Patents

Literature

1535results about "Apparatus for manufacturing conducting/semi-conducting layers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

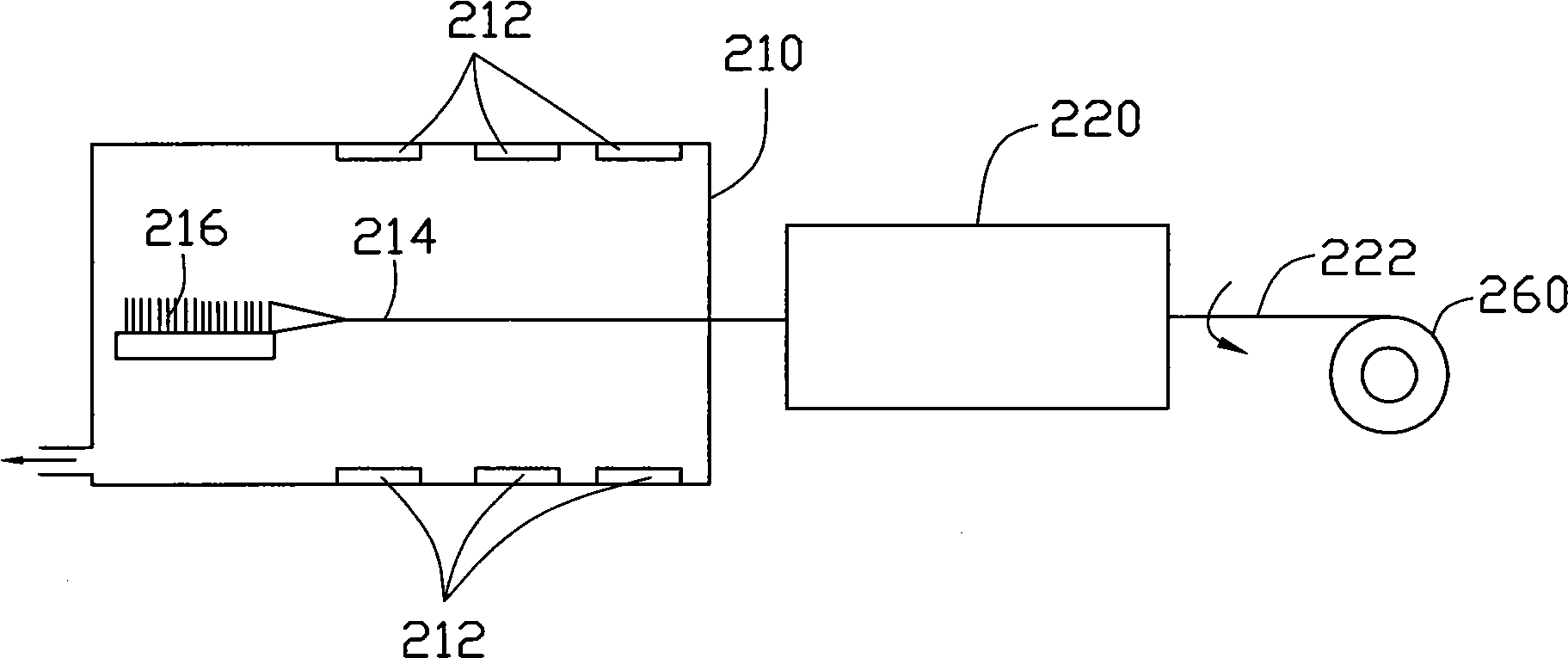

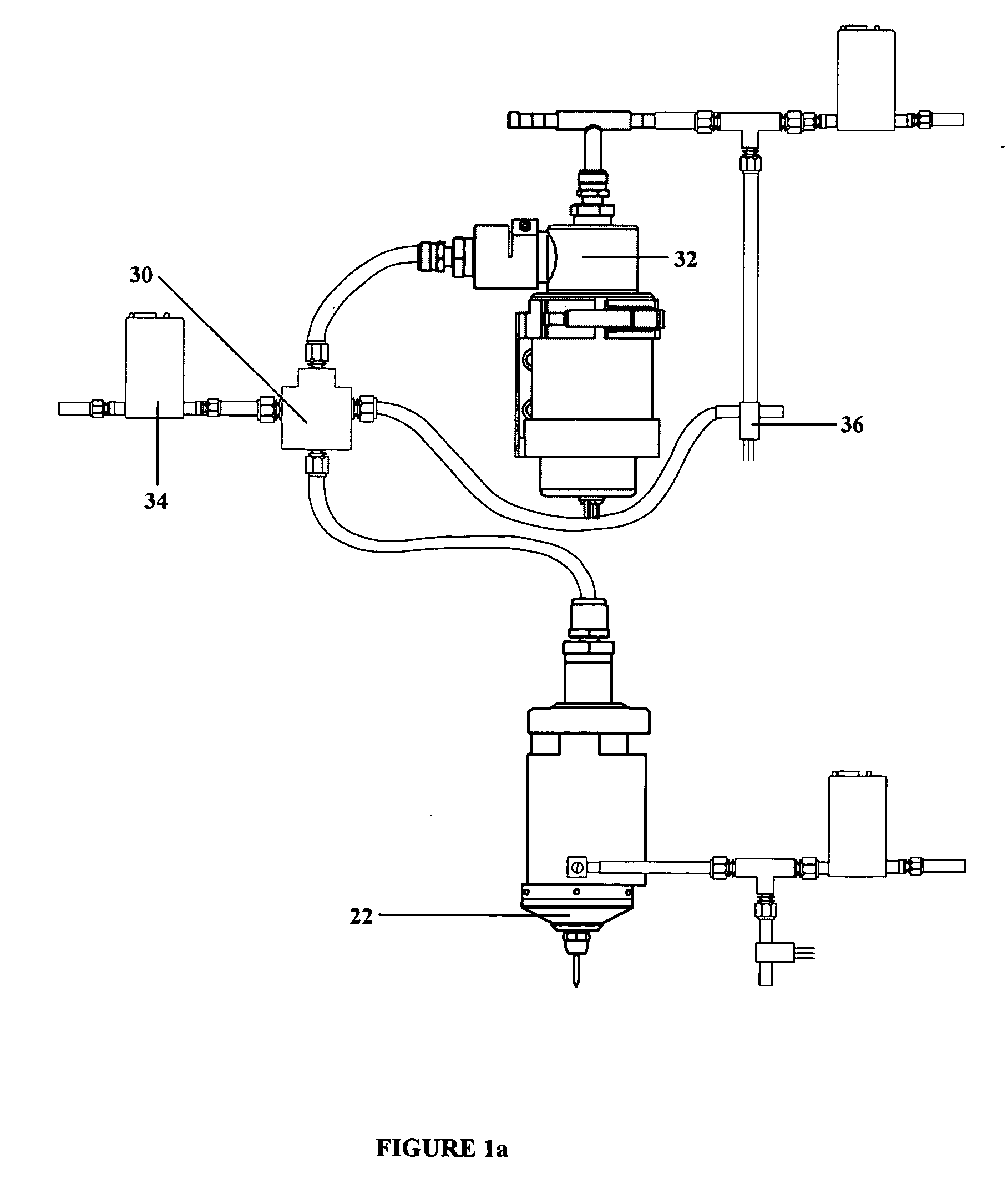

Aerodynamic jetting of aerosolized fluids for fabrication of passive structures

InactiveUS7674671B2Liquid surface applicatorsSemiconductor/solid-state device manufacturingOptical propertyDirect writing

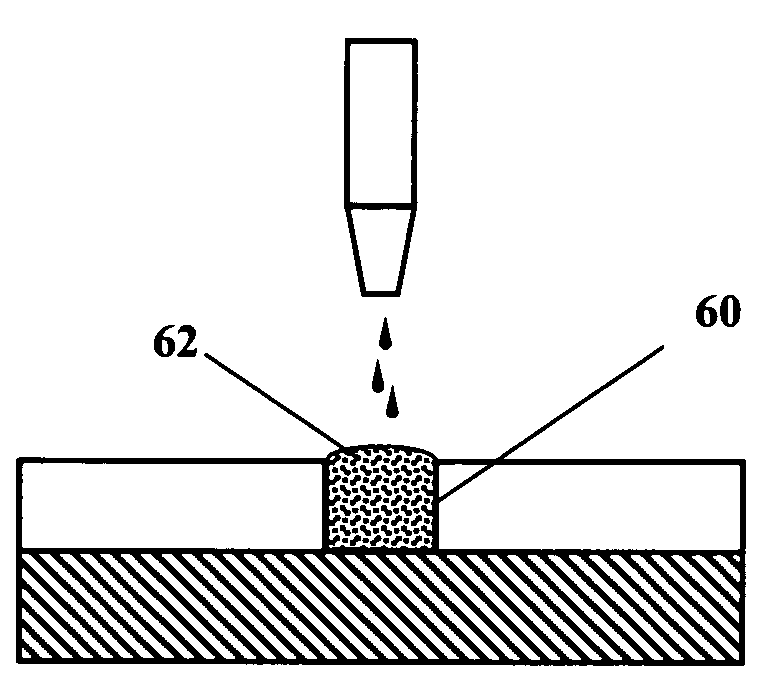

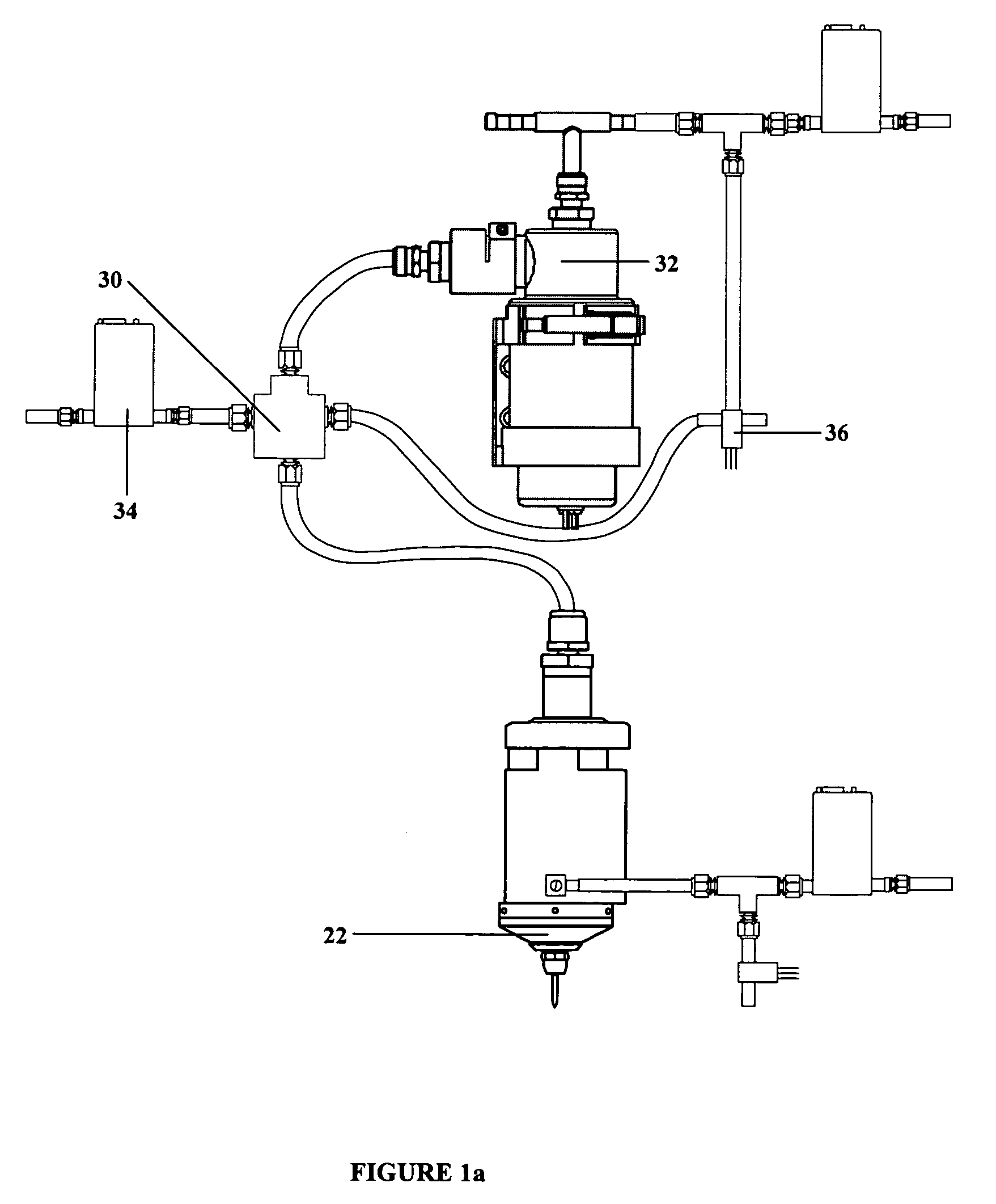

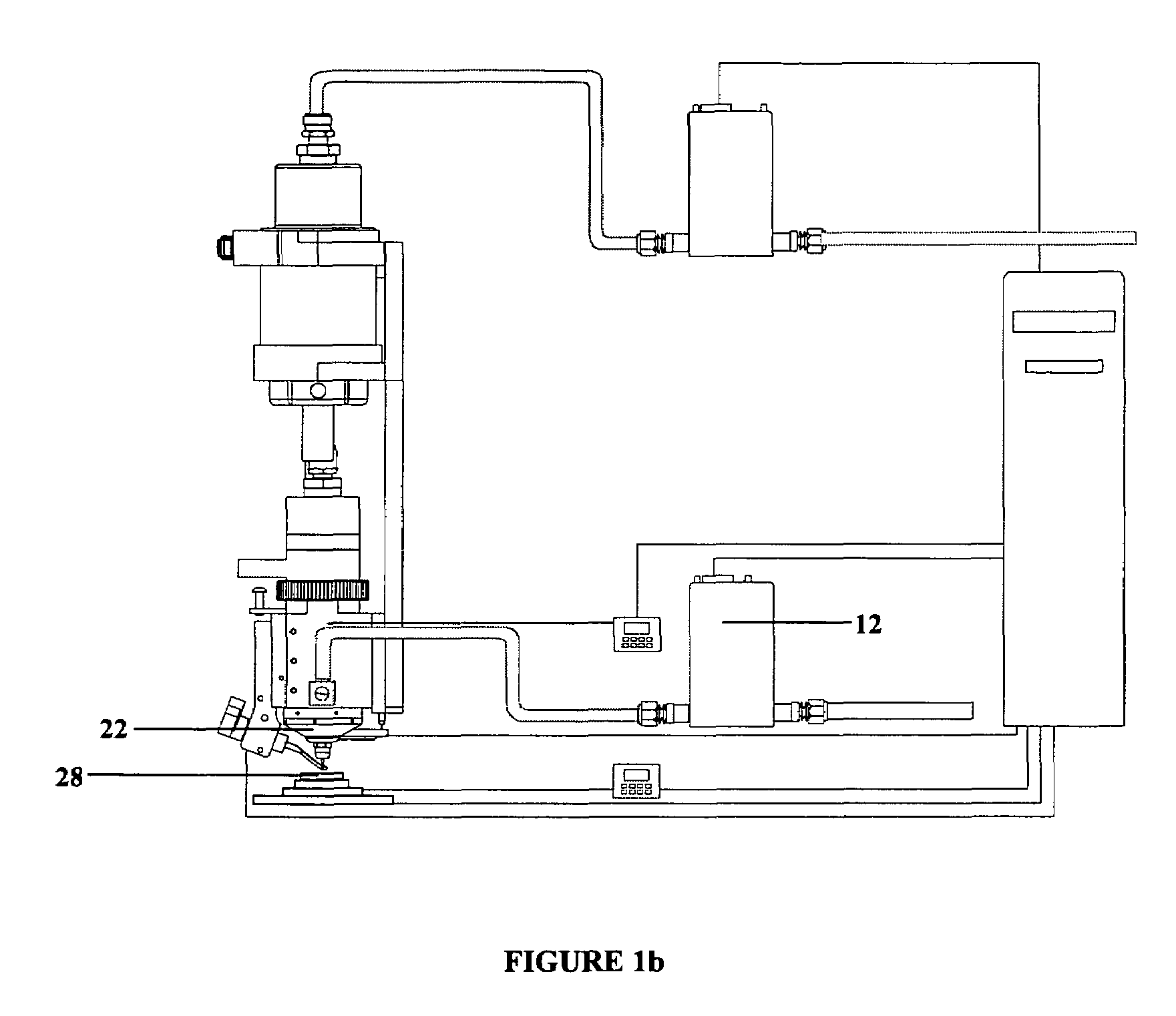

Method and apparatus for direct writing of passive structures having a tolerance of 5% or less in one or more physical, electrical, chemical, or optical properties. The present apparatus is capable of extended deposition times. The apparatus may be configured for unassisted operation and uses sensors and feedback loops to detect physical characteristics of the system to identify and maintain optimum process parameters.

Owner:OPTOMEC DESIGN CO

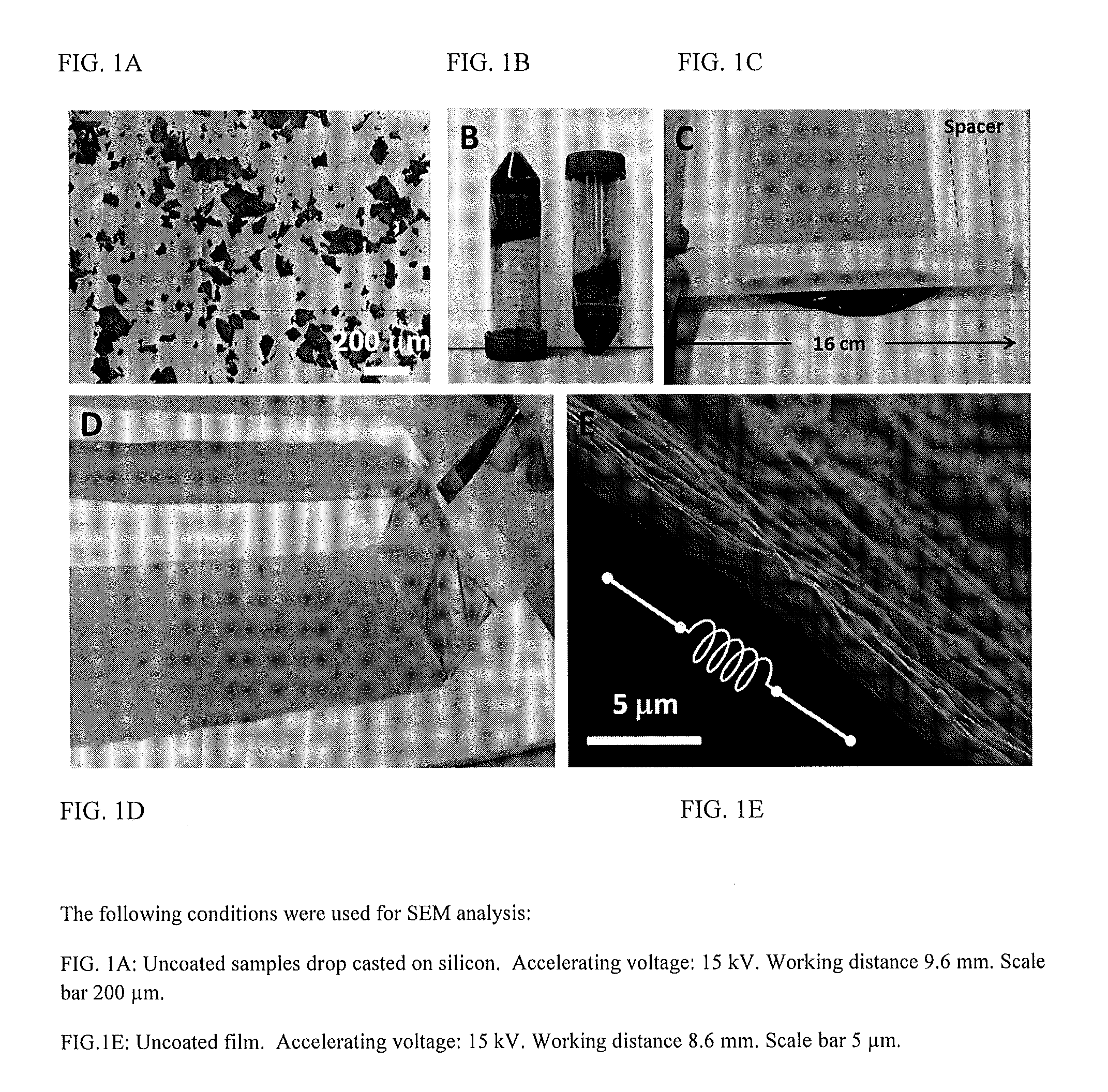

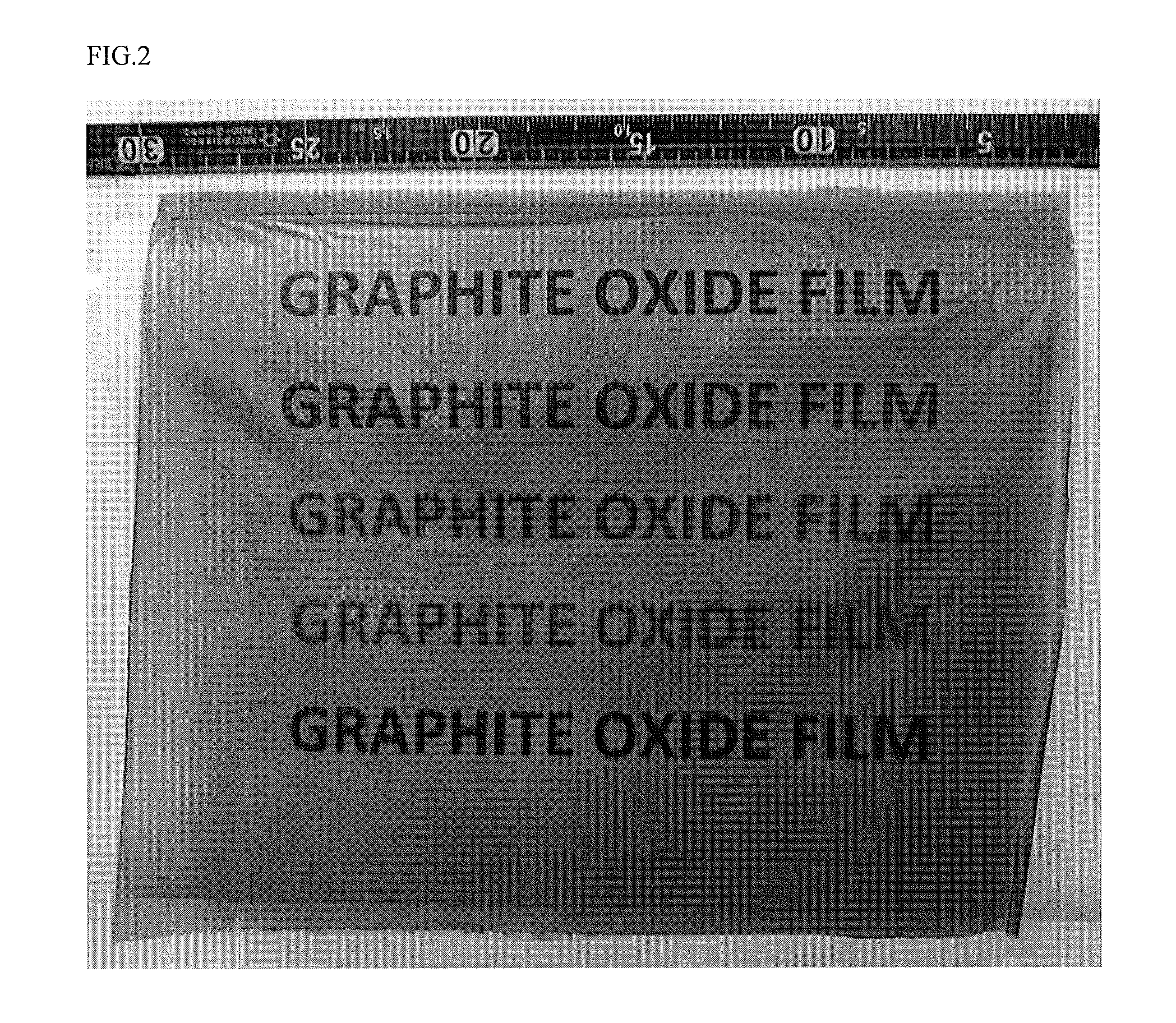

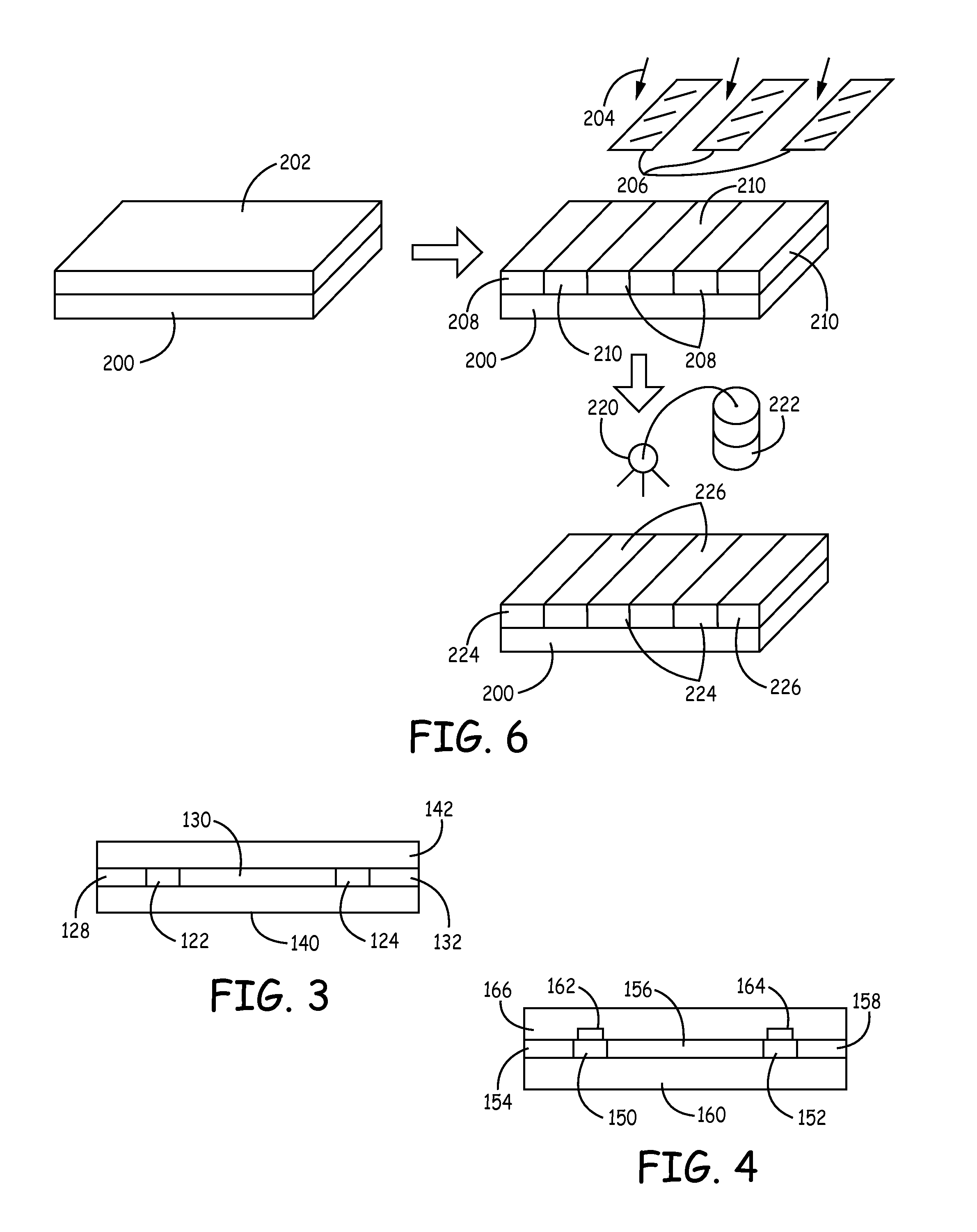

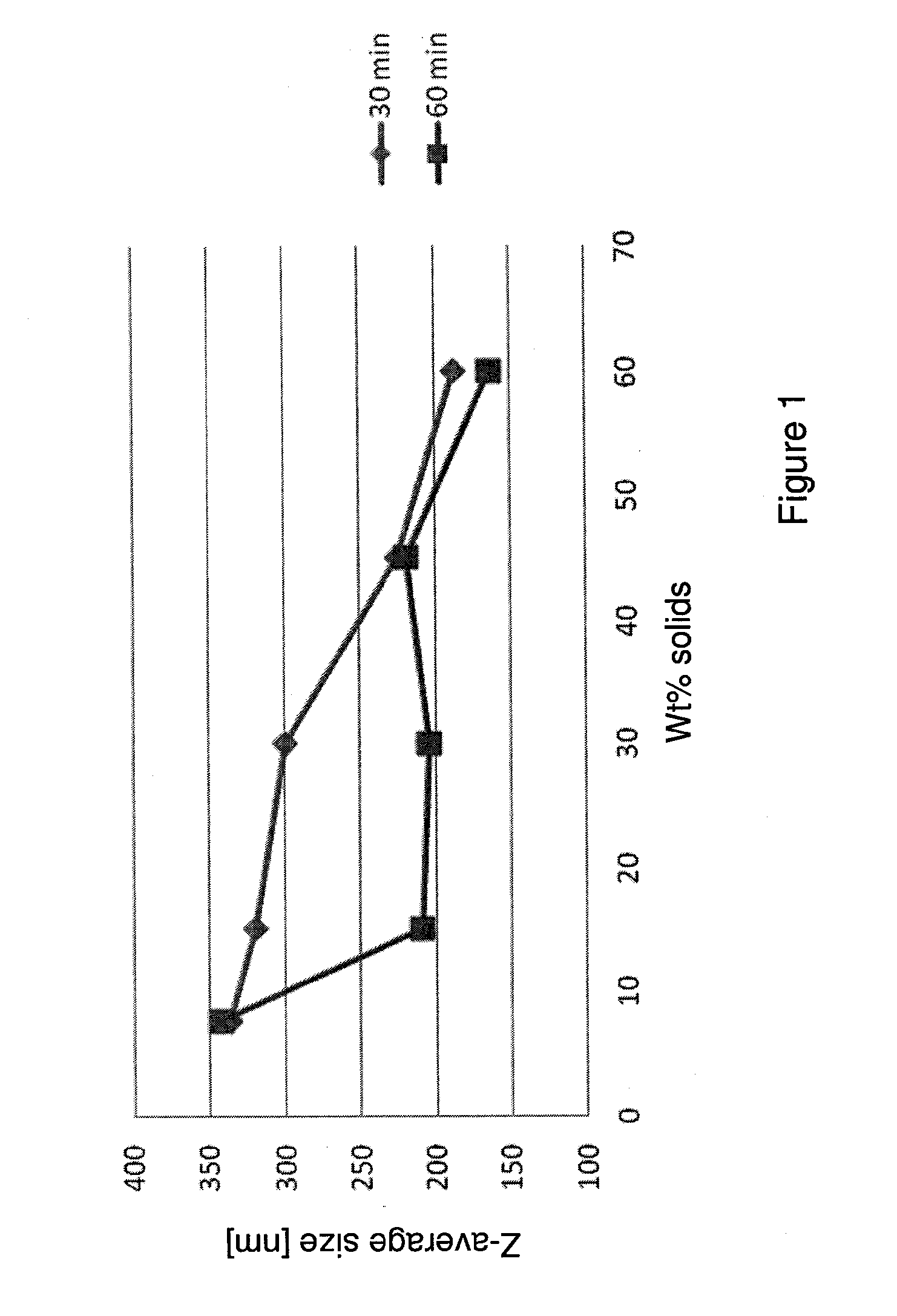

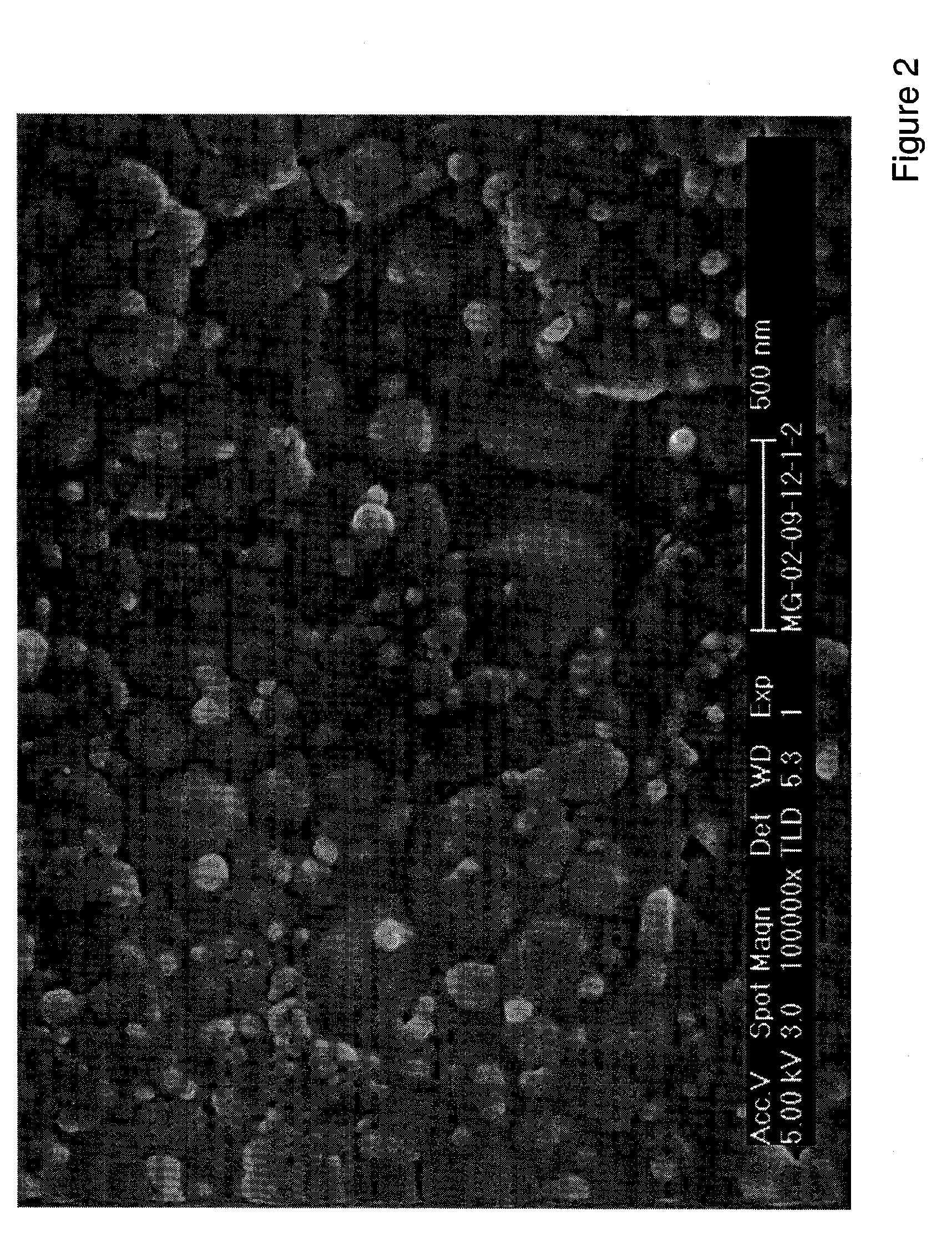

Method for preparing graphene oxide films and fibers

ActiveUS20150111449A1Improve conductivityHigh densityCarbon compoundsFilament/thread formingFiberSolid content

