Patents

Literature

905results about "Food ingredient as colour" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coloring substance composition and a method of manufacturing same

InactiveUS6500473B1Antioxidant activityReduce riskOrganic active ingredientsBiocideBiotechnologyAcetylation

A composition comprising coloring substance bodies that are at least partially coated with beet pectin, chicory pectin and / or Jerusalem artichoke pectin or other pectin types having a high degree of acetylation. The composition which may be water dispersible is useful for preparation of health improving products and / or coloring products for use in the coloring of edible products including food products and nutraceuticals, and for coloring of pharmaceutical products.

Owner:CHR HANSEN NATURAL COLORS

Soft drink replacer

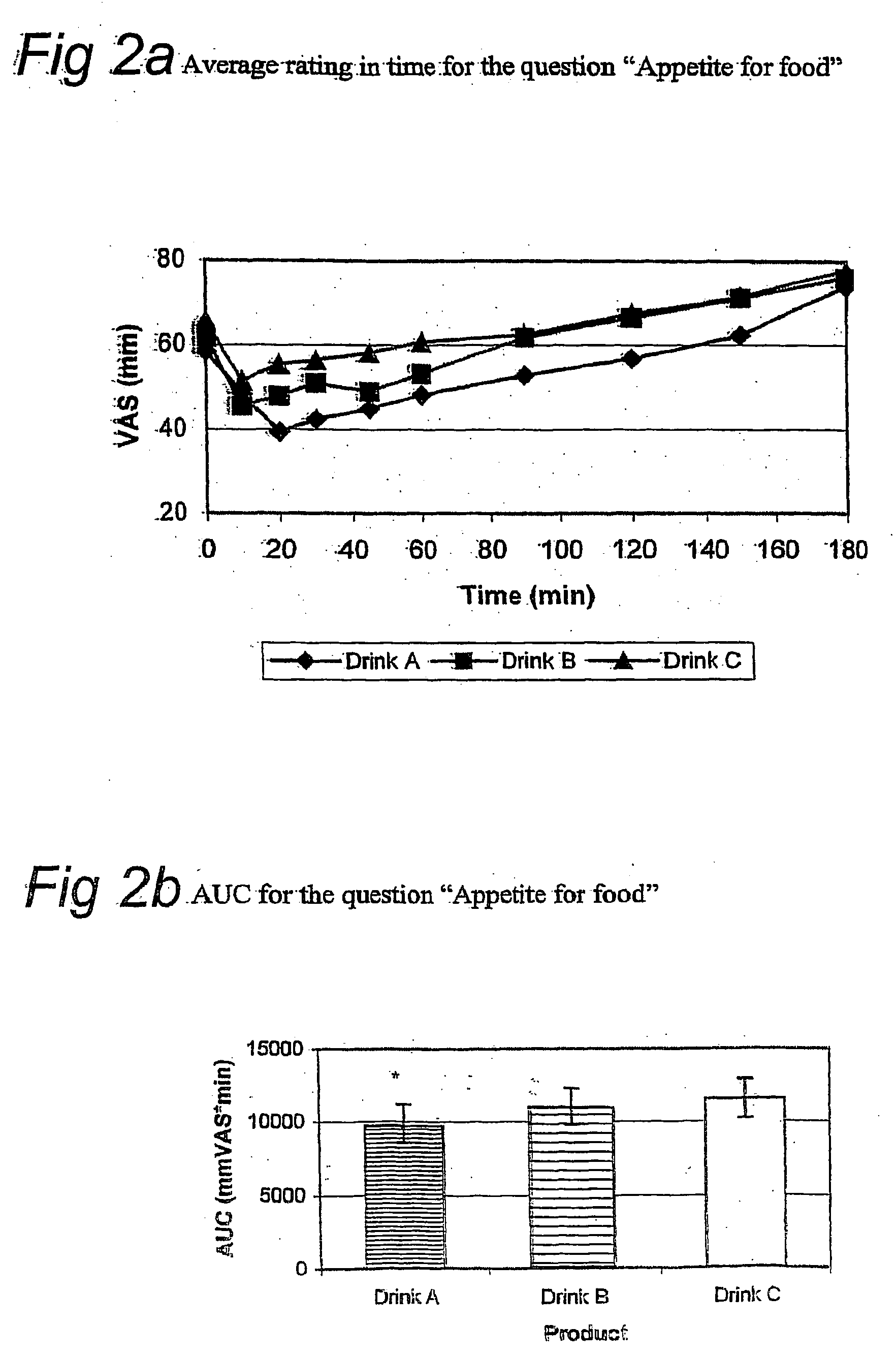

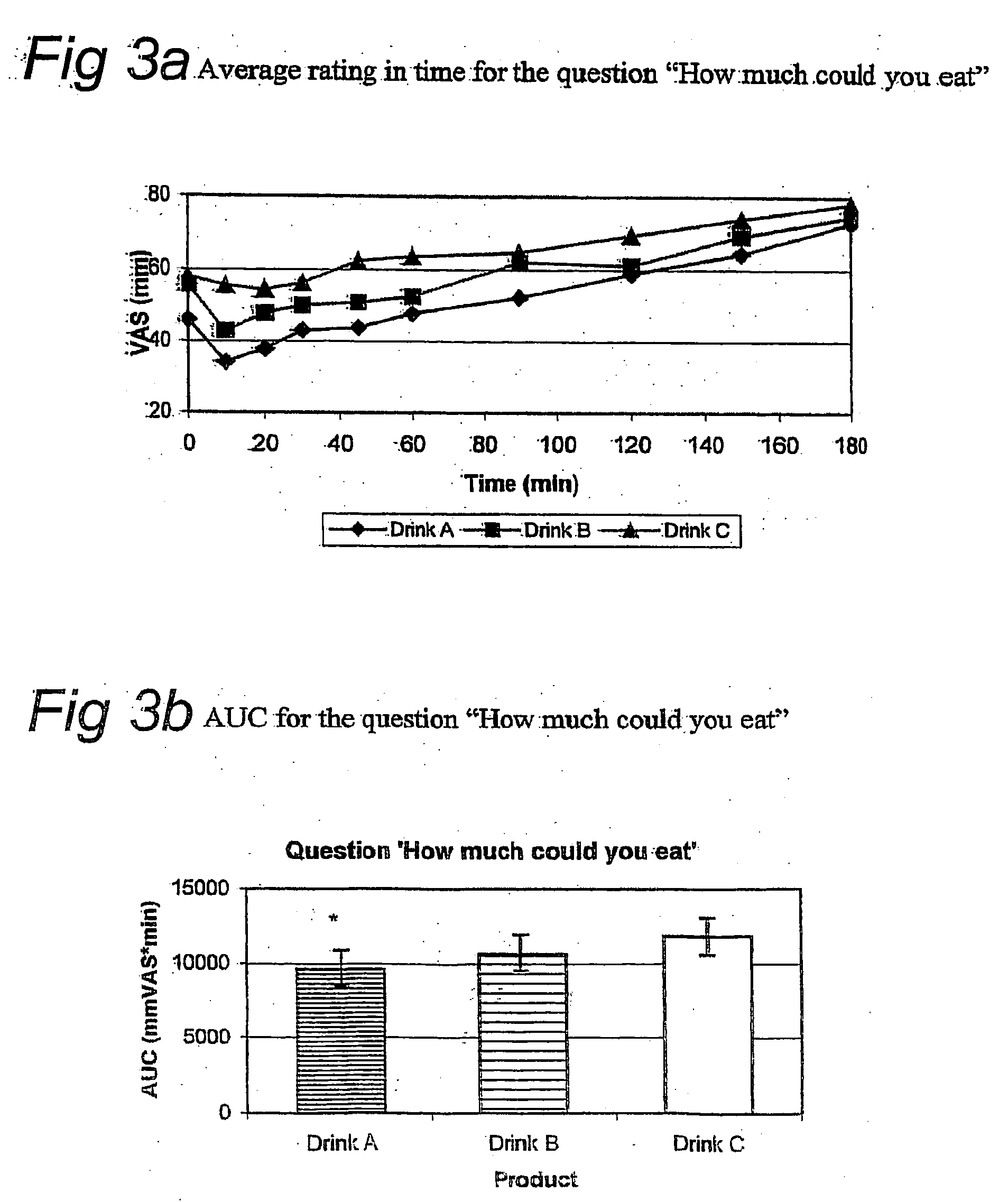

InactiveUS20030134027A1Reduced palatabilityEasy to handleBiocideOrganic active ingredientsShear rateOverweight

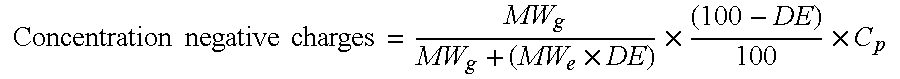

The present invention relates to a method for the treatment and / or prevention of overweight in a monogastric mammal. More particularly, the invention is concerned with such a method comprising administering to the mammal a liquid edible composition with a pH of more than 5, a viscosity below 50 mPas at a shear rate of 100 s-1 and 20° C., and a viscosity of at least 125% of the aforementioned viscosity at a pH 3 and a temperature of 37° C.; and with a caloric density between 0 and 500 kcal per liter, the composition comprising: c. between 0.01 and 5 wt. % of one or more polysaccharides selected from the group consisting of pectin and alginate; and between 0.01 and 3 wt. % calcium

Owner:NUTRICIA

Soft drink replacer

InactiveUS20040228903A1Reduced palatabilityEasy to handleBiocideOrganic active ingredientsBiotechnologyMonogastric

Owner:NV NUTRICIA

Matrix-forming composition containing pectin

InactiveUS6884445B2Viscosity is not sufficientGood effectOrganic active ingredientsSugar food ingredientsEnteral administrationShear rate

One aspect of the present invention relates to a liquid edible composition with a pH of more than 6, a viscosity below 600 mPas at a shear rate of 100s−1 and 20° C., and a viscosity of at least 125% of the aforementioned viscosity at a pH below 5 and a temperature of 37° C., the composition comprising at least 0.05 wt. % of pectin having a degree of methoxylation between 2 and 50 and / or of alginate; at least 5 mg calcium per 100 ml; and at least 0.1 wt. % indigestible oligosaccharide having a degree of polymerisation between 2 and 60.Another aspect of the invention relates to a method for the treatment or prevention of overweight or obesity in mammals, said method comprising the enteral administration to a mammal of an effective amount of the aforementioned composition.

