Patents

Literature

1279 results about "Drum brake" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A drum brake is a brake that uses friction caused by a set of shoes or pads that press outward against a rotating cylinder-shaped part called a brake drum. The term drum brake usually means a brake in which shoes press on the inner surface of the drum. When shoes press on the outside of the drum, it is usually called a clasp brake. Where the drum is pinched between two shoes, similar to a conventional disc brake, it is sometimes called a pinch drum brake, though such brakes are relatively rare. A related type called a band brake uses a flexible belt or "band" wrapping around the outside of a drum.

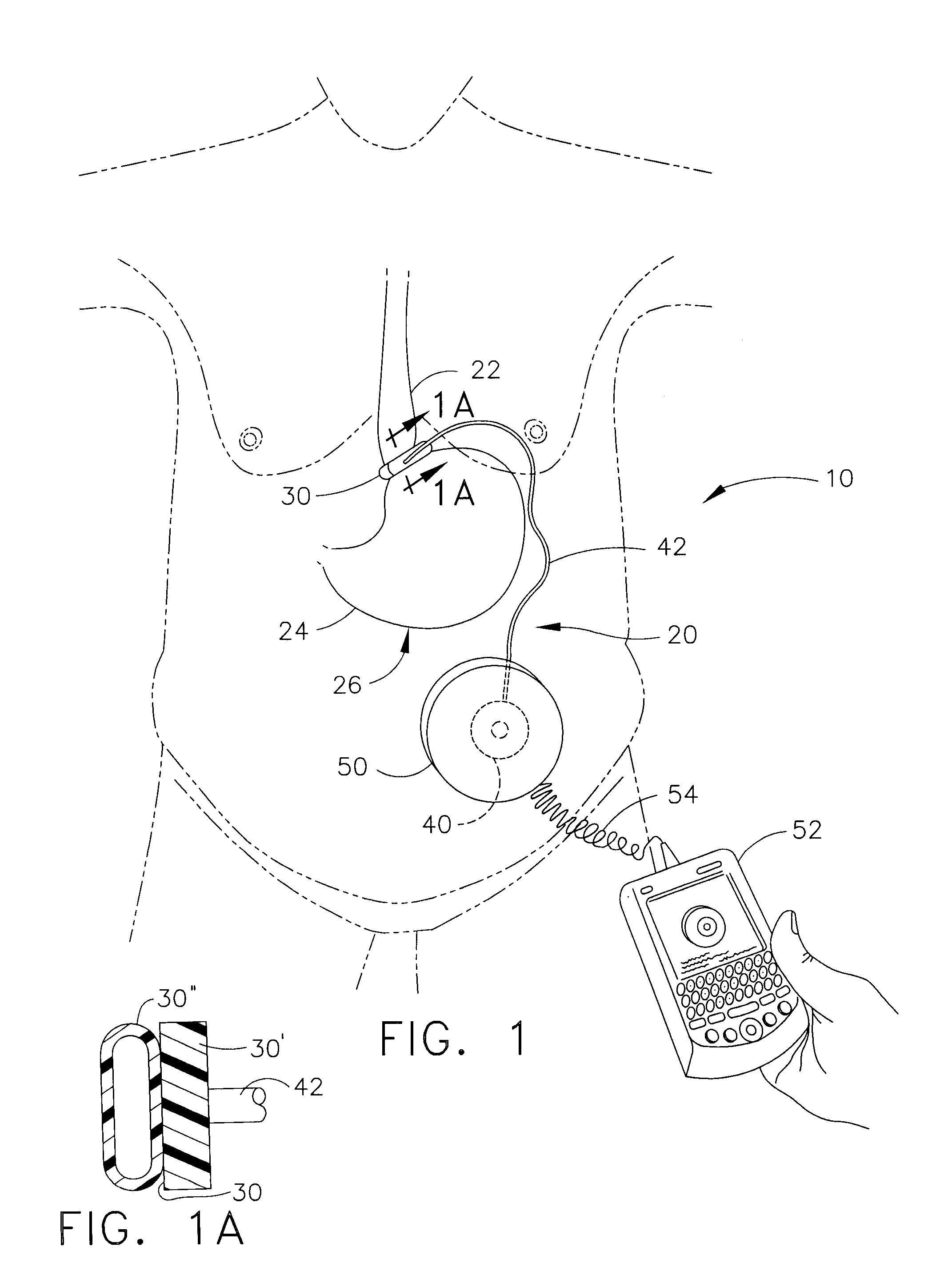

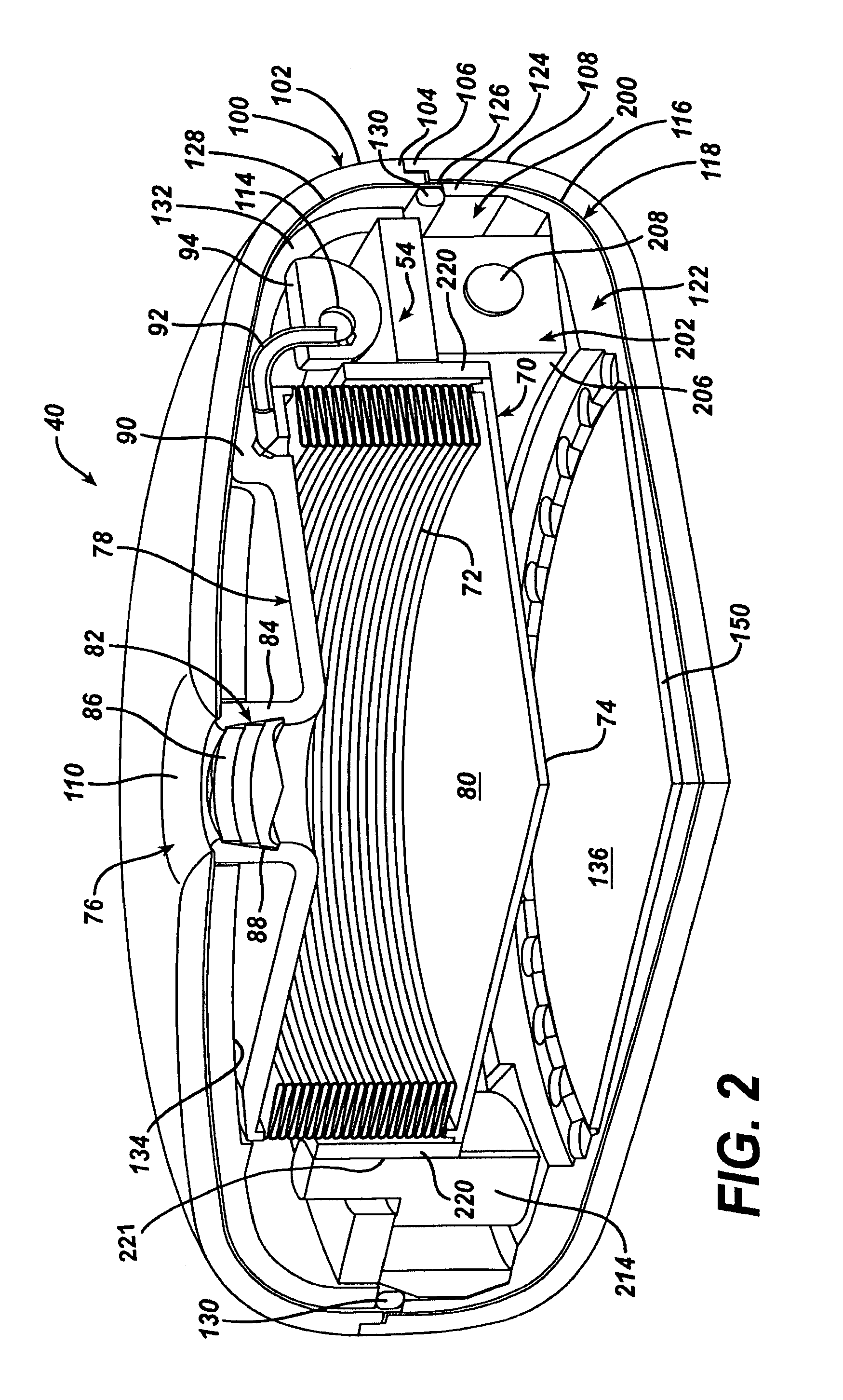

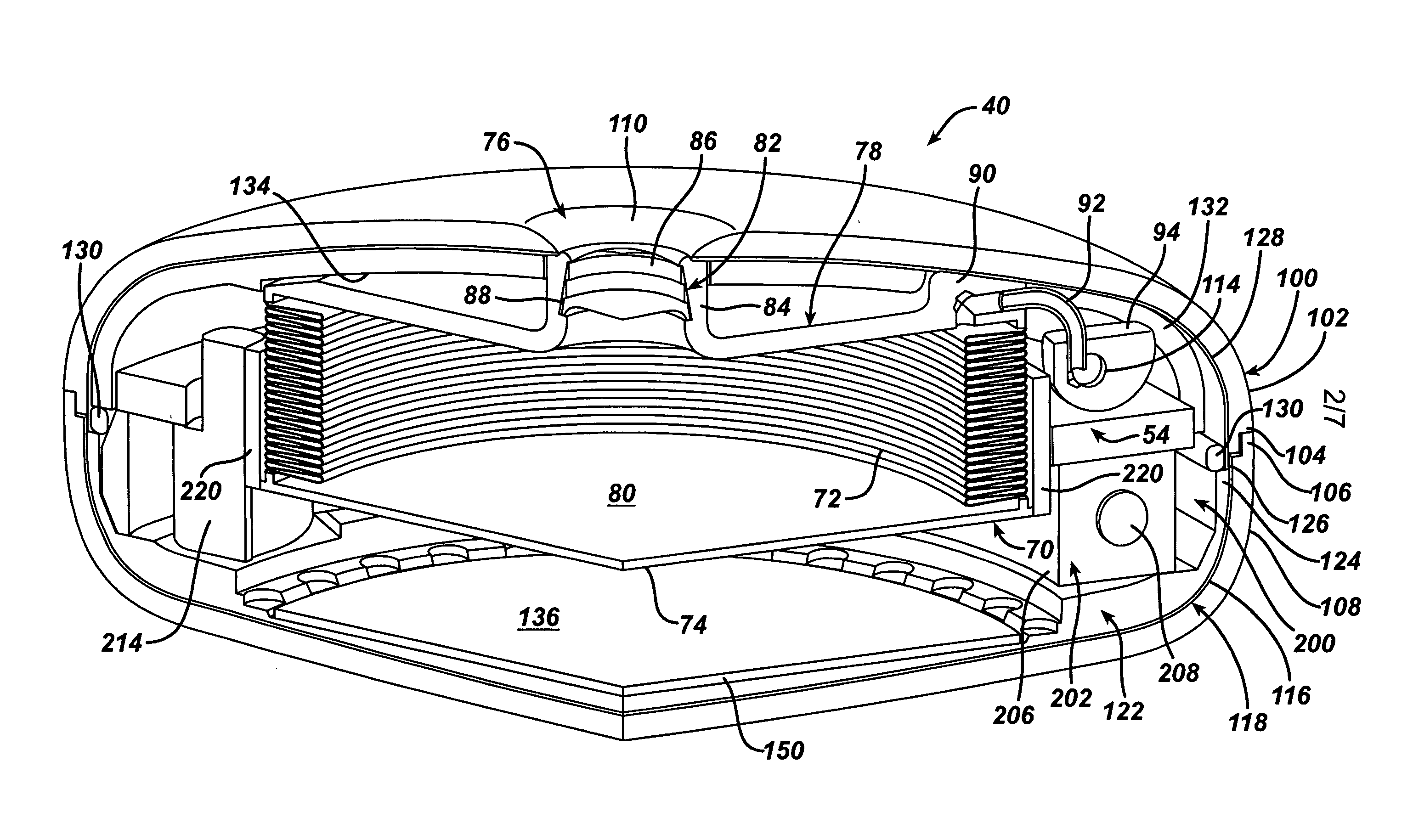

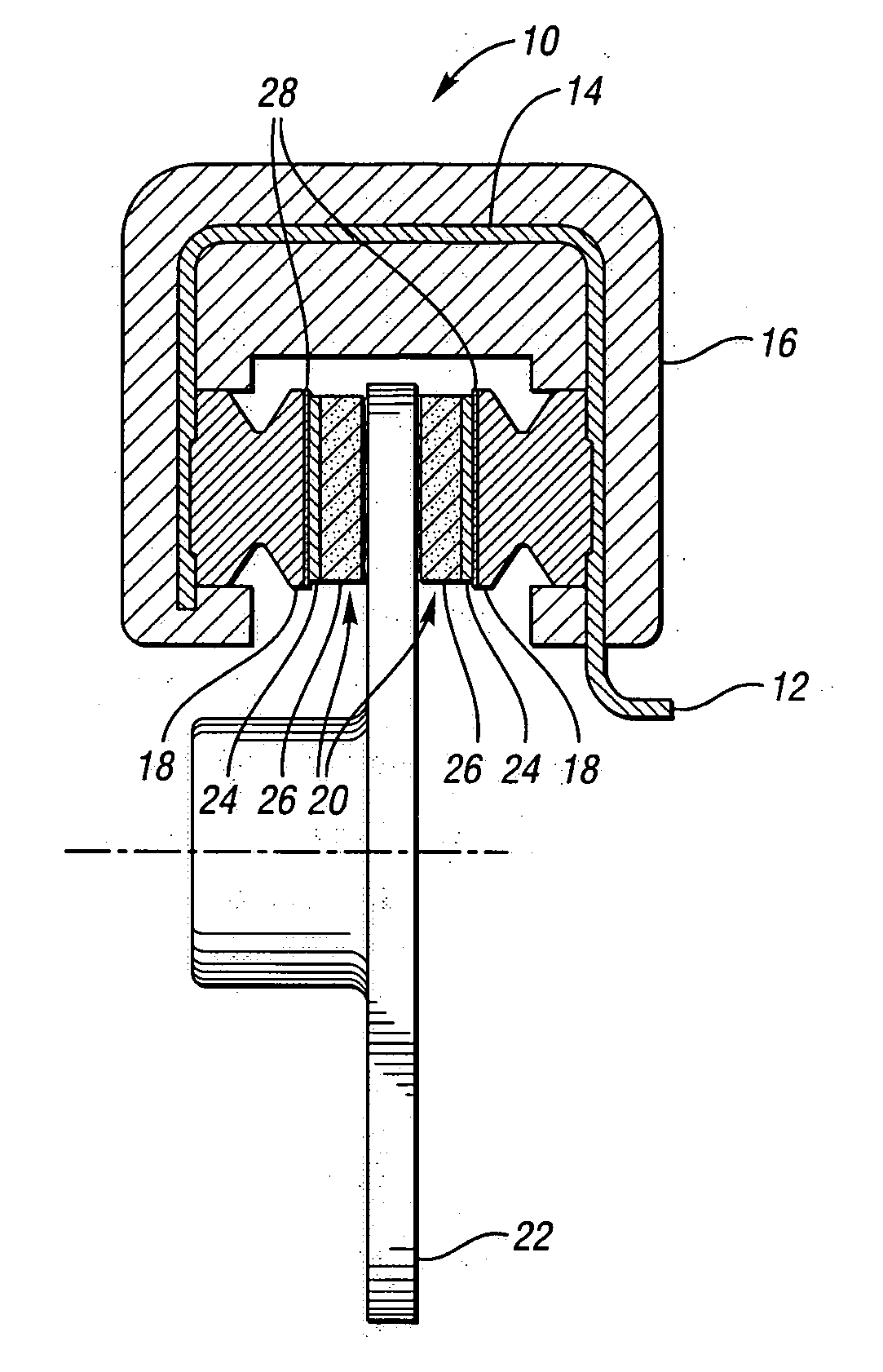

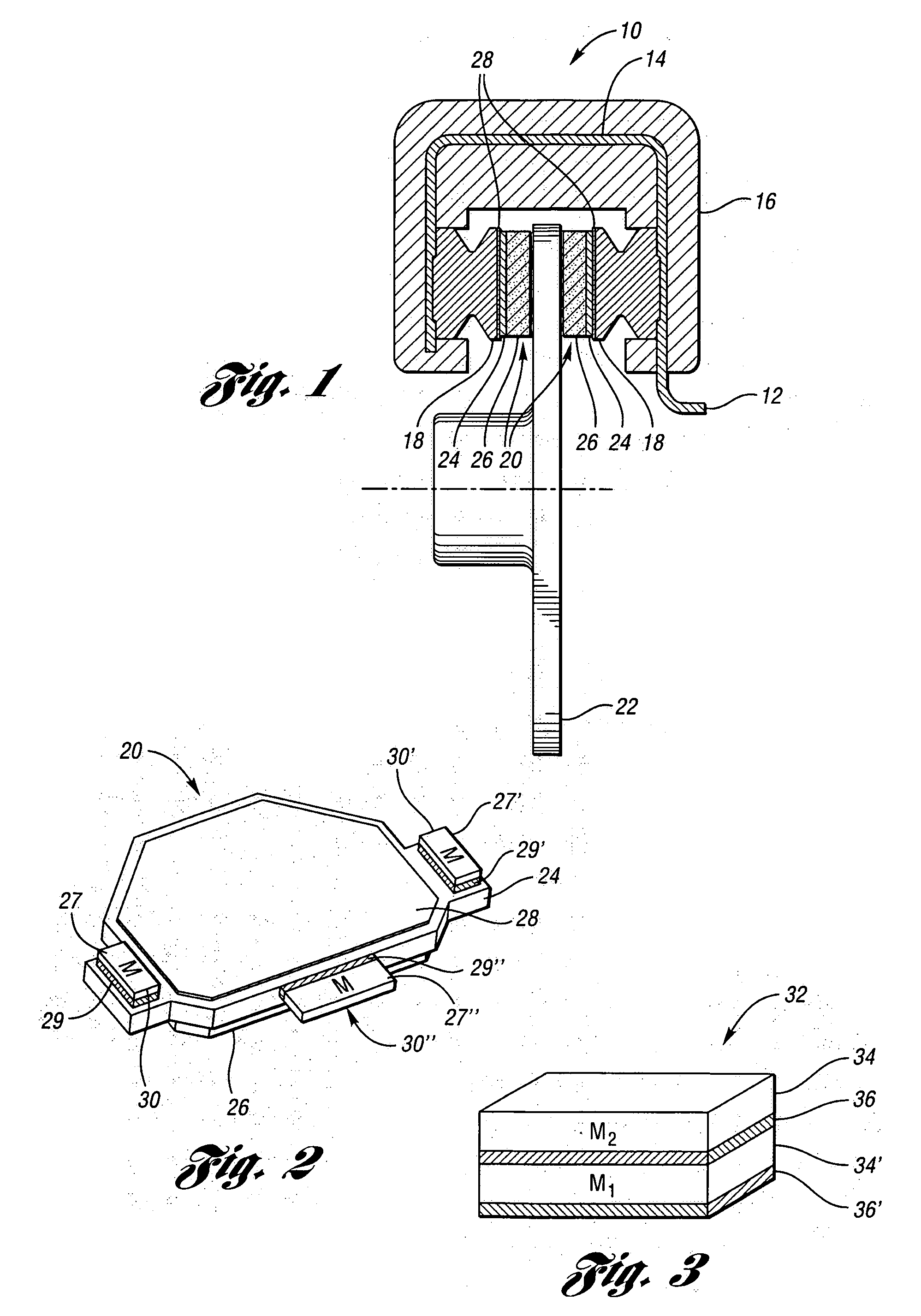

Thermodynamically driven reversible infuser pump for use as a remotely controlled gastric band

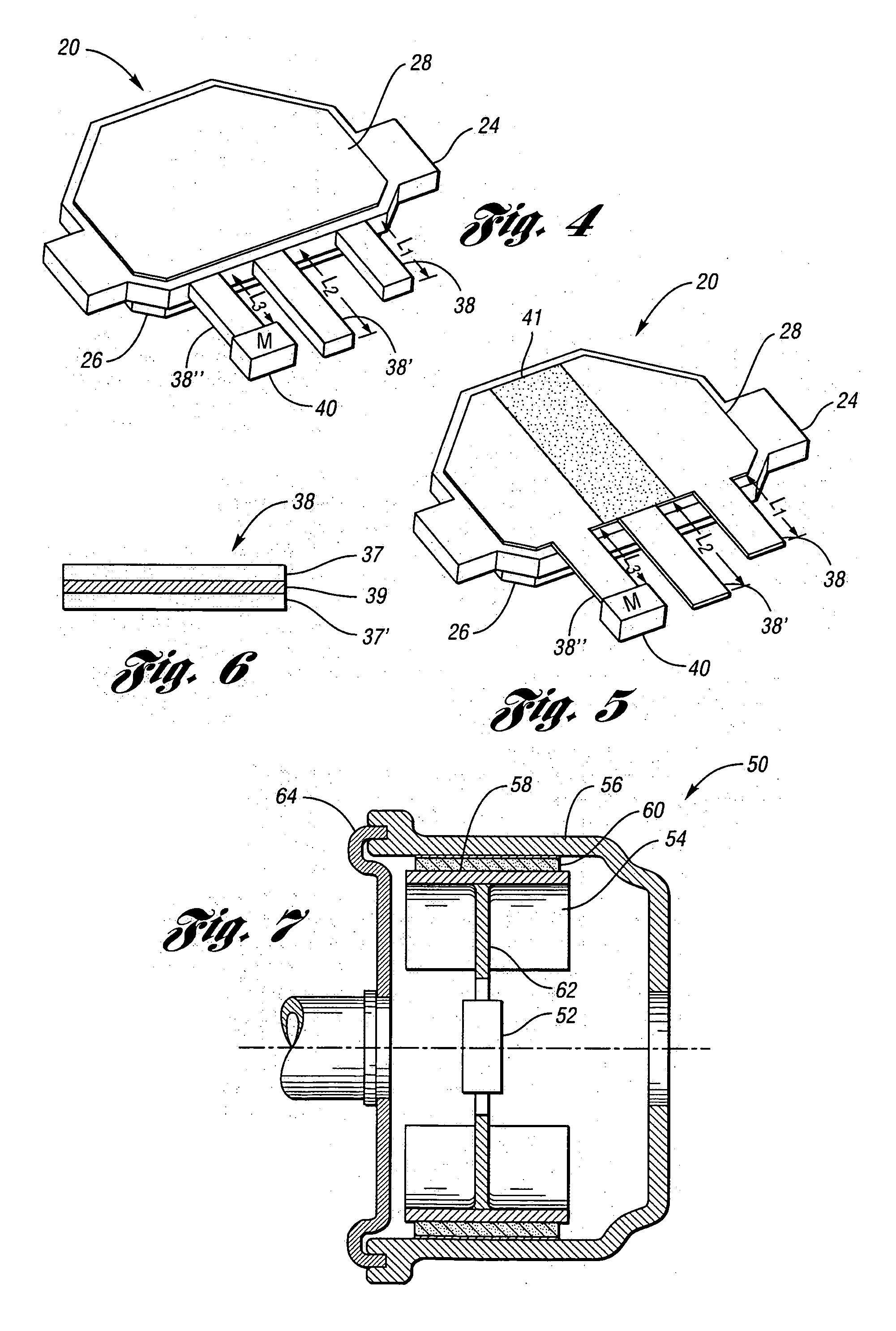

InactiveUS7351240B2Small volumeAvoid changeAnti-incontinence devicesFlexible member pumpsEngineeringPiezo electric

