Patents

Literature

298 results about "Cable machine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A cable machine is an item of equipment used in weight training or functional training. It consists of a rectangular, vertically oriented steel frame about 3 metres wide and 2 metres high, with a weight stack attached via a cable and pulley system to one or more handles. The cables that connect the handles to the weight stacks run through adjustable pulleys that can be fixed at any height. This allows a variety of exercises to be performed on the apparatus. One end of the cable is attached to a perforated steel bar that runs down the centre of the weight stack. To select the desired amount of resistance, move the metal pin into the labelled hole in the weight stack. The other end of the cable forms a loop, which allows the user to attach the appropriate handle for the exercise. Most cable machines have a minimum of 20 pounds (~9 kilograms) of resistance in order to counterbalance the weight of the typical attachment.

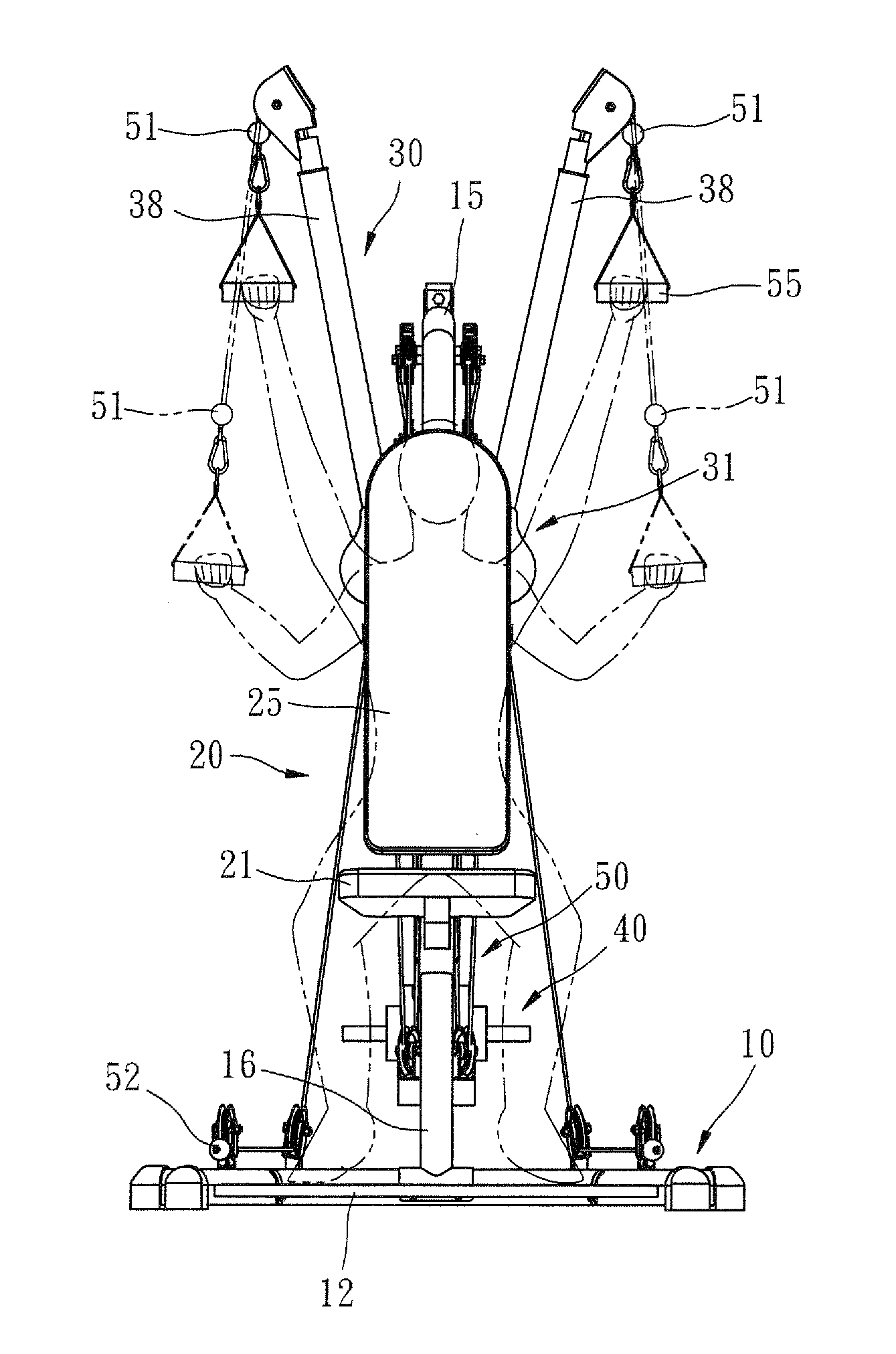

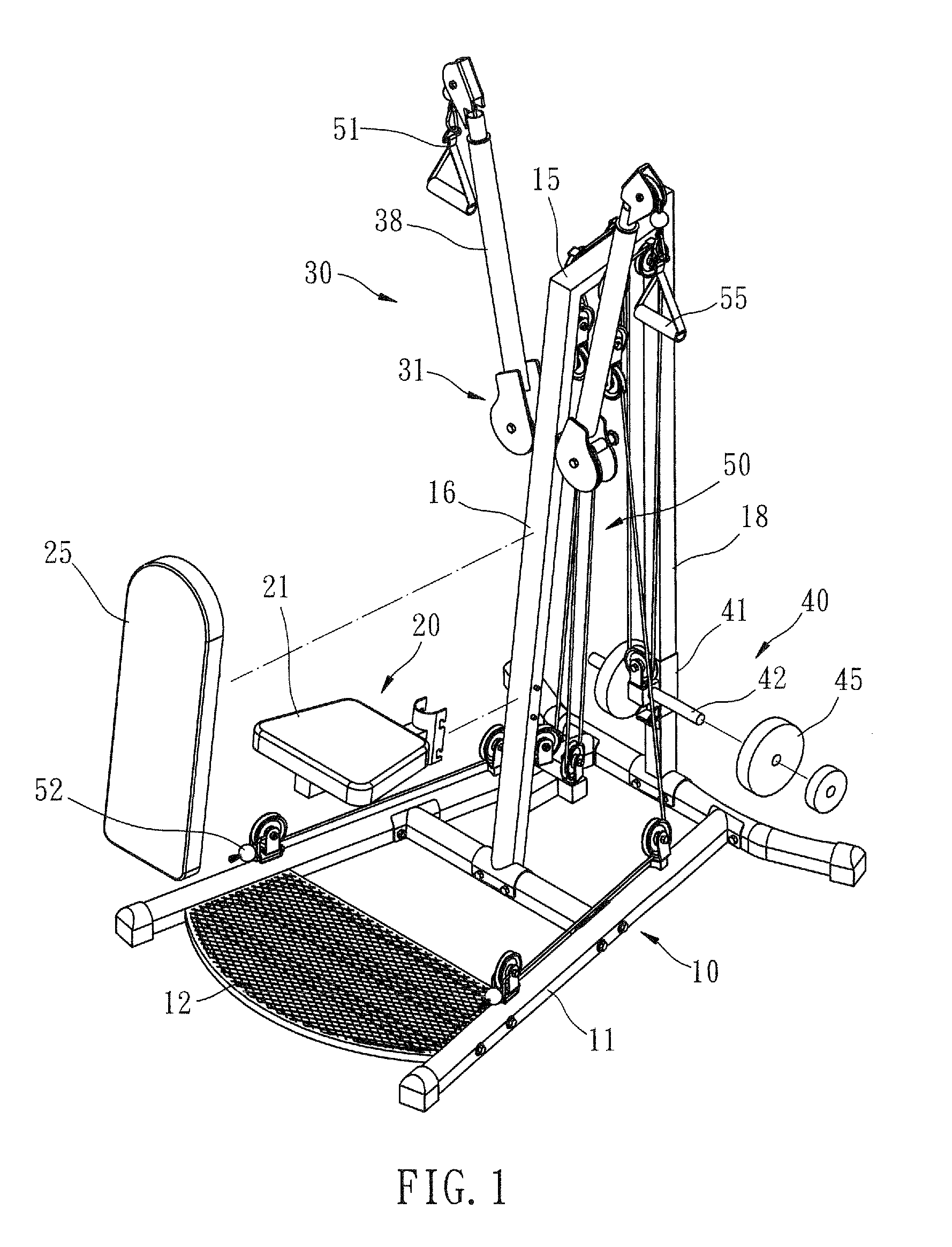

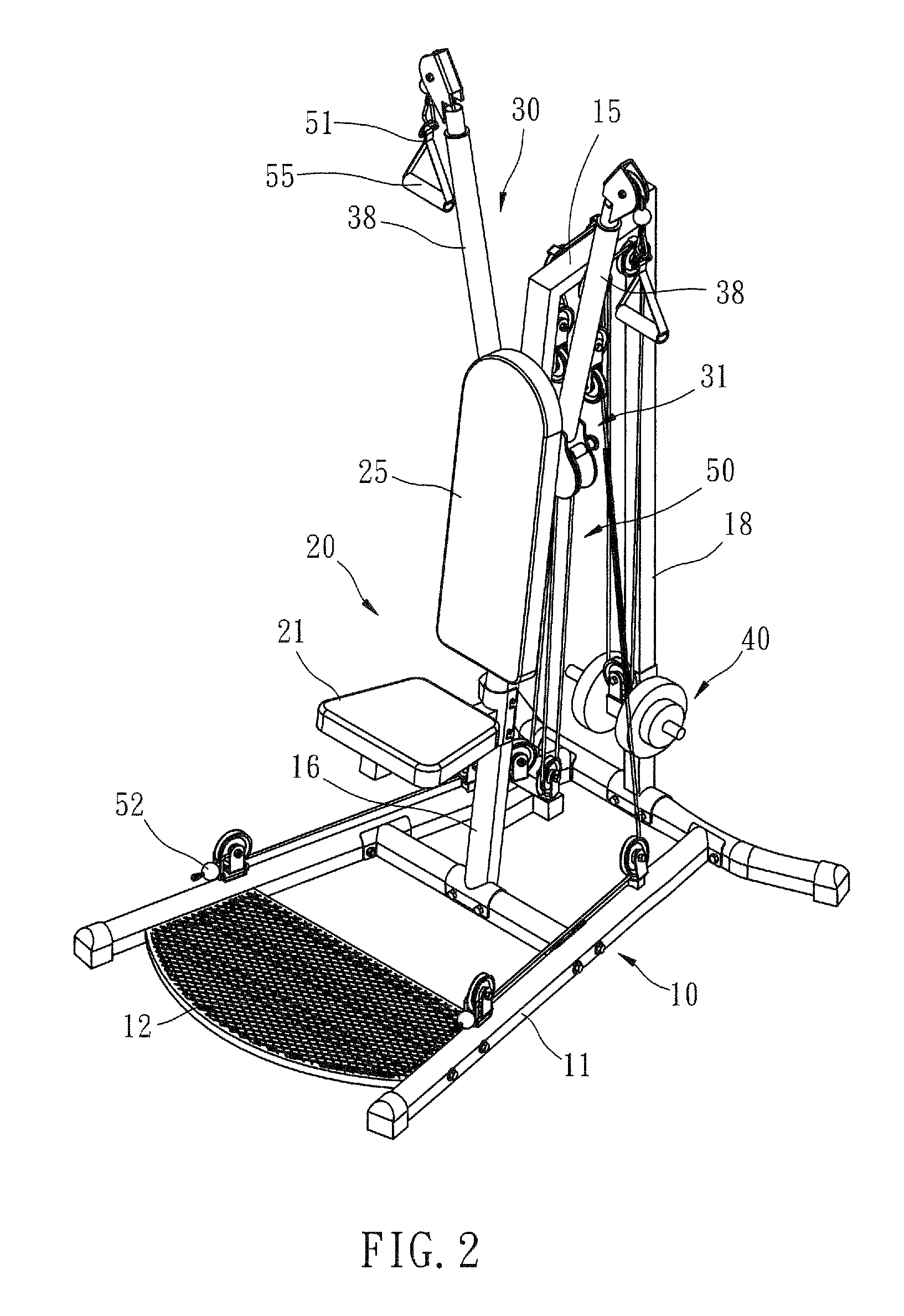

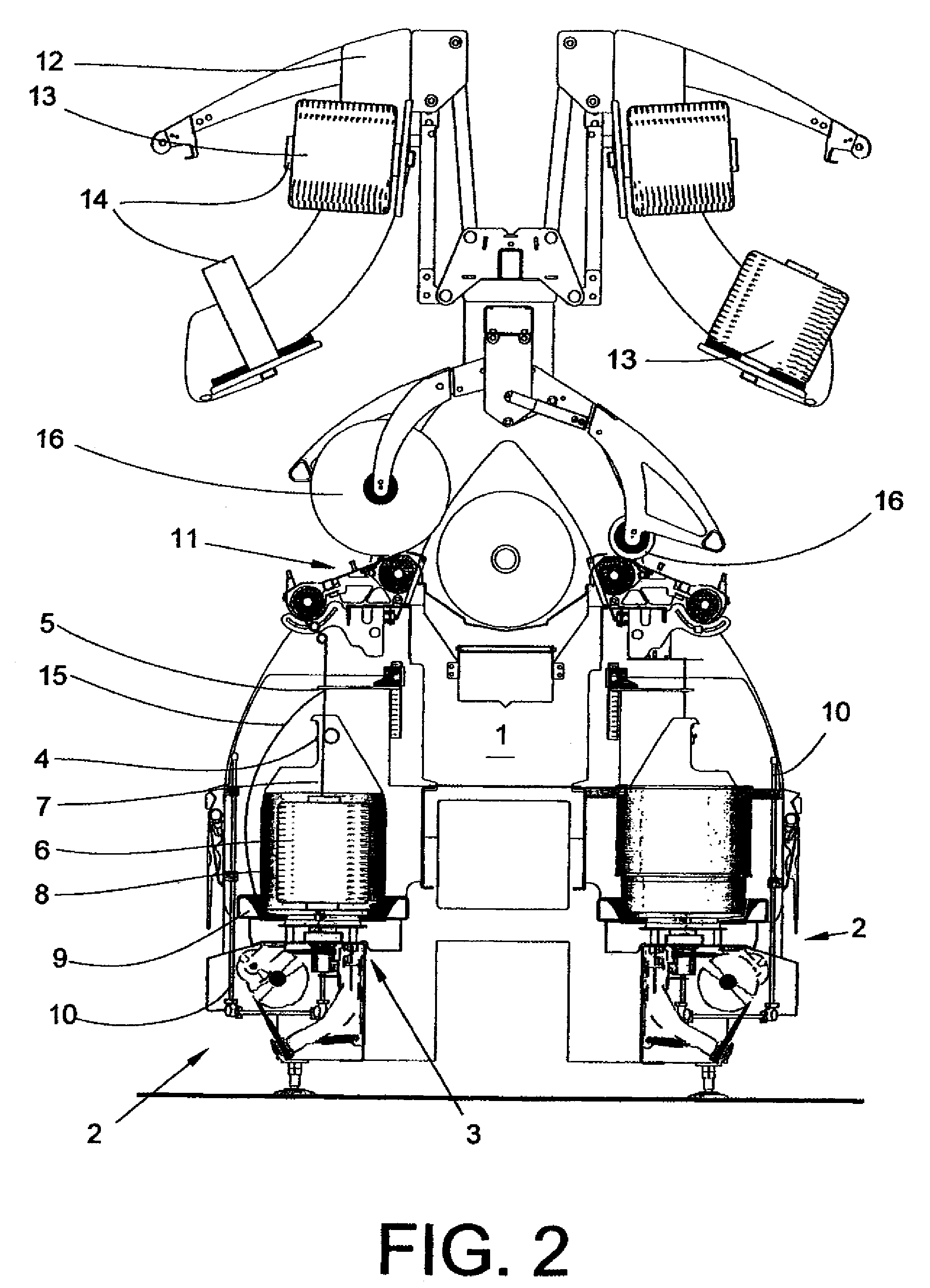

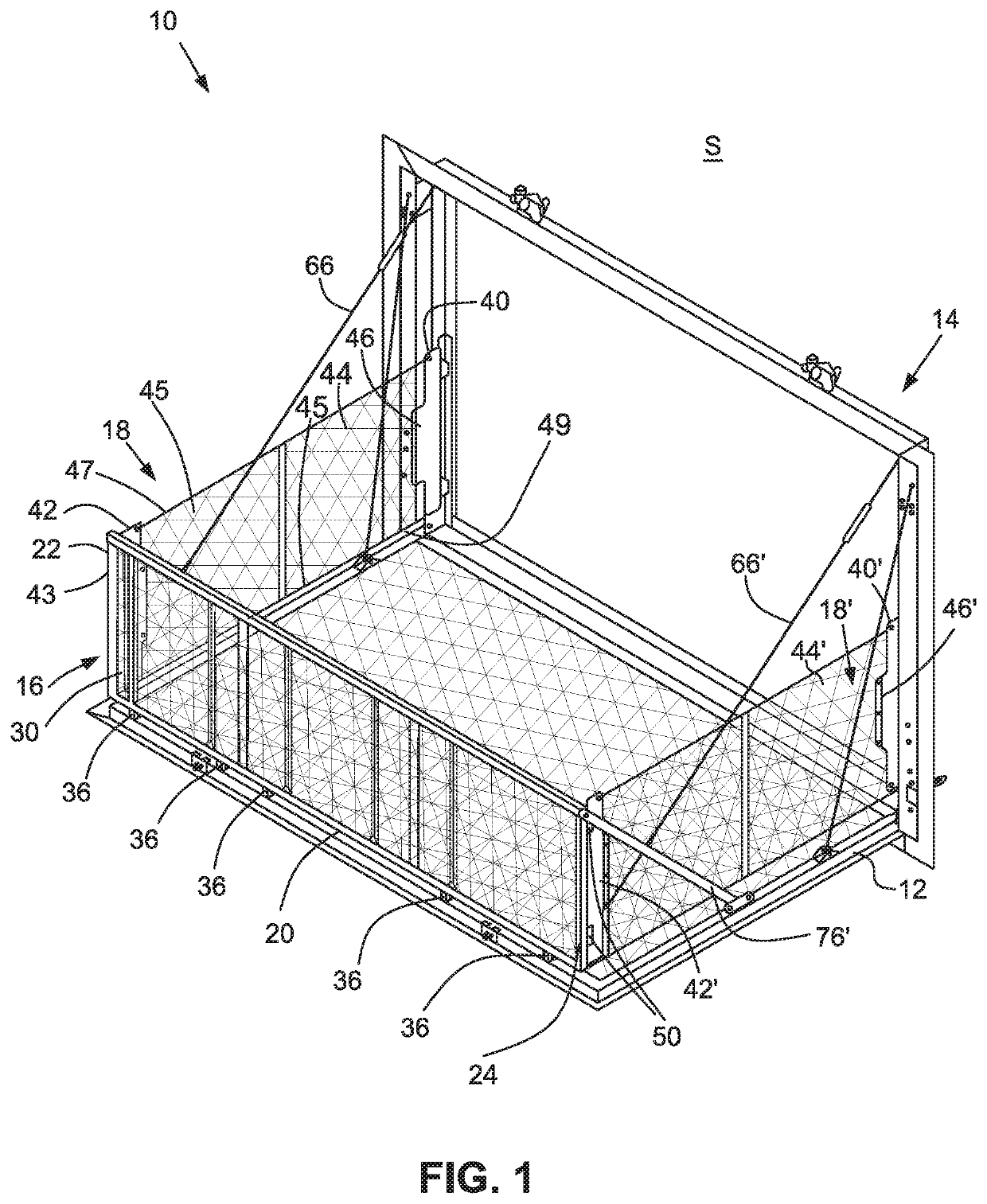

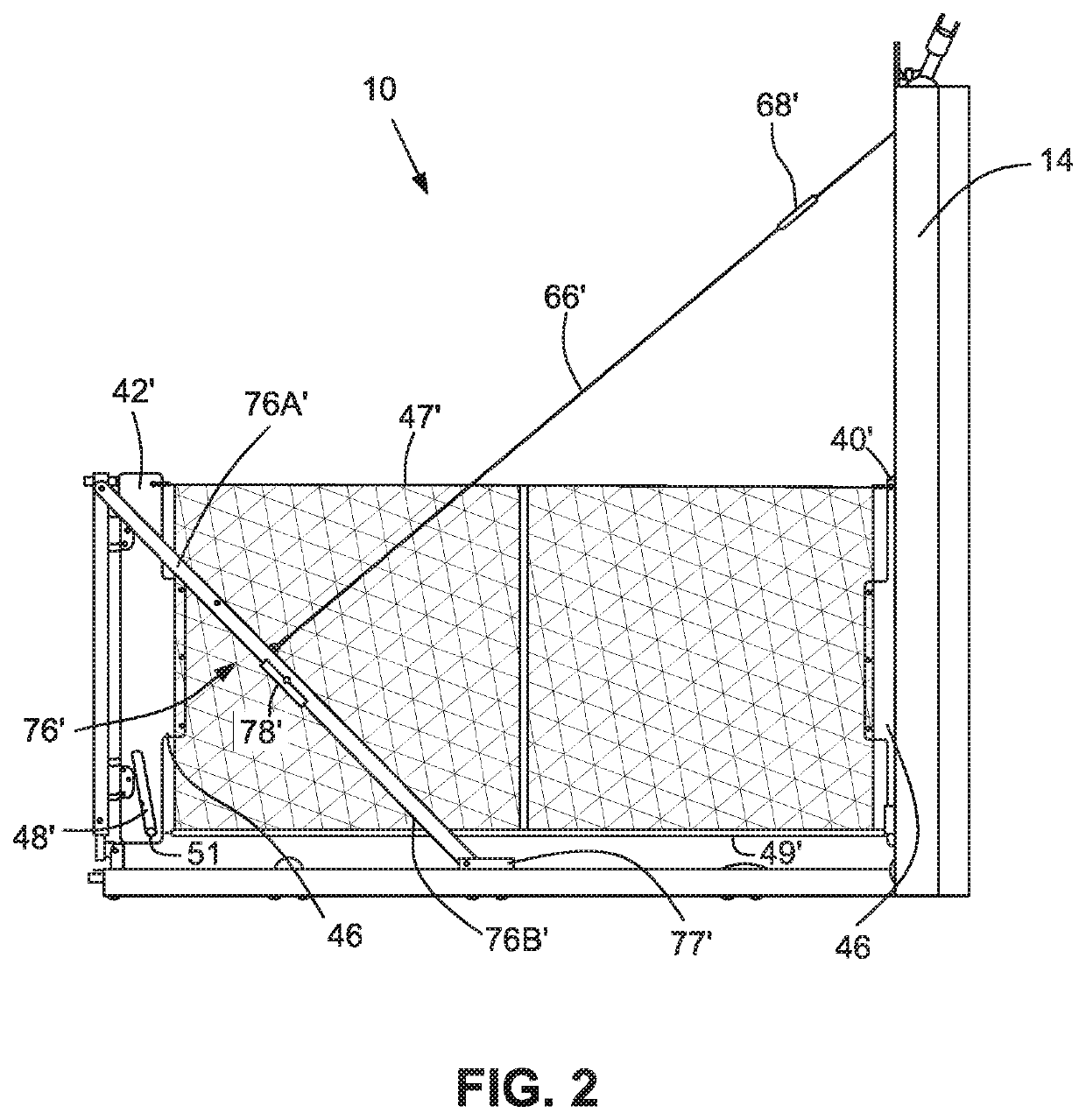

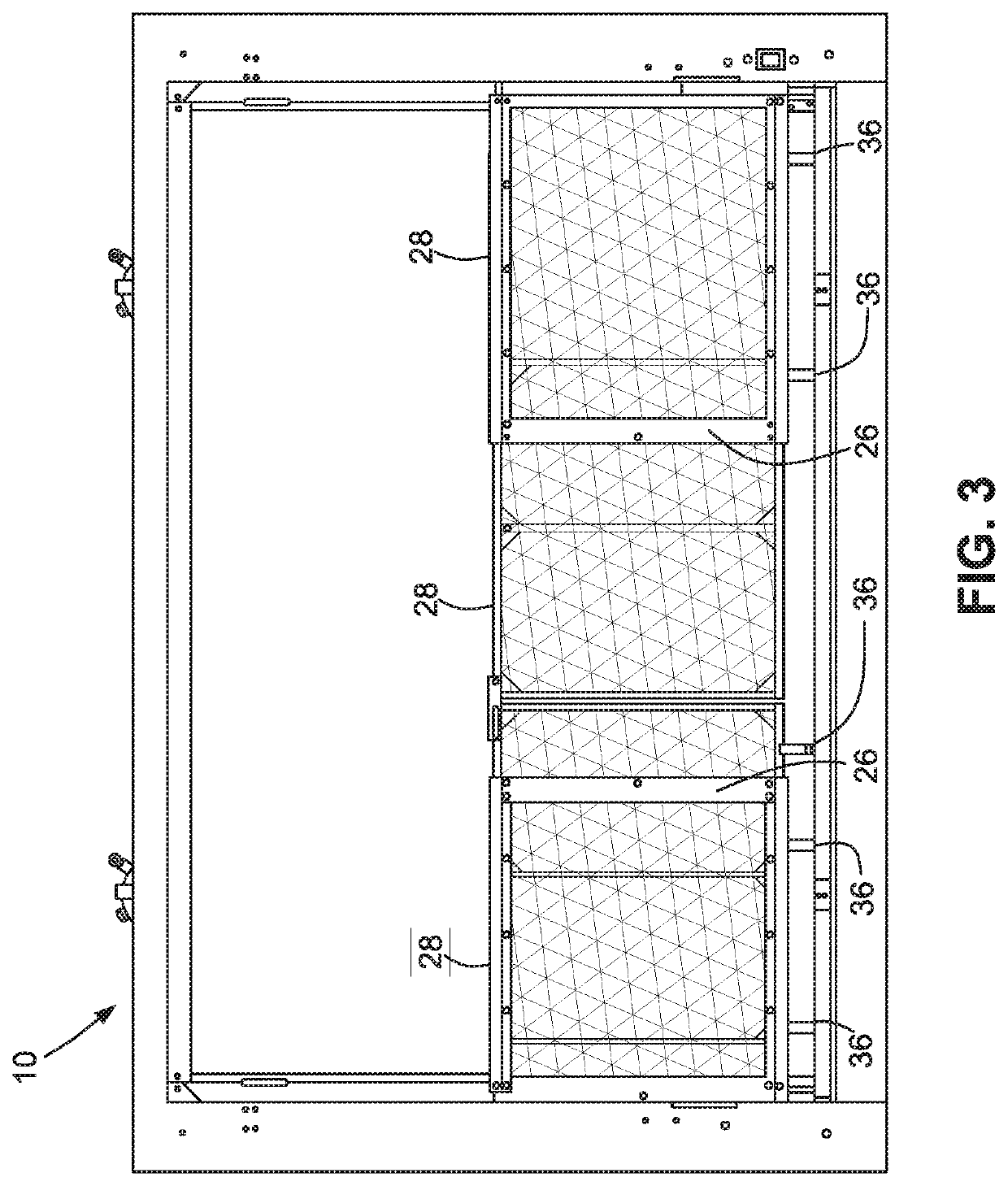

Adjustable cable machine

The adjustable cable machine contains a frame member raised on a base member having two ground bars. A seat member is configured in the front and a weight member capable of sliding vertically on the frame member. Two extension members are configured oppositely to the lateral sides of the frame member. Each extension member contains an adjustment element fixed to the frame member and an extension rod pivotally joined to the adjustment element. Each extension rod could be turned to adjust its angle relative to the frame member. A traction member composed of pulleys and cables is configured between the weight member and the extension members. A handle could be configured to an upper actuating ends at a top end of each extension rod or a lower actuating end in a front section of a ground bar.