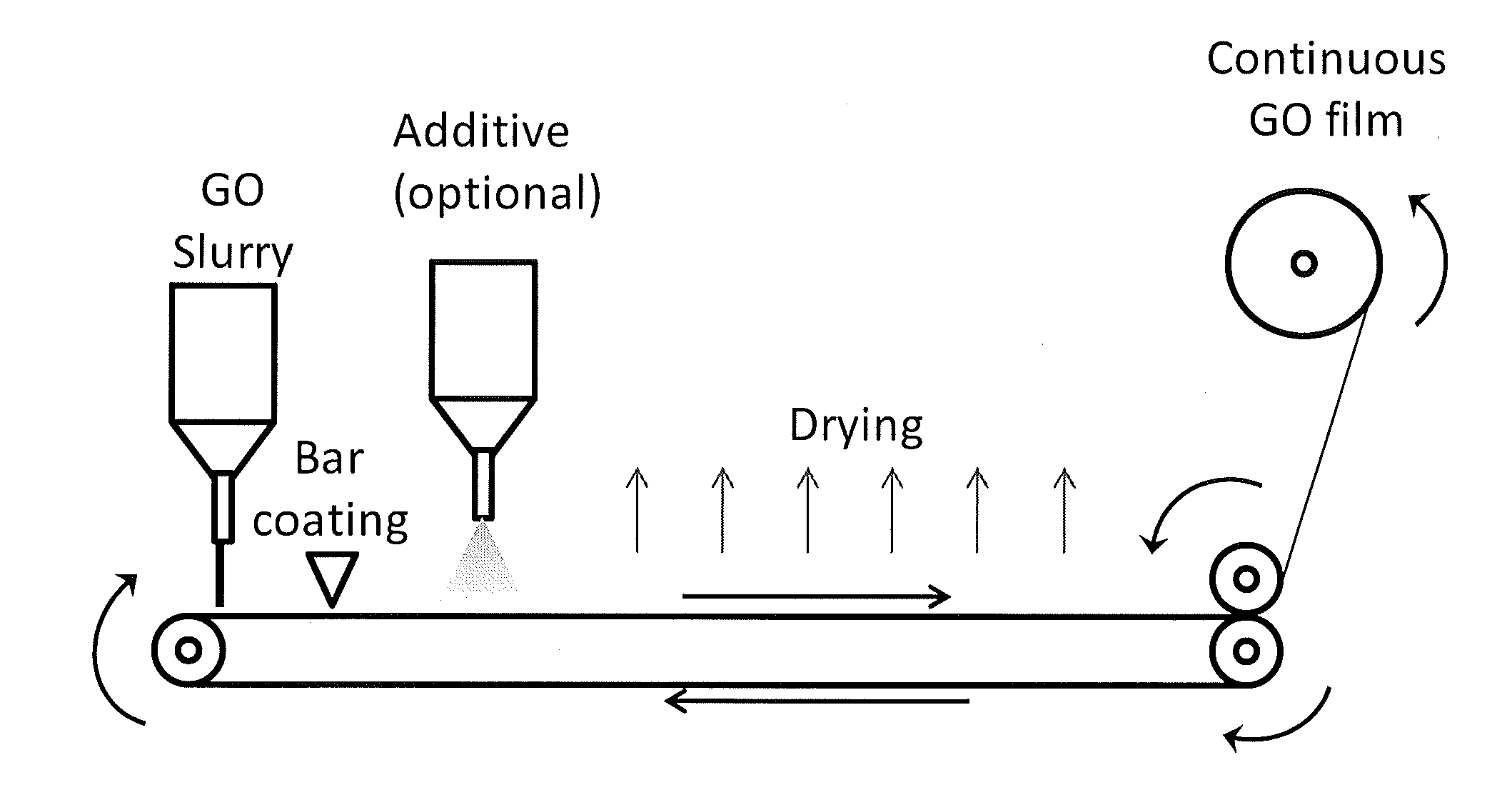

We report a method of preparation of highly elastic graphene oxide films, and their transformation into graphene oxide fibers and electrically conductive graphene fibers by spinning. Methods typically include: 1) oxidation of graphite to graphene oxide, 2) preparation of graphene oxide slurry with high solid contents and residues of sulfuric acid impurities. 3) preparation of large area films by bar-coating or dropcasting the graphene oxide dispersion and drying at low temperature. 4) spinning the graphene oxide film into a fiber, and 5) thermal or chemical reduction of the graphene oxide fiber into an electrically conductive graphene fiber. The resulting films and fiber have excellent mechanical properties, improved morphology as compared with current graphene oxide fibers, high electrical conductivity upon thermal reduction, and improved field emission properties.