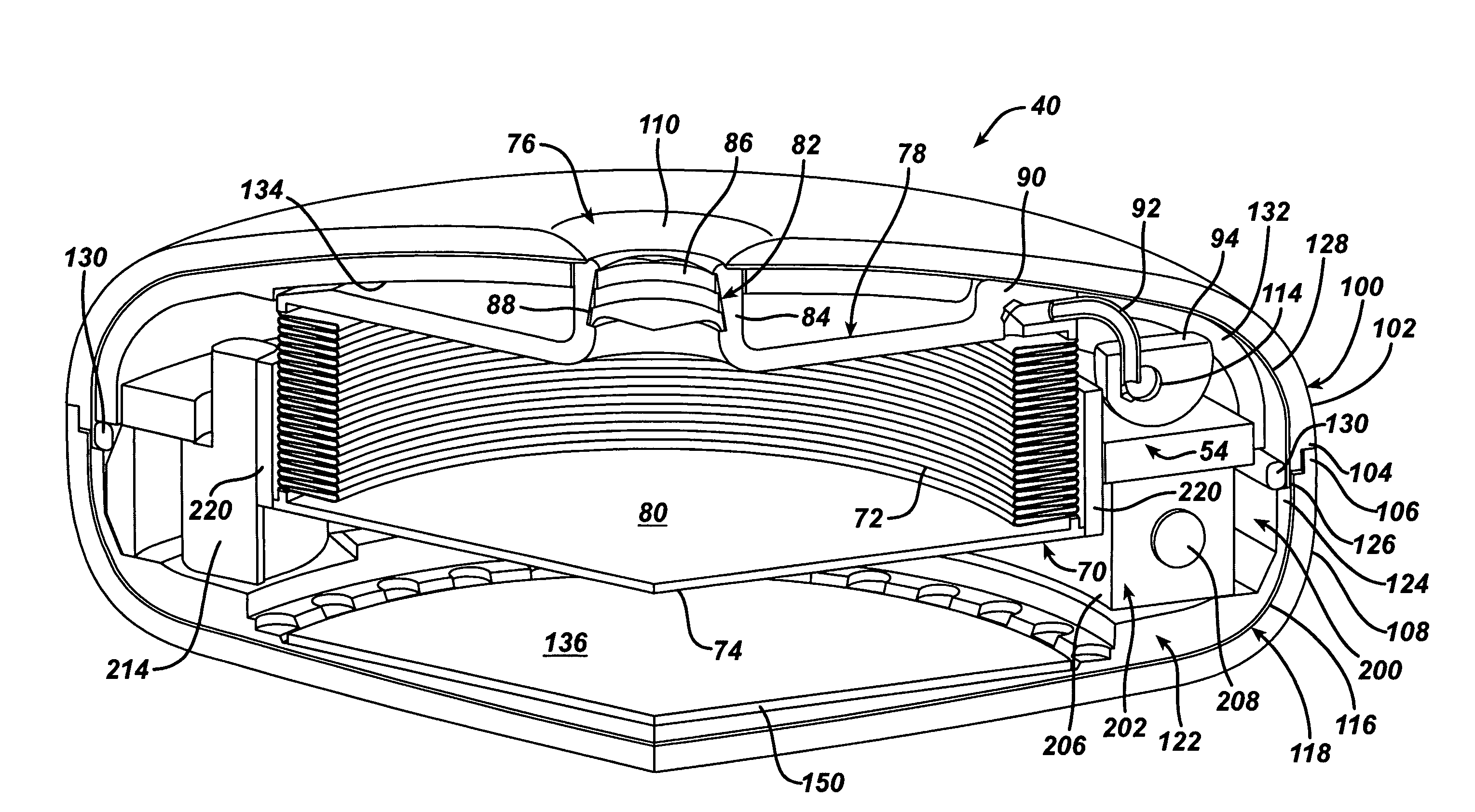

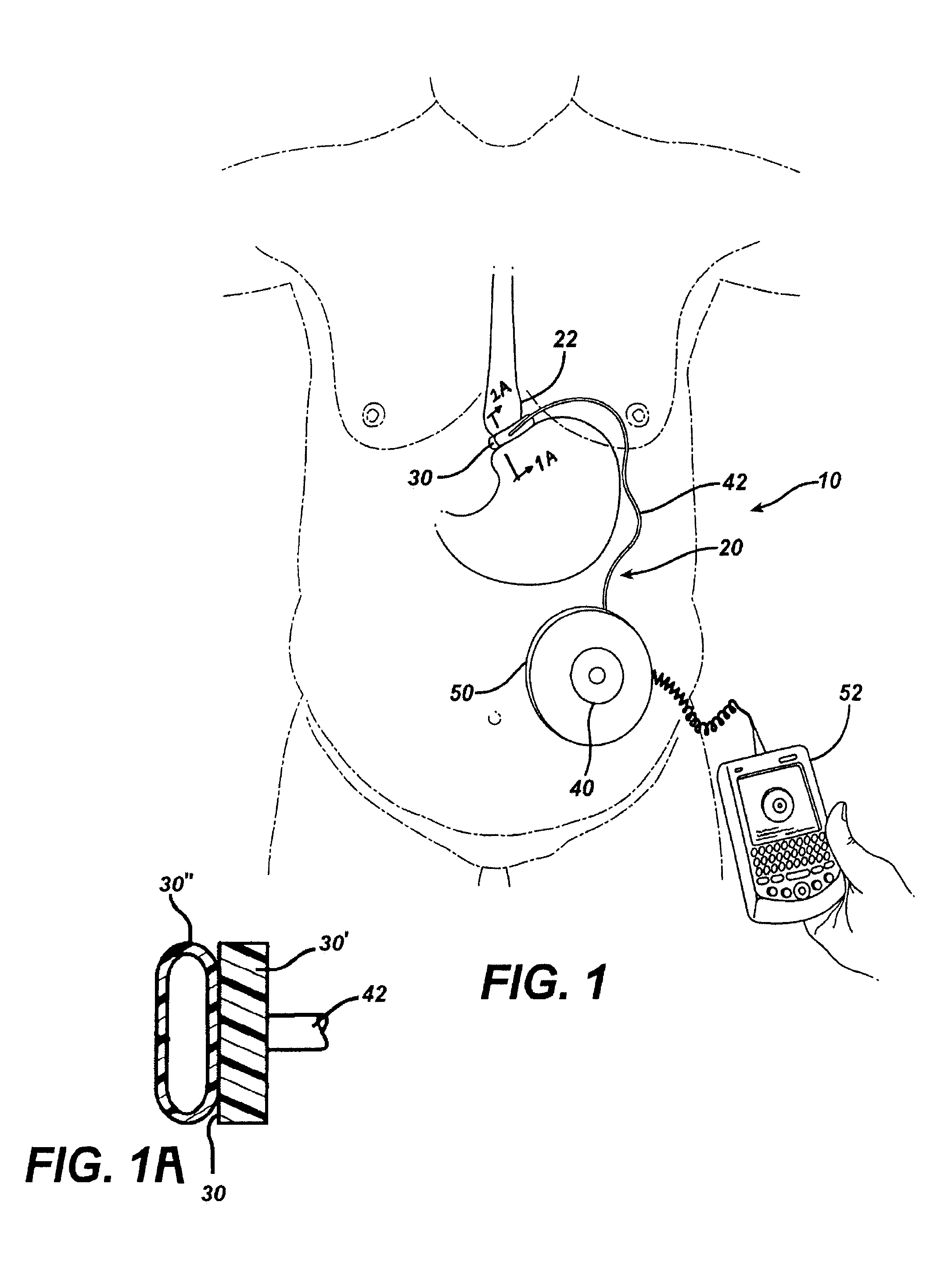

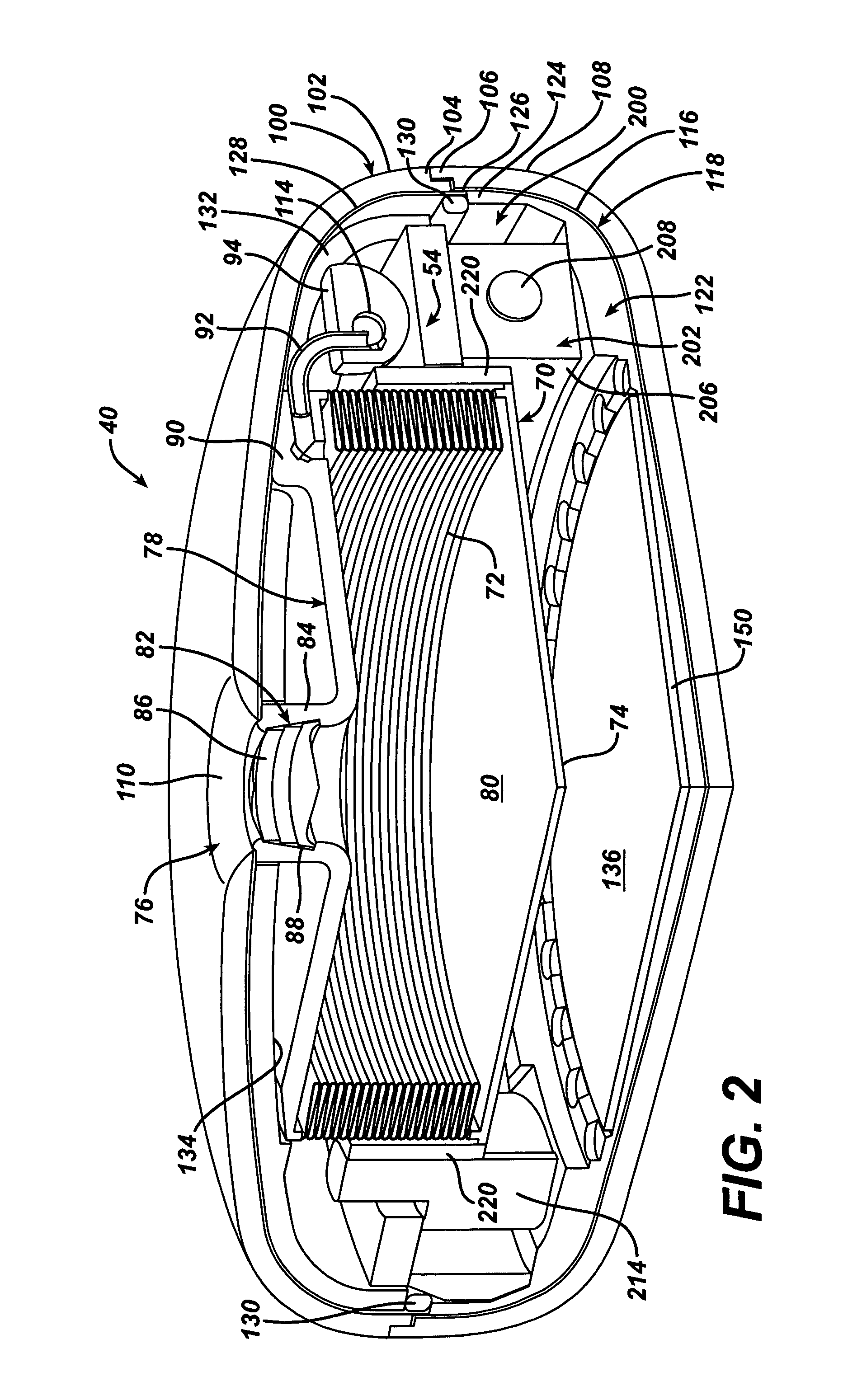

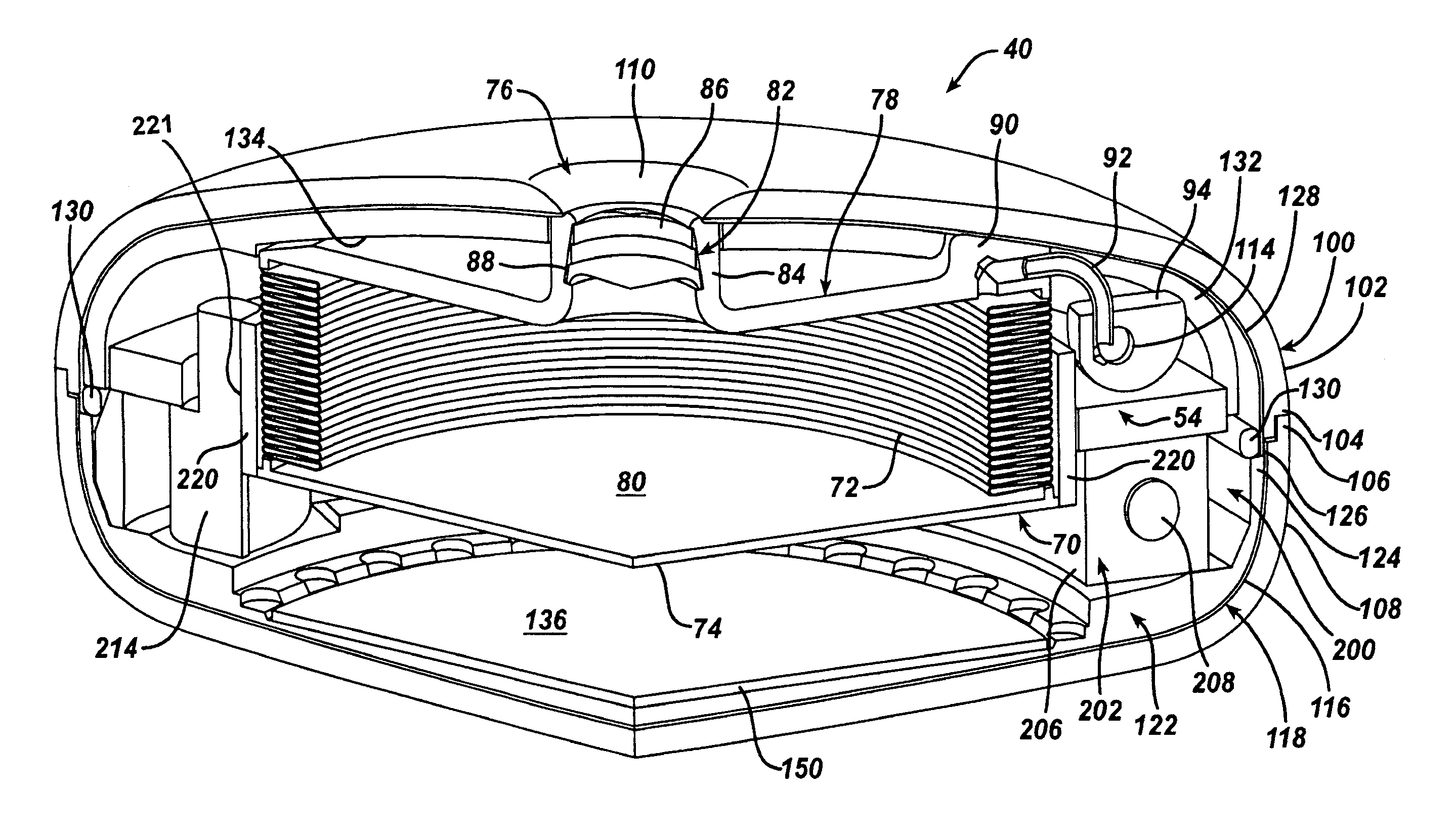

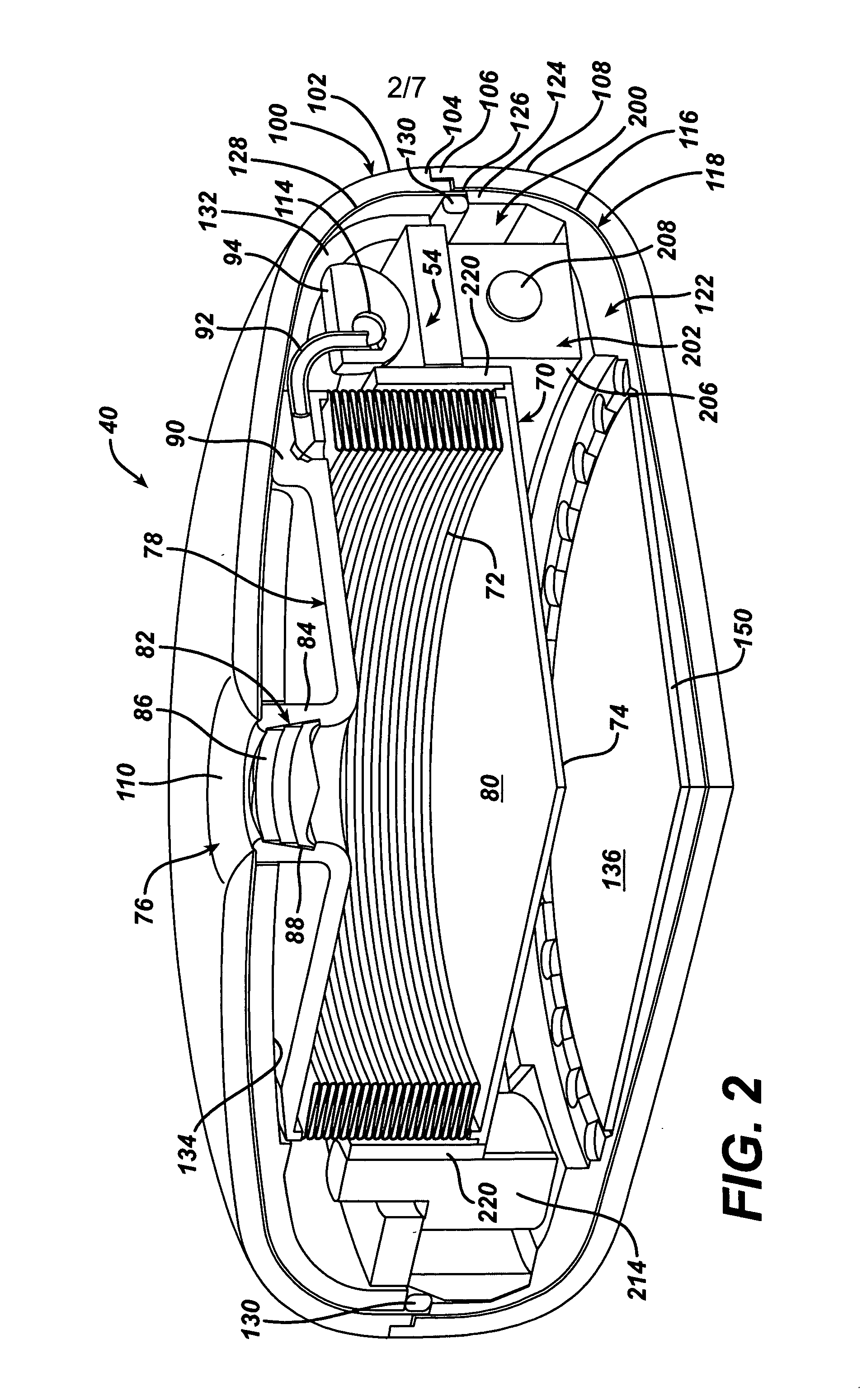

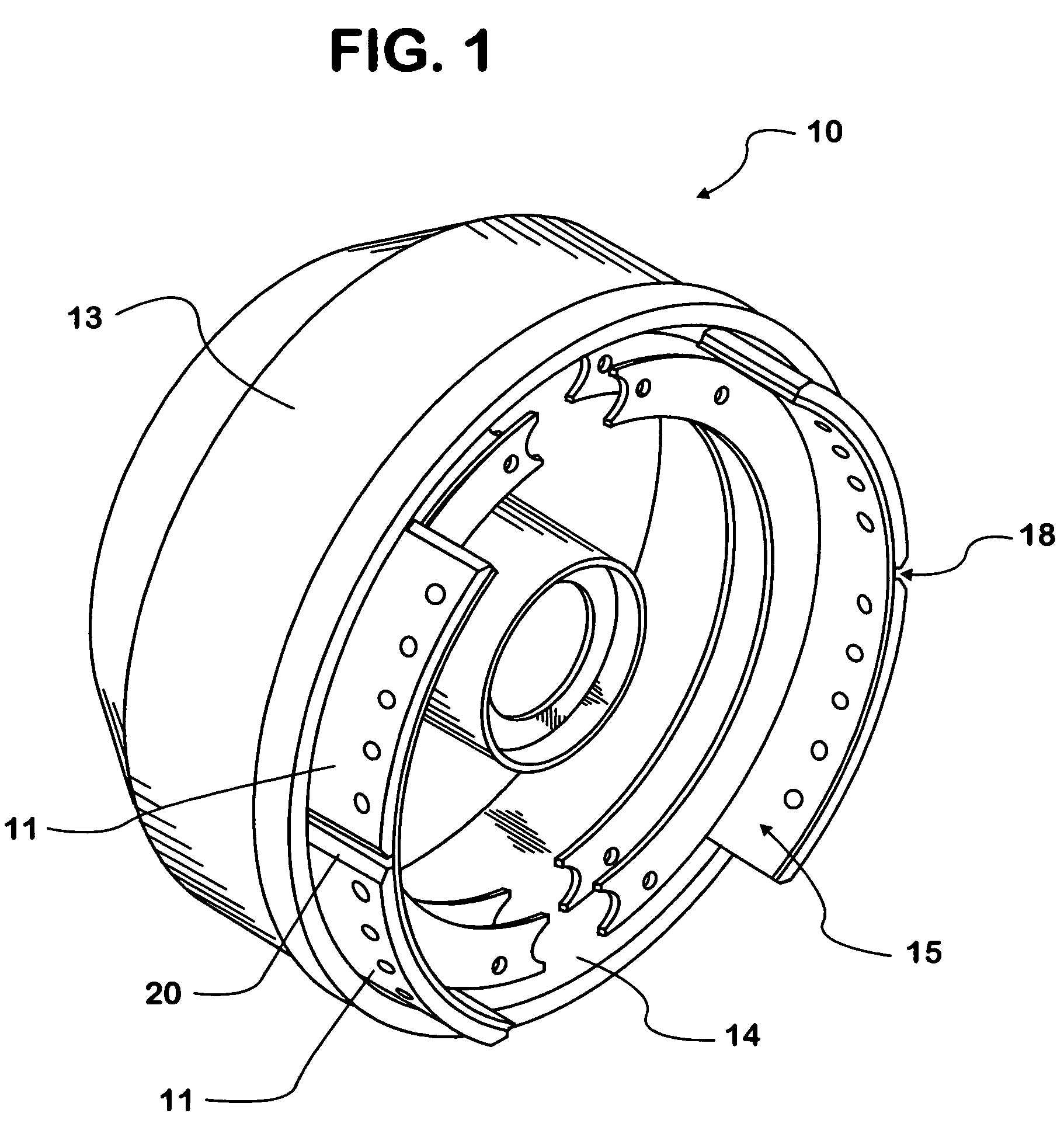

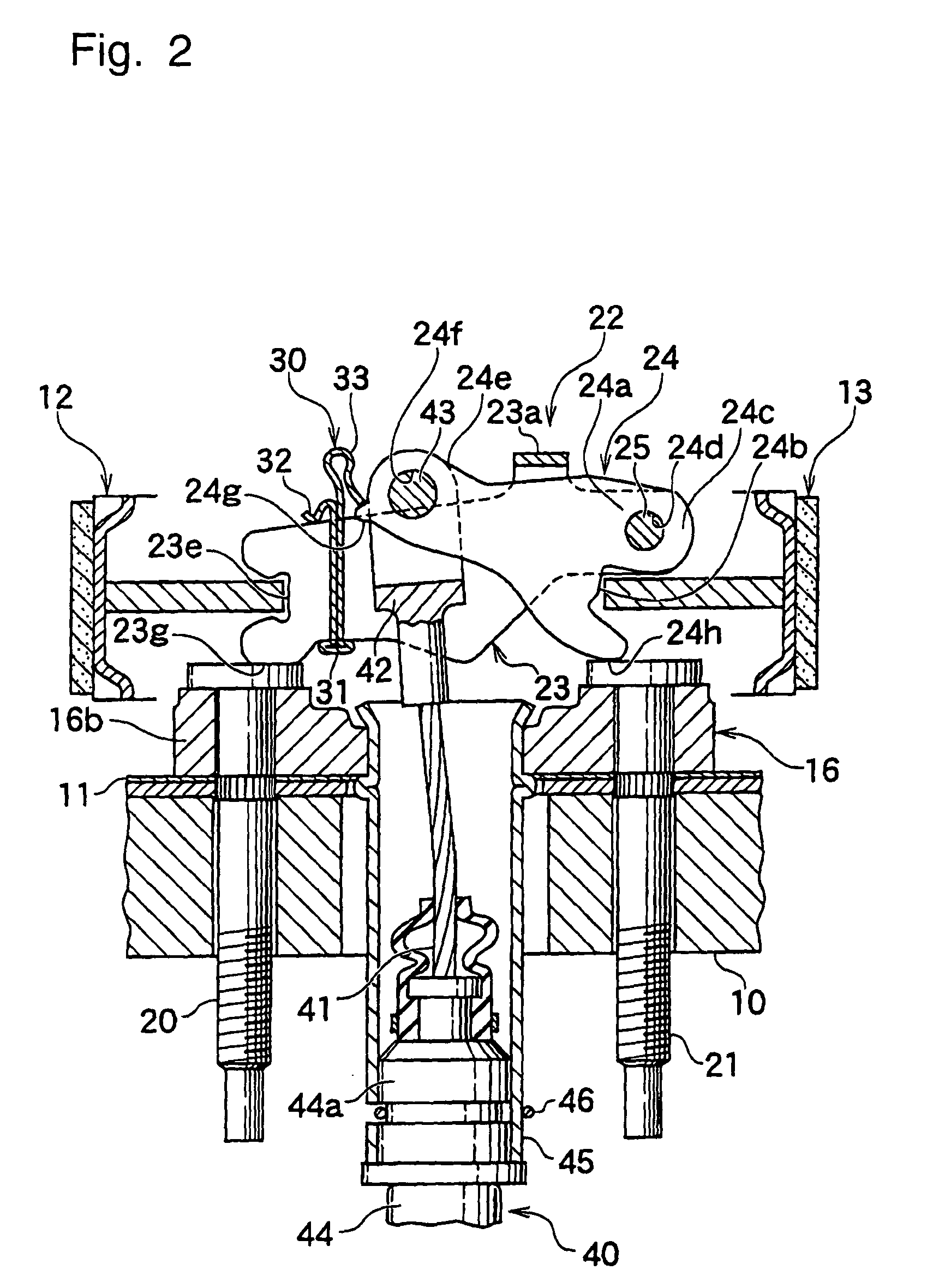

An implantable artificial sphincter system provides long-term adjustment via transcutaneous energy transfer (TET), minimizing invasive adjustment through adding or removing fluid via a syringe. An infuser device provides bi-directional fluid transfer via a flexible conduit to a sphincter band, such as a gastric band, by a combination of thermodynamic actuation and a piezo-electrically disengaged drum brake assembly that thereby achieves a desirable small volume device. A propellant within a propellant cavity surrounds a metal bellows accumulator biased at body temperature to either expand or collapse the bellows accumulator with the opposite direction of movement effected by a thermal element that heats in combination with a negatively-biased propellant or cools in combination with a positively-biased propellant. A drum brake assembly locks the metal bellows accumulator in place between adjustments by thermodynamic actuation by activating piezo-electric stack actuators that disengage calipers from a brake drum attached to the bellows accumulator.

Owner:ETHICON ENDO SURGERY INC

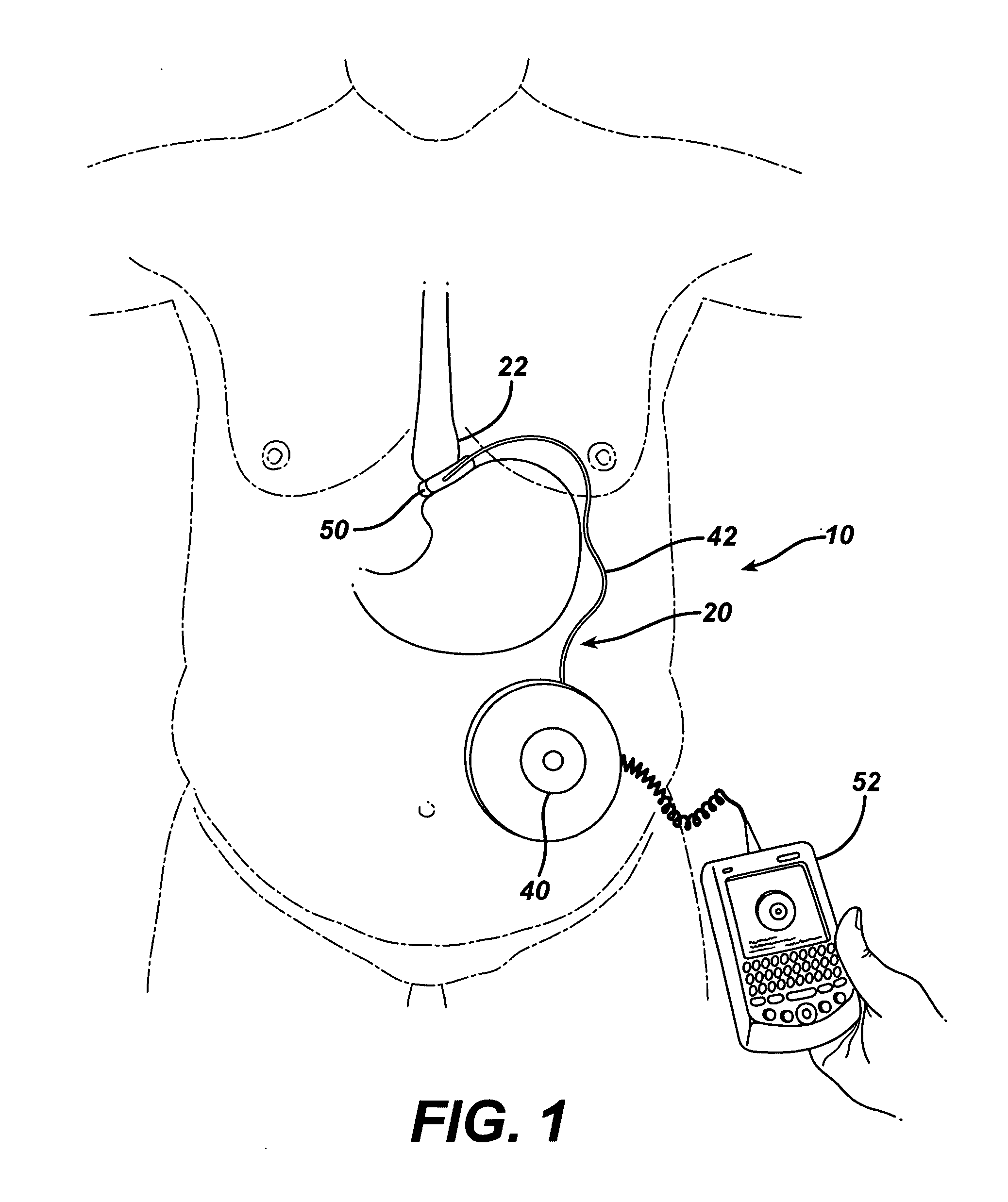

Bi-directional infuser pump with volume braking for hydraulically controlling an adjustable gastric band

InactiveUS7374565B2Increase varietyAvoid changeAnti-incontinence devicesPharmaceutical delivery mechanismPiezo electricEngineering

An implantable artificial sphincter system provides long-term adjustment via transcutaneous energy transfer (TET), minimizing invasive adjustment through adding or removing fluid via a syringe. An infuser device provides bi-directional fluid transfer via a flexible conduit to a sphincter band, such as a gastric band, by a combination of thermodynamic actuation and a piezo-electrically disengaged drum brake assembly that thereby achieves a desirable small volume device. A propellant within a propellant cavity surrounds a metal bellows accumulator biased at body temperature to either expand or collapse the bellows accumulator with the opposite direction of movement effected by a thermal element that heats in combination with a negatively-biased propellant or cools in combination with a positively-biased propellant. A drum brake assembly locks the metal bellows accumulator in place between adjustments by thermodynamic actuation by activating piezo-electric stack actuators that disengage calipers from a brake drum attached to the bellows accumulator.

Owner:ETHICON ENDO SURGERY INC

Thermodynamically driven reversible infuser pump for use as a remotely controlled gastric band

InactiveUS20050277974A1Avoid inconvenienceSmallAnti-incontinence devicesFlexible member pumpsEngineeringPiezo electric

An implantable artificial sphincter system provides long-term adjustment via transcutaneous energy transfer (TET), minimizing invasive adjustment through adding or removing fluid via a syringe. An infuser device provides bi-directional fluid transfer via a flexible conduit to a sphincter band, such as a gastric band, by a combination of thermodynamic actuation and a piezo-electrically disengaged drum brake assembly that thereby achieves a desirable small volume device. A propellant within a propellant cavity surrounds a metal bellows accumulator biased at body temperature to either expand or collapse the bellows accumulator with the opposite direction of movement effected by a thermal element that heats in combination with a negatively-biased propellant or cools in combination with a positively-biased propellant. A drum brake assembly locks the metal bellows accumulator in place between adjustments by thermodynamic actuation by activating piezo-electric stack actuators that disengage calipers from a brake drum attached to the bellows accumulator.

Owner:ETHICON ENDO SURGERY INC

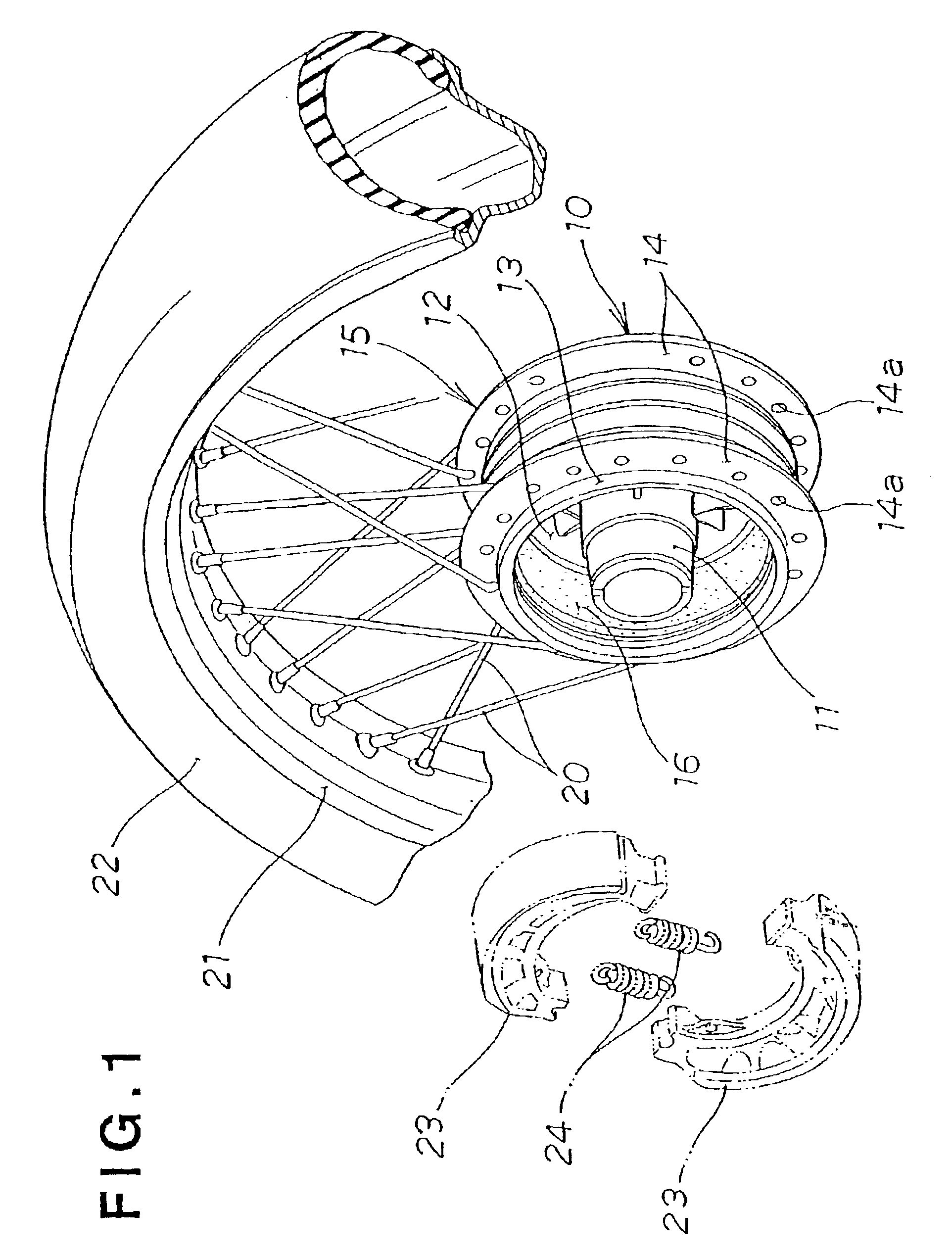

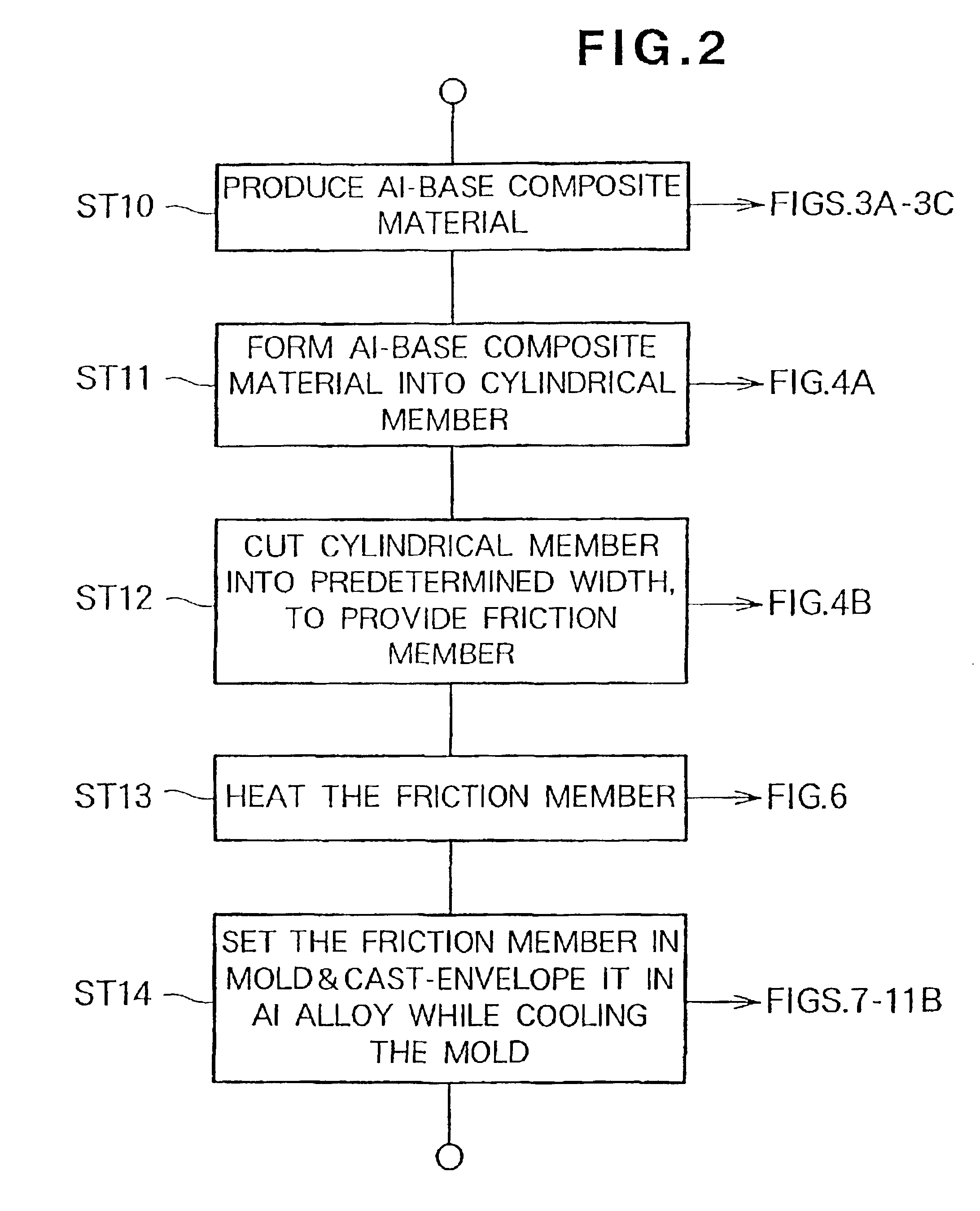

Brake drum and method for producing the same

Owner:HONDA MOTOR CO LTD

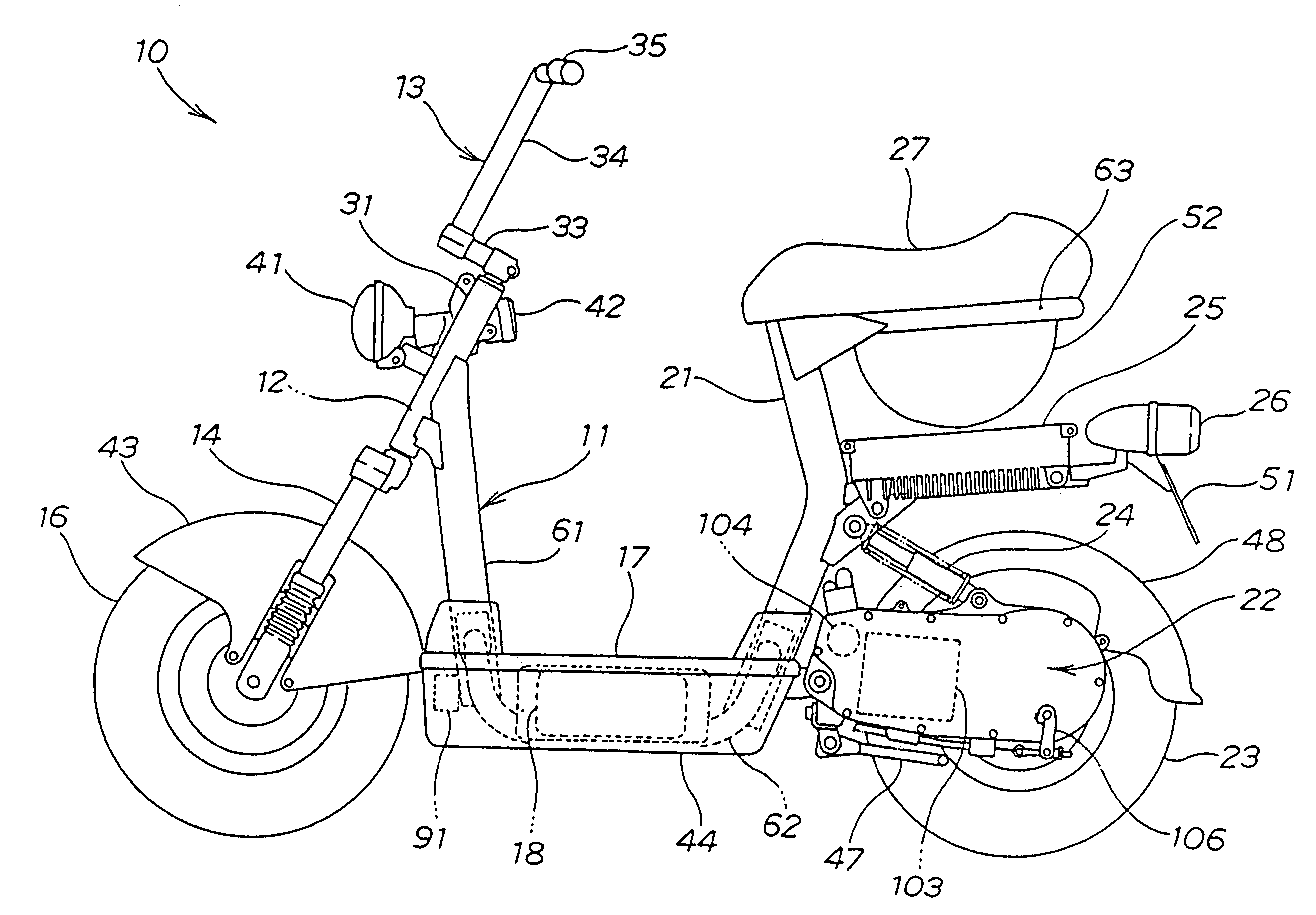

Electric vehicle

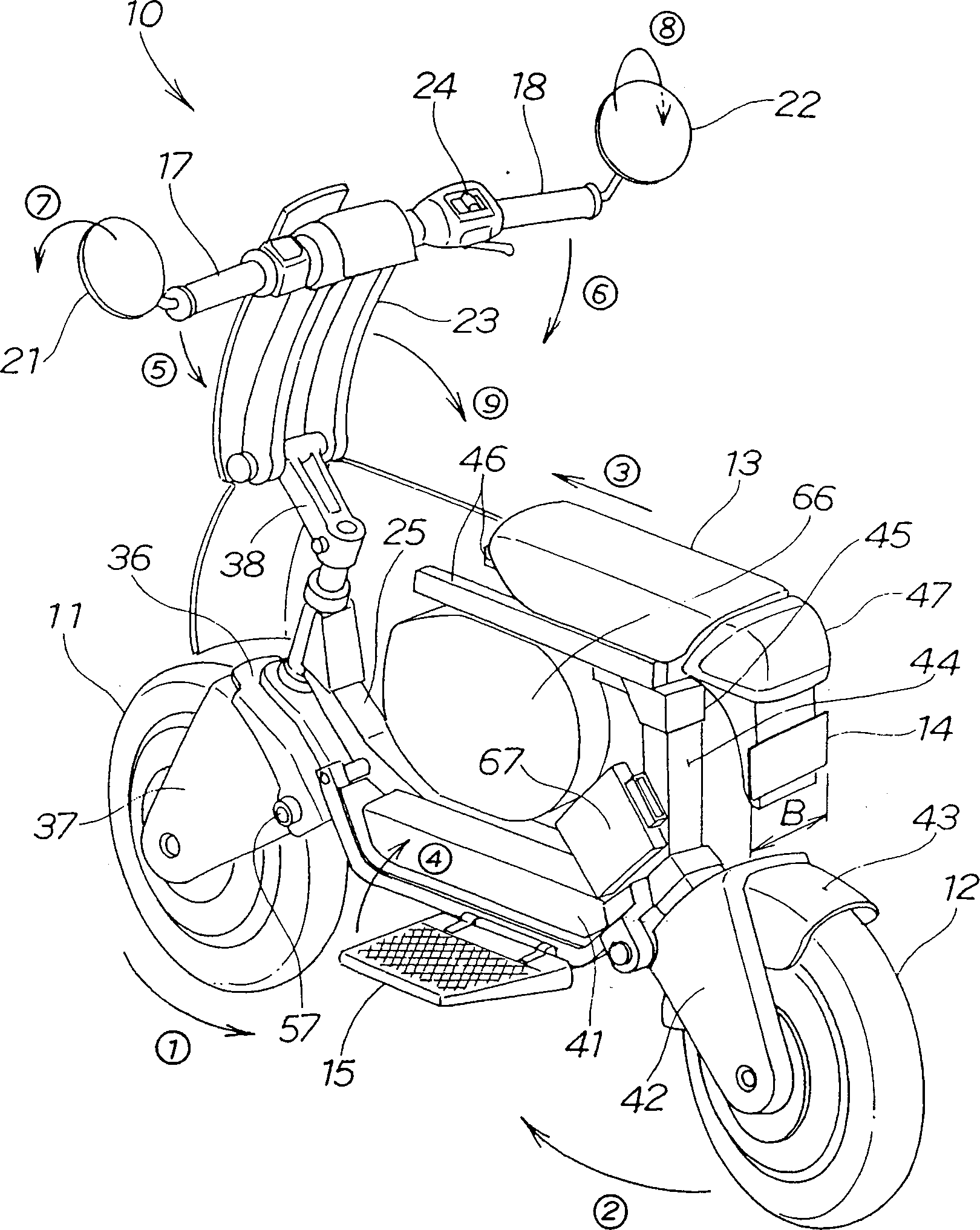

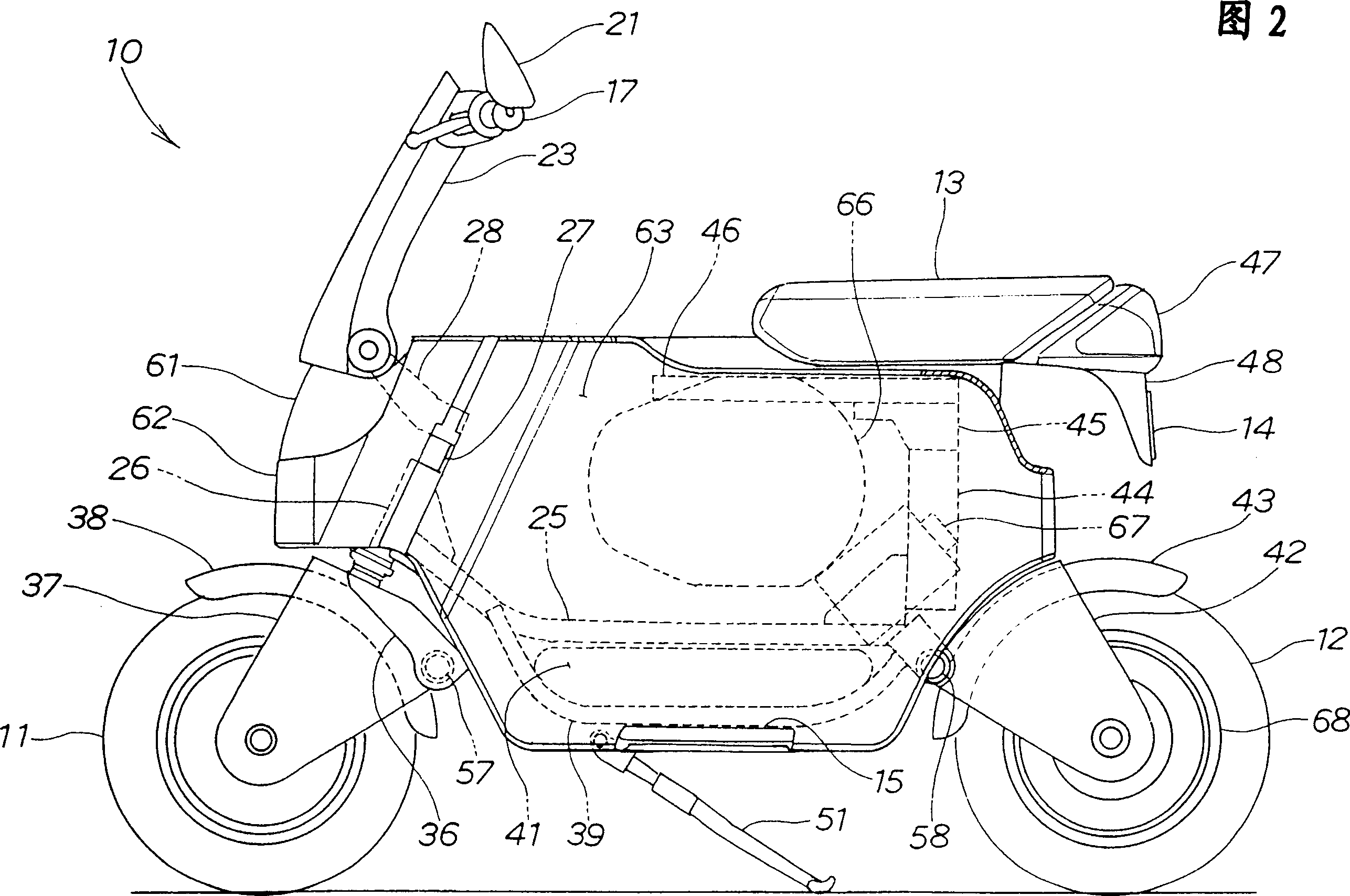

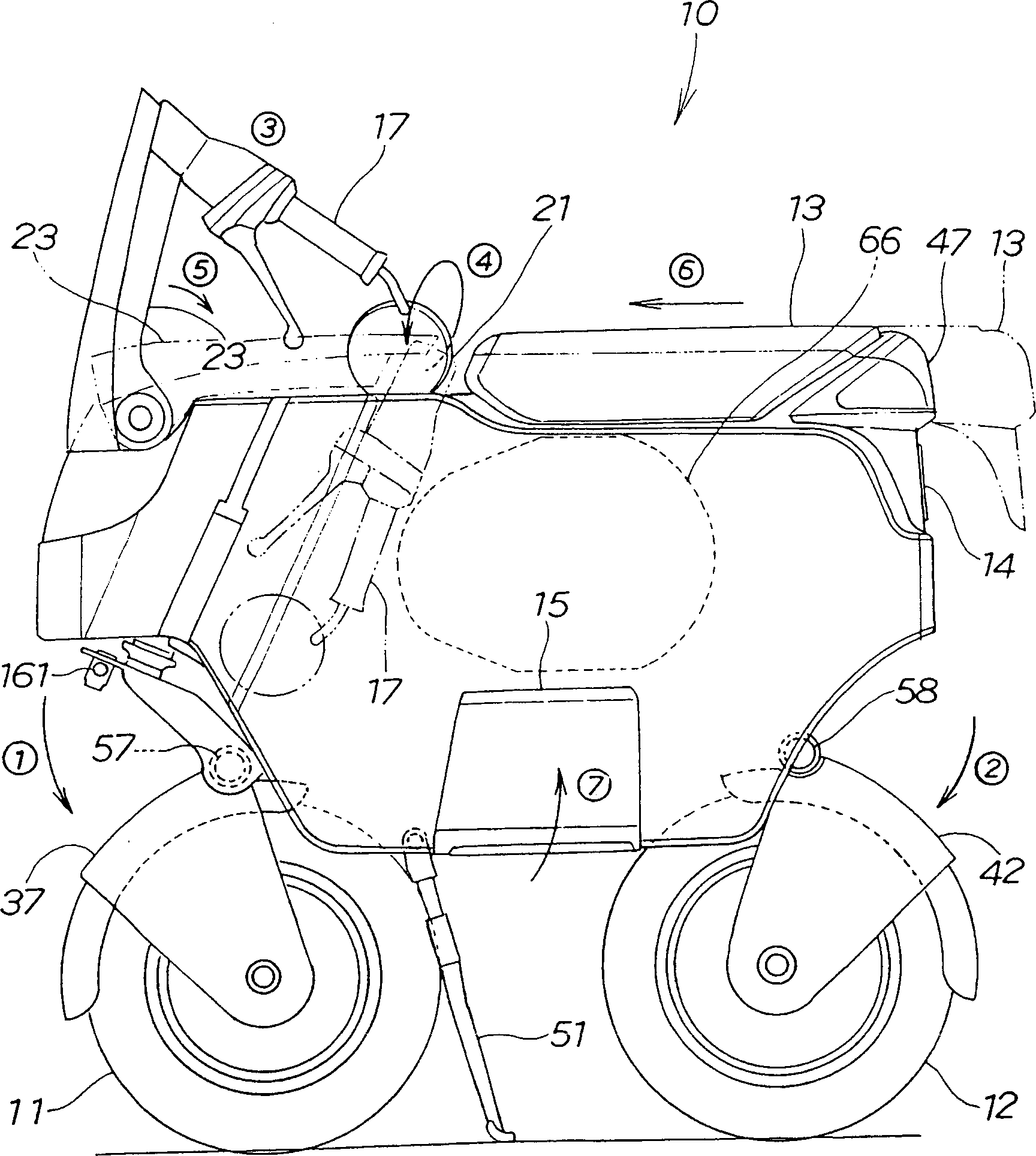

ActiveUS7249644B2Reduce weightResists heat transferElectric devicesMotorised scootersElectric vehicleDrum brake

An electric vehicle is provided with a drum brake unit on a rear wheel rotated by drive force of an electric motor. A first set of fins, for cooling the electric motor and the drum brake unit, are provided between the electric motor and the drum brake unit. Specifically, the first set of fins are provided on an inner side surface of a case body. It is possible to cool the electric motor using the first set of fins, and it is also possible to remove heat of the drum brake unit using the first set of fins. The fins act as a heat sink to dissipate heat generated by the drum brake unit, and to resist heat transfer from the drum brake unit to the electric motor, helping to more efficiently cool the electric motor.

