Continuous preparation device and preparation method for bismuth-series high temperature superconductive thick film

A technology for high-temperature superconductivity and device preparation, which is applied to the usage of superconductor elements, superconducting devices, superconducting/high-conducting conductors, etc. Restricting the performance of superconducting thick film and other issues, to achieve the effect of increasing the effective current-carrying area, convenient processing, installation and layout, and shortening the preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

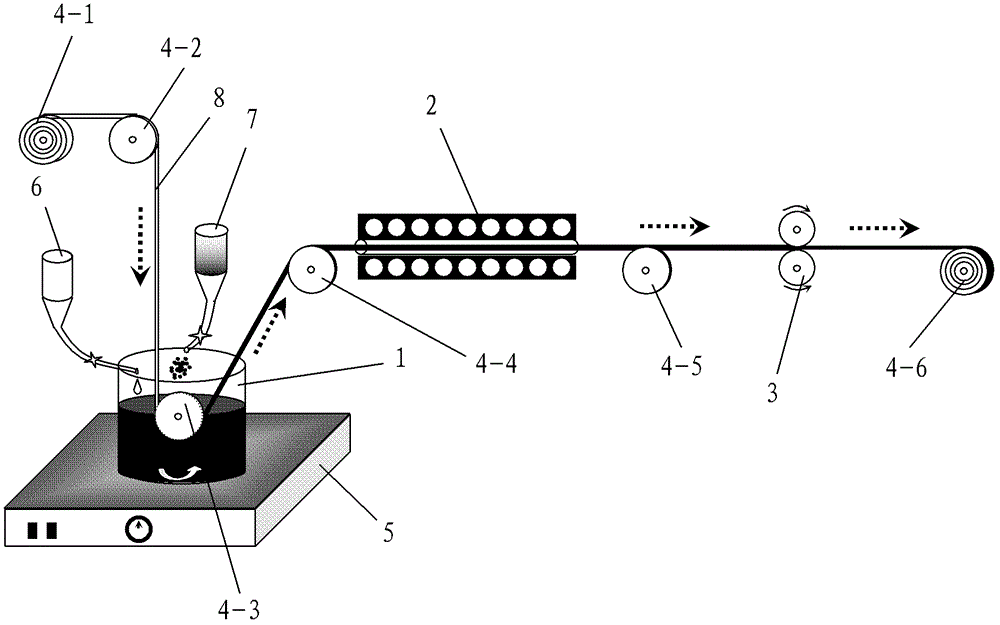

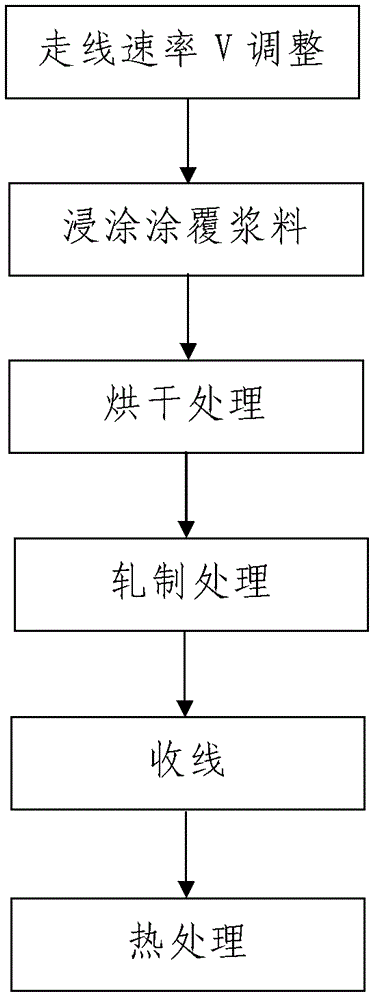

[0039] Such as figure 1 A continuous preparation device for a bismuth-based high-temperature superconducting thick film is shown, including dip-coating equipment for uniformly dip-coating coating slurry on the outer surface of the processed wire strip, and dip-coating with the coating slurry The drying equipment for drying the treated line strip, the rolling equipment for rolling the treated line strip after drying, and the treated line strip from the dip coating equipment, drying Drawing equipment for continuous drawing in dry equipment and rolling equipment. The dip coating equipment includes a mixing container 1 for uniformly mixing the coating slurry. The mixing container 1 is provided with a guide wheel 2 4-4, and the lower part of the guide wheel 4-4 is soaked in the mixing material. Inside the coating slurry in container 1. The wire pulling equipment includes a pay-off machine 4-1 and a wire take-up machine 4-2 arranged behind the pay-off machine 4-1 and used in conju...

Embodiment 2

[0075] In this embodiment, the structure, connection relationship and working principle of the bismuth-based high-temperature superconducting thick film continuous preparation device are the same as those in Embodiment 1.

[0076] In this example, the difference between the continuous preparation method of bismuth-based high-temperature superconducting thick film and Example 1 is that the strip to be processed in step 1 is made by cold rolling with a size of 4.0×0.1×1000mm Silver-based strip 8 with a line speed of V=0.1m / s; when dip-coating the coating slurry in step 2, the organic solvent used is ethanol, and the volume of the organic solvent added in every gram of Bi-2212 powder is 1.2ml , the adding rate of the liquid adding device is 0.57ml / s, and the adding rate of the solid powder adding device is 0.15g / s; when heat treatment is carried out after the winding-up in step 5, it is first incubated at 882°C for 20 Minutes, and then cooled to 840°C at a cooling rate of 5°C / h, ...

Embodiment 3

[0079] In this embodiment, the structure, connection relationship and working principle of the bismuth-based high-temperature superconducting thick film continuous preparation device are the same as those in Embodiment 1.

[0080] In this example, the difference between the continuous preparation method of bismuth-based high-temperature superconducting thick film and Example 1 is that the strip to be processed in step 1 is made by cold rolling with a size of 4.0×0.05×2000mm Silver-based strip 8 with a line speed of V=0.01m / s; when dip-coating the coating slurry in step 2, the organic solvent used is ethanol, and the volume of the organic solvent added in every gram of Bi-2212 powder is 1.2ml , the adding rate of the liquid adding device is 0.47ml / s, and the adding rate of the solid powder adding device is 0.02g / s; when heat treatment is carried out after the winding-up in step 5, it is first kept at a temperature of 890°C for 40 Minutes, and then cooled to 840°C at a cooling r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com