Passion fruit jam and preparation method thereof

A technology of passion fruit and jam, applied in food preparation, food science, food ingredients as color, etc., can solve the problems of peel discarding and waste, achieve the effect of improving production efficiency, reducing production cost, and maintaining bright colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The preparation method of passion fruit jam of the present invention, it comprises the steps:

[0038] (1) Selection and cleaning of passion fruit: select 10 kilograms of fresh, complete and non-rotten purple passion fruit, and wash it for later use;

[0039] (2) Freezing: Freeze the passion fruit completely at a temperature below 0°C.

[0040] (3) Ironing: Soak the frozen passion fruit completely in boiling water at 100°C for ironing, and the time is controlled within 4 minutes;

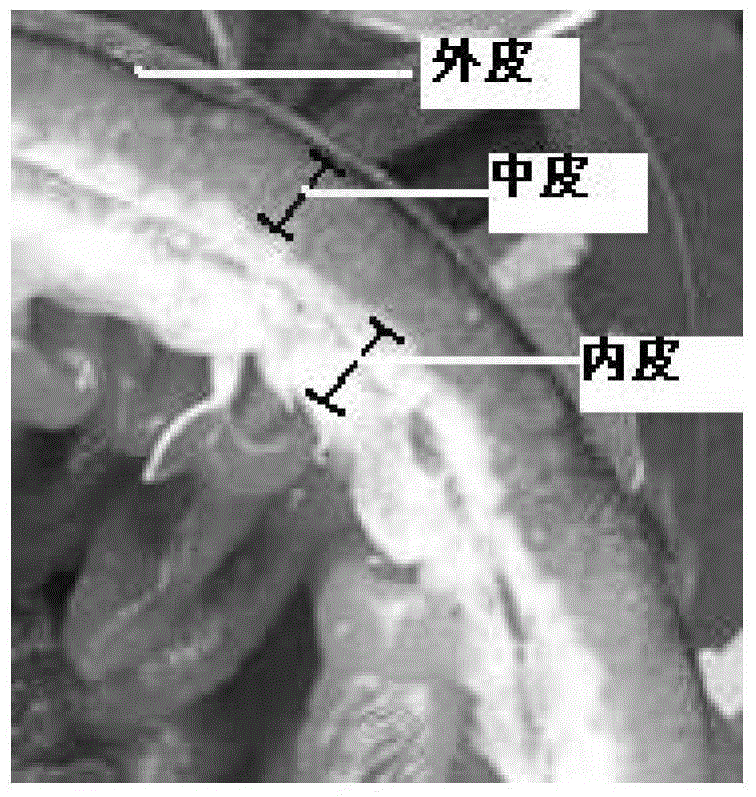

[0041] (4) Cold soaking to remove the outer skin: Soak the blanched passion fruit in cold water below 10°C for 5 seconds, and quickly peel off the outer skin.

[0042] (5) Soaking and thawing: The passion fruit after peeling off the outer skin is soaked in water containing 0.5% citric acid and 0.1% ascorbic acid for 10 minutes to thaw.

[0043](6) Separation and collection: Cut the passion fruit with the outer skin removed, take out the pulp, juice and seed kernels, and collect the remainin...

Embodiment 2

[0048] The production method of passion fruit jam of the present invention, it comprises the steps:

[0049] (1) Selection and cleaning of passion fruit: select 10 kilograms of fresh, complete and non-rotten purple passion fruit, and wash it for later use;

[0050] (2) Freezing: Freeze the passion fruit completely at a temperature below 0°C.

[0051] (3) Ironing: Soak the frozen passion fruit completely in boiling water for 1-2 minutes;

[0052] (4) Cold soaking to remove the outer skin: Soak the blanched passion fruit in cold water at 0-5°C for 1-2 seconds, and quickly peel off the outer skin.

[0053] (5) Soaking and thawing: The passion fruit after peeling off the outer skin is soaked in water containing 0.05% citric acid and 0.03% ascorbic acid for 10 minutes to thaw.

[0054] (6) Separation and collection: Cut the passion fruit with the outer skin removed, take out the pulp, juice and seed kernels, and collect the remaining peel. Add 5L of water by weight to the obtain...

Embodiment 3

[0059] The production method of passion fruit jam of the present invention, it comprises the steps:

[0060] (1) Selection and cleaning of passion fruit: select 1 kg of fresh, complete and non-rotten purple passion fruit, and wash it for later use;

[0061] (2) Freezing: Freeze the passion fruit completely at a temperature below 0°C.

[0062] (3) Ironing: Soak the frozen passion fruit completely in boiling water for 9-10 minutes;

[0063] (4) Cold soaking to remove the outer skin: Spray the blanched passion fruit in cold water at 15°C for 5 seconds to quickly peel off the outer skin.

[0064] (5) Soaking and thawing: The passion fruit after peeling off the outer skin is soaked in water containing 0.5% citric acid and 0.1% ascorbic acid for 1 minute to thaw.

[0065] (6) Separation and collection: Cut the passion fruit with the outer skin removed, take out the pulp, juice and seed kernels, and collect the remaining peel. Add 0.5L of water by weight to the obtained pulp, juic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com