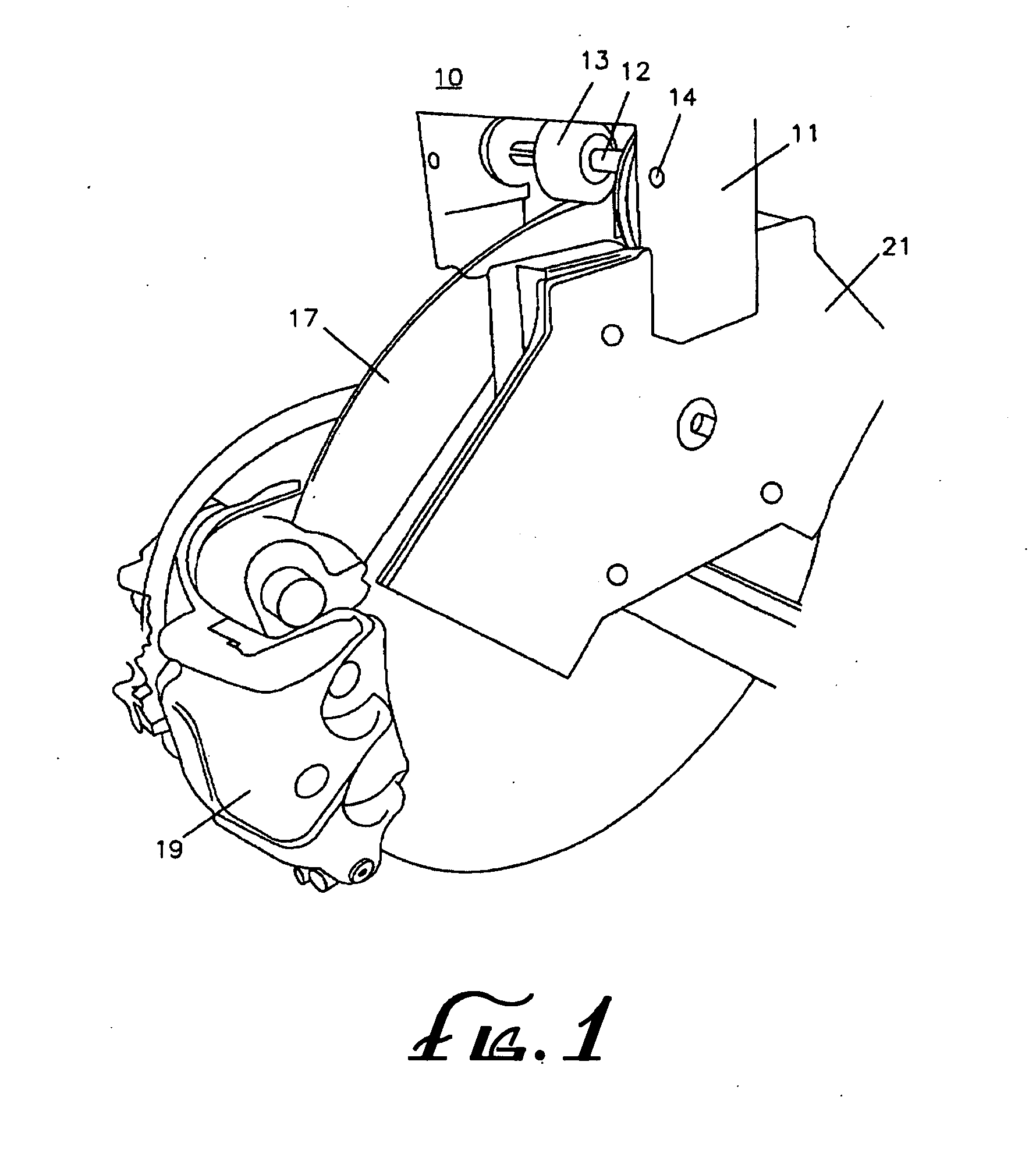

Wheel hub or hub unit allowing improved mounting and removal of a brake member

There is disclosed a wheel hub or hub unit of the type having a radial hub flange (13) providing connection to the wheel (40) and to a brake member (10) having an annular disc portion having a plurality of ears (11) radially protruding from its inner edge. The hub flange (13) defines a plurality of axial passages, in the form of peripheral radial recesses (19) or bores (17, 17') for slipping a plurality of axial pins (30) to be fitted in holes (12) obtained in the brake member ears (11) and in openings (22) obtained in at least one radial wall (23) of a brake carrier (20) rotatably fast with the hub (14) to rotationally secure the brake member (10) to the hub. When the wheel (40) is mounted on the outside of the hub flange, axial movement of the pins towards the outside is stopped by the wheel.

Owner:SKF IND SPA

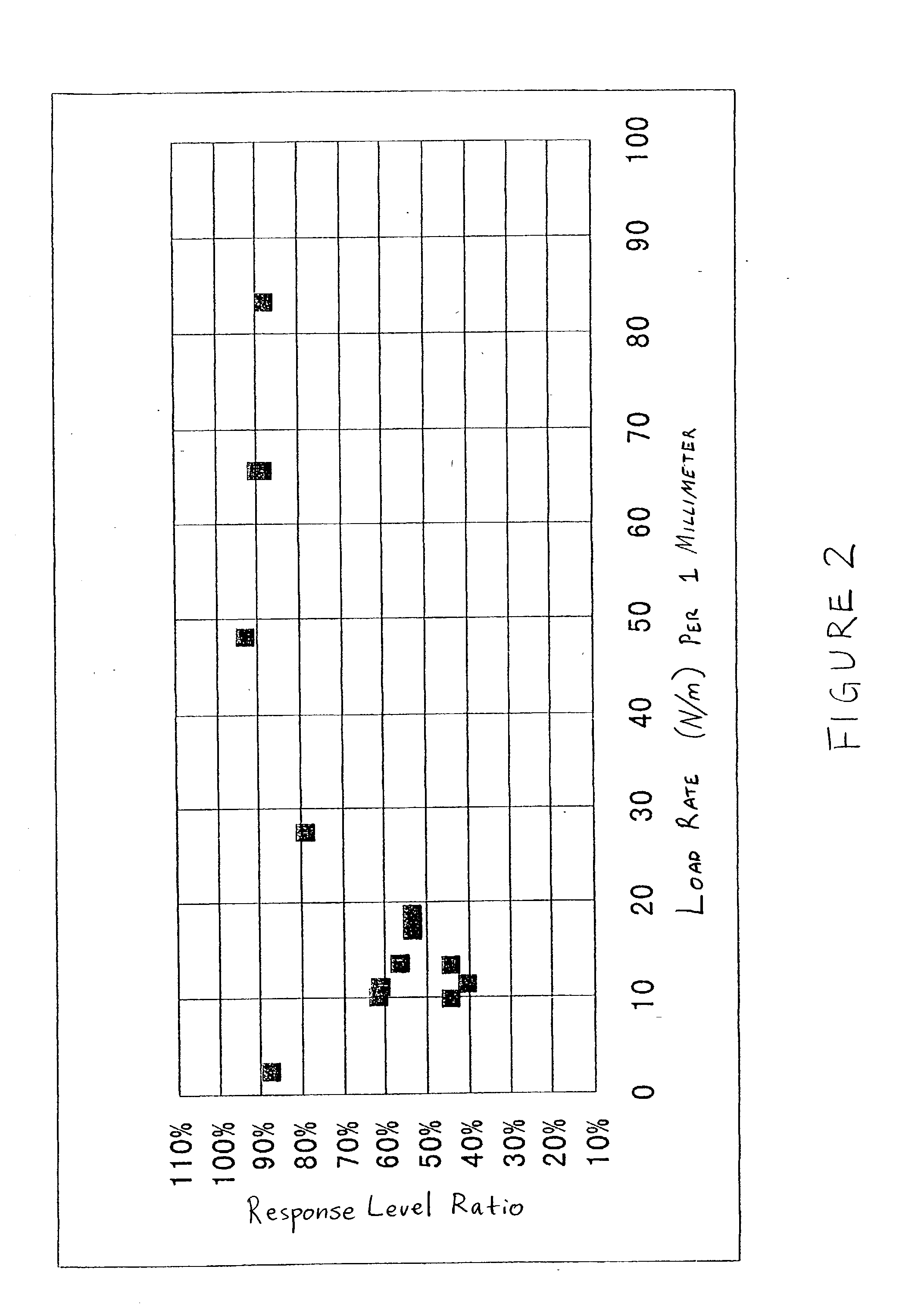

Vibration inhibiting structure for rotor

InactiveUS20030037999A1Improved vibration inhibiting structureSimple structureNoise/vibration controlBraking discsCoil springEngineering

A rotor such as a brake disk for a vehicle has a spring holder that circumferentially extends around an axis of the disk. A coil spring extends around the axis along the spring holder. The spring is loaded onto the spring holder by its own resilience. The spring has a load rate that generates a tension that allows the spring to move circumferentially relative to the spring holder.

