Preparation method for copper-niobium composite rod for Nb3Sn superconducting wire with high critical current density

A current density and superconducting wire technology, which is applied in the usage of superconductor elements, cable/conductor manufacturing, superconducting devices, etc., can solve the problems of stretching broken wires, uneven structure of Nb core wires, etc., to improve efficiency, The effect of reducing quality risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] A kind of high critical current density Nb of the present invention 3 A method for preparing a CuNb composite rod for a Sn superconducting wire, specifically comprising the following steps:

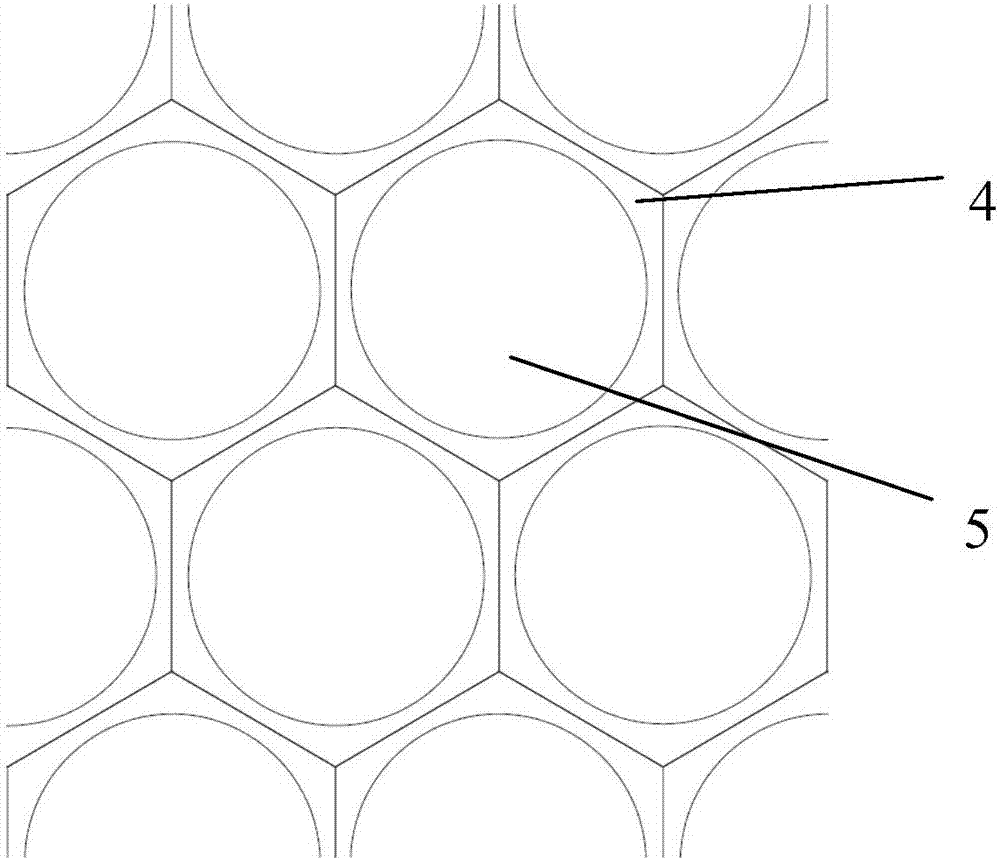

[0020] Step 1, the oxygen-free copper rod is obtained by extrusion, drawing, sawing and other processes to obtain an outer hexagonal inner circle thin-walled copper tube with a length of 300mm-800mm, an opposite side size of 5mm-15mm, and an inner hole diameter of Φ4mm-Φ14mm ;

