Patents

Literature

3621results about "Power cables with screens/conductive layers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

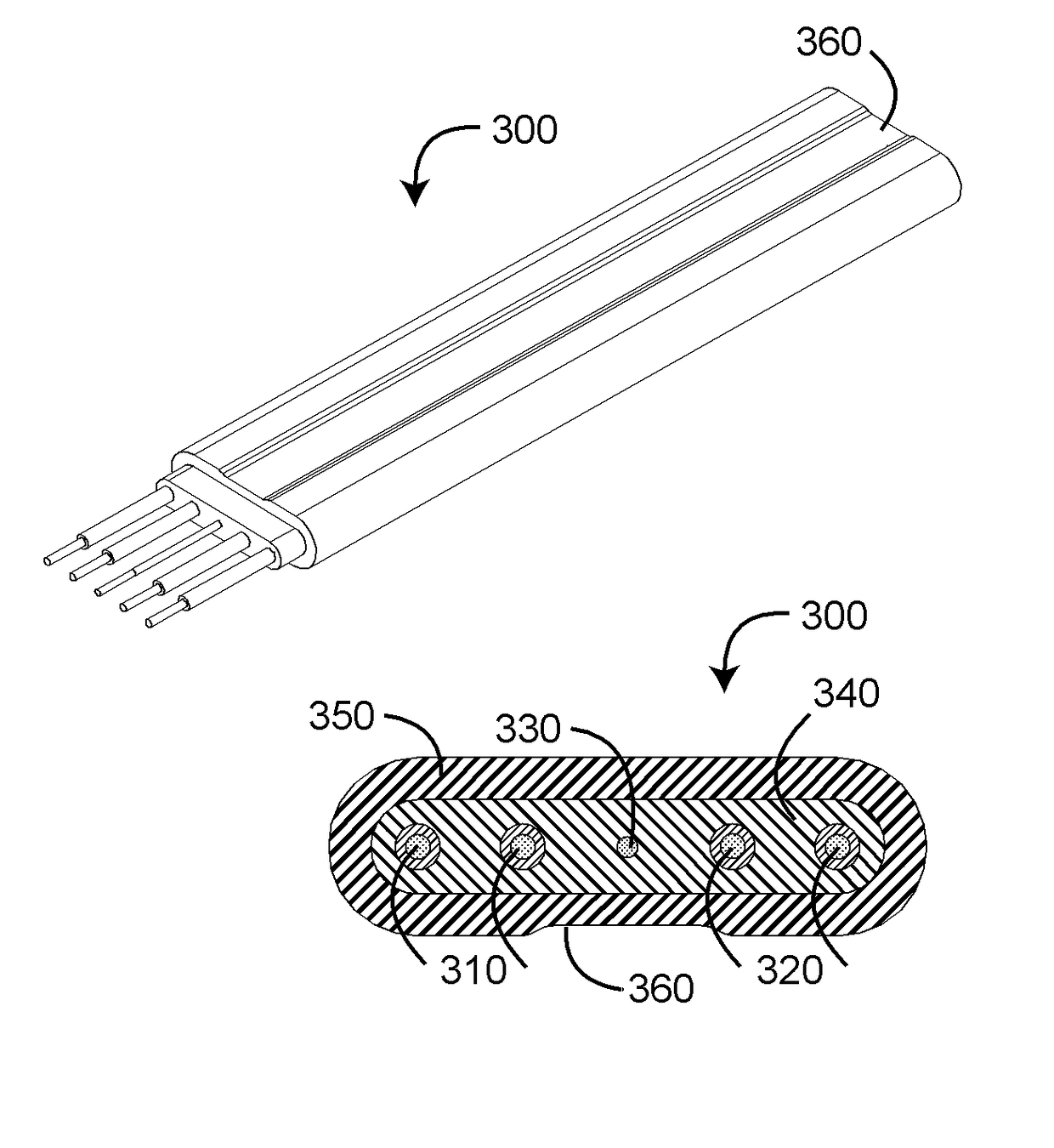

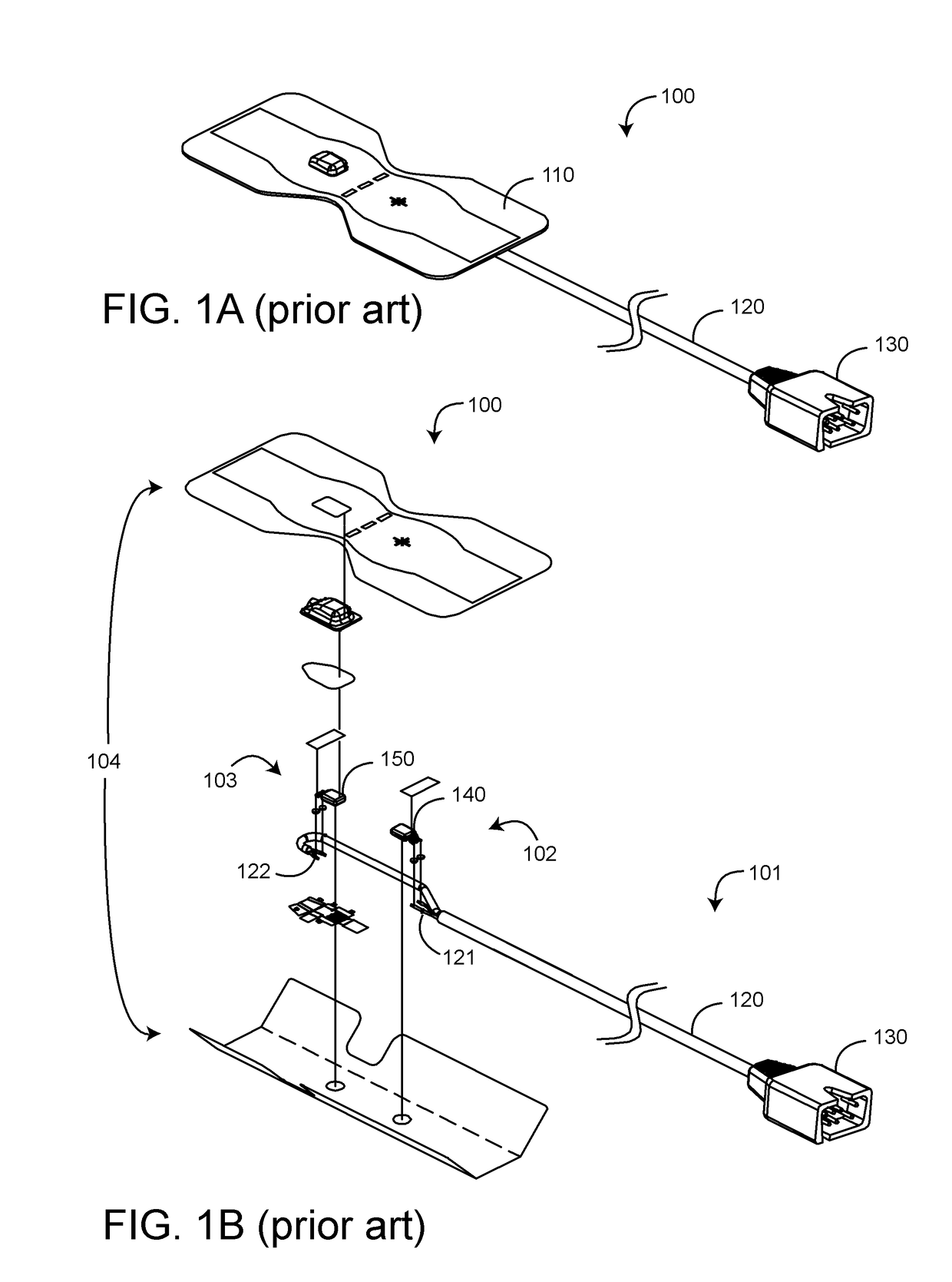

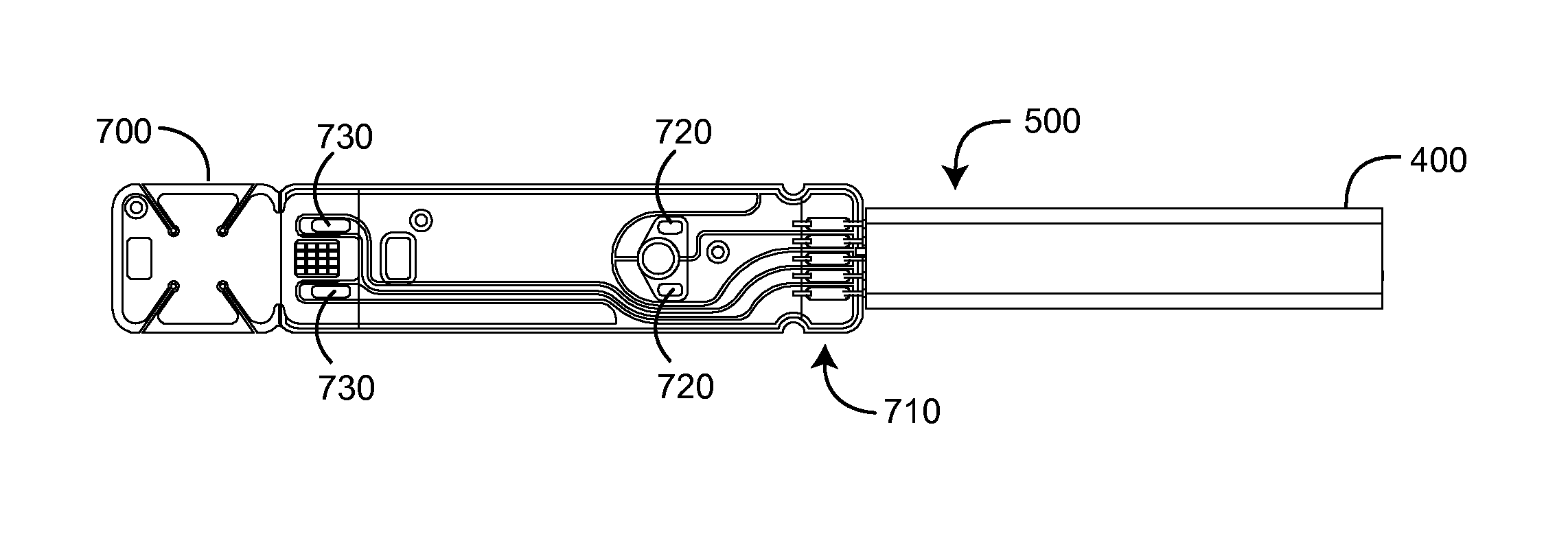

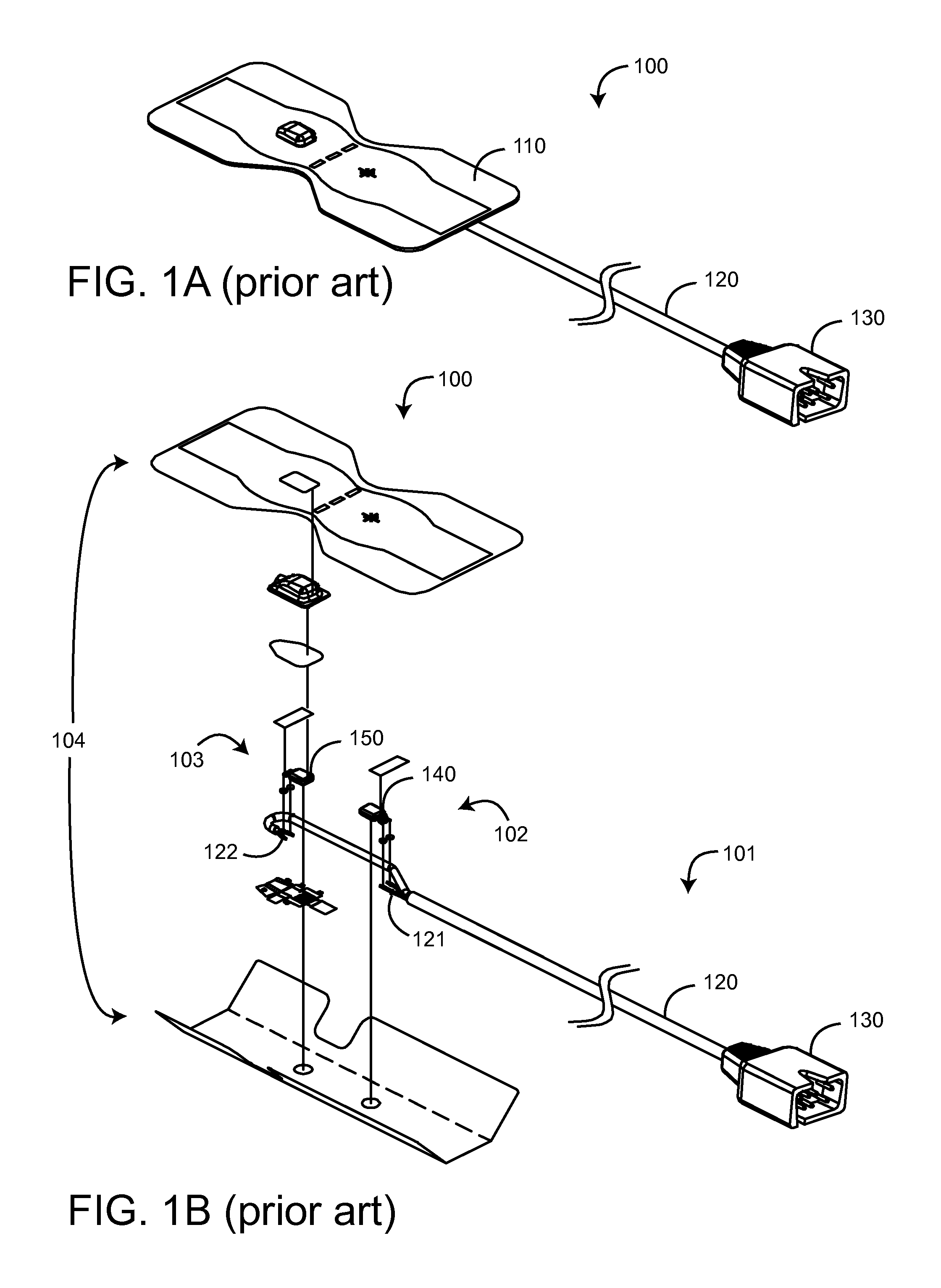

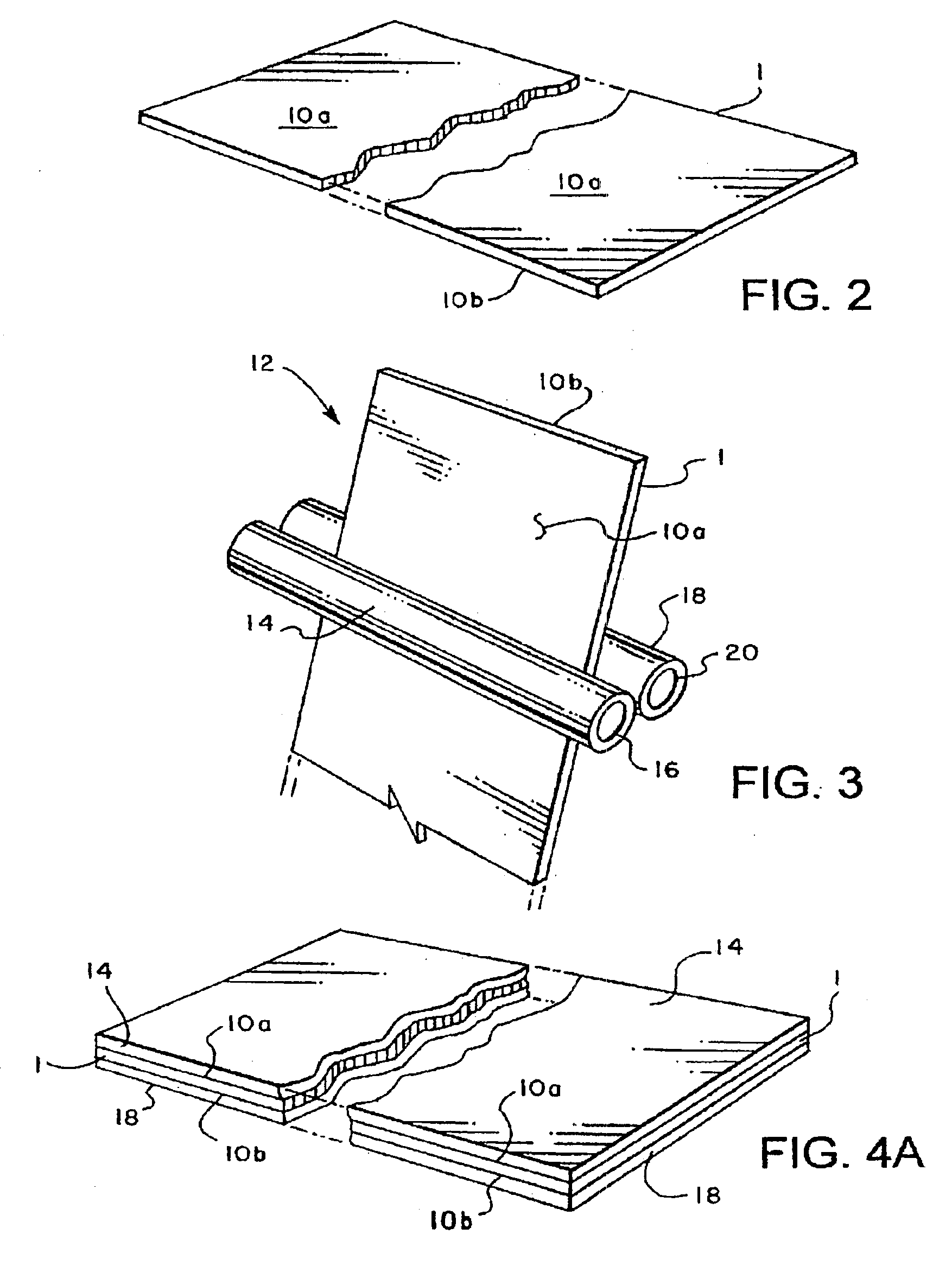

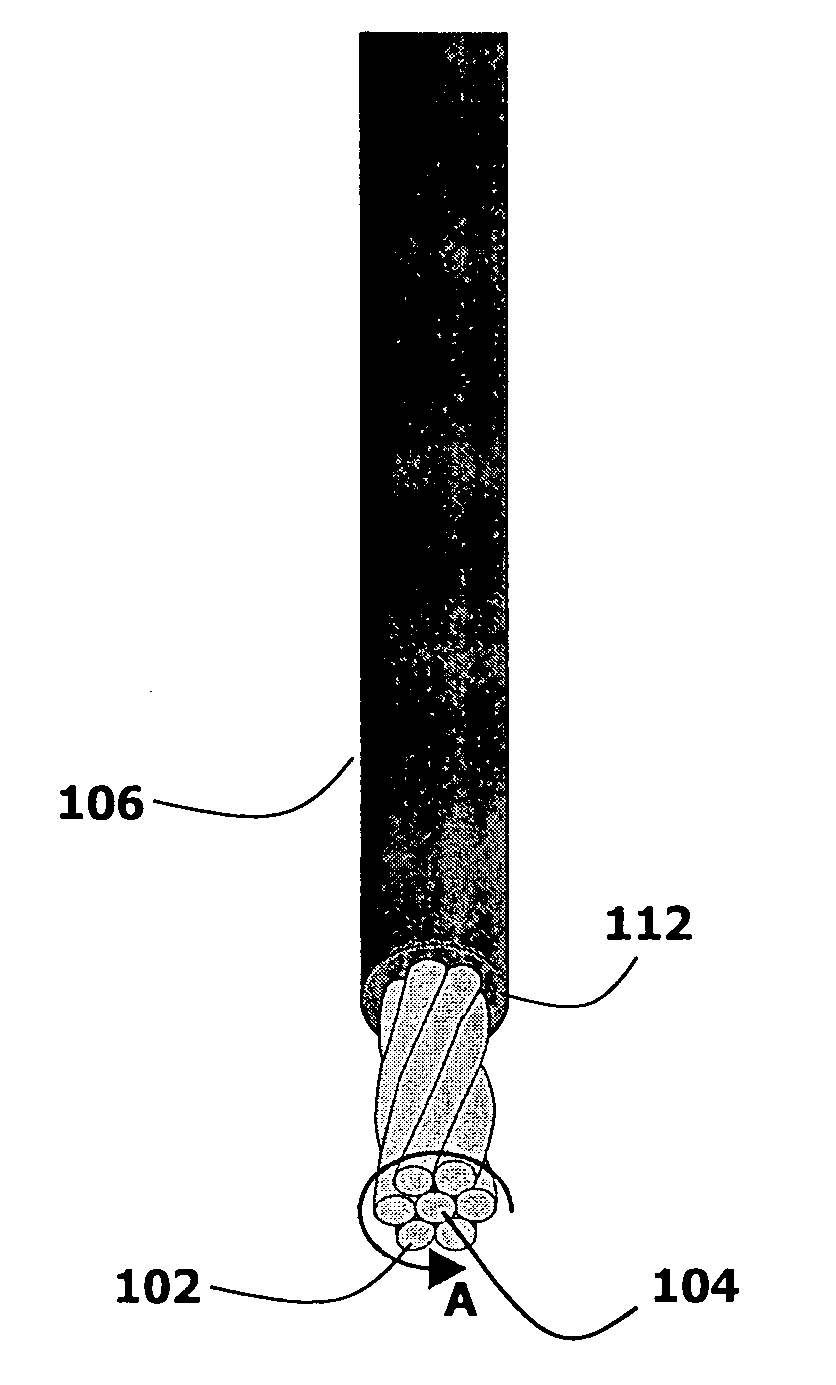

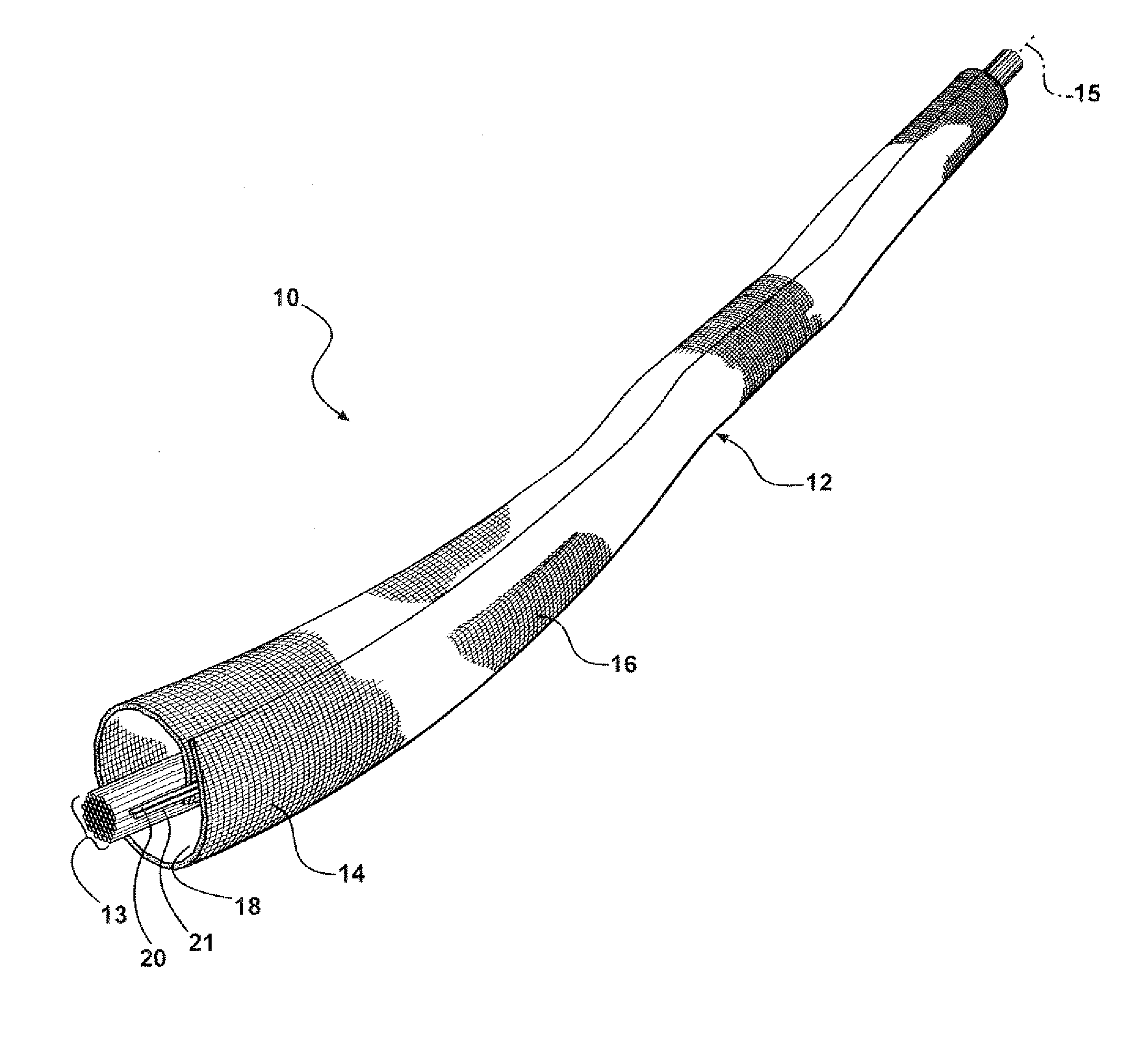

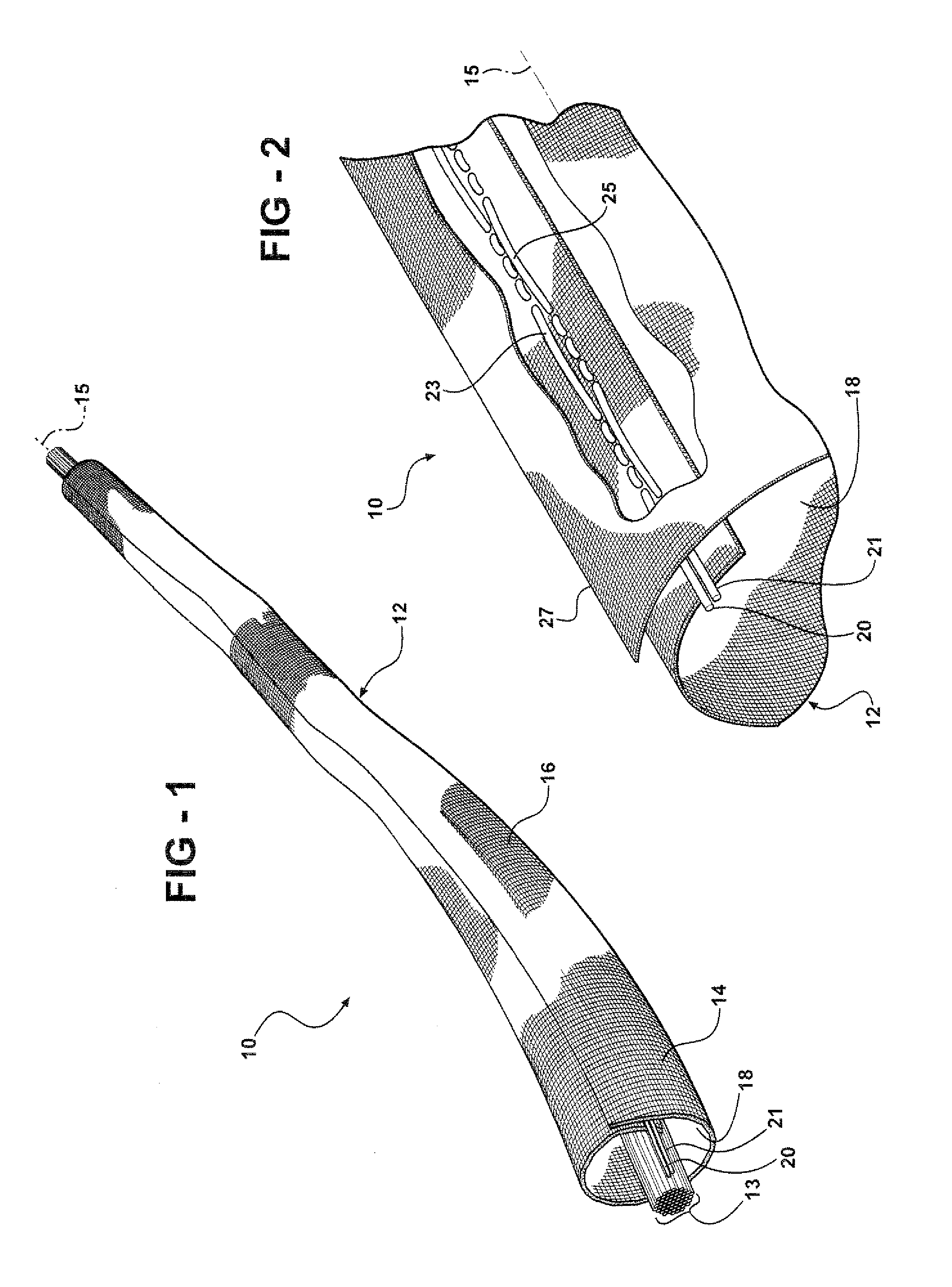

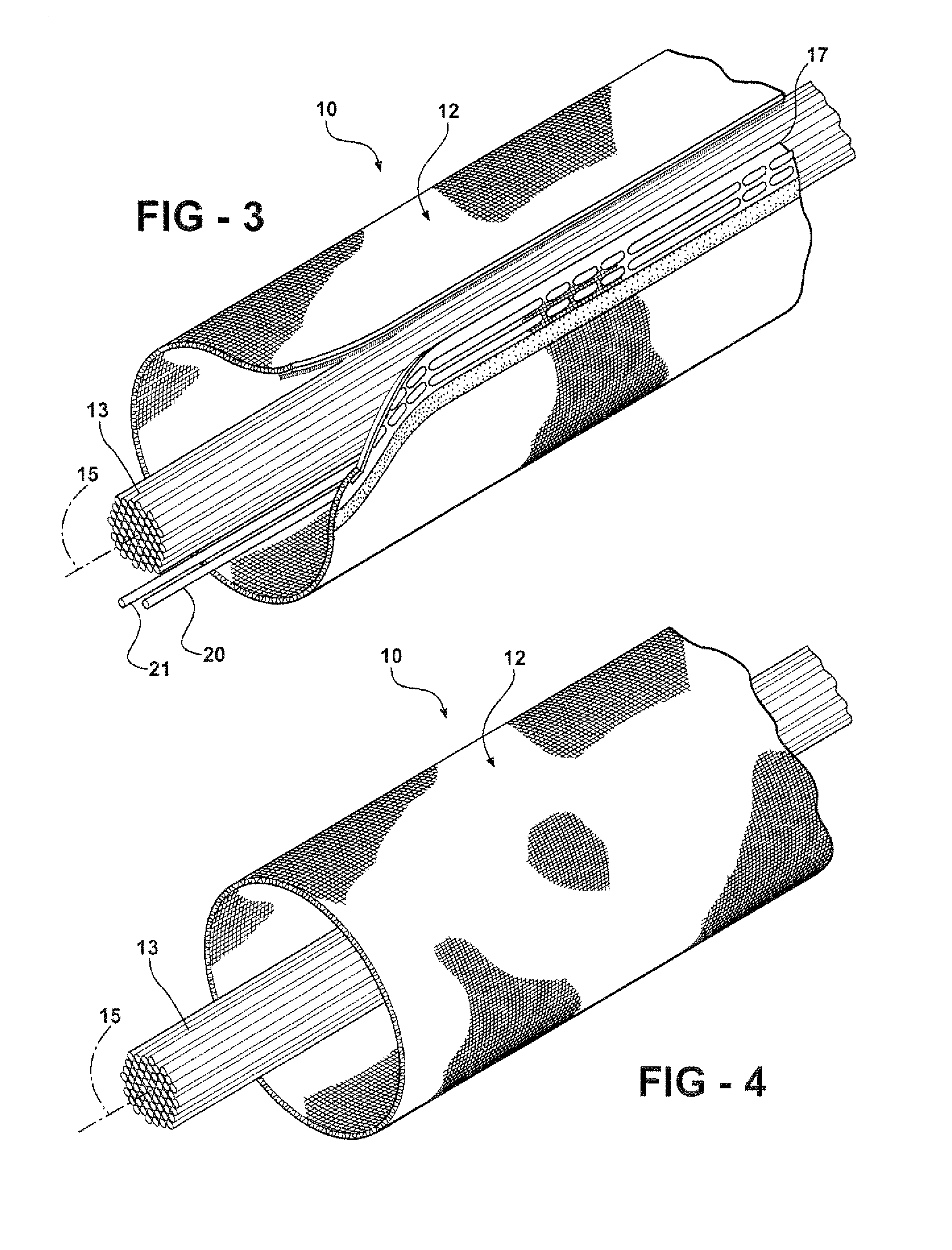

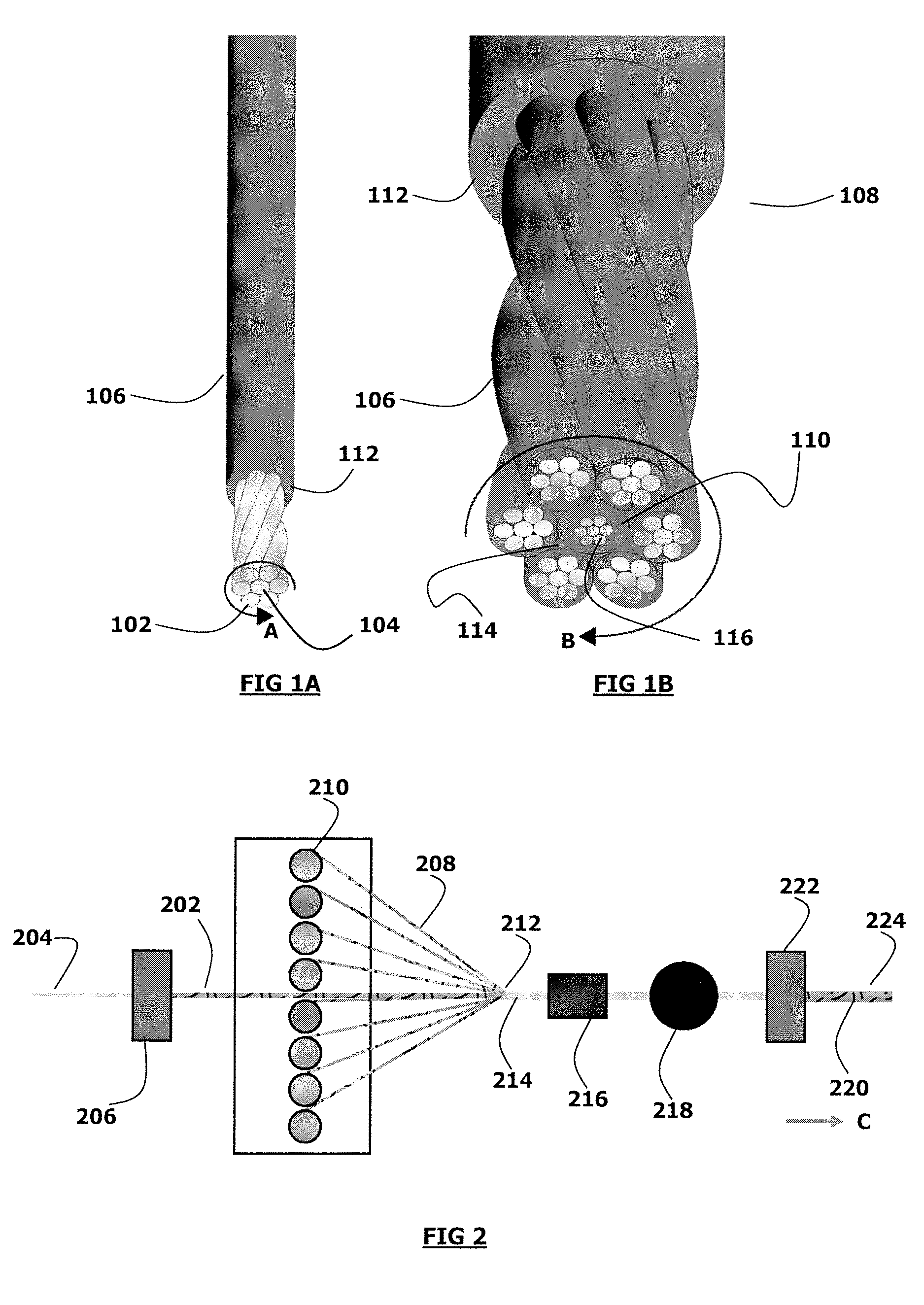

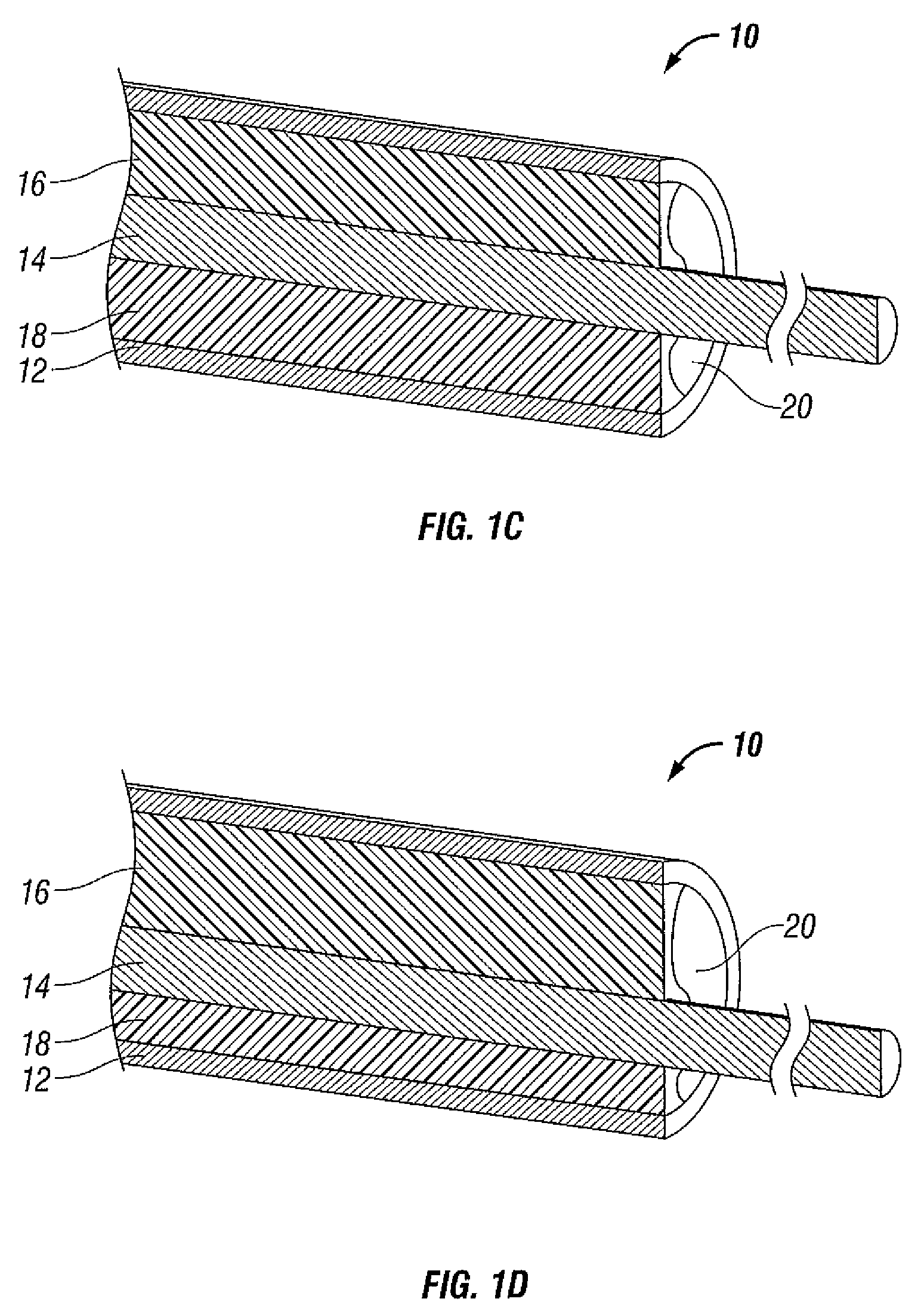

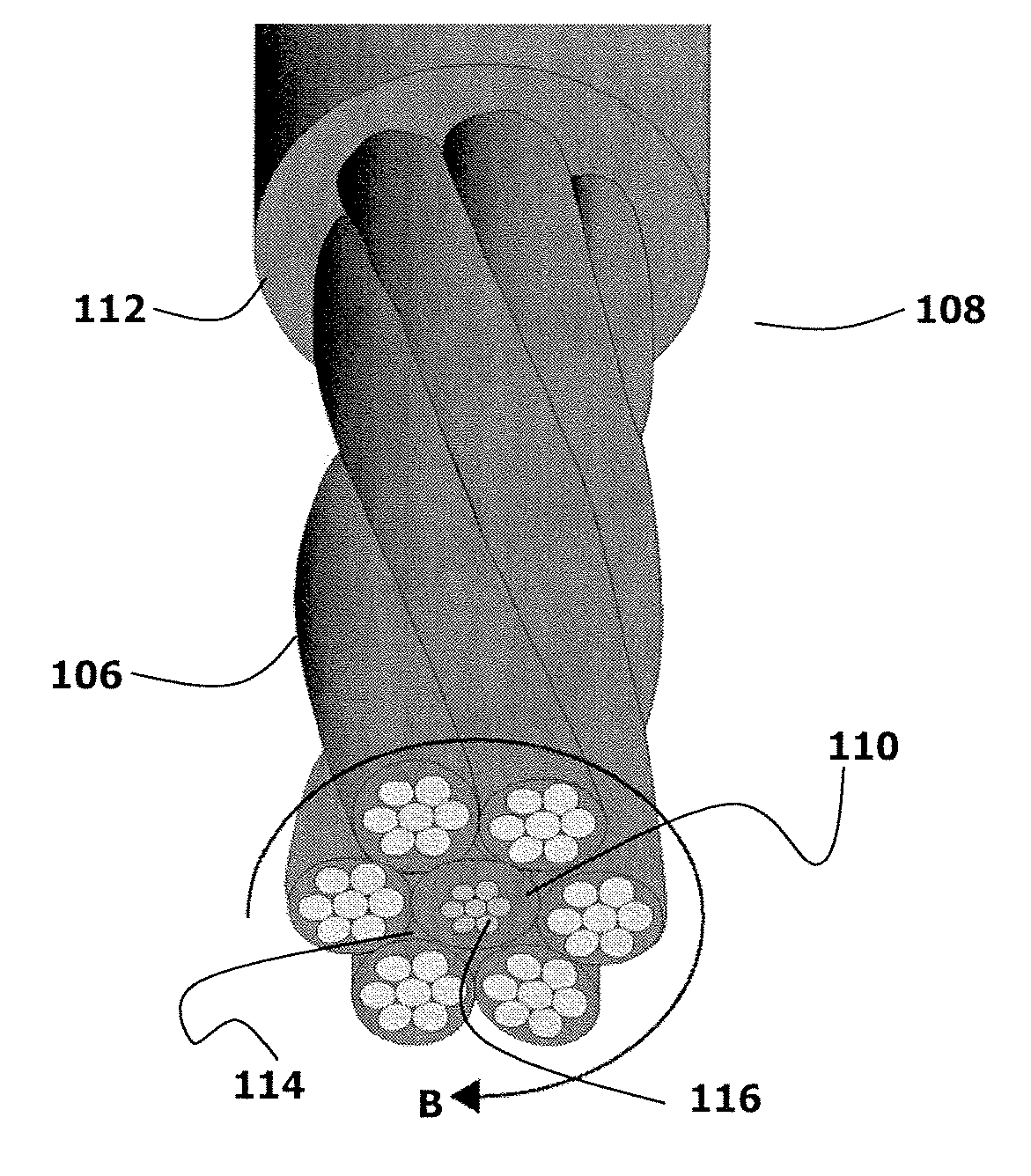

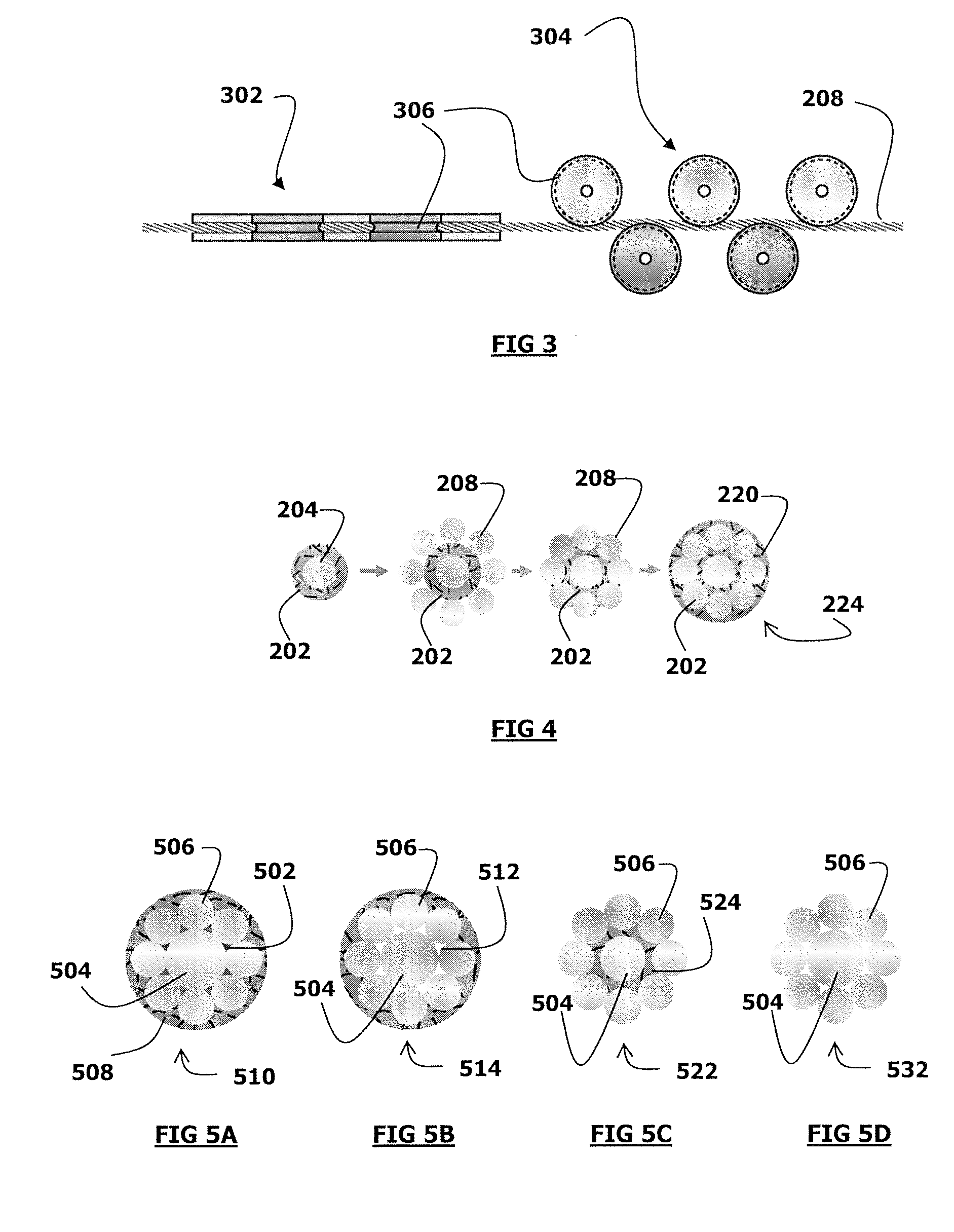

Automated assembly sensor cable

ActiveUS9697928B2High strengthPower cables with screens/conductive layersFlat/ribbon cablesElectrical conductorEngineering

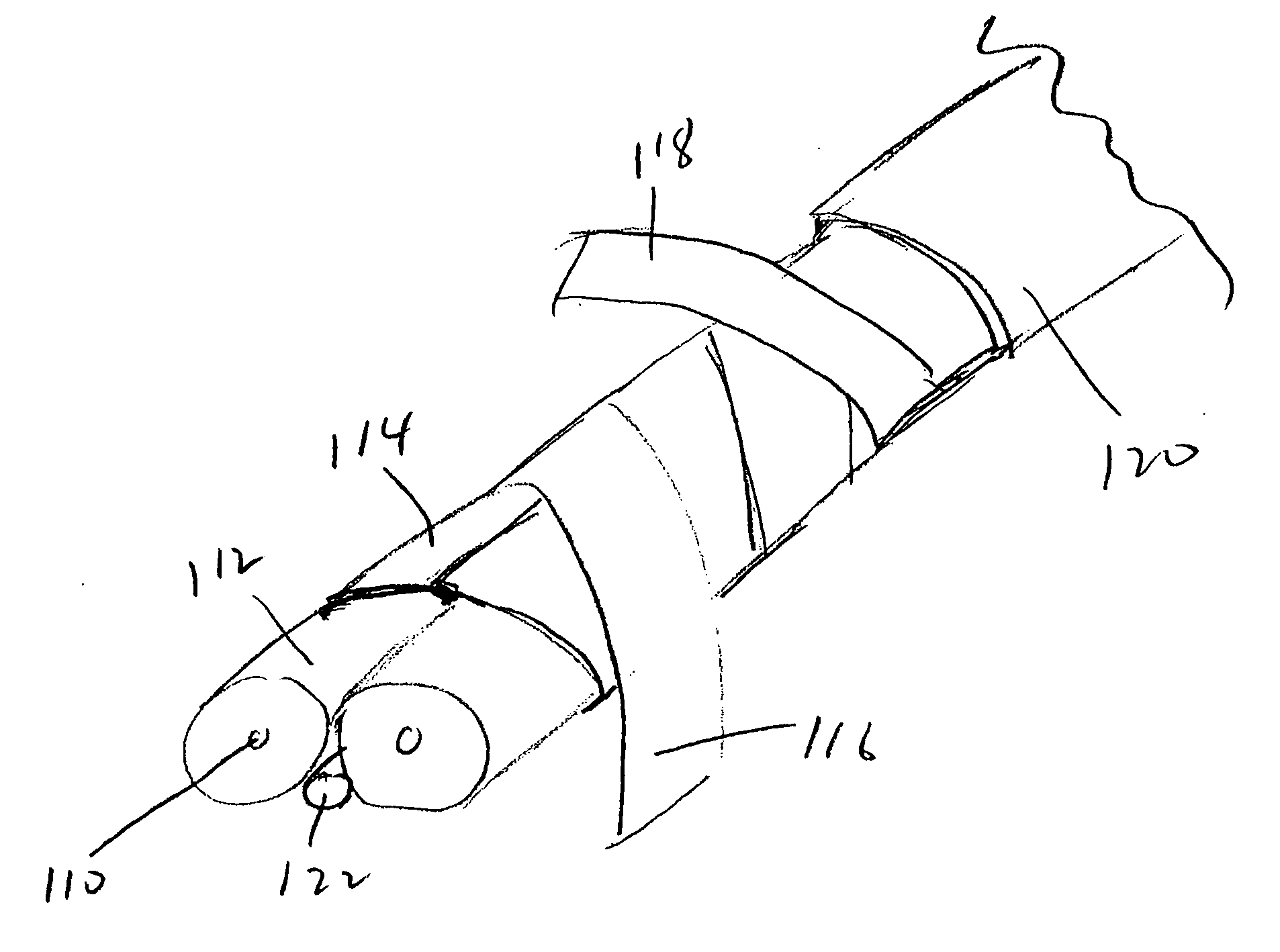

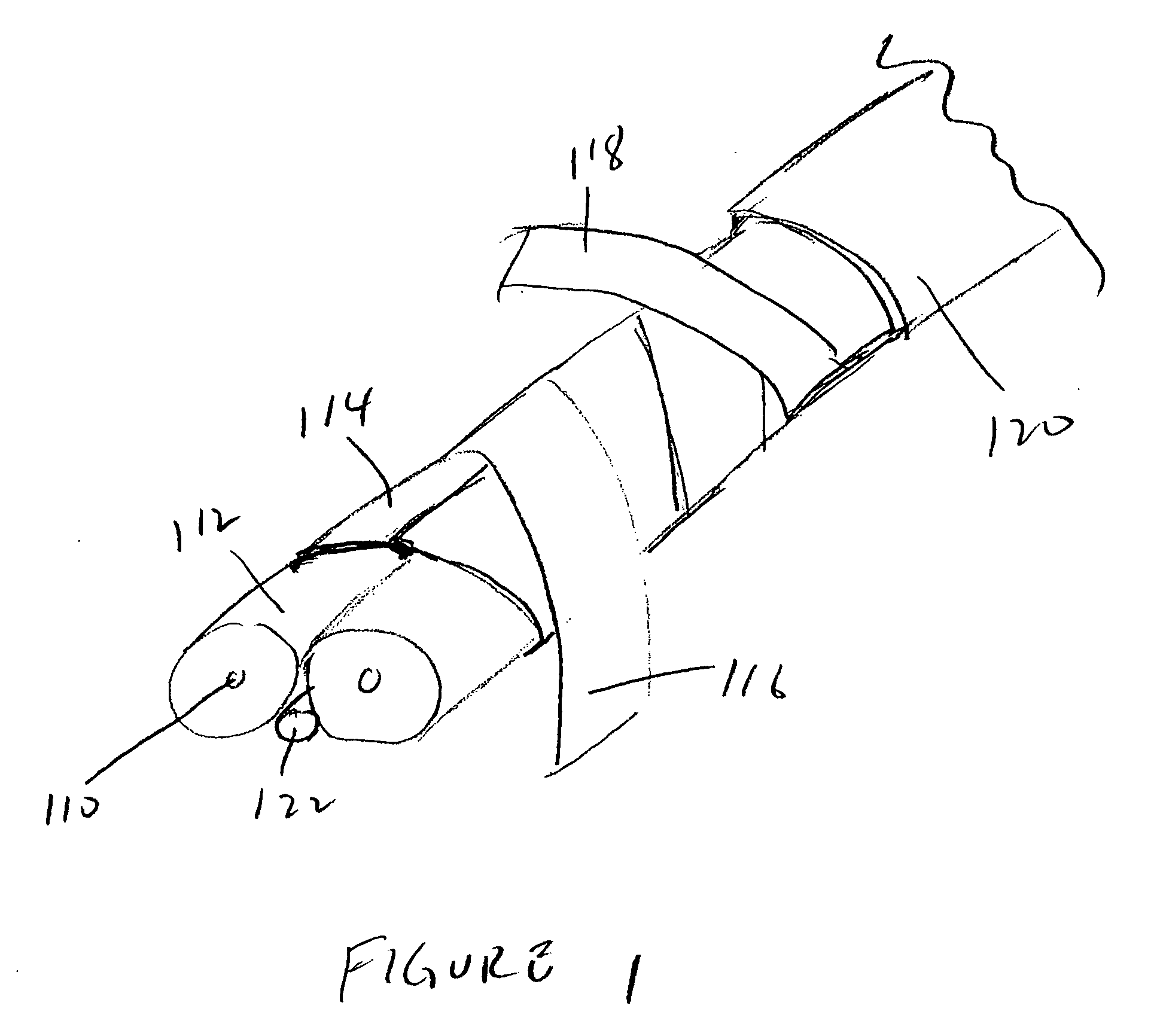

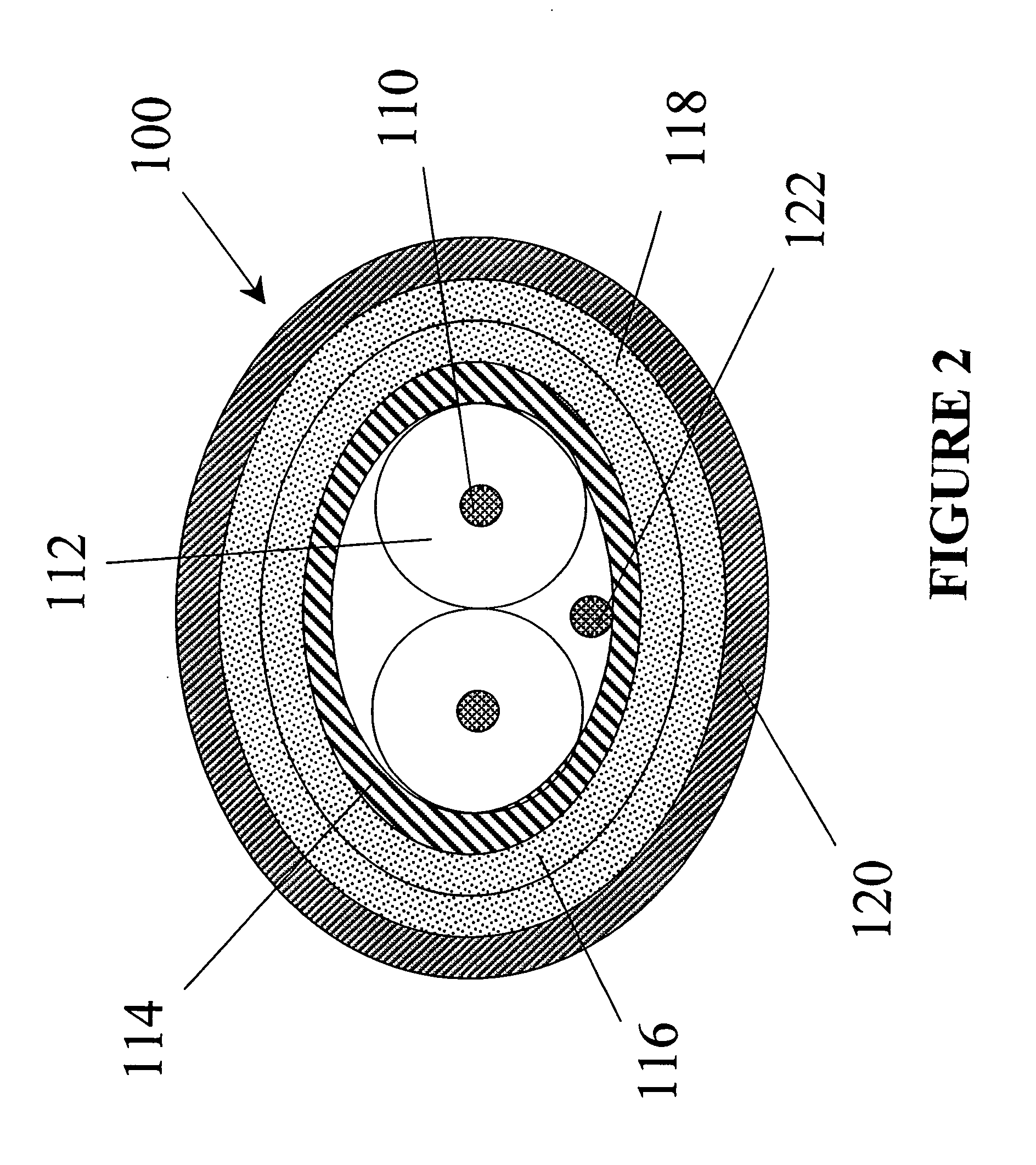

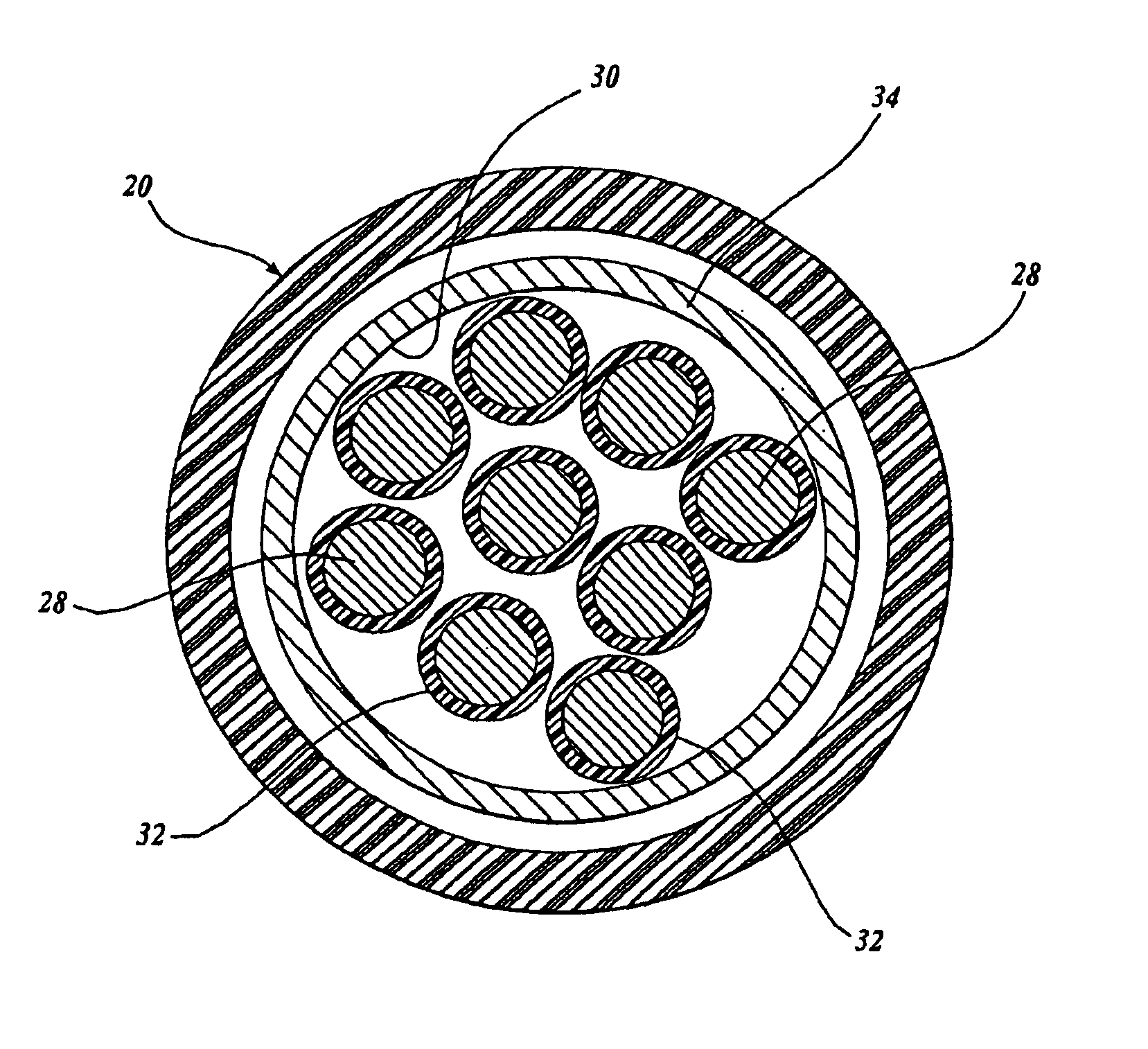

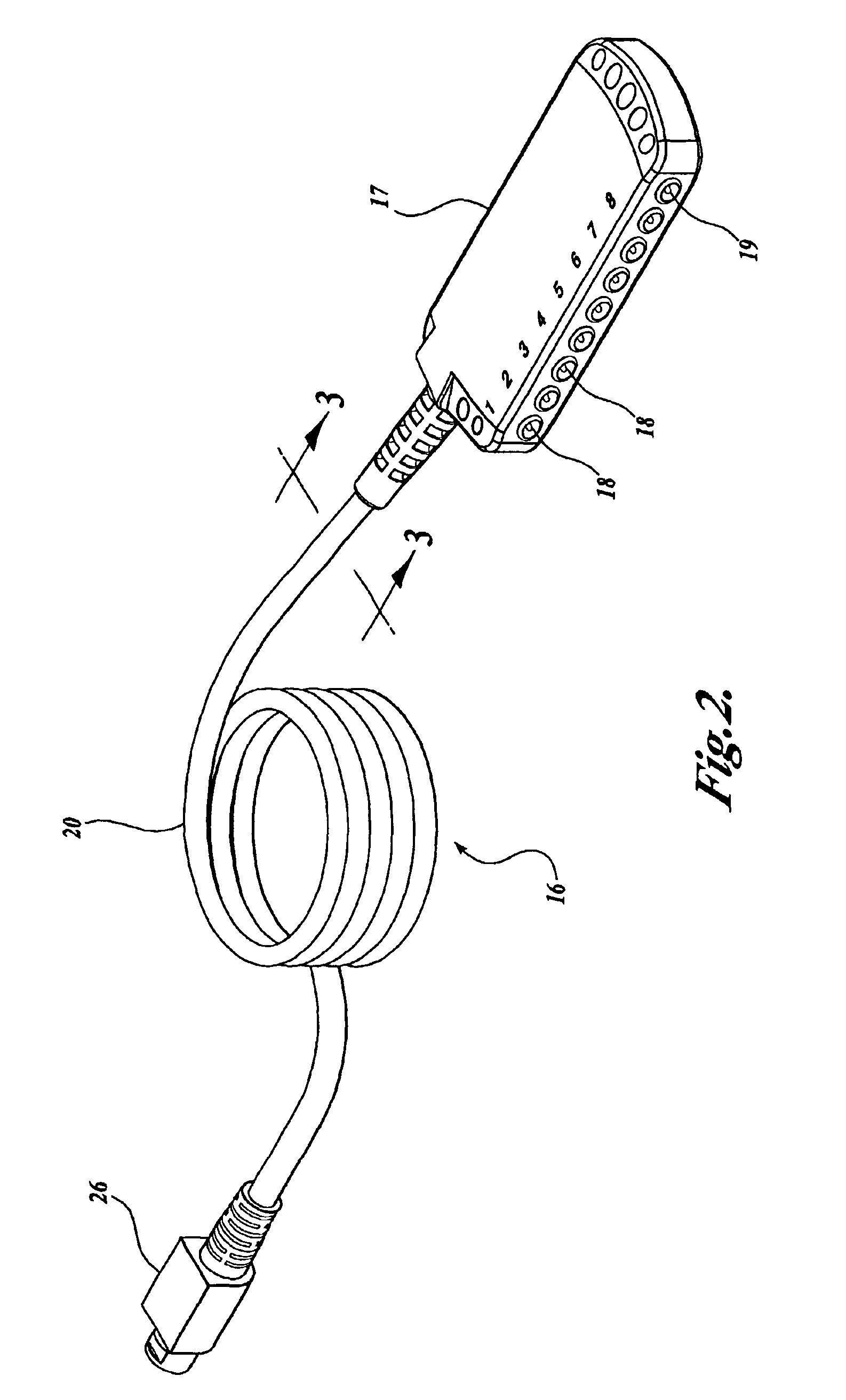

An automated assembly sensor cable has a generally wide and flat elongated body and a registration feature generally traversing the length of the body so as to identify the relative locations of conductors within the body. This cable configuration facilitates the automated attachment of the cable to an optical sensor circuit and corresponding connector. In various embodiments, the automated assembly sensor cable has a conductor set of insulated wires, a conductive inner jacket generally surrounding the conductor set, an outer jacket generally surrounding the inner jacket and a registration feature disposed along the surface of the outer jacket and a conductive drain line is embedded within the inner jacket. A strength member may be embedded within the inner jacket.

Owner:JPMORGAN CHASE BANK NA

Automated assembly sensor cable

ActiveUS20140034353A1High strengthLine/current collector detailsElectrically conductive connectionsElectrical conductorBiomedical engineering

An automated assembly sensor cable has a generally wide and flat elongated body and a registration feature generally traversing the length of the body so as to identify the relative locations of conductors within the body. This cable configuration facilitates the automated attachment of the cable to an optical sensor circuit and corresponding connector. In various embodiments, the automated assembly sensor cable has a conductor set of insulated wires, a conductive inner jacket generally surrounding the conductor set, an outer jacket generally surrounding the inner jacket and a registration feature disposed along the surface of the outer jacket and a conductive drain line is embedded within the inner jacket. A strength member may be embedded within the inner jacket.