Owner:PENN STATE RES FOUND +1

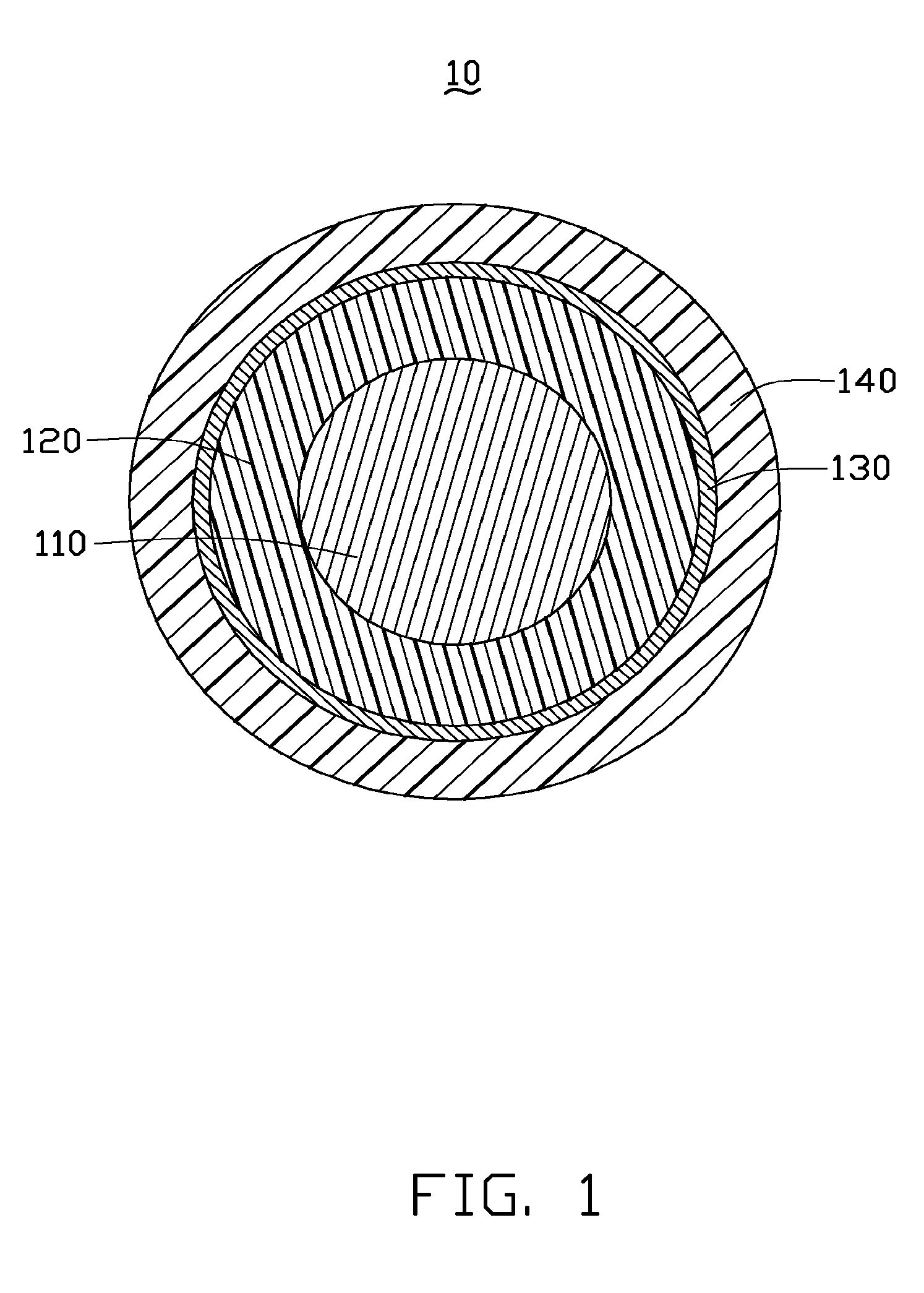

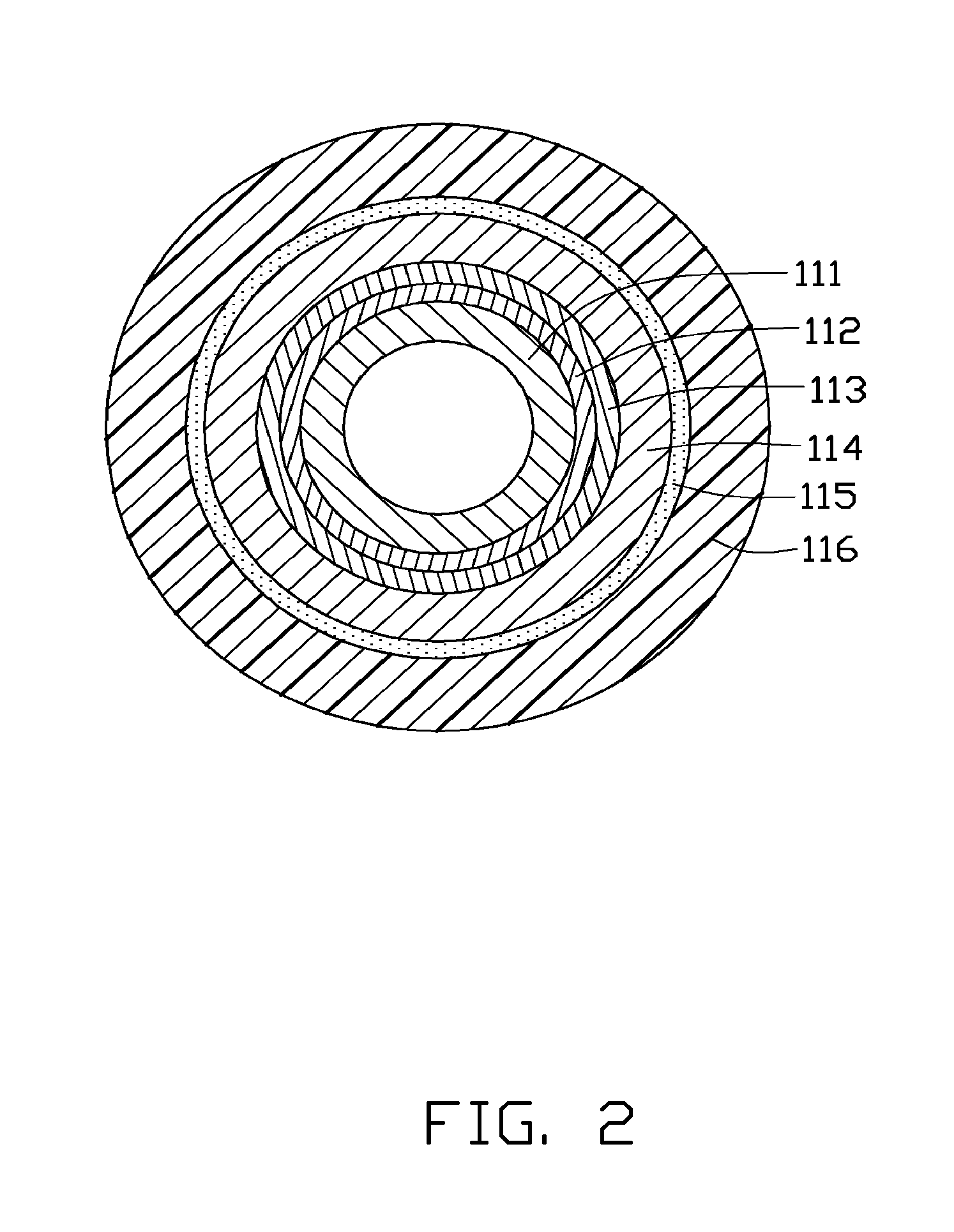

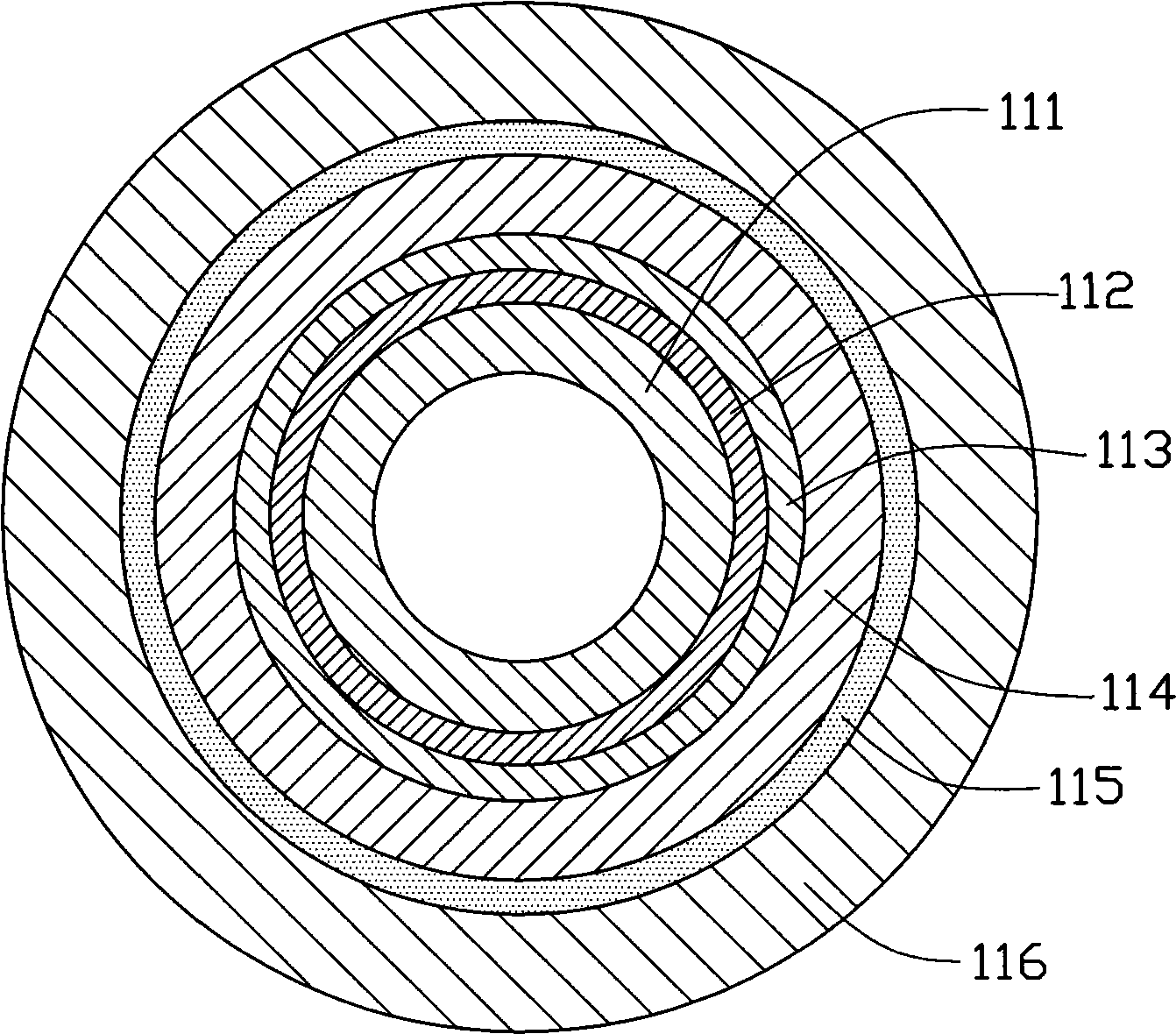

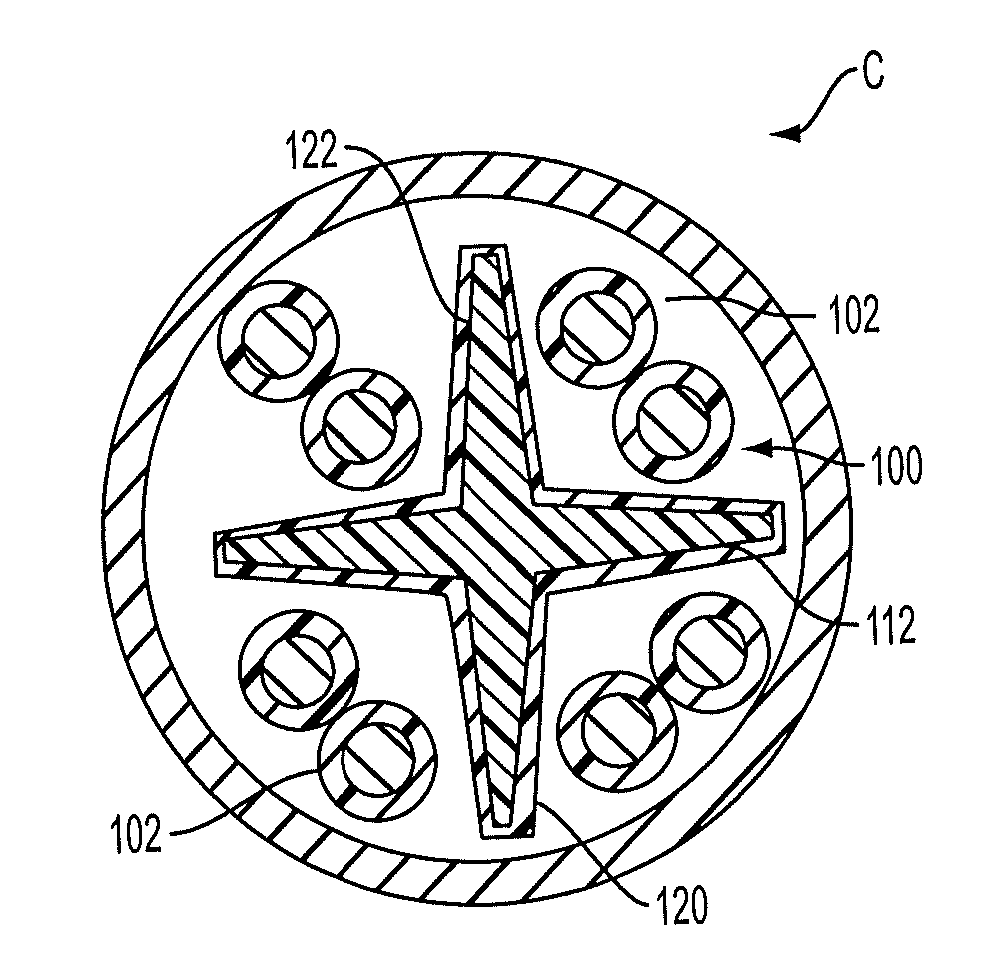

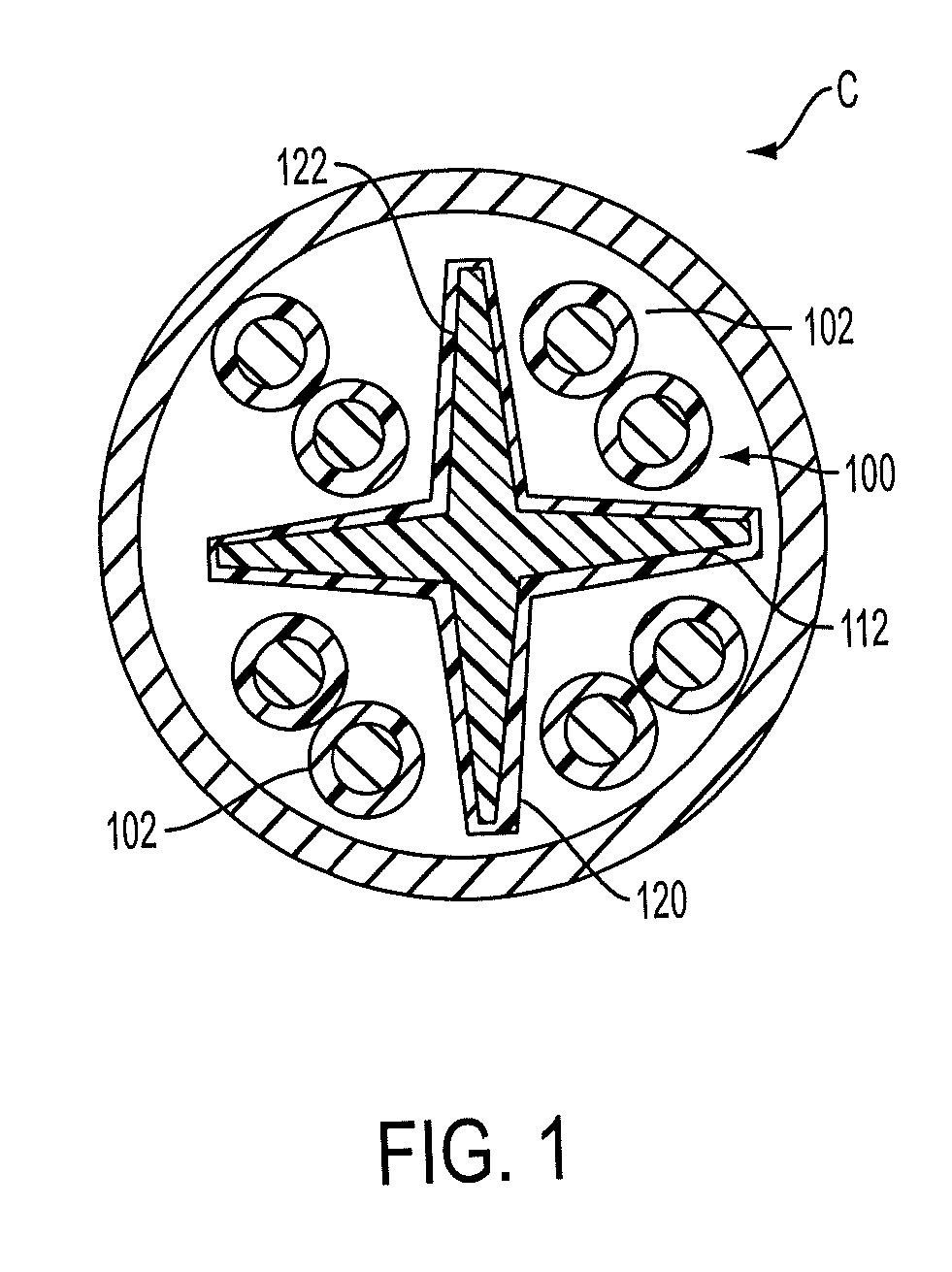

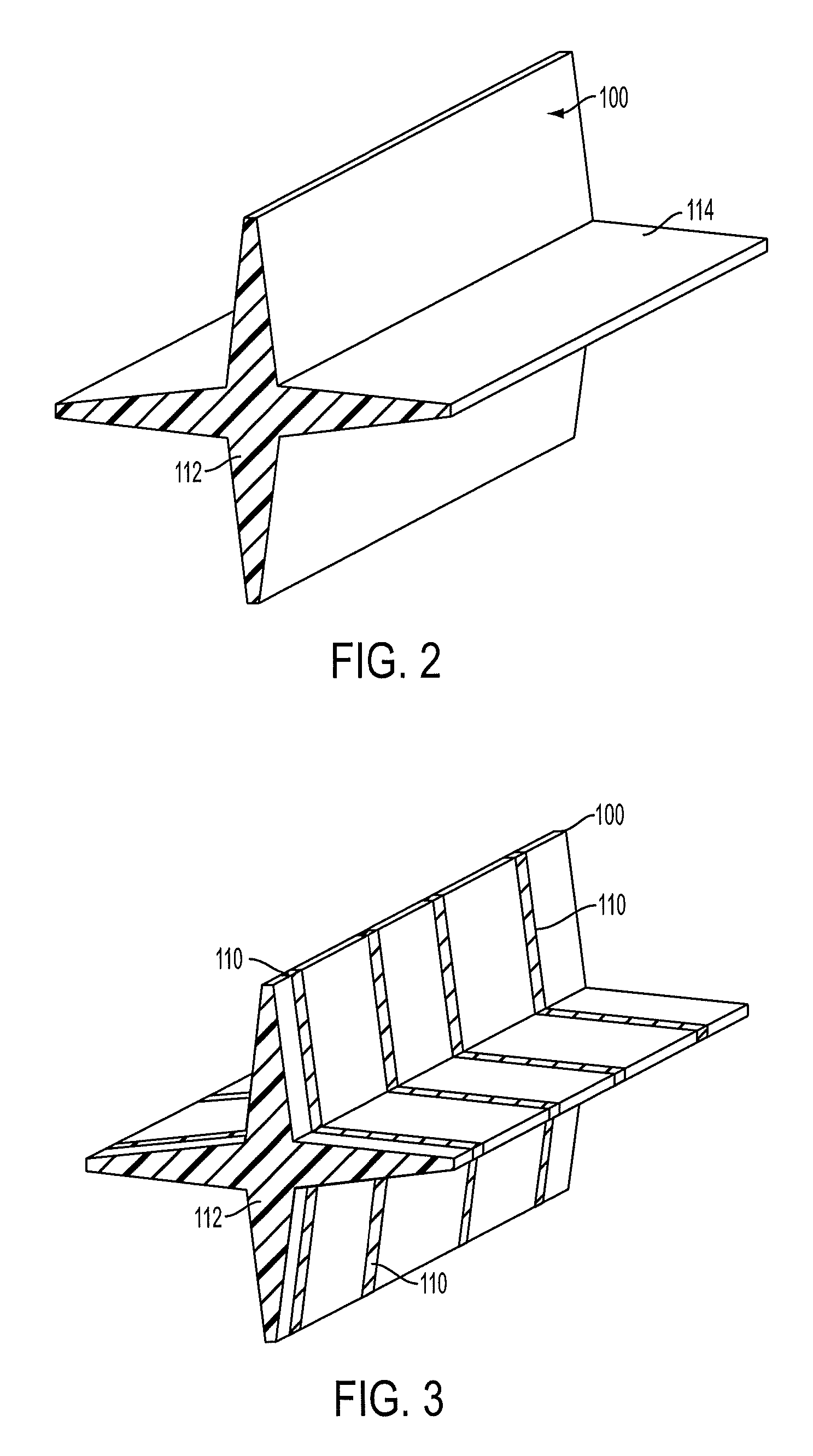

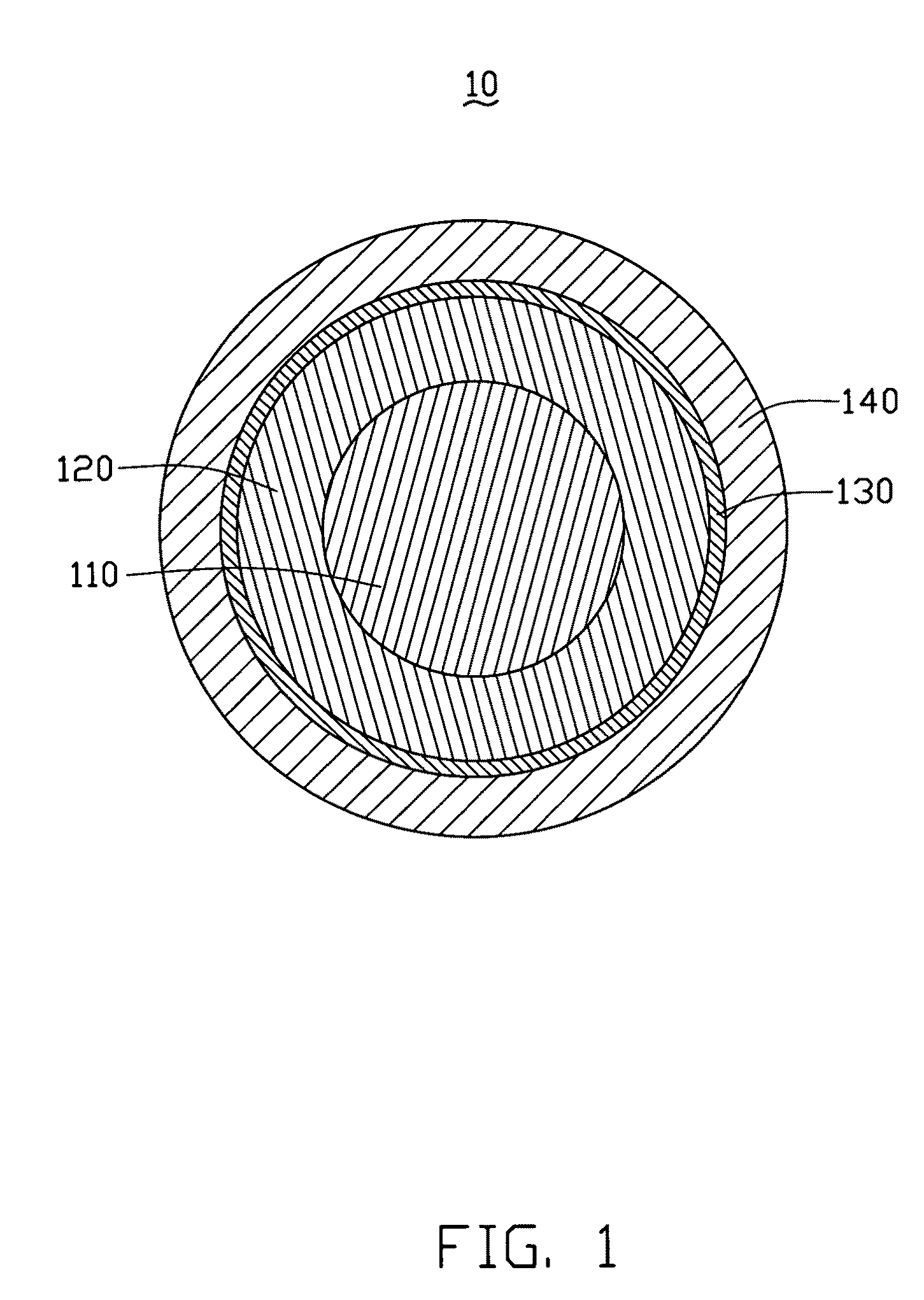

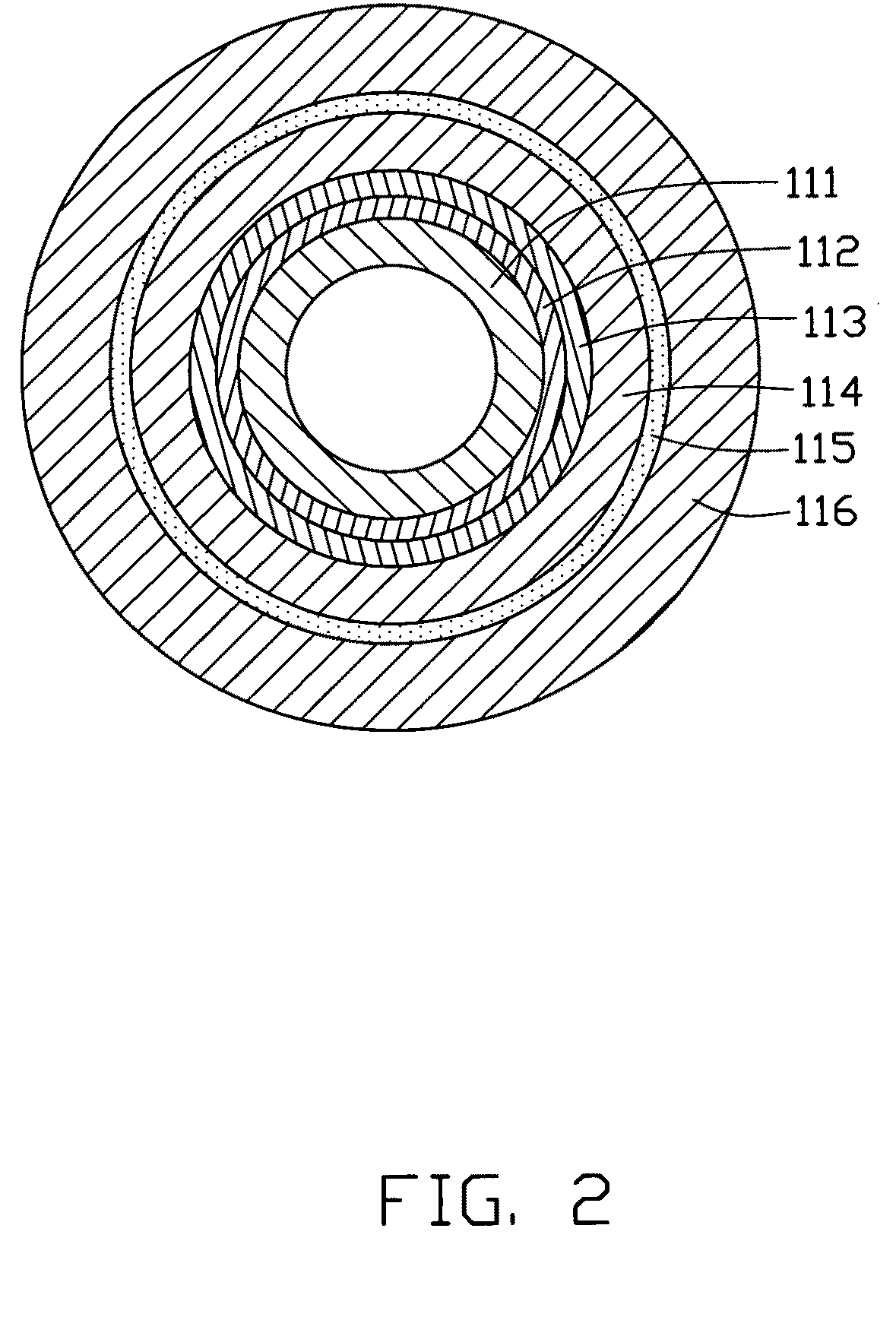

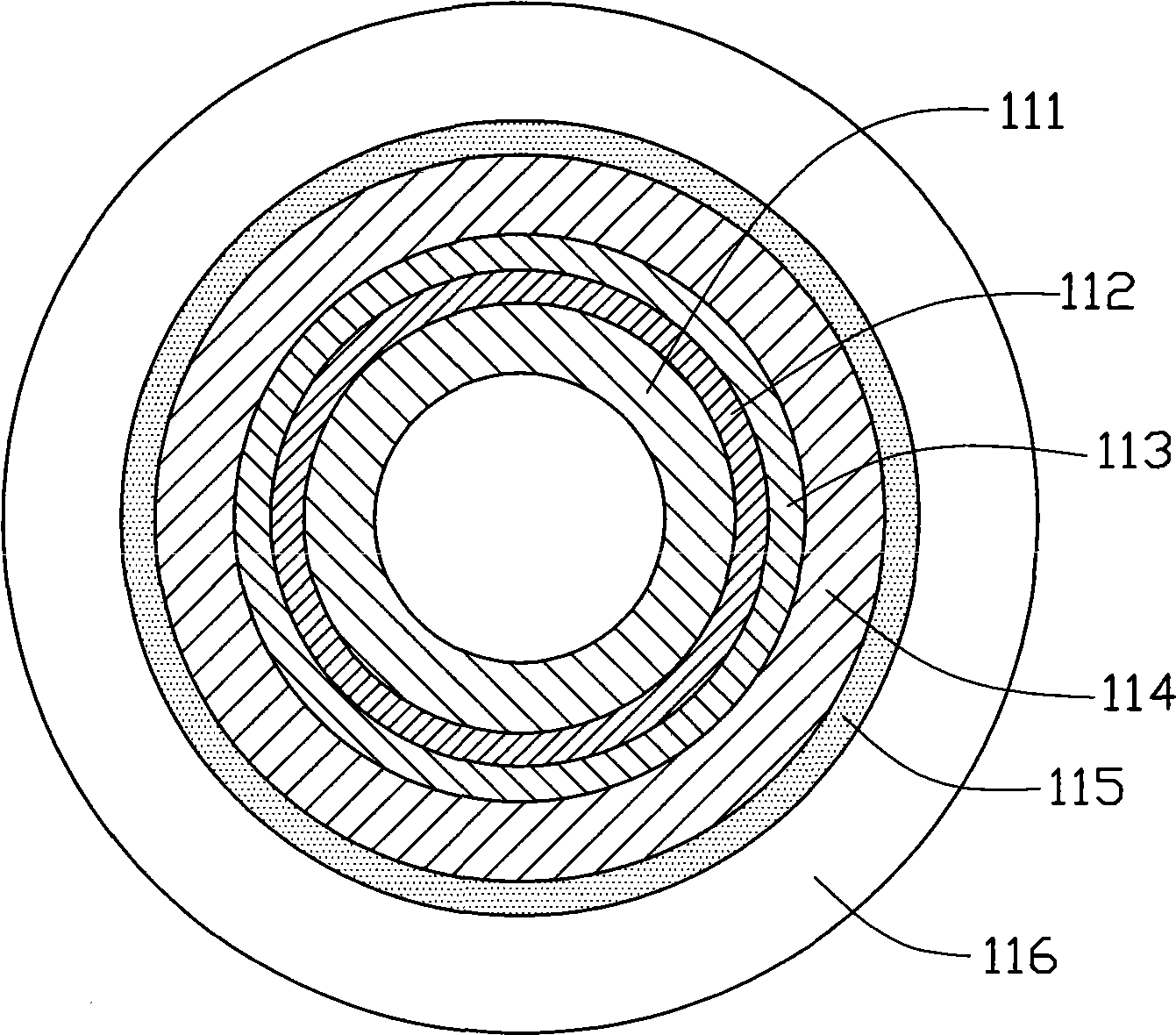

Coaxial cable

ActiveUS7750240B2Reduce intensityGreat in weight and diameterApparatus for manufacturing conducting/semi-conducting layersPower cables with screens/conductive layersCoaxial cableConductive coating

A coaxial cable includes a core, an insulating layer, a shielding layer, a sheathing layer. The core includes an amount of carbon nanotubes having at least one conductive coating disposed about the carbon nanotubes. The carbon nanotubes are orderly arranged. The insulating layer is about the core. The shielding layer is about the insulating layer. The sheathing layer is about the shielding layer.

Owner:ABBOTT CARDIOVASCULAR +2

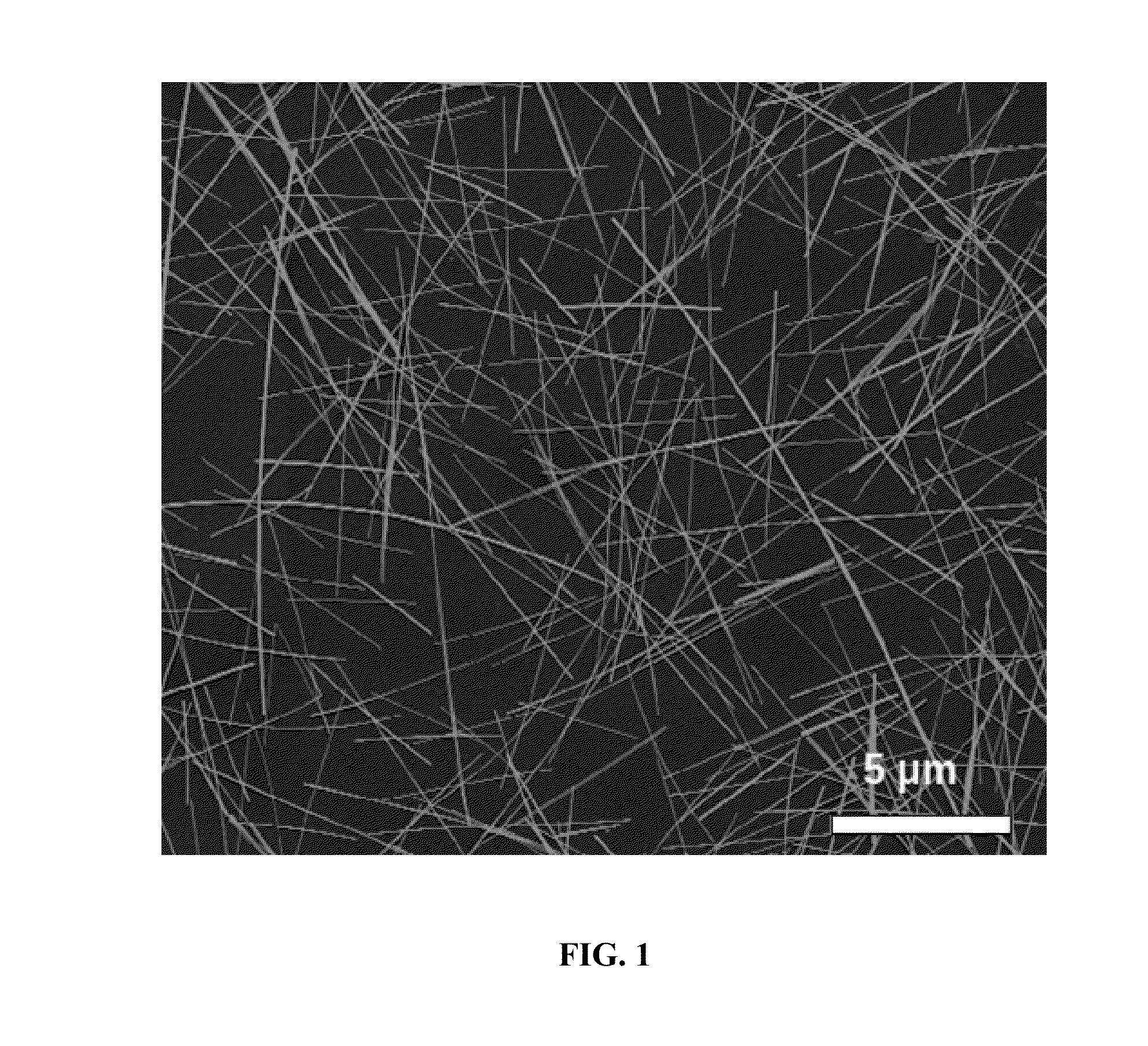

Transparent conductive coatings based on metal nanowires and polymer binders, solution processing thereof, and patterning approaches

Polymer binders, e.g., crosslinked polymer binders, have been found to be an effective film component in creating high quality transparent electrically conductive coatings or films comprising metal nanostructured networks. The metal nanowire films can be effectively patterned and the patterning can be performed with a high degree of optical similarity between the distinct patterned regions. Metal nanostructured networks are formed through the fusing of the metal nanowires to form conductive networks. Methods for patterning include, for example, using crosslinking radiation to pattern crosslinking of the polymer binder. The application of a fusing solution to the patterned film can result in low resistance areas and electrically resistive areas. After fusing the network can provide desirable low sheet resistances while maintaining good optical transparency and low haze. A polymer overcoat can further stabilize conductive films and provide desirable optical effects. The patterned films can be useful in devices, such as touch sensors.

Owner:C3 NANO INC

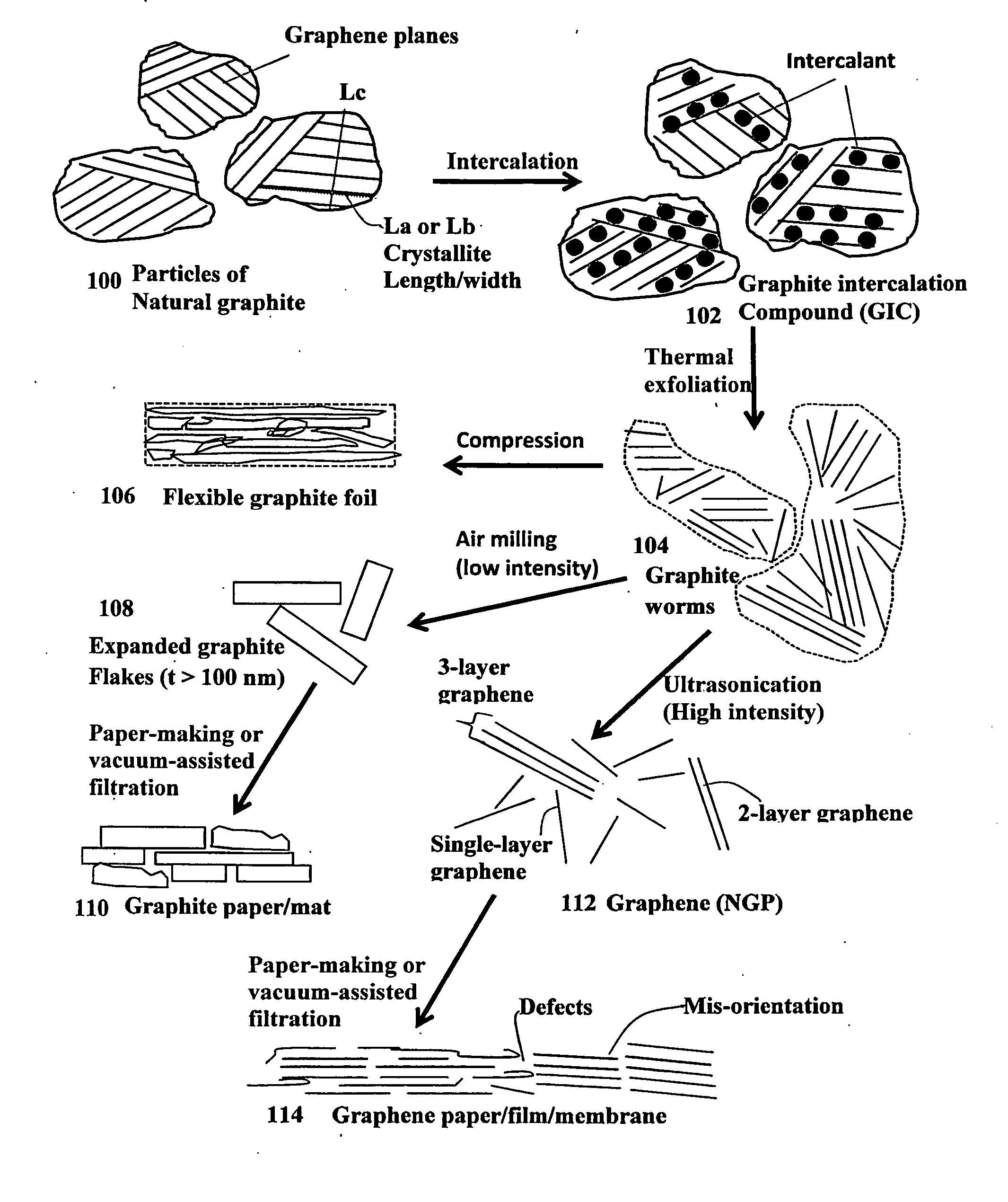

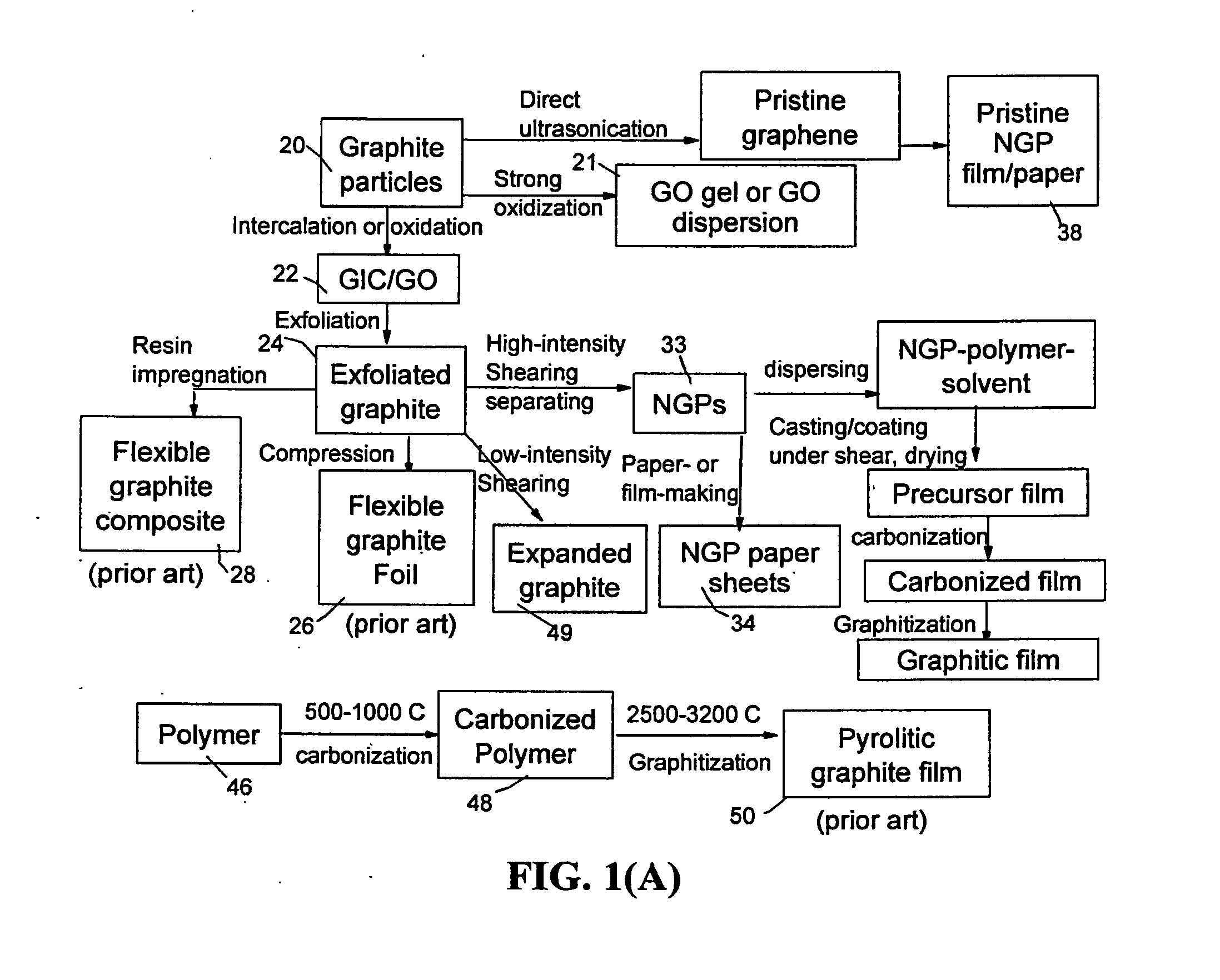

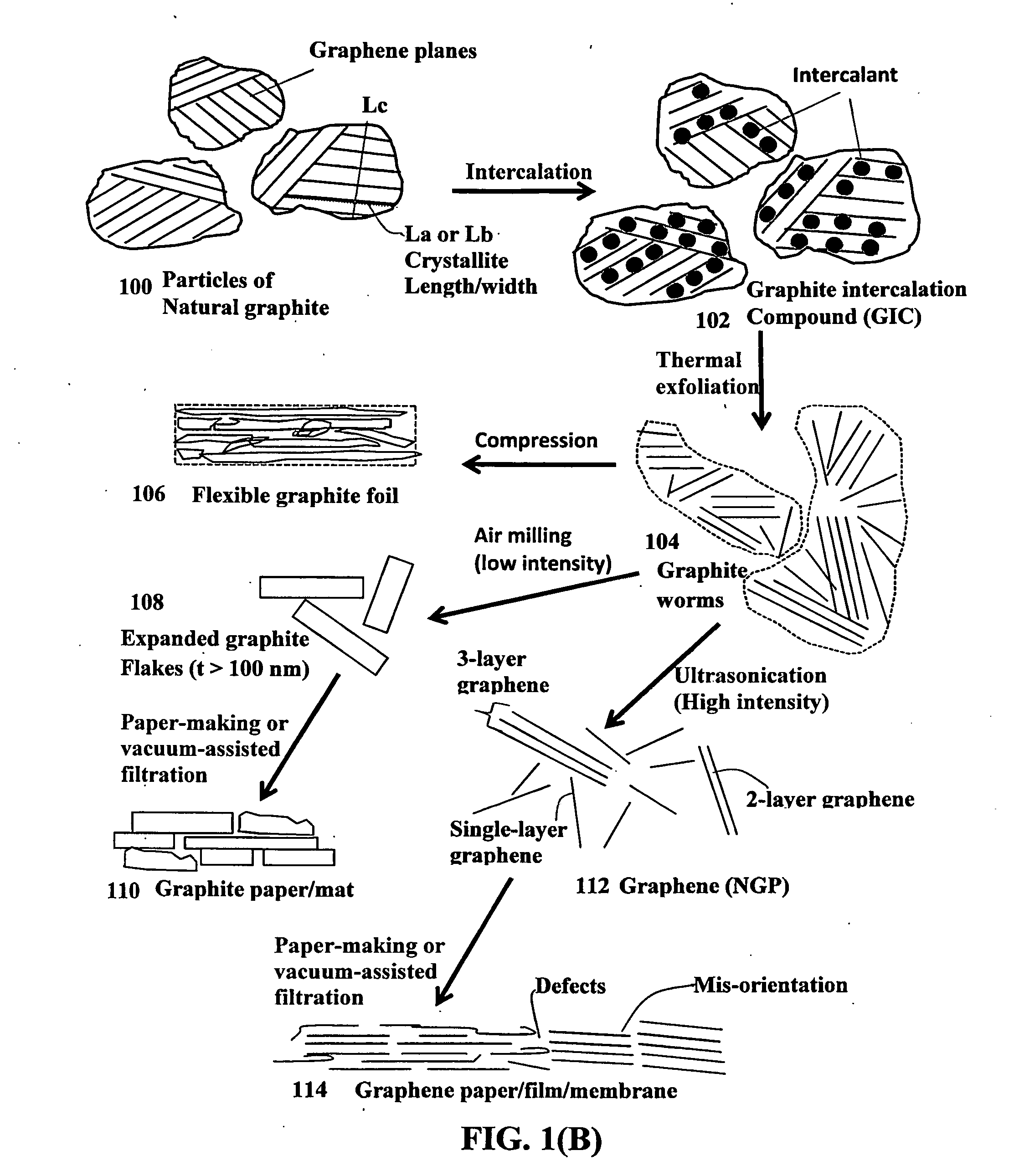

Production process for highly conductive graphitic films

ActiveUS20150266739A1Reduce thicknessImprove in-plane property of filmShielding materialsGraphiteComposite filmCarbonization

A process for producing a graphitic film comprising the steps of (a) mixing graphene platelets with a carbon precursor polymer and a liquid to form a slurry and forming the slurry into a wet film under the influence of an orientation-inducing stress field to align the graphene platelets on a solid substrate; (b) removing the liquid to form a precursor polymer composite film wherein the graphene platelets occupy a weight fraction of 1% to 99%; (c) carbonizing the precursor polymer composite film at a carbonization temperature of at least 300° C. to obtain a carbonized composite film; and (d) thermally treating the carbonized composite film at a final graphitization temperature higher than 1,500° C. to obtain the graphitic film. Preferably, the carbon precursor polymer is selected from the group consisting of polyimide, polyamide, polyoxadiazole, polybenzoxazole, polybenzobisoxazole, polythiazole, polybenzothiazole, polybenzobisthiazole, poly(p-phenylene vinylene), polybenzimidazole, polybenzobisimidazole, and combinations thereof.