Owner:HONDA MOTOR CO LTD

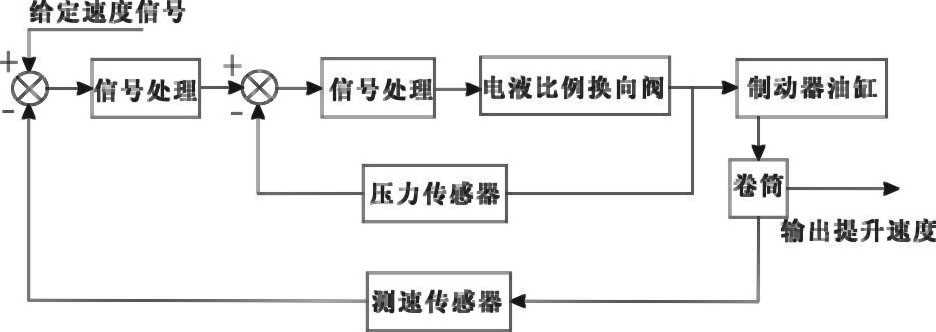

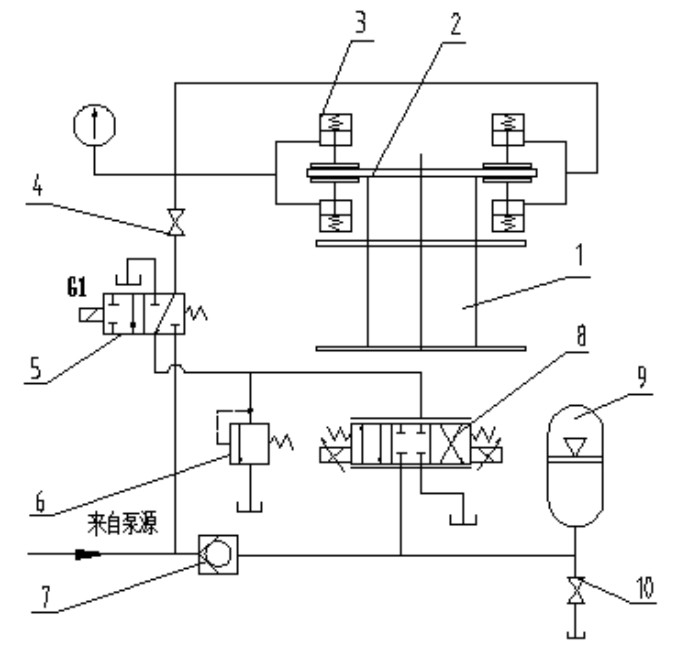

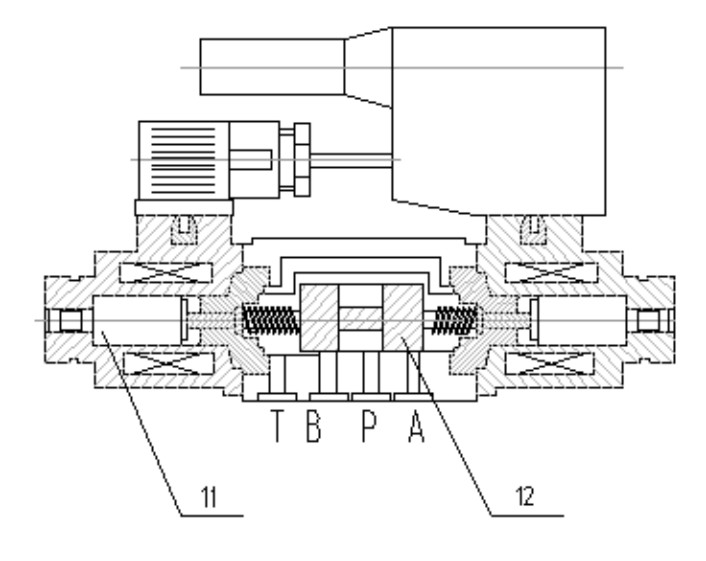

Mine-hoist constant deceleration safety braking system and braking method thereof

ActiveCN102030280AEasy to operateReduce stepsServomotor componentsHoisting equipmentsInput controlElectric control

The invention discloses a mine-hoist constant deceleration safety braking system and a braking method thereof, and relates to the technical field of mine-hoist safety braking control. The system comprises a disk brake, a hydraulic station, an electric control device and a detection feedback device which are arranged on a drum brake disk, wherein a speed sensor arranged on the drum acquires a hoist deceleration signal and inputs the hoist deceleration signal into the electric control device; the electric control device receives the signal and compares the signal with the given speed value to send out a control command; after the control command is processed into an electric signal and compared with an oil pressure signal which is fed back by a pressure sensor on the hydraulic pipeline arranged between the outlet end of an electrohydraulic proportion reversing valve and the disk brake cylinder, an electric signal control command is sent out; and the electrohydraulic proportion reversingvalve of the hydraulic station outputs a hydraulic pressure signal, which varies as the input control command varies, so as to control the motion state of the hoist by the disk brake, thereby realizing constant deceleration safety braking of the mine hoist.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

Control of brake noise by tuned mass dampers

InactiveUS20060266599A1Noise is producedImprove efficiencyNoise/vibration controlSlack adjustersTuned mass damperBrake pad

This invention relates to the braking system of a vehicle and a method to attenuate noise-producing vibrations of components of the braking system by the use of tuned mass dampers of various designs mounted with respect to the brake pads and / or damper plate of a disc brake system. In another embodiment, the tuned mass dampers are attached to the brake shoes and / or drum brake backplate of a drum brake system.

Owner:MATERIAL SCIENCES CORPORATION

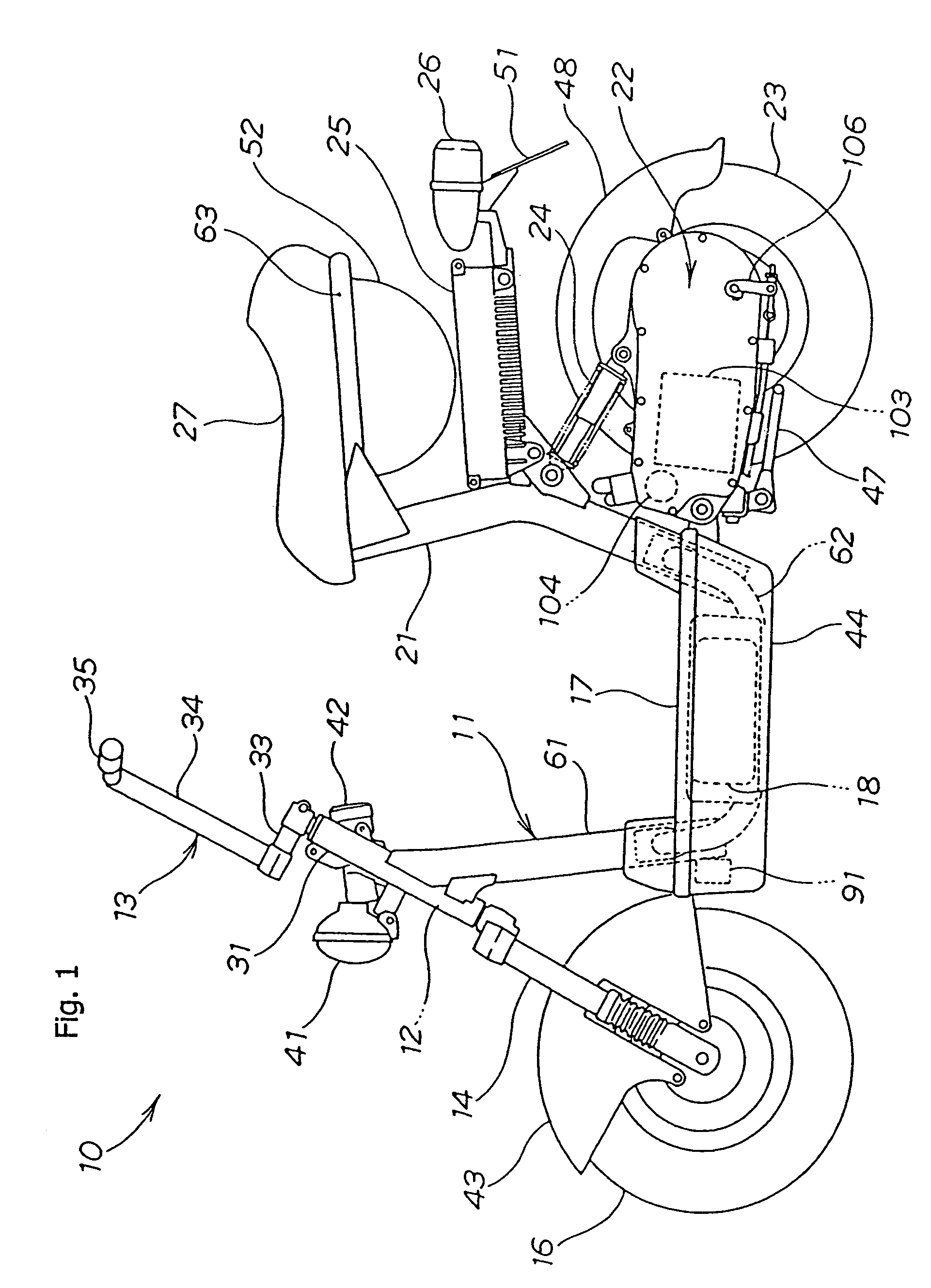

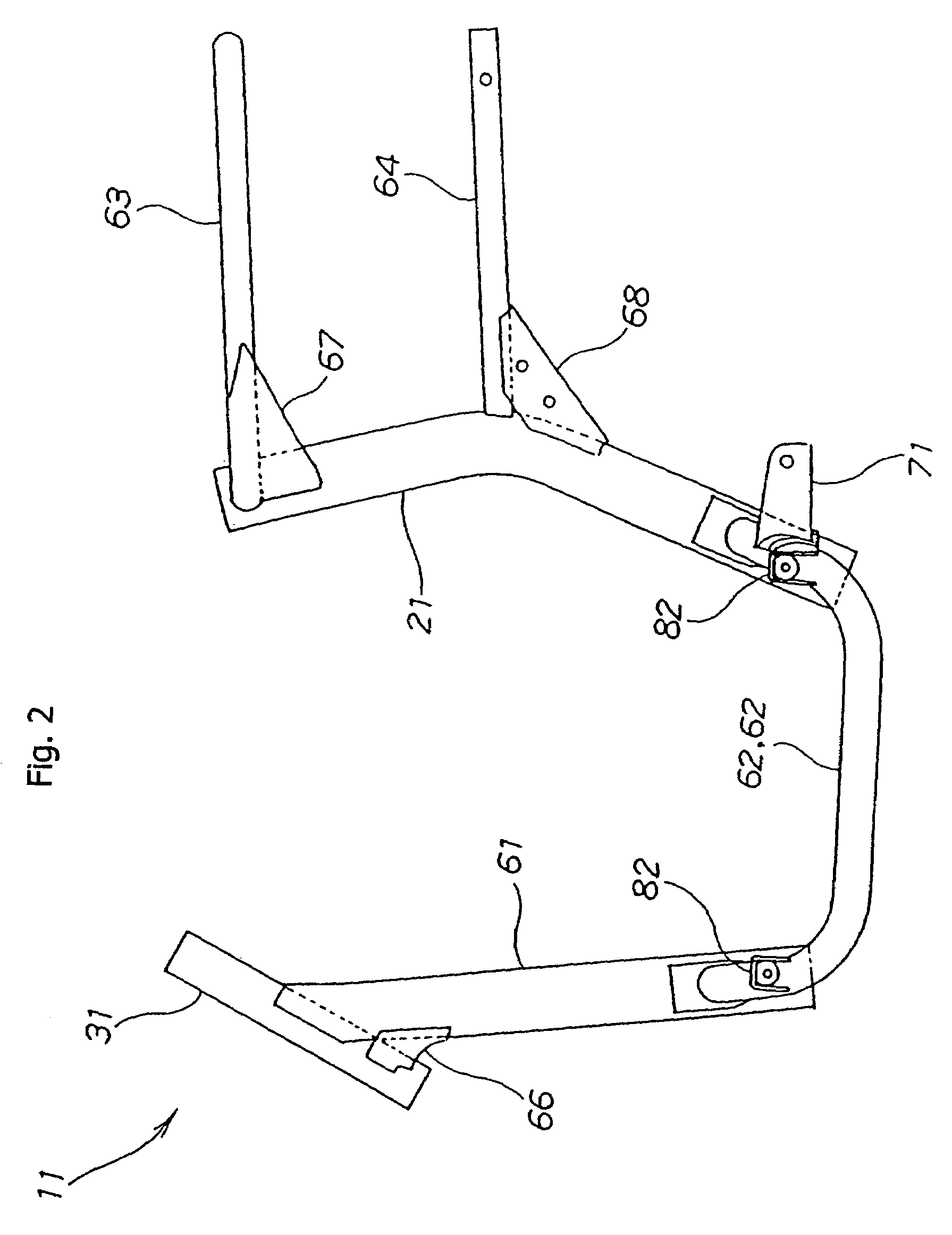

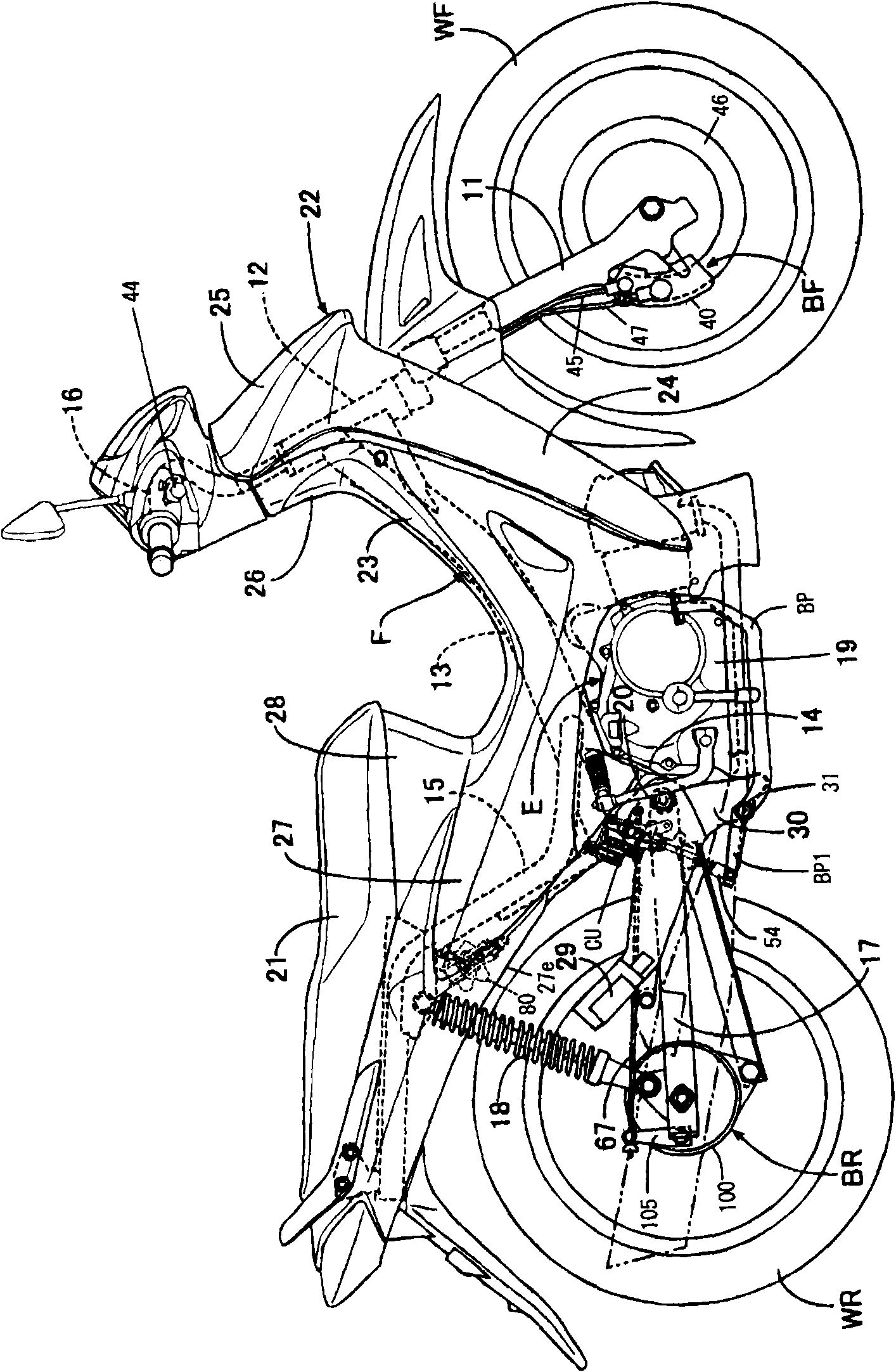

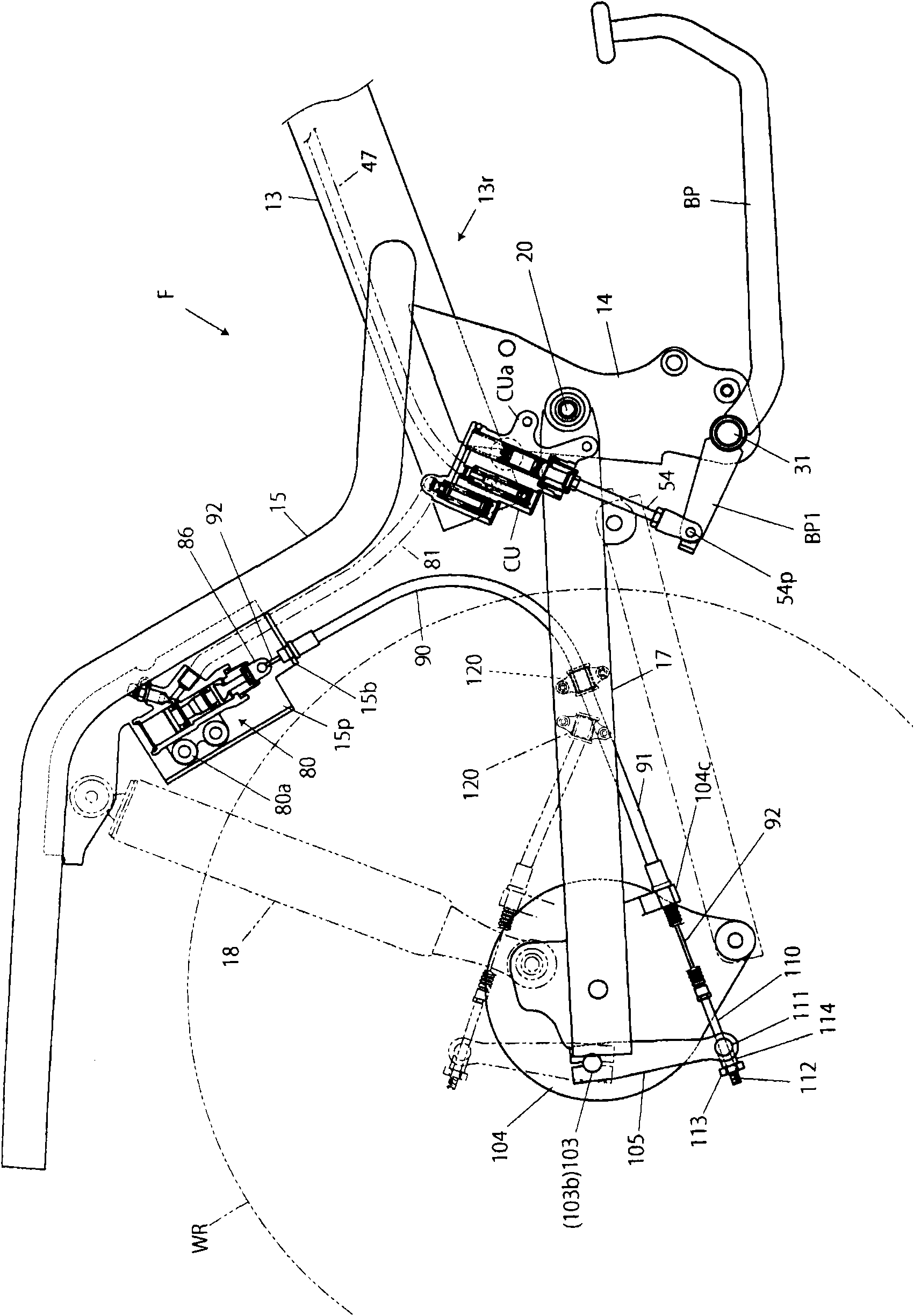

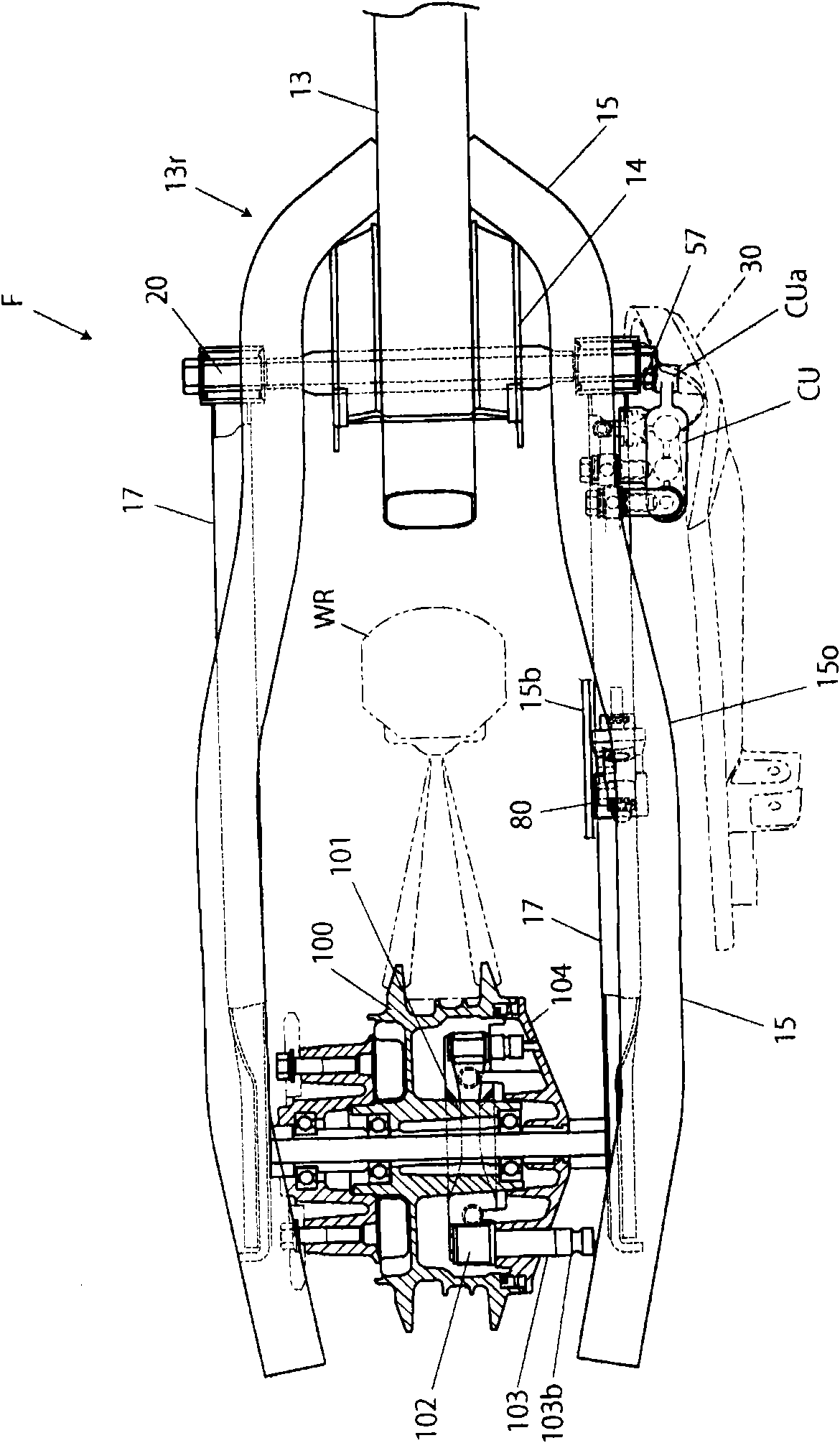

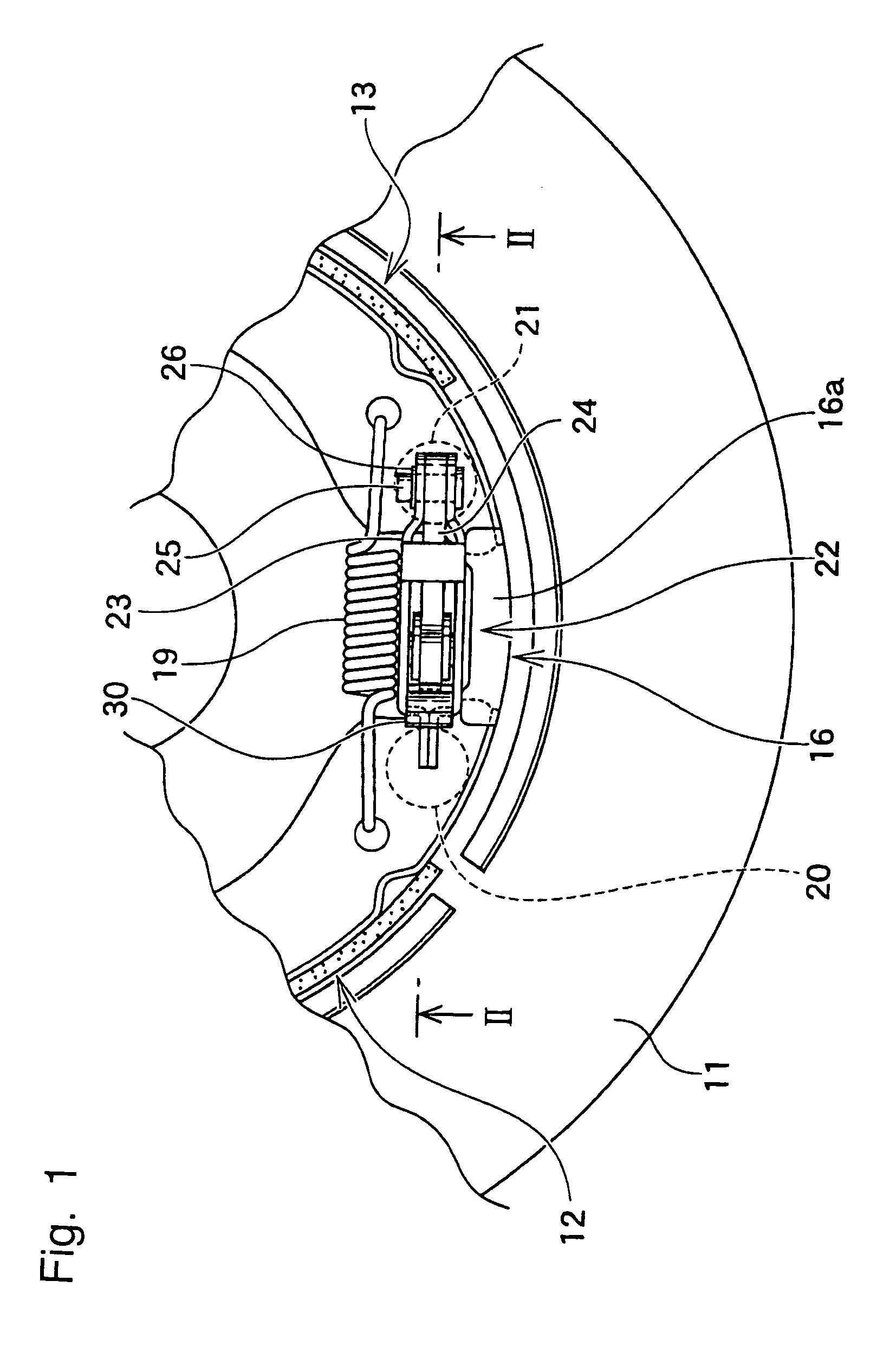

Interlocked brake device for two-wheel motorcycle

The present invention provides an interlocked brake device for a two-wheel motorcycle. Not only is a hydraulic front wheel brake mechanism and a mechanical back wheel brake mechanism adopted, but also a structure at the periphery of a pedal is simplified. The interlocked brake device is provided with the following components: a back carriage part (15) which extends upwards from a back end of a main carriage part (13); a pivot carriage part (14) which extends downwards from a back end of the main carriage part (13); a back drum type brake (BR) which brakes a back wheel; a front disc type brake(BF) which brakes a front wheel (WF); a main hydraulic cylinder (CU) which is interlocked with the operation of a brake pedal (BP) for generating a braking force that is applied to the back drum typebrake (BR) and the front disc type brake (BF); a front tube which transmits a hydraulic force generated by the motion of the main hydraulic cylinder to the front disc type brake (BF); and auxiliary hydraulic cylinder (80) which transmits the hydraulic force generated by the motion of the main hydraulic cylinder through the back tube and functions thereby; and a mechanical transmission component which is used for transmitting the output of the auxiliary hydraulic cylinder (80) to the back drum type brake (BR), wherein the auxiliary hydraulic cylinder (80) is supported on the back carriage part(15).

Owner:HONDA MOTOR CO LTD

Friction plate without asbestos and its preparation process

A non-asbestos friction disk for the brake of drilling machine, heavy machinery, etc is prepared from glass fibres, organic fibres, low-smelting-point metal powder and resin-rubber mixture. Its advantages are low hardness, high toughness, high friction coefficient, high mechanical strength, and low abrasion.