Owner:NUTRICIA

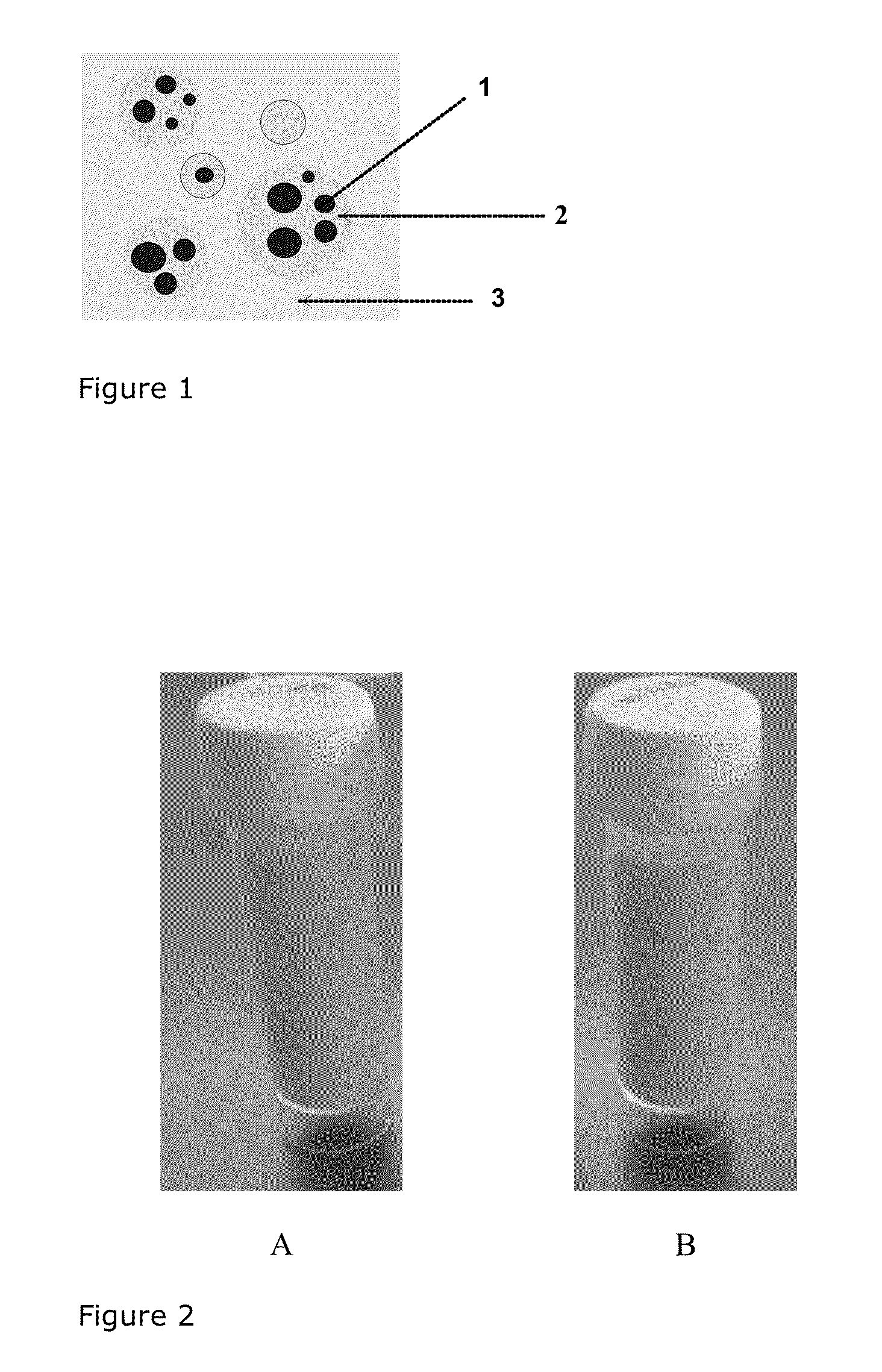

Multiple emulsions for colorants

The present invention is related to a multiple emulsion of the water-in-oil-in-water (W / O / W) type for stabilization of natural coloring agents, such as anthocyanin, phycocyanin, carthamus, huito, calcium carbonate, carmine and carminic acid, against changes in pH values, oxidation and light as well as against ingredient interactions.

Owner:OTERRA AS

Method to Prepare a Stable High-Load Paprika Extract in Powder Form

The invention relates to a preparation for foodstuffs. It is proposed in this case that the preparation comprise at least a fat soluble dye, dispersed in a lipid-based carrier medium; polyglycerol esters of edible fatty acids; citric acid esters of monoglycerides and / or diglycerides of edible fatty acids; or mixtures of these esters; and starch sodium octenyl succinate.

Owner:SENSIENT FOOD COLORS GERMANY

Nutrition bar or other food product and process of making

A nutrition bar or other food which incorporates pro-oxidants and / or polyunsaturated fatty acids or their sources in encapsulated form, especially as microcapsules. The pro-oxidants may be metal salts such as copper, manganese, iron and / or zinc salts. Sources of omega-3 fatty acids include fish oil. Processes for preparing the polyunsaturated fatty acid capsules are also disclosed. The polyunsaturated fatty acid capsules / microcapsules are prepared by forming an emulsion of the unsaturated fatty acid with a carrier, spray drying the emulsion to form a powder and encapsulating powder, especially with a fluid bed. The invention is especially useful for encapsulating polyunsaturated fatty acids, or oil sources thereof, most preferably omega-3 and omega-6 fatty acids, such as arachidonic acid, docosahexaenoic acid (DHA), eicosapentaenoic acid (EPA), lineoleic acid, linolenic acid (alpha linolenic acid), and gamma-linolenic acids, fish oil, and oil sources of C18:2 and C18:3 fatty acids such as canola oil, soybean oil or blends thereof.

Owner:SLIM FAST FOODS

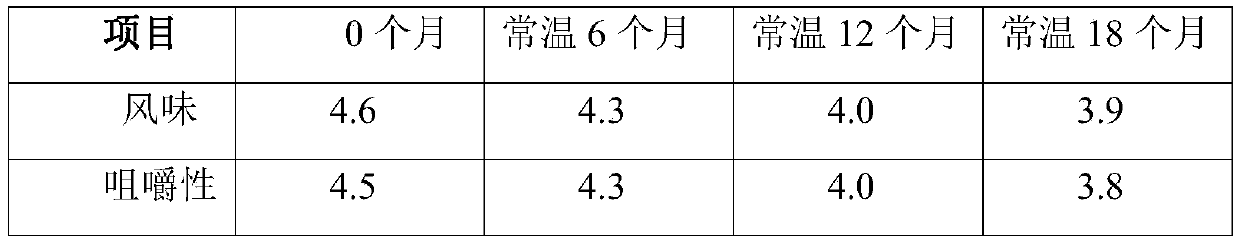

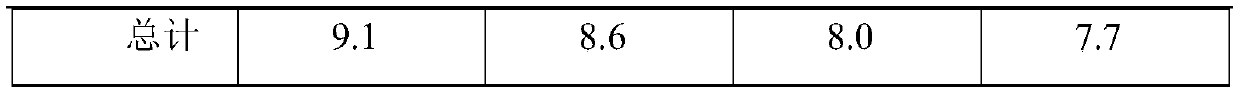

Long-shelf-life baking-resistant eggless salad sauce and preparation method and application thereof

ActiveCN106579318AEasy to useRich flavorFood ingredient as antioxidantSugar food ingredientsMonosodium glutamateFlavor

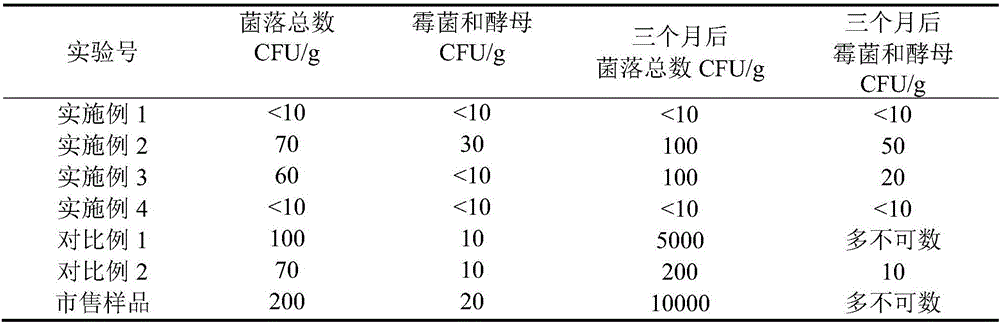

The invention discloses long-shelf-life baking-resistant eggless salad sauce and a preparation method and application thereof. The salad sauce is made from 20-42% of salad oil, 15-19.6% of sugars, 6-10% of white vinegar, 6-8% of sorbitol solution, 3.6-5.6% of pre-gelatinized modified starch, 2-3% of maltodextrin, 3-4% of glycerol, 0.15-0.35% of an emulsifier, 0.4-0.9% of colloid, 0.25-0.7% of whey protein, 0.5-2% of edible salt, 0.1-0.3% of a sourness agent, 0.003-0.03% of an antioxidant, 0-0.3% of monosodium glutamate, 0.-0.3% of an essence, 0-0.1% of a preservative, 0-0.1% of a pigment, and the balance of water. The salad sauce has low moisture activity, has reduced rancidity, and may be preserved at normal temperature for 6 months when not opened; the salad sauce may reasonably mate with a bread base, the original shape is kept after baking, no holes are generated, and strong flavor and good oral melting property are achieved.

Owner:广州合诚实业有限公司

Passion fruit jam and preparation method thereof

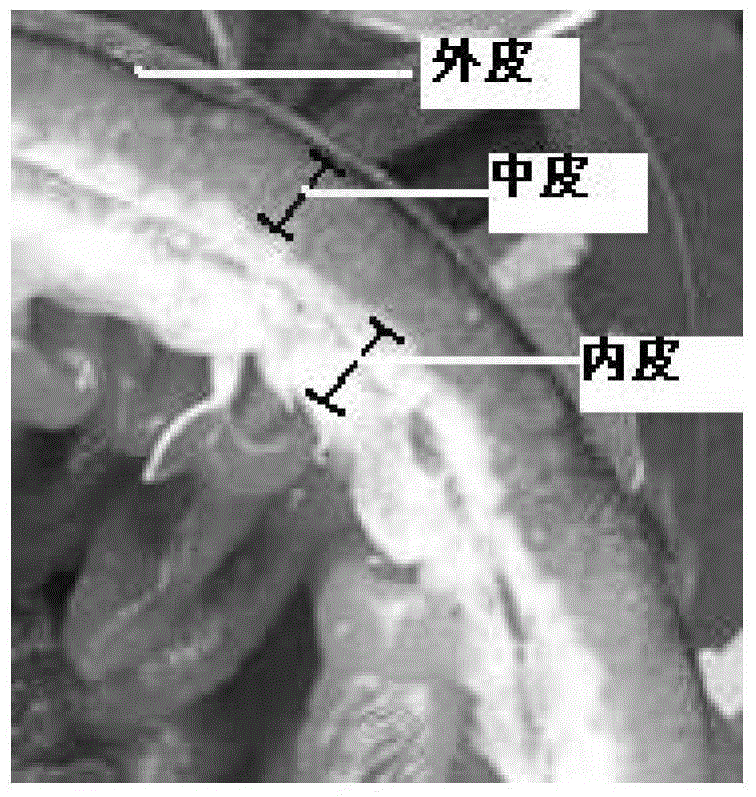

InactiveCN105010918AEfficient peelingIncrease productivityFood ingredient as colourFood preparationBiotechnologyPreservative

The invention discloses a passion fruit jam and a preparation method thereof. The preparation method comprises the following steps: selecting and cleaning passion fruit; freezing; scalding; carrying out cold leaching to remove outer skin; soaking to keep freshness; separating and collecting; circularly pulping; and seasoning. Through physical methods of freezing, scalding and cold leaching, the outer skin which is relatively hard in surface texture and coarse and dry in taste is efficiently removed from the fresh passion fruit; the jam which is free of a preservative or other pigment additives, pleasant in sweetness and sourness and abundant in nutrient is prepared from middle skin, inner skin, pulp and juice of the passion fruit; the production method is simple; the production cost is relatively low; and the passion fruit jam is economical, environment-friendly and suitable for large-scale industrial production.

