Patents

Literature

1119 results about "Superconducting wire" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Superconducting wires are wires made of superconductors. When cooled below their transition temperatures, they have zero electrical resistance. Most commonly, conventional superconductors such as niobium-titanium are used, but high-temperature superconductors such as YBCO are entering the market. Superconducting wire's advantages over copper or aluminum include higher maximum current densities and zero power dissipation. Its disadvantages include the cost of refrigeration of the wires to superconducting temperatures (often requiring cryogens such as liquid helium or liquid nitrogen), the danger of the wire quenching (a sudden loss of superconductivity), the inferior mechanical properties of some superconductors, and the cost of wire materials and construction. Its main application is in superconducting magnets, which are used in scientific and medical equipment where high magnetic fields are necessary.

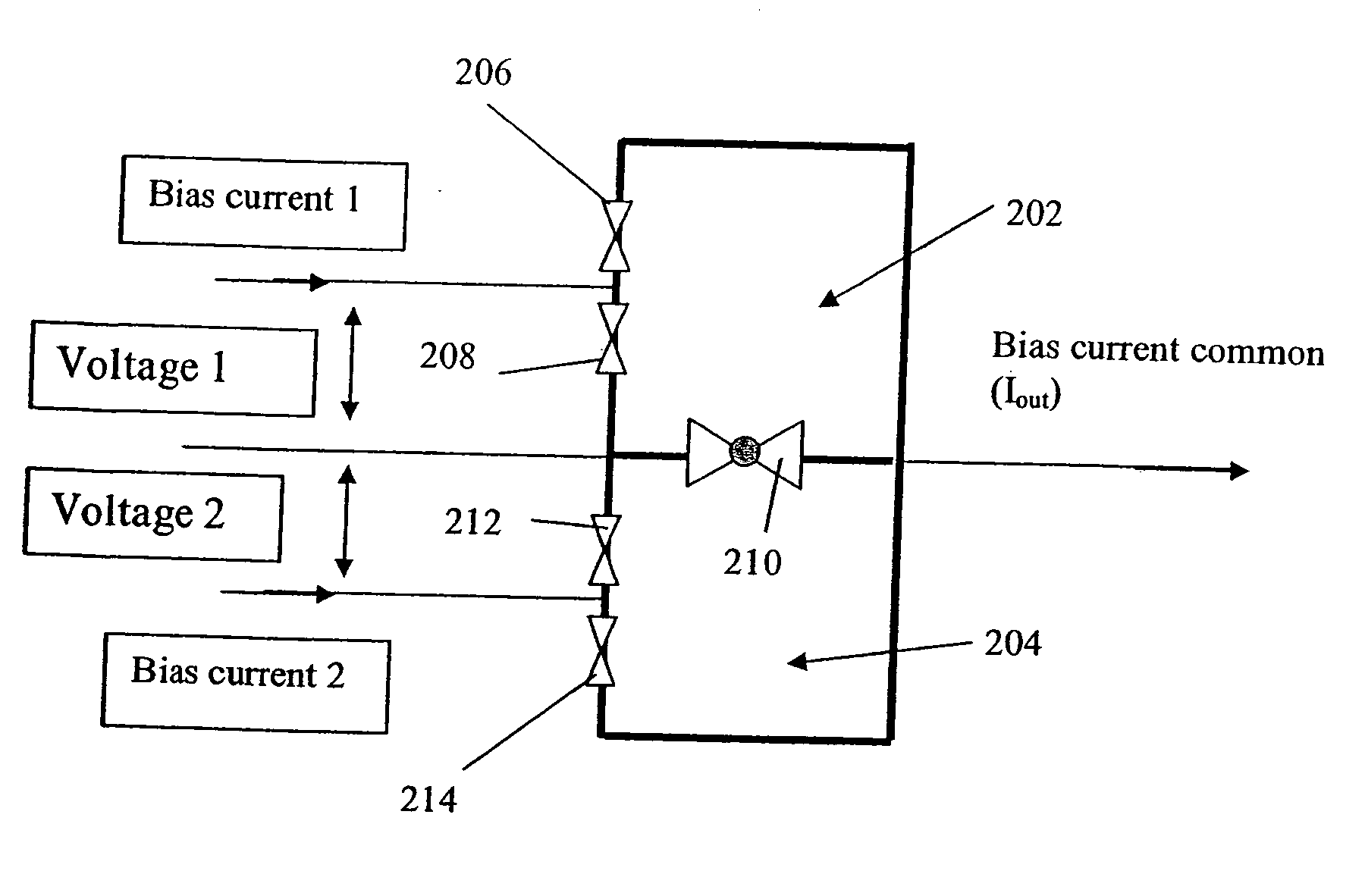

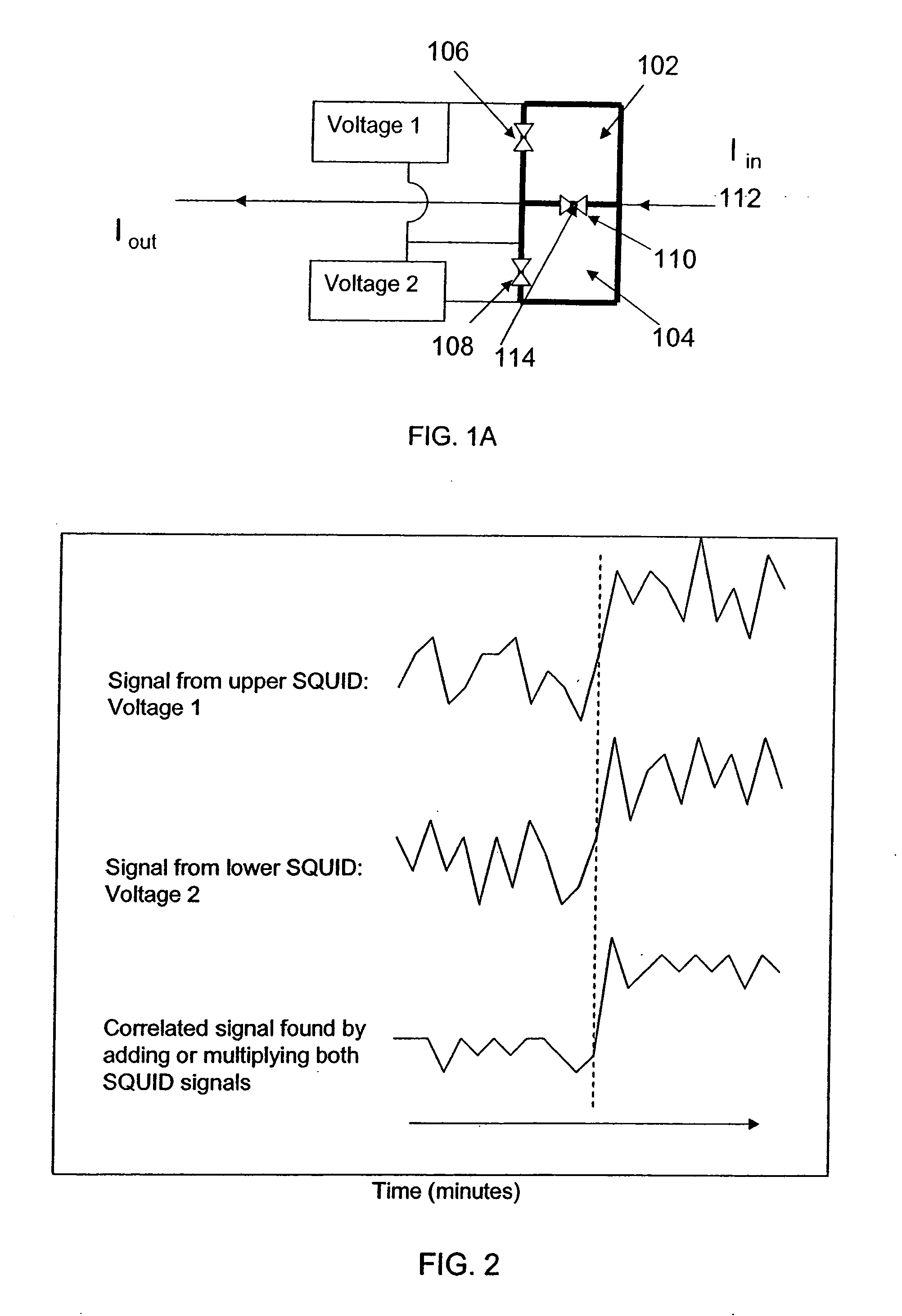

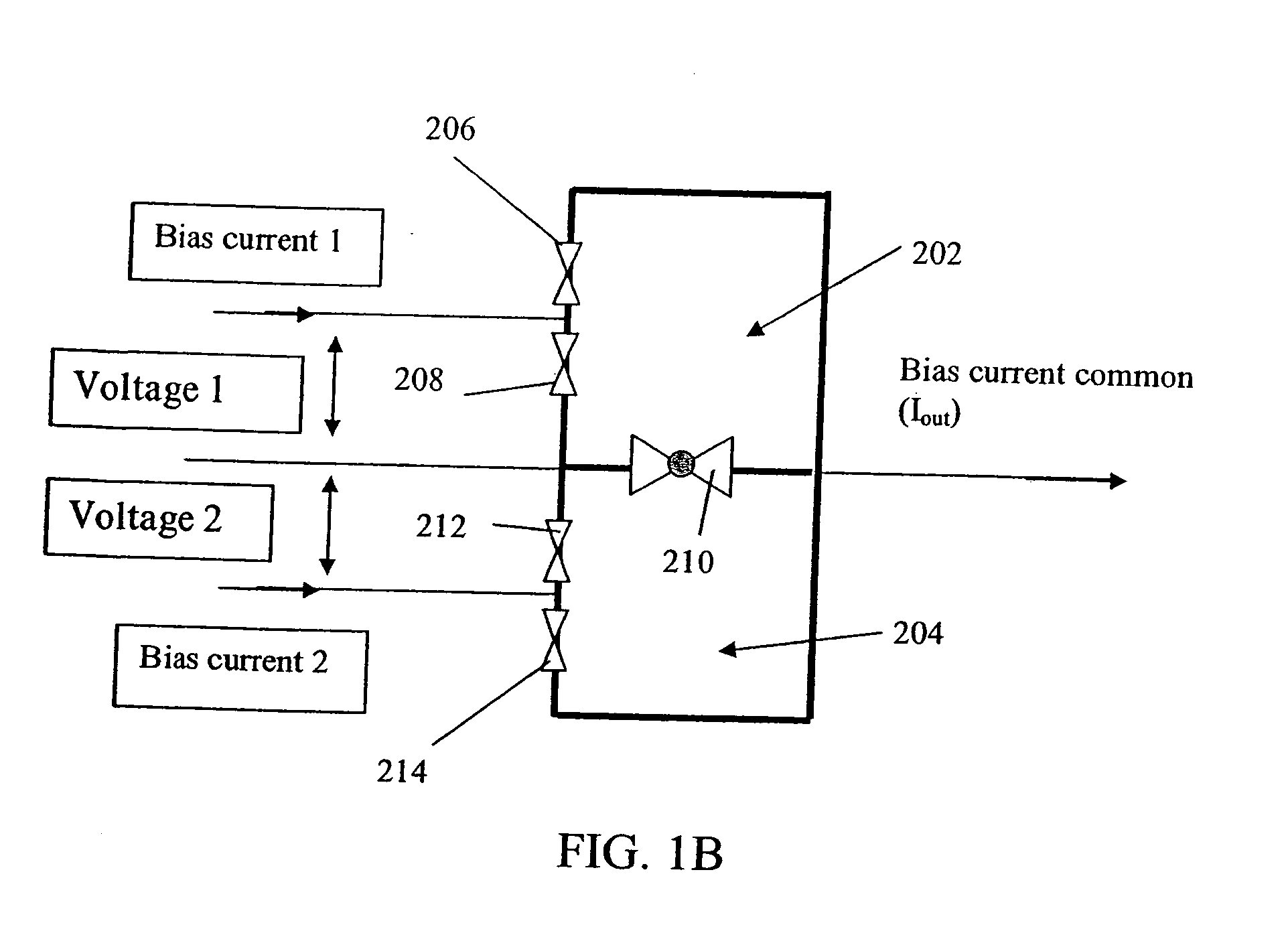

Multiple SQUID magnetometer

InactiveUS20070241747A1Avoid complicationsHigh sensitivitySuperconductors/hyperconductorsMagnetic field measurement using superconductive devicesCondensed matter physicsSQUID

Multiple SQUID magnetometers that include at least two SQUID loops, each of which is composed of at least two Josephson Junctions connected in parallel with superconducting wires, are provided. The SQUID loops are fabricated such that they share a common Josephson Junction. Devices and application that employ the multiple SQUID magnetometers are also provided.

Owner:FLORIDA STATE UNIV RES FOUND INC

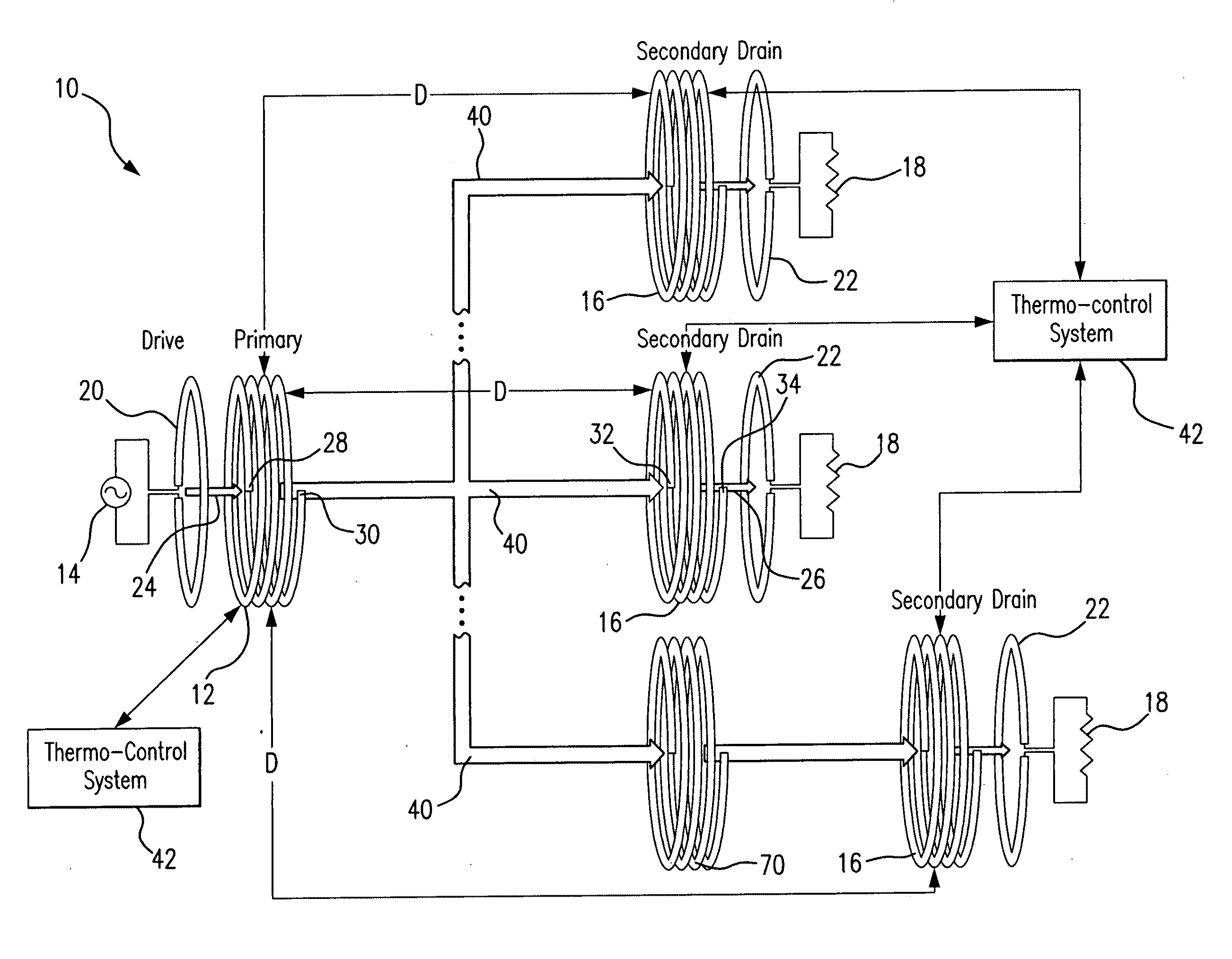

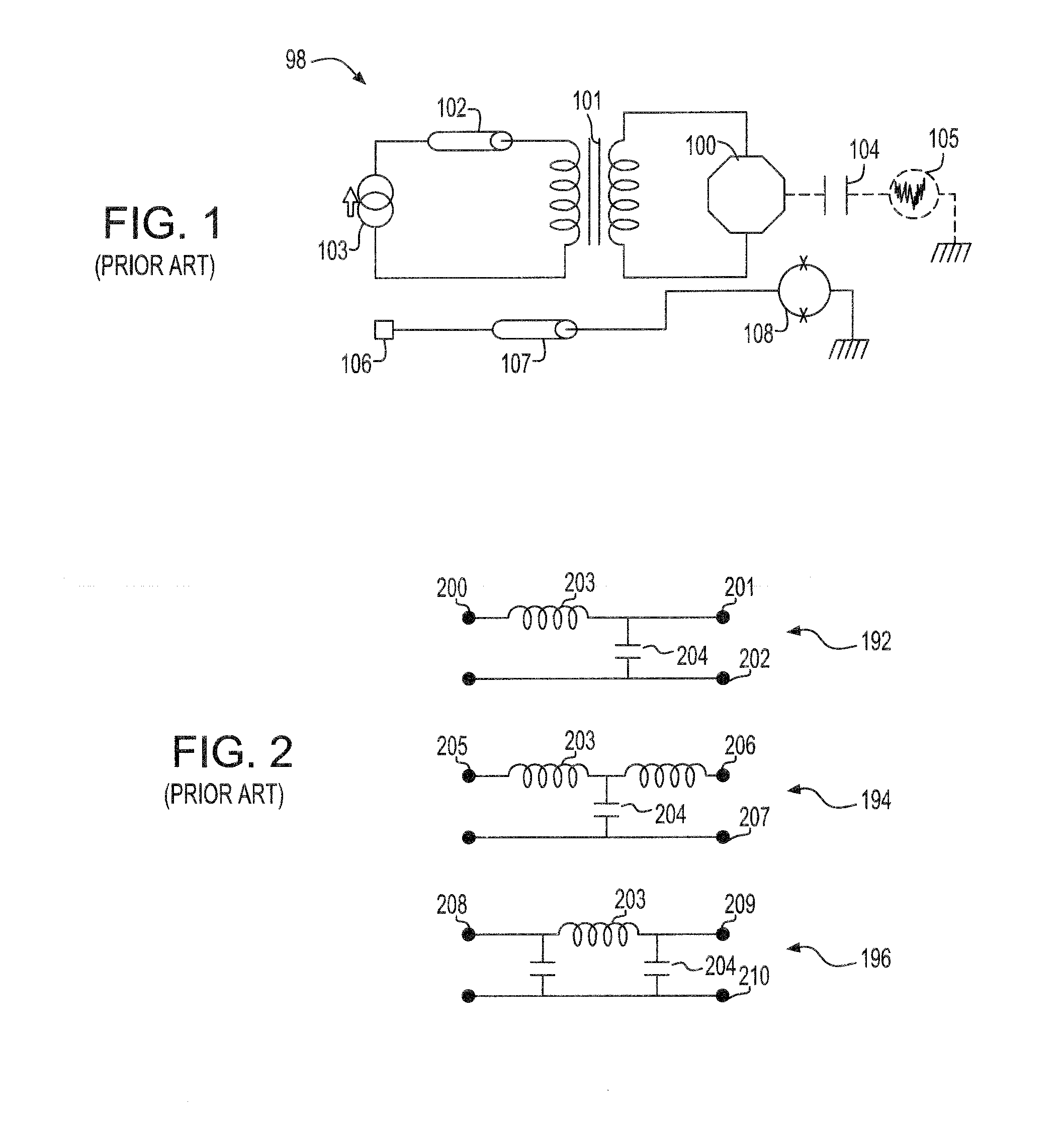

Method and system for long range wireless power transfer

ActiveUS20120010079A1Improve power transfer efficiencyReduce eliminateDc network circuit arrangementsElectromagnetic wave systemLow dissipationCapacitance

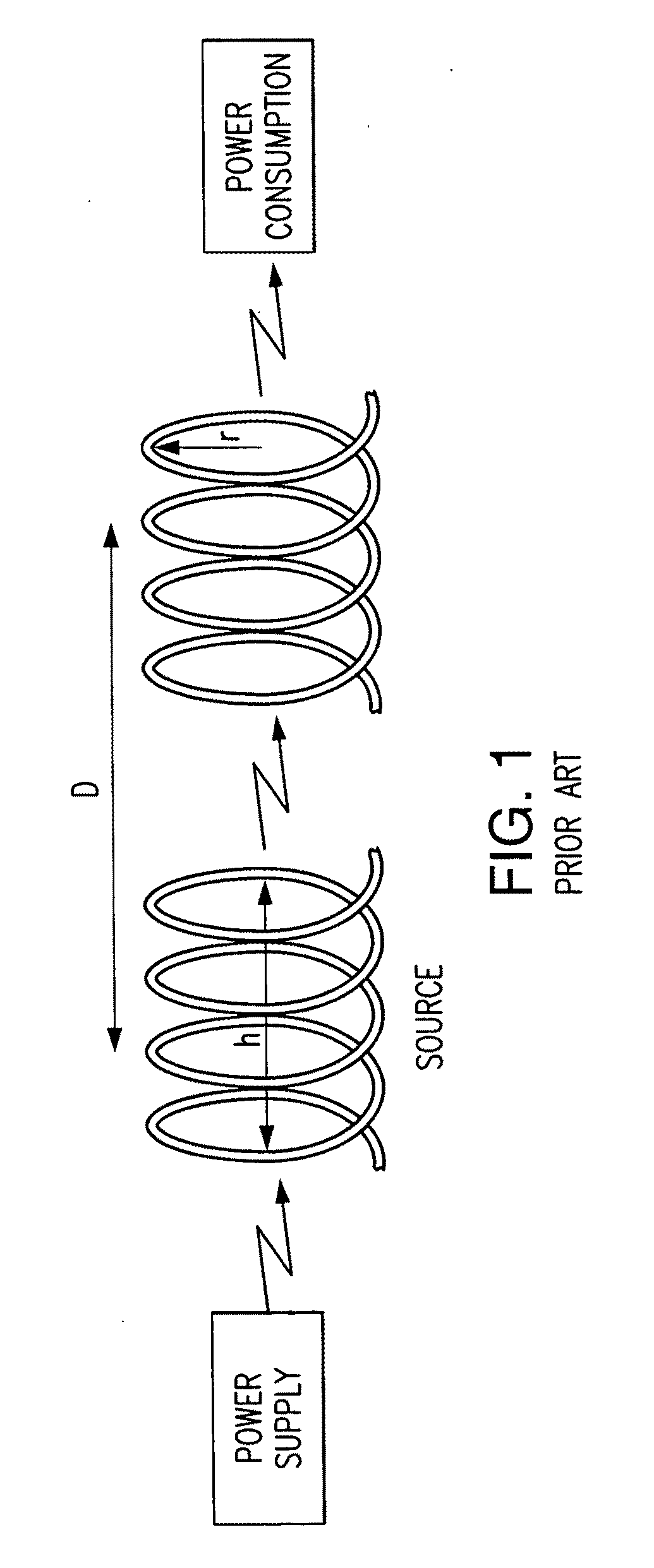

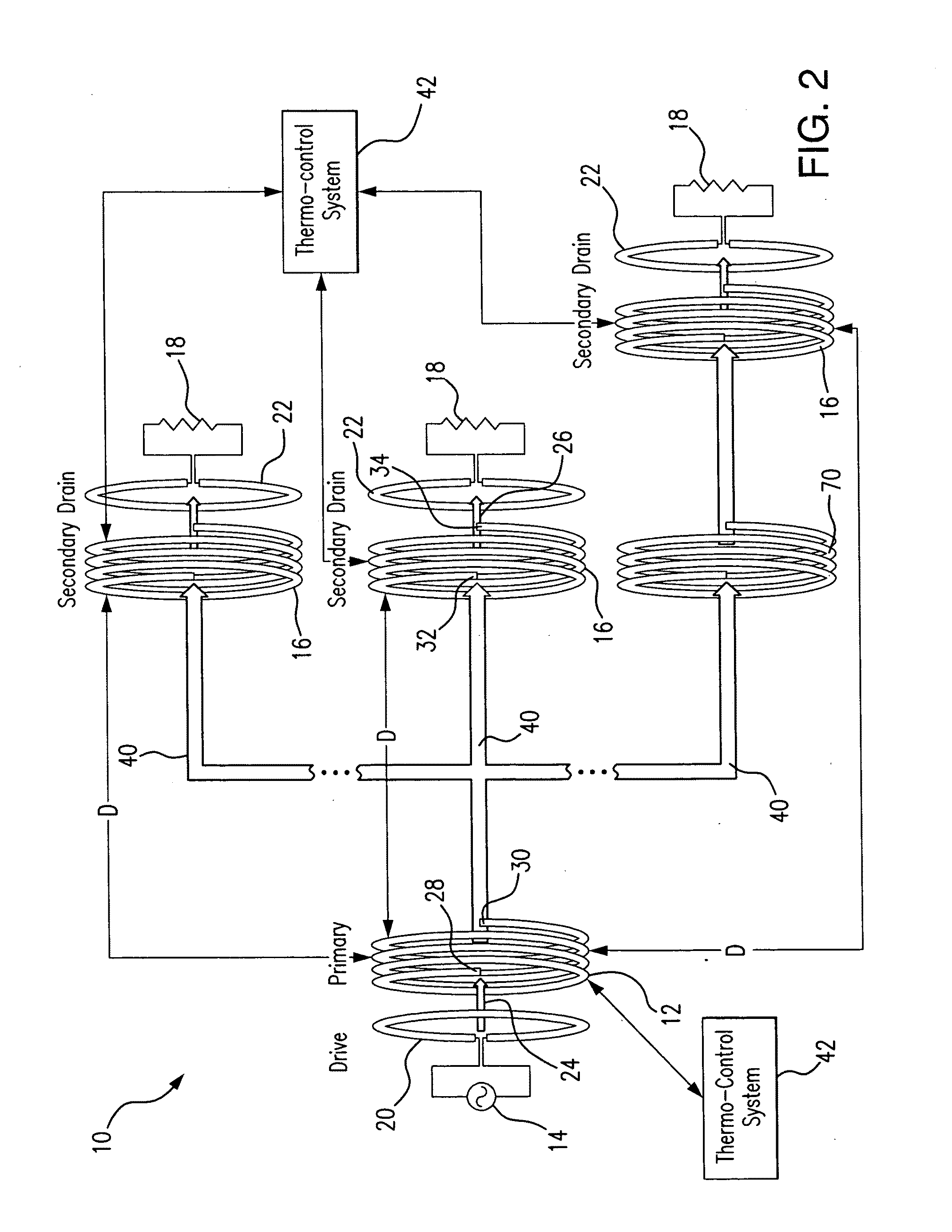

A wireless energy transfer system includes a primary and one (or more) secondary oscillators for transferring energy therebetween when resonating at the same frequency. The long range (up to and beyond 100 m) efficient (as high as and above 50%) energy transfer is achieved due to minimizing (or eliminating) losses in the system. Superconducting materials are used for all current carrying elements, dielectrics are either avoided altogether, or those are used with a low dissipation factor, and the system is operated at reduced frequencies (below 1 MHz). The oscillators are contoured as a compact flat coil formed from a superconducting wire material. The energy wavelengths exceed the coils diameter by several orders of magnitude. The reduction in radiative losses is enhanced by adding external dielectric-less electrical capacitance to each oscillator coil to reduce the operating frequency. The dielectric strength of the capacitor is increased by applying a magnetic cross-field to the capacitor to impede the electrons motion across an air gap defined between coaxial cylindrical electrodes.

Owner:MARYLAND UNIV OF

Low loss joint for superconducting wire

ActiveUS20100190649A1Easy to useUndesirable chemical interactionSuperconductors/hyperconductorsSuperconductor detailsNMR - Nuclear magnetic resonanceSuperconducting Coils

A device and method for making a persistent joint allowing end terminations of superconducting MgB2 wire to be joined with a superconducting bridge. Superconducting electromagnetic coils may be joined in series or joining of coil assemblies to current sources and the two ends of a persistent switch. The device includes wire filaments with end preparation exposing reacted MgB2, inserted into a block and surrounded with Mg+B and / or MgB2 in powder, solid, slurry or sol-gel form and subsequently reacted to establish a bridge of superconducting MgB2 electrically connecting the superconducting MgB2 wires. Autonomous operation of the superconducting background magnet coils in magnetic resonance imaging (MRI) and nuclear magnetic resonance (NMR) devices are allowed, or similar devices where autonomous operation of an MgB2 based superconducting magnet is required. The low resistant joint will also be beneficial for other superconducting applications such as fault current limiters, motors, generators, etc.

