Patents

Literature

37 results about "Texture formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

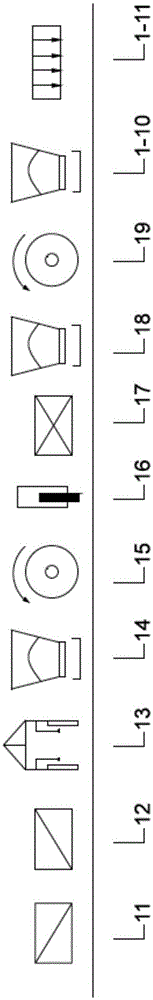

Ceramic polished brick and production method and production line of ceramic polished brick

ActiveCN105328782ASmooth transitionClear and smooth textureCovering/liningsCeramic shaping plantsYarnBrick

The invention discloses a ceramic polished brick and a production method and a production line of the ceramic polished brick. The production line comprises a range-shaped texture forming set, a material block forming set, an atomization spraying system, a third material distributing device, a first roll pressing device, a cutting device, a gorge-shaped texture forming set, a sixth material distributing device, a second roll pressing device, a seventh material distributing device and a press device, all of which are sequentially connected through a belt. According to a preparing method, color attaching pulp is attached to a micro powder stack jointly formed by material blocks formed by a range-shaped texture material belt subjected to the action of a texture manufacturing device and tooth roller crushing, the poking operation and super-through line material filling procedures are carried out on pressed powder through two sets of different mechanical arm combinations, wherein the pressed powder is formed through material supplementing, prepressing and cutting and edge removing. The polished brick obtains the polished brick decoration texture jointly composed of the range-shaped texture, the lava-shaped texture and the gorge-shaped texture. The range-shaped texture is smooth and natural, the edge of the lava-shaped texture has color lines fine like silk yarn, the texture is infinitely close to the difference texture of natural stone, and the stone imitating effect is extremely good.

Owner:GUANGDONG WINTO CERAMICS +3

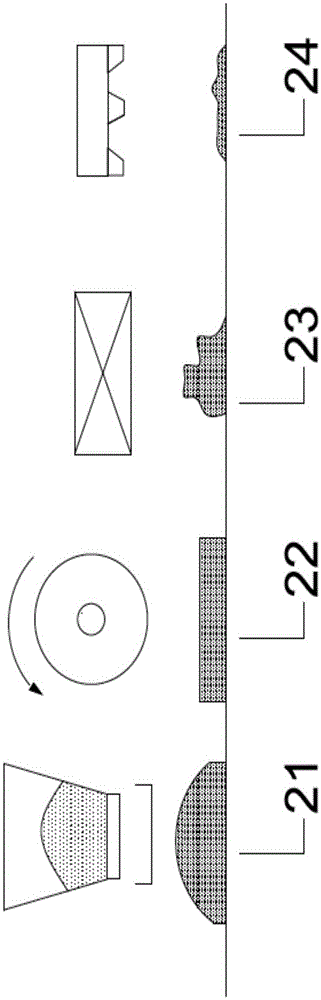

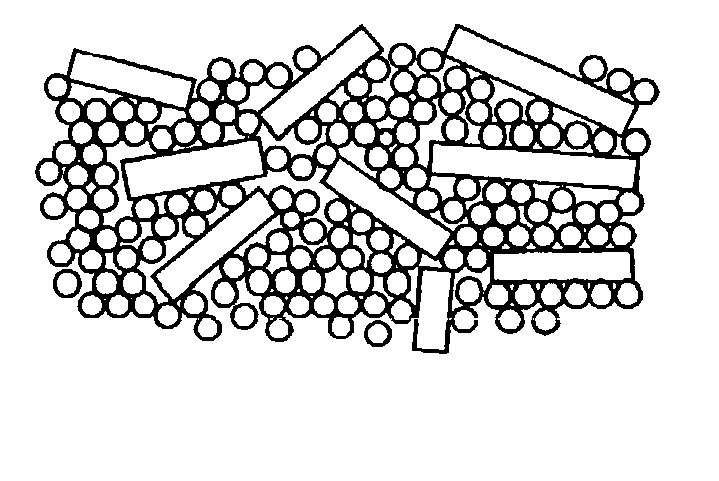

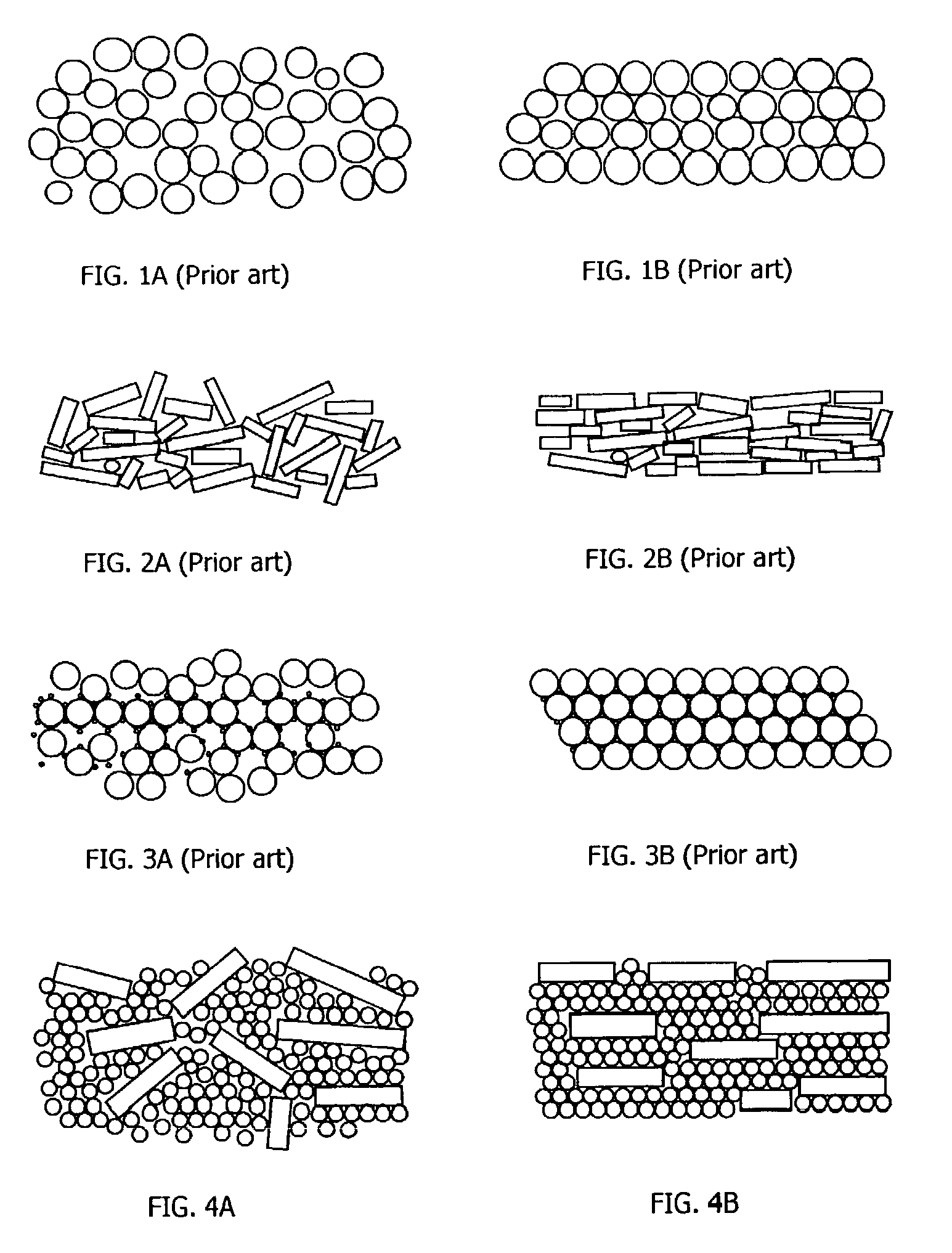

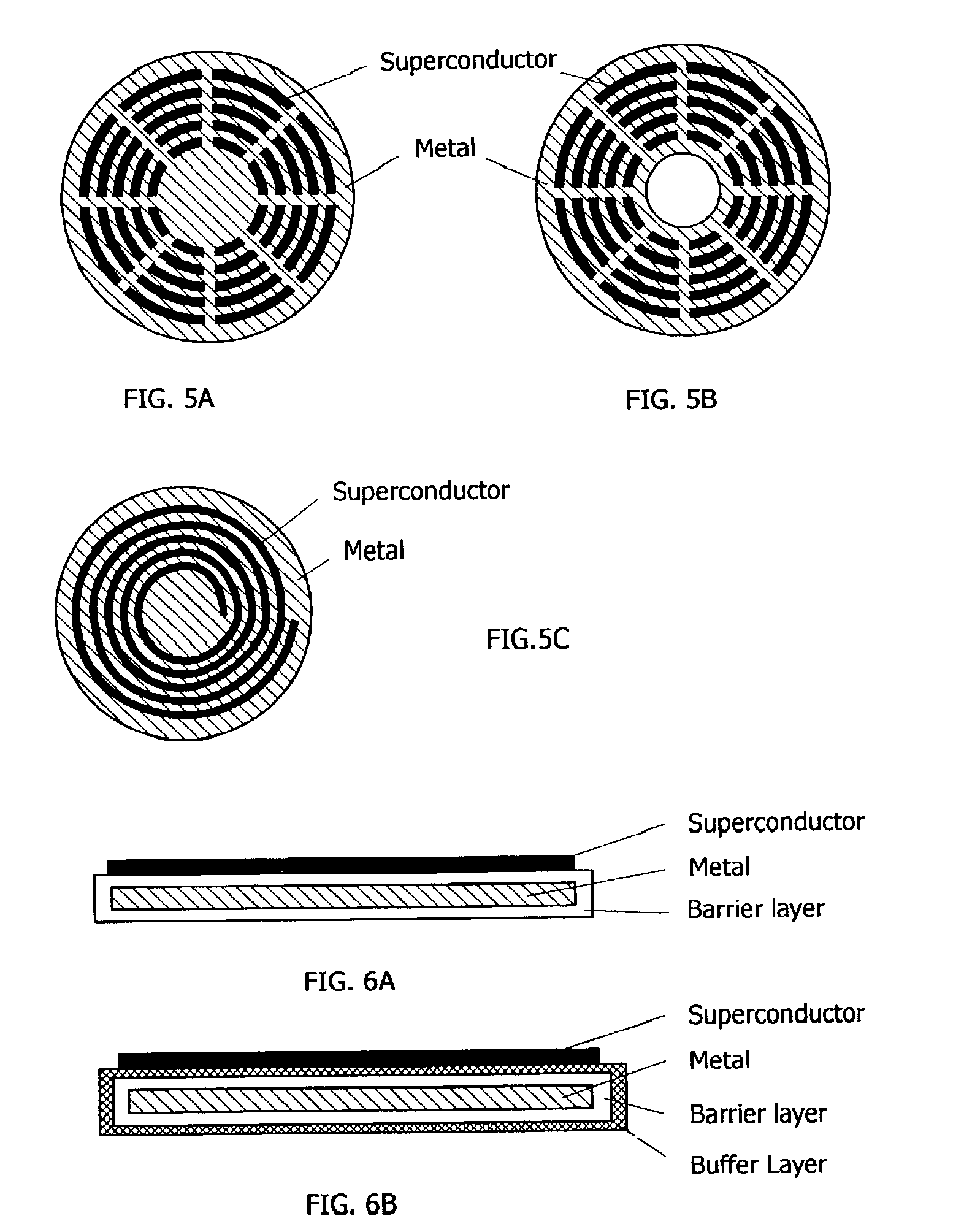

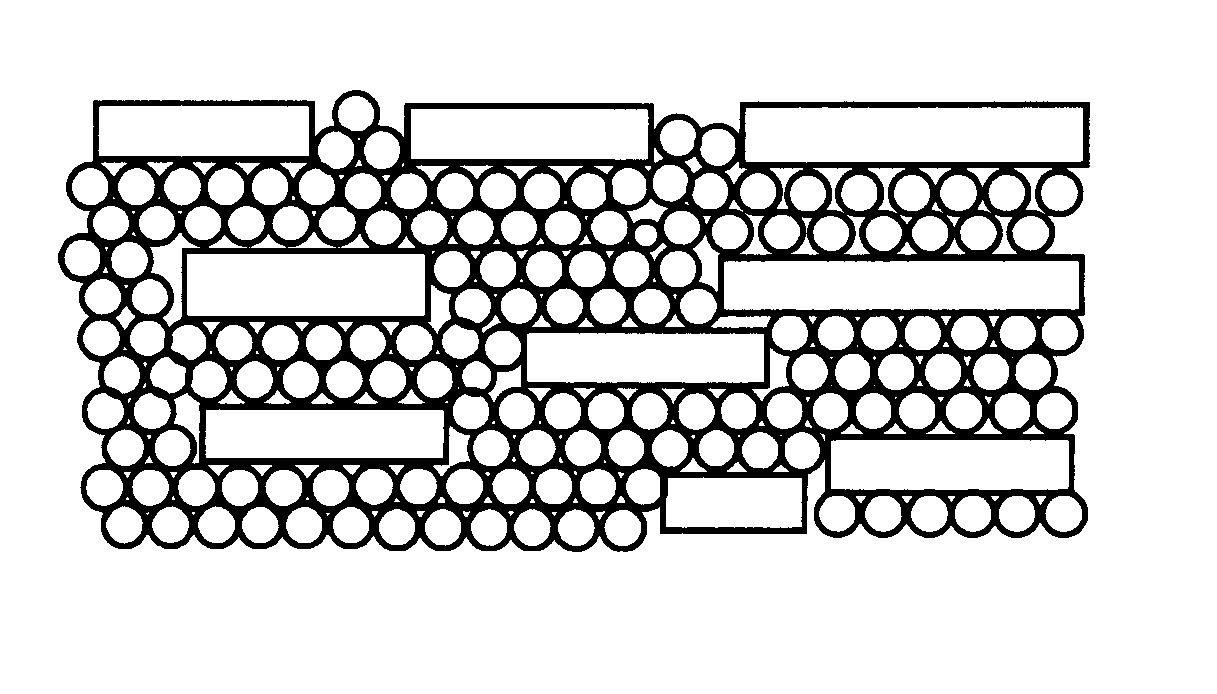

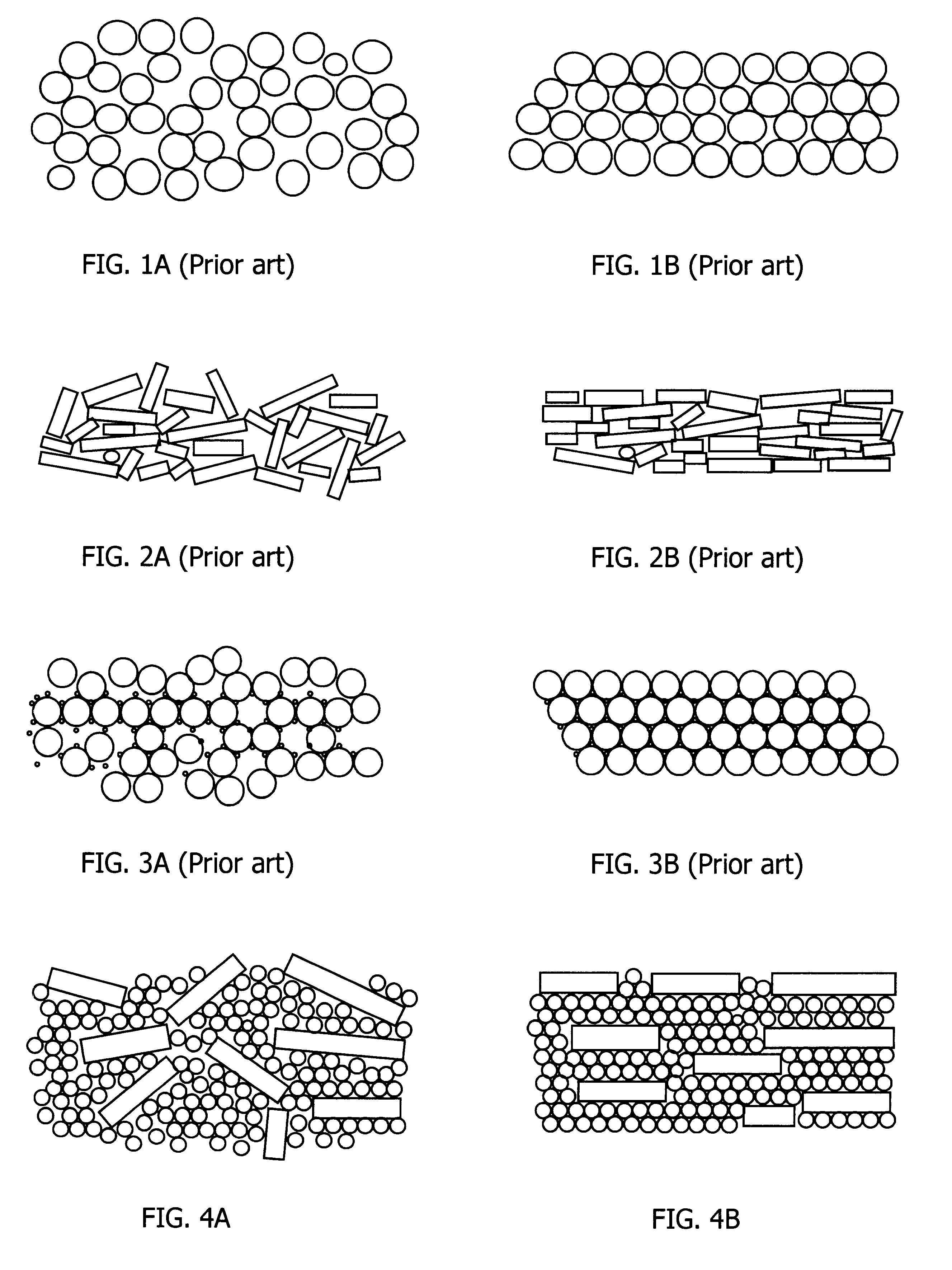

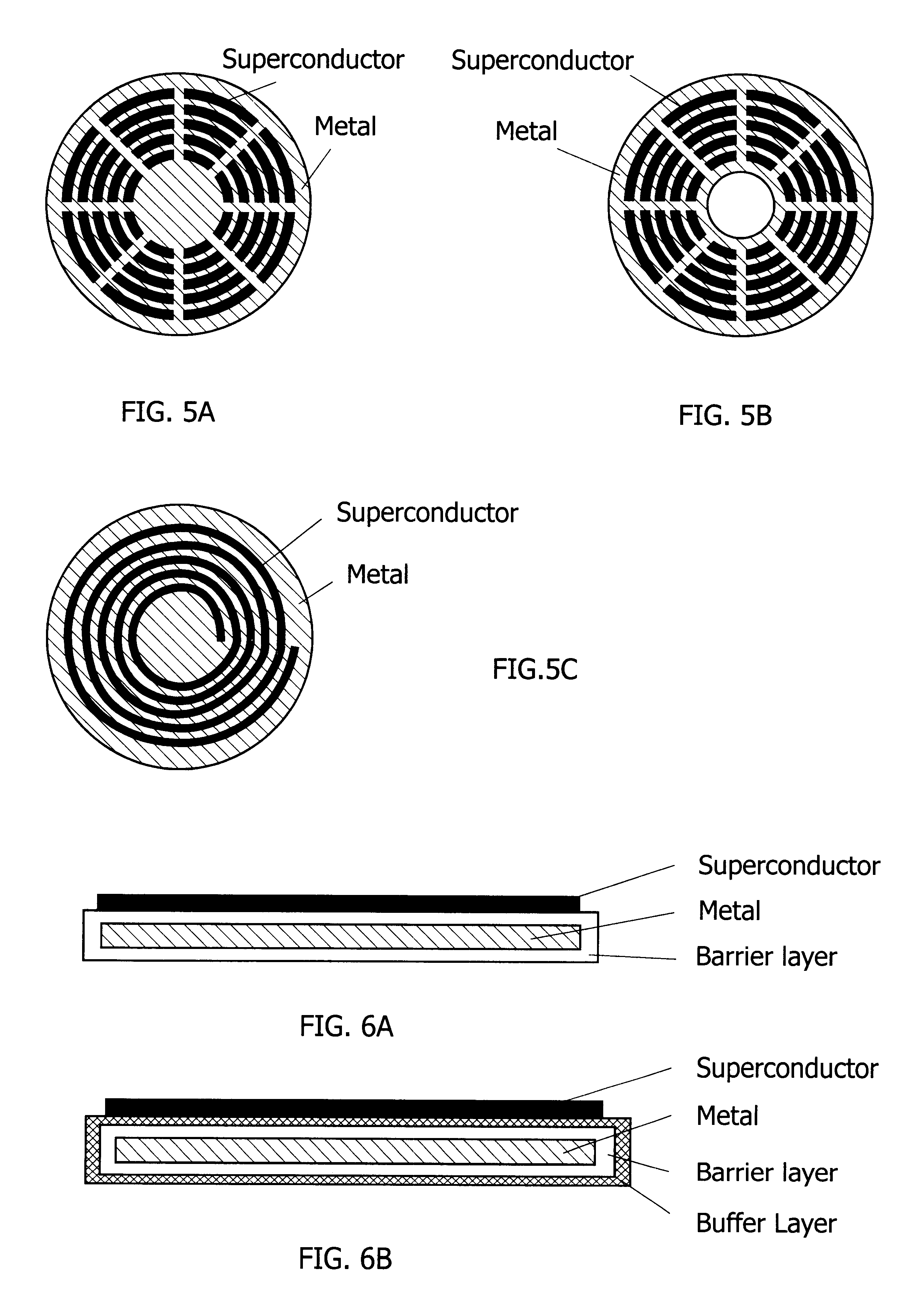

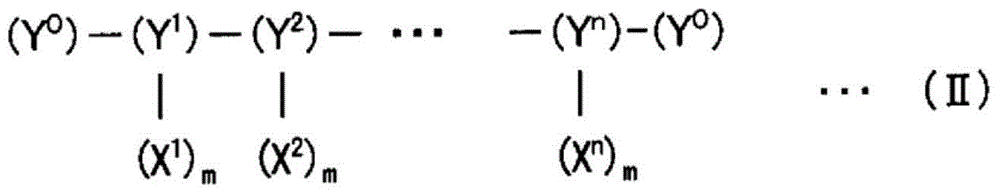

Method of preparing metal matrix composite with textured compound

InactiveUS20020198109A1Simple process conditionsHigh critical current densityNon-insulated conductorsSuperconductors/hyperconductorsPower flowVolumetric Mass Density

The present invention provides a generic method of preparing a metal matrix composite with a textured compound. A "roller-skate" structure starting powder with a mixture of plate-like particles and smaller particles provides better flow compatibility, higher packing density, better densification and texture formation in preparing a metal matrix composite with a textured compound. In particular, the invention provides a method of preparing a textured superconducting composite wire with an improved critical current density.

