Dual-motor cooperative control system and method

A collaborative control, dual-motor technology, applied in the direction of speed regulation of multiple motors, can solve the problems of error control accuracy, high system cost, complex collaborative control instructions, etc., to eliminate differences, simple system structure, and improve collaborative control performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

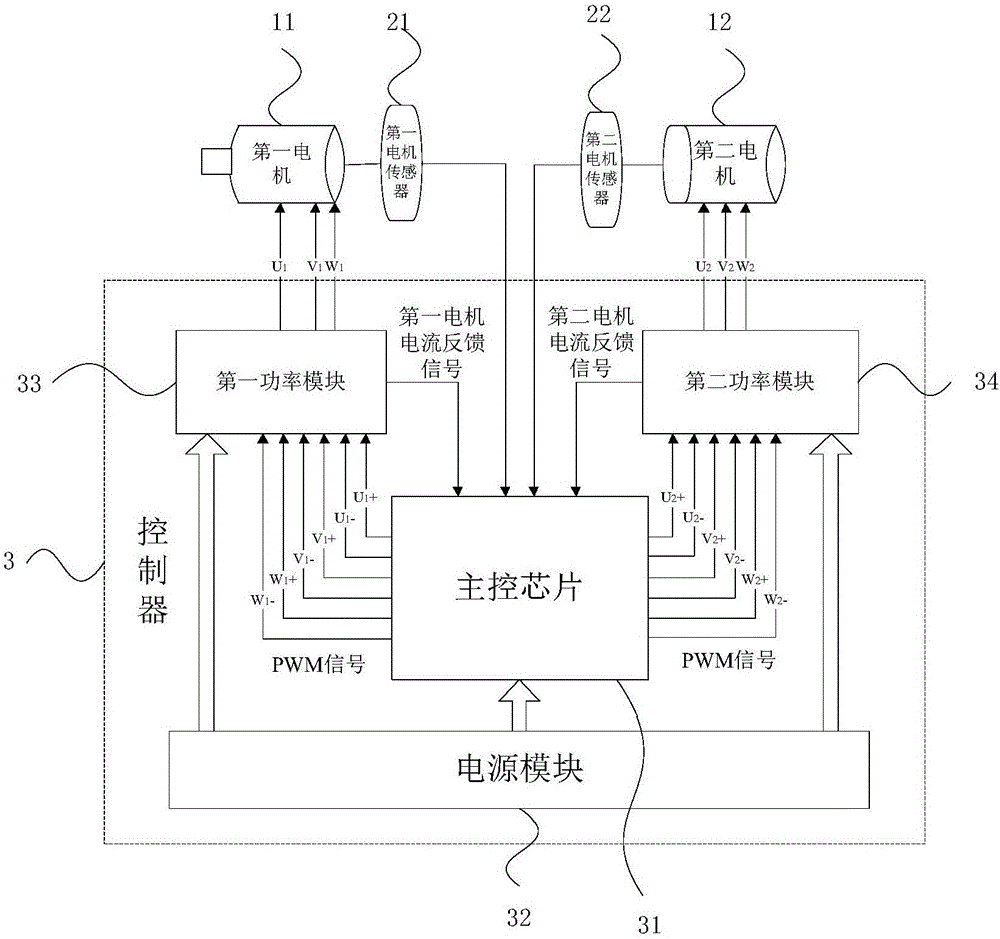

Embodiment 1

[0044] In this embodiment, the first motor sensor 21 and the second motor sensor 22 are position sensors, which respectively perform coordinated control on the position / displacement, speed and torque of the two motors.

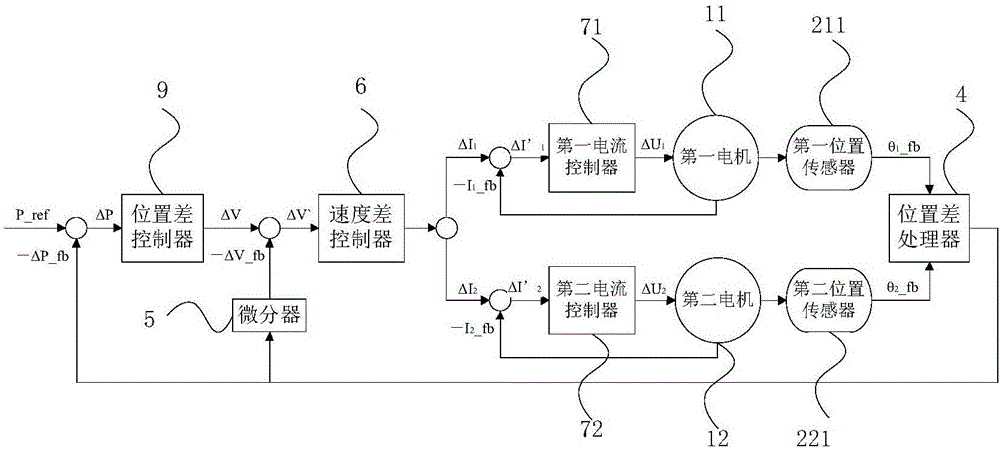

[0045] In this embodiment, the currents of the first motor 11 and the second motor 12 are respectively closed-loop controlled, and the respective positions and speeds of the first motor 11 and the second motor 12 are no longer respectively closed-loop controlled, but the first motor The position difference and speed difference between 11 and the second motor 12 are closed-loop controlled.

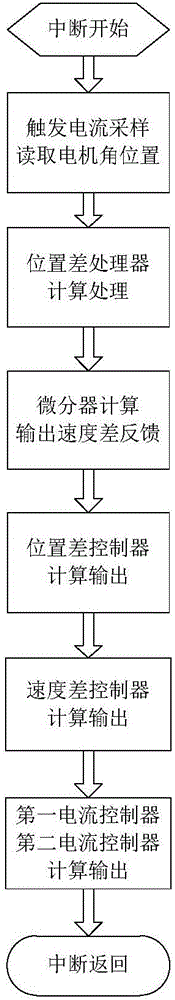

[0046] Such as figure 2 with image 3 As shown, the position cooperative control method for dual motors is as follows: after the position control interruption starts, trigger current sampling to obtain the feedback current I1_fb of the first motor 11 and the feedback current I2_fb of the second motor 12, and simultaneously read the first position sensor 211 to detect The...

Embodiment 2

[0050] In this embodiment, the first motor sensor 21 and the second motor sensor 22 are speed sensors, such as Figure 8 with Figure 9 As shown, the dual-motor speed cooperative control method is as follows: after the speed control interruption starts, trigger current sampling to obtain the feedback current I1_fb of the first motor 11 and the feedback current I2_fb of the second motor 12, and simultaneously read the detected output of the first speed sensor 212 The feedback speed V1_fb and the second speed sensor 222 detect the output feedback speed V2_fb; the speed difference processor 10 outputs the feedback speed difference ΔV_fb through calculation and processing according to the feedback speed V1_fb and the feedback speed V2_fb; the speed difference controller 6 according to the speed command V_ref and the feedback speed The difference ΔV of the difference ΔV_fb is calculated by calculating the output current difference target values ΔI1 and ΔI2; the first current cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com