Owner:HYPER TECH RES

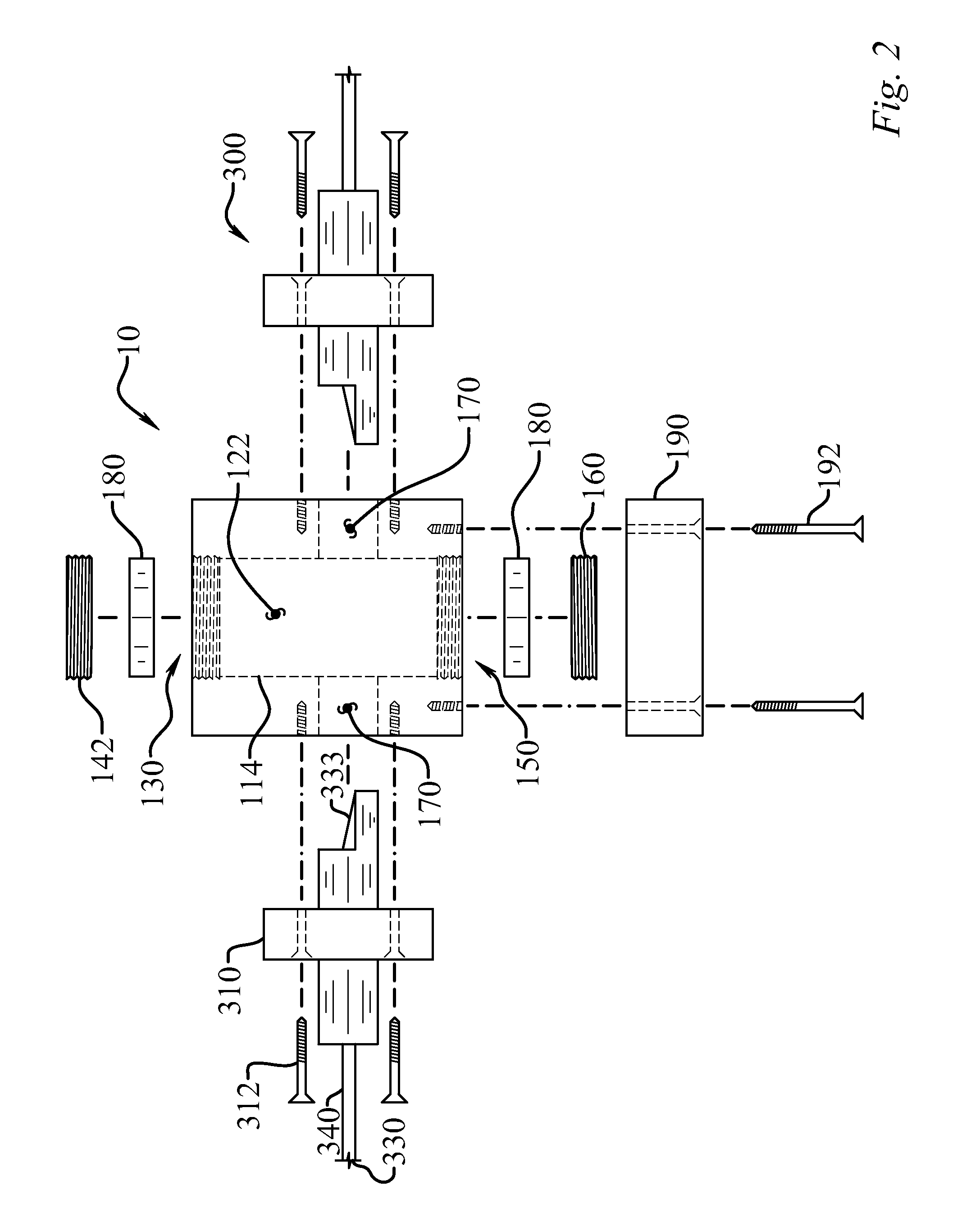

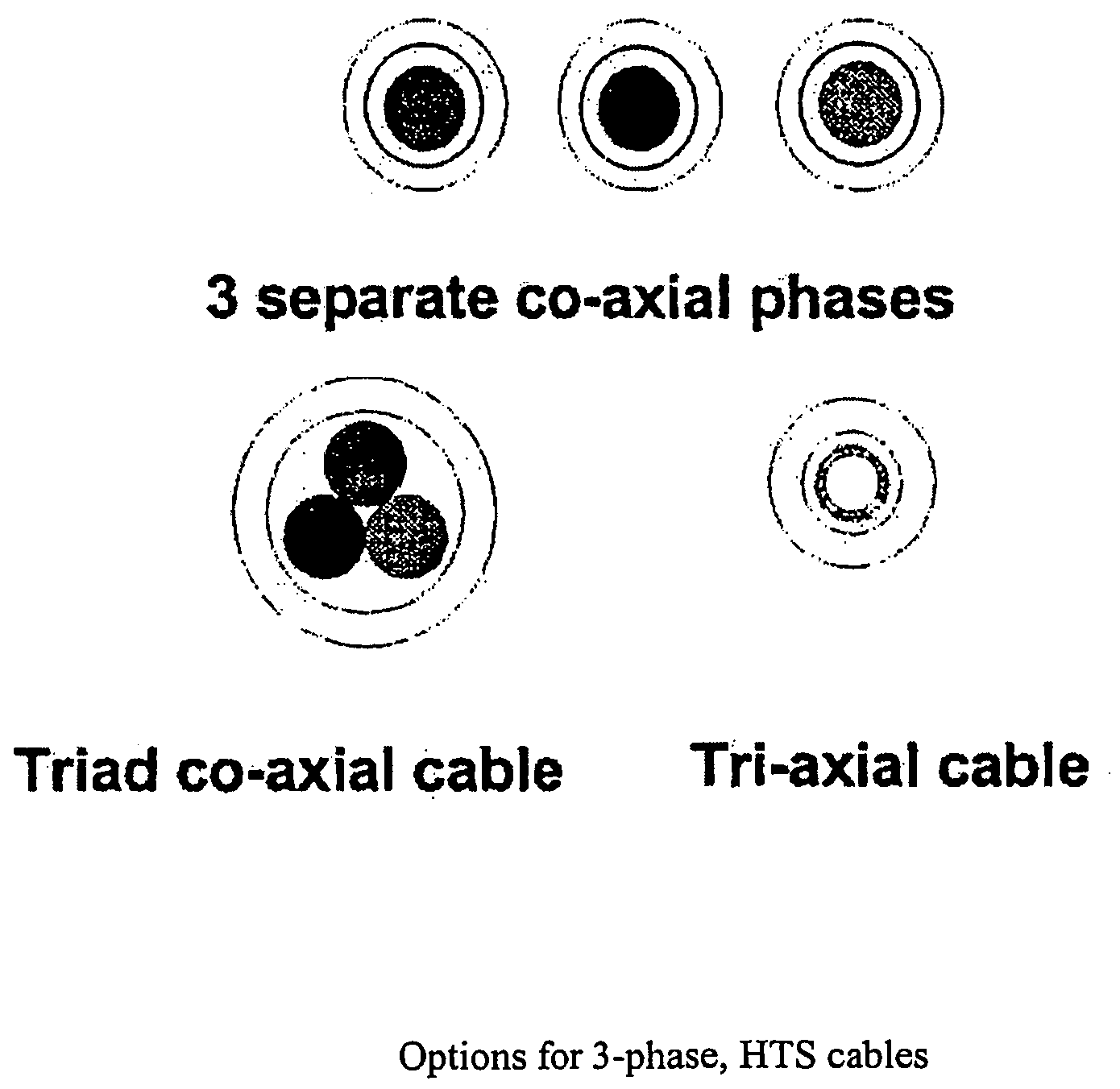

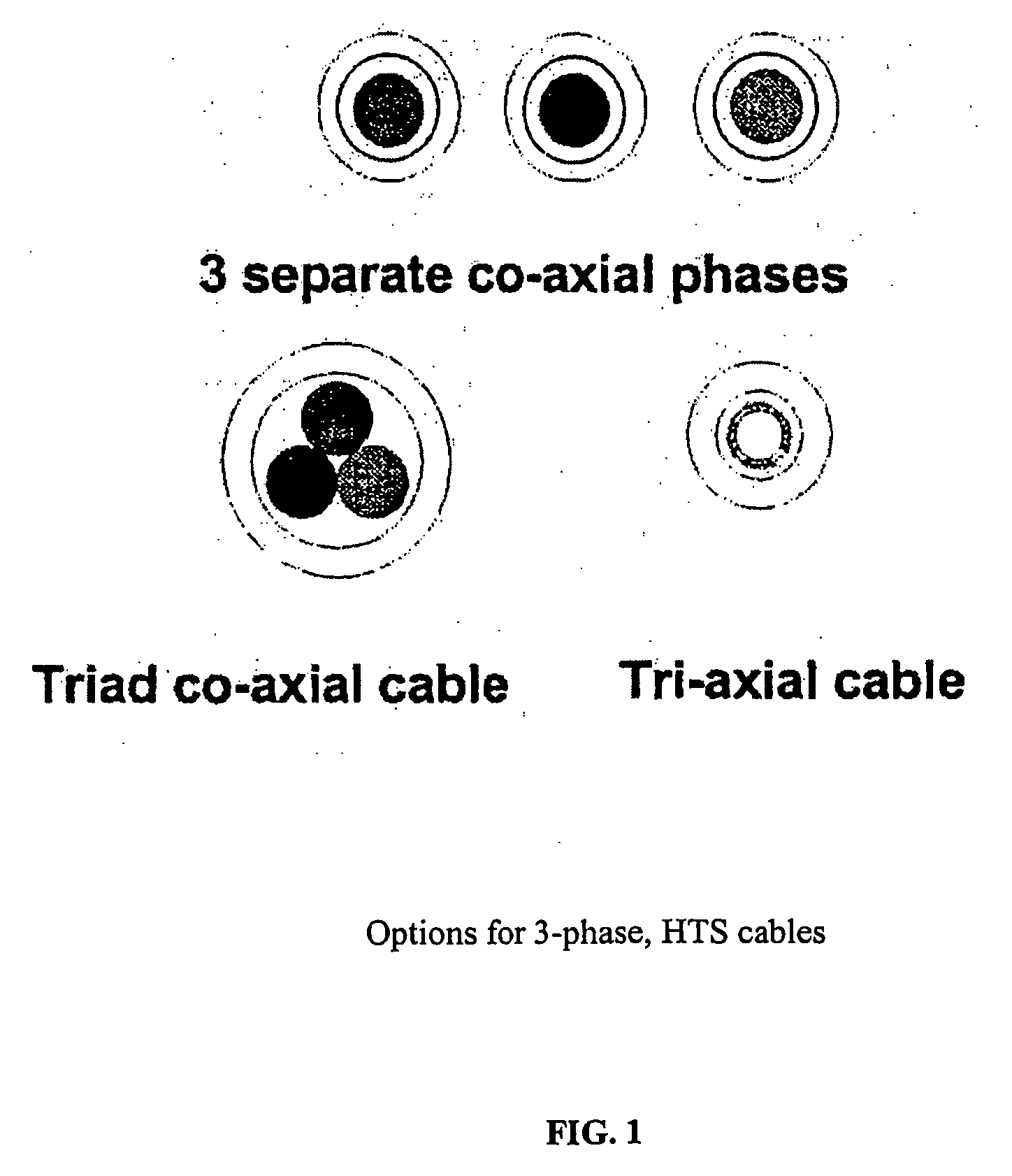

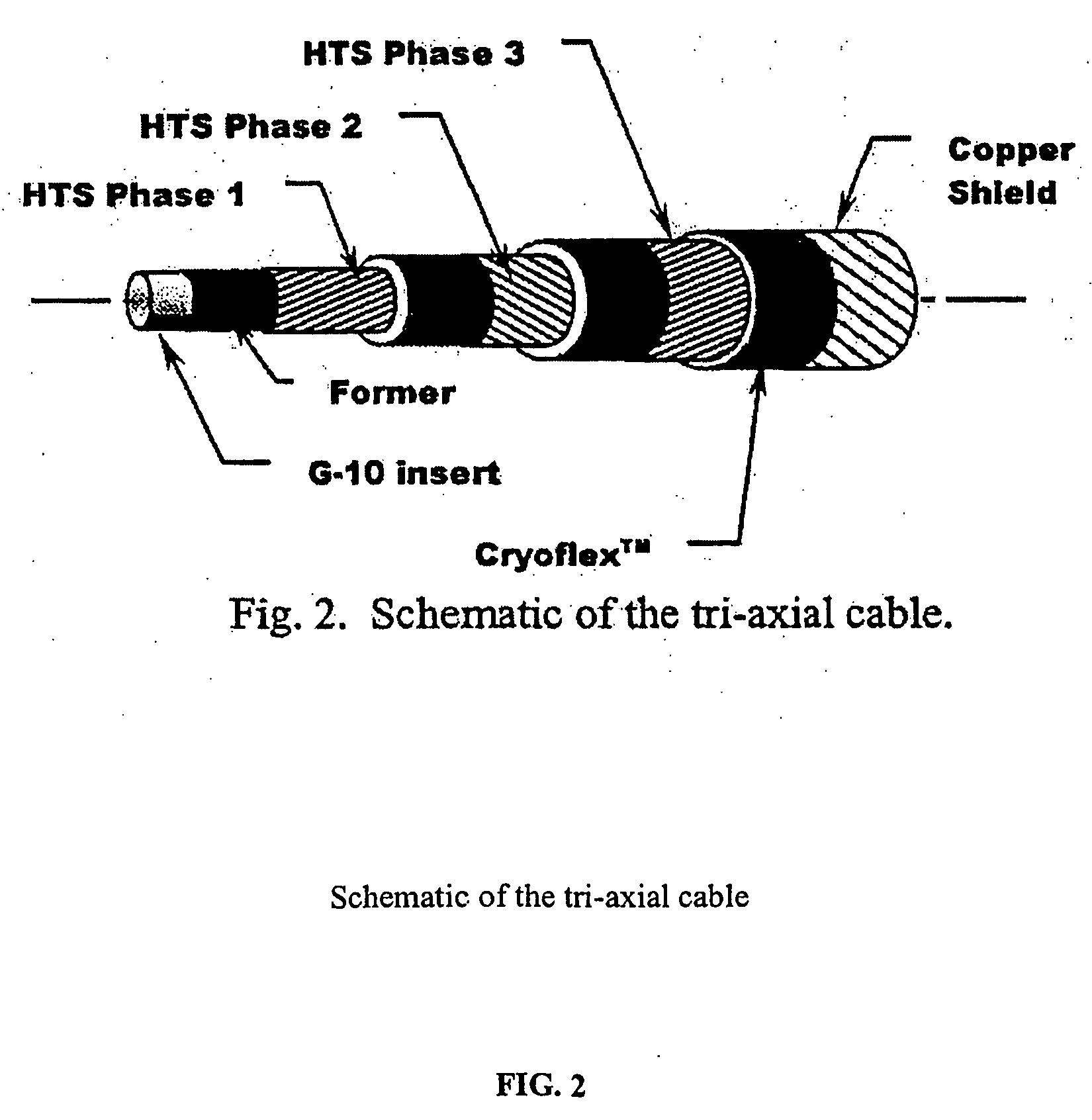

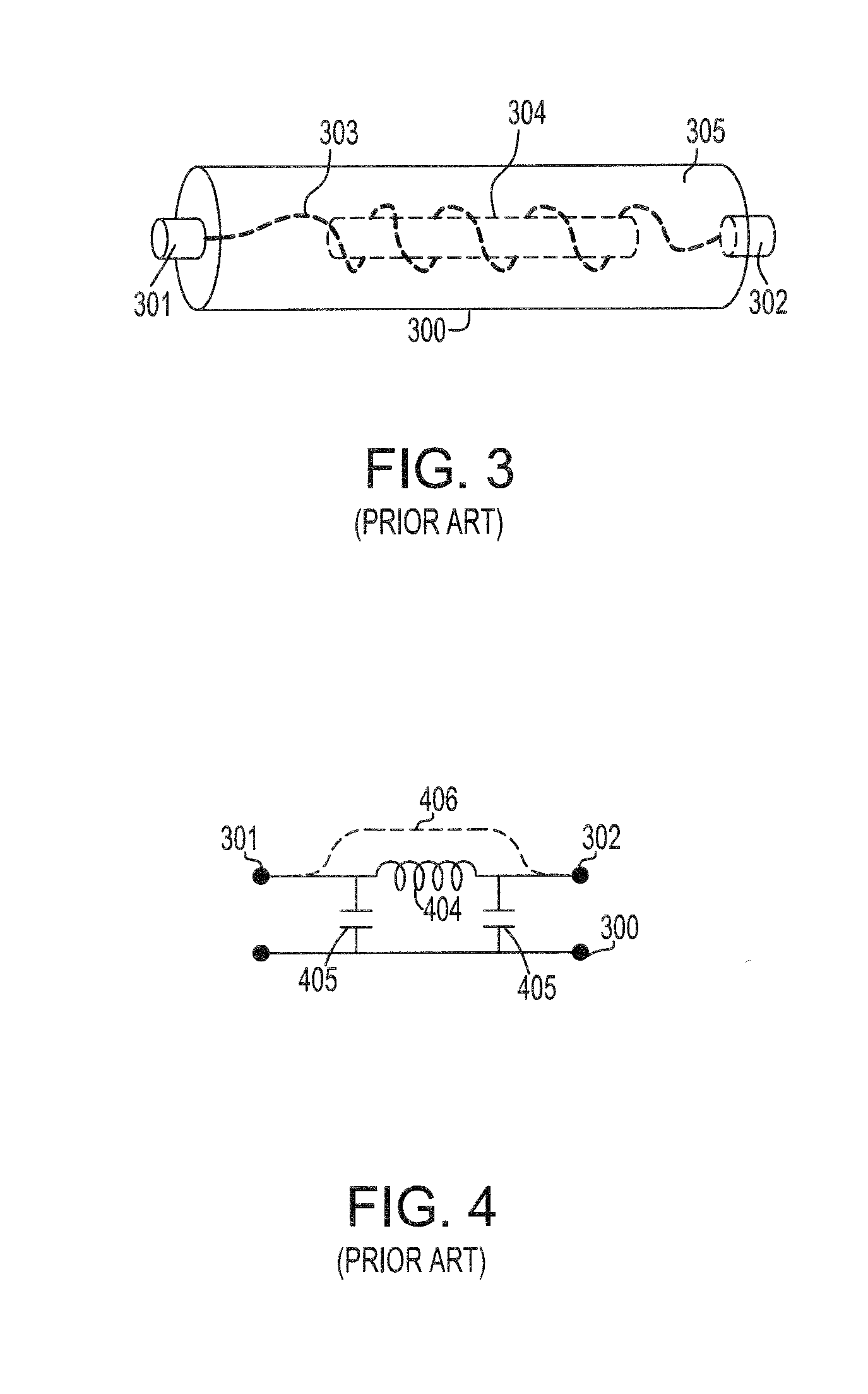

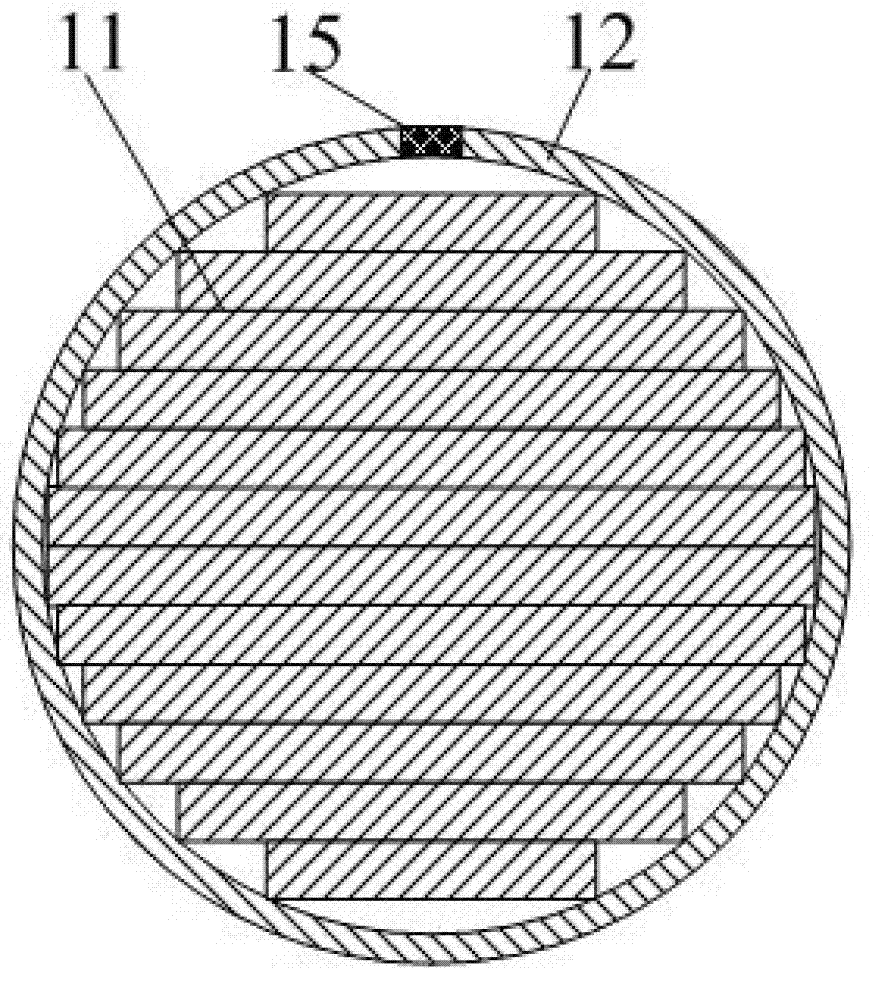

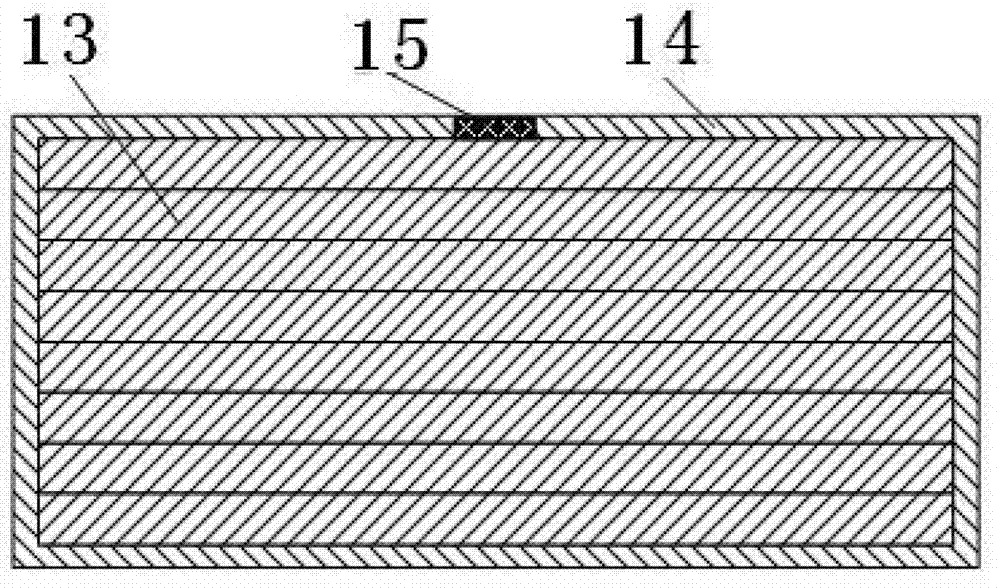

Triaxial superconducting cable and termination therefor

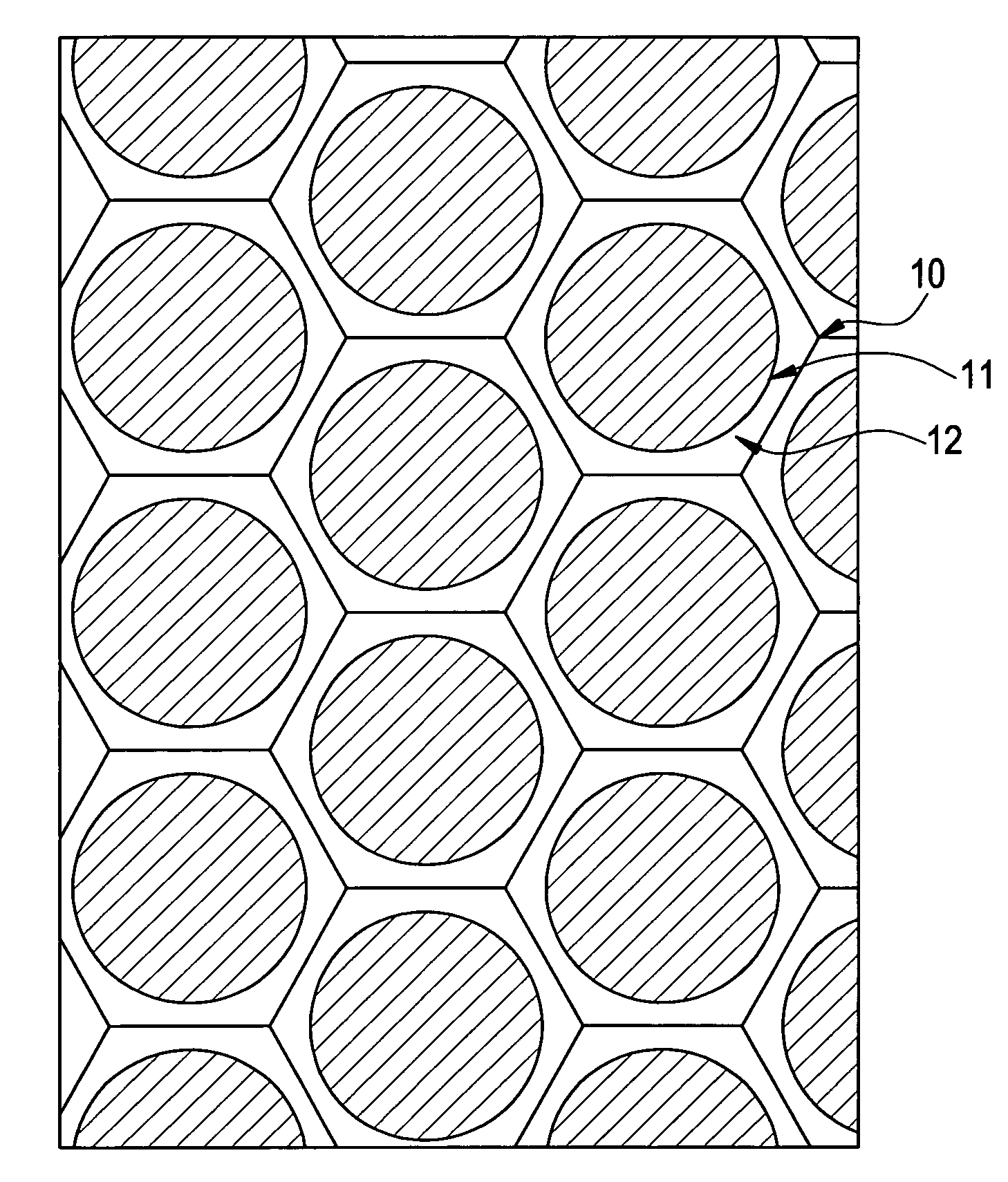

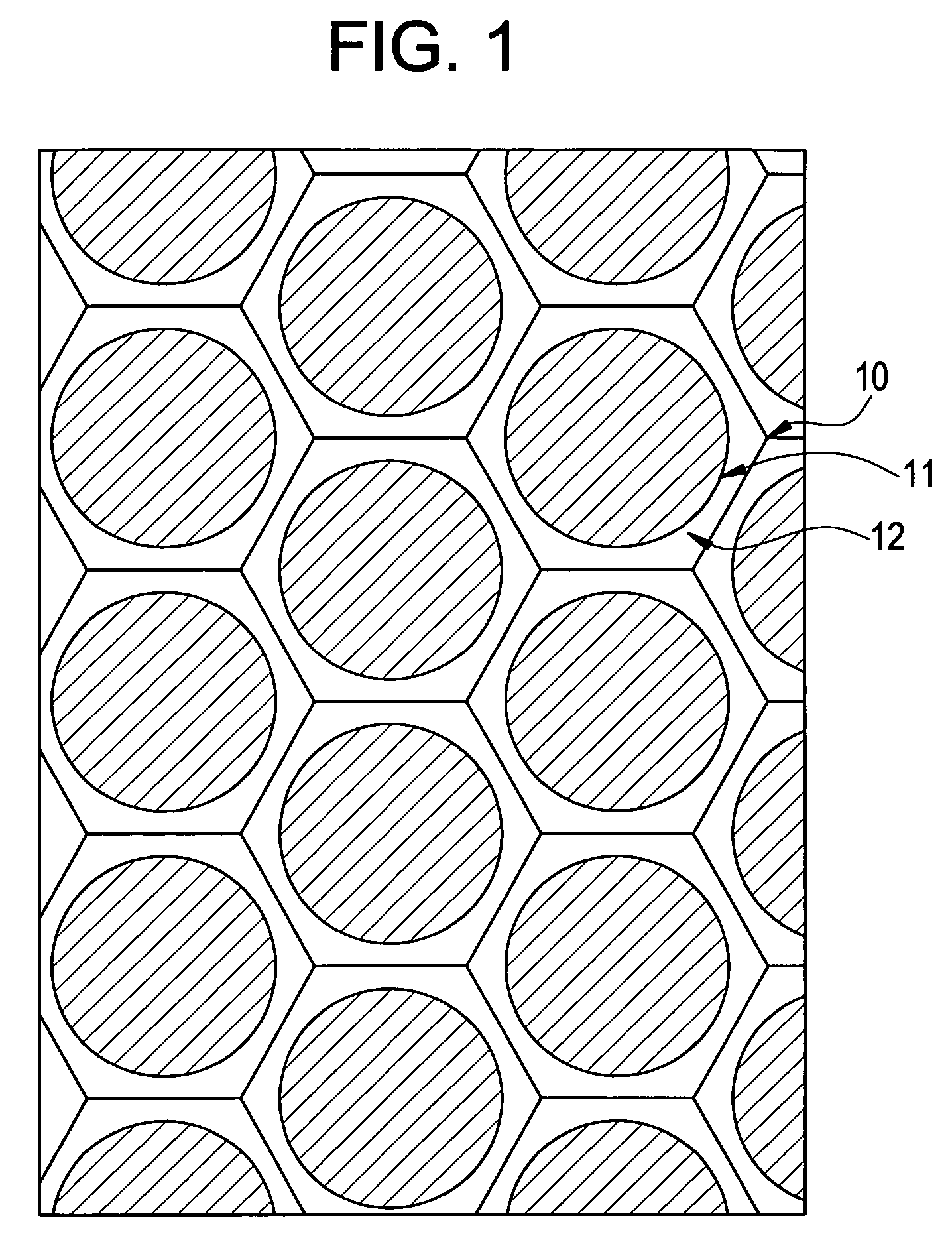

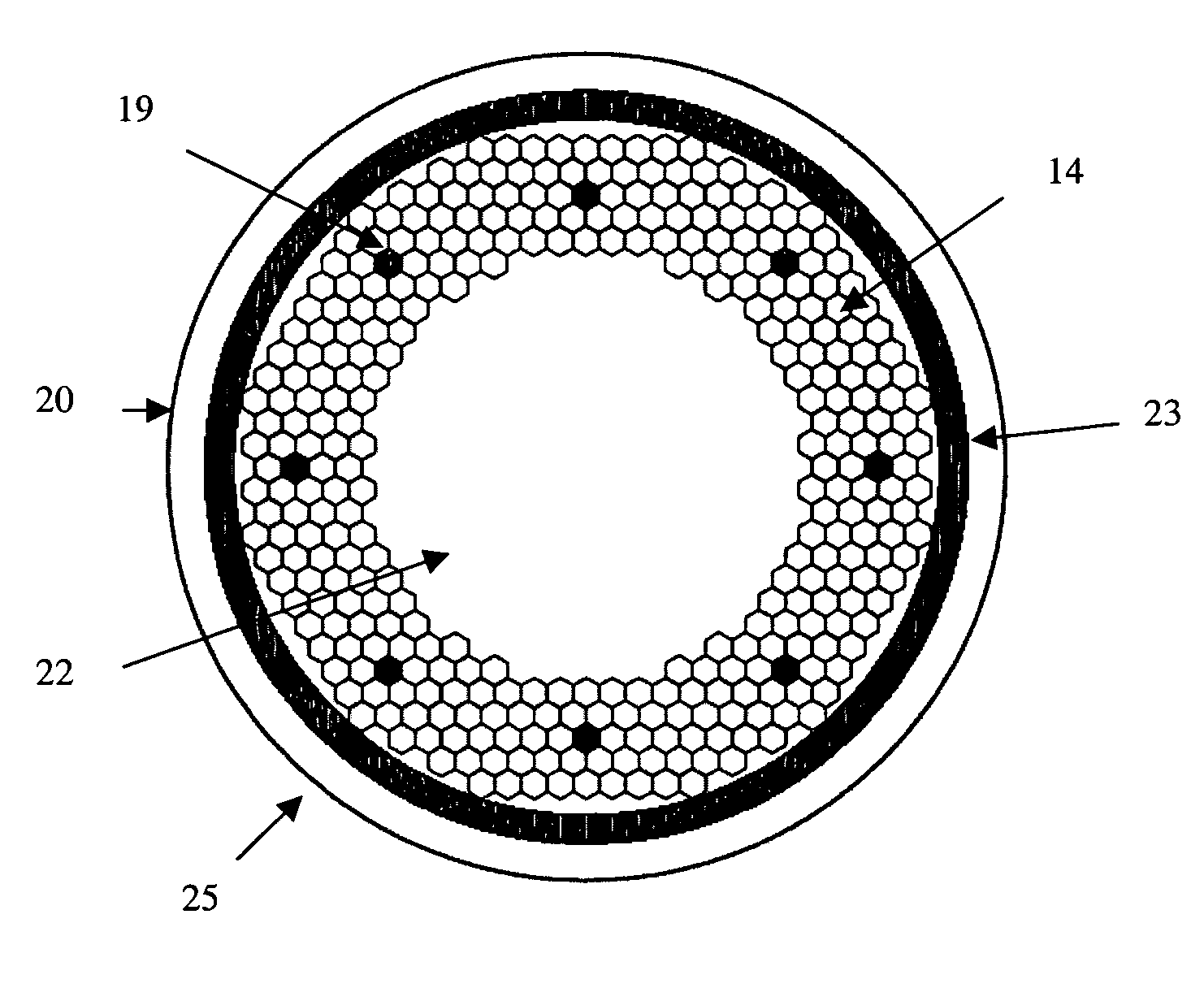

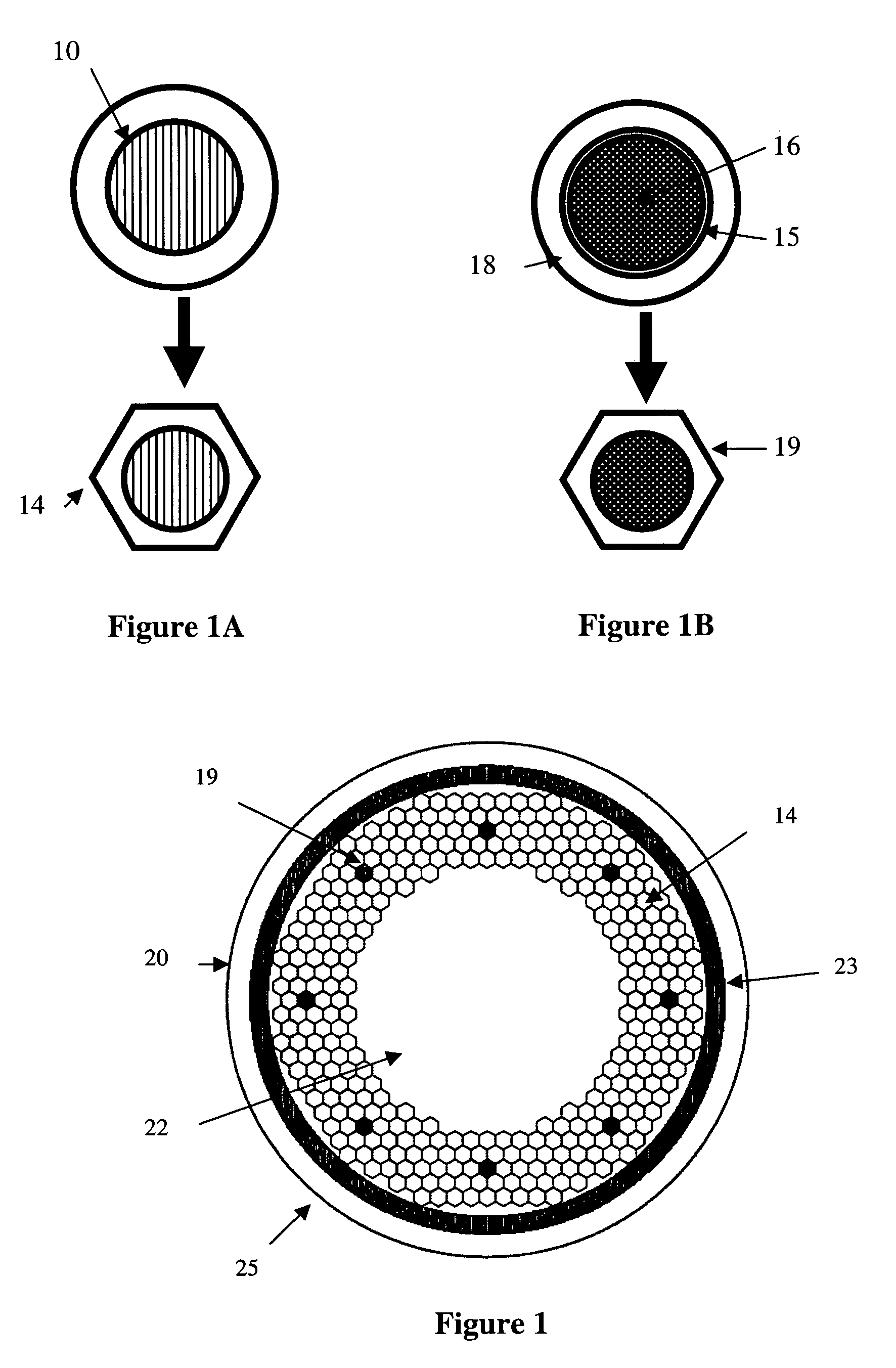

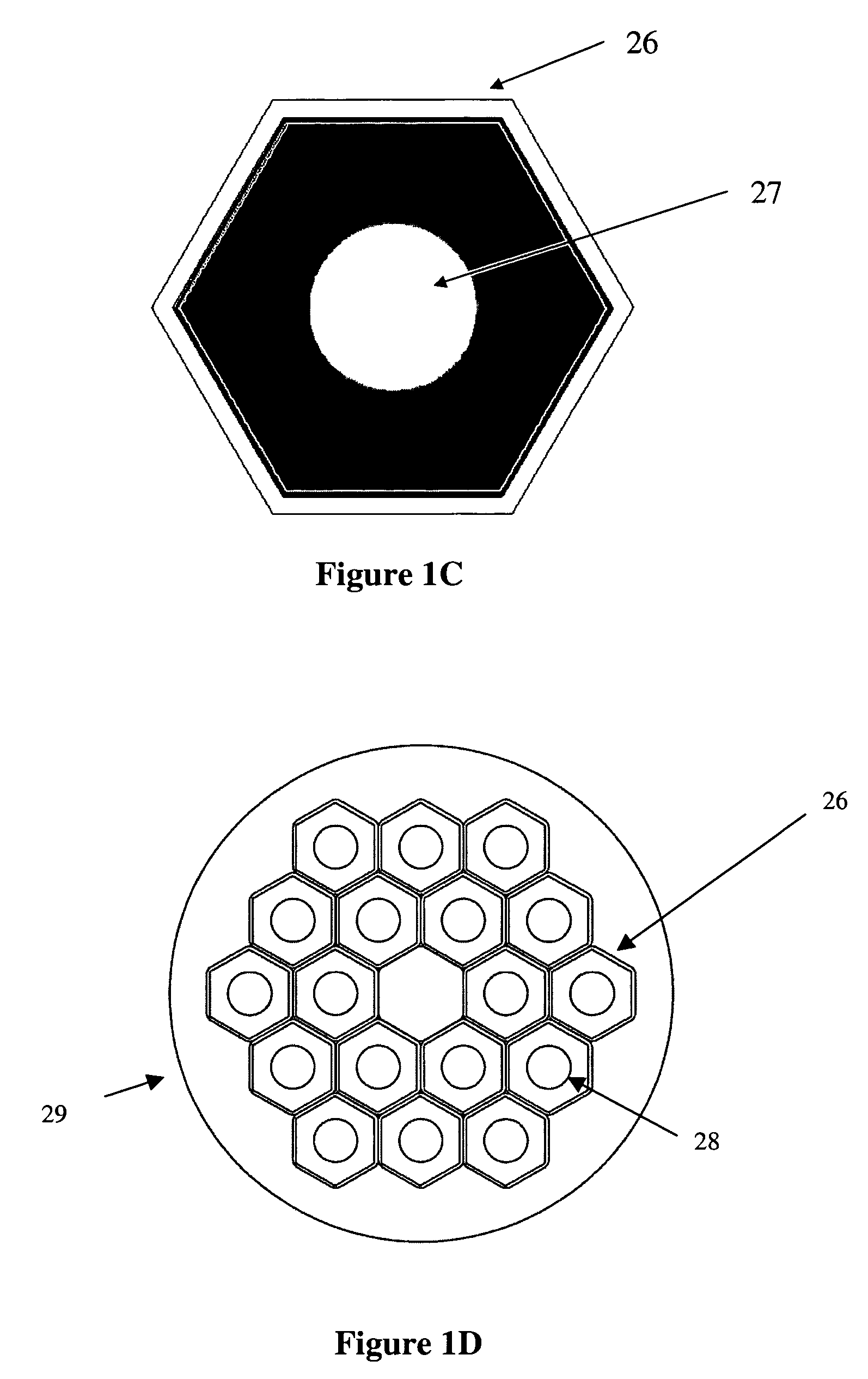

InactiveUS20050173149A1Improve superconductivityIncrease the critical currentSuperconductors/hyperconductorsCable fittings for cryogenic cablesBand shapeBending strain

In order to provide a flexible oxide superconducting cable which is reduced in AC loss, tape-shaped superconducting wires covered with a stabilizing metal are wound on a flexible former. The superconducting wires are preferably laid on the former at a bending strain of not more than 0.2%. In laying on the former, a number of tape-shaped superconducting wires are laid on a core member in a side-by-side manner, to form a first layer. A prescribed number of tape-shaped superconducting wires are laid on top of the first layer in a side-by-side manner, to form a second layer. The former may be made of a metal, plastic, reinforced plastic, polymer, or a composite and provides flexibility to the superconducting wires and the cable formed therewith. Methods of forming and terminating a triaxial superconductor are disclosed.