Owner:JPMORGAN CHASE BANK NA

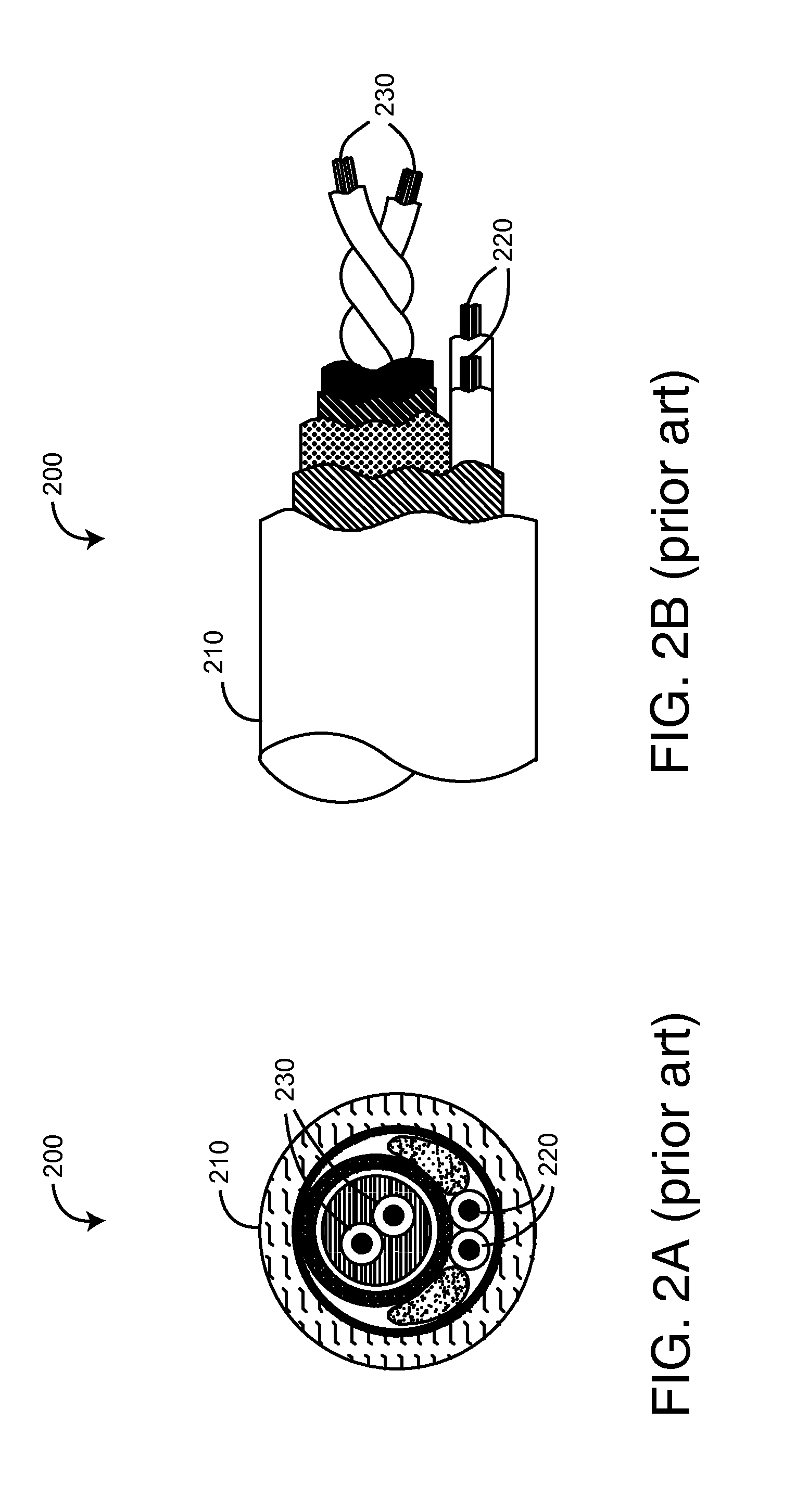

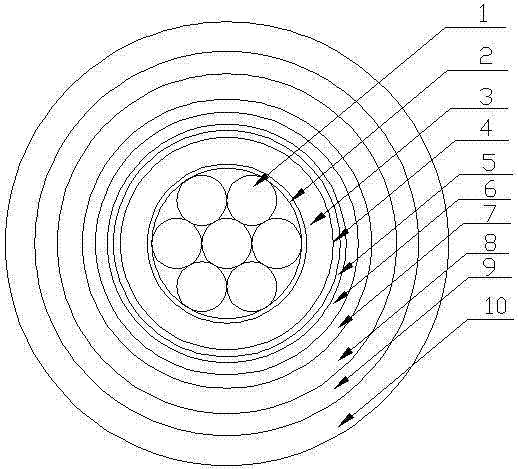

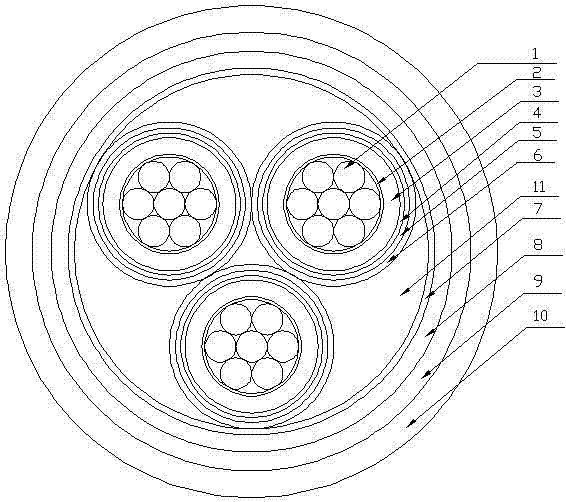

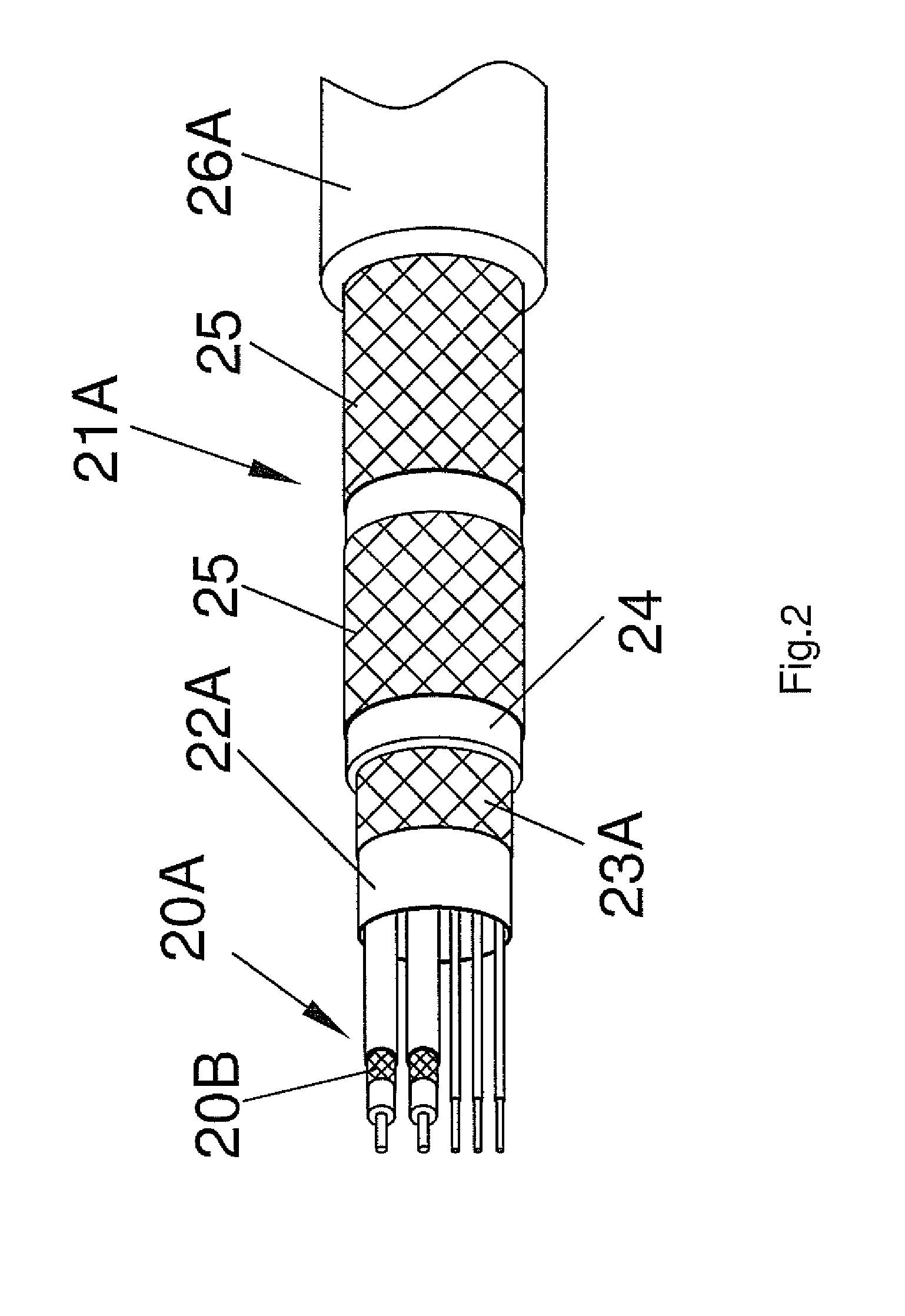

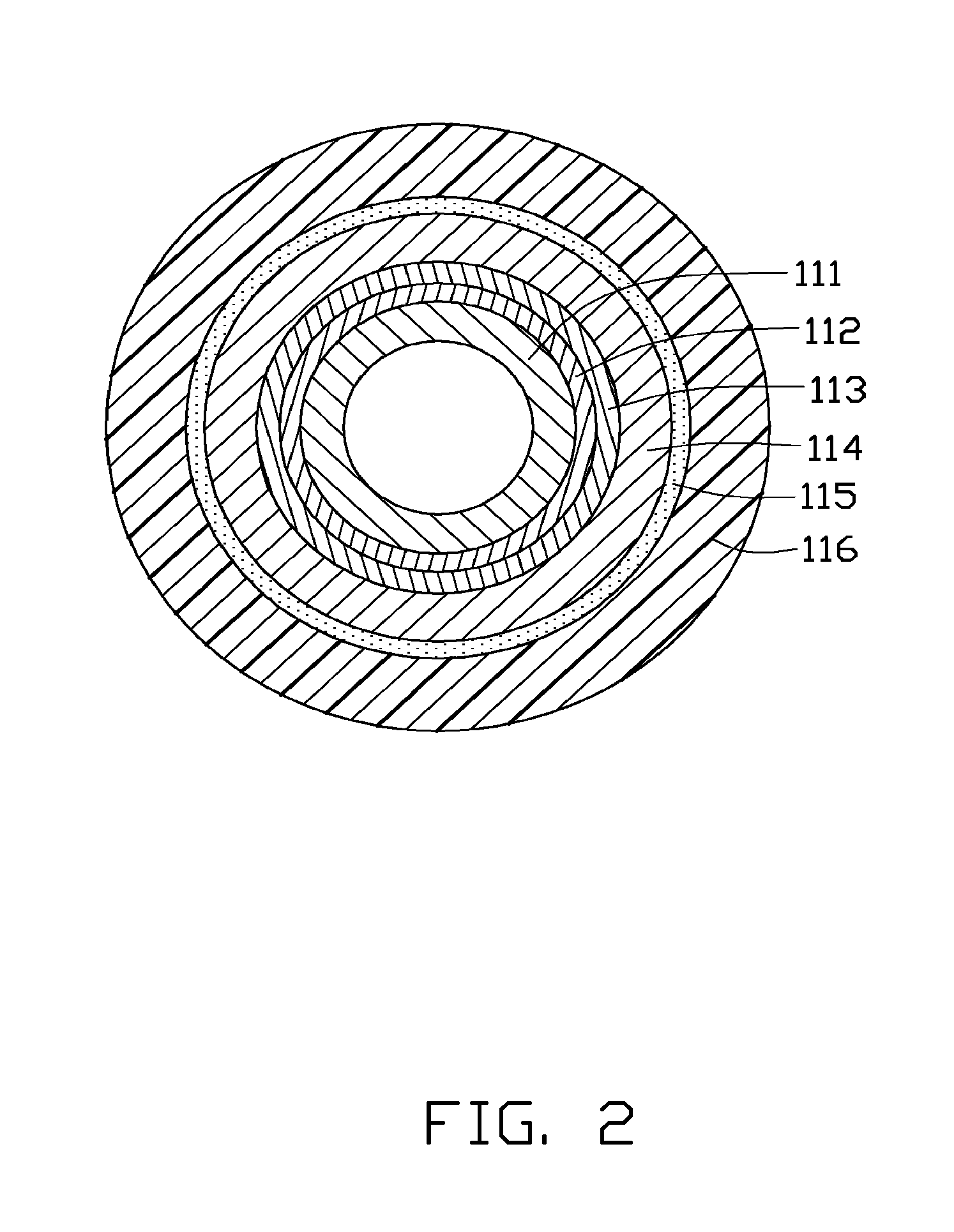

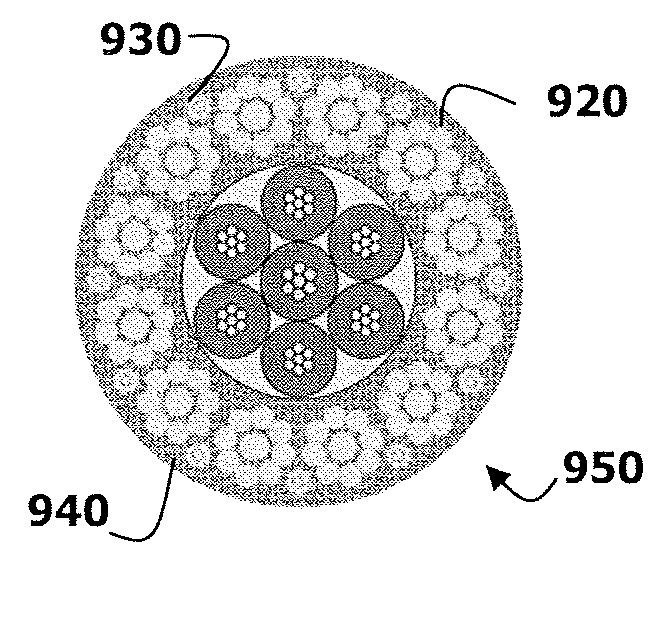

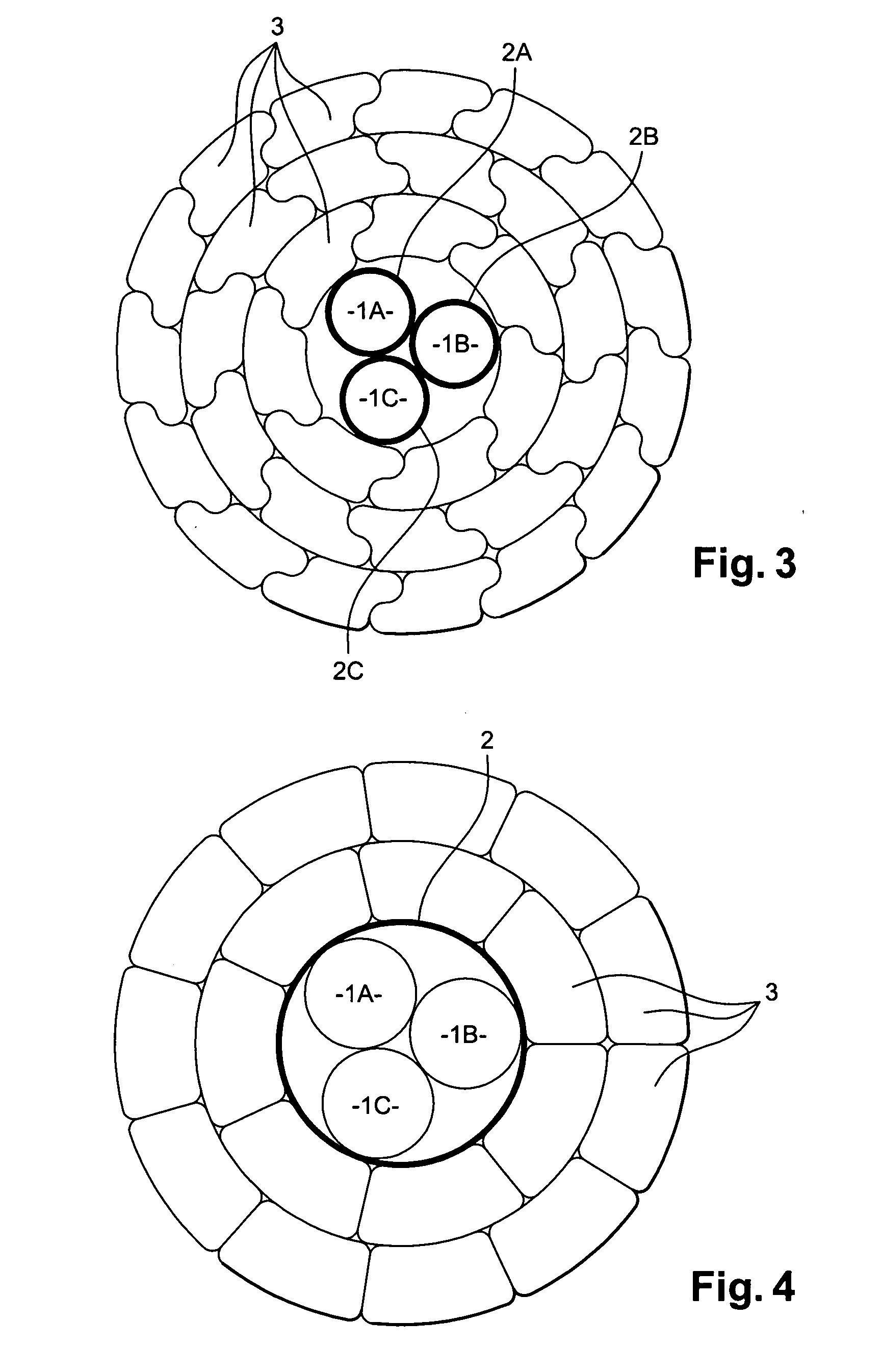

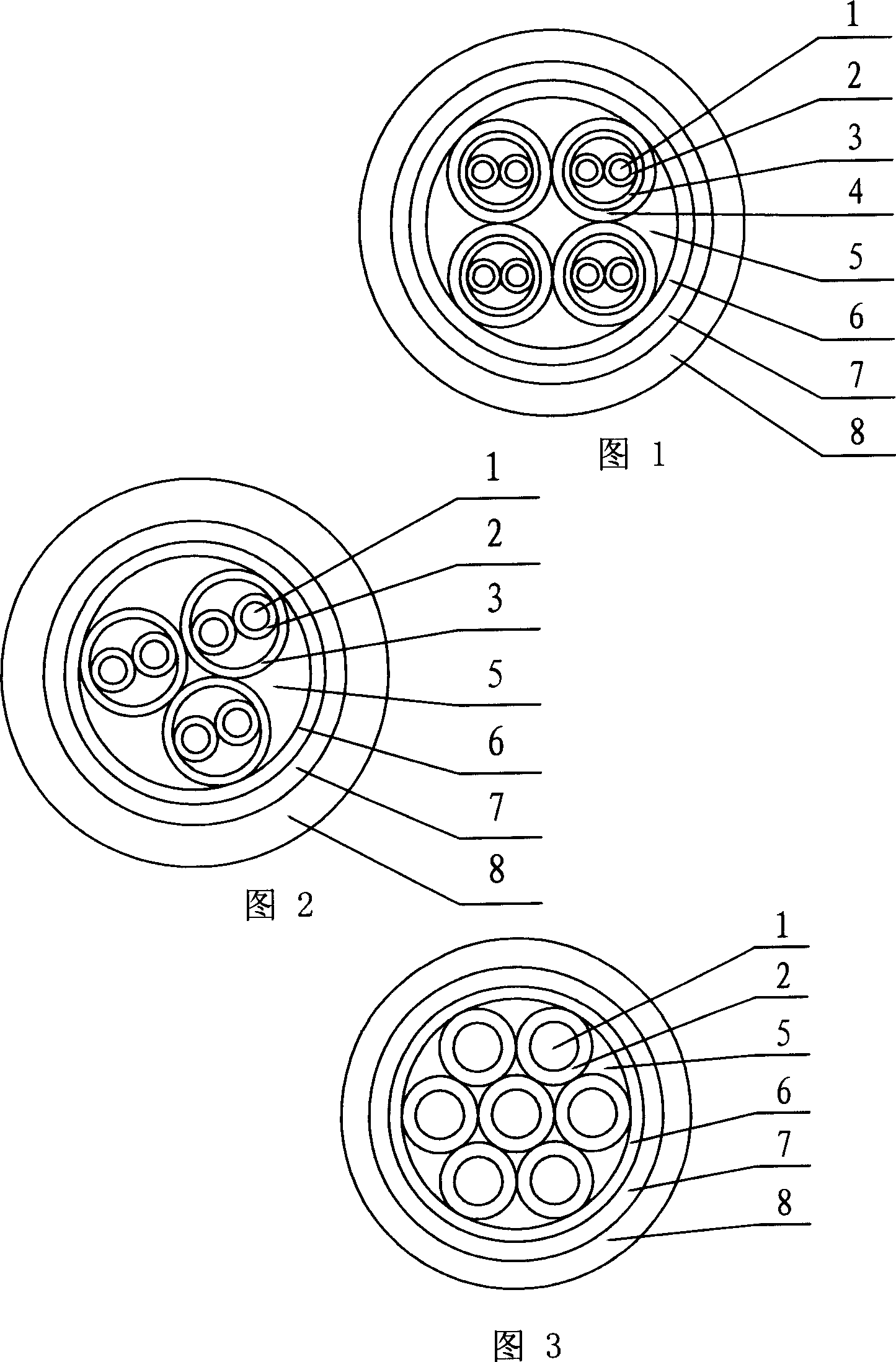

Water-blocking medium voltage aluminum alloy power cable

InactiveCN103700442AWith water blocking functionGood vertical water resistanceClimate change adaptationPower cables with screens/conductive layersElectrical conductorMemory effect

The invention discloses a water-blocking medium voltage aluminum alloy power cable which comprises an insulating cable core and an outer wrapping layer, wherein one or more insulating cable cores are provided; the insulating cable core is wrapped by the outer wrapping layer so as to form the water-blocking medium voltage aluminum alloy power cable. The cable is characterized in that each insulating cable core comprises an inner aluminum alloy conductor core (1), an inner shielding layer (2), an insulating layer (3), an outer shielding layer (4), a semiconductor resistor water-blocking zone (5) and a seamless metal sleeve (6) from inside to outside in sequence; the outer wrapping layer comprises a winding and wrapping layer (7), an inner protective layer (8), an armored layer (9) and an outer protective layer (10) from inside to outside The aluminum alloy power cable disclosed by the invention is made of an aluminum alloy material, the inner aluminum alloy conductor core is high in yield strength, small in resilience value, free of memory effect and easy to install, and compared with a copper core cable of the same mass, the cable is small in resistance, and the cost of the alloy material is smaller than that of copper.

Owner:江苏南瑞淮胜电缆有限公司 +1

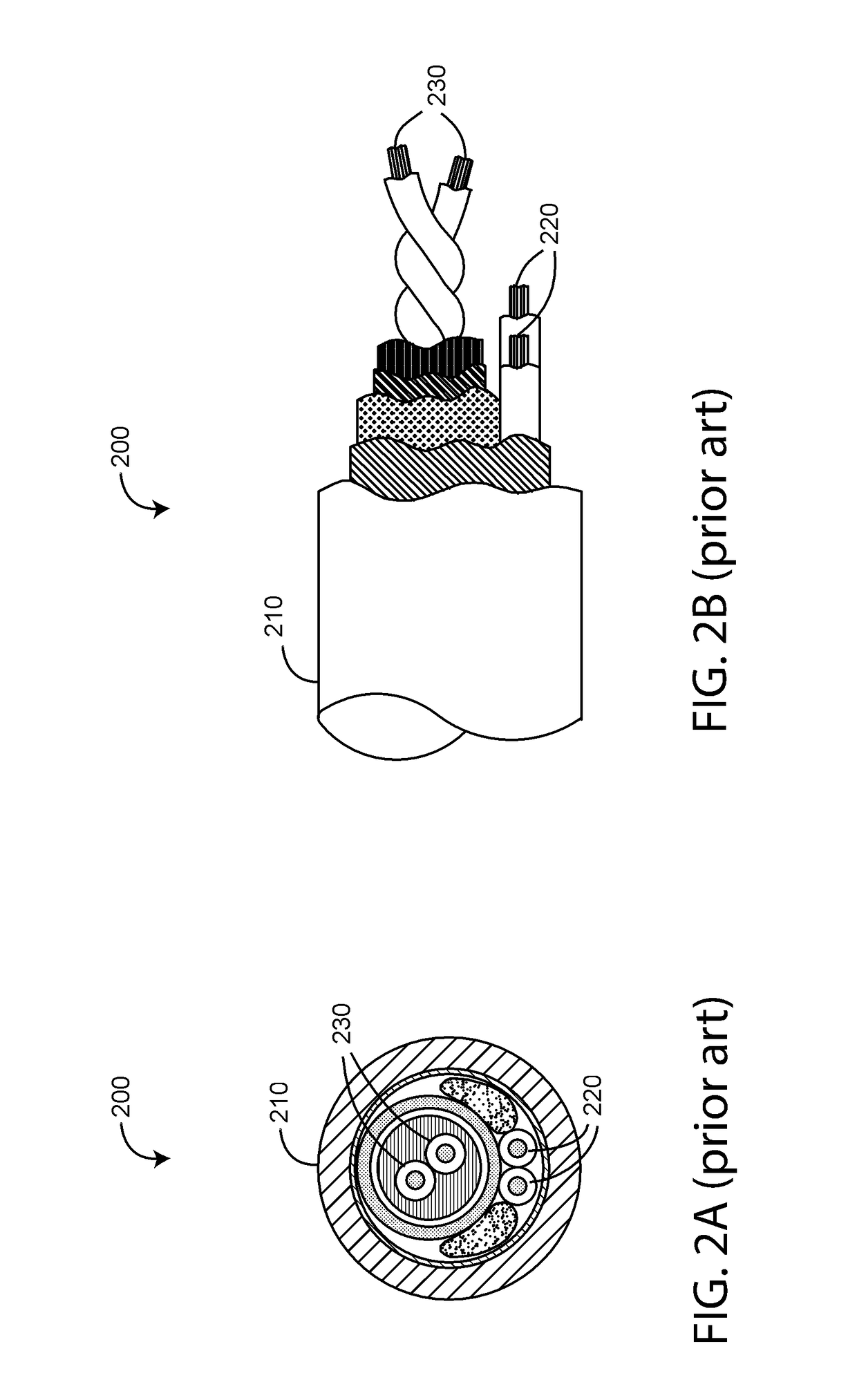

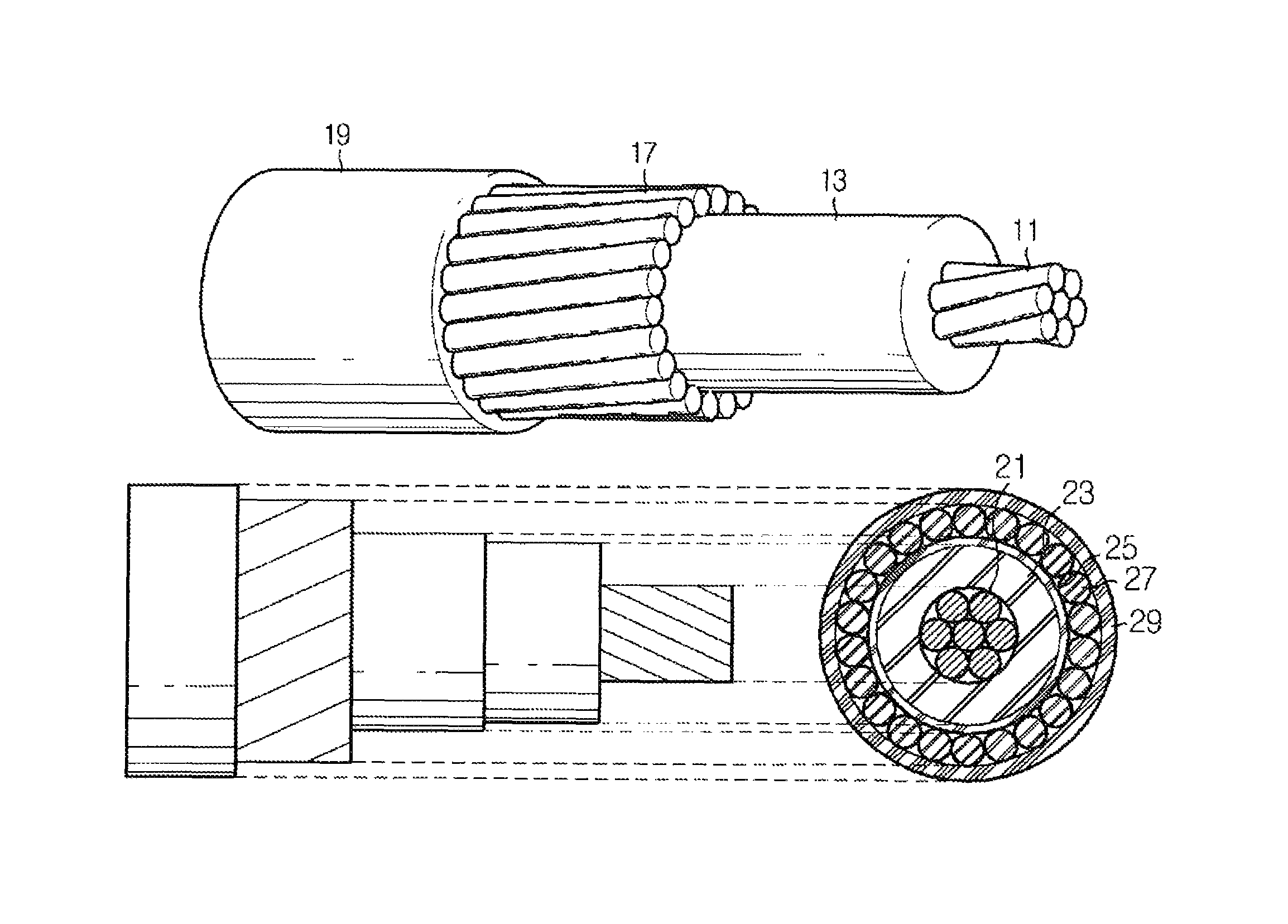

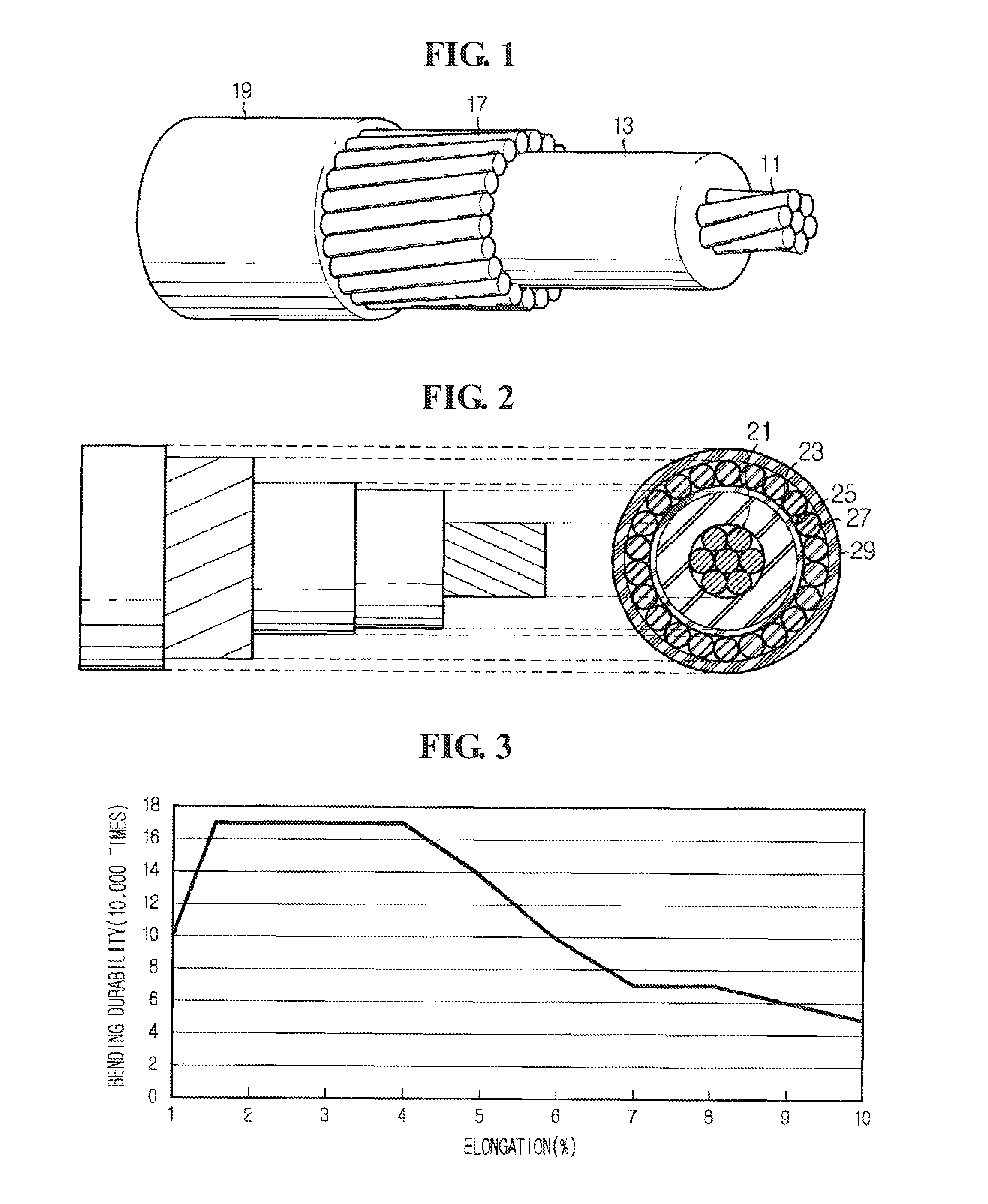

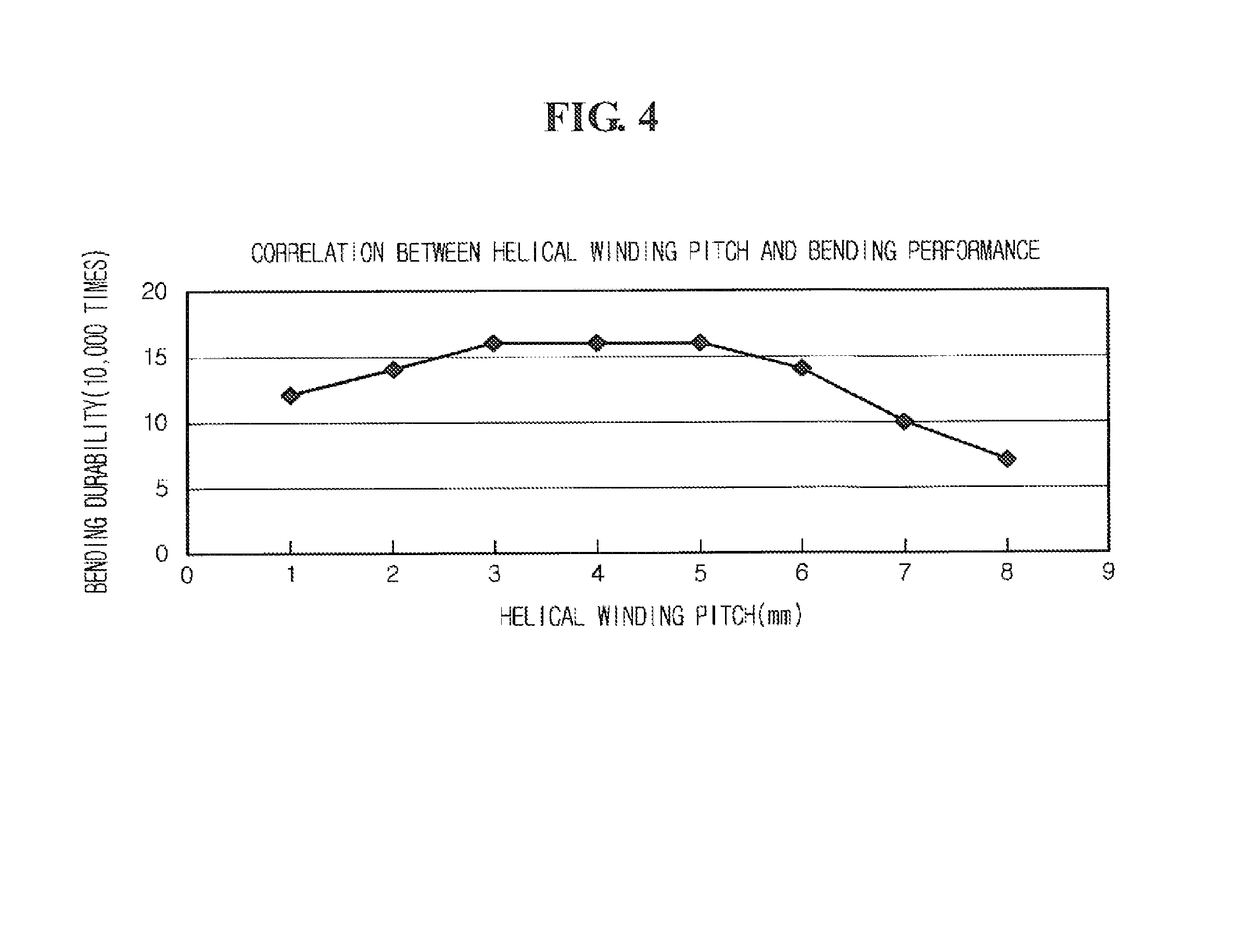

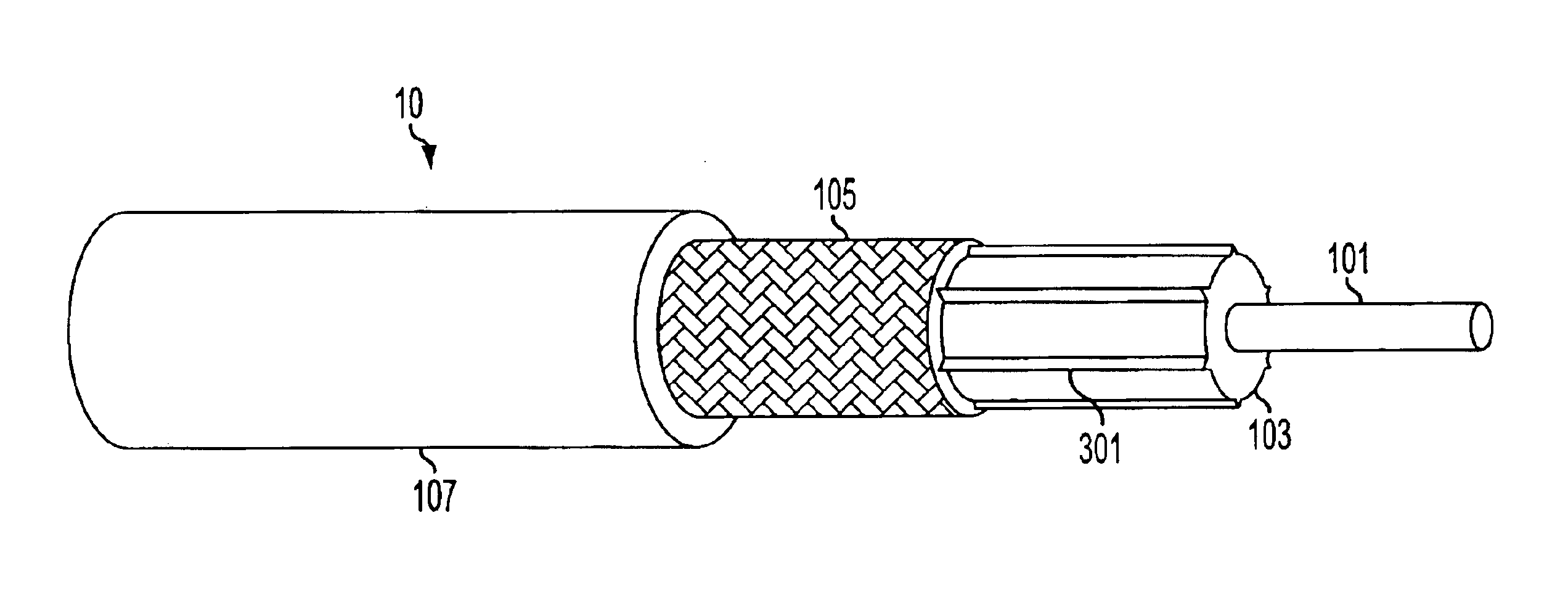

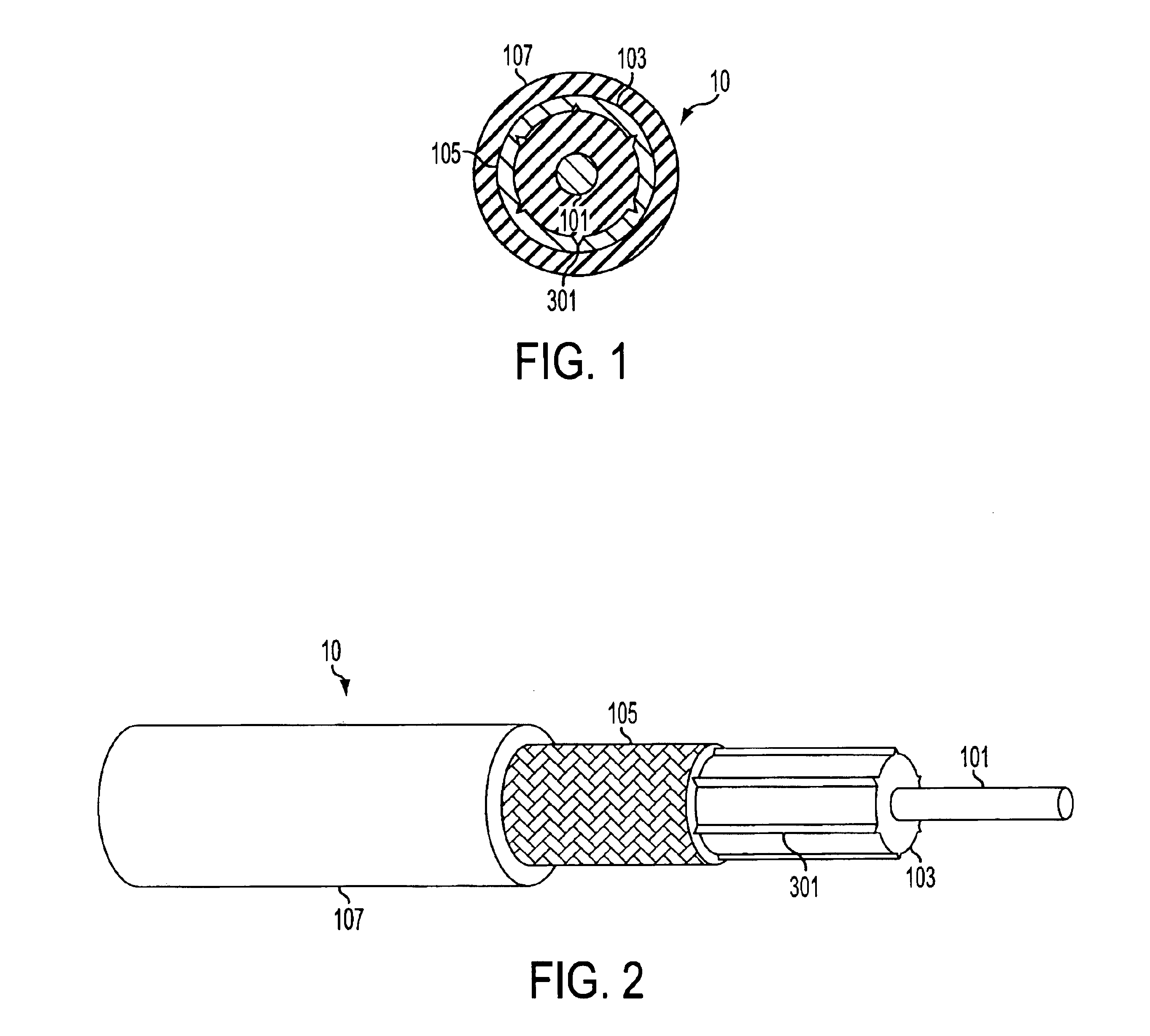

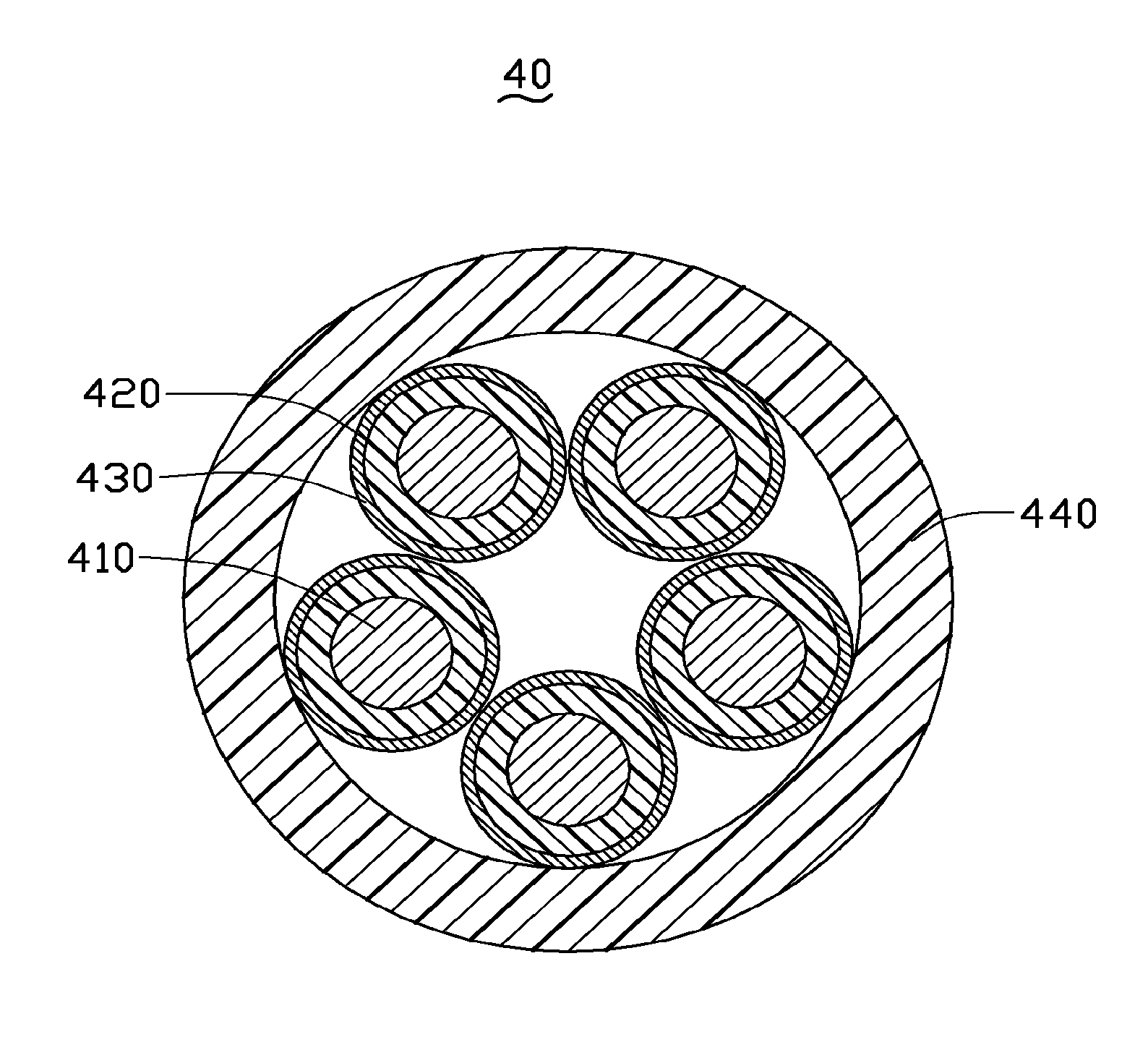

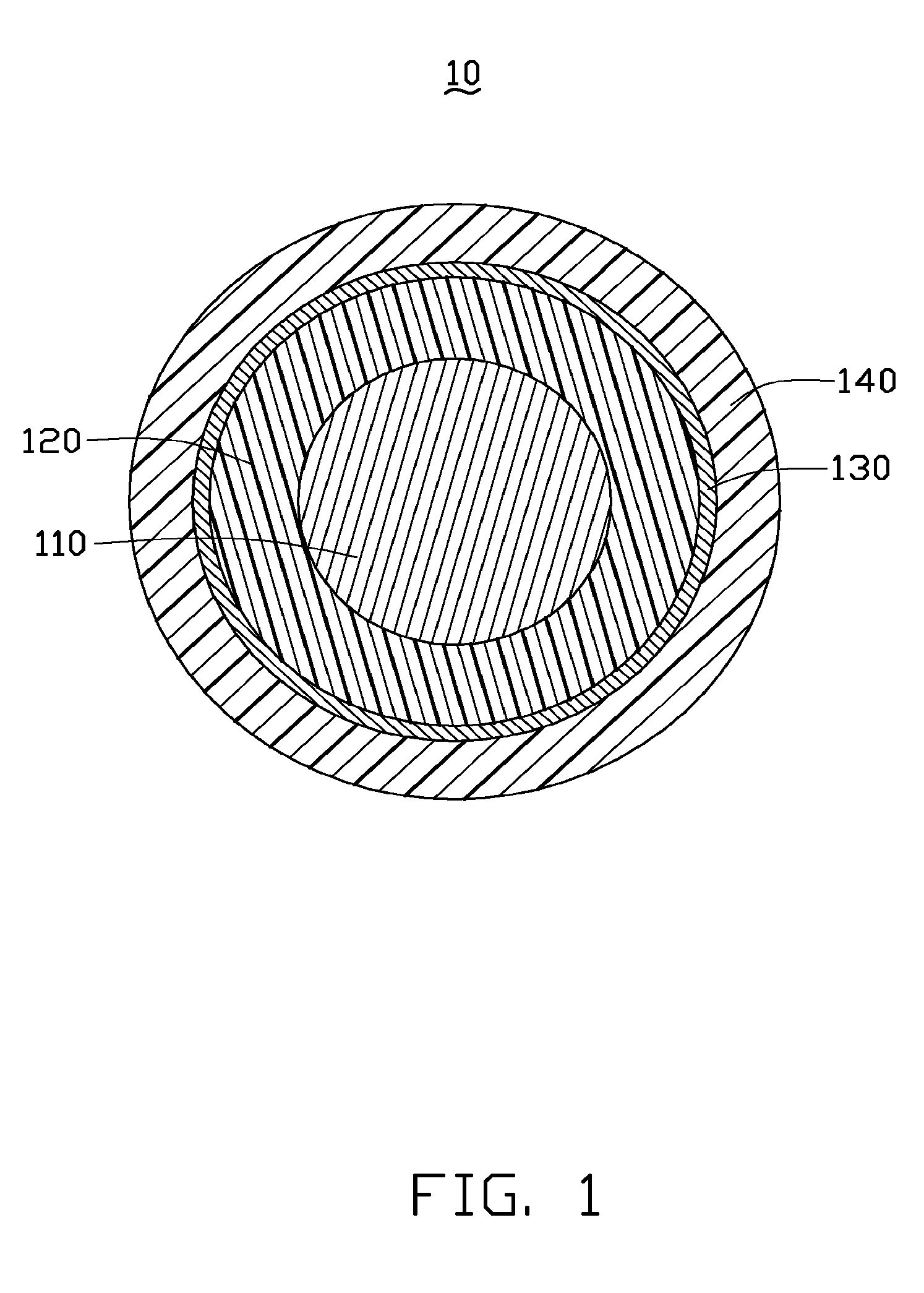

Micro coaxial cable for high bending performance

ActiveUS8242358B2Improve bending performanceLong-term reliabilityCable conductor constructionPower cables with screens/conductive layersElectrical conductorCoaxial cable

A micro coaxial cable with a high bending performance, having an inner conductor; an insulating layer configured to surround the inner conductor, and a helical winding conductor configured to surround the insulating layer and having an elongation of 1.5 to 4% and a pitch of 3.0 to 5.0 mm.