Owner:李海 +4

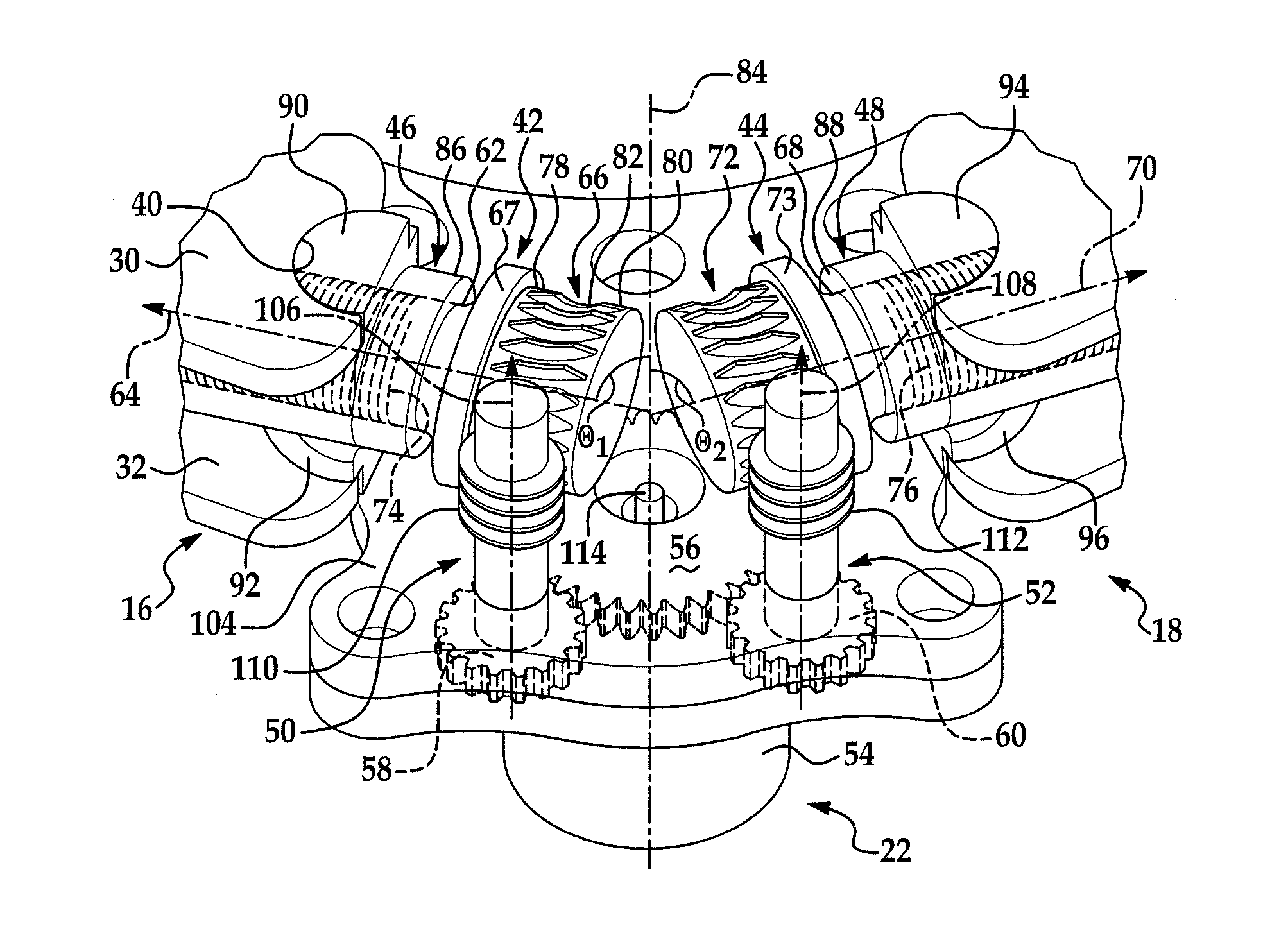

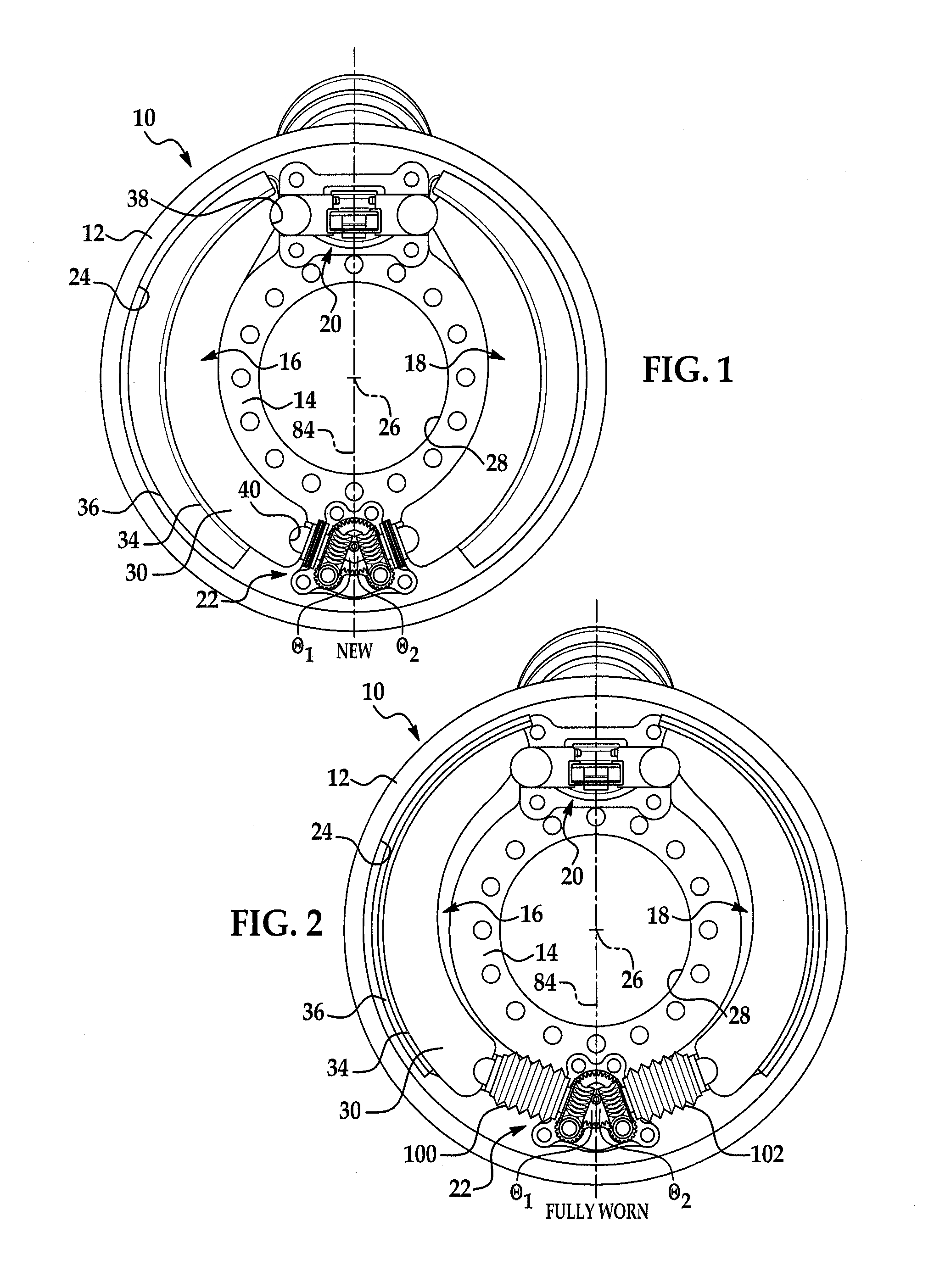

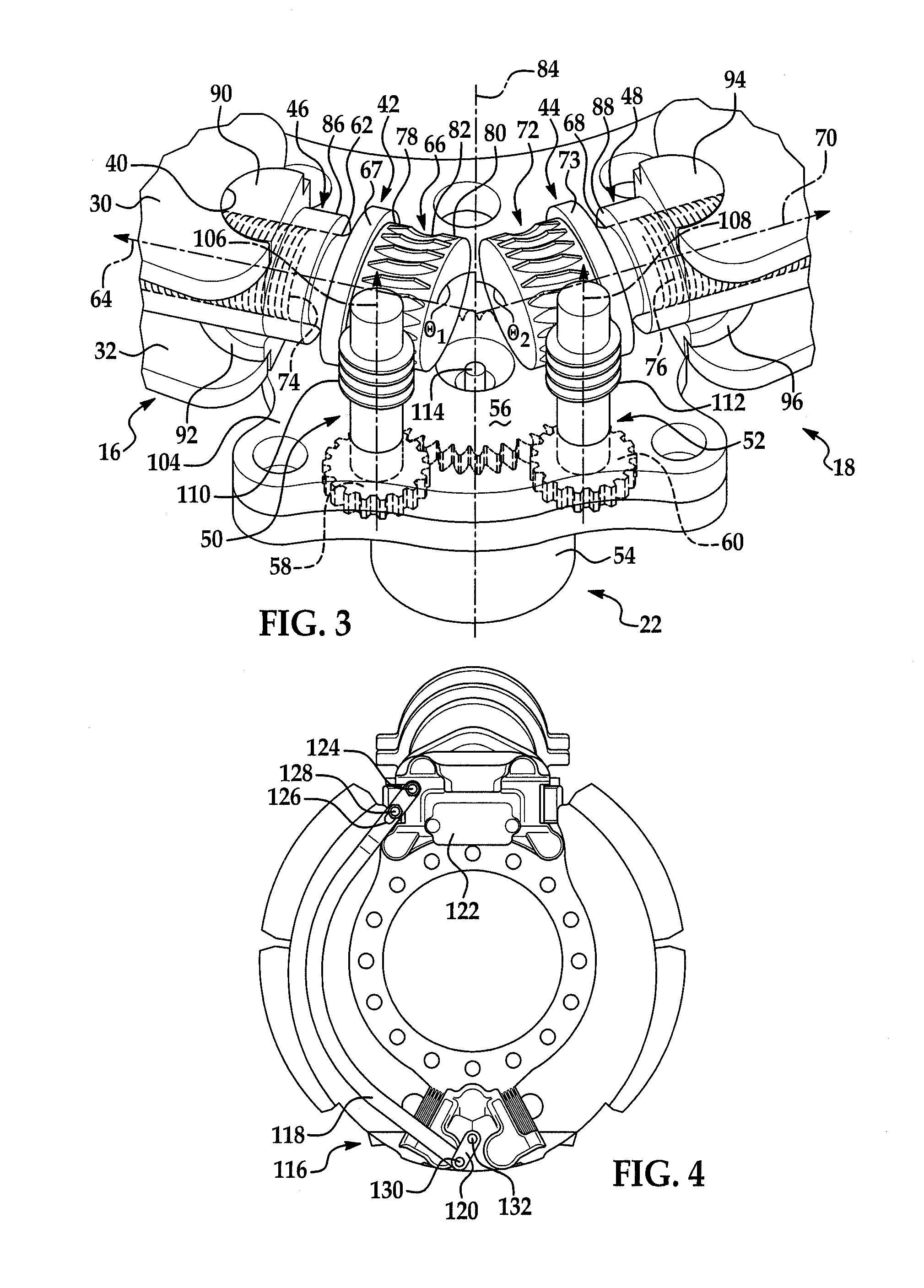

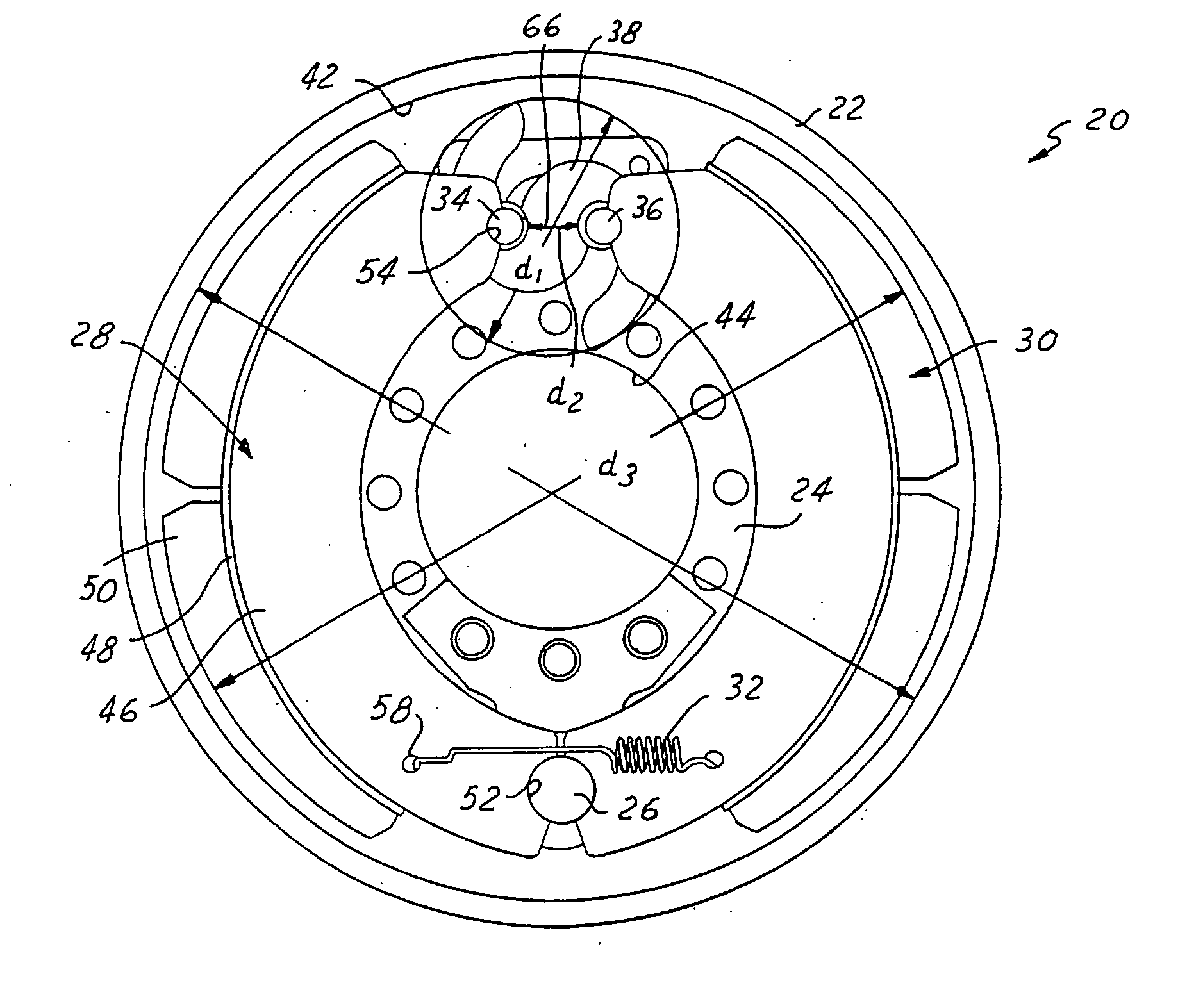

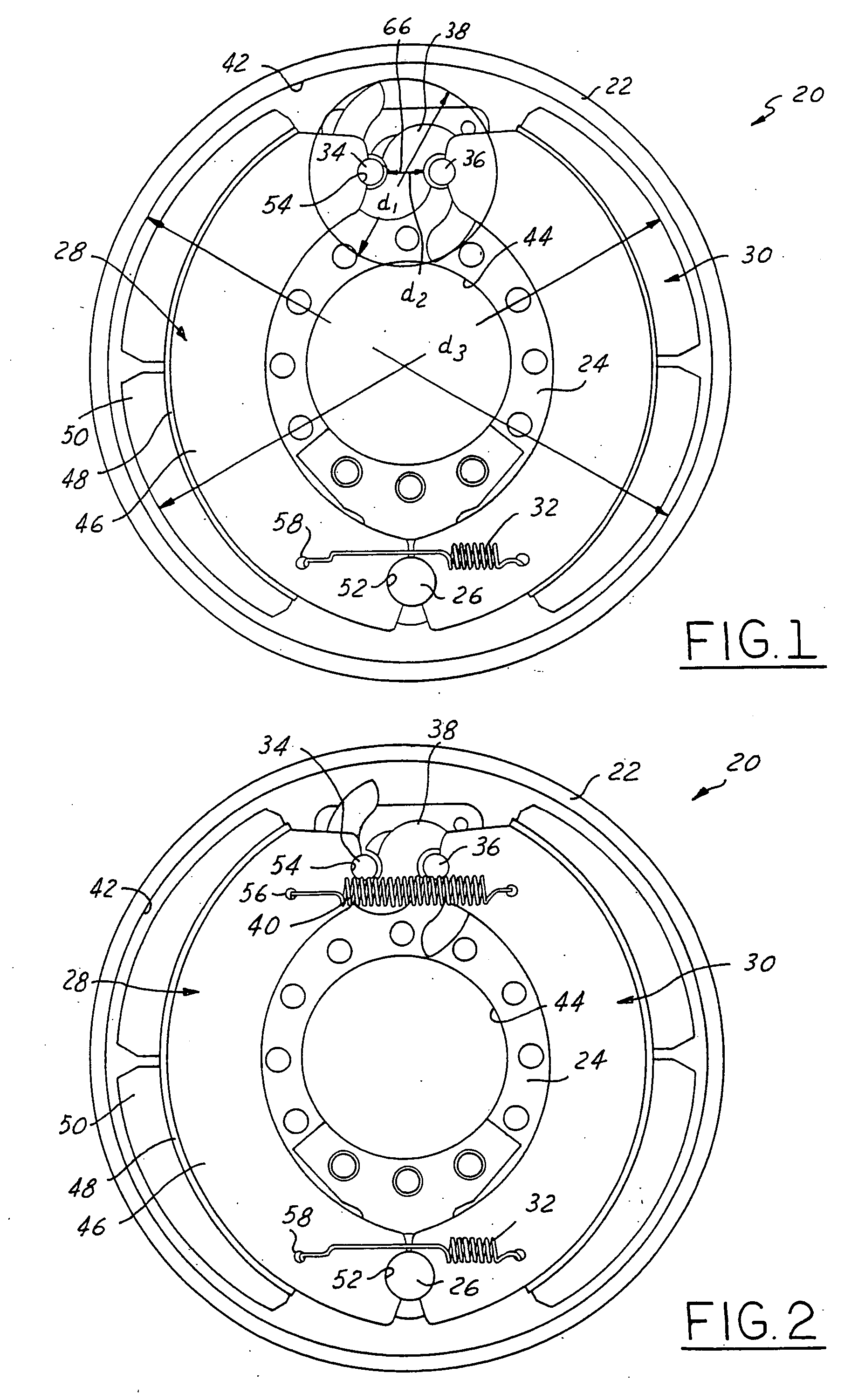

Variable position anchor assembly for adjusting brake shoes in a drum brake

InactiveUS20120031716A1Fine adjustment rangeReduce operating costsDrum brakesBrake actuating mechanismsEngineeringMechanical engineering

An anchor assembly is provided that permits adjustment of the brake shoes in a drum brake to account for wear. The assembly includes first and second adjuster shafts each having a plurality of threads and first and second pilot connectors. The pilot connectors each have a plurality of threads in engagement with the threads of a corresponding adjuster shaft. The pilot connectors each engage one end of a corresponding brake shoe. Rotation of each adjuster shaft causes longitudinal movement of a corresponding pilot connector in engagement with a corresponding brake shoe along an axis to adjust a position of the brake shoe.