Owner:SOUTHWIRE CO LLC

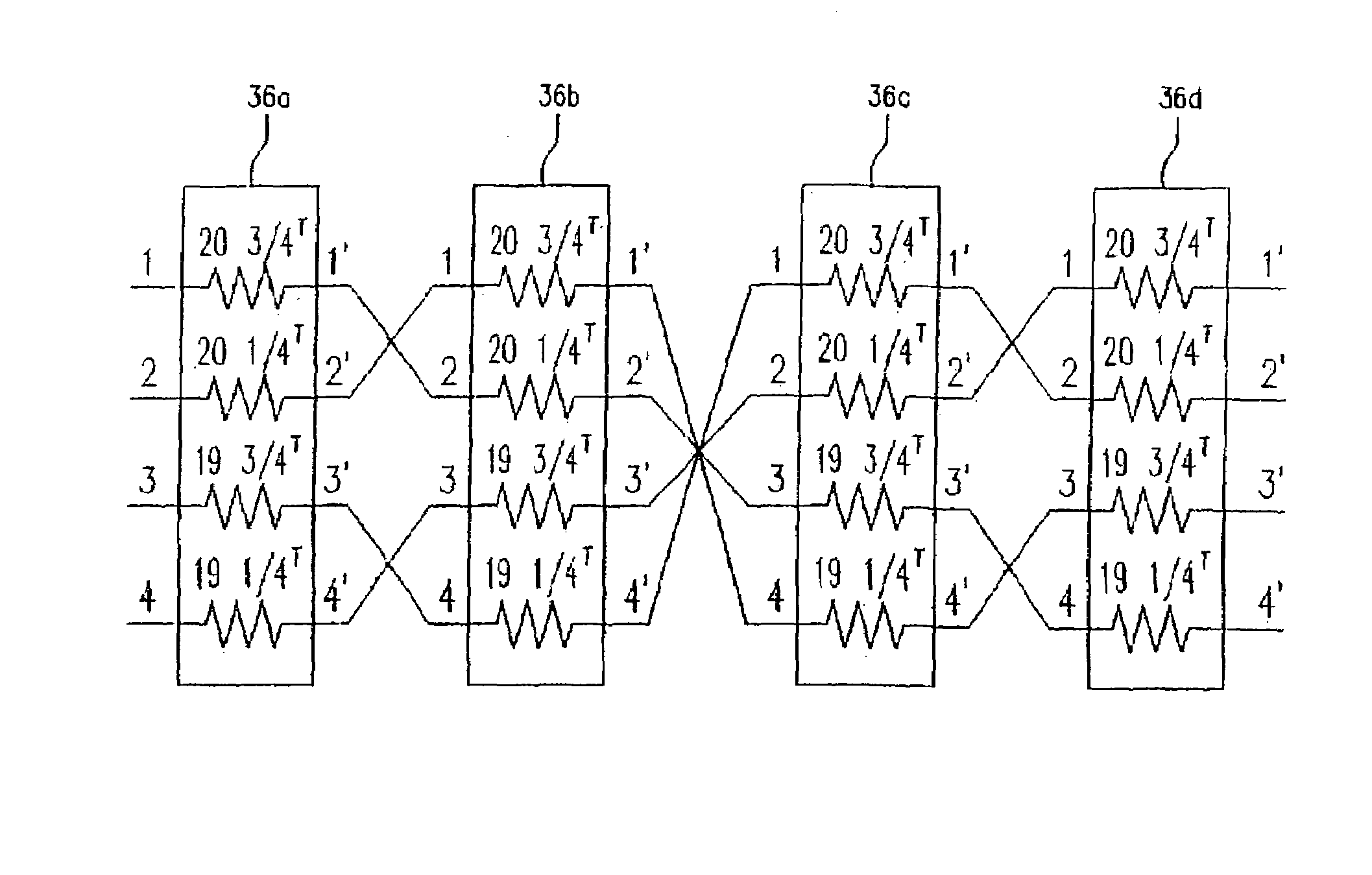

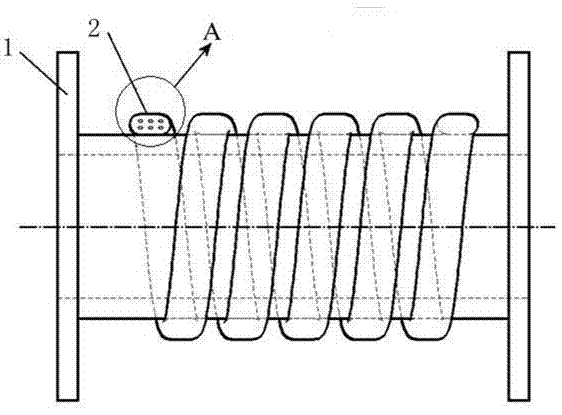

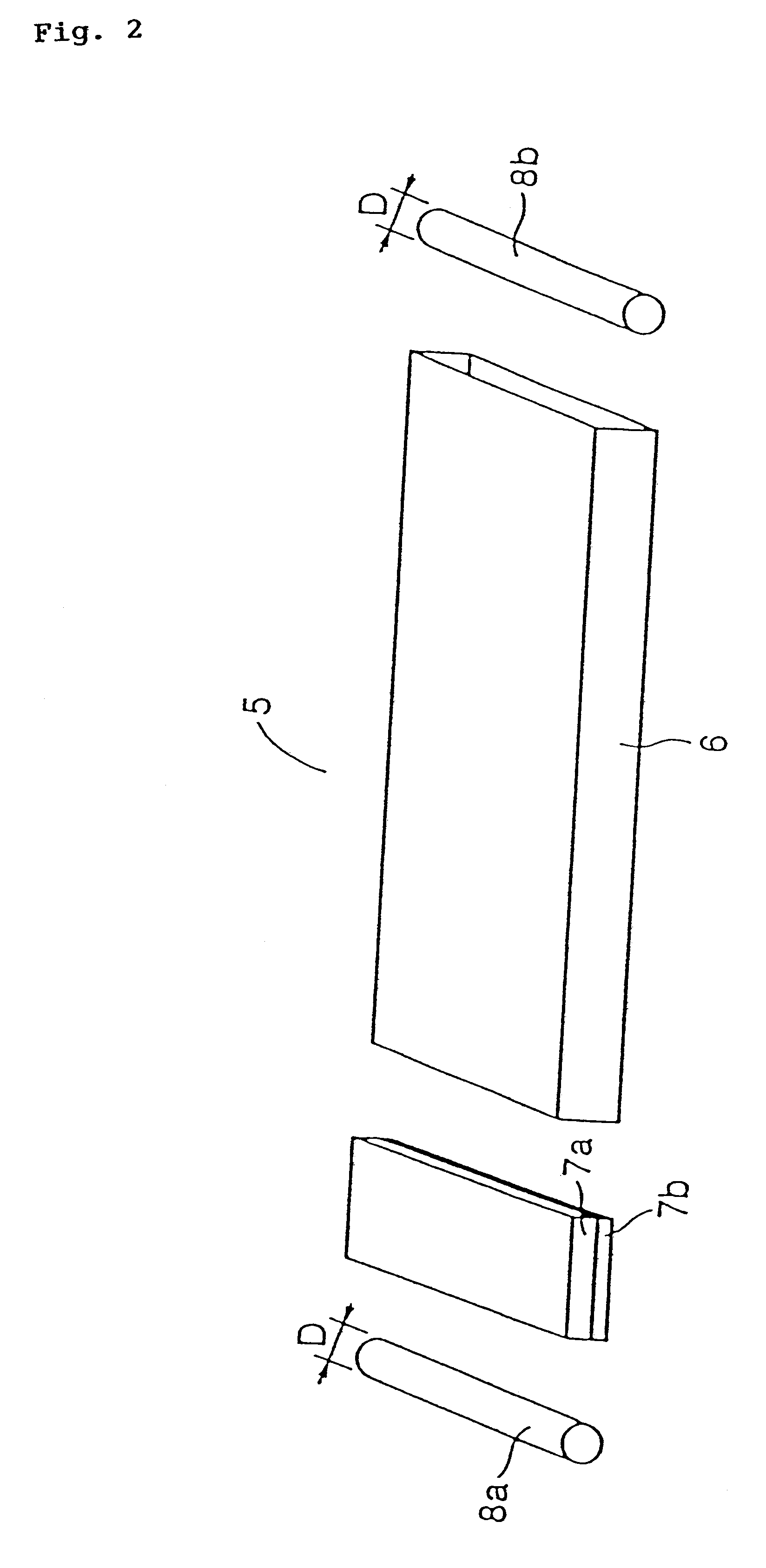

Superconducting wire transposition method and superconducting transformer using the same

InactiveUS7227438B2TransformersTransformers/inductances coils/windings/connectionsElectrical conductorTransformer

The present invention discloses a superconducting wire transposition method and superconducting transformer whose winding is formed of superconducting wire to enable the formation of transpositions. The superconducting wire transposition method characterized of different winding start positions of at least two disks wound with a plurality of parallel superconductive wires, and usage of different superconducting wires for conductors to be connected between the disks, thereby forming transpositions outside of the disks. Preferably, part of the plurality of disks are rotatably assembled in pairs so as to form transpositions while maintaining a total number of windings equally. Therefore, according to the present invention, transpositions can be formed without bending or welding superconducting wires and thus, deteriorations in superconductivity can be prevented.

Owner:HYOSUNG CORP

Superconducting Wires and Cables and Methods for Producing Superconducting Wires and Cables

InactiveUS20090258787A1Easy and efficientSuperconductors/hyperconductorsSuperconductor device manufacture/treatmentEngineeringHeat treated

Owner:HILLS CO

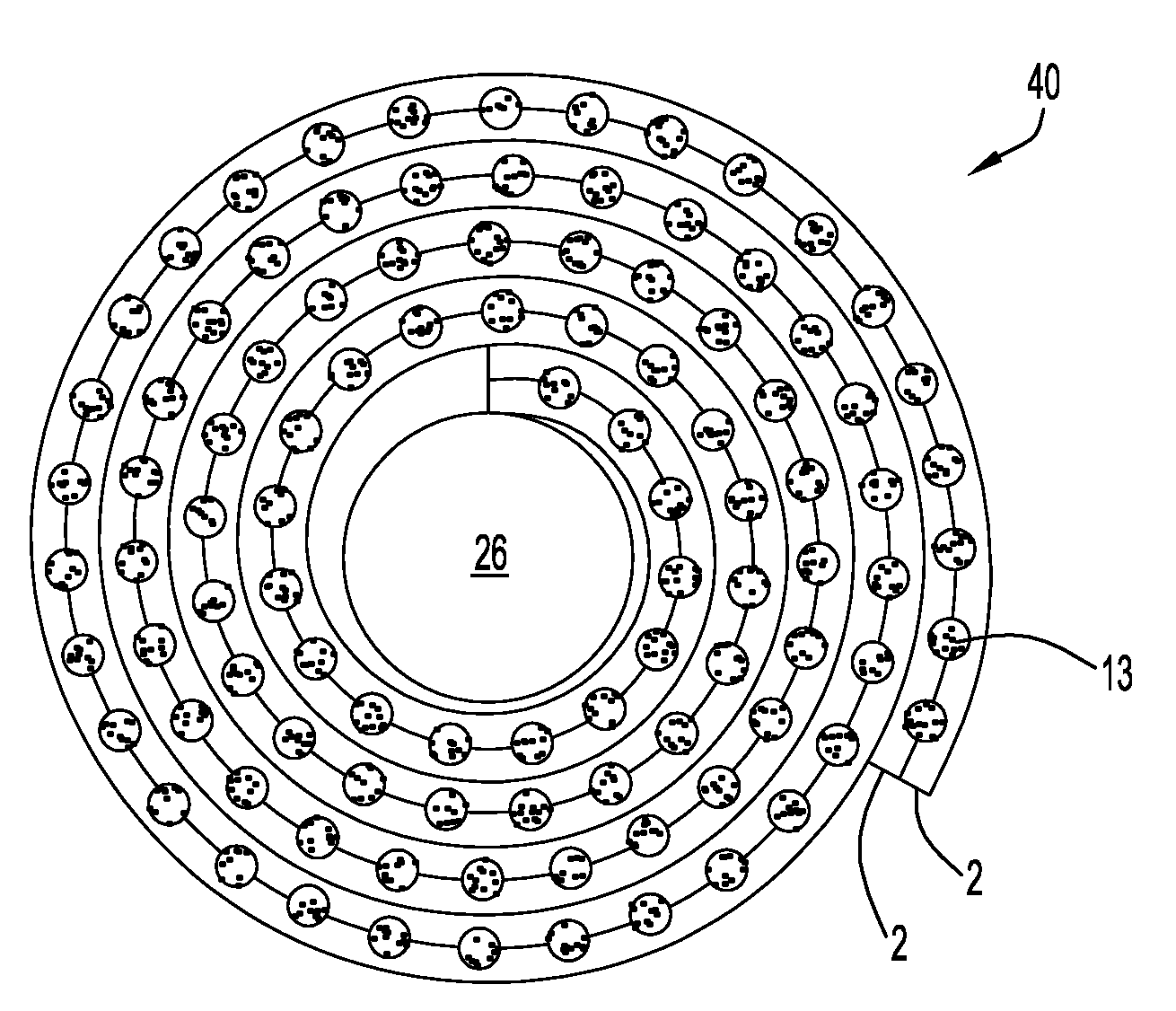

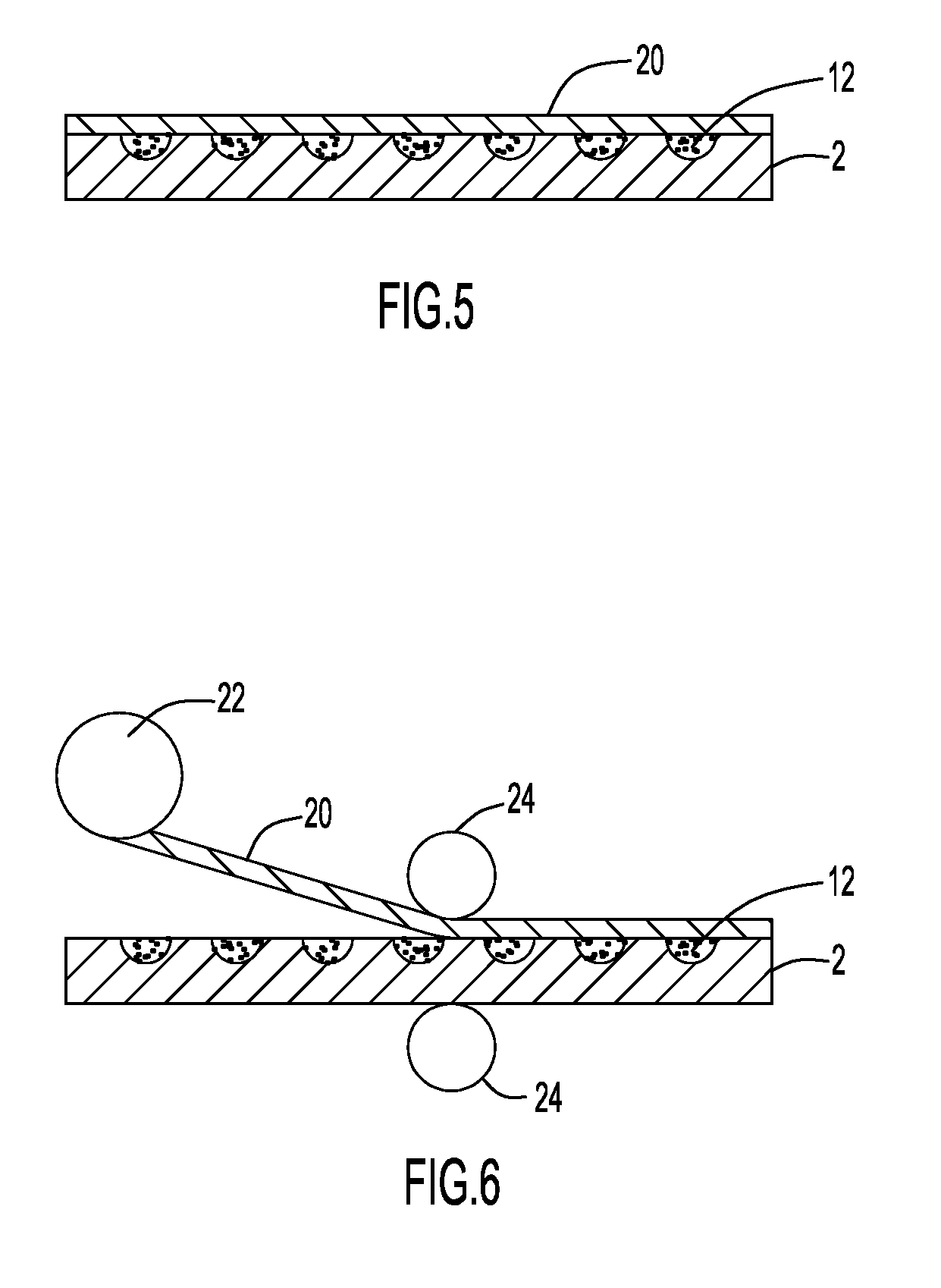

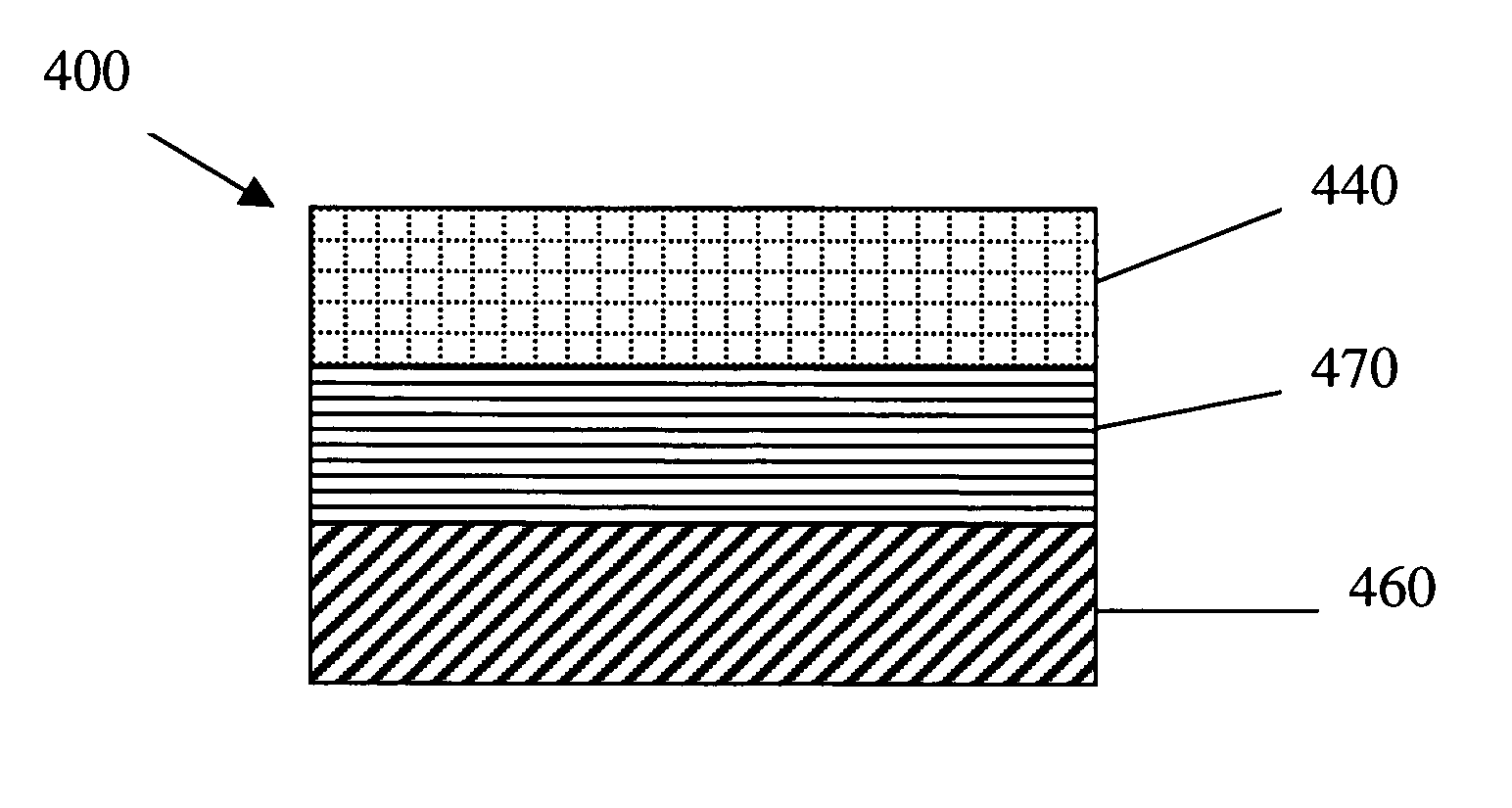

High temperature superconducting wires and coils

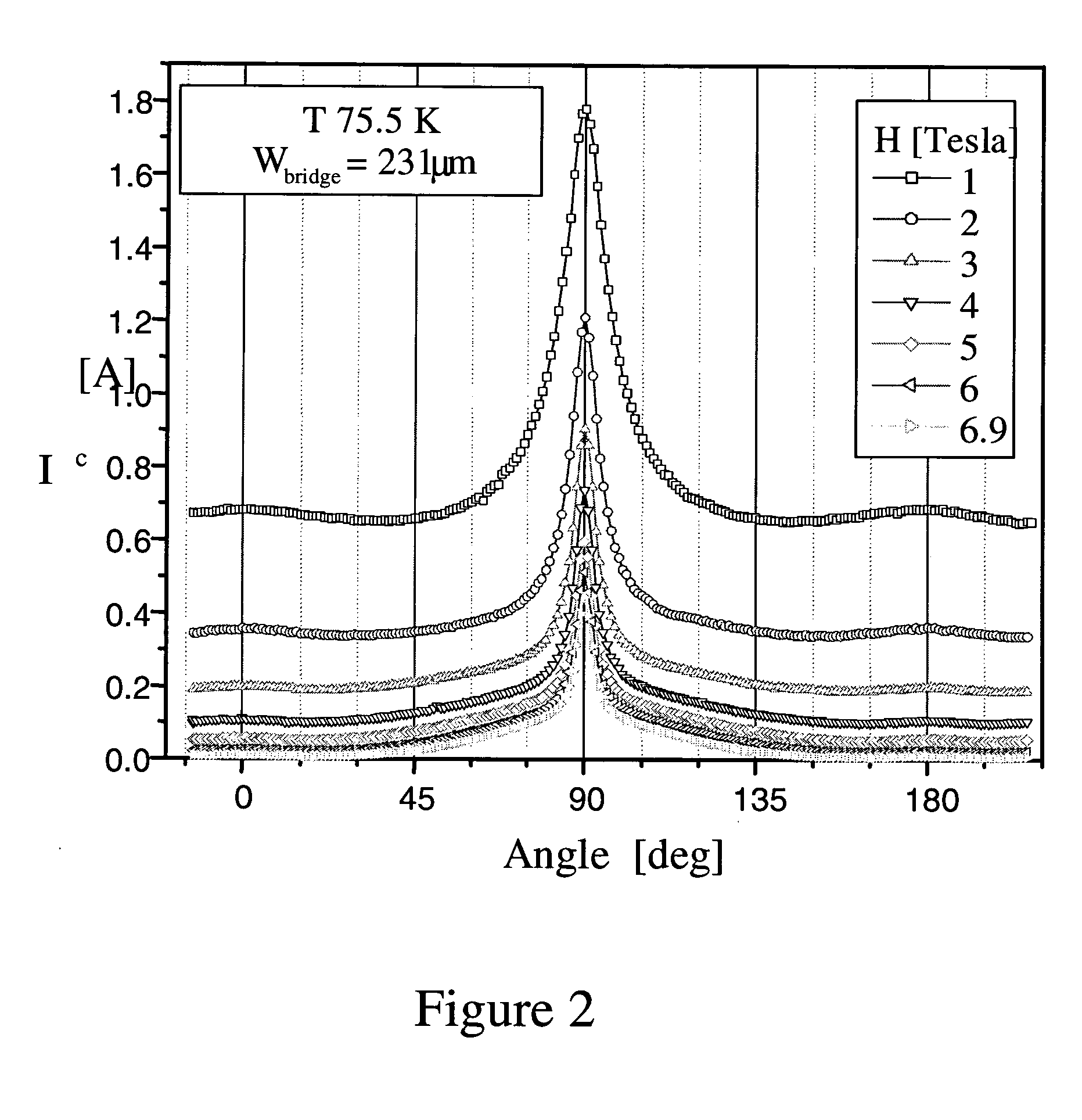

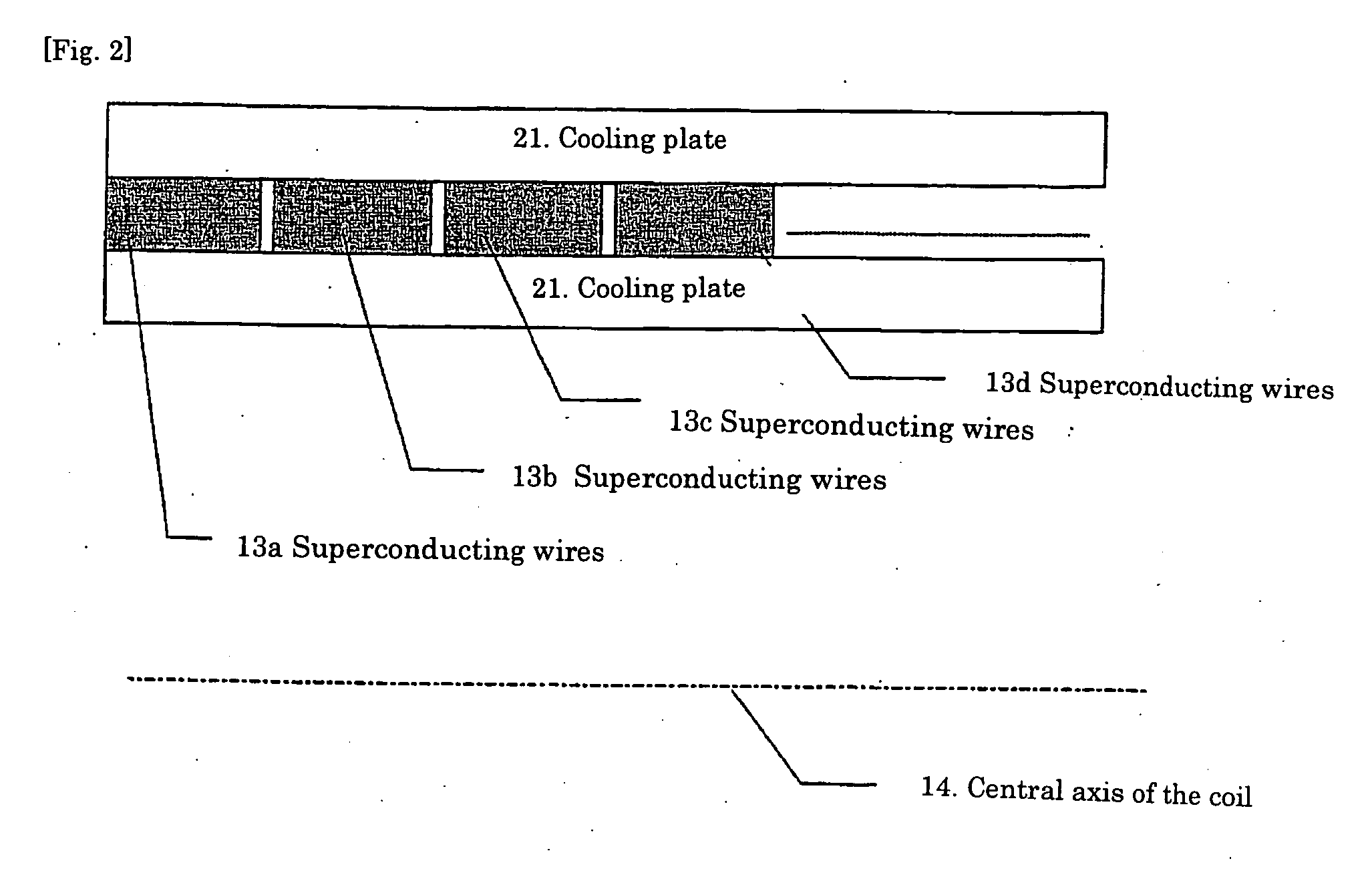

ActiveUS20070111893A1Enhance critical current densityHigh densitySuperconductors/hyperconductorsMagnetsElectrical conductorHigh-temperature superconductivity

A superconducting wire includes first and second superconducting layers disposed on one or more substrates in stacked relationship, the first superconducting layer comprising a high temperature superconducting oxide of a first composition and the second superconducting layer comprising a high temperature superconducting layer of a second composition, wherein the first and second compositions are different. The first superconductor layer optionally includes a high temperature superconductor composition selected to provide enhanced critical current (Ic(c)) in the presence of magnetic fields perpendicular to surface of the superconducting layer (H / / c). The second superconductor layer optionally includes a high temperature superconductor composition selected to provide enhanced critical current (Ic) in the presence of magnetic fields parallel to surface of the superconducting layer (H / / ab).

Owner:AMERICAN SUPERCONDUCTOR

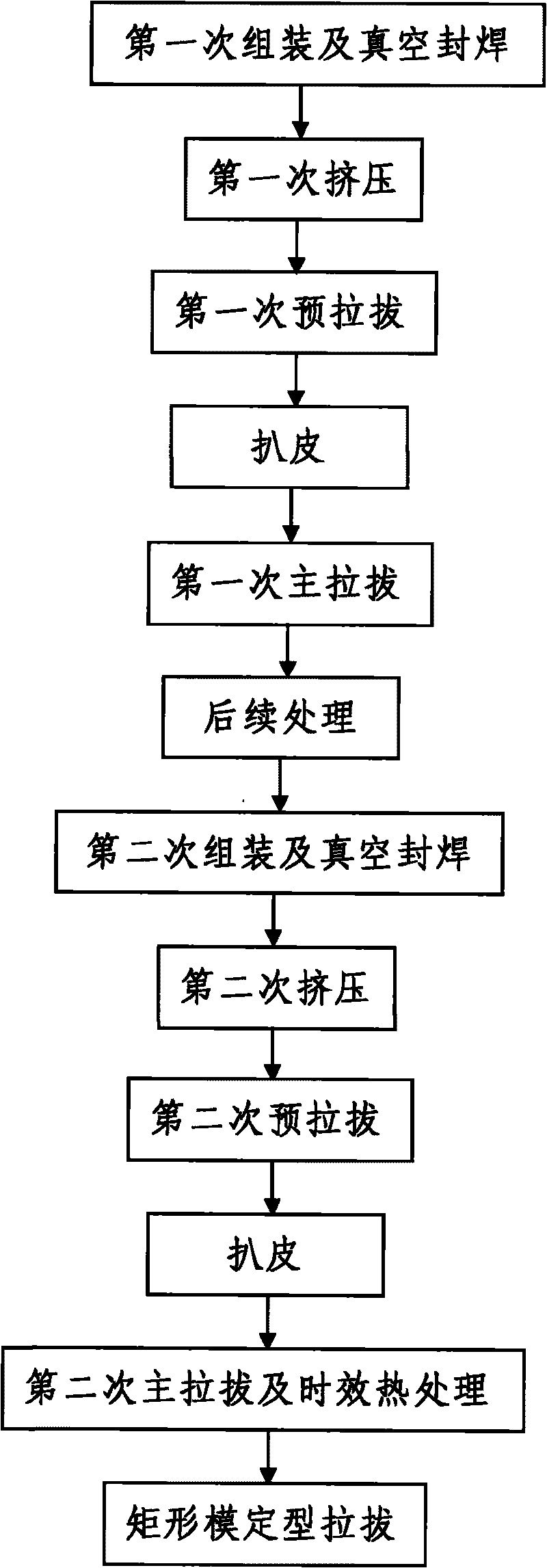

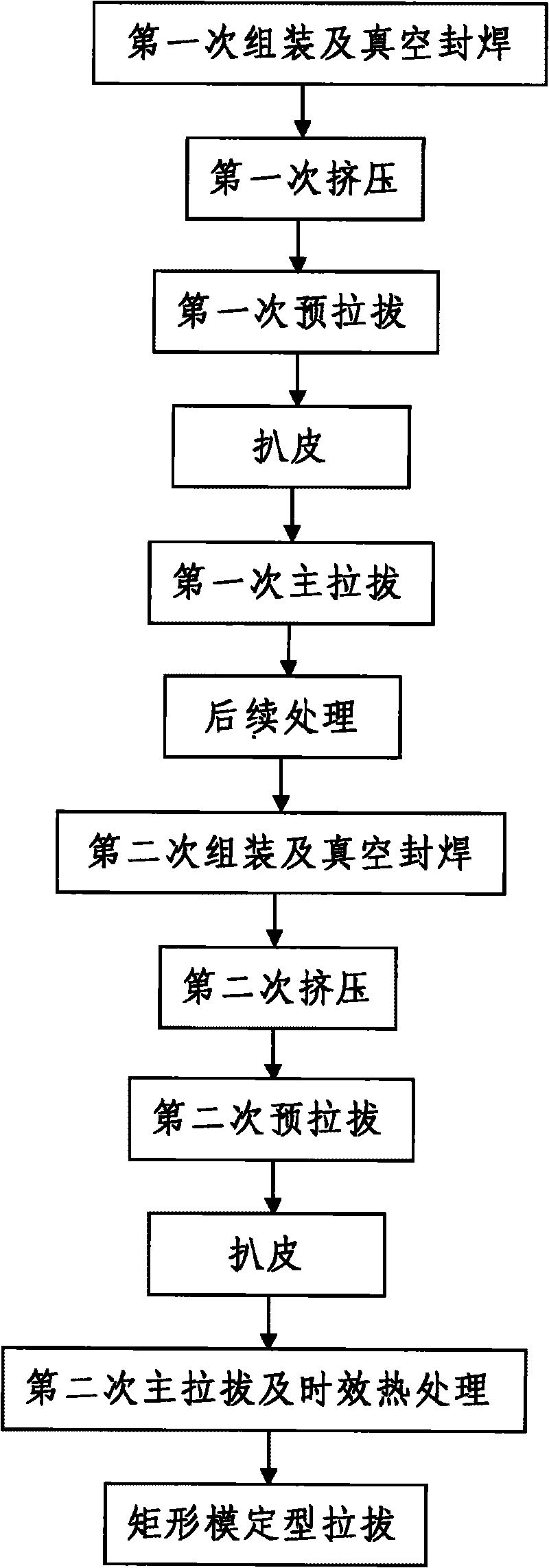

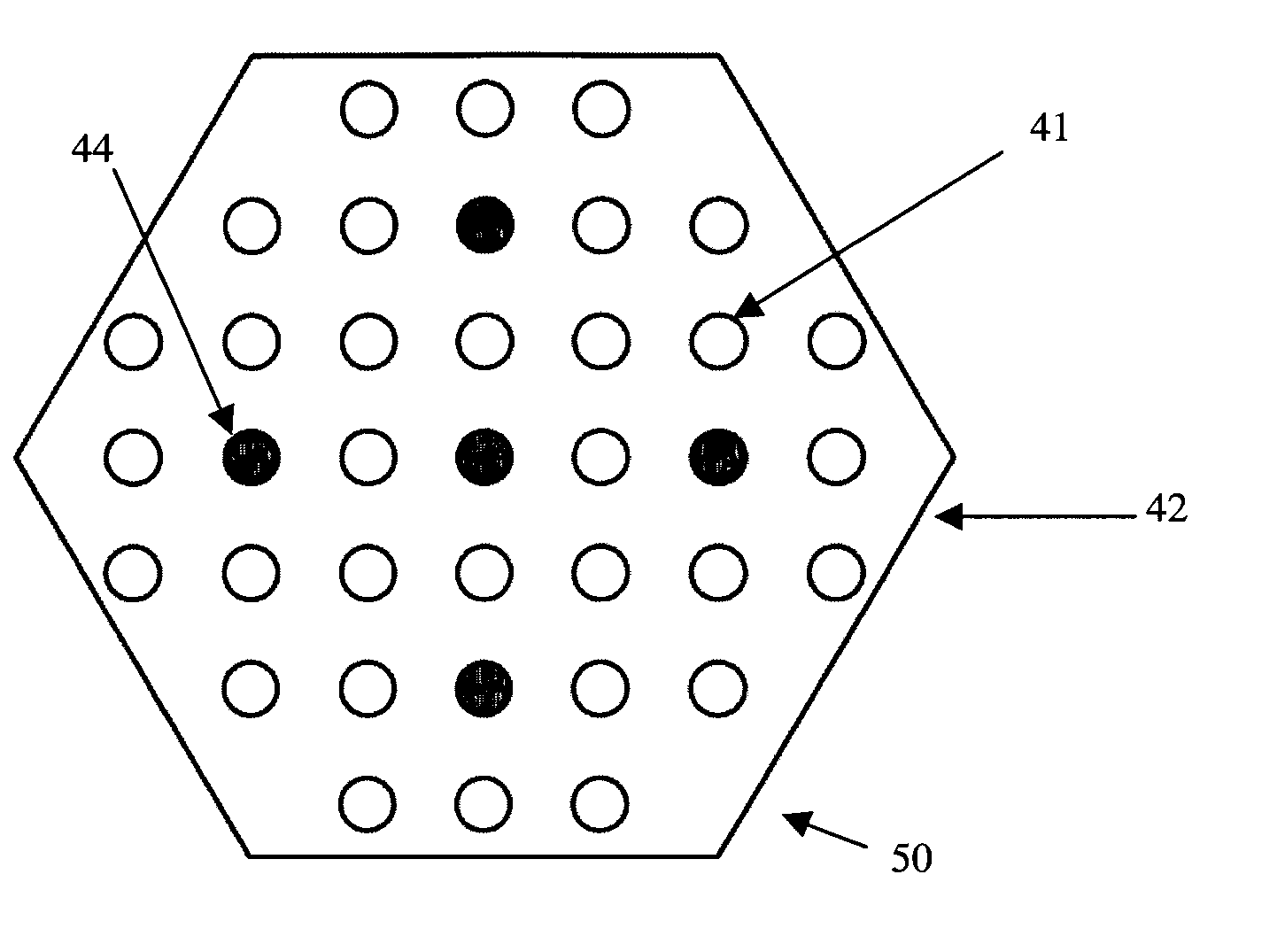

Preparation method for NbTi/Cu multi-core composite superconducting wire with rectangular section

InactiveCN101728029AThe process steps are simpleShort processSuperconductors/hyperconductorsSuperconductor devicesConductor CoilMaterials science

The invention discloses a preparation method for an NbTi / Cu multi-core composite superconducting wire with a rectangular section, which comprises the following steps of: firstly, assembling an NbTi bar, a pure Nb inner pipe and an oxygen-free copper sheath in turn to form an NbTi / Cu composite sheath, sealing an upper end cap and a lower end cap of the NbTi / Cu composite sheath through vacuum welding, and then performing primary extrusion to obtain an NbTi / Cu composite bar; secondly, drawing and scaling the composite bar, and keeping on drawing the composite bar to obtain a hexagonal core rod, and performing assembling for the second time; and thirdly, performing vacuum solder sealing, hot isostatic pressing, secondary extrusion, bar drawing and scaling on the sheath which is assembled in the second time to finally obtain the NbTi / Cu multi-core composite superconducting wire with the rectangular section. The preparation method has the advantages of simple process flow, low preparation cost and good preparation effect, improves the fill factor among windings in the process of coiling a superconducting magnet but simultaneously keeps high critical current density for the wire, and overcomes the defects that the conventional four-high mill or forming roll mill is unevenly stressed, is difficult to process and the like in the rolling process.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

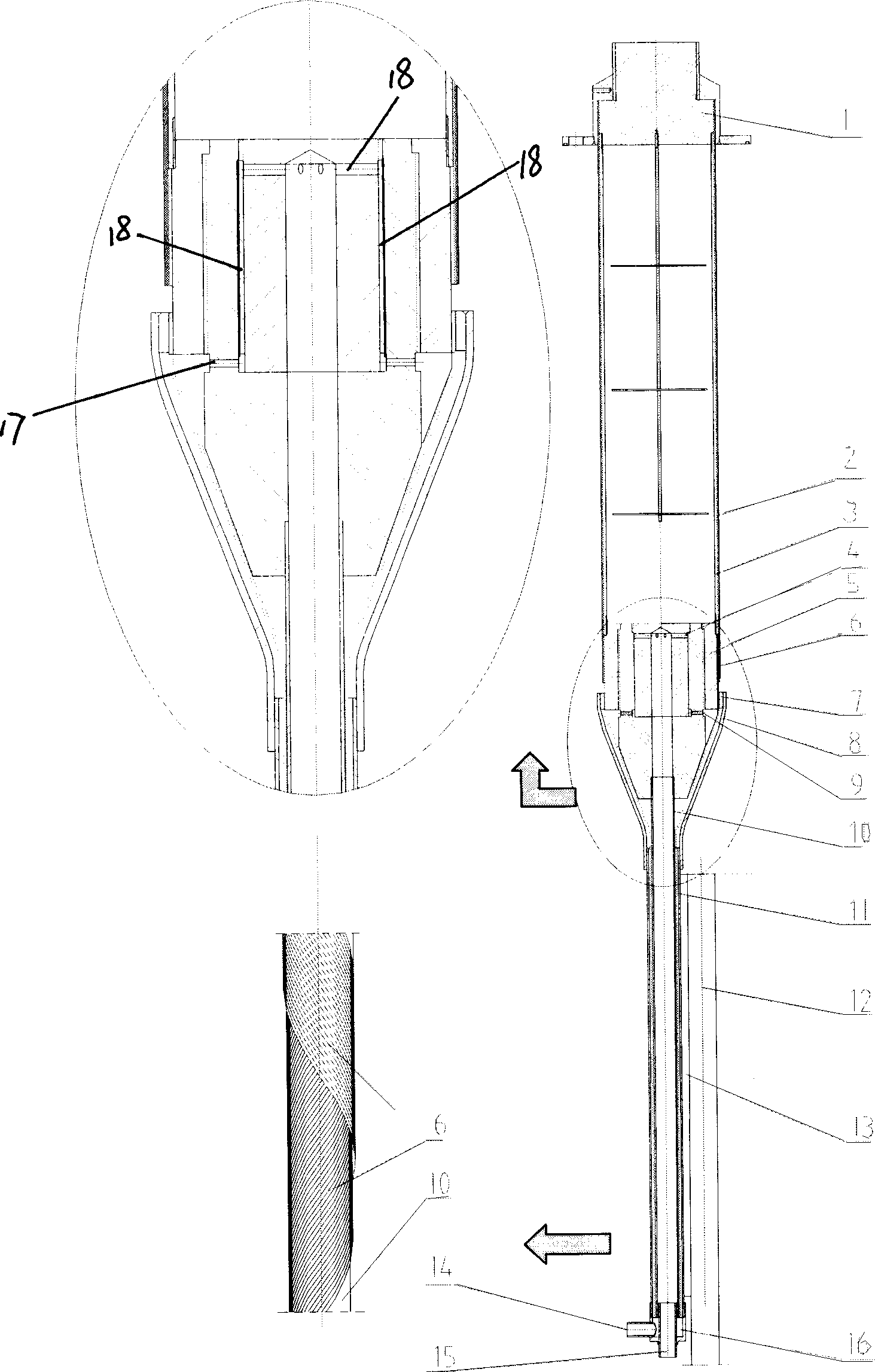

Cold end of heavy current lead out wire made from high-temperature superconductor, and low resistance connector of superconducting transmission line

InactiveCN1873847ASave cooling capacityLess investmentSuperconducting magnets/coilsEngineeringSuperconducting transmission lines

The disclosed adaptor between cold junction of leading wire in heavy current of high-temperature superconductor and low resistance of superconducting transmission line includes structure: welding piles of high-temperature superconductor arranged in spaces to outer wall of support tube made from stainless steel in low thermal conductance; welding warm end in piles of high-temperature superconductor to transition piece of copper; through braze welding, cold end in piles is joined to NbTi / Cu superconducting line; cross winding NbTi / Cu line on inner copper tube sheathed inside outer copper tube; cooling superconducting line and copper connector by using liquid helium between inner and outer copper tubes. Features are: simple structure, suitable to connection under 20kA. In the invention, resistance of adaptor is lowered as 1.4-4.6n ohm. In supercritical quantity of helium flow 4g / s, all loss of 6 pieces of adaptor and 12 pieces of butt end of transmission line is less than 0.1Mpa.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

Method for producing (Nb, Ti)3Sn wire by use of Ti source rods

ActiveUS20050178472A1Improve ductilityImprove diffusivitySuperconductors/hyperconductorsSuperconductor device manufacture/treatmentDopantWire rod

An improvement is disclosed in the method for producing a multifilament (Nb, Ti)3 Sn superconducting wire by the steps of preparing a plurality of Nb or Nb alloy rods where Nb or Nb alloy monofilaments are encased in copper or copper alloy sheaths; packing the Nb or Nb alloy rods within a copper containing matrix to form a packed subelement for the superconducting wire; providing sources of Sn, and sources of Ti within said subelement; assembling the subelements within a further copper containing matrix; and diffusing the Sn and Ti into the Nb or Nb alloy rods to form (Nb, Ti)3 Sn. The method is improved by diffusing the Ti into the Nb from a minor number of Ti dopant source rods which are distributed among the Nb or Nb alloy rods.

