Patents

Literature

514results about "Braking drums" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

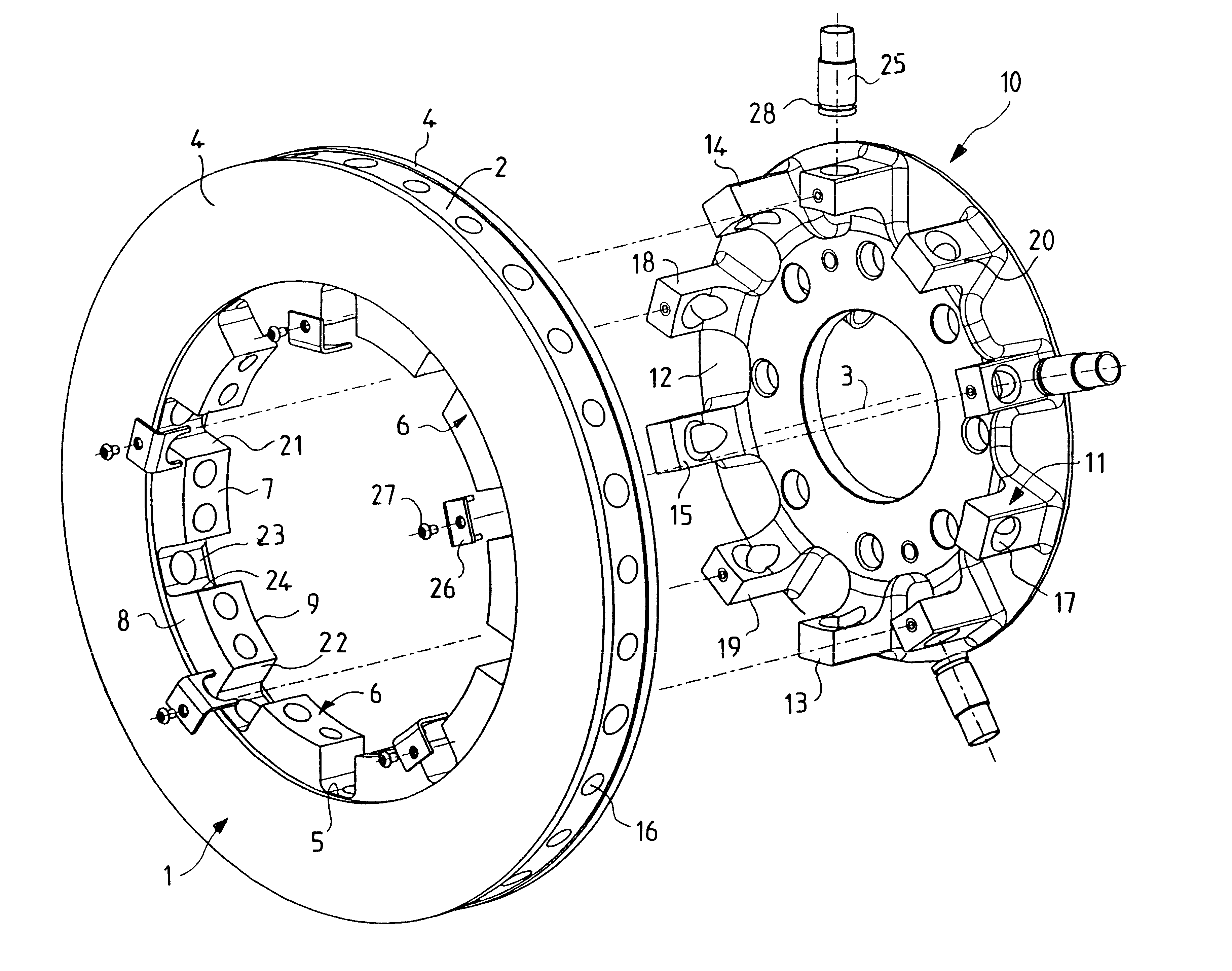

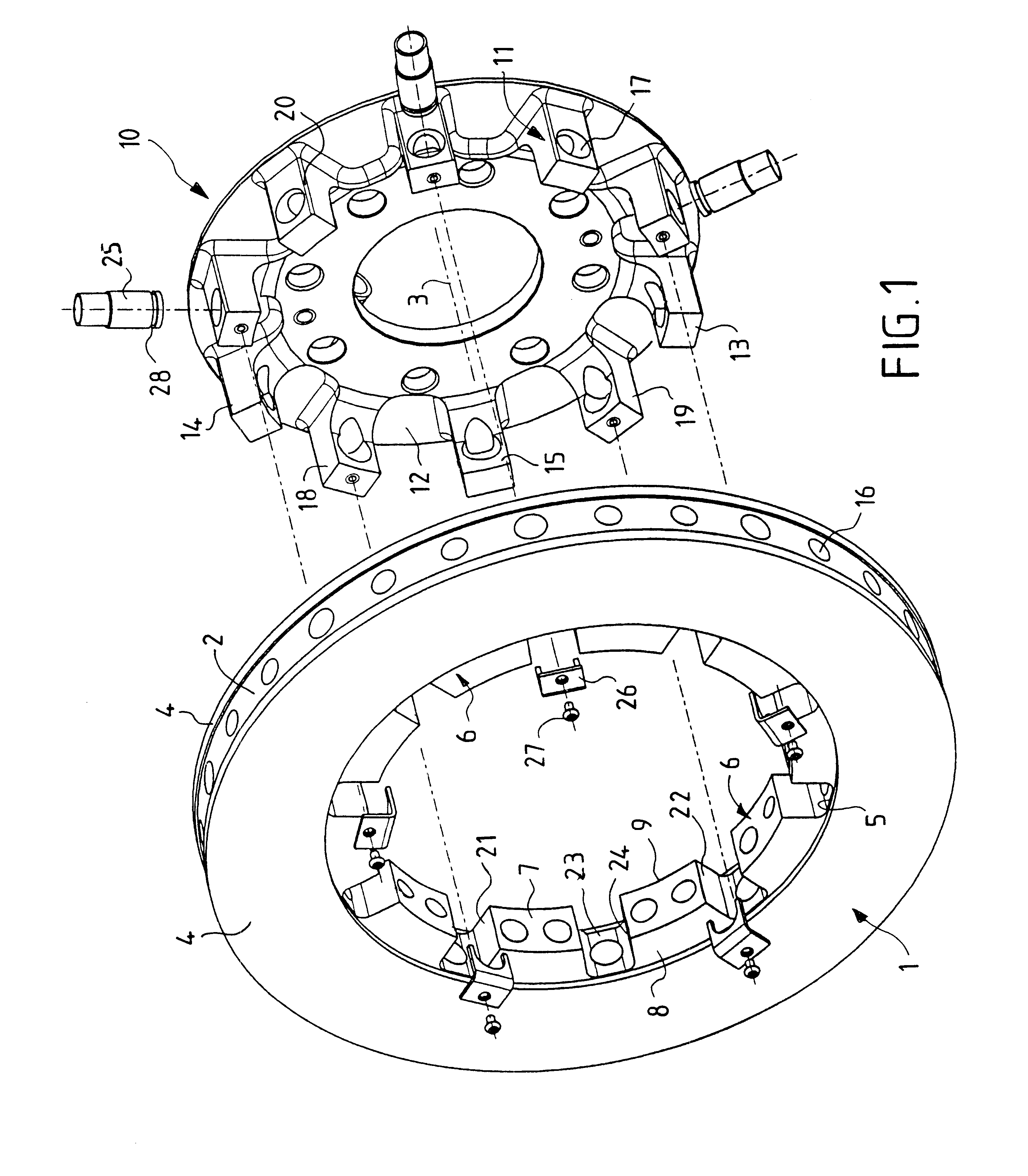

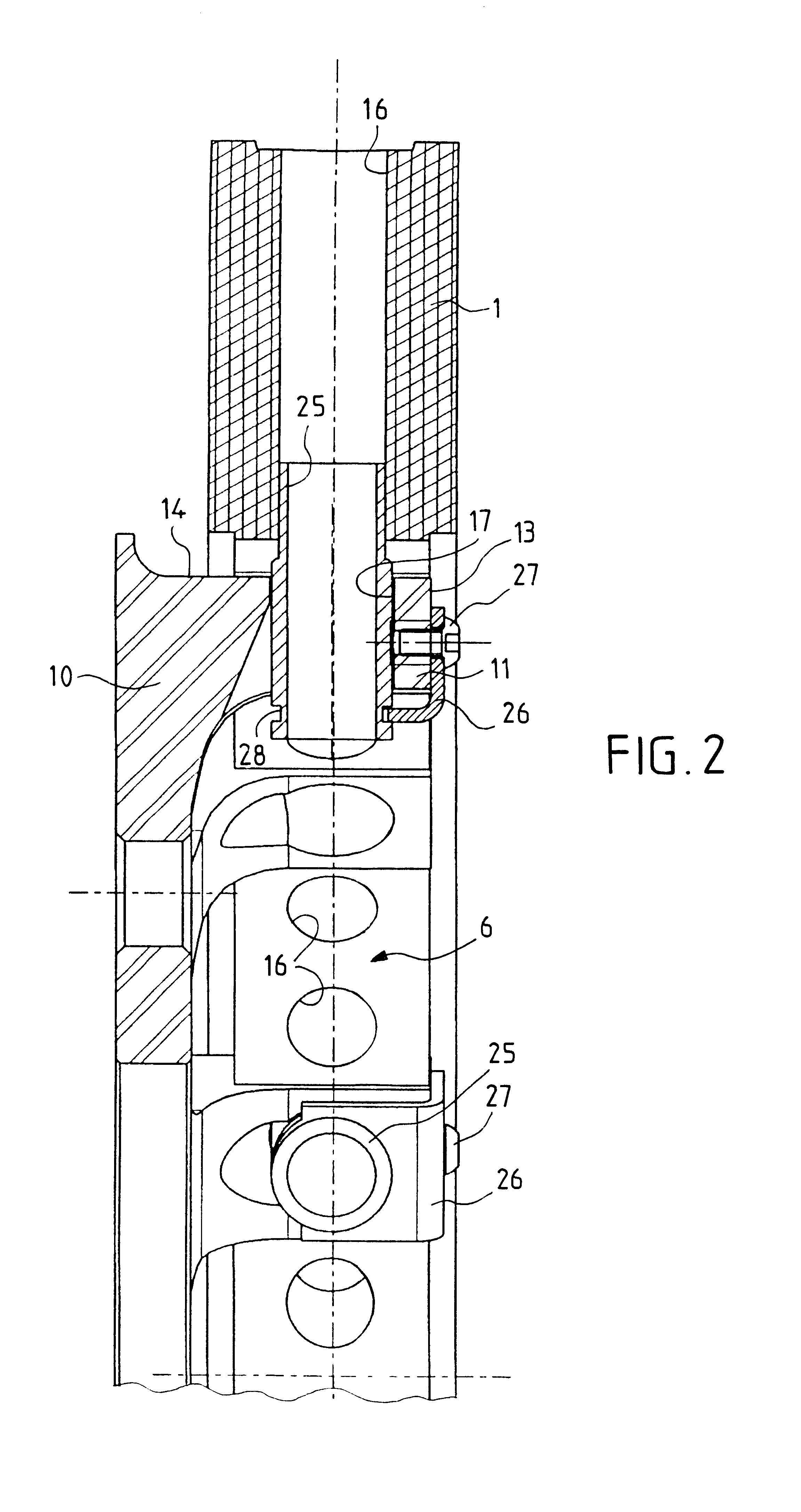

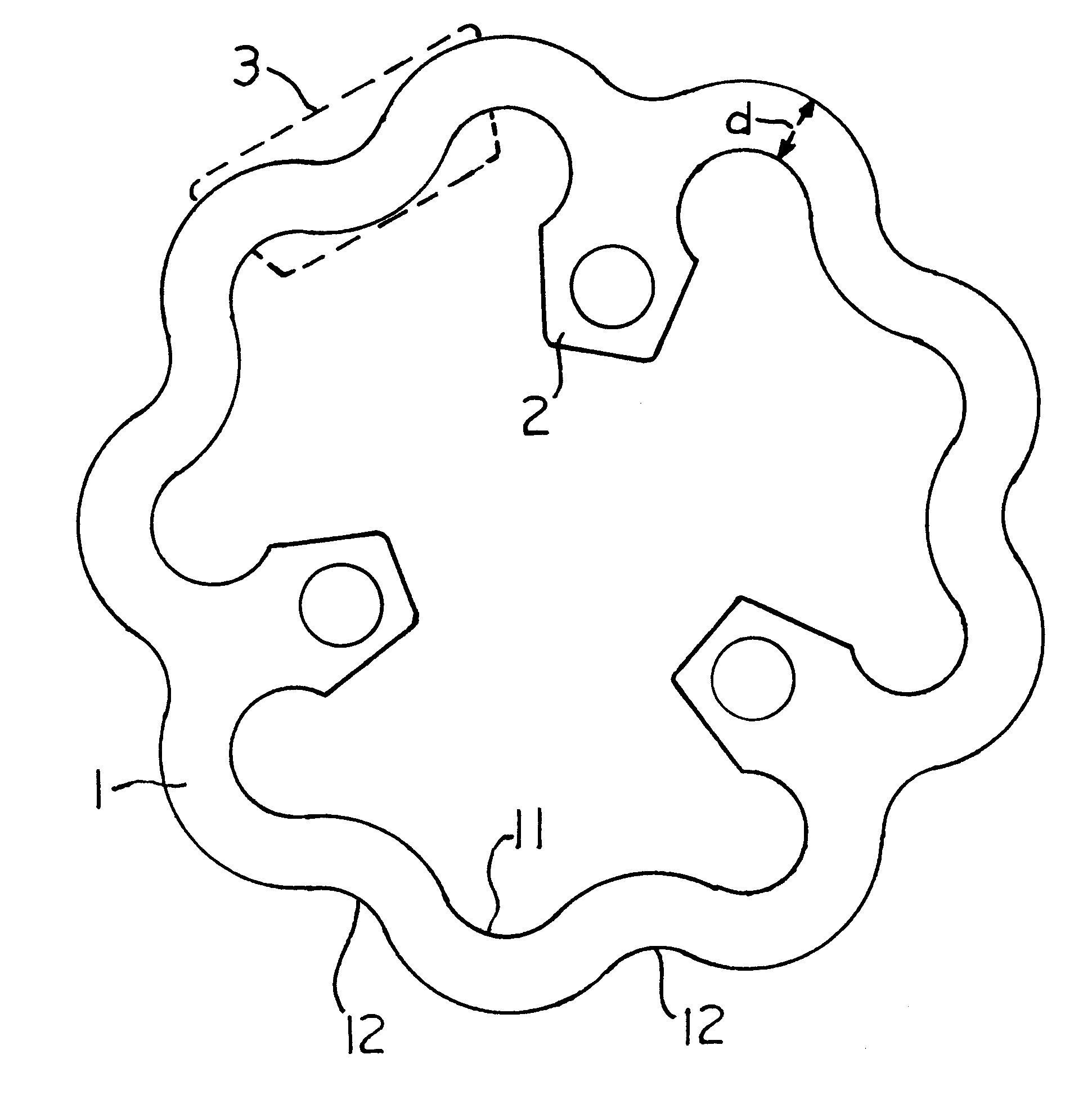

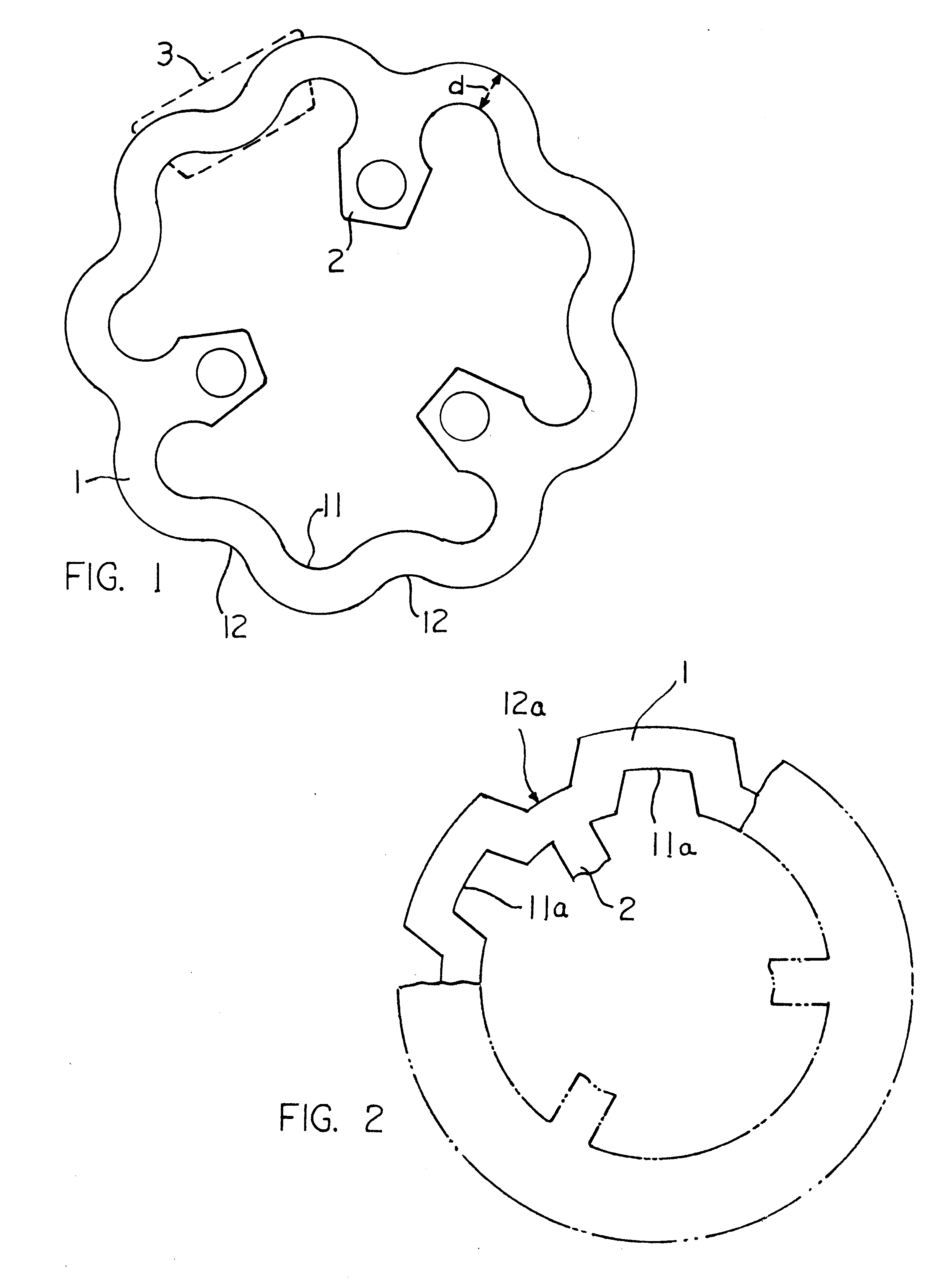

Device for fixing a ventilated brake disk axially on the hub of a motor vehicle wheel

InactiveUS6446765B1Easy to controlHigh speed usBraking element arrangementsAxially engaging brakesEngineeringMechanical engineering

An axial fixing device for axially fixing an annular brake disk on a wheel hub of a motor vehicle, the annular brake disk having the same axis of rotation as the hub and including radial ventilation ducts regularly distributed about its periphery. According to the invention, the hub has axial guide pieces in relief, or "lugs", for co-operating with fluting in an inner peripheral edge of the disk to center the disk, to lock it angularly, and to guide it axially relative to the hub, each lug of the hub having a radial through channel for co-operating with a corresponding ventilation duct of the disk, and the disk is held axially in the hub with play by axial holding means disposed between the disk and the hub.

