Patents

Literature

1303results about "Apparatus for heat treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

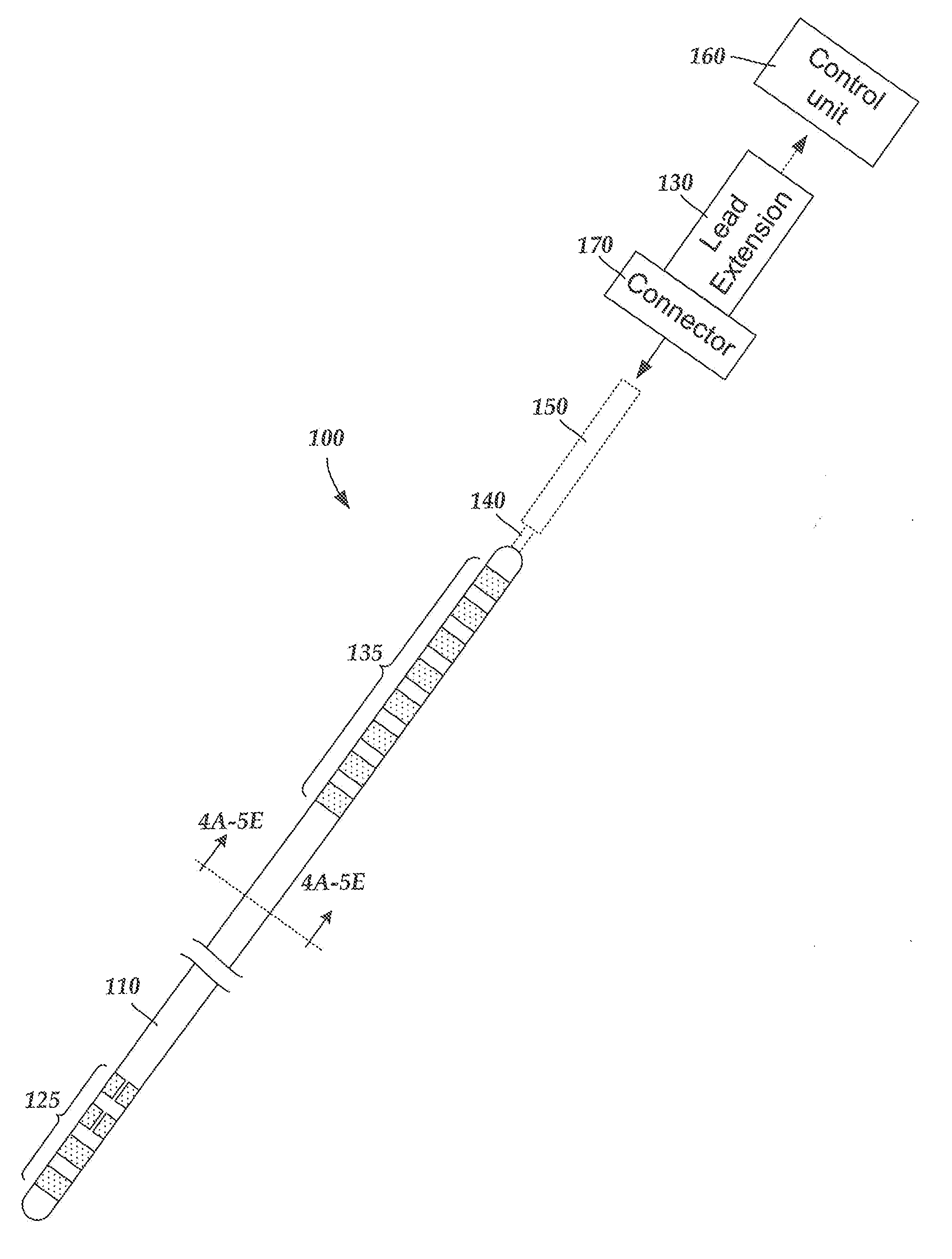

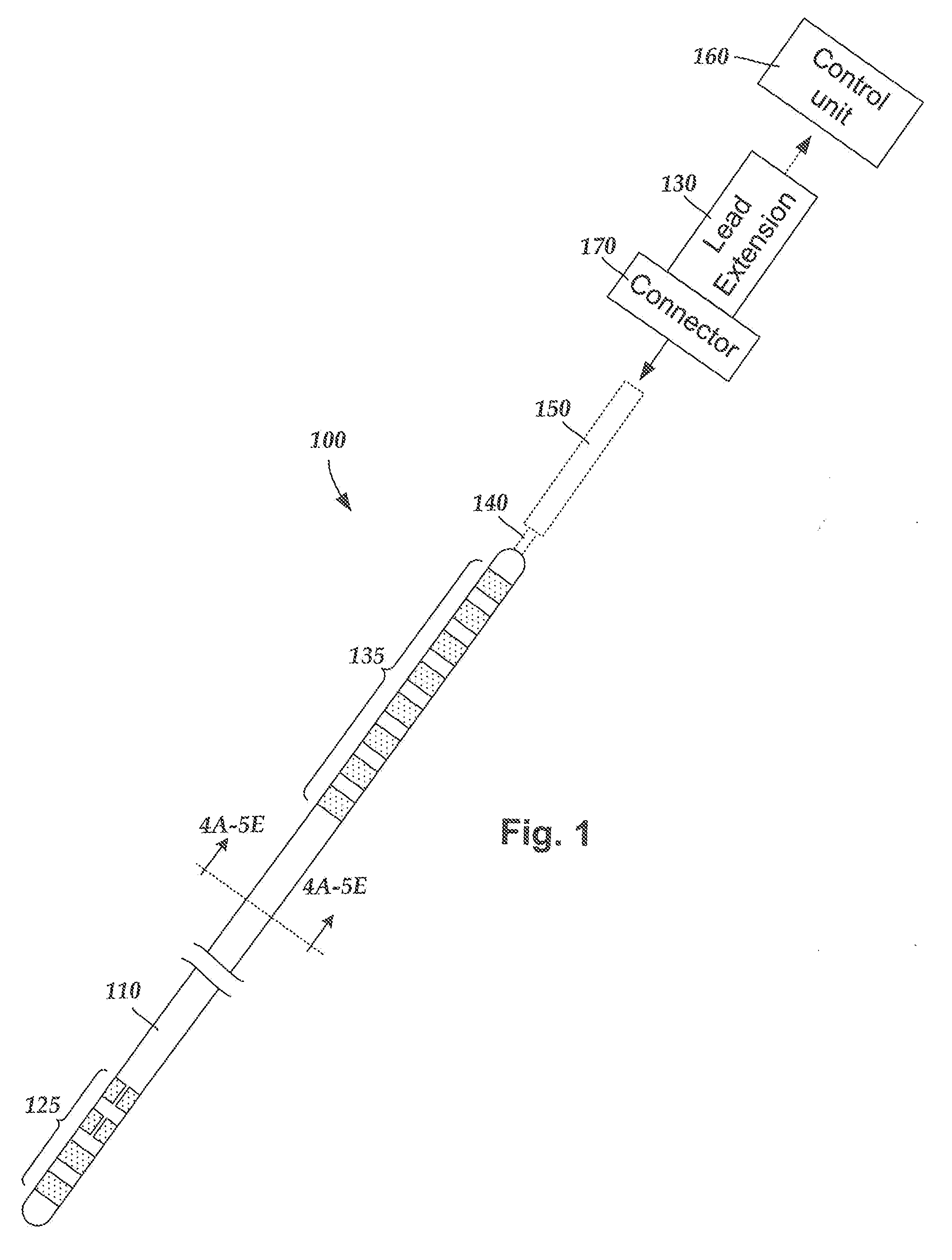

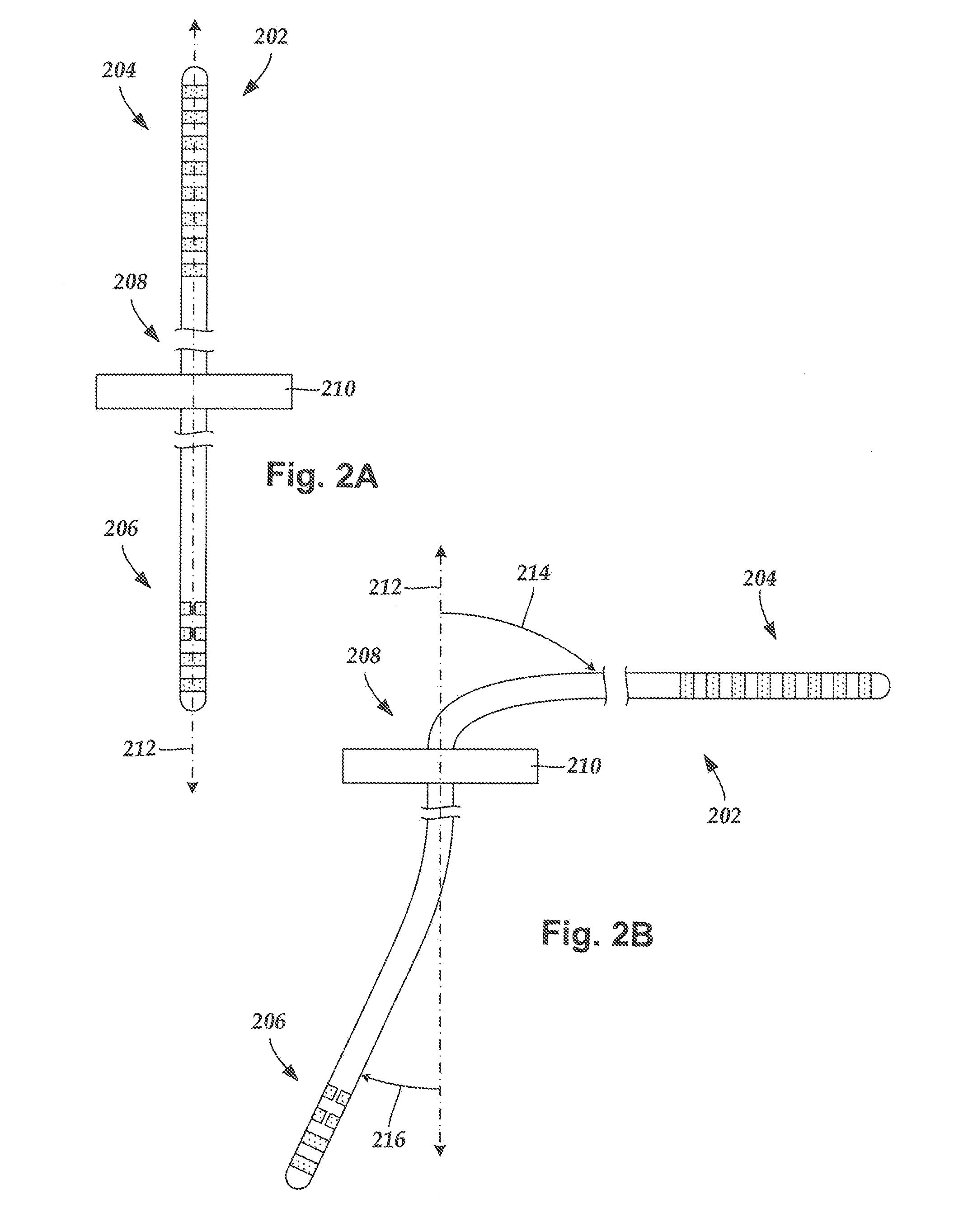

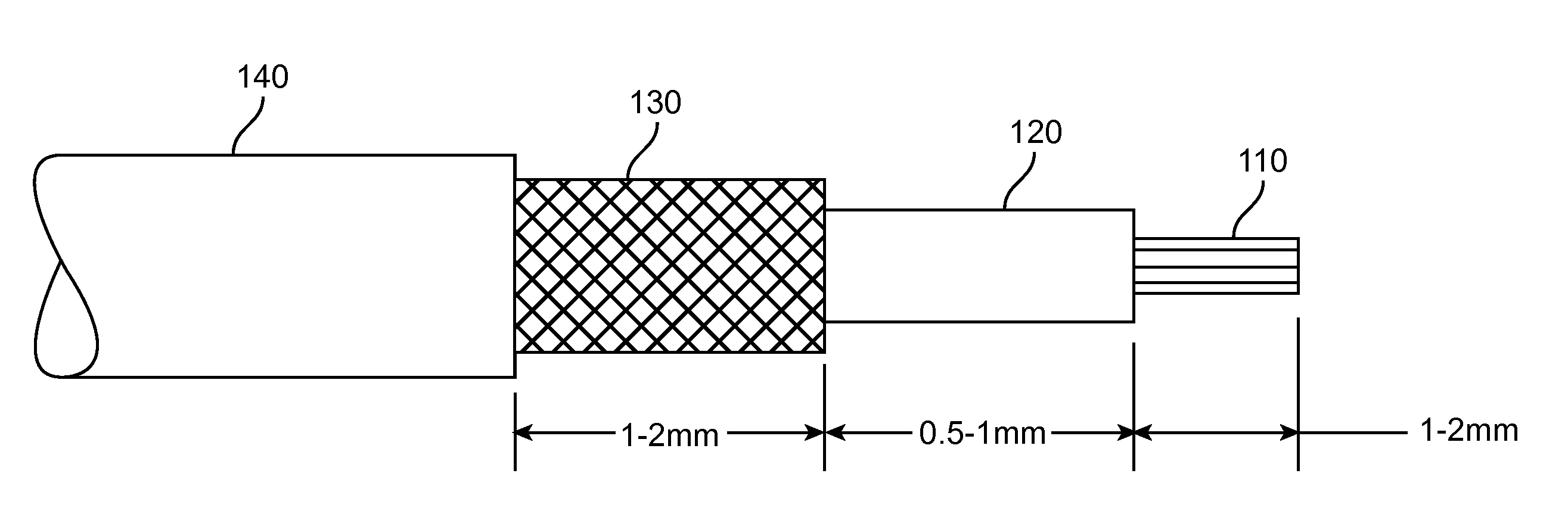

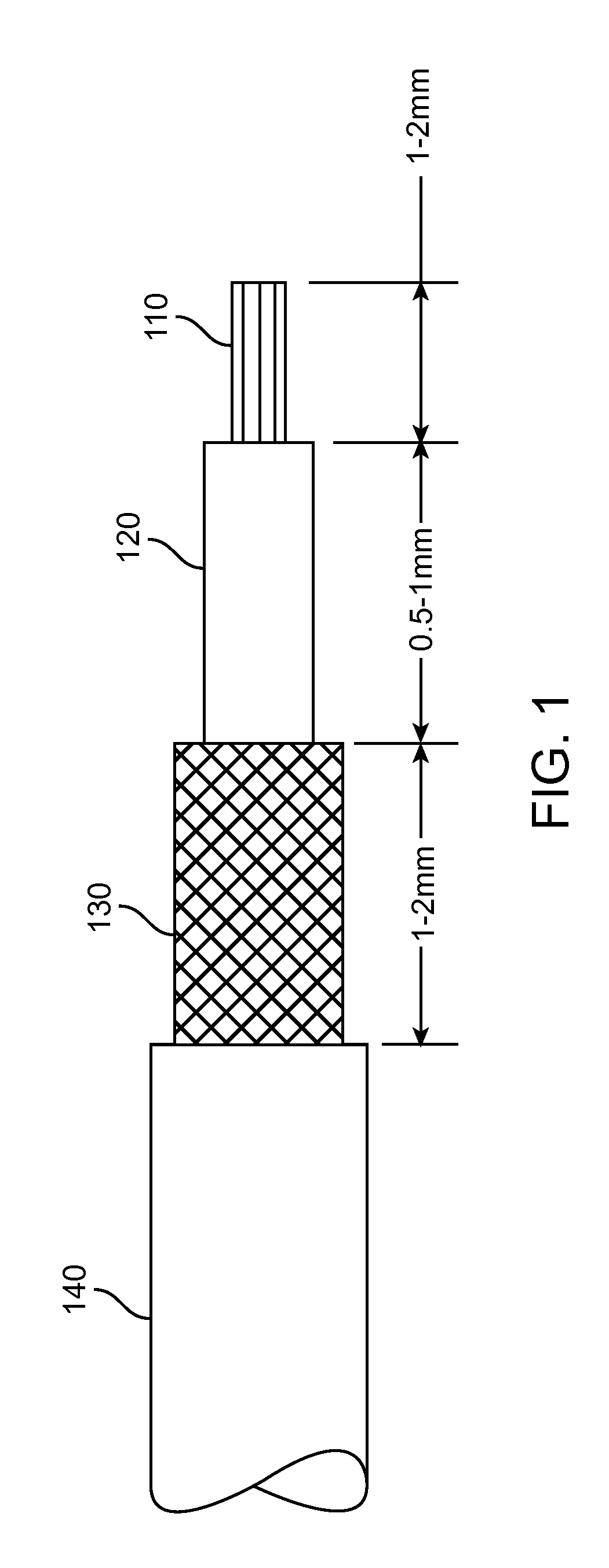

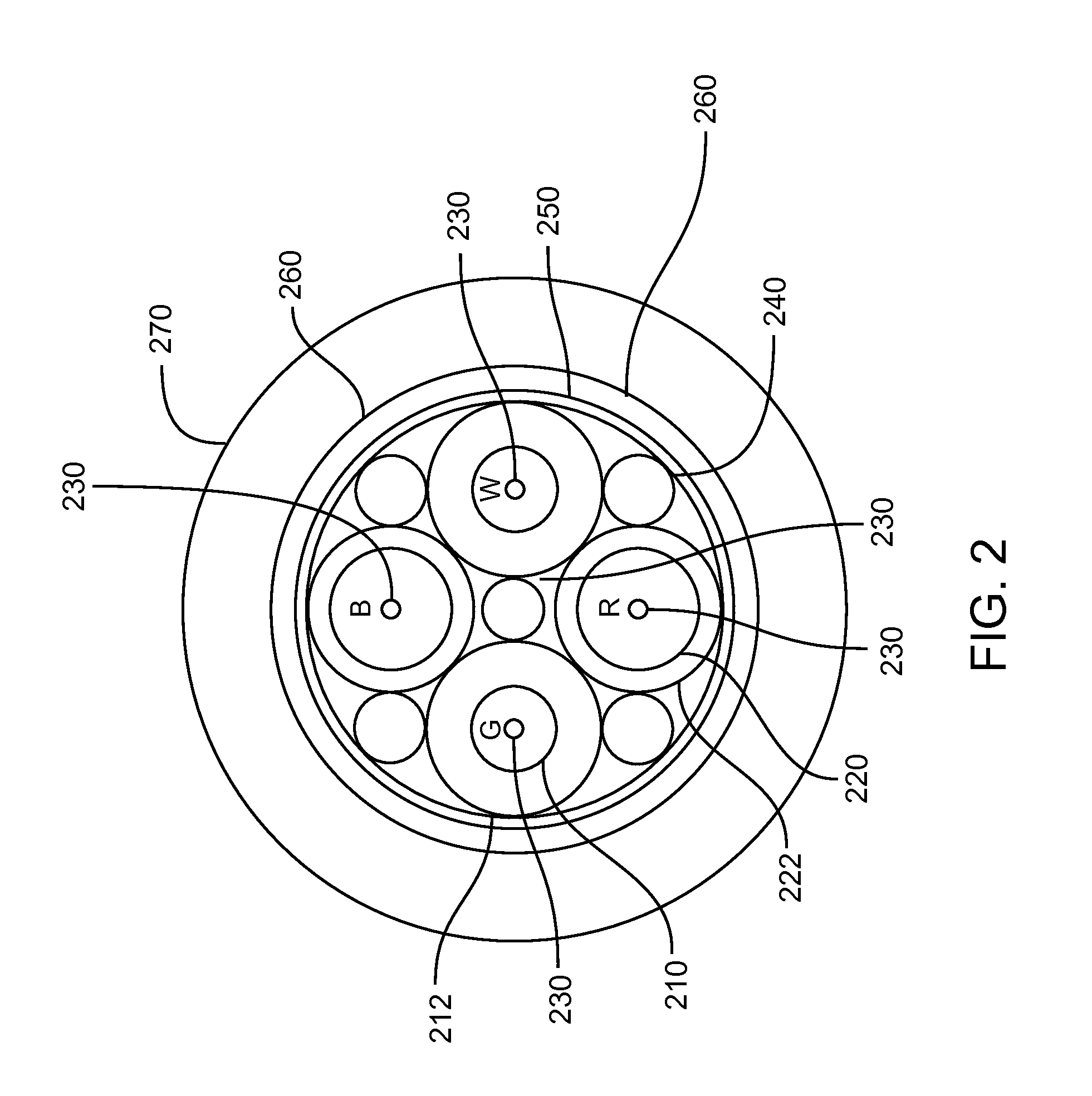

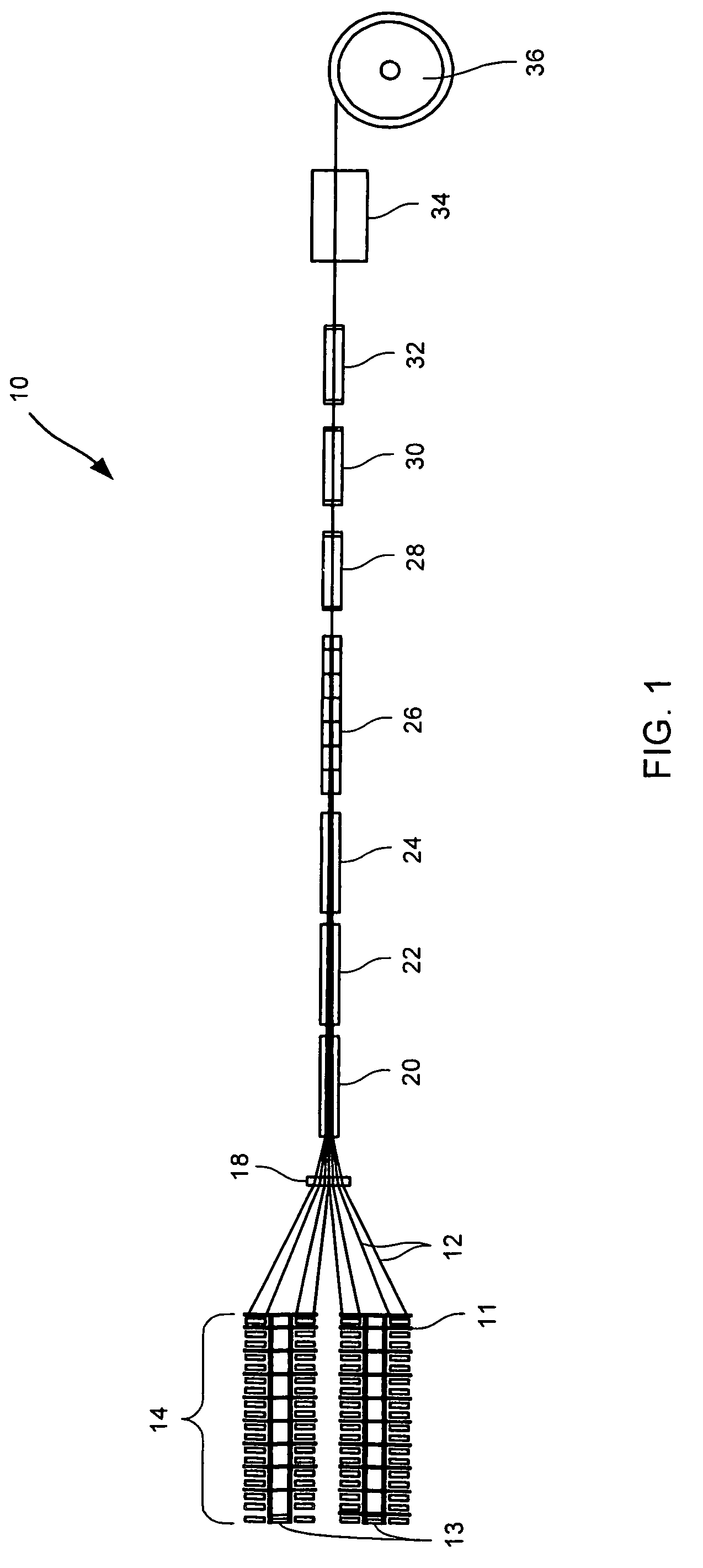

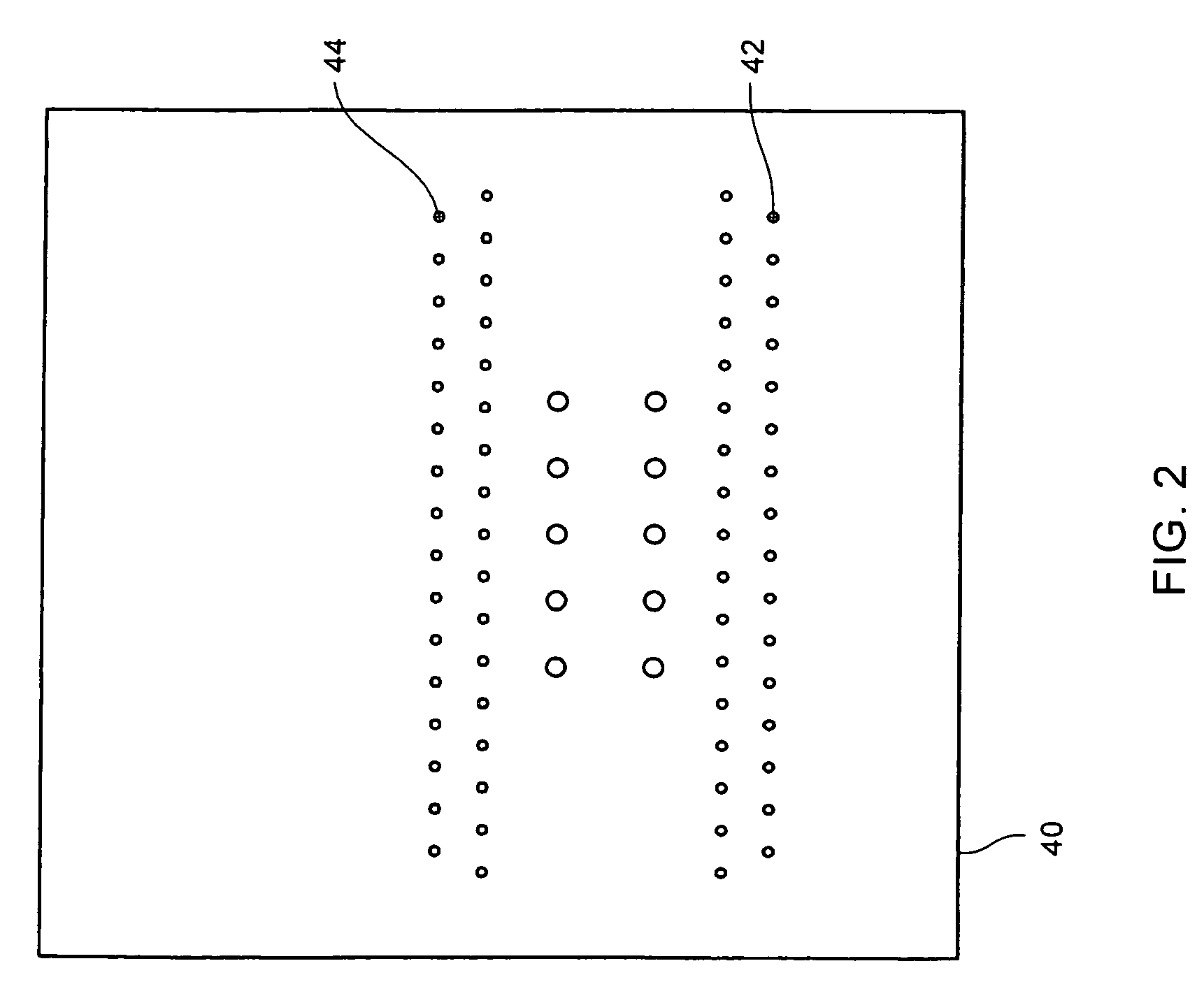

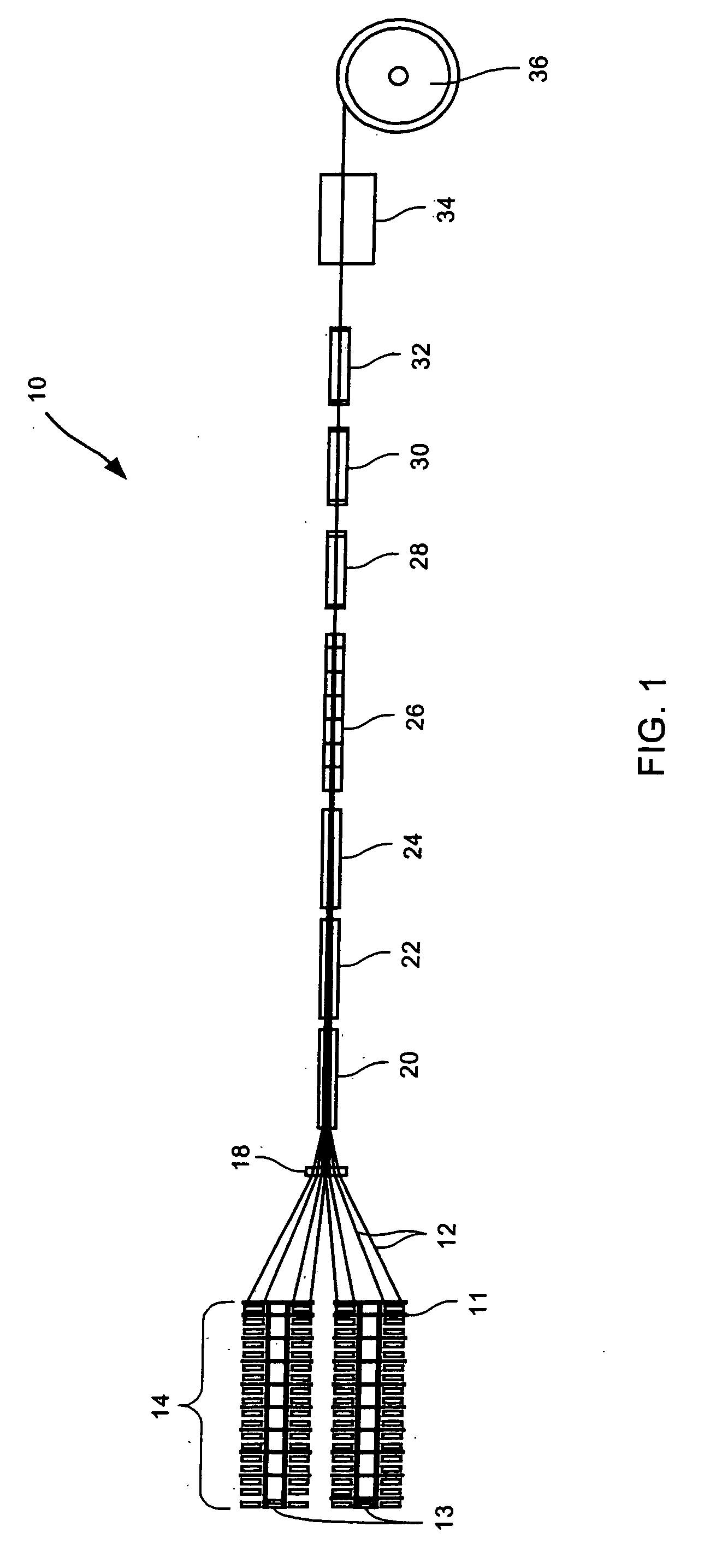

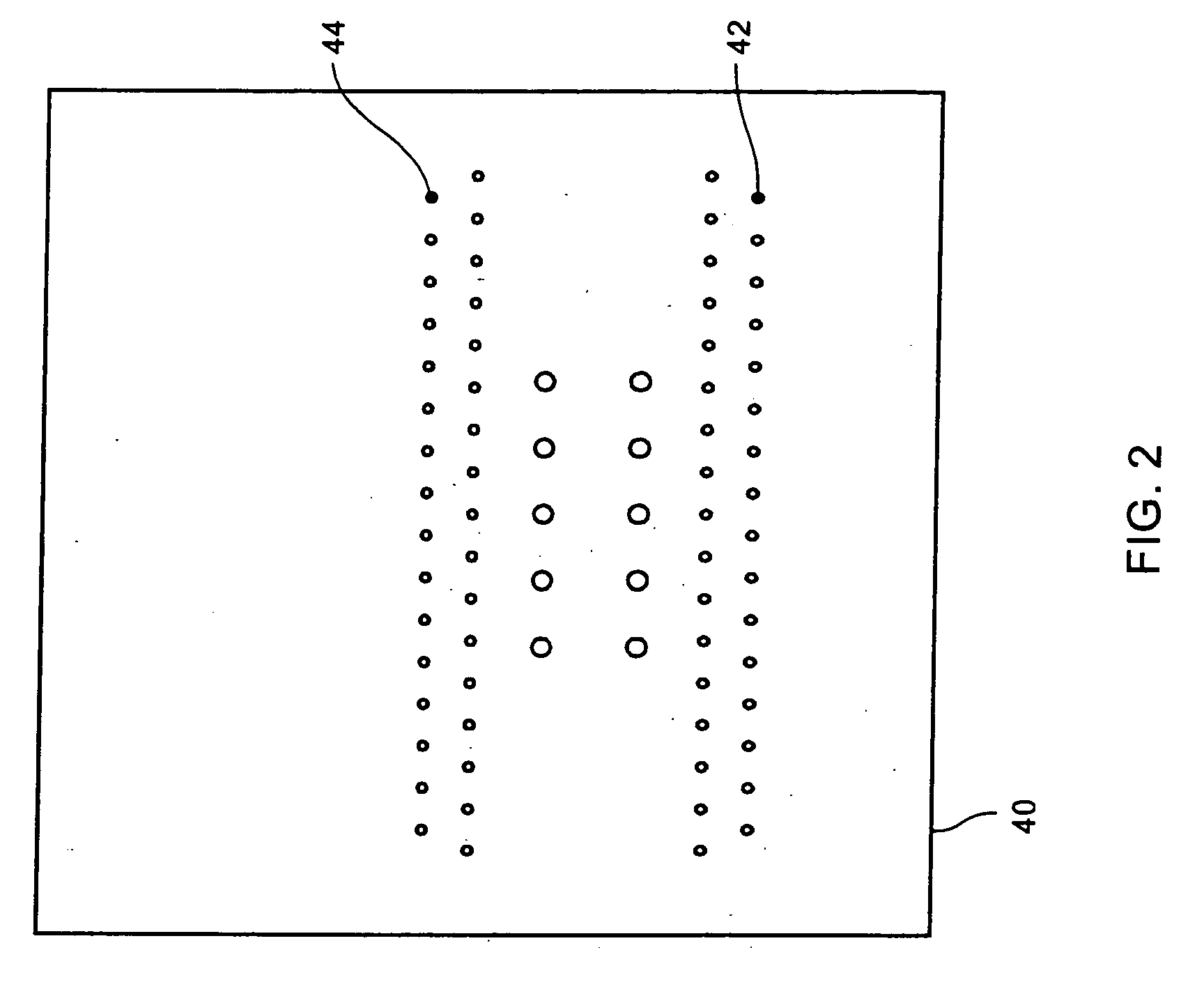

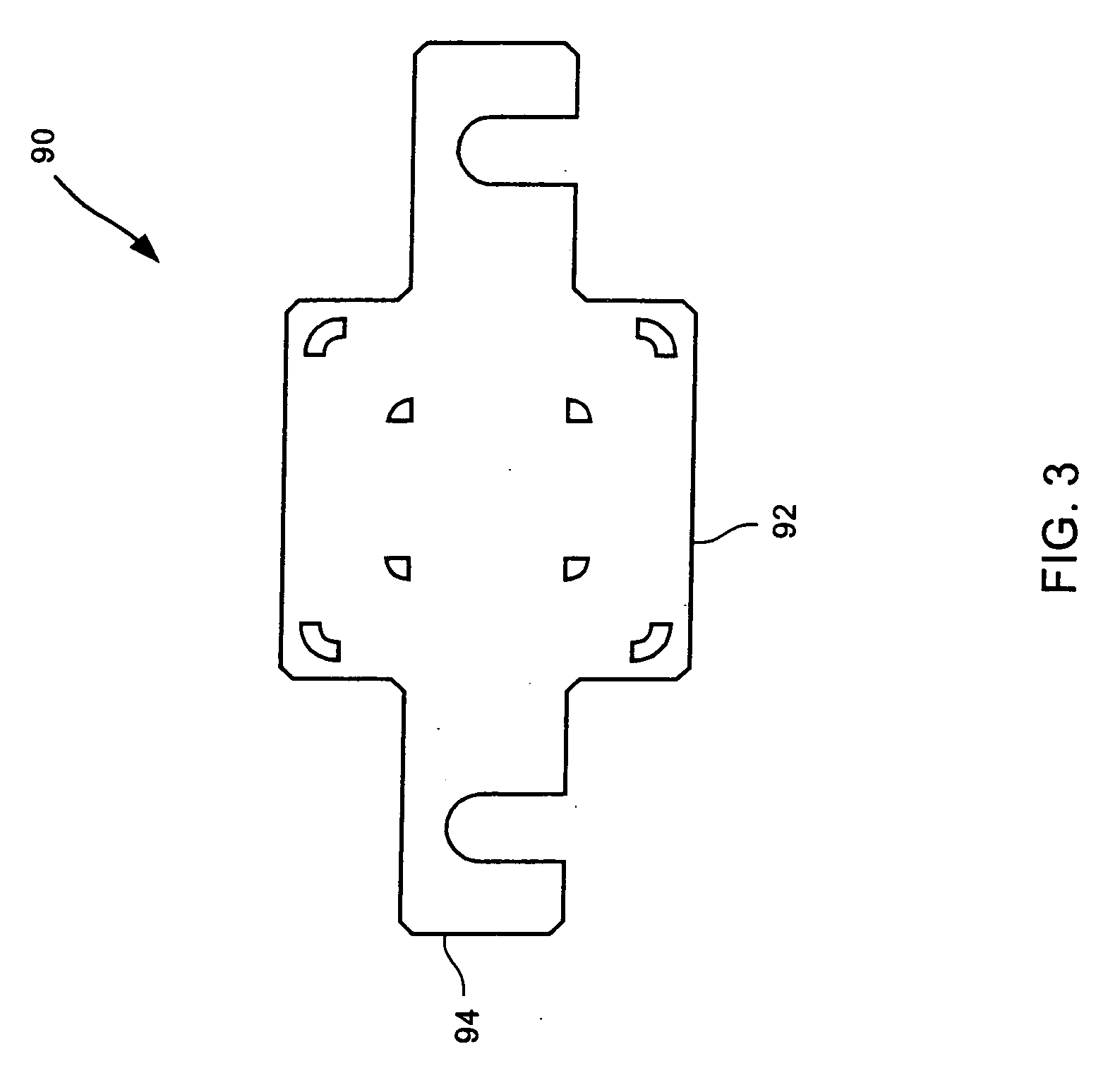

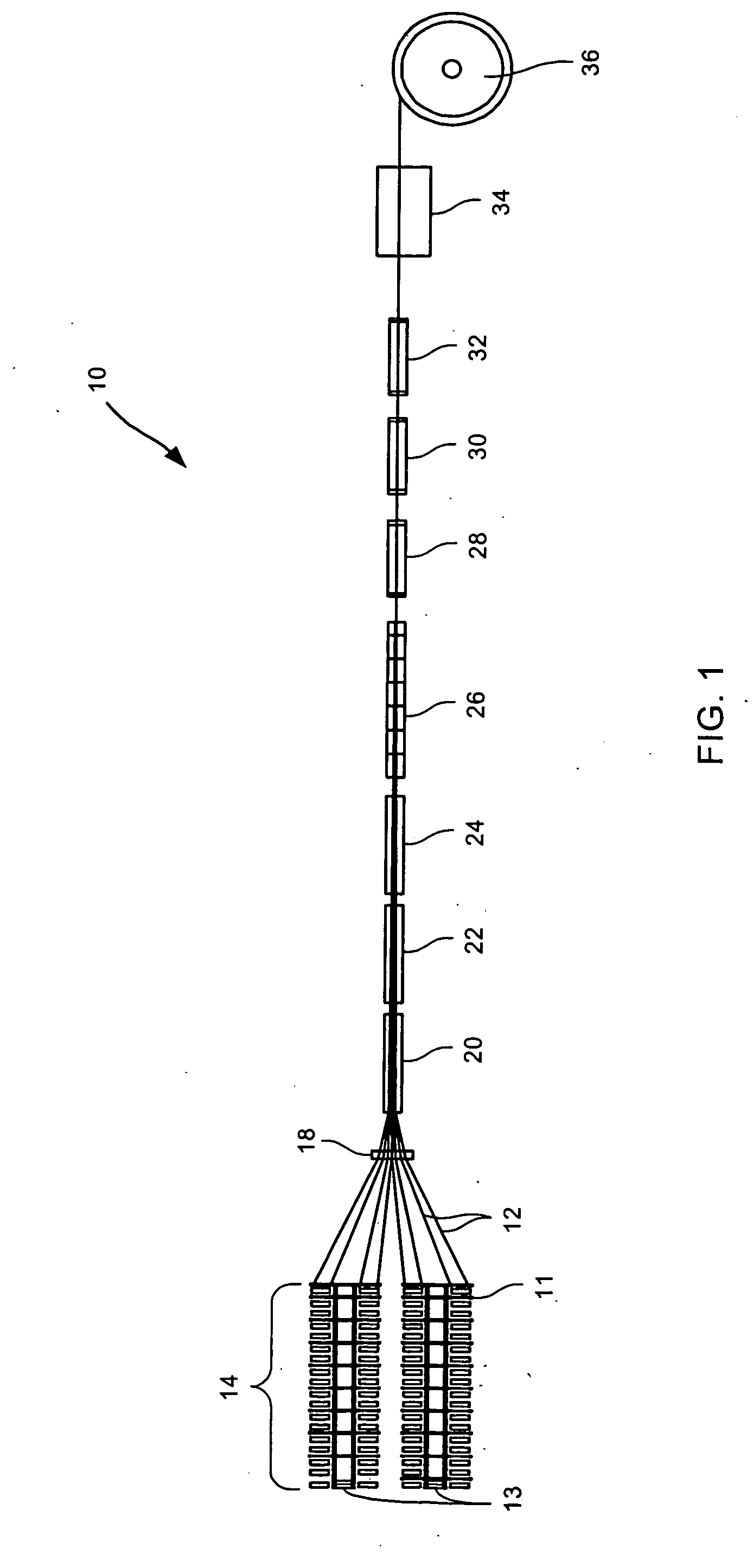

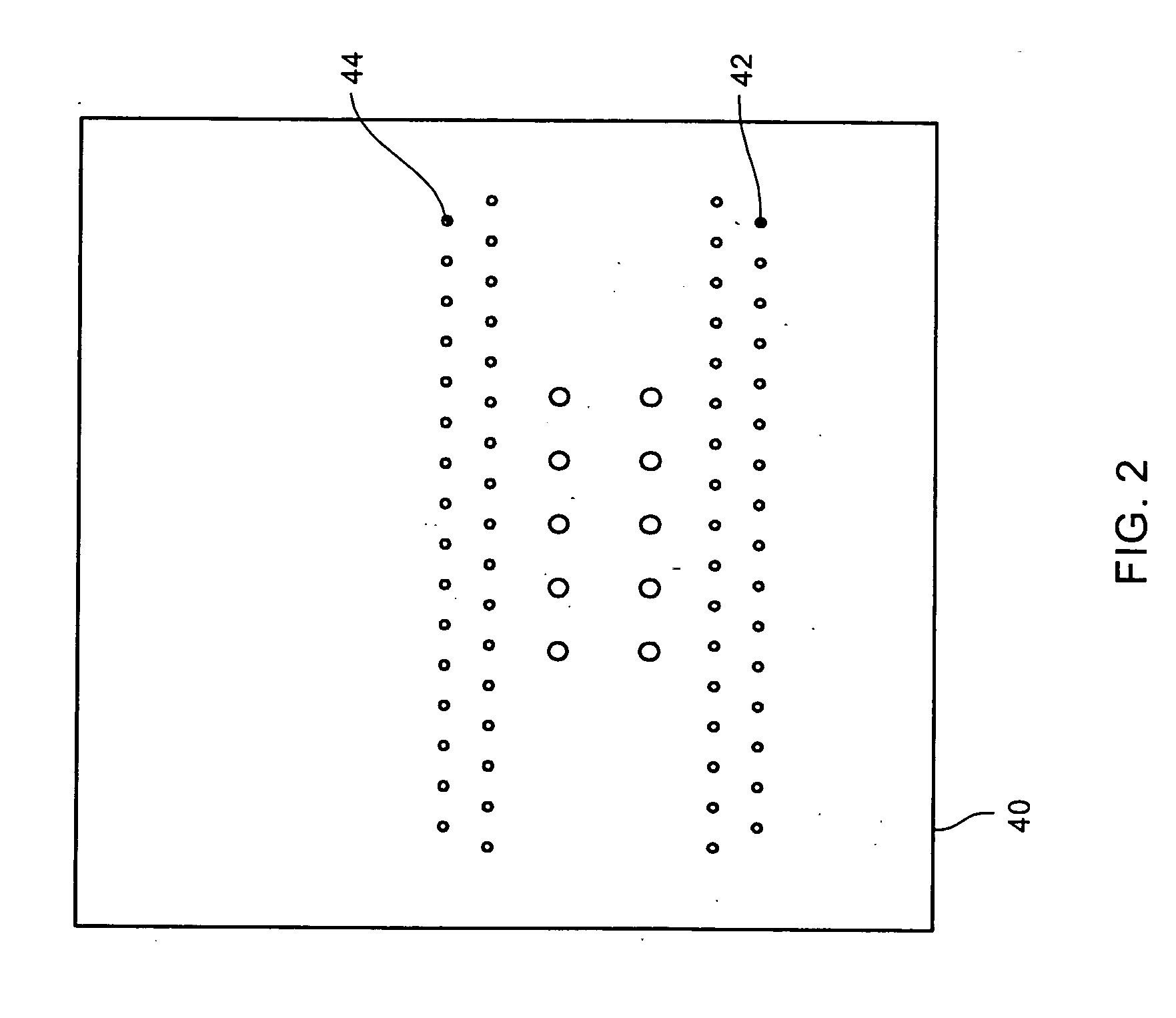

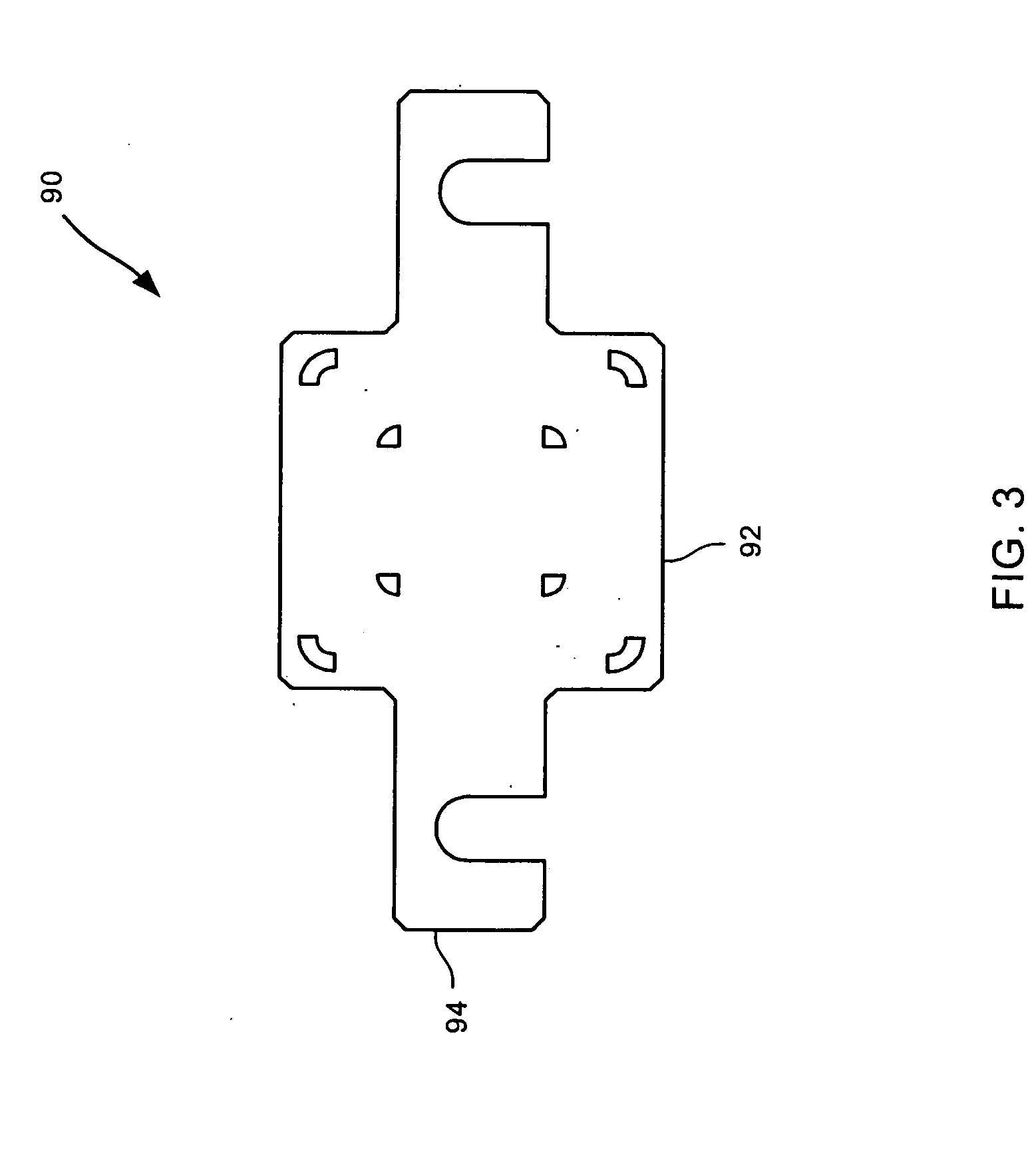

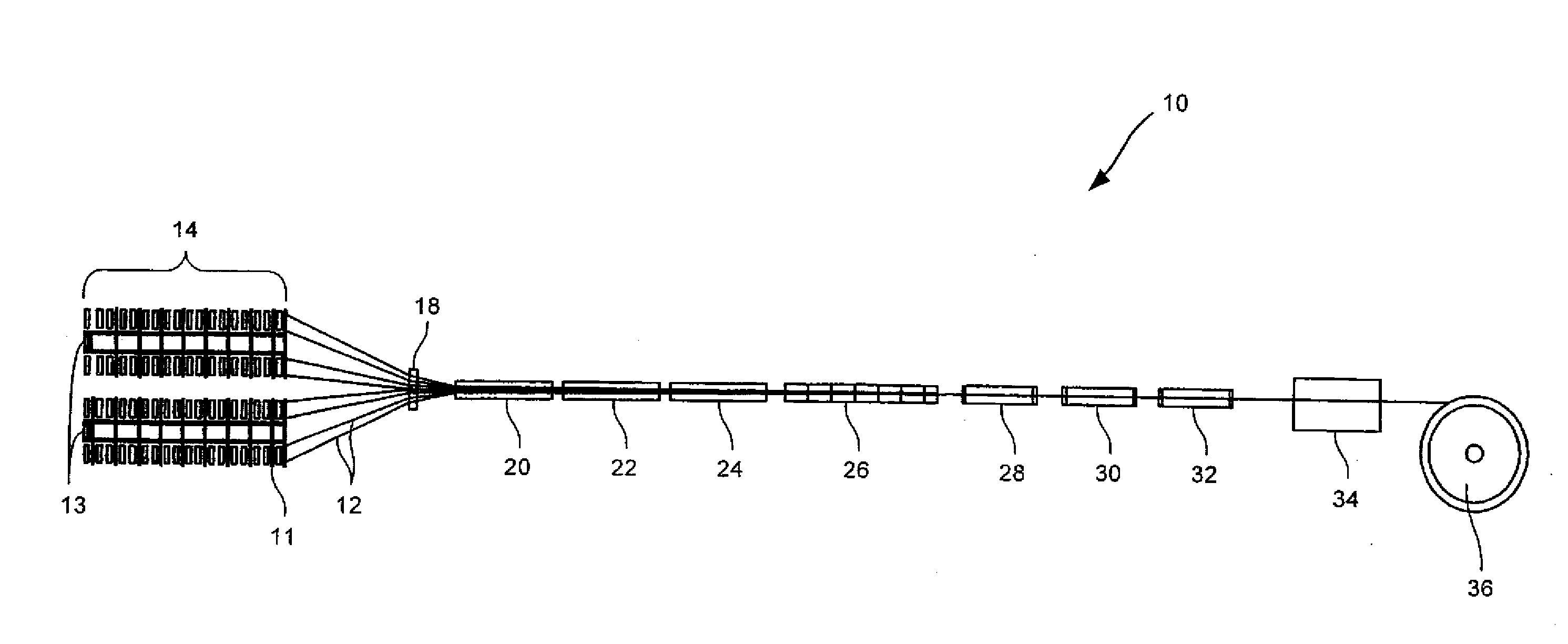

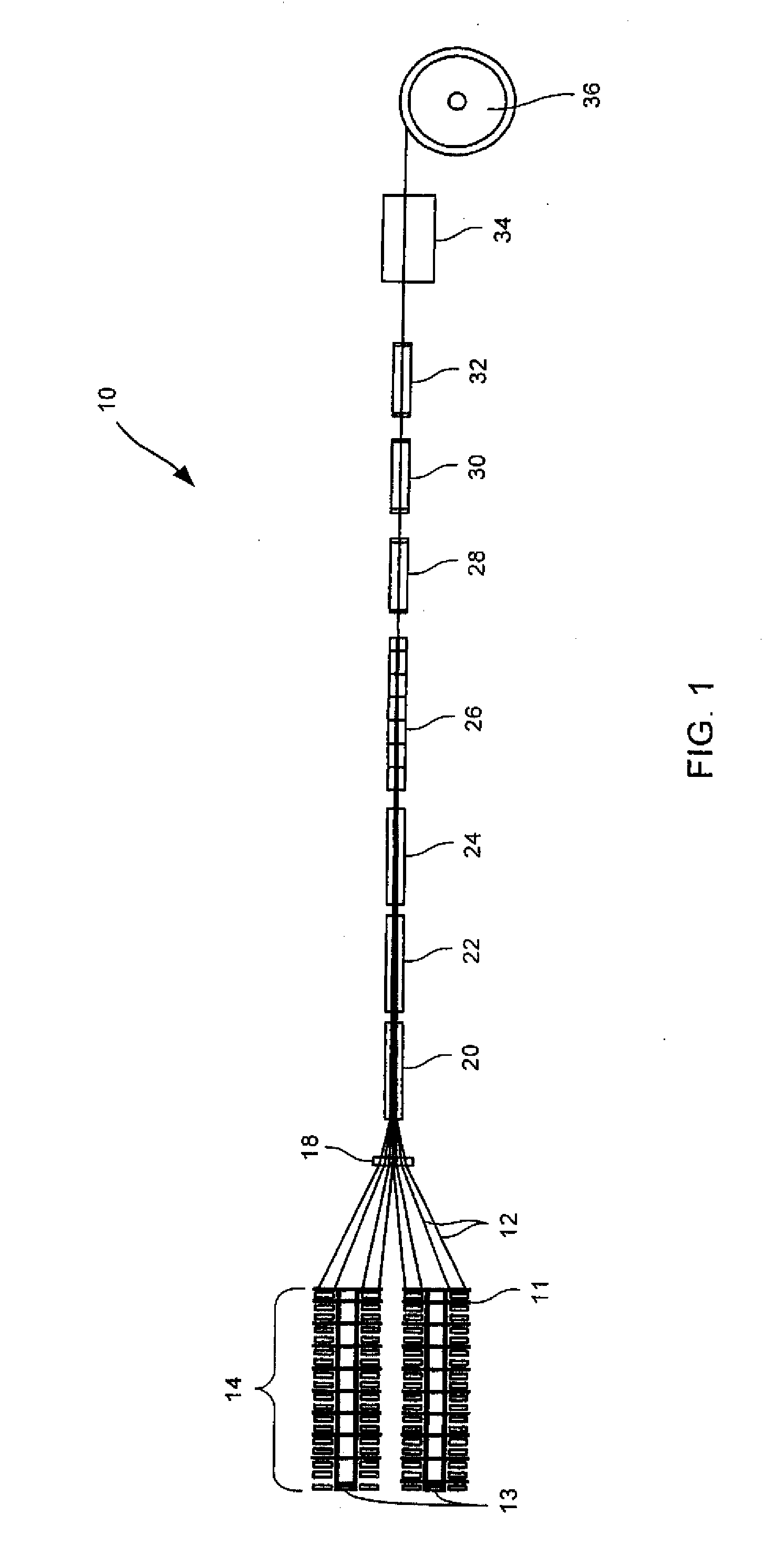