Owner:WU HENGNING

Method of preparing metal matrix composite with textured compound

InactiveUS6569360B2Simple process conditionsImprove superconductivityNon-insulated conductorsSuperconductors/hyperconductorsVolumetric Mass DensityMetal matrix composite

The present invention provides a generic method of preparing a metal matrix composite with a textured compound. A "roller-skate" structure starting powder with a mixture of plate-like particles and smaller particles provides better flow compatibility, higher packing density, better densification and texture formation in preparing a metal matrix composite with a textured compound. In particular, the invention provides a method of preparing a textured superconducting composite wire with an improved critical current density.

Owner:WU HENGNING

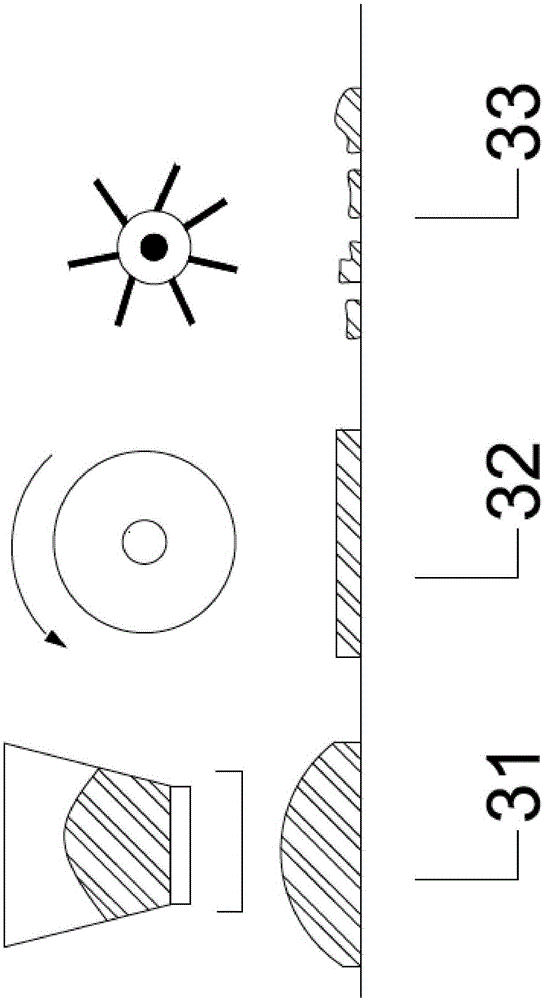

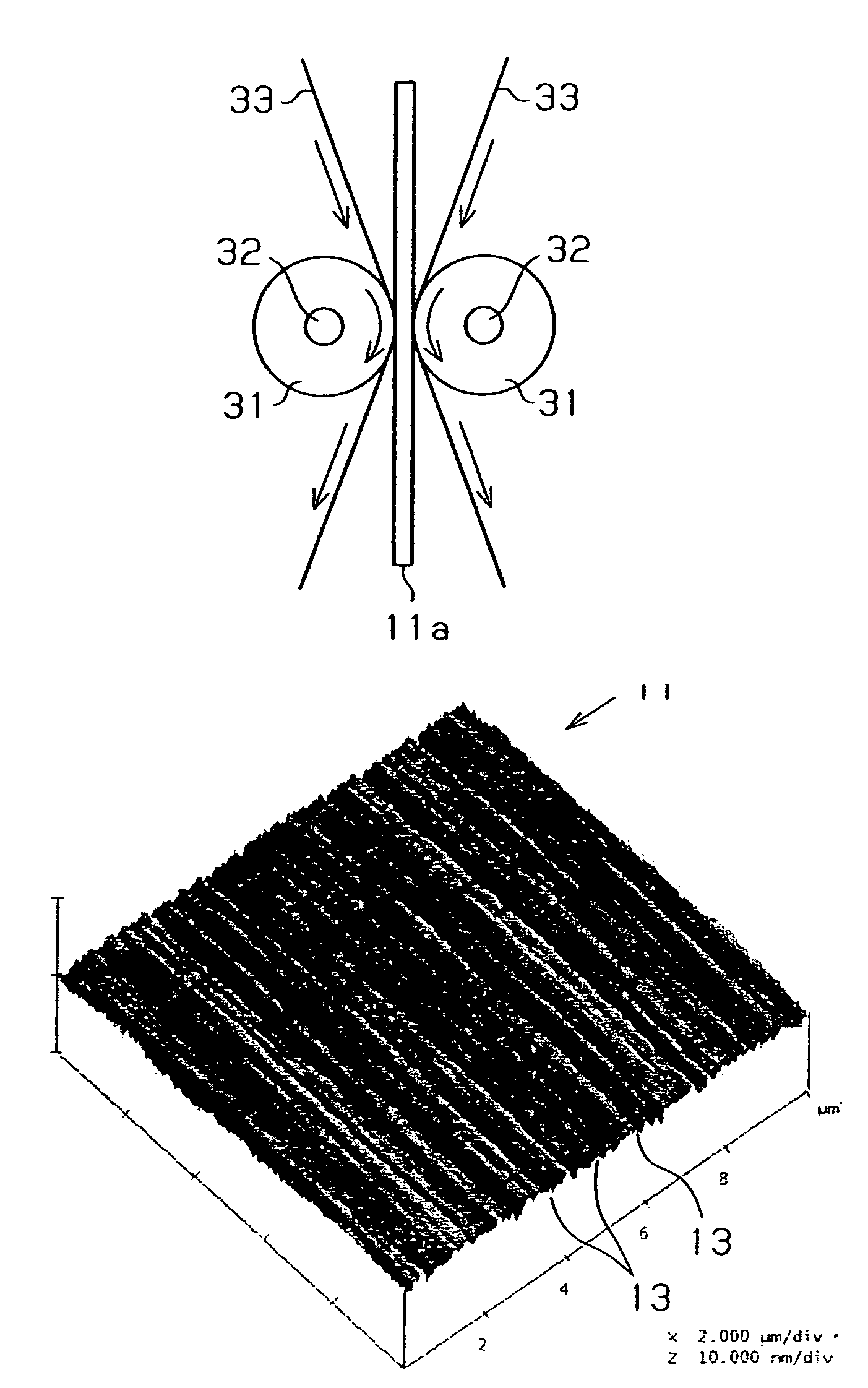

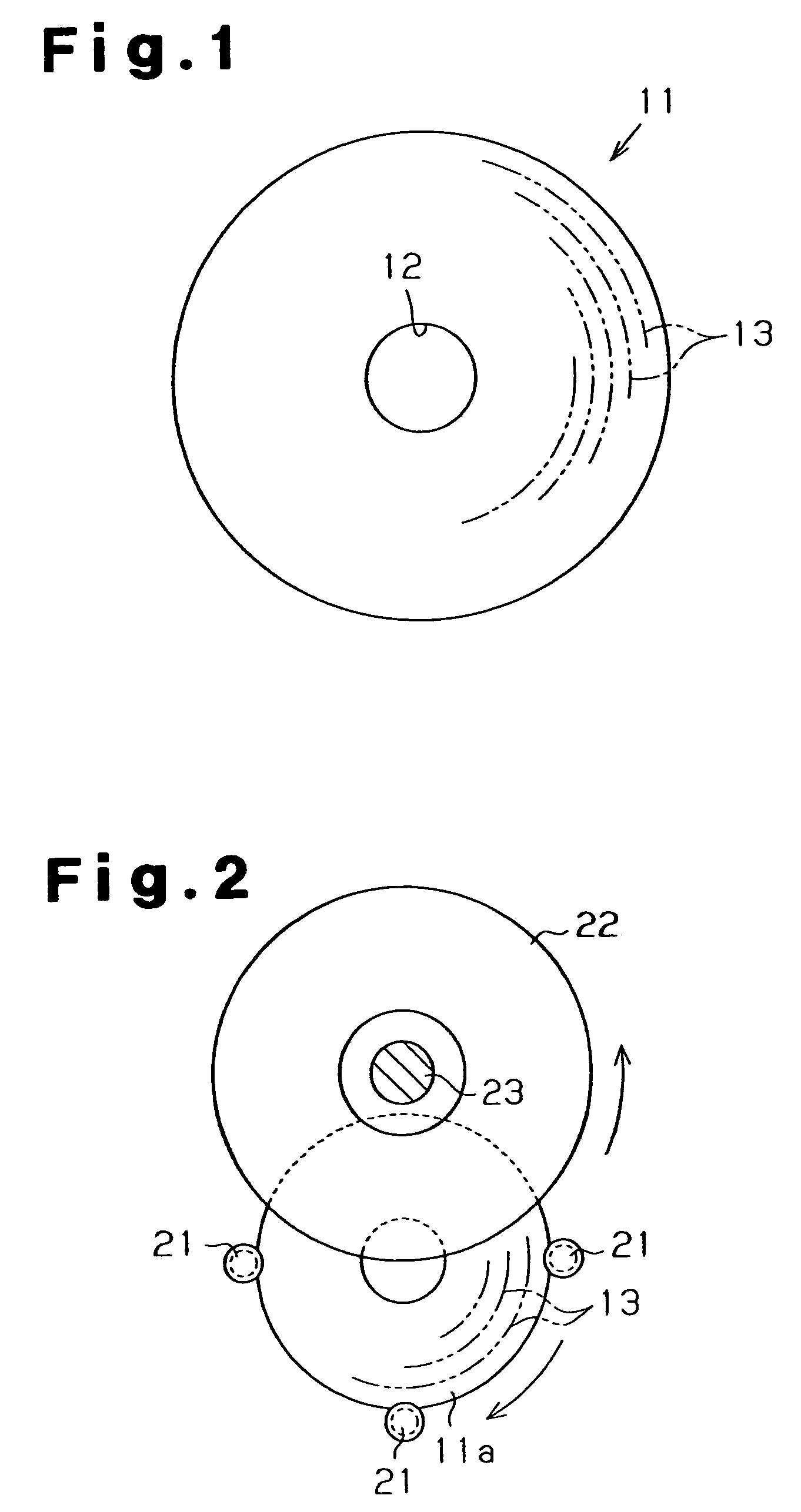

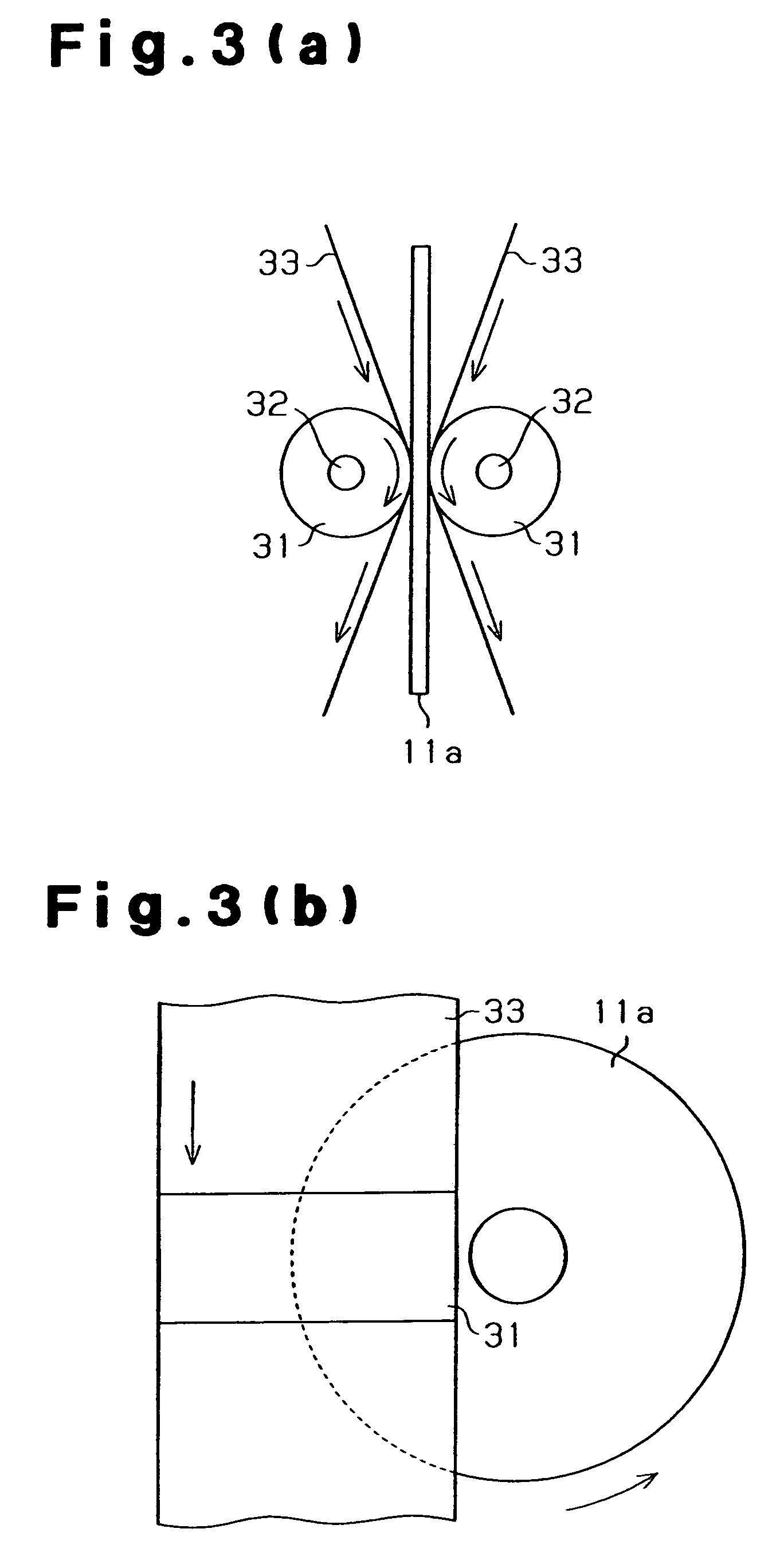

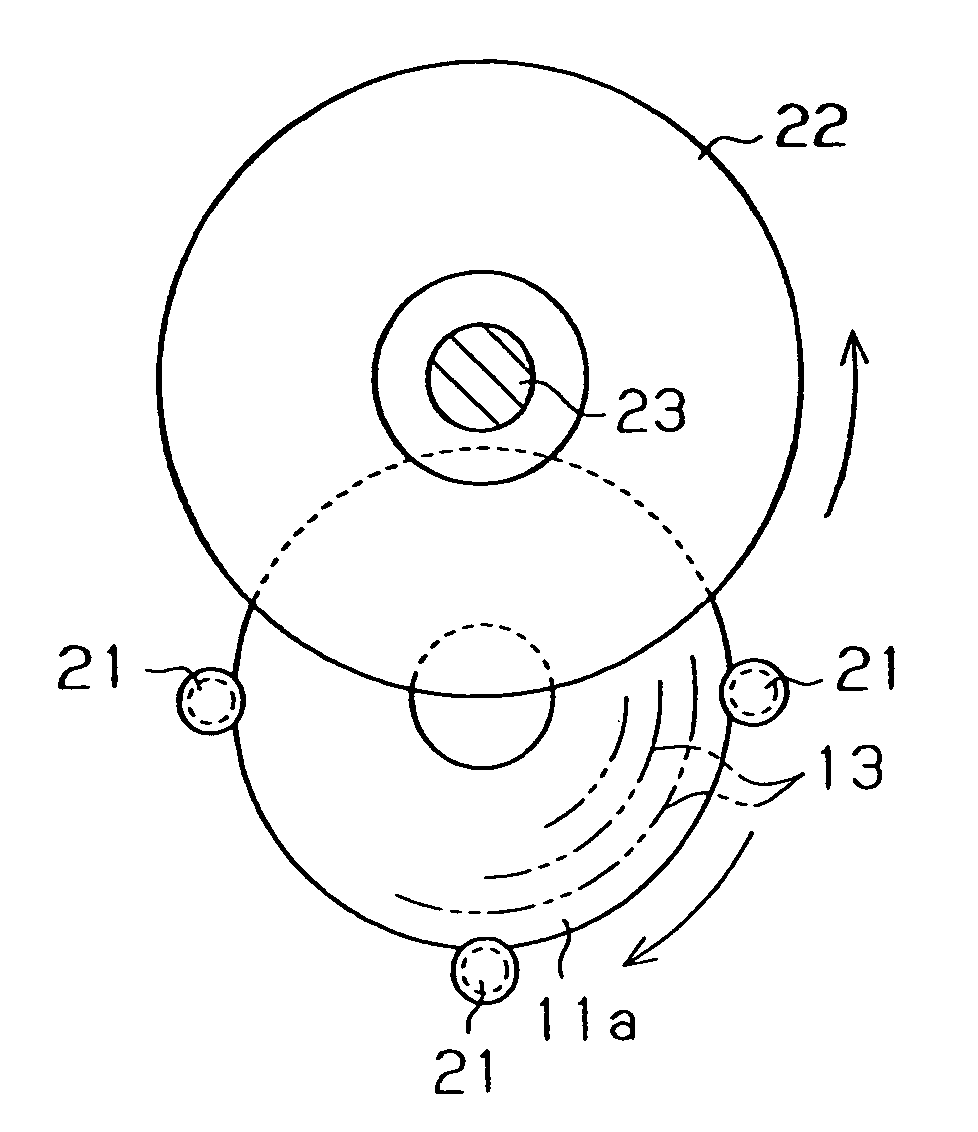

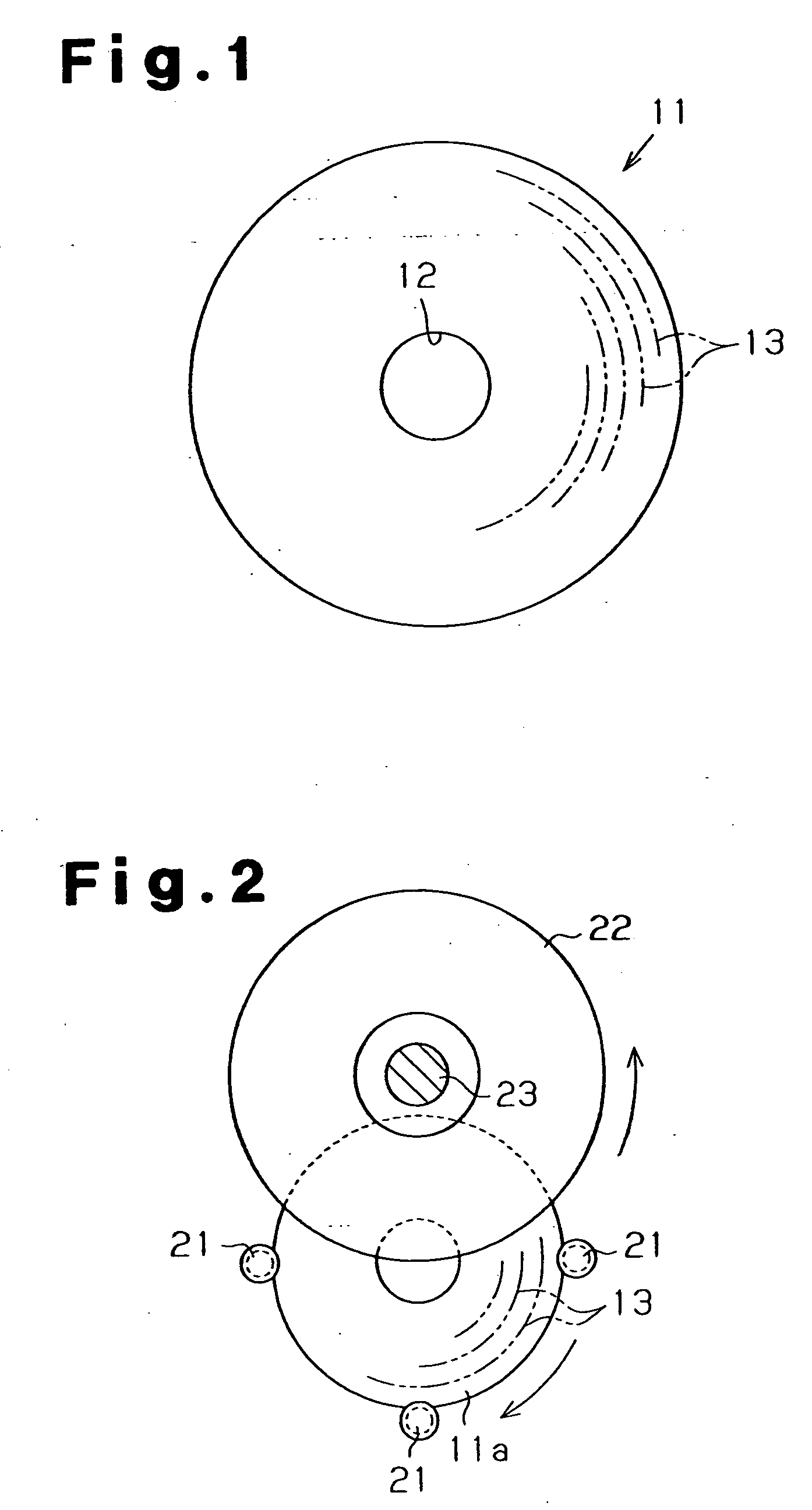

Glass substrate for information recording medium and process for manufacturing the same

A glass substrate for use in an information recording medium is manufactured by polishing a surface of a disc-shaped glass substrate and then performing texture processing on the surface. The texture processing includes the steps of forming lines of texture on the surface of the glass substrate extending along a circumferential direction of the glass substrate by performing a mechanical texture formation method in which the surface of the glass substrate is supplied with an abrasive slurry while an abrasive member slidably contacts the surface, and correcting the shape of the texture by removing burrs formed on the texture during the formation of the texture. The correction of the shape of the texture is performed by using a correcting pad made of foam of a synthetic resin having a 100% modulus of 3 to 40 MPa and scrubbing the surface of the glass substrate with the correcting pad in a direction intersecting the direction in which the texture extends.