Owner:HSIUNG BOB

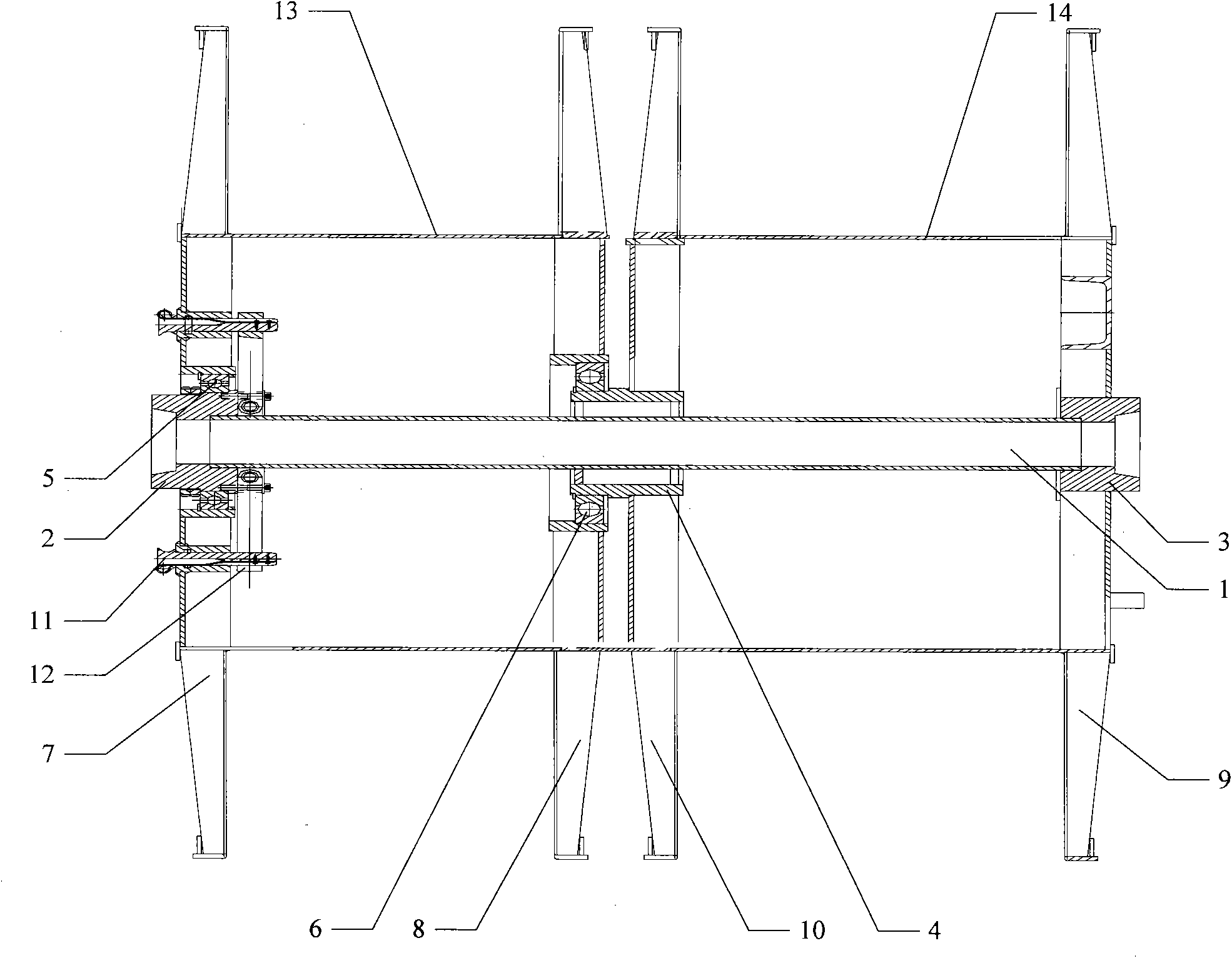

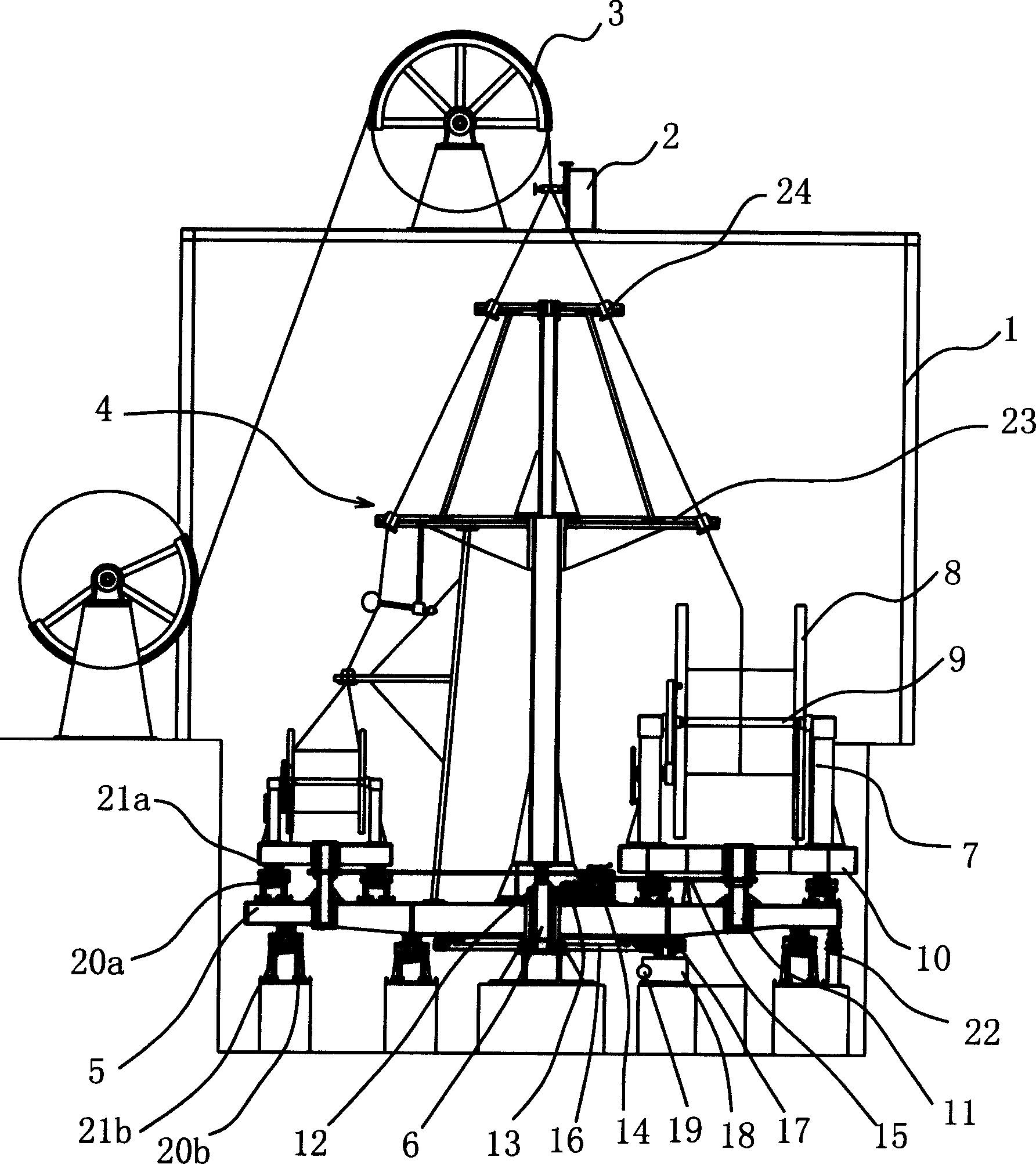

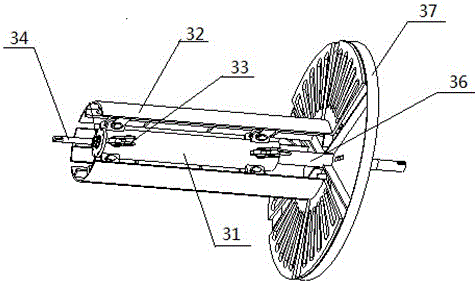

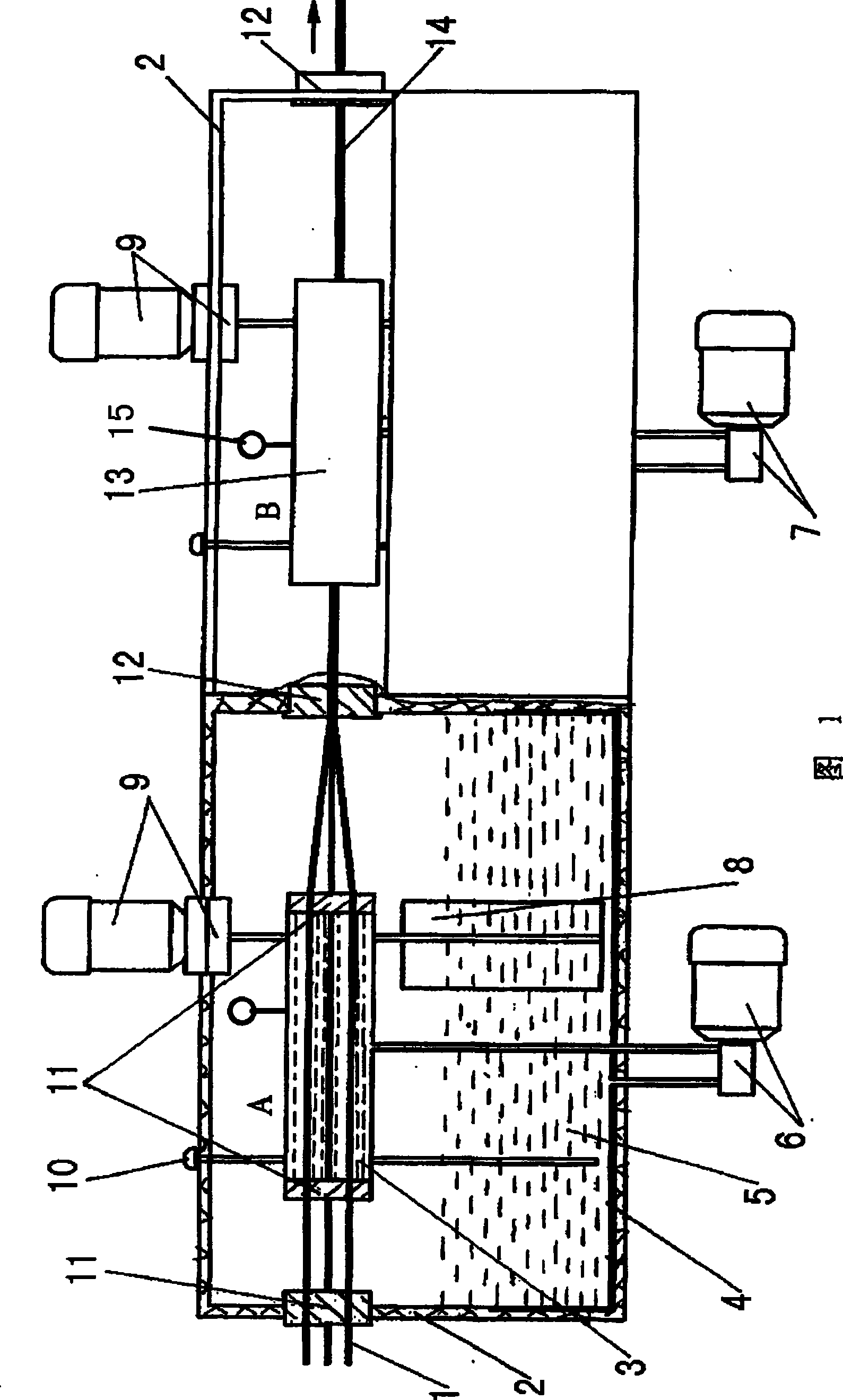

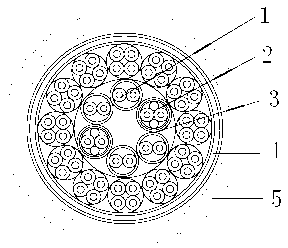

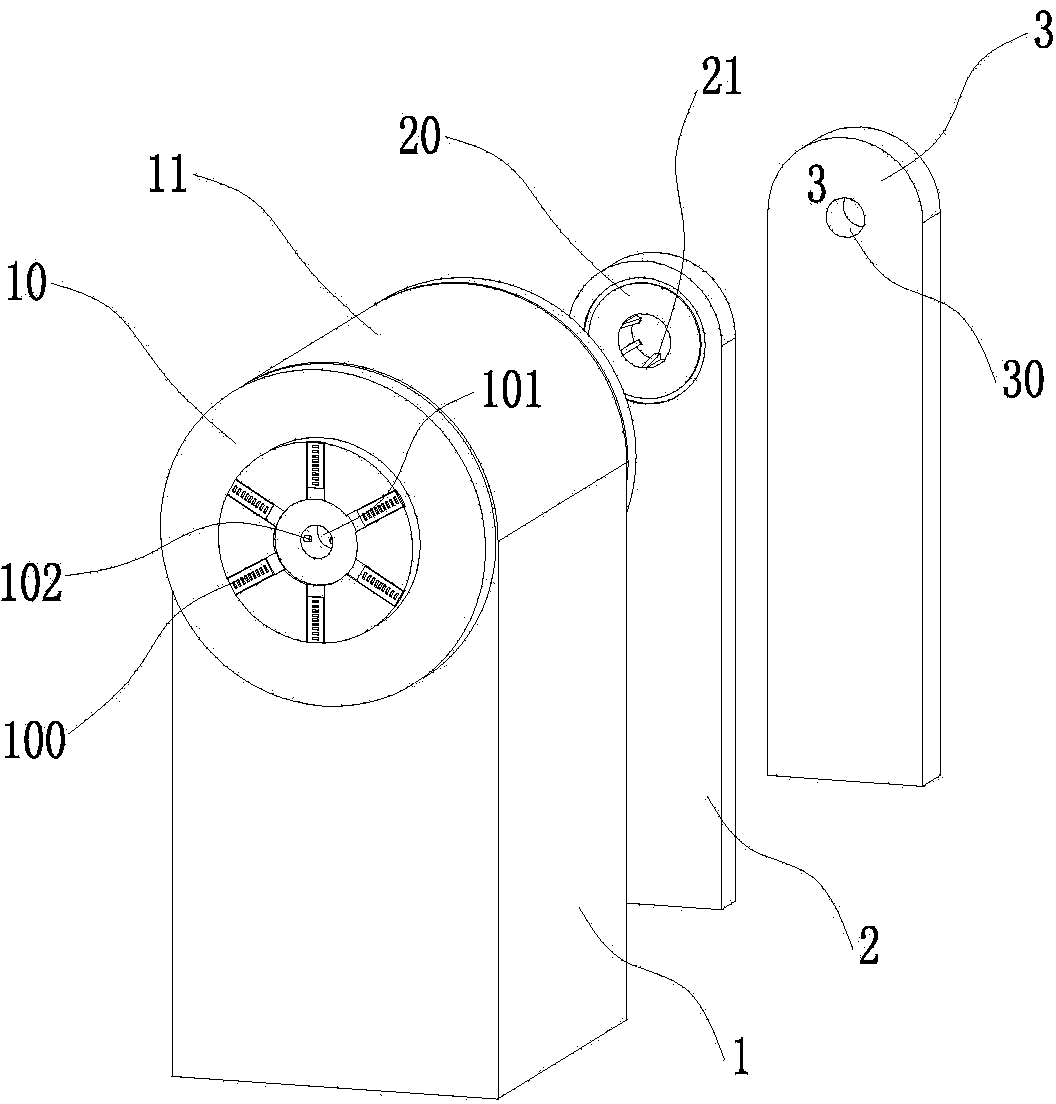

Disk type cabling machine, cage type cabling machine and wire coil for machine

ActiveCN101885436AMeet the requirements of the number of payoutsAchieve productionCable/conductor manufactureCable machineEngineering

The embodiment of the invention discloses a wire coil for a machine. The wire coil comprises a rotating shaft, a first shoulder, a second shoulder, a third shoulder, a first outer side plate, a first inner side plate, a second outer side plate, a second inner side plate, a first sleeve, a second sleeve, a positioning pin and a positioning baffle plate, wherein the first shoulder and the second shoulder are connected with the two ends of the rotating shaft respectively; the third shoulder is positioned between the first shoulder and the second shoulder and connected with the rotating shaft; the first outer side plate is connected with the first shoulder through a first bearing; the first inner side plate is connected with the third shoulder through the second bearing; the second outer side plate is fixedly connected with the second shoulder; the second inner side plate is positioned between the first inner side plate and the second outer side plate and fixedly connected with the third shoulder; the positioning pin is arranged on the first outer side plate; and the positioning baffle plate is provided with a positioning hole and connected with the first shoulder. The wire coil for the machine disclosed by the invention is provided with two sleeves, so the wire coil can take up and release two pieces of insulating wire cores. The invention also discloses a disk type cabling machine and a cage type cabling machine, which can be used for producing high-specification multi-core cables.

Owner:四川川东电缆有限责任公司

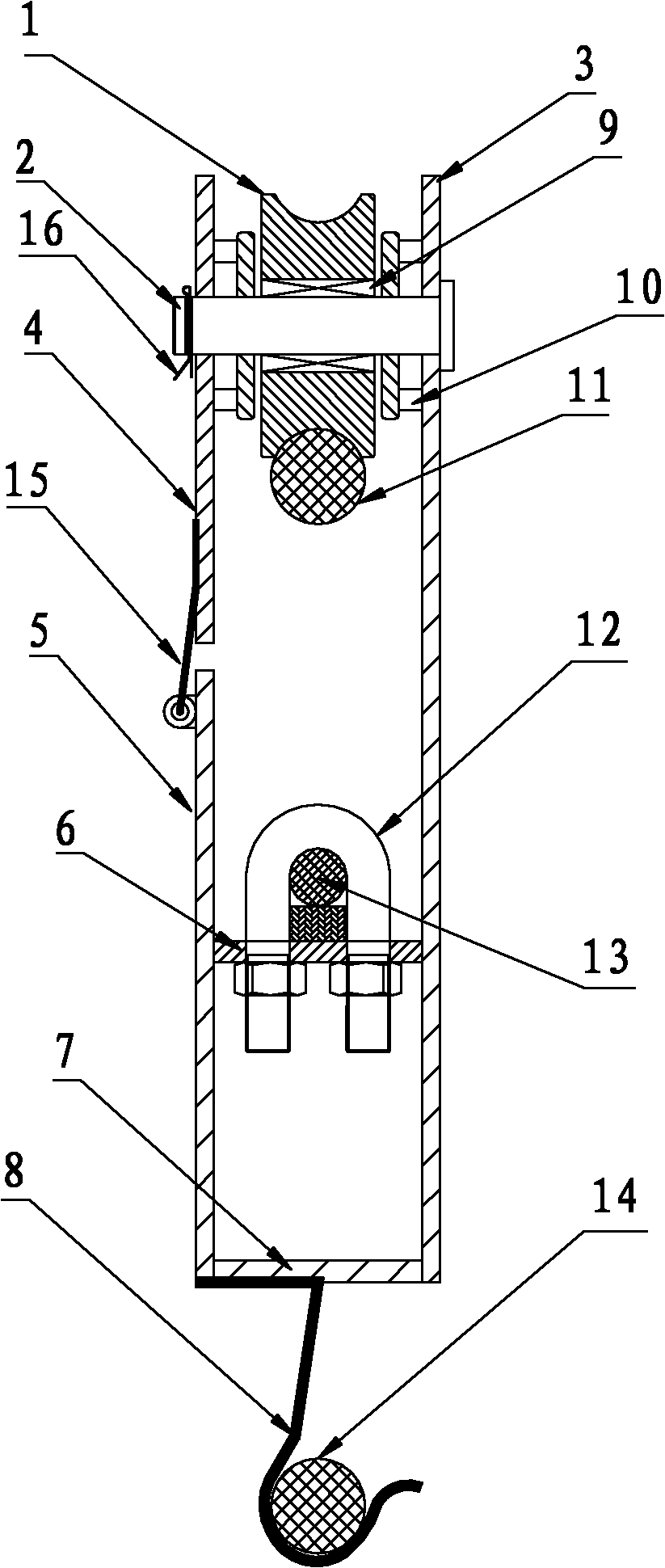

Vertical disc twisting head of cable forming machine

ActiveCN1758386AIncrease the lengthStable deliveryRope making machinesCable/conductor manufactureCable machine

This invention relates to the improvement of a rundle of a cabling machine including a platform, a cabling doubling die carrier set on it, a guide wheel set on one side of the die carrier and a frame set under it matched with the central shaft of the cabling disk characterizing that the axle wire of the shaft is vertical to the level, several cable paying out frames are set on the disk vertical to the axle wire of the disk shaft and the cable dial matched to the cable disk and several big riding wheel frames are set under the cable disk with big riding wheels on them advantaged that: long cabling at one run: it is prolonged from 1km at the present to 15km, the design of the torsion back device is reasonable and the cabling wires are turned back synchronously.