Owner:YAMAHA MOTOR CO LTD

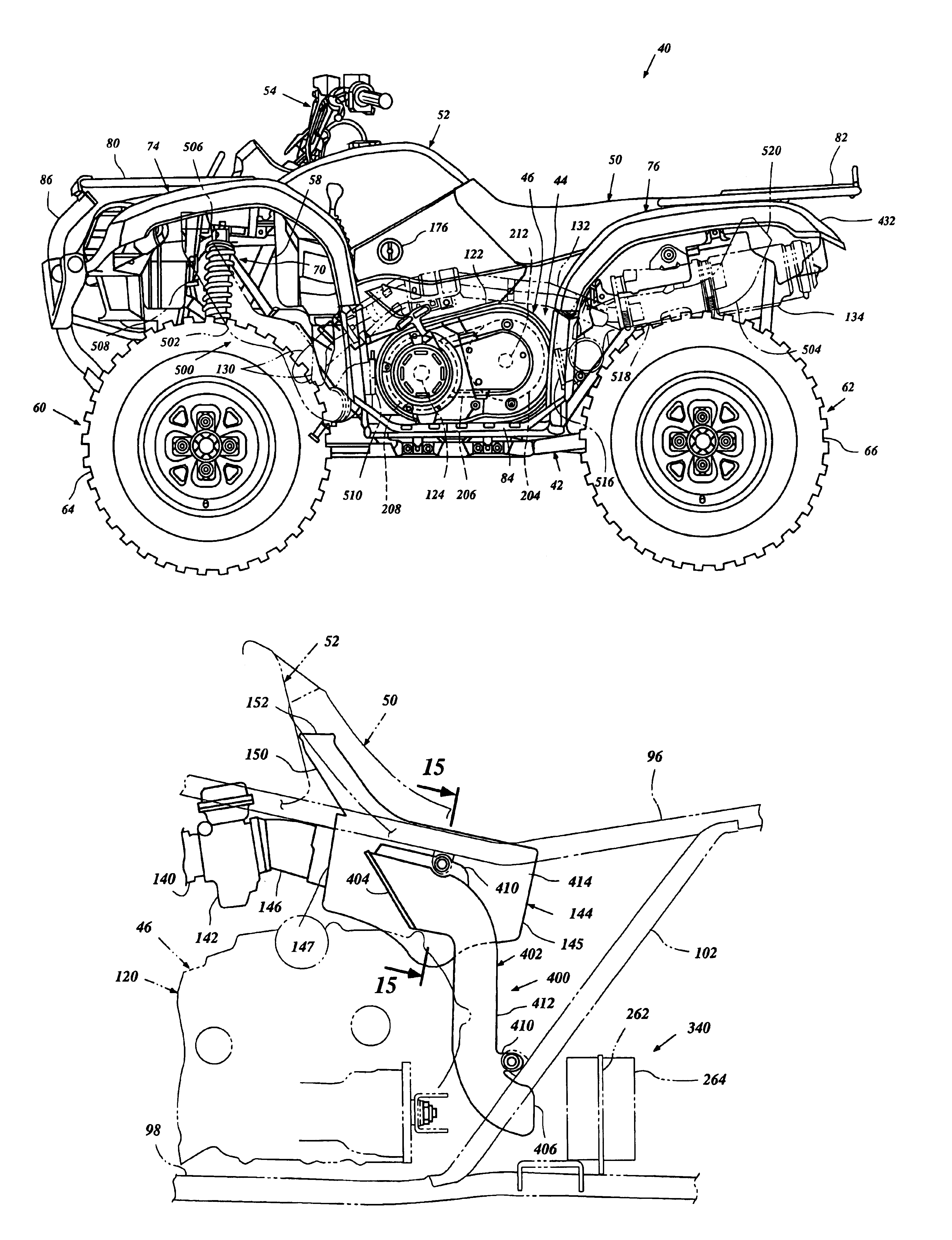

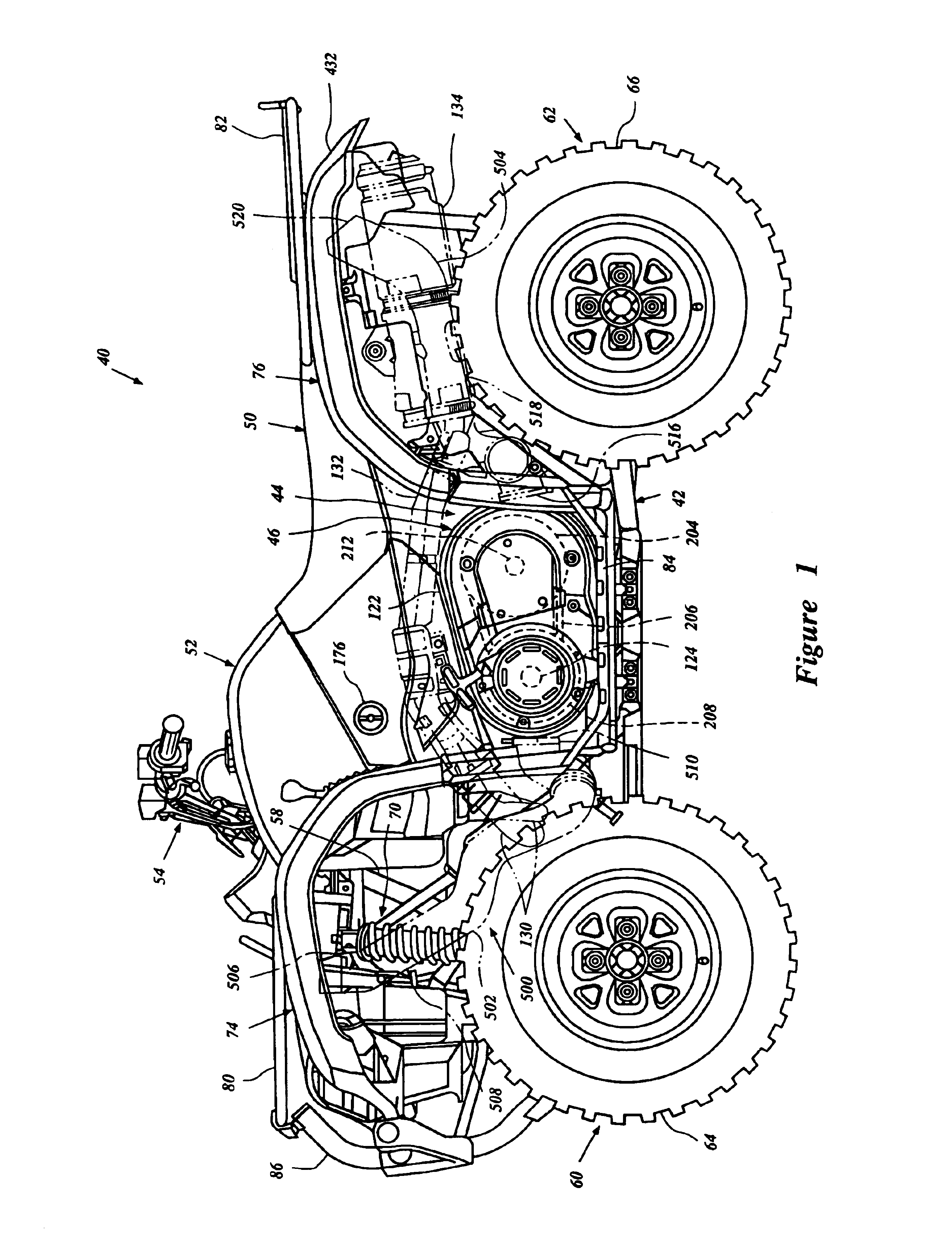

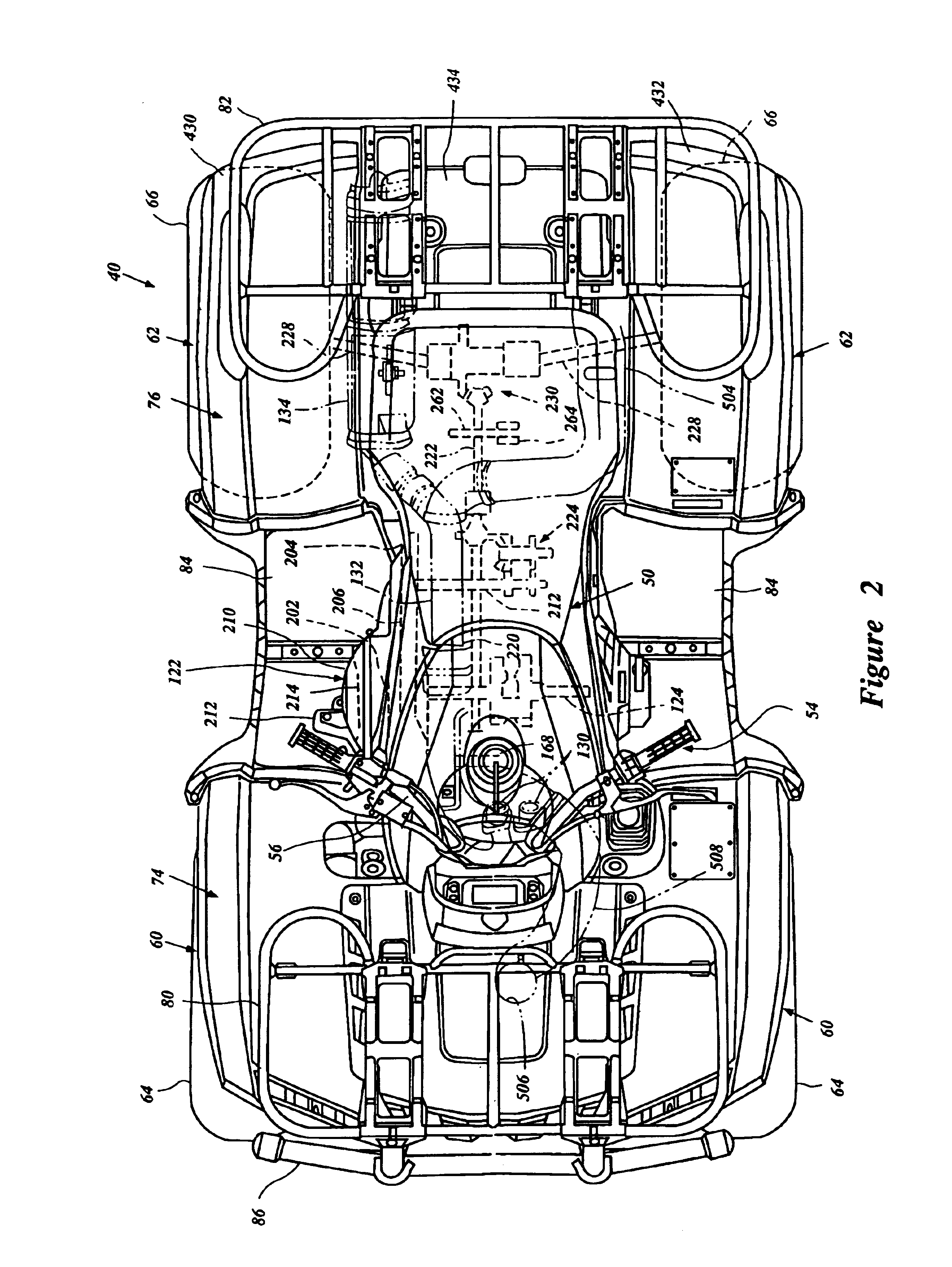

Cooling air system for small vehicle

A small vehicle has a frame assembly that is supported by rear wheels. An engine is supported by the frame assembly. The rear wheels are driven by the engine through a shaft drive arrangement. A brake assembly is connected to the shaft drive arrangement. An exhaust system extends away from the engine. An air cleaner is positioned along an air induction system of the engine. The air cleaner is positioned between the exhaust system and a cooling air duct that supplies cooling air to the brake assembly.