Owner:MESSIER BUGATTI INC

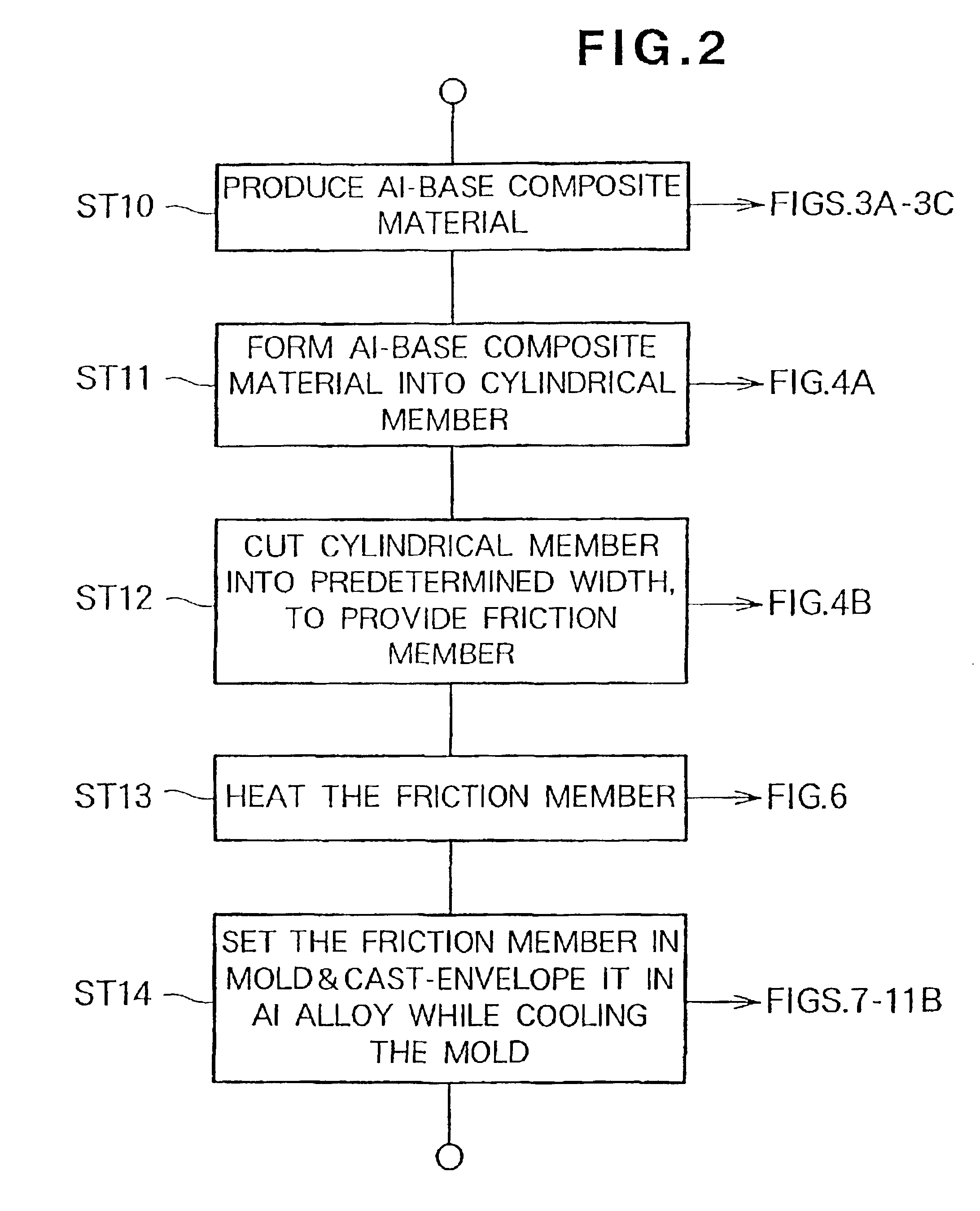

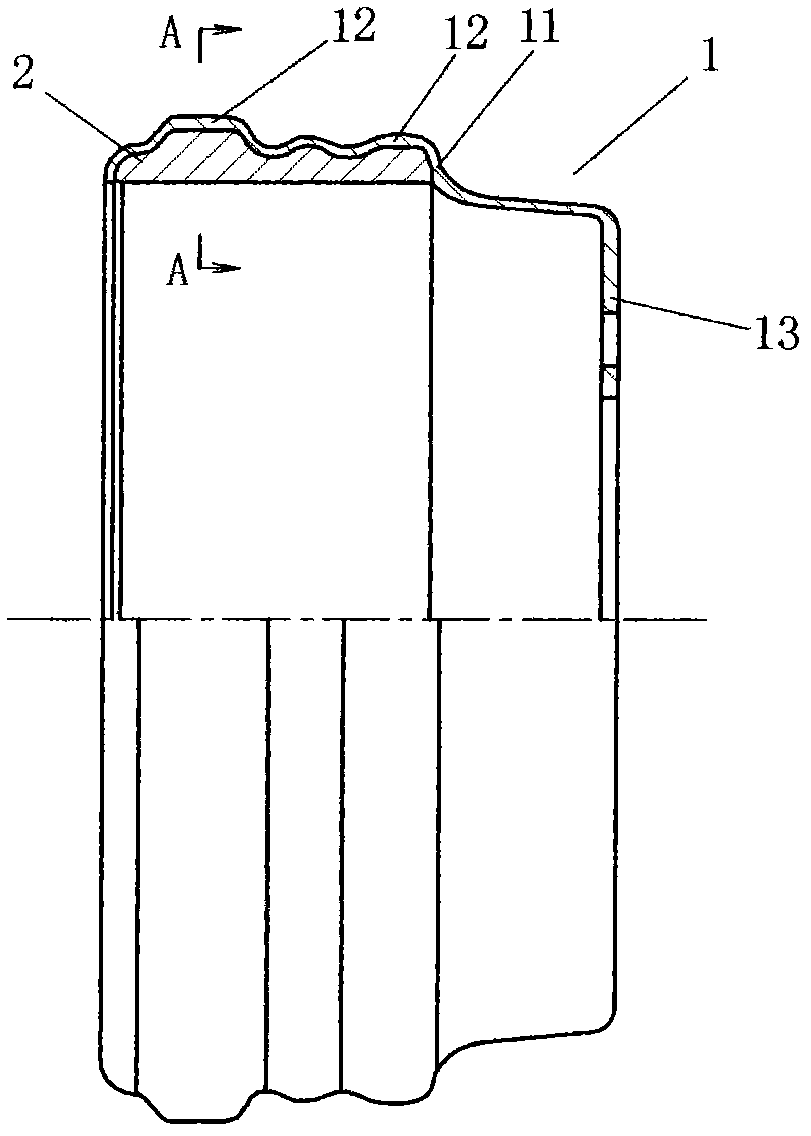

Brake drum and method for producing the same

Owner:HONDA MOTOR CO LTD

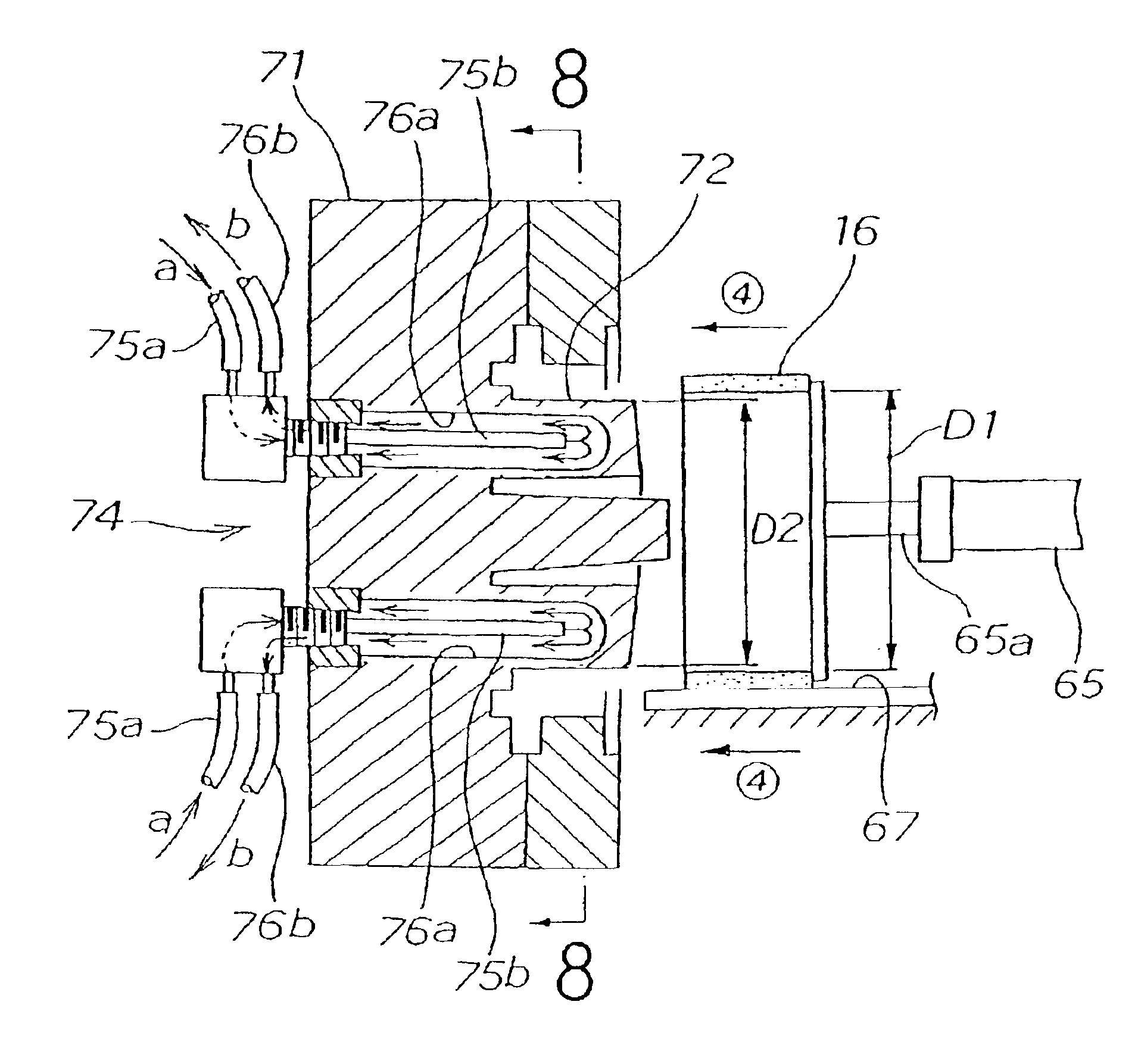

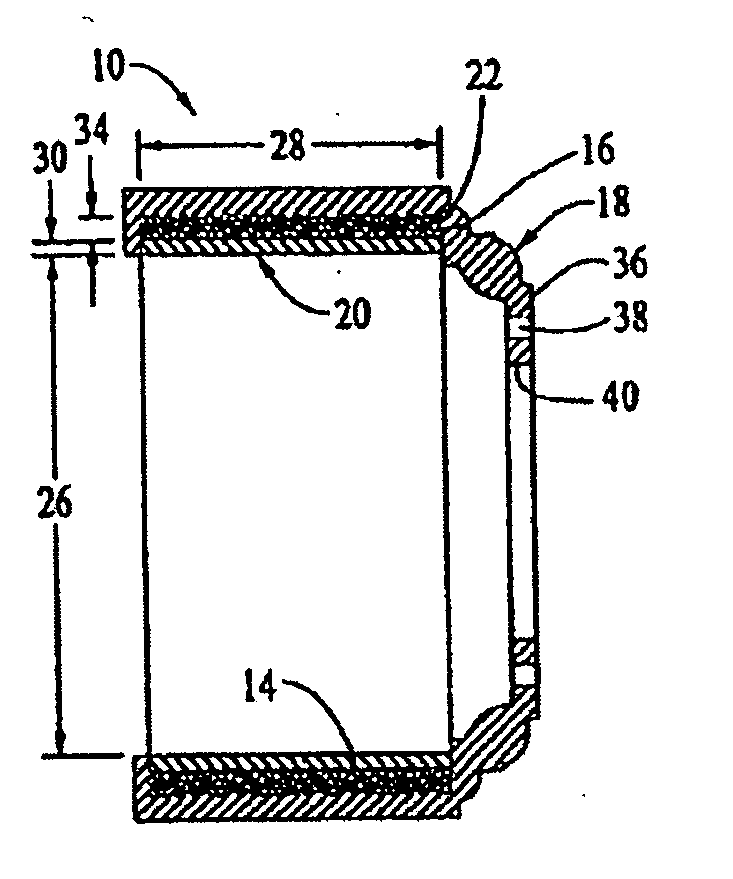

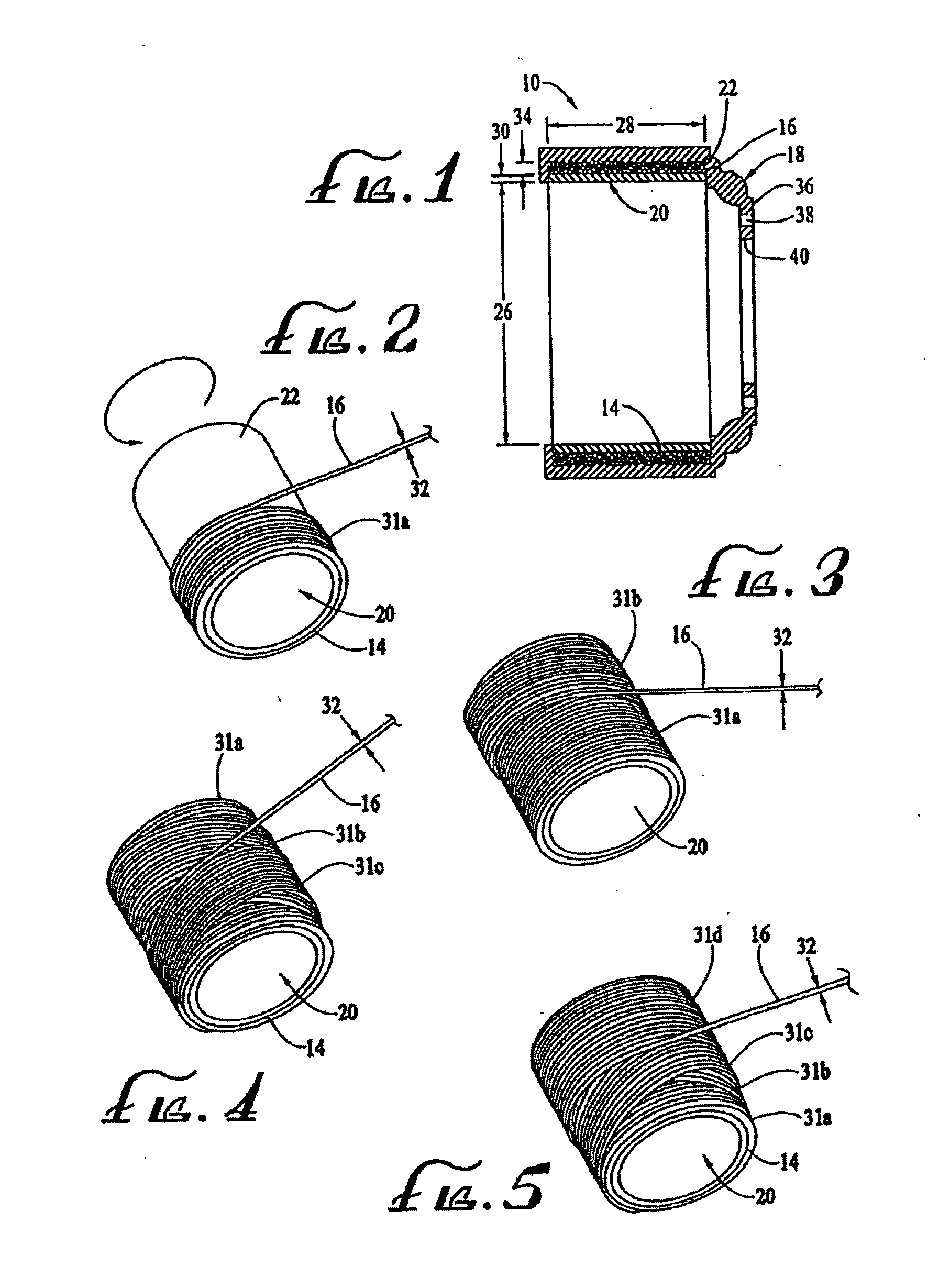

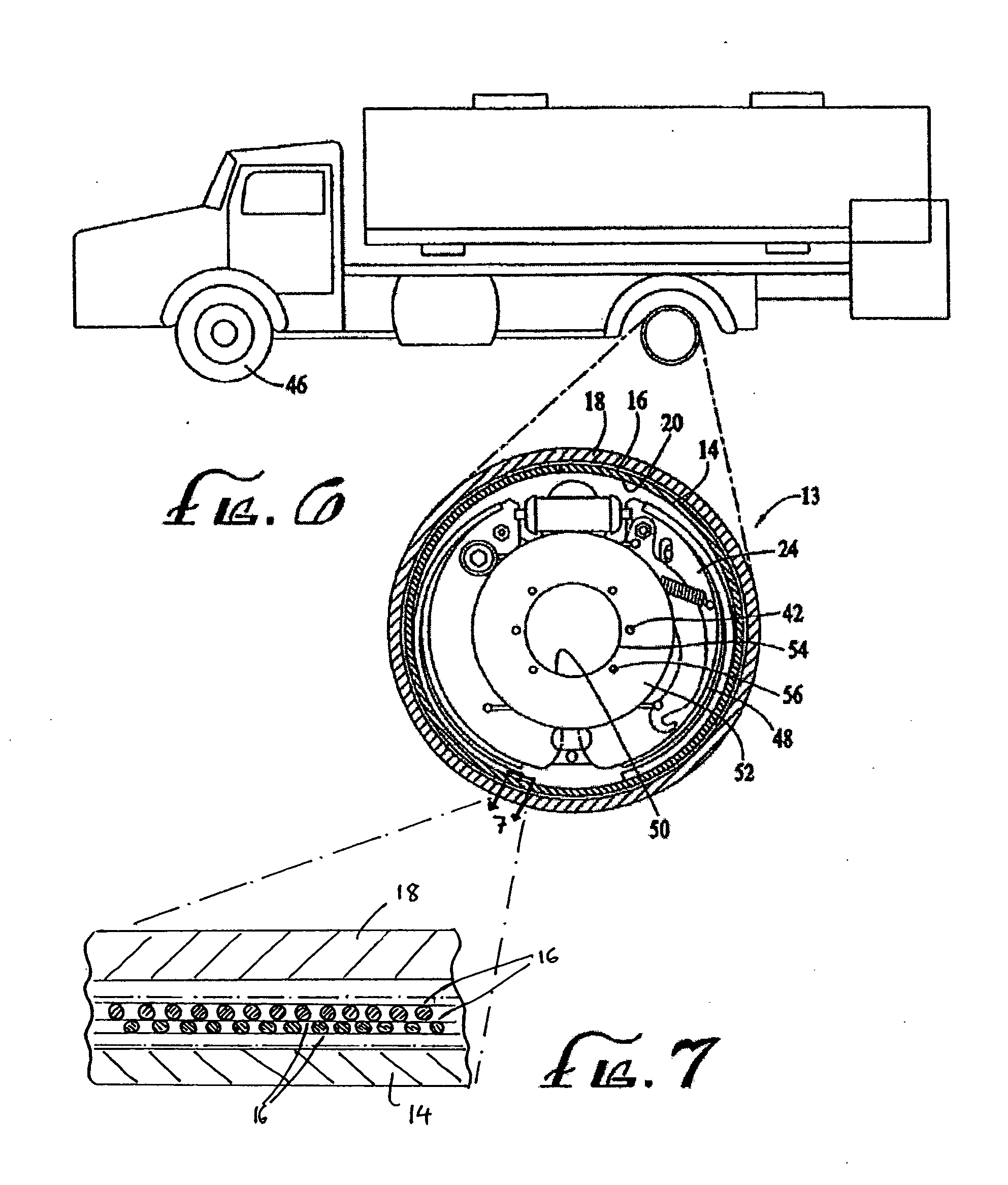

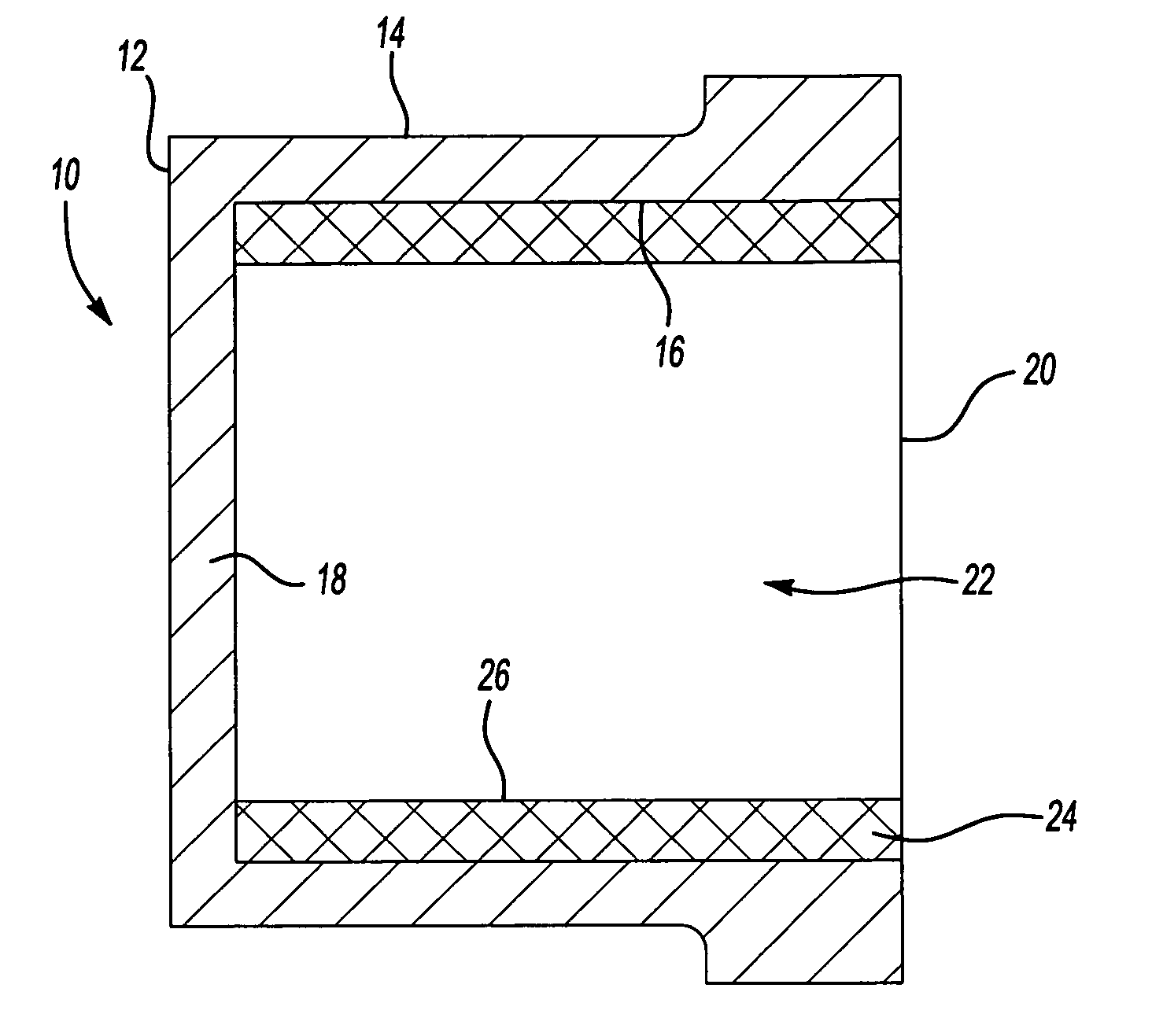

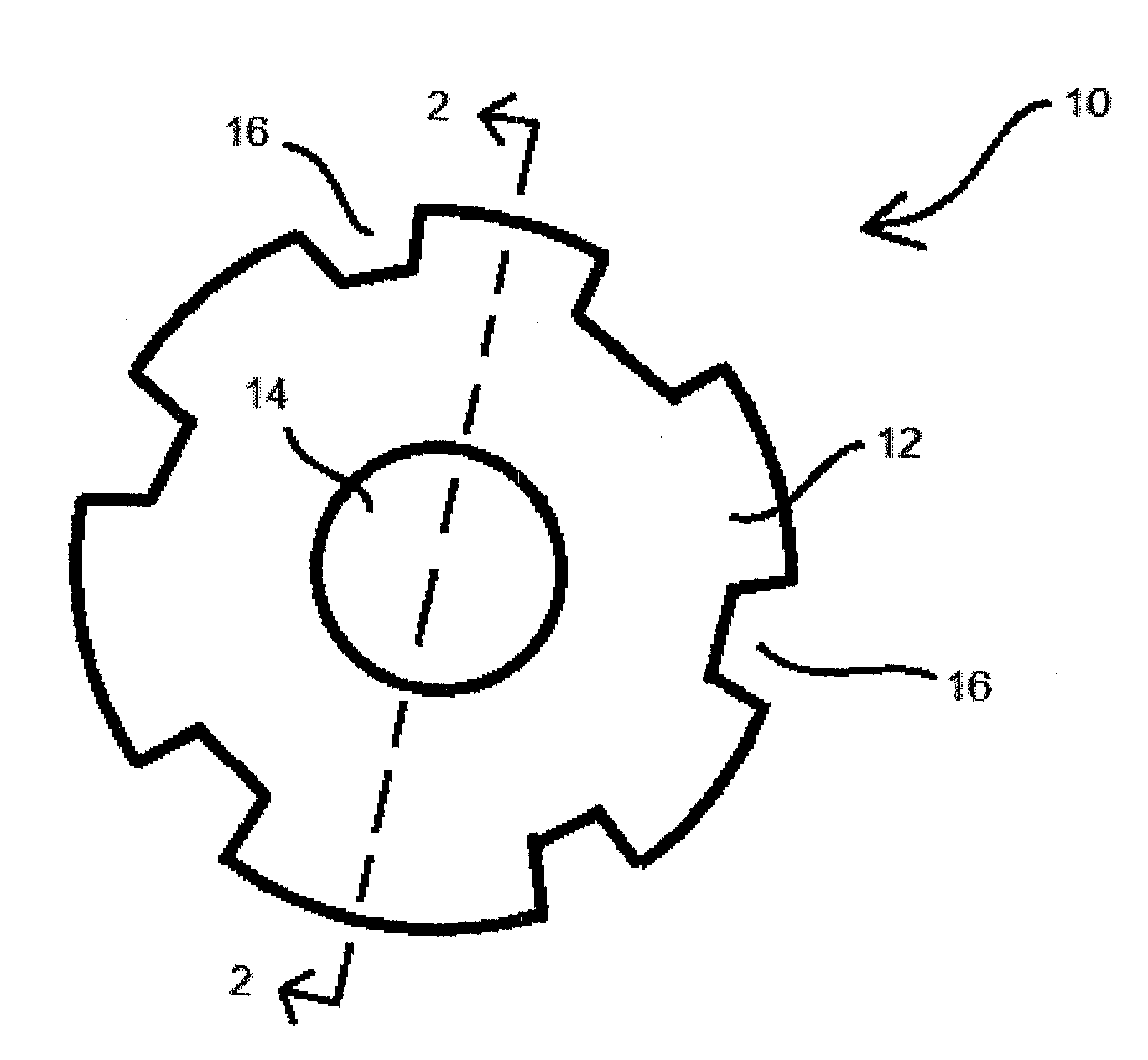

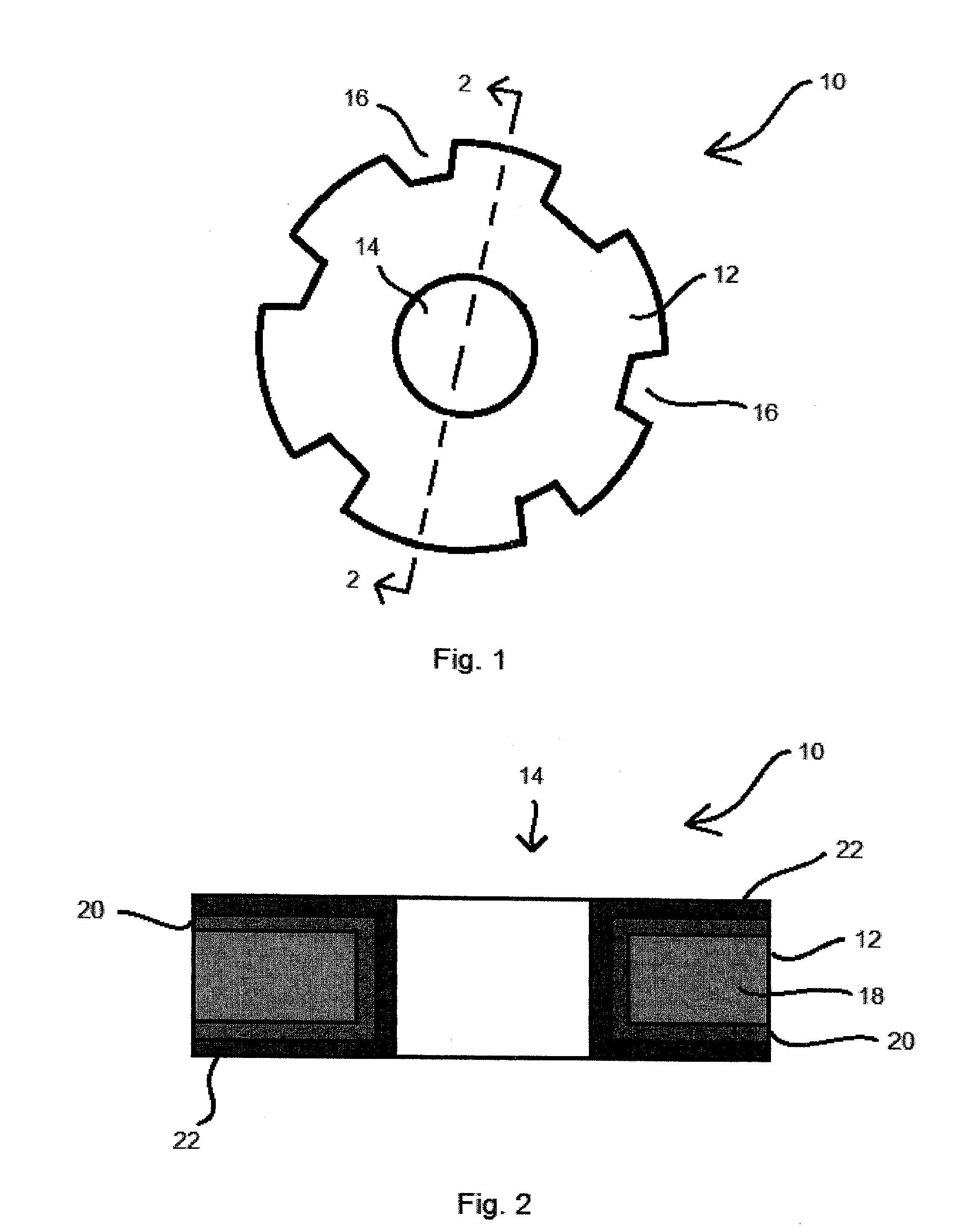

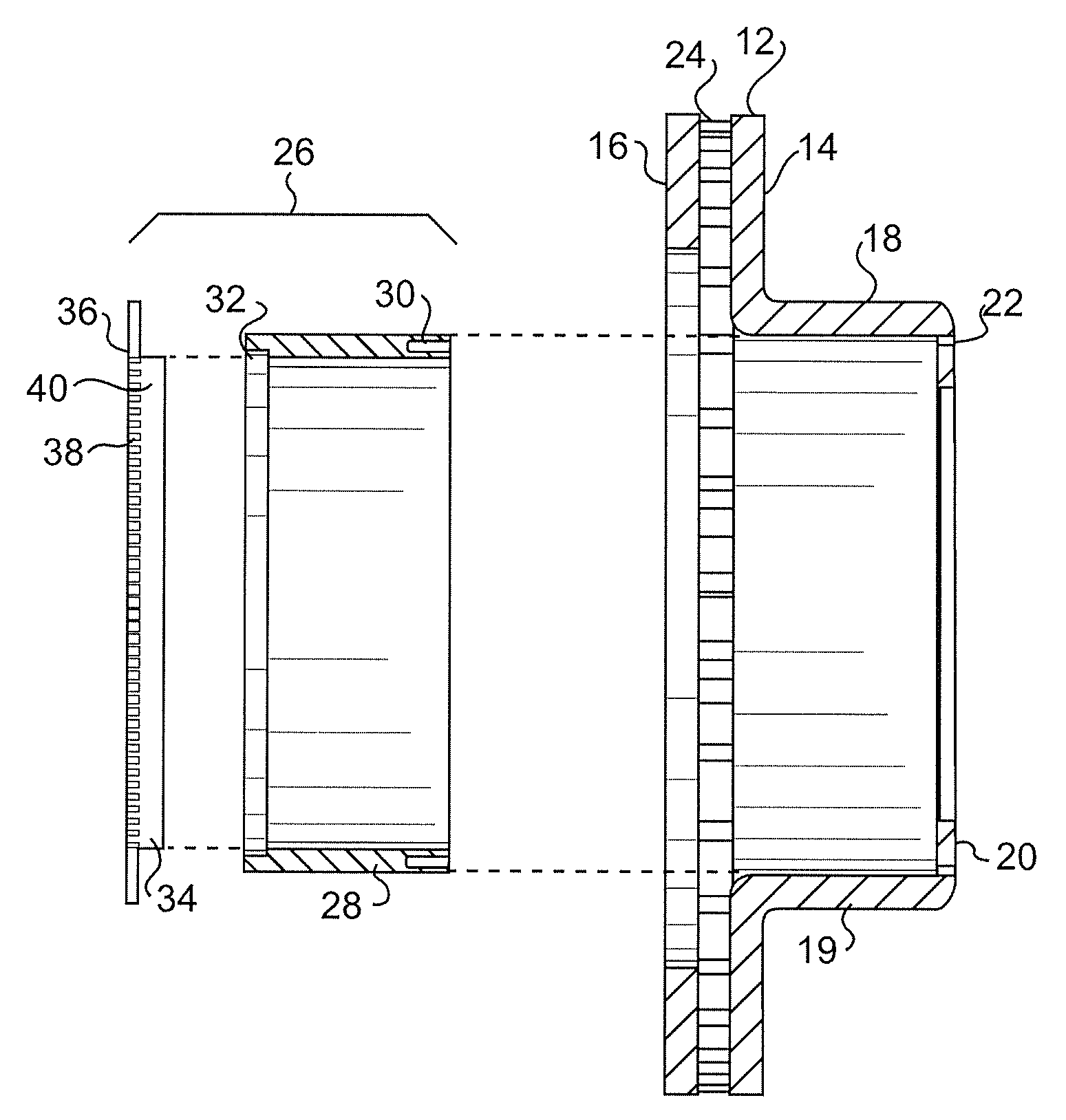

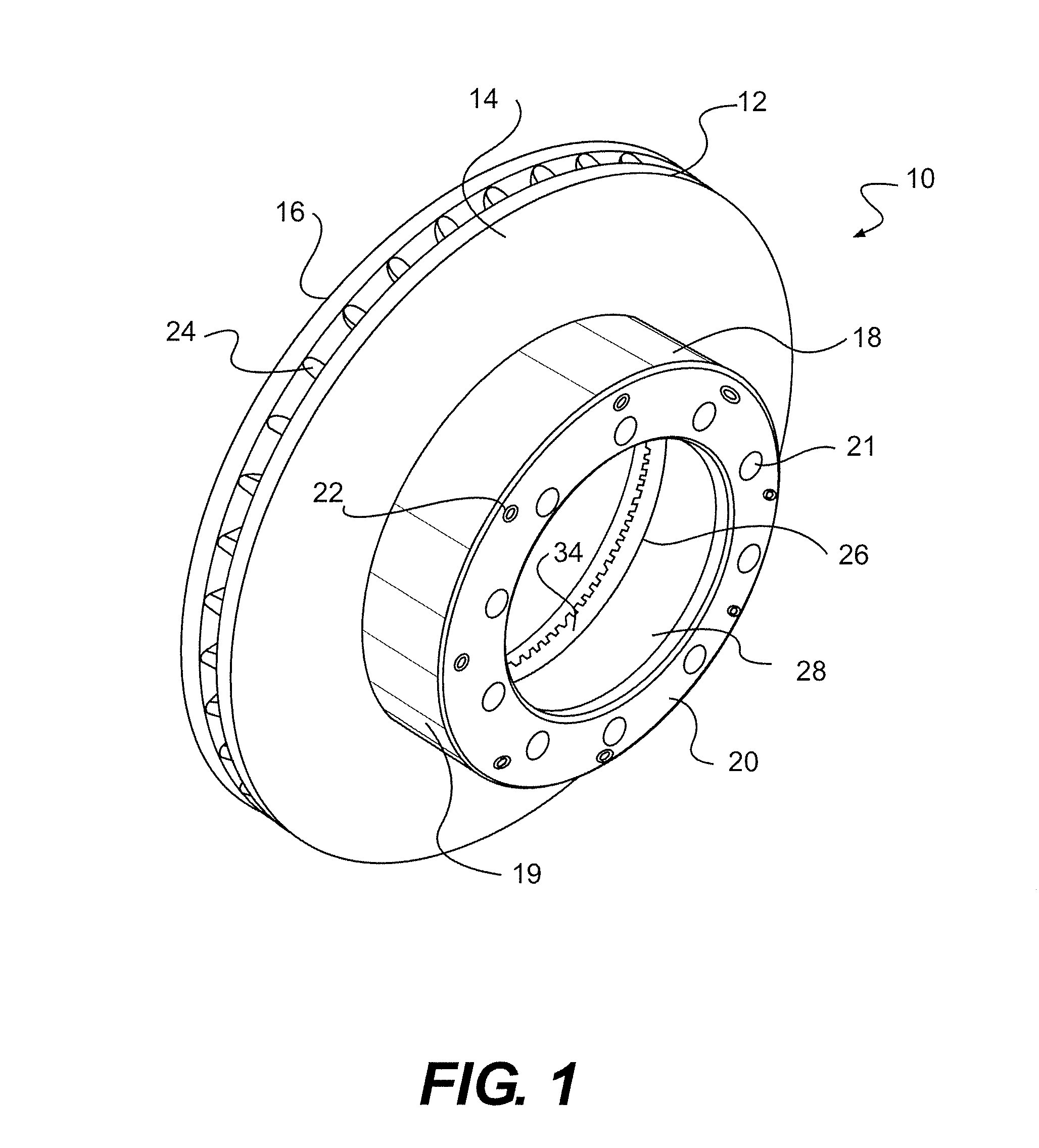

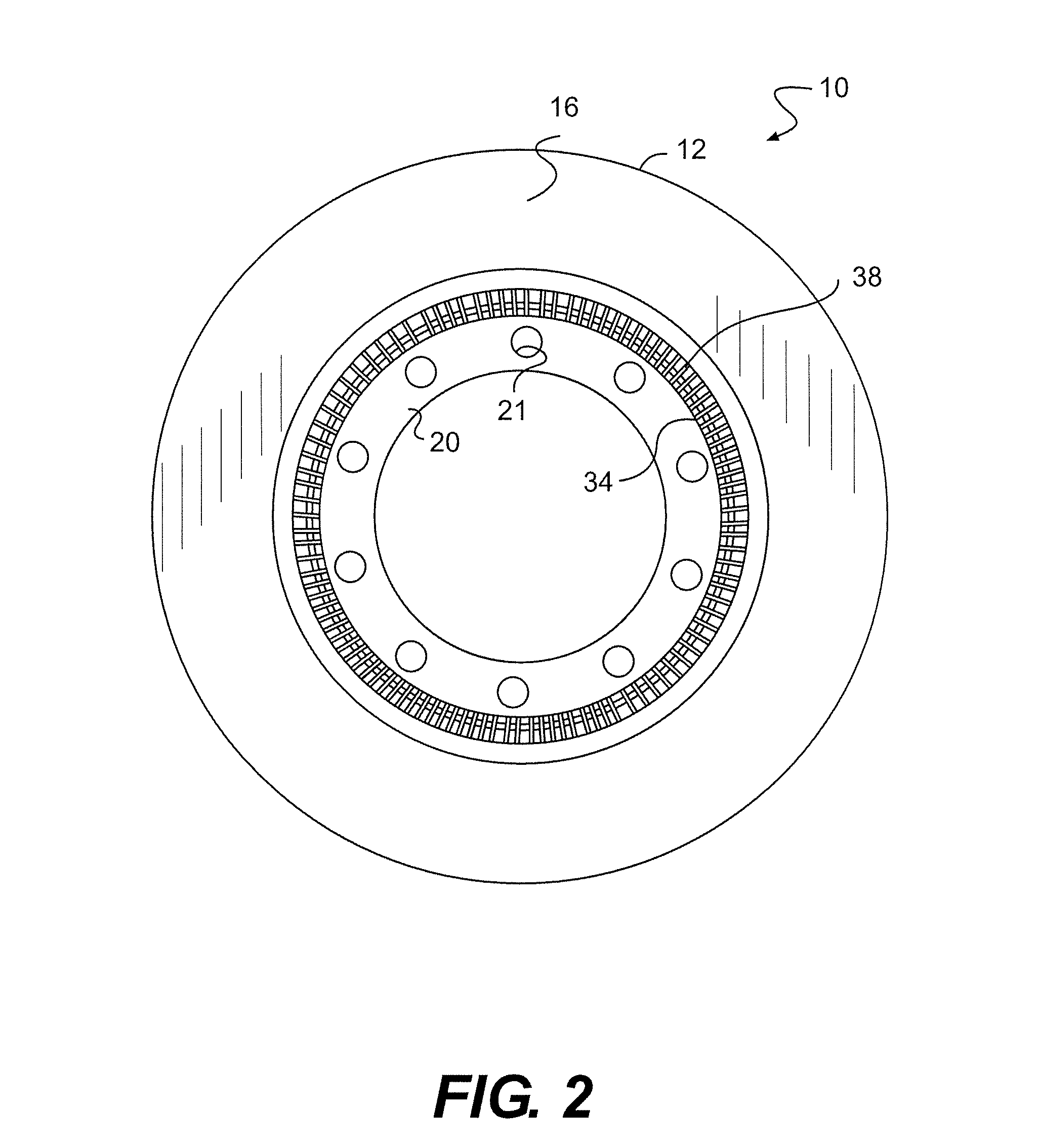

Lightweight reinforced brake drum and method for making same

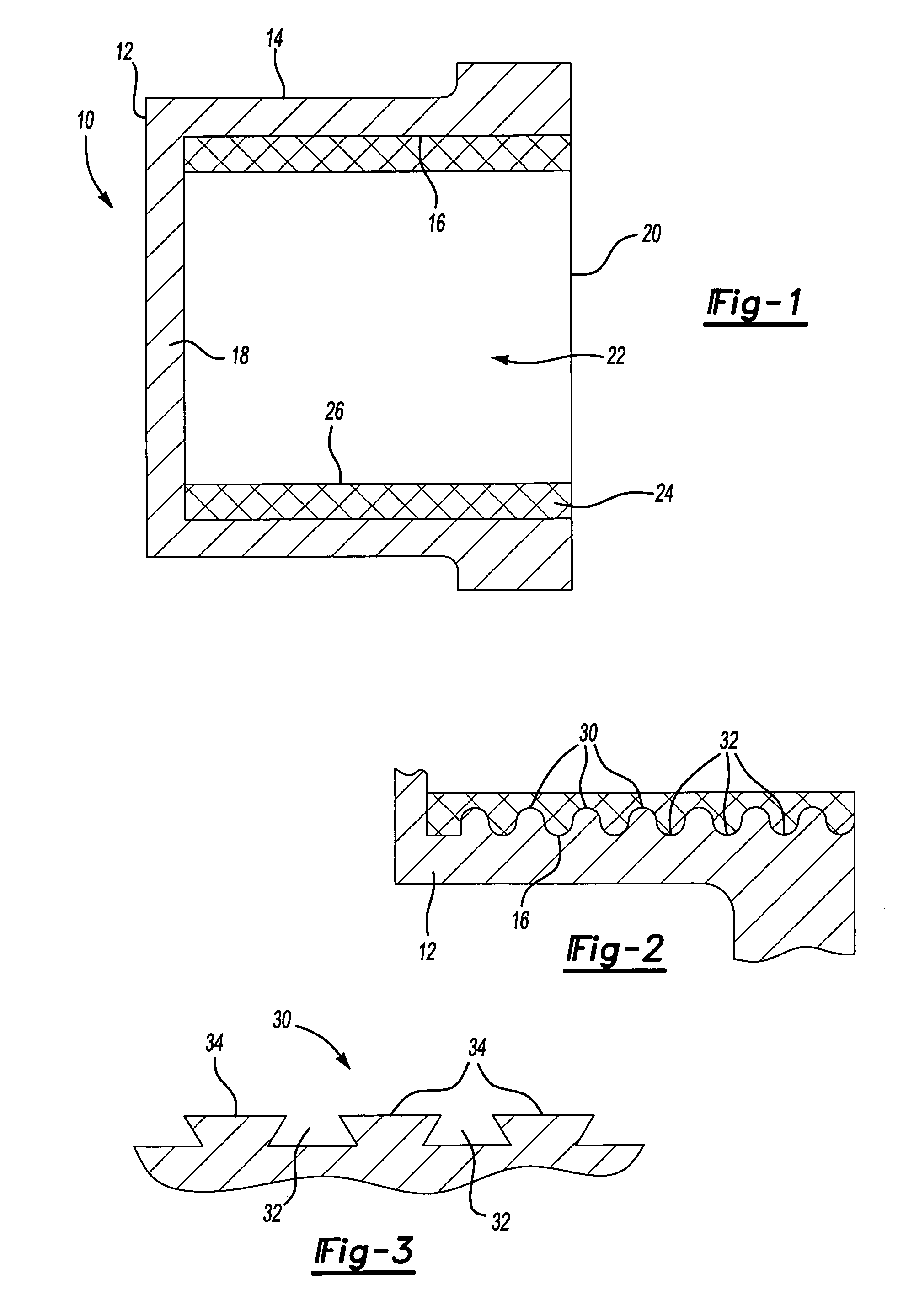

InactiveUS20050217950A1Reduce manufacturing costAdd supportBraking drumsCoatingsCarbon graphiteEngineering

The invention provides a lightweight brake drum (10) comprising a lightweight, tubular inner member (14) having a reinforcement wrapping retention pattern (e.g., groove) cast in the exterior surface thereof, a length of reinforcement material (e.g., wrapped wire, cable, mesh, fibers, etc.) (16) in communication with a reinforcement retention pattern (e.g., a groove around the inner member) (14), the drum including an outer shell (18). The inner member (14) and the outer shell (18) are made of lightweight materials. Single, or multiple layers of reinforcement material (e.g. wrapping) are applied (e.g., wrapped) around the inner member (14) to support and inhibit expansion of the inner member (14). Because the reinforcement material (16) provides support against expansion, the inner member (14) and the outer shell (18) can be made of lightweight materials. In preferred embodiments, a bonding layer (66) is applied to the exterior surface of the inner member prior to application of the reinforcement material thereon. In preferred embodiments the reinforcement material comprises a low-impedance material such as copper along with another material that has good tensile strength characteristics (e.g., steel, composite fibers, Basalt-fibers, etc.). Preferably, the inner member comprises at least one material selected from the group consisting of a aluminum-based metal matrix composite (MMC) with a particulate reinforcement, ceramic matrix composite (CMC), and carbon graphite foam.

Owner:BENMAXX

Brake assembly and coating

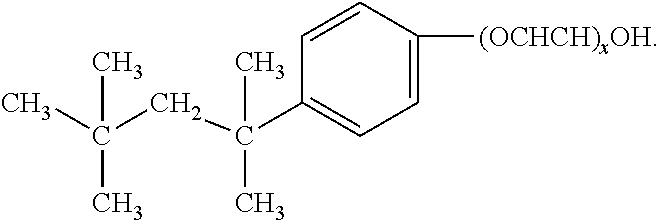

InactiveUS20060272909A1Reduce the possibilityMaintaining torqueMolten spray coatingAxially engaging brakesWear resistantCorrosion

A brake assembly is provided that includes a wear-resistant surface, or a surface prone to corrosion, wherein the surface is coated with a coating that optimizes wear-resistance, corrosion-resistance, adhesiveness, and friction factors of the coating. The coating includes a sacrificial corrosion constituent and a second constituent that is relatively harder than the sacrificial corrosion constituent wherein typical metals often employed as sacrificial anodes for example are contemplated. These include aluminum, zinc, and alloys thereof. The second constituent is potentially formed from a carbide, nitride, oxide, transitional metals and alloys thereof, and mixtures thereof.