Owner:宁波东方电缆股份有限公司

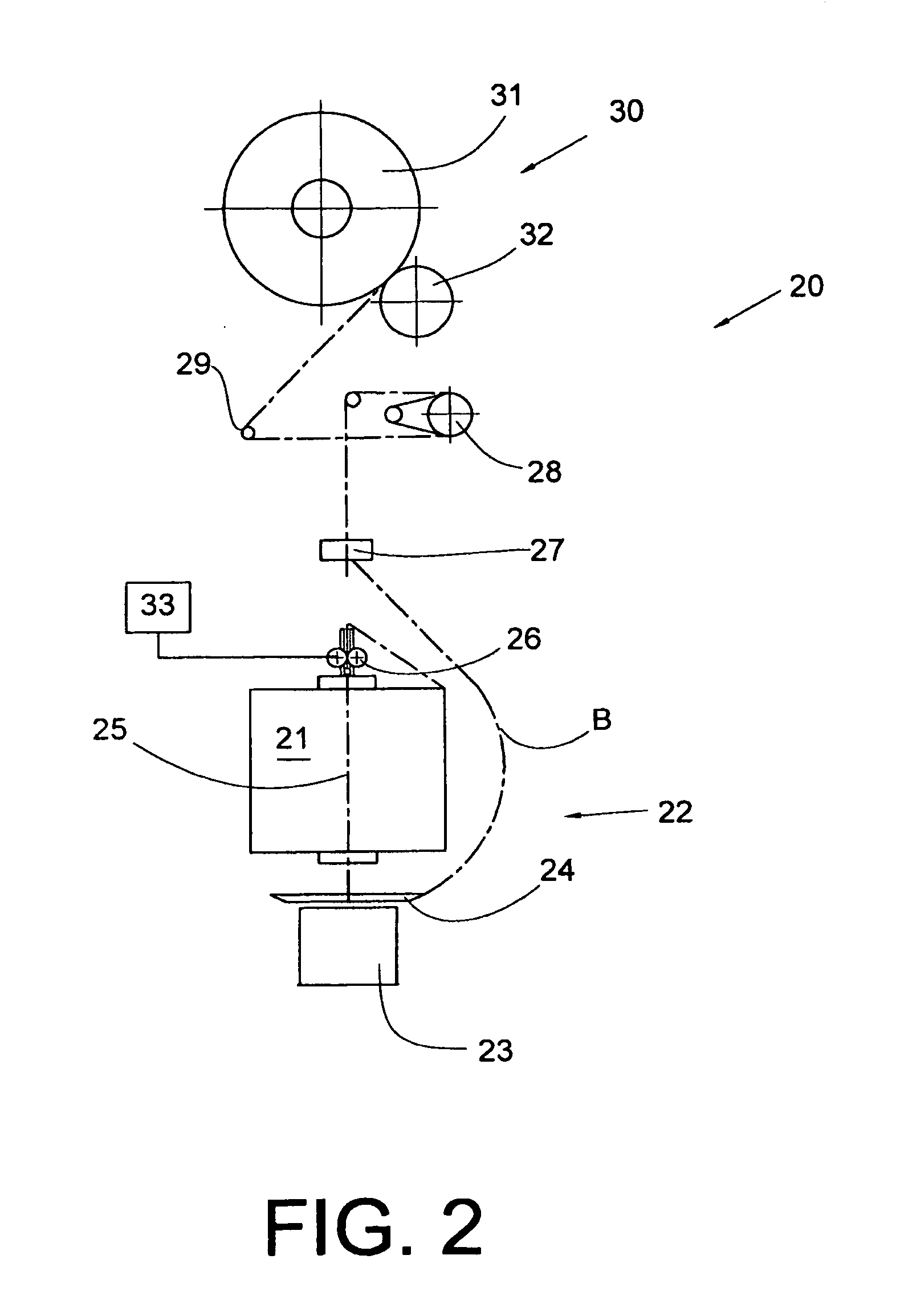

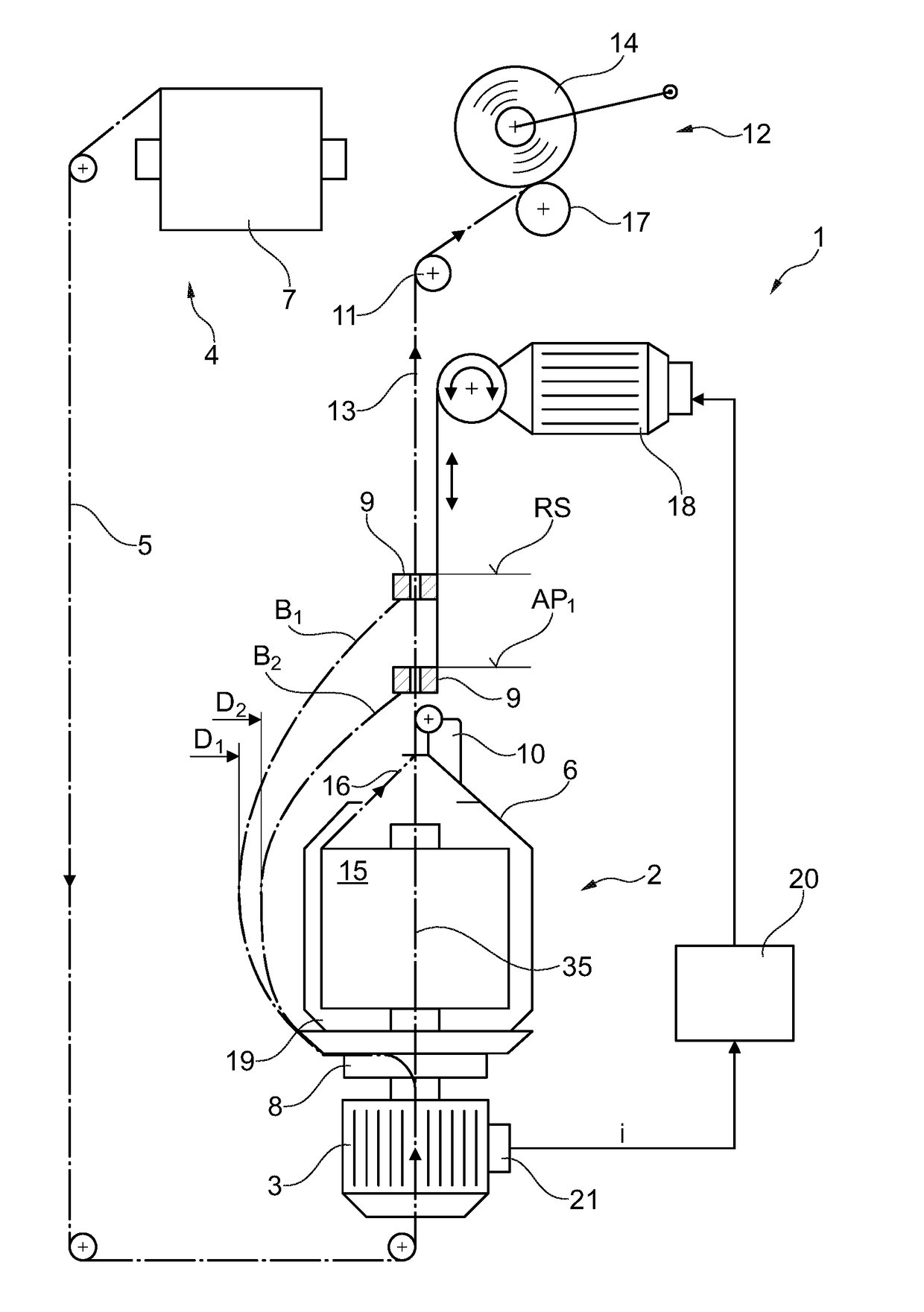

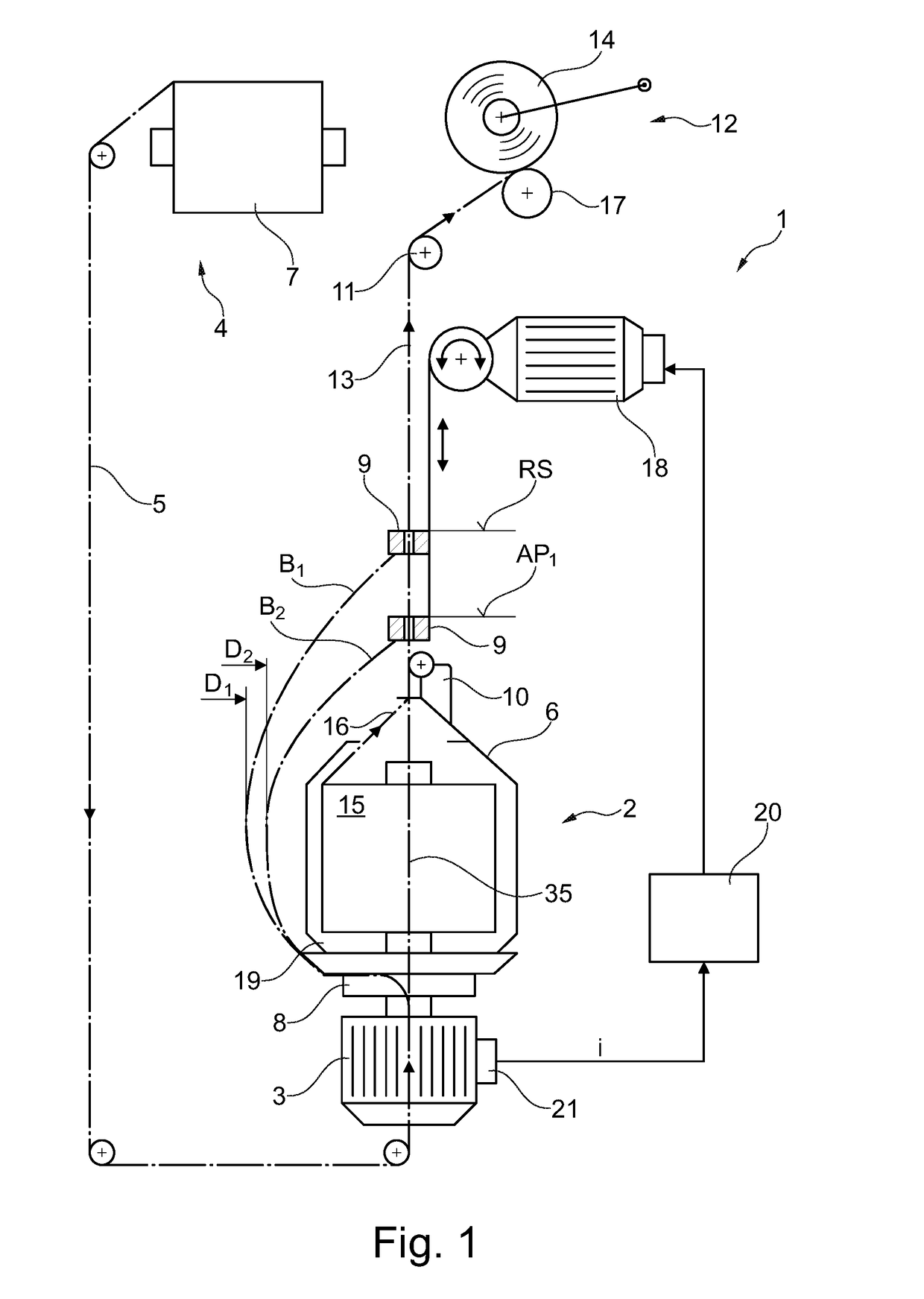

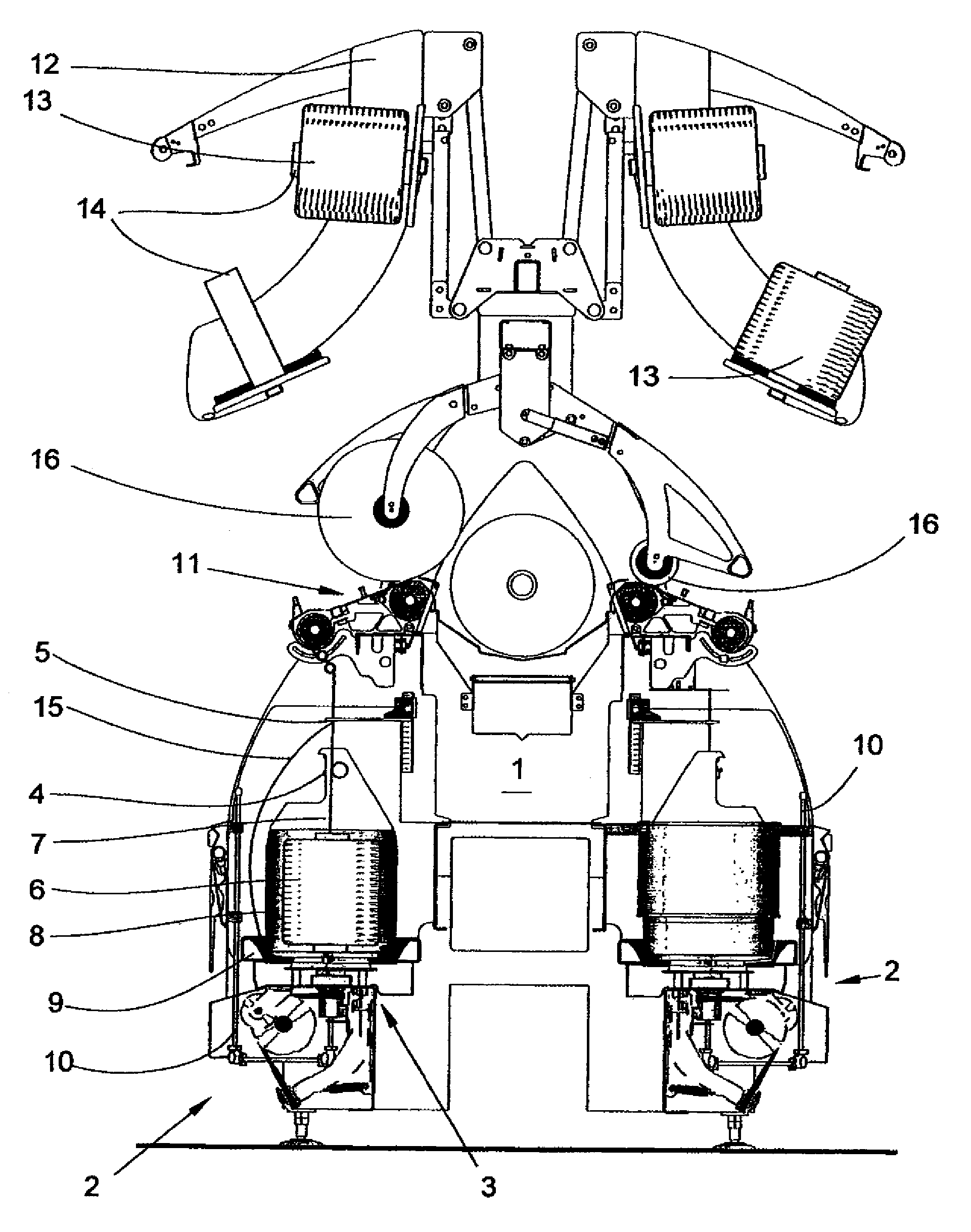

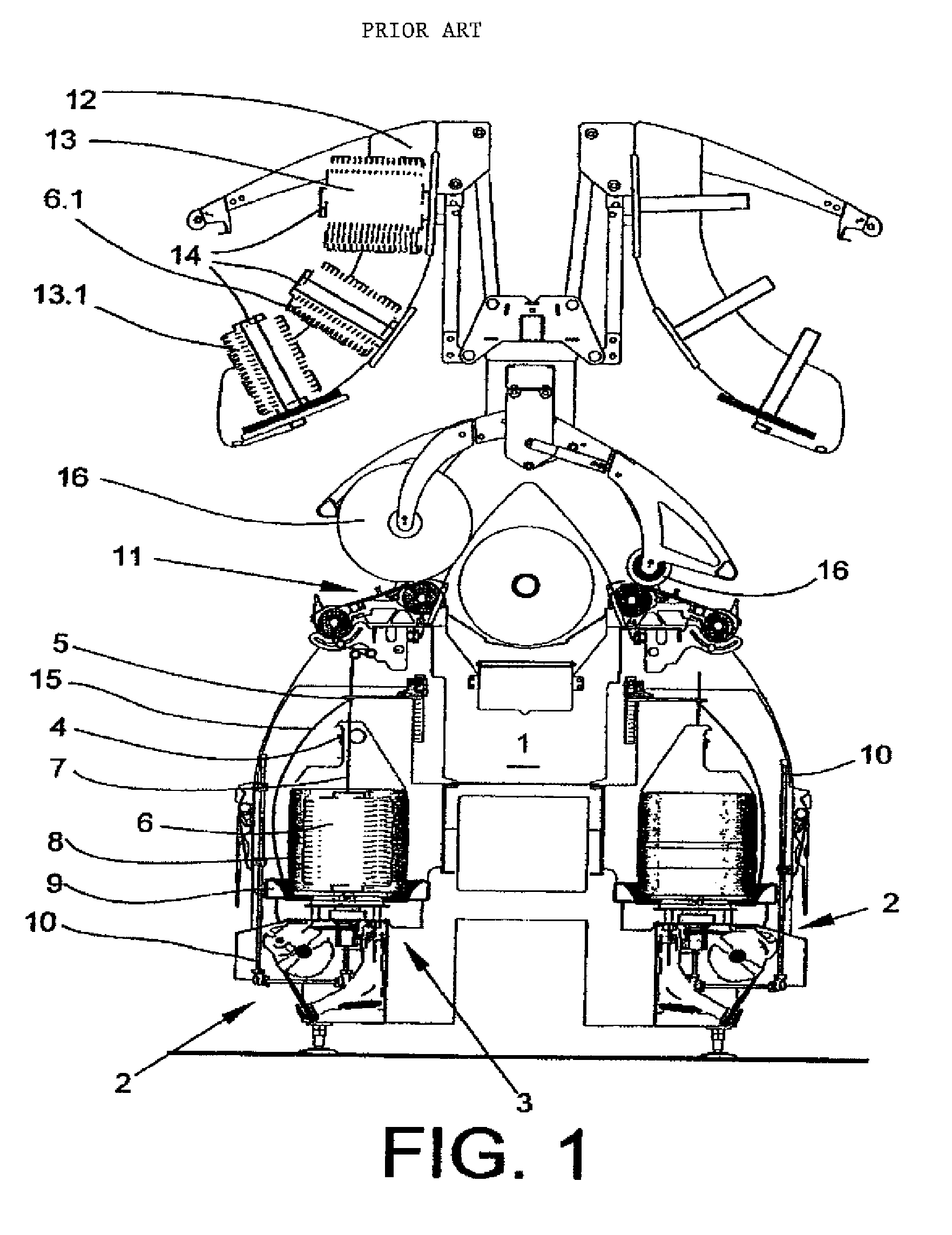

Method for operating a spindle of a two-for-one twister or cabling machine

ActiveUS20110126506A1Reduce energy consumptionDiameter minimizationContinuous wound-up machinesYarnBobbinCable machine

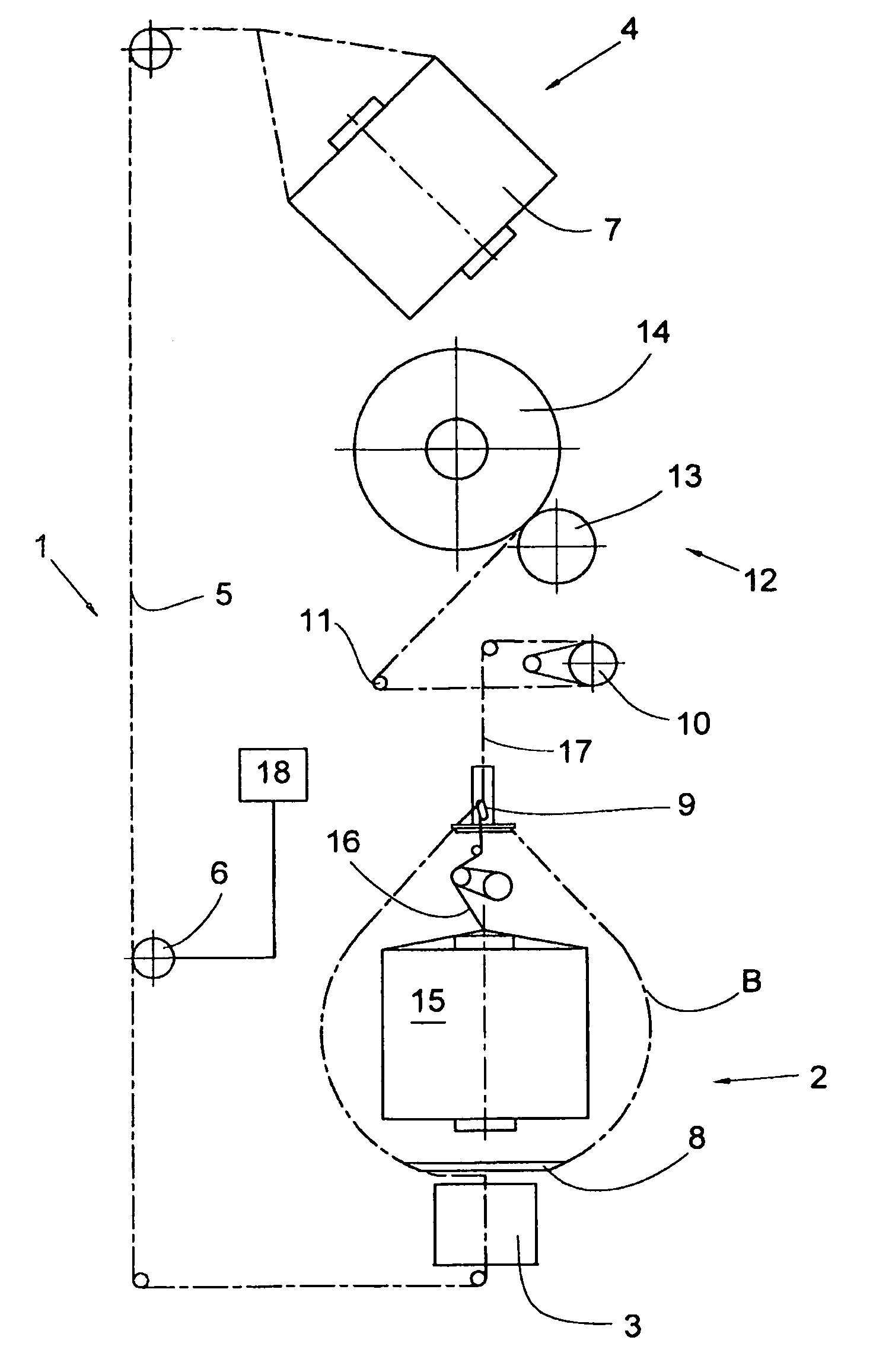

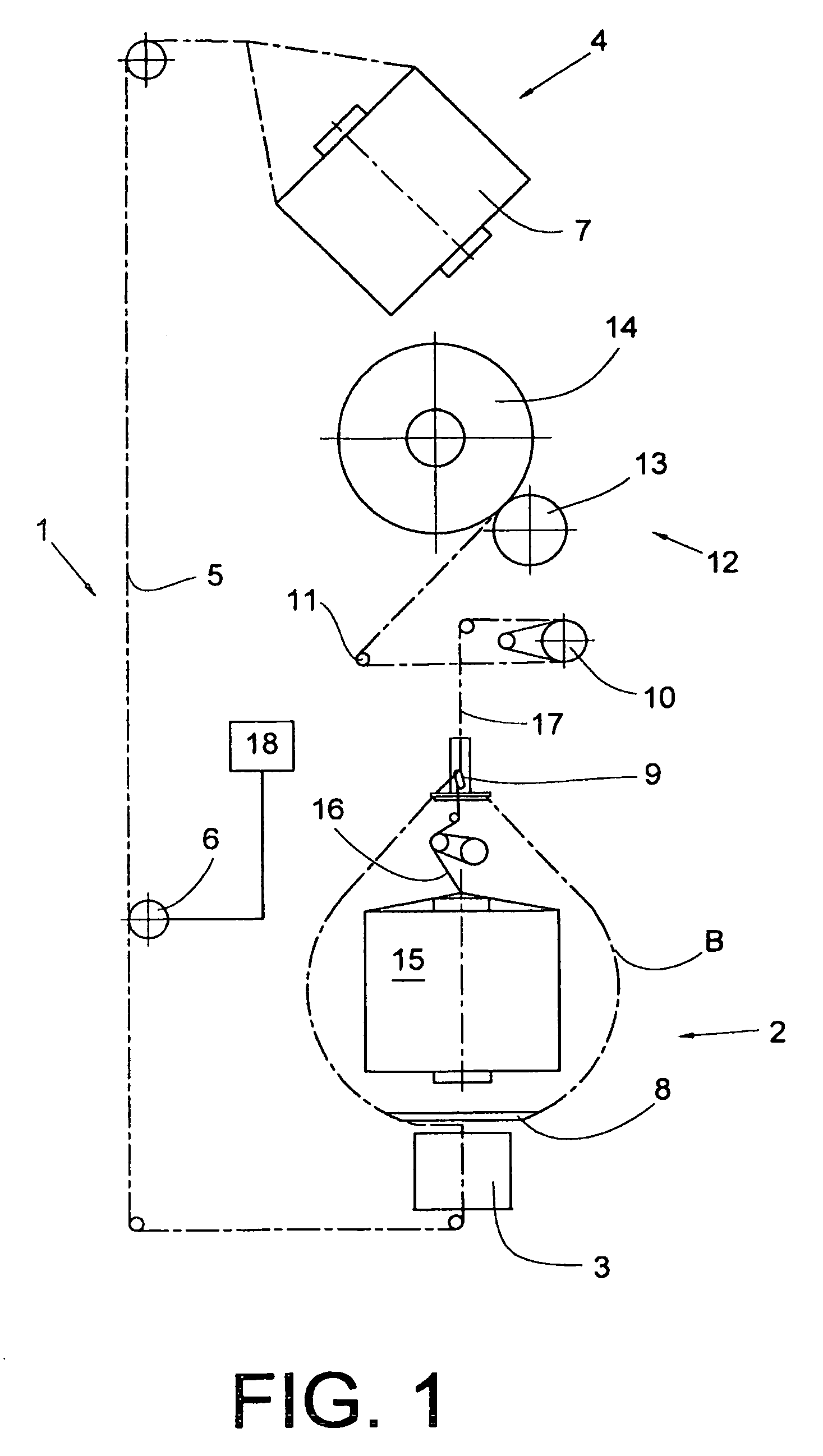

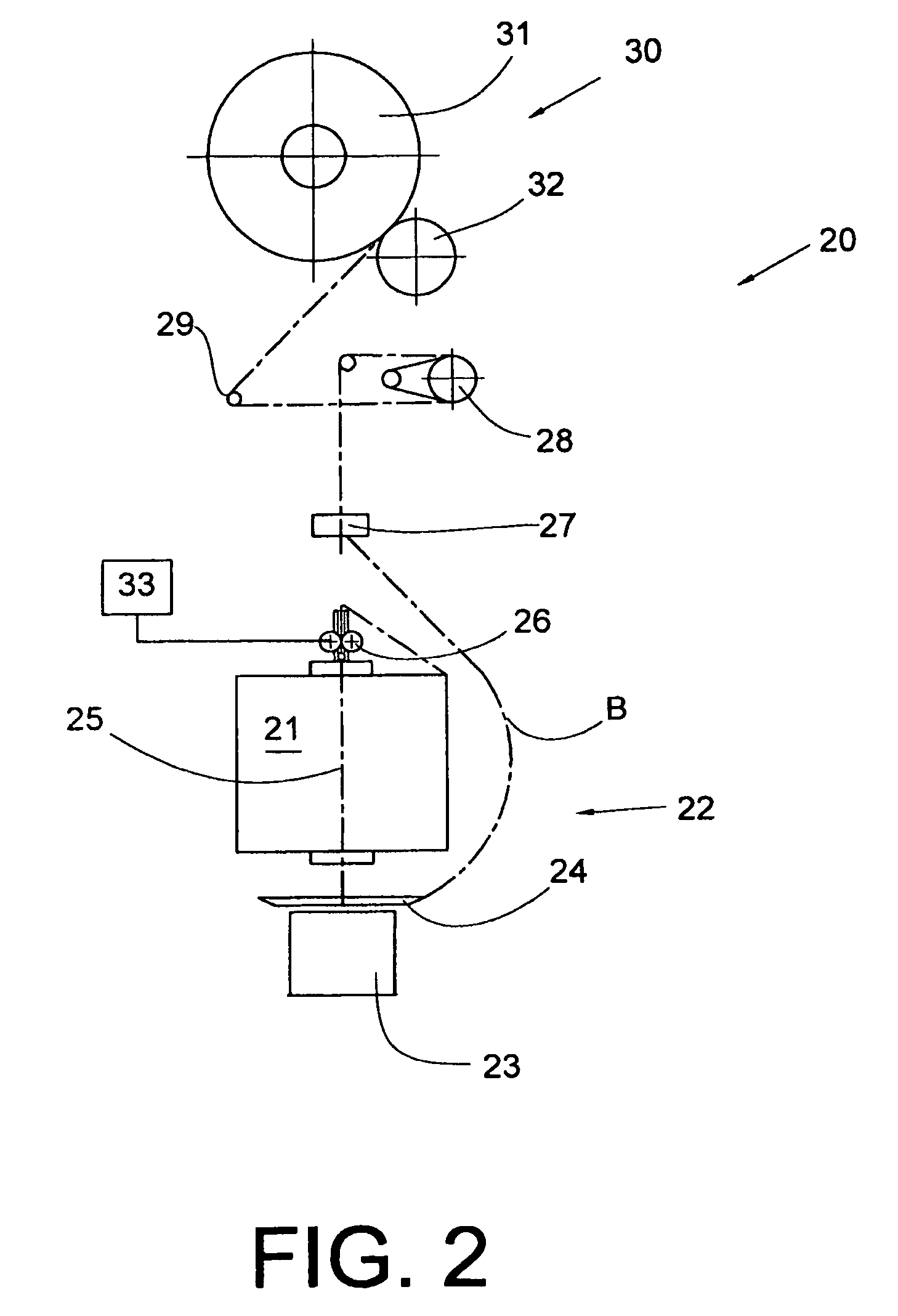

A two-for-one twister or cabling machine and a method for operation thereof, wherein a yarn (5, 25) is withdrawn from a supply bobbin (7, 21) and fed to a guide device below a twisted yarn plate (8, 24) of the spindle (2, 22) and from which the yarn (5, 25) exits virtually perpendicular to the axis of the spindle (2, 22) and is deflected to the outer edge of the twisted yarn plate (8, 24) and runs along the spindle (2, 22) as a free yarn balloon (B) encompassing the spindle (2, 22), until the yarn (5, 25) is fed into the twist or cabling point of a yarn guide device (9, 27) above the spindle (2, 22). The supply speed of the yarn (5, 25) is adjusted to achieve a yarn tension which minimizes the yarn balloon diameter as a function of the spindle geometry.