Owner:BRUKER OST LLC

Uninsulated superconducting magnet

InactiveCN103035354ASimple structureGive full play to the conductivitySuperconducting magnets/coilsElectrical resistance and conductanceHeat conducting

The invention belongs to the technical field of superconduction and particularly relates to an uninsulated superconducting magnet. The uninsulated superconducting magnet comprises a coil framework and a superconducting wire wound on the coil framework, wherein the surface of the superconducting wire is free from an insulating layer or is wrapped with an incomplete insulating layer, a mixture of an electroconductive material, a heat-conducting material, a curing material and a wetting material is filled among the turns of the superconducting wire, the inter-turn resistance is 0.1ohm-100kilohm, and in terms of volume percentage of all materials, the uninsulated superconducting magnet comprises 0.01-99.9% of the electroconductive material, 0-99.9% of the heat conducting material, 0-99% of the curing material and 0-5% of the wetting material. According to the uninsulated superconducting magnet disclosed by the invention, electroconductive components are filled in each turn of the superconducting coil so that the inter-turn resistance is maintained higher, not only is the inter-turn uninsulated characteristic brought into play, but also the charging excitation and the quench protection of the superconducting magnet are facilitated.

Owner:NORTHEASTERN UNIV

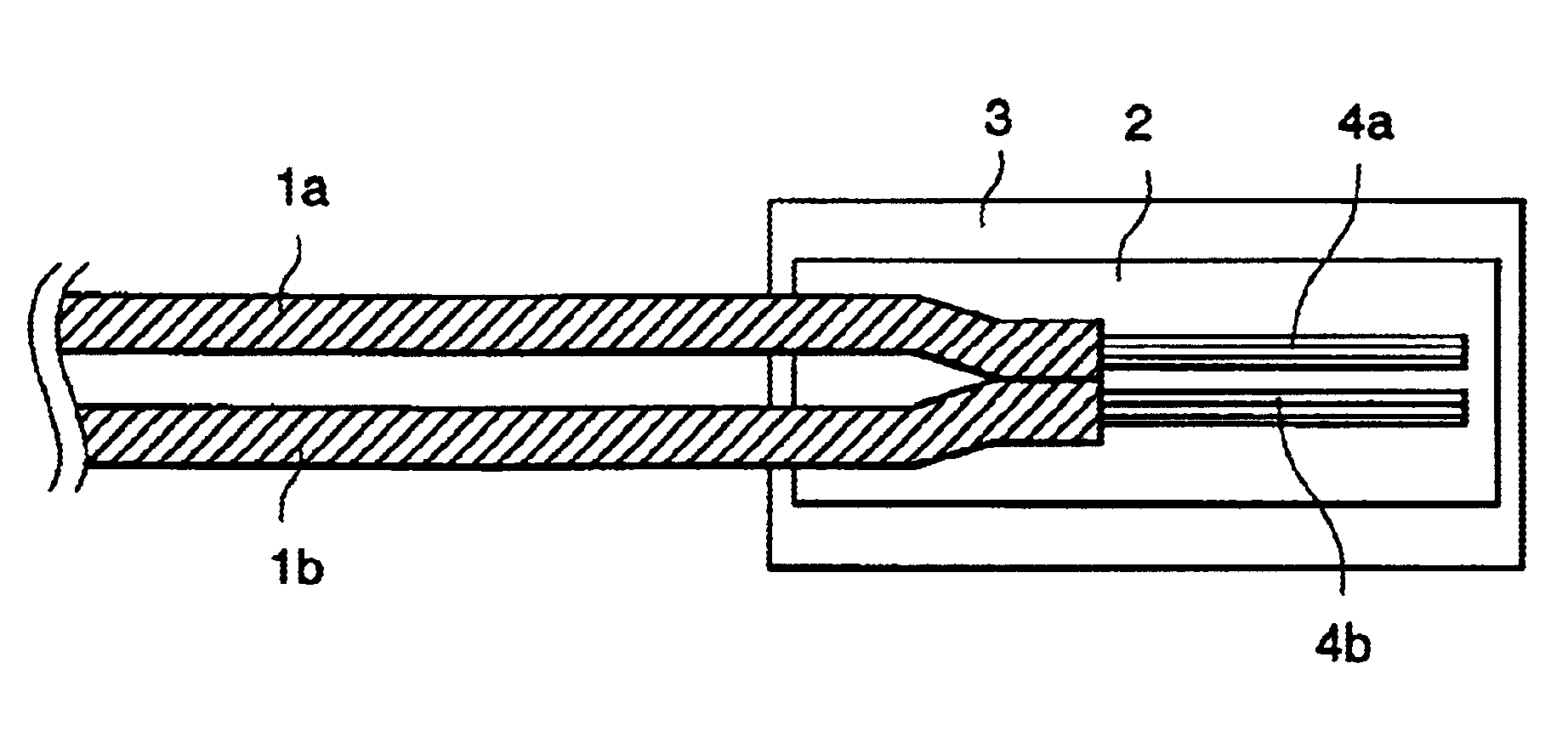

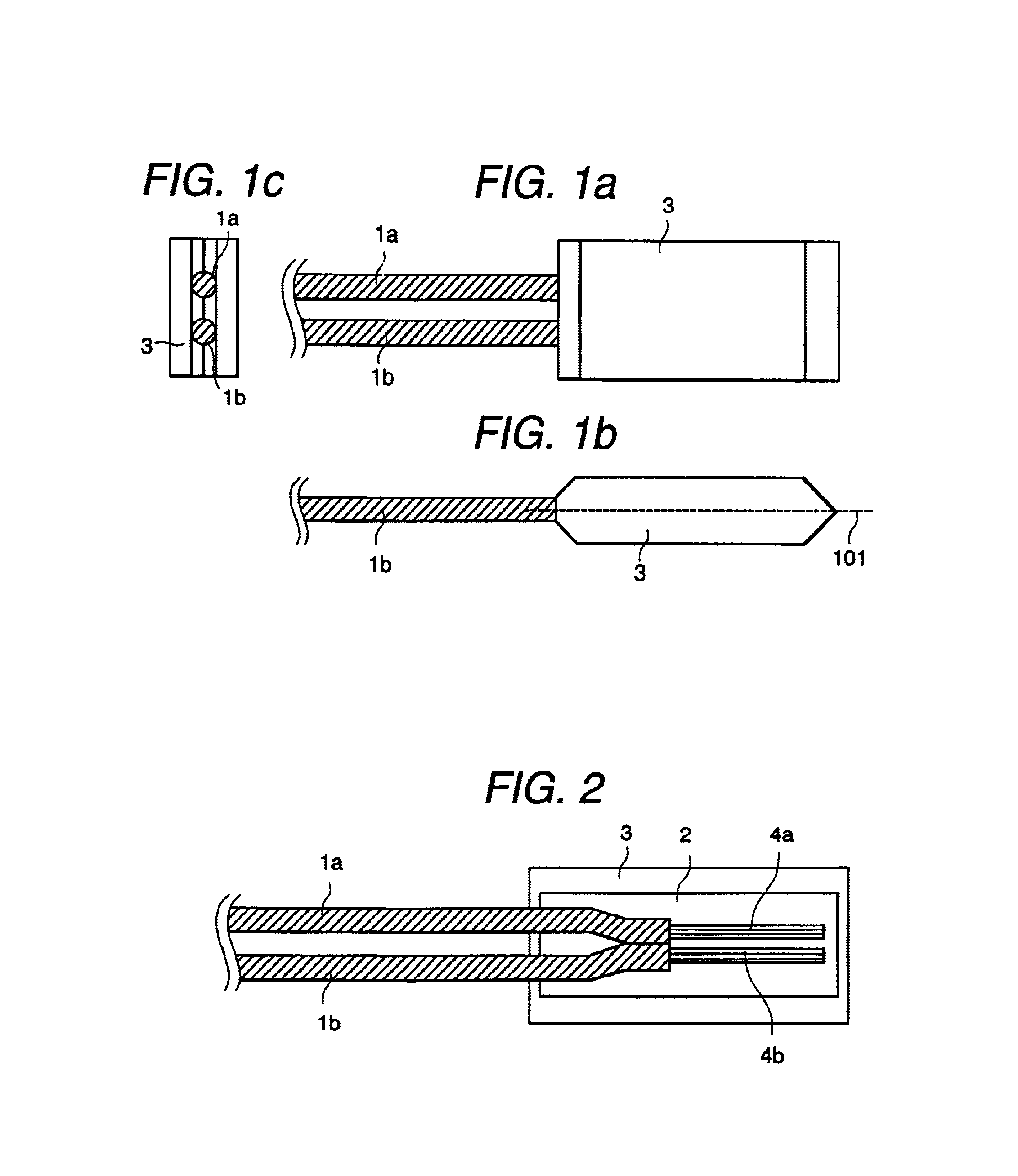

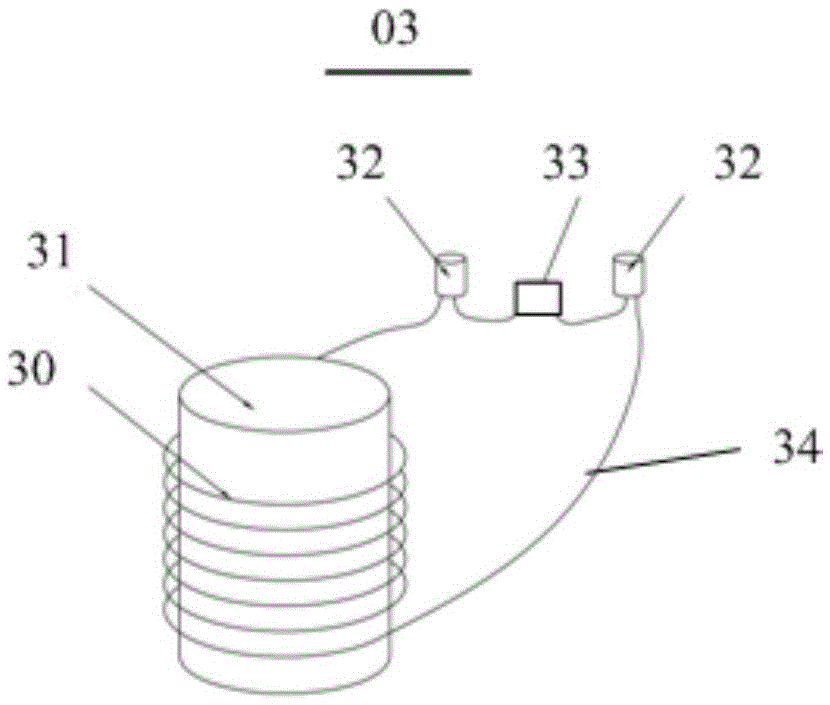

Superconductor connection structure

InactiveUS6921865B2Reduce power consumptionSimple connection structureSuperconductors/hyperconductorsSuperconductor detailsElectricityElectrical connection

Electrical connection of superconducting lines can be achieved by using a low-melting point metal, by mechanical contact of superconducting lines or by welding. According to these methods, however, critical current and critical magnetic field at the connection point are low, and stable connection in a superconducting state has been difficult. The present invention solves these problems and provides a structure and method for connecting superconducting lines. The present invention provides high-performance, high-stability connection of superconducting lines through magnesium diboride (MgB2) powder arranged between superconducting lines.