Owner:BENDIKS SPAJSER FAUNDEJSHN BREJK LLK

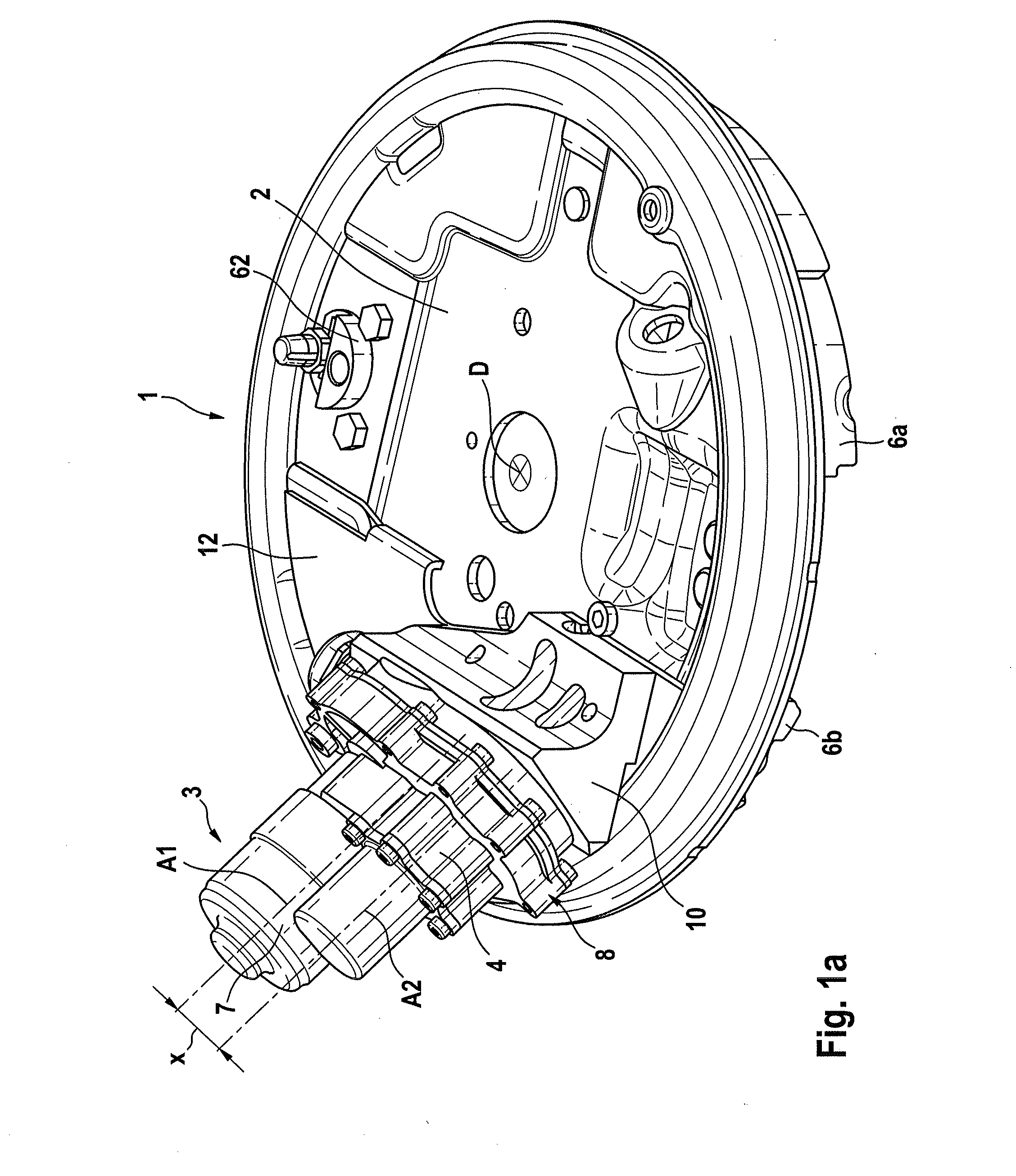

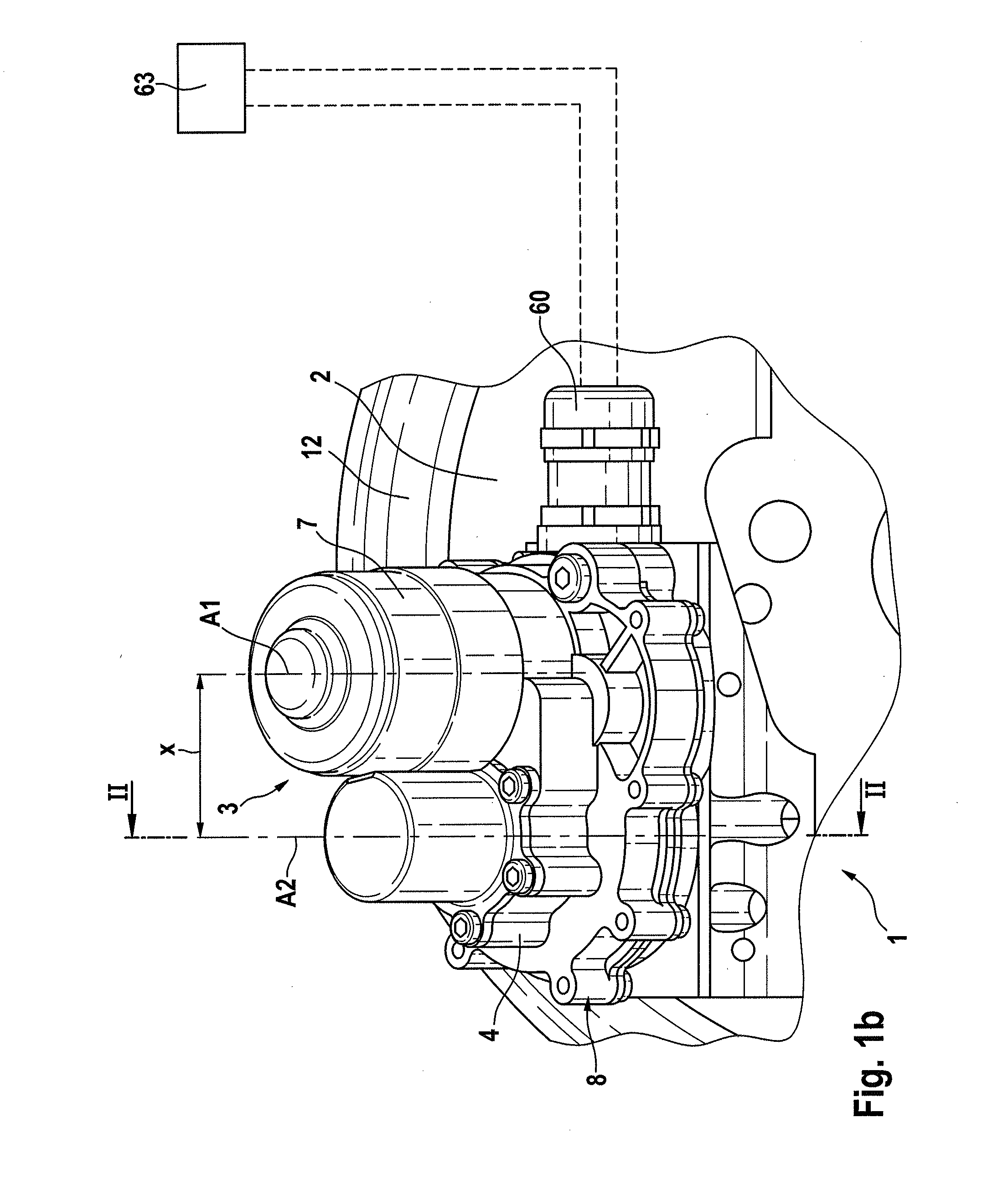

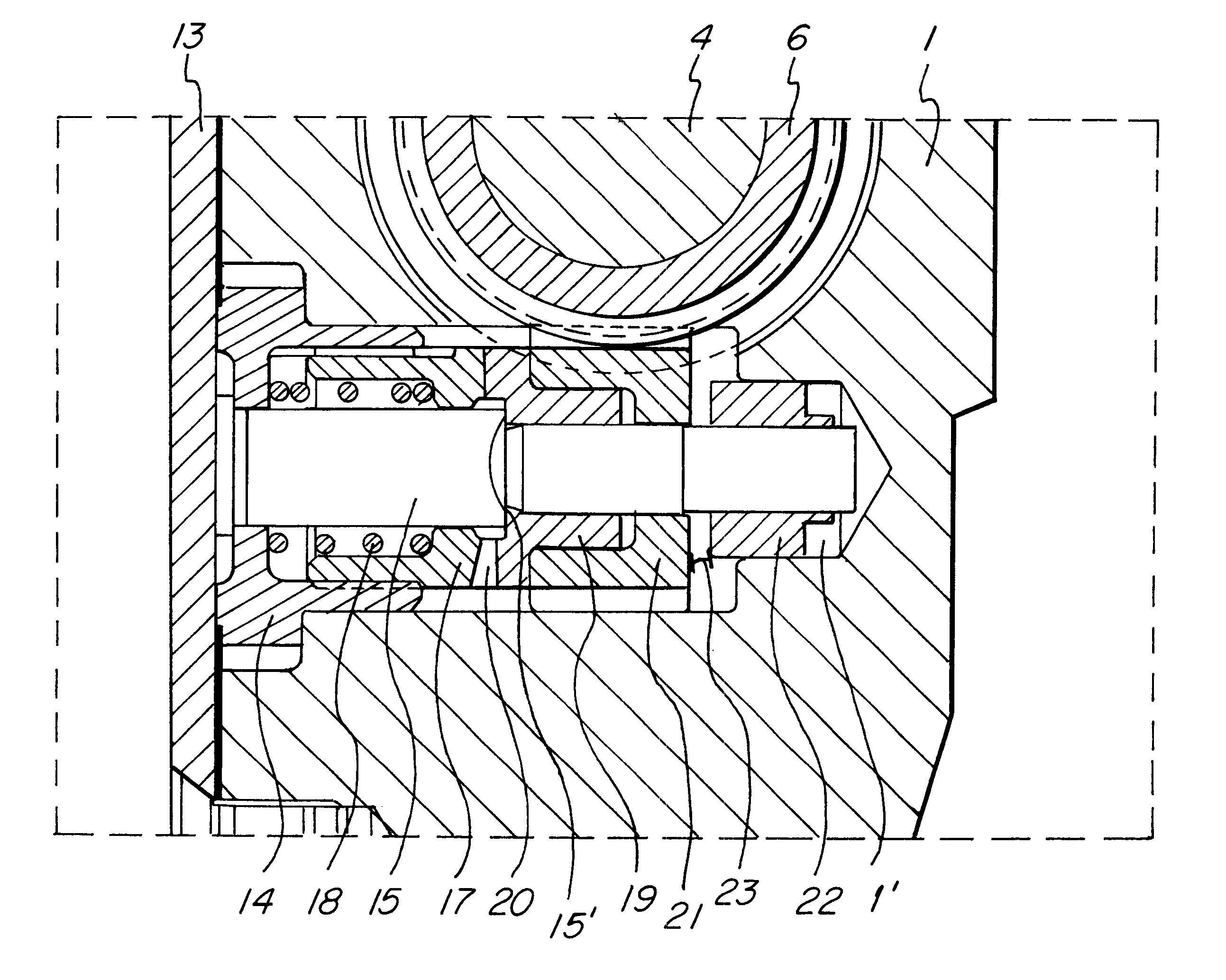

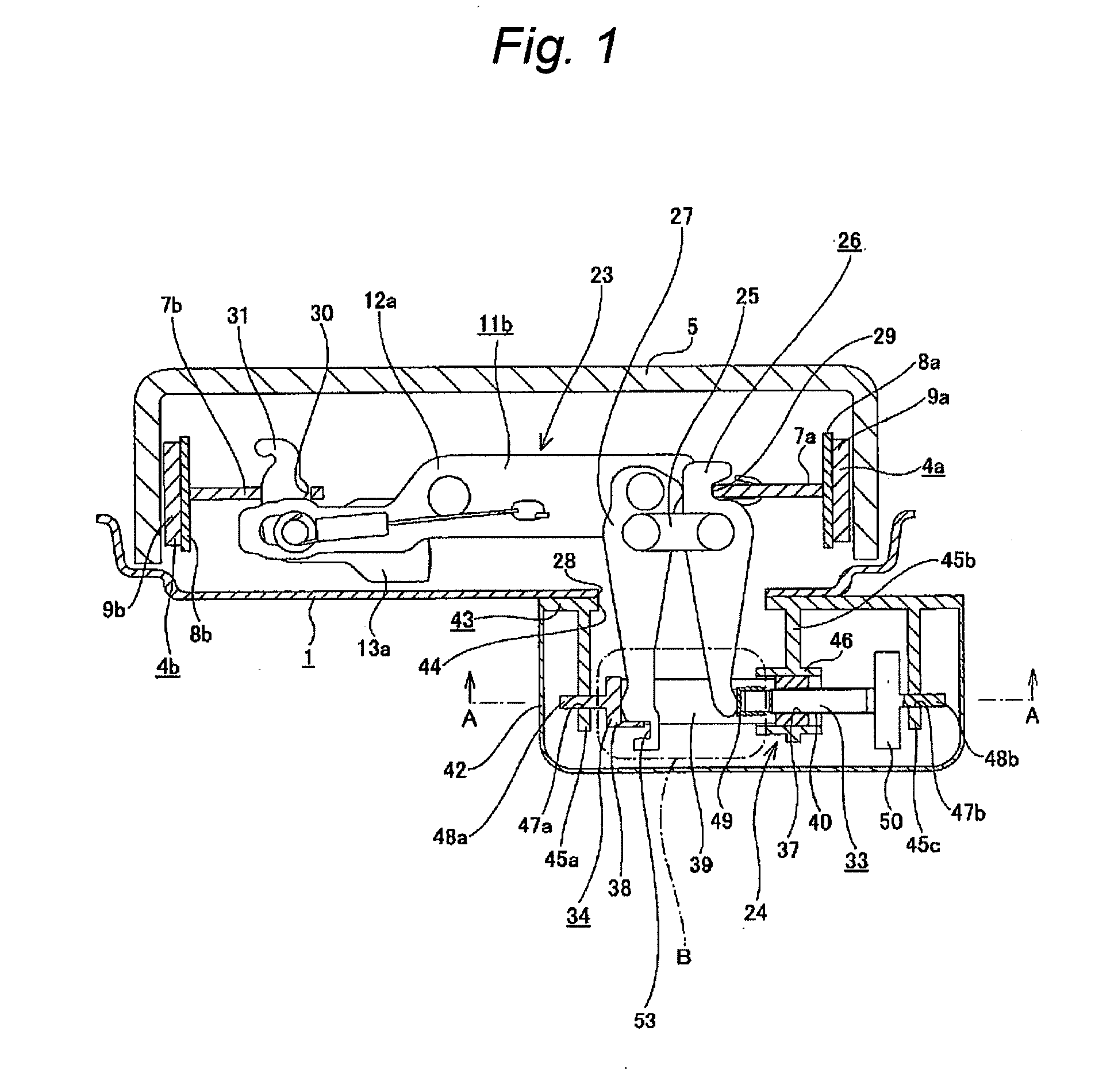

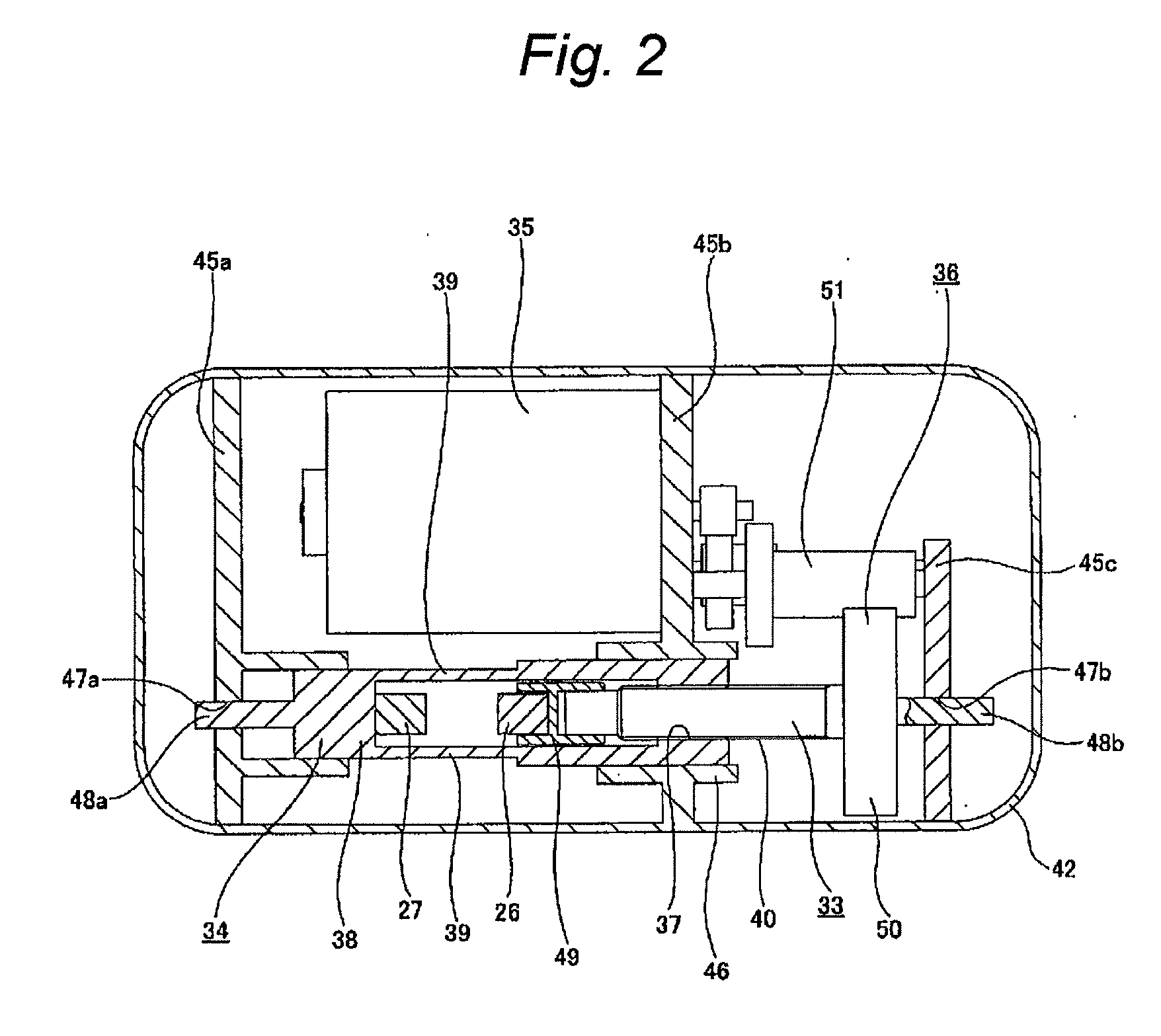

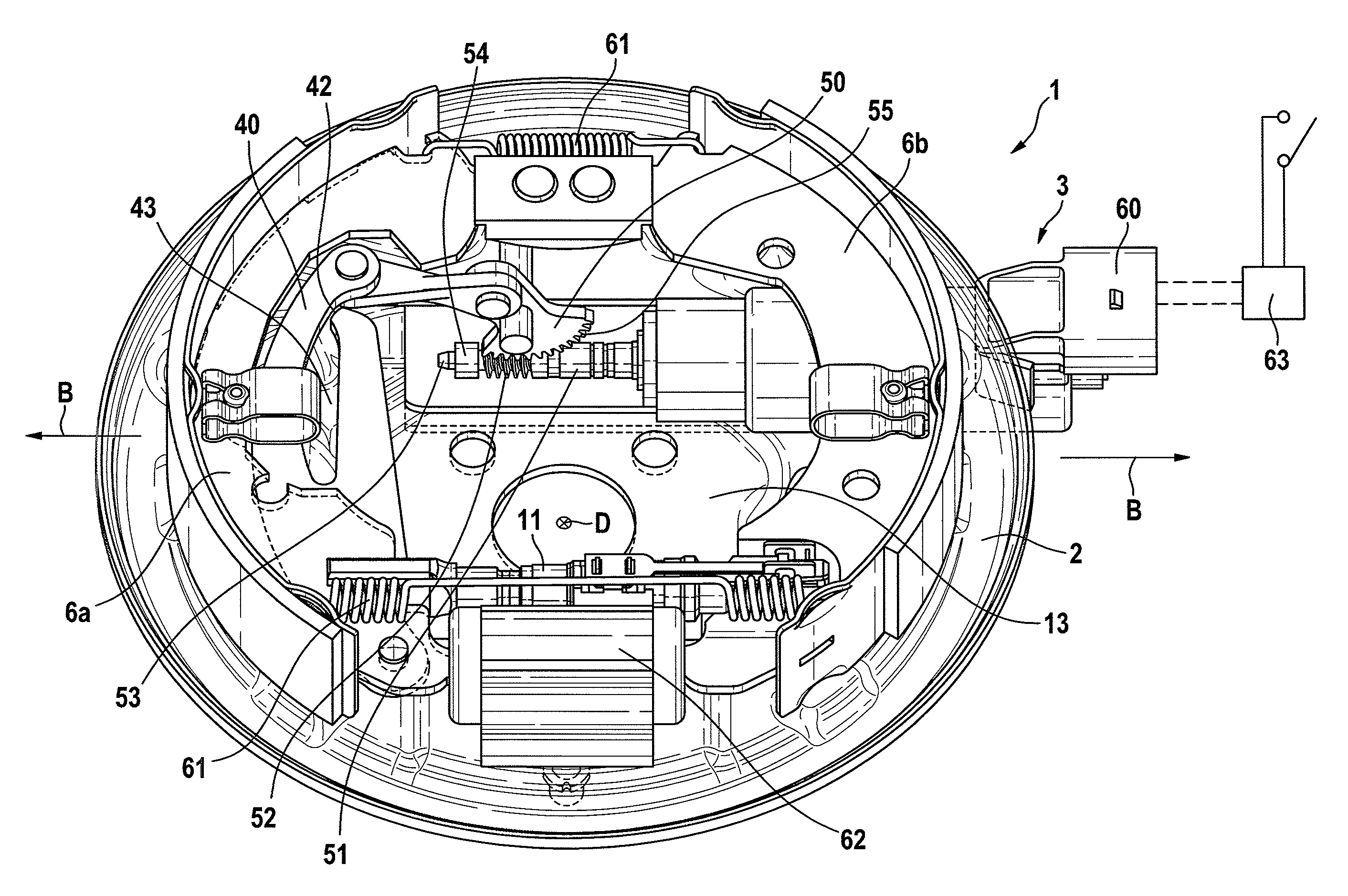

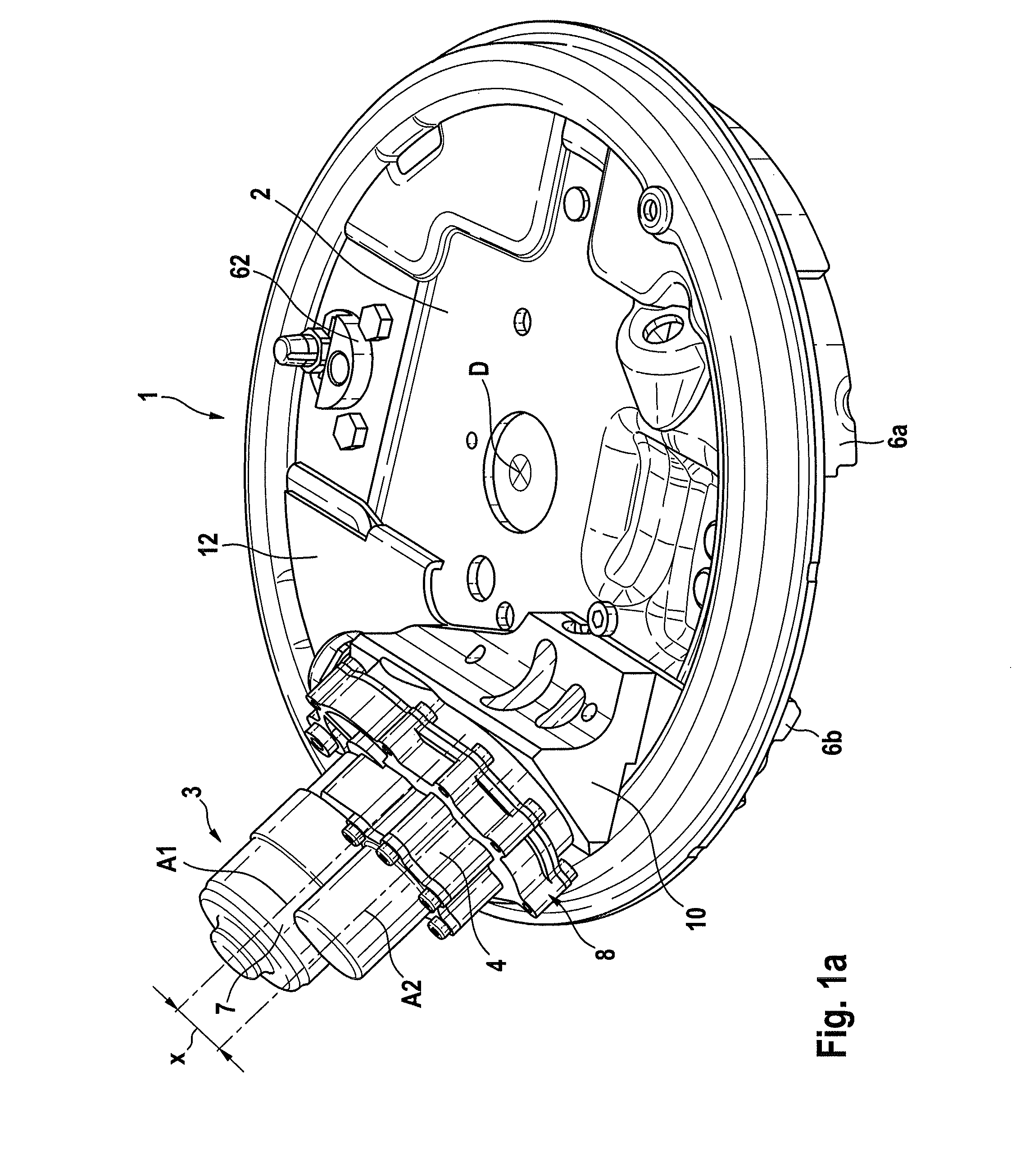

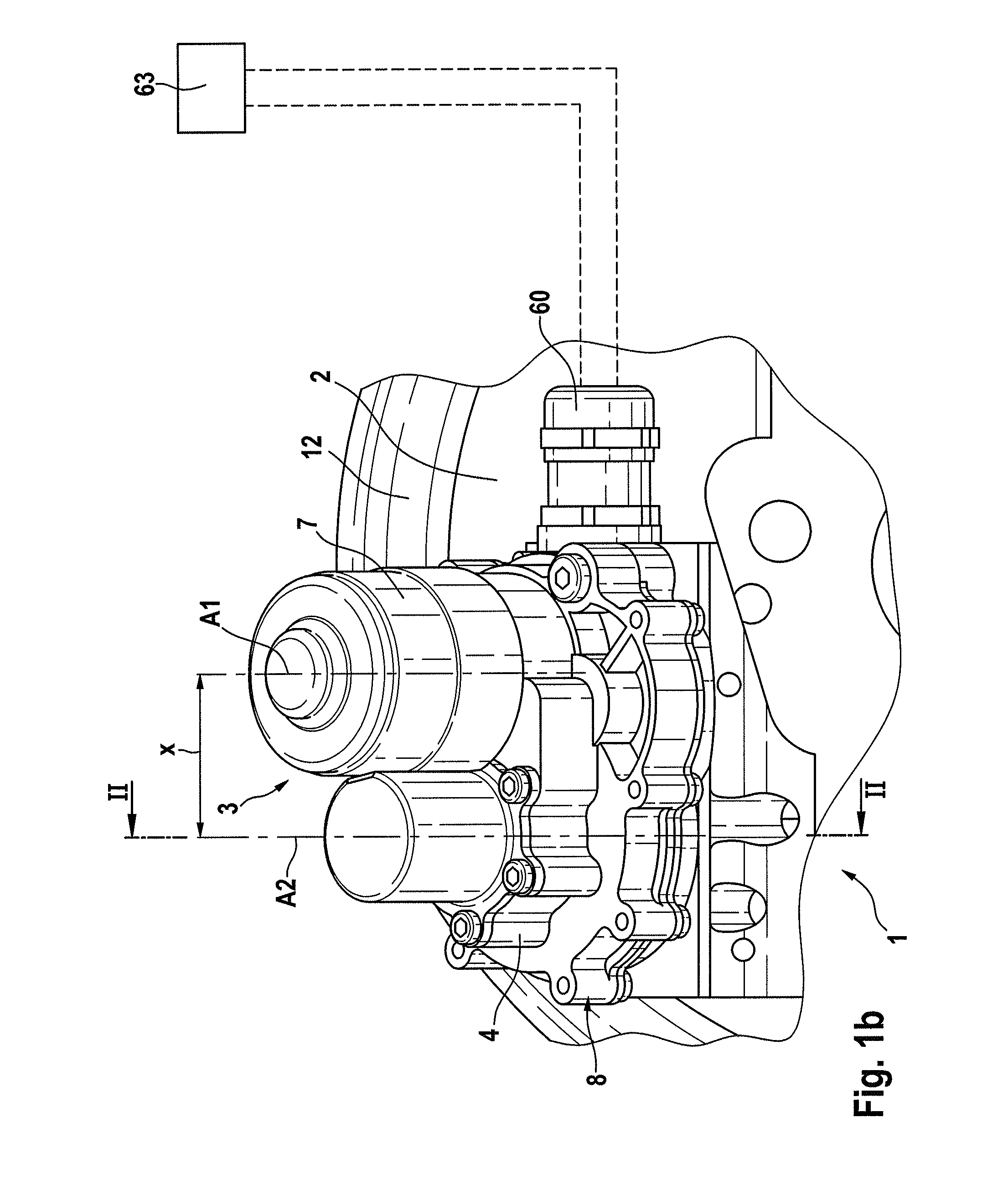

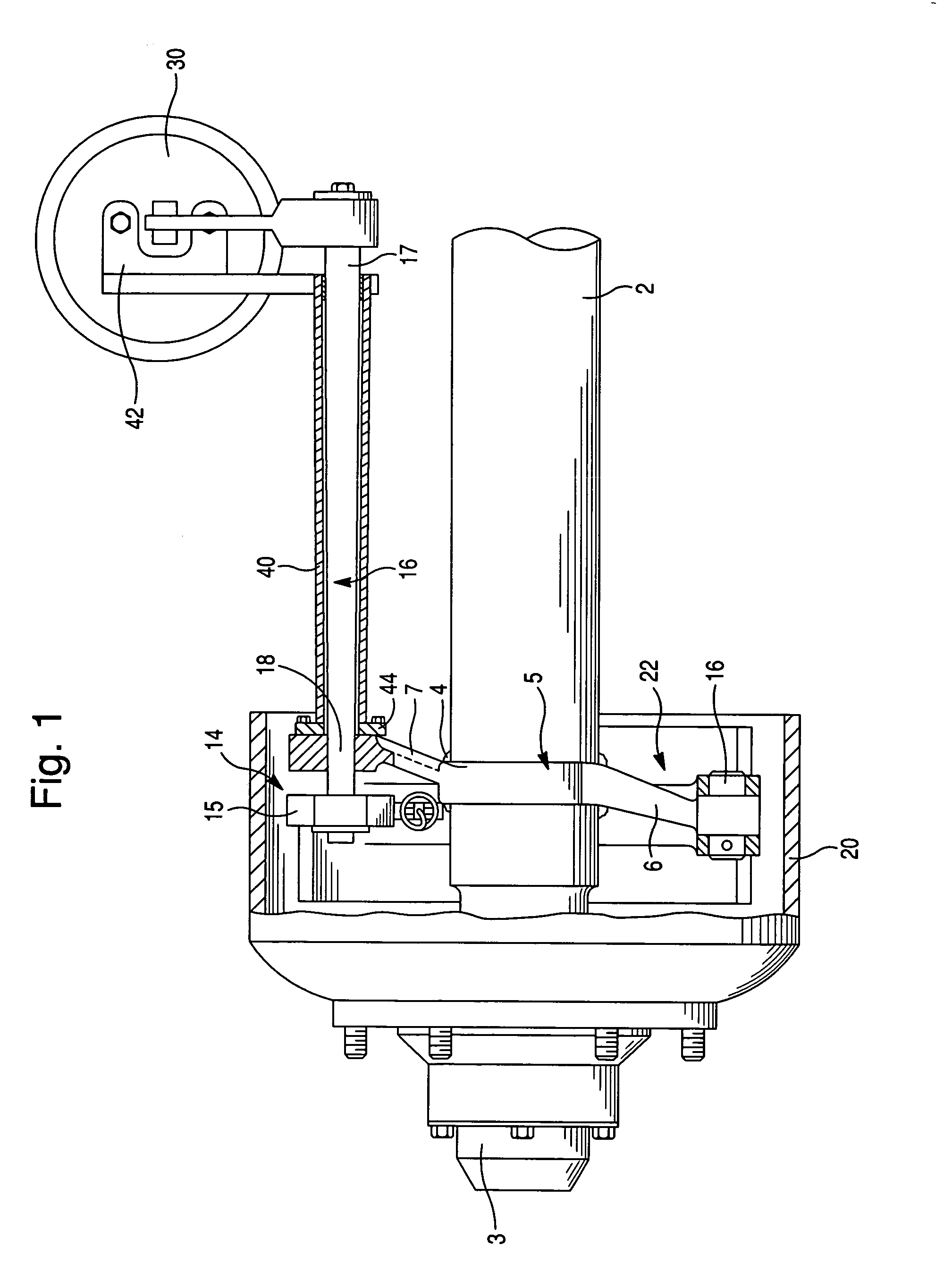

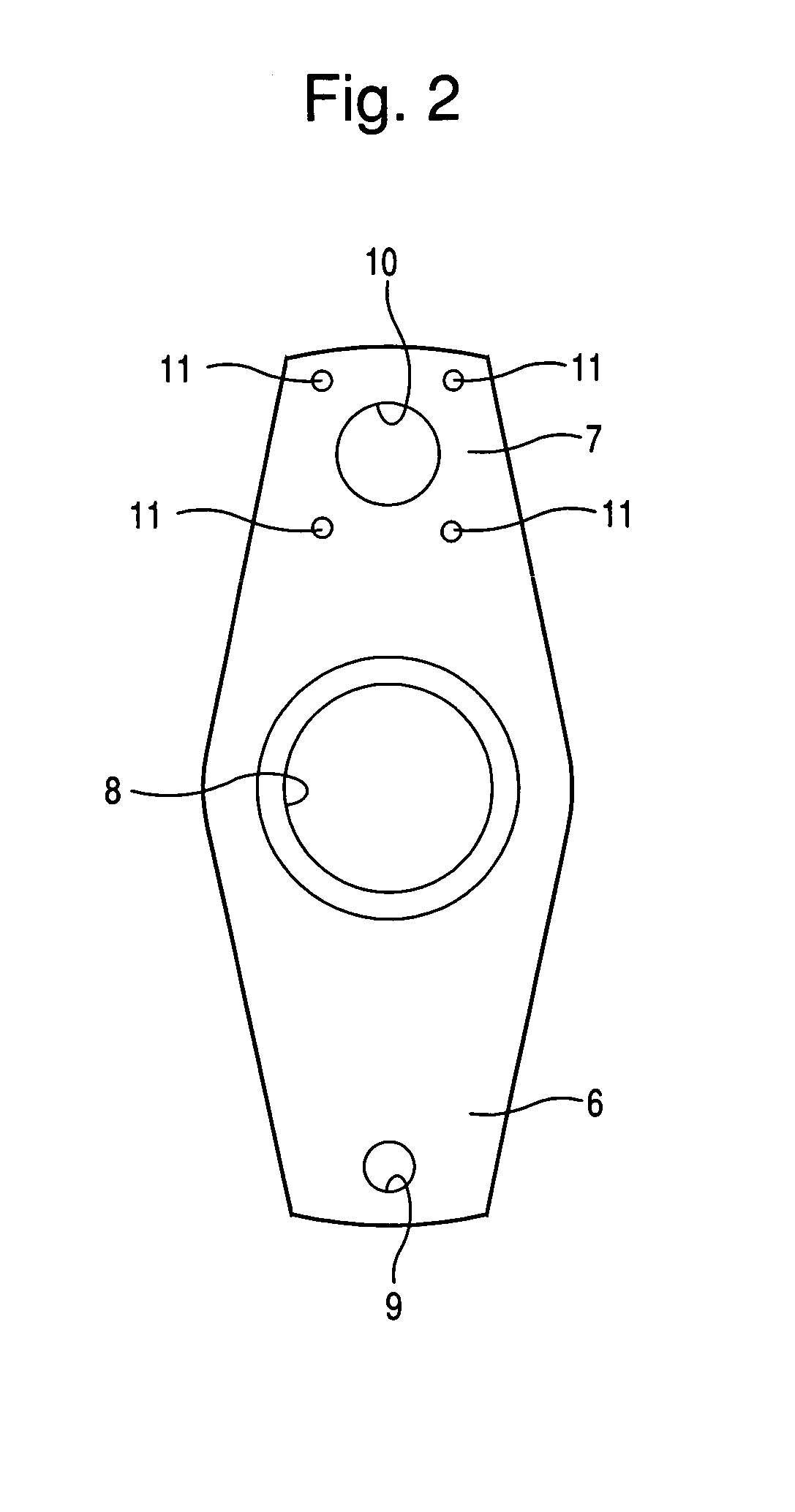

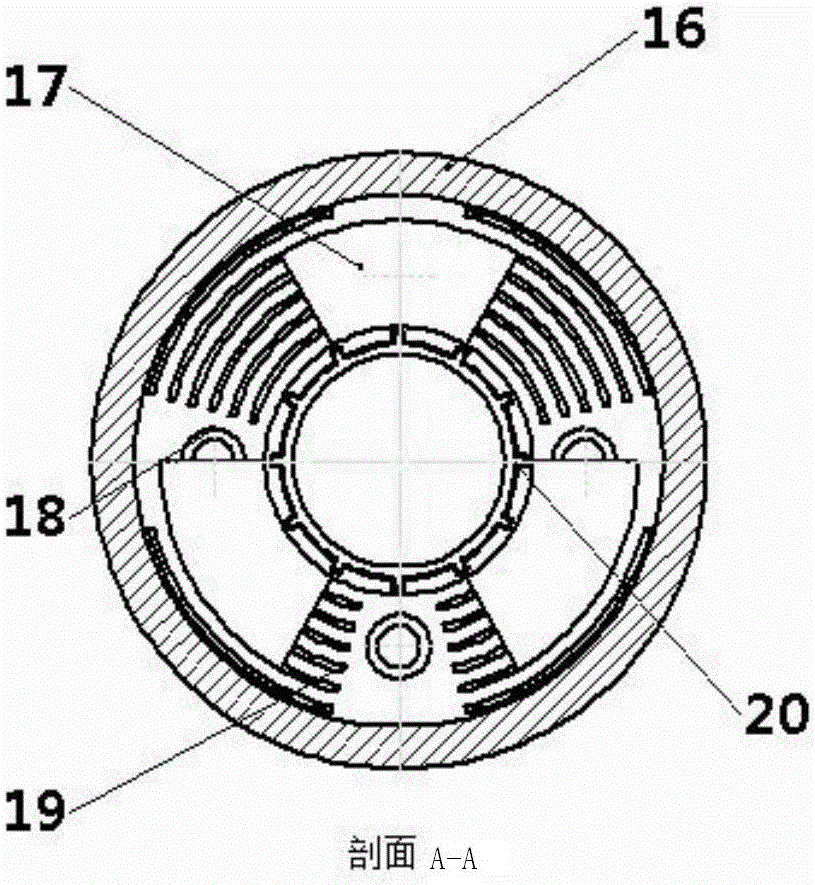

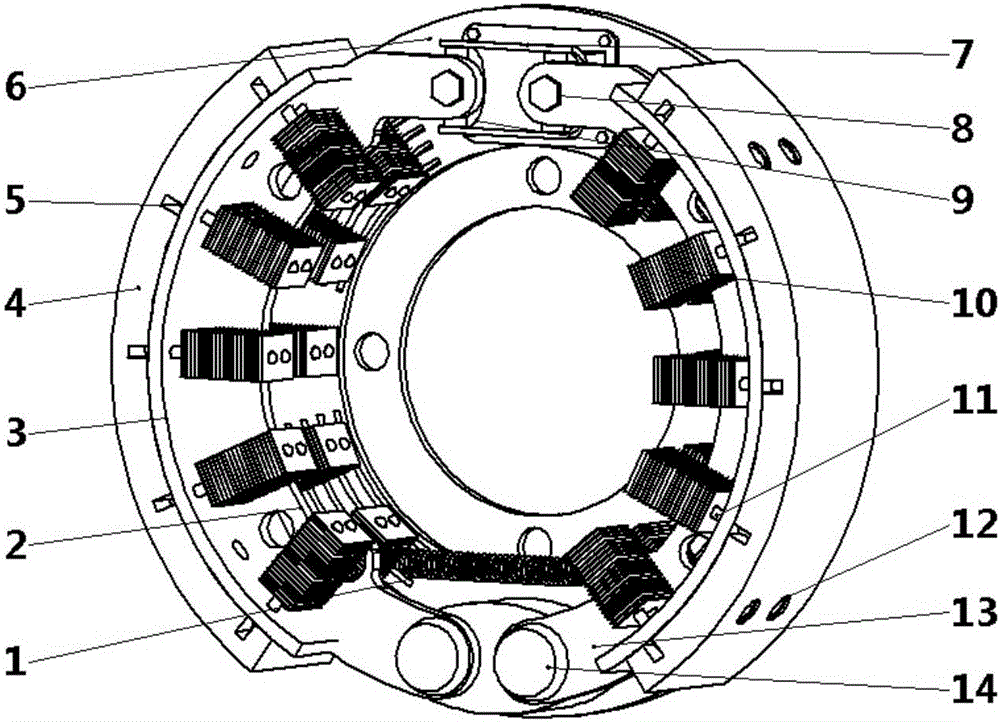

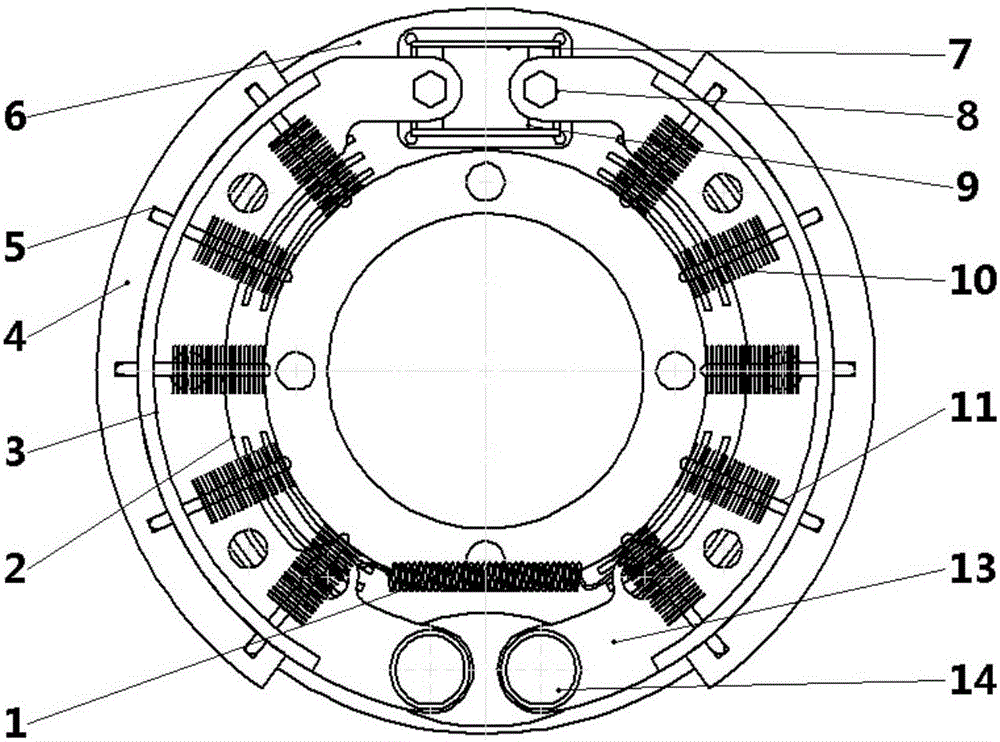

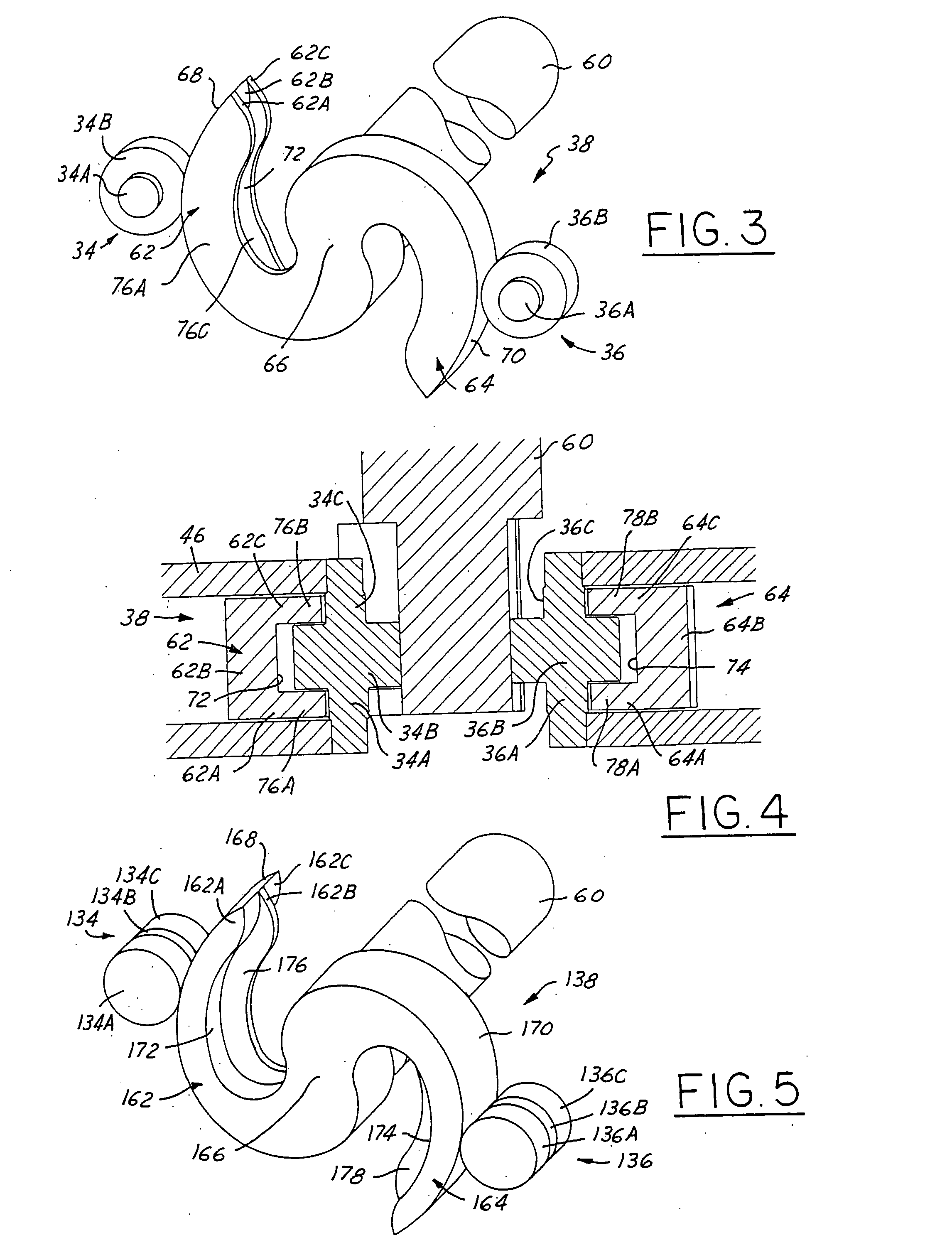

Drum brake module which can be operated by electric motor

ActiveUS20140020997A1Disadvantageous effect of contracting is avoidedAvoid distortionBrake actuating mechanismsMechanically actuated drum brakesEngineeringBiological activation

A drum brake module for motor vehicles operable by electric motor and performs at least one parking brake function, having an electromechanical actuator mounted on one side of the armature plate and a rotational-translational movement converter converting a rotational drive rotational movement into a translational activation movement of brake shoes arranged on a side of the armature plate facing away from the actuator in a brake drum, and including at least one supporting device between the brake shoes such that the latter can carry out an activation movement in the direction of the brake drum. A drive nut is supported by the rotational-translational movement converter in an axially secure and rotatable fashion on the armature plate to assist the braking force. The drive nut drives a spindle arrangement mounted in a rotationally fixed and axially displaceable fashion and engages with an activation cable on at least one brake shoe.

Owner:CONTINENTAL TEVES AG & CO OHG

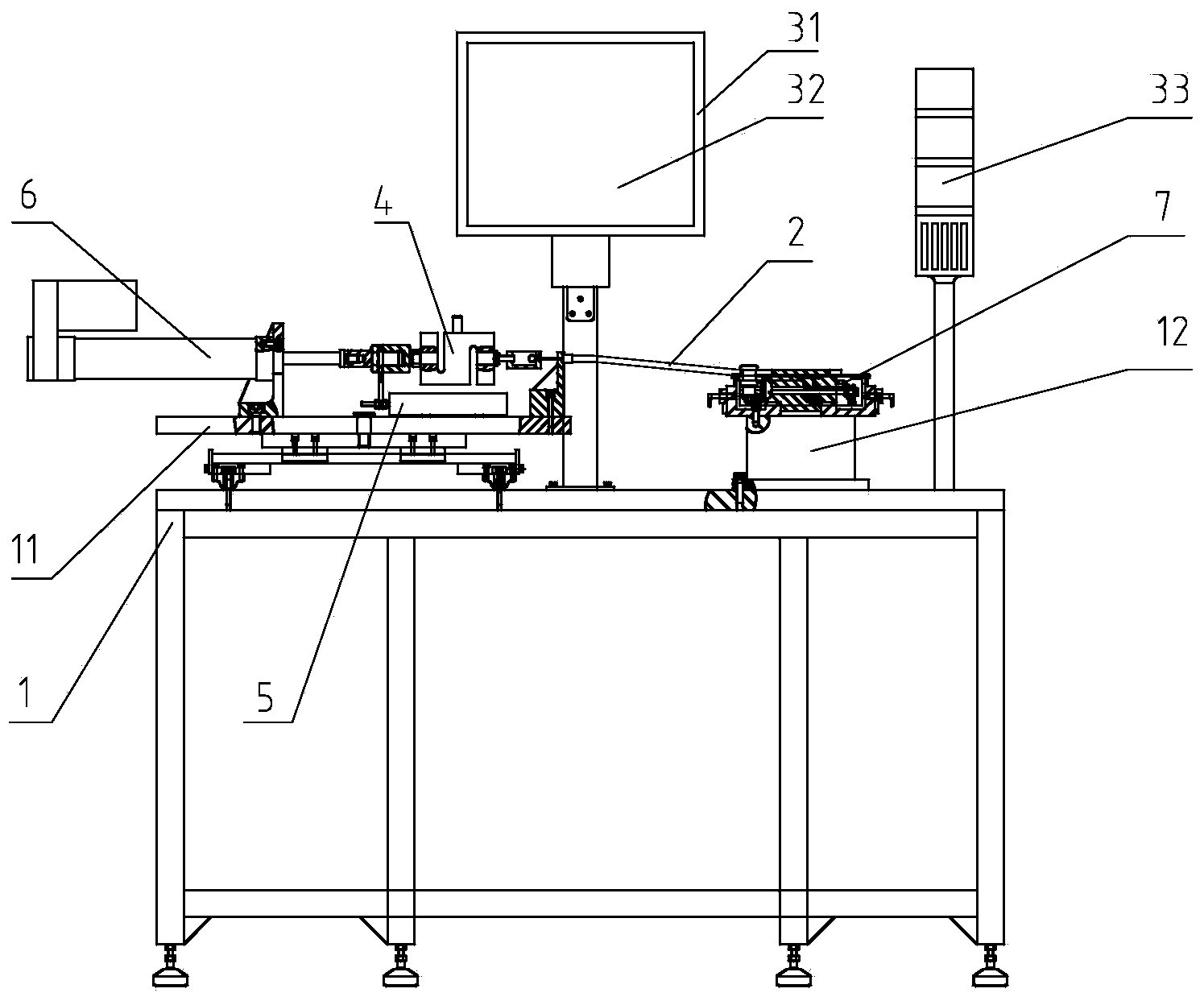

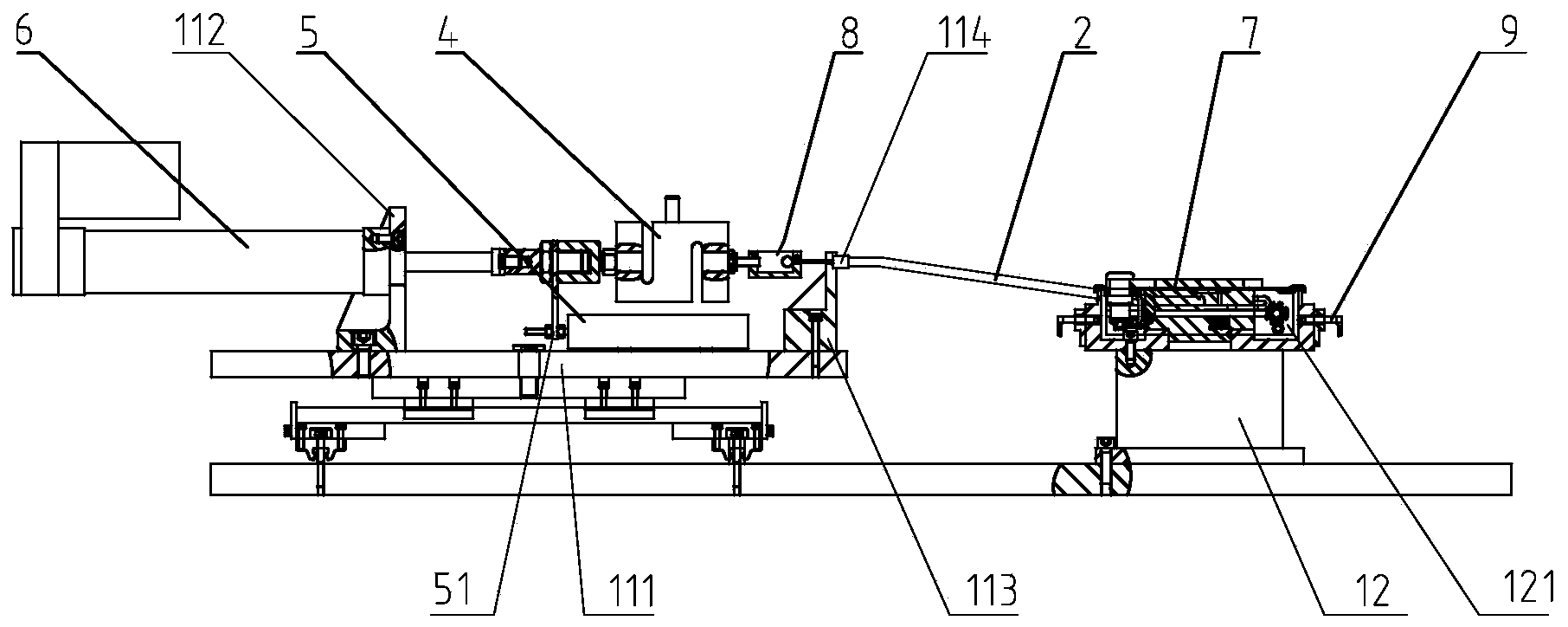

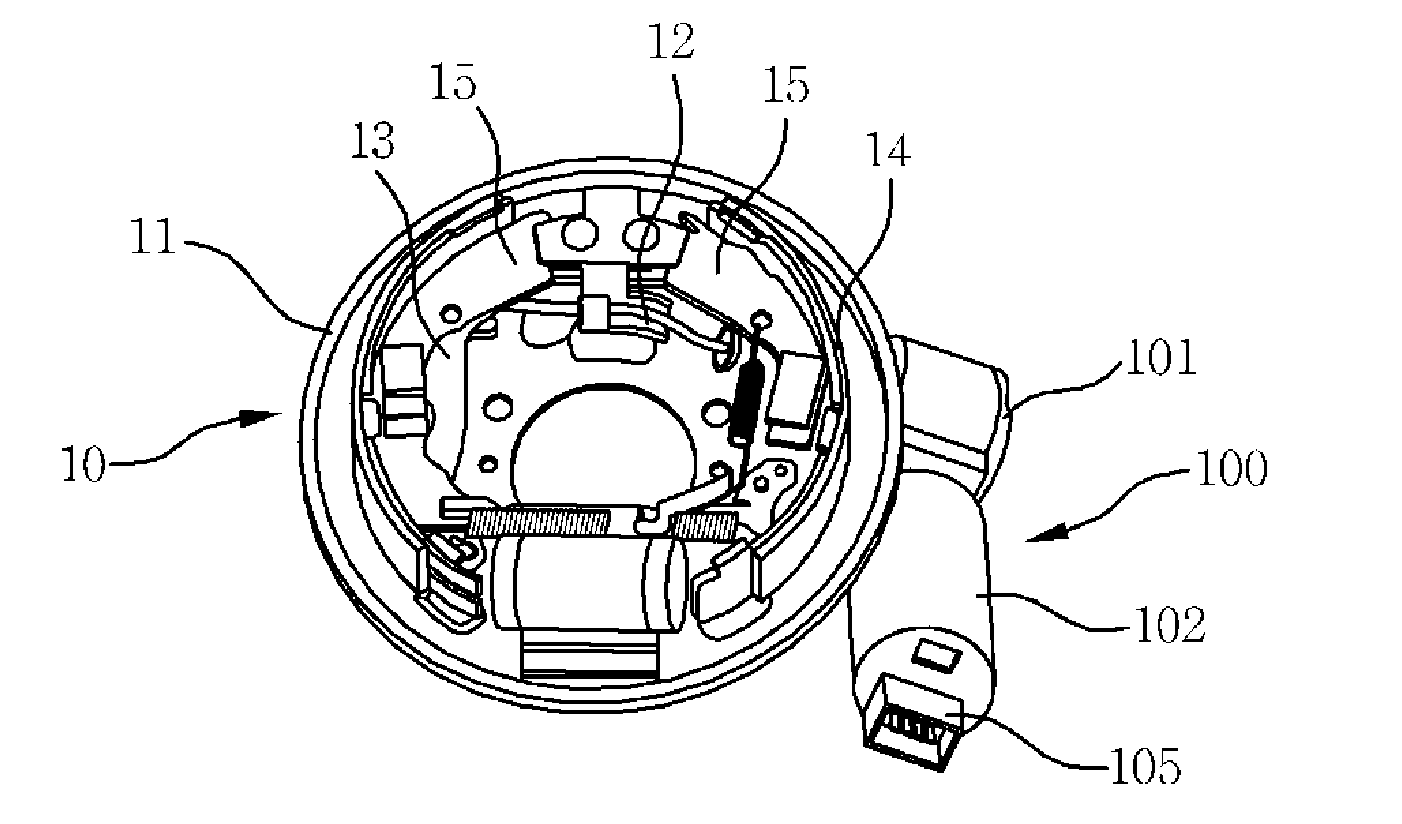

Detecting device for drum brake

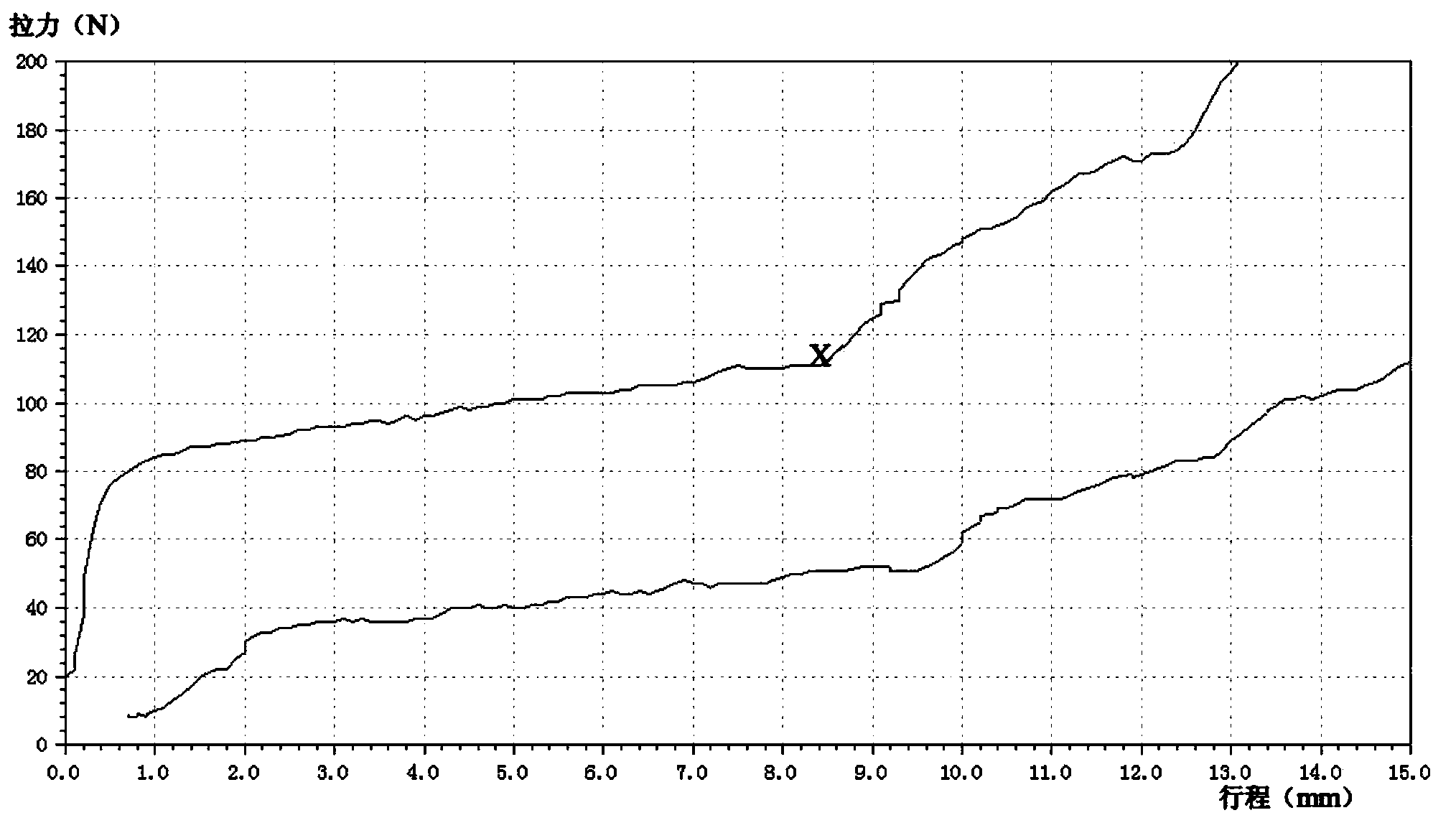

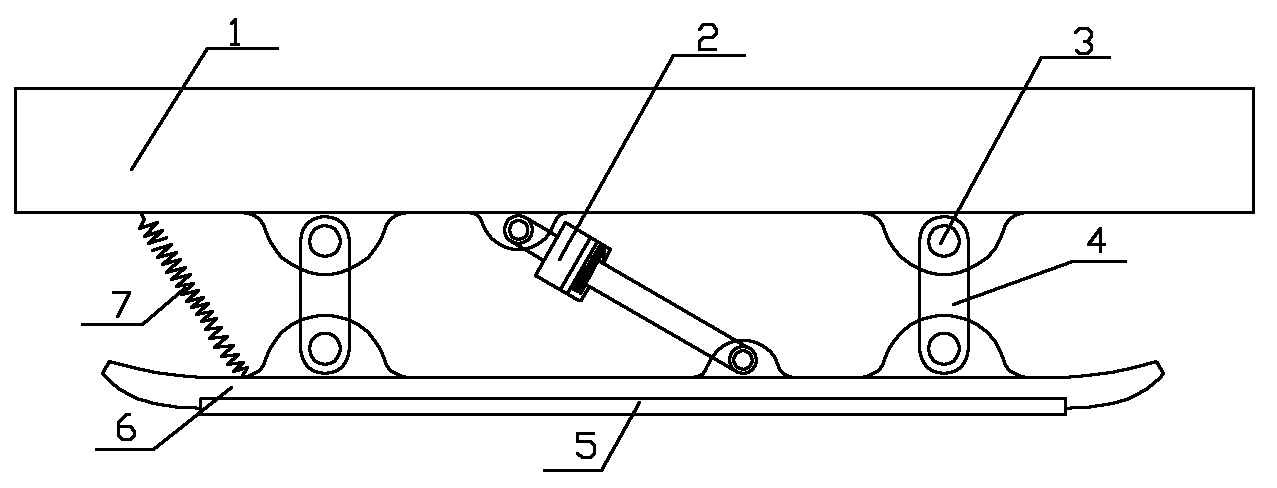

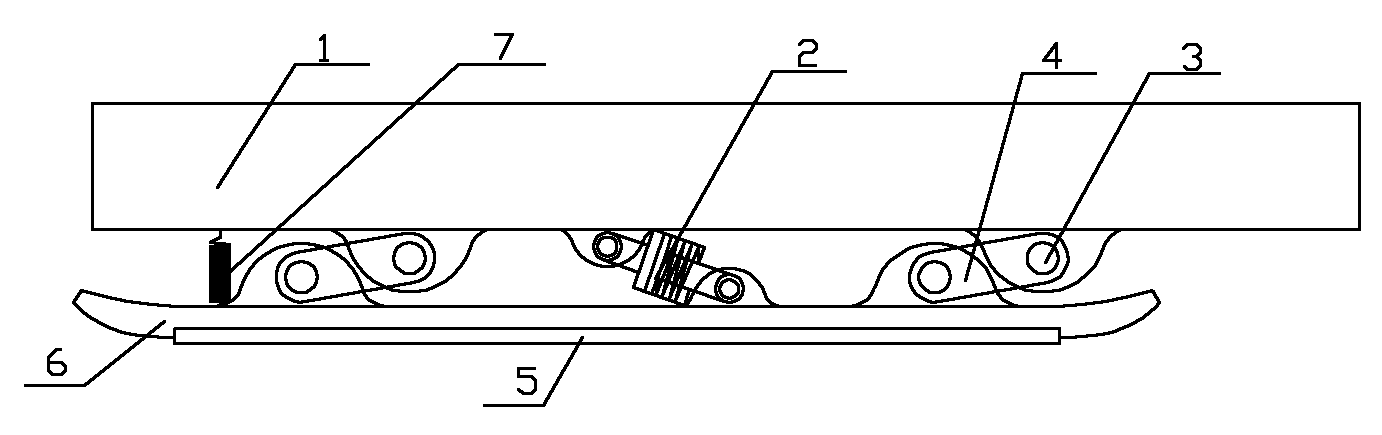

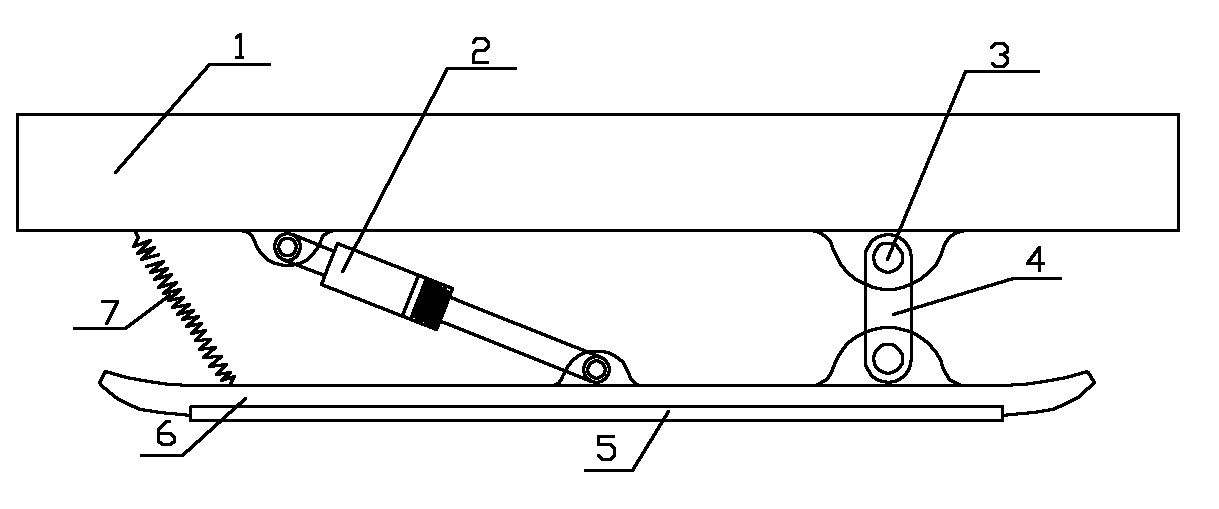

InactiveCN103439045ASimple structureEasy to operateVehicle testingApparatus for force/torque/work measurementPull forceControl system

The invention discloses a detecting device for a drum brake, and relates to the field of testing devices. The detecting device for the drum brake solves the technical problem that a detecting device of the drum brake is complex in structure and operation in the prior art. The detecting device of the drum brake comprises a detecting table and a control system. An actuator, a detecting member and a locating base for containing the drum brake are arranged on the detecting table, and the detecting member comprises a tension sensor and a displacement sensor. The tension sensor is connected with the drum brake in the locating base through a stay wire, the actuator drives the stay wire to pull the drum brake to achieve a parking brake state and releases the stay wire to enable the drum brake to reset to an original state, the tension sensor and the displacement sensor detect the tensile force and the stroke of the stay wire in the driving process of the actuator respectively, the tension sensor and the displacement sensor are electrically connected with the control system, and the control system can calculate the working starting force and the engineering displacement of the drum brake according to the feedback signals of the tension sensor and the feedback signals of the displacement sensor.