Owner:ZHUOLANG INTELLIGENT MACHINERY CO LTD

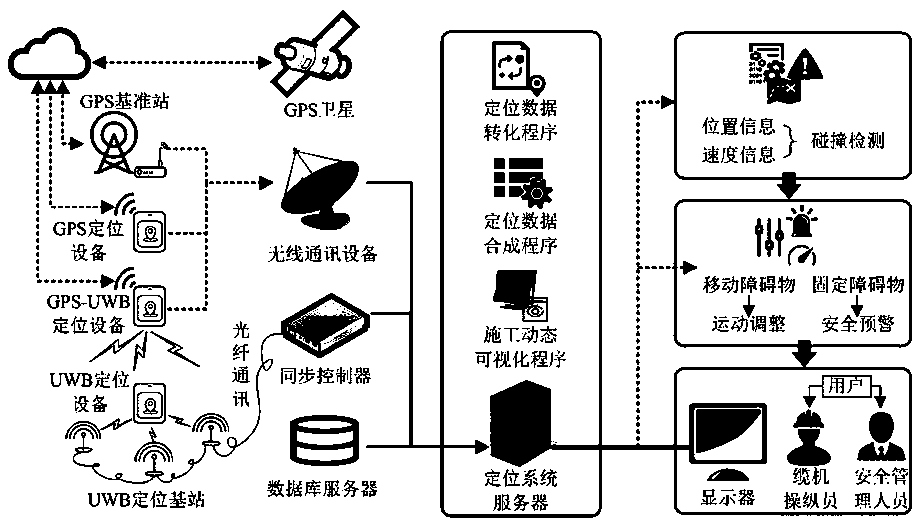

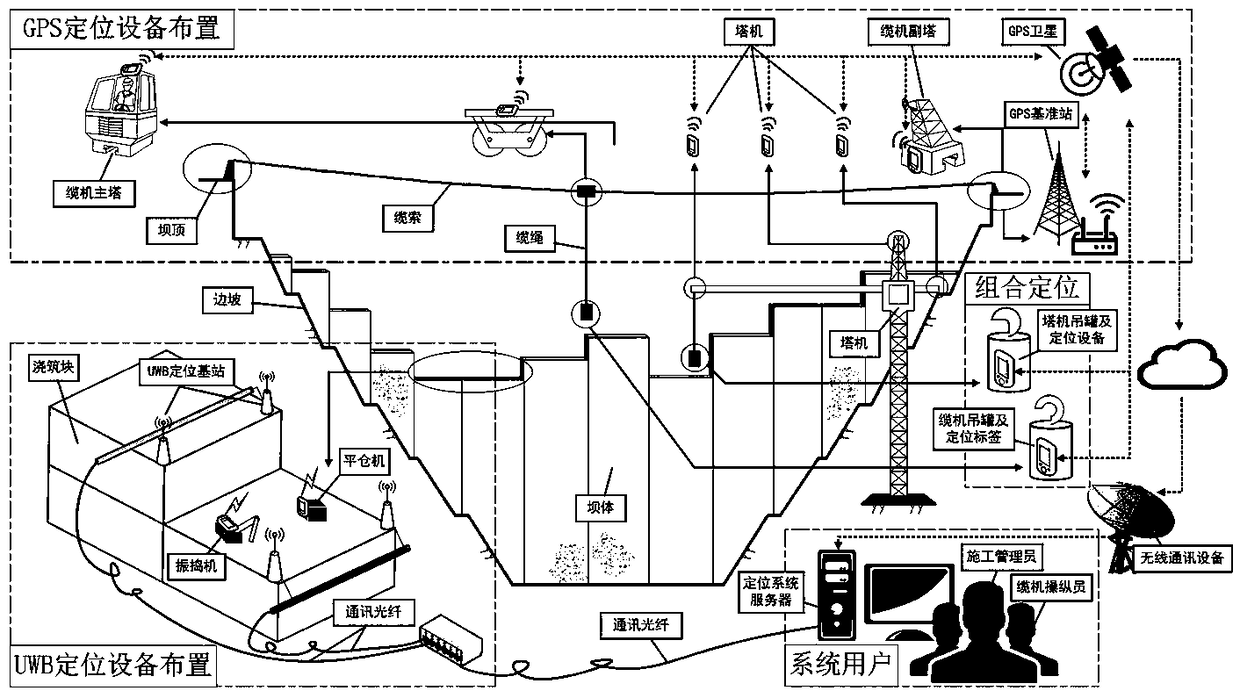

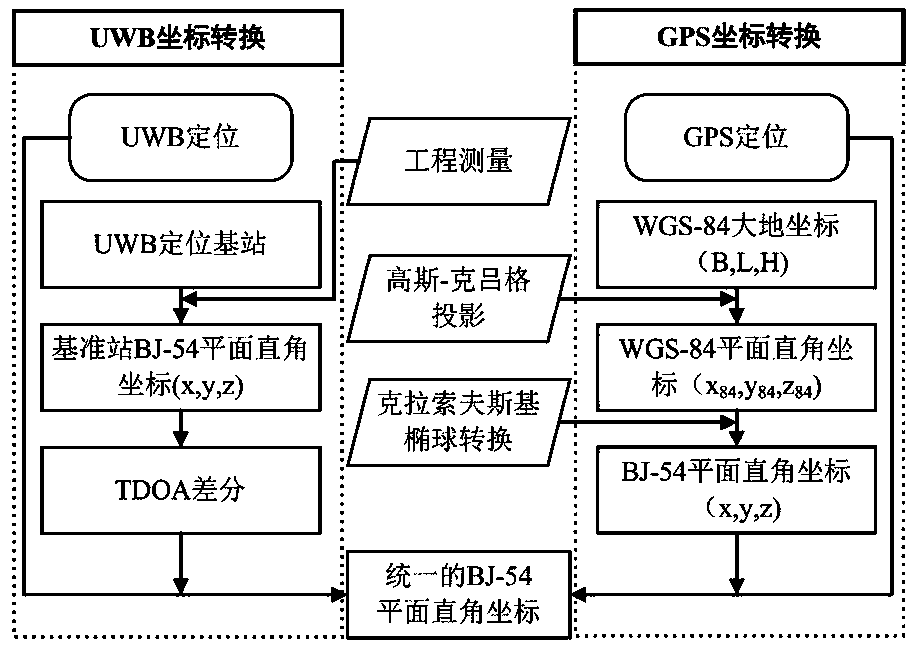

Combined positioning cable machine operation monitoring system and cable machine anti-collision regulation and control method

PendingCN108427134ARealize visualizationImprove securitySatellite radio beaconingTotal factory controlSynthesis methodsCollision detection

A combined positioning cable machine operation monitoring system and a cable machine anti-collision regulation and control method are disclosed. The system comprises a cable machine, a construction device, a first positioning device, a second positioning device, a combined positioning device, a first reference station, a second positioning base station, a wireless communication device, a synchronous controller, a positioning server, a database server and a display device. The invention also comprises a cable machine collision detection method, the cable machine anti-collision regulation and control method, a cable machine anti-collision shift up or shift down determining method and a data conversion and synthesis method for a combined positioning device. The system and the method disclosedin the invention are high in combined positioning precision and real time performance; a monitoring scope cannot be limited, a cable machine can be monitored in real time in a seamless manner, and cable machine construction processes can be monitored in a visualized manner; via the collision detection method and the anti-collision regulation and control method adopted in the invention, an effective cable machine anti-collision regulation and control mechanism is formed so as to ensure safe and highly efficient operation of the cable machine.

Owner:CHINA THREE GORGES UNIV

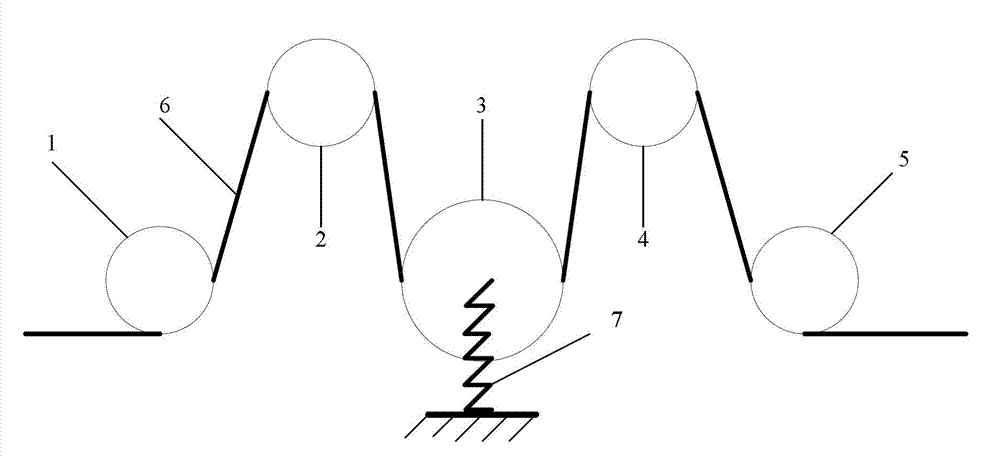

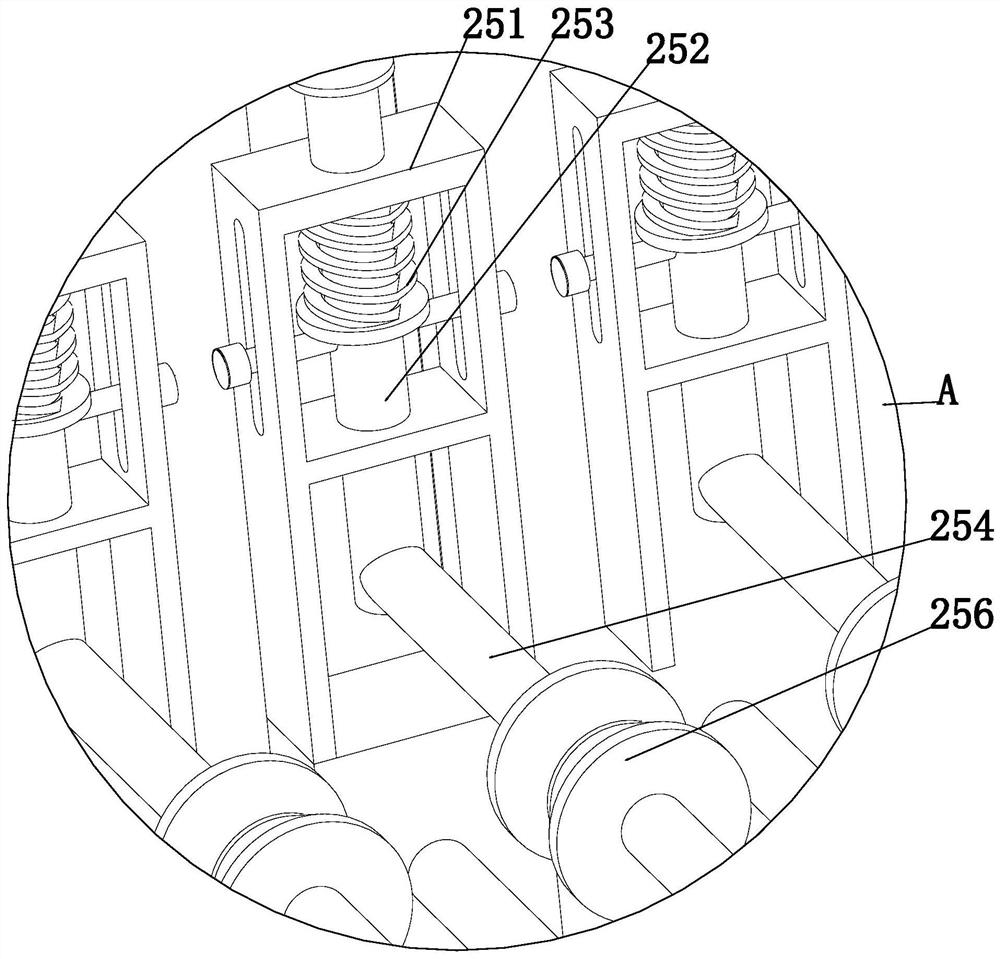

Cable tension control device of cabling machine

InactiveCN102963769AConstant tensionImprove cabling qualityFilament handlingElastic componentCable machine

The invention discloses a cable tension control device of a cabling machine. The cable tension control device comprises a wire releasing disc, a wire collecting disc, a first fixed pulley I, a first fixed pulley II and a movable pulley, wherein the wire releasing disc is positioned at the feeding end of the cabling machine, the wire collecting disc is positioned at the material discharging end of the cabling machine, the first fixed pulley I is fixedly arranged on the cabling machine, the first fixed pulley II is fixedly arranged on the cabling machine, the movable pulley forms a triangular shape with the first fixed pulley I and the first fixed pulley II and is connected with a work table of the cabling machine through an elastic component, and under the tension of cables and the elastic effect of the elastic component, the movable pulley moves in the direction vertical to the center connecting line of the first fixed pulley I and the first fixed pulley II. The cable tension control device has the advantages that the tension is regulated through the tension of the triangular pulley block structure on the cables, the constant tension is ensured, and the cabling quality is improved.

Owner:ANHUI TIANXING OPTICAL FIBER COMM EQUIP

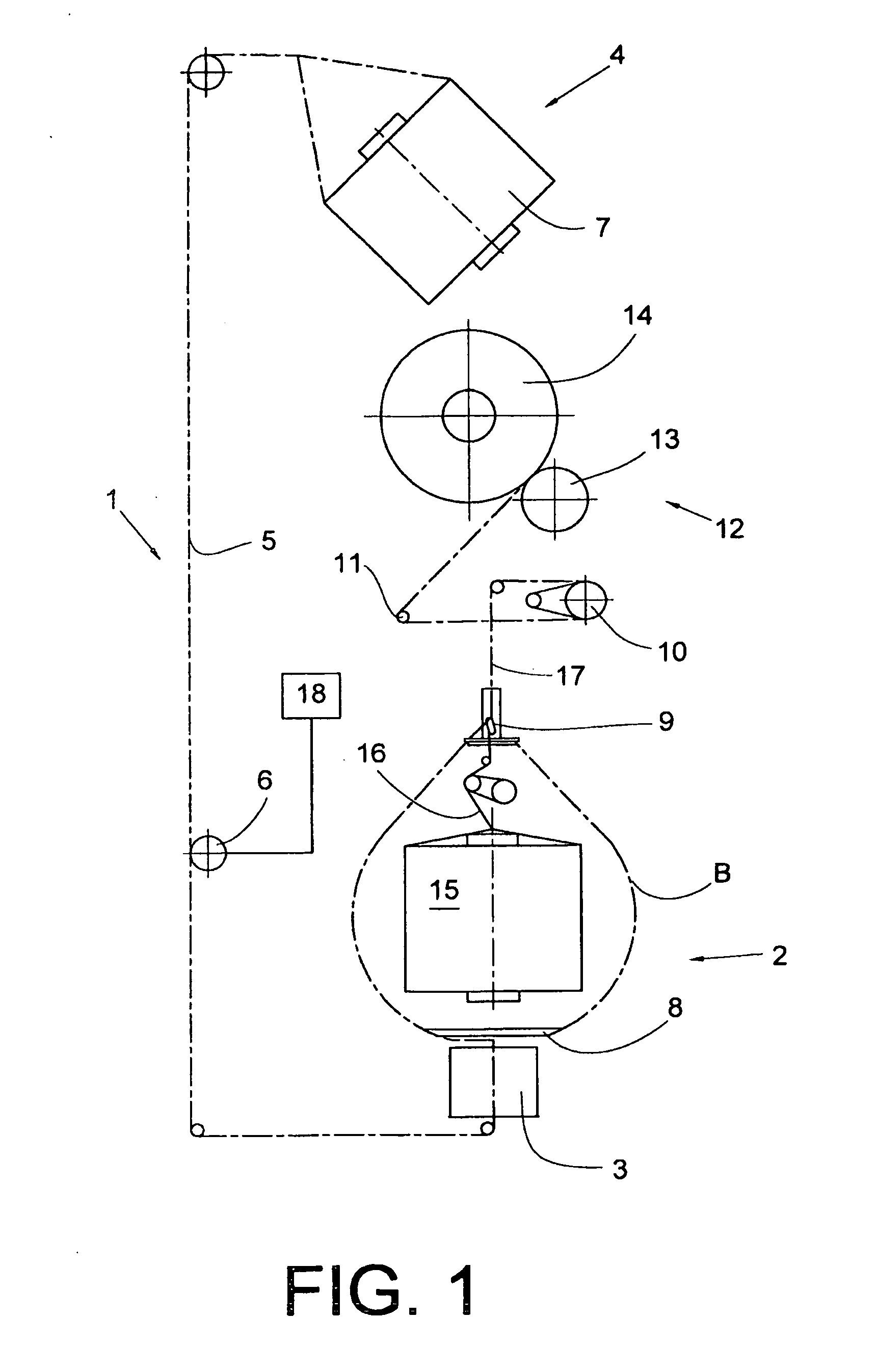

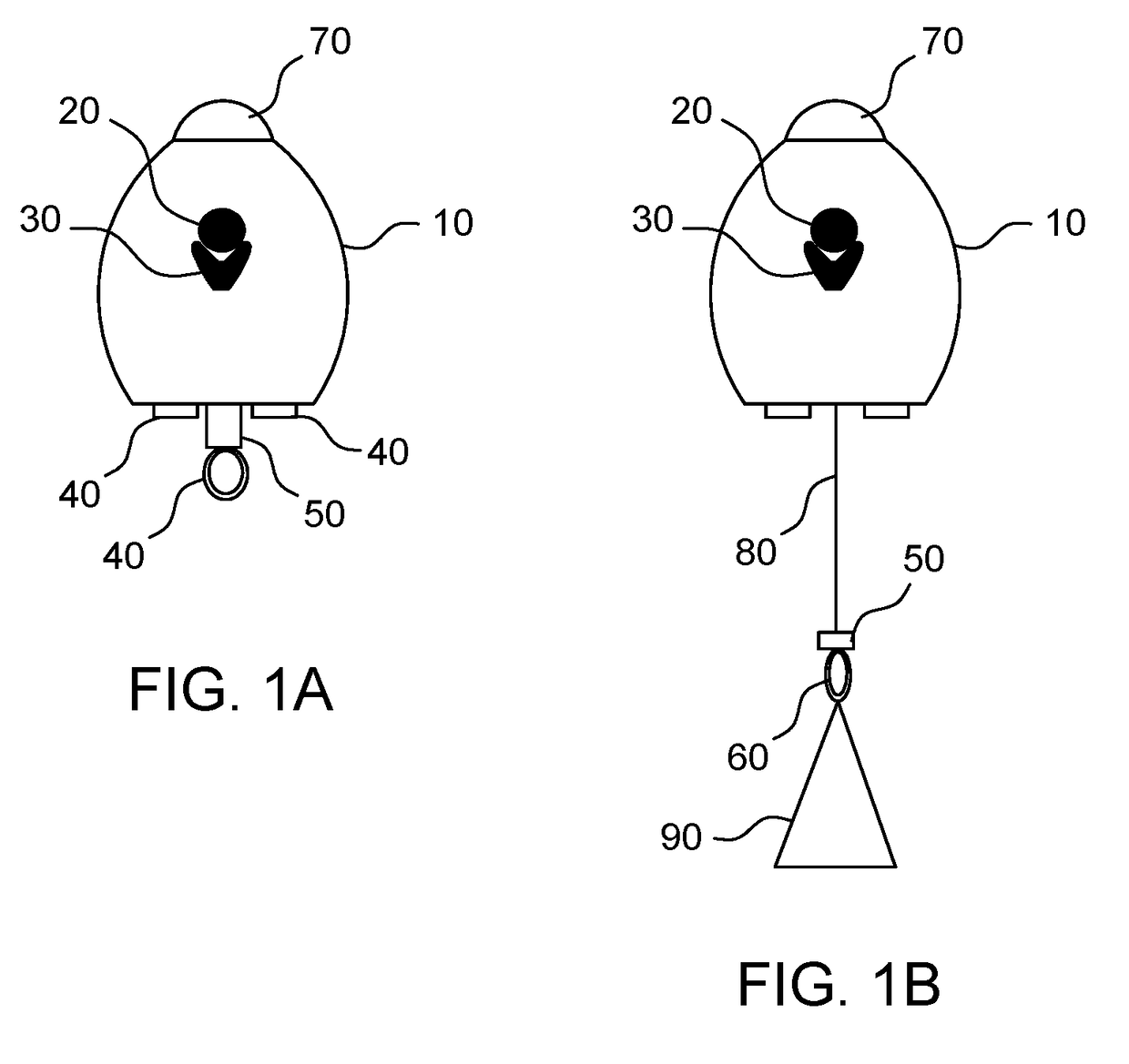

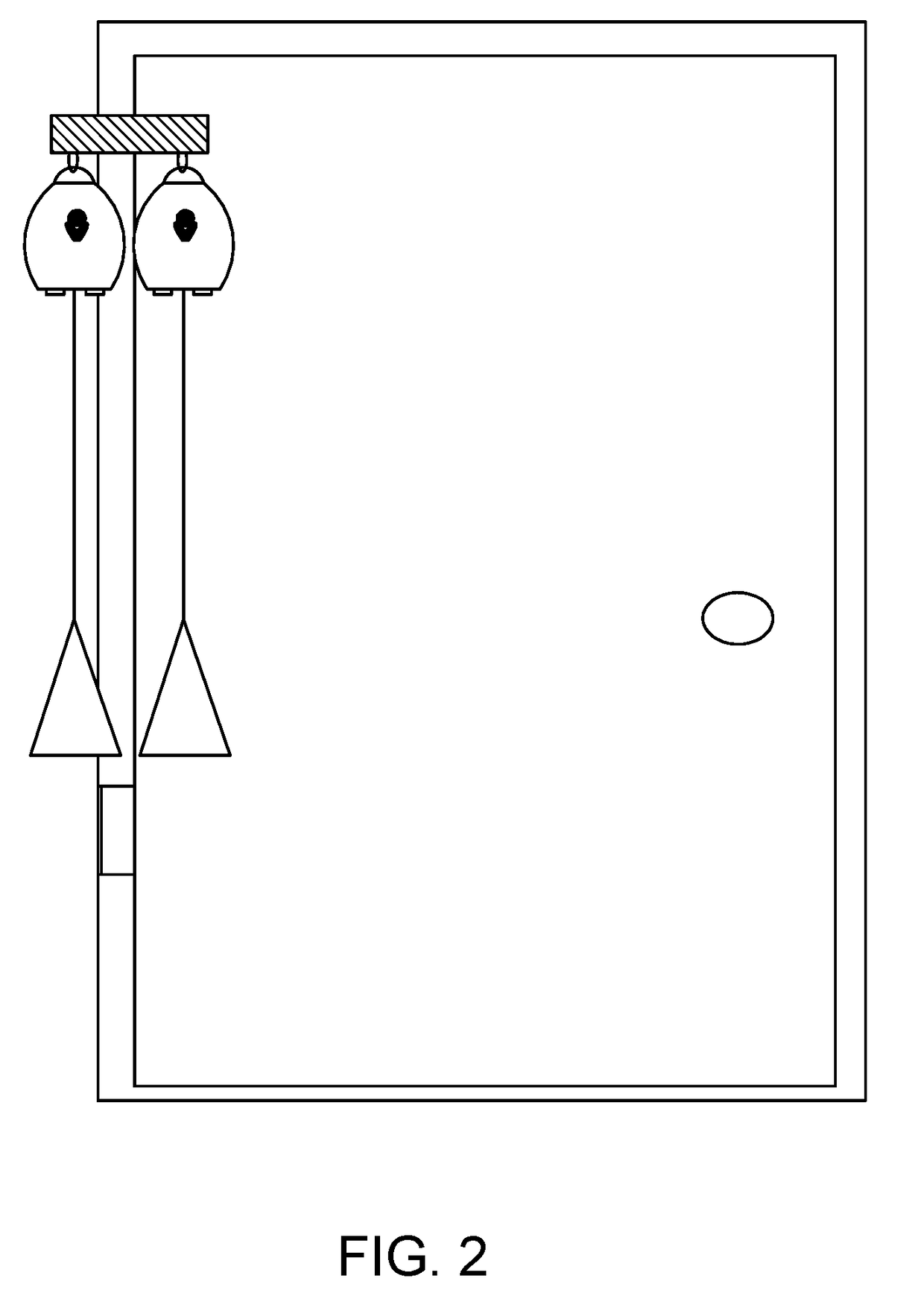

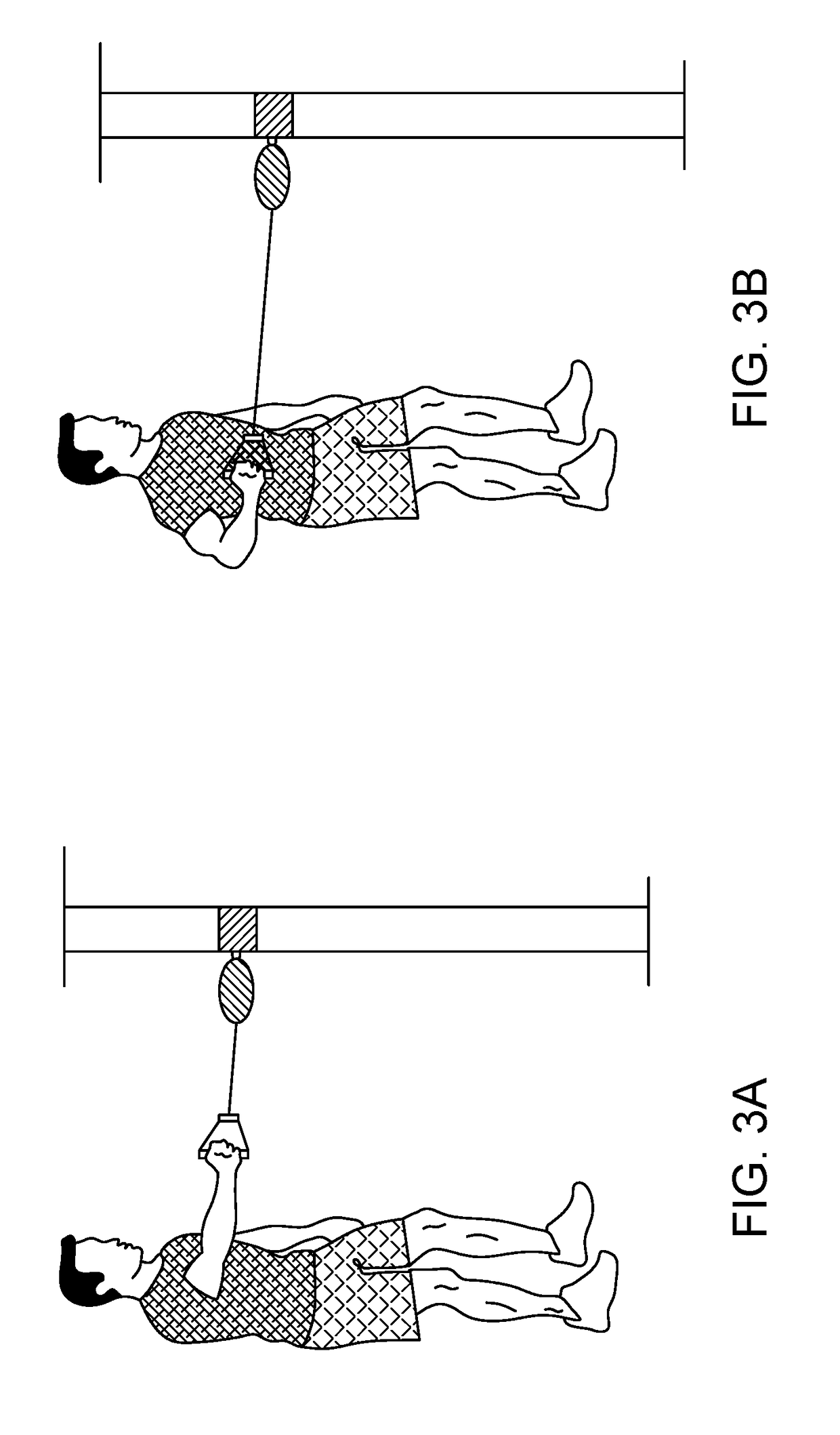

Portable functional training device

A lightweight portable device allows a user to accomplish both the exercises of a functional cable machine and a bodyweight suspension trainer. The device can include at least one non-elastic cord or strap, each retractably attached to a reel. The reel has a locking mechanism and a variable resistance mechanism. When the locking mechanism is engaged, it keeps the strap or cord in a fixed location. This allows the user to perform bodyweight suspension training exercises. The variable resistance mechanism of the reel can increase or decrease the amount of force that is needed to be applied to move the reel, thus giving the user the ability to perform the variable resistance exercises of a functional cable machine. The resistance mechanism can be designed as compact and lightweight, thus making the device able to be portable and compact in size.