Owner:谭强

Spiced egg manufacturing method

InactiveCN104000225AGuaranteed to tasteGuaranteed authentic tasteFood ingredient as colourFood processingSugarZoology

The invention provides a spiced egg manufacturing method. The spiced egg manufacturing method comprises the following steps of 1, carrying out egg cleaning, illumination, drying, sorting and sterilization, 2, steaming the egg, 3, removing the shell of the egg, 4, flushing the egg without shell by clear drinking water and drying the water on the surface of the egg without shell at a temperature of 50-60 DEG C for 20-40min, 5, carrying out pickling by adding a proper amount of clear water into anise, cassia bark, common fennel fruit, myrcia and table salt to obtain a pickling material, boiling the pickling material, cooling the pickling material to a temperature of 4-10DEG C, putting the egg without shell into the pickling material, and carrying out pickling for 8-12h so that the egg has a pickling material taste, 6, carrying out boiling coloring: preparing a coloring material from water, dry capsicum, Chinese prickly ash, myrcia, white sugar and soy sauce and putting the pickled egg into the coloring material for uniform coloring, 7, carrying out vacuum sealing packaging, and 8, carrying out high-temperature disinfection. Through drying and low-temperature pickling, the egg has a complete pickling material taste and energy is saved. The pickling process and the boiling coloring process are carried out respectively so that a pure taste of the spiced egg is guaranteed. The spiced egg has a quality guarantee period prolonged by at least 1-2 months.

Owner:房县天森食品有限公司

Composite clarifying agent for ginger juice and preparation method of extracting solution of clarified ginger juice

ActiveCN105942131AExtended shelf lifeComprehensive and thorough adsorptionFood ingredient as colourFood ingredient as taste affecting agentAdditive ingredientBiocompatibility Testing

The invention relates to a composite clarifying agent for ginger juice and a preparation method of an extracting solution of clarified ginger juice, and belongs to the technical field of food processing. The composite clarifying agent for the ginger juice is characterized in that attapulgite is used for supporting chitosan and matched with sodium alginate, sodium carboxymethyl cellulose, xanthan gum, collagen and tea polyphenol, the composite clarifying agent has excellent flocculation effect as well as good biocompatibility, adaptability and safety, can adsorb suspended solids, pigments and the other substances in the ginger juice more comprehensively and thoroughly, has antiseptic and bacteriostatic functions and can prolong the storage period of the ginger juice effectively. According to the preparation method of the extracting solution of the clarified ginger juice, the content of gingerol in extracted ginger juice is increased greatly while nutrients of raw materials are retained sufficiently, nutrient loss is small, the use amount of the clarifying agent is small, the stability of the ginger juice is improved remarkably, the prepared ginger juice is clear and transparent in appearance and glittering and translucent in color, the pungency of the ginger juice is reduced, the taste is mellow, and the sensory quality is improved obviously.