Owner:DELPHI TECH INC +1

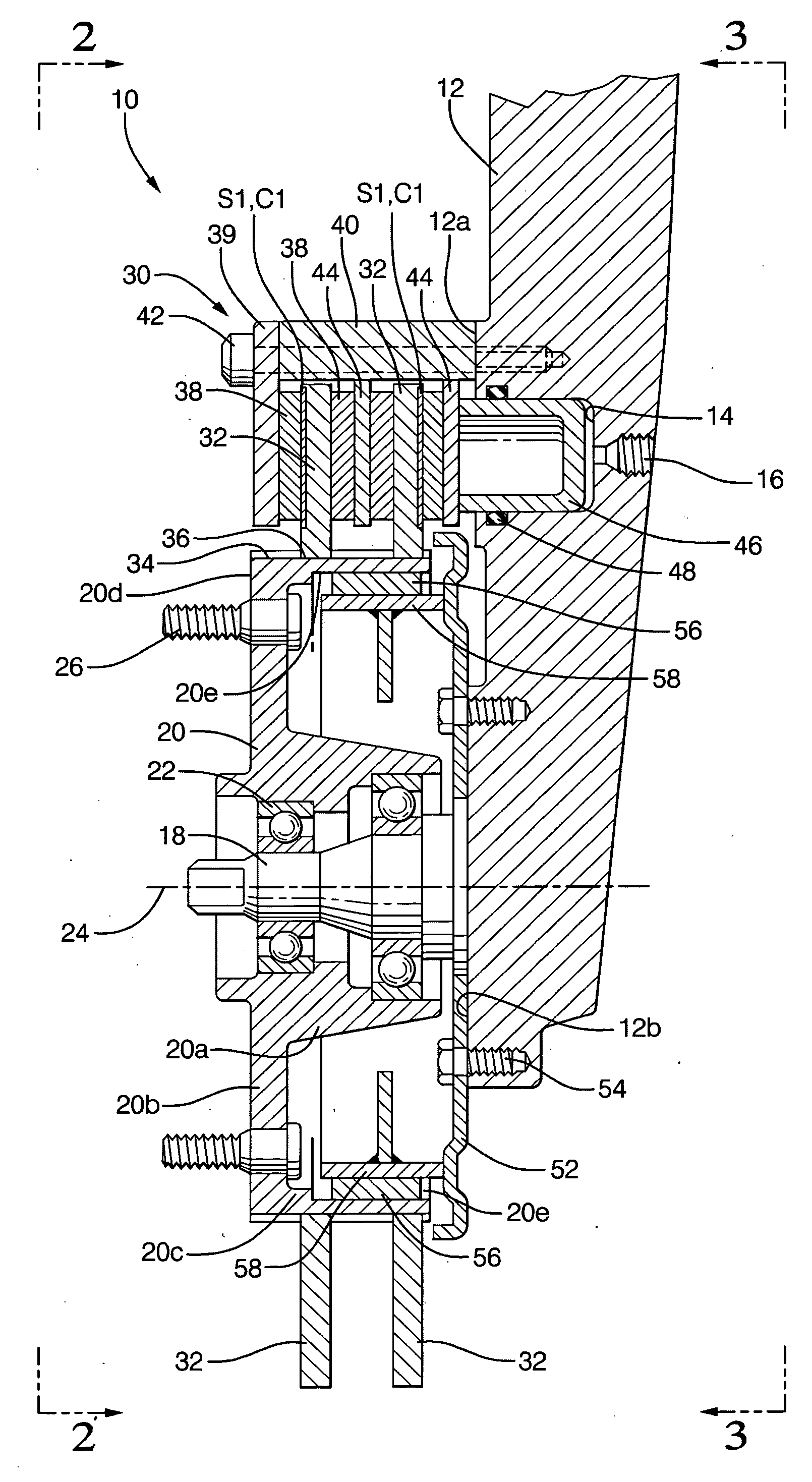

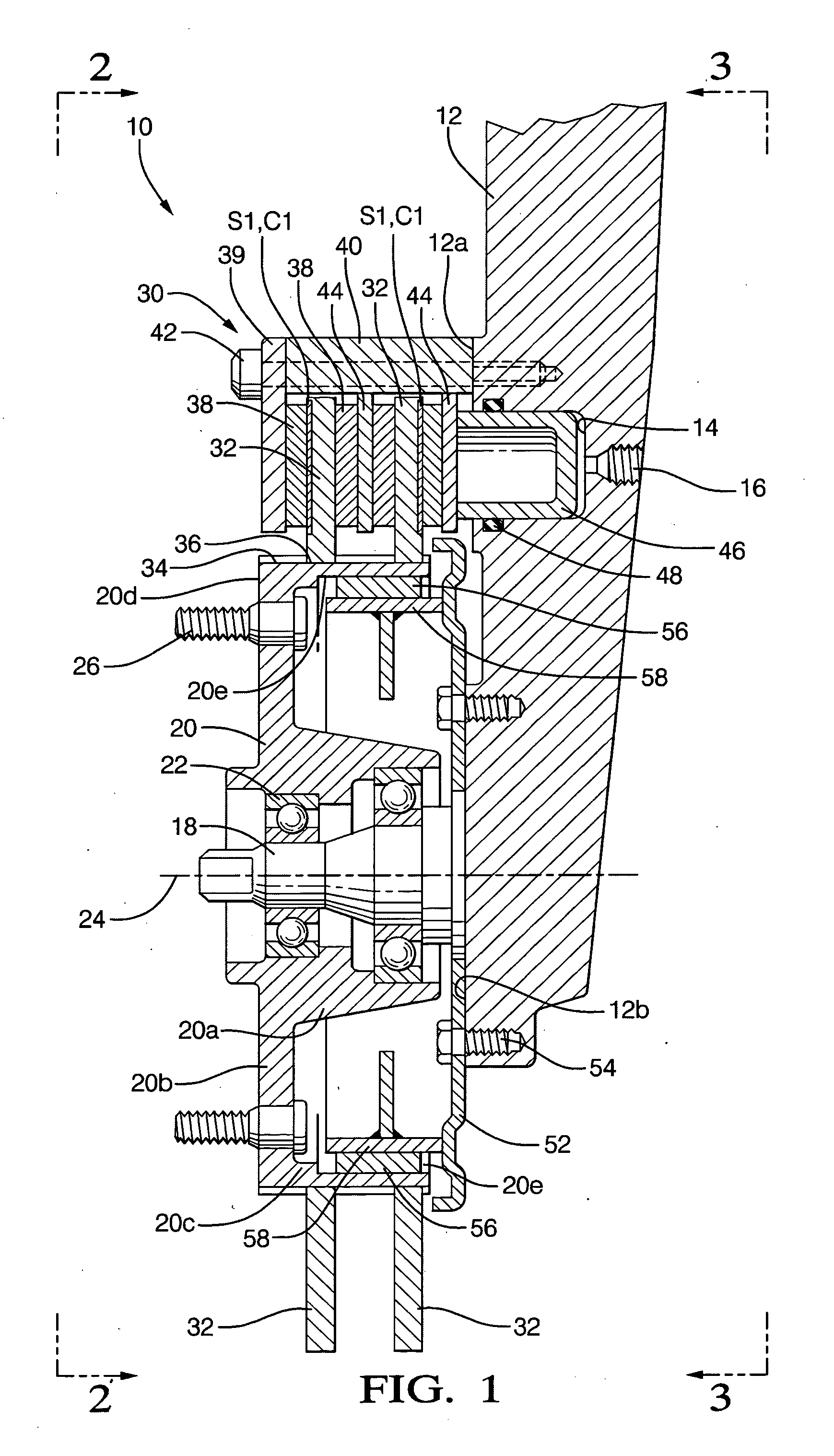

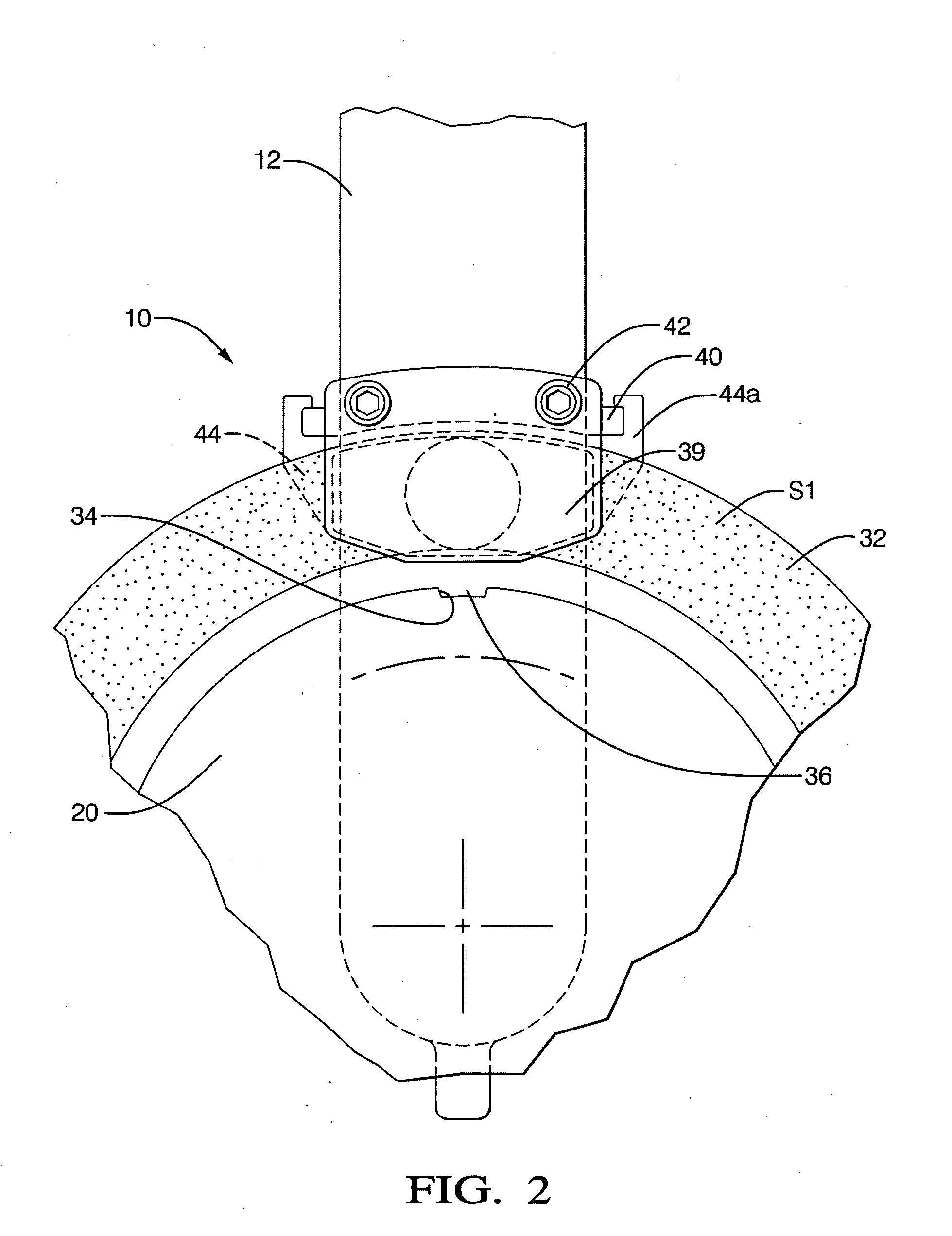

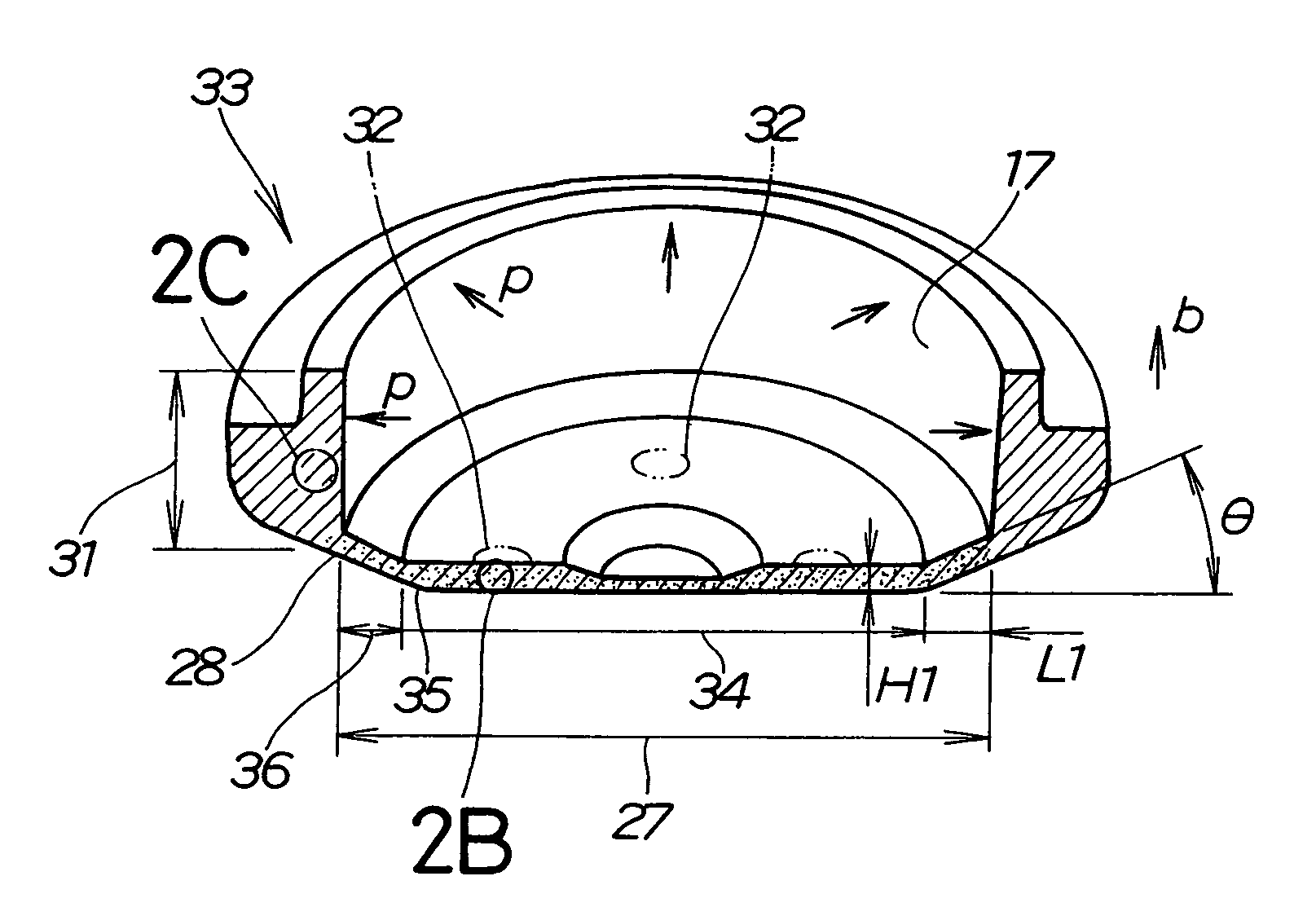

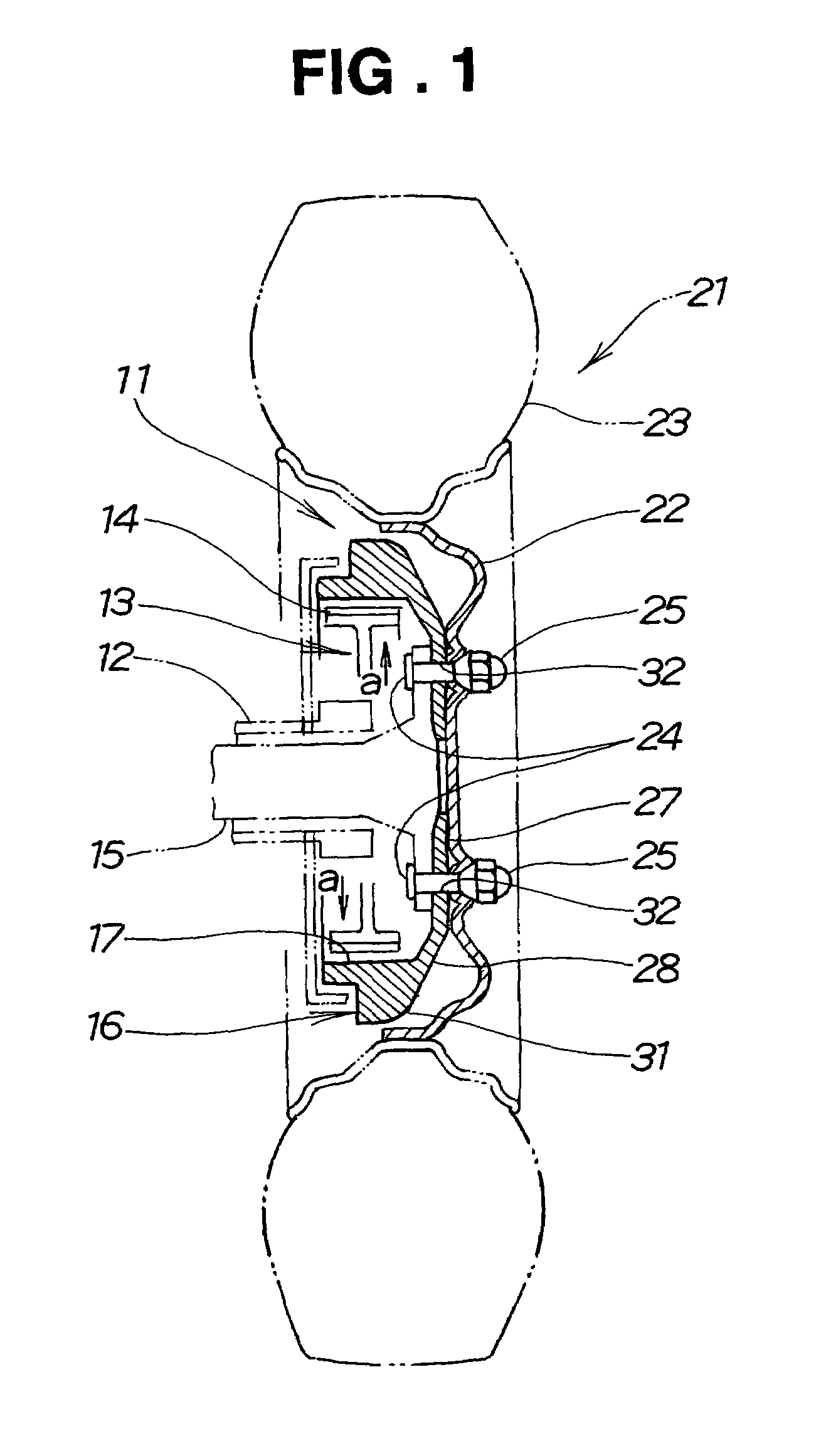

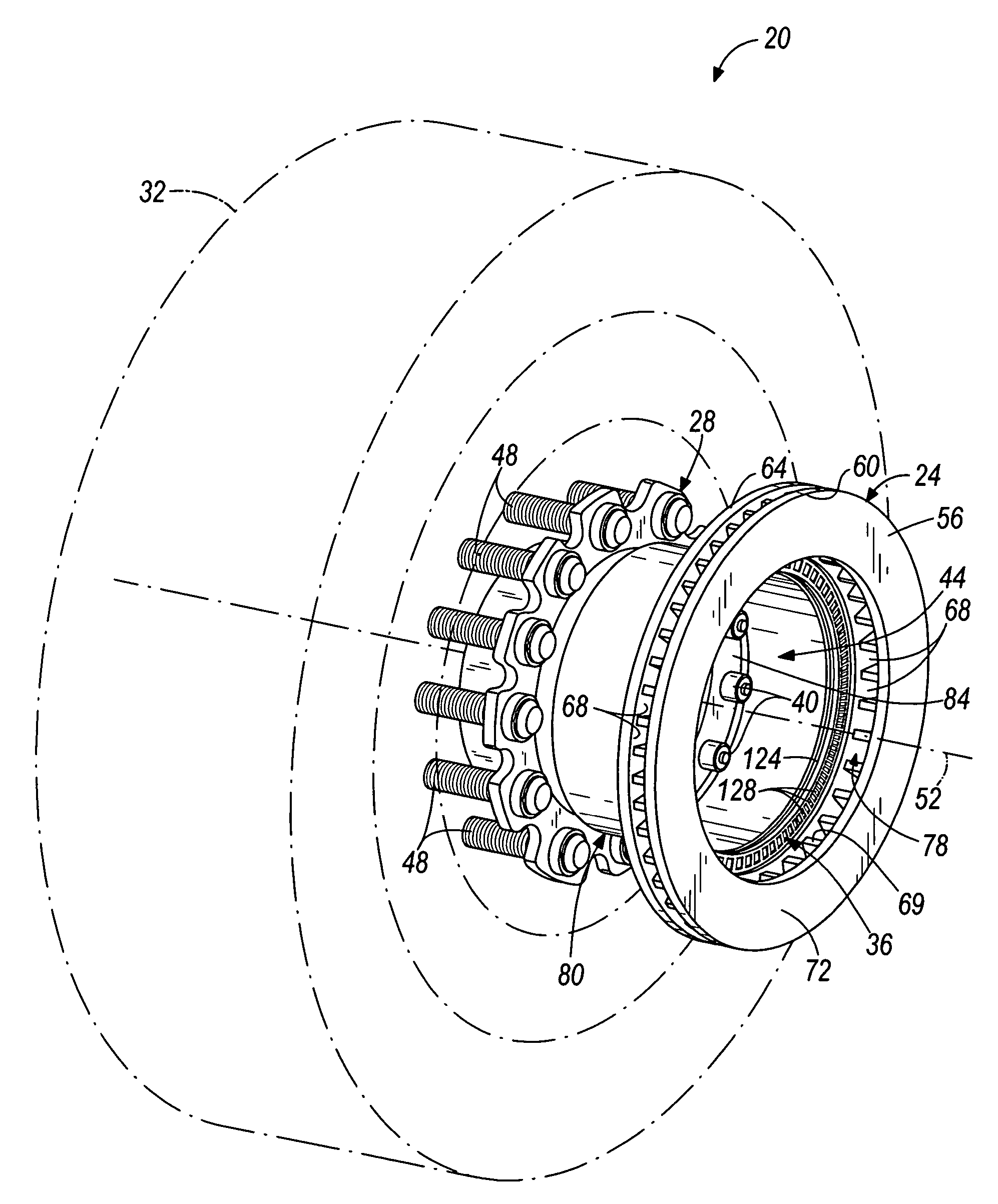

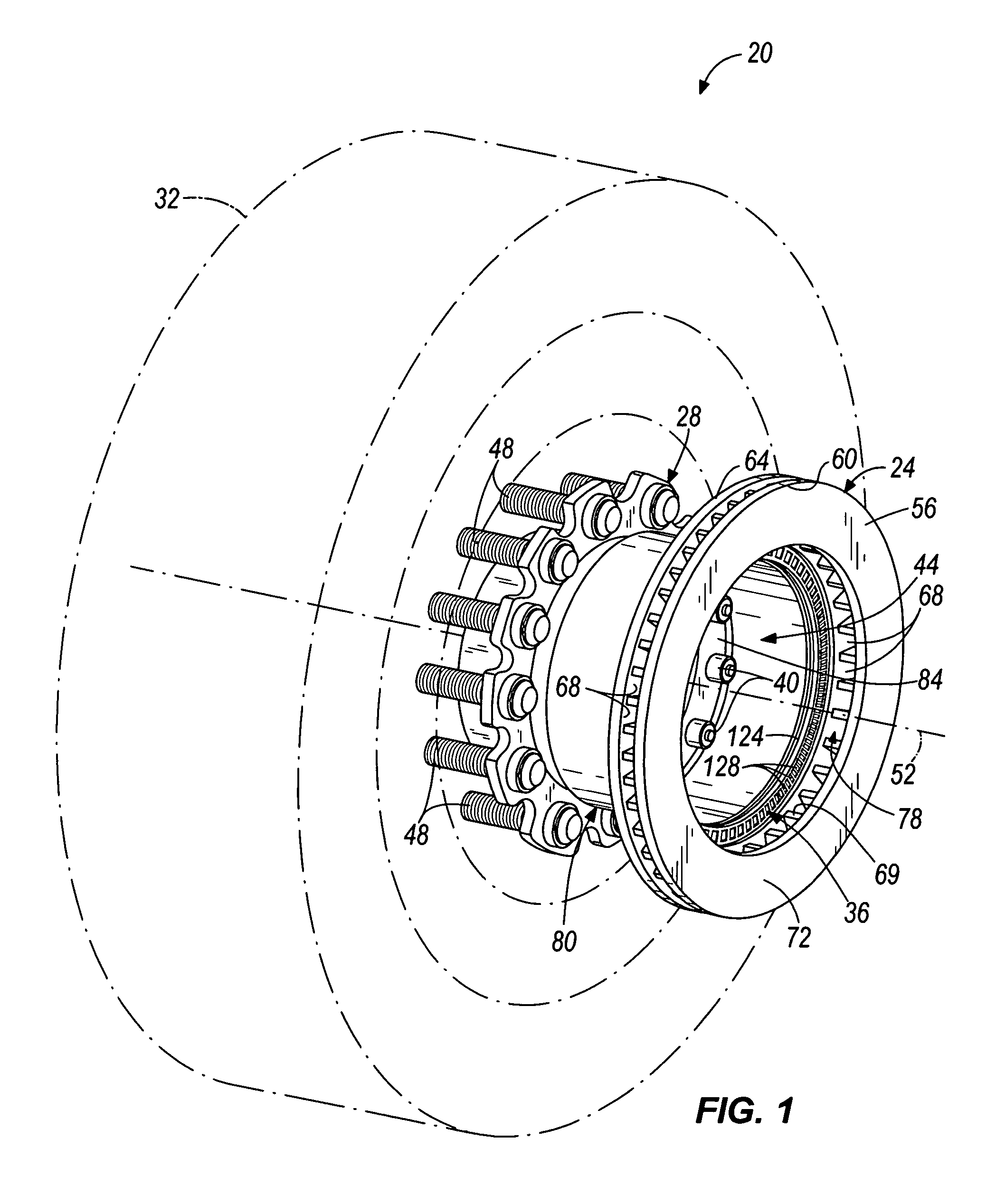

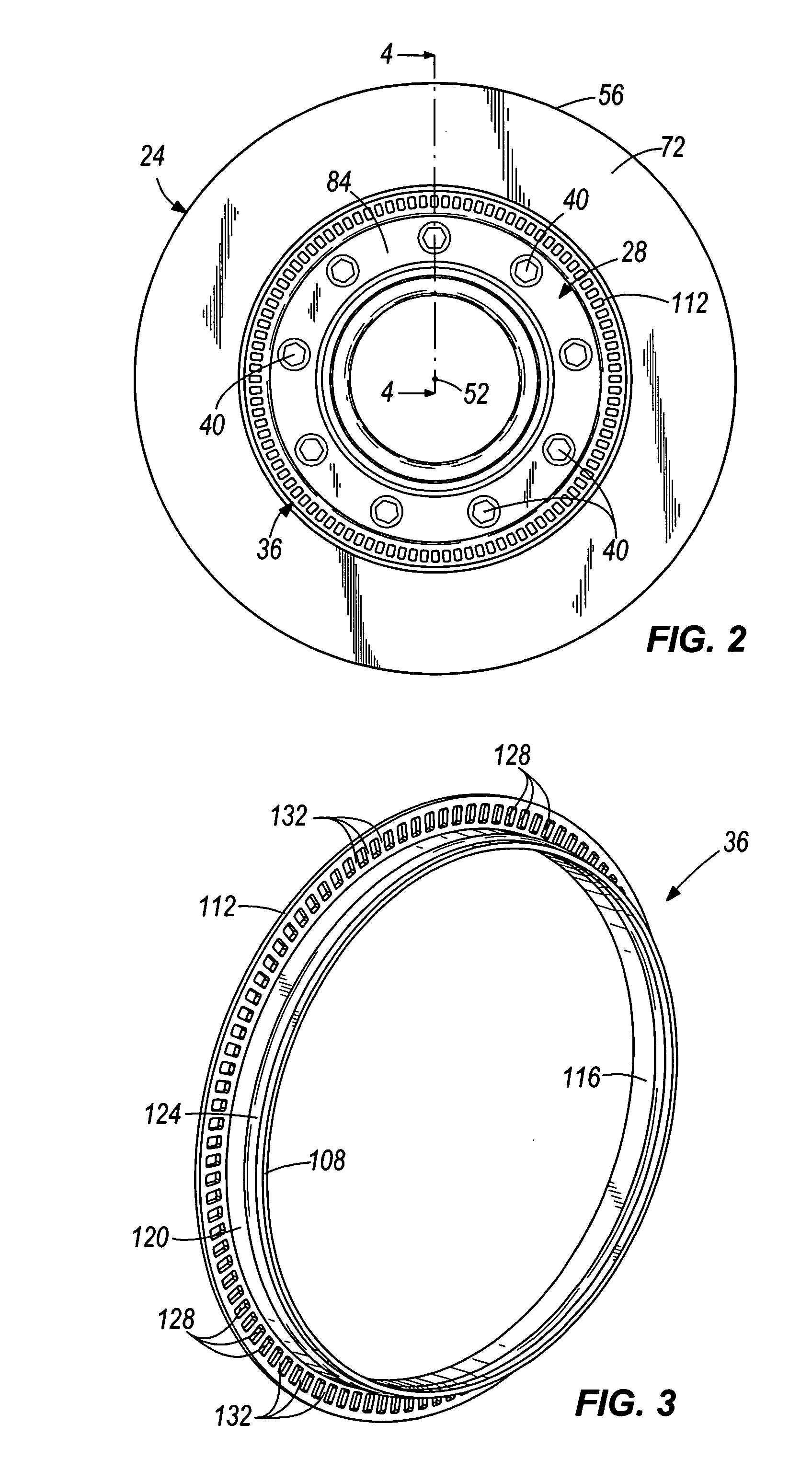

Rotor and exciter ring

ActiveUS6945367B1Reduce rotationBraking element arrangementsBraking drumsMagnetic reluctanceEngineering

A rotor assembly with a cylindrical body having a radial disc that is perpendicularly aligned with a hub of a vehicle and an exciter ring through which a sensor detects rotation of the radial disc. The exciter ring is concentrically installed within the cylindrical body to define a gap between a flange thereon and the radial disc. Reluctance sections on the flange are axially aligned with the sensor to generate a signal indicative of rotation. Friction members engage the radial disc and generate thermal energy that is conducted a mounting flange. Thermal energy level may cause the rotor assembly to expand and change the alignment of the radial disc from perpendicular and non-perpendicular with respect to the hub. The gap allows the radial disc and exciter ring to independently move such that the reluctance sections remain axially aligned with the sensor and sensed information is an accurate indication of rotation.

Owner:PERFORMANCE FRICTION

Disc brake debris collection system

A disc brake assembly includes a rotor, a caliper, brake pads and an optional filter. The optional filter can be disposed within a shroud which covers at least about 70% of the distal side periphery on at least one of the two sides of the rotor. The disc brake also includes an impeller or other means for providing air flow to the disc brake assembly. The impeller can be provided by the rotor itself or it can be provided by a separate component which is powered either directly or indirectly by the rotor.

Owner:GELB JOSEPH

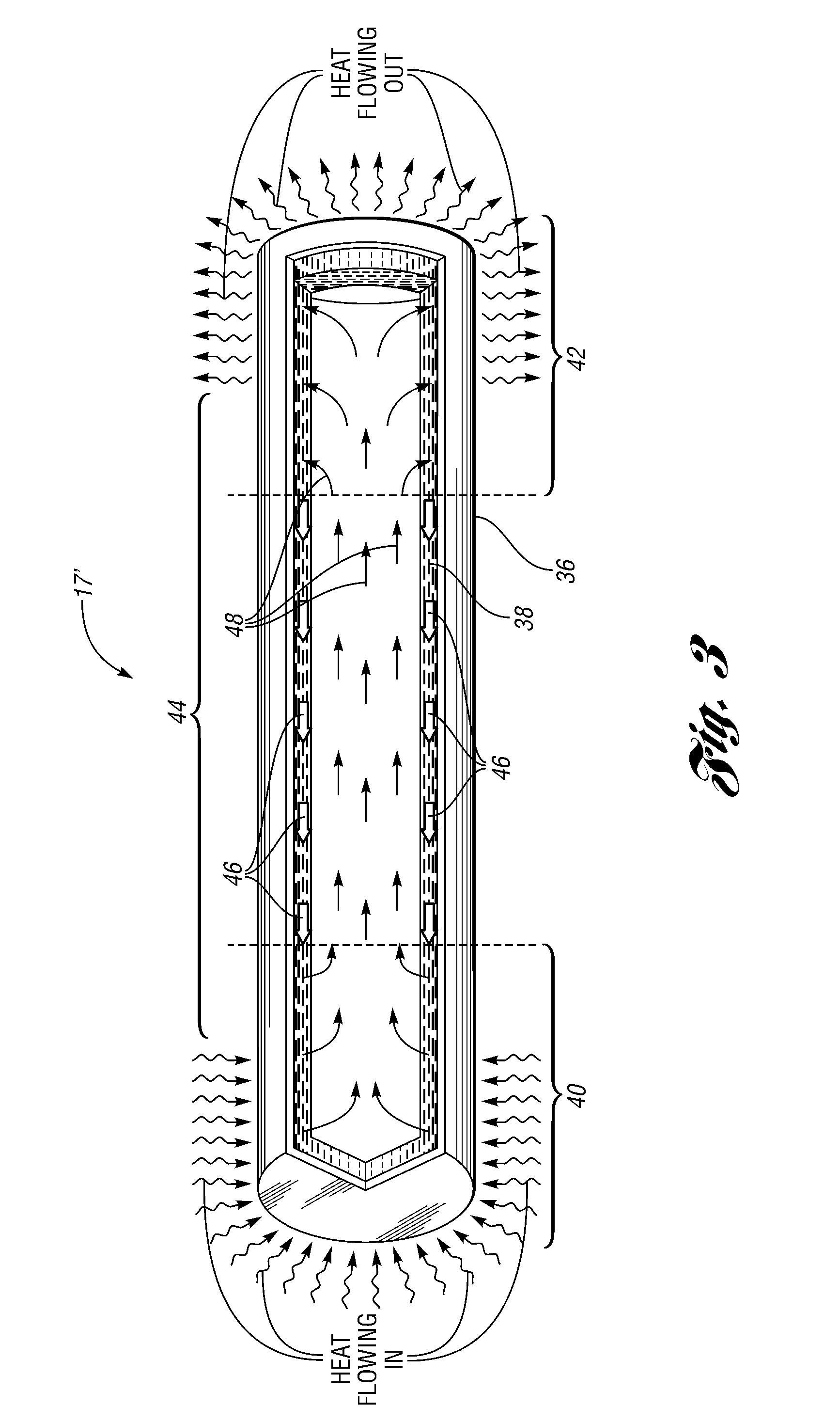

Brake caliper including heat pipes

A brake caliper including a caliper body and heat pipes at least partially embedded within the caliper body. The caliper body includes spaced inboard and outboard portions. In addition, at least one of the portions includes piston bores. The caliper body further includes a connector between the inboard and outboard portions whose spacing permits brake pads and a periphery of a brake rotor to be received between the inboard and outboard portions. Also, the brake caliper includes pistons disposed in the piston bores to press the brake pads against the periphery of the brake rotor when brake fluid moves the pistons and the brake pads toward the brake rotor. As the brake pads heat the brake caliper, the heat pipes transfer heat away from the piston bores thereby cooling the brake caliper and brake fluid in, around, or near the piston bores.

Owner:FINKEL BRIAN G

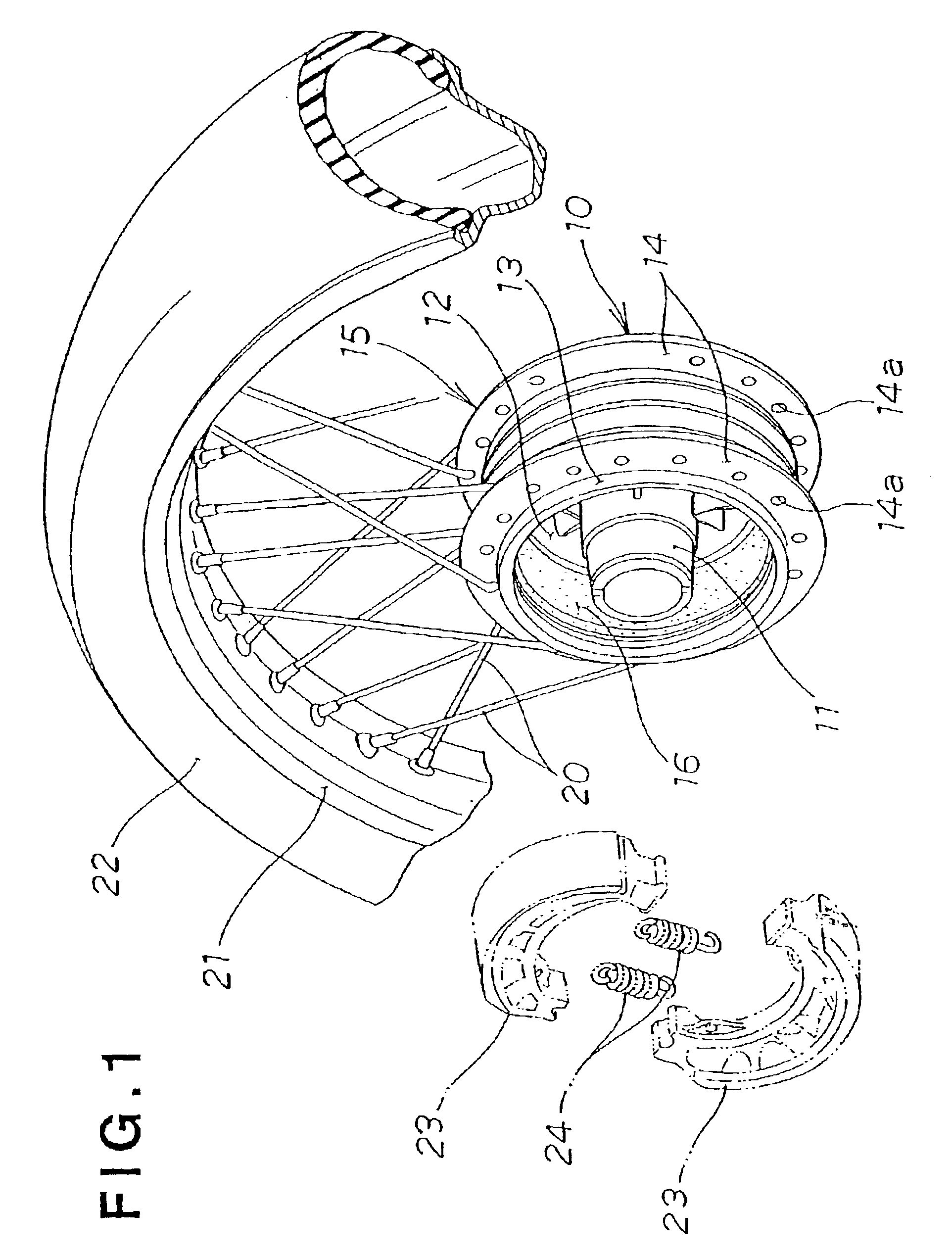

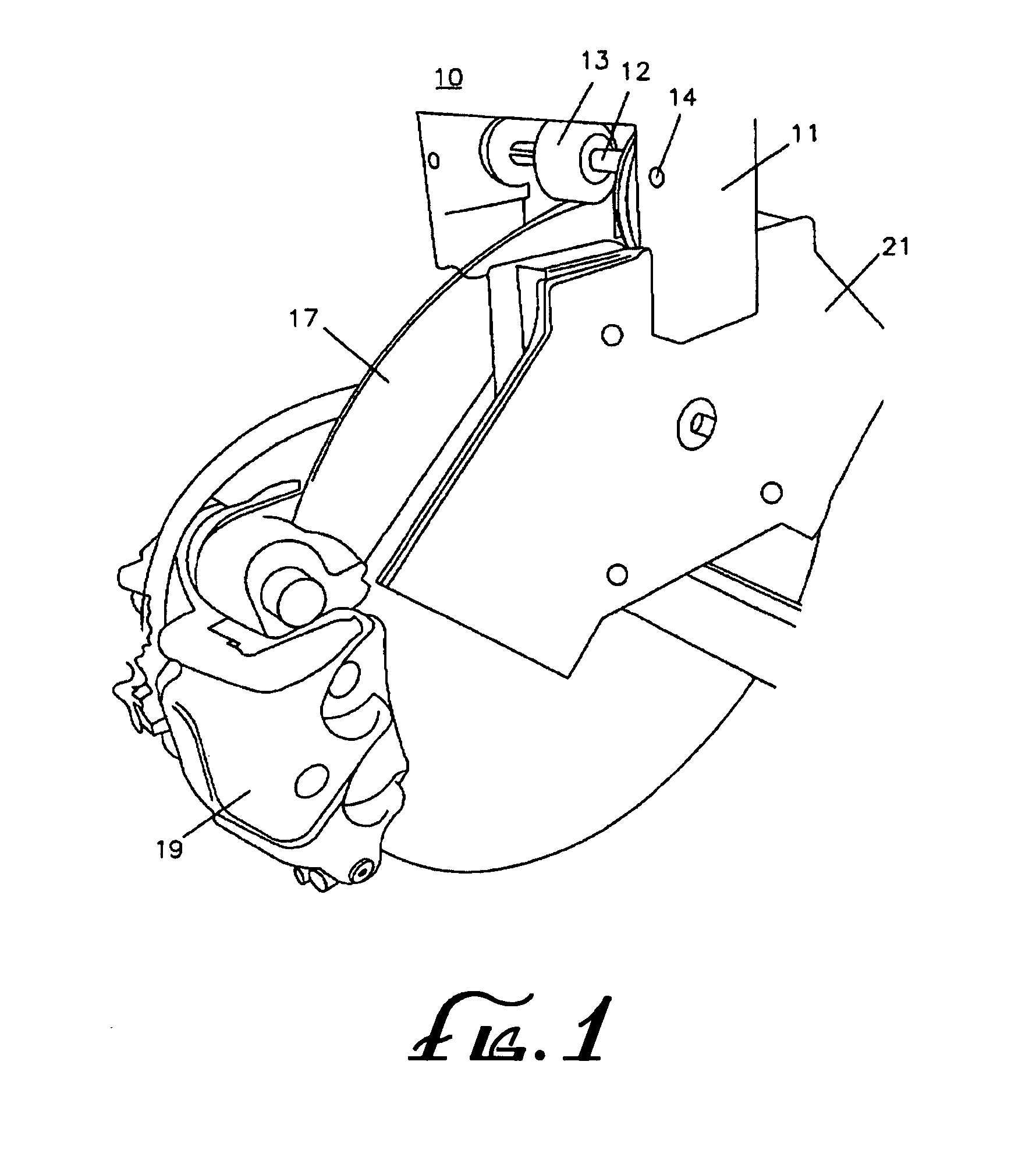

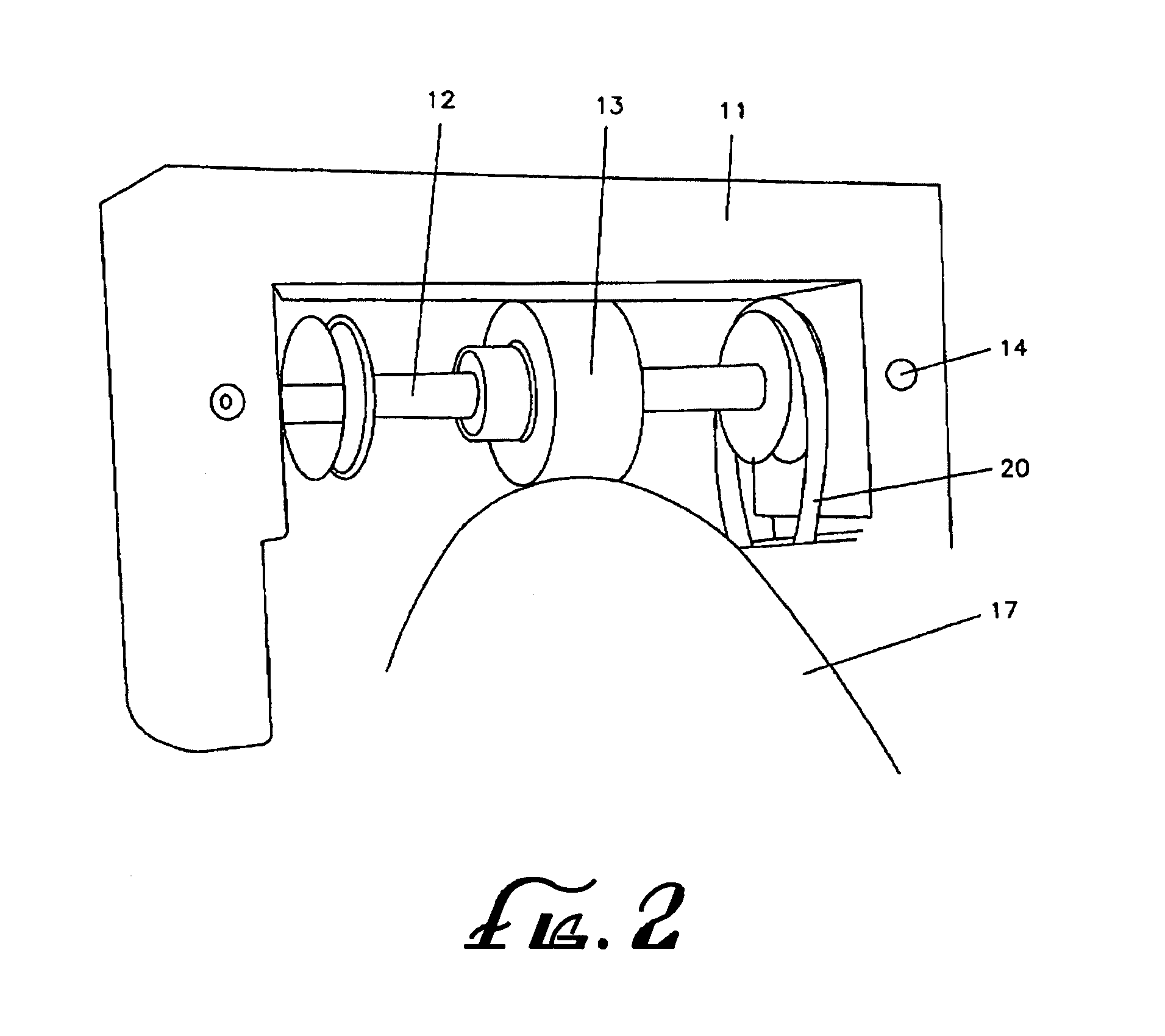

Motorcycle wheel brake mechanism

A brake disc for a wheel constituted by a peripheral section, forming a brake band with an interior form enabling it to be fitted to its wheel, the brake band forms two lateral flat and parallel surfaces on which a brake shoe can act, said peripheral section having a series of off-sets on its inside and outside edges.

