Patents

Literature

61 results about "Sensori motor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sensorimotor - of or relating to the sensory and motor coordination of an organism or to the controlling nerves.

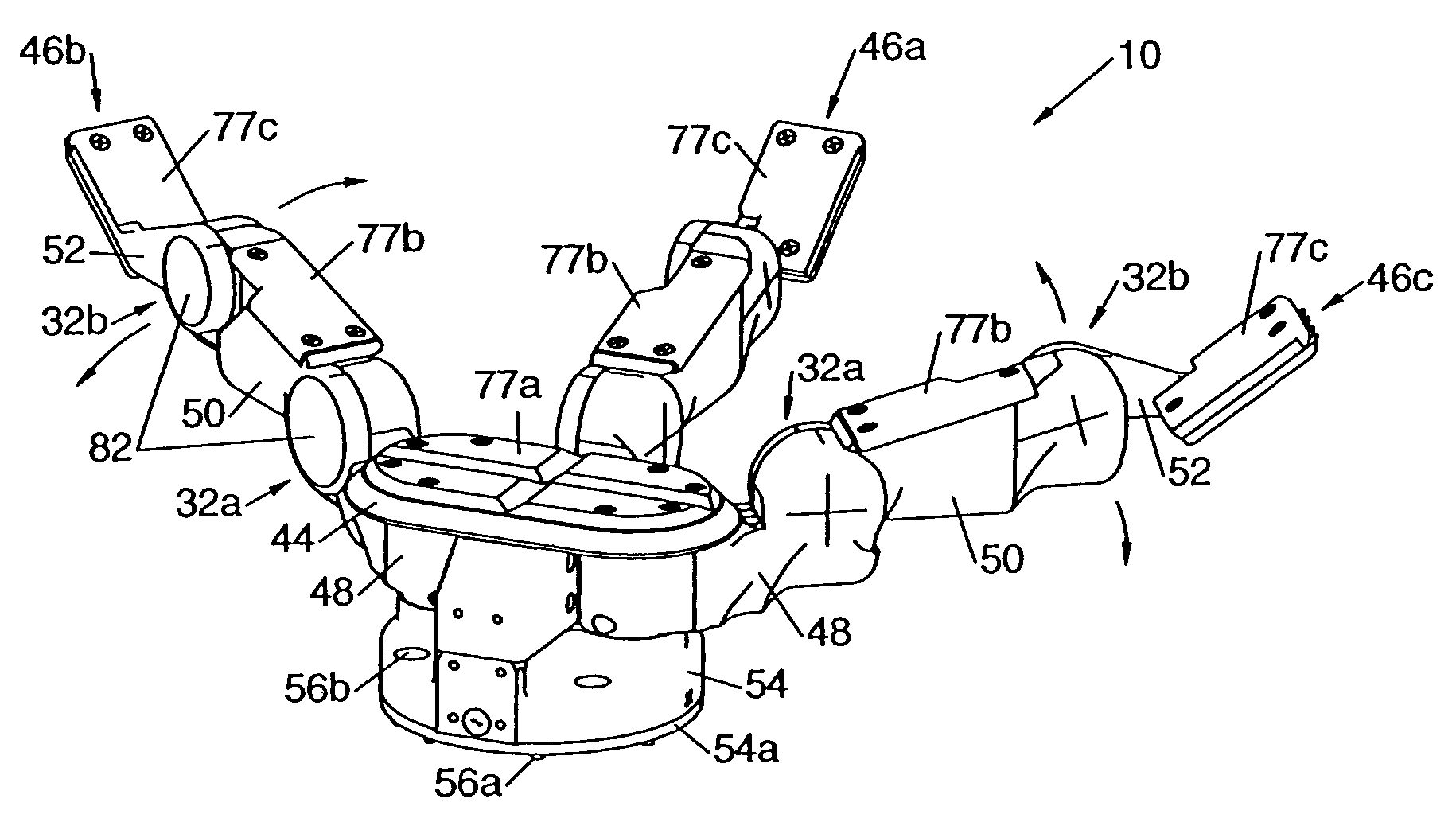

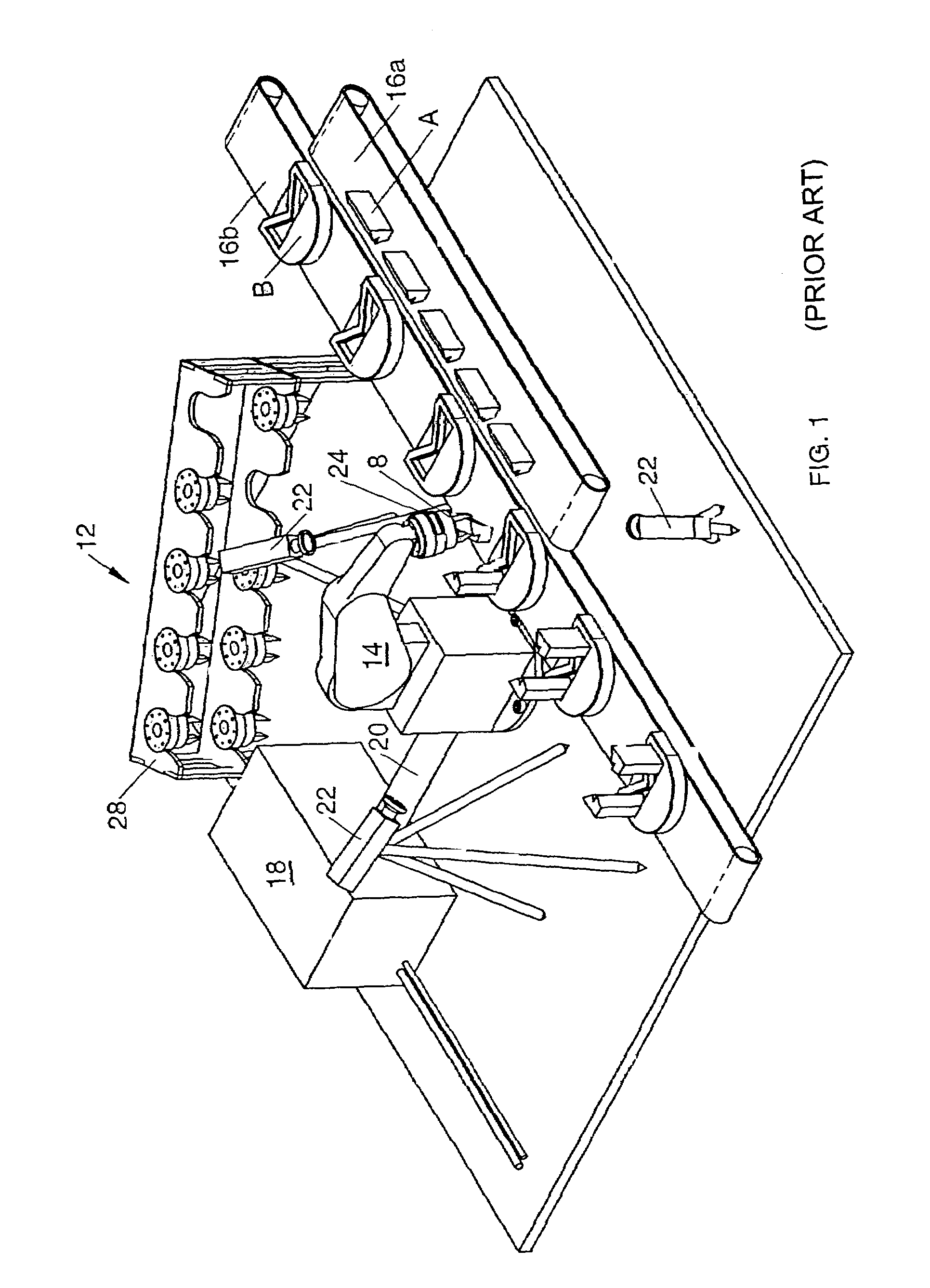

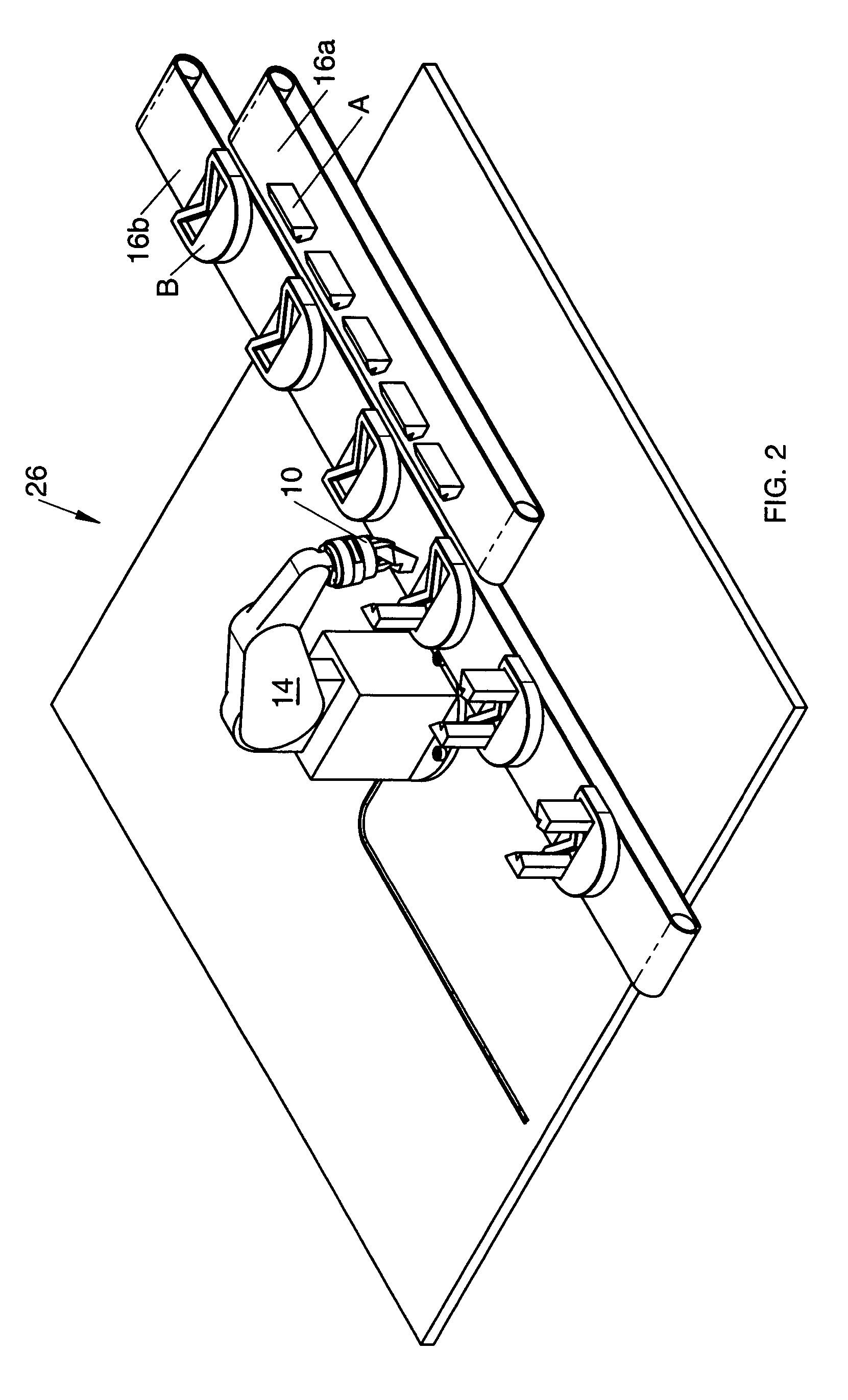

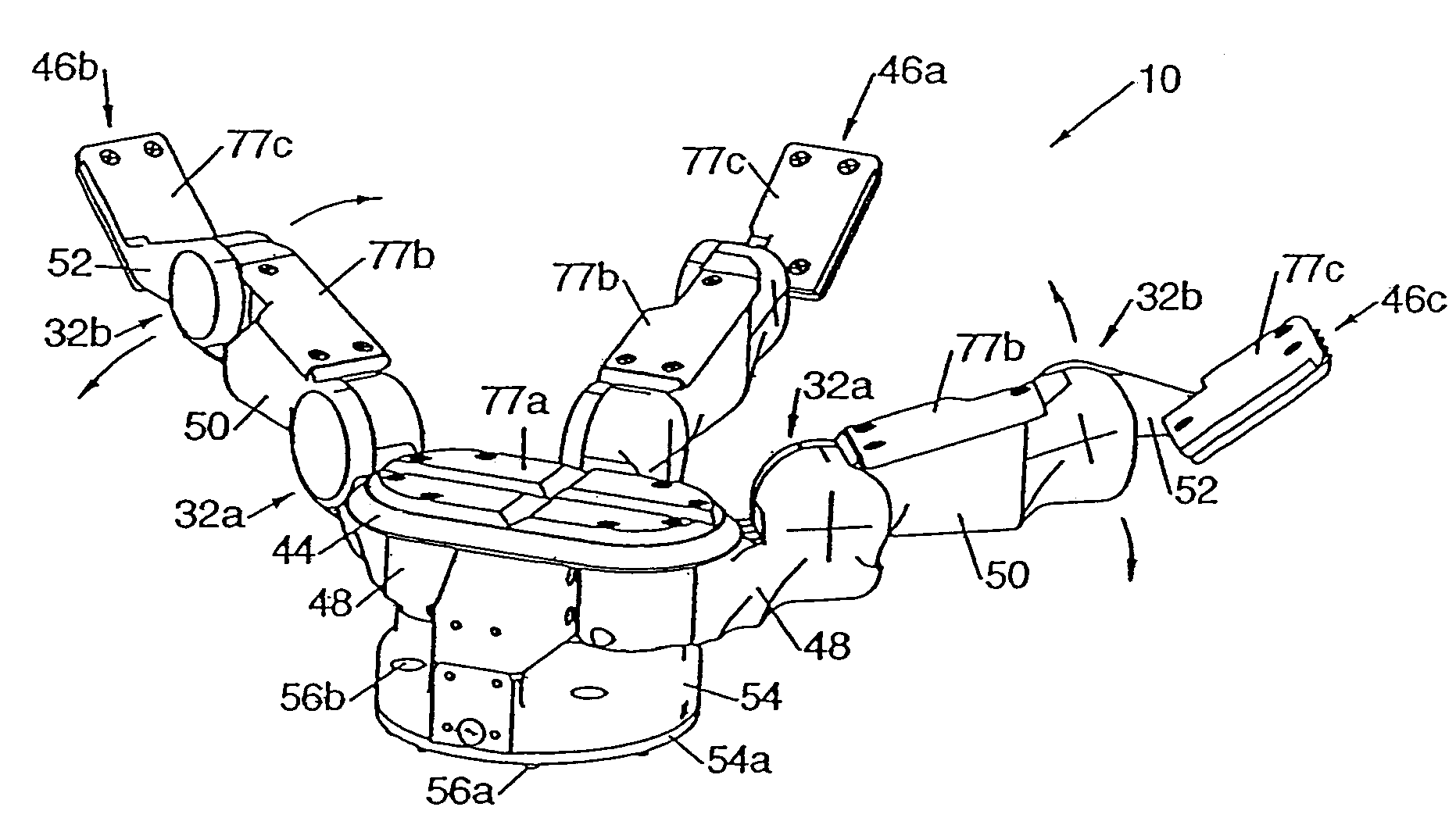

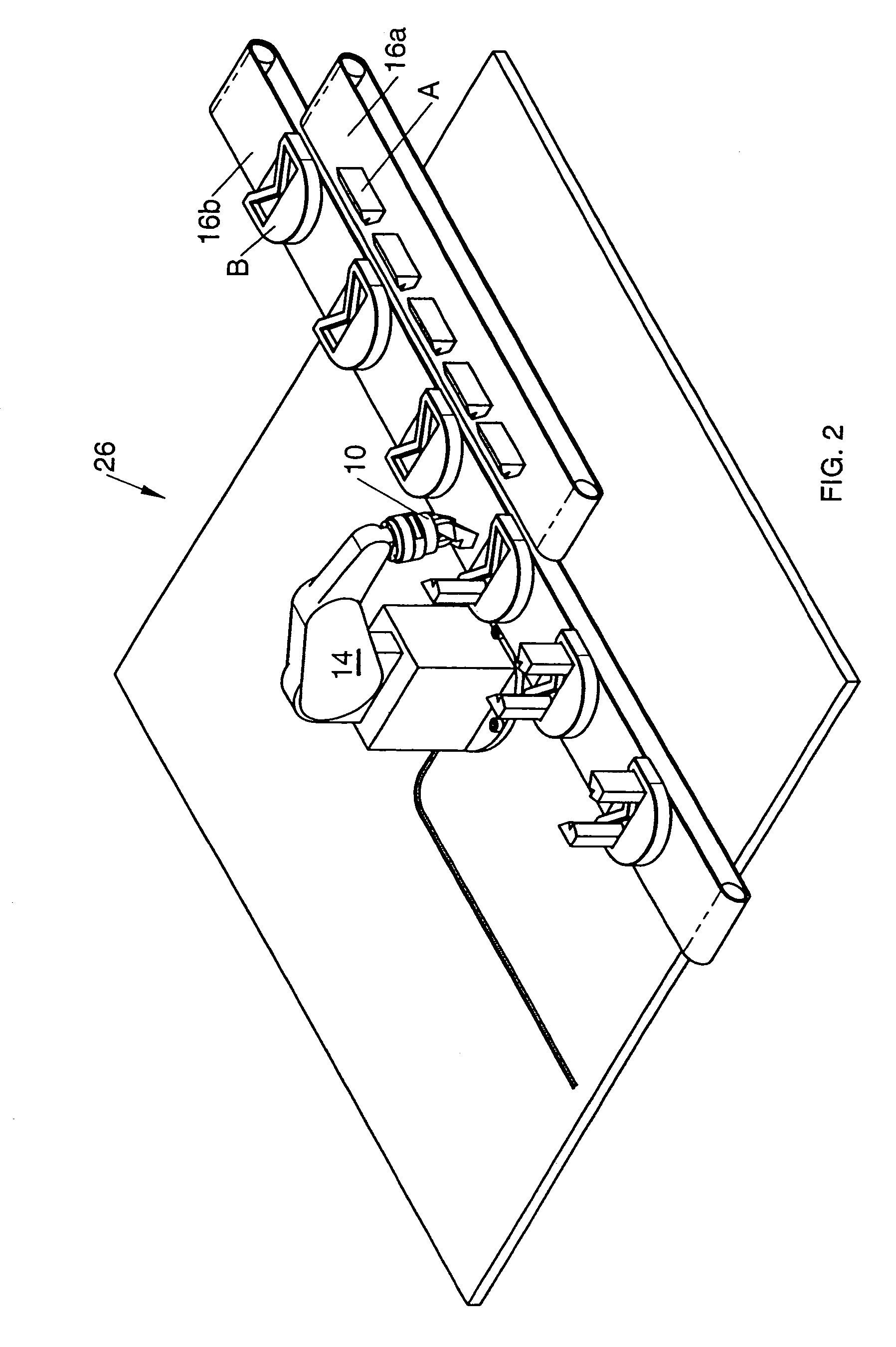

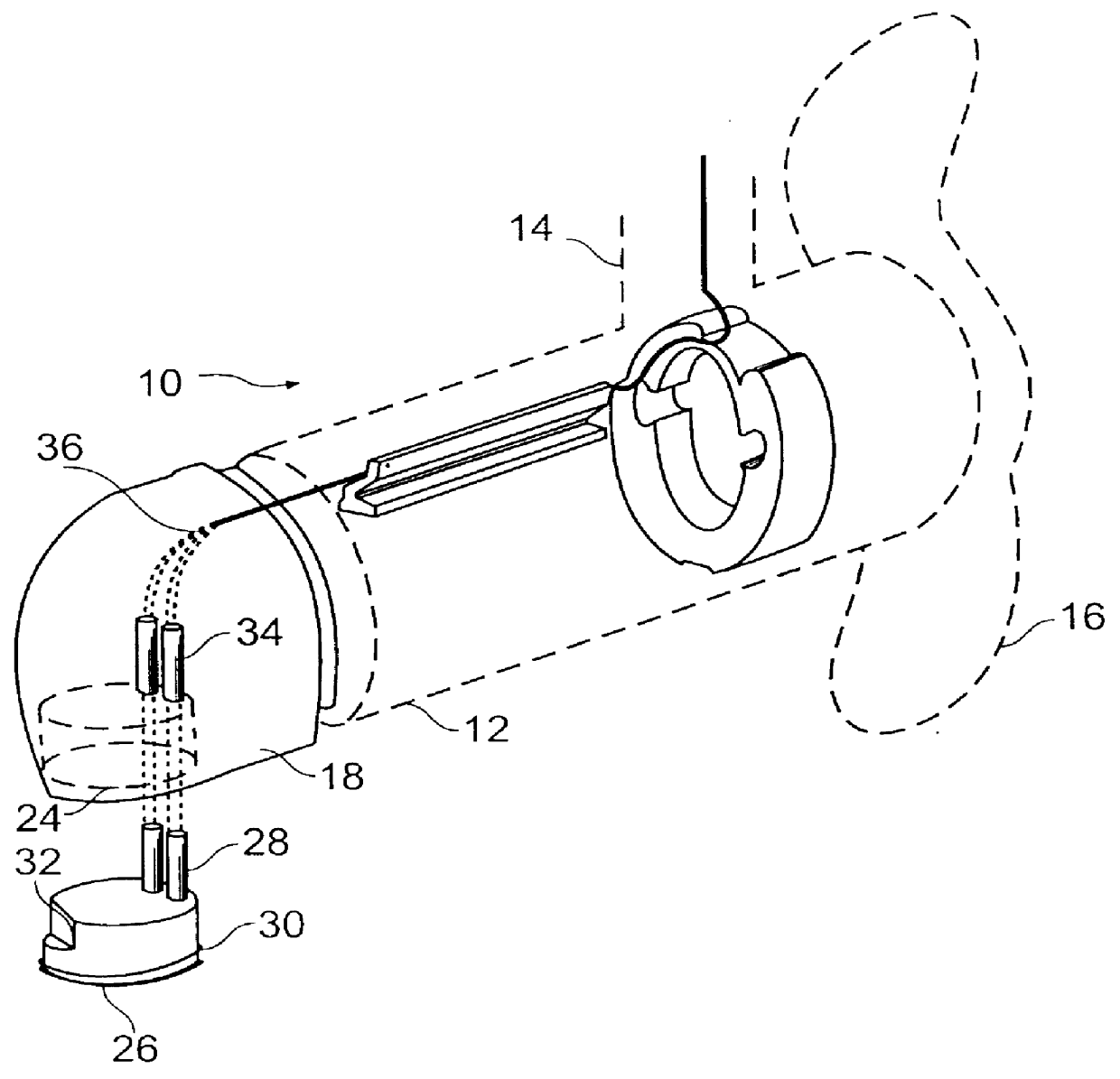

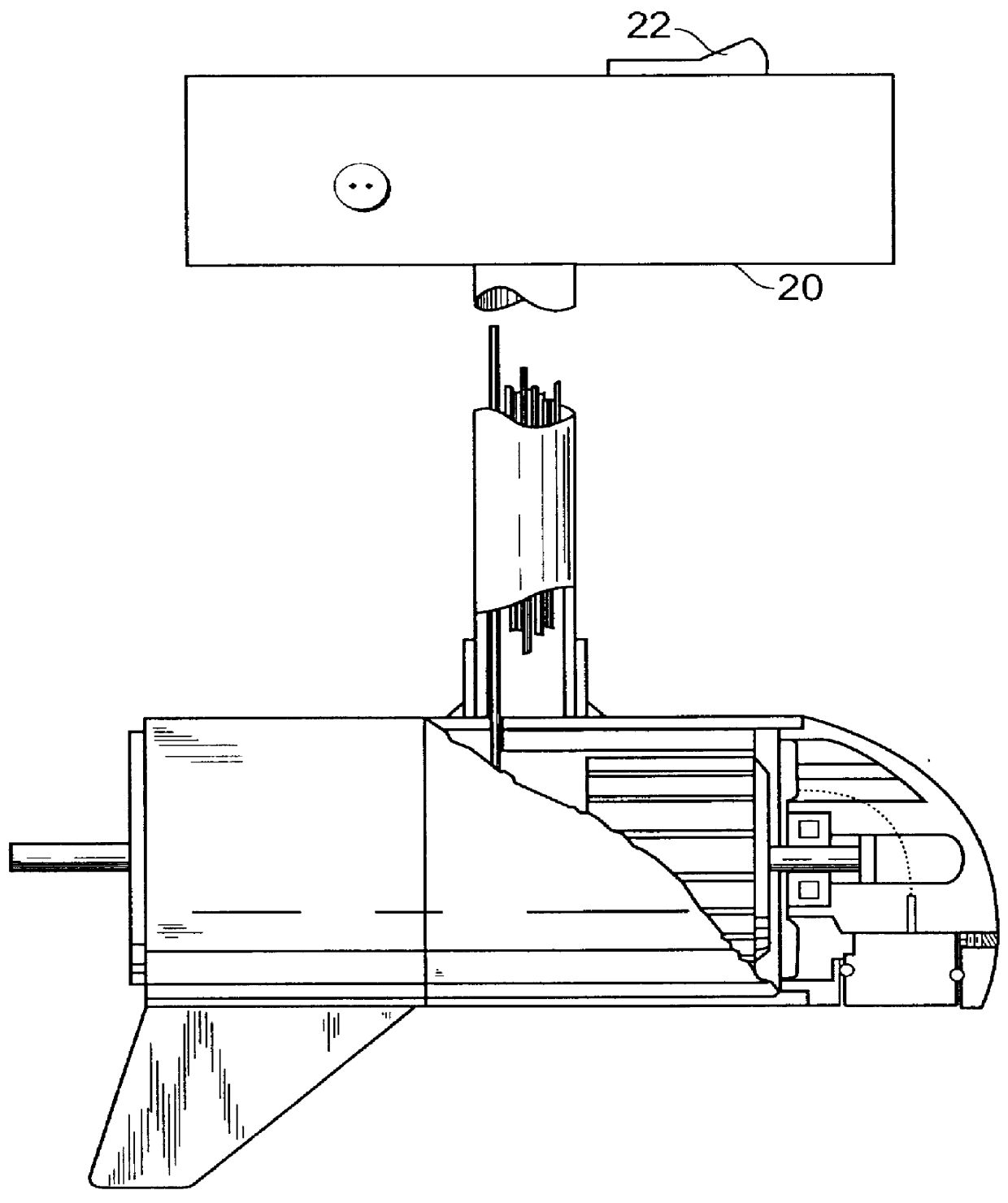

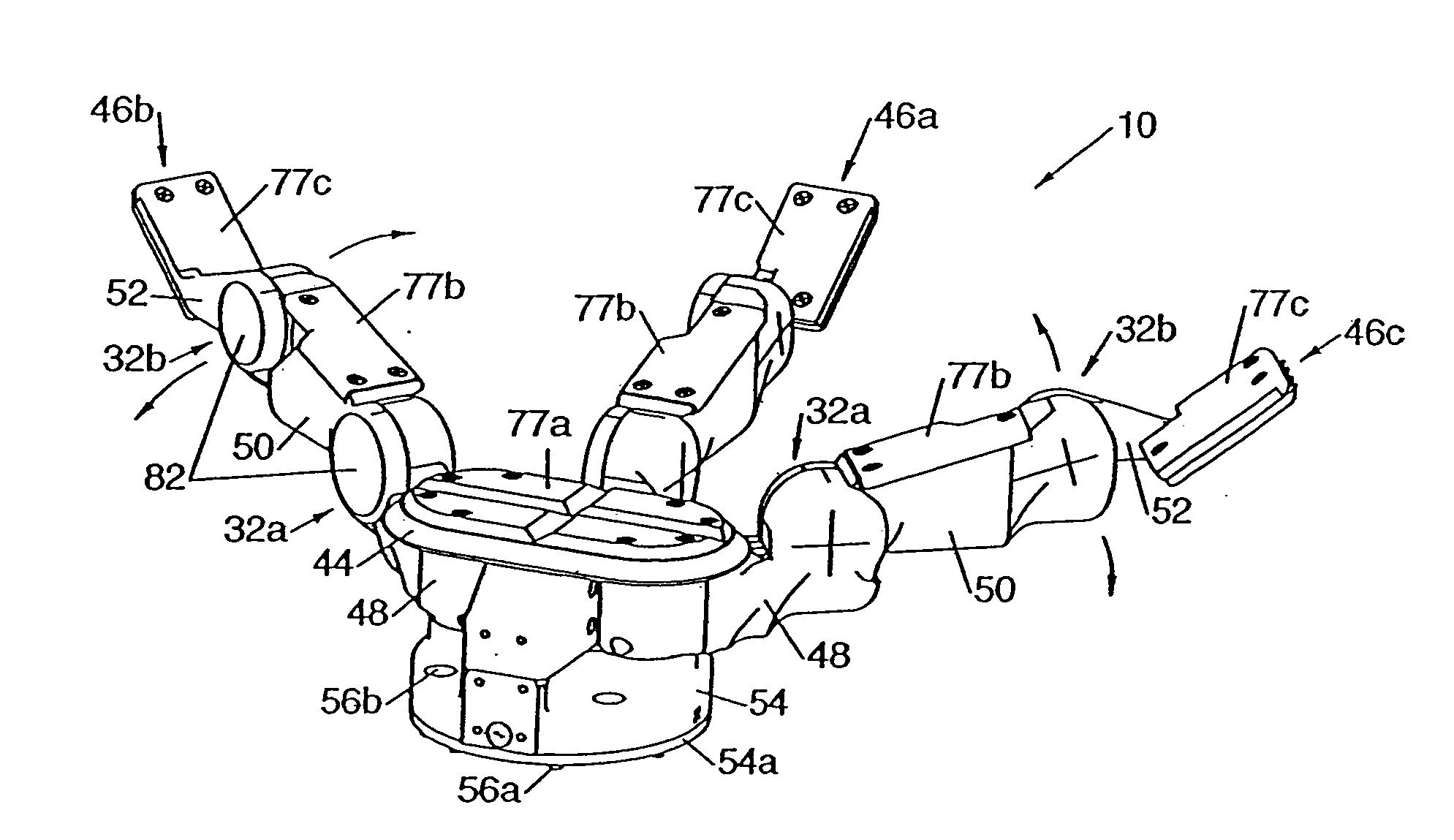

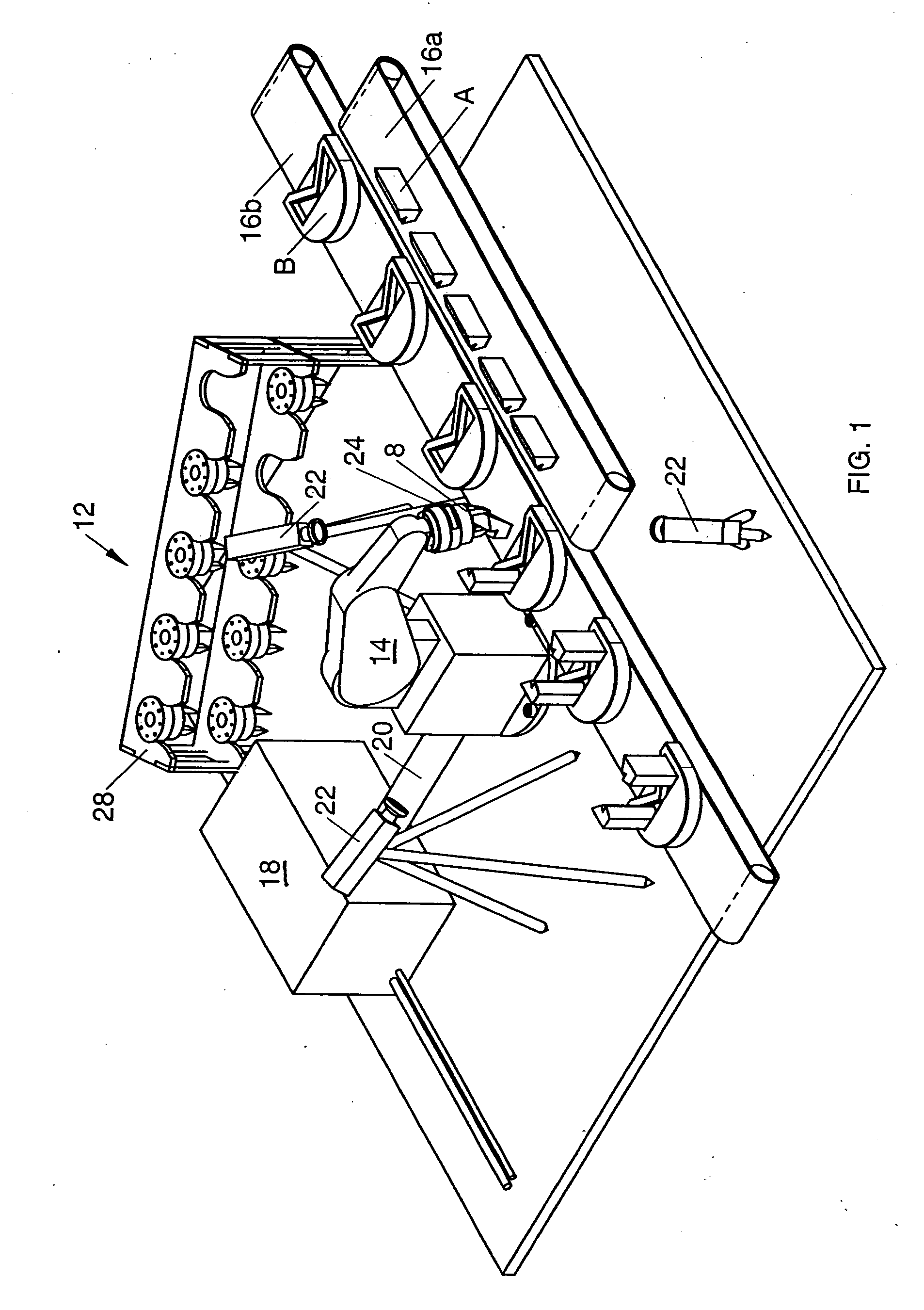

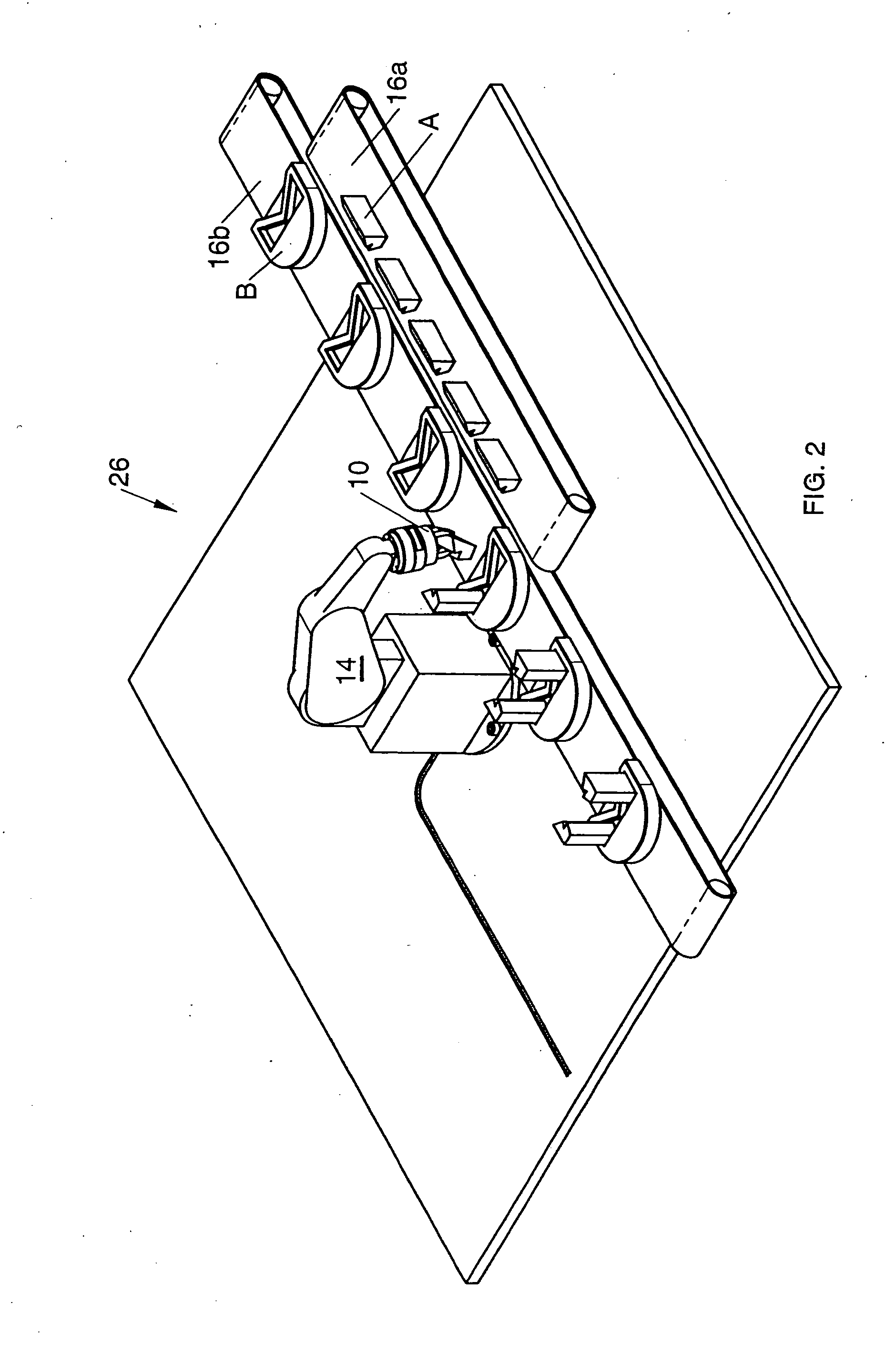

Intelligent, self-contained robotic hand

A robotic device has a base and at least one finger having at least two links that are connected in series on rotary joints with at least two degrees of freedom. A brushless motor and an associated controller are located at each joint to produce a rotational movement of a link. Wires for electrical power and communication serially connect the controllers in a distributed control network. A network operating controller coordinates the operation of the network, including power distribution. At least one, but more typically two to five, wires interconnect all the controllers through one or more joints. Motor sensors and external world sensors monitor operating parameters of the robotic hand. The electrical signal output of the sensors can be input anywhere on the distributed control network. V-grooves on the robotic hand locate objects precisely and assist in gripping. The hand is sealed, immersible and has electrical connections through the rotary joints for anodizing in a single dunk without masking. In various forms, this intelligent, self-contained, dexterous hand, or combinations of such hands, can perform a wide variety of object gripping and manipulating tasks, as well as locomotion and combinations of locomotion and gripping.

Owner:BARRETT TECH LLC

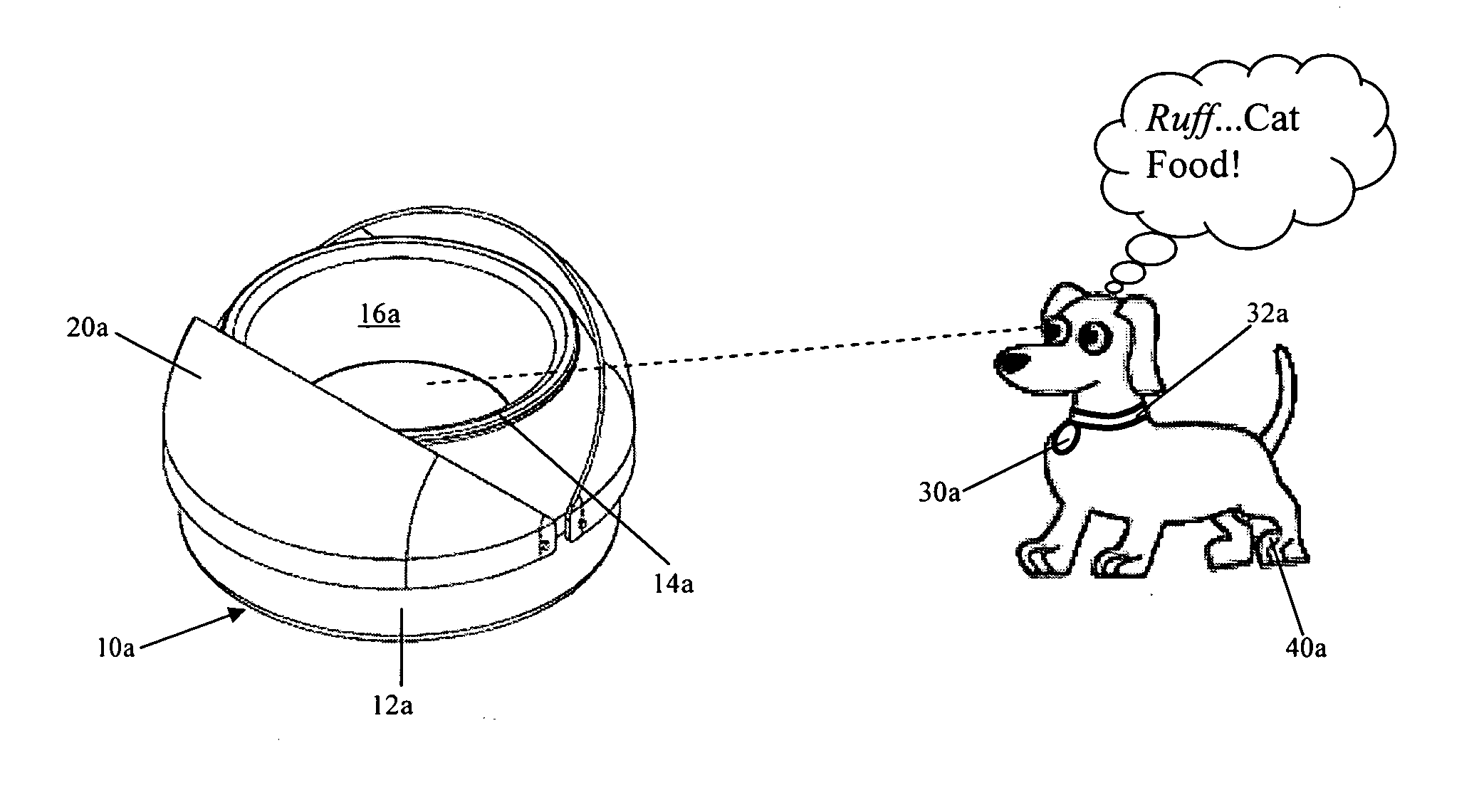

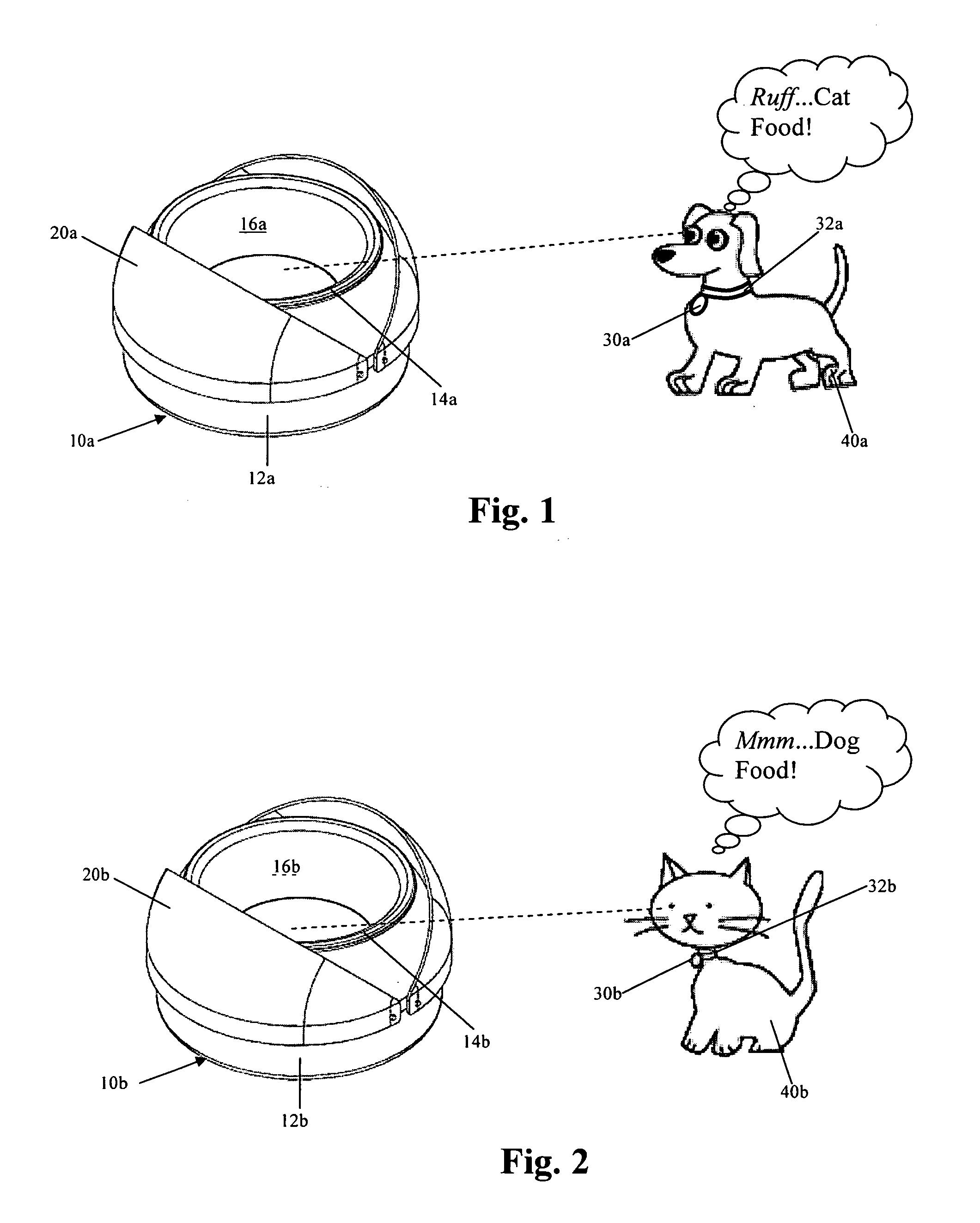

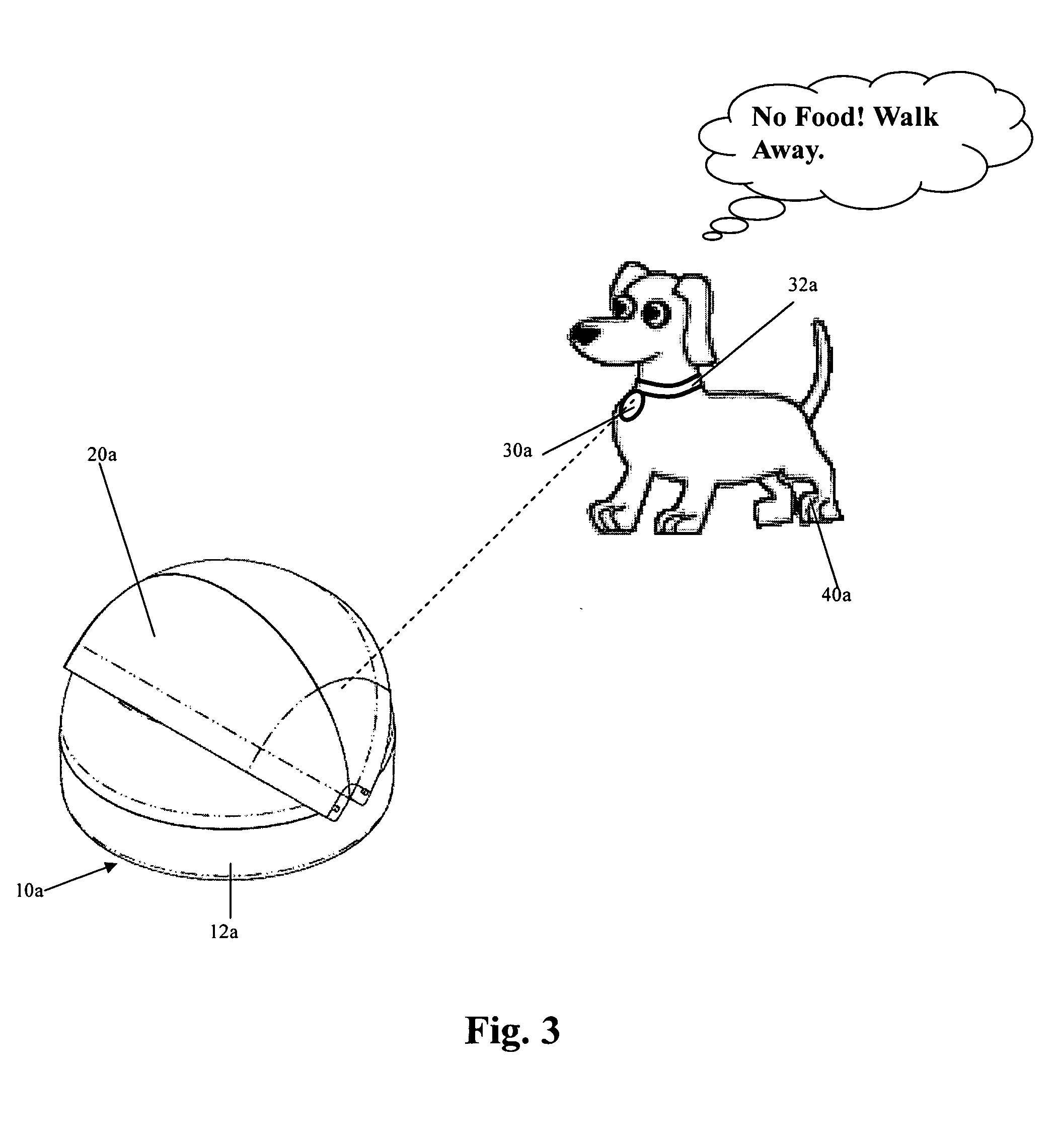

System for preventing access to a device by an unwanted animal and method of altering an animal's behavior