Owner:YAMAHA MOTOR CO LTD

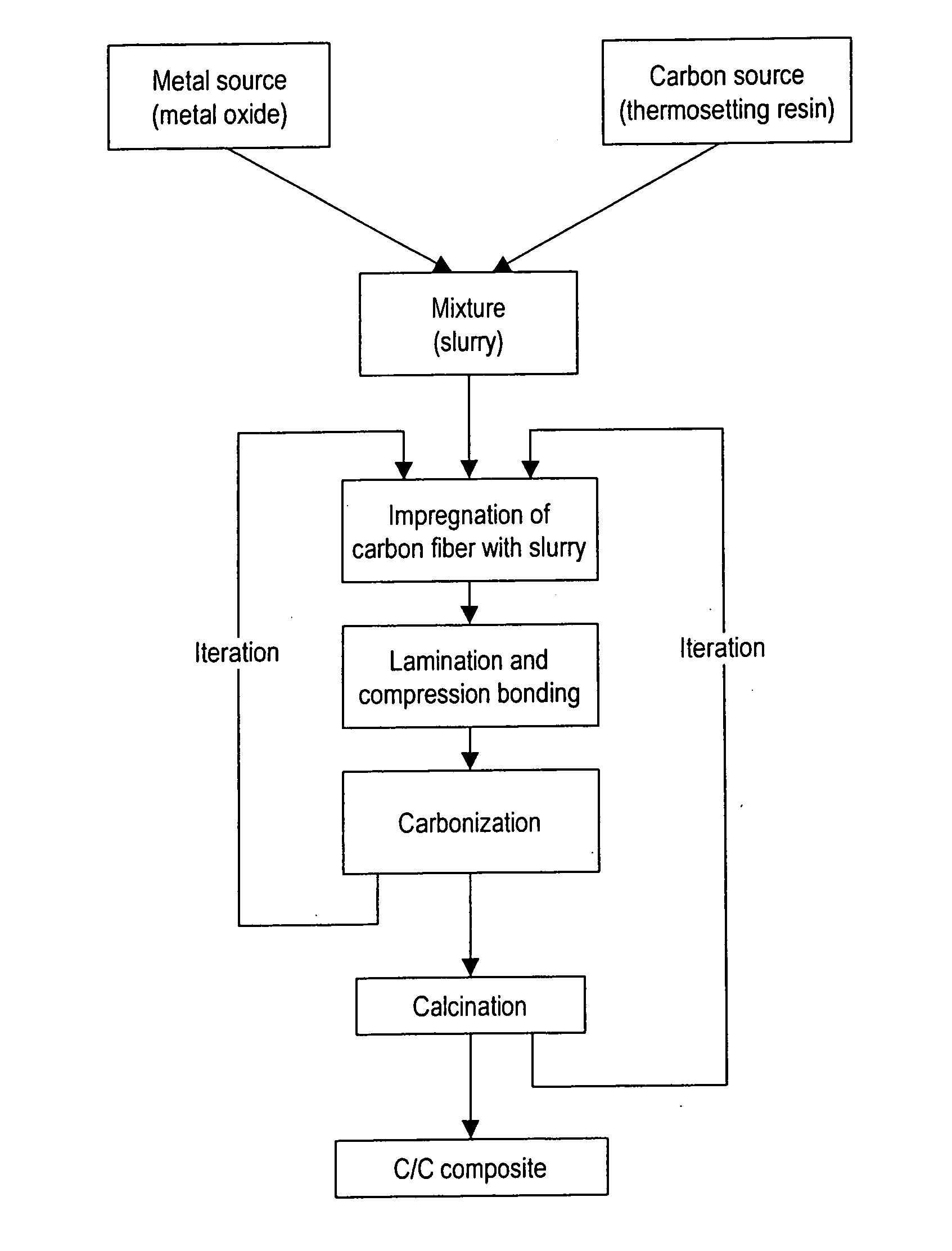

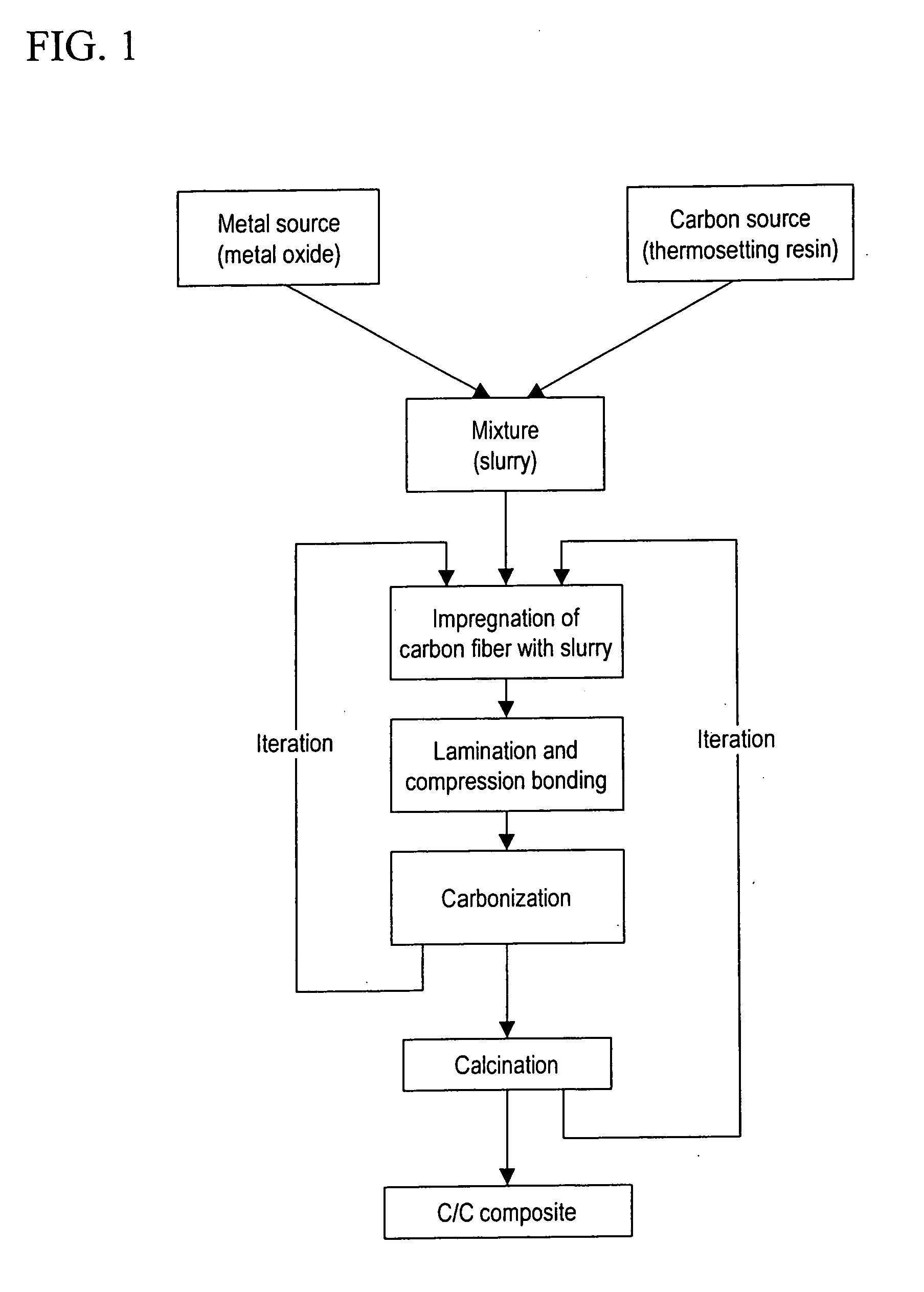

Carbon composite materials comprising particles of metal carbides dispersed therein and method for producing the same

InactiveUS20070166546A1Excellent abrasion resistanceReduce weightLayered productsBraking discsCarbon compositesCarbon fibers

This invention provides carbon composite materials, which comprise metal carbide particles, at least the particle surfaces or the entirety of which are metal carbides, synthesized in situ from a metal source, i.e., at least one member selected from the group comprising metal particles, metal oxide particles, and composite metal oxide particles, and a carbon source, i.e., a thermosetting resin, dispersed in a carbon, carbon fiber, or carbon / carbon fiber matrix, and contain no free metal particles. This invention also provides a method for producing such composite carbon materials, which enables the production of carbon composite materials having a high coefficient of friction, high thermostability, and abrasion resistance.

Owner:TOYOTA JIDOSHA KK

Disc brake assembly

A disc brake assembly includes a rotor, a caliper, brake pads and an optional filter. The optional filter can be disposed within a shroud which covers at least about 70% of the distal side periphery on at least one of the two sides of the rotor. The disc brake also includes an impeller or other means for providing air flow to the disc brake assembly. The impeller can be provided by the rotor itself or it can be provided by a separate component which is powered either directly or indirectly by the rotor.

Owner:GELB JOSEPH

Orientated carbon nanotube composite, process for producing orientated carbon nanotube, and, produced using orientated carbon nanotube composite, pneumatic tire, wheel for vehicle, tire wheel assembly and disk brake

InactiveUS20060061011A1Improve efficiencyImprove conductivityMaterial nanotechnologyBraking discsRubber materialCarbon nanotube

A carbon nanotube orientated composite formed by orientating carbon nanotubes in a given direction in a matrix having a heat conductivity lower than that of carbon nanotube, in which at least a part of carbon nanotubes are contacted with each other to be continuous from one end to the other end between both ends in the orientated direction, is provided as a material having a heat conductivity considerably higher than that of copper, aluminum or the like or a material to be disposed in rubber material having a low heat releasing characteristic to considerably improve the heat conduction, and also there are provided a method of producing the same as well as a pneumatic tire, a wheel for a vehicle, a tire-wheel assembly and a disc brake using this material.

Owner:BRIDGESTONE CORP

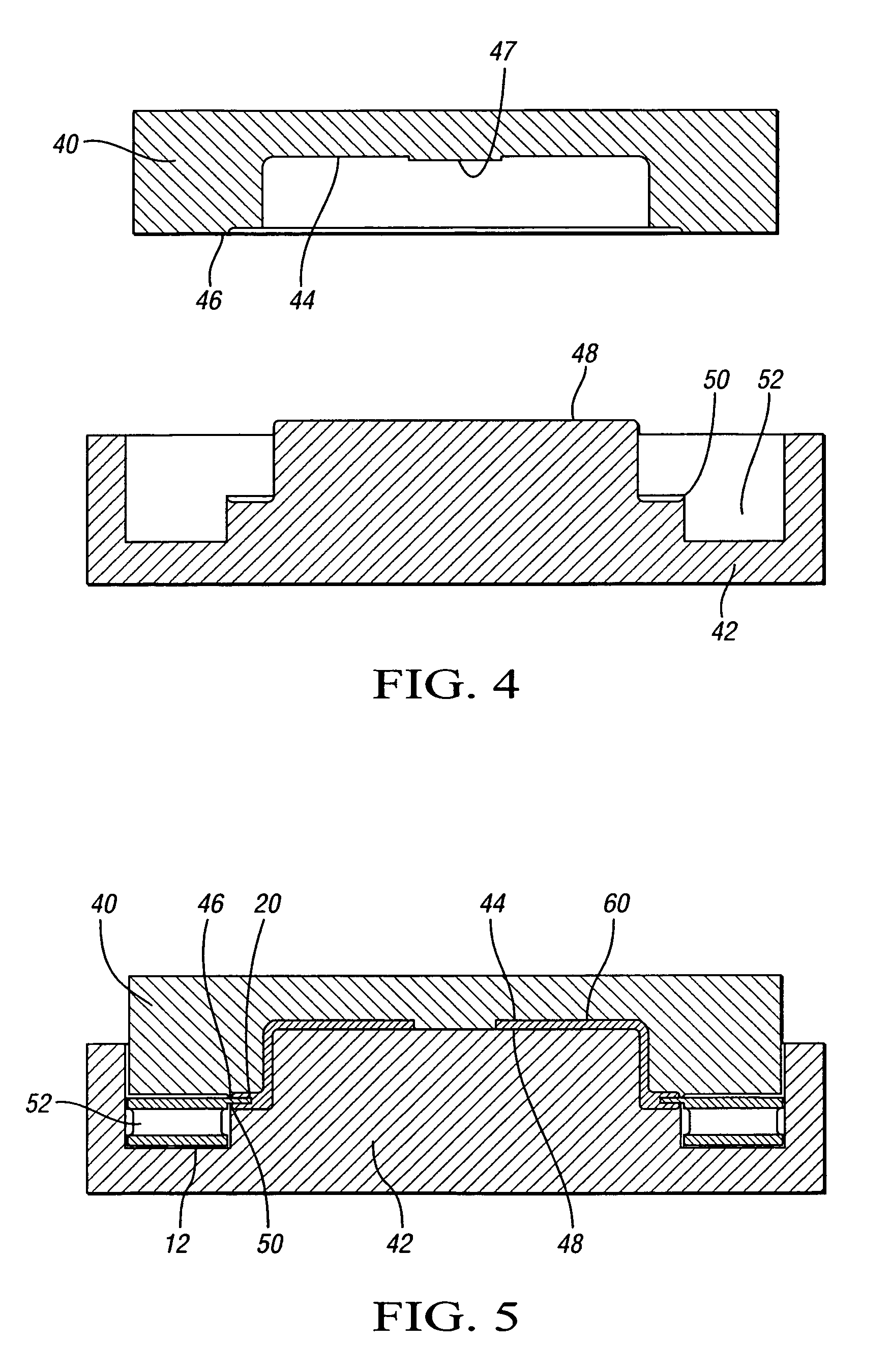

Method and apparatus for forming a part with dampener

InactiveUS6945309B2Dampening structureEffectively and efficiently constructedNoise/vibration controlBraking discsMaterials scienceShock absorber

