Manufacturing method and application of embedded metal grid flexible transparent electrode

A metal grid and transparent electrode technology, which is applied in cable/conductor manufacturing, additive manufacturing, equipment for manufacturing conductive/semiconductive layers, etc., can solve the limitations of embedded metal grid materials, difficulty in demoulding, falling off or peeling off and other issues, to achieve the effects of efficient continuous production, low production process cost, and widening types and types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

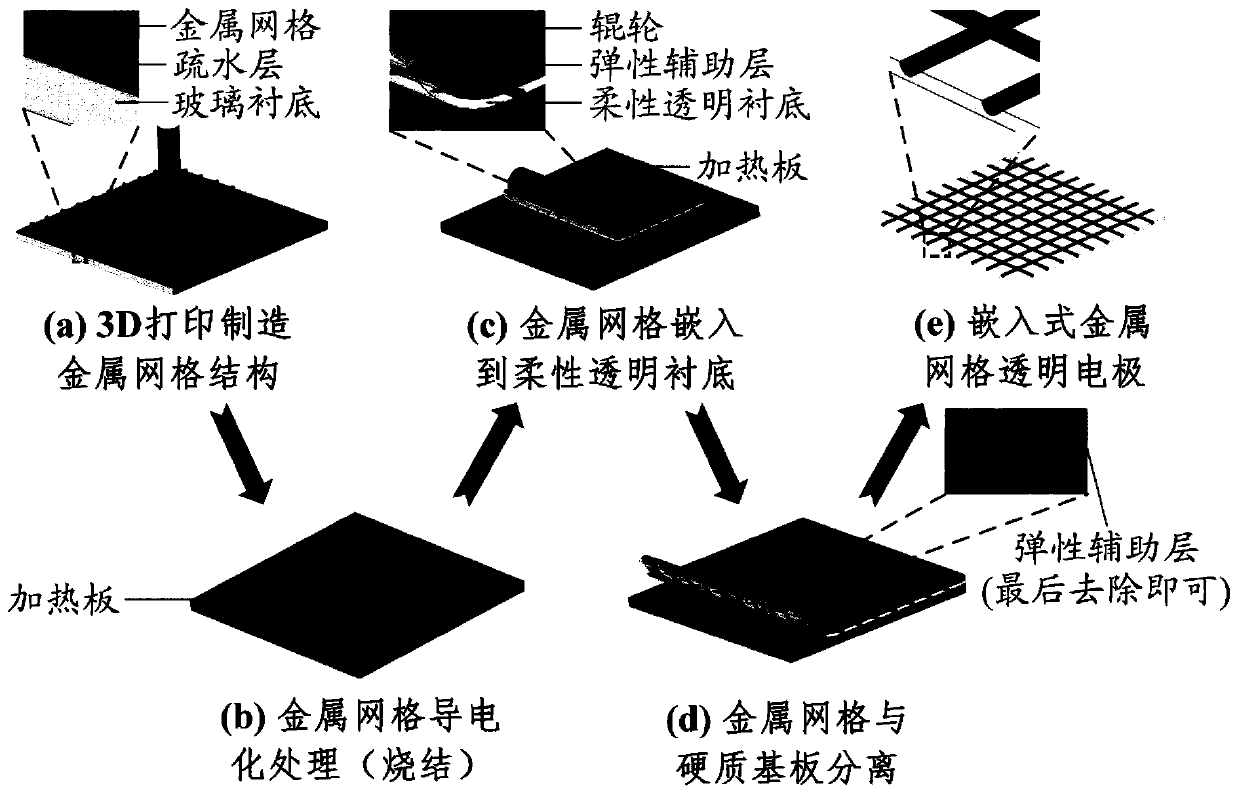

[0049] refer to Figure 2-4 , a method for manufacturing an embedded metal grid flexible transparent electrode, comprising the steps of:

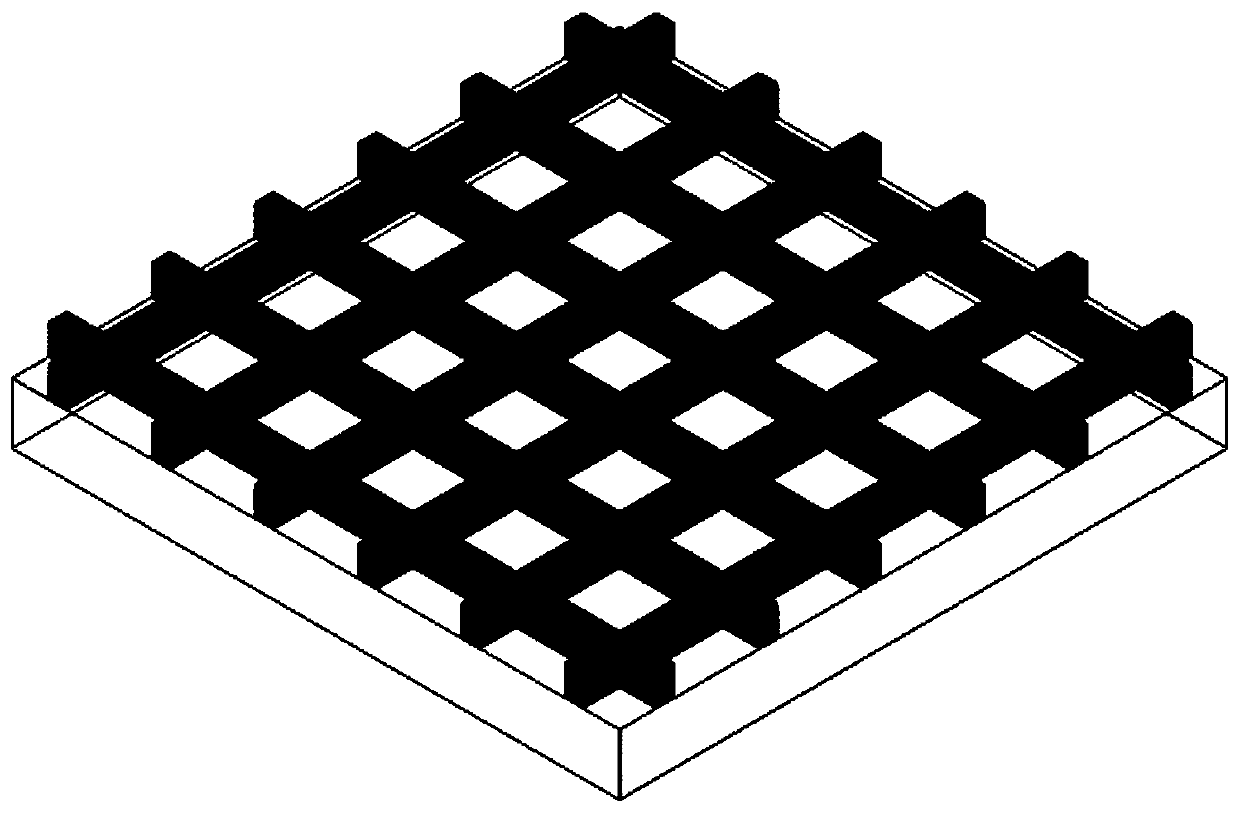

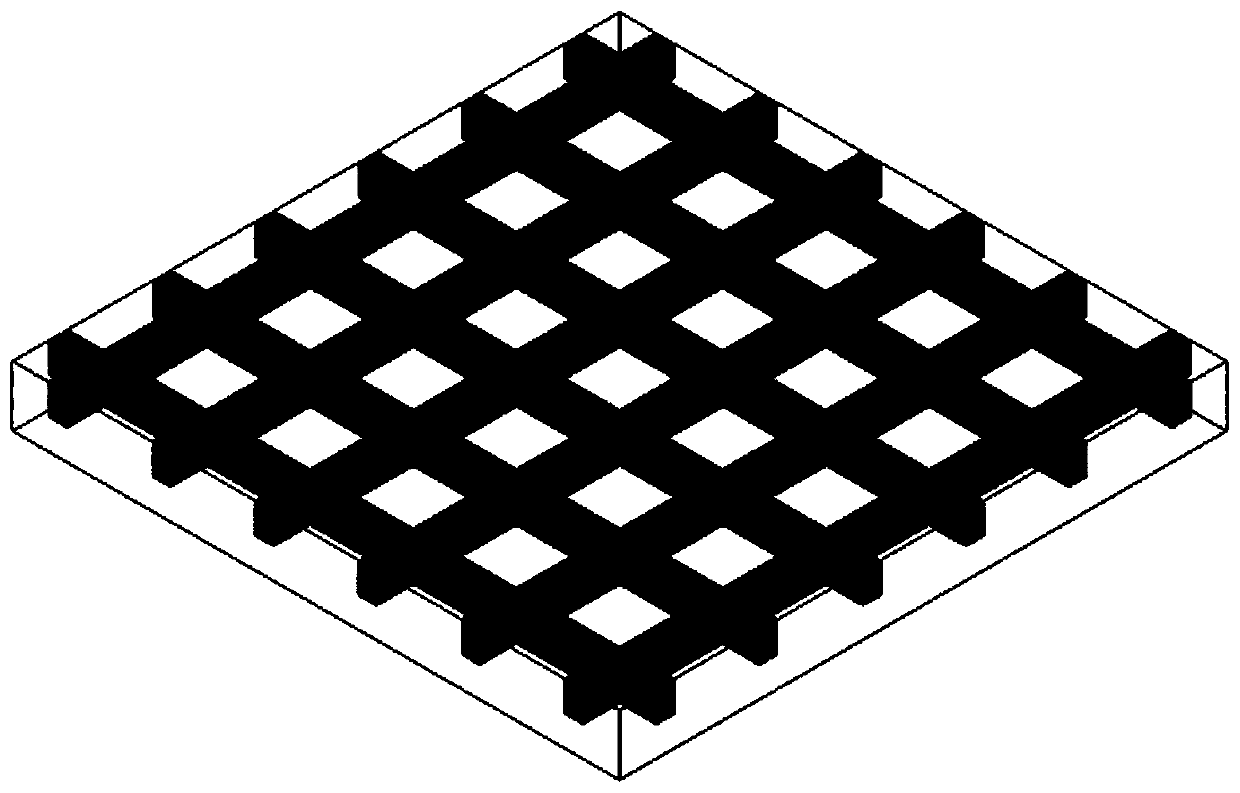

[0050] Step 1: Using electric field-driven spray deposition micro-nano 3D printing to manufacture large-area metal grid structures:

[0051] (1) Take an ordinary glass sheet as the substrate / substrate, after cleaning and drying it, apply a PDMS film on its surface by spin coating with a thickness of 10 μm, and cure the PDMS liquid in a heating environment of 80 °C After 20 minutes, the PDMS was formed into a film to form a hydrophobic layer to obtain a printed substrate. Among them, the hydrophobic layer can reduce the adhesion between the printed metal grid and the substrate, and facilitate the subsequent separation of the metal grid embedded in the flexible transparent substrate from the substrate. At the same time, the hydrophobic layer can increase the aspect ratio of the printed metal grid. It is convenient to improve the light trans...

Embodiment 2

[0059] refer to Figure 2-4 , a method for manufacturing an embedded metal grid flexible transparent electrode, comprising the steps of:

[0060] Step 1: Use micro-nano 3D printing to manufacture a large-area metal grid structure:

[0061] (1) Take an 8-inch silicon wafer as the substrate / substrate, clean it, and then soak it in a solution of heptadecafluorodecyltrichlorosilane + isooctane for 10 minutes to form a self-assembled film (hydrophobic layer) with a thickness of about 200nm. The printed substrate is obtained, wherein the hydrophobic layer can reduce the adhesion between the printed metal grid and the substrate, and facilitate the subsequent separation of the metal grid embedded in the flexible transparent substrate from the substrate. At the same time, the hydrophobic layer can improve the adhesion of the printed metal grid. The aspect ratio is convenient to improve the light transmittance of the subsequent embedded metal grid. The PDMS liquid used is Sylgard 184 ...

Embodiment 3

[0069] refer to Figure 2-4 , a method for manufacturing an embedded metal grid flexible transparent electrode, comprising the steps of:

[0070] Step 1: Using electric field-driven spray deposition micro-nano 3D printing to manufacture large-area metal grid structures:

[0071] (1) Take an ordinary glass sheet as the substrate / substrate, after cleaning and drying it, apply a PDMS film on its surface by spin coating with a thickness of 50 μm, and cure the PDMS liquid in a heating environment of 80 °C After 20 minutes, the PDMS was formed into a film to form a hydrophobic layer to obtain a printed substrate. Among them, the hydrophobic layer can reduce the adhesion between the printed metal grid and the substrate, and facilitate the subsequent separation of the metal grid embedded in the flexible transparent substrate from the substrate. At the same time, the hydrophobic layer can increase the aspect ratio of the printed metal grid. It is convenient to improve the light transmi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com