Owner:MILESI GIORGIO +2

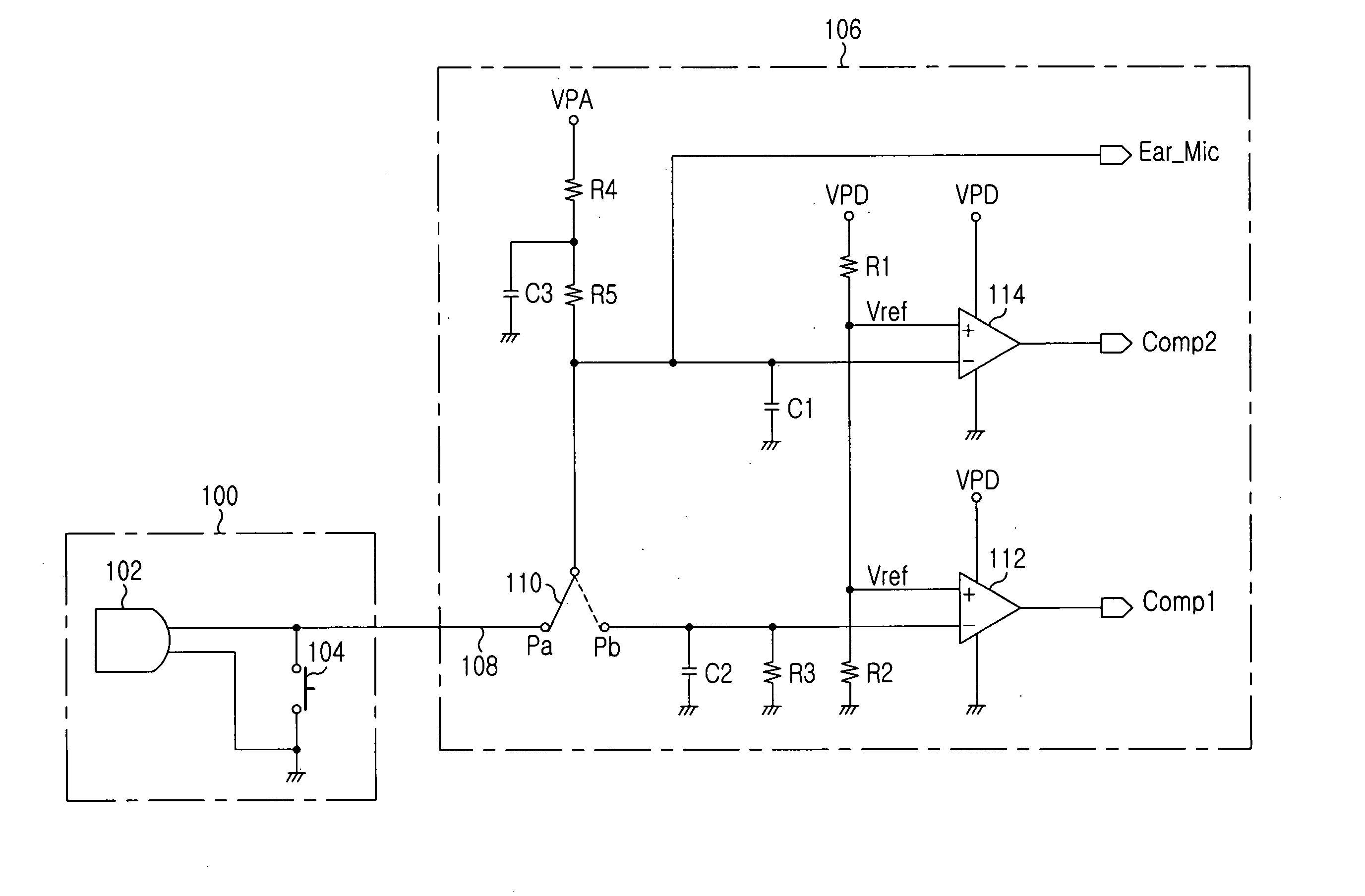

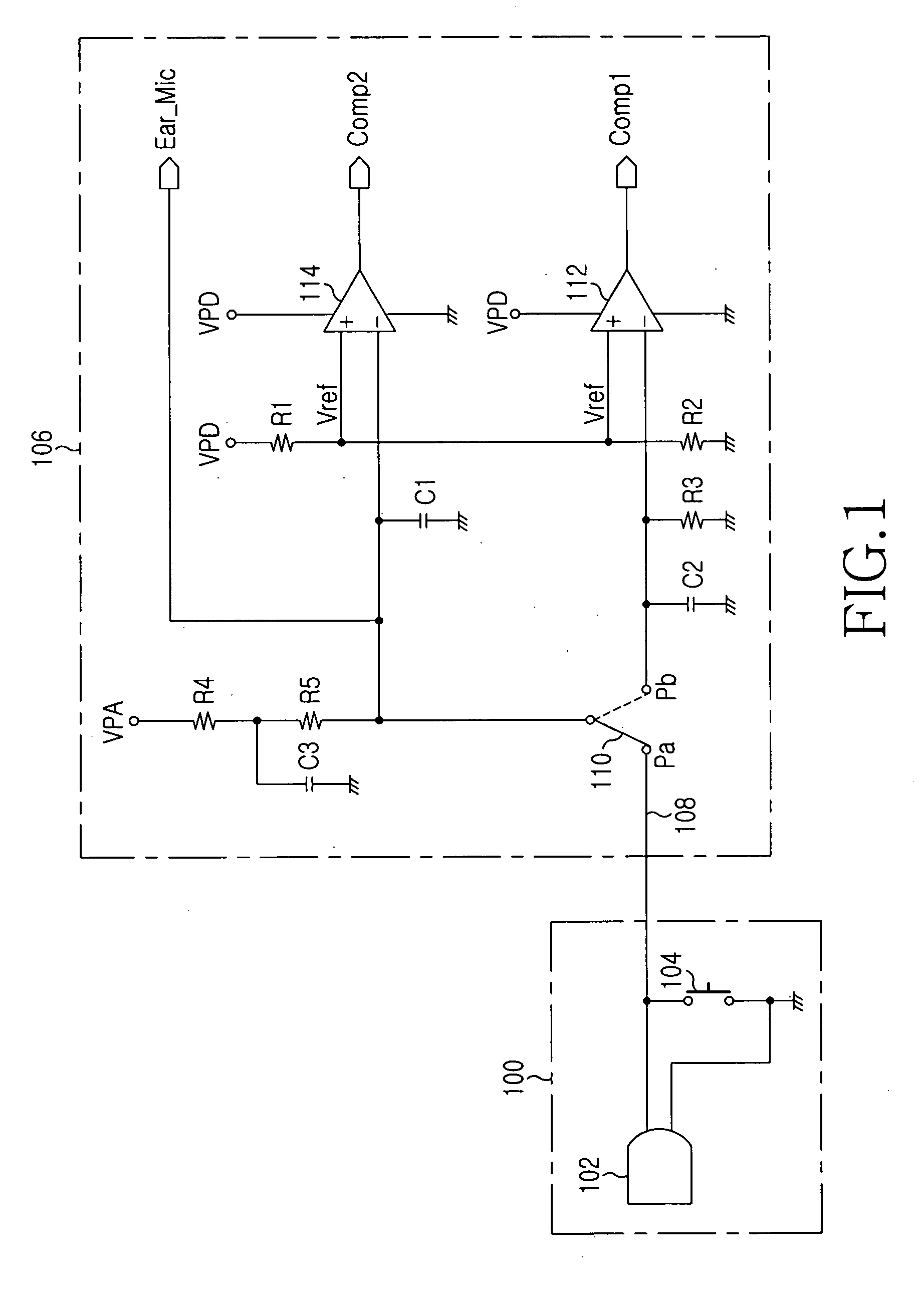

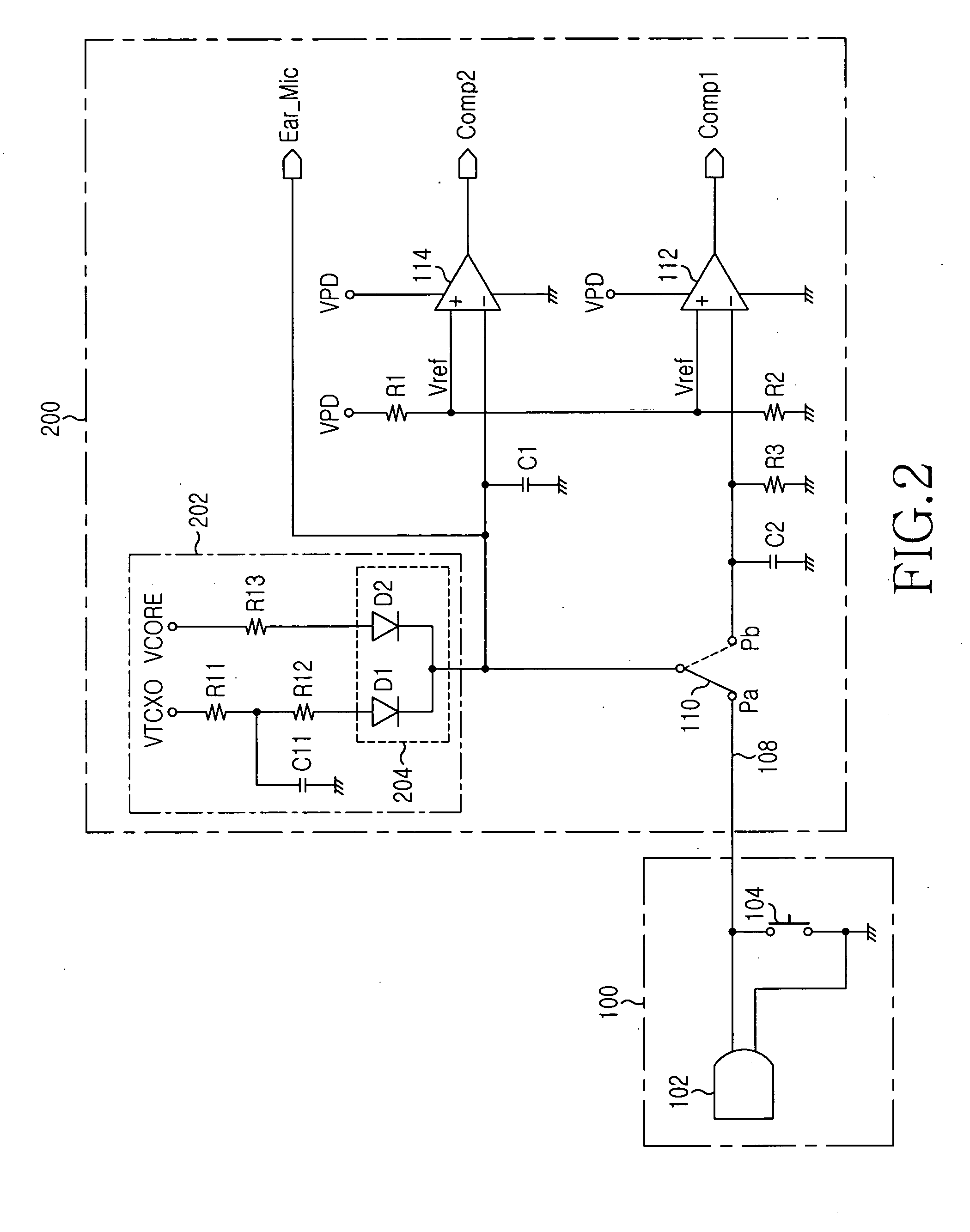

Circuit for supplying ear-microphone bias power for ear/microphone in mobile terminal

ActiveUS20050164631A1Reduce power consumptionPower managementEnergy efficient ICTEngineeringHeadphones

Disclosed is a circuit for supplying ear-microphone bias power in a mobile terminal that reduces power consumption due to unnecessary ear-microphone bias when the terminal is in a sleep mode with an ear / microphone being connected to the terminal through an ear-microphone line. The ear / microphone has a call switch connected to the ear-microphone line. The circuit receives first and second powers through first and second power input terminals, respectively. The first power is supplied when the terminal is not in the sleep mode, whereas the second power having a voltage lower than that of the first power is supplied also in the sleep mode. The circuit supplies ear-microphone bias power, based on the first power, to the ear-microphone line when not in the sleep mode, and supplies power for detecting a switching operation of the call switch, based on the second power, to the ear-microphone line in the sleep mode.

Owner:SAMSUNG ELECTRONICS CO LTD

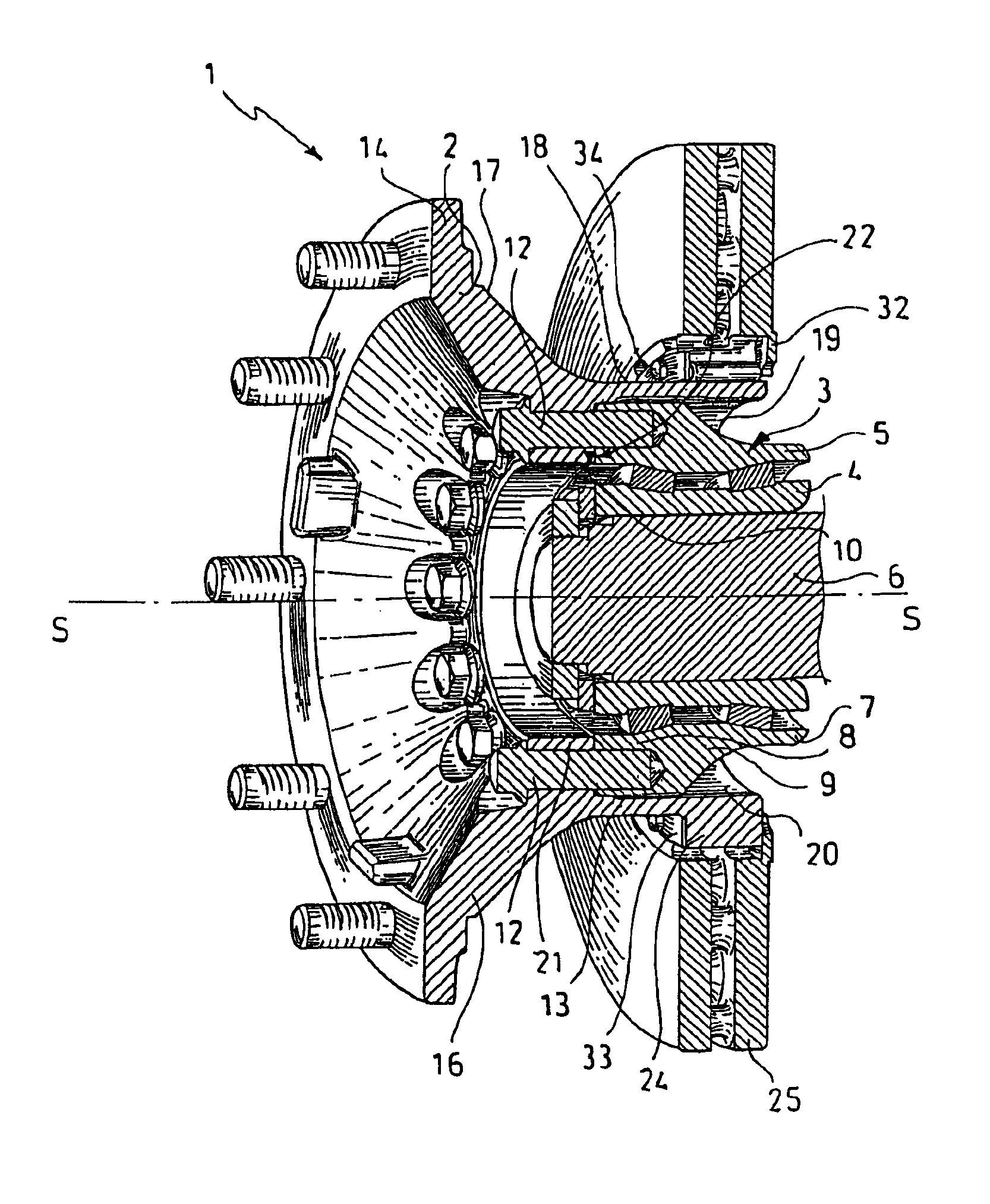

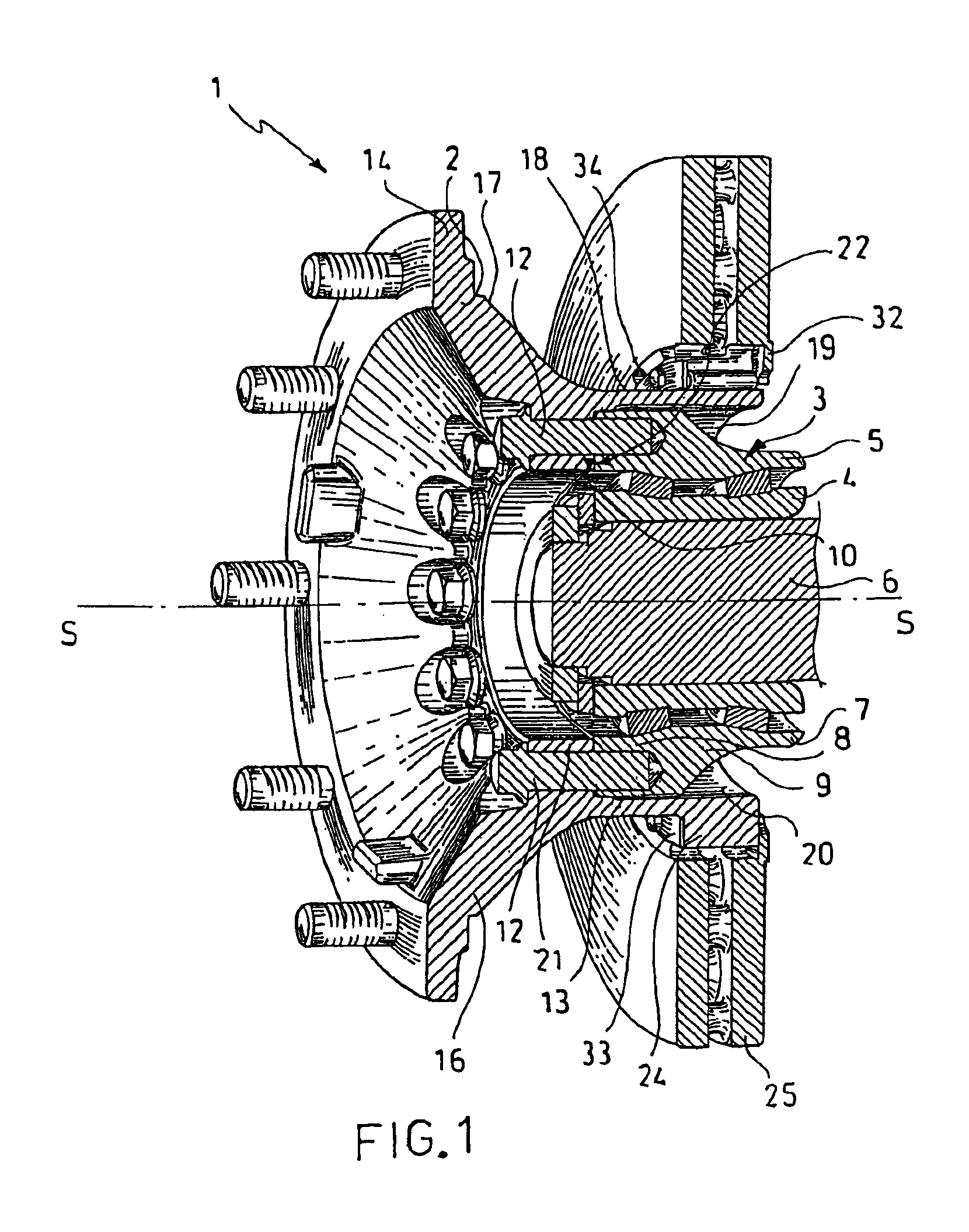

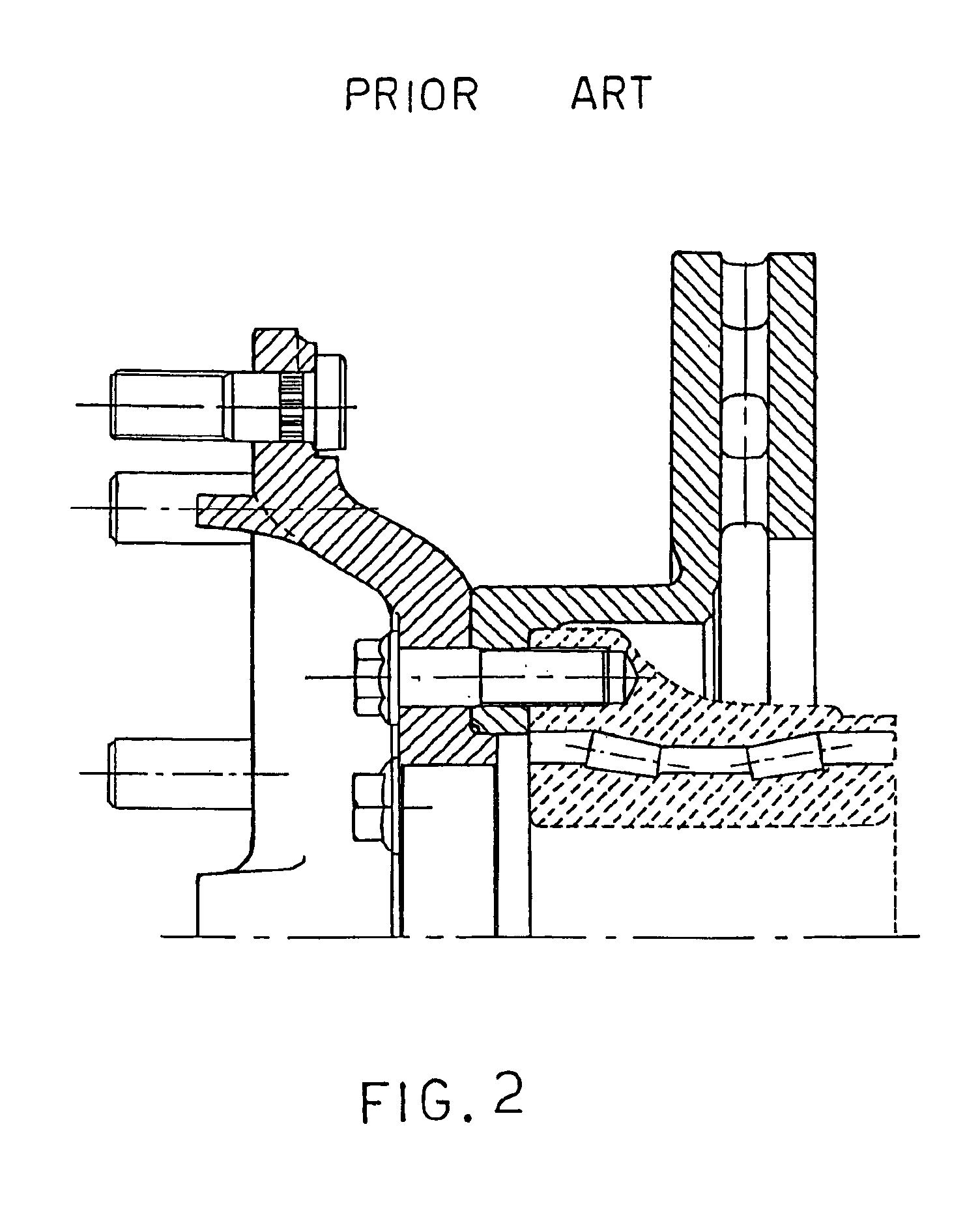

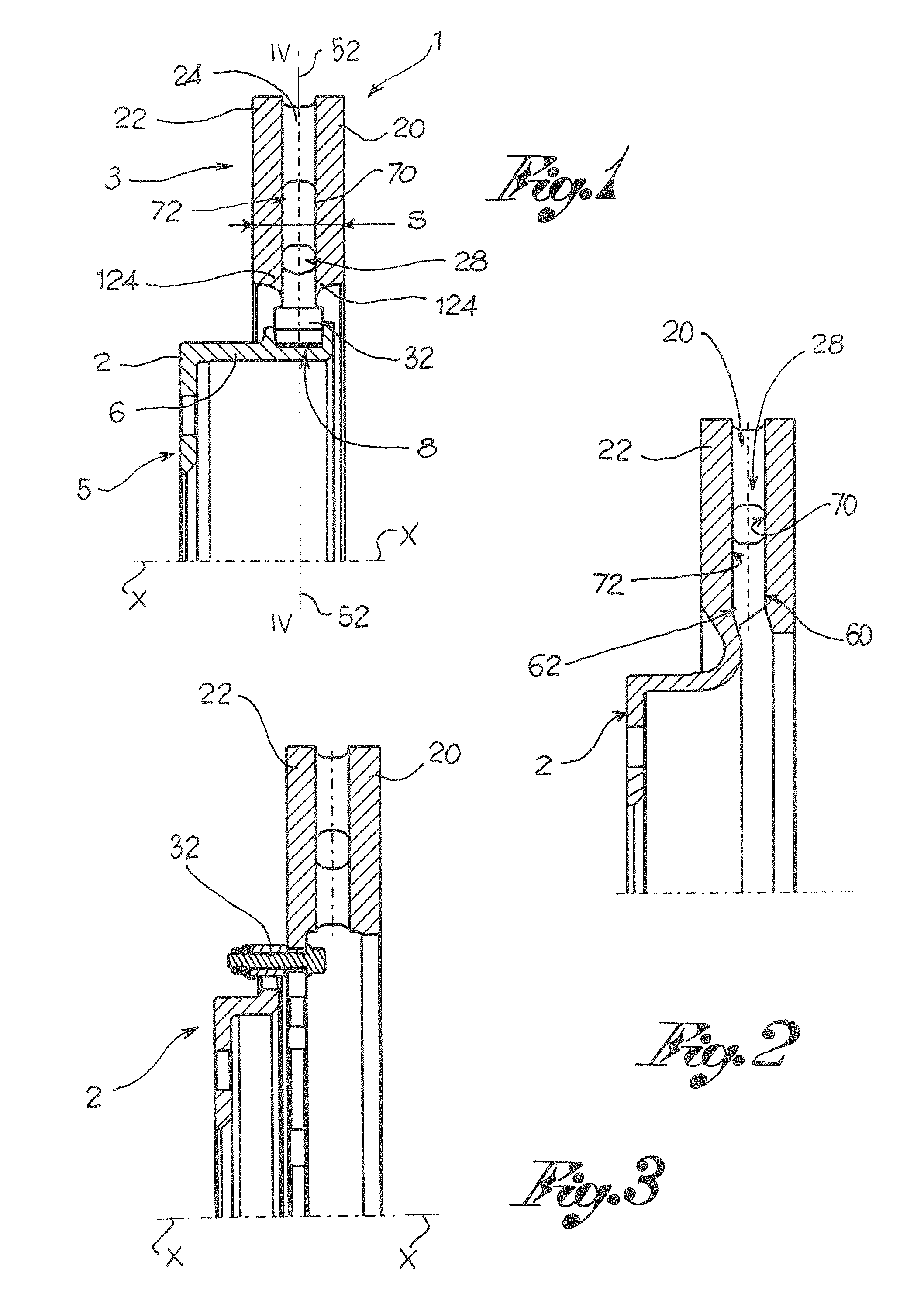

Wheel support for vehicles with disk brakes

InactiveUS6880682B2Safe and easy replacementEven by forceAxially engaging brakesHubsStub axleEngineering

A wheel support for providing a connection, rotatable about an axis (S), between a wheel of a vehicle which can be braked by a disk brake and the stub axle (6) of the vehicle comprises a bell (24) suitable for supporting a braking band (25) and a connection flange (14) for the connection of the vehicle wheel. The bell (24) and the connection flange (14) are formed integrally, constituting a single body (2) which can be connected rotatably and releasably to the stub axle (6) of the vehicle.

Owner:FRENI BREMBO SPA

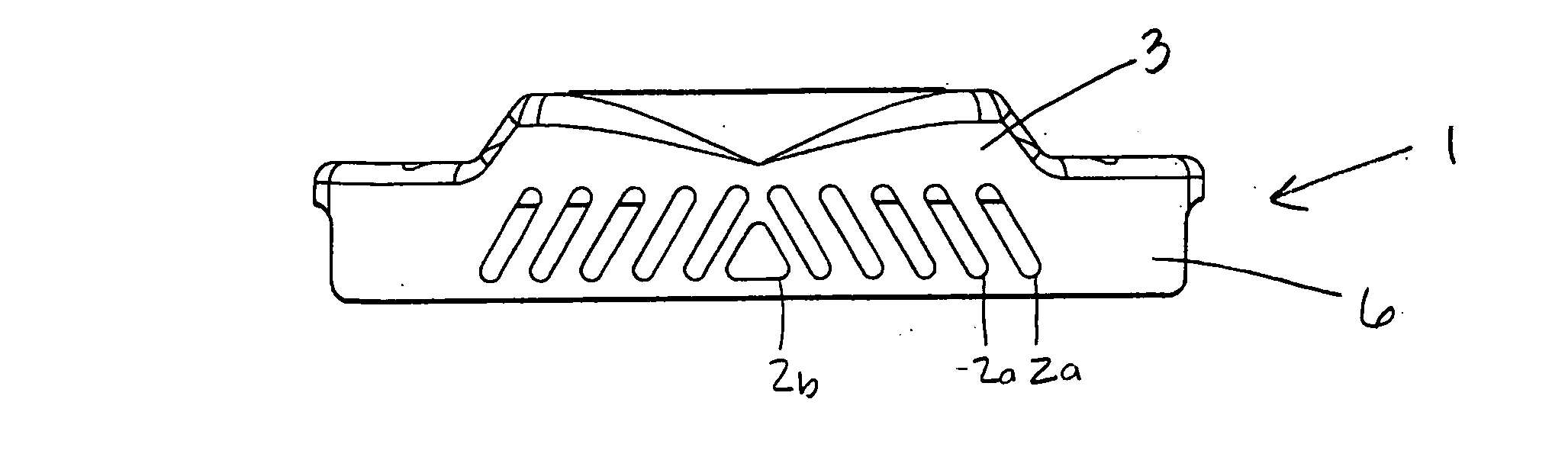

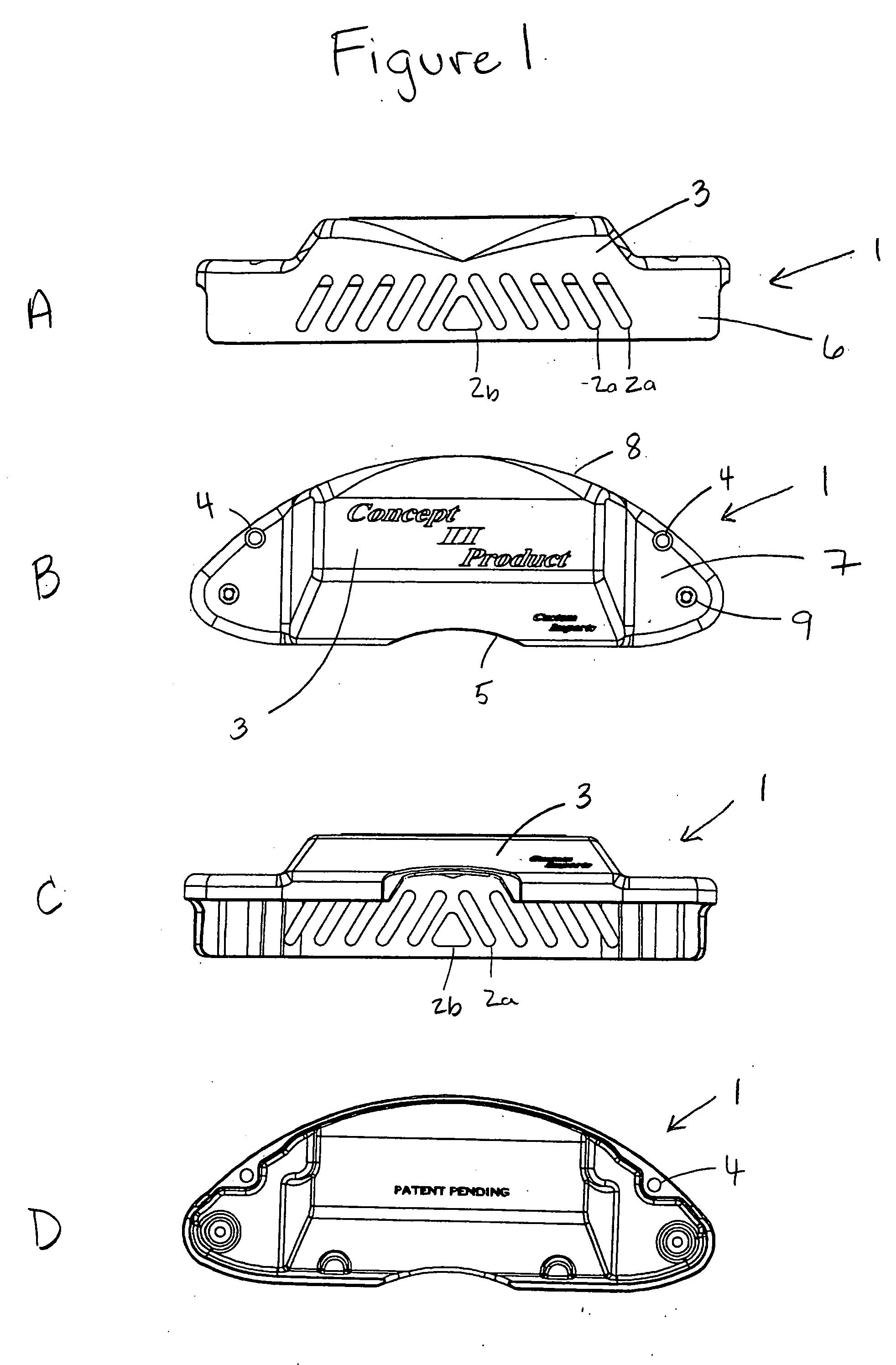

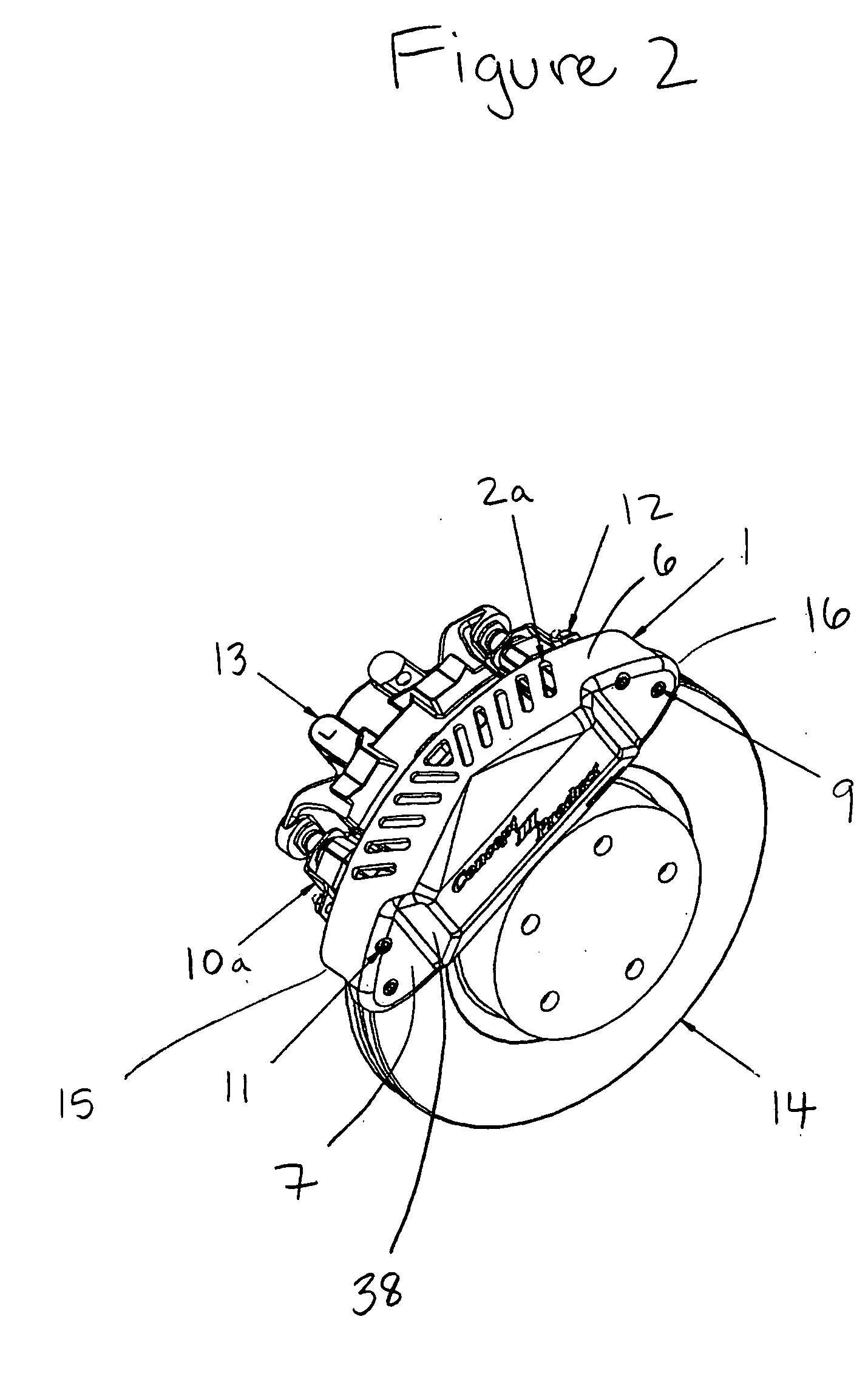

Caliper cover

InactiveUS20050258008A1Good lookingPreventing transferAxially engaging brakesBraking drumsAutomotive engineeringBrake fade

This invention provides caliper covers having vent openings, caliper cover kits, and methods for cooling caliper brake mechanisms that prevent brake fade and prevent brake malfunction caused by debris from the road, while improving the appearance of the caliper braking mechanism and preventing transfer of braking dust from the brake pads to the wheels.

Owner:KING WILLIAM J

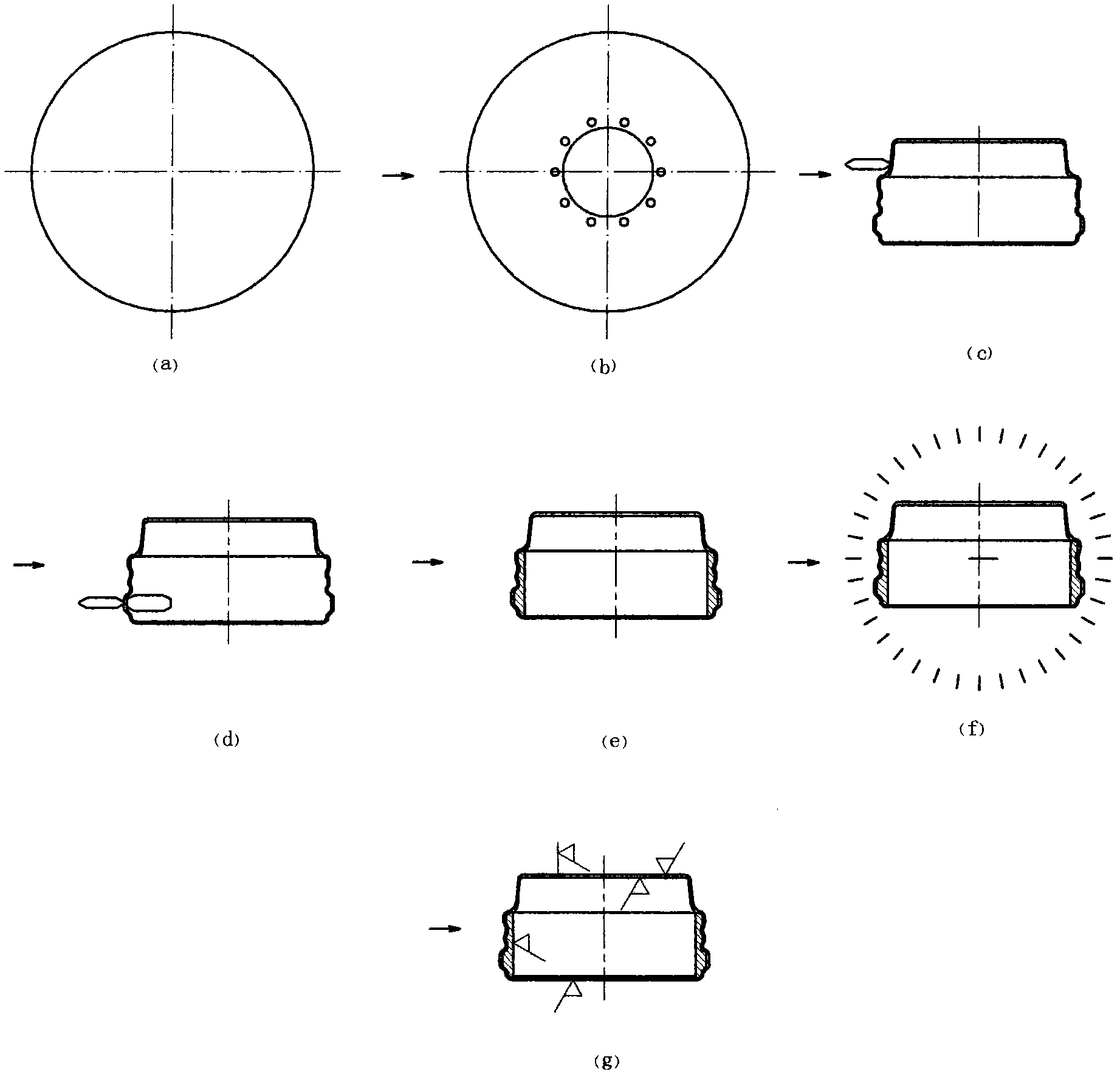

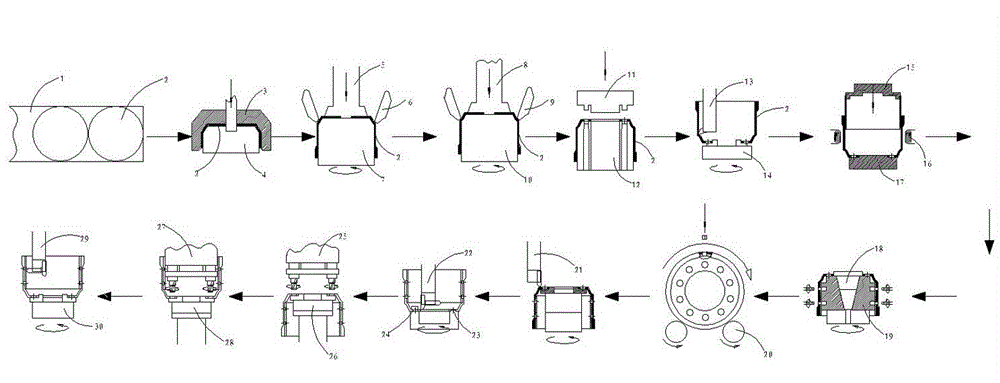

Manufacturing method of high-strength light bi-metal brake drum and high-strength light bi-metal brake drum thereof

InactiveCN102000950AExtended service lifeImprove bindingBraking drumsActuatorsEngineeringHeat treated

A manufacturing method of a high-strength light bi-metal brake drum includes the following steps: (a) blanking steel plates; (b) punching; (c) spinning, spinning an external edge of a semi-finished product obtained from the former step to be a cylindrical outer ring having a plurality of convex rings; (d) roll spinning, forming uniformly distributed inwards concave parts on an inner wall of the convex ring of the semi-finished product through roll spinning; (e) casting, casting a iron casting lining in the semi-finished product by a centrifugal casting method; (f) heat treatment, eliminating inner stress and enabling the iron casting lining to achieve a rigidity demanded by the brake drum; (g) processes of finish machining and the like. The bi-metal brake drum manufactured by the method can directly transmit a brake moment between the iron casting lining and a steel housing, fixing pieces, such as a bolt or a rivet and the like, are unnecessary for assembling the outer ring and the lining of the brake drum, and service life of the brake drum is prolonged; simultaneously, an originally designed structure combination of a drum disc, the lining and a thin wall of the outer ring is not changed, so that phenomena of crack caused by too thick drum wall and too much temperature difference are reduced, and braking conditions are improved.

Owner:JIAXING STONE WHEEL

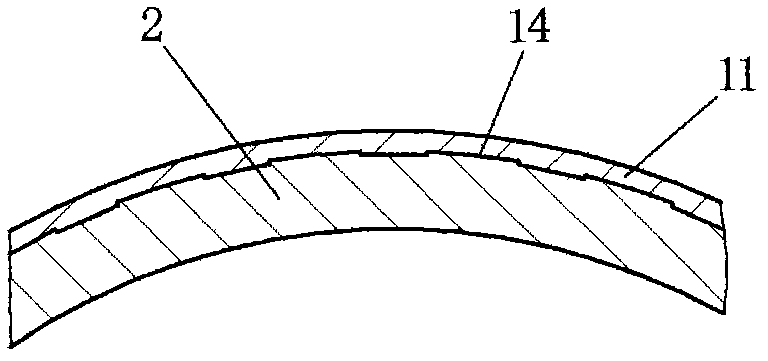

Composite brake drum

InactiveUS20060027429A1Improved lining-to-drum adhesion characteristicBraking drumsDrum brakesMetal matrix compositeMaterials science

A composite brake drum includes an outer component having an outer surface and an inner surface defining an internal cavity. The composite brake drum also includes an inner liner that is mounted within the internal cavity and is attached to the inner surface. The inner liner is made from a metal matrix composite such as silicon carbide aluminum (SiCAl), for example. The outer component is formed from cast iron or stamped steel. The metal matrix composite provides a braking surface that is less corrosive than a braking surface that would be provided by ferrous materials.

