Two-for-one twister

A two-for-one twister and frame technology, which is applied to spinning machines, continuous winding spinning machines, textiles and papermaking, etc., can solve the problems of high energy consumption and noise, easy to form wrapping angles, etc., and achieve energy saving consumption, noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

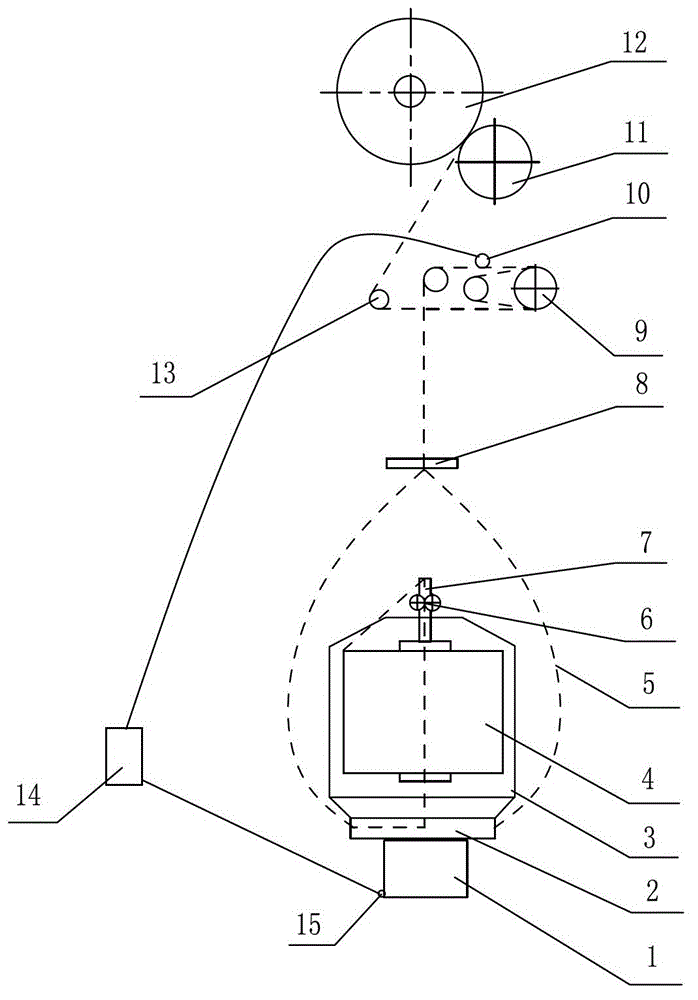

[0007] The specific implementation of the method of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0008] Such as figure 1 As shown, the two-for-one twister of the present invention includes the spindle 3 installed on the frame, the spindle drive motor 1, the yarn collector 8, the overfeeding device 9, the take-up device and the control system 14, and the spindle includes a yarn pot, located at The twisting disc 2 at the bottom of the yarn pot and the hollow spindle rod 7 located in the inner cavity of the yarn pot, the twisting disc 2 is provided with a radial yarn passing hole, the yarn passing hole communicates with the hollow inner cavity of the spindle rod, and the spindle rod 7 A tensioner 6 is provided, and the yarn to be twisted is led out from the stationary yarn feeding package 4, passed through the hollow spindle bar from the top of the spindle, and then passed through the yarn passing hole of the twisting di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com