Owner:藤蔬生物科技(嘉兴)有限公司

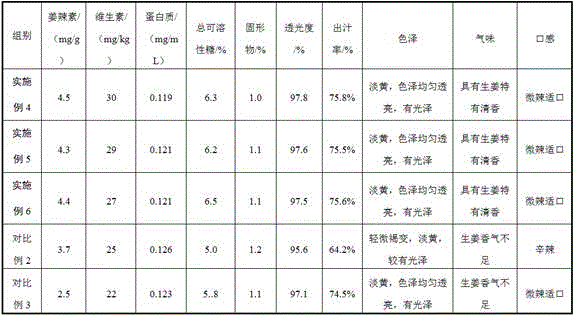

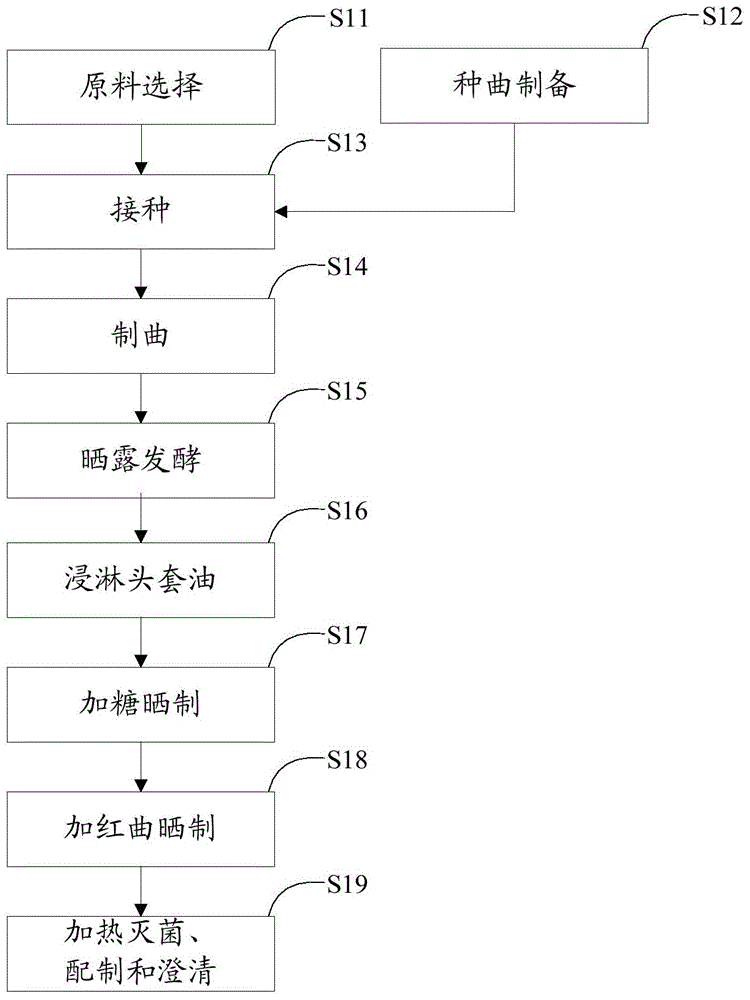

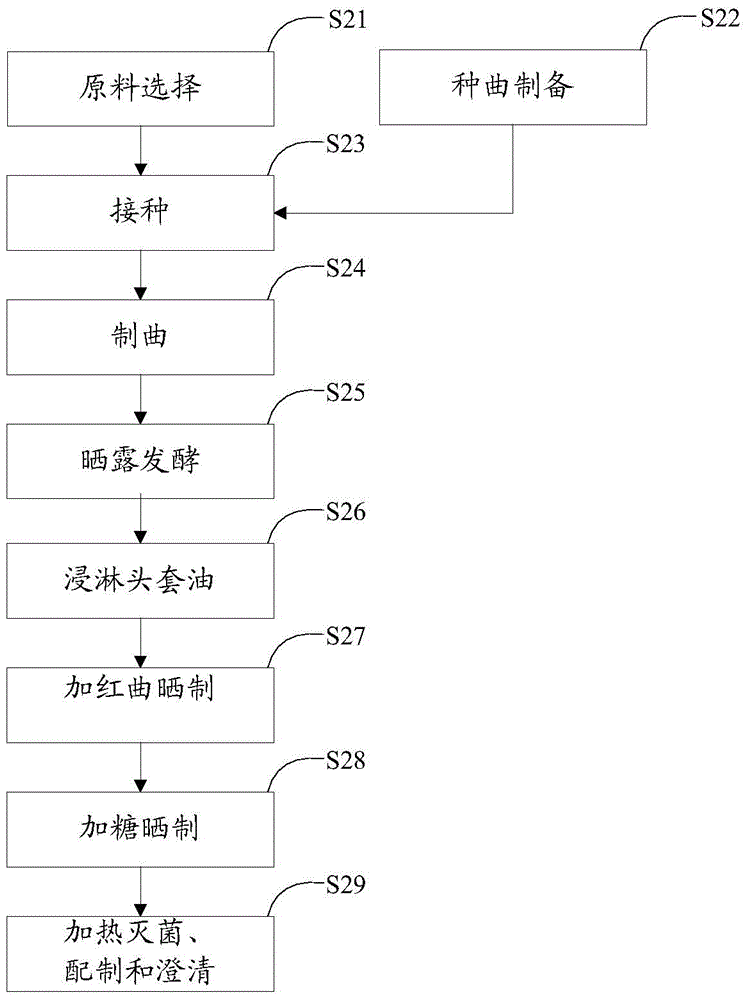

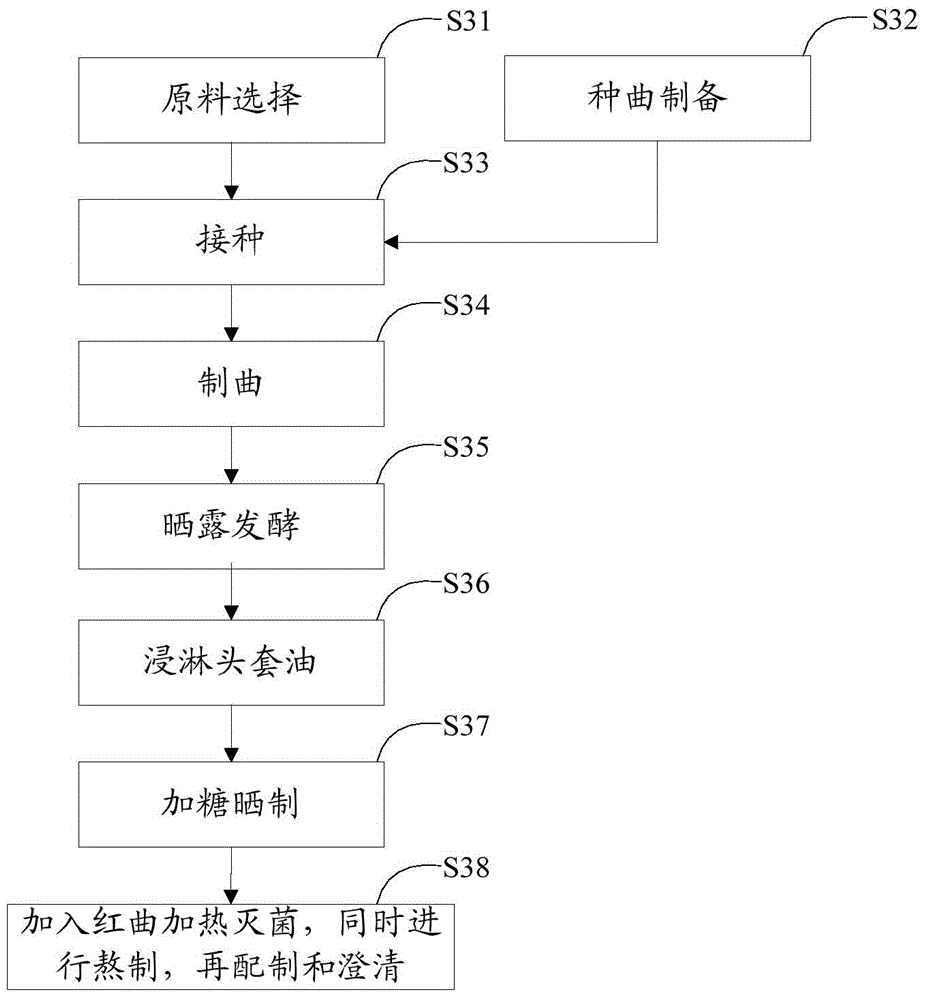

Production process of dark soy sauce and the dark soy sauce

InactiveCN104473126AGlossy and beautifulRaise the red indexSugar food ingredientsFood ingredient as colourCaramel FlavorSoya sauce

The invention discloses a production process of dark soy sauce and the dark soy sauce, and relates to the field of food processing, for overcoming the problem that dark soy sauce blended with caramel pigments in the prior art has a certain safety risk. The process includes: a raw material selection step, a starter propagation step, a step of fermentation in nature, a first-time oil spraying step and a heating and sterilization step. After the first-time oil spraying step, the process also comprises a step of color modulation by adoption of sugar and fermentum rubrum. The dark soy sauce provided by the invention is brewed by the process. In the brewing process of the dark soy sauce, the sugar and the fermentum rubrum are added and adopted as natural pigments to increase the red index and colority of a product, so as to allow a braised disk to be beautiful in color. In addition, eating safety risk does not exist and a healthcare function is added. The dark soy sauce which is healthier and more delicious is provided for customers.