Owner:HOYA CORP

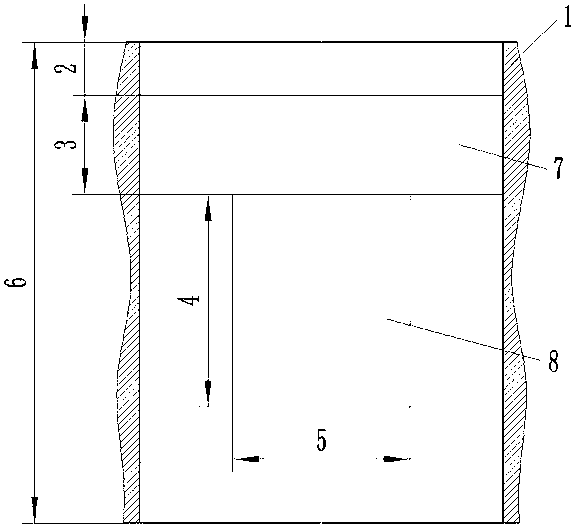

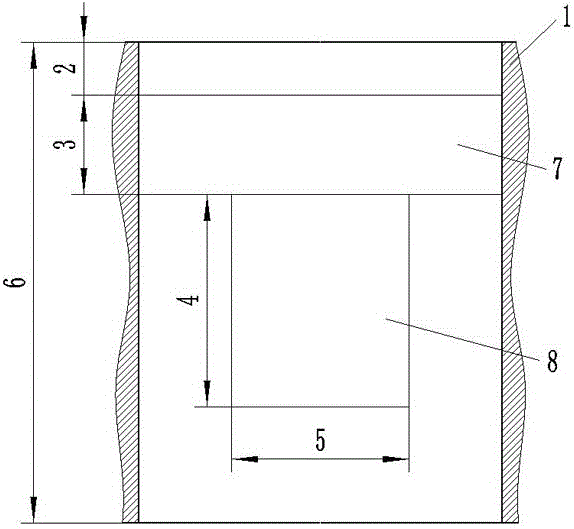

Cylinder bore machining method

The invention provides a cylinder bore machining method. The cylinder bore machining method comprises the steps of pretreatment, surface texture formation, aftertreatment and detection. A surface before machining is obtained through the pretreatment; texture features are machined on the surface of a cylinder bore through the surface texture formation; burrs on the surface of the cylinder bore are removed through the aftertreatment; quality test is finished through the detection process. The cylinder bore machining method has the advantages that the tribological performance of a cylinder bore-piston ring friction pair is remarkably improved, the abrasive resistance of the surface of the cylinder bore is enhanced, the fuel oil consumption is lowered by 1-3% for an engine, and the engine oil consumption is lowered by 30-50%.

Owner:JIANGSU UNIV

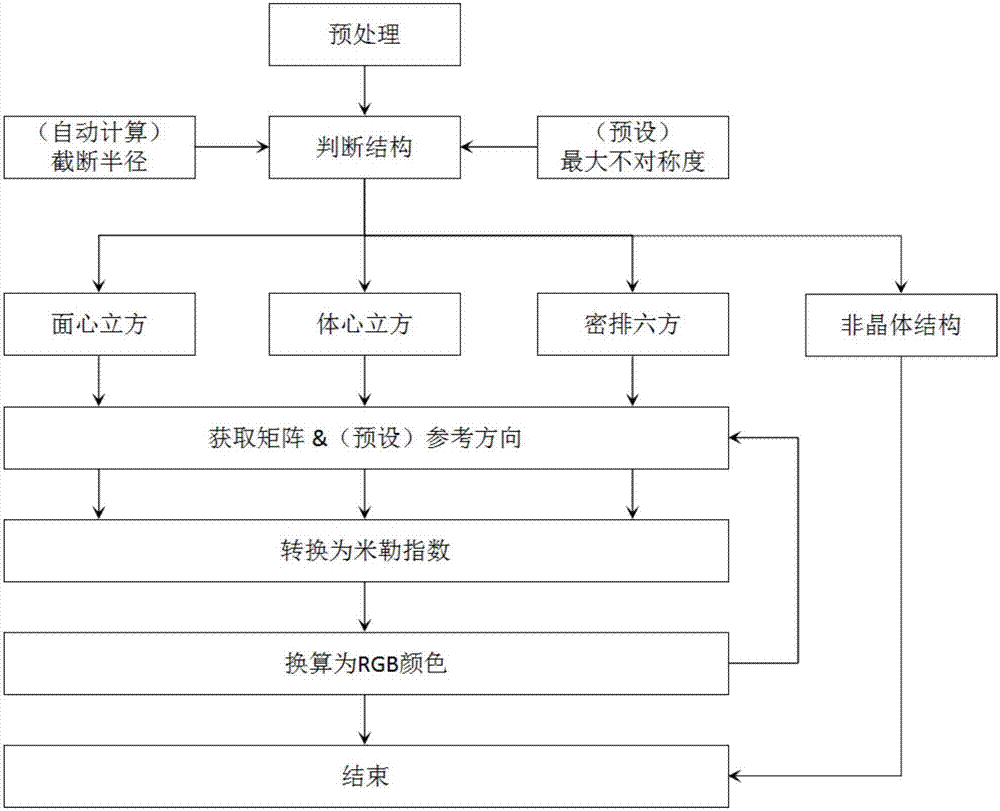

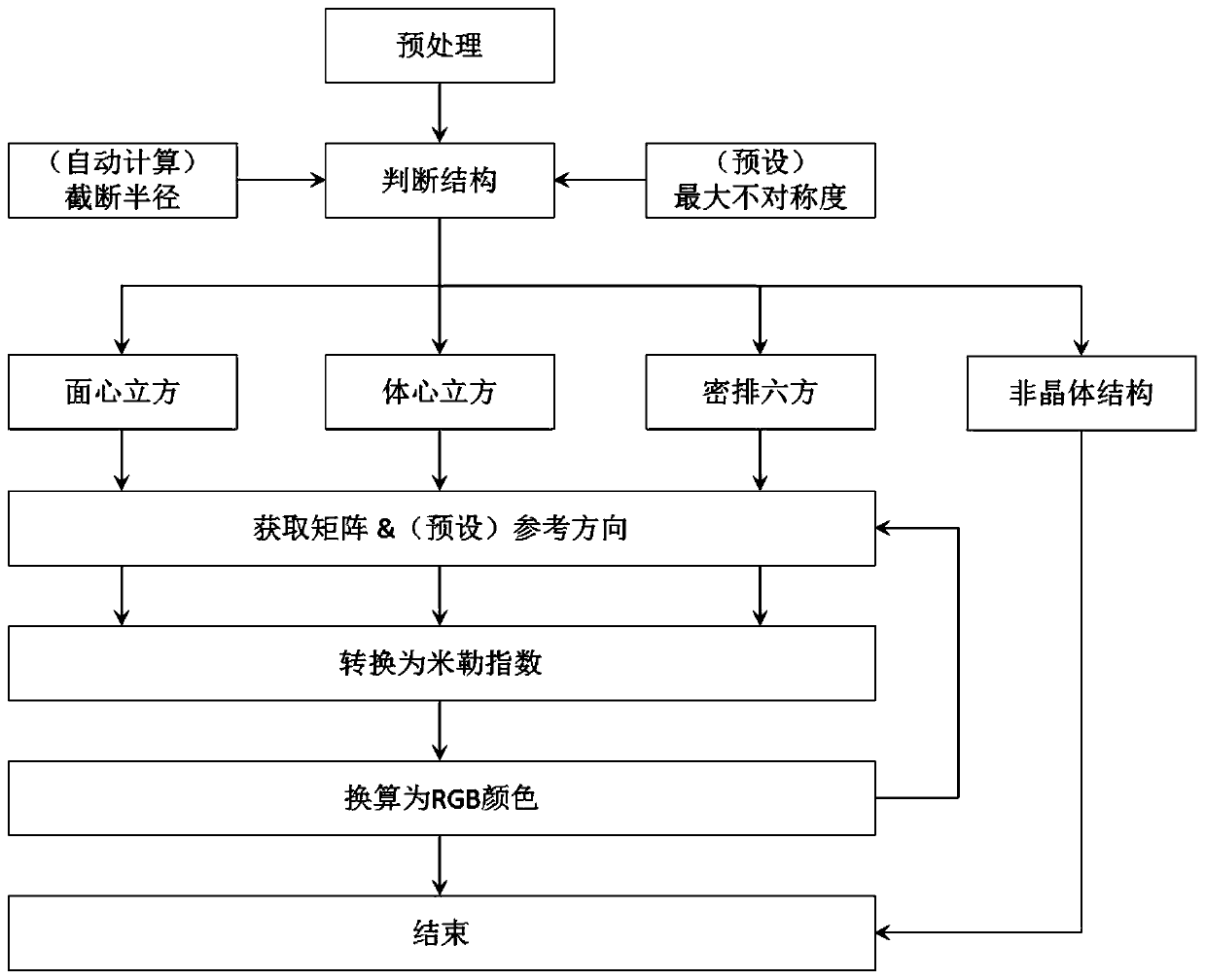

Atomic-scale crystal orientation analysis method based on crystal structure

ActiveCN107102016AOrientation Analysis ImplementationAutomate analysisMaterial analysis using wave/particle radiationCrystal orientationCrystal structure

The invention discloses an atomic-scale crystal orientation analysis method based on a crystal structure, and belongs to the technical field of metal materials. The analysis method includes the steps ofacquiring the surrounding environment of atoms, determining the crystal structure according to the atomic symmetry, acquiring an orientation matrix, converting the orientation matrix to color, and obtaining RGB color average value for all nearest atoms. The atomic-scale crystal orientation analysis method realizes the crystal orientation analysis in the process of nano metal tensile or impact simulation, and realizes the automatic analysis without external parameters. The method can understand the mechanism of crystal texture formation on the microcosmic scale and provides beneficial help for the new material design.

Owner:BEIHANG UNIV

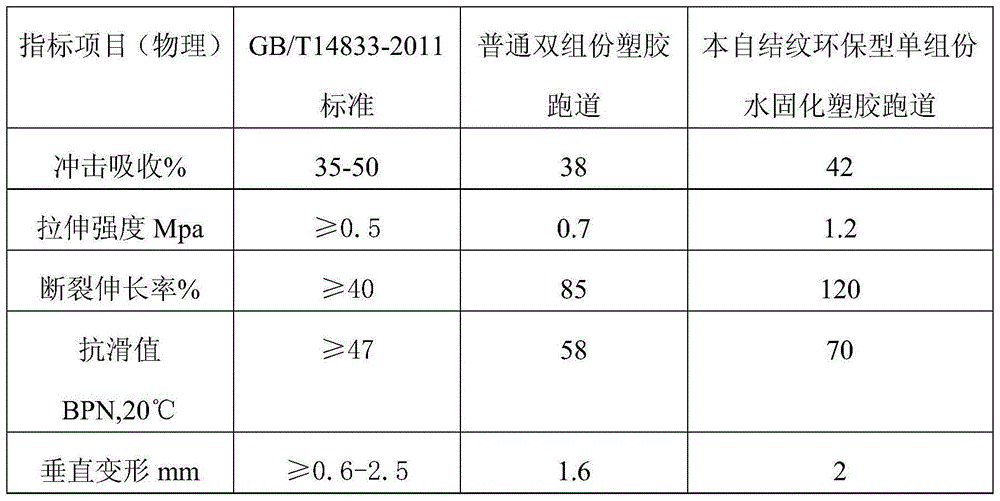

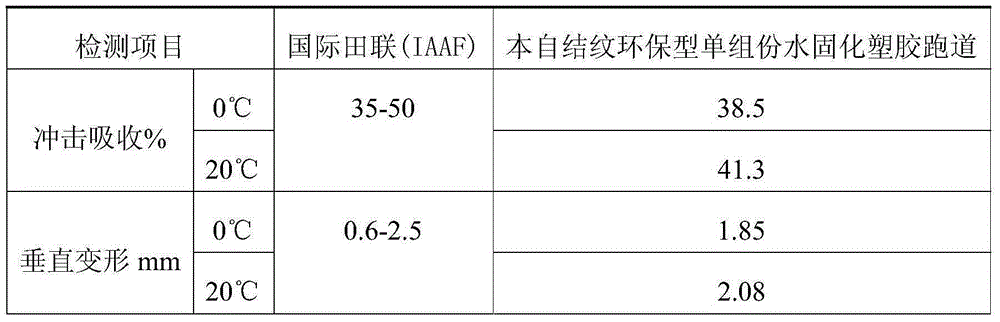

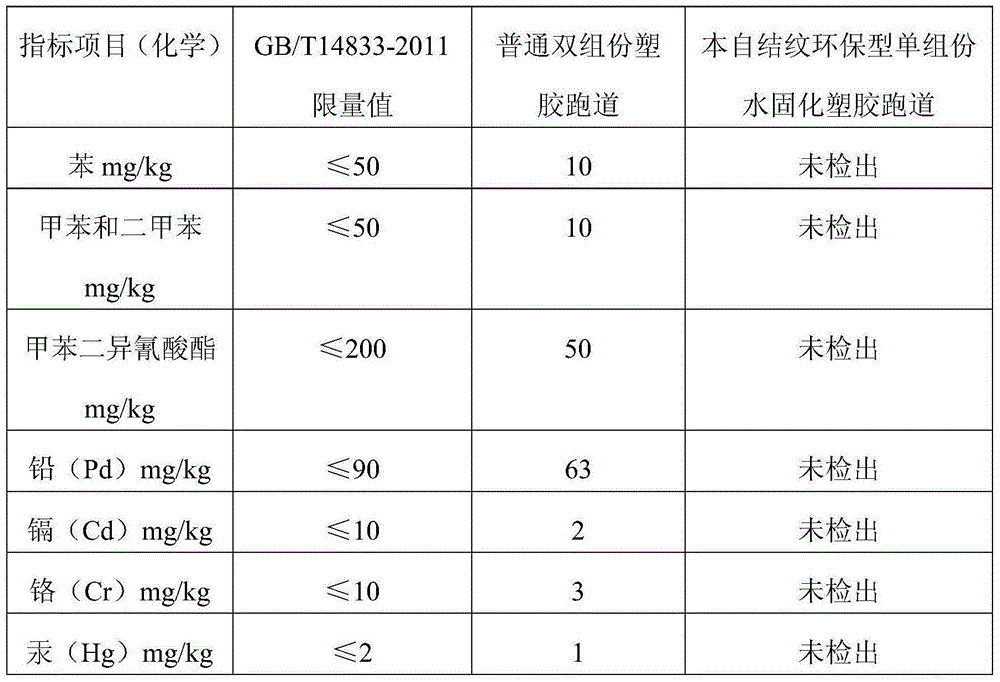

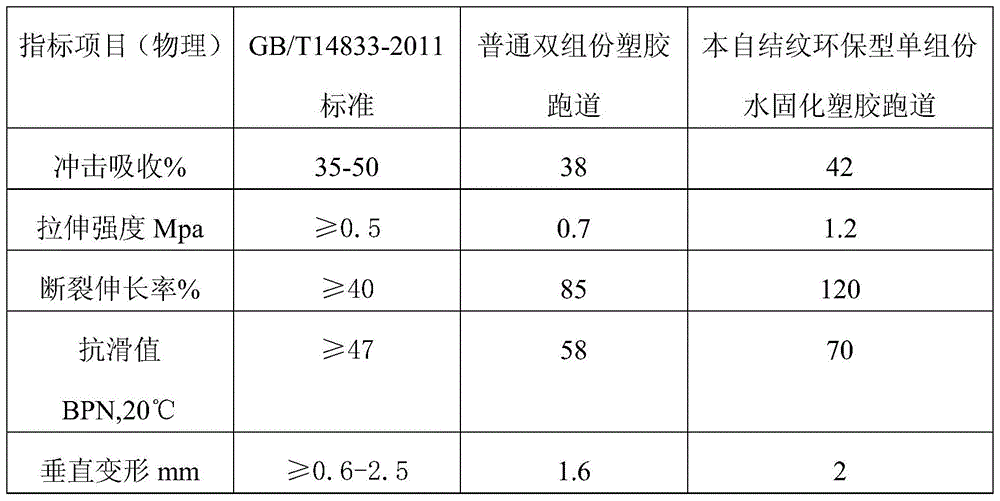

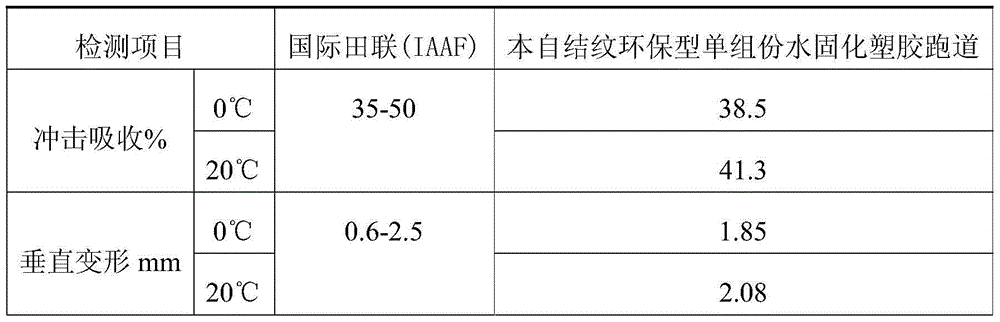

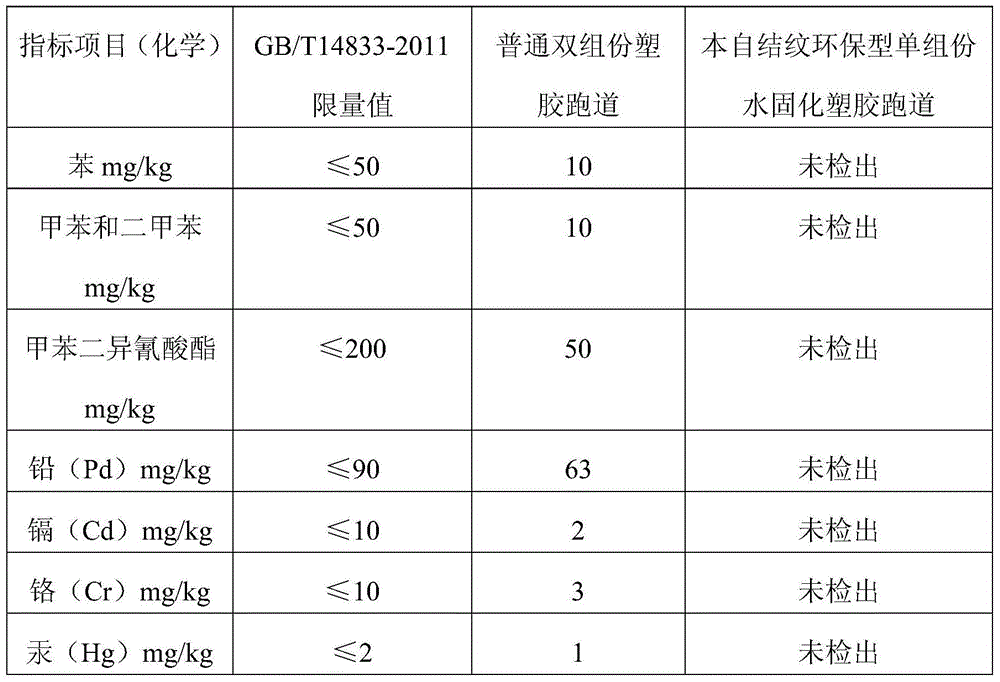

Laying method of automatic texture formation particle-free environmentally-friendly plastic track

The invention discloses a laying method of an automatic texture formation particle-free environmentally-friendly plastic track. The method comprises the following steps: S21, laying a substrate layer: mixing an environmentally-friendly single-component water solidified plastic track material with black micelles according to a weight ratio of 1:4-6, and laying the substrate layer on a dry and solidified cement base or asphalt base; S22, laying a reinforcing layer: spreading a layer of the black micelles on the dry and solid base layer, and lying the environmentally-friendly single-component water solidified plastic track material to cover the substrate layer; and S23, laying an automatic texture formation layer: uniformly mixing 10-12 parts of an automatic texture formation finish, 1-3 parts of EPDM particle rubber powder and 3-6 parts of quartz sand to form an automatic texture formation layer material, fully stirring, and spraying the obtained material on the dry and solidified reinforcing layer. The track has the advantages of environmentally friendly material, no shedding of particles, good durability, plump and uniform surface textures, high tensile strength and long service life, and all performance indexes of the track accord with technical requirements of International Association of Athletics Federations and GB / T14833-2011.