A system for preventing access by an unwanted animal is provided which includes a device having a cover, a motor, a sensor and a transmitter worn by the unwanted animal. Upon receiving the signal from the transmitter that the unwanted animal is in close proximity to the device, the sensor activates the motor in order to provide the cover in a closed condition that will prevent the unwanted animal from accessing the device. After the unwanted animal departs the area, the motor will activate in order to allow the cover to return to its open condition so that a wanted animal may have access to the device. The device may provide cues such as visual or audible cues that will train the unwanted animal not to approach the device.

Owner:BEECHER BRIAN T

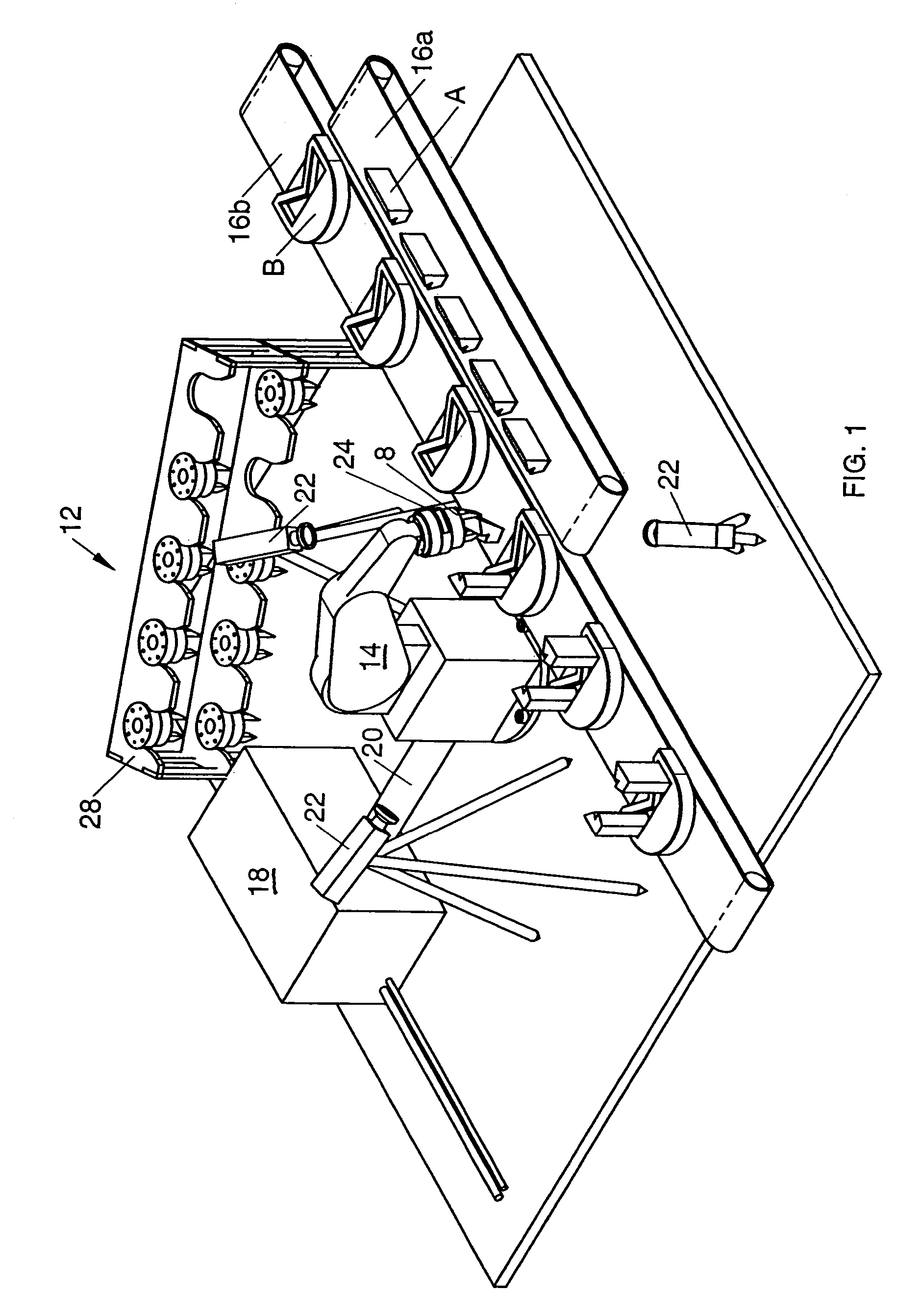

Process for anodizing a robotic device

A robotic device has a base and at least one finger having at least two links that are connected in series on rotary joints with at least two degrees of freedom. A brushless motor and an associated controller are located at each joint to produce a rotational movement of a link. Wires for electrical power and communication serially connect the controllers in a distributed control network. A network operating controller coordinates the operation of the network, including power distribution. At least one, but more typically two to five, wires interconnect all the controllers through one or more joints. Motor sensors and external world sensors monitor operating parameters of the robotic hand. The electrical signal output of the sensors can be input anywhere on the distributed control network. V-grooves on the robotic hand locate objects precisely and assist in gripping. The hand is sealed, immersible and has electrical connections through the rotary joints for anodizing in a single dunk without masking. In various forms, this intelligent, self-contained, dexterous hand, or combinations of such hands, can perform a wide variety of object gripping and manipulating tasks, as well as locomotion and combinations of locomotion and gripping.