Owner:WAGNER CHRISTOPHER LEE +2

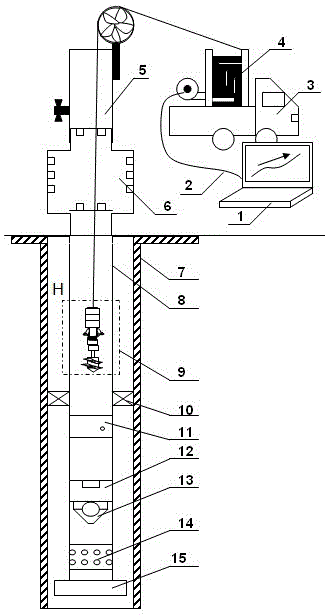

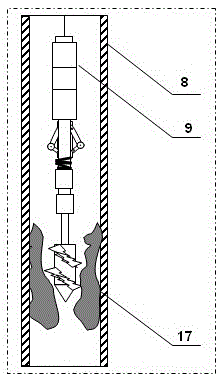

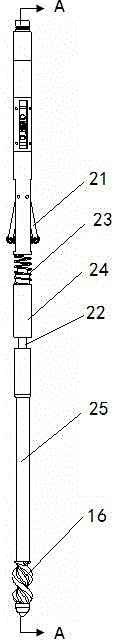

Separate injection well immovable tubular column mechanical-electrical integration scale removing system and method

ActiveCN105422048AIncrease the level of automationSolving obstacles encountered in testing and debuggingDrill bitsDrilling rodsThermodynamicsCable machine

The invention belongs to the technical field of oil field layered water injection development technology matching processes and particularly relates to a separate injection well immovable tubular column mechanical-electrical integration scale removing system and method. According to the separate injection well immovable tubular column mechanical-electrical integration scale removing system and method, an upper computer controls an electrical and mechanical descaling instrument to be turned on and turned off, a cable-carried electrical and mechanical descaling instrument is adopted for drilling and removing dirt in a separate injection well cylinder, separate injection well penetrating and scale removing are converted to cables from steel wires and to machine electricity from machinery, the automated level of a descaling and resistance reduction technology is raised, and the problems of blocking and sticking in the measurement and regulation processes caused by wellbore scaling of the oil field separate injection well are effectively solved.

Owner:PETROCHINA CO LTD

Method for operating a spindle of a two-for-one twister or cabling machine

ActiveUS8256199B2Reduce energy consumptionDiameter minimizationContinuous wound-up machinesYarnBobbinCable machine

A two-for-one twister or cabling machine and a method for operation thereof, wherein a yarn (5, 25) is withdrawn from a supply bobbin (7, 21) and fed to a guide device below a twisted yarn plate (8, 24) of the spindle (2, 22) and from which the yarn (5, 25) exits virtually perpendicular to the axis of the spindle (2, 22) and is deflected to the outer edge of the twisted yarn plate (8, 24) and runs along the spindle (2, 22) as a free yarn balloon (B) encompassing the spindle (2, 22), until the yarn (5, 25) is fed into the twist or cabling point of a yarn guide device (9, 27) above the spindle (2, 22). The supply speed of the yarn (5, 25) is adjusted to achieve a yarn tension which minimizes the yarn balloon diameter as a function of the spindle geometry.

Owner:ZHUOLANG INTELLIGENT MACHINERY CO LTD

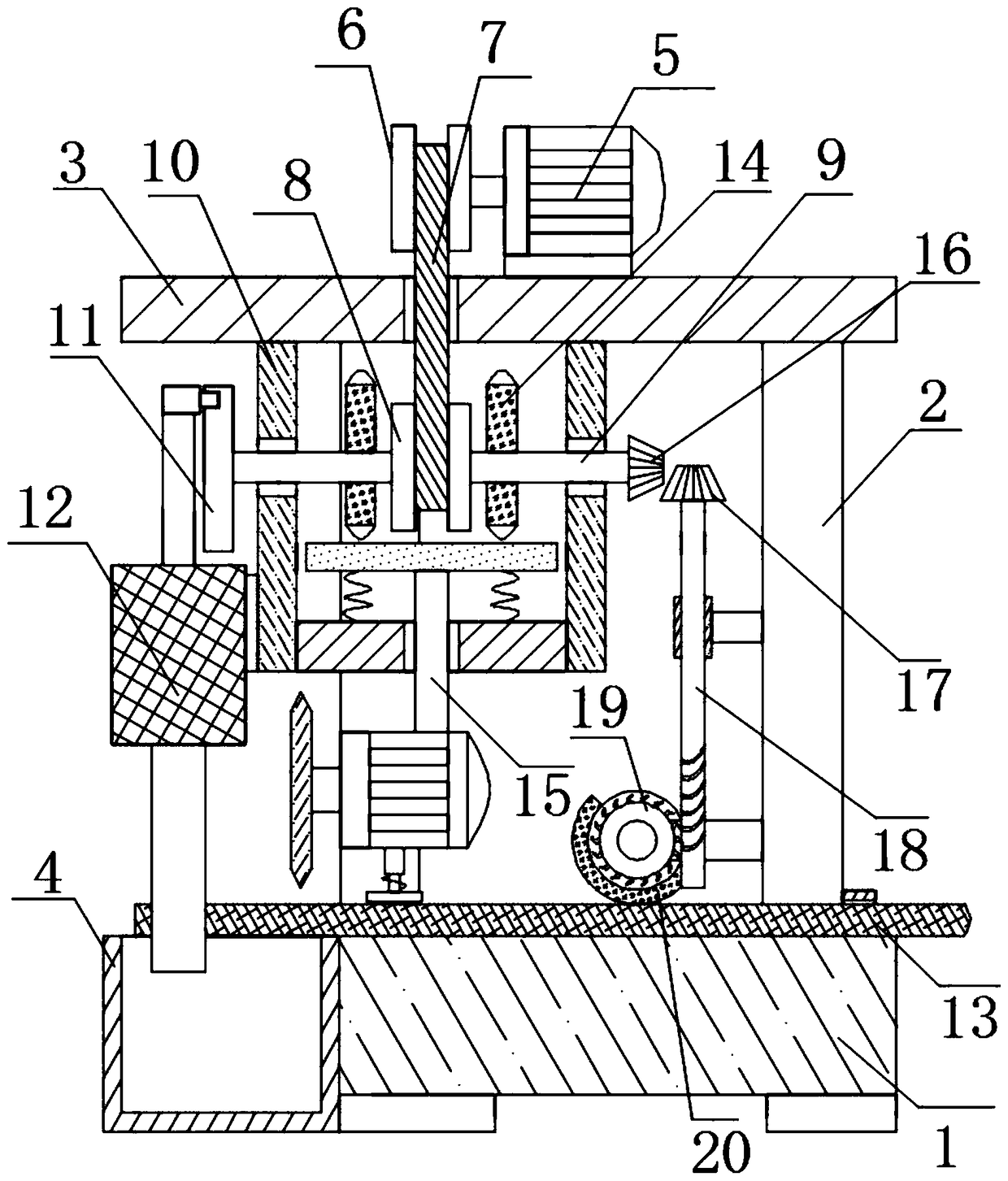

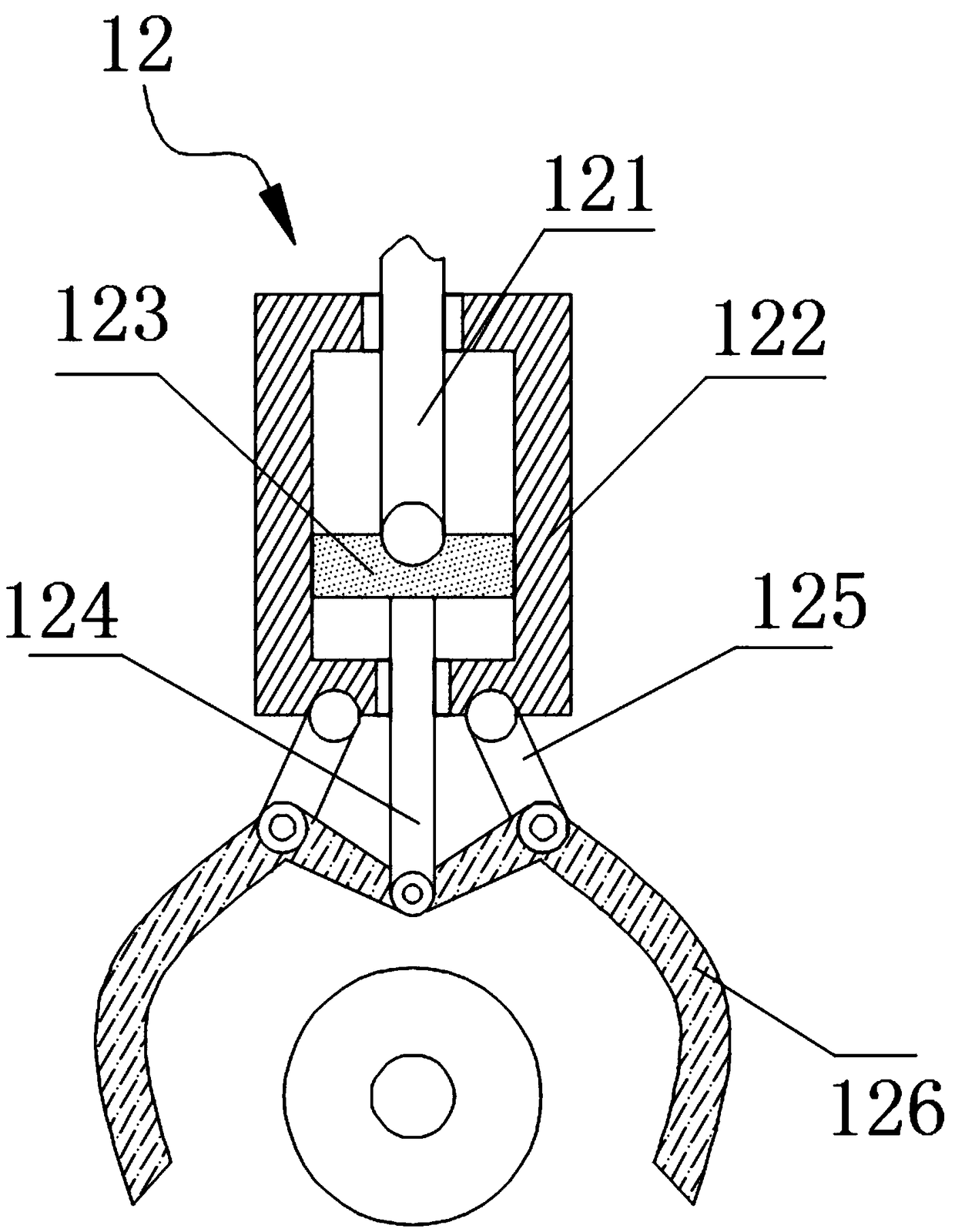

Cable machining cutting device with fixing function

The invention provides a cable machining cutting device with a fixing function. The cable machining cutting device comprises a base, multiple supporting feet connected to the lower end of the base, multiple supporting frames connected to the upper end of the base, the same top plate connected to the multiple supporting frames, a collecting box connected to the side wall of the base, and a first motor connected to the upper end of the top plate. The cable machining cutting device overcomes the defects in the prior art, design is reasonable, and the structure is compact; a first motor is used for driving two clamping claws to clamp a cable body, and therefore the cable body can be fixed; a second motor vertically moves to drive a saw blade to cut the cable body, and the cutting effect is improved; and meanwhile, the first motor is used for driving a rotating roller to rotate, then the cable body is continuously driven to move, the automatic feeding effect is achieved, and very high practicability is achieved.

Owner:天长市运成电缆辅料有限公司

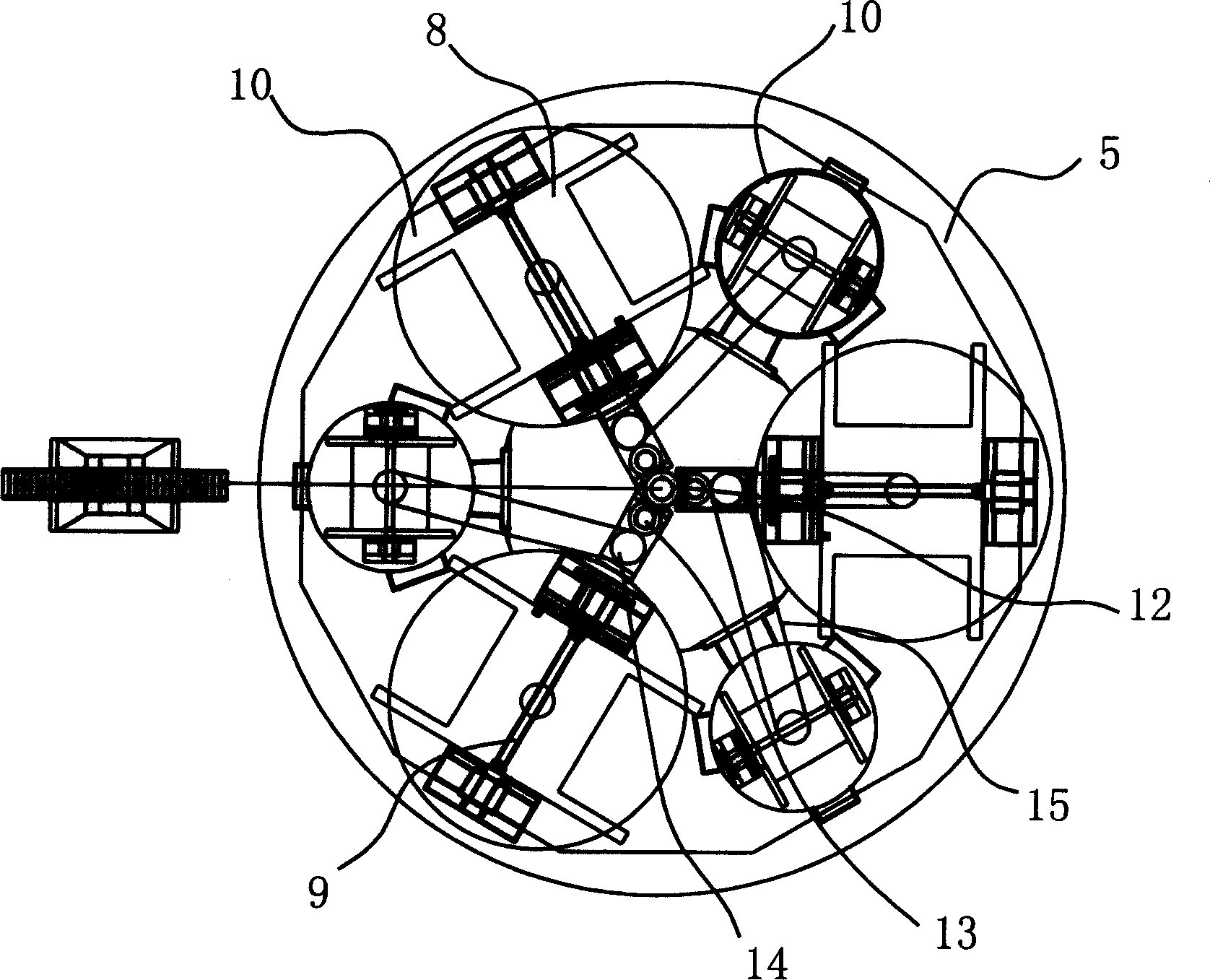

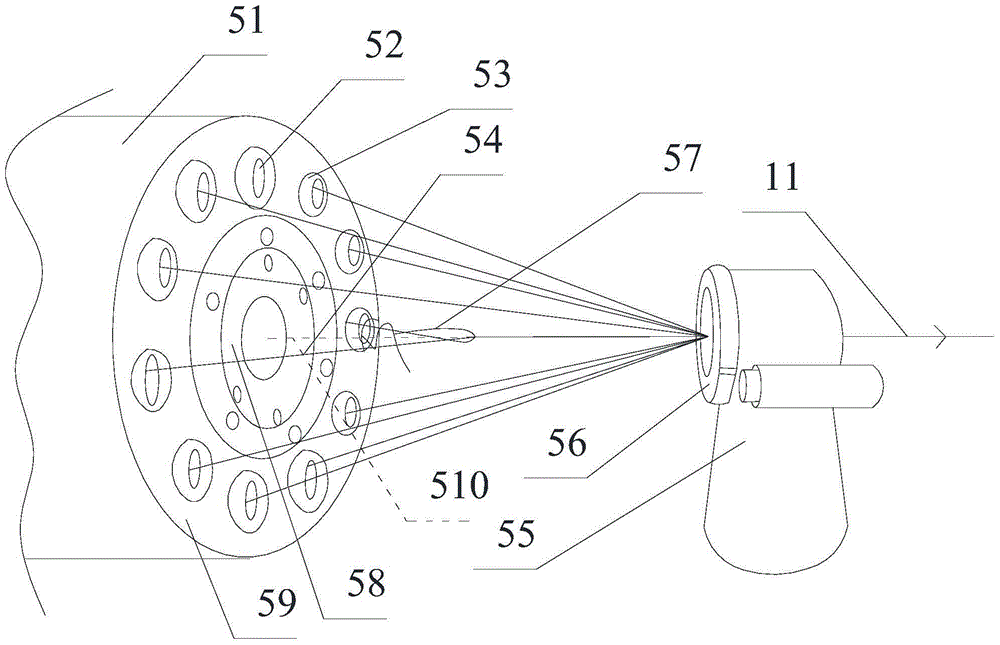

Cabling machine

InactiveCN104538122AAvoid self-twistingQuality improvementCable/conductor manufactureYarnCable machine

The invention discloses a cabling machine comprising a hollow shaft. The hollow shaft is provided with a back twisting mechanism. The hollow shaft is further provided with a front metal ring and a rear metal ring, a plurality of barriers are arranged between the metal rings, and a circular pay-off reel is mounted on each barrier. The end of the hollow shaft is provided with a distributor plate. One side of the distributor plate is sequentially provided with a mold, a yarn covering head, a traction wheel, a creel stand, and a take-up reel. Because the hollow shaft is provided with the back twisting mechanism, the pay-off reels and the barriers are always in a horizontal position in the rotating process of a stranding cage, and the phenomenon of cable self-twisting in the stranding process is avoided. The cabling efficiency is high, the quality of formed cables is greatly improved, and the demand of the market is well satisfied.

Owner:ZHANGJIAGANG JINHAIGANG WIRE & CABLE

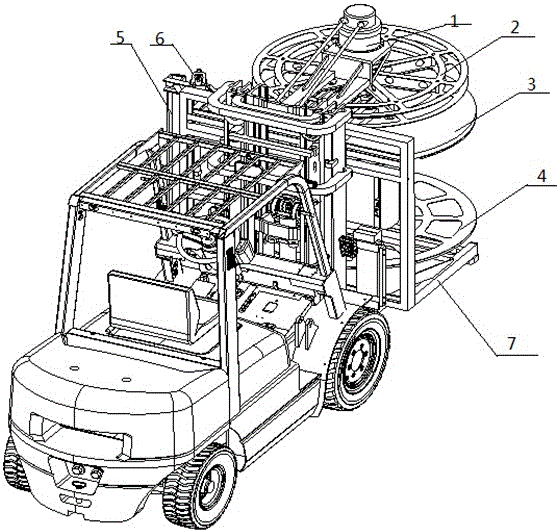

Forklift accessory optical cable automatic winding-unwinding mechanism

The invention discloses a forklift accessory optical cable automatic winding-unwinding mechanism. The forklift accessory optical cable automatic winding-unwinding mechanism comprises a hydraulic motor, a cable guiding reel, an expansion-contraction winding-unwinding device, a lower tray, a cable-arranging device, a cable-unwinding driving device and an optical cable machine rack; the optical cable machine rack is installed on a pallet fork of a forklift; the expansion-contraction winding-unwinding device is vertically assembled on the optical cable machine rack; the cable guiding reel is installed on a central spindle of the expansion-contraction winding-unwinding device; the upper end of the central spindle is connected with the hydraulic motor; the lower tray is installed under the expansion-contraction winding-unwinding device; the cable-unwinding driving device is installed on the left portion of the optical cable machine rack; and the cable-arranging device is vertically installed at the left side of the optical cable machine rack. The forklift accessory optical cable automatic winding-unwinding mechanism has the advantages that the structure is novel, time and labor are saved, manual operation is not relied on, and construction efficiency is greatly improved.

Owner:ANHUI VMAX MACHINERY

Method and apparatus for filling type communication cable compound filling

ActiveCN101369475AQualified water resistanceIncrease productivityInsulated cablesInsulated conductorsCable machineEngineering

The invention discloses a method and a device for filling a filling type communication cable belonging to cable machining technology range. When cabling producing large logarithm filling cable, adopting a compound section filling method of different temperatures, unit cabling lines are not firstly hinged or gathered, but are arranged in order, and through the corresponding dies, the unit cabling lines firstly enter into a first filling cavity to be filled with the compounds, after filling up with the compounds, the unit cabling lines are hinged or gathered, then enter into a second filling cavity to fill, air gaps between the unit cabling lines are filled with the compounds, thereby filling up the inner air gaps with the compounds tightly to ensure anti-water permeability of the filling type cable eligible. The invention can work continuously, improves production efficiency and product quality, and brings convenience for production and operation.

Owner:BEIJING HENGTONG SIBO COMM TECH CO LTD +2

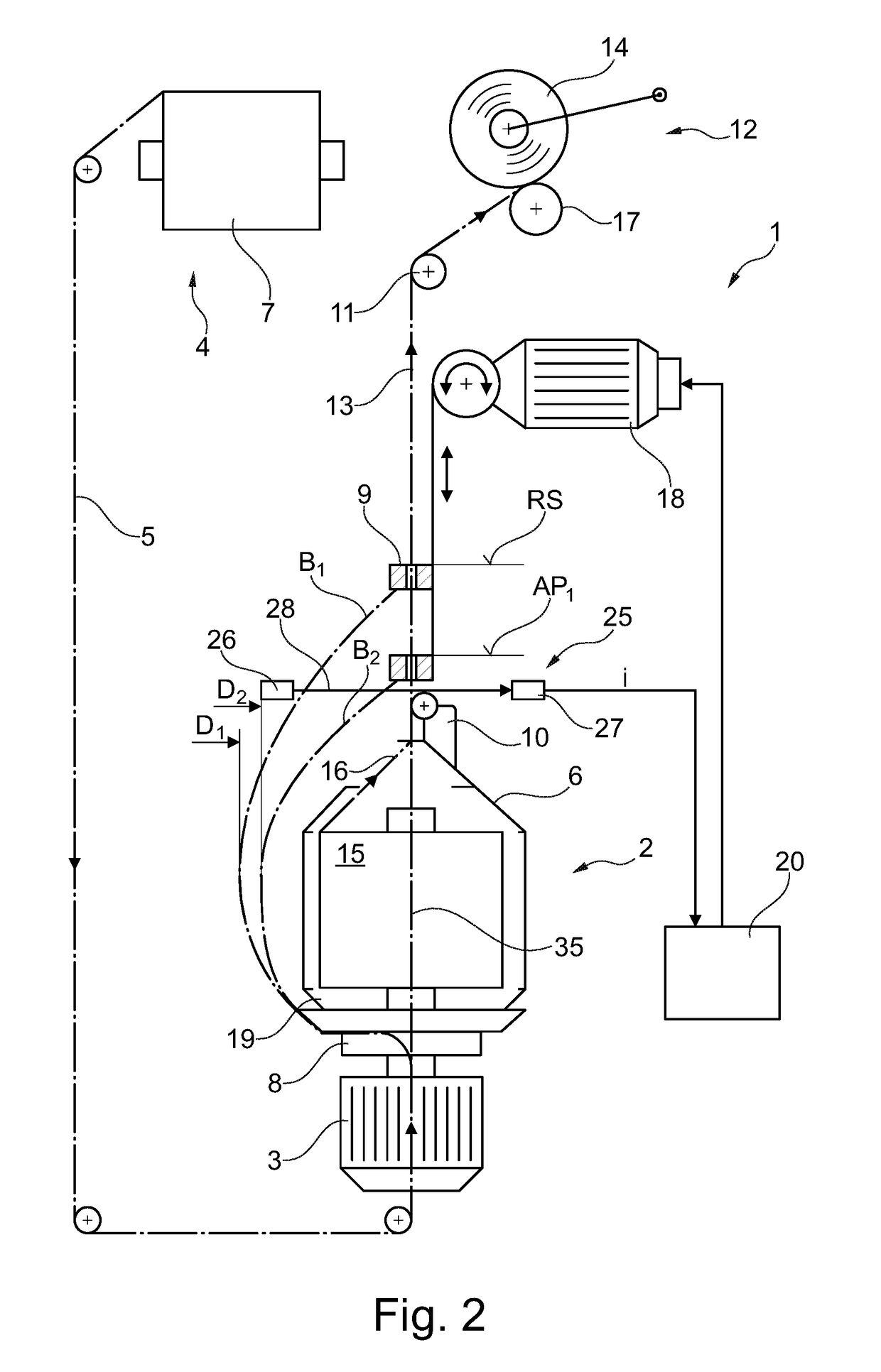

Method for operating a spindle of a two-for-one twisting or cabling machine

ActiveUS20170130369A1Free viewAccurate monitoringRope making machinesContinuous wound-up machinesYarnCable machine

A method for operating a spindle (2) of a two-for-one twisting or cabling machine which comprises an adjustable balloon-yarn-guide-eye (9), wherein for the operation of the spindle (2) under production conditions, the balloon-yarn-guide-eye (9) is adjusted, on the basis of a measured value (i) correlating with the energy consumption of the spindle drive (3), to a first operating position (AP1), in which a position-dependent minimum of the energy consumption of the spindle drive (3) is reached.