Owner:广州帝森康体设备有限公司

Glass substrate for information recording medium and process for manufacturing the same

A glass substrate for use in an information recording medium is manufactured by polishing a surface of a disc-shaped glass substrate and then performing texture processing on the surface. The texture processing includes the steps of forming lines of texture on the surface of the glass substrate extending along a circumferential direction of the glass substrate by performing a mechanical texture formation method in which the surface of the glass substrate is supplied with an abrasive slurry while an abrasive member slidably contacts the surface, and correcting the shape of the texture by removing burrs formed on the texture during the formation of the texture. The correction of the shape of the texture is performed by using a correcting pad made of foam of a synthetic resin having a 100% modulus of 3 to 40 MPa and scrubbing the surface of the glass substrate with the correcting pad in a direction intersecting the direction in which the texture extends.

Owner:HOYA CORP

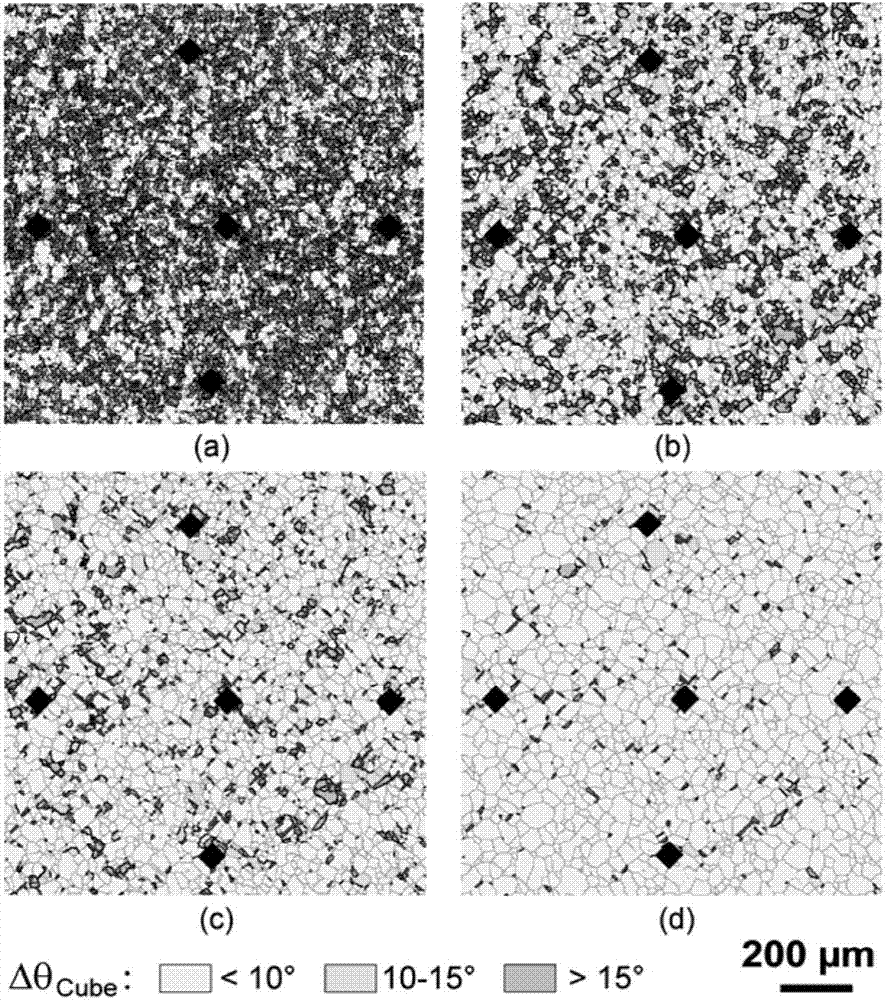

Method for improving content of cubic texture of Ni9.3W base band for YBCO superconductor

The invention relates to a method for improving the content of a cubic texture of a Ni9.3W base band for a YBCO superconductor, and belongs to the field of preparation of a texture metal base band for a coating superconductor. According to the method, the content of the cubic texture of the Ni9.3W base band is improved by combining a plurality of cubic texture improvement methods, and reference is provided for preparing high cubic texture Ni9.3W base band in future. Through the method that powder metallurgy blank forming and during-rolling heat treatment are combined, the content of the cubic texture of the Ni9.3W base band is improved. A spark plasma sintering technology is adopted in the billet preparing stage, and an initial billet which is high in compactness, few in impurity element and fine in grain is obtained. Then during-rolling heat treatment is adopted to remit work hardening in the rolling process, the basis of slippage deformation is provided for further follow-up rolling deformation, more grains trend to be a copper type rolling texture facilitating cubic texture formation, and finally the high cubic texture is obtained. The Ni9.3W base band prepared through the method has the higher cubic texture, and the requirement of the YBCO coating superconductor can be further met.

Owner:BEIJING UNIV OF TECH

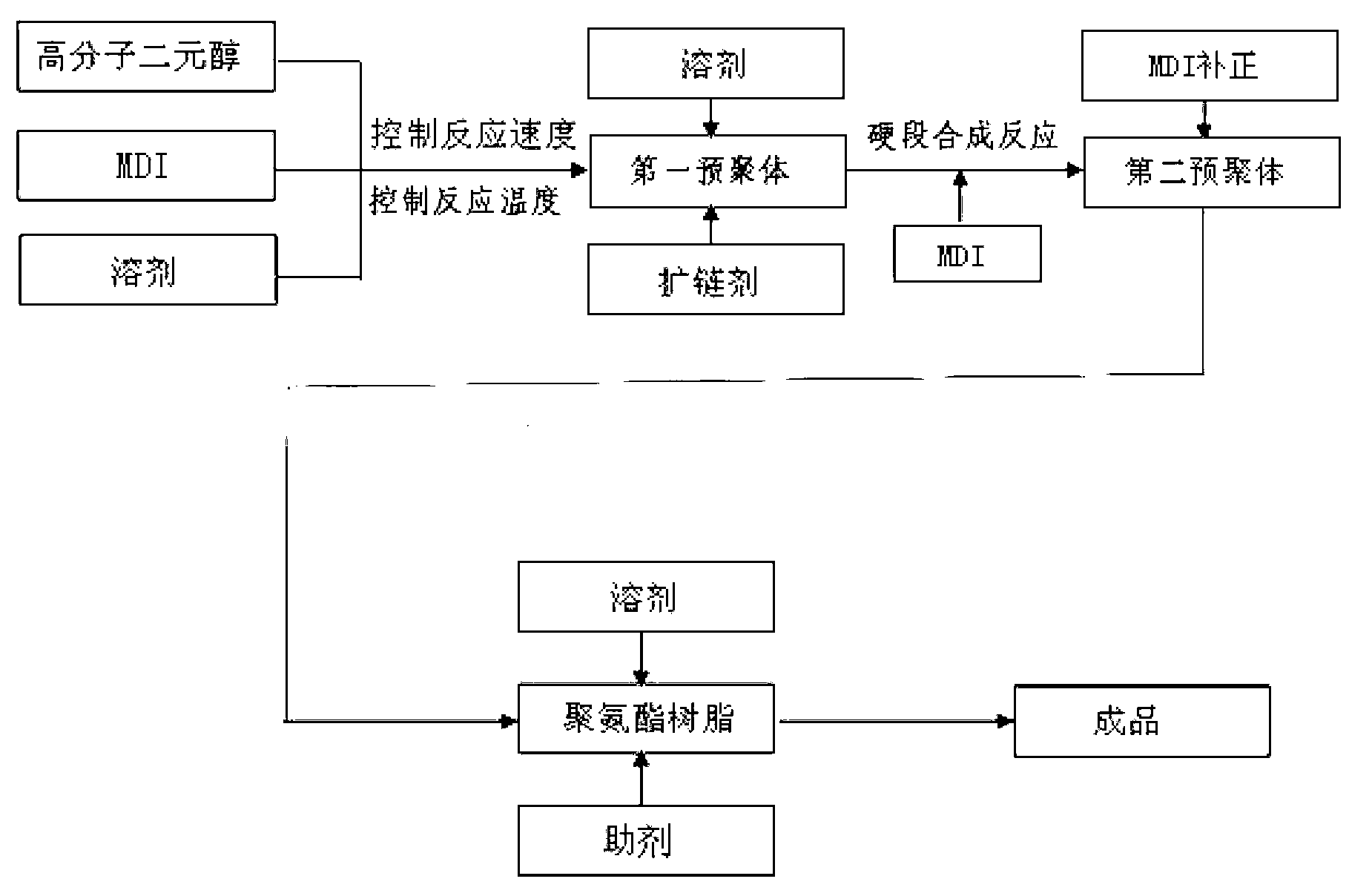

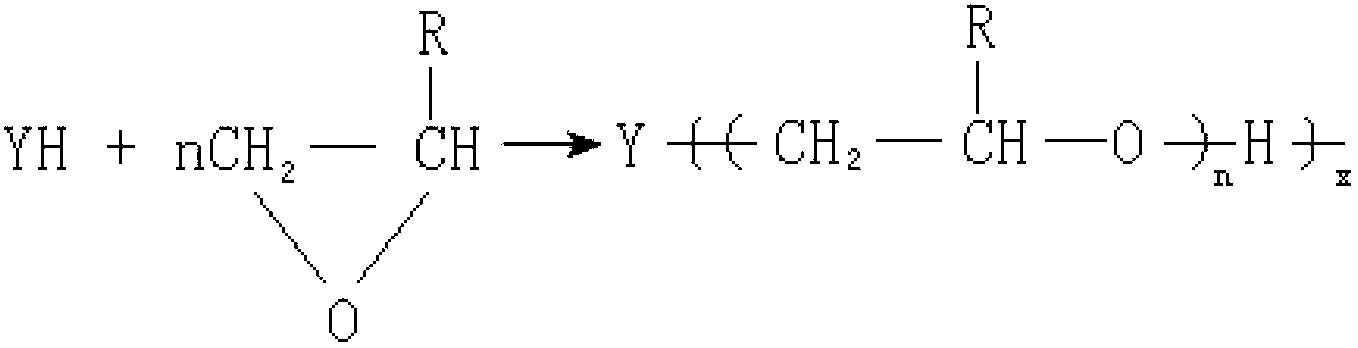

Wet type polyurethane resin, production process and application method thereof

ActiveCN102993398AHigh viscosityFeel fullSynthetic resin layered productsTextiles and paperAlcoholDiol

The invention provides a wet type polyurethane resin, a production process and an application method thereof. The production process mainly comprises the following steps: 1, carrying out a soft-segment synthetic reaction on macromolecule dihydric alcohol and diphenyl methane diisocyanate; 2, enabling a first prepolymer to react; 3, adding a chain extender, and carrying out hard-segment synthetic reaction; and 4, adding an auxiliary. The wet type polyurethane resin manufactured by the production process is in form of yellowish transparent and thick viscous fluid, has viscosity of 180,000 to 220,000 (cps / 25 DEG C), modulus of 100% under 4.5 to 5.5 Mpa, elongation of not less than 550% and strippability of not less than 12.0kg / 3cm, the hydrolysis resistance is that 10% of NaOH is hydrated for 24 hours, and the wet type polyurethane resin has texture formation of 50 to 65%. The production process has the advantages that the texture formation, peeling strength and hydrolysis resistance of the wet type polyurethane resin are improved; the auxiliaries are selected before forming the leather, so that the density of the wet type polyurethane resin is improved, the finished artificial leather has washing durability and is high in strippability and full in touch.

Owner:FUJIAN GUOBANG RESIN

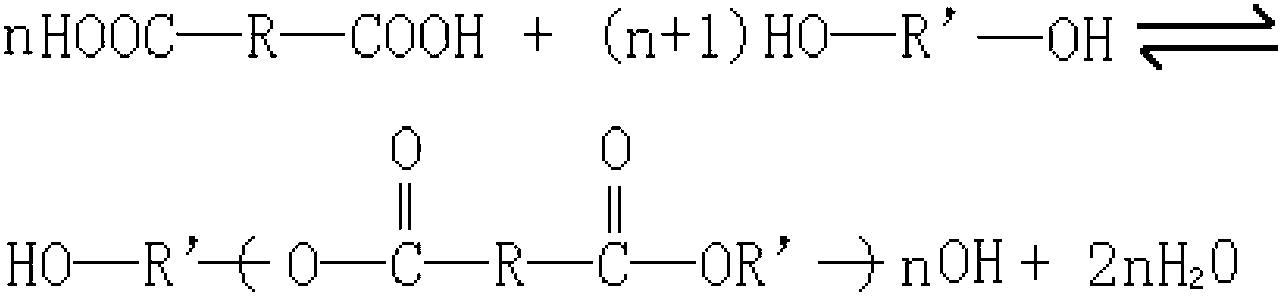

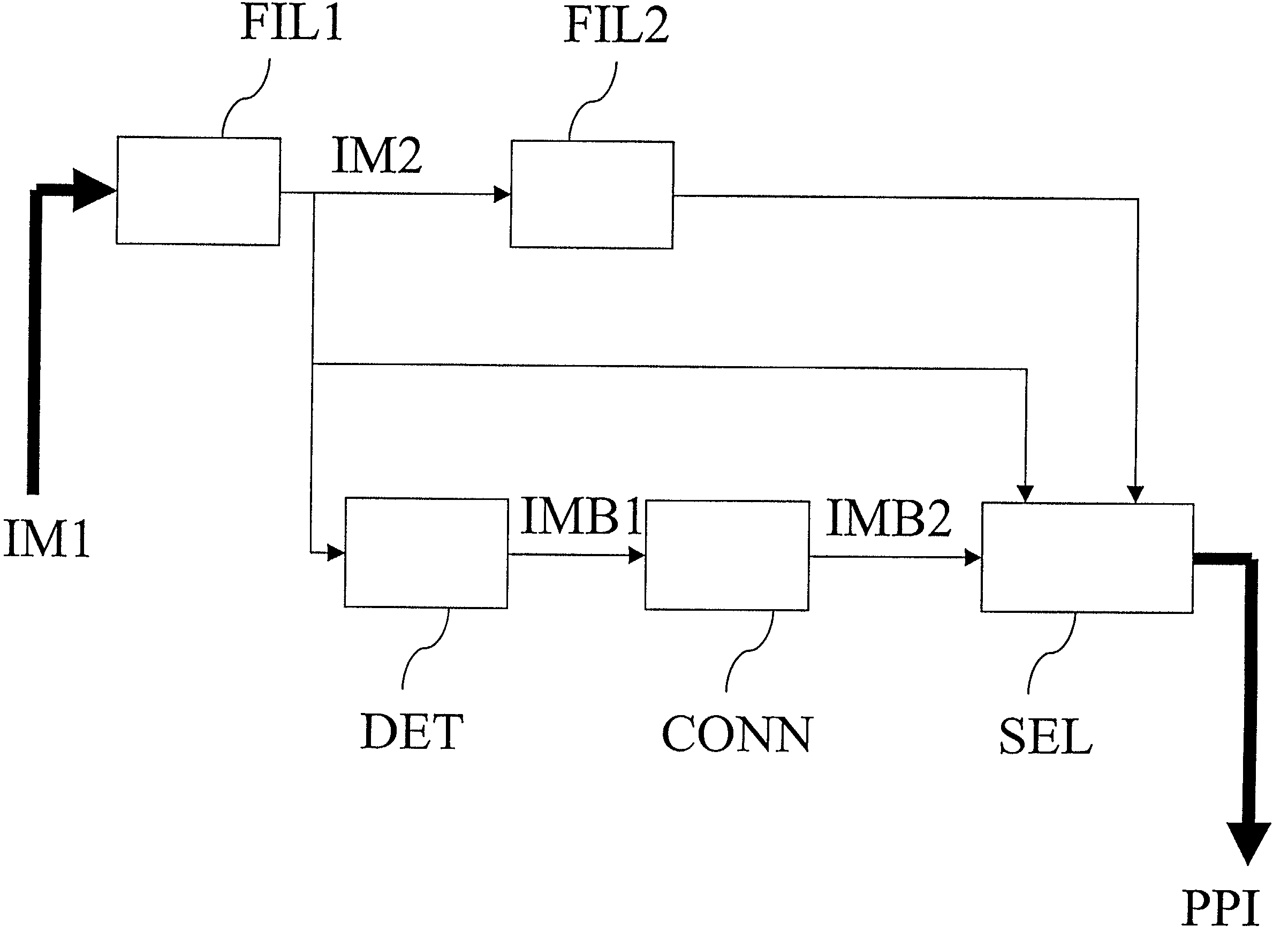

Noise reduction method

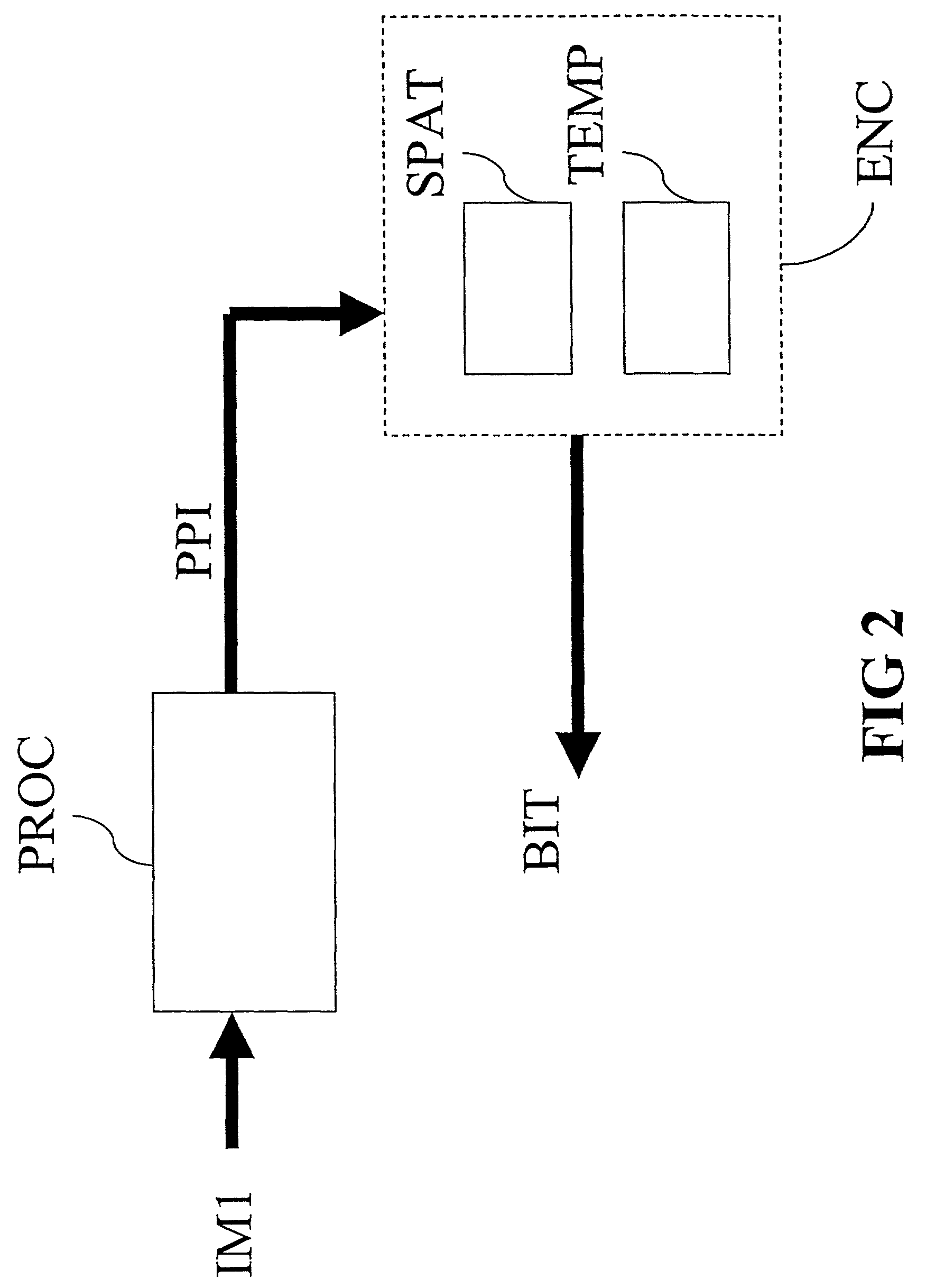

InactiveUS20040120601A1Reduce noiseRemove noiseImage enhancementTelevision system detailsPattern recognitionVideo encoding

A method of reducing noise in images formed by uniform regions and textures delimited by edges, comprises a step of filtering these images, a step of detecting edges and textures in these images, a sub-step of re-assigning or not re-assigning each image pixel to an edge or a texture in accordance with the result of a connectivity test, this sub-step taking place at the end of the step of detecting edges and textures, and a selection step of eliminating or, in contrast, applying this filtering to each image pixel according to whether this image pixel is associated or not associated with an edge or a texture. Such a method allows a noise reduction in an image or an unprocessed sequence of images while conserving the edges and the textures. The method concerned may be applied, for example, as a first link in a video encoding sequence such as an MPEG2 compression sequence.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Preparation method of metallic oxide textured ceramic material through quick sintering at normal temperature

The invention relates to a preparation method of a metallic oxide textured ceramic material through quick sintering at the normal temperature. According to the preparation method of the metallic oxidetextured ceramic or oxide solid solution textured ceramic or composite oxide textured ceramic through direct quick sintering and combination of a current heating effect and a direct-current electricfield orientation effect at the normal temperature, a high-temperature heating furnace is not needed. Compared with the prior art, namely textured ceramic sintering, according to the preparation method, high-temperature furnace equipment is not needed, it is unnecessary to heat a sample in advance, compact sintering and texture formation of various kinds of oxide ceramic materials can be achieved,the sintering time is short, the efficiency is high, hardware investment is low, and the energy utilization rate is high; the preparation method has the advantages of a wide application range, a simple technology, a good energy saving effect and low cost. The preparation method is suitable for large-scale preparation of the oxide textured ceramic and has a wide application prospect.