Owner:ARVINMERITOR TECH

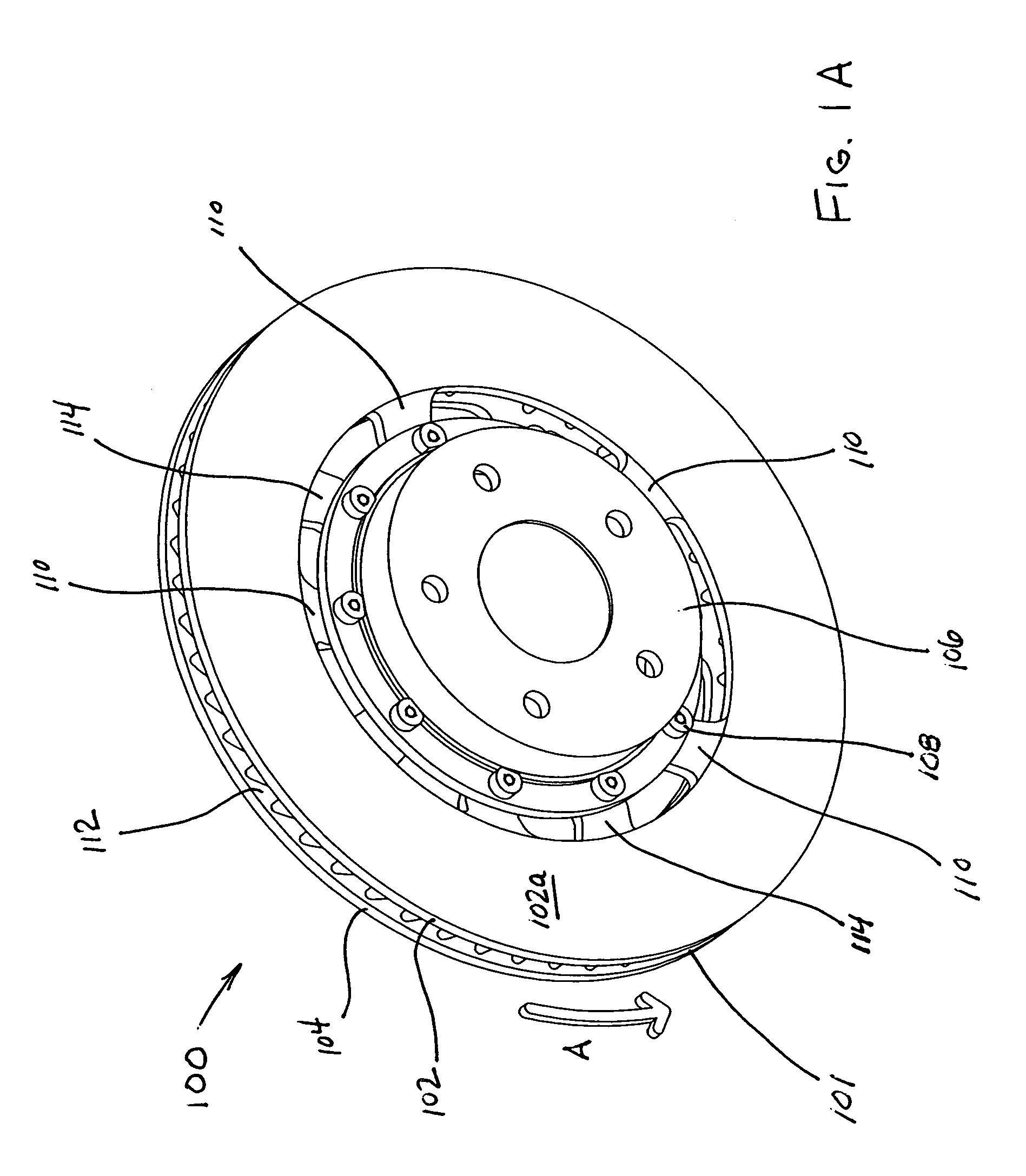

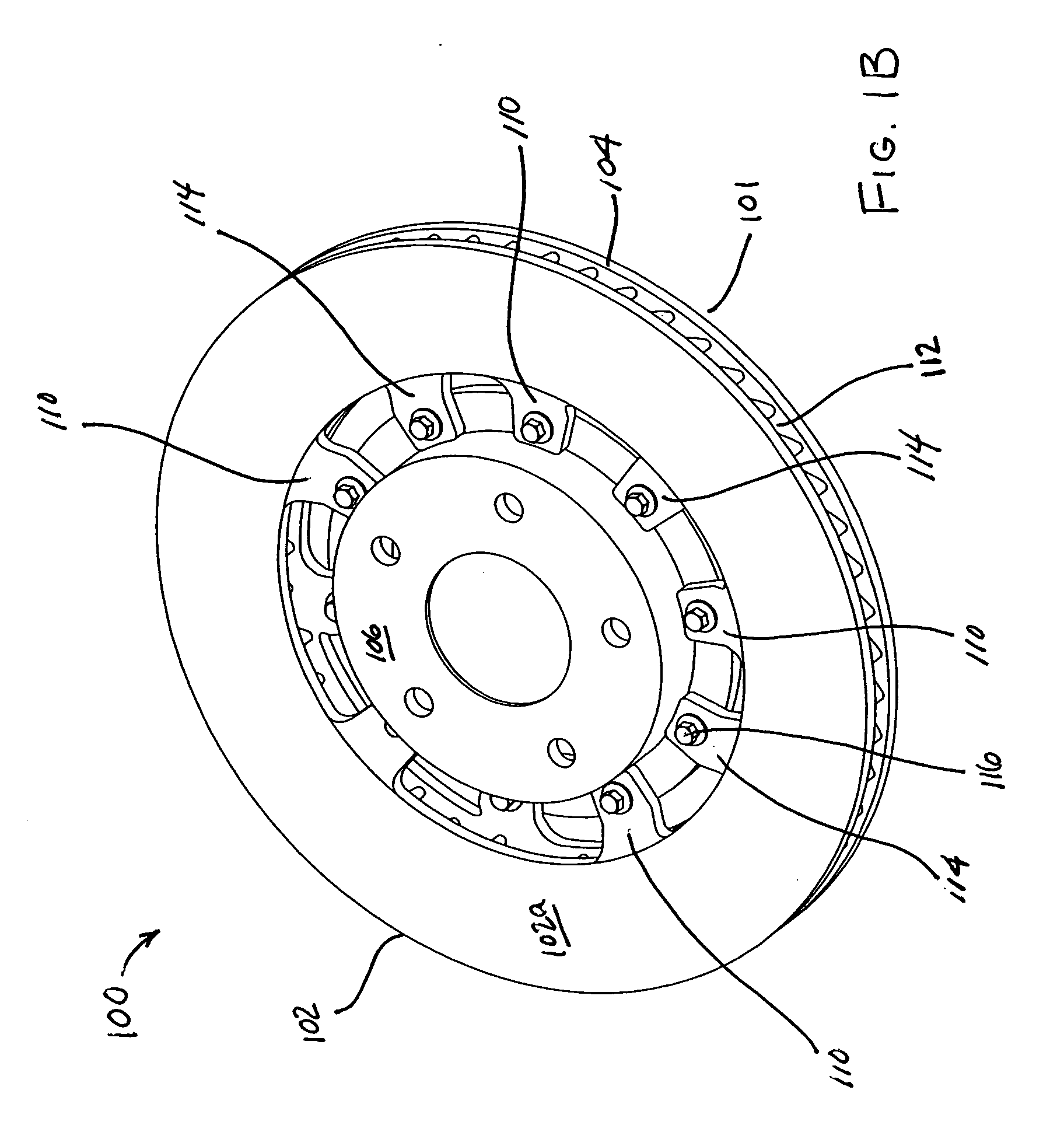

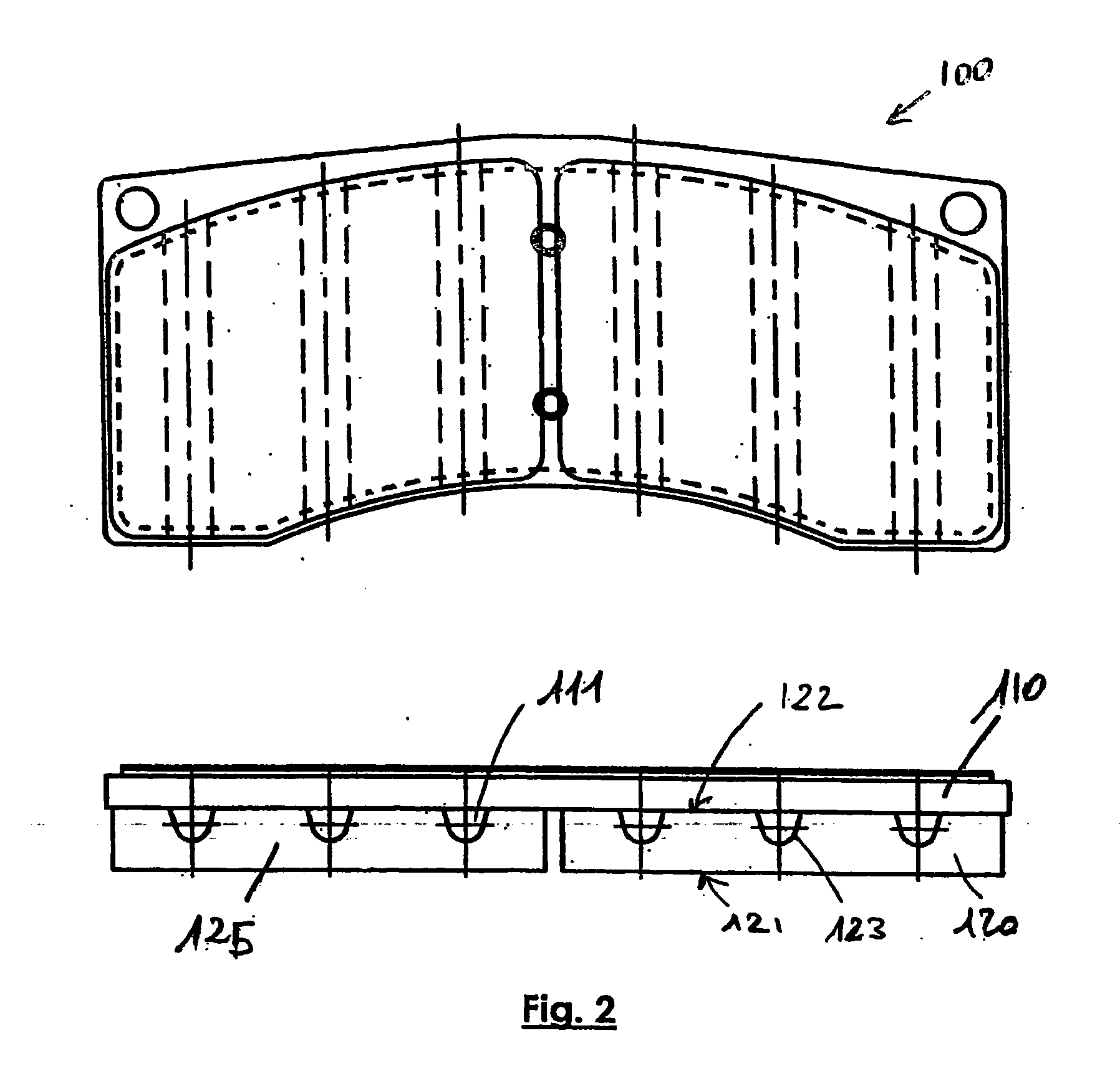

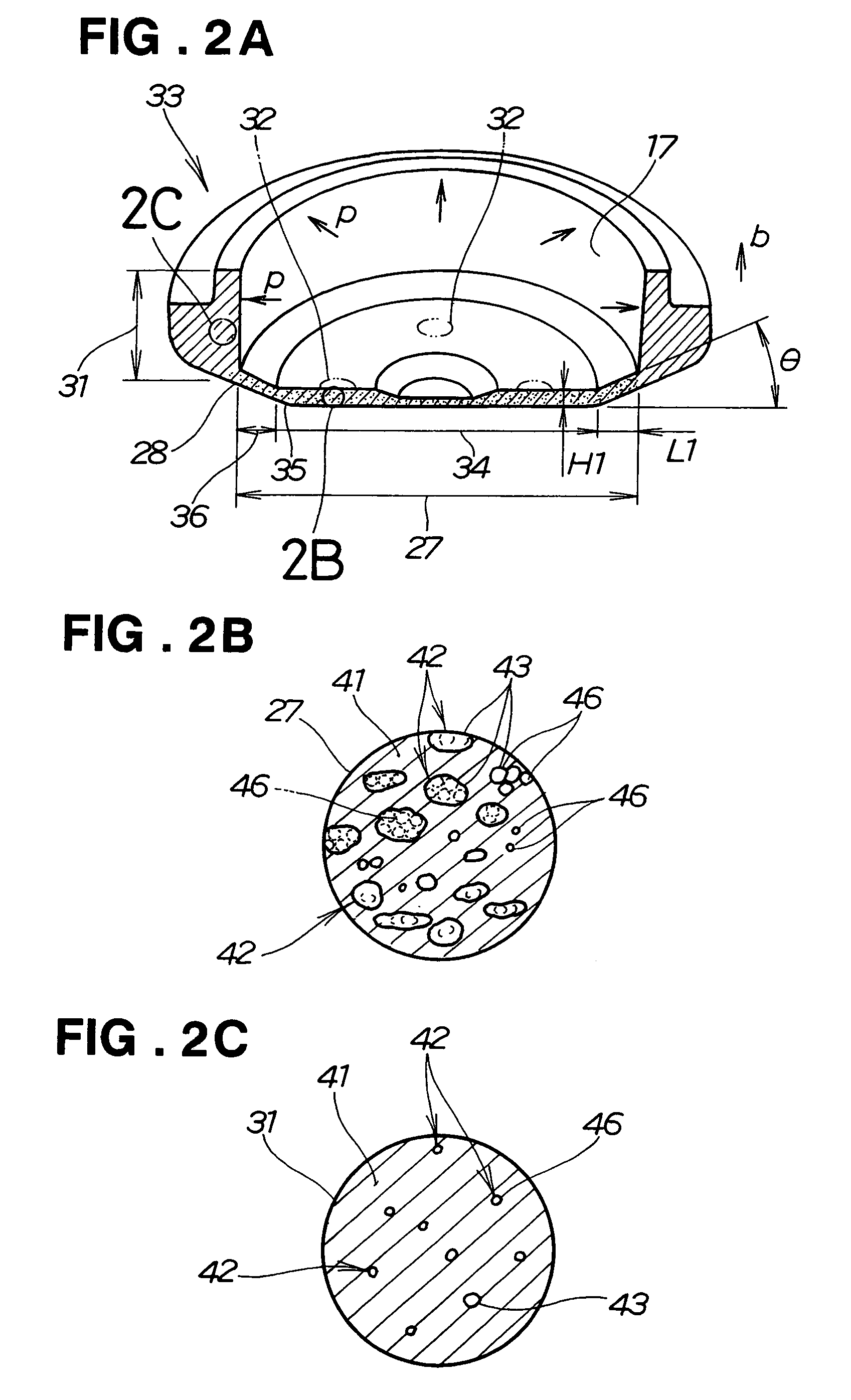

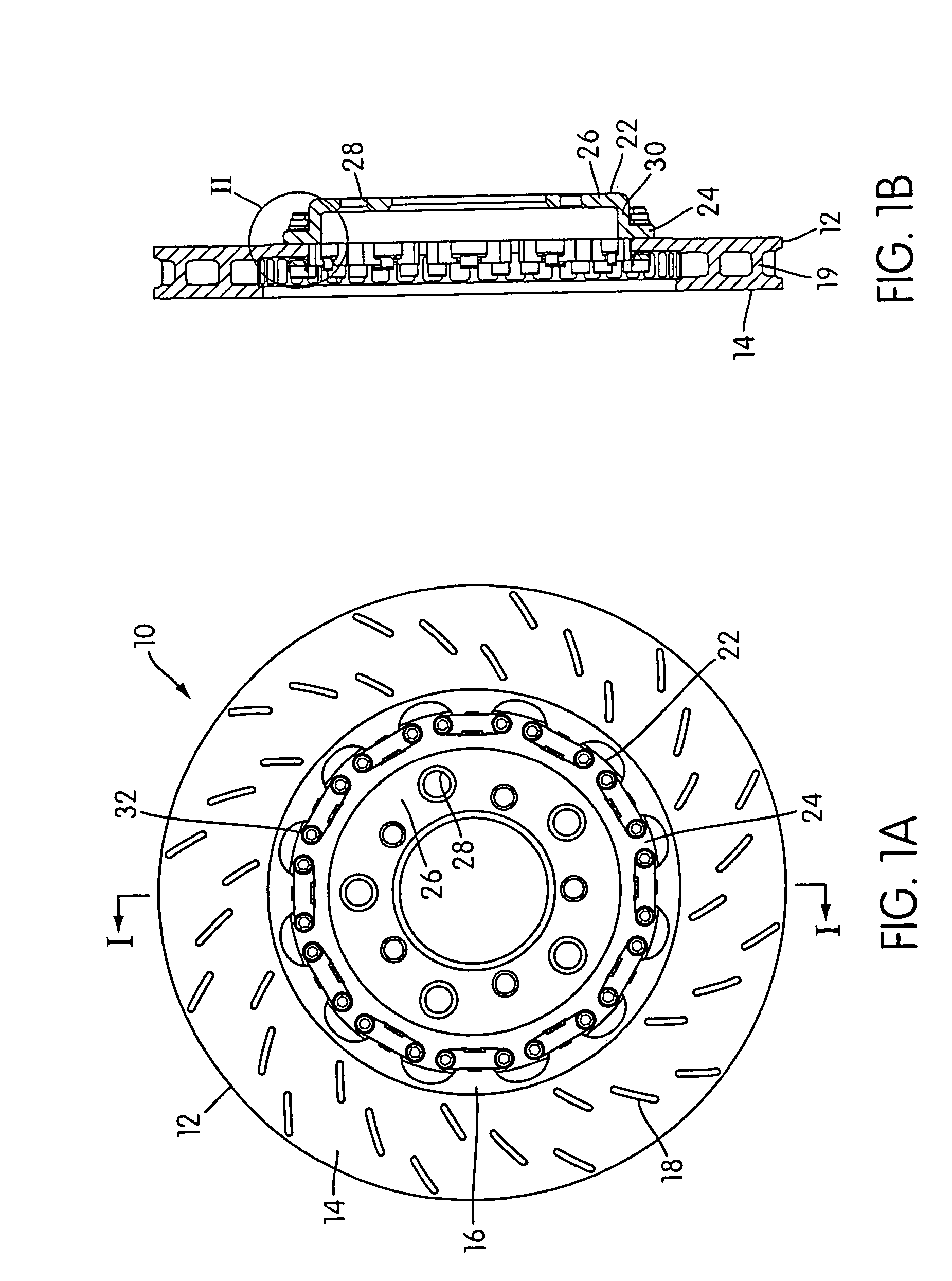

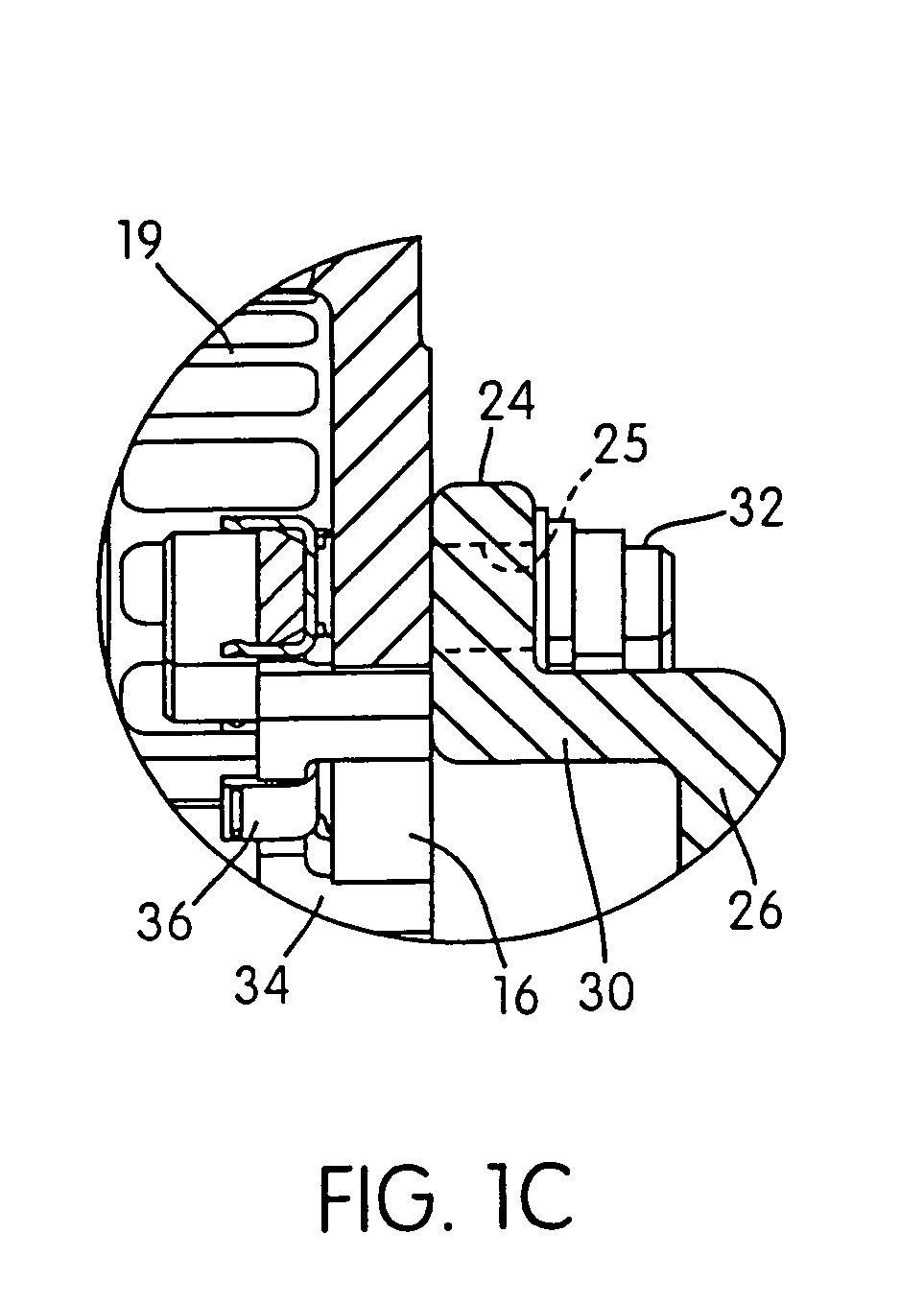

Brake rotor

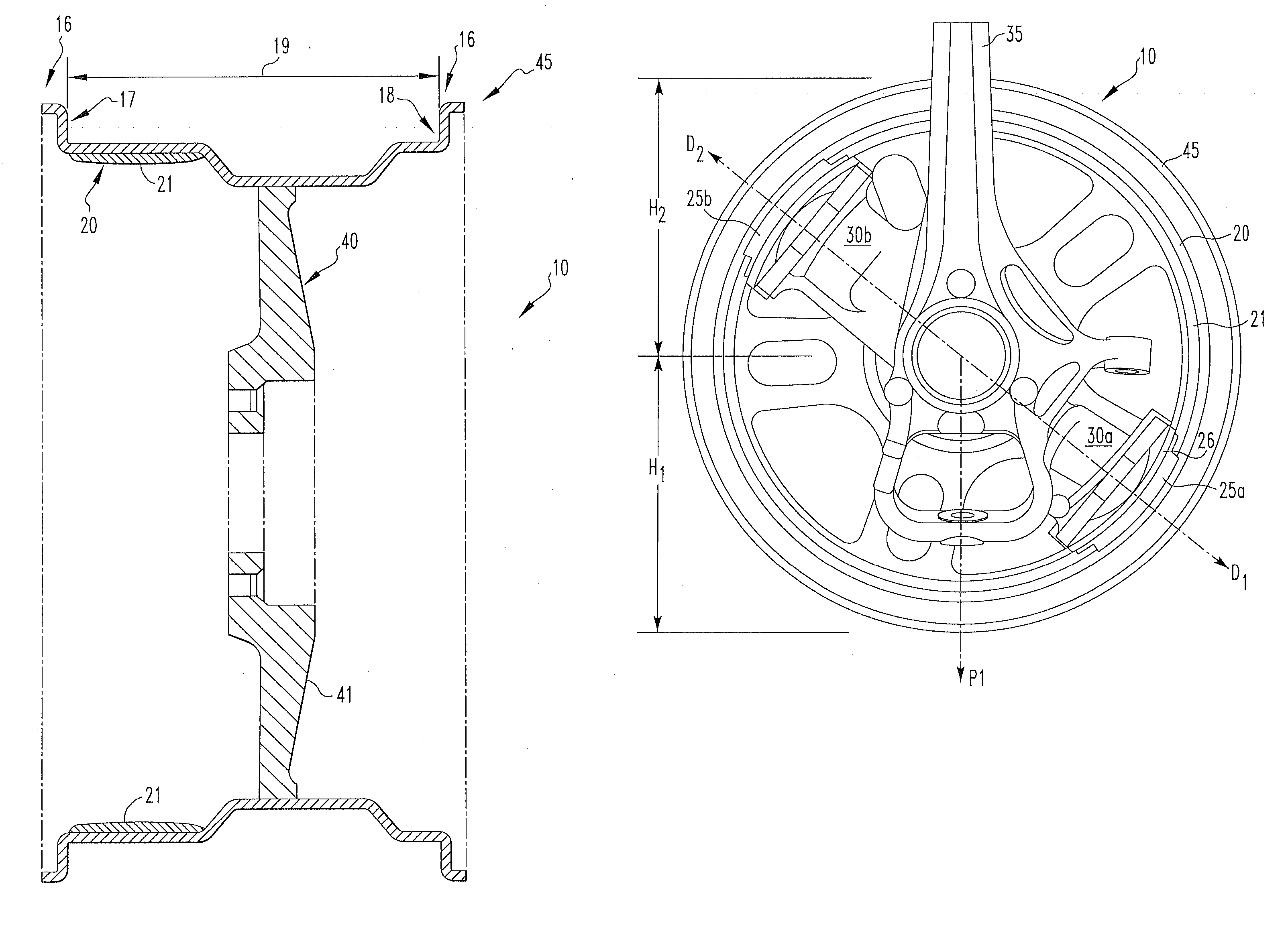

ActiveUS20050269174A1Improve efficiencyImprove performanceBraking element arrangementsBraking drumsEngineeringFlange

Embodiments of the present invention are directed to disc brake rotor assemblies which include disc brake rotor ring and a disc brake rotor hat. The disc brake rotor ring may include a first side including an inner perimeter and an outer perimeter, a first annular braking surface and a plurality of first mounting flanges positioned along the inner perimeter for affixing a corresponding portion of a rotor hat. Each flange may include an opening for receiving a fastener. The disc brake rotor ring may also include a second side parallel to and spaced apart from the first side thereby jointly defining a plurality of vents there-between, the second side including an inner perimeter and an outer perimeter, a second annular braking surface having and a plurality of second mounting flanges positioned on the inner perimeter of the for affixing a corresponding portion of a rotor hat. Each flange in the second side may also include an opening for receiving a fastener. Either the first side or the second side may be used as an outboard side when the brake rotor assembly is mounted on a wheel hub of a vehicle. In addition, the first mounting flanges may be alternately arranged and spaced apart from the second mounting flanges. The first mounting flanges and second mounting flanges are positioned in a central plane between the first side and the second side and the central plane is substantially parallel to the first side and the second side.

Owner:LIN WARREN

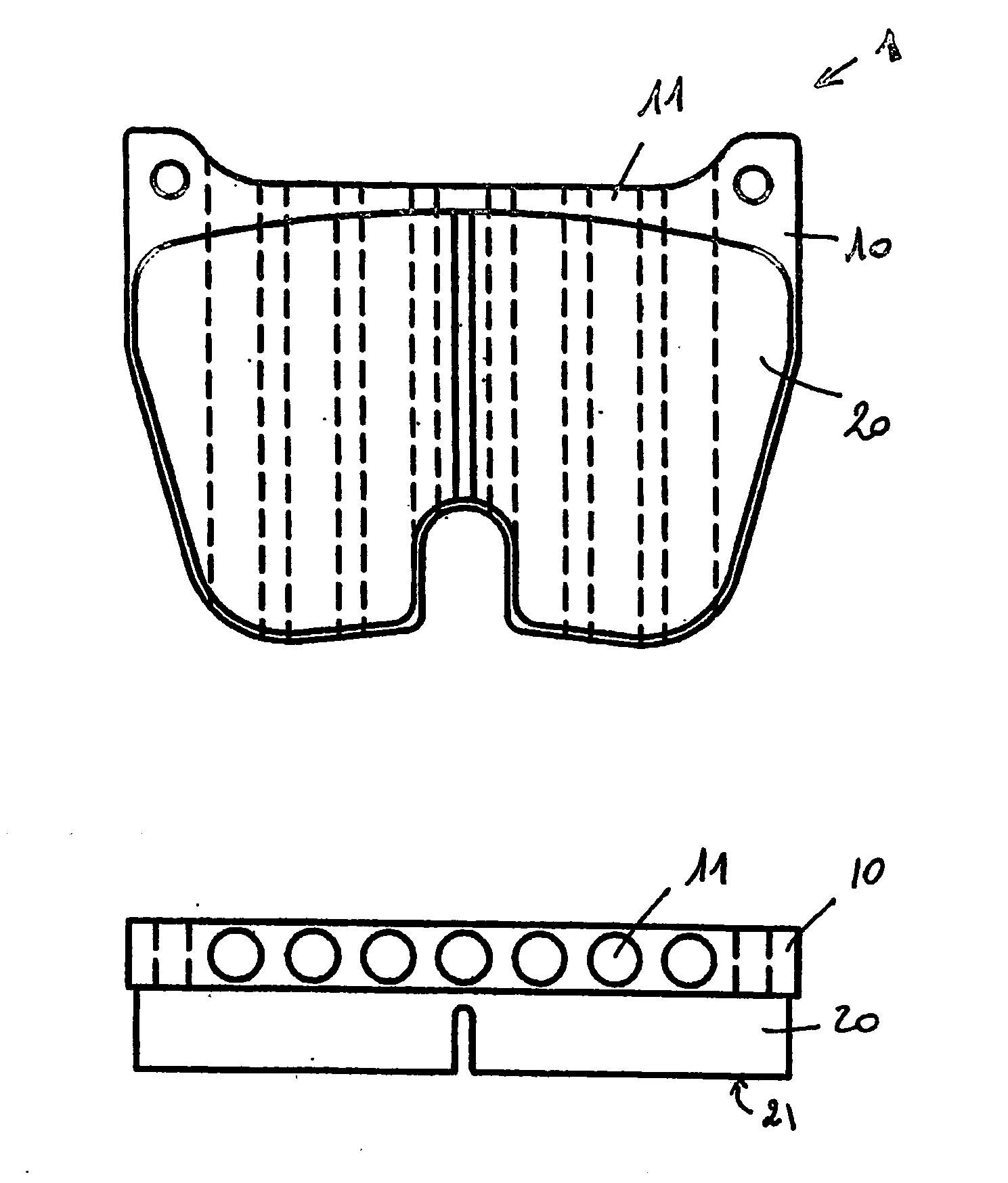

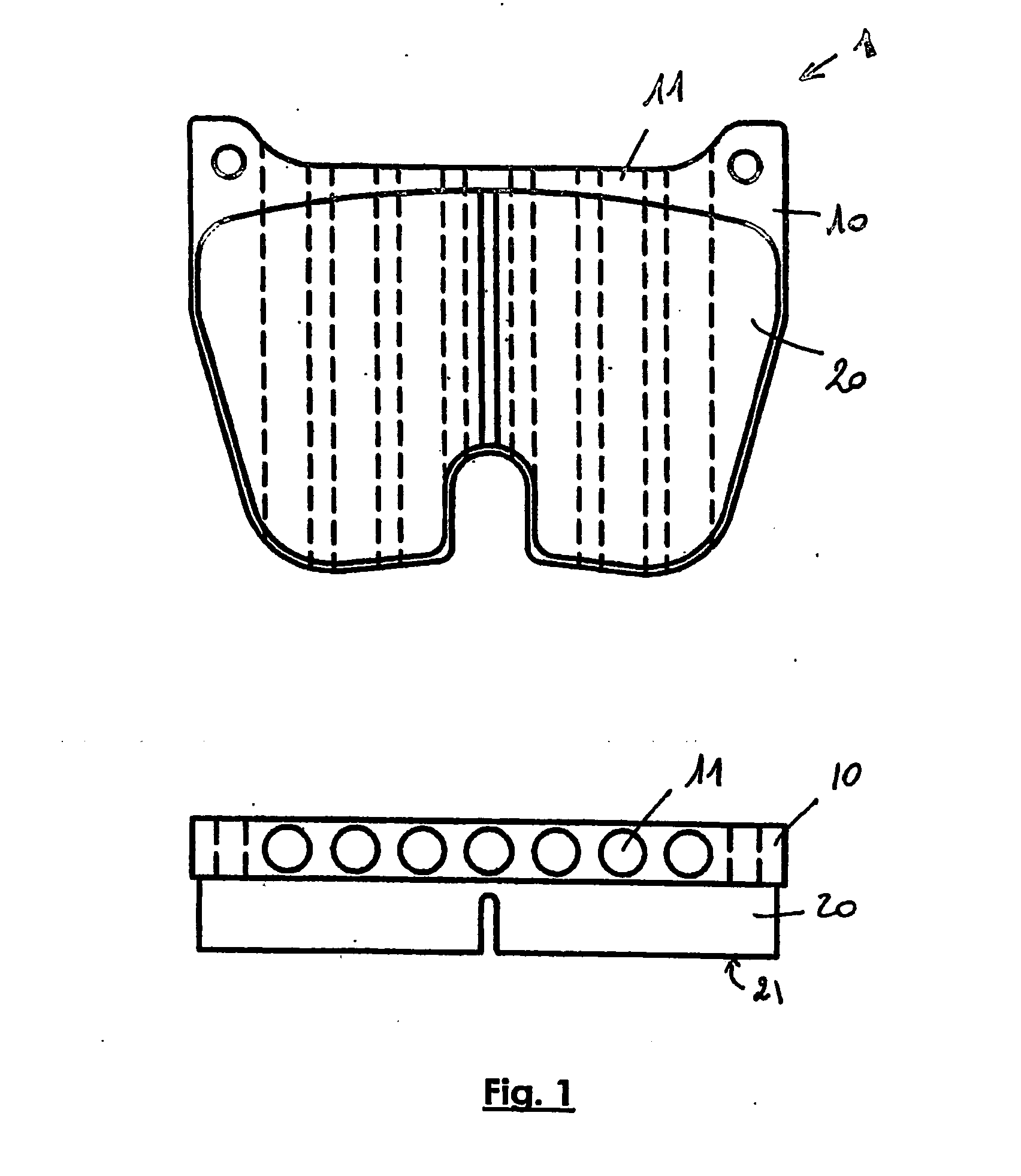

Ventilated brake pads

InactiveUS20070034462A1Increases the cooling fluxIncrease the exchange surface areaBraking drumsBraking discsElectrical conductorEngineering

A disc brake pad including a brake lining having at least one friction surface, and provided with a heat dissipating structure which circulates the heat to be dissipated in one or more directions substantially parallel to the plane of the friction surface. The structure is arranged in the lining and / or in a carrier plate if there is one, or at the interface. The structure may be formed from cylindrical holes with axes following one or more directions substantially parallel to the friction surface. These holes are through holes, such that the air can freely pass therethrough. The structure may also be formed from projections at the periphery of the carrier plate, optionally fitted with cooling fins, or bars which are good heat conductors enclosed a component of the pad.