Owner:HITACHI METALS LTD

Shielded parallel cable

ActiveUS20060054334A1Low insertion loss performanceLower performance requirementsPower cables with screens/conductive layersInsulated cablesMetal formingContact pad

The cable of the present invention contains at least one pair of insulated conductors and an optional drain wire. The insulate conductors and drain wire is longitudinally covered in a shielding tape, which preferably comprises a metallic sheet having an adhesive applied on selected portions of a surface of the metallic sheet. The adhesive is preferably applied in a checker board pattern so that the surface having adhesive thereon contains areas of uncoated, exposed metal forming contact pads. The shielding tape is then covered with two layers of polymeric tapes in opposite helical directions. The polymeric tape is preferably constructed of a polymeric sheet having a layer of adhesive disposed on a surface thereof. In a preferred embodiment, the tapes are wrapped around the shielding tape in opposite directions such that the adhesive surfaces face each other. The tapes are then optionally covered with a jacket.

Owner:AMPHENOL CORP

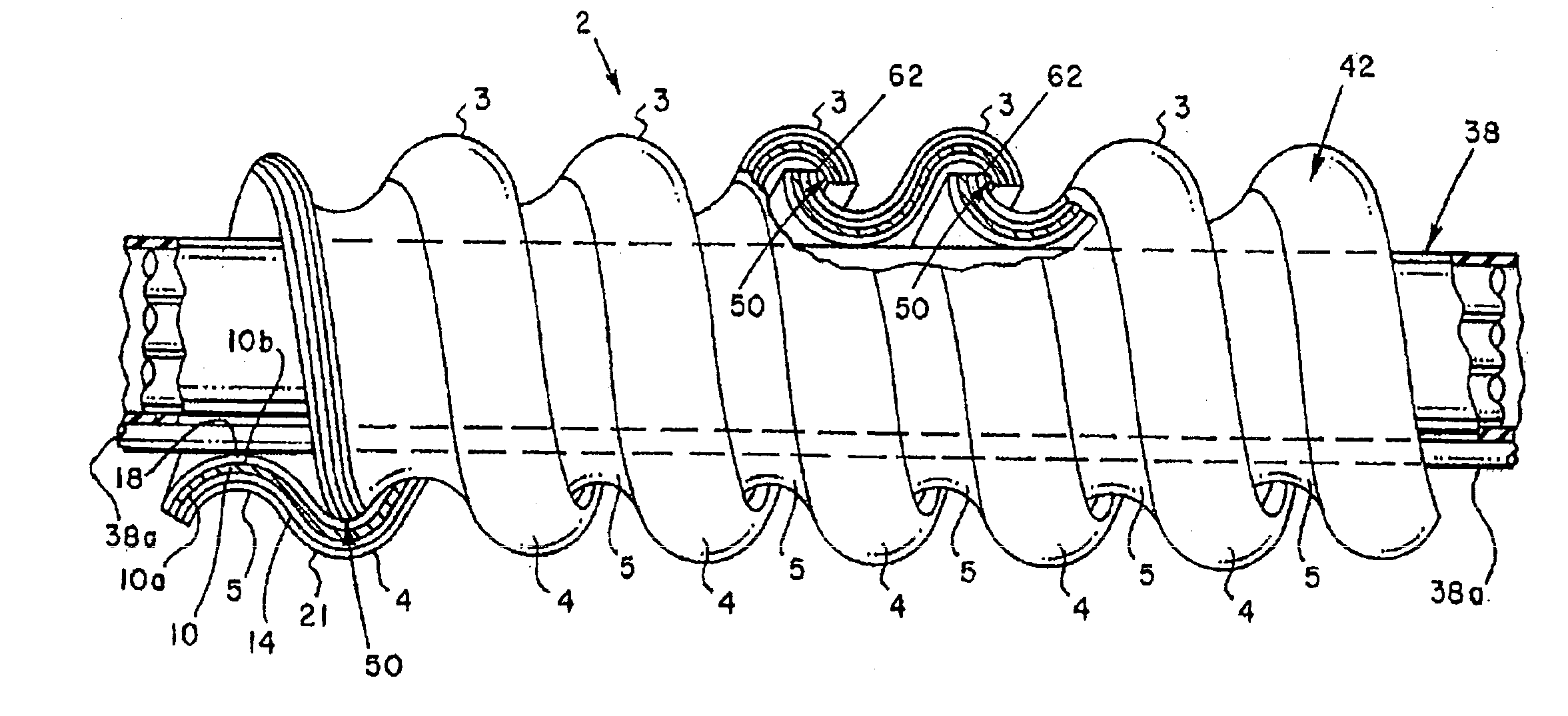

Fiber optic well logging cable

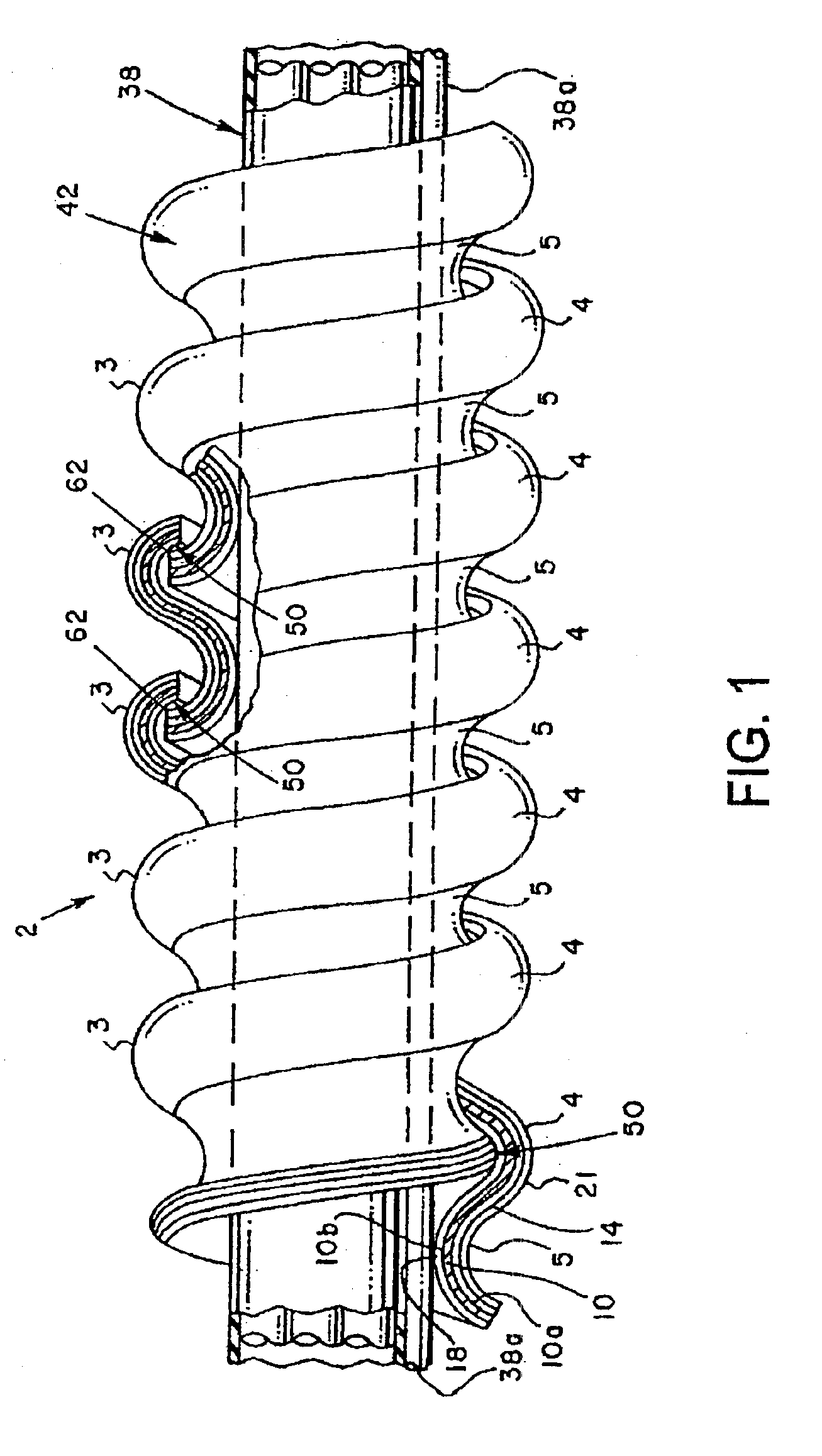

A well logging cable including an optical fiber and a pressure sealed enclosure surrounding the fiber. The enclosure is adapted to be able to be elongated to the maximum expected axial strain on the logging cable without permanent deformation. In one embodiment, the enclosure is a corrugated-wall tube surrounding the optical fiber. The tube contains toroidally shaped rings within the maximum diameter portions of the corrugations in the tube wall. The cable includes armor wires wound around the corrugated-wall tube. In the preferred embodiment, the tube is surrounded by an elastomeric jacket, and is filled with hydraulic oil or the like to prevent entry of wellbore fluids into the tube under hydrostatic pressure.