Owner:陕西智航昱铠新材料有限责任公司

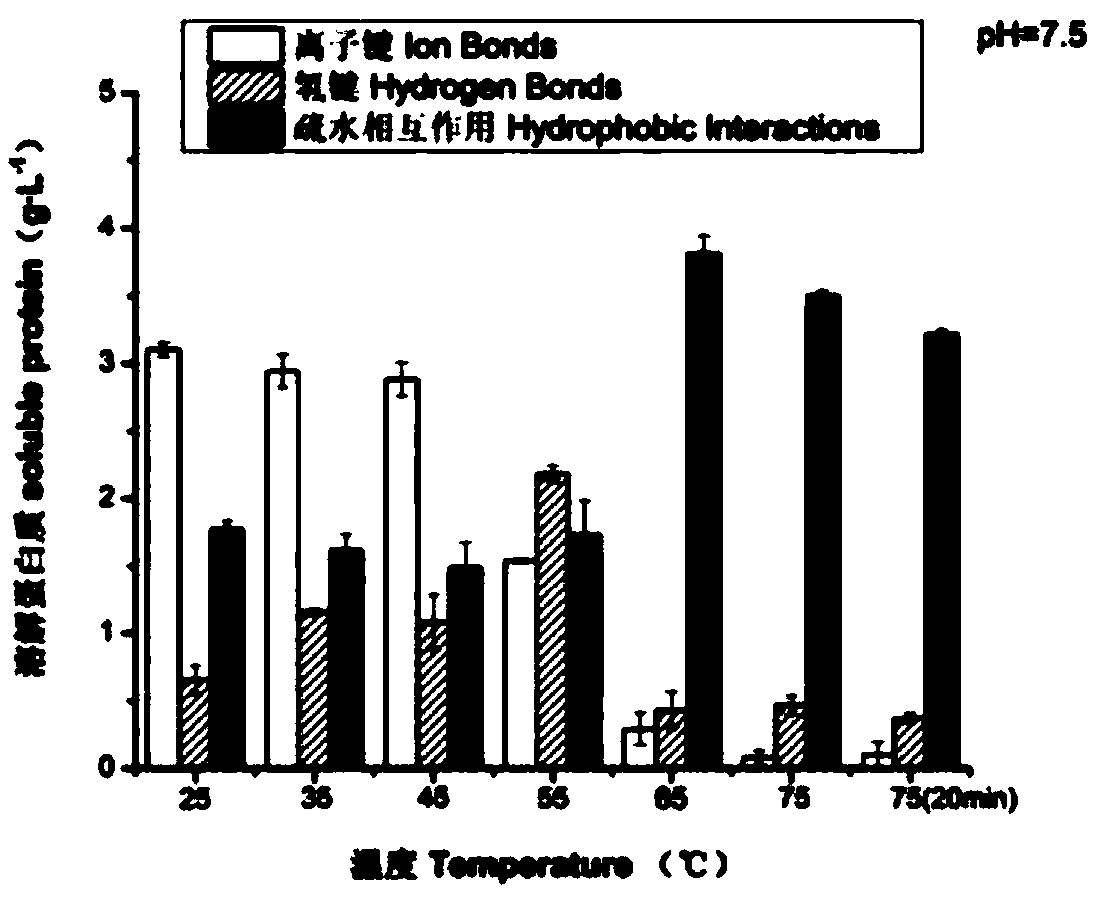

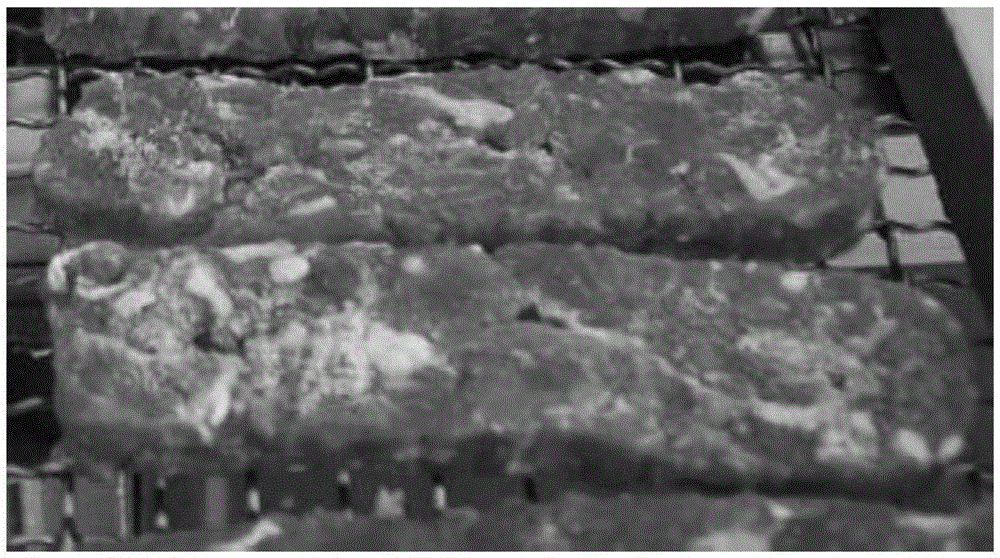

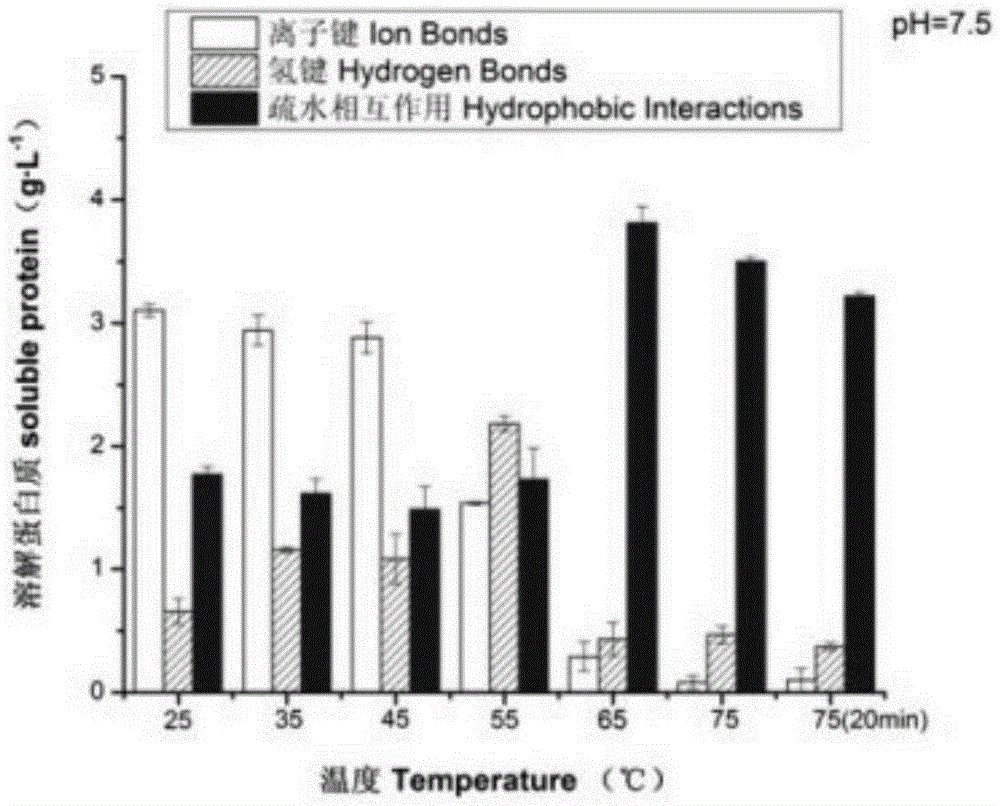

Texture forming method of air-dried beef and mutton

ActiveCN103719887AAchieve non-cryogenic constitutionReduce manufacturing costFood thermal treatmentFood mechanical treatmentFlavorCombined method

The invention relates to a texture forming method of air-dried beef and mutton. The method provided by the invention is a combined method of vacuum stirring and salting and gradient temperature air drying. The method specifically comprises the following steps: adding additives in minced raw material beef and mutton according to a proportion, and carrying out vacuum stirring to uniformly mix the raw material and form gel; putting the stirred meat stuffing in a stainless steel tray, leveling and compacting the meat stuffing, and statically salting the meat stuffing in a salting room; reversely pouring the salted raw material meat on a wire mesh screen, and pushing the wire mesh screen into an air drying room to air-dry the salted raw material meat to 60% of the original weight at a gradient temperature; and cutting the air-dried large meat pie to different specifications to finish the texture formation, and processing the meat according to different ripening processes. By adopting the texture forming method provided by the invention, non-refrigeration texture forming of minced raw material meat is achieved, the cost is low, the raw material source is wide, the yield of the air-dried beef and mutton is increased by 3-5%, the uniform transfer of the additives is guaranteed, and a technological base is laid for the development of air-dried beef and mutton products with a variety of flavors and appearances.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

High-protein vegetarian meat sausage and processing method thereof

InactiveCN110101029AGood adhesionGood texturizing effectSugar food ingredientsFood ingredient as colourLocust bean gumTexture formation

The invention discloses a high-protein vegetarian meat sausage and a processing method thereof. The processing method comprises the steps of preparation of egg white liquid, preparation of edible glueliquid, treatment of auxiliary materials, preparation of seasoning juice, making of vegetarian meat sausage stuffing, filling, thorough cooking, packaging for storage and the like. According to the high-protein vegetarian meat sausage and the processing method thereof, through the mutual effect of egg white protein and locust bean gum, carrageenan and konjac gum of a certain proportion, the excellent emulsification splicing and texture formation effect can be achieved, thus the product is endowed with excellent sliceable performance and elasticity, so that the product has features of high protein, low fat and low cholesterol, and has excellent color, luster, mouthfeel and taste, and the cost of the product is lower than that of meat sausages. Besides, the added konjac gum has a bonding effect, and is rich in dietary fiber at the same time, and thus the health-care function of the product is further improved.

Owner:CHENGDU UNIV

Process for Manufacturing Glass Substrate for Magnetic Recording Medium and Glass Substrate for Magnetic Recording Medium Obtained by the Process

InactiveUS20080032608A1Overall waviness of the substrate can be minimizedDefect can be manifestBase layers for recording layersBase layer manufactureHydrofluoric acidAqueous solution

A process for manufacturing a glass substrate for a magnetic recording medium, comprising polishing a glass substrate is polished using abrasive grains and then washing the substrate using a 0.02-0.3% aqueous hydrofluoric acid solution, and a glass substrate for a magnetic recording medium which is manufactured by the process. A polished glass substrate for a magnetic recording medium is manufactured, whereby during washing after polishing of the glass substrate, manifestation of substrate surface defects and overall waviness of the substrate can be minimized, and whereby texture formation in the subsequent texturing step can be accomplished in a uniform manner without creating variation between substrates.

Owner:SHOWA DENKO KK

Laying method of self-knotted grain-free environment-friendly plastic runway

The invention discloses a laying method of an automatic texture formation particle-free environmentally-friendly plastic track. The method comprises the following steps: S21, laying a substrate layer: mixing an environmentally-friendly single-component water solidified plastic track material with black micelles according to a weight ratio of 1:4-6, and laying the substrate layer on a dry and solidified cement base or asphalt base; S22, laying a reinforcing layer: spreading a layer of the black micelles on the dry and solid base layer, and lying the environmentally-friendly single-component water solidified plastic track material to cover the substrate layer; and S23, laying an automatic texture formation layer: uniformly mixing 10-12 parts of an automatic texture formation finish, 1-3 parts of EPDM particle rubber powder and 3-6 parts of quartz sand to form an automatic texture formation layer material, fully stirring, and spraying the obtained material on the dry and solidified reinforcing layer. The track has the advantages of environmentally friendly material, no shedding of particles, good durability, plump and uniform surface textures, high tensile strength and long service life, and all performance indexes of the track accord with technical requirements of International Association of Athletics Federations and GB / T14833-2011.

Owner:广州帝森康体设备有限公司

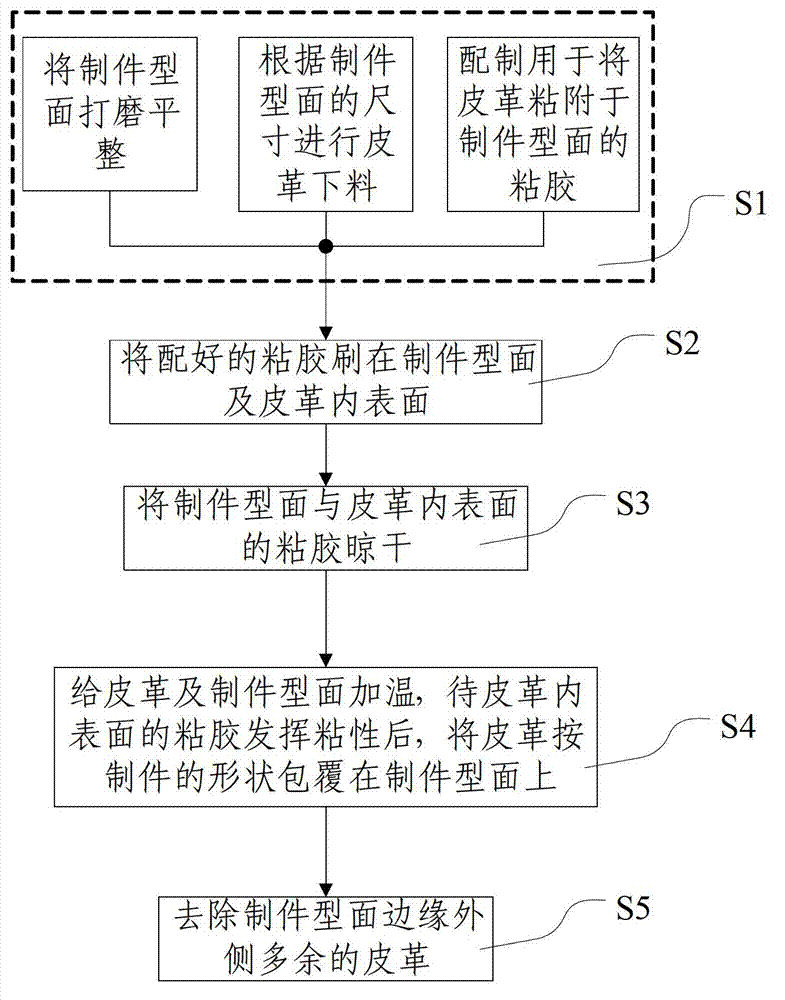

Method for quickly forming textures on surface of workpiece

InactiveCN103241048AQuick changeEasy to operateDecorative surface effectsVehicle componentsTexture formationMaterials science

The invention relates to the field of car decorations, and in particular relates to a method for quickly forming textures on the surface / surfaces of single workpiece / small-batch workpieces. The method comprises the following steps: S1, polishing and smoothing the molded surface of the workpiece, carrying out leather blanking according to the size of the molded surface of the workpiece, and configuring mucilage glue used for sticking leather to the molded surface of the workpiece; S2, applying the prepared mucilage glue onto the molded surface of the workpiece and the inner surface of the leather by brushing; S3, air-drying the mucilage glue on the molded surface of the workpiece and the inner surface of the leather; S4, heating the leather and the molded surface of the workpiece, and covering the molded surface of the workpiece with the leather according to the shape of the workpiece after the mucilage glue on the inner surface of the leather comes into effect; and S5, removing the excess leather on the outer side of the edge of the molded surface of the workpiece. The method is simple to operate and easy to master, can enable a beginner to master skills within a shorter time, is short in operation cycle, can form the textures on the surface of the workpiece within the short time, and is suitable for texture formation work of interior and exterior decoration workpieces of a sample car (a showing car); and the texture style of the molded surface can be easily and quickly changed.