Systems and methods for making and using improved leads for electrical stimulation systems

ActiveUS20120316615A1Line/current collector detailsHead electrodesElectrical conductorElectrical stimulations

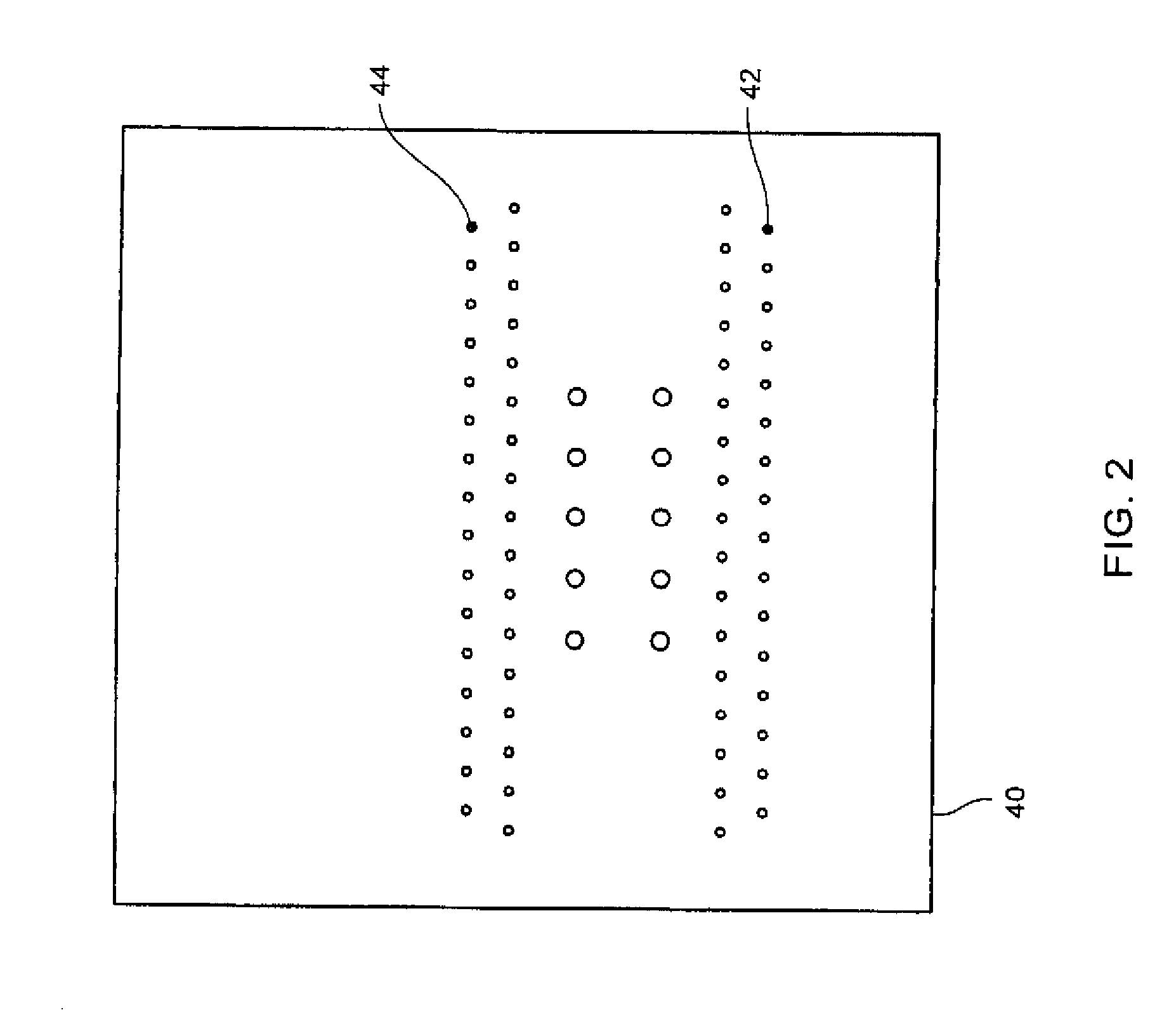

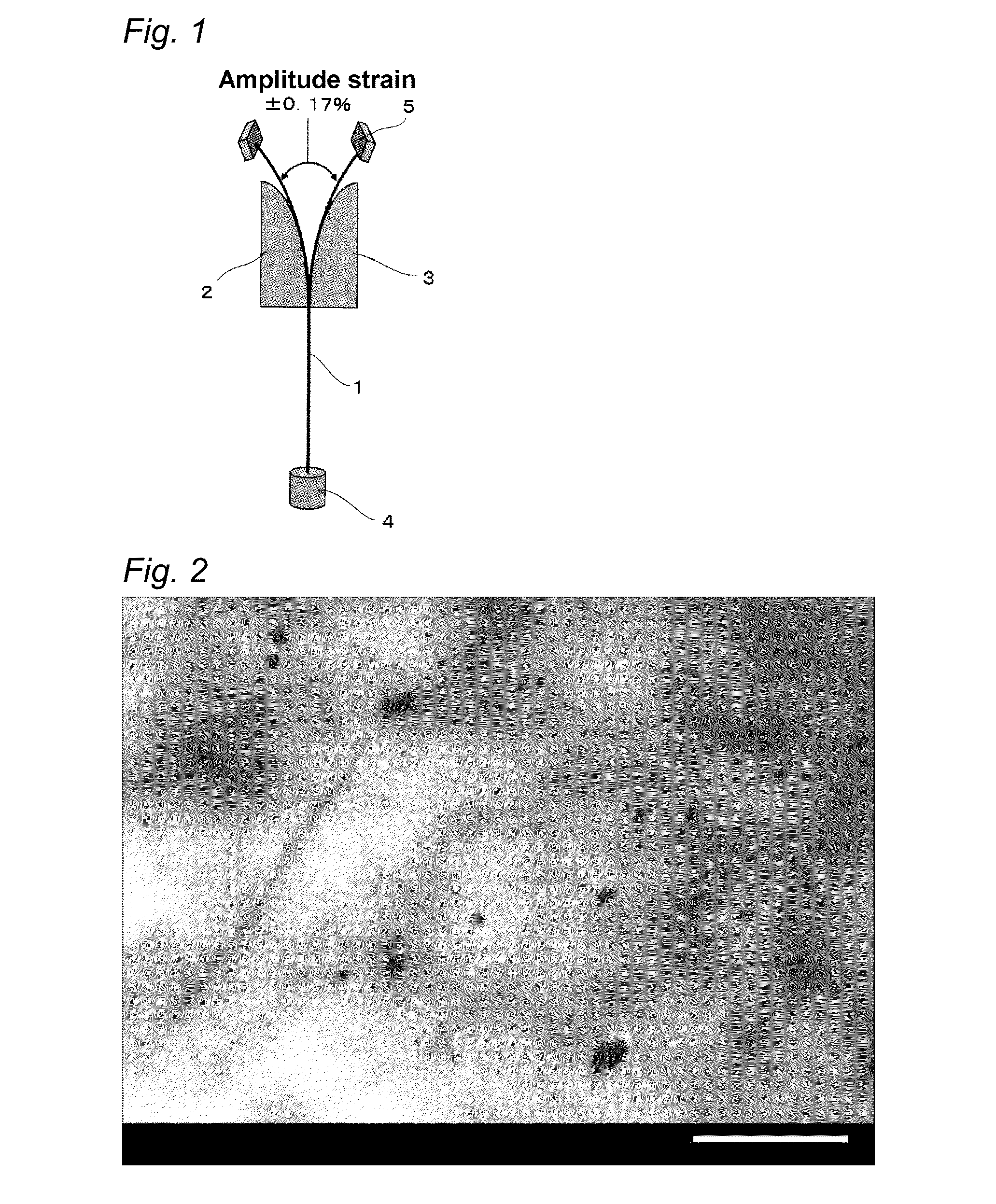

A method for manufacturing a lead includes forming an elongated multi-lumen conductor guide defining a central stylet lumen and a plurality of conductor lumens arranged around the stylet lumen. The multi-lumen conductor guide is twisted to form at least one helical section where the plurality of conductor lumens each forms a helical pathway around the stylet lumen. Each of the helical pathways of the at least one helical section has a pitch that is no less than 0.04 turns per centimeter.