Owner:BARRETT TECH LLC

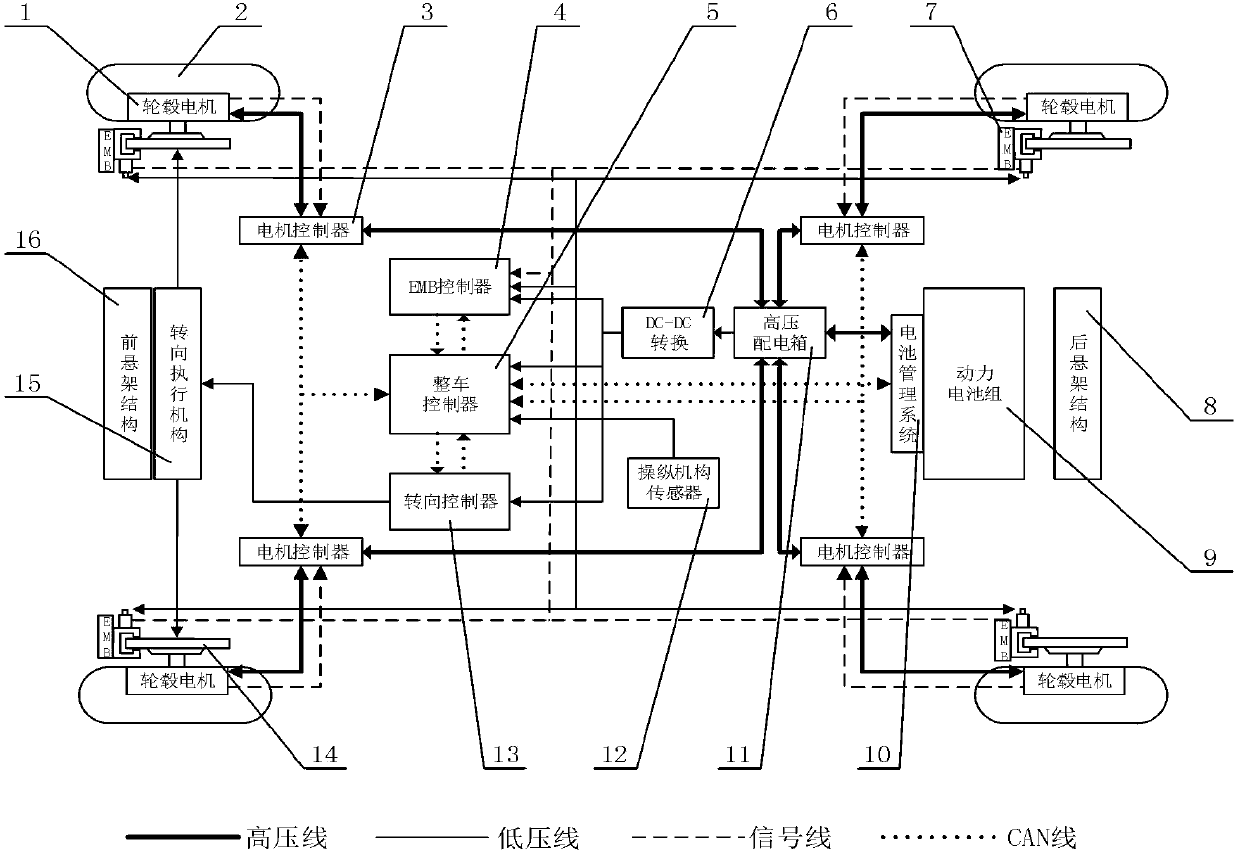

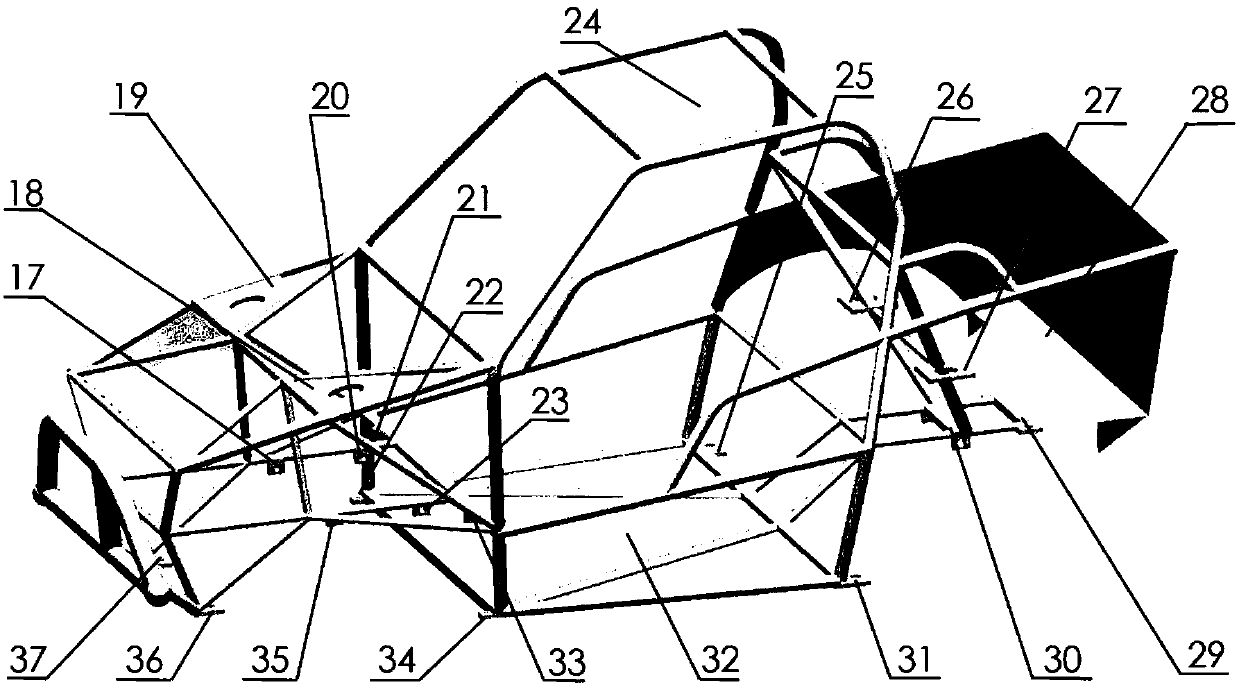

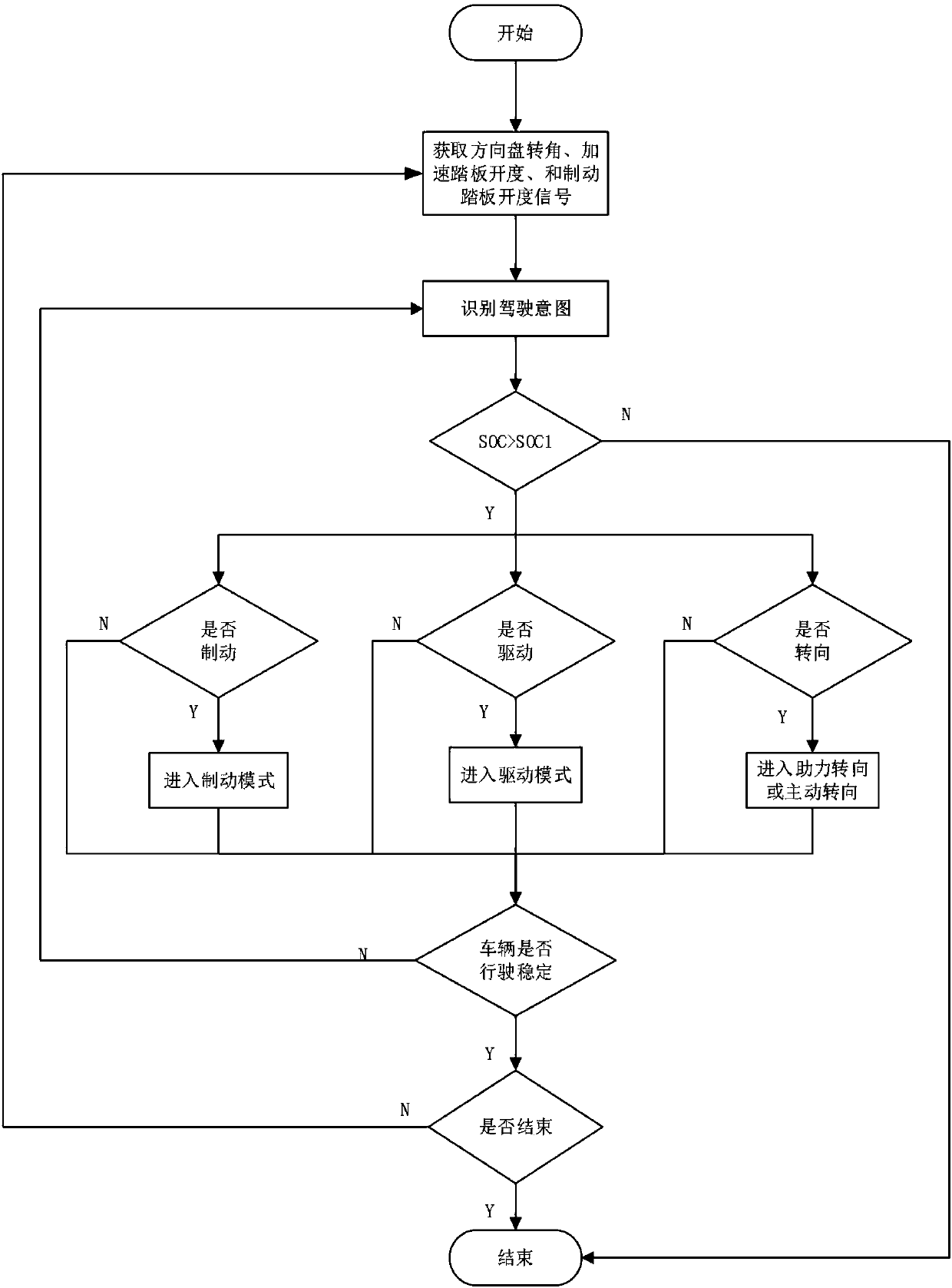

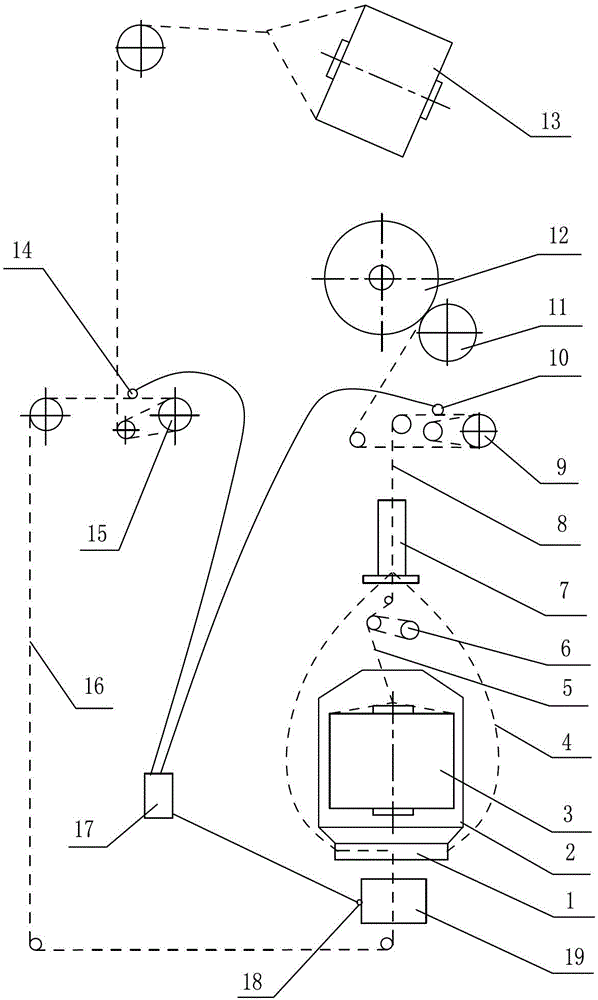

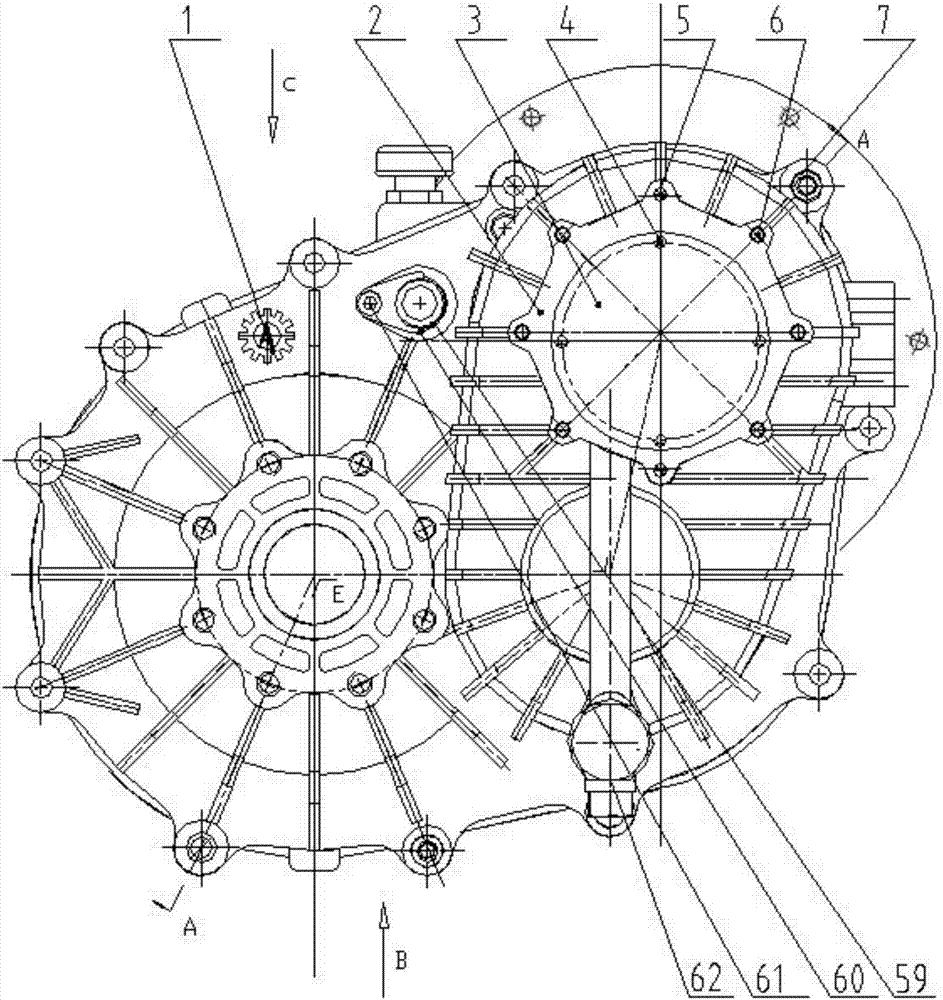

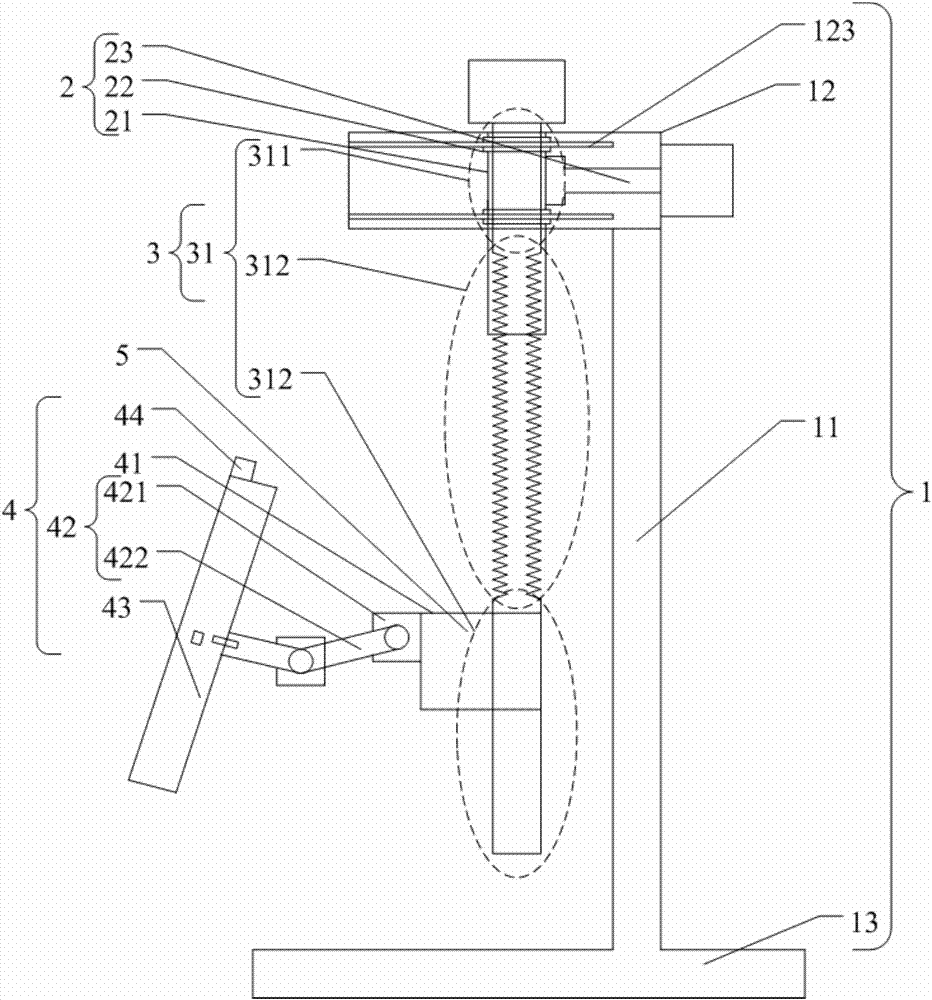

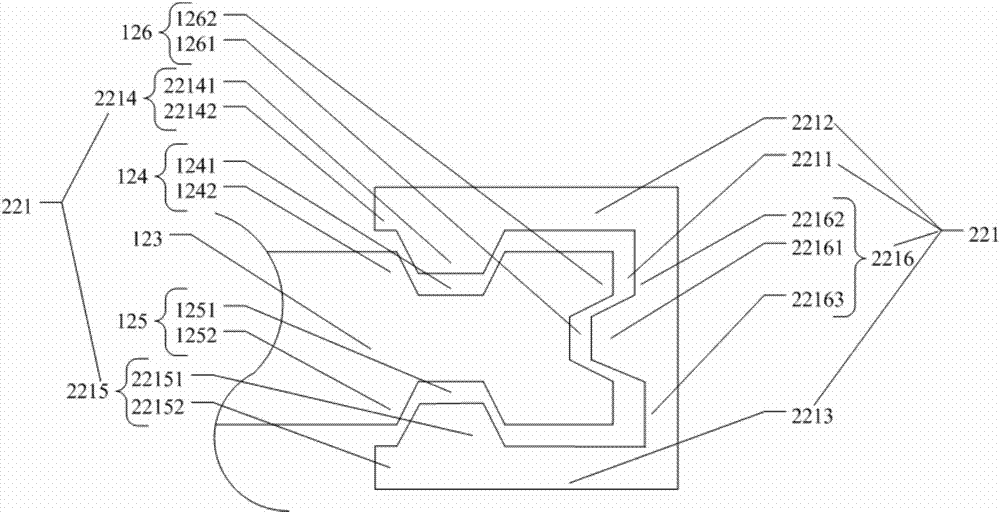

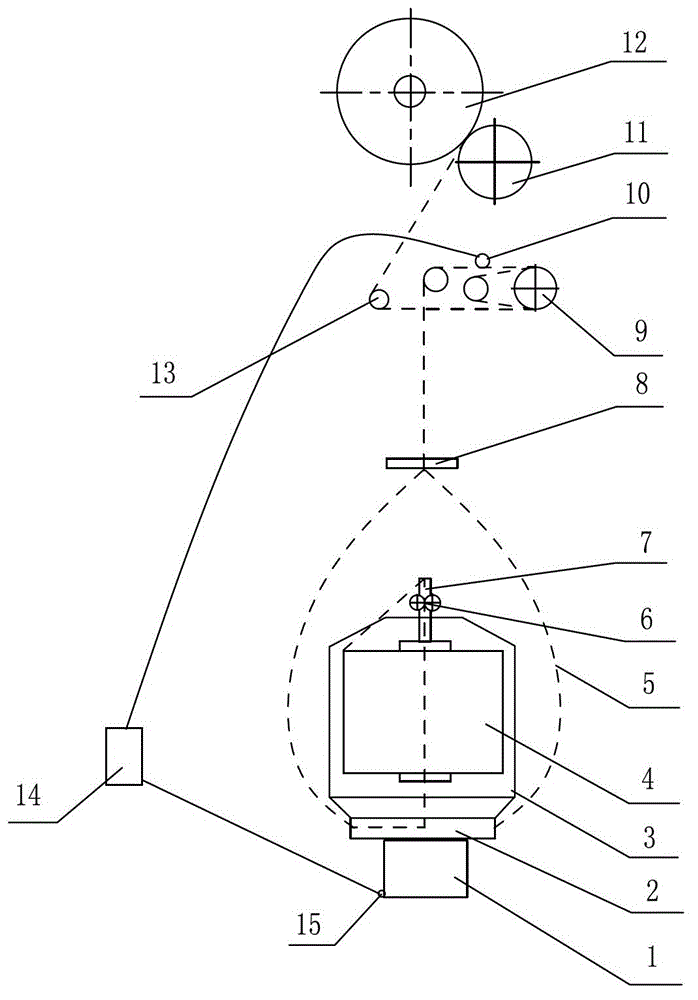

Hub motor driving automobile integrative design and cooperative control test platform and implementation method

ActiveCN108036953ARealize integrated designRealize collaborative controlVehicle testingSensori motorVehicle frame

The invention provides a hub motor driving automobile integrative design and cooperative control test platform and an implementation method. The platform comprises a whole vehicle control system, an active distributed driving system, an EMB electronic mechanical braking system, an active steering system, a power battery pack, a battery management system, a whole vehicle frame structure and a suspension module; the whole vehicle control system comprises a whole vehicle controller, a control mechanism sensor and a communication system; the active distributed driving system comprises four motor controllers, four hub motors, four wheels, an accelerator pedal and a hub motor sensor; the EMB electronic mechanical braking system comprises an EMB controller, four EMB brakes, a brake pedal sensor,a wheel cylinder pressure sensor and an EMMB brake angle and displacement sensor; the active steering system comprises a steering system control mechanism, a steering execution structure, a steering controller, and a steering knuckle angle and torque sensor. The whole vehicle frame is simple in structure, simple in process and high in expansibility.

Owner:YANSHAN UNIV

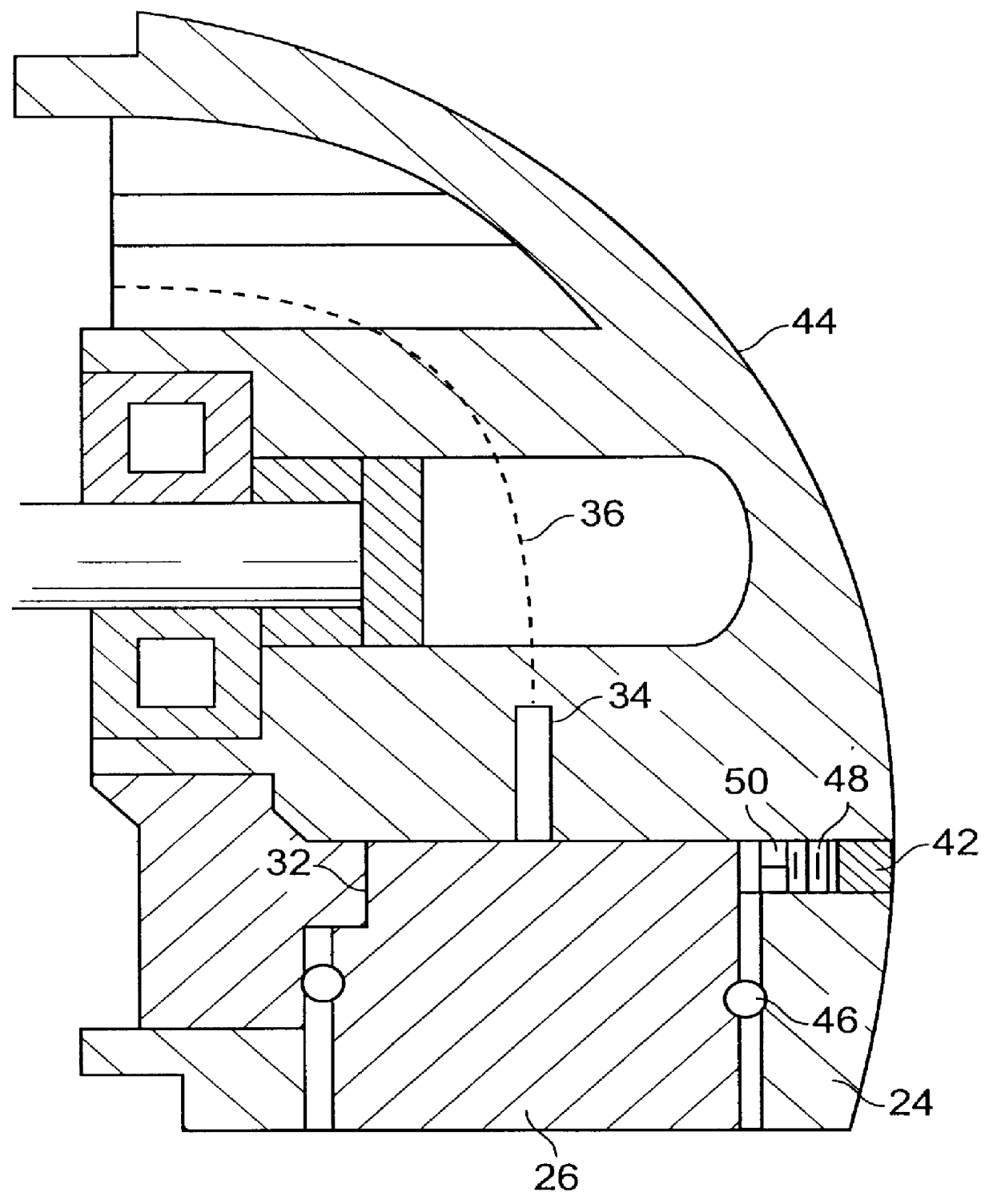

Replaceable trolling motor transducer

InactiveUS6160764AMinimal noiseMinimal disruptionNavigational aid arrangementsPropulsion power plantsSensori motorTransducer

An electric trolling motor for propelling a boat and comprising an electric propulsion motor having a substantially cylindrical motor housing and an electric trolling motor end cap for mounting and protecting a transducer therein, the end cap comprising a body portion having a recess integrally formed therein for receiving a transducer in the recess and a transducer removably mounted in the recess, a bore formed in the end cap creating a passageway extending from the exterior of the end cap to the interior of the recess, and a releasable air pressure seal for obturating the passageway and retaining the transducer in the recess when the passageway is obturated, and releasing the air pressure seal when the passageway is opened; also, a novel end cap for electric trolling motors.

Owner:MOLDED PARTS SPECIALISTS

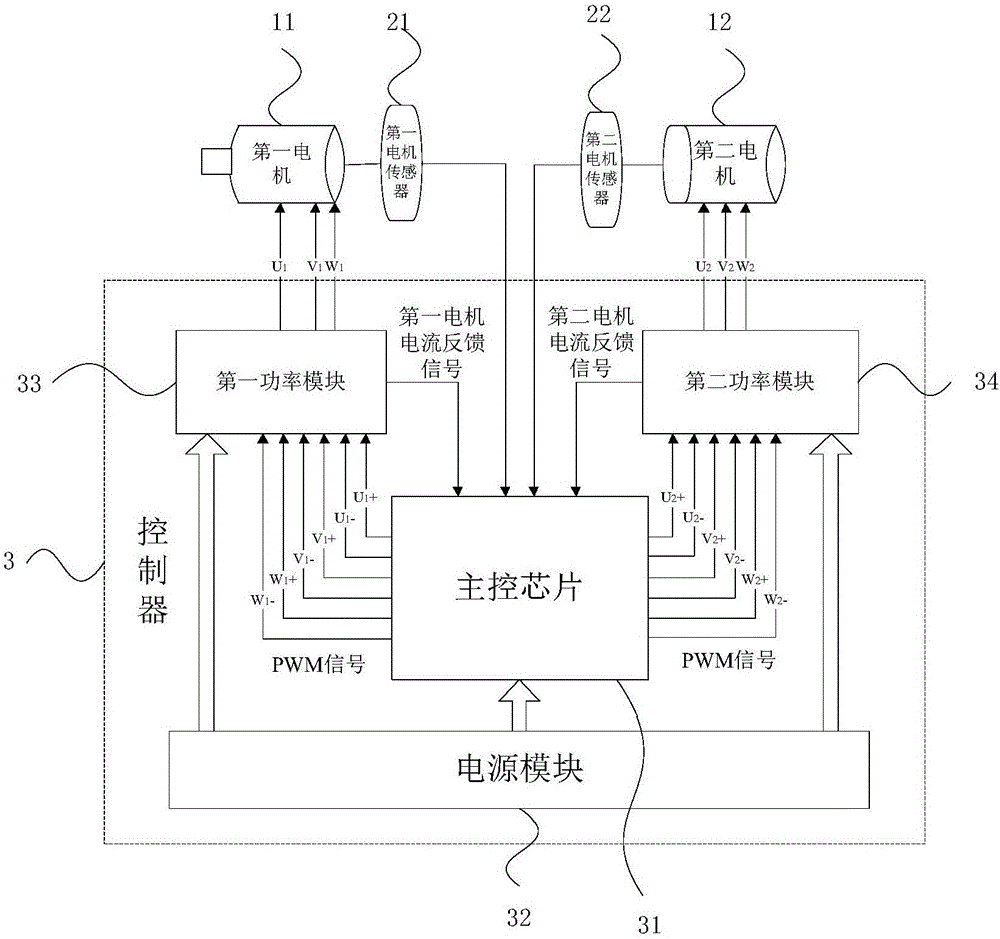

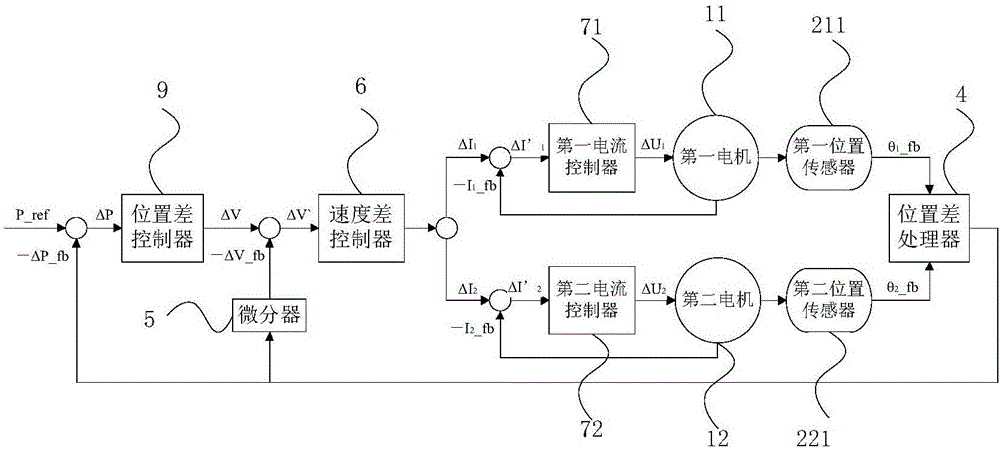

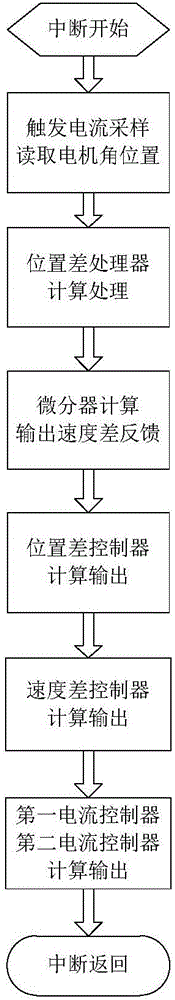

Dual-motor cooperative control system and method

PendingCN106787971ASimple structureImprove reliabilityMultiple dynamo-electric motors speed regulationSensori motorMotor drive

The invention belongs to the technical field of motor drive control, and specifically relates to a dual-motor cooperative control system and method. The system comprises a first motor, a first motor sensor, a second motor, a second motor sensor and a controller, wherein the controller comprises a main control chip, a power supply module, a first power module and a second power module; and the main control chip receives signals of the first motor sensor and the second motor sensor and current feedback signals of the first motor and the second motor, and respectively obtains multi-phase PWM signals for driving the first motor and the second motor through a control algorithm, and the first power module and the second power module generate corresponding multi-phase voltage signals to respectively drive the first motor and the second motor after receiving the multi-phase PWM signals. The control method comprises the following steps: respectively performing closed-loop control on the current of the two motors, and performing closed-loop control on the position difference and / or displacement difference and / or speed difference between the two motors. The dual-motor cooperative control system and method disclosed by the invention have the advantages of high cost performance, simple system structure and high control precision.

