air disc brake

A disc brake and air pressure technology, applied in the direction of brake type, axial brake, brake actuator, etc., can solve the problem that the braking force of the whole vehicle cannot reach the required value, affect the braking force transmission ratio, and the braking torque cannot be increased. Large and other problems, to achieve the effect of improved braking performance, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

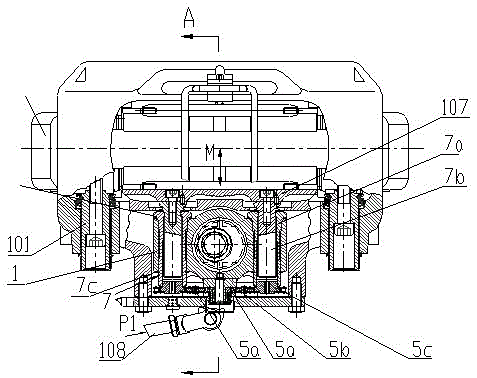

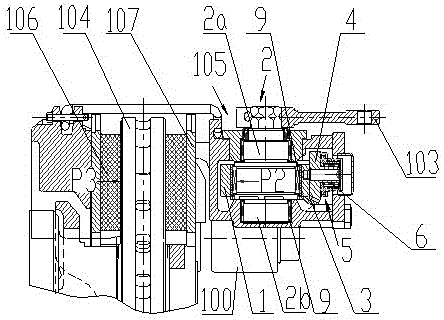

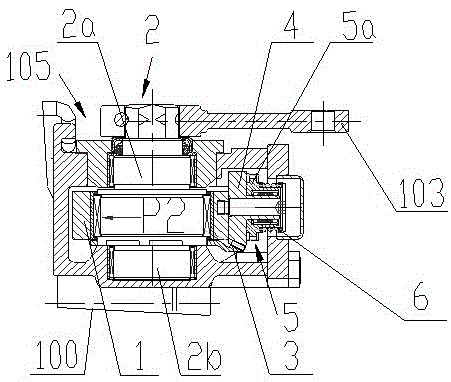

[0037] control figure 1 , 2 , image 3 The brake of the present invention includes a brake bracket 100, a brake disc 104 and a caliper body 105 arranged on the brake bracket 100, and a push plate 107 arranged on the caliper body and connected with a friction block 106, especially including a brake disc 107 mainly composed of Pressure seat assembly composed of pressure seat 1, eccentric shaft 2, bevel gear 3, bevel gear 4 and one-way clutch 6, gear transmission unit 5 and screw pushing unit 7.

[0038] The pressure seat assembly is slidably connected to the caliper body 105 through the pressure seat 1, the screw pushing unit 7 is arranged on the pressure seat 1, the pressure seat 1 is connected with the push plate 107 through the screw pushing unit 7, and the sliding of the pressure seat 1 relative to the caliper body is controlled by The eccentric shaft is driven to form. The eccentric shaft 2 includes a shaft body 2a and an eccentric disk 2b not coaxial with the shaft body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com