Owner:FAIVELEY TRANSPORT GENNEVILLIERS

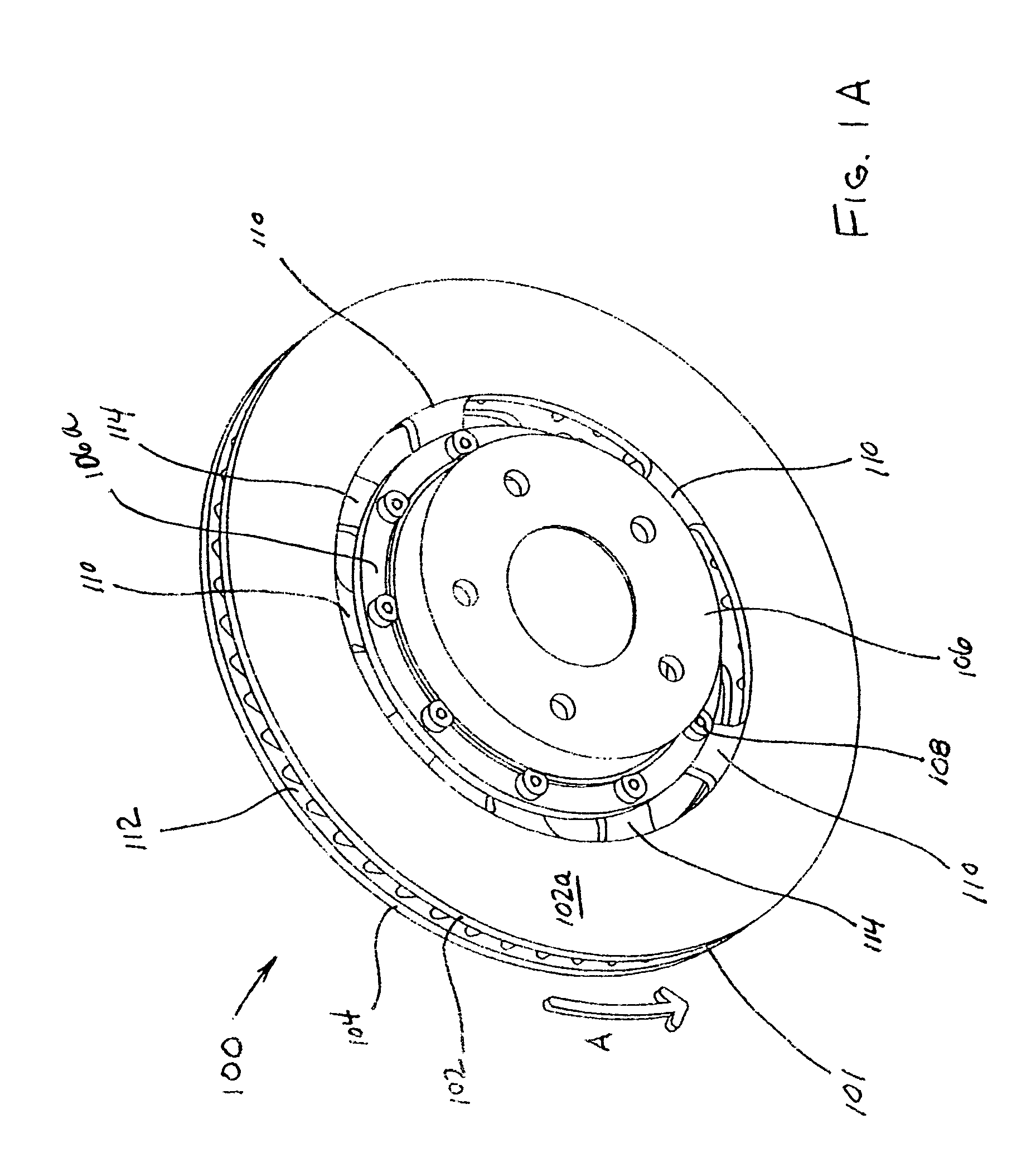

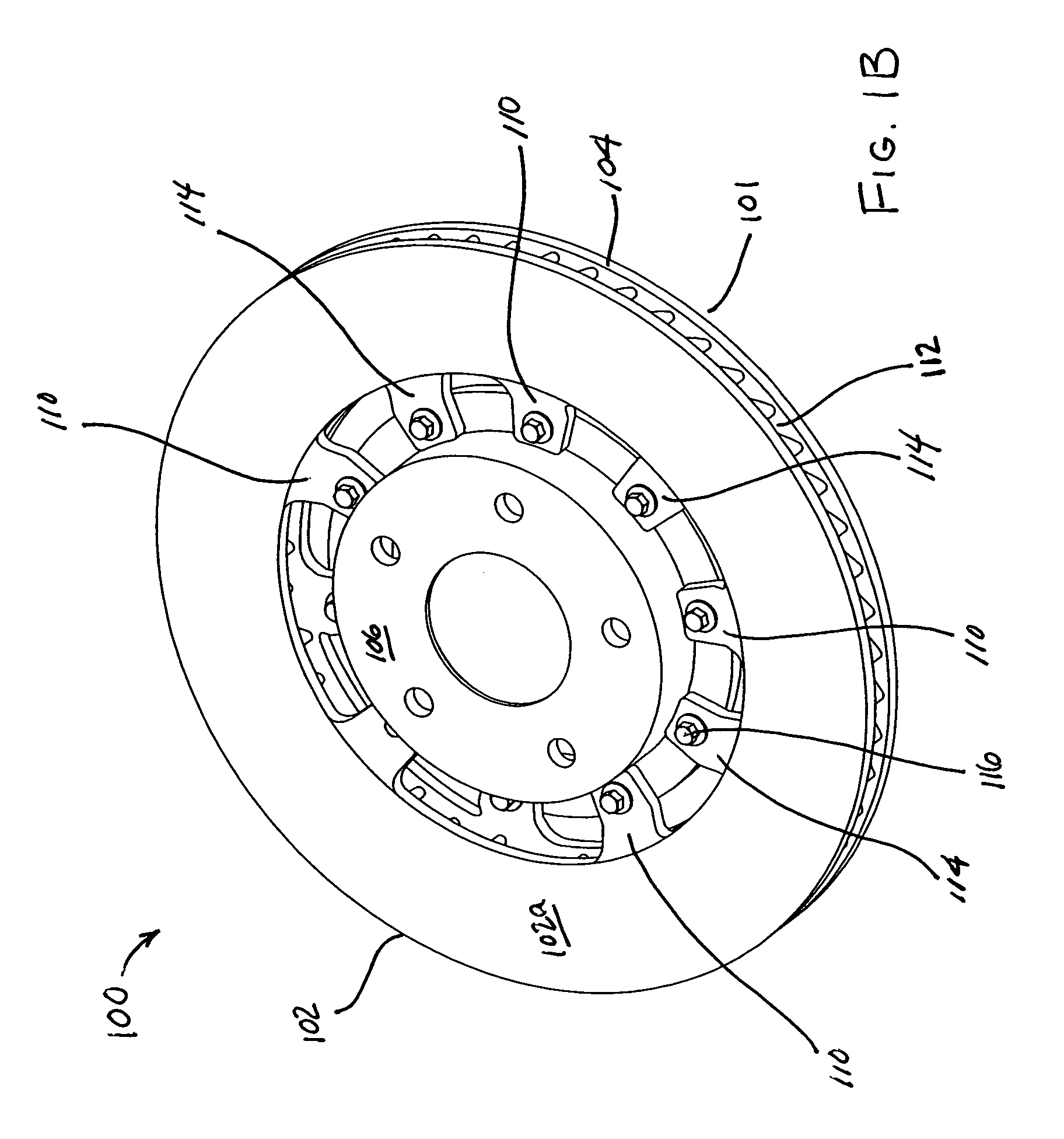

Center mount two piece brake rotor

ActiveUS7568560B2Improve efficiencyImprove performanceBraking drumsBraking discsEngineeringDisc brake

Owner:LIN WARREN

Brake drum and process for manufacturing the same

InactiveUS7216746B2Increase the compression ratioHigh strengthBraking drumsBraking discsHigh intensityCeramic

A brake drum has its strength elevated in its disk portion. The brake drum is formed from a composition having ceramics dispersed in a matrix. The disk portion has a high ceramic content and thereby a high strength. The brake drum has a disk portion and a cylindrical portion. The disk portion has a first ceramic content by volume and the cylindrical portion has a second ceramic content by volume that is less than the first ceramic content by volume as a result of the application of a higher compression ratio to the disk portion.

Owner:NISSIN KOGYO CO LTD +1

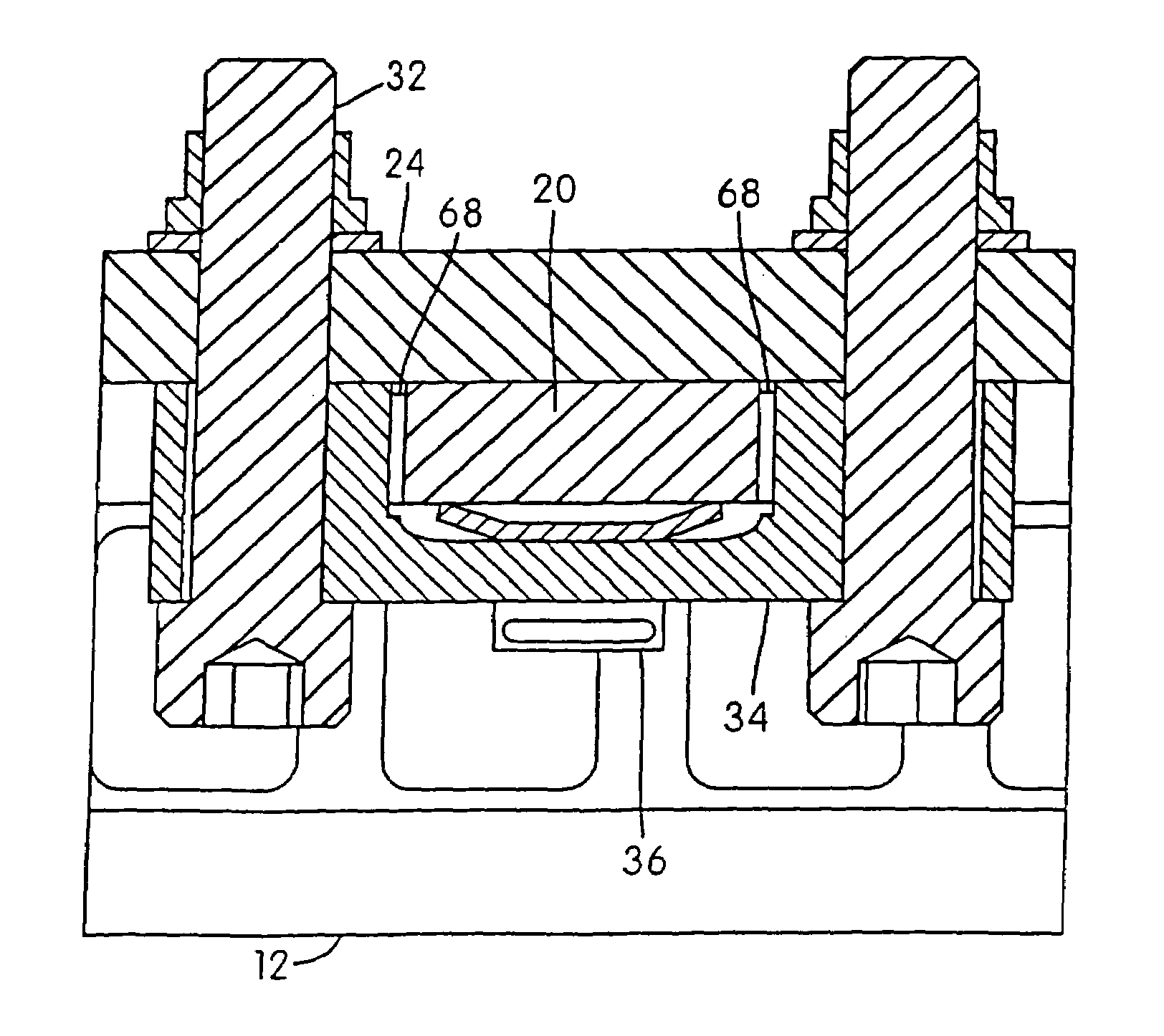

Brake rotor with embedded loose-mass damper system

ActiveUS20090173585A1Dissipate kinetic energySimple methodNoise/vibration controlMechanically actuated brakesEngineeringVehicle brake

A rotor is provided for use with a vehicle brake assembly that includes a forcing member operable to urge a friction member into mechanical communication with the rotor to thereby oppose movement of the same. The rotor includes a rotor body with an annular rim portion having first and second opposing contact faces. One or more loose-mass damper systems are interposed between the first and second contact faces, and operable to dissipate kinetic energy directly therefrom. Each of the loose-mass damper systems includes at least one mass operable to repeatedly impact against first and second inner faces respectively opposing the first and second contact faces to reduce oscillation of the rotor. Reducing oscillation of the rotor is independent of temperature and pressure. The loose-mass damper systems are preferably oriented proximate to an outer peripheral edge of the annular rim portion generally circumferentially equidistant from one another.

Owner:WOLVERINE ADVANCED MATERIALS

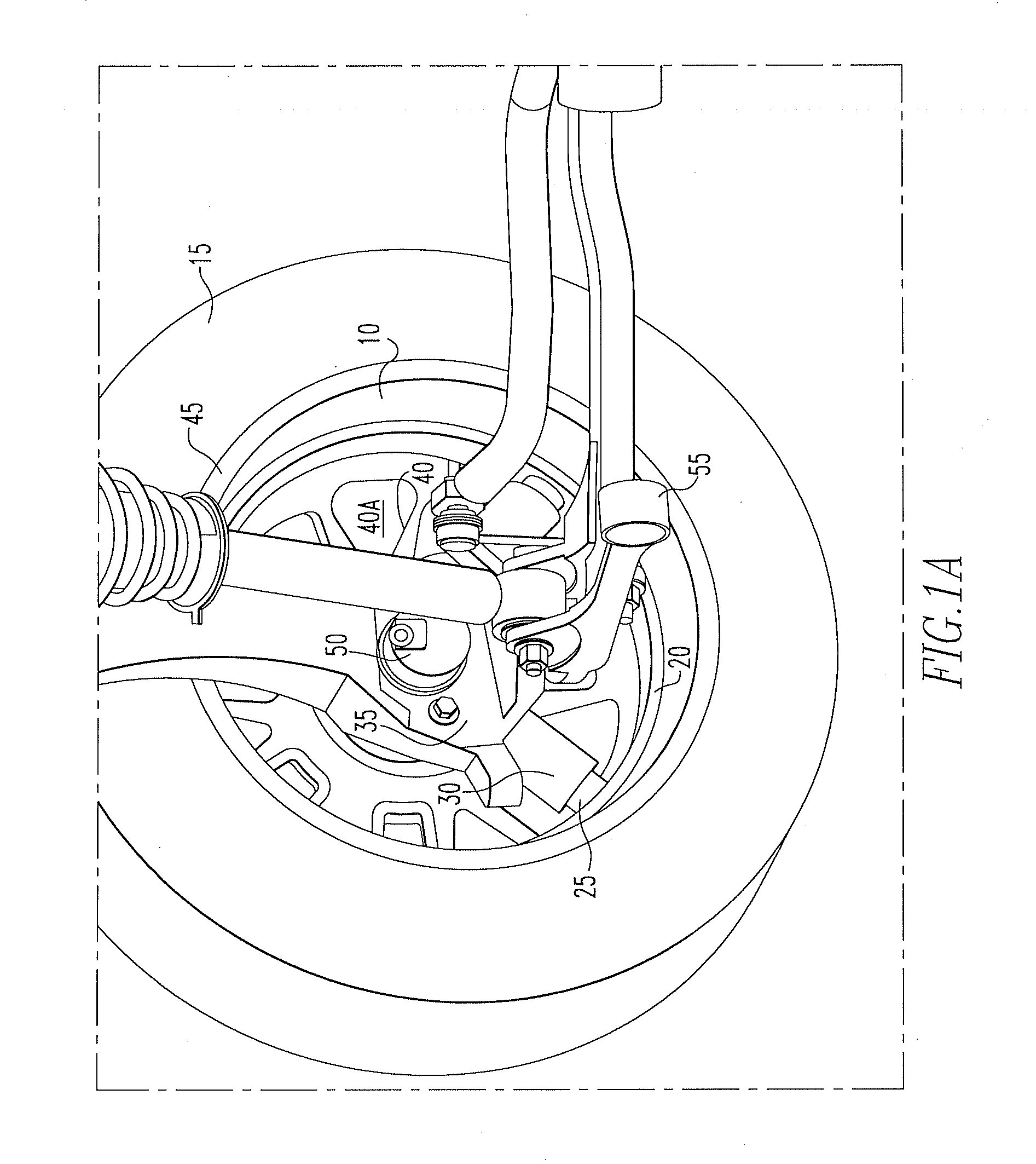

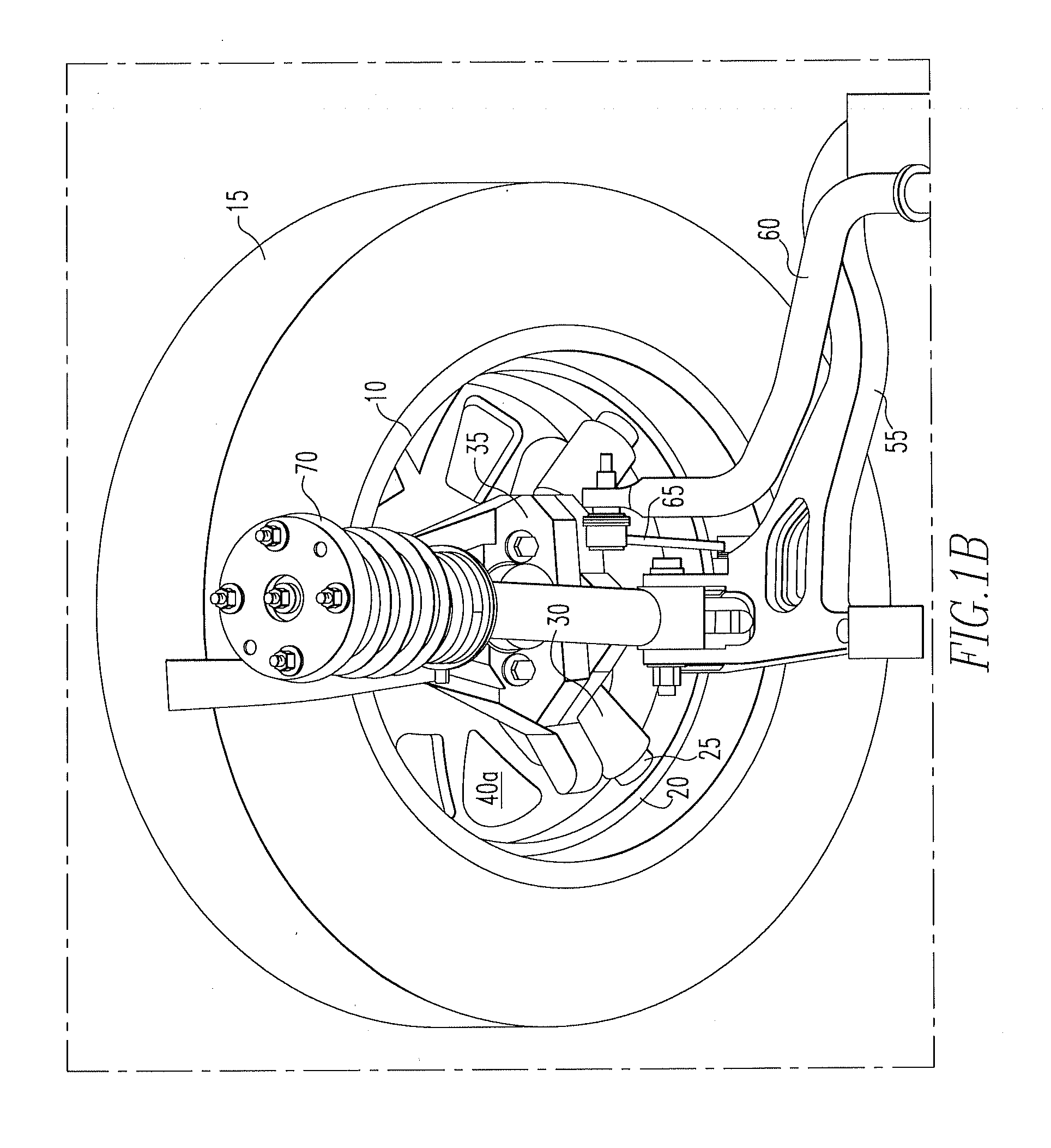

Integrated brake, suspension and wheel system

InactiveUS20070144839A1Reduce weightIncrease heating capacityMolten spray coatingRimsEngineeringMechanical engineering

A brake system including a suspension component housing at least one actuation piston to reversibly extend a brake pad; and a wheel that is in rotational engagement to the suspension component, the wheel having a rim portion with an interior surface that is contacted by the brake pad of at least one actuation piston when in an extended position.

Owner:ARCONIC INC

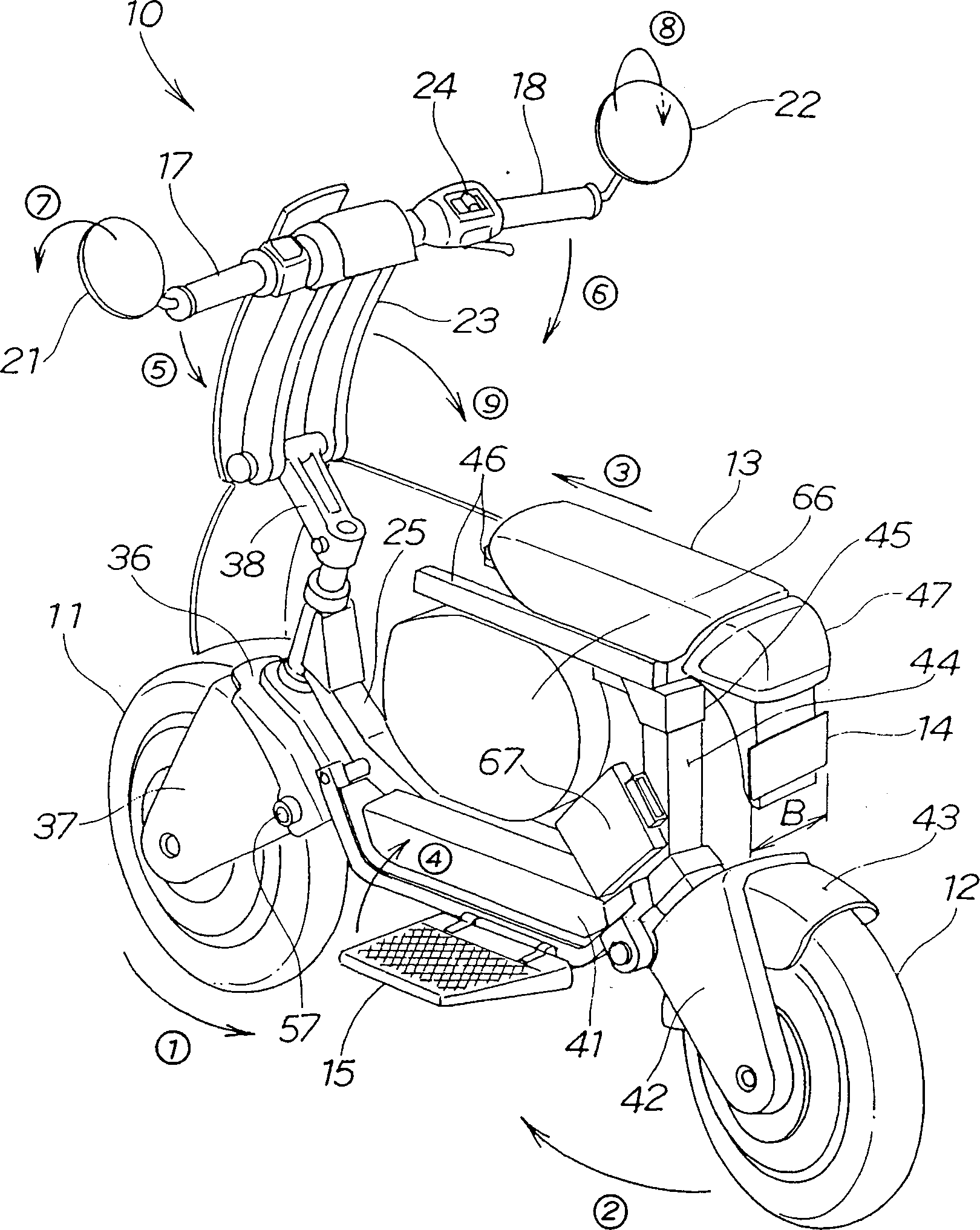

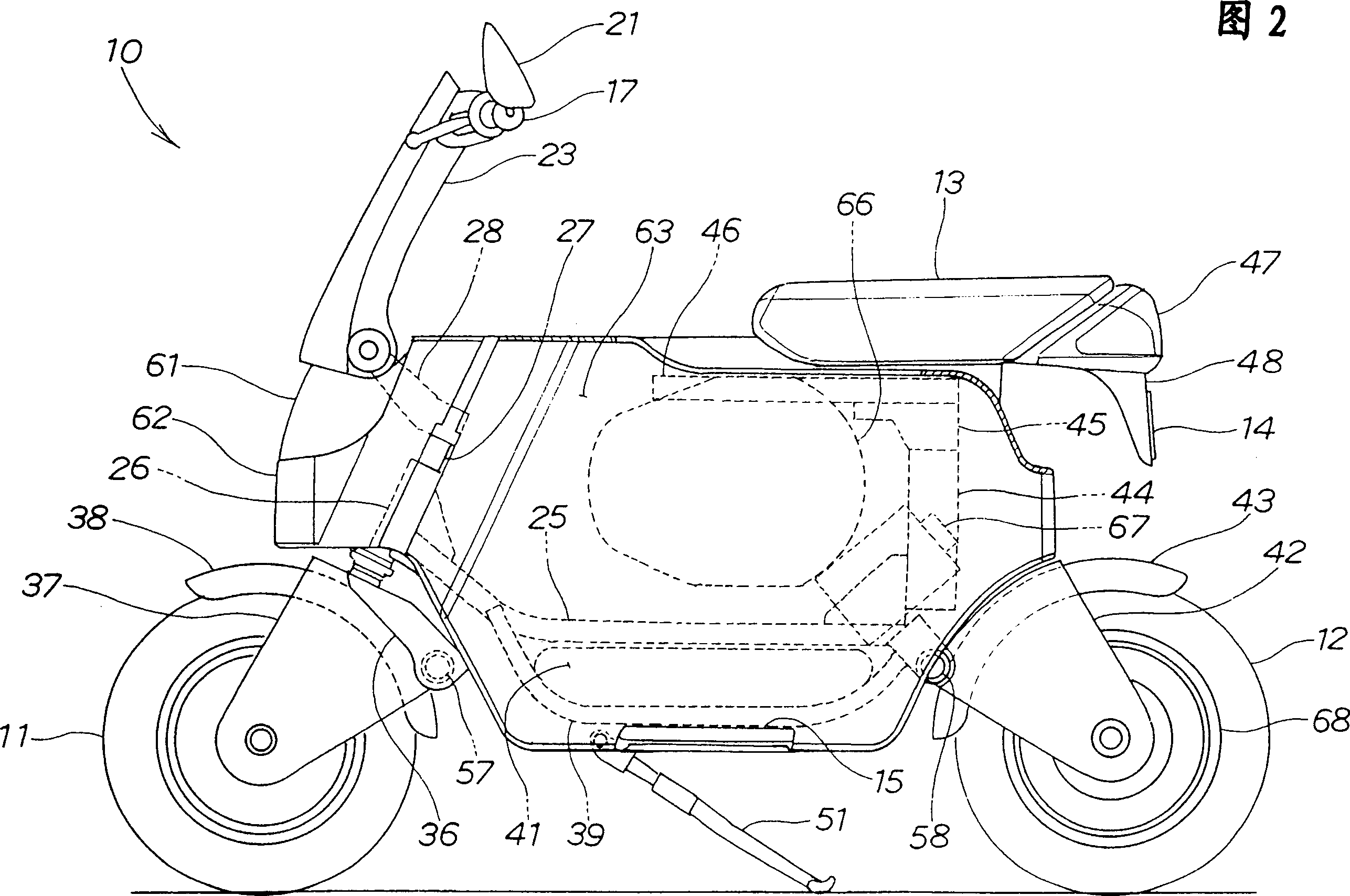

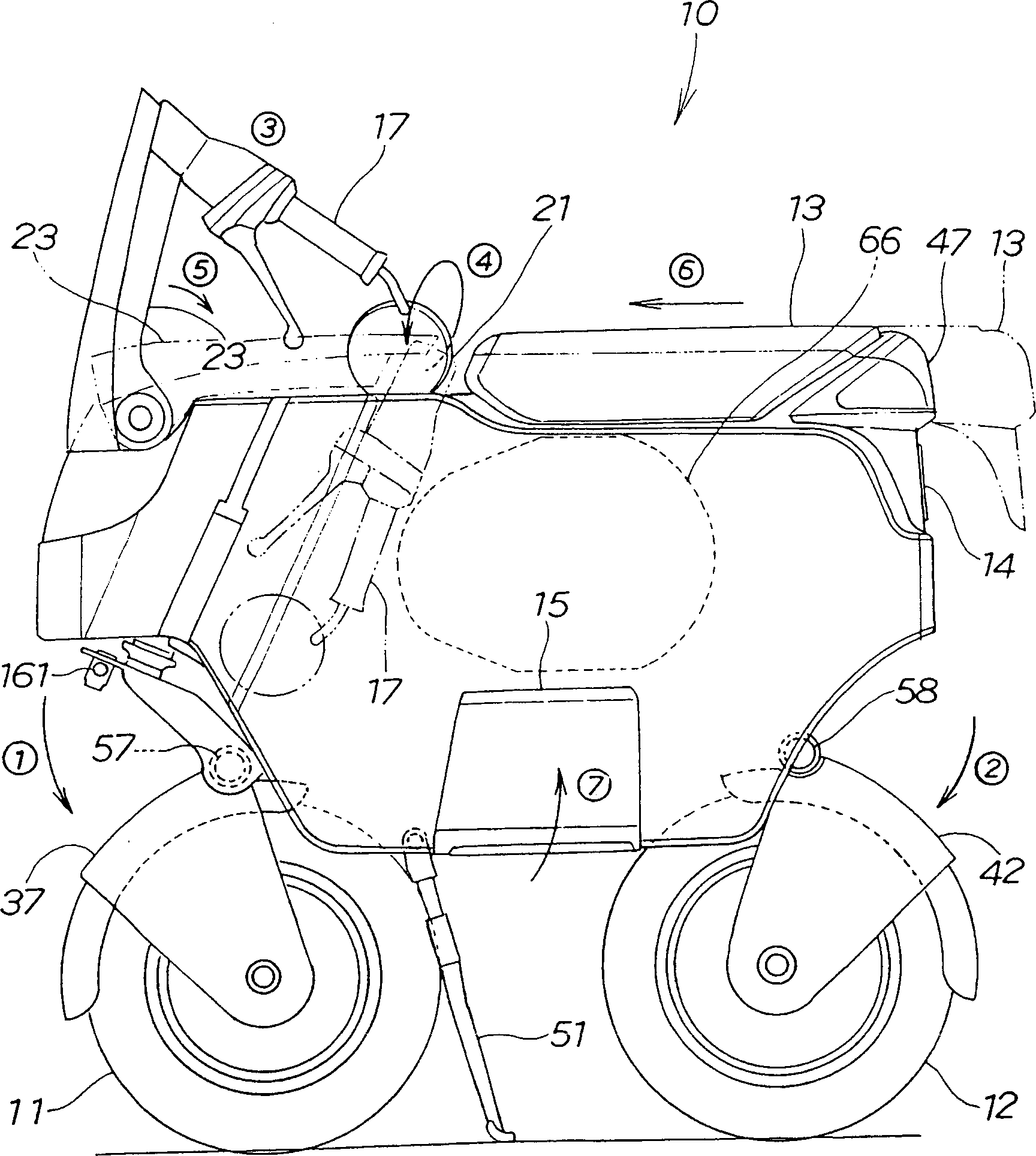

Vehicle wheel structure

InactiveCN1403310ASimple structureEasy to assembleBraking element arrangementsHubsEngineeringDrum brake

A drum brake for braking a wheel disposed on the inside in the radial direction of an electric motor. The drum of the drum brake and an electric motor are disposed separate from each other, and thus wear powders of a brake shoe do not adhere to a permanent magnet of the electric motor. As a result, the wear powders do not adversely influence the performance of the electric motor, and the performance of the electric motor is maintained. The electric motor and the drum brake are disposed concentrically, so that the width of the wheel is reduced. Thus, a small and compact wheel is realized.

Owner:HONDA MOTOR CO LTD

Exciter ring for a brake rotor

Exciter rings, wheel assemblies and methods of assembling. In some aspects, a wheel assembly includes a brake rotor including a barrel section having an interior surface defining a barrel cavity, and a projection extending from the interior surface of the barrel section into the barrel cavity. The wheel assembly also includes an exciter ring formed separately from the brake rotor and engagable with the projection within the barrel cavity to removably connect the exciter ring to the brake rotor. In other aspects, an exciter ring is formed separately from and removably connectable to a brake rotor and includes a body portion having an outer surface, the body portion including a detent protruding outwardly from the outer surface and extending around the outer surface of the body portion. The exciter ring also includes a flange extending radially outwardly from the body portion and having a plurality of apertures.

Owner:ROYAL BANK OF CANADA

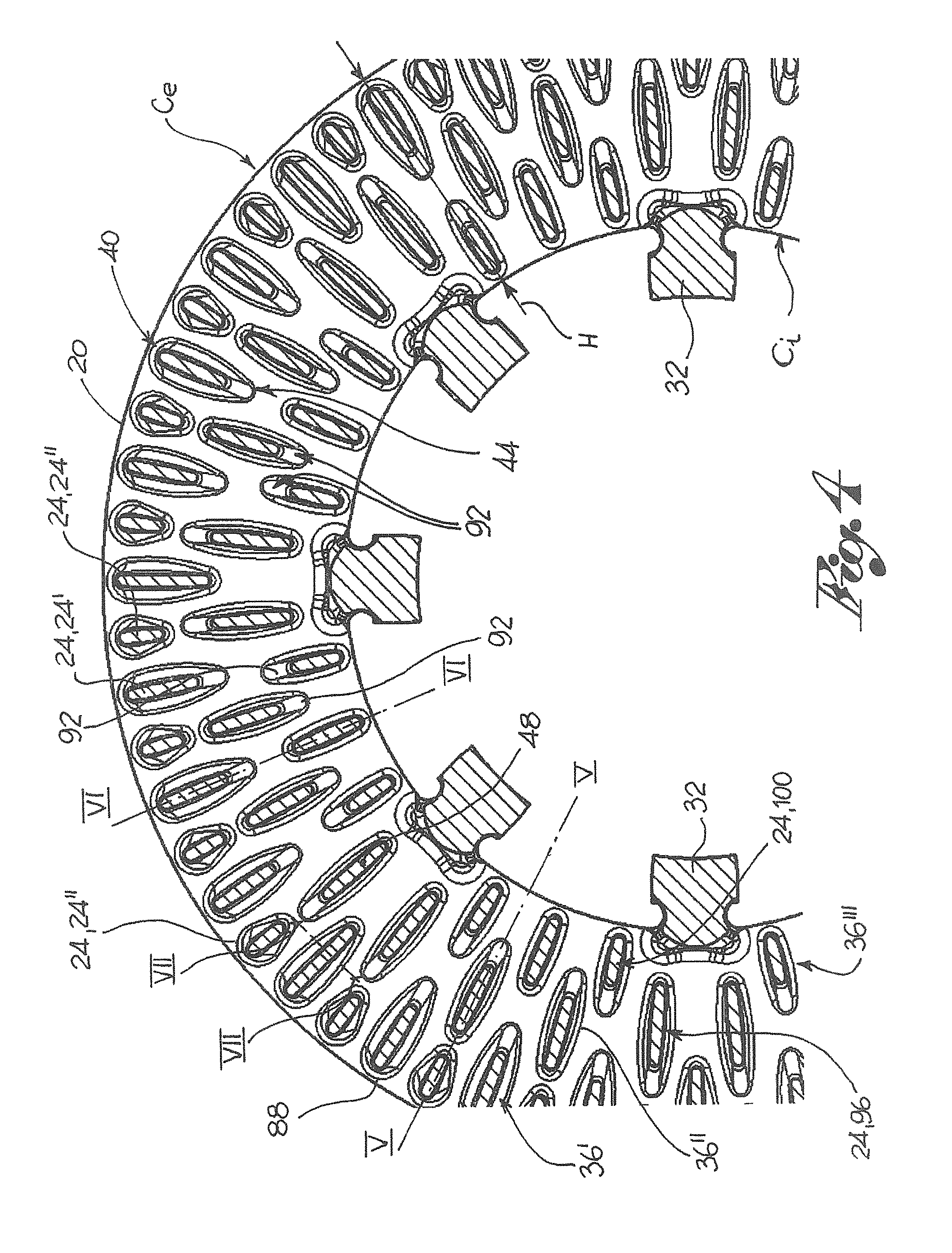

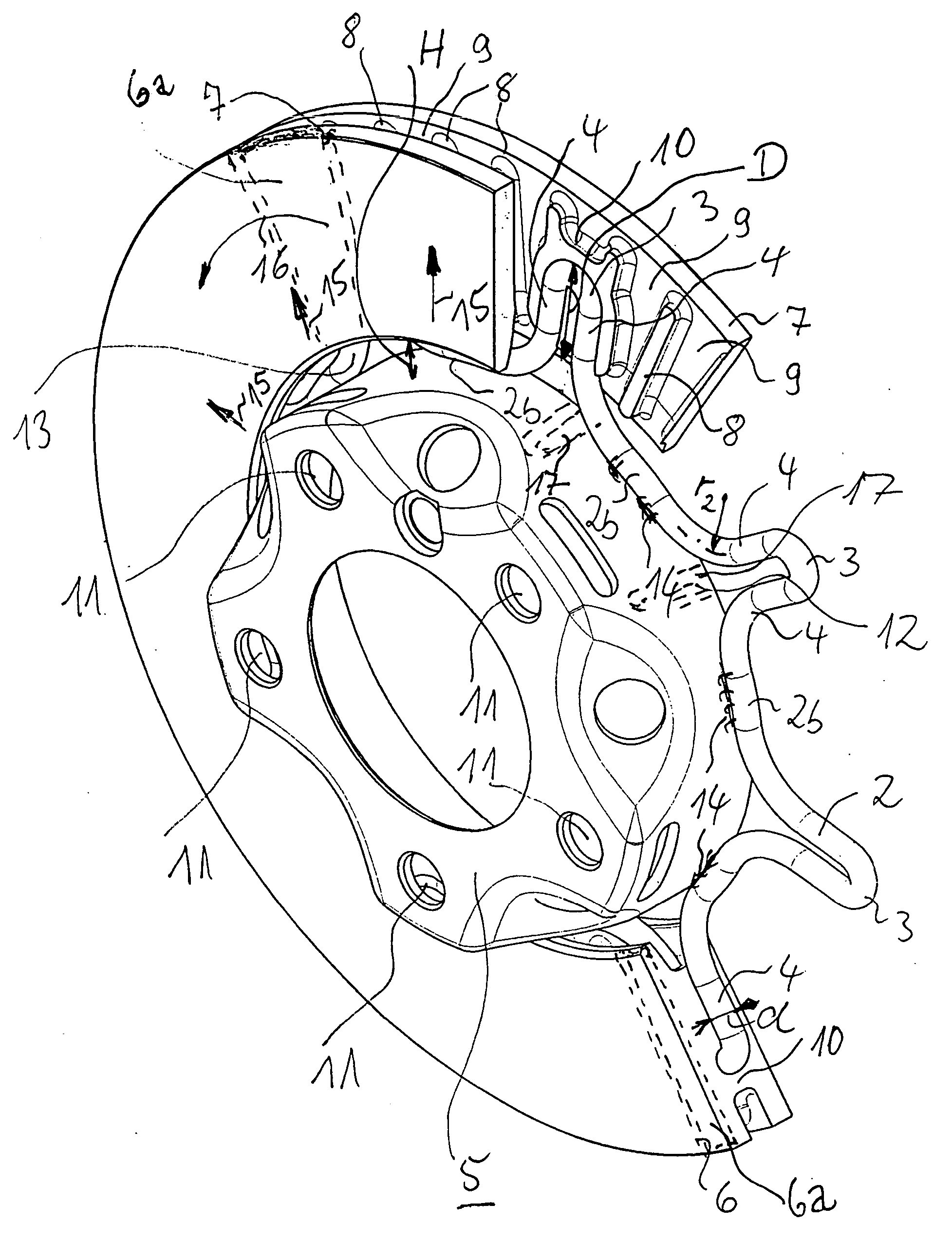

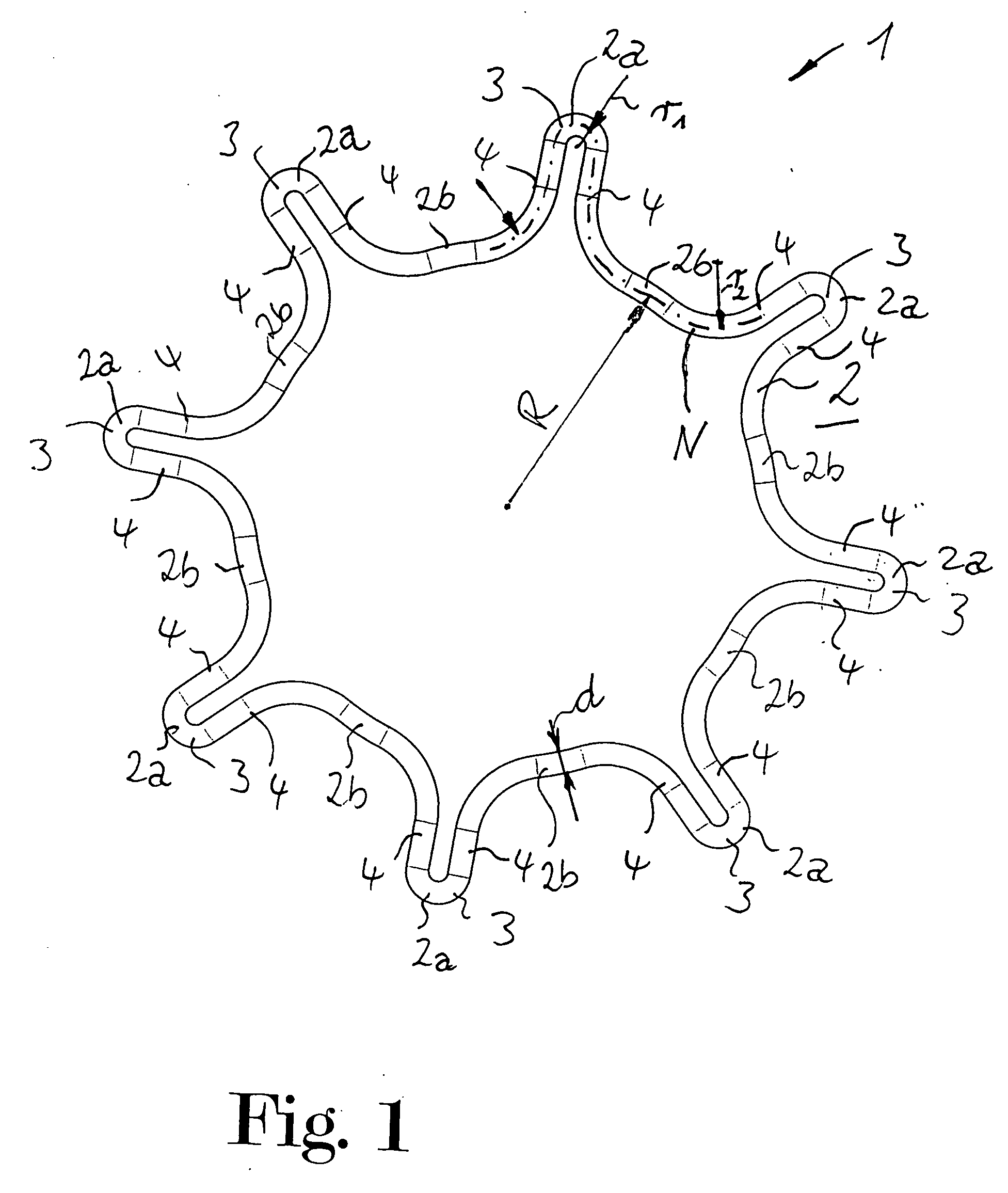

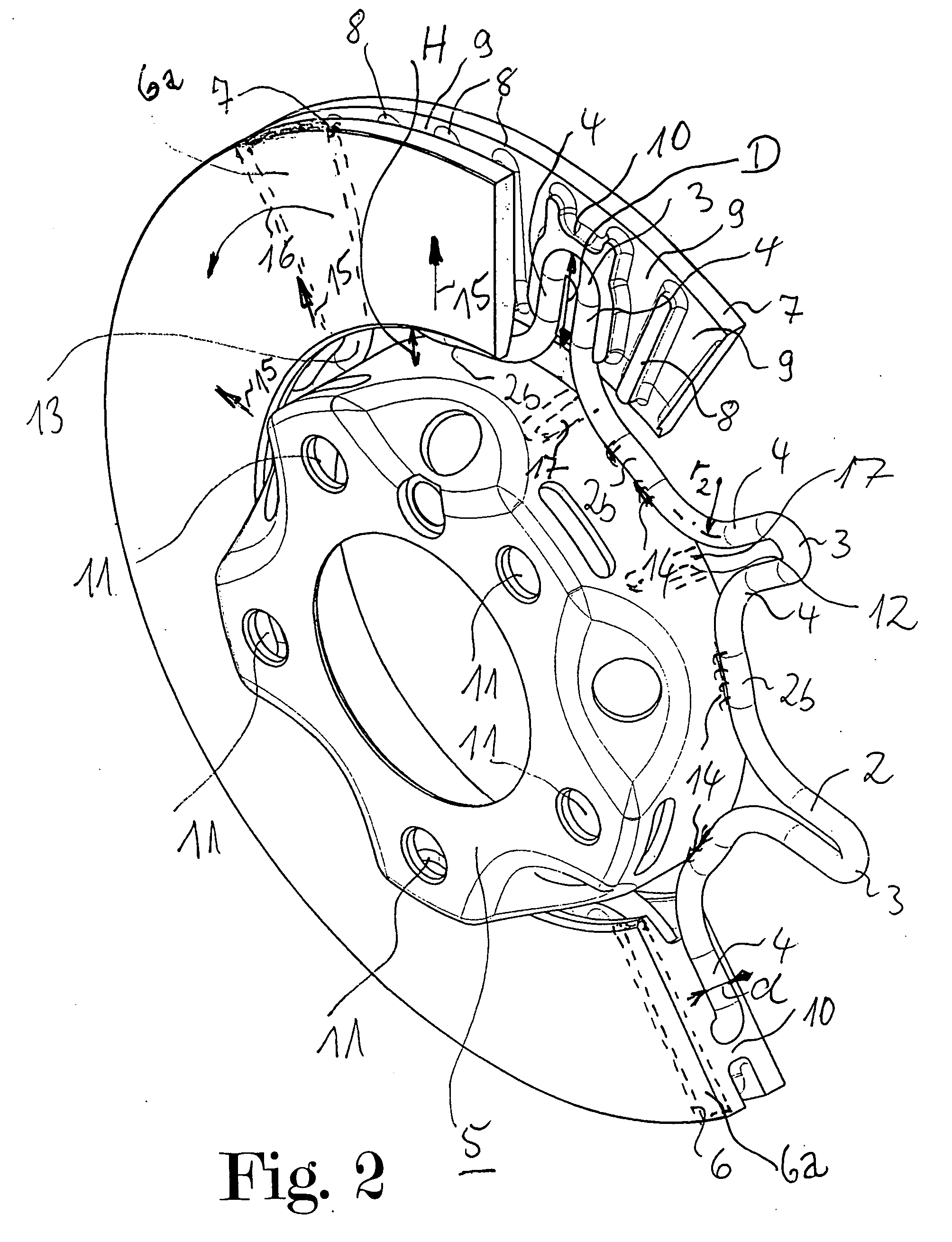

Brake disc ventilated

ActiveUS8733517B2Reduce the total massImprove cooling effectFluid actuated brakesBraking drumsEngineeringDriven element