Owner:GLOBAL GRAPHENE GRP INC

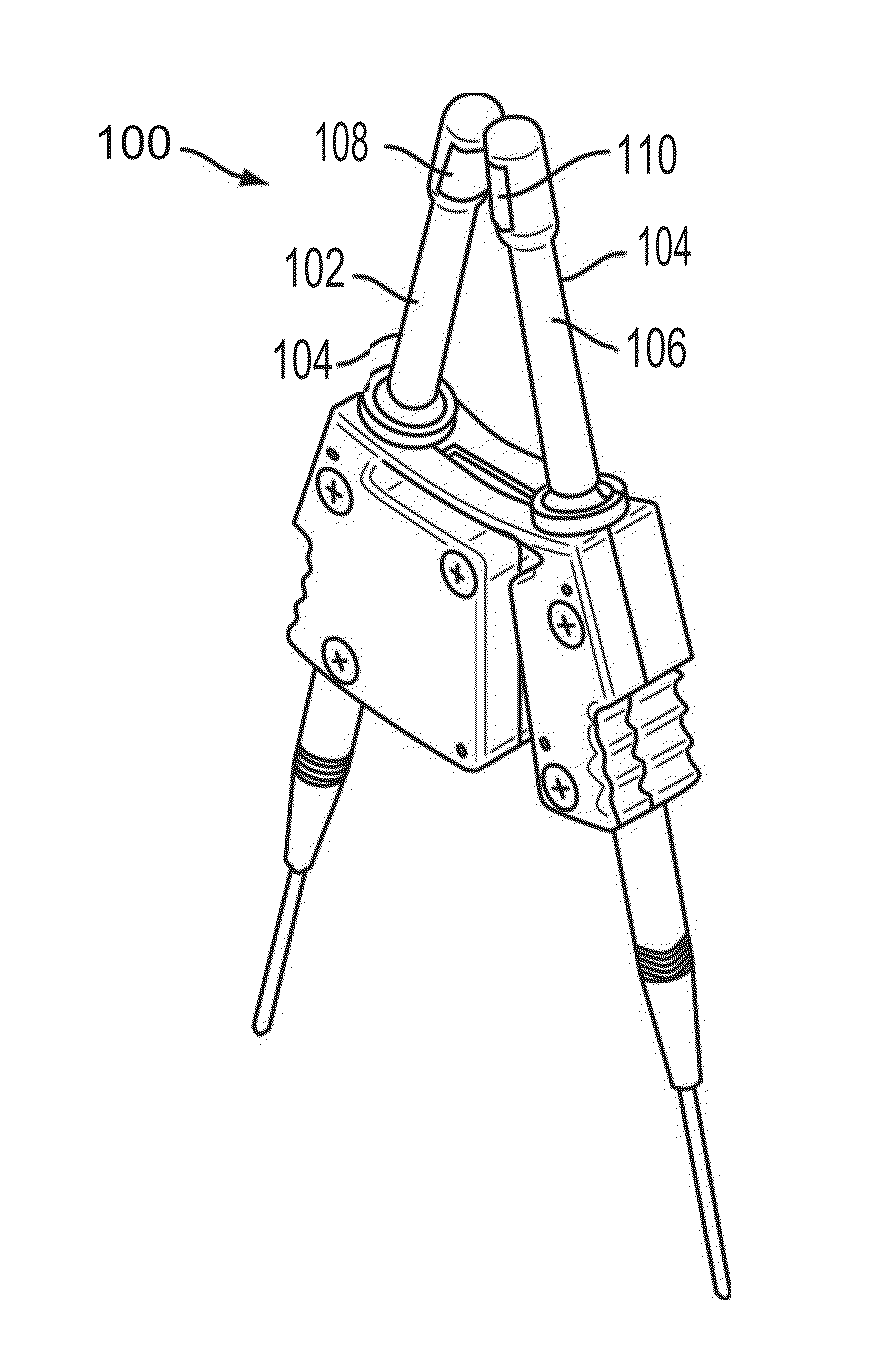

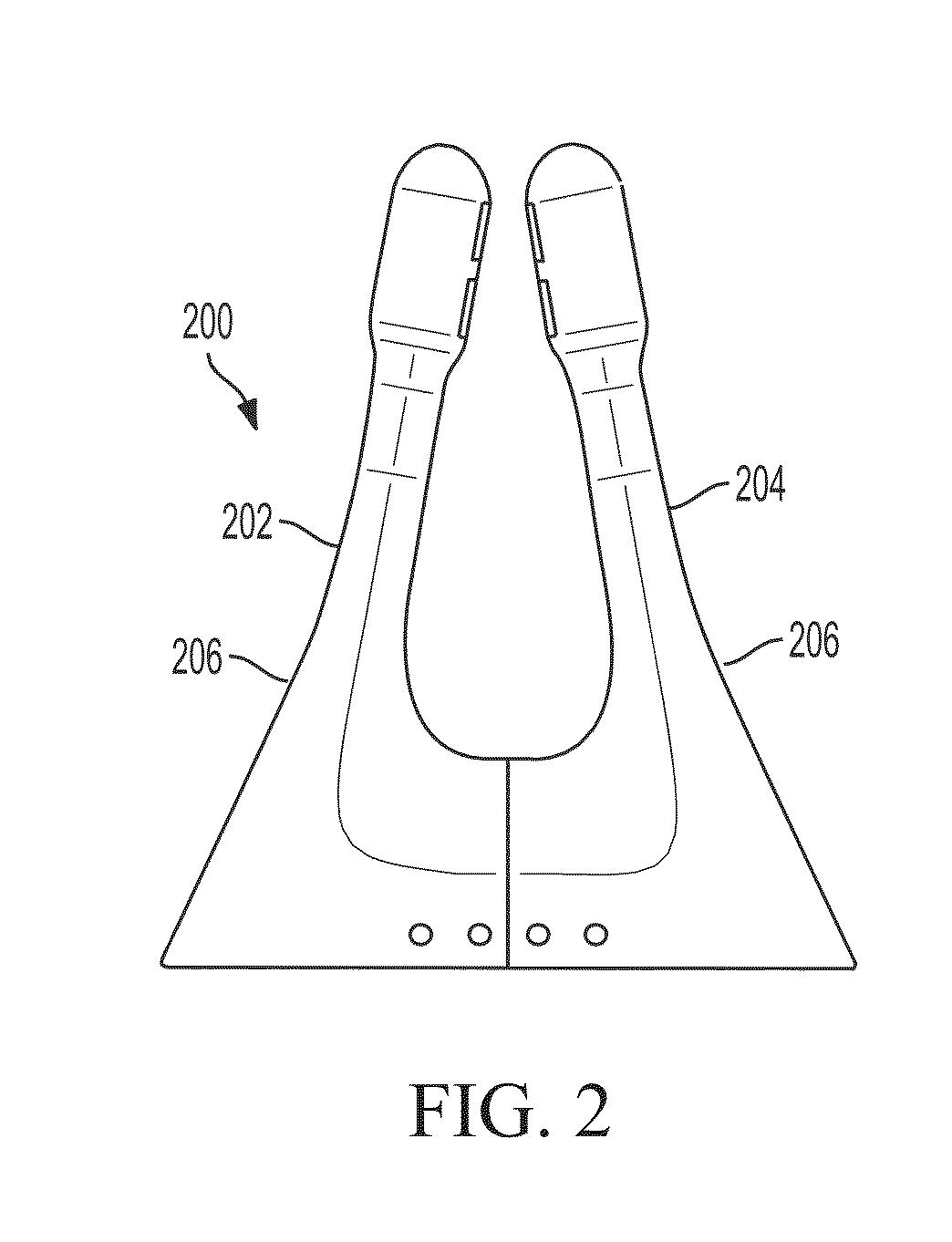

Polymer formulations for nasolacrimal stimulation

ActiveUS20150238754A1Smooth connectionReliable electrical connectionOrganic chemistryHead electrodesNoseAnesthesia

Described herein are polymer formulations for facilitating electrical stimulation of nasal or sinus tissue. The polymer formulations may be hydrogels that are prepared by a UV cross-linking process. The hydrogels may be included as a component of nasal stimulator devices that electrically stimulate the lacrimal gland to improve tear production and treat dry eye. Additionally, devices and methods for manufacturing the nasal stimulators, including shaping of the hydrogel, are described herein.

Owner:OCULEVE

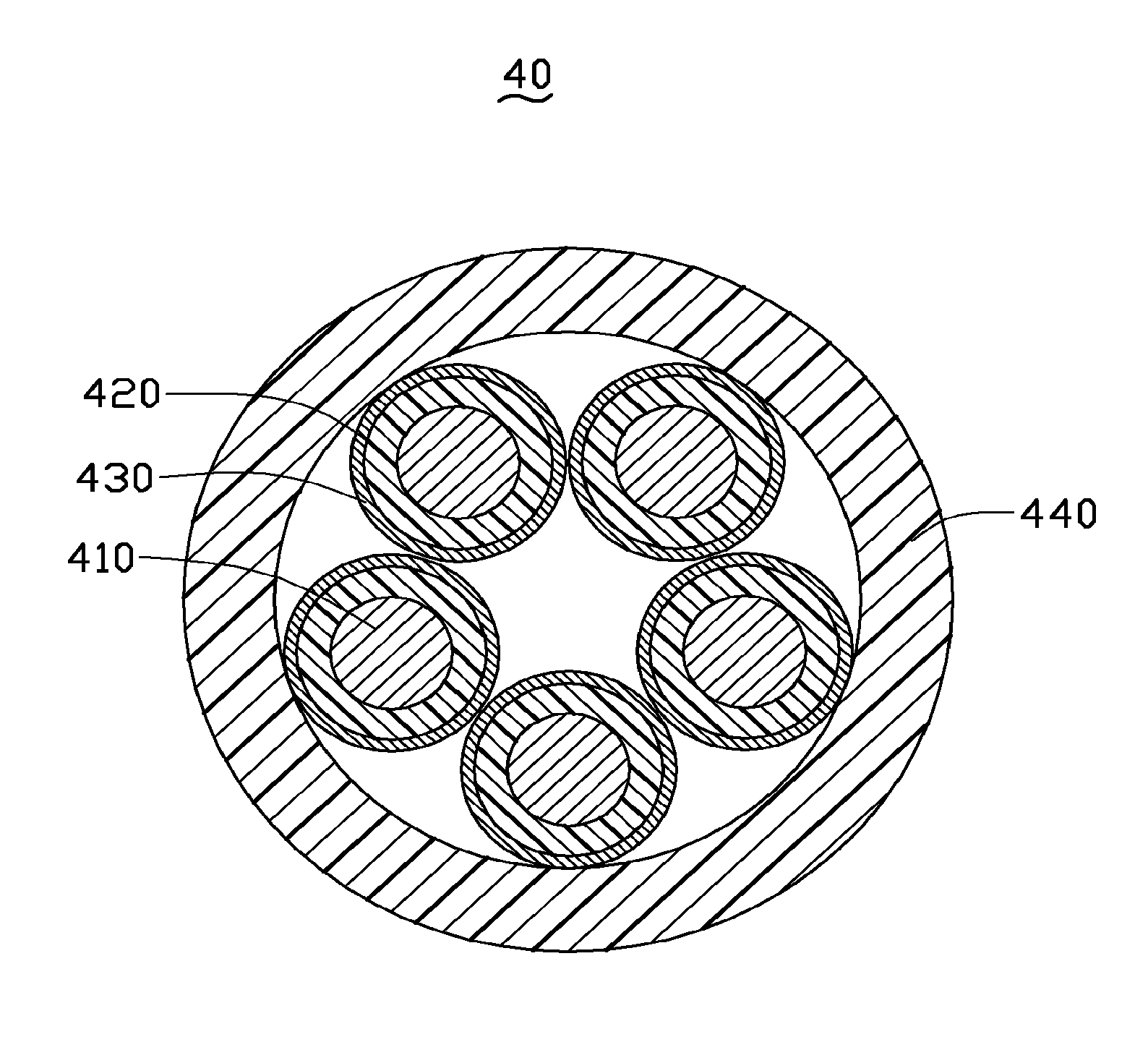

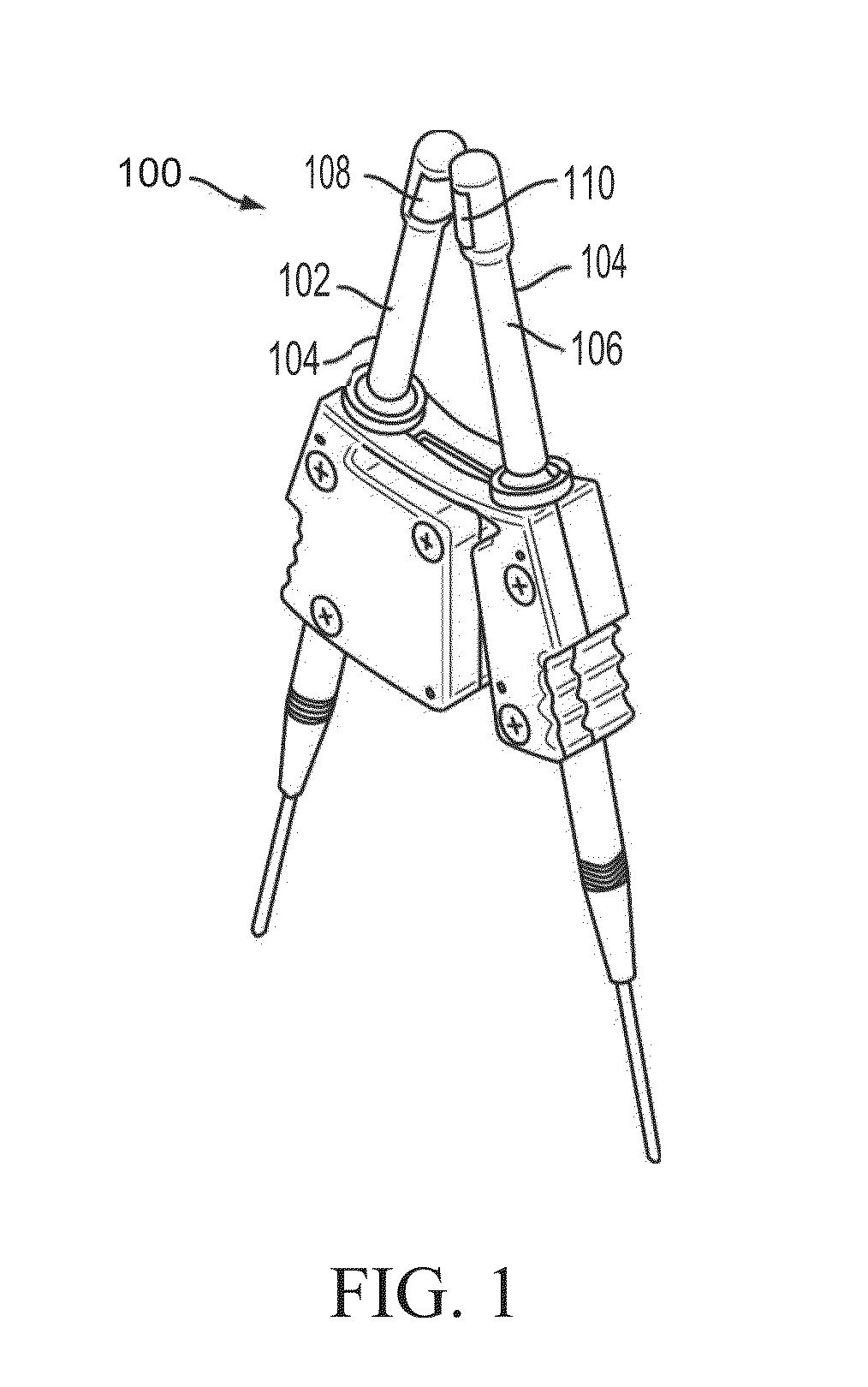

Stranded wire

ActiveCN101499328ALight in massHigh mechanical strengthNon-insulated conductorsIndividual molecule manipulationCarbon nanotubeConductive materials

The invention relates to a twisted line which comprises a plurality of carbon nano tubes that are connected with each other end to end by van der waals force, wherein the twisted line further comprises conducting materials covering on the surfaces of the carbon nano tubes.

Owner:TSINGHUA UNIV +1

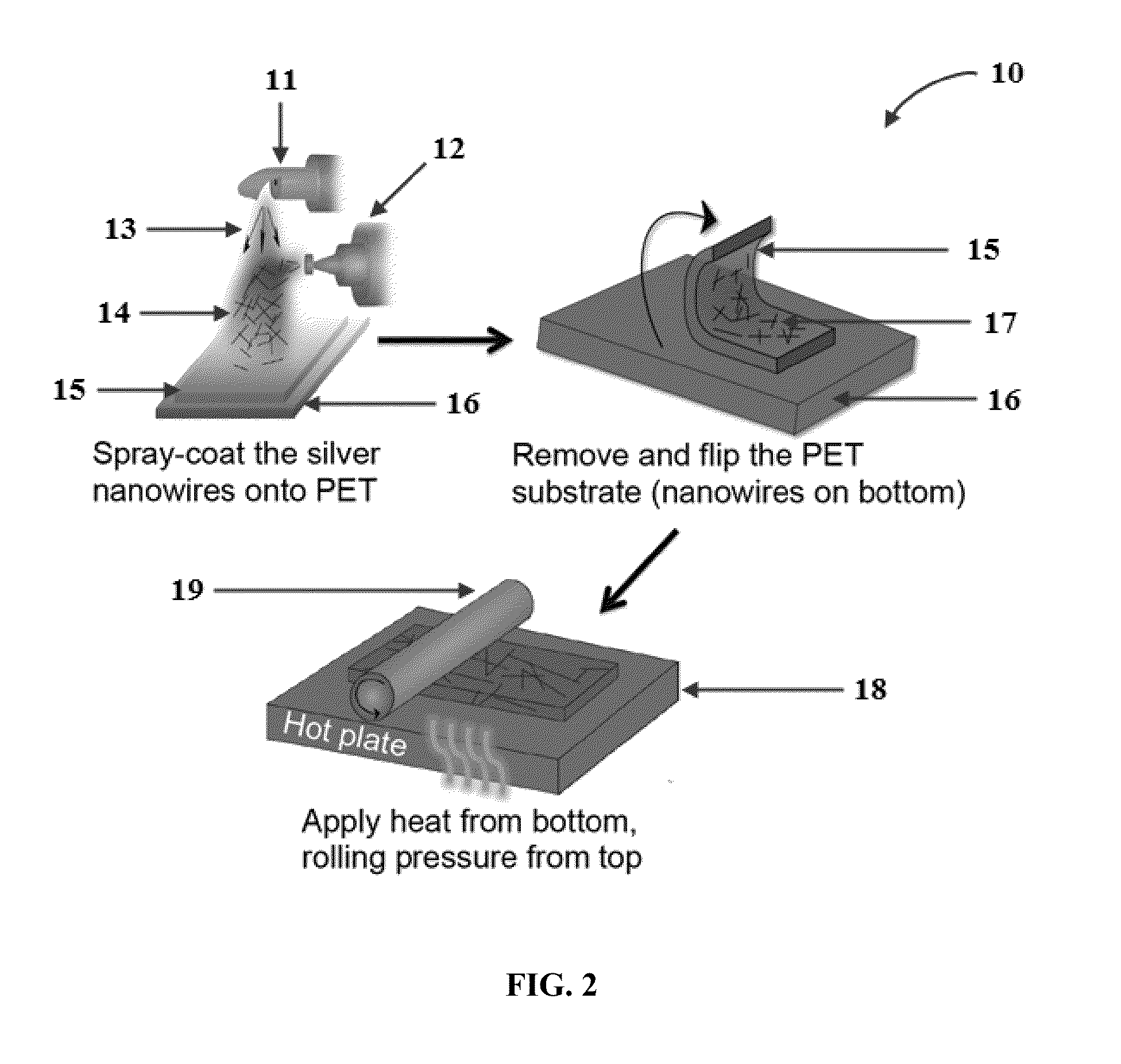

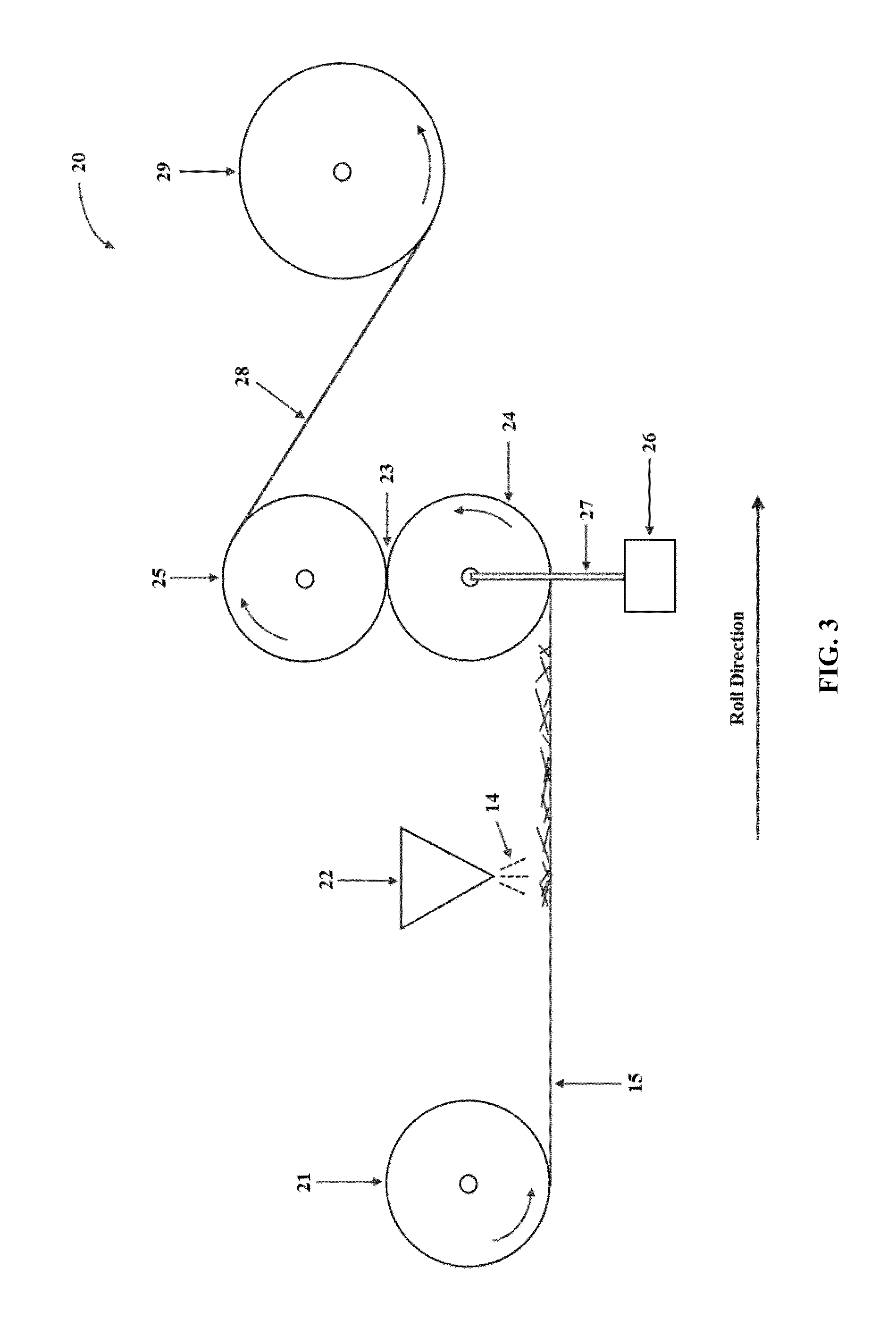

Process for making materials with micro- or nanostructured conductive layers

InactiveUS20150037517A1Reduce usageCost-efficient and scalableFinal product manufactureApparatus for heat treatmentVitrificationPre-condition

Disclosed are methods for making conductive materials. The methods can be used to make transparent, opaque, or reflective electrodes by using the same materials and equipment but varying the processing conditions or amounts of materials used. The methods can include: (a) providing a substrate comprising a first surface and an opposite second surface, wherein micro- or nanostructures are disposed on at least a portion of the first surface, and wherein the first surface is not pre-conditioned to increase attachment between the micro- or nanostructures and the substrate; (b) applying heat to heat the substrate surface to a temperature that is greater than the glass transition temperature or the Vicat softening temperature of the substrate and less than the melting point of the substrate; (c) applying pressure such that the substrate and the micro- or nanostructures are pressed together; and (d) removing the pressure to obtain the conductive material.

Owner:SABIC GLOBAL TECH BV

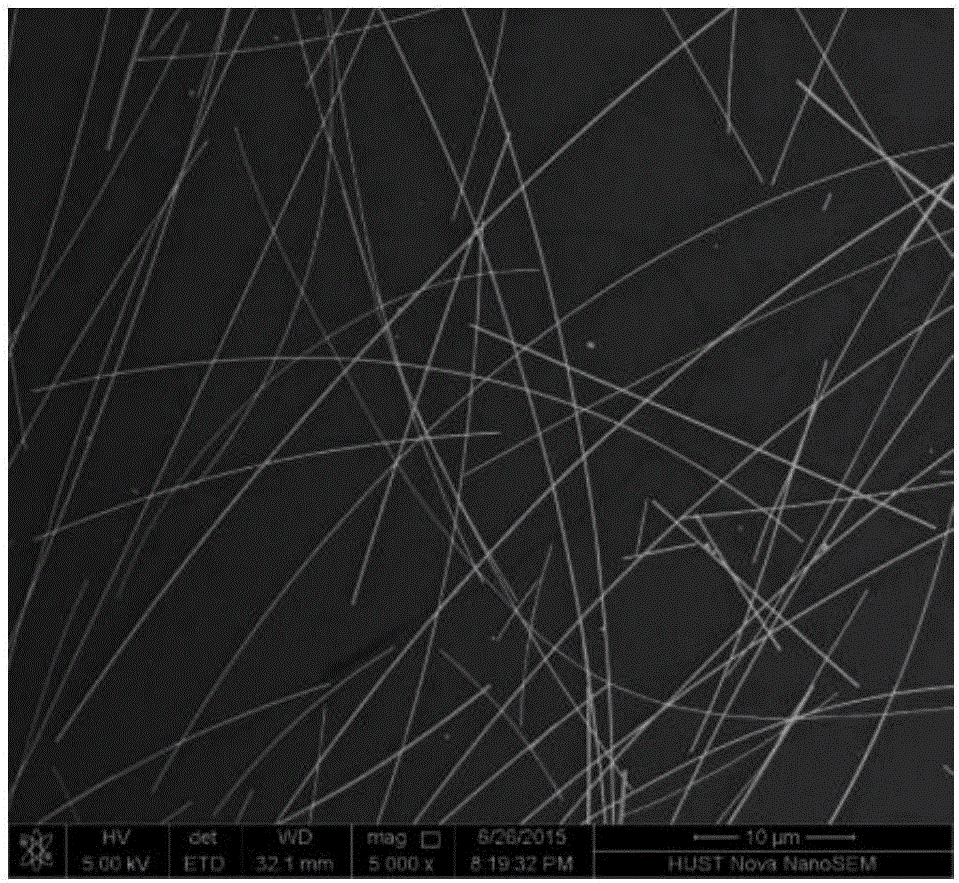

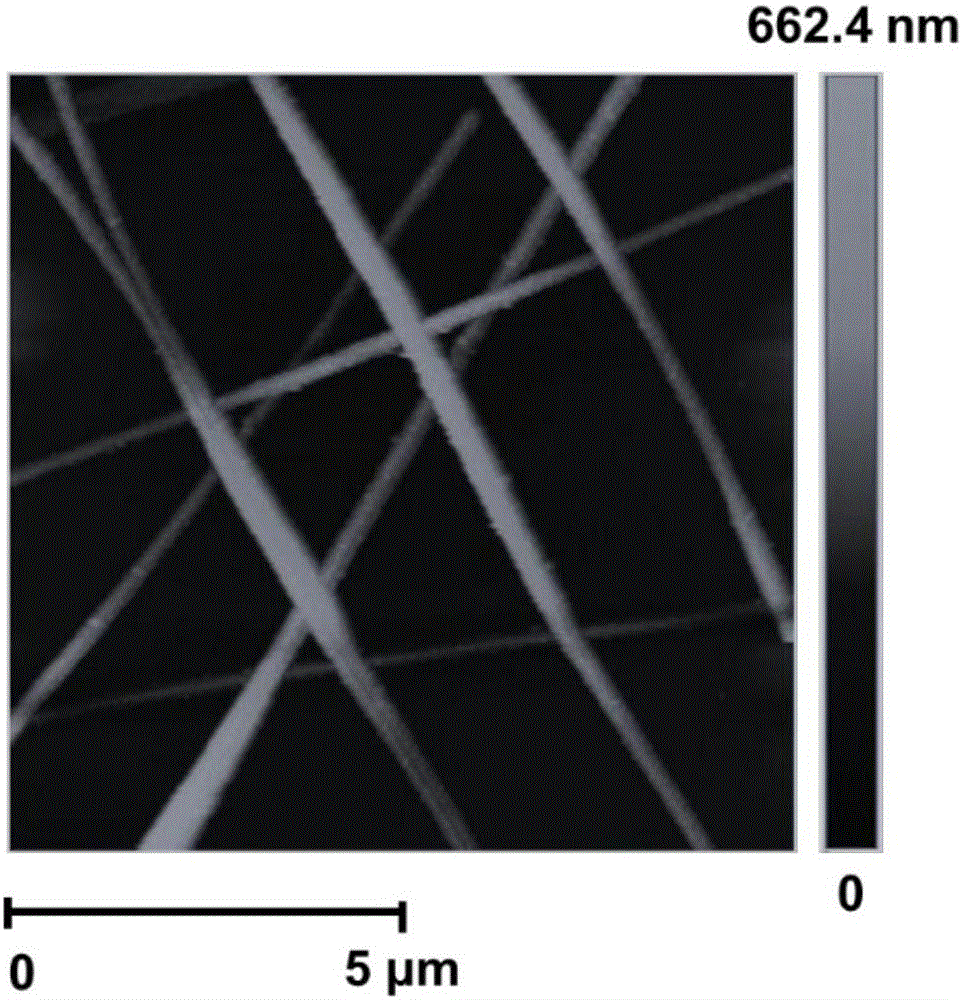

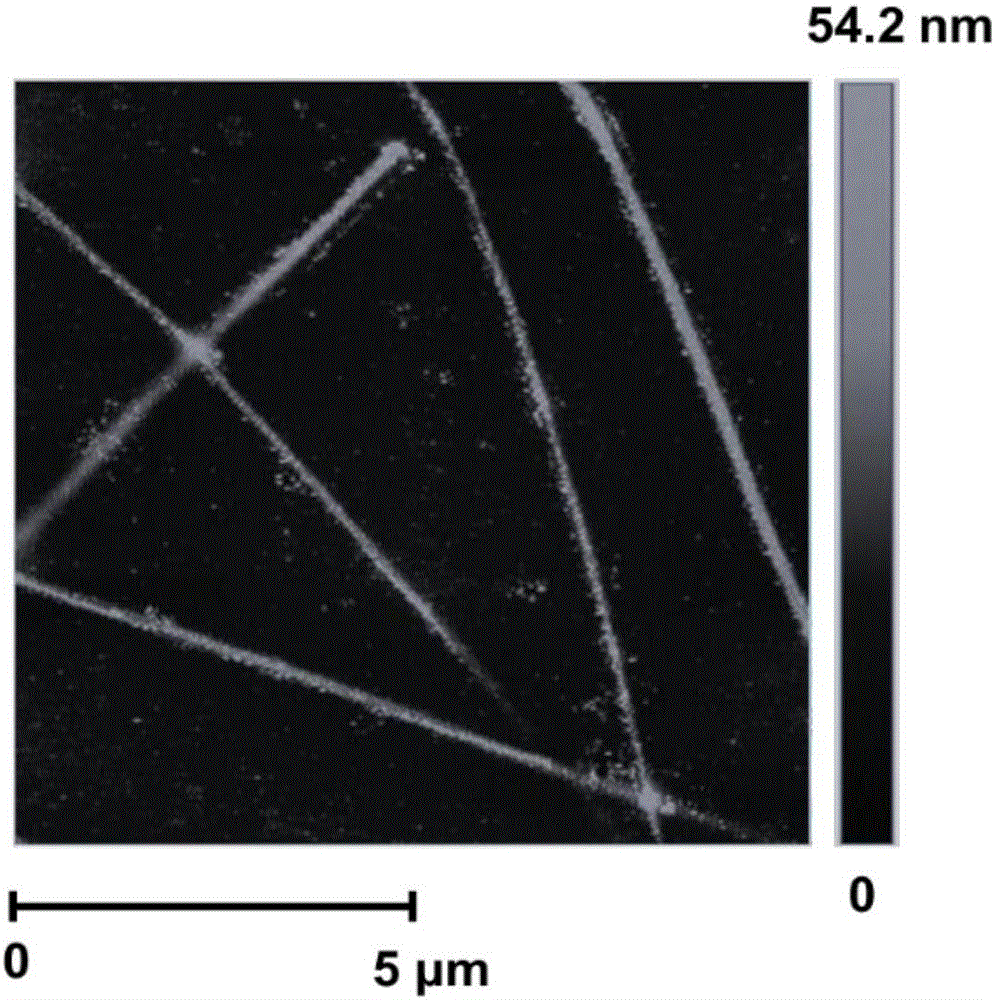

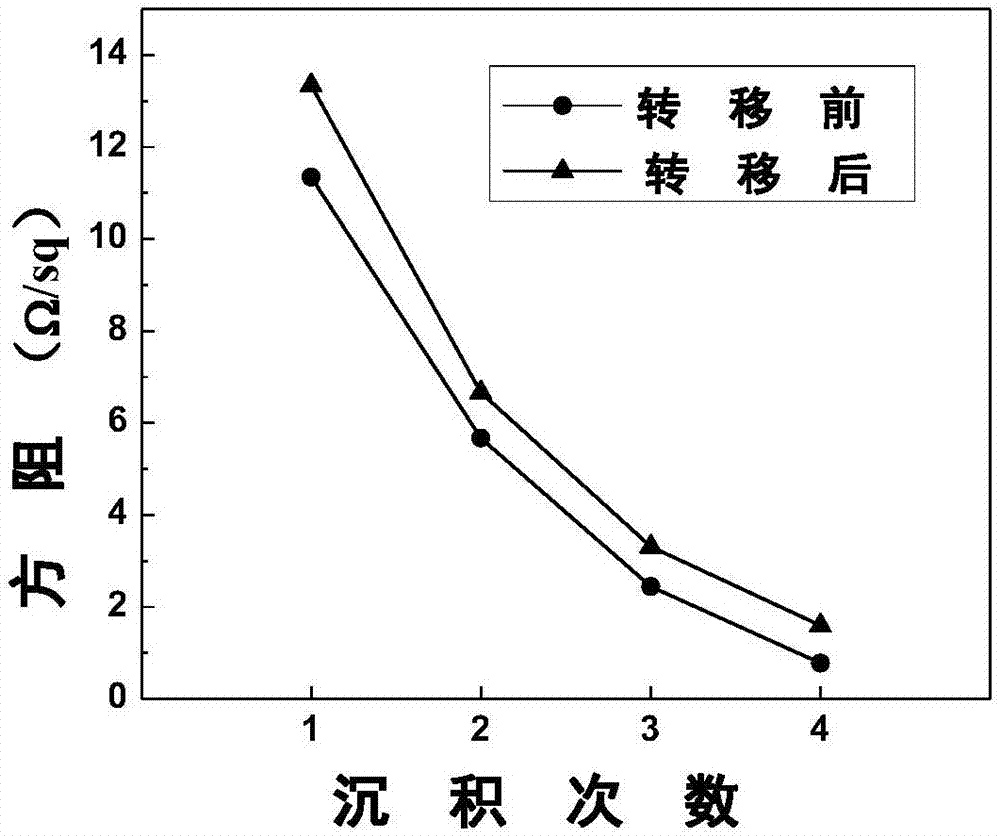

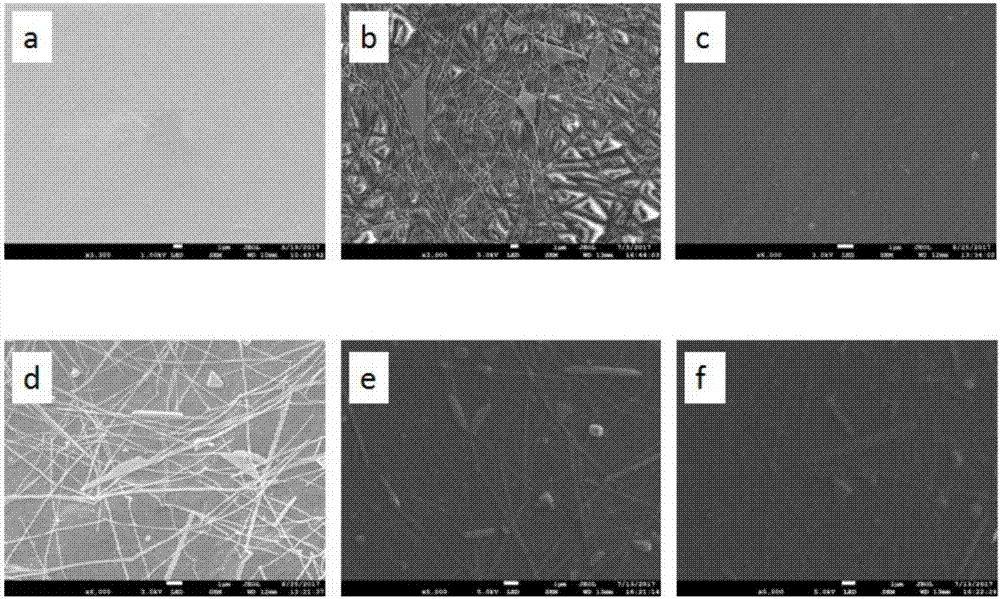

Low-roughness and low-square-resistance flexible transparent conductive composite thin film and preparation method therefor

