Control method of yarn balloon size on direct twisting machine

A size control and balloon technology, which can be used in spinning machines, continuous winding spinning machines, textiles and paper making, etc. It can solve the problems that the tension control of the outer yarn cannot be accurately controlled and the shape of the balloon cannot be optimal. , to achieve the effect of saving energy consumption and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

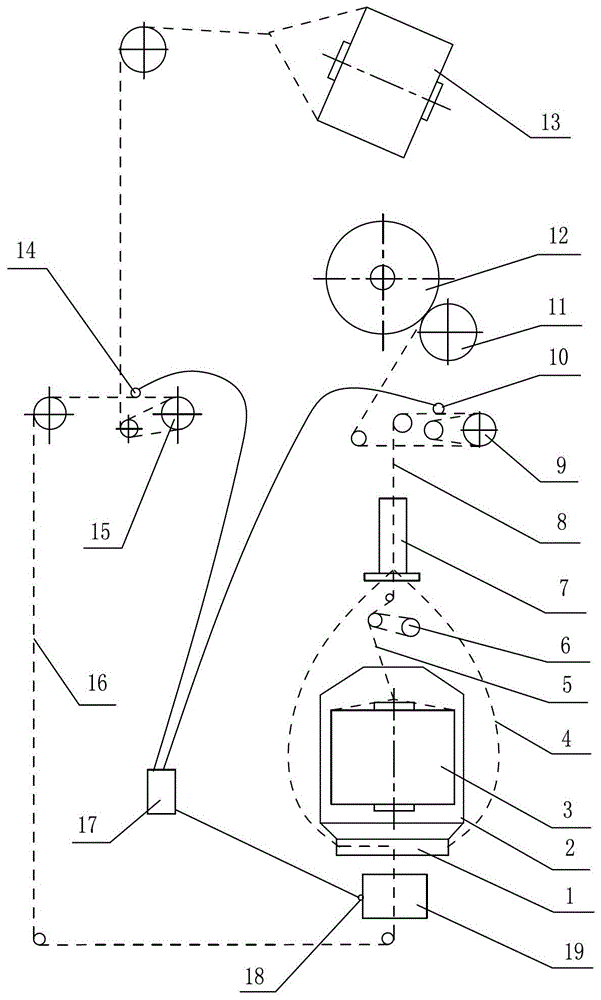

[0014] Implementation mode one: if figure 1 As shown, the direct twisting machine of the present invention includes the spindle 2 installed on the frame, the spindle drive motor 19, the leveling device 7, the overfeeding device 9, the outer yarn tensioner 15, the inner yarn tensioner 6 and the winding device, the winding device is mainly composed of a winding roller 11 and a yarn bobbin; one strand of yarn is drawn from the outer yarn package 13 as an outer yarn 16, and is guided by a plurality of yarn passing wheels on the spindle twisting disc 1 and The axis of the spindle 2 is deflected in an approximately vertical direction, and is introduced into the leveler 7 through the periphery of the spindle at the edge of the twisting disc 1, and another strand of yarn is drawn out from the inner yarn package 3 in the spindle 2 as the inner yarn 5, and the same Introduced into the leveling device 7, the outer yarn 16 and the inner yarn 5 are twisted into a ply yarn 8 in the leveling...

Embodiment approach 2

[0015] Embodiment 2: On the basis of Embodiment 1, a ply yarn sensor 10 is installed on the ply yarn path between the overfeeding device 9 and the twist leveler 7 to detect any one of the two parameters of ply yarn speed and ply yarn tension Or both detect, and the ply yarn sensor 10 is connected with the control system 17, and the detection result of the control system 17 outer yarn sensor 14 and the detection result of the ply yarn sensor 10 is arbitrarily combined into at least two control parameters to control the motor connected with the overfeeding wheel According to the tension value of the outer yarn to meet the requirements of the best shape of the outer yarn balloon, the variable speed movement is performed to adjust the pulling speed of the ply yarn.

Embodiment approach 3

[0016] Embodiment 3: On the basis of Embodiment 1, a motor sensor 18 is set on the spindle drive motor 19 to detect any one or both of these two parameters, the motor speed and the motor current, and the motor sensor 18 is connected to the control system 17 The detection result of the outer yarn sensor 14 and the detection result of the motor sensor 18 of the control system 17 are arbitrarily combined into at least two control parameters to control the motor connected with the overfeed wheel according to the tension value of the outer yarn to meet the best shape of the outer yarn balloon. It is required to make variable speed movement and adjust the pulling speed of ply yarn.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com