Owner:HUZHOU LAOHENGHE BREWING

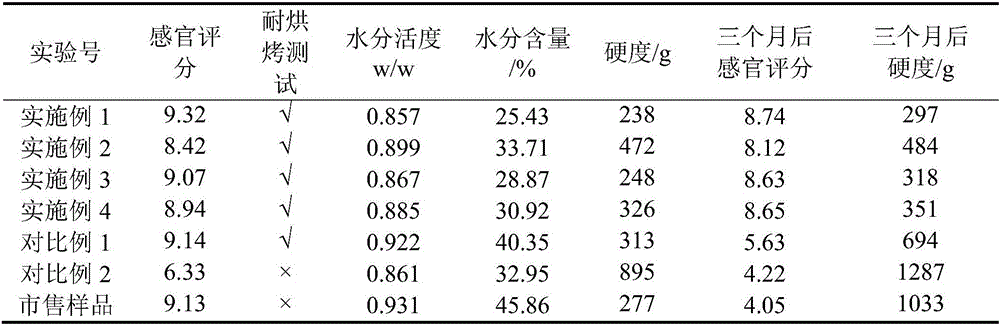

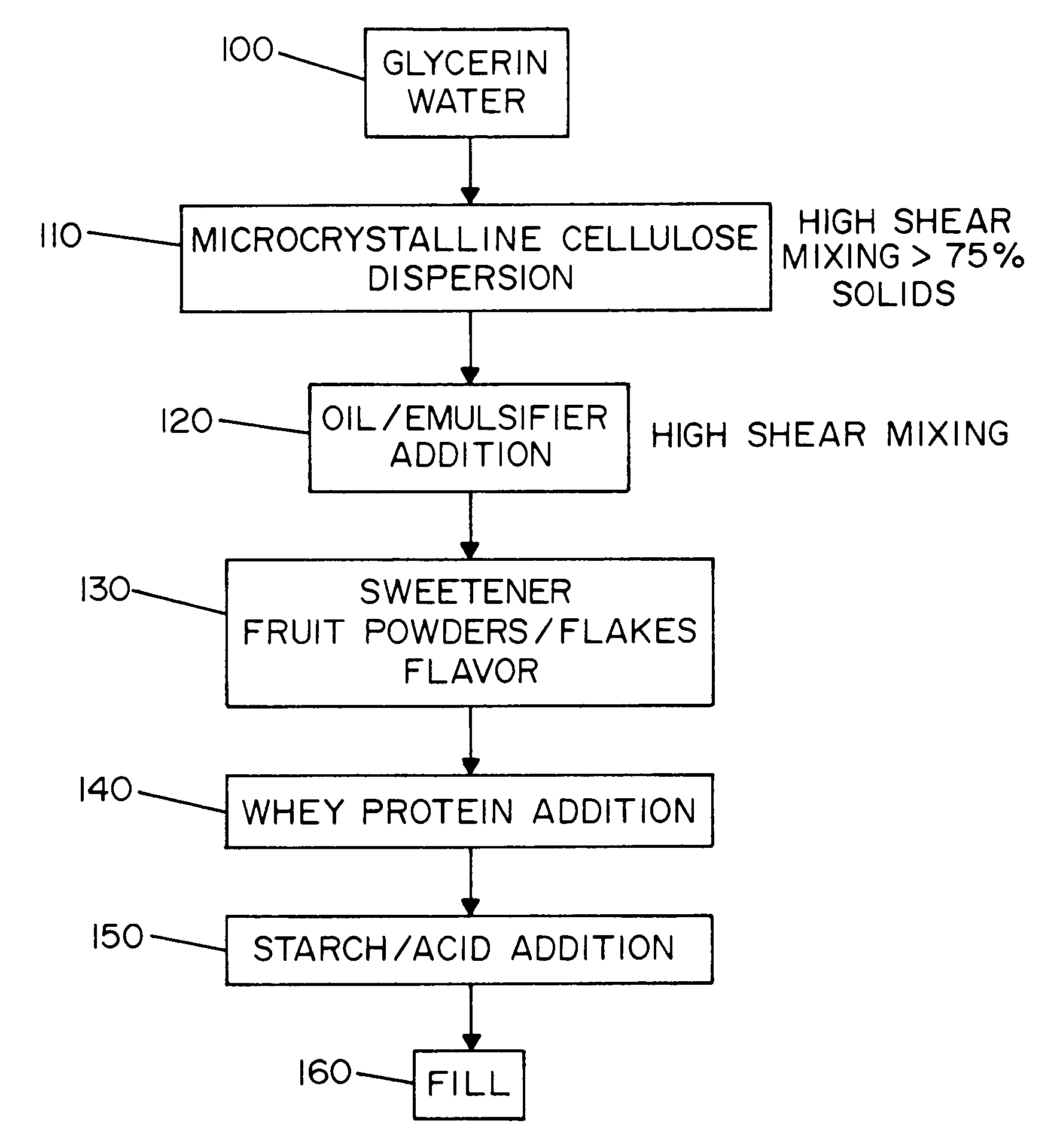

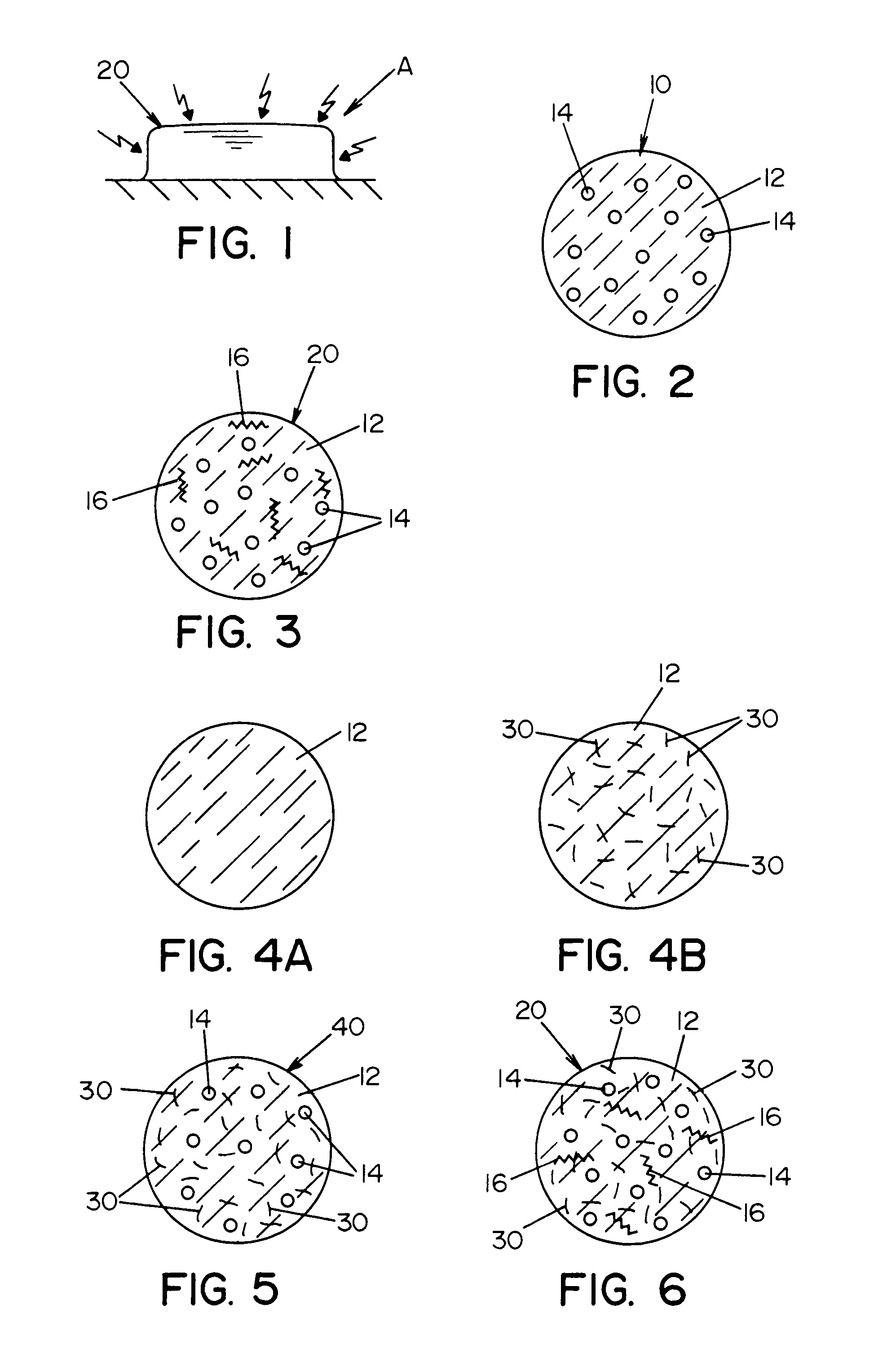

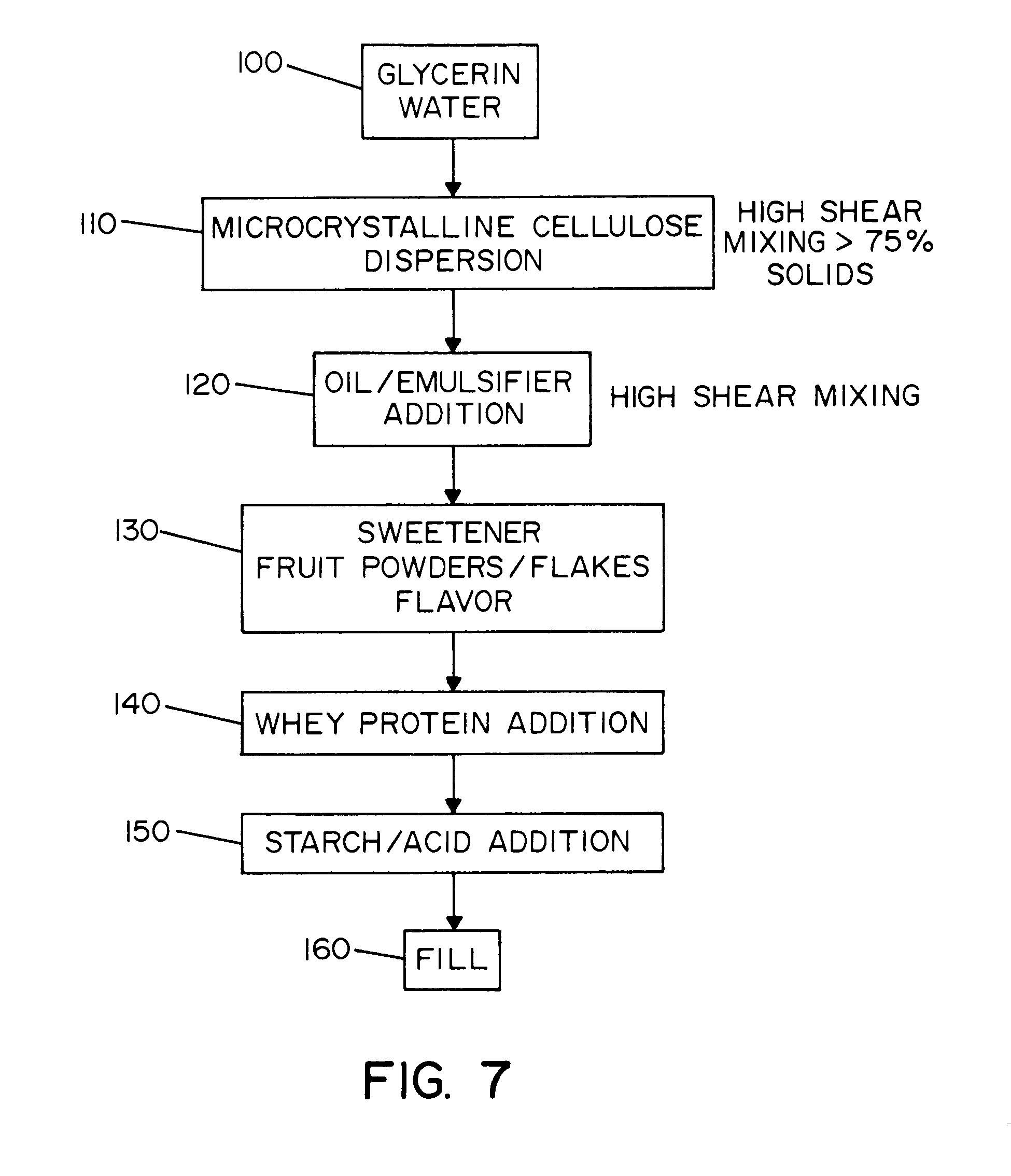

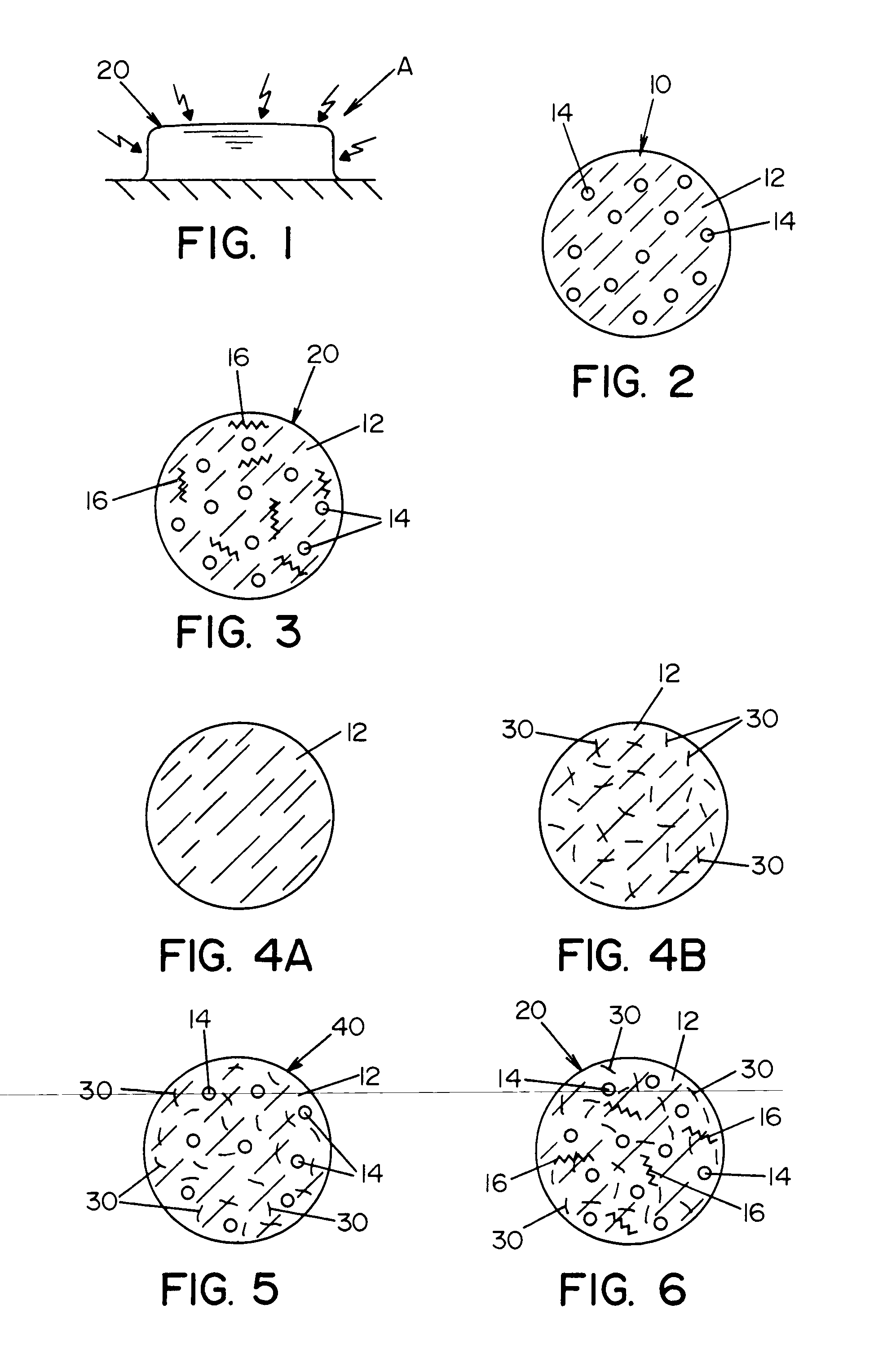

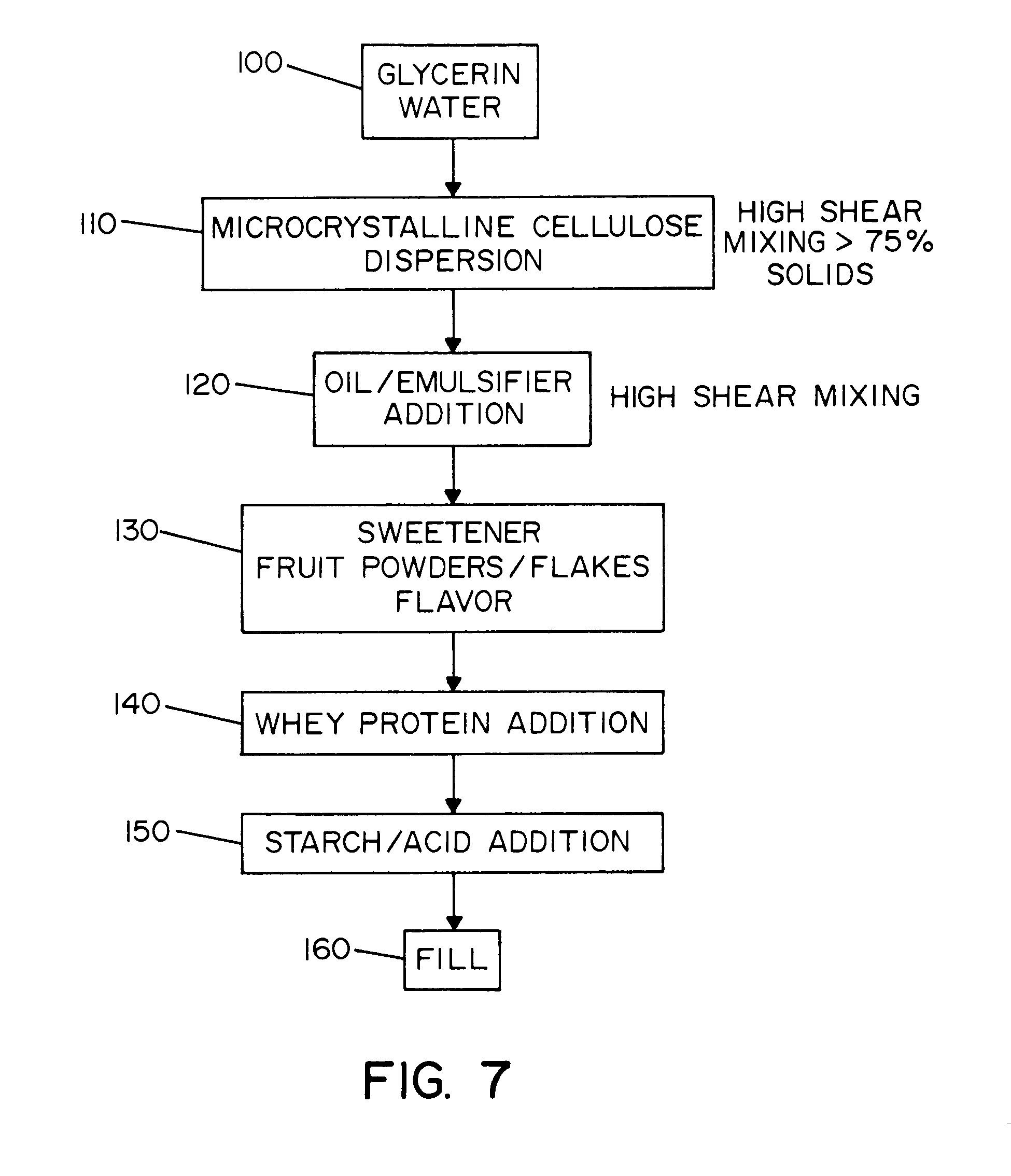

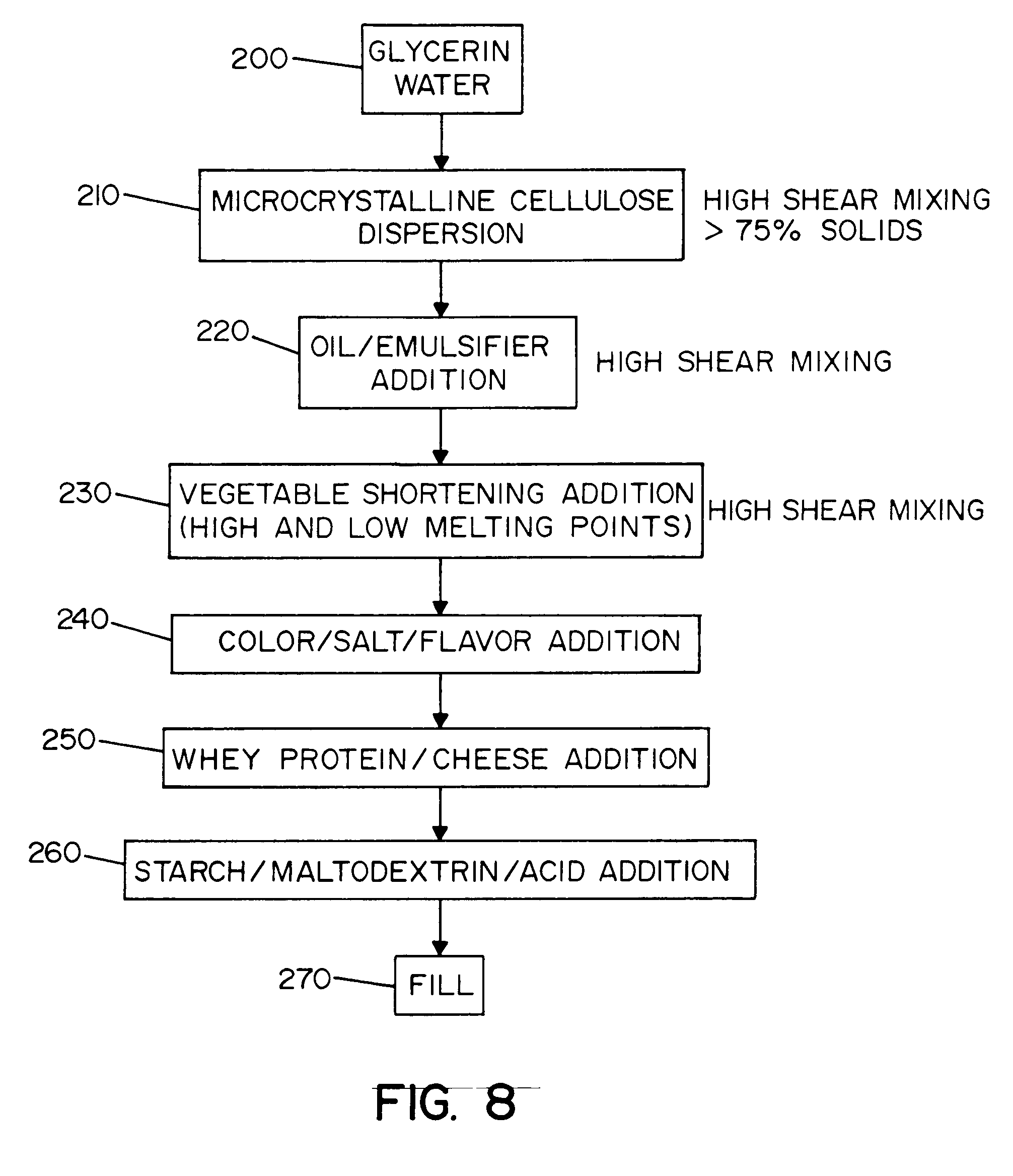

Bake stable low water activity filling and method of making

InactiveUS7452564B2Affects appearanceGood flavor release and organoleptic characteristicProtein composition from fishFood ingredient as colourWater activityGlobulin

A bake stable filling with a water activity of less than 0.60 comprising a matrix including a globulin protein with a dispersion of oil.

Owner:THE J M SMUCKER CO

Non deep-fried instant noodles and preparation method thereof

PendingCN107279724ASmooth tasteFast rehydrationFood freezingFood ingredient as thickening agentFreeze-dryingProcess engineering

The invention relates to non deep-fried instant noodles and a preparation method thereof. The non deep-fried instant noodles adopt a one-piece structure that an upper layer is a seasoning block and a lower layer is a cake. Cooked noodles and dishes processed in kitchens are integrated, and a vacuum freeze drying technique is used wholly, so that novel non deep-fried instant noodles are prepared. The non deep-fried instant noodles have the advantages that the non deep-fried instant noodles are low in fat, rapid in rehydration, good in soup sucking properties and pure and delicious in flavor, have the feel of conditioning in family kitchens, and can well reserve original nutrient components. Besides, the noodles and the dishes are integrated together to process a noodle product in a container, and the non deep-fried instant noodles can be eaten when being brewed with boiling water for 3min, so that the non deep-fried instant noodles are convenient and rapid, and tedious steps that when conventional instant noodles are brewed, material bags of seasoning powder bags, sauce bags, vegetable bags and the like need to be tore are omitted, and the non deep-fried instant noodles are time-saving, bag-material-saving, environmental-friendly and healthy.

Owner:JIN MAILANG MIANPIN CO LTD

Water-dispersible transparent astaxanthin emulsion and preparation method

ActiveCN105832569AImprove solubilityGood dispersionOrganic active ingredientsCosmetic preparationsSolubilityDispersity

The invention belongs to dosage form technology of functional additives, and particularly relates to a water-dispersible transparent astaxanthin emulsion and a preparation method. The astaxanthin emulsion comprises an oil phase, a water phase and an emulsifier, the oil phase is an astaxanthin solution and comprises astaxanthin and a solvent, mass-volume concentration of the astaxanthin solution is 1-30 mg / mL, the water phase is water or a mixture of glycerin and water, the solvent is edible oil, a volume ratio of the oil phase to the emulsifier is 1:3:3:1, and a volume ratio of the water phase to mixed liquid of the oil phase and the emulsifier is greater than or equal to 1:9. The preparation method includes: preparing the oil phase, preparing the water phase, and preparing the emulsion. The water-dispersible astaxanthin emulsion has high solubility and water dispersity, bioavailability of the water-dispersible astaxanthin emulsion is improved, and various physiological active functions of the water-dispersible astaxanthin emulsion are brought into effective play.

