Superconducting strand based on ReBCO high-temperature superconducting tape

A technology of high-temperature superconducting strips and superconducting strips, applied in the field of superconducting strands, can solve the problems of inconvenient application, insufficient flexibility and mechanical strength, etc., and achieve the effect of increasing engineering current density and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

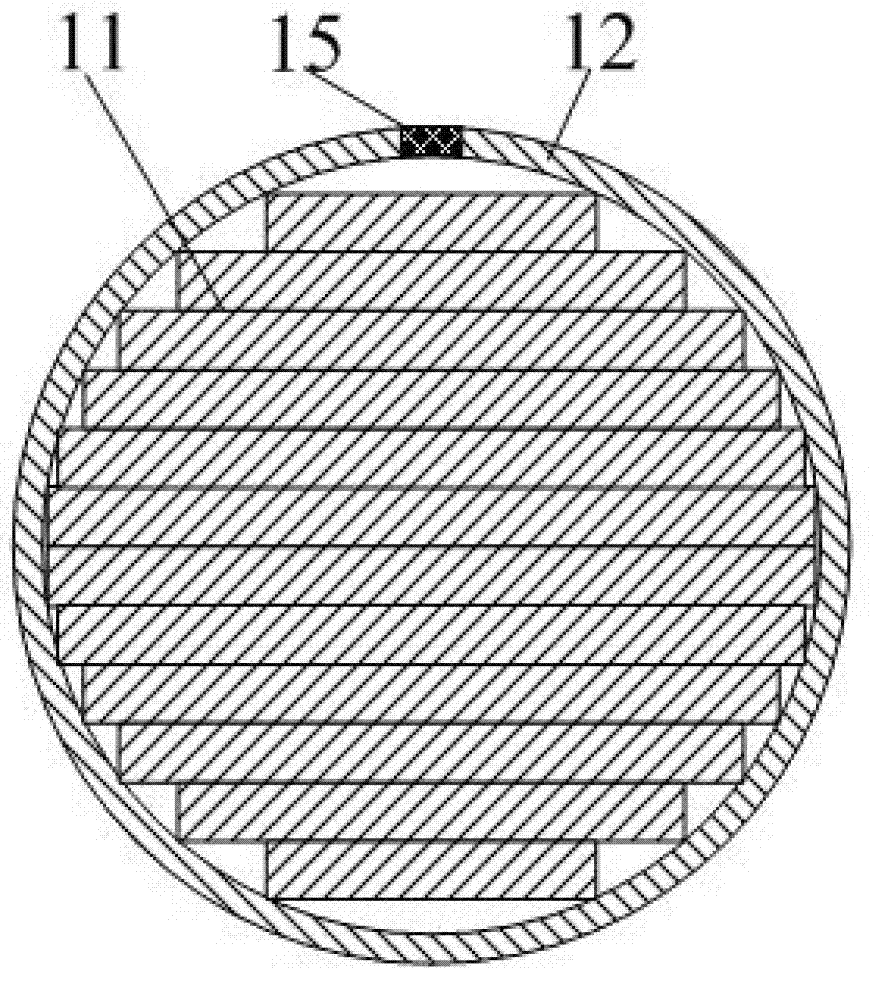

[0030] Example 1, a superconducting strand based on a circular cross-section of a ReBCO high temperature superconducting tape.

[0031] The cross-sectional structure of a circular cross-section superconducting strand based on ReBCO high-temperature superconducting tape is shown in figure 2 As shown, the superconducting strand is composed of a circular cross-section superconducting strand core and a cladding layer I12, and the circular cross-section superconducting strand core is stacked by coating superconducting tapes I11 of different widths The cladding layer I12 is rolled and coated on the circular cross-section superconducting strand core, and the Ag solder welds the cladding layer I12 in the rolling seam of the cladding layer I12 to form a welding seam 15 .