Owner:WESTERN ATLAS INTERNAIONAL INC

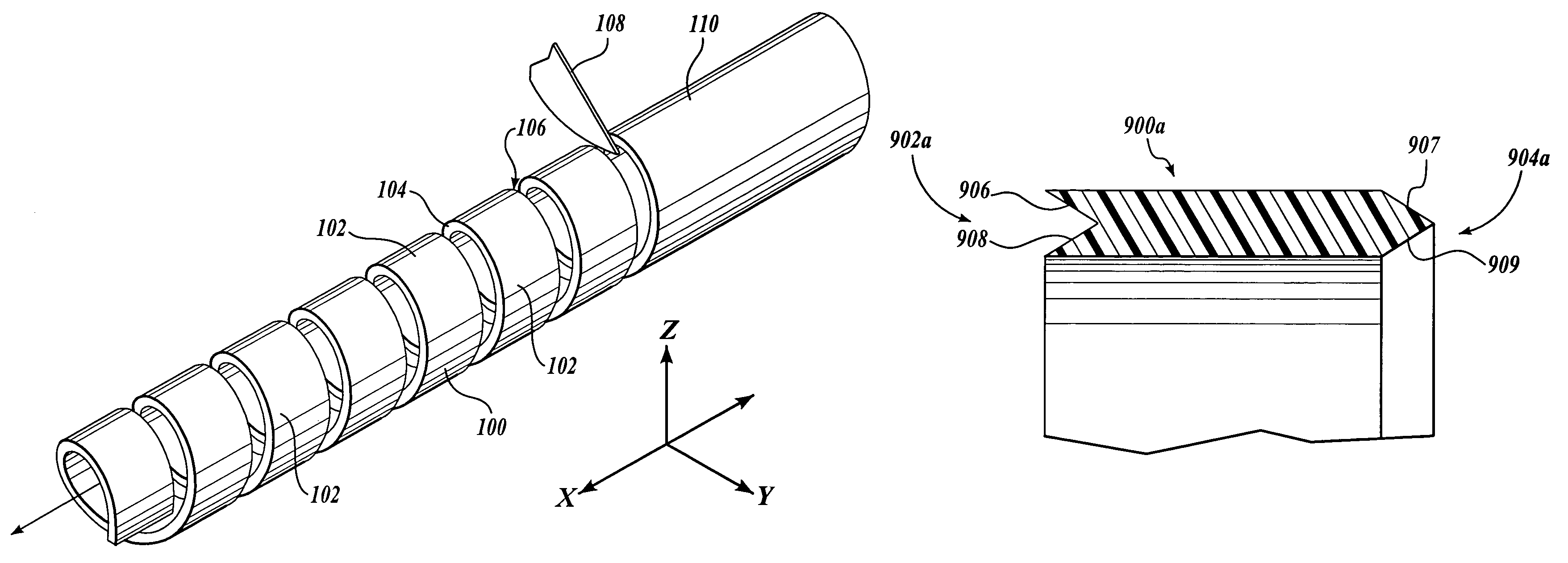

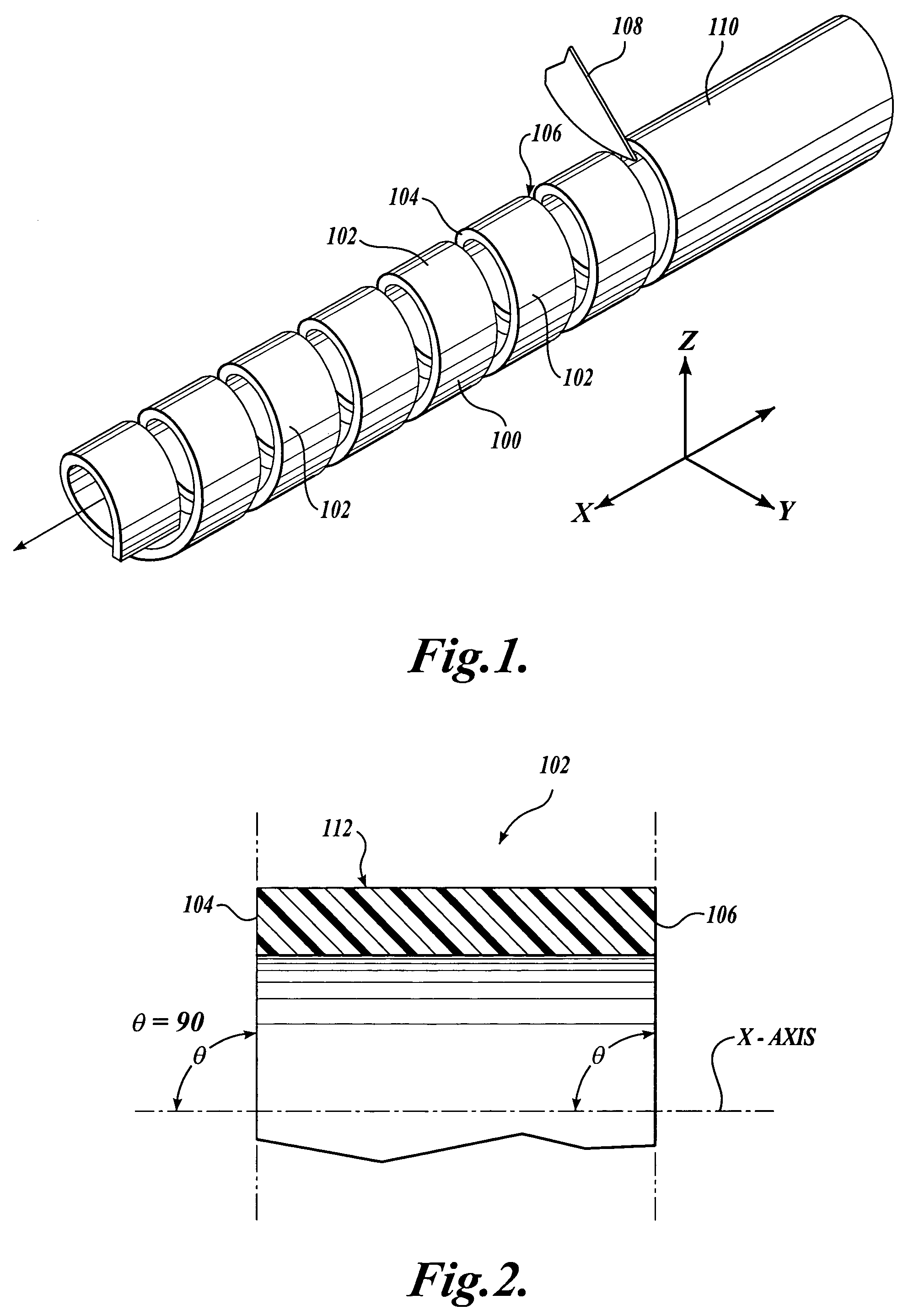

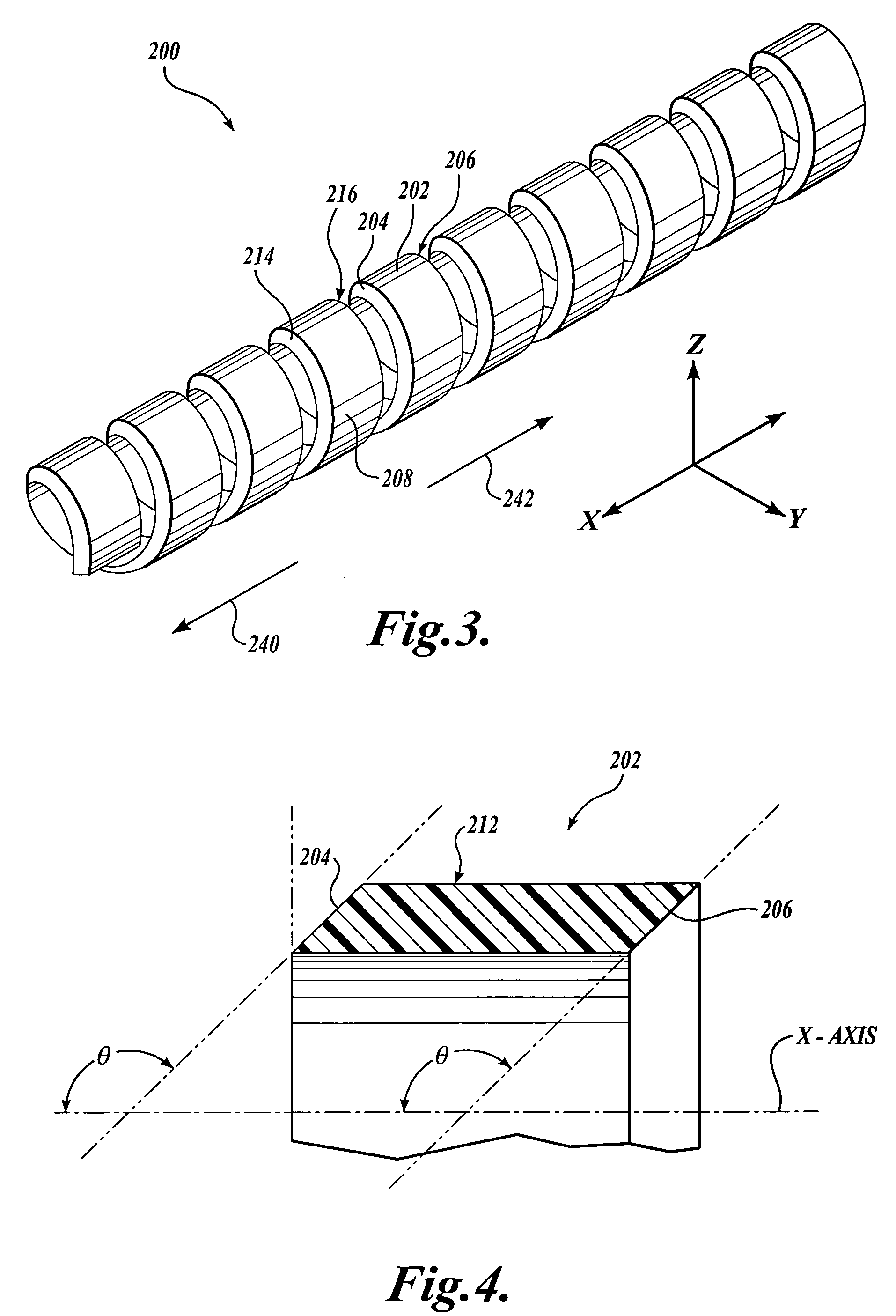

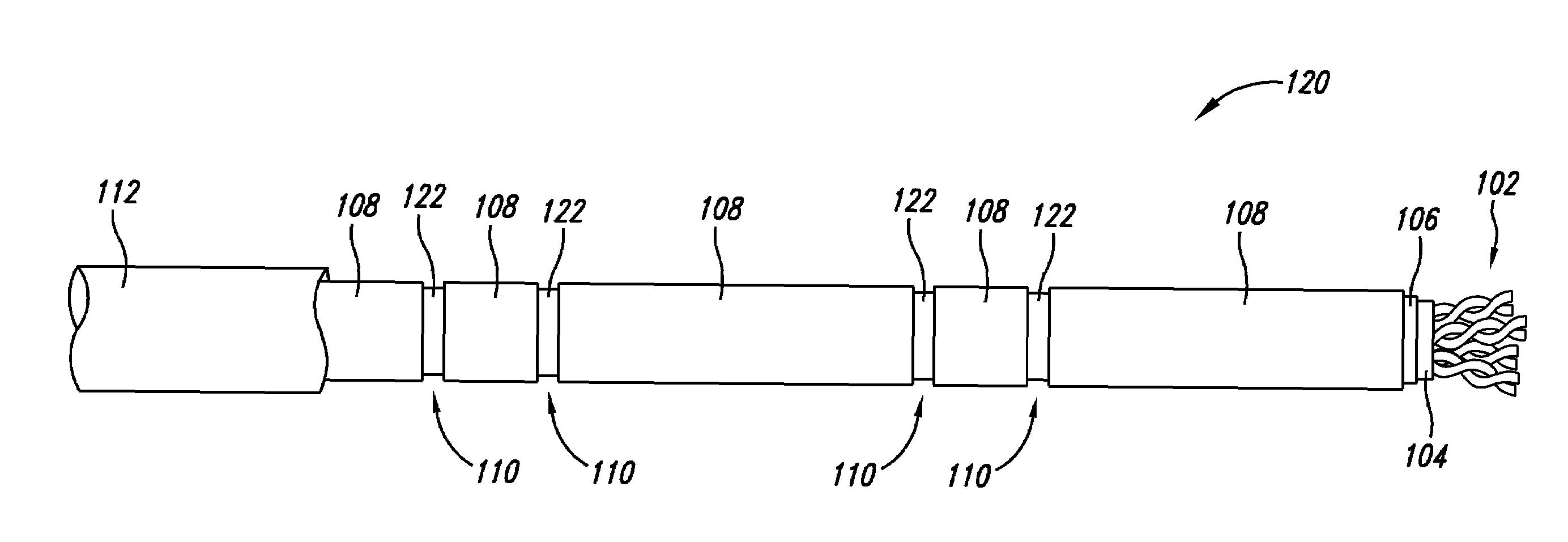

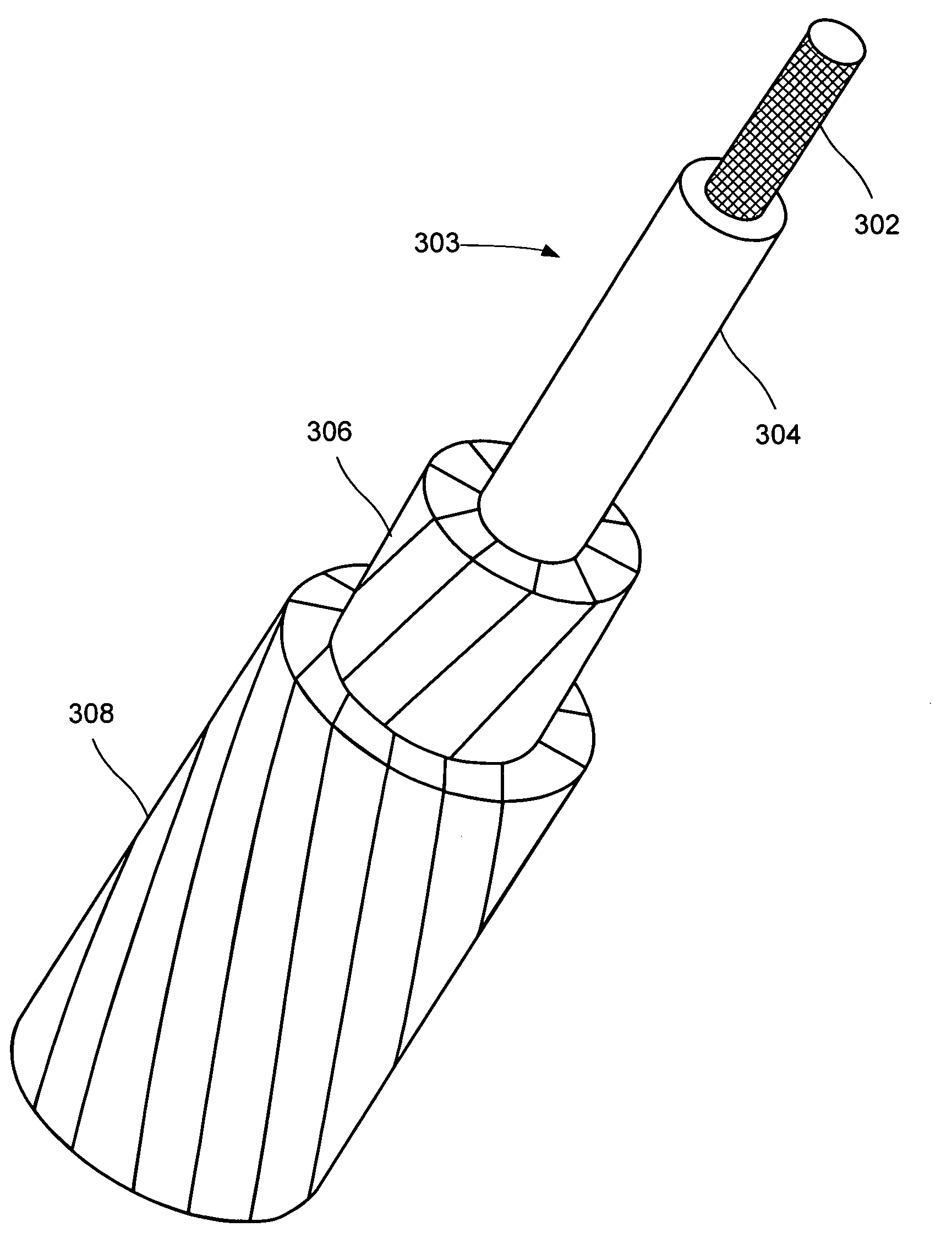

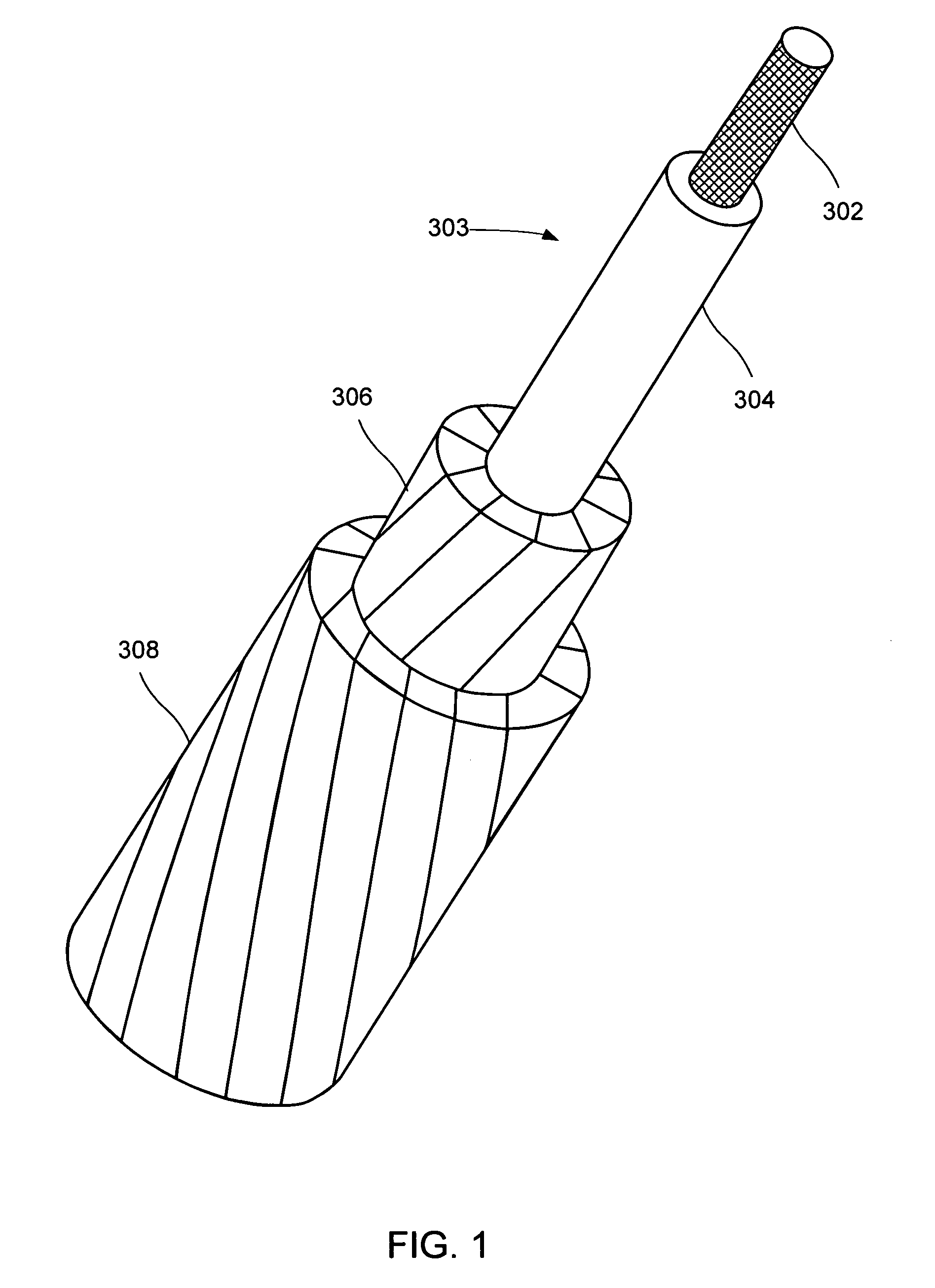

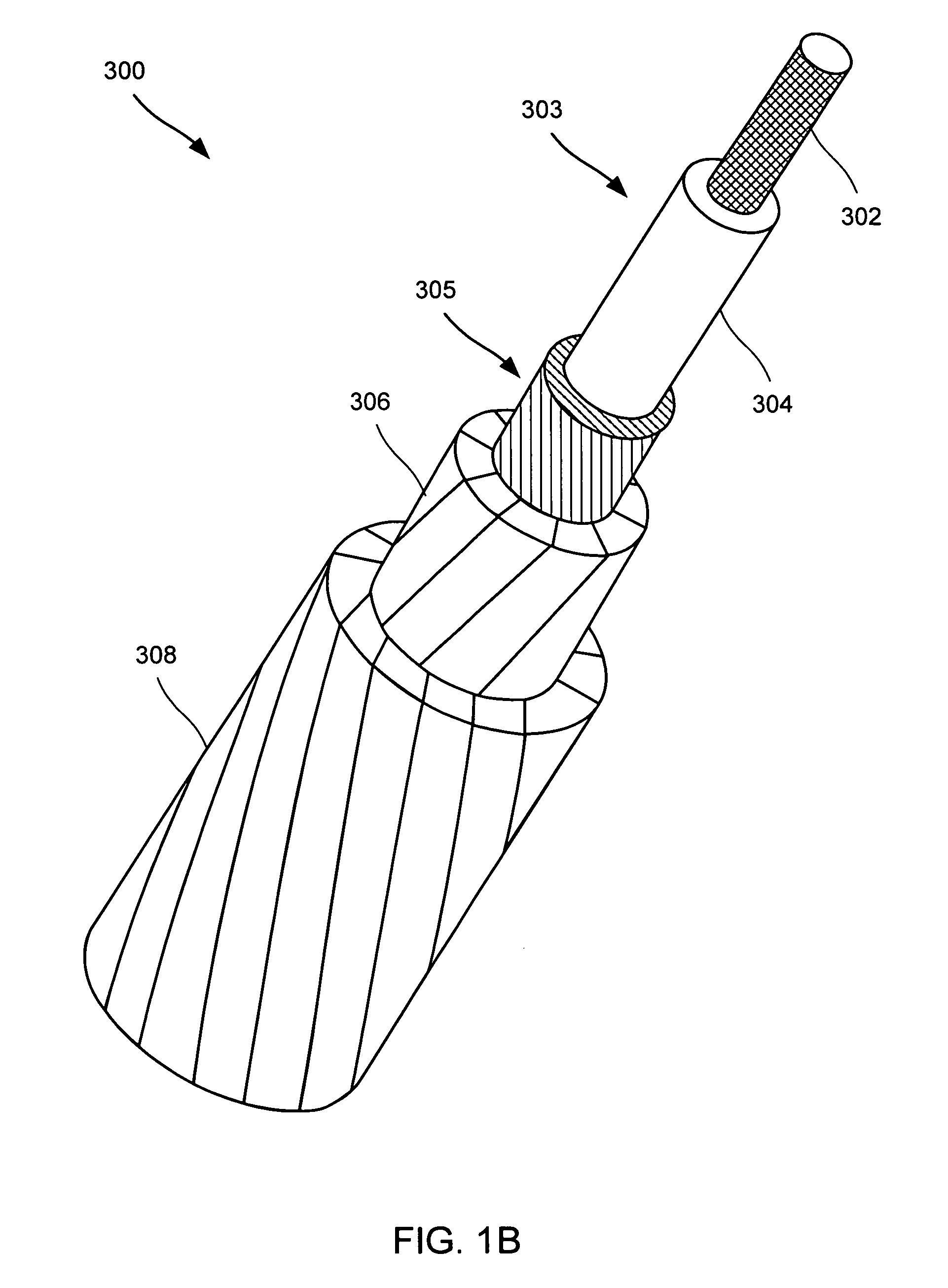

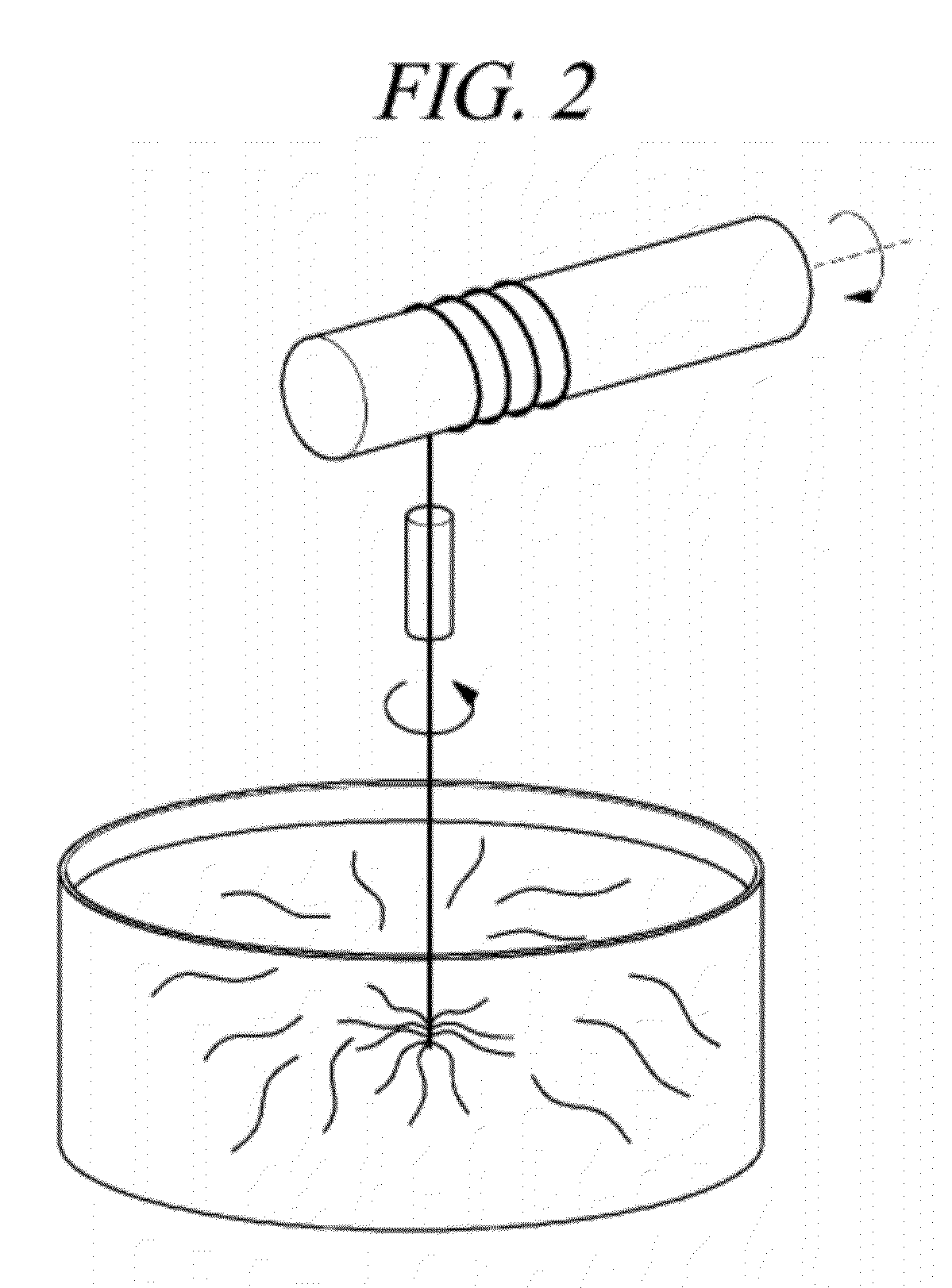

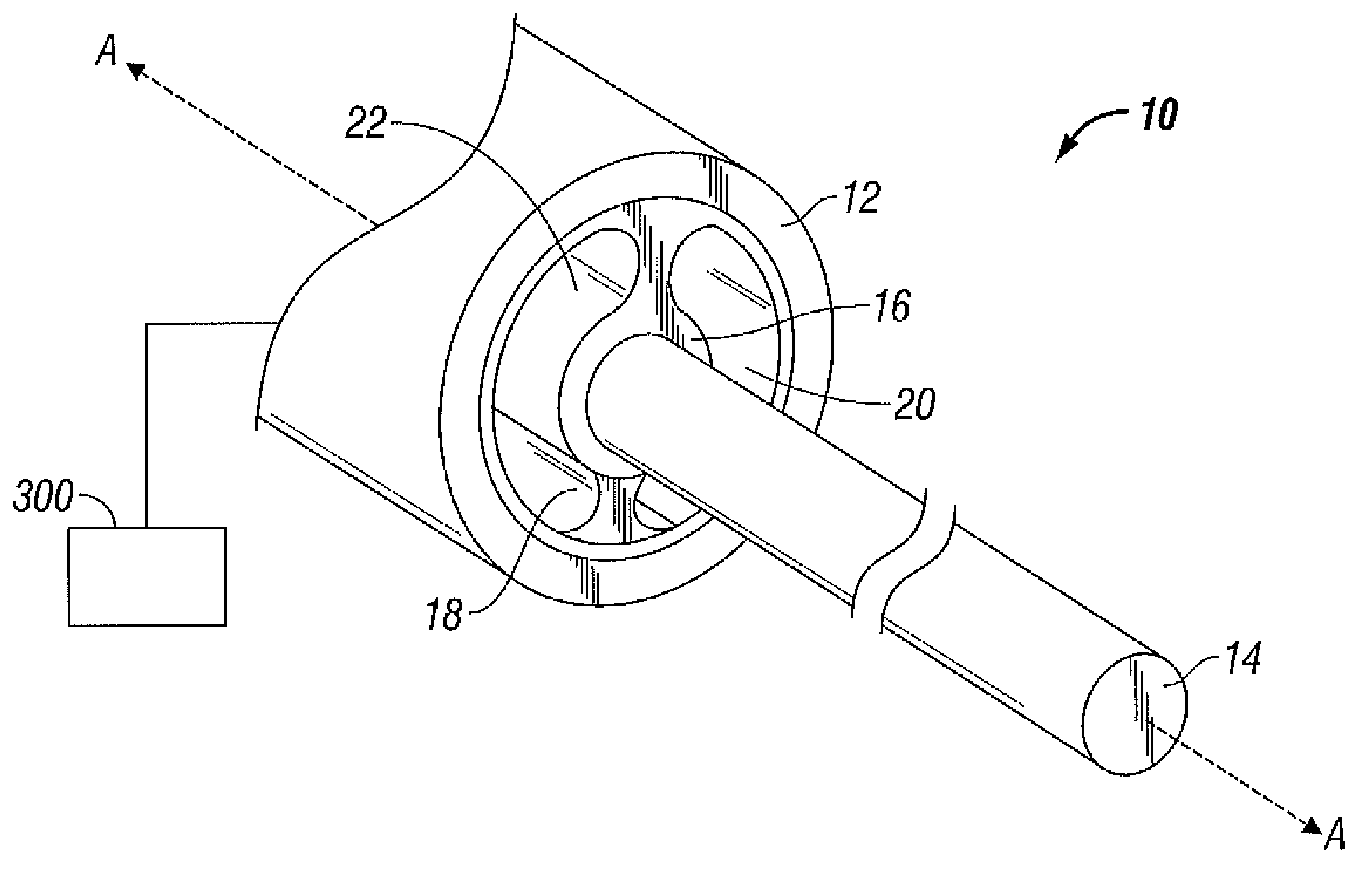

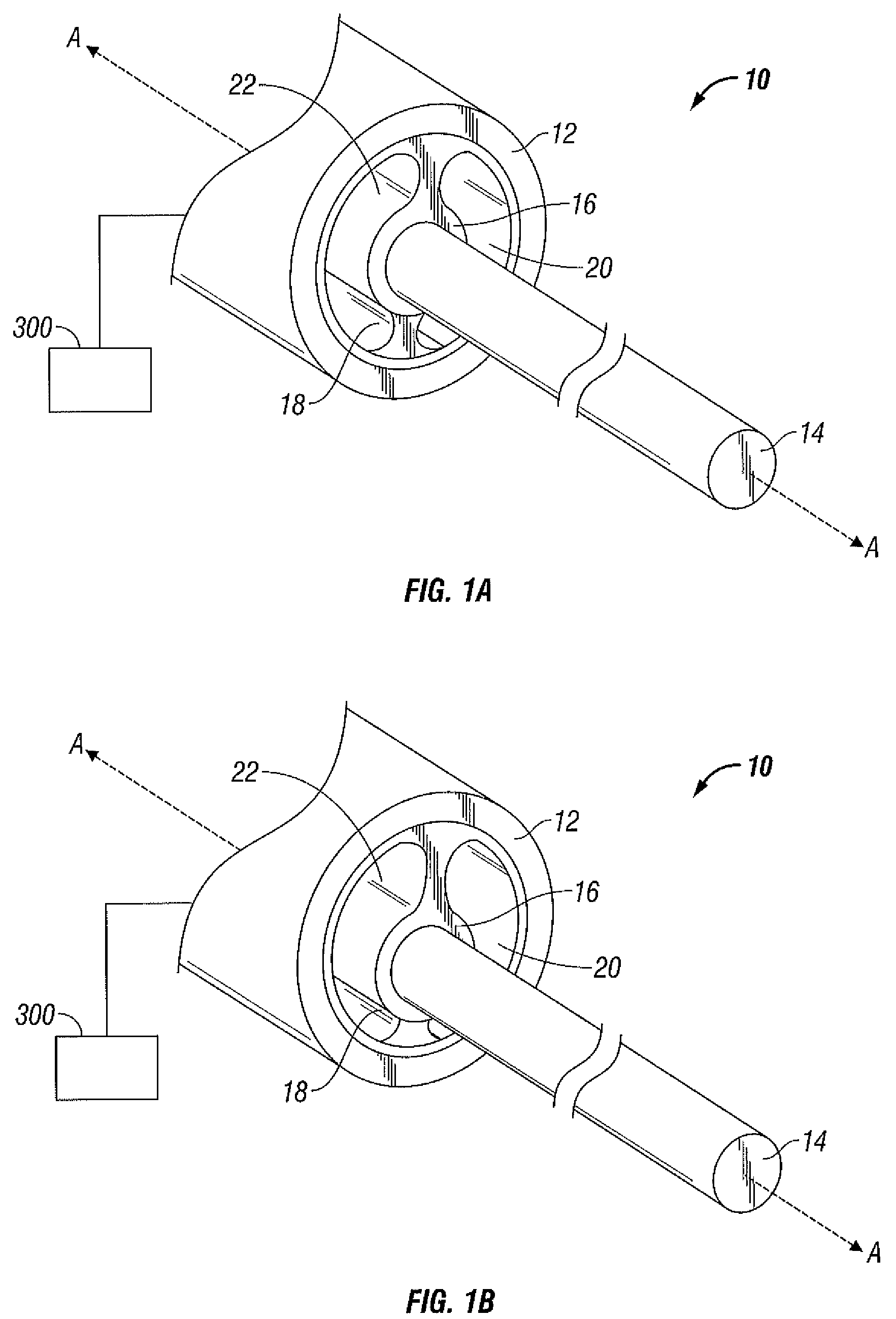

Flexible device shaft with angled spiral wrap

ActiveUS7579550B2Reduces inadvertent axial elongationGood flexibilitySurgeryEndoscopesSpiral woundEngineering

Spiral-wound materials, spirals, and shafts made therefrom that have wraps with edges that may nest within one another are described. Such edges allow the spiral to achieve a smaller bending radius, meaning tighter turns and more flexibility due to the ability of adjacent wraps to nest within each other when the shaft is bent. Spirals having wraps with edges capable of nesting can be used in the medical field for devices that track anatomy, such as endoscopes, colonoscopes, catheters, and the like.

Owner:BOSTON SCI SCIMED INC

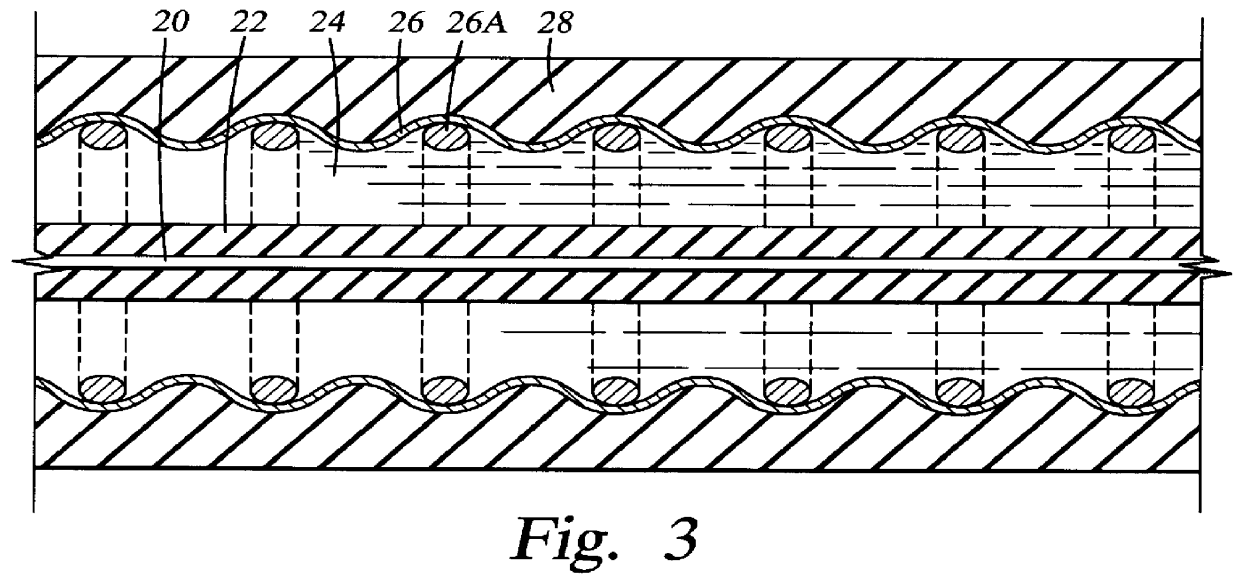

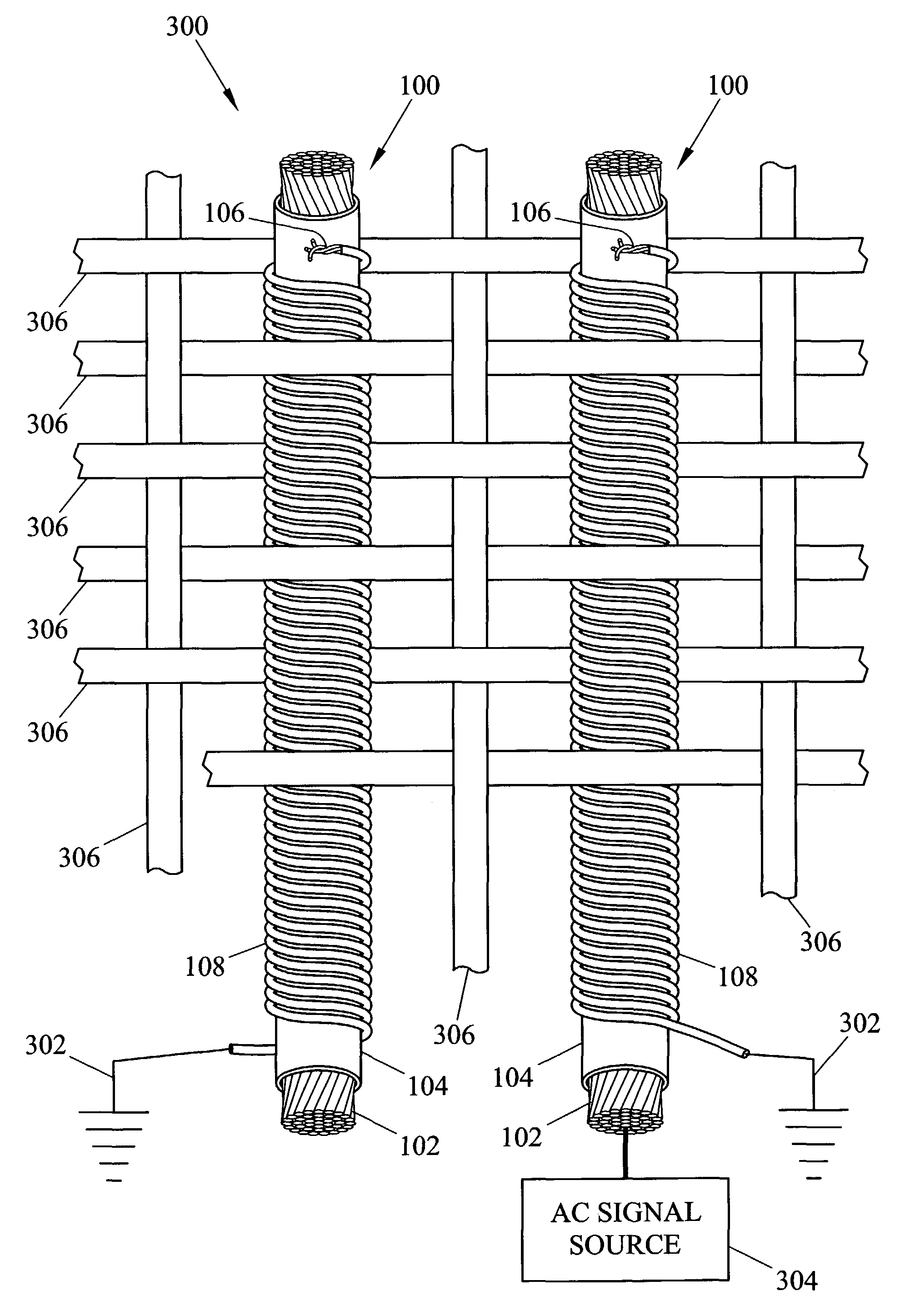

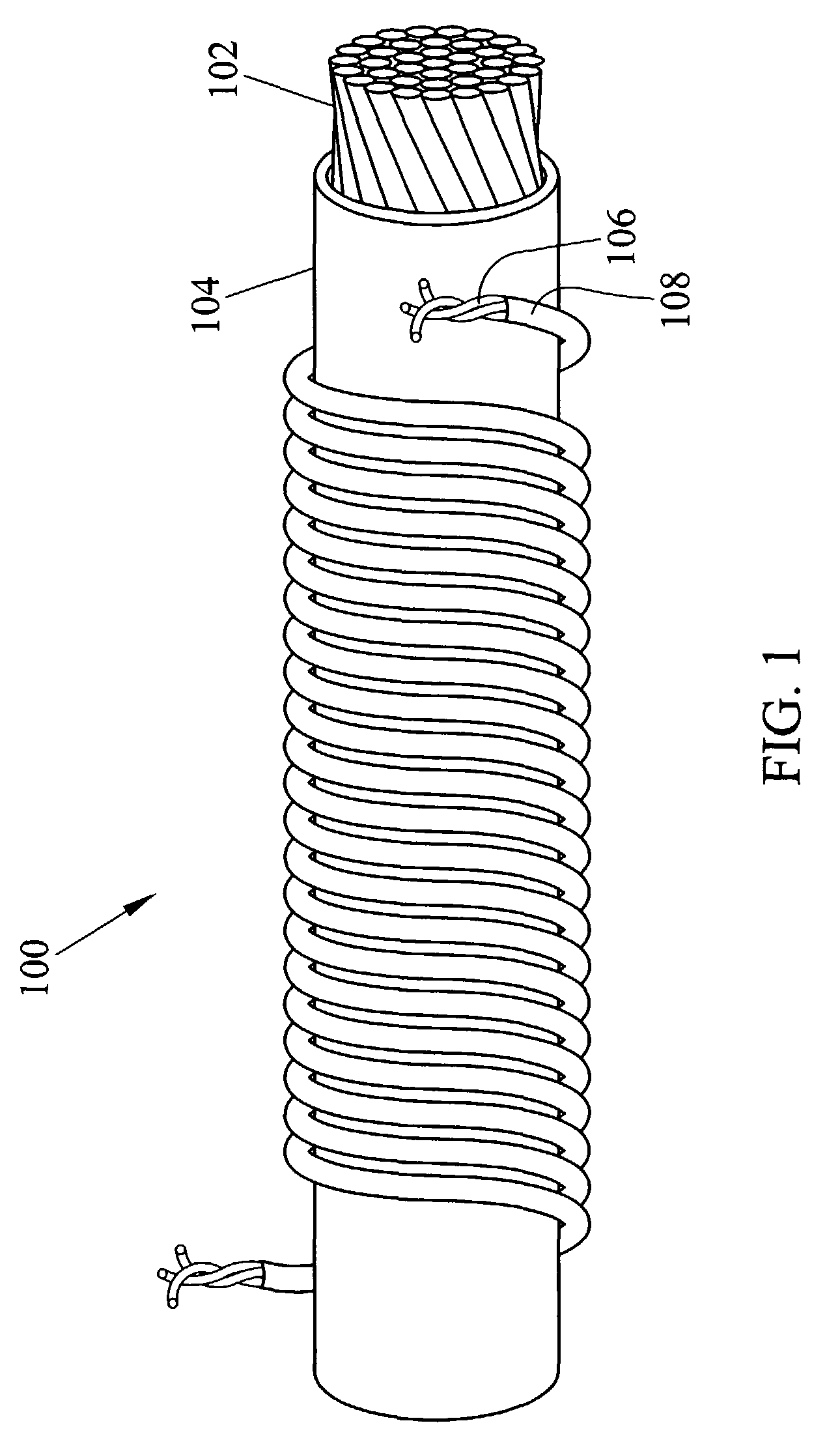

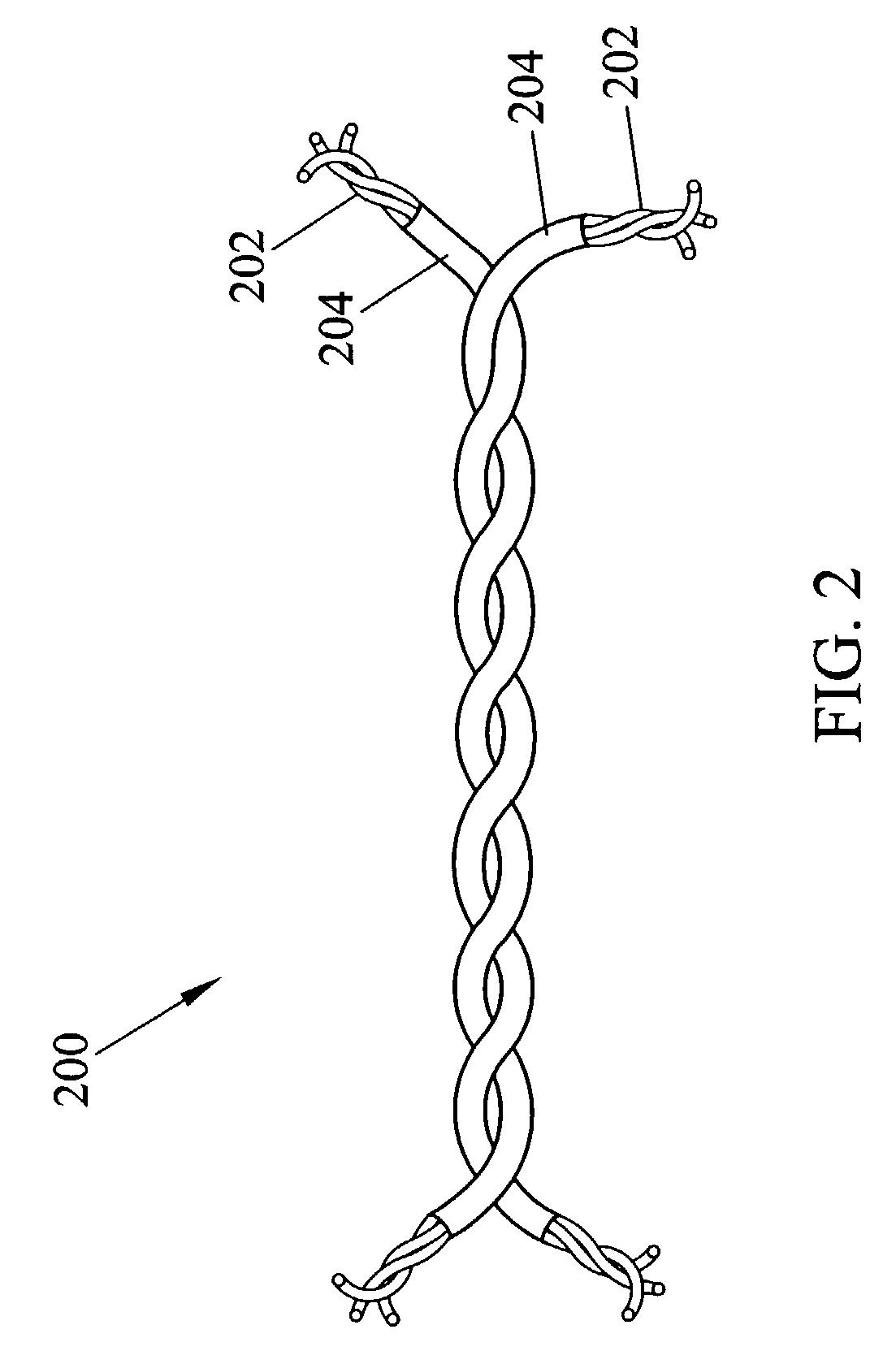

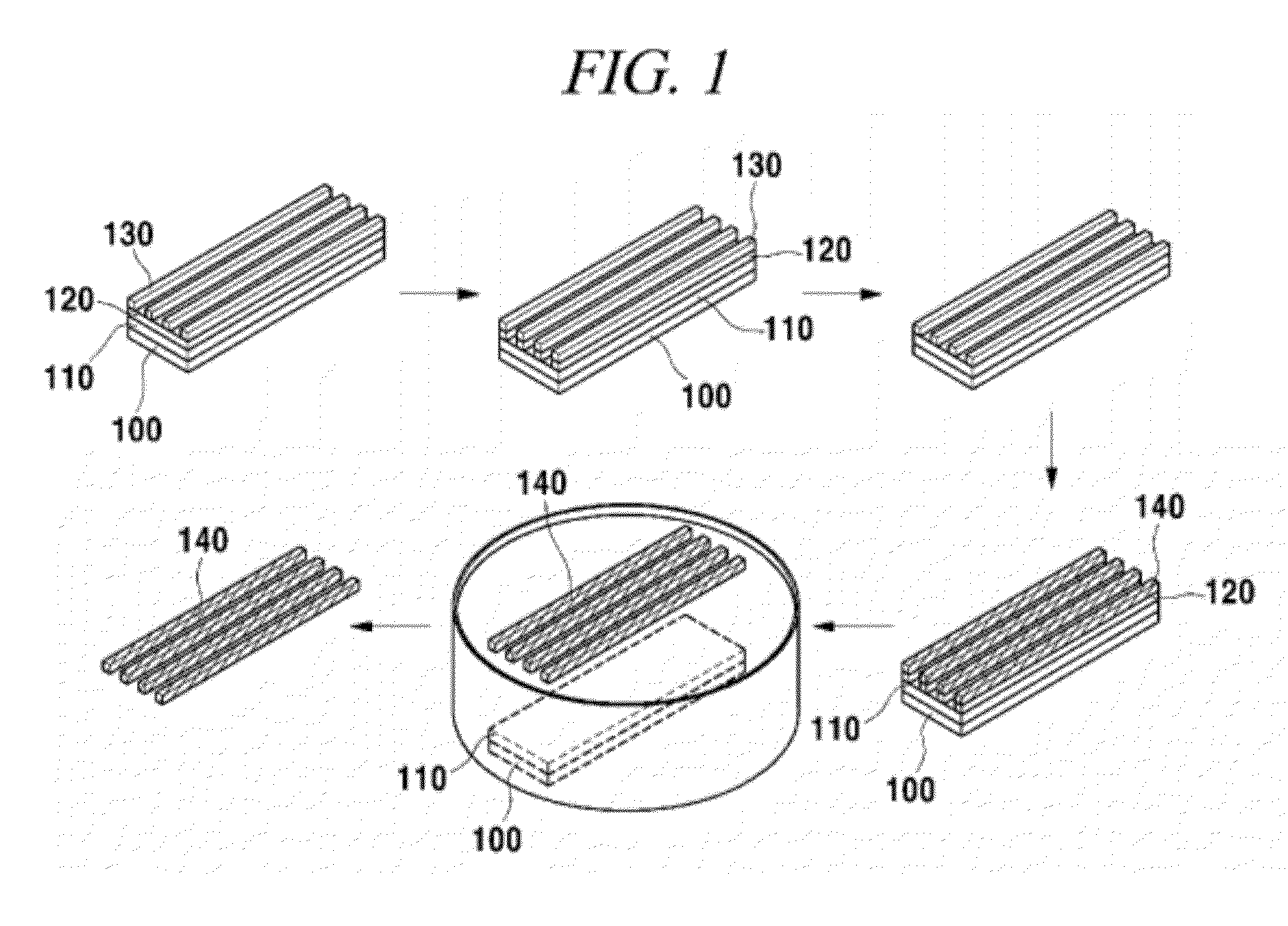

Fabric and yarn structures for improving signal integrity in fabric-based electrical circuits

InactiveUS7348285B2Reduce crosstalkImprove signal integrityAlcoholic beverage preparationPower cables with screens/conductive layersPower gridTwisted pair

Coaxial and twisted pair conductive yarn structures reduce signal crosstalk between adjacent lines in woven electrical networks. A coaxial conductive yarn structure includes an inner conductive yarn having a plurality of conductive strands twisted together. An outer conductive yarn is wrapped around the inner conductive yarn. An insulating layer separates the inner and outer yarns. A twisted pair conductive yarn structure includes first and second conductive yarns, each including a plurality of conductive strands being twisted together. The first and second conductive yarns are twisted together to form a helical structure. In a woven electrical network, at least one conductor of adjacent conductive yarn structures is connected to ground to reduce signal crosstalk. Coaxial and twisted pair yarn structures may also be formed simultaneously with weaving or knitting the threads that make up the structures into a fabric.

Owner:NORTH CAROLINA STATE UNIV

Cable semiconducting shields