Owner:CHINA AGRI UNIV

Nutritional composition useful in the treatment of ibd patients

ActiveUS20170368027A1Good for healthSugar food ingredientsVitamin food ingredientsInflammatory bowel diseaseNutritional composition

Compositions and methods are provided that are useful in the treatment of inflammatory bowel disease (IBD) patients. The Compositions and methods are suitable in the prevention or postponement of a relapse in inflammatory bowel disease patients.

Owner:SOC DES PROD NESTLE SA

Dried pork slices with oolong tea flavor and manufacturing method of dried pork slices

InactiveCN105876657ATaste bright red and shinyRich tastePre-extraction tea treatmentFood ingredient as colourFlavorCooking & baking

The invention discloses dried pork slices with an oolong tea flavor and a manufacturing method of the dried pork slice. The dried pork slices are prepared from the following raw materials in parts by weight: 100 parts of fresh pork hind leg muscle, 5 to 15 parts of condiments and 0.5 to 8 parts of oolong tea powder through preparation steps of checking and accepting the raw materials, washing, cutting, freezing, unfreezing, cutting pork, stirring and pickling, seasoning with oolong tea, smearing, drying, baking, cutting and packaging. The disadvantages of the prior art and existing products are overcome, the flavor of the products is improved and edible values and nutritional values of the products are improved; a novel dried pork slice product with the oolong tea flavor is obtained.

Owner:ZHANGZHOU COLLEGE OF SCI & TECH

Making method of preserved black jerusalem artichoke

ActiveCN105707778APromote browningImproves antioxidant activityFood freezingFood ingredient as colourFood additiveZymogen

The invention discloses a making method of preserved black jerusalem artichoke, and belongs to the technical field of food processing. The problems that in the existing preserved jerusalem artichoke production technology, preserved jerusalem artichoke is not suitable for glycosuria patients due to the fact that saccharose is exogenously added, and food safety is potentially affected due to the fact that sodium hydrogen sulfite and other food additives are added are solved. The processing technological process comprises the following steps of raw material freezing, sorting and cleaning, processing through zymogen, sealing, fermentation, drying, packaging, finished product forming and cold storage. Compared with raw jerusalem artichoke, in the preserved black jerusalem artichoke, the certain synanthrin content is reserved, the content of reducing sugar and polyphenols is obviously increased, a large number of melanoidins are produced, the product reserves the functions of regulating blood sugar in two ways, lowering blood fat, proliferating bifidobacteria, promoting mineral substance absorption, preventing and treating constipation, improving intestinal tract microenvironment, enhancing immunity, resisting cancer and preventing obesity of the synanthrin in the raw jerusalem artichoke to the certain degree, and the preserved black jerusalem artichoke has the stronger antioxidant function due to the fact that the content of the polyphenols and melanoidins is obviously increased.

