Drum brake cooled through heat pipes

A technology of drum brakes and heat pipes, which is applied in the field of auto parts, can solve the problems that heat cannot be removed in time and effectively, and achieve the effects of compact structure, strong heat dissipation capacity and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

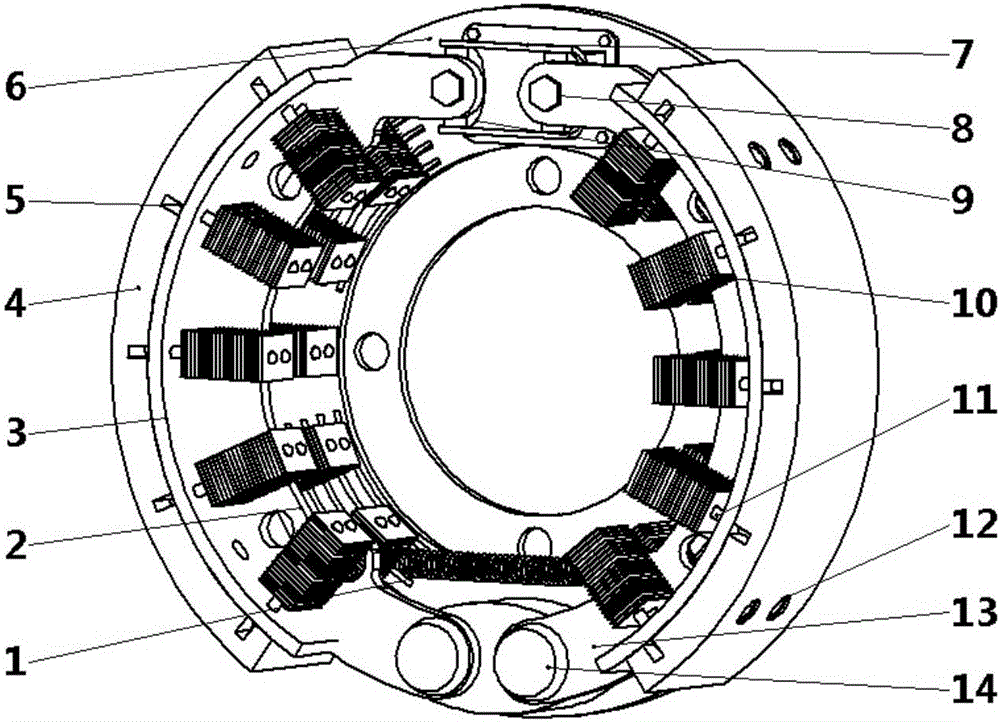

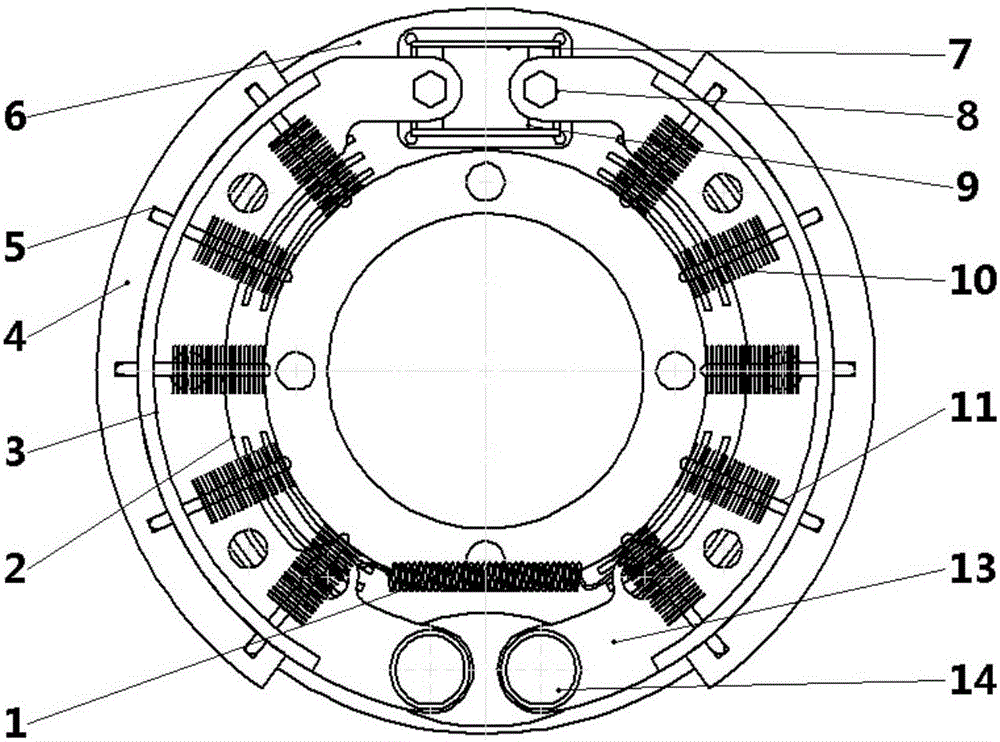

[0047] like Figure 1 to Figure 9 and Figure 14 to Figure 16 As shown, a drum brake that dissipates heat through heat pipes includes front brake shoes 2, rear brake shoes 13, friction plates 4, brake shoe return springs 1, brake wheel cylinders 7, heat pipes 11 and support pins 14 One end of the front brake shoe 2 and the rear brake shoe 13 are movably connected to the brake base plate 6 through two support pins 14 respectively, and the other ends of the front brake shoe 2 and the rear brake shoe 13 are respectively passed through the brake wheel cylinder The piston pin 8 is connected to the brake wheel cylinder piston 9, and the brake wheel cylinder piston 9 is arranged in the brake wheel cylinder 7; the brake shoe return spring 1 is respectively connected with the front brake shoe 2 and the rear brake shoe 13;