Owner:常州寻心电子科技有限公司

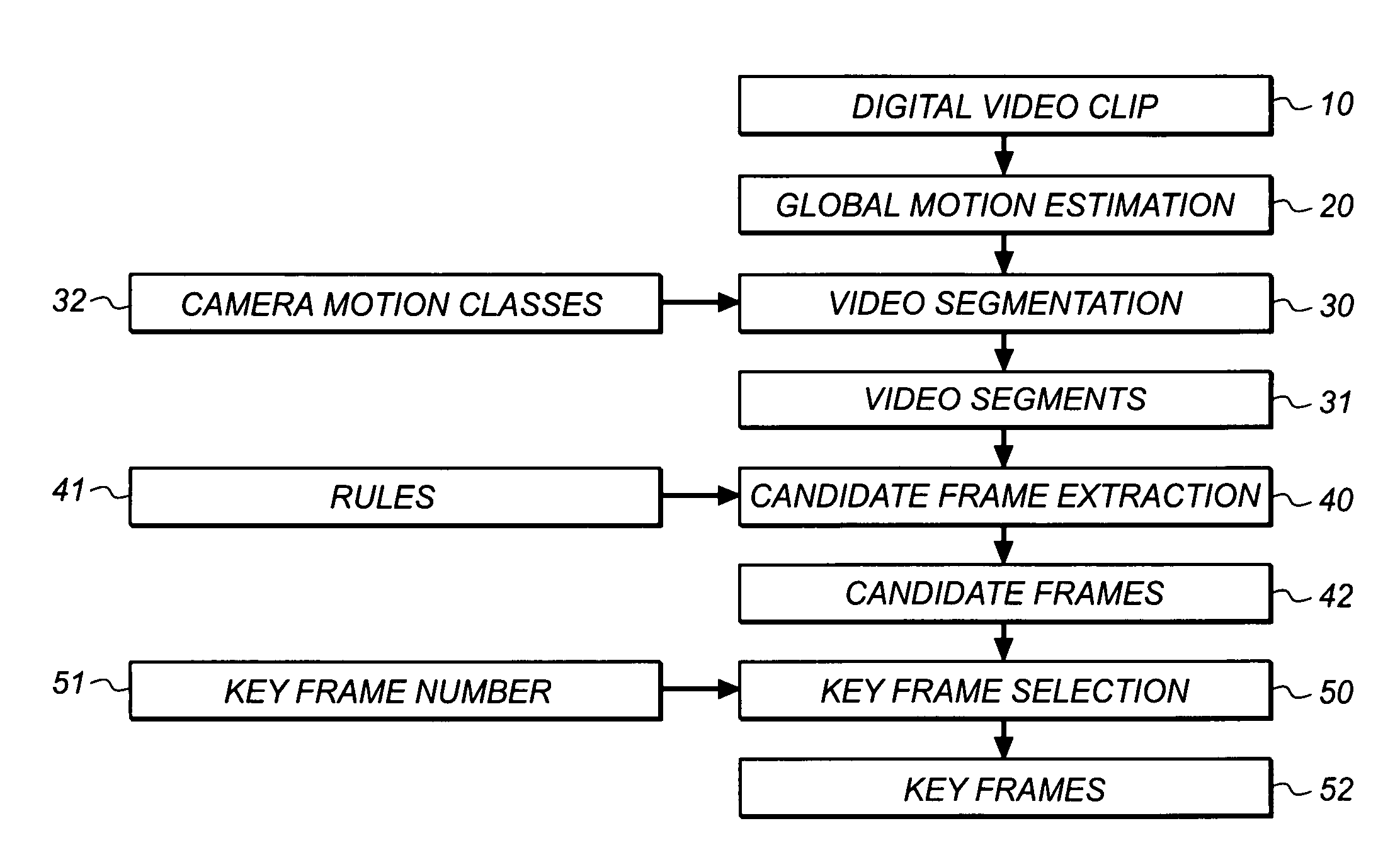

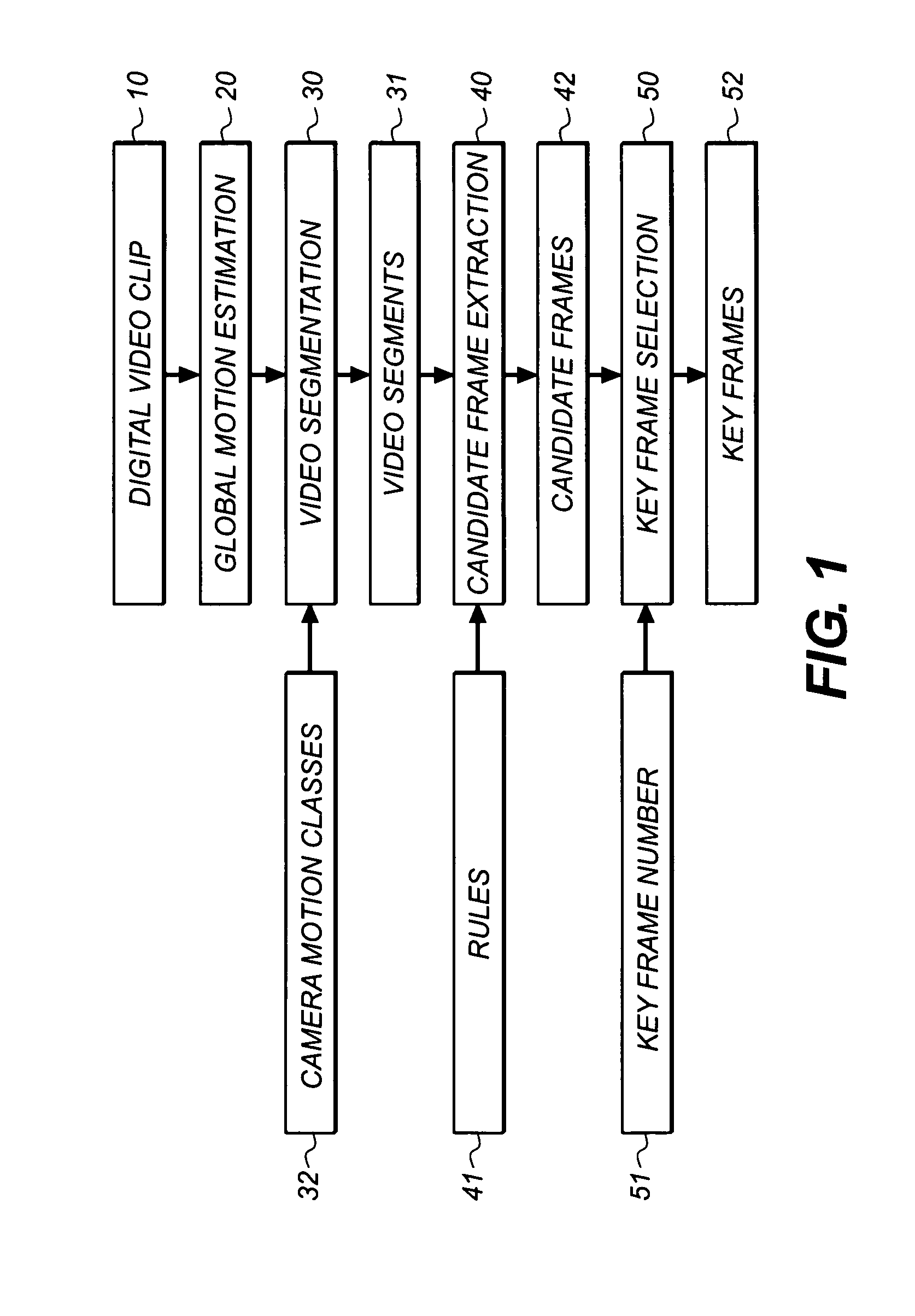

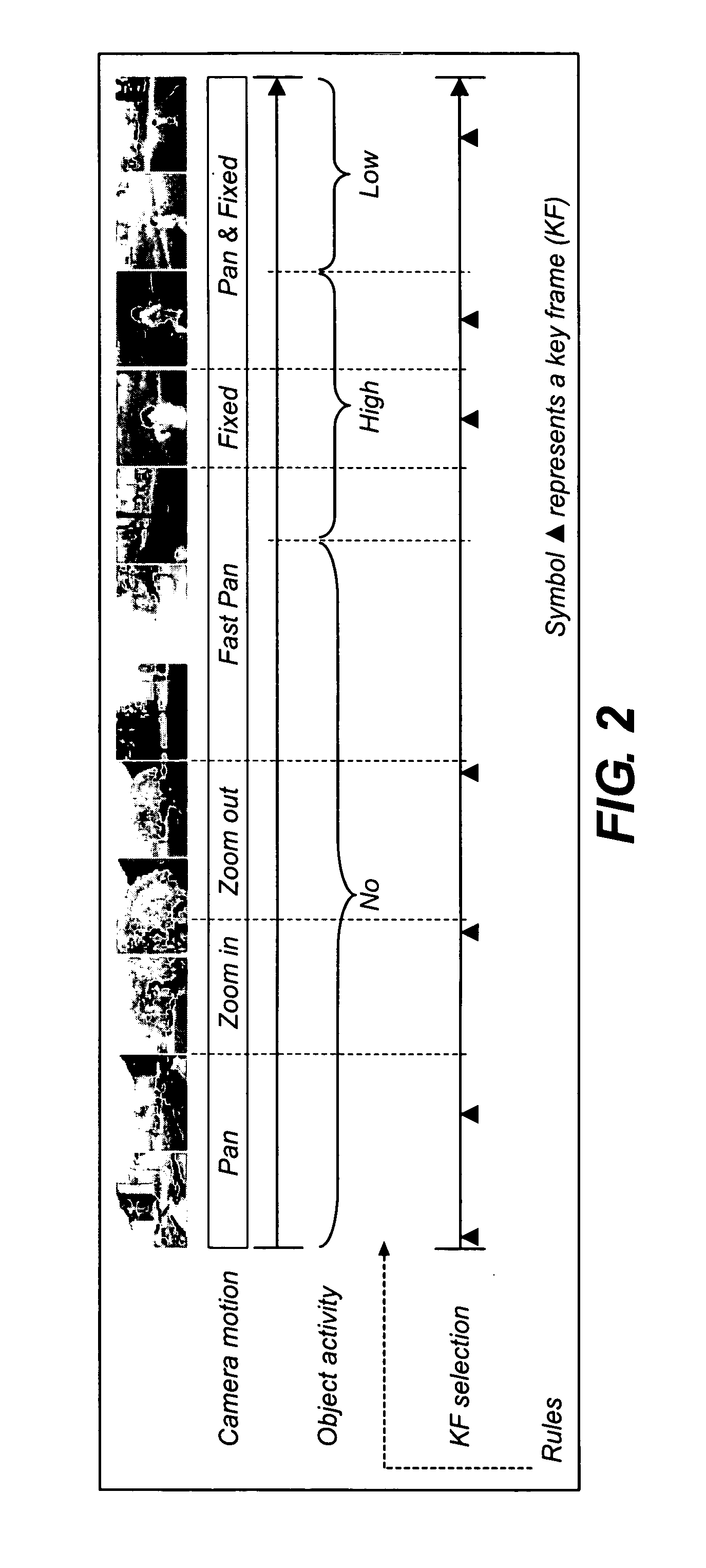

Analyzing camera captured video for key frames

InactiveUS8031775B2Satisfied with the resultTelevision system detailsTelevision system scanning detailsSensori motorDigital video

Owner:APPLE INC

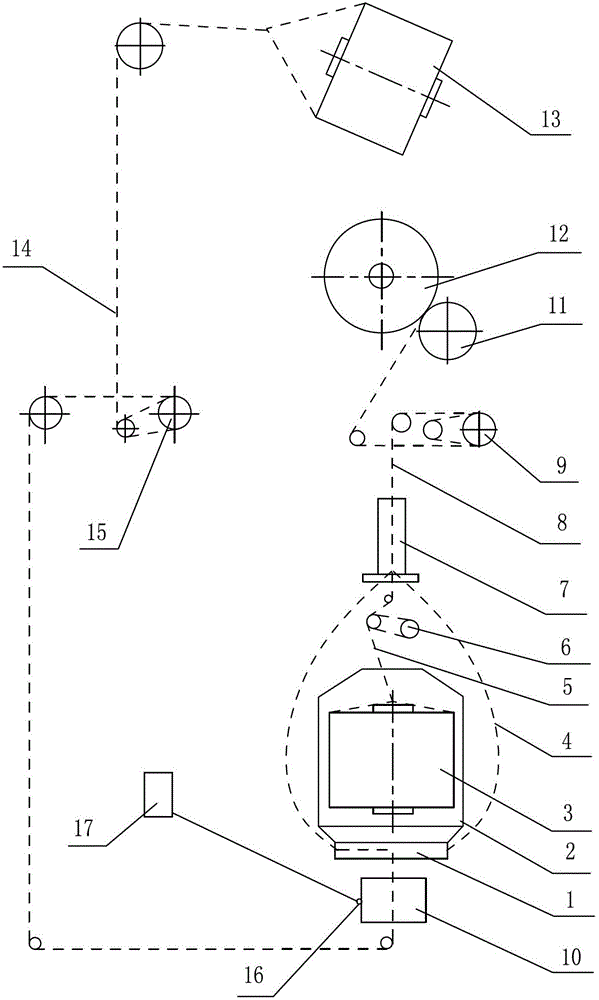

Control method for yarn ballooning size of straight twisting machine

ActiveCN103147188ASmall wrapping angleReduce energy consumptionContinuous wound-up machinesMotor speedSensori motor

The invention discloses a control method for a yarn ballooning size of a straight twisting machine, and belongs to the technical field of textile machinery. The problems that external yarn tension control is not accurate, and an optimum ballooning shape cannot be reached exist in the existing straight twisting machine. The straight twisting machine is characterized in that an external yarn sensor is arranged in a yarn path between a twisting tray and an external yarn tensioner and used for detecting an external yarn linear speed and yarn tension; a strand yarn sensor is arranged in a yarn path between an overfeeding device and an even twisting device and used for detecting a strand yarn linear speed and tension; or / and a motor sensor is arranged on a spindle drive motor and used for detecting a motor speed and motor current; the external yarn tensioner is driven by a separate motor to feed yarns actively; an overfeeding wheel of the overfeeding device is driven by a separate motor; and by taking one, two or three detection results of the three sensors as separate or combined control parameters, a control system controls a speed of the motor connected with the overfeeding wheel, adjusts a strand yarn pulling speed, and ensures that an external yarn tension value meets a requirement of the optimum yarn ballooning shape capable of allowing a wrapping angle to be minimum.

Owner:ZHEJIANG RIFA TEXTILE MACHINERY TECH CO LTD

Process for anodizing a robotic device

A robotic device has a base and at least one finger having at least two links that are connected in series on rotary joints with at least two degrees of freedom. A brushless motor and an associated controller are located at each joint to produce a rotational movement of a link. Wires for electrical power and communication serially connect the controllers in a distributed control network. A network operating controller coordinates the operation of the network, including power distribution. At least one, but more typically two to five, wires interconnect all the controllers through one or more joints. Motor sensors and external world sensors monitor operating parameters of the robotic hand. The electrical signal output of the sensors can be input anywhere on the distributed control network. V-grooves on the robotic hand locate objects precisely and assist in gripping. The hand is sealed, immersible and has electrical connections through the rotary joints for anodizing in a single dunk without masking. In various forms, this intelligent, self-contained, dexterous hand, or combinations of such hands, can perform a wide variety of object gripping and manipulating tasks, as well as locomotion and combinations of locomotion and gripping.

Owner:BARRETT TECH LLC

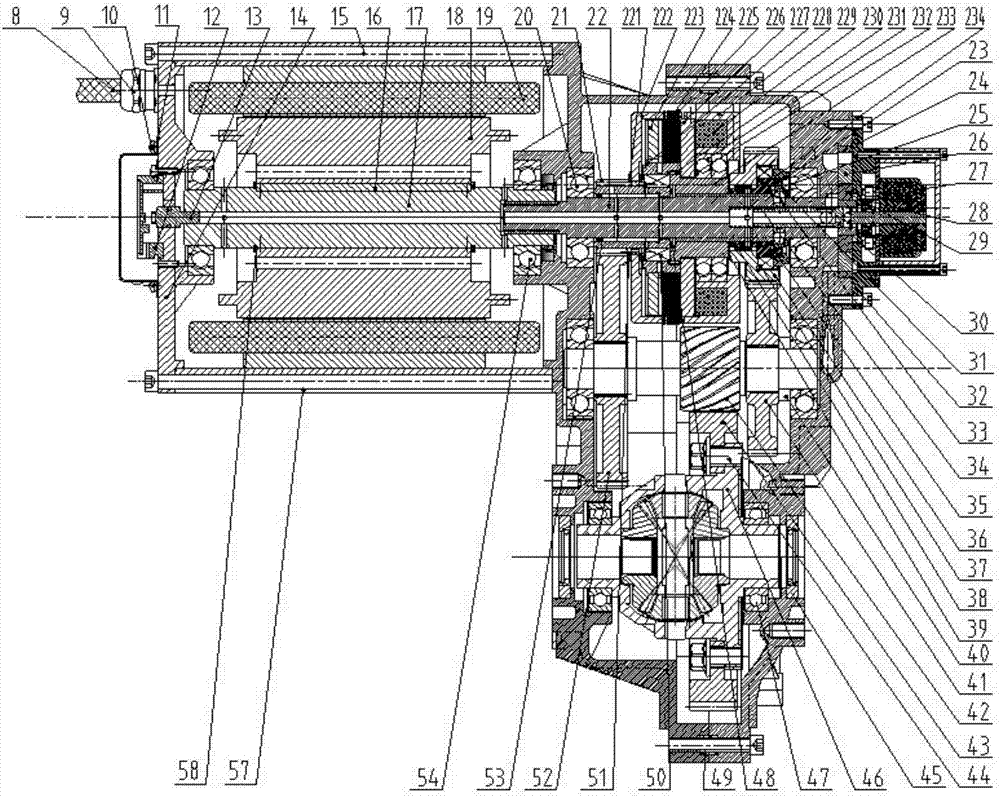

Electromobile power assembly and application thereof

PendingCN107020936AImprove work efficiencyImprove performanceElectric propulsion mountingElectric machinesSensori motorElectric machine

The invention relates to an electromobile power assembly and an application of the electromobile power assembly. The electromobile power assembly comprises an integrated drive motor, a transmission, a clutch, a differential mechanism and an oil pump; a motor shaft of the drive motor is in drive connection with one end of an input shaft of the transmission; the other end of the input shaft of the transmission is connected with the oil pump; the input shaft of the transmission is in drive connection with a differential mechanism gear of the differential mechanism through a first transmission gear and a second transmission gear; the clutch is arranged on the input shaft of the transmission and is in drive connection with the first transmission gear; and the drive motor is provided with a motor sensor. The electromobile power assembly effectively switches the gear according to the actual condition of an electromobile, so that the operating conditions of the electromobile better accords with the actual road condition, the working efficiency of the electromobile is improved, meanwhile, the performance of the existing electromobile is optimized, the starting is stable, the gear is smoothly and rapidly switched, the operation of the electromobile is efficient and safe, and the smoothness and the reliability of the operation the whole electromobile are improved.

Owner:荣成市荣佳动力有限公司

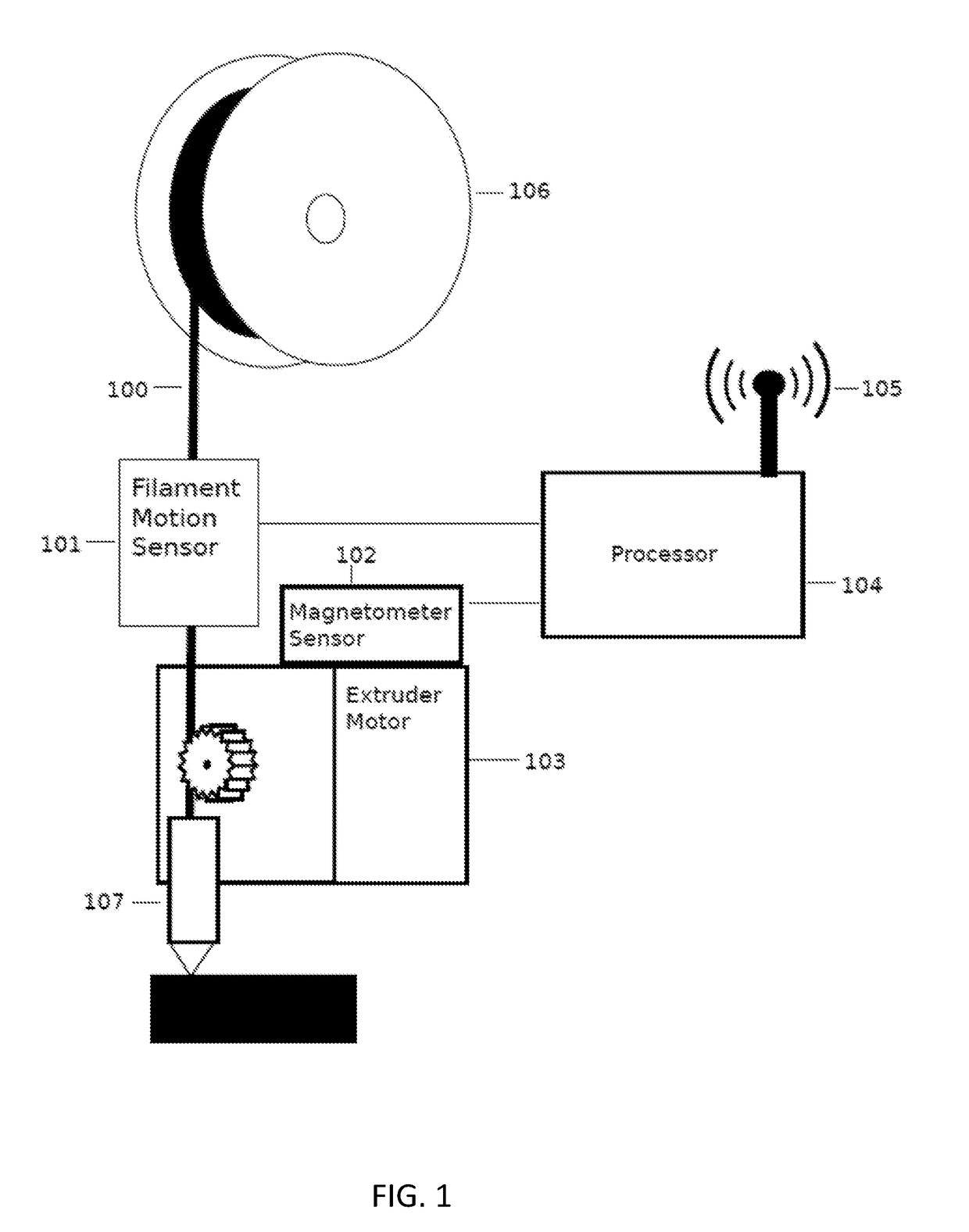

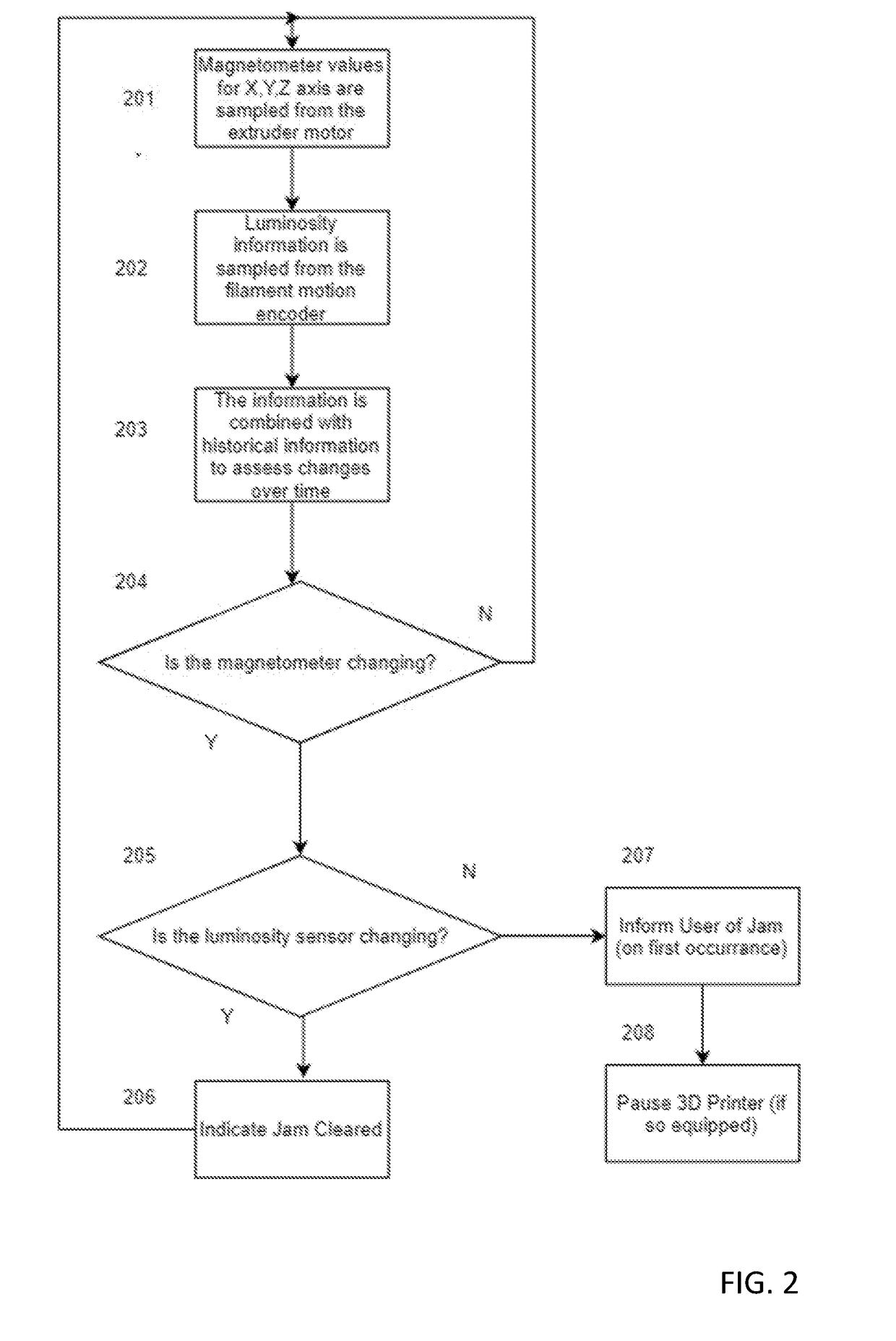

System and method for nonintrusive detection of 3D filament jams and runout

A system, method and computer program product for detecting filament jams and filament runout conditions on Fused Deposition Modeling (FDM) 3D printers, including a filament feed sensor configured to detect feeding of a filament by a filament drive motor and provide a feeding status thereof; a filament drive motor sensor configured to detect movement of the filament drive motor and provide a movement status thereof; and a processor configured to compare the feeding status and the movement status to detect at least one of a filament jam and filament runout condition on a Fused Deposition Modeling (FDM) 3D printer.

Owner:ROBOGARDENS LLC

Self-movement screen frame for preventing cervical spondylosis

InactiveCN106949349AIngenious designEasy to useStands/trestlesProgramme control in sequence/logic controllersSensori motorCervical spondylosis

The invention provides a self-movement screen frame for preventing cervical spondylosis. The self-movement screen frame comprises a bracket, a horizontal sliding mechanism, a vertical lifting mechanism, an inclined rotation mechanism and a control mechanism; the bracket comprises a supporting rod and a fixing frame; the horizontal sliding mechanism comprises a sliding frame and a push-rod device, and the push-rod device comprises a push rod and a push-rod motor; the vertical lifting mechanism comprises a lifting rod, gears and a lifting motor; the inclined rotation mechanism comprises an inclined fixing frame, a rotating angle arm and a screen frame body, the rotating angle arm comprises at least one inclined angle motor and a rotating rod, and the screen frame body is provided with a sensor; and the control mechanism is connected with the push-rod motor, the lifting motor, the inclined angle motors and the sensor through signals. By means of the self-movement screen frame for preventing cervical spondylosis, a screen can be adjusted correspondingly along with rotation of the head of a user, cervical spondylosis is prevented, and it is beneficial to prevention of shortsightedness.