Owner:HITACHI LTD

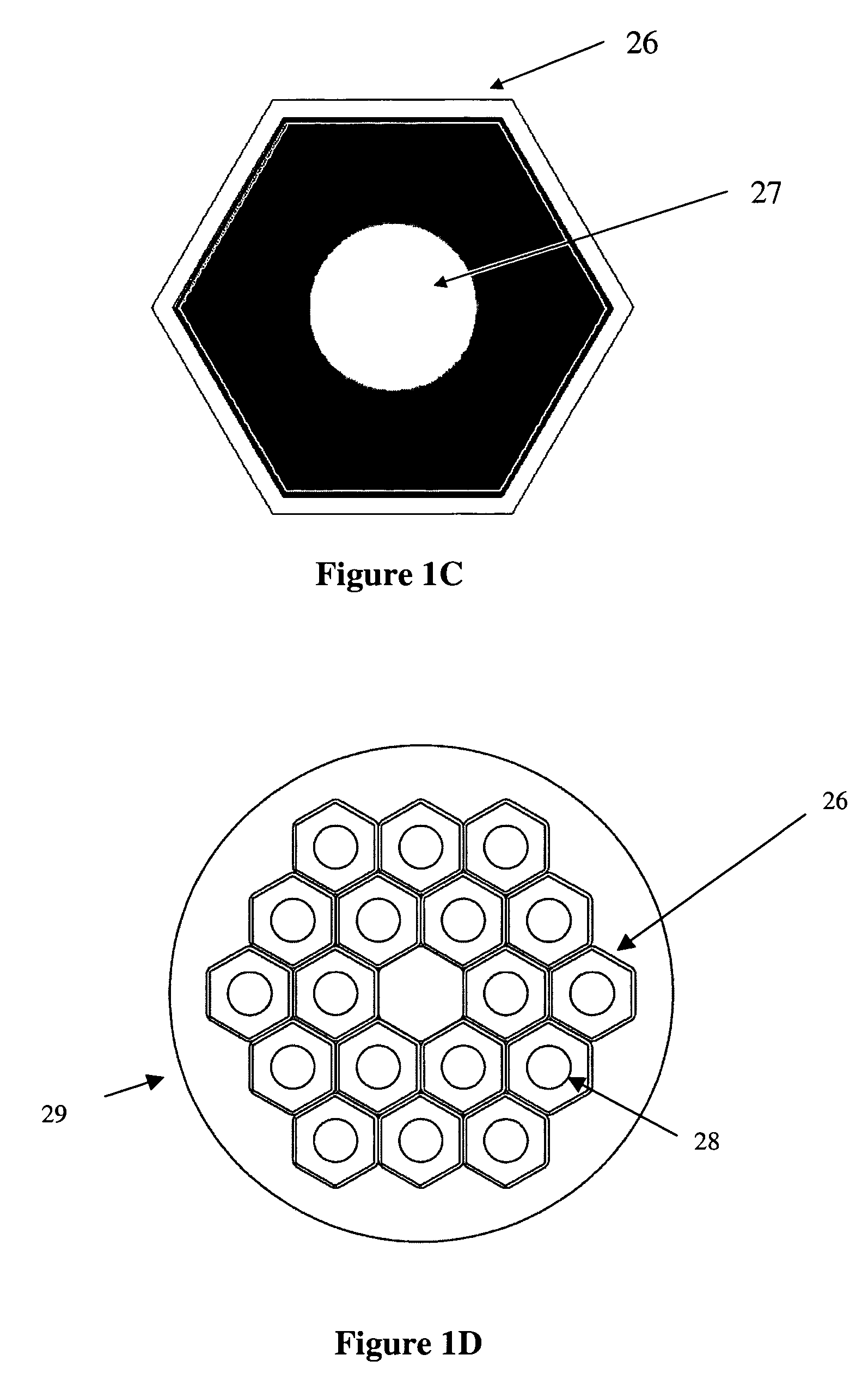

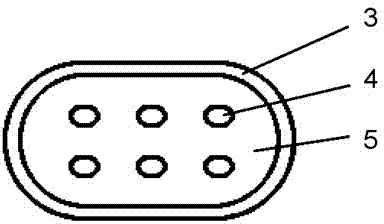

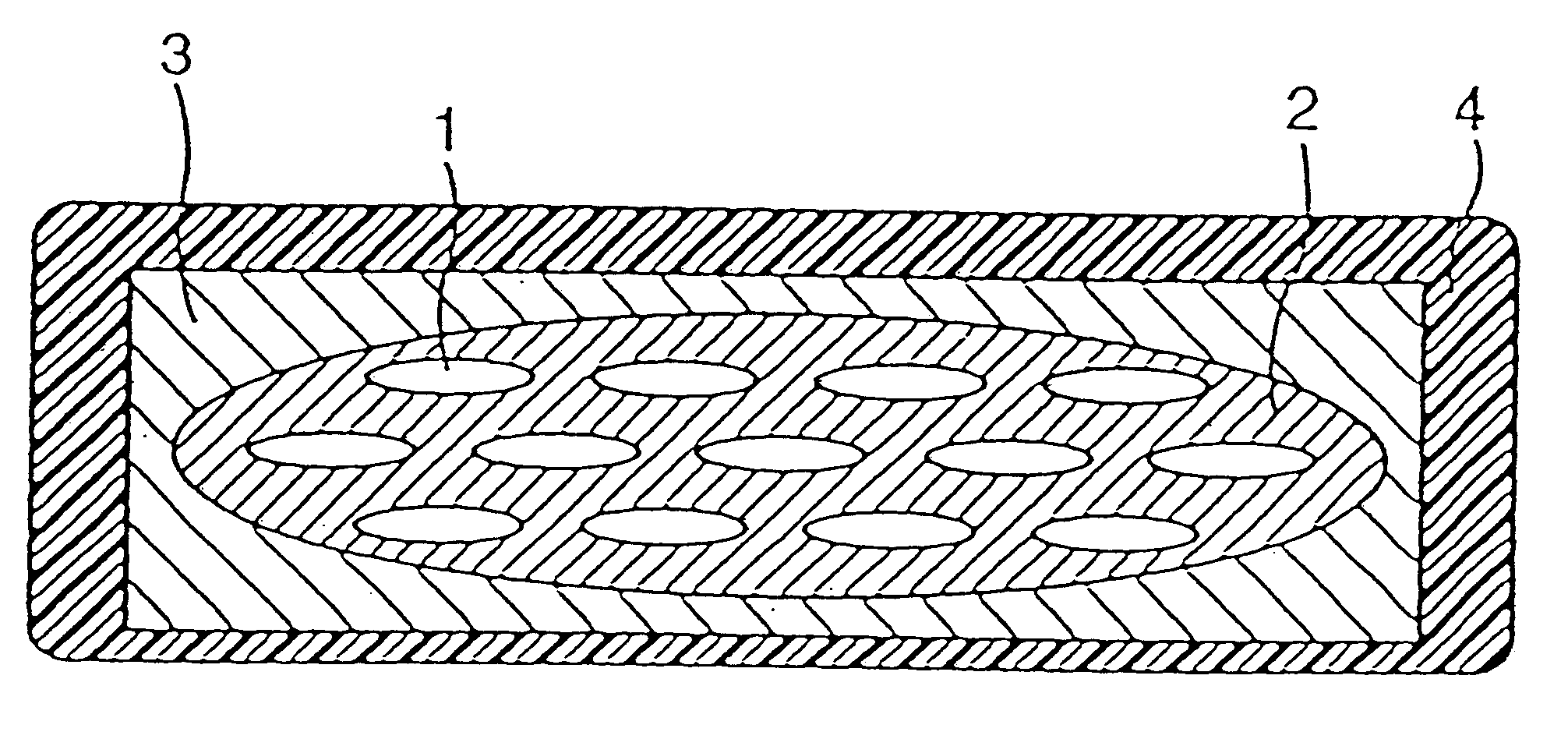

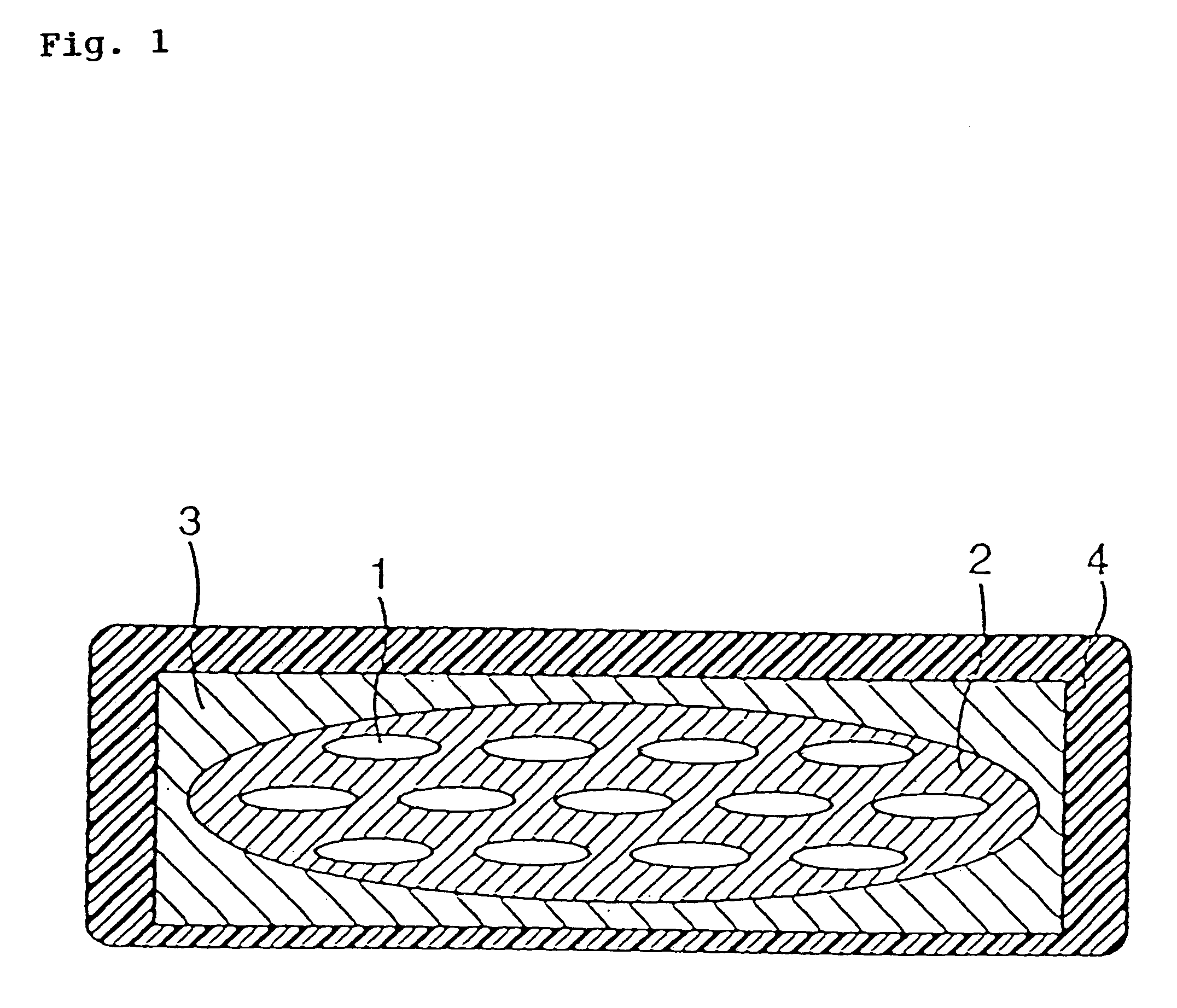

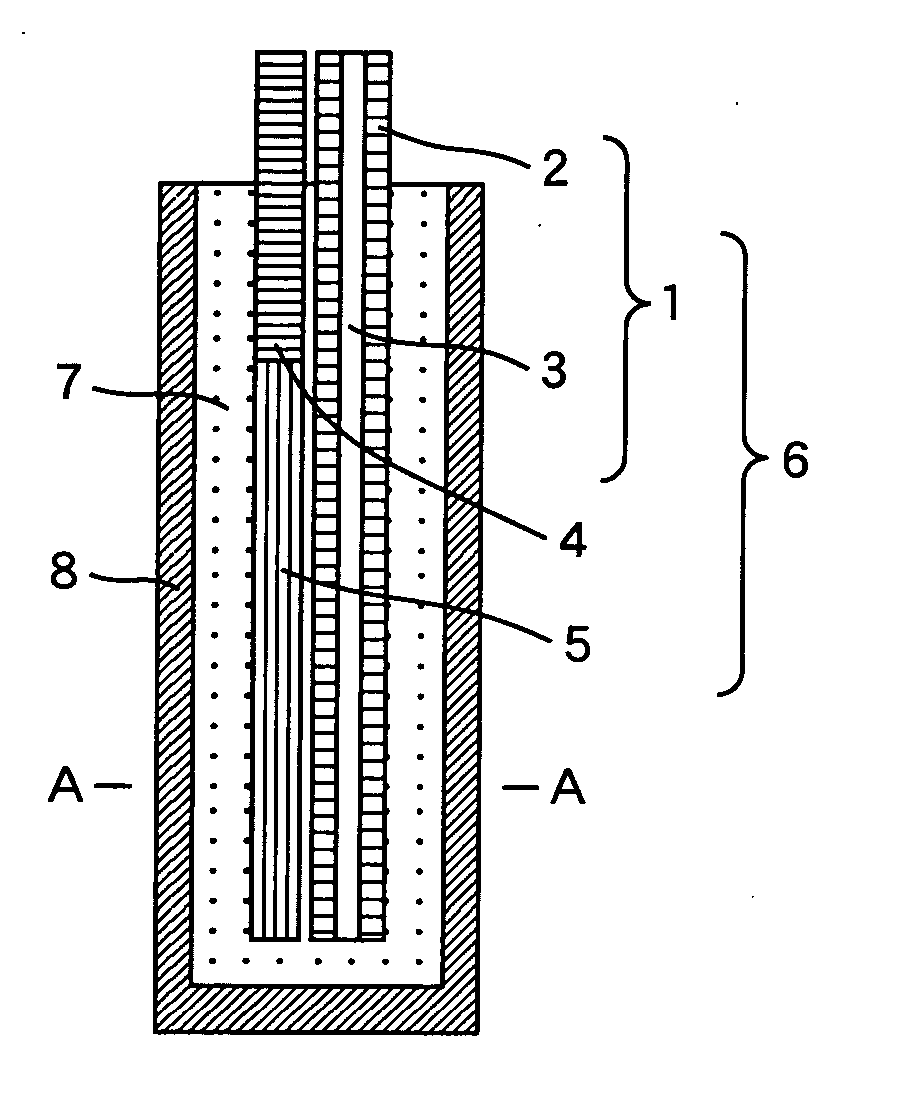

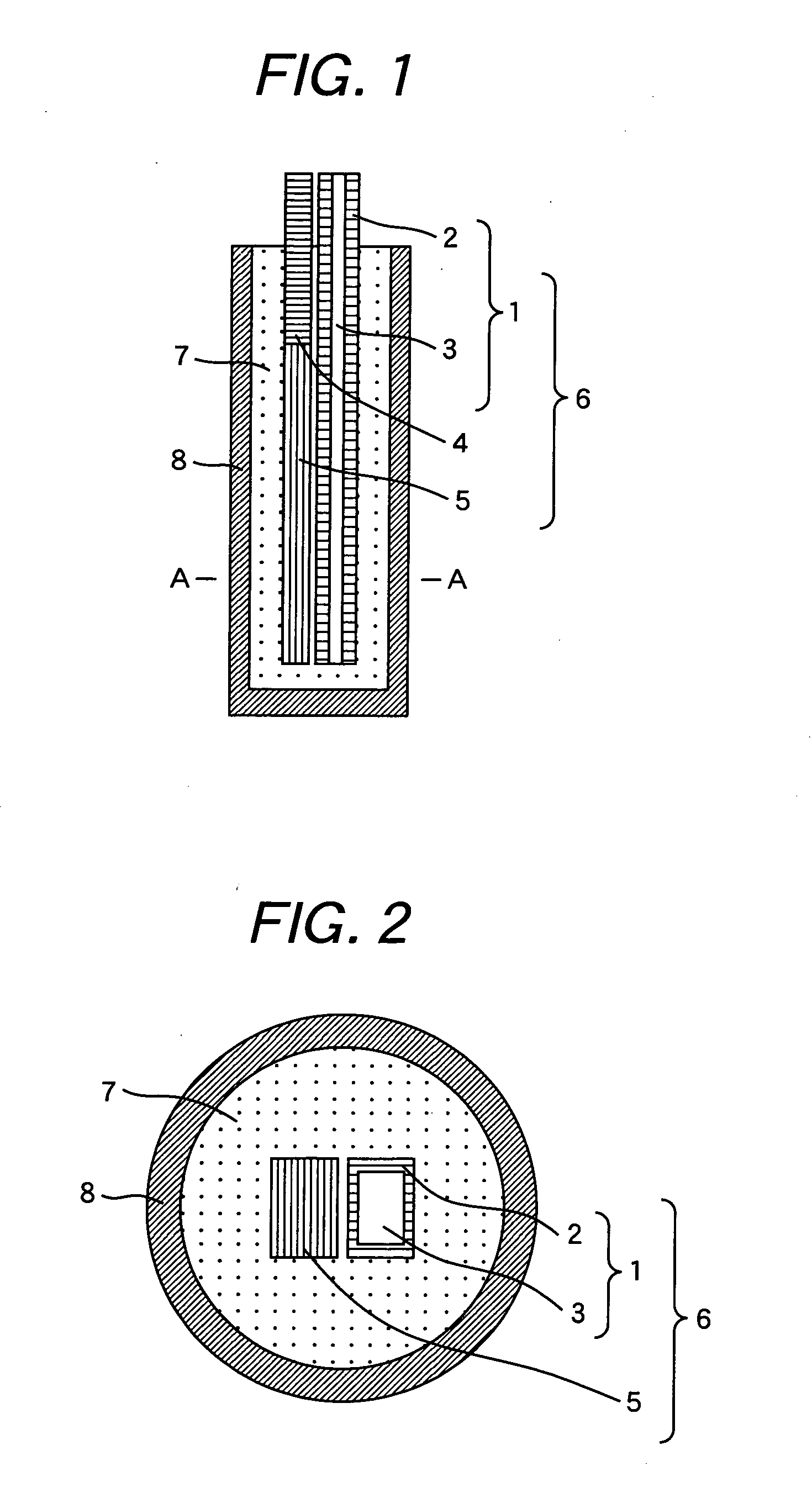

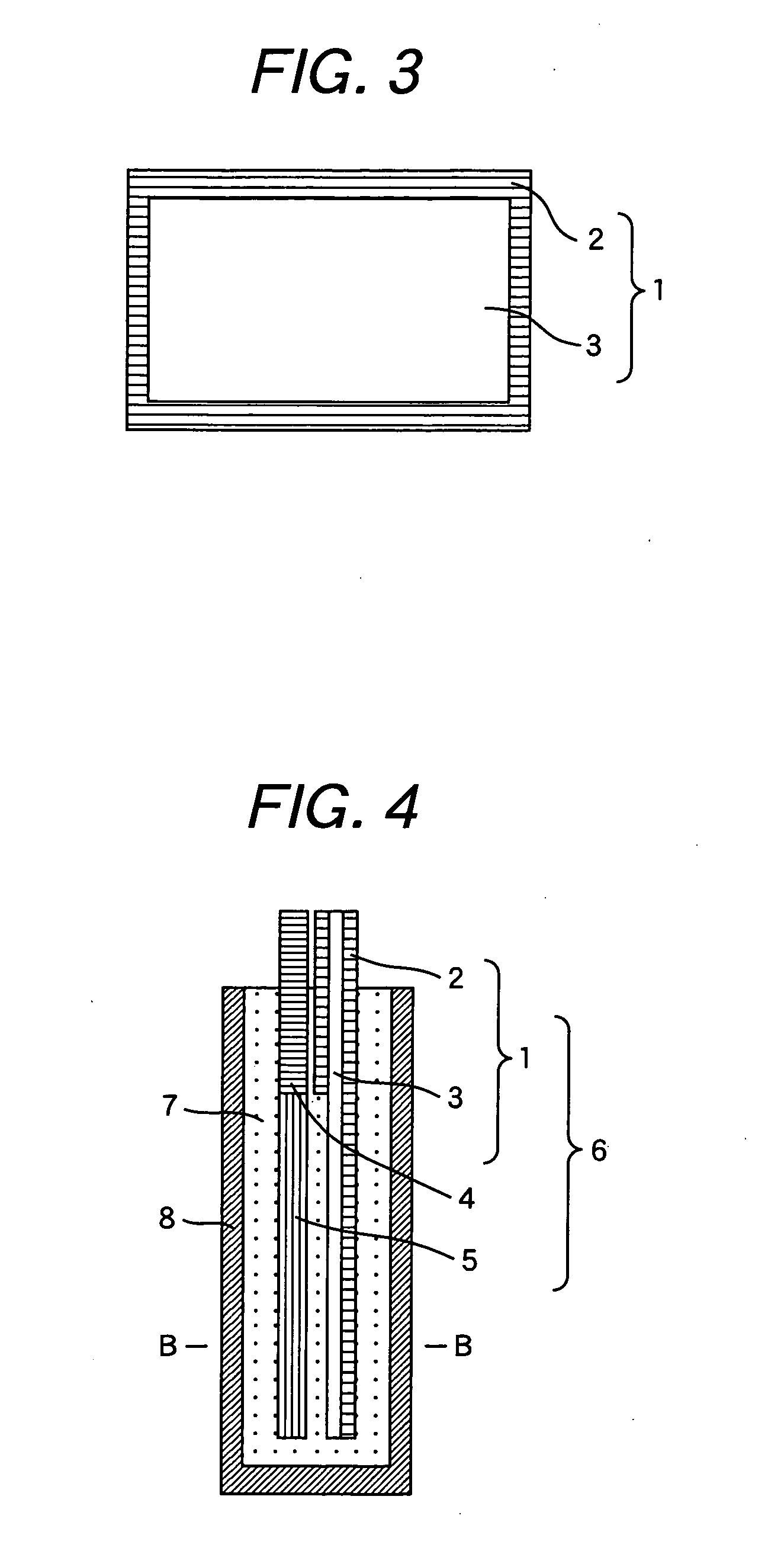

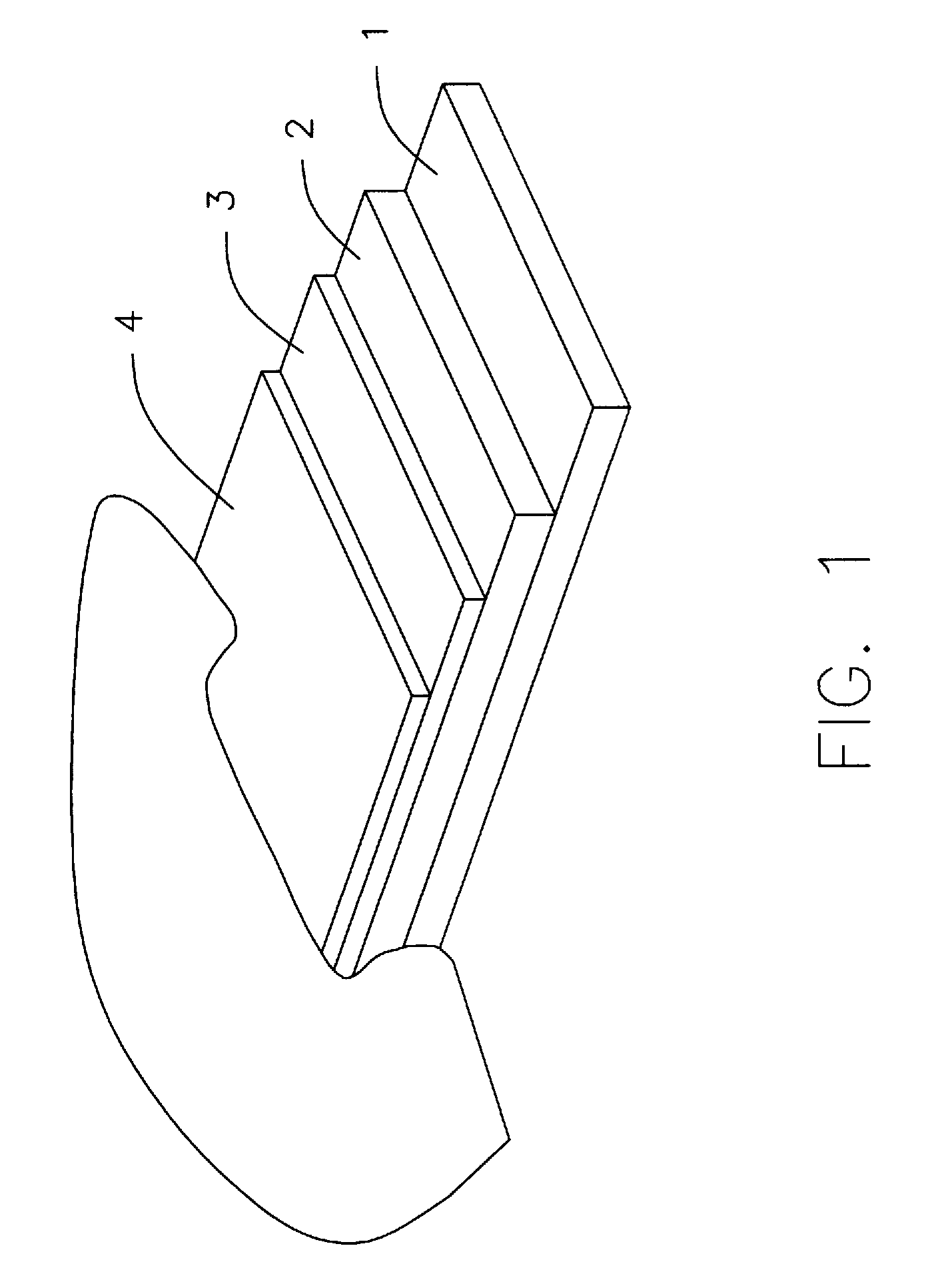

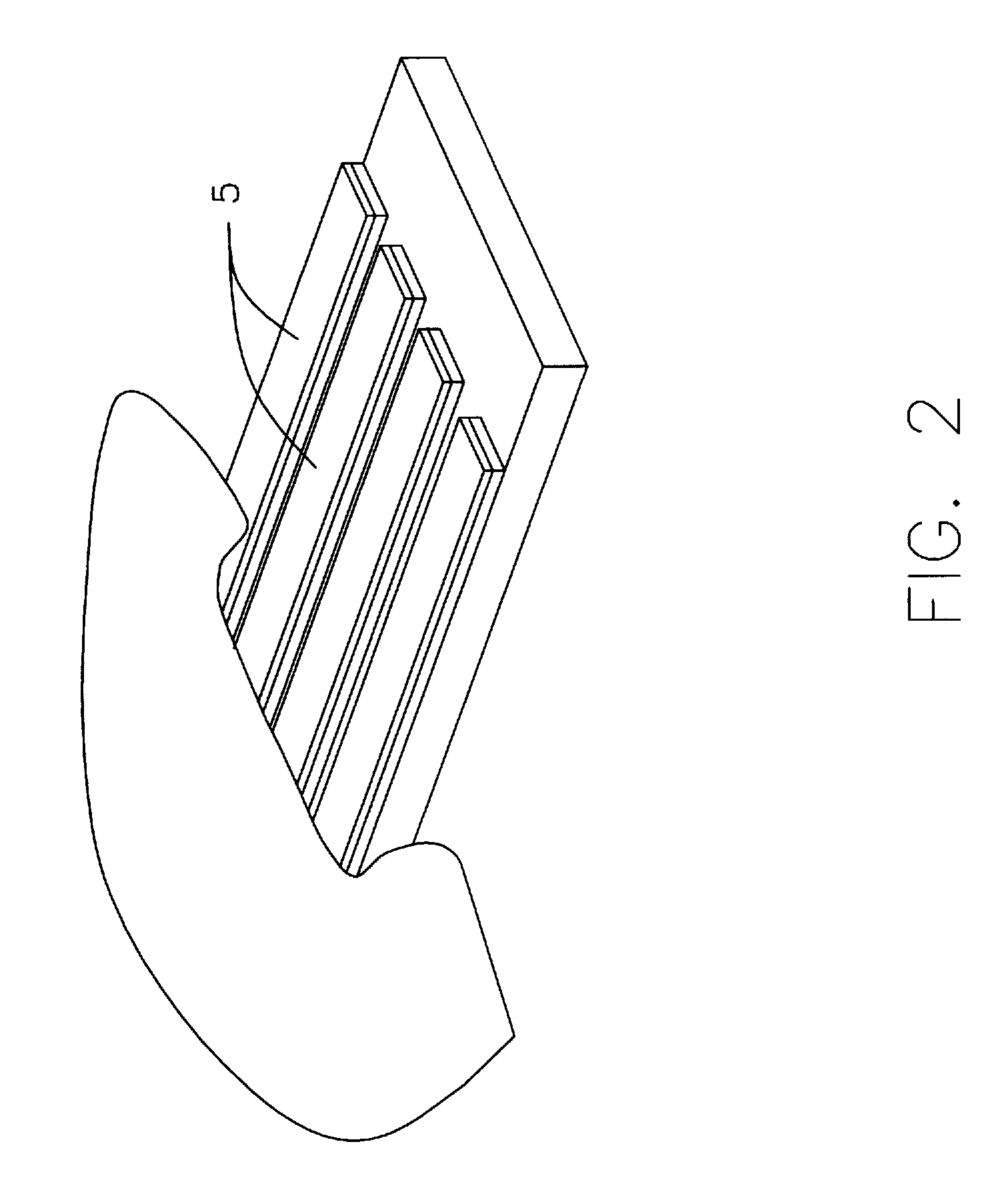

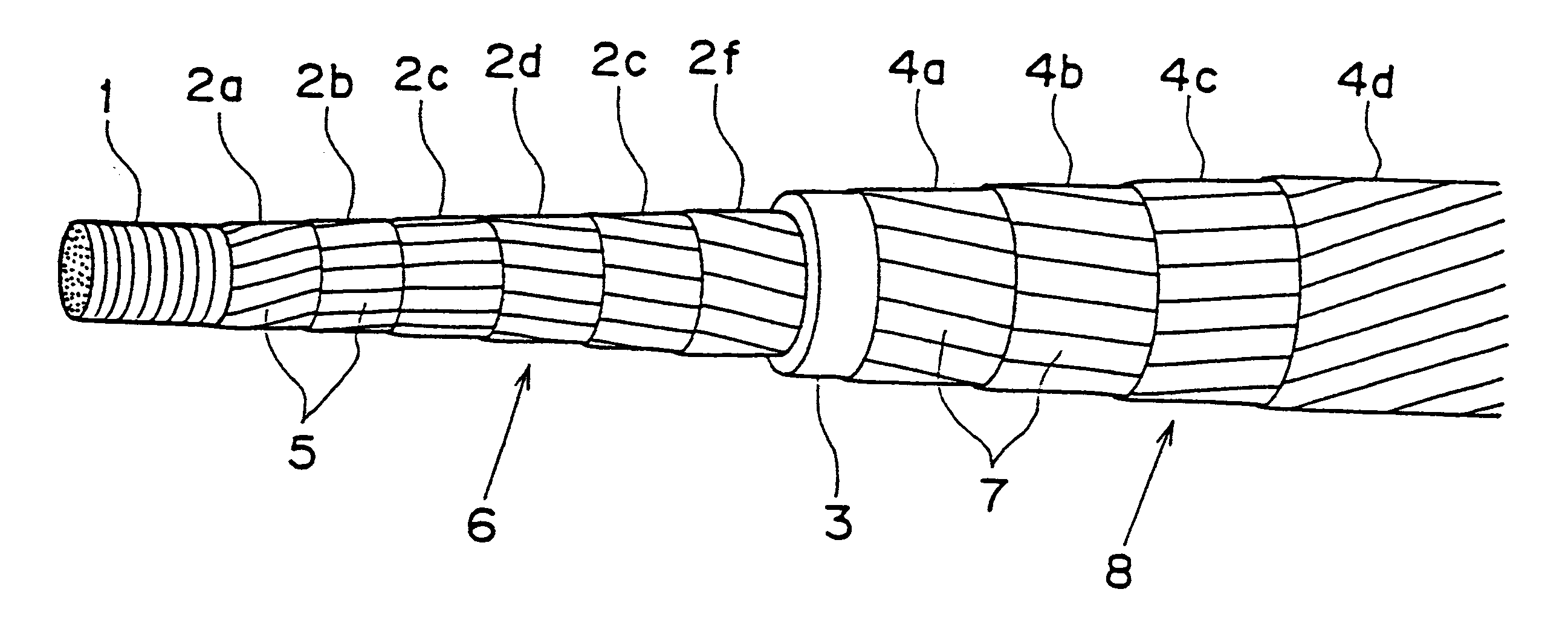

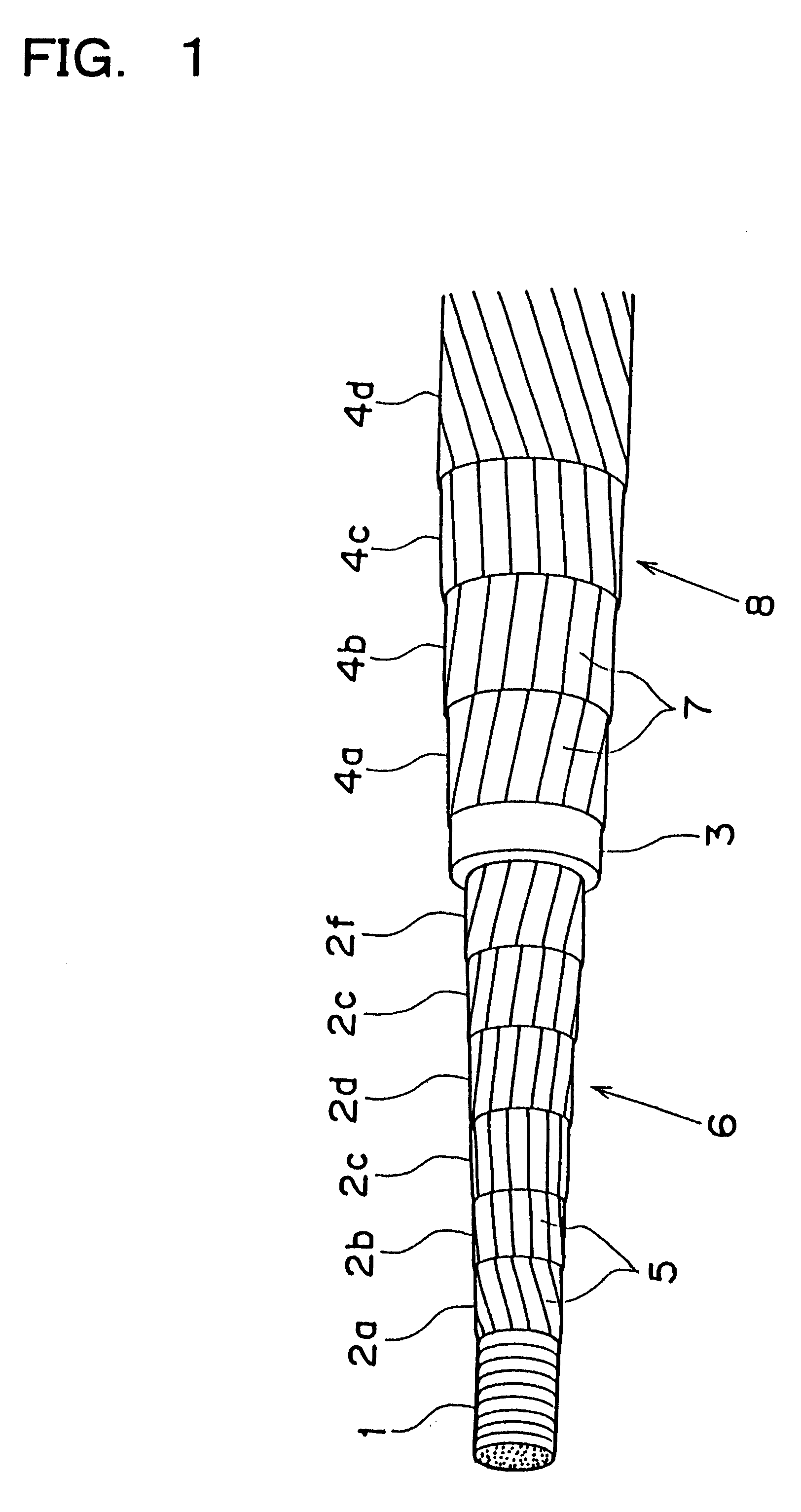

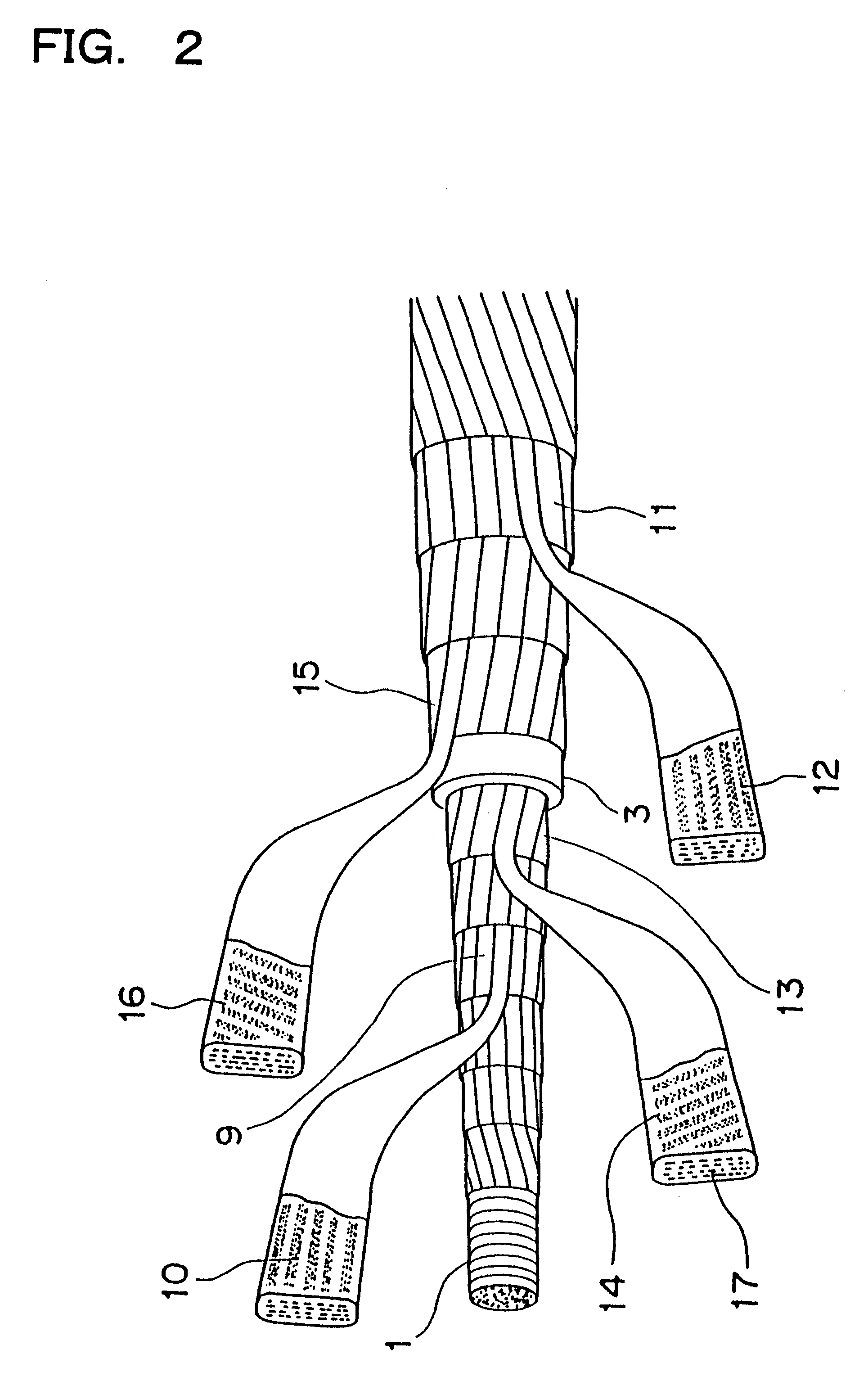

Oxide superconducting wire having insulating coat and production method thereof

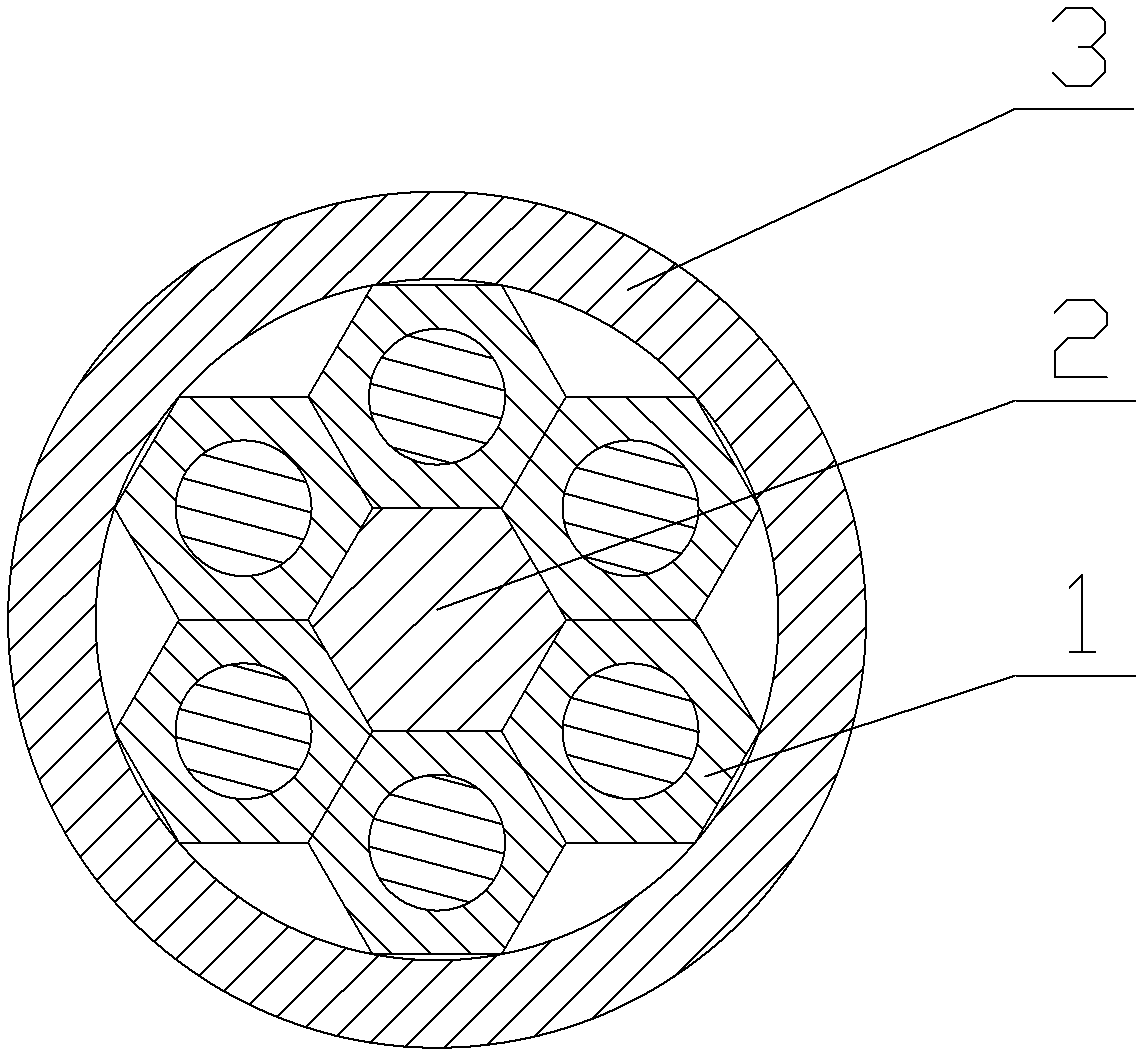

InactiveUS6555504B1High strengthPrevent exertion of excessive mechanical strainSuperconductors/hyperconductorsTransformers/inductances detailsManganeseMaterials science

An oxide superconducting wire includes oxide superconducting filaments 1, a matrix 2, a covering layer 3, and an insulating layer 4. The matrix 2 is placed so as to enclose the oxide superconducting filaments 1 and is made of silver. The covering layer 3 is placed so as to enclose the matrix 2, contains silver and manganese, and has a thickness of 10 mum to 50 mum. The insulating layer 4 is placed so as to enclose the covering layer 3.

Owner:SUMITOMO ELECTRIC IND LTD

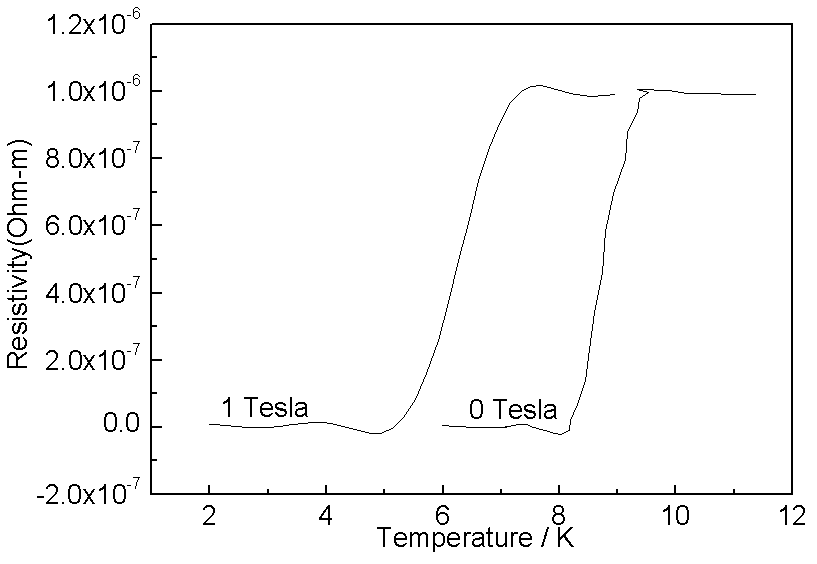

Critical current density in Nb3Sn superconducting wire

Owner:BRUKER OST LLC

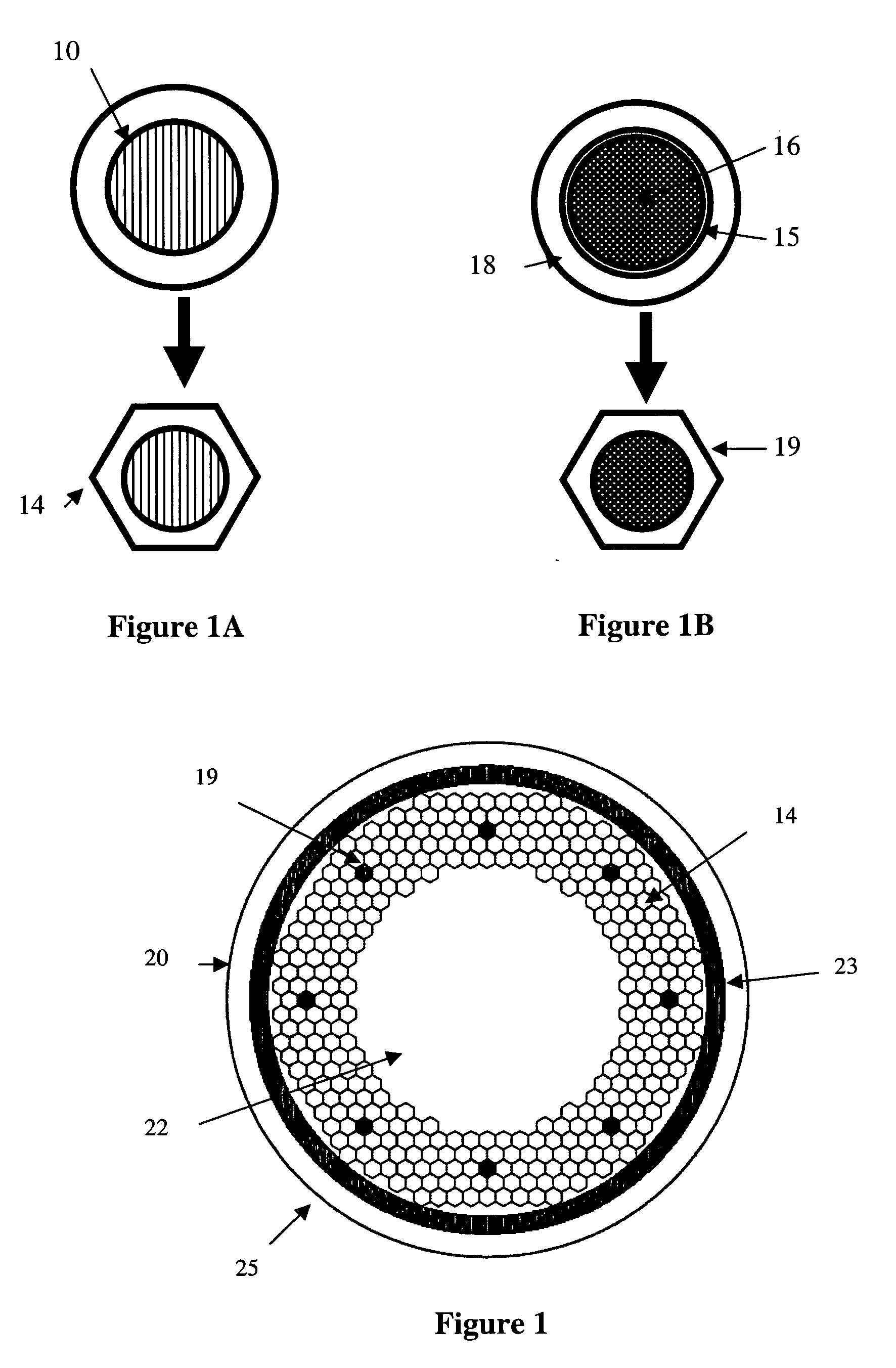

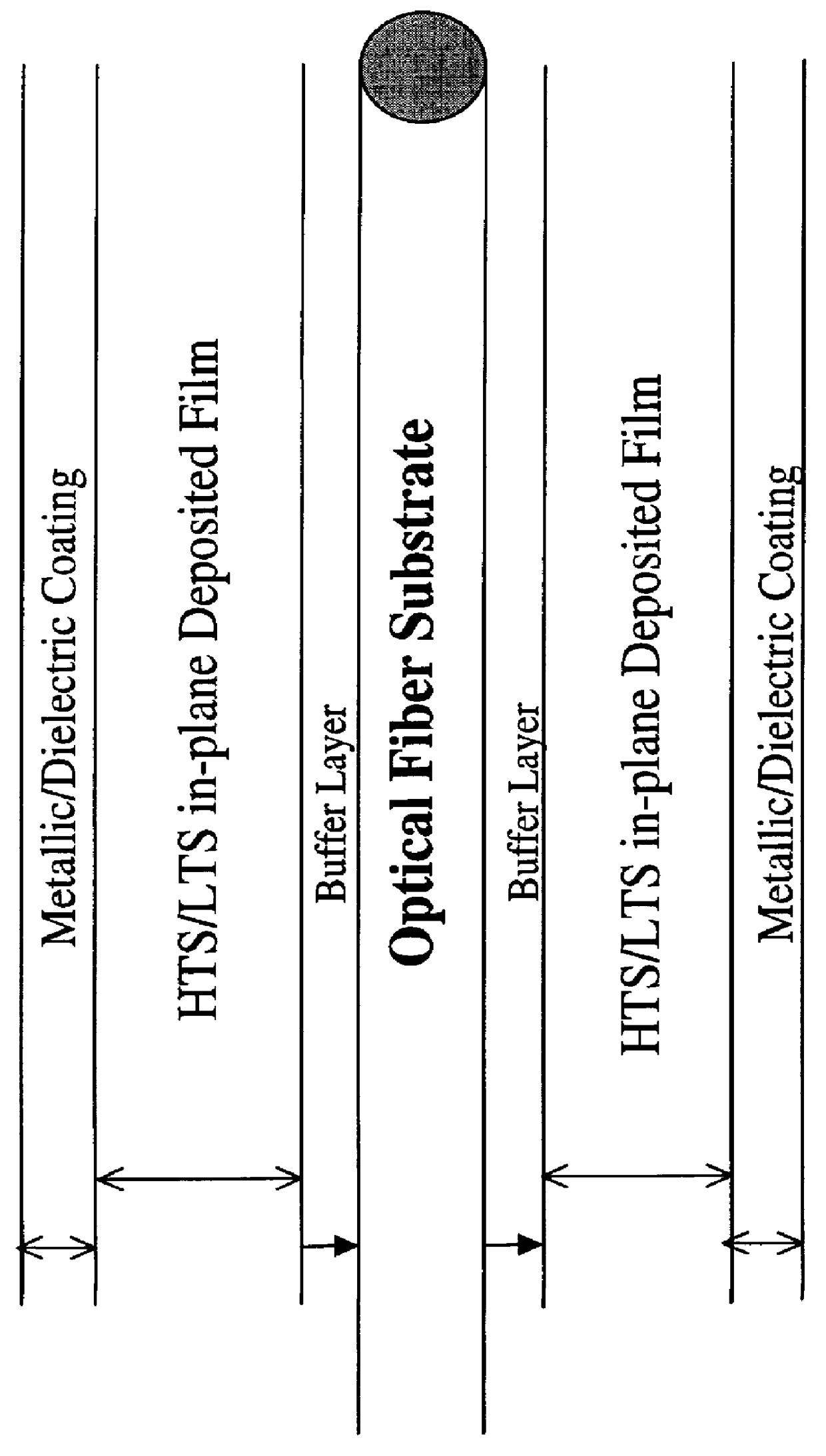

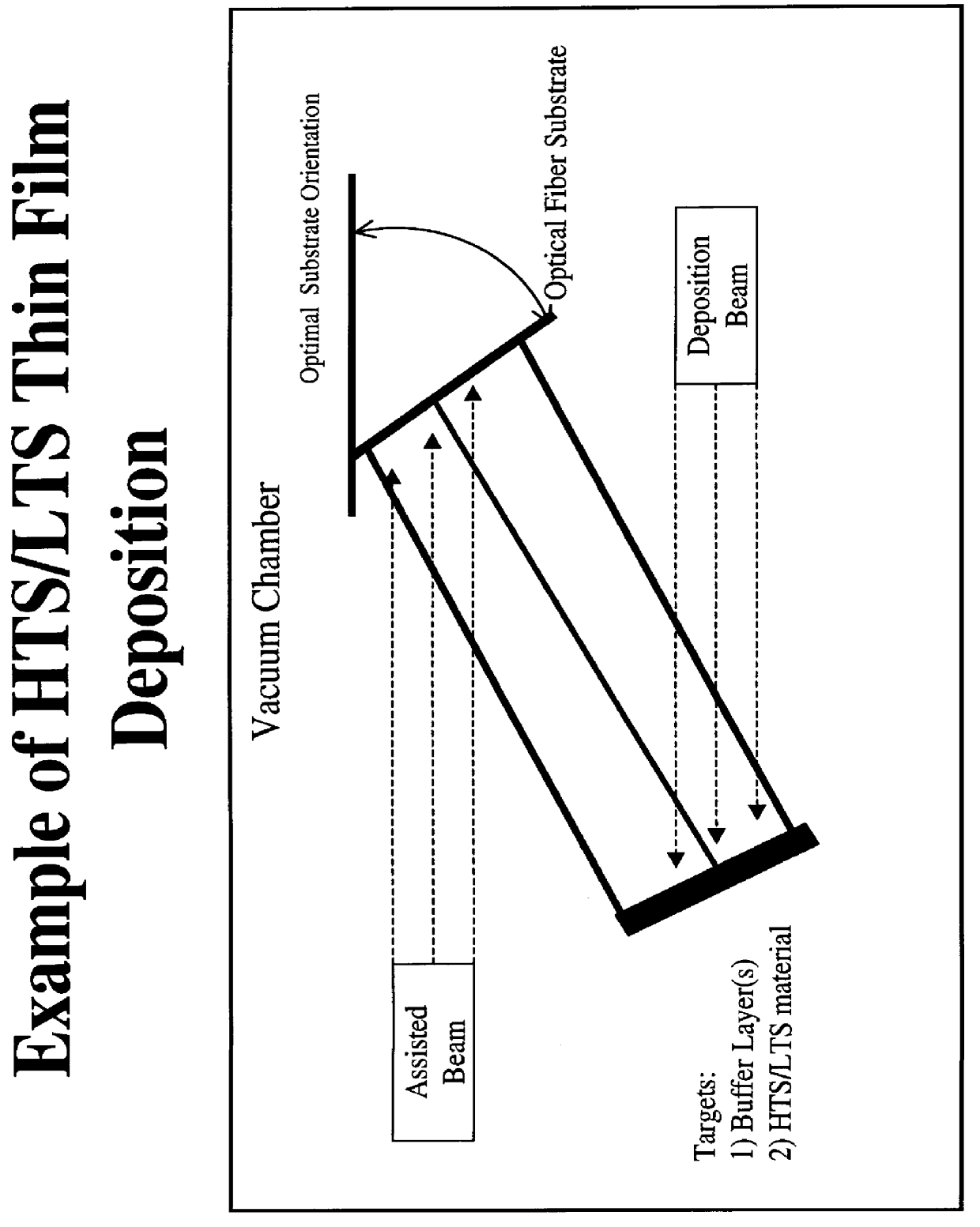

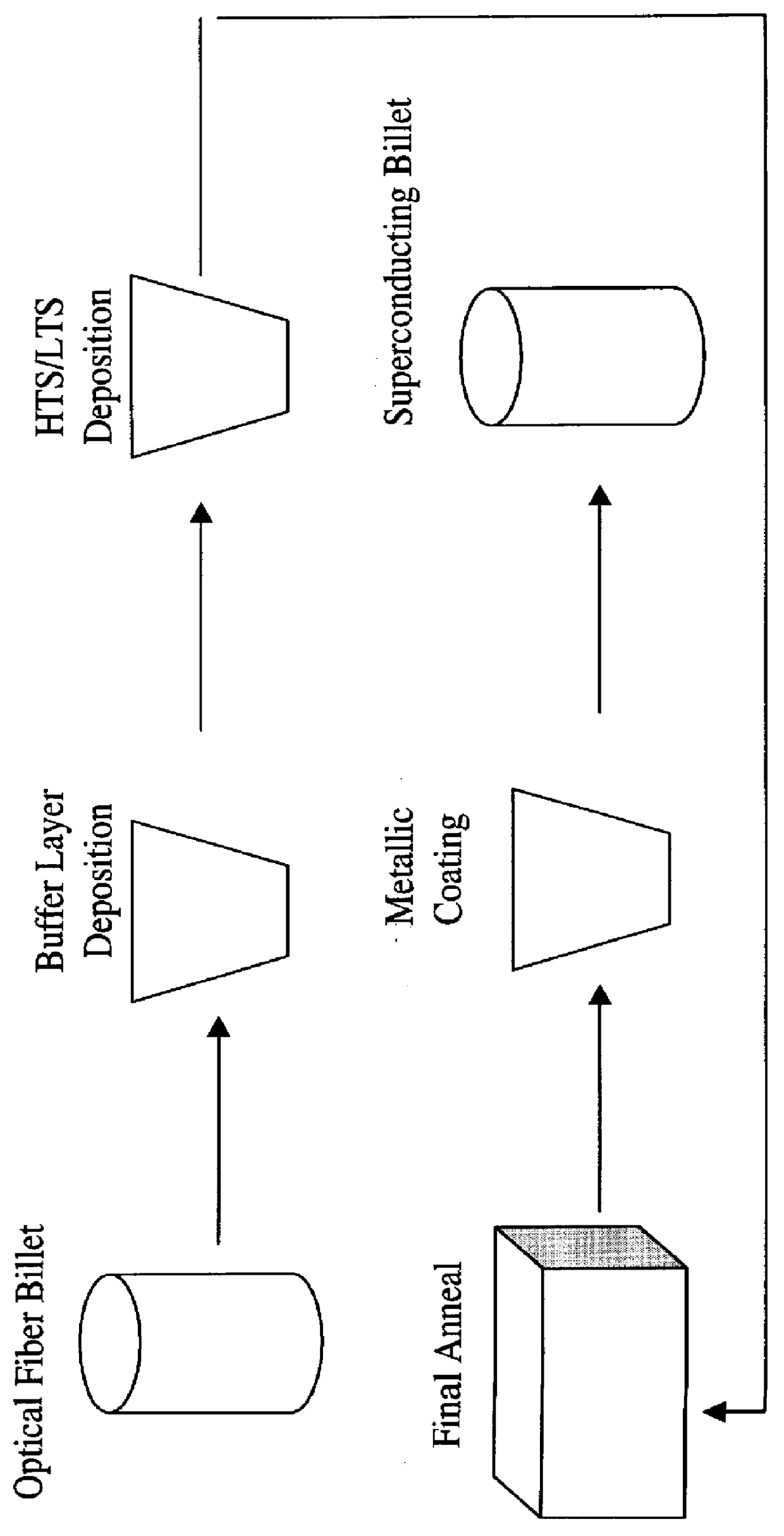

Superconducting wires fabricated using thin optical fibers

This patent application relates to the use of thin high temperature fibers, specifically optical fibers, for use as a substrate material in the fabrication of long-length low temperature superconducting and high temperature superconducting wire. The superconducting material is deposited on the fiber using either a thin or thick film deposition technique. The fiber can have a dual use in the transmission of data using either traditional optical means or the transmission of electrical current via the deposited superconductor. A buffer layer or layers is used between the high temperature fiber and the superconductor to promote grain alignment and enhance the current carrying capacity of the wire.