Owner:DAQING BRANCH OF HEILONGJIANG ACAD OF SCI

Complementary instant rice flour for infants and young children and processing method thereof

InactiveCN105124375APromote digestionPromote absorptionFood ingredient as colourFood ingredient as flavour affecting agentPolygonum fagopyrumPhospholipid

The present invention discloses complementary instant rice flour for infants and young children. The rice flour comprises the following raw materials in weight percentage: amino acid enriched rice 26-32%, selenium-enriched rice 15-20%, brown rice shoots 12-18%, soybean germs 6-12%, peanuts 5-10%, buckwheat 5-10%, whole milk powder 10-15%, refined phospholipids 2-5%, pumpkin powder 1-3%, and additives 1-2%. The complementary instant rice flour for infants and young children not only is scientific and rational in recipe, is rich in a variety of physiologically active ingredients, but also is convenient for consumption, is good in rehydration, is easy to be brewed, and after being blended with water, the rice flour is good in color, fragrance, taste, texture, physical appearance, and mouthfeel, and is high in digestion and absorbency.

Owner:ANHUI LUOLUO RICE IND

Method for extracting natural red pigment from pitaya and application thereof

InactiveCN106009763ALong storage timeAvoid residueMilk preparationFood ingredient as colourPectinaseFreeze-drying

The invention belongs to the technical field of extraction and discloses a method for extracting a natural red pigment from pitaya and application thereof. The method comprises the following steps: (1) selecting fresh red pitaya, peeling off, dicing and crushing flesh to obtain fruit pulp, and then refrigerating the fruit pulp; (2) taking out the refrigerated fruit pulp in the step (1) and unfreezing at the room temperature, then adding distilled water and pectinase and uniformly stirring, and extracting at 20-35 DEG C for 0.5h-2h; (3) filtering an extracting solution extracted in the step (2), and centrifuging the obtained filtrate to obtain a clarified pigment solution; and (4) mixing the clarified pigment solution obtained by the step (3) with wall materials, stirring at the room temperature for completely and uniformly mixing, and drying to obtain a dry pigment product. The method has the advantages of simplicity in operation, high efficiency and energy saving, environmental friendliness and capability of keeping natural active components in the pitaya to the greatest extent; the weight of freeze-dried products is light and the quality is good; the products can be stored for a long time and are convenient to transport; and the obtained pigment solution can be directly applied to food production.

Owner:SOUTH CHINA UNIV OF TECH

Fine dried black-fungus noodle

InactiveCN107373354AReservation of validityKeep the scentFood ingredient as colourFood ingredient as taste affecting agentAdditive ingredientLow calorie

The invention discloses a fine dried black-fungus noodle. The fine dried black-fungus noodle uses wheat flour as a main raw material, black fungus powder, konjac powder and whole potato flour as auxiliary materials, and salt as an additive. The fine dried black-fungus noodle comprises, by mass, 88-90 parts of wheat flour, 4.5-5 parts of black fungus powder, 0.5-1 parts of konjac powder, 3-5 parts of whole potato flour and 0.8-1 part of salt. A preparation method for the noodle comprises the following concrete procedures: preparation of black fungus powder, preparation of konjac gel, kneading, cooking, compounding, calendering, strip cutting, drying, cutting-off, packaging, etc. According to the invention, since black fungus powder, konjac powder and whole potato flour are used as the auxiliary materials and the corresponding preparation method is employed, so the noodle has improved taste and flavor, better toughness, unique delicate fragrance different from ordinary noodles, good cooking performance, excellent boiling resistance, abundant dietary fiber and various nutrients, low calorie, low fat, and enhanced nutritional value and therapeutic effect, and is beneficial for human health.

Owner:湖北金水源生物科技有限公司

Bake stable low water activity filling

InactiveUS20040202764A1Lower water activityImprove liquidityProtein composition from fishFood ingredient as colourWater activityOrganic chemistry

A bake stable filling with a water activity of less than 0.60 comprising a matrix including a globulin protein with a dispersion of oil.

Owner:THE J M SMUCKER CO

Spiced pot-stewed pork trotter and preparation method thereof

InactiveCN107307312AFlavor stimulatesKeep the flavorFood ingredient as colourClimate change adaptationPre treatmentSugar

The invention discloses a spiced pot-stewed pork trotter which is prepared from, by weight, 500-1000 parts of pork trotter, 15-35 parts of spiced powder, 30-50 parts of soy sauce, 20-40 parts of brown sugar, 80-120 parts of cooking wine, 2-5 parts of dry red pepper, 10-12 parts of green Chinese onion, 10-12 parts of fresh ginger and 5-10 parts of edible salt. A preparation method of the spiced pot-stewed pork trotter includes the steps: (1) pork trotter pretreatment; (2) pickling; (3) brine preparation; (4) stewing; (5) cooling, sterilization and vacuum packaging. The spiced pot-stewed pork trotter prepared by the technical scheme is short in marinating time, the prepared pork trotter is soft, delicious and fragrant and suitable for home and travel, serves as a present for relatives and friends and has the advantages of safety, health, rich nutrition and the like.

Owner:贵州道真旧城建辉黑猪生态养殖有限公司

Black coarse cereal powder with functions of kidney tonifying and hair blackening

InactiveCN108323719APromote circulationNovel compositionFood freezingFood ingredient as colourVomit blackFood material

The invention discloses black coarse cereal powder with functions of kidney tonifying and hair blackening, wherein the raw materials comprise, by weight, 1-5 parts of black Chinese wolfberry, 1-10 parts of Polygonatum sibiricum, 10-25 parts of black sesame, 10-15 parts of black rice, 1-30 parts ofblack bean, 1-10 parts of Chia seed, 1-10 parts of black fungus, and 1-10 parts of black mulberry. According to the present invention, the black coarse cereal powder is prepared by selecting the eight black food materials through scientific compatibility, wherein the formula is novel, the functions are significant, and various raw materials can provide the effects; and the black coarse cereal powder has effects of kidney tonifying, hair blackening, qi enriching, blood enriching, blood circulationimproving, immunity enhancing, swelling subsiding, qi descending, lung moistening, stomach benefiting, spleen strengthening, sleep improving, beautifying, face nourishing and the like, further has characteristics of convenient eating, good taste, excellent taste and low cost, is suitable for ordinary consumers, and has good application prospects.

Owner:ANHUI QIUGUO FOOD

High-nutrition oat beverage and preparation method of solid matrix thereof

ActiveCN103610193AFull of nutritionNutritional diversityFood ingredient as colourFood homogenisationCow milkSpray drying

The invention discloses a high-nutrition oat beverage and a preparation method of a solid matrix of the high-nutrition oat beverage, belonging to the field of deep grain processing. The oat beverage with a heavy oat characteristic flavor, milky white color, smooth mouth feel similar to that of milk and a stable system is prepared by the steps of washing raw materials, mixing, baking, pulping, enzymatically hydrolyzing, sieving, adding oil and mixing, homogenizing, sterilizing, filling and the like. The homogenized oat beverage is directly concentrated and subjected to spray-drying to prepare the white solid matrix with an oat typical favor. The oat beverage is heavy in oat flavor, rich in nutrition and suitable for being drunk by all people, and has a wide future industrialization prospect.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Ginseng and lycium barbarum composite health drink and making method thereof

ActiveCN104522809ASimple processLow costFood ingredient as colourFood preparationBiotechnologyLycium barbarum fruit

The invention relates to a method for making ginseng and lycium barbarum composite health drink. The making method comprises the following steps: by taking ginseng as a raw material, performing water extraction to obtain ginseng juice; by taking ginseng concentrate as a main raw material, adding lycium barbarum juice with a health effect, thereby obtaining the ginseng and lycium barbarum composite drink. According to the ginseng and lycium barbarum processing technology, the original nutrition characteristics, taste and effective functions of the raw materials are not damaged, and the natural property of the drink is guaranteed.

Owner:通化百泉保健食品有限公司

Preparation method of instant flammulina velutipe

InactiveCN104187596AEasy to controlThe total number of controllable communitiesFood ingredient as colourFood preparationHealth qualityFlammulina

The invention provides a preparation method of instant flammulina velutipe which has crisp and tasty taste. The crisp and tasty taste of the flammulina velutipe is maintained from the whole link by organic combination of fixation, blanching and sterilization steps, high-temperature sterilization is carried out for a plurality of times, the total number of bacterial communities is controlled, and the quality of the flammulina velutipe body is not affected. The instant flammulina velutipe product provided by the invention has the advantages of being unique, crisp, tasty, fresh and smooth in taste, convenient to eat, pure in taste, delicious, healthy and green, and has high health quality.

Owner:SICHUAN MEISHAN JIJIGAO FOOD

Oyster calcium gel candy and preparation method thereof

InactiveCN110024895AGood dispersionImprove solubilitySugar food ingredientsFood ingredient as colourFruit juiceOyster

The invention relates to a gel candy, in particular to an oyster calcium gel candy and a preparation method thereof. The candy comprises the following components in parts by weight: 40-100 parts of gelatin, 1-20 parts of polysaccharide gel, 500-850 parts of a filler, 60-100 parts of oyster calcium powder, 0.1-10 parts of a calcium absorption enhancer, 5-50 parts of concentrated fruit juice, 0.5-5parts of essence and 0-5 parts of a colorant. The calcium absorption enhancer consists of casein phosphopeptide, lysine, arabic gum, xylo-oligosaccharide and an auxiliary agent, wherein the auxiliaryagent is one or more of vitamin D3 or lactose. The candy has good calcium absorption effect, is in the form of candy, and is portable, easy to take and use, good in taste, easy to chew, rich in mouthfeel and good in quality. The invention also provides the preparation method of the candy, the raw materials are easy to obtain, the preparation operation is simple, and the cost is low.