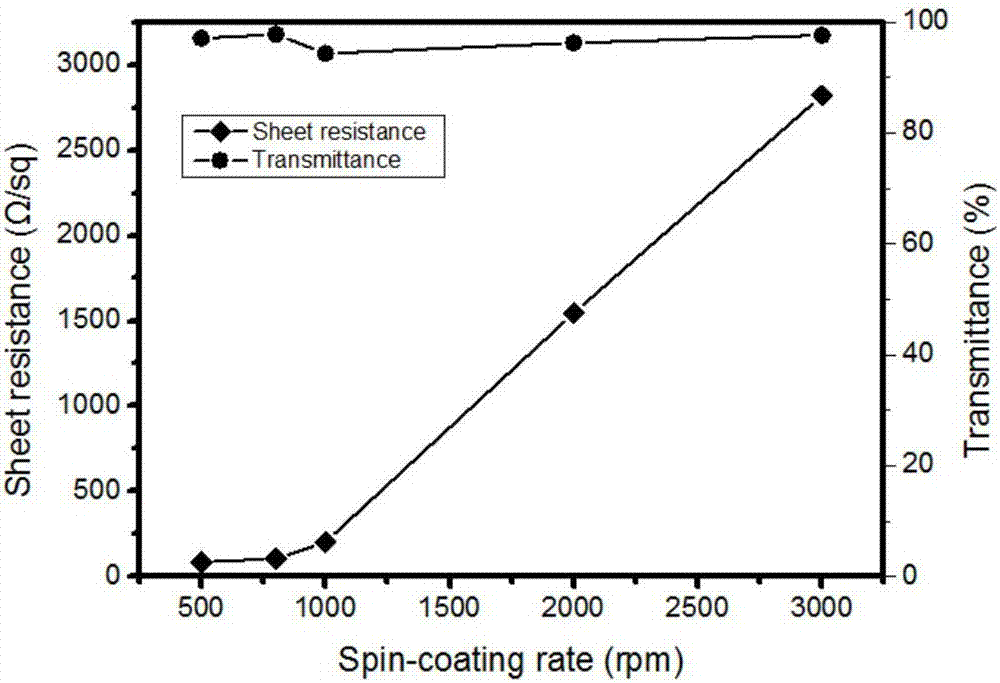

ActiveCN106782769AReduce roughnessImprove conductivityConductive layers on insulating-supportsApparatus for manufacturing conducting/semi-conducting layersPolymer thin filmsSolar battery

The invention belongs to the technical field of photo-electronics, and more specifically relates to a low-roughness and low-square-resistance flexible transparent conductive composite thin film, wherein the thin film adopts a three-layer composite structure; the lowest bottom layer is provided with a transparent polymer thin film; the middle layer is provided with a conductive network formed by metal nanowires; the topmost layer is a provided with a transparent conductive layer which uniformly covers the transparent polymer thin film and the conductive network; the flexible transparent conductive composite thin film is less than 20-nanometer in average roughness, less than 30-ohm / square meter in square resistance, and greater than 80% of light transmittance within a visible light range; and the transparent conductive thin film can bear bending with radius of curvature of 2mm. The invention also discloses a preparation method for the flexible transparent conductive composite thin film. The flexible transparent conductive composite thin film provided by the invention has low roughness, high conductivity, high light transmittance, simple preparation method and low cost, and is particularly suitable for flexible display and illumination, a flexible solar battery and flexible touch equipment.

Owner:HUAZHONG UNIV OF SCI & TECH

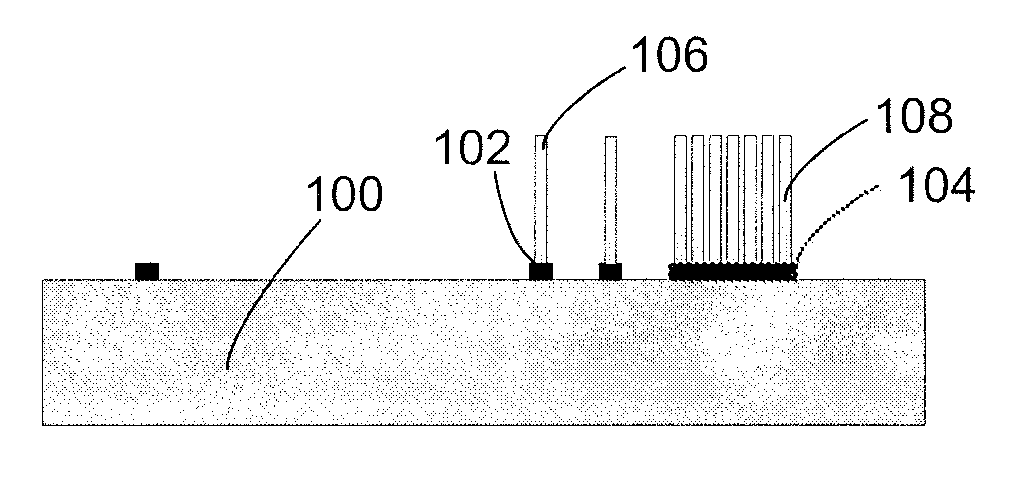

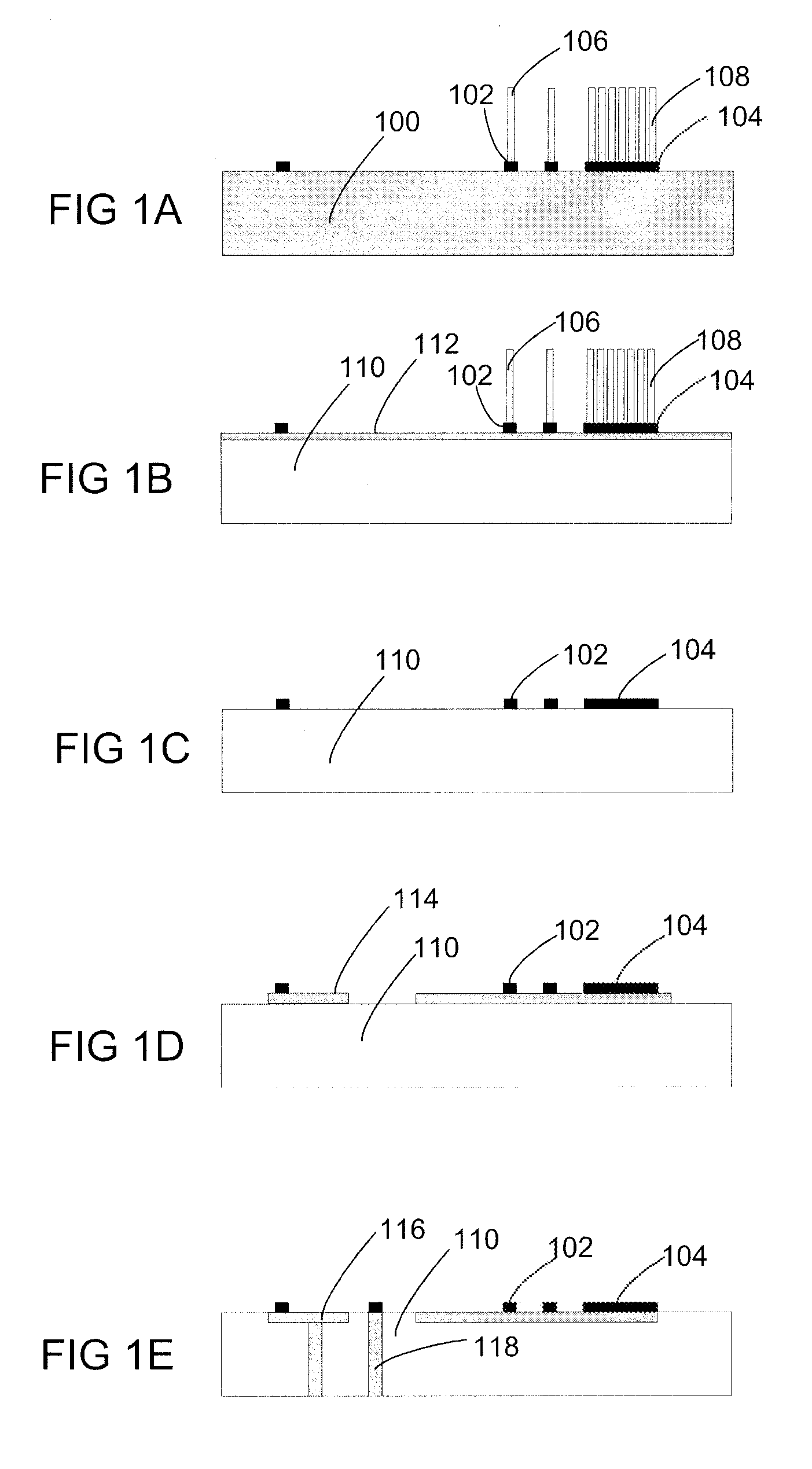

Deposition and Selective Removal of Conducting Helplayer for Nanostructure Processing

ActiveUS20090233124A1Harm reductionReduced compatibilityNanostructure manufactureDecorative surface effectsOptoelectronicsNanostructure

A method for making one or more nanostructures is disclosed, the method comprising: depositing a conducting layer on an upper surface of a substrate; depositing a patterned layer of catalyst on the conducting layer; growing the one or more nanostructures on the layer of catalyst; and selectively removing the conducting layer between and around the one or more nanostructures. A device is also disclosed, comprising a substrate, wherein the substrate comprises one or more exposed metal islands separated by one or more insulating areas; a conducting helplayer disposed on the substrate covering at least some of the one or more exposed metal islands or insulating areas; a catalyst layer disposed on the conducting helplayer; and one or more nanostructures disposed on the catalyst layer.

Owner:SMOLTEK AB

Inks containing metal precursors nanoparticles

ActiveUS20150056426A1Low costLow of productionRadiation applicationsApparatus for heat treatmentNanoparticleCoordination complex

Owner:SINGAPORE ASAHI CHEM & SOLDER IND

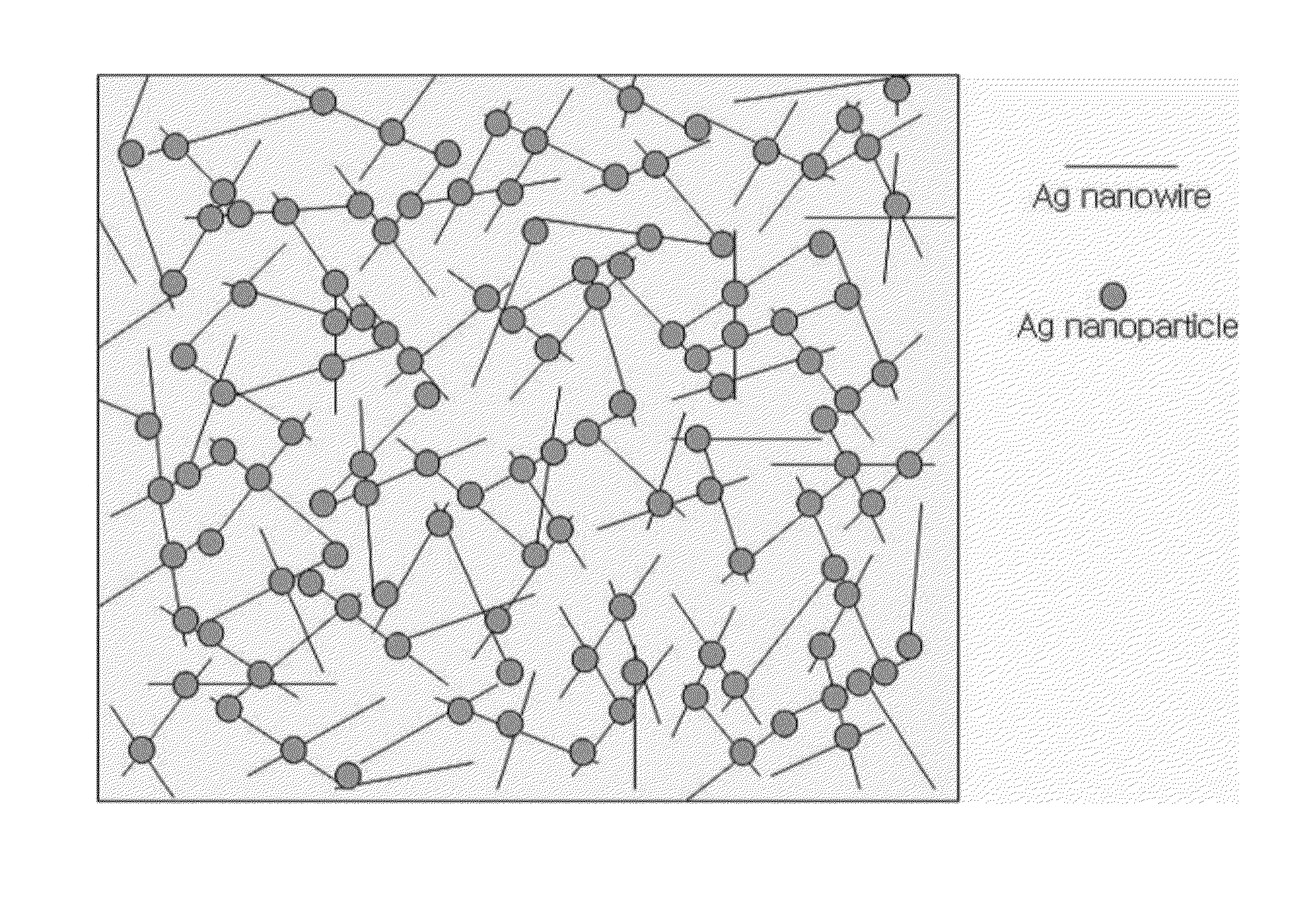

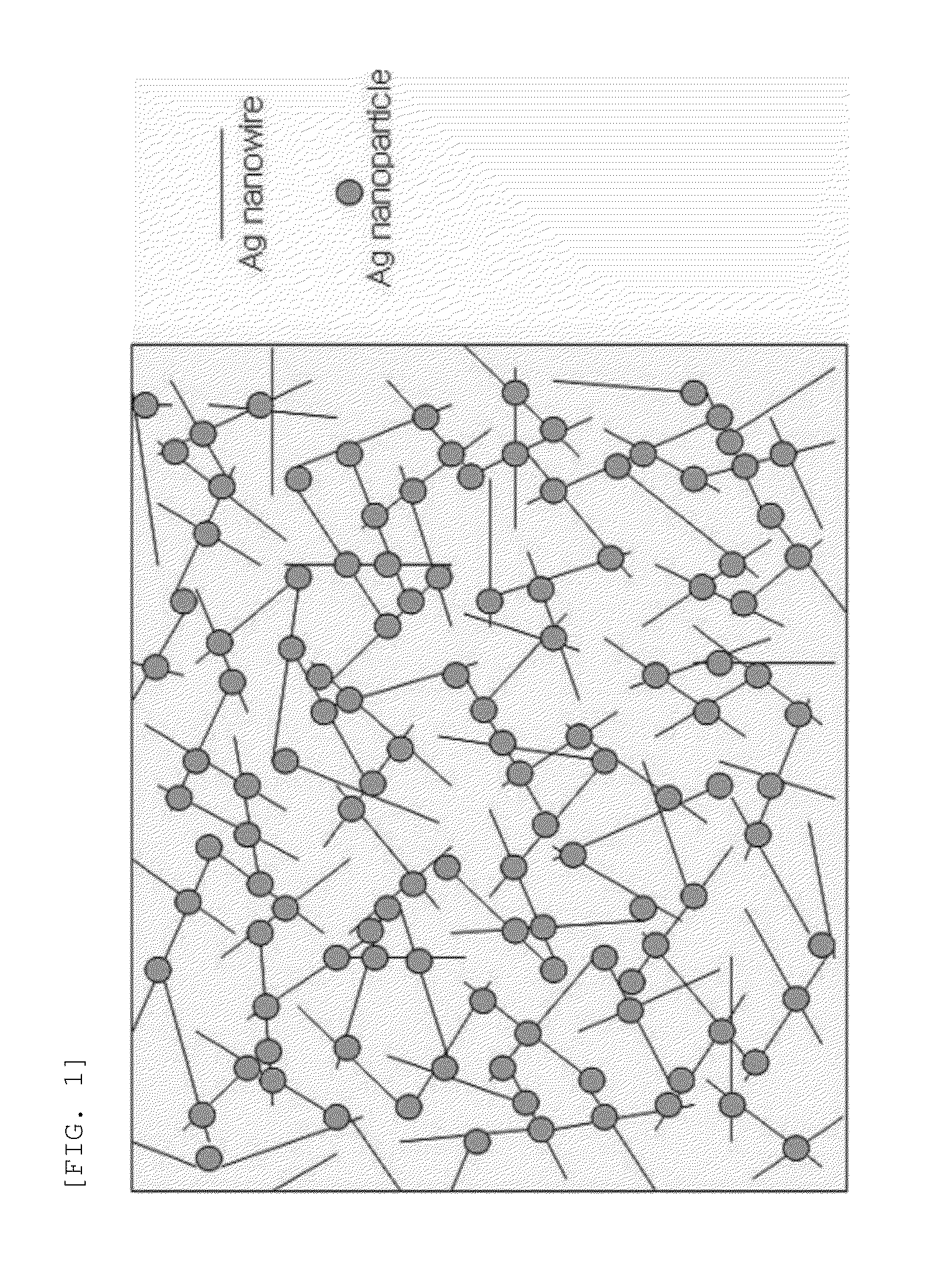

Method of Manufacturing a Transparent Conductive Layer and Transparent Conductive Layer Manufactured by Same

ActiveUS20140004371A1Improve conductivityImprove transmittanceNon-metal conductorsConductive layers on insulating-supportsNanowireMetal particle

The present invention relates to a method of manufacturing a transparent conductive layer and a transparent conductive layer manufactured by the method. The method of manufacturing the transparent conductive layer includes: a) a step of forming a conductive nanowire layer on a base material; b) a step of thermally treating the conductive nanowire layer; c) a step of applying a conductive metal ink on the conductive nanowire layer; and d) a step of thermally treating the base material coated with the conductive metal ink to electrically bridge the conductive nanowires with each other by conductive metal particles of the conductive metal ink.

Owner:INKTEC CO LTD

Aerodynamic jetting of aerosolized fluids for fabrication of passive structures

InactiveUS20060163570A1Liquid surface applicatorsSemiconductor/solid-state device detailsOptical propertyEngineering

Method and apparatus for direct writing of passive structures having a tolerance of 5% or less in one or more physical, electrical, chemical, or optical properties. The present apparatus is capable of extended deposition times. The apparatus may be configured for unassisted operation and uses sensors and feedback loops to detect physical characteristics of the system to identify and maintain optimum process parameters.

Owner:OPTOMEC DESIGN CO

Multi Shell Metal Particles and Uses Thereof

ActiveUS20140264191A1Reduced silver consumptionImprove conductivityTransportation and packagingConductive materialMetal particleCrystalline silicon

A composition comprising a plurality of coated metal particles with a metal core surrounded by nested shells formed by an electrically conductive layer and by a barrier layer, at least one of the shells being formed by electroless plating. The invention also comprises a method of producing such compositions as well as the use of the composition in, for example, crystalline-silicon solar cell devices having contact structures formed on one or more surfaces of a solar cell device, such as those used in back contact solar cell devices or emitter wrap through (EWT) solar cell devices.

Owner:INKRON

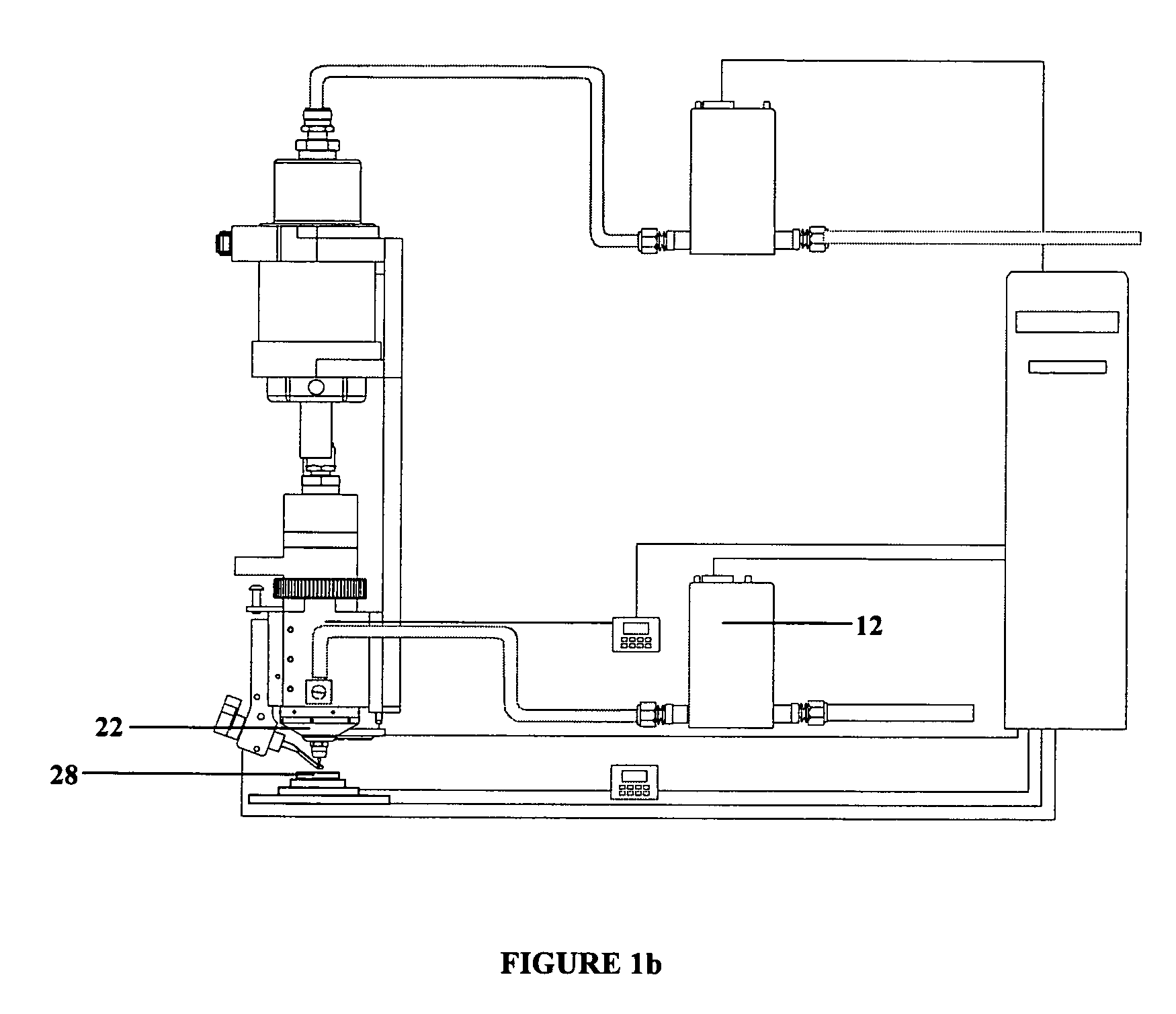

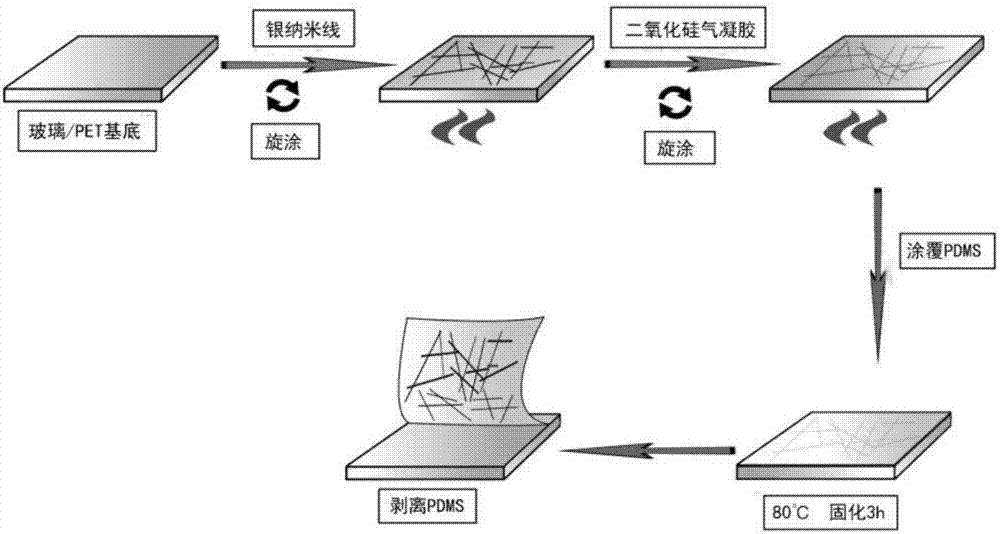

Method for transferring silver nanowire transparent conductive film to flexible substrate

InactiveCN107068291AImprove adhesionReduce surface roughnessApparatus for manufacturing conducting/semi-conducting layersSurface roughnessSilicon dioxide

The present invention provides a method for transferring a silver nanowire transparent conductive film to a flexible substrate. The method comprises the following steps: (1) performing spin coating of silver nanowire dispersion liquid on a cleaning substrate, obtaining a silver nanowire film, putting the silver nanowire film on a heating plate of 120 DEG C for drying, and performing heat treatment of the silver nanowire film in an oven of 220 DEG C; (2) performing spin coating of silicon dioxide aerogel dispersion liquid on the silver nanowire film, making a silver nanowire / silicon dioxide aerogel composite conductive film, and performing drying of the silver nanowire / silicon dioxide aerogel composite conductive film on the heating plate of 120 DEG C; (3) coating uniformly mixed PDMS to the surface of the composite conductive film to perform heating curing, and making an AgNWs-silicon dioxide aerogel-PDMS composite flexible transparent electrode; and (4) directing peeling off the cured PDMS from a glass substrate, and completing the transferring of the silver nanowire transparent conductive film. The method for transferring the silver nanowire transparent conductive film to the flexible substrate realizes the complete transferring of the silver nanowire transparent electrode to effectively reduce the node resistance between nanowires, reduce the surface roughness of a network, make a silver nanowire flexible transparent conductive film with good performances and have an actual application value.

Owner:WUHAN UNIV OF TECH

Shielding for cable components

InactiveUS20130008684A1Material nanotechnologyApparatus for manufacturing conducting/semi-conducting layersShielded cableEngineering

A shielded cable component and method that comprises a human body that has an outer surface and the main body is formed of a dielectric material and a coating that is applied to the outer surface of the main body where the coating includes a conductive or semi-conductive shielding material. An outer layer is disposed on the coating that completely encapsulates the coating and the main body and the outer layer is formed of a dielectric material.