Owner:SAURER TECH GMBH & CO KG

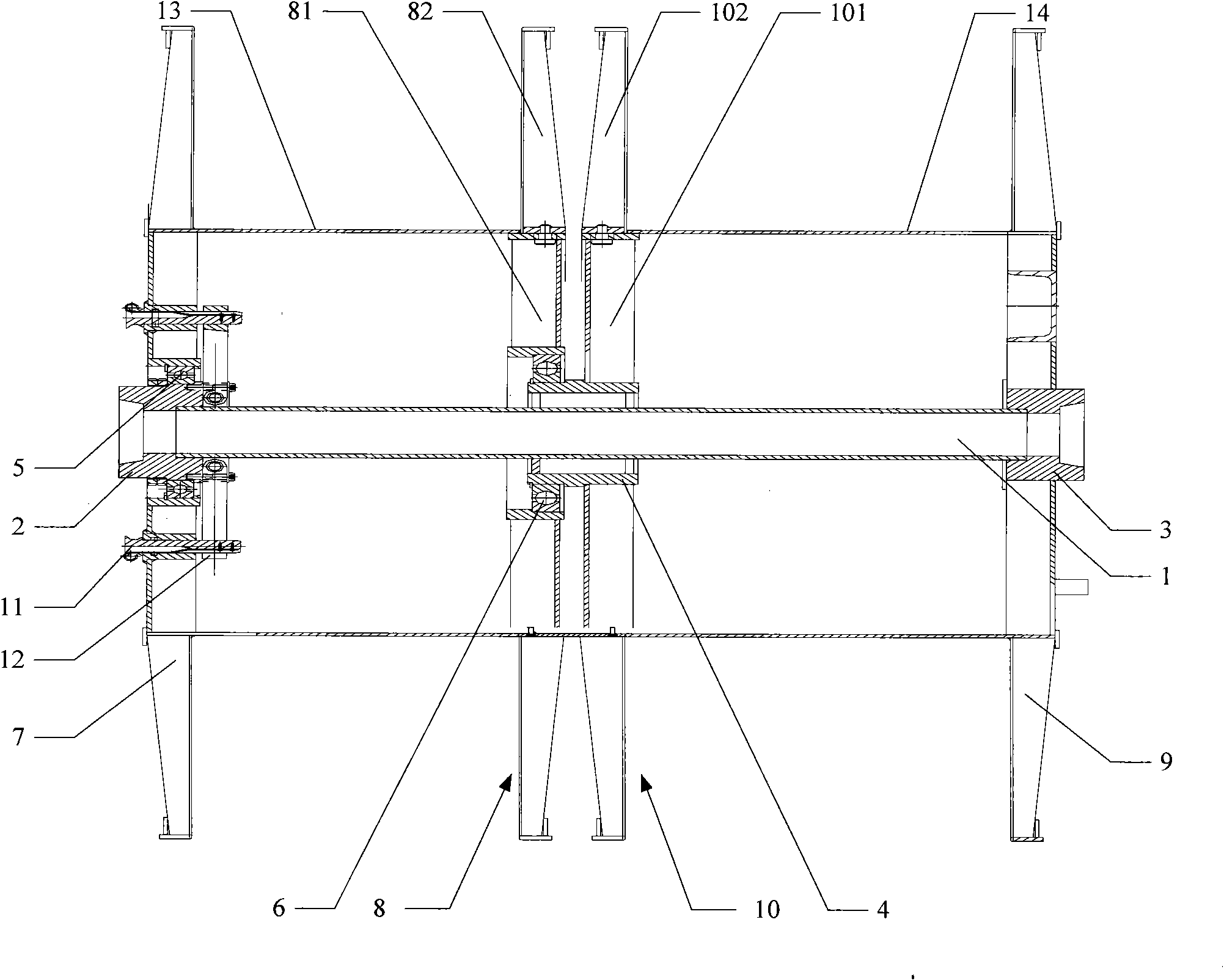

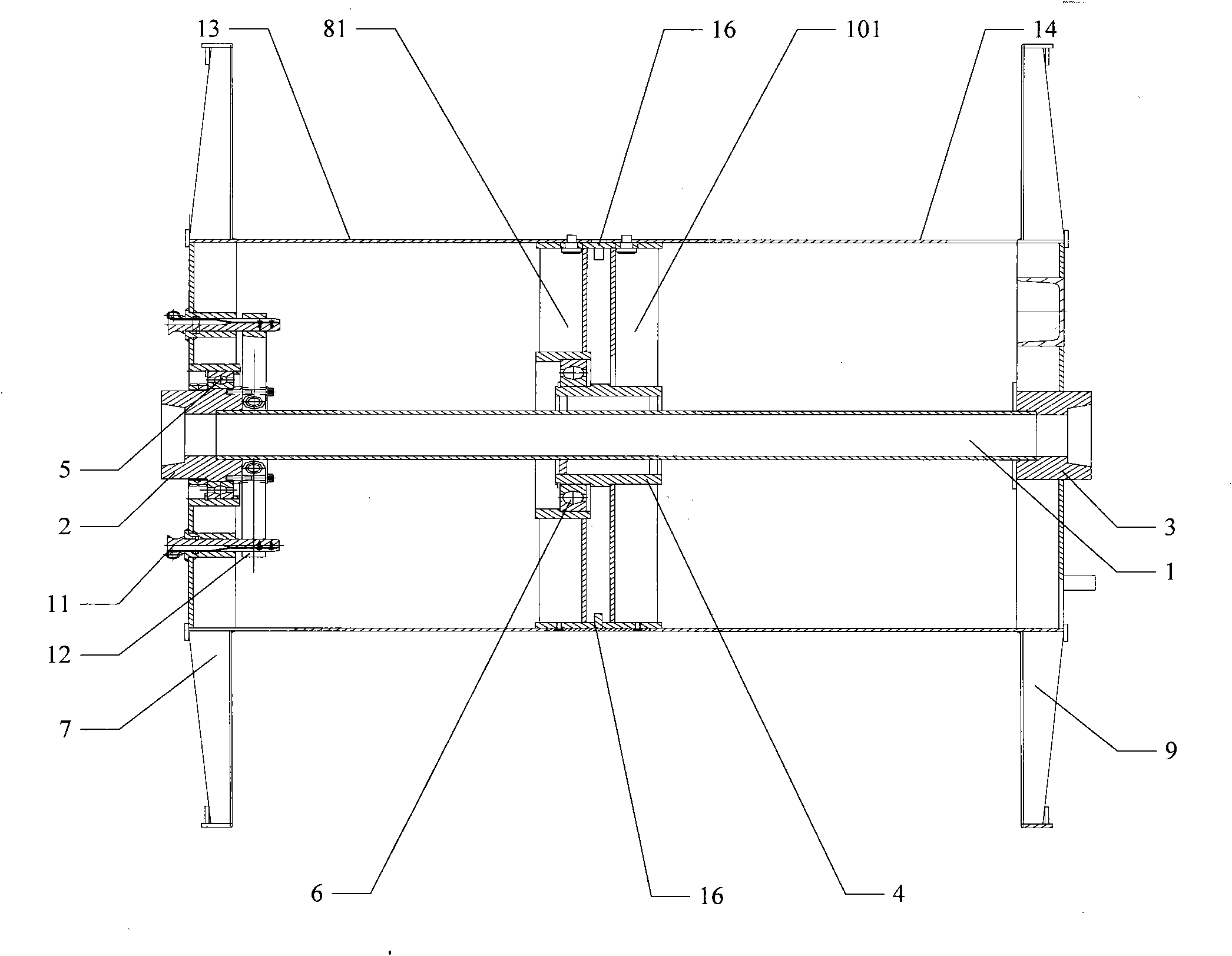

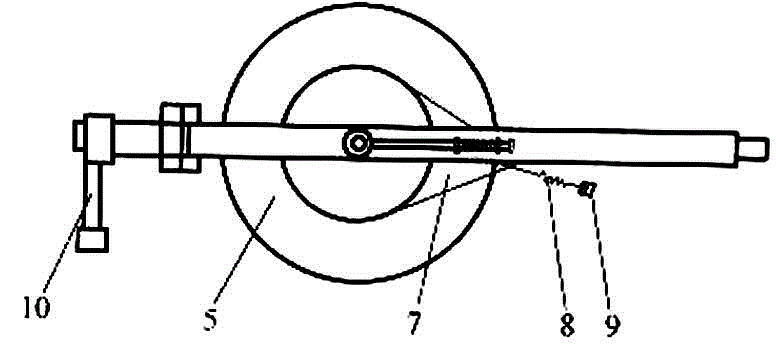

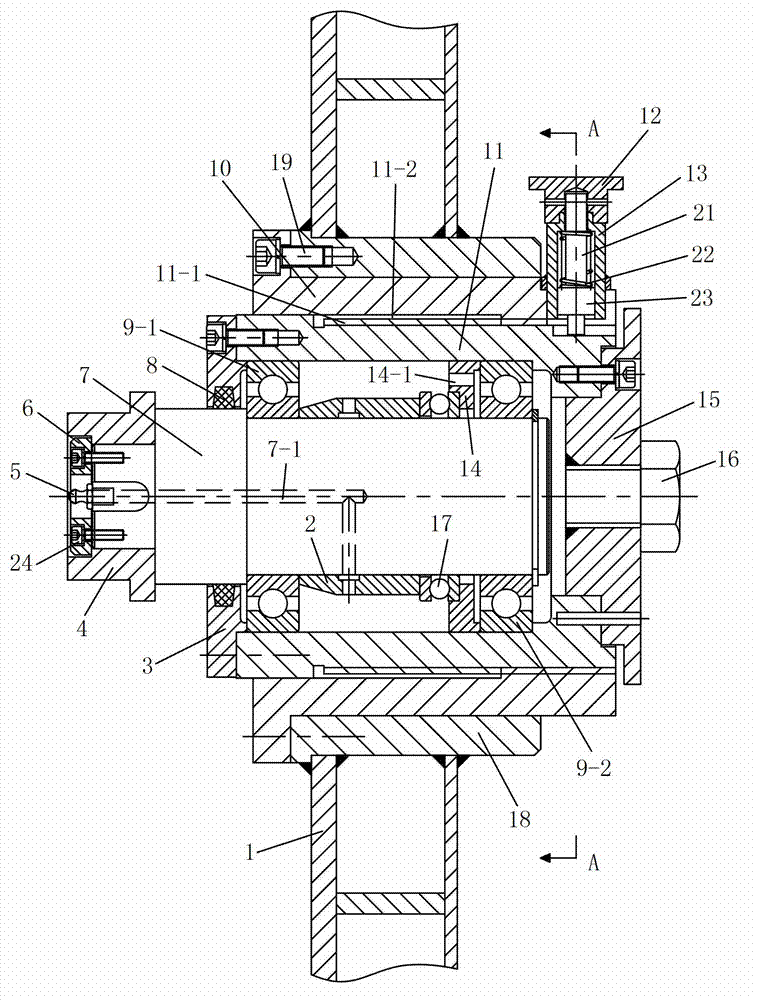

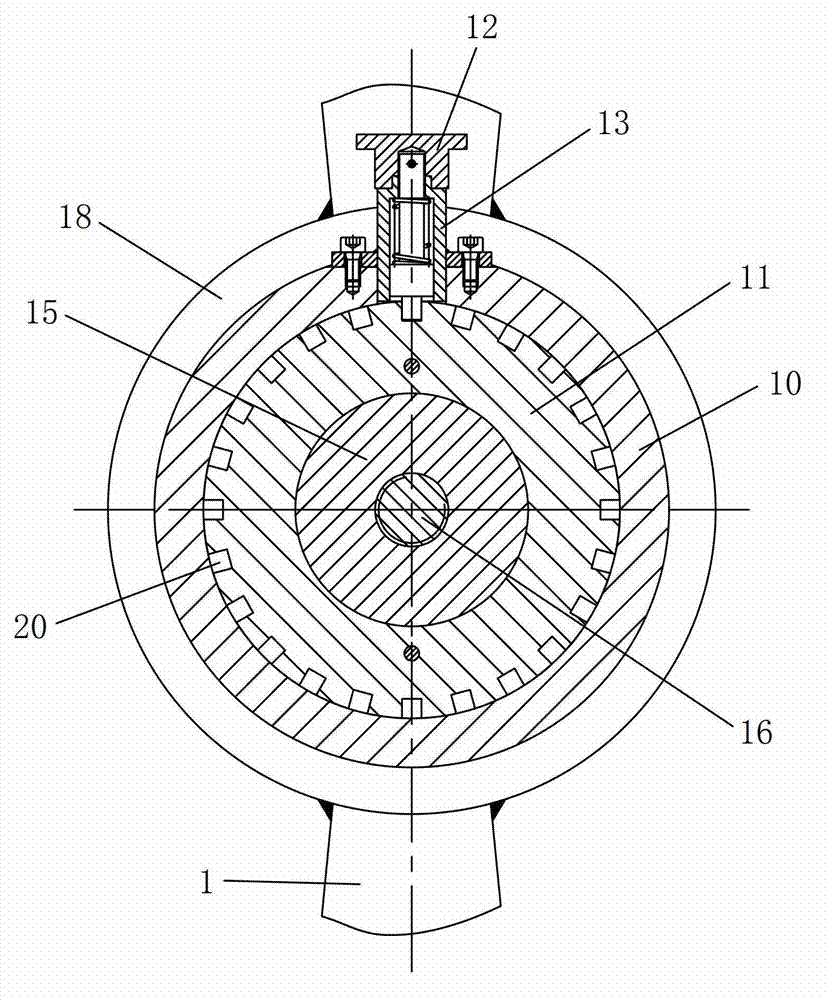

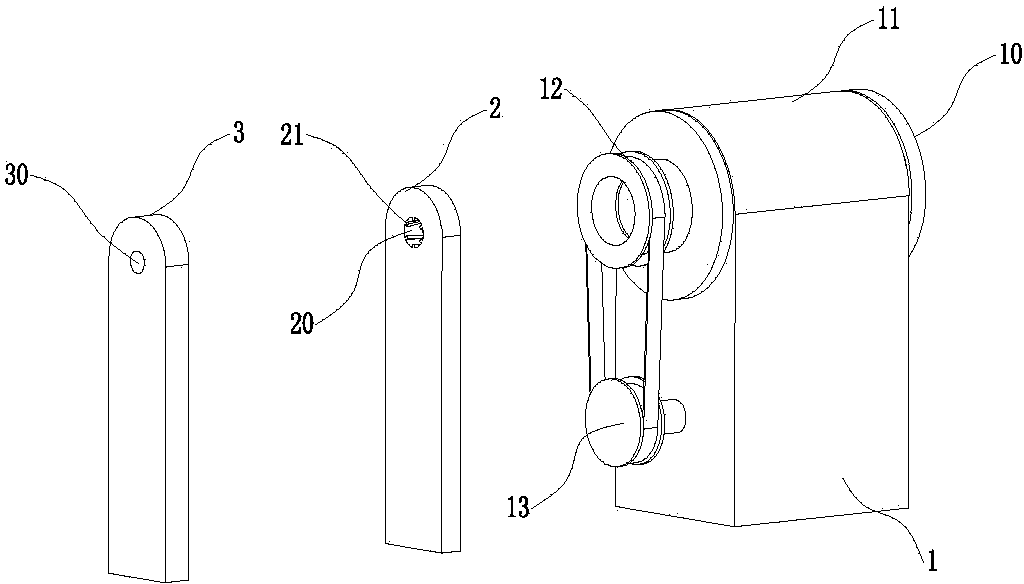

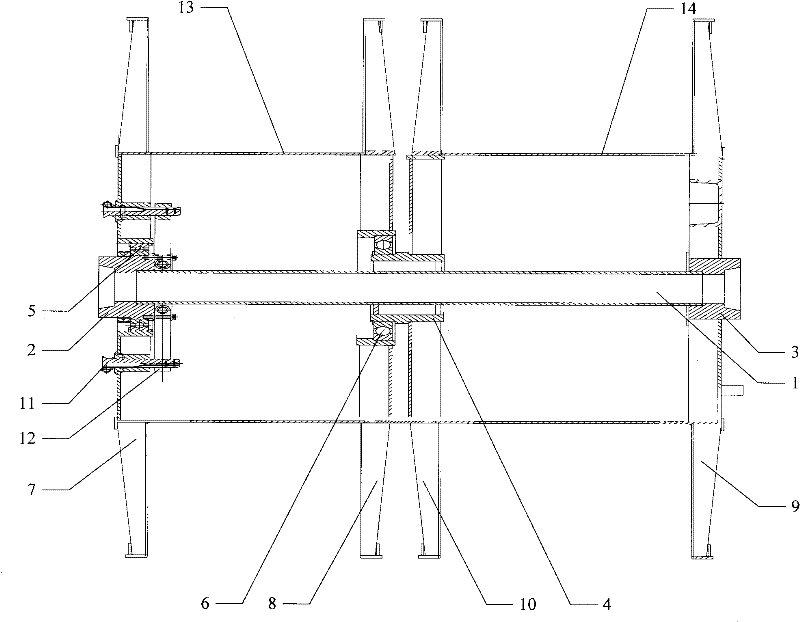

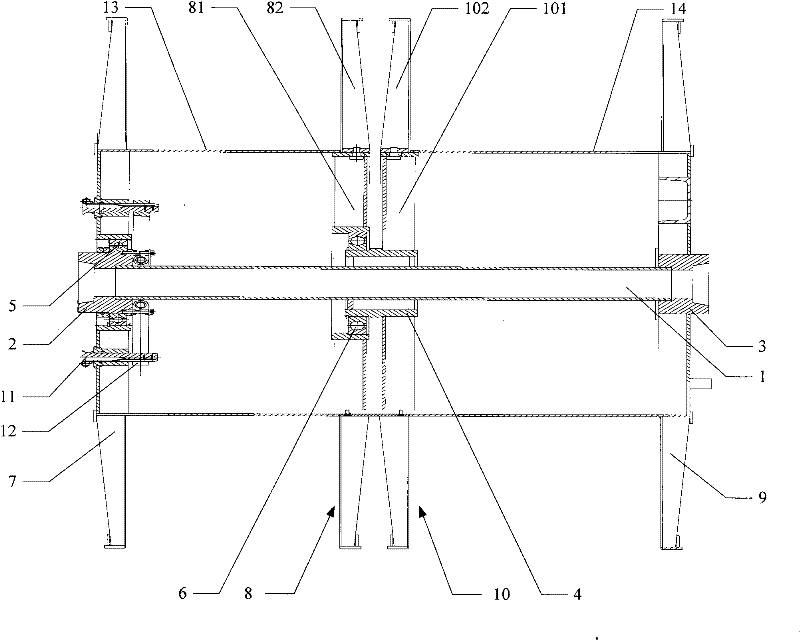

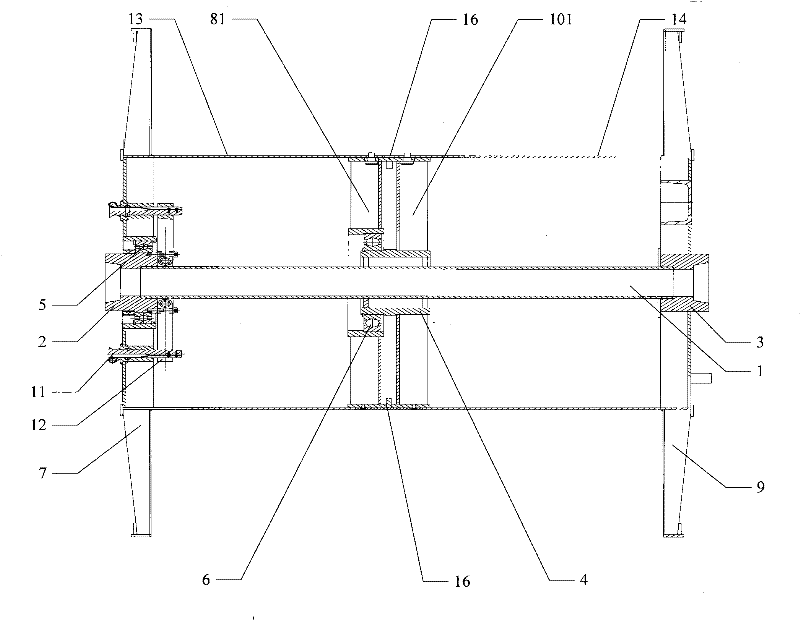

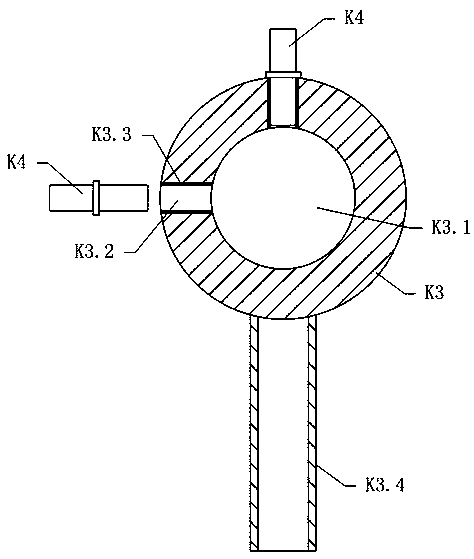

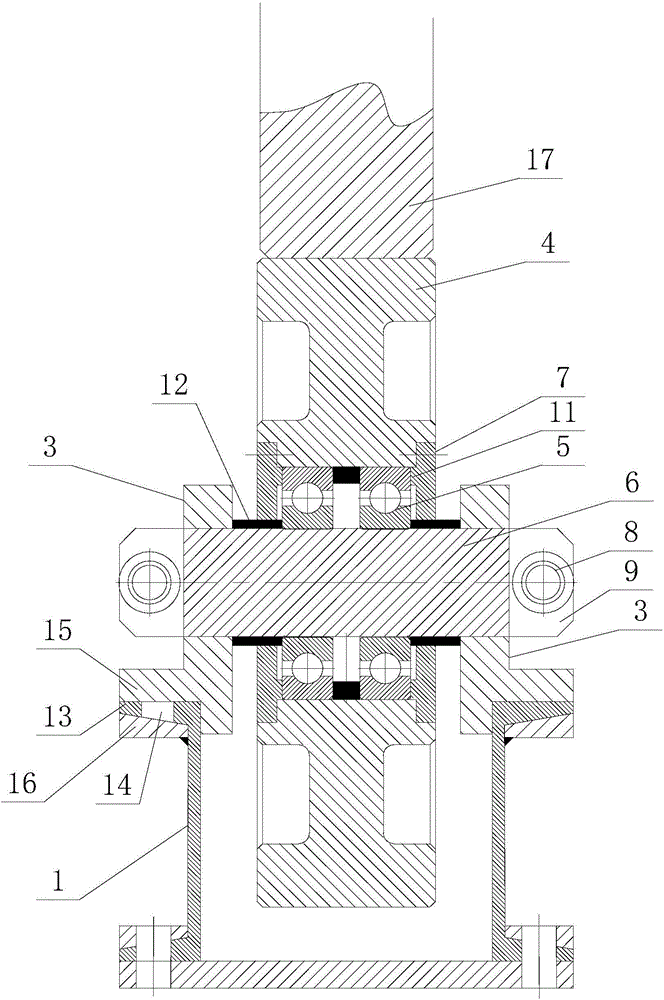

Live center mechanism of cabling machine cradle

ActiveCN102930938ACompact structureReasonable designCable/conductor manufactureCable machineScrew thread

The invention discloses a live center mechanism of a cabling machine cradle. The mechanism comprises a rack, a shaft, a fixed sleeve, a moving sleeve and a positioning mechanism, the positioning mechanism is used for positioning the moving sleeve, the shaft is arranged on the rack, the moving sleeve is rotatably installed on the shaft, the fixed sleeve is disposed on the outside of the moving sleeve and fixedly connected with the rack, a bearing cap is installed at the left end of the moving sleeve, a second gland is installed at the right end of the moving sleeve, the left end of the shaft penetrates through the bearing cap, a centre is installed at the end of the shaft, the right end of the shaft is located in the moving sleeve, a through hole is disposed at the center of the second gland, an outer hexagonal screw is welded on the through hole, a first screw thread is arranged on an inner circle of the fixed sleeve, a second screw thread which is matched with the first screw thread is arranged on an outer circle of the moving sleeve, and a plurality of positioning grooves which are close to the second gland are uniformly disposed on the periphery of the moving sleeve. The live center mechanism of the cabling machine cradle has the advantages that the structure is compact, the usage and operation are convenient, and problems that loading and unloading of wire coils of existing cabling machines are required to be completed by cooperation of numerous workers, the wire coil replacement is time and effort consuming, the operation procedures are verbose, and the production efficiency is low are solved.

Owner:THE NORTHWEST MACHINE

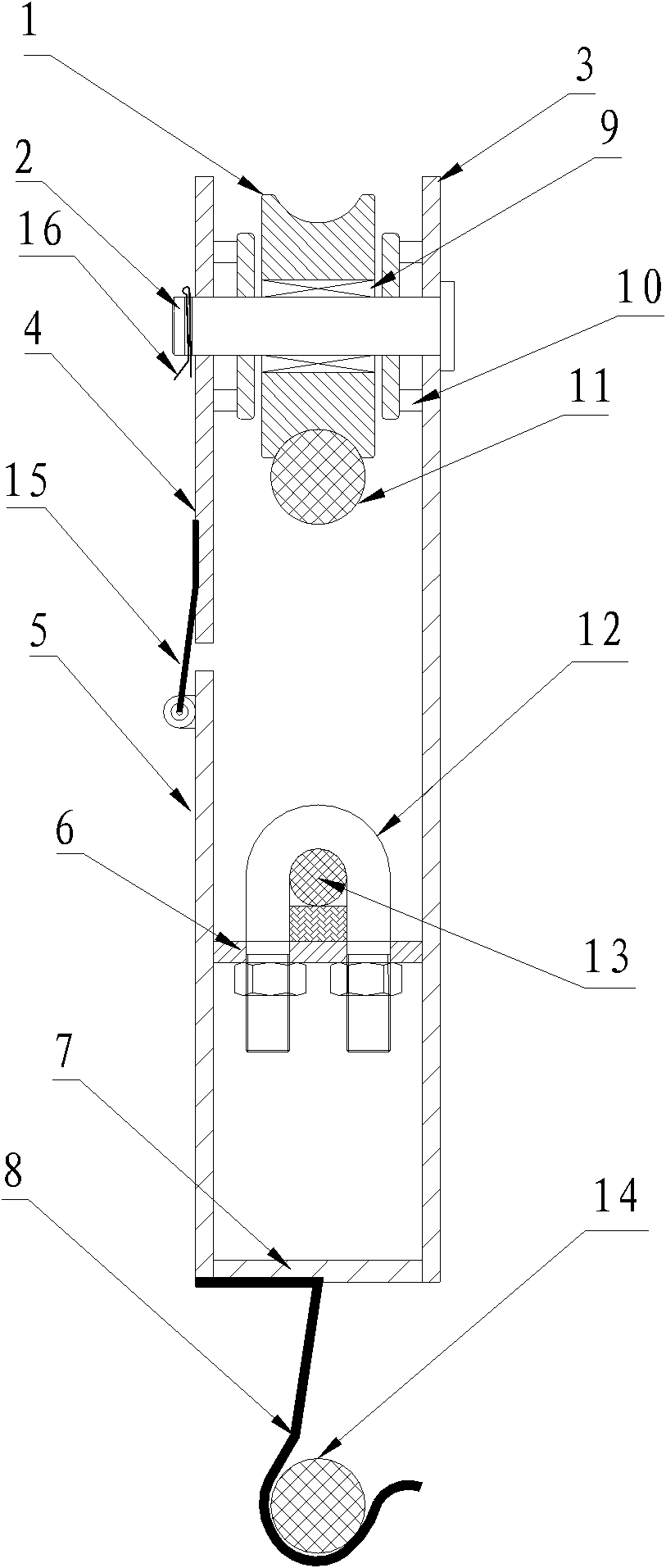

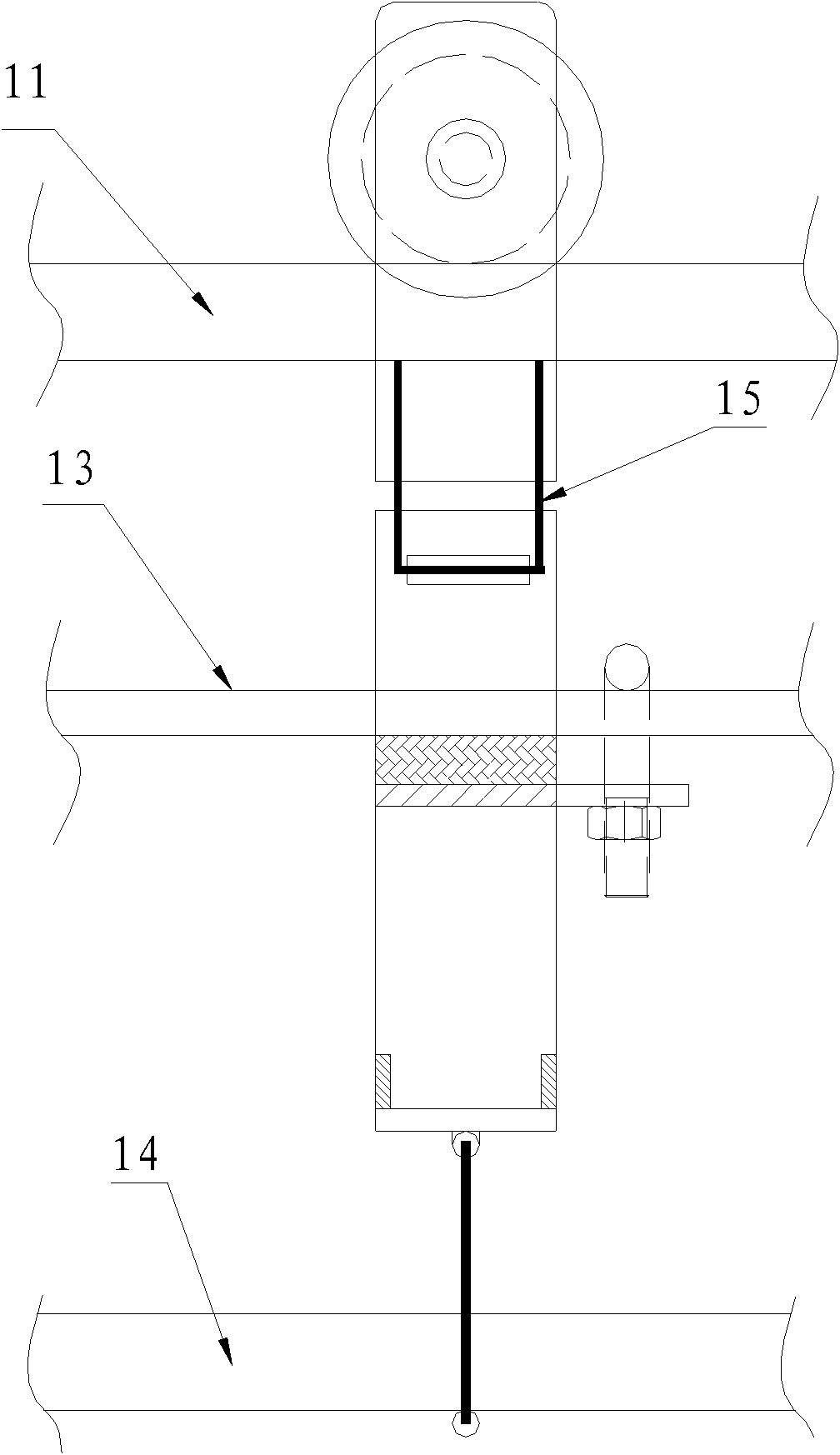

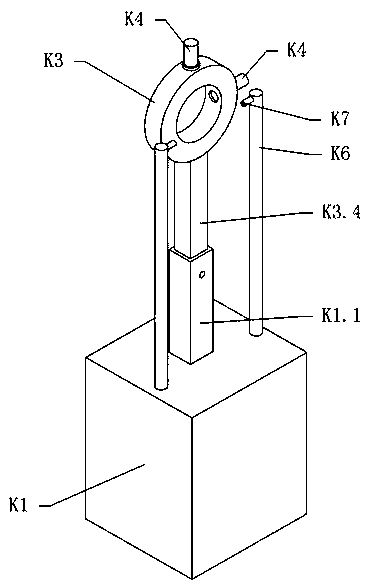

Temporary supporting piece for installation of ropeway of cabling machine

ActiveCN102040165AImprove installation efficiencyImprove securityCable carsRear quarterCable machine