Owner:ZHEJIANG ASIA PACIFIC MECHANICAL & ELECTRONICS

Asbestos-free metal-free drum brake lining used in vehicle and manufacture method therefor

The invention discloses a kind of drum brake staff facing used in cars with none asbestos and none metal and the production technology. The component recipes of drum brake staff facing said above are: polyacrylonitrile fiber 1~10%, the oil of cashew shell friction-type mix 2~10%, barite powder 8~20%, heavy calcium carbonate 5-25%, flour acrylonitrile butadiene rubber 2~15%, the mineral fiber 2~6%, the graphite 3~18%, zircon powder 1~10%, the oil of cashew shell phenol-formaldehyde resin modified 10~15%, premix compound 3~15%, glass fiber 2~15%. The production technology is that make the component told above into three times stir mixing and weigh the amount of last formed material with the need of ordinance about the drum brake facing then chill-pressing confectioning forms cool base and then heat pressing confectioning, heat processing and grind on, drill steps and so on then processing make into production. The recipe production is characterized in that: light weight, stabilize coefficient of friction, soft and sensitive braking, and comfort, noiseless and agree the requirement of environmental protection.

Owner:福建冠良汽车配件工业有限公司

Automobile auxiliary brake-powered speed-reduction friction device and braking method thereof

InactiveCN102009644AReduce the temperatureLarge braking forceBraking element arrangementsFluid braking transmissionRuns down a slopeControl circuit

The invention relates to an automobile brake device and a braking method thereof, in particular to an automobile auxiliary brake-powered speed-reduction friction device and a braking method thereof. The automobile auxiliary brake-powered friction device comprises an automobile chassis longitudinal beam, wherein the lower part of the automobile chassis longitudinal beam is provided with a friction brake pedal; a friction plate is arranged below the friction brake pedal; and a transmission mechanism which is connected with a control circuit is also arranged between the automobile chassis longitudinal beam and the friction brake pedal. The device and the method can increase a braking force effectively by using the friction force generated by friction between the friction brake pedal and the ground when an automobile is braked in emergency or runs down a slope continuously, so that the braking distance in emergent brake is reduced or traffic safe accidents caused by the braking failure of a drum brake at an overhigh temperature when the automobile runs down the slope continuously.

Owner:于宥源

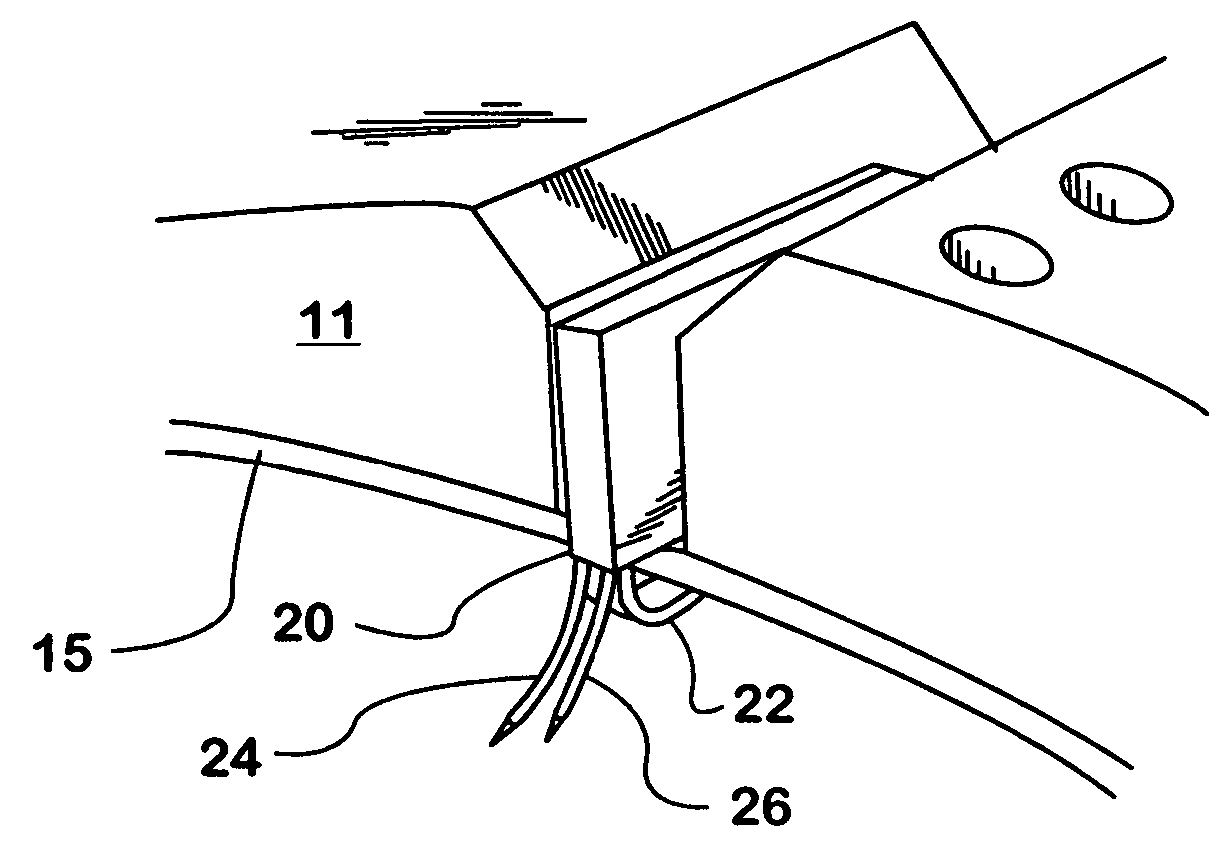

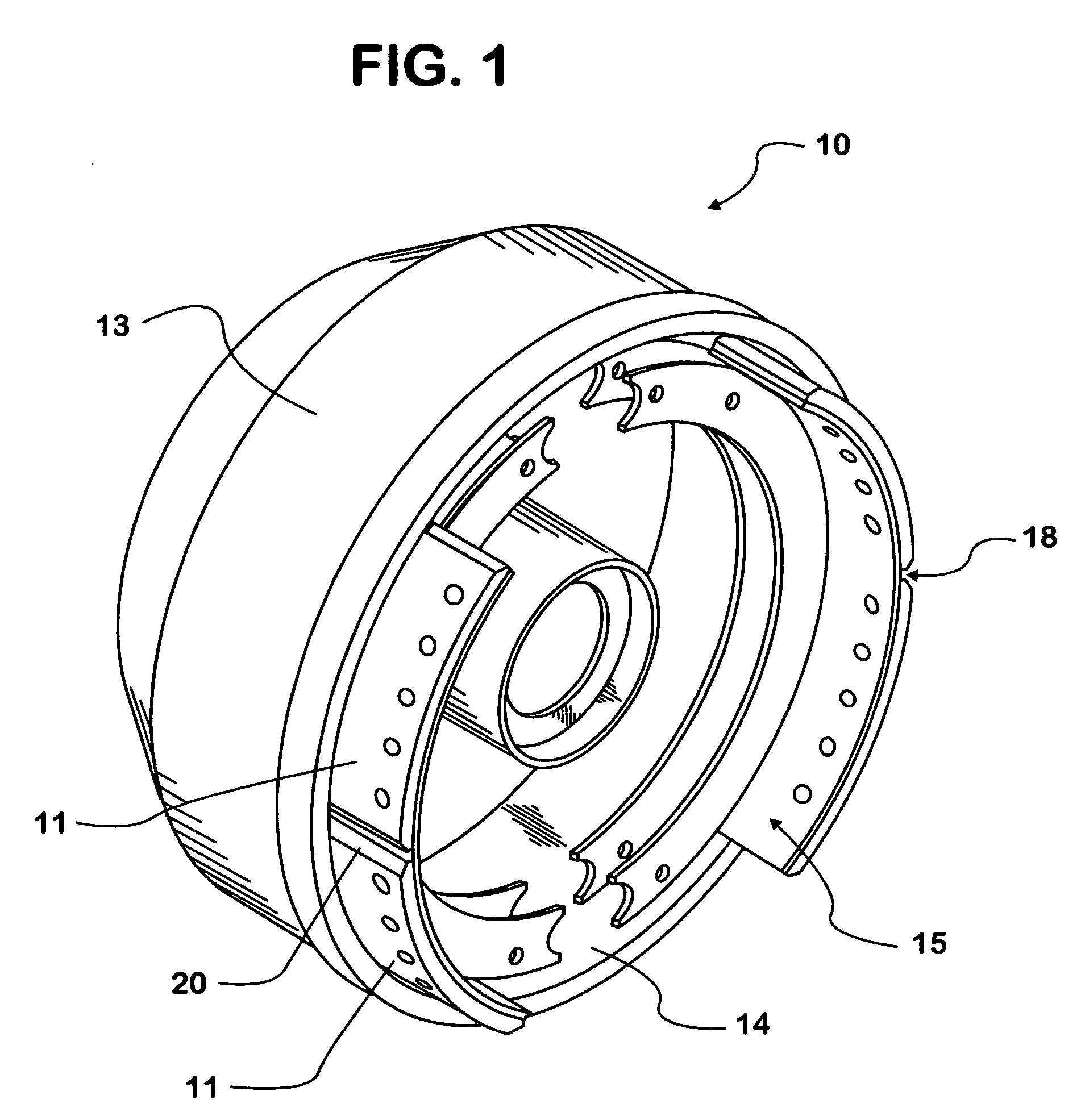

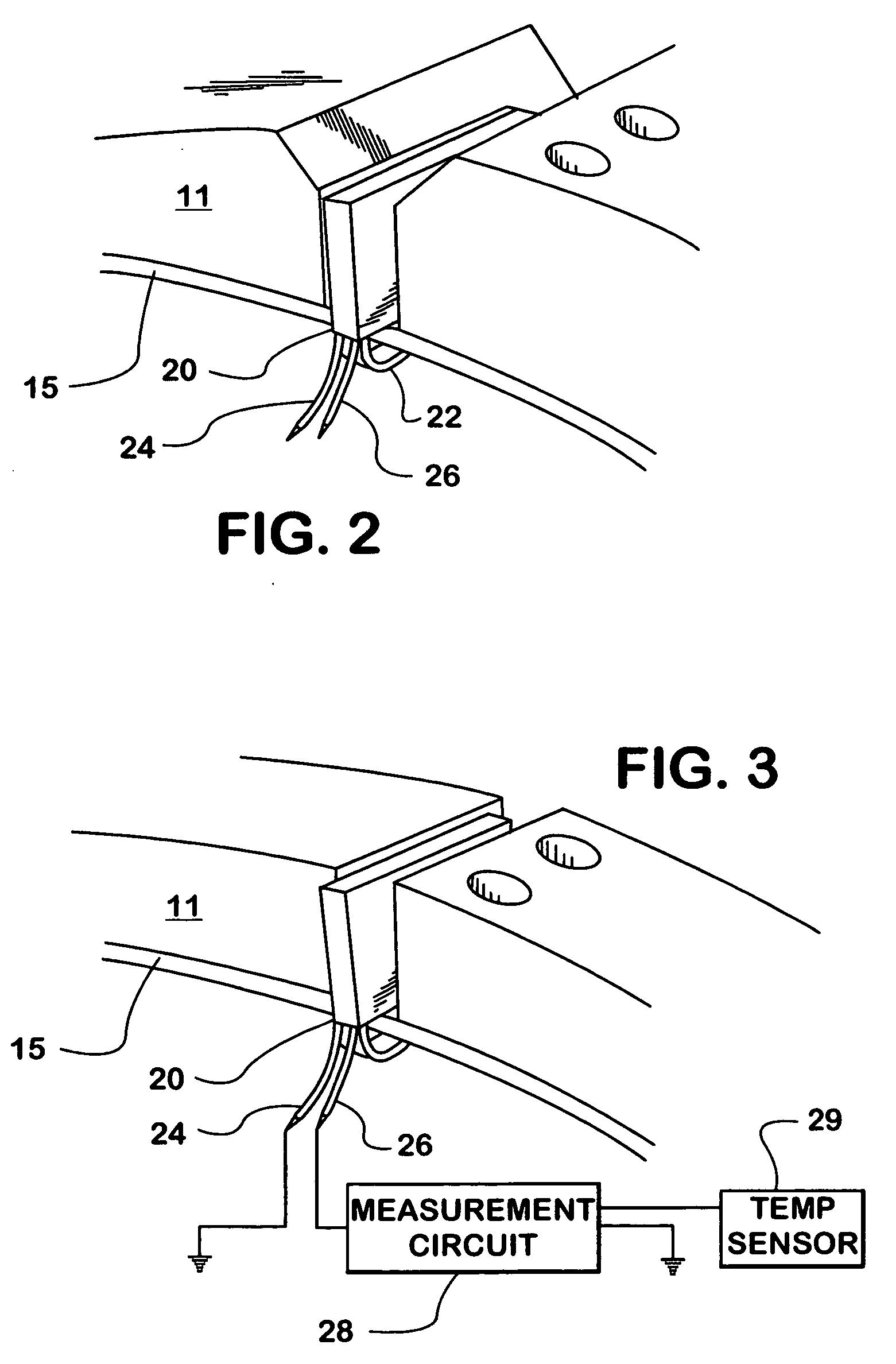

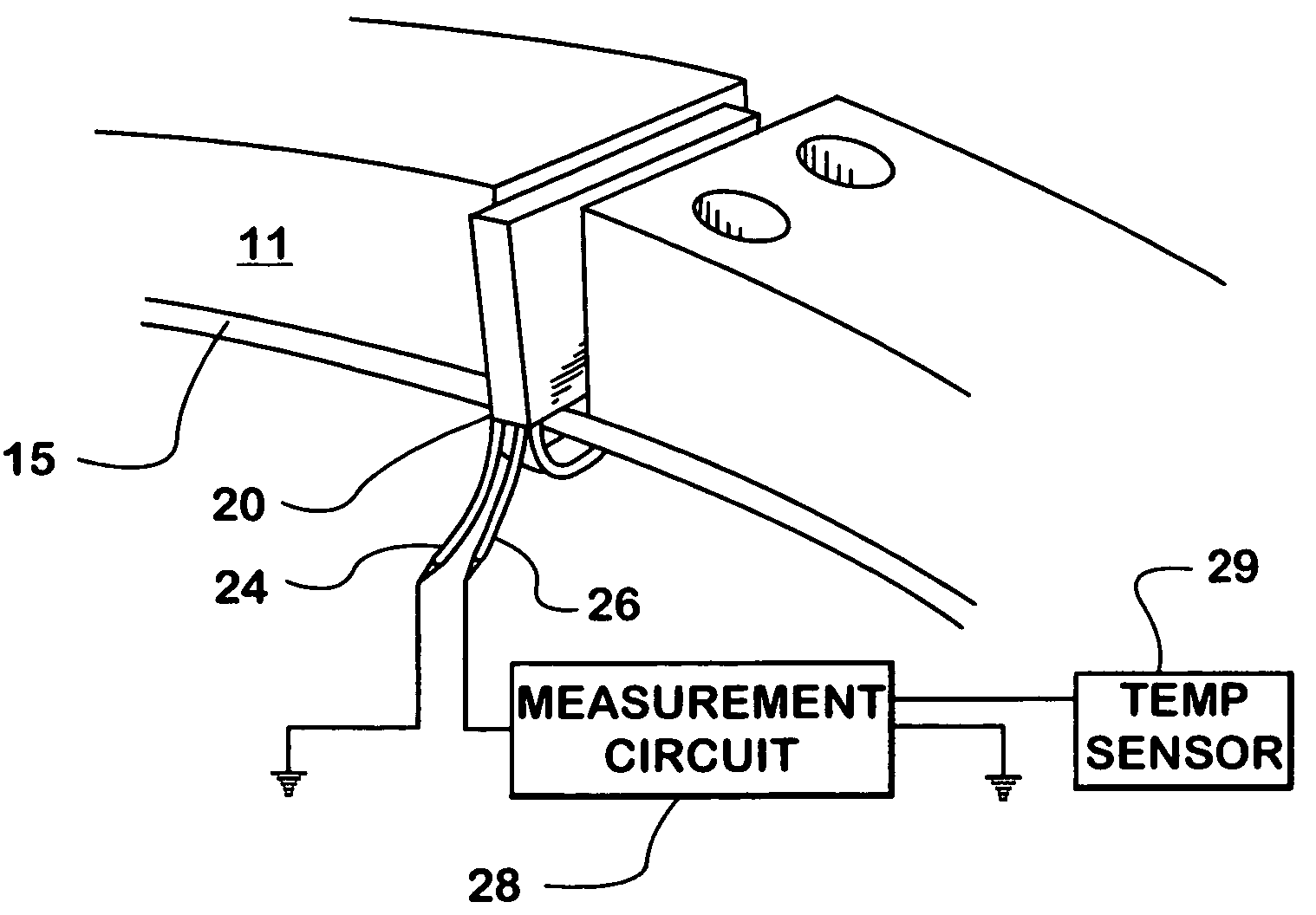

Thin film sensor for brake lining pad wear and brake temperature sensing

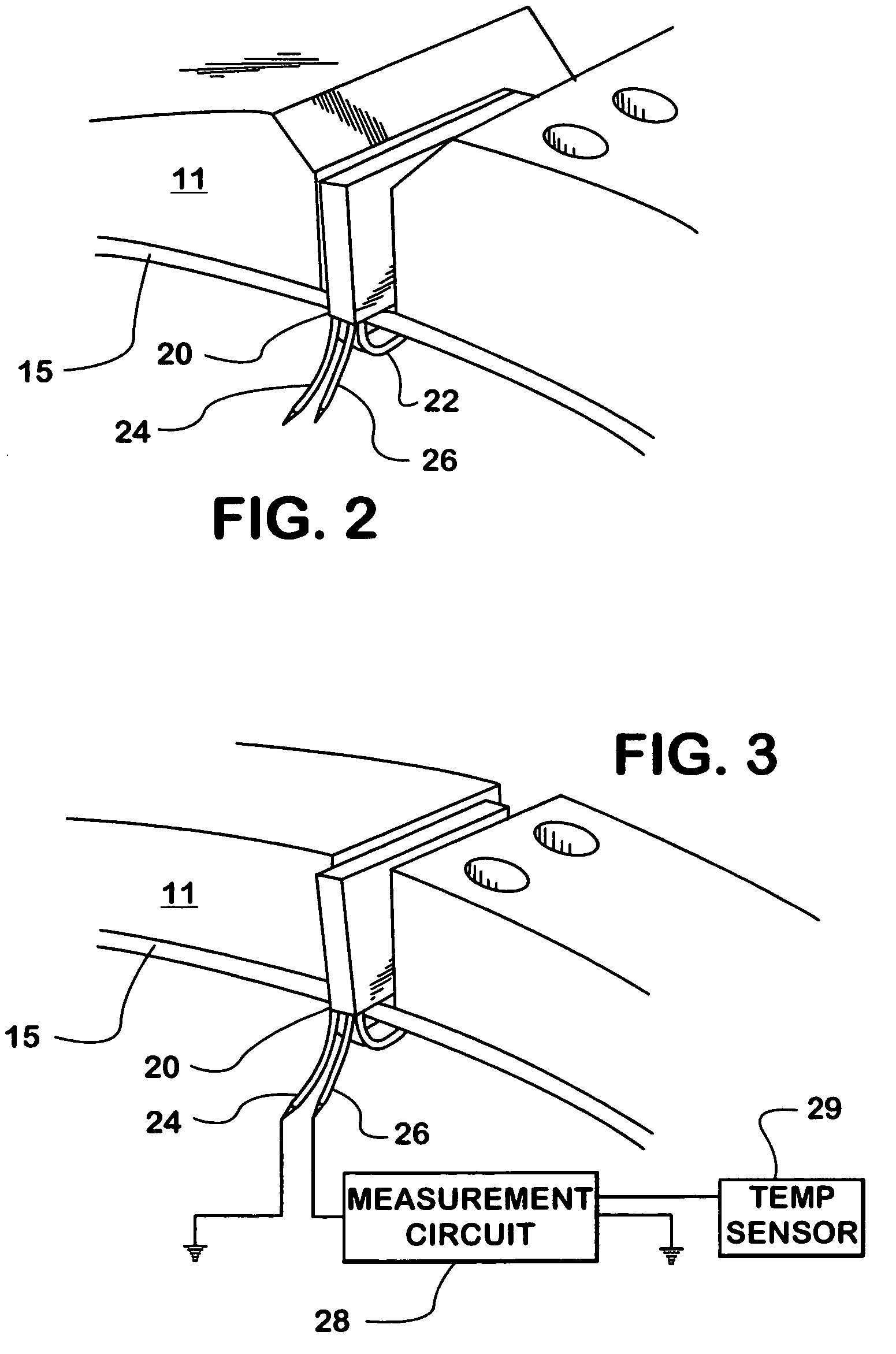

InactiveUS20060076196A1Improve electrical resistanceOptical signallingBrake typesThin film sensorElectrical resistance and conductance

A modular electrical resistance sensor is positionable in gaps between brake linings for a drum brake. The modular sensor is worn with the brake linings resulting in steadily increasing electrical resistance of the modular sensor. A measurement circuit associated with the modular sensor is programmed to equate electrical resistance to the degree of wear when the sensor has assumed a steady state temperature at or near the ambient temperature. Otherwise, particularly during periods of use of the brakes, resistance and the degree of wear last calculated become arguments into a function for determining brake lining temperature.

Owner:INT TRUCK INTPROP LLC

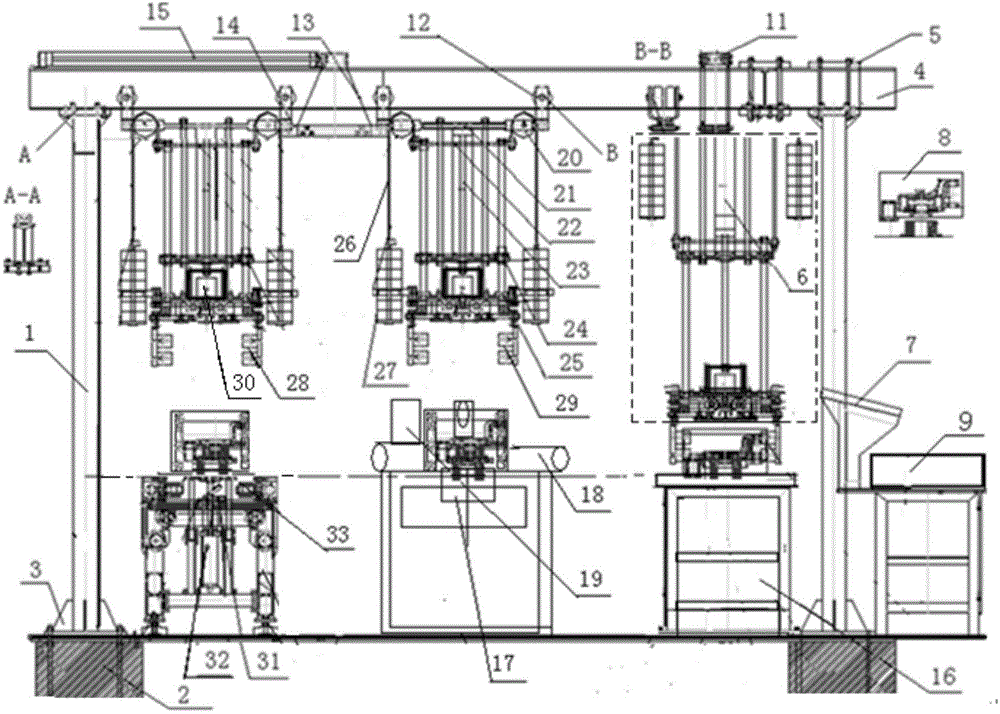

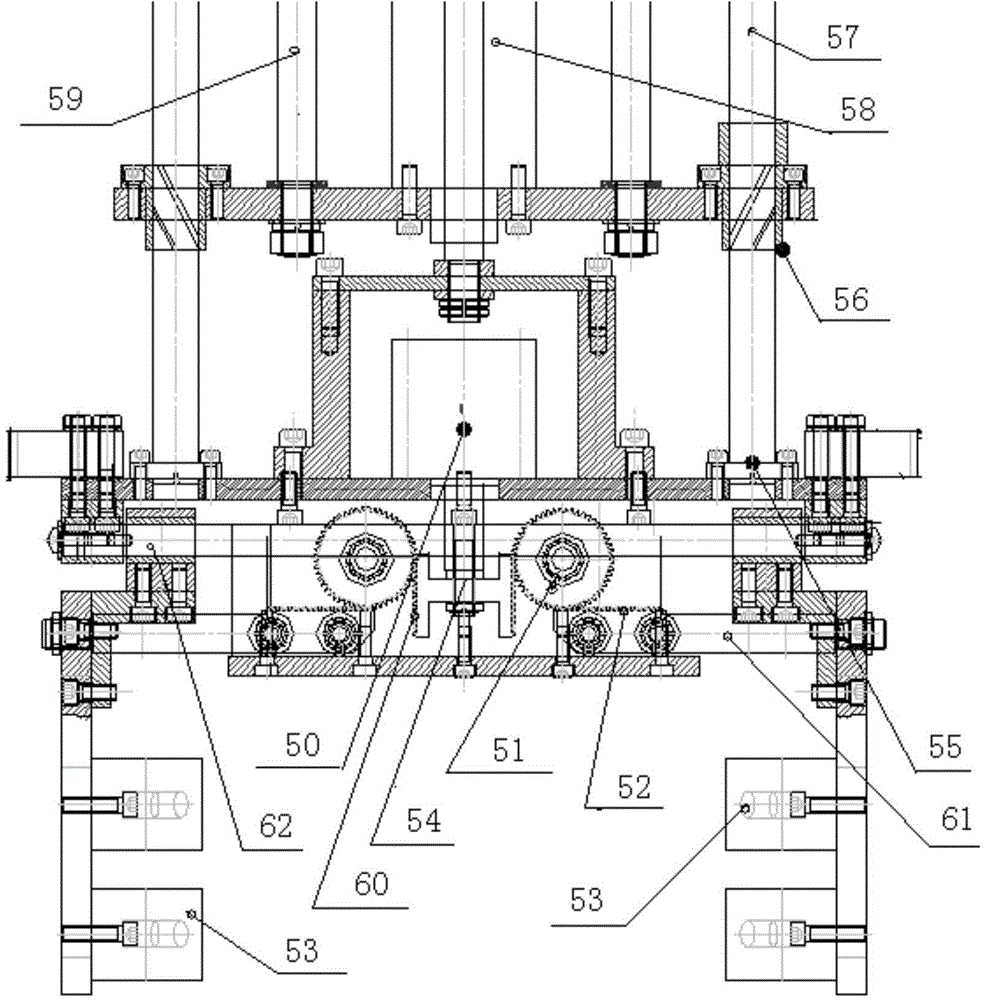

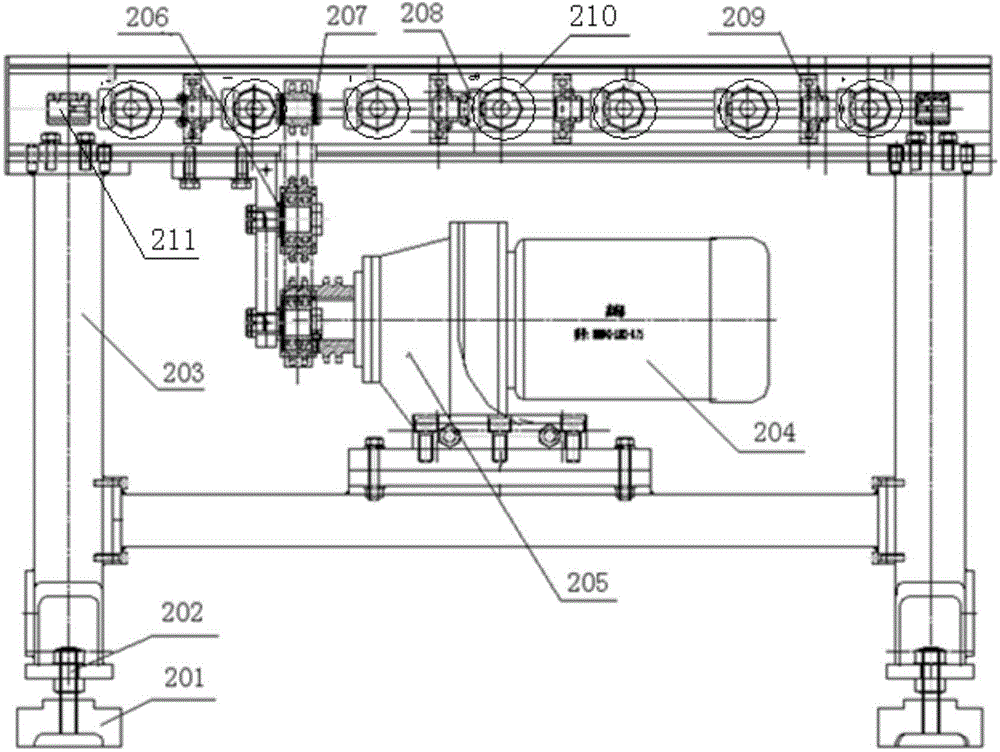

Automatic loading and unloading manipulator of drum type brake assembling line

InactiveCN104476155AGuaranteed stabilityAction in place and preciseProgramme-controlled manipulatorAutomatic workpiece supply/removalControl systemElectrical control

The invention discloses an automatic loading and unloading manipulator of a drum type brake assembling line. By the adoption of a portal type dual-station automatic loading and unloading dual-manipulator linkage mode, the automatic loading and unloading manipulator is characterized in that two manipulators are simultaneously used for carrying out loading, carrying and unloading control on workpieces at two stations; a system mainly comprises a portal frame and two automatic manipulators, wherein the two automatic manipulators are provided with lifting cylinders, clamping cylinders, carrying translationing cylinders, unloading rollerways, jacking cylinders, stop cylinders and PLC (programmable logic control) electrical control systems; the portal frame is divided into three stations, namely an assembling station, a turning station and an unloading jacking rollerway, and a pneumatic control manipulator finishes processing, clamping / releasing, rising / falling and translationing carrying of a brake assembly; unloading adopts rollerway conveying, and the workpieces are automatically conveyed and unloaded in turn through the jacking mechanism. According to the automatic loading and unloading manipulator, the automation degree and the processing efficiency of processing production are improved; three workers are reduced to one person, and the production processing cost is greatly lowered.

Owner:十堰市华迪汽车零部件有限公司

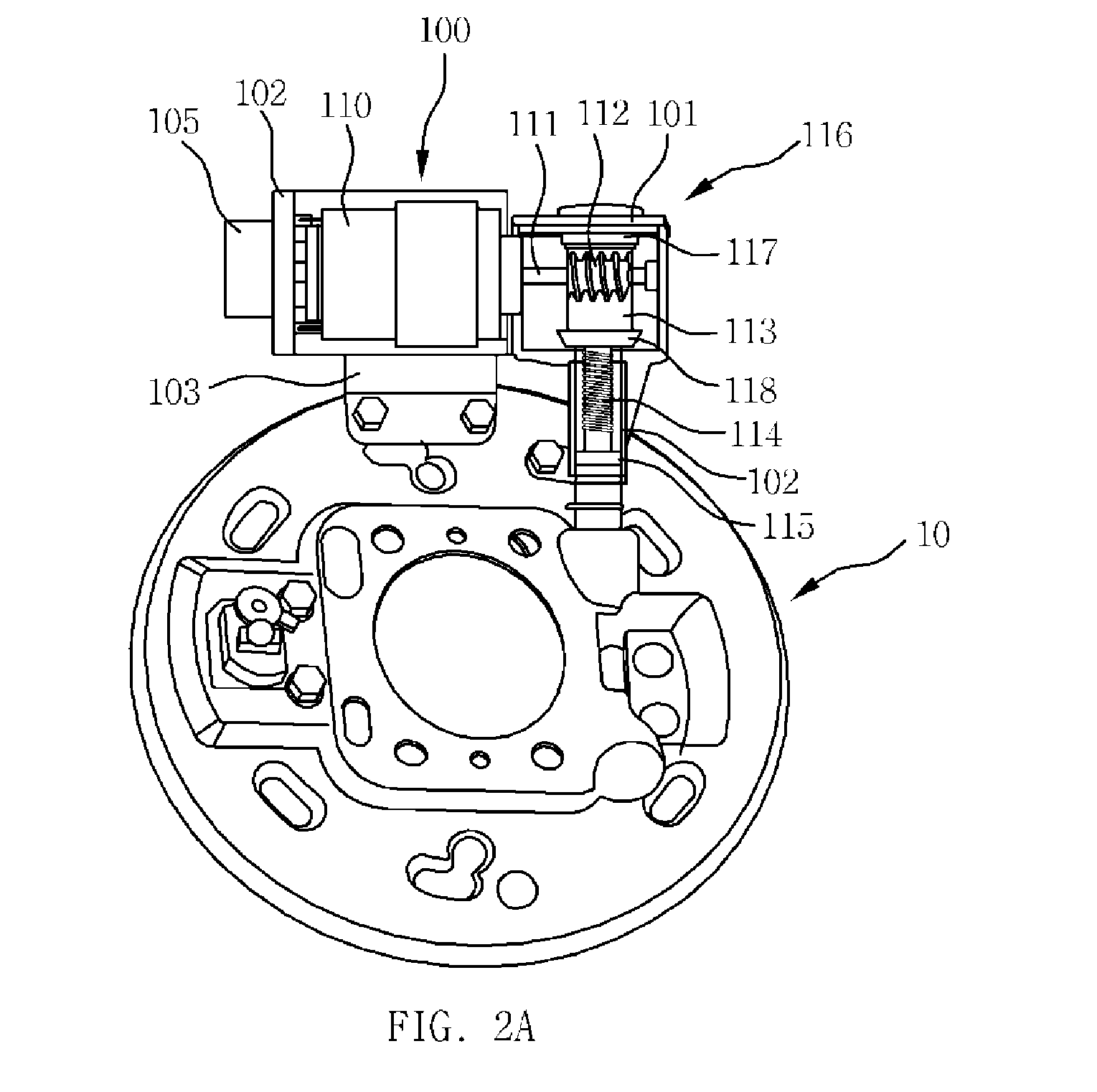

Drum-integrated electric parking brake

ActiveUS20130087418A1Reduce manufacturing costLow weight costBraking element arrangementsDrum brakesElectric parking brakeEngineering

A drum-integrated electric parking brake apparatus may include a drum brake in which a lining may be pivotally installed, and extends and presses a drum when a parking cable engaged with the lining may be pulled, an actuator selectively pulling the parking cable, a sensor member for detecting a rotation number of the actuator, and a controller for controlling the amount of current supplied to the actuator by detecting a change in the rotation number of the actuator.