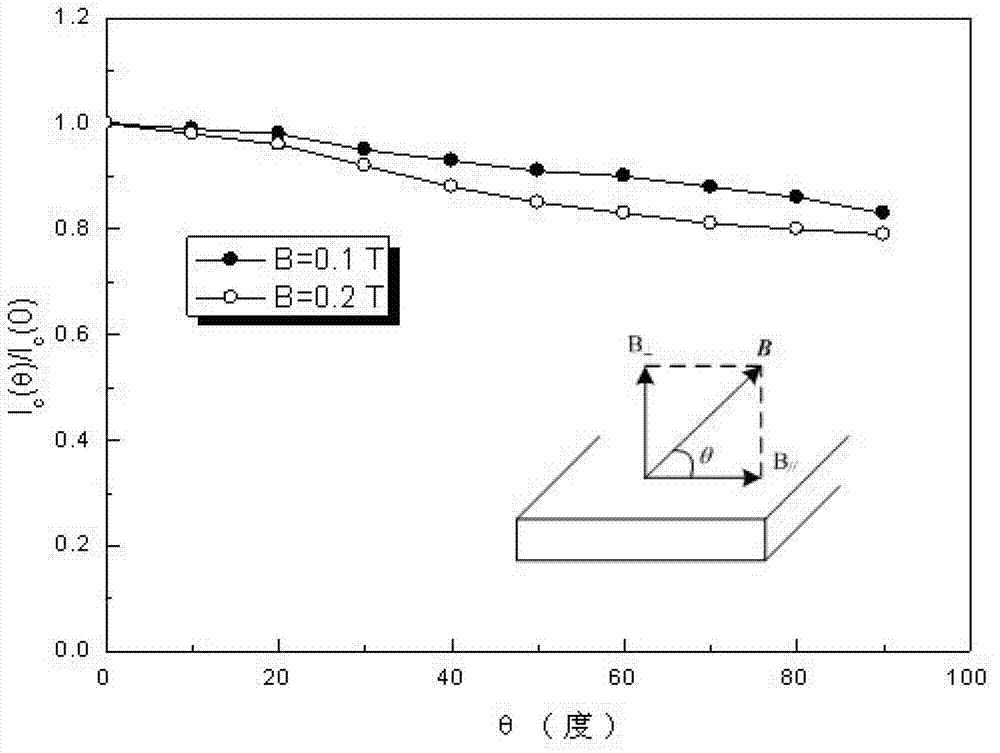

[0032] The material of coated superconducting tape I11 is YBCO coated superconducting plate in ReBCO (rare earth barium copper oxide system). The width of the coated superconducting tape I11 is cut according to the...

Embodiment 2

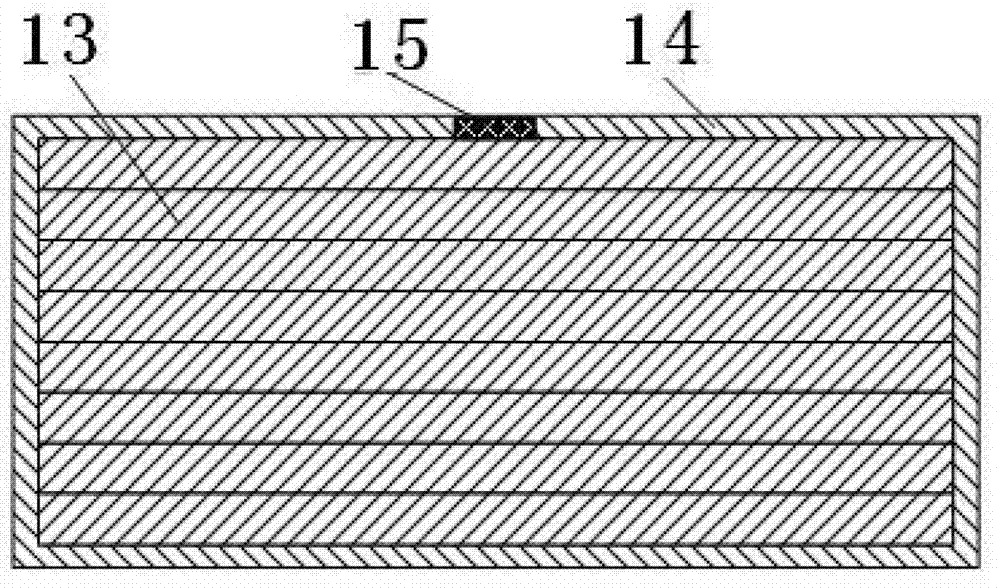

[0036] Example 2, a superconducting strand based on a ReBCO high temperature superconducting tape with a rectangular cross-section.

[0037] The cross-sectional structure of a rectangular cross-section superconducting strand based on ReBCO high-temperature superconducting tape is shown in figure 2 As shown in A, the superconducting strand is composed of a superconducting strand core with a square cross-section and a cladding layer II14, and the superconducting strand core with a rectangular cross-section is arranged by coating superconducting strips II13 cut into equal widths Stacked, the width of the coated superconducting tape II13 is greater than the thickness of the superconducting strand core after stacking, and the cladding tape material used for the cladding layer II14 is copper tape. The cladding layer II14 is rolled and coated on the superconducting strand core with a rectangular cross section, and the Ag solder welds the cladding layer II14 in the rolling seam of th...

Embodiment 3

[0041] Example 3, a superconducting strand based on a ReBCO high temperature superconducting tape with a square cross-section.

[0042] The cross-sectional structure of the square cross-section superconducting strand based on the ReBCO high-temperature superconducting tape is as follows figure 2 As shown in B, the superconducting strand is composed of a superconducting strand core with a square cross-section and a cladding layer II14, and the superconducting strand core with a square cross-section is arranged by coating superconducting strips II13 cut into equal widths Stacked, the width of the coated superconducting strip II13 is equal to the thickness of the superconducting strand core after stacking, and the cladding strip material used for the cladding layer II14 is an aluminum alloy strip. The cladding layer II14 is rolled and coated on the superconducting strand core with a rectangular cross section, and the Ag solder welds the cladding layer II14 in the rolling seam of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com