Owner:SHANDONG SHENGHAI HEALTH PROD CO LTD

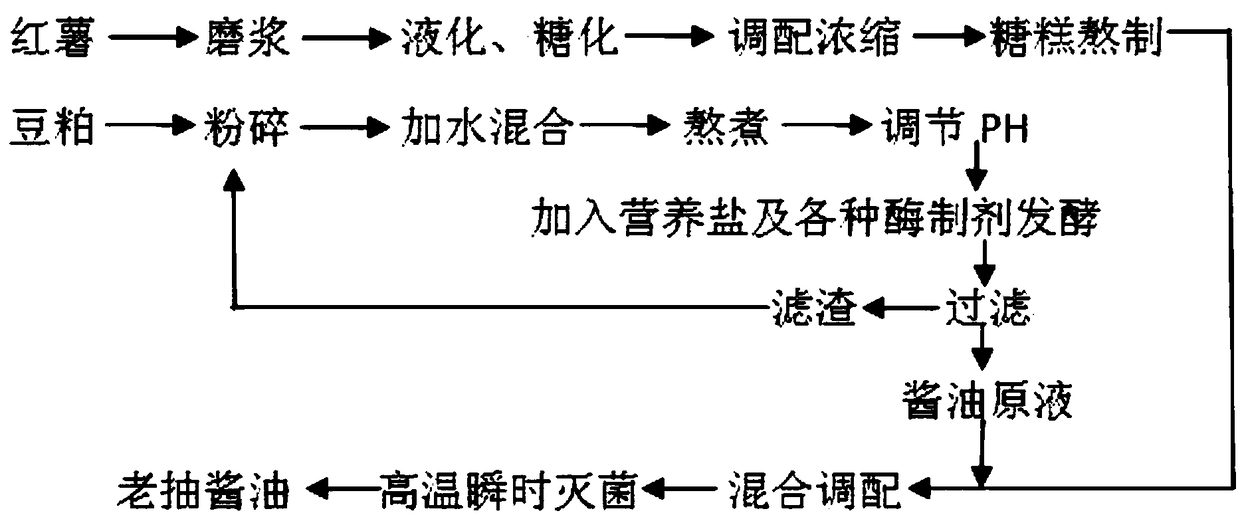

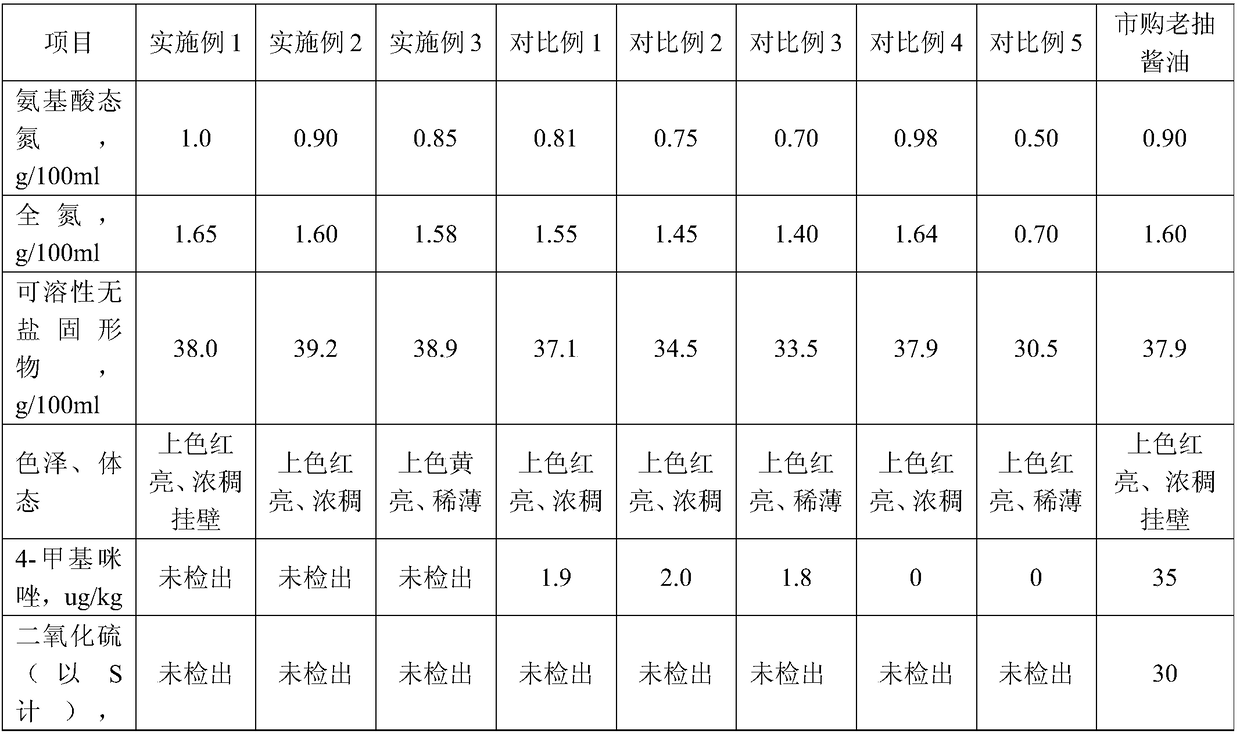

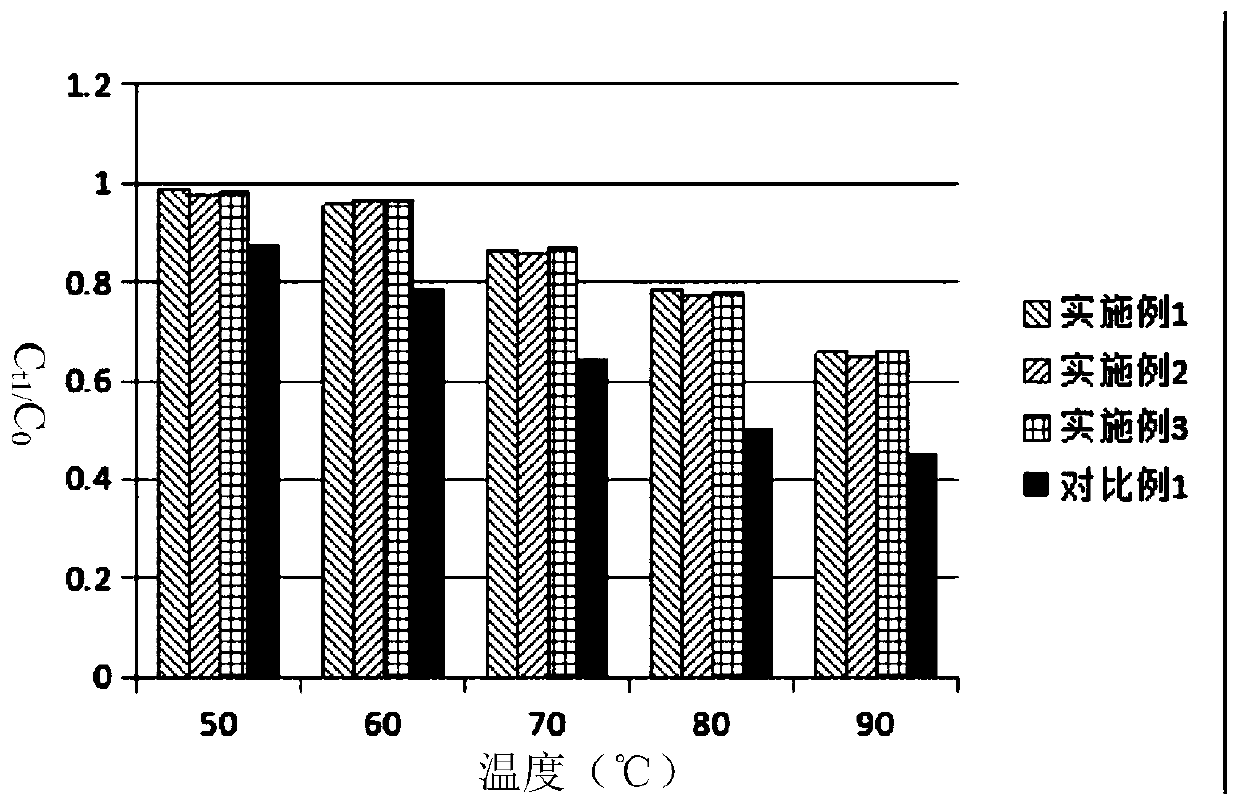

Preparation method of dark soy sauce

InactiveCN108606301AImprove use valueTake advantage ofFood ingredient as colourInorganic compound food ingredientsAmylaseAcetic acid

The invention discloses a preparation method of a dark soy sauce. Soybean meal is used as raw materials, and is sequentially subjected to crushing, boiling, fermenting and filtering, so that a soy sauce stock solution is obtained; sugar paste is added to the soy sauce stock solution, and high-temperature instantaneous sterilization is performed, so that the dark soy sauce is obtained. According tothe sugar paste, sweet potatoes are used as raw materials, and are refined to obtain pulp, amylases and glucamylase are sequentially added and liquefying and saccharification are separately performed, so that a pure sugar solution is obtained; and the pure sugar solution is subjected to negative pressure concentration to obtain a concentrated mixed sugar solution, food-grade sodium hydroxide andacetic acid are added to the concentrated mixed sugar solution, and boiling is performed, so that the sugar paste is obtained. The preparation method solves the problem that in the prior art, caramelcolor is used for coloring, so that the soy sauce contains 4-methyl glyoxaline and sulfur dioxide.

Owner:QIANHE CONDIMENT & FOOD CO LTD

Microencapsulation method capable of increasing stability of anthocyanin, product prepared by microencapsulation method and use of product

InactiveCN110013034AEnsure structural stabilityImprove structural stabilityOrganic active ingredientsOrganic chemistryVegetable oilOil phase

The invention discloses a microencapsulation method capable of increasing stability of anthocyanin, a product prepared by the microencapsulation method and use of the product. The microencapsulation method comprises the following steps of S1, using sodium alginate as a wall material, adding the sodium alginate and calcium carbonate to water, and performing swelling for 1-2h so as to obtain a wallmaterial gel system; S2, using anthocyanin obtained through a special preparation technology as a core material, sufficiently and uniformly mixing the wall material gel system with a anthocyanin solution for standby application so as to obtain a water phase; S3, mixing Span80 with vegetable oil so as to obtain an oil phase, mixing the water phase with the oil phase, performing magnetic stirring, and performing emulsifying so as to obtain W / O emulsion; and S4, adjusting the pH of the W / O emulsion to acid, mixing the W / O emulsion with a table salt buffer solution, performing standing for 1-2h, and separating the oil phase from the water phase so as to obtain liquid anthocyanin microcapsules. The anthocyanin is prepared through a special preparation technology, so that yield and purity are increased; and besides, the microencapsulation method and the drying condition of the anthocyanin are optimized through improved technological parameters, so that the structural stability of the anthocyanin is guaranteed, and the cost is reduced.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com