Owner:FRENI BREMBO SPA

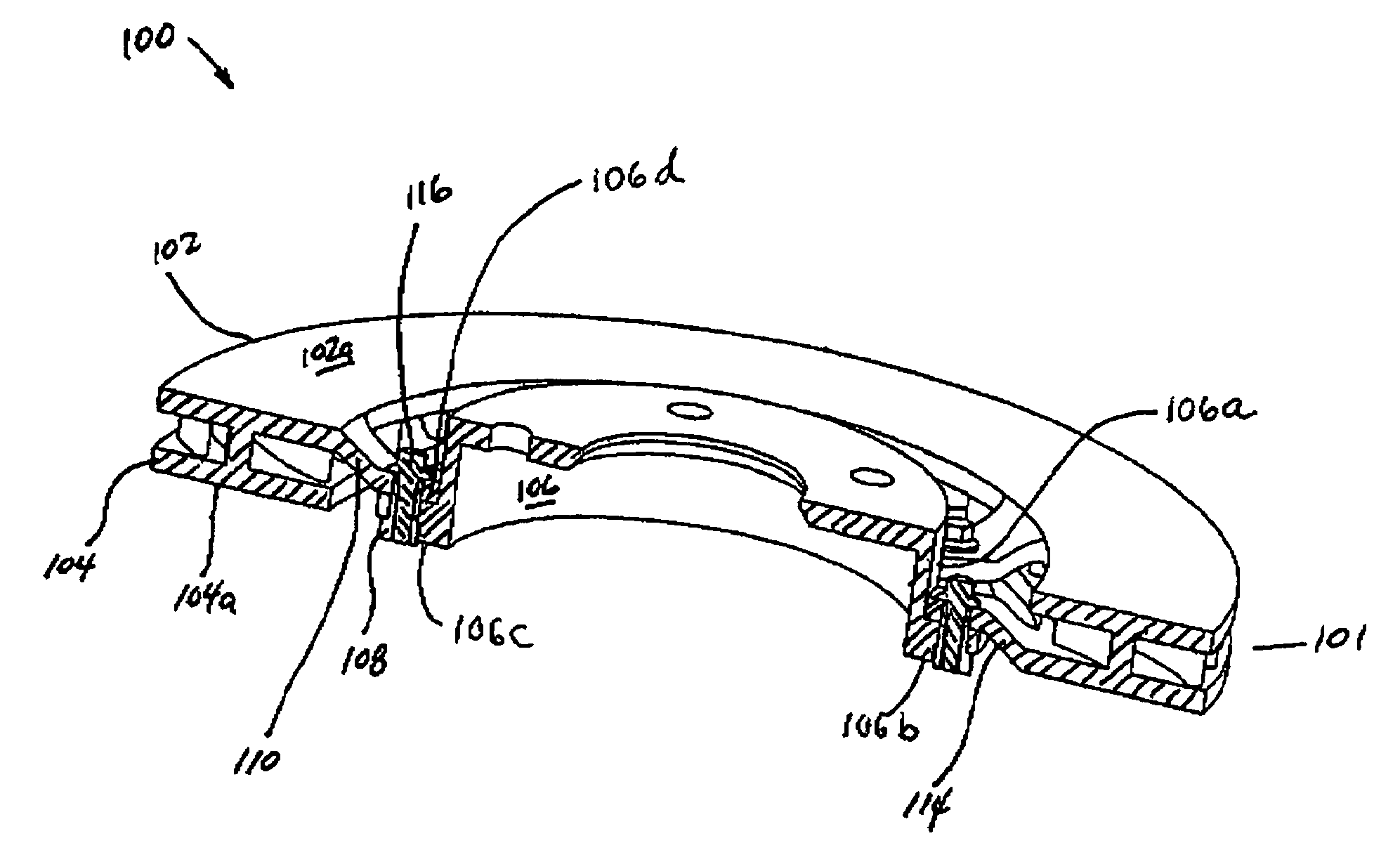

Assembly comprised of a brake disk with a hub

InactiveUS20050126870A1Easy and cost-effective to manufactureAvoid deformationHubsBraking drumsMechanical engineering

An assembly comprised of a brake disk with a hub. Webs which are adjacent to one another in the circumferential direction extend between and are anchored to the brake disk and are attached to the hub. At least two of the webs which are adjacent to one another in the circumferential direction are formed together in one piece, either from a bent section joining the webs or because adjacent segments having respective adjacent webs are attached. The webs absorb stresses between the brake disk and the hub.

Owner:FAG KUGELGISCHER GEORG SCHAFER

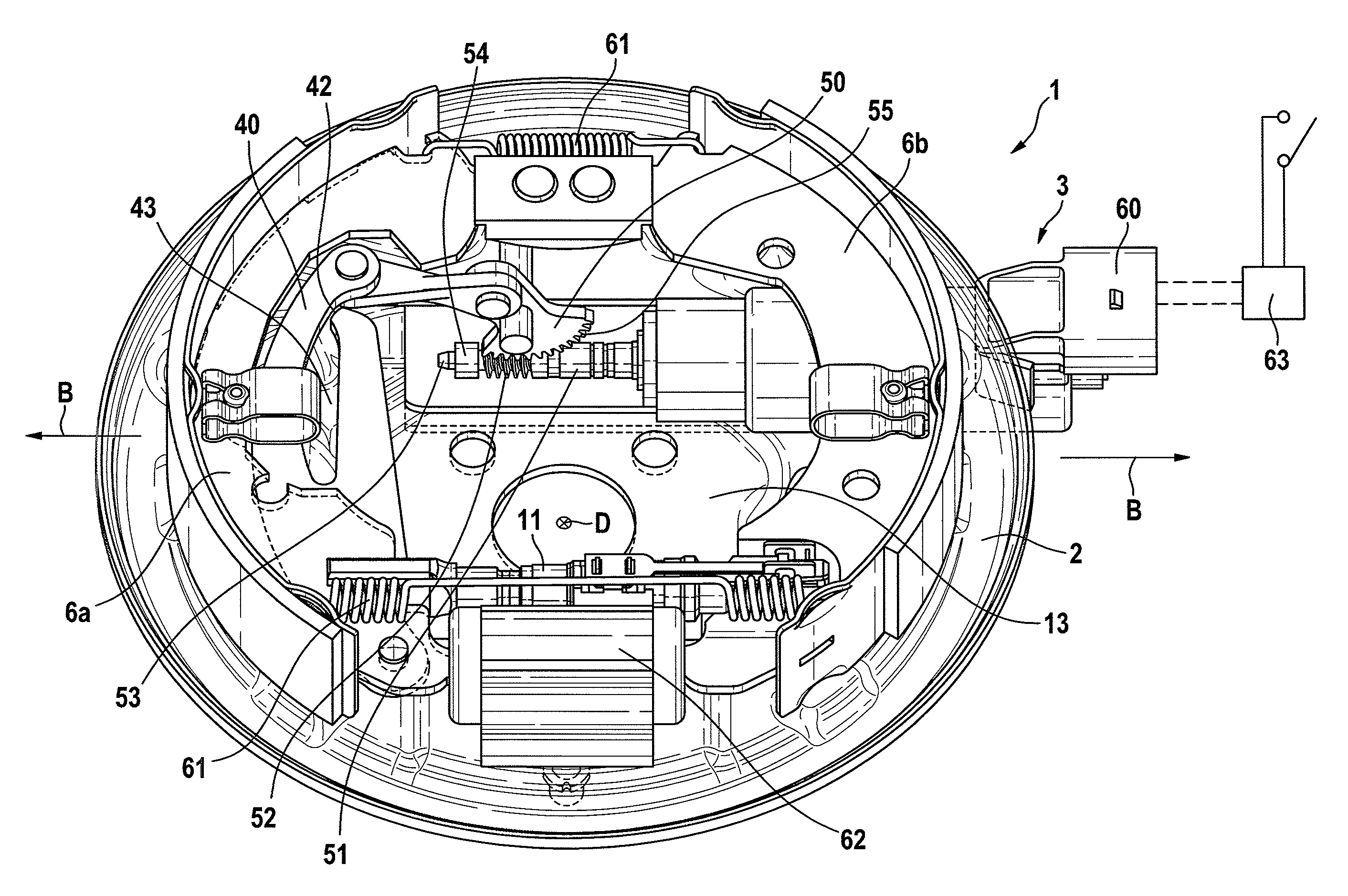

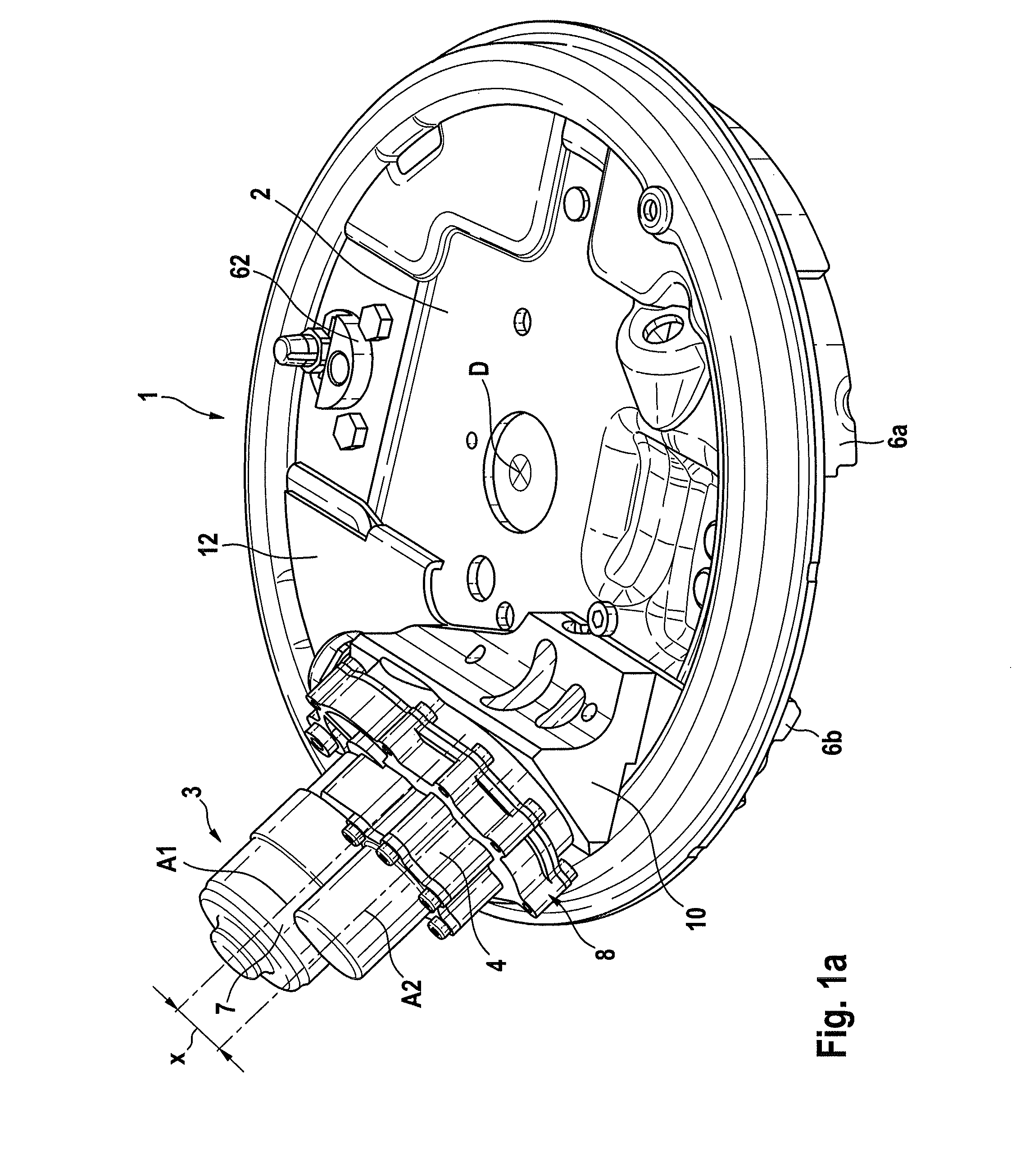

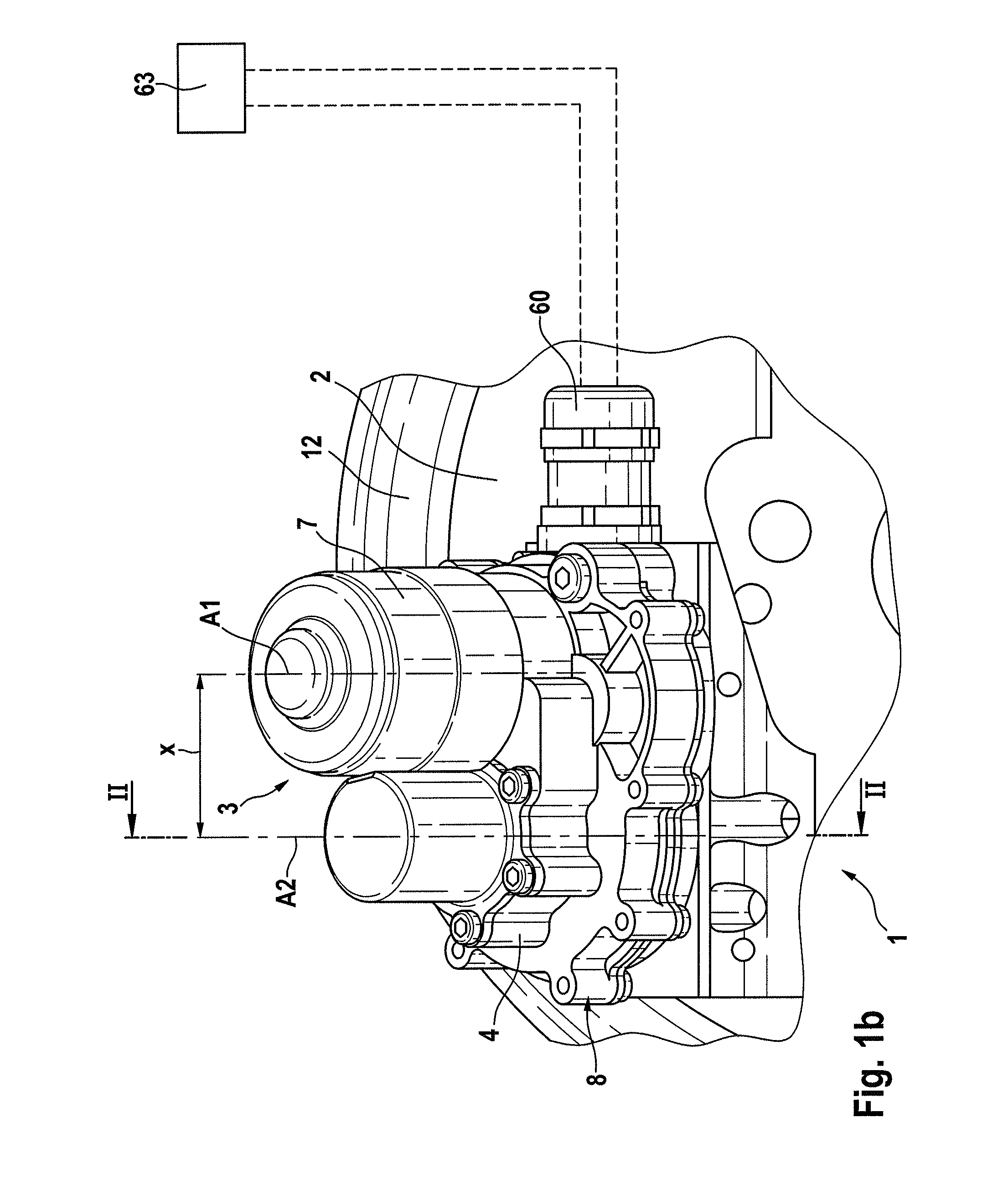

Drum brake module which can be operated by electric motor

ActiveUS9175737B2Easy to assembleImprove efficiencyBraking drumsBrake actuating mechanismsEngineeringBiological activation

A drum brake module for motor vehicles operable by electric motor and performs at least one parking brake function, having an electromechanical actuator mounted on one side of the armature plate and a rotational-translational movement converter converting a rotational drive rotational movement into a translational activation movement of brake shoes arranged on a side of the armature plate facing away from the actuator in a brake drum, and including at least one supporting device between the brake shoes such that the latter can carry out an activation movement in the direction of the brake drum. A drive nut is supported by the rotational-translational movement converter in an axially secure and rotatable fashion on the armature plate to assist the braking force. The drive nut drives a spindle arrangement mounted in a rotationally fixed and axially displaceable fashion and engages with an activation cable on at least one brake shoe.

Owner:CONTINENTAL TEVES AG & CO OHG

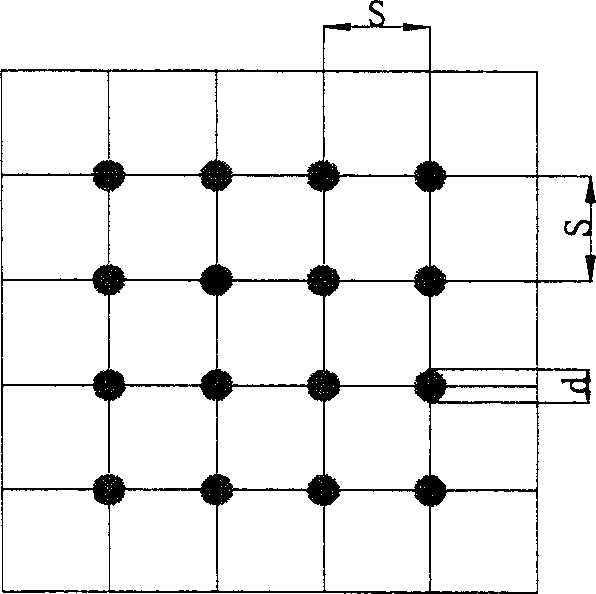

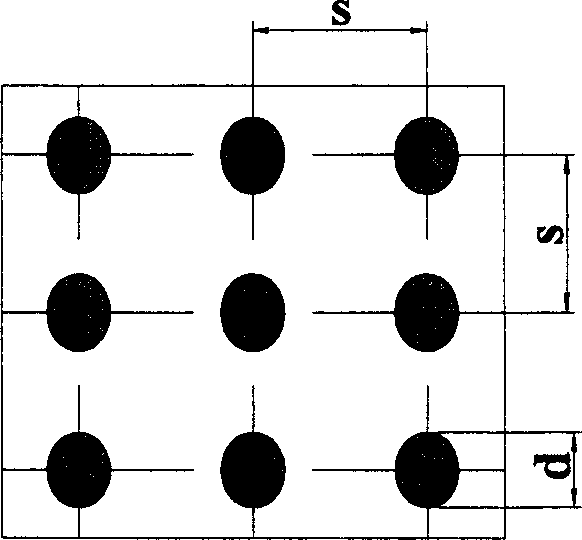

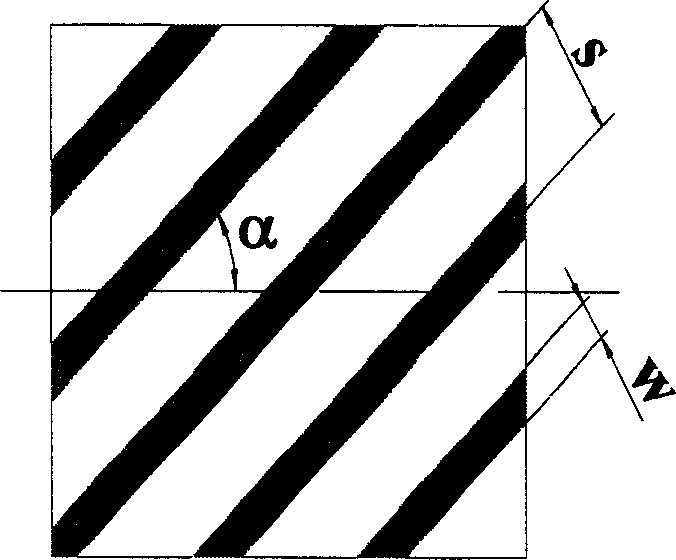

Braking drum with bionic non-smooth surface

InactiveCN1644950AIncrease coefficient of frictionImprove wear resistanceBraking drumsRough surfaceEngineering

A drum break with bionic rough surface characters high friction index, anti-wear, anti-heat fatigue. On the surface of the drum break distribute knaggy units of height 0.15-0.5 mm in parallel or net. The structure and chemical components of the knaggy units increase the ability of anti-friction and anti-heat fatigue of the drum break. The structure of the knaggy units changes a surface friction to point friction therefore reduce wearniess of the drum break. The life this knagg drum break is 1.5-3 times of that of same material in smooth.

Owner:JILIN UNIV

Carbon Article Having an Improved Anti-Oxidant Coating

A carbon article shaped as a brake disc, the brake disc being coated with an anti-oxidant coating obtained by applying as a primer coat a composition including orthophosphoric acid, aluminum chloride hydrated, a surfactant, industrial methylated spirits, and demineralized water; curing the primer coat; applying as a barrier coat a composition including orthophosphoric acid, aluminum chloride hydrated, a surfactant, industrial methylated spirits, demineralized water, colloidal silica, and boron nitride; and curing the barrier coat.

Owner:MEGGITT AEROSPACE

Double-metal hot jacket integrated automobile brake drum and machining method thereof

ActiveCN103953669AHigh strengthIncrease the strength of actionBraking drumsSlack adjustersEngineeringMachining

The invention provides a double-metal hot jacket integrated automobile brake drum, which consists of a drum-shaped shell and a tube-shaped casting liner, wherein the tube-shaped casting liner is arranged on the inner wall of the drum-shaped shell; the wall of the drum-shaped shell is made of constant-strength spinning steel. According to the double-metal hot jacket integrated automobile brake drum, a shell of the brake drum is made by a spinning technique of a spinning machine, the material of the brake drum shell is compact and has high strength, and the tube-shaped casting is taken as the liner so as to have the uniform thickness and simpleness and convenience in machining; a step of heating the shell of the brake drum specifically comprises the steps of bushing the tube-shaped casting liner into the shell under the condition of expansion of the diameter of the shell, condensing, fixedly fastening, and reinforcing the fixation between the shell of the brake drum and the casting liner by utilizing a pin; therefore the brake drum is ensured to have the advantages that the integrated strength is high, the material is utilized reasonably, the weight is light, the heat radiation performance is good, and the manufacturing technique process is suitable for automatic line operation.

Owner:泉州市泰智机械发展有限公司

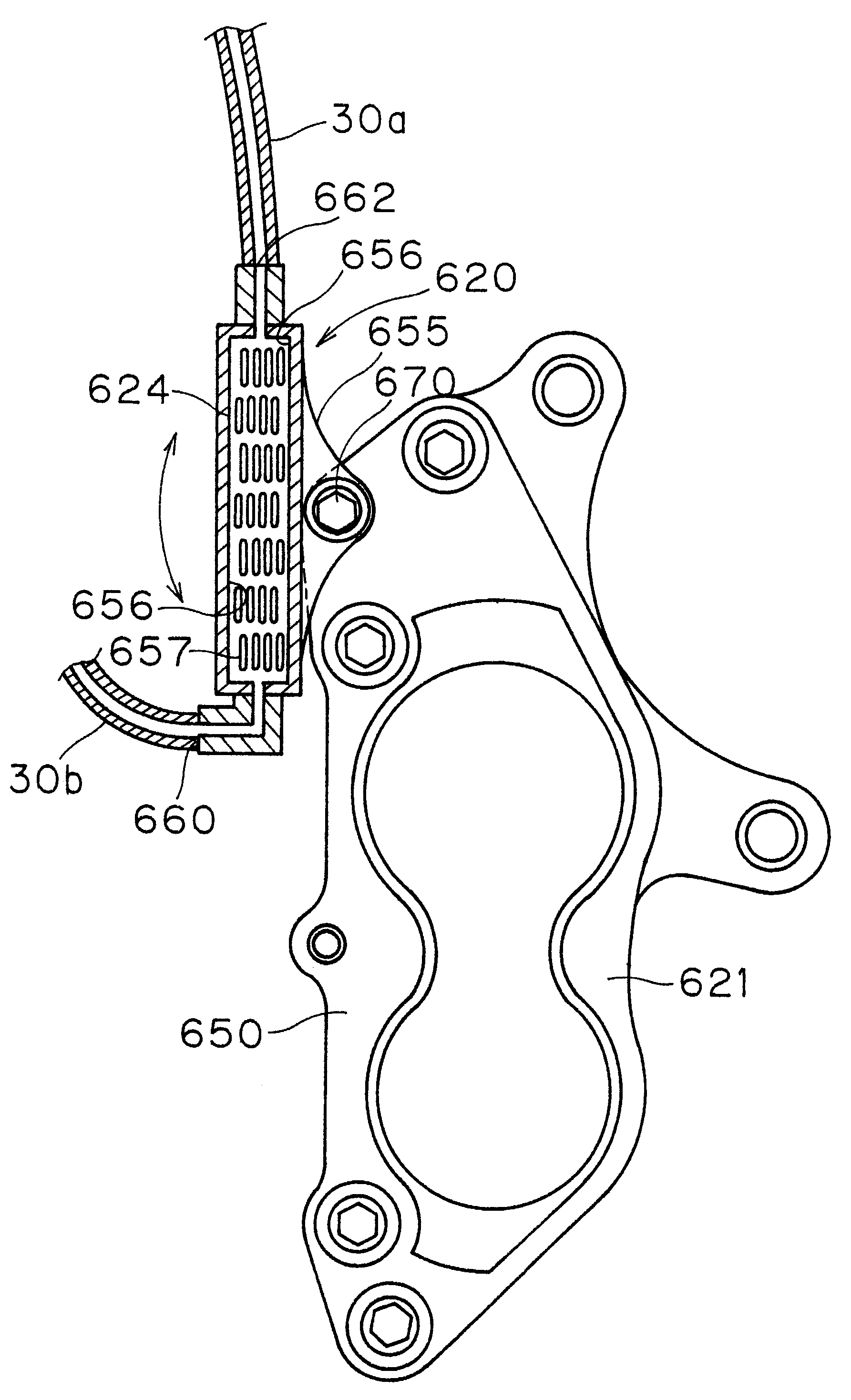

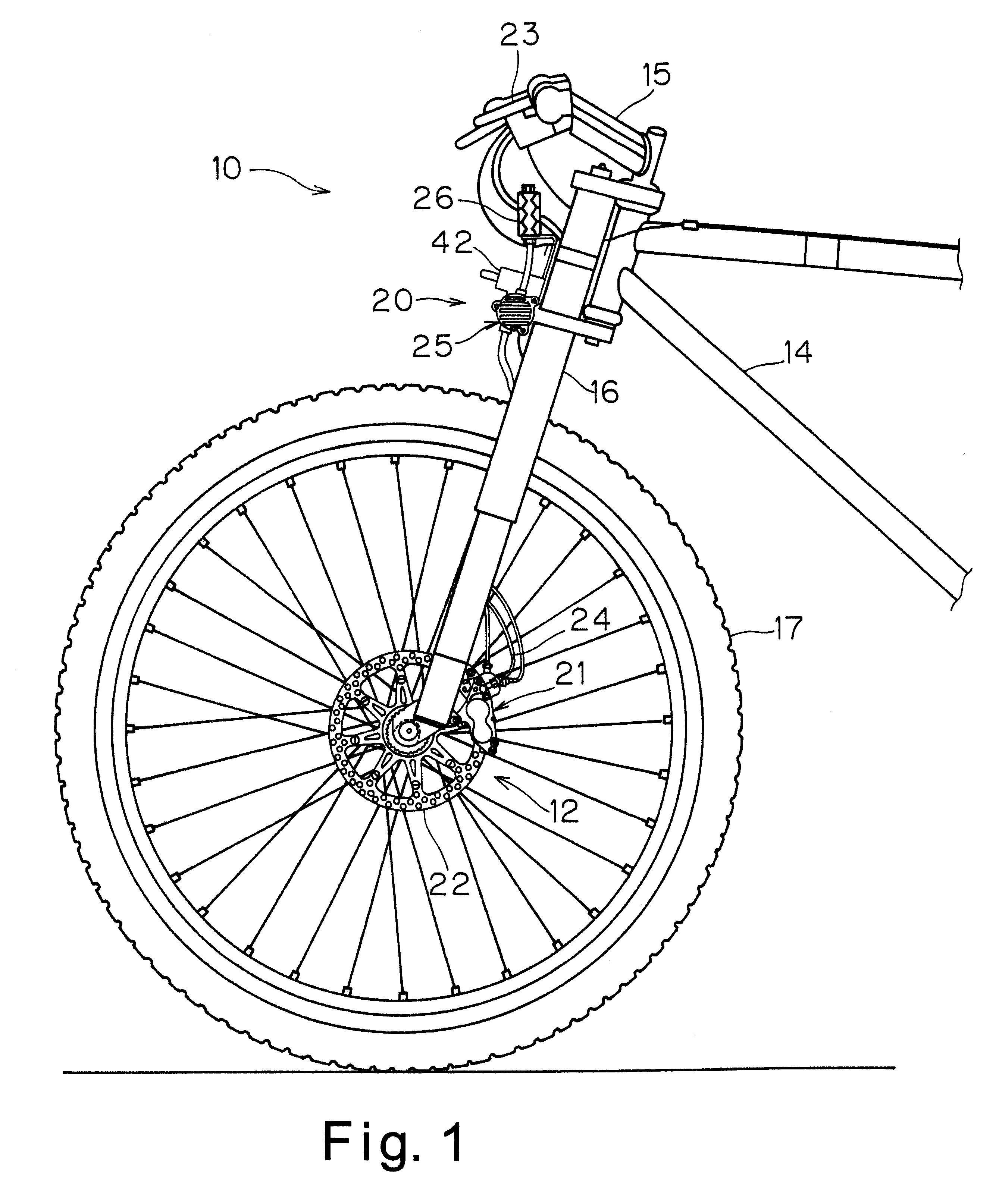

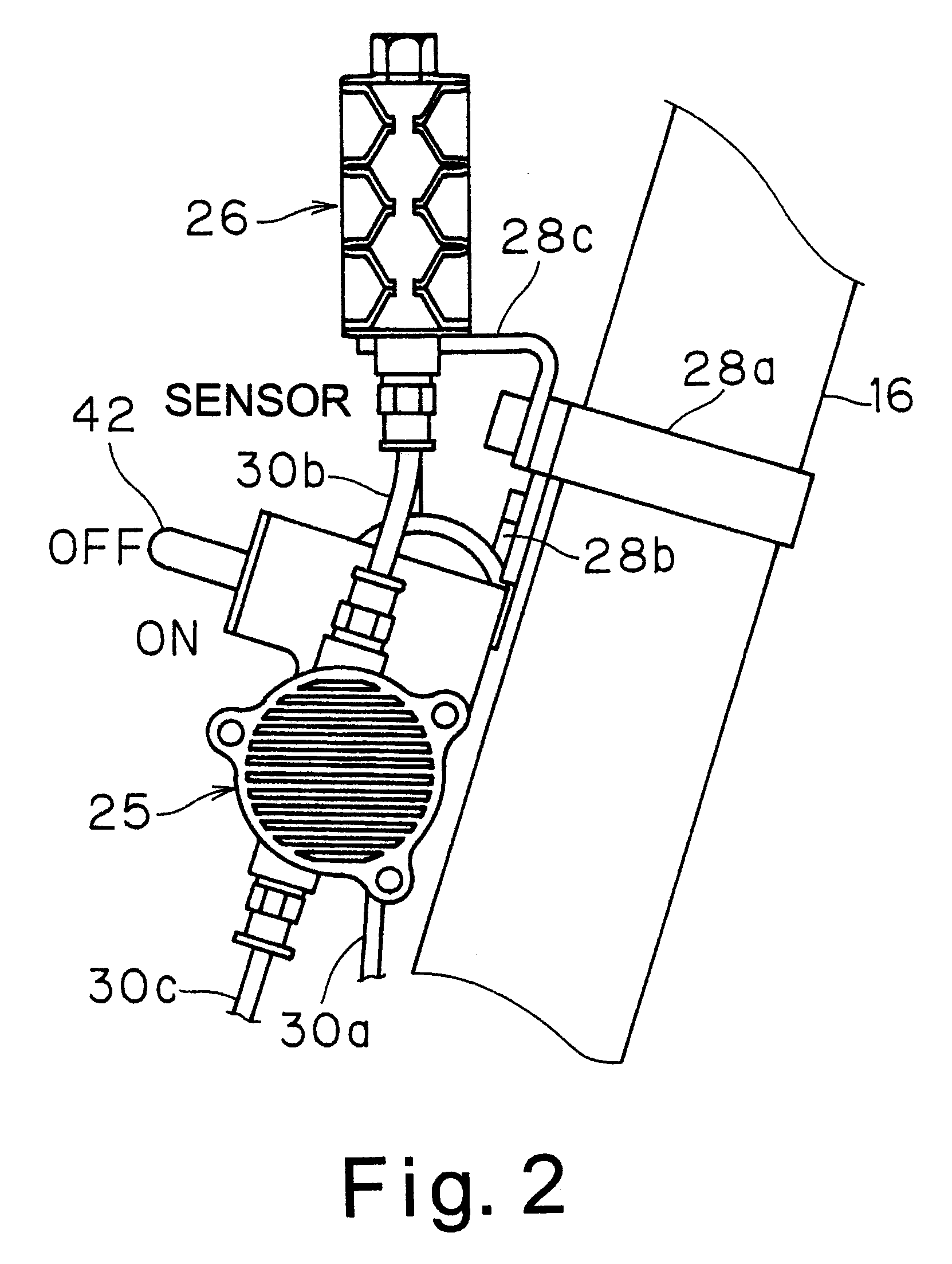

Detachable fluid cooling system for bicycle disc brake

A bicycle disc brake caliper is provided with a detachable cooling system that transfers heat away from the actuating fluid. Basically, the bicycle disc brake caliper has a housing and a piston unit, with a coolant member of the cooling system attached to the housing. The housing has a frame mounting member sized to be coupled to a portion of a bicycle frame. The piston unit is movably coupled to the housing between a release position, in which the piston unit is spaced from a brake disc mounted to a wheel of a bicycle, and a braking position, in which the piston unit engages the brake disc of the bicycle wheel. The coolant member has a coolant area for receiving coolant to create a coolant heat sink that transfers heat from the housing. The housing has an actuating passage in fluid communication with the piston unit to move the piston unit via an actuating fluid. In one embodiment, the cooling system includes a pump and a reservoir. In another embodiment, a coolant or water bottle is attached to the coolant member for manually adding coolant thereto. In another embodiment, the coolant member is filled with a high specific heat gel.