Owner:GENERAL CABLE TECH CORP

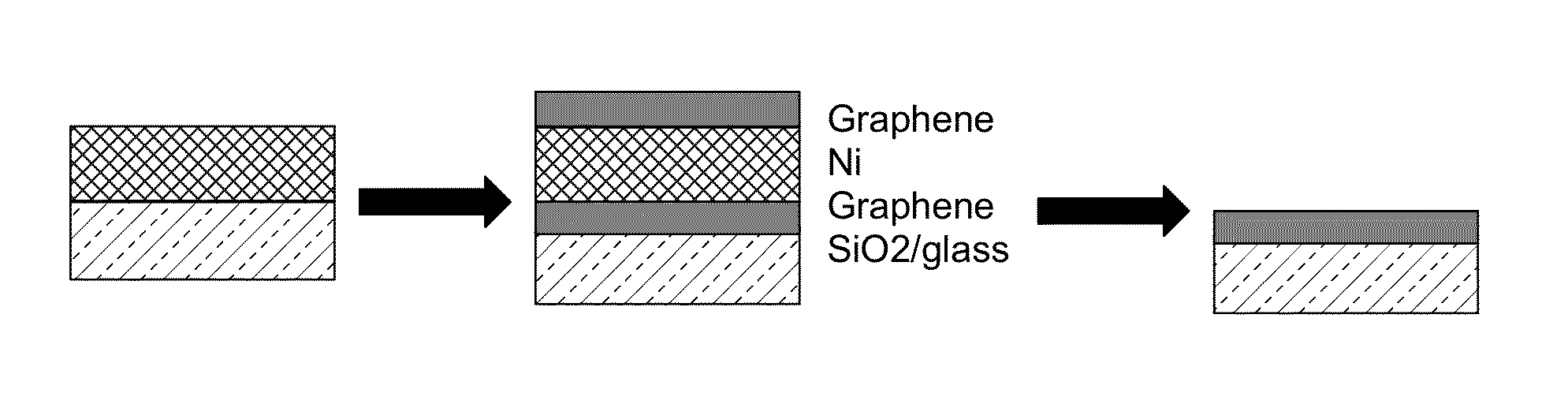

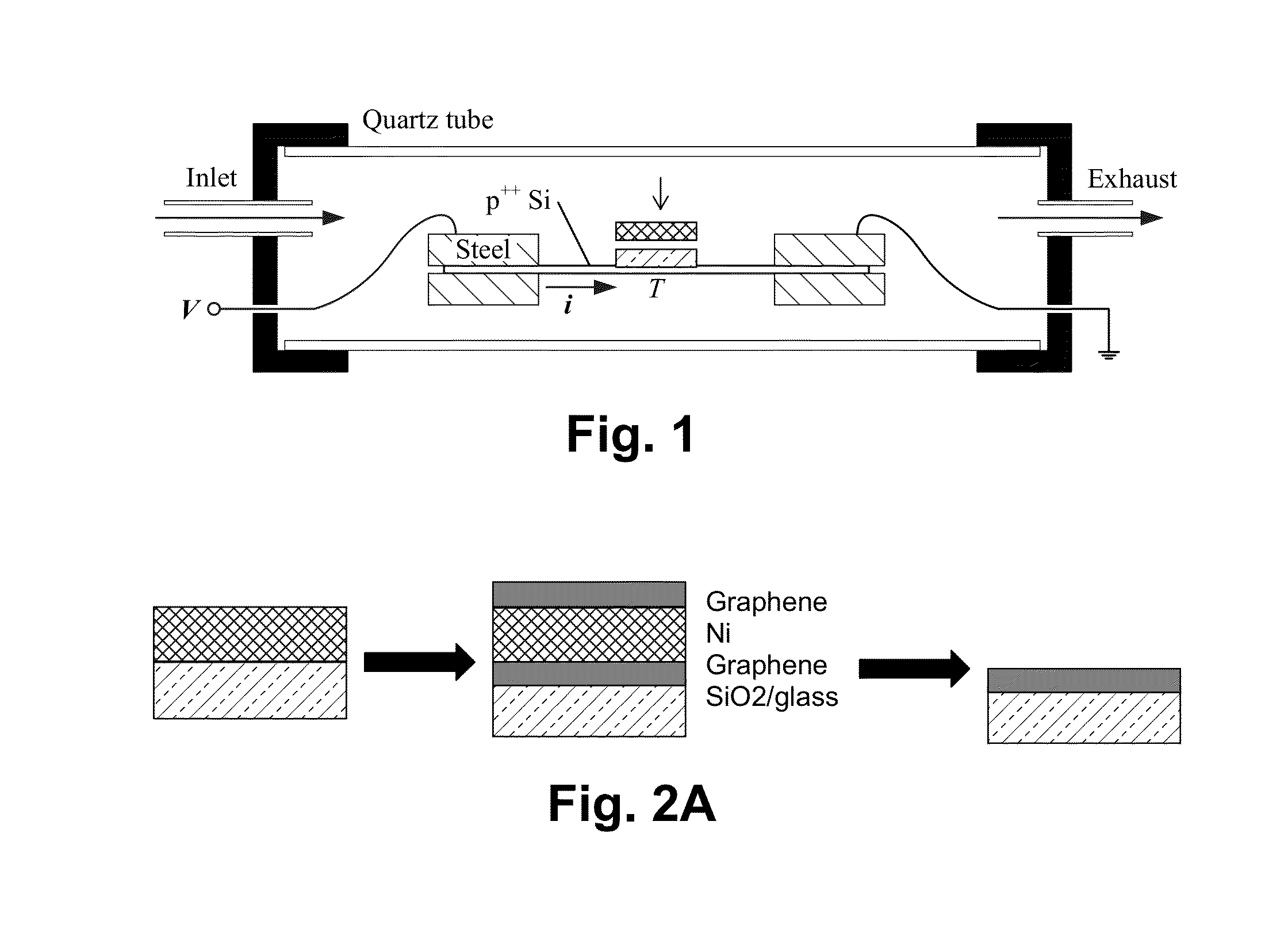

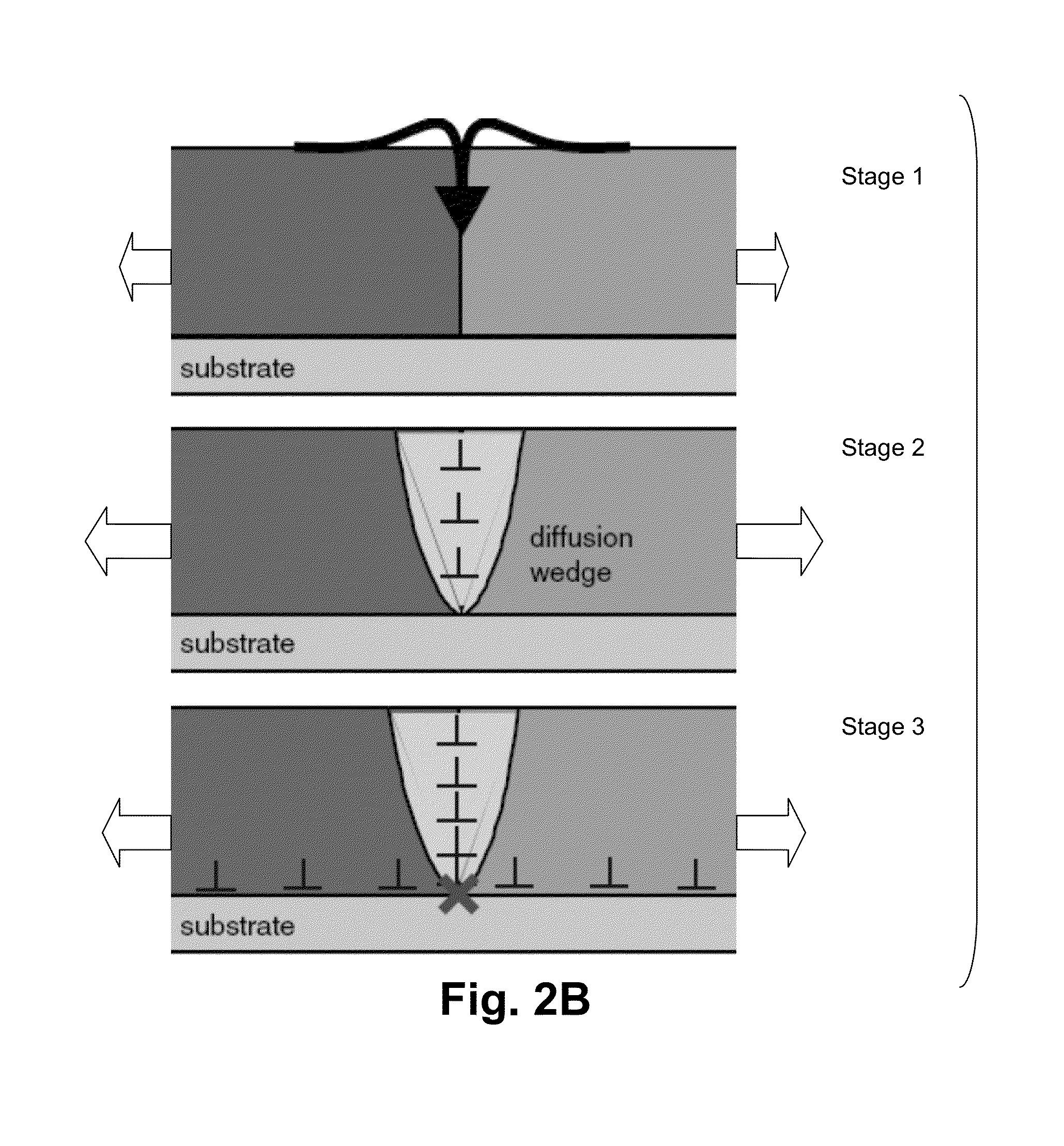

Methods for direct production of graphene on dielectric substrates, and associated articles/devices

ActiveUS20140308523A1Material nanotechnologyWave amplification devicesDielectric substrateCvd graphene

Certain example embodiments of this invention relate to methods for large area graphene precipitation onto glass, and associated articles / devices. For example, a coated article including a graphene-inclusive film on a substrate, and / or a method of making the same, is provided. A metal-inclusive catalyst layer (e.g., of or including Ni and / or the like) is disposed on the substrate. The substrate with the catalyst layer thereon is exposed to a precursor gas and a strain-inducing gas at a temperature of no more than 900 degrees C. Graphene is formed and / or allowed to form both over and contacting the catalyst layer, and between the substrate and the catalyst layer, in making the coated article. The catalyst layer, together with graphene formed thereon, is removed, e.g., through excessive strain introduced into the catalyst layer as associated with the graphene formation. Products including such articles, and / or methods of making the same, also are contemplated herein.

Owner:GUARDIAN GLASS LLC +1

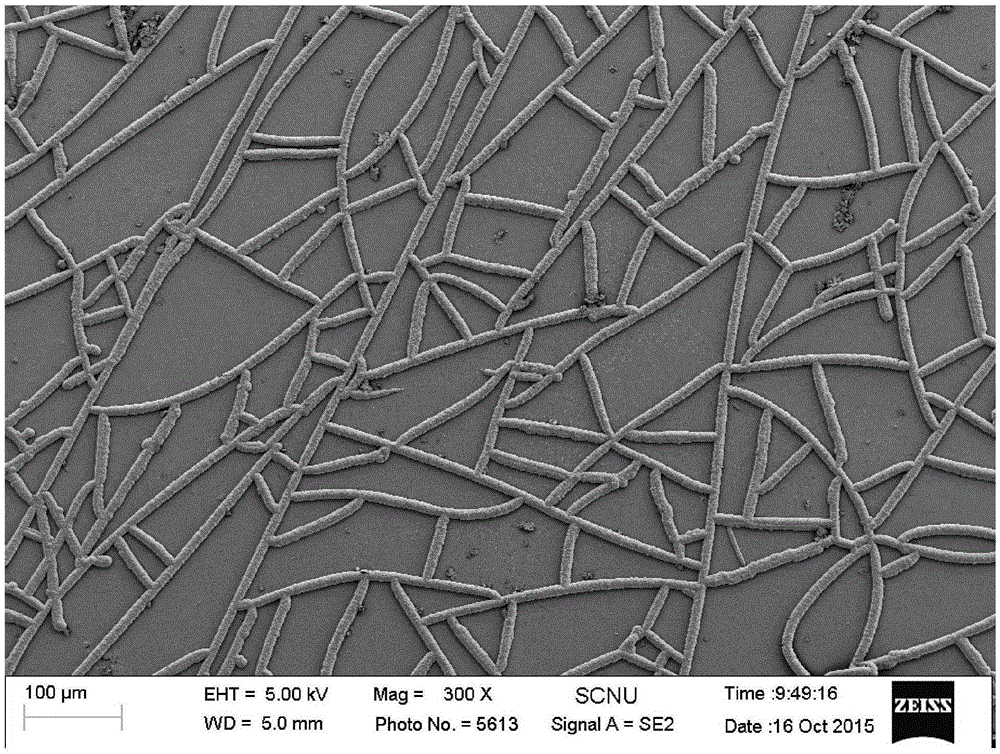

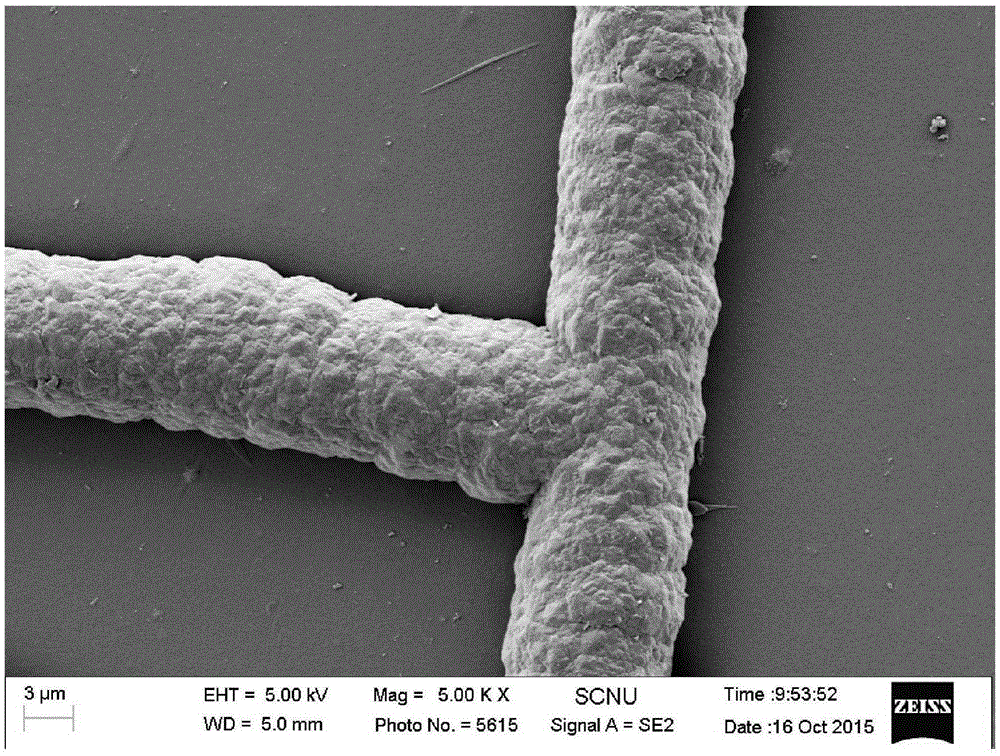

Method for preparing high-performance metallic network transparent conducting electrode through metal plating method

ActiveCN105350043AEasy to prepareLow costApparatus for manufacturing conducting/semi-conducting layersElectrical resistance and conductanceResource consumption

The invention discloses a method for preparing a high-performance metallic network transparent conducting electrode through a metal plating method. The method includes the following steps: (1) a fracturing sacrificial layer template is prepared on a substrate; (2) a metallic conducting seed layer is deposited on the fracturing sacrificial layer template; (3) the fracturing sacrificial layer is removed to form a metallic conducting seed layer network; and (4) metal is continuously deposited on the metallic conducting seed layer through the metal plating method, a continuous metal network with the larger thickness and the lower resistance is formed, and therefore the high-performance metallic network transparent conducting electrode is prepared. The transparent conducting electrode is mainly obtained through the metal plating method, the metal plating method belongs to a chemical liquid phase method, the preparing process is simple, resource consumption is low, and the high-performance metallic network transparent conducting electrode is suitable for large-area continuous preparation. The prepared transparent conducting electrode has the extremely-low surface resistance and the better light transmittance; meanwhile, the mechanical property and the environmental stability are good, the transparent conducting electrode is a beneficial replacer of a traditional metallic oxide electrode, and it is expected that the method is used for industrialization of the large-area transparent conducting electrode.

Owner:SOUTH CHINA NORMAL UNIVERSITY

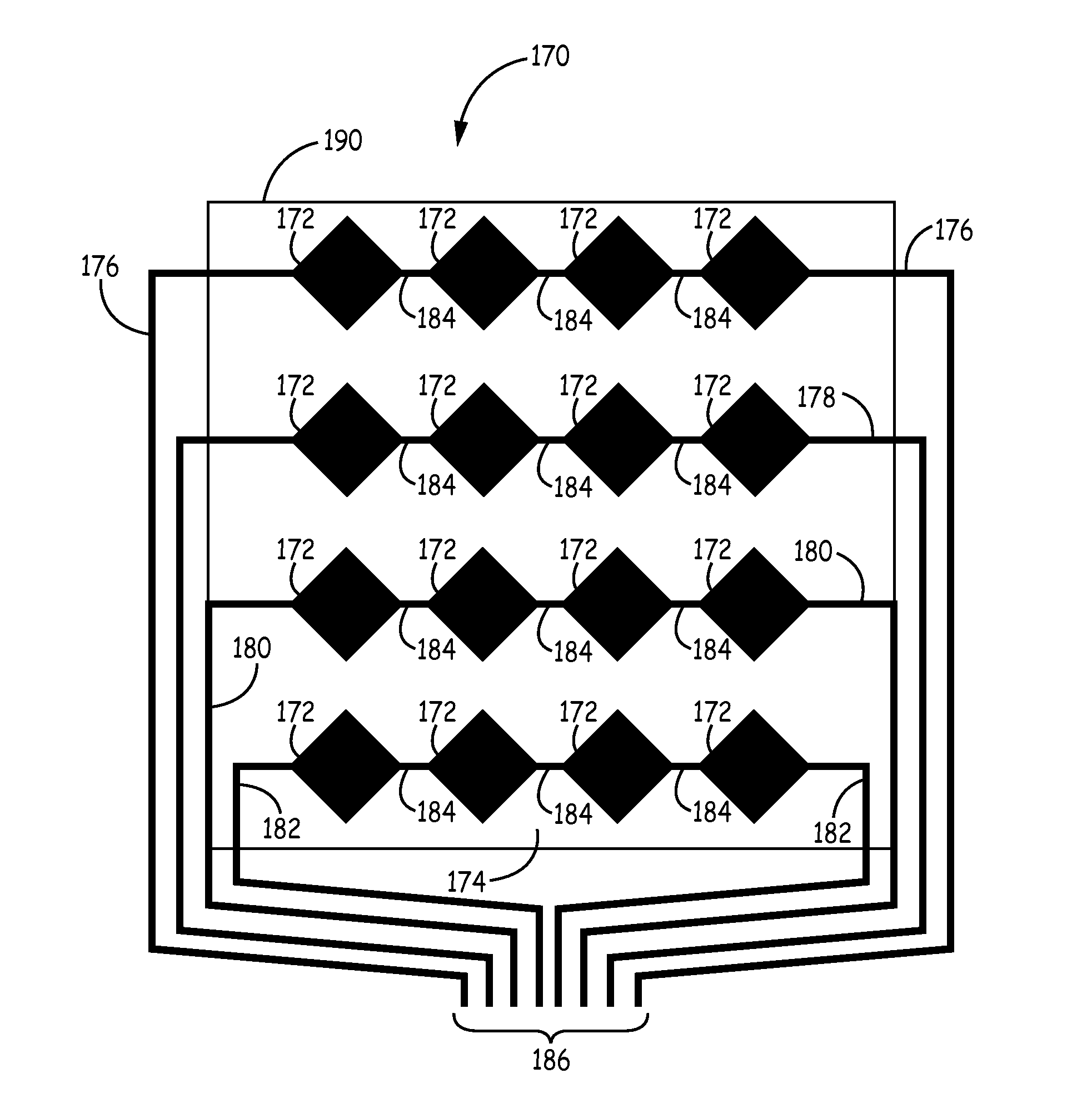

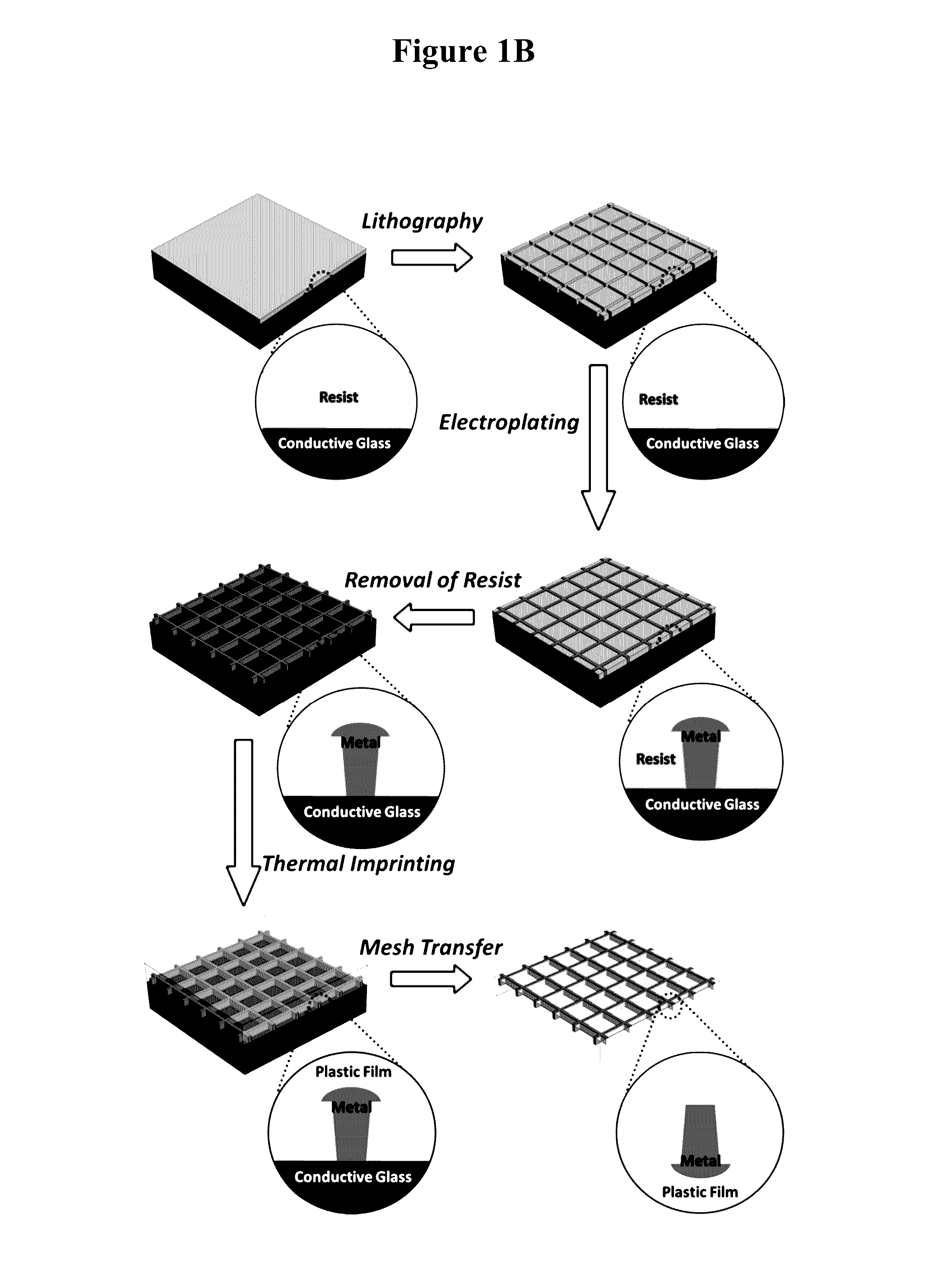

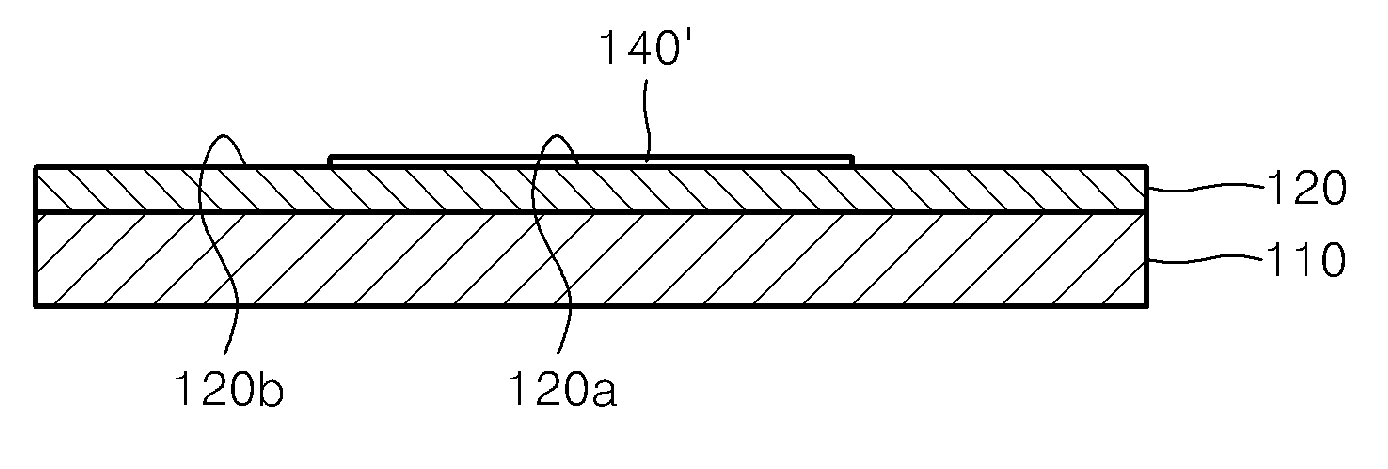

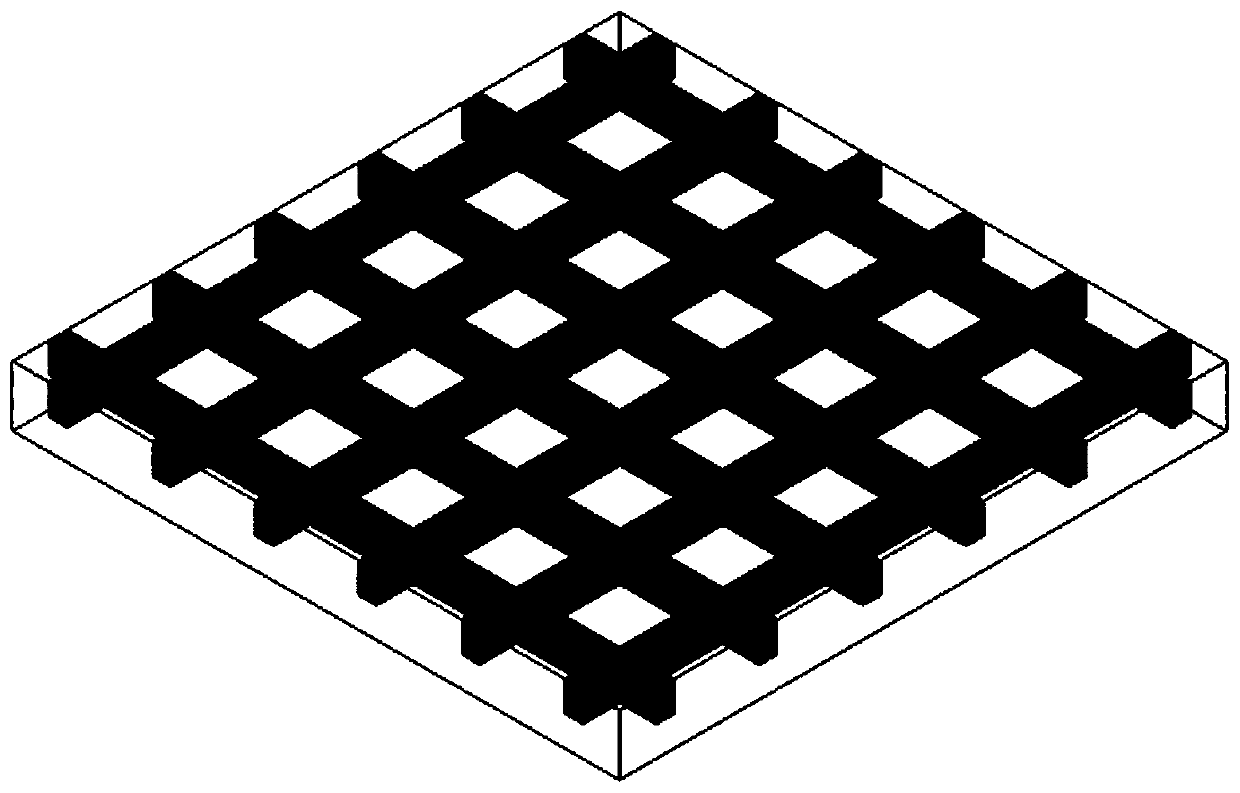

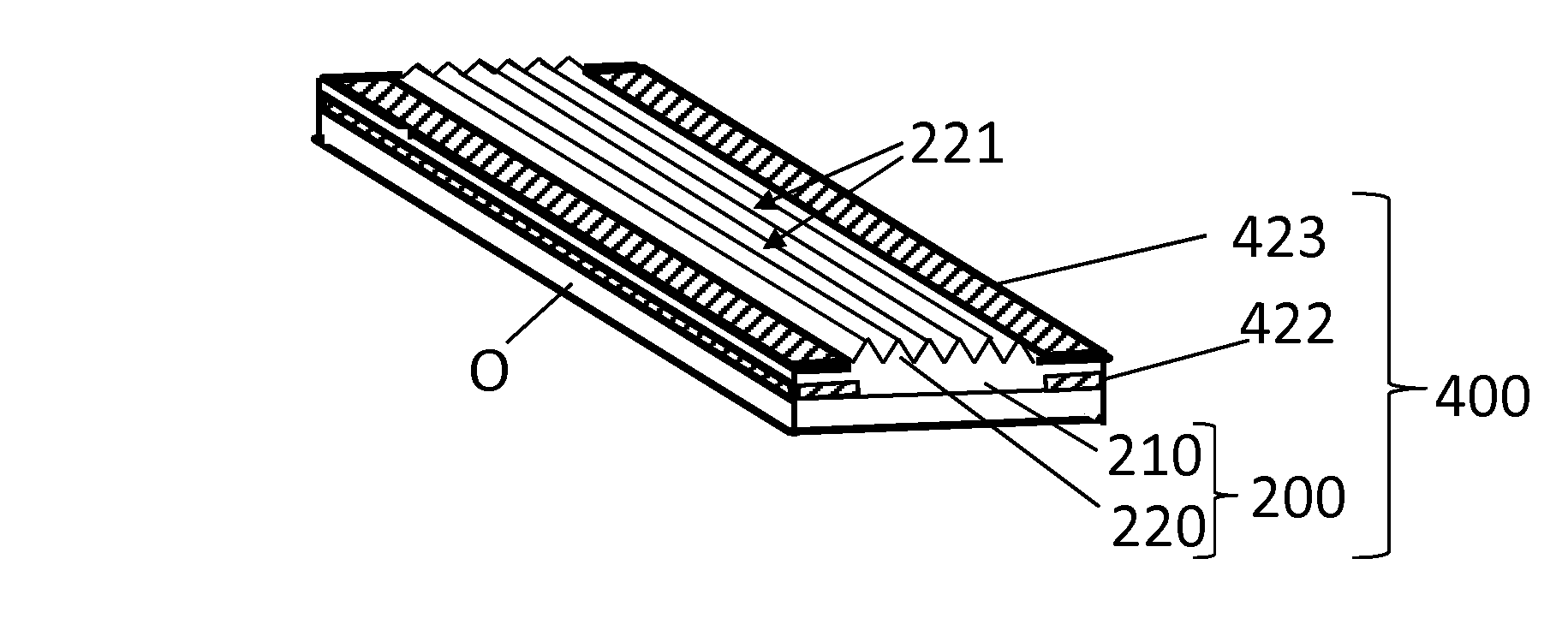

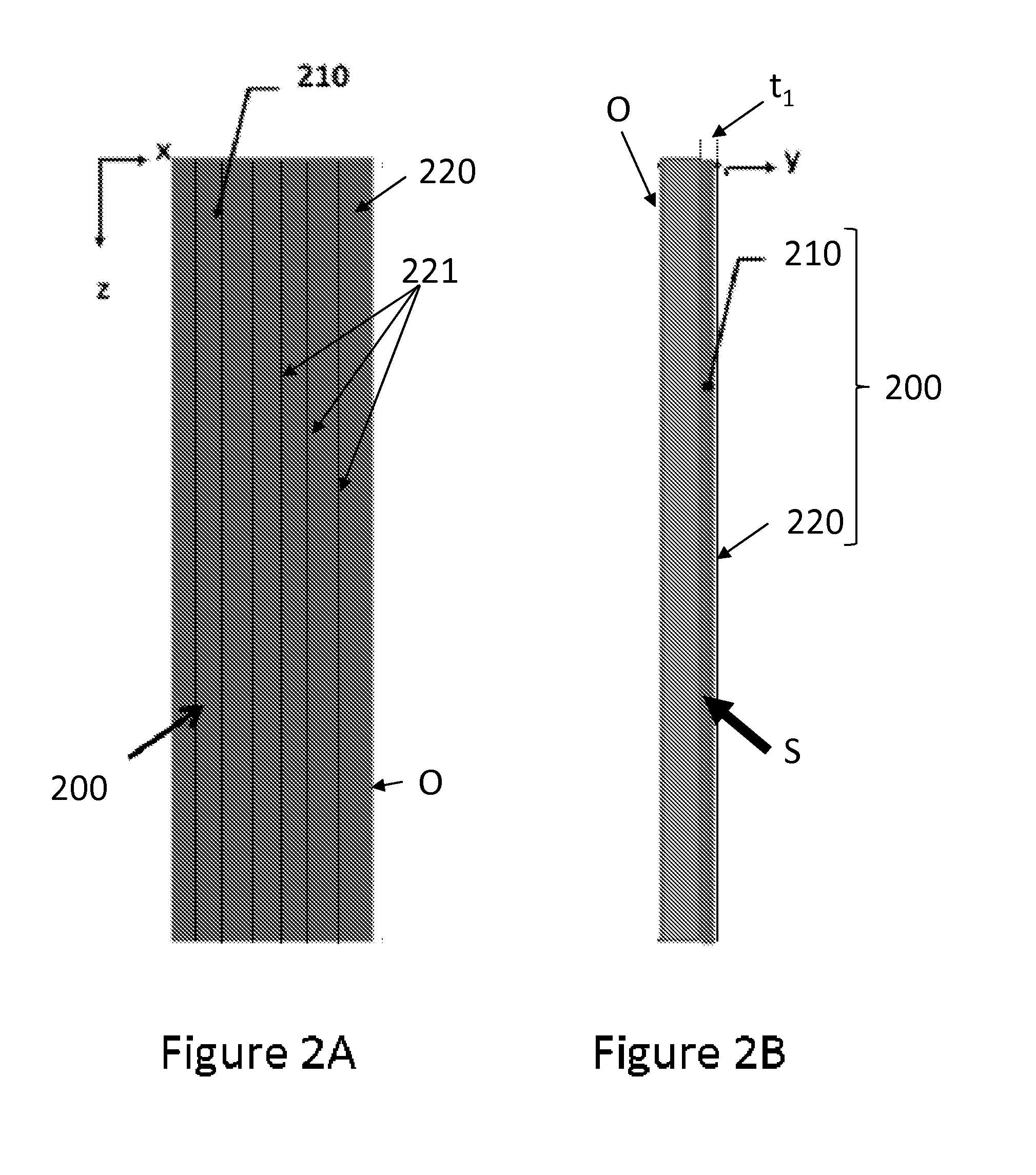

Transparent conductive films with embedded metal grids

ActiveUS20160345430A1Improve stabilityHigh strengthConductive layers on insulating-supportsCircuit optical detailsMechanical stabilityTransparent conducting film

A transparent conductive film with a metal mesh embedded in a substrate and a method of fabrication thereof is provided. The metal mesh has a cap that is pressed and embedded in a substrate or a deformable material on a substrate, providing superior mechanical stability by mechanical interlocking. The embedding mechanism also provides superior chemical and environmental stability. A fabrication method is provided and includes a vacuum-free and low-cost process for large-volume manufacturing of the transparent conductive film with tunable performance.