Owner:BOSTON SCI NEUROMODULATION CORP

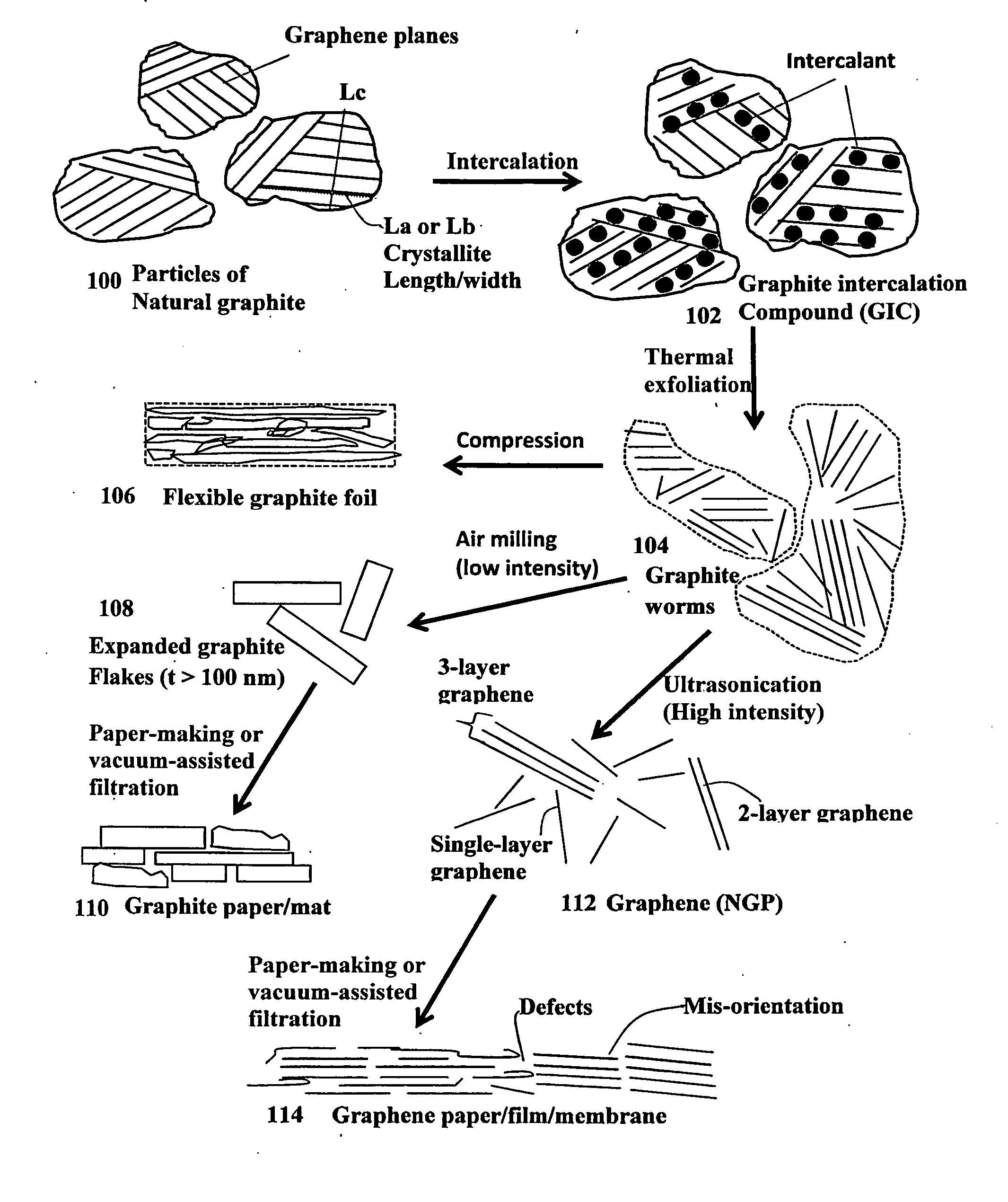

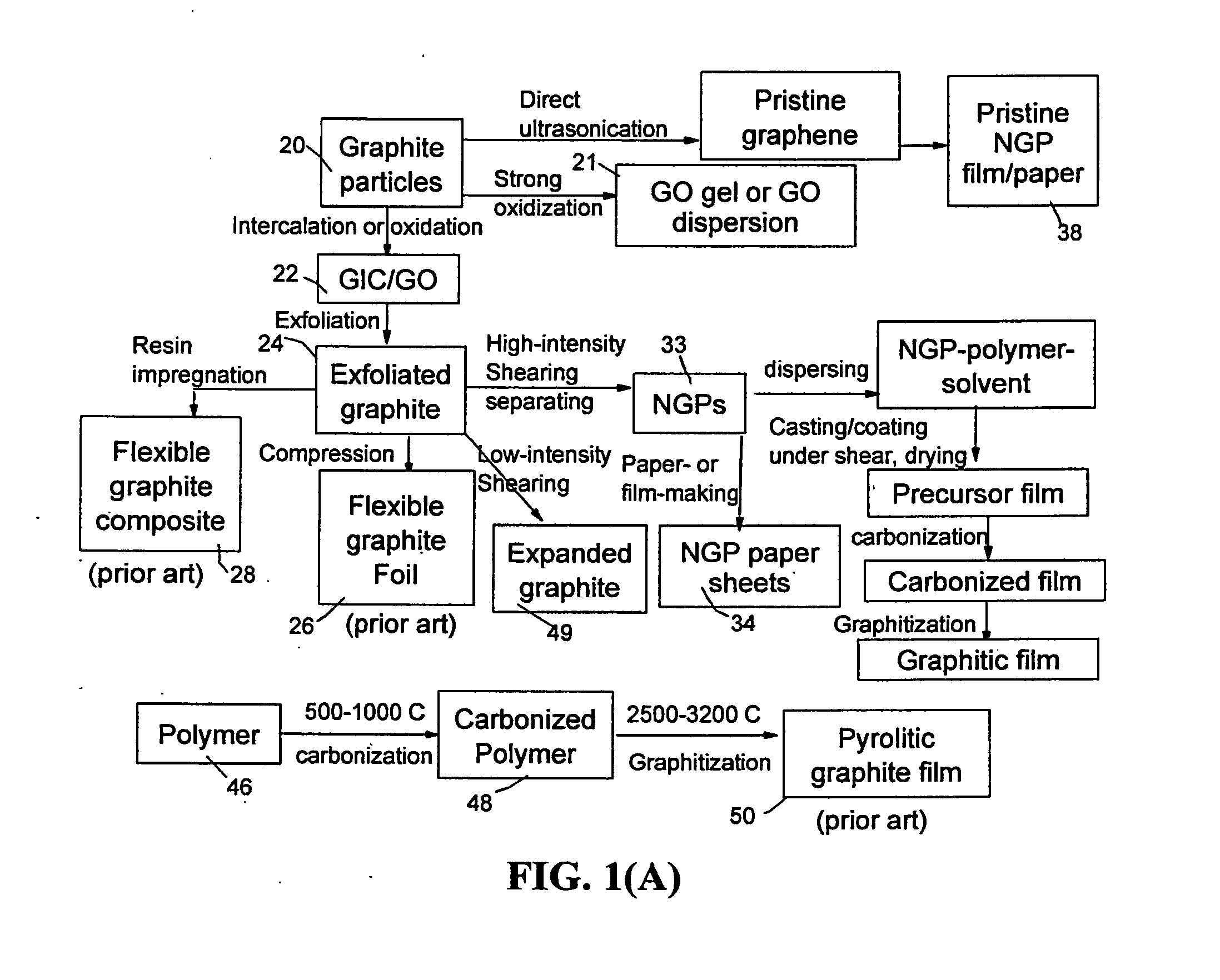

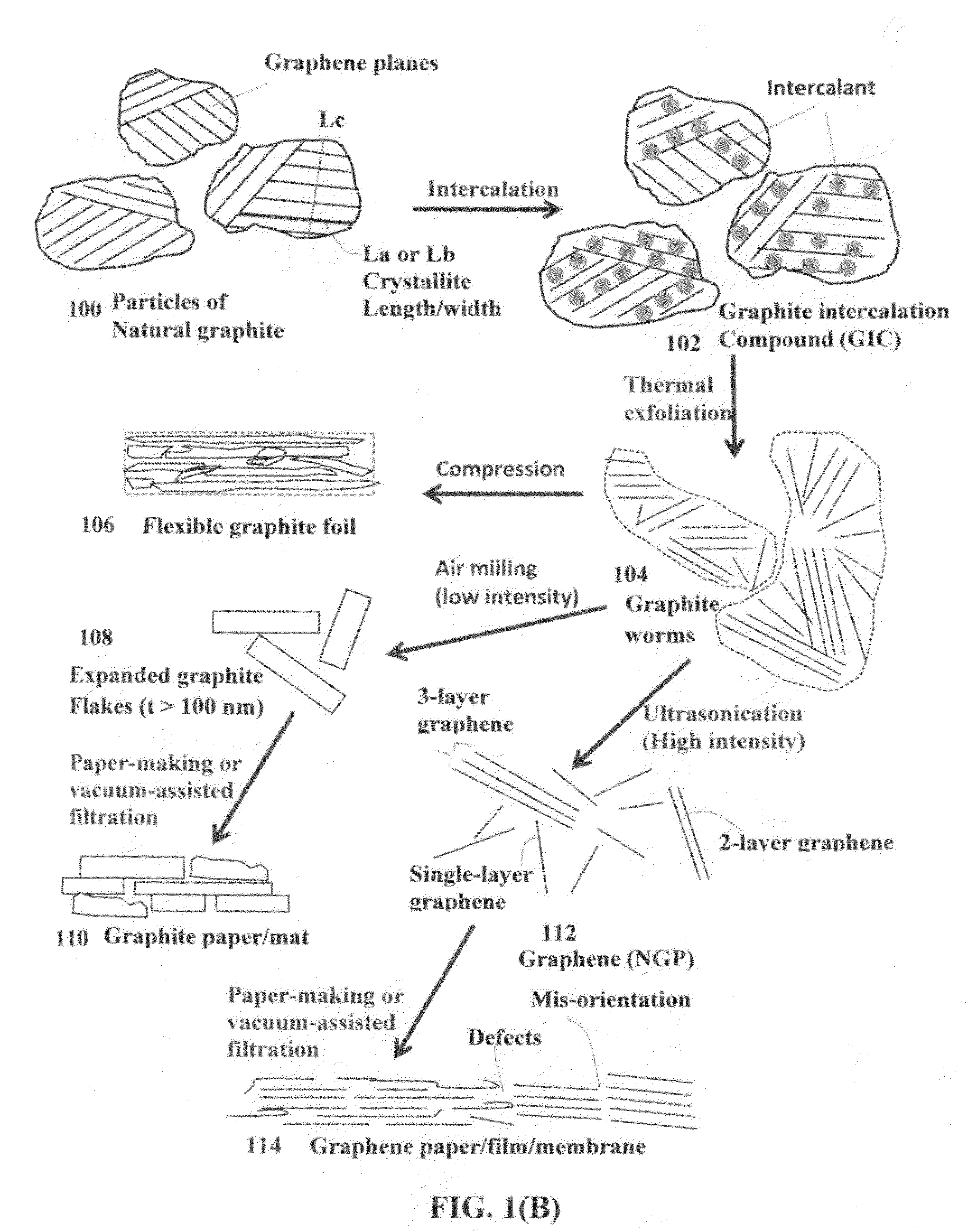

Production process for highly conductive graphitic films

ActiveUS20150266739A1Reduce thicknessImprove in-plane property of filmShielding materialsGraphiteComposite filmCarbonization

A process for producing a graphitic film comprising the steps of (a) mixing graphene platelets with a carbon precursor polymer and a liquid to form a slurry and forming the slurry into a wet film under the influence of an orientation-inducing stress field to align the graphene platelets on a solid substrate; (b) removing the liquid to form a precursor polymer composite film wherein the graphene platelets occupy a weight fraction of 1% to 99%; (c) carbonizing the precursor polymer composite film at a carbonization temperature of at least 300° C. to obtain a carbonized composite film; and (d) thermally treating the carbonized composite film at a final graphitization temperature higher than 1,500° C. to obtain the graphitic film. Preferably, the carbon precursor polymer is selected from the group consisting of polyimide, polyamide, polyoxadiazole, polybenzoxazole, polybenzobisoxazole, polythiazole, polybenzothiazole, polybenzobisthiazole, poly(p-phenylene vinylene), polybenzimidazole, polybenzobisimidazole, and combinations thereof.

Owner:GLOBAL GRAPHENE GRP INC

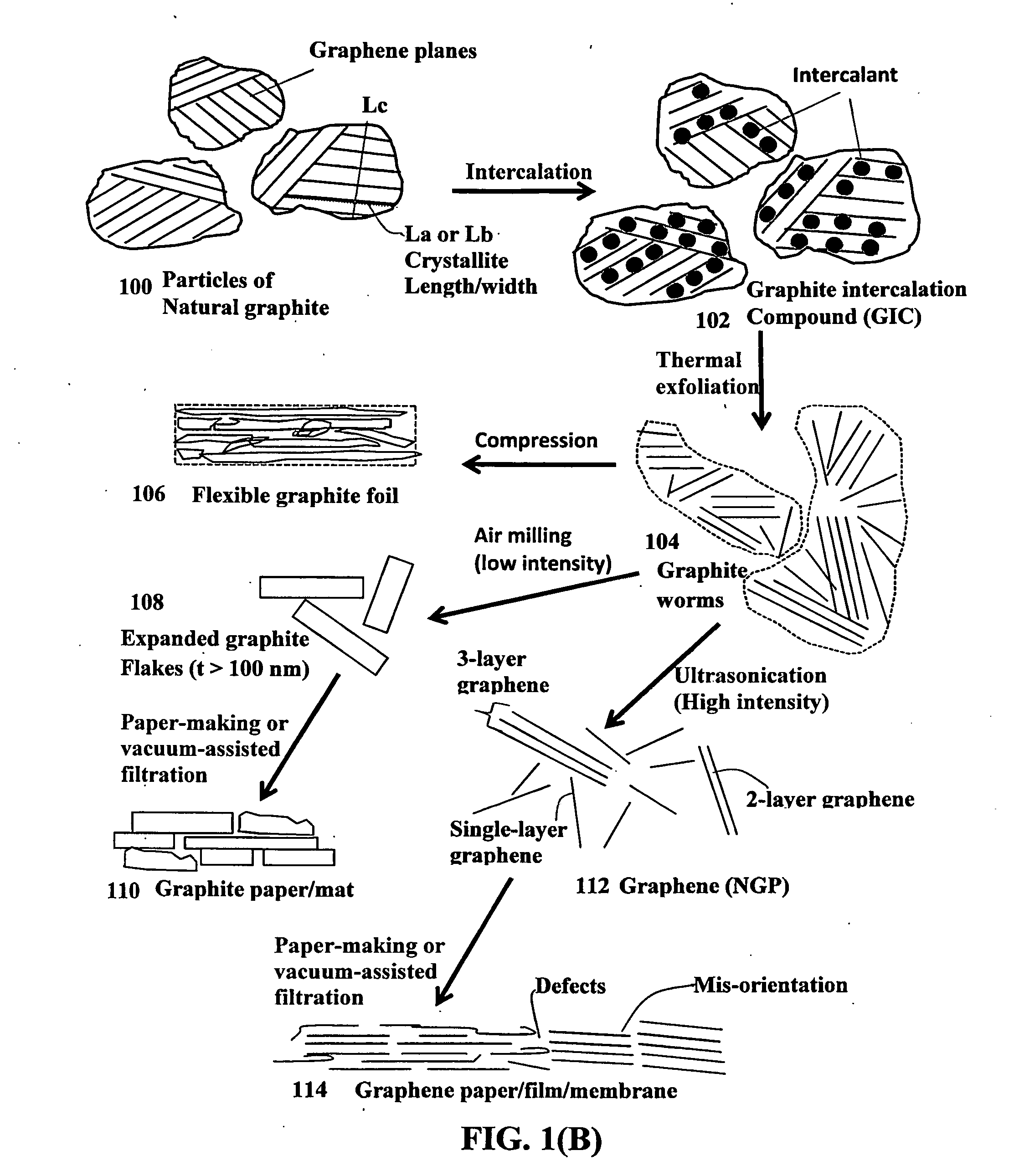

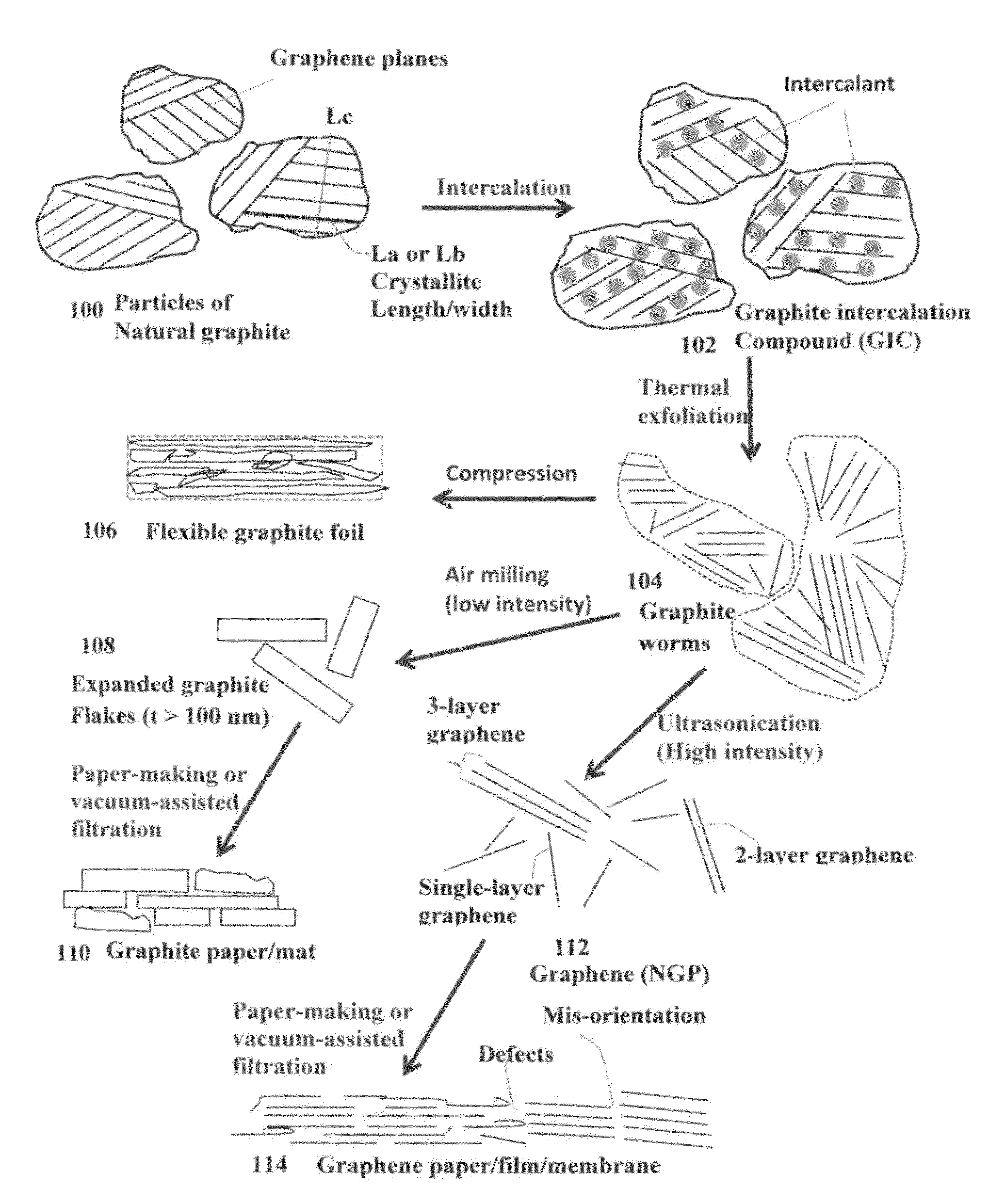

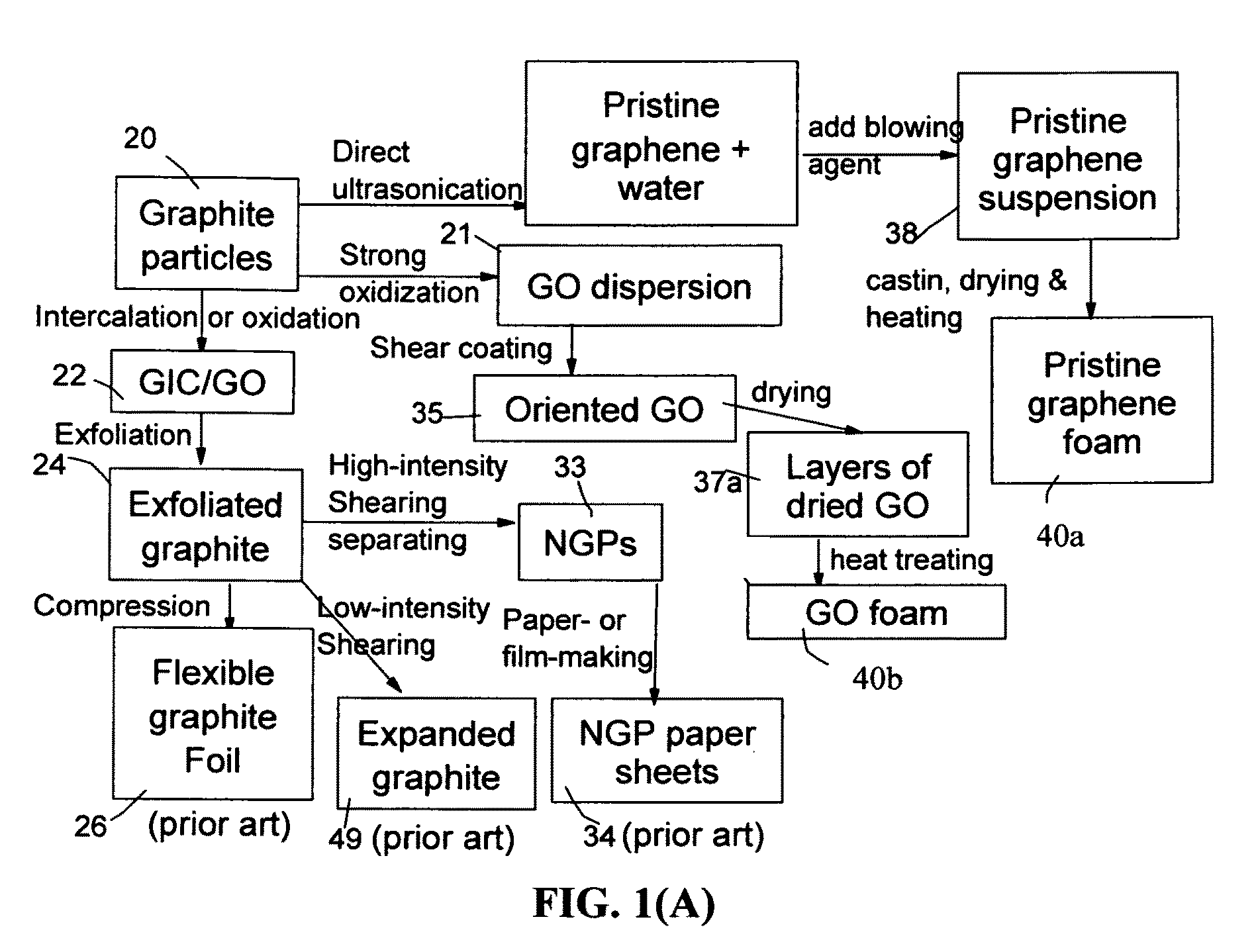

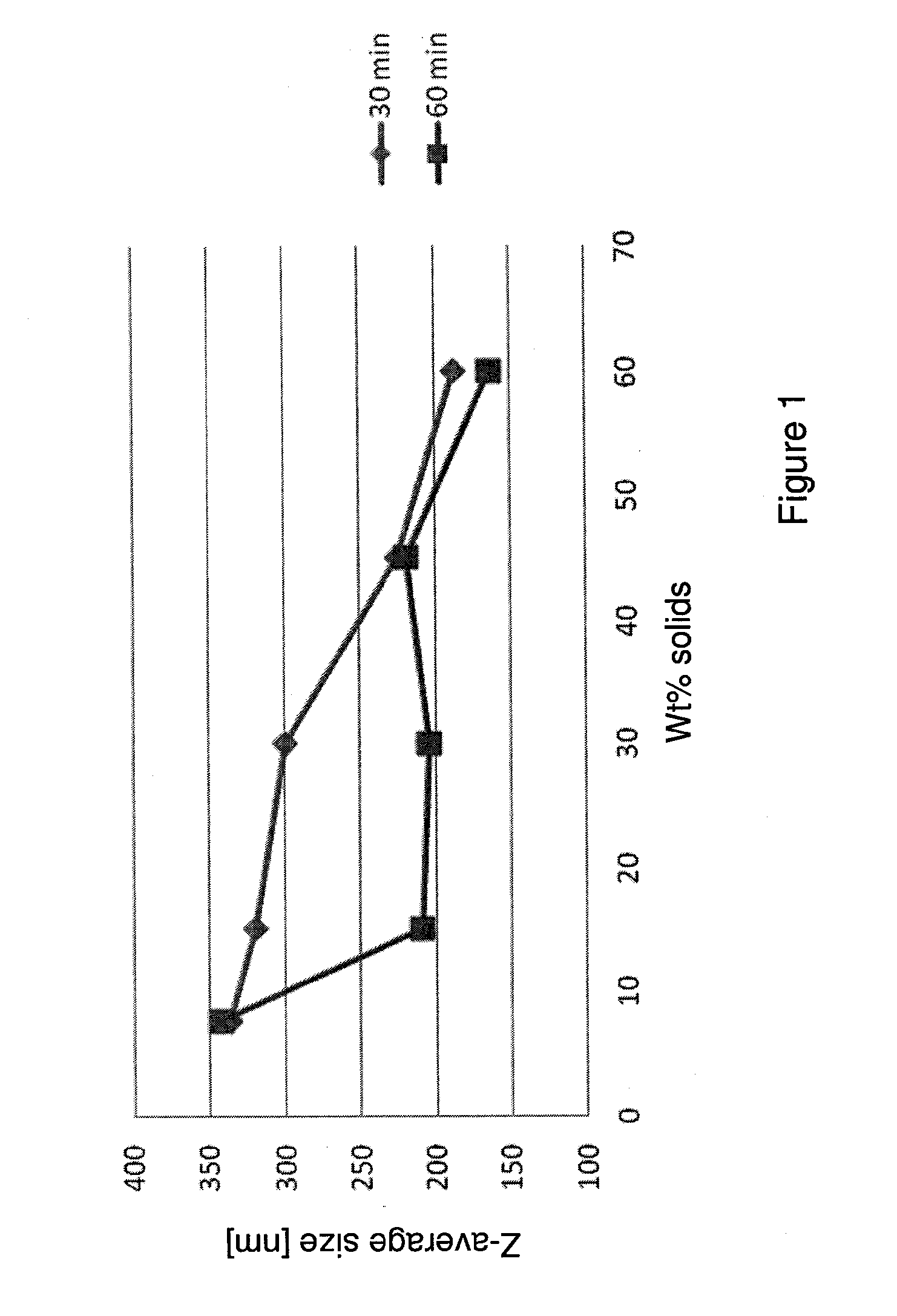

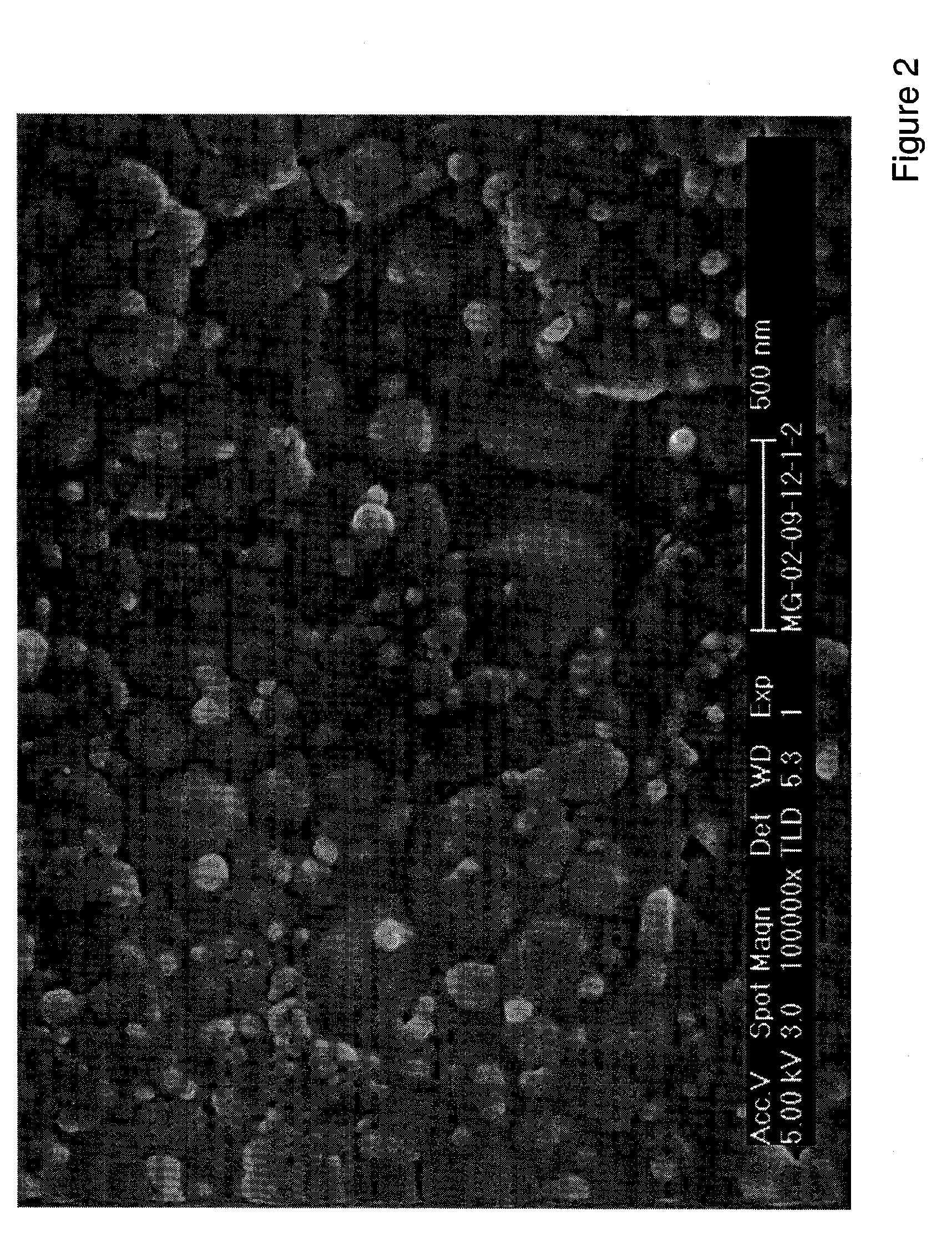

Highly conductive graphene foams and process for producing same

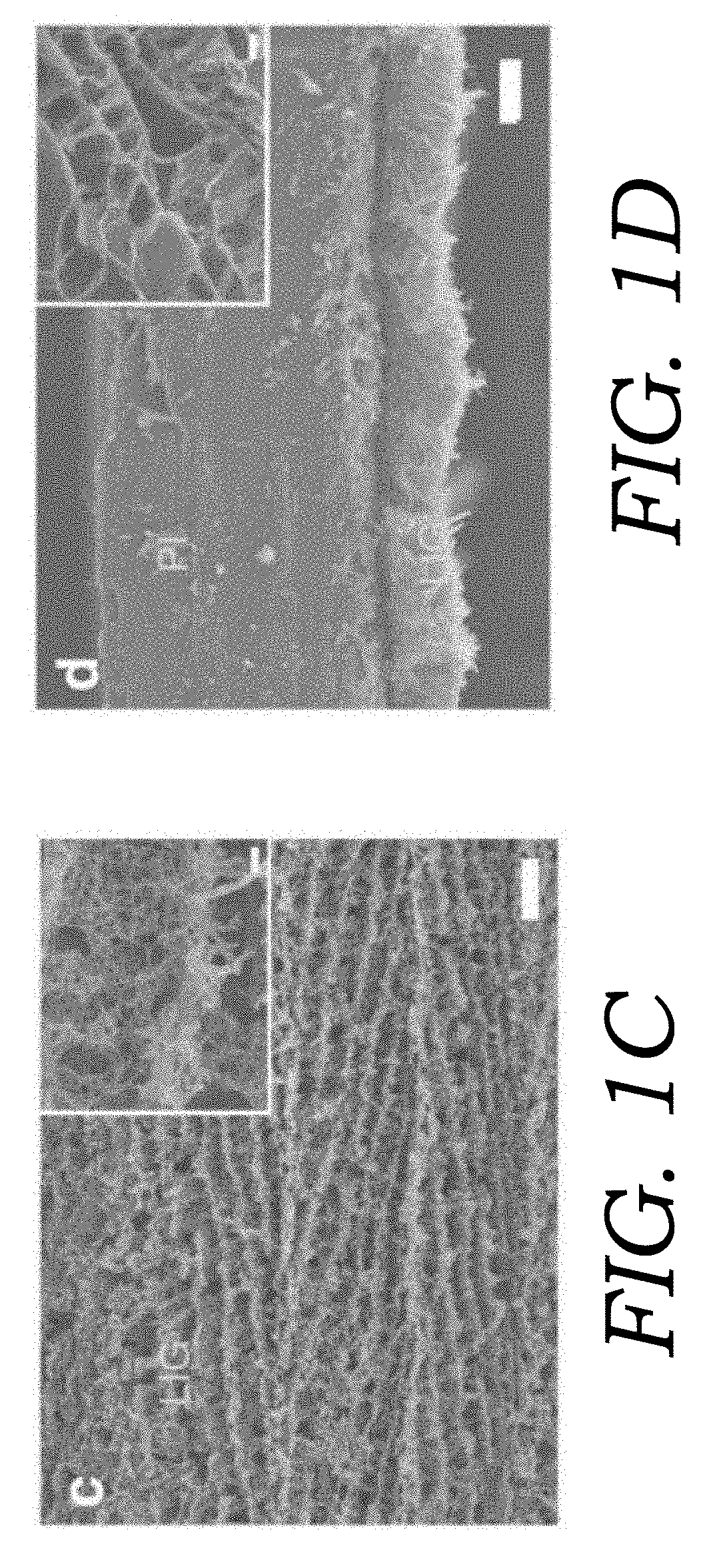

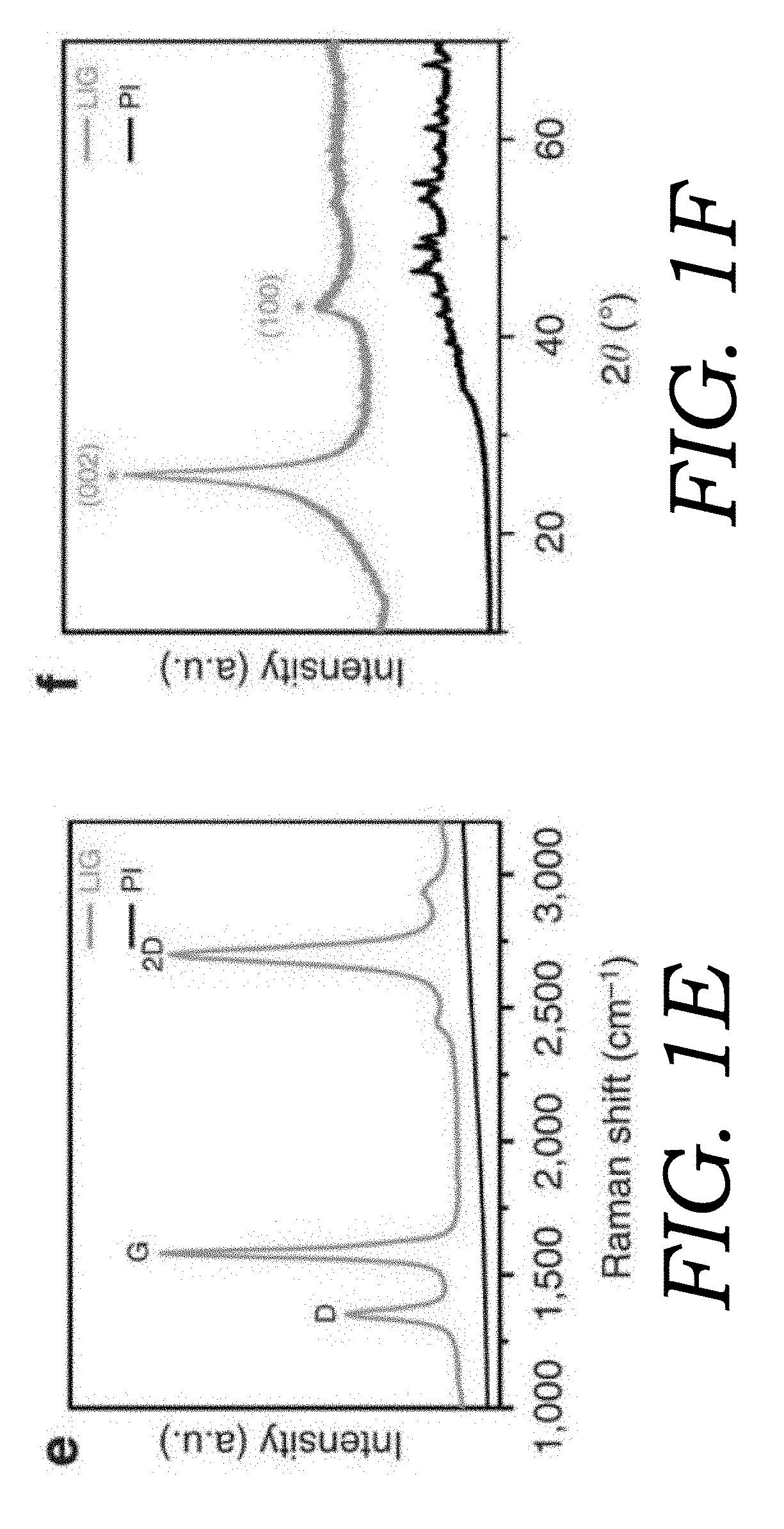

ActiveUS20160019995A1Effective orientation-inducing stressIncrease flexibilityNon-insulated conductorsGraphitePolymer scienceLiquid medium