Owner:FUDAN UNIV

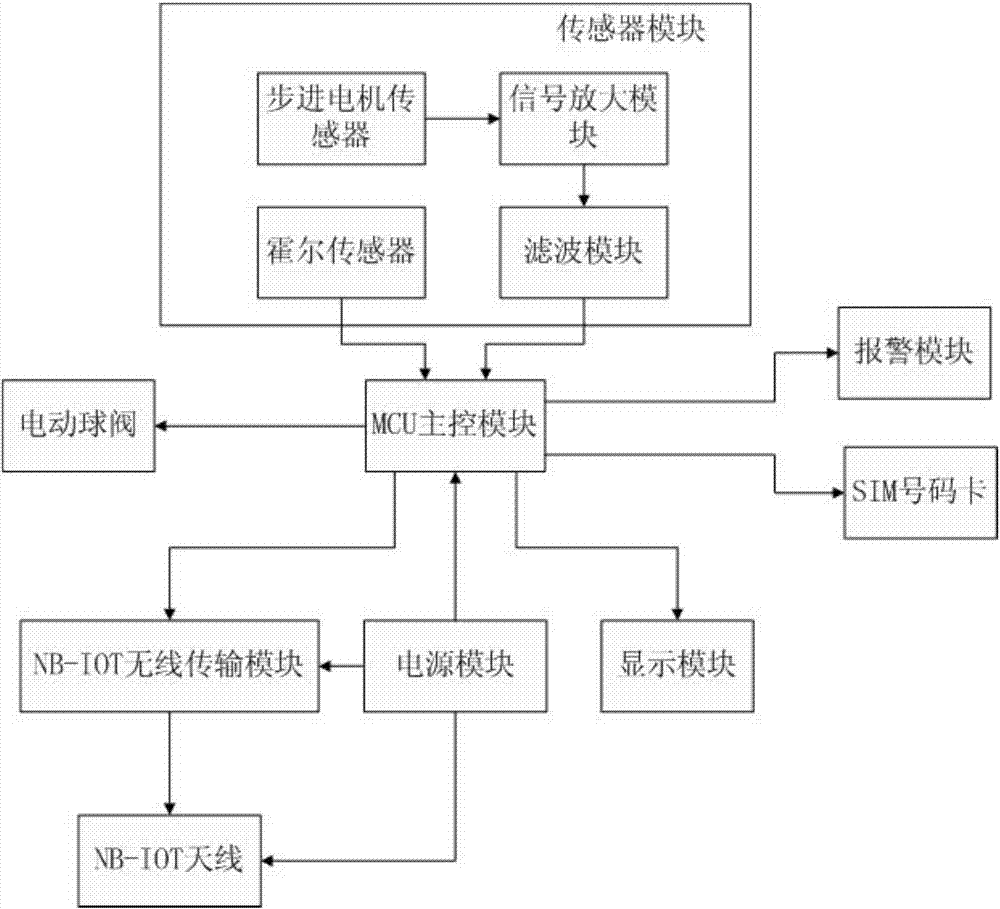

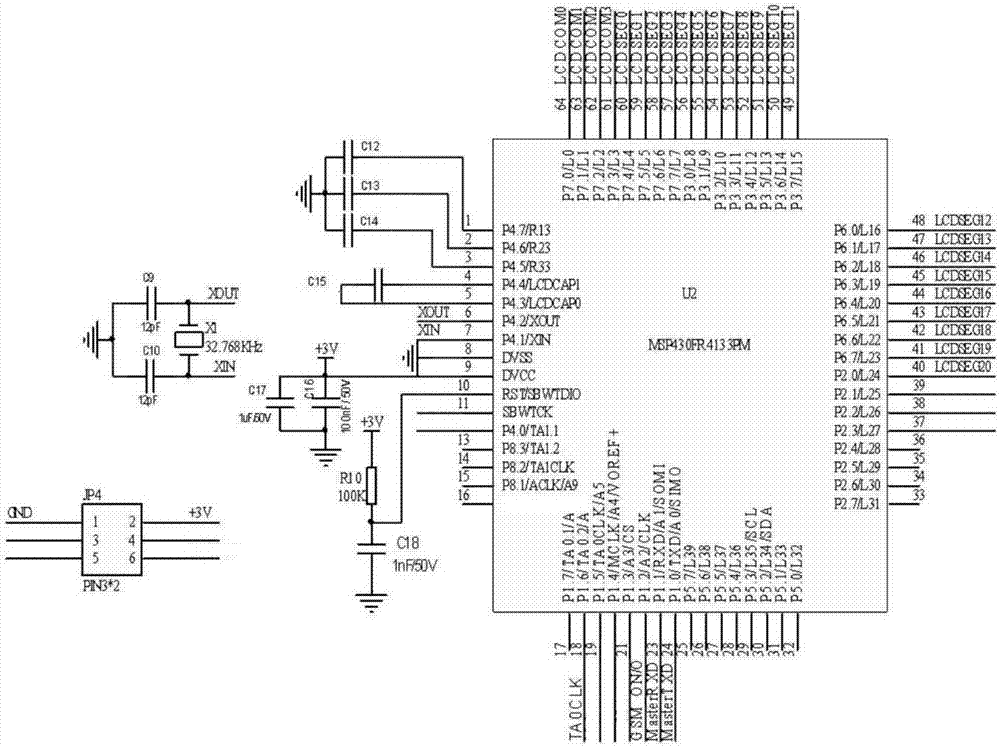

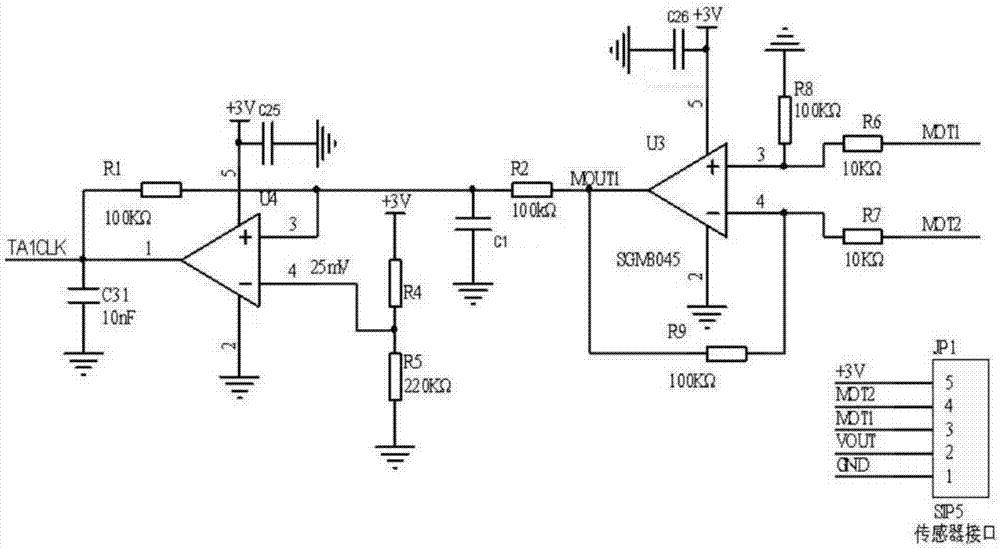

Wireless intelligent remote water meter based on NB-IOT

PendingCN107576358AExtended service lifeHealth effectsVolume/mass flow measurementVolume indication and recording devicesSensori motorWireless transmission

The invention relates to a wireless intelligent remote water meter based on NB-IOT. The water meter comprises a control circuit arranged in an upper cavity of the water meter body, and the control circuit comprises an MCU master control, a sensor module, a display module, an NB-IOT wireless transmission module, a warning module and a power supply module; the MCU master control module is used for converting collected signals into water flow information, the sensor module is used for collecting voltage and pulse signals, and the sensor module, the display module, the NB-IOT wireless transmissionmodule, the warning module and the power supply module are connected with the MCU master control module; the sensor module comprises a stepping motor sensor and one or more hall sensors; the output end of the NB-IOT wireless transmission module is connected with an NB-IOT antenna and connected with a cloud server through an NB-IOT cellular base station. According to the water meter, by arrangingthe NB-IOT wireless transmission module, the water meter works in an authorized frequency band so as to achieve wireless meter reading.

Owner:FUJIAN WIDE PLUS PRECISION INSTR

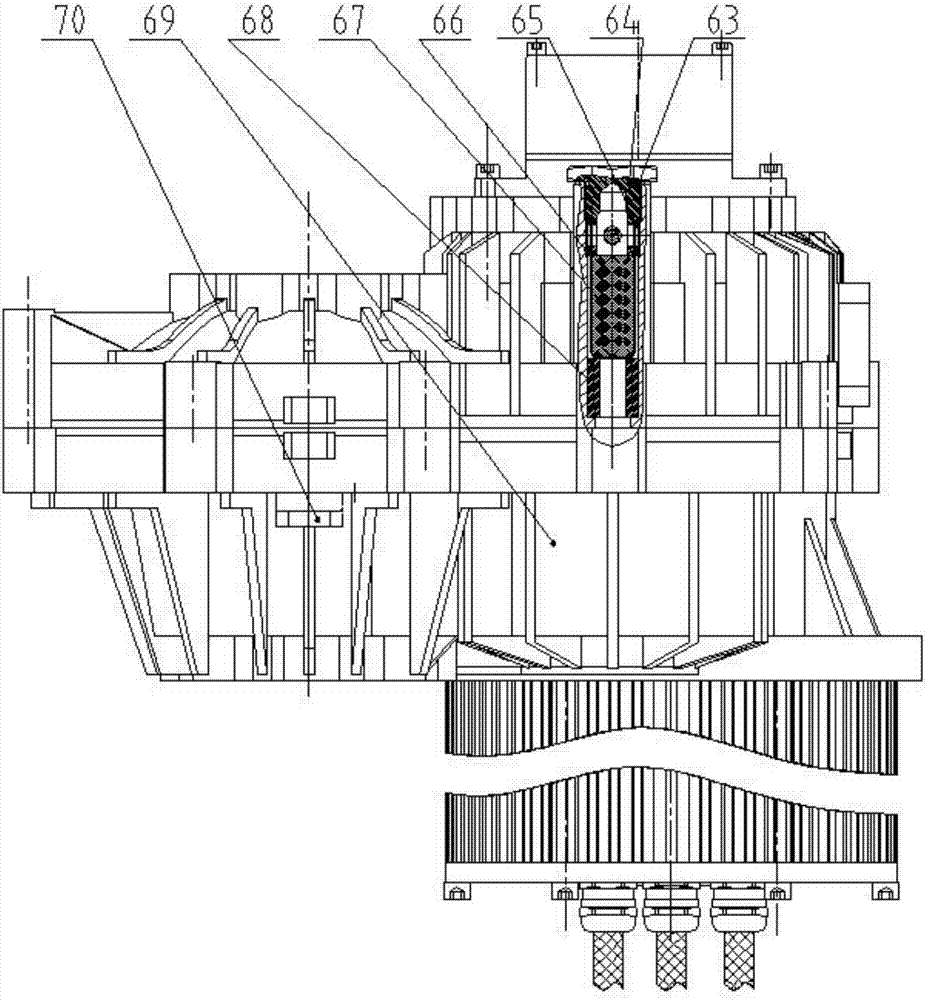

Two-for-one twister

ActiveCN103147185ASmall wrapping angleReduce energy consumptionContinuous wound-up machinesMotor speedSensori motor

The invention discloses a two-for-one twister, and belongs to the field of textile machinery. The problems that the energy consumption is great, and noise is high due to the fact that an optimum ballooning shape cannot be reached exist in the existing two-for-one twister. The two-for-one twister comprises a spindle mounted on a rack, a spindle drive motor, a yarn collecting device, an overfeeding device, a coiling device and a control system, wherein a radial yarn passing hole in a spindle twisting tray is communicated with a hollow inner cavity of a spindle blade; a tensioner is arranged on the spindle blade; a yarn sensor is arranged in a yarn path between the yarn collecting device and the overfeeding device and used for detecting a yarn speed and yarn tension; a motor sensor is arranged on the spindle drive motor and used for detecting a motor speed and motor current; an overfeeding wheel of the overfeeding device is driven by a separate motor; by taking the yarn speed, the yarn tension, the spindle drive motor speed, and the motor current fed back by the sensors as control parameters, the control system controls the motor connected with the overfeeding wheel to operate, adjusts a yarn pulling speed, and ensures that a yarn tension value meets a requirement of the optimum yarn ballooning shape capable of allowing a wrapping angle to be minimum; and energy conservation and noise reduction are achieved.

Owner:ZHEJIANG RIFA TEXTILE MACHINERY TECH CO LTD

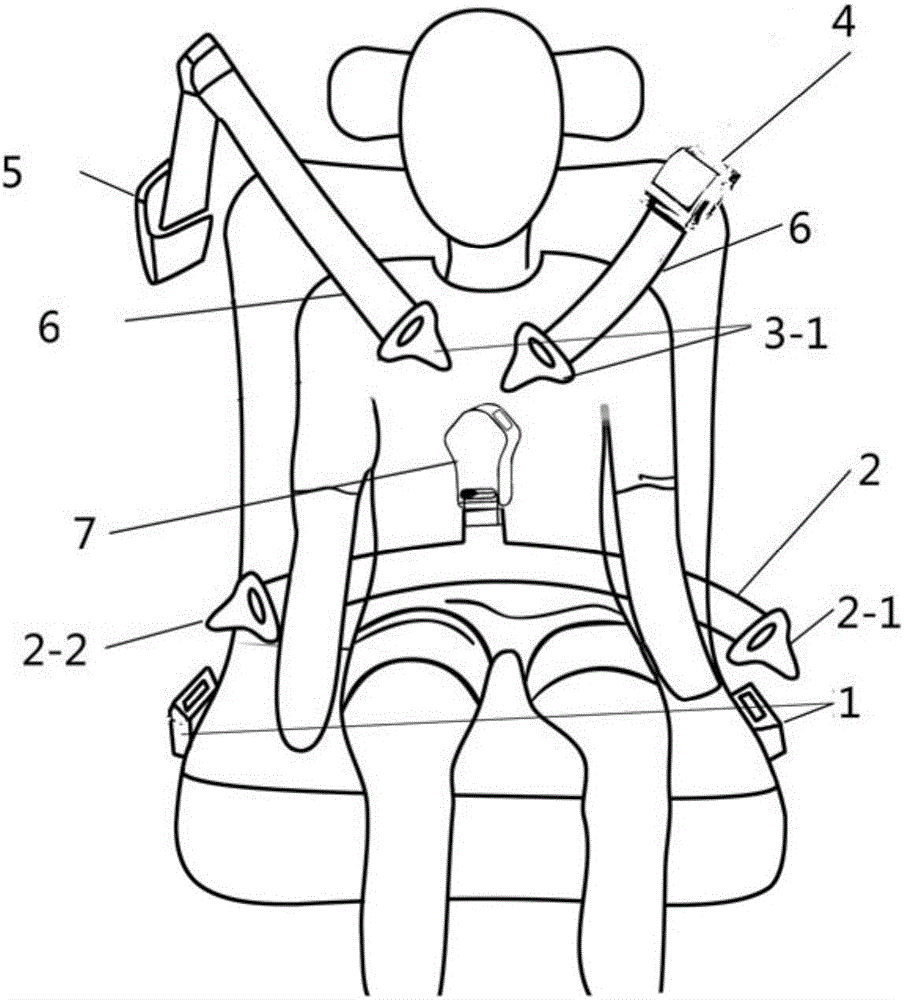

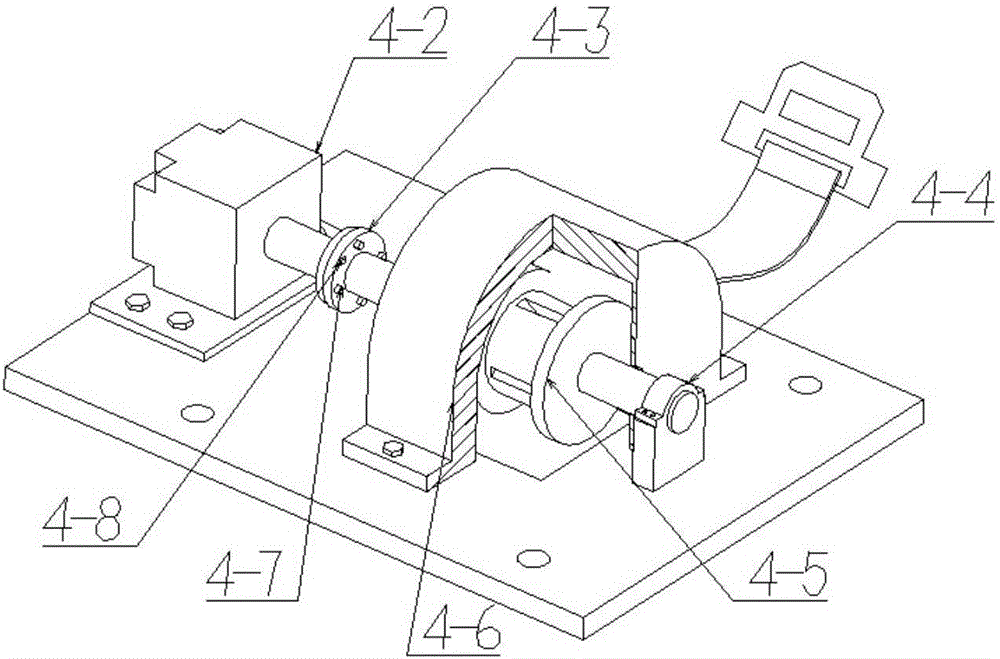

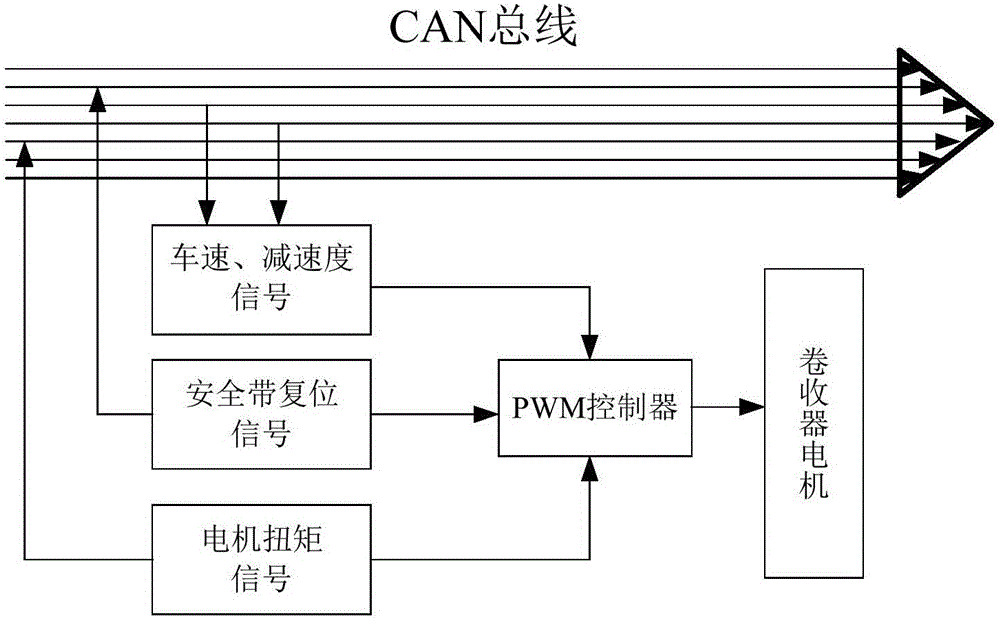

Vehicle safety belt and control system thereof and control method thereof

InactiveCN105774743ASimple structureIncrease the bearing areaBelt retractorsBelt control systemsSensori motorDrive shaft

The invention discloses a vehicle safety belt and a control system thereof and a control method thereof. The vehicle safety belt specifically comprises side locking buckle seats and waistbands, wherein the side locking buckle seats are mounted on the two sides of the bottom of a vehicle seat; and two ends of the waistbands are respectively provided with left waistband buckles and right waistband buckles; front bridle buckling seats are arranged in the middle of the waistbands; a left retractor and a right retractor are mounted on the two sides of the upper end of the vehicle seat; front bridles are arranged in both the left retractor and the right retractor; the front ends of the front bridles are provided with front bridle inserting buckles; retractor returning motor sensors and wiring harnesses are arranged on the front bridle inserting buckles; the retractors comprise stepping motors fixed on a vehicle body; through shaft couplings, the stepping motors are connected with one ends of transmission shafts, on which safety belt wheels are mounted; and one ends of the front bridles are fixed on the safety belt wheels. Through adoption of the separated bridles, the force bearing area of a passenger can be effectively increased, comfortable damages suffered by passengers due to sudden deceleration is prevented, and due to the selectively worn waistband design, the vehicle safety belt can become the traditional three-point safety belt only by removing the waistbands. The vehicle safety belt disclosed by the invention is simply structured and can provide different wearing experiences to the passengers.

Owner:CHANGAN UNIV

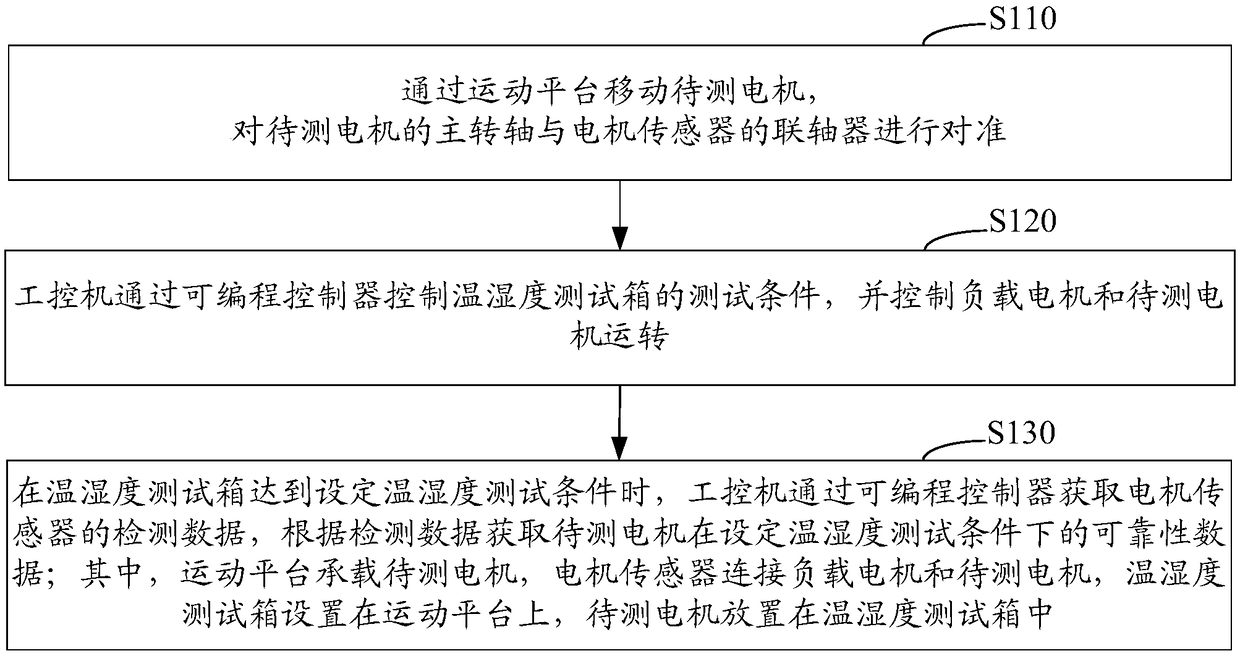

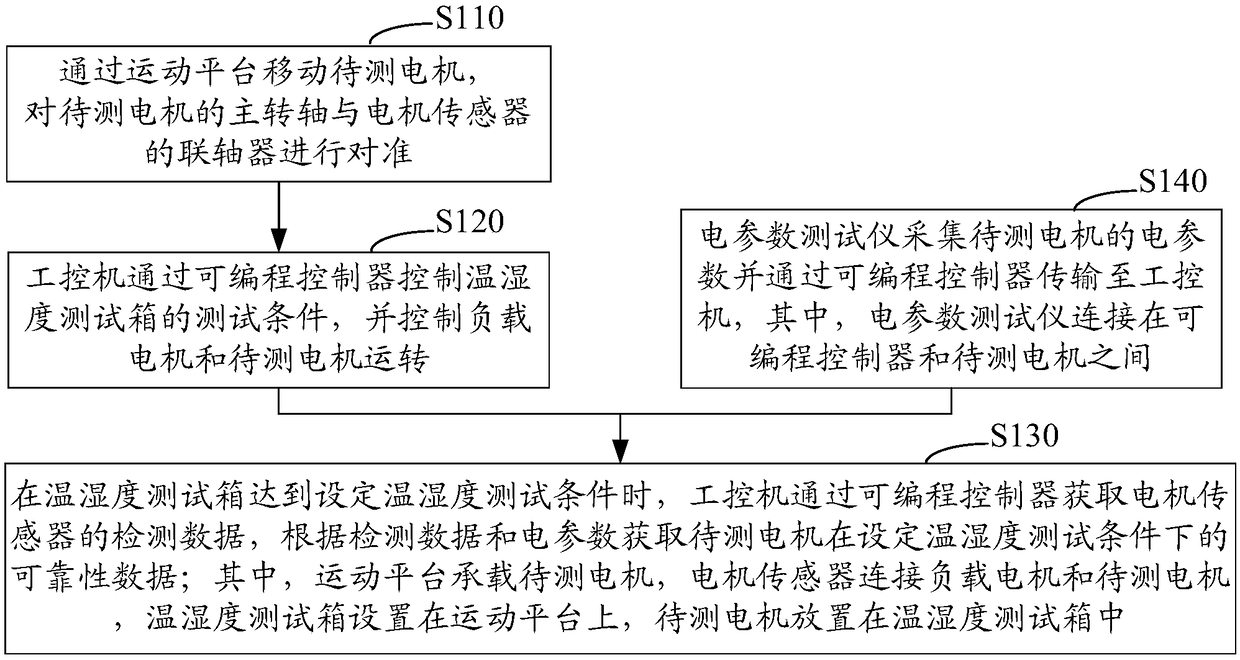

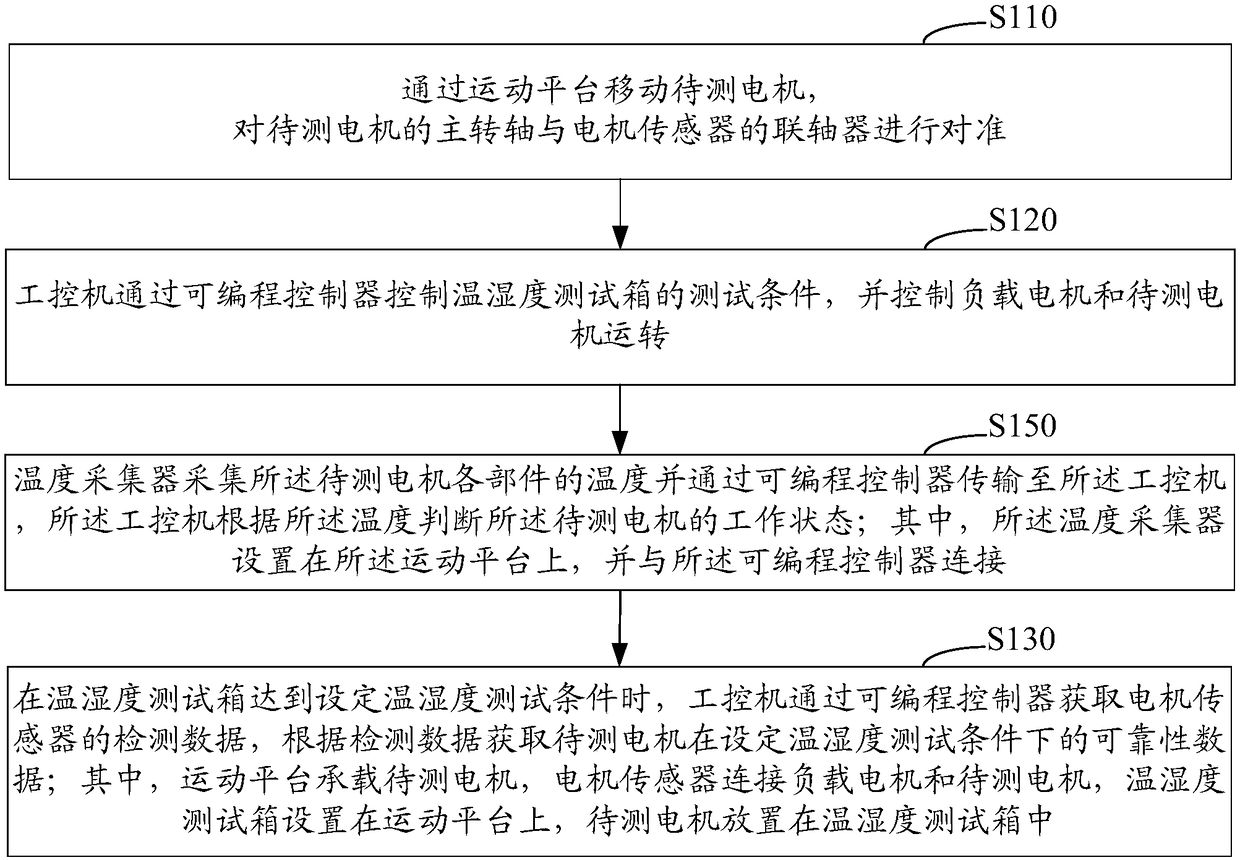

Motor reliability testing method

InactiveCN108363005AImproved reliability testingAccurate connectionDynamo-electric machine testingSensori motorCoupling

The invention relates to a motor reliability testing method and belongs to the technical field of reliability testing. A main spindle of a to-be-tested motor is aligned with a coupler of a motor sensor through a motion platform, so that the to-be-tested motor can be connected with a load motor accurately. An industrial personal computer controls testing conditions of a humidity and temperature testing box through a programmable controller, so that a working environment of the to-be-tested motor in practical working can be simulated. The industrial personal computer controls operation of the load motor and the to-be-tested motor through the programmable controller and acquires detection data of the motor sensor, and acquires reliability data of the to-be-tested motor according to the detection data. By utilizing the industrial personal computer, automatic testing of motor reliability in a practical working condition can be simulated and accuracy of motor reliability testing can be improved.