A semiconducting composition comprising (i) an olefinic polymer and (ii) about 25 to about 45 percent by weight, based on the weight of the composition, of a carbon black having the following properties: (a) a particle size of at least about 29 nanometers; (b) a tint strength of less than about 100 percent; (c) a loss of volatiles at 950 degrees C in a nitrogen atmosphere of less than about 1 weight percent based on the weight of the carbon black; (d) a DBP oil absorption of about 80 to about 300 cubic centimeters per 100 grams; (e) a nitrogen surface adsorption area of about 30 to about 300 square meters per gram or an iodine adsorption number of about 30 to about 300 grams per kilogram; (f) a CTAB surface area of about 30 to about 150 square meters per gram; and (g) a ratio of property (e) to property (f) of greater than about 1.1.

Owner:UNION CARBIDE CHEM & PLASTICS TECH CORP

Color-coded armored cable

ActiveUS6906264B1Extend your lifeEasy to manufacturePower cables with screens/conductive layersInsulated cablesMetal stripsHelical line

A color coded flexible armored cable includes a tubular sheath formed from a metal strip having a continuous, non-patterned, non-conductive color coating applied to the entirety of an abraded outer surface of the strip. The color coating is of a predetermined precise thickness and includes a polyethylene based wax lubricant in a percent by volume of about 0.45 to 0.55. The strip is formed into helical convolutions having a cross-sectional shape which provides for overlap and interlocking of adjacent convolutions and contact between adjacent convolutions along a helical line such that, upon bending the sheath, the convolutions remain in contact at a trailing edge of one convolution and the inner surface of an adjacent convolution in a way such that the color coating is not scraped off of the outer surface of the sheath. The sheath is preferably formed such that the number of convolutions per unit length of sheath is maximum for sheath flexibility and retention of the coating on the outer surface of the sheath.

Owner:SOUTHWIRE CO LLC

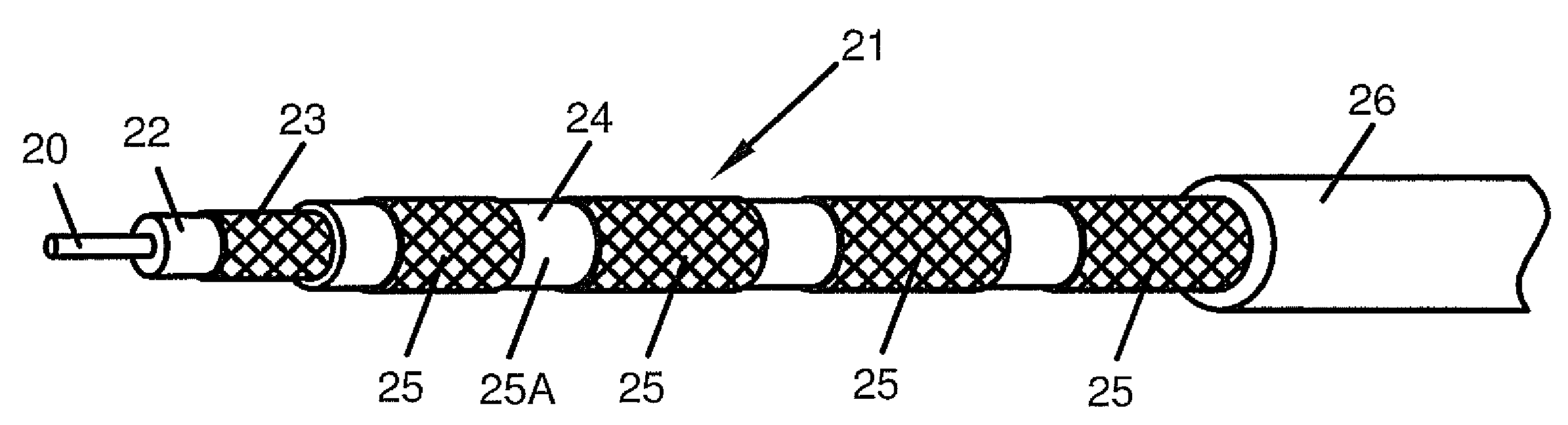

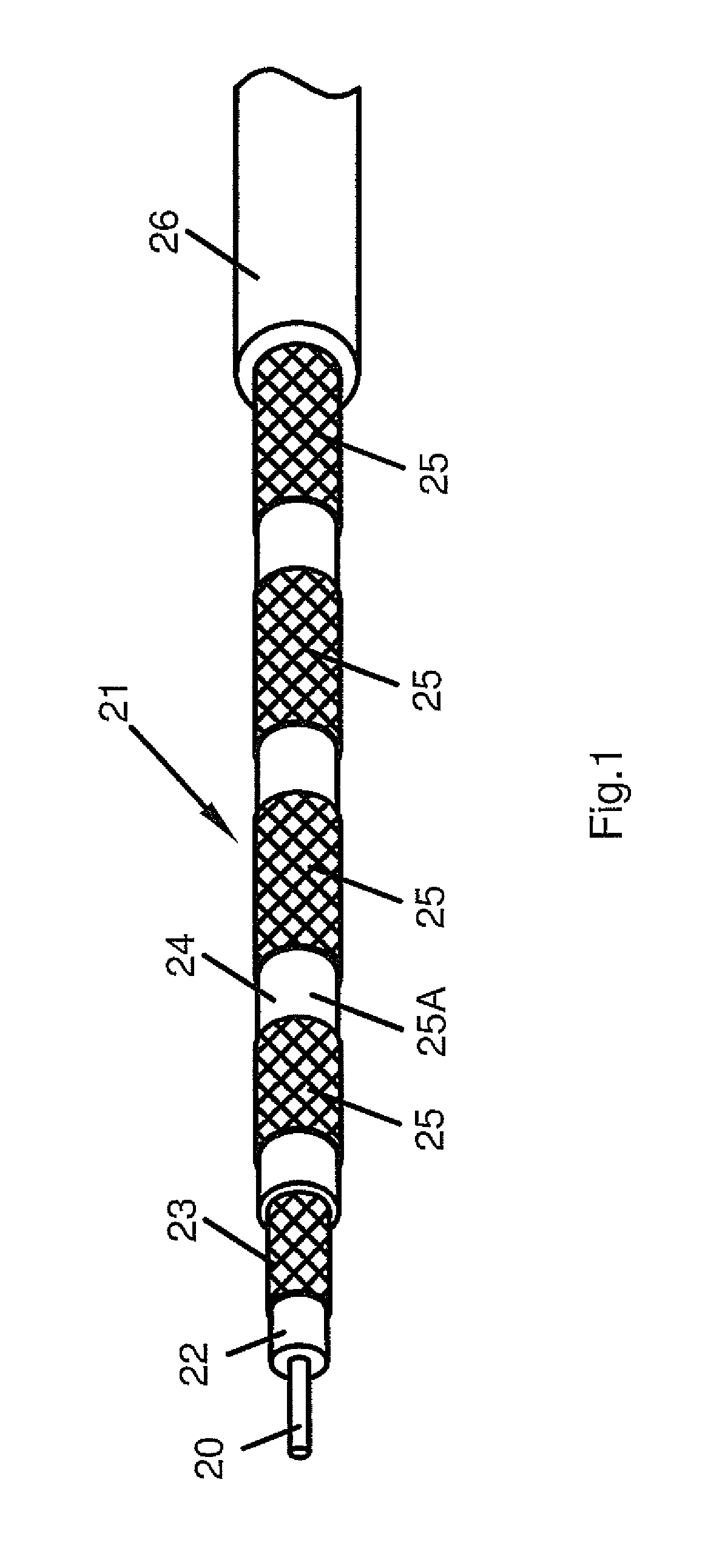

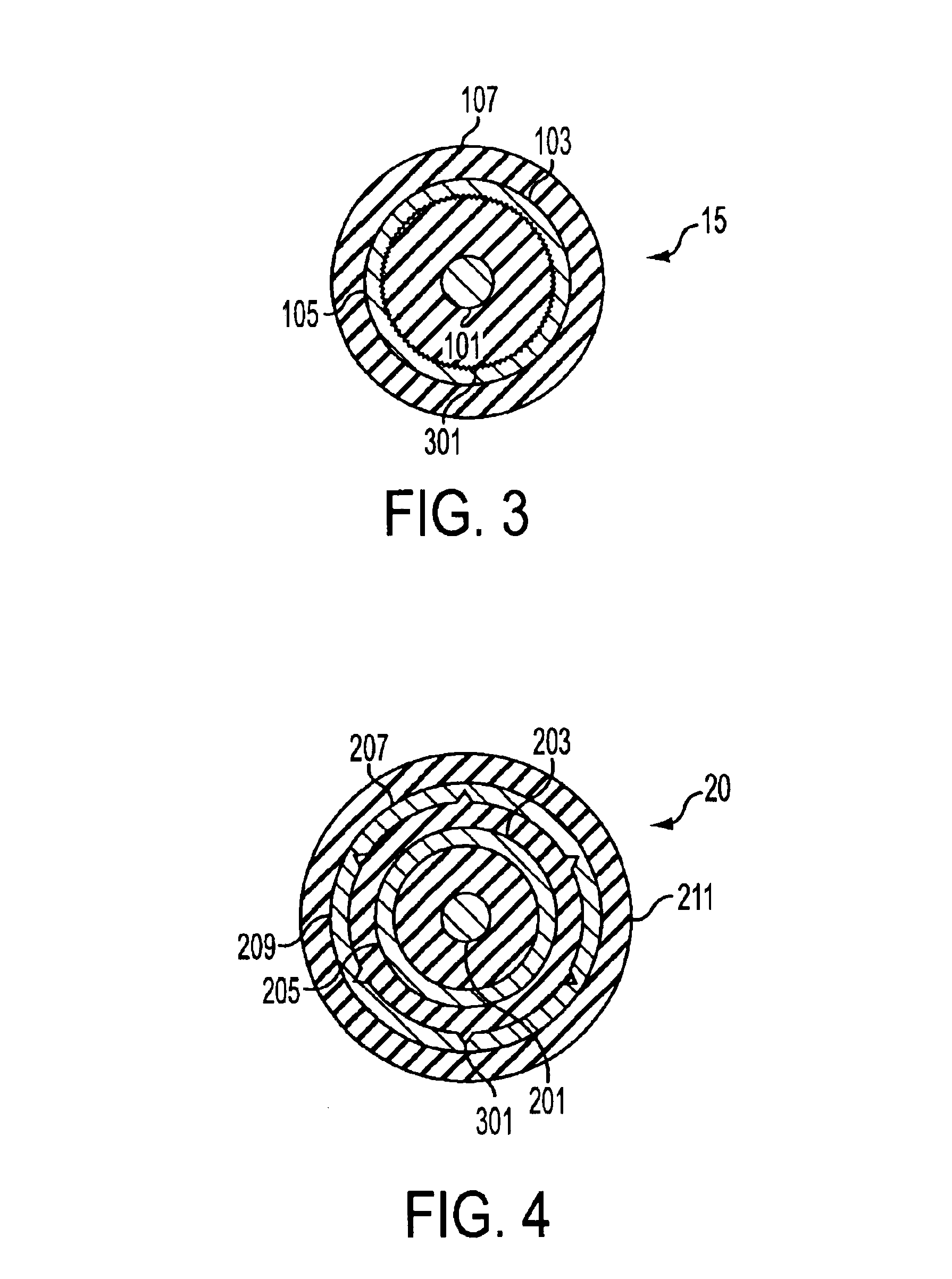

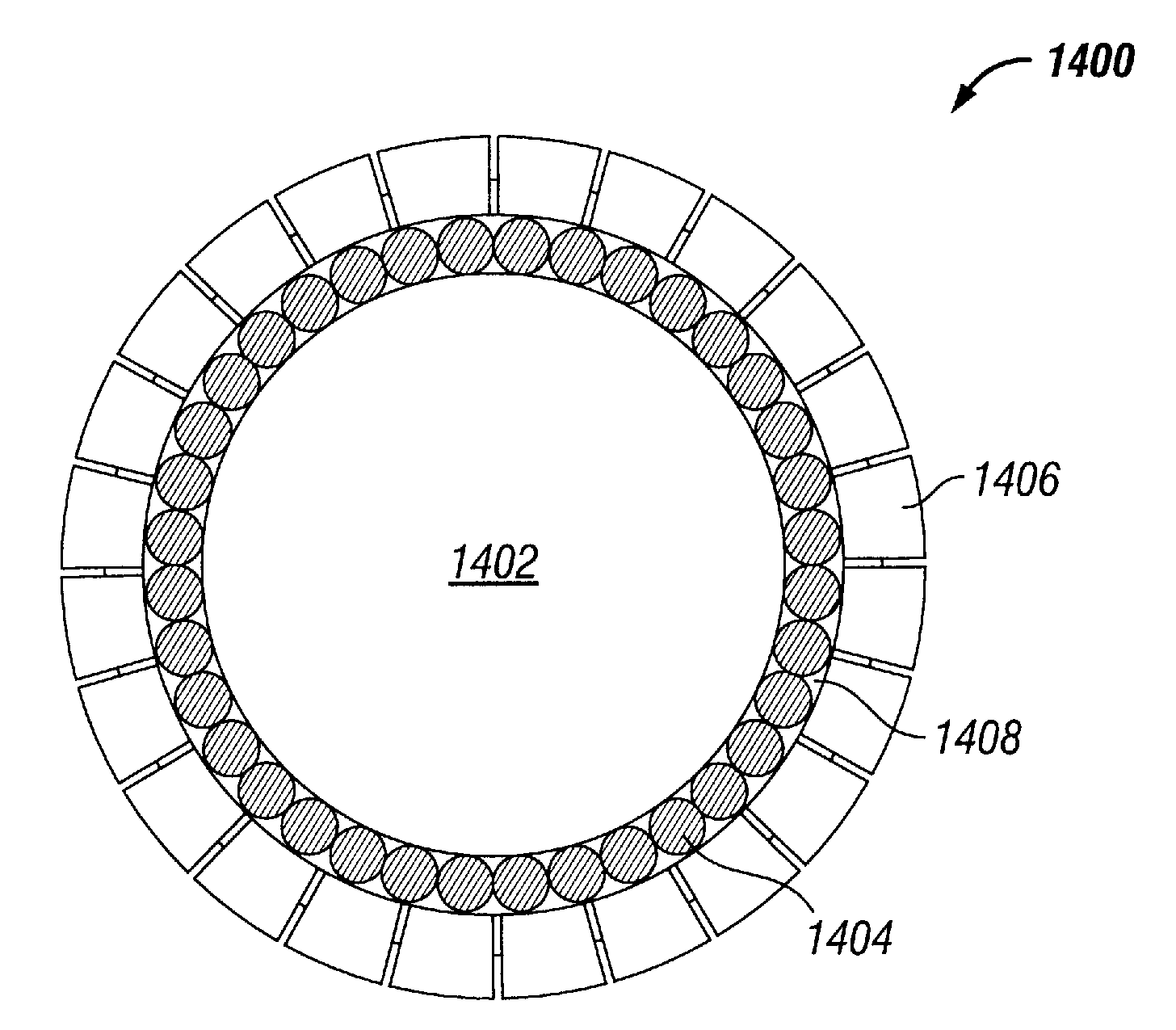

Floating segmented shield cable assembly

InactiveUS7834270B2Reduce creationMagnetic/electric field screeningPower cables with screens/conductive layersDielectricShielded cable

Signals in an RF field, such as that of an MRI system, are communicated through an inner conductor having an outer shield with a dielectric material therebetween and an outer cable jacket. Current in the shield caused by the RF field from the transmit body coil is reduced by providing a second dielectric material around the shield conductor and a plurality of segmented shield conductor portions formed of non-magnetic braid or wrapped non-magnetic foil tape outside the second dielectric material and inside the jacket at spaced positions along the cable, with the portions being electrically separated from each other and from the shield so that the segmented shield conductor portions act to shield the outer shield conductor to reduce the generation of current thereon while the electrical separation of the segmented shield conductor portions each from the others prevents the generation of a current along the portions.