Owner:FRENI BREMBO SPA

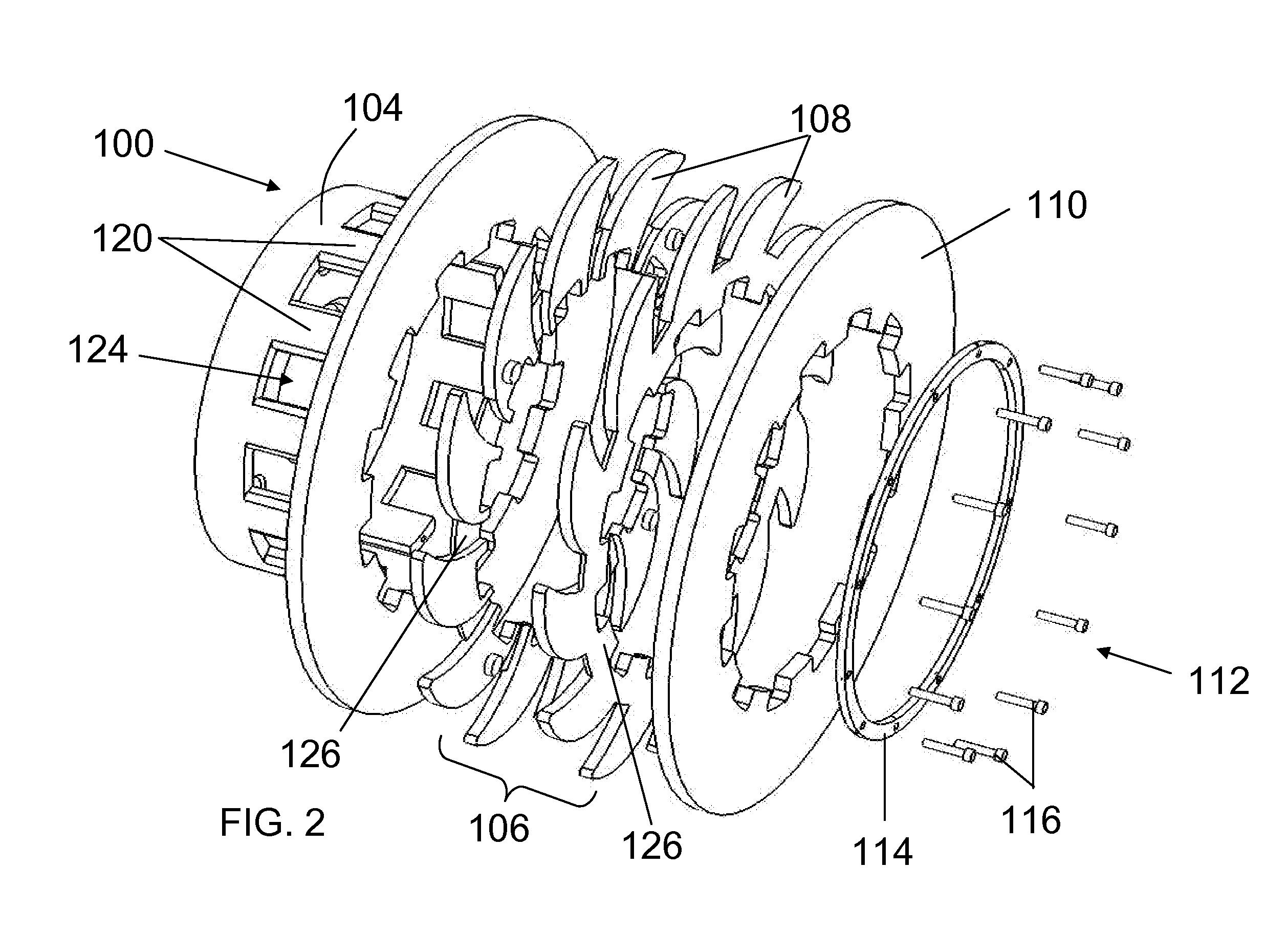

Segmented core plate and friction disc

Segmented steel core plates for either double sided or single sided wet clutch friction plates or separator plates and a process for making the same are disclosed.