Owner:VERSITECH LTD

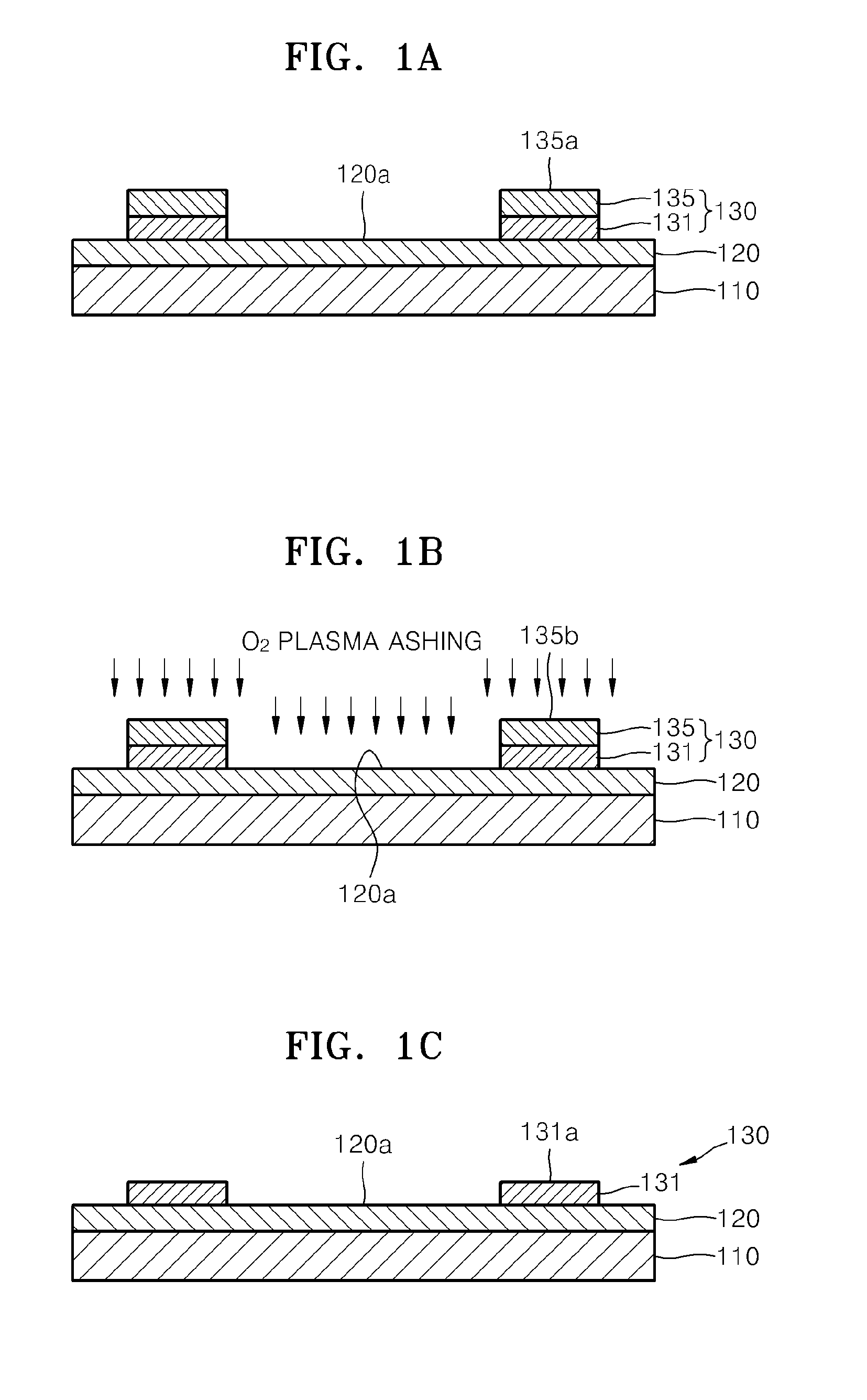

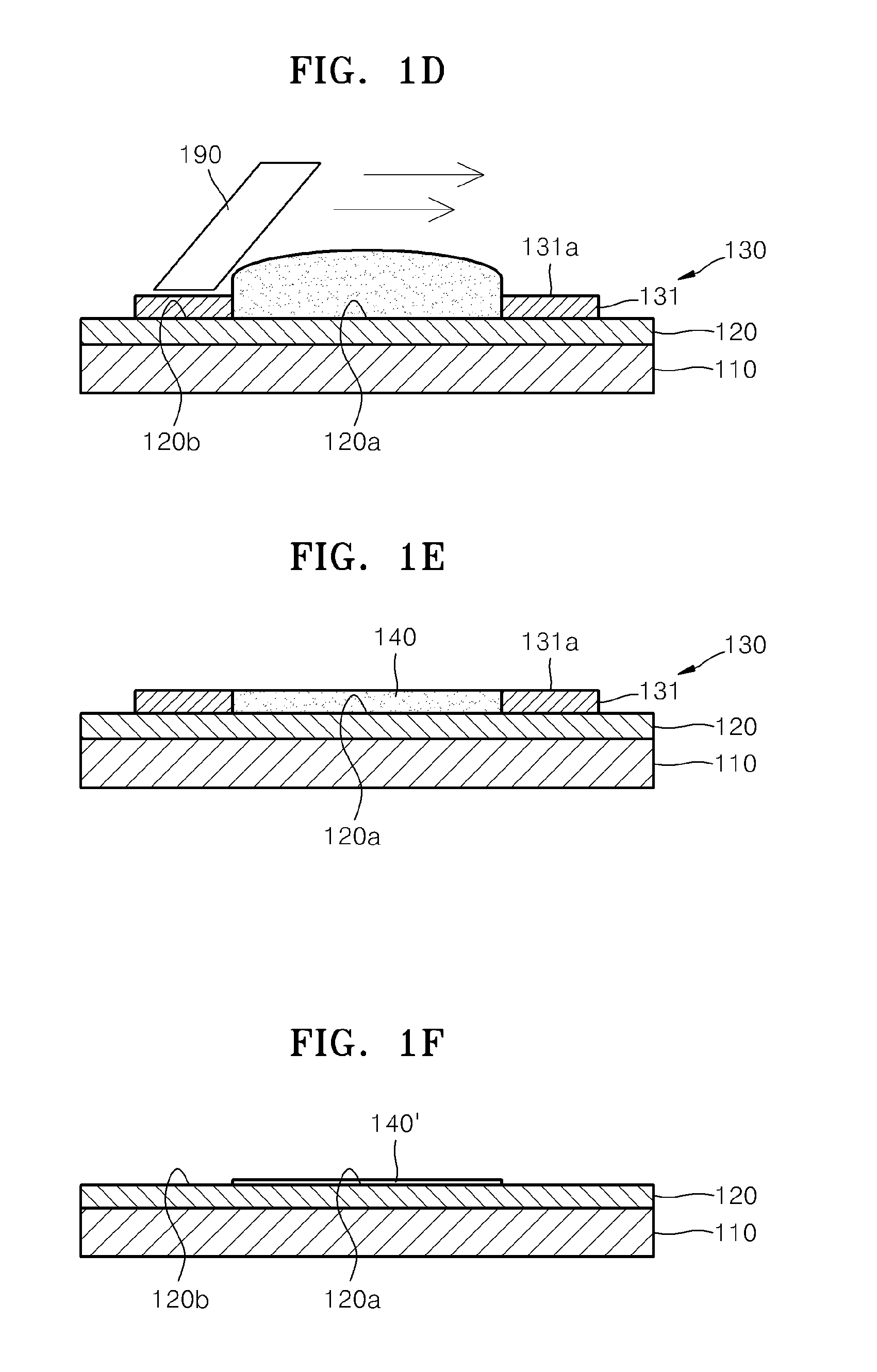

Method of manufacturing polymer electrode and polymer actuator employing the polymer electrode

ActiveUS20120200200A1Piezoelectric/electrostrictive device manufacture/assemblyConductive layers on insulating-supportsPolymer scienceConductive polymer

A method of manufacturing a polymer electrode and a polymer actuator employing the polymer electrode, the method including: adhering a shadow mask onto a substrate, forming a hydrophilic electrode pattern on the substrate, coating the hydrophilic electrode pattern of the substrate with a conductive polymer water solution, removing the shadow mask, and drying the conductive polymer water solution, thus forming the polymer electrode. The method may be applied to electrodes disposed on both surfaces of a polymer deformation layer of a polymer actuator.

Owner:SAMSUNG ELECTRONICS CO LTD

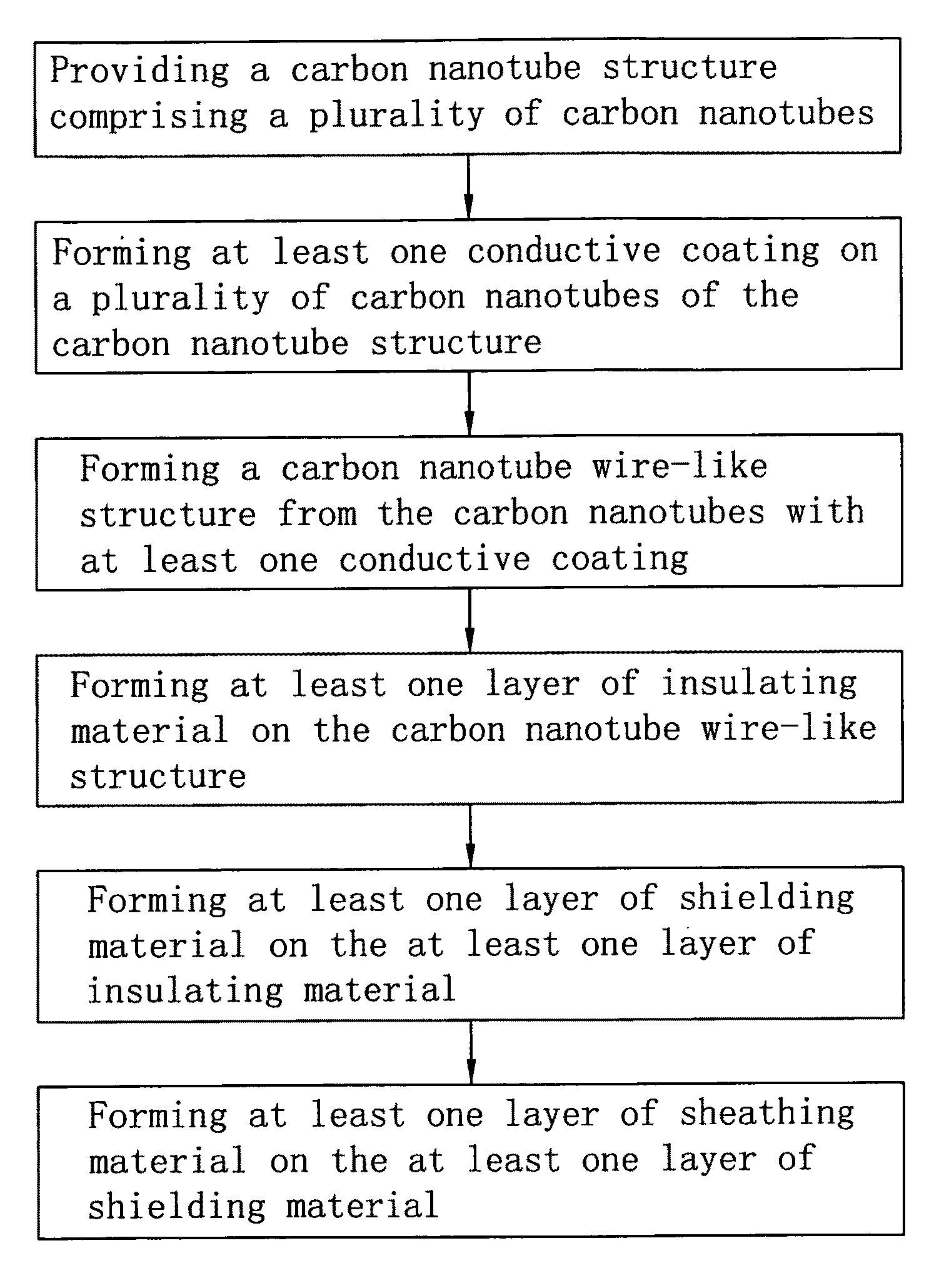

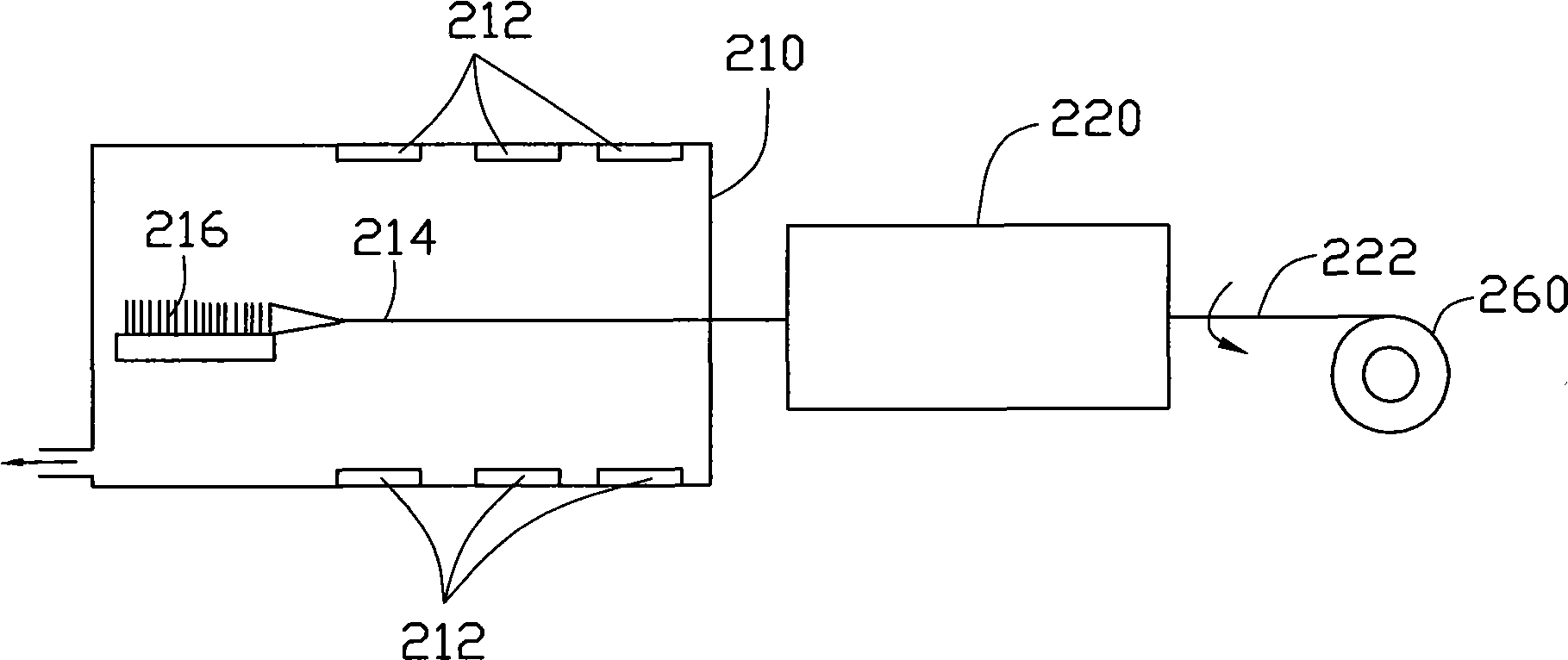

Method for making coaxial cable

ActiveUS8247036B2Improve conductivityImprove mechanical propertiesFibre treatmentVacuum evaporation coatingCoaxial cableConductive coating

A method for making a coaxial cable, the method comprises the steps of: providing a carbon nanotube structure; and forming at least one conductive coating on a plurality of carbon nanotubes of the carbon nanotube structure; a carbon nanotube wire-like structure from the carbon nanotubes with at least one conductive coating; at least one layer of insulating material on the carbon nanotube wire-like structure; at least one layer of shielding material on the at least one layer of insulating material; and one layer of sheathing material on the at least one layer of shielding material.

Owner:TSINGHUA UNIV

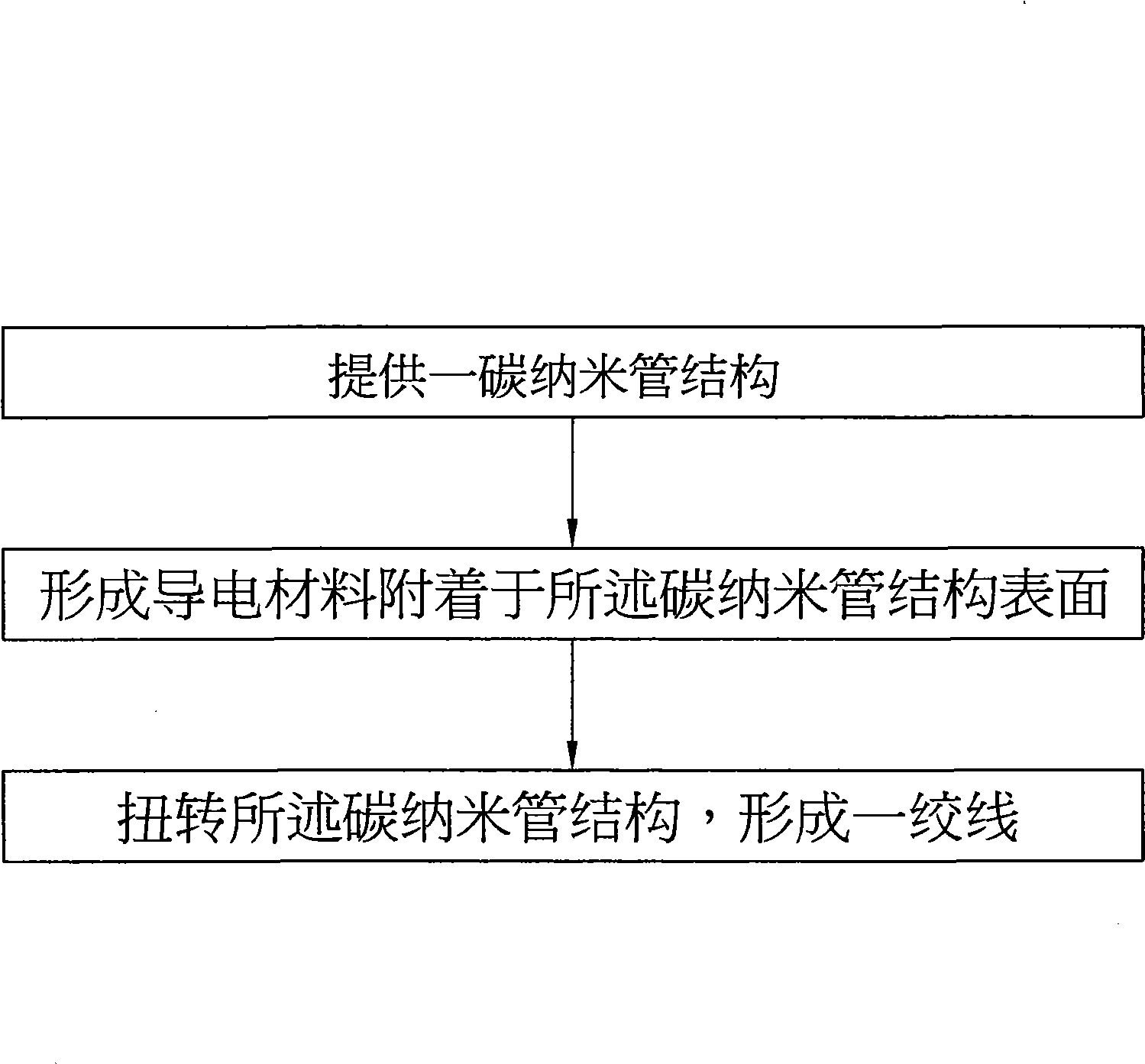

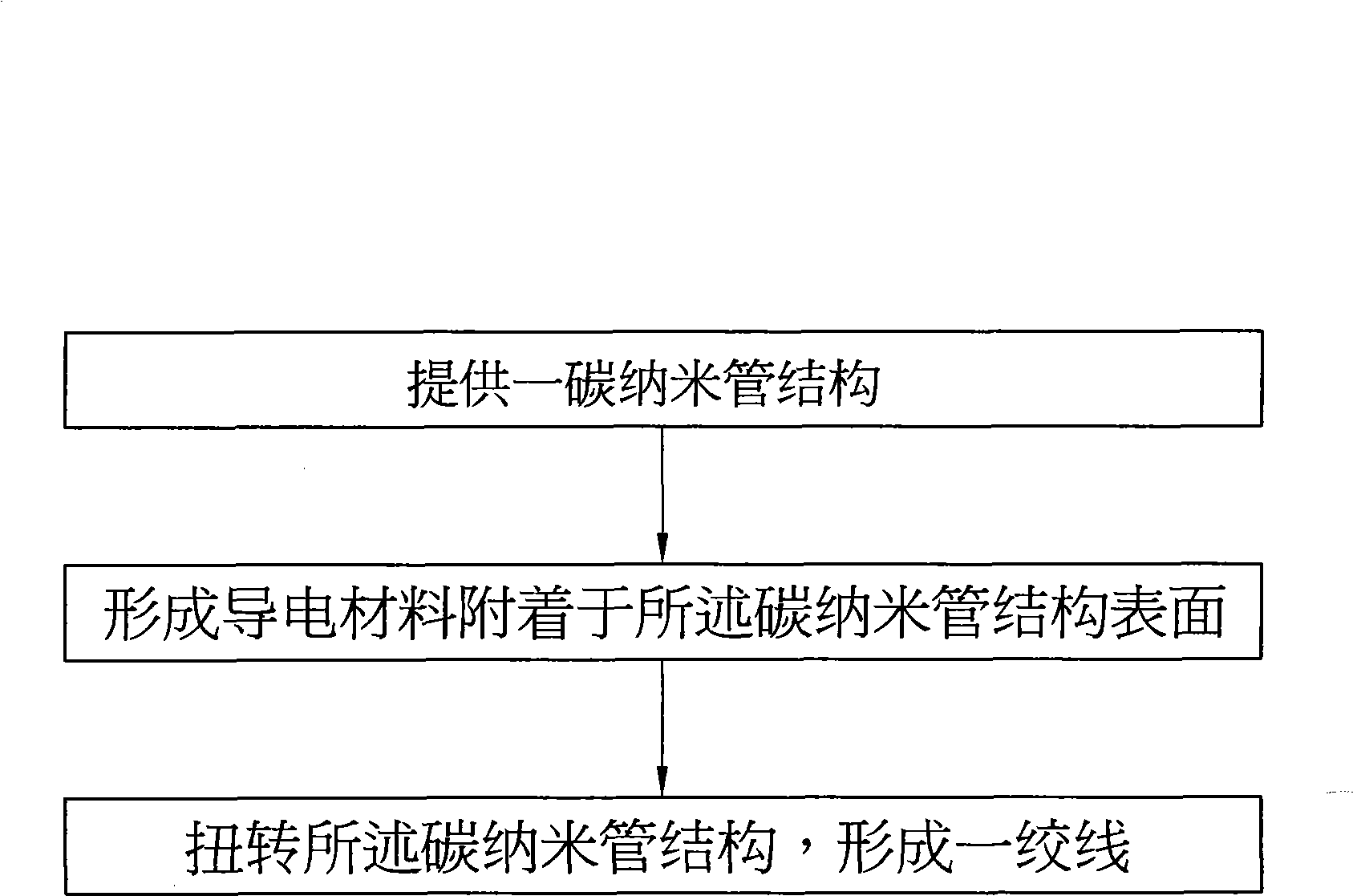

Stranded wire production method

ActiveCN101499338AImprove conductivityEasy to prepareNon-insulated conductorsConductive materialCarbon nanotubeNano tube

The invention relates to a method for preparing a twisted line, comprising the steps as follows: a carbon nano tube structure is provided; a conducting material is formed and attached on the surface of the carbon nano tube structure; and the carbon nano tube structure is twisted to form the twisted line.

Owner:TSINGHUA UNIV +1

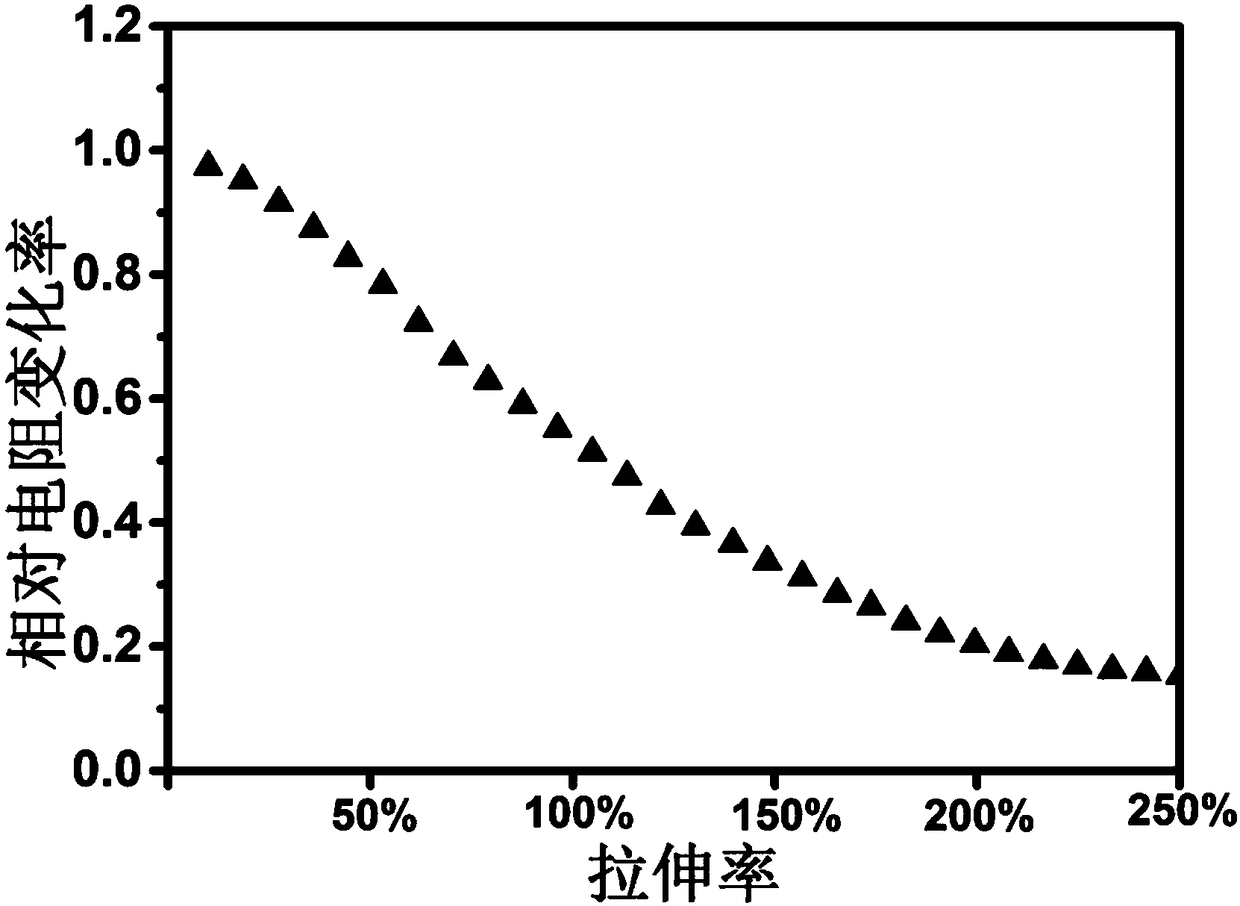

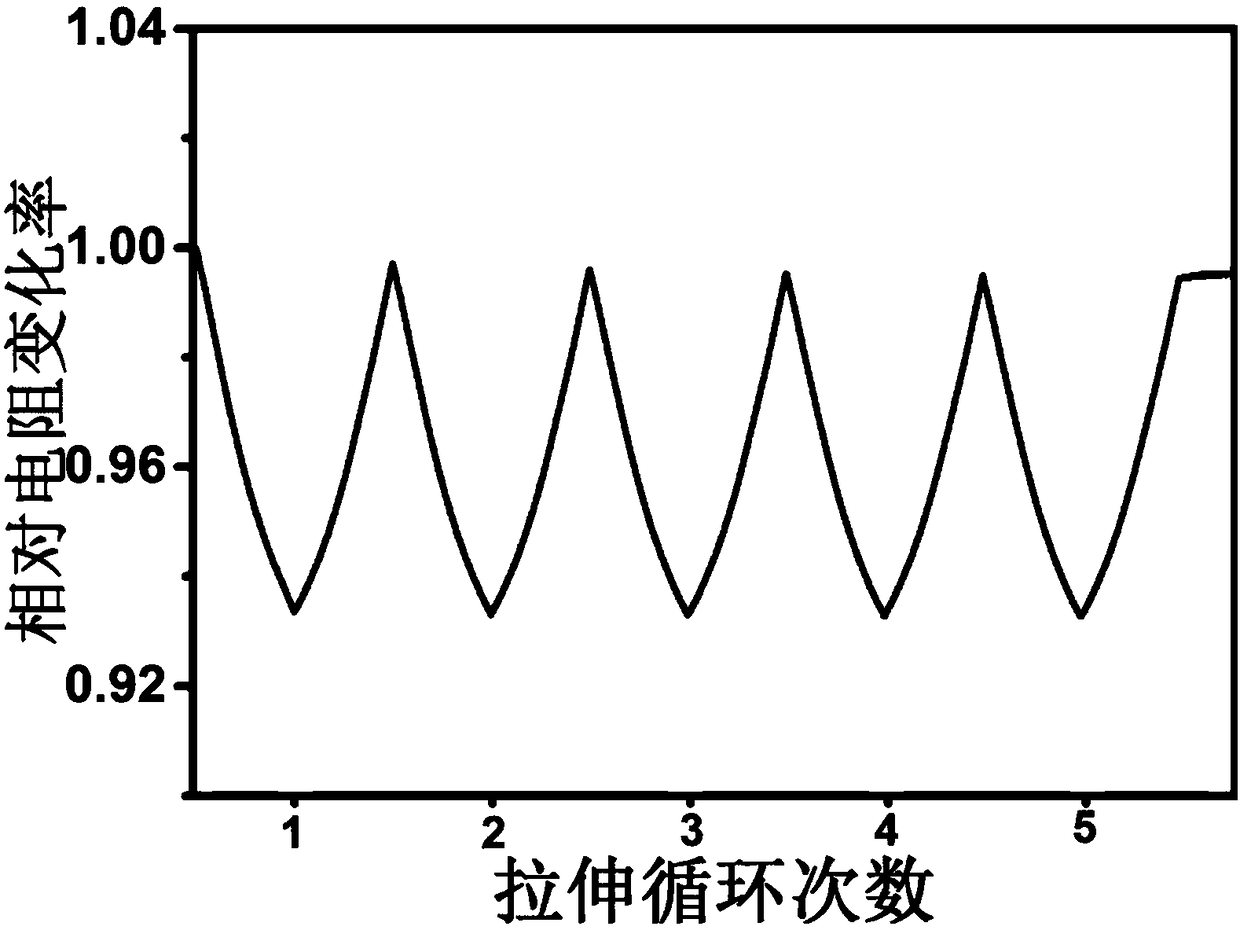

Liquid metal-based stretchable flexible functional conductor and preparation method thereof

InactiveCN108447592AWith tensile deformation-resistance reduction effectReduce distanceConductive layers on insulating-supportsForce measurementElectrical resistance and conductanceLiquid state

The invention discloses a liquid metal-based stretchable flexible functional conductor and a preparation method thereof. The method comprises the following steps: (1) a polymer solution and a liquid metal are blended uniformly to obtain a conductive composite material; (2) the conductive composite material is loaded on a flexible carrier to obtain the liquid metal-based stretchable flexible functional conductor. The liquid metal-based stretchable flexible functional conductor is non-toxic and safe, and has a tensile deformation-resistance reduction effect in the stretching process, the resistance decreases as strain increases, and the stretchable flexible functional conductor has important application prospects in the field of force conductive materials.