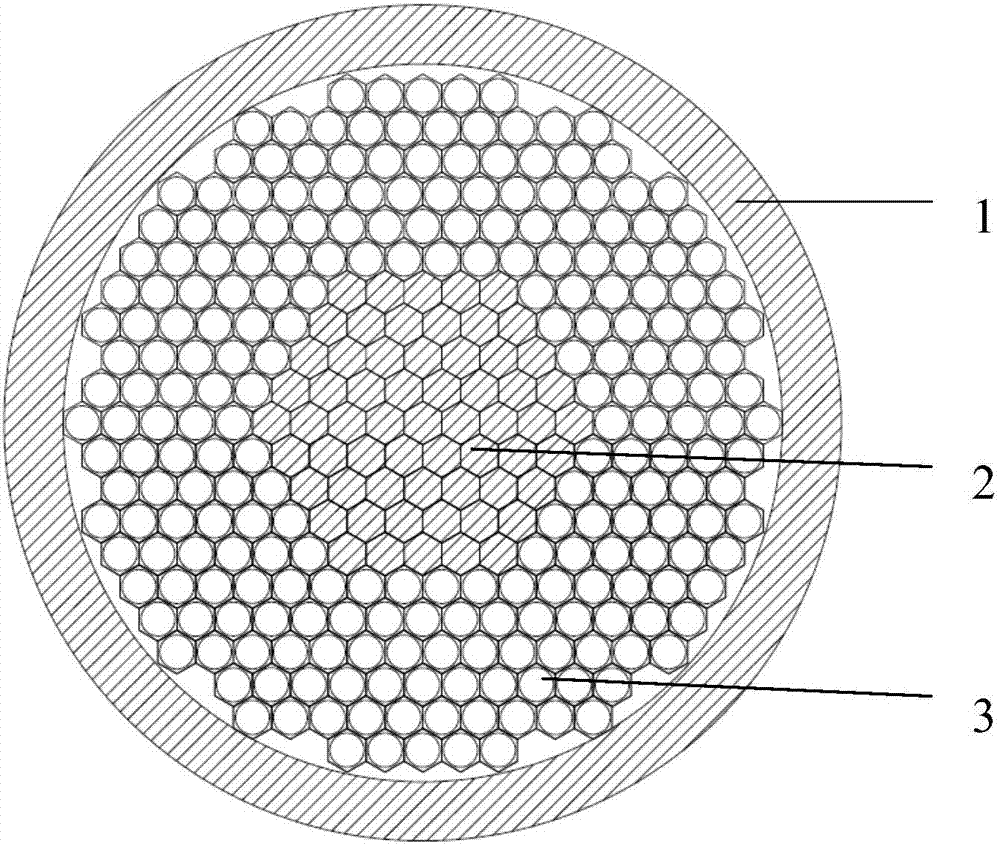

[0021] Step 2, put Nb rods into the hexagonal copper tube obtained in step 1 after cleaning, the number is 150-800, and then stack them in a hexagonal arrangement and put them into an oxygen-free copper sheath with a diameter of Φ150mm~Φ300mm , the oxygen-free copper rod with the same specifications as the hexagonal copper tube is placed in the central area, and the copper caps are added to the two ends and sealed with electron beams to obtain a CuNb composite sheath; the obtained CuNb composite sheath str...

Embodiment 1

[0025] Step 1, the oxygen-free copper rod is obtained by extruding, drawing, sawing and other processes to obtain an outer hexagonal inner circle thin-walled copper tube with a length of 300mm, an opposite side size of 5mm, and an inner hole diameter of Φ4mm;

[0026] Step 2, put the Nb rods into the hexagonal copper tubes obtained in step 1 after cleaning, the number is 150, and then stack them in a hexagonal arrangement and put them into the oxygen-free copper sheath, the diameter of the sheath is Φ150mm, and the central area Put the oxygen-free copper rods with the same specifications as the hexagonal copper tubes, the number of oxygen-free copper rods is 100, add copper caps at both ends and seal with electron beams to obtain a CuNb composite sheath;

[0027] In step 3, the CuNb composite sheath obtained in step 2 is heated to 580° C., kept for 2 hours, and then extruded to obtain a CuNb composite rod.

Embodiment 2

[0029] Step 1, the oxygen-free copper rod is obtained by extruding, drawing, sawing and other processes to obtain an outer hexagonal inner circle thin-walled copper tube with a length of 800mm, an opposite side size of 10mm, and an inner hole diameter of Φ9mm;

[0030] Step 2, put the Nb rods into the hexagonal copper tubes obtained in step 1 after cleaning, the number is 800, and then stack them in a hexagonal arrangement and put them into the oxygen-free copper sheath, the diameter of the sheath is Φ300mm, and the central area Put oxygen-free copper rods with the same specifications as the hexagonal copper tubes, the number of oxygen-free copper rods is 400, add copper caps at both ends and seal with electron beams to obtain CuNb composite sheaths;

[0031] Step 3: Heat the CuNb composite sheath obtained in step 2 to 650° C., hold the temperature for 1 hour, and extrude to obtain a CuNb composite rod.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com