Owner:BORGWARNER INC

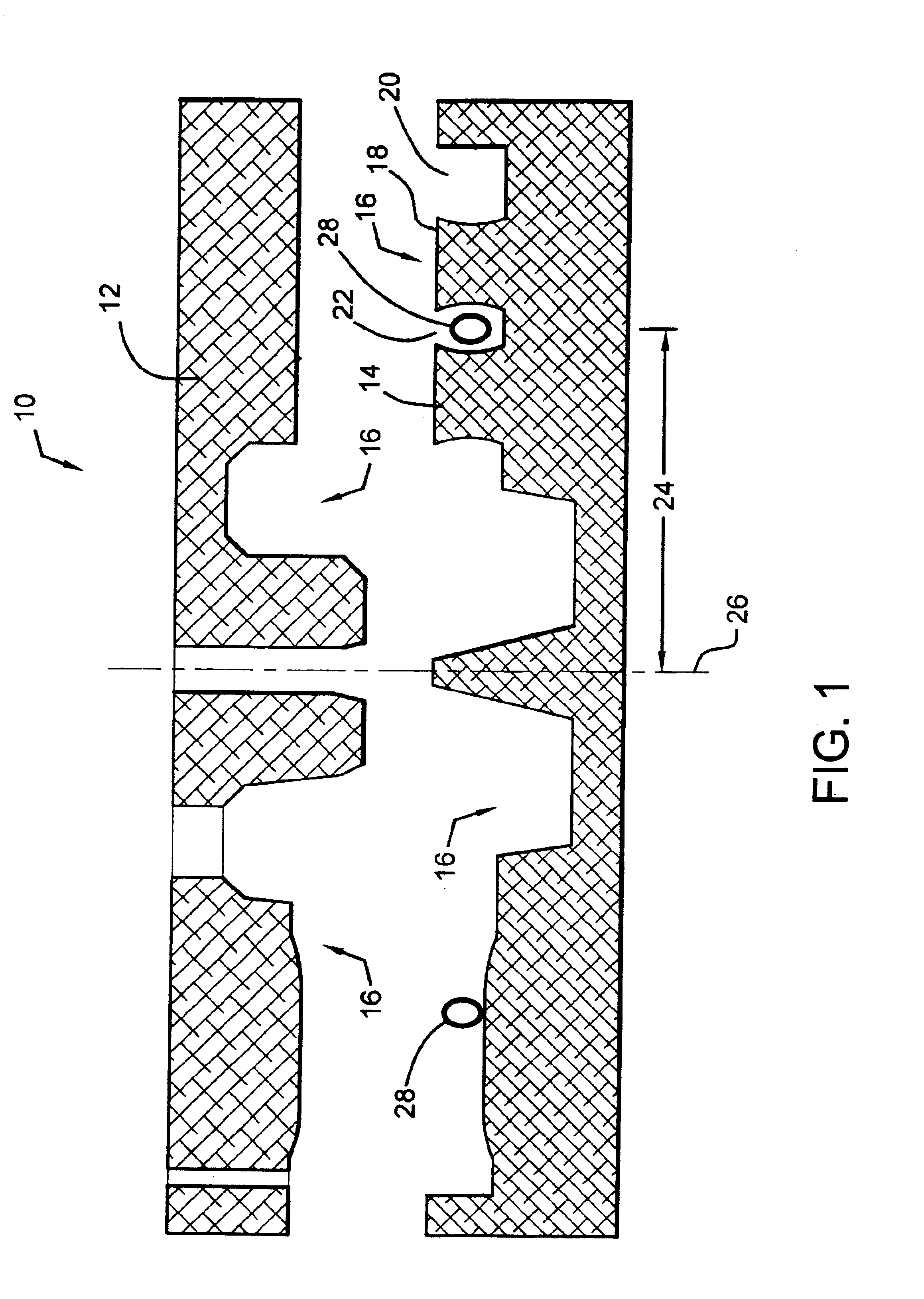

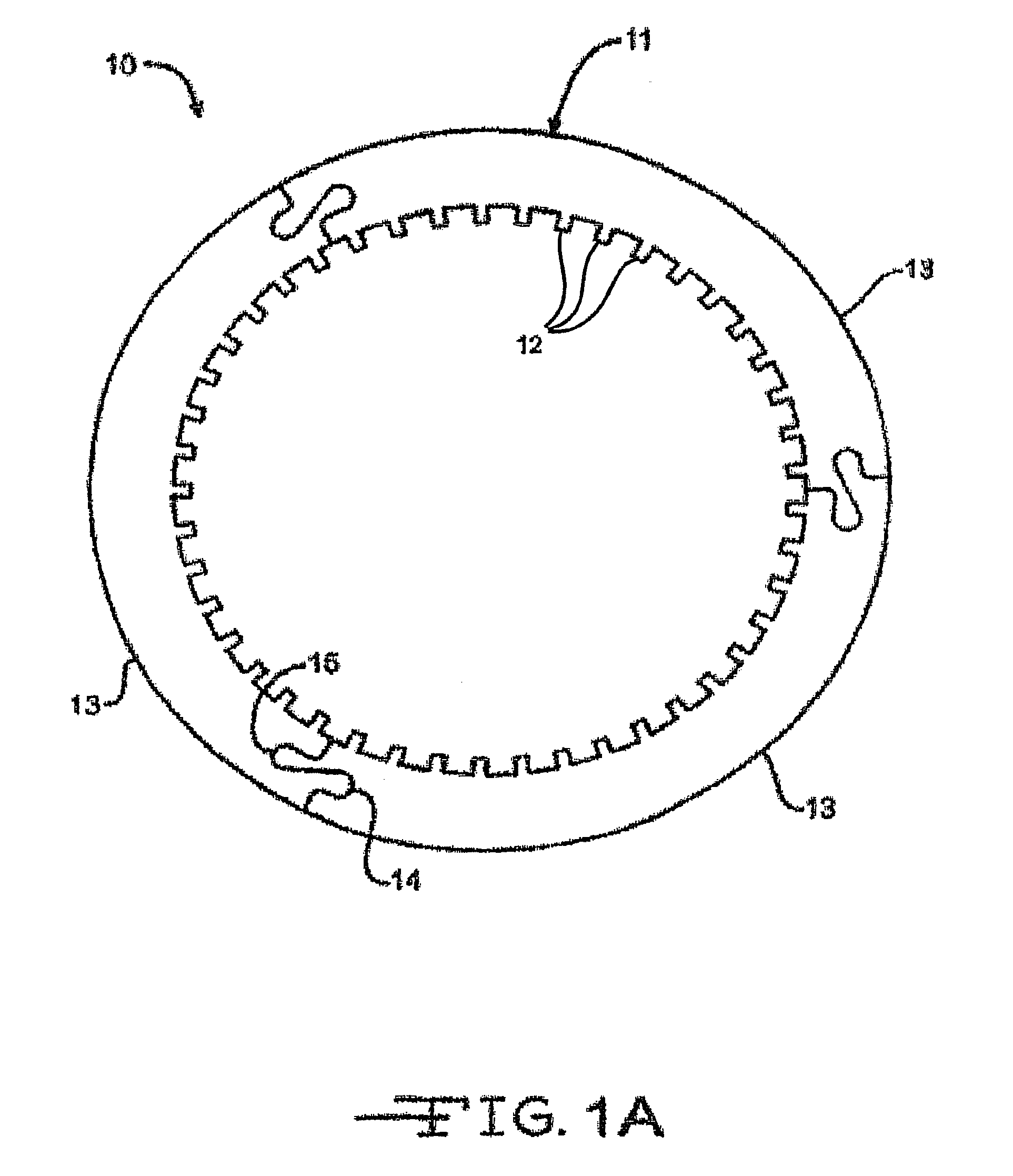

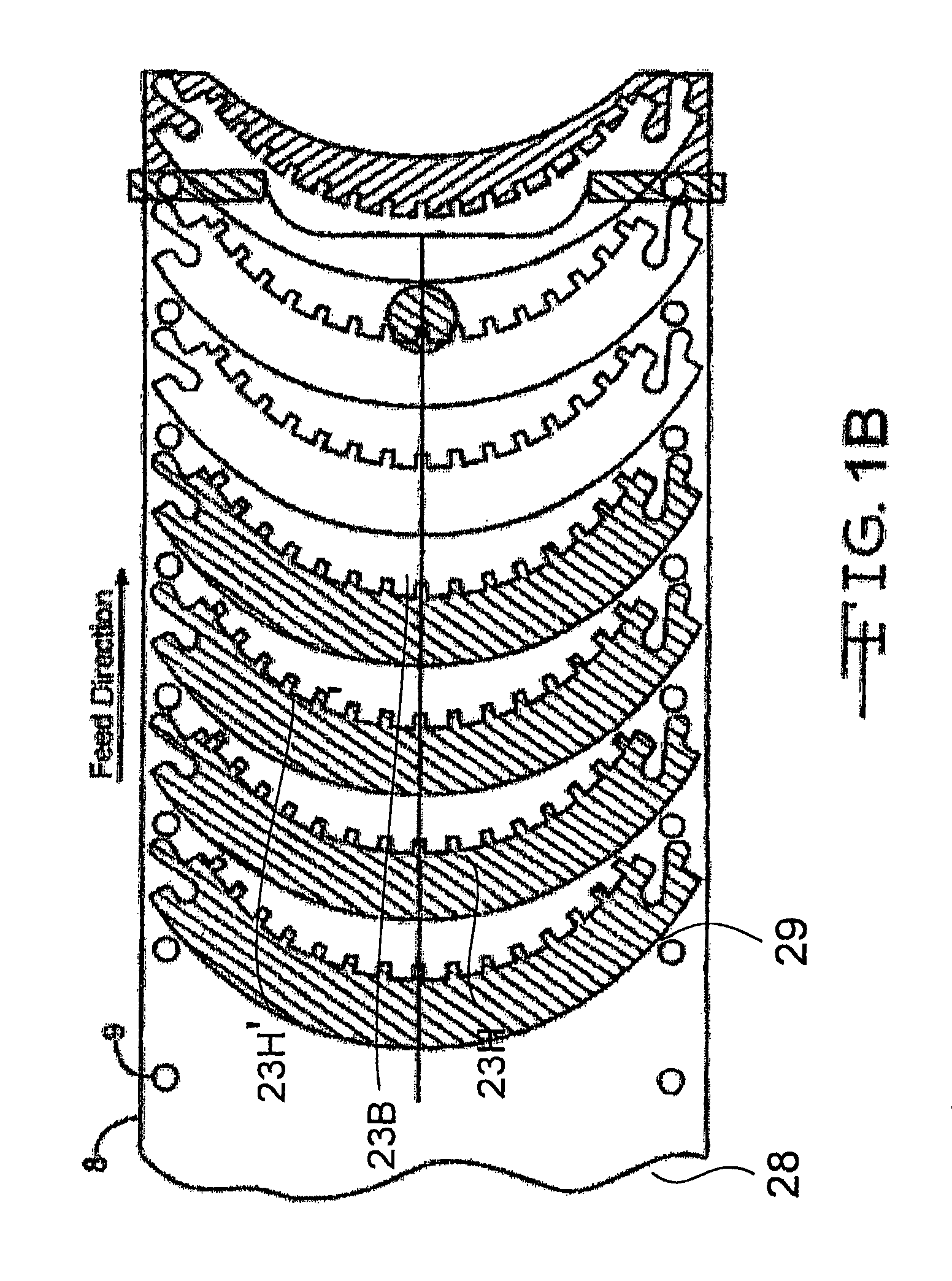

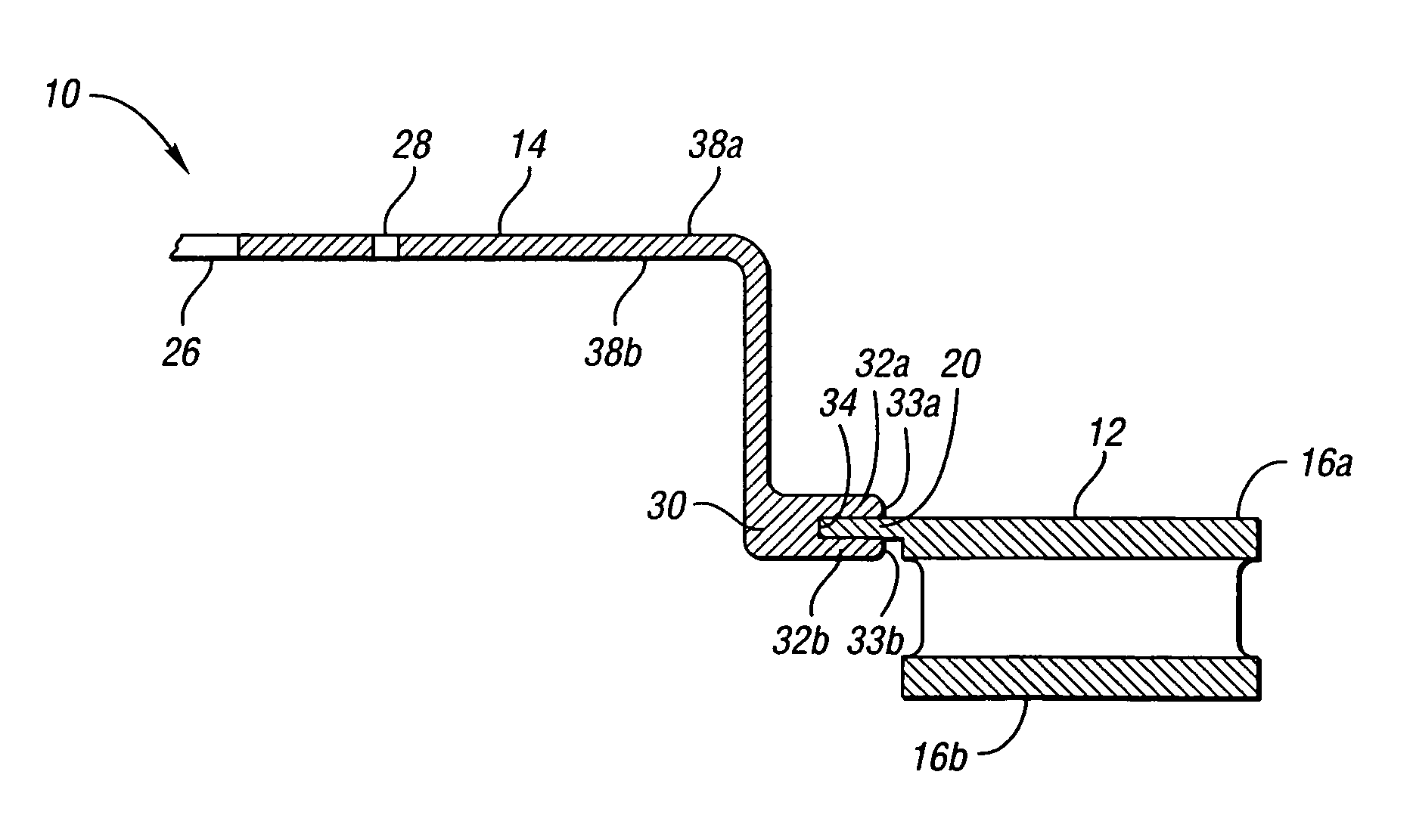

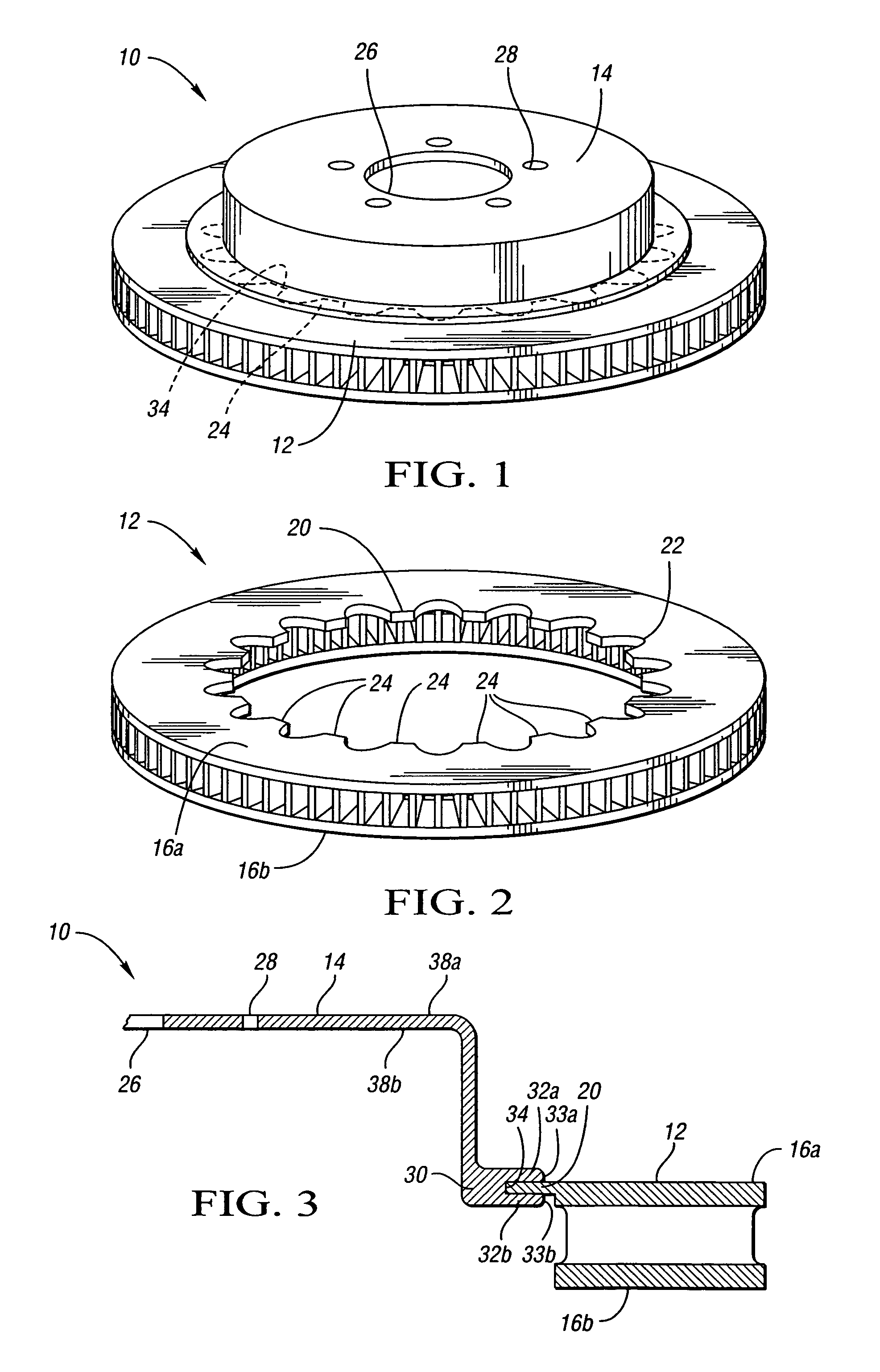

Rotor assembly and method

The apparatus of the present invention provides a brake rotor assembly. The brake rotor assembly includes a generally annular rotor having a frictional surface and a radially inner rotor flange defining a plurality of rotor teeth. The brake rotor assembly also includes a hub section integrally formed onto the rotor. The hub section has a peripheral hub flange configured to engage the plurality of rotor teeth and thereby prevent rotation of the hub section relative to the rotor. The rotor is preferably composed of a first material such as steel or cast iron, and the hub section is preferably composed of a second material such as aluminum or magnesium that is lighter by volume than the first material. Accordingly, the overall weight of the rotor assembly is less than that of a comparable rotor assembly composed entirely of steel or cast iron.