A process for producing a solid graphene foam composed of multiple pores and pore walls The process comprises: (a) preparing a graphene dispersion having a graphene material dispersed in a liquid medium, which contains an optional blowing agent; (b) dispensing and depositing the graphene dispersion onto a supporting substrate to form a wet layer of graphene material having a preferred orientation; (c) partially or completely removing the liquid medium from the wet layer of graphene material to form a dried layer of graphene material having a content of non-carbon elements no less than 5% by weight (including blowing agent weight); and (d) heat treating the layer of graphene material at a first heat treatment temperature from 80° C. to 3,200° C. at a desired heating rate sufficient to induce volatile gas molecules from the non-carbon elements or to activate the blowing agent for producing the graphene foam having a density from 0.01 to 1.7 g / cm3 or a specific surface area from 50 to 3,000 m2 / g.

Owner:GLOBAL GRAPHENE GRP INC

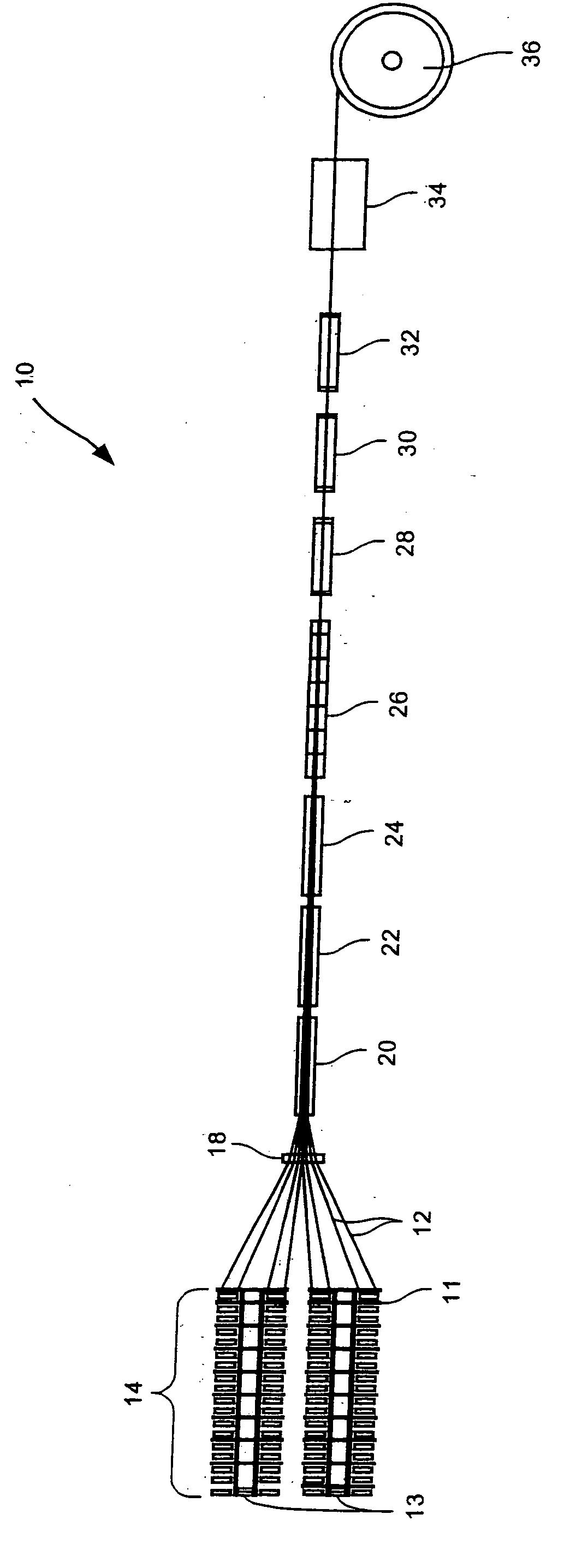

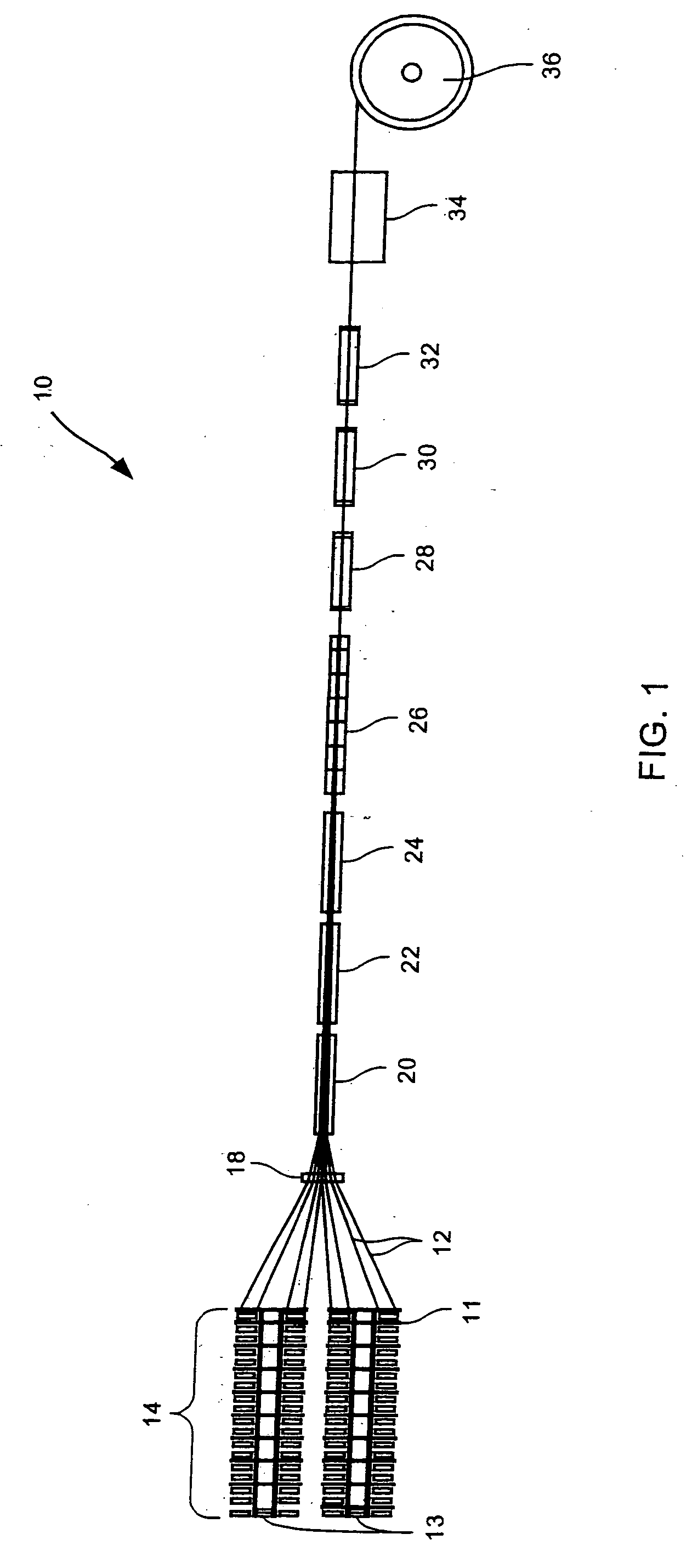

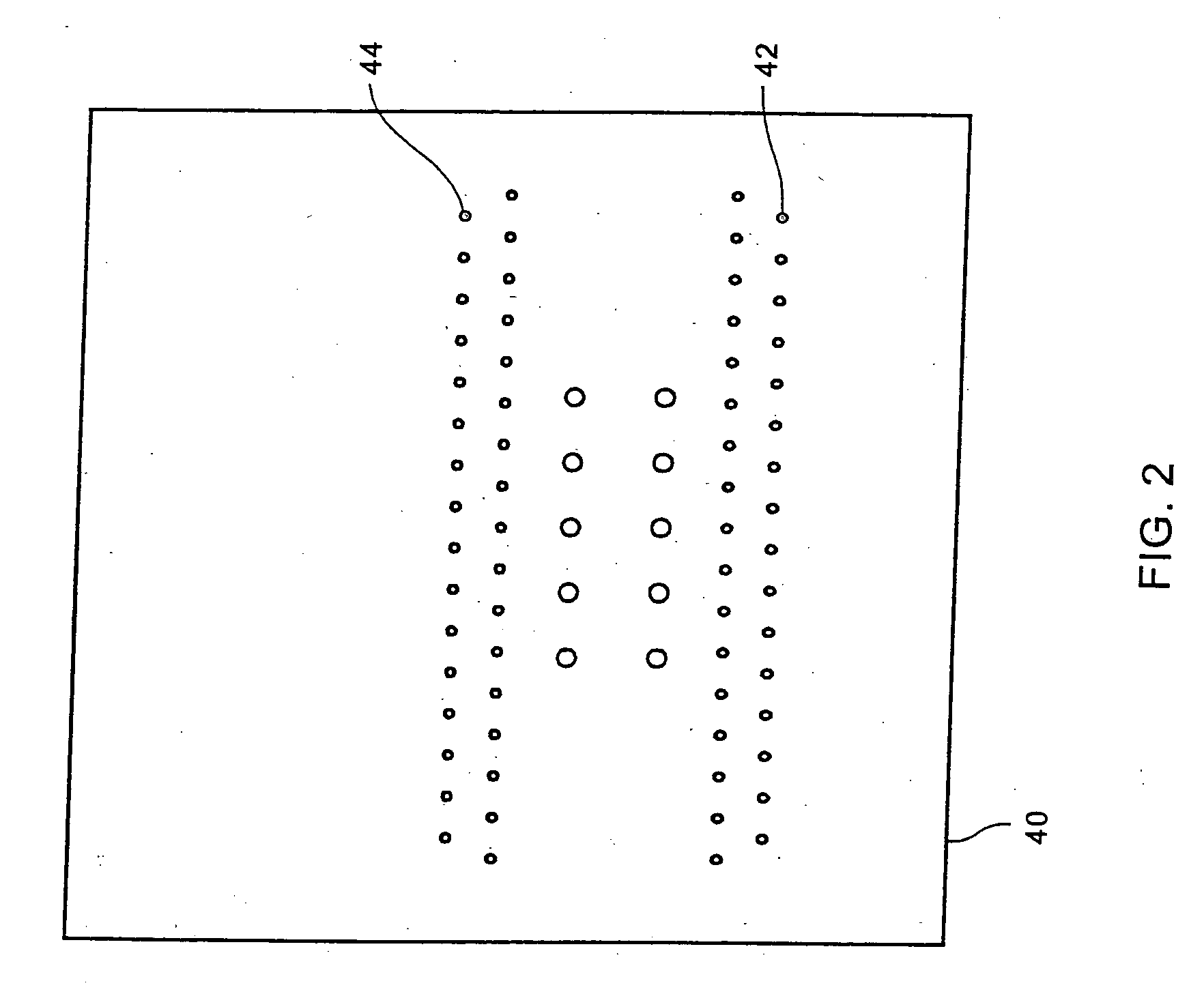

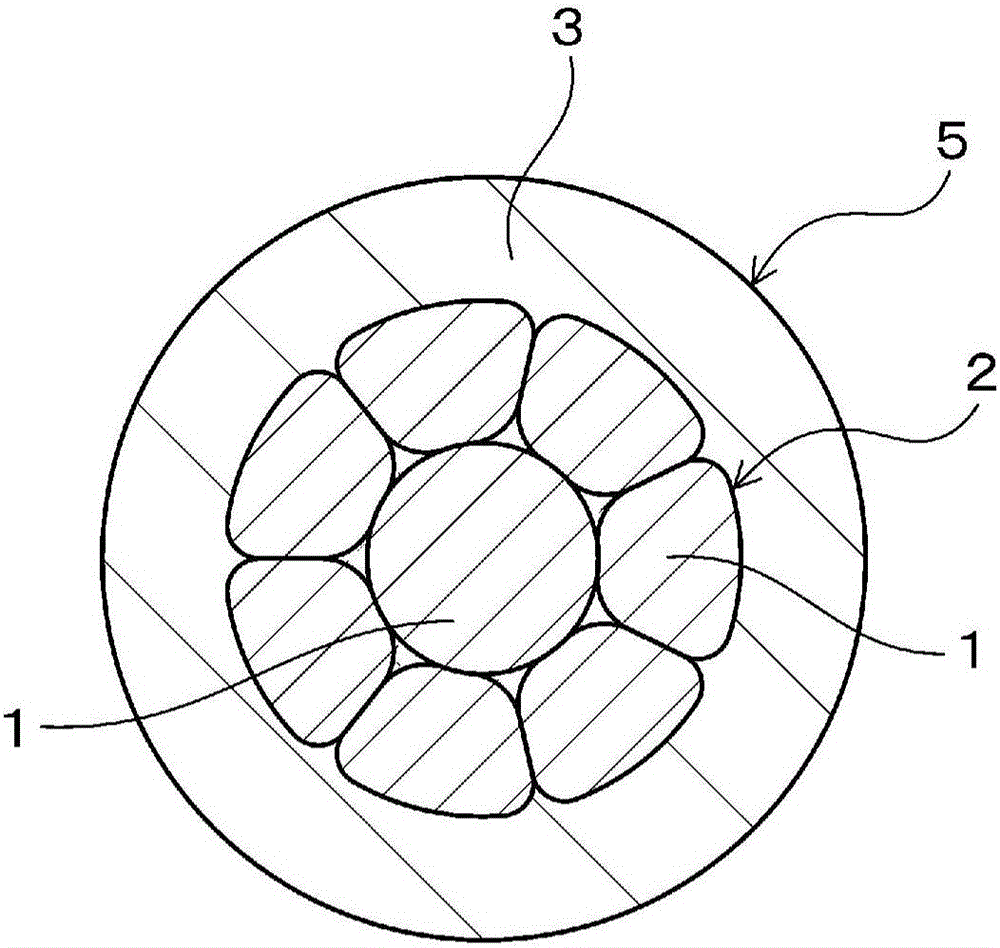

Aluminum conductor composite core reinforced cable and method of manufacture

InactiveUS20040131834A1High strengthIncrease ampacityNon-insulated conductorsApparatus for heat treatmentElectrical conductorThermal expansion

This invention relates to an aluminum conductor composite core reinforced cable (ACCC) and method of manufacture. An ACCC cable has a composite core surrounded by at least one layer of aluminum conductor. The composite core comprises a plurality of fibers from at least one fiber type in one or more matrix materials. The composite core can have a maximum operating temperature capability above 100° C. or within the range of about -45° C. to about 230° C., at least 50% fiber to resin volume fraction, a tensile strength in the range of about 160 Ksi to about 370 Ksi, a modulus of elasticity in the range of about 7 Msi to about 37 Msi and a coefficient of thermal expansion in the range of about -0.7x10<-6 >m / m / ° C. to about 6x10<-6 >m / m° C. According to the invention, a B-stage forming process may be used to form the composite core at improved speeds over pultrusion processes wherein the speeds ranges from about 9 ft / min to about 60 ft / min.

Owner:CTC GLOBAL CORP

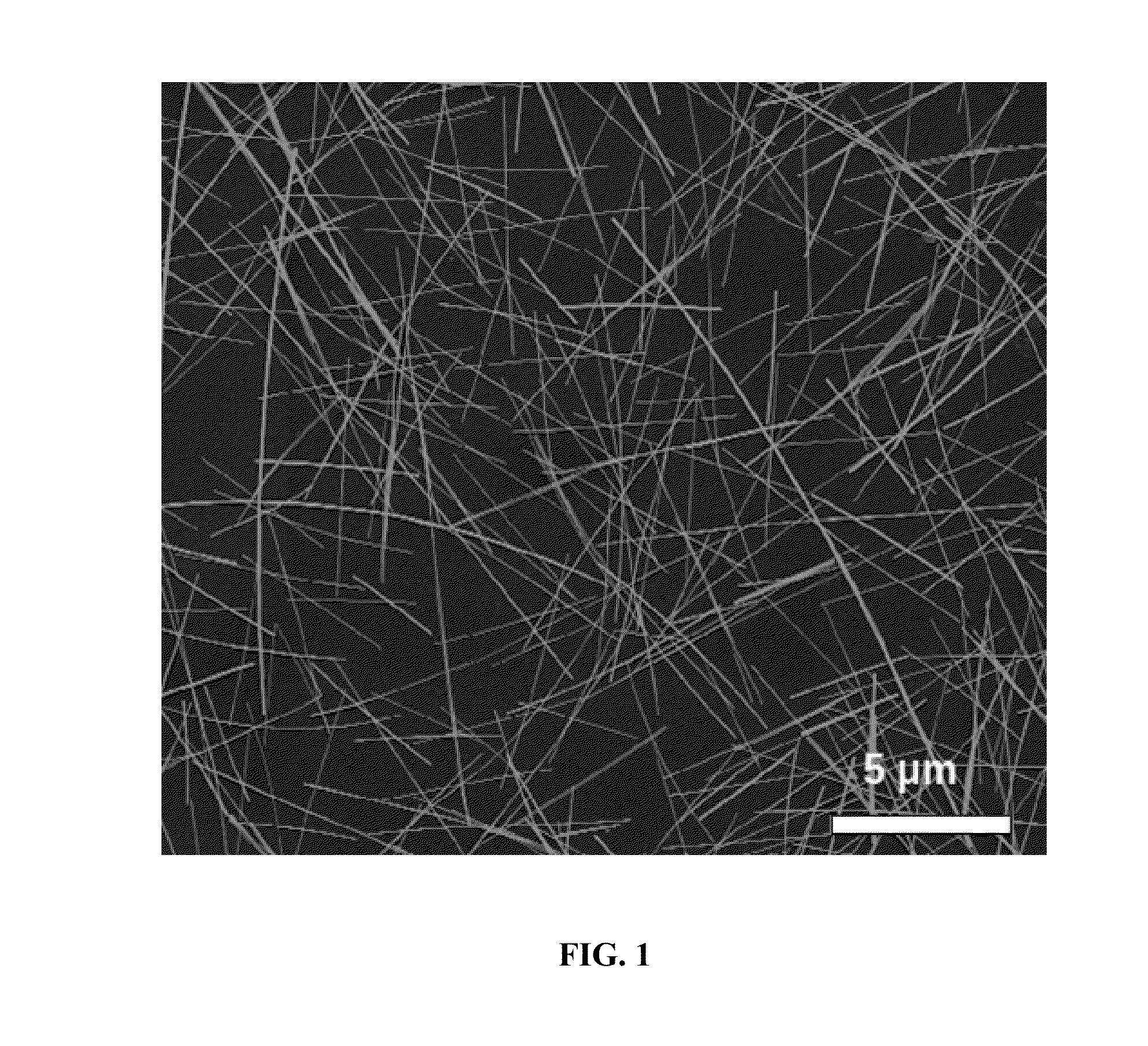

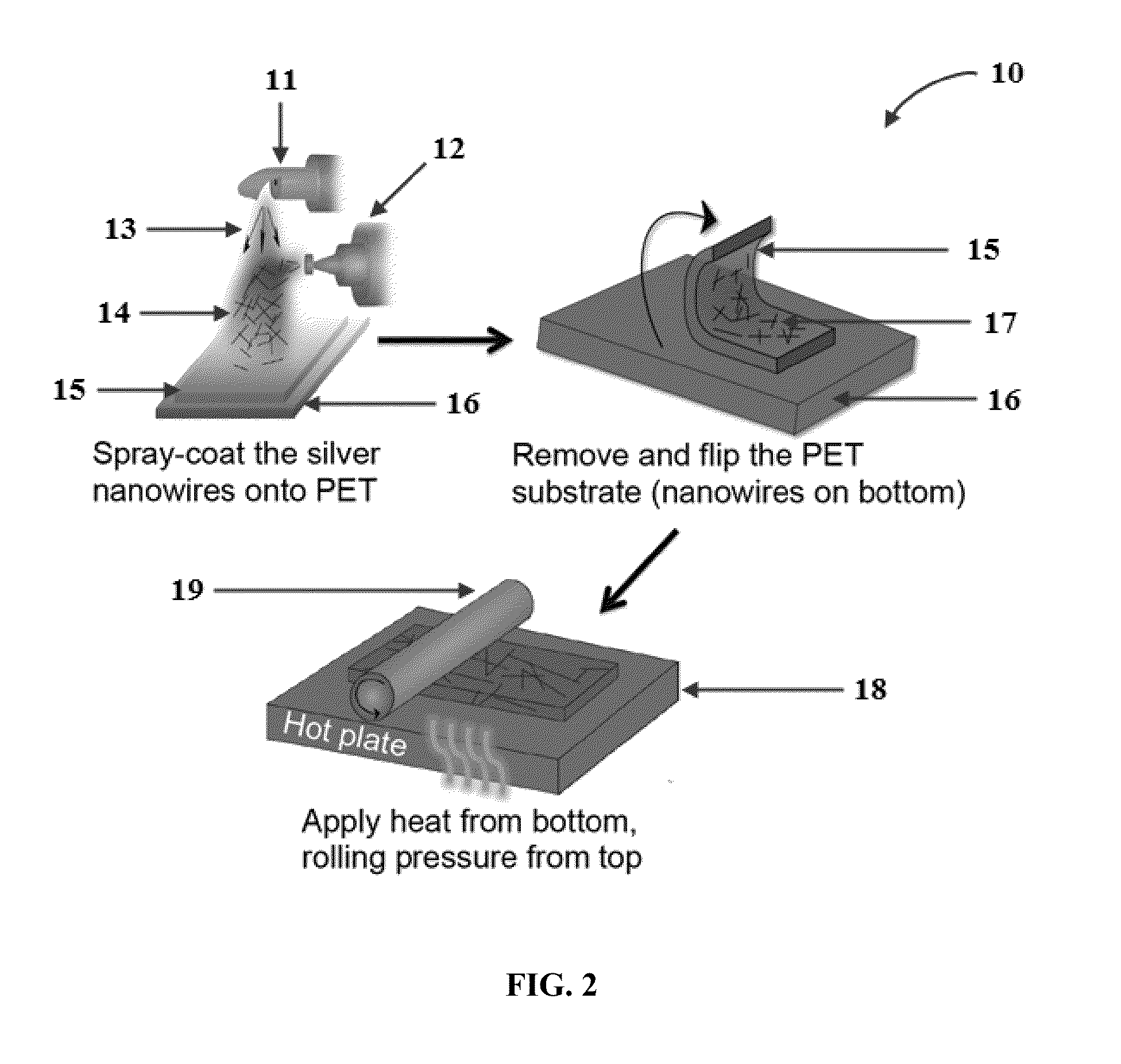

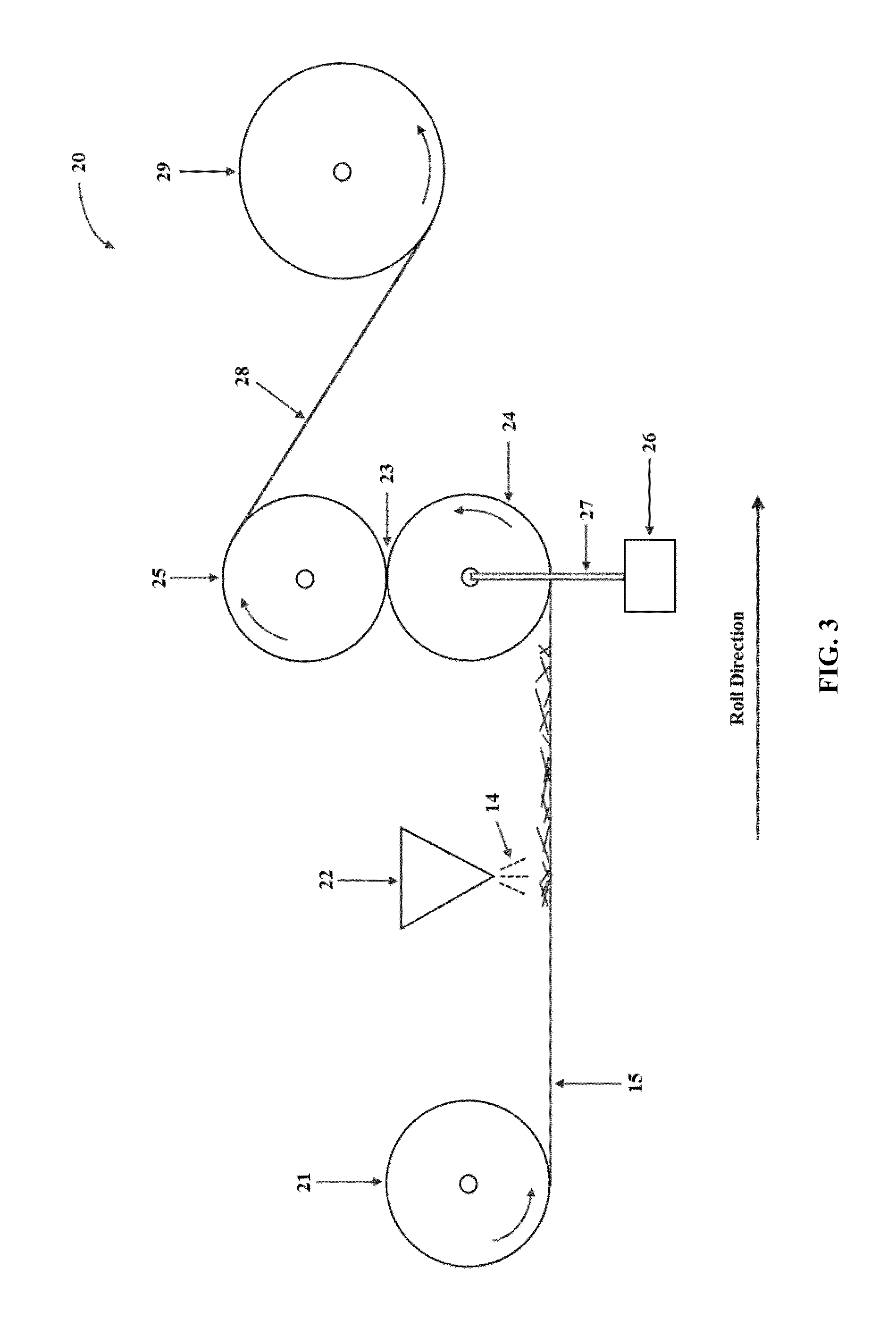

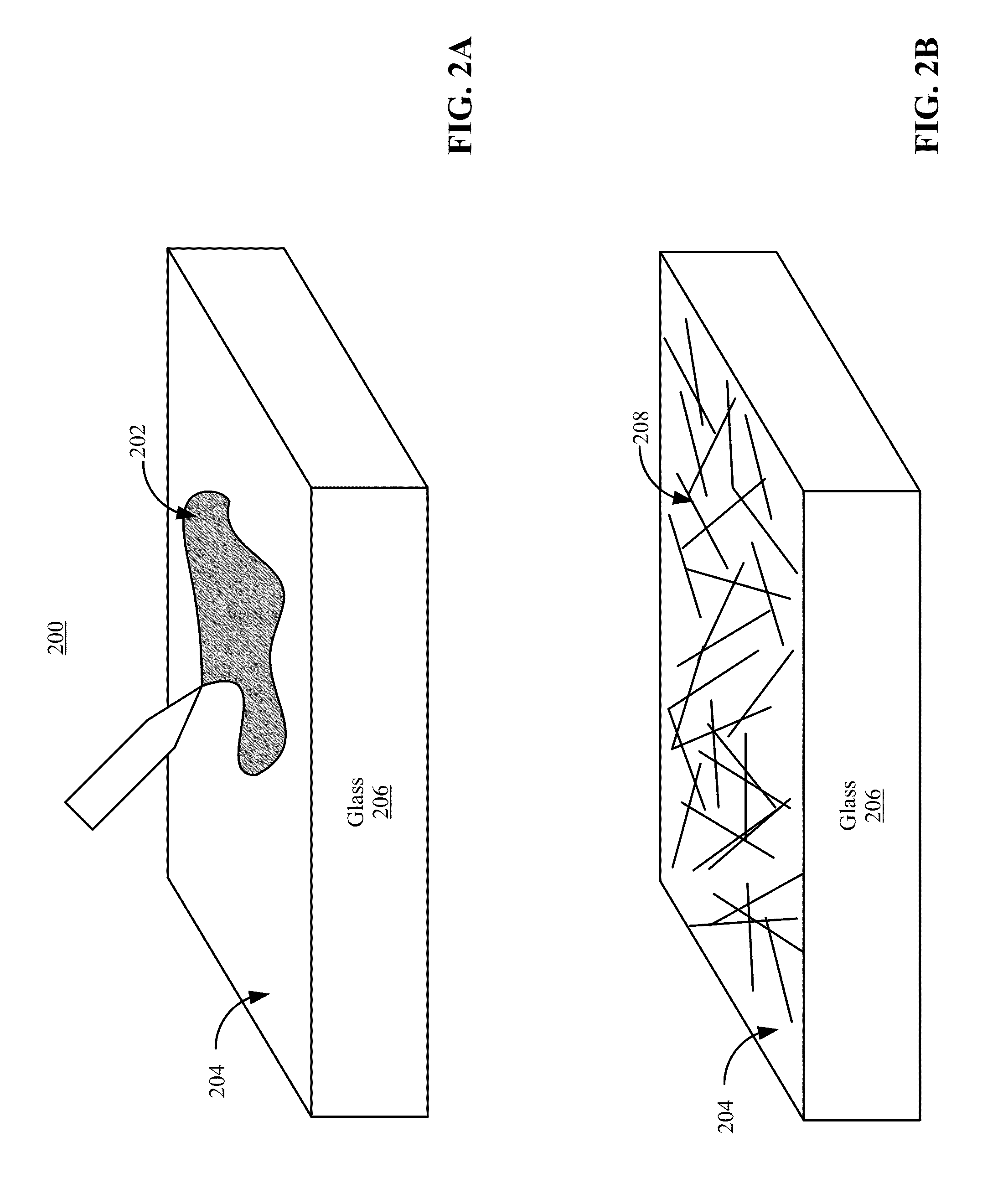

Process for making materials with micro- or nanostructured conductive layers

InactiveUS20150037517A1Reduce usageCost-efficient and scalableFinal product manufactureApparatus for heat treatmentVitrificationPre-condition

Disclosed are methods for making conductive materials. The methods can be used to make transparent, opaque, or reflective electrodes by using the same materials and equipment but varying the processing conditions or amounts of materials used. The methods can include: (a) providing a substrate comprising a first surface and an opposite second surface, wherein micro- or nanostructures are disposed on at least a portion of the first surface, and wherein the first surface is not pre-conditioned to increase attachment between the micro- or nanostructures and the substrate; (b) applying heat to heat the substrate surface to a temperature that is greater than the glass transition temperature or the Vicat softening temperature of the substrate and less than the melting point of the substrate; (c) applying pressure such that the substrate and the micro- or nanostructures are pressed together; and (d) removing the pressure to obtain the conductive material.