The invention discloses a temporary supporting piece for installation of a ropeway of a cabling machine, belonging to the technical field of installation of a ropeway system, comprising a traveling wheel, a bearing and a pin shaft and further comprising a main side plate, an upper side plate and a lower side plate, wherein the bearing and the pin shaft are embedded in the traveling wheel; the pin shaft penetrates through the main side plate, the bearing and the upper side plate in sequence and is clamped by a beta pin; the upper side plate is connected with the lower side plate by a hinge; the lower side plate is fixedly connected with the main side plate by a bottom plate; the lower end of the bottom plate is welded with a bearing hook; a partitioning plate is welded between the middle of the lower side plate and the main side plate, and is provided with a connecting hole which is sheathed with a U-shaped clamping ring fixed by a bolt; and gaskets are arranged among the traveling wheel, the main side plate and the upper side plate. By utilizing the temporary supporting piece, the rope-bearing force for installing auxiliary systems (ground anchors, winch pulley blocks and the like) of a cable-rope type crane can be greatly reduced, the safety of erecting the ropeway system can be improved and the efficiency of installing the cable-rope type crane can be improved.

Owner:SINOHYDRO BUREAU 7 CO LTD

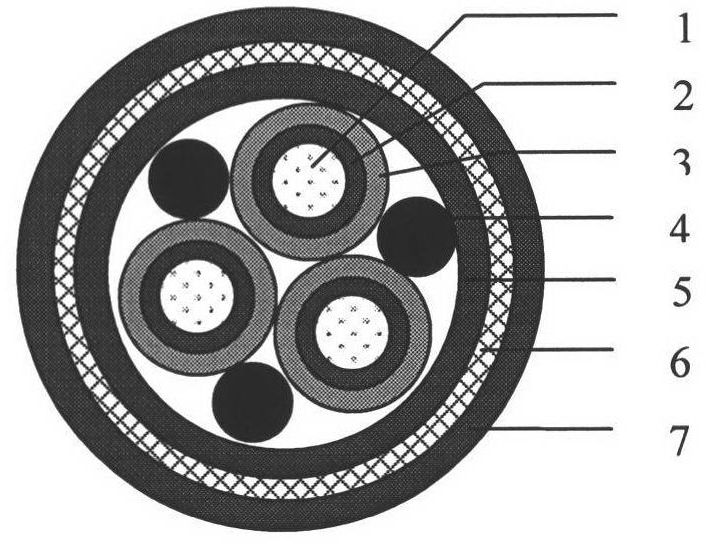

Nuclear electromagnetic pulse resisting cable and manufacturing process thereof

ActiveCN103345969AEasy to hardenSolve problems such as brittle cracksFlexible cablesCable/conductor manufactureElastomerElectrical conductor

The invention relates to a nuclear electromagnetic pulse resisting cable which structurally comprises a conductor, an insulator, a separated shield part, a combined shield part and a protection sleeve. The high-temperature-resisting fluoroplastic insulator extruded by high-temperature extruding equipment is arranged at the periphery of the conductor using a tin-plated round copper stranded wire or a sliver-plate round copper stranded wire, the separated shield part woven by high-weaving tin-plated round copper wires is arranged at the periphery of the high-temperature fluoroplastic insulator, the combined shield part formed by a control line and a data line which are stranded by a cabling machine is positioned at the periphery of the separated shield part, and the low-temperature-resisting elastic protection sleeve extruded by a normal-temperature extruding machine is positioned outs of the combined shield part. Manufacturing process uses a combined method of lapped shield and braided shield and primarily uses 300T conductive cloth lapping materials to substitute metal lapping materials. The nuclear electromagnetic pulse resisting cable has the advantages of resisting to nuclear electromagnetic pulse, being soft, being high in abrasion resistance, preventing mould, resisting to moist, resisting to acid-base corrosion, being capable of keep good data transmission performance in complex electromagnetic environment, being applied to a hydraulic information control system and having the information transmission function in special portions of the hydraulic information control system.

Owner:NANJING QUANXIN CABLE TECH

Method for operating a two-for-one twisting or cabling machine and two-for-one twisting or cabling machine

InactiveUS8033089B2Lower energy requirementsReduce stepsFilament handlingContinuous wound-up machinesYarnBobbin

Method for operating a two-for-one twisting or cabling machine (1) with multiple workstations (2), each equipped with at least two feed bobbins (6, 13), one feed bobbin (6) being creeled on a spindle (3) of the workstation (2) and at least one further feed bobbin (13) being creeled on a creeling device (12) associated with the workstation (2). The yarns (7, 15) of the feed bobbins (6, 13) are guided together in a balloon yarn guide (5) and cabled, and the cabled yarn is wound to form a take-up bobbin (16). The feed bobbin (6) creeled on the spindle (3) has half the weight of the take-up bobbin (16) to be produced and the dimensions of the spindle (3) are adapted to the diameter of the reduced feed bobbin (6).

Owner:SAURER GERMANY GMBH & CO KG

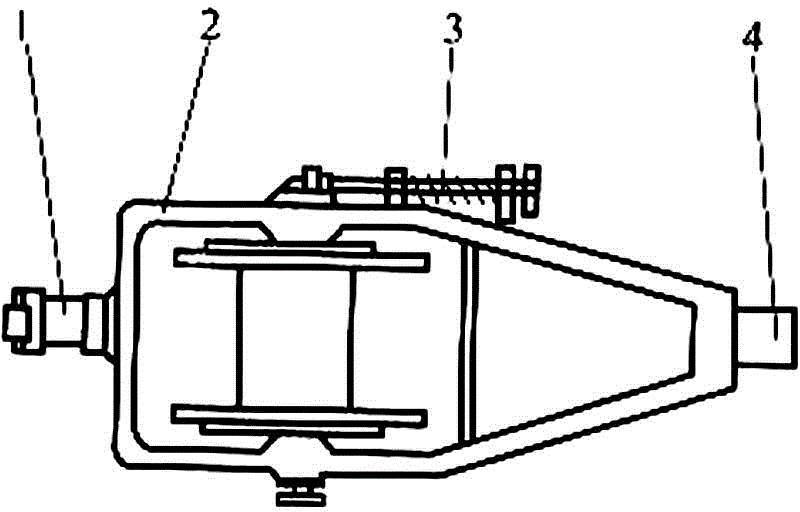

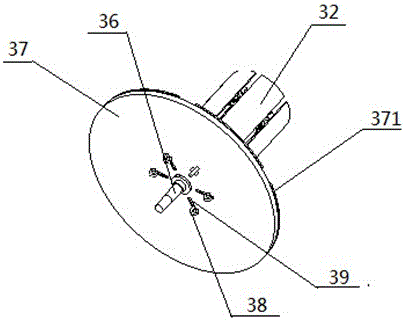

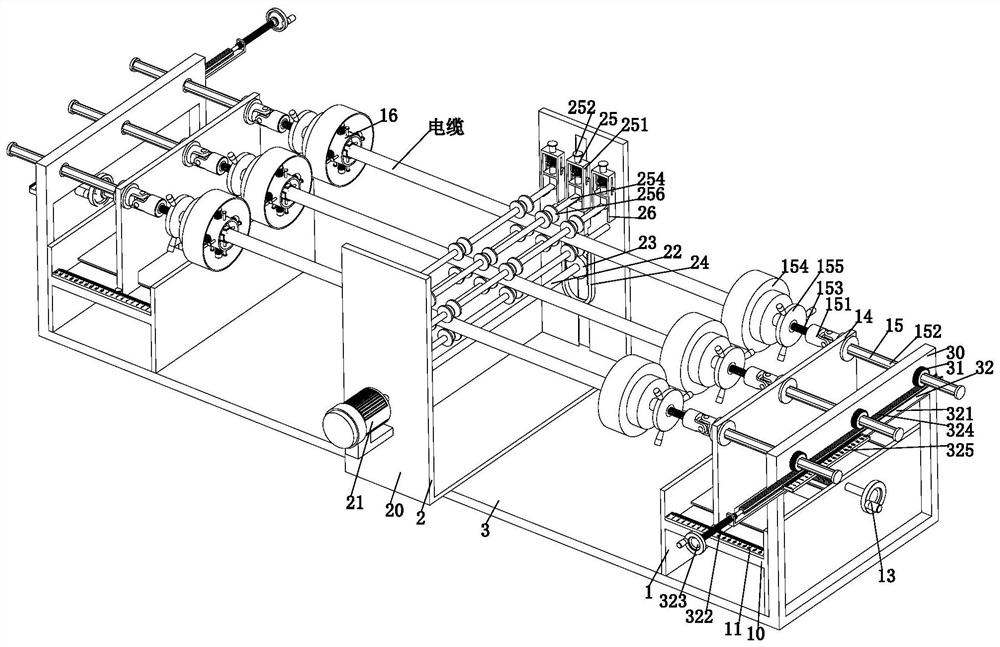

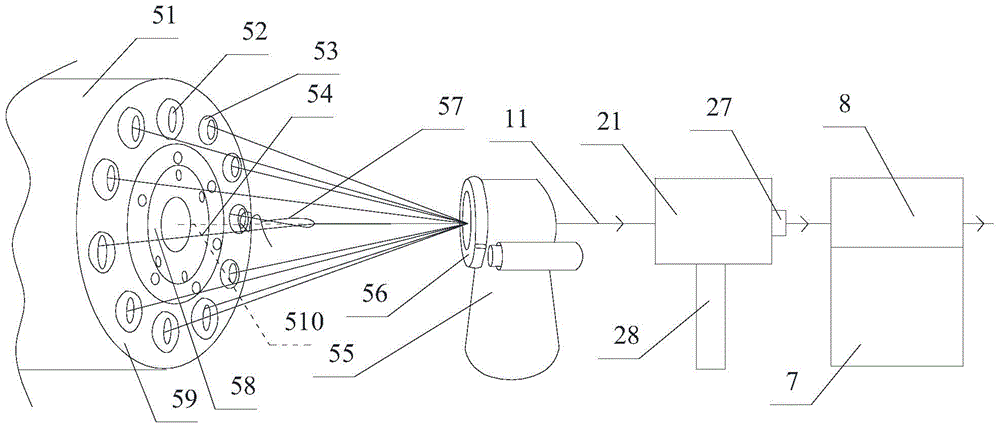

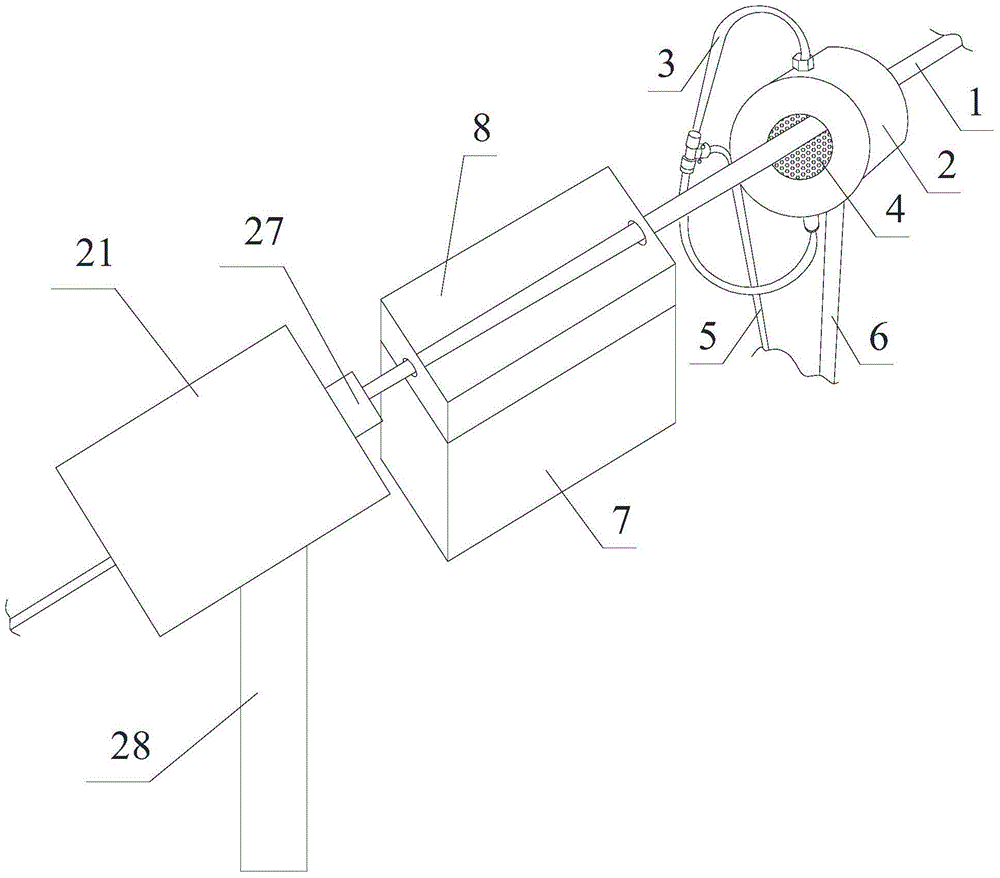

Skeleton type optical fiber ribbon cabling machine and cabling method using cabling machine

ActiveCN103645550AAccurate slottingGuaranteed smooth productionFibre mechanical structuresGear driveCable machine

The invention relates to the field of optical cable manufacturing, and particularly relates to a skeleton type optical fiber ribbon cabling machine and a cabling method using the skeleton type optical fiber ribbon cabling machine. The structure of the skeleton type optical fiber ribbon cabling machine comprises a control bench, a cable-releasing device, a groove-entering device and a cable-returning device. The groove-entering device comprises a twisting device which comprises a twisting bearing seat, a groove entering adjustment disc, a sensing gear and a sensing device. The sensing gear drives the sensing device to rotate. The groove entering adjustment disc is provided with a lead-in groove and a central hole. The central hole is internally provided with a protruding tooth which is embedded into a skeleton groove. The rotation state of the groove entering adjustment disc is detected via the sensing device and transmitted to the control bench. A rotation angle error is calculated via the control bench and distance between cabling twisted sections is automatically adjusted according to the rotation angle error so that the distance between the cabling twisted sections is matched with practical distance between the twisted sections of the skeleton groove, and an optical fiber ribbon is ensured to be stably and accurately put into the skeleton groove.

Owner:GUANGDONG HENGTONG PHOTOELECTRIC SCI & TECH +1

System and method for testing performance of copper core low-voltage cable after manufacturing and processing

ActiveCN113376006AReduce frictional resistanceFlexible operationMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesLow voltageCable machine

The invention provides a system and a method for testing the performance of a copper core low-voltage cable after manufacturing and processing, and the system comprises a double-item detection mechanism, a single-item detection mechanism and a joint control mechanism. Since an existing cable mechanical performance testing device can only test the cable of one model and size, when mechanical performance testing is carried out on cables of different models and sizes, testing can be carried out only by replacing devices of corresponding models, and mechanical performance testing of the cables has limitation and is high in testing cost; and testing of the mechanical performance of the cables is divided into a plurality of specific small testing, and the existing testing device for the mechanical properties of the cable cannot meet the operation execution of various tests, is difficult to ensure the comprehensive detection of different mechanical properties of the cable, and cannot meet the strict test requirements of various properties of the cable after being manufactured and processed, and the like.

Owner:山东兖矿集团长龙电缆制造有限公司

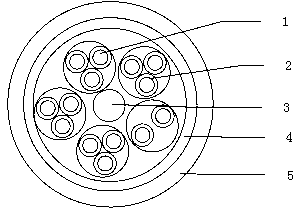

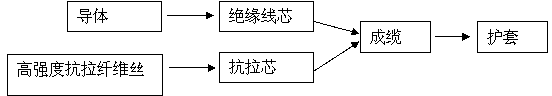

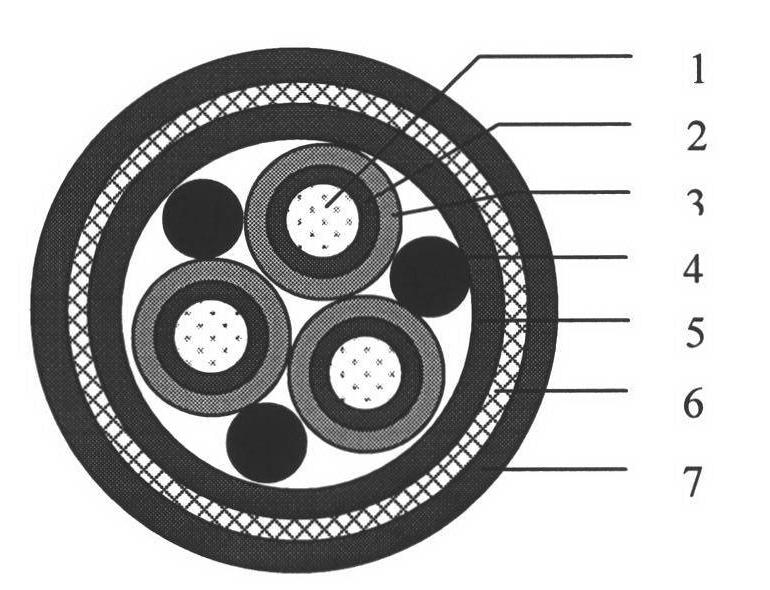

Towline cable and manufacturing process thereof

ActiveCN103295681AHigh mechanical strengthAging resistantFlexible cablesCable/conductor manufactureEnvironmental resistanceFiber

The invention relates to a towline cable and a manufacturing process thereof. The towline cable structurally comprises a conductor, an insulator, a tensile core, an inner sheath and an outer sheath. The radiation ethylene propylene rubber insulator is arranged on the periphery of the conductor, the low temperature resistant elastic body inner sheath is arranged on the periphery of the radiation ethylene propylene rubber insulator, and the flexible polyurethane outer sheath is arranged on the periphery of the inner sheath. The manufacturing process is that a tinned copper wire is stranded by a wire cable stranding machine to server as the conductor, an extruder device is utilized to extrude the environment-friendly radiation ethylene propylene rubber insulator on the outside of the conductor, the stranding machine is utilized to strand high-strength tensile fibers, flexible polyvinyl chloride (PVC) is extruded by the extruder device on the outer layer to serve as the tensile core, then a cabling machine is utilized to strand an insulation wire core and the tensile core together, and the extruder device is utilized to extrude low temperature elastic body sheath materials to serve as the sheaths. The cable has the advantages of high mechanical strength, flexibility, high abrasion resistance, aging resistance, cracking resistance, mould resistance, moisture resistance and acid-base corrosion resistance, is flexible under the low temperature condition and suitable for special environments such as weapons, electronics, high-level civil use.

Owner:NANJING QUANXIN CABLE TECH

Ramp door with self-deploying rail

Owner:LIPPERT COMPONENTS

Disk type cabling machine, cage type cabling machine and wire coil for machine

ActiveCN101885436BMeet the requirements of the number of payoutsAchieve productionCable/conductor manufactureCable machineEngineering

Owner:四川川东电缆有限责任公司

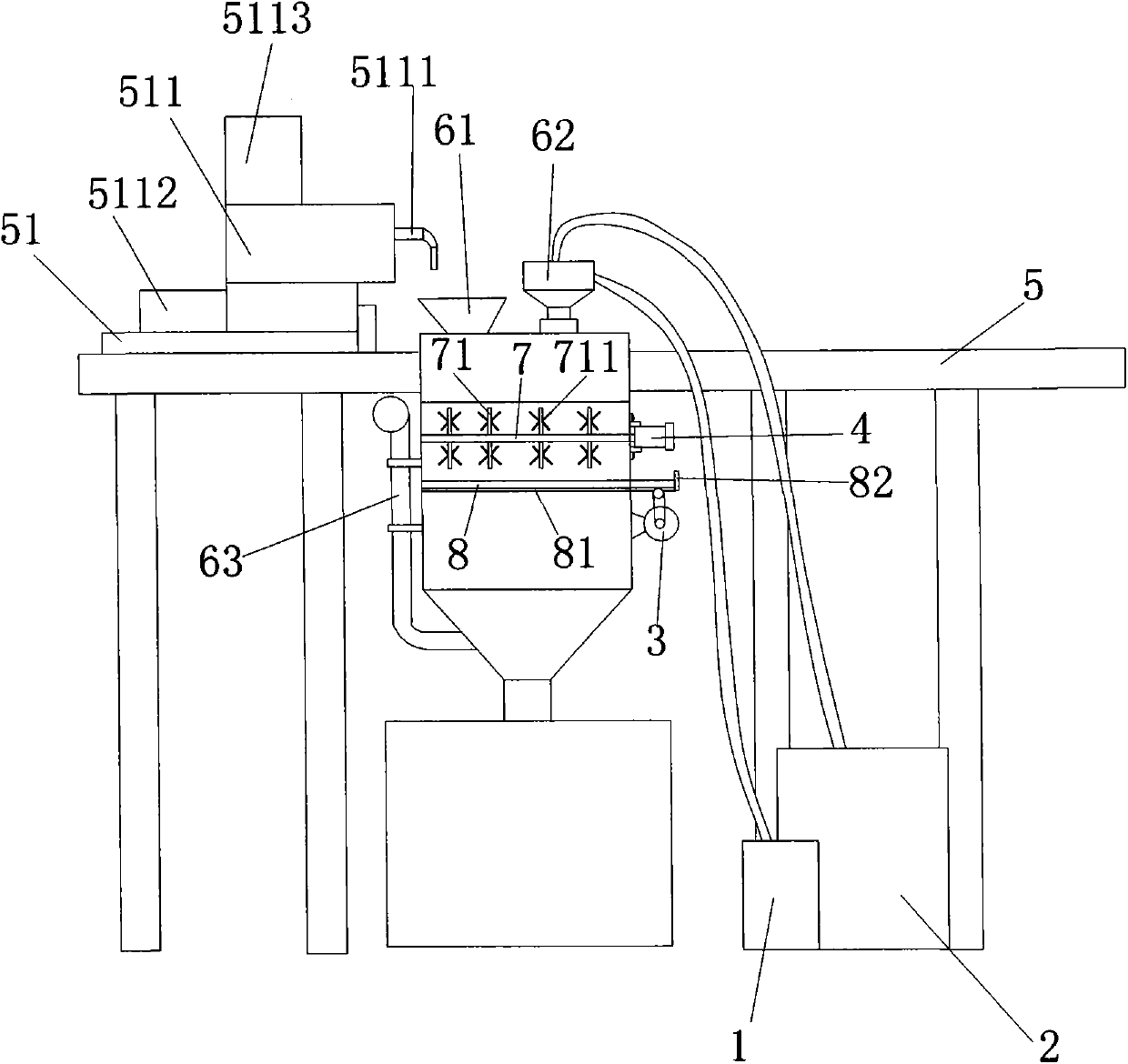

Improved cable machining discharging device

The invention relates to an improved cable machining discharging device. The improved cable machining discharging device comprises a material suction machine, a material storage cylinder, a first motor, a second motor and a rack body, and further comprises an injection molding machine machining material cylinder, a main feeding hopper and an auxiliary feeding hopper are arranged on the injection molding machine machining material cylinder, a rotating shaft is arranged in the middle of the injection molding machine machining material cylinder, blending blades are arranged on the rotating shaft, bending sub-blades are arranged in the middles of the blending blades, an adjusting plate is further arranged on the injection molding machine machining material cylinder, a rack is solidified at the lower end of the adjusting plate, the rack is connected with the first motor through a gear, and a positioning block is arranged at the right end of the adjusting plate. Through the blending blades with the bending sub-blades, raw materials can be conveniently and evenly blended, uniformity of product materials is facilitated, through the adjusting plate with the rack, uneven mixed liquid can be separated from even mixed liquid, the mixed liquid is evenly blended and then is conveyed, and the device is simple in structure, convenient to operate, economical and practical.