Owner:GM GLOBAL TECH OPERATIONS LLC

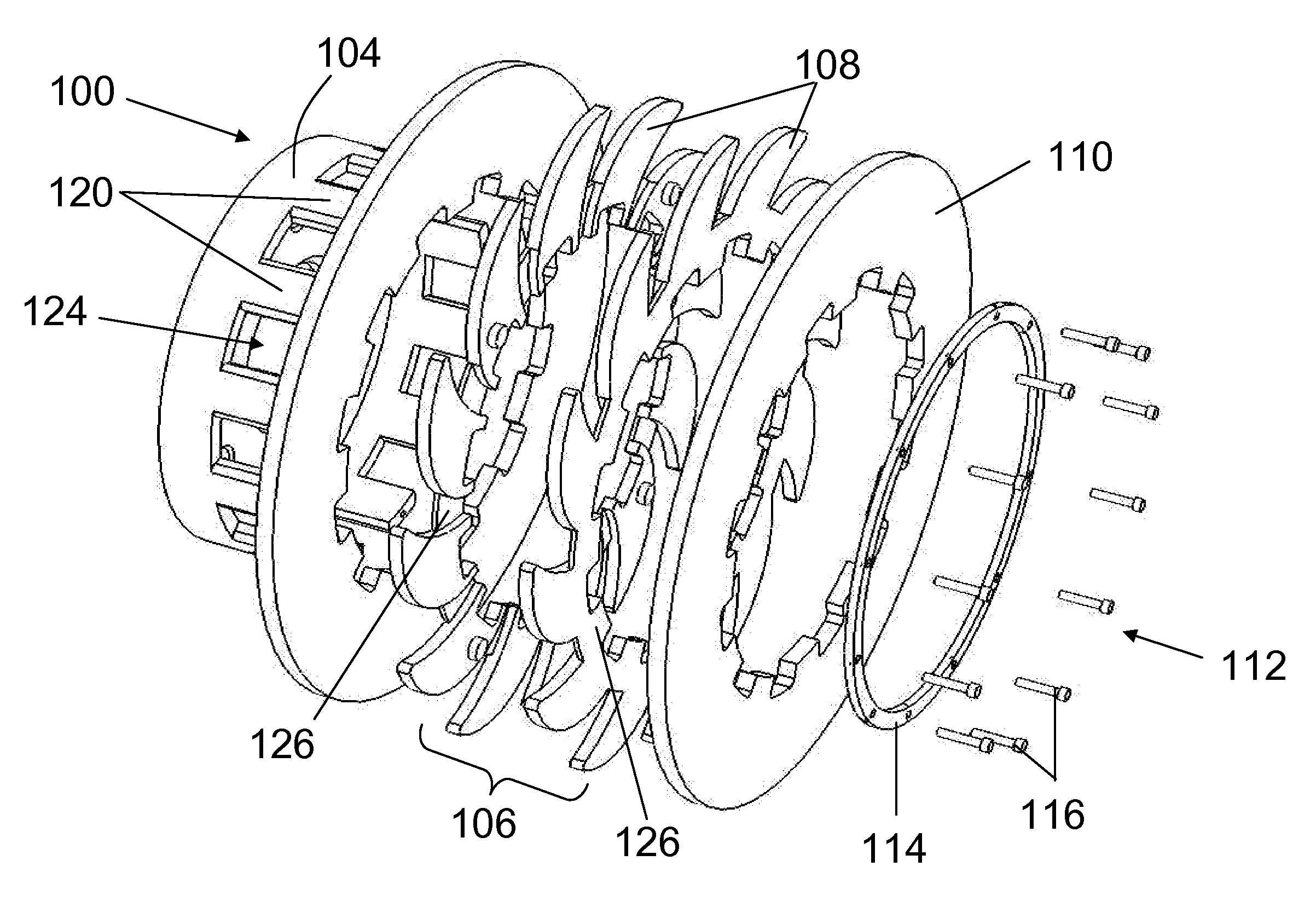

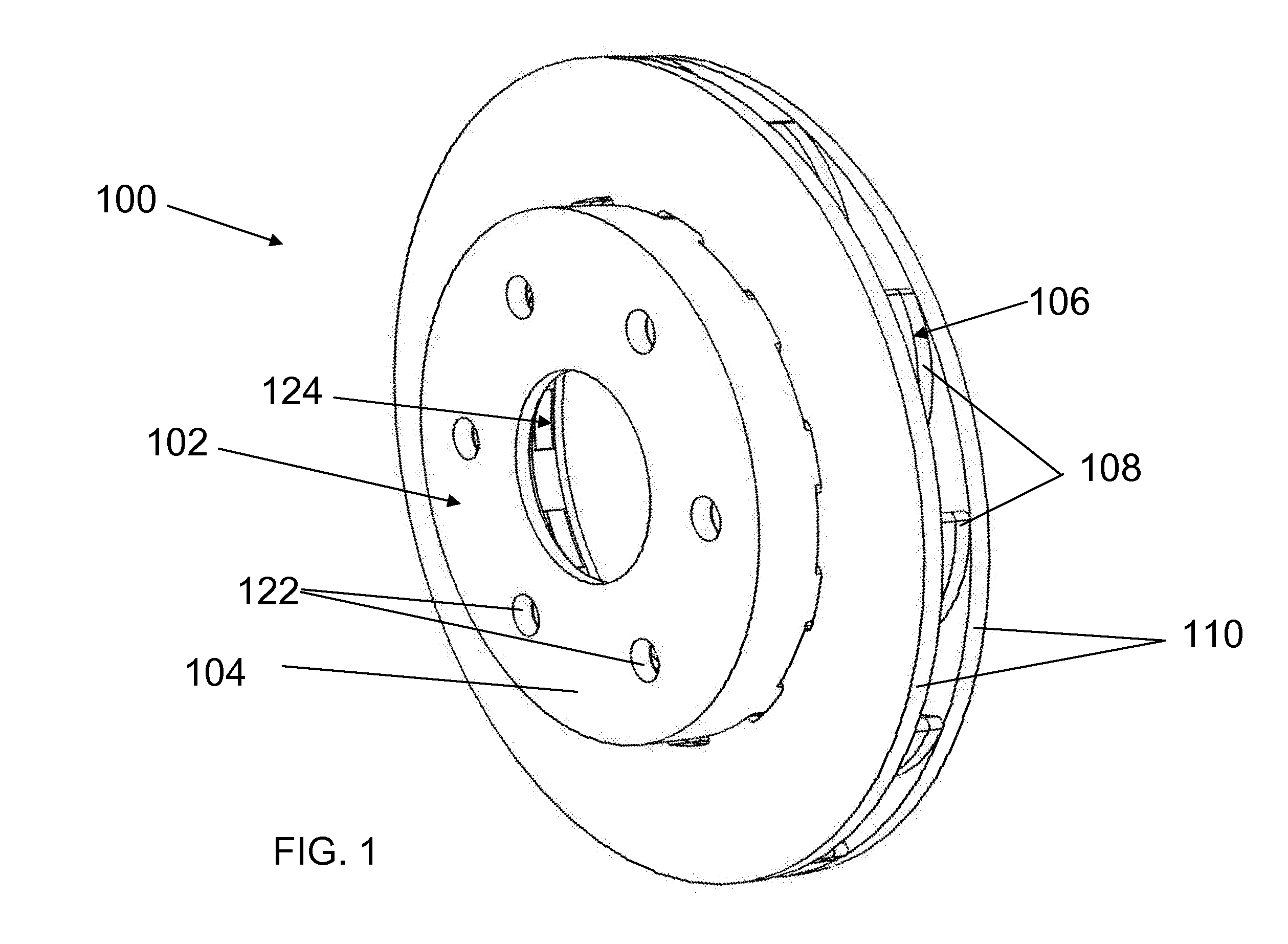

Low Mass Multi-Piece Sound Dampened Article

ActiveUS20090020379A1Reduce weightImproved performance characteristicsBraking discsActuatorsMetal alloyEngineering

A multi-piece sound dampened brake rotor comprises a relatively light weight hub with a hub flange and a heavier rotor body with a sound damping insert and a rotor body flange. The hub and rotor body are attached at their flanges. The flanges may be mechanically attached such as with bolts. Or the hub and rotor may be attached by casting the hub of a lower melting metal alloy against the rotor body and rotor body flange. The rotor body may have vanes for air cooling and a sound damping insert may be incased in either or both body portions sandwiching the vanes.