Owner:REY CHRISTOPHER M

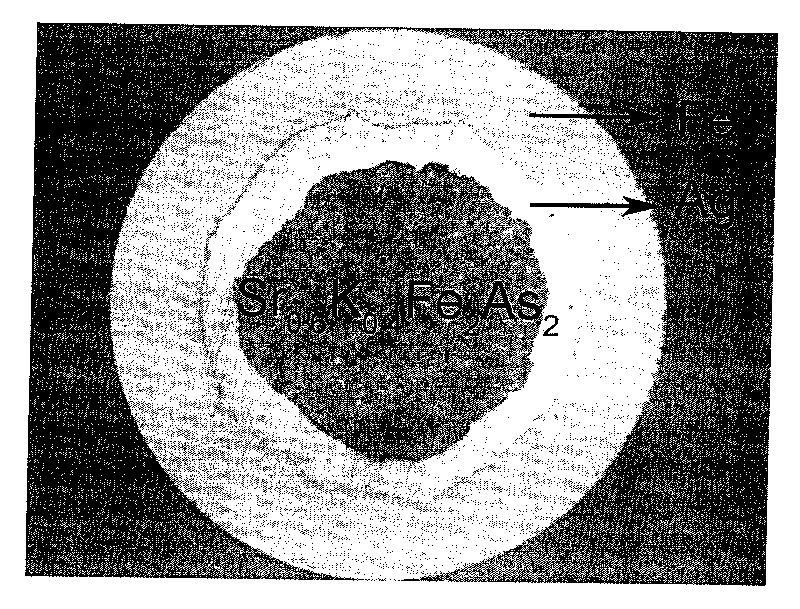

Iron-based compound superconducting wire or tape prepared from silver sheath

ActiveCN101707083APromote growthFirmly connectedSuperconductors/hyperconductorsSuperconductor devicesAlloySingle-core

The invention relates to a single-core or multicore iron-based compound superconducting tape prepared from a silver sheath. The conductor core of the tape is an iron-based compound with superconducting property, and silver or silver alloy material is coated outside the conductor core. Other metals or alloy materials can also be coated outside a silver or silver alloy sheath. The superconducting tape is prepared by using a powder tubulated method comprising the following steps of: putting the initial powder of the iron-based compound into a silver tube, a silver alloy tube or a composited tube of silver and other metals; compactly filling the initial powder in the tube; after both ends of the tube are closed, swaging, drawing, rolling and processing the metal tube into wires and tapes; and then obtaining the superconducting tape by vacuum or inert atmosphere annealing. Due to the fact that a conversion zone does not exist between the superconducting core and the sheathed material after annealing and silver steam generated by the silver sheath at the temperature removes FeAs phase, the crystal grain connectivity of the iron-based superconductor is improved. The novel iron-based compound superconducting wire or tape has good current transportation property.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

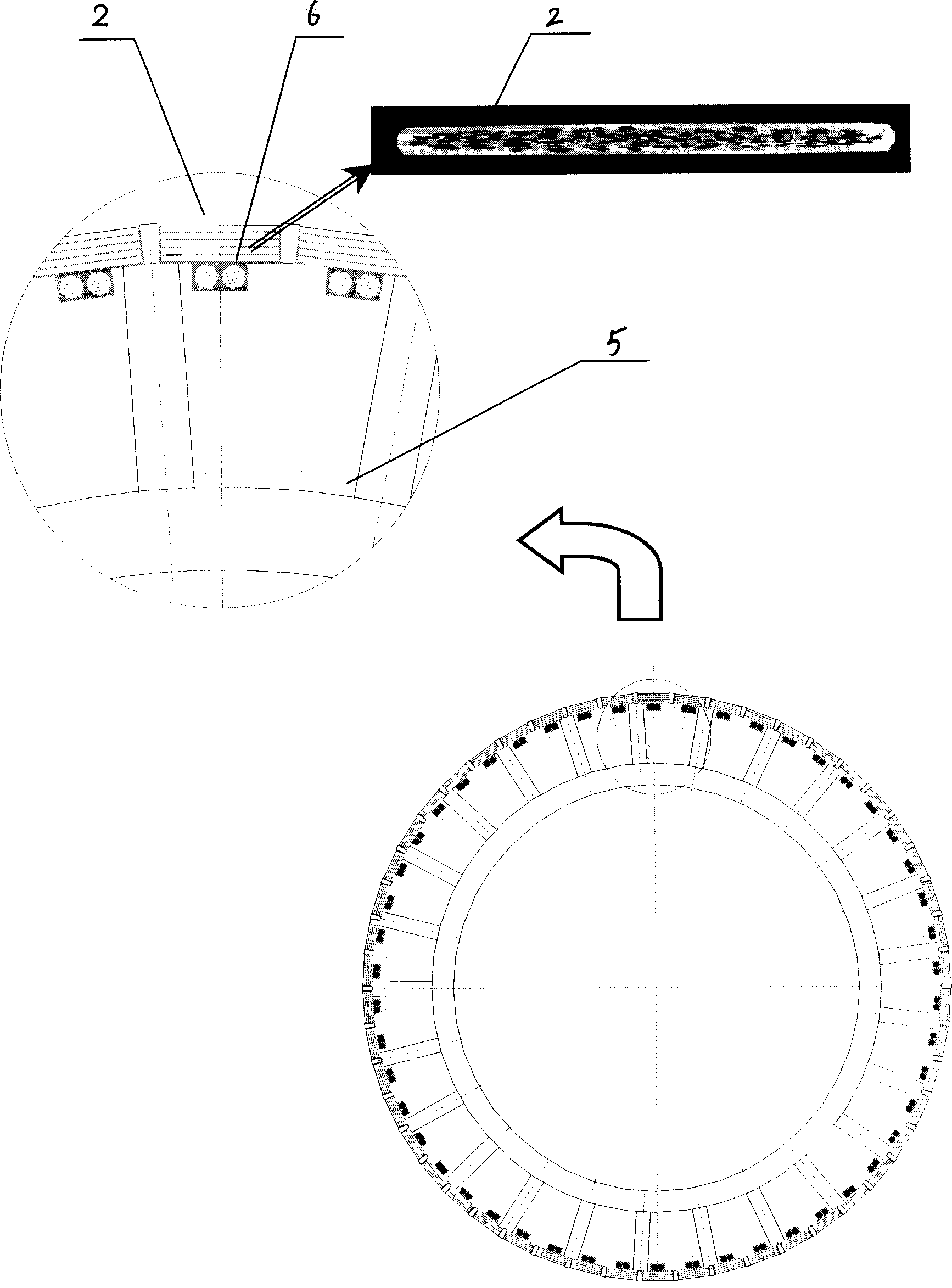

Low temperature superconducting assembly with low joint resistance for high temperature superconducting current lead cold end

InactiveCN101694908ASatisfy <1 nano-oh requirementSuperconducting magnets/coilsConnection contact member materialElectrical resistance and conductanceHigh-temperature superconductivity

The invention discloses a low temperature superconducting assembly with low joint resistance for a high temperature superconducting current lead cold end. The resistance of a 40-70kA high temperature superconducting super current lead of which the lower end is connected with a low temperature superconducting bus must be as low as 1 nano-ohm. A rectangular section niobium-titanium / copper superconducting wire or a high conductivity copper material and a paired box type joint structure connected with the superconducting bus are adopted in the low temperature superconducting assembly. Tests prove that the joint resistance of the low temperature superconducting assembly and a high temperature superconducting assembly can be as low as 0.5 nano-ohm, and the joint resistance of the superconducting bus is lower than 1 nano-ohm. The low temperature superconducting assembly is a middle result for developing super current leads of an international thermonuclear fusion test reactor and has the characteristics of novel conception and low manufacturing cost.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

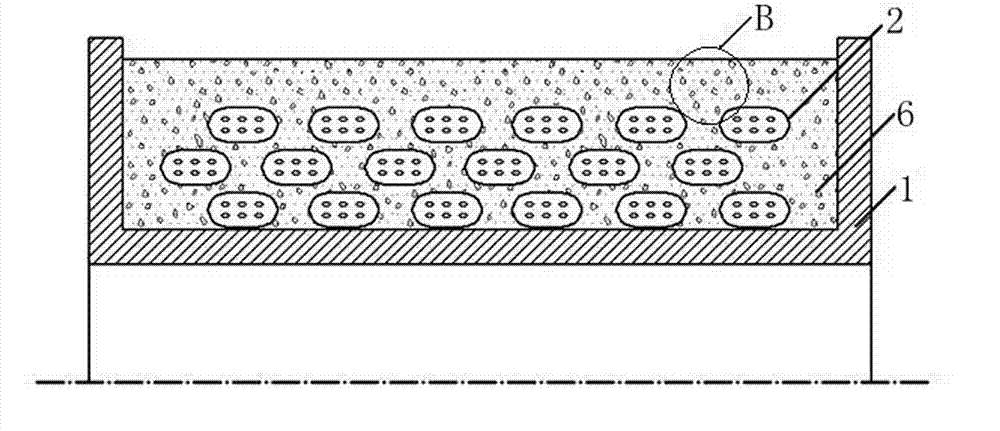

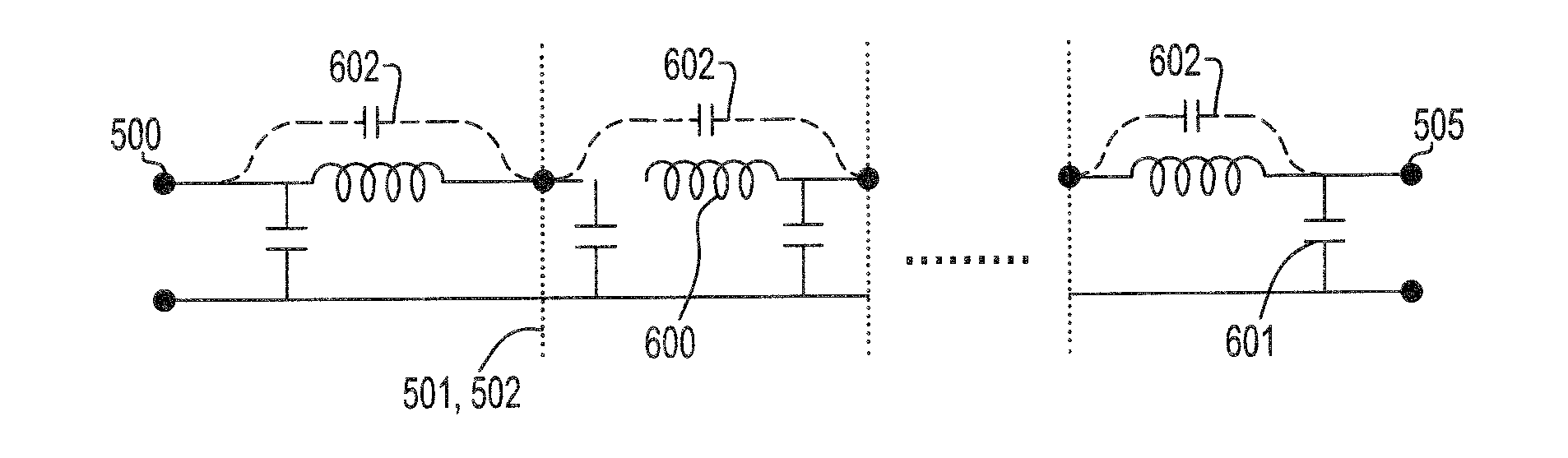

Superconducting Low Pass Filter for Quantum Computing and Method of Manufacturing the Same

ActiveUS20110152104A1Improve thermal conductivityMultiple-port networksQuantum computersElectricityLow-pass filter

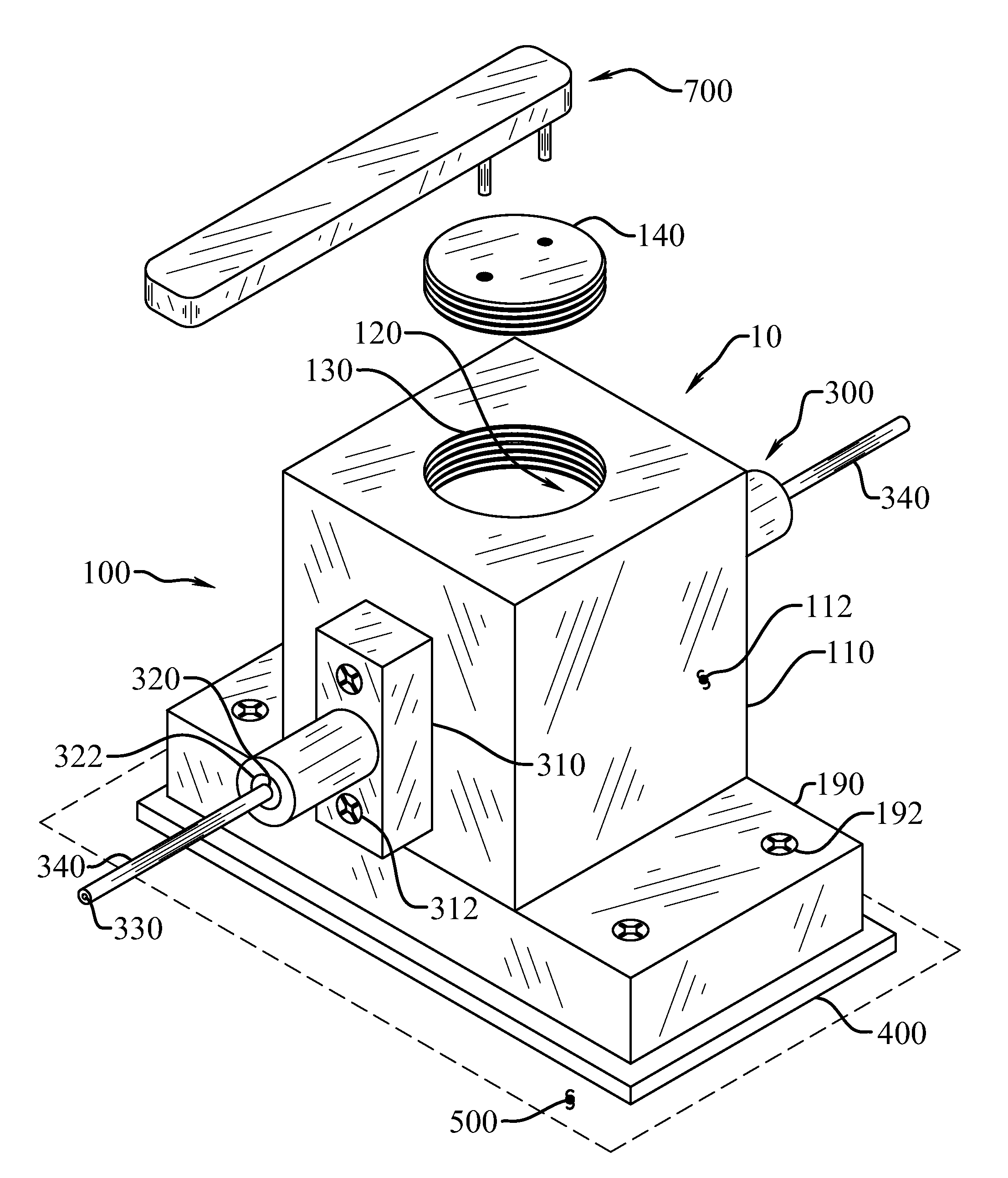

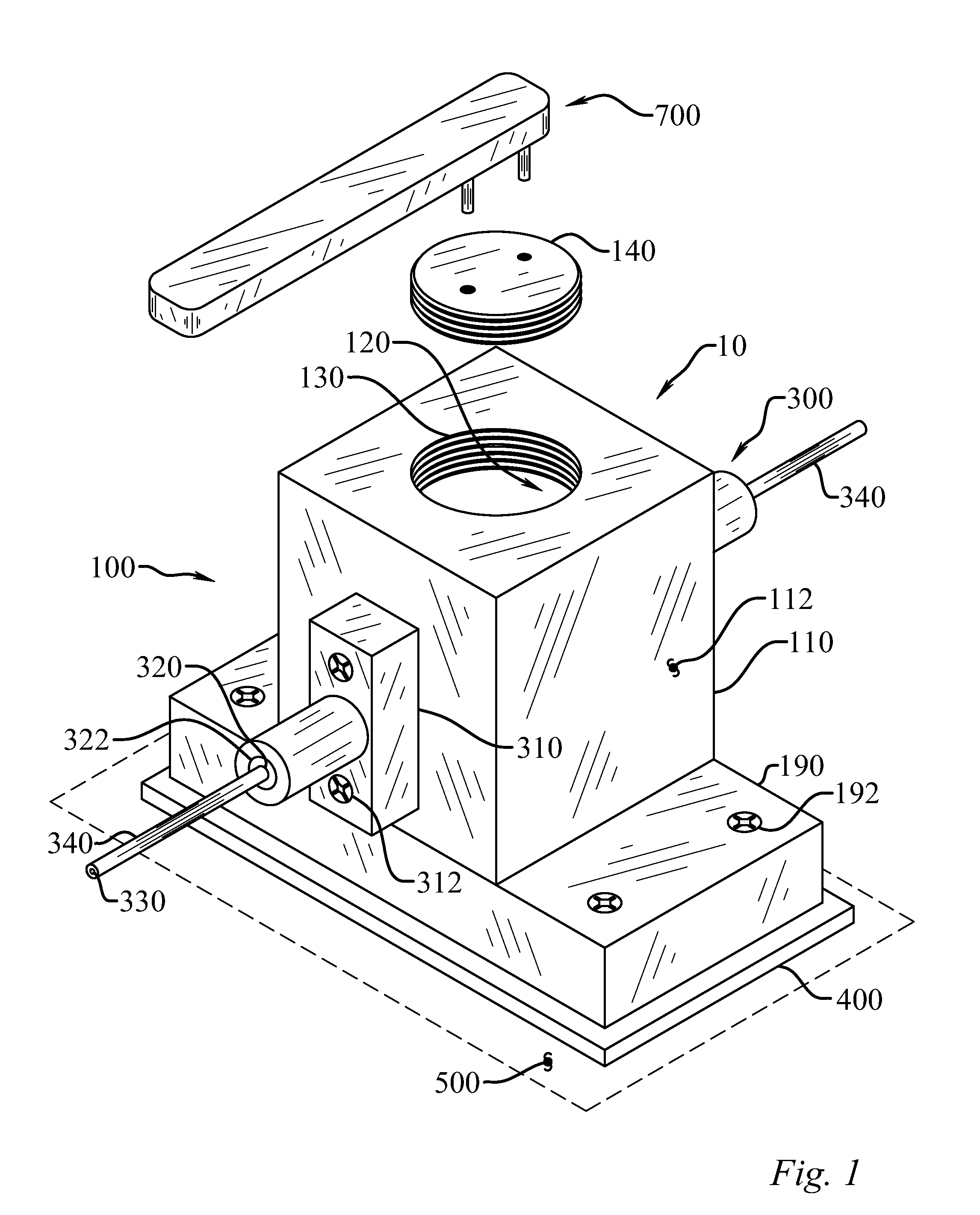

An apparatus and method for manufacturing a superconducting low-pass filter for quantum computing devices. The apparatus includes a plurality of containers and input and output ports connected to opposite ends of the apparatus. A plurality of coils of superconducting wire are wound using a mandrel. An adhesive is applied to the coils for maintaining a wound state. Each of the coils are positioned in each of the containers and electrically connected to each other with at least one coil being connected to the input port and at least one coil being connected to the output port. The coils are released or expanded from their wound state using an adhesive solvent. The containers are then filled with a conductive polymer and the containers are closed with one or more covers.

Owner:GLOBALFOUNDRIES US INC

Connecting structure for magnesium diboride superconducting wire and a method of connecting the same

InactiveUS20060240991A1Excellent current conduction propertyImprove stabilitySuperconductor detailsSuperconductor device manufacture/treatmentMagnesium diborideMetal

A magnesium diboride superconducting wire has excellent conduction property and stability. The superconductive connection of the magnesium diboride superconducting wire covered with a superconducting coating layer and a same or different kind of another superconducting wire are connected in a metal tube filled with a solder by way of the superconductive coating layer.

Owner:HITACHI LTD

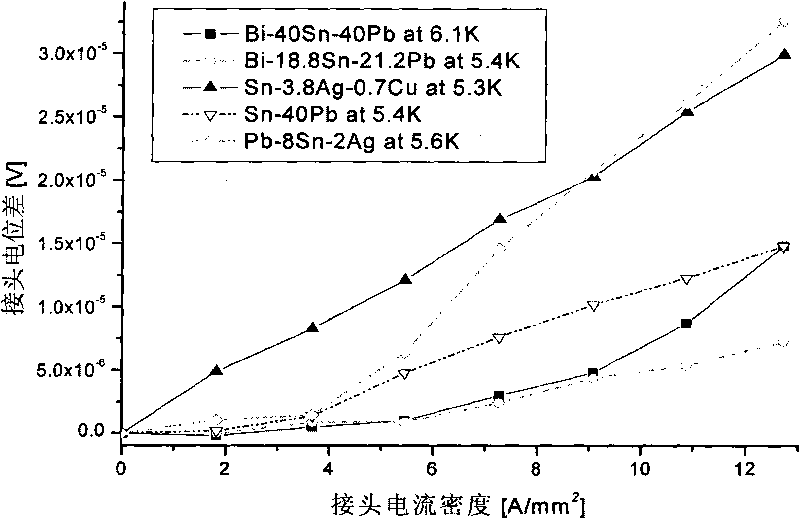

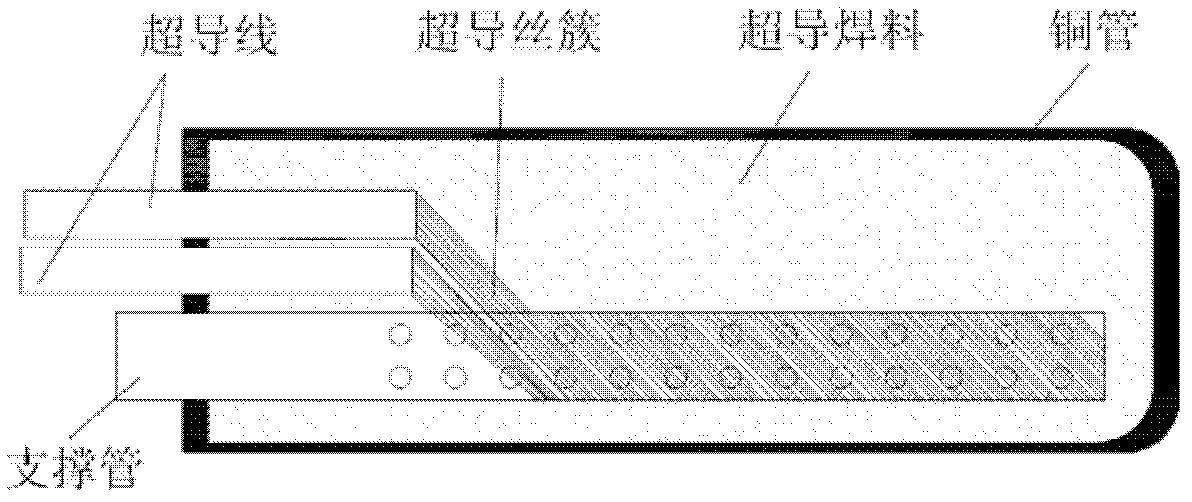

Superconducting wire joint

ActiveCN102593621ALower resistanceRealize superconducting direct connectionLine/current collector detailsSuperconductors/hyperconductorsEngineeringAlloy

The invention provides a superconducting wire joint which comprises a support tube, a superconductive filament cluster of a superconducting wire to be connected, a copper pipe and superconductive solder. An external cylindrical surface of the support tube is provided with a spiral groove, and both the external cylindrical surface and the groove are provided with through holes along a radial direction. After the superconductive filament cluster of the superconducting wire to be connected is twisted round the spiral groove of the support tube, the support tube which is twisted with the superconductive filament cluster is integrally inserted into the copper pipe with a segment of the superconducting wire, and other space in the copper pipe is filled with the superconductive solder. Material purity of the copper pipe is 99.999%, and in an annealing state, the support tube is NbTi superconductive alloy material. Components of the superconductive solder are Bi, Pb and Sn with the following mass ratio by weight: 53%-55% of Bi, 36% of Pb and allowance of Sn. The superconducting wire joint prepared by the invention has the advantages of low resistivity, simple preparation process, small damage and threat to superconducting wire performance and suitability for project field practical operation.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

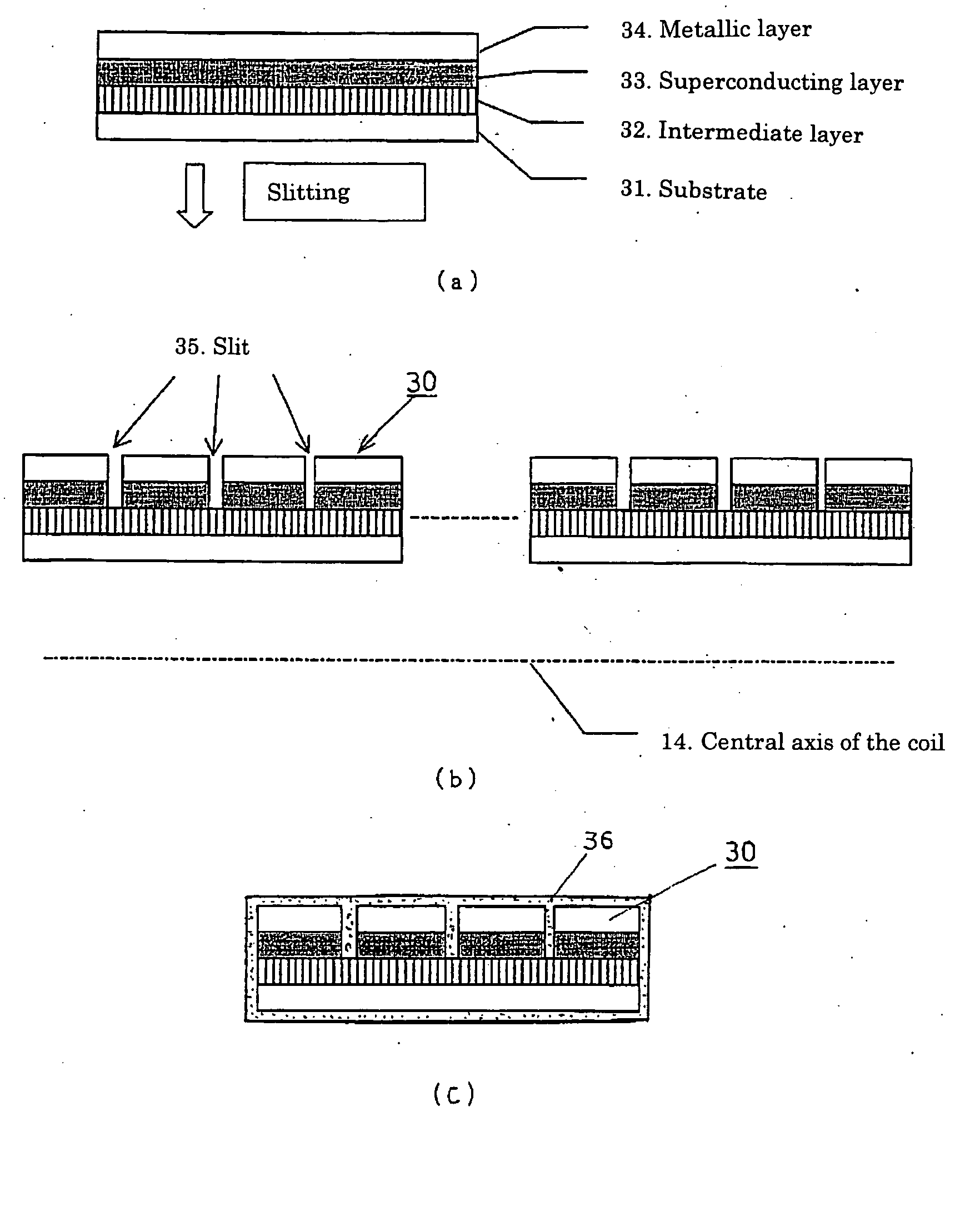

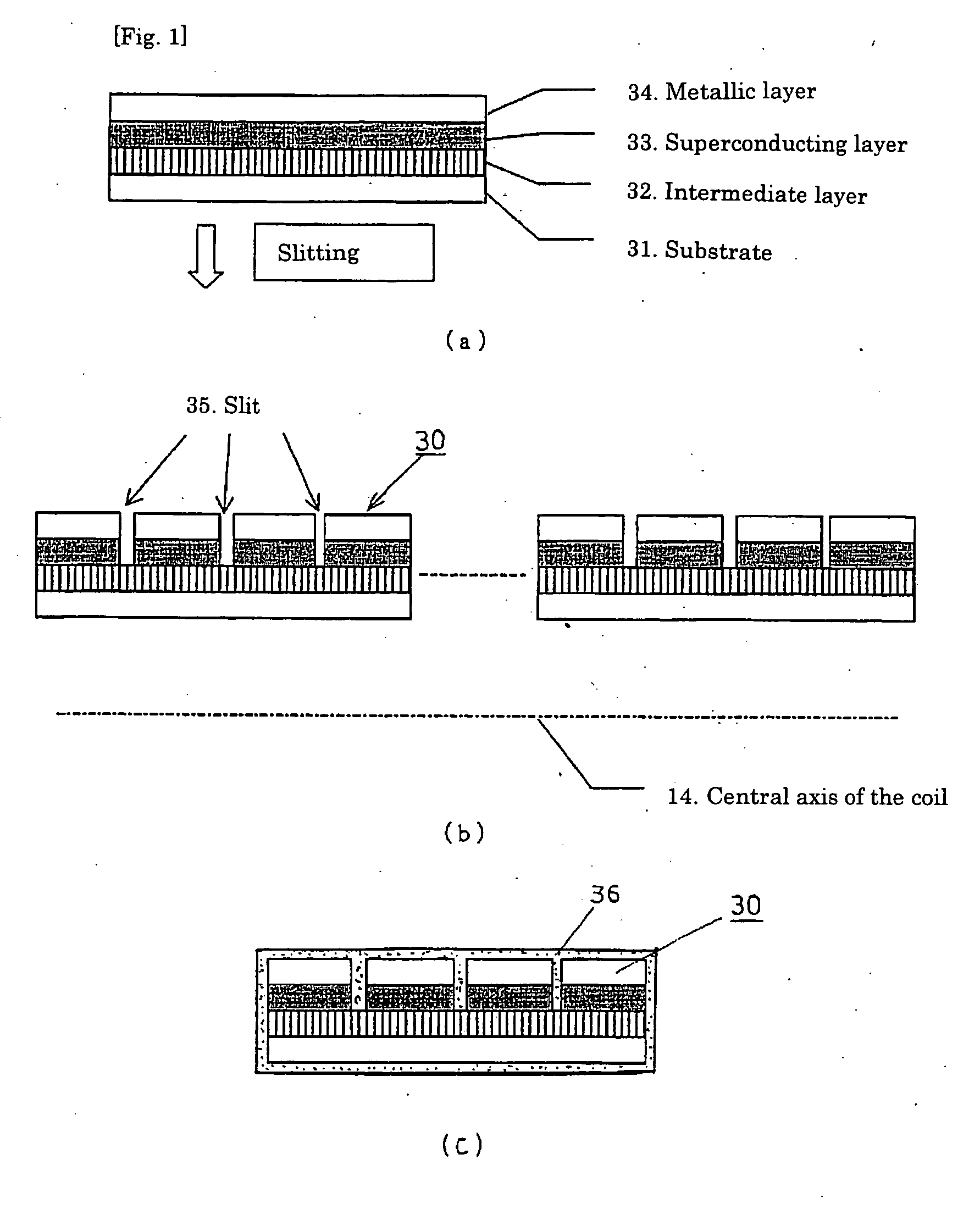

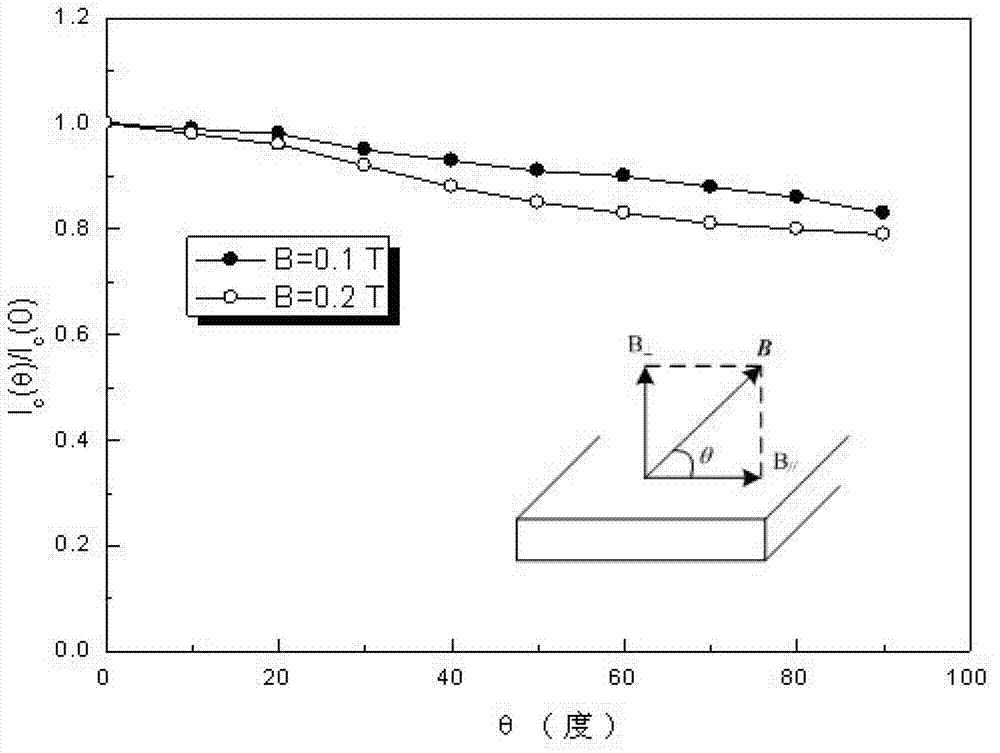

Superconducting wire and superconducting coil employing it

ActiveUS20060077025A1Improve thermal stabilityReduce operating costsSuperconductors/hyperconductorsTransformers/inductances coils/windings/connectionsElectrical conductorBand shape

Tape-shaped superconducting wires are made by forming a superconducting film on the substrate. At least the superconducting film is slit, electrically separated into a plurality of superconducting film parts each having a rectangular cross section and arranged in parallel to form parallel conductors. This provides superconducting wires capable of containing AC loss. A superconducting coil is made by winding the superconducting wires described above, wherein the provision of a coil structure containing at least partially a part wherein the perpendicular interlinkage magnetic flux acting among various conductor elements of the parallel conductors by the distribution of the magnetic field generated by the superconducting coils cancel mutually enables a simple structure without transposition to cancel mutually the interlinkage magnetic flux by the perpendicular magnetic field against wires, to contain circulating current within the wires by the perpendicular magnetic field and to make shunt current uniform. This provides a low-loss superconducting coil.