Owner:SHIMANO INC

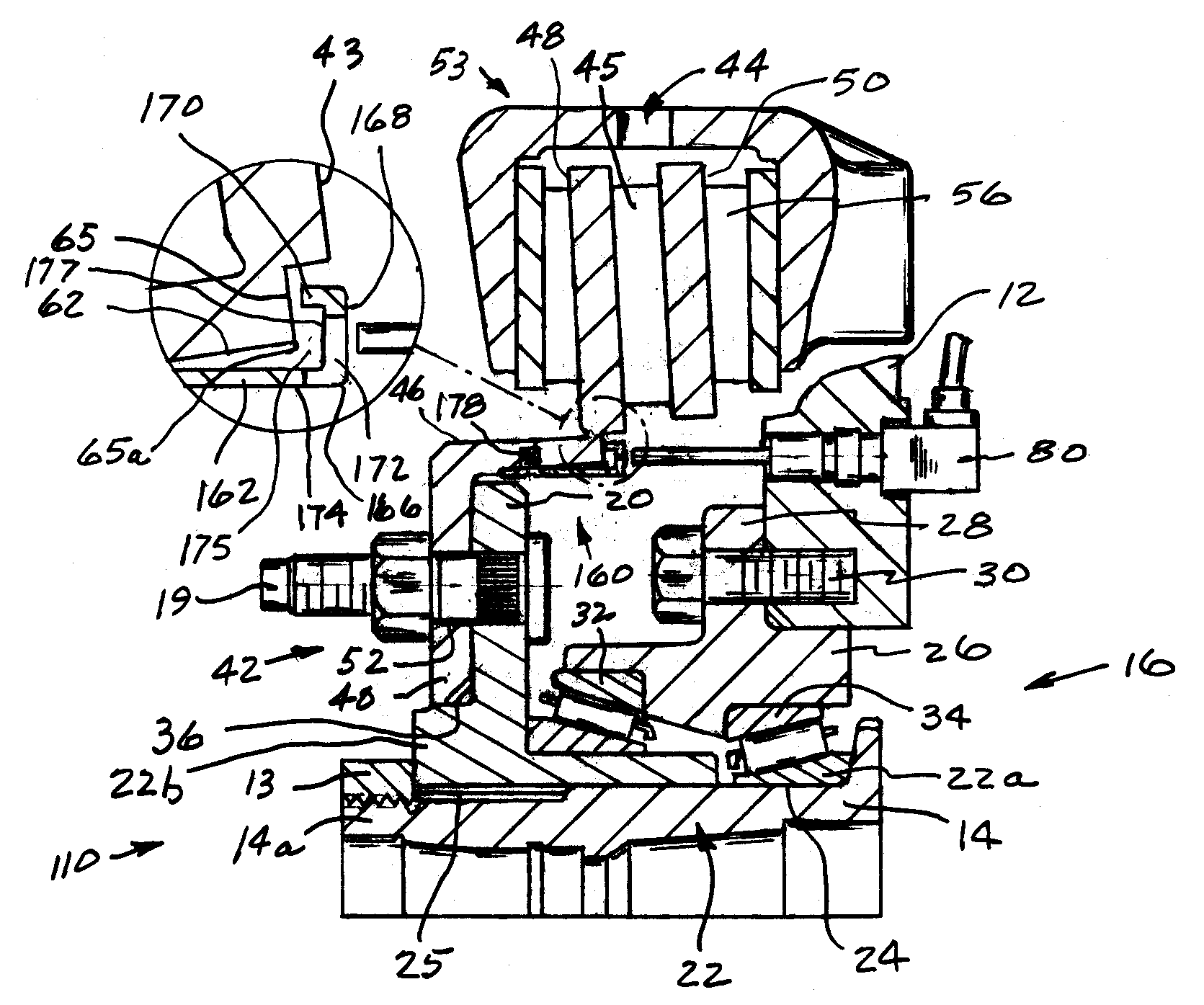

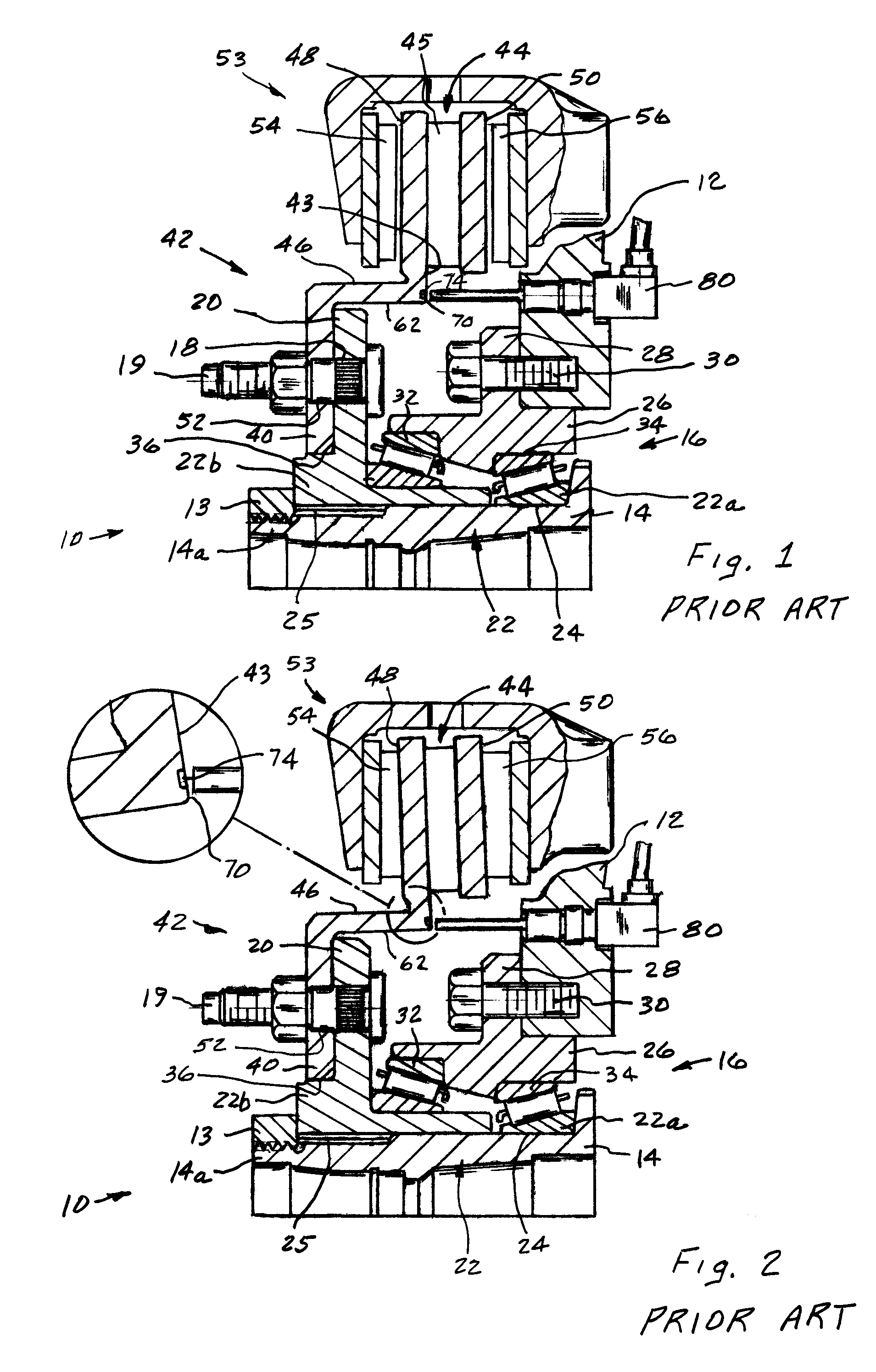

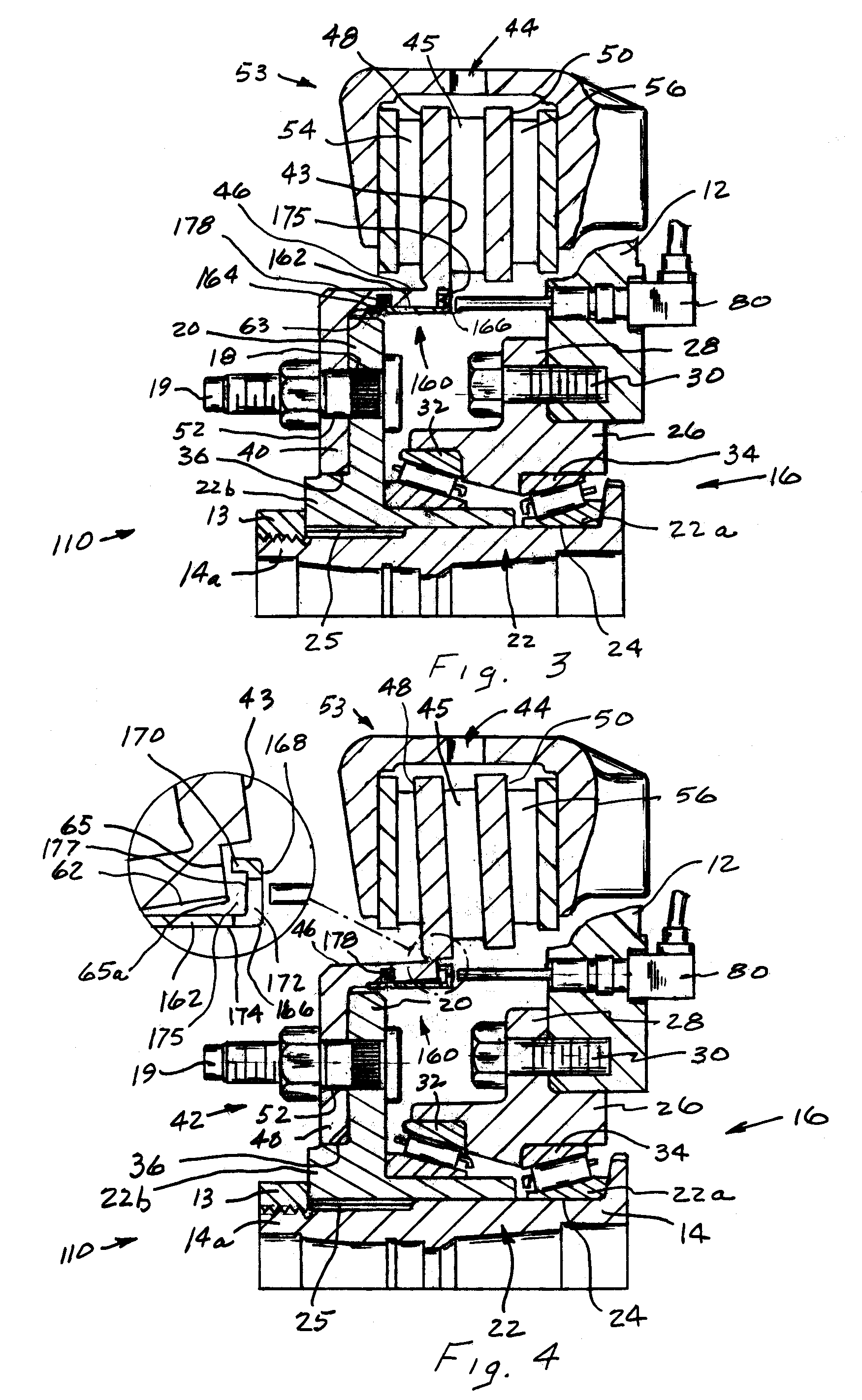

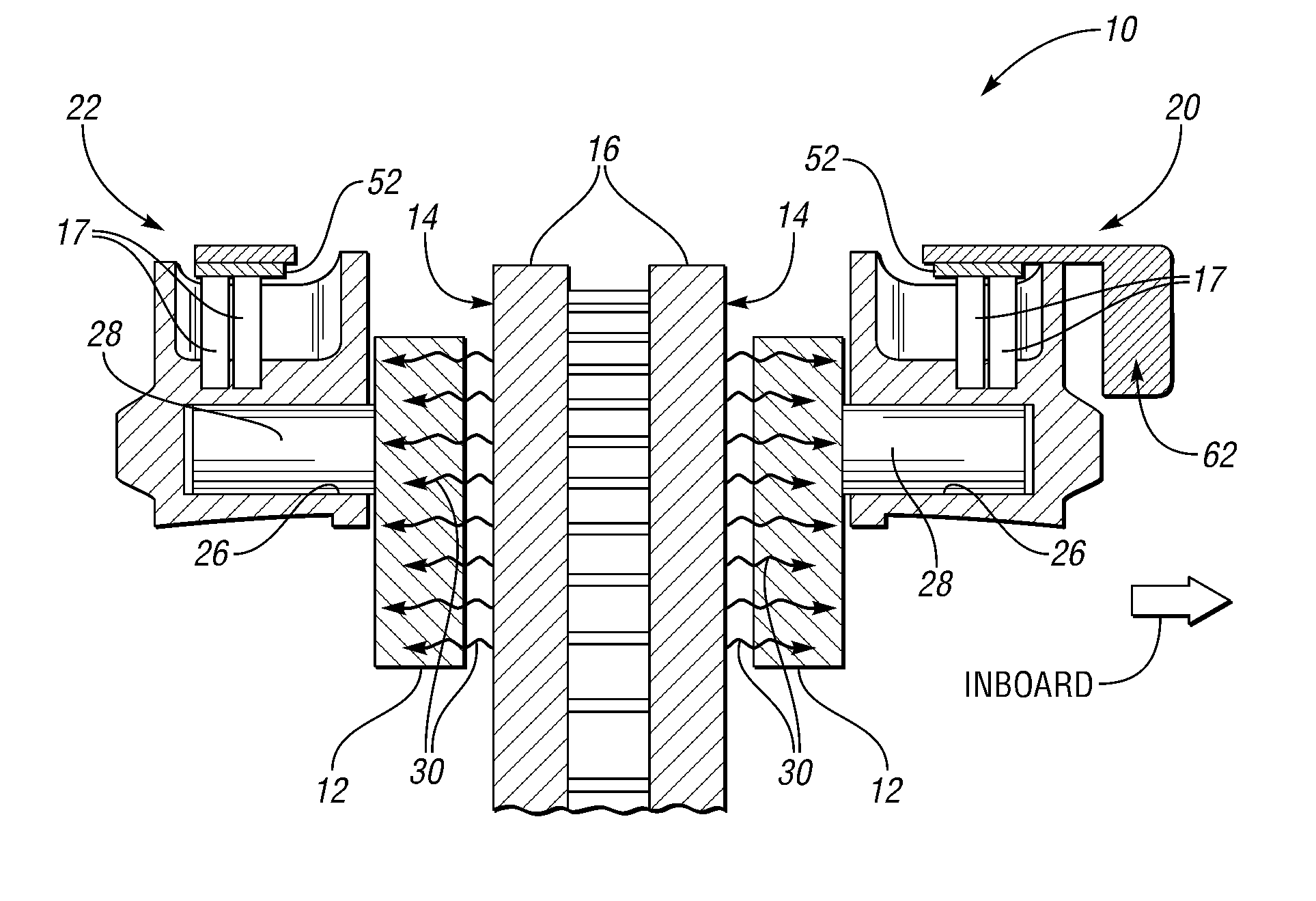

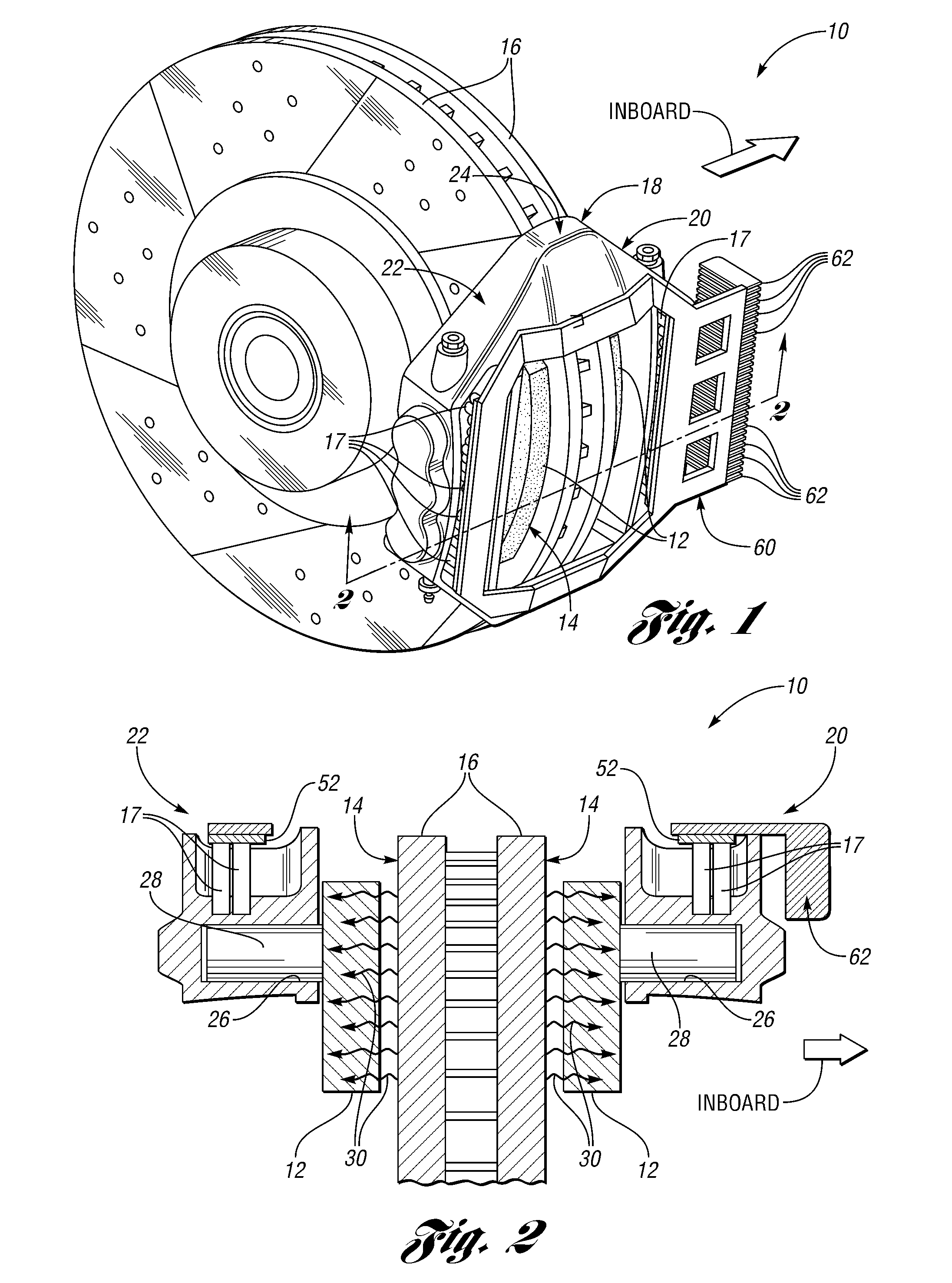

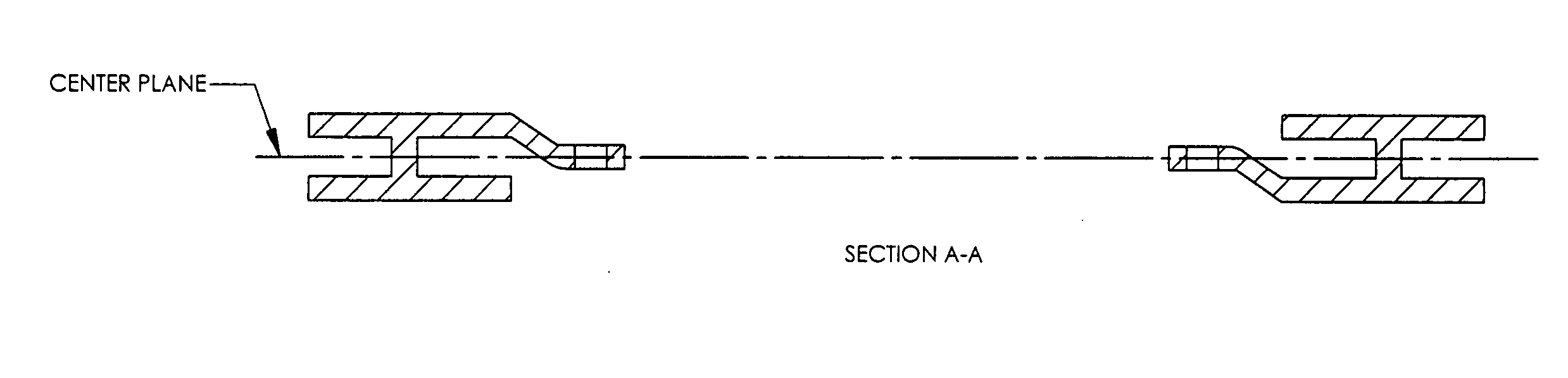

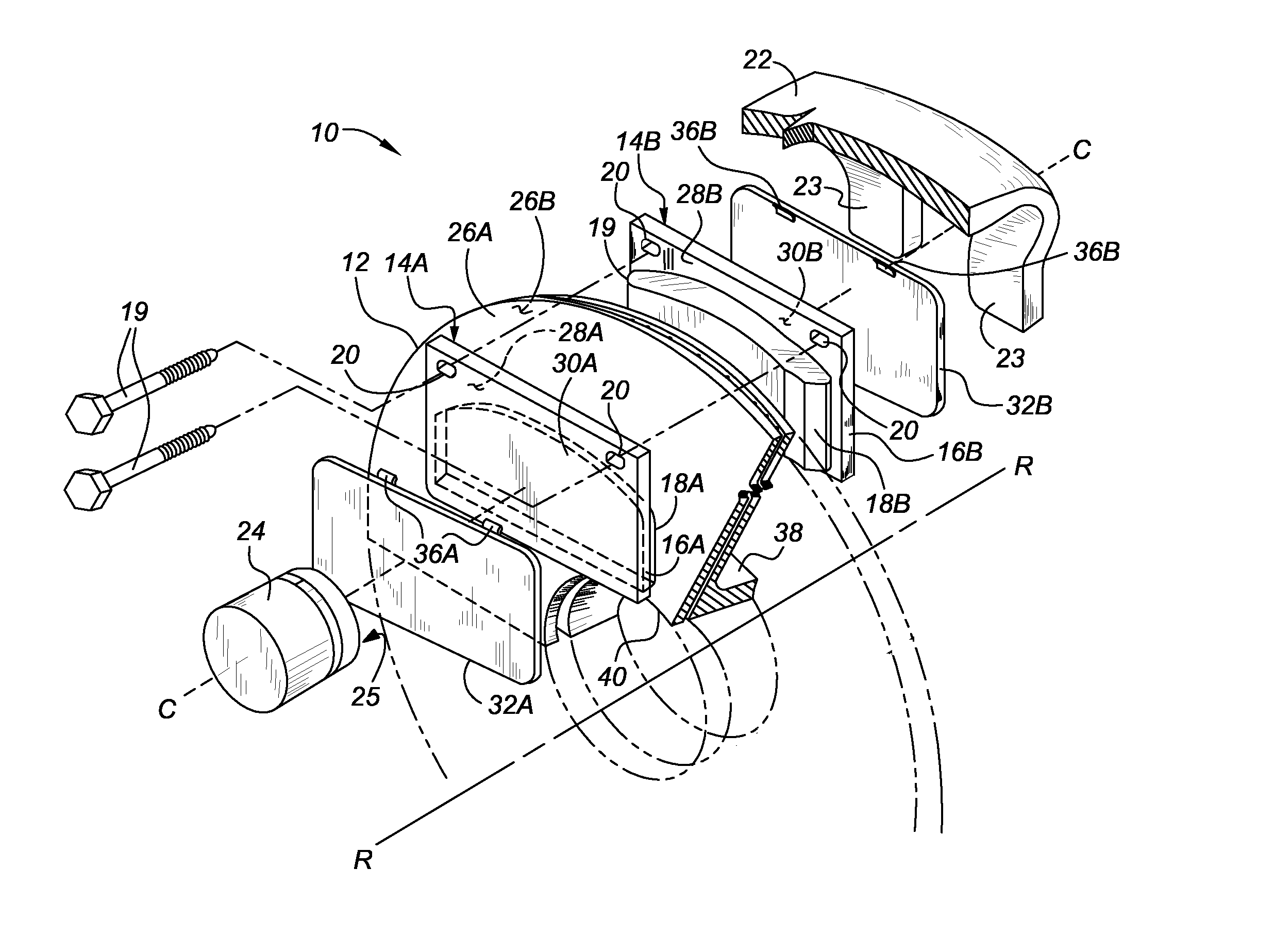

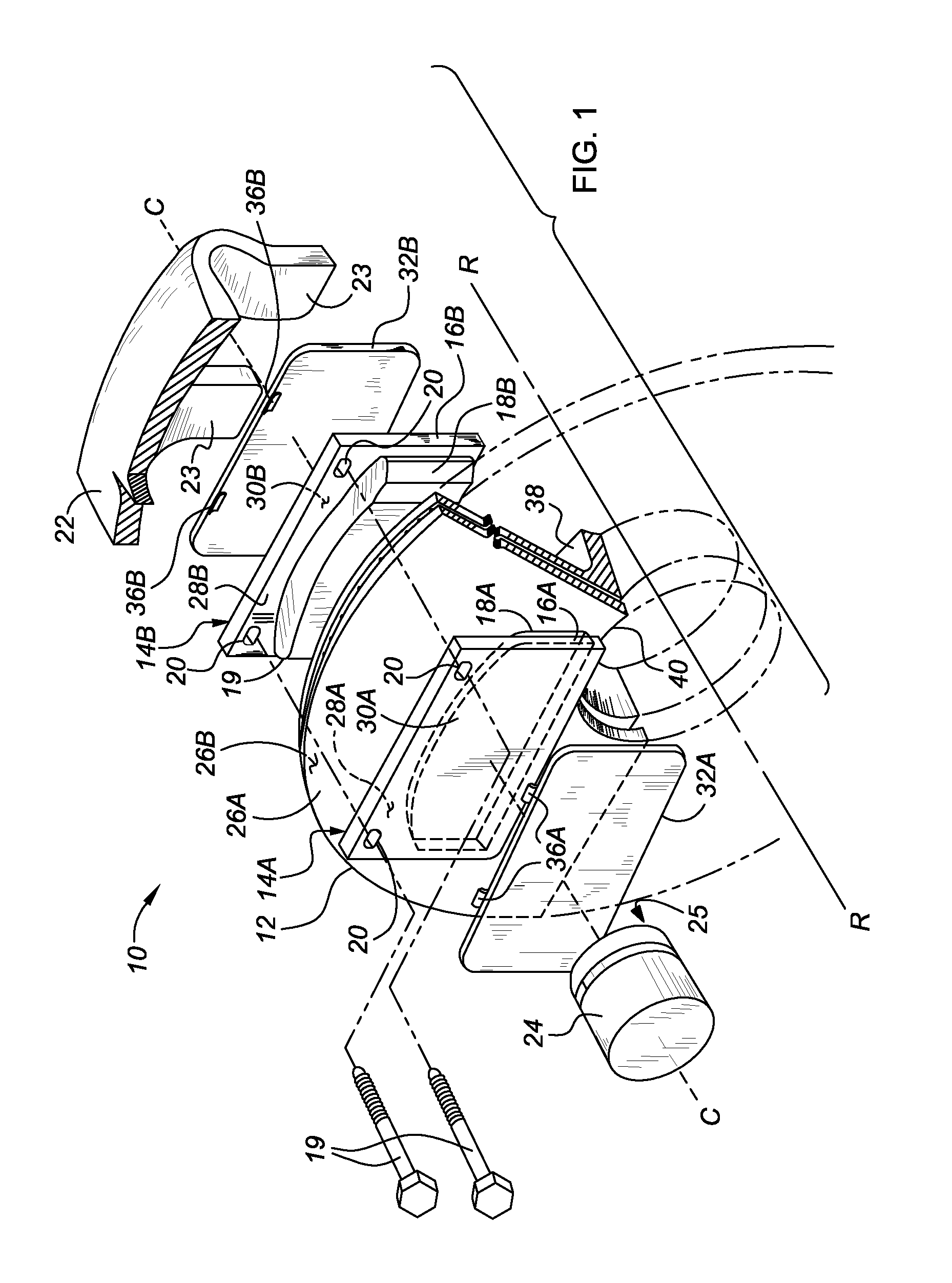

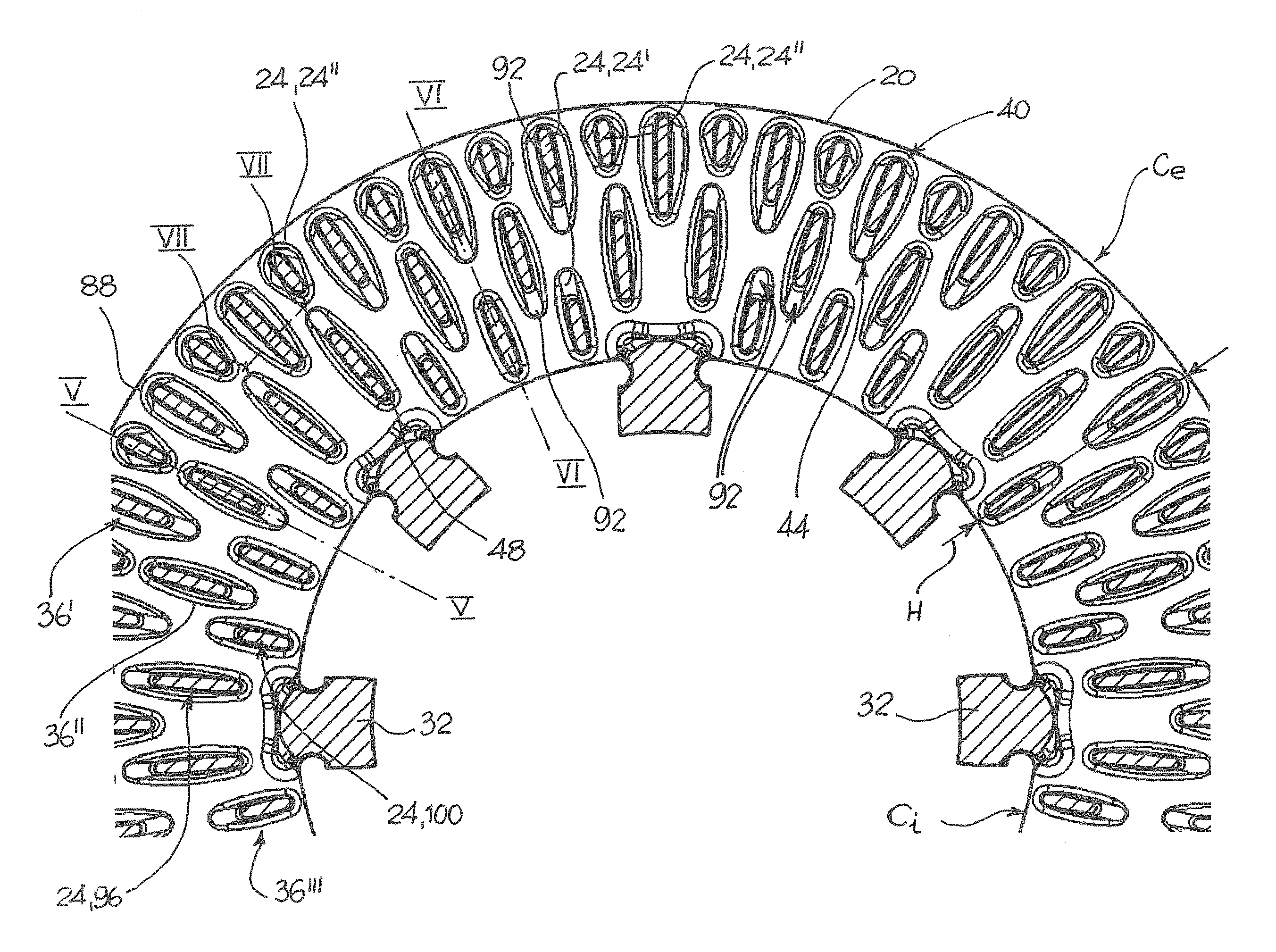

Brake rotor attachment assembly that promotes in plane uniform torque transfer distribution

InactiveUS7077247B2Eliminate concentrationEliminate fatigueBraking element arrangementsBraking drumsIn planeBobbin

A brake assembly for use on vehicles includes a rotor and a wheel mount, formed as a hat portion, fastened to the rotor with a bobbin assembly. The rotor has a flange formed as a series of spaced tabs, and the bobbin assembly is bolted to the hat portion with the rotor flange clamped therebetween. A spring clip can be used with the bobbin to accommodate thermal expansion of the rotor and eliminate rotor rattling. The bobbin has a binocular shape that receives a pair of bolts. A crush zone can be provided between the rotor and the bobbin yields to accommodate machining tolerances of the rotor and promote uniform torque transfer distribution to the hub. Torque is transferred from the brake rotor to the hat portion in a common plane to prevent twisting in the fastener connection.

Owner:PERFORMANCE FRICTION

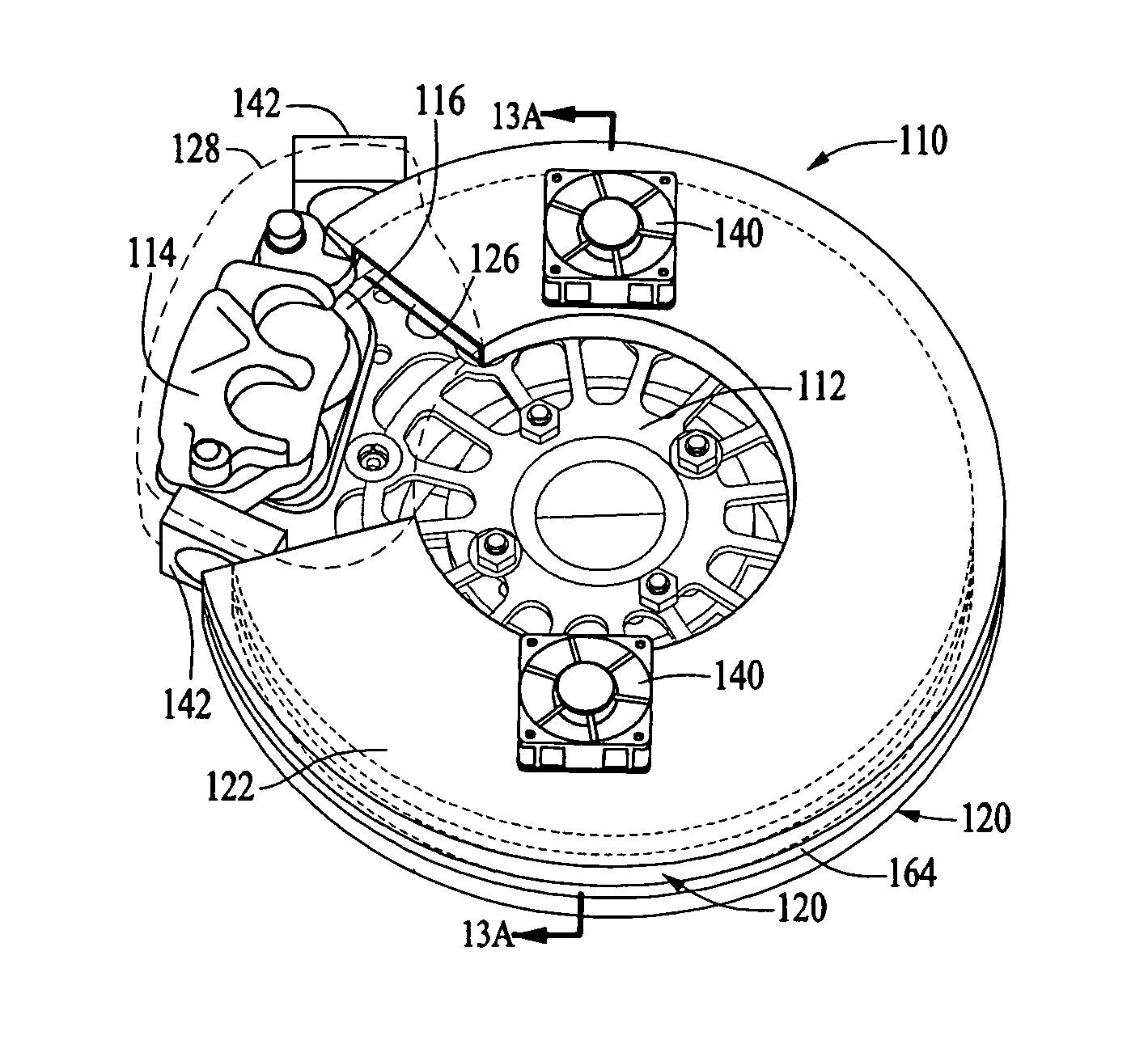

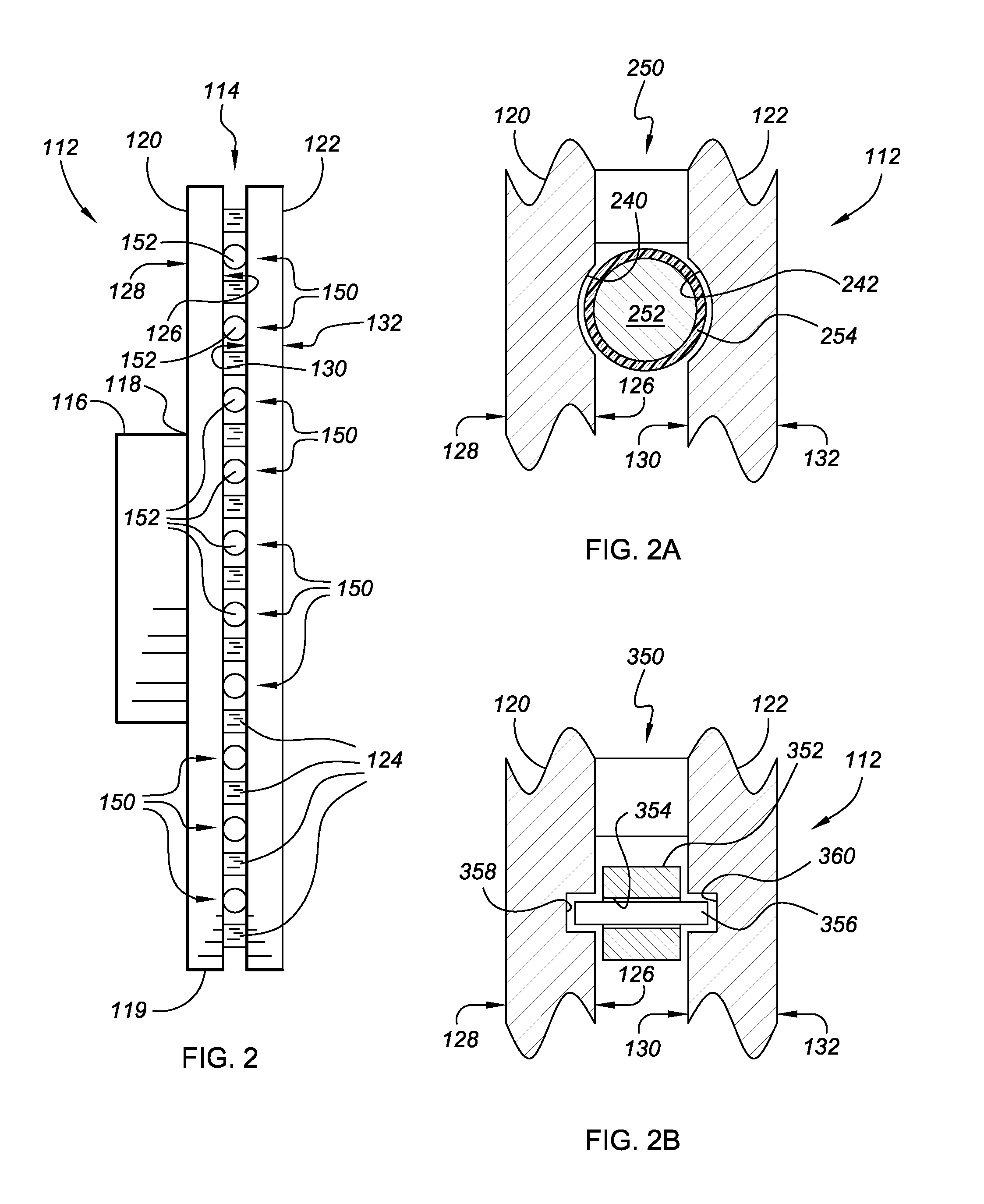

Anti-lock brake device for use with a brake rotor disc

ActiveUS7997391B2Accurate and reliable readingEasy to useBraking element arrangementsHubsVoice coilCost savings

A disc brake assembly includes a rotor with an ABS tone ring insert assembly that functions as a rotation indicator in an anti-lock braking system. The insert is positioned in the hat of a rotor disc in a spaced relationship and is mounted to the mounting flange of the rotor disc. Forming the ring insert separately from the rotor disc also allows different coating materials to be used on the tone ring that may be more heat resistant. The ring insert assembly can be made of powder metal or made as a cast iron cylinder with a toothed cap made of powder metal having a corrosion resistant coating. Cost savings can be realized along with high performance when only a portion of the assembly if made of powder metal and coated.

Owner:PERFORMANCE FRICTION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com