Owner:GM GLOBAL TECH OPERATIONS LLC

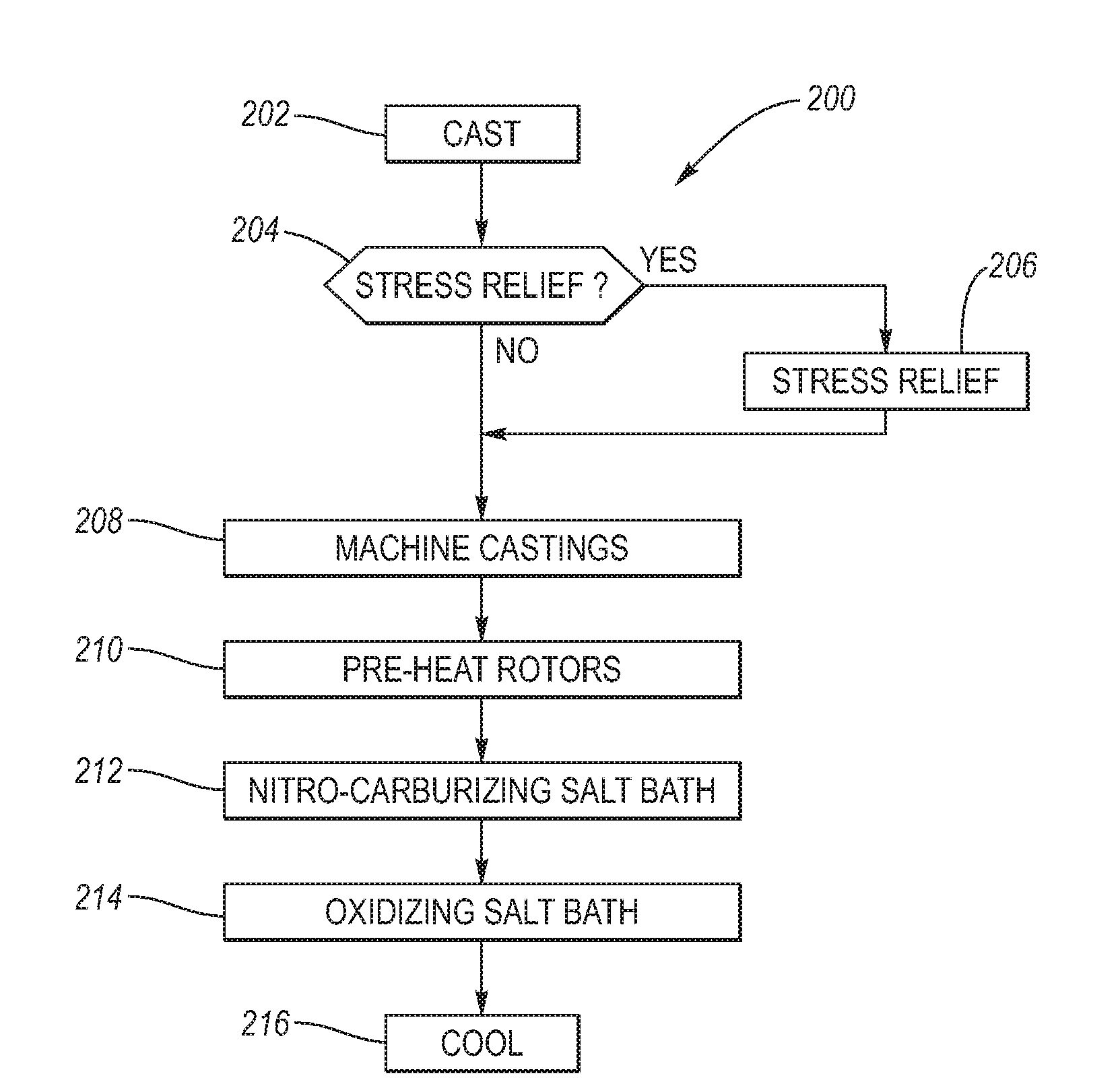

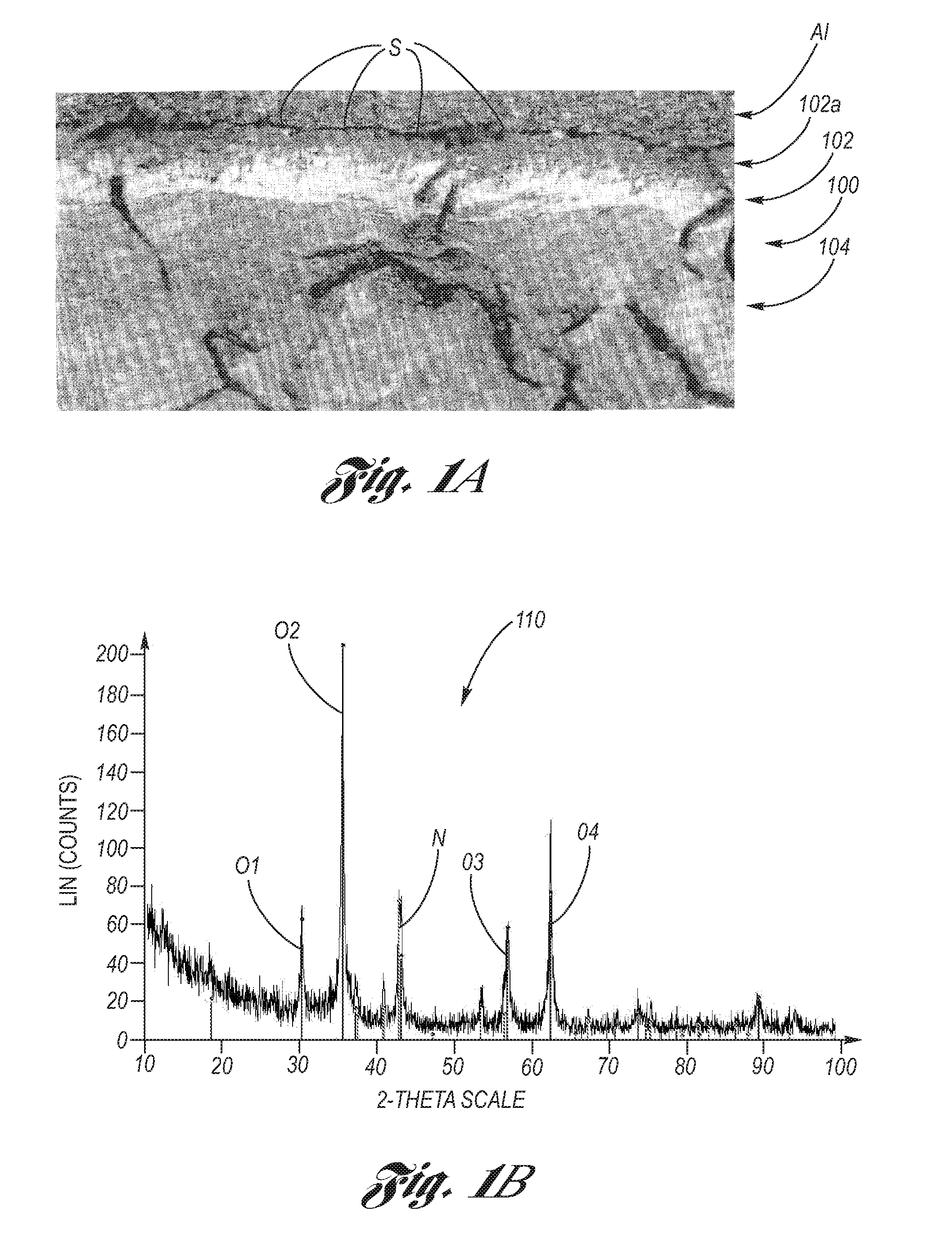

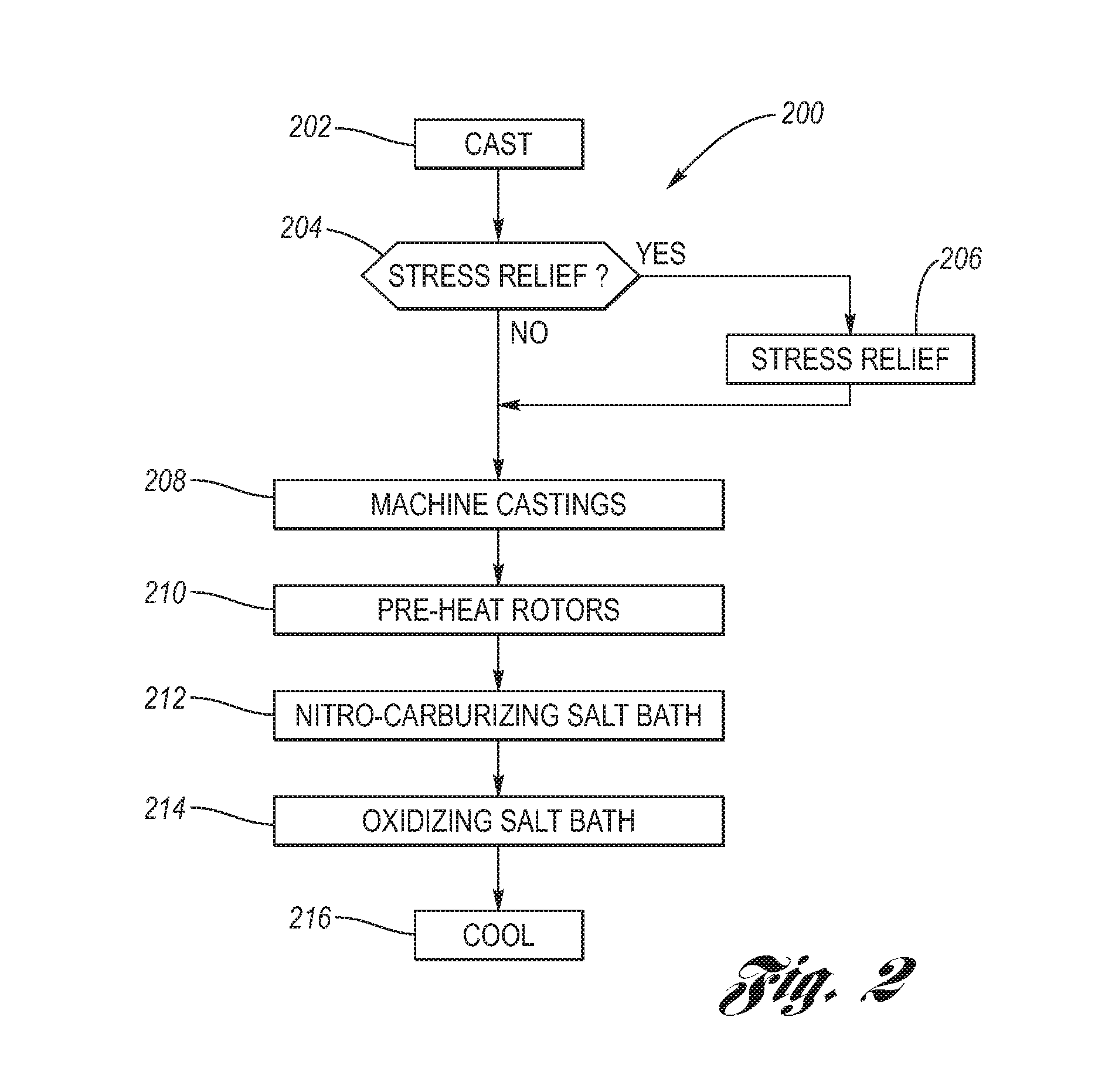

Salt Bath Ferritic Nitrocarburizing of Brake Rotors

ActiveUS20080000550A1Absence of distortionProvide resistanceBraking discsSolid state diffusion coatingRoom temperatureNitrogen

Ferritic nitrocarburized surface treatment of cast iron brake rotors providing oxidation resistance, good braking performance and absence of distortion. Machined brake rotors are pre-heated, then immersed into a high temperature molten nitrocarburizing salt bath for a first predetermined dwell time. After removing the brake rotors from the nitrocarburizing salt bath, the brake rotors are directly immersed into an oxidizing salt bath at a lower temperature than the nitrocarburizing salt bath so that the brake rotors are thermally quenched. After a predetermined second dwell time in the oxidizing salt bath, the brake rotors are removed therefrom and further cooled to room temperature, either by water application thermal quenching or slow cooling in air. A fixture provides stable holding the brake rotors with a minimum of contact during placement in the salt baths.

Owner:KOLENE +1

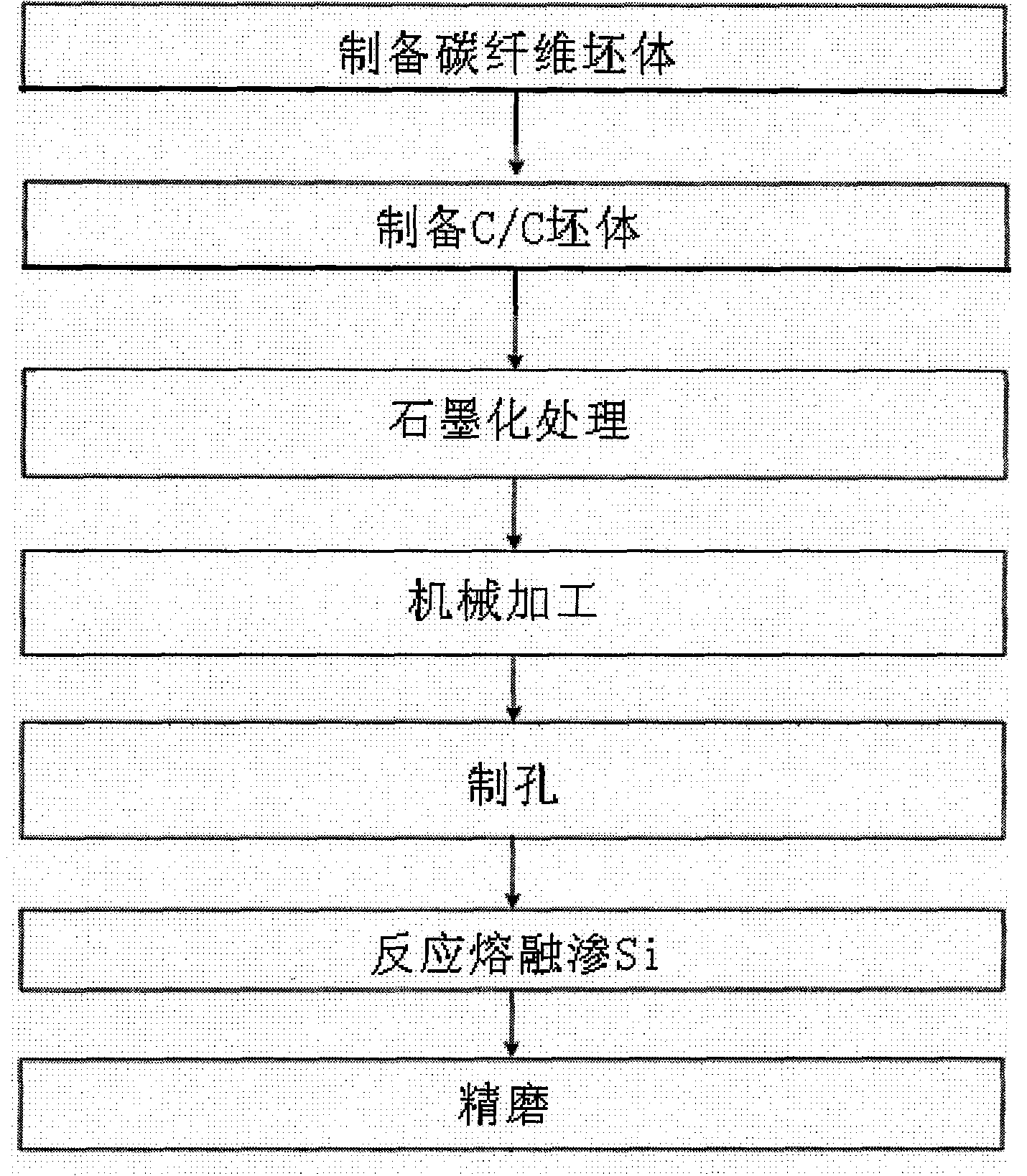

Method for manufacturing carbon ceramic brake disc

The invention relates to a method for manufacturing a carbon ceramic brake disc, which comprises the following steps of: preparing a carbon fiber blank body, performing natural gas chemical vapor immersion (CVI), graphitizing, machining, making holes, performing a melting reaction and grinding accurately to prepare a carbon ceramic composite brake disc, wherein in the hole making step, a plurality of through holes are distributed on a disc surface of the brake disc fully, and the center line of each through hole is perpendicular to the disc surface of the brake disc. In the method, the through holes distributed on the disc surface of the brake disc fully allows liquid state Si to permeate in the thickness direction of the brake disc uniformly and permeate on the whole friction surface uniformly in a melting Si permeating reaction and ensure the melting Si permeating reaction occurs at an area in the thickness direction intensively and influences the size of the thickness direction only without influencing the size at an area in the radial circumferencial direction basically, so that in the subsequent carbon ceramic machining, the thickness area is machined only. Therefore, the method has the characteristics that the Si permeating depth is desirable; the Si permeation is uniform; and products are easy to machine.