Owner:DEERFIELD IMAGING INC

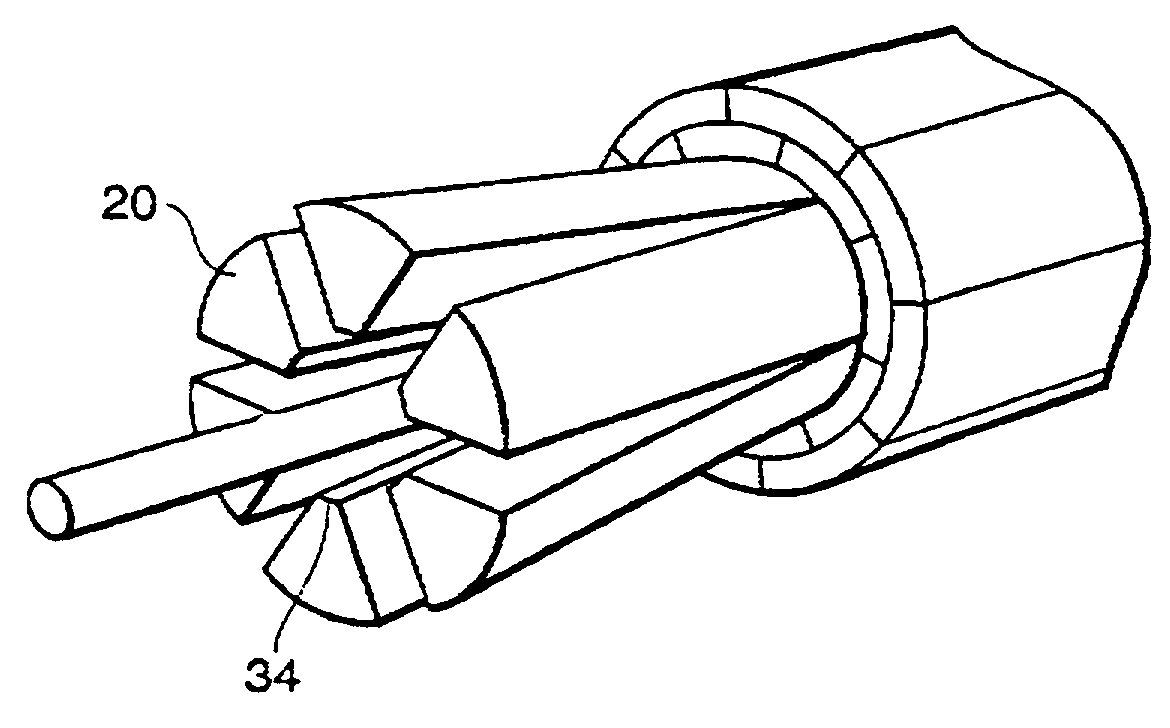

Composite reinforced electrical transmission conductor

InactiveUS7015395B2Avoid excessive labor intensityLow costNon-insulated conductorsPower cables with screens/conductive layersFiberElectrical conductor

A composite reinforced electrical transmission conductor primarily designed for transmission of electrical signals. The conductor is comprised of a reinforced plastic composite inner core along with an outer highly electrically conductive sheath therearound. In this way, the inner core provides the necessary strength and the outer sheath provides for transmission of the electrical signals. In a preferred embodiment, the reinforced composite core is comprised of individual sections which cooperate together to provide the necessary loading capabilities. Further, a fiber optic cable may also be carried by the composite reinforced core. A splicing arrangement for securing ends of the cable together is also provided.

Owner:GIFT TECH LP

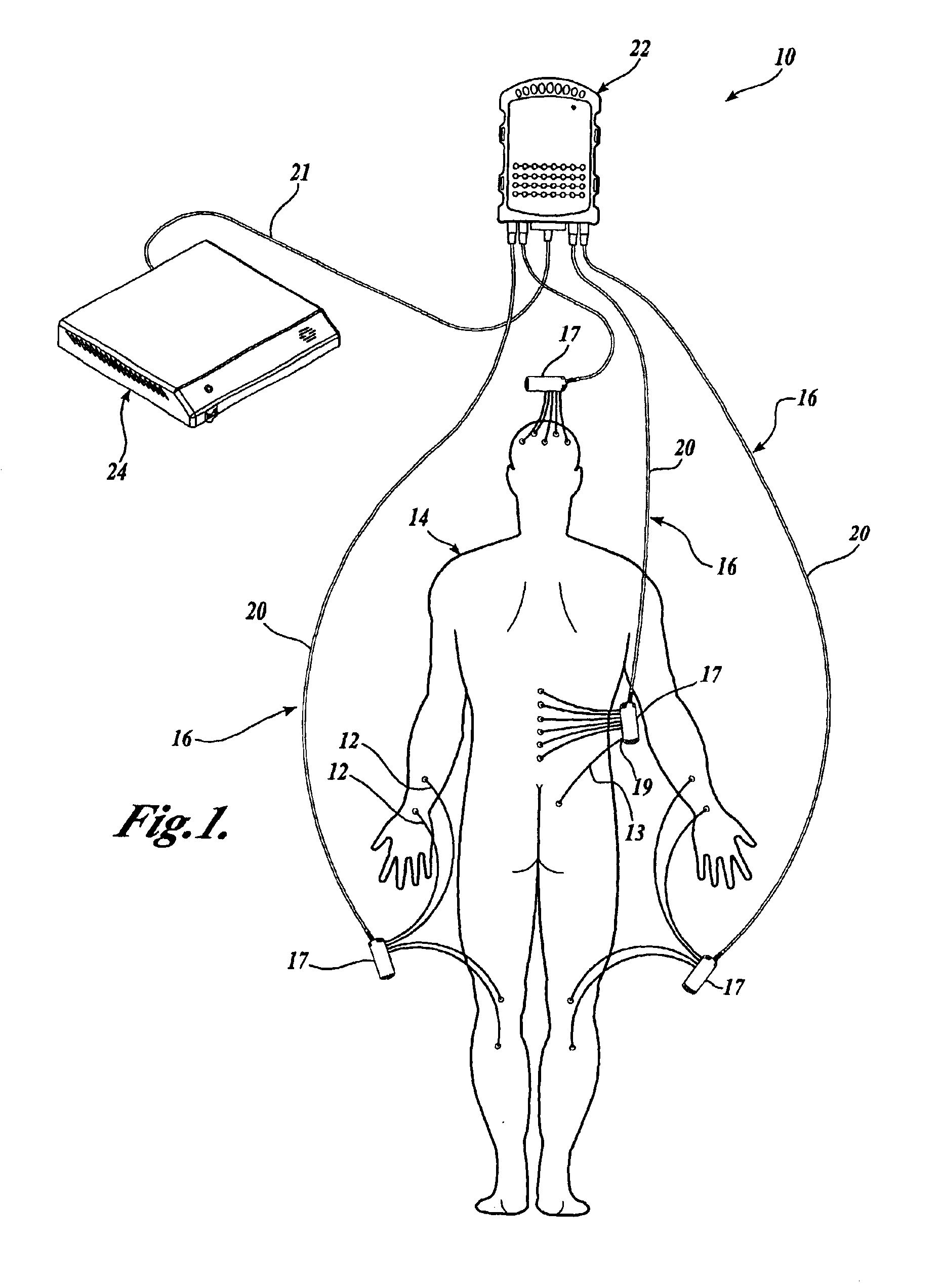

System and device for reducing signal interference in patient monitoring systems

InactiveUS6870109B1Reduce signal interferenceBioelectric signal measurementPlastic/resin/waxes insulatorsShielded cableMonitoring system

A system and device for mitigating interference in patient physiological monitoring is provided, particularly in surgical environments. One or more sets of electrodes are placed on a patient's body and connected to corresponding terminals of an input extender. The terminals of the input extender are connected to a set of signal wires encased by a ferrous shielded cable. The ferrous shielded cable connects to a signal processing unit, which includes a differential amplifier and an active drive topology to drive the shield with a common mode signal. The signal processing unit connects to physiological monitoring equipment.

Owner:CADWELL INDS

Discontinued cable shield system and method

ActiveUS7332676B2Power cables with screens/conductive layersInsulated cablesDifferential transmissionEngineering

Implementations of a discontinuous cable shield system and method include a shield having a multitude of separated shield segments dispersed along a length of a cable. The separated shield segments can serve as an incomplete, patch-worked, discontinuous, ‘granulated’ or otherwise perforated shield for differential transmission lines such as with twisted wire pairs.

Owner:LEVITON MFG

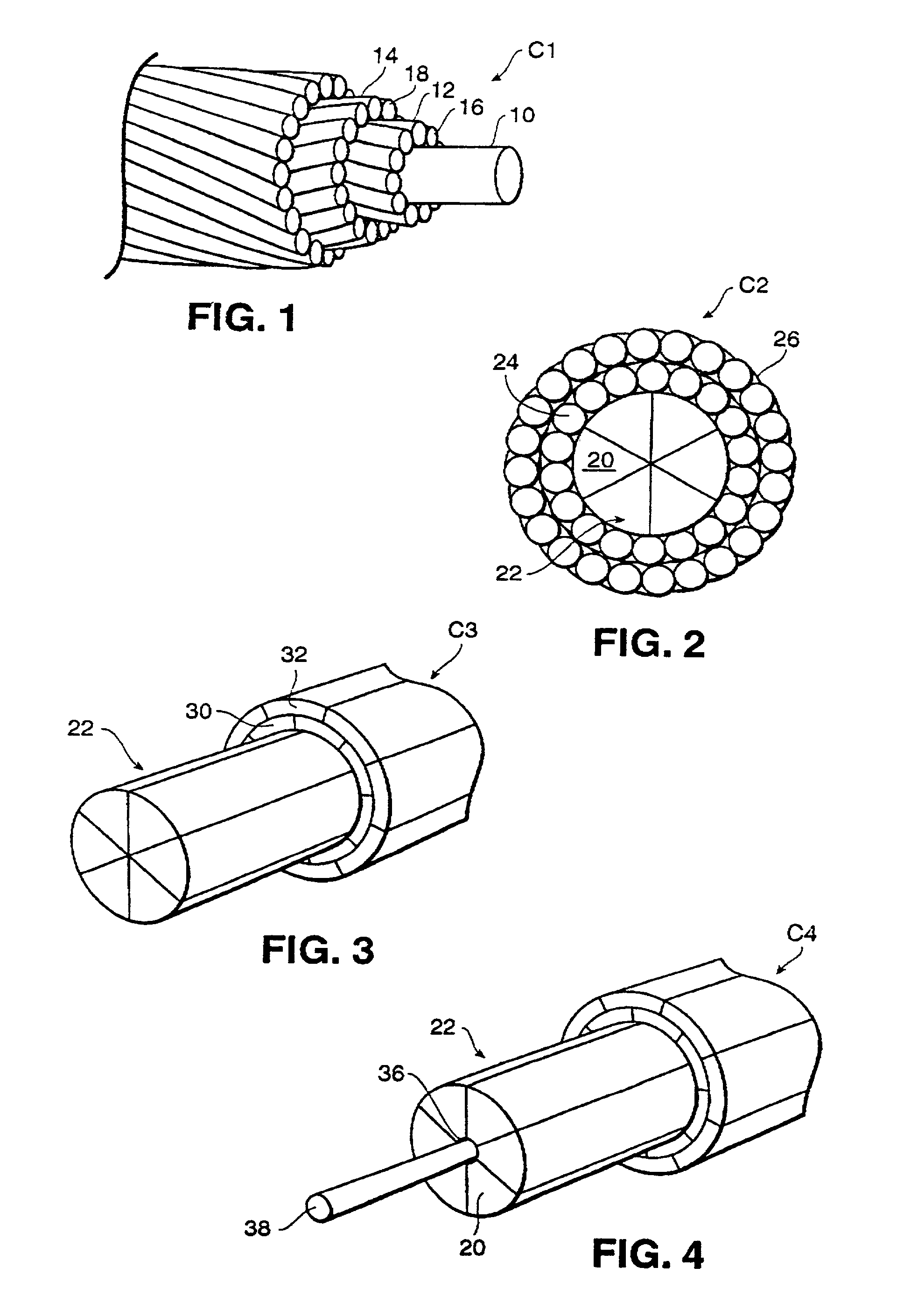

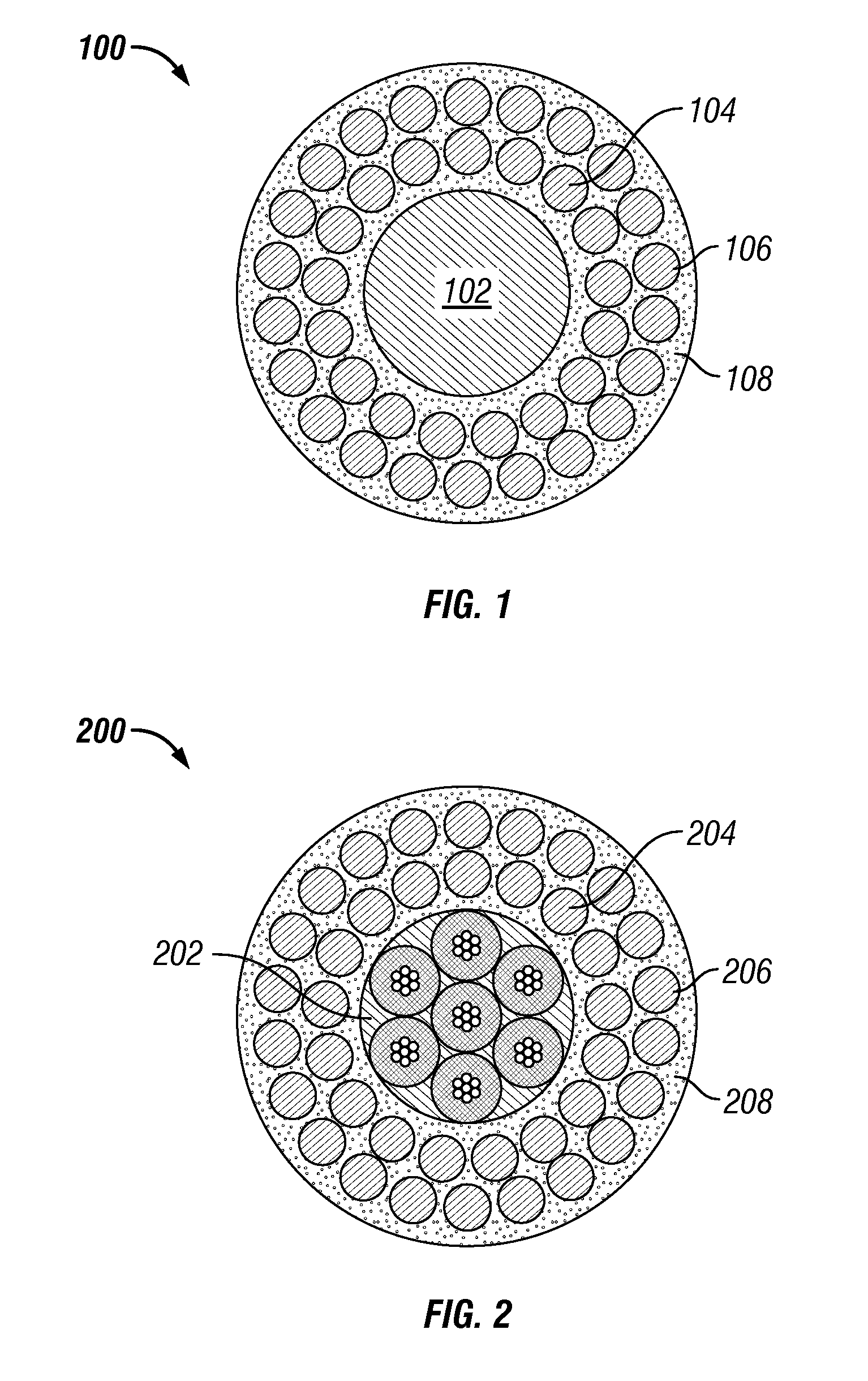

Aluminum conductor composite core reinforced cable and method of manufacture

InactiveUS7179522B2Change in weightMaintain stable propertiesNon-insulated conductorsSynthetic resin layered productsElectrical conductorThermal expansion

This invention relates to an aluminum conductor composite core reinforced cable (ACCC) and method of manufacture. An ACCC cable has a composite core surrounded by at least one layer of aluminum conductor. The composite core comprises a plurality of fibers from at least one fiber type in one or more matrix materials. The composite core can have a maximum operating temperature capability above 100° C. or within the range of about −45° C. to about 240° C. or higher, at least 50% fiber to resin volume fraction, a tensile strength in the range of about 160 Ksi to about 370 Ksi, a modulus of elasticity in the range of about 7 Msi to about 37 Msi and a coefficient of thermal expansion in the range of about −0.6×10−6 per deg. C. to about 1.0×10−5 per deg. C. According to the invention, unique processing techniques such a B-Staging and / or film-coating techniques can be used to increase production rates from a few feet per minute to sixty or more feet per minute.

Owner:CTC GLOBAL CORP

Serrated cable core

InactiveUS6815617B1Cable insulation constructionPower cables with screens/conductive layersContact forceEngineering

An axially arranged cable, such as a coaxial, triaxial, twinaxial, or armored cable which includes at least one serration on an insulative or conductive layer internal thereto and methods of manufacturing the same. These serrations may appear on insulators or inner jackets and are in physical contact with conductive layers such as shields which axially surround the insulative layers. The serrations generally increase the contact force between the insulative layers and the conductiver layers to help prevent separation of the cable core during stripping of the axial cable.

Owner:BELDEN TECHNOLOGY INC

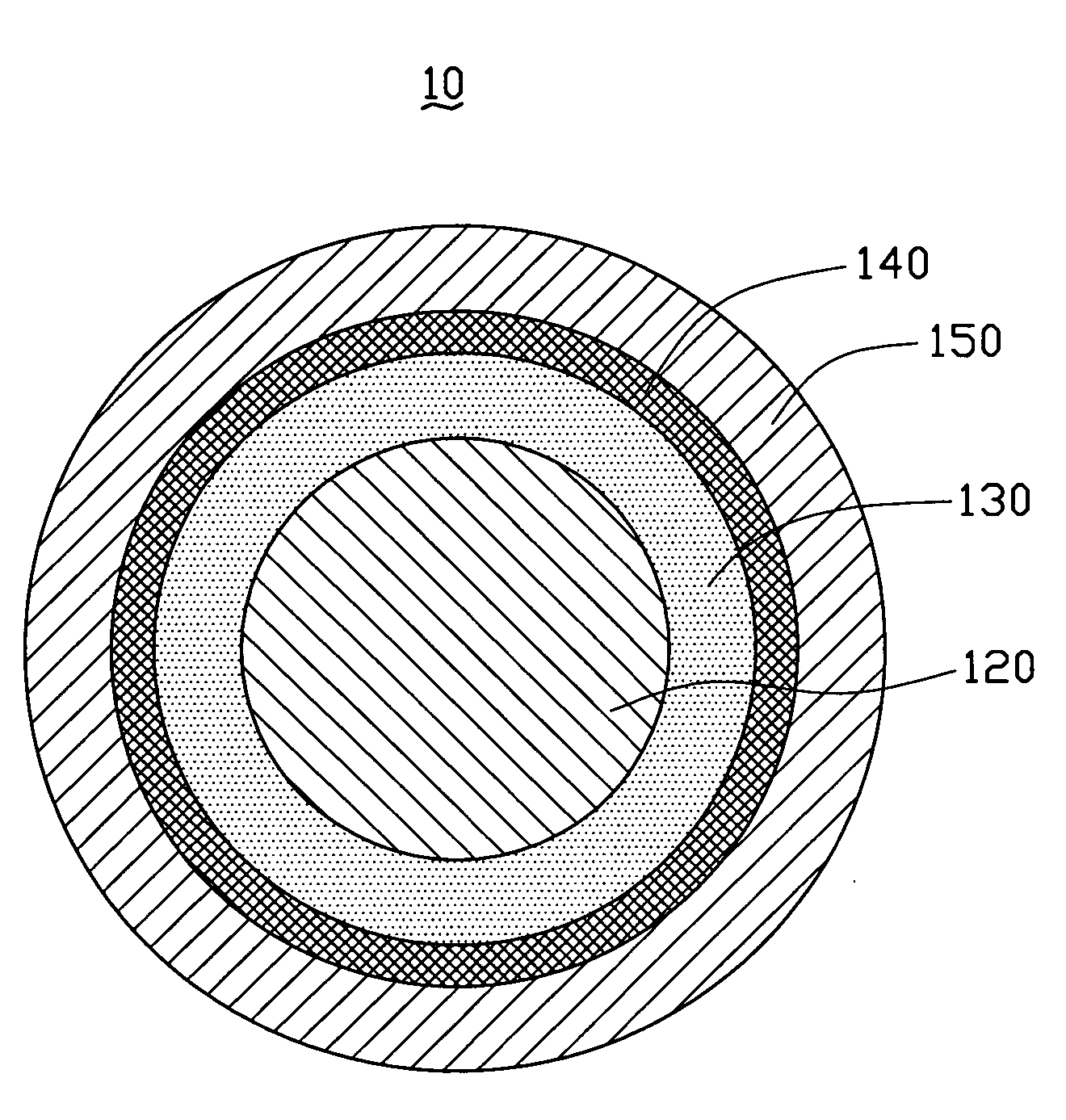

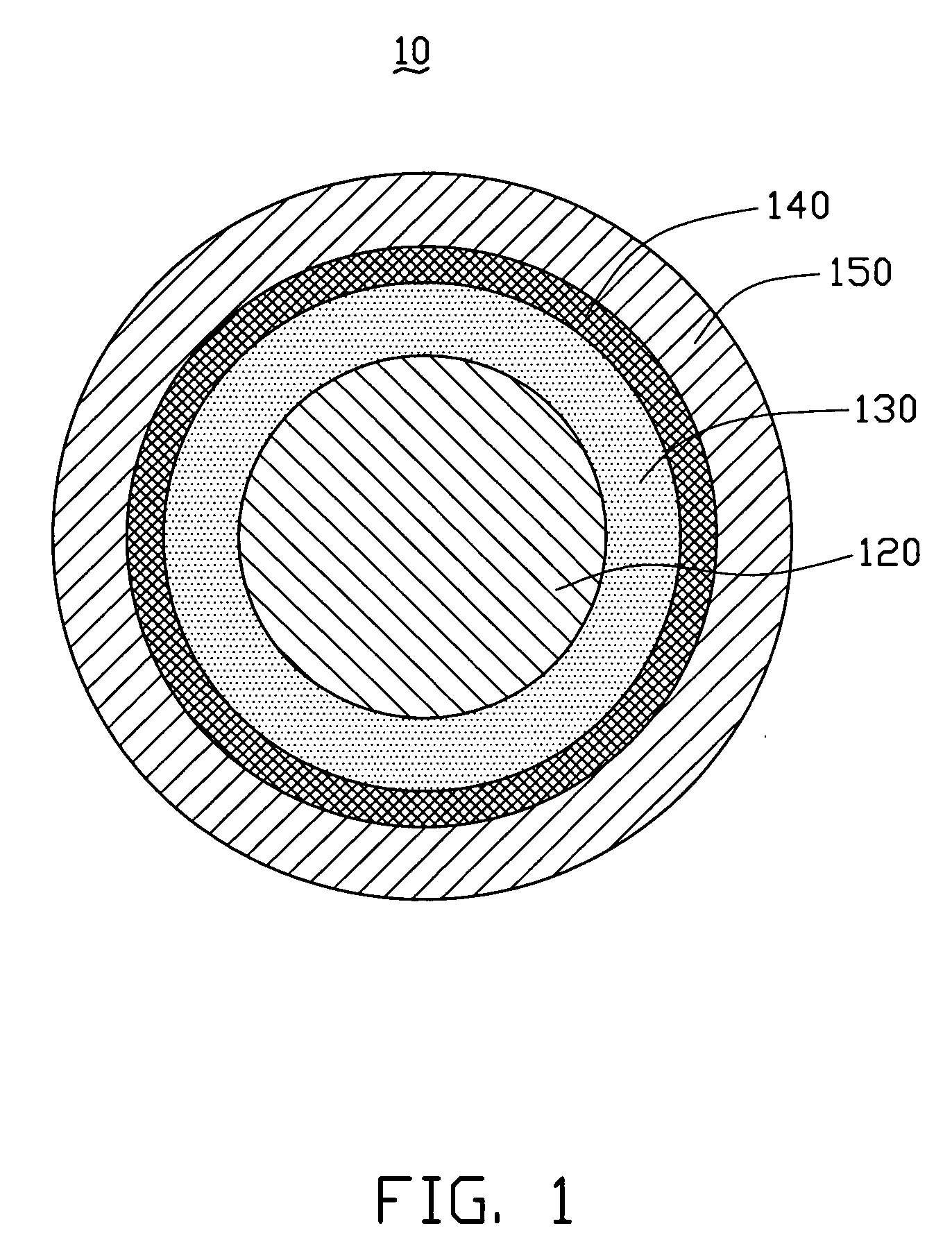

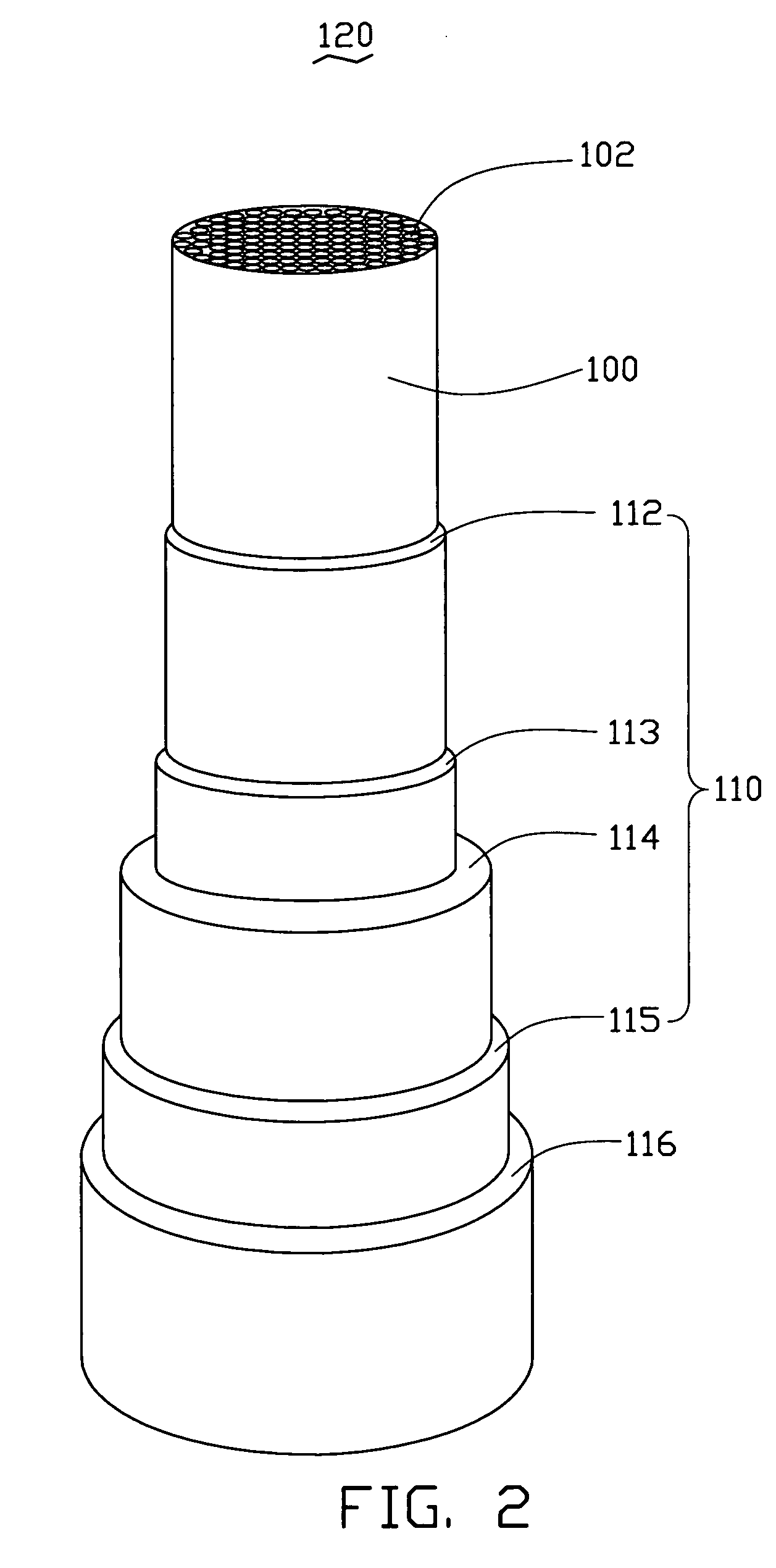

Coaxial cable

ActiveUS20090255706A1Reduce intensityGreat weight and diameterNon-insulated conductorsCable conductor constructionCoaxial cableCarbon nanotube

A coaxial cable includes a core, an insulating layer, a shielding layer, and a sheathing layer. The core includes a carbon nanotube wire-like structure and at least one conductive material layer is disposed on the outside surface of the carbon nanotube wire-like structure. The carbon nanotube wire-like structure includes a plurality carbon nanotubes orderly arranged.