[0048] The outer circumference of the front brake shoe 2 and the rear brake shoe 13 is connected with the friction plate 4, preferably the front brake shoe 2 and t...

Embodiment 2

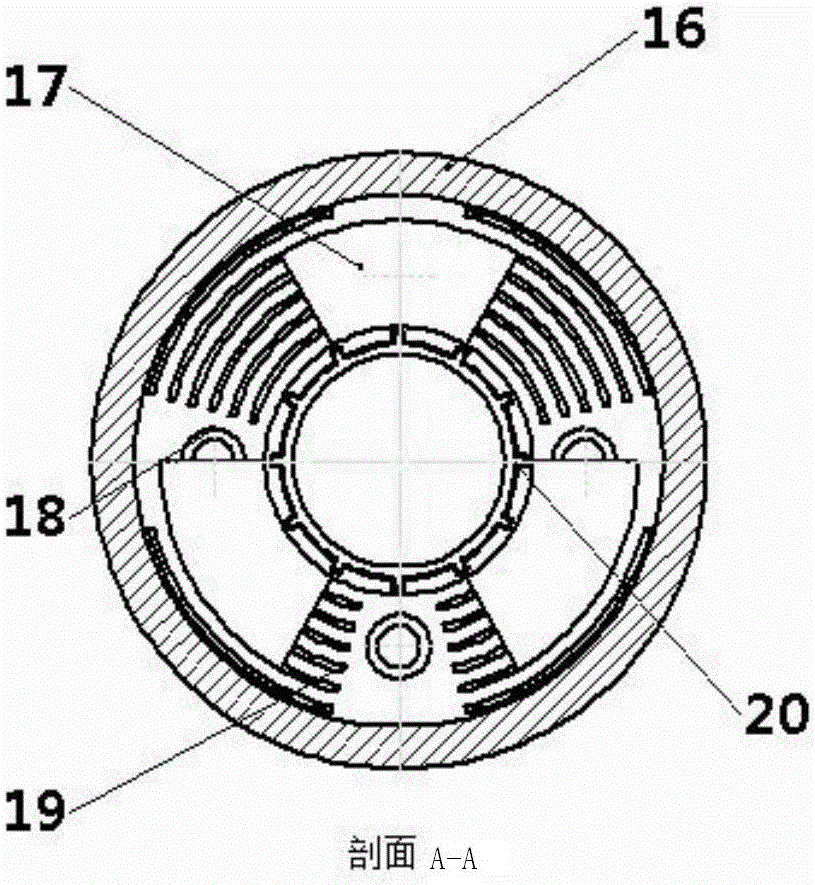

[0055] like Figure 10 to Figure 13 As shown, a drum brake that dissipates heat through heat pipes includes front brake shoes 2, rear brake shoes 13, friction plates 4, brake shoe return springs 1, brake wheel cylinders 7, heat pipes 11 and support pins 14 One end of the front brake shoe 2 and the rear brake shoe 13 are movably connected to the brake base plate 6 through two support pins 14 respectively, and the other ends of the front brake shoe 2 and the rear brake shoe 13 are respectively passed through the brake wheel cylinder The piston pin 8 is connected to the brake wheel cylinder piston 9, and the brake wheel cylinder piston 9 is arranged in the brake wheel cylinder 7; the brake shoe return spring 1 is respectively connected with the front brake shoe 2 and the rear brake shoe 13;

[0056] The outer circumference of the front brake shoe 2 and the rear brake shoe 13 is connected with the friction plate 4, preferably the front brake shoe 2 and the rear brake shoe 13 are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com