Owner:SOUTH CHINA UNIV OF TECH

Method for producing conductive film

InactiveCN104903981AEasy to adjust the diameterEasy to prepareSpecific nanostructure formationMaterial nanotechnologyMetal catalystCarbon nanotube

Provided is a method for producing a conductive film in which a size of a particle of a metal catalyst for synthesizing carbon nanotubes is adjusted to adjust a minor axis diameter of the carbon nanotube, such that the conductive film containing the carbon nanotube having an adjusted diameter may have excellent film properties.

Owner:HANWHA CHEMICAL CORPORATION

Polymer composition for w&c application with advantageous electrical properties

ActiveUS20130081854A1Improve electrical performanceLow conductivityConductive layers on insulating-supportsPlastic/resin/waxes insulatorsElectricityPower cable

The invention relates to a use of a polymer composition with improved DC electrical properties in a power cable layer and to a cable surrounded by at least one layer comprising the polymer composition.

Owner:BOREALIS AG

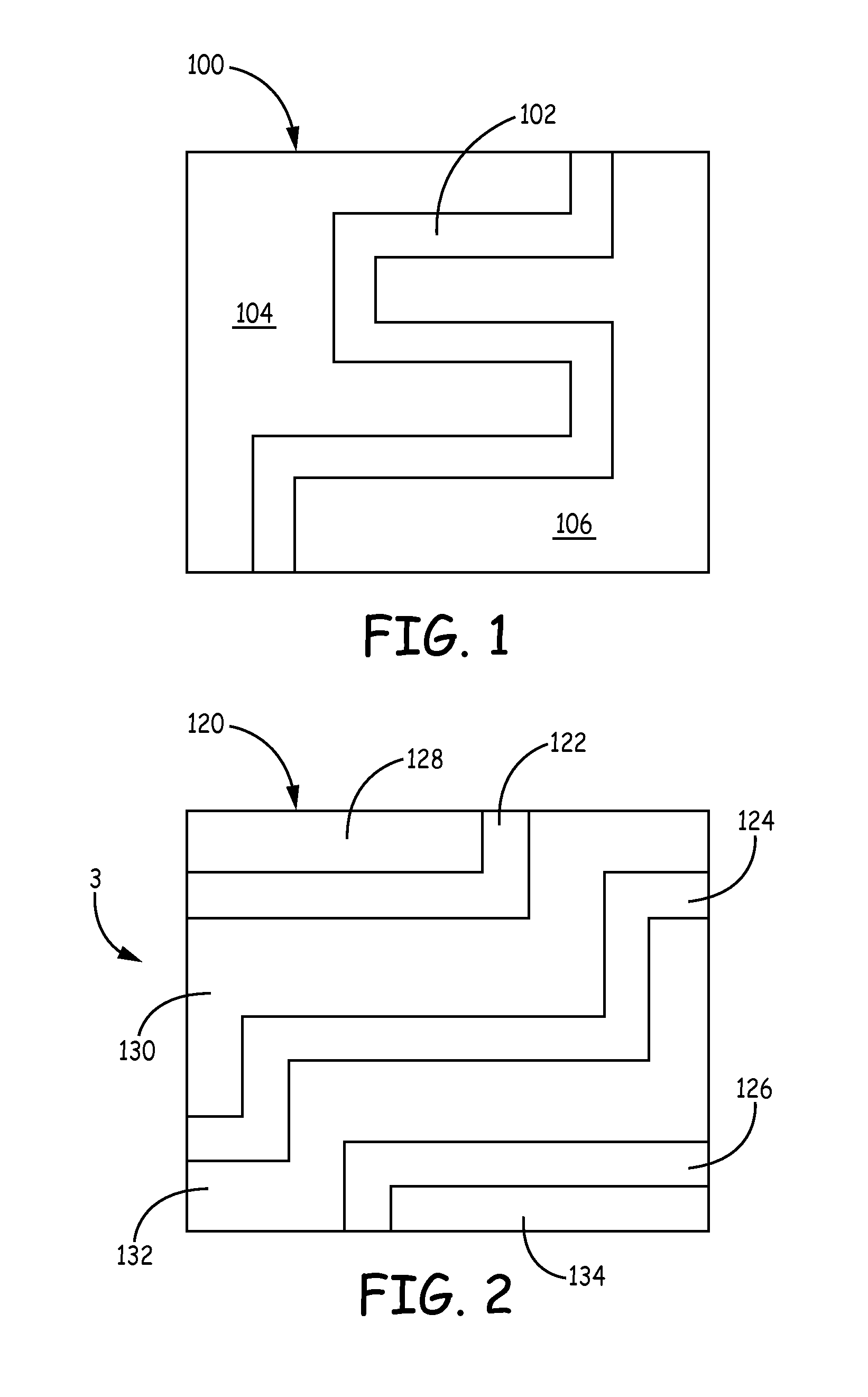

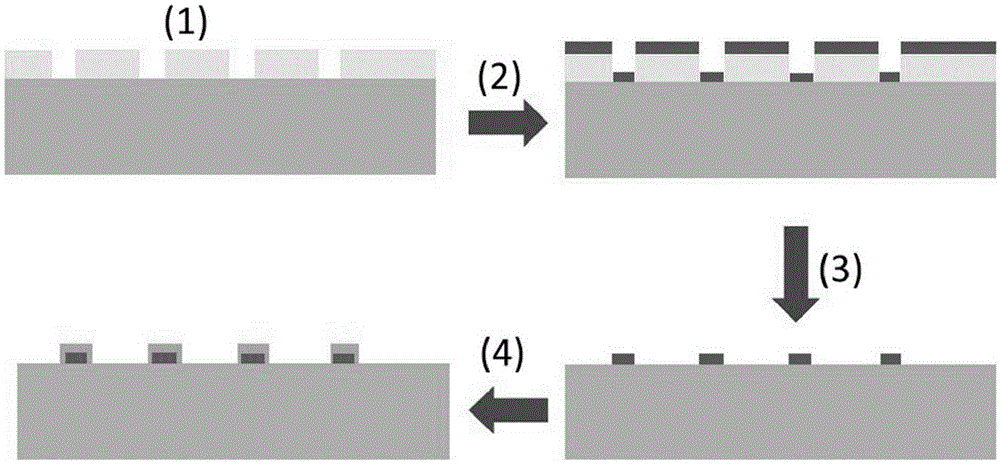

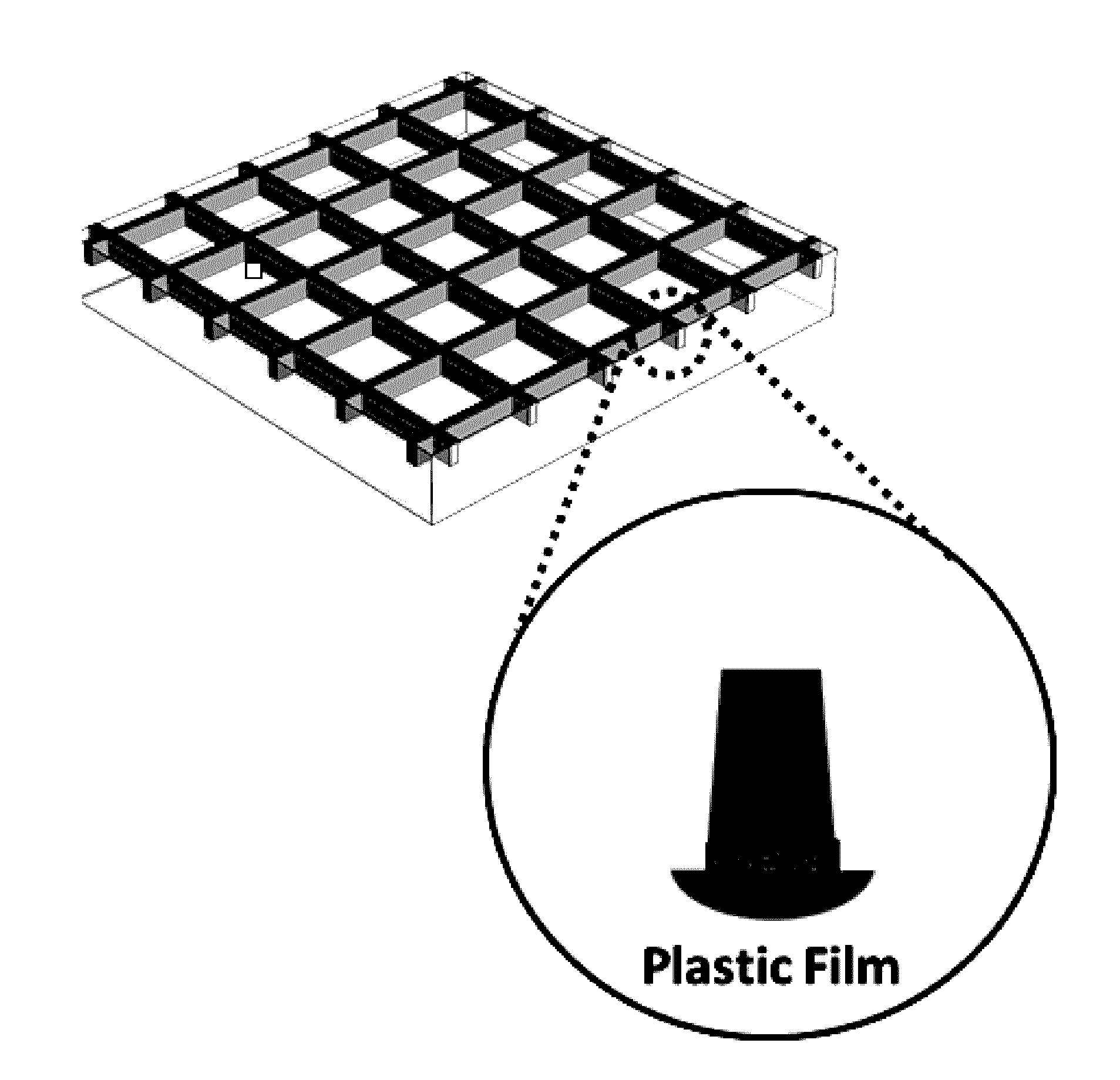

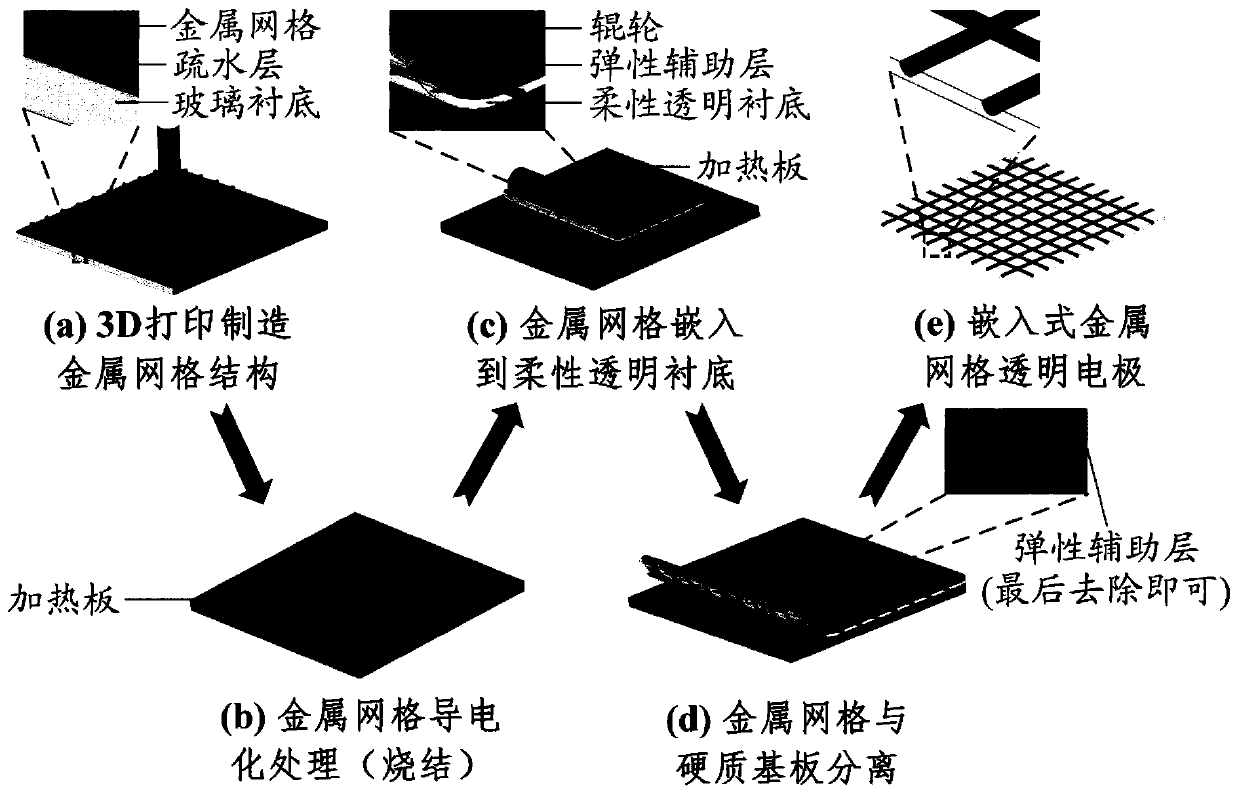

Manufacturing method and application of embedded metal grid flexible transparent electrode

ActiveCN110021462AIncrease profitNo wasteAdditive manufacturing apparatusConductive layers on insulating-supportsHot stampingMicro nano

The invention belongs to the field of flexible transparent electrodes, and particularly relates to a manufacturing method and an application of an embedded metal grid flexible transparent electrode. The method comprises the following steps: 1) by use of an electric field driven spray deposition micro-nano 3D printing technology, a metal grid transparent electrode is directly printed on a hard substrate; 2) conductive treatment is carried out on a printed metal grid structure by adopting a sintering process so as to realize conductive treatment of a metal grid; 3) a flexible transparent substrate and the hard substrate are heated to a set temperature, and a hot stamping process is adopted for completely embedding the metal grid structure on the hard substrate into the flexible transparent substrate; and 4) the metal grid which is completely embedded into the flexible transparent substrate is separated from the hard substrate to obtain the embedded metal grid flexible transparent electrode. According to the method, the electric field driven spray deposition micro-nano 3D printing technology is combined with the roller pair plane hot stamping technology to realize efficient and low-cost batch manufacturing of the large-sized embedded metal grid flexible transparent electrode; and the prepared transparent electrode also has excellent square resistance and light transmittance.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

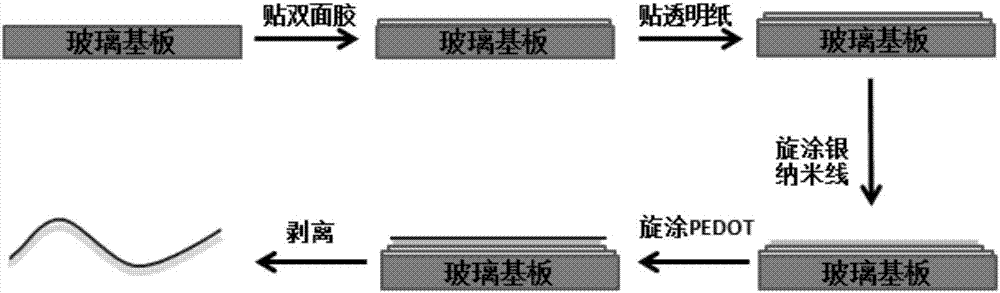

Rapid preparation method of paper-based flexible transparent electrode based on silver nanowires and PEDOT

InactiveCN107507676ANo pollution in the processLow costApparatus for manufacturing conducting/semi-conducting layersPaper basedViscose

The present invention discloses a rapid preparation method of a paper-based flexible transparent electrode based on silver nanowires and PEDOT, belonging to the nanometer photoelectric material technology field. The method comprises: dissolving a certain amount of linters into pre-cooling urea solution to form viscose solution and then form film of cement gel after film curing, and preparing transparent paper after drying of the film of cement gel; and uniformly performing spin coating of the silver nanowires on the surface of the transparent paper, performing spin coating of the PEDOT at the surface of the silver nanowires, and finally forming a final paper-based flexible transparent electrode after the silver nanowires with the PEDOT are thoroughly dried. The flexible transparent electrode provided by the invention is simple to operate and low in cost, is degradable and is wide in application range. The method is rapid and simple and can perform large-area preparation, and the prepared paper-based flexible transparent electrode is flexible, foldable and stable in electrical property.

Owner:NANJING UNIV OF TECH

Condensation inhibiting layer, method of forming the layer, and condensation inhibiting device

InactiveUS20150177480A1Attain and maintain clarityAttain and maintain of surfacePiezoelectric/electrostriction/magnetostriction machinesRadiation applicationsEngineeringActuator

Owner:LOCKHEED MARTIN CORP

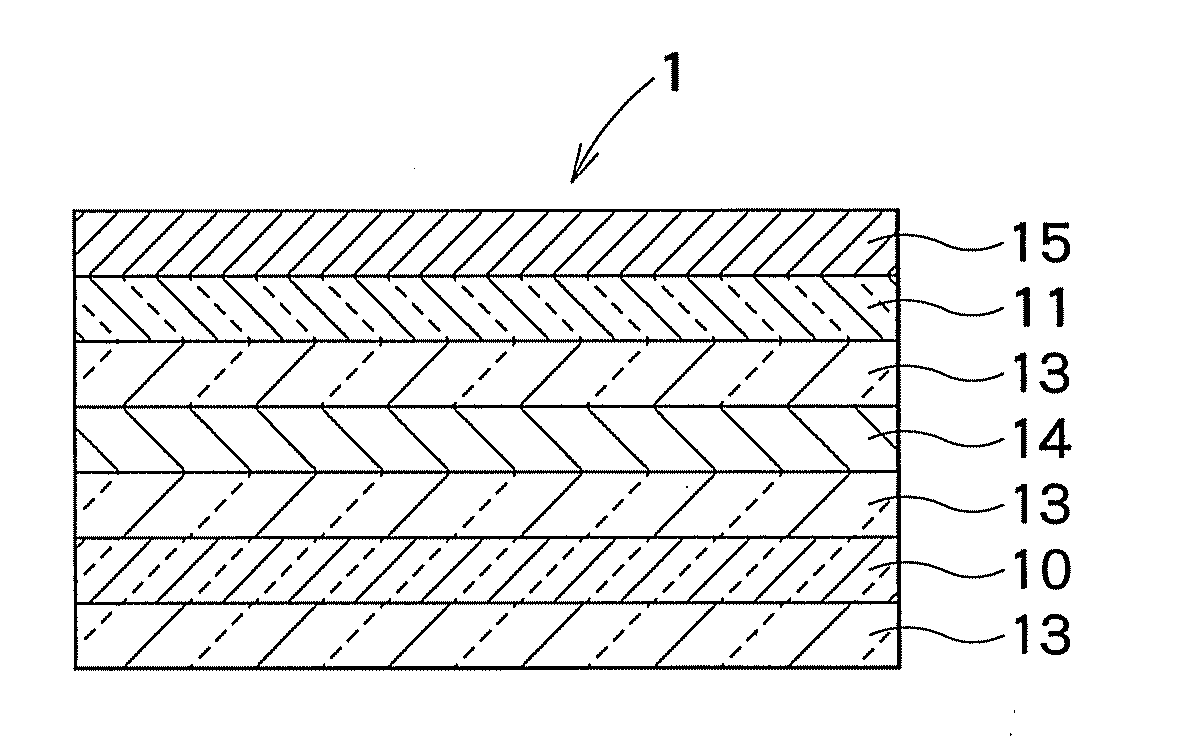

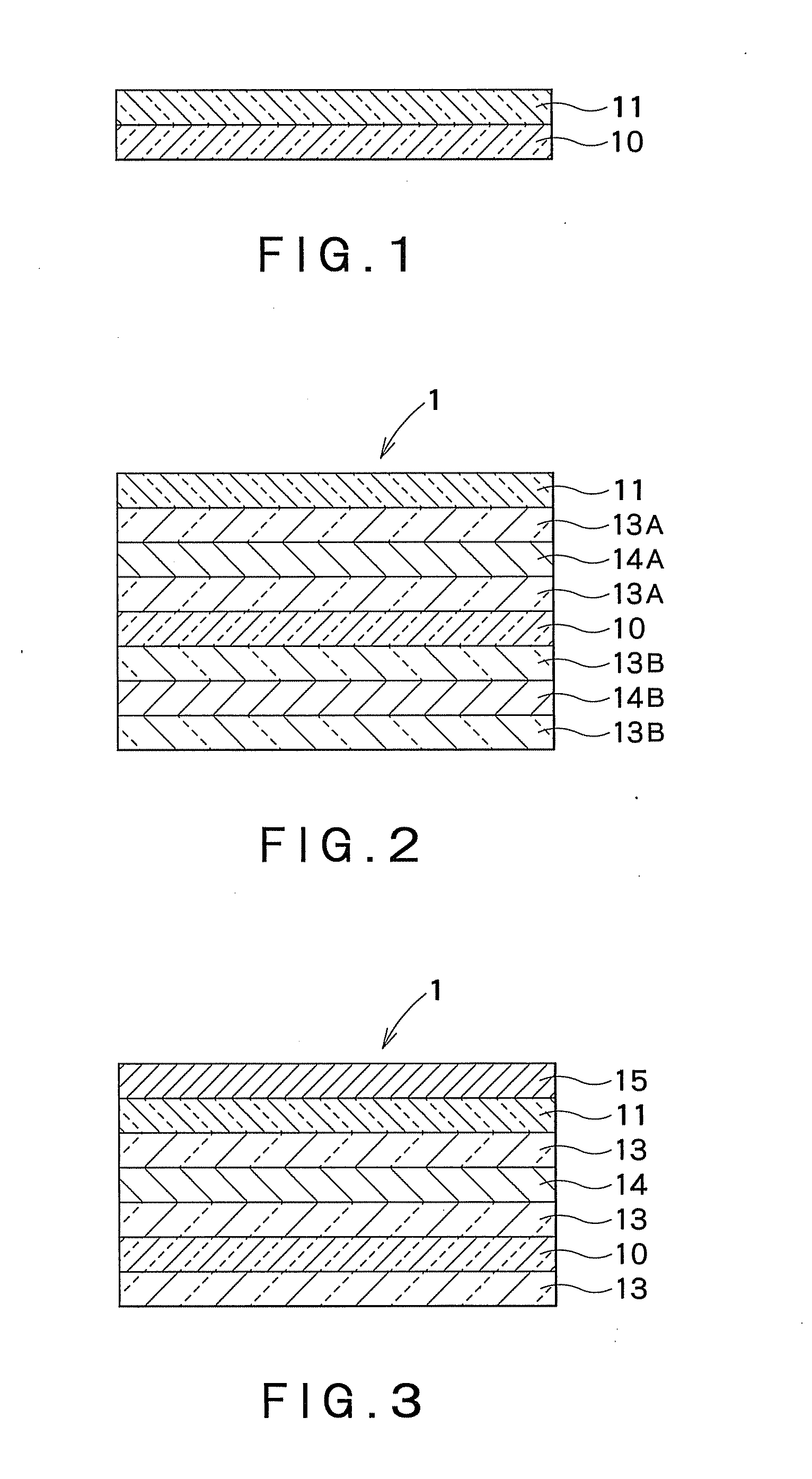

Film with transparent electroconductive membrane and its use

InactiveUS20090291293A1Good surface smoothnessHigh luminous brightnessConductive layers on insulating-supportsLayered productsLiquid-crystal displayDisplay device

This invention provides a film with a transparent electroconductive membrane, which can provide a display having a good surface flatness and possessing a high luminescence brightness, and a substrate for a display, a display, a liquid crystal display device, and an organic EL element using the film with a transparent electroconductive membrane. More specifically, this invention provides a film with a transparent electroconductive membrane, comprising a transparent base material and a transparent electroconductive membrane, the transparent electroconductive membrane having on its surface crystalline secondary particles having an average particle diameter of 0.1 to 1 μm in an amount of 1 to 100 particles / μm2, and a substrate for a display, a display, a liquid crystal display device, and an organic EL element using the film with a transparent electroconductive membrane.

Owner:DAI NIPPON PRINTING CO LTD

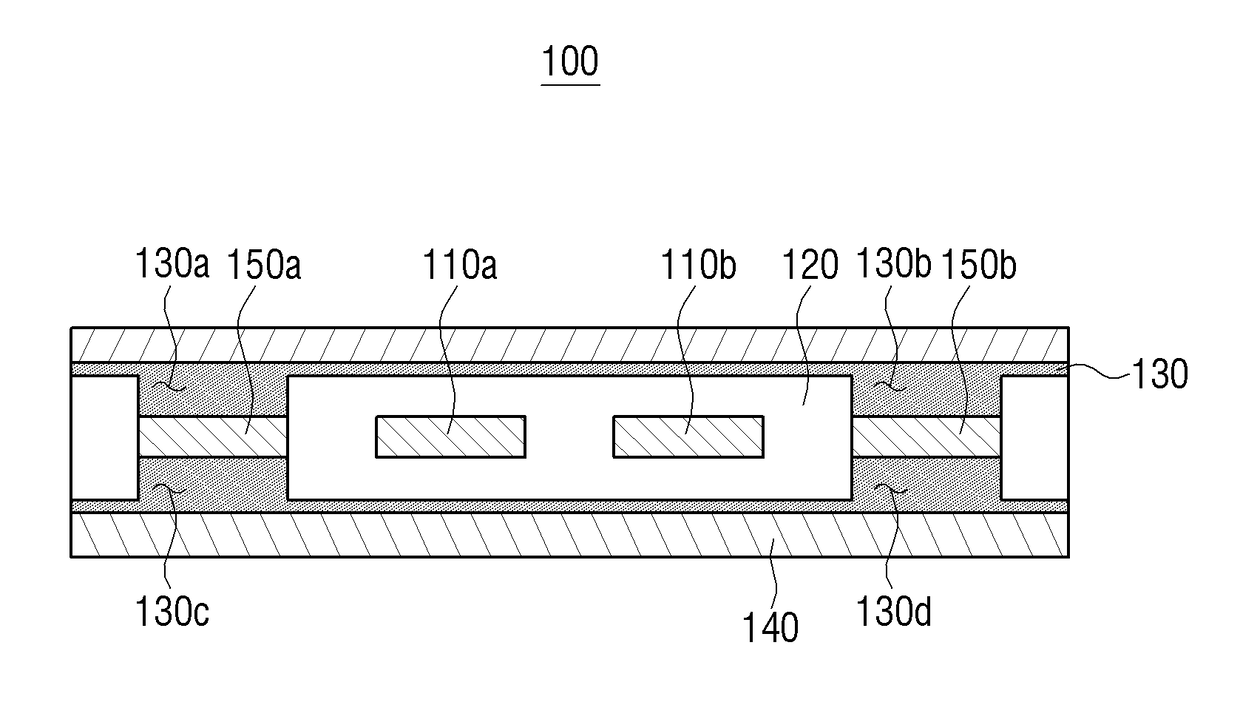

Flexible flat cable and method for manufacturing the same

ActiveUS20180053981A1Small widthCross-talk/noise/interference reductionPrinted circuit aspectsBand shapeConductive materials

A flexible flat cable and a manufacturing method thereof are provided. The flexible flat cable includes a plurality of ground parts comprising a conductive material disposed at intervals, a plurality of signal transmission parts comprising a conductive material disposed between the plurality of ground parts, an outer skin covering the signal transmission parts and the ground parts, and a conductive adhesive layer disposed between the ground parts and the signal transmission parts and the outer skin part, the signal transmission part comprising an insulating member and a strip line disposed within the insulating member and the ground part comprising a ground member having the same cross section as the strip line and a conductive adhesive block coupled to the ground member with the conductive adhesive layer.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com