Owner:TSINGHUA UNIV +1

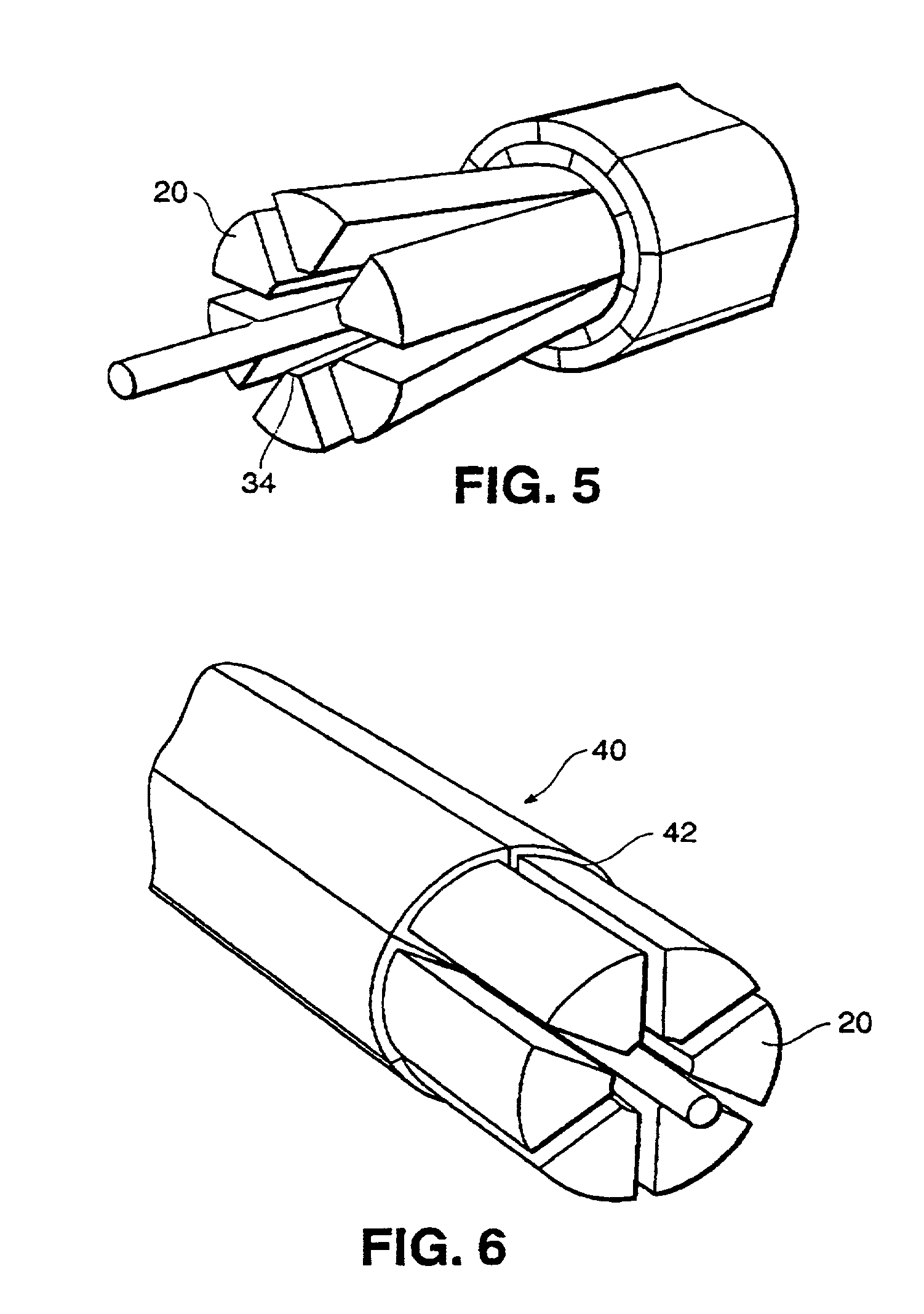

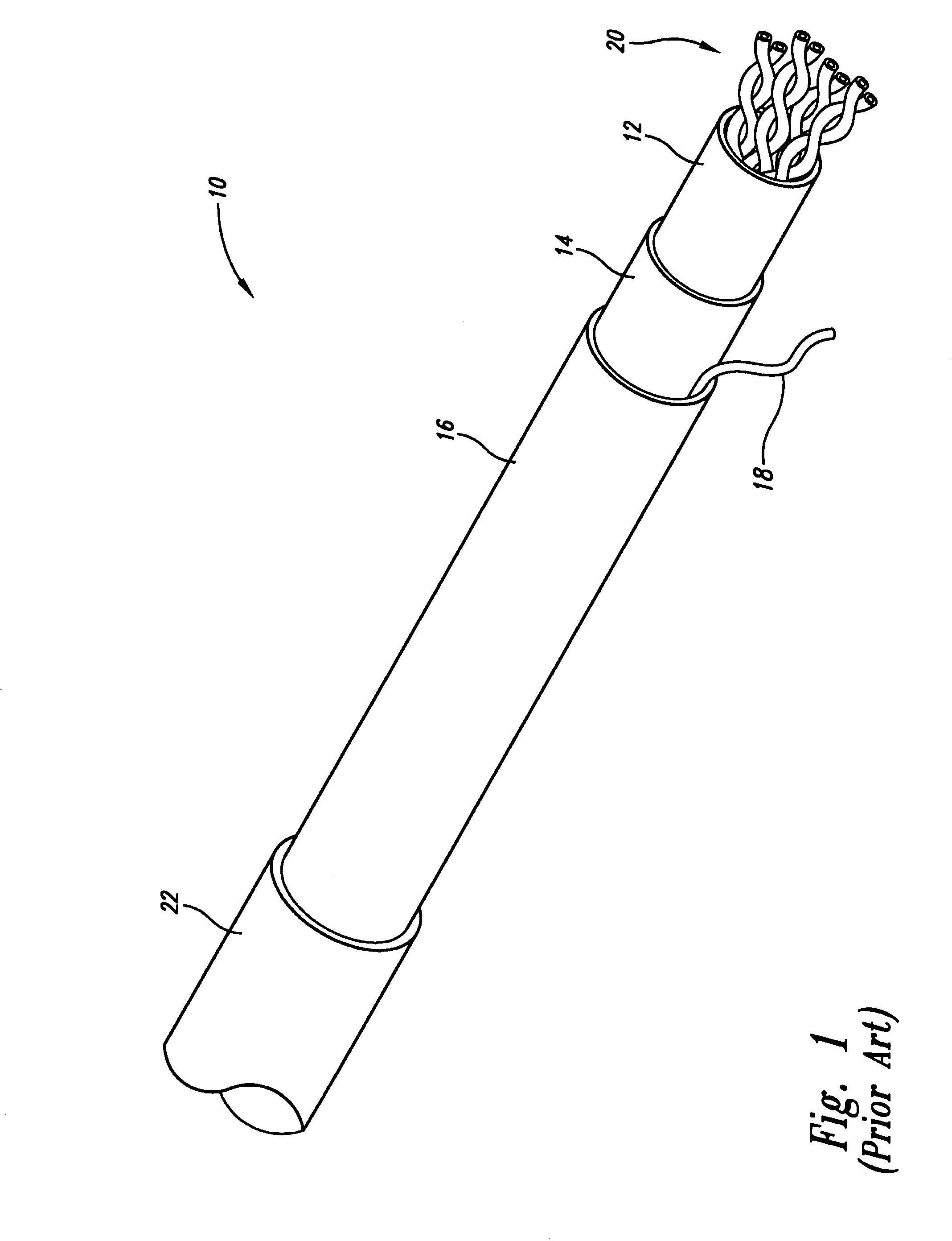

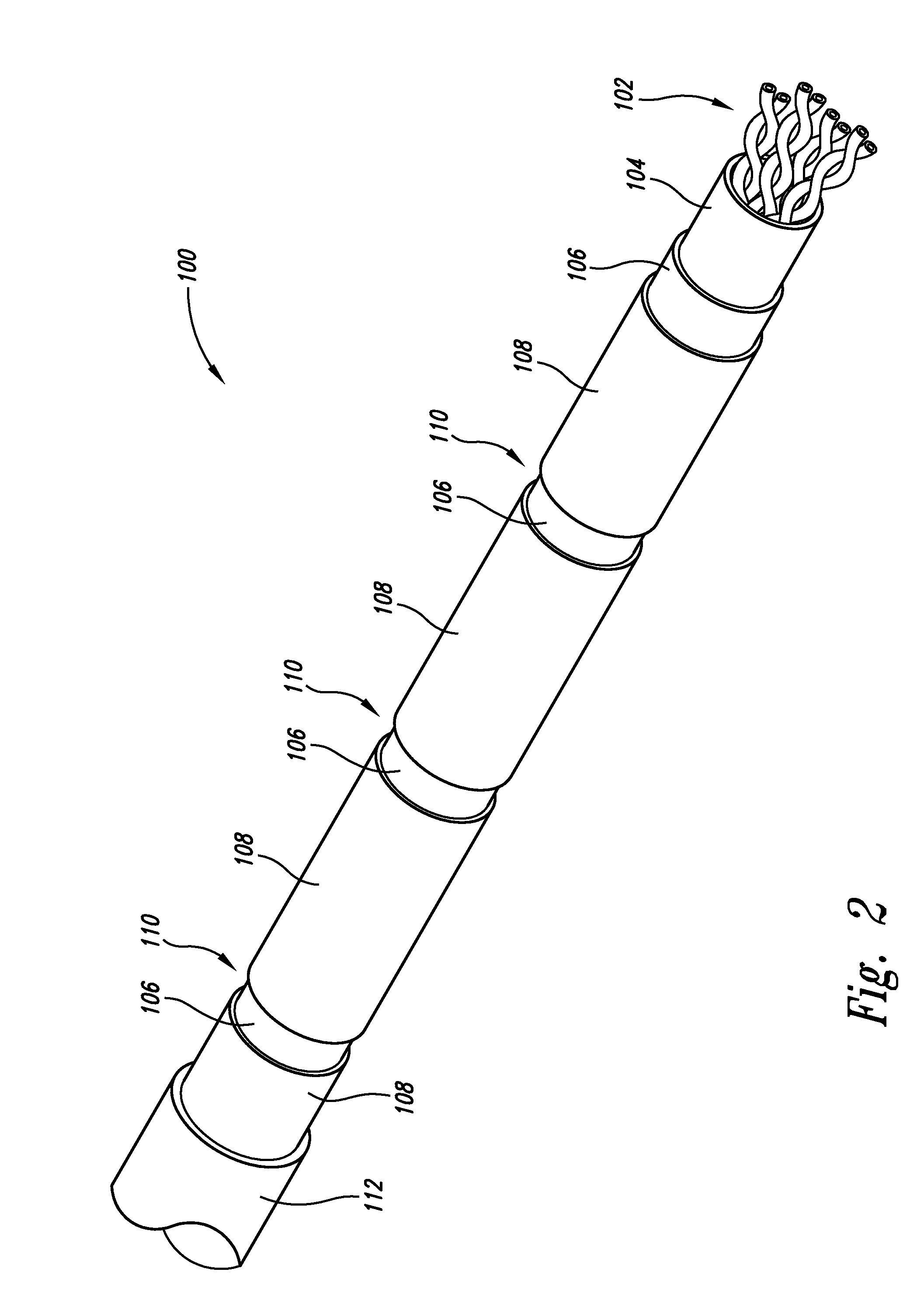

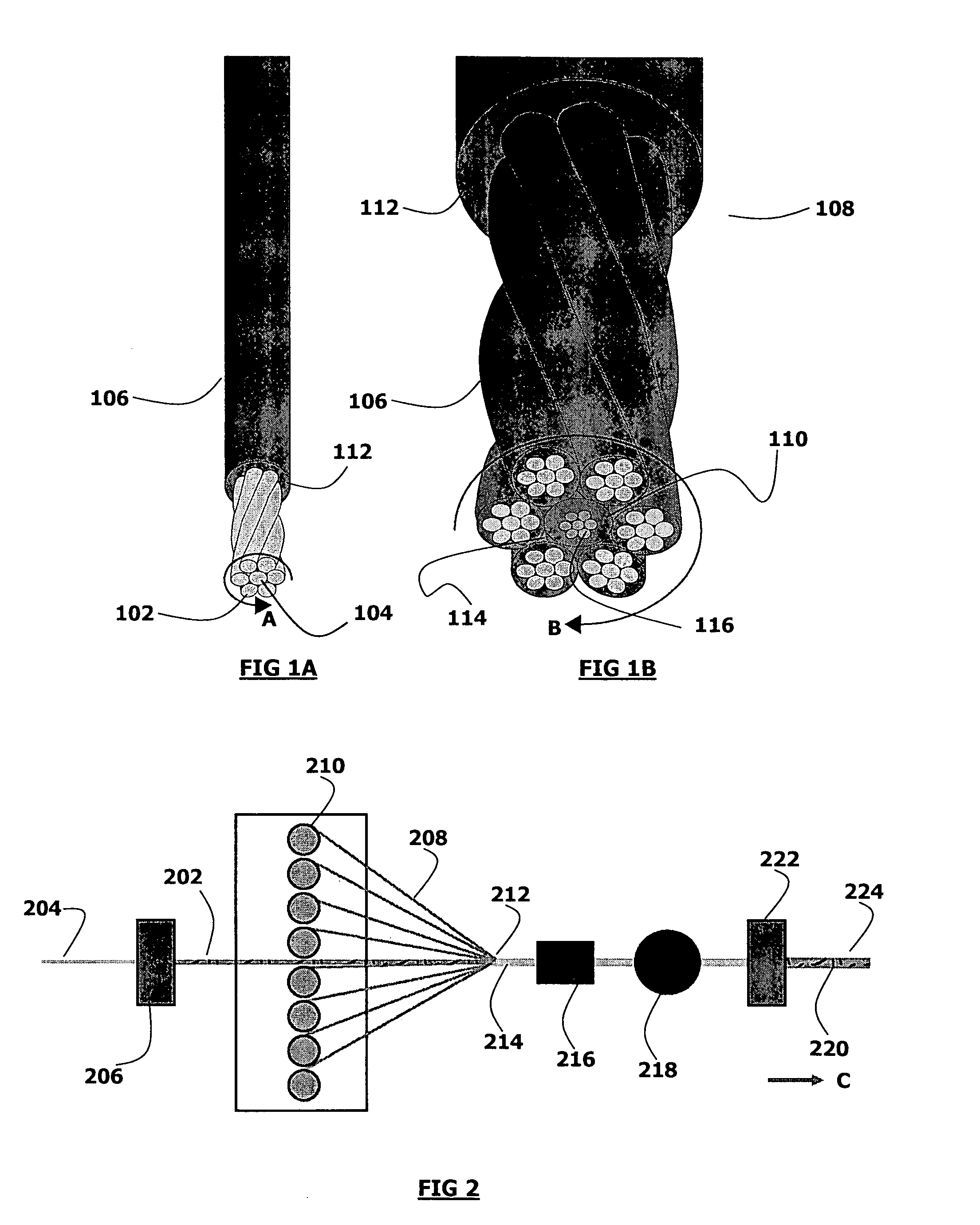

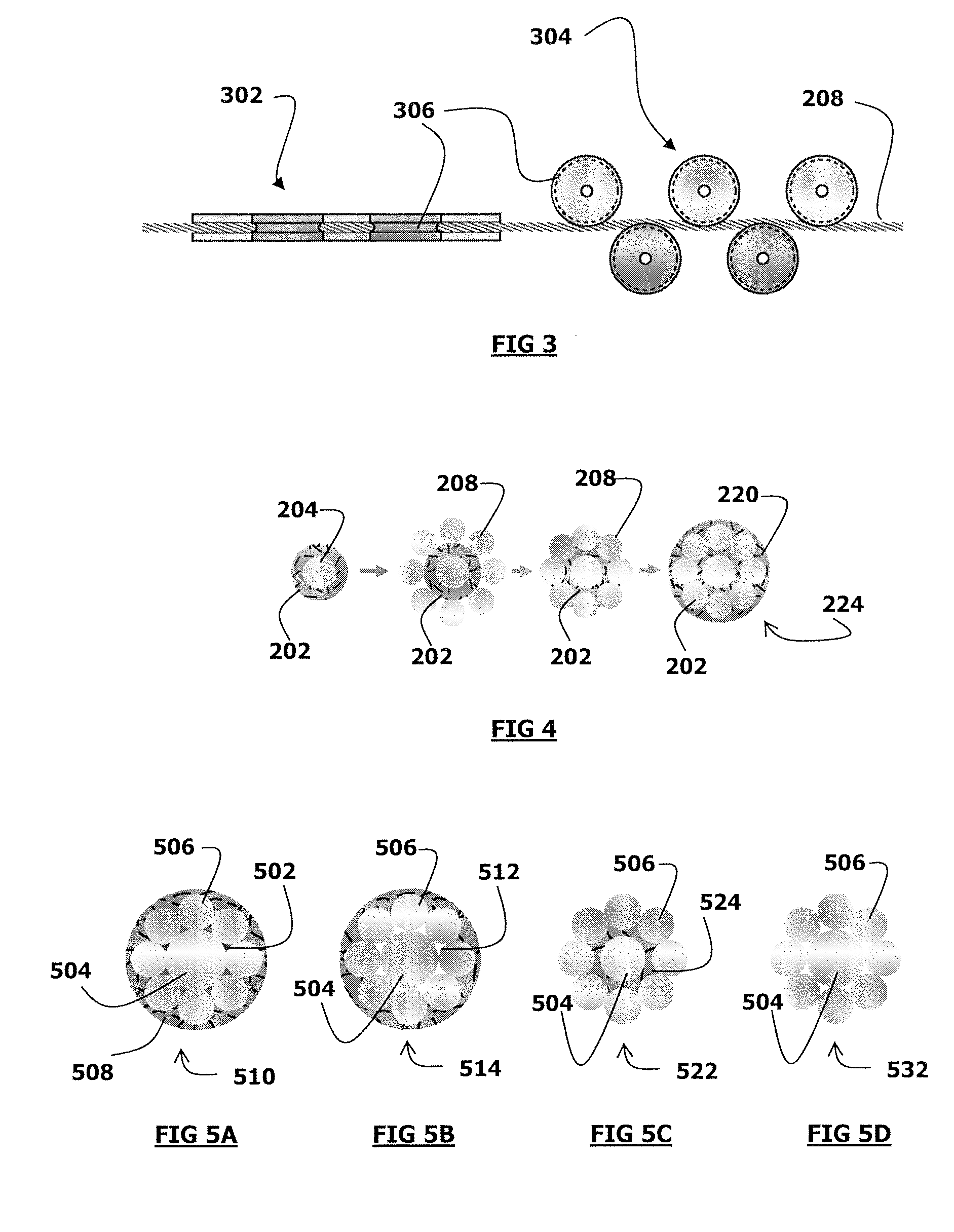

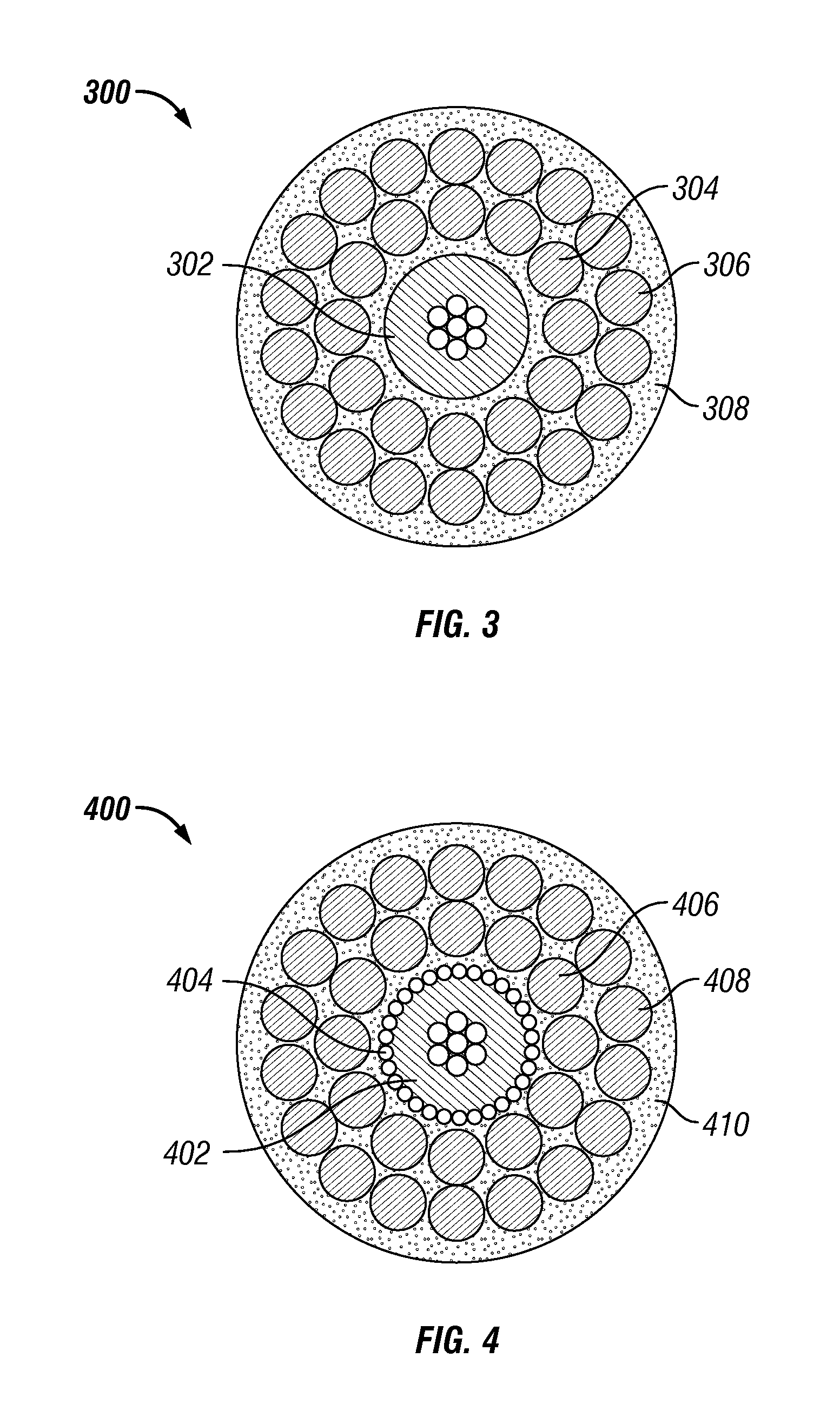

Electrical cables with stranded wire strength members

ActiveUS20070000682A1Improve corrosion resistancePrevent and minimize dangerous gas migrationNon-insulated conductorsPower cables with screens/conductive layersCoaxial cableEngineering

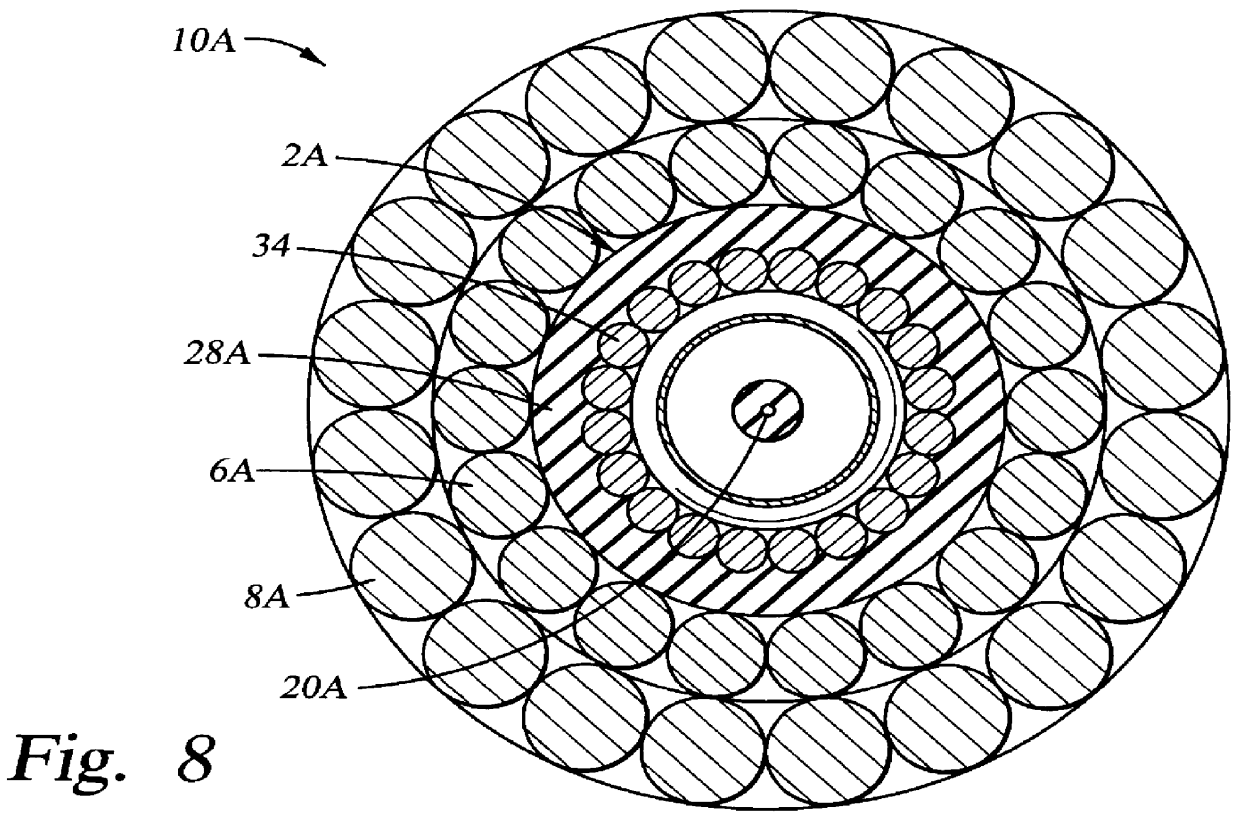

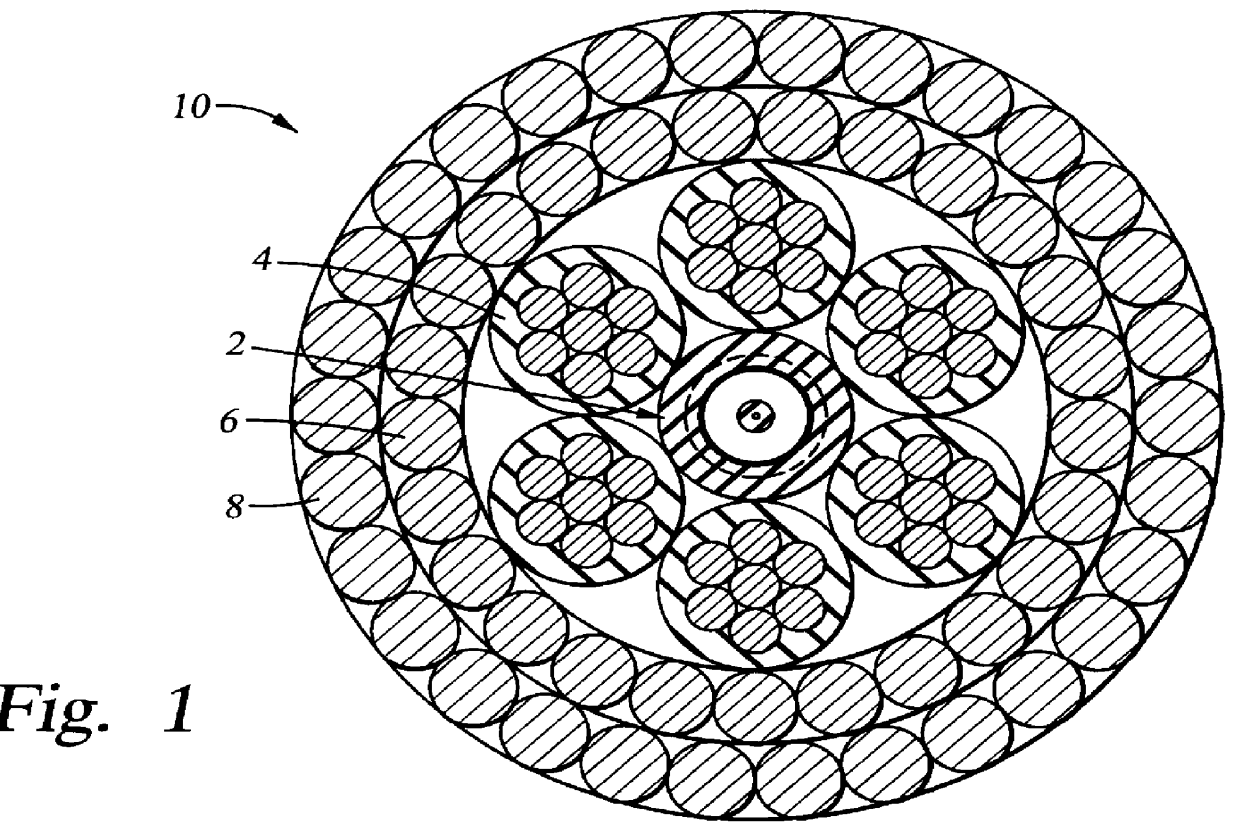

Disclosed are high strength wellbore electric cables, which are formed from a plurality of strength members. The strength members are formed from several stranded filament wires which may be encased within a jacket of polymeric material. The strength members may be used as a central strength member, or even layered around a central axially positioned component or strength member, to form a layer of strength members. Cables of the invention may be of any practical design, including monocables, coaxial cables, quadcables, heptacables, slickline cables, multi-line cables, etc., and have improved resistant to corrosion, torque balancing, and gas migration from a wellbore to the surface.