Owner:广东中创智腾技术服务有限公司

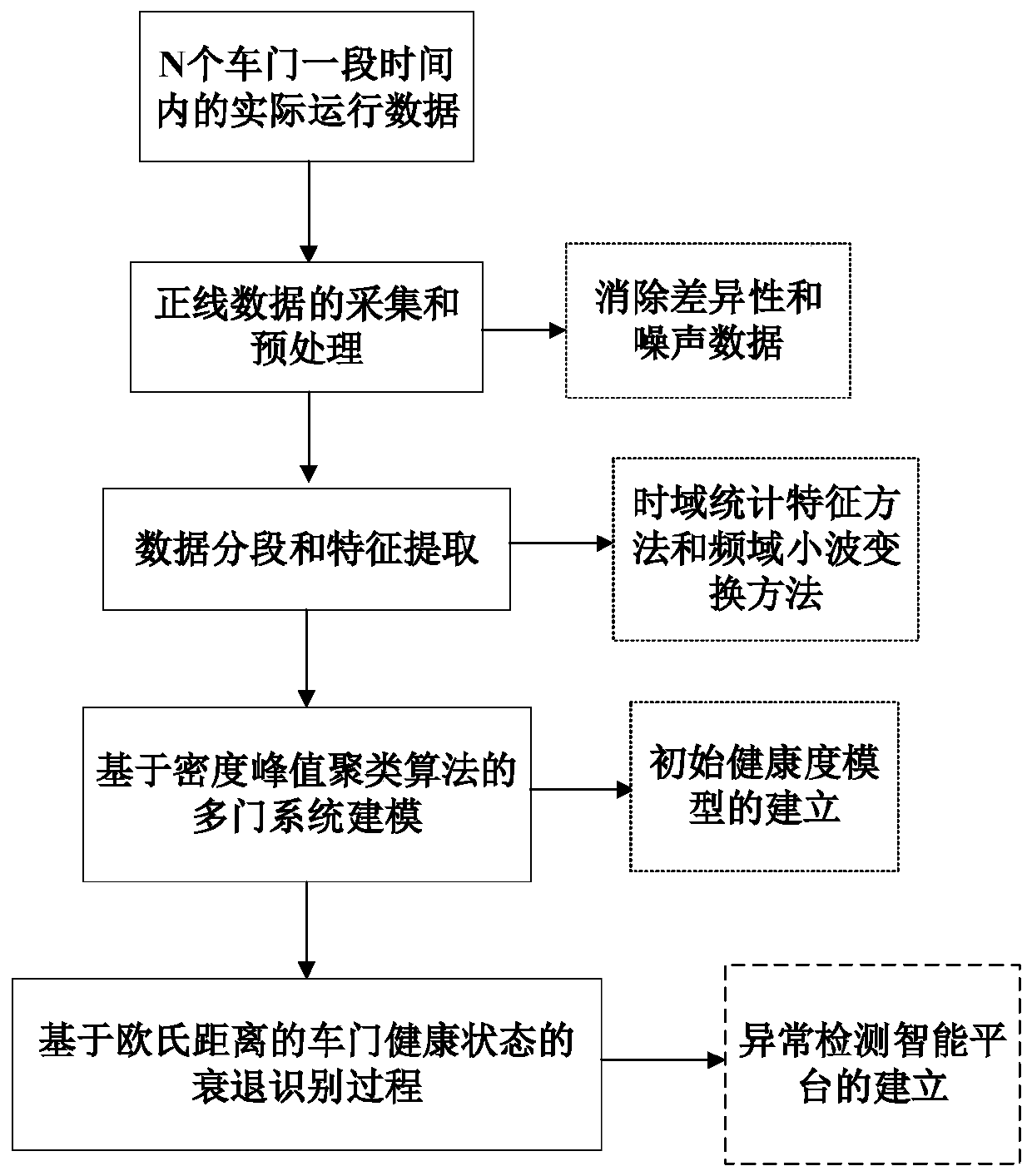

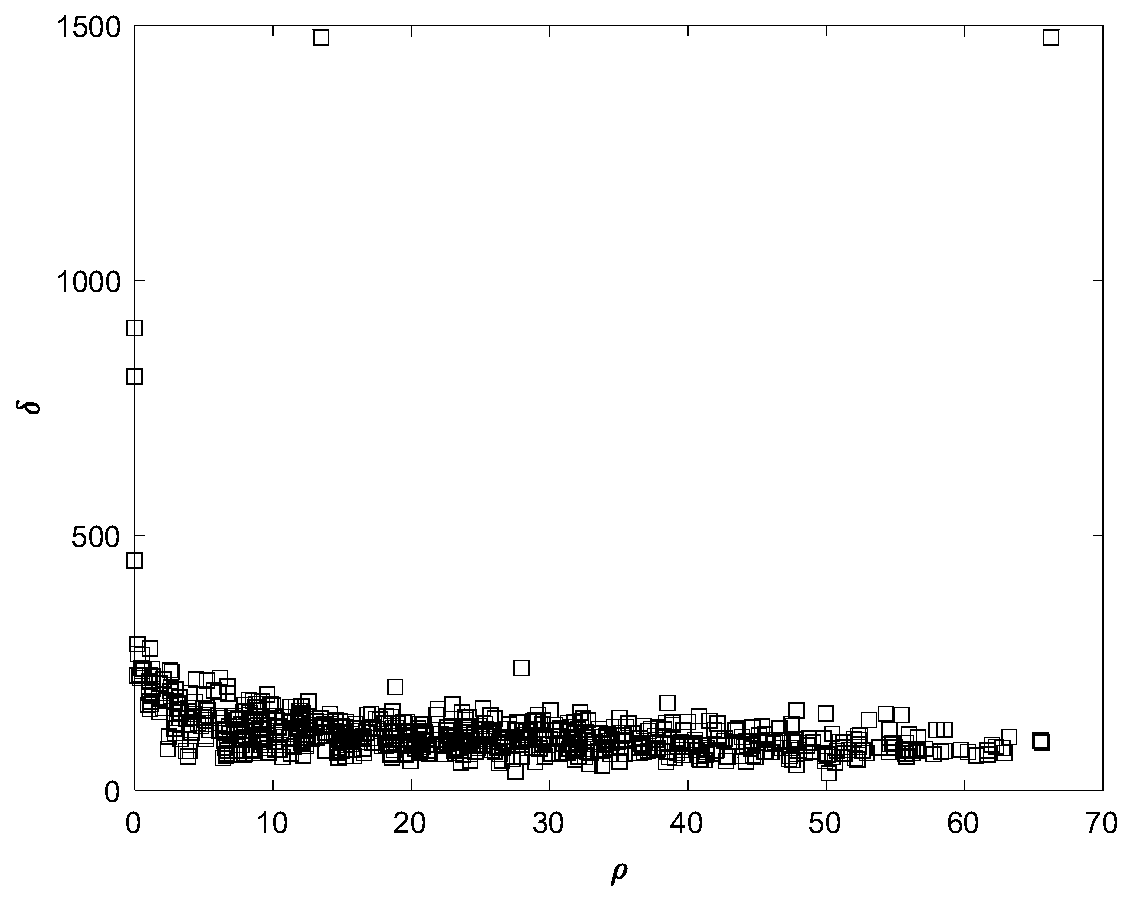

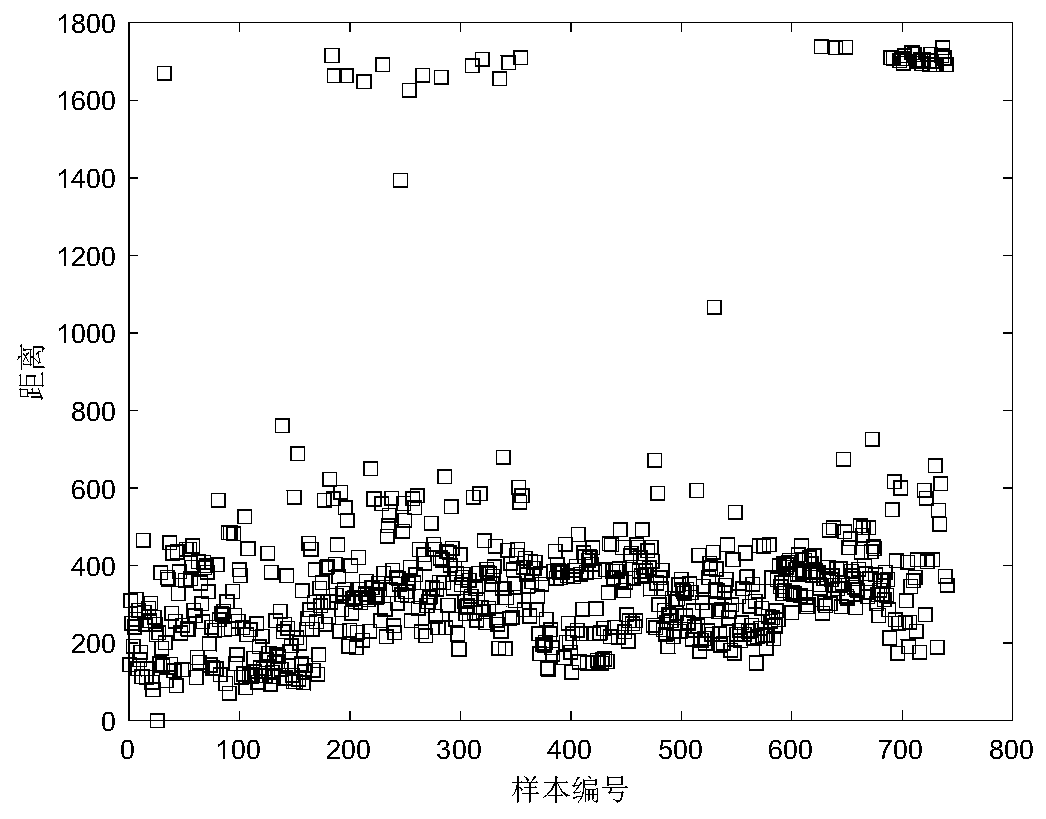

DPC-based subway train door system performance degradation detection method

InactiveCN110398382ARemove Noisy DataFull feature setMachine part testingElectrical testingTime domainSensori motor

The invention discloses a DPC-based subway train door system performance degradation detection method. The method comprises the following steps: (1) acquiring main line data of operation of a subway train door system through a motor sensor, and preprocessing the main line data and eliminating noise data; (2) performing piecewise feature extraction for the preprocessed data, analyzing time-domain characteristics through a univariate statistical analysis method, and obtaining a feature set which can completely embody states of the subway train door system; (3) based on a density peak clusteringalgorithm, building a system multi-door health initial state model for extracted system features; (4) identifying a degradation process of each train door performance in the multi-door system throughEuclidean distance. The DPC-based subway train door system performance degradation detection method provided by the invention can detect and judge whether train door system performance degrades, can reduce repetitive experimental design and data acquisition works, cannot be affected by train door types and types of locking devices, and has good universality.

Owner:NANJING KANGNI MECHANICAL & ELECTRICAL +1

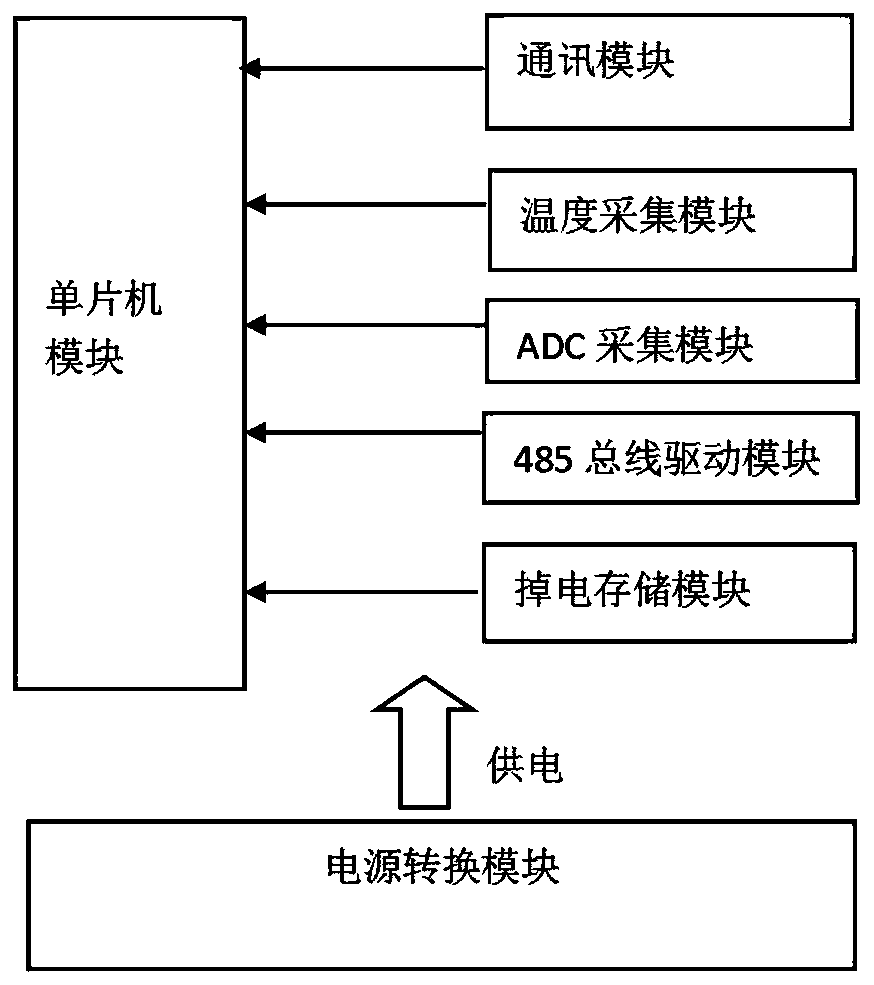

Motor sensor data acquisition unit and method

InactiveCN110597144AReduce the burden onReduce upload bandwidthProgramme controlComputer controlMicrocomputerMicrocontroller

The invention discloses a motor sensor data acquisition unit and method, and the unit comprises a single-chip microcomputer, and a temperature acquisition module, an ADC acquisition module, a 485 busdrive module and a storage module connected to the single-chip microcomputer, wherein the single-chip microcomputer starts a DSP unit, processes the temperature, voltage and current signals collected,removes periodic and sudden interference noise by a filtering algorithm, and identifies the characteristic fault of the motor by a mechanism model algorithm. When a known type is detected, the single-chip microcomputer accelerates the sampling and more accurately identifies fault information. The comprehensive collection of signals about vibration, current and temperature of the motor can determine at the acquisition end that an edge computing has been carried out, without waiting for the network host to issue a command to the bottom to execute. In the field environment where the network bandwidth is not too high, the need for data upload to the network can be reduced to improve the real-time performance of the network. The network can also be prevented from interfering with the scene tocause production accidents when the network is abnormal.

Owner:鞍钢集团自动化有限公司

Method for controlling external yarn tension of straight twisting machine

InactiveCN103147187AReduce energy consumptionReduce noiseContinuous wound-up machinesMotor speedSensori motor

The invention discloses a method for controlling external yarn tension of a straight twisting machine, and belongs to the technical field of textile machinery. The problems that external yarn tension control is not accurate, and an optimum ballooning shape cannot be reached exist in the existing straight twisting machine. The method is characterized in that a motor sensor is arranged on a spindle drive motor and used for detecting a motor speed and motor current; an external yarn tensioner is driven by a separate motor to feed yarns actively; an overfeeding wheel of the overfeeding device is driven by a separate motor; by taking a speed of the motor sensor and / or the motor current as control parameters, a control system controls the speed of the motor connected with the overfeeding wheel, adjusts a strand yarn pulling speed, and ensures that a tension value of an external yarn meets a requirement of the optimum yarn ballooning shape capable of allowing a wrapping angle to be minimum; energy consumption is saved; and noise is reduced.

Owner:浙江日发纺织机械股份有限公司

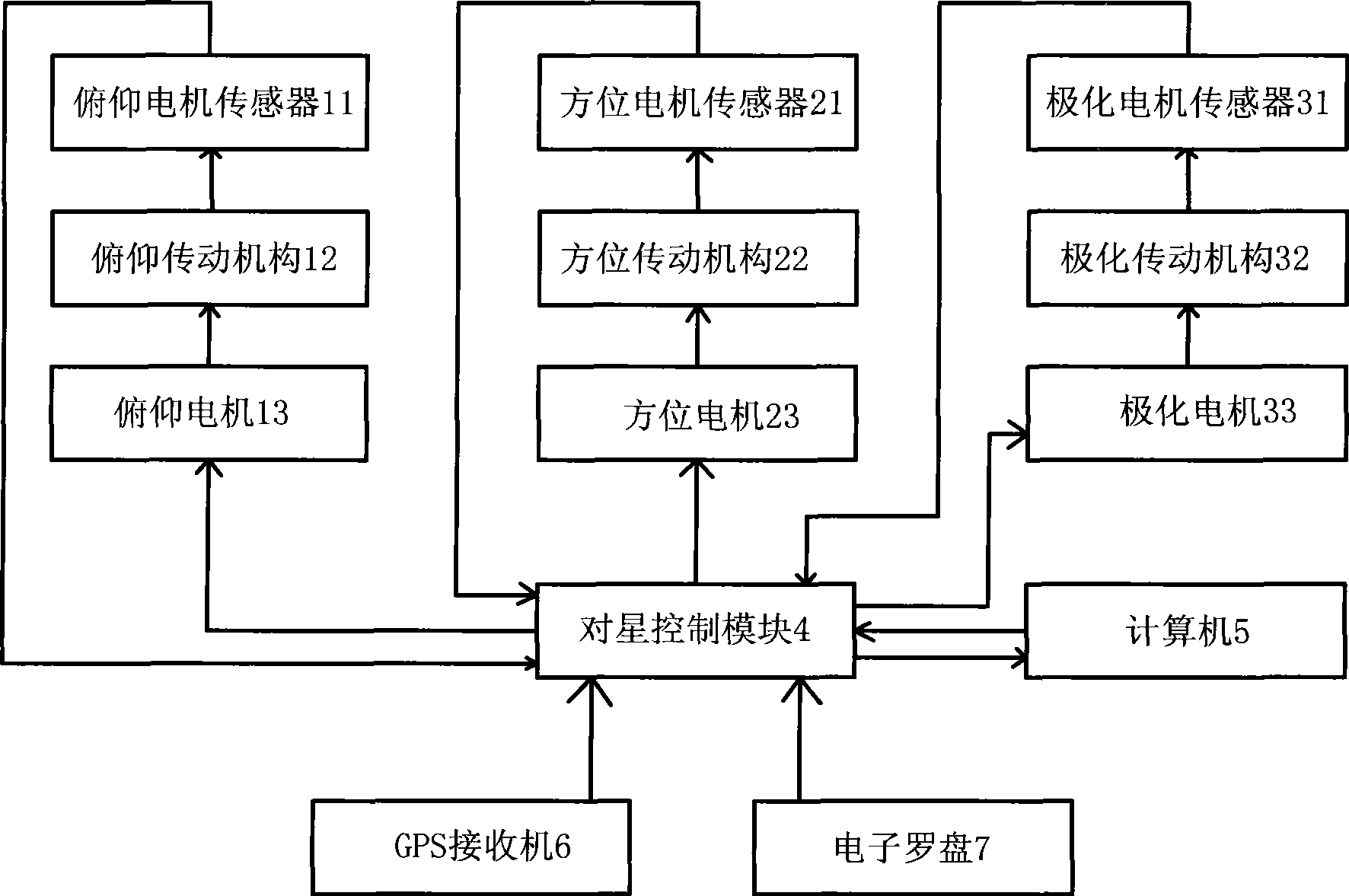

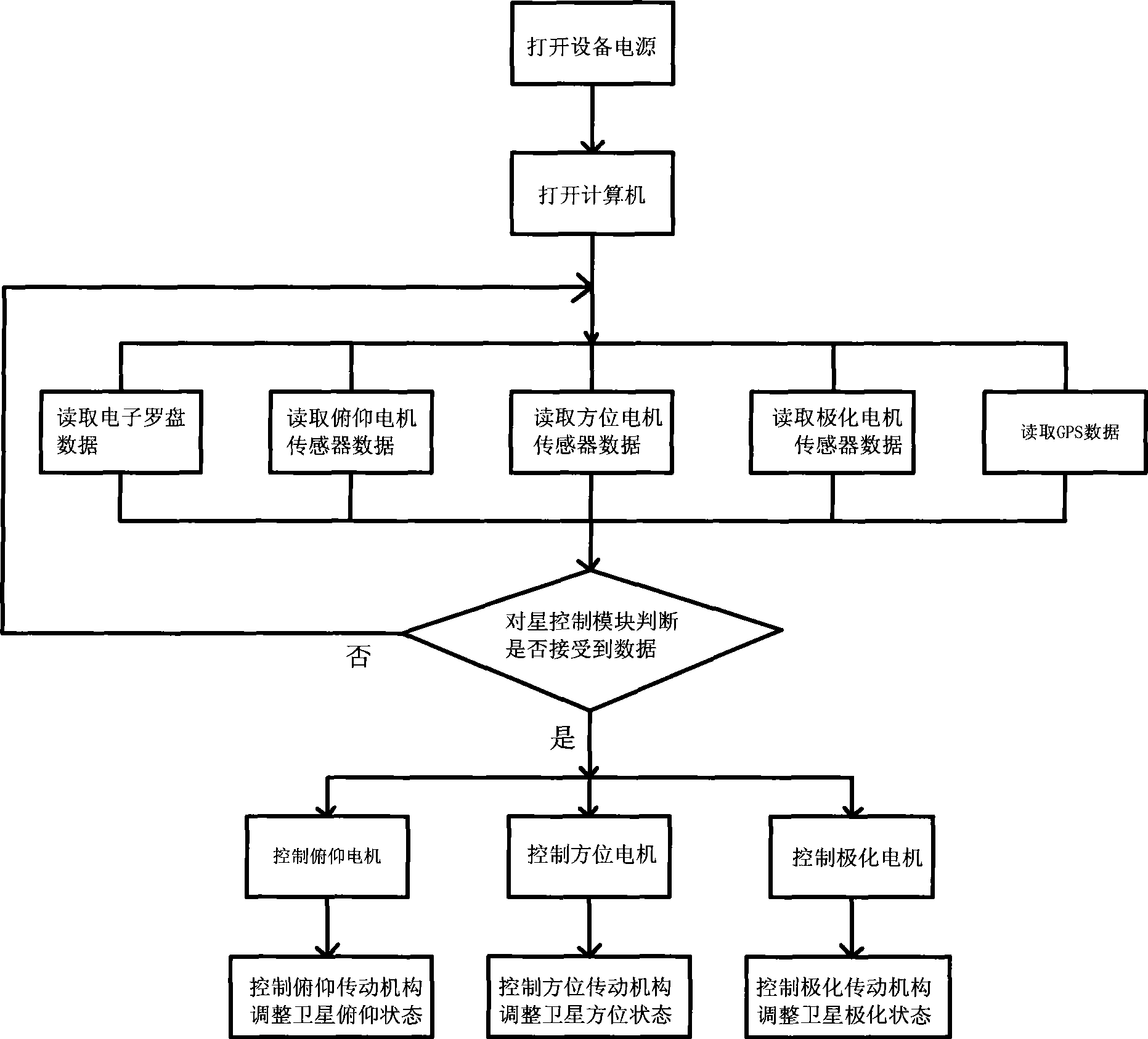

Control device for closed-loop star searching system and control method thereof

InactiveCN101393460AEasy to controlCompensate for motion errors in real timeControl using feedbackRadio transmissionSensori motorClosed loop

The invention provides a device for controlling a closed-loop star-finding system and a control method thereof, which relate to the technical field of closed-loop satellite star-finding system. The signal output ends of a pitch motor sensor are respectively connected with the signal input ends of a pitch transmission mechanism and a paired star control module; the signal output ends of an azimuth motor sensor are respectively connected with the signal input ends of an azimuth transmission mechanism and the paired star control module, the signal output ends of a polarizing motor are respectively connected with a polarizing transmission mechanism and the paired star control module; the signal output ends of the paired star control module are respectively connected with the signal input ends of the pitch motor, the azimuth motor, the polarizing motor and a computer, and the signal output end of the computer is connected with the paired star control module; and the signal output ends of a GPS receiver and an electronic compass are respectively connected with the paired star control module. The device achieves aims of low cost, simple control, convenient operation, short time and high stability.

