Walking power cable and preparation method thereof

A power cable, flexible technology, applied in the field of floating power cables and its preparation, can solve the problems of increasing the tensile capacity of cable conductors, broken cores, etc., achieve excellent mechanical and electrical properties, reduce laying space, and round the structure stable effect

Active Publication Date: 2011-06-15

NANJING QUANXIN CABLE TECH

View PDF6 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The present invention proposes a swimming power cable and its preparation method, the inner conductor of which is multi-strand tinned annealed copper stranded wire plus special fiber wire reinforcement, and the outer conductor is braided with tinned copper wire, which increases the resistance of the cable conductor. Tension ability, solves the problem of conductor core breakage in high-strength occasions, and improves the flexibility of the cable

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

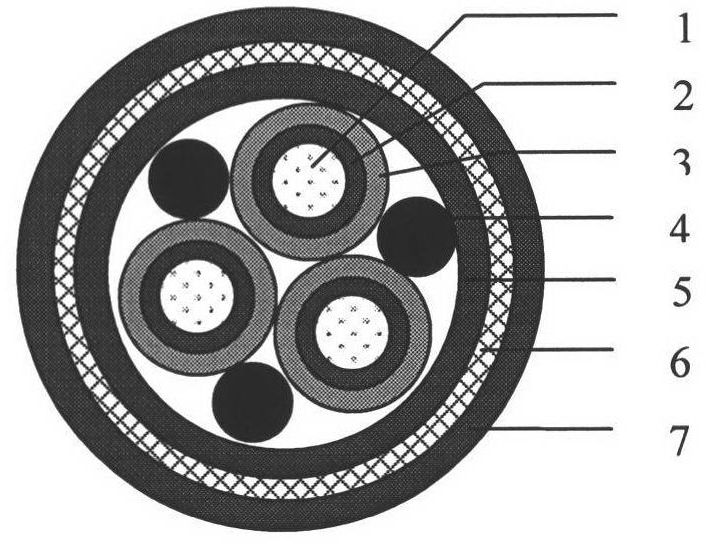

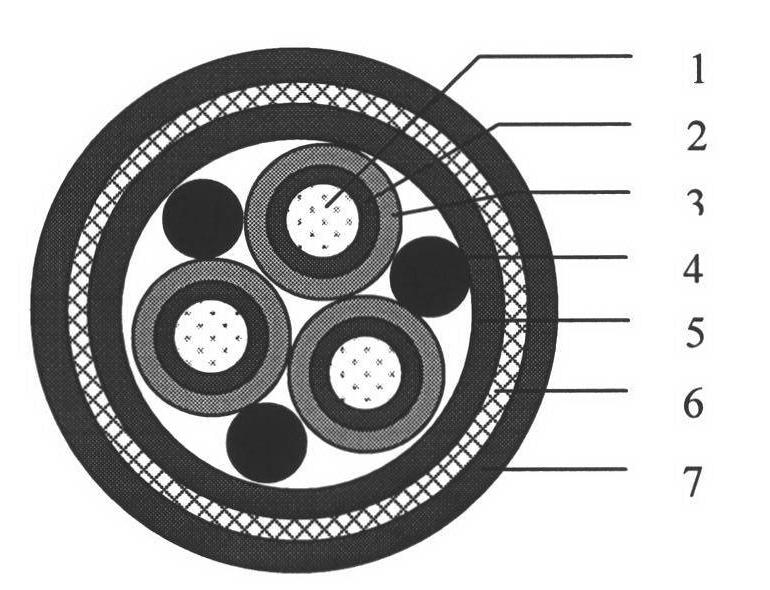

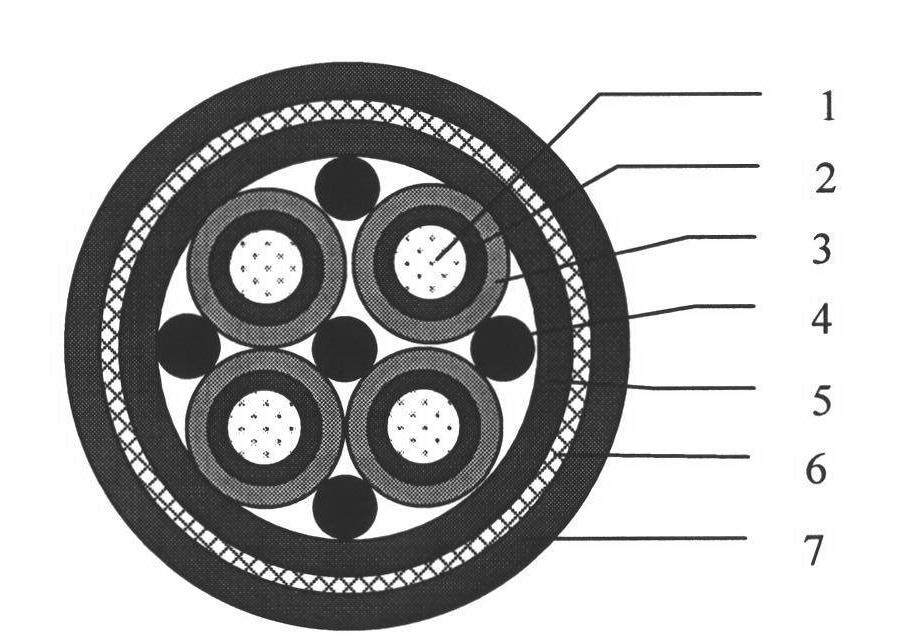

The invention provides a walking power cable and a preparation method thereof. The cable is characterized in that an insulating layer is arranged on the outer layer of each combined conductor and is formed by stranding a plurality of insulated cores; filling cores are arranged between two insulating layers and an inner sheath; a tensile layer is arranged on the outer layer of the inner sheath; and an outer sheath is arranged on the outer layer of the tensile layer. The preparation method is characterized in that tinned copper wires and special fibers are stranded by a wire and cable stranding machine to serve as inner conductors; the tinned copper wires are braided by a braiding machine to serve as outer conductors; inner insulating layers are manufactured by extruder equipment and are processed by an electron accelerator through radiation crosslinking, and outer insulating layers are manufactured by the extruder equipment; the filling cores are stranded by a cabling machine; the tensile layer is formed by a braiding machine through braiding; and the inner and outer sheathes are manufactured by the extruder equipment. The cable has the advantages of softness, low temperature and aging resistance, tear resistance, high flame retardance and high strength, has softness characteristic under low temperature, improves the tensile strength, is suitable for the special environment such as reciprocation and has excellent mechanical property and electrical property.

Description

Swimming power cable and preparation method thereof Technical field: The invention relates to a swimming power cable and a preparation method thereof. The product can adapt to uninterrupted work in the field environment, and is suitable for use in special environments such as low temperature, high humidity, high tension, high strength, and reciprocating movement. It is suitable for cables for outdoor mobile power and electrical equipment used in special environments such as coal mines and oil fields. Background technique: At present, there is no relevant floating power cable standard in the world. In the GB / T12706.1-2008 "Rated Voltage 1kV to 35kV Extruded Insulated Power Cable and Accessories" standard, there is no relevant product in a special environment such as ① resistance to flexing; ②Cold resistance; ③Aging resistance and other performance standards. Also can't satisfy the user to the special requirements such as product low temperature, softness, high strength. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01B9/02H01B5/10H01B5/12H01B13/00

Inventor 李峰许宪成樊群梁芬芝欧荣金成绍强张宁宁

Owner NANJING QUANXIN CABLE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com