Owner:GREAT WALL MOTOR CO LTD

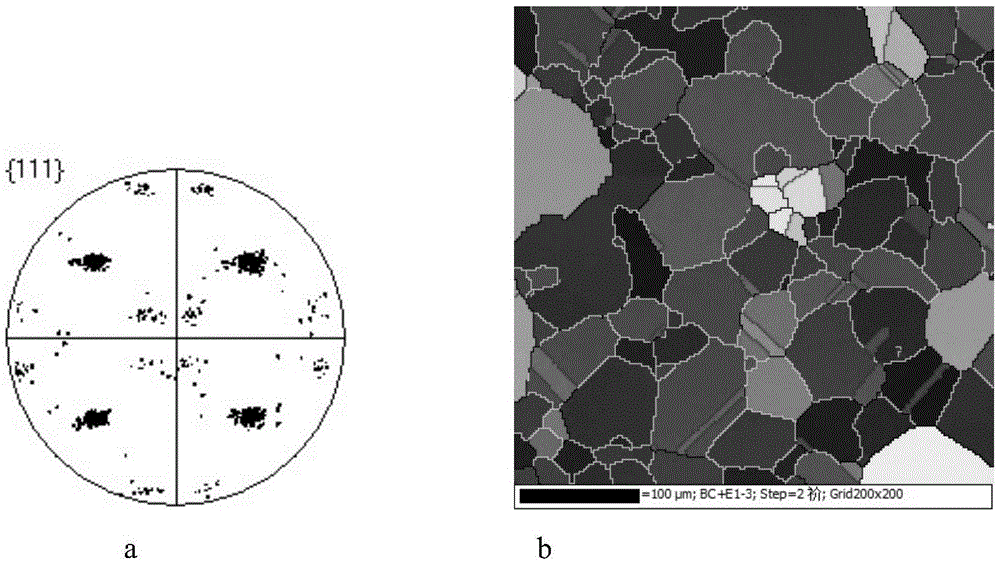

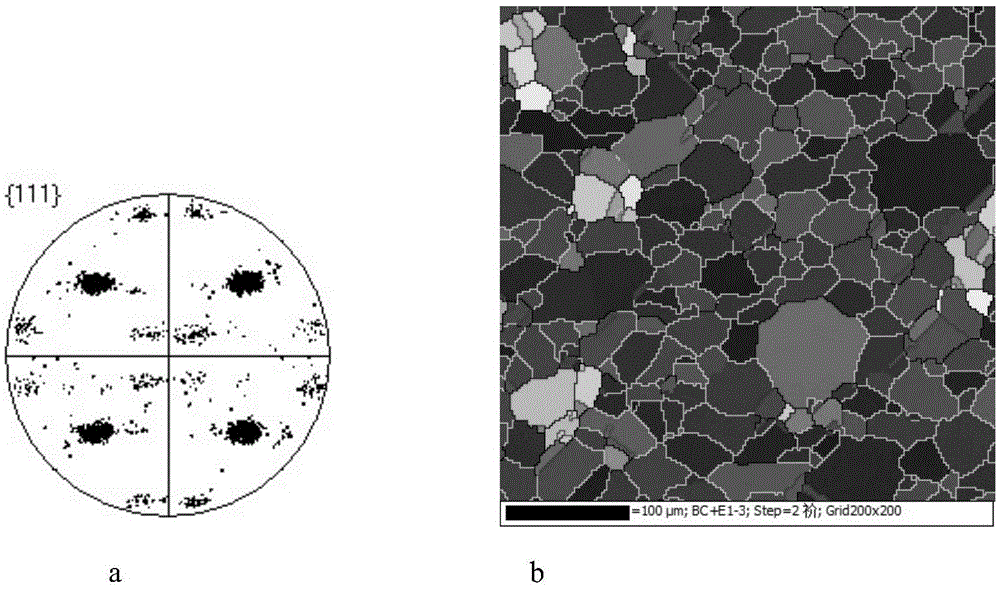

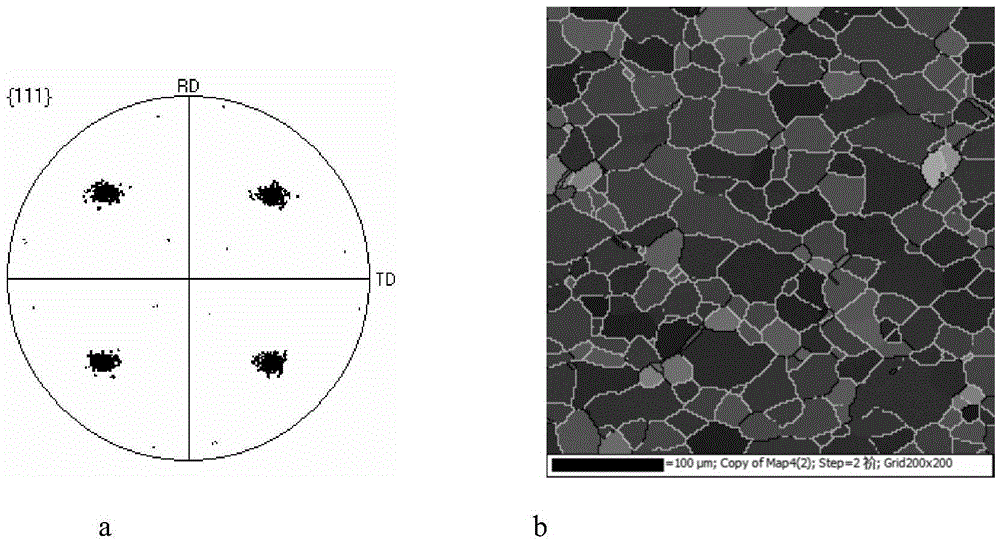

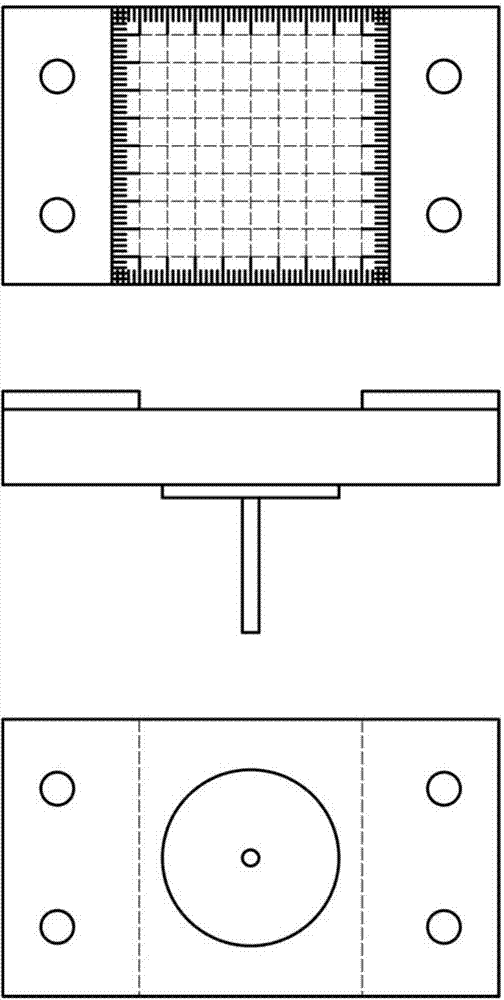

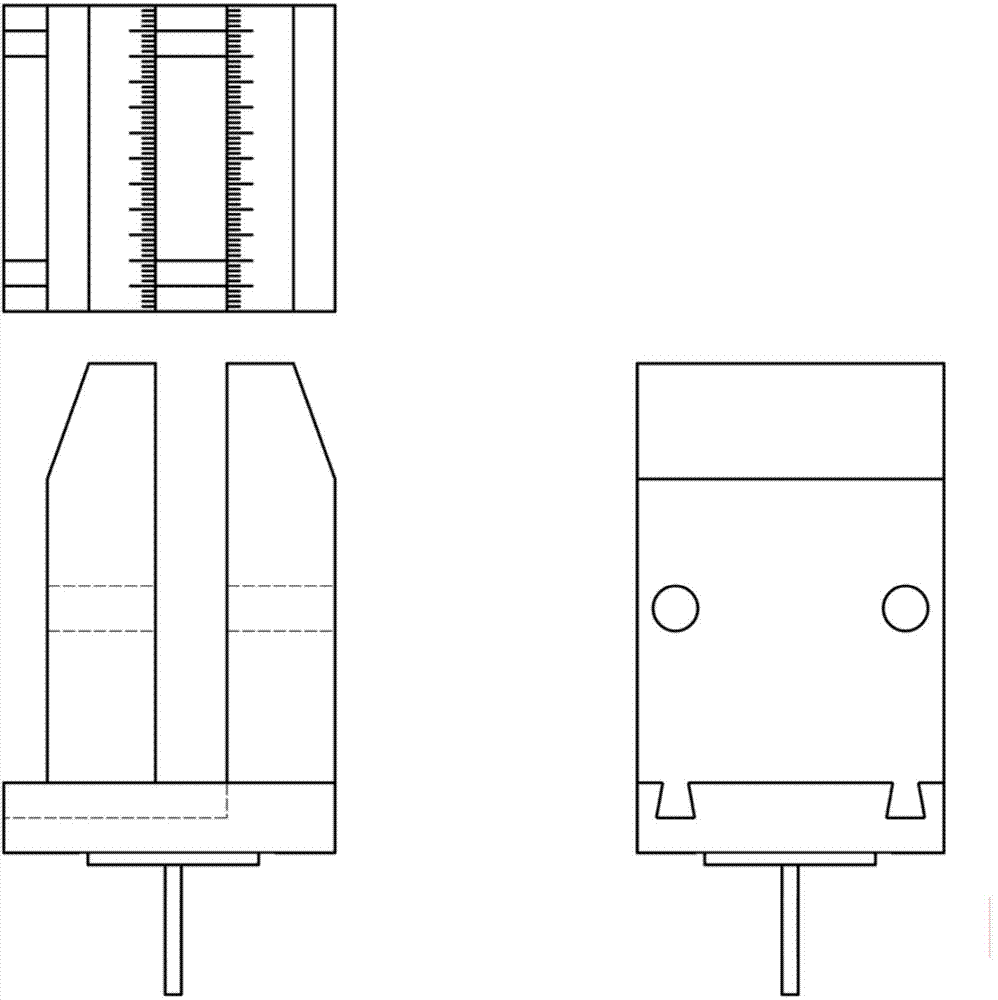

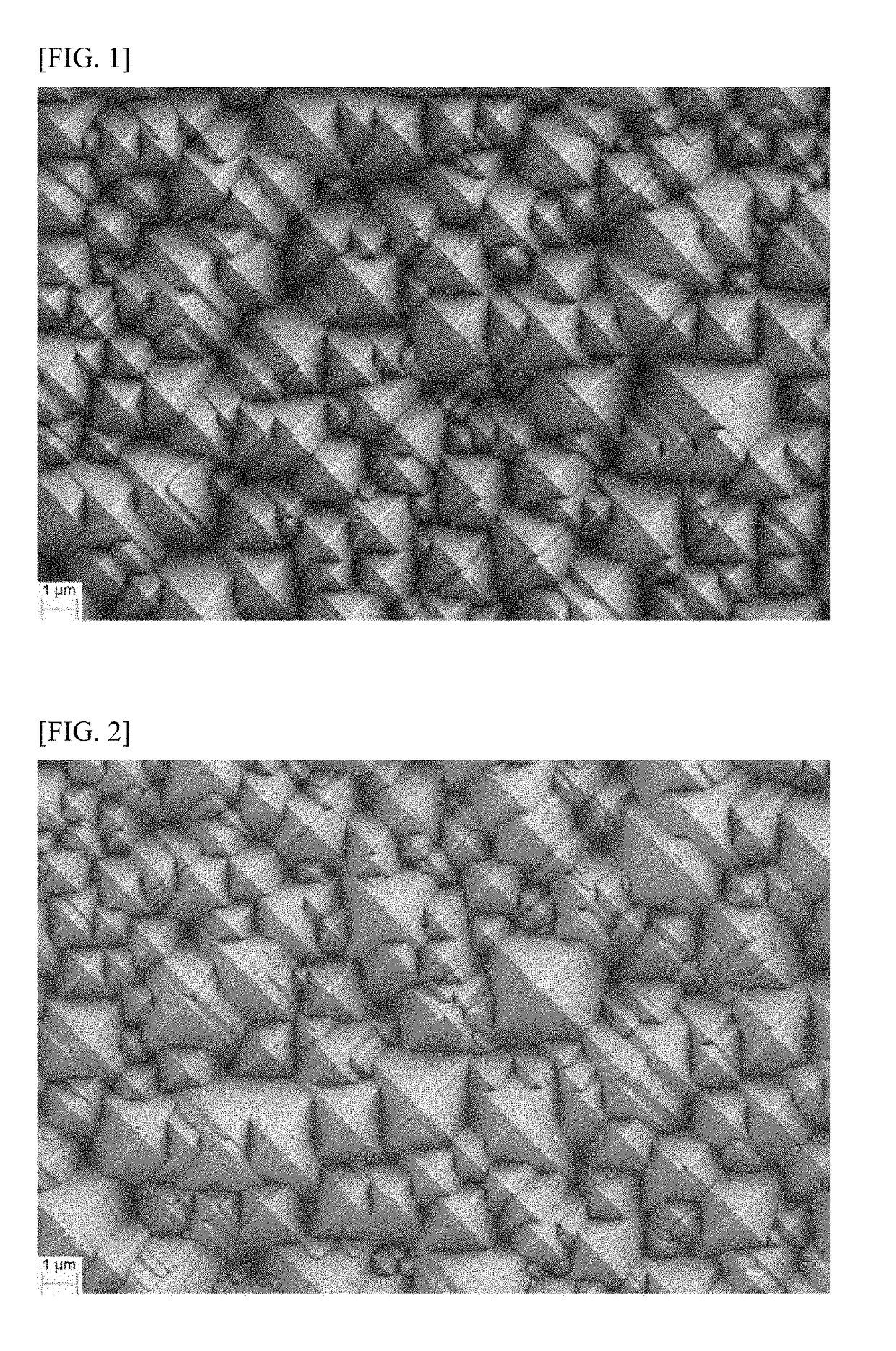

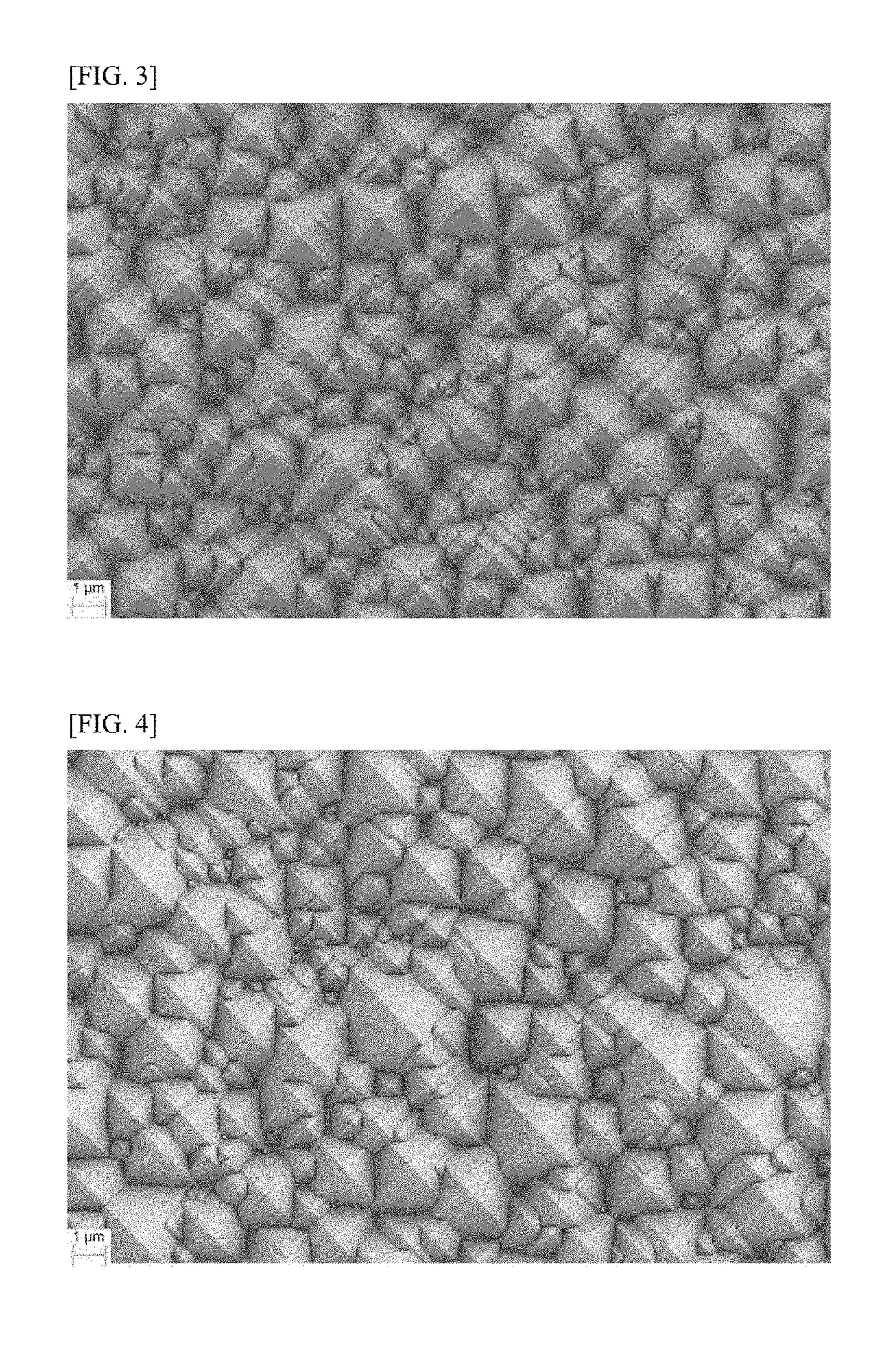

Method for researching alloy baseband recrystallization and cubic texture forming mechanisms through quasi in-situ electron back scattered diffraction (EBSD) technology

ActiveCN103926263AMaterial analysis using wave/particle radiationElectrical conductorHigh-temperature superconductivity

The invention discloses a method for researching an alloy baseband recrystallization and cubic texture forming mechanisms through a quasi in-situ electron back scattered diffraction (EBSD) technology and belongs to the field of research of texture alloy basebands of high-temperature superconducting coating conductors. Because conventional EBSD equipment cannot be heated at a high temperature, a mechanism for researching the alloy baseband recrystallization and cubic texture formation at high temperature by the in-situ EBSD technology is limited. The method provided by the invention is used for researching the alloy baseband recrystallization and cubic texture forming mechanisms through the quasi in-situ EBSD technology, and a sample stage for a quasi in-situ EBSD test is designed according to the difference (of planes or sections) of researched samples. According to the quasi in-situ EBSD technology, the novel method is provided for researching the alloy baseband recrystallization and cubic texture forming mechanisms.

Owner:深创超导(深圳)科技有限公司

Process for manufacturing glass substrate for magnetic recording medium and glass substrate for magnetic recording medium obtained by the process

InactiveCN1993298AManufacturingNo surface defectsBase layers for recording layersBase layer manufactureHydrofluoric acidAqueous solution

A process for manufacturing a glass substrate for a magnetic recording medium, comprising polishing a glass substrate is polished using abrasive grains and then washing the substrate using a 0.02-0.3% aqueous hydrofluoric acid solution, and a glass substrate for a magnetic recording medium which is manufactured by the process. A polished glass substrate for a magnetic recording medium is manufactured, whereby during washing after polishing of the glass substrate, manifestation of substrate surface defects and overall waviness of the substrate can be minimized, and whereby texture formation in the subsequent texturing step can be accomplished in uniform manner without creating variation between substrates.