Owner:HYUNDAI MOTOR CO LTD

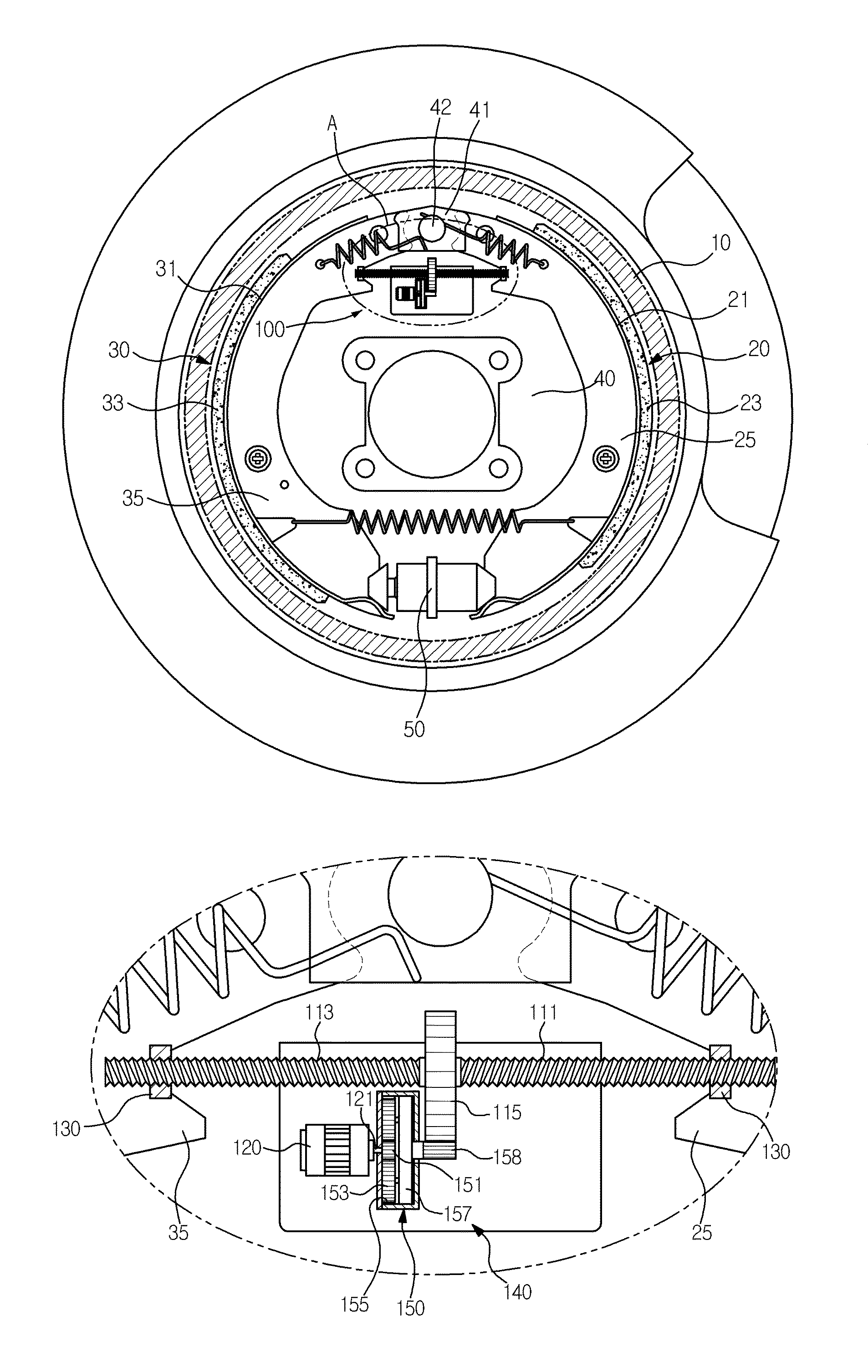

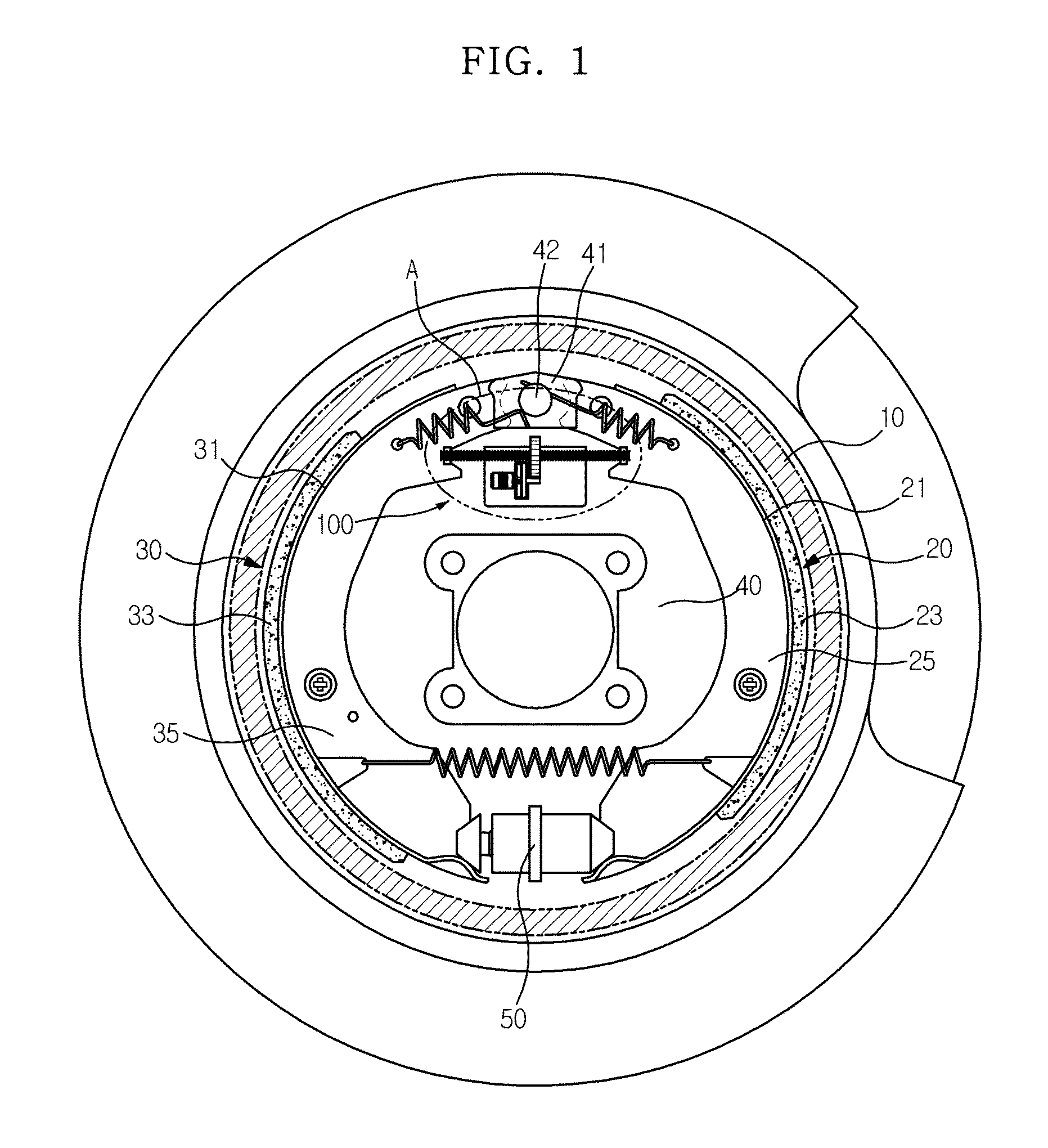

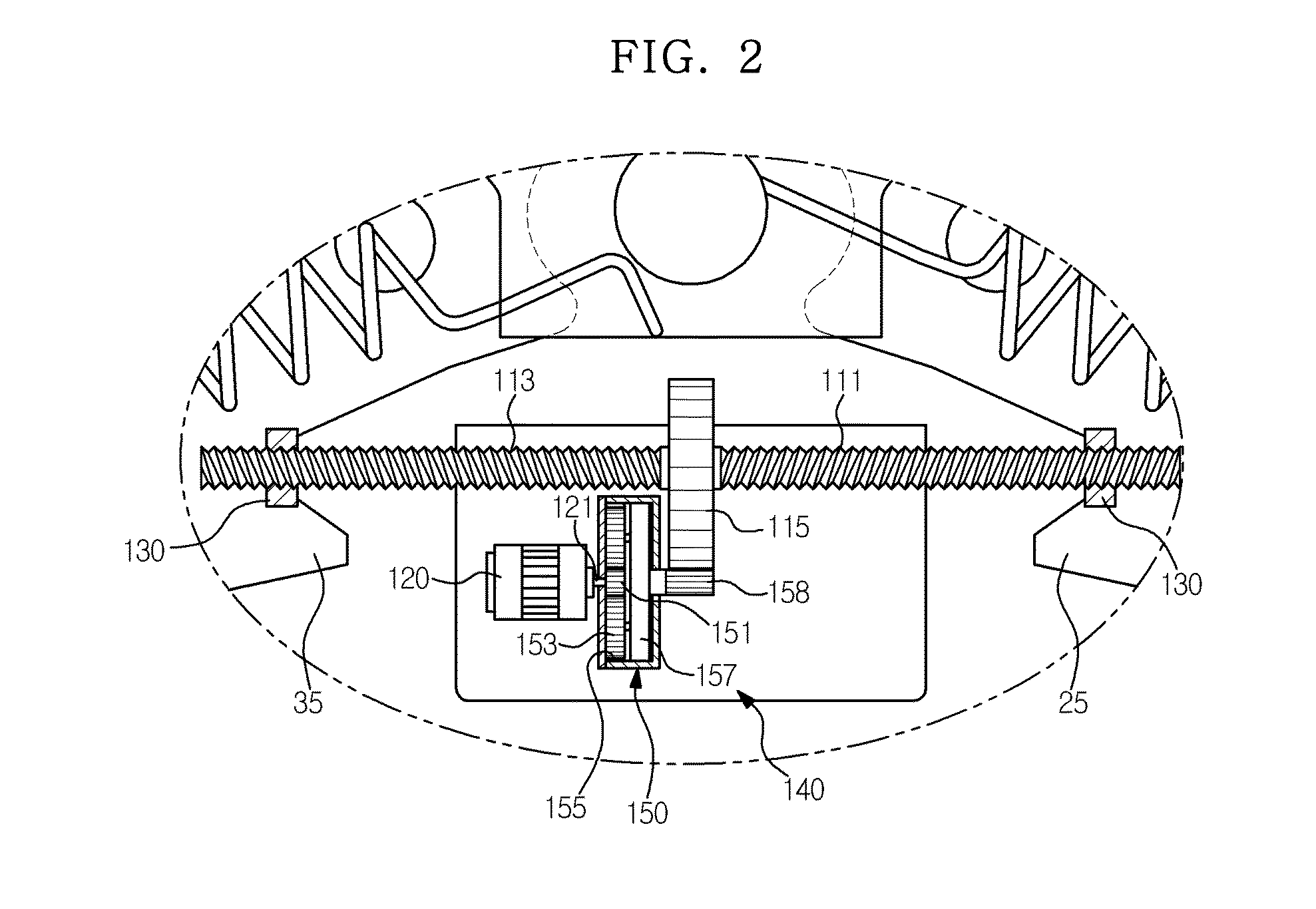

Electronic mechanical drum brake

ActiveUS20100096224A1Simple mechanical configurationLarge braking forceMechanically actuated brakesBraking membersDrive motorEngineering

Disclosed herein is an electronic mechanical drum brake. In the electronic mechanical drum brake including a drum rotated together with a wheel, a pair of brake shoes respectively including rims provided with linings, which rub against the inner circumferential surface of the drum and generate braking power, attached thereto and webs provided on the inner circumferential surfaces of the rims to reinforce rigidity of the rims, and an actuator provided between the webs of the pair of brake shoes, the actuator includes a screw shaft provided with a driven gear formed integrally therewith and a left-handed thread at one side thereof and a right-handed thread at the other side thereof, a driving motor to rotate the screw shaft in a regular direction and its reverse direction, a booster unit to increase rotary force of the driving motor and then to transmit the increased rotary force to the driven gear, and nuts screw-connected to both ends of the screw shaft and fixed to the webs. Thereby, the electronic mechanical drum brake has a large braking power and improved space efficiency.

Owner:HL MANDO CORP

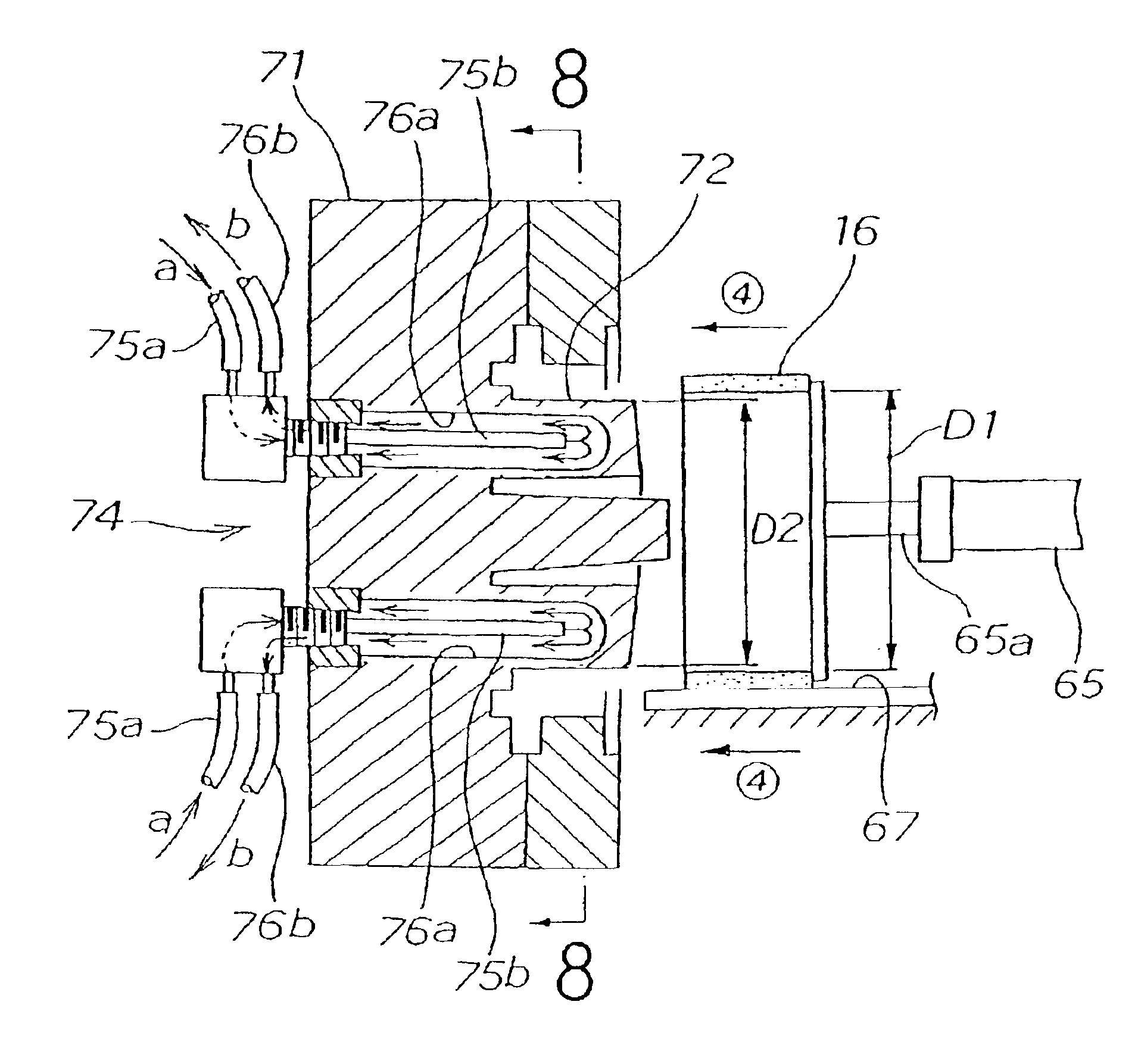

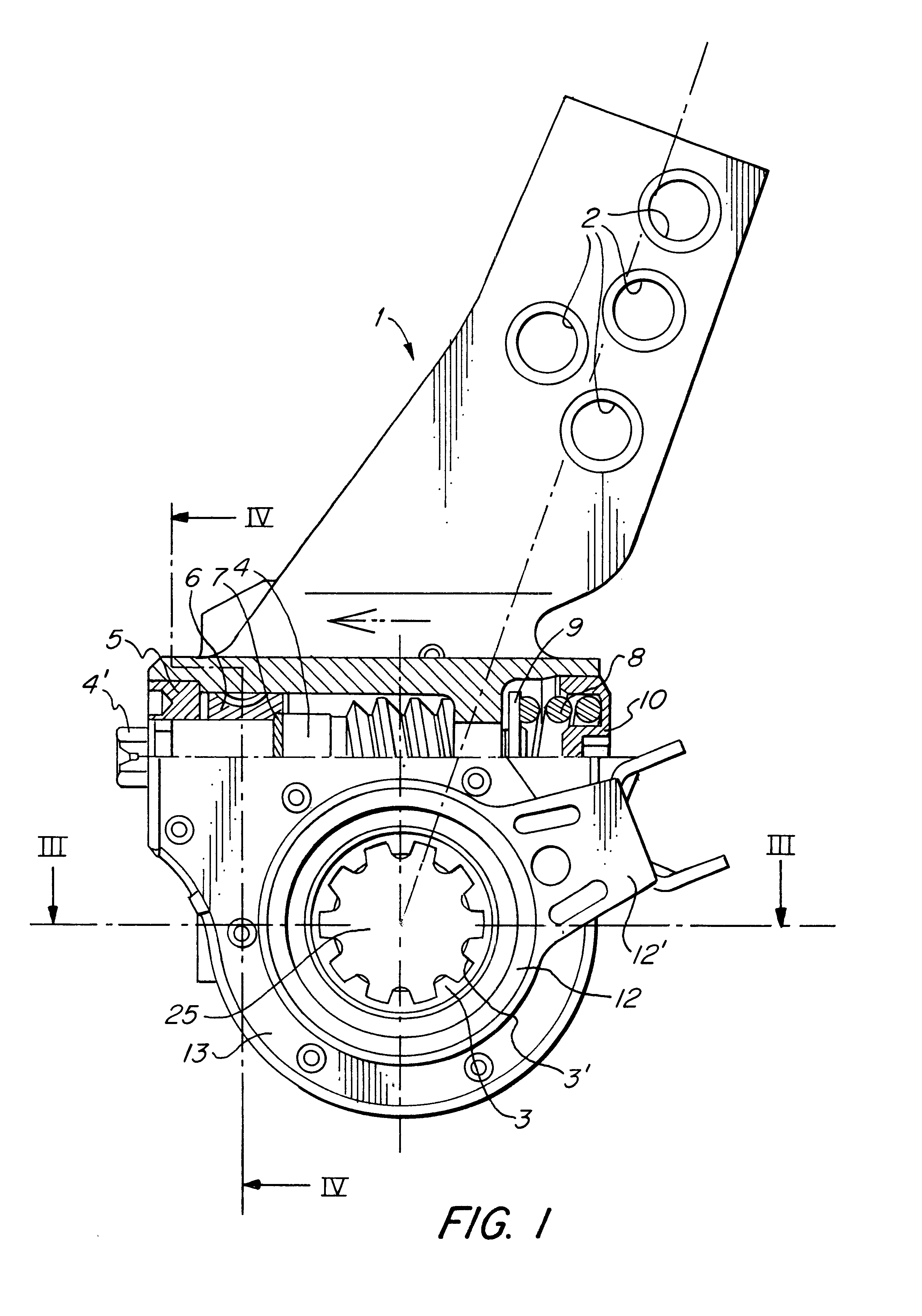

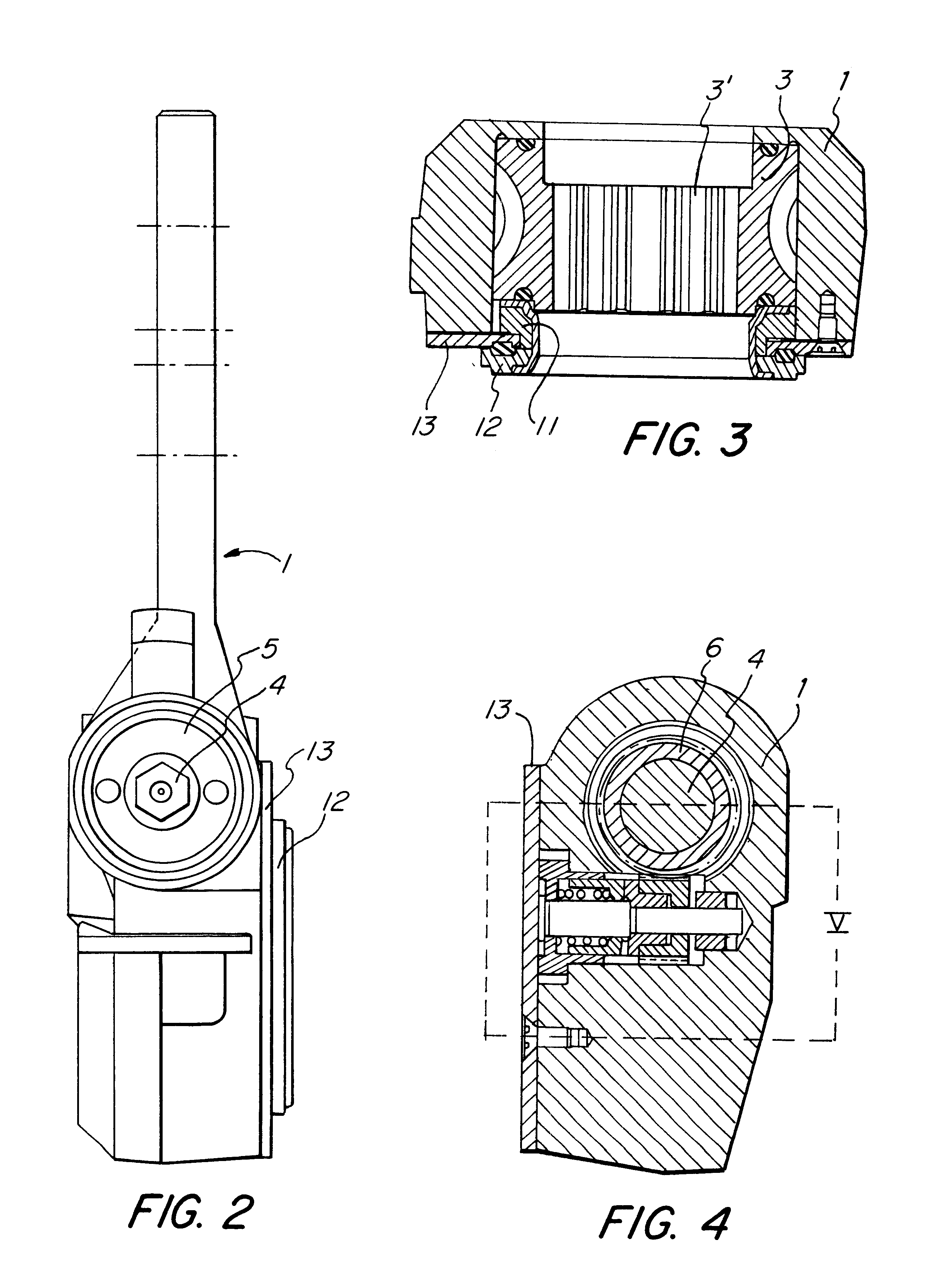

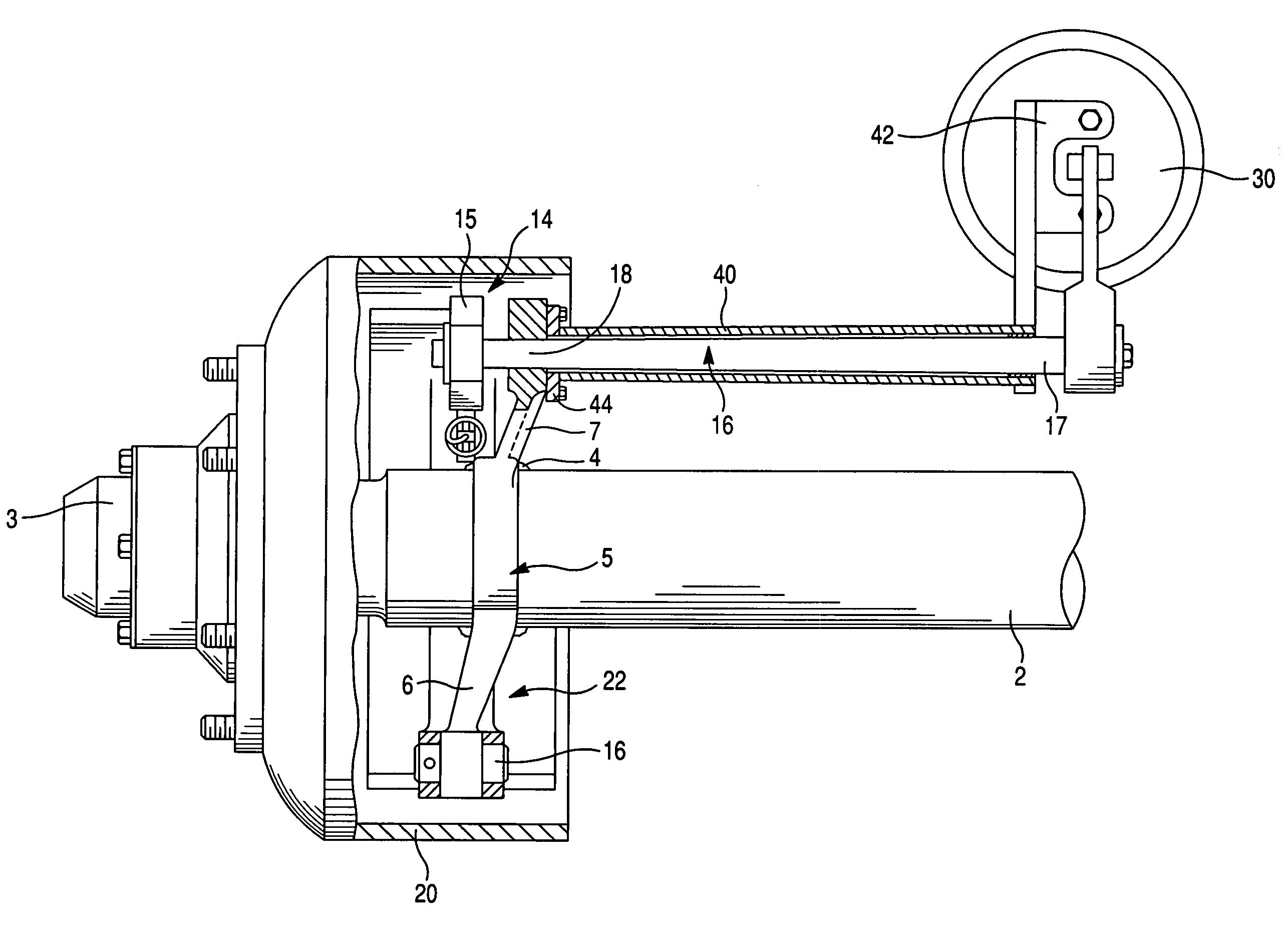

Control arrangement for a brake lever

A brake lever is to be attached to a splined S-cam shaft of an automotive drum brake and to be connected to a brake cylinder push rod. The lever has a control arrangement for transmitting a control movement from a control disc with a reference point to a clutch wheel of the lever mechanism depending on the angular movement of the brake lever. The control disc is in gear engagement with a pinion, and an adjustment screw coaxial with the pinion is in engagement with the clutch wheel. A cylindrical driver is axially but non-rotatably movable in relation to the pinion coaxial therewith and forms a one-way clutch with a unit including the adjustment screw, which is axially movable a distance corresponding to a desired control distance or A-measure for the brake lever, the one-way clutch being spring-biased into engagement.

Owner:HALDEX BRAKE PROD AB BOX 501 261 24

Thin film sensor for brake lining pad wear and brake temperature sensing

InactiveUS7165657B2Optical signallingBrake typesThin film sensorElectrical resistance and conductance

A modular electrical resistance sensor is positionable in gaps between brake linings for a drum brake. The modular sensor is worn with the brake linings resulting in steadily increasing electrical resistance of the modular sensor. A measurement circuit associated with the modular sensor is programmed to equate electrical resistance to the degree of wear when the sensor has assumed a steady state temperature at or near the ambient temperature. Otherwise, particularly during periods of use of the brakes, resistance and the degree of wear last calculated become arguments into a function for determining brake lining temperature.

Owner:INT TRUCK INTPROP LLC

Vehicle wheel structure

InactiveCN1403310ASimple structureEasy to assembleBraking element arrangementsHubsEngineeringDrum brake

A drum brake for braking a wheel disposed on the inside in the radial direction of an electric motor. The drum of the drum brake and an electric motor are disposed separate from each other, and thus wear powders of a brake shoe do not adhere to a permanent magnet of the electric motor. As a result, the wear powders do not adversely influence the performance of the electric motor, and the performance of the electric motor is maintained. The electric motor and the drum brake are disposed concentrically, so that the width of the wheel is reduced. Thus, a small and compact wheel is realized.

Owner:HONDA MOTOR CO LTD

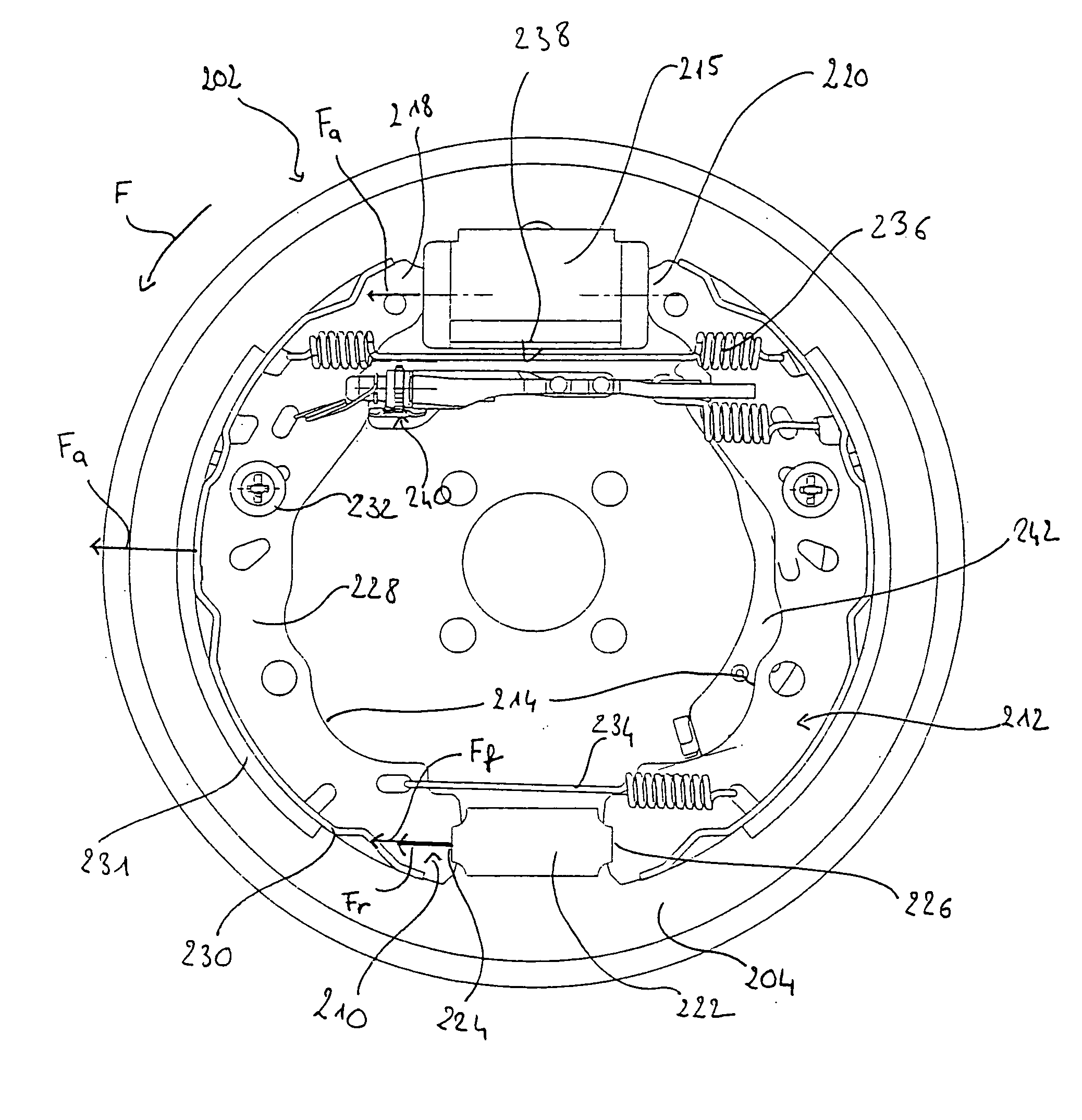

Drum brake type parking brake apparatus

InactiveUS20120205209A1Braking element arrangementsBrake actuating mechanismsEngineeringParking brake

Owner:AKEBONO BRAKE IND CO LTD

Drum brake module which can be operated by electric motor

ActiveUS9175737B2Easy to assembleImprove efficiencyBraking drumsBrake actuating mechanismsEngineeringBiological activation

A drum brake module for motor vehicles operable by electric motor and performs at least one parking brake function, having an electromechanical actuator mounted on one side of the armature plate and a rotational-translational movement converter converting a rotational drive rotational movement into a translational activation movement of brake shoes arranged on a side of the armature plate facing away from the actuator in a brake drum, and including at least one supporting device between the brake shoes such that the latter can carry out an activation movement in the direction of the brake drum. A drive nut is supported by the rotational-translational movement converter in an axially secure and rotatable fashion on the armature plate to assist the braking force. The drive nut drives a spindle arrangement mounted in a rotationally fixed and axially displaceable fashion and engages with an activation cable on at least one brake shoe.

Owner:CONTINENTAL TEVES AG & CO OHG

Vehicle axle beam and brake assembly

InactiveUS7055662B1Easy to assembleMore variationBraking membersBrake actuating mechanismsActuatorHeavy duty

An improved axle beam and self-contained drum brake assembly, particularly for heavy duty trucks, is disclosed. The assembly includes a brake spider and actuating members mounted thereto via a mounting assembly comprising a mounting sleeve attached to the brake spider by means of a second mounting bracket, and a first mounting bracket securing a pneumatic brake actuator cylinder to the mounting sleeve. A brake actuating camshaft is positioned and rotationally supported therewithin. The disclosed brake assembly allows for numerous variations of axle beam and suspension arrangements.

Owner:DANA CORP

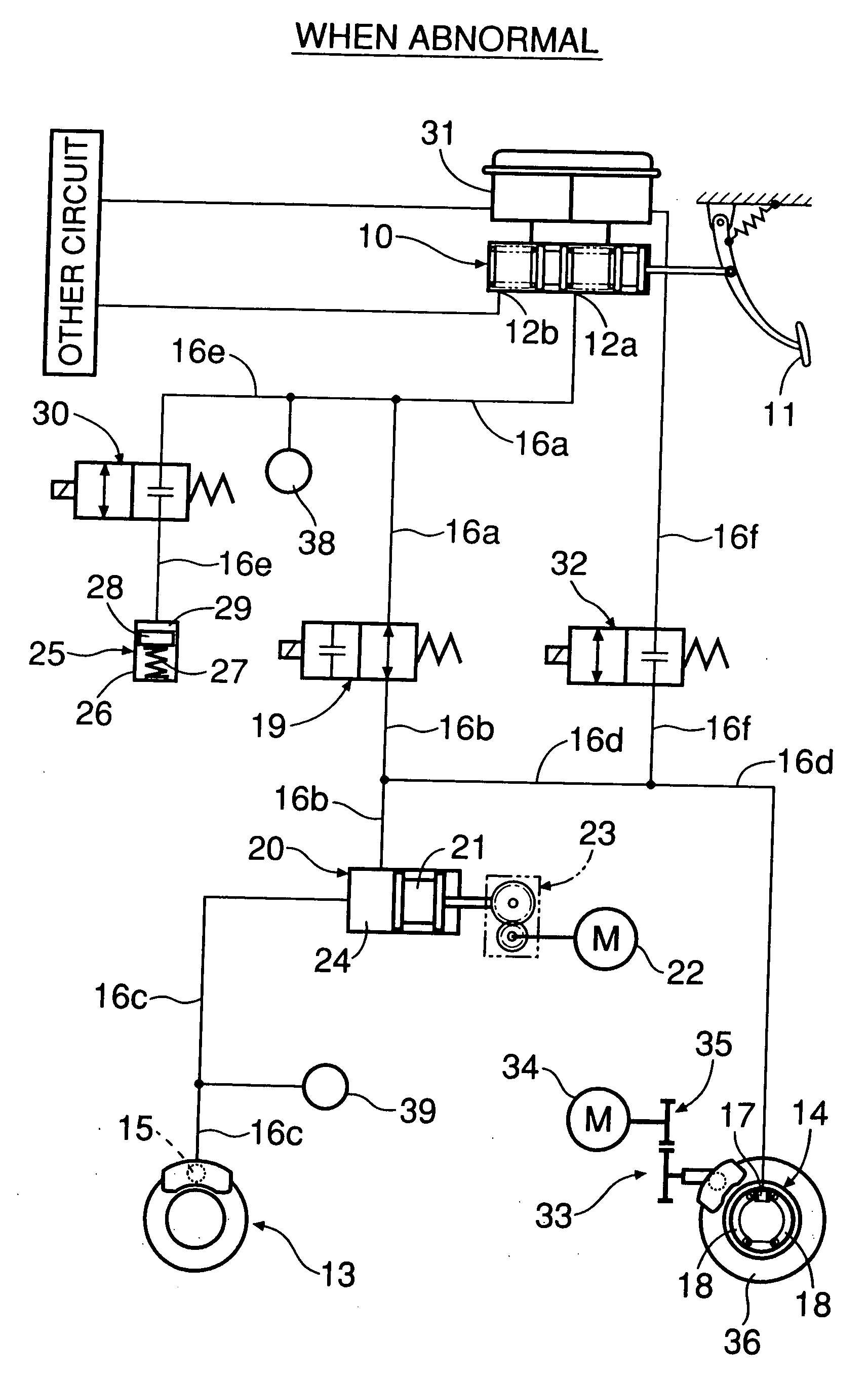

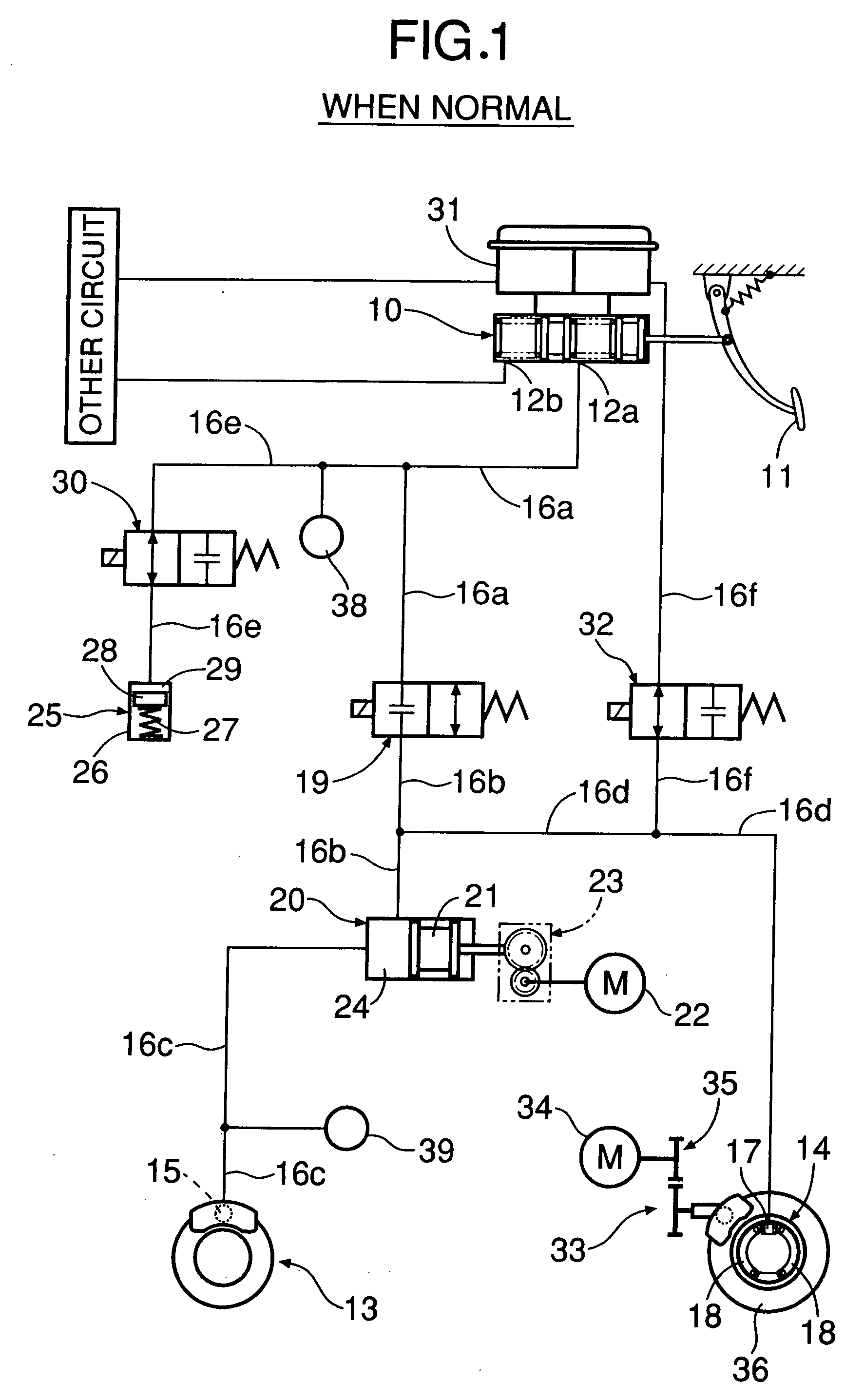

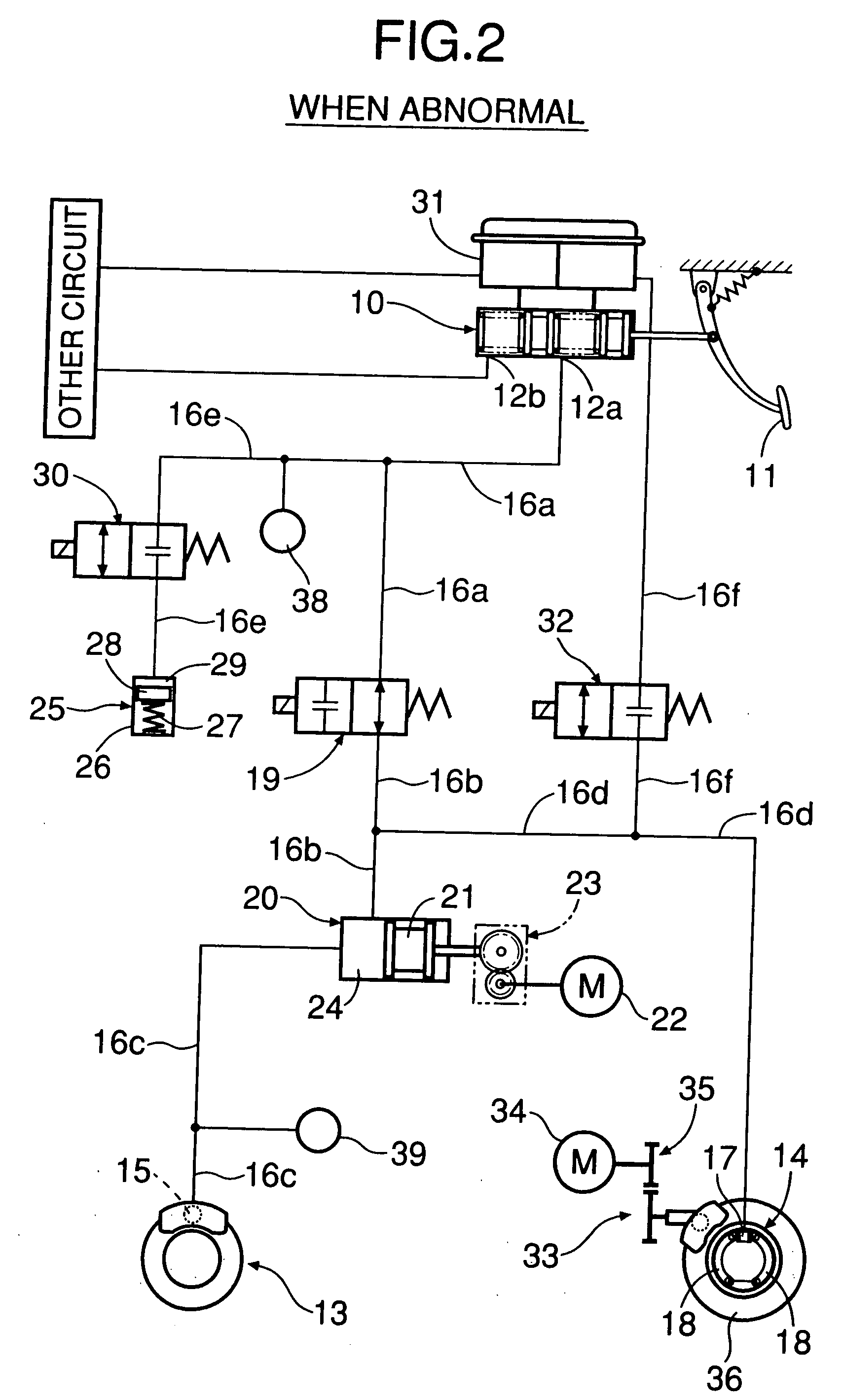

Brake system

InactiveUS20060091726A1Large braking forceHighly functionalBraking action transmissionBrake control systemsDriver/operatorWheel cylinder

During normal operation in which an electric braking device is operative, when a depressing force cut-off valve is closed and communication between a master cylinder and a disk brake system of a front wheel is cut off, the front wheel is braked by a brake pad directly driven by drive force of the electric braking device. When there is an abnormality in which the electric braking device breaks down, a wheel cylinder of a drum brake system of a rear wheel is operated by brake fluid pressure generated by the master cylinder operated by a driver's braking operation. Thus, since the drum brake system having a high braking function is operated in case of abnormality, the braking force is higher than the braking force during normal operation, thereby reliably stopping the vehicle.