Owner:SABIC GLOBAL TECH BV

Aluminum alloy wire

ActiveUS20120217060A1Excellent bending characteristicHigh strengthNon-insulated conductorsLine/current collector detailsUltimate tensile strengthMaterials science

An aluminum alloy wire having excellent bending characteristics, strength, and electrically conductive characteristics, an aluminum alloy stranded wire, a covered electric wire including the above-described alloy wire or stranded wire, and a wire harness including the covered electric wire are provided. The aluminum alloy wire contains not less than 0.1% and not more than 1.5% by mass of Mg, not less than 0.03% and not more than 2.0% of Si, not less than 0.05% and not more than 0.5% of Cu, and a remainder including Al and an impurity, satisfies 0.8≦Mg / Si ratio by mass ≦3.5, has an electrical conductivity from 35% IACS to 58% IACS, a tensile strength from 150 MPa to 400 MPa, and an elongation not less than 2%. The aluminum alloy wire is manufactured through the steps of casting→rolling→wiredrawing→solution heat treatment.

Owner:SUMITOMO ELECTRIC IND LTD +2

Cable for electrical and optical transmission

InactiveUS20120080225A1Easy to operateHigh tensile strengthApparatus for heat treatmentOptical articlesEngineeringUltimate tensile strength

Owner:APPLE INC

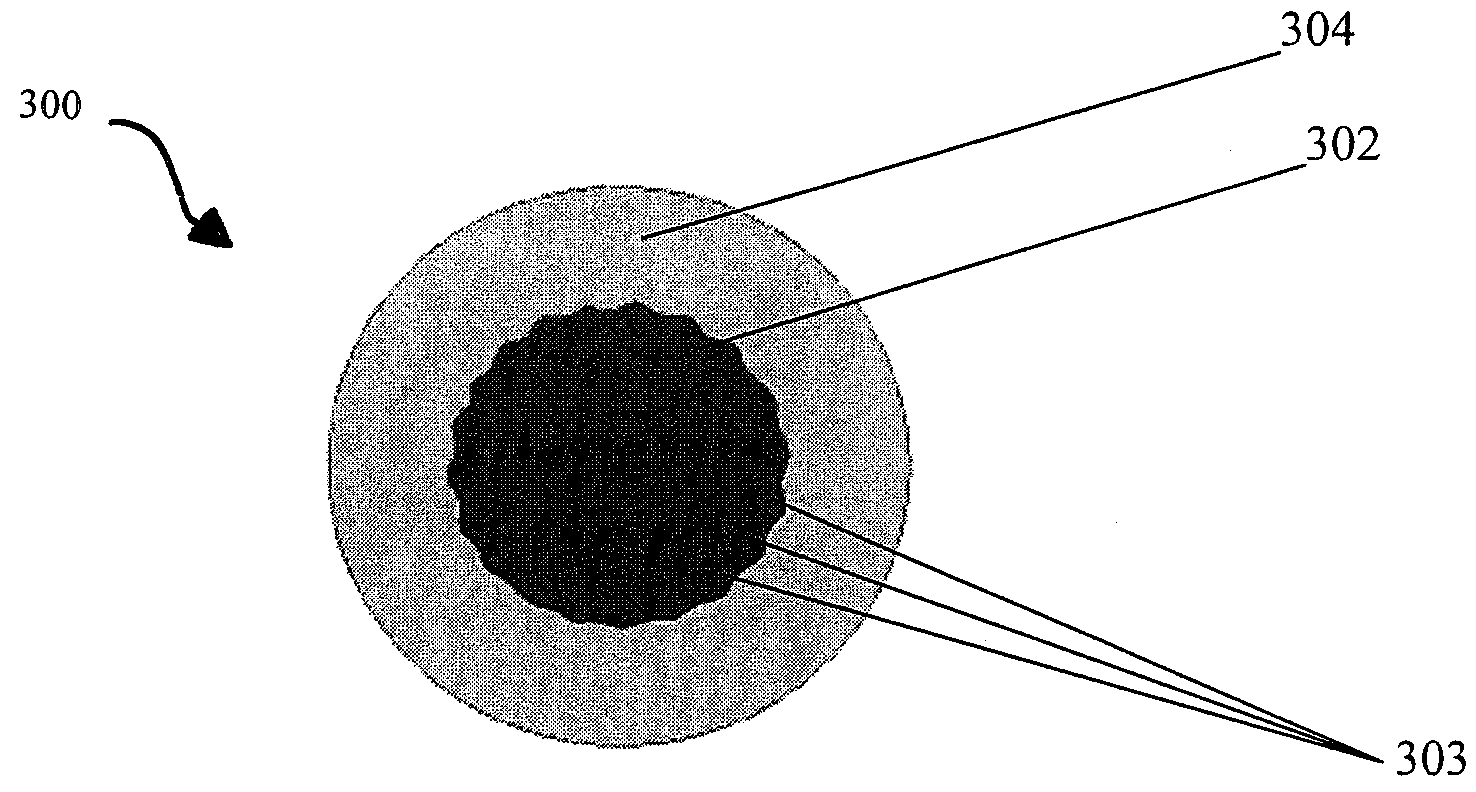

Inks containing metal precursors nanoparticles

ActiveUS20150056426A1Low costLow of productionRadiation applicationsApparatus for heat treatmentNanoparticleCoordination complex

Owner:SINGAPORE ASAHI CHEM & SOLDER IND

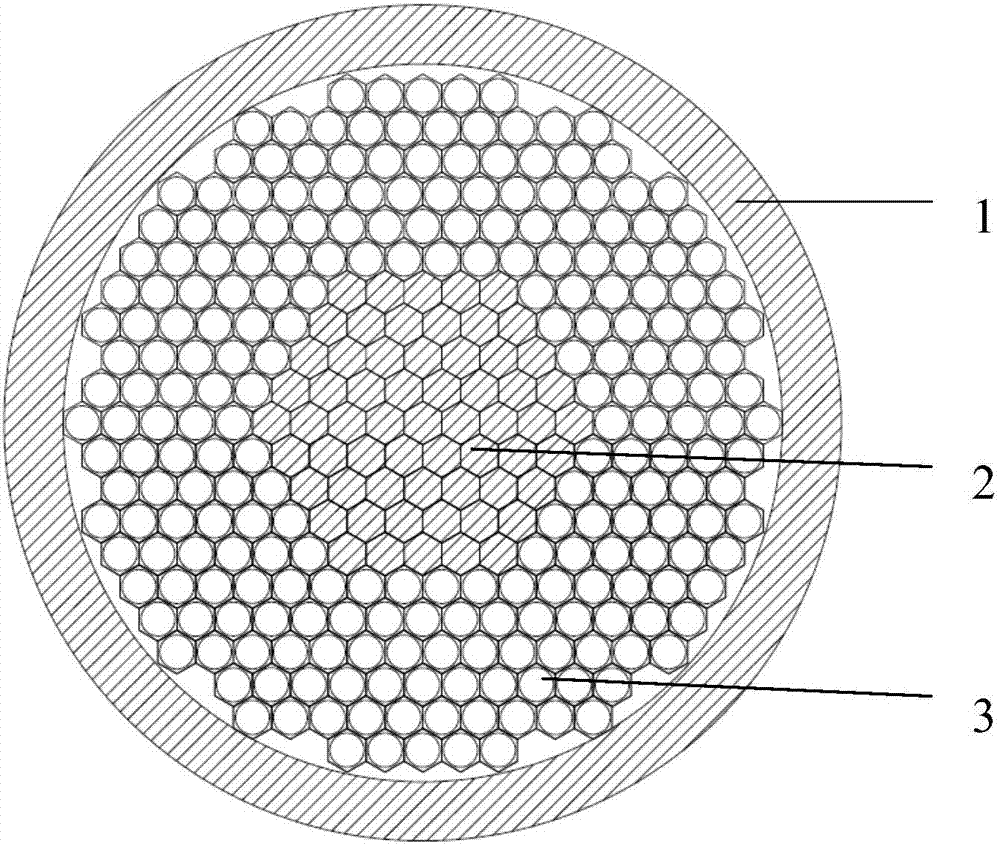

Off-axis fiber reinforced composite core for an aluminum conductor

ActiveUS20080233380A1Reduce decreaseNon-insulated conductorsApparatus for heat treatmentElectrical conductorResin matrix

A composite core for an electrical cable, the composite core defining a longitudinal axis that defines a center of the composite core, the core comprising a plurality of longitudinally extending reinforcing fibers embedded in a resin matrix, the fibers oriented substantially parallel to the longitudinal axis and a sheath surrounding the plurality of longitudinally oriented fibers. The sheath may further comprise a plurality of off-axis reinforcing fibers oriented at an angle relative to the longitudinal axis surrounding the longitudinally extending fibers. The sheath may comprise a type of resin, including for example, thermosetting resin or thermoplastic resin.

Owner:CTC GLOBAL CORP

Aluminum conductor composite core reinforced cable and method of manufacture

InactiveUS20040131851A1High strengthIncrease ampacityNon-insulated conductorsApparatus for heat treatmentElectrical conductorThermal expansion

This invention relates to an aluminum conductor composite core reinforced cable (ACCC) and method of manufacture. An ACCC cable has a composite core surrounded by at least one layer of aluminum conductor. The composite core comprises a plurality of fibers from at least one fiber type in one or more matrix materials. The composite core can have a maximum operating temperature capability above 100° C. or within the range of about 45° C. to about 230° C., at least 50% fiber to resin volume fraction, a tensile strength in the range of about 160 Ksi to about 370 Ksi, a modulus of elasticity in the range of about 7 Msi to about 37 Msi and a coefficient of thermal expansion in the range of about -0.7x10<-6 >m / m / ° C. to about 6x10<-6 >m / m / ° C. According to the invention, a B-stage forming process may be used to form the composite core at improved speeds over pultrusion processes wherein the speeds ranges from about 9 ft / min to about 60 ft / min.

Owner:CTC GLOBAL CORP

Aluminum conductor composite core reinforced cable and method of manufacture

InactiveUS20050227067A1Increase ampacityMaintain stable propertiesNon-insulated conductorsApparatus for heat treatmentElectrical conductorResin matrix

This invention relates to an aluminum conductor composite core reinforced cable (ACCC) and method of manufacture. An ACCC cable having a composite core surrounded by at least one layer of aluminum conductor. The composite core comprises at least one longitudinally oriented substantially continuous reinforced fiber type in a thermosetting resin matrix having an operating temperature capability within the range of about 90 to about 230° C., at least 50% fiber volume fraction, a tensile strength in the range of about 160 to about 240 Ksi, a modulus of elasticity in the range of about 7 to about 30 Msi and a thermal expansion coefficient in the range of about 0 to about 6×10−6 m / m / C. According to the invention, a B-stage forming process may be used to form the composite core at improved speeds over pultrusion processes wherein the speeds ranges from about 9 ft / min to about 50 ft / min.

Owner:CTC GLOBAL CORP

Electrically and Thermally Non-Metallic Conductive Nanostructure-Based Adapters

ActiveUS20090042455A1Low resistance couplingMaximizing numberApparatus for heat treatmentSoldered/welded conductive connectionsEngineeringNanostructure

A conductive adapter for carrying relatively high current from a source to an external circuit without degradation is provided. The adapter includes a conducting member made from a conductive nanostructure-based material and having opposing ends. The adapter can also include a connector portion positioned on one end of the conducting member for maximizing a number of conductive nanostructures within the conducting member in contact with connector portion, so as to enable efficient conduction between a nanoscale environment and a traditional electrical and / or thermal circuit system. The adapter can further include a coupling mechanism situated between the conducting member and the connector portion, to provide a substantially uniform contact between the conductive nanostructure-based material in the conducting member and the connector portion. A method for making such a conductive adapter is also provided.

Owner:NANCOMP TECHNOLOGIES INC

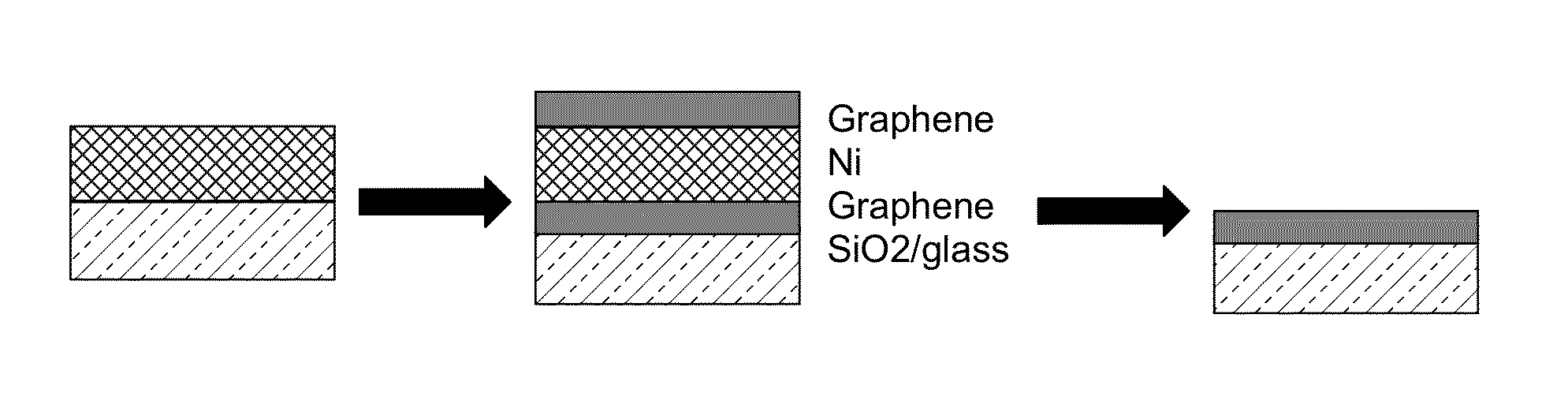

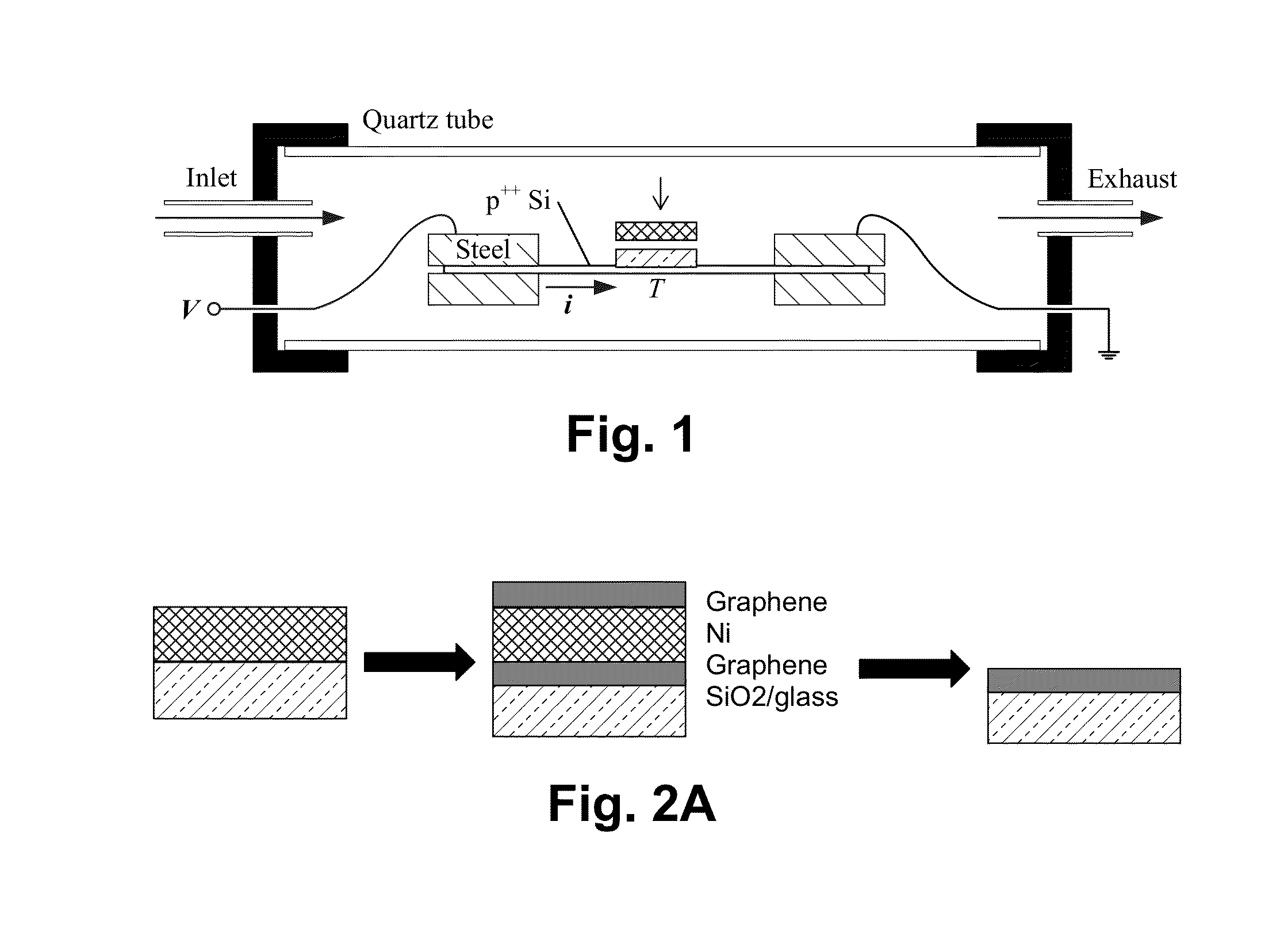

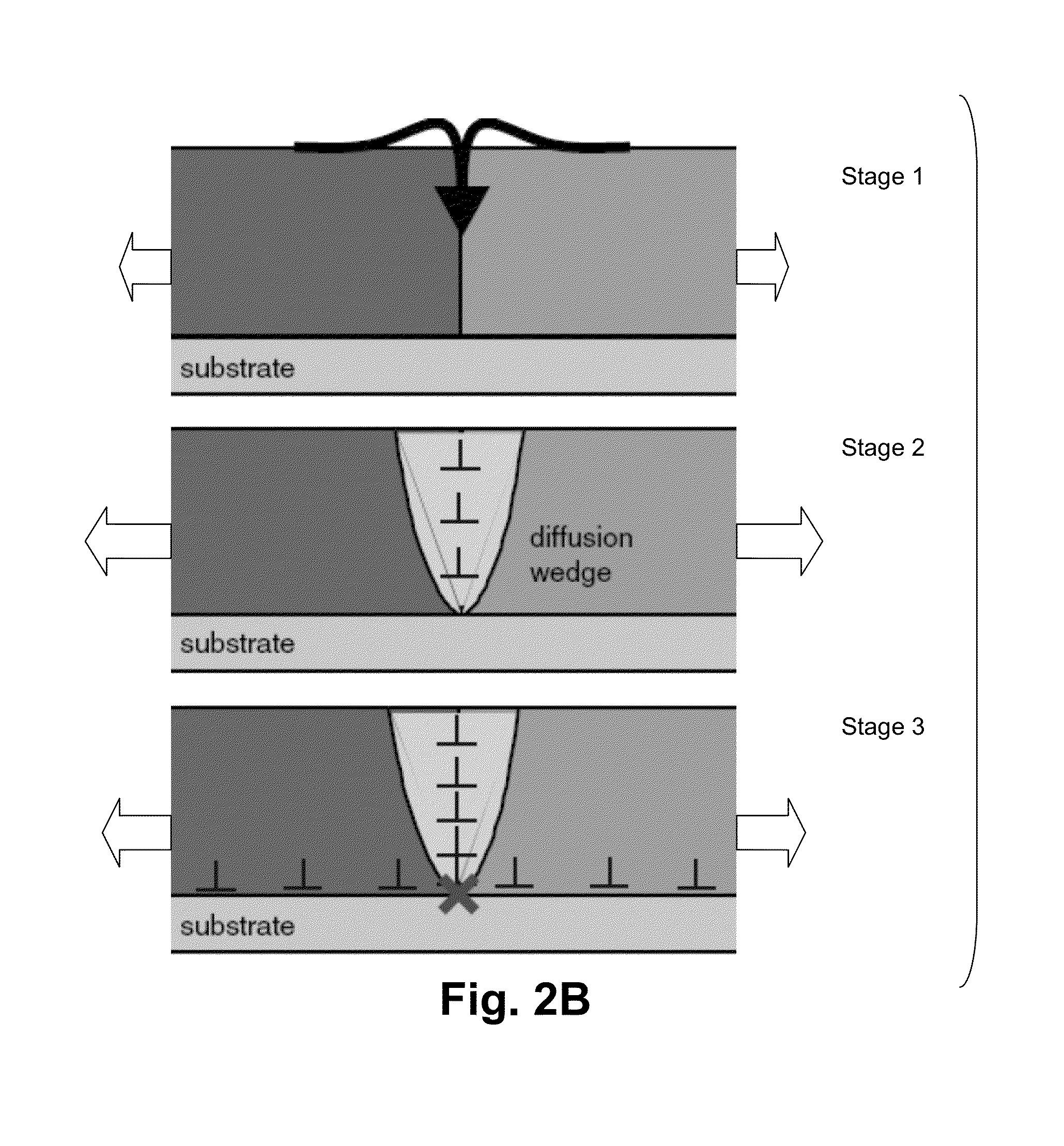

Methods for direct production of graphene on dielectric substrates, and associated articles/devices

ActiveUS20140308523A1Material nanotechnologyWave amplification devicesDielectric substrateCvd graphene

Certain example embodiments of this invention relate to methods for large area graphene precipitation onto glass, and associated articles / devices. For example, a coated article including a graphene-inclusive film on a substrate, and / or a method of making the same, is provided. A metal-inclusive catalyst layer (e.g., of or including Ni and / or the like) is disposed on the substrate. The substrate with the catalyst layer thereon is exposed to a precursor gas and a strain-inducing gas at a temperature of no more than 900 degrees C. Graphene is formed and / or allowed to form both over and contacting the catalyst layer, and between the substrate and the catalyst layer, in making the coated article. The catalyst layer, together with graphene formed thereon, is removed, e.g., through excessive strain introduced into the catalyst layer as associated with the graphene formation. Products including such articles, and / or methods of making the same, also are contemplated herein.

Owner:GUARDIAN GLASS LLC +1

Method for the manufacture of a composite core for an electrical cable

A method for the manufacture of a composite core for an electrical cable. The method may include pulling carbon fiber tows and glass fiber tows through a composite core processing system. The carbon fiber tows and the glass fiber tows are contacted with a resin, such as a thermosetting resin, to impregnate the fiber tows with the resin. The glass fiber tows are disposed on the outside of the carbon fiber tows to form a glass fiber layer around the carbon. The resin is then cured to form the composite core, which is adapted for use in an electrical transmission and distribution cable.

Owner:CTC GLOBAL CORP

Functional flexible electrode and preparation method thereof

ActiveCN106601338ARich preparation methodImprove reliabilityConductive layers on insulating-supportsApparatus for heat treatmentTerra firmaShape change

The invention provides a functional flexible electrode which comprises a flexible substrate, wherein an electrode material is arranged on one surface of the flexible substrate and a functional material is arranged on the other surface of the flexible substrate. A preparation method for the functional flexible electrode provided by the invention is various; the shape change can be realized through the stimulation of temperature, humidity, light, and the like; the mode is various; the control is convenient; and a firm basis is established for the application of the functional flexible electrode in the wearing and implantable medical fields.

Owner:SHENZHEN INST OF ADVANCED TECH

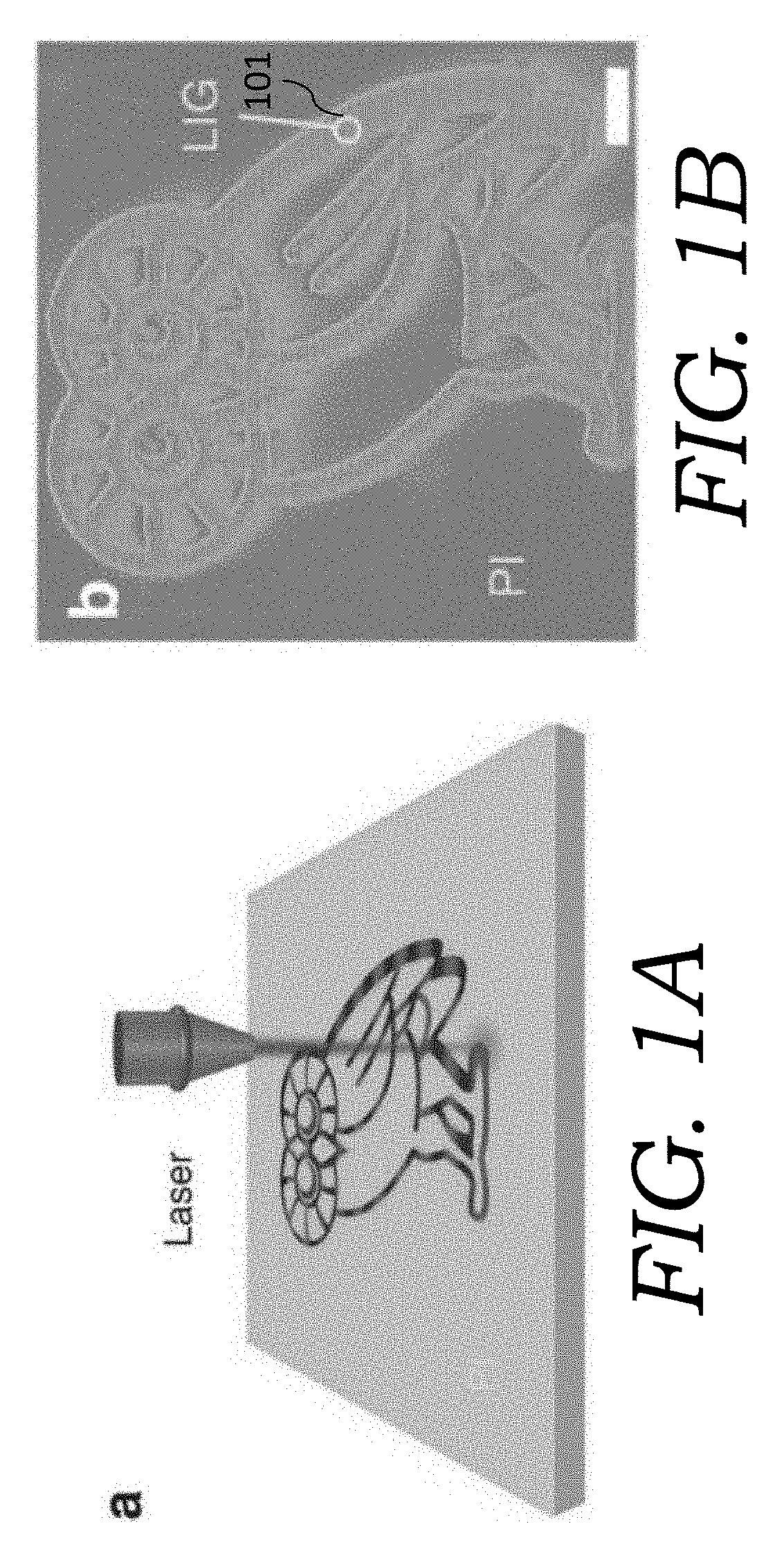

Three-dimensional (3D) printing of graphene materials

PendingUS20190308880A1Additive manufacturing apparatusHybrid capacitor electrodesSucroseCvd graphene

Three-dimensional (3D) printing of graphene materials and methods and apparatuses for making same. In some embodiments, combined metal powder and carbon growth sources (such as powder Ni and sucrose) are utilized in the 3D printing process. In other embodiments, metal powders with binders (such as powder Ni and a polymer bases binder) are utilized in the 3D printing process. The metal in the resulting 3D printed composite material can then be etched or otherwise removed yielding the 3D printed graphene materials.