Owner:NANJING CHINA SPACENET SATELLITE TELECOM

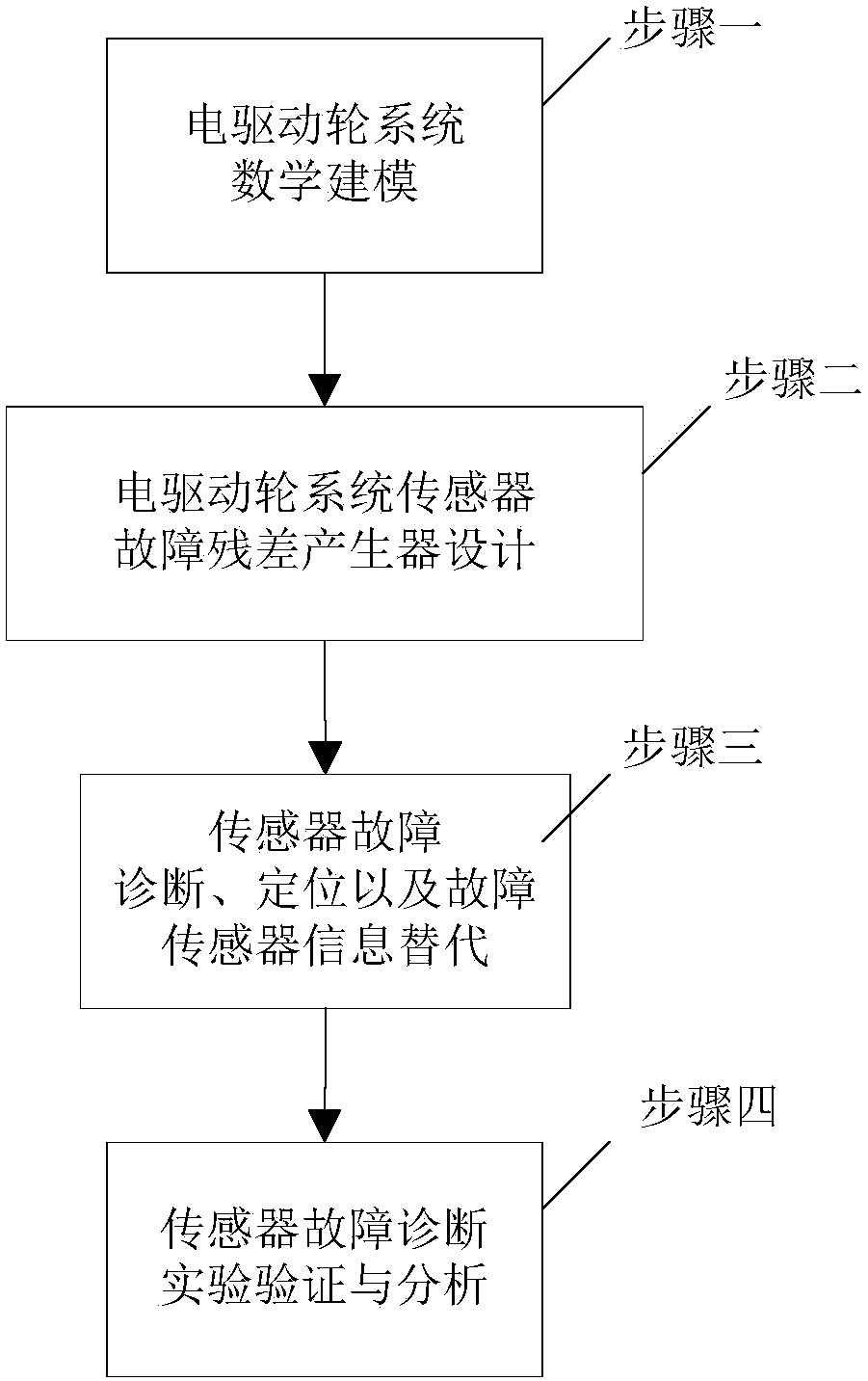

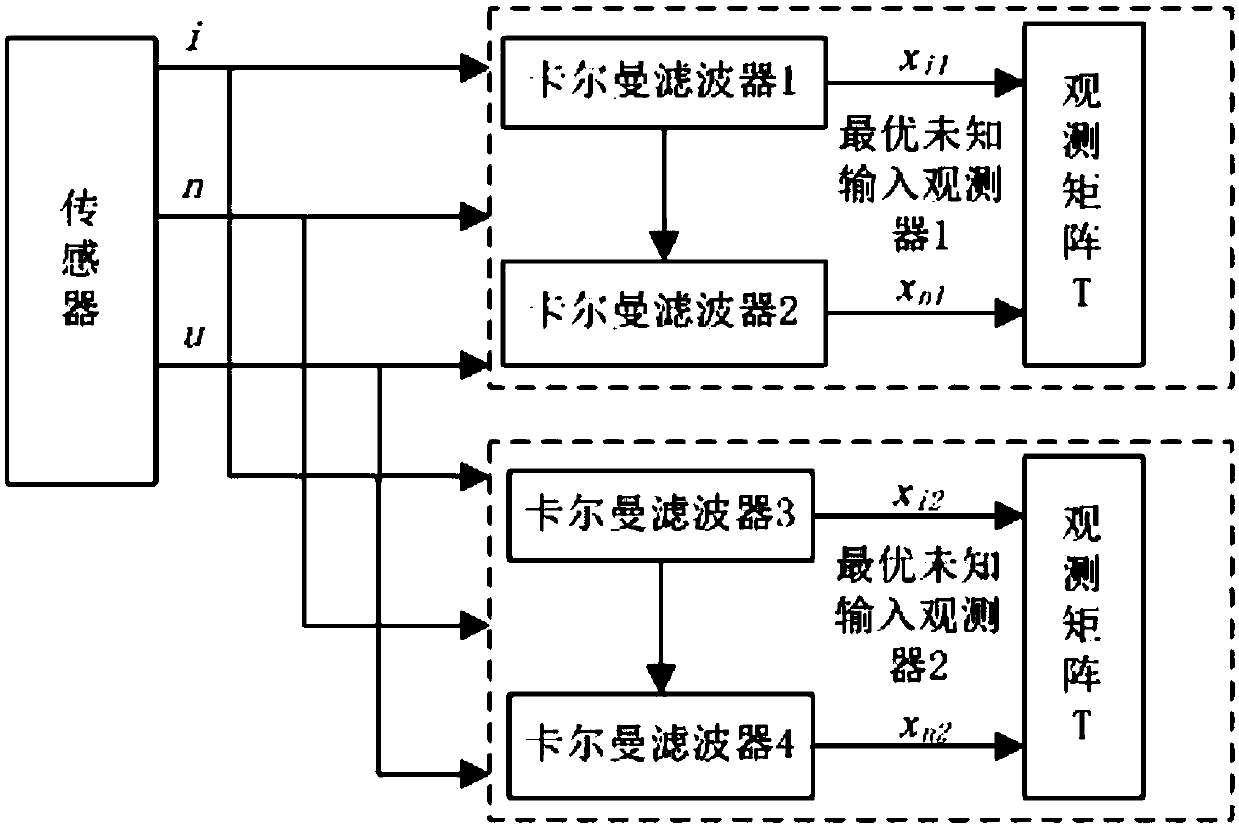

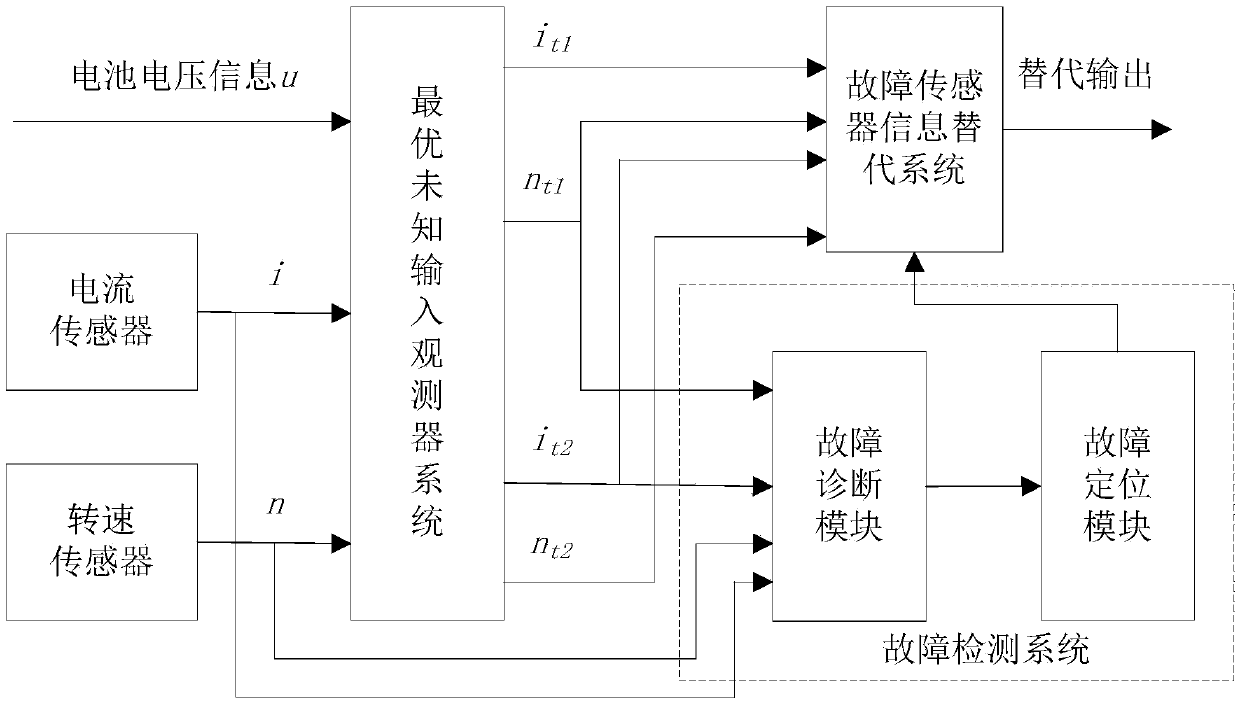

Method for diagnosing and locating fault of vehicle direct drive motor sensor and replacing fault information

InactiveCN108121858AModeling is precise and fitDesign optimisation/simulationSpecial data processing applicationsSensori motorMathematical model

The invention discloses a method for diagnosing and locating a fault of a vehicle direct drive motor sensor and replacing fault information, the method comprises the steps of step one, electric driving wheel system mathematical modeling; step two, optimal unknown input observer design based on the electric driving wheel system mathematical model; step three, sensor fault diagnosis and locating andfault sensor information replacing; step four, sensor fault diagnosis experimental verification and analysis. According to the method, the system characteristics of the vehicle direct drive motor sensor are combined, unknown input and noise are considered for system mathematical modeling, the optimal unknown input observer is designed for system state estimation to obtain the fault residual errorinformation, accordingly, the strategy for diagnosing and locating the fault of the vehicle direct drive motor sensor and replacing the fault information is put forward, and the feasibility of the method is verified.

Owner:JIANGSU UNIV

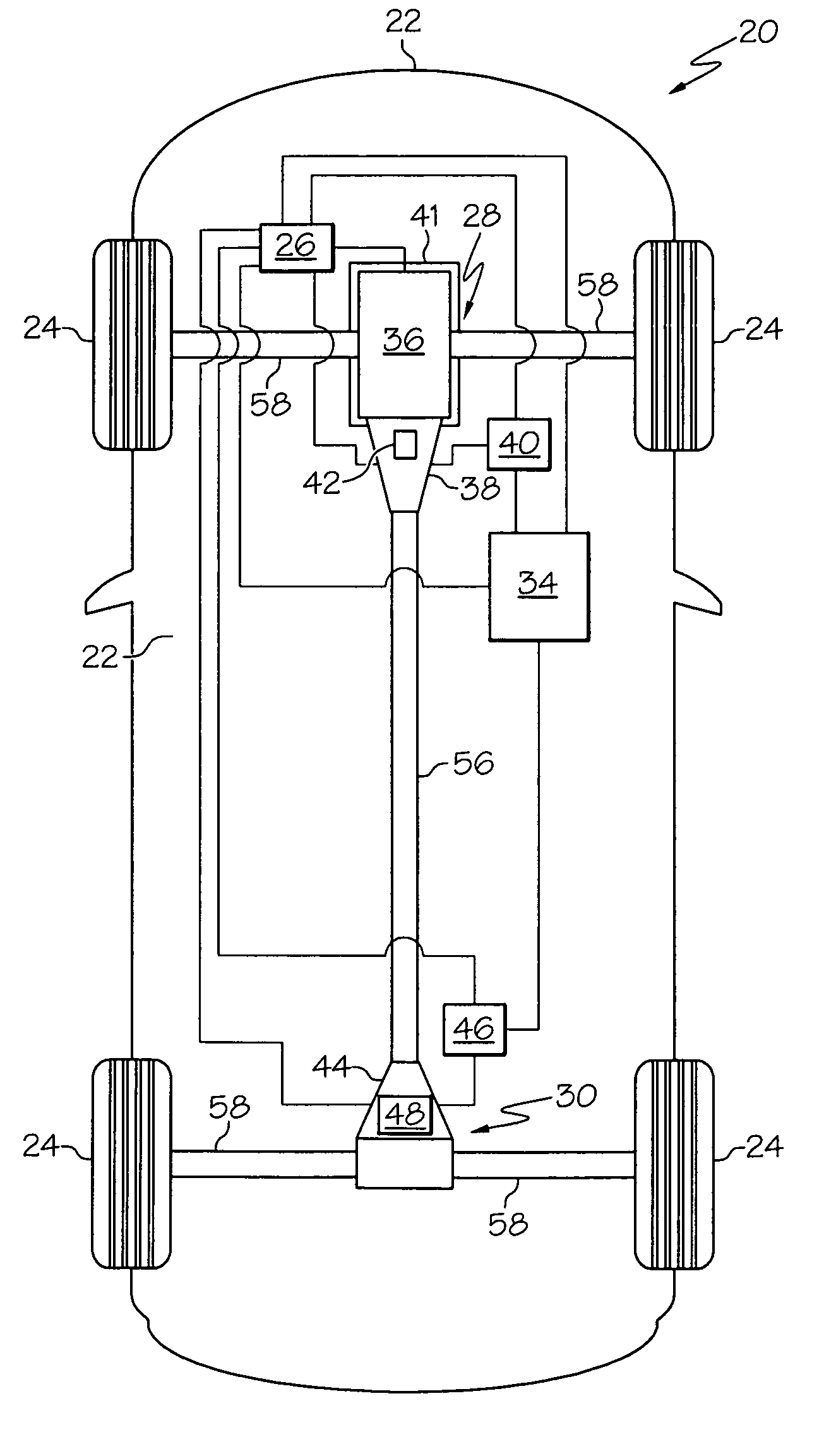

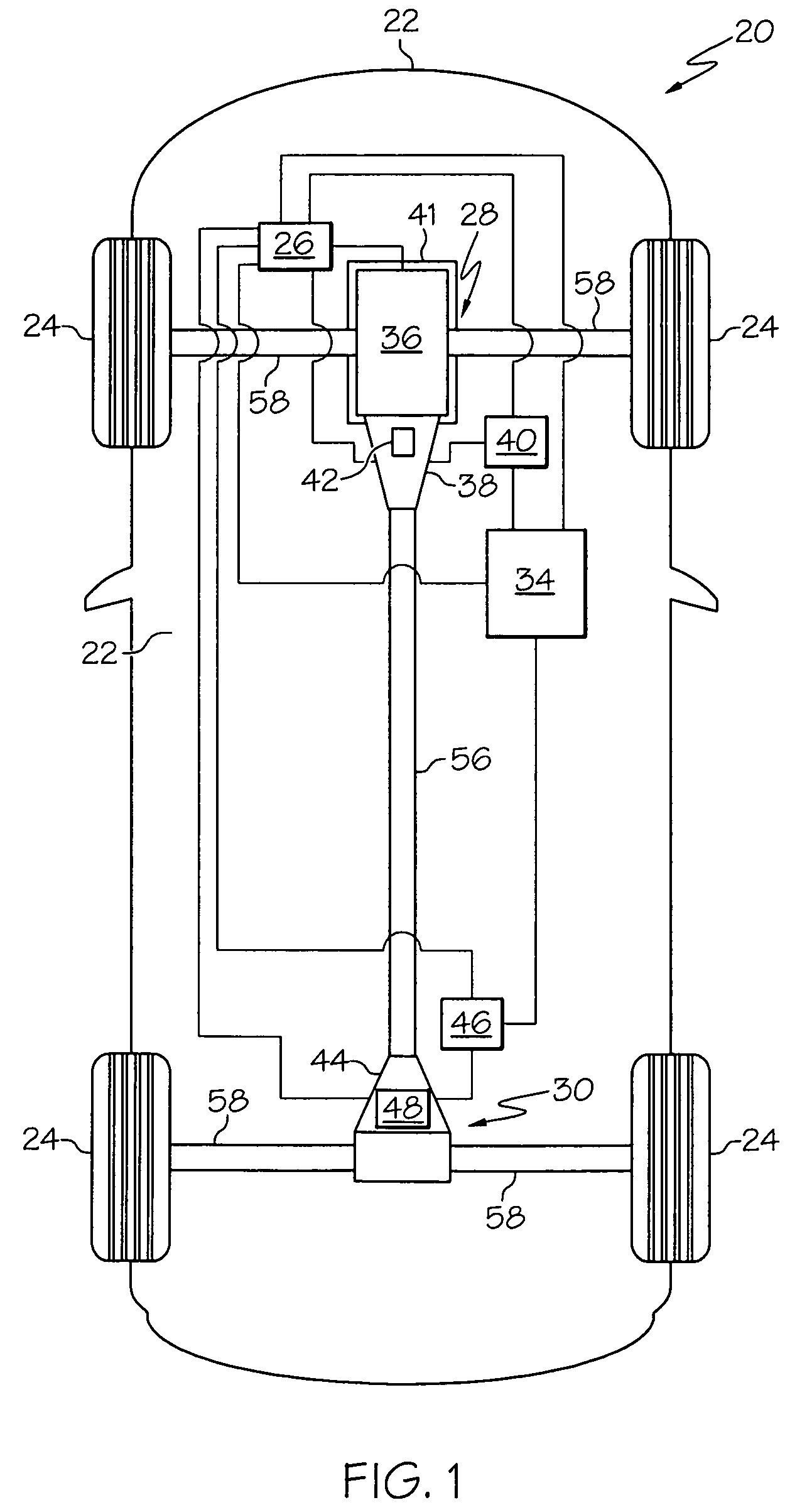

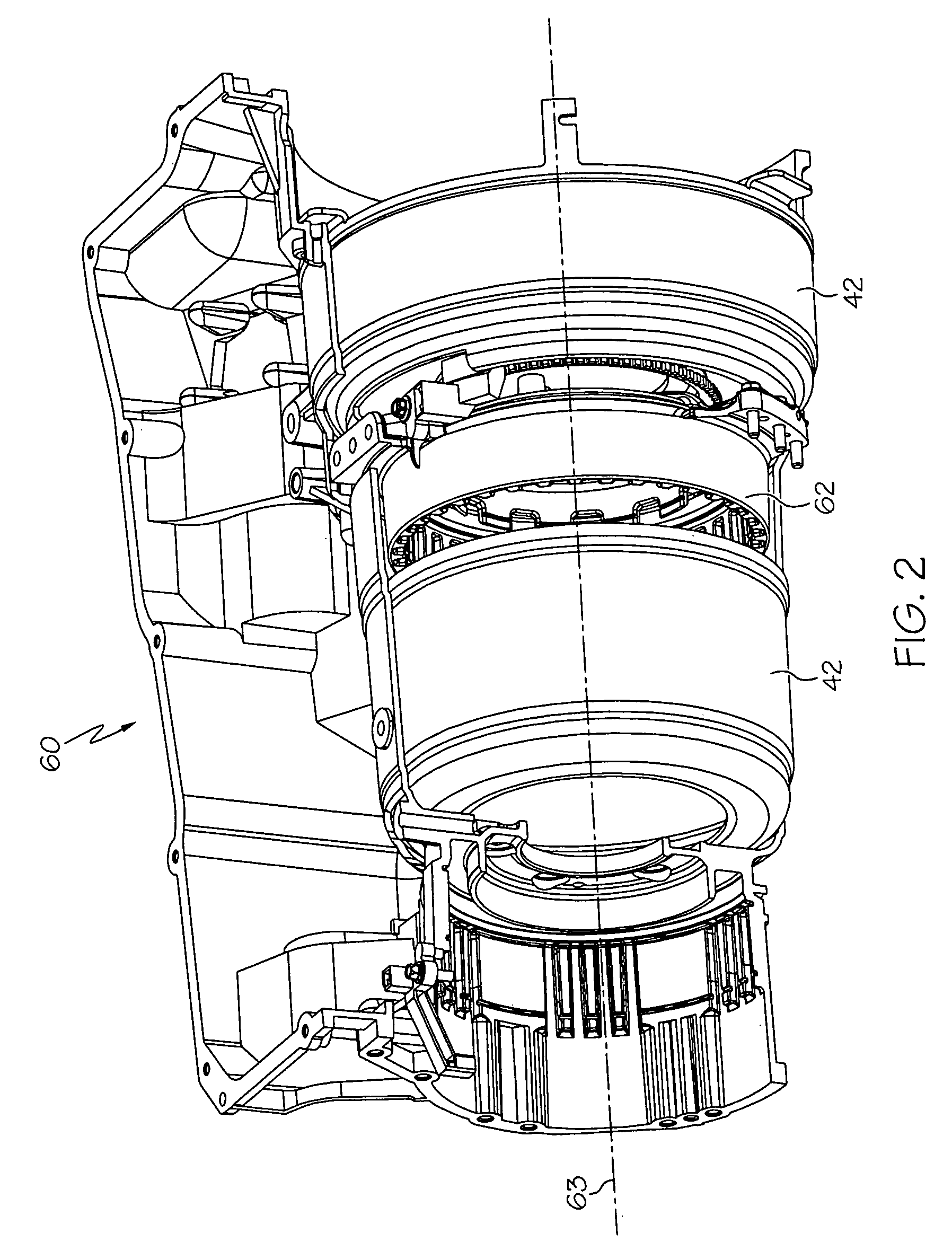

Motor sensor assembly for alternative fuel vehicles

An automotive drive system includes a transmission comprising a plurality of gears, an electric motor having a rotor and being coupled to the transmission such that operation of the electric motor causes actuation of the gears, and a sensor assembly coupled to and located on the exterior of at least one of the transmission and the electric motor, the sensor assembly being configured to detect movement of at least one of the rotor and the plurality of gears and generate a signal representative thereof.

Owner:GM GLOBAL TECH OPERATIONS LLC

Straight twisting machine

InactiveCN103147177ASmall wrapping angleReduce energy consumptionContinuous wound-up machinesSensori motorMotor speed

The invention discloses a straight twisting machine, and belongs to the field of textile machinery. The problems that external yarn tension control is not accurate, and an optimum ballooning shape cannot be reached exist in the existing straight twisting machine. The straight twisting machine is characterized in that an external yarn sensor is arranged in an external yarn path between a twisting tray and an external yarn tensioner and used for detecting an external yarn linear speed and external yarn tension; a strand yarn sensor is arranged in a strand yarn path between an overfeeding device and an even twisting device and used for detecting a strand yarn linear speed and strand yarn tension; a motor sensor is arranged on a spindle drive motor and used for detecting a motor speed and current; the external yarn tensioner and an overfeeding wheel of the overfeeding device are respectively driven by separate motors; a control system connected with the motors is connected with the external yarn sensor, the strand yarn sensor and the motor sensor; and by taking the external yarn speed, the external yarn tension, the spindle drive motor speed, the current, the strand yarn linear speed and the strand yarn tension as parameters, the control system controls the external yarn tensioner to actively feed yarns at a constant speed or a variable speed, adjusts a strand yarn pulling speed, and ensures that a tension value of an external yarn can allow a wrapping angle to be minimum.

Owner:ZHEJIANG RIFA TEXTILE MASCH CO LTD

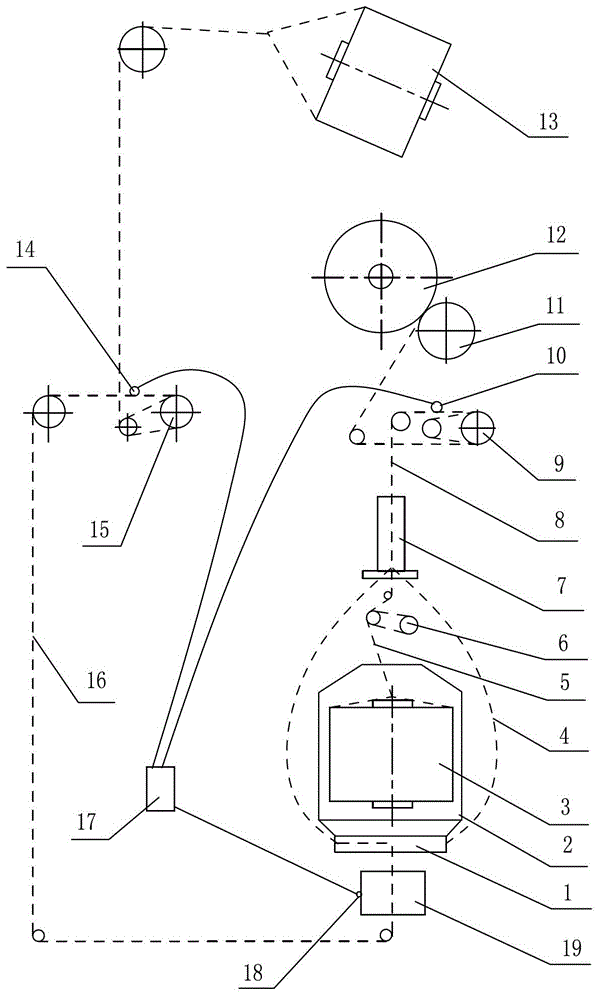

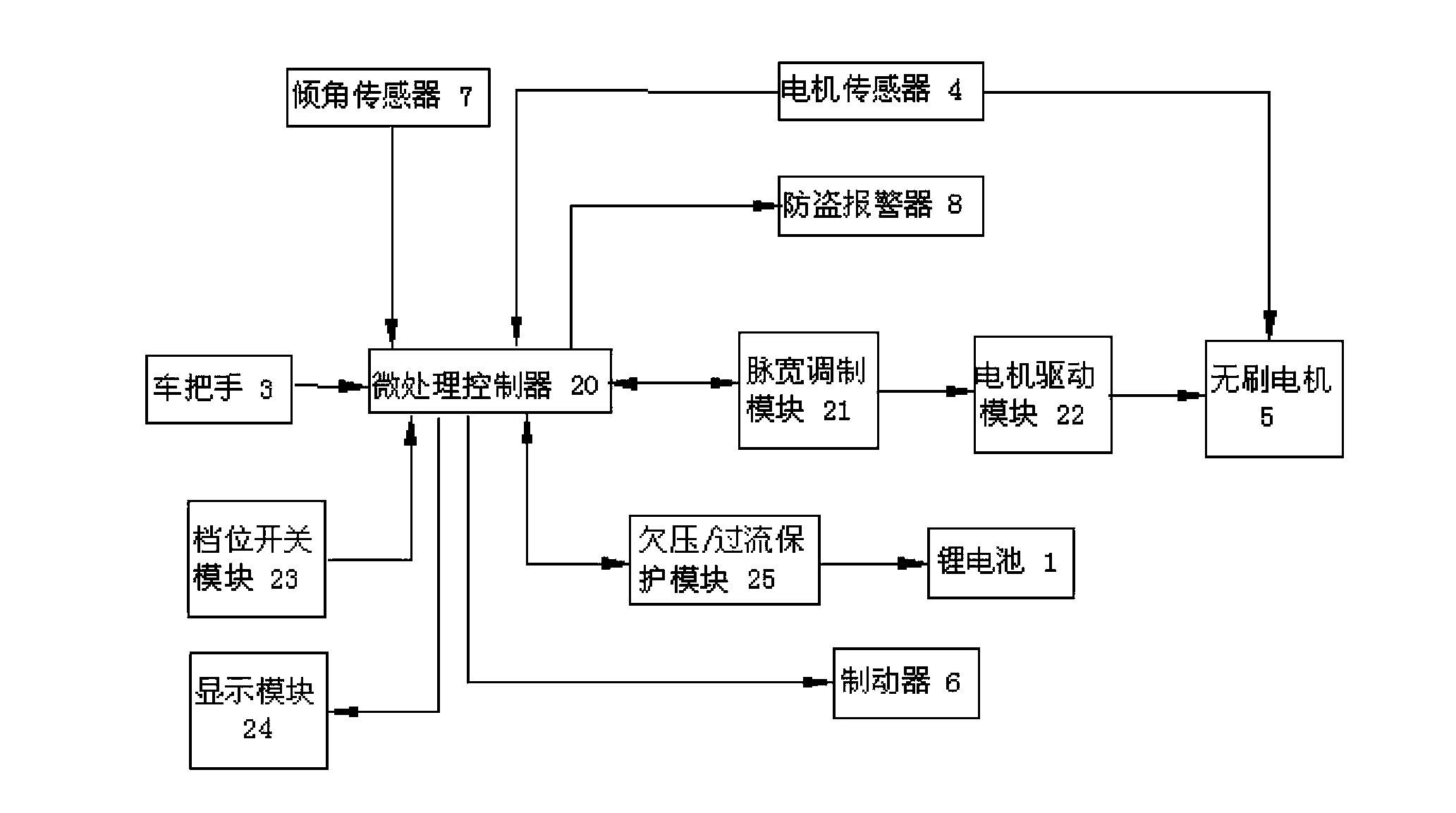

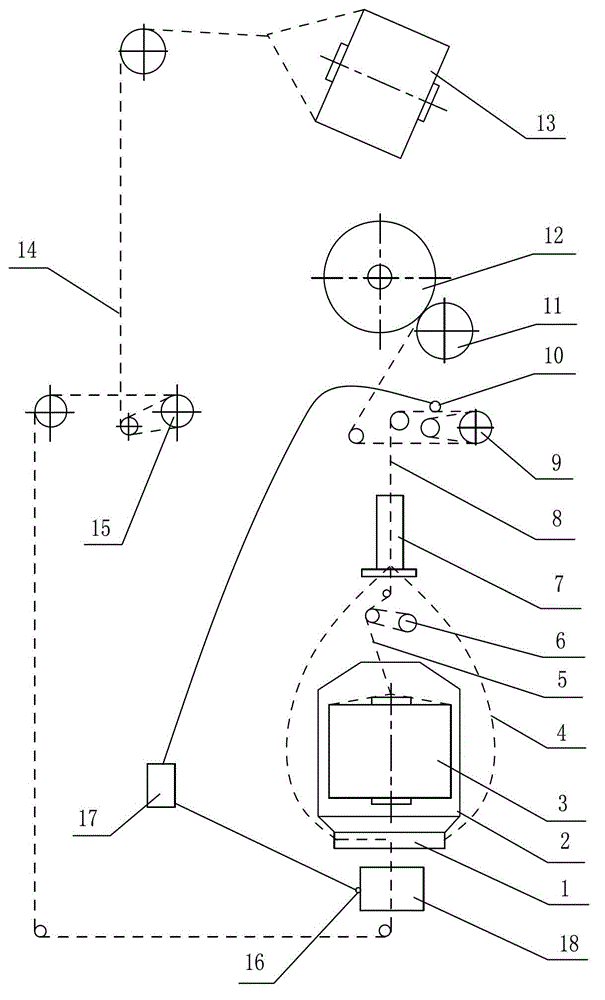

Intelligent control system of electric tricycle

ActiveCN103879302AHigh intelligencePrevent rolloverSpeed controllerAutomatic initiationsSensori motorBrushless motors

The invention discloses an intelligent control system of an electric tricycle. The intelligent control system comprises a lithium battery, an intelligent controller, a tricycle handle, a motor sensor, a brushless motor and a brake, wherein the lithium battery provides the electric tricycle with an electric energy, and the intelligent controller is integrated with a microprocessor controller and a motor driving module; the tricycle handle outputs a voltage signal to the microprocessor controller, the microprocessor controller operates and analyzes a voltage signal, and the brushless motor is controlled to start, close and adjust the rotating speed through the motor driving module; additionally, the motor sensor can acquire the rotating direction and speed signal of a rotor in the brushless motor, and transmit the rotating direction and speed signal of the rotor to the microprocessor controller, and the microprocessor controller operates and analyzes the rotating direction and speed signal of the rotor and controls the brake to be started and closed. The control system is high in intelligent degree, and is capable of guaranteeing the safety of a rider well.