Owner:HONDA MOTOR CO LTD

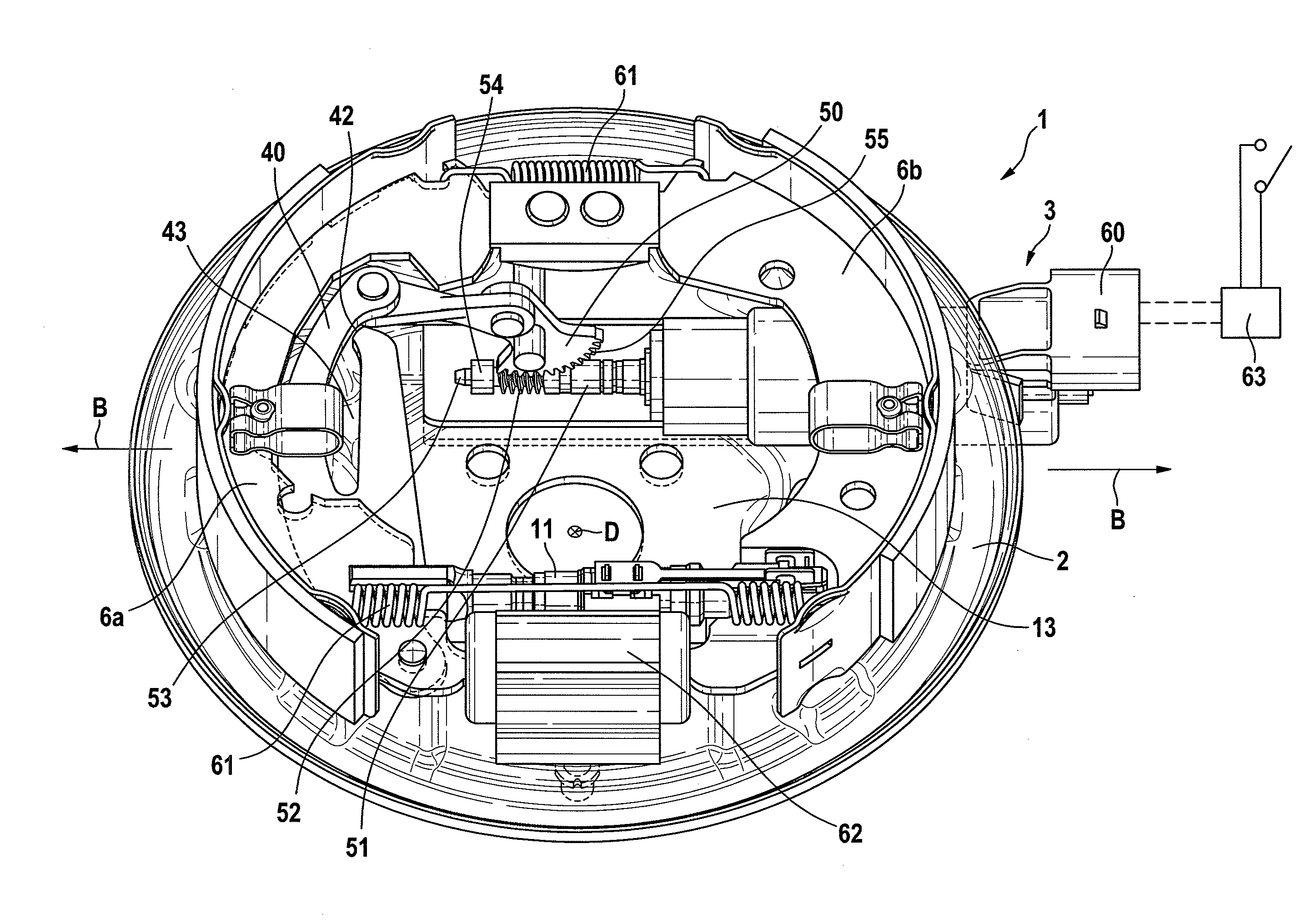

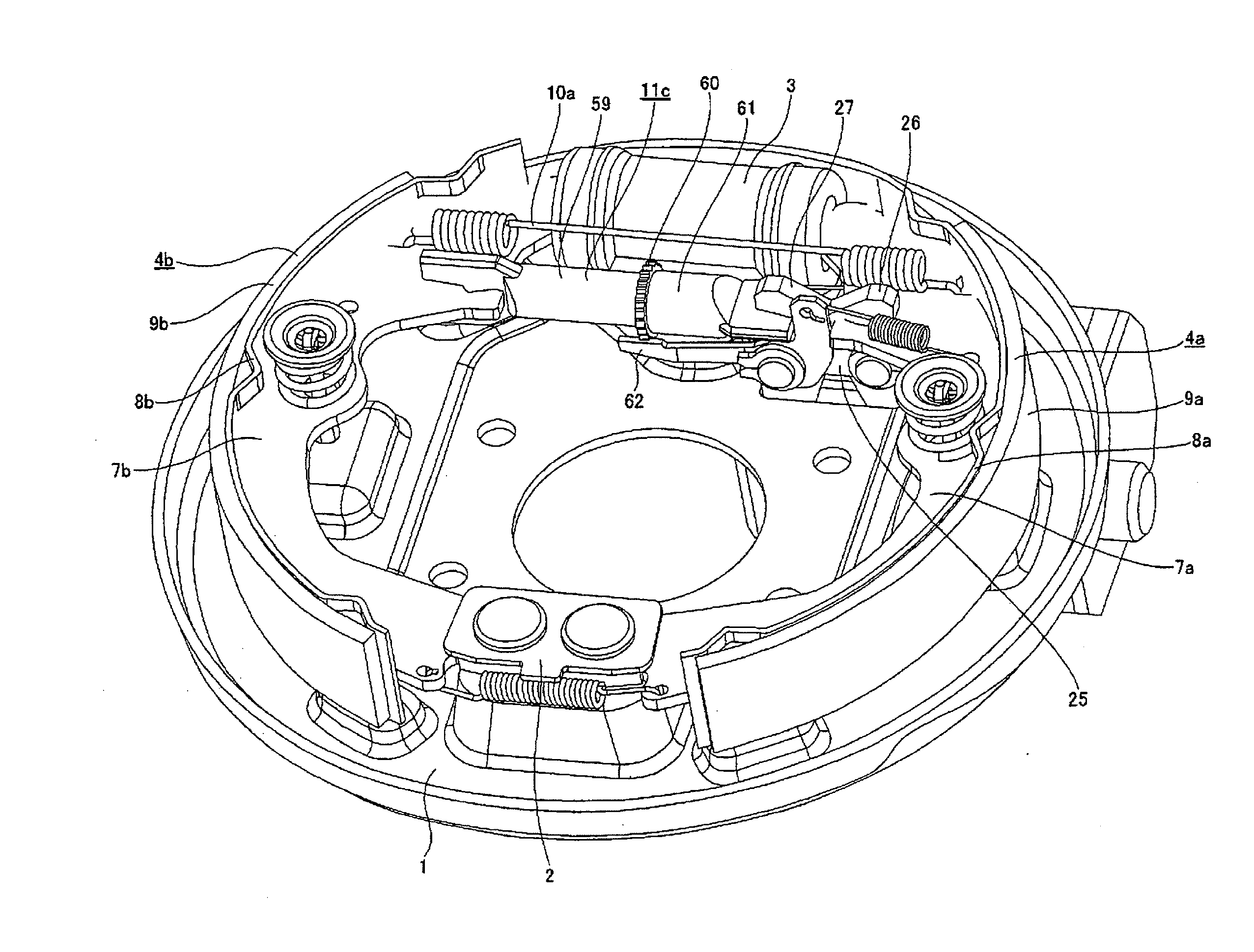

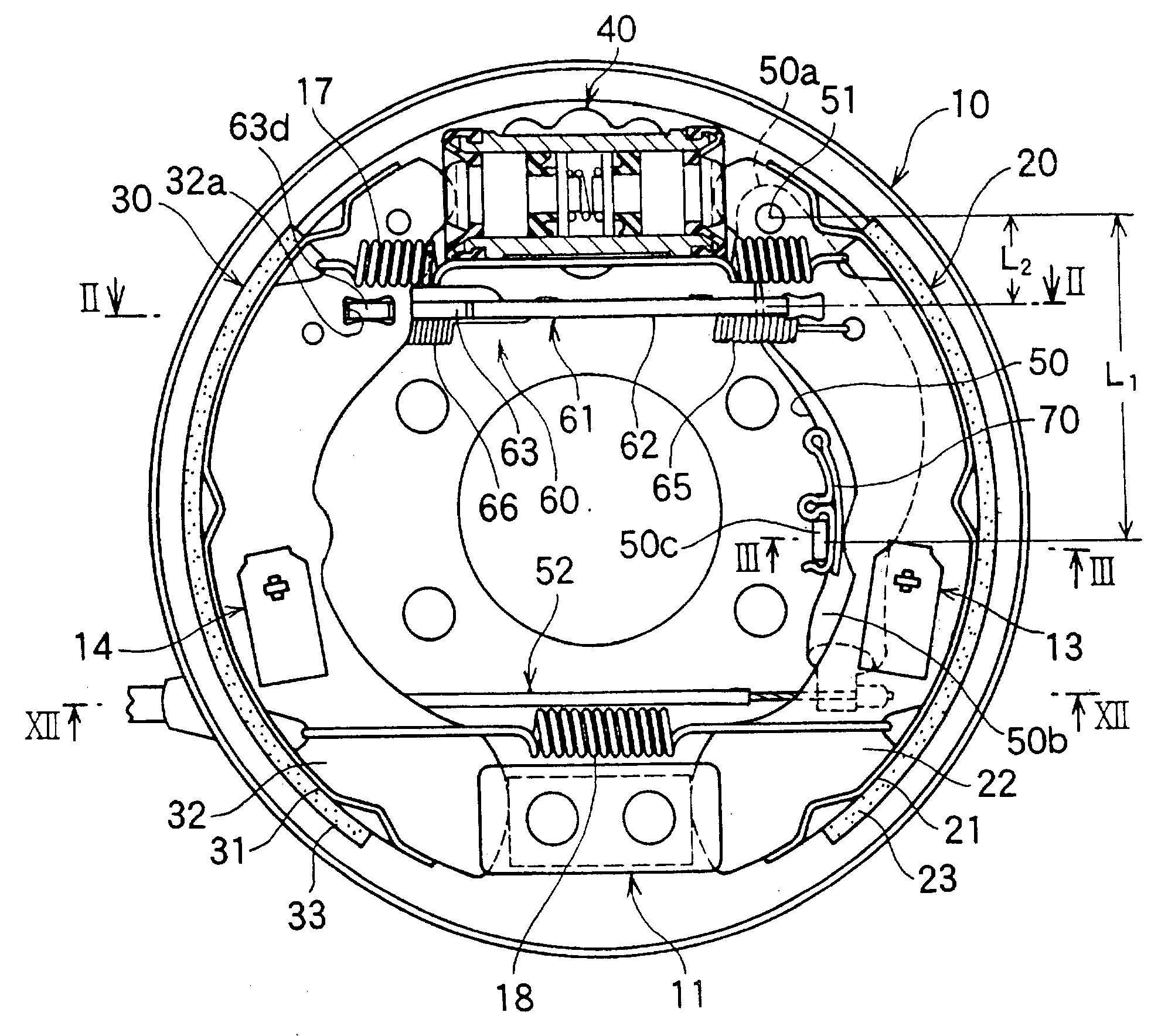

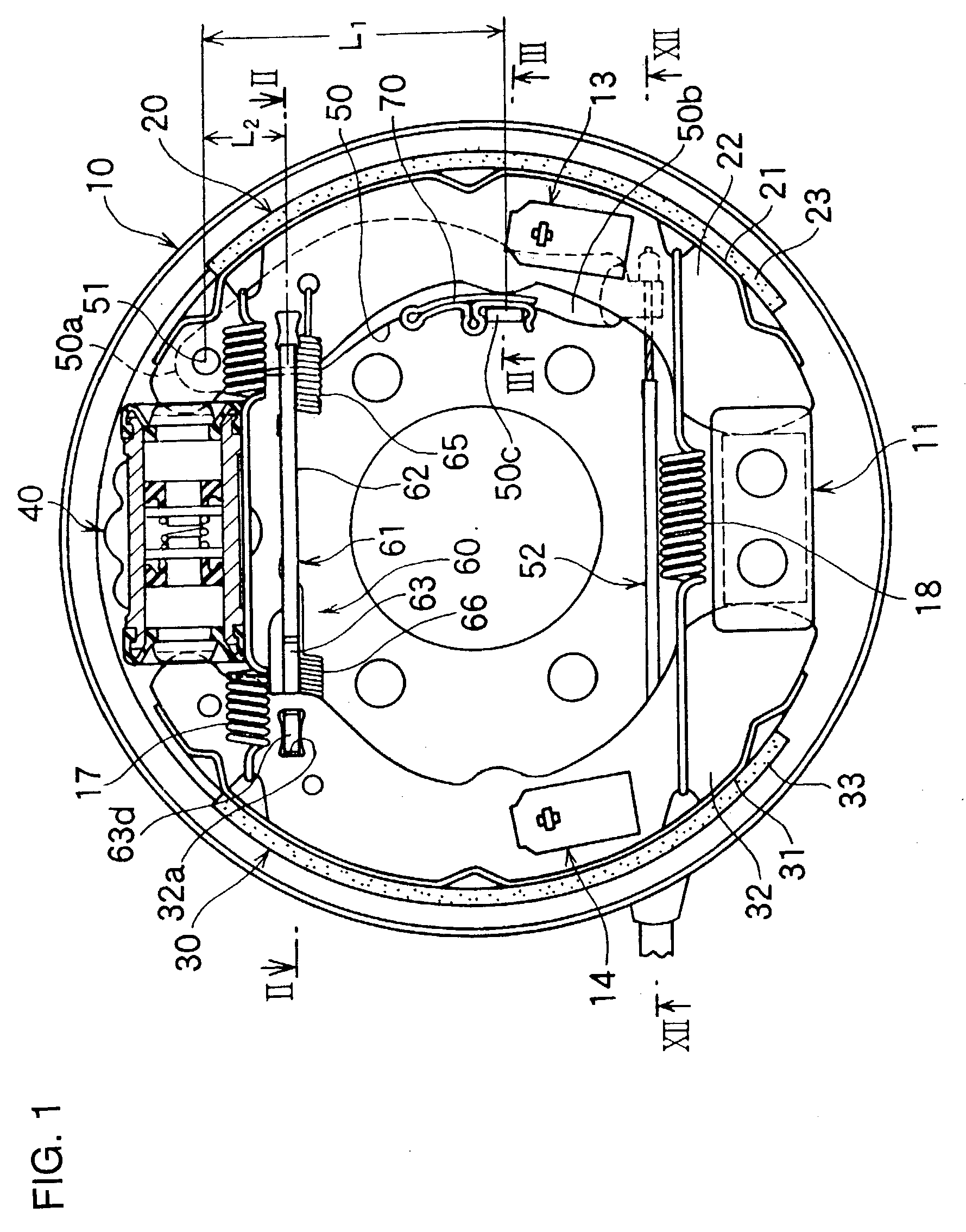

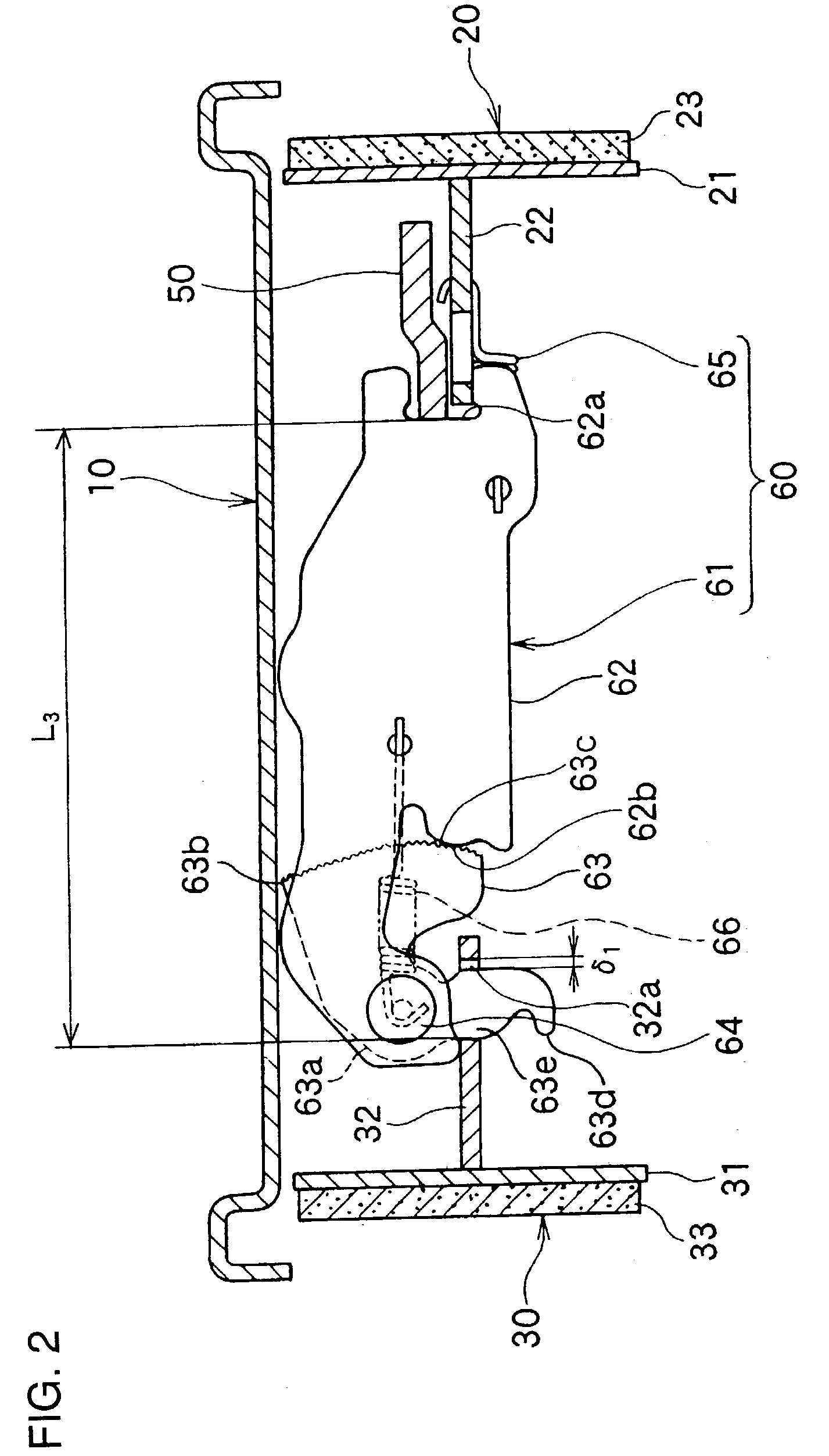

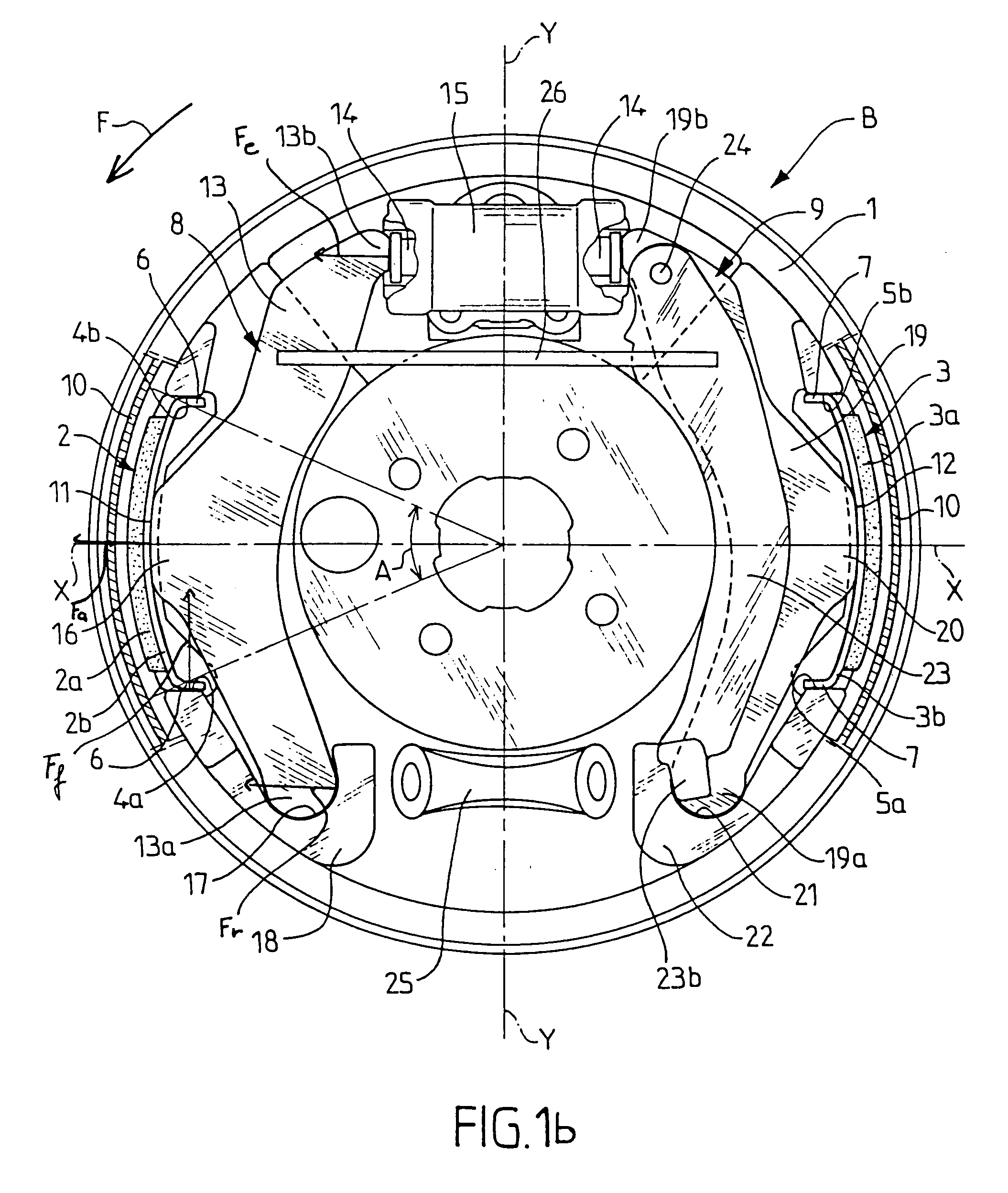

Drum brake device with an automatic shoe clearance adjustment apparatus

InactiveUS20030183465A1Small designMaterial minimizationSlack adjustersMechanically actuated drum brakesEngineeringMechanical engineering

A drum brake device prevents shoe clearance over-adjustment by means of a thermo-sensitive member with a lower leg opening force and provides a smaller thermo-sensitive member with a lower cost. A portion between both ends of the brake lever (50) in a direction of crossing the shoe return inhibitor (61) engages with one end of the shoe return inhibitor (61) automatically restricting the return position of the pair of brake shoes (20) and (30); the proximate portion (50a) of the brake lever (50) is pivotally supported on the brake shoe (20); and the free end (50b) side of the brake lever (50) is supported at the brake shoe (20) via the thermo-sensitive member (70).

Owner:NISSHINBO IND INC

Drum brake cooled through heat pipes

ActiveCN105065520AStable brakingReduce the temperatureBraking elementsFriction liningHeat pipeDrum brake

The invention discloses a drum brake cooled through heat pipes. The drum brake comprises a front brake shoe, a rear brake shoe, a friction plate, a brake shoe return spring, a brake cylinder, fan blades, the heat pipes and supporting pins. The multiple heat pipes are arranged on the front brake shoe, the rear brake shoe and the friction plate in a spaced mode. A brake drum body is mounted on the periphery of the friction plate and mounted on a wheel through brake drum mounting holes. The fan blades are mounted on the brake drum body which is provided with arc vent grooves. The heat pipe array is embedded between the brake shoes of the drum brake and the friction plate, the fan blades are arranged in the brake drum, and the role of a fan is played in the vehicle running process. Through the structural features, a large amount of heat generated in mutual friction of the friction plate and the brake drum in the vehicle braking process can be quickly conducted into a brake drum chamber through the heat pipes, the heat is taken into the external environment through air flowing into the brake drum chamber, and therefore the temperature of the brake drum and the temperature of the friction plate are reduced, and the braking performance of the brake is more stable.

Owner:SOUTH CHINA UNIV OF TECH

Cam actuated drum brake

ActiveUS20060016652A1Increase the itineraryThicker brake liningBraking membersDrum brakesEngineeringCam

A cam for a brake is provided that allows for greater brake shoe travel and thicker brake linings while providing the same or greater mechanical force as compared to conventional cams. One or more lobes of the cam include multiple portions having varying profiles in axial cross-section. The variation in the cam profiles results in a cam in which the outermost ends or tips of the lobes are longer than in conventional cams yet retain the same mechanical strength.

Owner:BENDIKS SPAJSER FAUNDEJSHN BREJK LLK

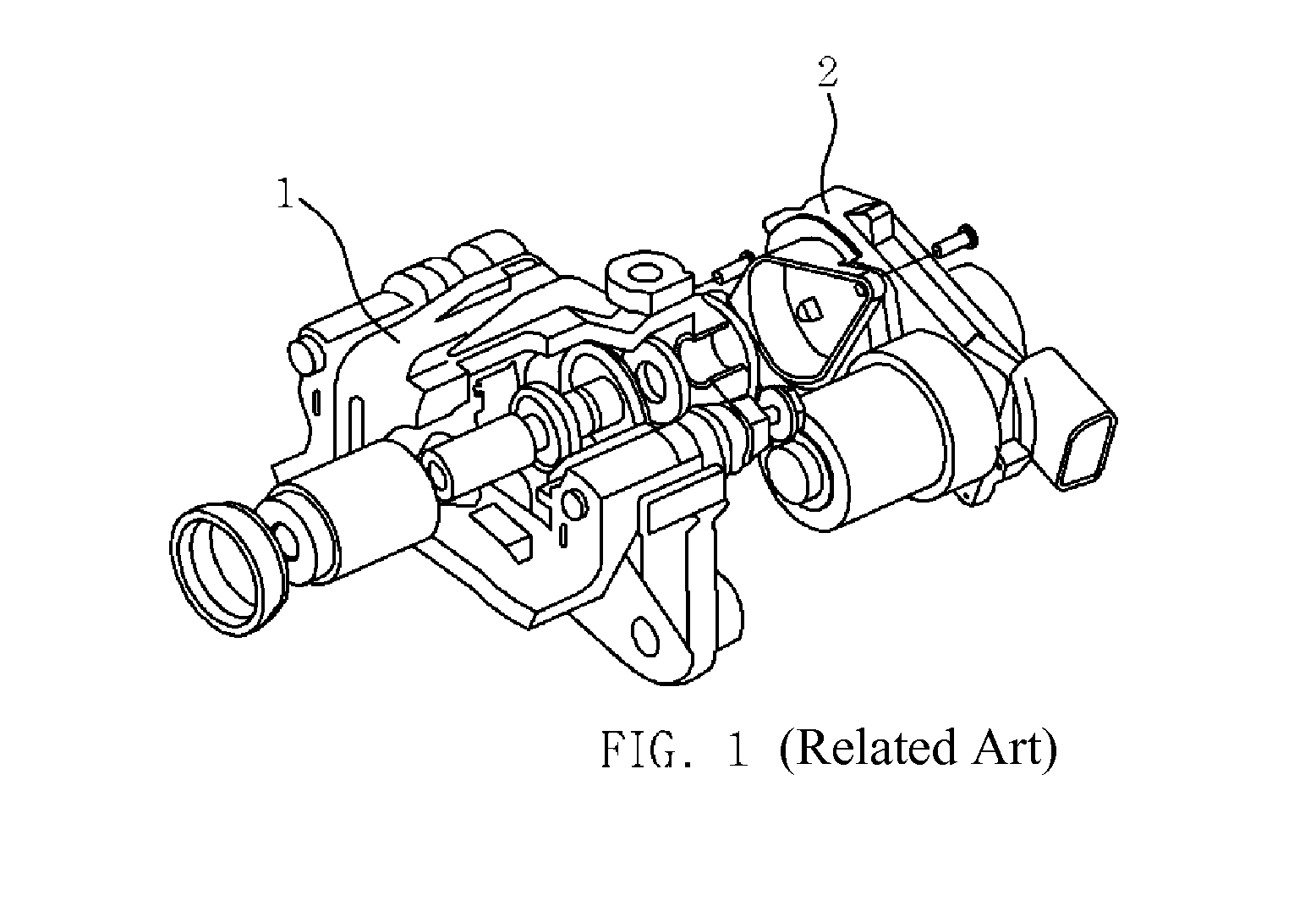

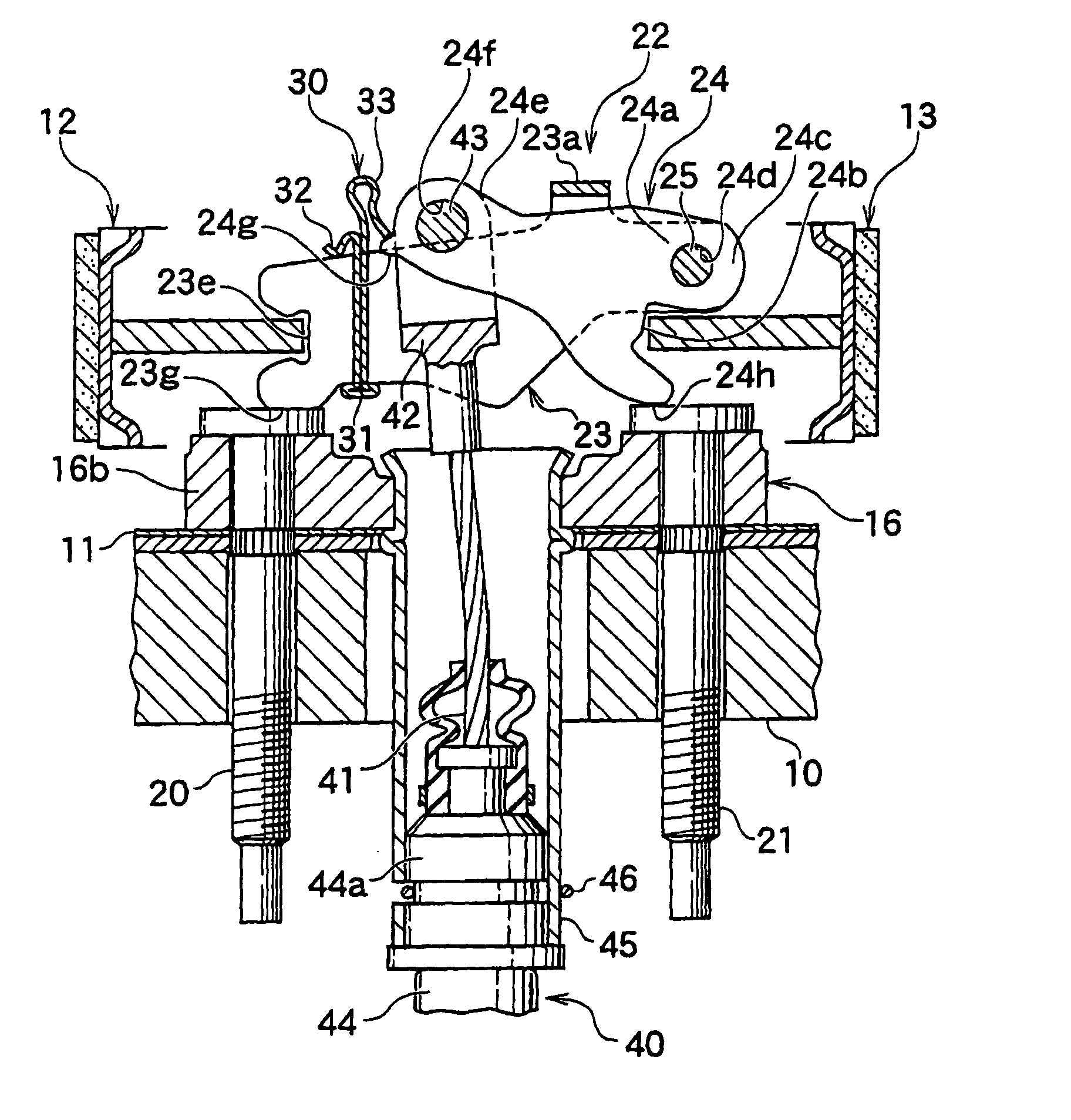

Brake cable connecting apparatus for drum brake

InactiveUS20040055833A1Reduced durabilityIntensive impact noiseMechanical braking transmissionBrake actuating mechanismsEngineeringMechanical engineering

A brake cable connecting apparatus ensures prevention of brake cable disengagement by a simple structure that offers simple and accurate assemblability. The brake cable connecting apparatus comprises the strut 23 engaging with the brake shoe 12 and the plate-like brake lever engaging with the brake shoe 13. The proximal portion 24a of the brake lever 24 is pivotally positioned in the wider space 23c formed between the two facing surface walls of the strut 23. The cable end 42 of the brake cable 40 is connected with the free end 24e of the brake lever 24 by the connecting pin 43. The inner cable 41 is operated to effectuate braking, and the projection 24g of the free end 24e interferes with the resilient stopper 33 of the resilient member 30 mounted on the strut 23 and is positioned on the rotating trajection of the brake lever 24.

Owner:AH BRAKE CO LTD

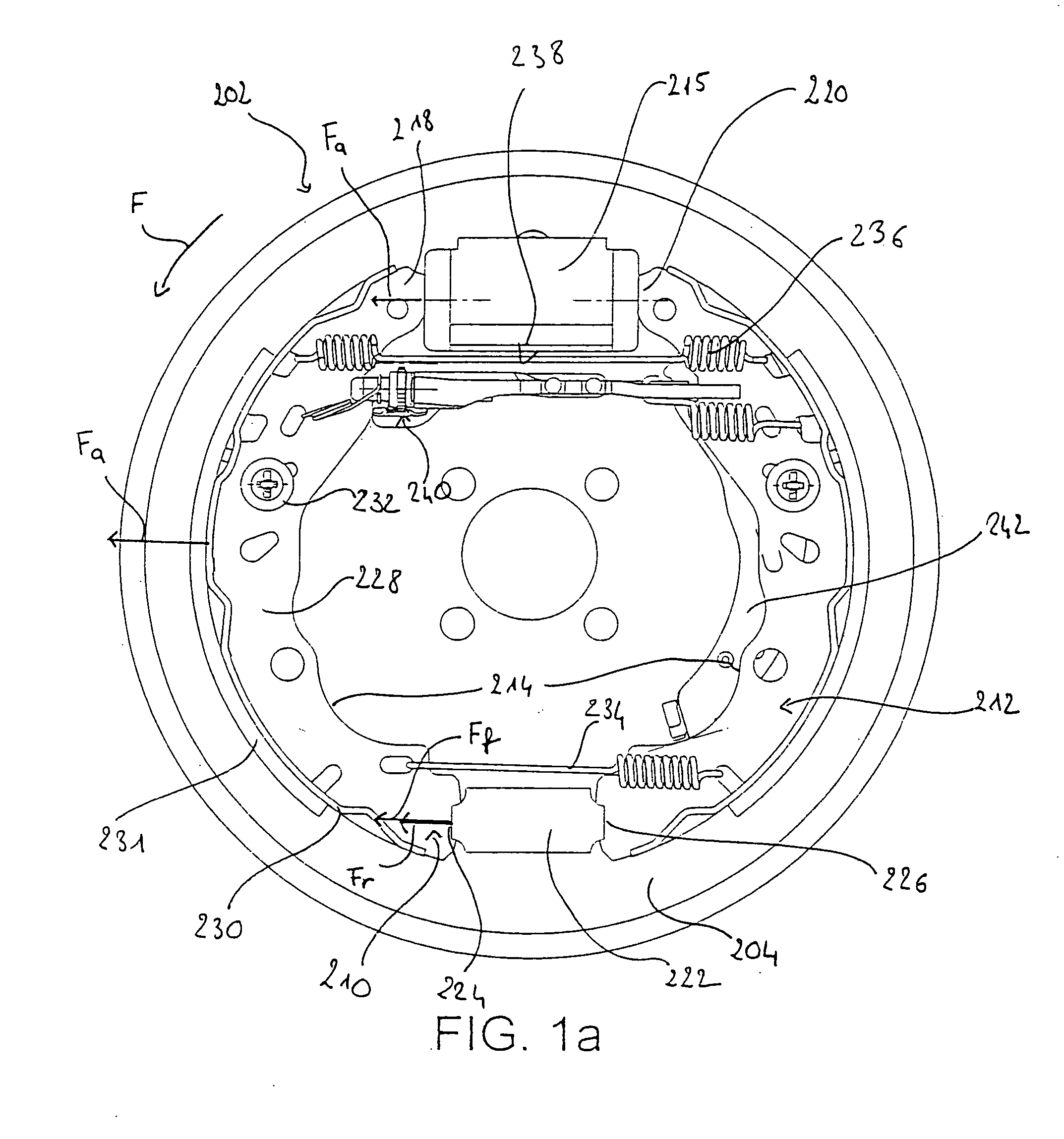

Drum brake and brake shoe for one such brake

ActiveUS20050205367A1Easy to replaceImproved torque stabilityMechanically actuated brakesFluid actuated drum brakesEngineeringMechanical engineering

A drum brake comprising a plate on which at least one shoe having a friction lining is mounted. A lever moves the shoe against a wheel drum in response to a braking command to effect a brake application. A resilient return spaces the shoe apart from the drum when braking ceases. The shoe is mounted to slide along an essentially radial axis between two guide walls secured to the plate The lever for applying the shoe bears against the inside wall of the shoe for exerting a substantially radial force.

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com