Owner:HEFEI LANGJIA MECHANICAL & ELECTRICAL EQUIPCO

Cabling machine

PendingCN109767877AWon't fallEasy to change jobsFilament handlingCable/conductor manufactureYarnMotor drive

The invention provides a cabling machine comprising a hollow shaft, a back-twist mechanism, a hurdle, a circular pay-off spool, a branching board, a main mould frame, a yarn covering head, a winding head mould frame, a traction wheel and a wire take-up device, wherein the wire take-up device comprises a base, a take-up reel vertically arranged on the base, an active chuck and a driven chuck respectively clamped on the upper and lower ends of the take-up reel, a first motor driving the active chuck to rotate, and a cutting mechanism disposed in front of the take-up reel; the driven chuck is disposed on the base, the active chuck and the first motor are disposed on a lifting plate that is driven by a first lifting mechanism to operate; and the cutting mechanism is used for cutting the cable.The cabling machine can avoid the loss of support of the take-up reel during the replacement process and is convenient to use.

Owner:FOSHAN YUEJIAXIN WIRE & CABLE

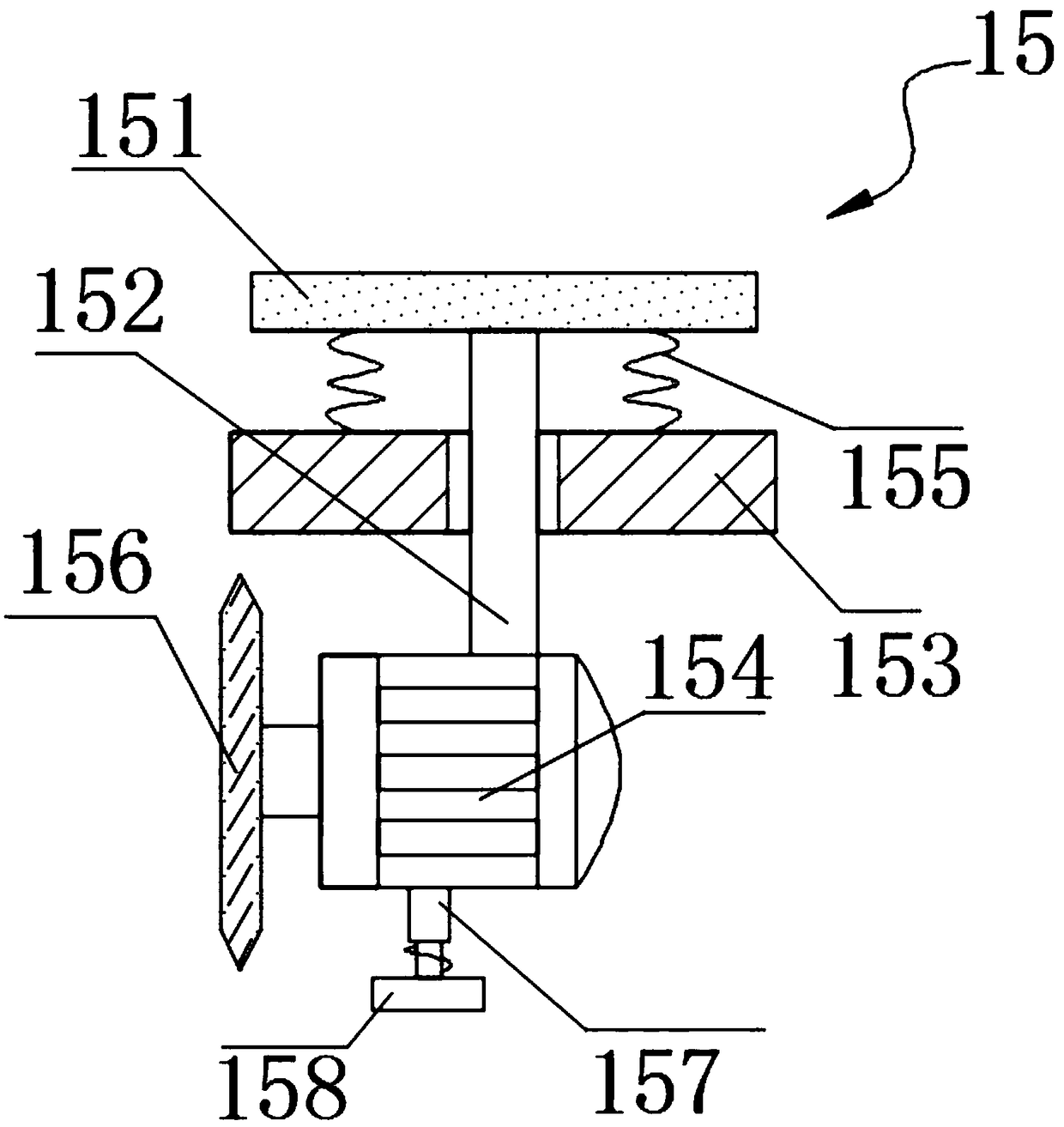

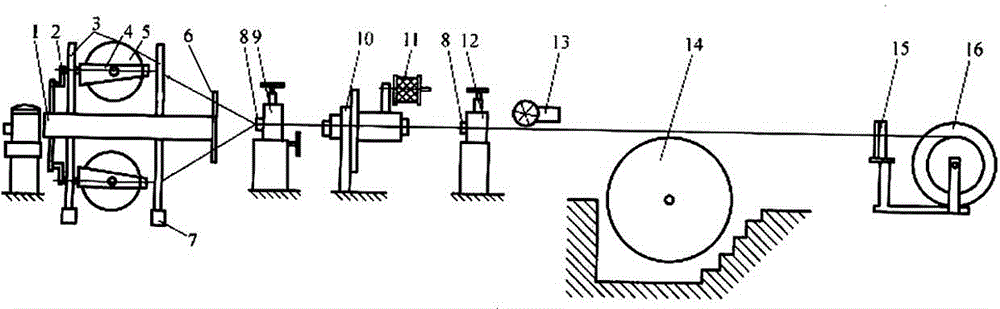

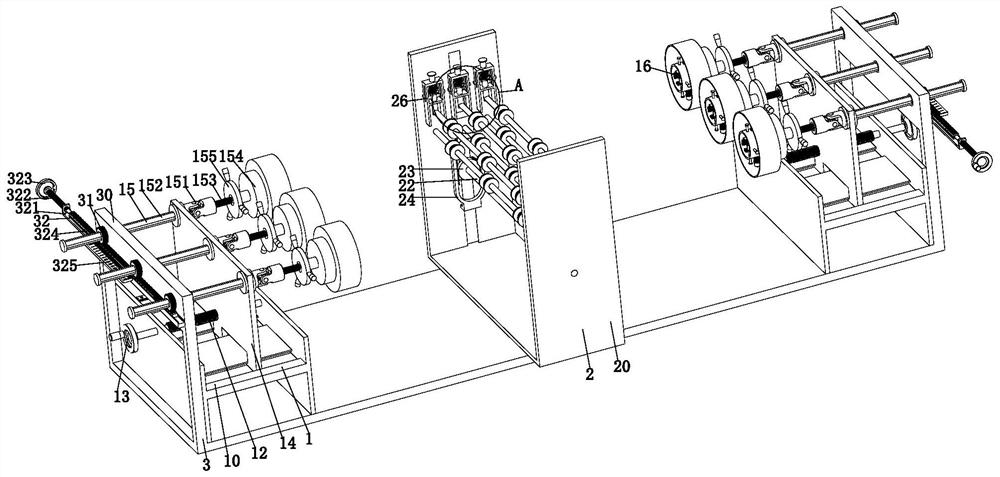

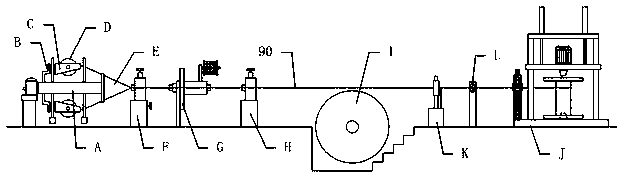

A production line for cable synthesis, sheath production, sheath cooling, and sheath air drying

ActiveCN105070419BExtrude evenlyExtended service lifeCable/conductor manufactureFiberProduction line

The invention discloses a production line for cable synthesis, sheath production, sheath cooling and sheath air dying. The production line comprises a sheath production device for forming a sheath at the outer surface of a cable, a water tank for cooling the sheath, and a cable blower for air-drying water drops on the sheath coming out of a water surface. The sheath production device comprises a circle-shaped rubber container which extrudes rubber and forms the sheath at the outer surface of the cable. The inner side of one end surface of the rubber container is provided with a hole platform, and the hole platform is provided with a ring of uniformly distributed rubber discharging holes. The cable blower comprises a hollow-structured cylindrical shell, a gas source and an air passage mechanism for communicating the gas source with the cylindrical shell. A cabling machine comprises a deconcentrator and a synthesizer. The deconcentrator outputs a plurality of wires to the synthesizer, and these wires comprise a plurality of copper wires and a plurality of fiber wires. One of the fiber wires is bound by use of a rope, the fiber wire is drawn to the extension line of the central axis of the deconcentrator through the rope, and the center of the cable is the fiber wire.

Owner:江苏江扬特种电缆有限公司

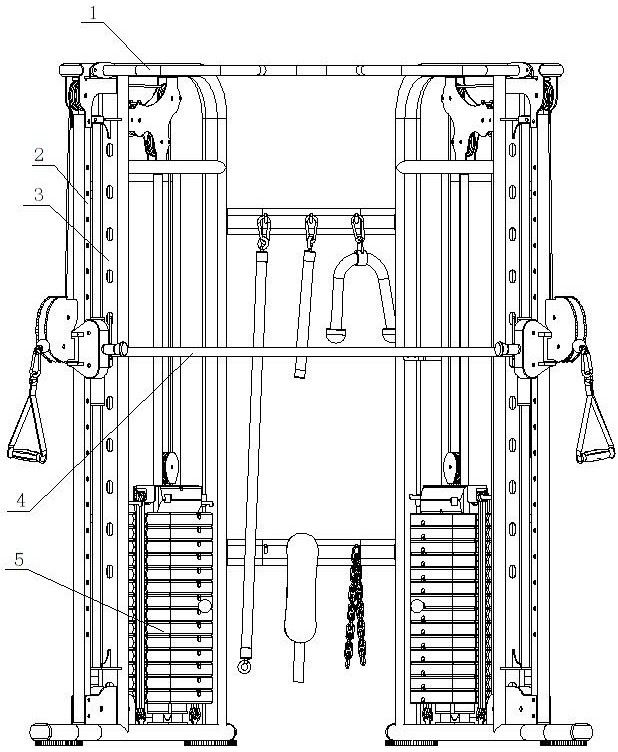

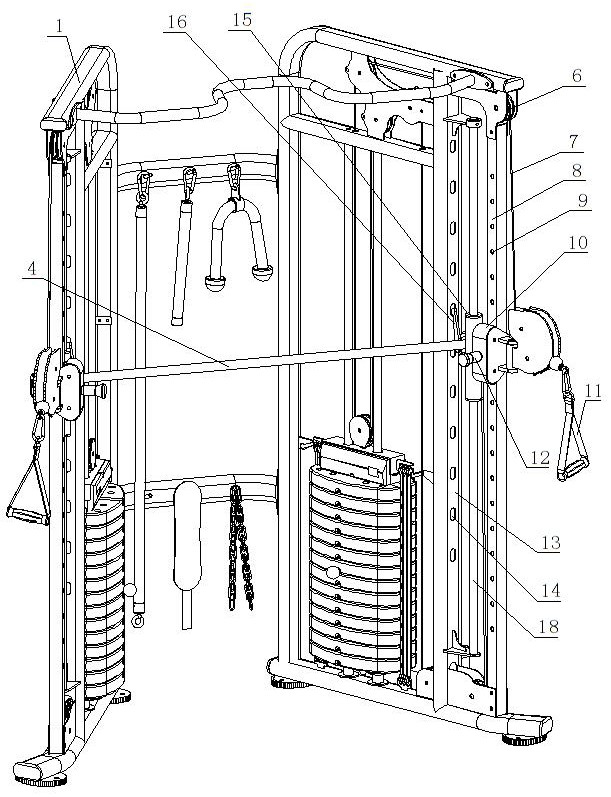

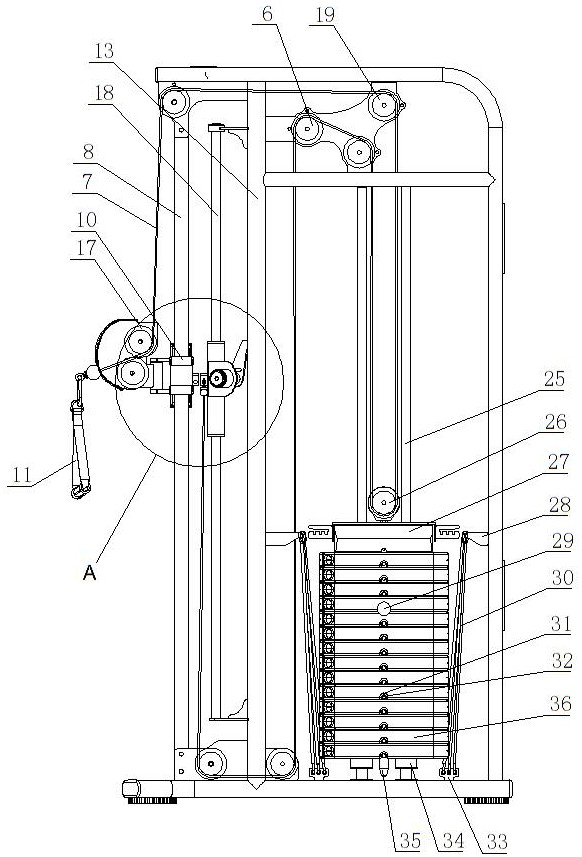

Comprehensive trainer capable of being switched quickly

The invention discloses a comprehensive trainer capable of being switched quickly, and relates to fitness equipment; the comprehensive trainer comprises a frame, two groups of steel cable machine assemblies, two groups of barbell rod assemblies, a barbell rod and two groups of counterweight systems. Each steel cable machine assembly comprises a steel cable machine adjusting pipe, a steel cable machine sliding base and a pull handle pulley. A first fixing piece is fixedly connected to each steel cable machine sliding base, and a first plug pin hole is formed in each first fixing piece; each barbell rod assembly comprises a barbell adjusting pipe, a barbell sliding guide rod and a barbell sliding seat; a second fixing piece is fixedly connected to each barbell sliding seat, and a second bolthole is formed in each second fixing piece; a movable pulley is connected above each counterweight system; each steel cable machine assembly further comprises a steel cable, a first pulley and a second pulley, the middle of the steel cable is arranged on the movable pulley, one end of the steel cable is inserted into the first bolt hole or the second bolt hole through a bolt after passing throughthe first pulley, and the other end of the steel cable is connected with a pull handle after passing through the second pulley and the pull handle pulley. Rapid switching between steel cable machinemovement and barbell rod movement is achieved.

Owner:YANGZHOU JIUYI HARDWARE & MACHINERY

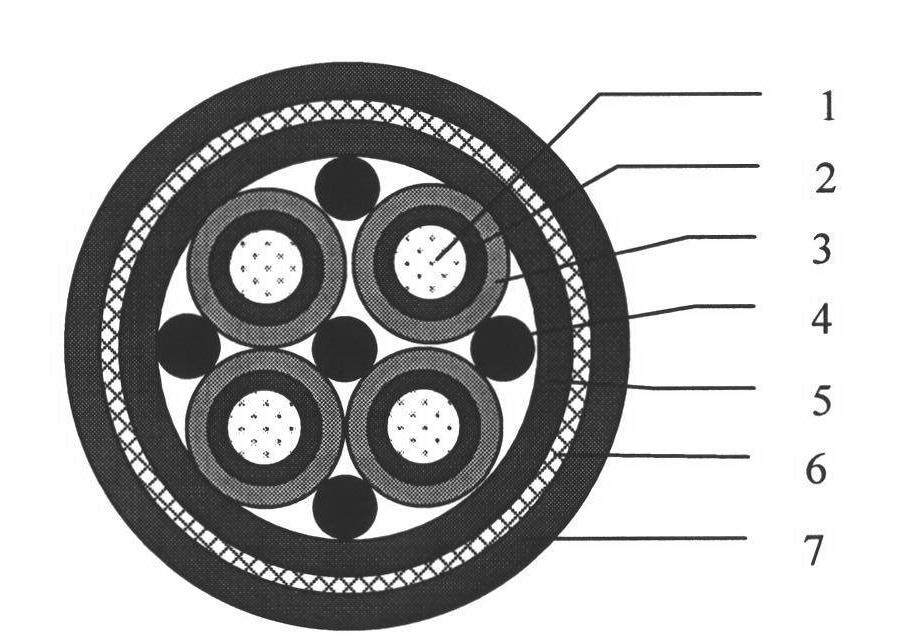

Walking power cable and preparation method thereof

ActiveCN102097177AGood flexibilityHigh tensile strengthBraided wire conductorsPower cables with screens/conductive layersFiberElectrical conductor

The invention provides a walking power cable and a preparation method thereof. The cable is characterized in that an insulating layer is arranged on the outer layer of each combined conductor and is formed by stranding a plurality of insulated cores; filling cores are arranged between two insulating layers and an inner sheath; a tensile layer is arranged on the outer layer of the inner sheath; and an outer sheath is arranged on the outer layer of the tensile layer. The preparation method is characterized in that tinned copper wires and special fibers are stranded by a wire and cable stranding machine to serve as inner conductors; the tinned copper wires are braided by a braiding machine to serve as outer conductors; inner insulating layers are manufactured by extruder equipment and are processed by an electron accelerator through radiation crosslinking, and outer insulating layers are manufactured by the extruder equipment; the filling cores are stranded by a cabling machine; the tensile layer is formed by a braiding machine through braiding; and the inner and outer sheathes are manufactured by the extruder equipment. The cable has the advantages of softness, low temperature and aging resistance, tear resistance, high flame retardance and high strength, has softness characteristic under low temperature, improves the tensile strength, is suitable for the special environment such as reciprocation and has excellent mechanical property and electrical property.

Owner:NANJING QUANXIN CABLE TECH

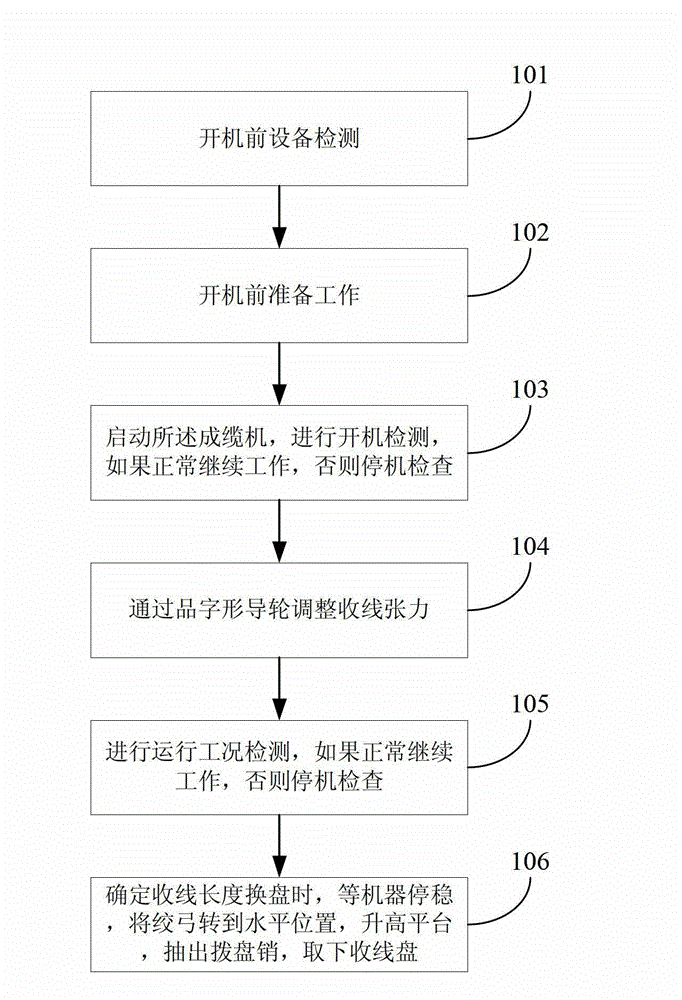

Harness cabling method

ActiveCN102982906AConstant tensionQuality improvementManufacturing wire harnessesCable machineEngineering

The invention discloses a harness cabling method applied to a cabling machine comprising a pay-off rack, a cable wheel, a distributing board, a cabling die, an arranging sliding rod and a take-up spool. The method includes the steps of starting the cabling machine for power on self test, continuing operation if the machine is normal, otherwise shutting down for detection; adjusting the take-up tension through a triangular guide roller; detecting operation conditions, continuing the operation if the conditions are normal, otherwise shutting down for detection; shutting down when the take-up length is determined and the spool is replaced, turning a twisting bow to the horizontal position, and replacing the take-up spool. According to the method, during operation of the cabling machine, the tension of cables is constant, and quality of the cables is improved; and damage to appearances of the cables due to mechanical faults during processing can be discovered and adjusted timely, and the rate of finished products is improved.

Owner:ANHUI TIANXING OPTICAL FIBER COMM EQUIP

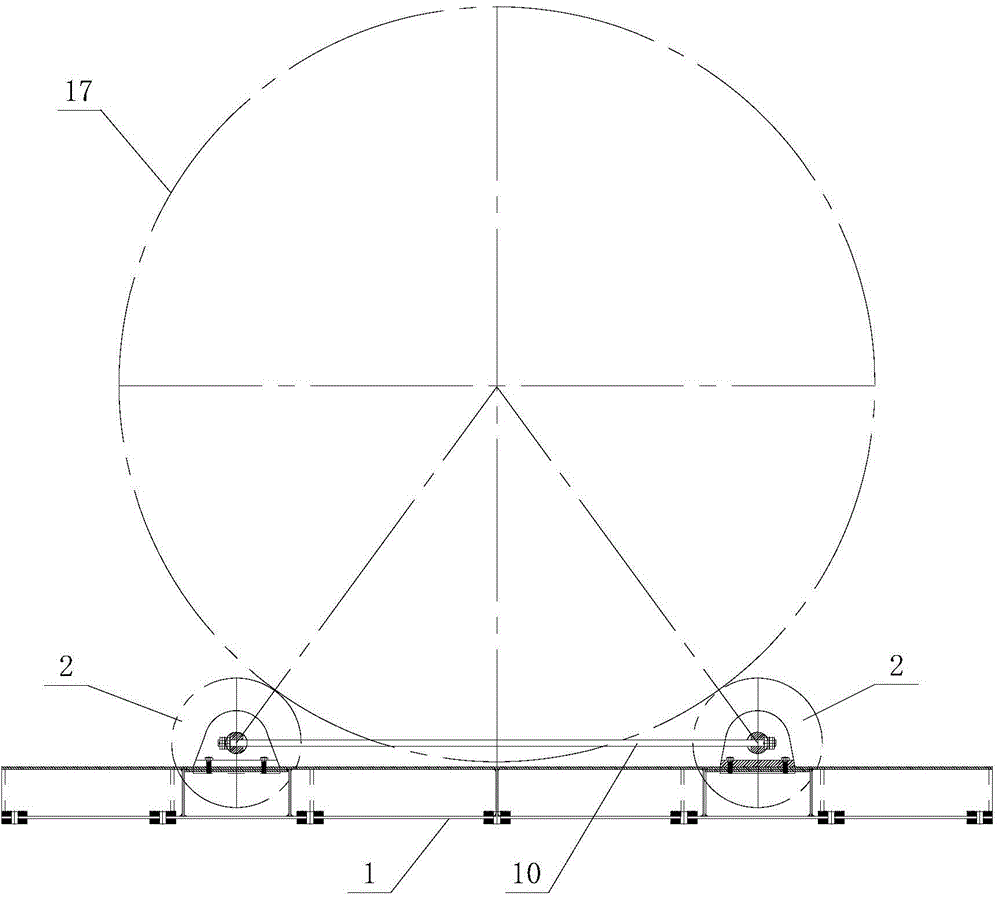

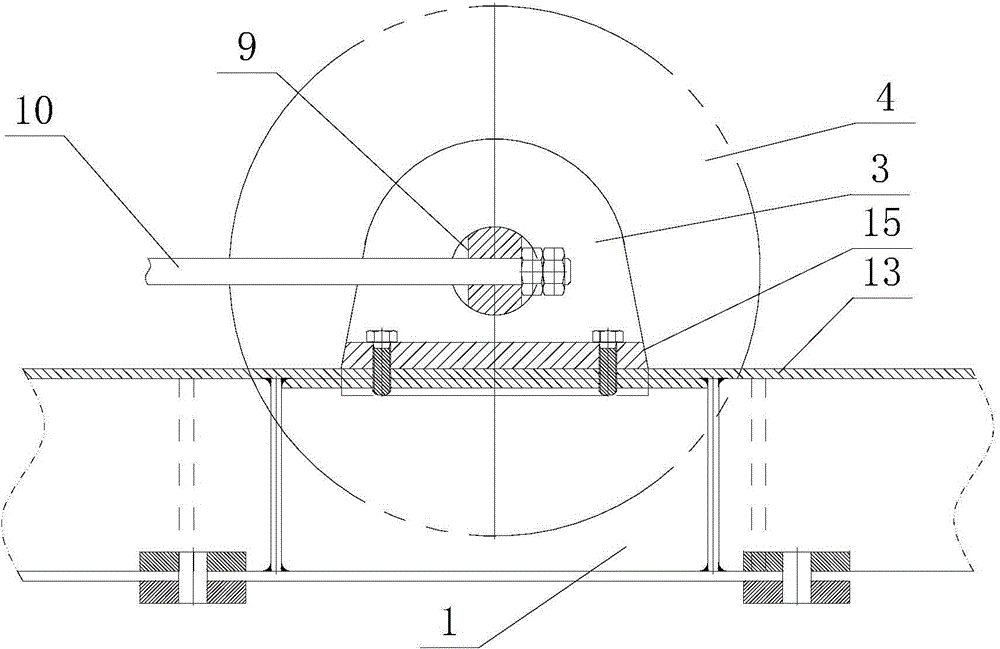

Supporting wheel device used for cabling machine

ActiveCN104103377AReduce labor intensityImprove running stabilityCable/conductor manufactureCable machineEngineering

The invention discloses a supporting wheel device used for a cabling machine. The supporting wheel device comprises a chassis and two set of supporting wheel assemblies arranged on the chassis; each supporting wheel assembly comprises two supporting seats which are fixed on the chassis and a supporting wheel arranged between the two supporting seats; each supporting wheel sleeves a rotating shaft through a bearing; the rotating shaft is provided with penetrating covers which are located at two sides of the bearing; two ends of the rotating shaft respectively extend out from corresponding supporting seats; through holes are formed in portions of the rotating shaft which extend out from the supporting seats; the rotating shaft is provided with two fixing planes which are located at two ends of the through holes; through holes at the same side of the rotating shaft of each set of supporting wheel assembly are connected with each other through a connecting rod; and two ends of the connecting rod are respectively provided with a screw thread. According to the supporting wheel device of the invention, through the effect of the connecting rod, one set of supporting wheel assembly can be adjusted, and thereafter, the other set of supporting wheel assembly can be pulled to the center through the connecting rod until acting forces at two sides of the connecting rod are balanced, and contact surfaces are fittingly attached to each other, and therefore, labor intensity of installation personnel can be reduced, time and labor can be saved; and after installation, operational stability of equipment is higher, and noises are low, and the bearing strength of the installed supporting wheels is larger.

Owner:PINGHU DIGONG MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com