Owner:ACTIVE CYCLES

Control method for yarn tension of straight twisting machine

ActiveCN103147186ASmall wrapping angleReduce energy consumptionContinuous wound-up machinesMotor speedSensori motor

The invention discloses a control method for yarn tension of a straight twisting machine, and belongs to the technical field of textile machinery. The problems that external yarn tension control is not accurate, and an optimum ballooning shape cannot be reached exist in the existing straight twisting machine. The straight twisting machine is characterized in that a strand yarn sensor is arranged in a yarn path between an overfeeding device and an even twisting device and used for detecting a strand yarn linear speed and tension; a motor sensor is arranged on a spindle drive motor and used for detecting a motor speed and motor current; an external yarn tensioner is driven by a separate motor to feed yarns actively; an overfeeding wheel of the overfeeding device is driven by a separate motor; and by taking one or two detection results of the two sensors as separate or combined control parameters, a control system controls a speed of the motor connected with the overfeeding wheel, adjusts a strand yarn pulling speed, and ensures that an external yarn tension value meets a requirement of the optimum yarn ballooning shape capable of allowing a wrapping angle to be minimum.

Owner:ZHEJIANG RIFA TEXTILE MACHINERY TECH CO LTD

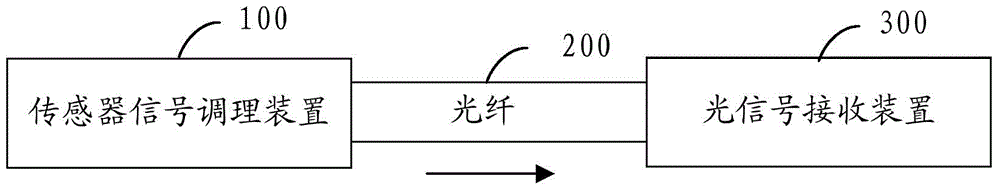

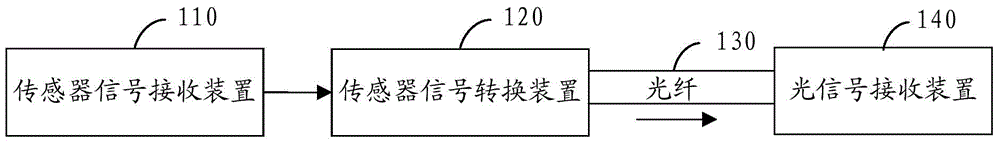

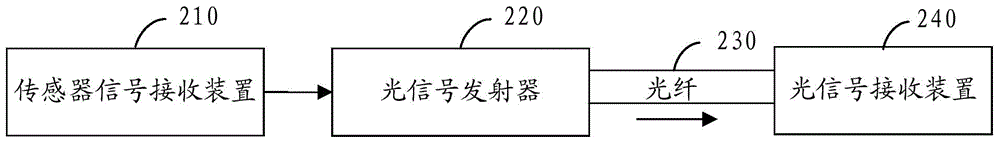

Device for enhancing anti-interference capability of transmission signal of motor sensor and device for enhancing anti-interference capability of transmission signal of motor sensor

InactiveCN104361742AImprove anti-interference abilityIncrease speedNon-electrical signal transmission systemsSensori motorSignal conditioning

The invention discloses a device for enhancing an anti-interference capability of a transmission signal of a motor sensor and a device for enhancing the anti-interference capability of the transmission signal of the motor sensor. The device comprises a sensor signal conditioning device, an optical fiber and an optical signal receiving device, wherein the sensor signal conditioning device is connected with the motor sensor and is used for receiving an output signal of the motor sensor and converting the output signal of the motor sensor into an optical signal to be output; the input end of the optical fiber is connected with the sensor signal conditioning device, and the output end of the optical fiber is connected with the optical signal receiving device and is used for transmitting the optical signal output by the sensor signal conditioning device to the optical signal receiving device; and the optical signal receiving device is connected with a motor controller and is used for receiving the optical signal transmitted by the optical fiber, converting the received optical signal to an electric signal and transmitting the electric signal to the motor controller. According to the device disclosed by the invention, the influences on a transmission signal, caused by factors including surrounding transmission environments and the like can be greatly reduced in a long-distance transmission process, and the anti-interference capability of the transmission signal between the motor sensor and the motor controller is enhanced.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

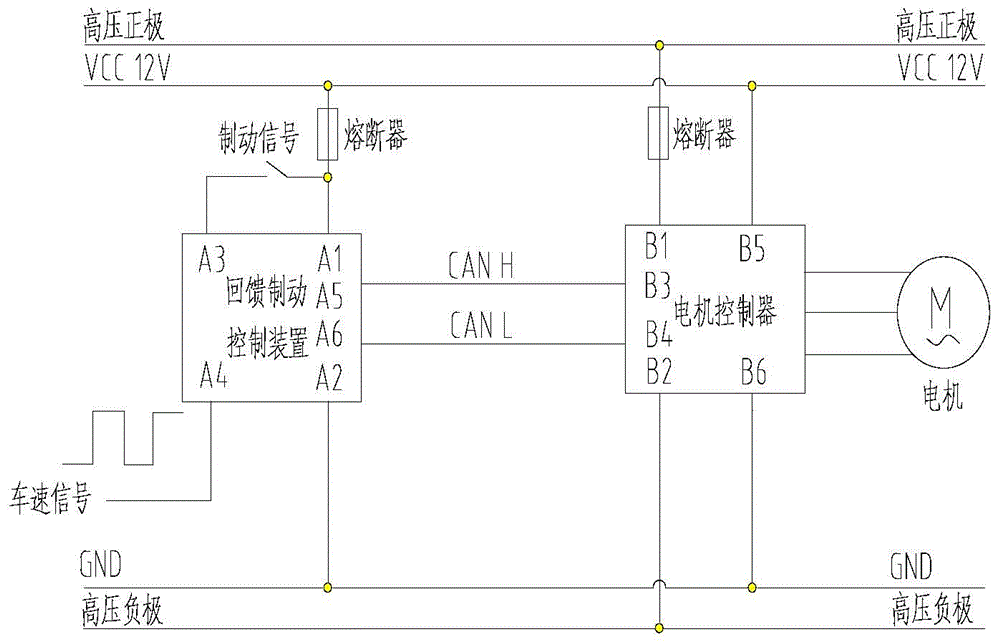

Energy feedback control method and control system for electric vehicle provided with multispeed transmission

ActiveCN104527437AEnsure driving comfortWithout compromising comfortSpeed controllerElectrodynamic brake systemsSensori motorControl system

The invention provides an energy feedback control method and a control system for an electric vehicle provided with a multispeed transmission. A brake pedal sensor, an acceleration pedal sensor, a vehicle speed sensor and a motor sensor transmit brake signals, acceleration signals, vehicle speed and motor output conditions to an energy feedback control device, the energy feedback control device judges whether energy is fed back or not according to received information, and the energy feedback control device feeds back the energy according to data in real-time communication with a motor controller, recovers the energy and stores the energy into an energy storage system through a conduction device if energy feedback is needed. The energy of the electric vehicle provided with the multispeed transmission is fed back according to different gears and different conditions of the vehicle, energy recovery rate is maximized, and an energy feedback device for the electric vehicle provided with the multispeed transmission is implemented without affecting vehicle comfort or adding a motor.

Owner:CHONGQING SOKON IND GRP CO LTD

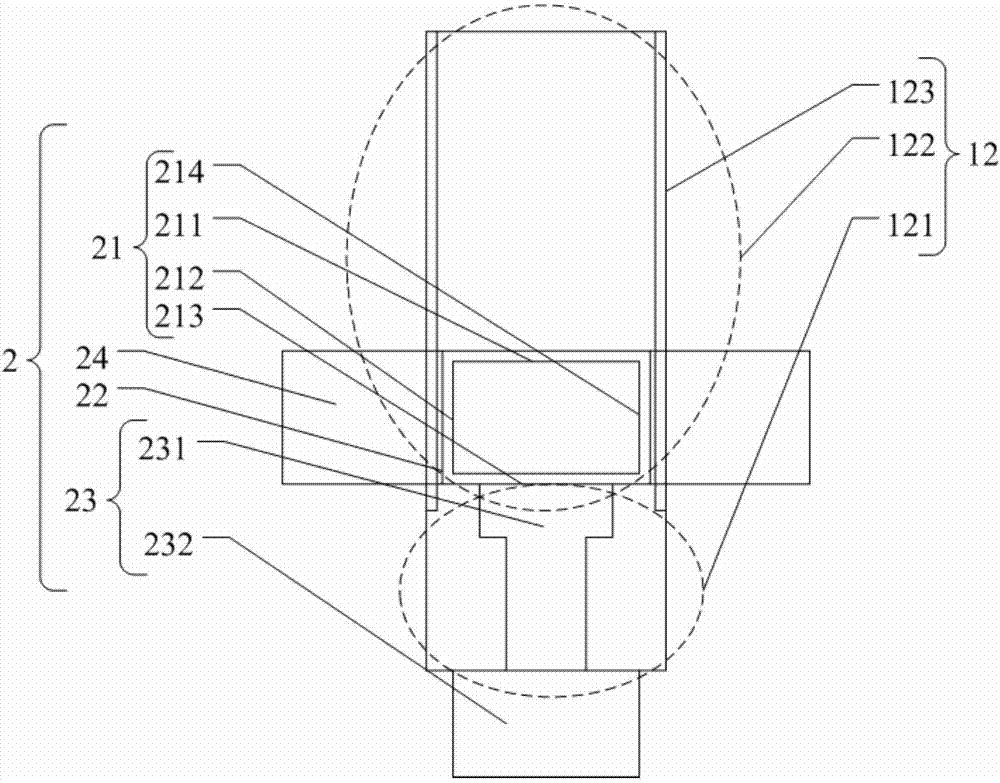

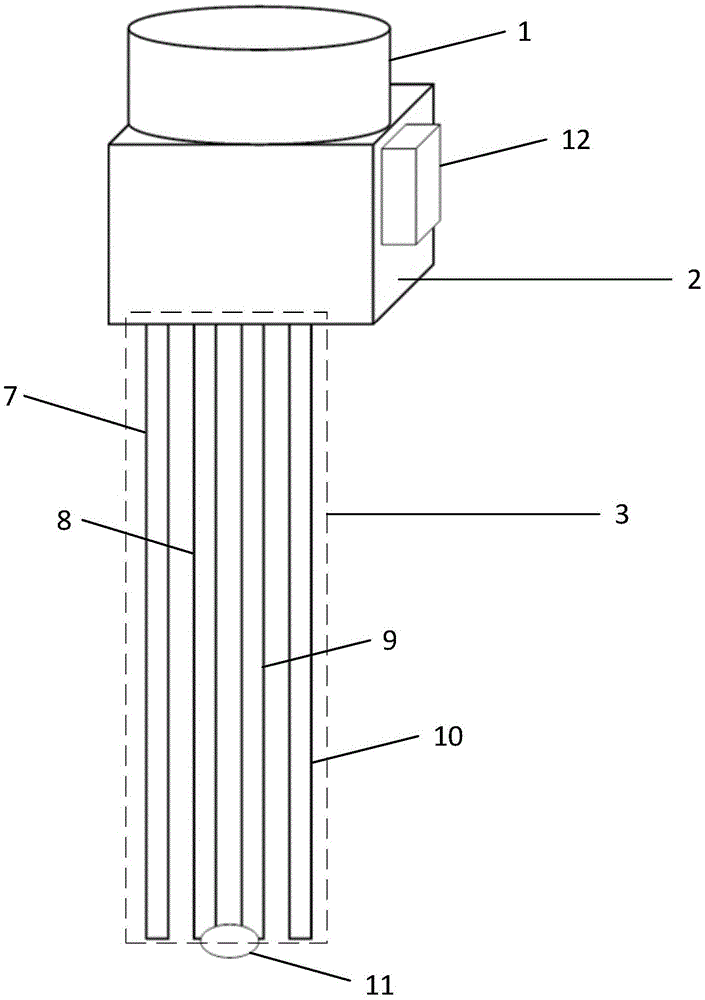

Motor sensor

The invention provides a motor sensor. The motor sensor comprises a first assembly arranged at an outer wall of a motor and a second assembly arranged in the motor, the first assembly comprises a vibration monitoring plate, a noise monitoring plate, a current circuit board, an electromagnetic field circuit board, and a temperature circuit board, and the second assembly comprises a current monitoring antenna electrically connected with the current circuit board, an electromagnetic field monitoring antenna electrically connected with the electromagnetic field circuit board, and a temperature monitoring antenna electrically connected with the temperature circuit board. According to the motor sensor, multiple sensors are integrated together, multiple parameters in the operation of the motor can be simultaneously detected, and the operation state during the operation of the motor is effectively monitored.

Owner:BEIJING ZHIGAN SENSOR TECH RES INST CO LTD

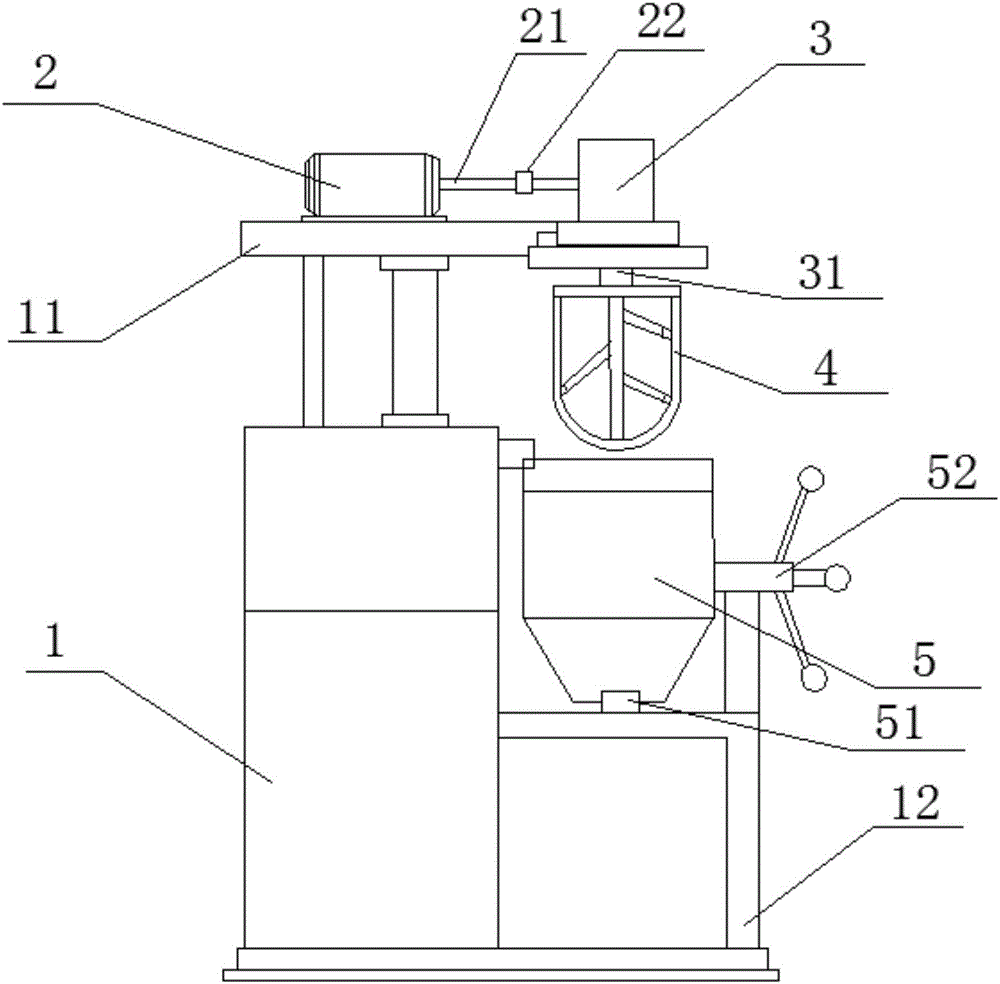

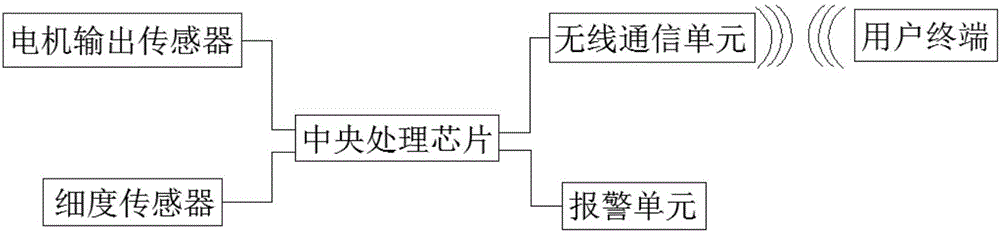

Food mixer

The invention provides a food mixer which comprises a base, a mixing motor, a transmission device, a mixing paddle and a mixing tank. The base comprises a motor support and a mixing tank support, the mixing motor is arranged on the motor support, the mixing tank is hinged to the mixing tank support through a hinge block, a regulating and controlling hand wheel is arranged on one side of the mixing tank, an output shaft of the mixing motor is in transmission connection with the transmission device, and the lower end of the transmission device is connected with the mixing paddle through a lifting rod; a control system is arranged in the base and comprises a central processing chip, a wireless communication unit and an alarming unit, a motor sensor and a fineness sensor are connected to the central processing chip separately, and the wireless communication unit is connected to a user terminal through a wireless signal. The food mixer has the advantages that rotating speed information of the mixing motor and mixed fineness information can be communicated with the user terminal in real time, a user can regulate and control the rotating speed of the mixing motor according to the actual demands, the mixing tank is easy and convenient to use and operate, and the mixing efficiency is improved.

Owner:素膳美(天津)食品科技有限公司

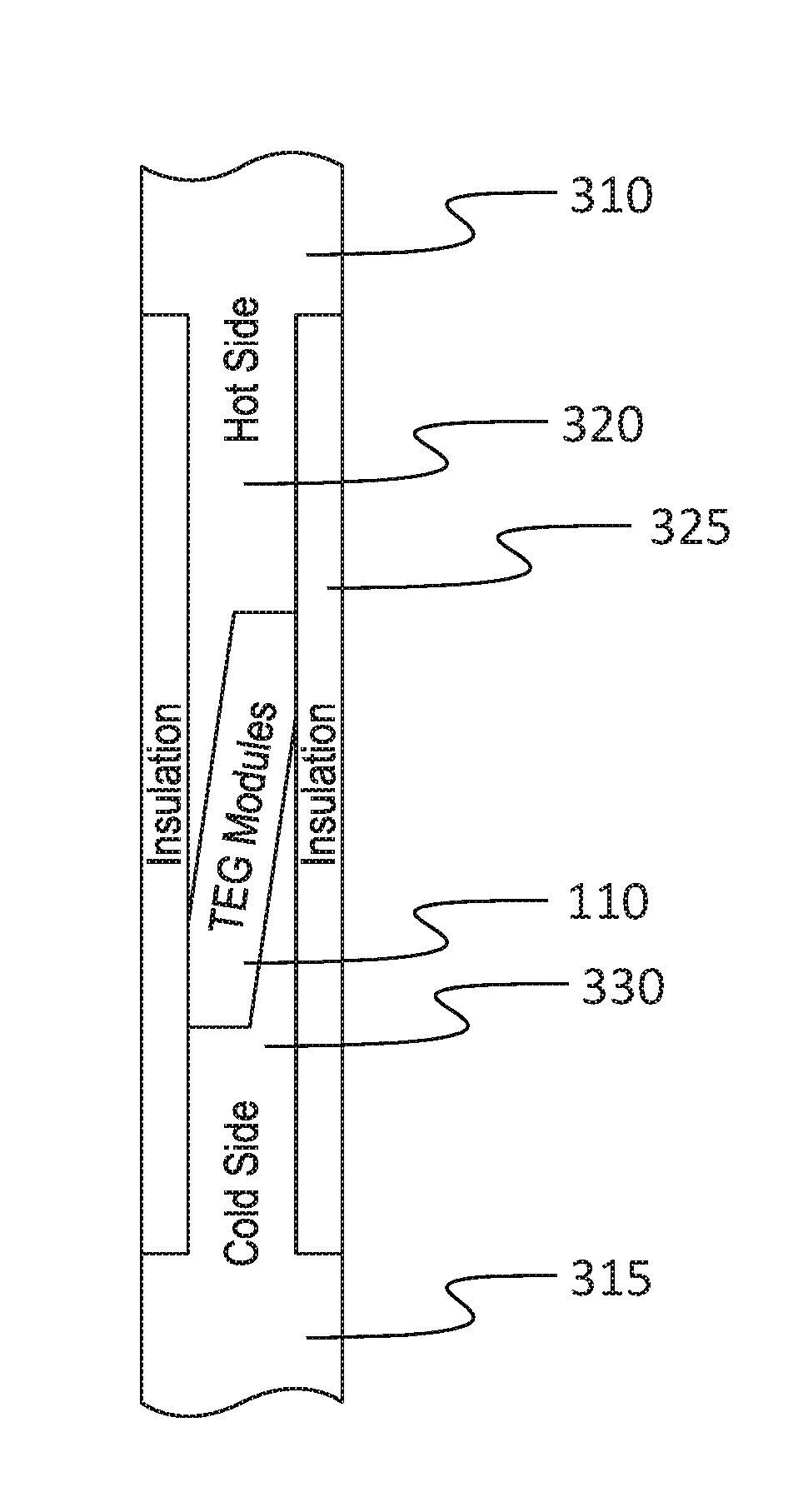

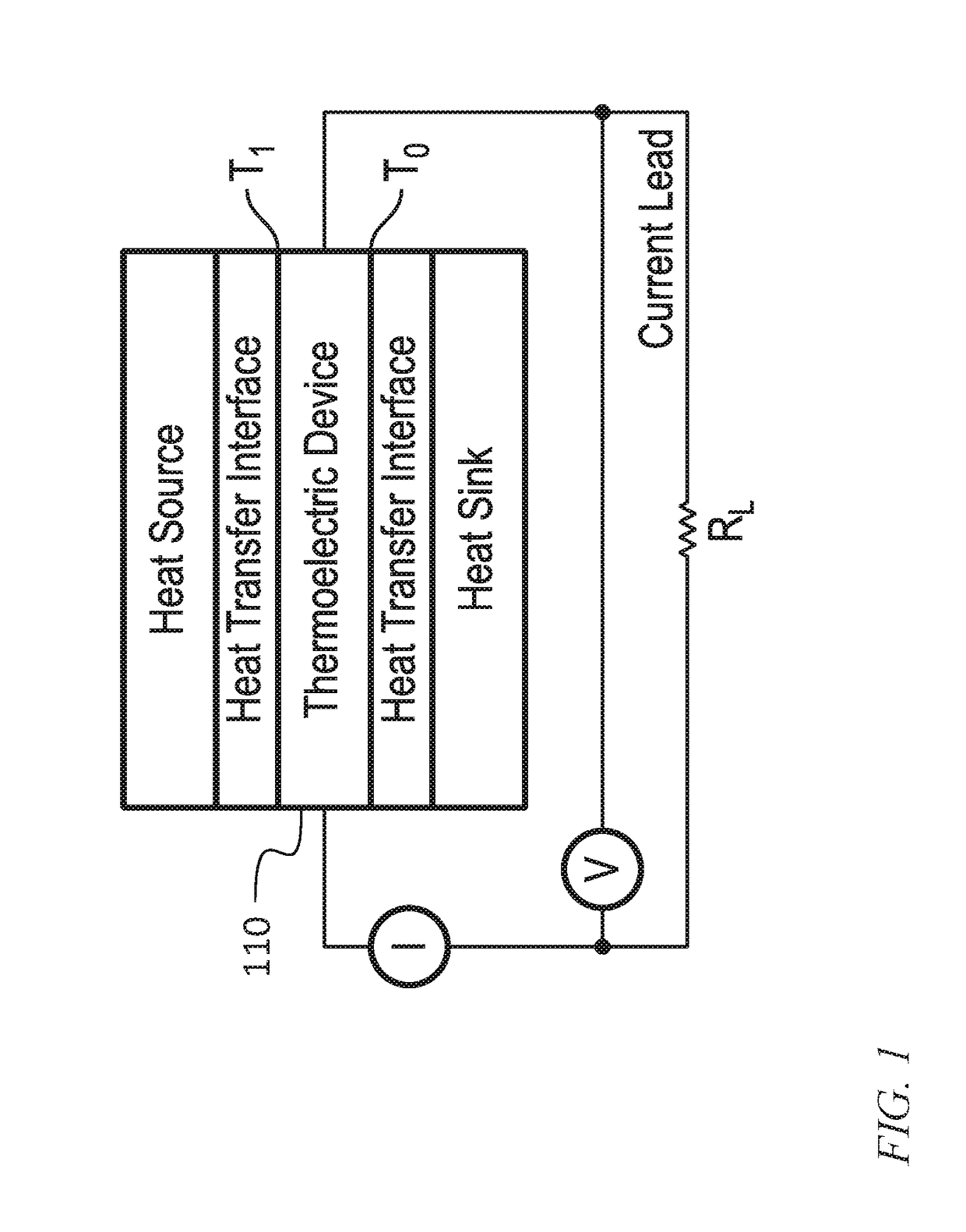

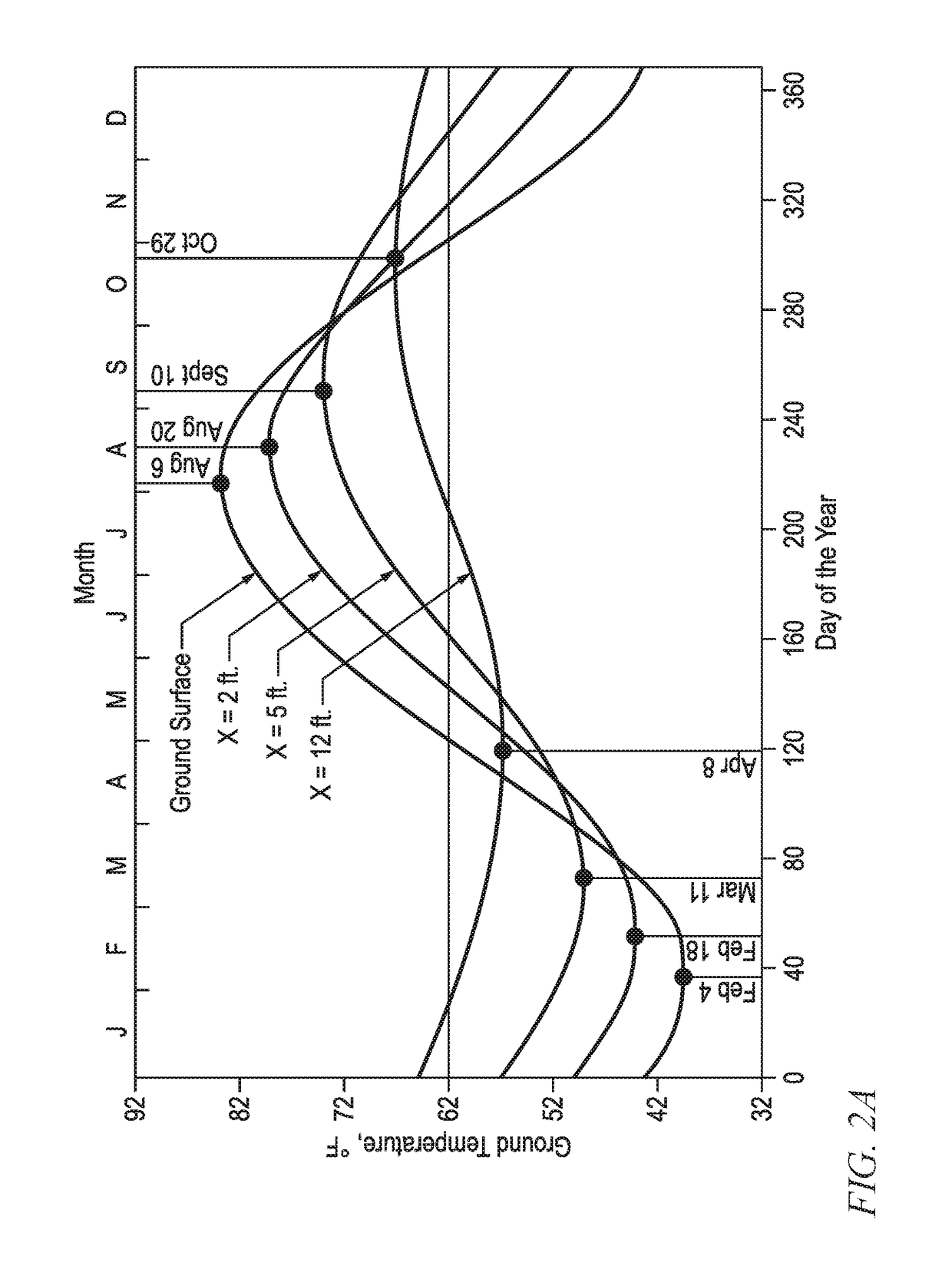

Buried sensor system

ActiveUS20180013048A1Thermoelectric device with peltier/seeback effectLighting and heating apparatusPower sensorSensori motor

A sensing system including in-ground sensors not requiring battery power. A thermoelectric generator sensor rod includes an upper thermal contact and a lower thermal contact at or near its two ends. When the thermoelectric generator sensor rod is buried in the ground with one end buried more deeply than the other, a temperature gradient in the soil produces a temperature difference between the upper thermal contact and the lower thermal contact. The upper thermal contact and the lower thermal contact are thermally connected to a thermoelectric generator, e.g., by heat pipes or thermally conductive rods. Electrical power generated by the thermoelectric generator powers sensors for monitoring conditions in the ground, and circuitry for transmitting sensor data to a central data processing system.

Owner:RAYTHEON BBN TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com