Owner:SHOWA DENKO KK

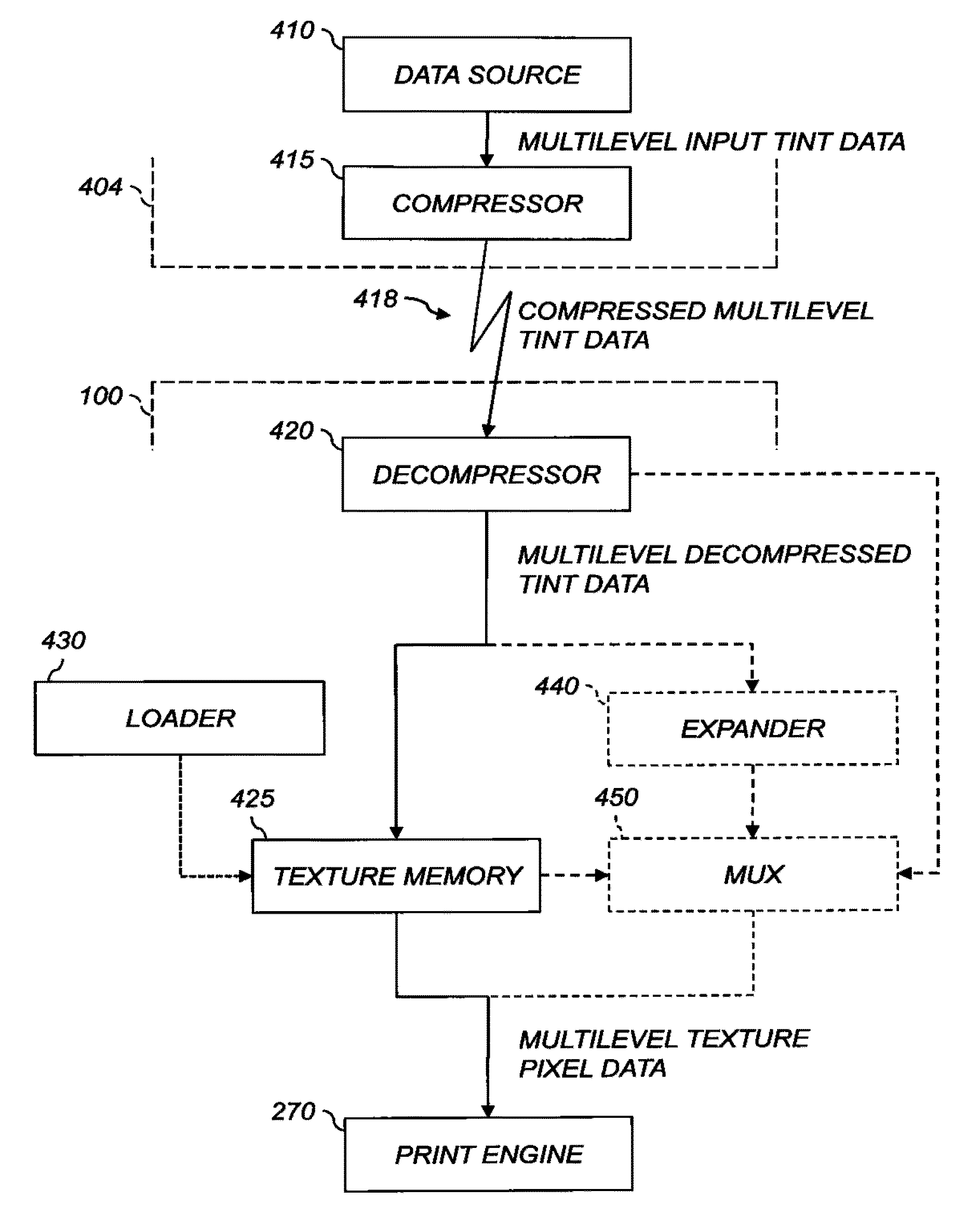

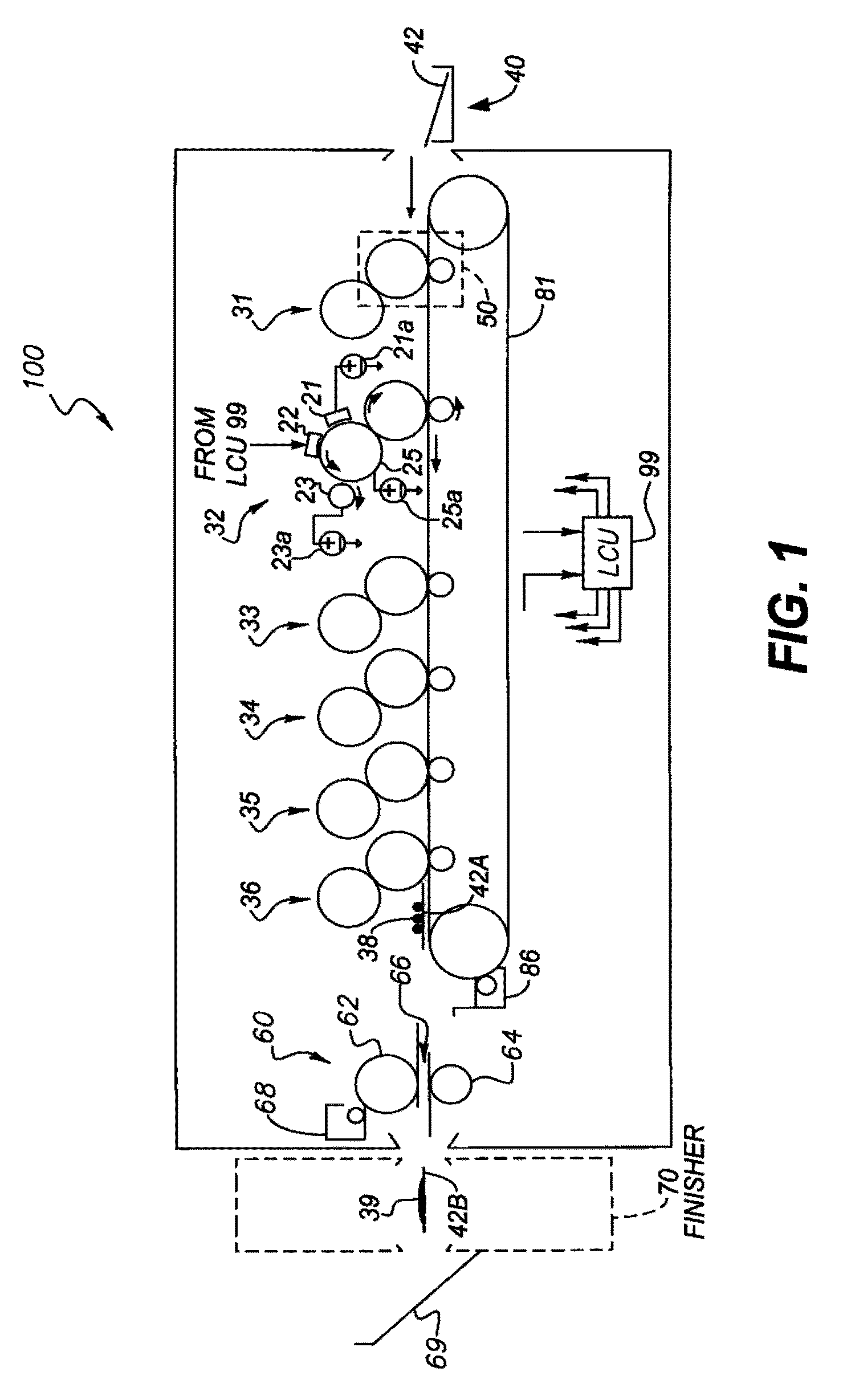

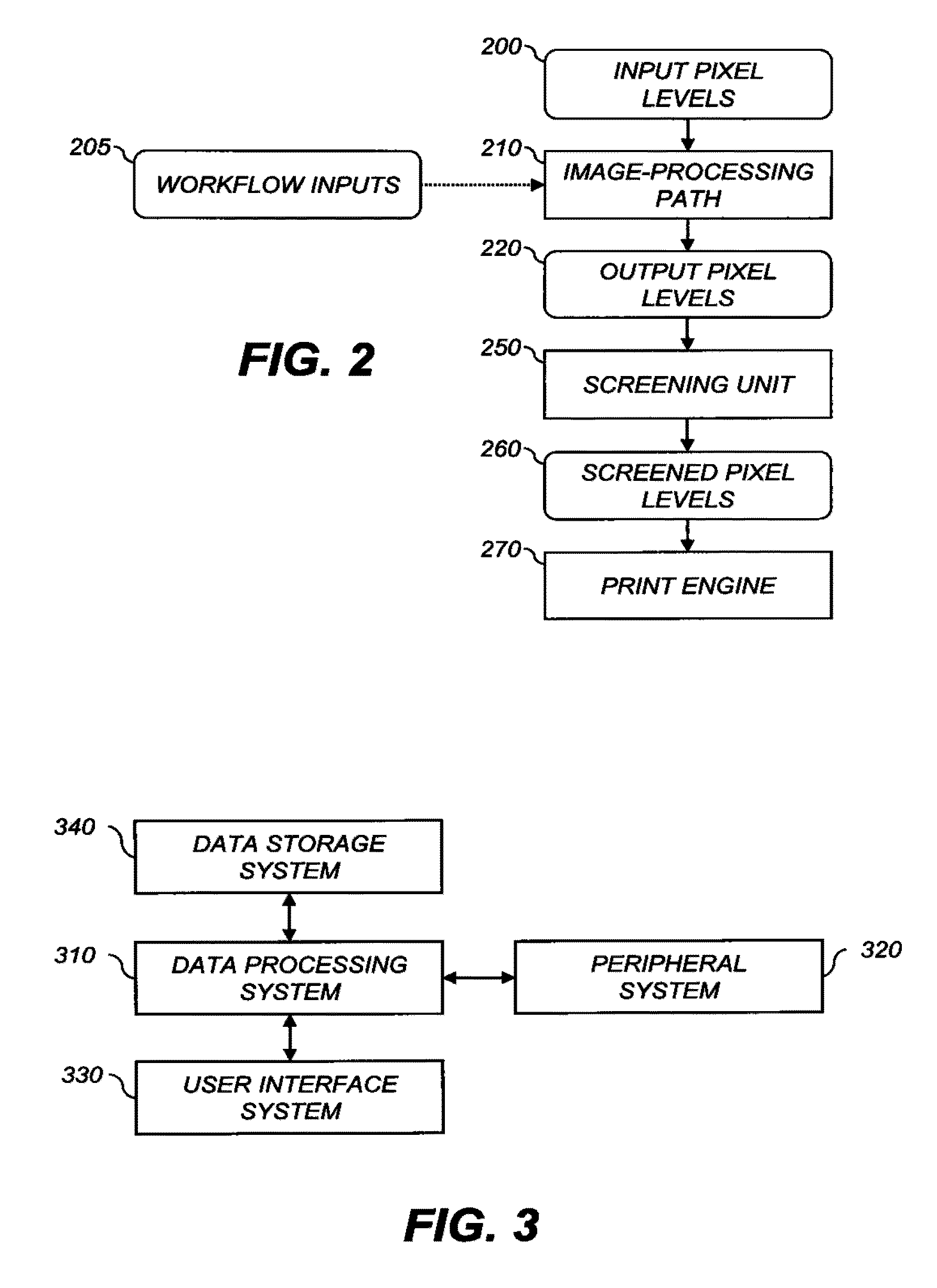

Depositing texture on receiver

ActiveUS8605333B2Without increasing bandwidth requirementProvide robustnessDigital computer detailsCharacter and pattern recognitionComputer graphics (images)Data source

Apparatus for depositing a texture on a receiver includes a data source that provides multilevel input tint data values. A lossy compressor produces compressed multilevel tint data values from the multilevel input tint data values. A decompressor produces multilevel decompressed tint data values from the compressed multilevel tint data values. A texture memory receives those values from the decompressor and provides corresponding multilevel texture pixel data values. A print engine deposits at each of a plurality of pixel sites on the receiver an amount of texture-forming material corresponding to the respective multilevel texture pixel data value. A loader loads into the texture memory a texture set including multilevel texture pixel data values for each of a plurality of textures, and each texture in the texture set corresponds to a respective selected range of multilevel decompressed tint data value.

Owner:EASTMAN KODAK CO

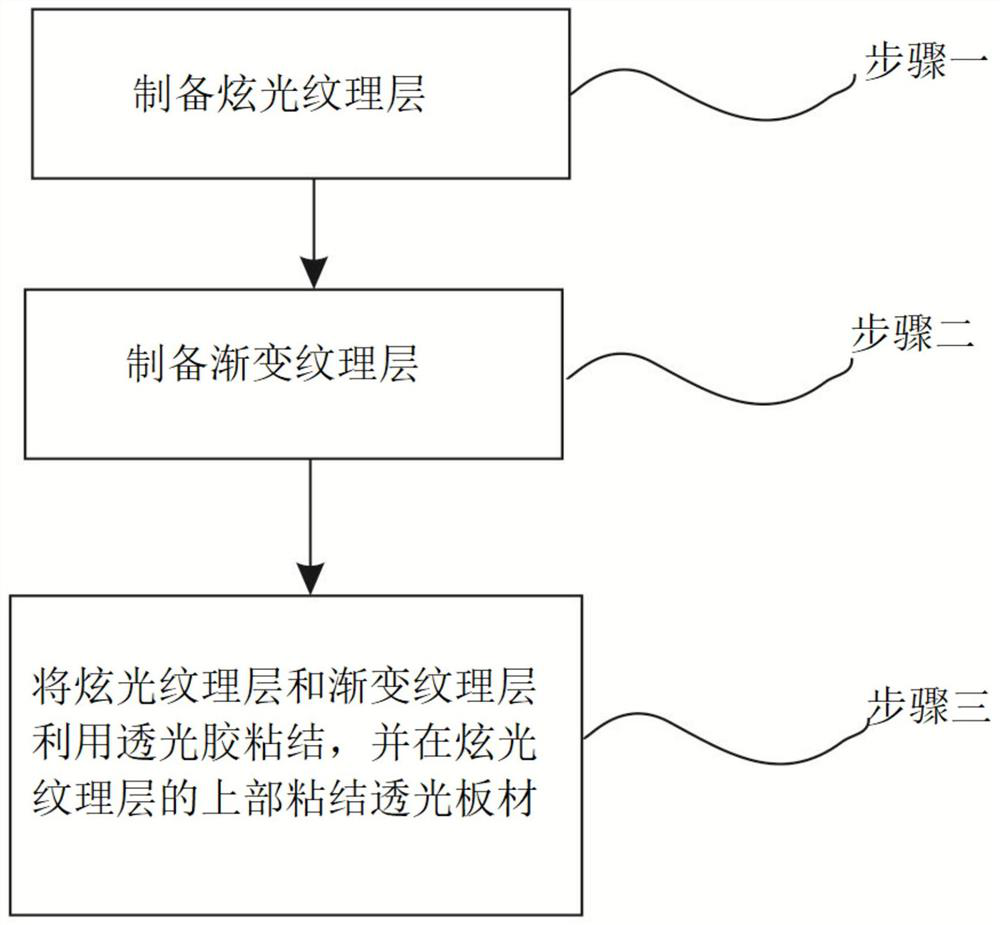

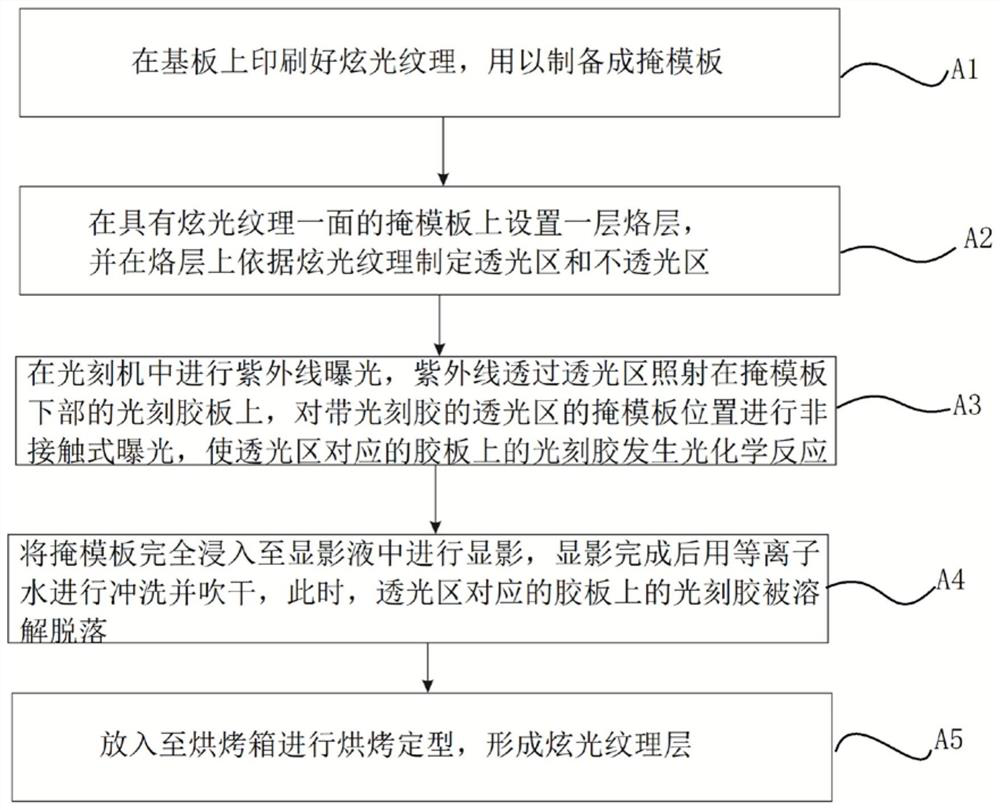

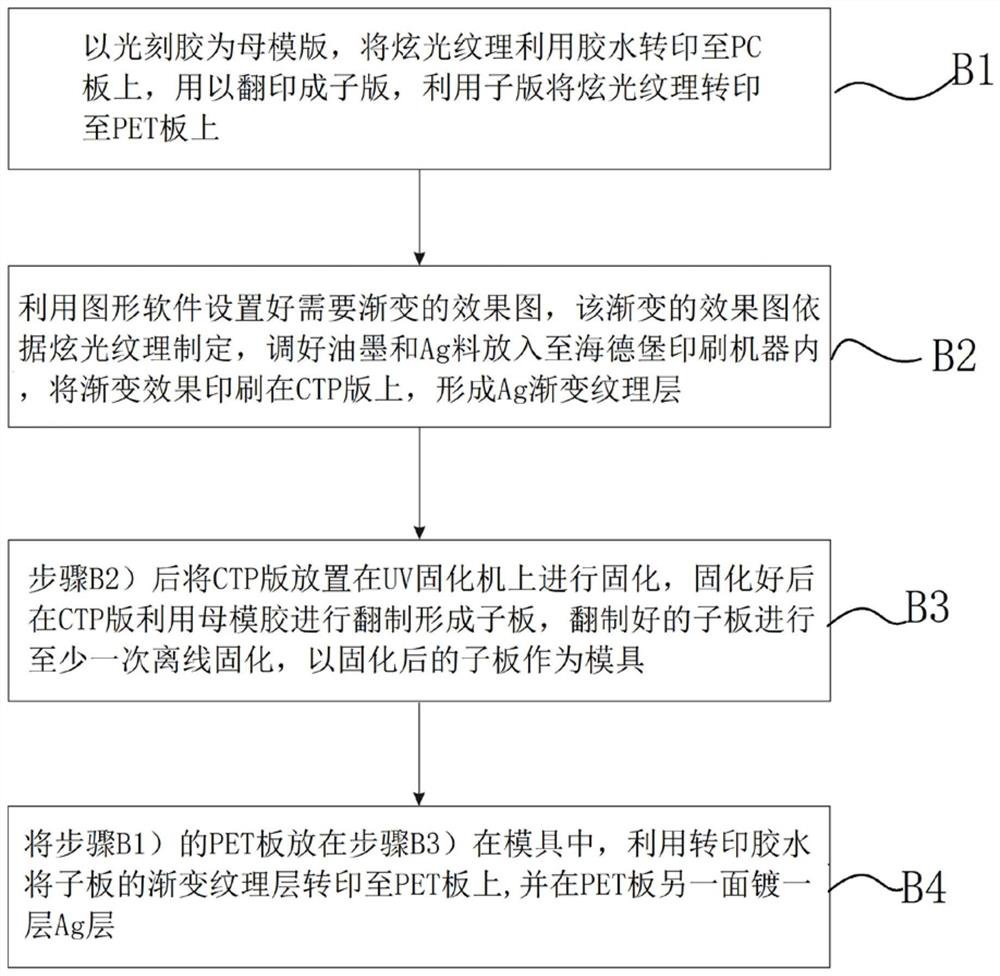

Preparation process of double-layer texture back shell

PendingCN112810341AIncrease texture displayIncrease diversityIrregular area designDecorative surface effectsBi layerStructural engineering

Owner:东莞正广精密科技有限公司

A method for preparing metal oxide textured ceramic materials by rapid sintering at room temperature

Owner:陕西智航昱铠新材料有限责任公司

Carbon fiber composite material plate and ceramic plate welding method

The invention belongs to the technical field of dissimilar material connection, and particularly relates to a carbon fiber composite material plate and ceramic plate welding method which includes thesteps: sequentially overlapping a carbon fiber composite material plate, a nano-brazing filler metal and a ceramic plate from top to bottom; performing pressing assembly to form an assembly part; brazing the assembly part under inert gas atmosphere protection of an external magnetic field; performing heat preservation, cooling and heat treatment after welding to finish connection of the carbon fiber composite material plate and the ceramic plate. The nano-brazing filler metal is combined with inert gas protection brazing of the external magnetic field for the first time, texture formation anddefect inhibition in the brazing process are facilitated, and the performance of a connecting joint is obviously improved.

Owner:济南英维新材料科技合伙企业(有限合伙)

A Crystal Structure-Based Atomic Scale Crystal Orientation Analysis Method

ActiveCN107102016BOrientation Analysis ImplementationAutomate analysisMaterial analysis using wave/particle radiationChemical physicsAtomic pair

Owner:BEIHANG UNIV

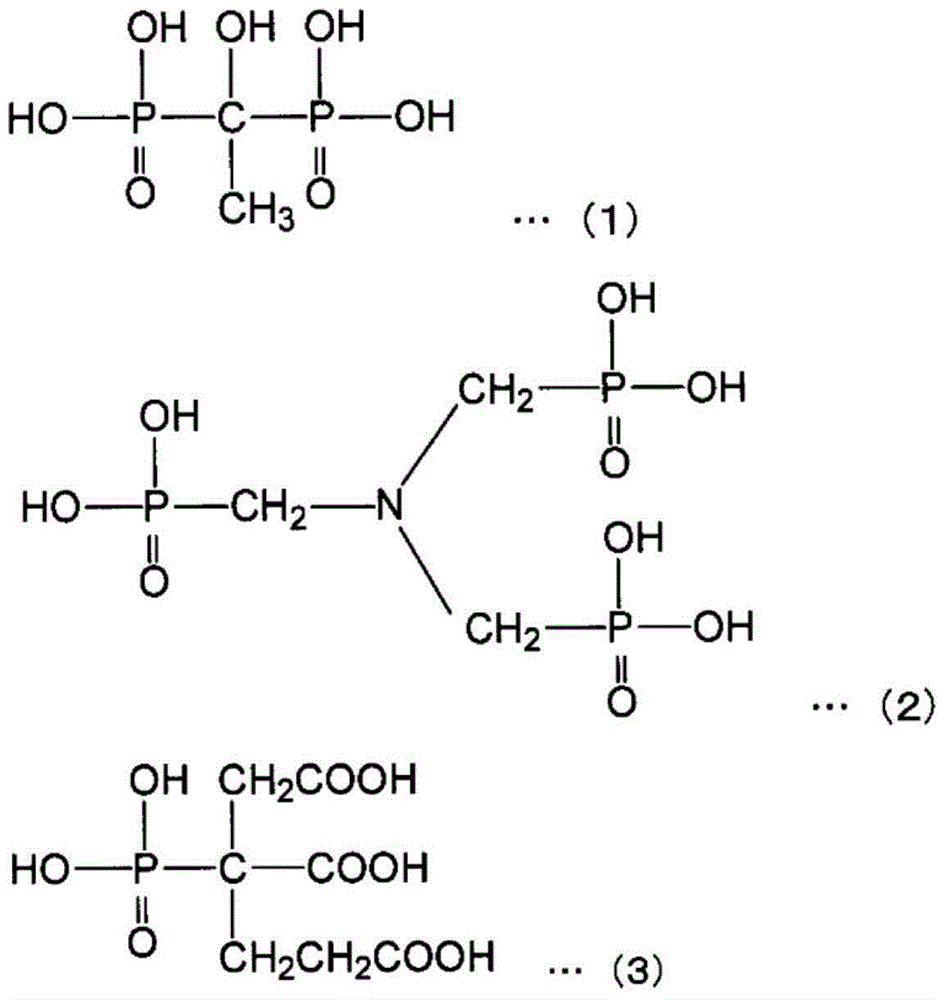

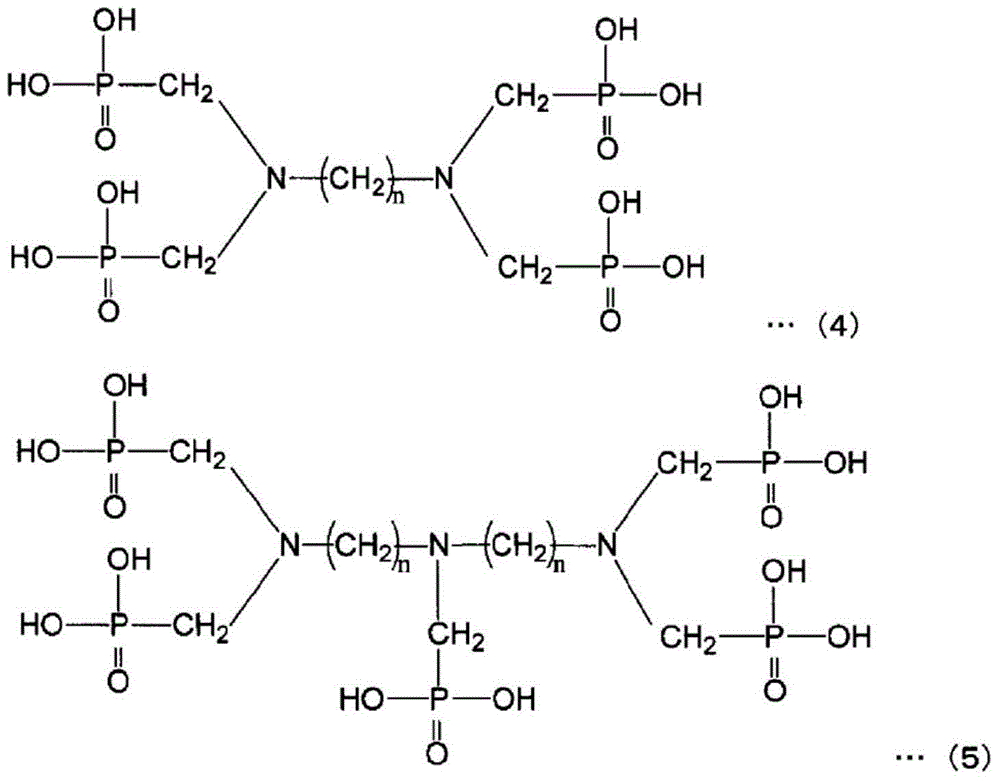

Etching fluid for forming texture and texture-forming method using same

ActiveCN104584232AStable mass productionImprove qualitySemiconductor devicesPhosphanilic acidSubstrate surface

Provided are: an etching fluid for forming texture on a silicon substrate, applicable to both silicon substrates manufactured using a loose-abrasive grain method and silicon substrates manufactured using a fixed-abrasive grain method, which can stably form a good texture uniformly on the substrate surface, and does not have volatility of additive components in the normal usage temperature range of 60-95°C; and an etching method. An etching fluid is used that contains an alkali component (A), a phosphonic acid derivative (B) or salt thereof, and a compound (C) having at least one type of group selected from a group comprising a carboxyl group, a sulfo group, groups thereof forming a salt, and a carboxymethyl group.