Owner:RICE UNIV

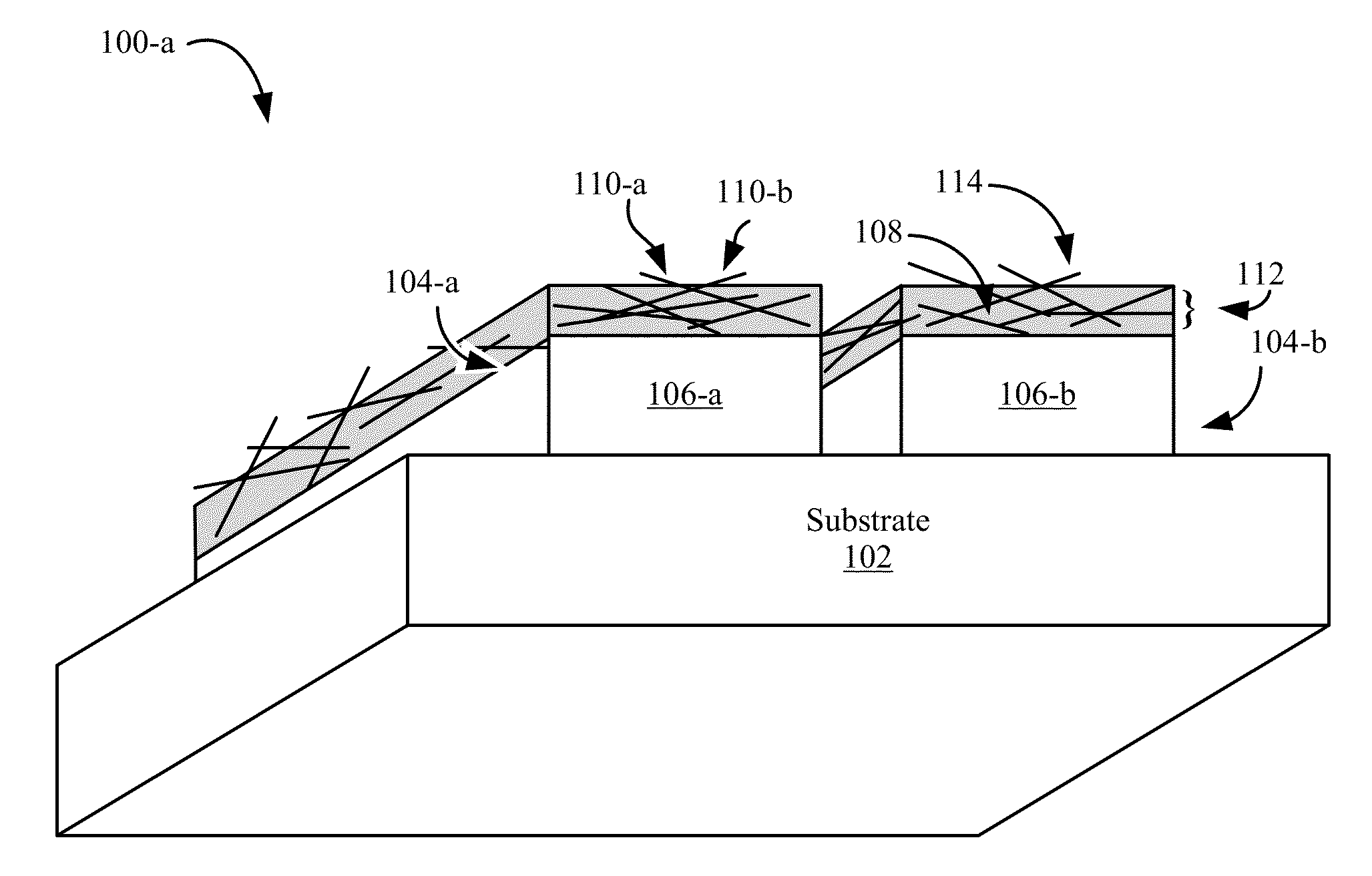

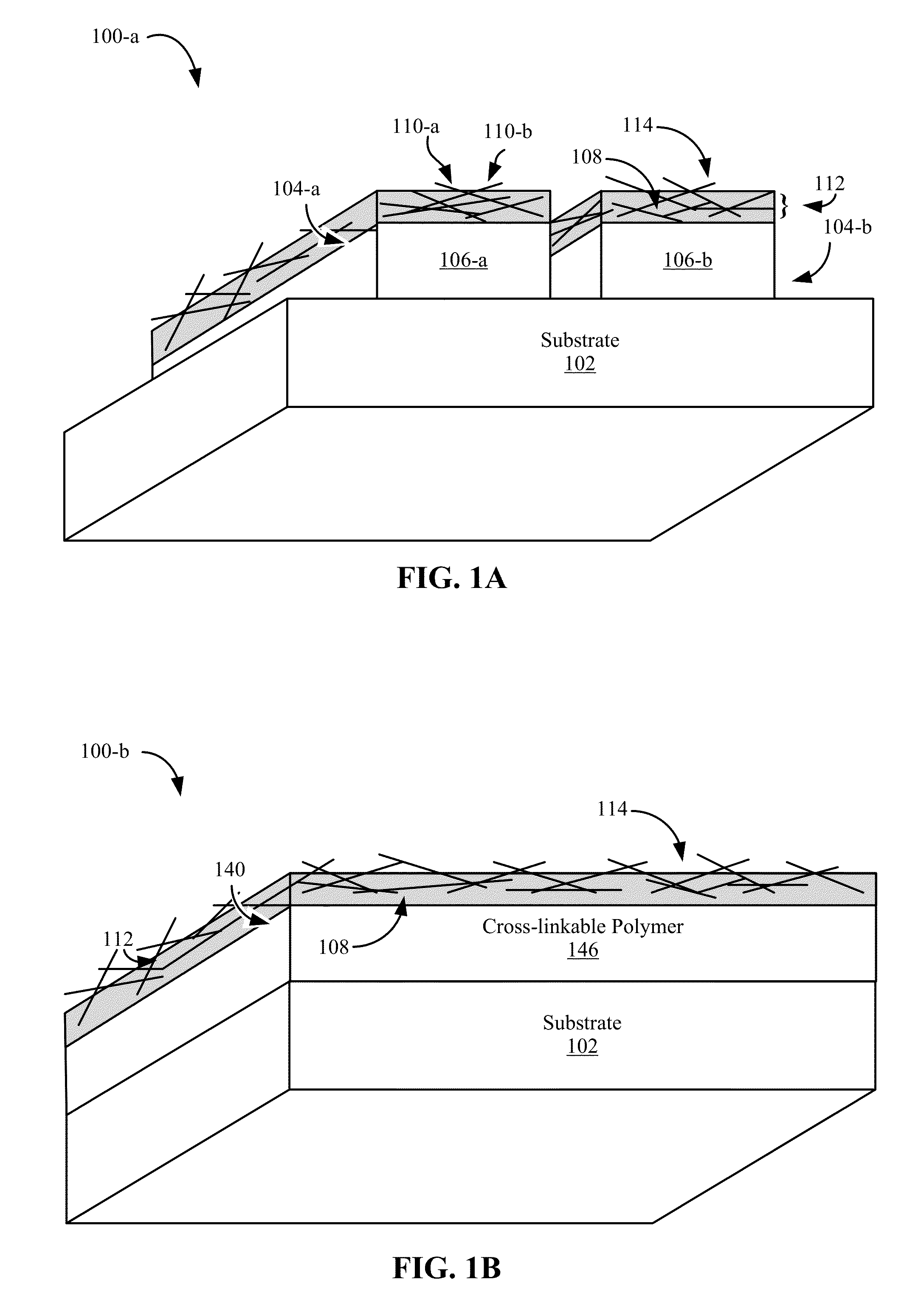

Composite Conductive Films with Enhanced Thermal Stability

ActiveUS20150038033A1Enhanced hardness propertyImprove temperature stabilityNanoinformaticsApparatus for heat treatmentCross-linkNanowire

A composite conductive film is provided that includes a layer of cross-linked polymer having a surface and an inorganic mesh comprising a plurality of nanowires of an inorganic material. The nanowires are, in isolated form, characterized by a first conductivity stability temperature. Further, the plurality of nanowires is embedded within at least a region of the layer of cross-linked polymer, where the region is continuous from the surface of the layer of cross-linked polymer. The layer of cross-linked polymer and the inorganic mesh are arranged to form the composite conductive film having a second conductivity stability temperature that is greater than the first conductivity stability temperature.

Owner:SINOVIA TECH

Copper-iron alloy material electromagnetic shielding wire and preparation method thereof

ActiveCN110229972AIncrease profitRealize continuous productionApparatus for heat treatmentConductive materialWire rodElectromagnetic shielding

The invention provides a copper-iron alloy material electromagnetic shielding wire and a preparation method thereof, and belongs to the technical field of electromagnetic shielding wire material. Thecopper-iron alloy material comprises the following chemical components of, in percentage by weight, 5%-20% of Fe, less than or equal to 0.2% of Ni, less than or equal to 0.2% of Mn, less than or equalto 0.1% of Pb and the balance of Cu. The preparation method comprises the following steps of S1, preparing material; S2, smelting, and up leading continuously casting to obtain a phi 10 mm-20 mm copper rod blank; step 3, drawing, and repeatedly carrying out high-temperature annealing during drawing to obtain a phi 1 mm-2 mm copper-iron alloy wire rod; S4, carrying out heat preservation; S5, carrying out multi-pass drawing again to obtain an electromagnetic shielding wire with the diameter of phi 0. 05 mm-0.5 mm; and S6, weaving to obtain a net wire with electromagnetic shielding. According tothe method, the performance, the structure, the material utilization rate, the industrialization and other aspects of the prepared copper-iron alloy shielding wire are further improved, and a new path is provided for the application and the development of the copper-iron alloy shielding wire.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

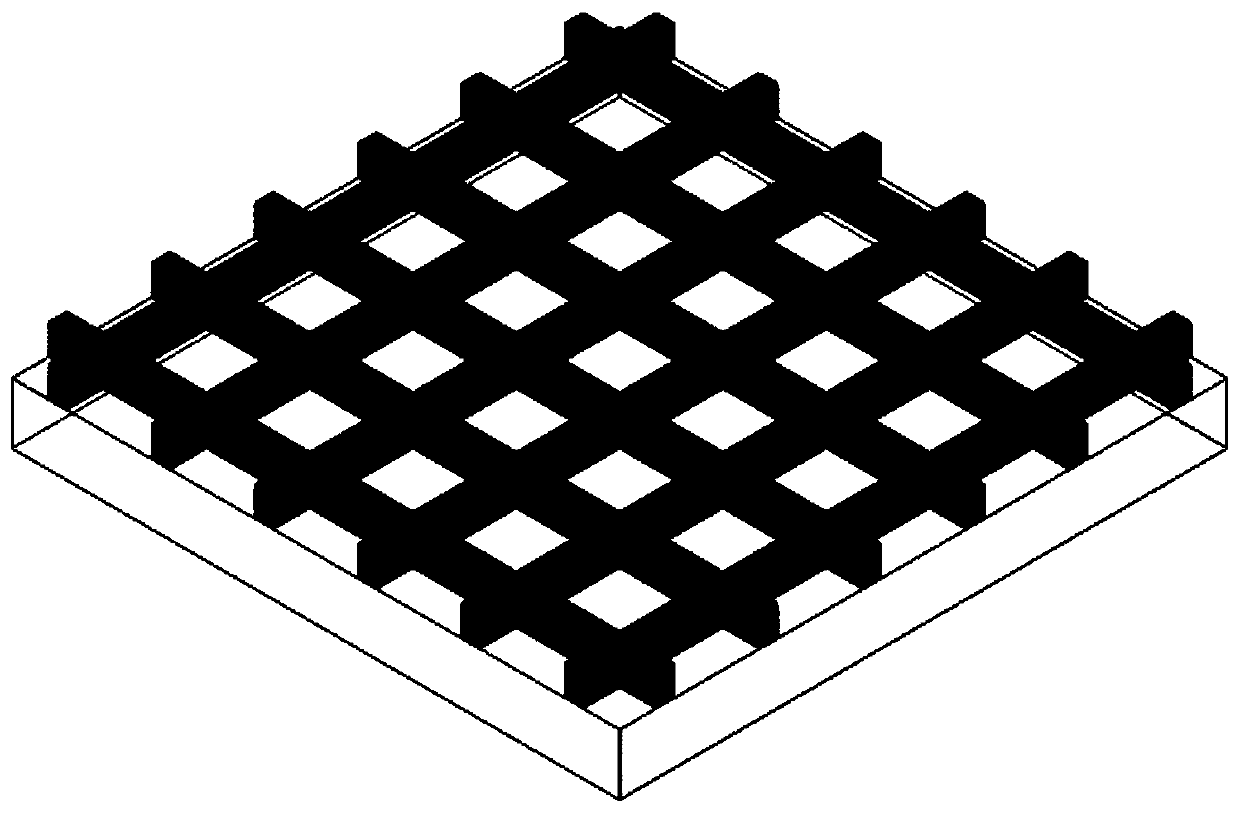

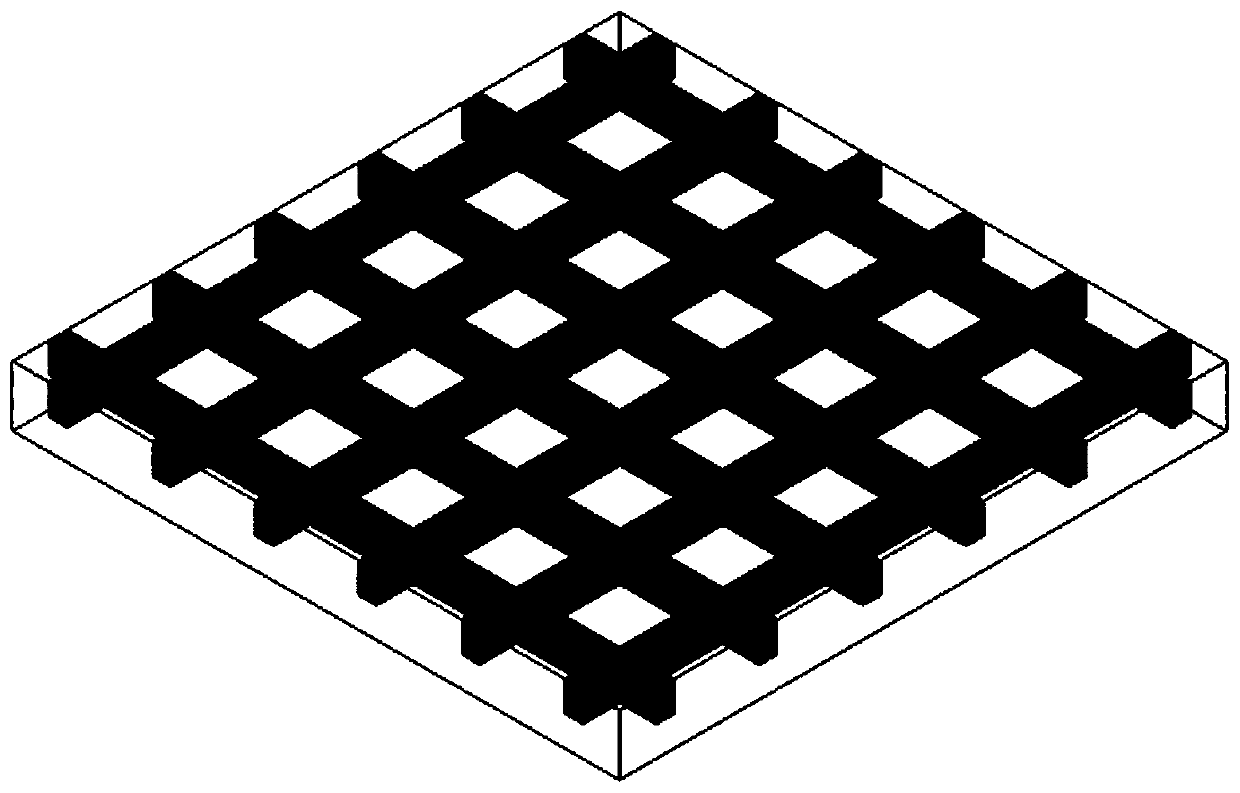

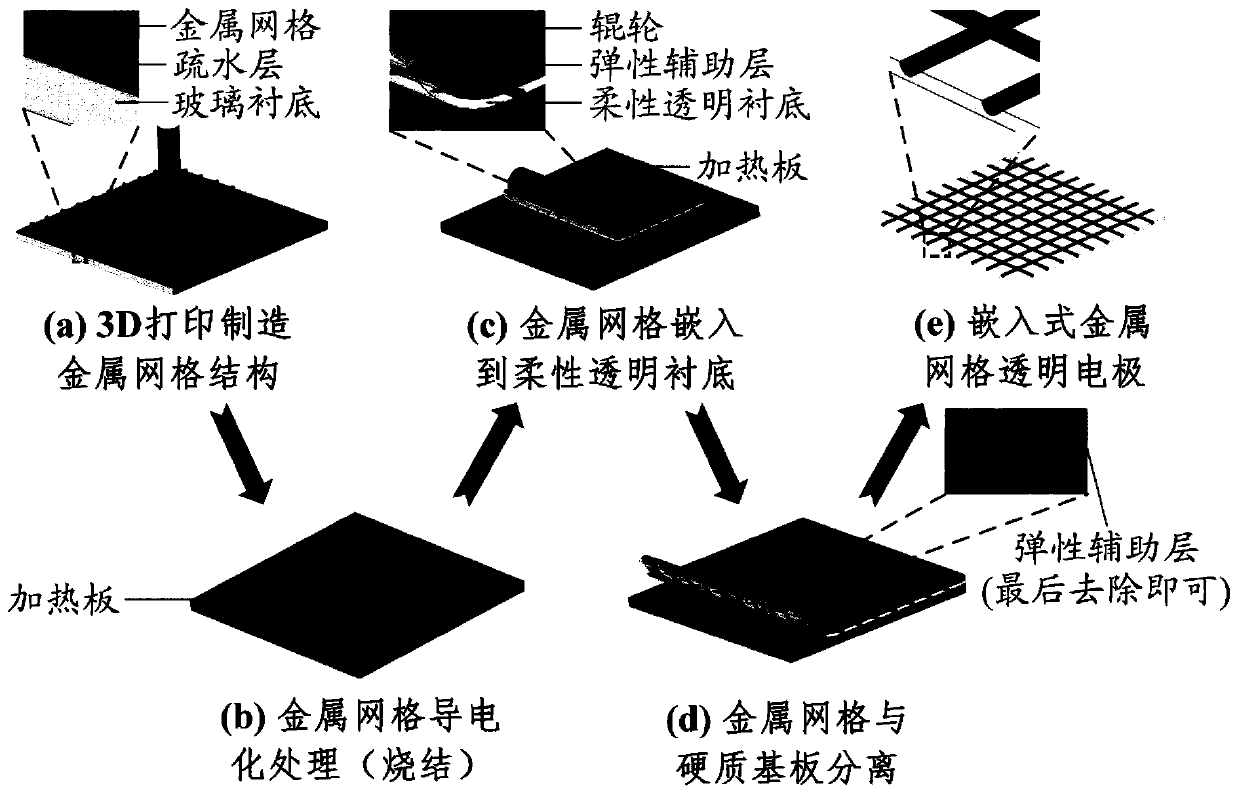

Manufacturing method and application of embedded metal grid flexible transparent electrode

ActiveCN110021462AIncrease profitNo wasteAdditive manufacturing apparatusConductive layers on insulating-supportsHot stampingMicro nano

The invention belongs to the field of flexible transparent electrodes, and particularly relates to a manufacturing method and an application of an embedded metal grid flexible transparent electrode. The method comprises the following steps: 1) by use of an electric field driven spray deposition micro-nano 3D printing technology, a metal grid transparent electrode is directly printed on a hard substrate; 2) conductive treatment is carried out on a printed metal grid structure by adopting a sintering process so as to realize conductive treatment of a metal grid; 3) a flexible transparent substrate and the hard substrate are heated to a set temperature, and a hot stamping process is adopted for completely embedding the metal grid structure on the hard substrate into the flexible transparent substrate; and 4) the metal grid which is completely embedded into the flexible transparent substrate is separated from the hard substrate to obtain the embedded metal grid flexible transparent electrode. According to the method, the electric field driven spray deposition micro-nano 3D printing technology is combined with the roller pair plane hot stamping technology to realize efficient and low-cost batch manufacturing of the large-sized embedded metal grid flexible transparent electrode; and the prepared transparent electrode also has excellent square resistance and light transmittance.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

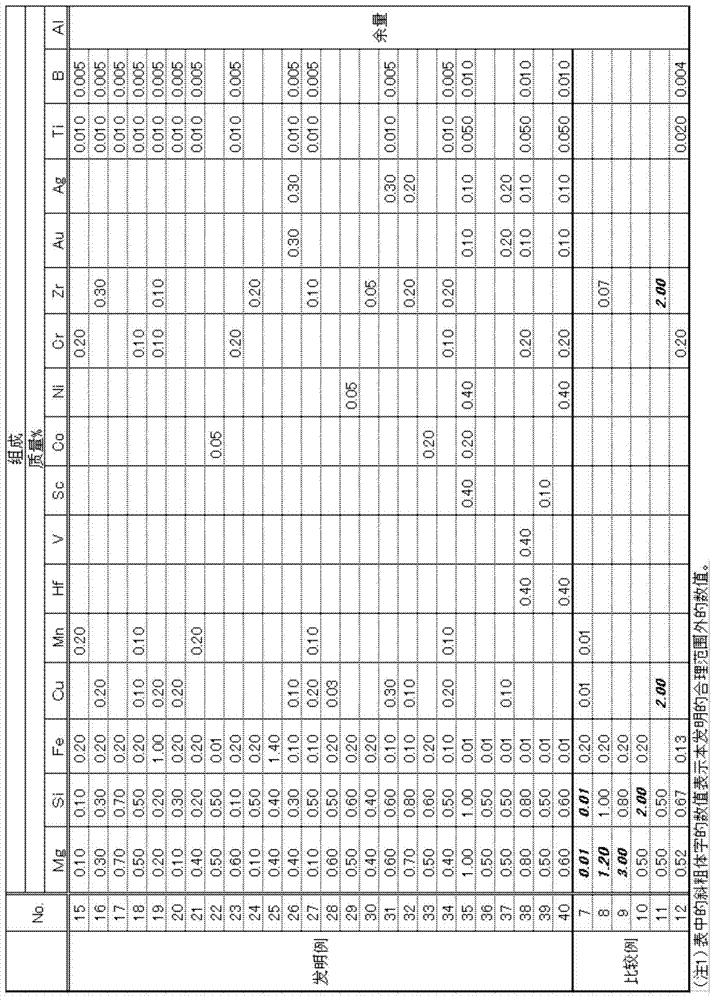

Aluminum alloy conductor, alum1inum alloy stranded wire, sheathed wire, wire harness, and method for manufacturing aluminum alloy conductor

ActiveCN104781431AShock resistantImproved bending fatigue resistancePlastic/resin/waxes insulatorsSingle bars/rods/wires/strips conductorsHigh conductivityElectrical resistivity and conductivity

Owner:FURUKAWA ELECTRIC CO LTD +1

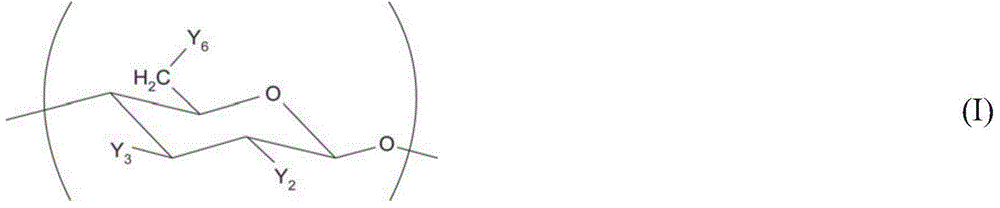

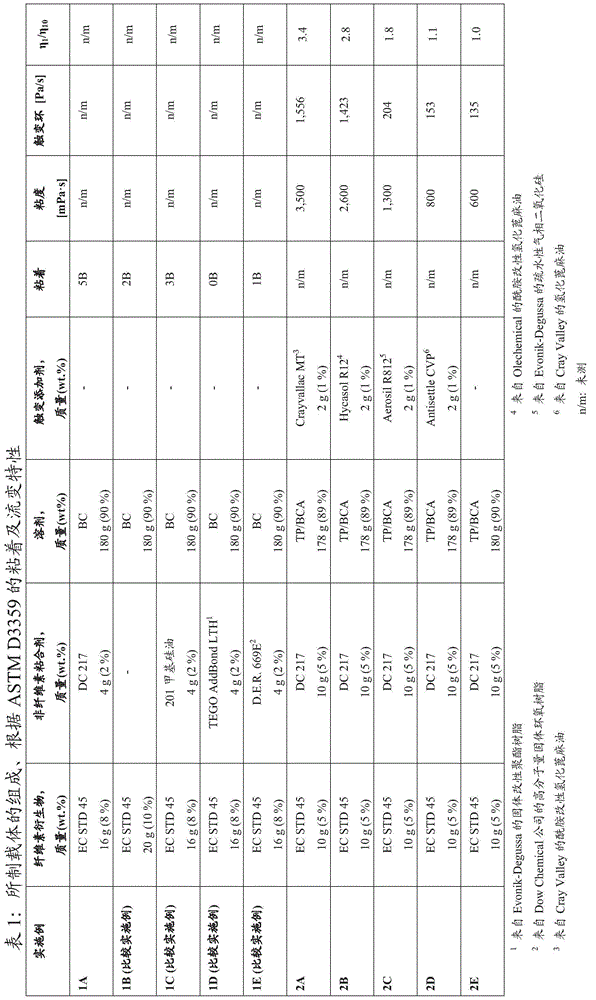

Conductive composition

InactiveCN104981911AExcellent adhesionGood dispersionApparatus for heat treatmentNon-conductive material with dispersed conductive materialParticulatesGlass particle

Disclosed is a conductive composition useful for the preparation of electrically conductive structures on a substrate comprising a plurality of metal particles, a plurality of glass particles and a vehicle comprising at least one cellulose derivative and at least one solid organopolysiloxane resin dissolved in a mutual organic solvent. The solid organopolysiloxane resin acts as adhesion promoter and assists in stably dispersing the metal and glass particles to avoid an agglomeration of such particles without degrading the rheological properties. From such conductive compositions uniform well adherent electrically conductive structures essentially free from defects in the form of cracks, bubbles or coarse particulates can be prepared on dielectric or semiconductor substrates such as silicon wafers in an efficient and cost-saving manner e.g. by screen printing, drying and sintering while inducing only low warping of the substrate. These characteristics render said conductive compositions particularly useful for the fabrication of electrodes of a semiconductor solar cell helping to increase the cell conversion efficiency.

Owner:NUTRITION & BIOSCIENCES USA 1 LLC

Copper alloy wire, copper alloy stranded wire, coated electric wire, wire harness and manufacturing method of copper alloy wire

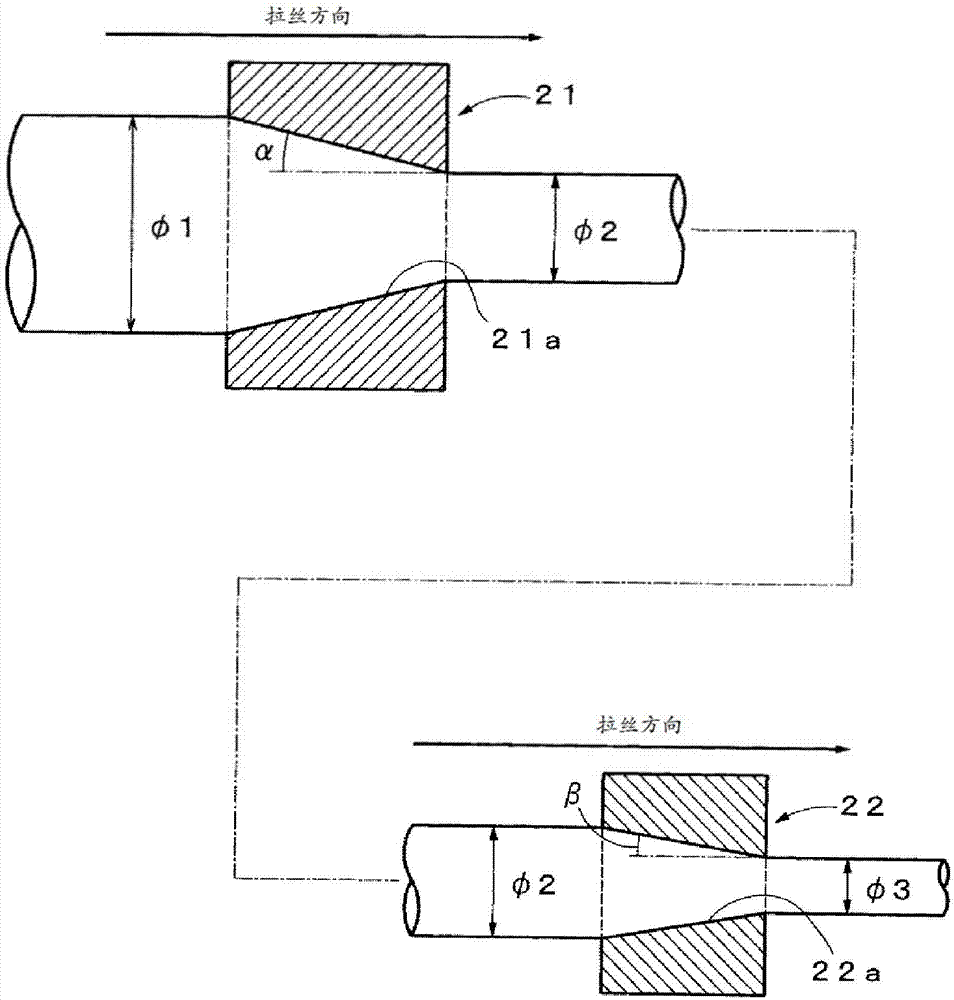

InactiveCN105705665ASuppresses reduction in wire drawing workabilitySuppresses conductivity dropSingle bars/rods/wires/strips conductorsApparatus for heat treatmentElectrical conductorMetallurgy

The invention provides a copper alloy wire, a copper alloy stranded wire, a coated electric wire, a wire harness and a manufacturing method of the copper alloy wire. This copper alloy wire used as the conductor in a wire for use in vehicles contains 0.4-2.5 mass% Fe, 0.01-1.0 mass% Ti, and a total of 0.01-2.0 mass% of one or more species selected from Mg, Sn, Ag, Ni, In, Zn, Cr, Al and P, the remainder being Cu and unavoidable impurities. The O content is preferably 20ppm or less. The tensile strength is preferably 450MPa or greater. The element wire stretchability is preferably 5% or greater. The conductivity is preferably 62% IACS or greater.