Owner:KISU TAKANOBU +4

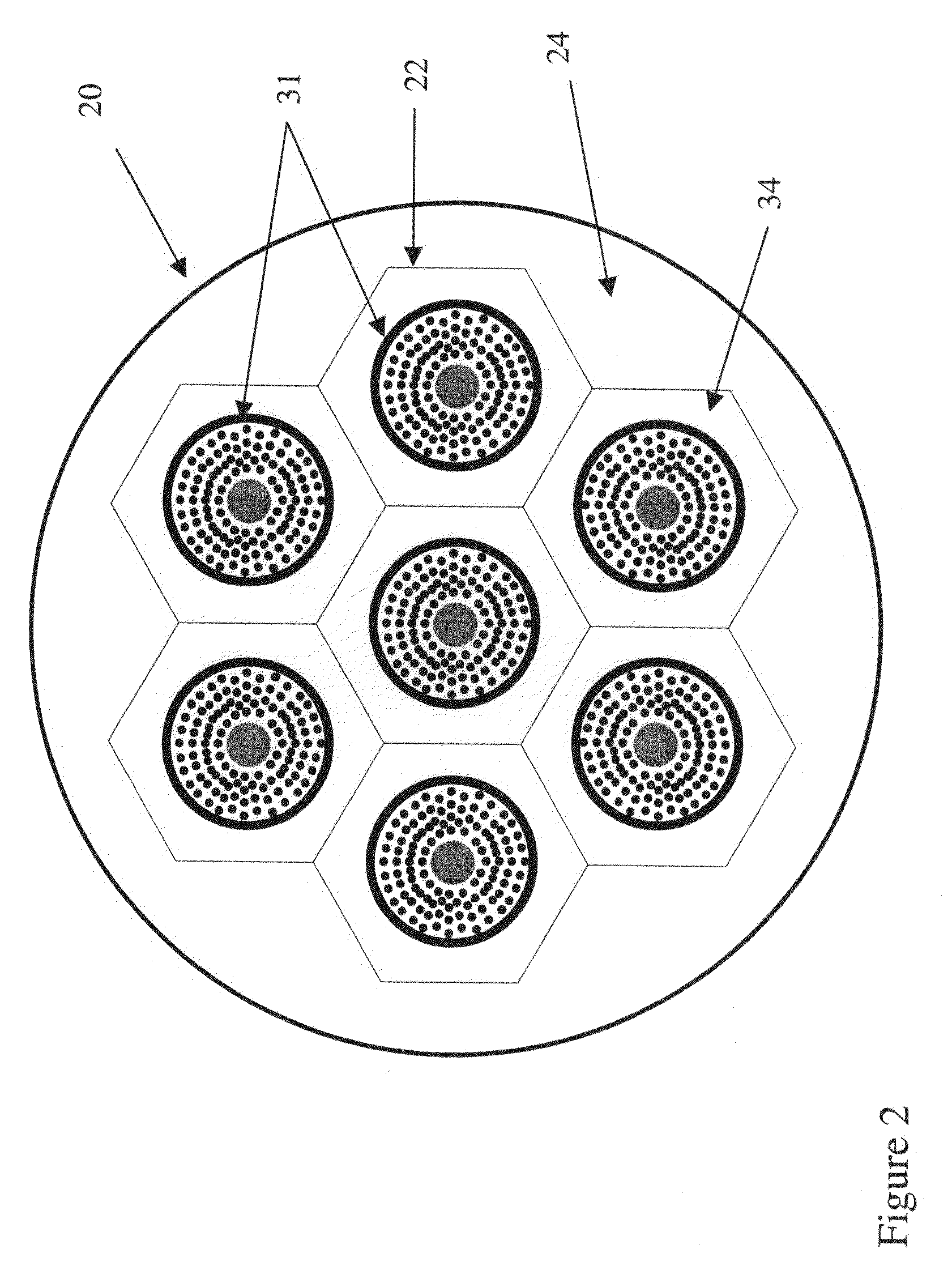

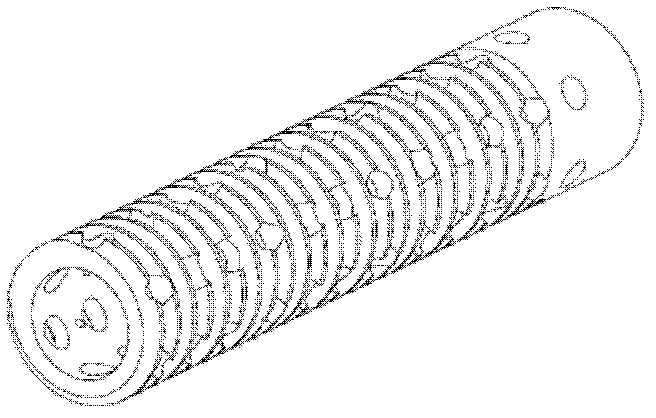

Superconducting strand based on ReBCO high-temperature superconducting tape

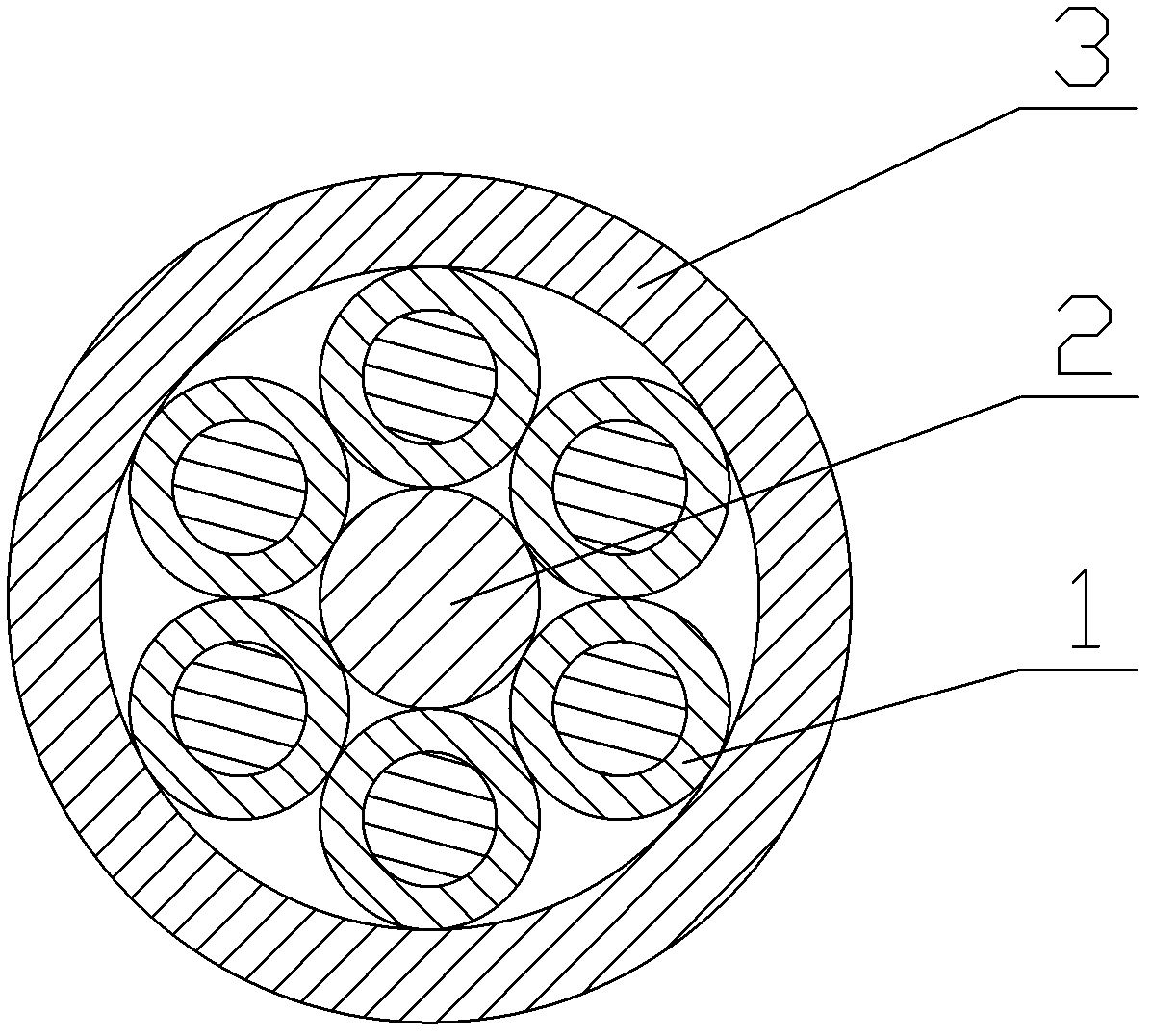

InactiveCN102779581AImprove engineering current densityImprove toughness and strengthSuperconductors/hyperconductorsSuperconductor devicesHigh temperature superconductingSeam welding

The invention belongs to the field of superconducting material and relates to a superconducting strand based on a ReBCO high-temperature superconducting tape. The superconducting strand comprises a superconducting strand core and a coating layer. The ReBCO high-temperature superconducting tape is cut into tapes which are arranged and stacked to be the superconducting strand core with circular, square or rectangular cross section; the coating layer is made of copper tapes, aluminum tapes, aluminum alloy tapes, stainless steel tapes or ReBCO coating superconducting tapes; the coating layer is rolled and coated on the superconducting strand core. A laser Ag welding technology is used for carrying out butt-seam welding on the coating tapes. The superconducting strand provided by the invention expands the application range of the coating superconductor, improves engineering current density, flexibility and mechanical strength of the superconducting wire, and is applicable to a superconducting cable, a current guide wire, and the like.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +2

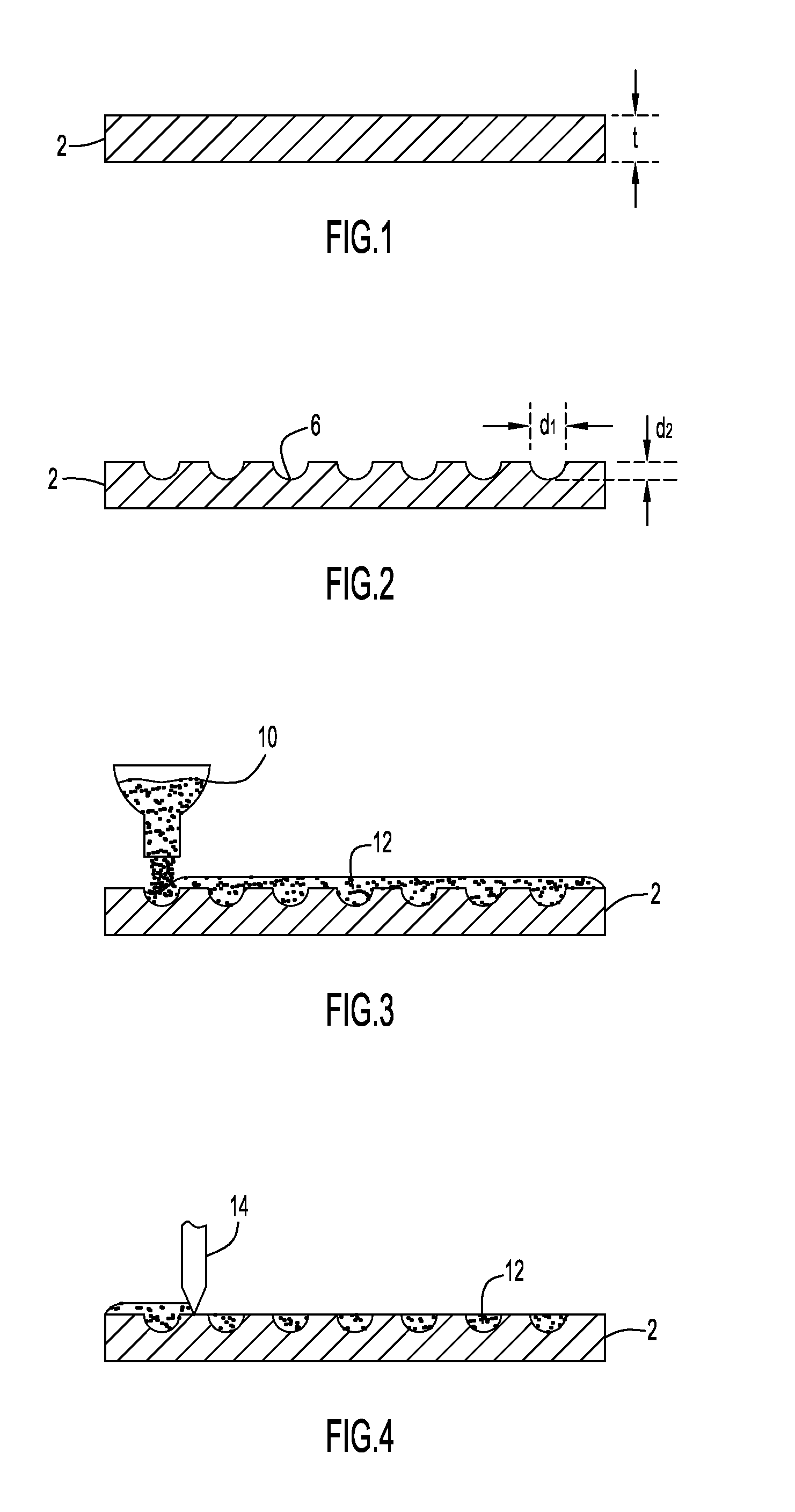

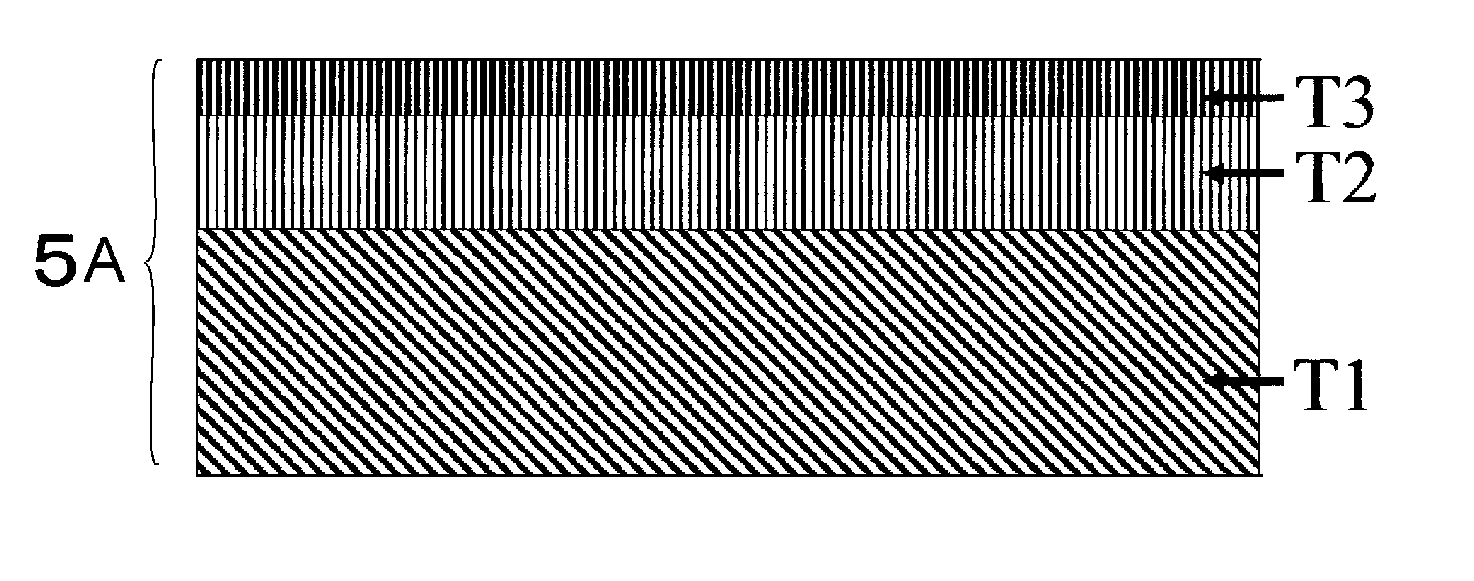

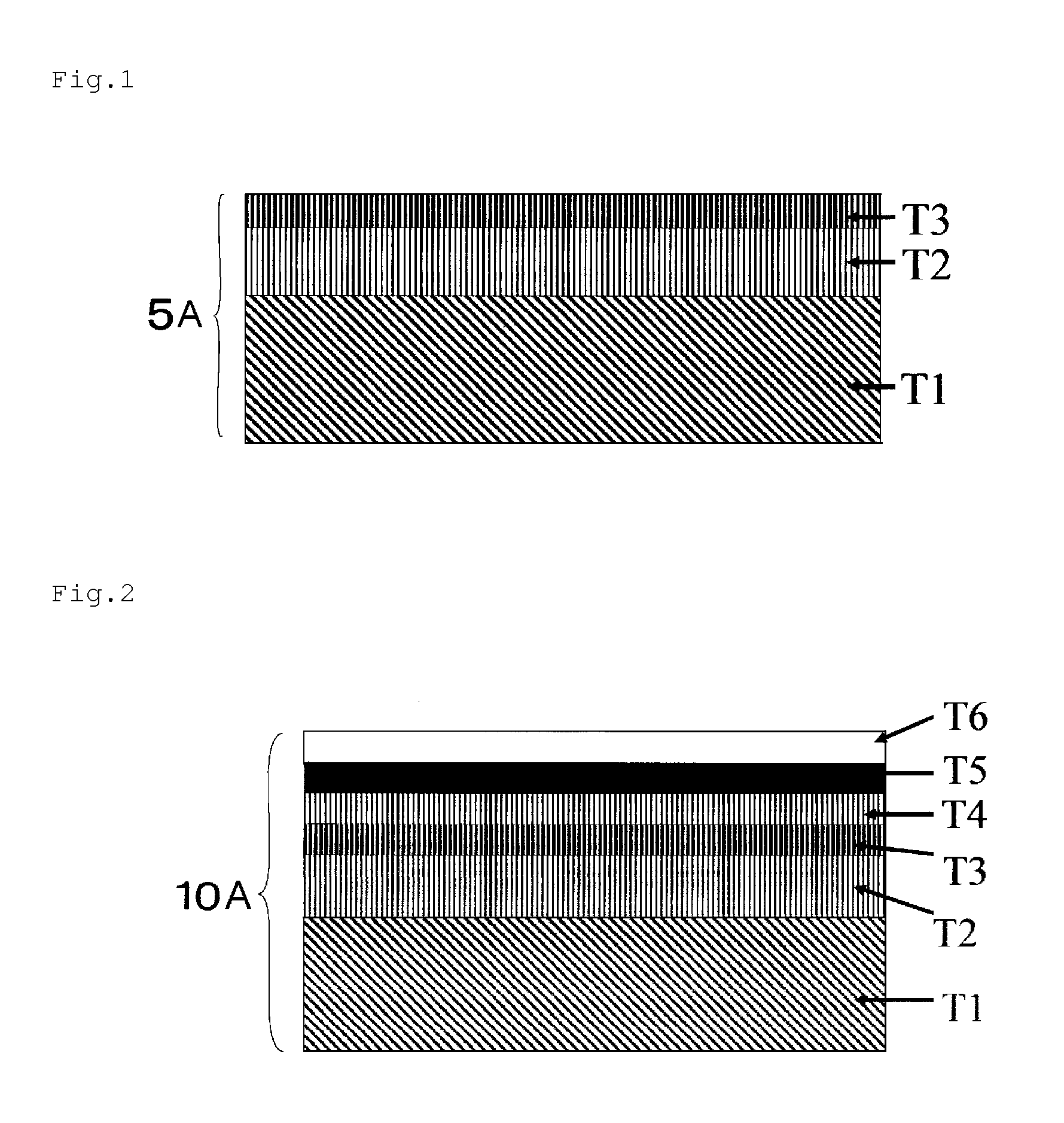

Method for producing metal laminated substrate for oxide superconducting wire, and oxide superconducting wire using the substrate

ActiveUS20120040840A1Poor workabilityLarge widthSuperconductors/hyperconductorsSuperconductor device manufacture/treatmentMetal foilRoom temperature

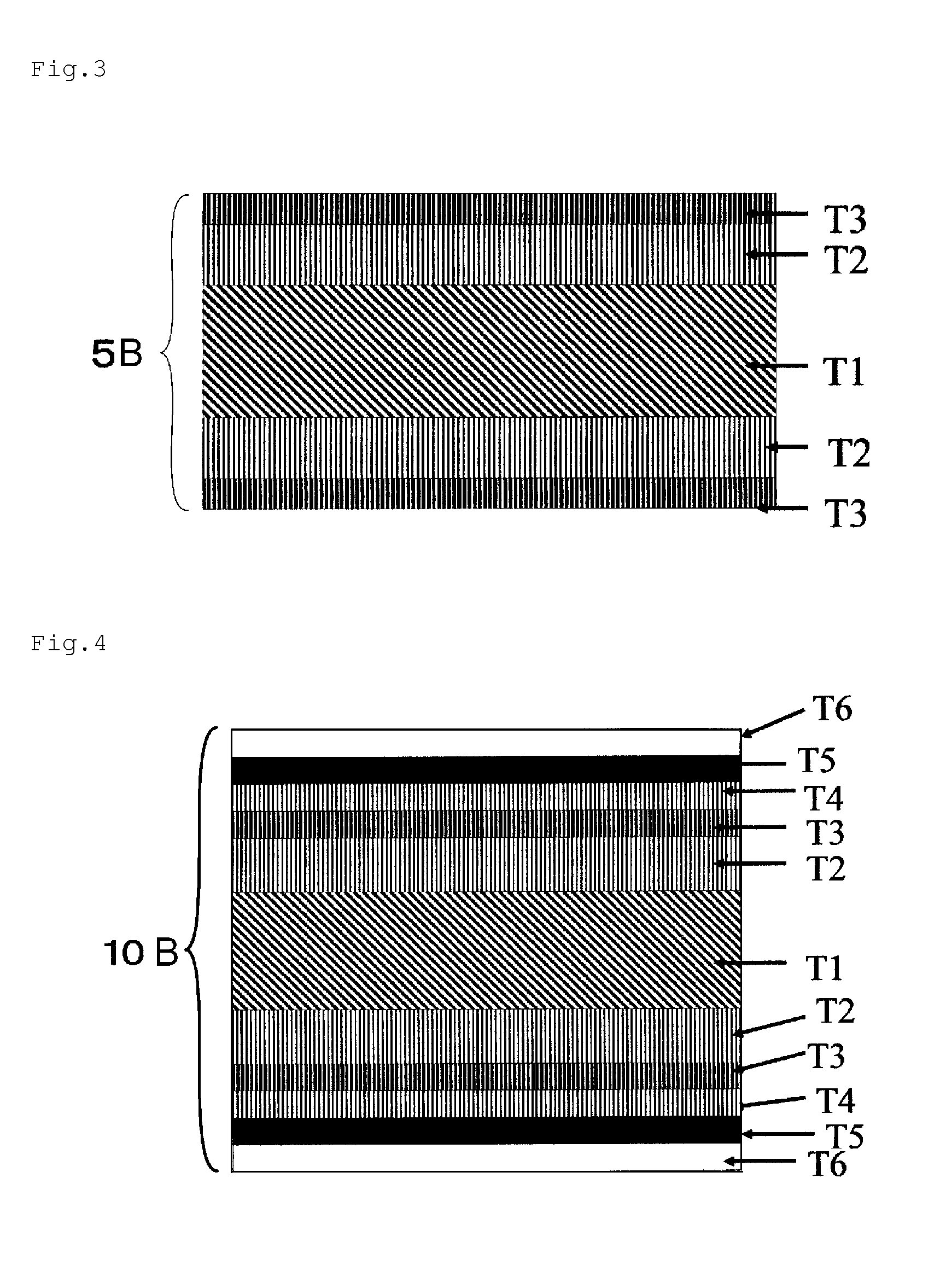

[Problem]A metal laminated substrate for an oxide superconducting wire is provided at a low cost. The metal laminated substrate has high strength, and stable high biaxial orientation in the longitudinal direction.[Means for Resolution]A metal laminated substrate for an oxide superconducting wire is manufactured such that a non-magnetic metal plate T1 having a thickness of not more than 0.2 mm and a metal foil T2 made of Cu alloy which is formed by cold rolling at a draft of not less than 90% and has a thickness of not more than 50 μm is laminated to each other by room-temperature surface active bonding, after lamination, crystal of the metal foil is oriented by heat treatment at a temperature of not less than 150° C. and not more than 1000° C. and, thereafter, an epitaxial growth film T3 made of Ni or an Ni alloy having a thickness of not more than 10 μm is laminated to the metal foil.

Owner:TOYO KOHAN CO LTD +1

A kind of preparation method of multi-core mgb2 superconducting wire/tape

ActiveCN102280198AIncrease the critical current densityHigh densitySuperconductors/hyperconductorsMetal boridesElectrical conductorNiobium

The invention discloses a preparation method for a multi-core MgB2 superconducting wire / band. The method comprises the following steps of: 1, preparing precursor powder; 2, feeding the precursor powder into a Nb / Cu composite metal tube to obtain a tubing complex; 3, performing rotary swaging and drawing treatment, and thus obtaining single-core wires; 4, placing a copper-niobium composite rod anda plurality of single-core wires into an anaerobic copper tube for secondary assembly to obtain a secondary composite rod, performing the rotary swaging and drawing treatment, and thus obtaining multi-core wires; and 5 sintering in vacuum, and thus obtaining the multi-core MgB2 superconducting wire; or rolling into multi-core bands, then sintering in vacuum, and thus obtaining the multi-core MgB2superconducting band. By the preparation method, powder is subjected to high-temperature heat treatment, so that the condition that high-activity carbon which is decomposed from SiC can better replace boron can be ensured, and the improvement on the critical current density of the wire / band in a magnetic field is better facilitated. Due to the adoption of a center copper-niobium composite bar enhanced conductor structure, the improvement on the density of the MgB2 superconducting wire is facilitated, the connectivity of MgB2 crystal grains is enhanced, and the critical current density of the wire / band is improved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

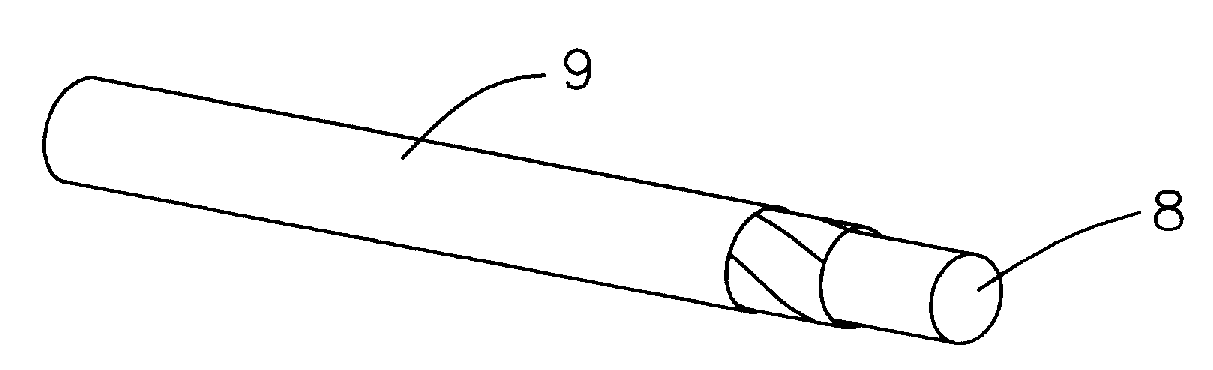

Superconducting wire with low ac losses

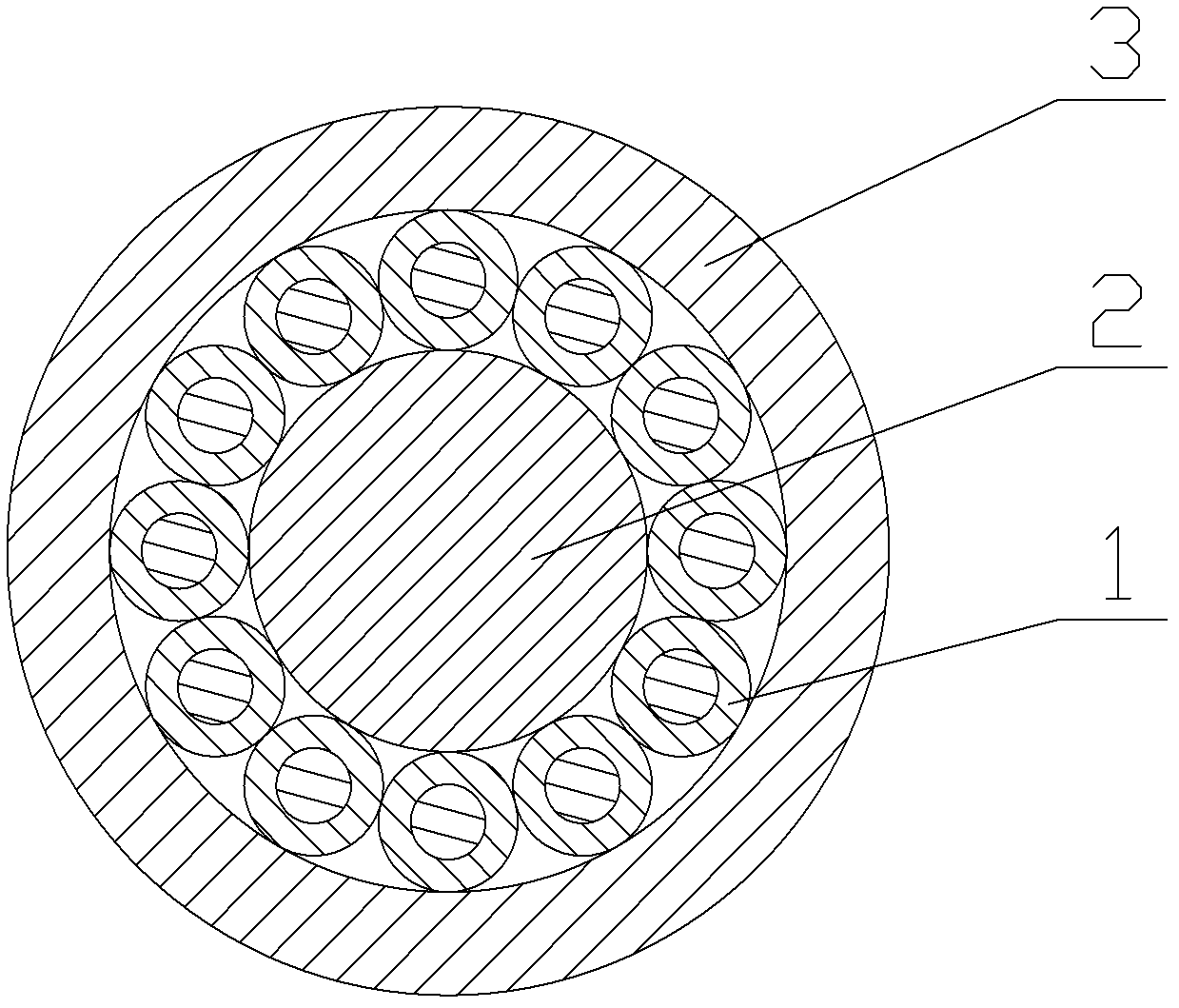

InactiveUS20100197505A1Superconductors/hyperconductorsSuperconductor device manufacture/treatmentHigh-temperature superconductivityElectrical conductor

A multilayer superconducting wire 7 with essentially round cross sectional area where the outer surface of the round wire is provided with a high temperature superconductor layer 3 and where at least the high temperature superconductor layer 3 is fabricated as a spiral running along the length of the superconductor wire 7 in parallel lanes 15.