Owner:DAI ICHI KOGYO SEIYAKU CO LTD

A method for forming dry matter of air-dried beef and mutton

ActiveCN103719887BAchieve non-cryogenic constitutionReduce manufacturing costFood thermal treatmentFood mechanical treatmentFlavorRipening

The invention relates to a texture forming method of air-dried beef and mutton. The method provided by the invention is a combined method of vacuum stirring and salting and gradient temperature air drying. The method specifically comprises the following steps: adding additives in minced raw material beef and mutton according to a proportion, and carrying out vacuum stirring to uniformly mix the raw material and form gel; putting the stirred meat stuffing in a stainless steel tray, leveling and compacting the meat stuffing, and statically salting the meat stuffing in a salting room; reversely pouring the salted raw material meat on a wire mesh screen, and pushing the wire mesh screen into an air drying room to air-dry the salted raw material meat to 60% of the original weight at a gradient temperature; and cutting the air-dried large meat pie to different specifications to finish the texture formation, and processing the meat according to different ripening processes. By adopting the texture forming method provided by the invention, non-refrigeration texture forming of minced raw material meat is achieved, the cost is low, the raw material source is wide, the yield of the air-dried beef and mutton is increased by 3-5%, the uniform transfer of the additives is guaranteed, and a technological base is laid for the development of air-dried beef and mutton products with a variety of flavors and appearances.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

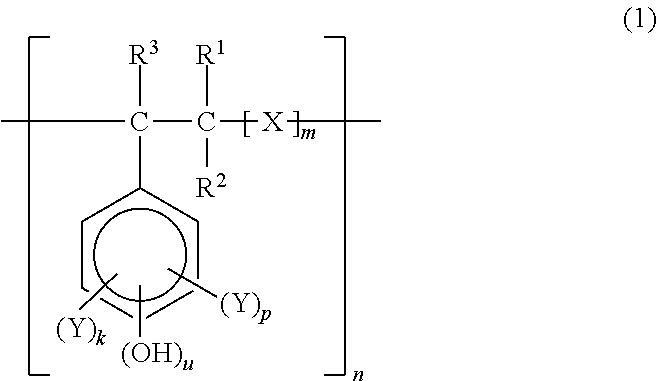

Etching agent for semiconductor substrate

InactiveUS20170306229A1Increase production capacityShort amount of timePhotovoltaic energy generationSurface treatment compositionsProduction rateSolar cell

The present invention relates to an alkaline etching agent for treating a surface of a semiconductor substrate for solar cells, containing at least one hydroxystyrene polymer represented by the general formula (1) and an alkaline agent. According to the present invention, some effects are exhibited that the texture formation is made possible to a semiconductor substrate for solar cells at relatively lower temperatures with a shorter amount of time, thereby having excellent productivity.

Owner:SETTSU OIL MILL

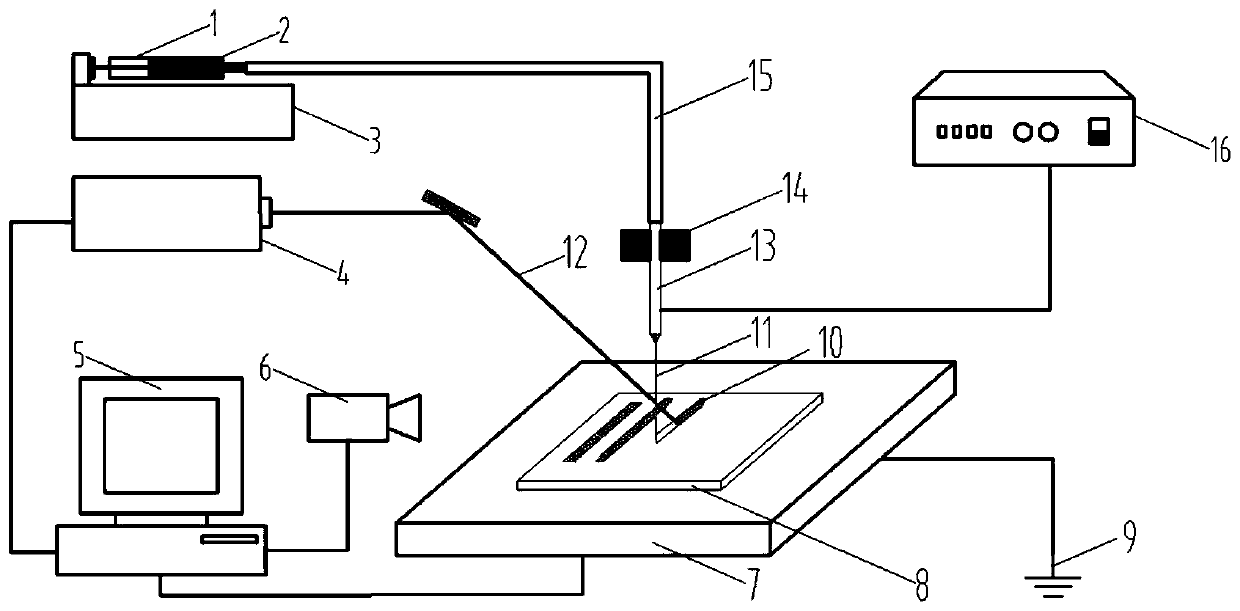

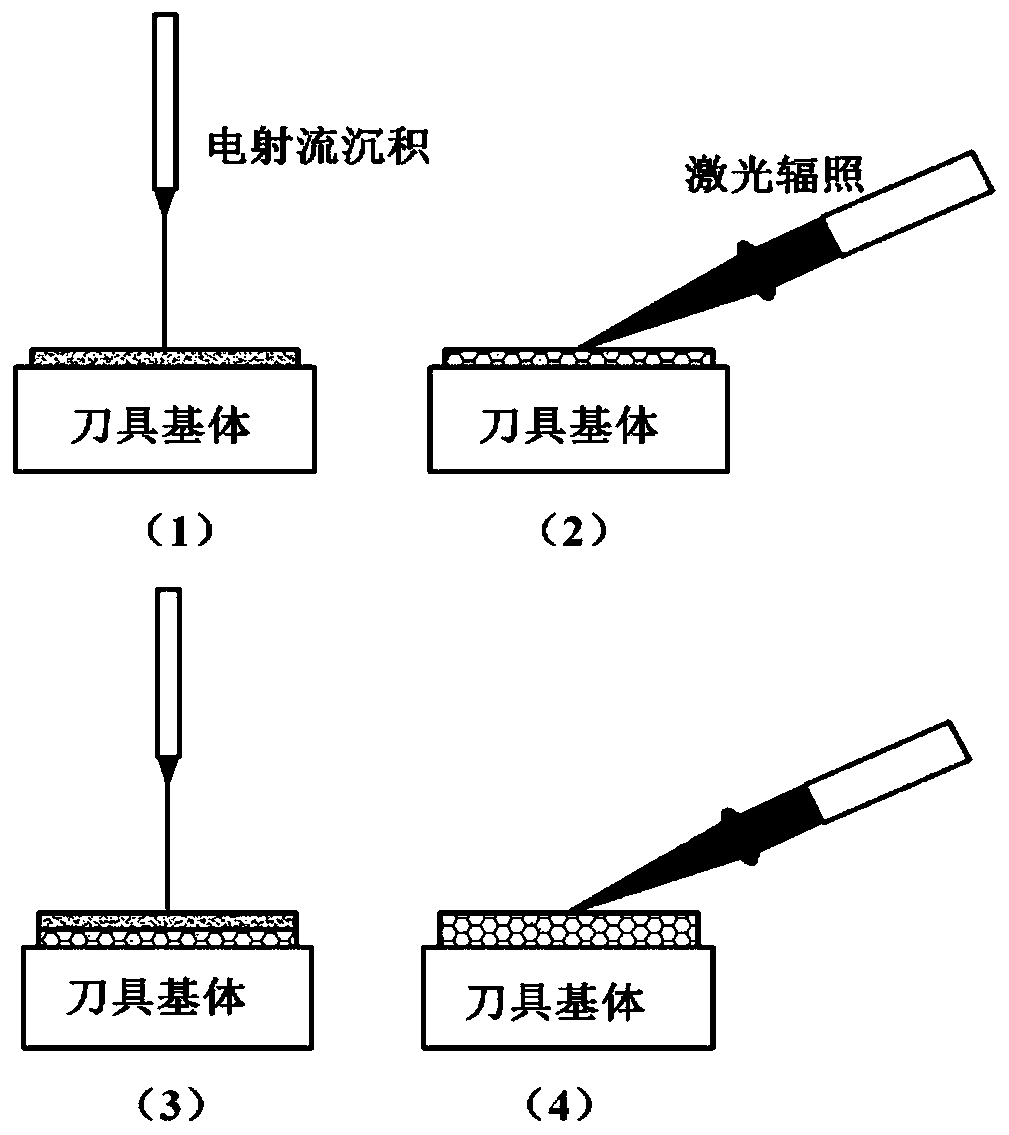

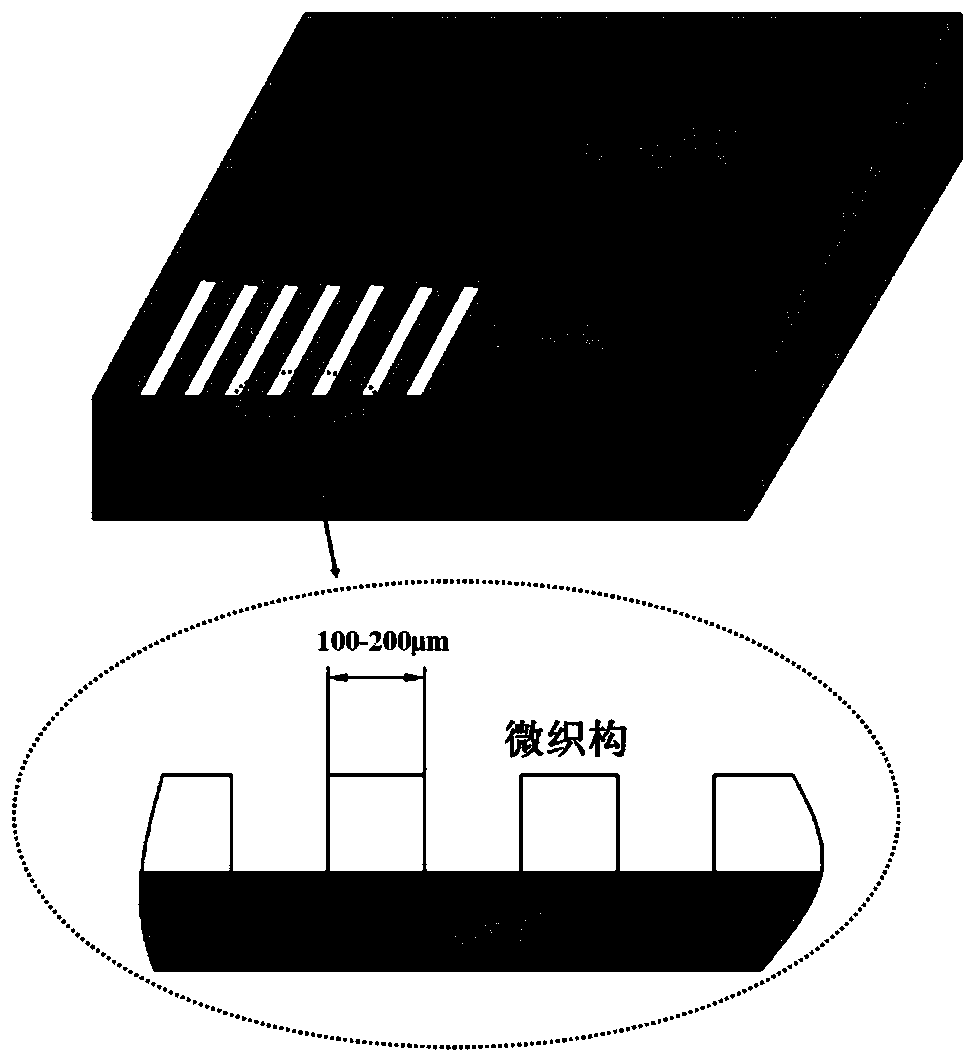

A preparation method of electro-jet deposition-laser cladding micro-textured tool

InactiveCN107805808BFast and reliable curing moldingAdaptableMetallic material coating processesManufacturing technologyEngineering

The invention belongs to the technical field of mechanical cutting tool manufacturing, and provides a preparation method for an electrohydrodynamic jet deposition and laser cladding microtexture tool.According to the preparation method, firstly, a certain pressure is applied to functional liquid to make the functional liquid flow out of the jet hole of a jet needle according to a certain flow; then, a certain of electric field is applied to the functional liquid to make the functional liquid form the fine jet flow with the diameter much less than the inner diameter of the jet hole, and the microtexture is formed on a tool matrix through jet deposition; and meanwhile, irradiation heat treatment on the deposited texture material with lasers so that the texture material can quickly solidify,shape up and be reliably fused with the tool matrix. The preparation method for an electrohydrodynamic jet deposition and laser cladding microtexture tool synthesizes the technical advantages of electrohydrodynamic jet deposition and laser machining, and has the advantages of being high in texture formation accuracy and material adaptability, simple in machining technology, easy to control and the like.

Owner:SHANDONG UNIV

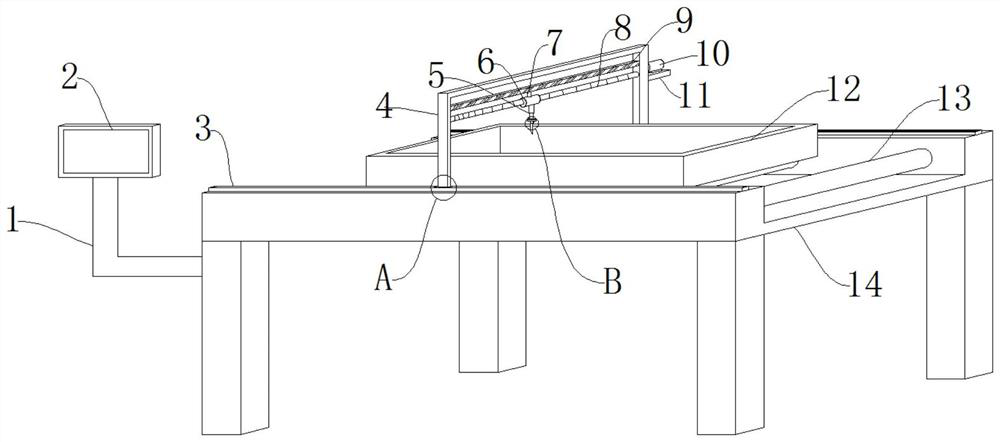

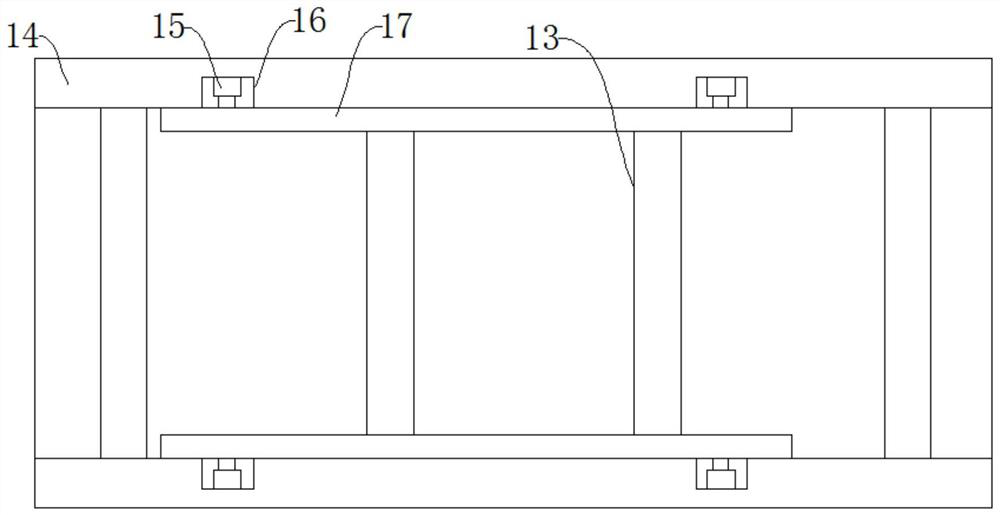

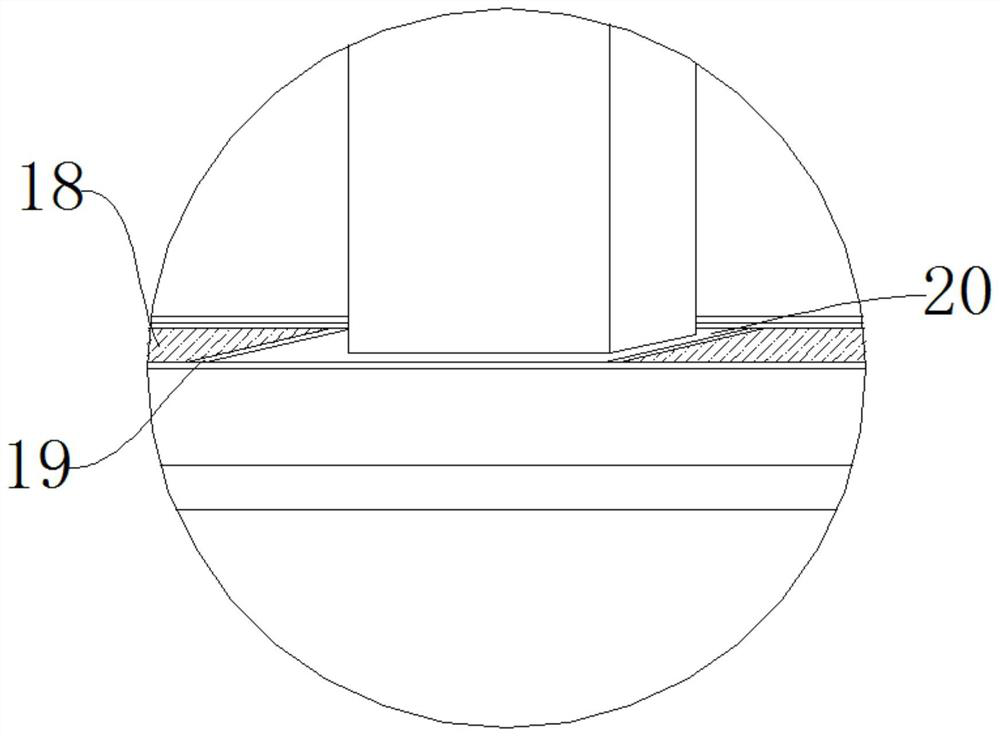

Texture forming equipment for artificial quartz stone plate and use method of texture forming equipment

The invention discloses texture forming equipment for an artificial quartz stone plate and a using method of the texture forming equipment. The texture forming equipment comprises a workbench, a conveying shaft, a mold cavity and air cylinders, wherein the conveying shaft is installed in the workbench, the mold cavity is formed in the upper end of the conveying shaft, concave cavities are formed in the two side walls in the workbench, the air cylinders are installed in the concave cavities, a push plate is fixed to one end of each air cylinder, electric sliding rails are fixed to the two sides of the upper end of the workbench, and sliding blocks are installed in the electric sliding rails. The texture forming equipment has the beneficial effects that by arranging connecting plates and folding sealing covers, in the moving process of the sliding blocks, the folding sealing covers on the connecting plate are folded and stretch out and draw back, so that the electric sliding rails are sealed all the time, a quartz material is prevented from falling into the electric sliding rails, the transmission performance of the electric sliding rail and the working efficiency of the equipment are guaranteed, and the practicability of the equipment is improved.

Owner:湖北中瓷万佳新材料科技股份有限公司

A method for machining cylinder bores

The invention provides a cylinder bore machining method. The cylinder bore machining method comprises the steps of pretreatment, surface texture formation, aftertreatment and detection. A surface before machining is obtained through the pretreatment; texture features are machined on the surface of a cylinder bore through the surface texture formation; burrs on the surface of the cylinder bore are removed through the aftertreatment; quality test is finished through the detection process. The cylinder bore machining method has the advantages that the tribological performance of a cylinder bore-piston ring friction pair is remarkably improved, the abrasive resistance of the surface of the cylinder bore is enhanced, the fuel oil consumption is lowered by 1-3% for an engine, and the engine oil consumption is lowered by 30-50%.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com