Owner:AUTONETWORKS TECH LTD +2

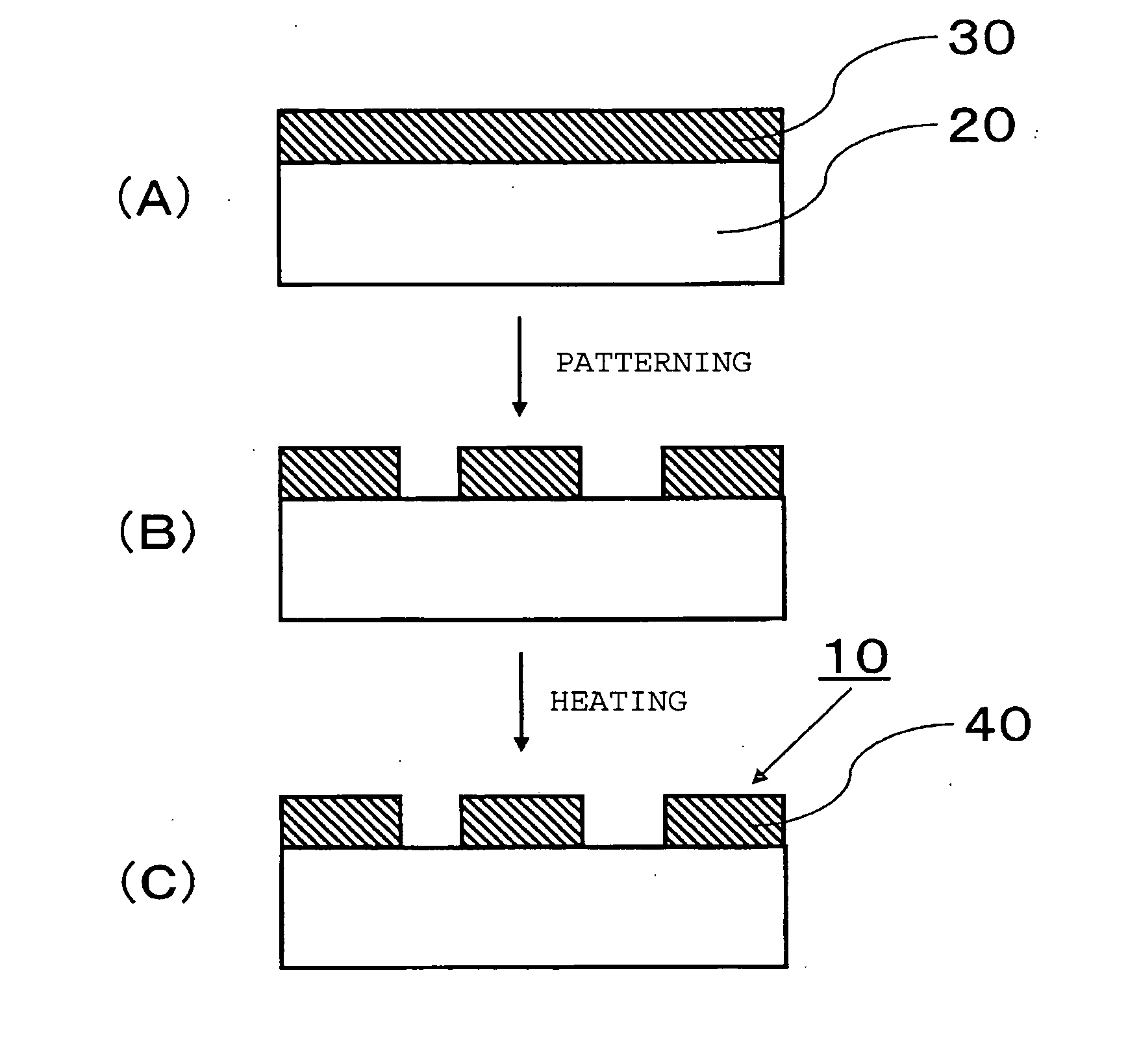

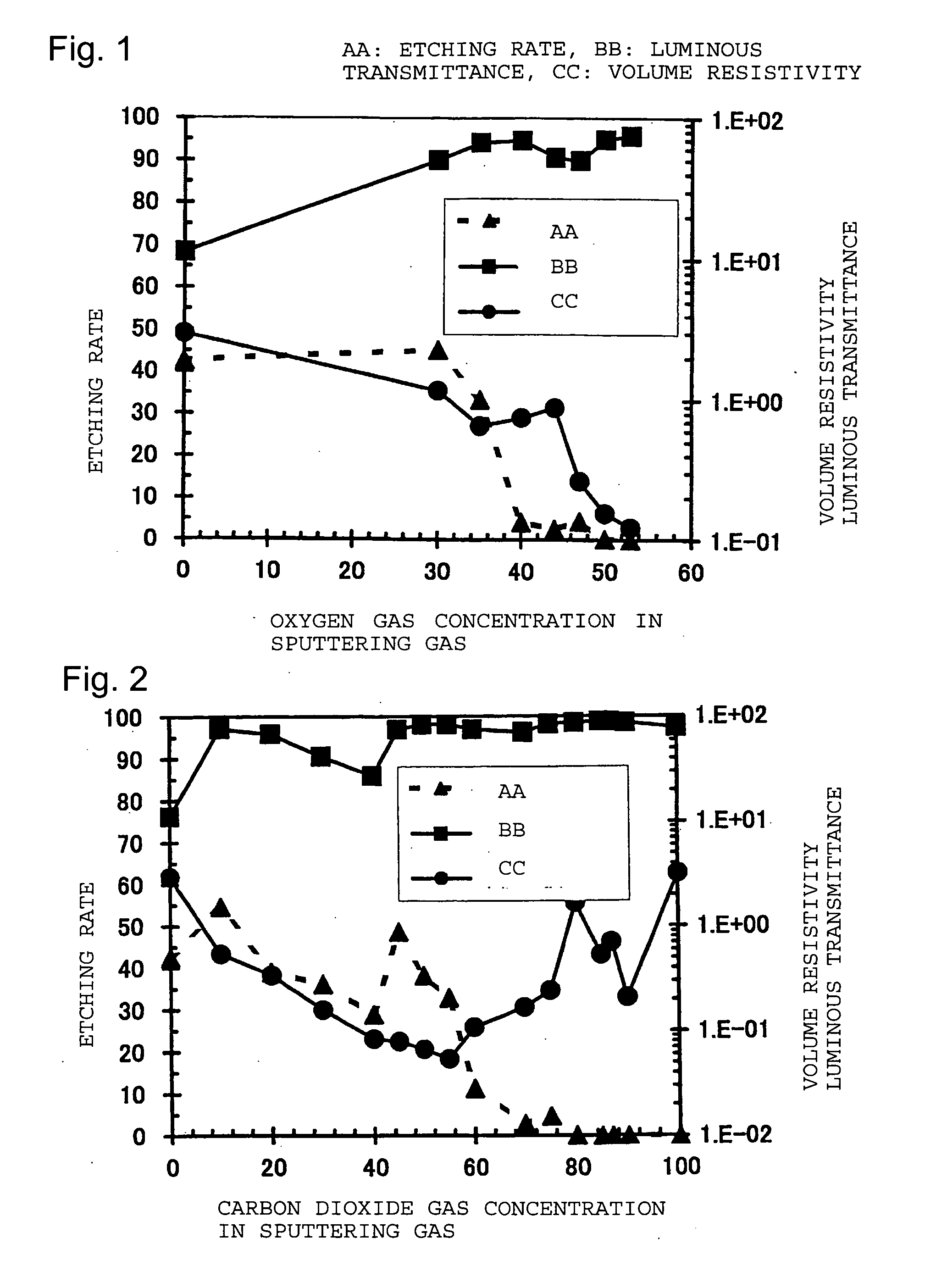

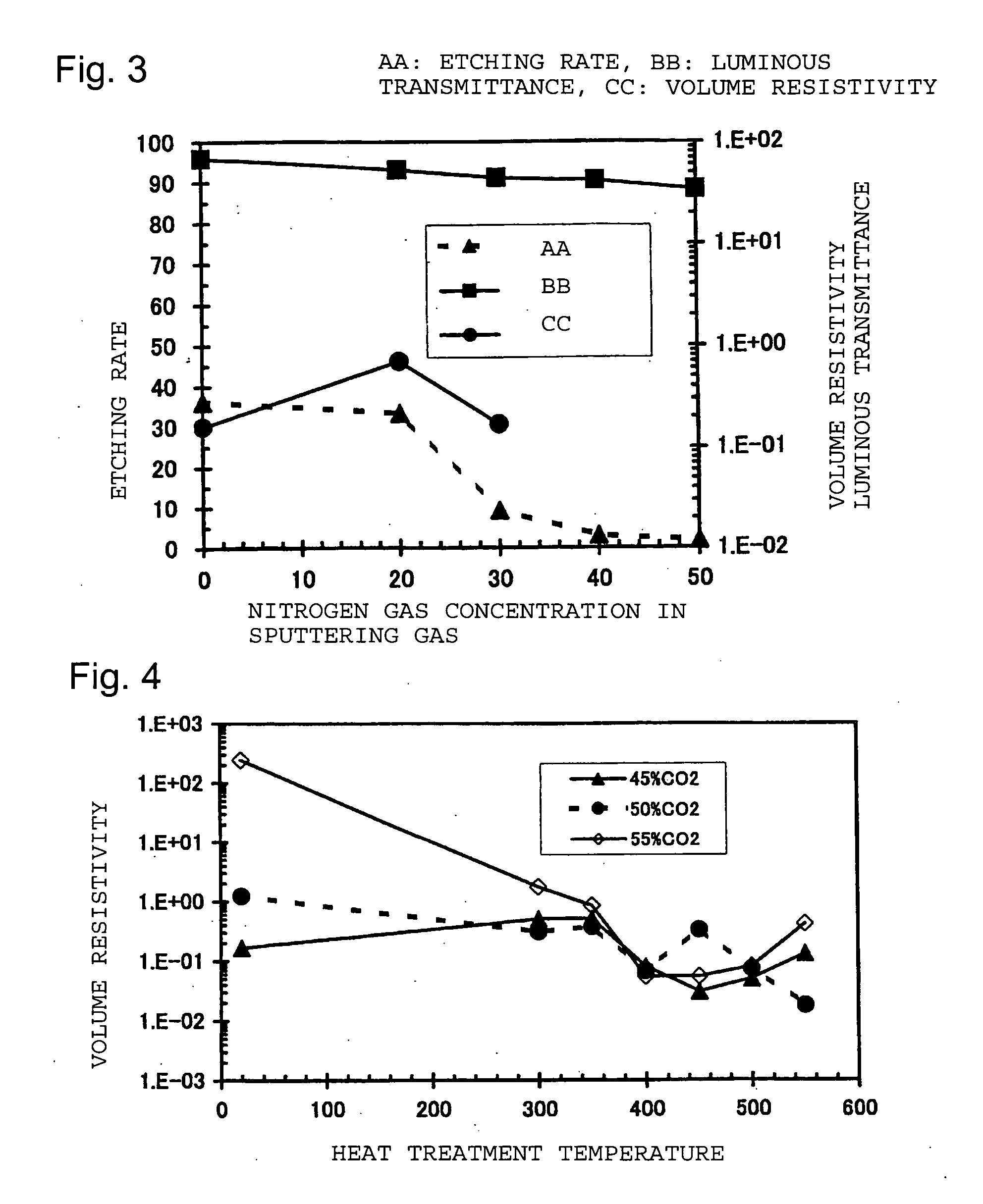

Process for producing transparent electrode

InactiveUS20060270209A1Low costImprove conductivityConductive layers on insulating-supportsGas-filled discharge tubesOptoelectronicsHeat treated

To provide a process for producing a transparent electrode comprising a tin oxide film which can readily be patterned, which can be realized at a low cost, and which has low resistivity and is excellent in transparency. A process for producing a transparent electrode having a patterned tin oxide film formed on a substrate, which comprises a step of forming a tin oxide film having light absorption characteristics on a substrate, a patterning step of removing part of the tin oxide film having light absorption characteristics, and a step of subjecting the patterned tin oxide film having light absorption characteristics to heat treatment to obtain a tin oxide film.

Owner:ASAHI GLASS CO LTD

A production method of high-strength large-elongation aluminum-clad steel wire

InactiveCN108986989AChange heat treatment temperatureHigh tensile strengthSingle bars/rods/wires/strips conductorsApparatus for heat treatmentWire rodHigh carbon

The invention relates to a production method of high-strength large-elongation aluminum-clad steel wire, comprising the following steps: 1) hot-drawing high-carbon steel wire rod to different wire diameters through cold drawing; 2) carry out lead bath quenching treatment on that steel wire, and carry out on-line pickling and rinsing to obtain a pretreated steel wire; 3) uniformly cover an outer lay of that pretreated steel wire with a layer of aluminum to form a cladding blank; 4) that coat blank is drawn into a super-high-strength aluminum clad steel wire semi-finished product through multiple passes of a bimetal synchronous deformation wire draw machine; 5) age that semi-finished product of the high-strength aluminum-clad steel wire through a high-temperature box. The method of the invention changes the traditional lead bath heat treatment temperature, The tensile strength of Al-clad steel wire is increased by multi-pass synchronous deformation and drawing with small compression ratio, and the elongation of Al-clad steel wire is increased by high temperature aging treatment. The ultimate tensile strength >= 1700 MPa, elongation >= 3. 0%, and other indexes are in accordance with the requirements of Al-clad steel GB / T17937-2009 standard, thereby meeting the requirements of high strength and high elongation and meeting the application requirements.

Owner:HUBEI LONGSKY COMM TECH

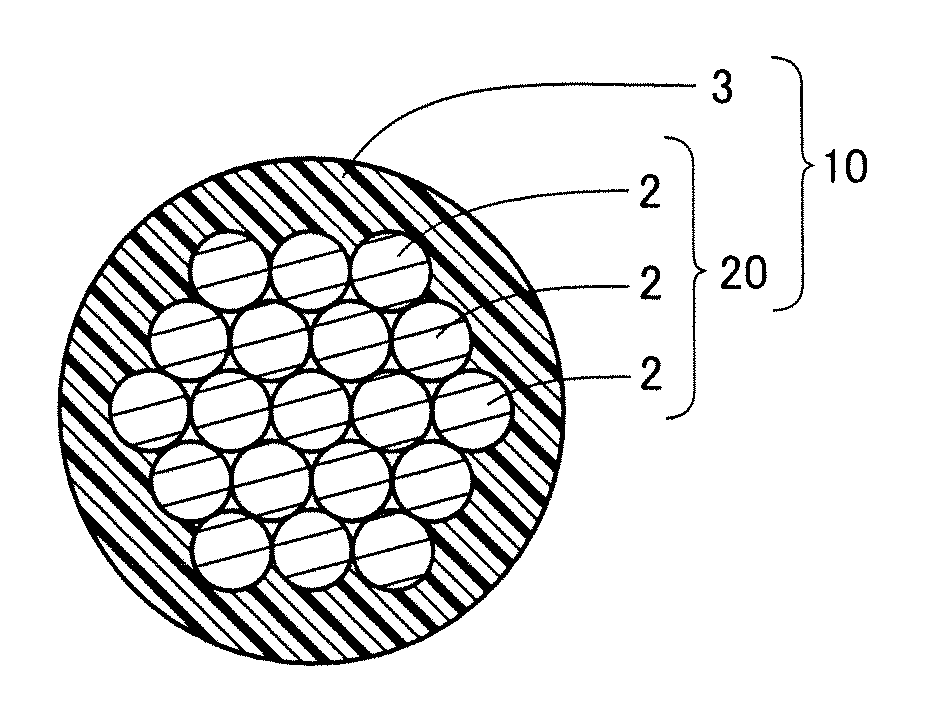

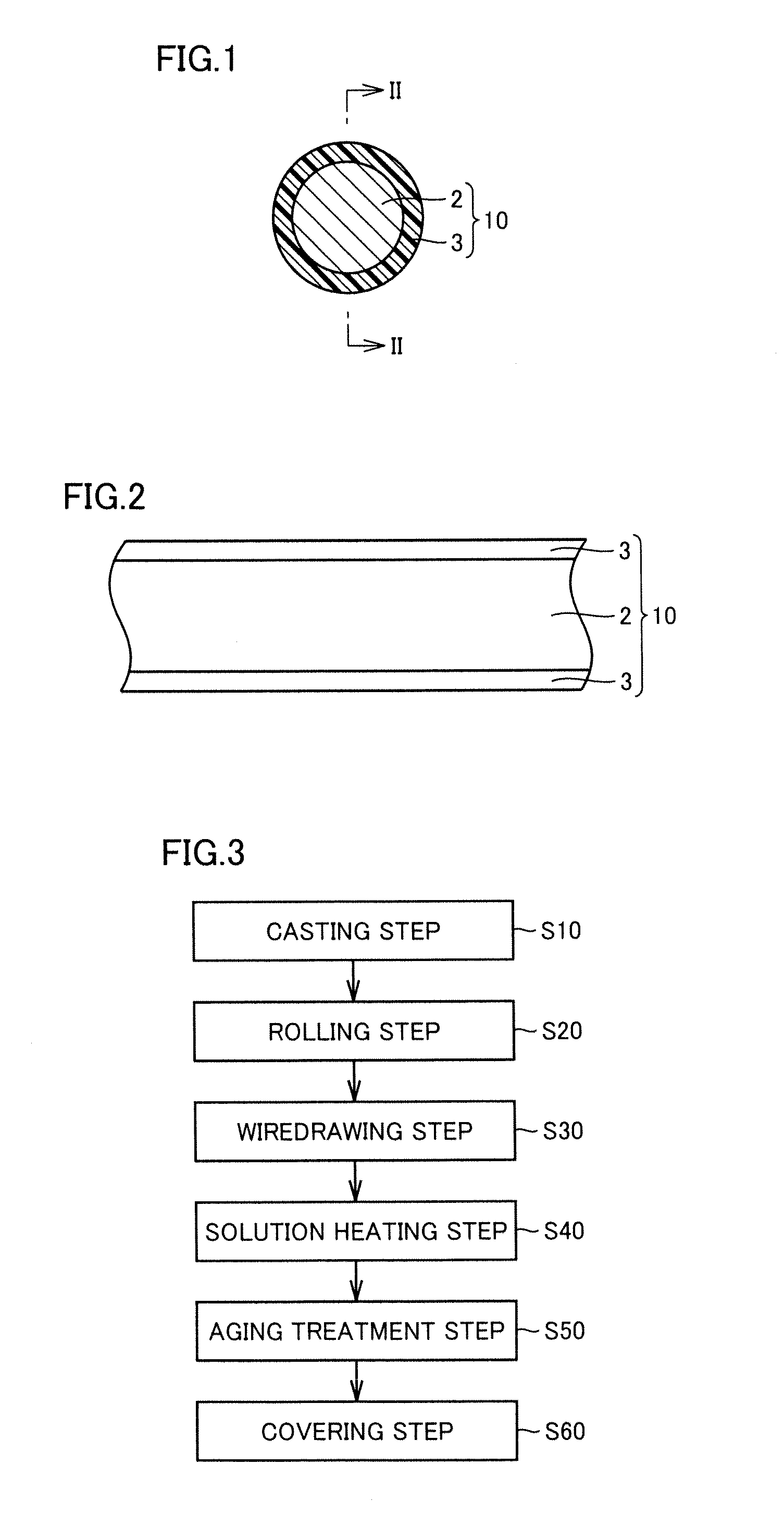

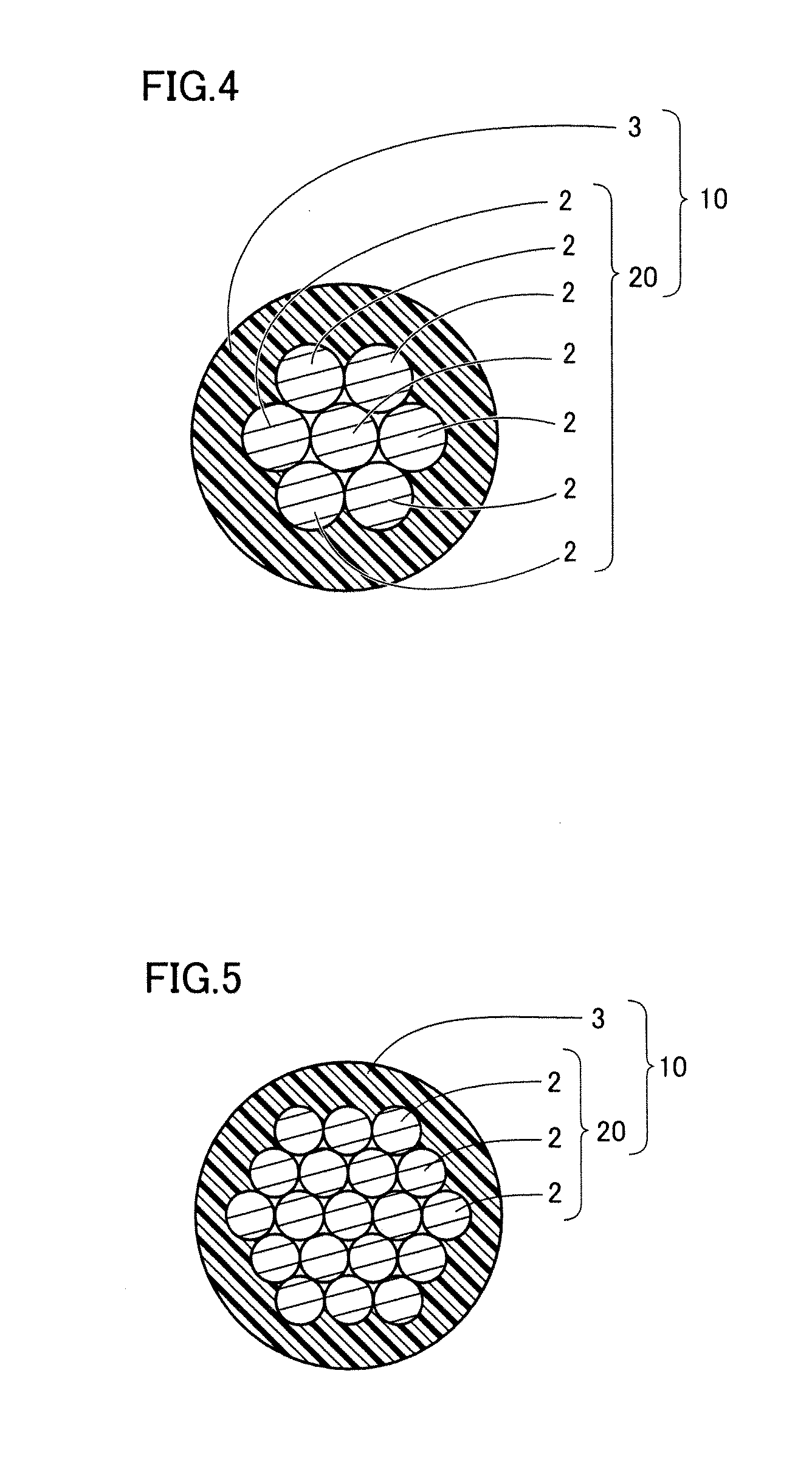

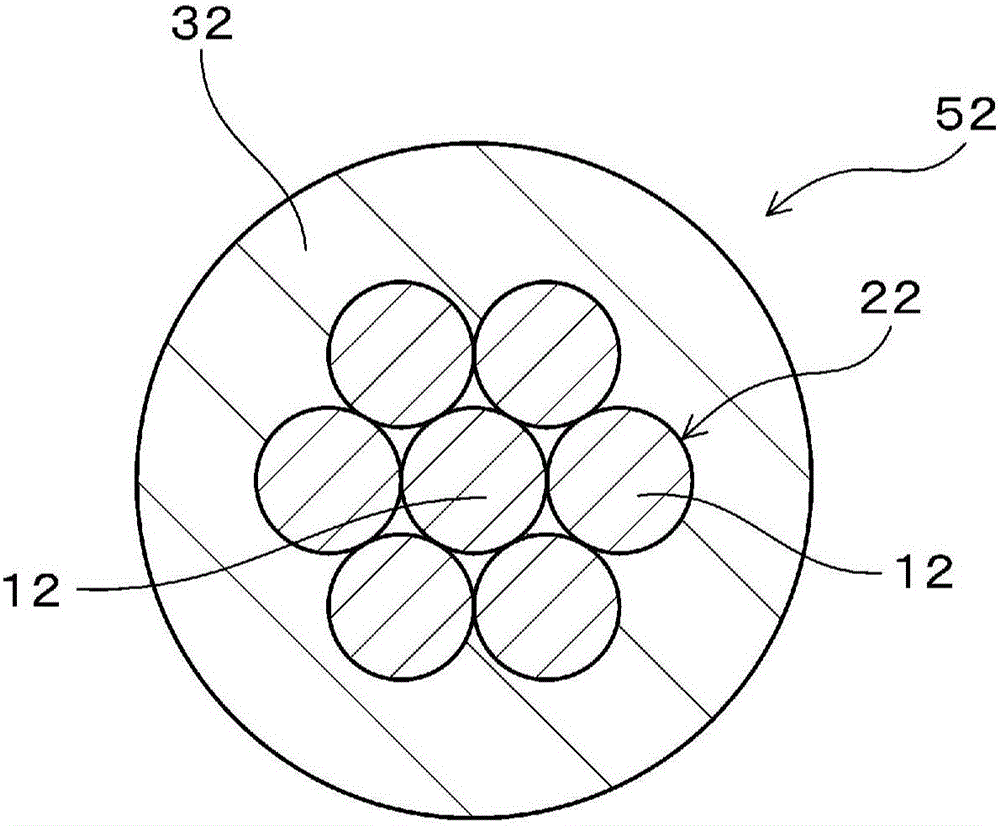

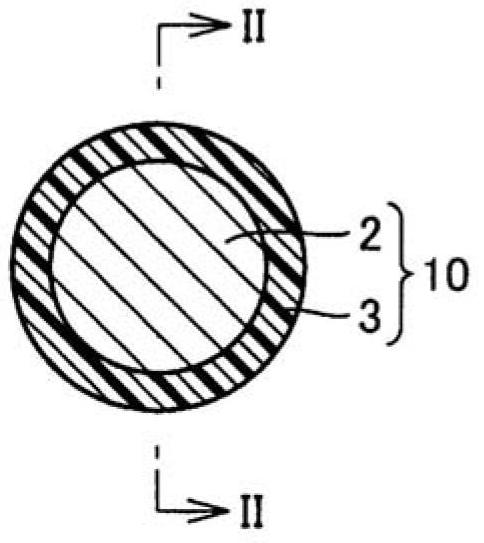

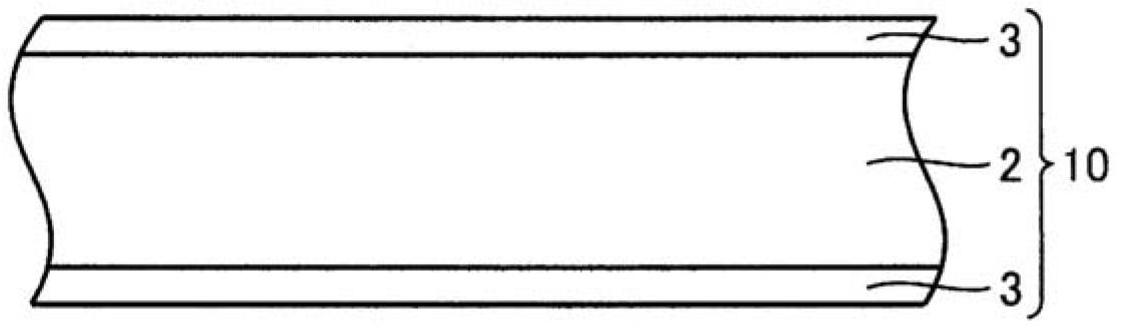

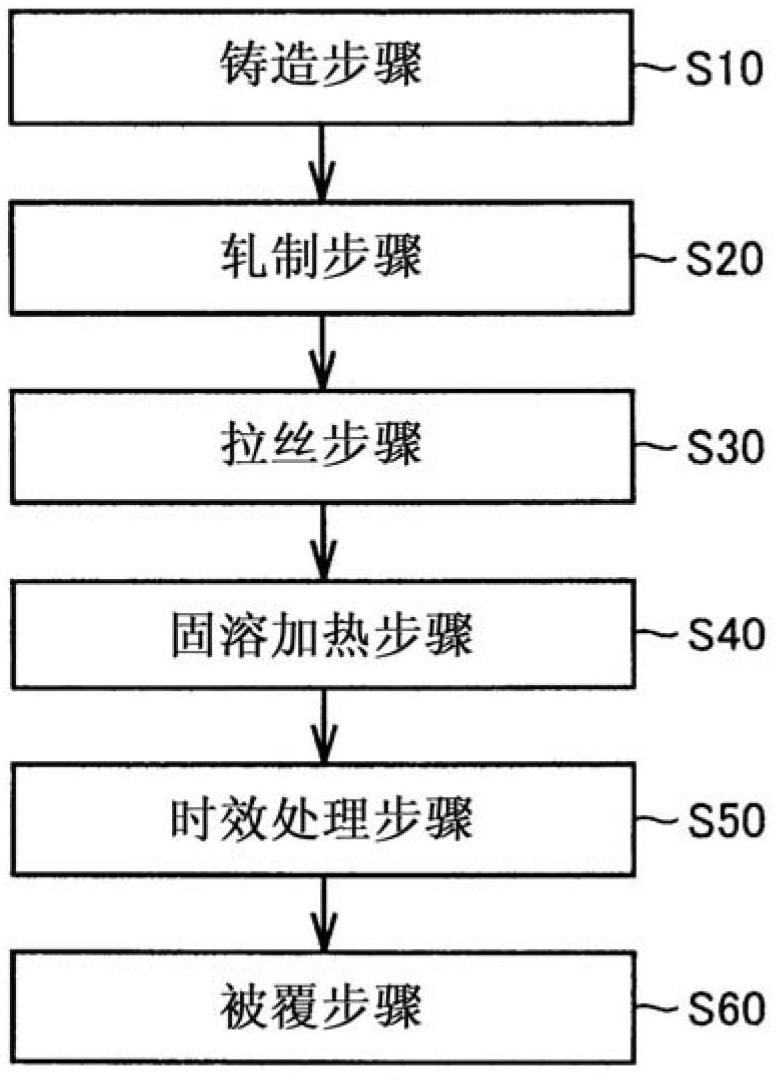

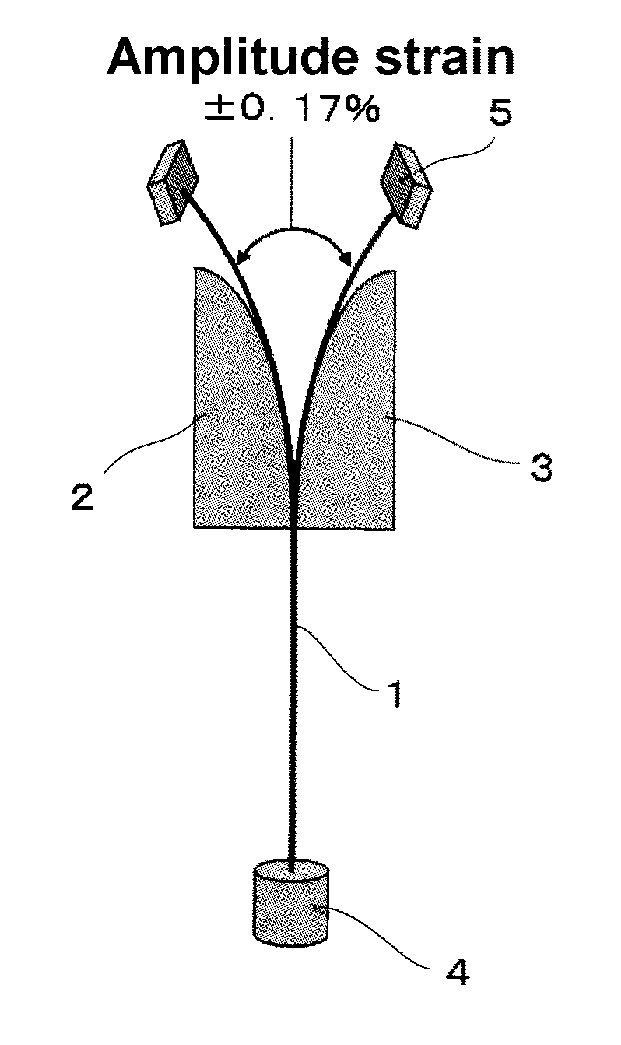

Aluminum alloy wire

ActiveCN102695813AGood bending propertiesGood strength propertiesSingle bars/rods/wires/strips conductorsApparatus for heat treatmentSolid solutionUltimate tensile strength

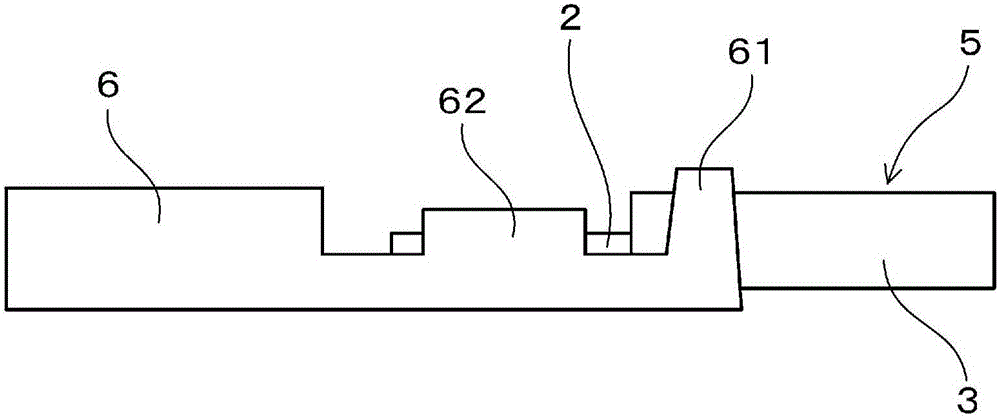

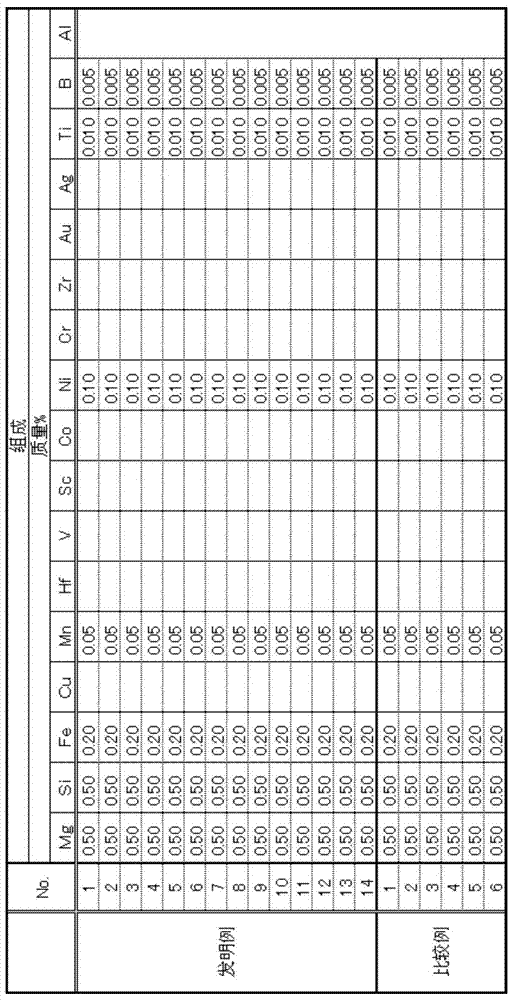

Provided are an aluminum alloy wire (2) having excellent flexing characteristics, strength, and electrical conductivity, a twisted aluminum alloy wire, a covered electric wire (10) including the alloy wire or twisted wire, a wire harness including the covered electric wire (10), a process for producing the aluminum alloy wire, and a process for producing the covered electric wire (10). The aluminum alloy wire (2) contains, in mass%, 0.1-1.5% Mg, 0.03-2.0% Si, and 0.05-0.5% Cu, the remainder comprising Al and impurities. The aluminum alloy wire (2) satisfies the relationship 0.8=Mg / Si (by mass)=3.5, and has a conductivity of 35-58 %IACS, a tensile strength of 150-400 MPa, and an elongation of 2% or more. This aluminum alloy wire (2) is produced through the steps of casting, rolling, wire drawing, and solution heat treatment in this order. By using the specific composition and by conducting a solution heat treatment after wire drawing to sufficiently bring the additional elements into a solid-solution state, the aluminum alloy wire (2) having excellent flexing characteristics can be obtained.