Owner:SCHLUMBERGER TECH CORP

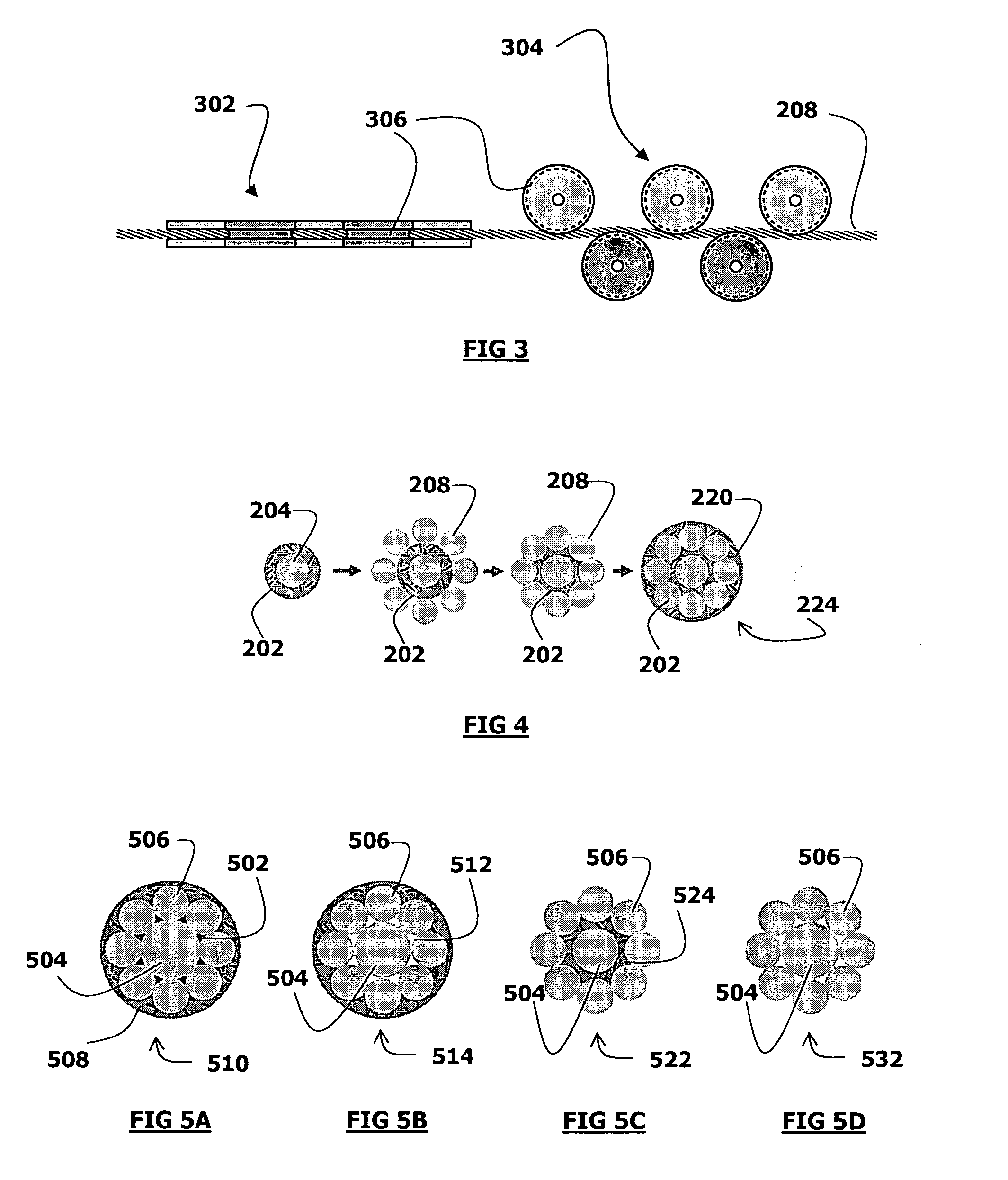

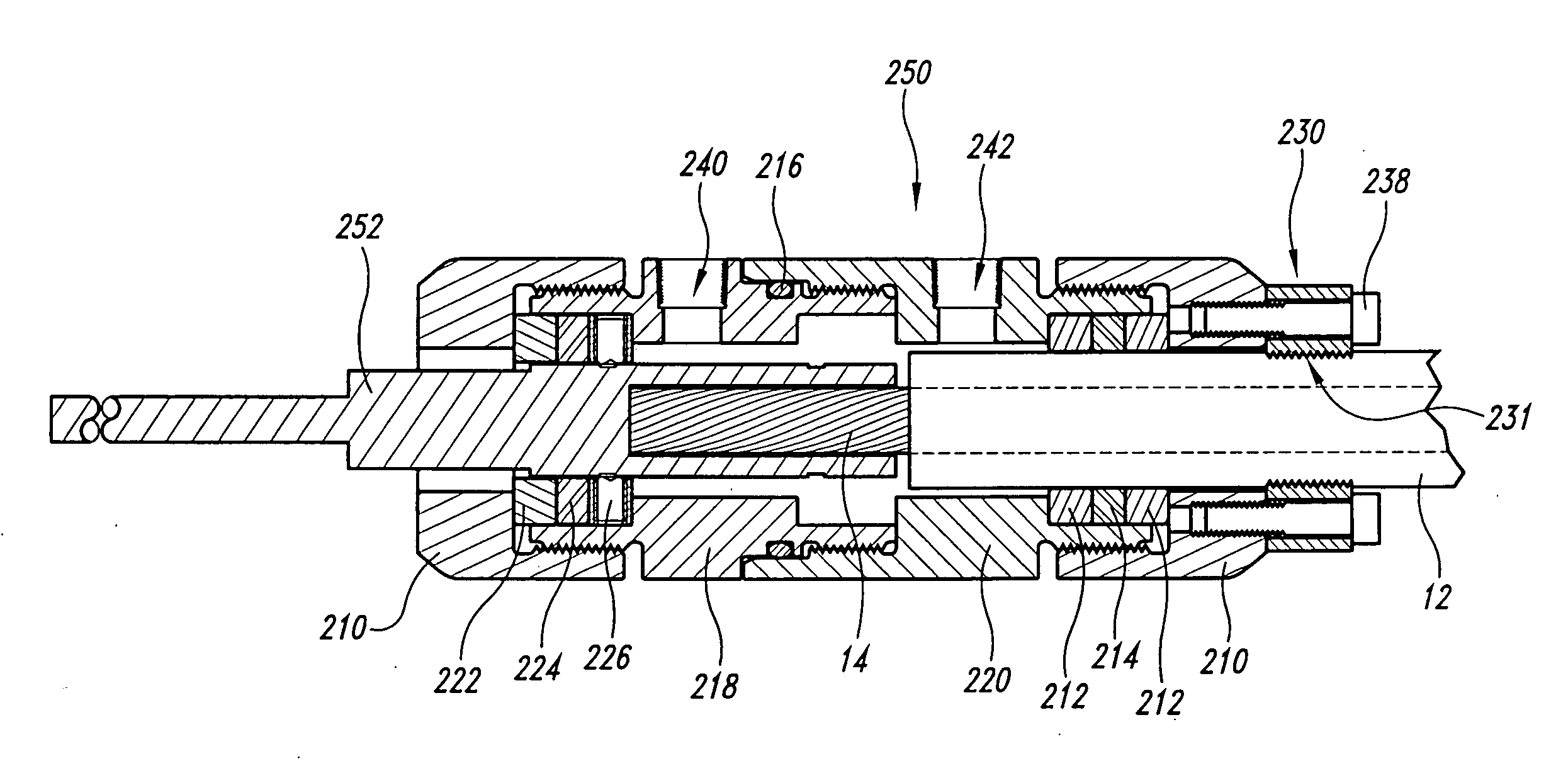

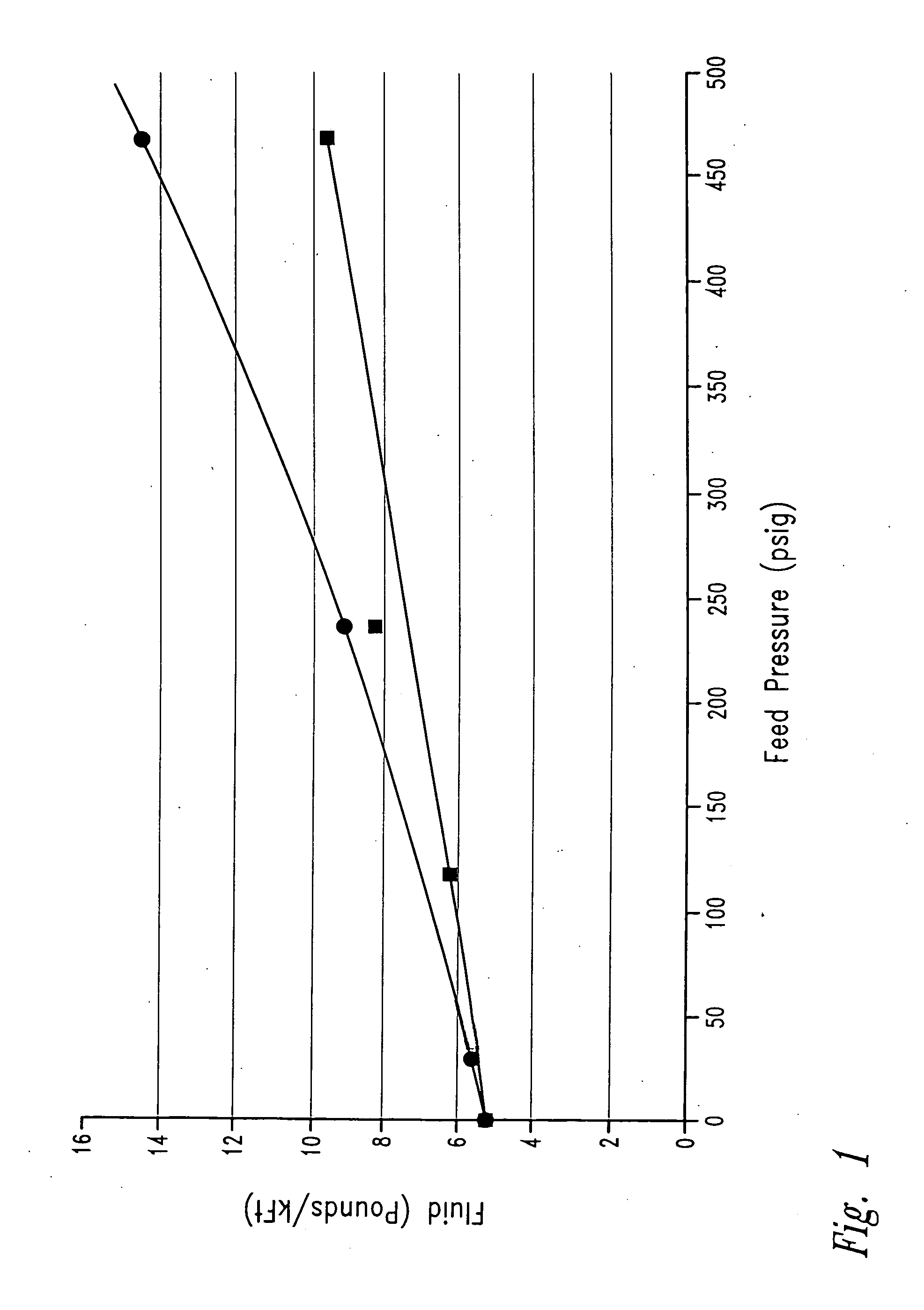

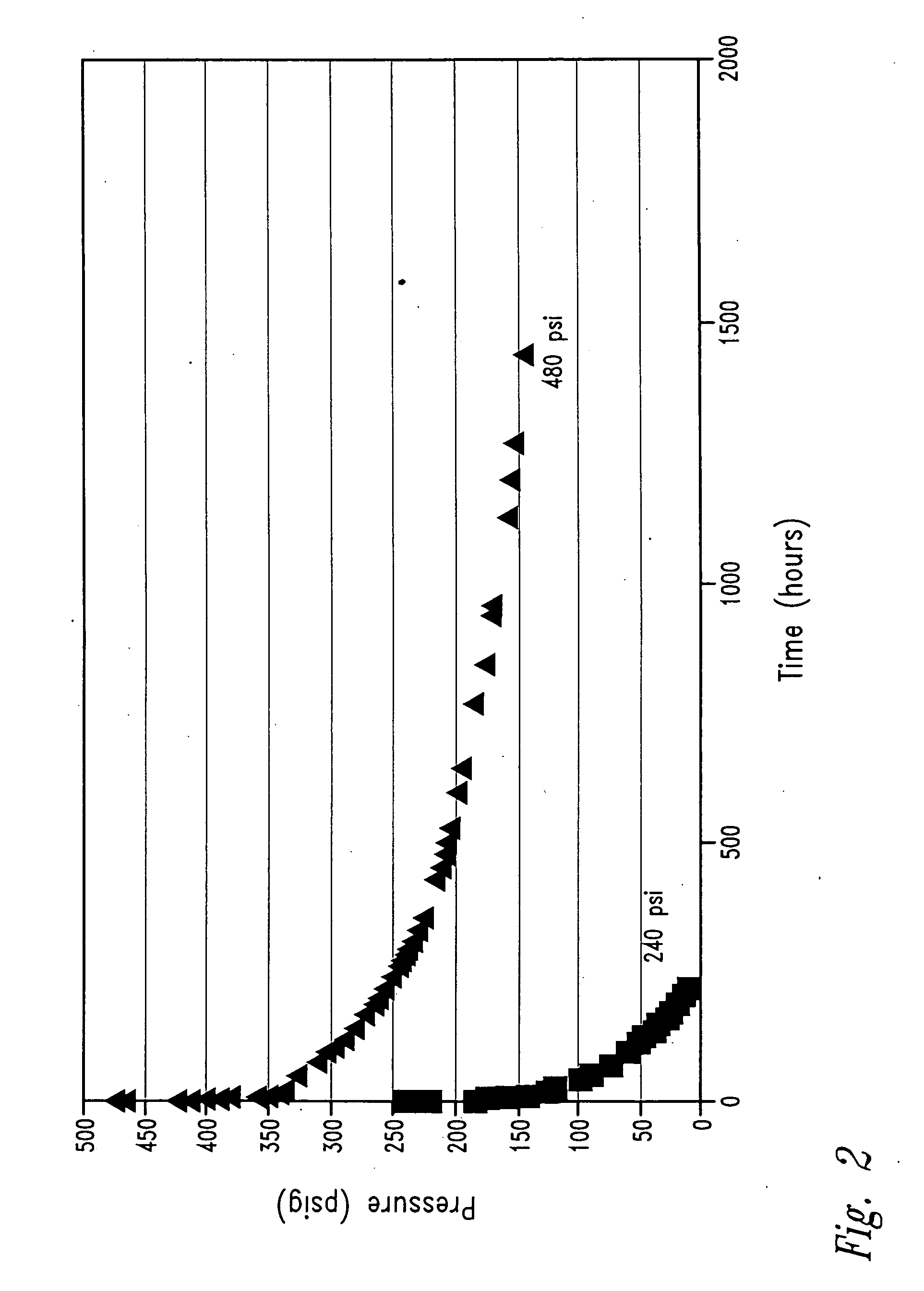

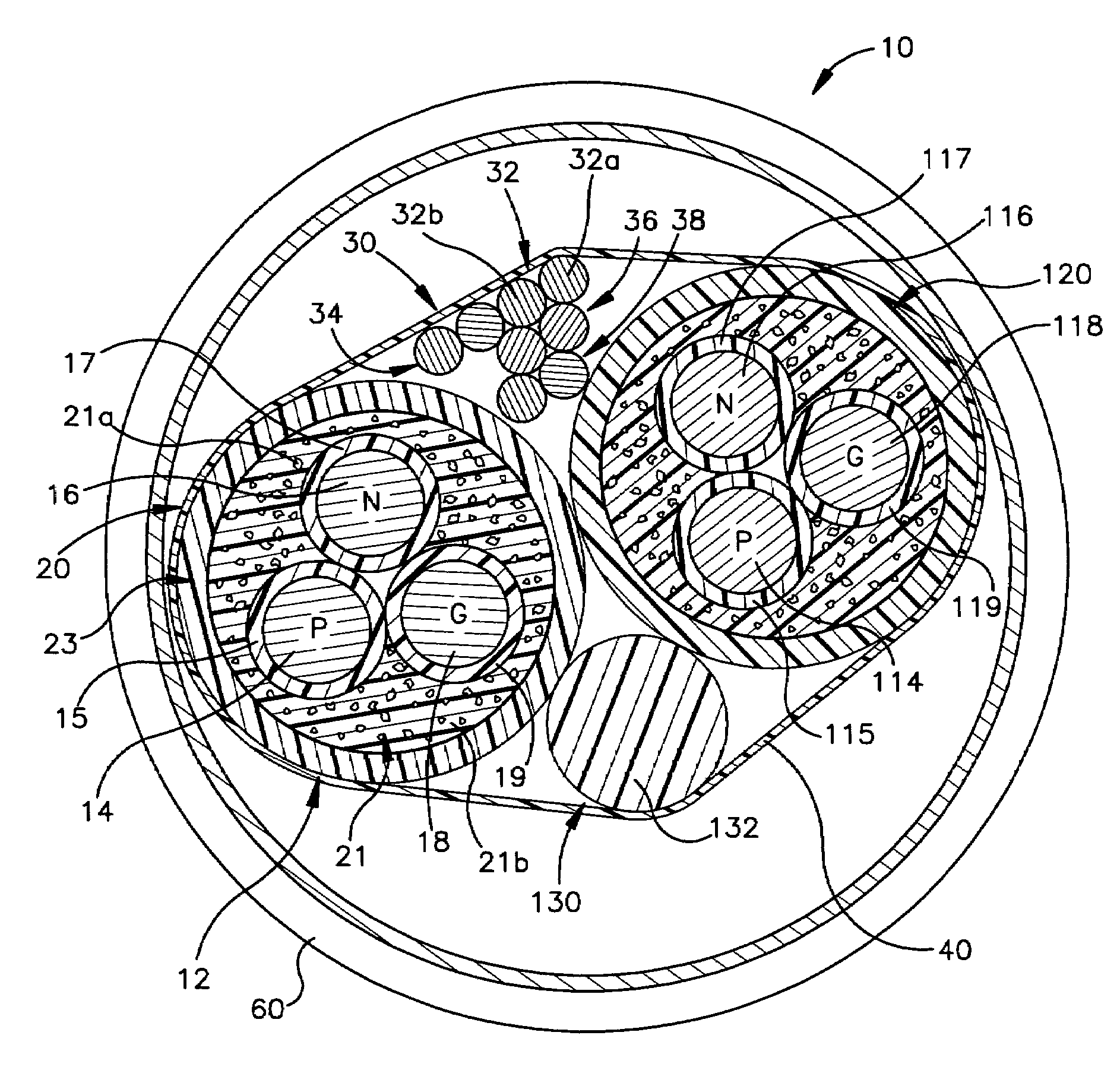

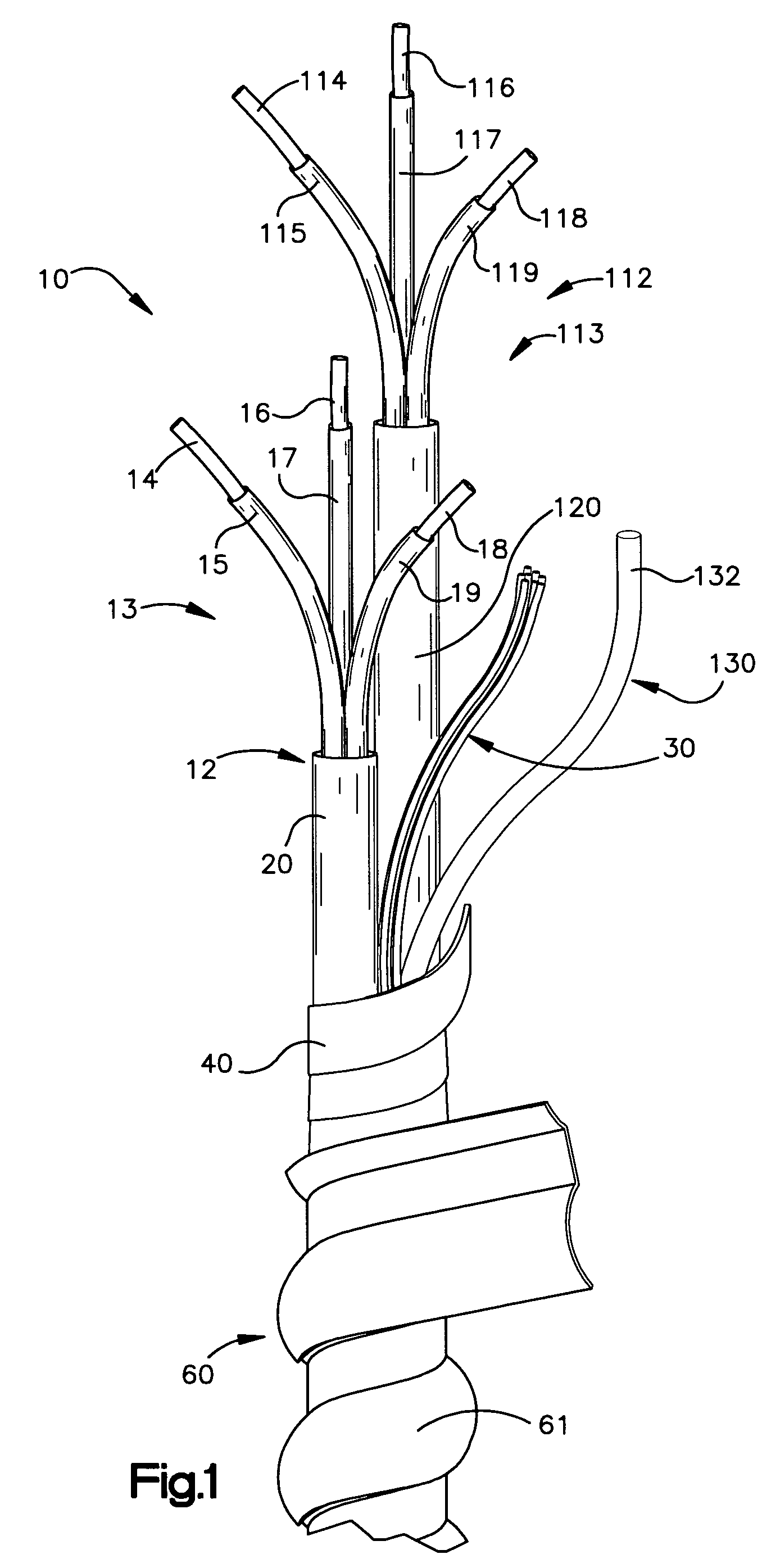

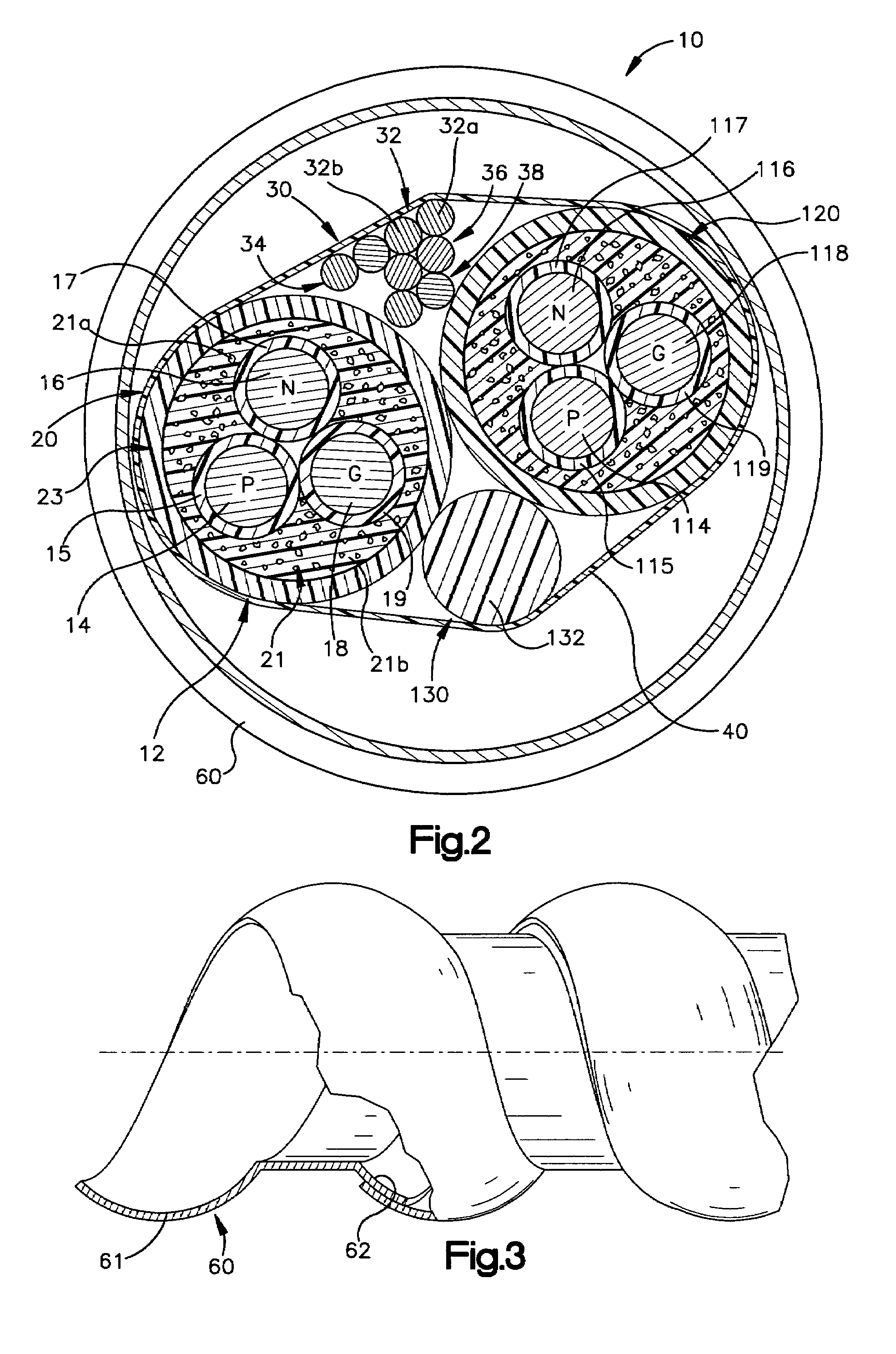

Method for treating electrical cable at sustained elevated pressure

ActiveUS20100095521A1Effective treatmentExcellent dielectric propertiesClimate change adaptationPower cables with screens/conductive layersElectrical conductorPolymer insulation

A method for enhancing the dielectric properties of an electrical cable segment having a central stranded conductor encased in a polymeric insulation jacket and an interstitial void volume in the region of the conductor, including filling the interstitial void volume with a dielectric property-enhancing fluid at a pressure below the elastic limit of the polymeric insulation jacket, and confining the fluid within the interstitial void volume at a residual pressure greater than about 50 psig, with the pressure being imposed along the entire length of the segment but below the elastic limit of the polymeric insulation jacket. Preferably, the residual pressure is sufficient to expand the interstitial void volume along the entire length of the cable segment by at least 5%.

Owner:NOVINIUM LLC

Insulated, high voltage power cable for use with low power signal conductors in conduit

ActiveUS7208684B2Excessive signalingEliminate needPower cables including communication wiresPower cables with screens/conductive layersPower cableElectrical conductor

The present invention is directed to a high voltage, insulated electrical power cable suitable for use adjacent to one or more low power signal communications conductors in metal or plastic conduit or raceway. In one preferred embodiment, the power cable includes a first group of one or more conductors for supplying power and a power conductor insulation jacket enclosing the first group of one or more conductors. The power conductor insulation jacket includes a soft magnetic material that functions as an electromagnetic field shield in the radio frequency range of approximately 1 megahertz to 400 megahertz thereby protecting the integrity of signals transmitted on the adjacent signal communications conductors.

Owner:ULECTRA CORP

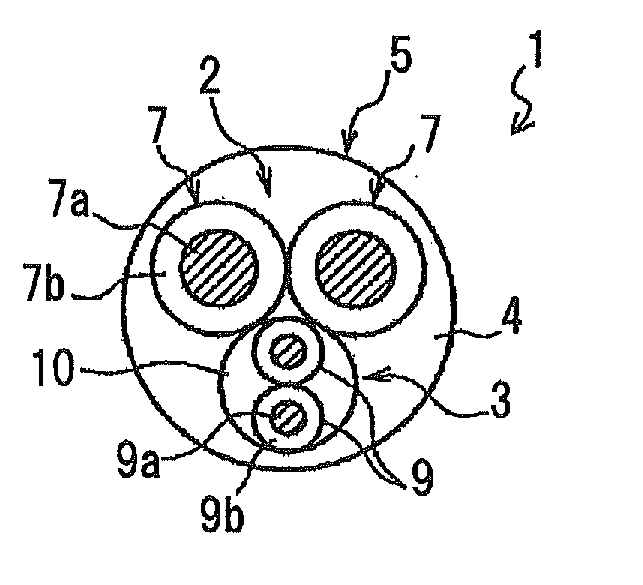

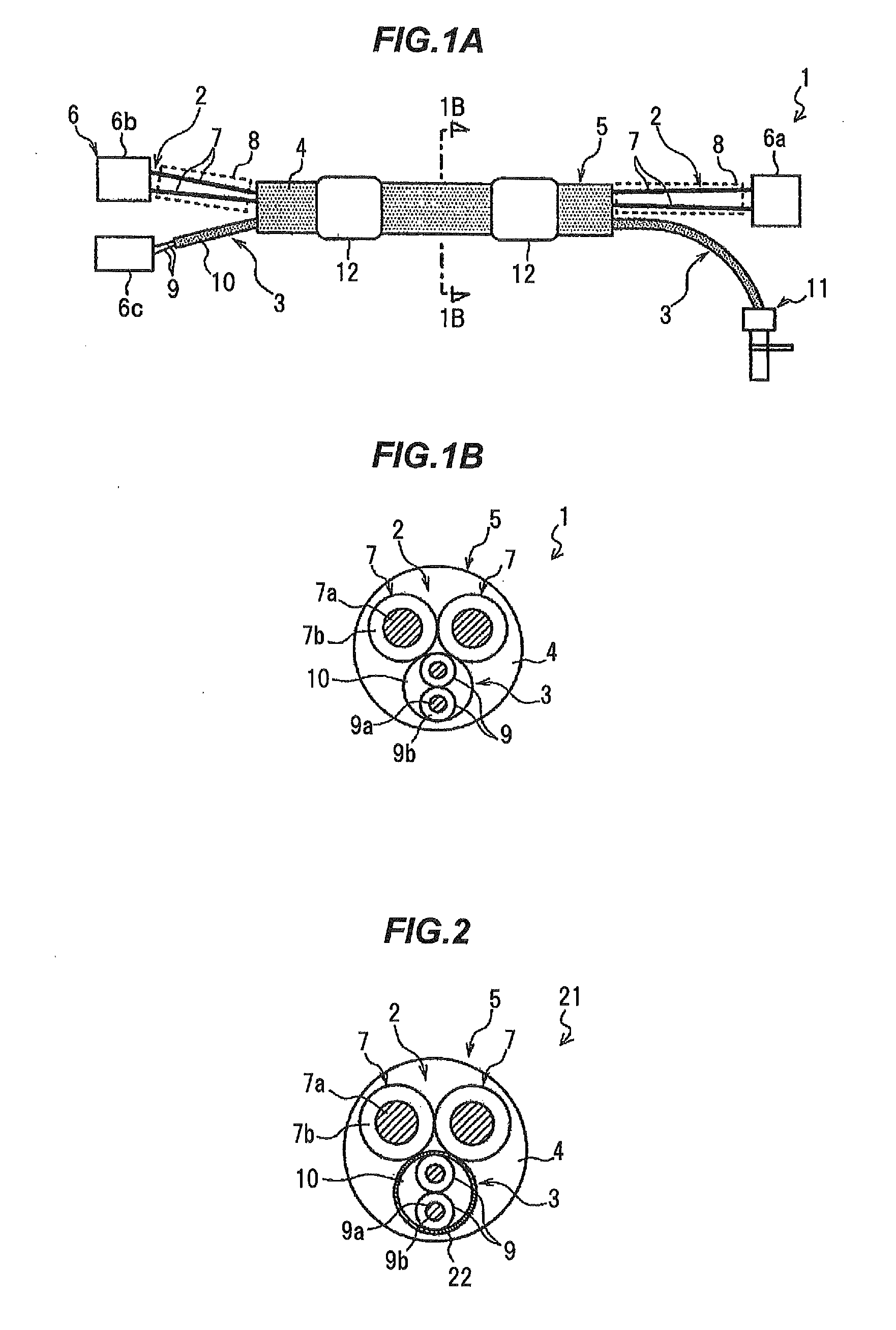

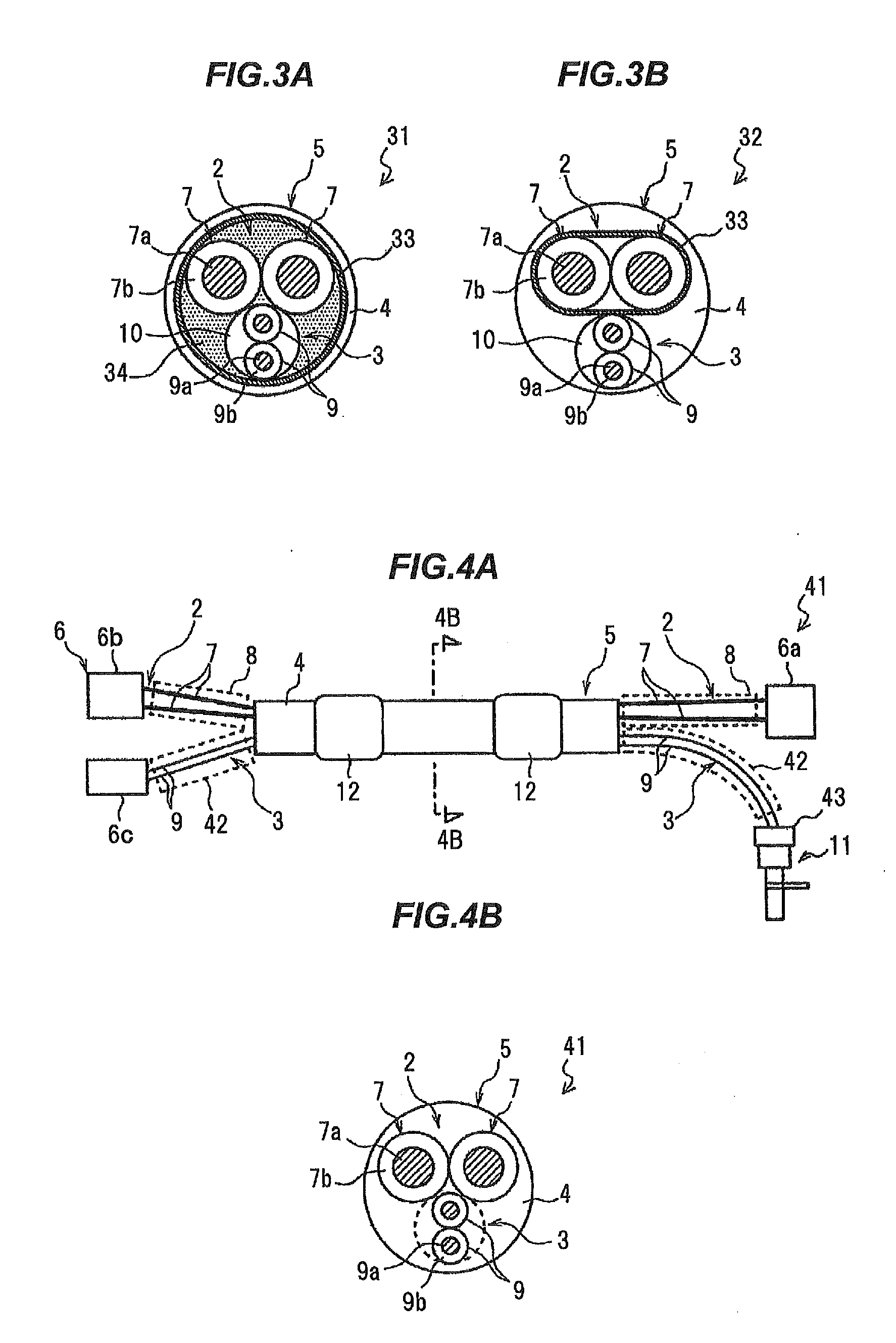

Complex harness

ActiveUS20130277087A1Easy to useConvenience to workPlastic/resin/waxes insulatorsPower cables including communication wiresEngineeringCable harness

Owner:HITACHI METALS LTD

Coaxial cable

ActiveUS7750240B2Reduce intensityGreat in weight and diameterApparatus for manufacturing conducting/semi-conducting layersPower cables with screens/conductive layersCoaxial cableConductive coating

A coaxial cable includes a core, an insulating layer, a shielding layer, a sheathing layer. The core includes an amount of carbon nanotubes having at least one conductive coating disposed about the carbon nanotubes. The carbon nanotubes are orderly arranged. The insulating layer is about the core. The shielding layer is about the insulating layer. The sheathing layer is about the shielding layer.

Owner:ABBOTT CARDIOVASCULAR +2

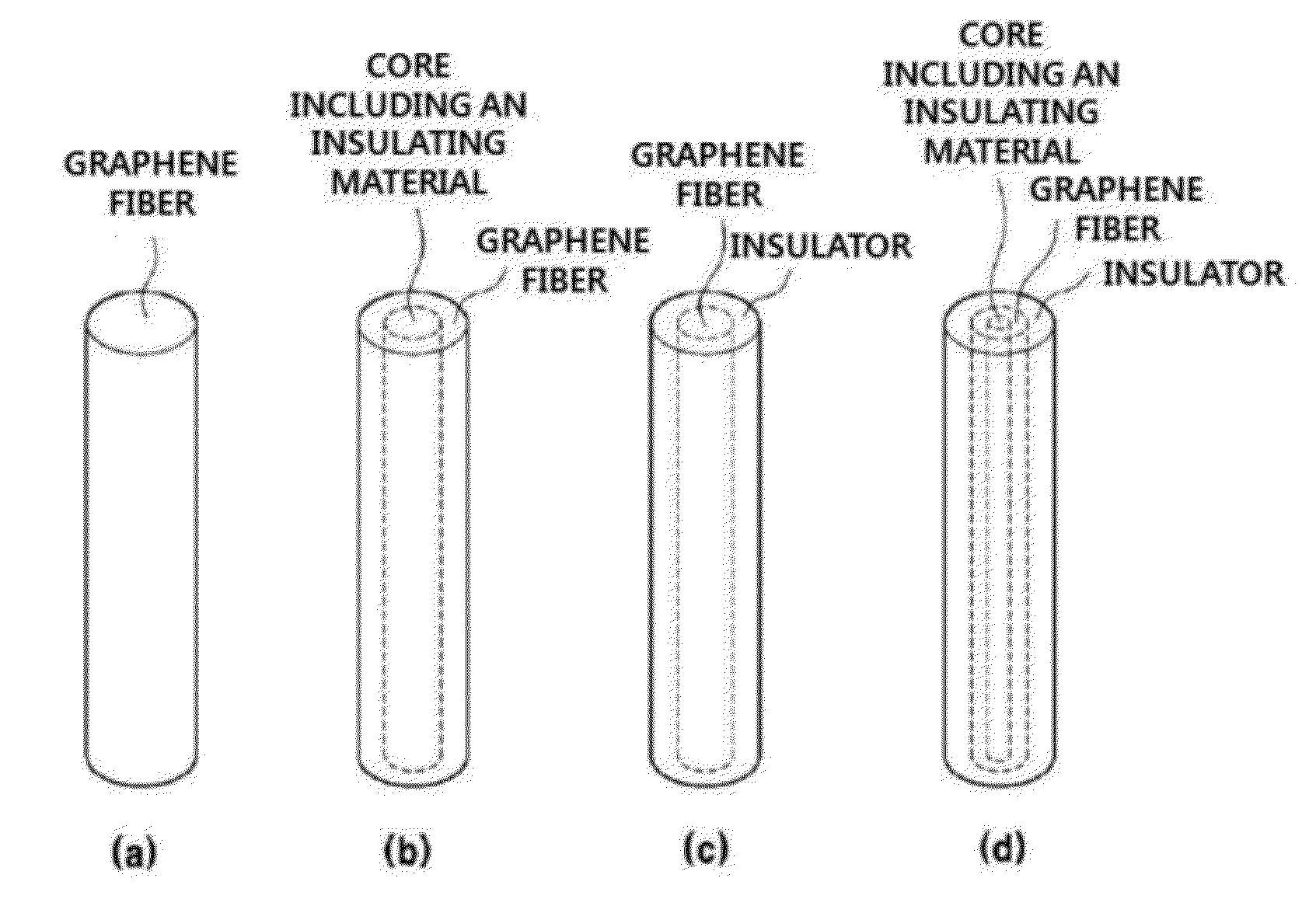

Graphene fiber, method for manufacturing same and use thereof

ActiveUS20120298396A1Quality improvementLow costCoaxial cables/analogue cablesMaterial nanotechnologyFiberCoaxial cable

The present disclosure relates to a manufacturing method of a graphene fiber, a graphene fiber manufactured by the same method, and use thereof. The graphene fiber formed by using graphenes of linear pattern can be applied to various fields such as an electric wire and coaxial cable.

Owner:GRAPHENE SQUARE

Protective sleeve fabricated with hybrid yard, hybrid yarn, and methods of construction thereof

ActiveUS20100084179A1Improve conductivityNon-insulated conductorsMagnetic/electric field screeningYarnArchitectural engineering

A hybrid yarn filament and sleeve constructed therefrom for protecting elongate members against at least one of EMI, RFI or ESD is provided, along with methods of constructing the hybrid yarn filament and sleeves. The hybrid yarn filament has a nonconductive filament and at least one conductive wire filament overlying an outer surface of the nonconductive filament. The hybrid yarn filament is arranged in electrical communication with itself or other hybrid yarn filaments during construction of the sleeve to provide uniform shielding against EMI, RFI, and and / or ESD.

Owner:FEDERAL MOGUL POWERTAIN LLC

Cables with stranded wire strength members

ActiveUS7326854B2Improve corrosion resistancePrevent and minimize dangerous gas migrationNon-insulated conductorsPower cables with screens/conductive layersCorrosion resistant alloyCoaxial cable

High strength cables formed from strength members. The strength members are formed from bimetallic filament wires which may be encased within a jacket of polymeric material. The bimetallic filament wires wherein the filaments include a high strength core and a corrosion resistant alloy clad forming the outer layer of the filament. The strength members may be used individually, as a central strength member, or even layered around a central axially positioned component or strength member, to form a layer of strength members. Cables of the invention may be of any practical design, including monocables, coaxial cables, quadcables, heptacables, slickline cables, multi-line cables, suspension cables, and the like.

Owner:SCHLUMBERGER TECH CORP

Thermally tuned coaxial cable for microwave antennas

ActiveUS7642451B2Cable insulation constructionPower cables with screens/conductive layersCoaxial cableMicrowave

A coaxial cable, including an outer conductor and an inner conductor adapted to connect to an energy source for treating tissue and first and second dielectric materials disposed between the inner conductor and the outer conductor which position the inner conductor relative to the outer conductor in general concentric relation thereto. The first dielectric material has a first coefficient of thermal expansion and the second dielectric material has a second coefficient of thermal expansion different from the first coefficient of thermal expansion.

Owner:TYCO HEALTHCARE GRP LP

Cables with stranded wire strength members

ActiveUS20070044991A1Improve corrosion resistancePrevent and minimize dangerous gas migrationNon-insulated conductorsPower cables with screens/conductive layersCorrosion resistant alloyCoaxial cable

High strength cables formed from strength members. The strength members are formed from bimetallic filament wires which may be encased within a jacket of polymeric material. The bimetallic filament wires wherein the filaments include a high strength core and a corrosion resistant alloy clad forming the outer layer of the filament. The strength members may be used individually, as a central strength member, or even layered around a central axially positioned component or strength member, to form a layer of strength members. Cables of the invention may be of any practical design, including monocables, coaxial cables, quadcables, heptacables, slickline cables, multi-line cables, suspension cables, and the like.

Owner:SCHLUMBERGER TECH CORP

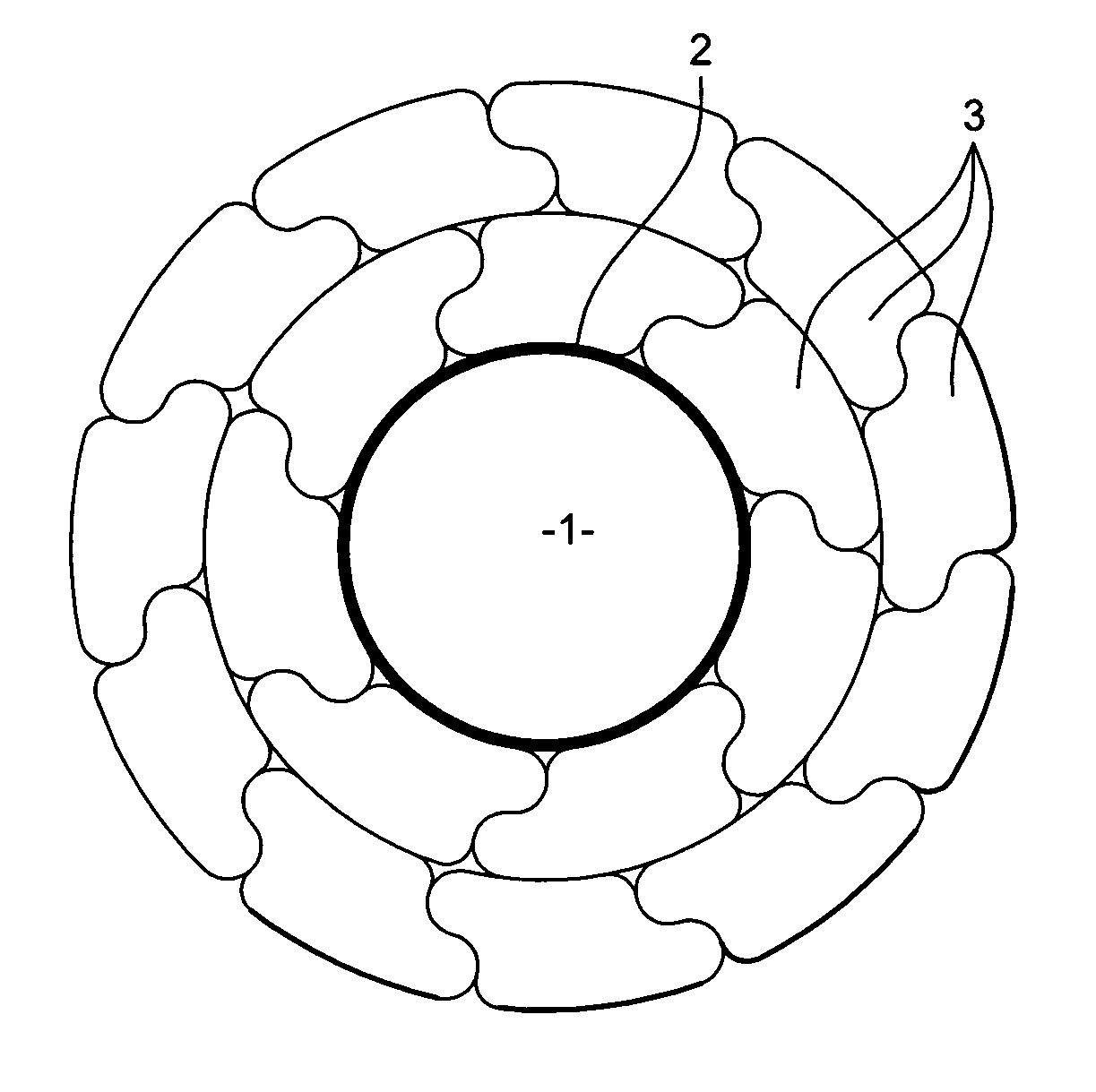

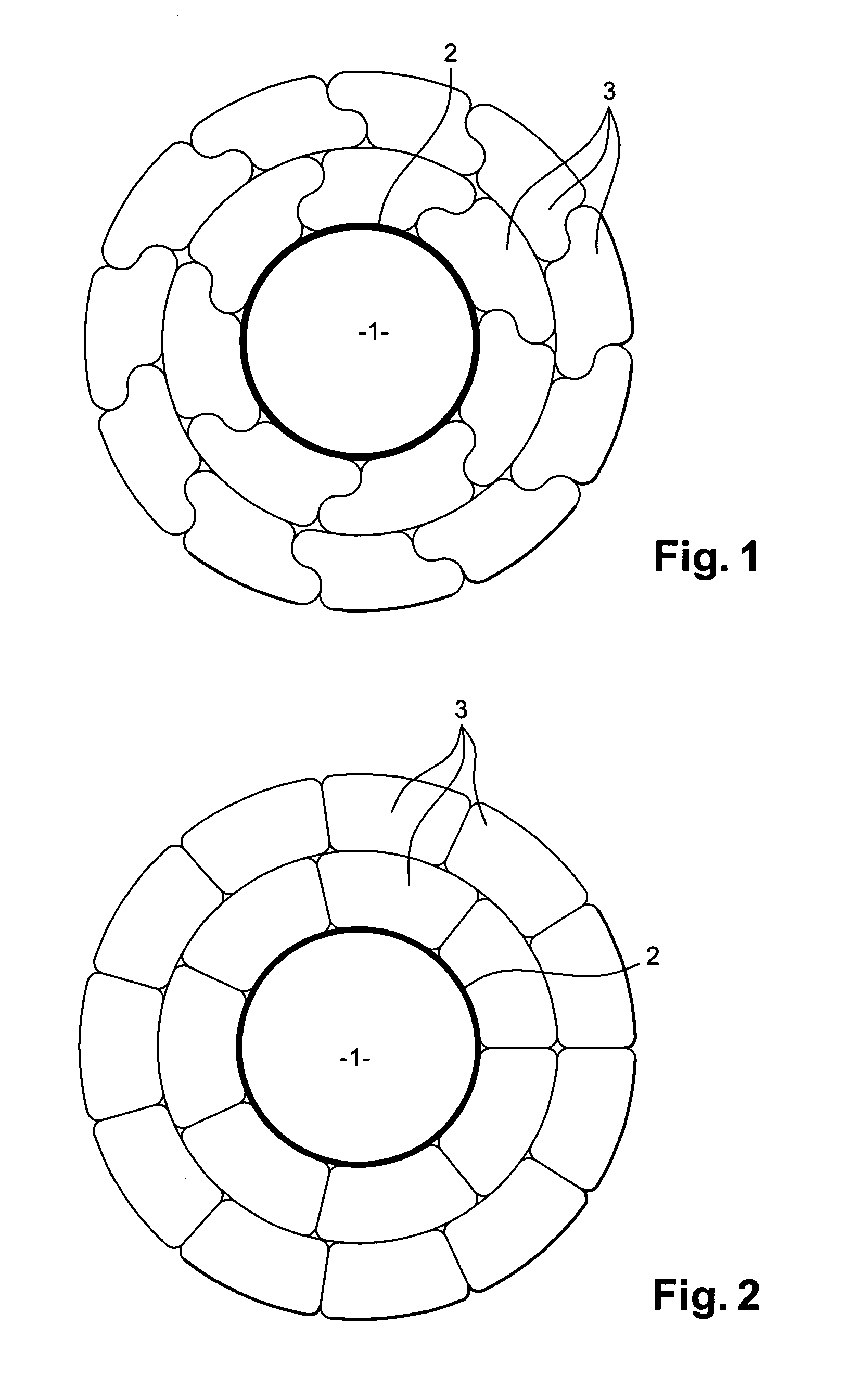

Electricity transport conductor for overhead lines

The invention relates to a method of fabricating an electricity transport conductor, in particular for overhead power lines, that are to operate at an operating temperature greater than or equal to 200° C., and comprising at least one composite central core 1 made of continuous fibers impregnated with an epoxy resin matrix, the core being covered in at least one layer of insulating material 2, and conductor wires 3 of aluminum or aluminum alloy being wound around the core. According to the invention, said insulating material is compatible with said operating temperature and is put into place on said core 1 without subsequent heating.

Owner:NEXANS

Shield cable

InactiveCN1758384ASimple structureEasy to producePlastic/resin/waxes insulatorsPower cables with screens/conductive layersShielded cableElectrical conductor

A new screen cable includes insulation coil cores on the conductor, a filling material, a belting layer, a screen layer and a sheathing characterizing that the screen layer is a wired layer of copper-clad aluminum or copper-clad aluminum alloy wires, the copper is uniformly distributed longitudinally on the outer surface of the aluminum or its alloy wires, both of them are concentric and are jointed by melt.

Owner:BAOSHENG SCI & TECH INNOVATION

Enhanced electrical cables

ActiveUS7402753B2Reduce frictionPower cables with screens/conductive layersInsulated cablesElectrical conductorEngineering

Owner:SCHLUMBERGER TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com