Owner:NEXANS

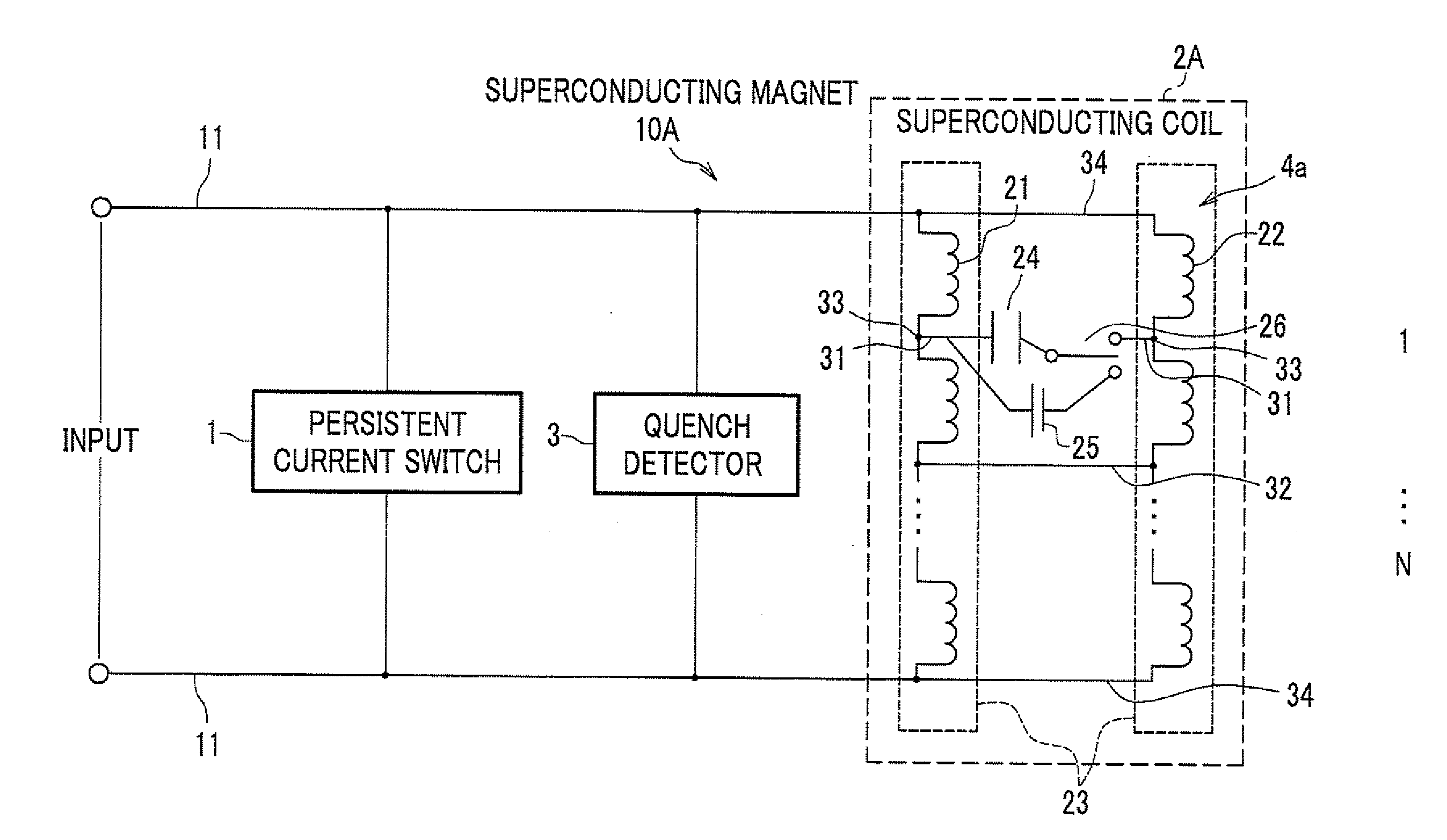

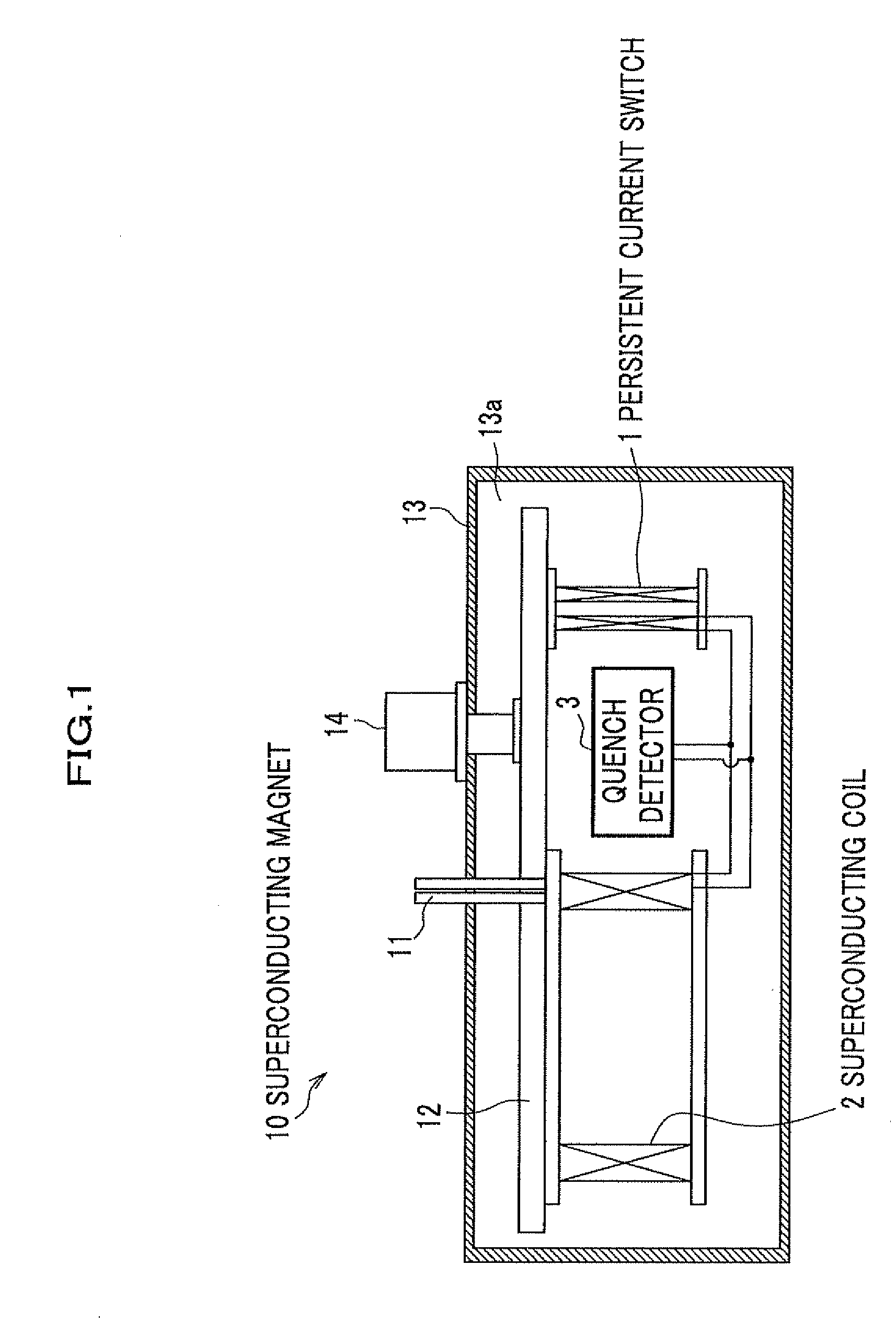

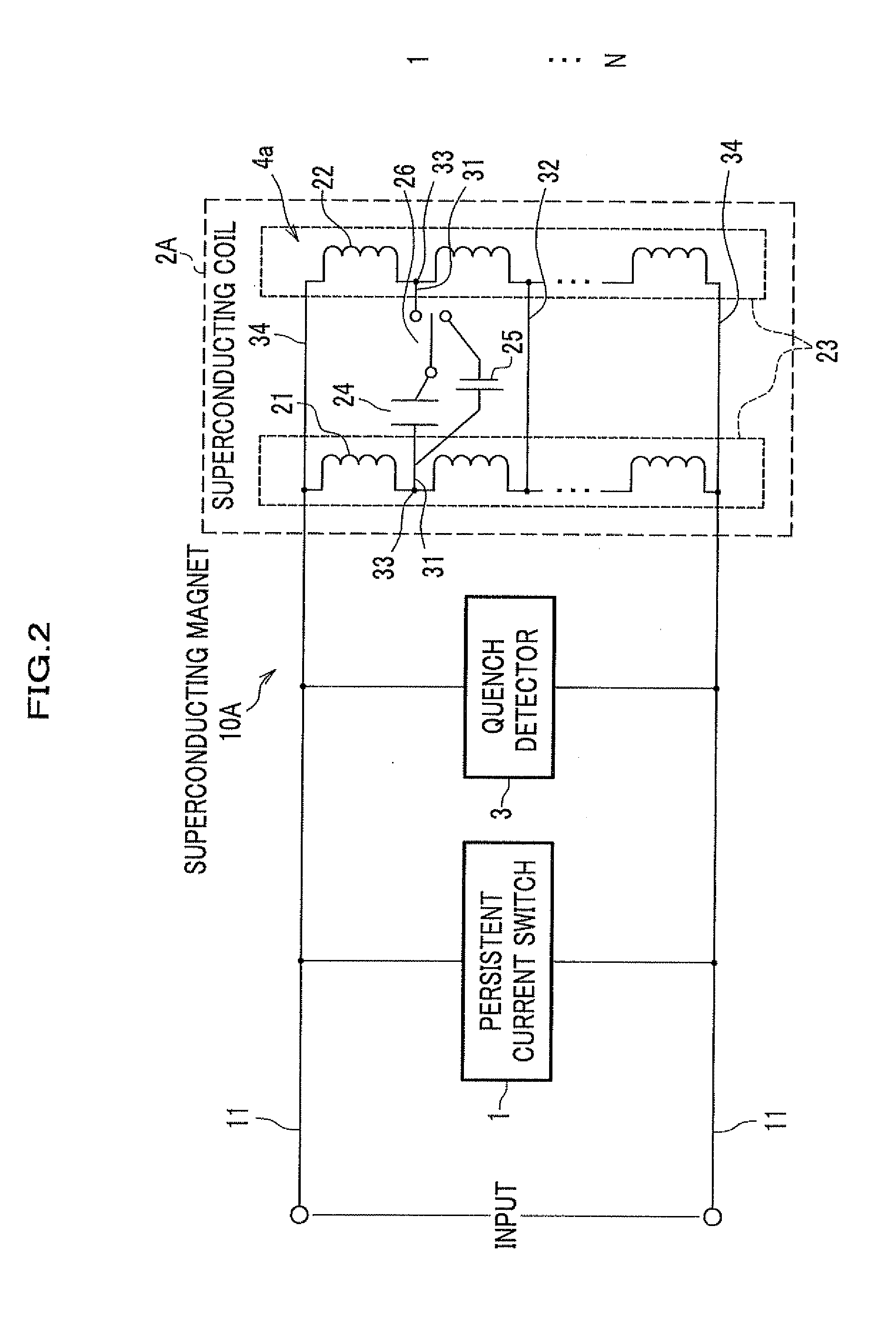

Superconducting coil, superconducting magnet, and method of operating superconducting magnet

ActiveUS20120014030A1Avoid burnsPreventing the superconducting coil from burningMagnetsMagnetic materialsElectrical conductorSuperconducting Coils

In a superconducting coil, a parallel conductor includes a plurality of superconducting wires bundled and wound in a coil. The superconducting wires have at least two connections therebetween. A current source connected to the superconducting wires to form a loop via the superconducting wires and the connection to supply a current in the loop when a quench is detected. A superconducting magnet includes the superconducting coil, a persistent current switch connected to the superconducting coil, and a quench detector configured to detect quench occurring in the superconducting coil.

Owner:HITACHI LTD

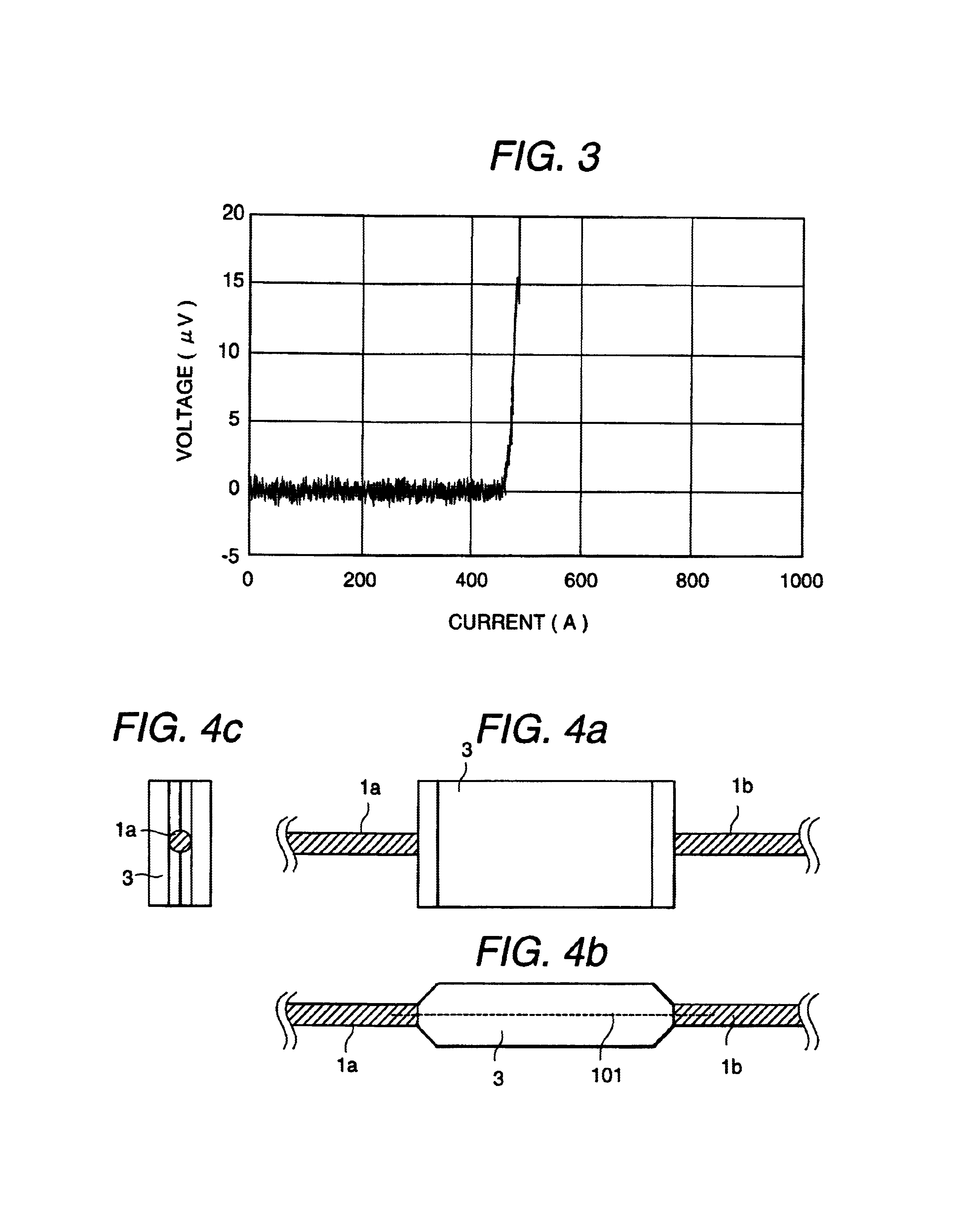

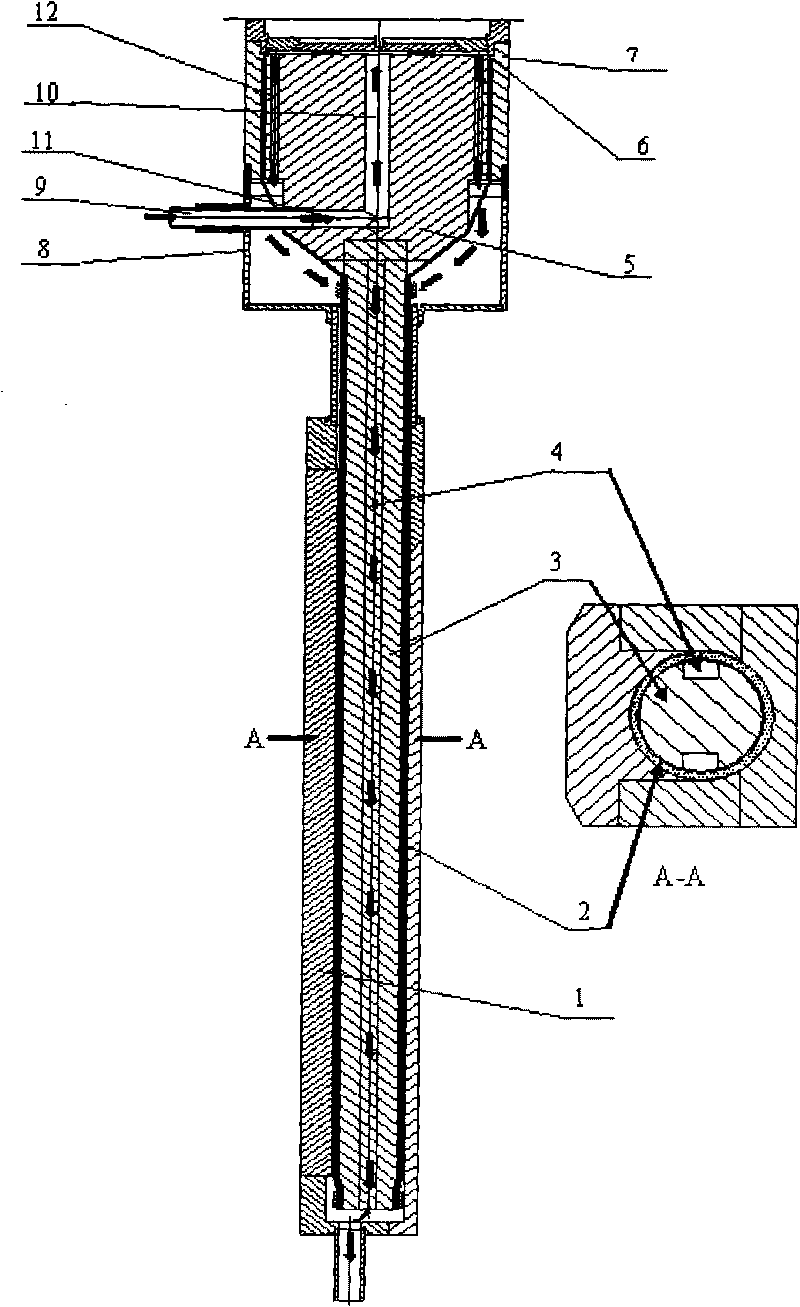

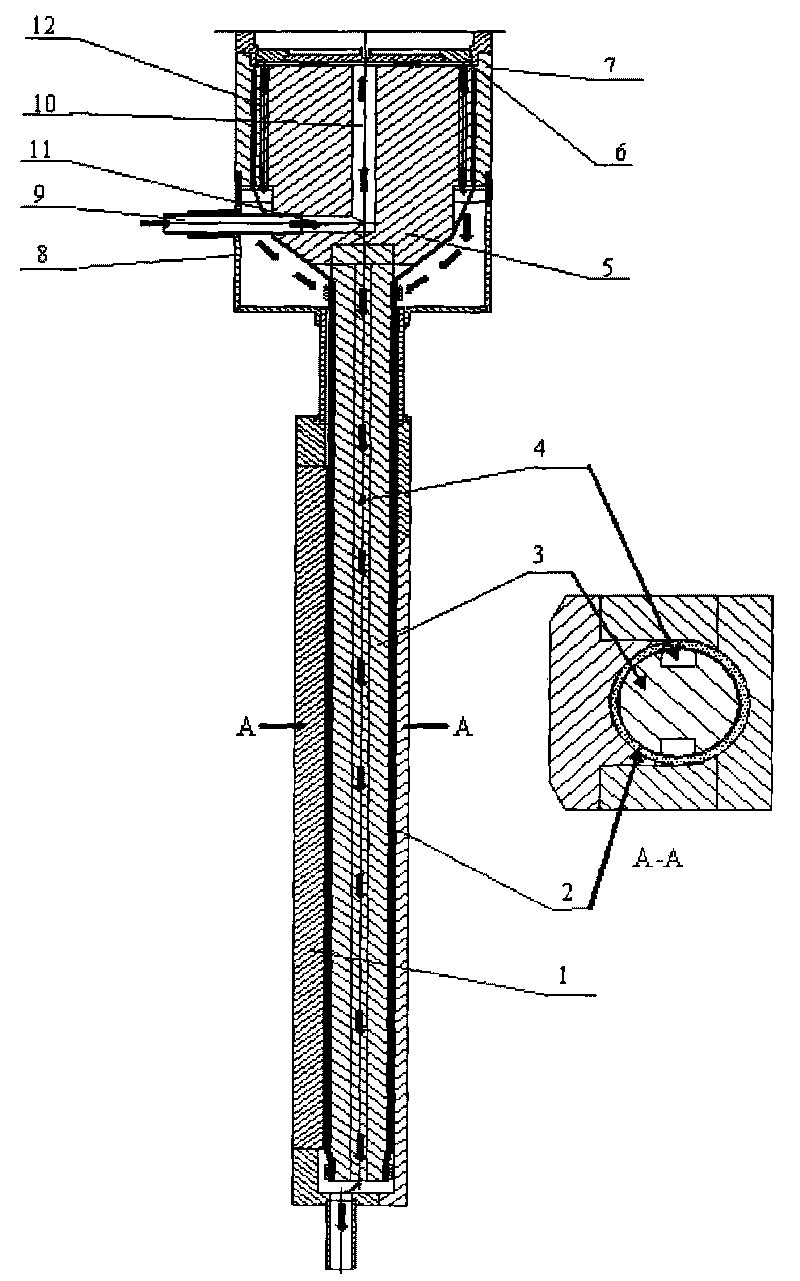

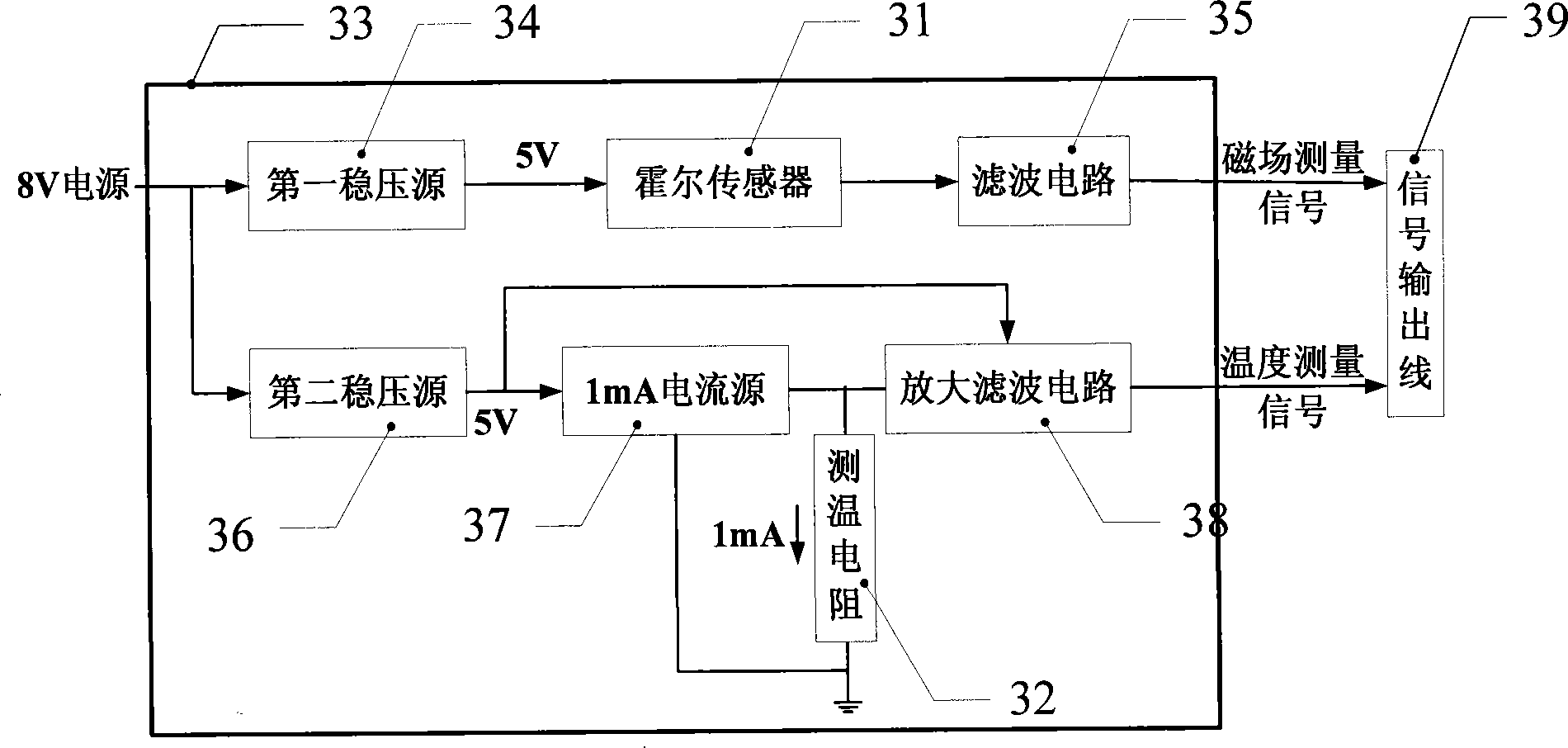

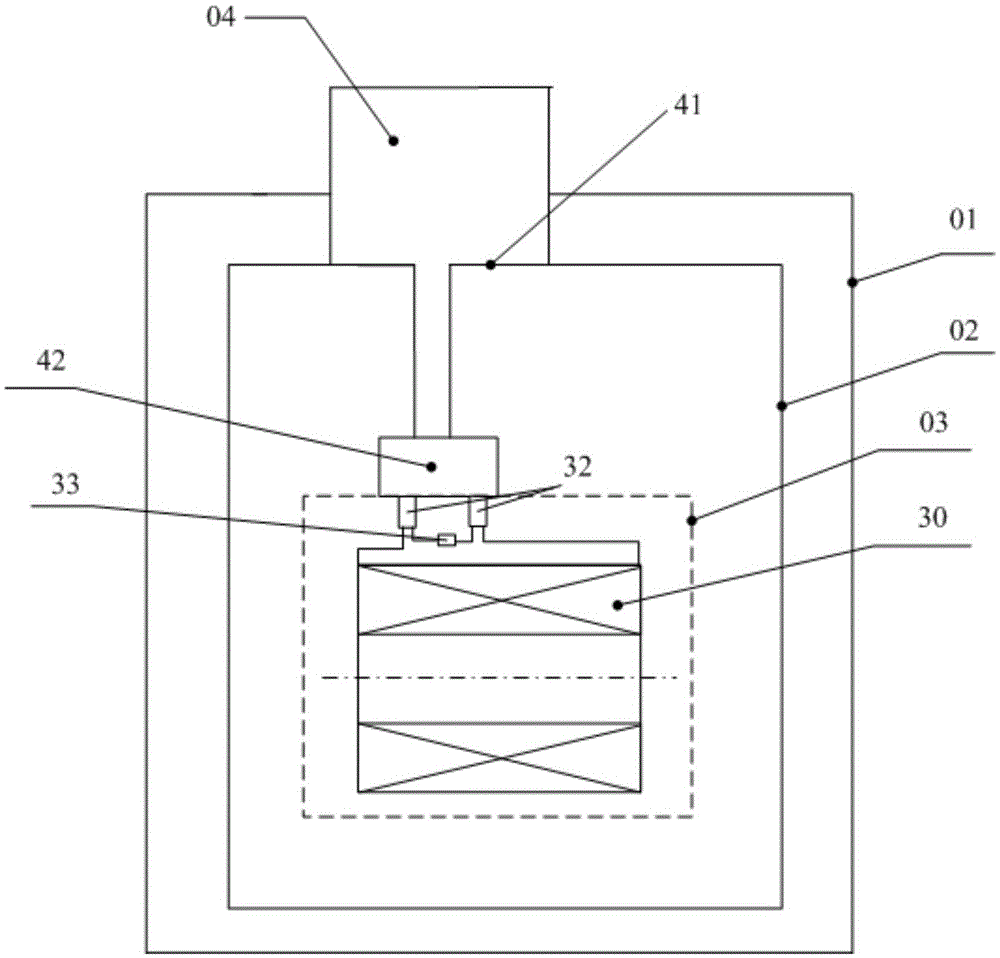

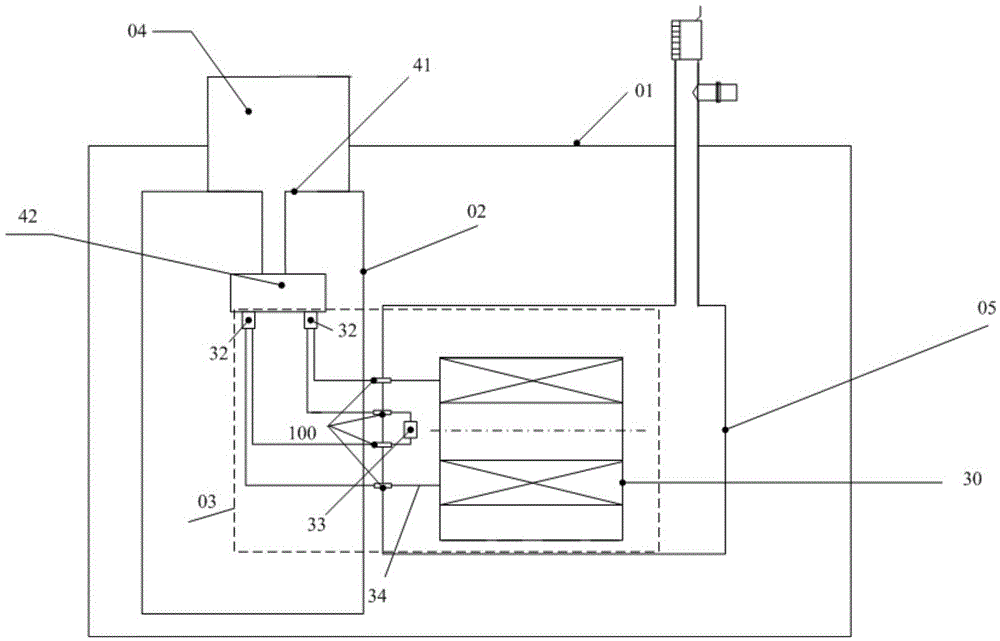

Special purpose device for measuring superconducting line joint resistance

InactiveCN101251558AEasy to replaceReduce volatilityMagnetic measurementsResistance/reactance/impedenceElectrical resistance and conductanceHall element

The present invention discloses a specialized device for measuring the resistance of a superconducting line joint, comprising a low temperature Dewar unit, a room temperature tube unit, a background magnet unit, an excitation magnet unit, a linkage frame unit, a weakening magnetic field measuring unit, etc. The specialized device has the advantages that only the room temperature tube is required to be moved out from the low temperature Dewar via a guide rail when a sample loop of the measured superconducting line joint is replaced, so that the volatilization amount of the liquid helium in an experimental process is reduced. The background magnet is positioned on the lateral side of a Hall element which measures the weakening magnetic field of the sample loop of the superconducting line joint. Compared with being positioned at the lower side of the Hall element, the background magnet positioned at the lateral side of the Hall element reduces the influence of the background magnet to the fact that the Hall element measures the weakening magnetic field generated by the sample loop of the superconducting joint. With the room temperature tube technical, the Hall element is arranged inside the room temperature tube, namely a normal temperature Hall sensor measures the weakening magnetic field of the sample loop of the superconducting joint. The cost of the device is reduced and the reliability of the measurement is improved.

Owner:TSINGHUA UNIV

Method for producing (Nb, Ti)3Sn wire by use of Ti source rods

ActiveUS6981309B2Improve diffusivityImprove ductilityLine/current collector detailsSuperconductors/hyperconductorsWire rodMaterials science

An improvement is disclosed in the method for producing a multifilament (Nb, Ti)3Sn superconducting wire by the steps of preparing a plurality of Nb or Nb alloy rods where Nb or Nb alloy monofilaments are encased in copper or copper alloy sheaths; packing the Nb or Nb alloy rods within a copper containing matrix to form a packed subelement for the superconducting wire; providing sources of Sn, and sources of Ti within said subelement; assembling the subelements within a further copper containing matrix; and diffusing the Sn and Ti into the Nb or Nb alloy rods to form (Nb, Ti)3Sn. The method is improved by diffusing the Ti into the Nb from a minor number of Ti dopant source rods which are distributed among the Nb or Nb alloy rods.

Owner:BRUKER OST LLC

Superconducting cable for alternating current

InactiveUS6417458B1Superconductors/hyperconductorsSuperconductor device manufacture/treatmentElectrical conductorSoftware engineering

A superconducting cable for alternating current, comprising conductor layers formed by a plurality of tape-shaped superconducting wires wound around a center member, an electric insulating layer formed outside the conductor layers, and a plurality of shielding layers formed outside the insulating layer, wherein, the conductor layers are formed, where N is a number of layers in the conductor layers and expressed by an integer, by gradually increasing a winding pitch of conductor layers in the same direction from an inner first layer to an N / 2 layer when the number of layers is even, or from an inner first layer to a (N-1) / 2 layer when the number of layers is odd, and then by gradually decreasing a winding pitch of conductor layers in an opposite direction to the inner layers from a N / 2+1 layer to an N layer when the number of layers is even, or from a (N+1) / 2 layer to an N layer when the number of layers is odd.

Owner:FURUKAWA ELECTRIC CO LTD

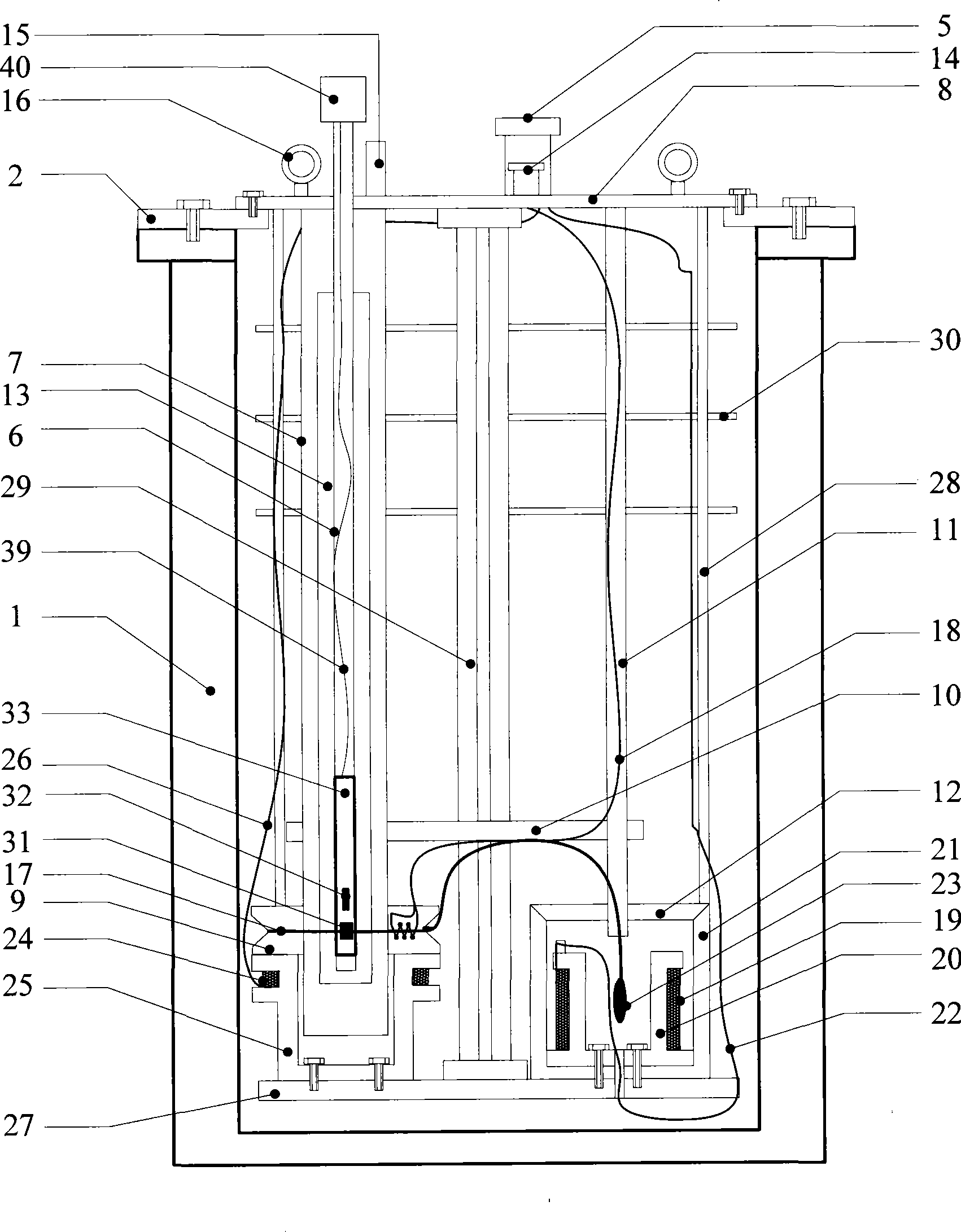

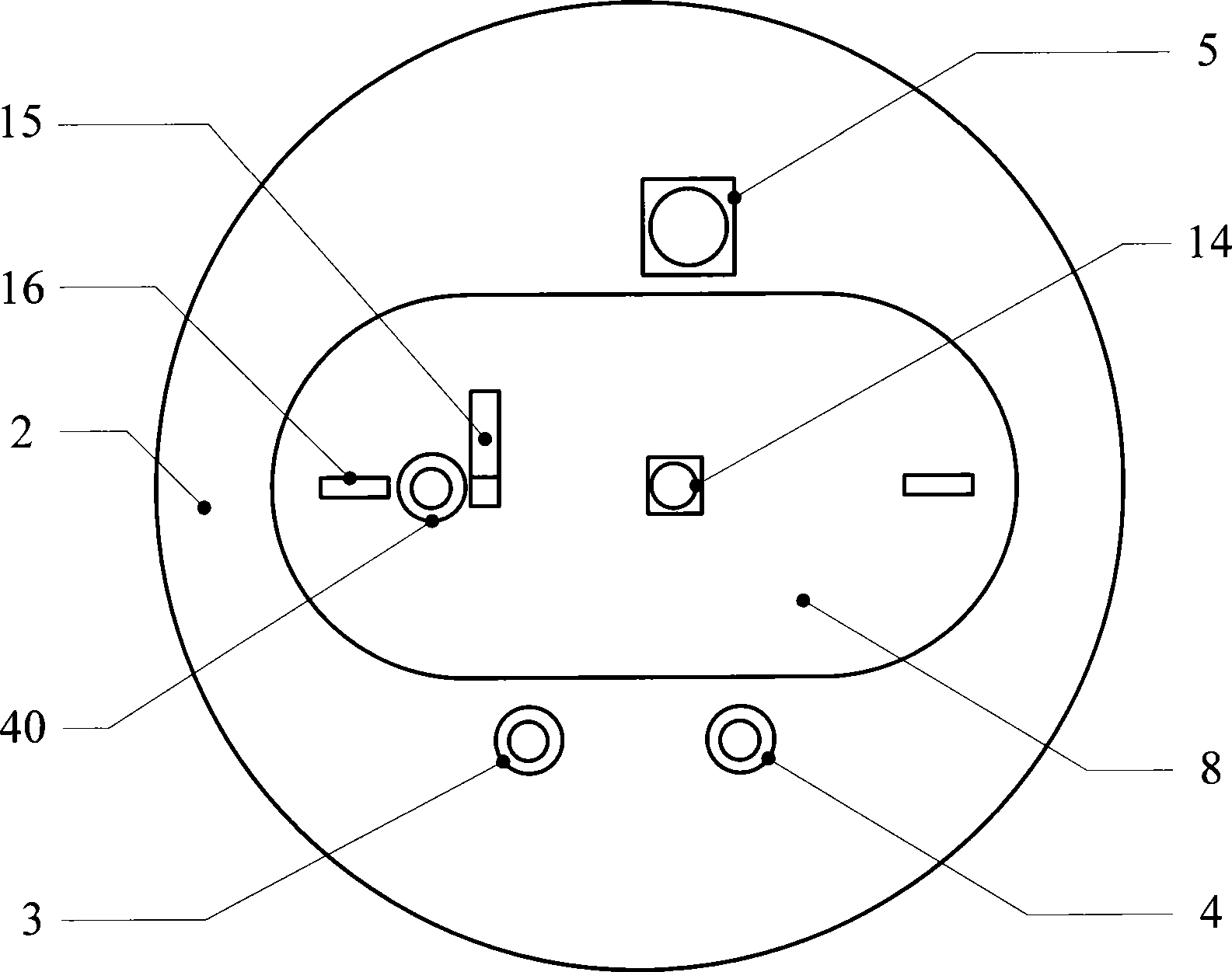

Superconducting magnet

ActiveCN105655084AEasy to replaceImprove stabilitySuperconducting magnets/coilsClosed loopSuperconducting Coils

The invention provides a superconducting magnet which comprises a vacuum container and a refrigerator. A cold screen and a superconducting coil are arranged in the vacuum container; superconducting wires are wound on a coil framework to form the superconducting coil, and two free ends of the superconducting coil are connected with a superconducting switch by superconducting connectors to form a closed superconducting circuit; the refrigerator is arranged on the vacuum container and comprises a primary cold head and a secondary cold head, and the primary cold head is thermally connected with the cold screen; the superconducting wires are made of superconducting materials with critical superconducting transit temperatures higher than 35 K; the superconducting connectors are made of superconducting welding flux with a low melting point, can be cooled by the aid of the secondary cold head or cooling media and accordingly can be assuredly in superconducting states. Compared with low-temperature closed-loop superconducting magnets in the prior art, the superconducting magnet has the advantage of high superconducting stability.

Owner:NINGBO JANSEN SUPERCONDUCTING TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com