Owner:SUMITOMO ELECTRIC IND LTD +2

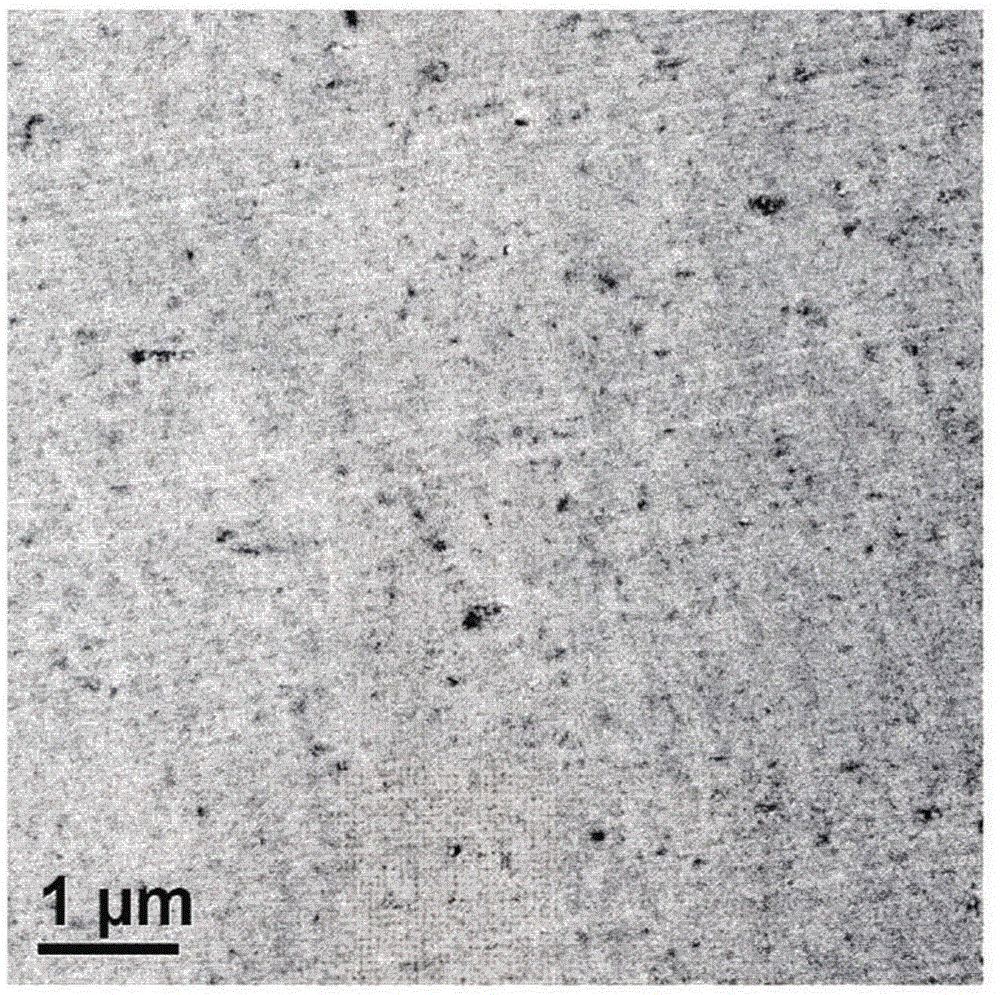

Aluminum alloy conductor and method of producing the same

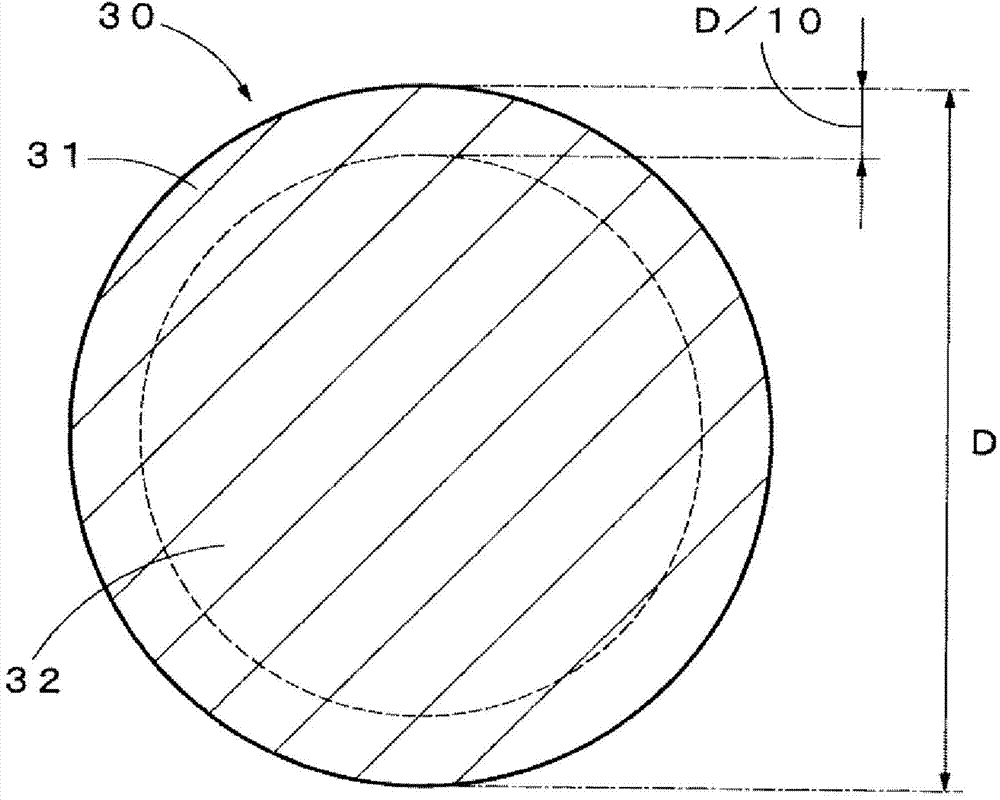

InactiveUS20130126055A1High resistance to bending fatigueImprove machinabilityApparatus for heat treatmentConductive materialElectrical conductorTin

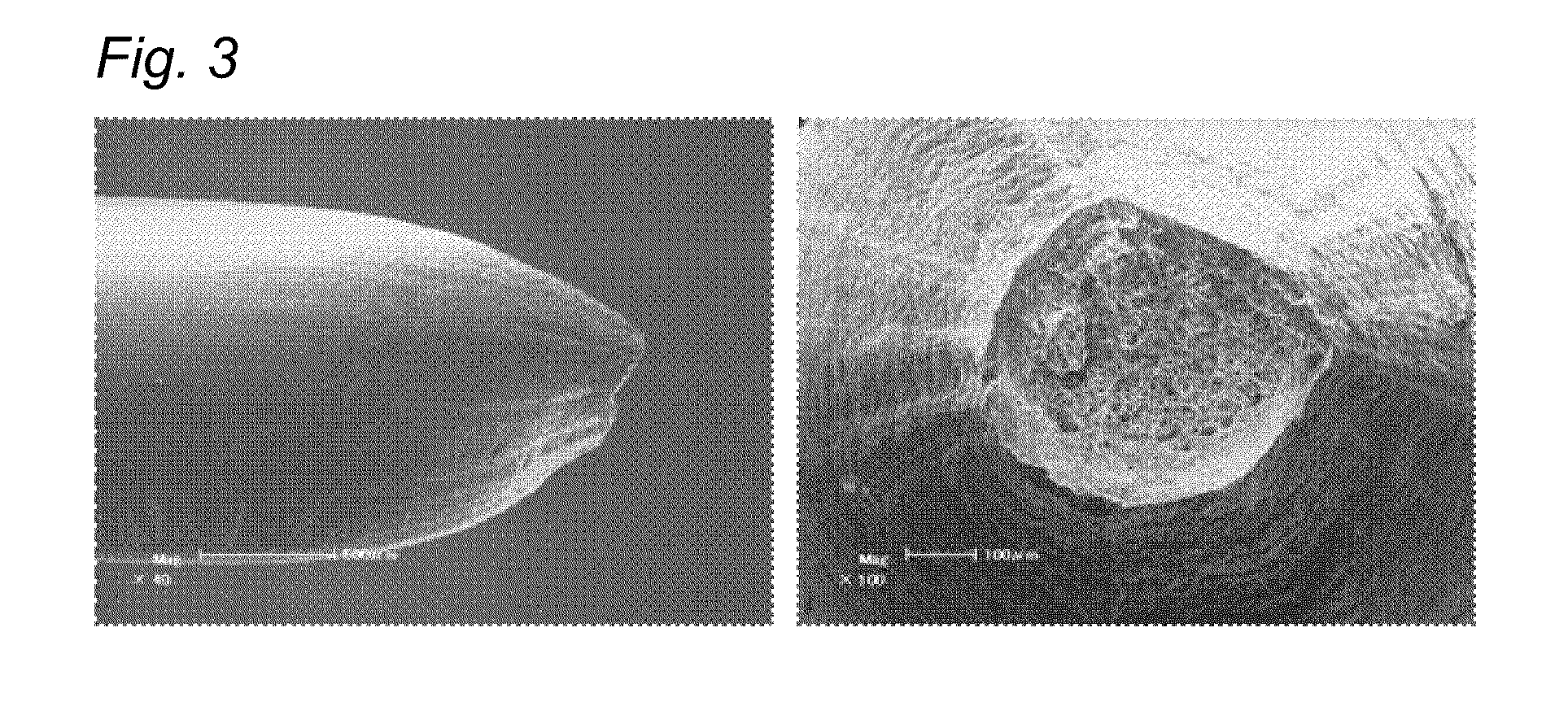

An aluminum alloy conductor, having a specific aluminum alloy composition of Al—Fe—Cu—Mg—Si—(TiN) or Al—Fe—(Cu / Mg / Si)—(TiN), in which, on a cross-section vertical to a wire-drawing direction, a grain size is 1 to 20 μm, and a distribution density of a second phase with a size of 10 to 200 nm is 1 to 102 particles / μm2; and a production method thereof.

Owner:FURUKAWA ELECTRIC CO LTD +1

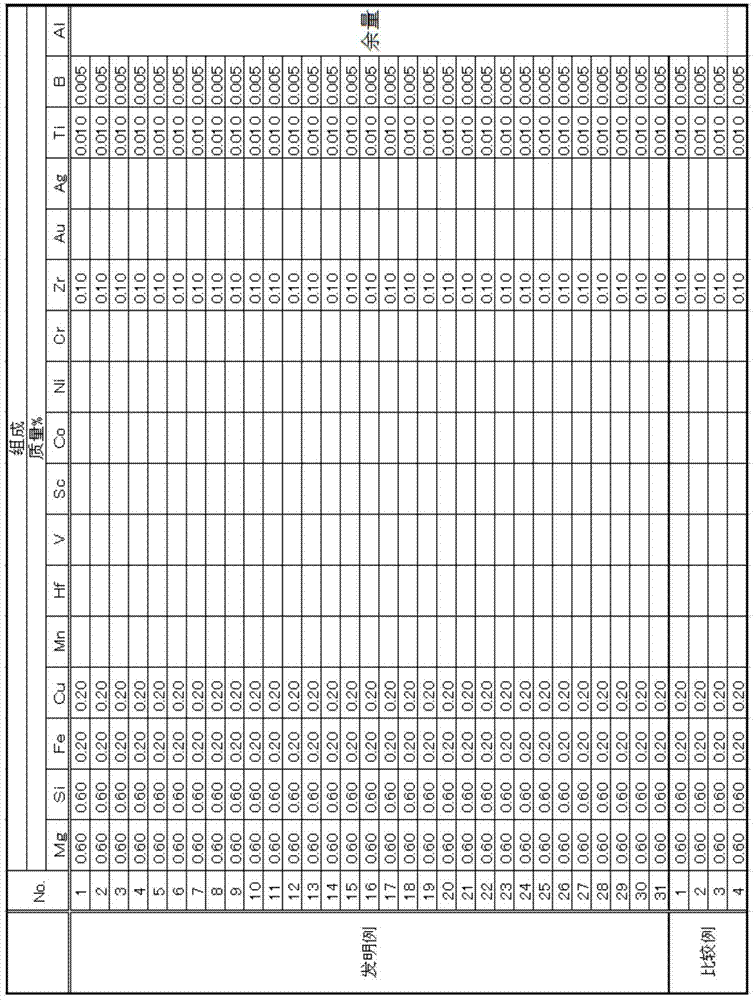

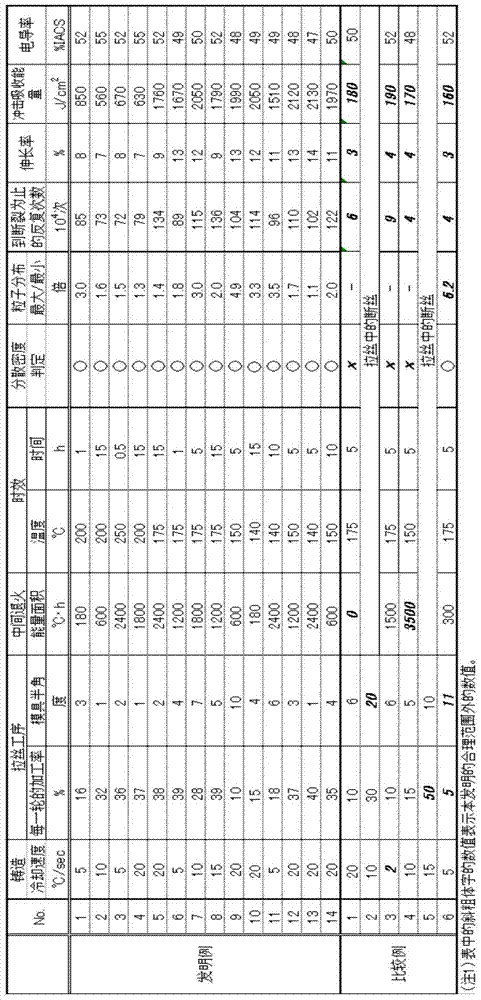

Aluminum alloy conductor, aluminum alloy stranded wire, sheathed wire, wire harness, and method for manufacturing aluminum alloy conductor

InactiveCN104781432AImproved bending fatigue resistanceImprove impact absorption performanceSingle bars/rods/wires/strips conductorsApparatus for heat treatmentElectrical resistivity and conductivityHigh conductivity

An aluminum alloy conductor having a high conductivity and a high bending fatigue resistance, and further achieving a high impact absorption property and a high elongation at the same time is provided. An aluminum alloy conductor of the present invention has a composition consisting of Mg: 0.10 mass% to 1.00 mass%, Si: 0.10 mass% to 1.00 mass%, Fe: 0.01 mass% to 1.40 mass%, Ti: 0.000 mass% to 0.100 mass%, B: 0.000 mass% to 0.030 mass%, Cu: 0.00 mass% to 1.00 mass%, Ag: 0.00 mass% to 0.50 mass%, Au: 0.00 mass% to 0.50 mass%, Mn: 0.00 mass% to 1.0 mass%, Cr: 0.00 mass% to 1.00 mass%, Zr: 0.00 mass% to 0.50 mass%, Hf: 0.00 mass% to 0.5 mass%, V: 0.00 mass% to 0.5 mass%, Sc: 0.00 mass% to 0.50 mass%, Ni: 0.00 mass% to 0.10 mass%, and the balance: Al and incidental impurities, wherein a dispersion density of compound particles having a particle size of 20 nm to 1000 nm is greater than or equal to 1 particle / µm 2 .

Owner:FURUKAWA ELECTRIC CO LTD +1

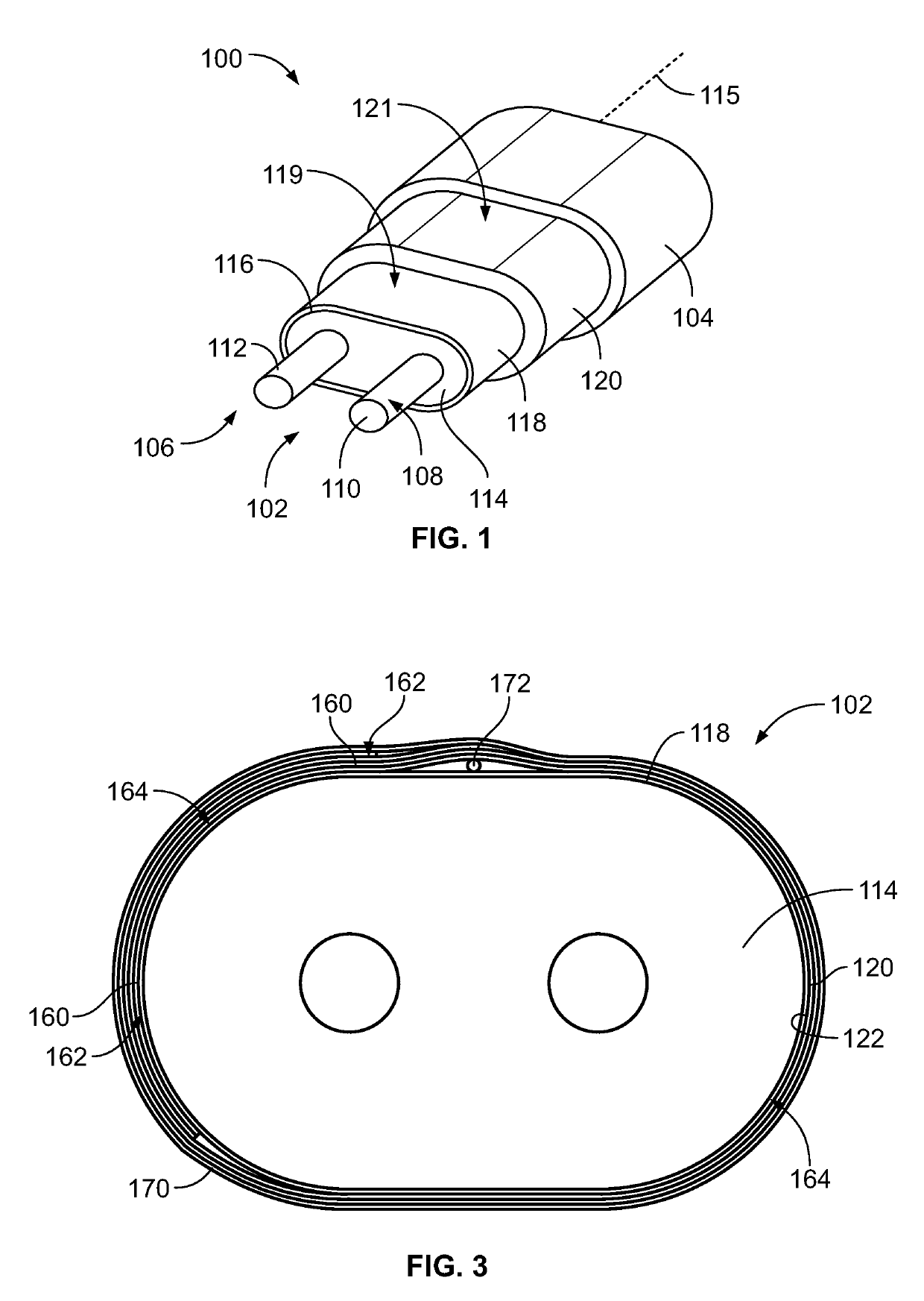

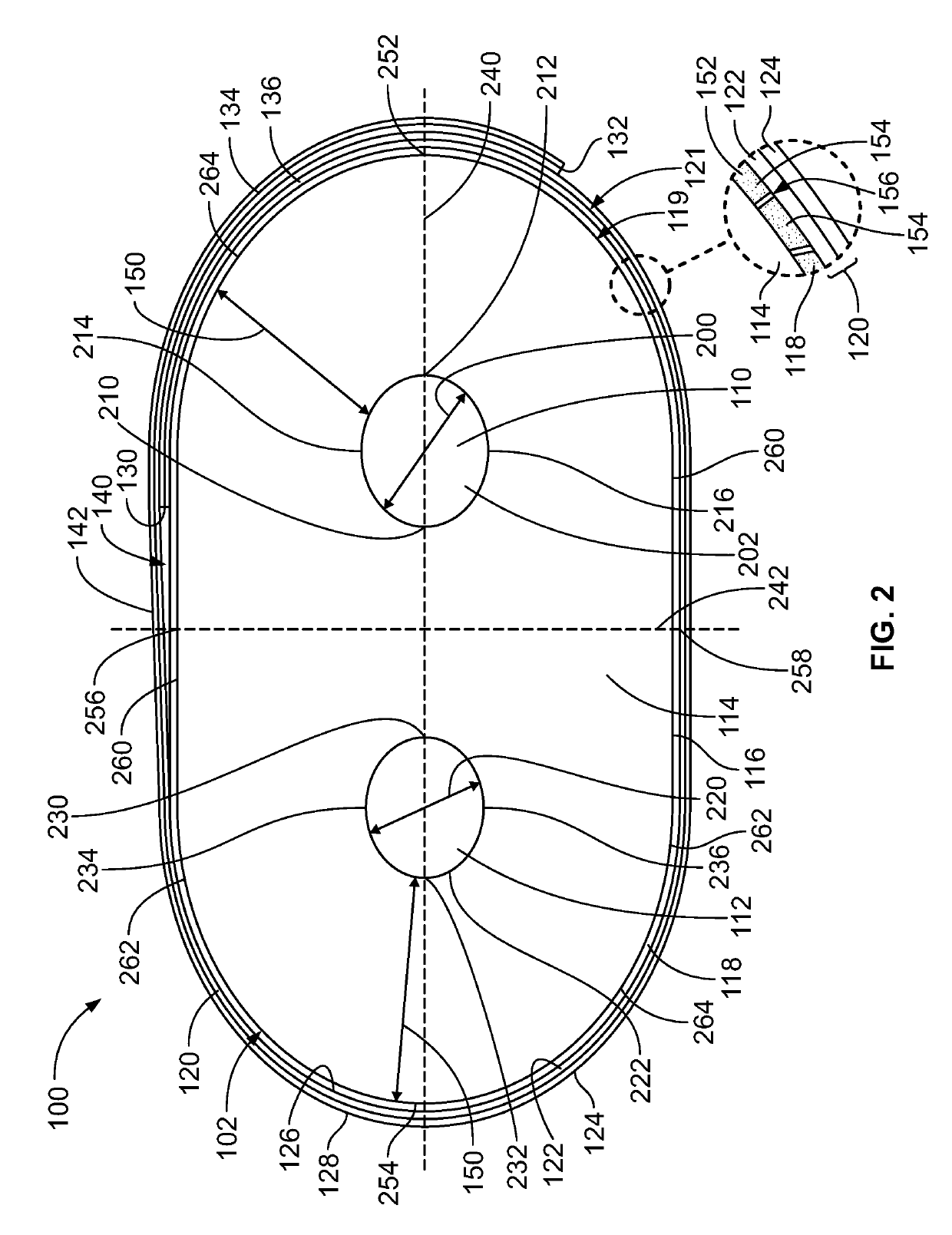

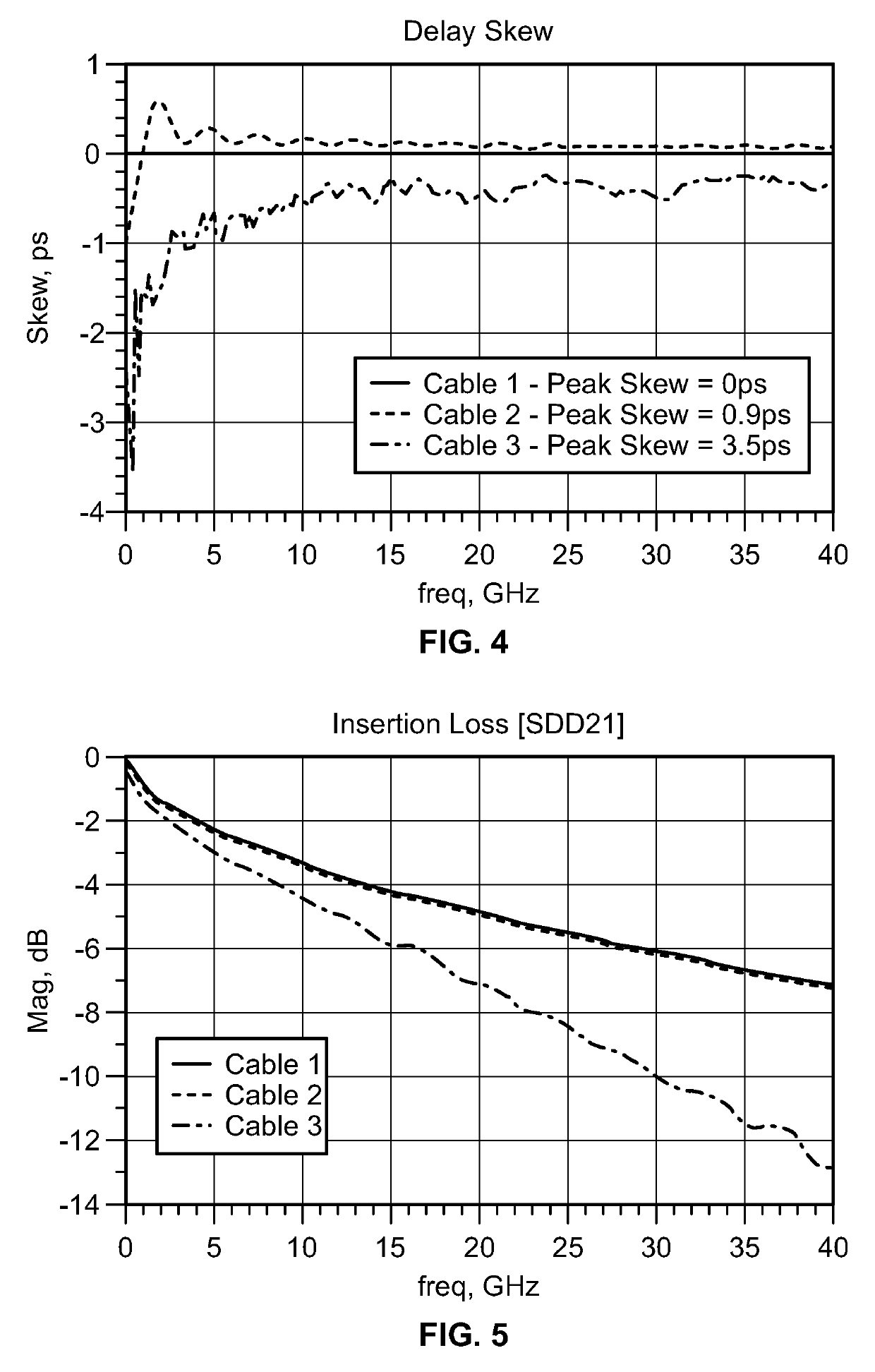

Electrical cable

ActiveUS20190318841A1Magnetic/electric field screeningApparatus for heat treatmentElectrical conductorEngineering

An electrical cable includes a conductor assembly having a first conductor, a second conductor and an insulator surrounding the first conductor and the second conductor. The insulator has an outer surface and extends along a longitudinal axis for a length of the electrical cable. The conductor assembly has a coating layer on the outer surface of the insulator being conductive defining an inner electrical shield of the electrical cable. A cable shield is wrapped around the conductor assembly and has an inner edge and an outer edge. The outer edge is wrapped over the inner edge to form a flap covering the inner edge and extending along the longitudinal axis. The cable shield engages the inner electrical shield and forms an outer electrical shield exterior of the inner electrical shield.

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

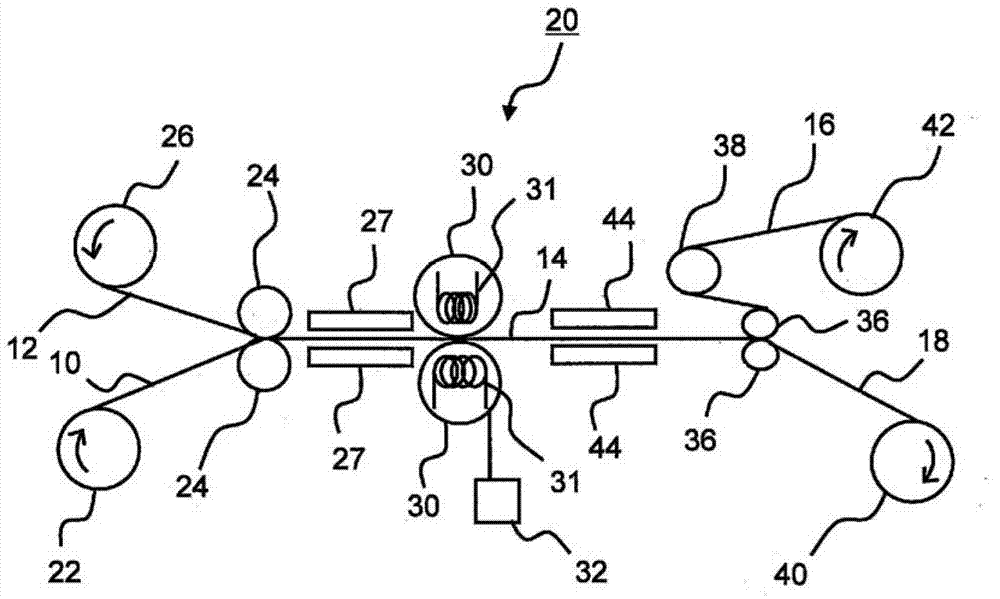

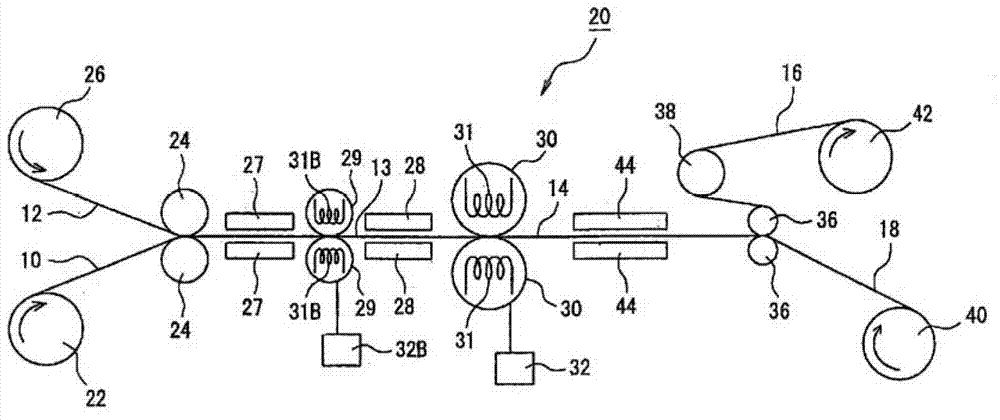

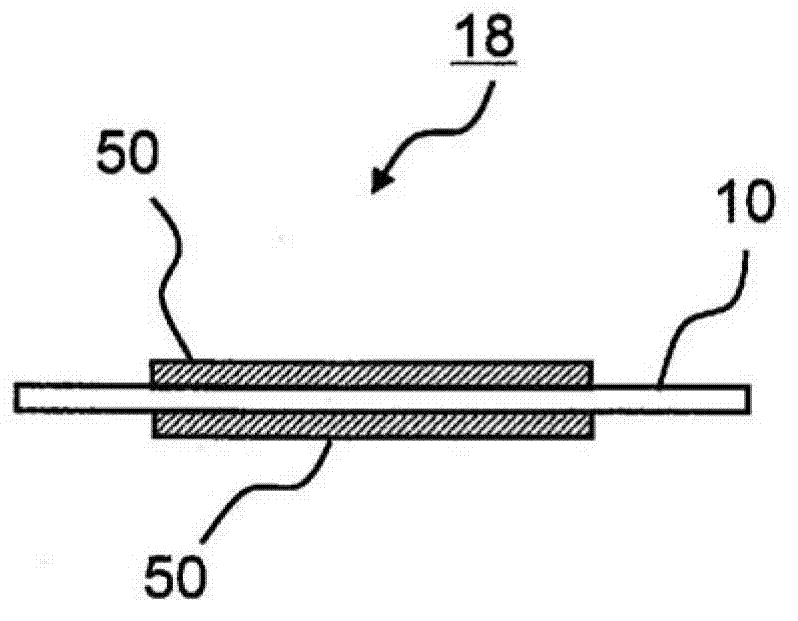

Apparatus for manufacturing membrane electrode assembly, and method for manufacturing membrane electrode assembly

InactiveCN102823041APrevent peelingHigh bonding strengthCell electrodesFinal product manufacturePolymer electrolytesPolymer chemistry

Disclosed is an apparatus for manufacturing a membrane electrode assembly, whereby a high-quality membrane electrode assembly, which has high adhesiveness between a solid polymer electrolyte membrane and a catalyst layer, and which does not have wrinkles, can be manufactured, while using a hot roll method. Also disclosed is a method for manufacturing the membrane electrode assembly. The apparatus for manufacturing a membrane electrode assembly is provided with: a preheating means, which preheats the solid polymer electrolyte membrane (10) and a catalyst layer supporting base material (12) that supports the catalyst layer on one surface of a transfer base material; a thermocompression bonding means, which forms a bonded member (14) by integrating the catalyst layer supporting base material (12) and the solid polymer electrolyte membrane (10) by applying heat and pressure; and a peeling means, which peels the transfer base material (16) from the bonded member (14).

Owner:TOPPAN INC

Preparation method for copper-niobium composite rod for Nb3Sn superconducting wire with high critical current density

ActiveCN107170526AReduce processing stepsImprove efficiencySuperconductors/hyperconductorsApparatus for heat treatmentThermal insulationNiobium

The invention discloses a preparation method for a copper-niobium composite rod for an Nb3Sn superconducting wire with high critical current density. The method comprises the following steps of firstly, processing an oxygen-free copper rod into an outer hexagonal inner-circle thin-wall copper pipe; secondly, placing an Nb rod into the hexagonal copper pipe, placing the hexagonal copper pipe into an oxygen-free copper sheath, placing the oxygen-free copper rod at the central zone of the oxygen-free copper sheath and sealing to obtain a CuNb composite sheath; and lastly, carrying out heating, thermal insulation and extrusion on the CuNb composite sheath to obtain the CuNb composite rod. According to the method, the Nb rod with the fine initial grain size is placed into the hexagonal thin-wall copper pipe to carry out assembly, welding and extrusion to obtain the CuNb composite rod, so that the processing of a CuNb single rod is removed, and the problems of line breakage and core breakage after stretch in the subsequent processing process of the superconducting wire, which are caused by uneven texture after extrusion due to the coarse initial grain size of an Nb ingot, are solved, the efficiency is improved and the quality risk of the processing process is reduced.

Owner:西安聚能超导线材科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com