Owner:XIAN AVIATION BRAKE TECH

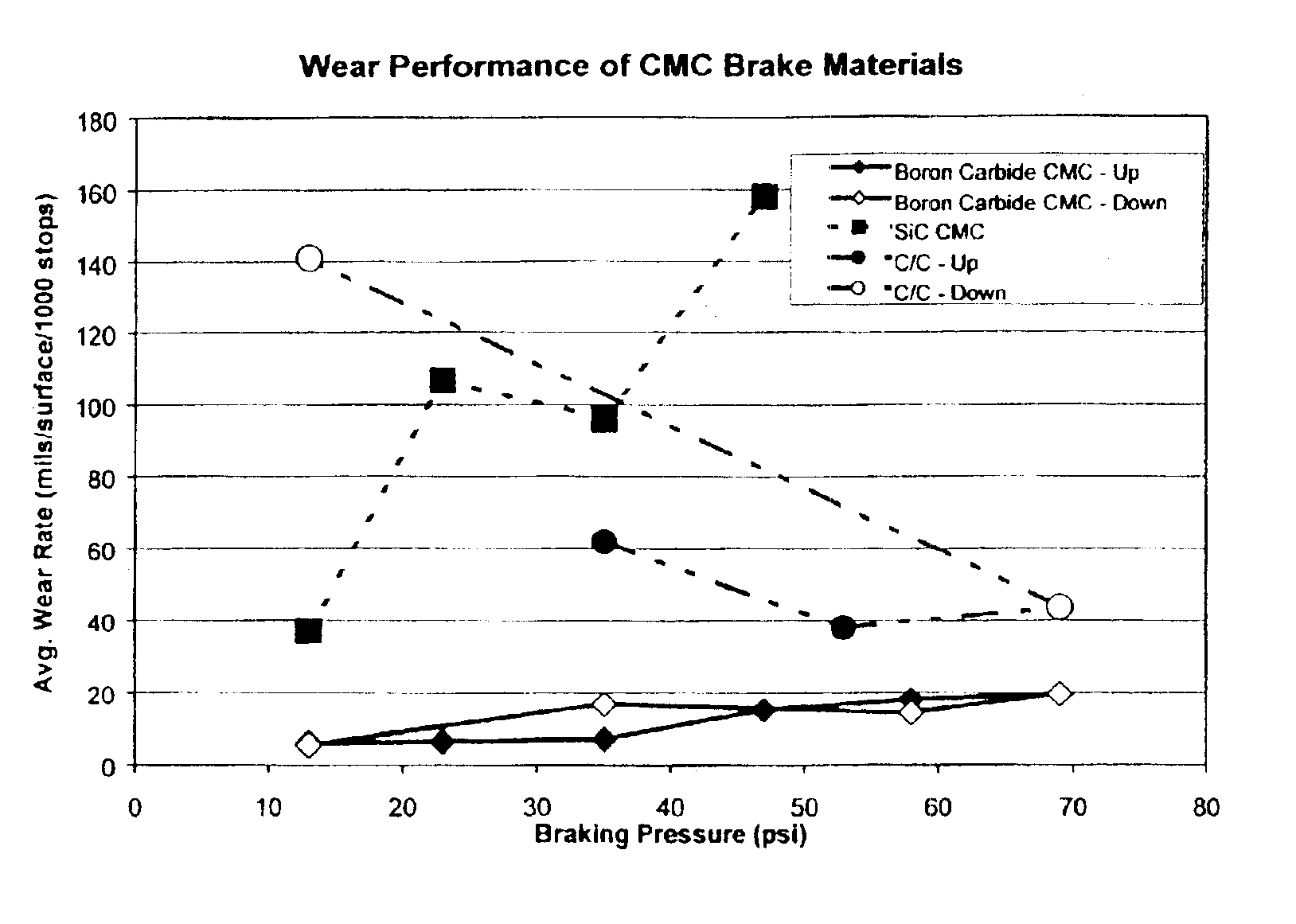

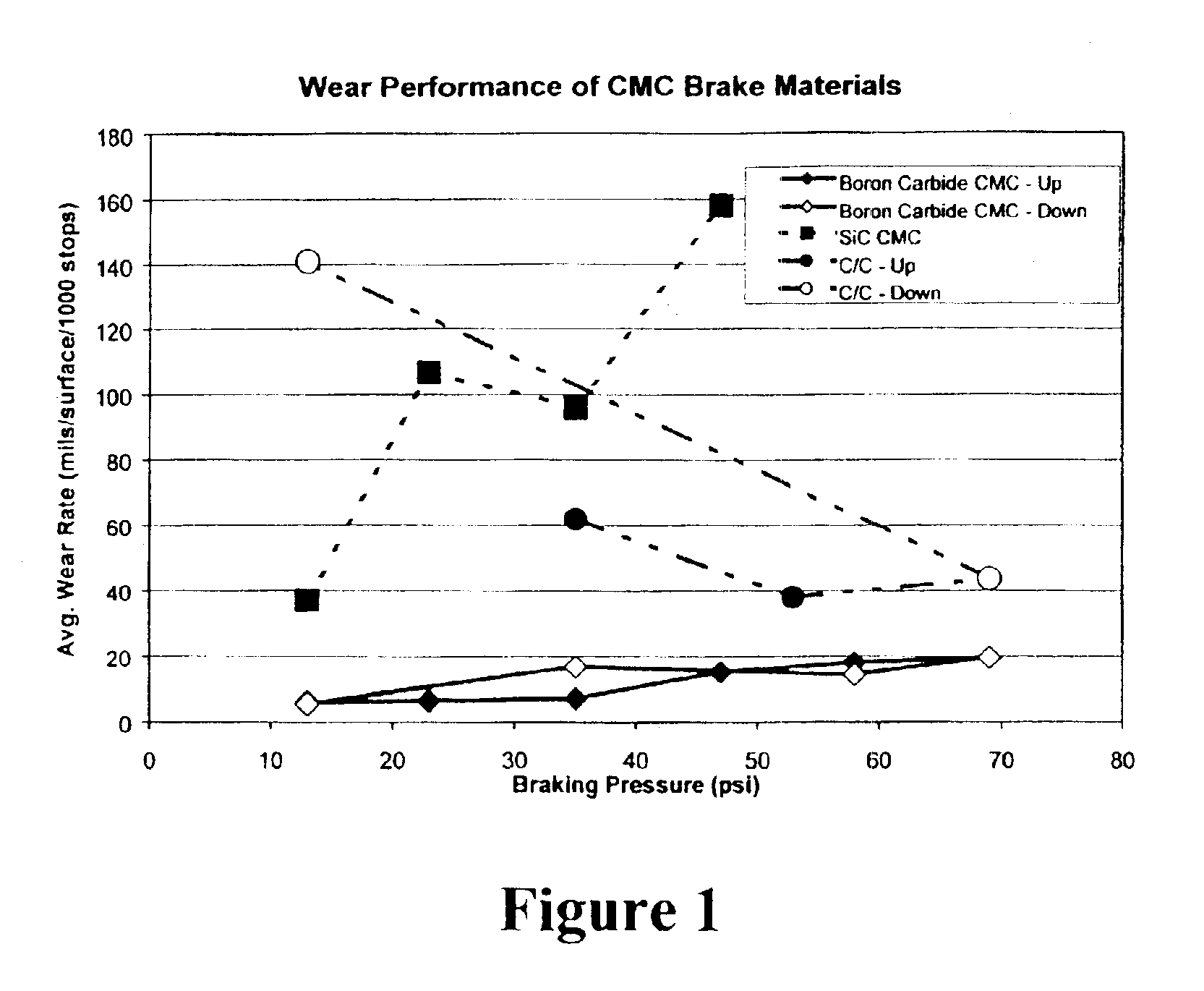

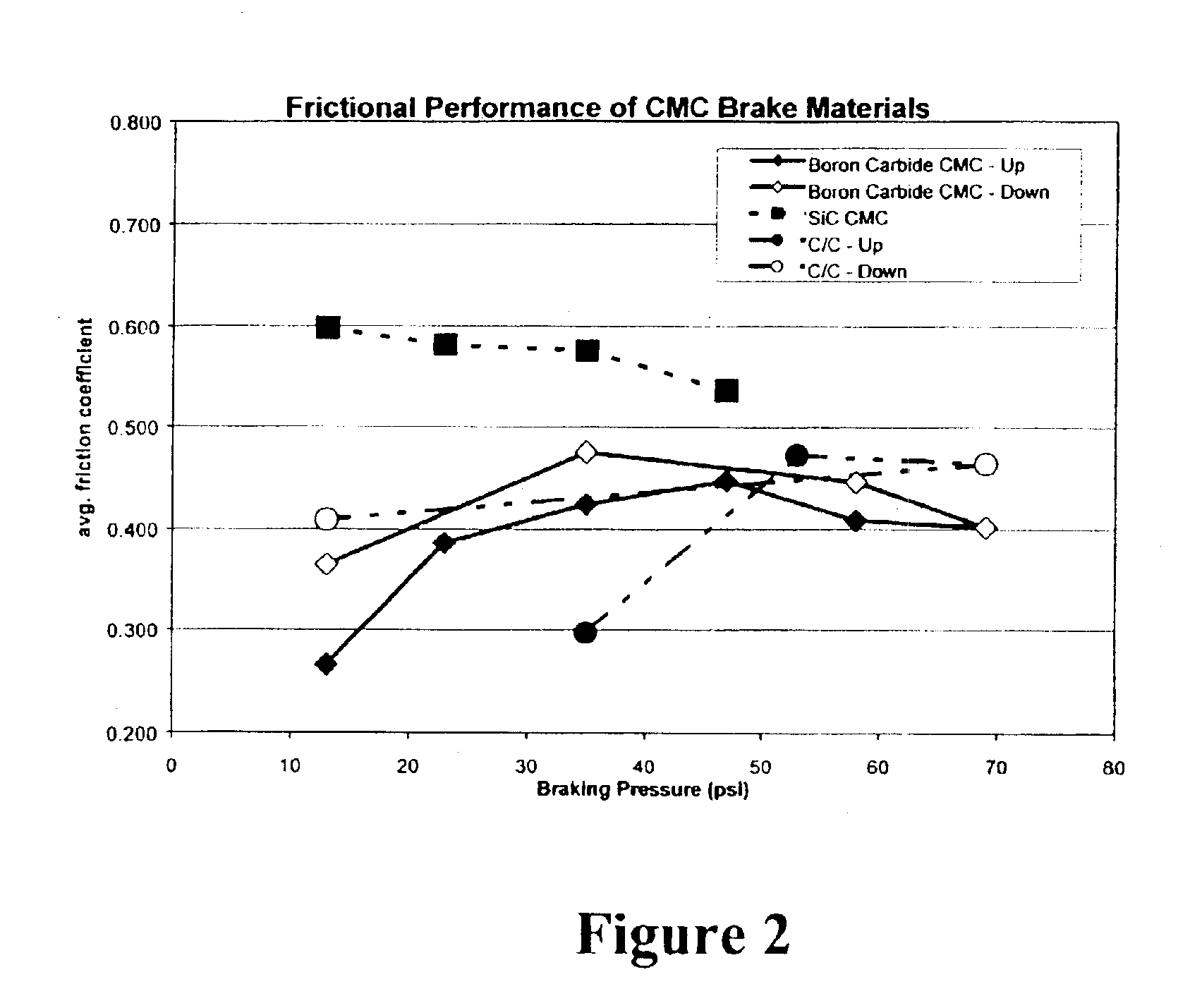

Boron carbide based ceramic matrix composites

InactiveUS6855428B2Big advantageReduce wear rateBraking discsPretreated surfacesSilicon matrixBoron carbide

The present invention is a composite material and process to produce same. That material comprises a fibrous structure which is initially predominantly coated with elemental carbon; that fibrous structure is then subsequently predominantly coated with at least one ceramic material, e.g., boron carbide, which is non-reactive with silicon. The composite material also comprises a silicon matrix which is continuous and predominantly surrounds the fibrous structure, which has been initially predominantly coated with elemental carbon and subsequently predominantly coated with at least one ceramic material. The matrix which has a fine grain crystalline structure of predominantly 20 microns or less in size. The at least one ceramic material is discontinuous within that matrix. The fibrous material pulls out of the elemental carbon, which initially predominantly coats that fibrous structure, when the composite is subjected to fracture.

Owner:THE BF GOODRICH CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com